Method for continuous synthesis of dialkyl phosphite in micro-channel reactor

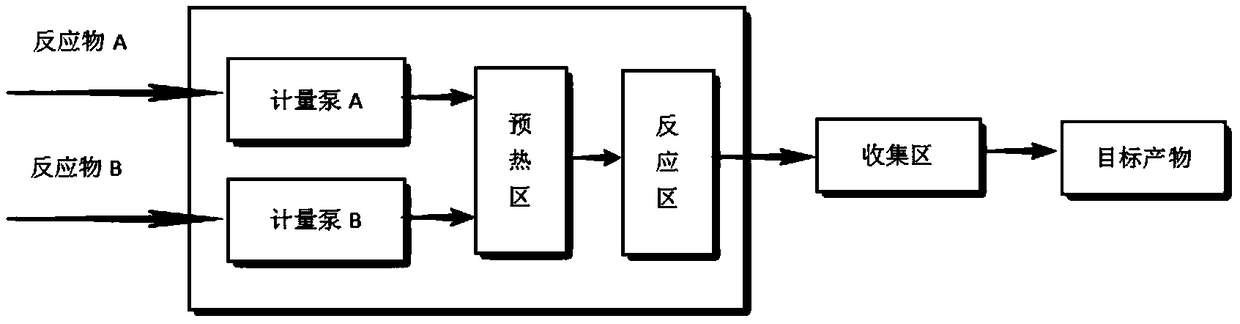

A dialkyl phosphite, microchannel reactor technology, applied in chemical instruments and methods, climate sustainability, sustainable manufacturing/processing, etc., can solve the problem of low yield of target products, achieve temperature and safety Good controllability, high production efficiency, flexible production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

