Patents

Literature

500results about How to "Expand production scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

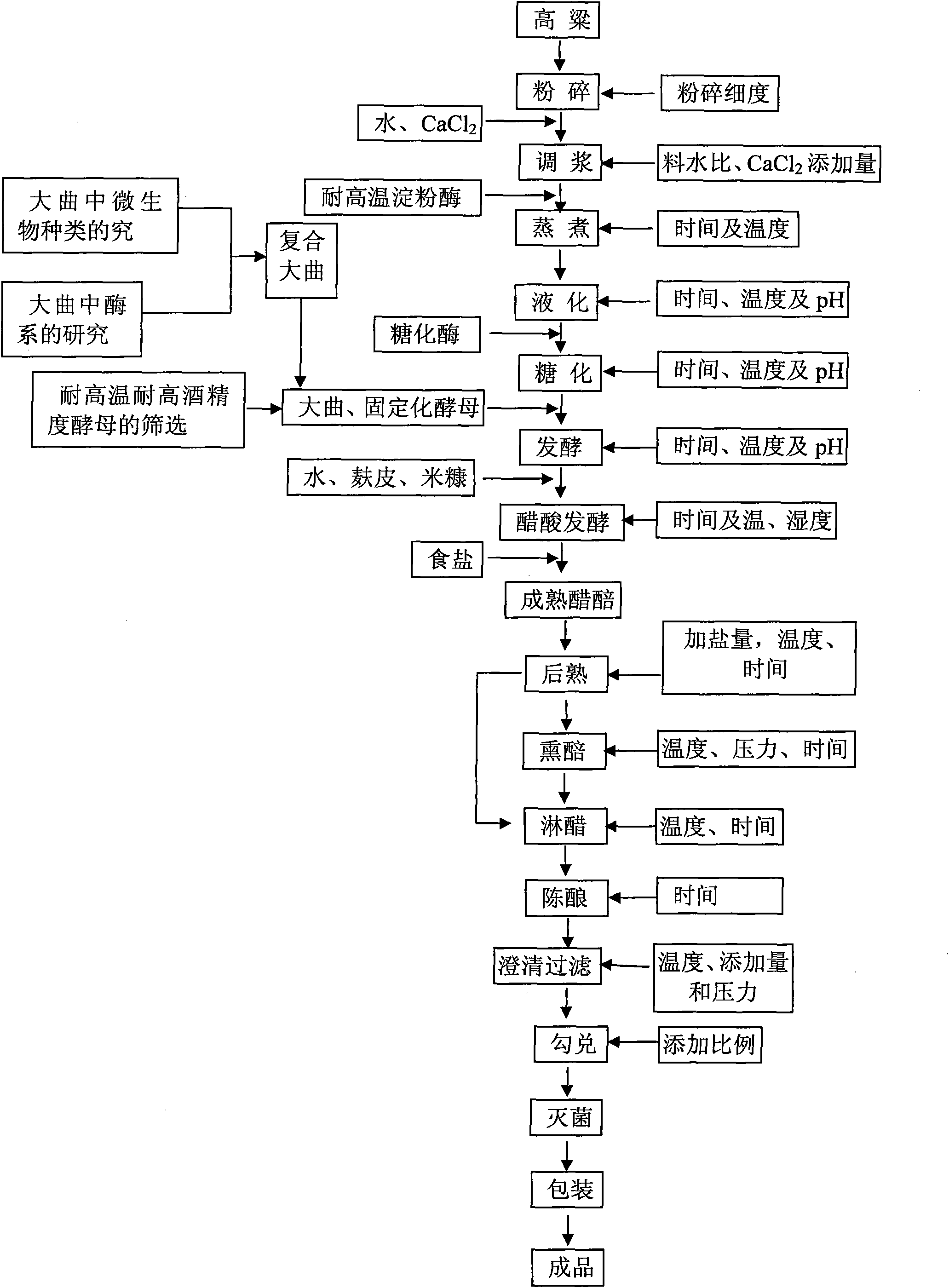

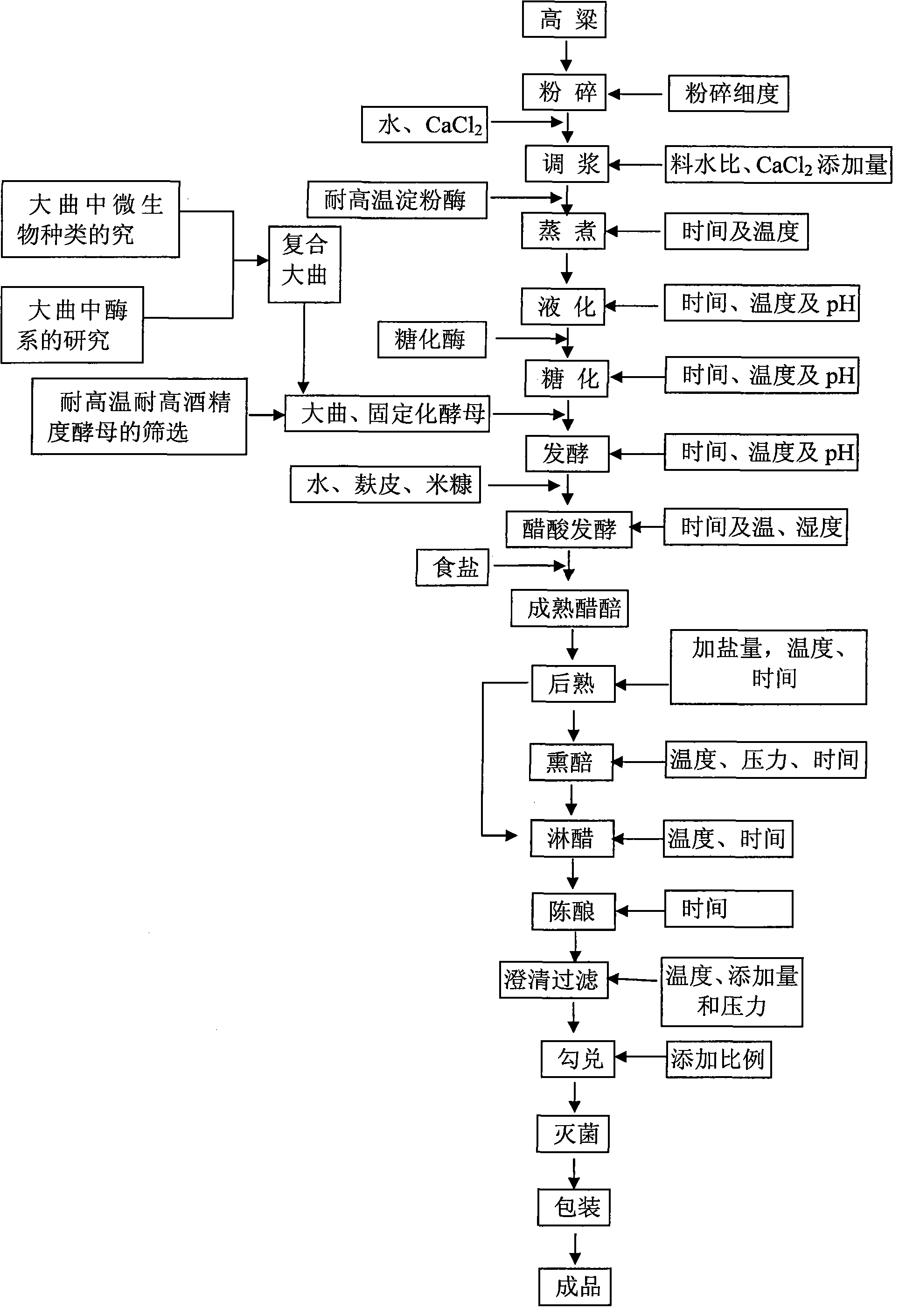

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

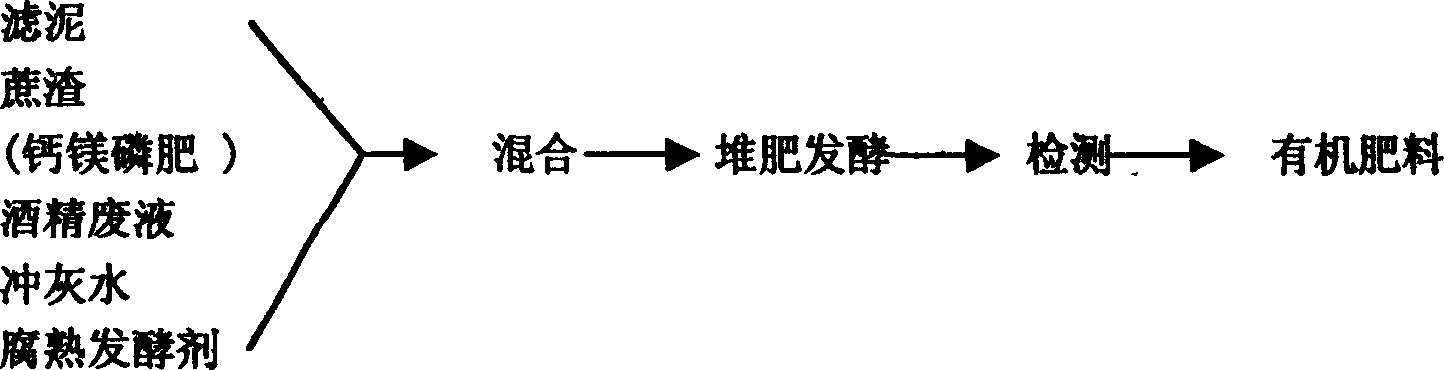

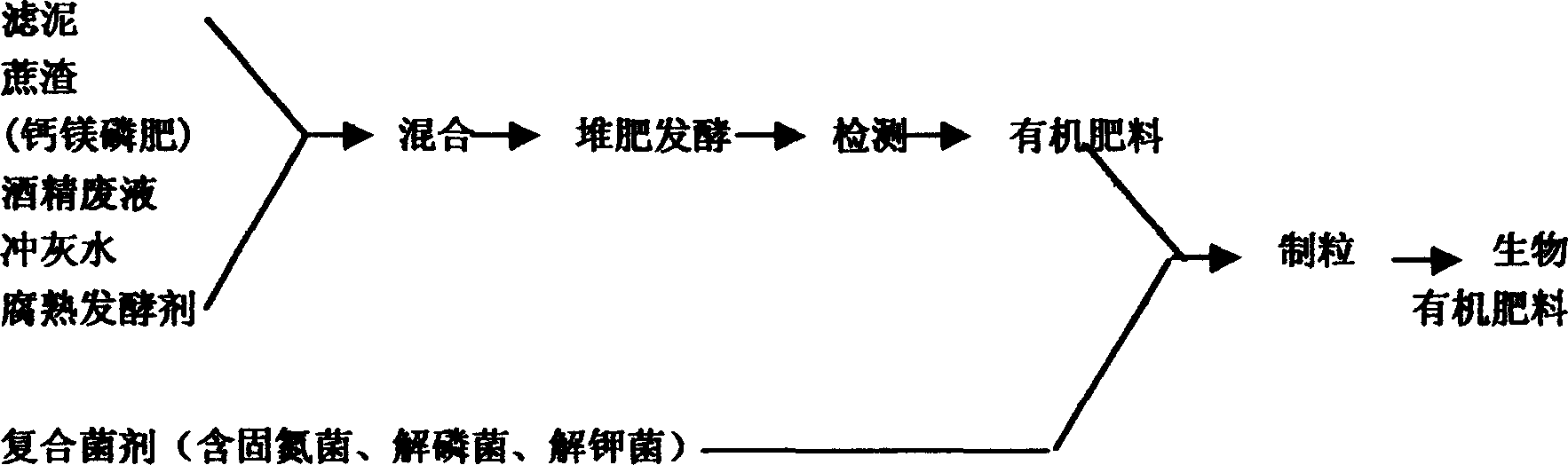

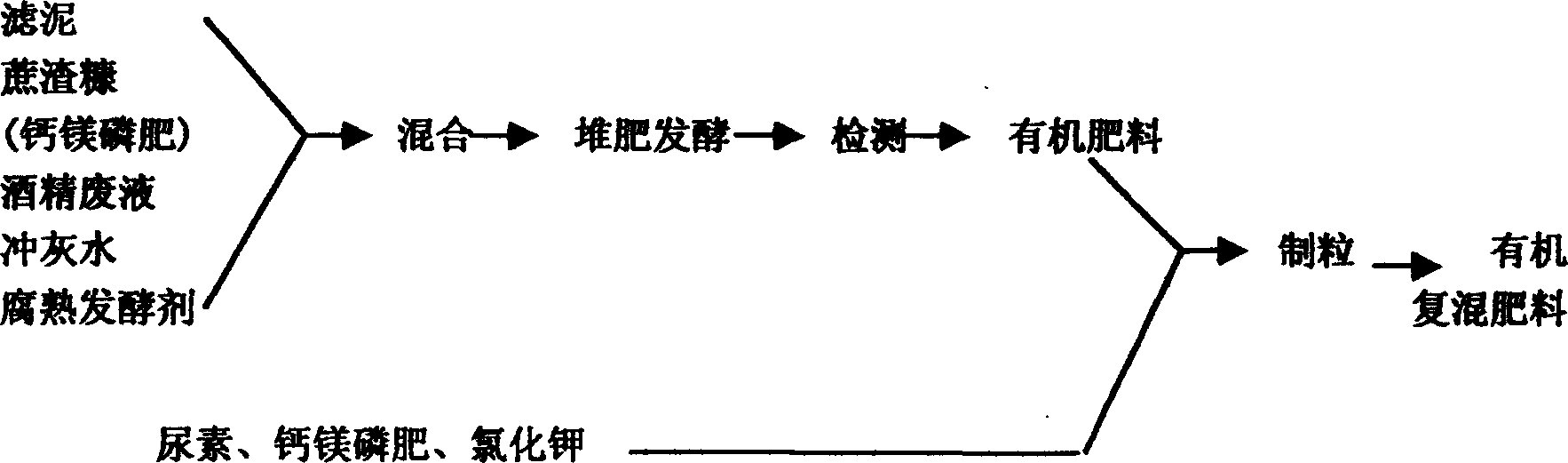

Organic fertilizer composed of waste liquid and waste residue and decomposing leaven from sugar refinery and method for preparing the same

InactiveCN1546437AExpand production scaleFast fermentationBio-organic fraction processingOrganic fertiliser preparationInorganic fertilizerSlag

The invention relates to an organic fertilizer mainly comprises sugar factory discard solution and waste slag as well as decomposed leaven and process for preparation, which comprises fermentation material and decomposed leaven, wherein the composition and weight ratio of the fermentation material are, molasses alcohol discard solution or / and ash flushing water 10-82%, cane trash or / and filtering mud 18-90%, and the rest is one or combination of combination stalks, turfy soil, animal excrement, inorganic fertilizer and soil, whose weight percent is 0-15%. The decomposed leaven comprises cellulose decomposition bacteria, himicellulose disassembling bacterium, protein disassembling bacterium.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

Process for preparing high purity mangiferin

InactiveCN1844133AHighlight substantive featuresSignificant progressSugar derivativesPolymer scienceGlycoside formation

The invention relates to a process for preparing high purity mango glycosides by using mango leaf or amygdale leaf as the raw material through resin method decolorization. The extracted mango glycosides has a purity higher than 90%.

Owner:广西中医学院

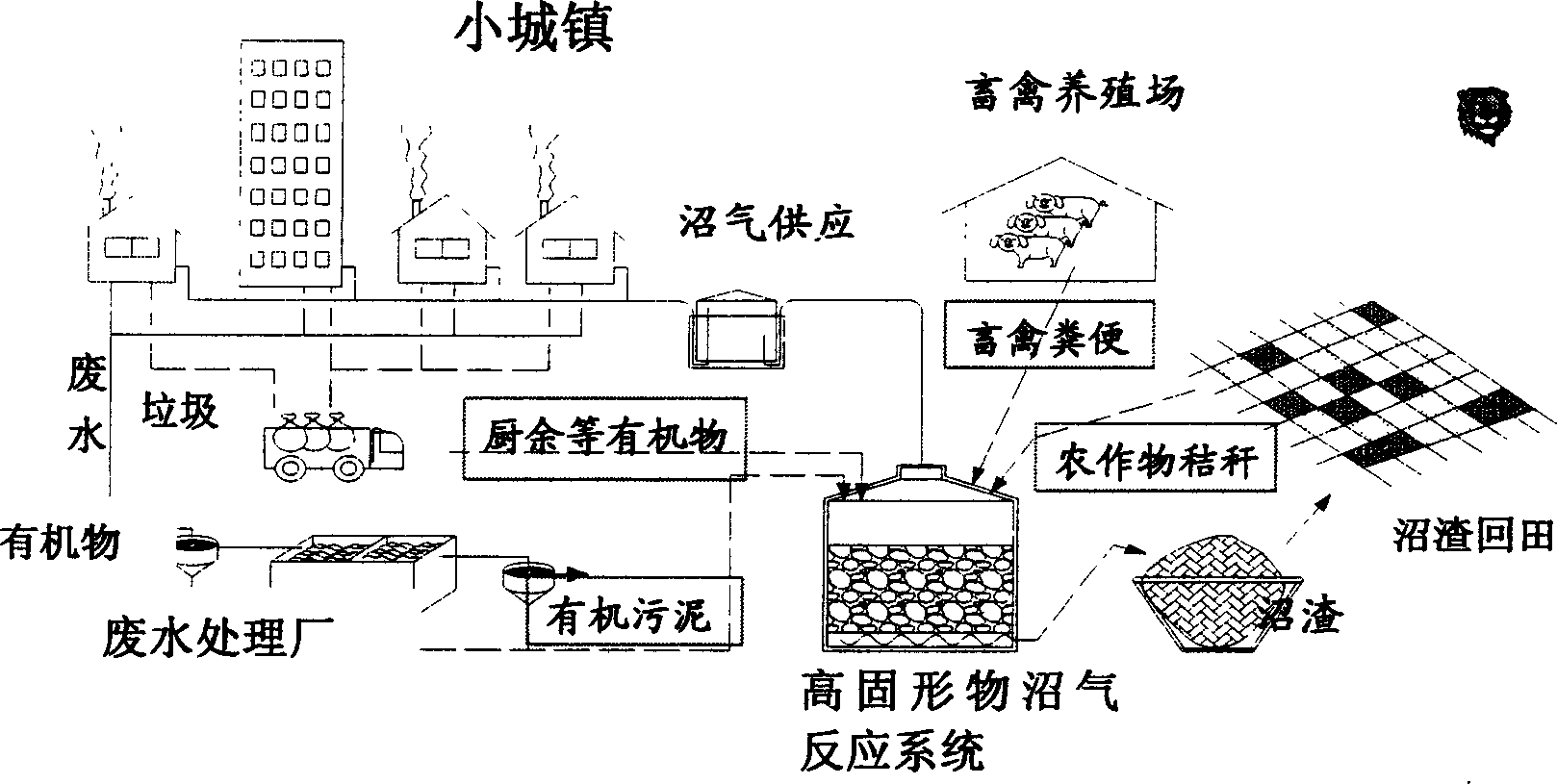

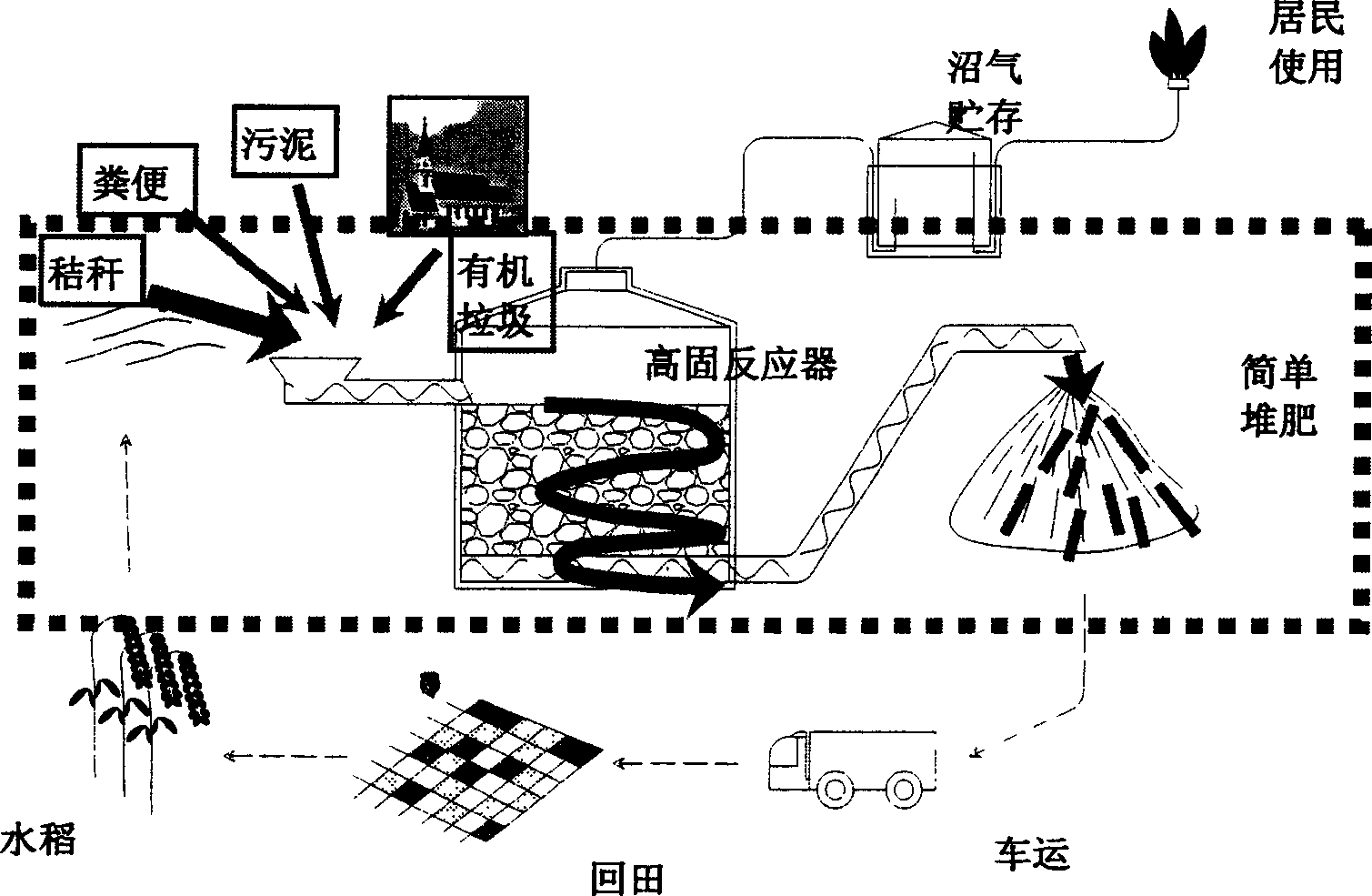

Marsh gas production technology using kitchen residue, straw, stock and fowl dejecta and active mud as material

InactiveCN1769220AReduce pretreatment costsHigh outgassing rateWaste based fuelEnergy based wastewater treatmentBiotechnologyFowl

The invention discloses a technique for producing methane with kitchen residue, straw fecal and active sludge as raw material, and relates to the key technique of methane production and a high solid methane fermentation reactor. It is characterized in: rigid anaerobic environment, adequate and good inoculum, necessary fermentation temperature, proper acid-base scale, proper fermentation concentration and carbon-hydrogen ration; the breeding speed safeguard of zymogeneous bacteria in fermentate; the killing of toxic and harmful bacterium; and the high solid reactor of stable operation. The invention is characterized in that it has significant academic meaning and practical meaning for producing methane with low investment, high stability and clean production.

