Patents

Literature

2393results about "Insulating bodies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical connector

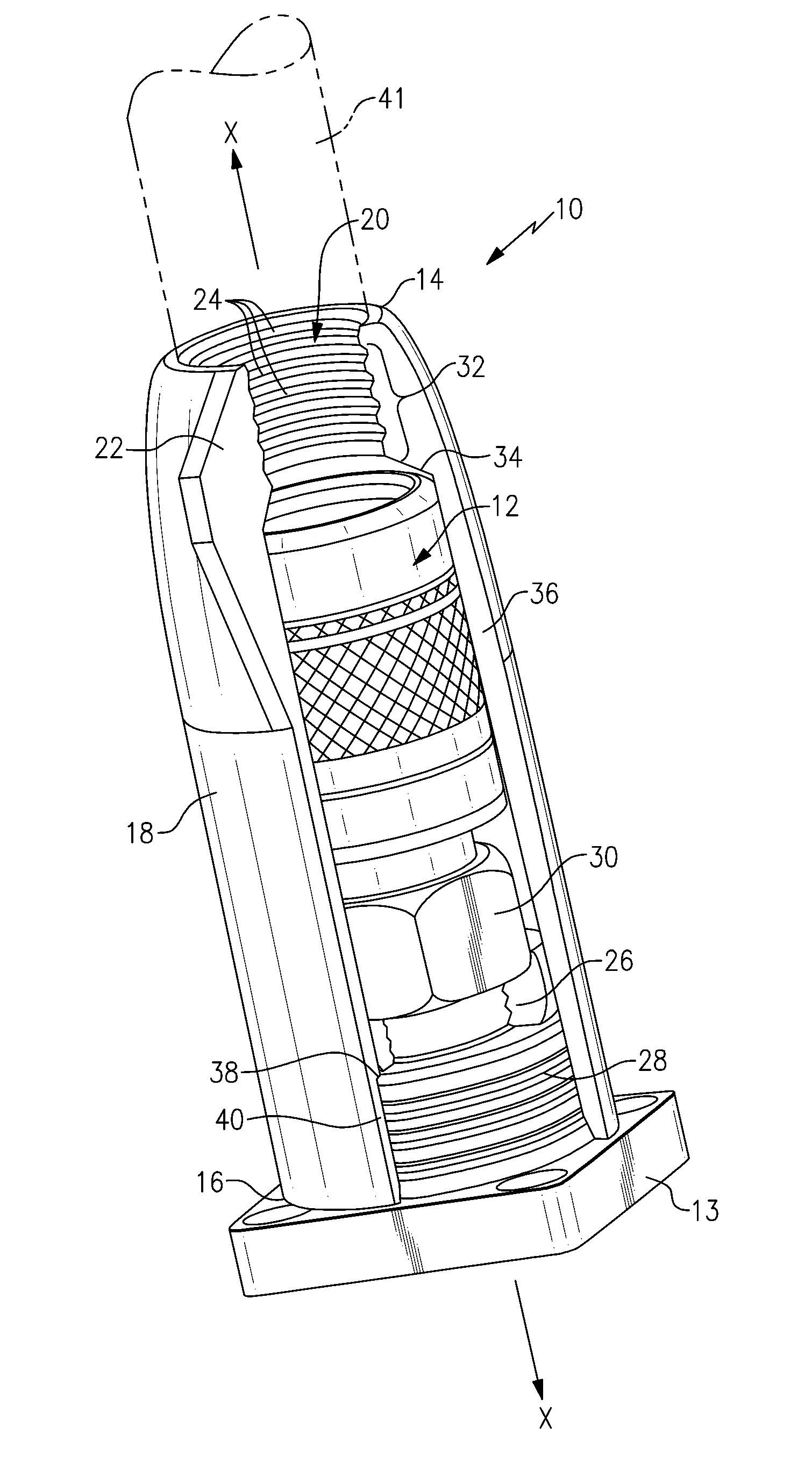

According to the present invention there is provided a snap in locking cable connector with a cylindrical housing having an entry end aperture and an exit end aperture. The entry end aperture can accept the snap-in spring steel adapter of U.S. Pat. No. 6,080,933 as well as the exit end peripheral spring steel locking ring described in this patent to provide a connector that allows rapid and simplified installation of armored cable into a junction or circuit box. The cylindrical housing includes an annular groove or ridge about the inner periphery thereof in the area of the entry end for retention of the spring steel adapter. An electrical cable connector of this type that relies upon frictional or interference fit for retention of the spring steel adapter is also described. Retention of the spring steel adapter with a screw, rivet or similar fastener is also described.

Owner:ARLINGTON INDS

Enhanced dielectric strength mica tapes

InactiveUS6190775B1Low costHigh voltageWindings insulation materialSynthetic resin layered productsDielectric strengthMetal

