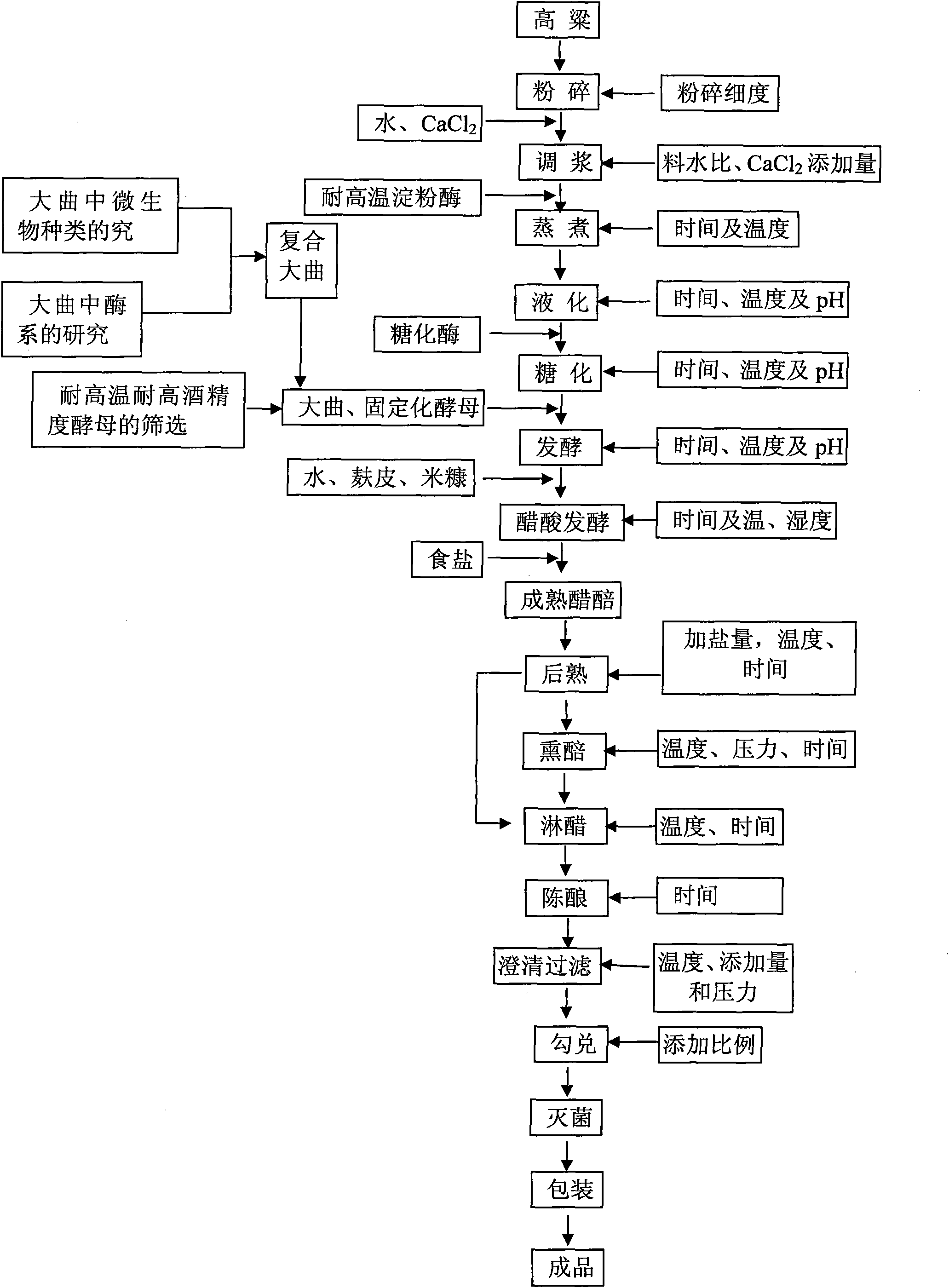

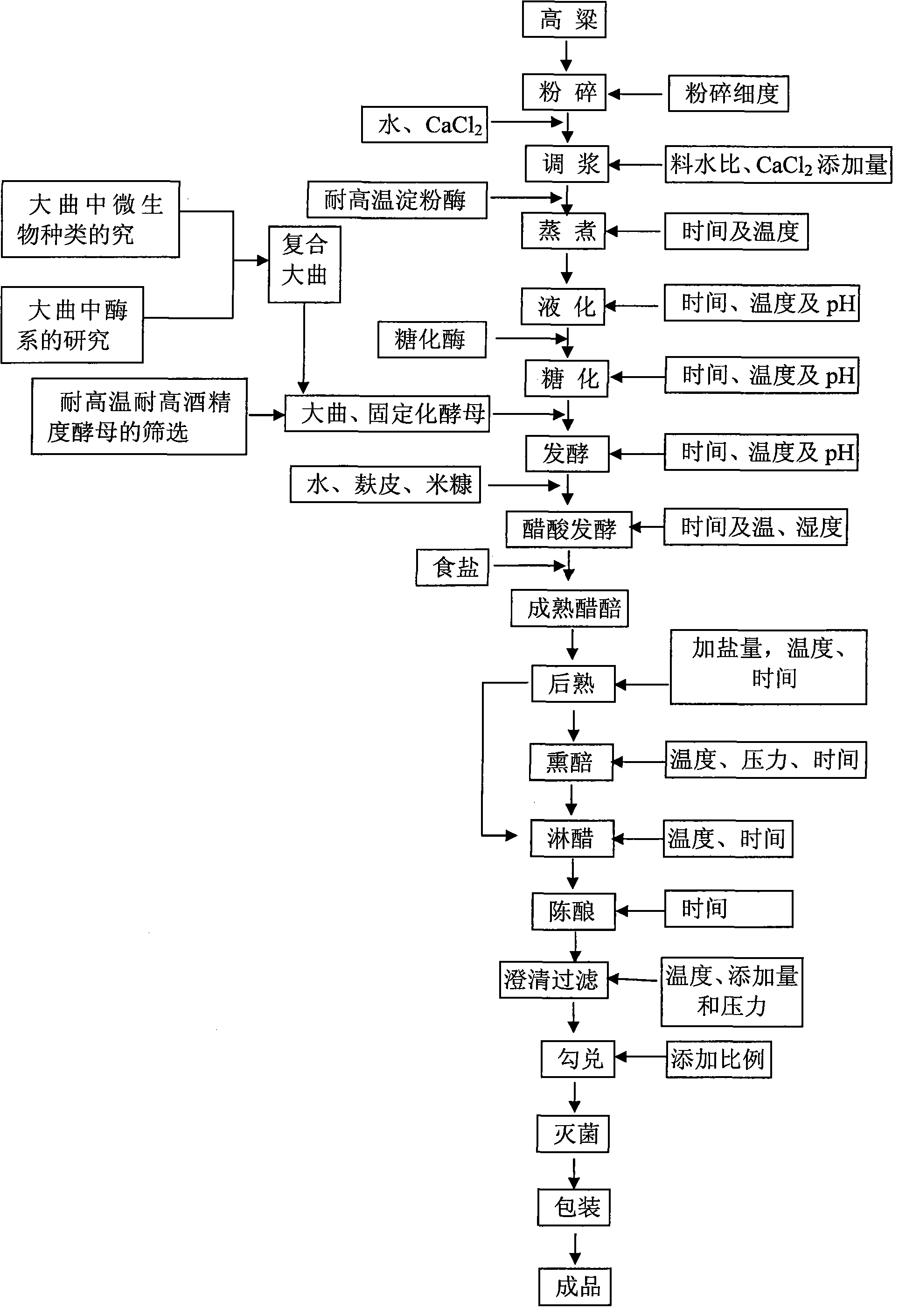

Standardized and industrialized production process for Shanxi mature vinegar

A production process, the technology of aged vinegar, which is applied in the preparation of vinegar, microorganisms, and methods based on microorganisms, etc., can solve the problems of long production cycle, unstable product quality, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] A kind of Shanxi mature vinegar standardization industrial production process, comprises the following steps:

[0099] (1) Material treatment before alcohol fermentation

[0100] A, sorghum raw material: selected fresh sorghum without mildew (at least it can be sorghum produced in Qingxu, Taiyuan City, Shanxi Province), with a starch content of 60%; Pulverizer is pulverized into 30 mesh sorghum flour; C, pulping: the obtained sorghum flour is mixed with 50°C warm water, so that the starch content is adjusted to 13%, and NaCO 3 Adjust the pH to 5.0 and add CaCl 2 For stabilizing enzyme activity, the amount added is 60mg CaCl per kilogram of sorghum flour 2 D, liquefaction: 20000U / ml high temperature resistant α-amylase is used for liquefaction, the liquefaction temperature is 80°C, the liquefaction time is 2.5h, the amount of amylase added is 0.5ml amylase per kilogram of sorghum flour, and the pH value is 5.0; E. Saccharification: Saccharification uses 50000U / g high-...

Embodiment 2

[0116] A kind of Shanxi mature vinegar standardization industrial production process, comprises the following steps:

[0117] (1) Material treatment before alcohol fermentation