Owner:JIANGNAN UNIV

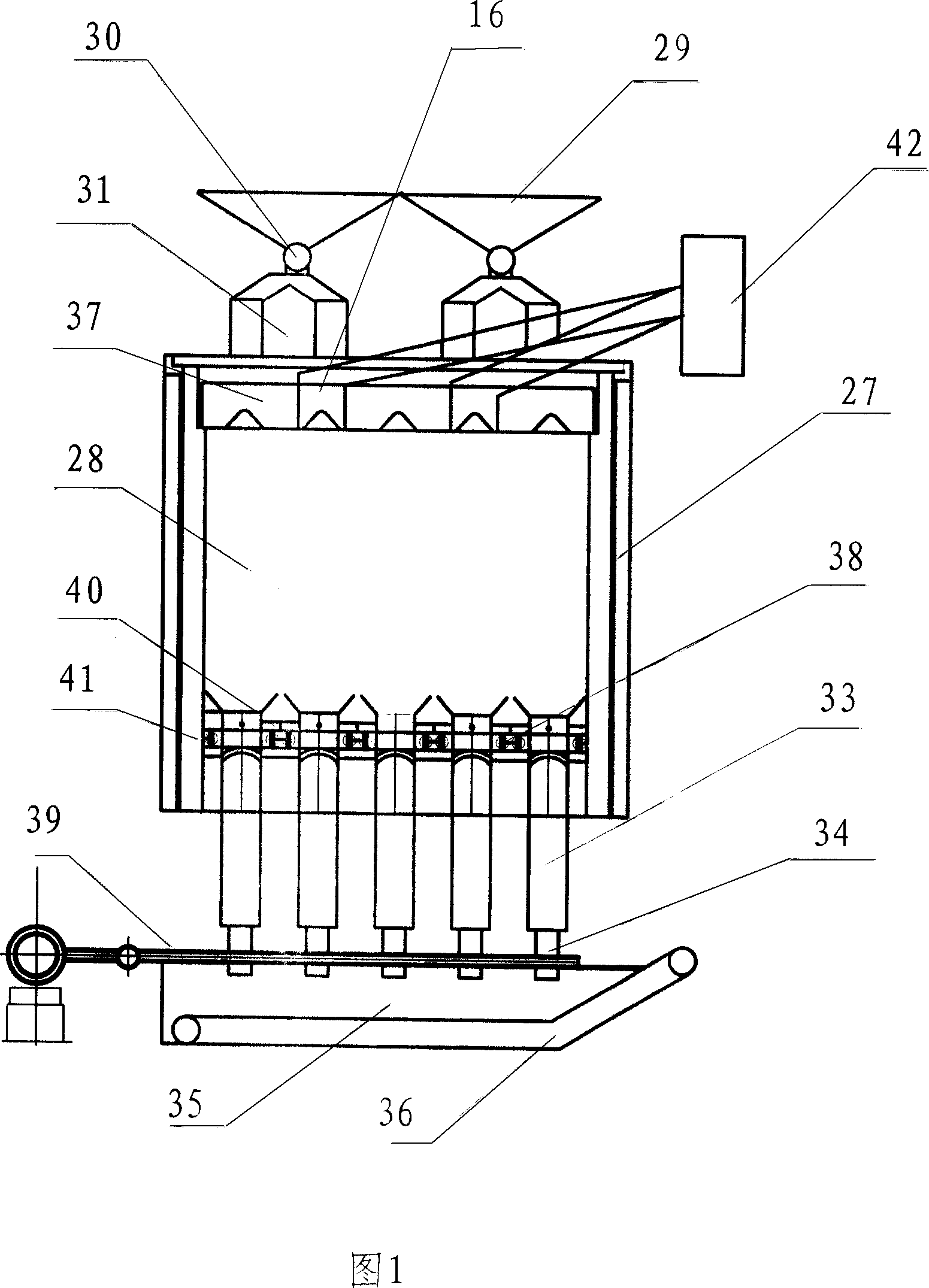

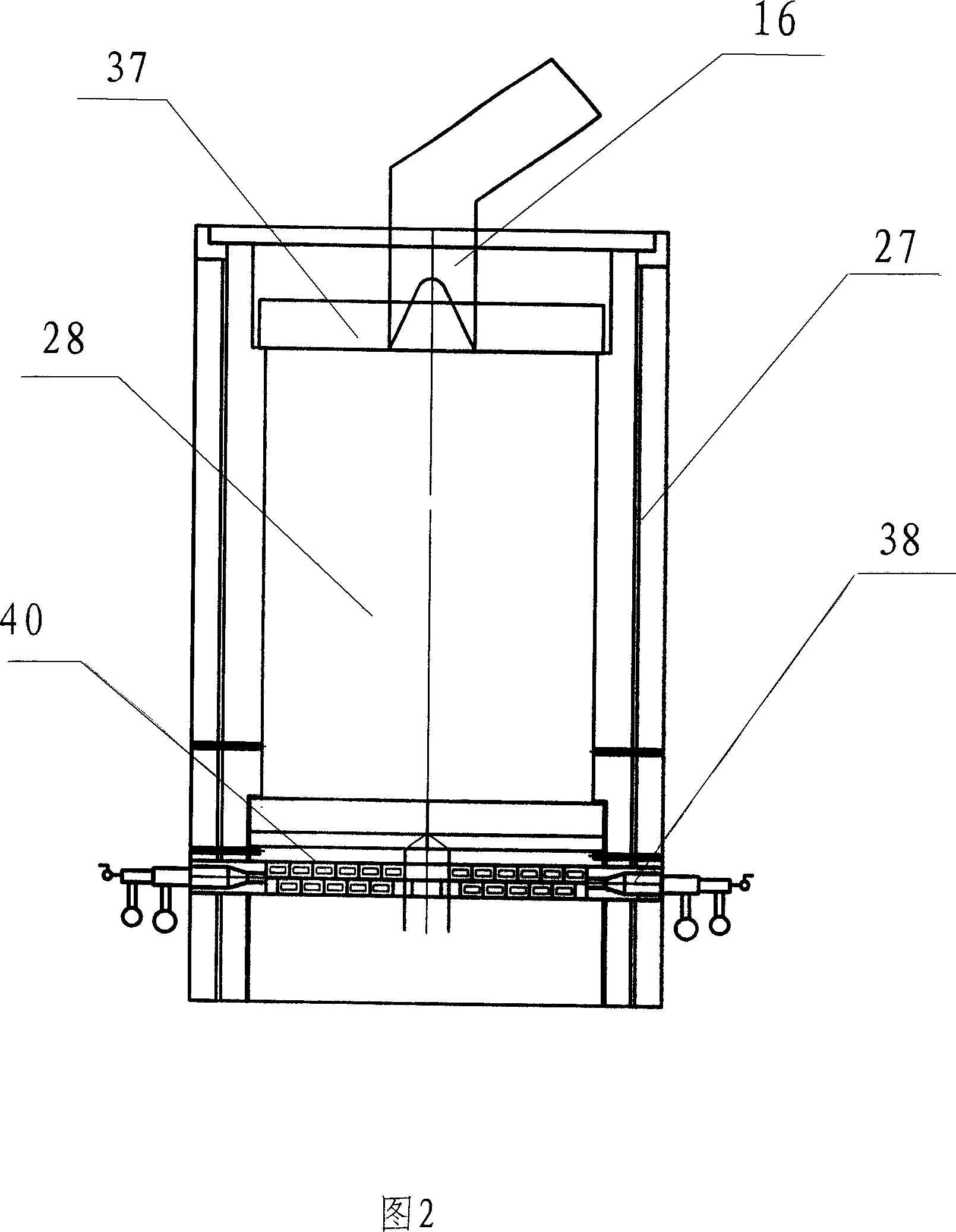

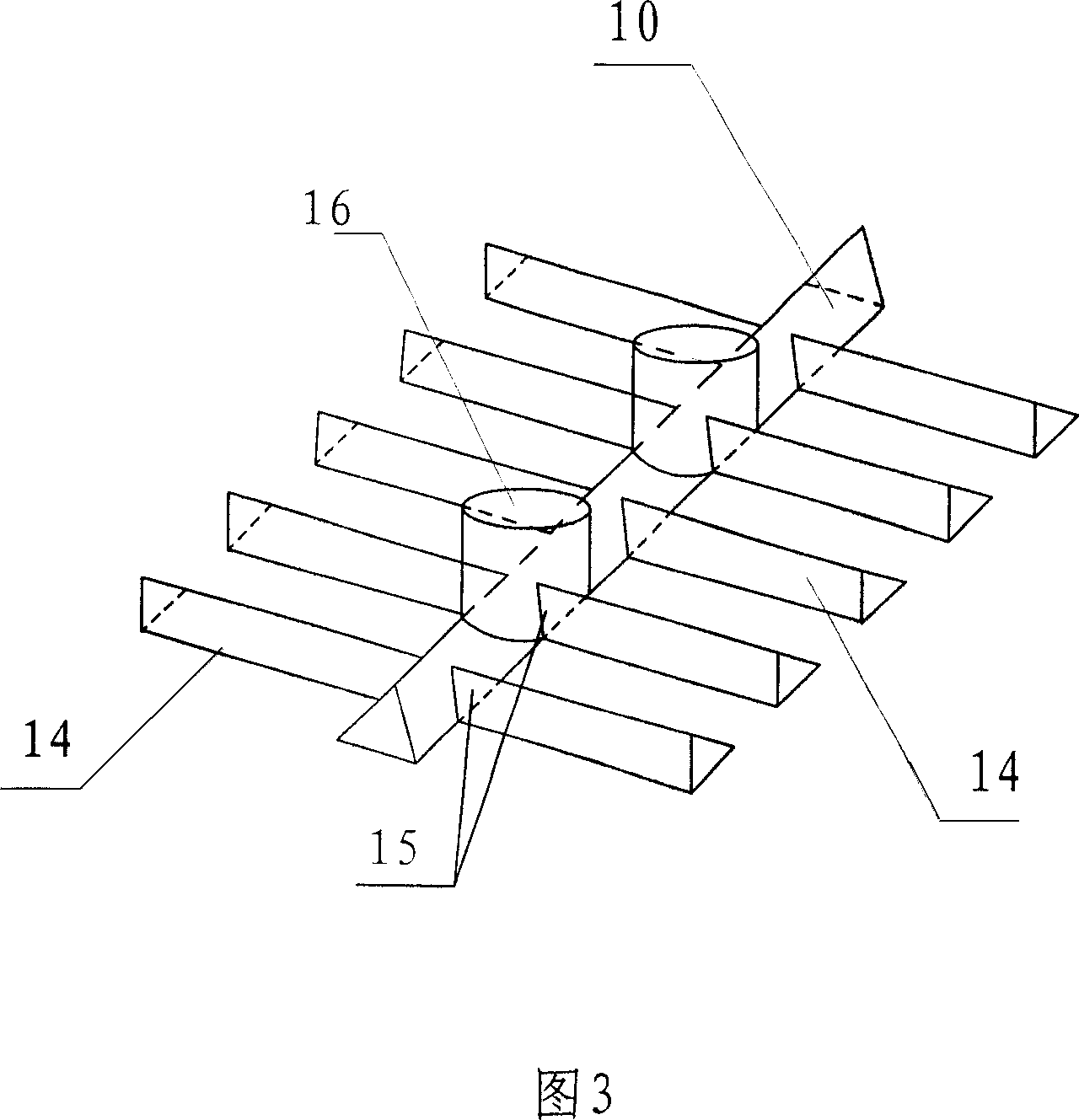

Low-temperature coal carbonization kiln

ActiveCN1966609AIncrease effective volumeHigh yieldRetortsDischarging devicesAutomatic controlCarbonization

The invention disclosed a kind of low temperature coal dry distillating square stove which includes stove body, coal cup, dant-pushing machine and branch admixer. On the top of the hearth there is installed the gas collecting umbrella, inside the stove it is cavity structure; on the bottom of the cavity there are installed several rows of emitting gas walls, every row of emitting gas wall is parallel to the interval between two side umbrella of the gas collecting umbrella; the consecutive emitting gas walls are pedestalled by arch wall; on both sides of the emitting gas walls there are two branch admixer respectively; the bottom of the stove connects the dant discharging box, the bottom of which connects the dant leading slot; the bottom of the dant leading slot is dant-pushing machine, the bottom of which is aqua sealing slot, in the slot there is scraper machine. The invention adopts the heating scheme of endo-burnning and calor internus which can heat uniformly. The gas collecting umbrella and accessory coalbox can make the material and gas-collecting uniformly while the dant-pushing machine can make the product uniform. The advantage of the invention: it can bring into full play of the producing ability and decrease the investment as well as increase the benefits; besides, it is easy to operate, it needs less people and can be controlled automatically.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

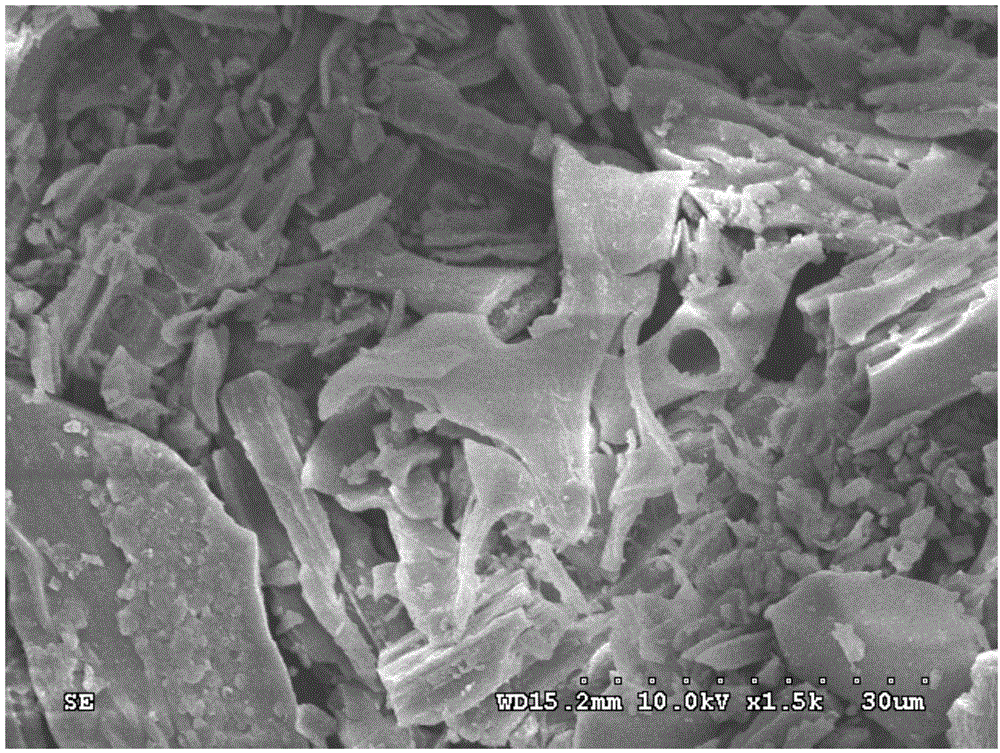

Method for preparing activated carbon with chitosan used as raw material and obtainedactivated carbon

The invention discloses a method for preparing activated carbon with chitosan used as a raw material. The chitosan is used as the raw material, and the specific processcomprises steps as follows: firstly, the chitosan is fully dispersed in an acetic acid aqueous solution with themass fraction of 1-10%, a chitosancolloidal solution with the mass fraction of 1-10% is prepared, hydro-thermal treatment is performed, a reaction is conducted at the temperature of 80-250 DEG C for 1-20 h, carbonizedchitosan is obtained through filtration, washing and drying treatment after the reaction, then thecarbonizedchitosan and sodium hydroxide powder are evenly mixed in the mass ratio ranging from 1:10 to 10:1 and placed into a vacuum tube type furnace to be calcined at the temperature of 100-1200 DEG C for 1-10 h, finally, a product is washed with deionized water and filtered until the pH ranges from 6 to 8, and an activated carbon material can be obtained through drying and grinding. According to the method,the activated carbon preparation process is simple, the production cost is low, and the obtained activated carbon is high in strength and large in specific surface area and has very high adsorption capacity.

Owner:HAINAN UNIVERSITY

Method for preparing earthworm cultivation substratum

InactiveCN102812931AEnhance immune functionImprove digestion and absorption rateAnimal husbandryBiotechnologyEdible mushroom

The invention discloses a method for preparing earthworm cultivation substratum. By mixing livestock dung and edible fungus residue without foreign matters to carry out anaerobic fermentation, the method obtains the substratum for cultivating and reproducing earthworms, the livestock dung is pig dung or cow dung or the mixture of pig dung and cow dung, and the edible fungus residue is residue which is left over in the growth of cultured saprophytic lignicolous fungi or coprophilous fungi. Since the method utilizes the livestock dung and the edible fungus residue as the cultivation substratum to raise the earthworms, the method not only solves the problem of dung accumulation and waste and prevents environment pollution, but also increases the cultivation scale and growth quality of the earthworms by adding the edible fungus residue, thus effectively increasing the output of the earthworms.