Owner:SIEMENS ENERGY INC

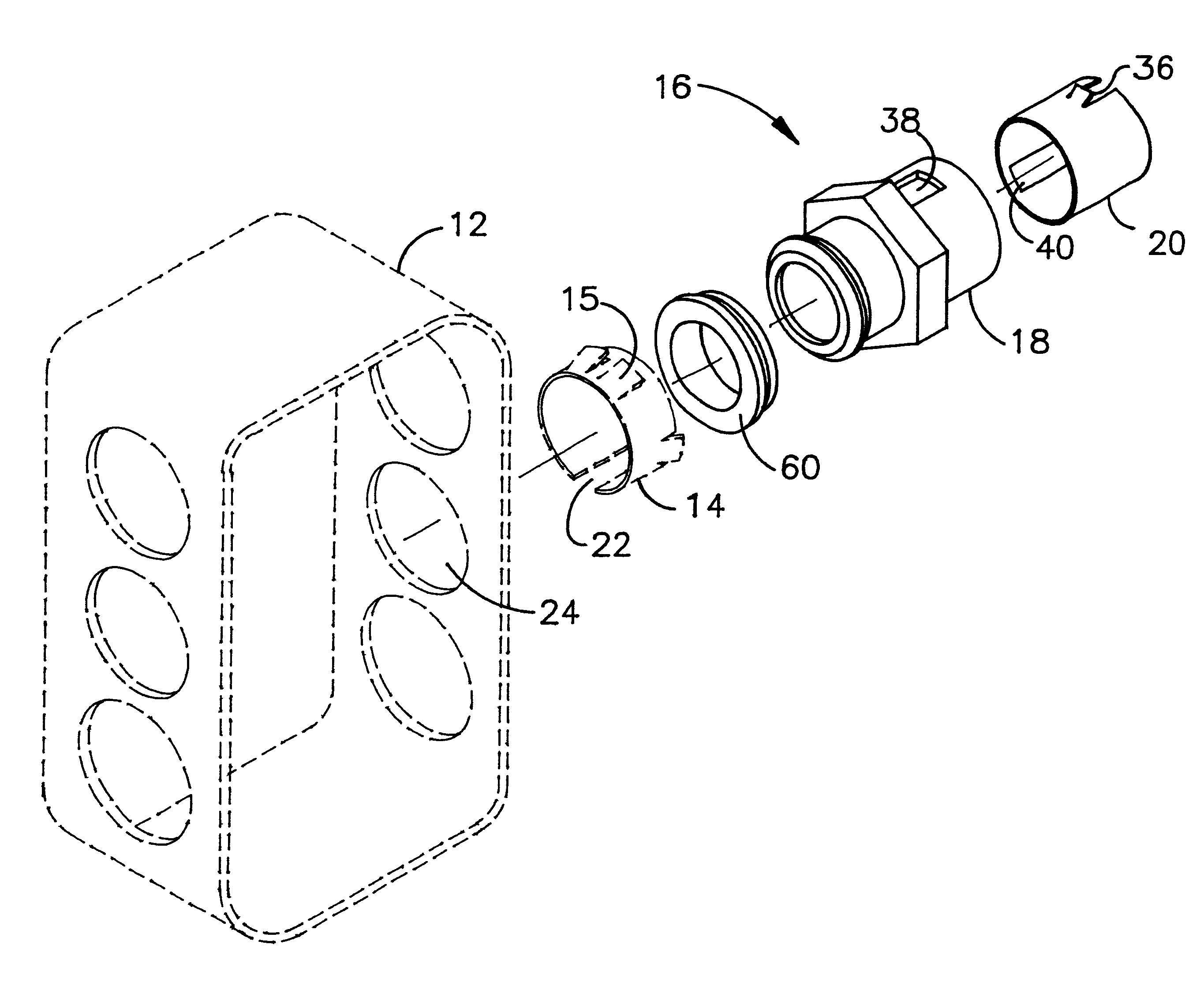

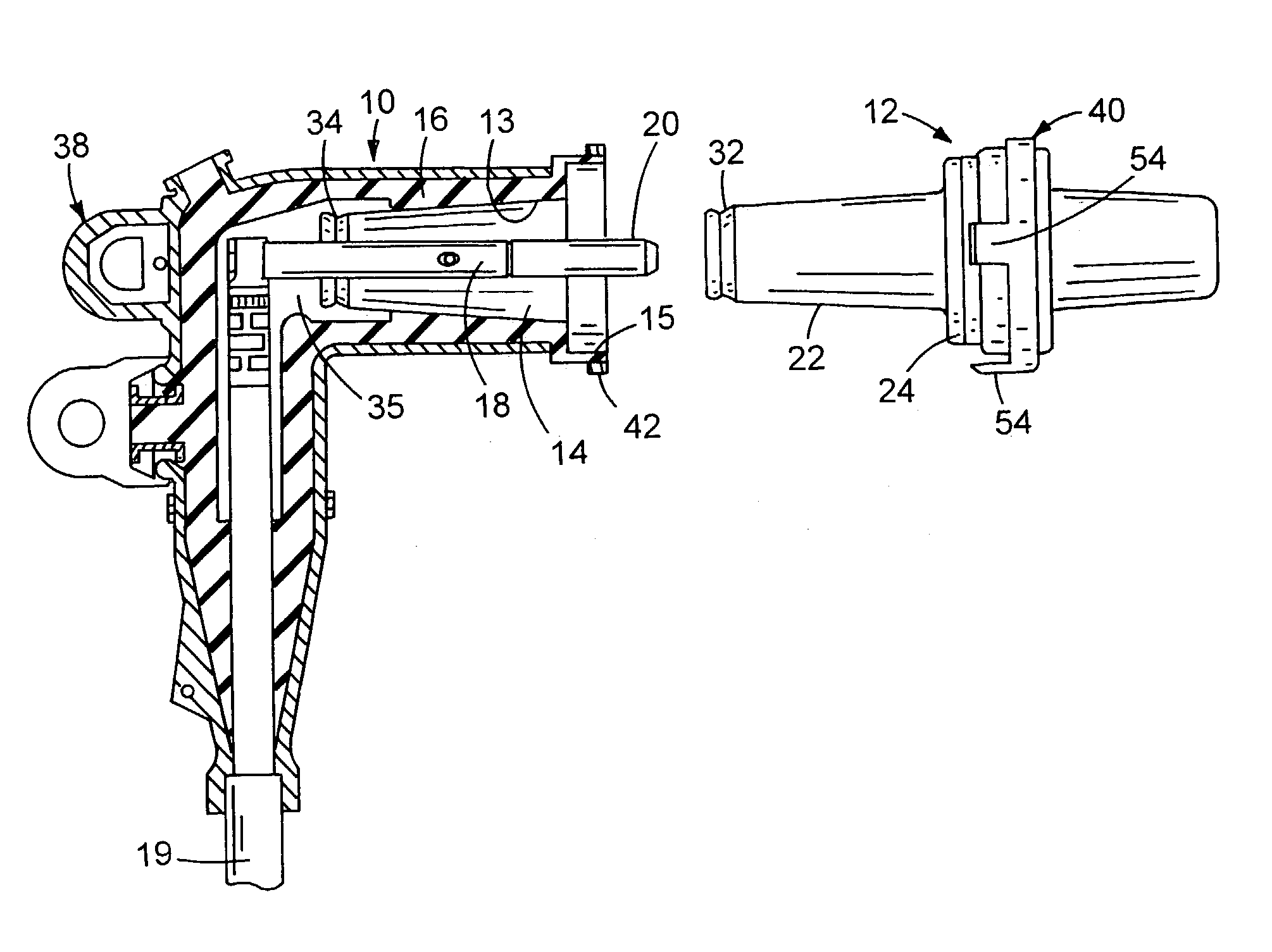

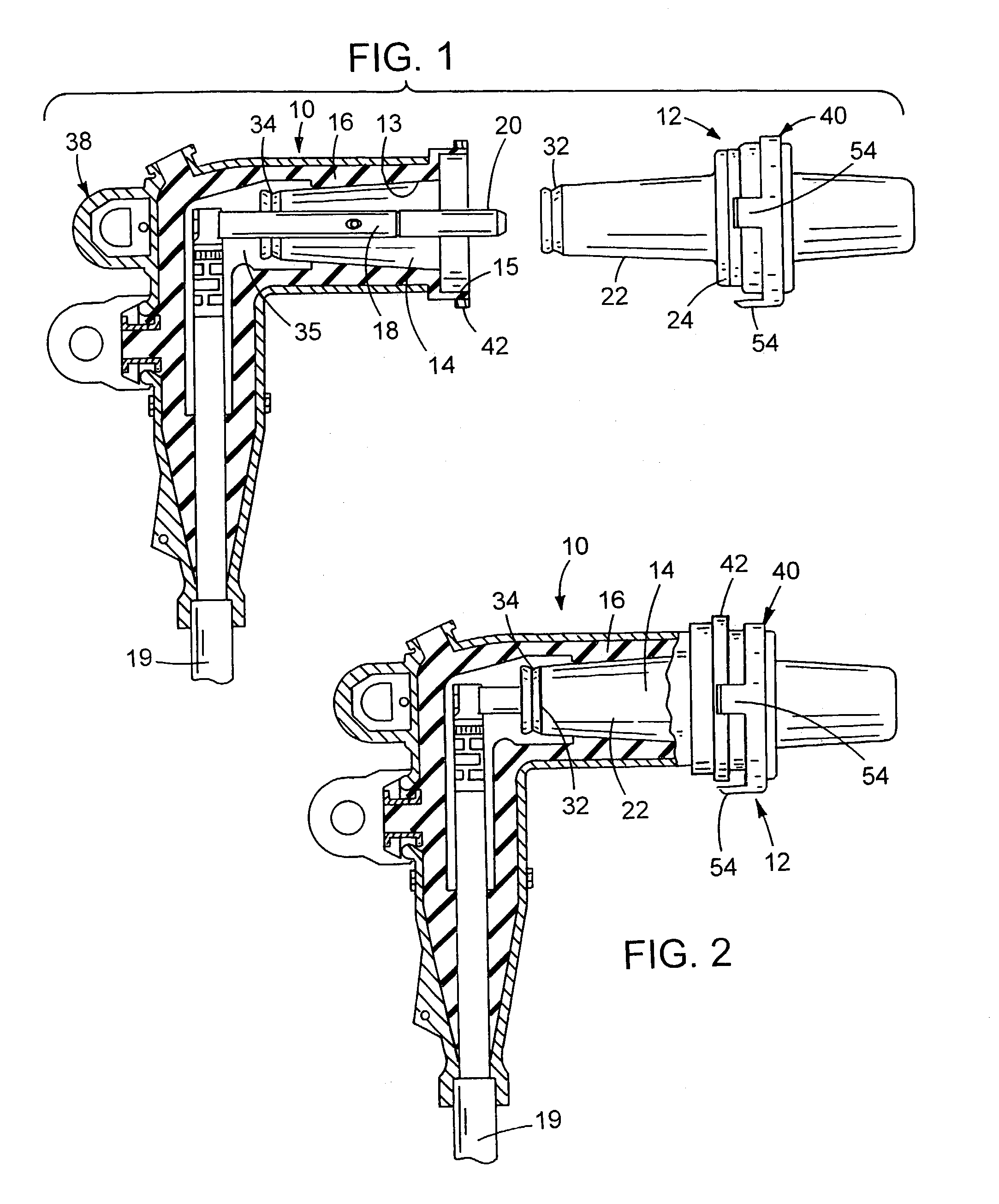

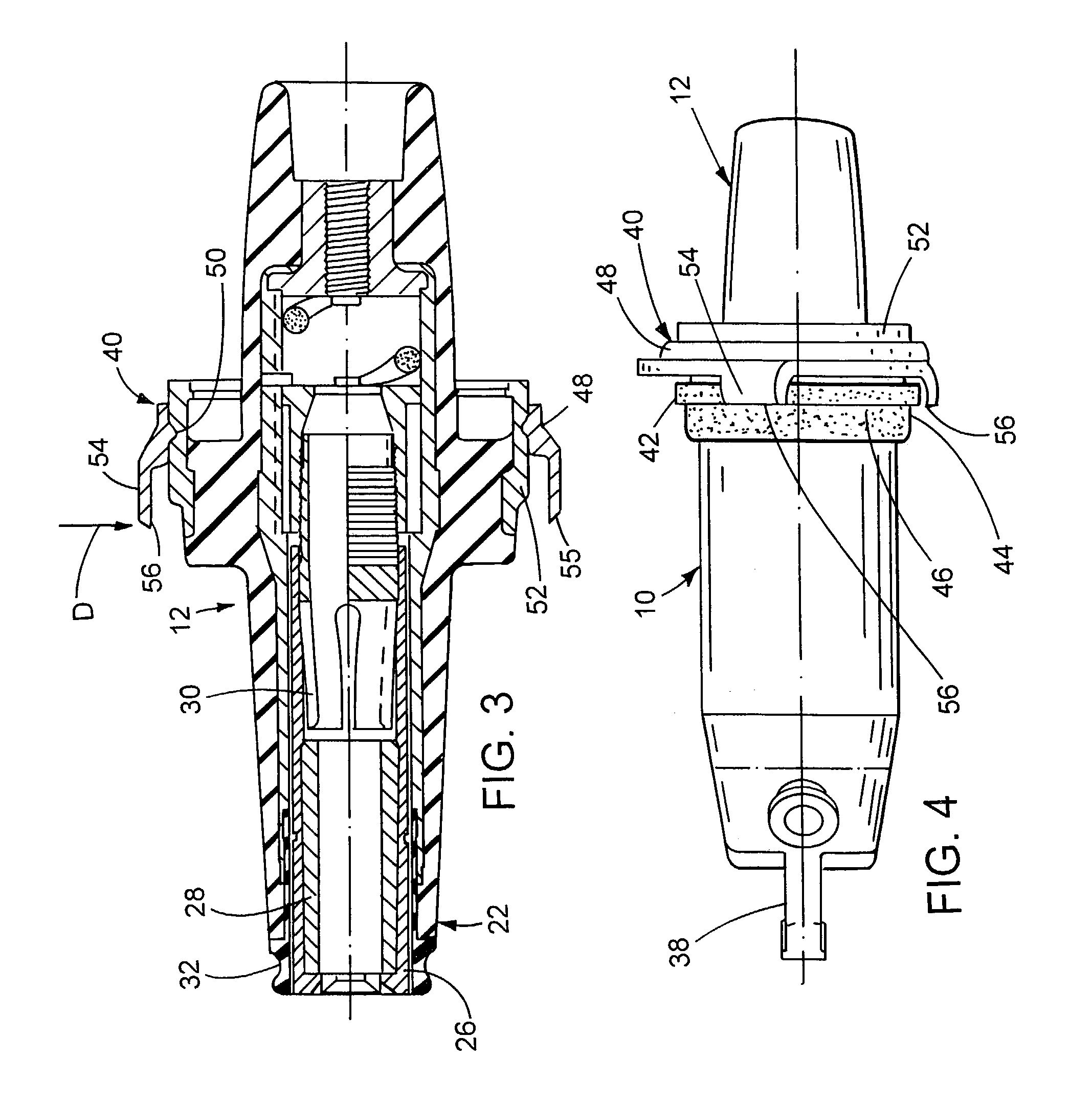

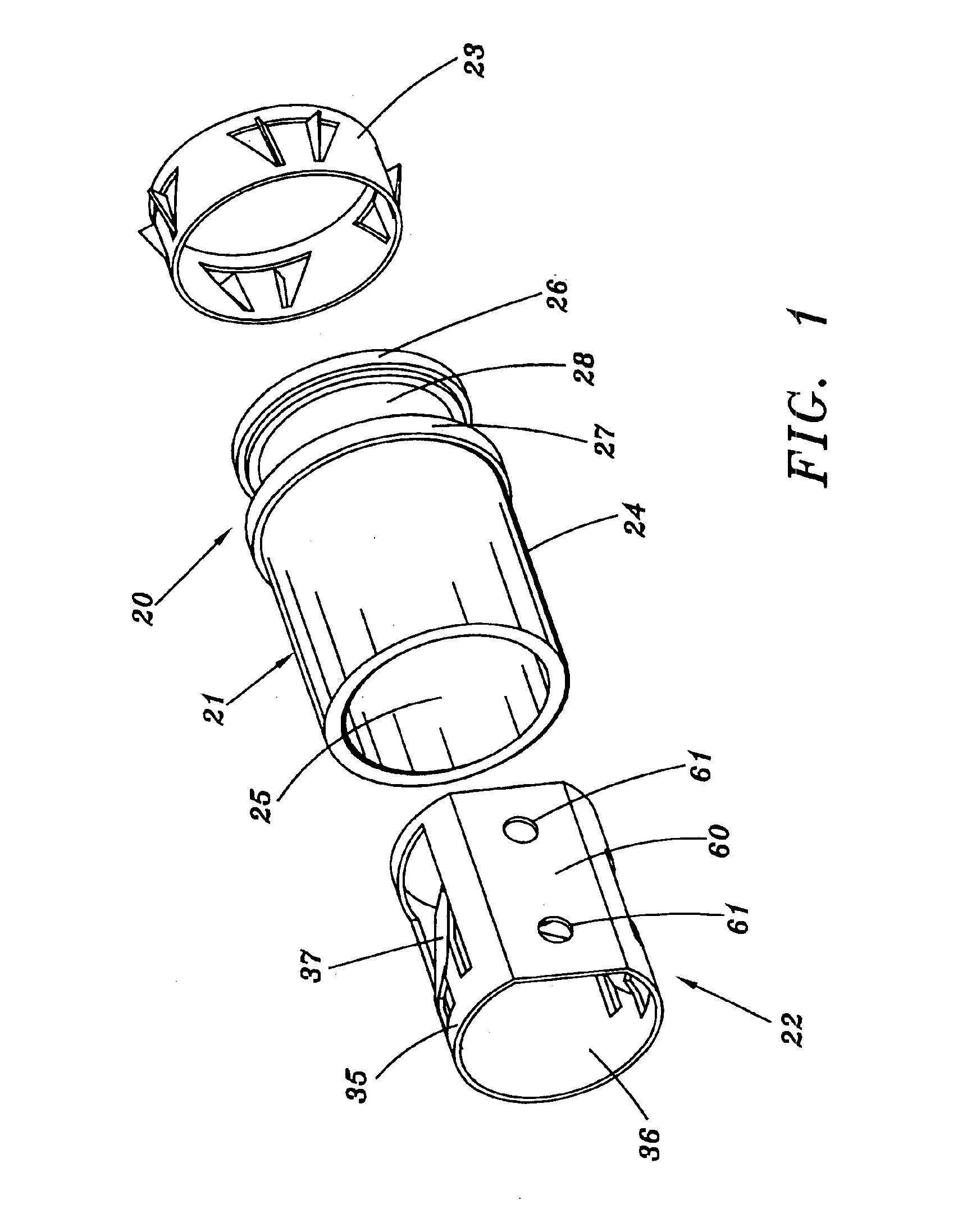

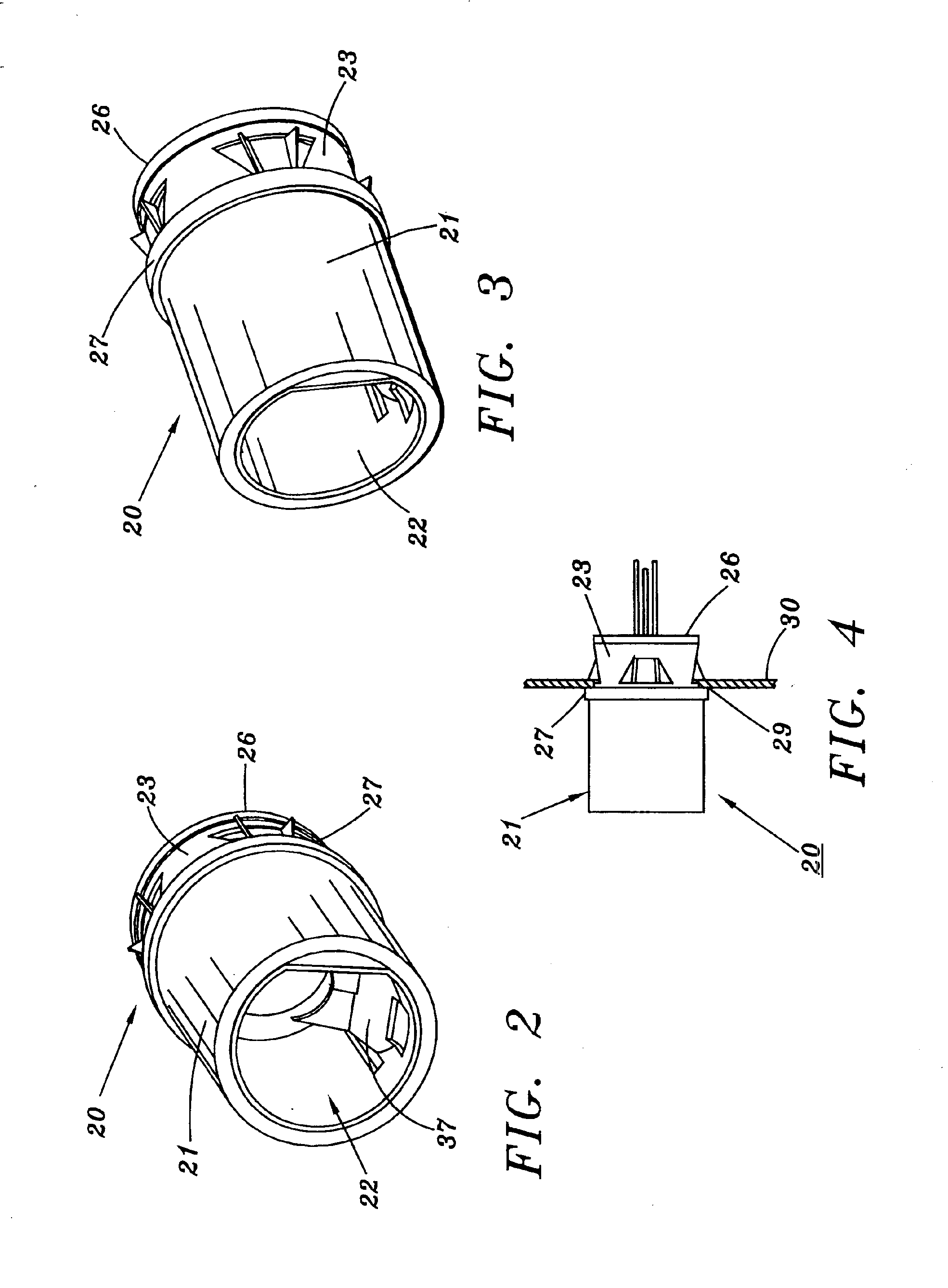

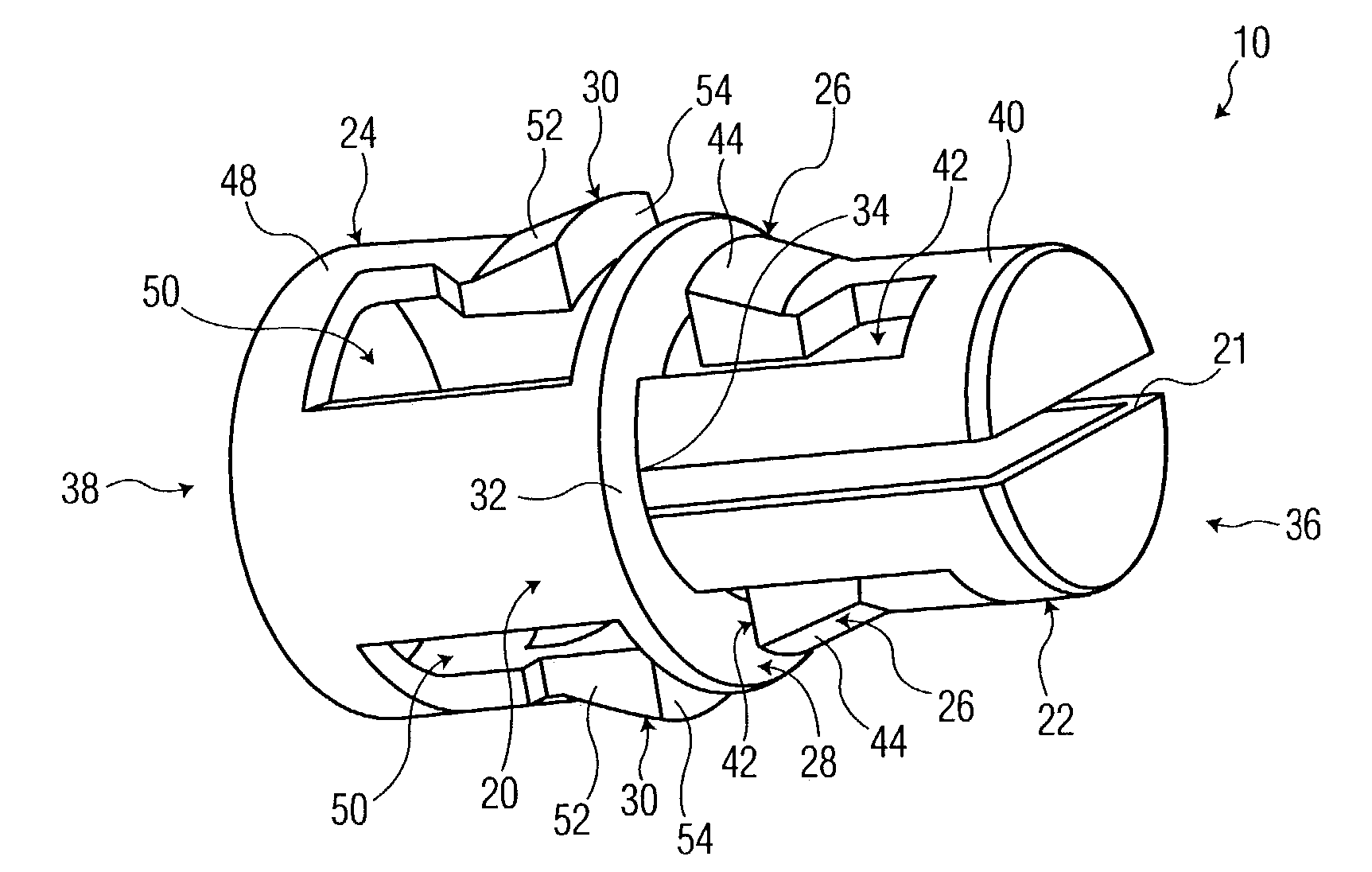

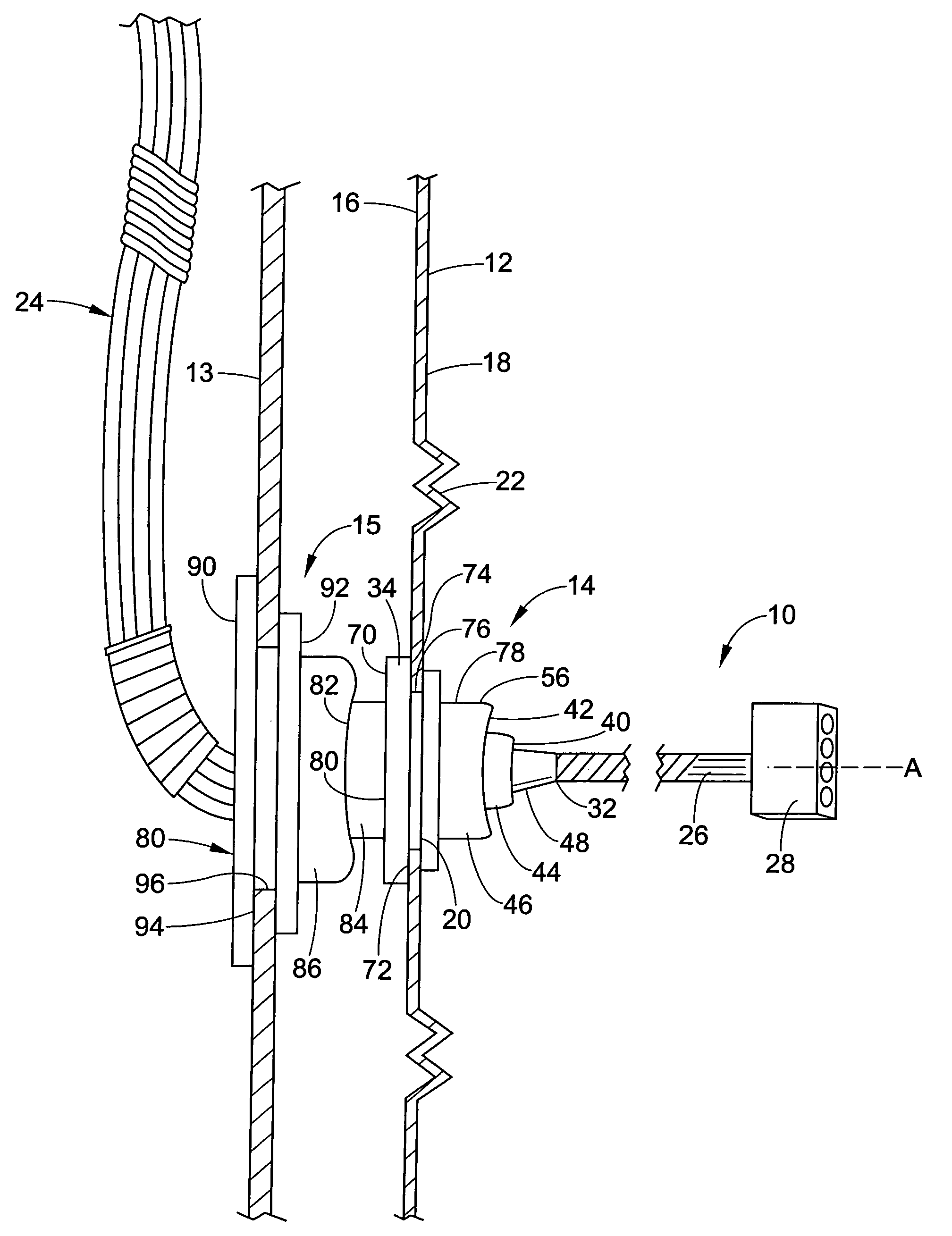

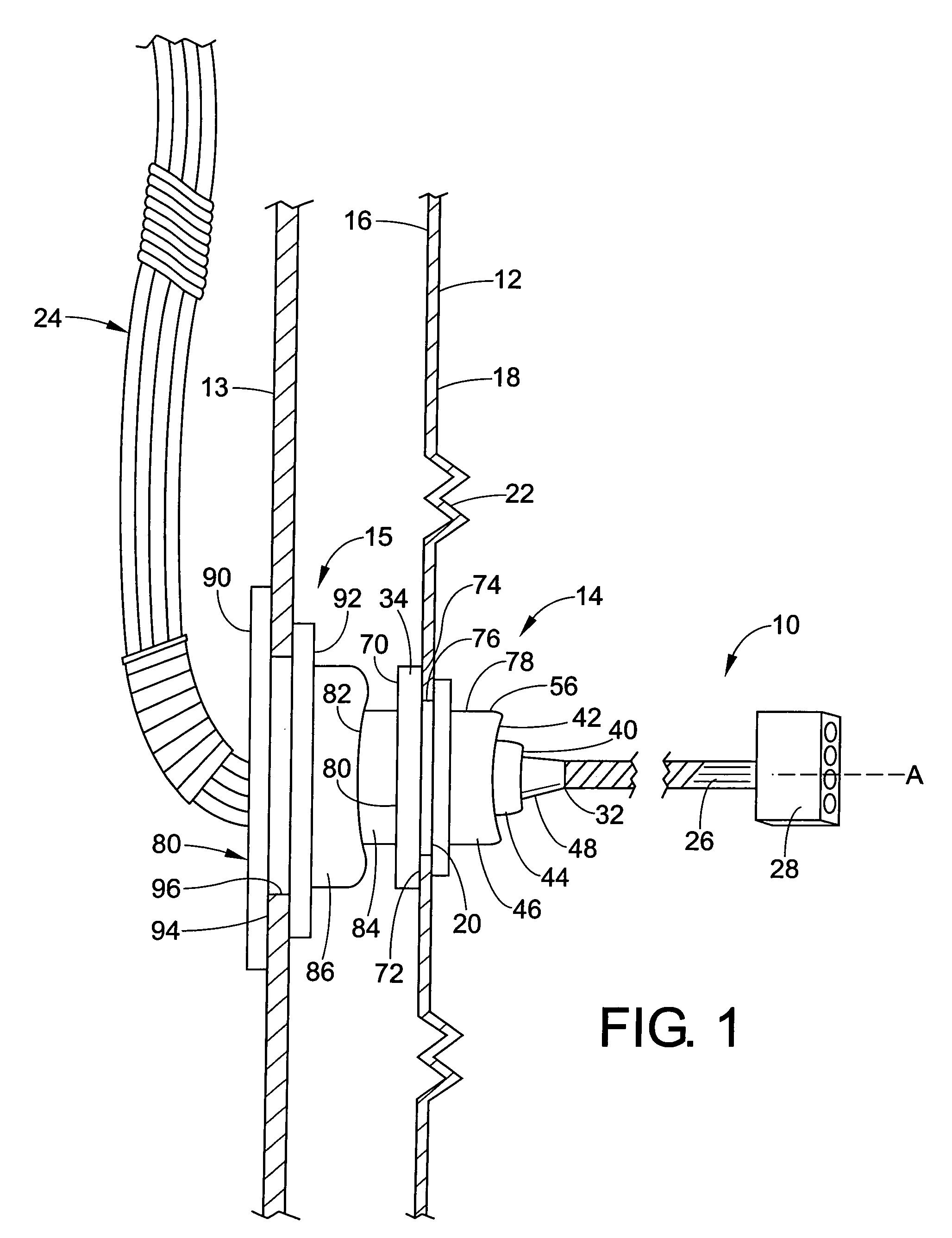

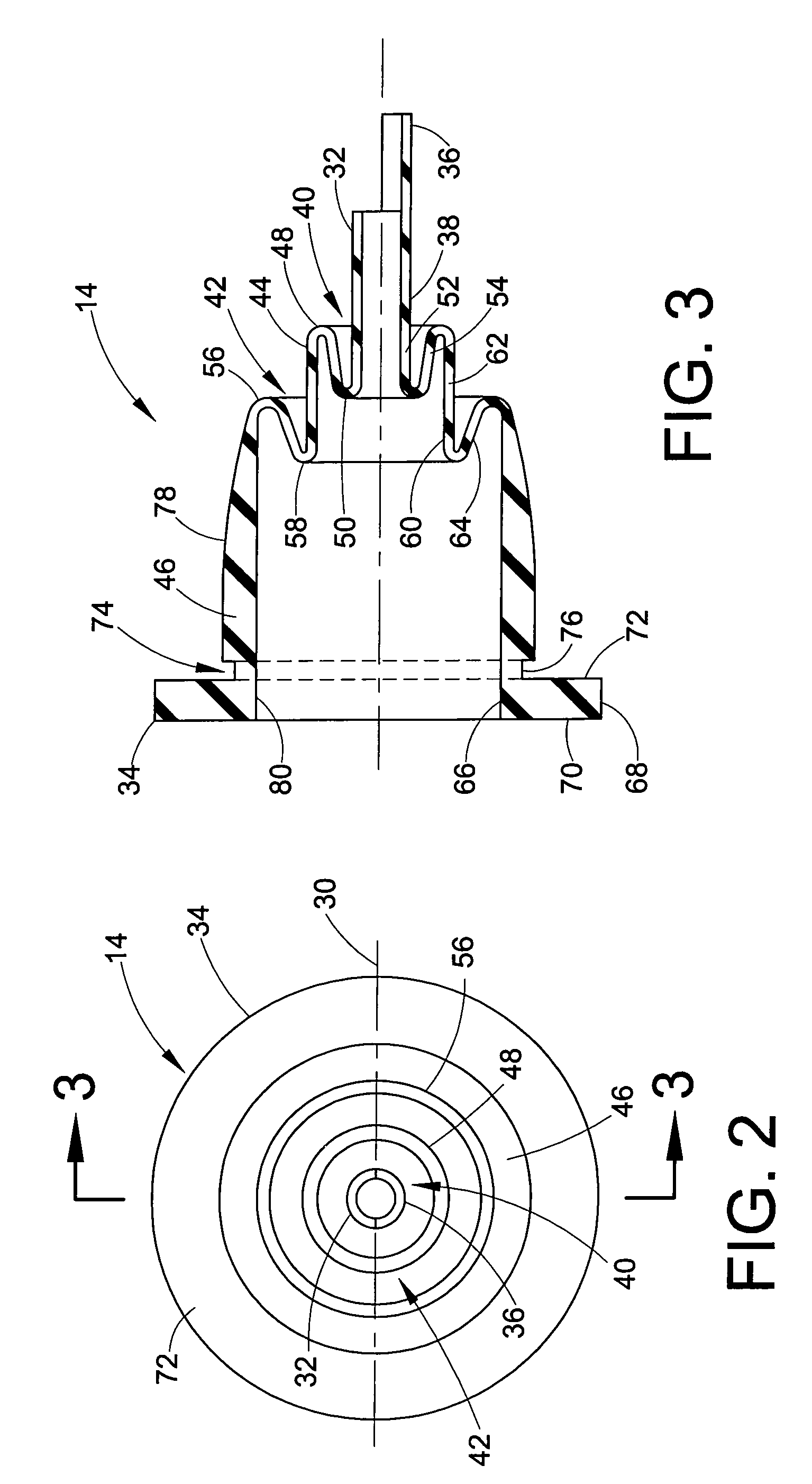

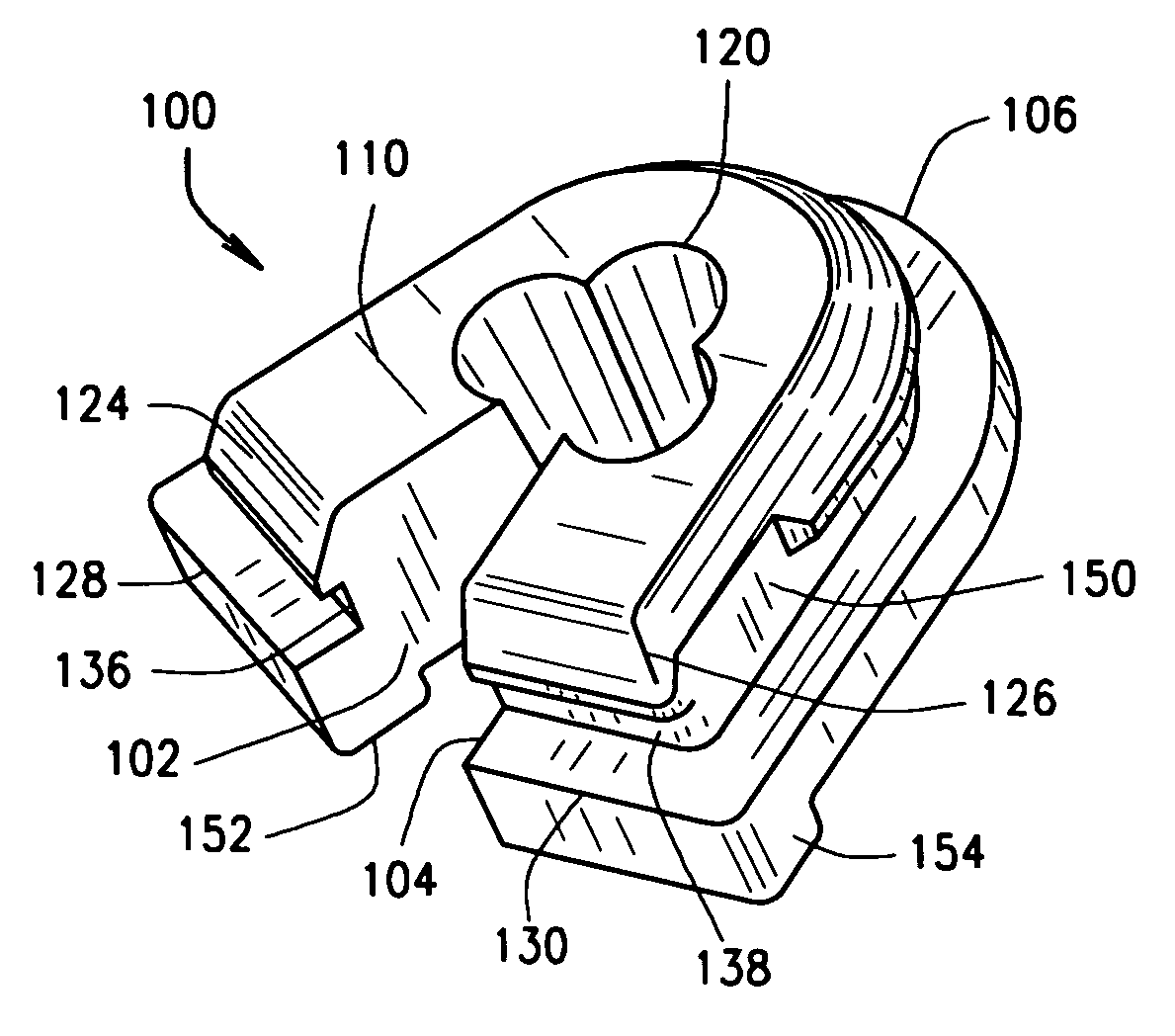

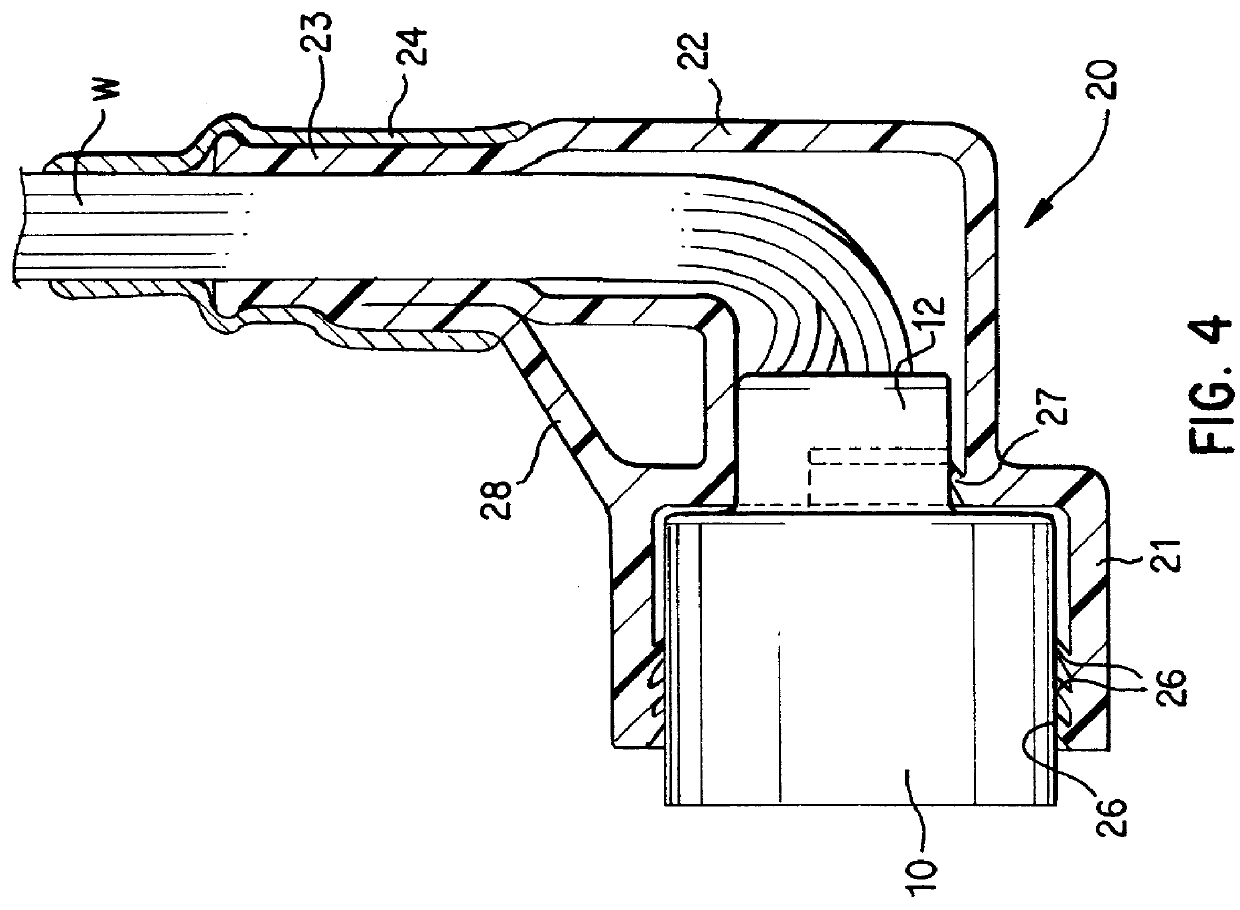

Snap in cable connector

InactiveUS6335488B1Easy to insertElectrically conductive connectionsPipesElectrical junctionDie casting

