Patents

Literature

604 results about "Thermal coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

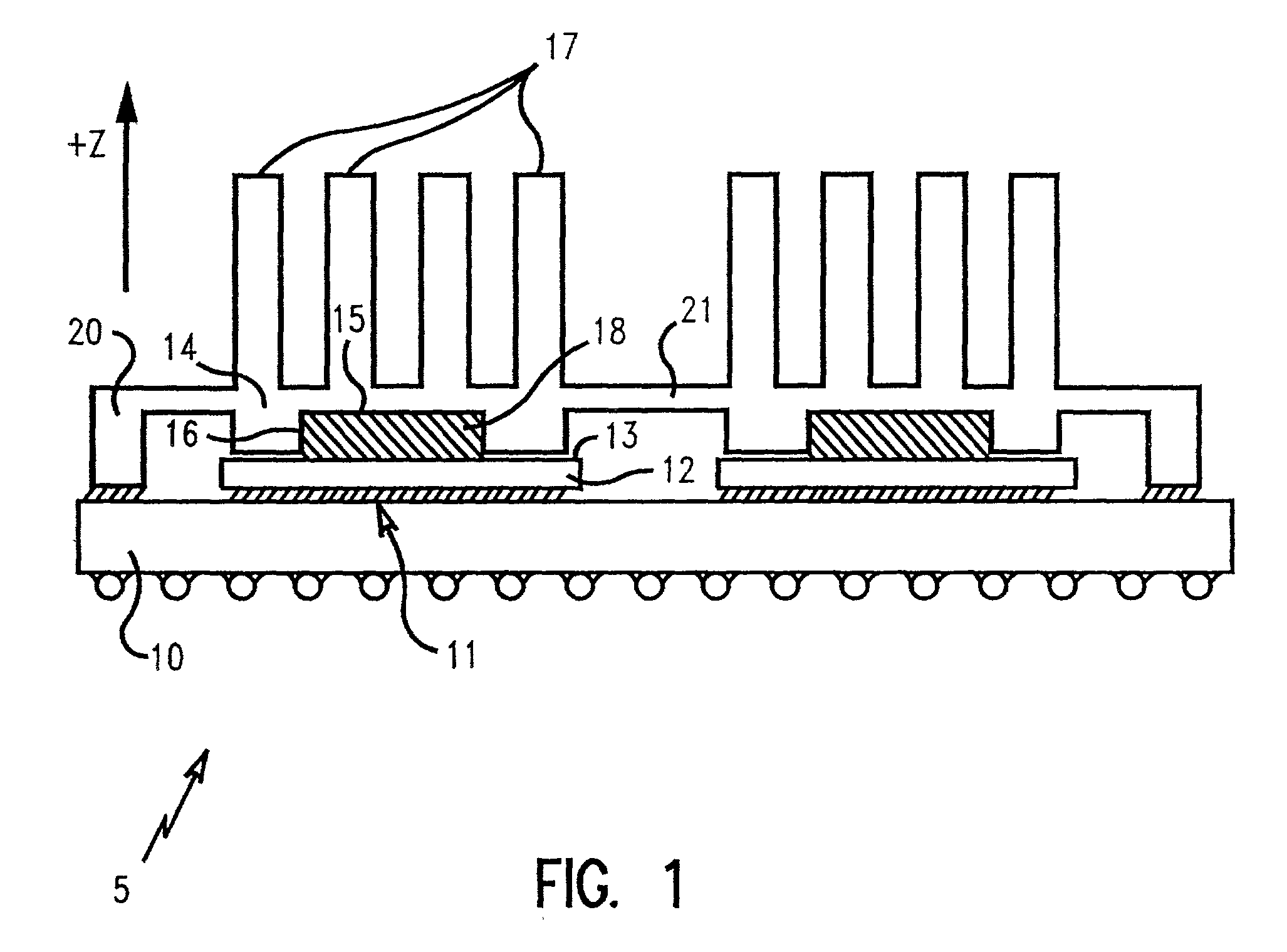

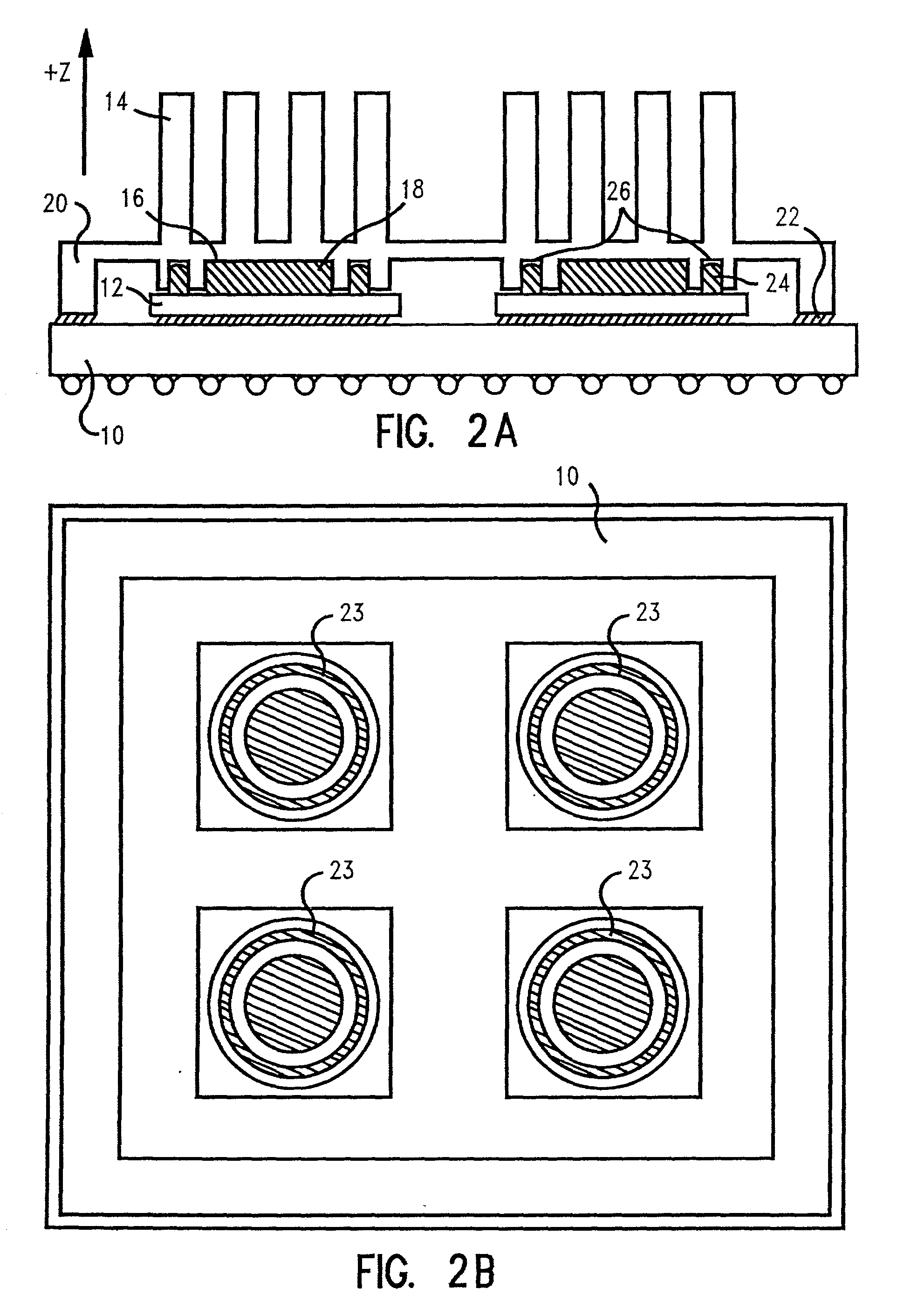

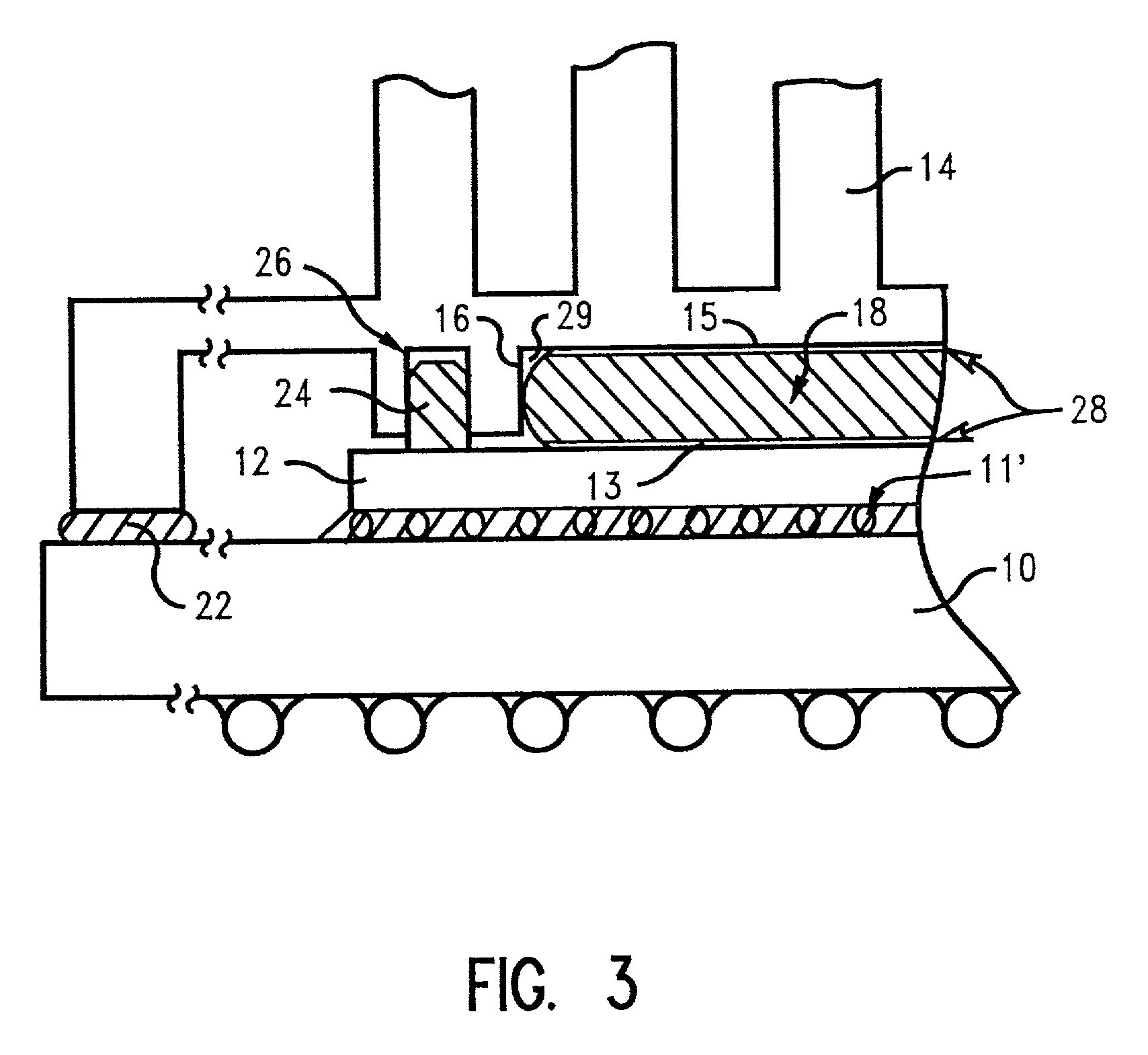

Thermal enhancement approach using solder compositions in the liquid state

InactiveUS6281573B1Lower resistanceThermal mismatchPrinted electric component incorporationSemiconductor/solid-state device detailsThermal energyThermal coefficient

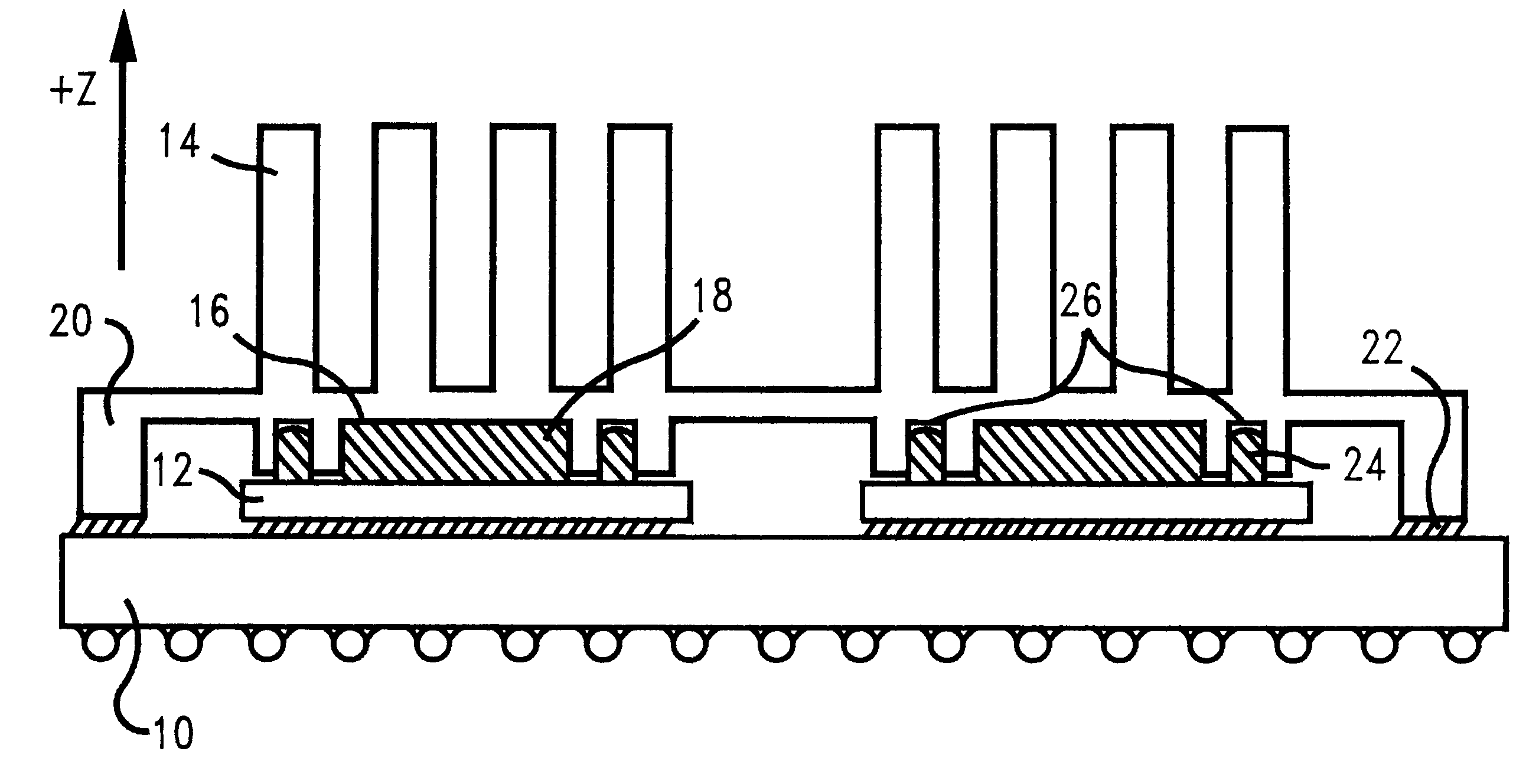

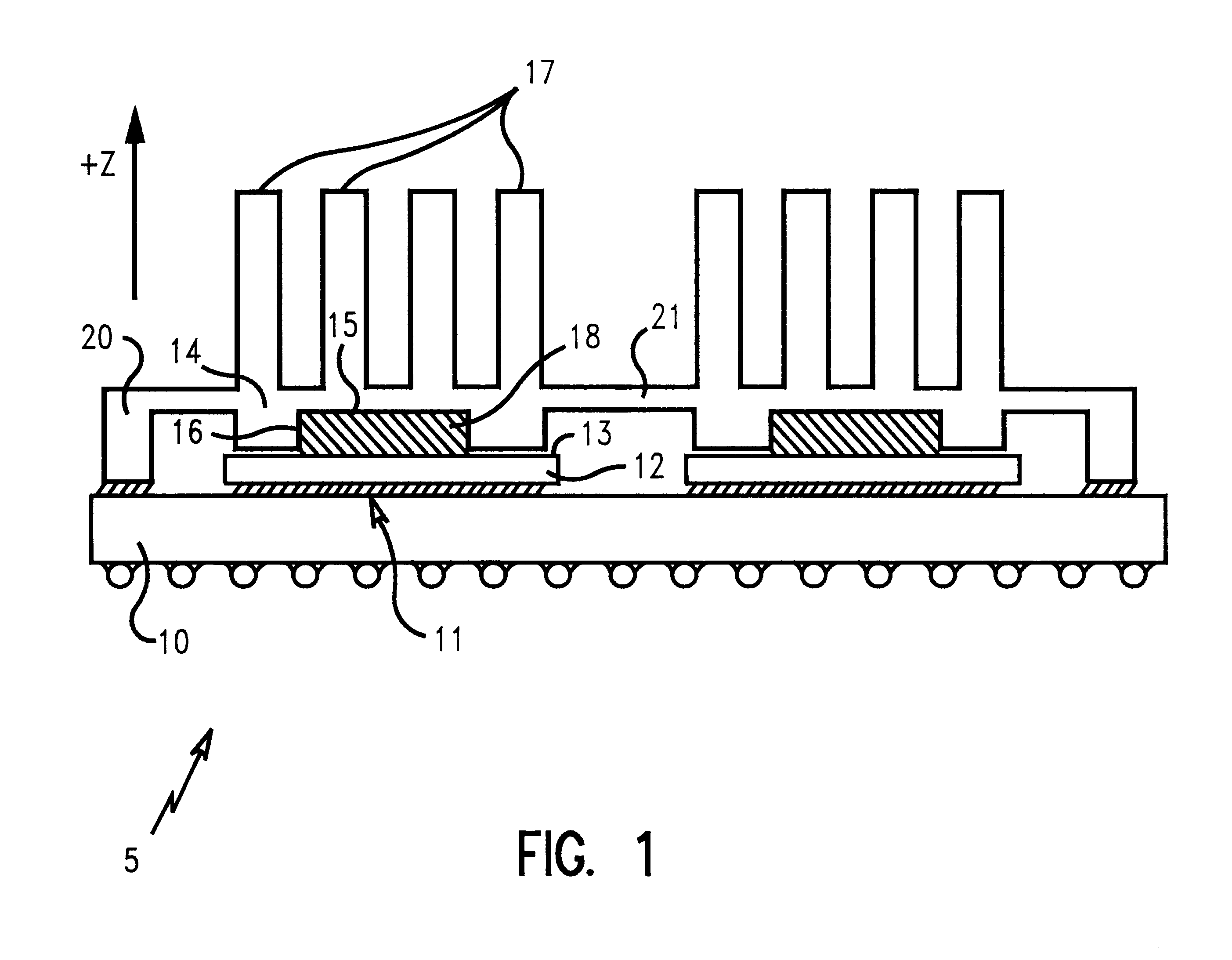

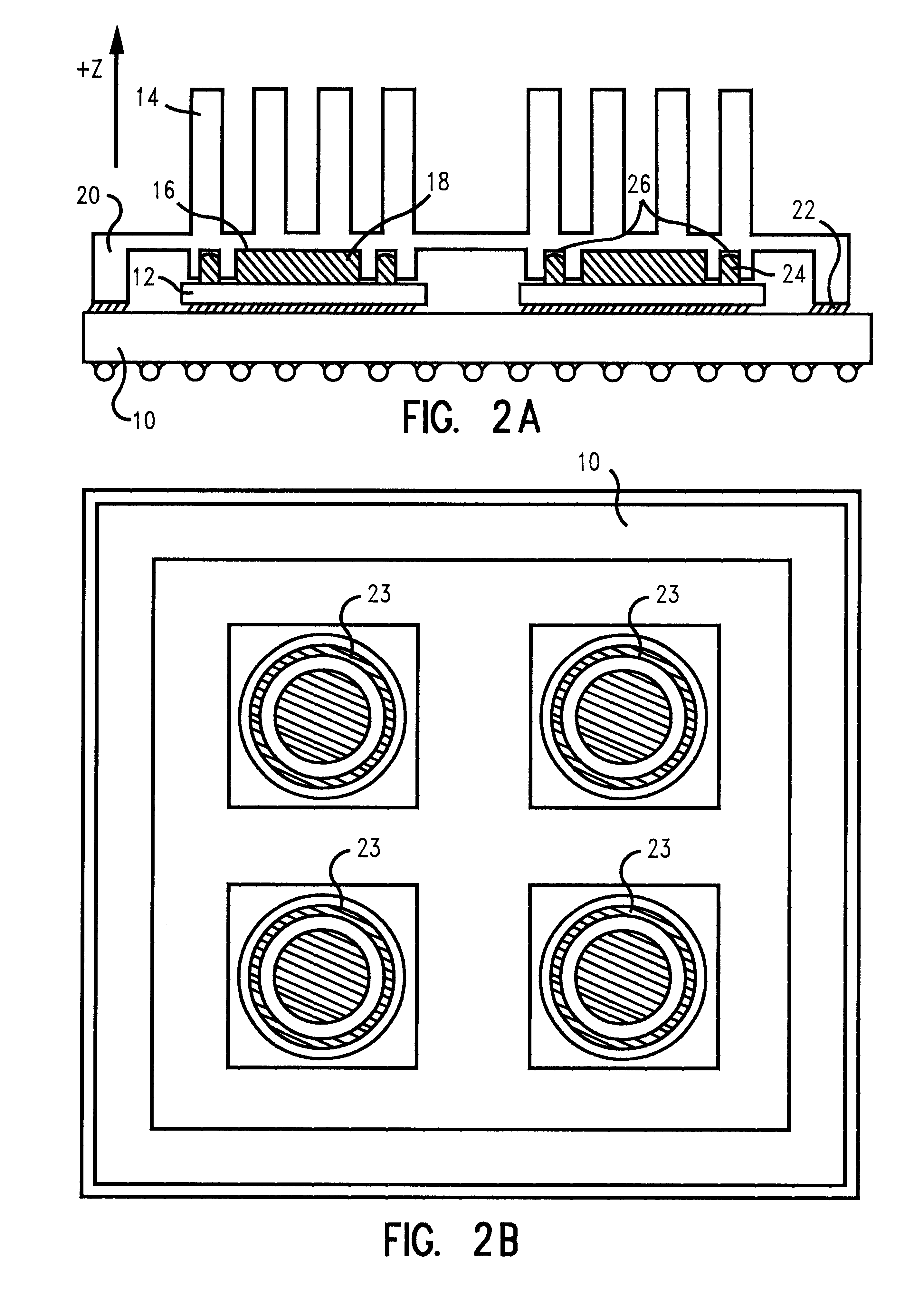

Solder compositions are introduced to interface between an IC chip and its associated heat exchanger cover. The solder compositions have a solidus-liquidus temperature range that encompasses the IC chip operational temperature range. The solder composition has the desired property of absorbing and rejecting heat energy by changing state or phase with each temperature rise and decline that result from temperature fluctuations associated with the thermal cycles of the integrated circuit chips. A path for high thermal conduction (low thermal resistance) from the IC chip to the heat exchanger to the ambient air is provided by an electronic module cover, configured as a cap with a heat exchanger formed or attached as a single construction, and made of the same material as the substrate, or made with materials of compatible thermal coefficients of expansion to mitigate the effects of vertical displacement during thermal cycling. The cap-heat exchanger cover is constructed to be compliant, and to contact both the IC chip and substrate.