Owner:NANJING AGRICULTURAL UNIVERSITY

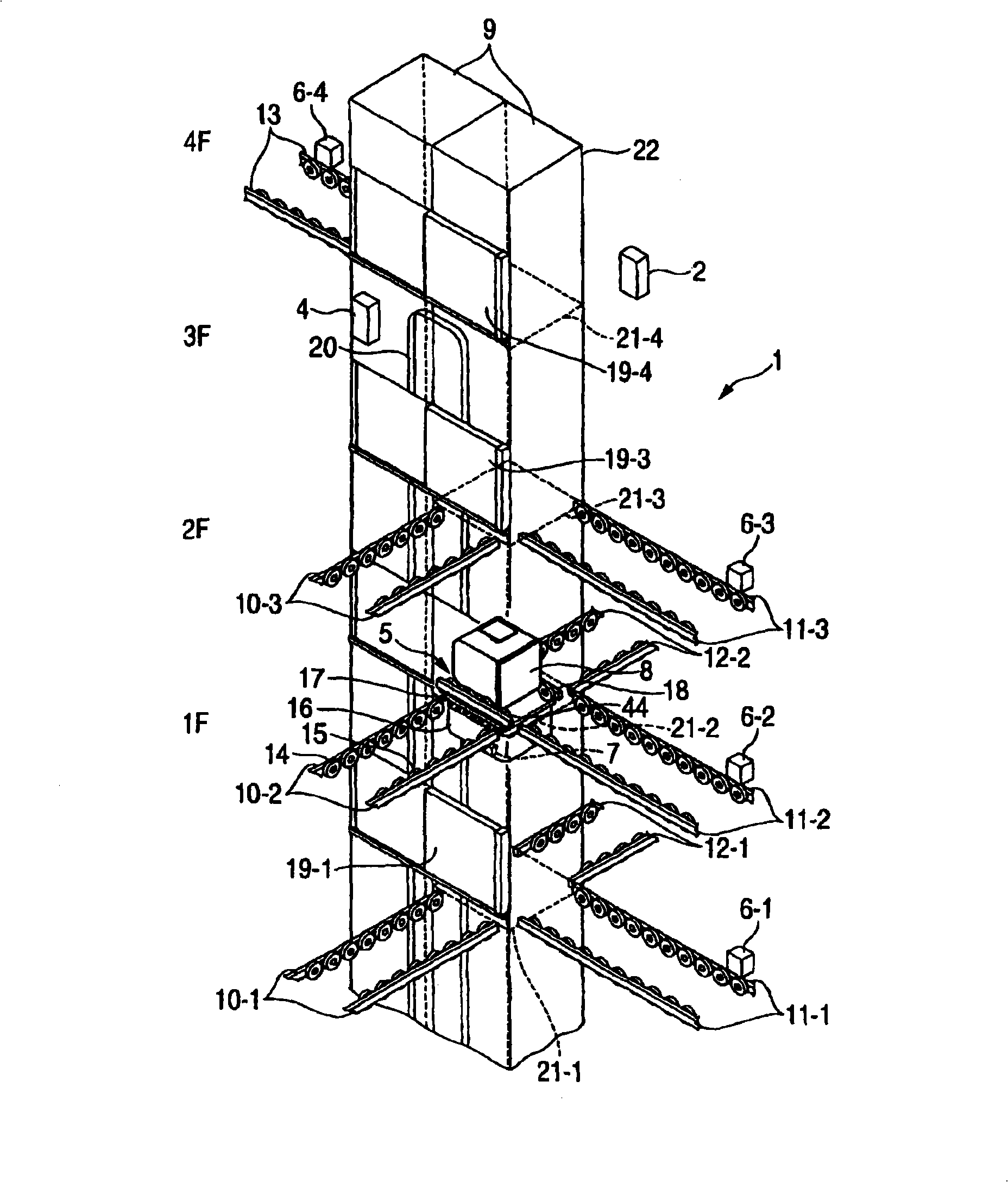

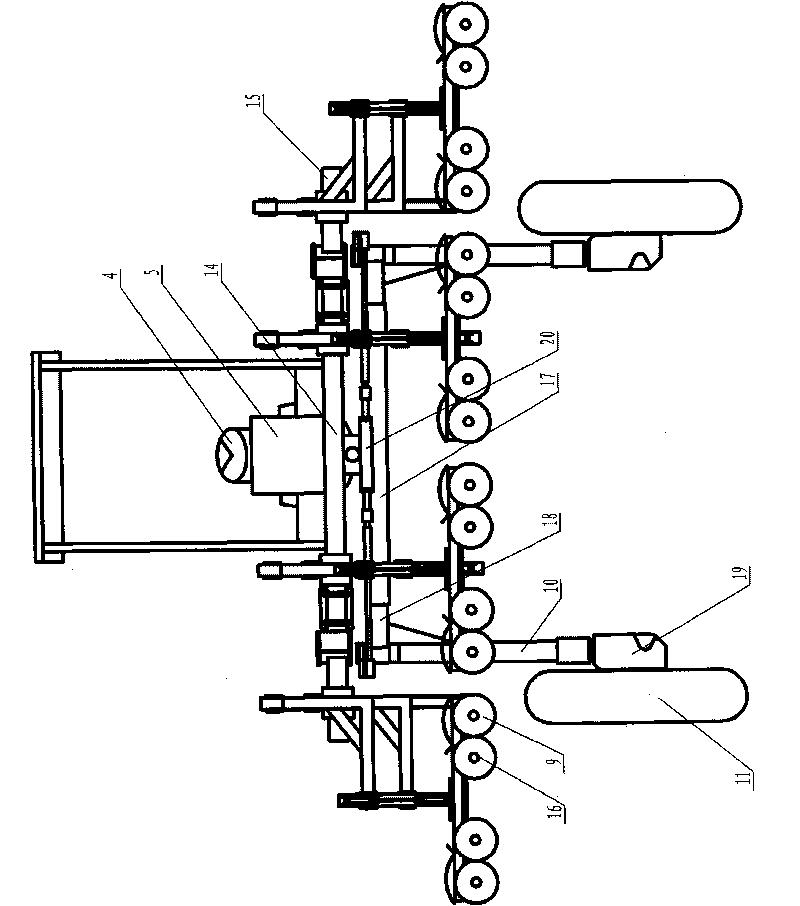

Vertical conveyance device

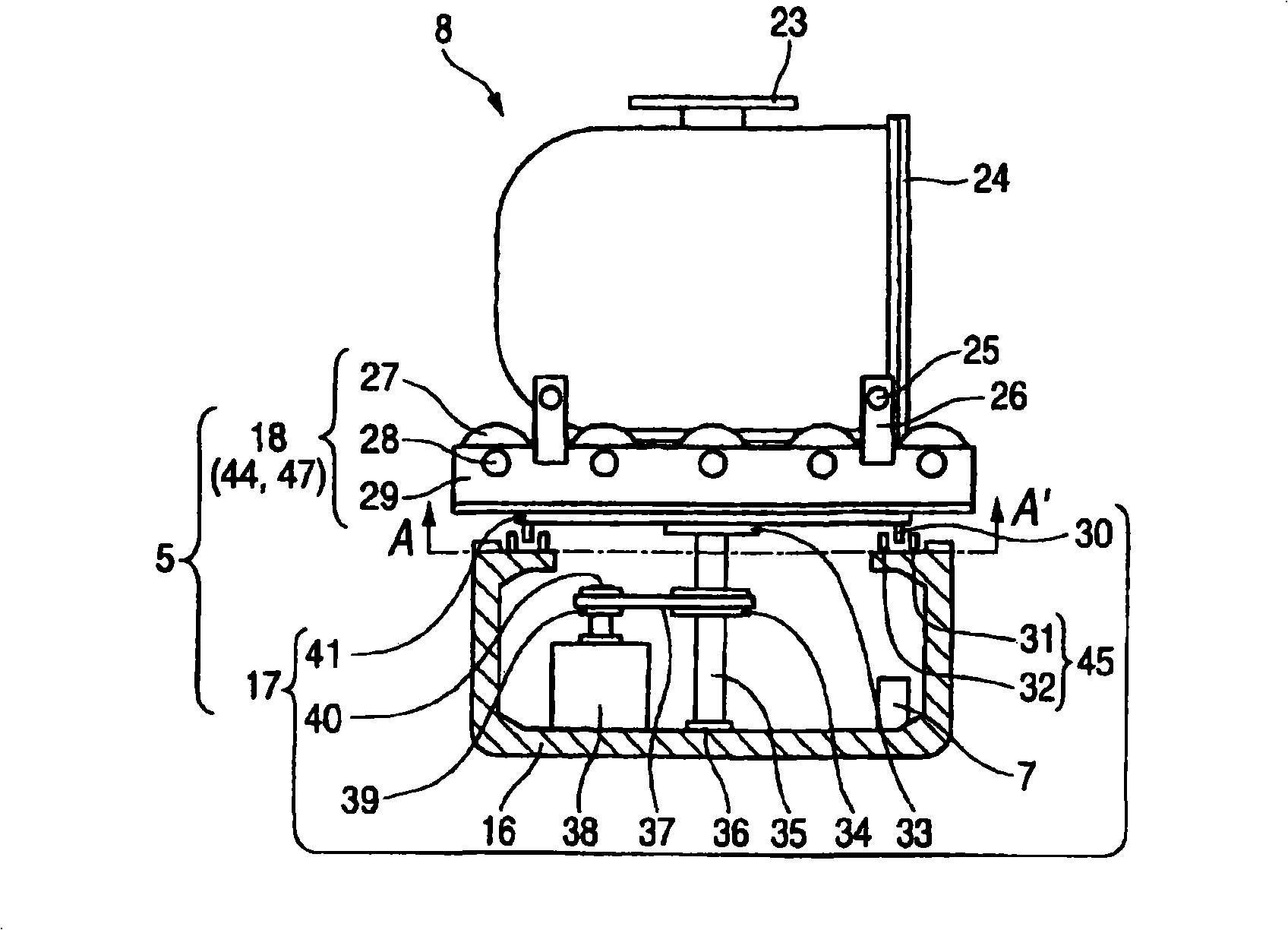

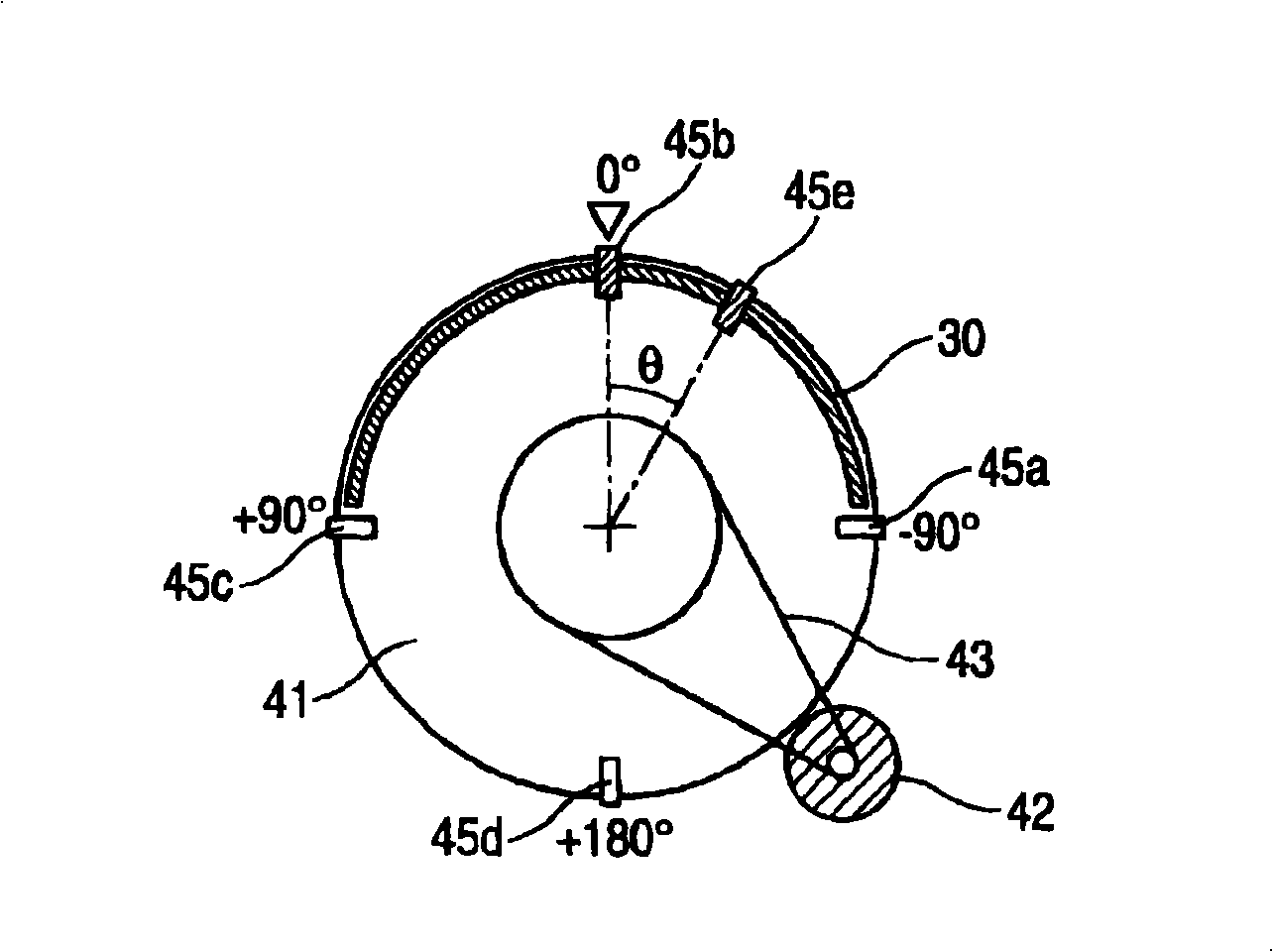

InactiveCN101331074AImprove handling efficiencyRealize handlingSemiconductor/solid-state device manufacturingThin material handlingEngineeringMechanical engineering

Provided is a vertical conveyance deivce. A lifting conveyor (5) is constructed from a turntable (17) and a roller conveyor (18). The roller conveyor (18) is supported on the turntable (17). A conveyor rail performs delivery or reception of a load. The turntable (17) is turned by a turntable controller (7) to align the conveyance direction of the conveyor rail with the roller conveyor (18), and after that, the conveyor rail and the roller conveyor (18) are driven to deliver or receive a FOUP (8). The lifting conveyor (5) is supported by a cable (20a) placed in a hoistway space (9) by a joint member (20b) of a cable bearer (20), and the cable bearer (20) is vertically circulated in a reciprocating manner by a lifting conveyor controller (4). In association with the movement of the cable bearer (20), the lifting conveyor (5) stops in a vertically movable manner at a port (21) placed at each floor.

Owner:MURATA MASCH LTD

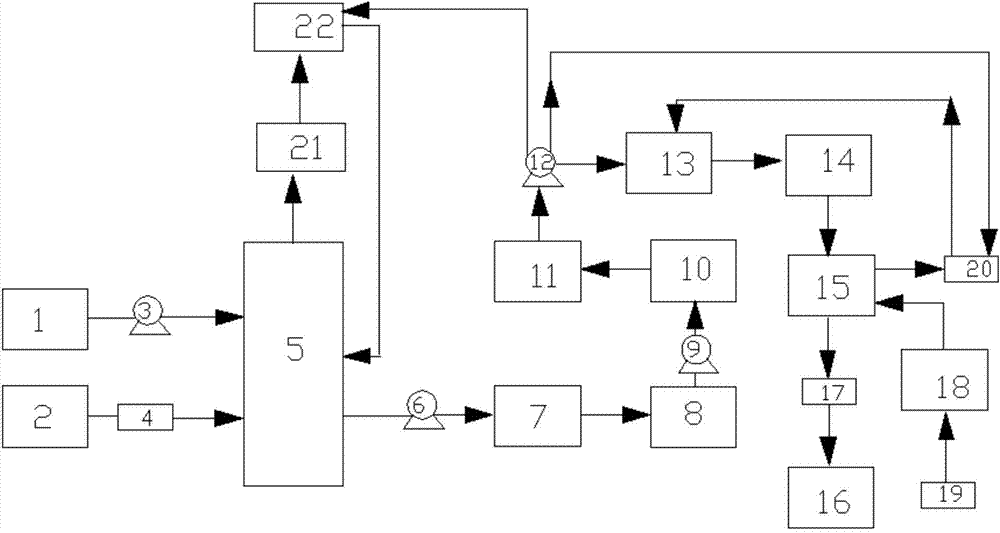

System for producing anhydrous calcium chloride by using industrial waste hydrochloric acid, and technology thereof

ActiveCN104773750AExpand production scaleReduce energy consumptionCalcium/strontium/barium chloridesUsing liquid separation agentEvaporationLarge Calorie

The invention discloses a system for producing anhydrous calcium chloride by using industrial waste hydrochloric acid, and a technology thereof. The reaction system of the technology is connected to an evaporation system through a refined calcium chloride conveying device, and the evaporation system, a calcium chloride forming machine, a drying system, a finished calcium chloride conveying device and a finished calcium chloride bunker are sequentially connected; the reaction system is mutually connected with a reaction tail gas treatment system; and the refined calcium chloride conveying device is also connected with a dry tail gas washing device, and the gas outlet end of the drying system is connected to the inlet end of the evaporation system through the dry tail gas washing device. The reaction tail gas washing device adopts a clean calcium chloride solution as an absorbent, and the hydrogen chloride absorbed calcium chloride solution returns to a calcium chloride reactor, so the concentration of hydrochloric acid is not diluted, and the energy consumption of the evaporation system is reduced; and the calcium chloride solution is used to wash dust-containing tail gas with calories to make dusts not exist in vented tail gas, and a circulating absorption solution absorbing the calories in the tail gas returns to the evaporation system and is reused, so the energy consumption of the evaporation system is reduced.

Owner:LIAOCHENG LUXI CHEM ENG DESIGN

Special culture material formula capable of remarkably improving content of various amino acids in dictyophora fruit body and cultivation method

InactiveCN102557799ARealize resource reuseHigh in amino acidsHorticultureFertilizer mixturesEngineeringMonopotassium phosphate

The invention discloses a special culture material formula capable of remarkably improving content of various amino acids in dictyophora fruit body and a cultivation method. The special culture material formula is characterized by comprising the following raw materials in parts by weight: 20-30 parts of bamboo, 20-30 parts of wood chips or sawdust or roots of other trees, 20-30 parts of bagasse, 10-20 parts of chaff, 1-3 parts of urea (or 5-10 parts of ammonia bicarbonate), 0.3-0.5 parts of potassium dihydrogen phosphate, 0.2-0.3 parts of magnesium sulfate and 1.0-1.2 parts of calcium carbonate, wherein 20-40kg of swine waste is added into every 100kg of mixed cultivation material. The cultivation method comprises the following steps of: selection of a cultivation place, preparation of materials, stockpile fermentation, blanking and seeding, earthing, spawn running and harvesting. According to the invention, the content of various amino acids in dictyophora fruit body is remarkably improved, the discharge of pollutants in the pig industry can be reduced, the pollutants of the pig industry are reduced, and the resource recycling of the swine waste is realized.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

Method for preparing potash manure (kali salt) from potassium-rich rock using hydrothermal chemical reaction

InactiveCN1508092AHigh potassium dissolution rateSimplified separation and purification processAlkali metal carbonatesAlkali metal sulfites/sulfatesChemical reactionLiquid ratio

The method for preparing potash fertilizer (kaili salt) by using potassium-rich rock through the process of hydrothermal chemical reaction is characterized by that its adopted alkaline raw material can be lime or light-burned magnesia or dolomite lime and gypsum, and said method includes the following steps: coarse-crushing and medium crushing the above-mentioned raw materials to below 3 mm; according to the ratio of that potassium-rich rock; lime or light-burned magnesia or dolomite lime; gypsum is 1:0.8-1:0.2-0.25 feeding the above-mentioned raw materials into vibration grinding machine and grinding them to below 200 meshes, uniformly mixing them, conveying obtained mixture material into storage tank device, adding water, regulating solid-liquid ratio to 1:1-3, stirring and mixing, transferring said material into high-pressure reactor, introducing high-pressure steam, making hydrothermal reaction at 130-250 deg.C constant temperature for 5-24 hr. so as to obtain the invented prdouct.

Owner:ZHONGKE JIANCHENG MINERAL TECH BEIJING

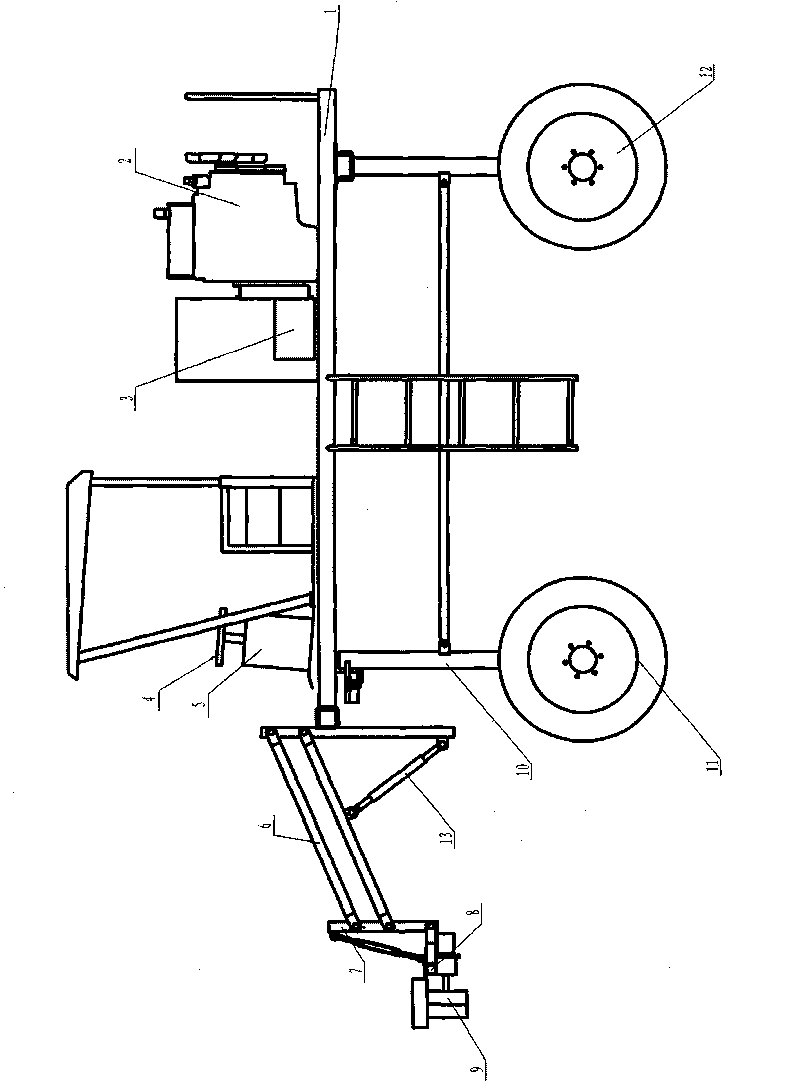

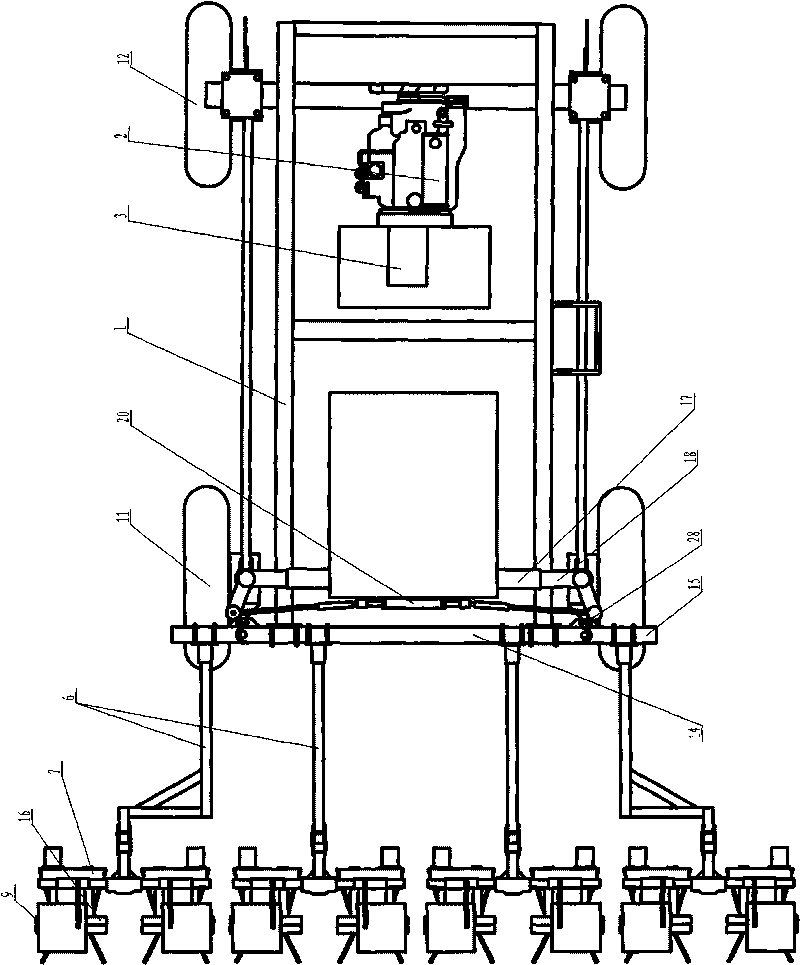

Self-propelled over-partition type machinery for removing stamens of corns

InactiveCN101711503AExpand production scaleImprove work efficiencyPlant genotype modificationHydraulic cylinderHydraulic motor

This invention belongs to a machinery for mechanically removing stamens of corns in the operation of planting corn, specifically to a self-propelled over-partition type corn detasseling machine, comprising a hydraulic pump and a hydraulic control system, which are driven by an engine, disposed on a carriage equipped with wheels; a steering wheel and a hydraulic steering gear are further arranged on the carriage; a steering hydraulic cylinder mounted on the carriage controls the turning of front wheels by a connecting bar and a crank; front and rear wheels are mounted respectively in the lower portions of the front and rear crossbars of the carriage by supporting arms, and are respectively driven by a hydraulic motor; and a four-bar mechanism equally hinged with the supporting arms is arranged in the front portion of the carriage, which is controlled to rise or descend by the hydraulic cylinder; a detasseling device driven by the hydraulic motor is arranged on the front bracket of the four-bar mechanism. The invention replaces manual detasseling with mechanical operation with high working efficiency; the machine reduces agro-industrial labour intensity and cost for detasseling per area, besides, the invention can enlarge the production scale of corn seed production and prompt the industrialization of corn seed production.

