Variable thermal conductivity factor measuring apparatus and method

A technology of thermal conductivity, measuring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

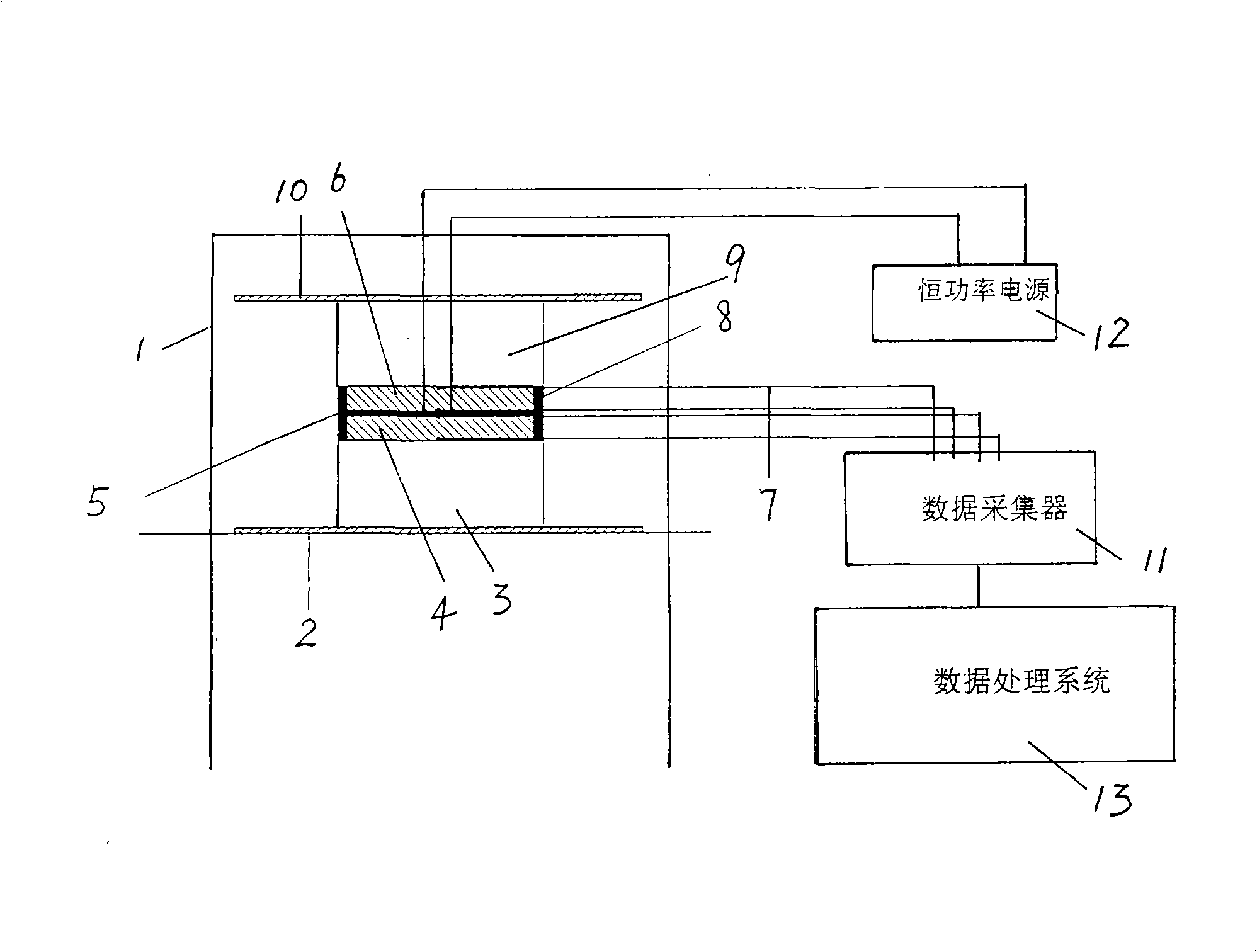

[0026] As shown in Figure 1, the entire experimental device includes a closed support frame, in which the sample, heater, heat insulation layer, heat dissipation block, fastening cover plate, and thermocouple are all placed, and the air flow and other factors can be excluded in the closed area. Influence on the thermal insulation of the system, the thermocouple is placed on the upper and lower surfaces of the sample, and the surface temperature change of the sample is measured by the thermocouple. High pressure is applied to the cooling block, so that the cooling block and the sample are closely combined, thereby reducing the thermal resistance of the contact surface between the cooling block and the sample and the heater and the sample; the heat insulating material is surrounded around the sample and the heater to ensure that the system Good heat insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com