Owner:IBM CORP

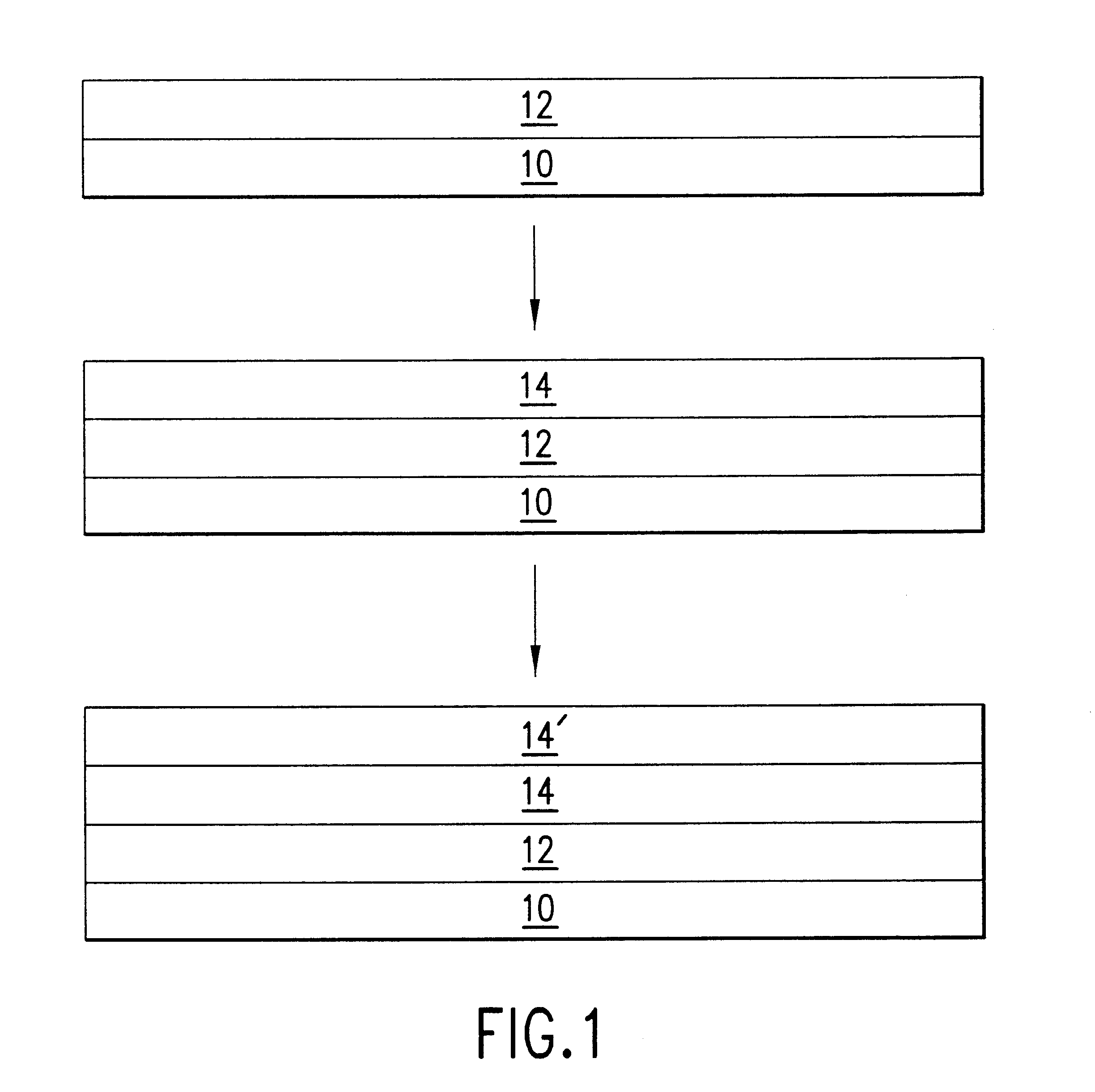

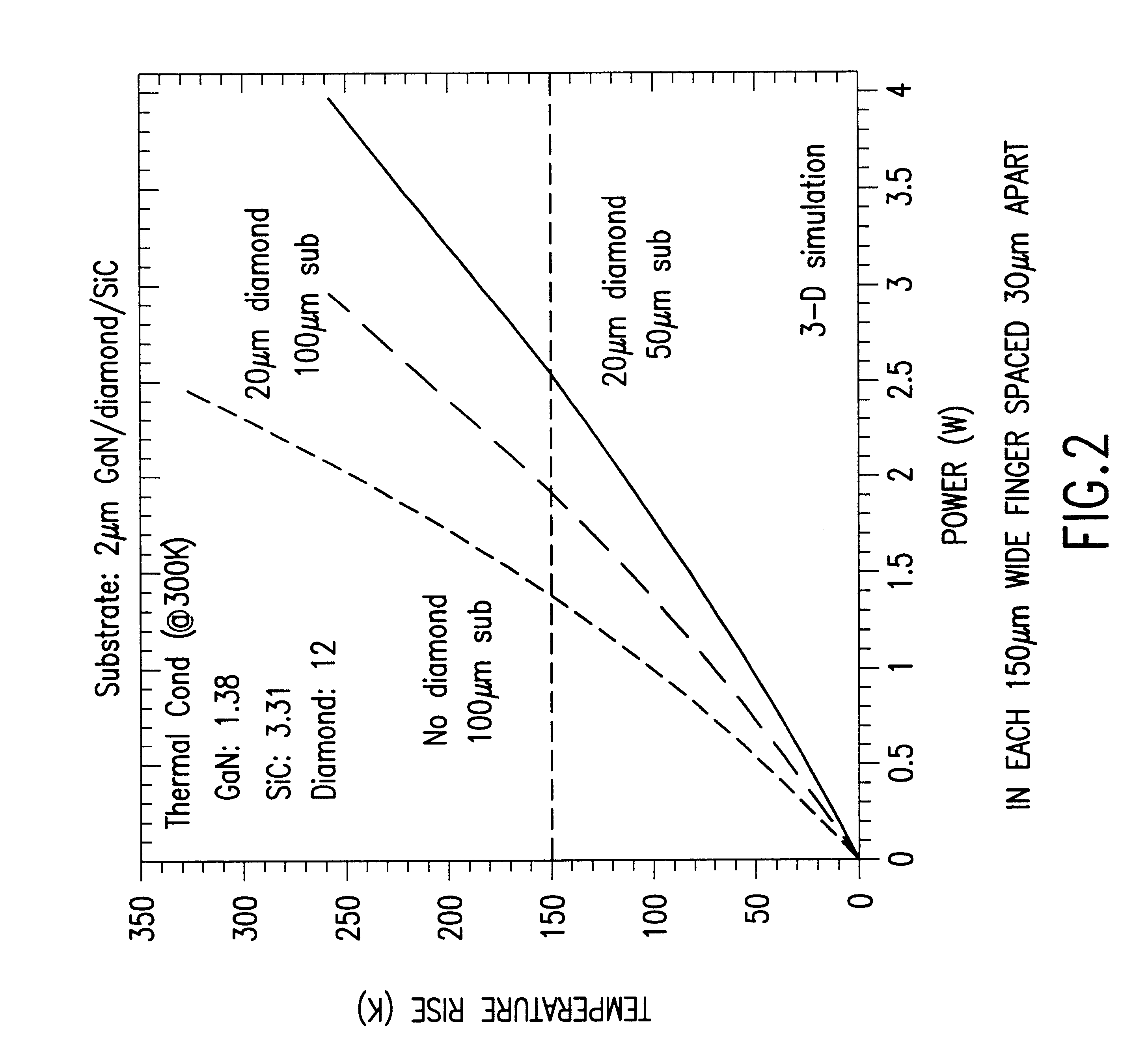

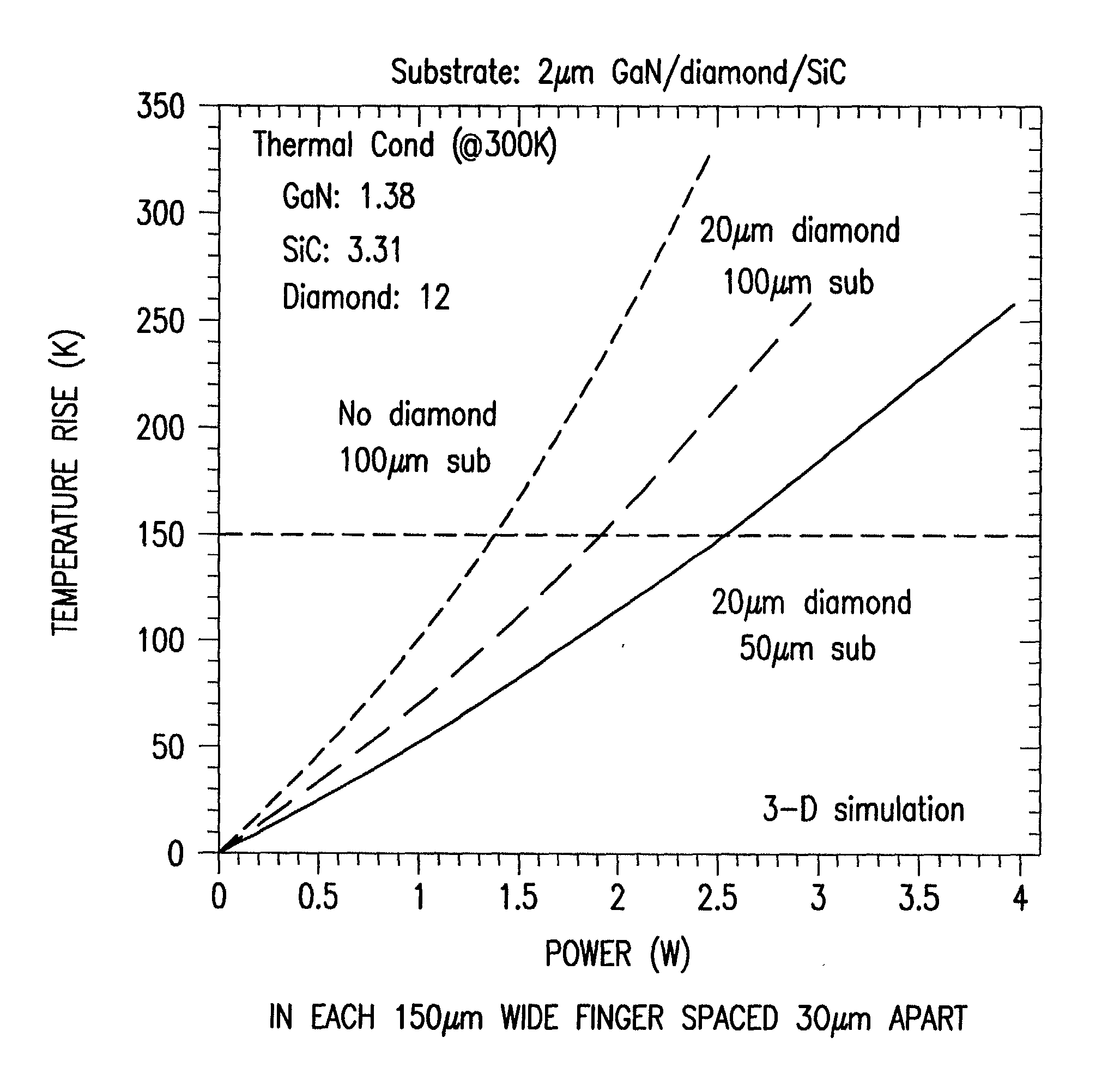

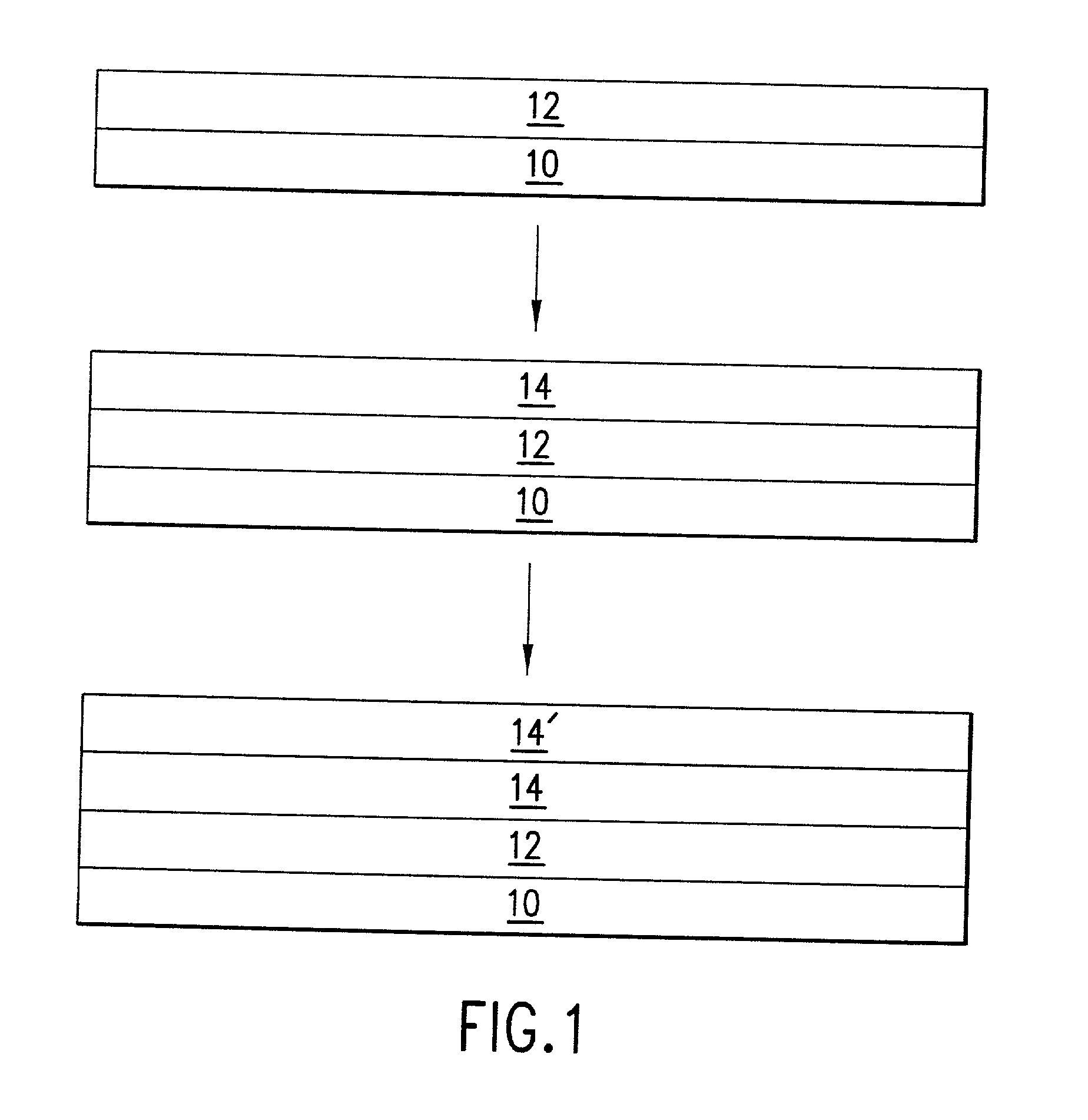

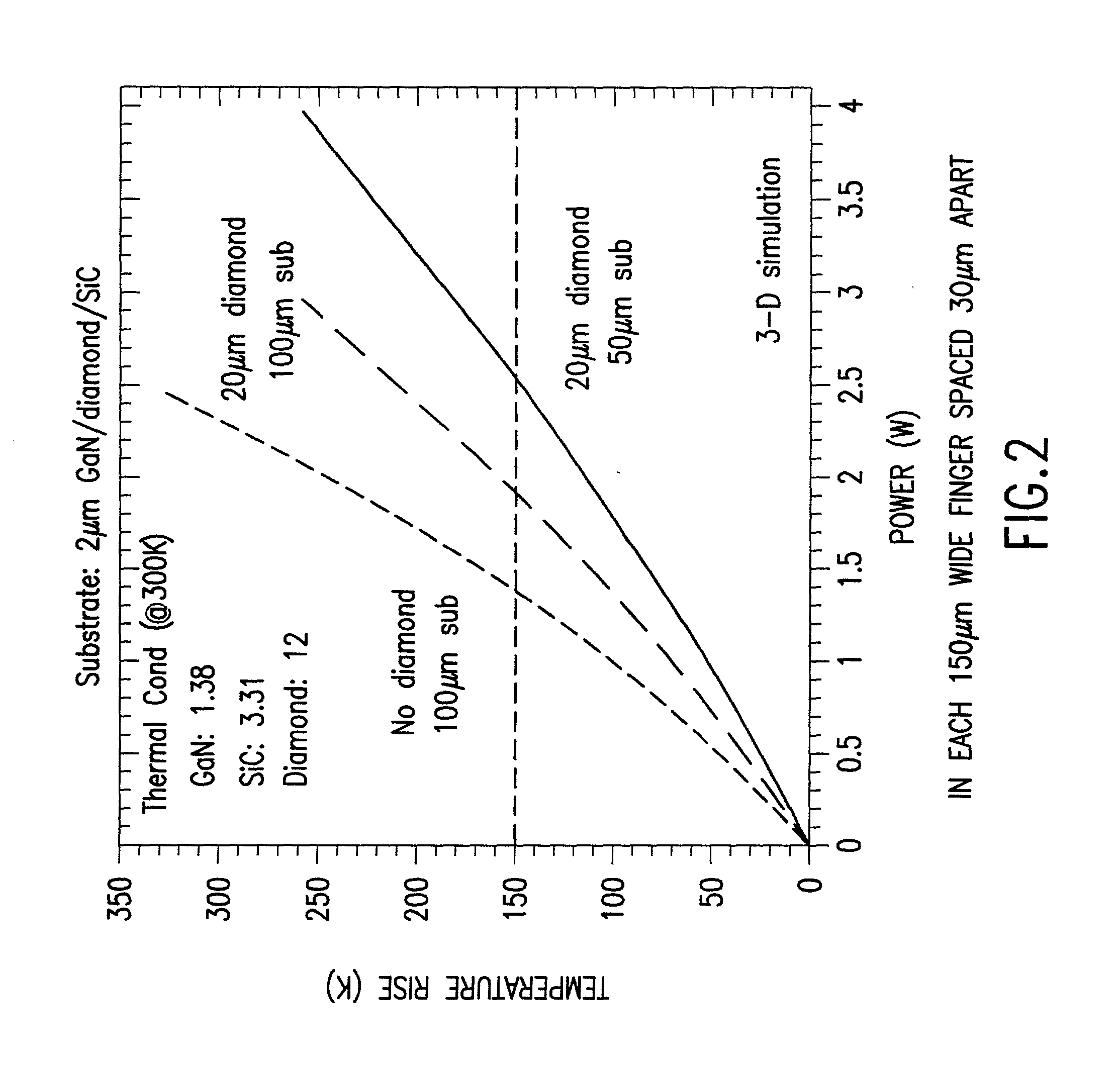

Electronic device with composite substrate

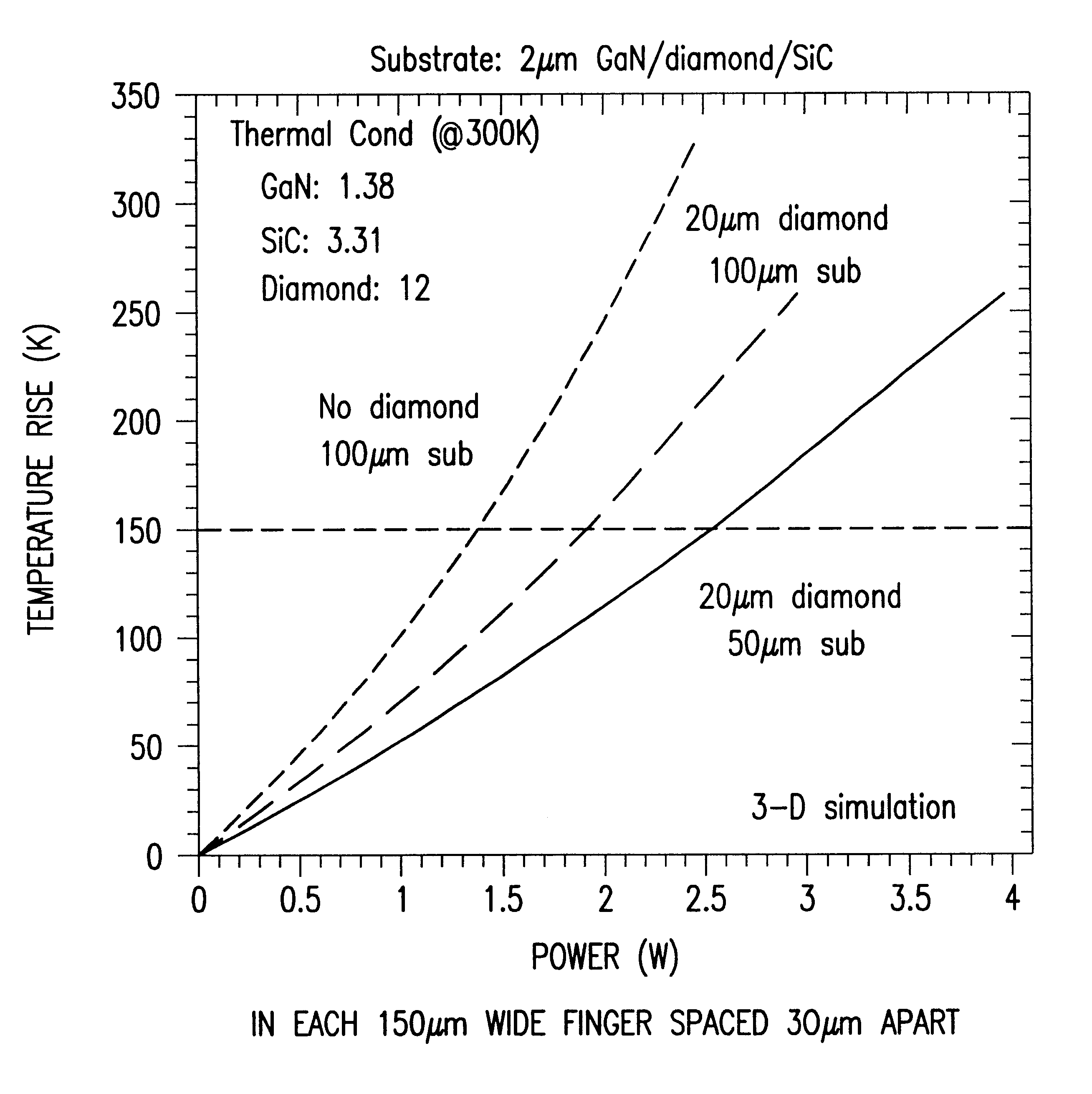

InactiveUS6497763B2Improve scalabilityImprove electronic performancePolycrystalline material growthSemiconductor/solid-state device manufacturingThermal coefficientComposite substrate

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

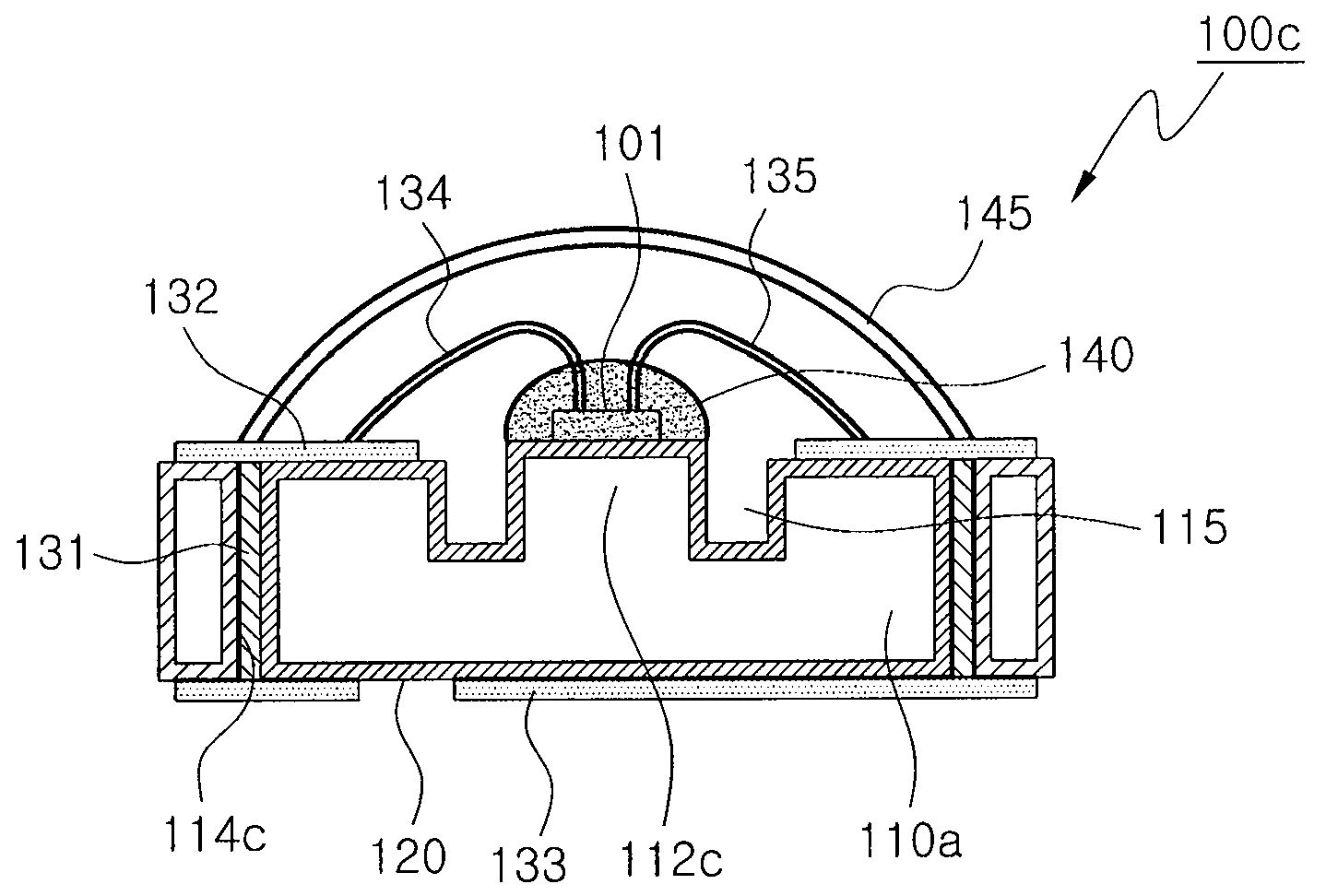

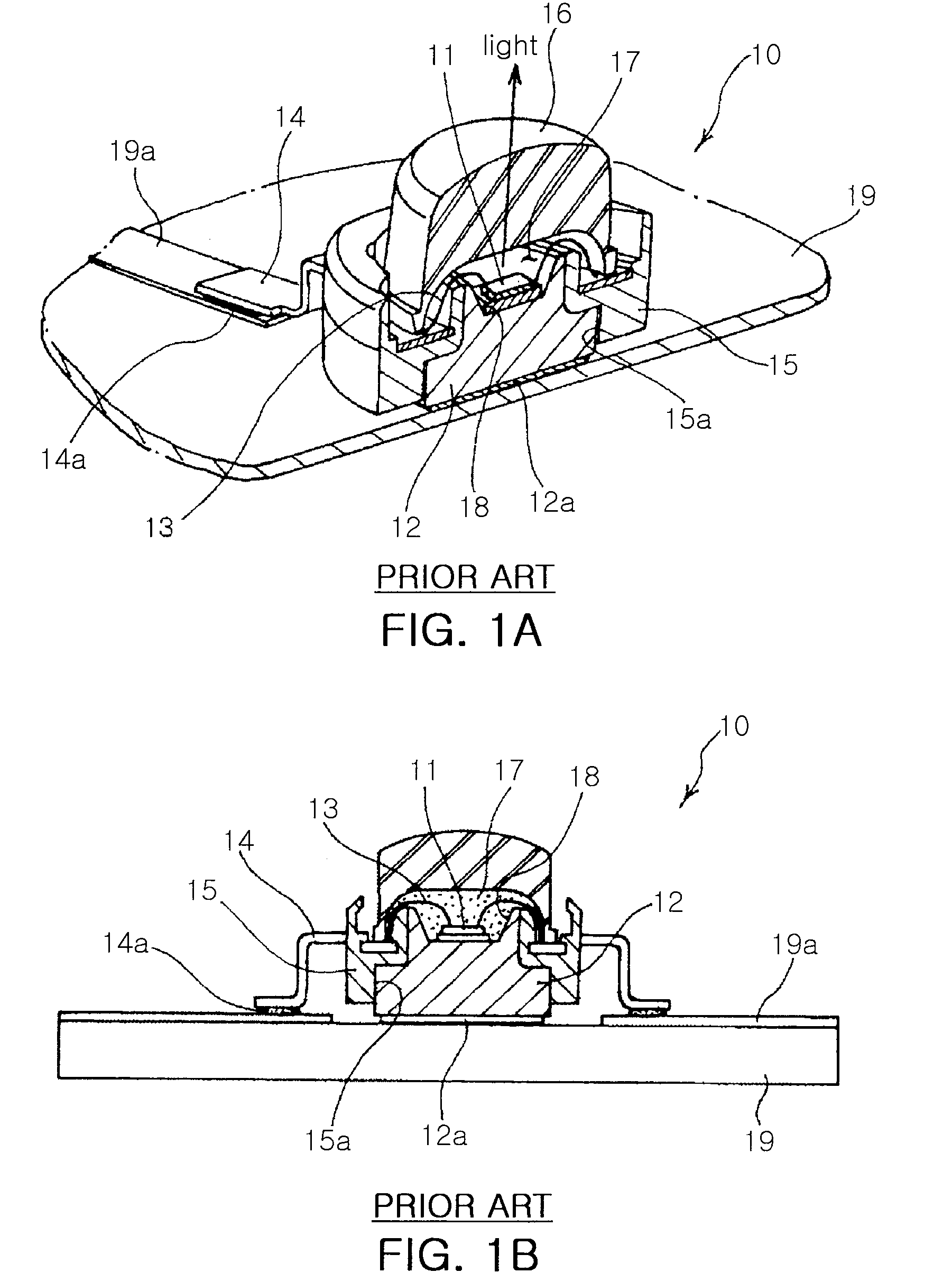

High power light emitting diode package and manufacturing method thereof

InactiveUS20090166664A1Improve cooling effectMinimized in optical lossSolid-state devicesSemiconductor/solid-state device manufacturingThermal impactThermal coefficient

There is provided a high power LED package and a method of manufacturing the same. The method includes: forming at least one chip mounting part and at least one through hole in a metal plate; forming an insulating layer of a predetermined thickness on an entire outer surface of the metal plate; forming an electrode part to be electrically connected to a light emitting chip mounted on the chip mounting part; and cutting the metal plate along a trimming line to separate the package. The LED package is free from thermal impact resulting from different thermal coefficients among components, thus ensuring stable heat radiation characteristics in a high temperature atmosphere. Also, the LED package is minimized in optical loss to improve optical characteristics. In addition, the LED package is simplified in a manufacturing and assembly process and thus can be manufactured in mass production at a lower cost.

Owner:SAMSUNG ELECTRONICS CO LTD

Electronic device with composite substrate

InactiveUS20020096106A1Fast heat conductionGood thermal expansionPolycrystalline material growthSemiconductor/solid-state device manufacturingThermal dilatationComposite substrate

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

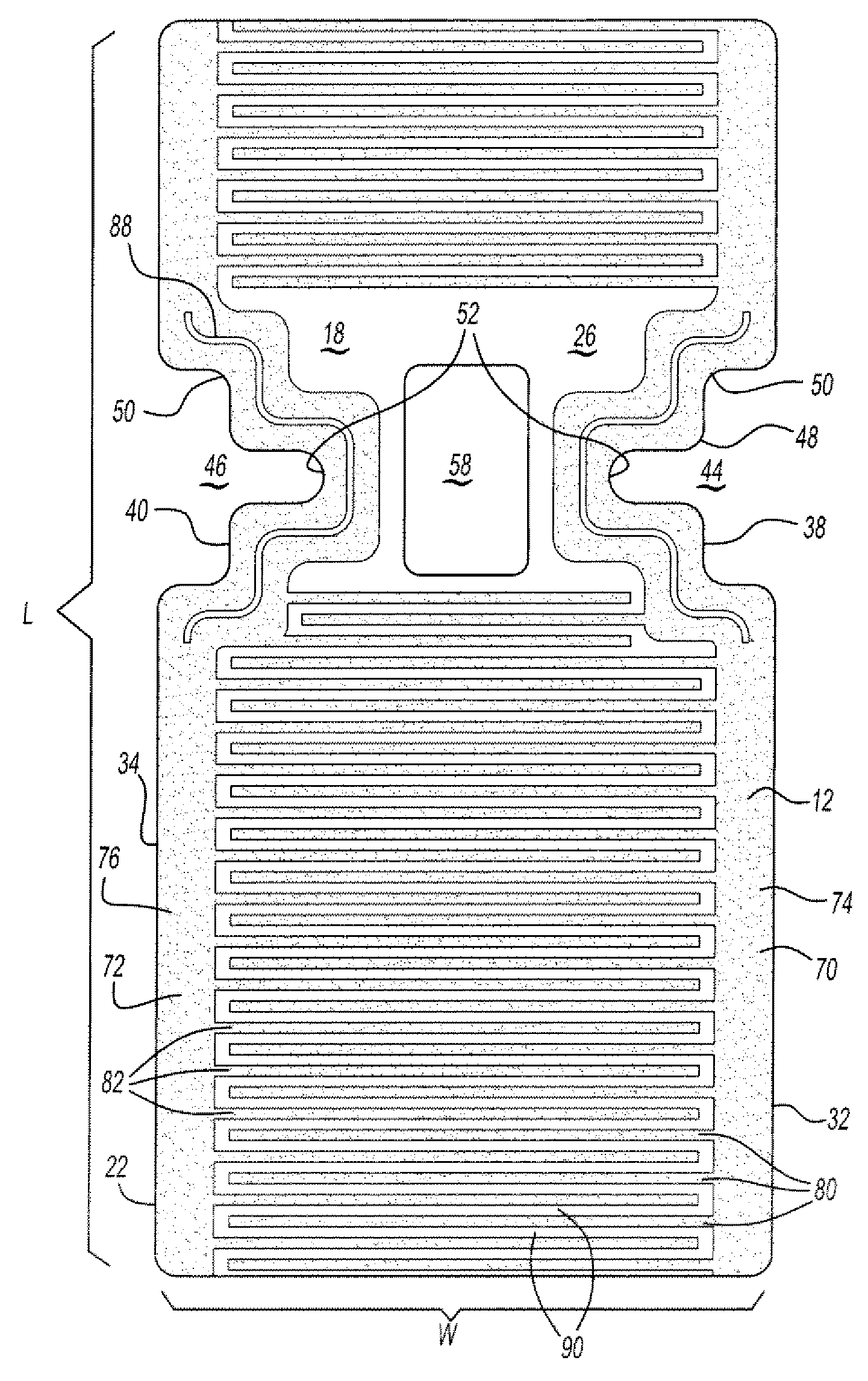

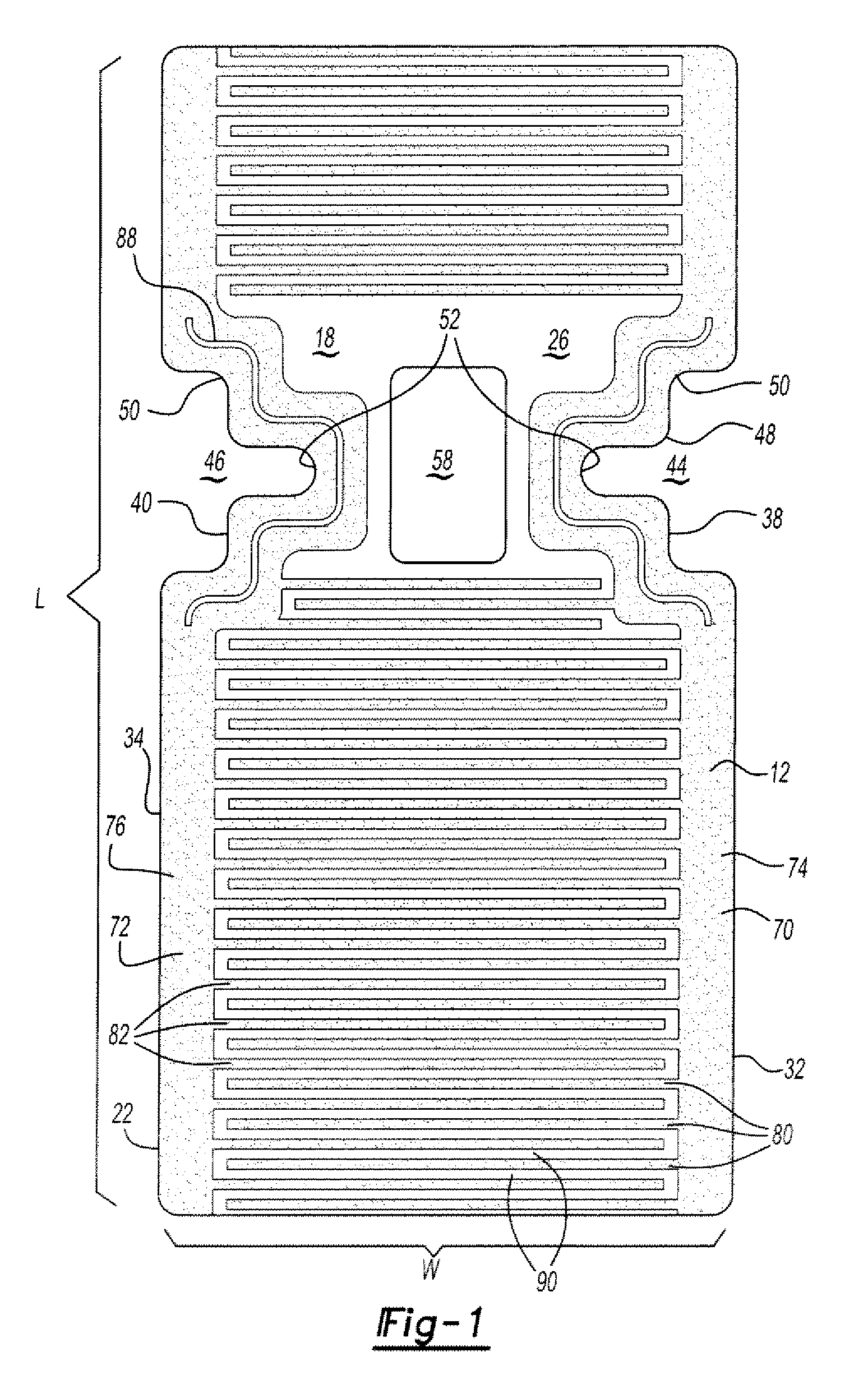

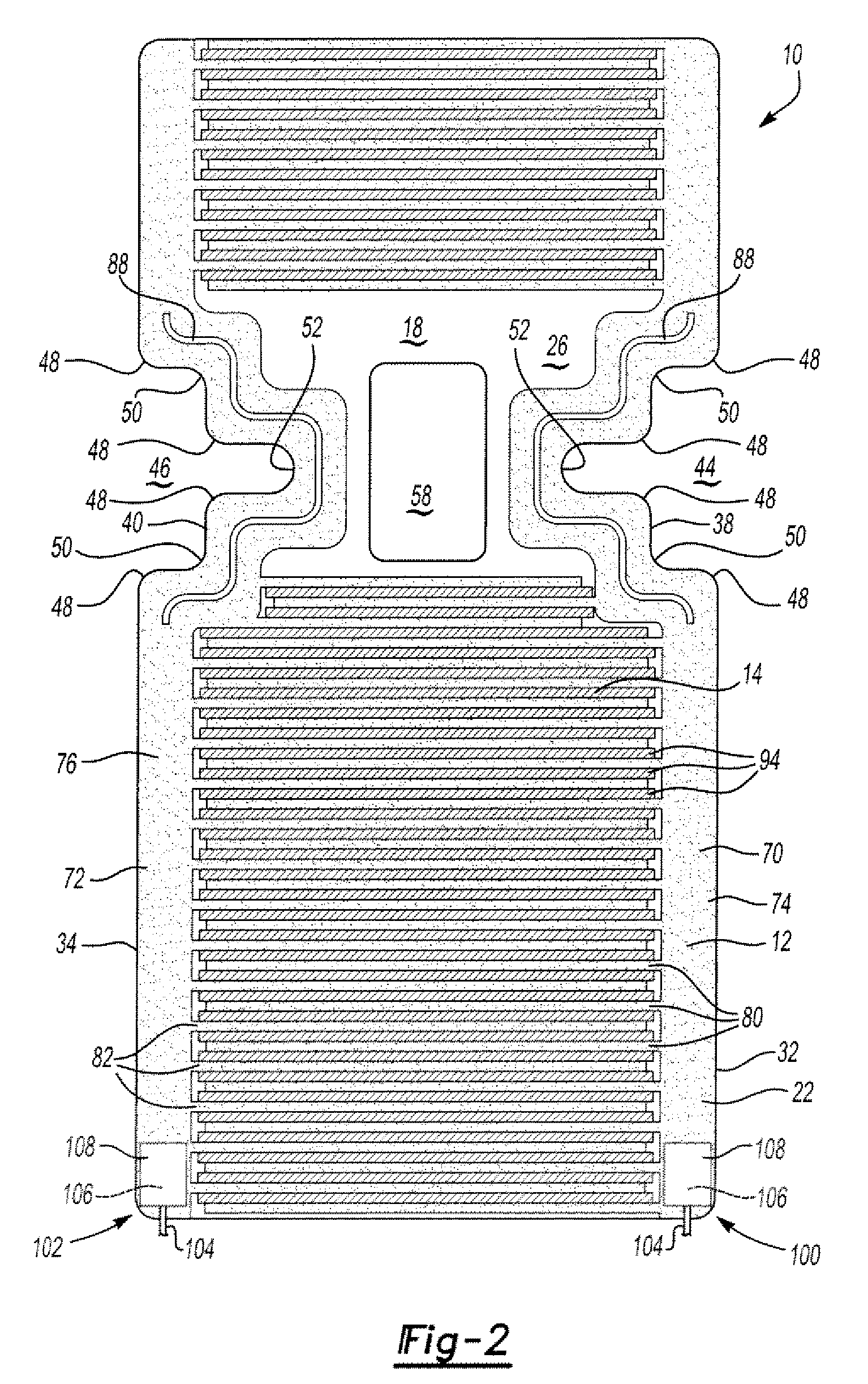

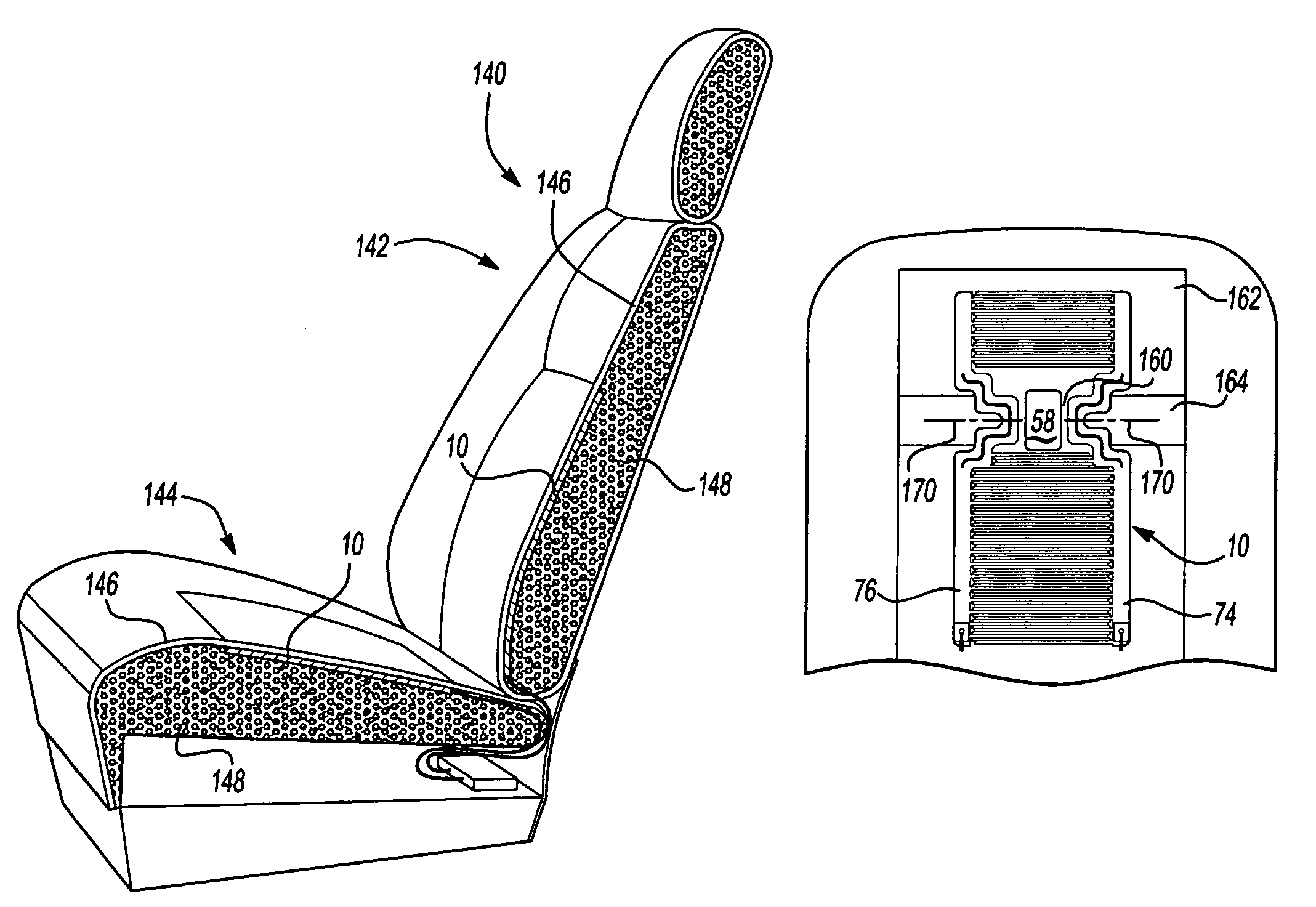

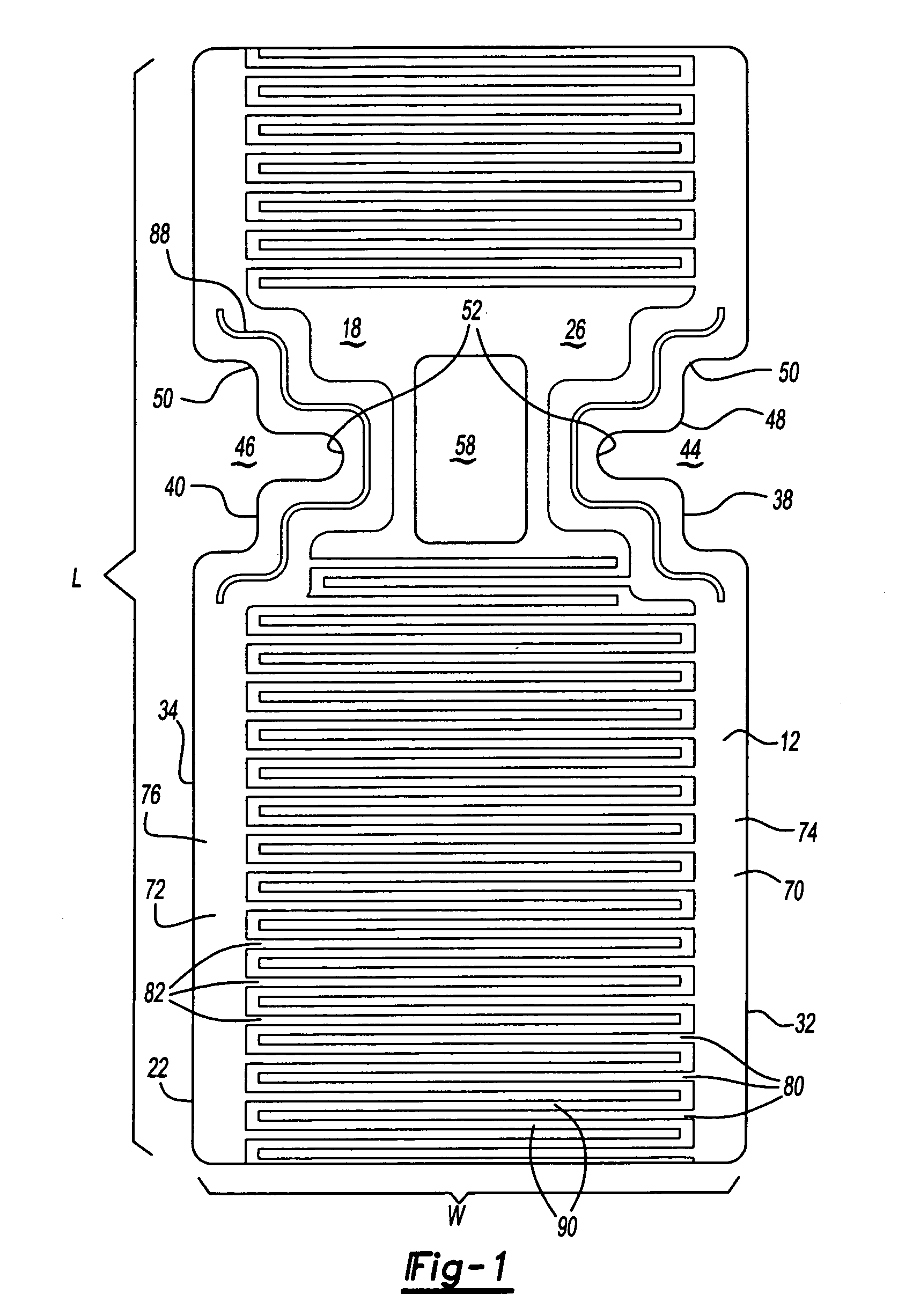

Heater for an automotive vehicle and method of forming same

There is disclosed a heater for an automotive vehicle or other article of manufacture. The heater typically includes a first conductive medium and a second conductive medium disposed upon a carrier. In a preferred embodiment, the first conductive medium includes a first section and a second section that are electrically connected by a second conductive medium. The second conductive medium preferably exhibits a positive thermal coefficient.

