Patents

Literature

531results about How to "Flexible production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

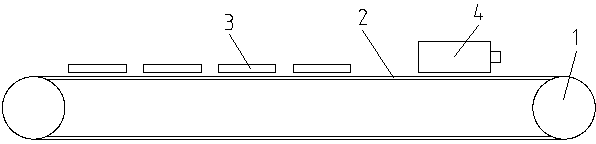

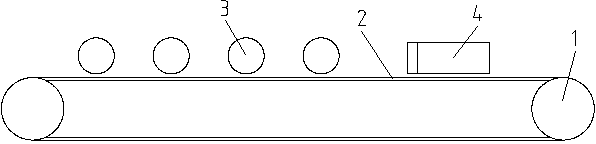

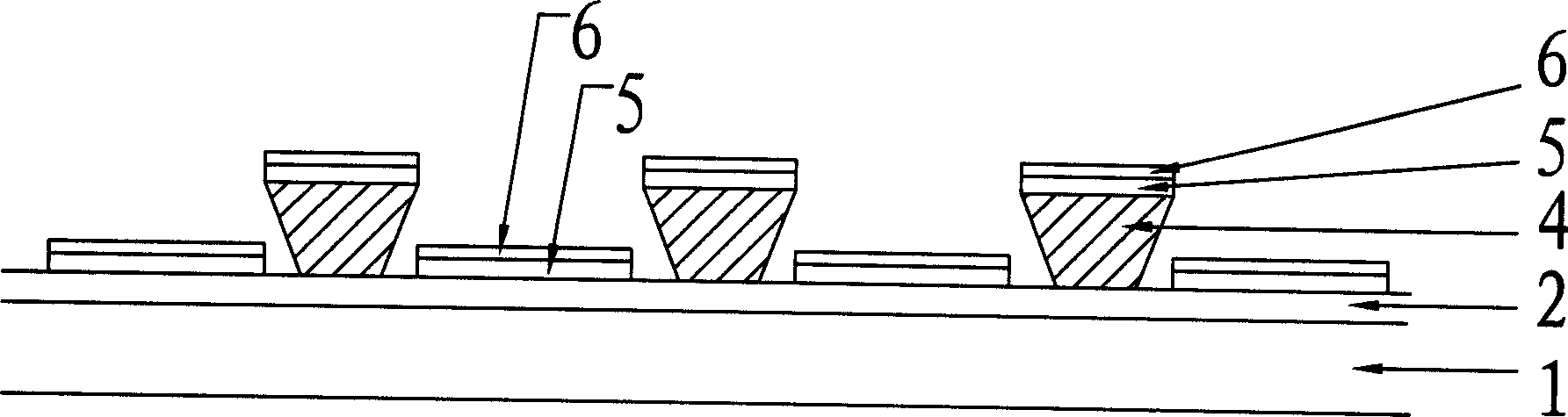

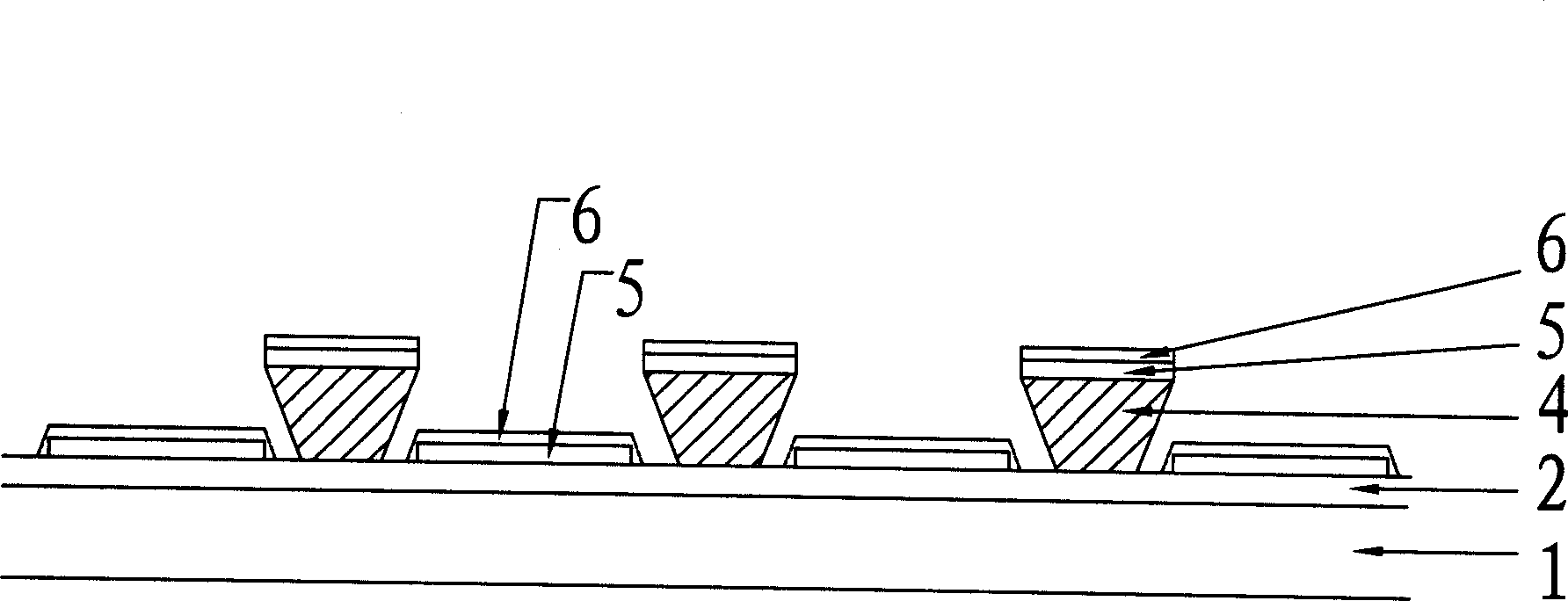

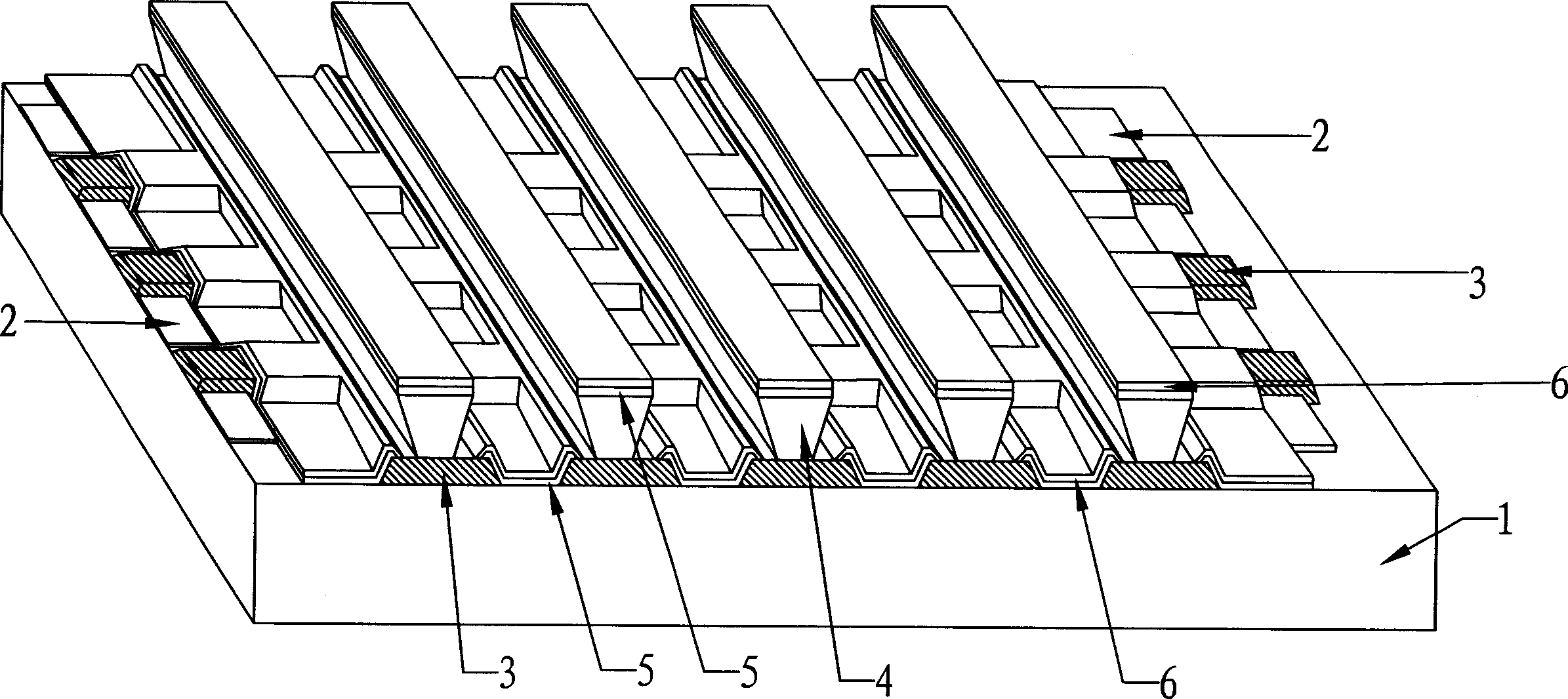

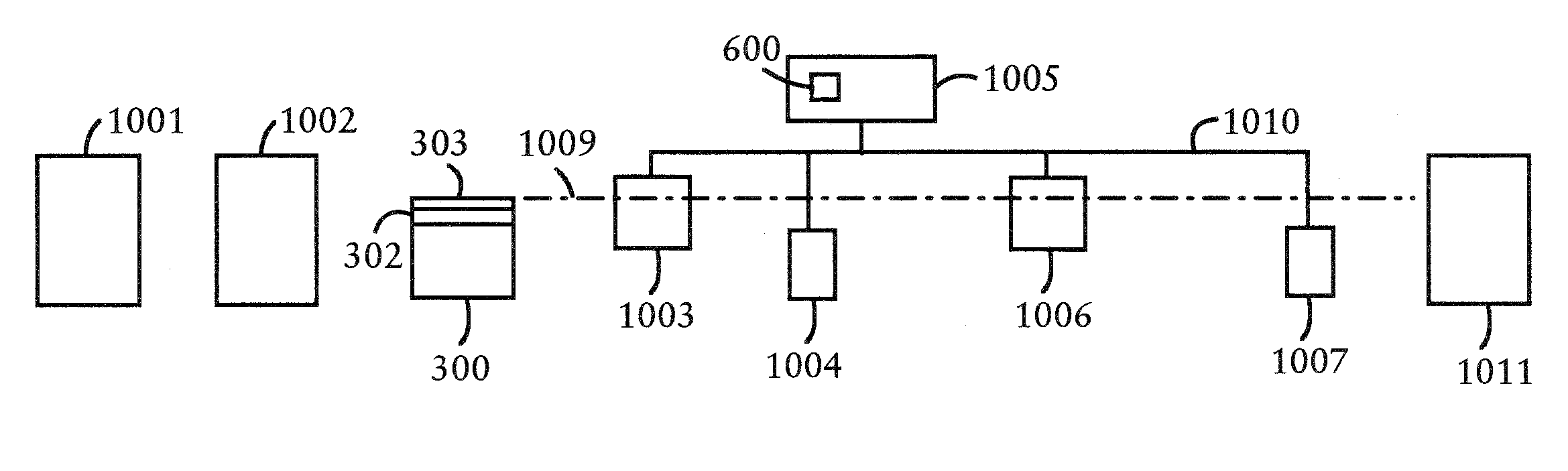

Screen printing and digital printing combined printing device and printing method thereof

ActiveCN103350561AReasonable structural designReliable performanceDuplicating/marking methodsRotary pressesDigital printingPrint-through

The invention relates to a screen printing and digital printing combined printing device and a printing method of the screen printing and digital printing combined printing device. At present, no printing method or printing method which is high in printing precision and printing speed exist. The printing device is characterized by comprising a machine frame, a rotating roller, a conveyer belt, a screen printing mechanism and a digital printing mechanism, the conveyer belt is installed on the rotating roller, the screen printing mechanism is installed on the machine frame, the digital printing mechanism is installed on the machine frame, and the screen printing mechanism is matched with the digital printing mechanism. The printing method is characterized in that shell fabric is driven to move through the conveyer belt, the shell fabric is printed through the screen printing mechanism and the digital printing mechanism, and if patterns needing to be printed on the shell fabric include large pieces of patterns, the patterns are printed through the screen printing mechanism; if the patterns needing to be printed on the shell fabric include high-precision patterns, the patterns are printed through the digital printing mechanism. The printing device and the printing method are reasonable in structural design, reliable in performance, high in printing precision and high in printing speed.