Owner:XINJIANG NONGKEN ACAD OF SCI INST OFMACHINERY & EQUIP

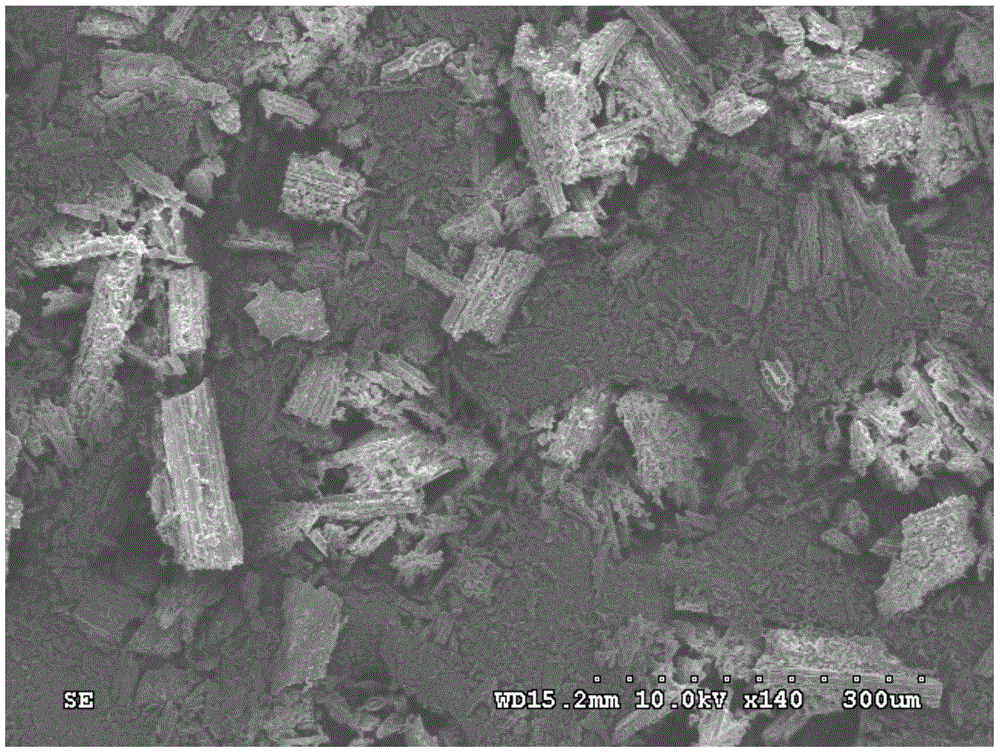

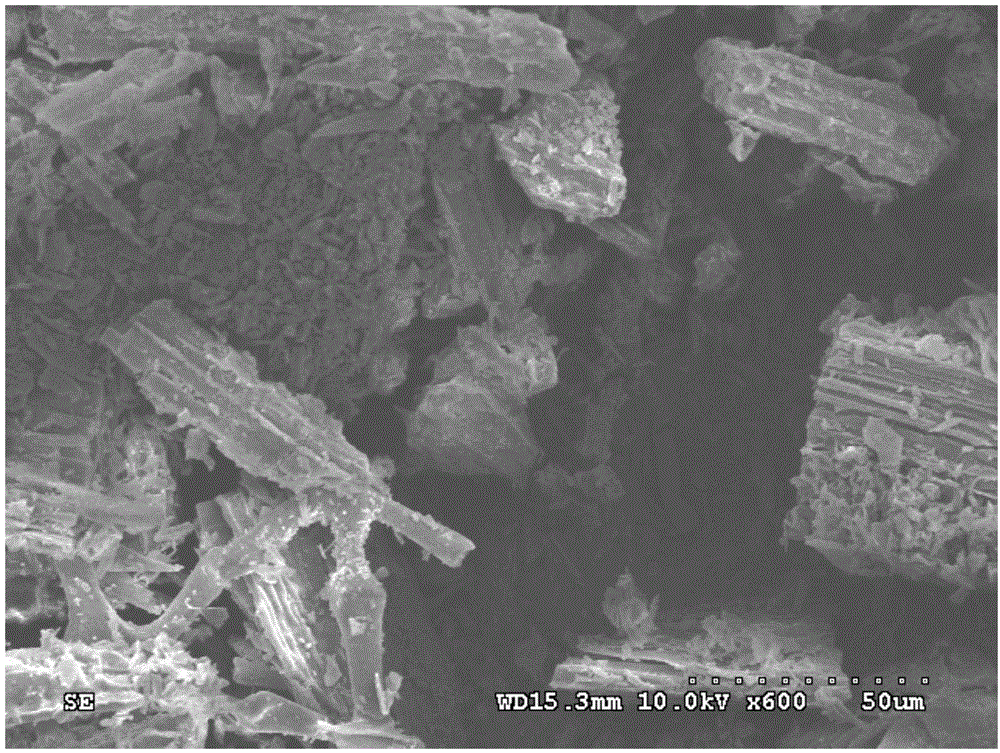

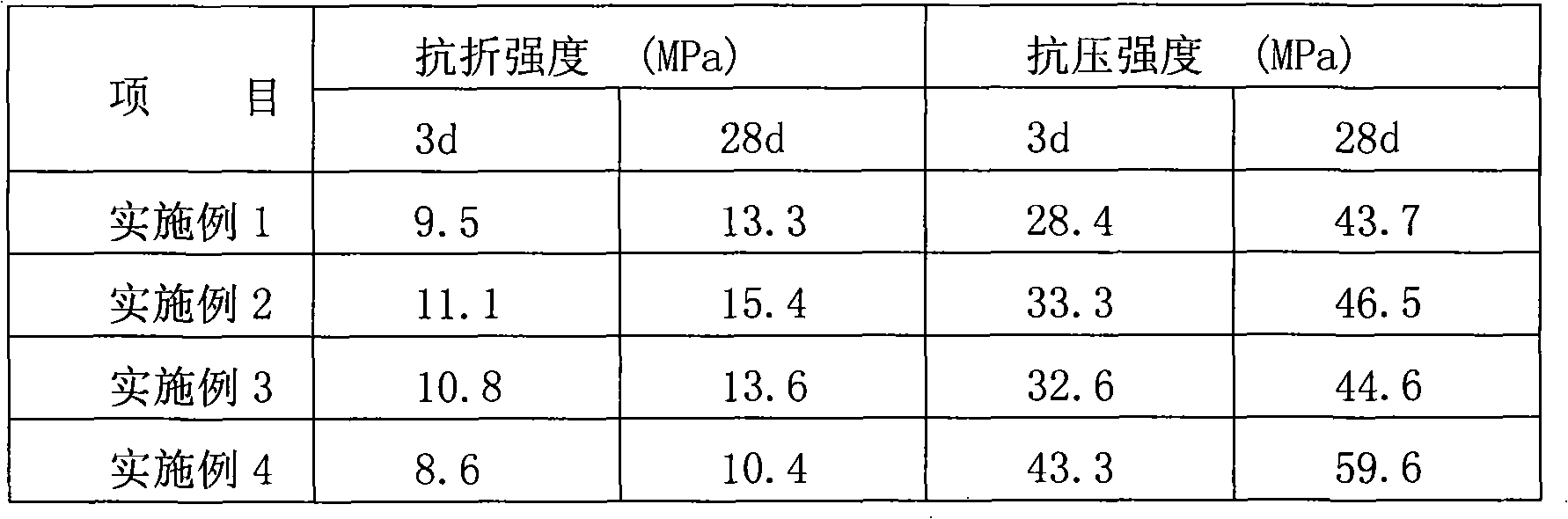

Steel scoria tail mud composite slag micro mist agglutination material

InactiveCN101492261APromote sustainable economic developmentEliminate slag damageSolid waste managementSlagBall mill

The invention relates to a cementing material of steel slag tailings and composite slag micro powder, which comprises the composite slag micro powder and the steel slag tailings, and the weight ratio of the composite slag micro powder to the steel slag tailings is between 1 to 1 and 1 to 3; the specific surface area of the composite slag micro powder is larger than 350 m / kg, the composite slag micro powder comprises a combined material and the slag micro powder, wherein the combined material accounts for 8 to 35 percent of the composite slag micro powder by weight, and the slag micro powder accounts for 65 to 92 percent of the composite slag micro powder by weight; and the combined material comprises gypsum. The cementing material has the advantages that: 1, the method is an effective method utilizing large amount of waste slag; 2, the raw material of the composite slag micro powder has wide source; 3, the steel slag tailings are natural-grade tailings after steel slag wet-type ball milling magnetic separation particles are toughened, and the settled tailings do not need to be dried and are directly used as an auxiliary material; and 4, the steel slag tailings account for large proportion, and can fully utilize waste slag resources.

Owner:武钢集团有限公司

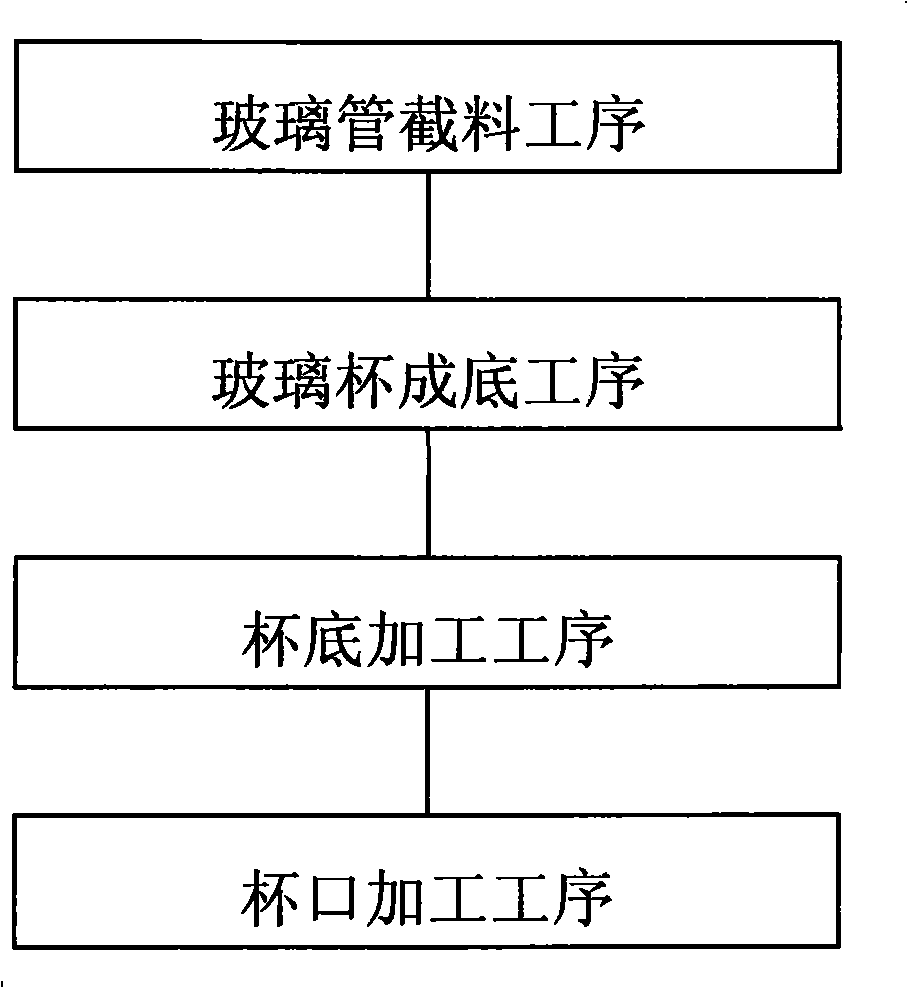

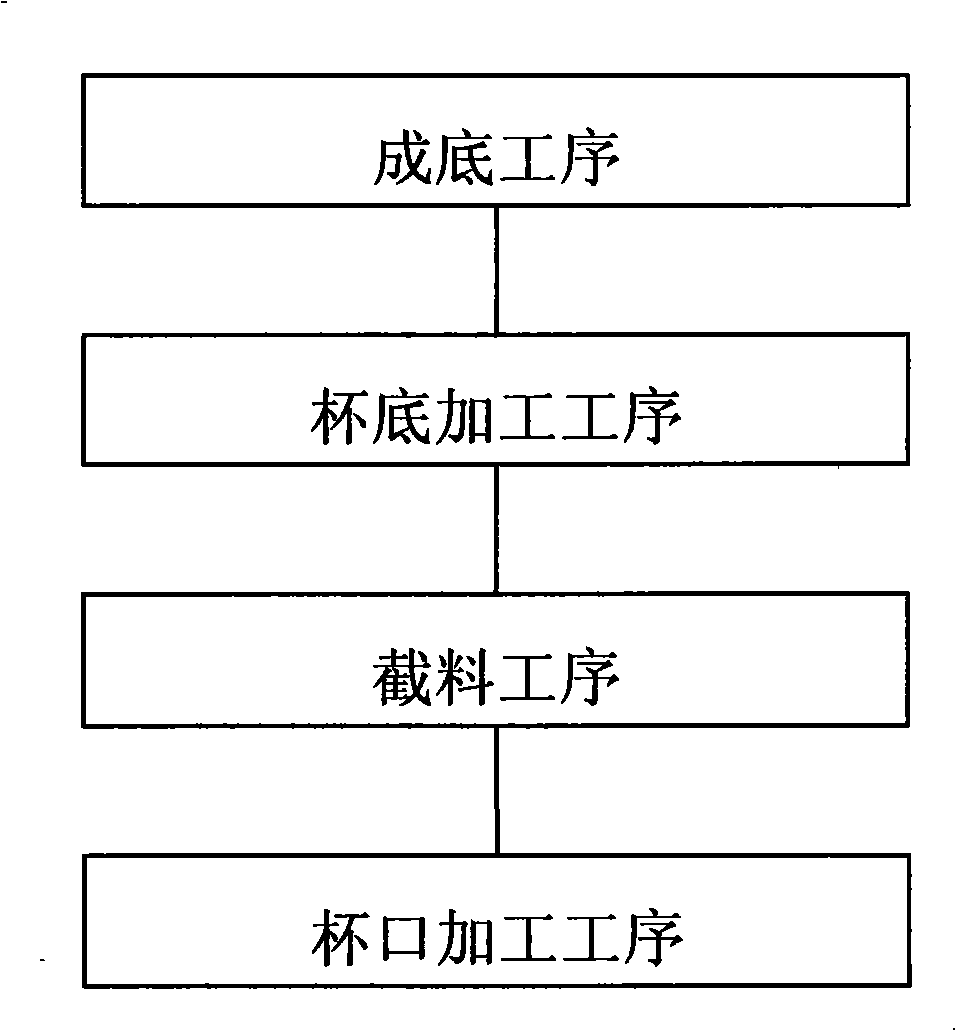

Method for preparing single layer glass by glass tube

InactiveCN101357820AGood light transparencyImprove yieldGlass reforming apparatusGlass productionCutting glassSoftening

The invention relates to a method for producing a single-layer glass cup by using a glass tube. The method comprises the following steps: A. material cutting process: the glass tube is cut into the glass tube material section with the height which is twice that of the finished glass cup; B. bottom forming process: the both ends of the cut glass tube material are clamped on a rotary device to locally heat the middle part of the tube material till the softening of the glass, a heat-resistant material blade with the thickness which is less than the width of a heating zone and does not have the affinity with the glass is used for cutting the middle part of the heating zone to form blanks of two cup bottoms; C. cup bottom processing process: the cup-shaped glass tube material is clamped on the rotary device, flames are used for heating the bottom part of the glass cup-shaped tube material along the transverse direction at the same time of rotation till the melting of the glass, and the cup bottoms are thickened to meet the design requirements. The method has simple production technology, greatly improved yield, good overall transparency of the cup and no need of polishing. The production efficiency is greatly improved, and the method can be used for large-scale production and family workshop operation. The equipment cost is greatly reduced, and the method can be used for the production by only using a special burning device, thereby eliminating the constraints of a kiln on the production scale and the place.

Owner:郝身峙

Producing process for alkali proof glass beads

InactiveCN1500753AHigh clarityQuality improvementGlass furnace apparatusGlass shaping apparatusGlass ballBrick

The present invention is production process of glass ball for producing alkali resisting glass fiber. The materials including quartzite, calcite, zirconite, rutile, fluorite, potassium nitrate, sodium carbonate and chamotte are crushed and mixed to form the mixed material; and the mixed material is smelted in natural gas burning smelting furnace with zircon corundum brick lining and further processed through cooling, clarification, ball making and annealing to produce alkali resisting glass ball with high zirconia content. The said production process has high product output, low production cost and high product quality and low power consumption, and is easy to control.

Owner:自贡市宏洋新型材料制品有限公司

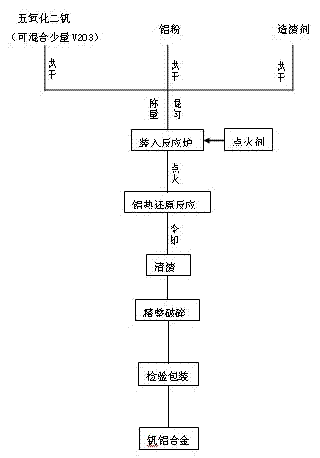

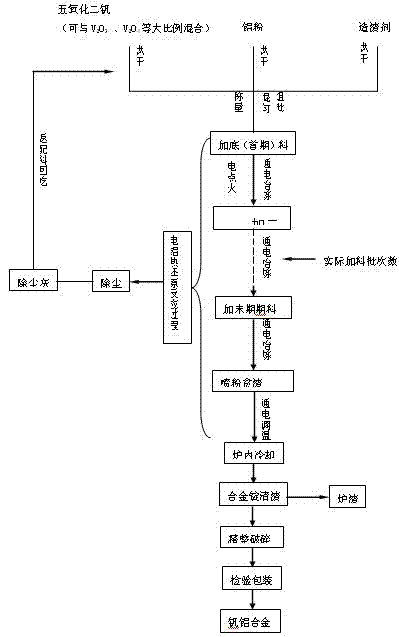

Method for smelting vanadium-aluminum alloy by electro-aluminothermic process

Owner:HEBEI IRON AND STEEL

Formula of special culture material capable of increasing content of each amino acid in grey mushroom fruiting body and culture method

InactiveCN102557800ARealize resource reuseHigh in amino acidsHorticultureFertilizer mixturesPig breedingMonopotassium phosphate

The invention relates to the formula of a special culture material capable of increasing the content of each amino acid in a grey mushroom fruiting body and a culture method. The formula provided by the invention is characterized in that the formula of the special culture material consists of the following raw materials in part by weight: 20 to 30 parts of straw, 20 to 30 parts of sawdust, 20 to 27 parts of cottonseed hull, 10 to 15 parts of bran, 0.3 to 0.5 part of monopotassium phosphate, 0.2 to 0.3 part of magnesium sulfate and 1.0 to 1.2 parts of calcium carbonate or calcium sulfate, wherein 10 to 30 kilos of pig excrement residues are added into 100 kilos of mixed culture material. According to the invention, the grey mushroom fruiting body has a round and attractive mushroom flower and greatly increases the content of each amino acid in the grey mushroom fruiting body, wherein the content of sulfur amino acid, branched chain amino acid, children amino acid, essential amino acid, flavor amino acid and sweet amino acid is greatly increased respectively. The grey mushroom fruiting body can increase the health-care medicinal function, increase the production additional value, reduce pollutants in the pig breeding industry and recycle the pig excrement residues.