Owner:GENTHERM GMBH

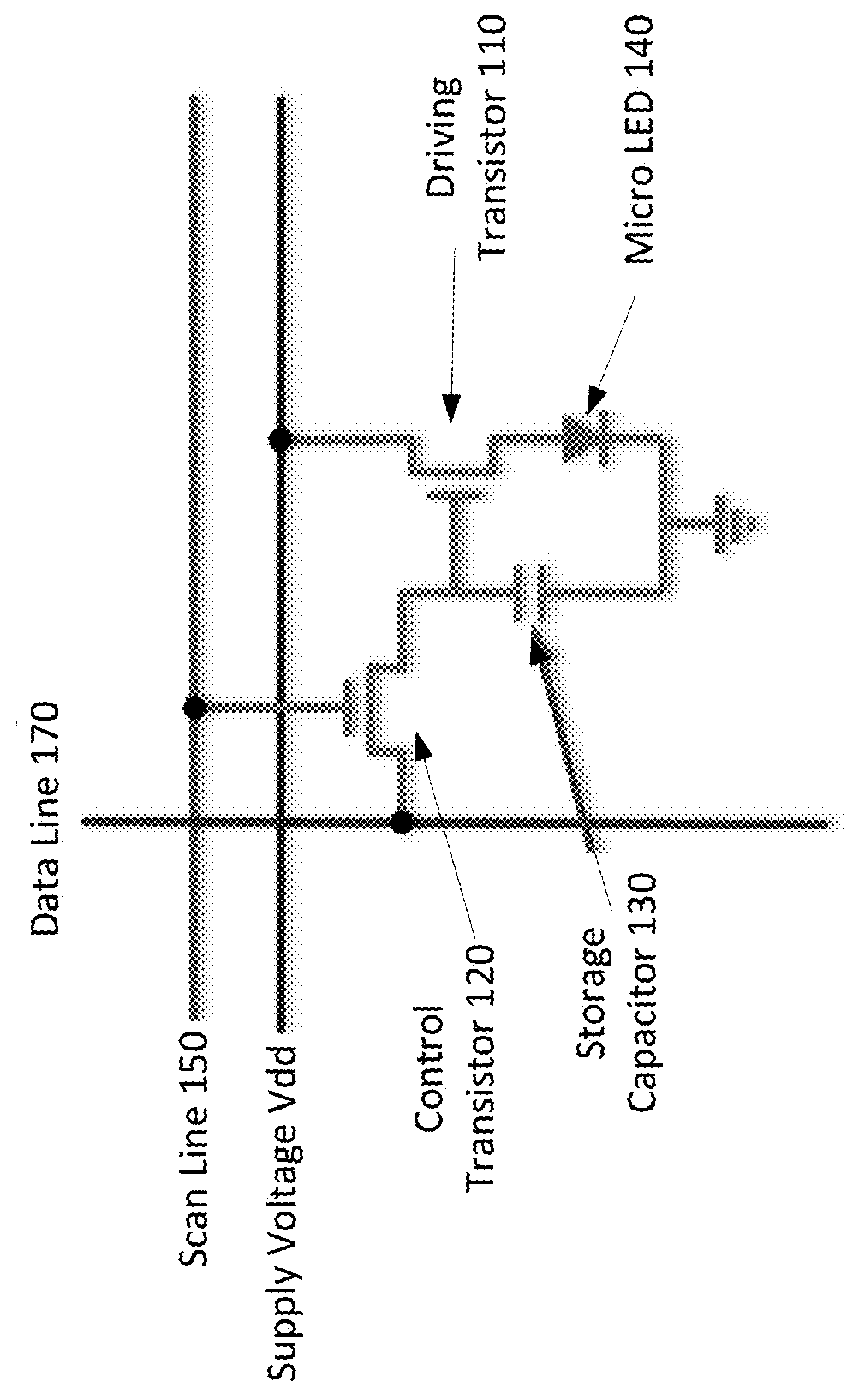

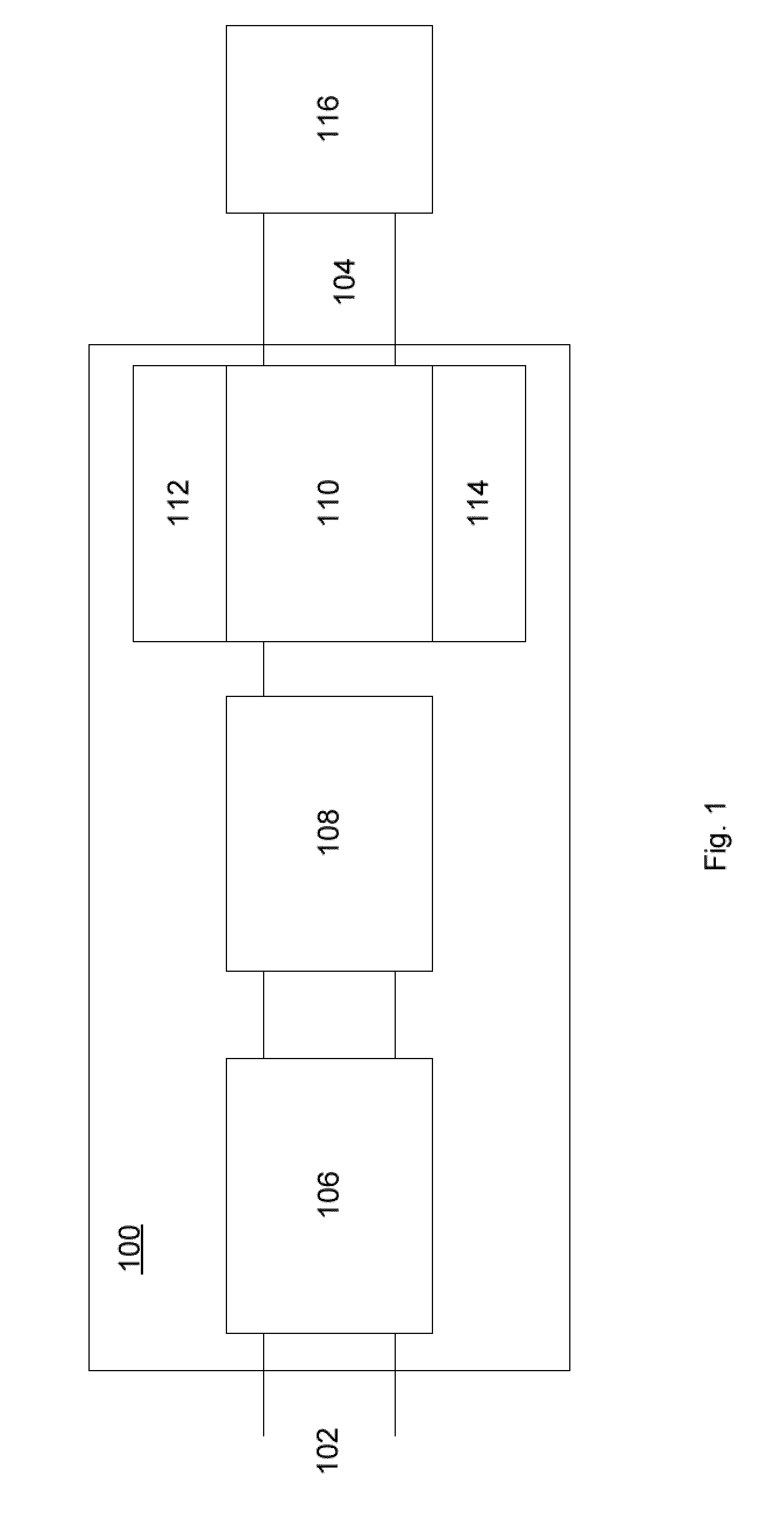

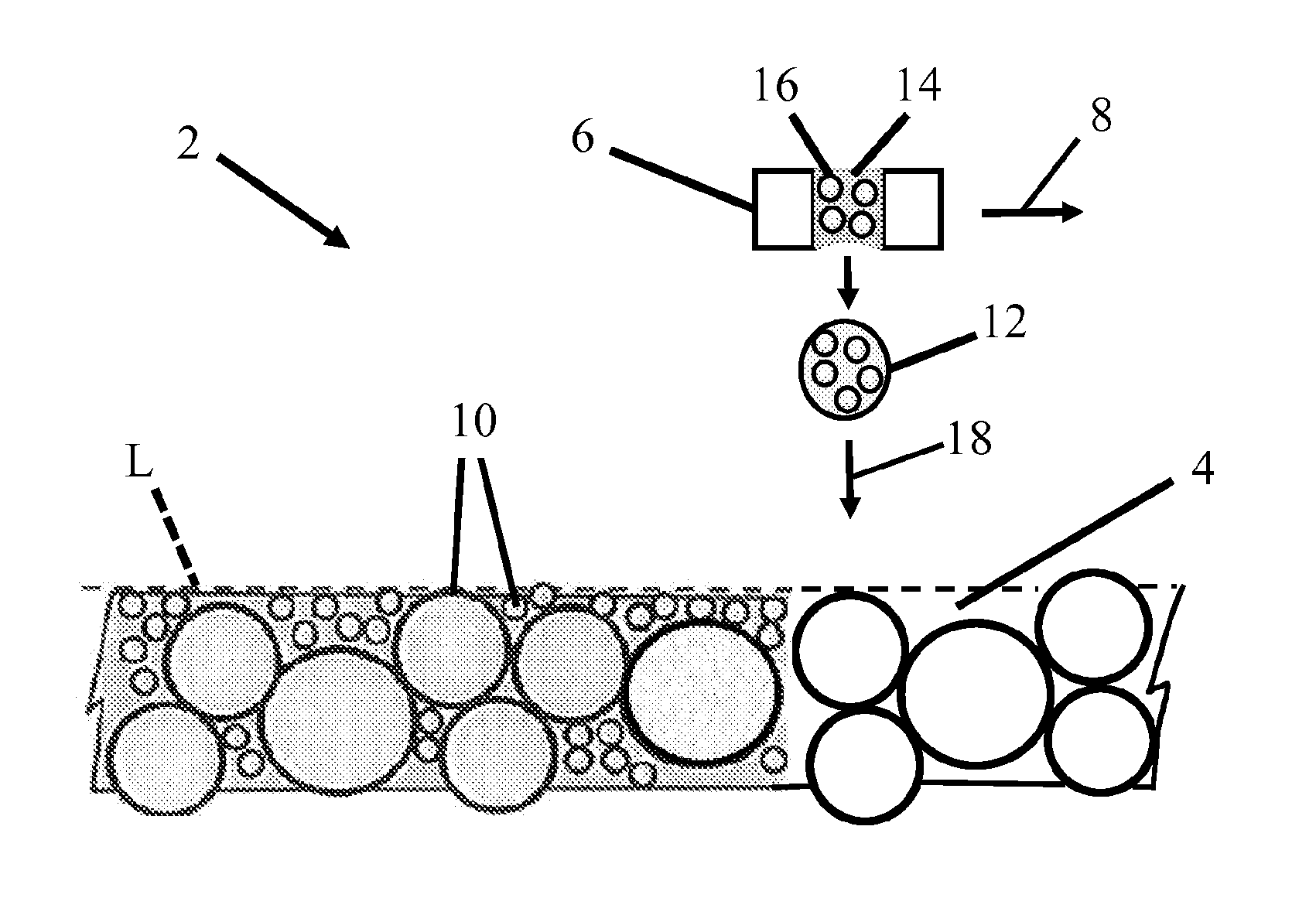

Mass Transfer Of Micro Structures Using Adhesives

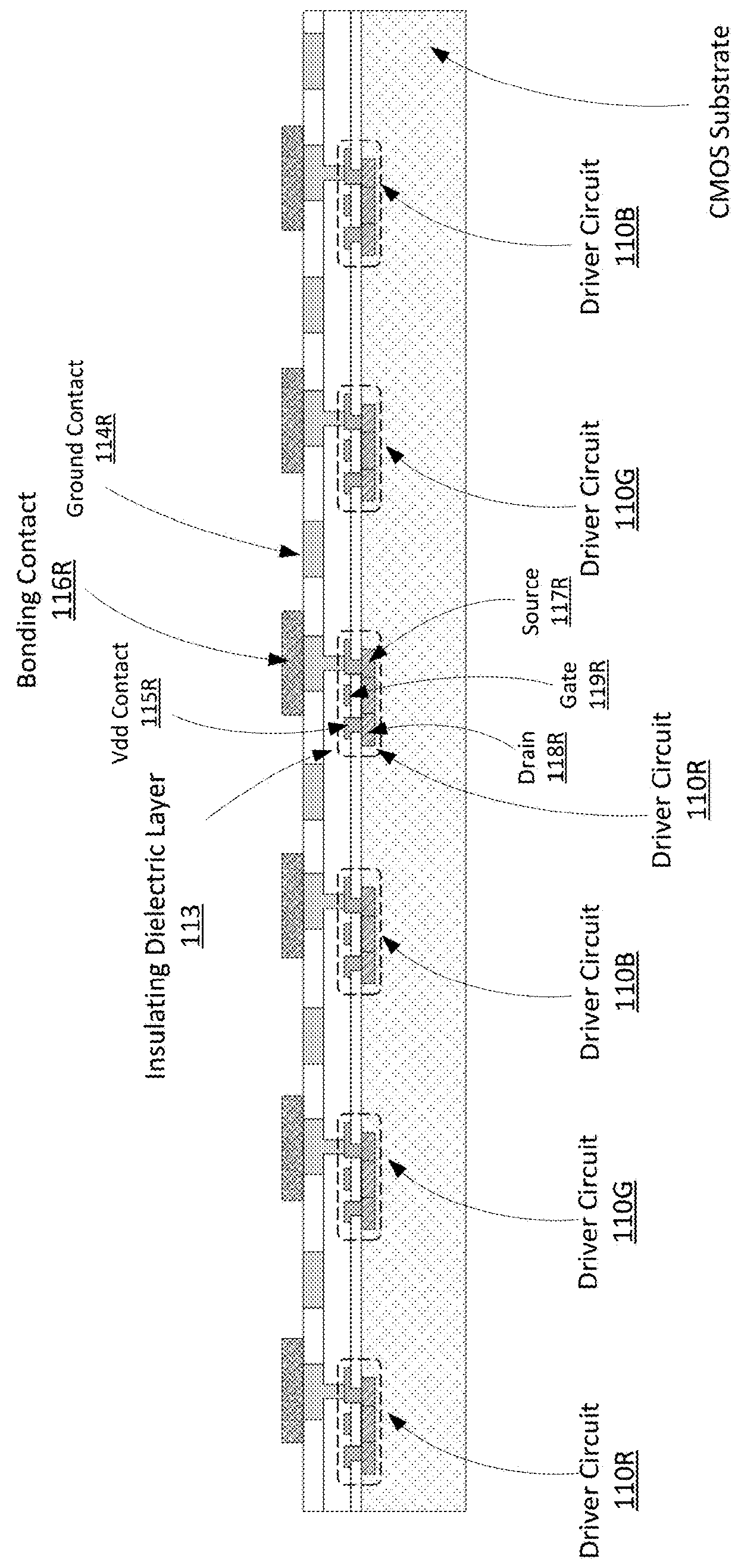

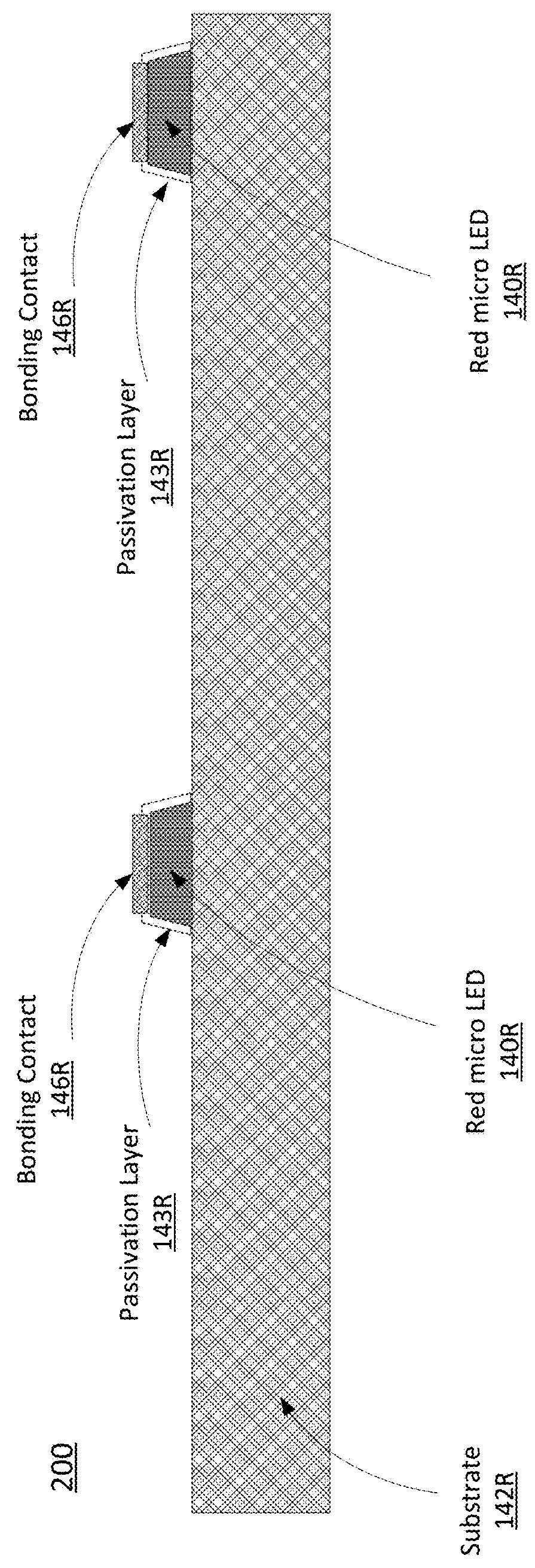

ActiveUS20180166429A1Solid-state devicesSemiconductor/solid-state device manufacturingMicro structureLED display

Mass transfer of micro structures are effected from one substrate to another using adhesives. In the context of an integrated micro LED display, a micro LED array is fabricated on a native substrate and corresponding CMOS pixel drivers are fabricated on a separate substrate. The micro LED substrate (e.g., sapphire) and the CMOS substrate (e.g., silicon) may be incompatible. For example, they may have different thermal coefficients of expansion which make it difficult to bond the micro LEDs to the pixel driver circuitry. The micro LED array is transferred to an intermediate substrate (e.g., silicon) by use of an adhesive. This intermediate substrate may be used in a process of bonding the micro LED array to the array of pixel drivers. The intermediate substrate is separated from the micro LED array by releasing the adhesive.

Owner:JADE BIRD DISPLAY SHANG HAI LTD

Heater for an automotive vehicle and method of forming same

ActiveUS7306283B2Seat heating/ventillating devicesTransparent/reflecting heating arrangementsMobile vehicleThermal coefficient

There is disclosed a heater for an automotive vehicle or other article of manufacture. The heater typically includes a first conductive medium and a second conductive medium disposed upon a carrier. In a preferred embodiment, the first conductive medium includes a first section and a second section that are electrically connected by a second conductive medium. The second conductive medium preferably exhibits a positive thermal coefficient.