Owner:HANGZHOU HONGHUA DIGITAL TECH

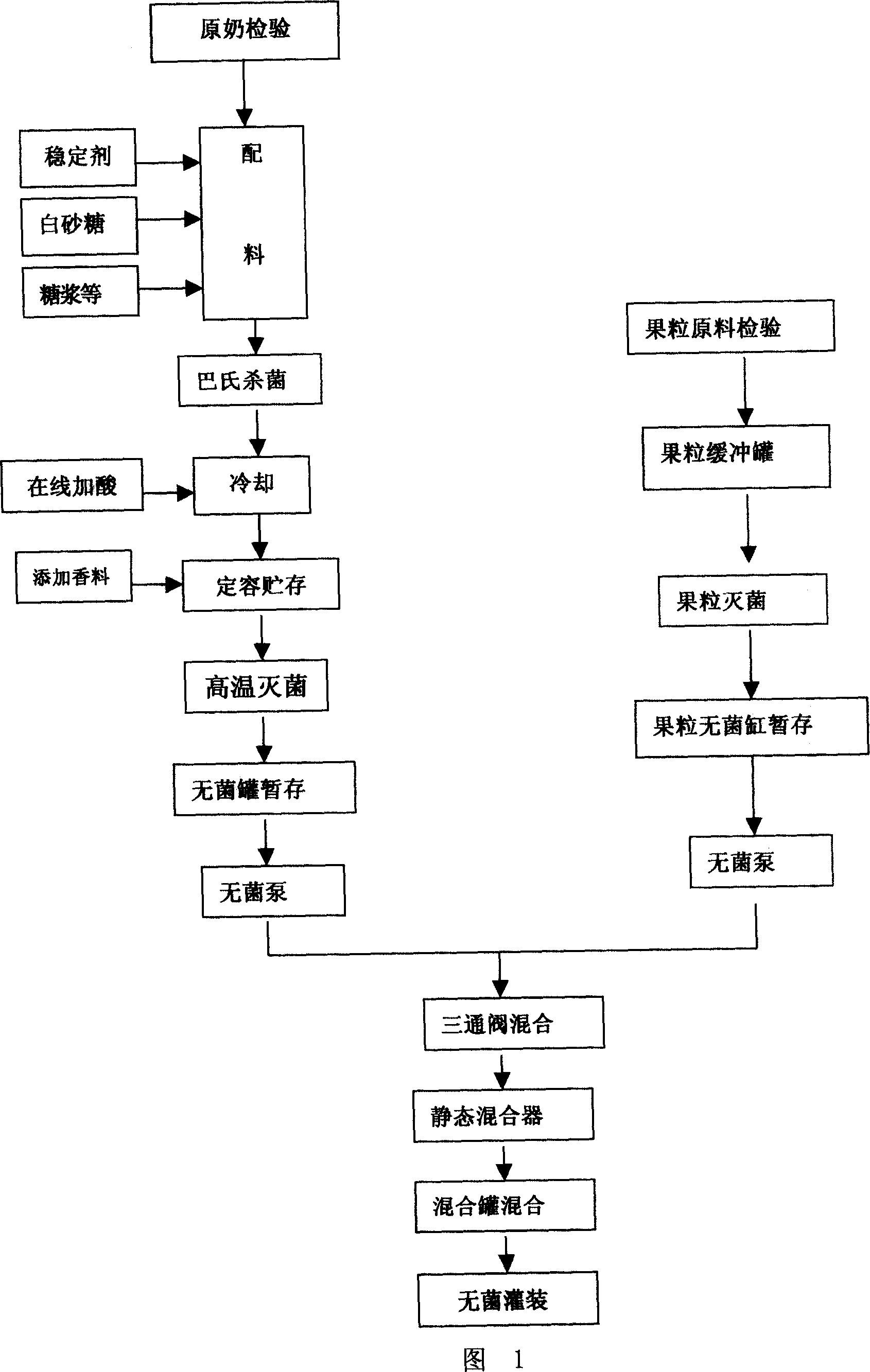

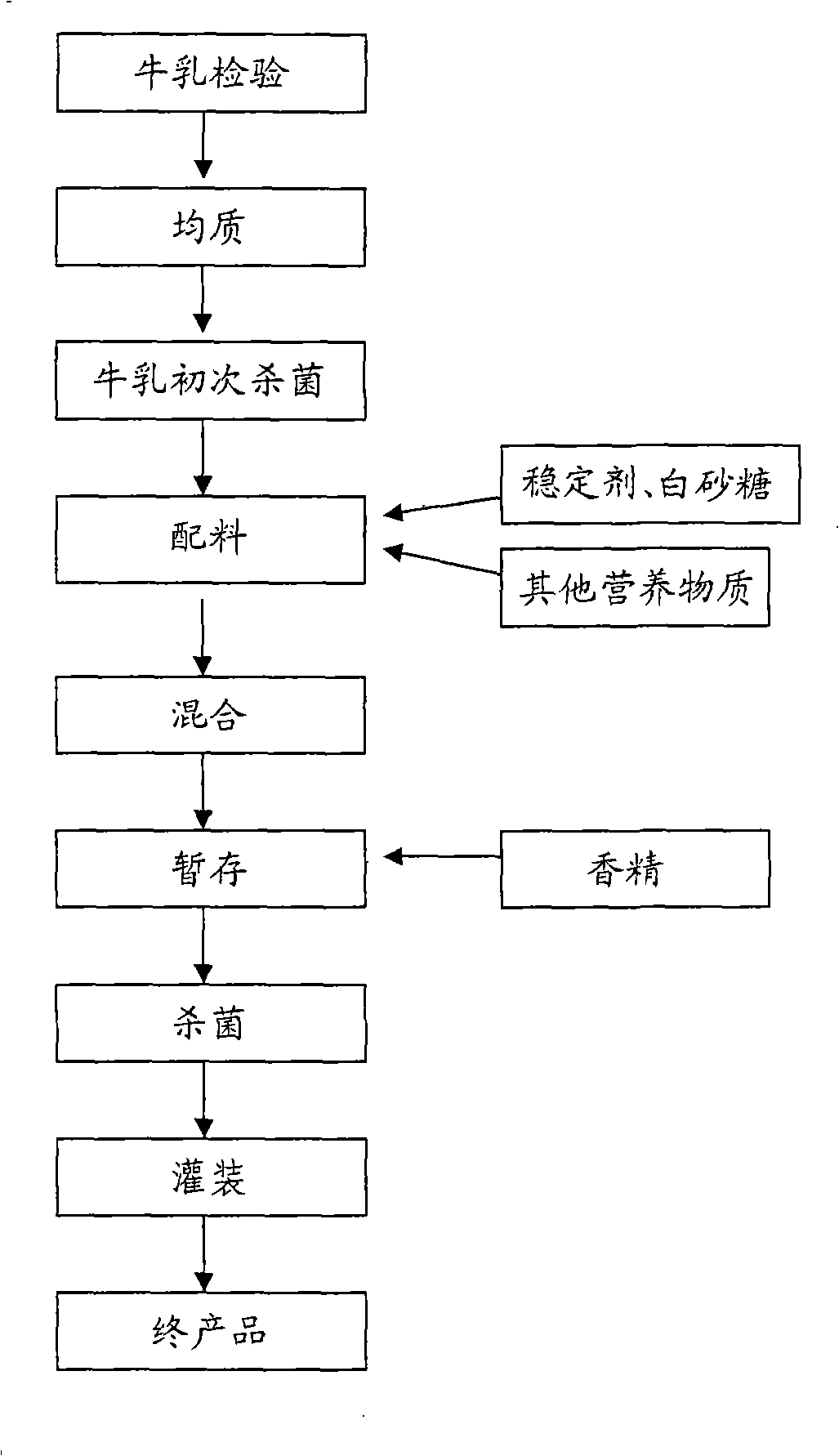

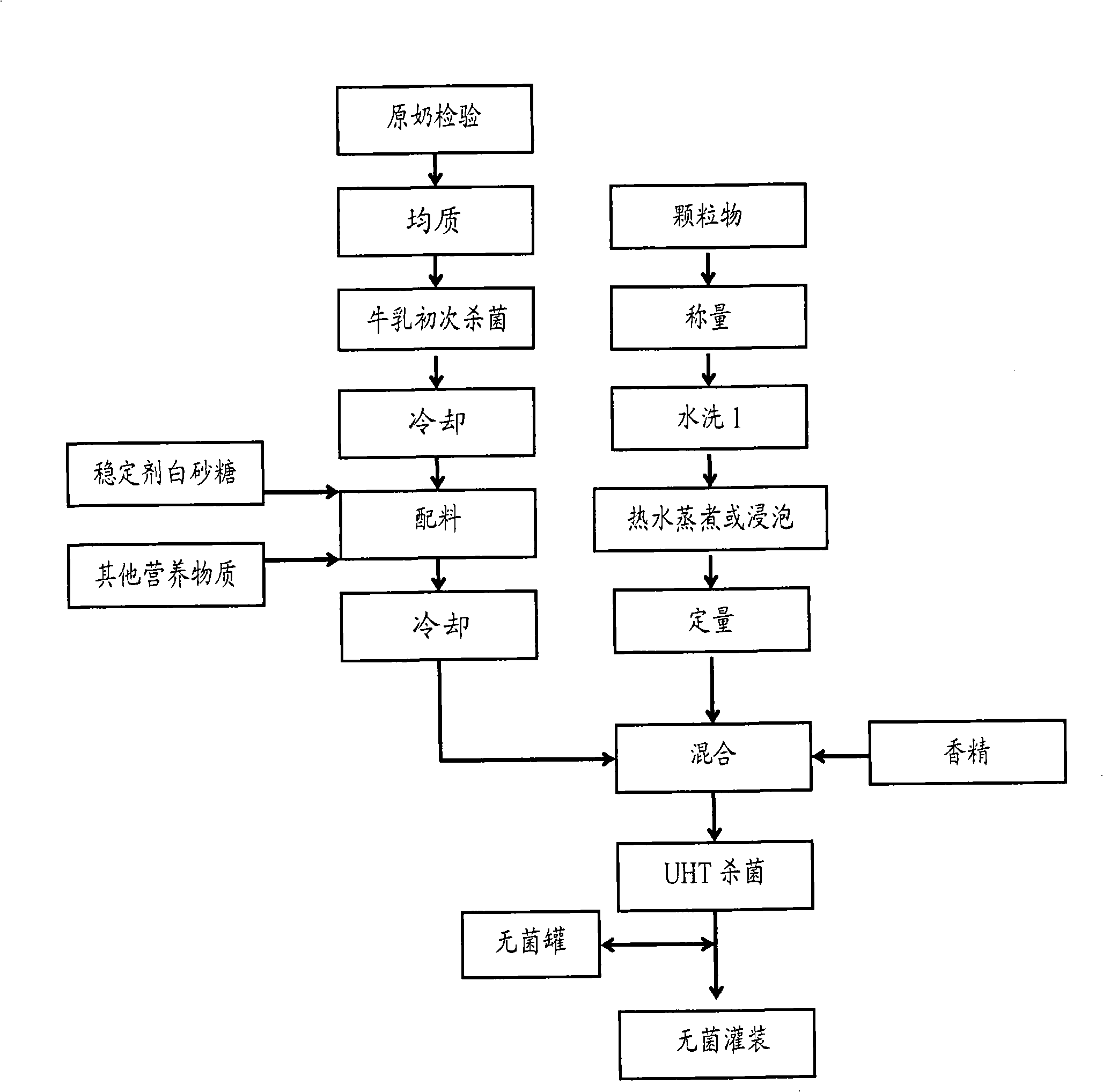

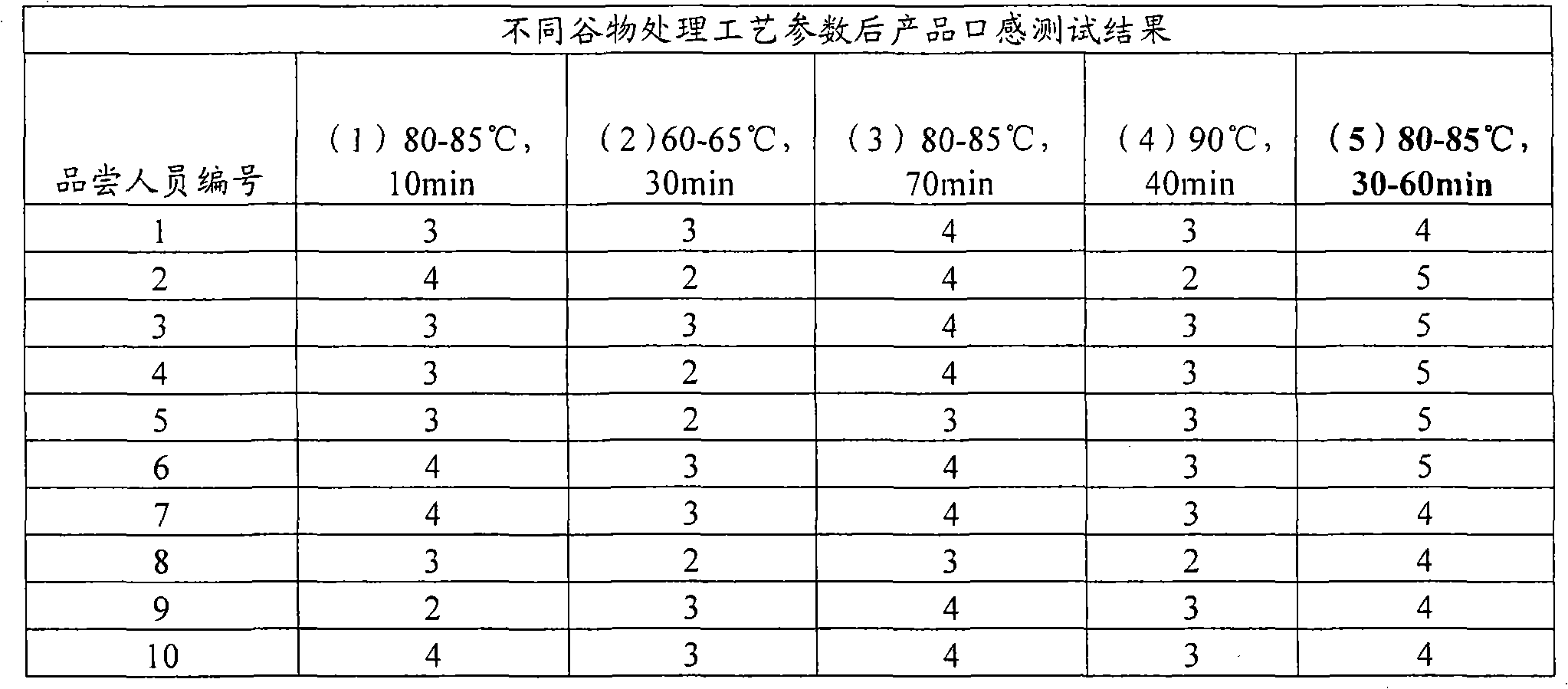

Method for producing lactic acid drink containing flesh grains

ActiveCN101040634ASolve incomplete sterilizationProtect fruit typeMilk preparationMilk preservationCow milkChemistry

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

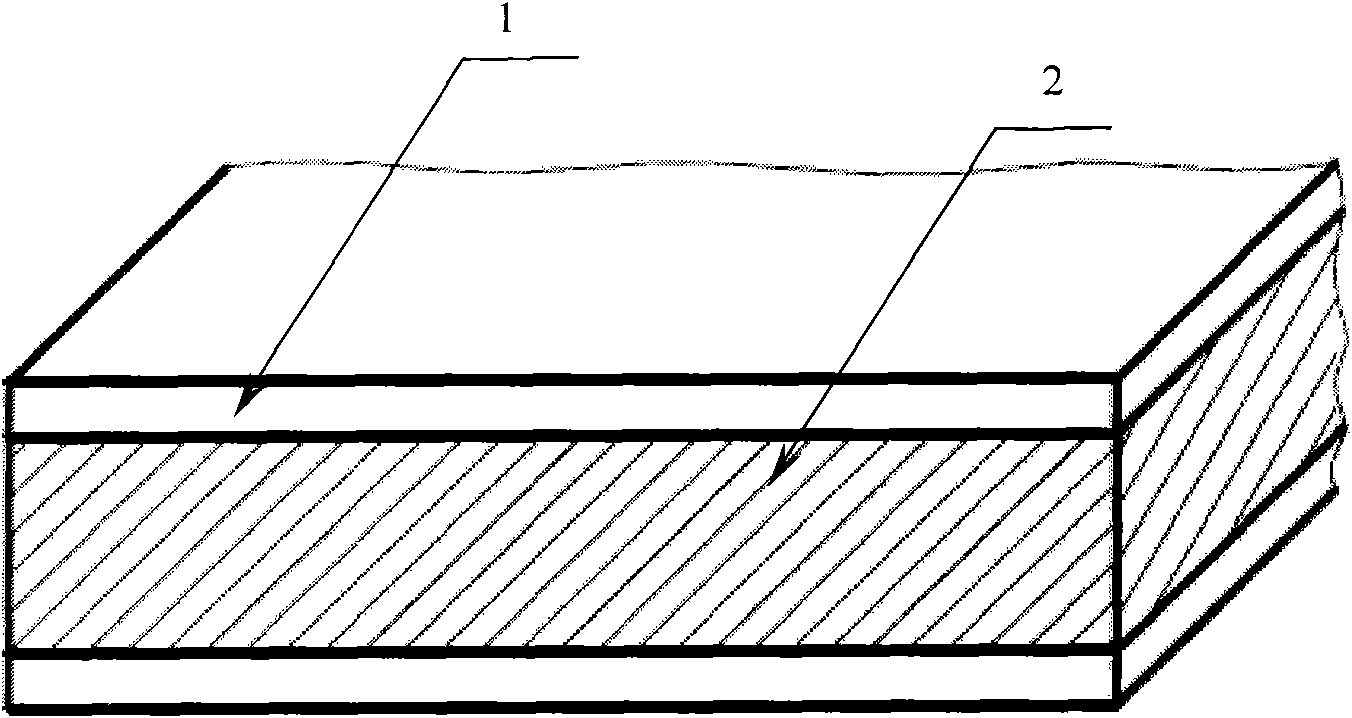

Aluminium-plated particle reinforced aluminum-matrix composite material and preparation method thereof

InactiveCN102114719AEnhanced powder densificationImprove mechanical propertiesMetal layered productsSurface layerElectromagnetic shielding

The invention belongs to the technical filed of particle reinforced aluminum-matrix composite materials and in particular relates to an aluminium-plated particle reinforced aluminum-matrix composite material and a preparation method thereof. The aluminium-plated particle reinforced aluminum-matrix composite material is characterized in that the surface layer of the aluminium-plated particle reinforced aluminum-matrix composite material is made of pure aluminium, and the core interlayer of the aluminium-plated particle reinforced aluminum-matrix composite material is composed of a particle reinforced aluminum-matrix composite material. The aluminium plating of the aluminium-plated particle reinforced aluminum-matrix composite material is realized in the process of carrying out vacuum hotpressing or hot isostatic pressing by using a powder metallurgic method. The method disclosed by the invention comprises the following steps: carrying out powder densification on particle reinforced aluminum-matrix composite materials through vacuum hotpressing or hot isostatic pressing, and simultaneously, carrying out metallurgical bonding on an aluminum die-sleeve and a composite material blank at high temperature and high pressure so as to obtained the aluminium-plated particle reinforced aluminum-matrix composite material. The aluminium-plated particle reinforced aluminum-matrix composite material can be subjected to one or more subsequent processing such as extrusion, forging, rolling and heat treatment so as to obtain various aluminium-plated particle reinforced aluminum-matrix composite materials with different specifications and properties. The aluminium-plated particle reinforced aluminum-matrix composite material can be applied to occasions with anticorrosion or electromagnetic shielding demands.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