Owner:AGRI ECOLOGY INST FUJIAN ACADEMY OF AGRI SCI

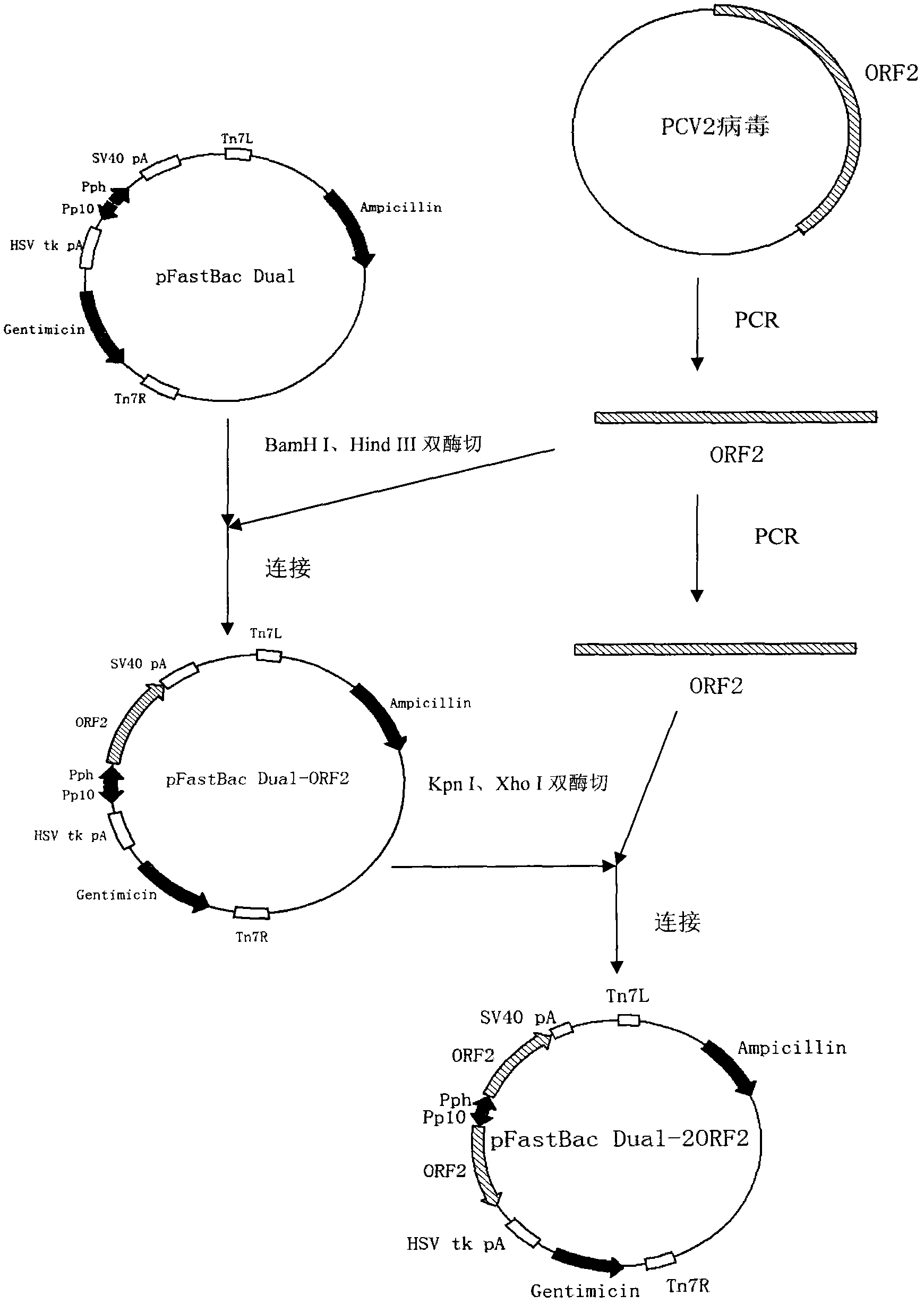

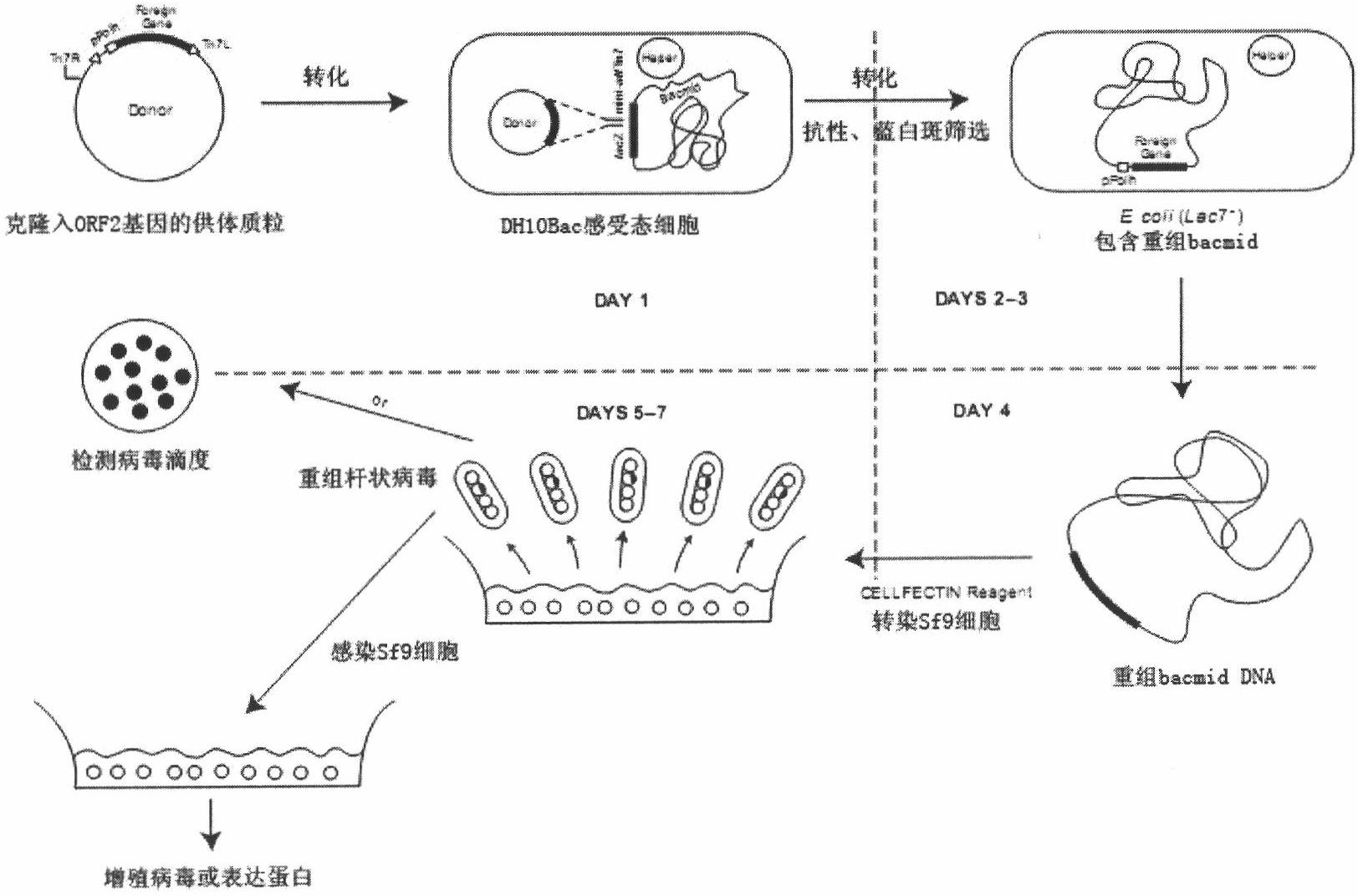

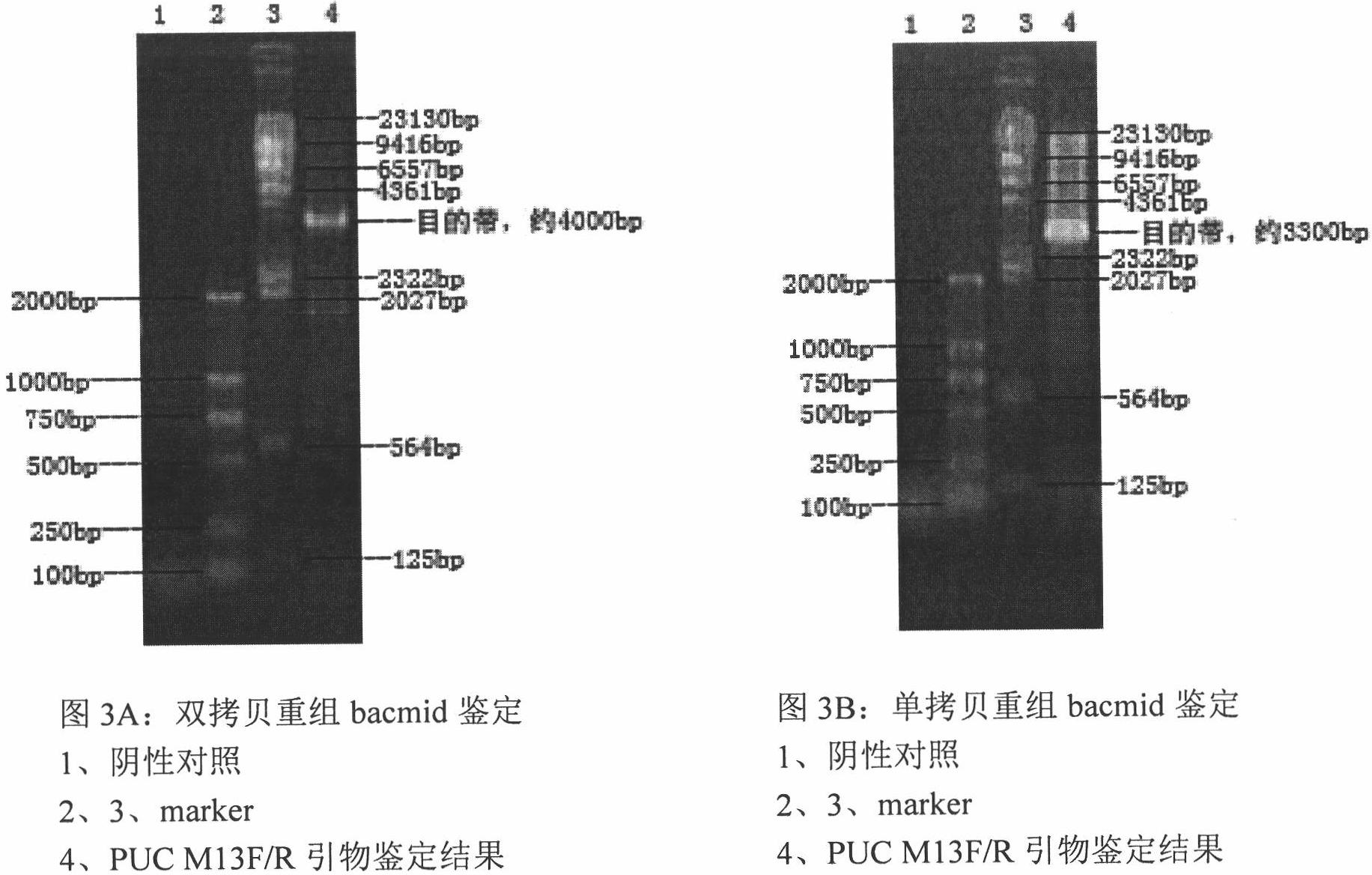

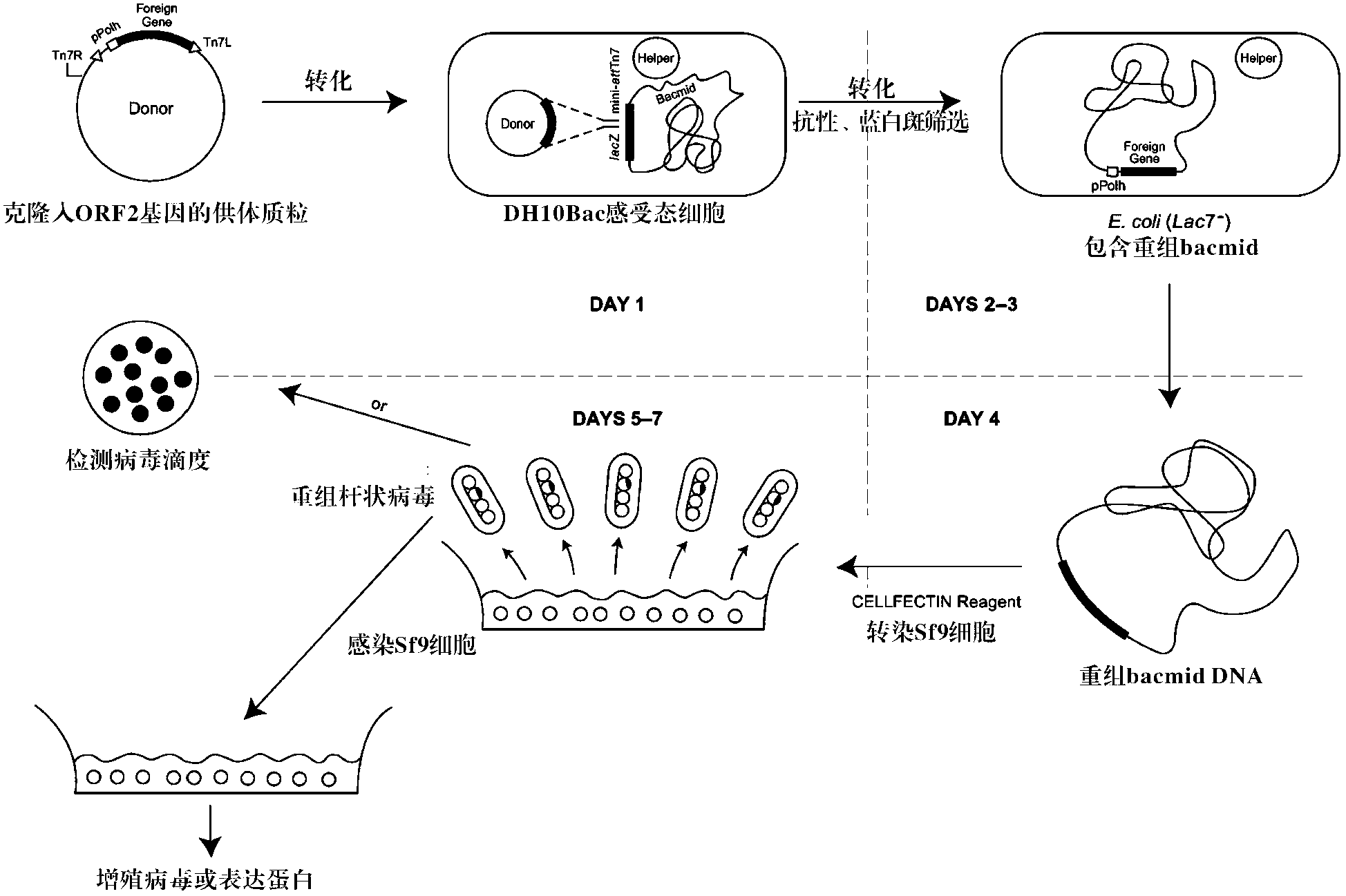

2 type subunit vaccine for porcine circovirus as well as preparation method and application thereof

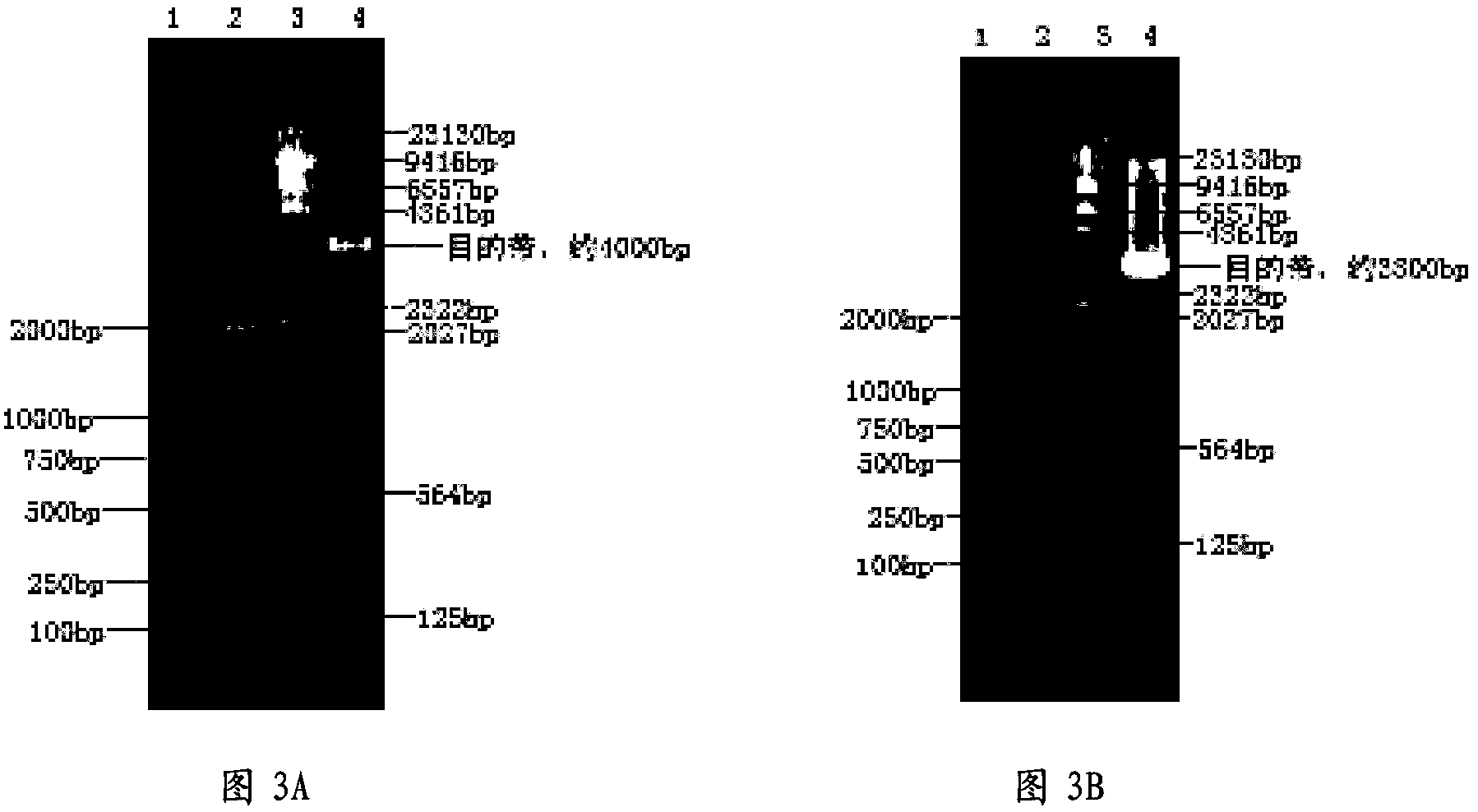

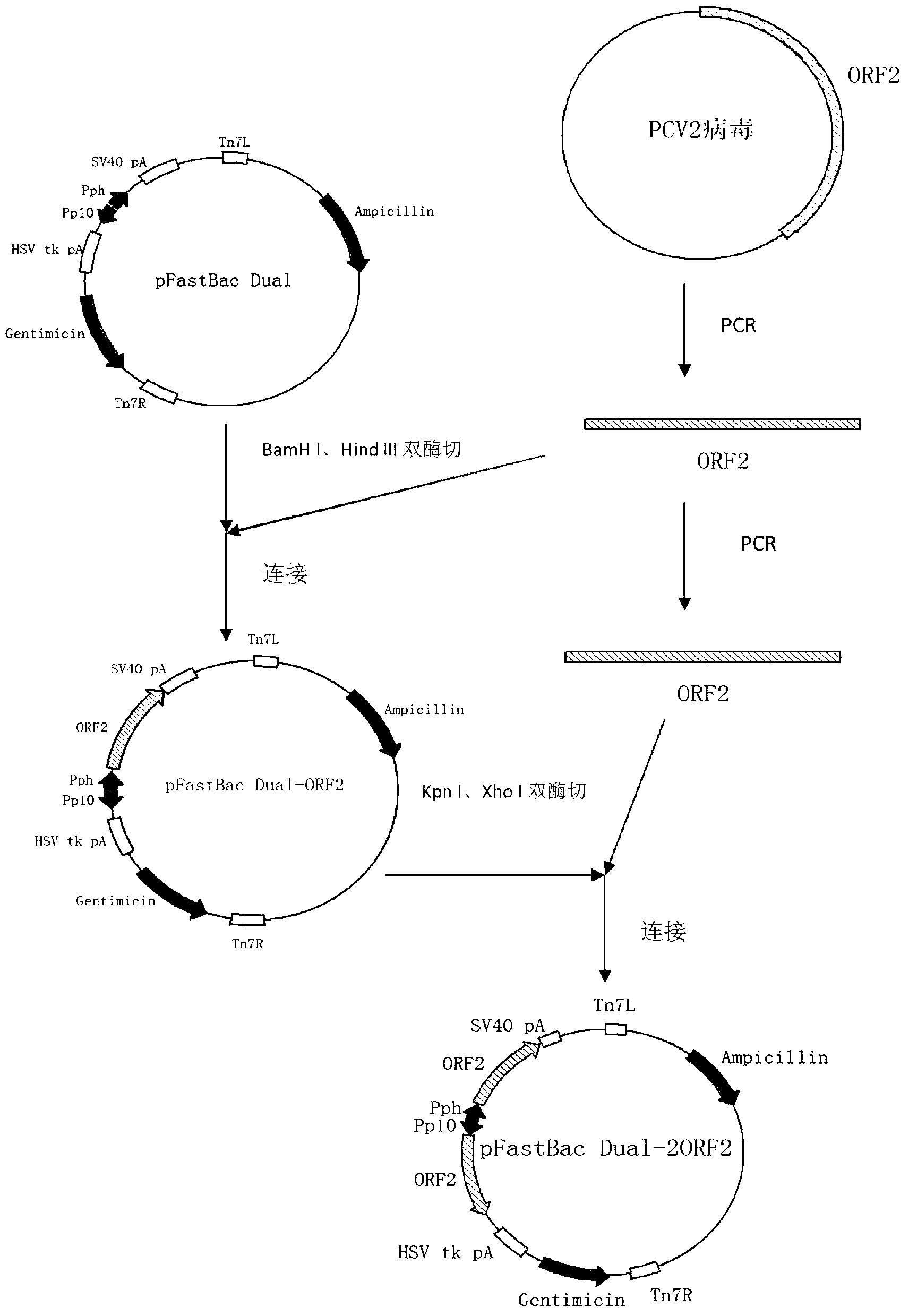

InactiveCN102517331AQuick responseHigh activityViral antigen ingredientsVirus peptidesImmune effectsVirus-like particle

The invention relates to a 2 type subunit vaccine for a porcine circovirus as well as a preparation method and application thereof. A recombinant bacilliform virus contains double promoters (a polyhedrin promoter and a P10 promoter), a coding gene of a Cap protein with double copying can be expressed, and the expression efficiency of the protein is obviously enhanced; moreover, the Cap protein expressed by an inserted foreign gene does not contain an excess sequence, virus-like particles (VLPs) can be effectively formed, and the immunogenicity of an expressed protein is enhanced; furthermore, a produced antigen has high content; and according to the 2 type subunit vaccine for the porcine circovirus, which is disclosed by the invention, the productivity ratio and the quality of a viral protein of the 2 type subunit vaccine for the porcine circovirus are obviously enhanced, and a prepared vaccine composition has the advantages of stable and persistent immune effect, high safety and the like.