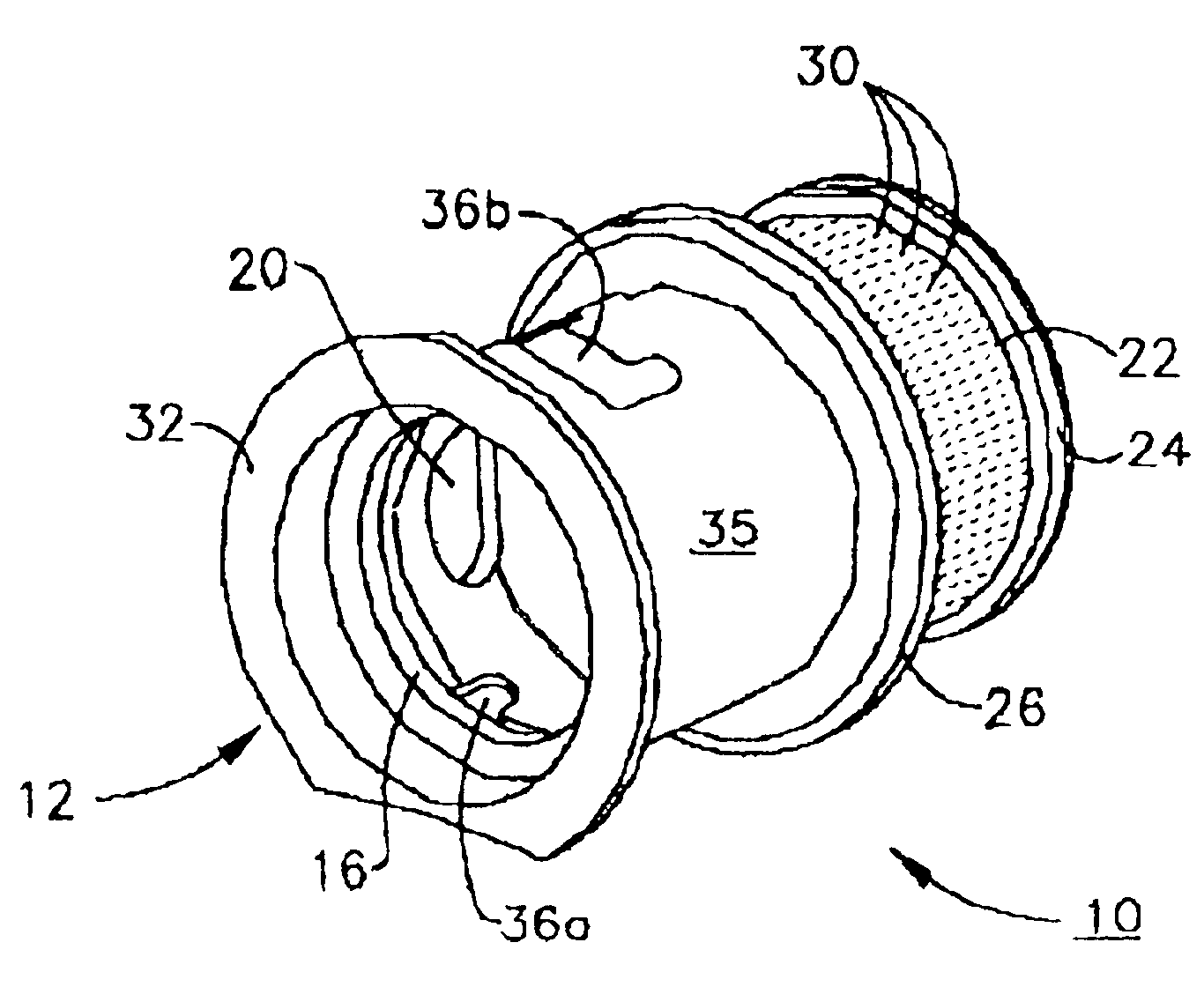

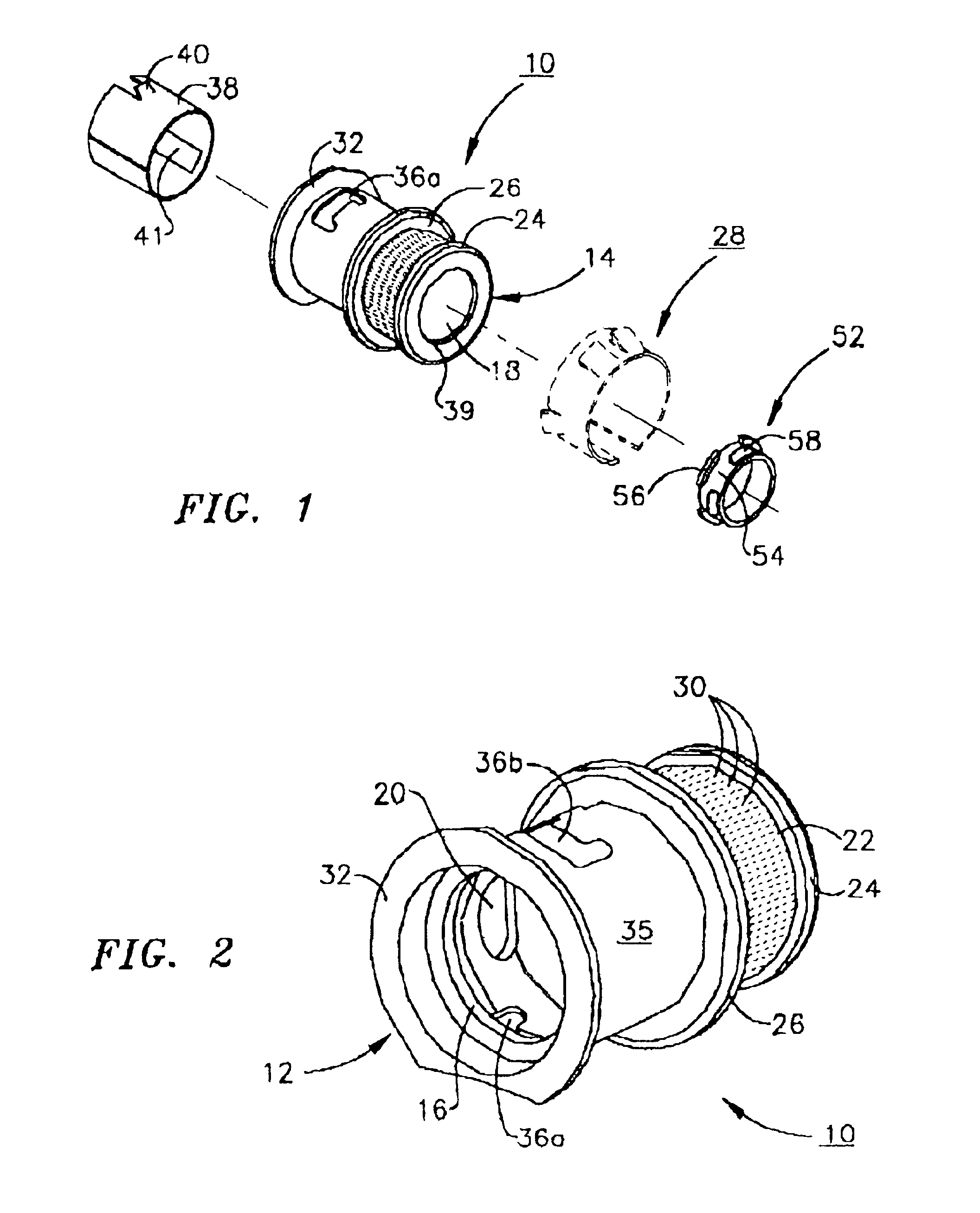

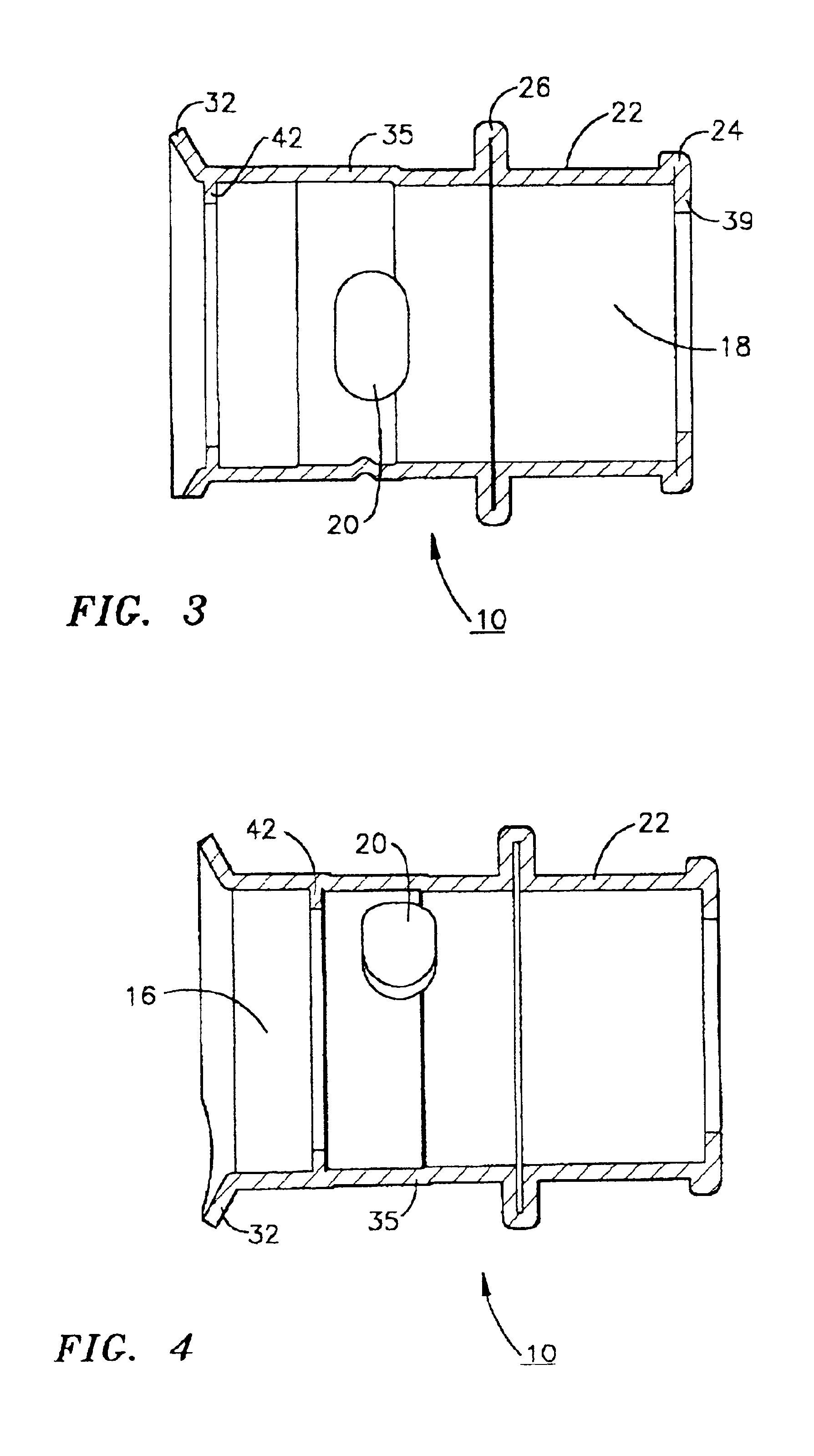

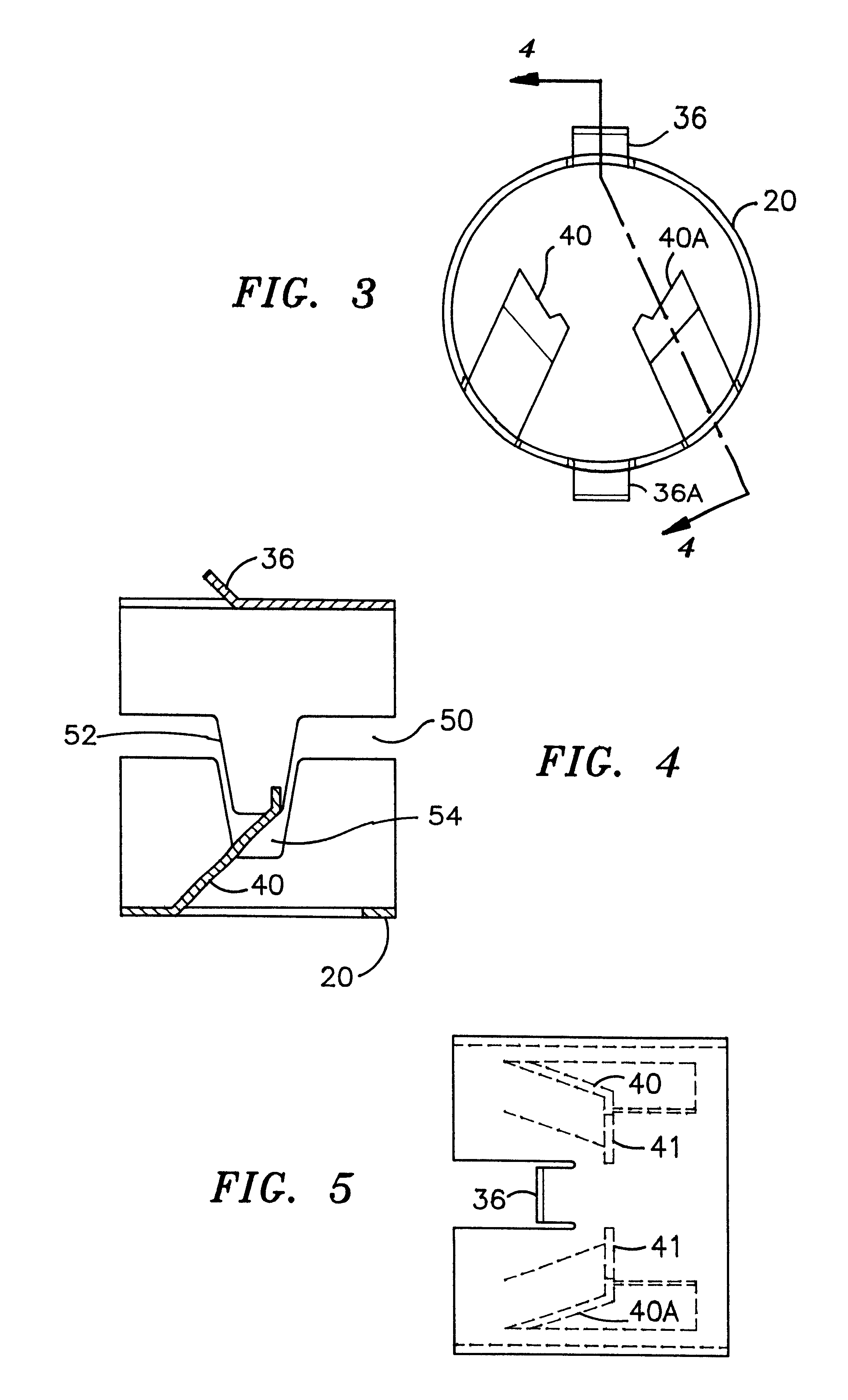

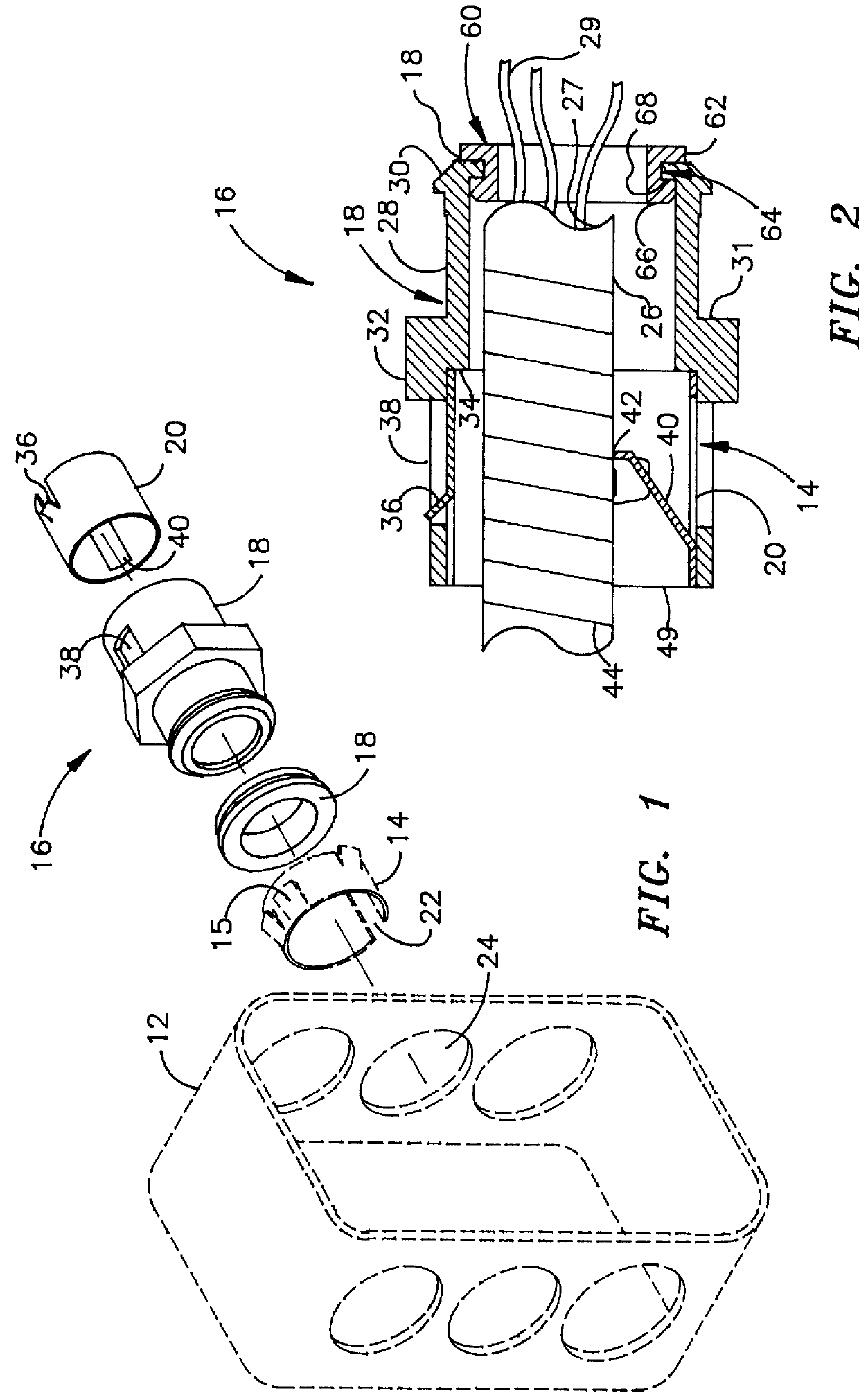

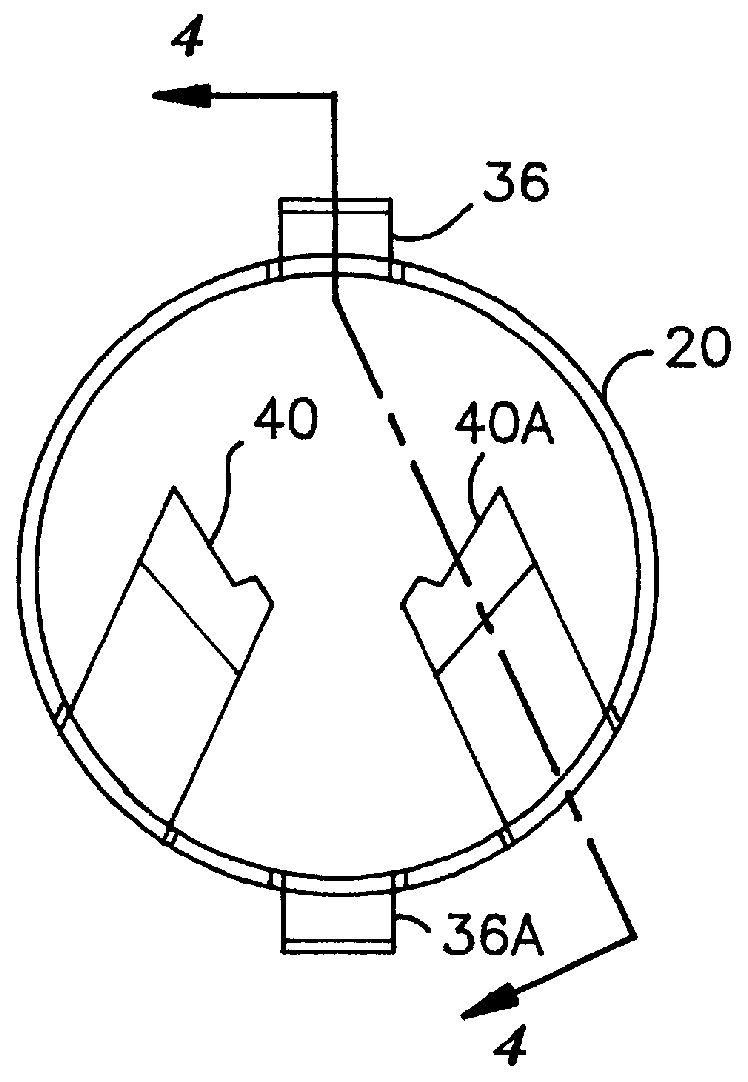

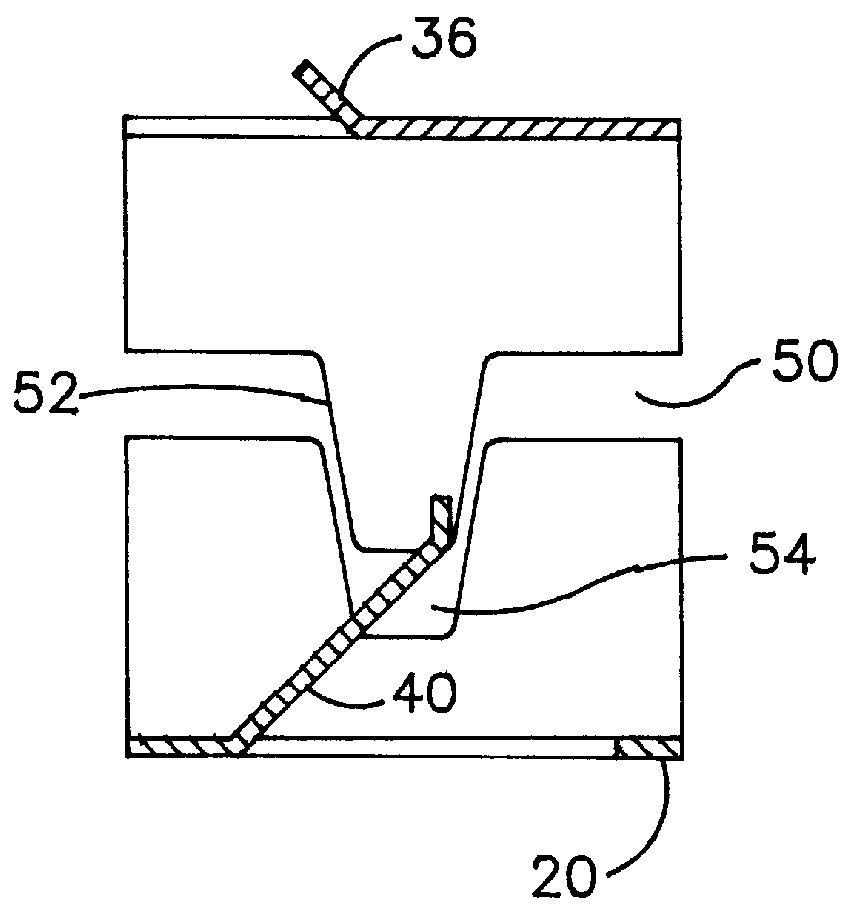

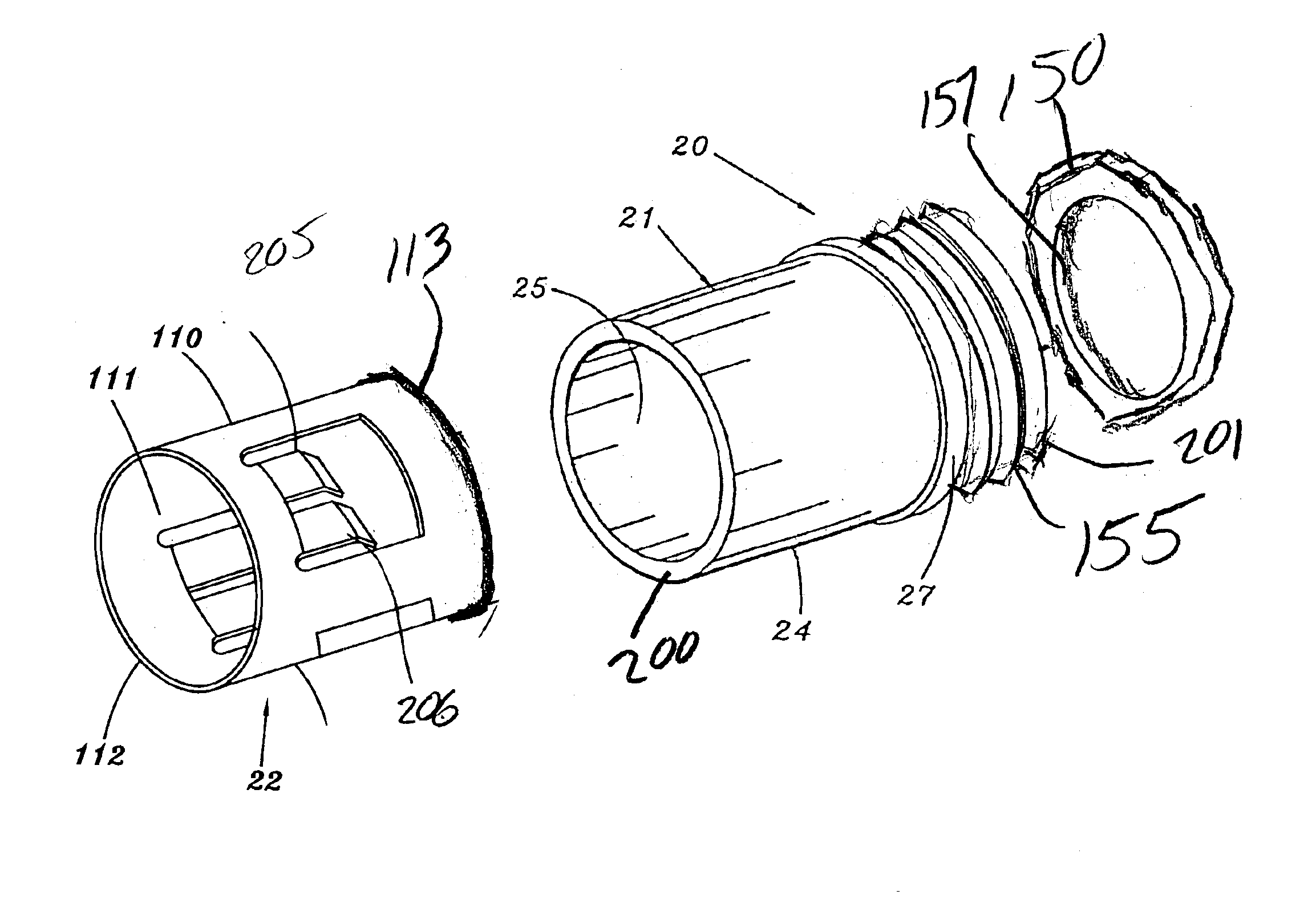

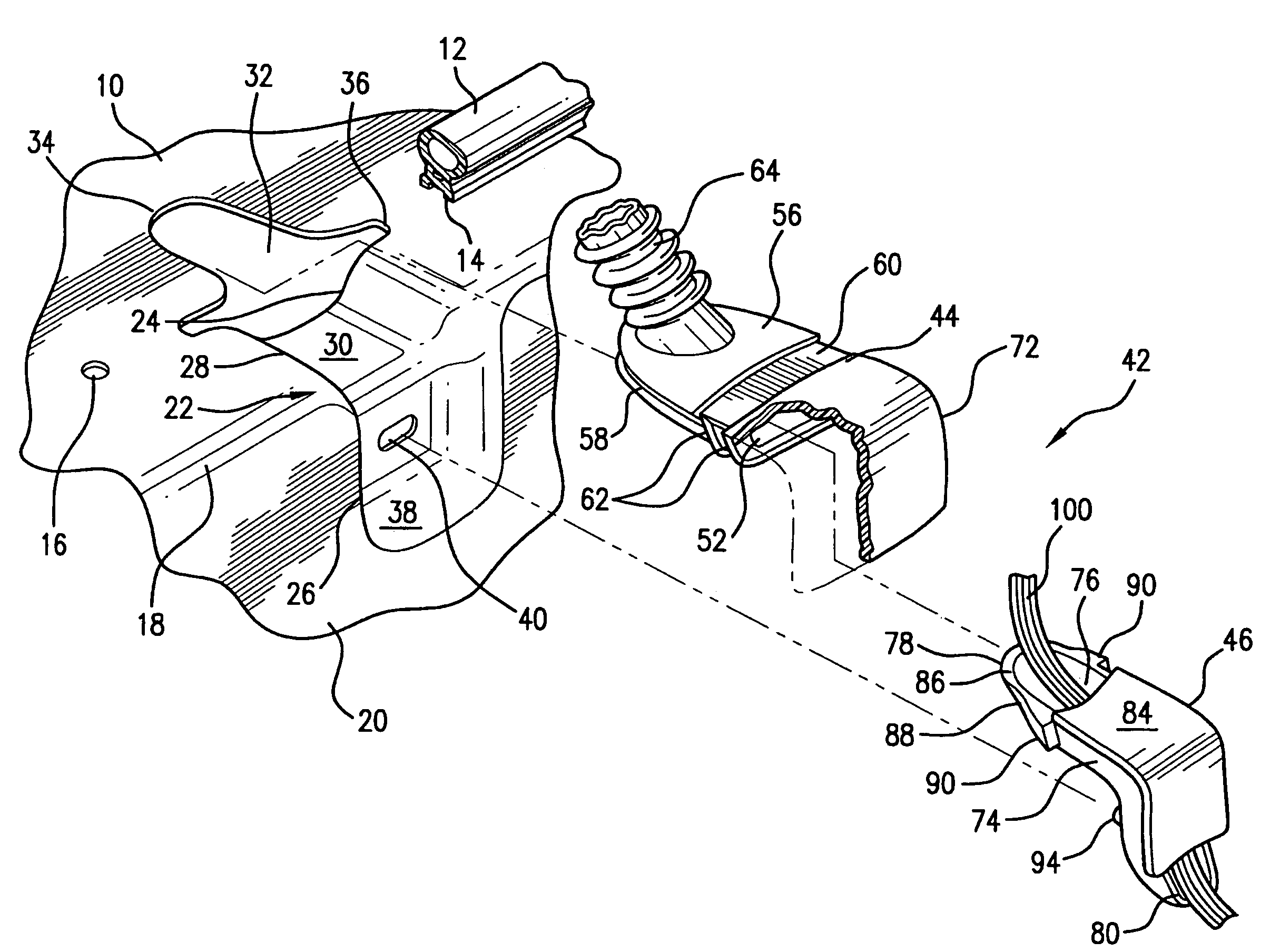

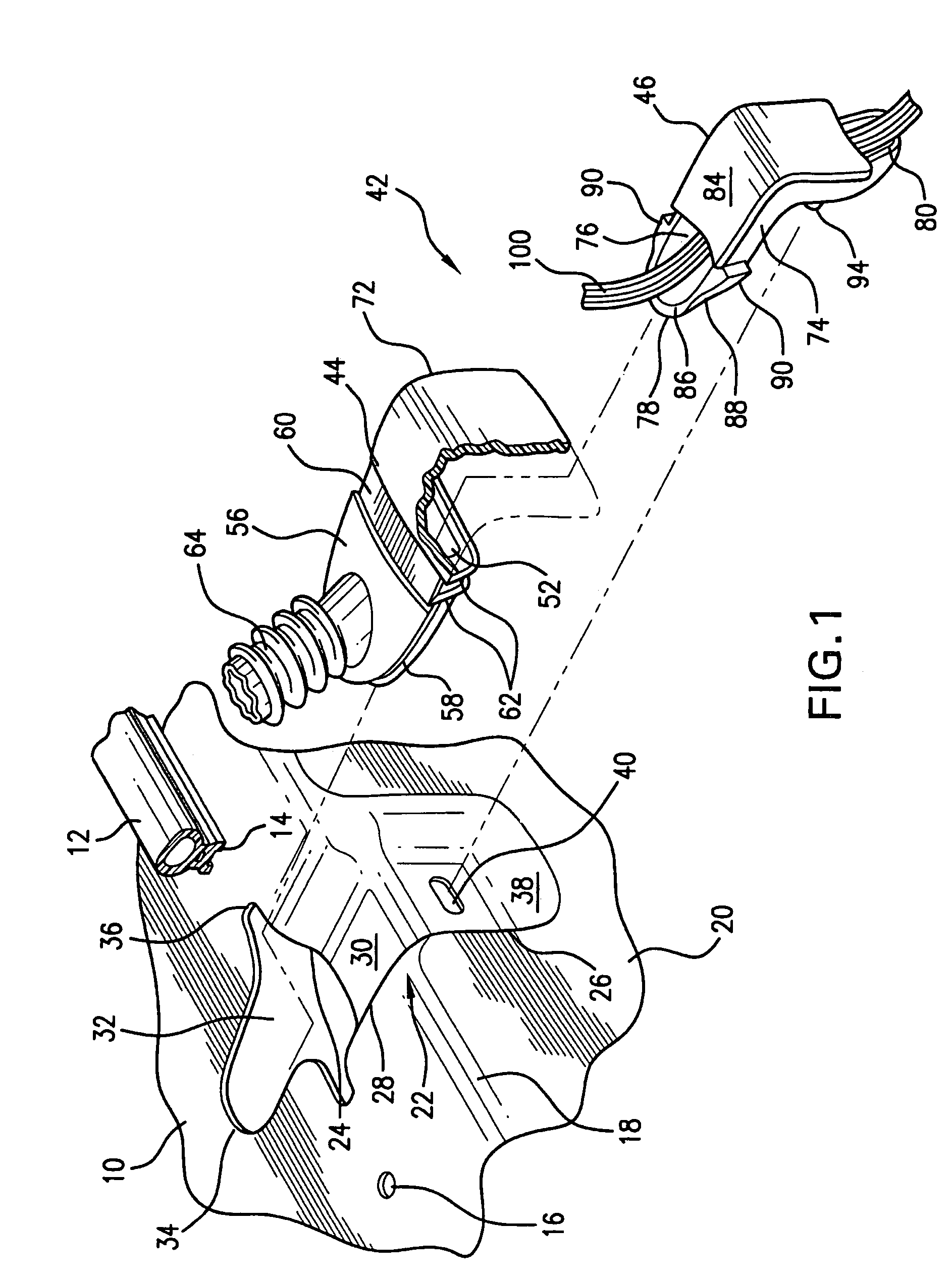

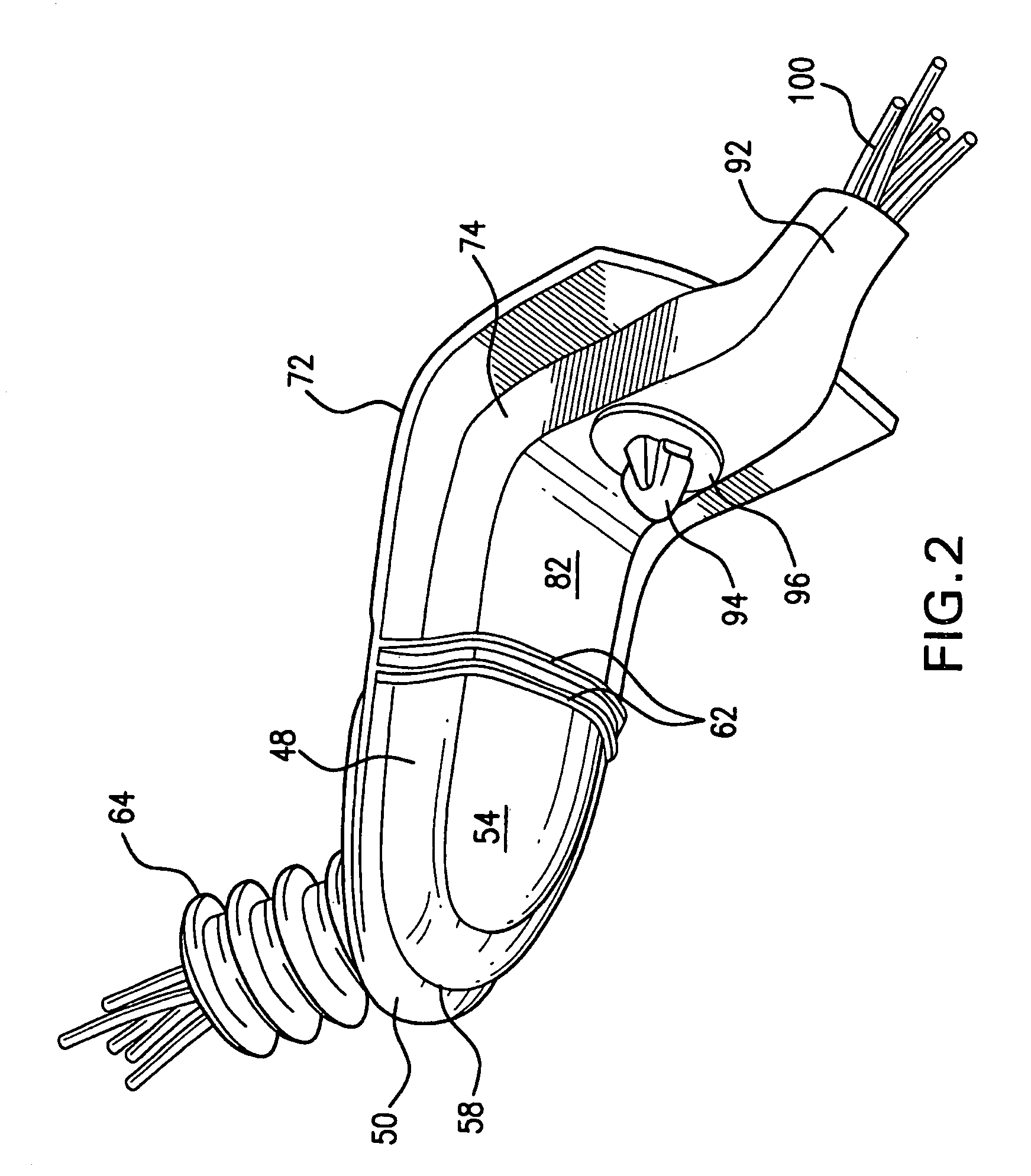

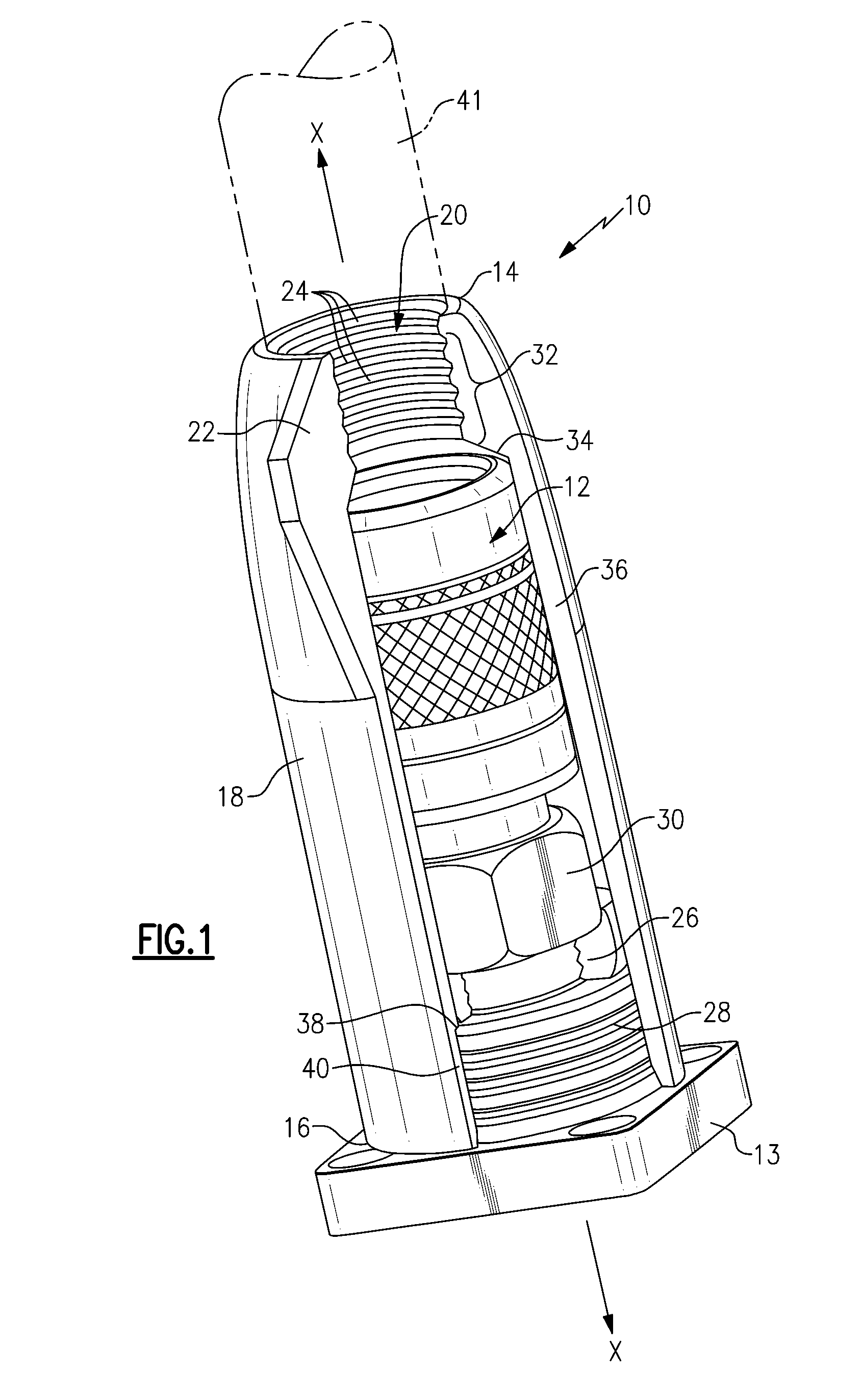

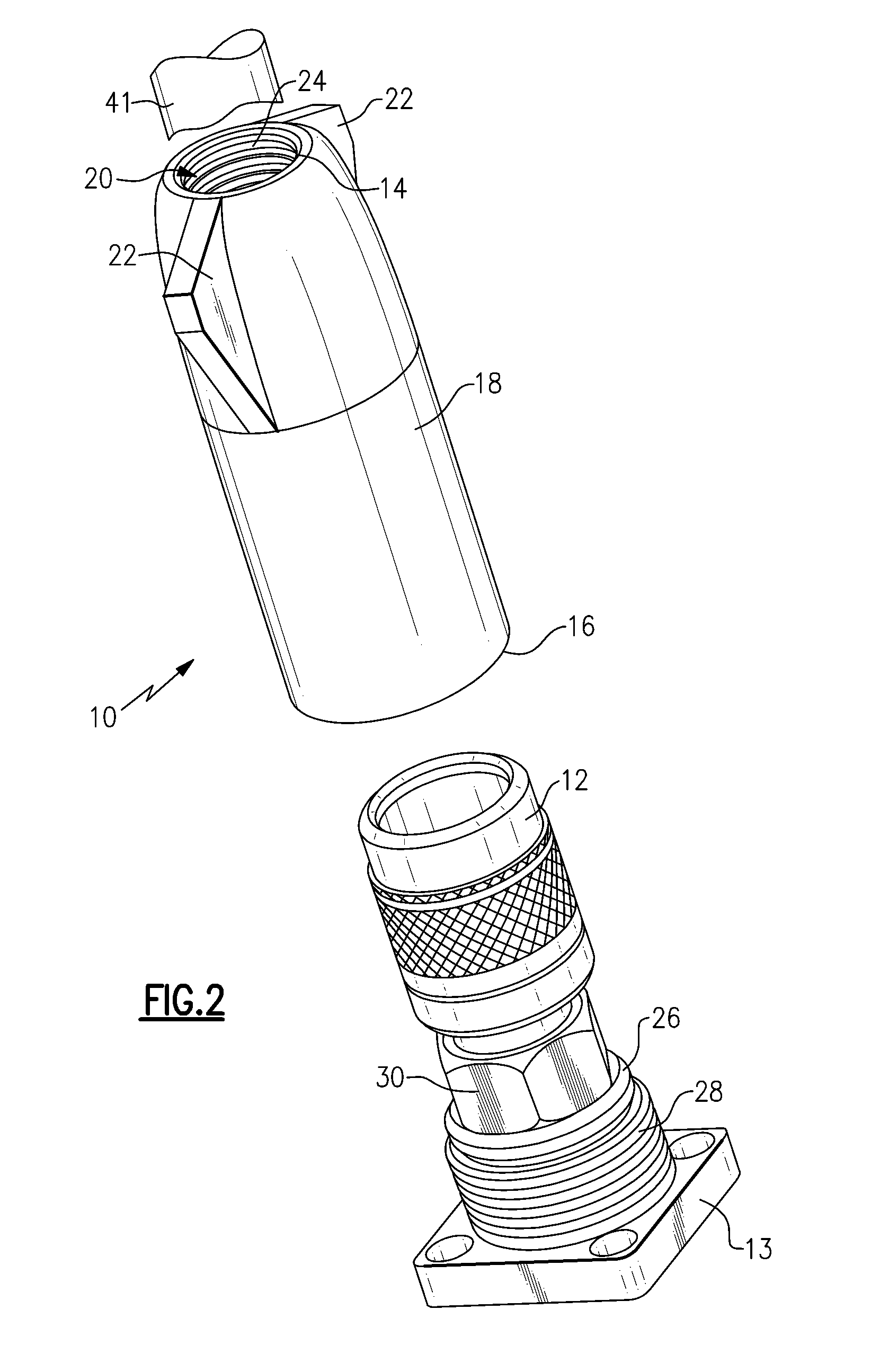

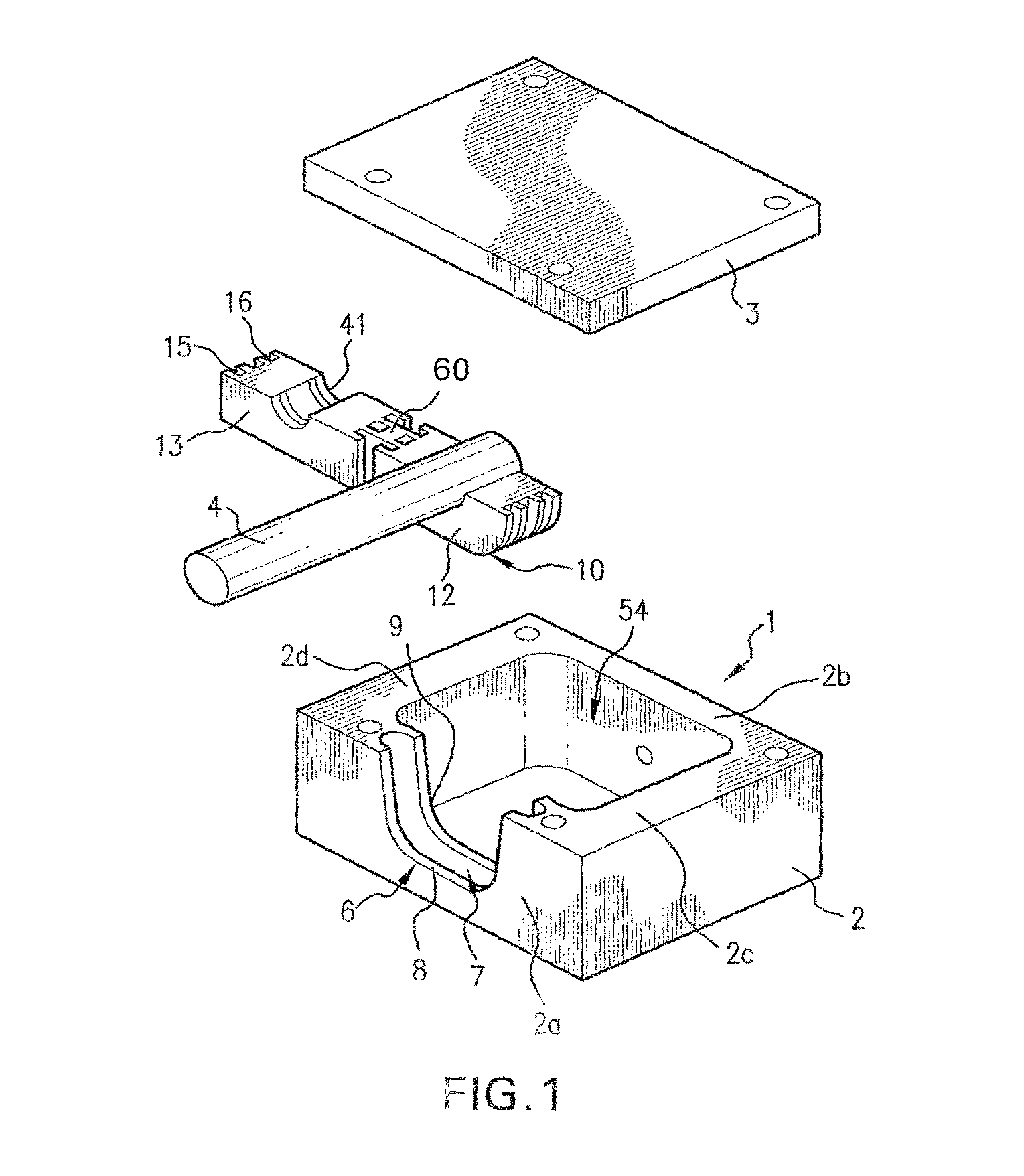

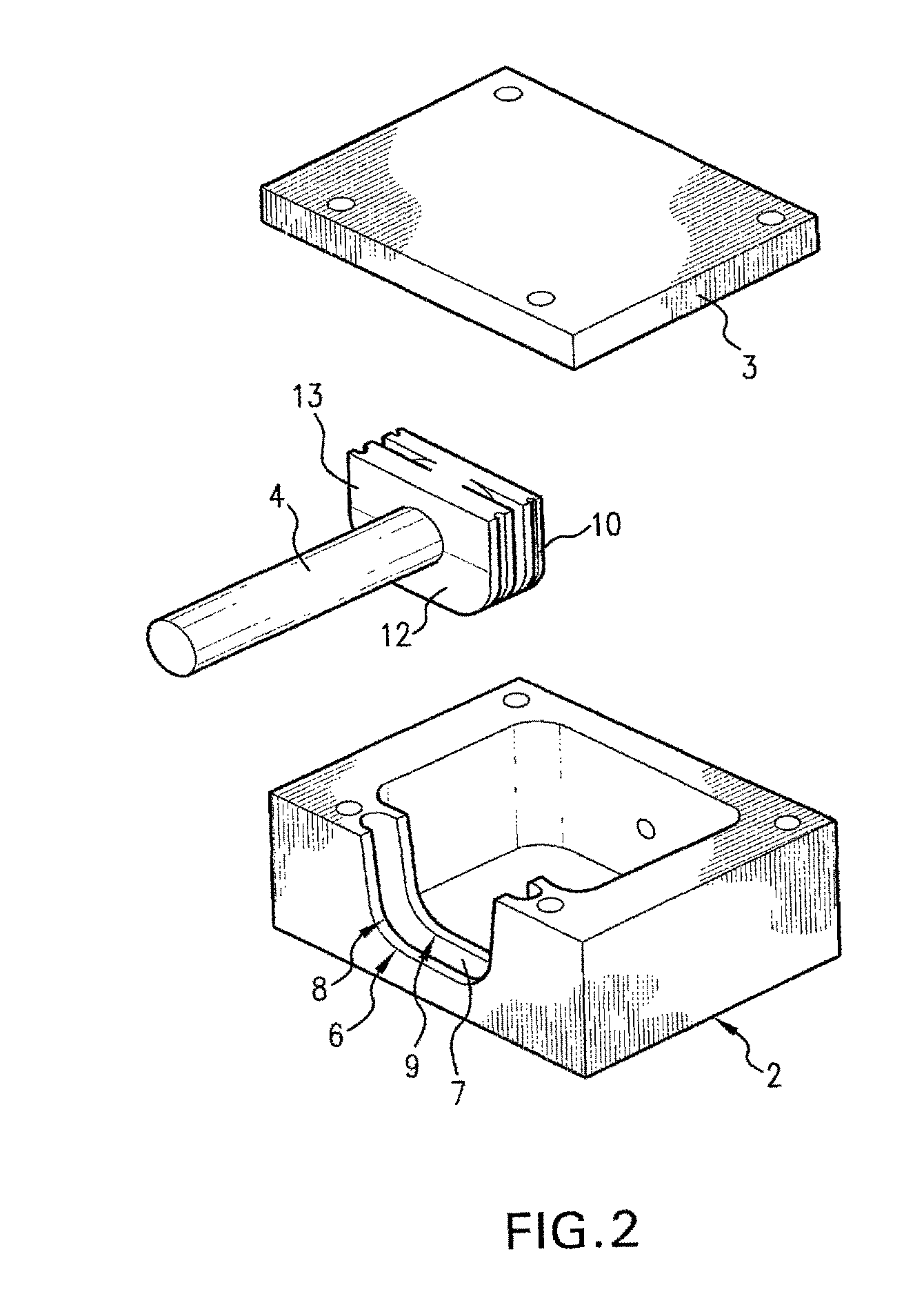

A snap in locking cable connector is composed of two mating pieces that snap together and provide a connector for armored or metal clad electrical conducts. One piece includes a die cast member including a smooth outer cylindrical section having an inner diameter that may accommodate a spring steel adaptor with flanges to hold the spring steel adaptor in place. The spring steel adaptor is used in conjunction with an electrical junction box to fix the location of the locking cable connector with respect to the junction box. Another piece includes a spring steel locking ring provided to receive an armored cable and lock into the die cast member. The spring steel locking ring has tangs allowing unidirectional insertion into the die cast member and restricting withdrawal motion from the die cast member. The spring steel locking ring also includes oppositely directed tangs to permit reception of the armored cable in one direction and restrict its movement in the reverse direction.

Owner:ARLINGTON INDS

Snap in cable connector

A snap in locking cable connector is composed of two mating pieces that snap together and provide a connector for armored or metal clad electrical conductors. One piece includes a member including a smooth outer cylindrical section having an inner diameter that may accommodate a spring steel adaptor with flanges to hold the spring steel adaptor in place. The spring steel adaptor is used in conjunction with an electrical junction box to fix the location of the locking cable connector with respect to the junction box. Another piece includes a spring steel locking ring provided to receive an armored cable and lock into the member. The spring steel locking ring has tangs allowing unidirectional insertion into the member and restricting withdrawal motion from the member. The spring steel locking ring also includes oppositely directed tangs to permit reception of the armored cable in one direction and restrict its movement in the reverse direction.

Owner:ARLINGTON INDS

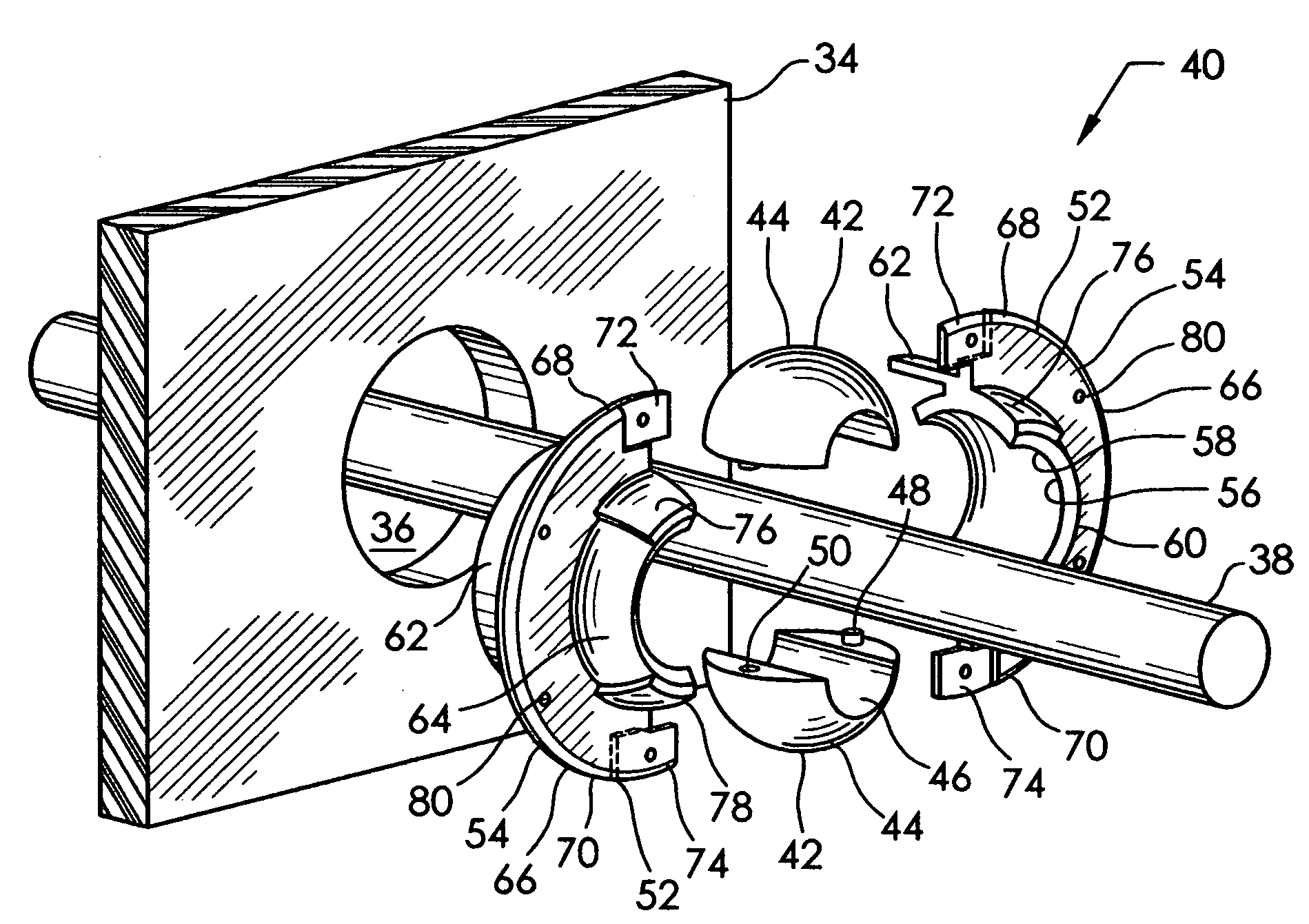

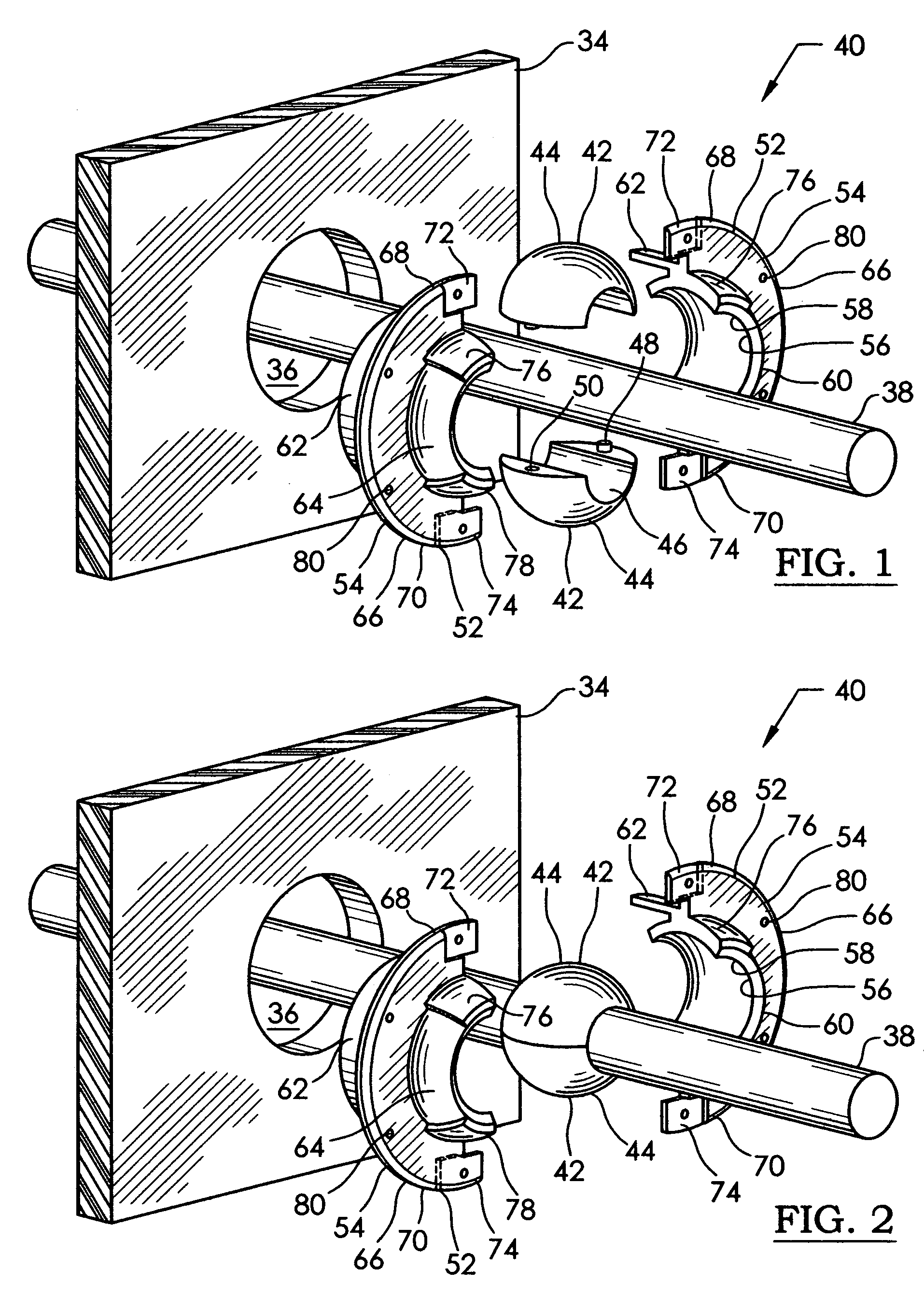

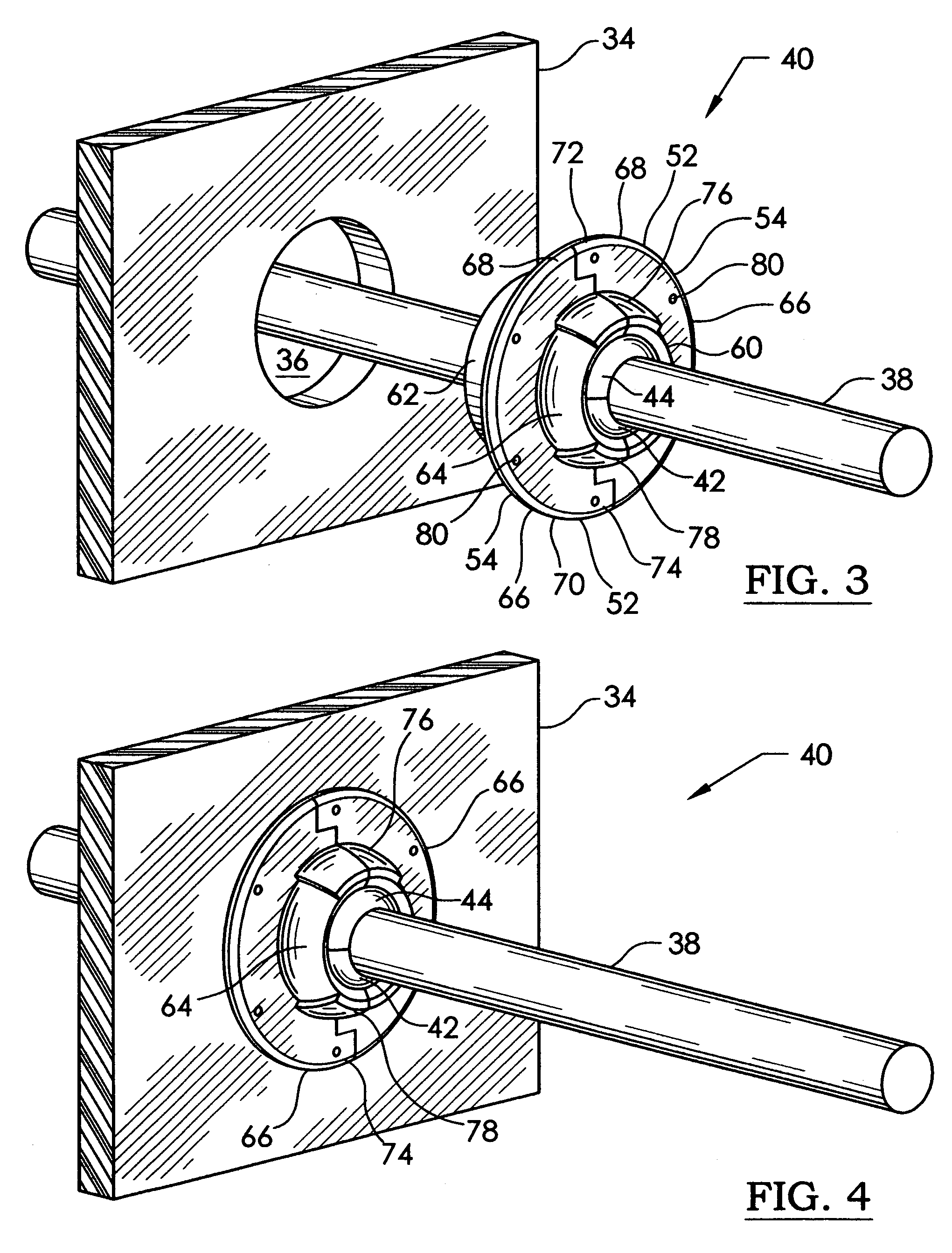

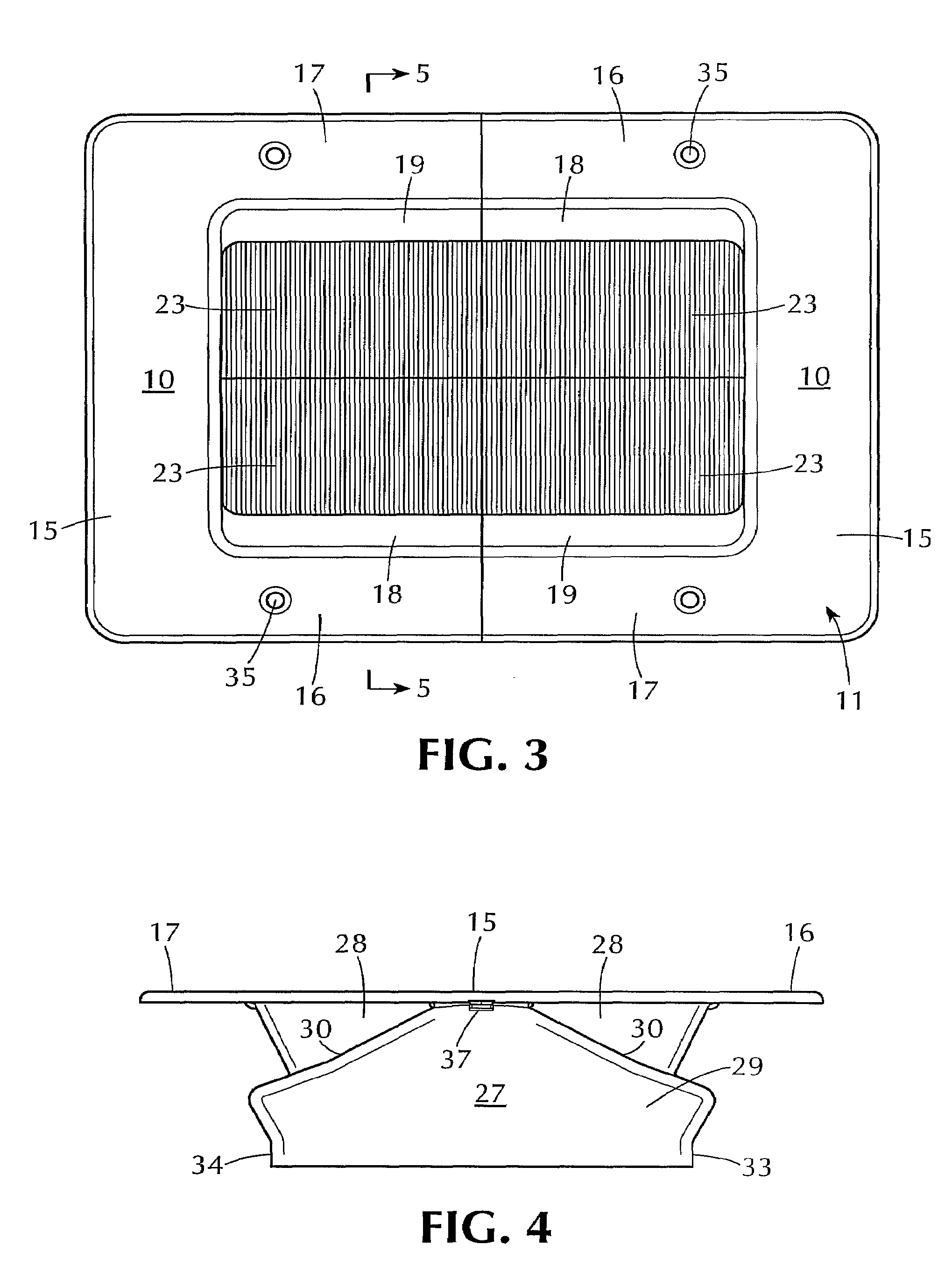

Cable grommet with ball and socket

InactiveUS7534965B1Increasing the thicknessEnlarged cavityPipesInsulated cablesVertical planeEngineering

A cable grommet with ball and socket is used in connection with an elongated member passing through a hole in a panel. The ball has a pair of opposed hemispherical members juxtaposed along a ball central axis and horizontal plane. The ball has a hole through it aligned with the central axis, to receive the elongated member. A socket supports and retains the ball securely, while allowing the ball to pivot in any direction. The socket has a pair of opposed cup members, each with a hemispherical cavity therein centered on a socket central axis and vertical plane. A pilot aligns the socket with the panel hole. The cup members each have two tabs projecting transversely from a semicircular flange. The tabs of the opposed cup members overlap. Each cup member has an upper and lower thickened brow portion on the cavity adjacent the flange ends to strengthen the cavity. An adapter allows mounting the grommet in an oversized panel hole.