Owner:GENTHERM GMBH

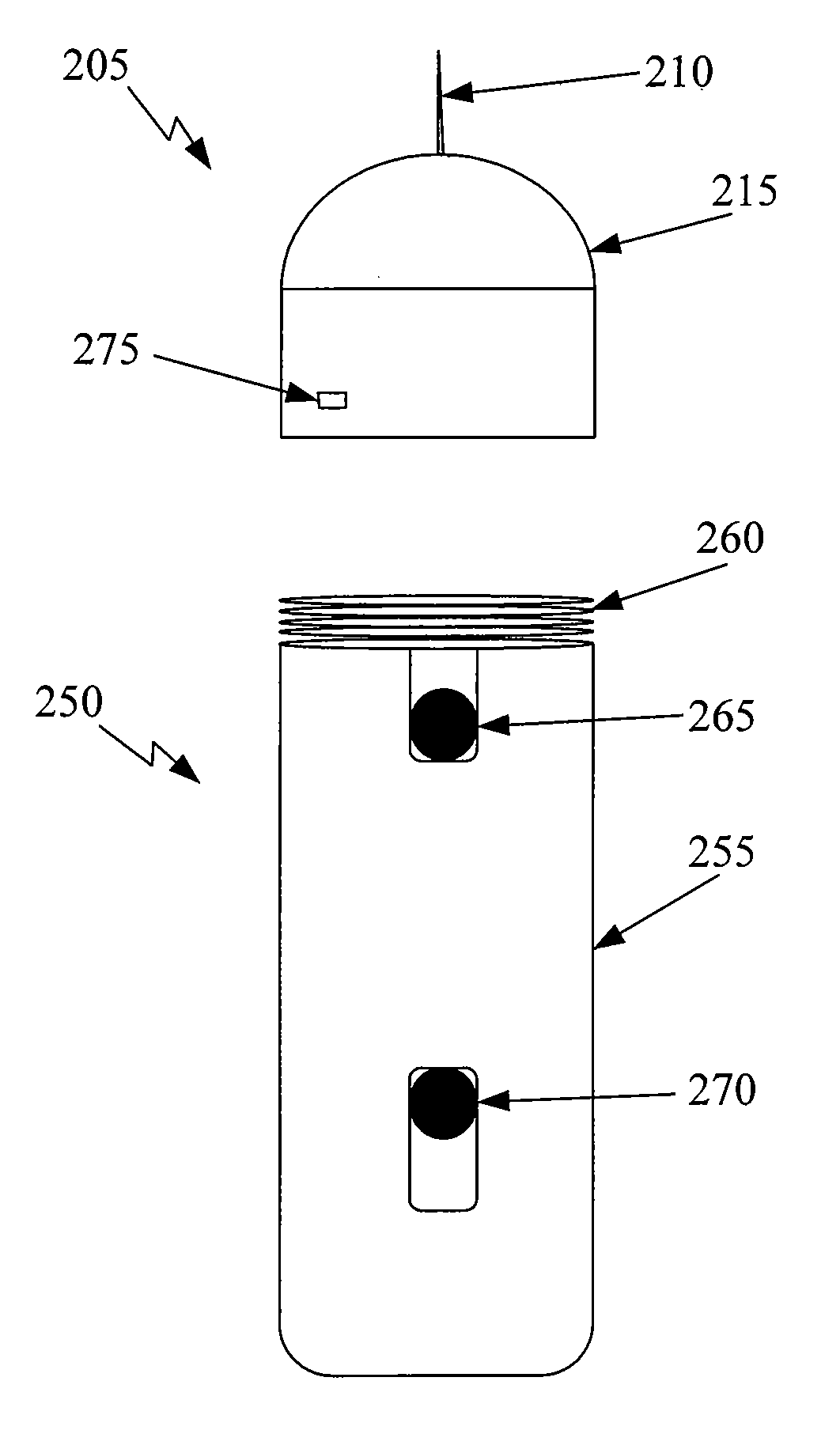

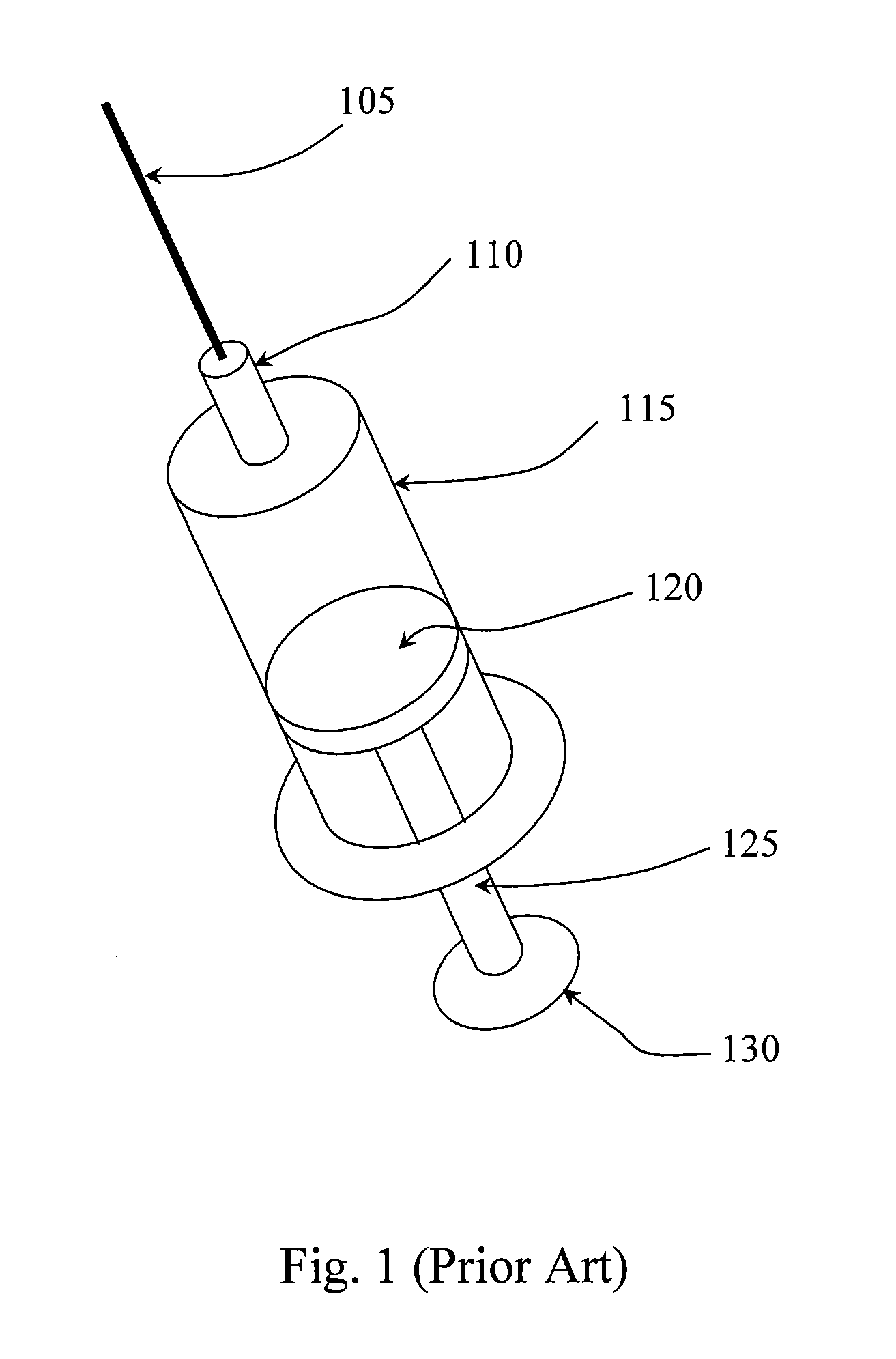

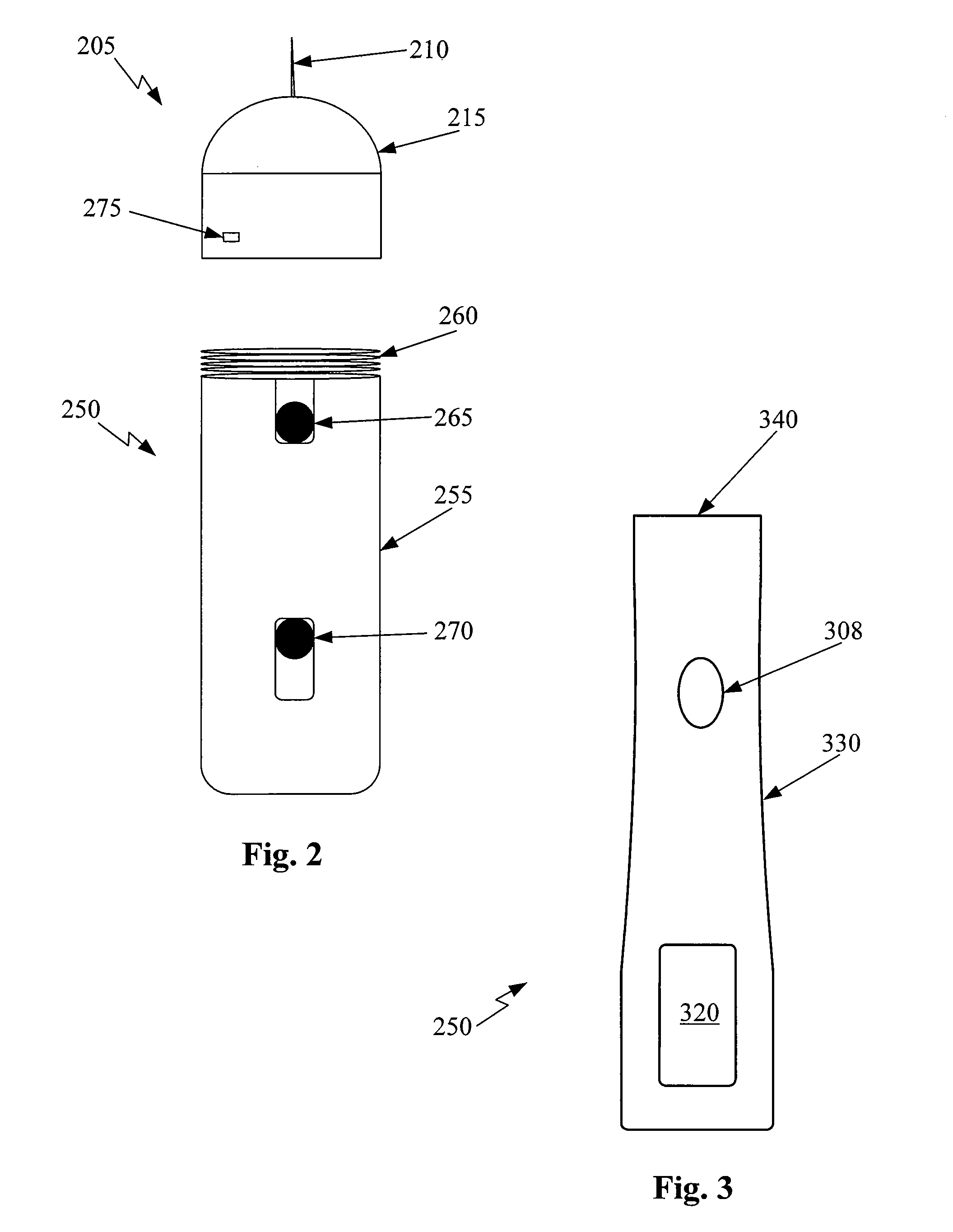

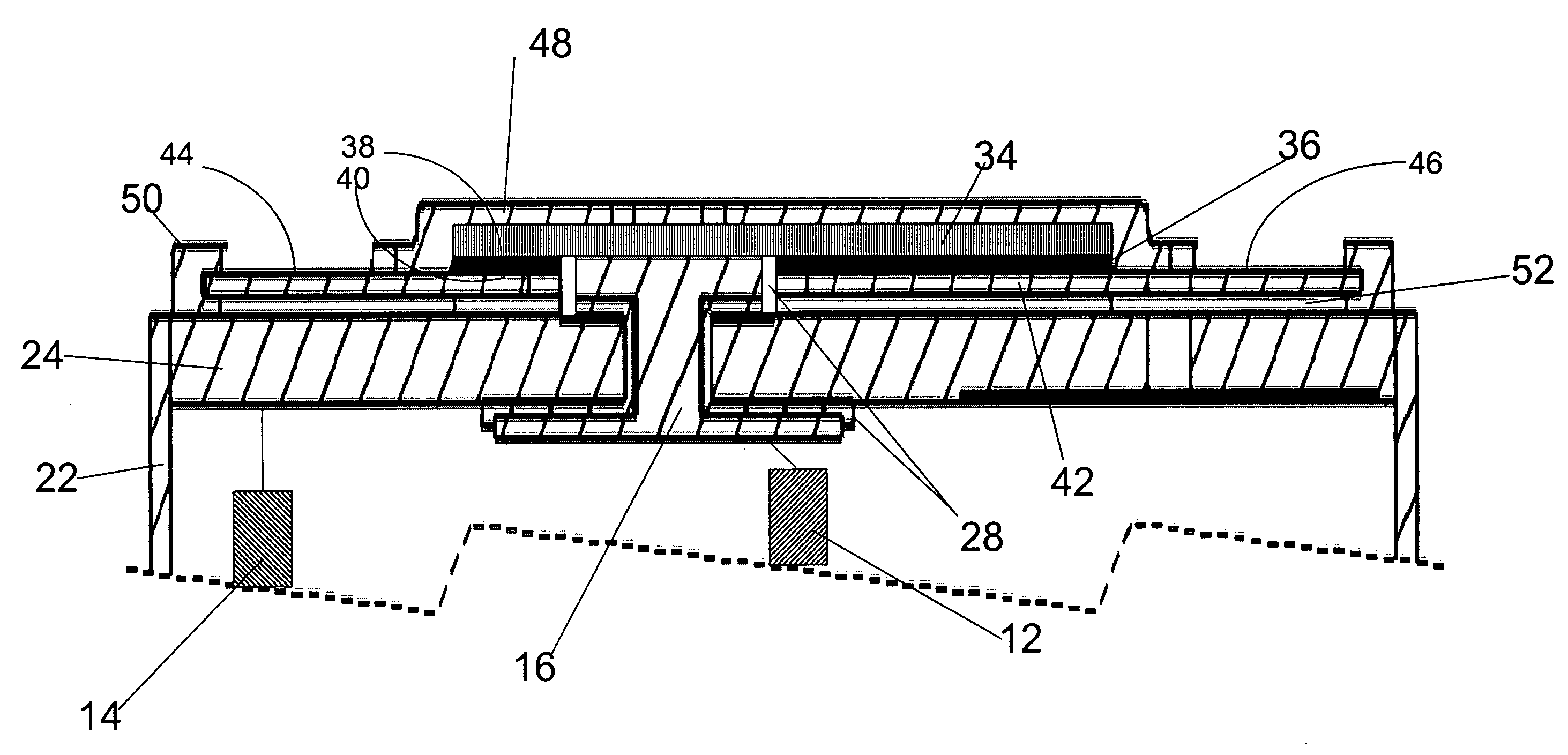

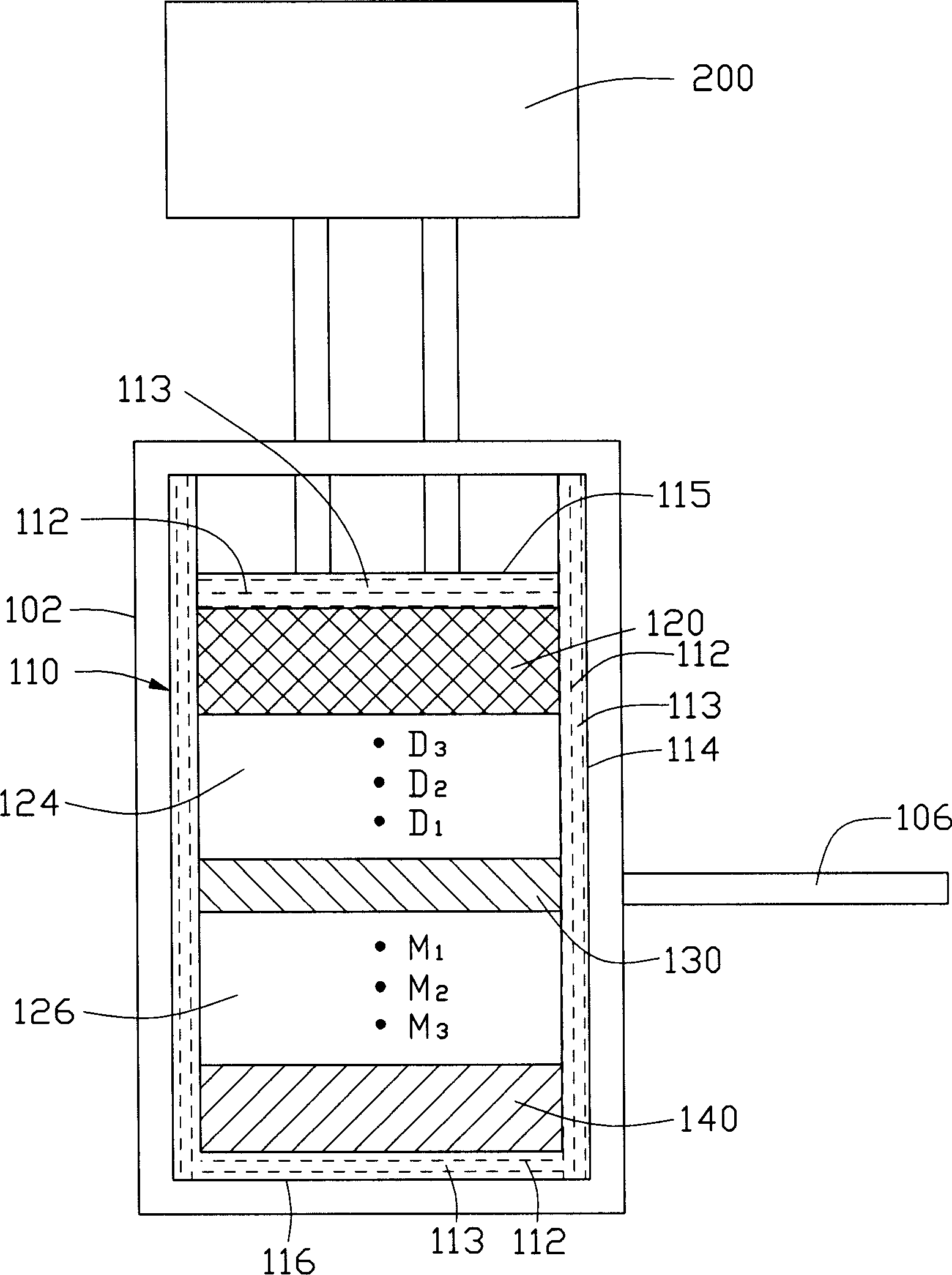

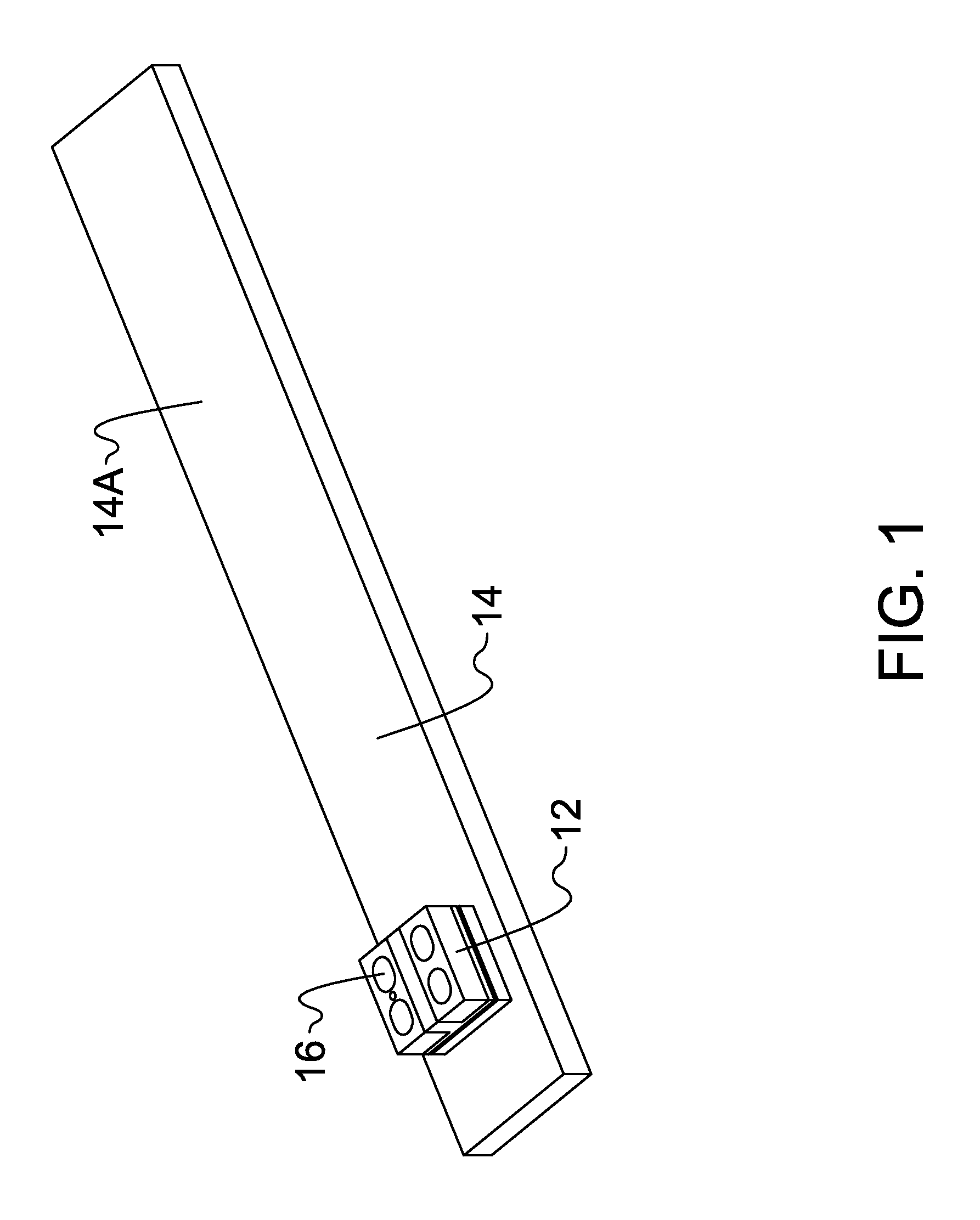

Dual Thermal Coefficient Dispensing Chamber

An injection device has a dispensing chamber housing, a plunger, and a temperature control device. The dispensing chamber housing has a first part and a second part. The first part is thermally coupled to a needle. The second part is thermally coupled to the first part. The second part has an inner surface and an outer surface. The inner surface partially defines a dispensing chamber for holding a quantity of a substance. The plunger is engaged with an inner surface of the dispensing chamber housing, is capable of sliding in the dispensing chamber housing, and is fluidly sealed to the inner surface of the dispensing chamber housing. The temperature control device at least partially surrounds the dispensing chamber housing and is capable of altering a temperature of the substance in the dispensing chamber. The second part has a greater thermal coefficient than the first part.

Owner:ALCON INC

Thermal enhancement approach using solder compositions in the liquid state

InactiveUS20010026957A1Thermal mismatchAvoid environmental degradationSemiconductor/solid-state device detailsSolid-state devicesThermal energyThermal coefficient

Solder compositions are introduced to interface between an IC chip and its associated heat exchanger cover. The solder compositions have a solidus-liquidus temperature range that encompasses the IC chip operational temperature range. The solder composition has the desired property of absorbing and rejecting heat energy by changing state or phase with each temperature rise and decline that result from temperature fluctuations associated with the thermal cycles of the integrated circuit chips. The electronic module cover is a cap with a heat exchanger formed or attached as a single construction, and made of the same material as the substrate, or made with materials of compatible thermal coefficients of expansion to mitigate the effects of vertical displacement during thermal cycling. The cap-heat exchanger cover is constructed to be compliant, and to contact both the IC chip and substrate in order to provide, in conjunction with the solder composition, a path of high thermal conduction (low thermal resistance) from the IC chip to the heat exchanger to the ambient air.

Owner:INT BUSINESS MASCH CORP

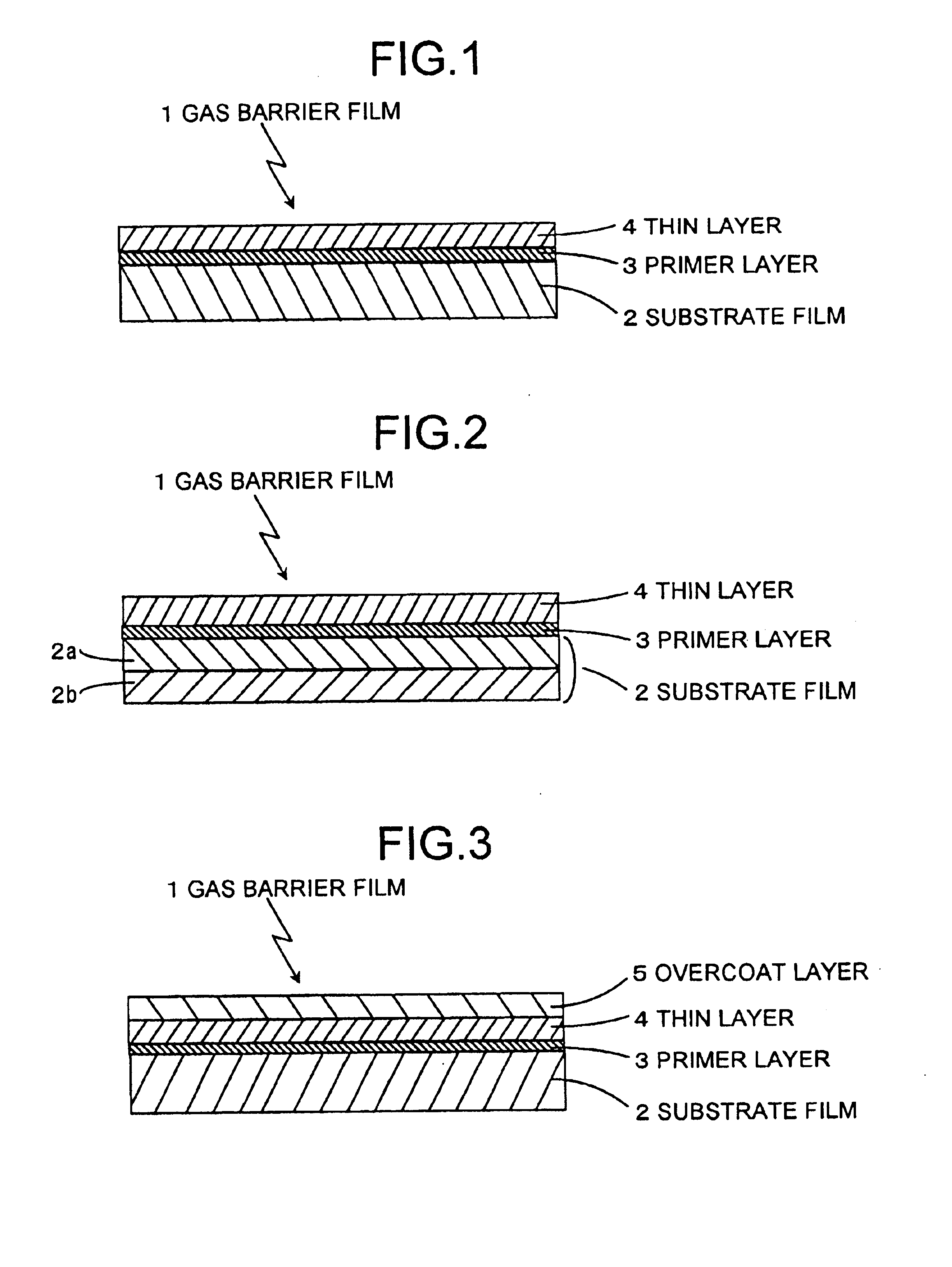

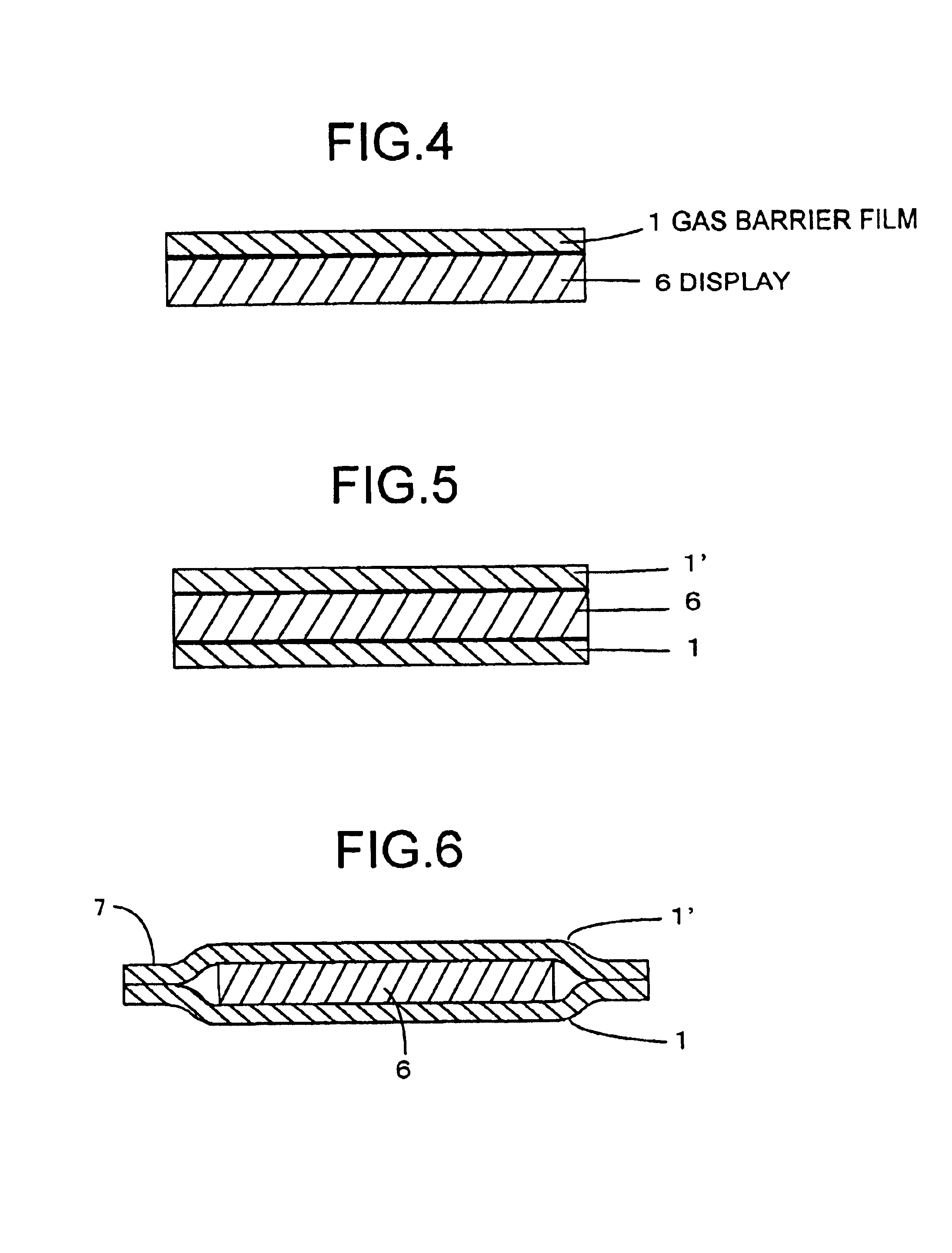

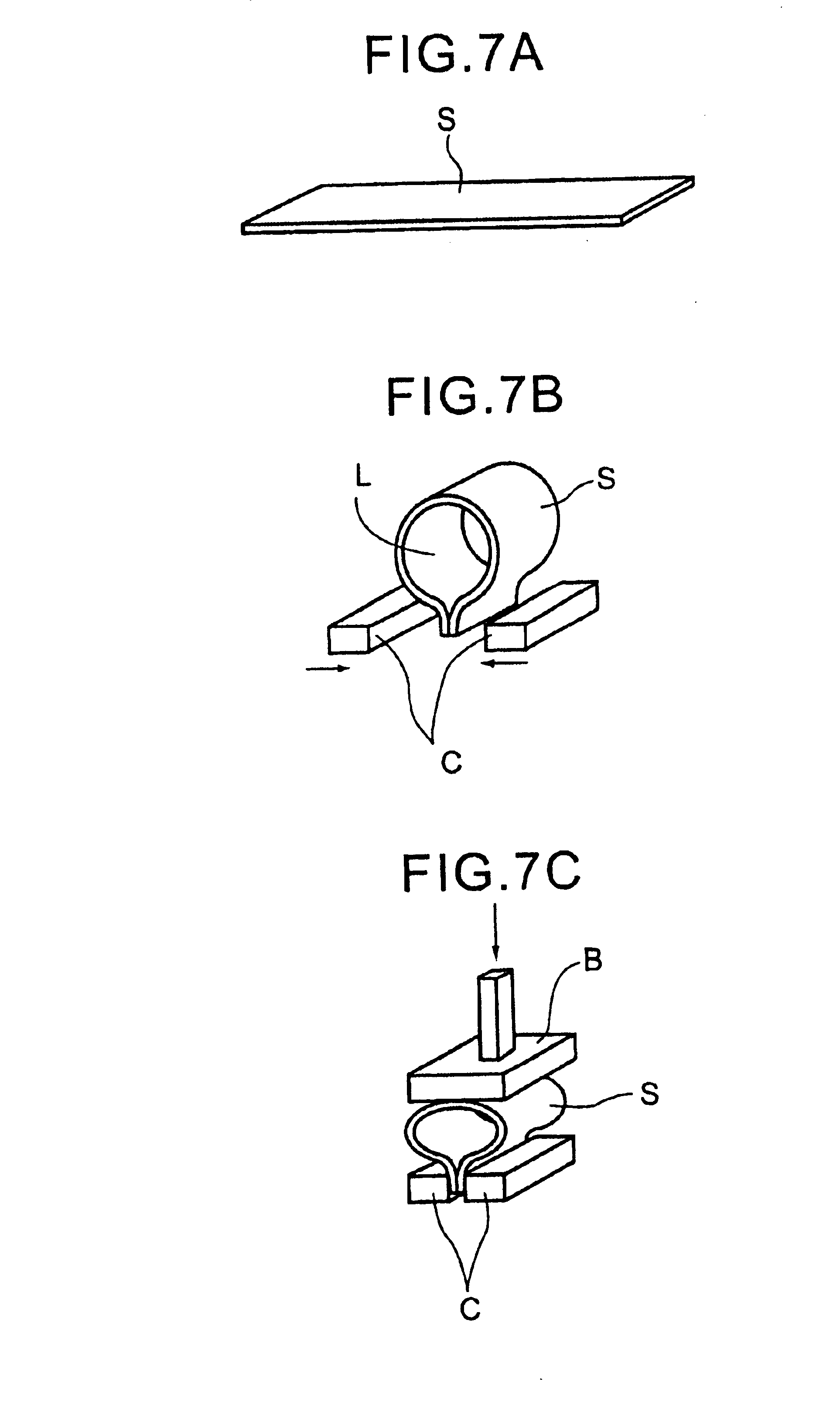

Substrate film, gas barrier film, and display using the same

InactiveUS6866949B2Excellent gas barrier performanceIncreasing the thicknessLiquid crystal compositionsSolid-state devicesVitrificationComposite film

The present invention provides a gas barrier film comprising a composite film provided with a gas barrier layer having a laminated structure including at least a metal oxide thin layer on a substrate film having a (1) 80 ppm / ° C. or less coefficient of thermal expansion at 50° C. to 150° C. and / or a 10 ppm / % RH or less coefficient of humidity expansion at 25° C., and a (2) 150 C. ° or more glass transition temperature, and a display with a display element covered with the same.

Owner:DAI NIPPON PRINTING CO LTD

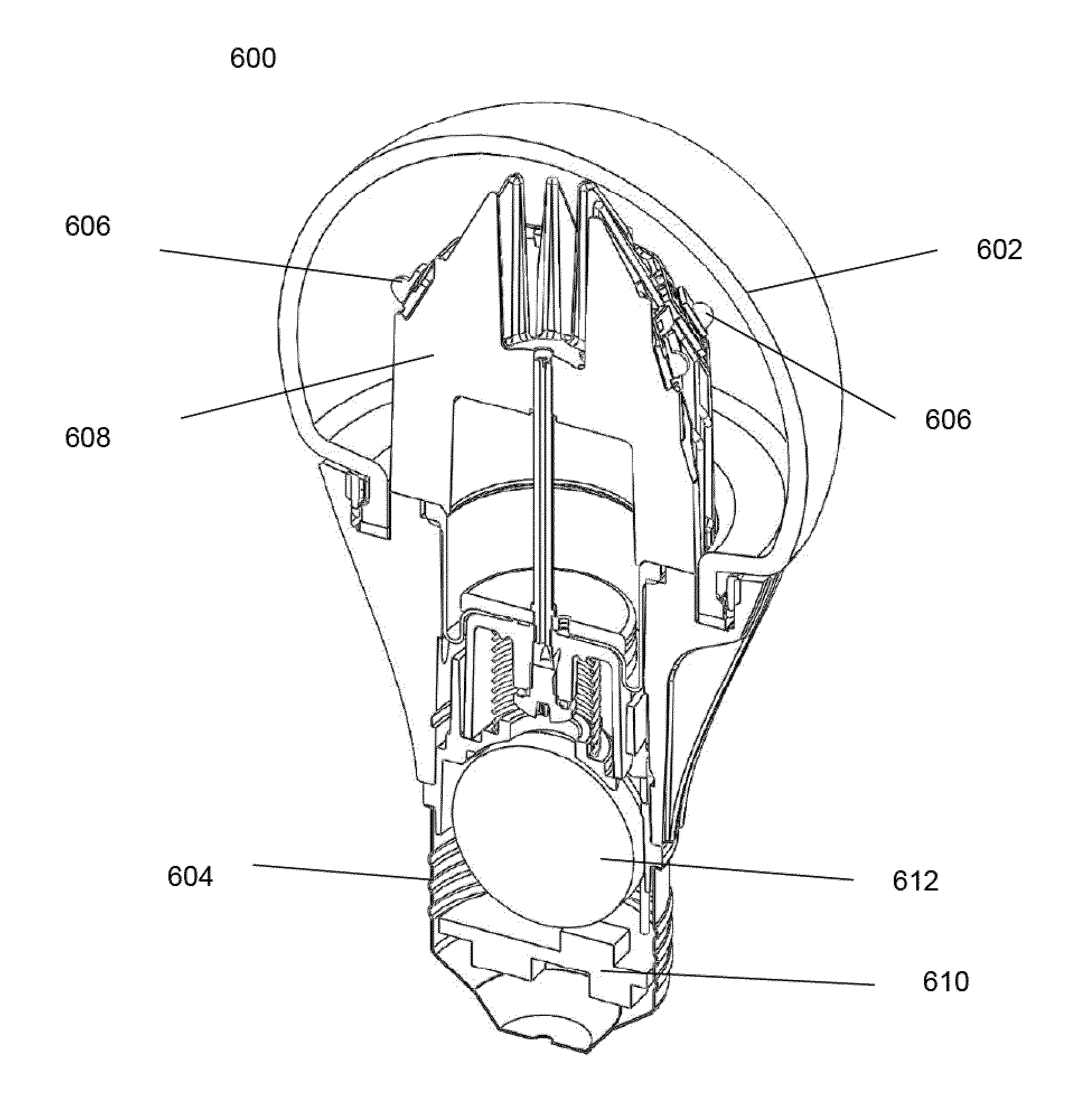

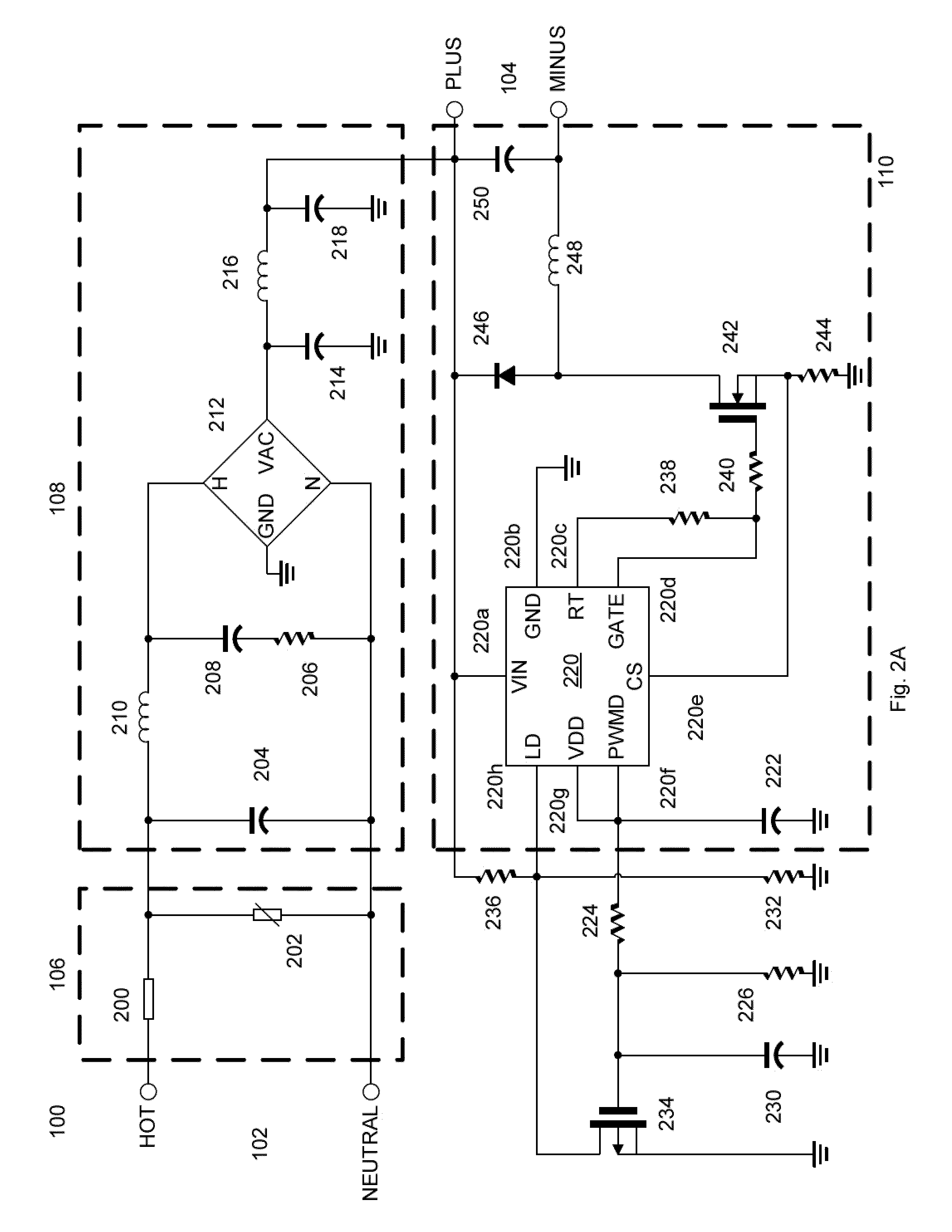

Thermal protection circuit for an LED bulb

InactiveUS20110298374A1Coupling device connectionsLighting support devicesDriver circuitThermal coefficient

A light-emitting diode (LED) bulb has an LED within a shell. The LED bulb also includes a driver circuit for providing current to the LED. The drive circuit has a thermal protection circuit, which includes a thermistor having a positive thermal coefficient and a switching temperature. The driver circuit also includes a switch-mode power supply (SMPS) controller with an input pin and an output pin. The thermistor is connected to the input pin. When the thermistor temperature is above the switching temperature, the thermal protection circuit causes the SMPS controller to produce a signal with a second duty cycle on the output pin. When the thermistor temperature is below the switching temperature, the thermal protection circuit causes the SMPS controller to produce a signal with a first duty cycle on the output pin. The second duty cycle is higher than the first duty cycle.

Owner:SWITCH BULB CO INC

Heat insulating layer based on la2zr2o7 for high temperatures

InactiveUS20040101699A1Improve the overall coefficientLow thermal conductivityMolten spray coatingEfficient propulsion technologiesThermal coefficientLanthanum

The invention relates to a heat insulating layer on a metallic substrate for using for high temperatures, especially for temperatures above 1300° C. Starting with a base of La2Zr2O7, the properties of the heat insulating substance to be used as the heat insulating layer are regularly improved, by substituting lanthanum cations with ions of elements Nd, Eu, Dy, Sm and / or Gd. An additional, at least partial substitution of the zirconium cations by Ce, Hf or Ta is advantageous. Improving the properties results especially in a high thermal coefficient of dilation alpha and low heat conductivity lambda.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

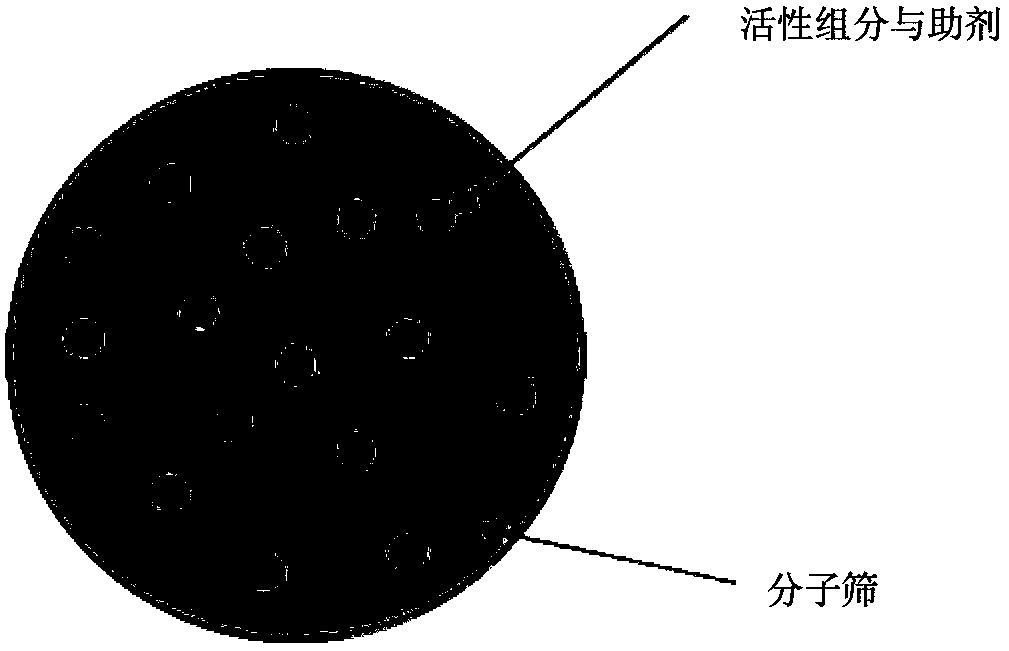

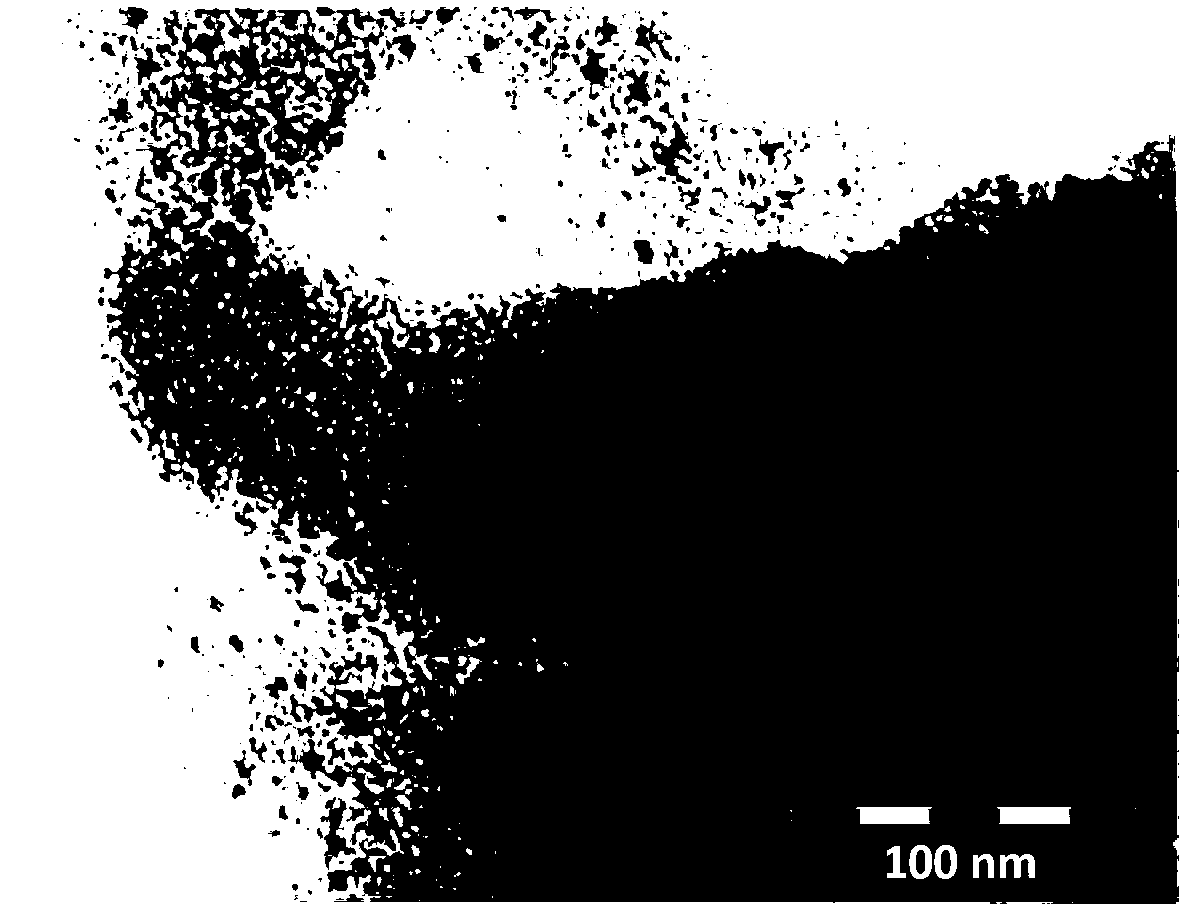

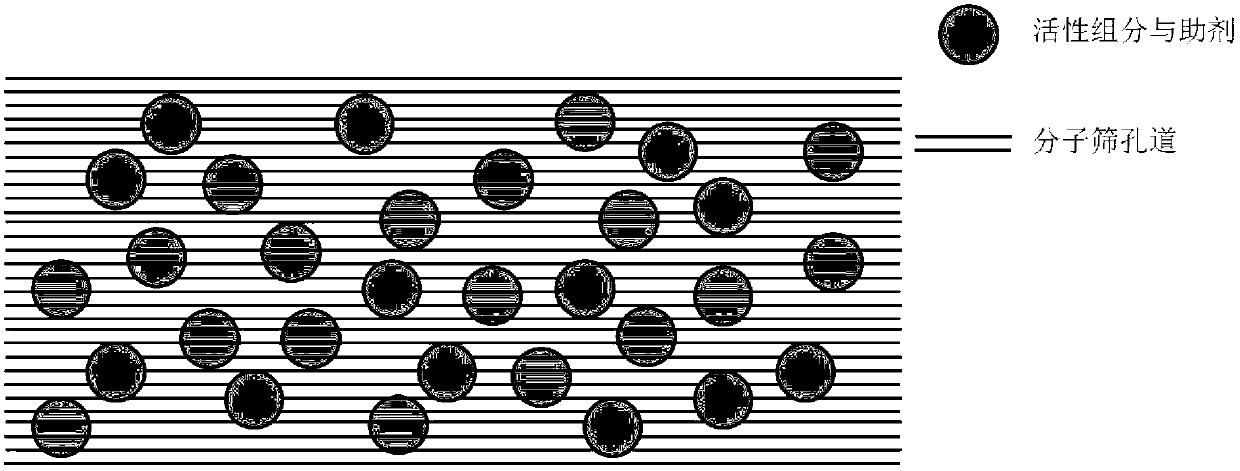

Catalyst with active component nano particles embedded in molecular sieve to crystallize, method and application

InactiveCN103100415AAdjust pHEasy to synthesizeHydrocarbon from carbon oxidesMolecular sieve catalystsThermal coefficientMethane

The invention discloses a catalyst with active component nano particles embedded in a molecular sieve to crystallize. The catalyst comprises metal active component nano particles and a molecular sieve, the catalyst comprises metal active component nano particles are embedded and dispersed in the molecular sieve, the content of the active component nano particles in the catalyst is 2-70wt%, the particle size of the active component nano particles is 4-200nm, the crystal grain size of the molecular sieve is 1-10mu m; and the invention further discloses a preparation method and an application of the catalyst. The active metal in the catalyst disclosed by the invention is embedded and dispersed in the molecular sieve, the particle size is small; the metal active centre is effectively matched with an acid centre, the heavy constituent product can be effectively cracked; the catalytic activity is high, the metal reducibility is high, and the methane selectivity is low; the Fischer-Tropsch reaction activity cannot be reduced; the preparation process is simple, the cost is recued, and the catalyst is suitable for large industrial application; and the molecular sieve cannot break due to the difference of thermal coefficients of expansion, and the mechanical strength is high.