Owner:WUHAN CHOPPER BIOLOGY

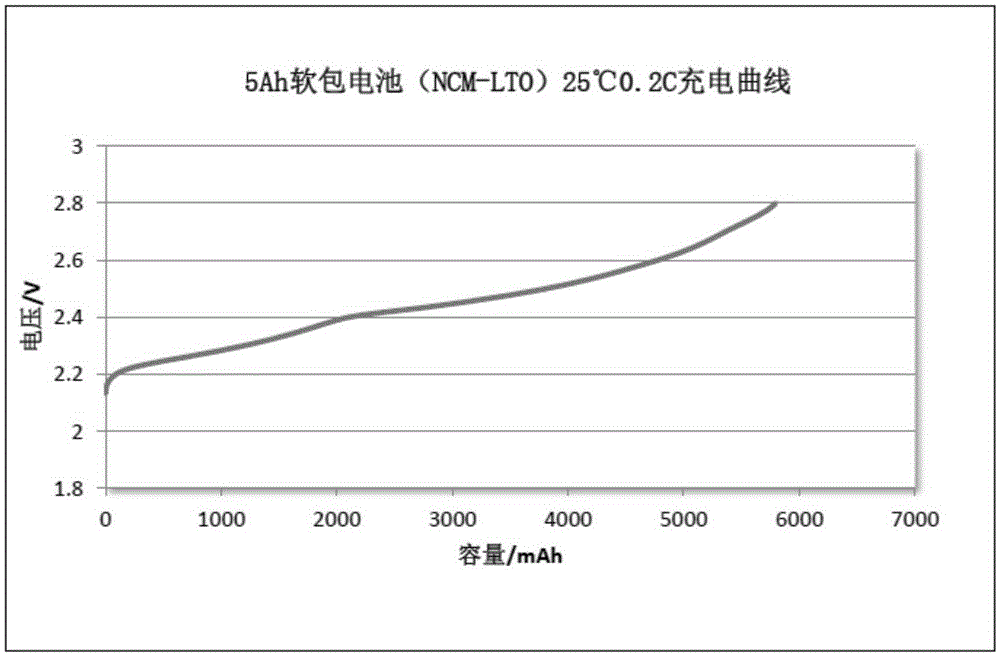

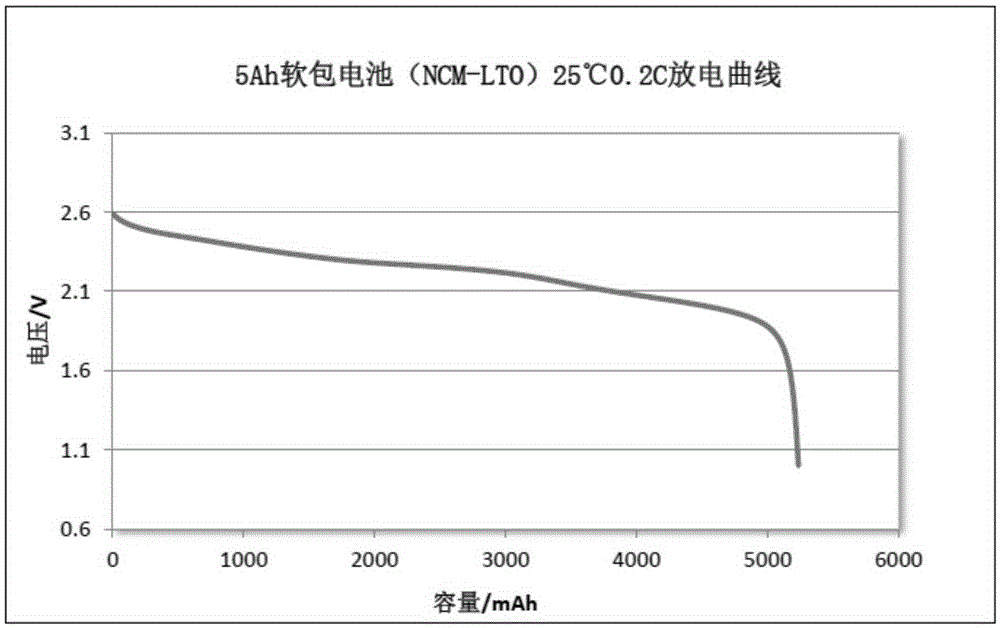

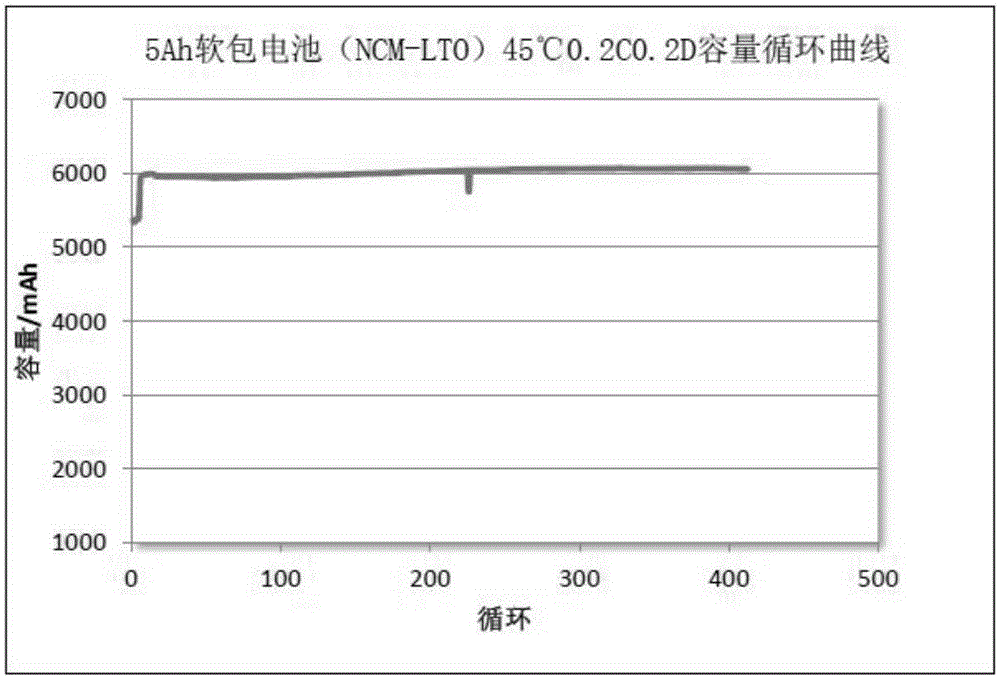

Preparation method for ionic liquid and secondary battery

ActiveCN105826596AWide range of choicesMild reaction conditionsSecondary cellsOrganic electrolytesPhosphoniumQuaternary ammonium cation

The invention relates to a preparation method for ionic liquid, especially to a one-step method for synthesis of a quaternary ammonium or quaternary phosphonium compound. According to the method, a nitrogen compound or phosphorus-containing compound, a proton compound and carbonic ester are added into a reactor together for a one-step reaction so as to synthesize corresponding quaternary ammonium or quaternary phosphonium ionic liquid, wherein the reaction is a one-pot reaction involving three reactants. The invention also provides a lithium ion secondary battery of the ionic liquid prepared by using the preparation method. The preparation method for the ionic liquid can broaden the selection scope of preparation raw materials for the ionic liquid, so the varieties of synthesized ionic liquid are enriched; and the preparation method utilizes nontoxic and harmless raw materials, has mild reaction conditions, low requirements on production equipment and low production cost, and meets demands of green industry and large-scale industrial production.

Owner:MICROVAST POWER SYST CO LTD

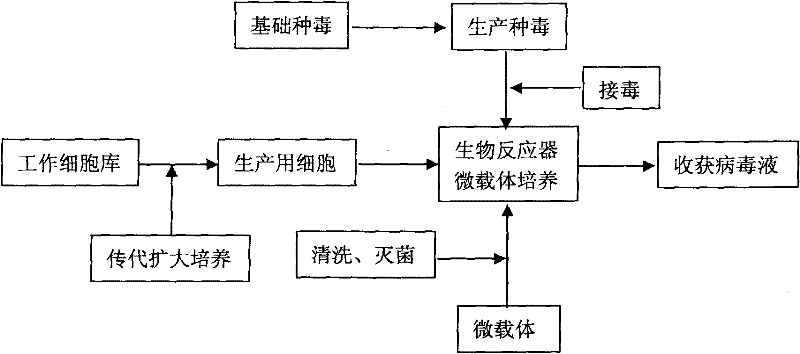

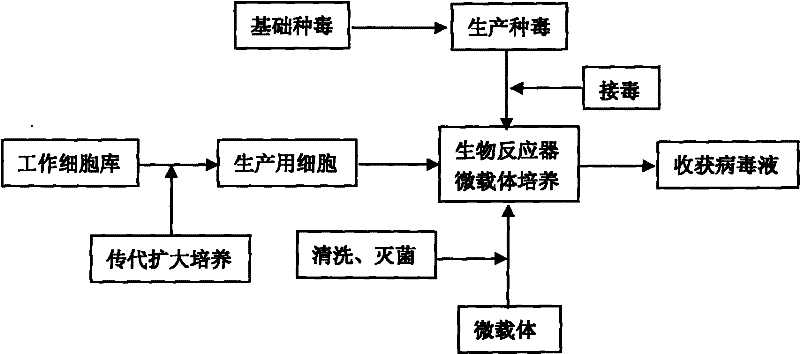

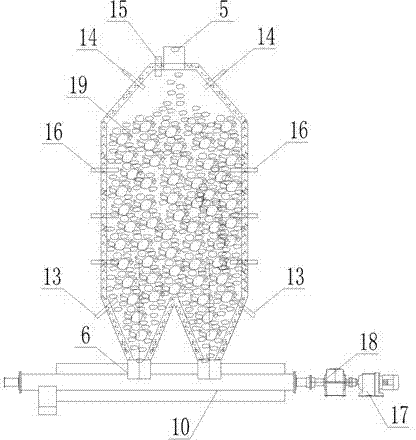

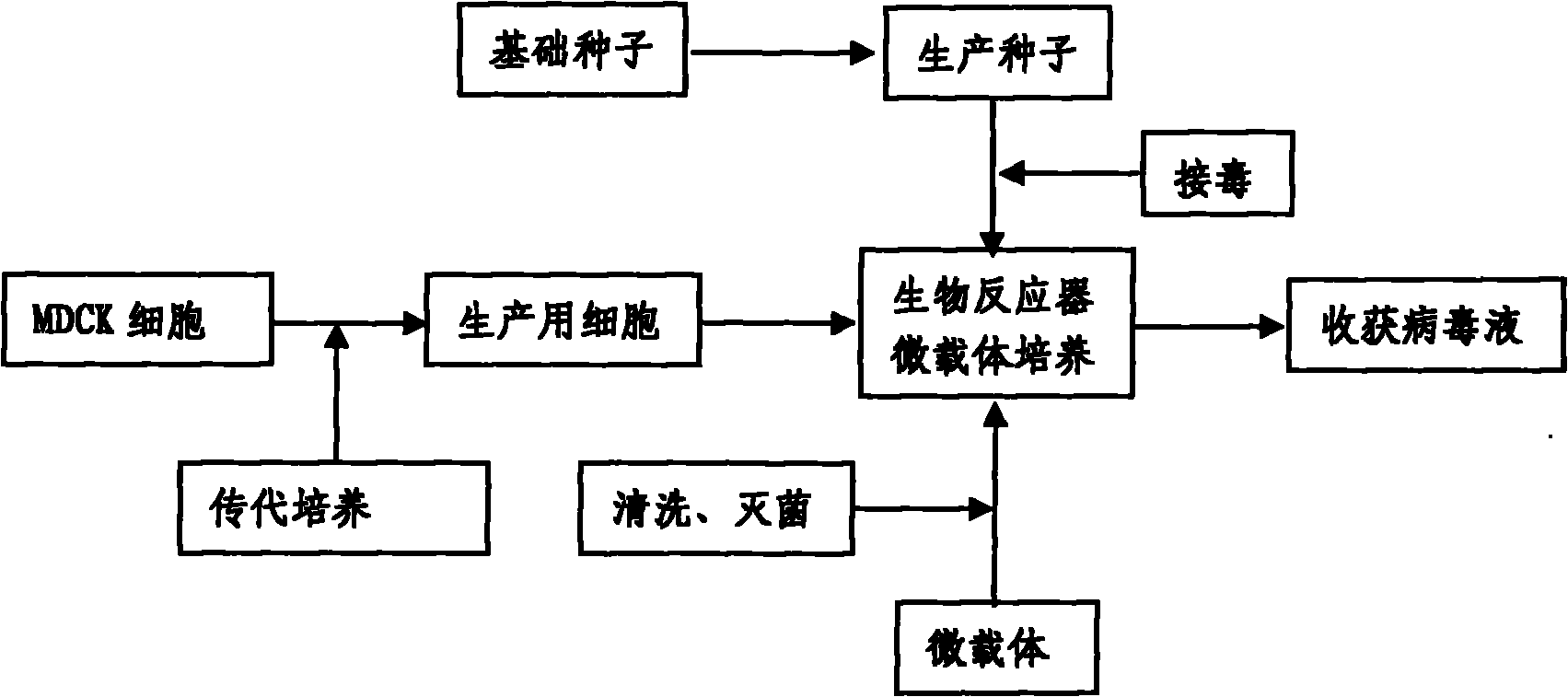

Method for production of porcine epidemic diarrhea virus

The invention discloses a technology for the production of porcine epidemic diarrhea virus by means of the microcarrier culture of VREO cells using a bioreactor, and comprises the technology for the production of different porcine epidemic diarrhea virus strains. The technology comprises the following technical steps: (1) selection of VERO cells as cell line for vaccine; (2) passage and culture of cells for vaccine; (3) propagation of seed culture of the porcine epidemic diarrhea virus; (4) microcarrier suspension culture of the VERO cells in the bioreactor; (5) propagation of porcine epidemic diarrhea virus antigen; and (6) treatment of acquired virus antigen liquid. The production method can remarkably lower production cost and enhance output-input ratio by 5 to 10 times, and has the advantages of short production period, small occupied space, great easiness for enlarging production scale rapidly, little environmental pollution, easy processing, high automation degree, a small number of staff, easy implementation of even and stable quality, obviously lowered production cost and enhanced yield and quality of vaccine.

Owner:成都史纪生物制药有限公司

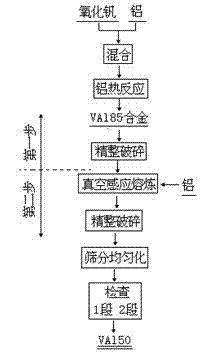

Method for manufacturing soft-magnetic alloy powder

The production method of soft magnetic alloy powder includes the following steps: smelting soft magnetic mother alloy, making molten metal be quickly coagulated into crystalline sheet alloy, breaking the sheet alloy to obtain alloy powder, and making the alloy powder undergo the processes of activation, annealing treatment and passivation treatment. Said soft magnetic alloy powder is low in oxygen content, stable in property and good in magnetic powder core performance.

Owner:CENT IRON & STEEL RES INST

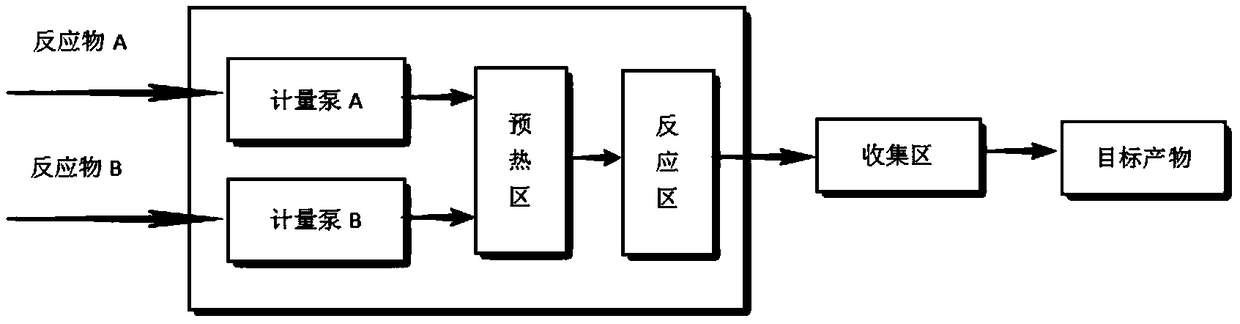

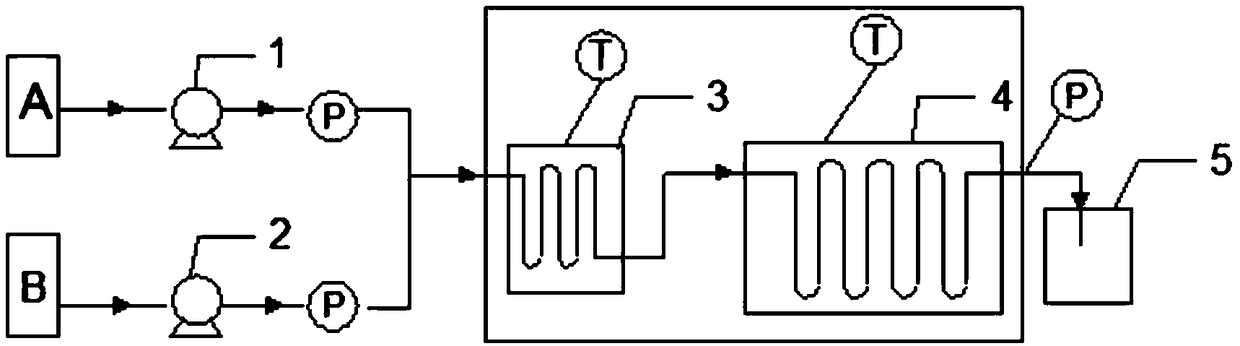

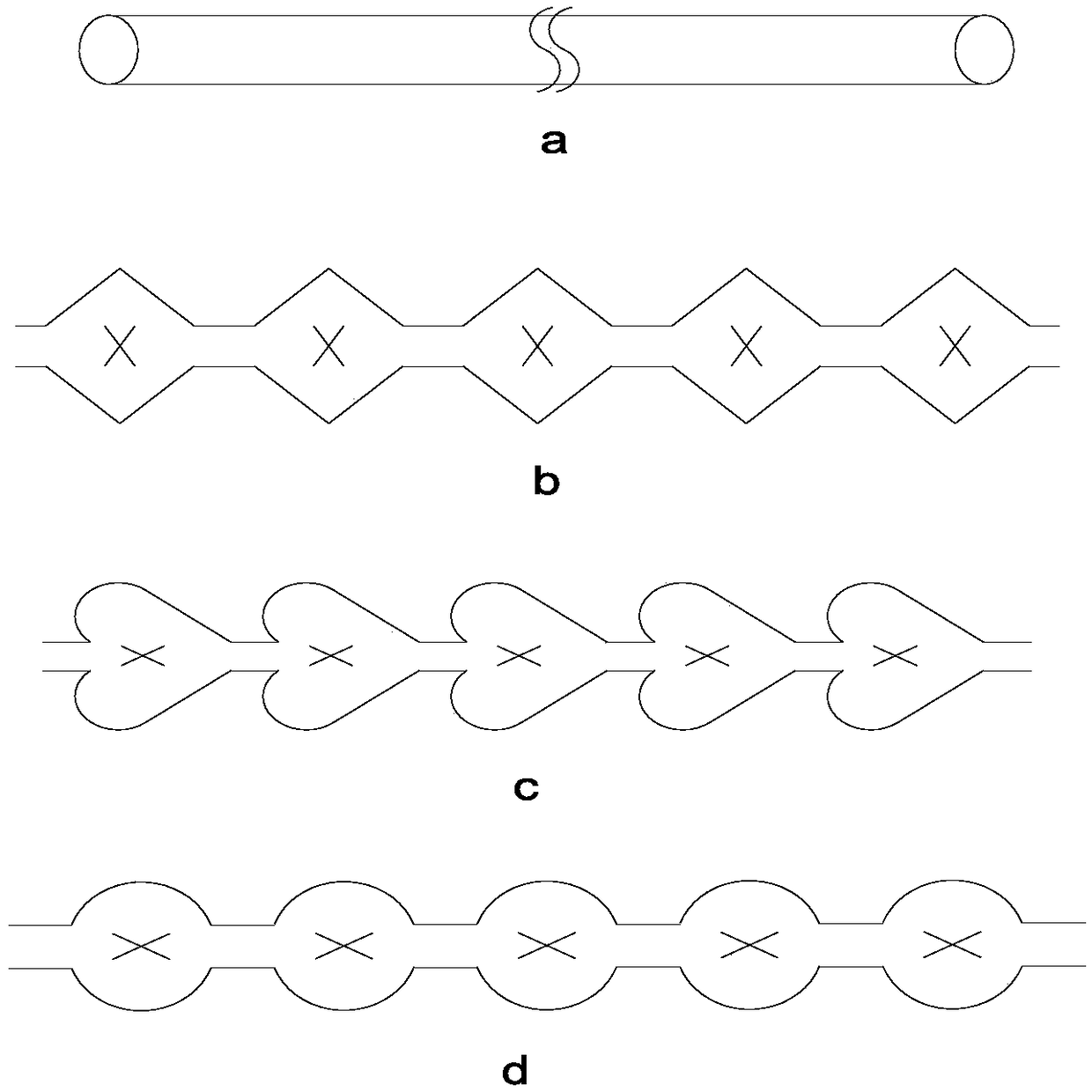

Method for continuous synthesis of dialkyl phosphite in micro-channel reactor

InactiveCN108840884AShort reaction timeIncrease temperatureGroup 5/15 element organic compoundsChemical industryAlcoholDolichyl phosphate

The invention discloses a method for continuous synthesis of dialkyl phosphite in a micro-channel reactor and belongs to the technical field of organic synthesis technologies. The method is used for generating the dialkyl phosphite through continuous reaction in the micro-channel continuous-flow reactor by using alcohol and phosphorus trichloride as substrates. Phosphorus trichloride is used as the material A, an alcohol solution is used as the material B, and the material A and the material B enter a micro-channel simultaneously through a metering pump for the continuous esterification reaction. According to the technological method, the high mass and heat transfer efficiency of the micro-channel reactor is utilized, the mass transfer rate between the two phase materials is effectively increased, and the safety and the operability of a test are greatly improved.