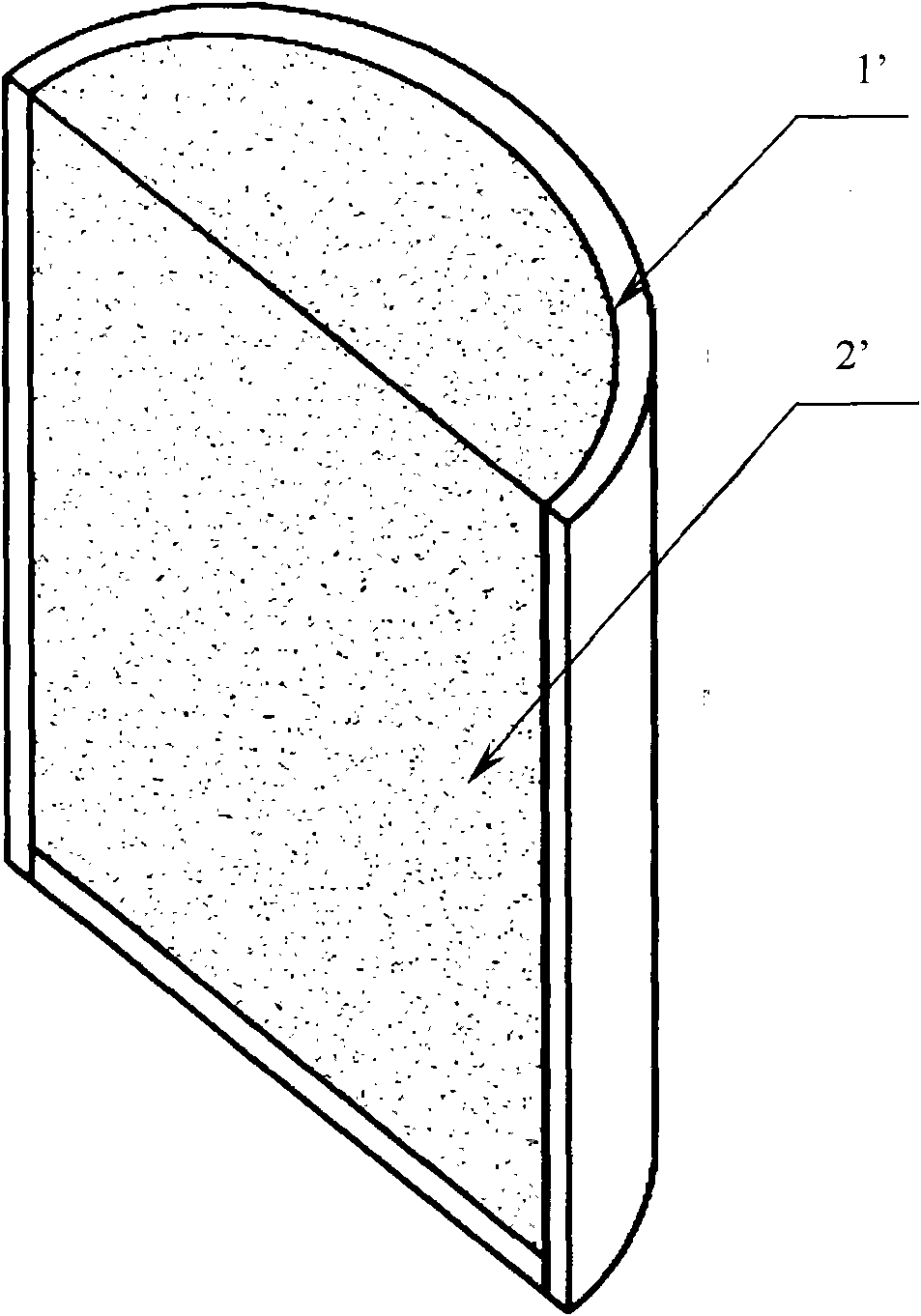

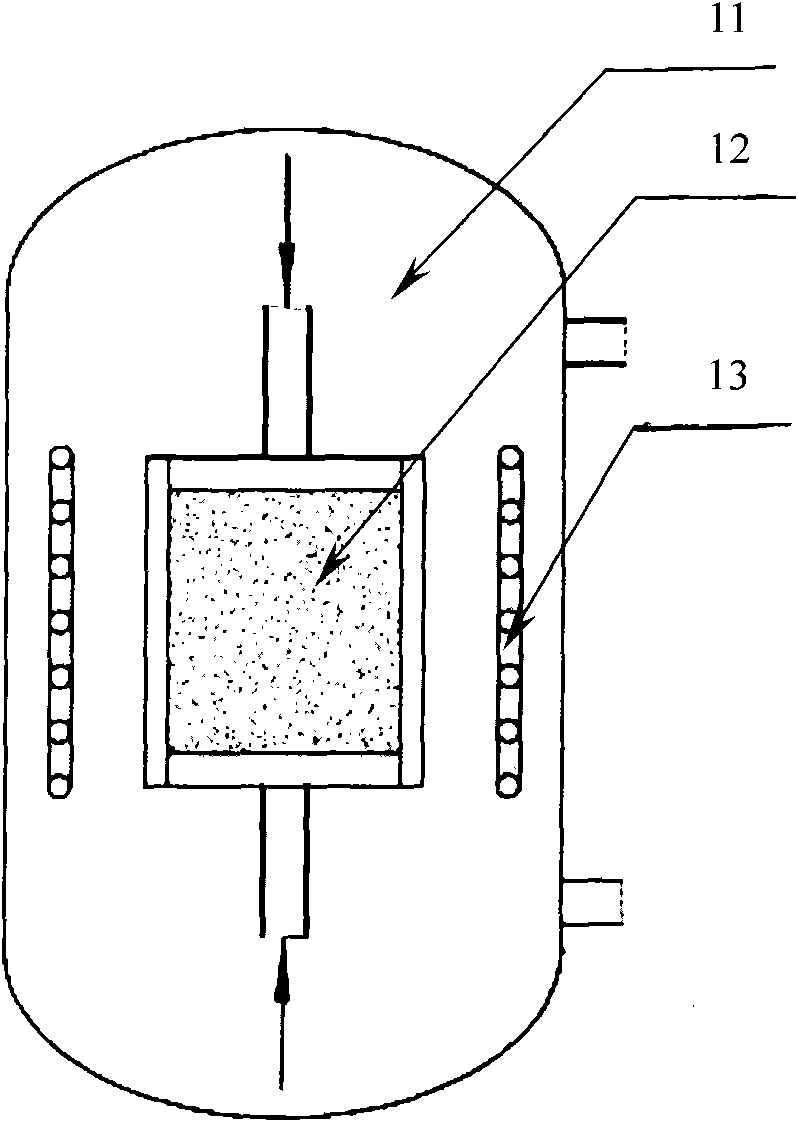

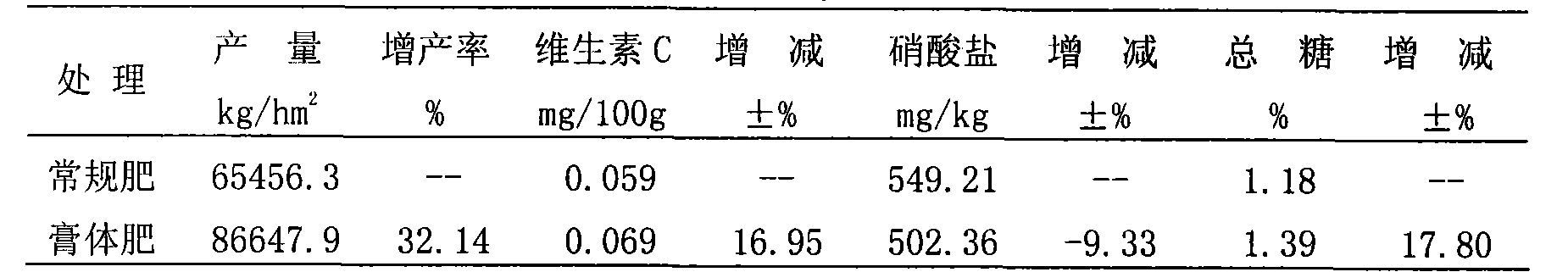

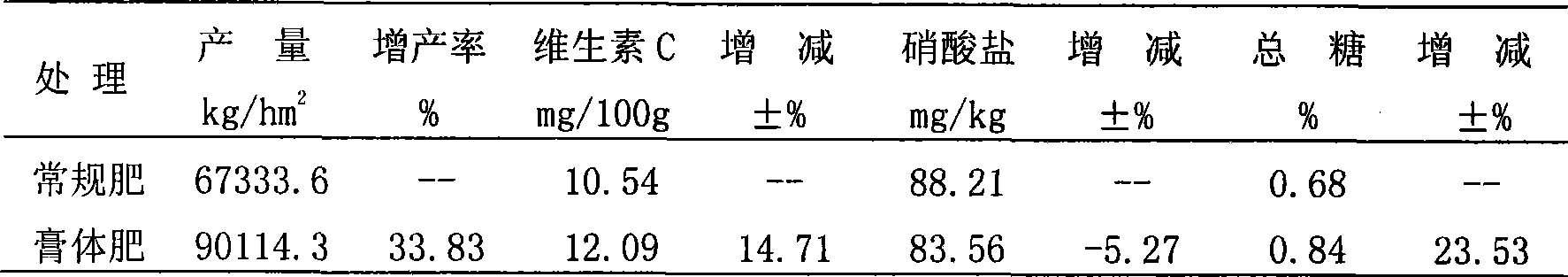

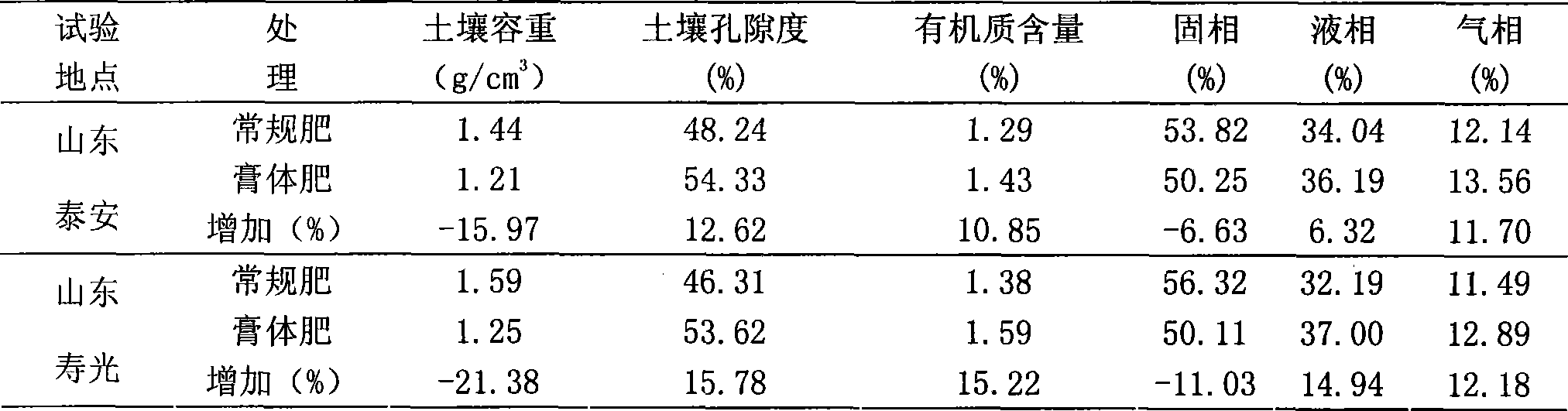

Fermented liquid pasty fertilizer and preparation method thereof

InactiveCN101544522AFull of nutritionReasonable ratioBio-organic fraction processingClimate change adaptationSolubilityLivestock manure

The invention discloses fermented liquid pasty fertilizer which relates to the technology of utilizing fermented liquid for producing pasty and organic compound fertilizer, in particular to a method mixing fermented liquid of livestock manure with humic acid raw materials to prepare the pasty fertilizer and the application of the method, belonging to the technical field of novel organic fertilizer and the cyclic utilization of the resource of agricultural wastes. The pasty fertilizer includes the main component of fermented liquid, and is additionally provided with carbamide, diammonium phosphate, lemery, aminated wood coal, thickening agent and other additives; and the carbamide, the diammonium phosphate, the emery, the aminated wood coal, the thickening agent and the other additives are added to and uniformly mixed and stirred with the fermented liquid, and the mixture is pulverized to form a pasty shape. The invention which utilizes the fermented liquid to prepare the pasty fertilizer turns the wastes into resources, the preparation method is easy, and required equipment is simple, thereby the invention is easy to be easily popularized and applied to the fertilizer industry. The pasty fertilizer has the advantages of favorable dissolvability, full nutrition and obvious effect of yield and quality improvement and can be widely applied to vegetables, fruits, foodstuffs, forests and various cash crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

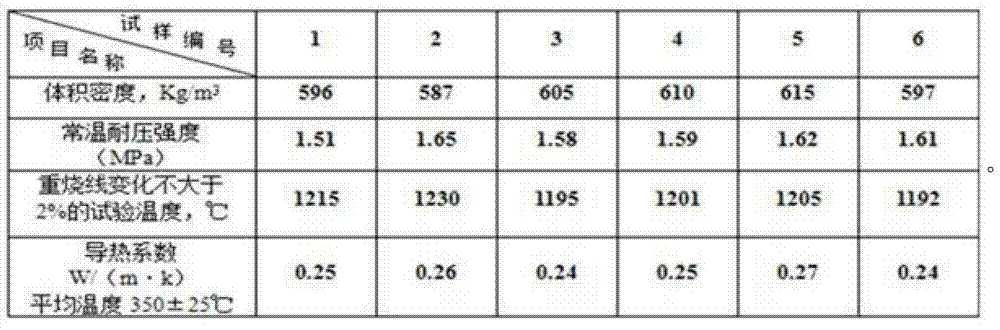

Foam light refractory casting material and preparation method thereof

The invention discloses a foam light refractory casting material. The foam light refractory casting material consists of a refractory raw material, a combined raw material and an auxiliary raw material, wherein the raw materials are pulped to be mixed with special foam at a high speed, and the mixture is hardened to obtain the microporous light refractory material. The foam light refractory casting material does not utilize a light refractory raw material but directly adopts the heavy refractory raw material, so that the raw material is abundant and easily available and is flexible in preparation, the production cost of the casting material is only half to one third of that of an original light refractory casting material, and the casting material has the characteristic that the cost is lower when the volume weight of the material is lighter, which is contrary to the characteristic that the cost is higher when the volume weight is higher of the original light refractory casting material; and light materials with different volume weights, different strengths and different application temperatures can be designed by selecting different material formulas and adding different quantities of foam. The foam light refractory casting material can be used for making a heat preserving layer and an insulation layer of a stove as well as an inner fire retardant coating of the stove.