Owner:BEIJING UNIV OF CHEM TECH +1

Lithium battery with external positive thermal coefficient layer

InactiveUS20070298314A1Increase surface areaMinimized increase in heightPrimary cellsCell temperature controlThermal coefficientLithium-ion battery

A lithium-ion battery includes a first terminal in electrical communication with a first electrode of the battery, a second terminal in electrical communication with a second electrode of the battery, a cell casing that includes a lid electrically connected to the cell casing, and a positive thermal coefficient (PTC) layer in electrical communication with the first terminal and over the lid of the cell casing. A battery pack includes a plurality of such lithium-ion batteries as described above.

Owner:BOSTON POWER INC

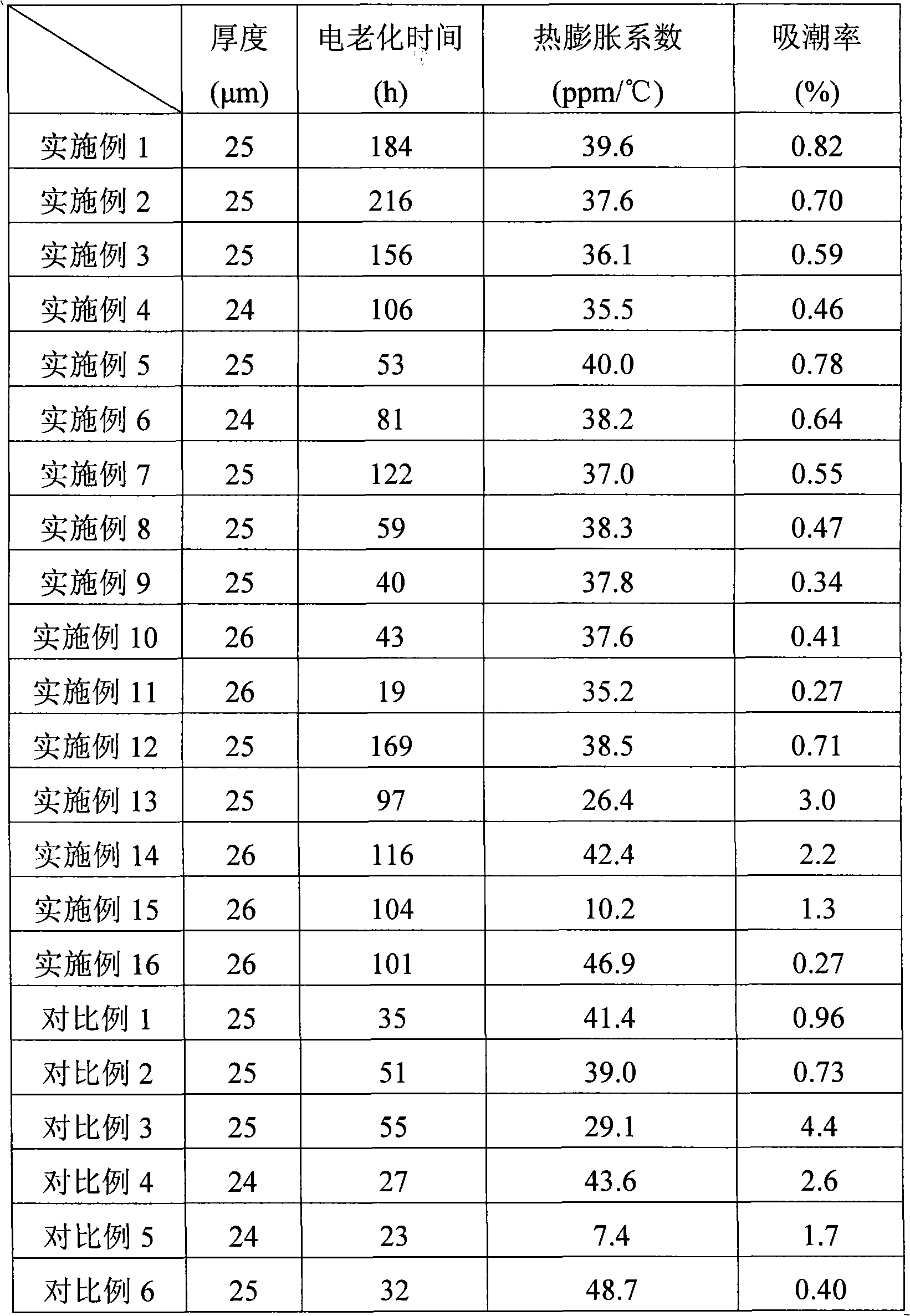

Spherical silica/polyimides composite membrane, preparation thereof and applications

ActiveCN101289542ACorona resistantImprove corona resistanceInsulating bodiesAdhesiveThermal coefficient

The invention discloses a spherical silicon dioxide / polyimide composite film and a method for making the same as well as an application. The method for making the spherical silicon dioxide / polyimide composite film comprises the following steps that: 1) spherical silicon dioxide particles are scattered into an organic solvent evenly to obtain the spherical silicon dioxide particle suspension liquid; 2) a surface treatment agent, a molecular weight modifying agent, an auxiliary adhesive, a flatting agent and aromatic series diamine are dissolved inside the spherical silicon dioxide particle suspension liquid; organic dicarboxylic anhydride is added to be stirred in order to obtain a spherical silicon dioxide / polyamide acid mixing resin solution; 3) the mixing resin solution is coated on the surface of a flat substrate and is heated up to make the solvent volatilize and complete the imide reaction to obtain the spherical silicon dioxide / polyimide composite film. The spherical silicon dioxide / polyimide composite film has good mechanical property, good corona resistance, low thermal coefficient of expansion and low moisture absorption ratio, and has important application value in an insulating system of a frequency conversion speed motor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Heater for an automotive vehicle and method of forming same

ActiveUS20050242081A1Amount be controlSeat heating/ventillating devicesStoolsMobile vehicleThermal coefficient

There is disclosed a heater for an automotive vehicle or other article of manufacture. The heater typically includes a first conductive medium and a second conductive medium disposed upon a carrier. In a preferred embodiment, the first conductive medium includes a first section and a second section that are electrically connected by a second conductive medium. The second conductive medium preferably exhibits a positive thermal coefficient.

Owner:GENTHERM GMBH

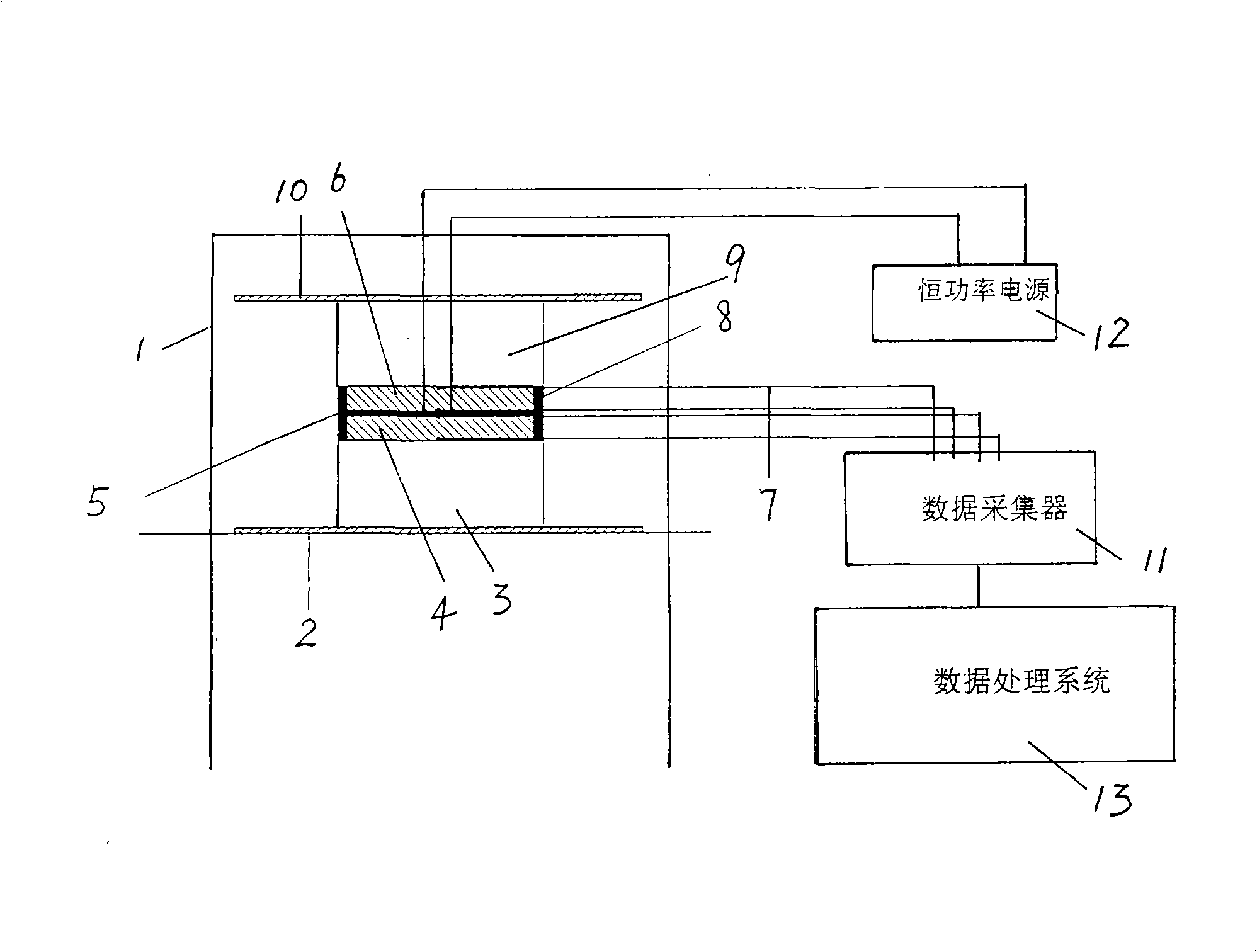

Device for measuring thermal coefficient

InactiveCN1657923AGuaranteed measurementGood insulation performanceMaterial heat developmentMeasurement deviceHeat conducting

The invention discloses a heat conducting coefficient measuring device which consists of a sealed heat insulation device and a vacuum system. The heat insulation device consists of heat source, two metal blocks, samples, a cooling device. The heat insulation device is made by spark-plasma sintering the aluminum oxide ceramic basal material with carbon nanometer tube uniformly arranged in with a intensity of 5 to 10 percent. The carbon nanometer tube distributes along the direction perpendicular to the direction which the heat travels. By pumping out the inner gas with the vacuum system, the adverse effect of the gas is eliminated which the carbon nanometer tube reflect the heat back in consequence that the carbon nanometer tube is radial heat insulation.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

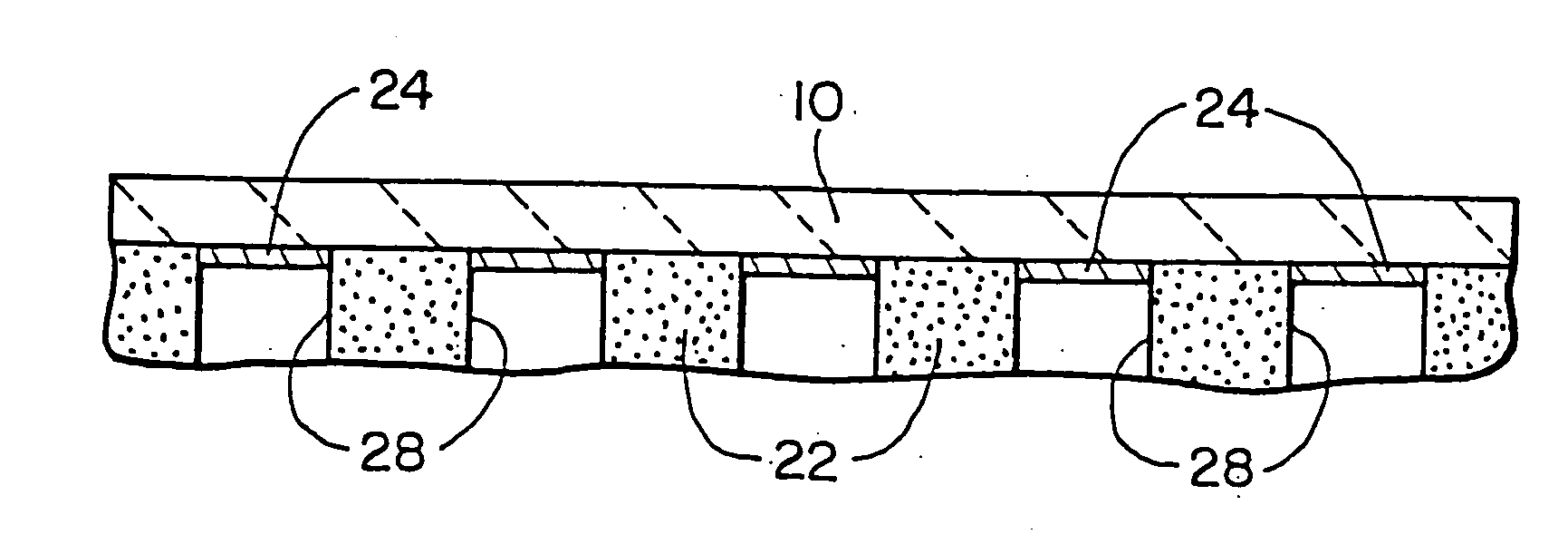

Semiconductor flip-chip package and method for the fabrication thereof

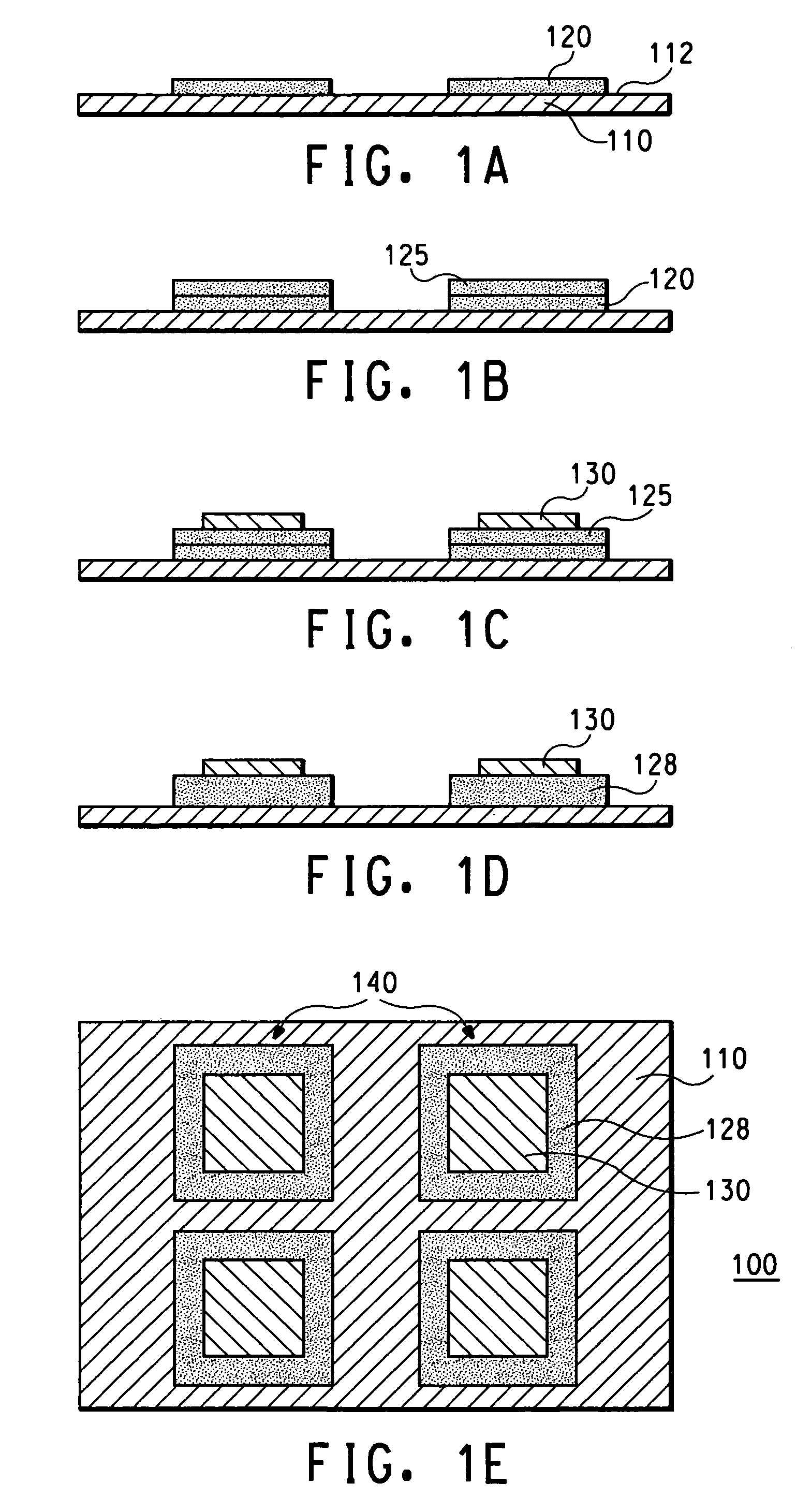

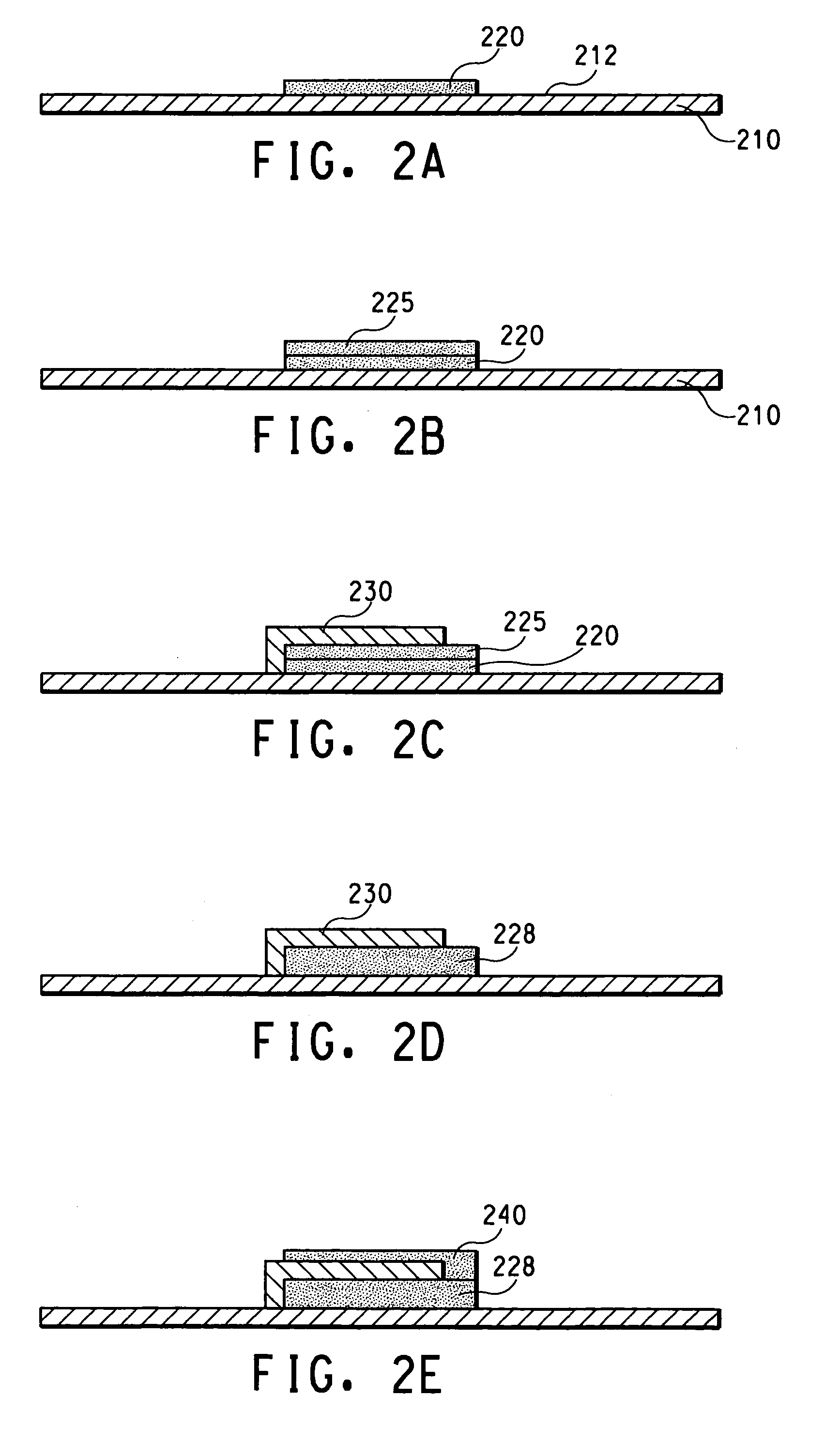

InactiveUS20050218517A1Reduction factorMinimal effect on the reliability of the flip-chip structurePrinted circuit assemblingLayered productsRedistribution layerFilling materials

A simplified process for flip-chip attachment of a chip to a substrate is provided by pre-coating the chip with an encapsulant underfill material having separate discrete solder columns therein to eliminate the conventional capillary flow underfill process. Such a structure permits incorporation of remeltable layers for rework, test, or repair. It also allows incorporation of electrical redistribution layers. In one aspect, the chip and pre-coated encapsulant are placed at an angle to the substrate and brought into contact with the pre-coated substrate, then the chip and precoated encapsulant are pivoted about the first point of contact, expelling any gas therebetween until the solder bumps on the chip are fully in contact with the substrate. There is also provided a flip-chip configuration having a complaint solder / flexible encapsulant understructure that deforms generally laterally with the substrate as the substrate undergoes expansion or contraction. With this configuration, the complaint solder / flexible encapsulant understructure absorbs the strain caused by the difference in the thermal coefficients of expansion between the chip and the substrate without bending the chip and substrate.

Owner:M A CAPOTE

Semiconductor flip-chip package and method for the fabrication thereof

InactiveUS20030218261A1Avoid entrapmentDisassembled from substratePrinted circuit assemblingLayered productsRedistribution layerFilling materials

A simplified process for flip-chip attachment of a chip to a substrate is provided by precoating the chip with an encapsulant underfill material having separate discrete solder columns therein to eliminate the conventional capillary flow underfill process. Such a structure permits incorporation of remeltable layers for rework, test, or repair. It also allows incorporation of electrical redistribution layers. In one aspect, the chip and pre-coated encapsulant are placed at an angle to the substrate and brought into contact with the pre-coated substrate, then the chip and pre-coated encapsulant are pivoted about the first point of contact, expelling any gas therebetween until the solder bumps on the chip are fully in contact with the substrate. There is also provided a flip-chip configuration having a complaint solder / flexible encapsulant understructure that deforms generally laterally with the substrate as the substrate undergoes expansion or contraction. With this configuration, the complaint solder / flexible encapsulant understructure absorbs the strain caused by the difference in the thermal coefficients of expansion between the chip and the substrate without bending the chip and substrate.

Owner:INVENSAS CORP

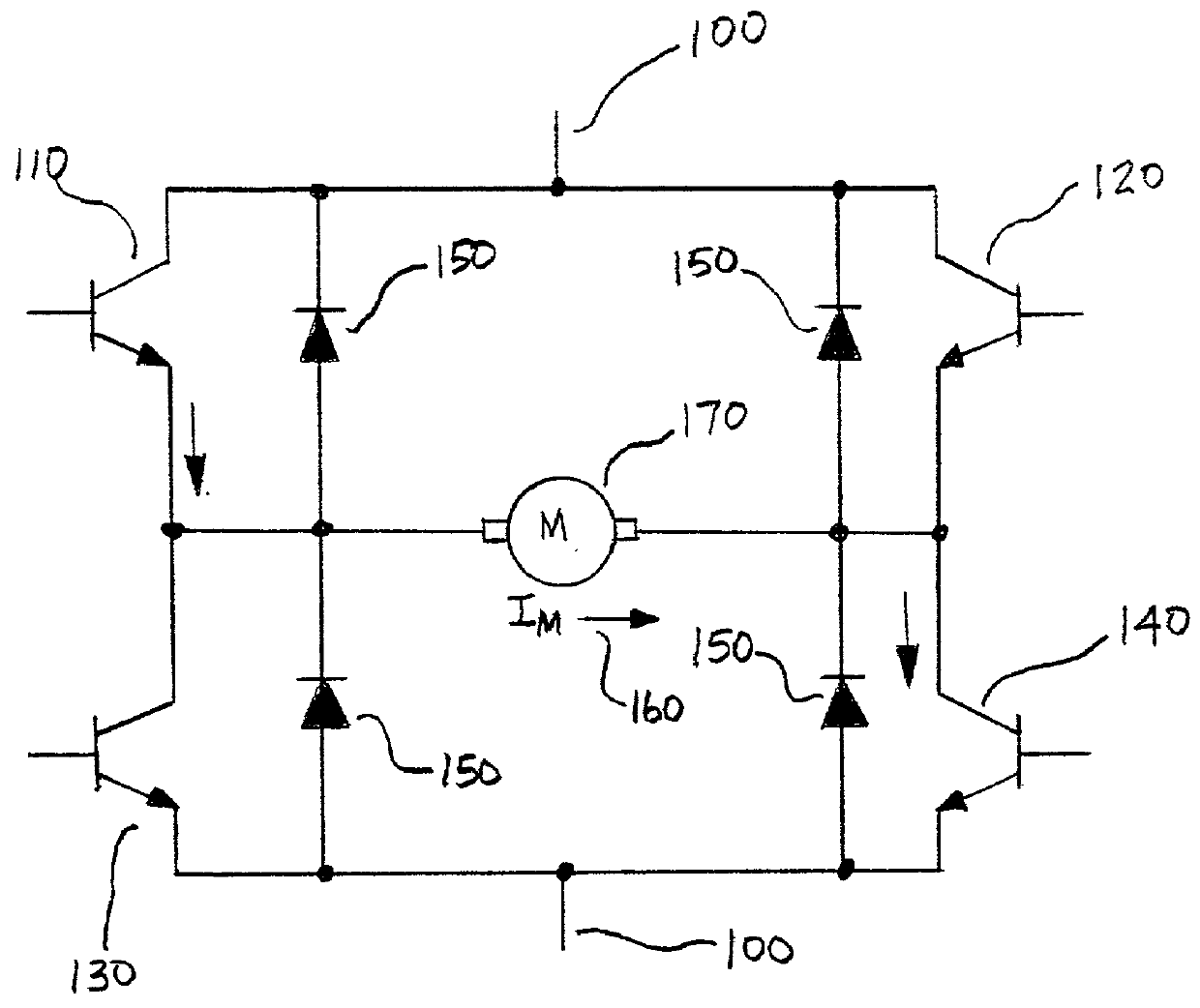

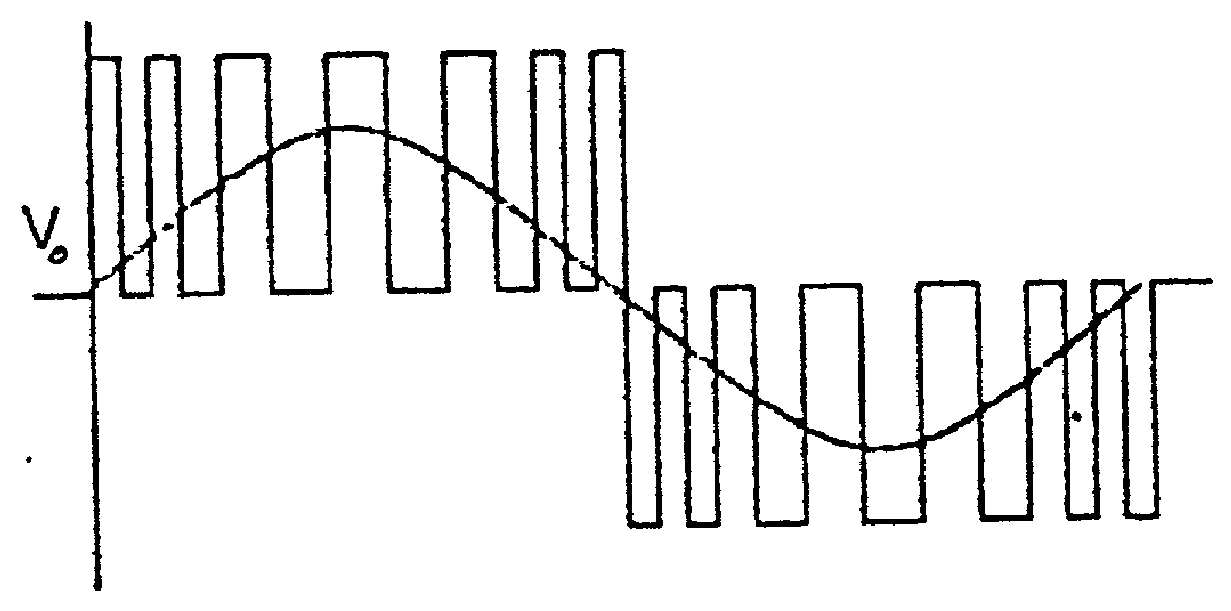

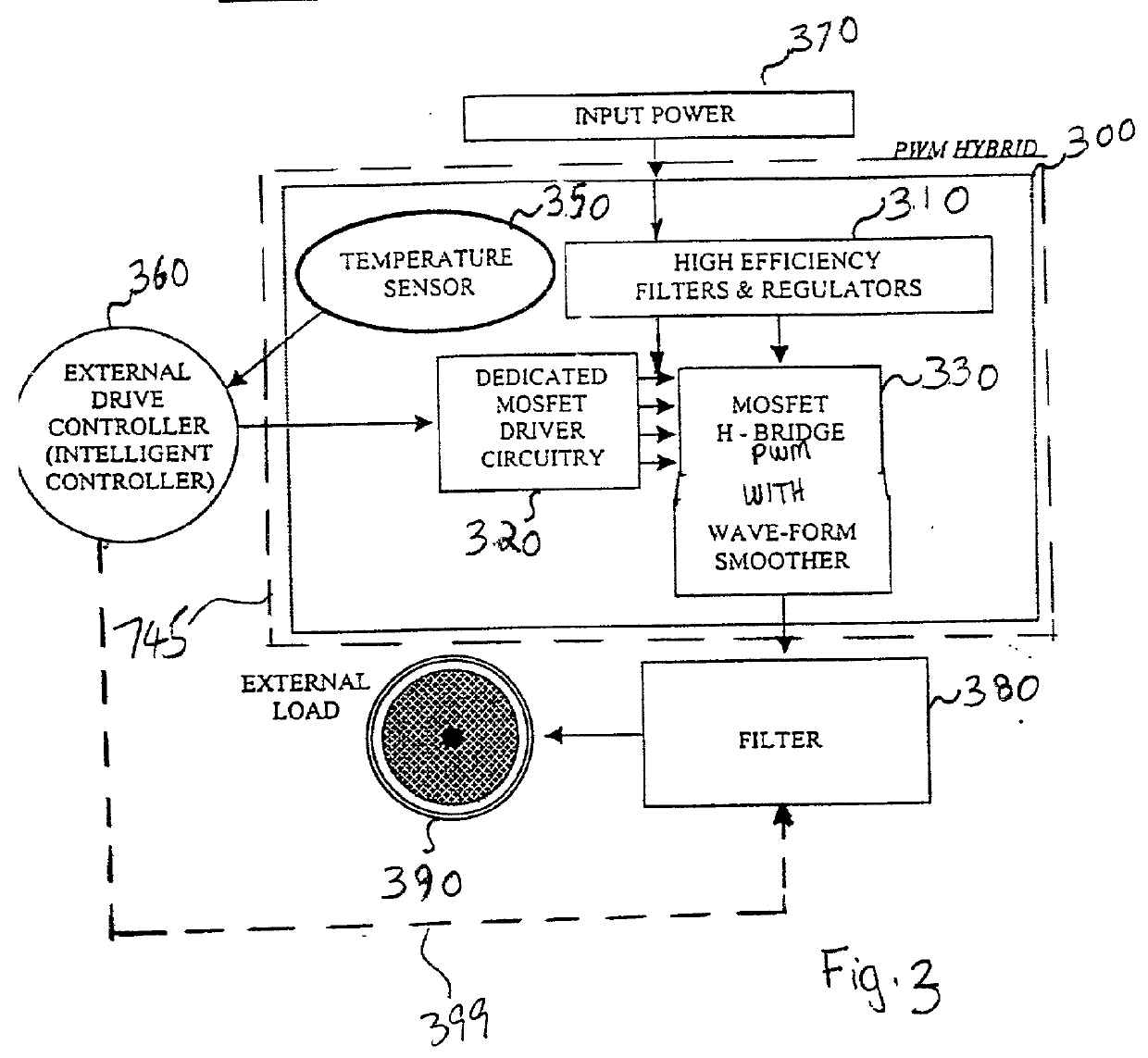

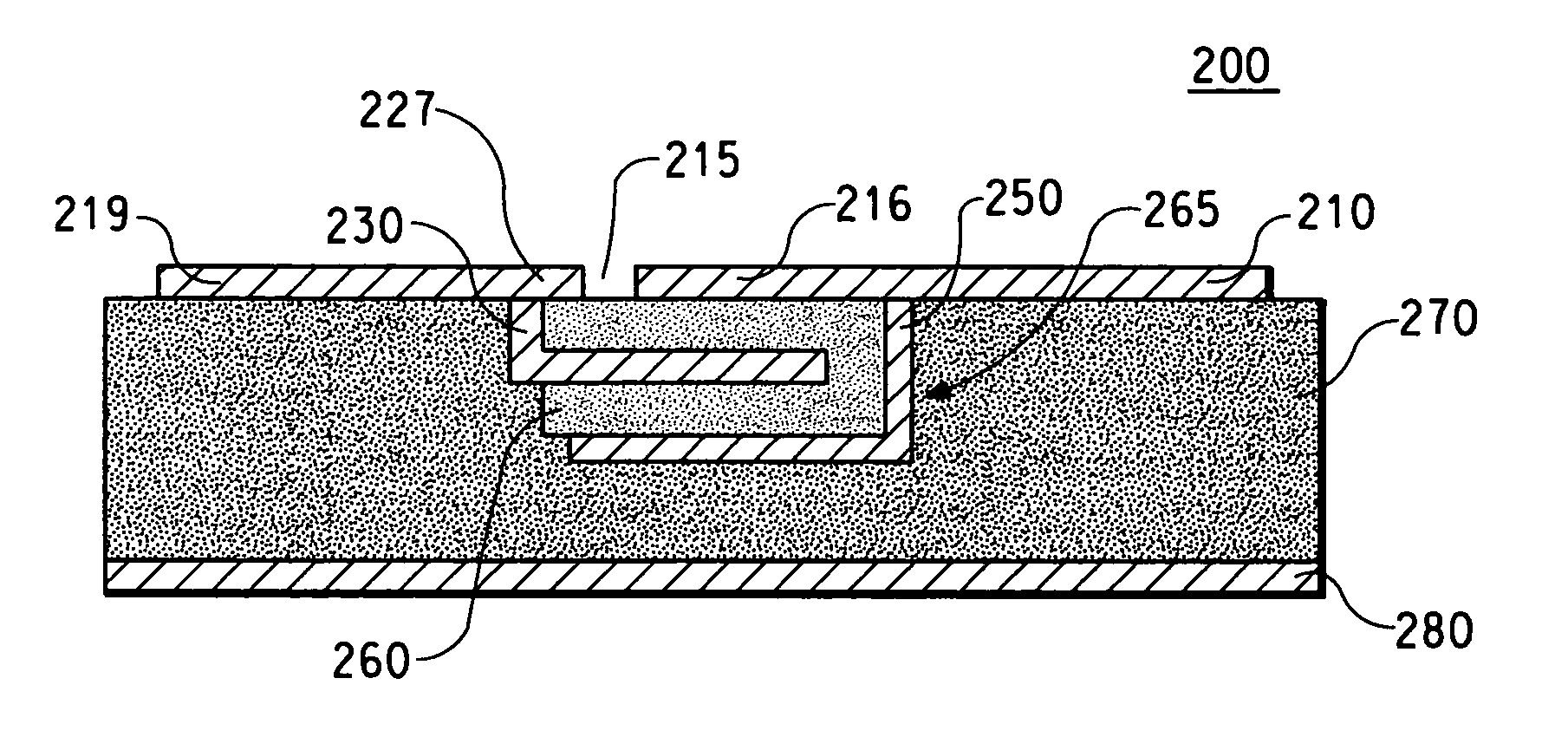

Hybridized, high performance PWM amplifier

A high performance, high-speed, cost-effective pulse width modulation circuit for the delivery of linear and efficient power to a load. The inventive aspects include: (a) removing certain MOSFET current limiting resistors and reducing impedance paths between components to decrease switching transition time; (b) providing an ultra-fast transient protection circuitry between the Gate and the Source, and between the Drain and the Source of the MOSFETs; (c) providing a hermetically sealed Faraday cage over the circuit; (d) providing a temperature sensor to monitor the temperature of the circuit; (e) providing an electrically and geometrically symmetrical circuit, having multiple pieces of interconnected substrates to reduce electrical and mechanical stress across the junctions and matching thermal coefficient of adjoining components; (f) using costly BeO material only for the substrate in the MOSFETs where most heat is generated and less costly Alumina substrate for the rest of the circuit.