Owner:THOMPSON DAVID M

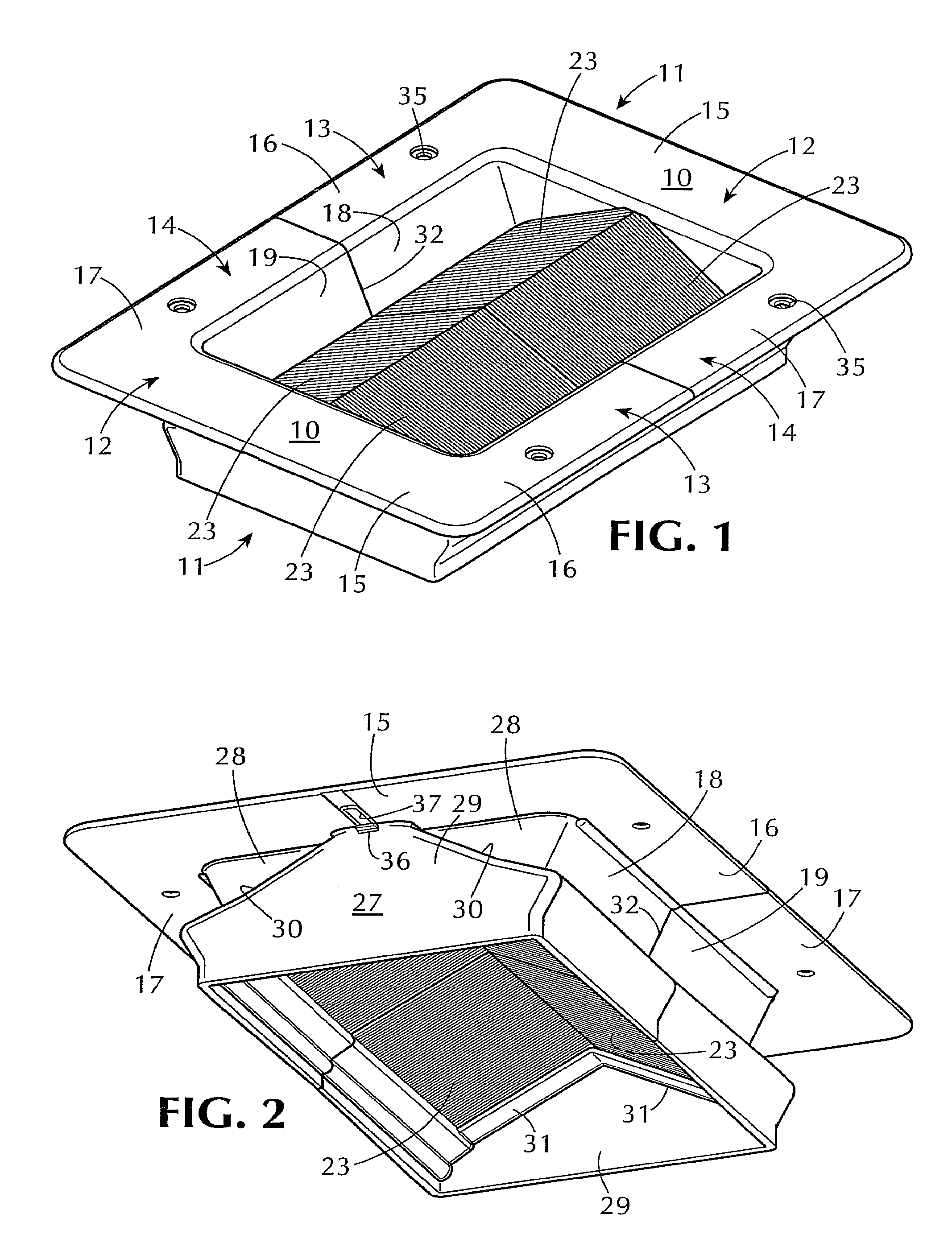

Grommet for cables

ActiveUS7507912B1Improve sealingReadily accommodating easy passagePipesStands/trestlesElectrical conductorAcute angle

A cable grommet system for installation in data centers, offices and the like, for sealing cable openings in raised flooring, wall or ceiling panels, server cabinets, etc. to facilitate the installation and revision of wiring and cabling to server installations while minimizing losses of any provided conditioned air. A wide variety of grommet configurations is possible with a limited number of component parts. An advantageous acute angle mounting of sealing brushes enhances the sealing effectiveness thereof, particularly for smaller sizes of cable openings. In some embodiments, a novel arrangement of electrical conductors is incorporated into the grommet structures for dissipation of electrostatic charges, enabling the basic frame components to be formed of a flame retardant material.

Owner:AQUILA INC

Visual latching indicator arrangement for an electrical bushing and terminator

InactiveUS6984791B1Electrically conductive connectionsCouplings bases/casesEngineeringElectrical probe

An elbow terminator has a socket in which an electrical probe is disposed. The terminator is insertable onto an electrical bushing such that a tongue of the bushing is received in the socket of the terminator, and the probe of the terminator is electrically coupled to a contact sleeve disposed within the tongue. A latching mechanism produces positive latching between the tongue and socket when the tongue has been inserted to a predescribed depth within the socket. In order to enable an operator to visually observe that the tongue has been inserted to the prescribed depth, the bushing carries a color band which becomes completely disposed (invisible) in the socket when positive latching occurs. Alternatively, the bushing can be provided with gauge tabs which become aligned with a witness line formed on the terminator when positive latching occurs.

Owner:COOPER TECH CO

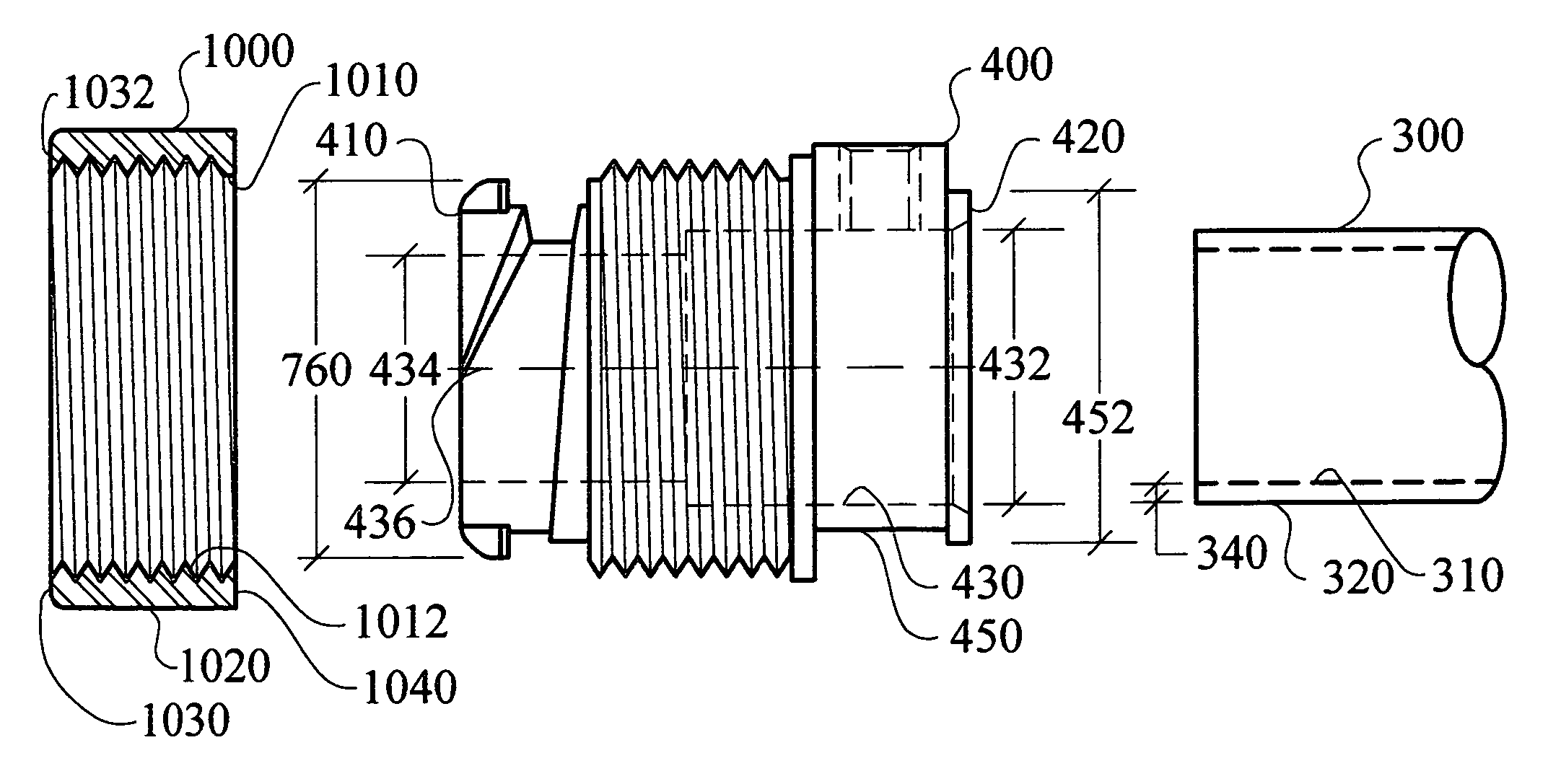

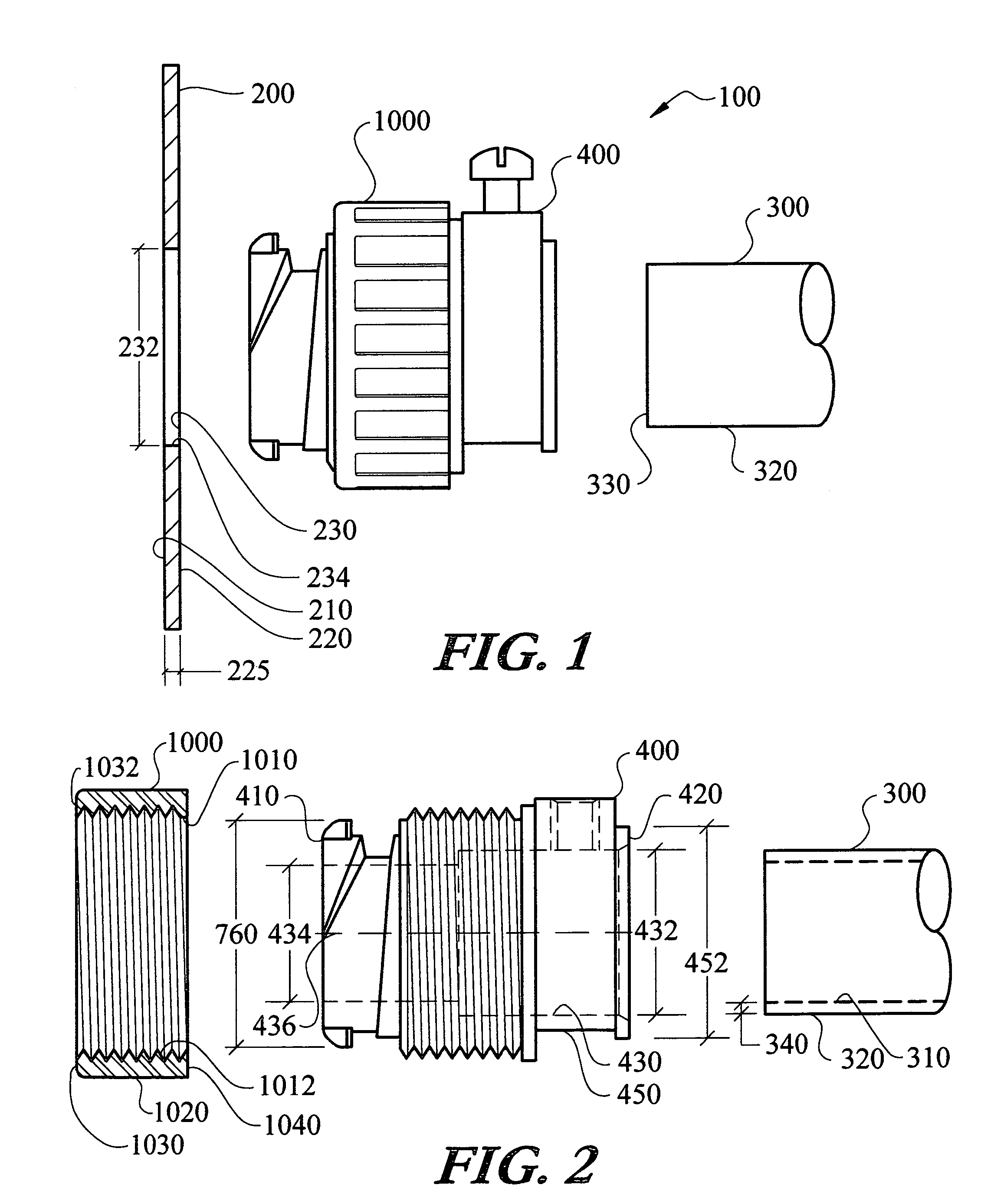

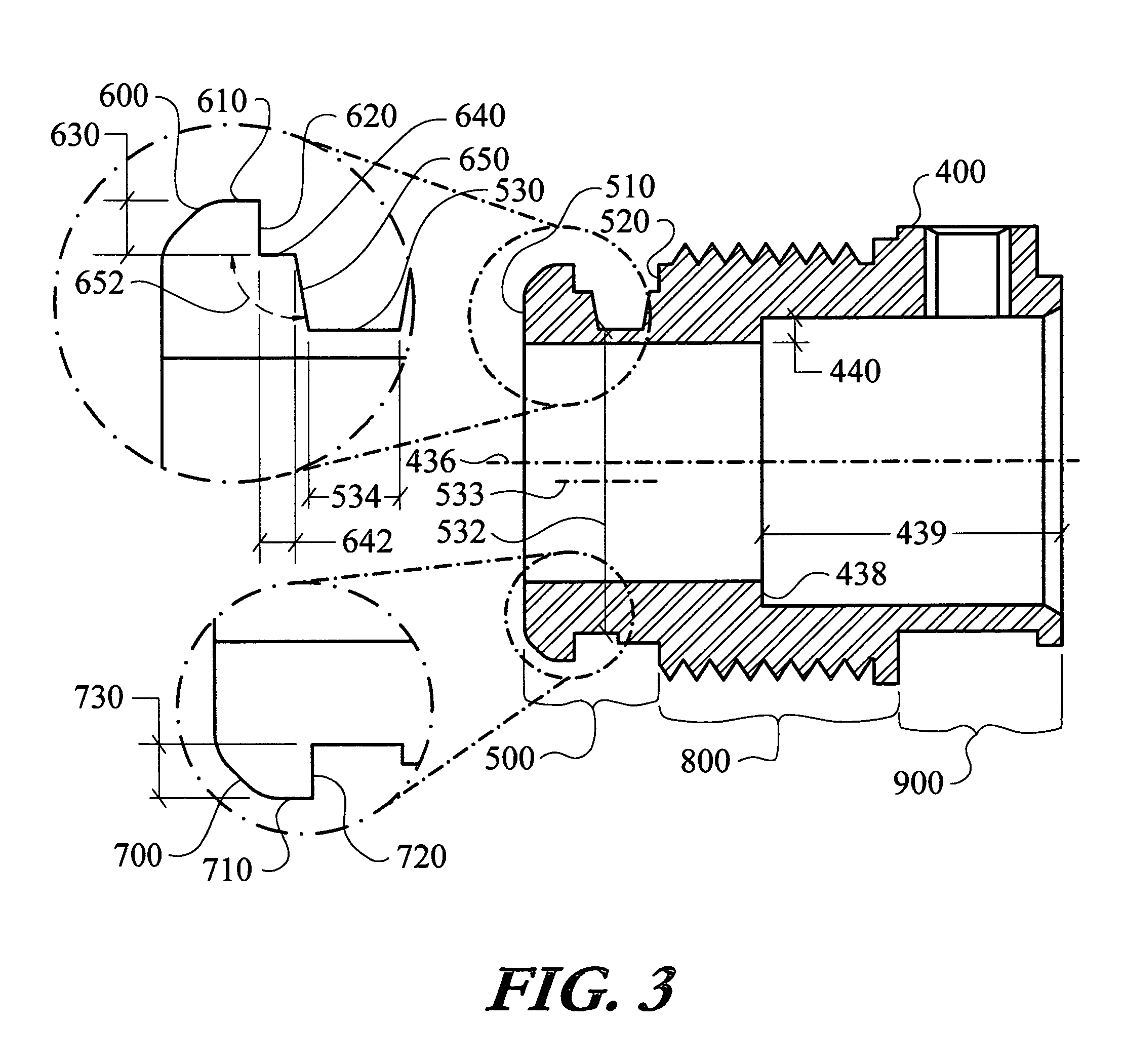

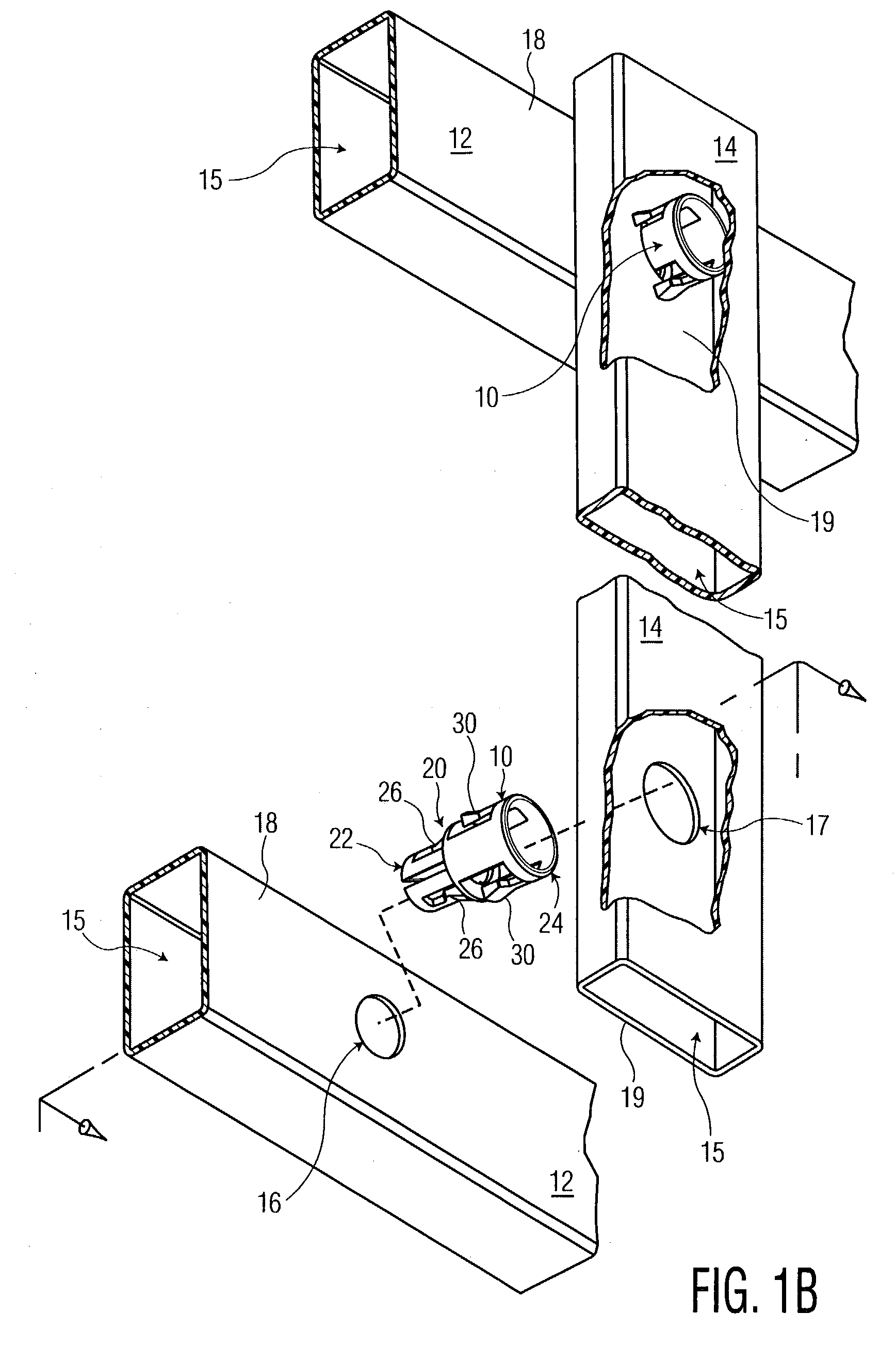

Electrical conduit to junction box connection system

InactiveUS7078623B1Save spaceSaving tight connectionInsulated cablesFlexible pipesRoot surfaceElectrical conduit

An electrical conduit to junction box connection system is designed connect conduit to junction boxes. The system incorporates a compression nut and a body. The body includes a box engagement region, a nut engagement region, and a conduit engagement region. The box engagement region includes a radially extending leading and follower tab, a root surface, a tab centering ledge, and a tab centering flank. The nut engagement region includes a nut engagement region thread that cooperates with the compression nut. The conduit engagement region includes a conduit compression system. During installation, the leading tab is inserted into the knockout. An edge of the knockout is positioned in contact with the root surface. The body is reoriented which positions the follower tab inside the junction box. The compression nut is manipulated to compress the junction box between the compression nut and the leading and follower tabs.

Owner:RJS ELECTRICAL PROD

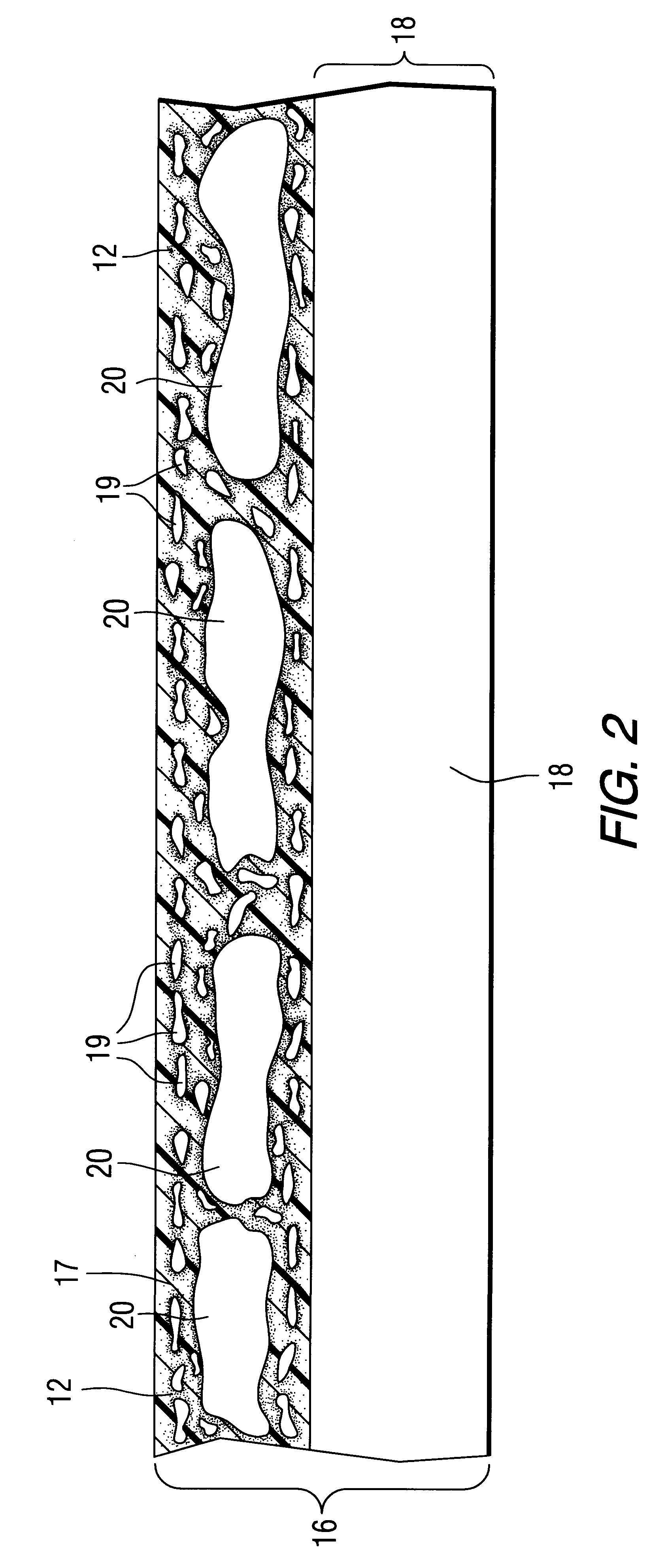

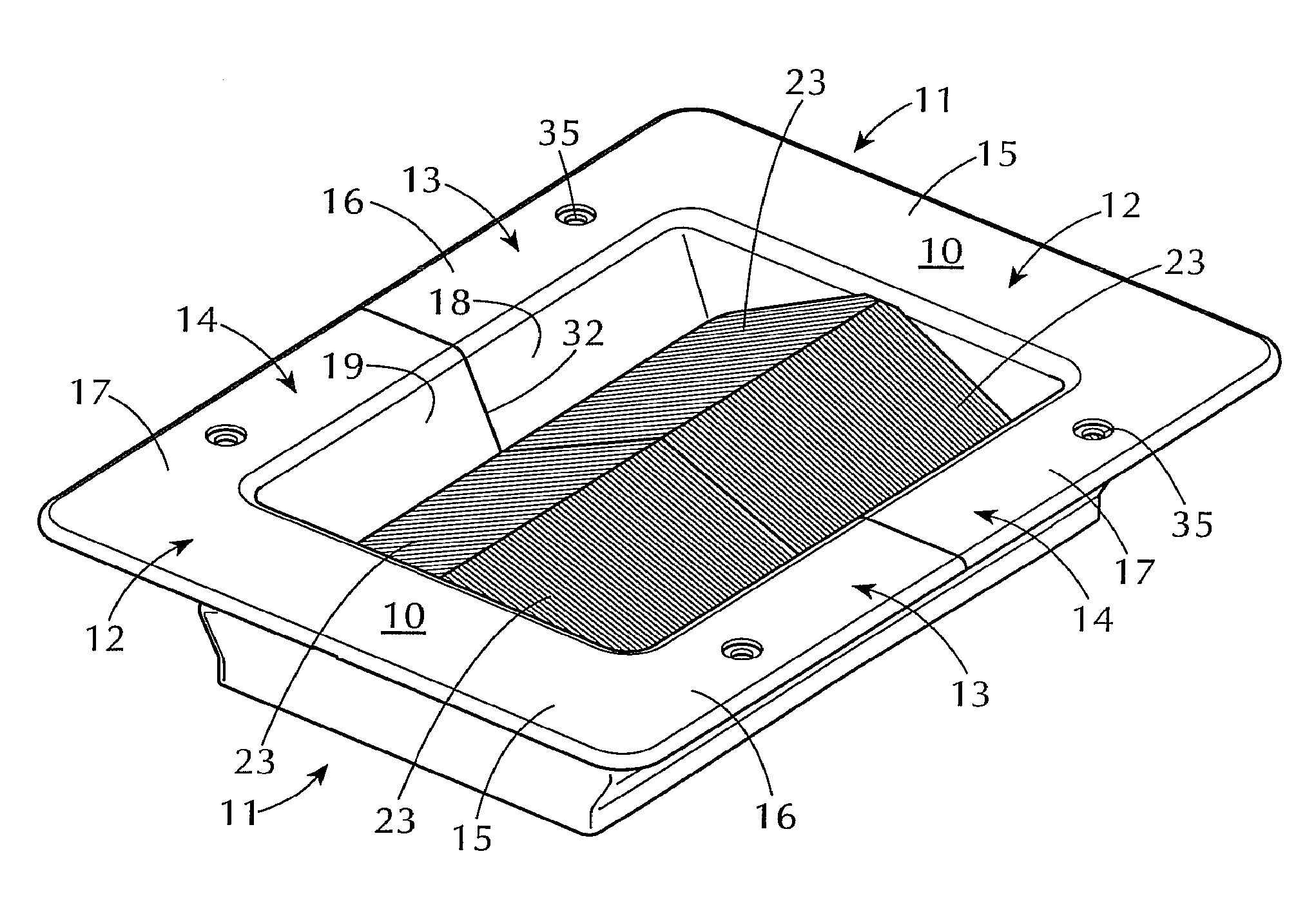

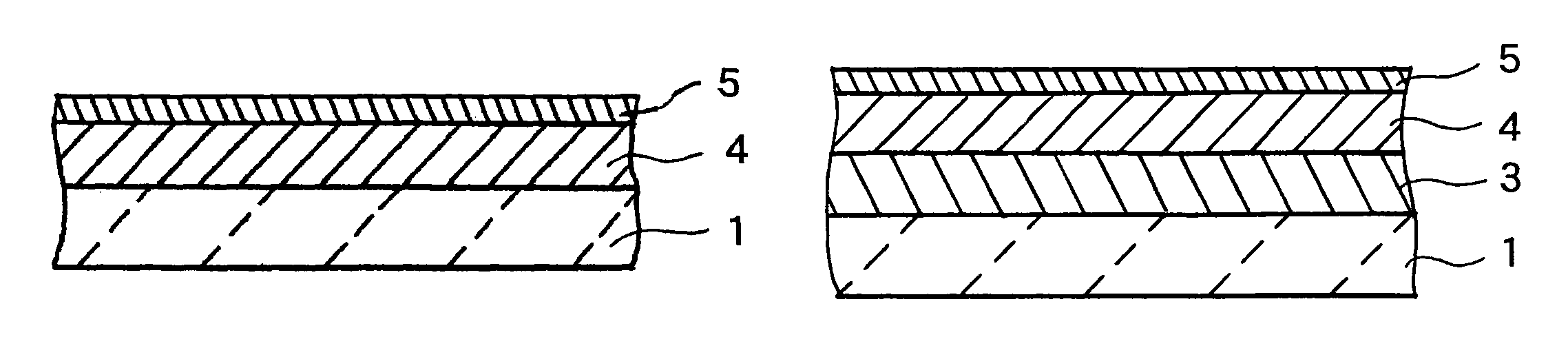

Compression of resin impregnated insulating tapes

ActiveUS20050274450A1Easy to disperseReduces phonon scatteringWindings insulation materialAdhesive processes with surface pretreatmentThermal conductivity