Owner:MIANYANG HSBC FURNACES MATERIAL

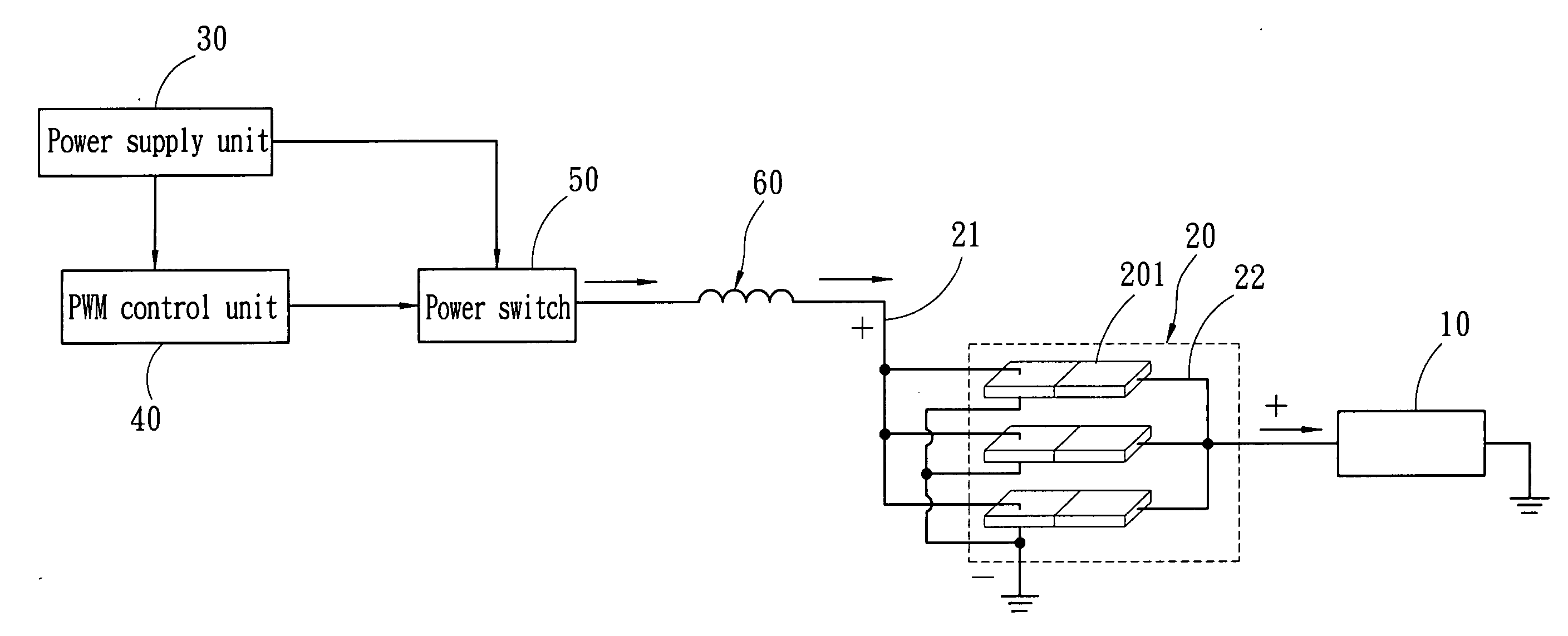

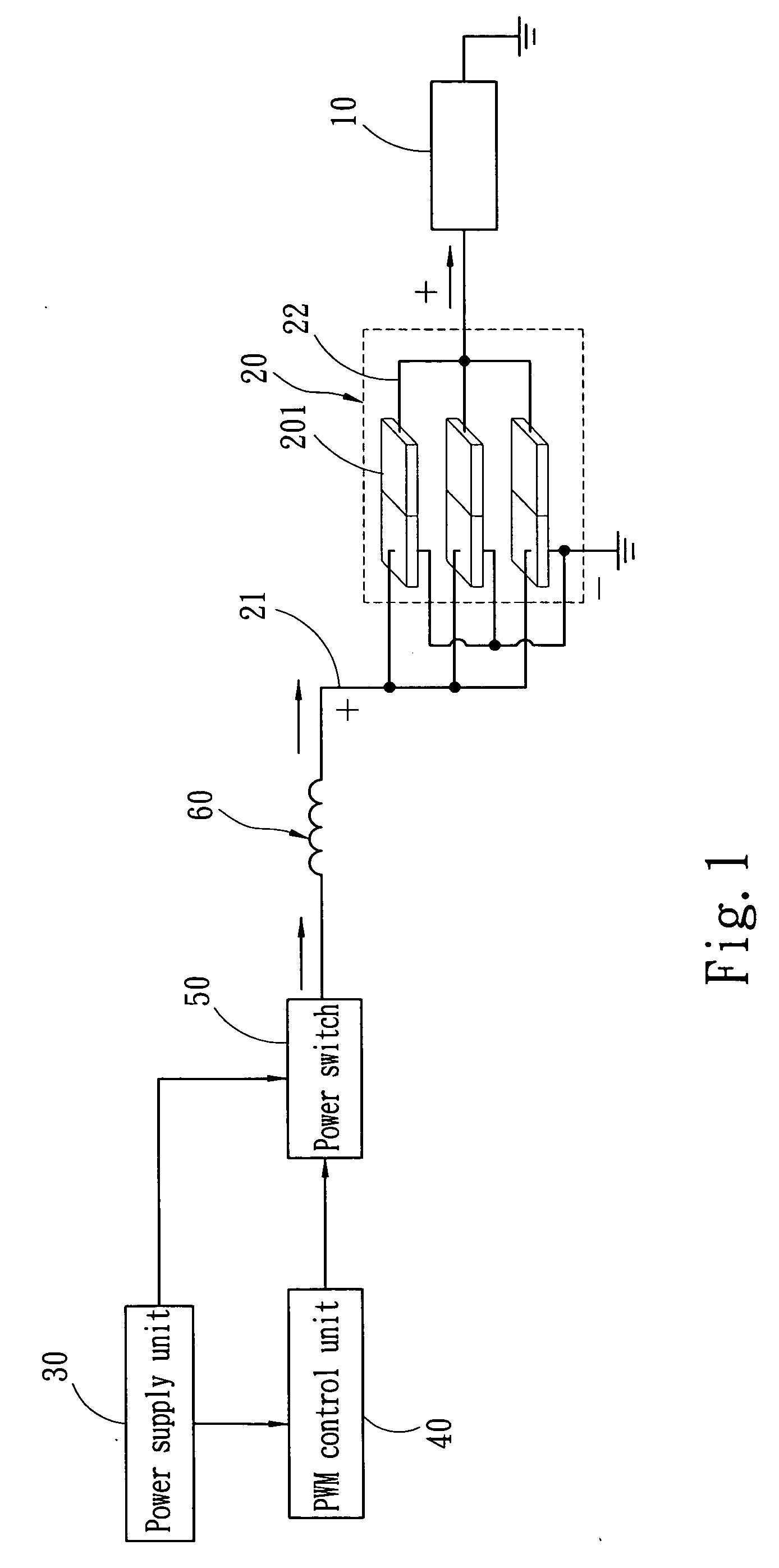

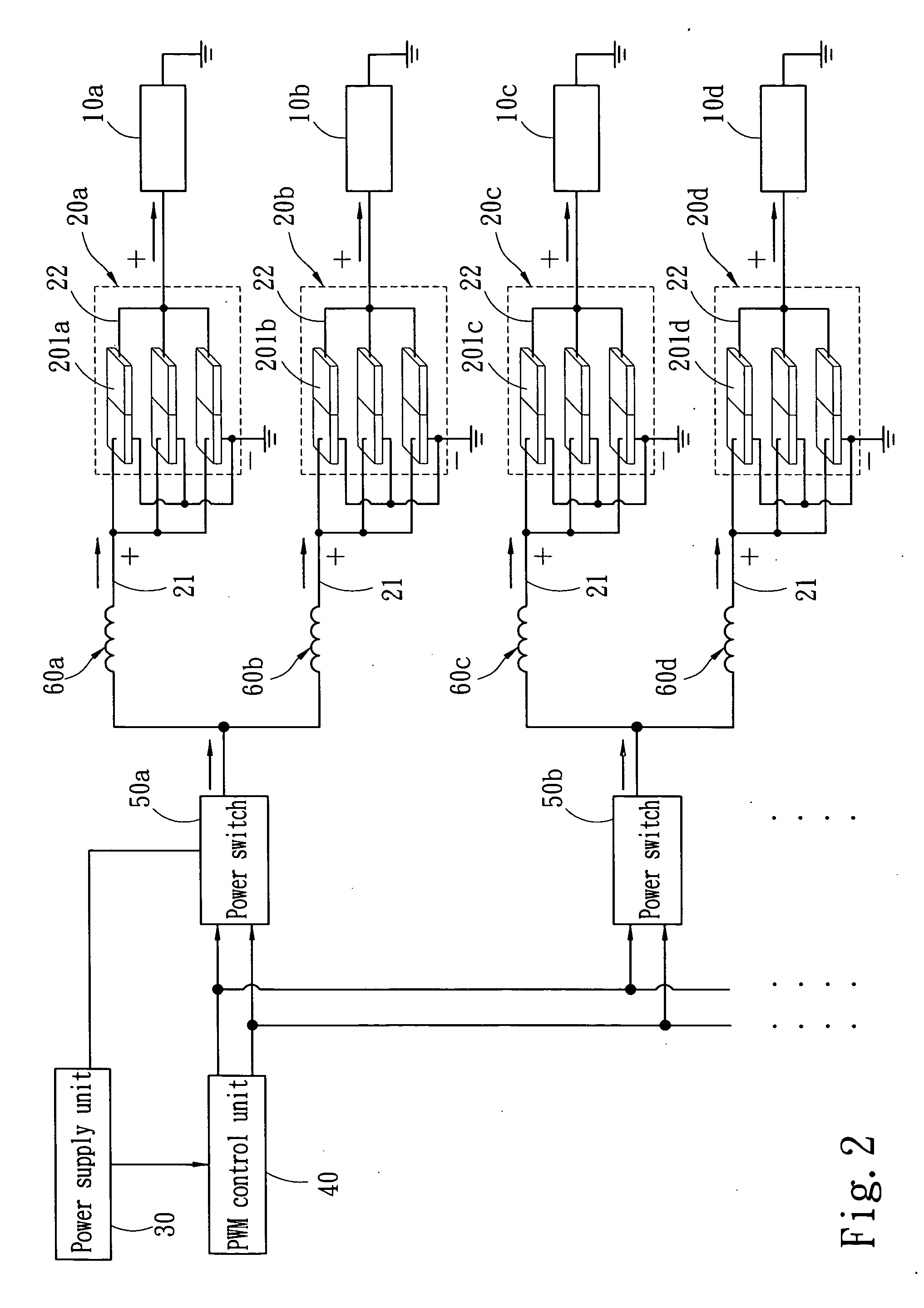

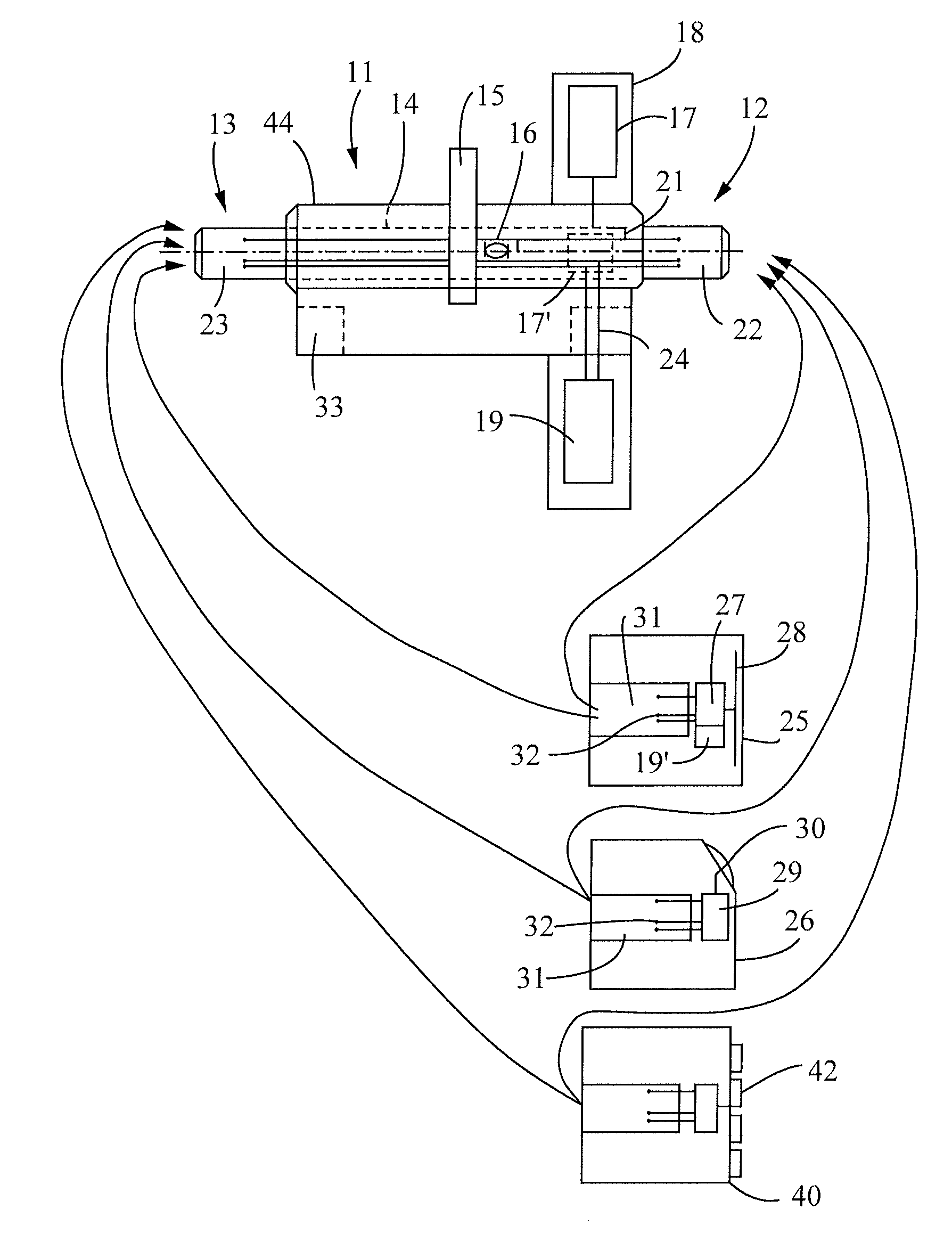

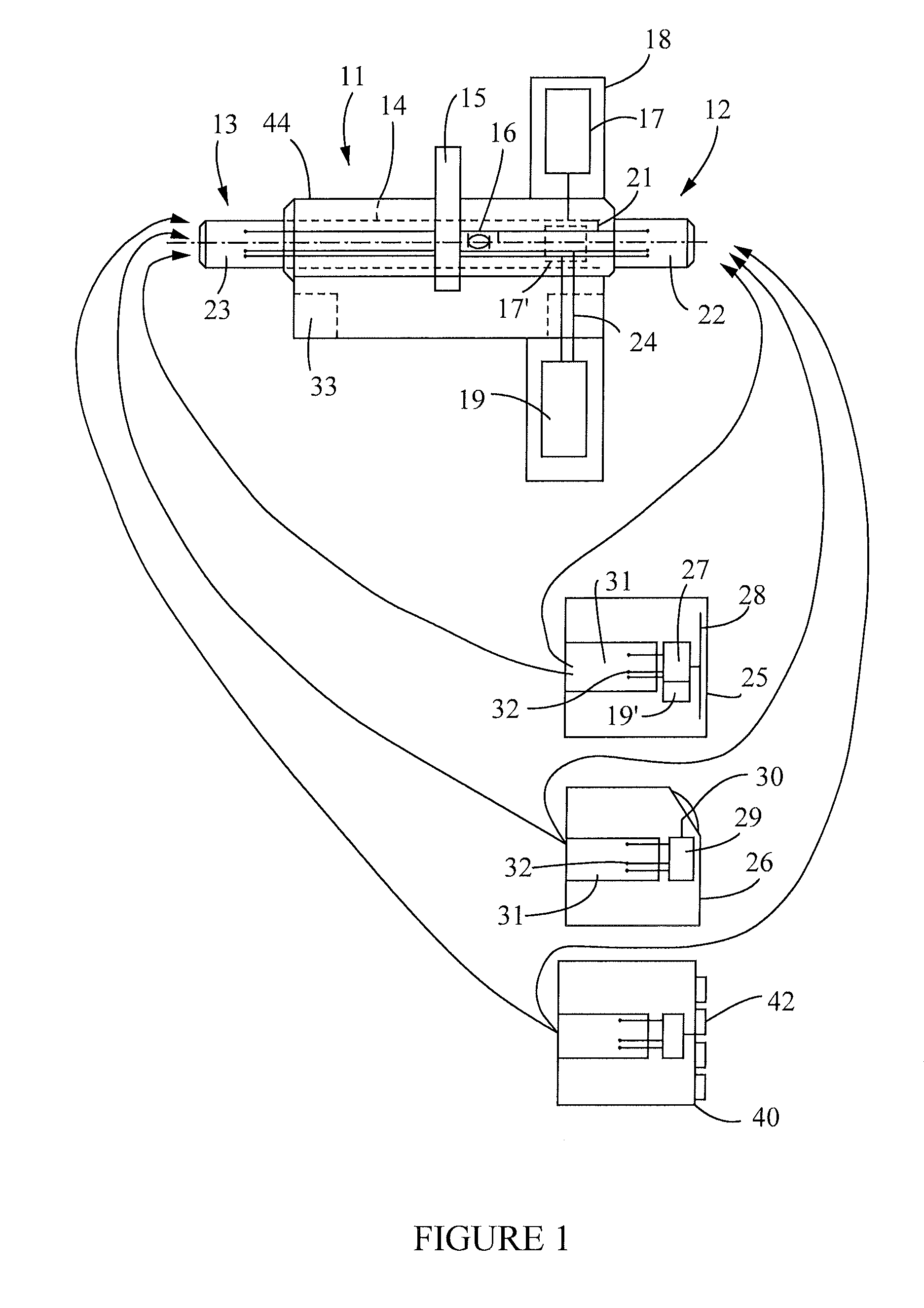

Piezoelectric power supply

InactiveUS20050285476A1Great power outputFlexible productionPiezoelectric/electrostriction/magnetostriction machinesElectric lighting sourcesMOSFETInductor

A piezoelectric power supply has a piezoelectric transformer circuit configuration which is alterable flexibly according to varying loading power requirements. It includes a control unit (control IC), a power switch (MOSFET) and an inductor to drive a piezoelectric transformer unit to actuate a high voltage and power load such as a cold cathode fluorescent lamp. The piezoelectric transformer unit consists of a plurality of piezoelectric transformers coupled in parallel. The specification of the piezoelectric transformers (single sheet piezoelectric transformers or low level laminated piezoelectric transformers) and parallel coupling number may be altered according to the required power of the load to change the voltage and current output by the piezoelectric transformers.

Owner:ZIPPY TECH

Carbon nanotube/polyurethane/polyacrylonitrile composite conductive fiber and preparation method thereof

InactiveCN103031617AConductiveHigh strengthElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentCarbon nanotubeMicrofiber

The invention discloses a carbon nanotube / polyurethane / polyacrylonitrile composite conductive fiber. The composite conductive fiber consists of 1 to 10 mass percent of carbon nanotube, 9 to 40 mass percent of polyurethane and 50 to 90 mass percent of polyacrylonitrile. The carbon nanotube / polyurethane / polyacrylonitrile composite conductive fiber is prepared by a wet spinning method and by modifying the polyacrylonitrile by using the carbon nanotube and polyurethane. Polyurethane is formed into microfiber in situ in the spinning process by a shape control method in the polymer mixture spinning process, and the carboxyl on the surface of the carbon nanotube which is acidized and polyurethane form a hydrogen bond, so the carbon nanotubes are selectively distributed in the in-situ microfiber. The carbon nanotube / polyurethane microfiber forms a continuous network chain-shaped microfiber conductive channel in the polyacrylonitrile substrate so as to obtain the composite conductive fiber.