Owner:CHANGZHOU UNIV

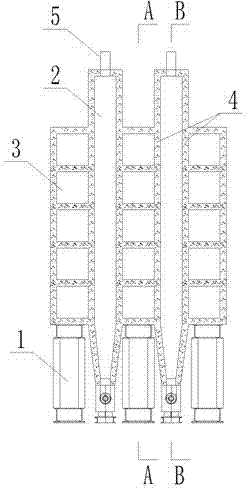

Coal-based direct reduced iron shaft furnace

The invention discloses a coal-based direct reduced iron shaft furnace and belongs to the technical field of coal-based direct reduced iron process equipment. The furnace body of the coal-based direct reduced iron shaft furnace is erected at a support steel structure, and the furnace body comprises a reduction cavity, burning cavities, and a discharge device; the reduction cavity is a rectangular structure cavity body composed of two parallel heat-conduction walls and the upper and lower parts of the reduction cavity are respectively provided with a sealed feed port and a sealed discharge port; the burning cavities provided with multiple layers of horizontal fire gas baffling channels are positioned at the both sides of the reduction cavity; and the discharge device is a spiral conveyer, the cylindrical shell of the spiral conveyer is of a jacket water cooling structure, and a spiral rotating shaft is a hollow water cooling structure. Compared with the tradition tubular reduction cavity body, the coal-based direct reduced iron shaft furnace provided by the invention has the advantages of high efficiency of heat transmission, and uniform heating of the inner and outer layers of a pelletized material in the furnace. The coal-based direct reduced iron shaft furnace can be used for effectively reducing the energy consumption of reduced iron and improving the merchantable quality and the production efficiency of a single furnace.

Owner:ZHENGZHOU ANLIANKAI IND CO LTD

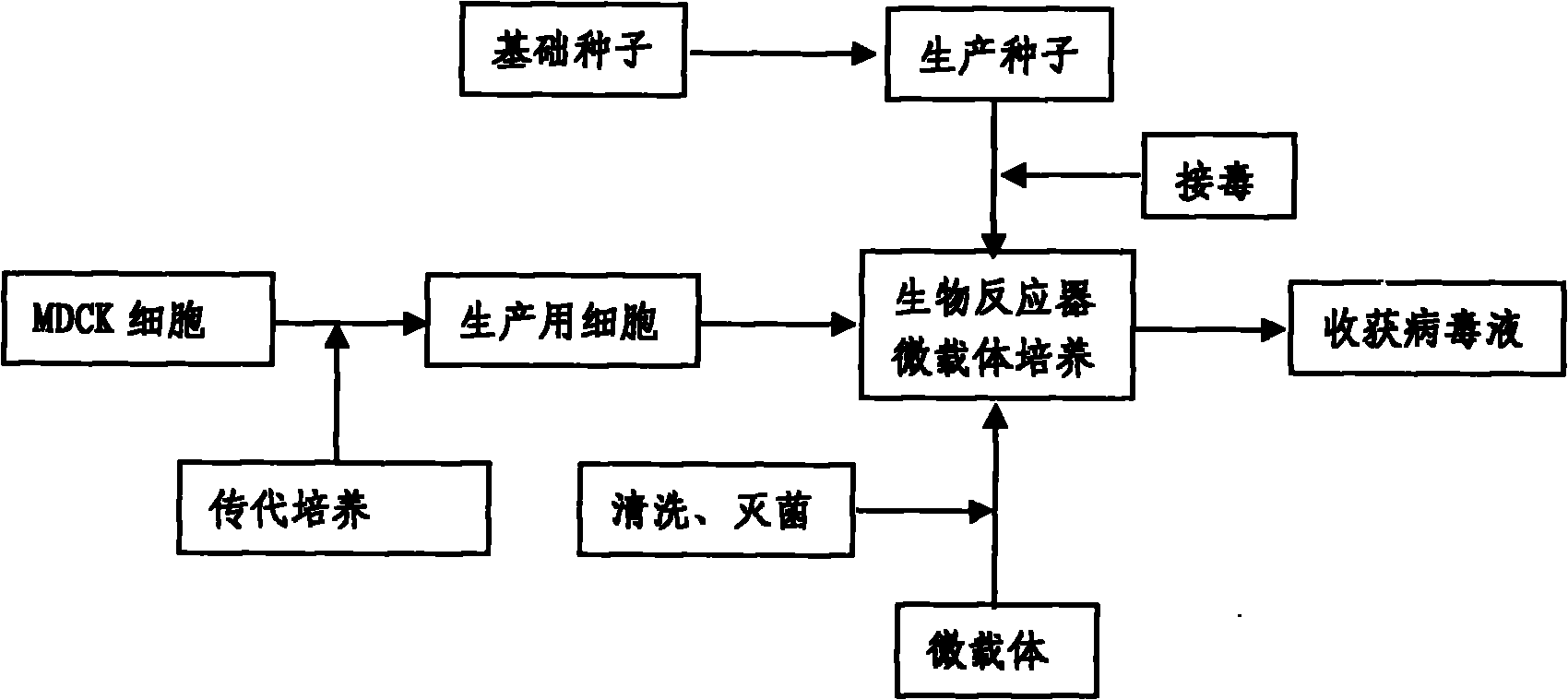

Production method for influenza virus vaccines

InactiveCN101818131ASolve yourselfSolve pollutionAntiviralsViruses/bacteriophagesEquine influenza vaccineBioreactor

The invention discloses a production method for vaccines of avian influenza virus and other influenza virus such as swine influenza, dog influenza and equine influenza, which comprises the following steps of: (1) transfer of culture and cultivation of vaccine-made cells; (2) reproduction of vaccine-made virus seeds; (3) microcarrier suspension culture of MDCK cells in a bioreactor; (4) reproduction of vaccine-made virus liquid; and (5) harvest of the virus liquid. The production method has the advantages of reducing the production cost greatly and improving the yield and quality of the vaccines obviously, along with short production period, no restriction to raw material supply, small occupied area, easy and quick expansion of production scale, light environmental pollution, easy processing, high automaticity, low employment and easy realization of balanced and stable quality.

Owner:成都史纪生物制药有限公司

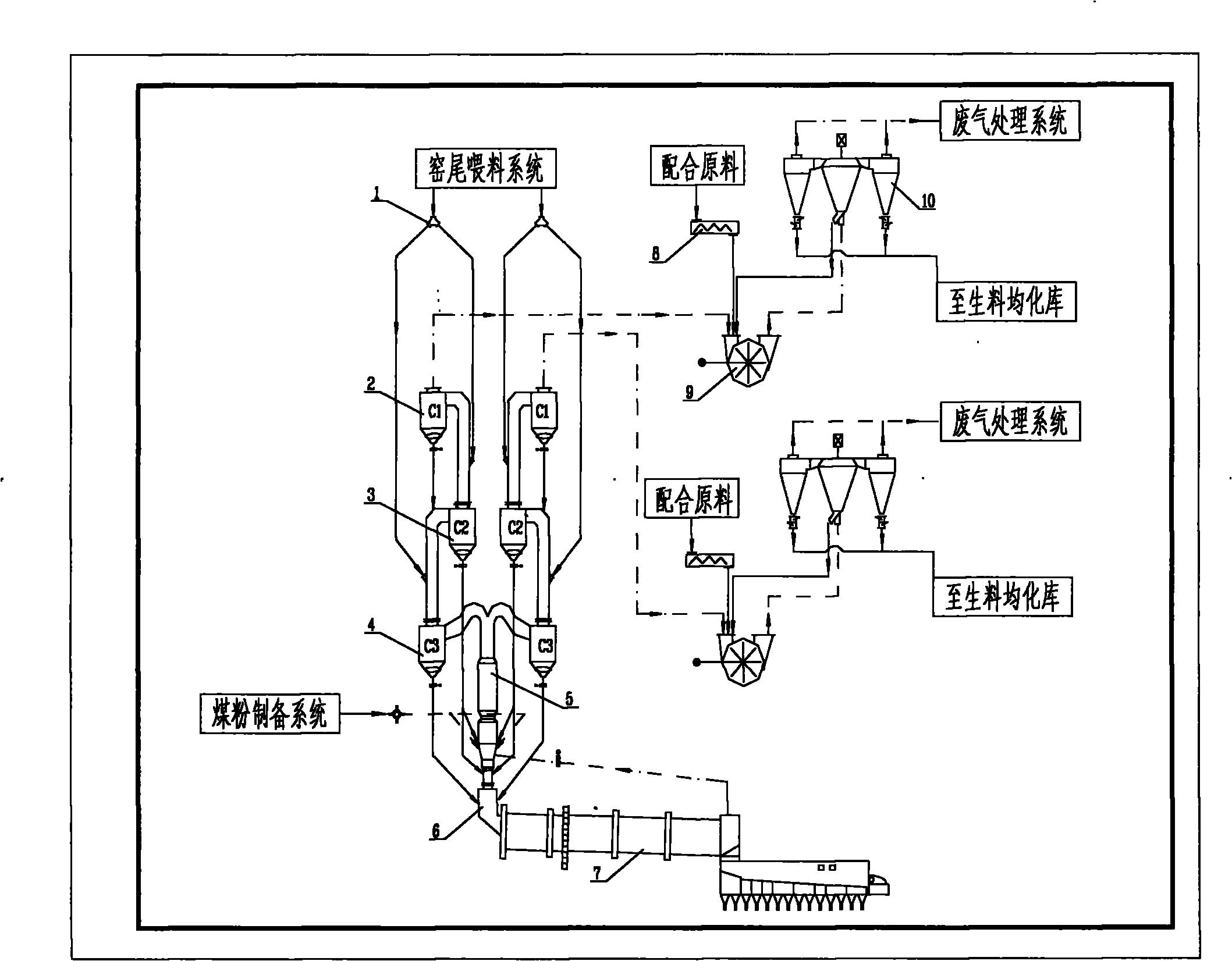

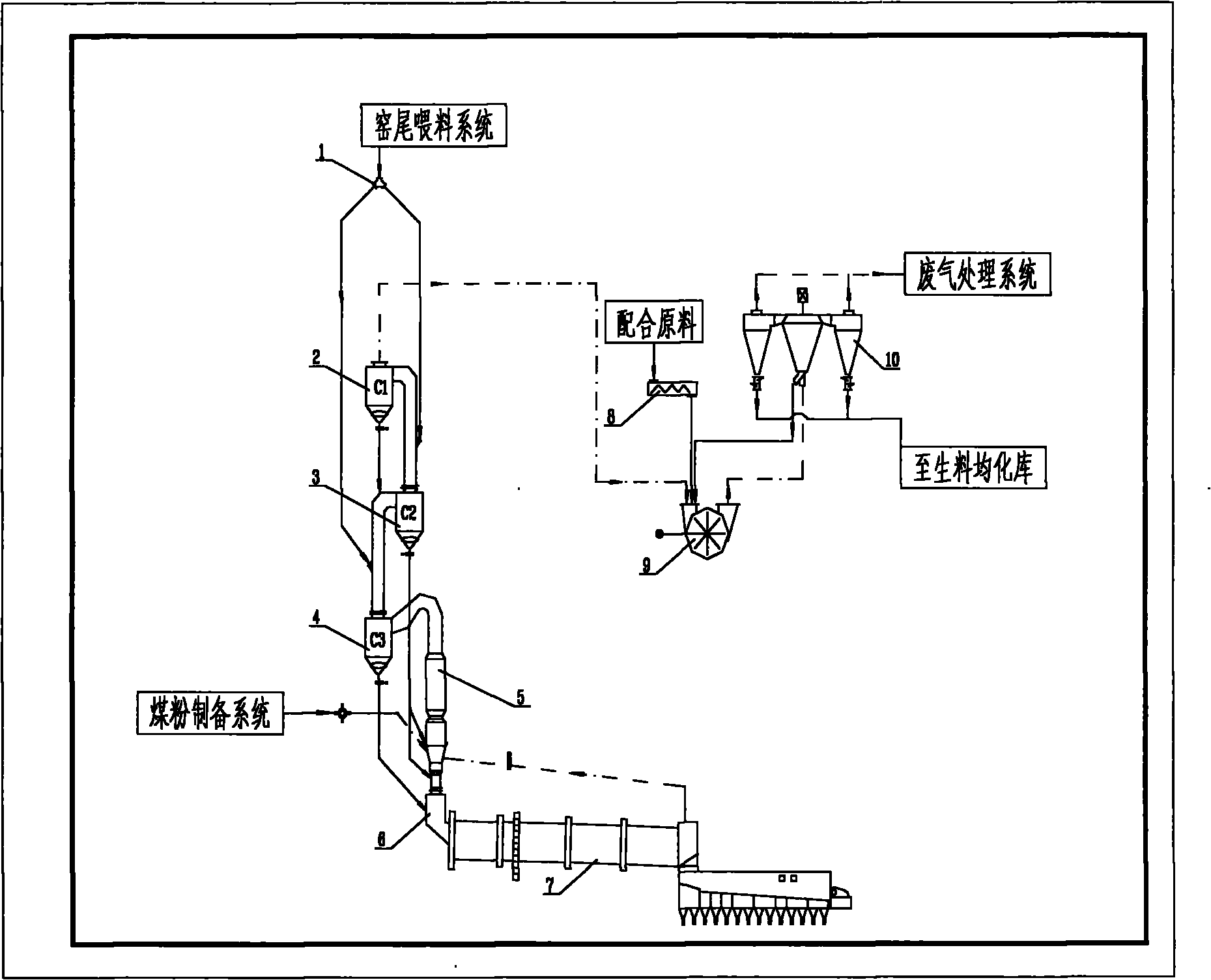

Method for producing cement clinker by calcining chalk

ActiveCN101811839AEmission reductionImprove protectionClinker productionProcess systemsMetallic materials

The invention relates to a method for producing cement clinker by calcining chalk, which belongs to the technical field of inorganic nonmetallic materials. The invention takes high moisture content chalk (moisture content of 20-35%) as calcareous raw materials, and is characterized by adopting a dry pre-heating and pre-decomposing technique to calcine the cement clinker, and realizing the organicintegration of three process systems of a raw material drying preparation system, a pre-heating and pre-decomposing system and a clinker calcination system. The method comprises the following steps: (1) the raw material drying preparation system: a drying crusher and a powder concentrator are adopted to dry and sort the prepared chalk raw materials; (2) the pre-heating and predecomposing system: a cyclone preheater and a decomposing furnace system are adopted to preheat and pre-decompose the chalk raw materials, wherein the outlet temperature (600-750 DEG C) of the preheater is adjustable; and (3) the cement clinker calcination system: the predecomposed raw materials enter a rotary kiln system to be calcined into the cement clinker. The invention has the advantages of low comprehensive energy consumption, stable production capacity, high system operation rate and the like.

Owner:成都建筑材料工业设计研究院有限公司

Automatic seeding technique for growing sapphire crystal by Kyropoulos method

ActiveCN102877120AExpand production scaleReduce labor costsPolycrystalline material growthBy pulling from meltGrowth phaseEngineering

The invention belongs to the field of growth technologies of sapphire single crystal and particularly relates to an automatic seeding technique for growing sapphire crystal by a Kyropoulos method. The automatic seeding technique for growing sapphire crystal by the Kyropoulos method is characterized in that a weighing mechanism is automatically zeroed first; weight change of seed crystal is automatically calculated by a program according to curves, if weight changes from 10g to 20g, ring pulling is performed automatically by the program, and if not, the program automatically regulates voltage to enable the weight change to meet the requirements; and change rate in crystal weight is automatically calculated during weighing in ring pulling, the program automatically regulates the voltage and continuously calculates the change rate, seeding is completed till the change rate in crystal weight is controlled in the range of 0.1-0.5, and growth phase starts automatically. The number of seeding in a furnace is no longer limited by the number of seeding engineers by using the seeding technique to grow the sapphire crystal, production scale can be increased quickly, mass labor cost is saved, and production cost is reduced greatly.