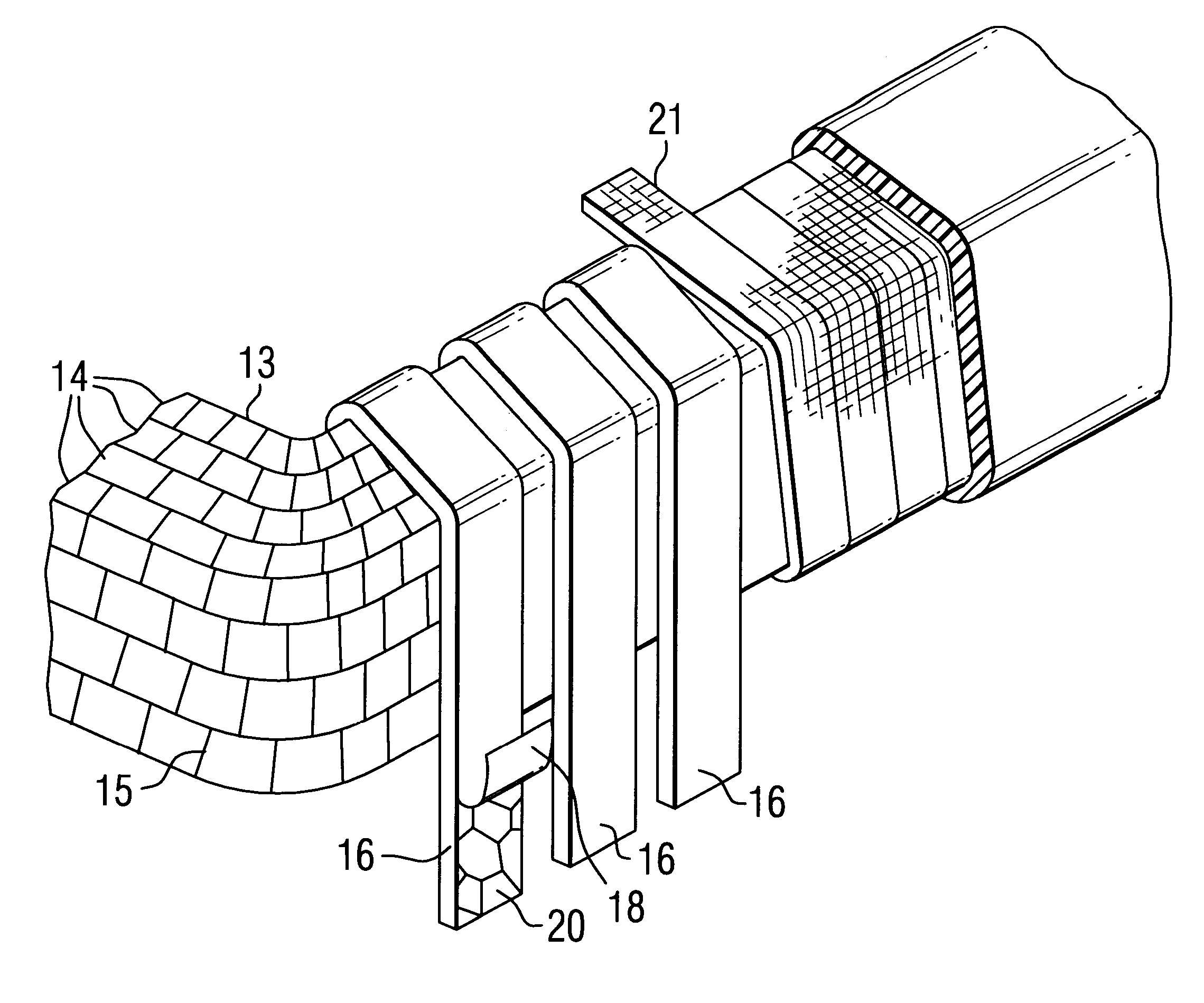

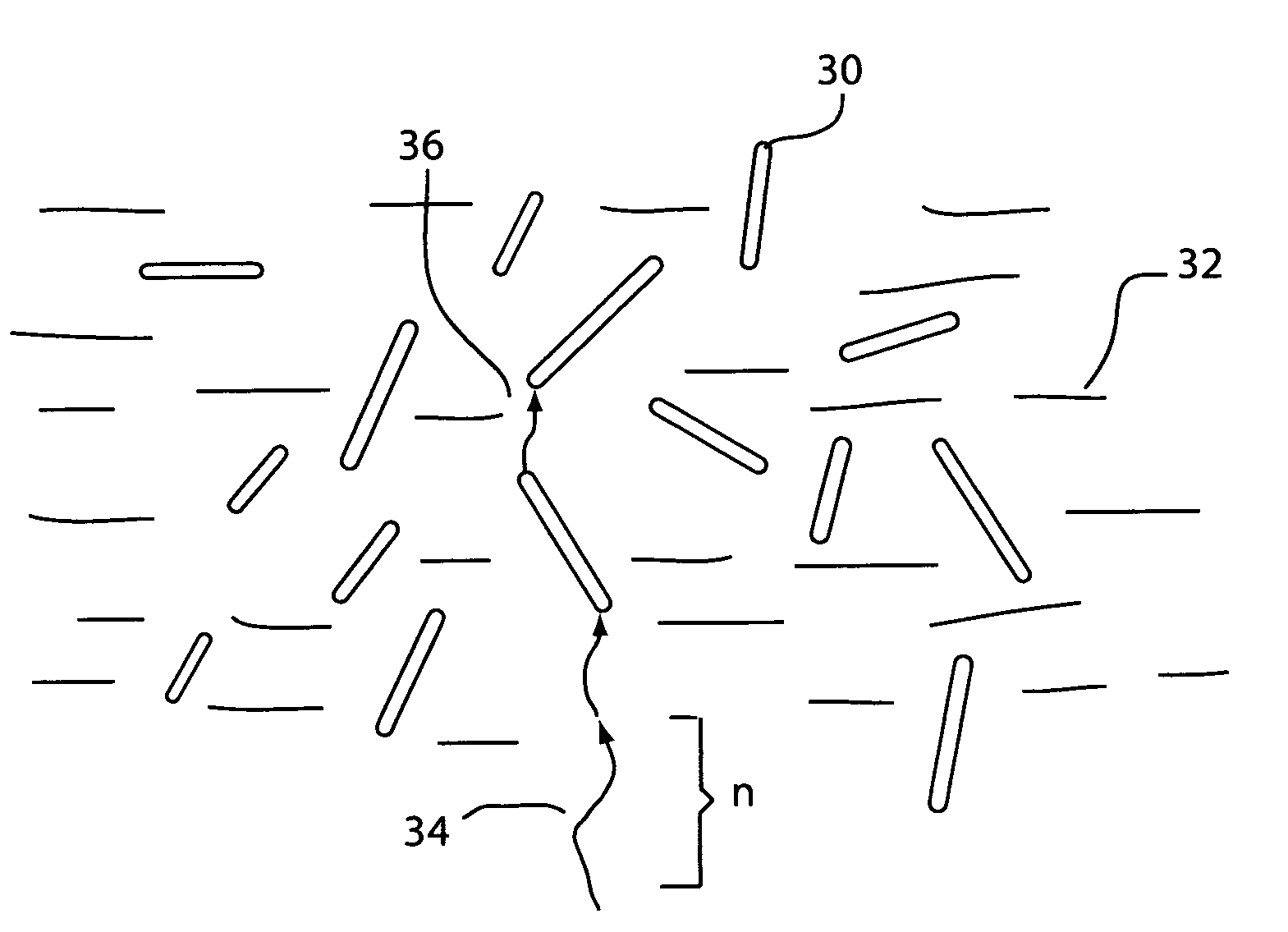

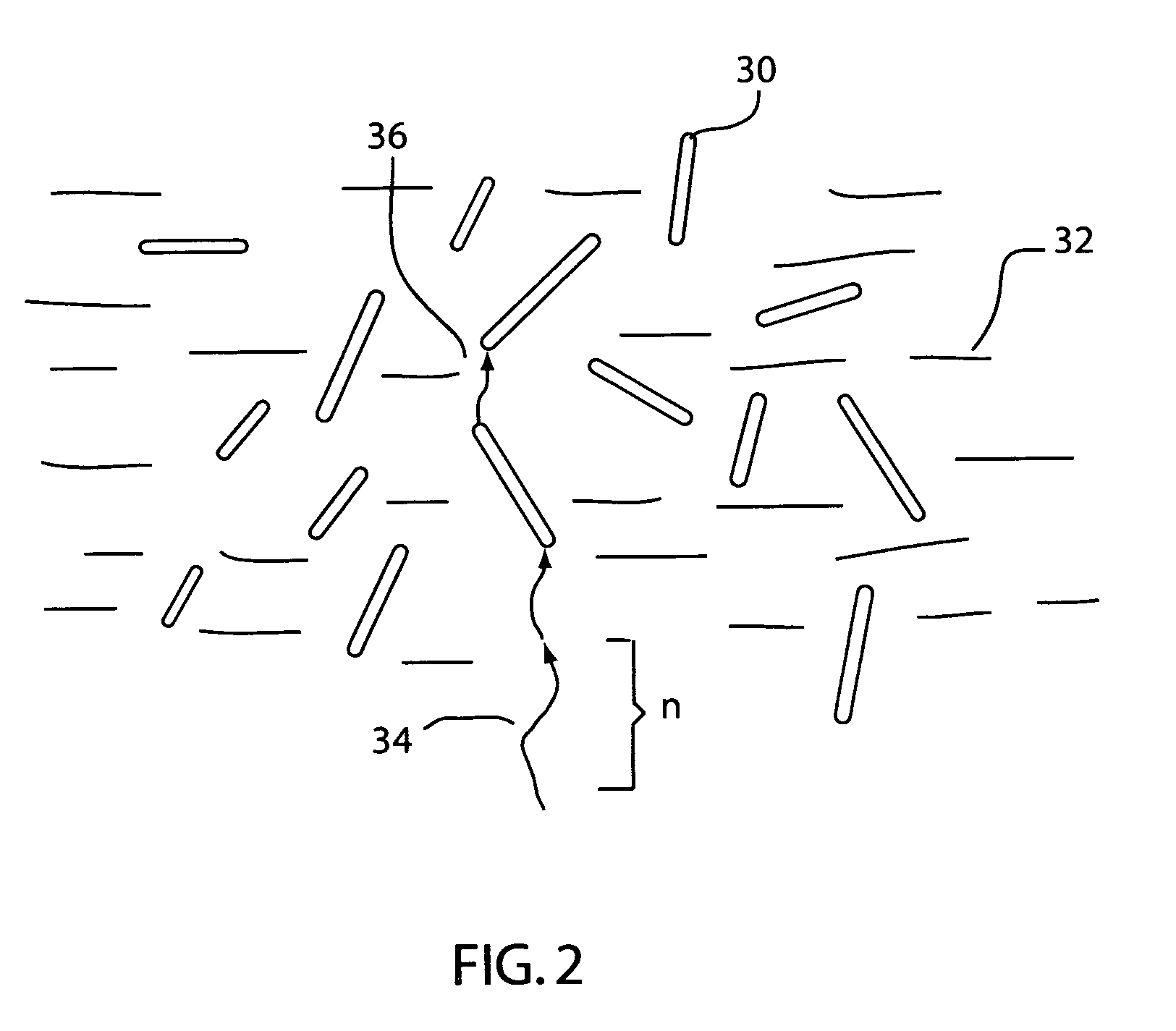

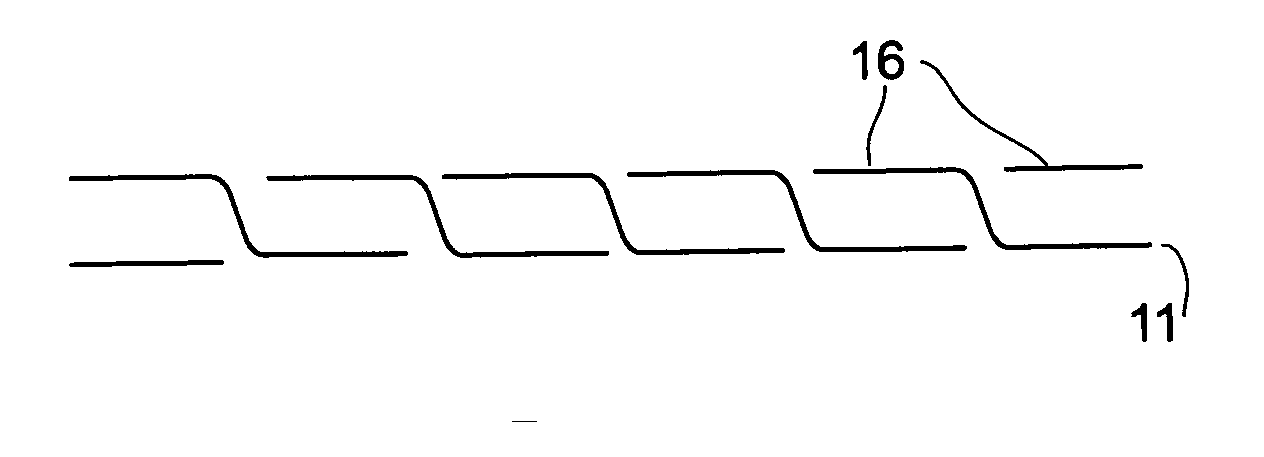

The present invention provides for a method of impregnating a matrix with a high thermal conductivity filled resin 32, which produces a resin impregnated matrix. The high thermal conductivity material 30 comprises 5-60% by volume of the resin 32. This is compressed by approximately 5-30%, and the distances between the high thermal conductivity materials loaded in the resin are reduced, and the resin is then cured.

Owner:SIEMENS ENERGY INC

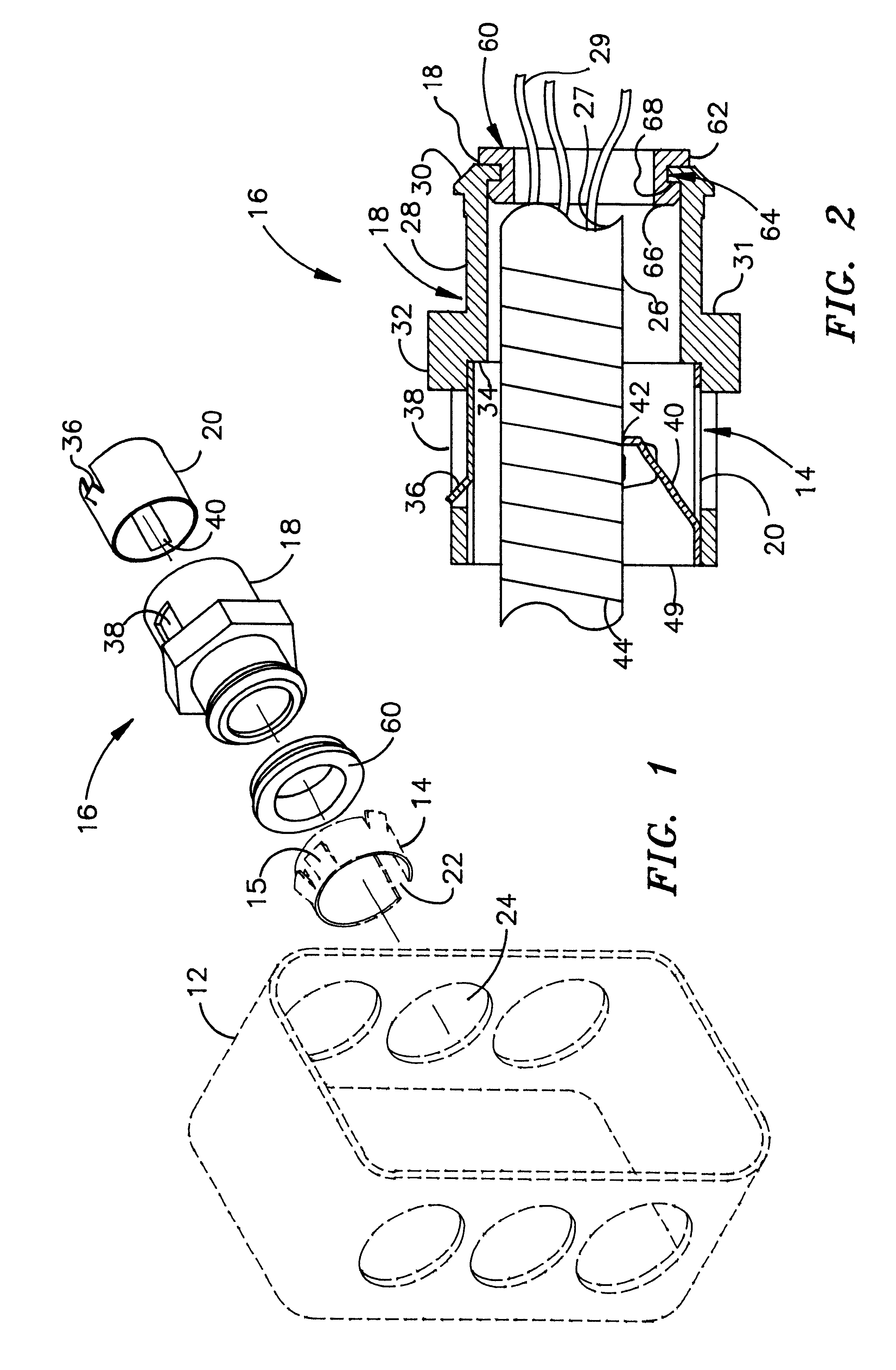

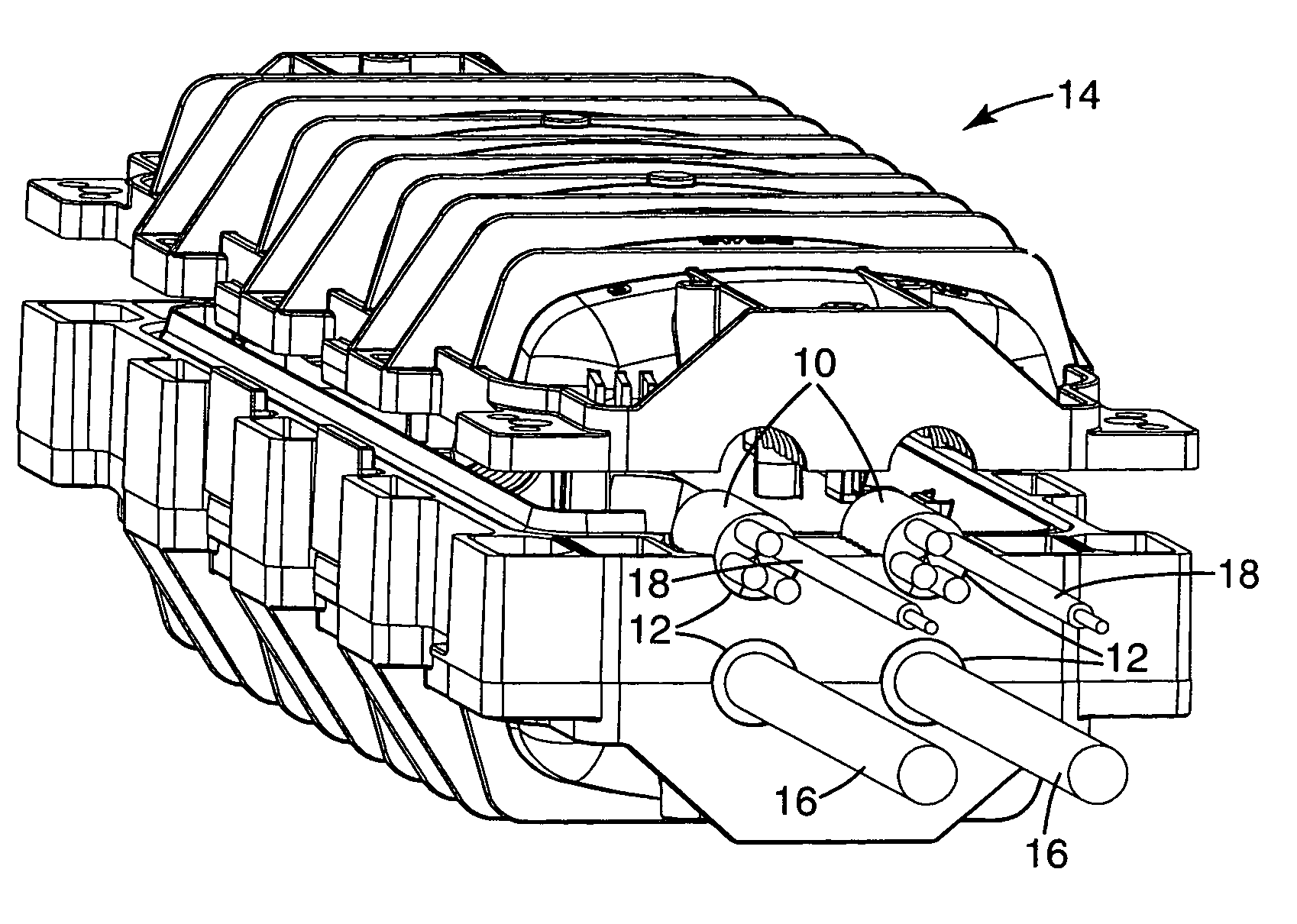

Electrical cable connector

InactiveUS6872886B2Quickly and easily securedEasy to assembleRelieving strain on wire connectionInstallation of lighting conductorsMechanical engineeringStructural engineering

Owner:BRIDGEPORT FITTINGS LLC

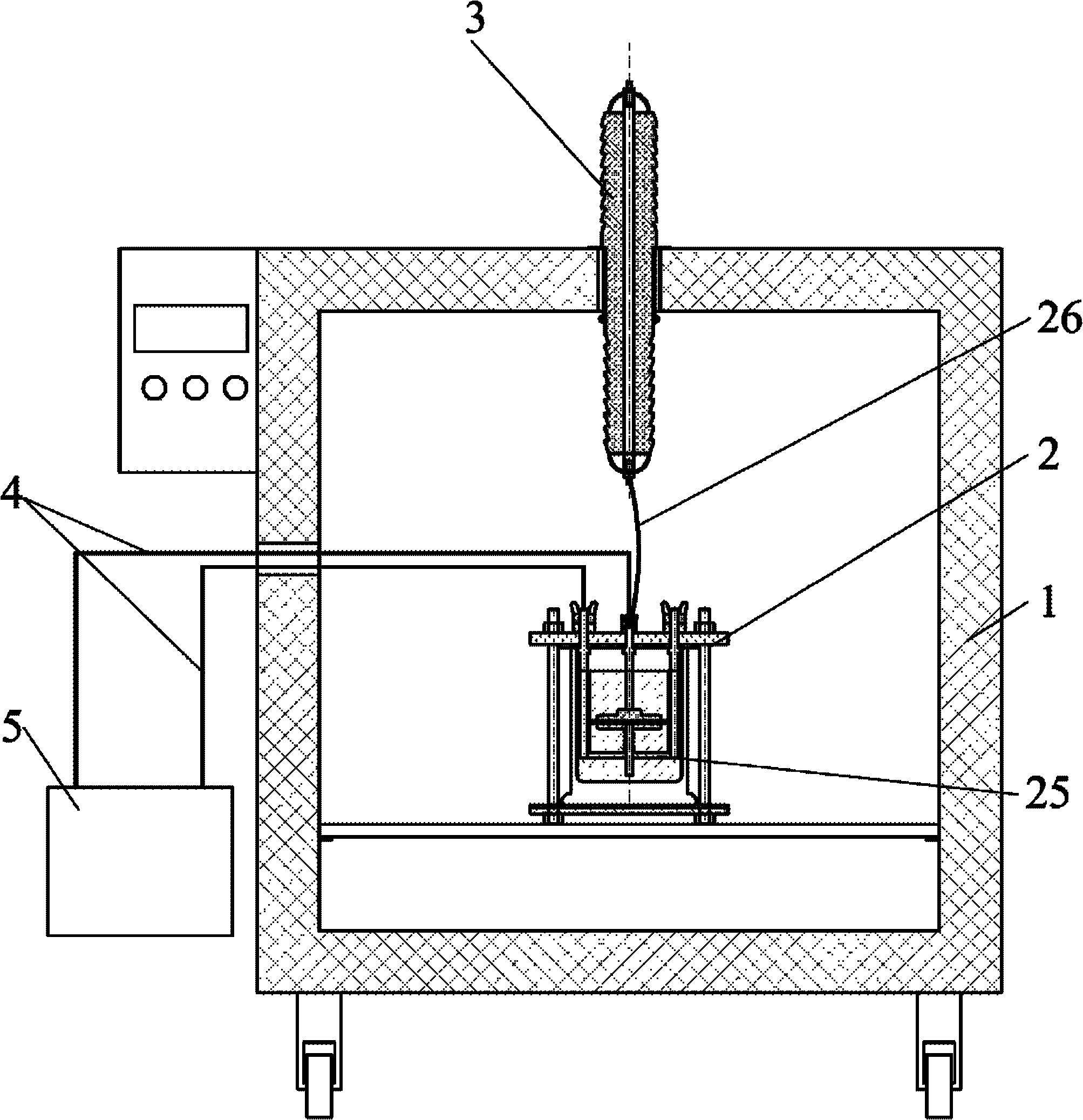

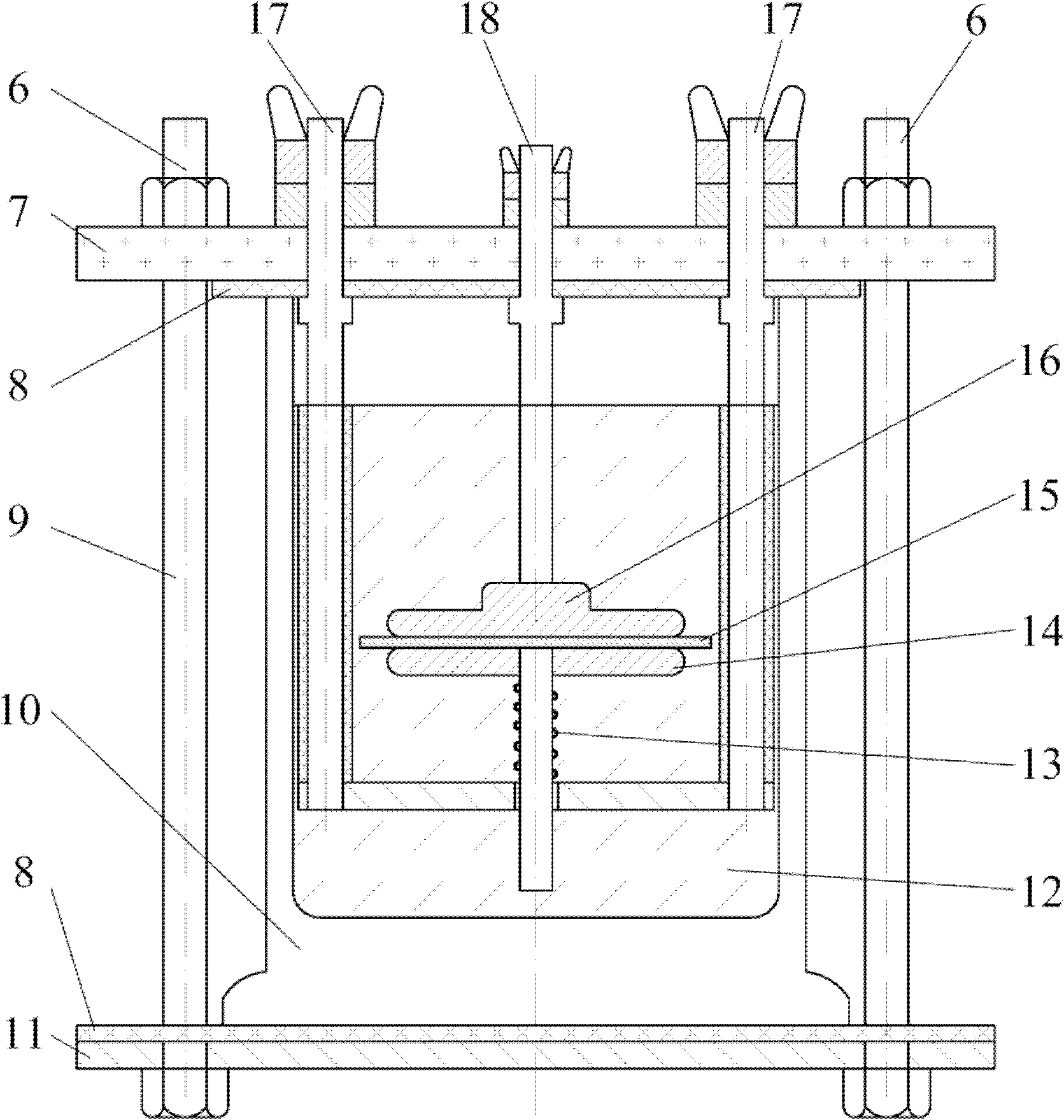

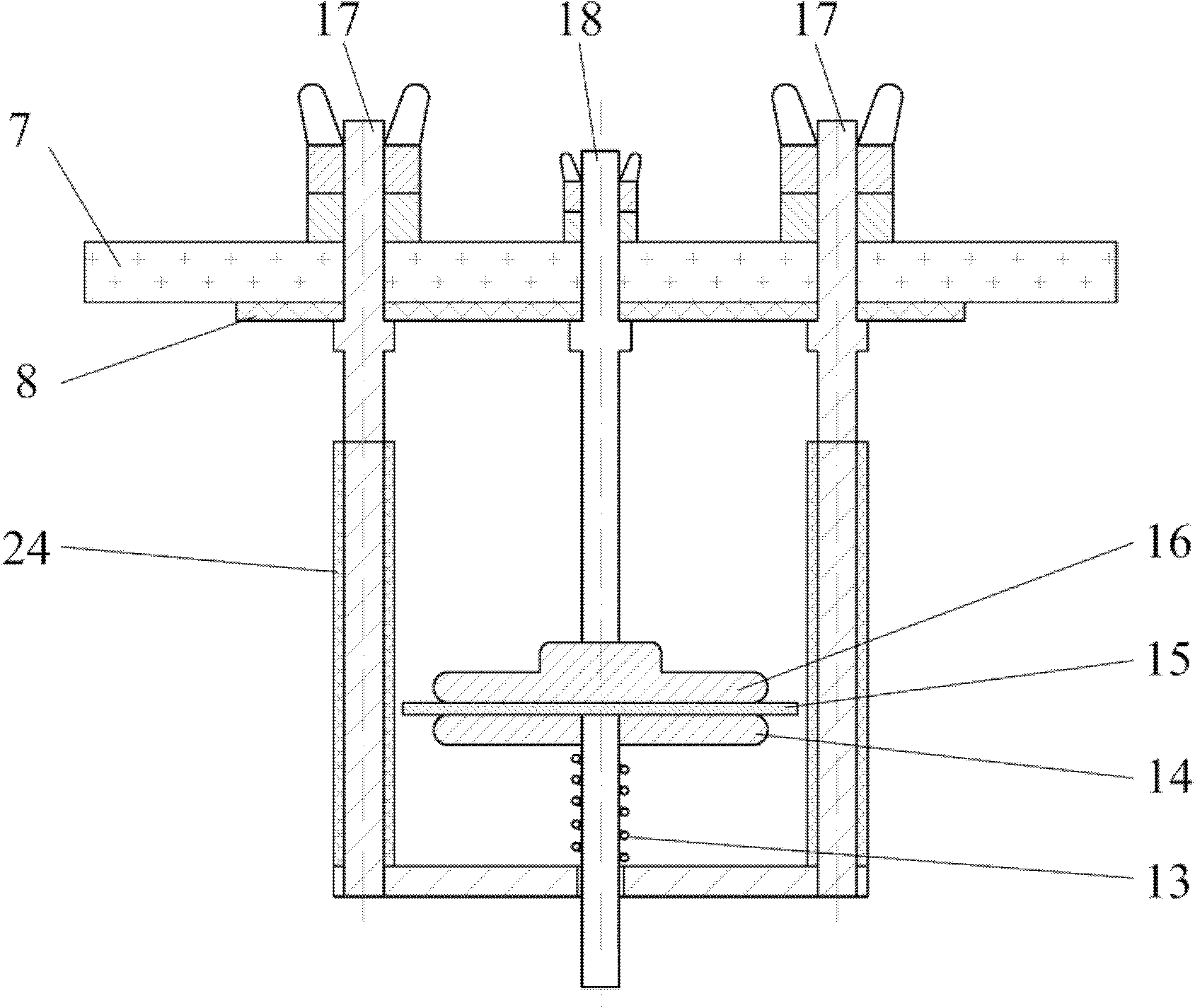

Experimental facility and method for electric heating combined stress aging with oil-paper insulation of transformer

ActiveCN102096032AMonitor and measure thermal stress levels in real timeTo achieve the purpose of comparative analysisTesting dielectric strengthTransformers/inductances coils/windings/connectionsLow voltageEngineering

The invention relates to an experimental facility and method for electric heating combined stress aging with oil-paper insulation of a transformer, wherein the facility has the advantages of simple structure and good use effect, is safe in running and convenient in sampling. The experimental facility comprises an outer cavity which is internally provided with at least one sealed inner cavity; theinner cavity is internally provided with a testing device which is provided with a high-voltage electrode and a low-voltage electrode; a sample is arranged between the high-voltage electrode and the low-voltage electrode which are mutually pressed; and the high-voltage electrode is connected with a high-voltage power supply and a current measurement and display system outside the outer cavity respectively.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

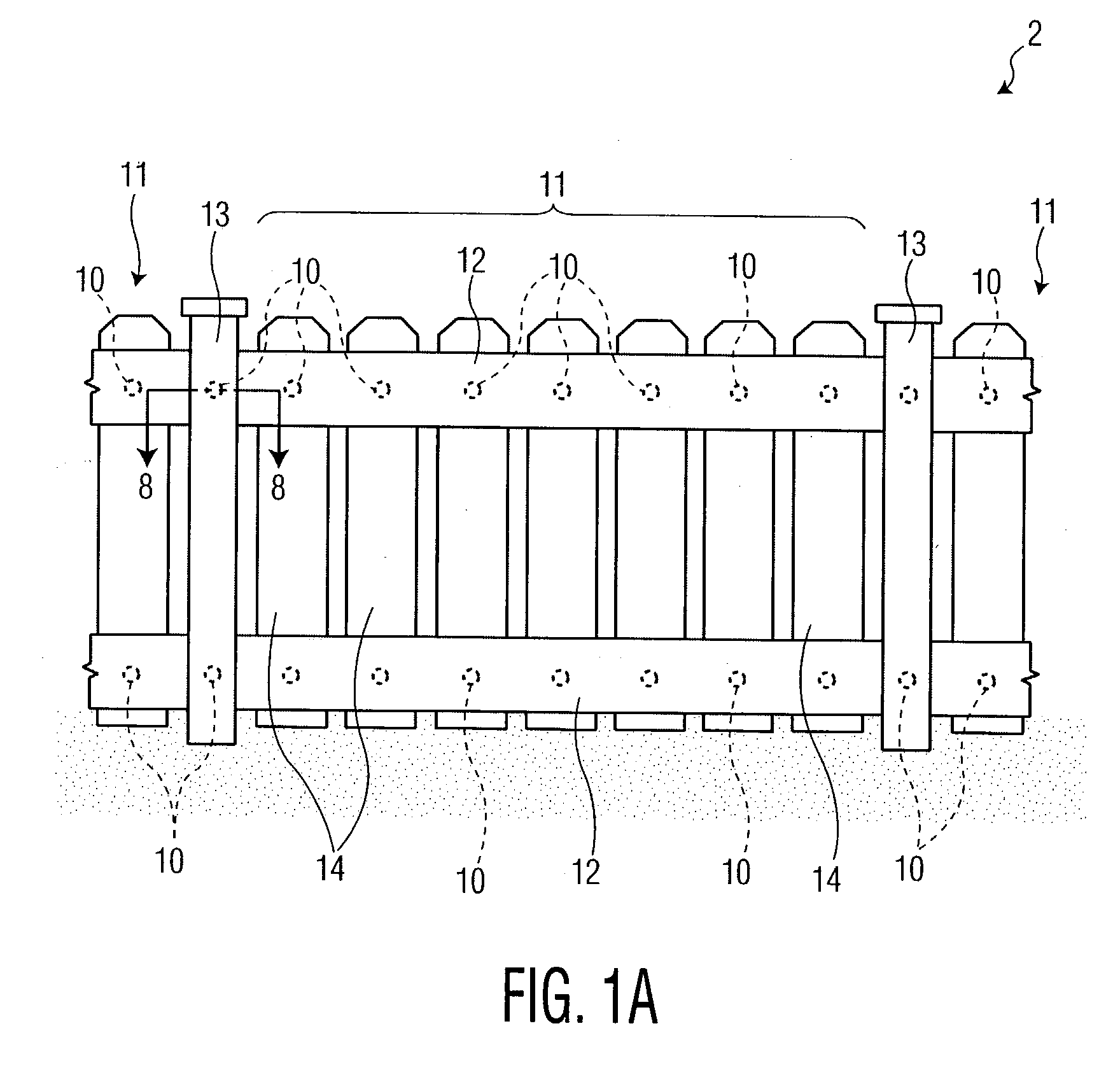

Self-locking fastener

InactiveUS6971831B2Effective protectionEasy to installSnap-action fastenersSubstation/switching arrangement detailsSelf lockingEngineering

A fastener for securing first and second members together at opposing respective flat surfaces thereof, whereby at the point of joining the first member has an aperture concentric with an aperture of the second member, the fastener comprising first and second tubular portions concentric with one another, whereby the second tubular portion is of reduced outside diameter relative to the first tubular portion, a circular flange forming a transverse interior end of the first tubular portion, an interior end of the second tubular portion being rigidly joined to the circular flange, at least one resilient arm being formed in and extending from a sidewall of each one of the first and second tubular portions toward the flange, the at least one resilient arm of each portions each having a free end including a retaining end surface adapted for having close proximity to a side portion surrounding the respective apertures of the first and second members.

Owner:LMT MERCER GROUP

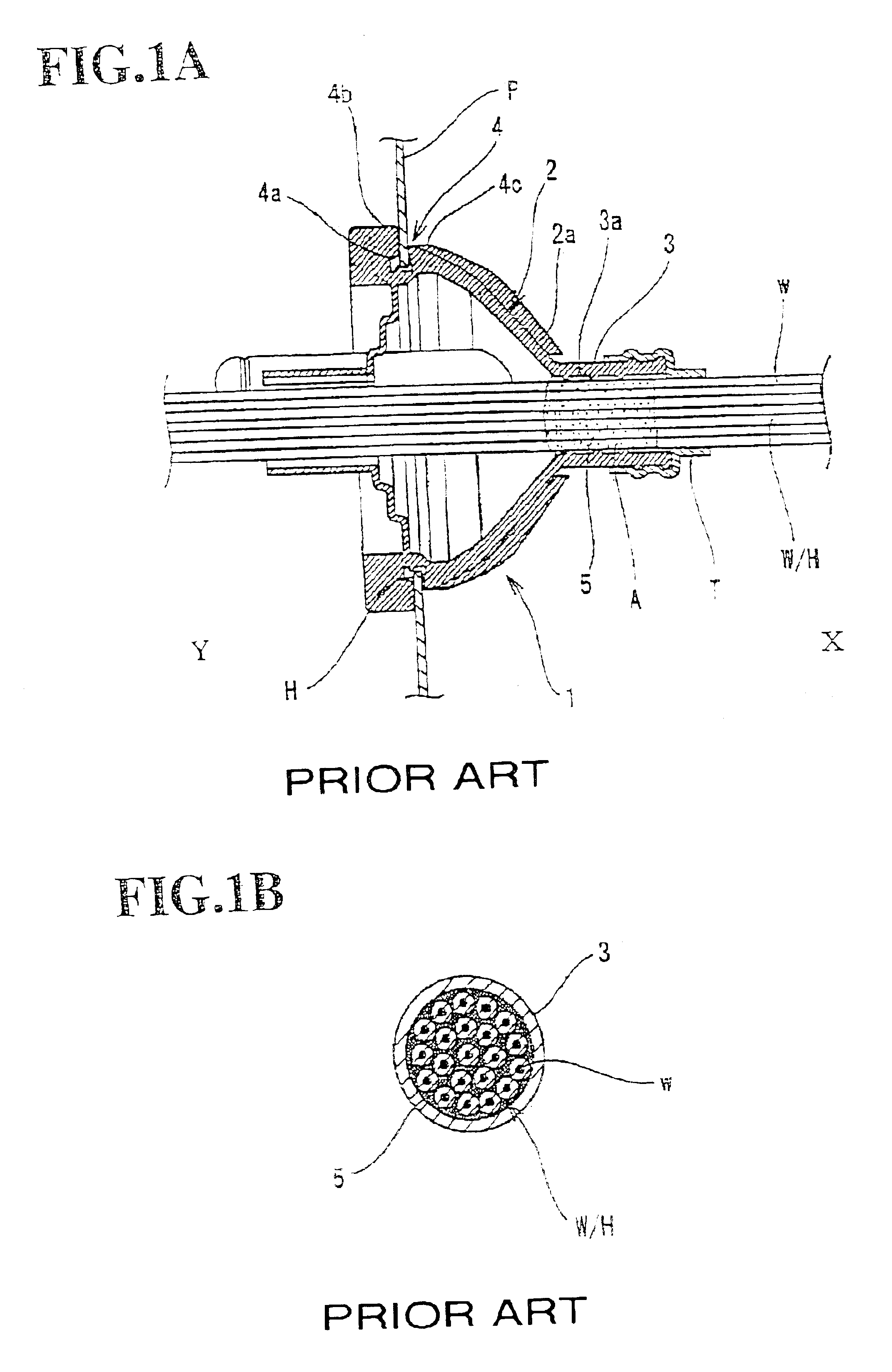

Grommet for a vehicle door assembly

A grommet routes a wire harness from an inner side of a vehicle door into a vehicle body. A depression wraps around an edge of the door with a first part on a hinge surface of the door and a second part on the inner side. The grommet has an elastic member for fitting within the first part and a rigid retainer member extending around the edge into the second part. The members are secured together. The elastic member has a grooved periphery for receiving a flange surrounding an opening linked to the first part of the depression. The retainer member is secured in the second part of the depression by a fastener inserted into an aperture in the second part. The members have passageways to route the harness around the edge of the door. Fins on an underside of the elastic member seal against the first part.