[0118] A, sorghum raw material: selected fresh sorghum without mildew (at least it can be sorghum produced in Qingxu, Taiyuan City, Shanxi Province), with a starch content of 70%; Pulverizer is pulverized into 60 mesh sorghum flour; C, pulping: the obtained sorghum flour is mixed with warm water at 65°C so that the starch content is adjusted to 16%, and NaCO 3 Adjust the pH to 6.0 and add CaCl 2 For stabilizing enzyme activity, the amount added is 80mg CaCl per kilogram of sorghum flour 2 D. Liquefaction: 20000U / ml high temperature resistant α-amylase is used for liquefaction, the liquefaction temperature is 100°C, the liquefaction time is 3.5h, the amount of amylase added is 1.0ml amylase per kilogram of sorghum flour, and the pH value is 6.0; E. Saccharification: Saccharification uses 50000U / g hi...

Embodiment 3

[0134] A kind of Shanxi mature vinegar standardization industrial production process, comprises the following steps:

[0135] (1) Material treatment before alcohol fermentation

[0136] A, sorghum raw material: selected fresh sorghum without mildew (at least it can be sorghum produced in Qingxu, Taiyuan City, Shanxi Province), with a starch content of 70%; Pulverizer is pulverized into 30 mesh sorghum flour; C, pulping: the obtained sorghum flour is mixed with 50°C warm water so that the starch content is adjusted to 16%, and the starch content is adjusted to 16%, and the powder is mixed with NaCO 3 Adjust the pH to 6.0 and add CaCl 2 For stabilizing enzyme activity, the amount added is 80mg CaCl per kilogram of sorghum flour 2 D, liquefaction: 20000U / ml high temperature resistant α-amylase is used for liquefaction, the liquefaction temperature is 80°C, the liquefaction time is 2.5h, the amount of amylase added is 0.7ml amylase per kilogram of sorghum flour, and the pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com