Owner:NIKON CORP

Co-fired ceramic capacitor and method for forming ceramic capacitors for use in printed wiring boards

InactiveUS7072167B2Increase capacitance densityAnti-noise capacitorsFixed capacitor electrodesDielectricCeramic capacitor

A capacitor structure is fabricated by forming a pattern of first dielectrics over a foil, forming first electrodes over the first dielectrics, and co-firing the first dielectrics and the first electrodes. Co-firing of the dielectrics and the electrodes alleviates cracking caused by differences in thermal coefficient of expansion (TCE) between the electrodes and the dielectrics. Co-firing also ensures a strong bond between the dielectrics and the electrodes. In addition, co-firing allows multi-layer capacitor structures to be constructed, and allows the capacitor electrodes to be formed from copper.

Owner:CHEMTRON RES

Implantable shunt system and associated pressure sensors

ActiveUS20140243703A1Reduce overpressureElectrotherapyCircuit arrangementsDual stageThermal coefficient

A hermetically sealed biocompatible pressure sensor module configured for implant at a desired site at which a pressure is to be measured. Anodic bonding of the pressure module package components which have similar thermal coefficients of expansion provides low stress bonding and maintains long term reliability, dependability and accuracy. The pressure sensor module includes a pressure sensitive membrane which is in direct contact with the environment at which a pressure is to be measured. The pressure sensor module forms a part of a pressure measuring system which uses a telemetry link between the pressure sensor module and an external controller for data transmission and transfer. Operating power for the pressure sensor module is provided by the external controller and an internal rechargeable energy storage component. Accordingly, the pressure measuring system provides a dual stage power and data transfer capability for use with an implantable system. An exemplary use of the pressure sensor module is in a three pressure sensor system including a flow control valve in a shunt to treat hydrocephalus. The use of integrated circuit chips and an internal coil with an optional ferrite core in the pressure sensor module provides for low power consumption and reliable signal processing. An embodiment of the invention includes a pressure sensor and associated electromagnetic coils embedded in the tip portion of the shunt for measuring the pressure of fluid externally of the shunt at the tip portion.

Owner:ALFRED E MANN FOUND FOR SCI RES

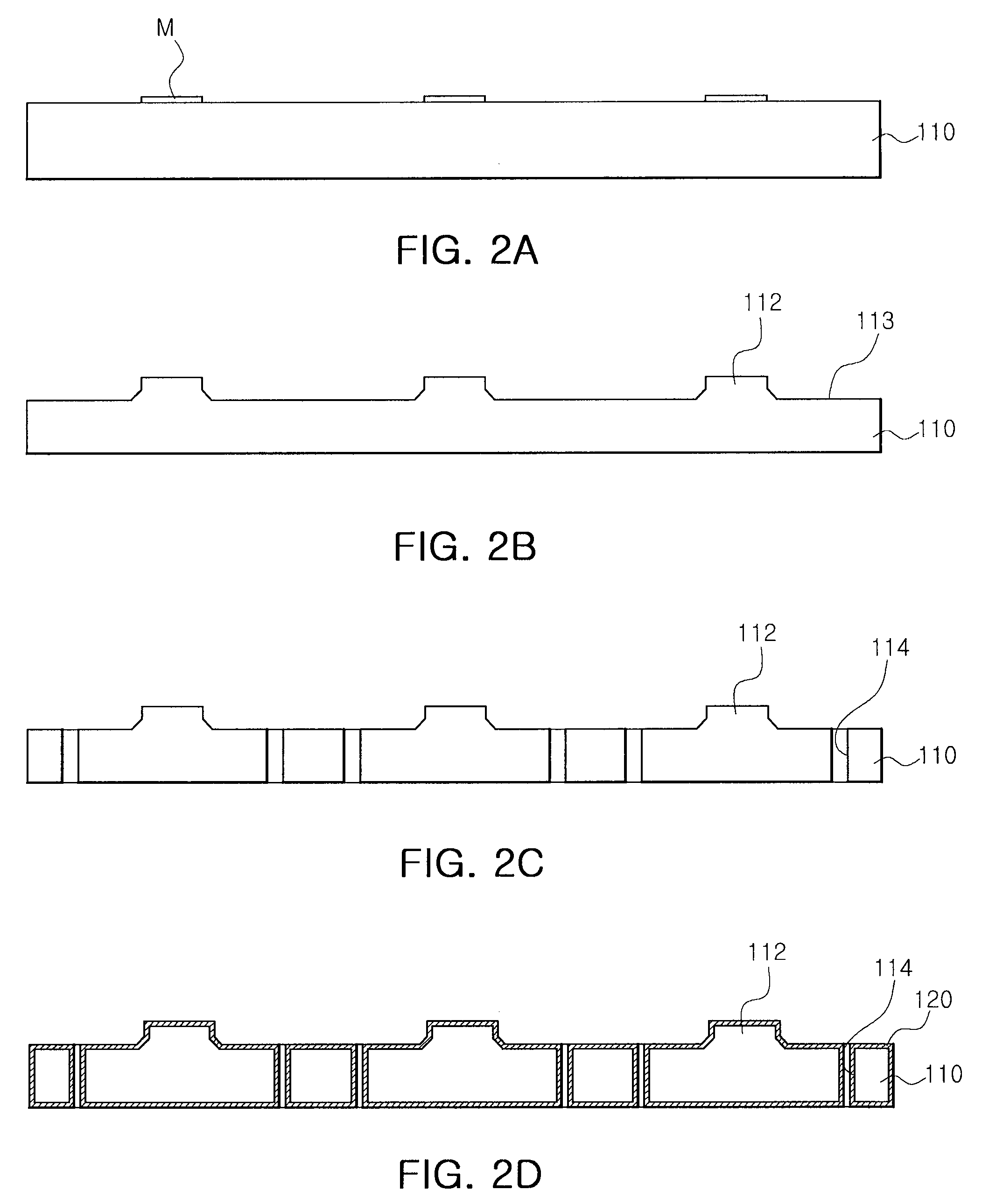

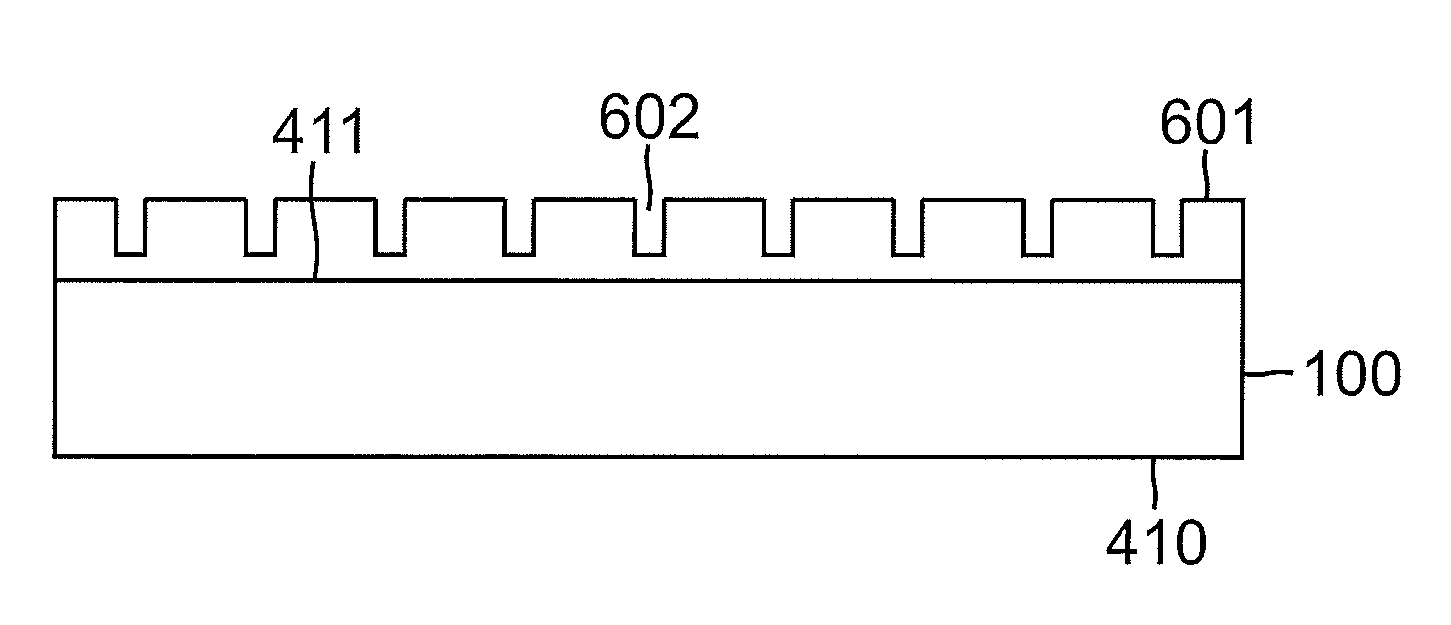

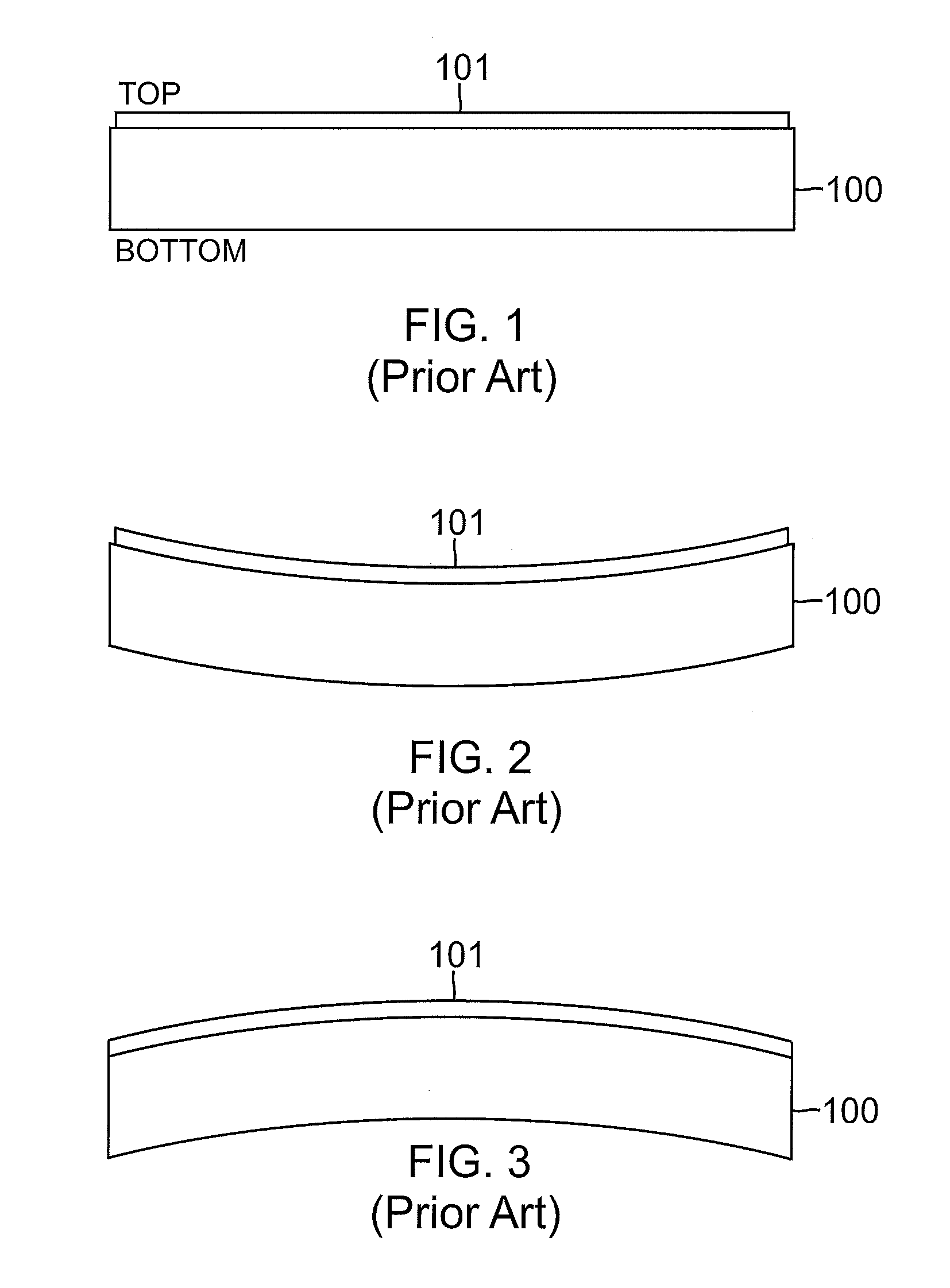

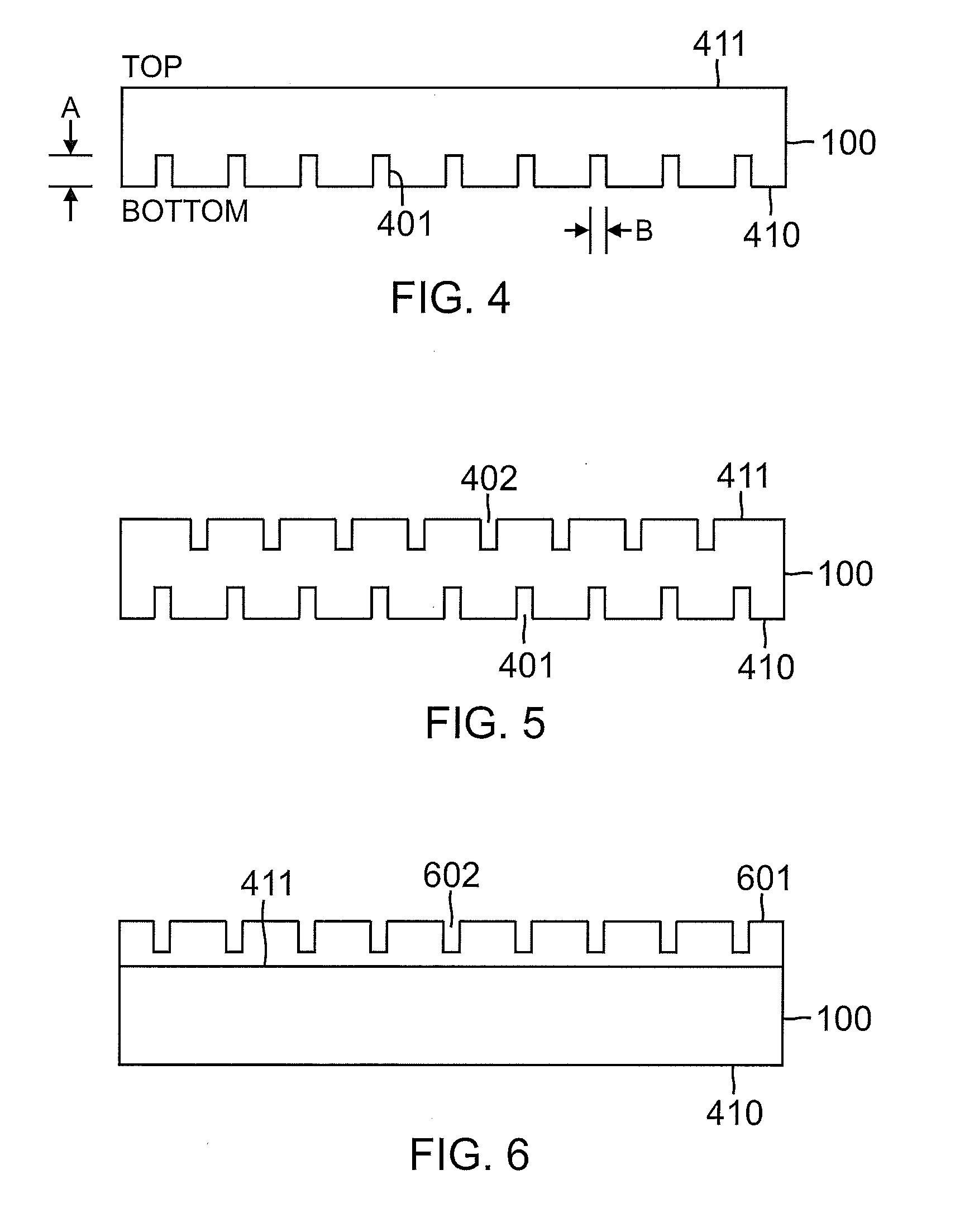

Trenched substrate for crystal growth and wafer bonding

InactiveUS20090267083A1Relieve pressureReduce stress buildupSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsWafer dicing

A substrate for a light emitting diode (LED) can have one or more trenches formed therein so as to mitigate stress build up within the substrate due to mismatched thermal coefficients of expansion between the substrate and layers of material, e.g., semiconductor material, formed thereon. In this manner, the likelihood of damage to the substrate, such as cracking thereof, is substantially mitigated.

Owner:KK TOSHIBA

Insulated door assembly with low thermal deflection

InactiveUS6226958B1Increase and decrease viscosityViscosity modifierNatural patternsThree-dimensional effectsCompression moldingShell molding

Compression molded pigmented door skins fabricated by compression molding a pigmented, curable, unsaturated polyester sheet molding compound containing a co-curable unsaturated monomer, a low profile additive, and a microvoid-reducing thermoplastic polymer, exhibit uniform stainability while maintaining a low linear thermal coefficient of expansion. Such door skins are suitable for preparing wood grain textured exterior insulated doors which exhibit minimal thermal deflection when exposed to interior / exterior temperature differentials, even at eight foot door heights. The doors may be stained without first applying a seal coat.