Owner:YAZAKI NORTH AMERICA

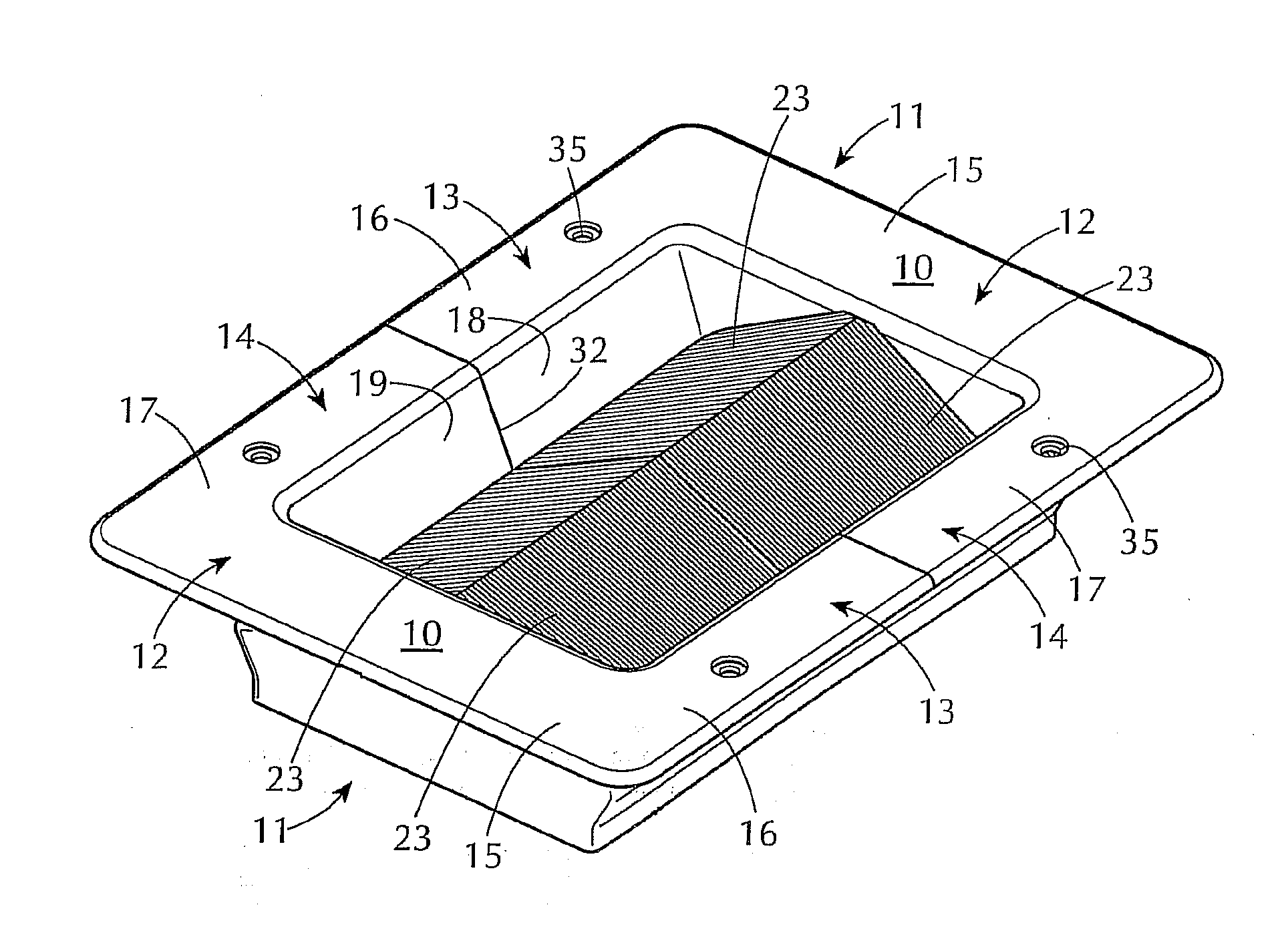

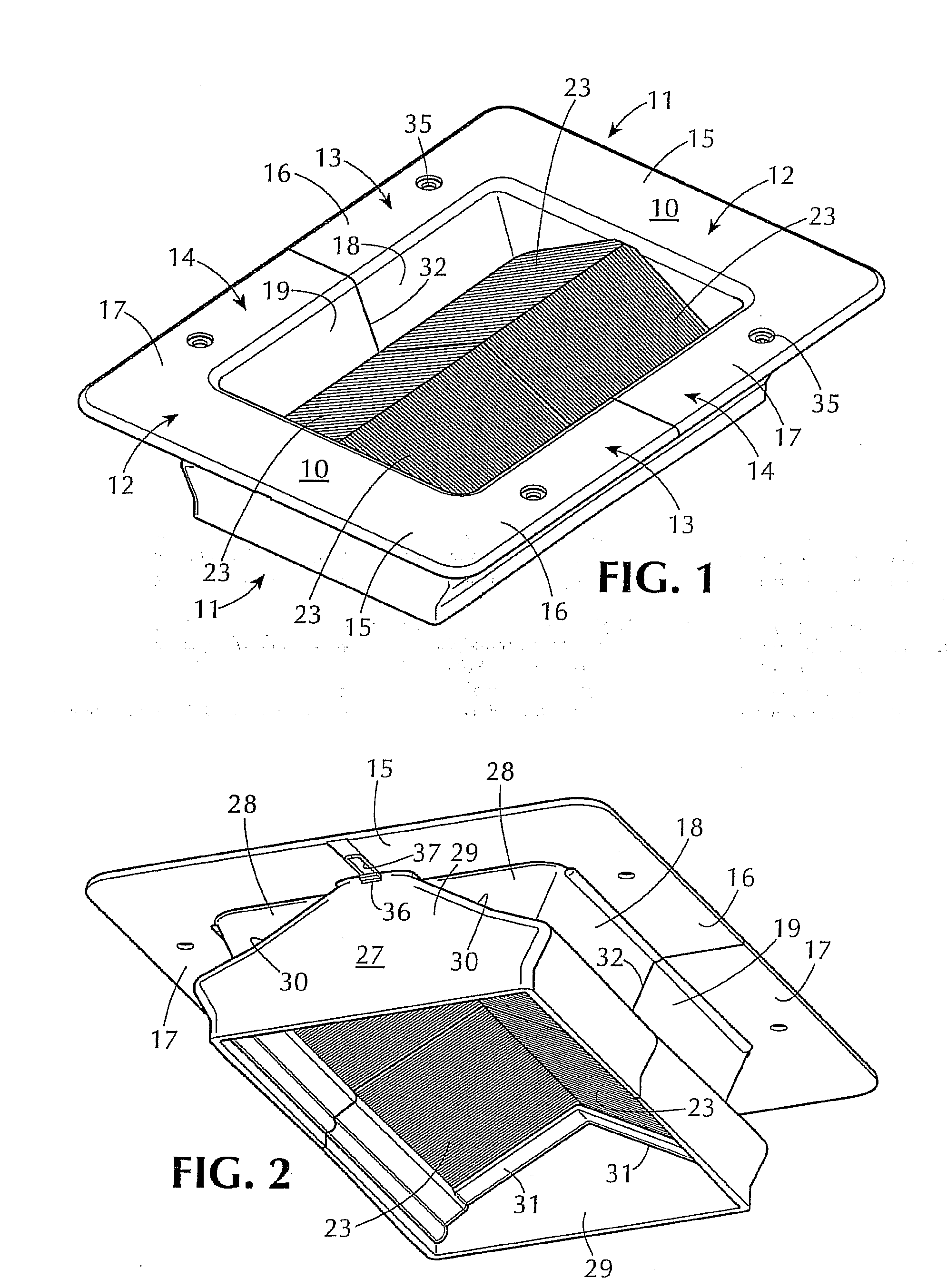

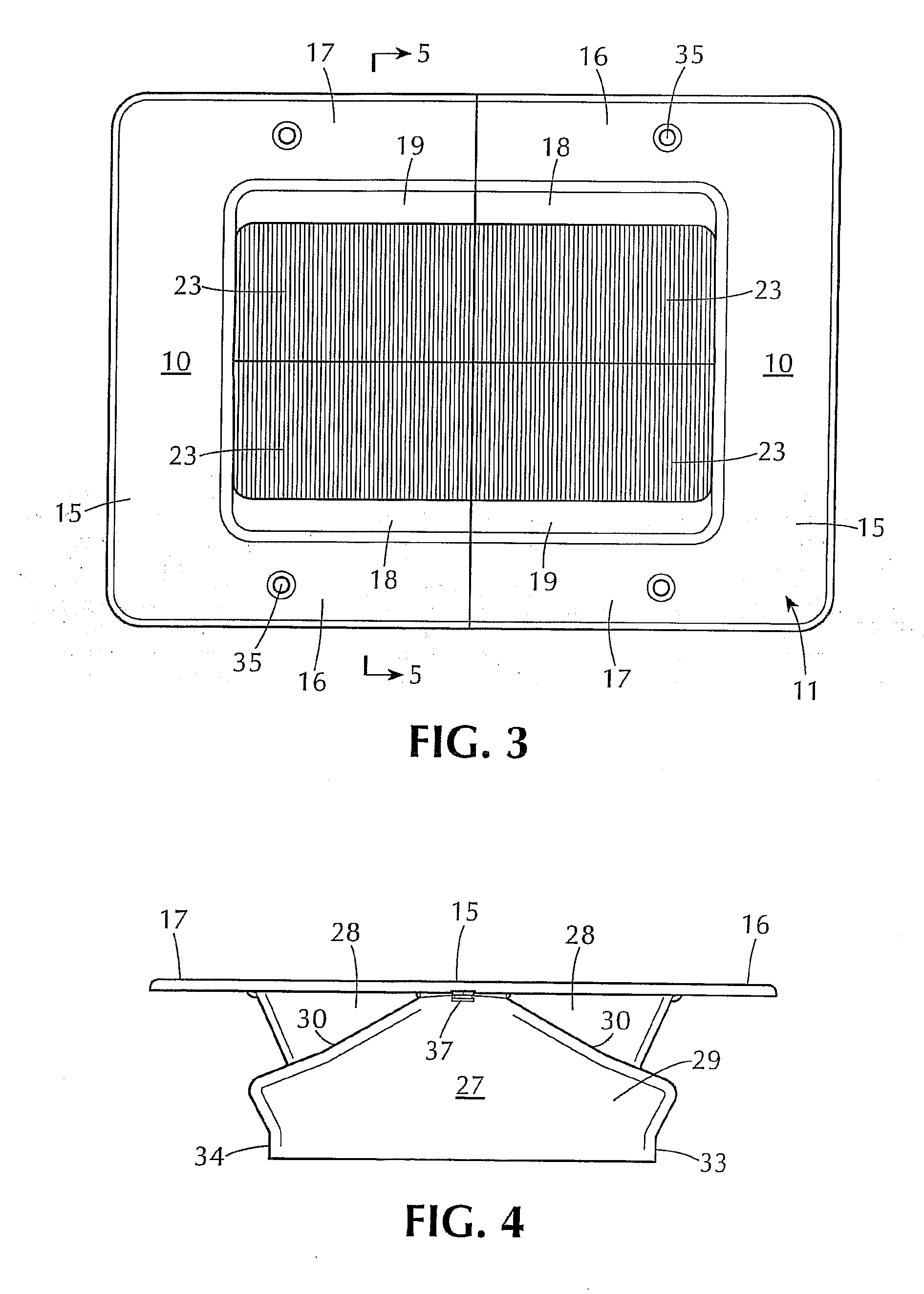

Cover for cable connectors

ActiveUS7838775B2Quick installation and removalKeep tightTwo pole connectionsCouplings bases/casesEngineeringTower

A cover / boot and a system of covers / boots for placement in sealed relation over a connector or pair of connectors that is or are adapted to terminate a cable or splice together a pair of cables, preferably cables that carry signals received by a receiving apparatus on a cell tower. The covers include a cable end that sealingly receives a cable therein, an elongated body that provides secure cover to a cable connector, and an end that abuts a bulkhead or sealingly engages with a second cover when used in a splicing application.

Owner:JOHN MEZZALINGUA ASSOC INC

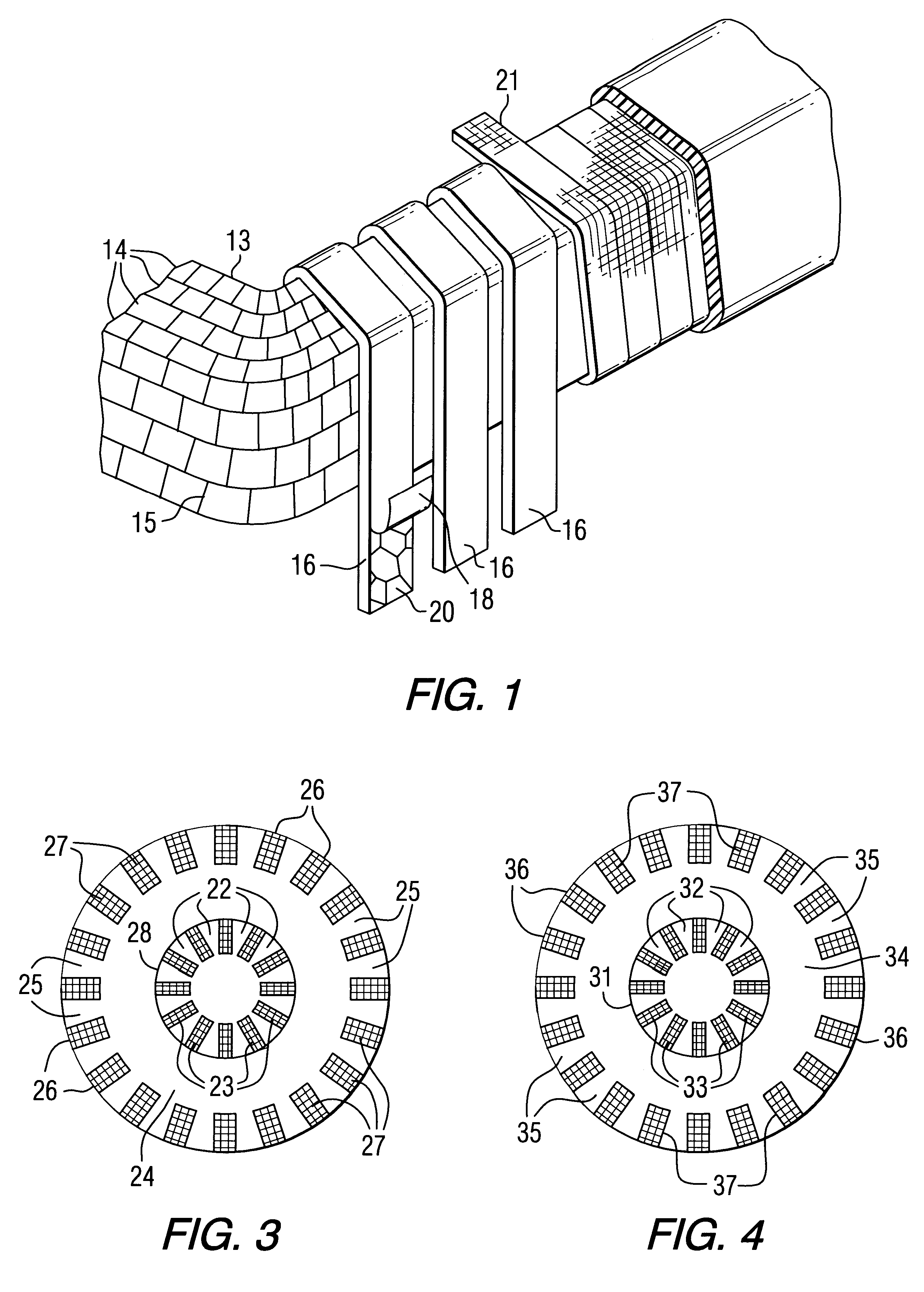

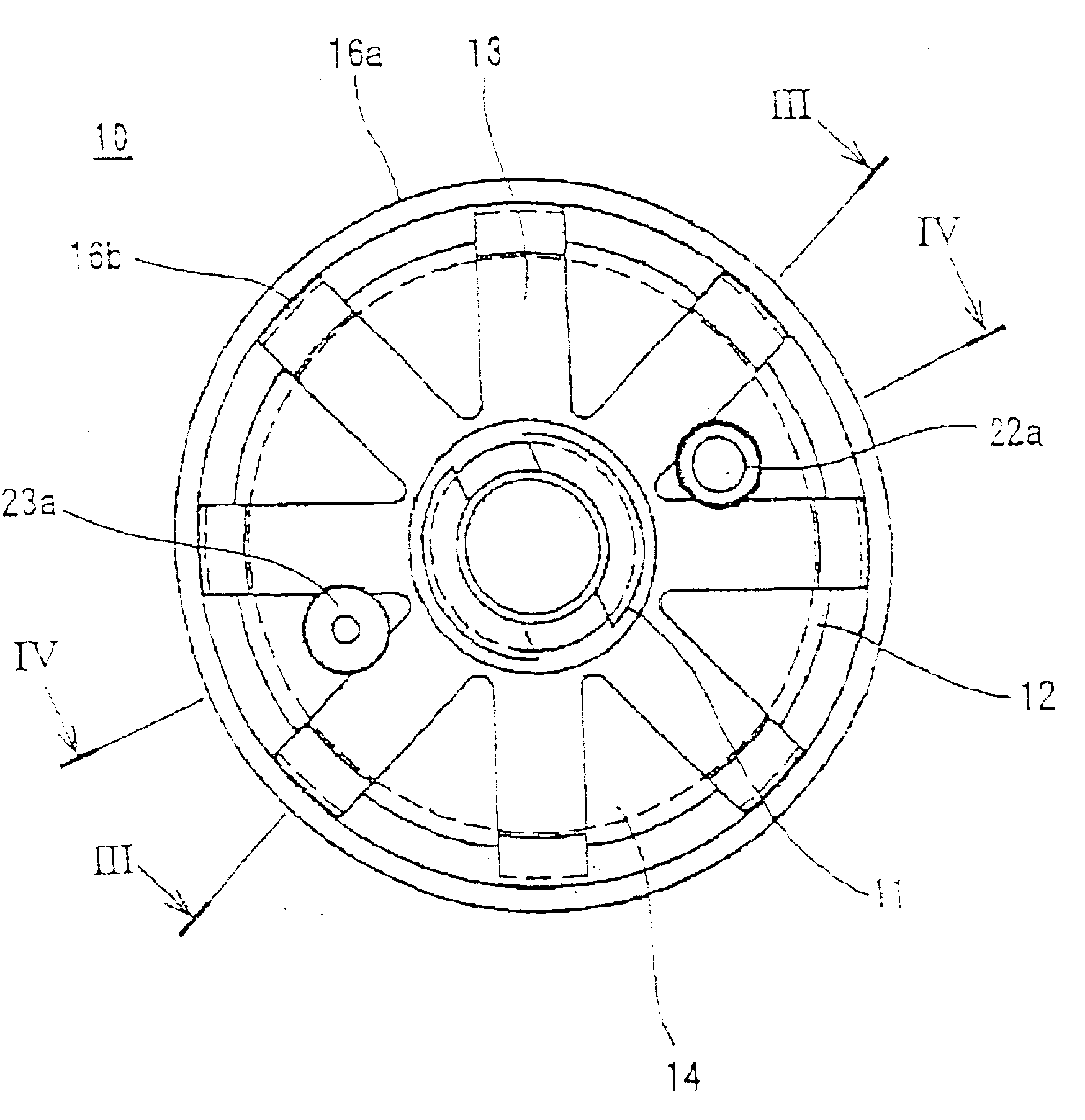

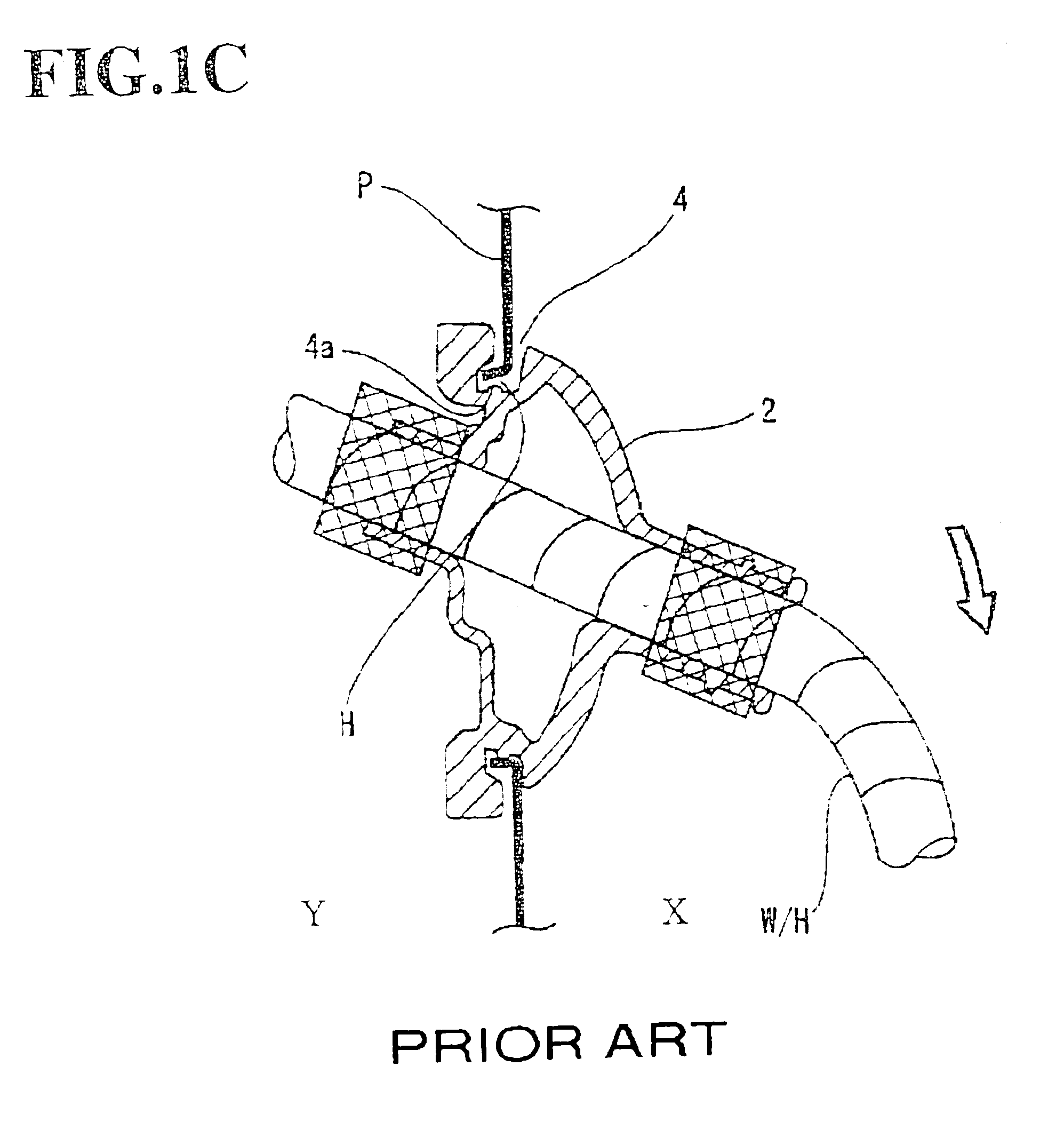

Surface coating of lapped insulation tape

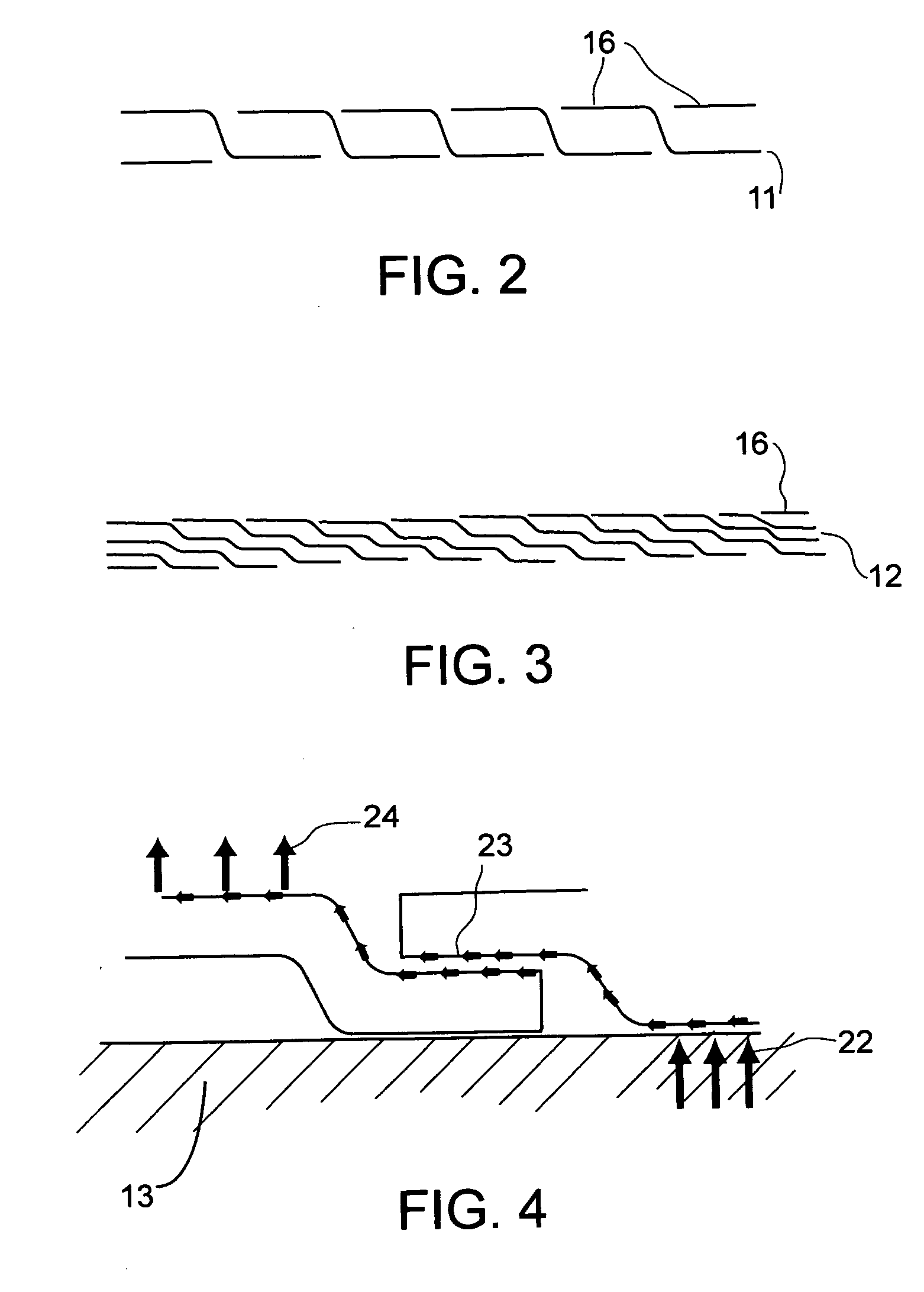

ActiveUS20050274540A1Facilitates surface coatingImprove thermal conductivityWindings insulation materialWindings insulation shape/form/constructionHeat flowMagnetic tape

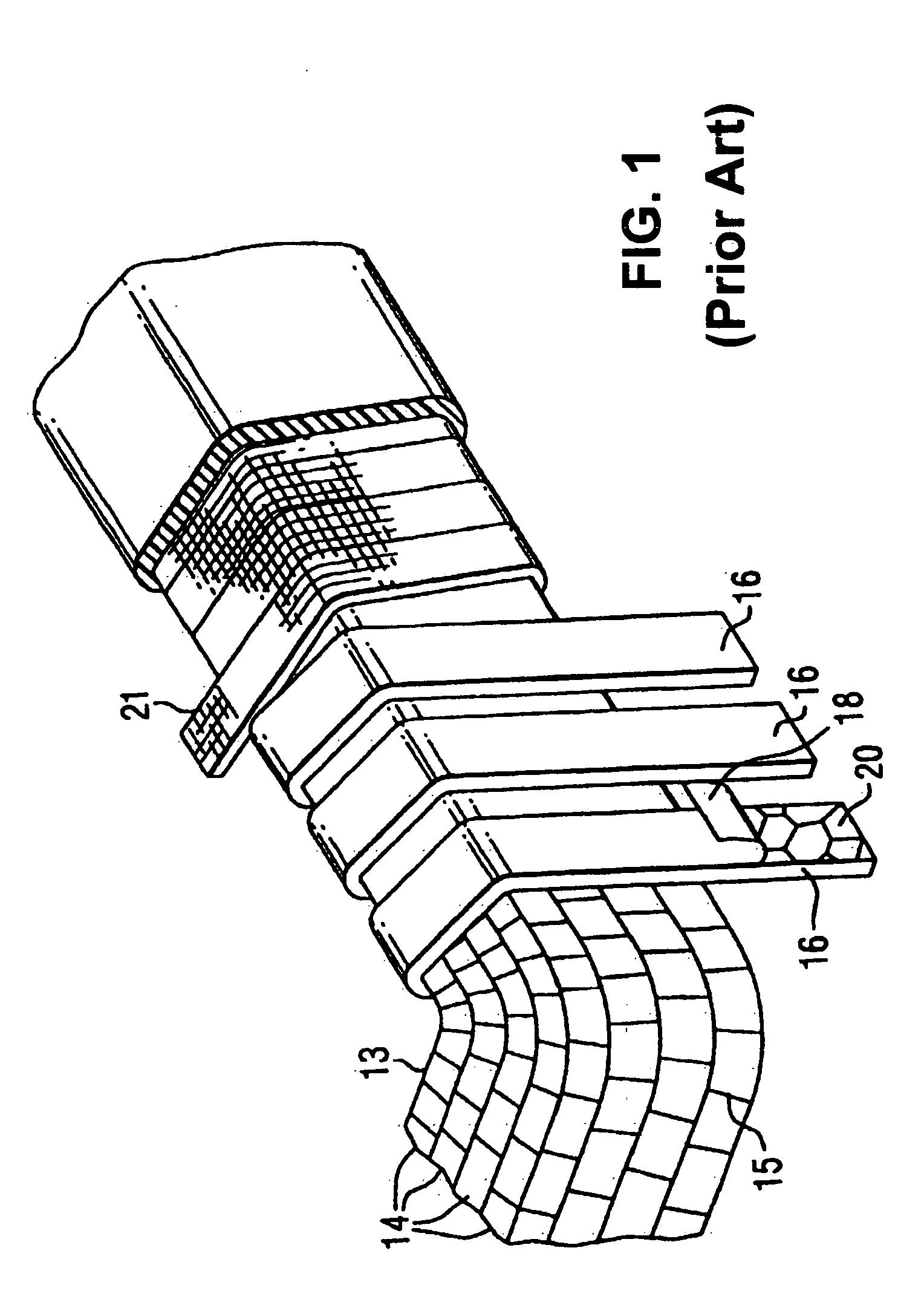

In one embodiment the present invention improves the heat flow from an electrically insulated object 13 by providing an enhanced conduit at the interface between the layers of insulating tape 16. The tape 16 has been surface coated with a high thermal conductivity (HTC) material, so that the interface between the layers of tape 23 provides a pathway for the heat to reach the environment 24. The radiation of heat through the tape layers is also increased by the surface coatings.

Owner:SIEMENS ENERGY INC

Special material for polychloroethylene insulating electrical casing pipe

The invention discloses a special material of polyvinyl chloride for electric isolated sleeve, comprising polyvinyl chloride, stabilizing agent, modifying agent for processing, shock resistance modifying agent, plasticizer, stearic acid, calcium stearate, polyethylene (PE) wax, pigment and 6000 mesh inorganic materials powder. The preparation method is as below: combine the measured 6000 mesh inorganic materials powder and the stearic acid first and then add shock resistance modifying agent to modify the inorganic materials powder. The combined material is granulated by an extruder for reservation. Then mix the measured material evenly by the high mixing machine to form the special powder material for polyvinyl chloride insulated sleeve or granulate the special powder material for polyvinyl chloride insulated sleeve by the extruder to form the special granule for polyvinyl chloride insulated sleeve which is later molded by the plastic extruding machine to form insulated electric sleeve with various specifications. The invention has the advantages of sound dispersion and compatibility, better product quality and lower cost.

Owner:TIANJIN DEHAO NEW MATERIALS

Passive layer for attenuation of near-field electromagnetic waves and heatdissipation including graphene, and electromagnetic device including the same

ActiveUS20140218867A1Reduce distractionsReduce noiseMagnetic/electric field screeningDecorative surface effectsUltrasound attenuationGraphene

The present invention relates to a passive layer including graphene for the attenuation of near-field electromagnetic waves and heat dissipation. The passive layer blocks electromagnetic waves radiated from an external electronic device or prevents electromagnetic waves generated in an electronic device from emitting to the outside. The passive layer is designed to reduce interference between transmission circuits of a device in the near-field region or influence such as malfunction caused by external electromagnetic waves. The present invention also relates to an electromagnetic device and a circuit board, each including the passive layer.

Owner:KOREA INST OF SCI & TECH +1

Grommet for cables

InactiveUS20090151983A1Readily accommodating easy passage and removalSubstantial air leakageMulti-purpose toolsInsulating bodiesElectrical conductorData center

A cable grommet system for installation in data centers, offices and the like, for sealing cable openings in raised flooring, wall or ceiling panels, server cabinets, etc. to facilitate the installation and revision of wiring and cabling to server installations while minimizing losses of any provided conditioned air. A wide variety of grommet configurations is possible with a limited number of component parts. An advantageous acute angle mounting of sealing brushes enhances the sealing effectiveness thereof, particularly for smaller sizes of cable openings. In some embodiments, a novel arrangement of electrical conductors is incorporated into the grommet structures for dissipation of electrostatic charges, enabling the basic frame components to be formed of a flame retardant material.

Owner:AQUILA INC

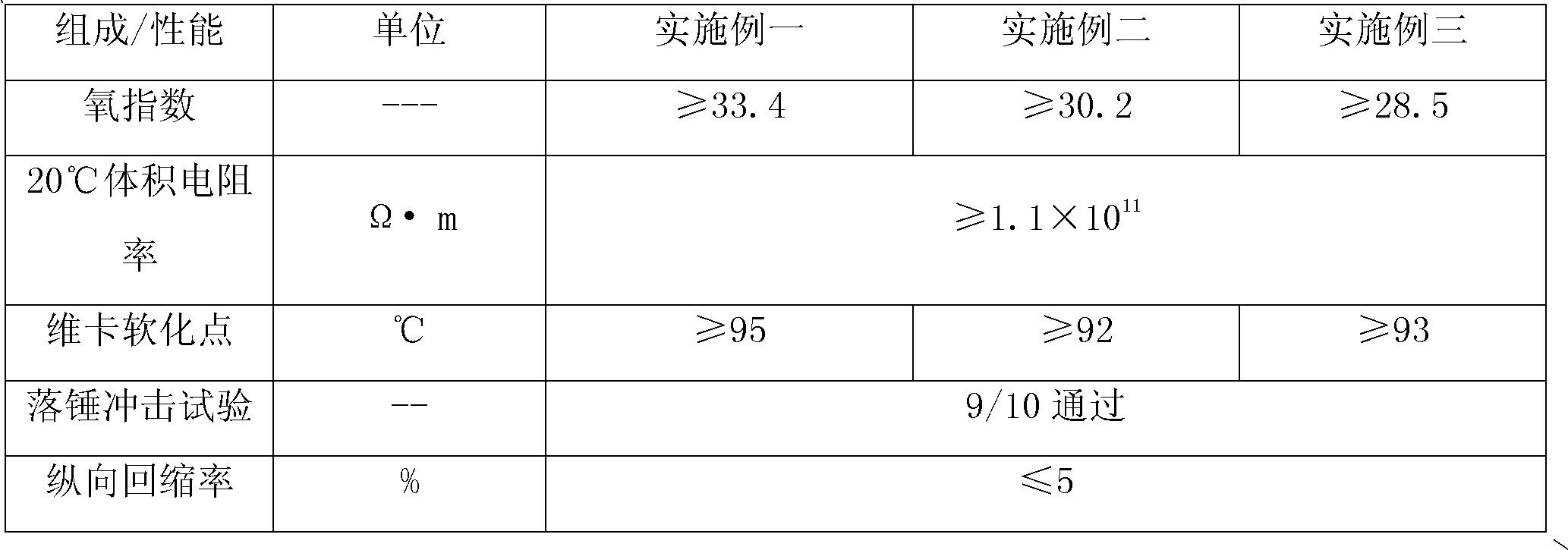

Fire-retardant insulating polyvinyl chloride material and electrical sleeve

InactiveCN102093652AImprove flame retardant performanceImprove insulation performanceInsulating bodiesLow voltagePolyvinyl chloride

The invention discloses a fire-retardant insulating polyvinyl chloride material and an electrical sleeve made from the material. The fire-retardant insulating polyvinyl chloride material comprises the following raw materials in part by weight: 100 to 150 parts of polyvinyl chloride, 0.2 to 5 parts of heat stabilizer, 5 to 20 parts of compatibilizer, 20 to 60 parts of fire retardant master batch, 0.3 to 1 part of lubricant, 1 to 3 parts of titanium white powder, 10 to 20 parts of impact modifier, 2 to 4 parts of processing aid and 5 to 20 parts of calcium carbonate. The fire-retardant insulating polyvinyl chloride material provided by the invention has excellent flame retardant property and insulating property; the oxygen index can be over 33.4; the test is up to V-0 level according to the measurement standard of GB / T2048-2008 plastic combustibility; and the resistivity can be up to 1.1*1,011 Omega.m. Therefore, the material can meet the requirement on insulation and fire retardance of a low-voltage wire cable.