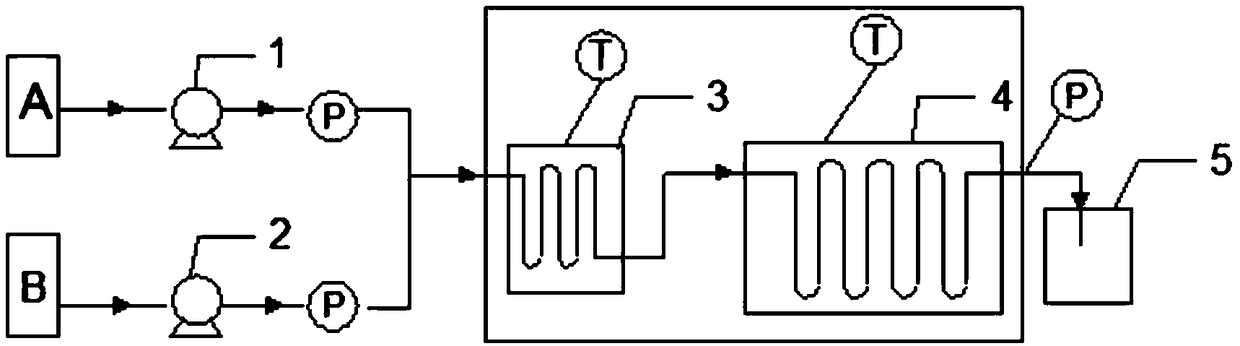

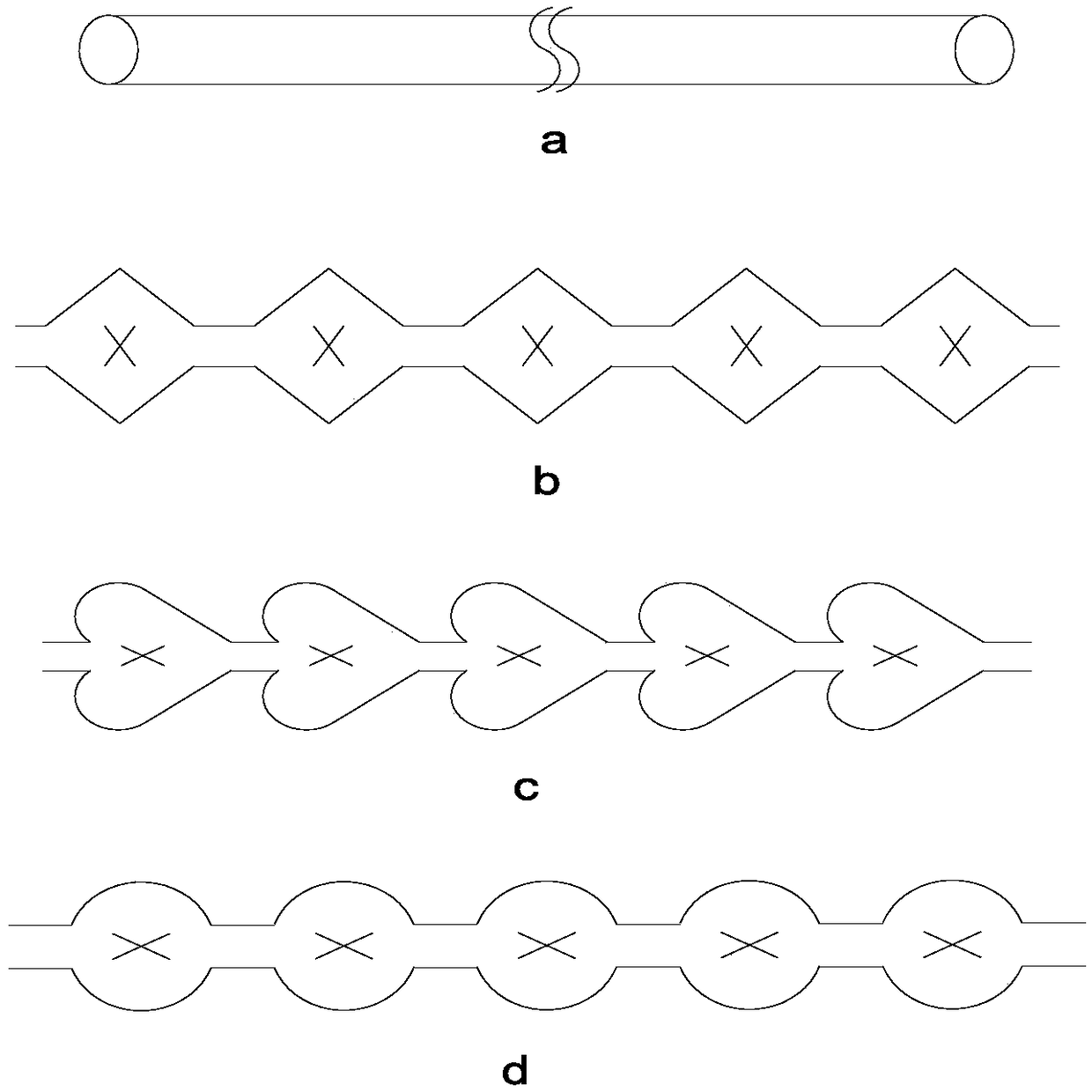

[0035] (1) Refer to figure 2 Determine the connection mode of the tubular reactor, the pipe type is a straight-line structure and a rhombus structure, the pipe volume and flow rate determine the reaction molar ratio, and the heat exchange medium is heat transfer oil.

[0036] Phosphorus trichloride is regarded as raw material A; Dehydrated alcohol solution is regarded as raw material B, and two streams of materials are injected in the reactor by metering pump with the flow rate of 9ml / min and 29ml / min respectively, now n (trichloride Phosphorus): n (absolute ethanol) = 1:3, using figure 2 In a microchannel reactor, the temperature was controlled at 30° C., and the residence time was 60 s. The reaction solution was collected quantitatively and then distilled under reduced pressure. Finally, it was weighed and calculated to obtain a yield of 99.1% of the product diethyl phosphite. The selectivity of diethyl phosphite was 99.4% by GC analysis.

Embodiment 2

[0038] (1) Refer to figure 2 Determine the connection mode of the tubular reactor, the pipe type is a straight-line structure and a heart-shaped structure, the pipe volume and flow rate determine the reaction molar ratio, and the heat exchange medium is heat transfer oil.

[0039] Phosphorus trichloride is regarded as raw material A; Methanol solution is regarded as raw material B, and two streams of materials are injected in the reactor through metering pumps with the flow velocity of 11ml / min and 35ml / min respectively, at this moment n (phosphorus trichloride) : n (methanol) = 1:4, using figure 2 In a microchannel reactor, the temperature is controlled at 40° C., and the residence time is 300 s. The reaction solution is quantitatively collected, then distilled under reduced pressure, and finally weighed and calculated to obtain a yield of 99.4% of the product dimethyl phosphite. The selectivity of dimethyl phosphite was 99.3% by GC analysis.

Embodiment 3

[0041] (1) Refer to figure 2 Determine the connection mode of the tubular reactor, the pipe type is a straight-line structure and a circular structure, the pipe volume and flow rate determine the reaction molar ratio, and the heat exchange medium is heat transfer oil.

[0042] Phosphorus trichloride is regarded as raw material A; Virahol solution is regarded as raw material B, and two streams of materials are injected in the reactor through metering pumps with the flow rate of 13ml / min and 31ml / min respectively, at this moment n (trichloride Phosphorus): n (isopropanol) = 1:3.8, using figure 2 In a microchannel reactor, the temperature is controlled at 55° C., and the residence time is 60 s. The reaction solution is quantitatively collected and then distilled under reduced pressure. Finally, it is weighed and calculated to obtain a yield of 99.1% of the product diisopropyl phosphite. The selectivity of diisopropyl phosphite was 99.5% by GC analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com