Owner:THERMA TRU HLDG

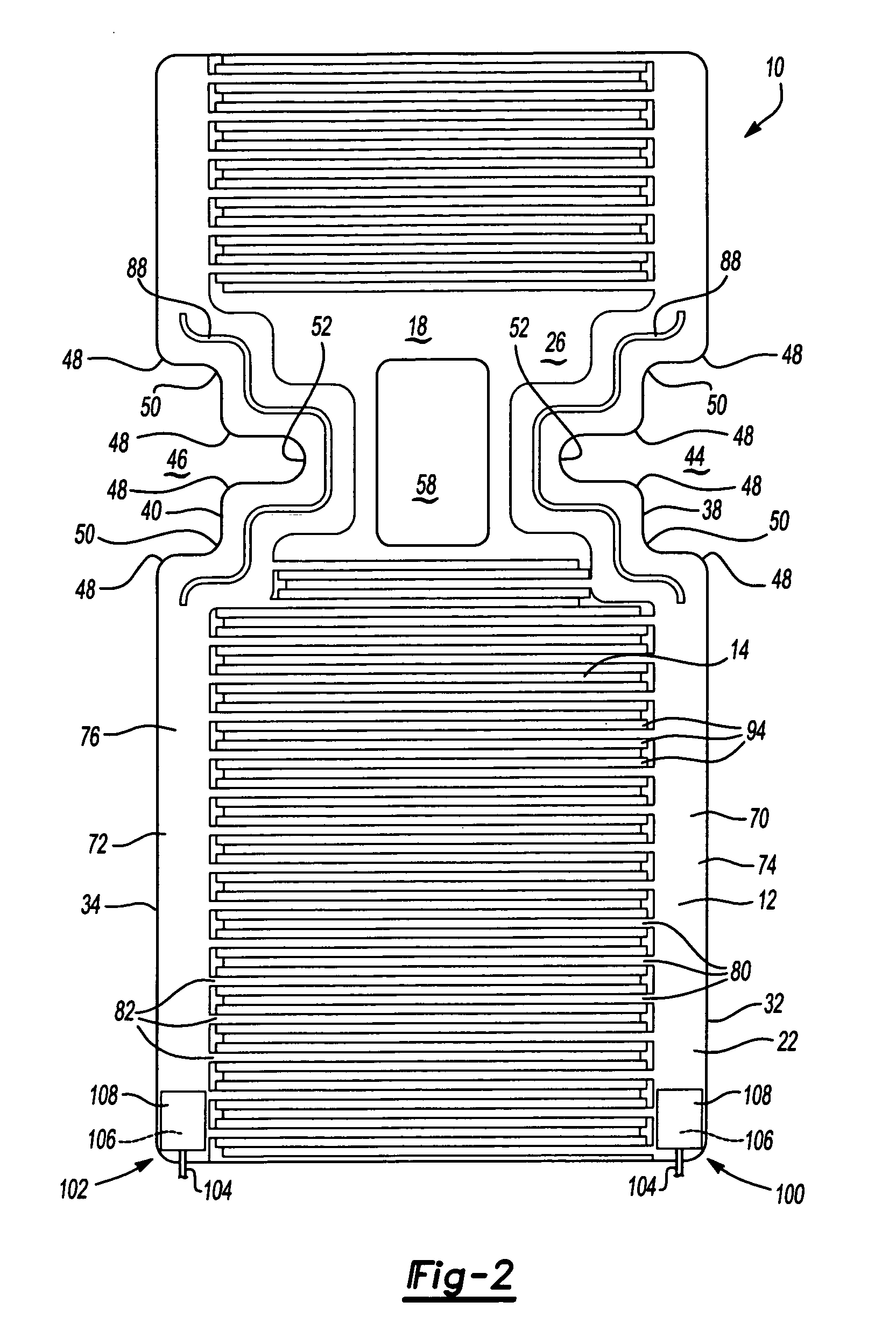

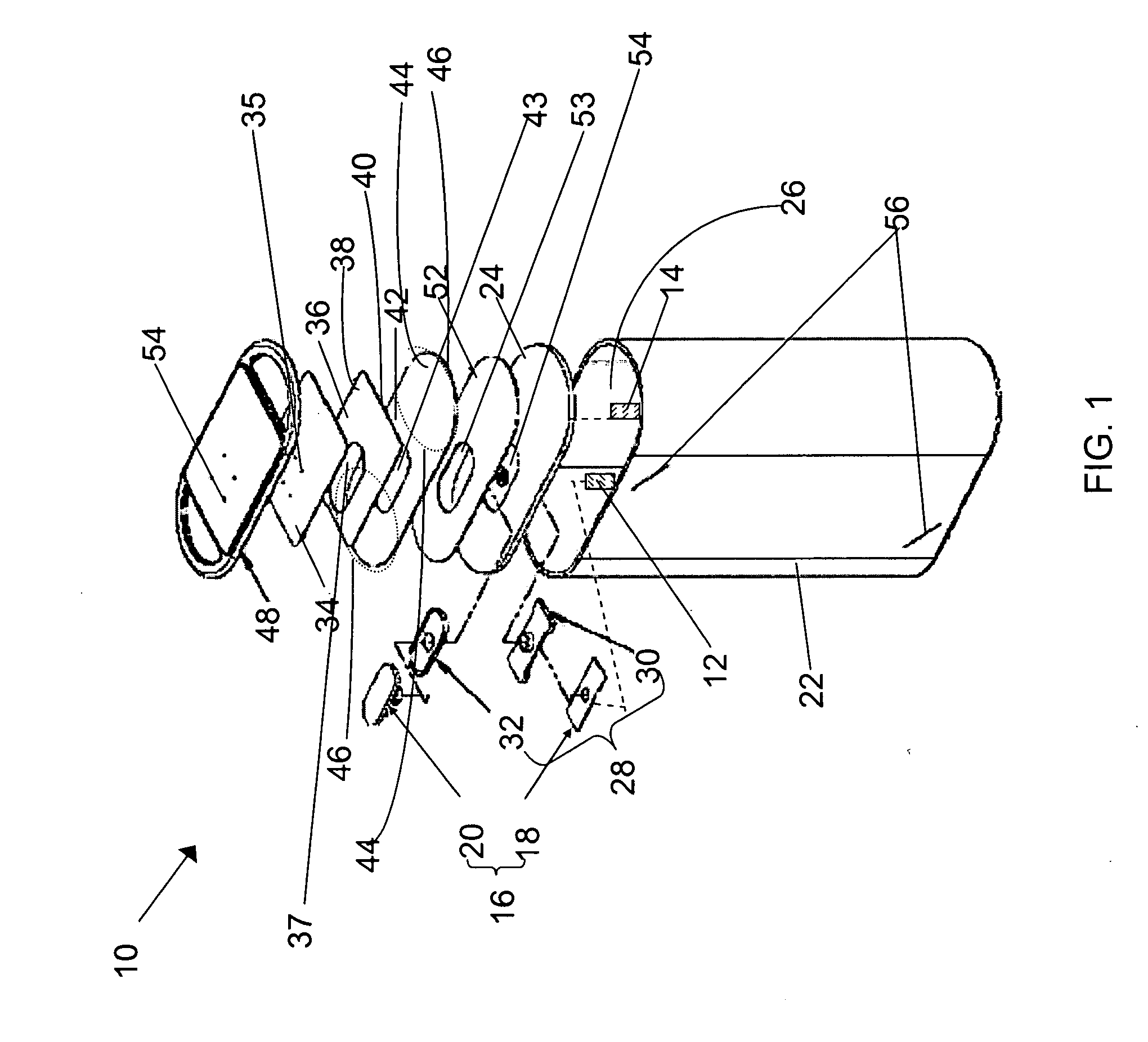

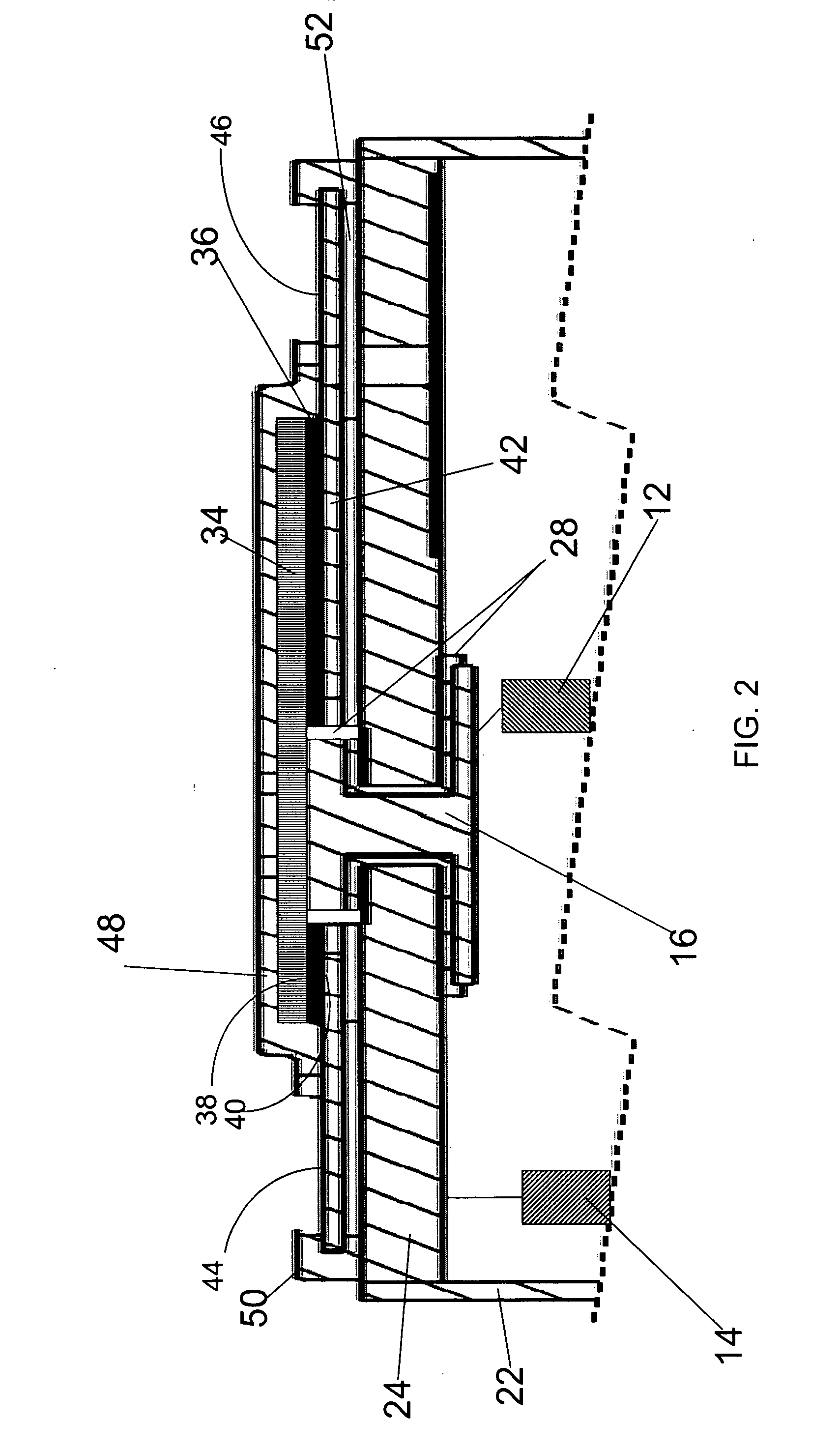

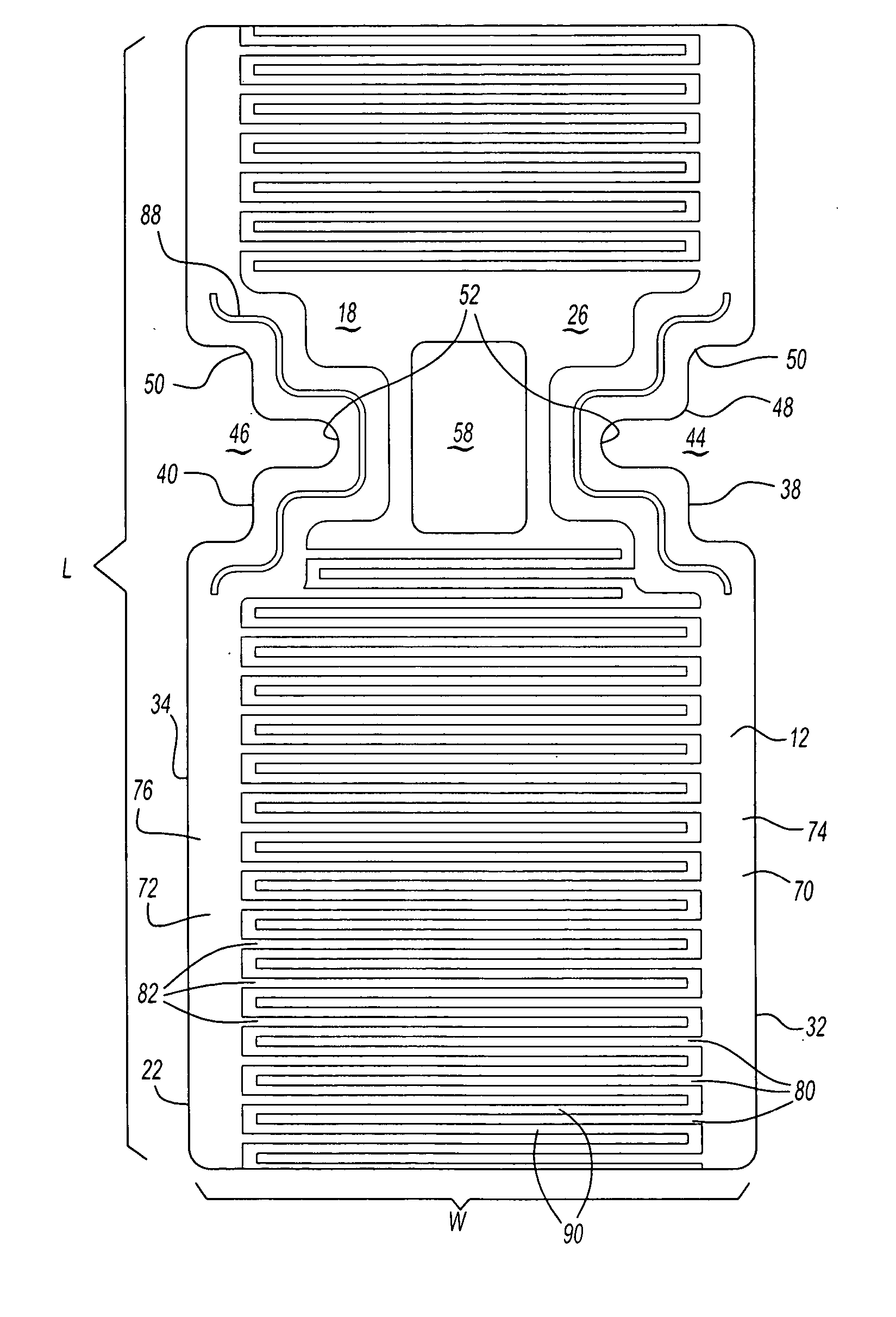

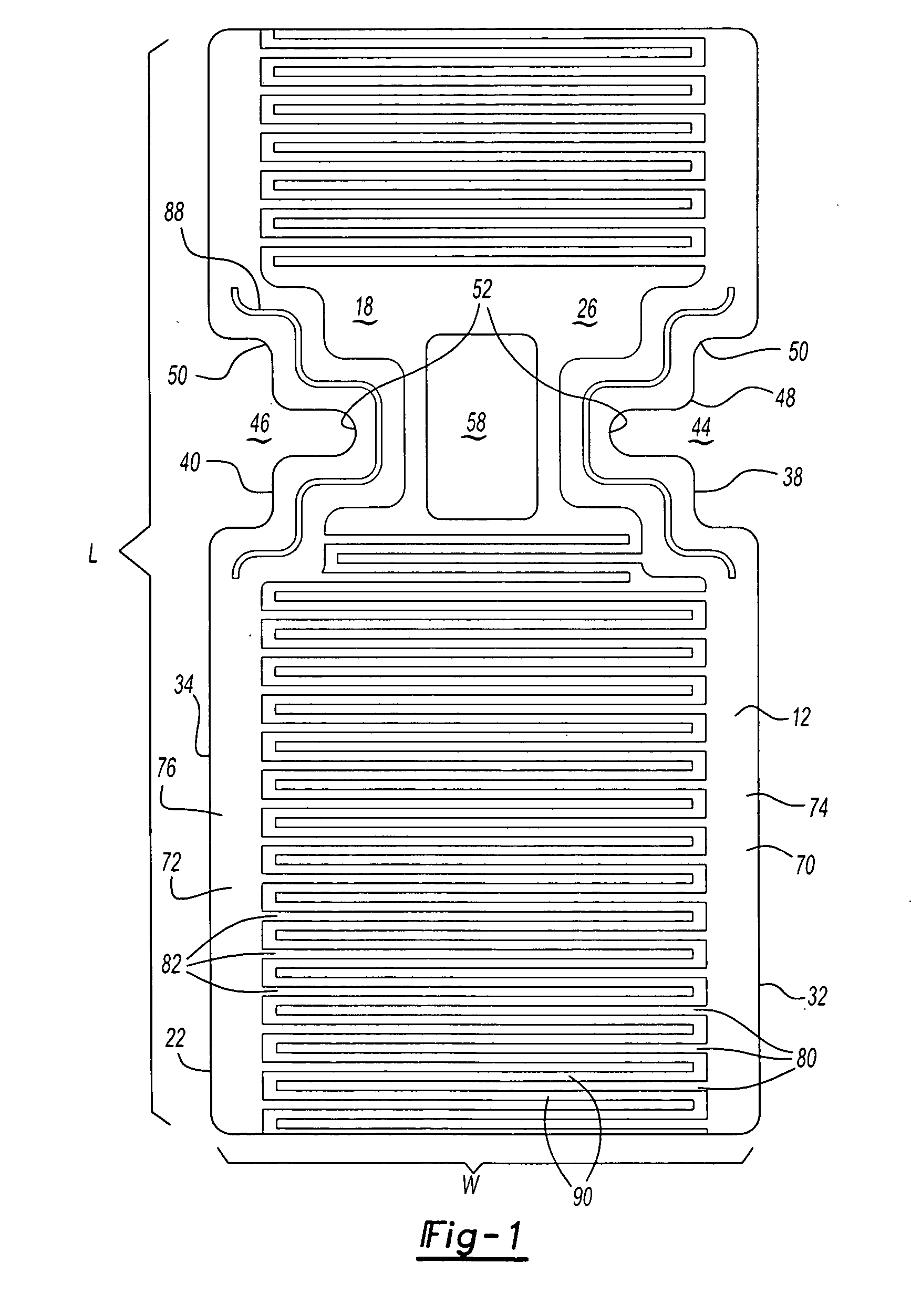

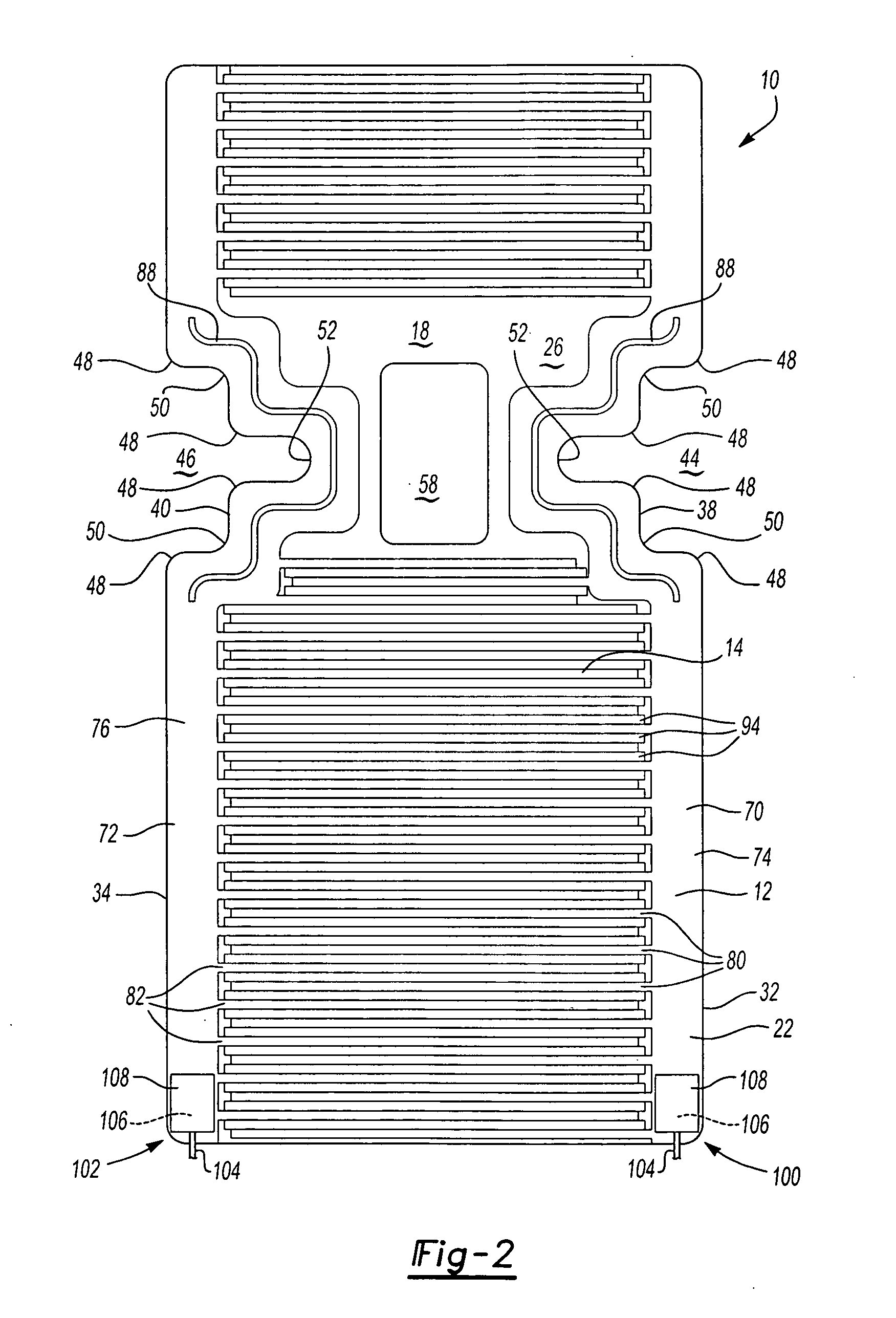

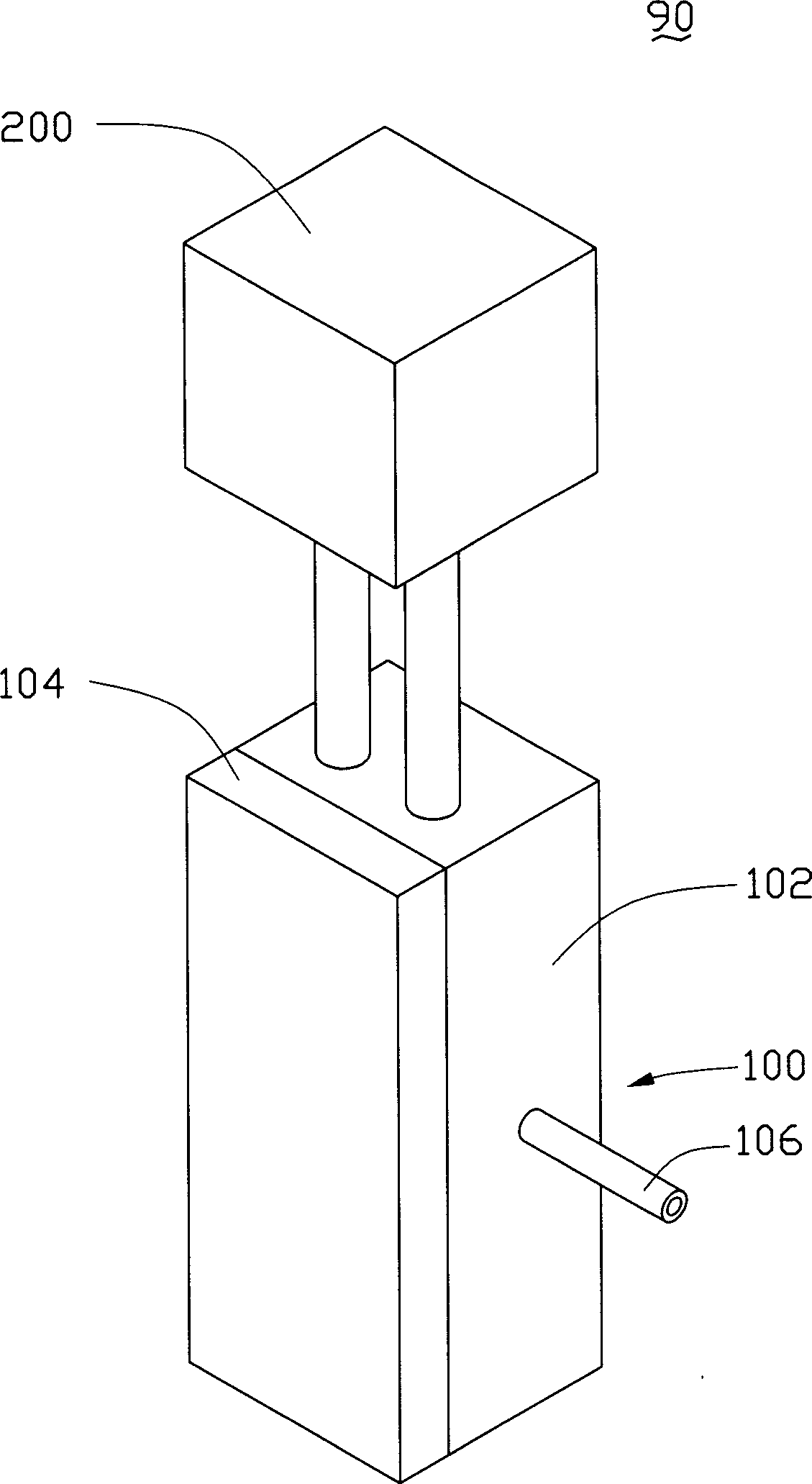

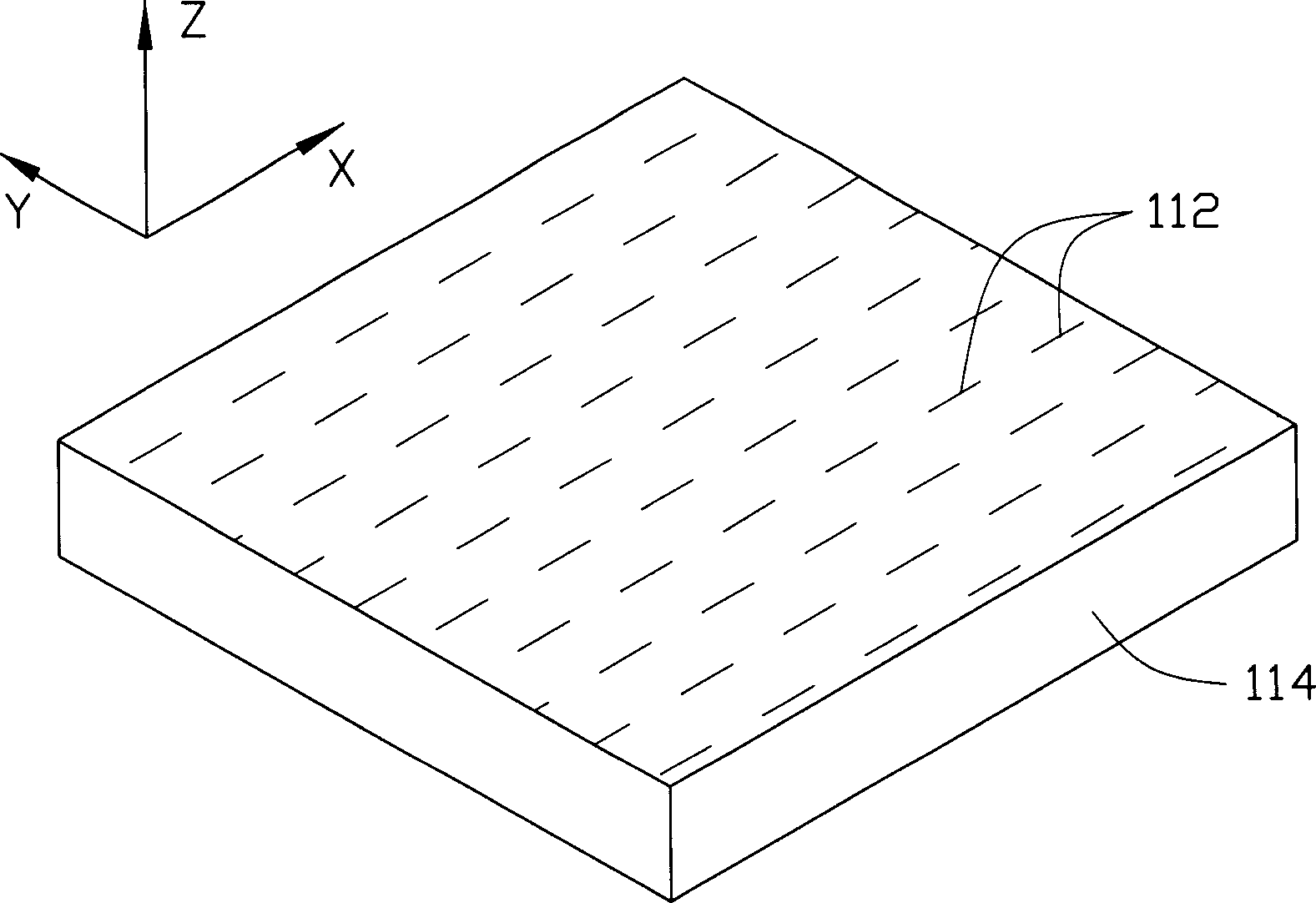

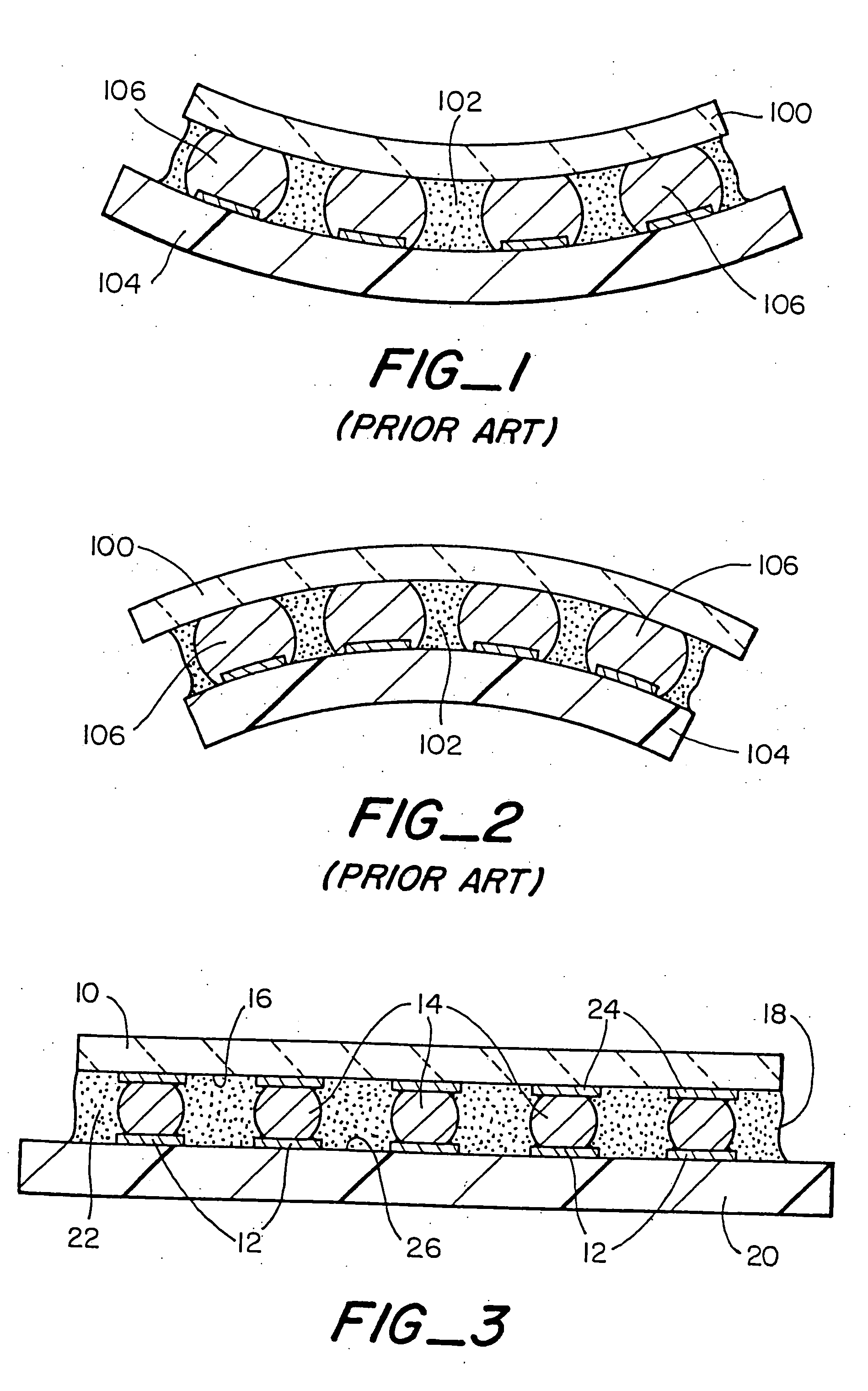

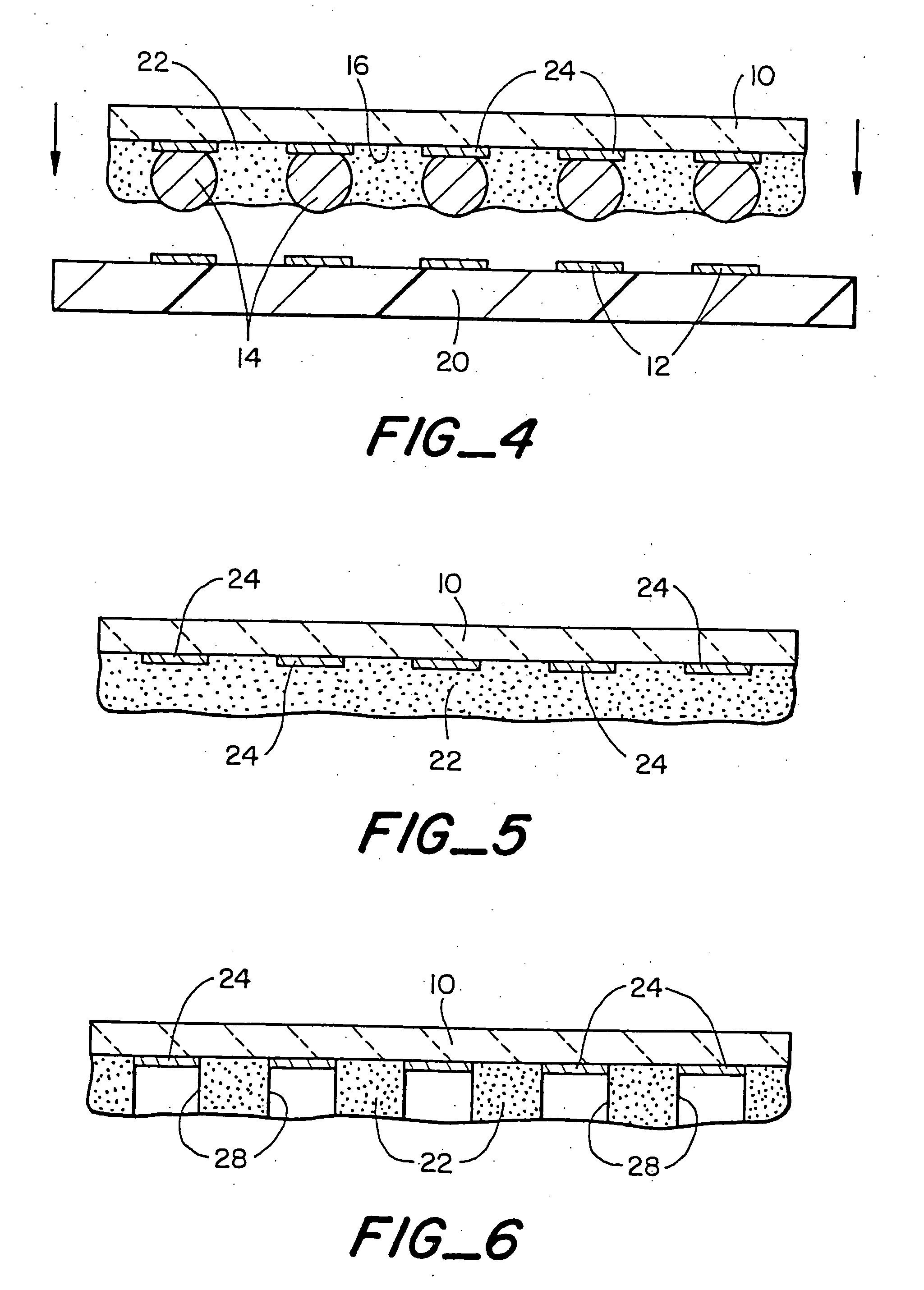

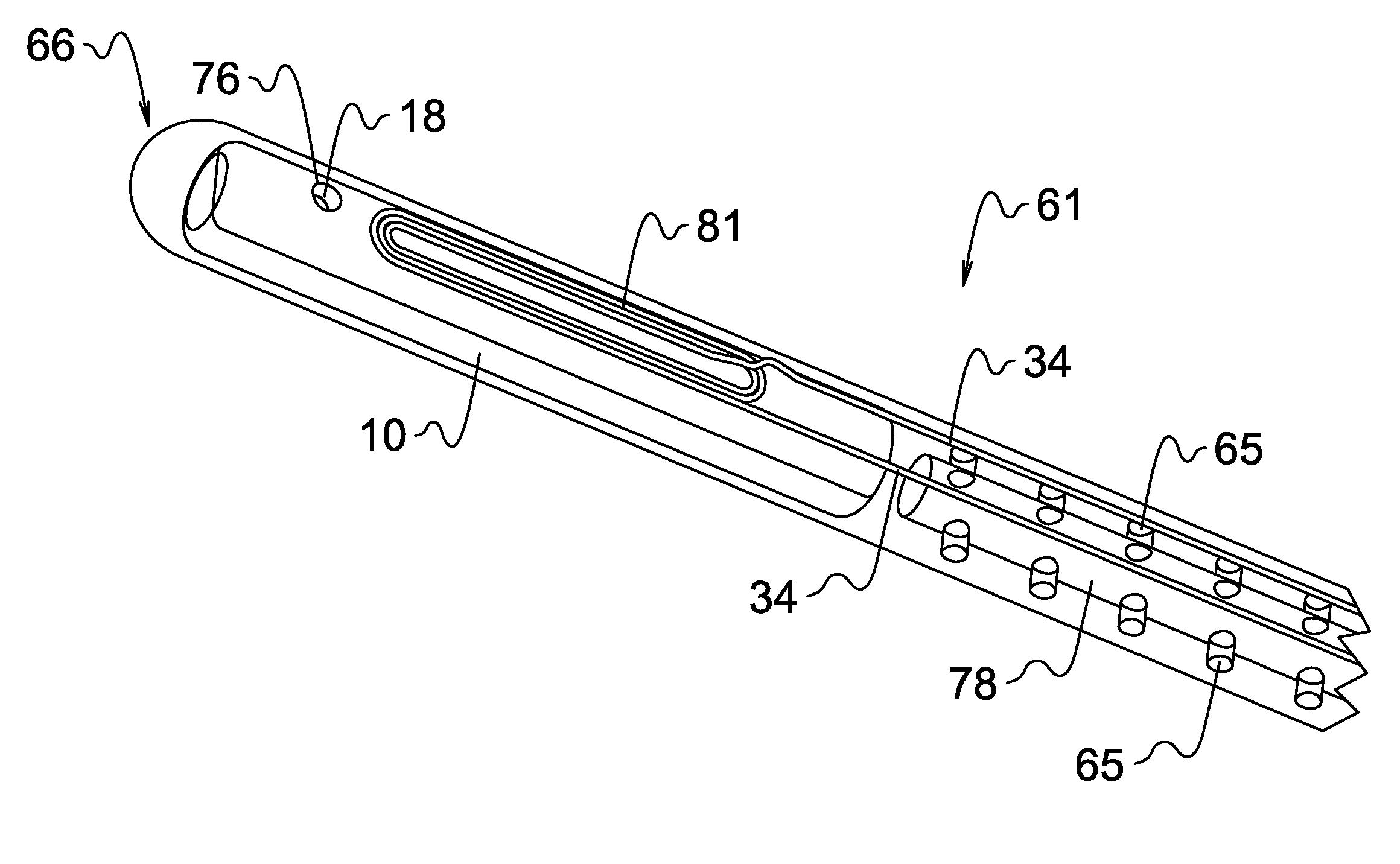

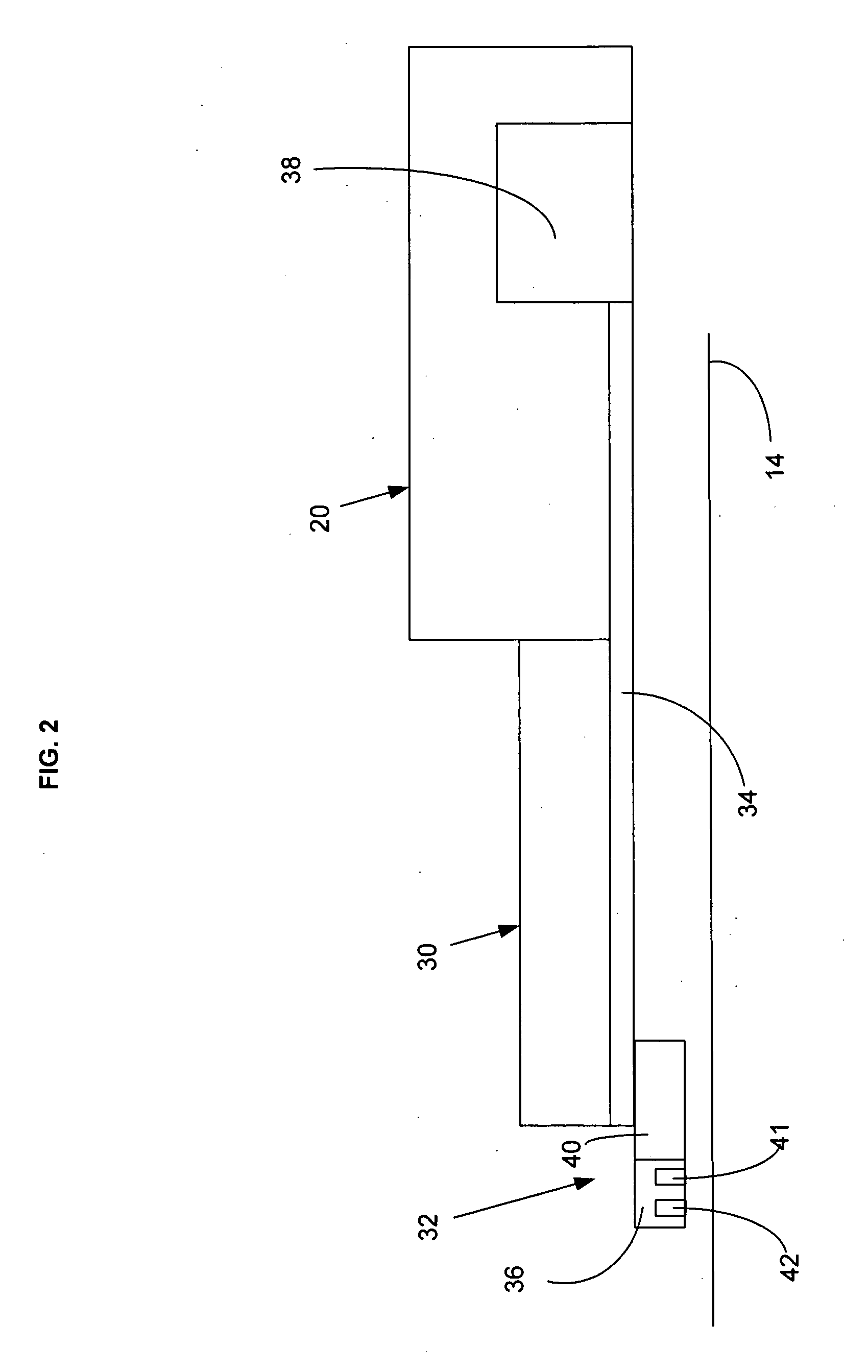

Friction fit target assembly for high power sputtering operation

InactiveUS7114643B2Low thermal conductivityImprove thermal conductivityCellsElectric discharge tubesSputteringThermal coefficient

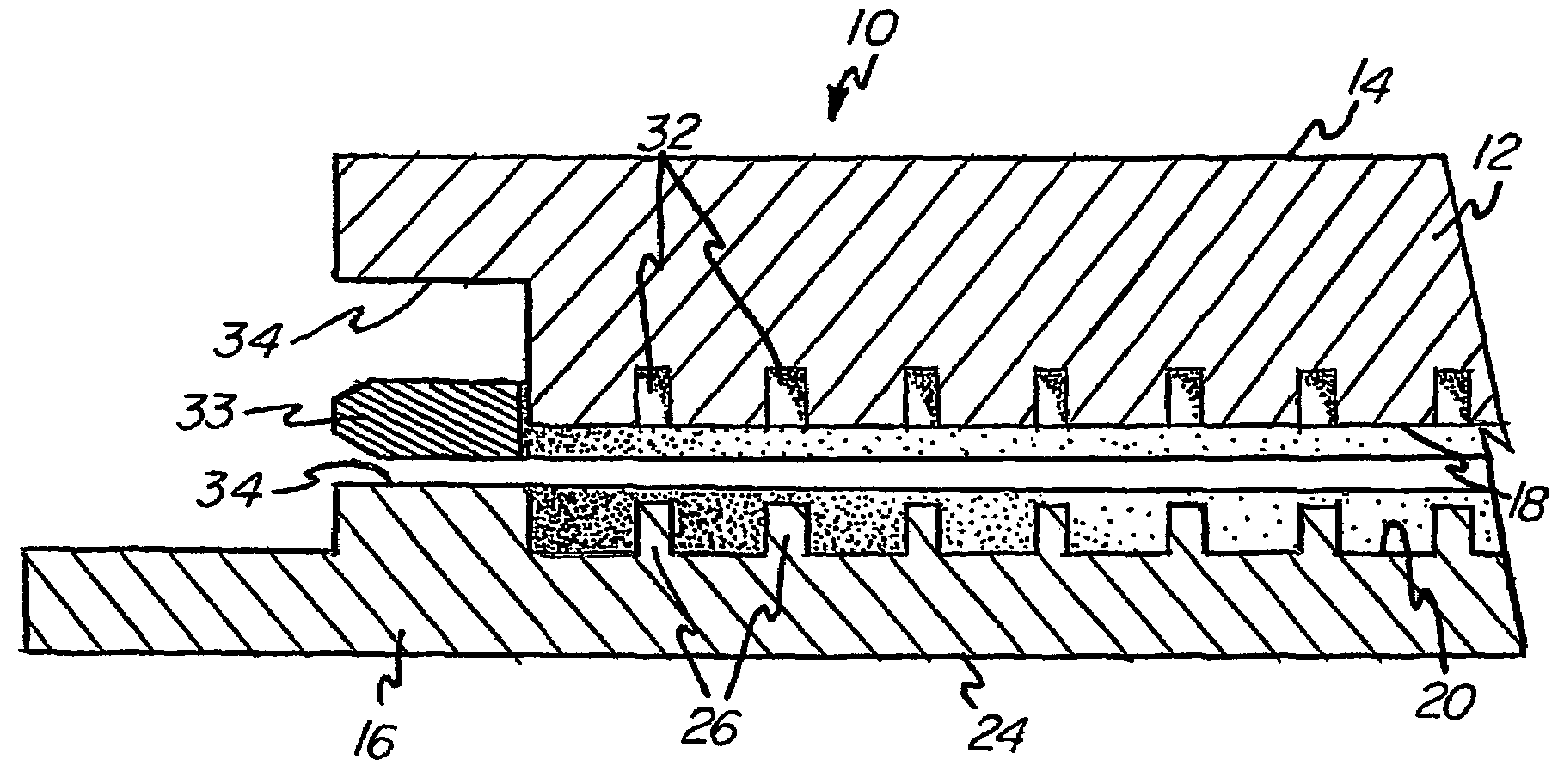

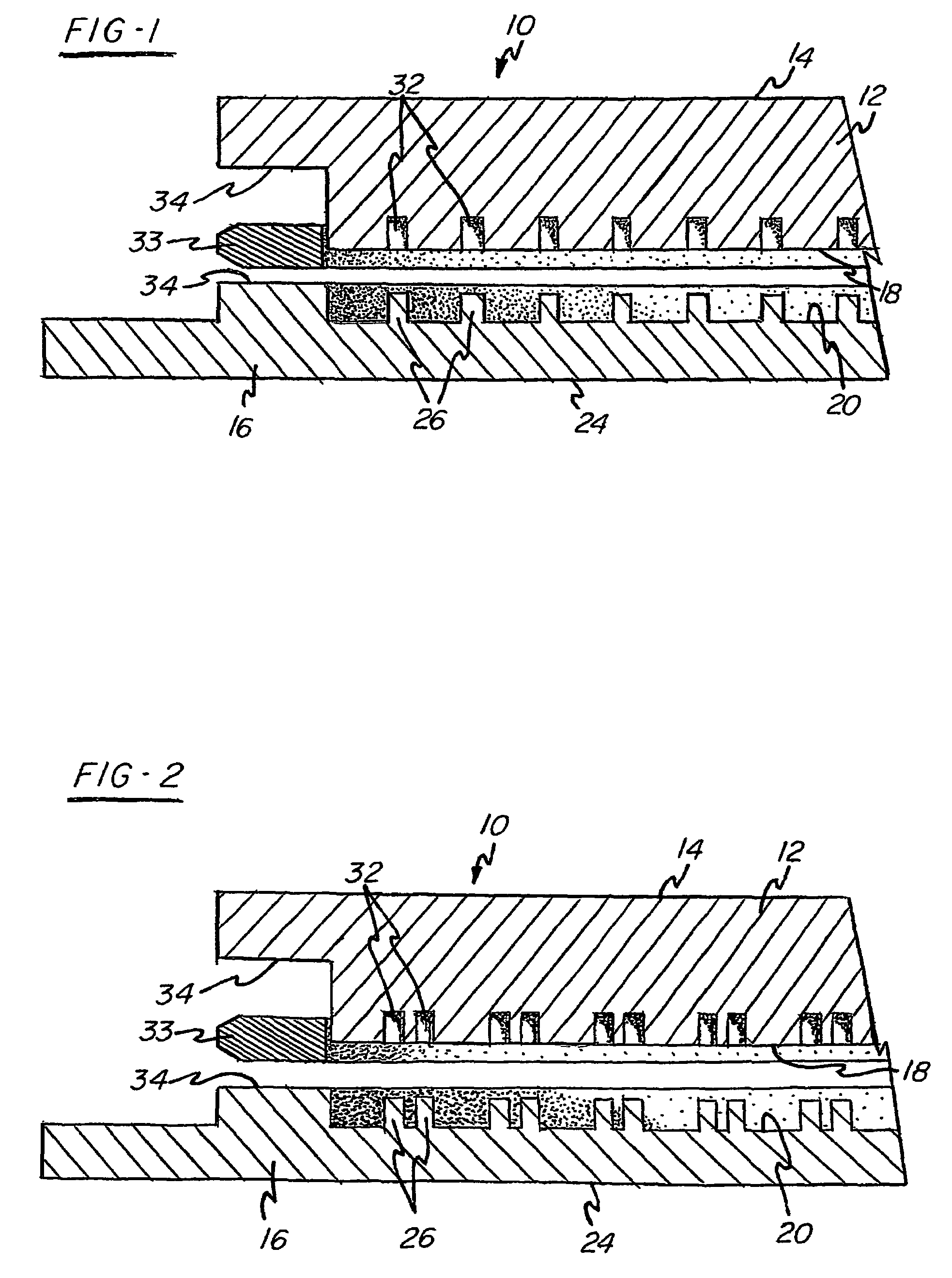

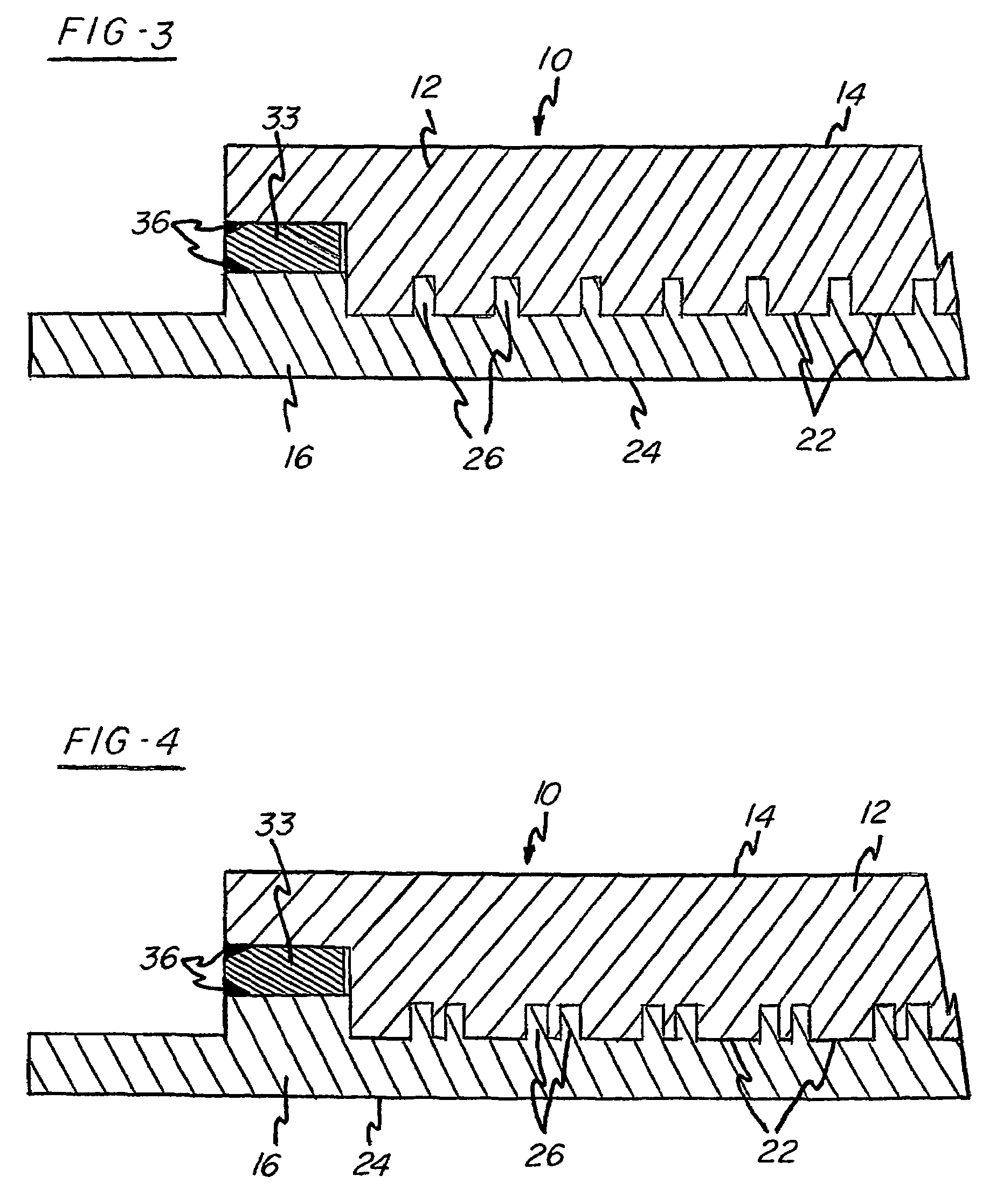

The present application pertains to unconventional sputter target / backing plate assemblies (10) for high power operation and to the low temperature method of making them. The sputter target / backing plate assemblies (10) comprise targets (12) and backing plates (16) having dissimilar thermal coefficients of expansion. Although the consolidated targets (12) and backing plates (16) have dissimilar thermal coefficients of expansion, they are able to be bonded together and used at high sputtering temperatures without bowing or bending and are able to utilize backing plates (16) normally associated with a specified target metal. In the method of making, a plurality of male projections (16) are formed in one member of the assembly (10) with a plurality of corresponding female grooves (32) formed in the other surface. The assembly (10) is bonded by conventional techniques around an annular zone that surrounds the male (26) and female portions (32). The assembly (10) is then pressure consolidated at low temperature so that the projections are force fit into the female recesses.