Owner:黄山东晶电子有限公司

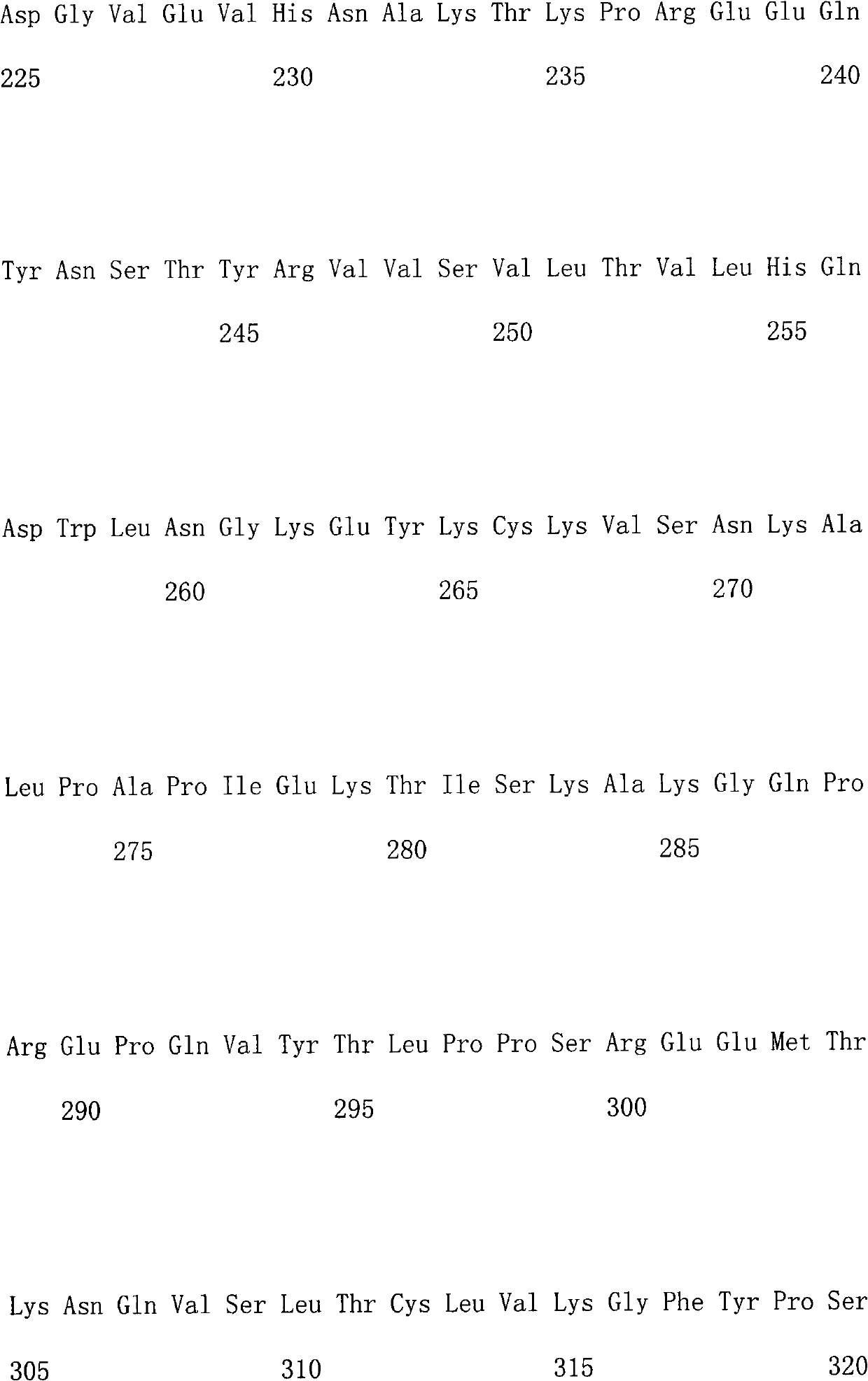

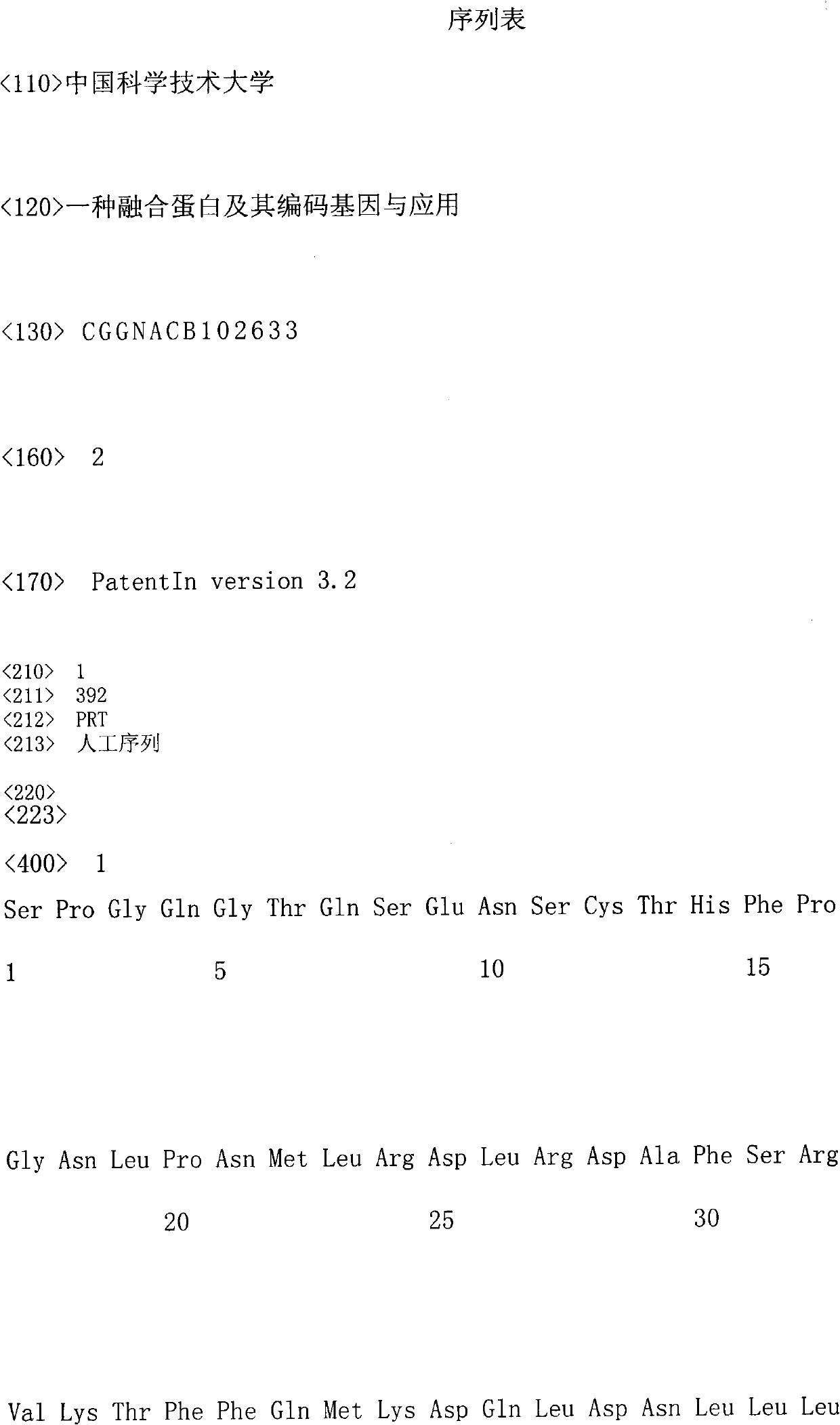

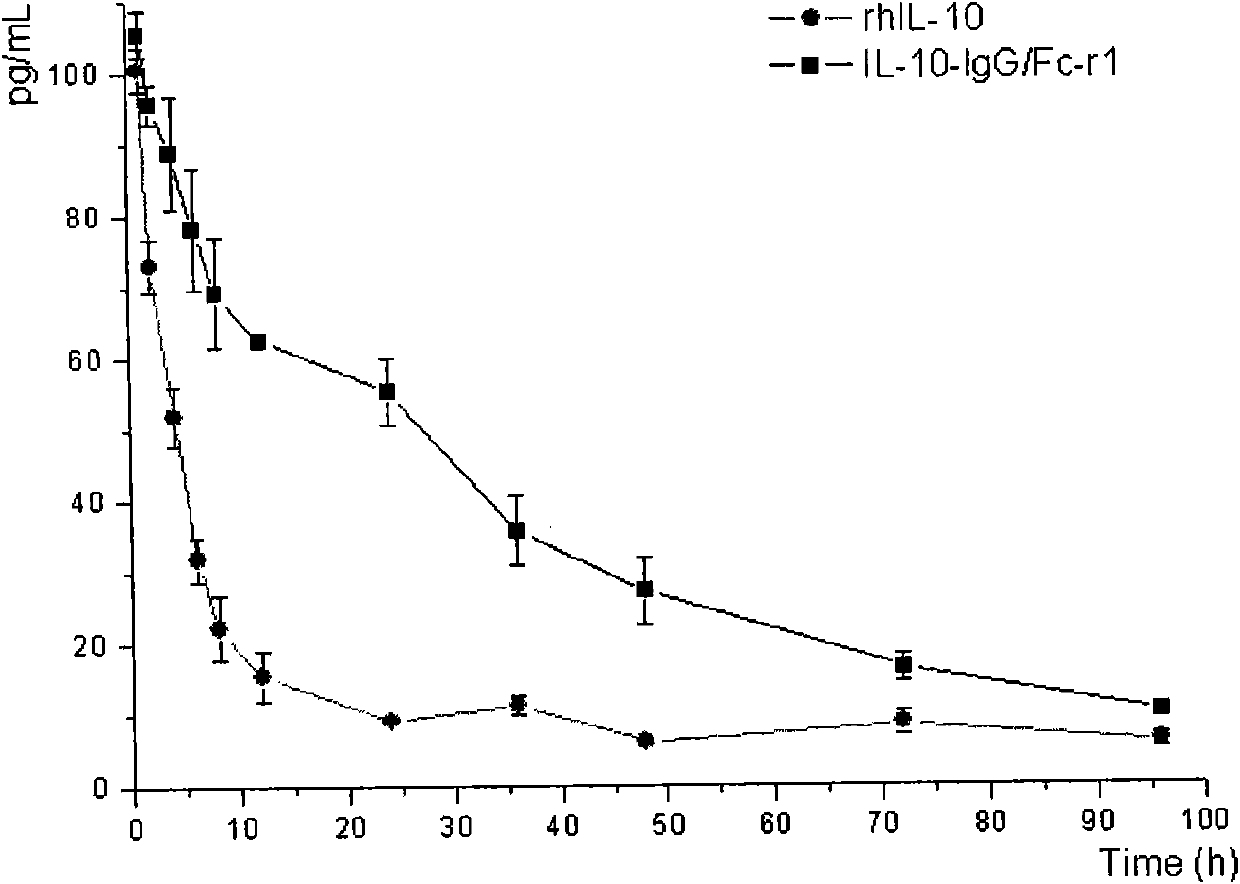

Fusion protein and coding gene and application thereof

The invention discloses a fusion protein and a coding gene and application thereof. The fusion protein provided by the invention is formed by connecting any one of the following proteins at the carboxyl terminal of human interleukin-10 protein: 1) human IgGFc-gamma 1 or mutant protein thereof, and 2) human IgGFc-gamma 2 or mutant protein thereof, wherein the amino acid sequence of the human interleukin-10 protein is an amino acid sequence from 1st to 160th site of the amino terminal of the sequence 1 in a sequence table. Proved by experiments, the IL-10-IgG / Fc fusion protein of interleukin-10activity is produced by using a pichia pastoris fermentation expression system, and a foundation for clinically researching the treatment effect of the IL-10-IgG / Fc fusion protein in the next step.

Owner:UNIV OF SCI & TECH OF CHINA

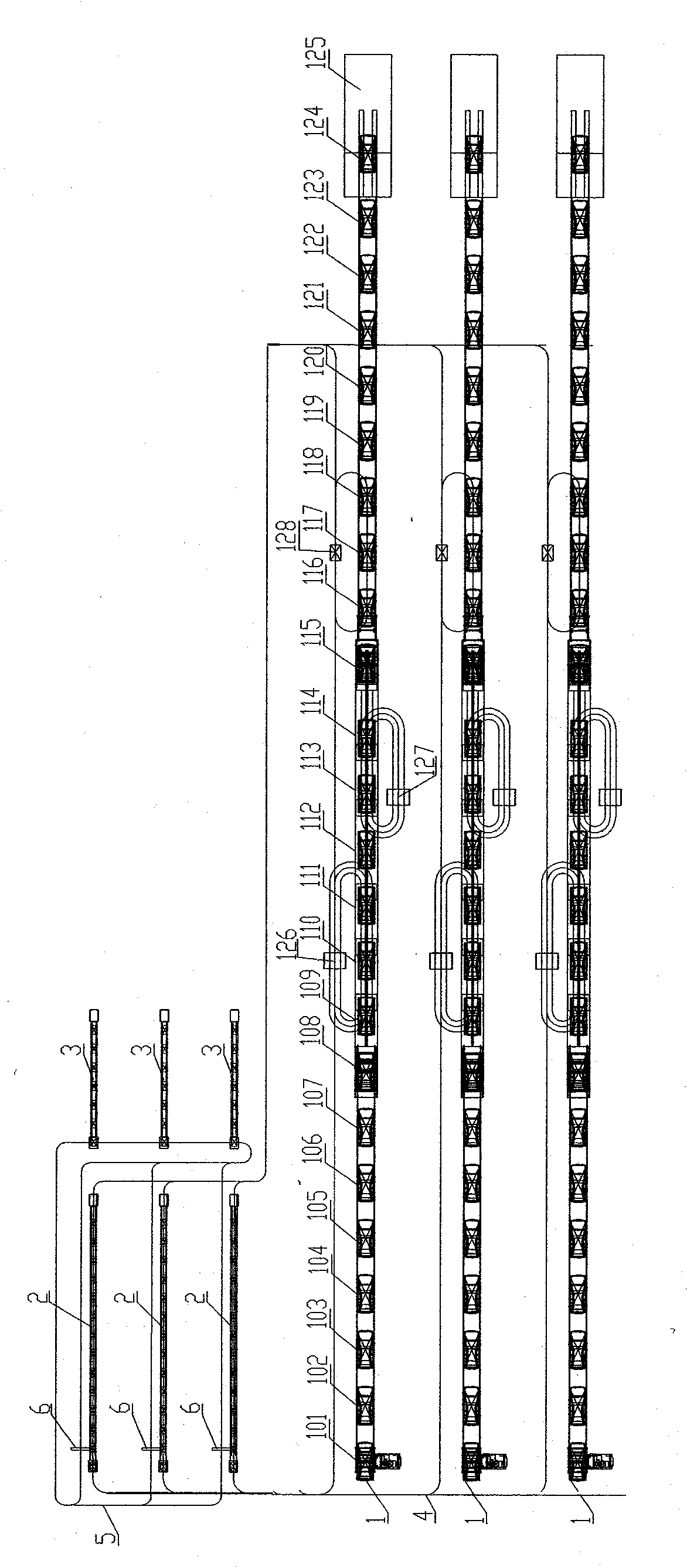

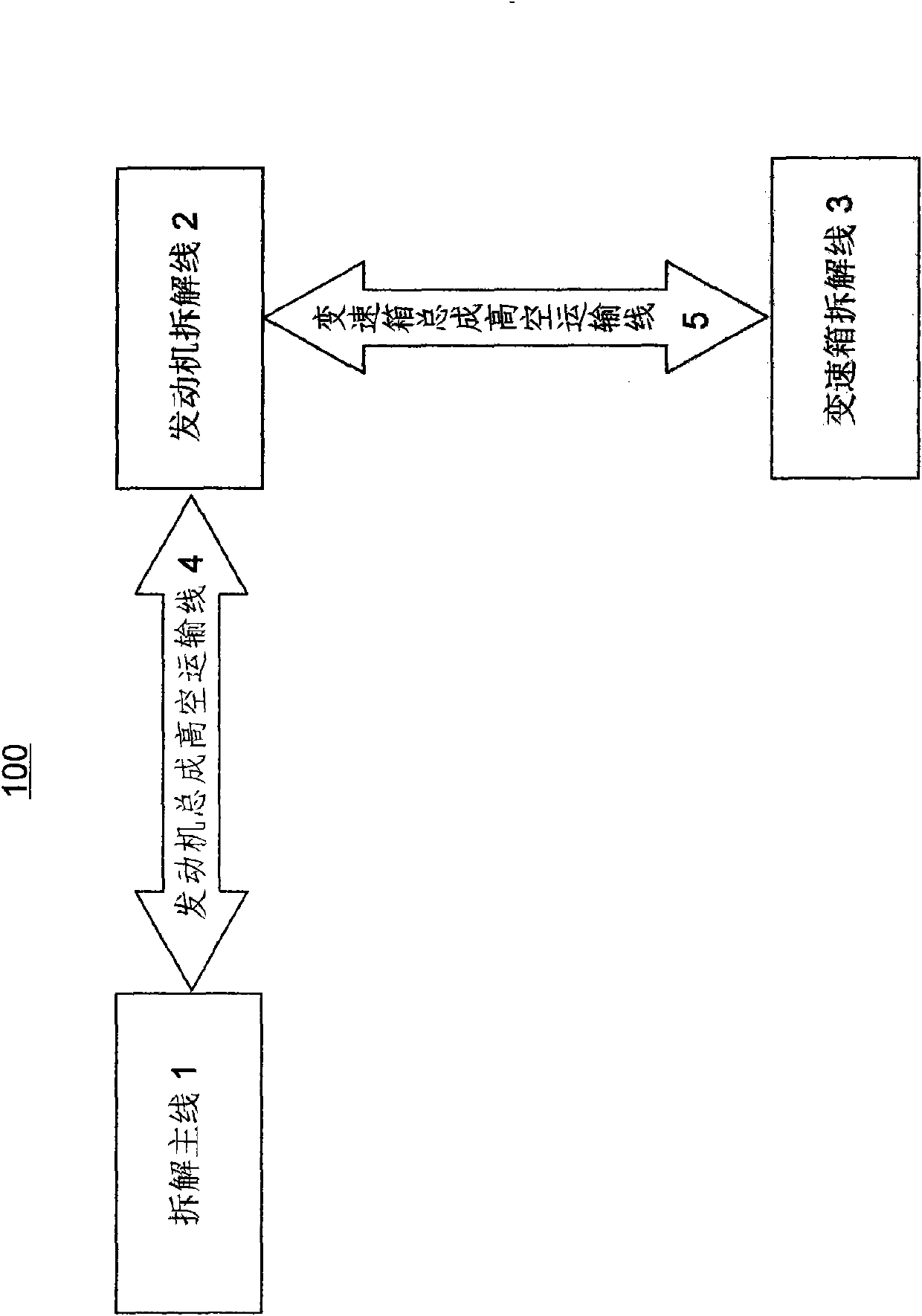

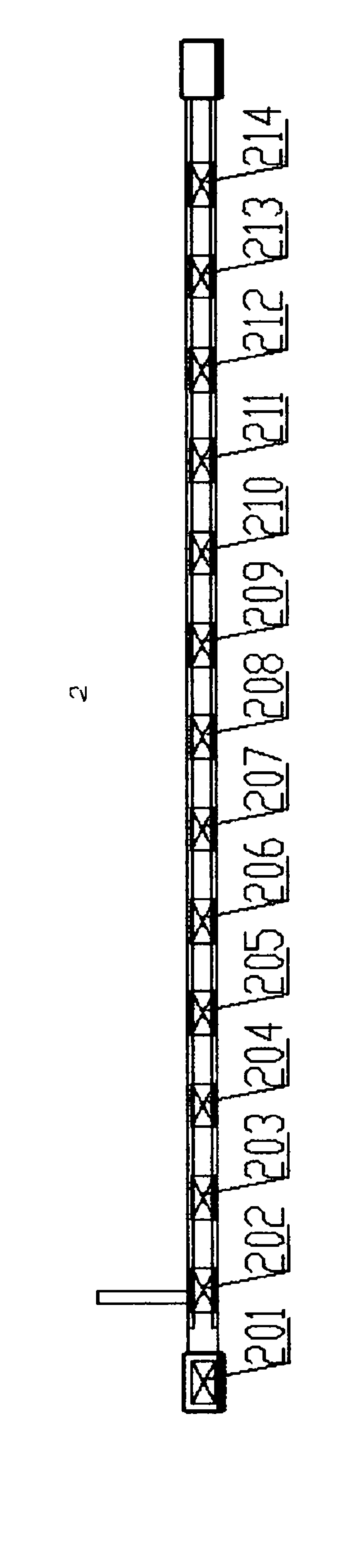

Disassembly reclamation system for scrapped motor vehicle

InactiveCN102107695AEasy to sort and recycleEasy to recycleVehicle dissasembly recoverySolid waste disposalMobile vehicleResource recovery

The invention discloses a disassembly reclamation system for a scrapped motor vehicle. By connection and operation of a main disassembly line, a high-altitude engine assembly transport line, an engine disassembly line, a high-altitude gearbox assembly transport line and a gearbox disassembly line, the purposes of large production scale and high disassembly efficiency are fulfilled; and the system is operated automatically, is convenient for reclaiming and classifying parts and favorable for resource reclamation and environmental protection, simultaneously has simple layout, and is convenient for expanding the scale.

Owner:张家港永峰泰环保科技有限公司

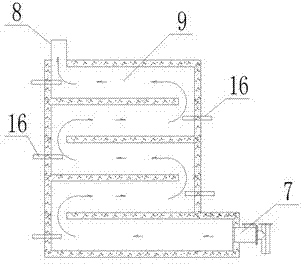

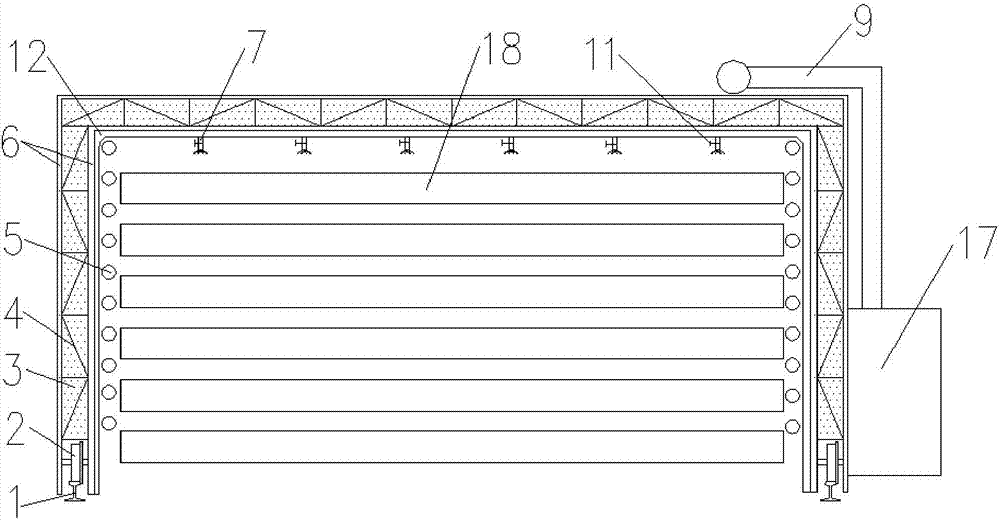

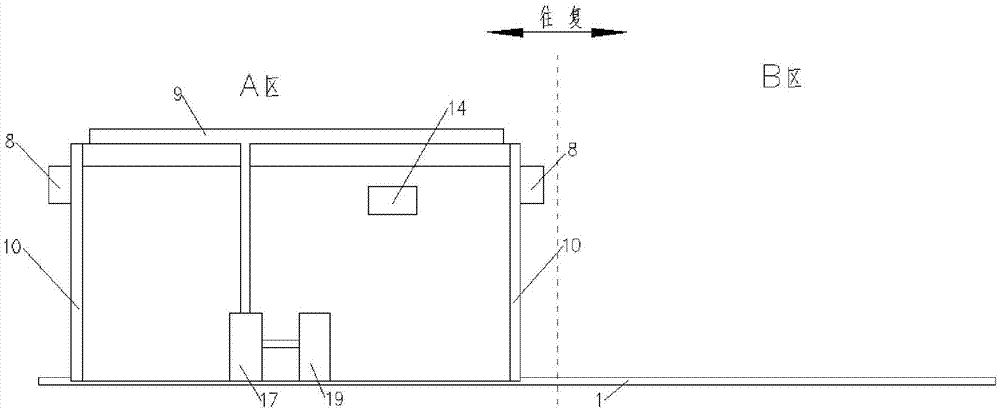

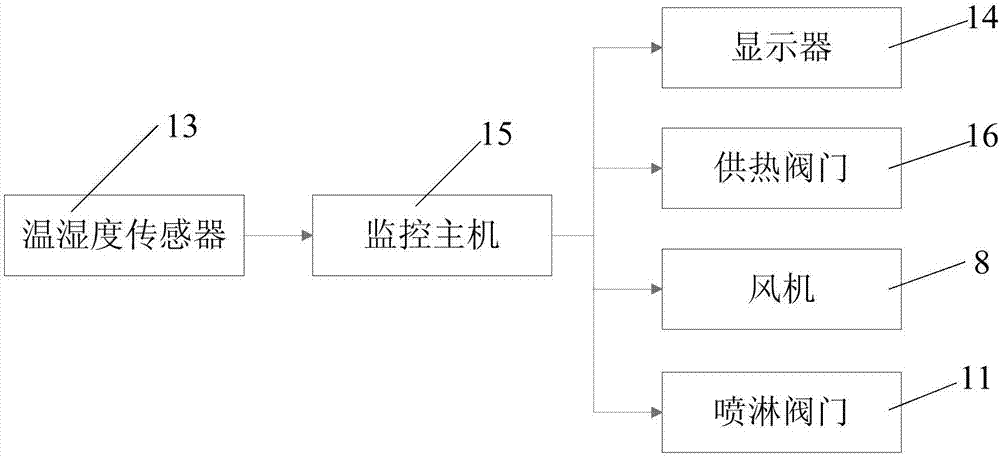

Reciprocating type circular curing device and technology

The invention discloses a reciprocating type circular curing device. The reciprocating type circular curing device comprises tracks and a curing chamber moving along the tracks. Track wheels matched with the tracks are arranged at the bottom of the curing chamber. Sealing doors are arranged on the two sides, perpendicular to the moving direction, of the curing chamber. The inner wall of the curing chamber is coated with a waterproof layer. The curing chamber is provided with a heat supply system, a spraying system, a temperature and humidity monitoring system and a temperature and humidity adjusting system. The curing chamber is externally provided with a monitoring host. Meanwhile, the invention further provides a technology for achieving concrete product curing through the reciprocating type circular curing device. The reciprocating type circular curing device and technology are suitable for medium-small-sized enterprises to improve the existing manual curing technology, accordingly, high-quality concrete products can be produced, reciprocating continuous production can be achieved, and the occupied area is small. By means of the curing device, circular reciprocating curing work on the concrete products can be achieved, the curing efficiency is greatly improved, huge profits are brought to the medium-small-sized enterprises, and application and popularization are convenient.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Porcine circovirus type 2 subunit vaccine, and preparation method and application thereof

ActiveCN102925486AImprove expression efficiencyImproving immunogenicityViral antigen ingredientsVirus peptidesImmune effectsVirus-like particle

The invention relates to a porcine circovirus type 2 subunit vaccine, and a preparation method and an application thereof. The recombinant baculovirus contains double promoters (a polyhedrin protein promoter and a P10 promoter), and can express double copies of Cap protein coding genes, such that protein expression efficiency is substantially improved. Also, Cap protein expressed by an inserted exogenous gene does not contain excess sequences, such that virus-like particles (VLPs) can be effectively formed, expressed protein immunogenicity is improved, and the content of produced antigen is high. According to the porcine circovirus type 2 subunit vaccine provided by the invention, protein yield and quality of porcine circovirus type 2 subunit vaccine are substantially improved, and prepared vaccine compositions have the advantages of stable and long-lasting immune effect, high safety, and the like.

Owner:WUHAN CHOPPER BIOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com