Owner:KANGTAI PLASTIC SCI & TECH GRP

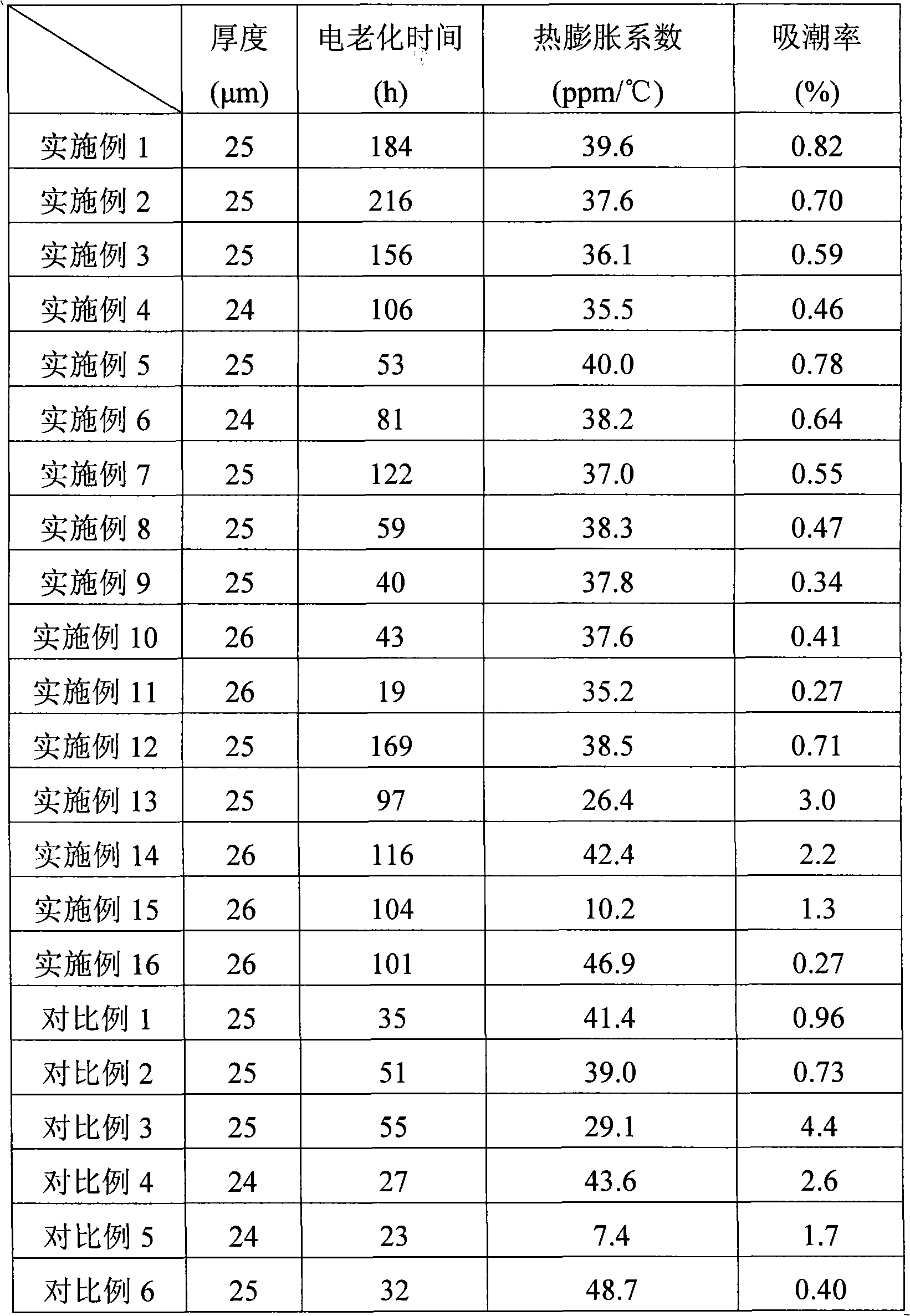

Spherical silica/polyimides composite membrane, preparation thereof and applications

ActiveCN101289542ACorona resistantImprove corona resistanceInsulating bodiesAdhesiveThermal coefficient

The invention discloses a spherical silicon dioxide / polyimide composite film and a method for making the same as well as an application. The method for making the spherical silicon dioxide / polyimide composite film comprises the following steps that: 1) spherical silicon dioxide particles are scattered into an organic solvent evenly to obtain the spherical silicon dioxide particle suspension liquid; 2) a surface treatment agent, a molecular weight modifying agent, an auxiliary adhesive, a flatting agent and aromatic series diamine are dissolved inside the spherical silicon dioxide particle suspension liquid; organic dicarboxylic anhydride is added to be stirred in order to obtain a spherical silicon dioxide / polyamide acid mixing resin solution; 3) the mixing resin solution is coated on the surface of a flat substrate and is heated up to make the solvent volatilize and complete the imide reaction to obtain the spherical silicon dioxide / polyimide composite film. The spherical silicon dioxide / polyimide composite film has good mechanical property, good corona resistance, low thermal coefficient of expansion and low moisture absorption ratio, and has important application value in an insulating system of a frequency conversion speed motor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Double wire pass through seal with grommets

InactiveUS6995317B1Improve stabilityQuicker and more efficientlyPipesSignal boxes station blockingElectrical conductorEngineering

A double wire seal has a first grommet for sealing a conductor relative to a substrate having opposite sides and an opening therethrough for a conductor. The first grommet has axially opposite ends. A second grommet for sealing the conductor relative to a door panel having opposite ends and an opening therethrough for the conductor. The second grommet has axially opposite ends. The first grommet secures the conductor to the substrate. The second grommet secures the conductor to the door panel.

Owner:EXCELLO ENGINEERED SYST

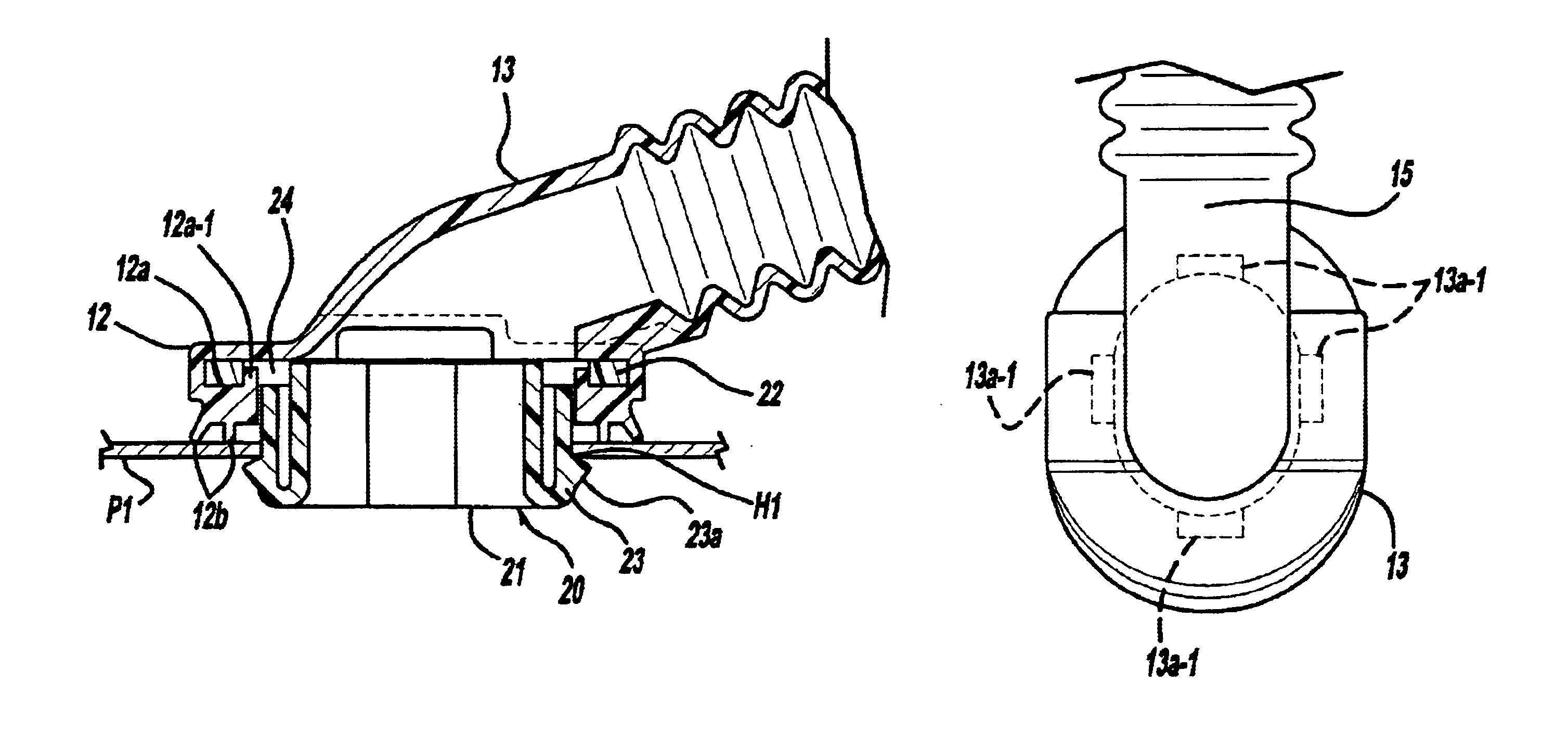

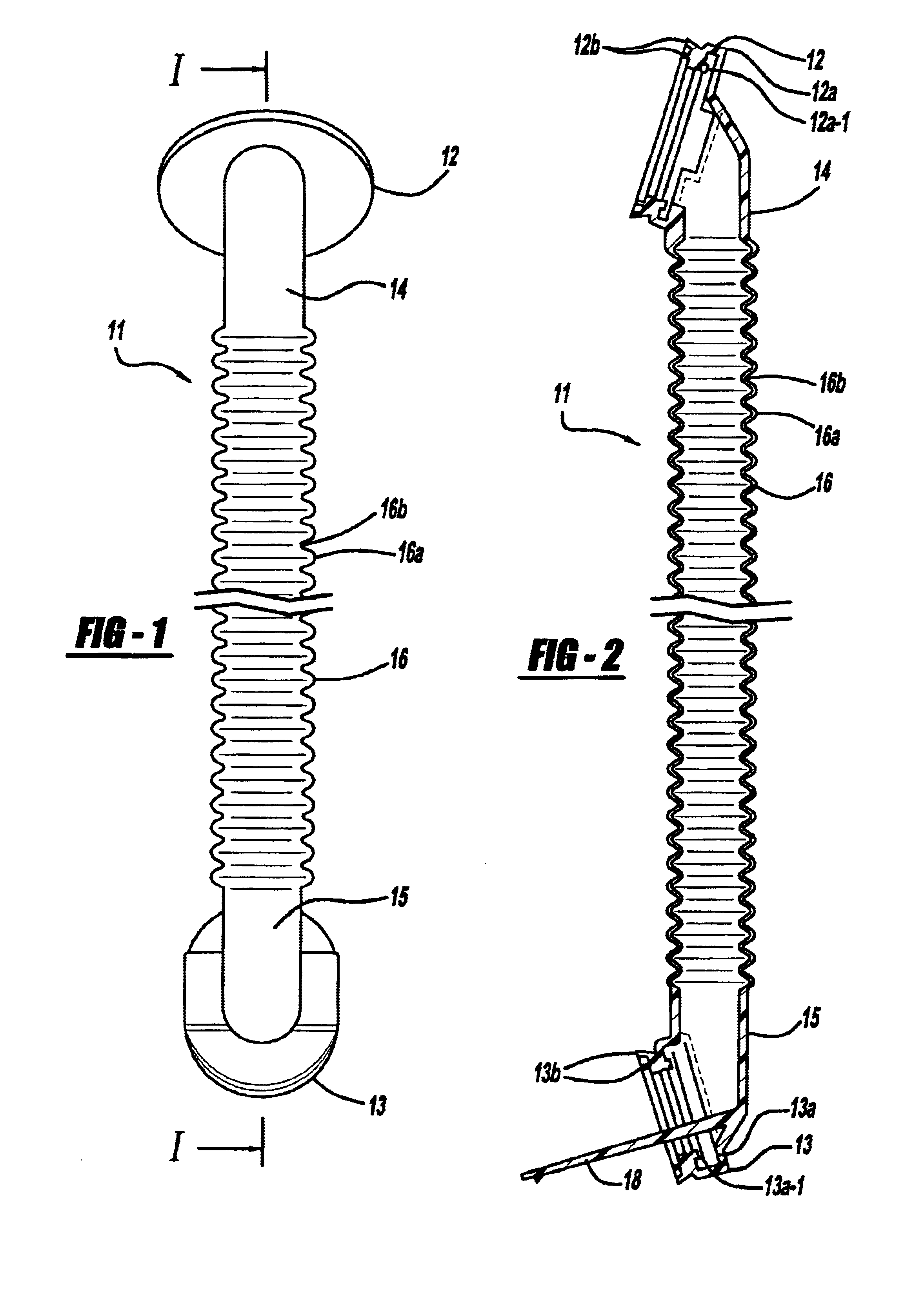

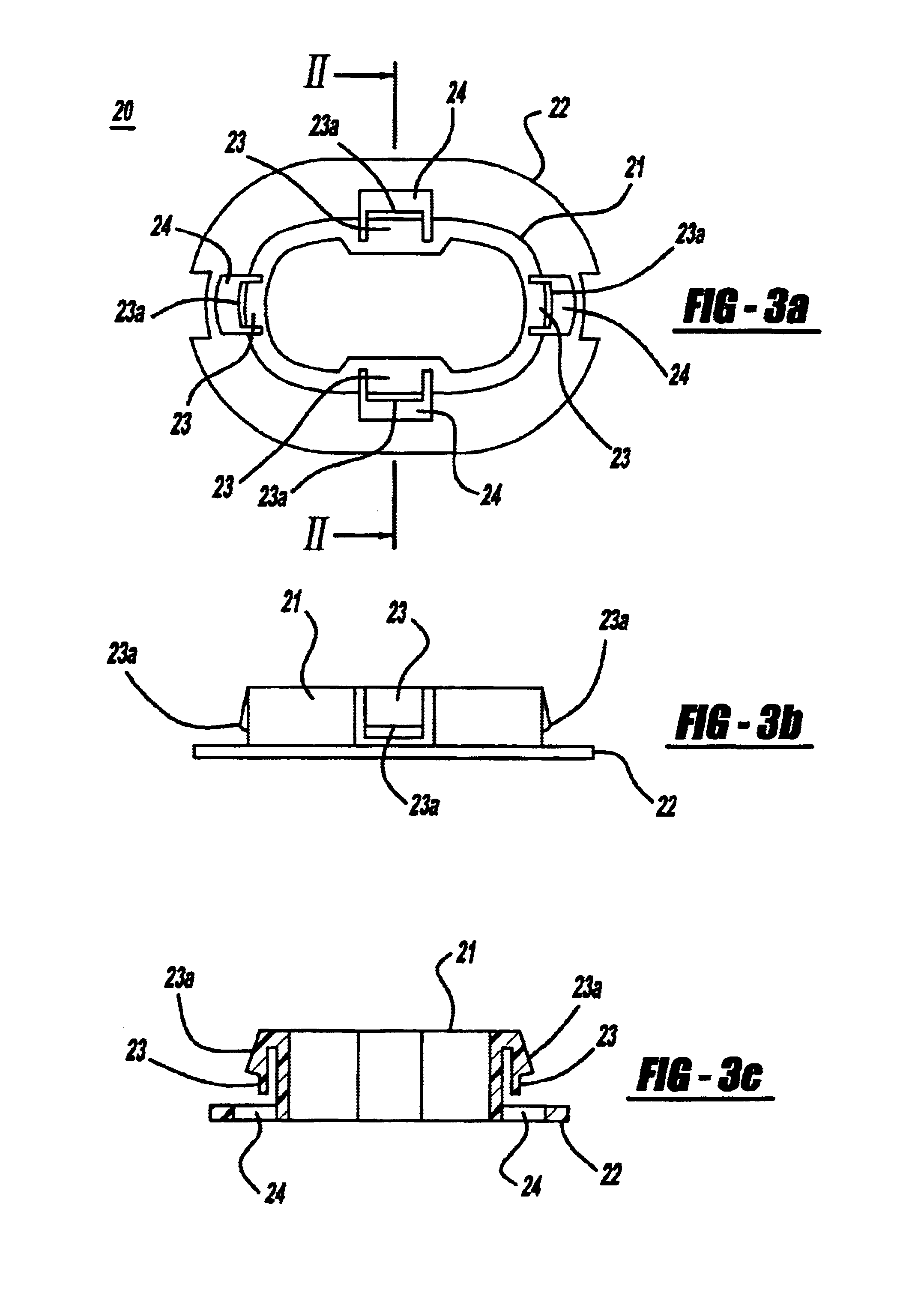

Resin inner member-provided grommet

InactiveUS6901627B2Improve dustproof performanceImprove waterproof performancePipesCable arrangements between relatively-moving partsEngineeringGrommet

A locking claw (23a) to be locked to a through-hole (H) projects outwardly from a peripheral wall (21) of a resinous inner member (20). At least one pair of locking holes (24) is formed on a locking flange part (22) projecting from the peripheral wall (21). An annular concavity (12a) (13a), on which the locking flange part (22) fits, is formed on an inner peripheral surface of a large-diameter cylindrical part (12, 13). Locking projections (12a-1, 13a-1) project from a leading end of a side wall of the annular concavity (12a, 13a). The locking projections (12a-1, 13a-1) are inserted into and locked with the locking holes (24). Locking claws (123a-126a) project from the resinous inner member (120) and are locked to a through-hole (H1) of the body panel (P1). A pair of flexible locking pieces (123-126), to be locked to the body panel (P1), project from each of a shorter side and a longer side of an elliptic peripheral wall (121) of the resinous inner member (120) projecting from an open end of the large-diameter cylindrical part (112, 113). A leading end of the locking pieces (123-126) project outwardly from an intermediate position of an outer surface of the locking pieces (123-126). The locking pieces on the longer side are curved longitudinally to form a circular arc shape.

Owner:SUMITOMO WIRING SYST LTD

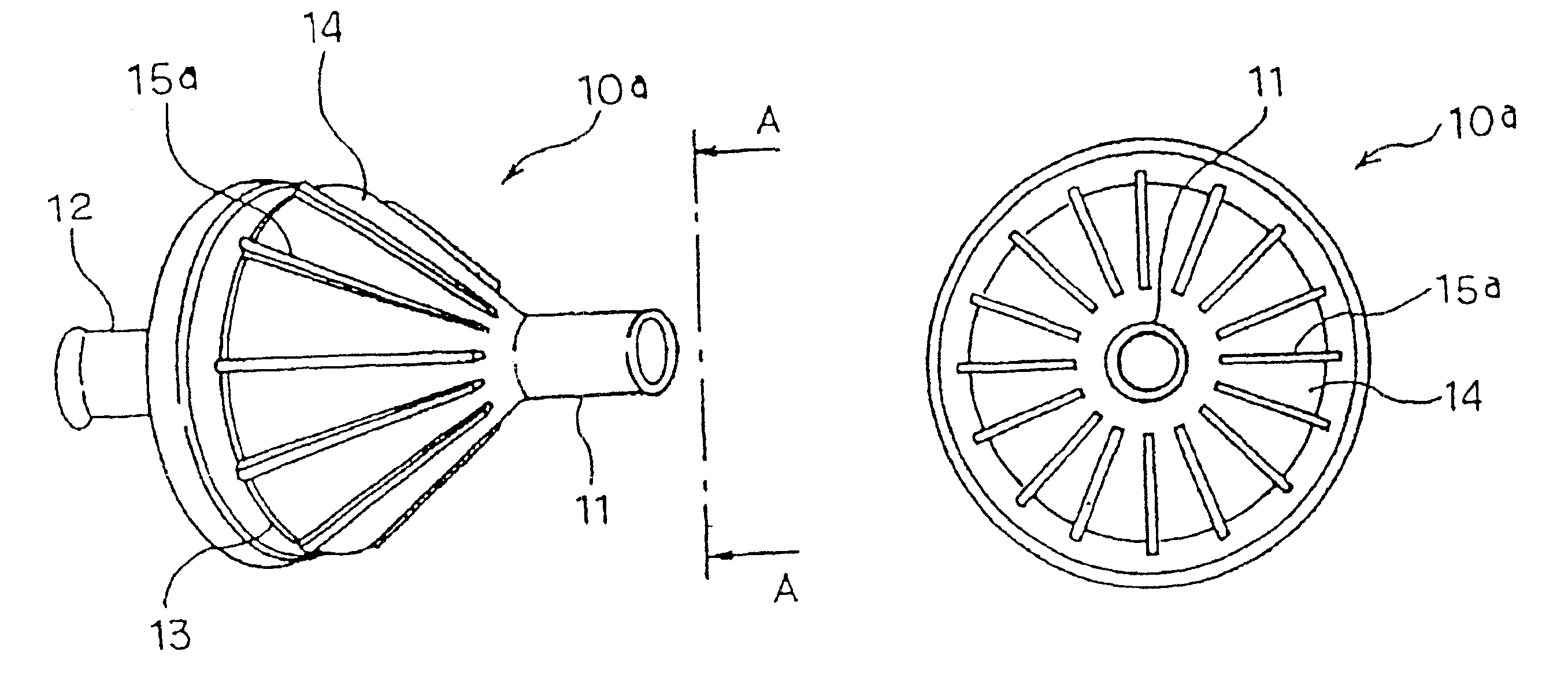

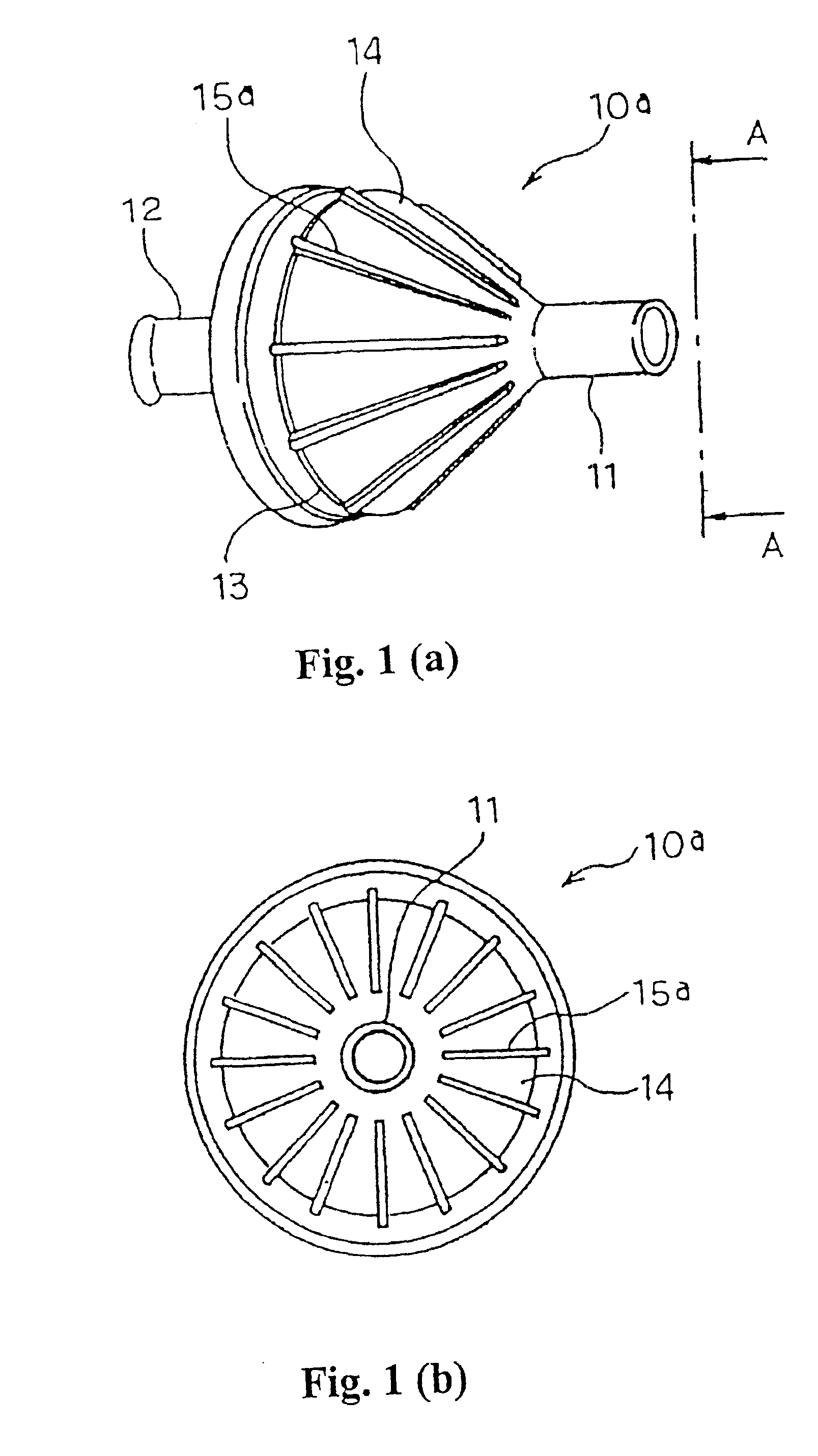

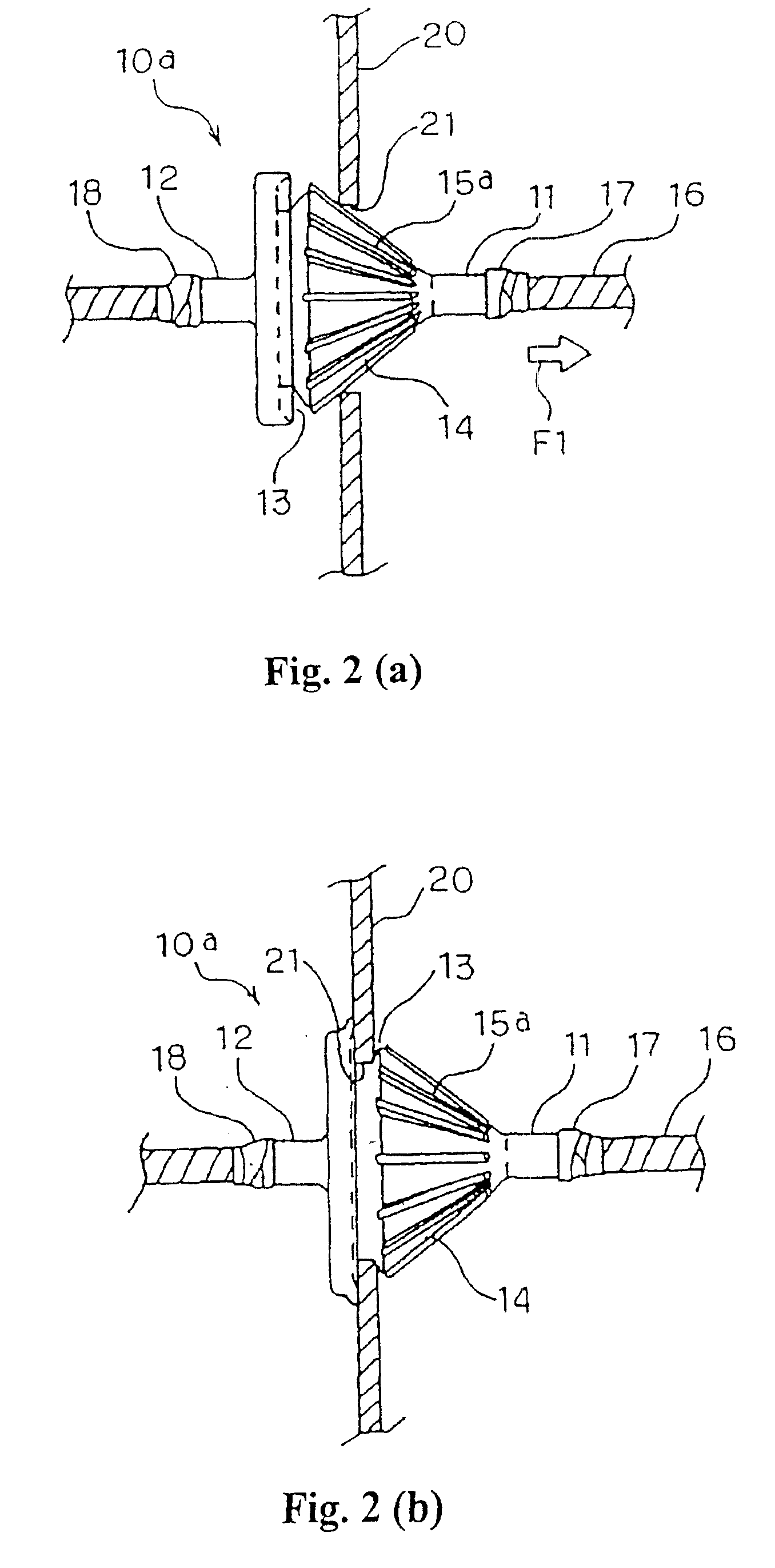

Grommet for a wire harness

ActiveUS6897380B2Less push forceContact resistanceRelieving strain on wire connectionInstallation of lighting conductorsWater trapEngineering

The grommet having a longitudinal axis includes a funnel shaped portion having a flared end, a narrowed end and a conical wall with external and internal conical faces. The external conical face includes an external circular groove having a groove base. The grommet further includes a tubular portion extending outwardly from a circular joint section formed at the narrowed end of the funnel shaped portion. The grommet is configured to mount a wire harness for vehicles containing a water-trapping zone, and to be installed into a through-hole formed in a body panel of a vehicle. The funnel-shaped portion includes at least one device for improving the flexibility of and / or space availability for the wire harness to be mounted including an extended tubular portion to hold the water-trapping zone of the wire harness, a structural configuration allowing the length along the longitudinal axis of the funnel shaped portion to be reduced such that the wire harness can be wired substantially alongside the body panel, and a plurality of funnel ribs having closely arranged first end sections that form a circular space around the tubular portion.

Owner:SUMITOMO WIRING SYST LTD

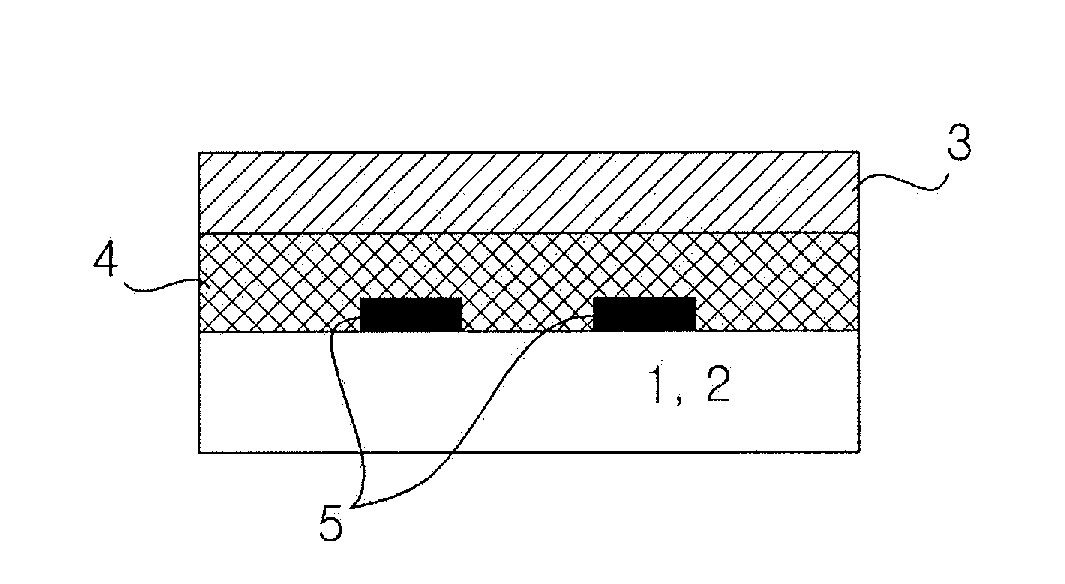

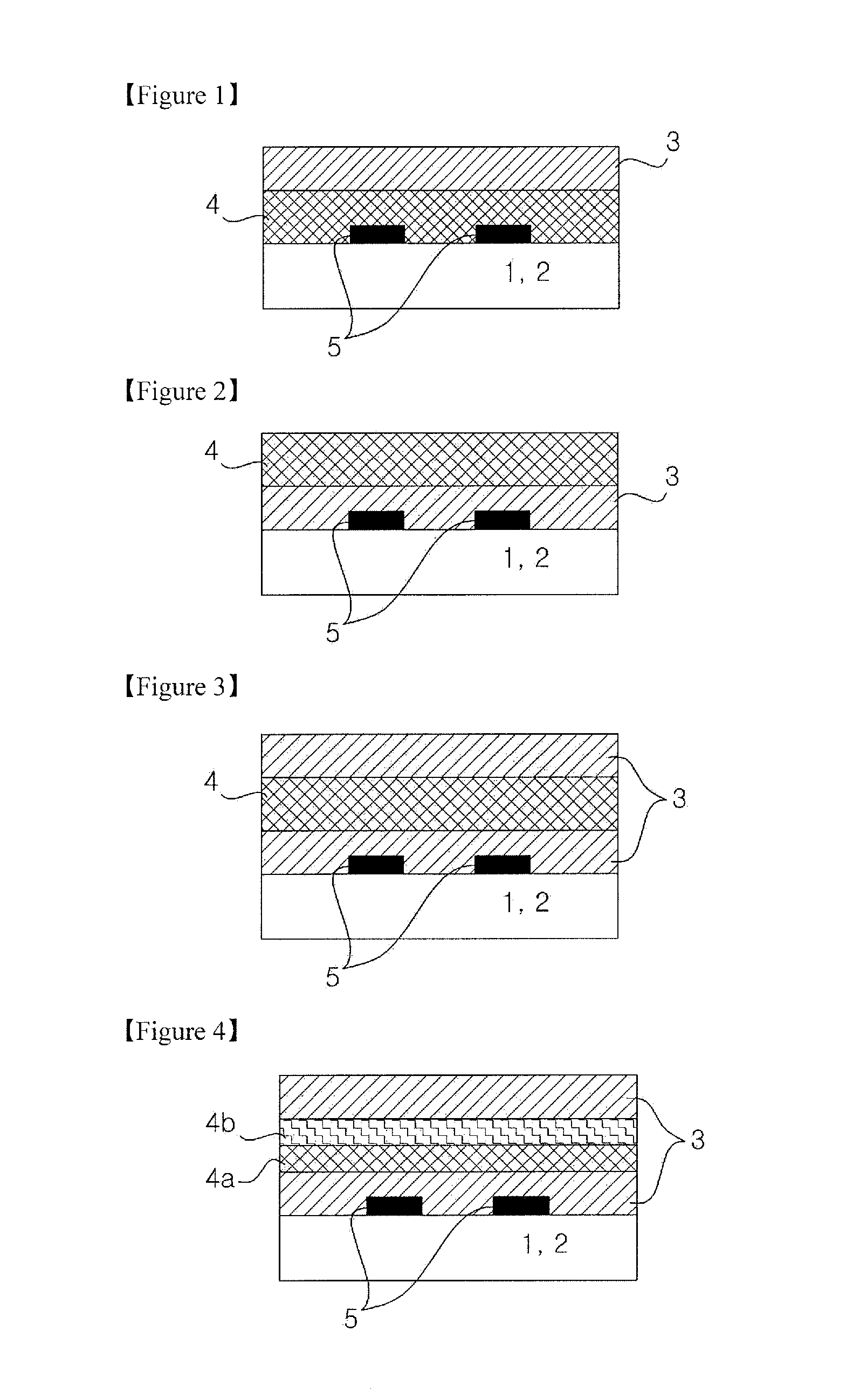

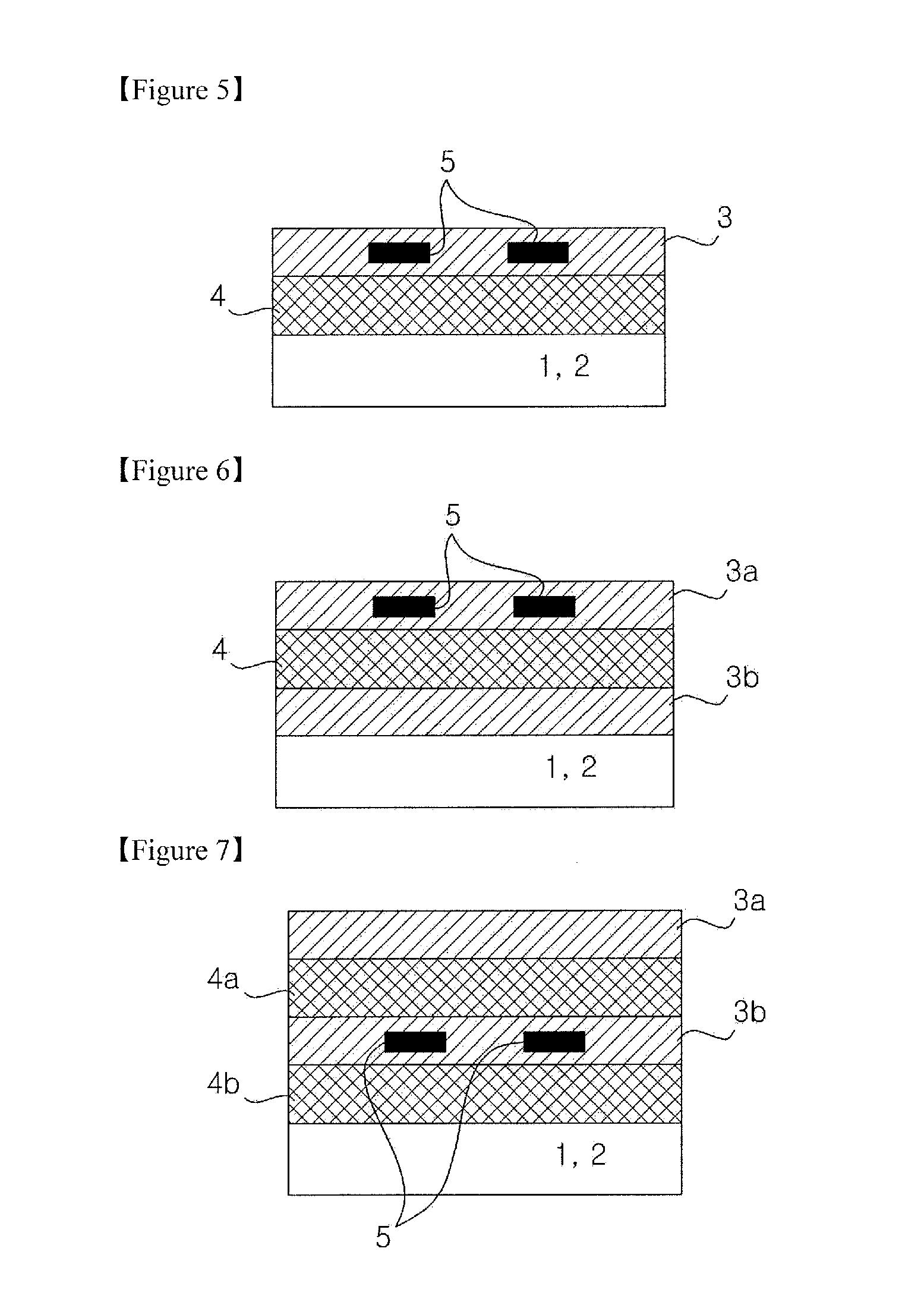

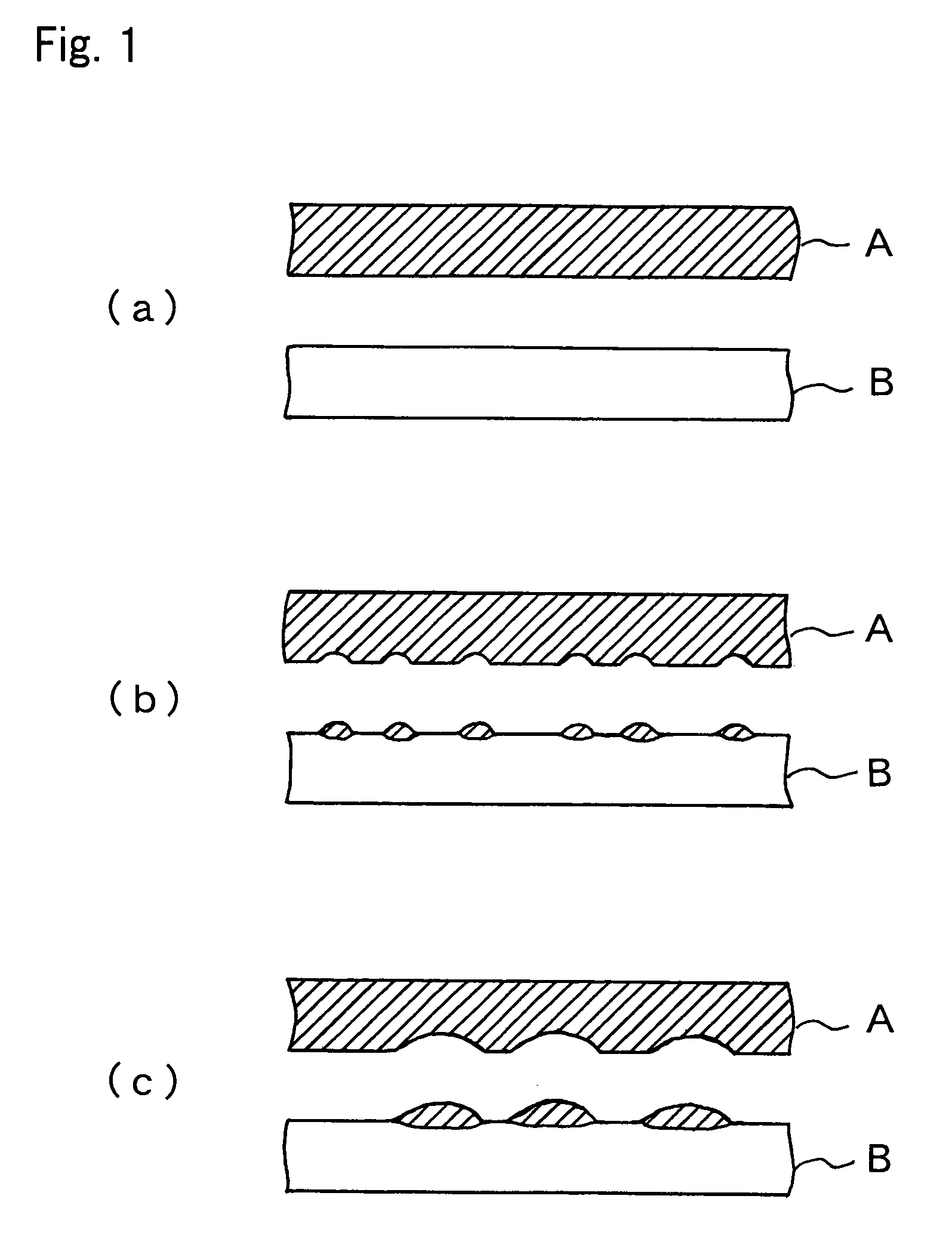

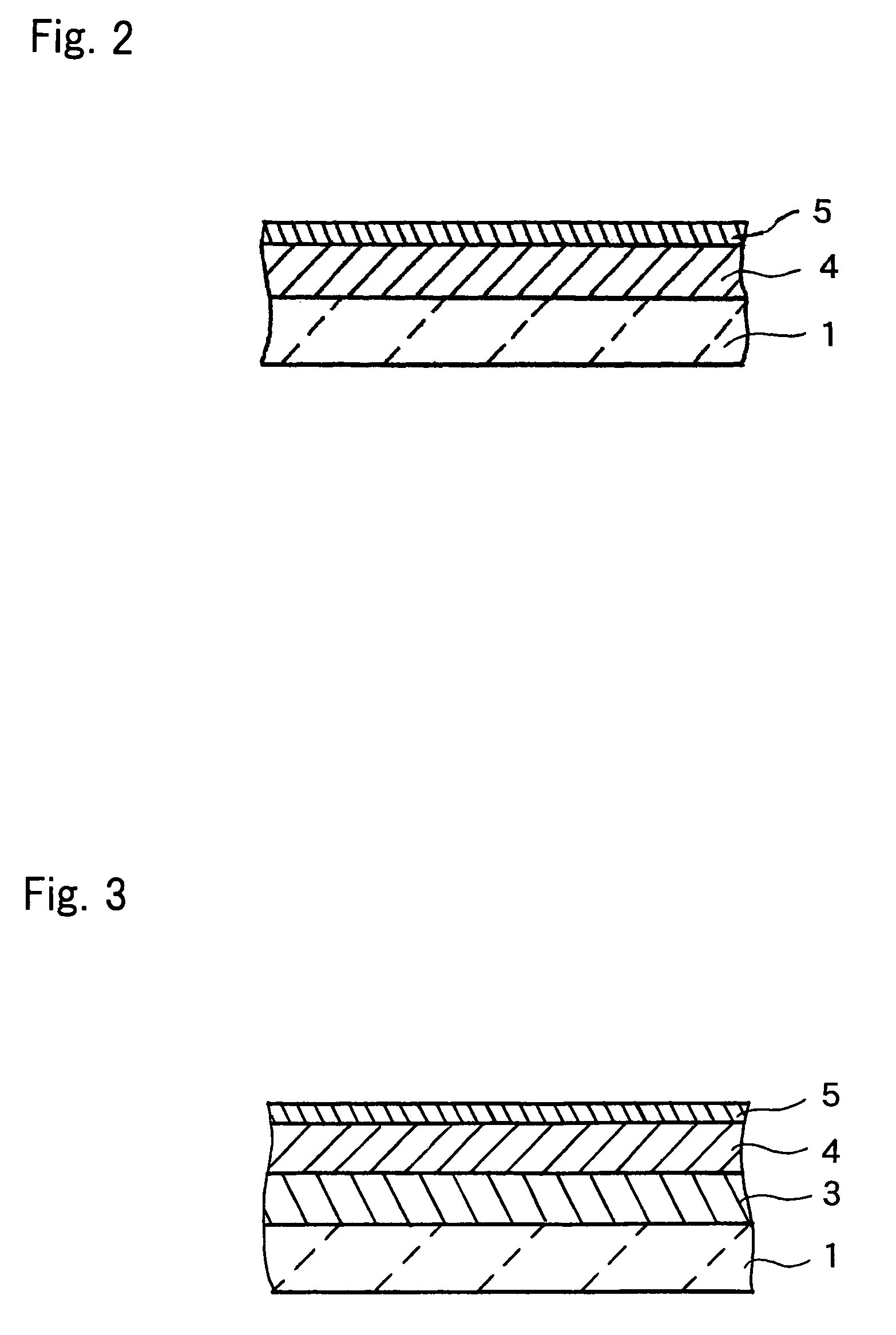

Functional film for transfer having functional layer, object furnished with functional layer and process for producing the same