Owner:TOSOH SMD

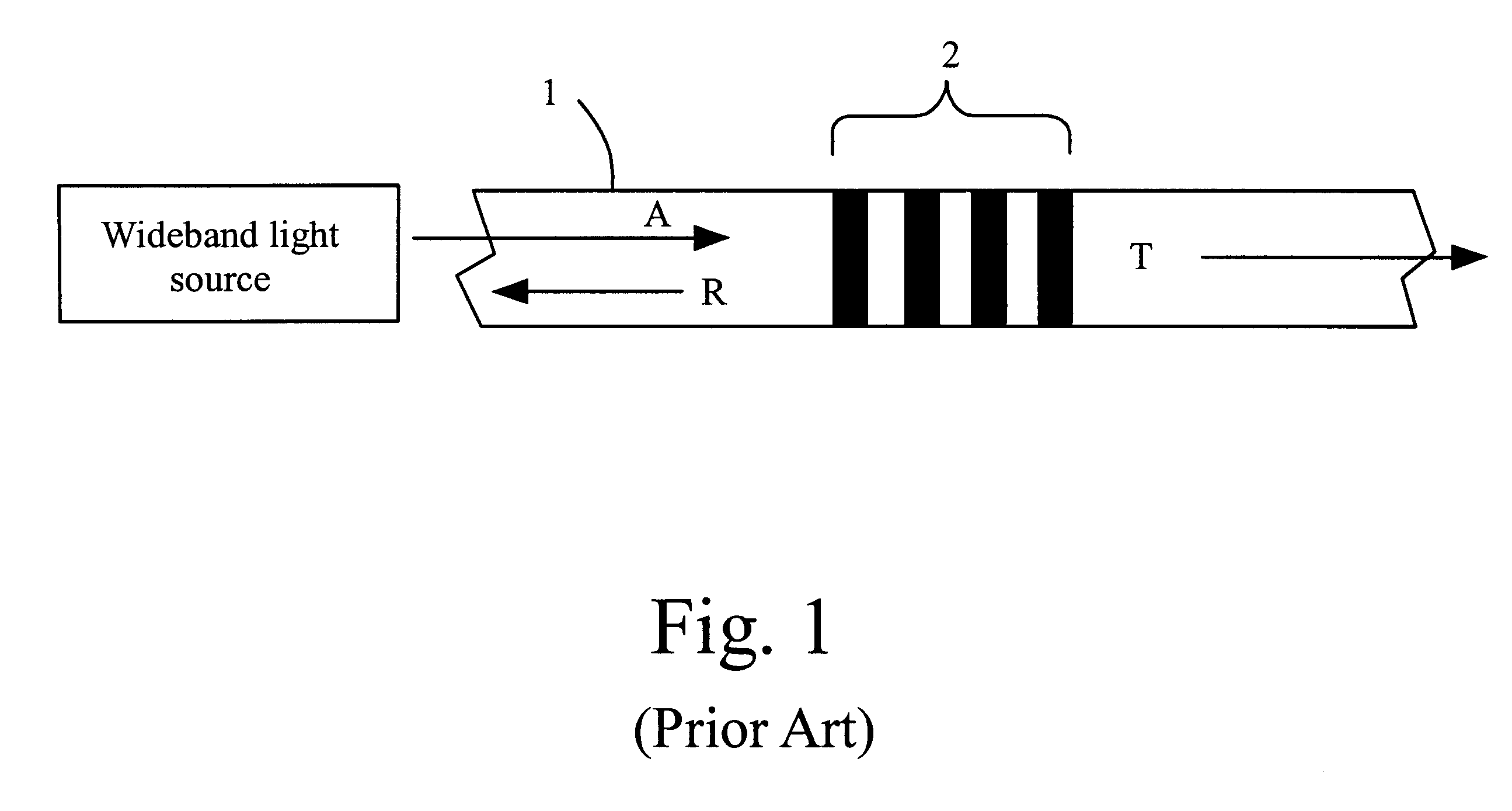

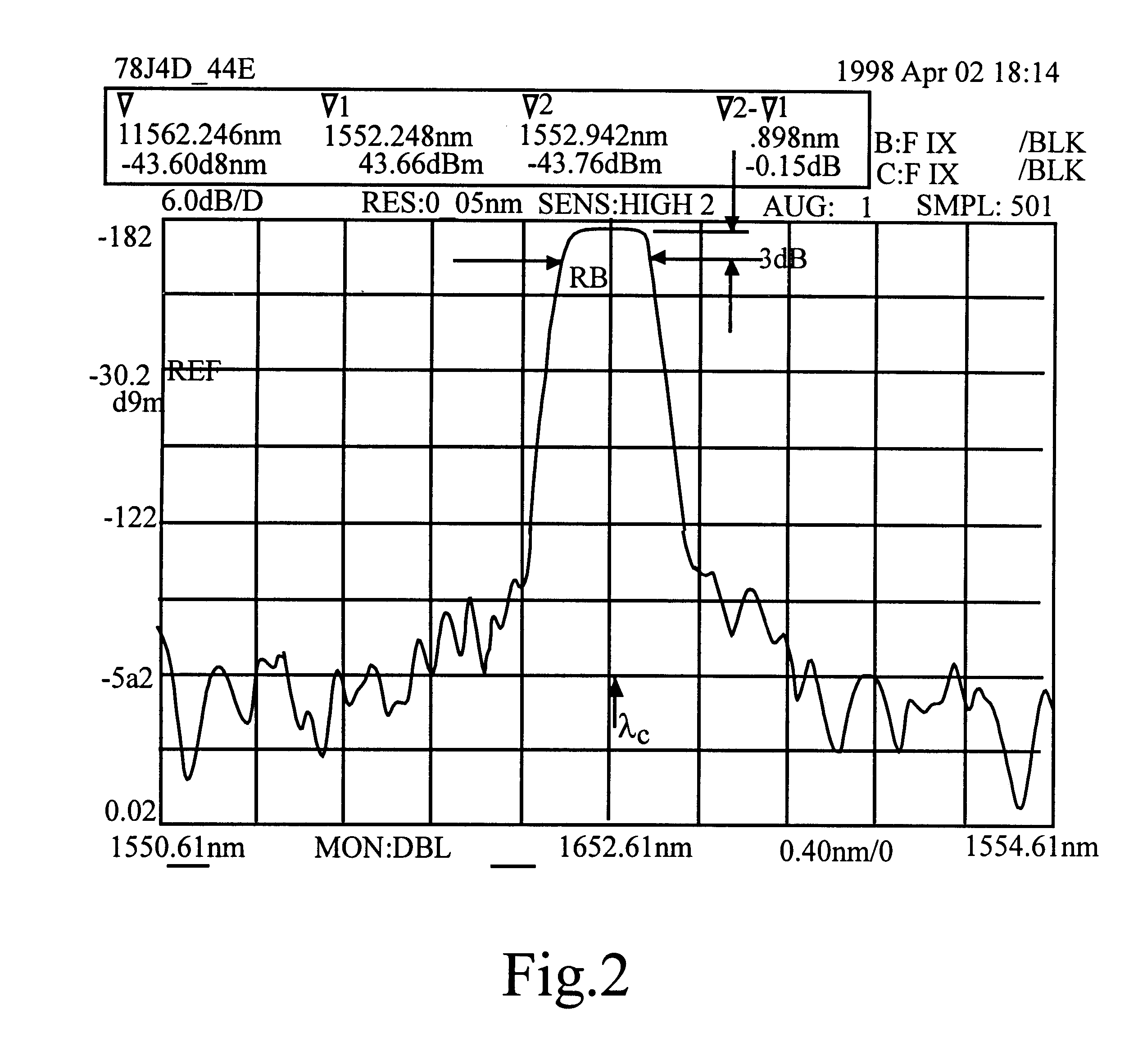

Thermal compensated compact bragg grating filter

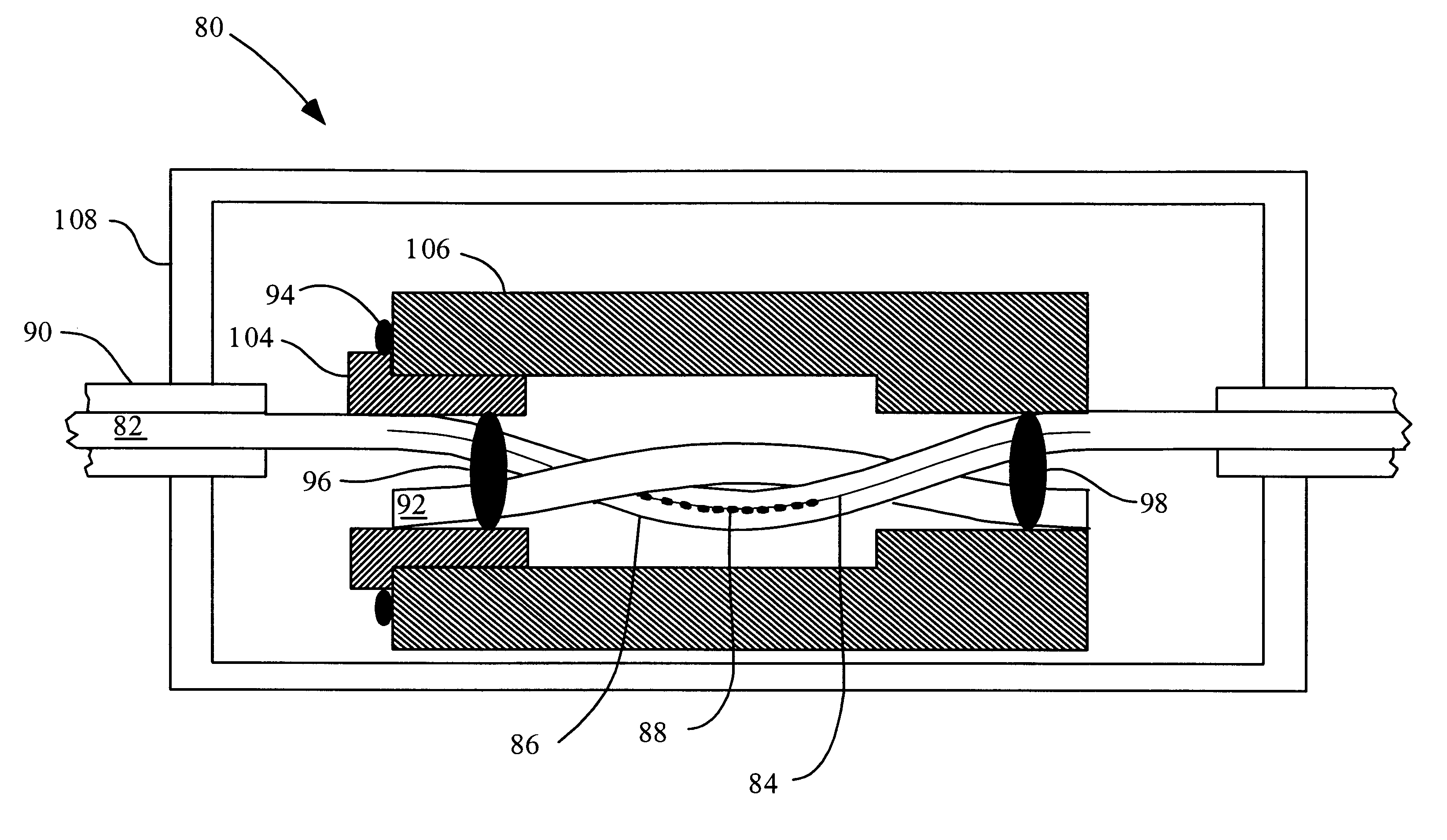

Various aspects of thermal compensated Bragg grating filters are disclosed. In one disclosed aspect, an optical fiber having a Bragg grating therein is laid adjacent to a torsion member, and the two are then rigidly affixed between a torsion adjusting member and a compensating member. The torsion adjusting member may then be rotated, twisting the optical fiber around the torsion member, and thus applying torsion to the optical fiber containing the Bragg grating, and changing the period of the Bragg grating. A further disclosed aspect provides an optical fiber, containing a Bragg grating filter therein, which is rigidly affixed between a torsion adjusting member and a compensating member in an axis other than the compensating member's longitudinal axis. The torsion adjusting member may then be rotated to apply torsion to the optical fiber, and change the period of the Bragg grating. Another disclosed aspect comprises an optical fiber, containing a Bragg grating filter therein, and a compensating member having a desired thermal coefficient of expansion. The optical fiber is bent through a curve and affixed to the compensating member such that torsion is applied to the Bragg grating region of the optical fiber.

Owner:II VI DELAWARE INC

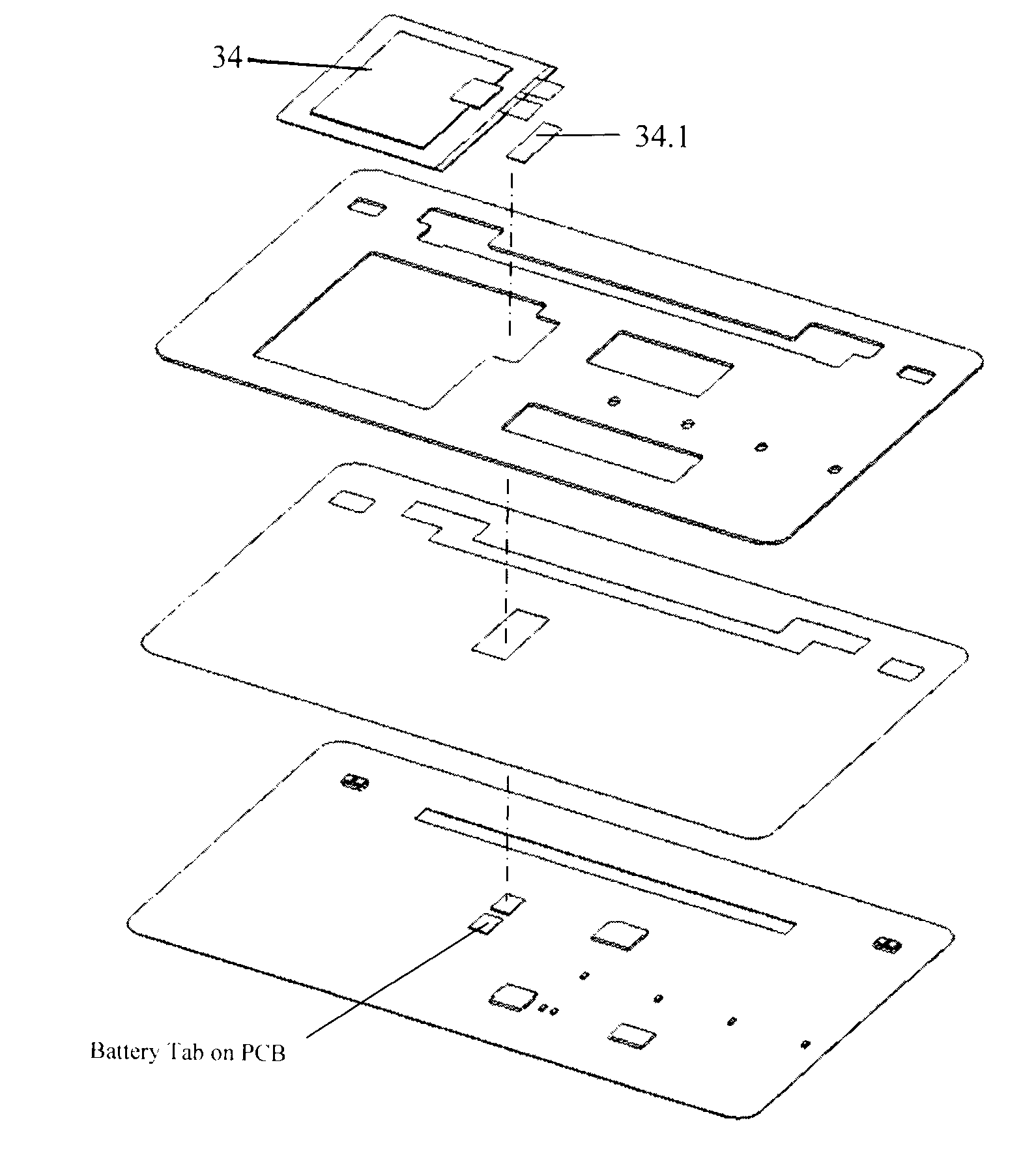

Laminated electronic card assembly

InactiveUS8540165B2Reduce manufacturing costAcutation objectsLaminationThermal coefficientHeat sensitive

An electronic card is assembled from top and bottom graphic layers, top and bottom thermal sensitive adhesion tapes and an inlay assembly laminated together. The inlay assembly is made of a sub-assembly of a PCB base with one or more electronic components mounted to it, thermal sensitive adhesion tape and a stiffening substrate, all laminated together, while a battery insert and possible additional inserts made of PVC are mounted in openings in the sub-assembly around electronic components such as the battery. The stiffening substrate has a thermal coefficient substantially the same as that of the PCB base. The card need not contain any solder connections and is ISO 7810 compliant. Lamination is performed at a warm, not hot, temperature that does not damage the battery or melt any components together.

Owner:PRIVASYS

Variable thermal conductivity factor measuring apparatus and method

ActiveCN101290299AGuaranteed stabilityReduce mistakesMaterial thermal conductivityMaterial heat developmentCold sideMeasurement device

The invention discloses a method for measuring a variable thermal coefficient. The method is characterized by comprising the following steps that: A. a sample is arranged inside a closed supporting frame; one end of the sample closely contacts a plane heater and the other end of the sample closely contacts a heat-dissipation block; thermocouples are respectively arranged on both ends of the sample and contact a data acquisition unit; B. the sample is heated by the plane heater; measured values are acquired by the data acquisition unit; the hot-side temperature and the cold-side temperature of the sample are calculated; the thermal coefficient is calculated according to the cold-side temperature and the hot-side temperature; C. when the variation of the thermal coefficient value calculated does not exceed 0.01 within 10 minutes, the thermal coefficient calculated is the thermal coefficient of the sample. The method has the advantages that: firstly, the stability of heat currents is guaranteed; secondly, due to adoption of a heat insulating layer, the errors caused by heat dissipation are reduced; thirdly, when the thermal coefficient is calculated, the thermal losses are modified and the measurement precision is improved.

Owner:SHANGHAI TIRE & RUBBER TIRE RES INST +1

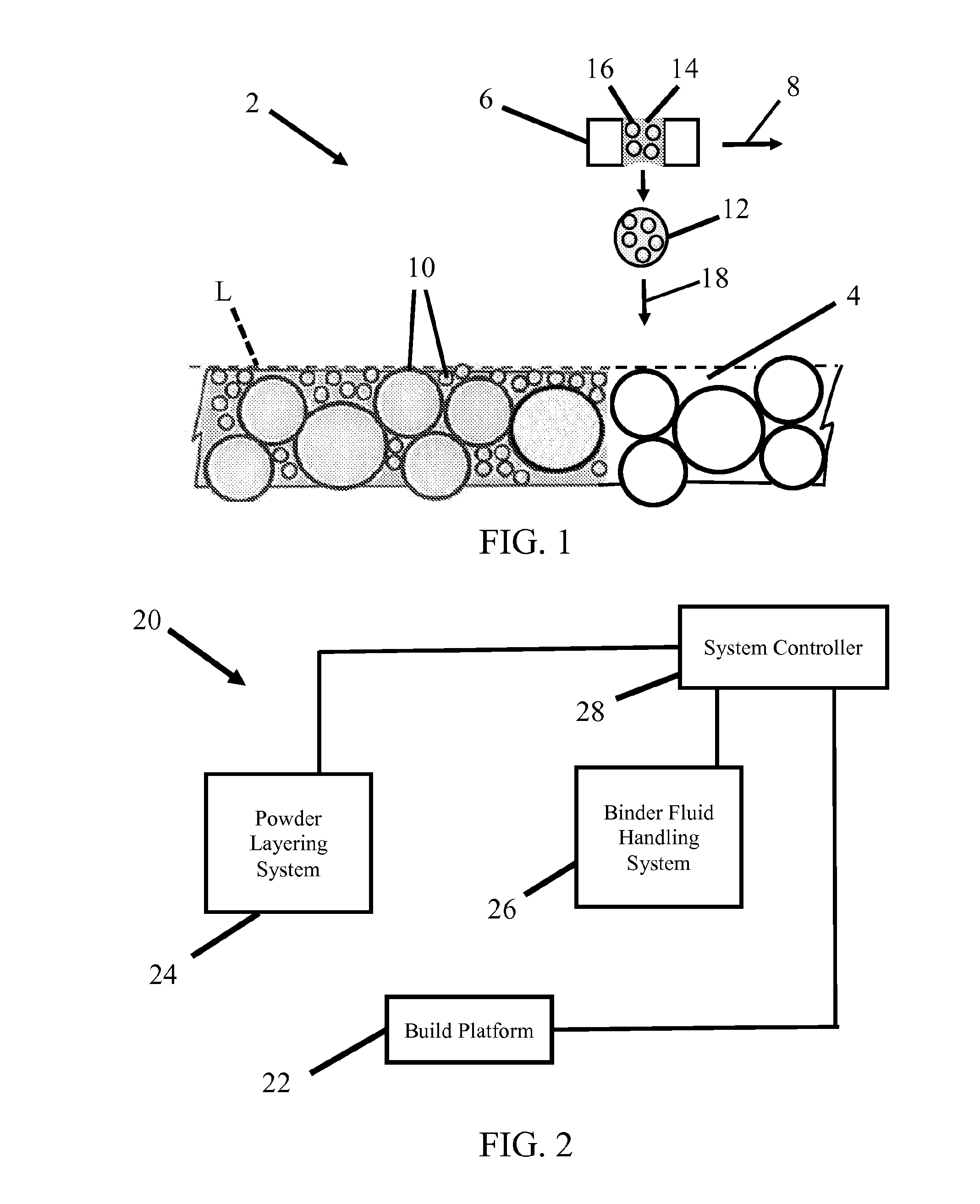

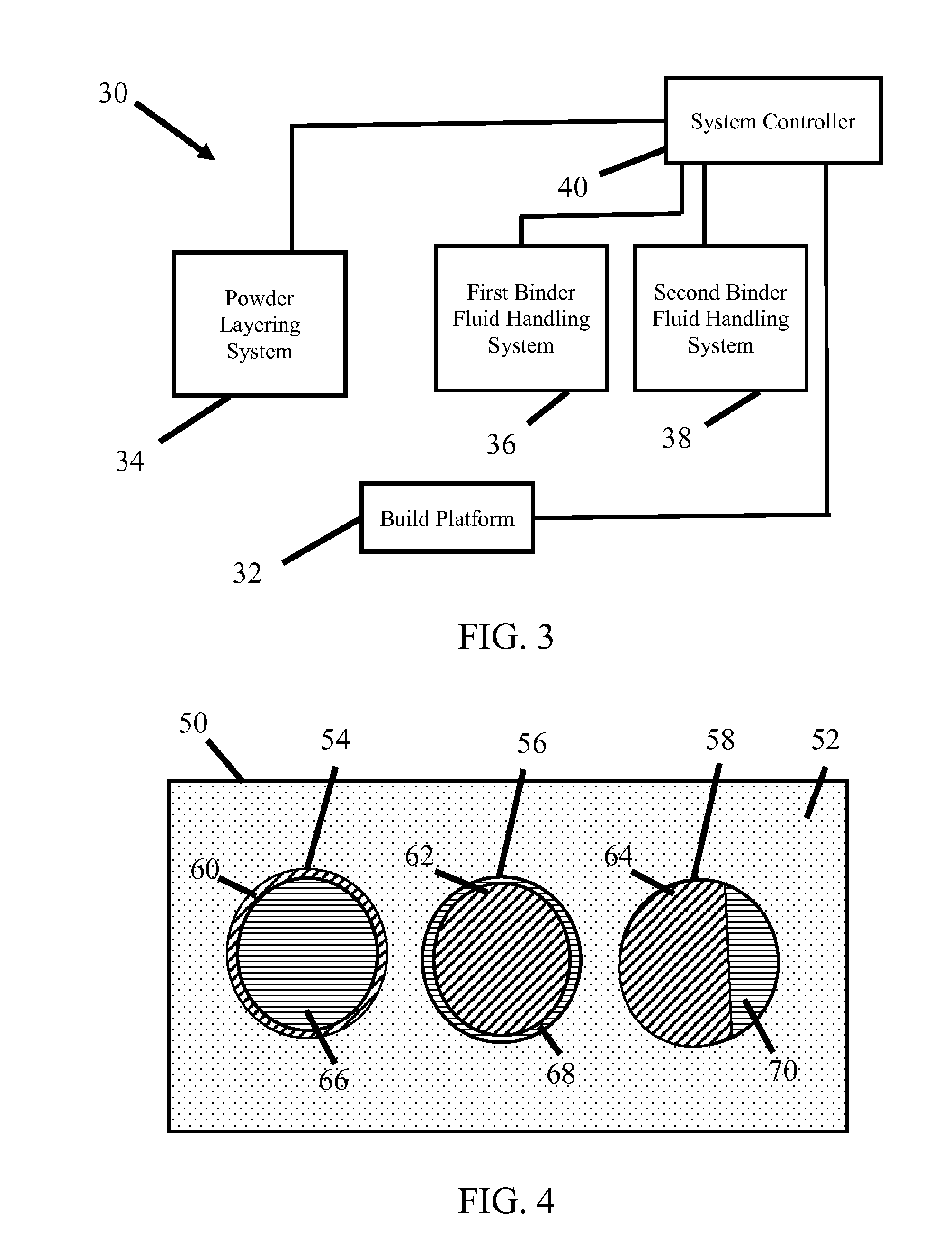

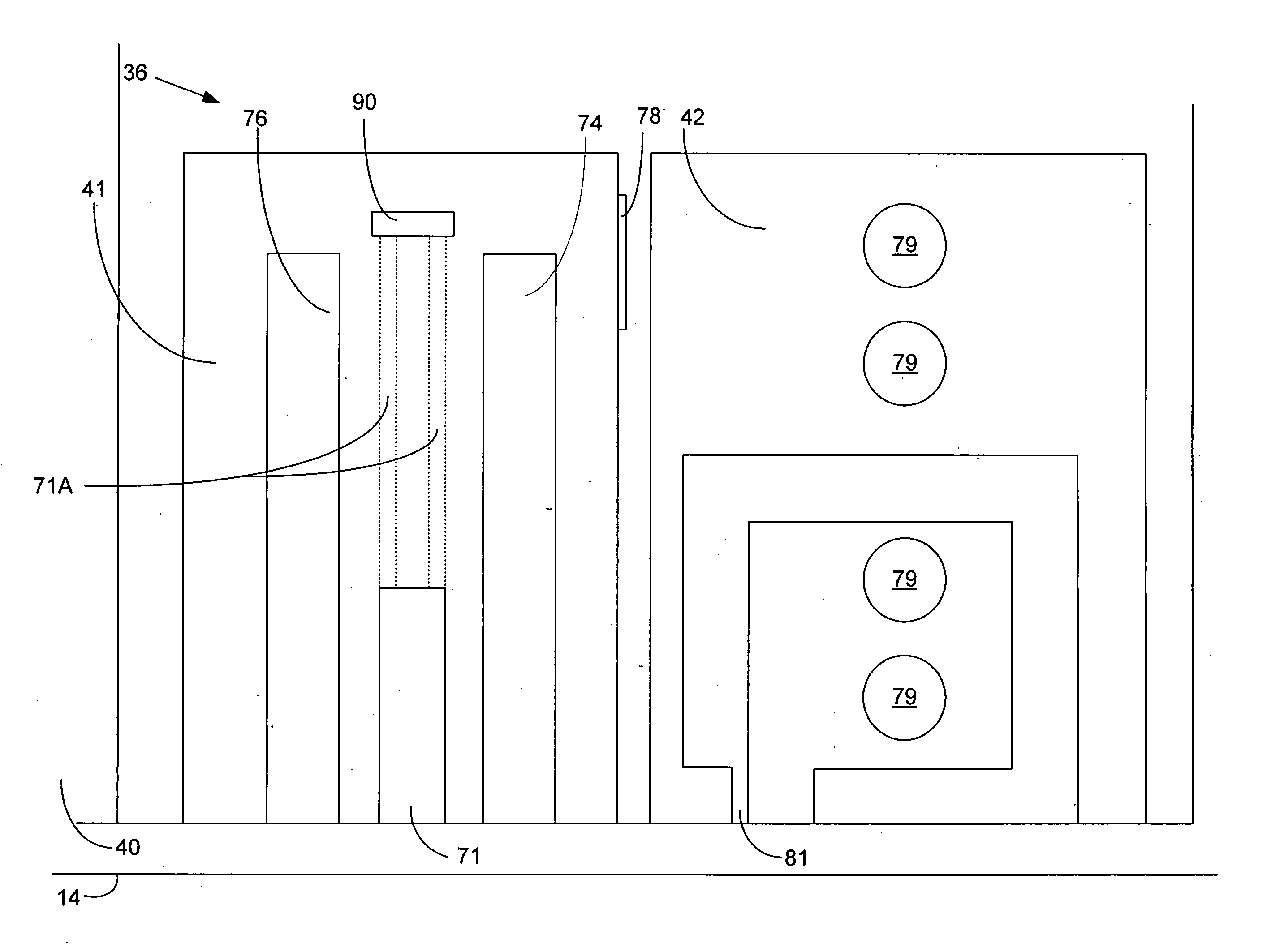

Methods and Systems for Three-Dimensional Printing Utilizing Multiple Binder Fluids

InactiveUS20160332373A1High densityImprove resolutionAdditive manufacturing apparatus3D object support structuresSurface finishThermal coefficient

Methods and systems (2) are disclosed for making articles (114) by three-dimensional printing. The methods include selectively printing by jet deposition on successive layers (4) of a build material powder (10) at least one of a first binder fluid and a second binder fluid. At least one of the first and second binder fluids includes a particulate matter (16) having mean particle size diameter which is less than that of the build material powder (10). The first binder fluid is characteristically different from the second binder fluid. The particulate matter (16) selectively deposited with a binder fluid can be used to locally tailor the physical properties of the article (114), e.g. by alloying with the build material powder, increasing densification, acting as a local infiltrant or infiltrant stop during heat treatment, locally modulating the local stress fields (e.g. by a mismatch of thermal coefficients of expansion), etc. Among the possible locally tailored properties is the surface finish of an interior or exterior surface of the article (114).

Owner:THE EX ONE

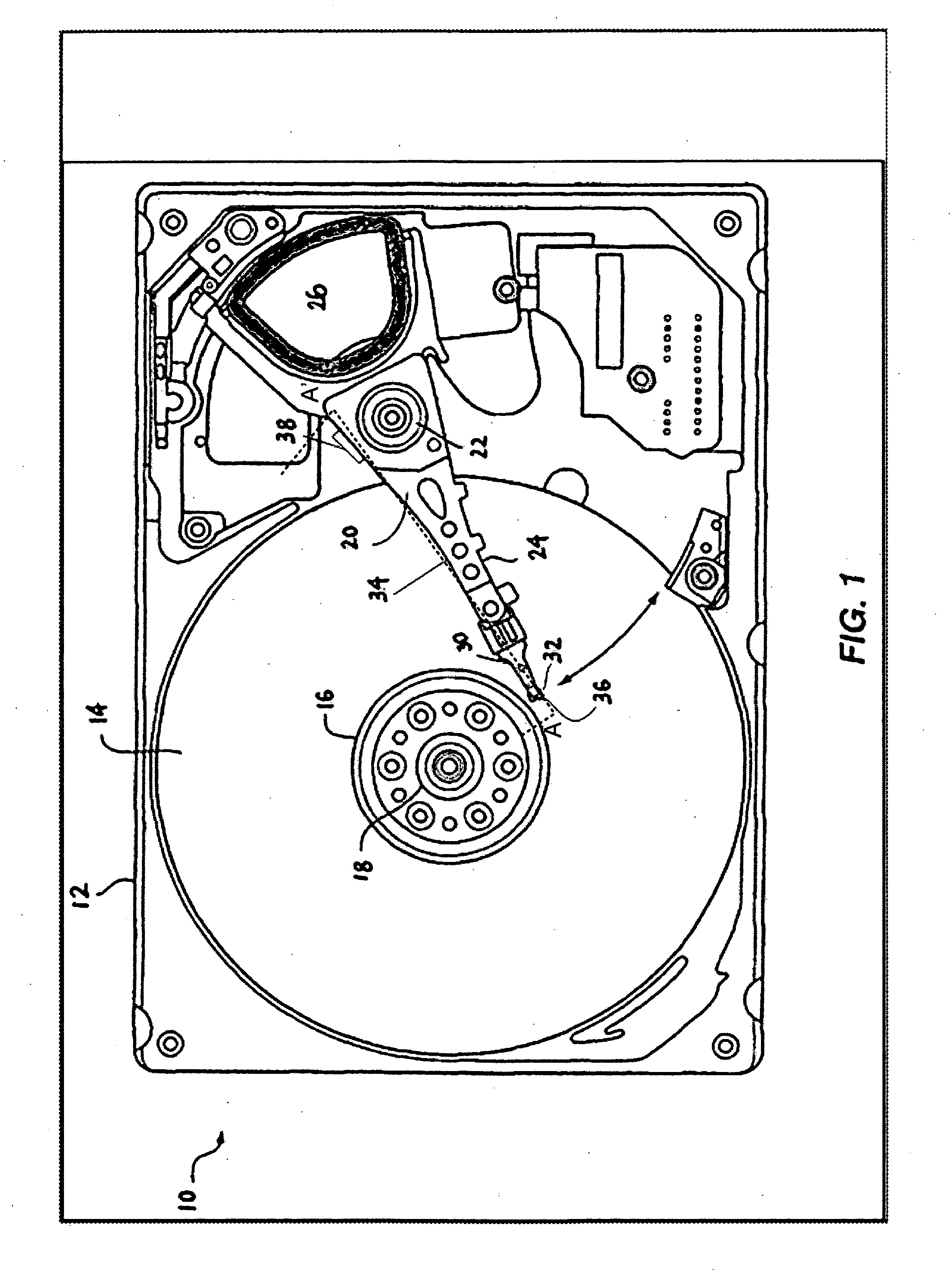

Low thermal coefficient of resistivity on-slider tunneling magneto-resistive shunt resistor

InactiveUS20070091512A1High strengthImprove signal-to-noise ratioManufacture head surfaceRecord information storageHigh signal intensityMagnetic reluctance

A slider includes a Tunneling Magneto-Resistive (TuMR) read sensor and a shunt resistor connected in parallel. The shunt resistor may be located in a read structure of the slider. The shunt resistor may reduce a total resistance of the read structure and any corresponding impedance mismatch between the read structure, a transmission line, and a preamplifier. The shunt resistor may be made of a material having a near zero thermal coefficient of resistivity (TCR) to test a quality of the TuMR read sensor. The TuMR read sensor may be deemed defective if its TCR deviates from a population average by a specific criterion. The TuMR read sensor may include a MgO tunneling barrier to improve signal strength. The TuMR read sensor may include a free layer that is able to be saturated with a perpendicular background field to calculate a more accurate TCR of the TuMR read sensor.

Owner:SEAGATE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com