Owner:ZHONGYUAN ENGINEERING COLLEGE

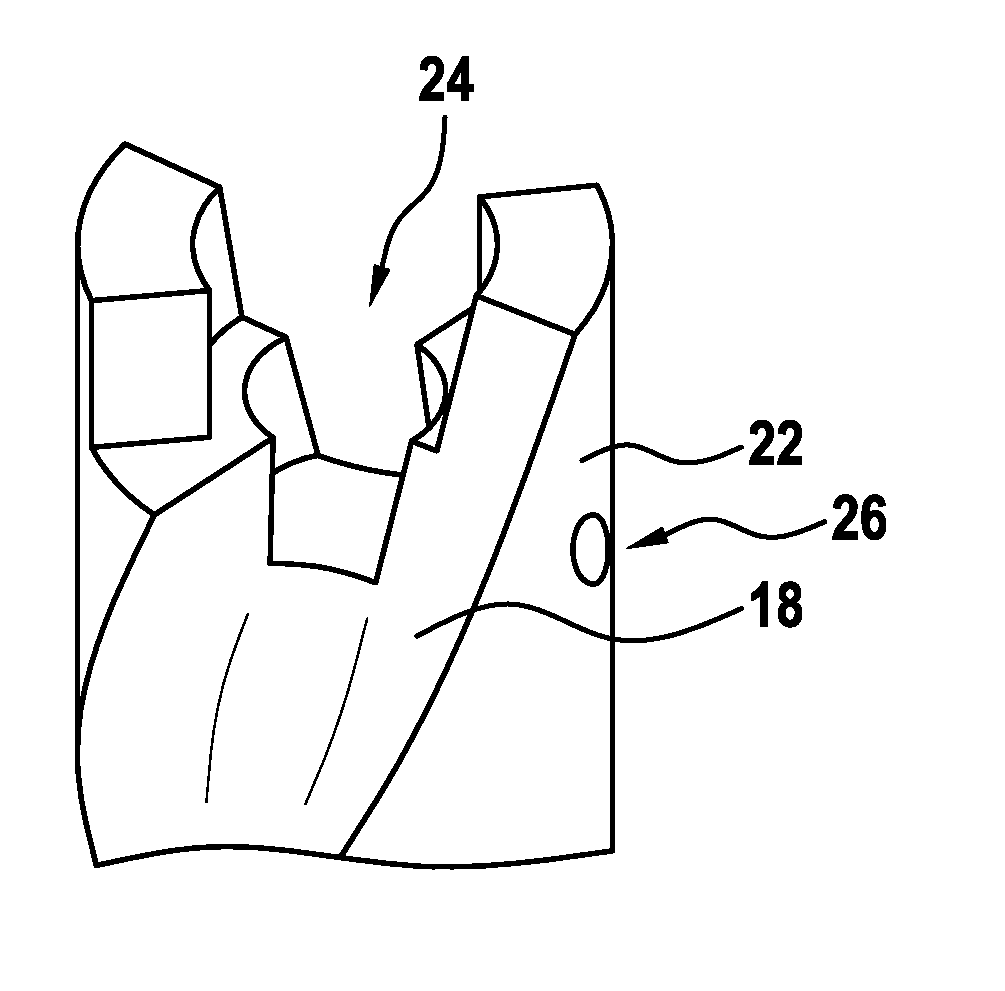

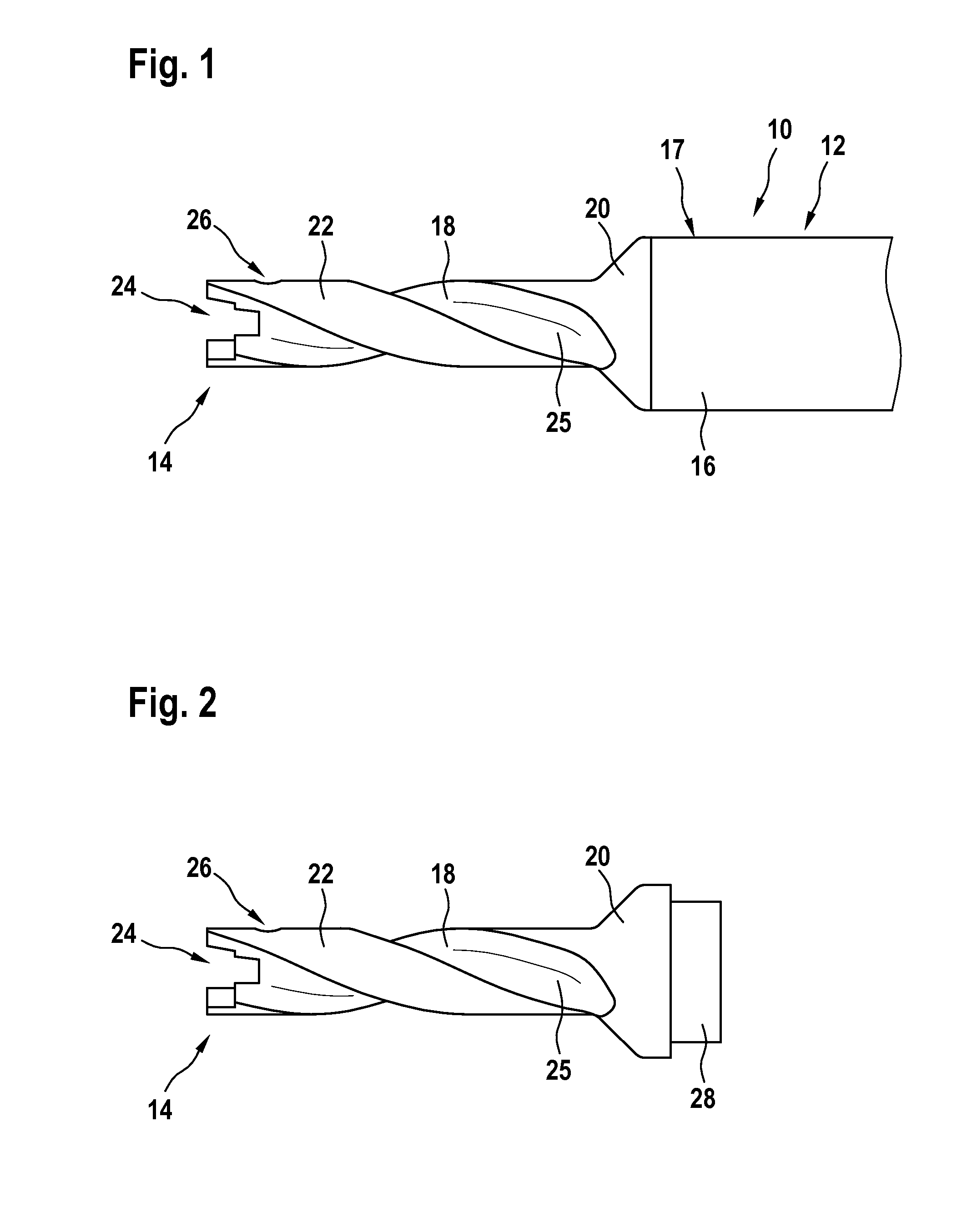

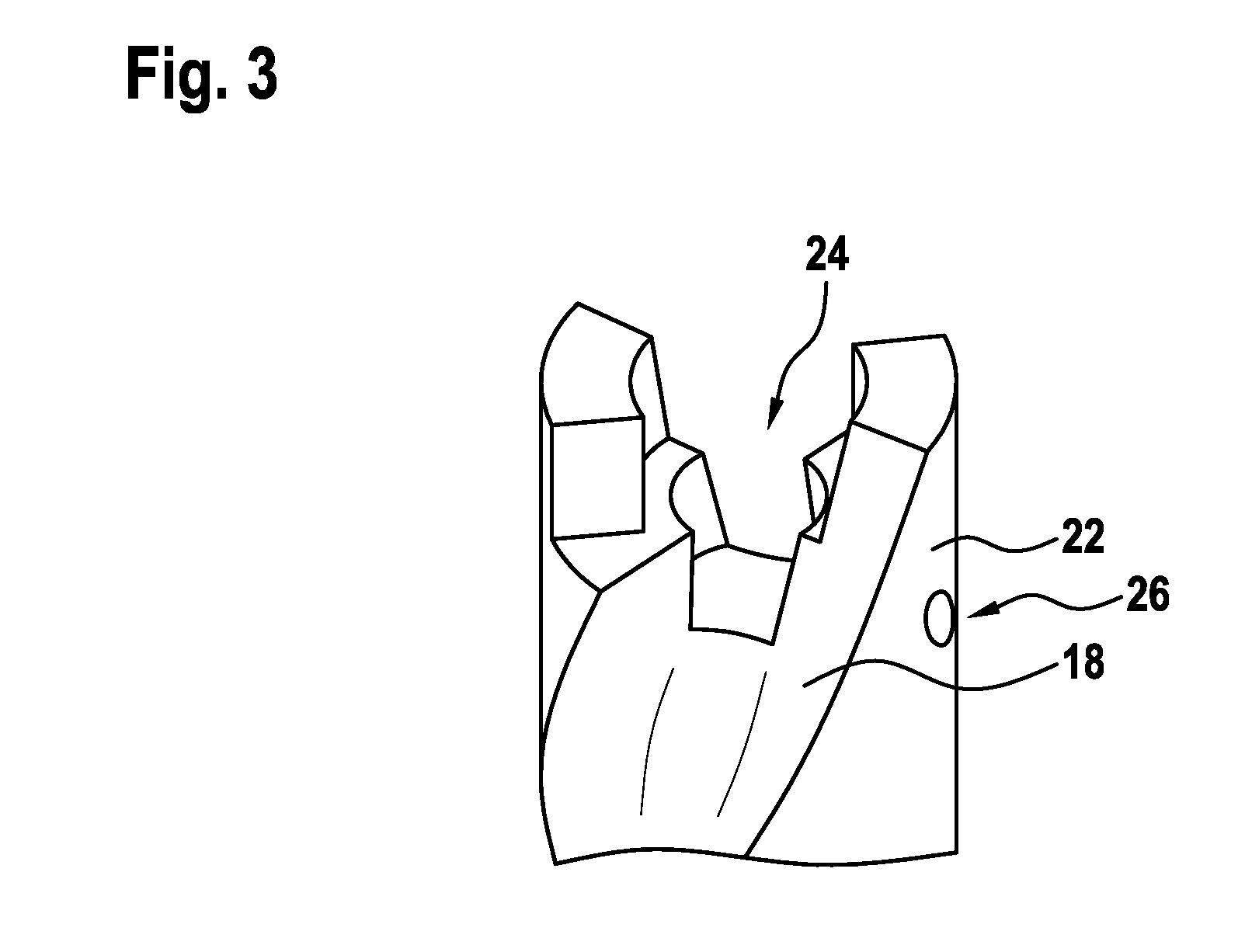

Hybrid cutting tool, chip transporting portion and process for producing a cutting tool

InactiveUS20140321931A1Complex structureSimple and cost-effective processThread cutting toolsTool workpiece connectionMilling cutterEngineering

Provision is made of a cutting tool, in particular a drill or a milling cutter, having a shank and a chip transporting portion, which receives a cutting insert, wherein the cutting tool is a hybrid composite body. Furthermore, a chip transporting portion for a cutting tool and also a process for producing a cutting tool are described.

Owner:KENNAMETAL INC

Artificial stone with irregular pore and preparation method thereof

The invention provides an artificial stone with irregular pores and a preparation method thereof. The artificial stone composed of a cementitious material, a pore forming agent and a thickener is prepared by the following method: preparing a slurry; casting the prepared slurry in a mould; and vibrating for molding in a vibration table. Compared with the natural stone, the artificial stone with irregular pores provided by the invention has the advantages of low cost, multiple effect changes, environment-friendliness, no radiation, low density, excellent thermal insulation, sound insulation and refractory properties, and good mechanical property; and the artificial stone with irregular pores has strong durability and color stability in all kinds of weather conditions, and is an ideal decorative material.

Owner:SHANGHAI APE STONE

Modular electromechanical lock cylinder

ActiveUS8028553B2Flexible productionFlexible preparationAnti-theft cycle devicesWing handlesElectricityAuthorization

A lock cylinder with a lock cylinder housing is provided. A knob shaft, rotatable by way of a knob, is mounted to rotate on one side or both sides of the lock cylinder. An authorization signal causes at least one electromechanically operating coupling device to connect a lock element to rotate in unison with the knob shaft and in order to operate a lock. The authorization signal is generated by evaluation electronics based on an input or input signal. It is proposed that at least one reading unit with an input unit to record the input and / or a receiving unit to receive the input signal is present, that the reading unit with the input unit and / or receiving unit is arranged in at least one knob and are spatially separated from the evaluation electronics, that the knob is connected electrically and mechanically releasable to the knob shaft, and that the reading unit generates, from the input or input signal, an access signal that can be evaluated by the evaluation electronics.

Owner:ASSA ABLOY AB

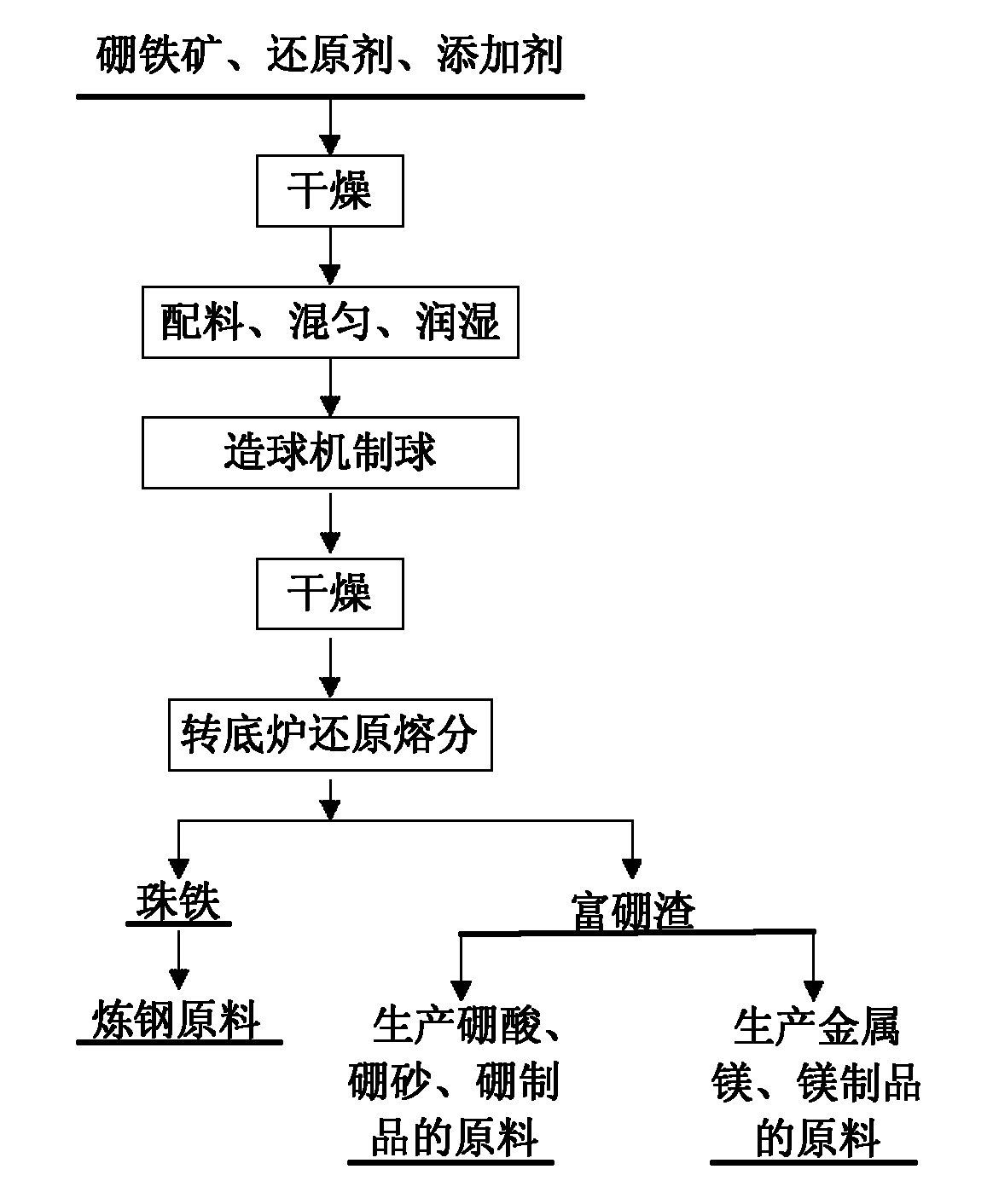

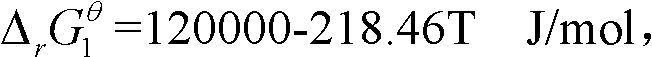

Method for comprehensively utilizing paigeite by rotary hearth furnace iron bead process

The invention relates to a method for comprehensively utilizing paigeite by a rotary hearth furnace iron bead process, belonging to the field of iron making. The method for comprehensively utilizing paigeite is a method for separating and concentrating boron and iron in paigeite, and is used for exploiting and utilizing paigeite. The method for comprehensively utilizing paigeite is characterized by taking paigeite powdered ore, a carbonaceous reducing agent, a binding agent and additives as raw materials, and comprising the processes of proportioning, evenly mixing, agglomerating, reducing and melting by a rotary hearth furnace, breaking, magnetically separating and the like for preparing iron beads with the boron element content of 0.05-0.1% and boron-rich slag with the B2O3 content of 12-20%. The produced iron beads can be used as a raw material for electric steelmaking or converter steelmaking, and the boron-rich slag can replace ascharite ore for producing boric acid or borax, thereby fully utilizing the boron resource and the iron resource, and realizing comprehensive utilization of the paigeite. The method can meet the requirements of the boron industry and the iron and steel industry, and has better social and economic benefits.