InactiveUS7294298B2Lower resistanceImprove adhesionConductive layers on insulating-supportsSynthetic resin layered productsElectrical resistance and conductanceEngineering

The present invention provides a functional film for transfer in order to furnish a surface of an article, even an article poor in flexibility, such as a board material, with a functional layer having a uniform thickness and a higher function, e.g. a transparent conductive layer having a lower electric resistance; an article furnished with the functional layer; and a method for producing the article furnished with the functional layer. A functional film for transfer comprising at least a functional layer 4 on a support 1, said functional layer 4 being releasable from the support 1, wherein the functional layer 4 is a compressed layer of functional fine particles, and further, on the functional layer 4 an adhesive layer 5 comprising at least an acrylic type monomer (M) and a silicone type resin (S) is provided. The functional film for transfer is stuck, through the adhesive layer 5, onto a surface of an object article to be furnished with the functional layer; the adhesive layer 5 is cured; the support 1 is released; and subsequently calcining is performed.

Owner:TDK CORPARATION

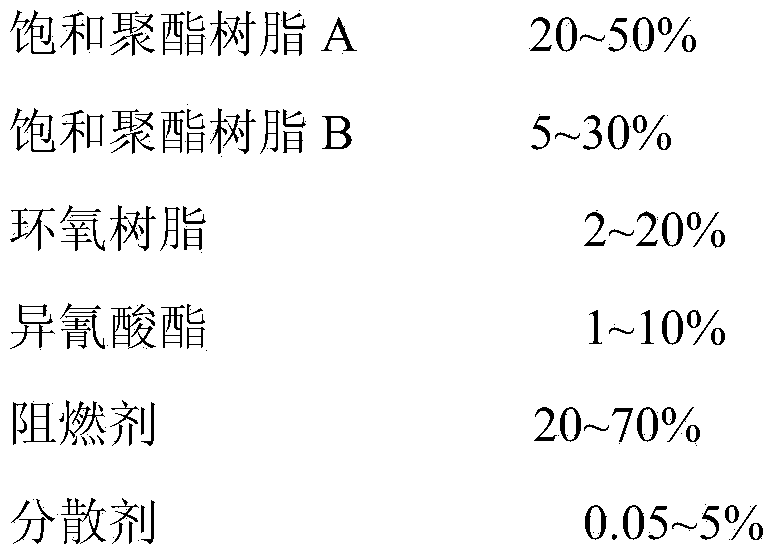

Insulating adhesive film for laminated bus bar and laminated bus bar

ActiveCN104178044AHigh bonding strengthImprove insulation performanceFilm/foil adhesivesPolyureas/polyurethane adhesivesVitrificationEpoxy

The invention relates to an insulating adhesive film for a laminated bus bar. The insulating adhesive film comprises an insulating film layer, and a hardened or semi-hardened adhesion agent layer which coats on the insulating film layer, wherein the thickness of the insulating film layer is 0.025-0.50mm; the thickness of the adhesion agent layer is 0.010-0.1mm; the formula of the adhesion agent layer comprises the following raw materials by weight percent: 20-50% of saturated polyester resin A, 5-30% of saturated polyester resin B, 2-20% of epoxy resin, 1-10% of isocyanate, 20-70% of a fire retardant and 0.05-5% of a dispersing agent; the limiting viscosity of the saturated polyester resin A is 0.2-1.2dl / g; the glass transition temperature Tg is -40 DEG C to 50 DEG C; the limiting viscosity of the saturated polyester resin B is 0.2-1.2dl / g; the glass transition temperature Tg is 51 DEG C to 100 DEG C; and the number-average molecular weight of epoxy resin is 500-70,000. The adhesion agent layer of the insulating adhesive film has the characteristics of after-tack resistance, insulativity, good fire resistance and the like, and has the characteristics of high adhesion with a metal plate, excellent bending processability, cold and hot shock resistance and the like after the laminated bus bar is prepared.

Owner:CYBRID TECHNOLOGIES INC

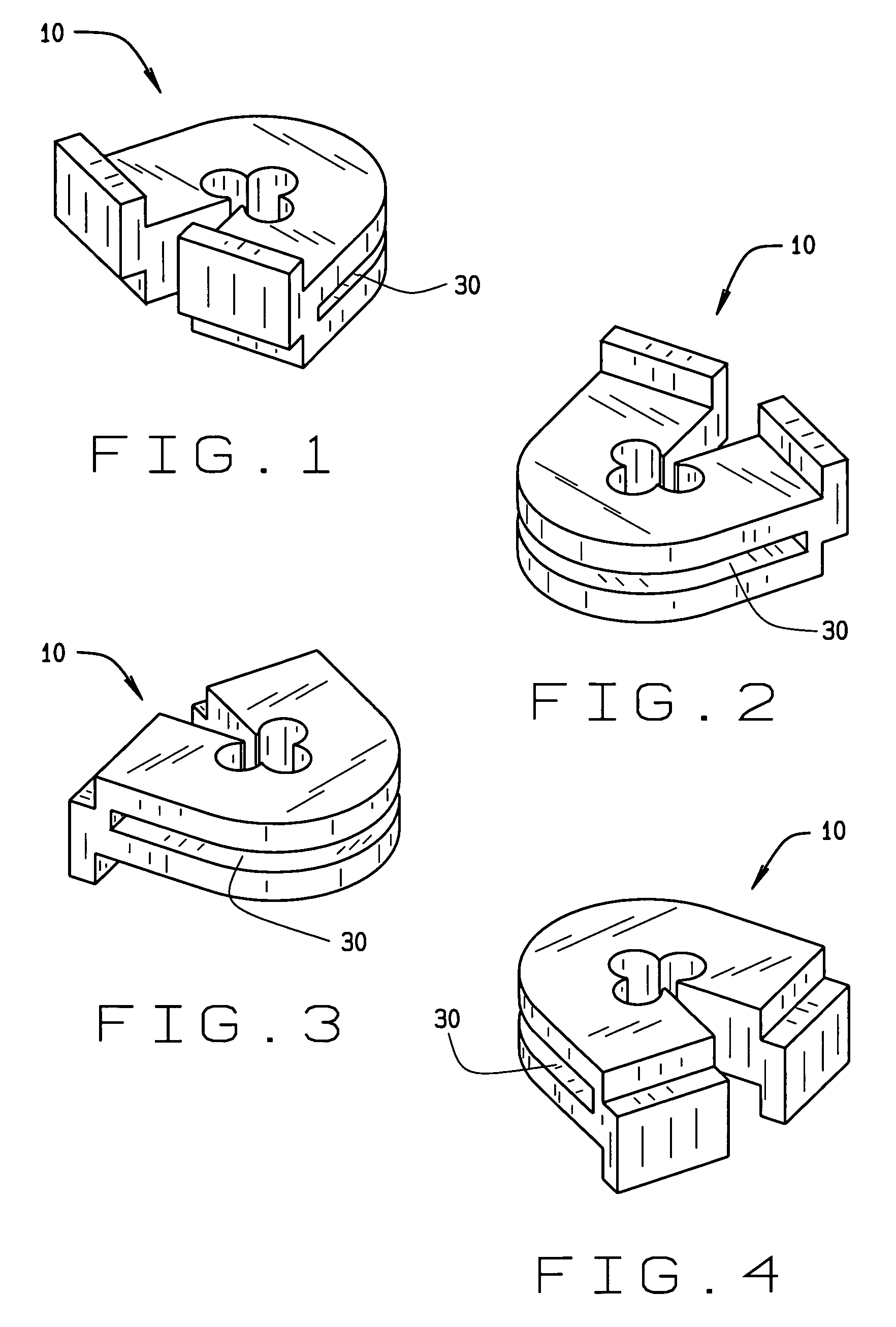

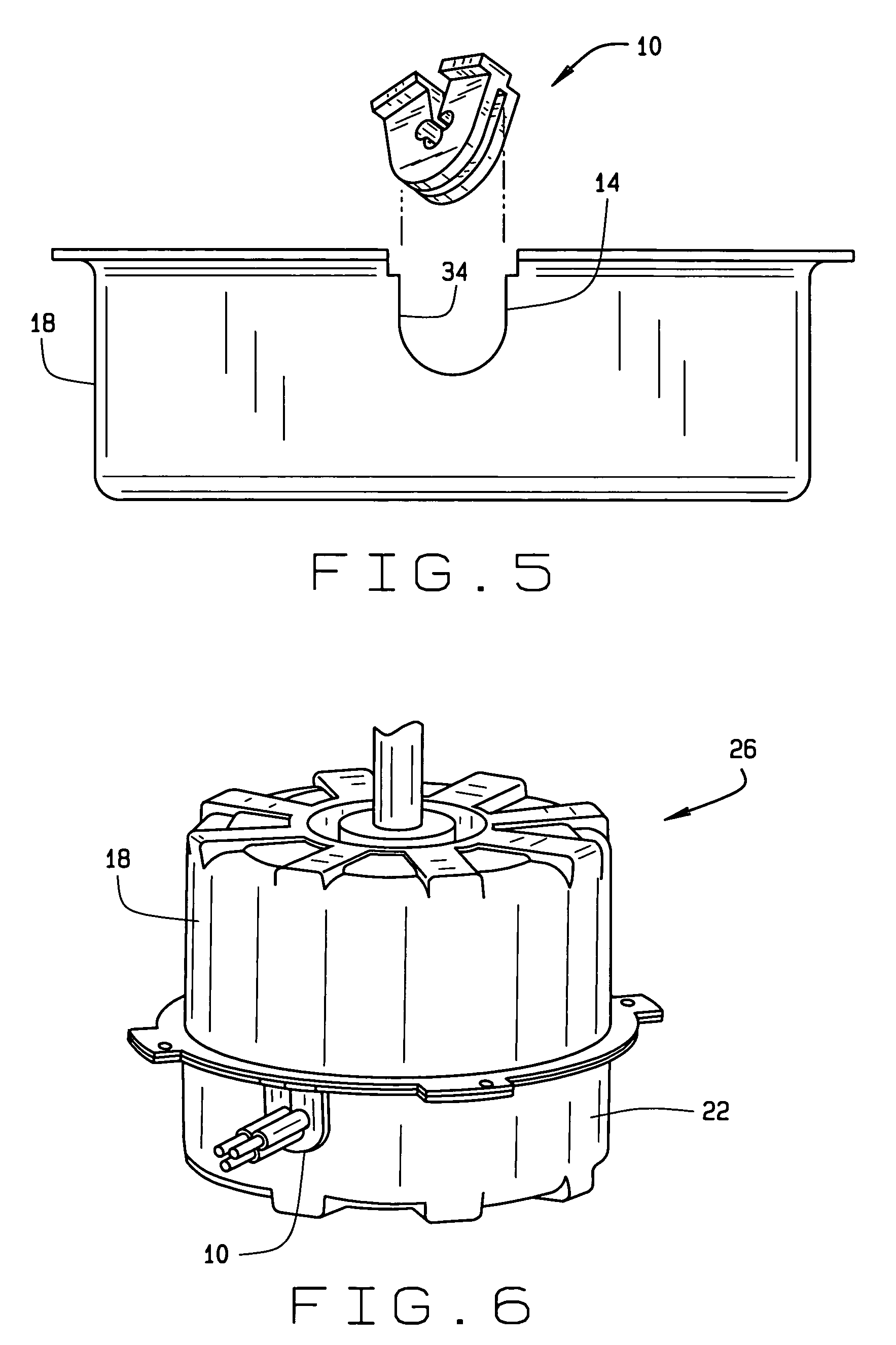

Grommets for sealing a hole in an electrical device housing through which electrical connectors exit

A grommet is provided for insertion into a hole defined through and surrounded by a housing wall of an electrical device through which one or more electrical connectors exit. The grommet generally includes first and second legs connected by a connecting portion. The first and second legs have flange portions and lip portions extending outwardly from the first and second leg's end portions generally opposite the connecting portion. The flange and lip portions collectively define at least one groove for receiving a portion of the housing wall. The grommet also includes a slit extending at least partially between the first and second legs, and at least one aperture for engagingly receiving at least one electrical connector therethrough. The grommet, when engaged with the hole, seals against the housing wall and the electrical connector within the aperture to thereby inhibit the ingress of moisture through the hole.

Owner:NIDEC MOTOR CORP

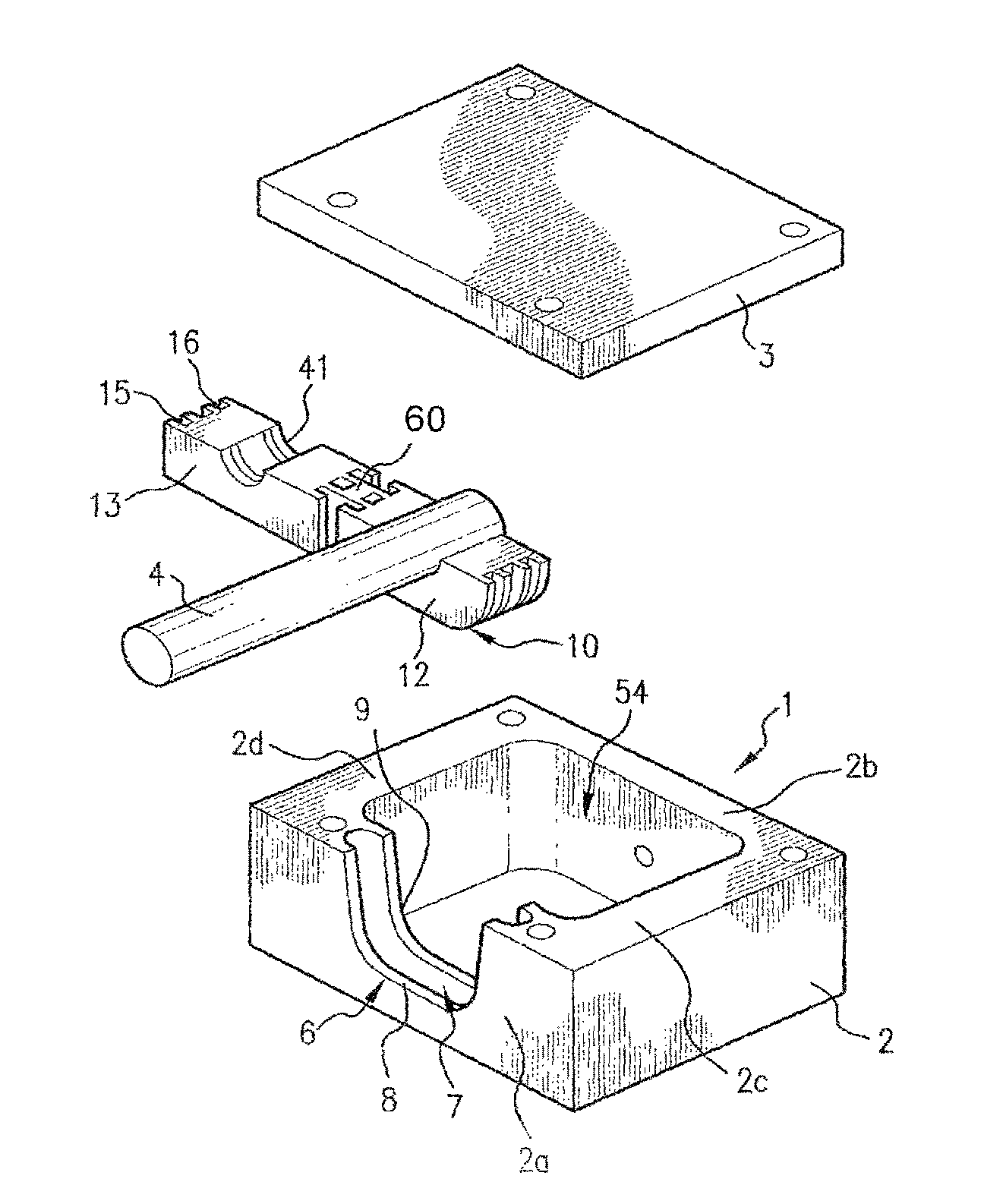

Insulating gasket means for supporting a cable in a housing opening

A compressible sealing gasket for supporting a cable in a wall opening contained in a housing wall includes a pair of gasket sections each having a planar surface that contains a recess, and at least one integral compressible sealing projection extending from the planar surface adjacent the recess. When the gasket sections are placed in an assembled condition with their planar surfaces in contiguous engagement, the recesses cooperate to define a cable opening for receiving a cable, and the projection is compressed between the gasket sections to seal the space between the gasket sections adjacent the cable opening. Preferably two laterally spaced integral sealing ribs are provided in each recess, which sealing ribs extend transversely completely across the recess and terminate at each end in a sealing projection that extends upwardly from the associated planar surface.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

Boot

InactiveUS6162087ACouplings bases/casesInsulating bodiesElectrical connectorElectrical and Electronics engineering

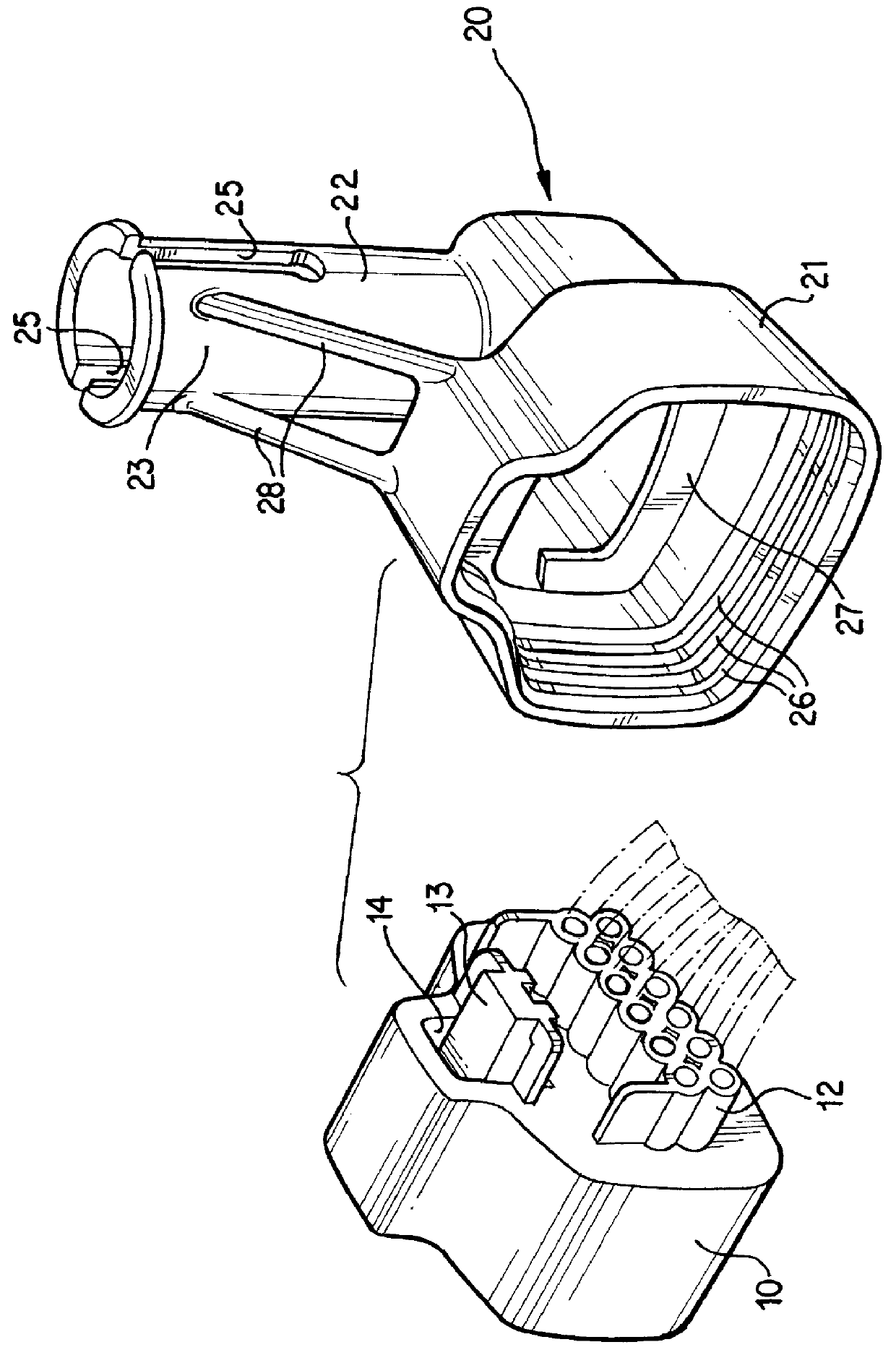

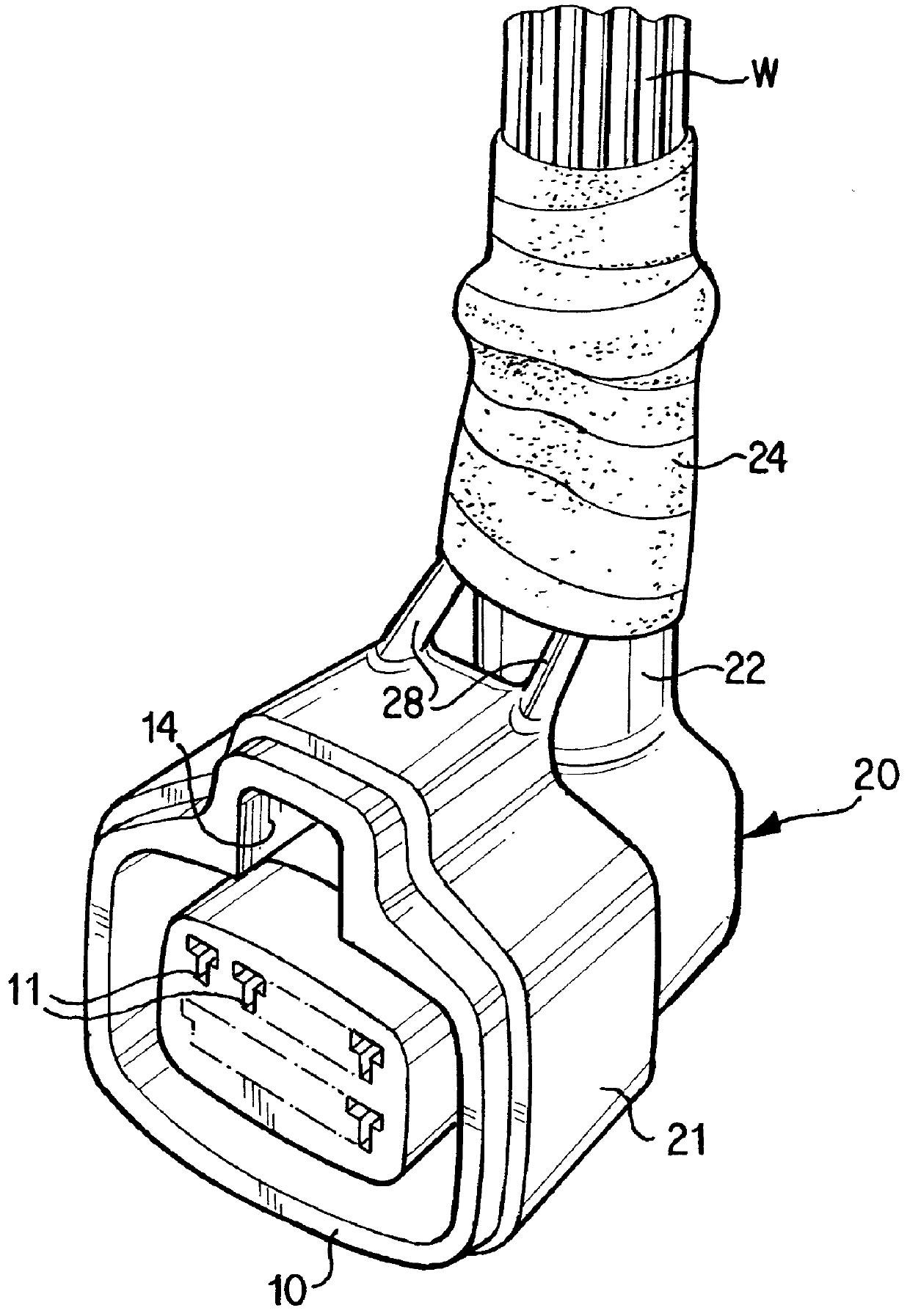

Anti-skid protrusions 26 and 27 are formed on the inside of a rubber boot 20 which fits on the smooth external surface of an electrical connector housing 10. Since the connector housing 10 has no molded supports for the boot, production cost is reduced.

Owner:SUMITOMO WIRING SYST LTD

Grommet

InactiveUSRE38788E1Complicated processShort processing timePipesMulti-purpose toolsEngineeringGrommet

The present invention relates to a grommet capable of easy installation by reducing an insertion resistance when conducting an insertion of the grommet into an opening of a vehicle panel. The configuration of the grommet allows molds for forming the grommet to have reduced processing costs, and molding and installation time can also be decreased. The grommet includes wire harness holding areas for tightly engaging around the periphery of the wire harness and an engagement area which fixedly engages an opening provided on a vehicle panel. A tapered area connects a wire harness holding area and an engagement area with a near-conical tapered surface extending over the outer surface of a tapered area, and a plurality of linear convex areas are provided to extend from a wire harness holding area to the engagement area, in an insertion direction of the grommet over the entire periphery on the tapered area.

Owner:SUMITOMO WIRING SYST LTD

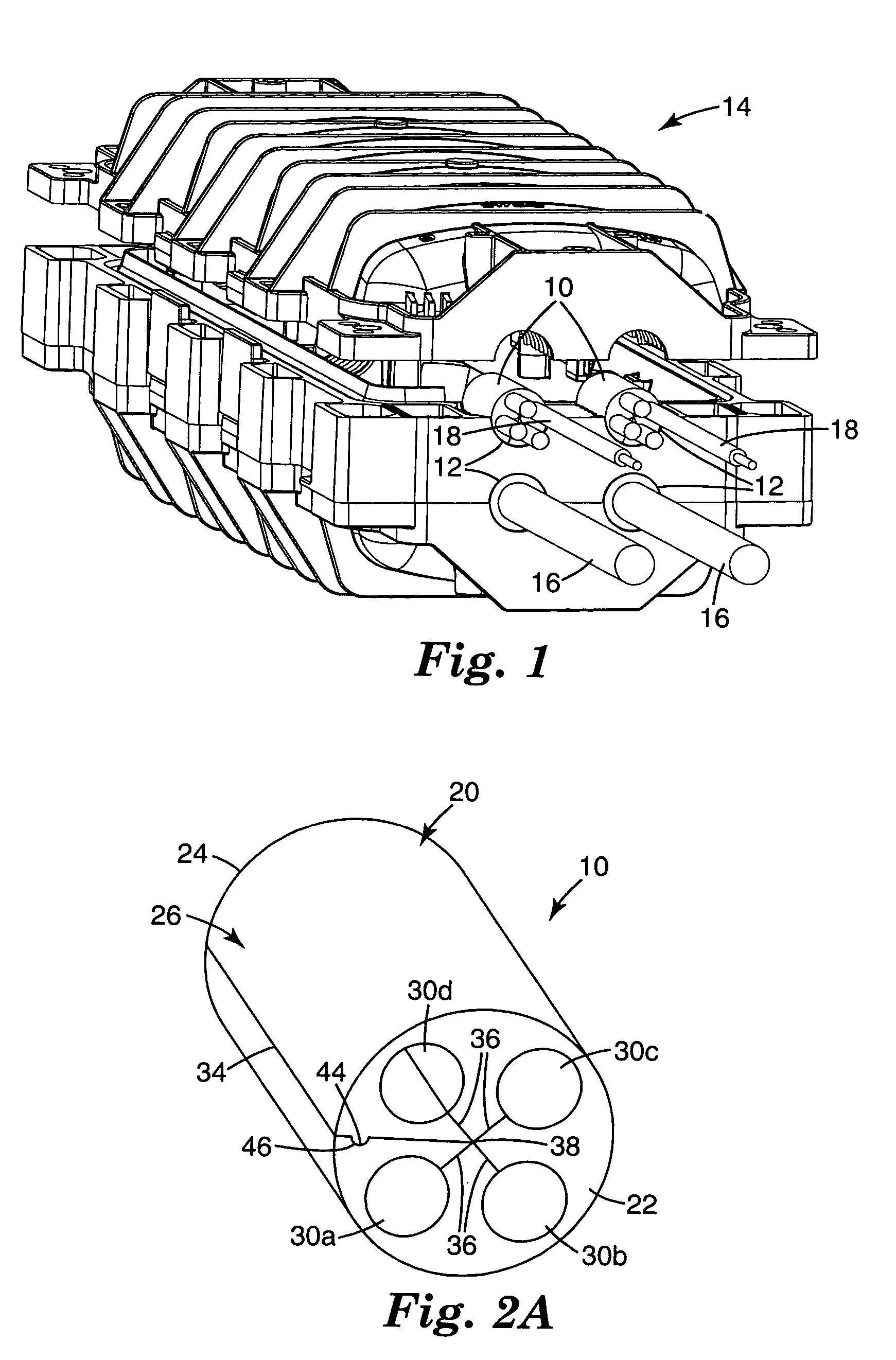

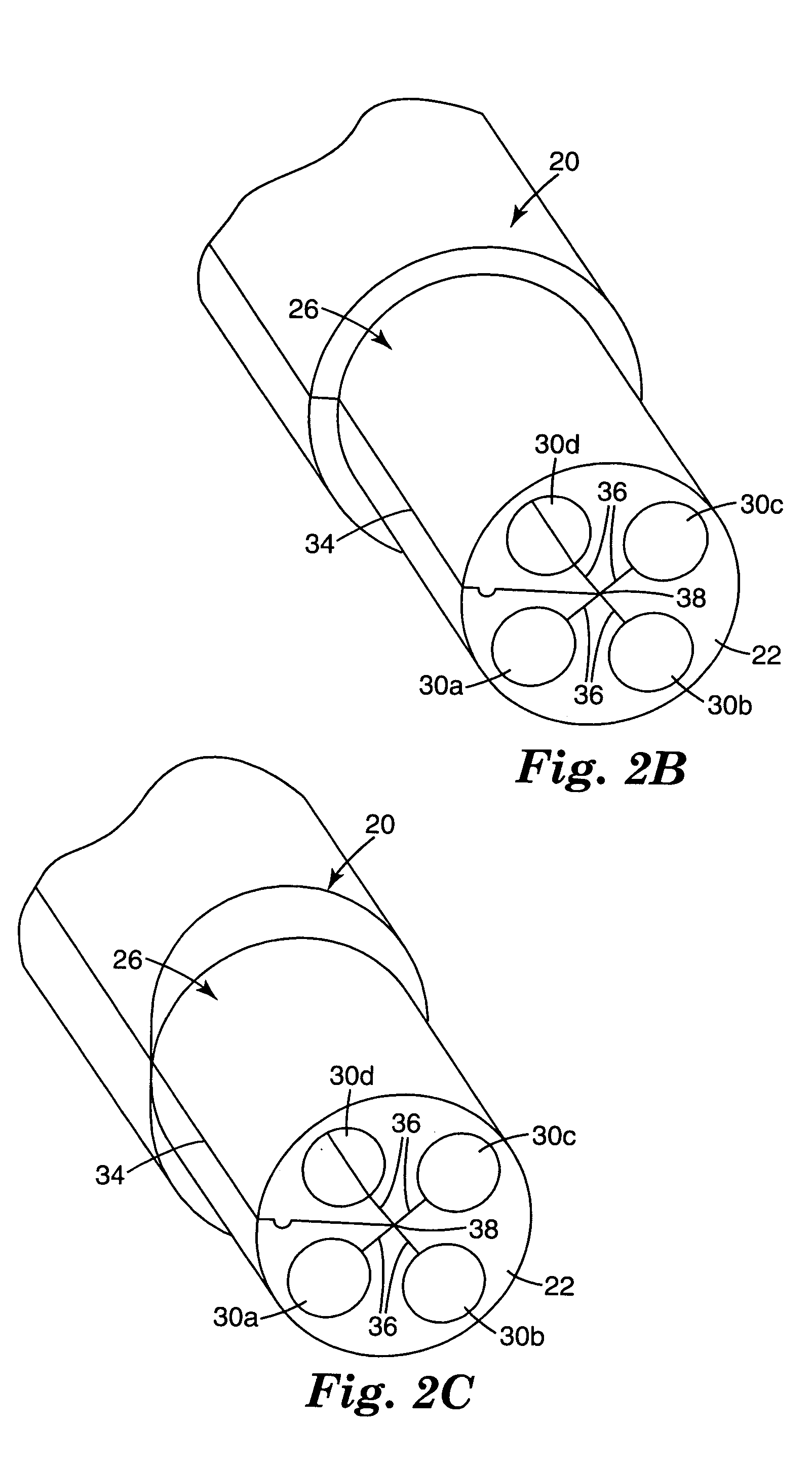

Sealing member for enclosures

A seal includes a body having an exterior surface configured for sealing engagement with an entry port of an enclosure. A plurality of passages extend from a first end of the body to a second end of the body. Each of the plurality of passages is configured to receive at least one component therein. A body slit extends from the first end to the second end, and passes through the body from the exterior surface to an interior point in the body. A plurality of passage slits extend from the first end to the second end. Each of the plurality of passage slits pass through the body from the interior point in the body to a corresponding one of the plurality of passages.

Owner:CORNING RES & DEV CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com