Owner:UNIV OF SCI & TECH BEIJING

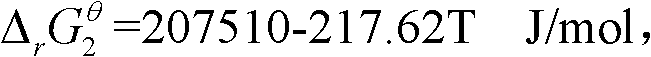

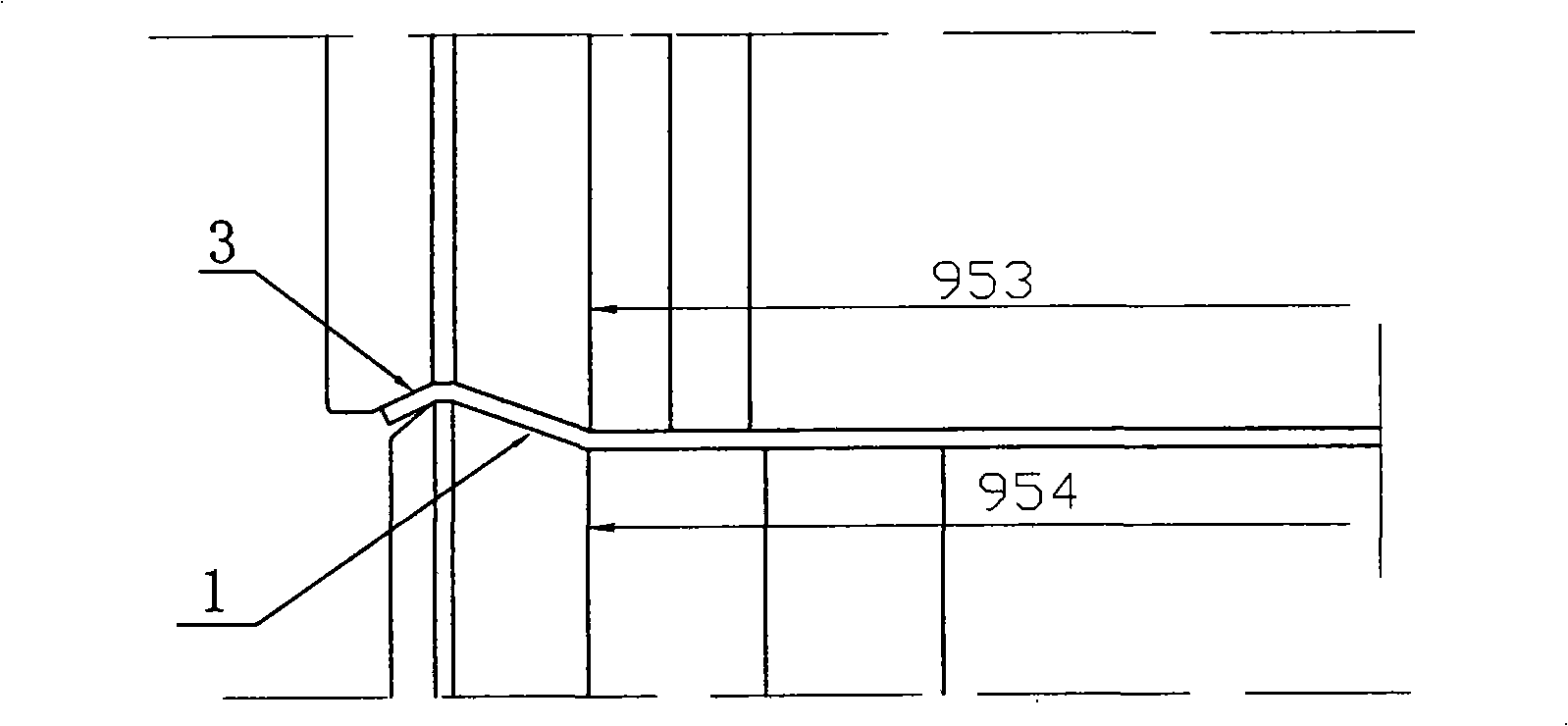

Continuous roller type cold bending shaping method for metal sheet pile

The invention relates to a continuous roll type cold-bending forming method for a steel sheet pile, including scrolling, continuous cold-bending forming and cutting; the method is characterized in that the continuous cold-bending forming refers to that the scrolled steel band is fed into a production line of a multi-pass continuous roll type cold-bending forming machine set for multi-pass continuous roll type cold-bending forming, a frame at each pass is provided with an upper rotation axis and a lower rotation axis which are equipped with inosculated dies, the upper rotation axis and the lower rotation axis rotate oppositely, one rotates along the clockwise direction, while the other rotates along anticlockwise direction; in this way, a scrolled steel plate moves forwards depending on friction force in the roll gap of rotation dies inosculated up and down after being well adjusted and enters the next pass for continue forming, when entering each pass for forming, the steel plate is forced to deform under the action of the inosculated dies, each pass completes setting forming amount, and the forming of the steel sheet pile is finally completed through a plurality of passes, thus rolling the products of the steel sheet pile in line with requirements. The method has the advantages of energy saving, environmental protection, high production efficiency and complete specification, length and size of products.

Owner:江苏顺力冷弯型钢实业有限公司

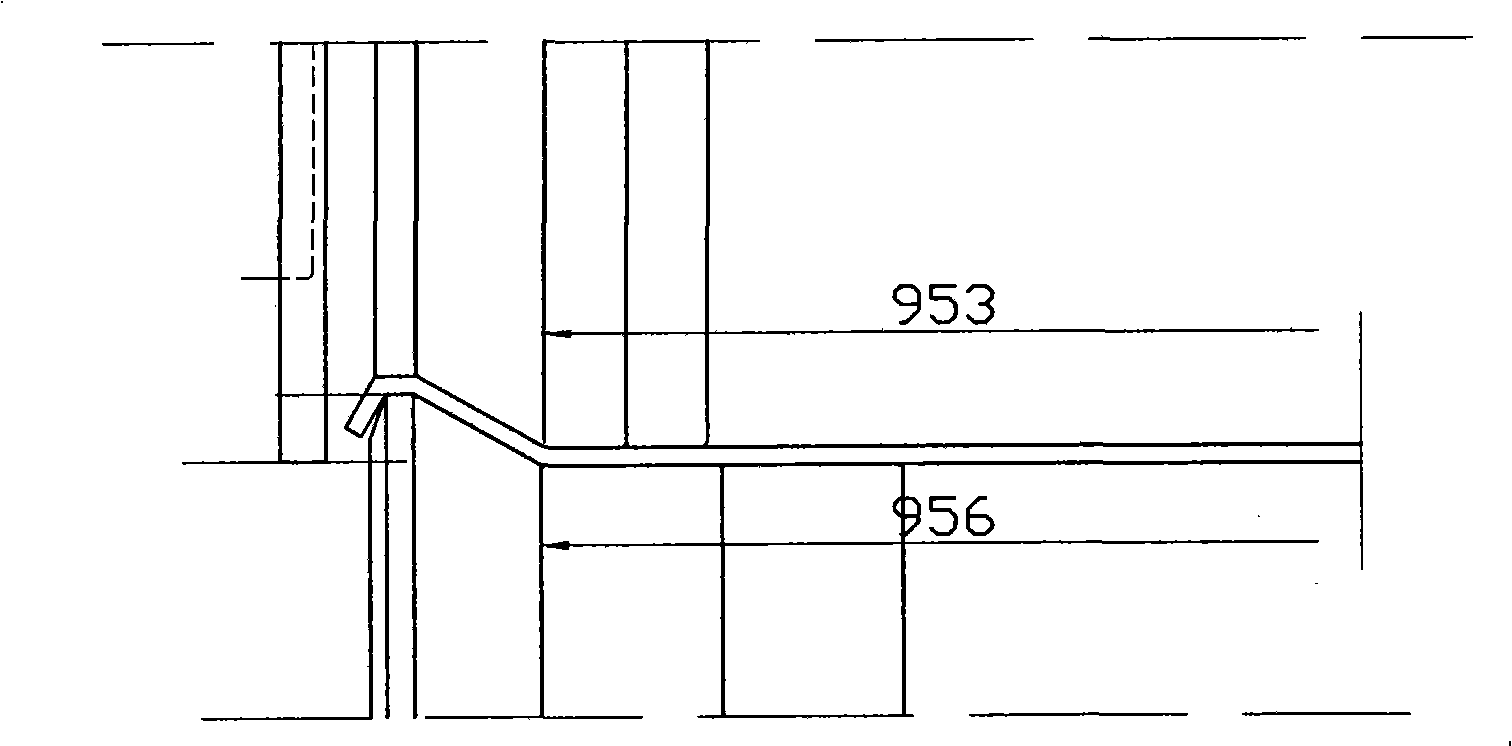

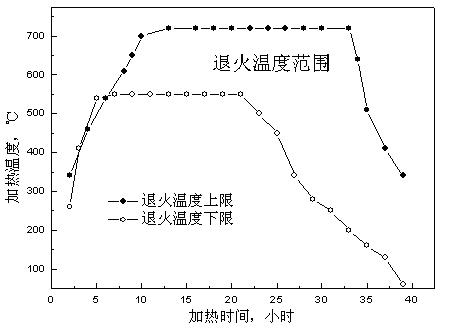

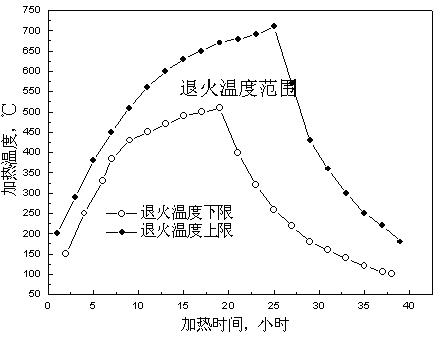

Preparation method of 1, 3-butylene glycol

ActiveCN109422624AControl PH valueTemperature controlOrganic compound preparationHydroxy compound preparationFixed bed1,3-Butanediol

The invention provides a preparation method of 1, 3-butylene glycol. The preparation method comprises following steps: A, acetaldehyde is introduced into a fixed bed reactor, under the effect of a supported type solid basic catalyst, aldol condensation reaction is carried out so as to obtain 3-hydroxybutyraldehyde; and B, 3-hydroxybutyraldehyde is subjected to continuous hydrogenation reaction inthe fixed bed reactor so as to obtain 1, 3-butylene glycol. According to the preparation method, the fixed bed reactor is adopted, at the same time, the supported type solid basic catalyst is adoptedto replace a conventional liquid alkali (such as sodium hydroxide) catalysts, and in the step of hydrogenation reduction, a supported nickel hydrogenation catalyst is adopted. The preparation method is capable of solving problems in the prior art product quality is poor, product yield is low, technology process is complex, and a large amount of waste water and waste residue is generated; aldol condensation quenching step is avoided; side reactions are reduced; relatively high reaction conversion rate and yield are achieved; no neutralizing or desalting process is needed in reaction process; and great improvement of traditional 1, 3-butylene glycol preparation technology is realized.

Owner:DONGYING HI TECH SPRING CHEM IND

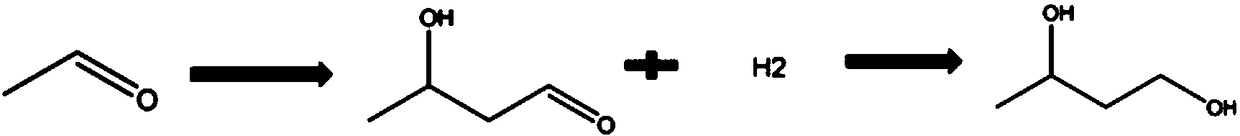

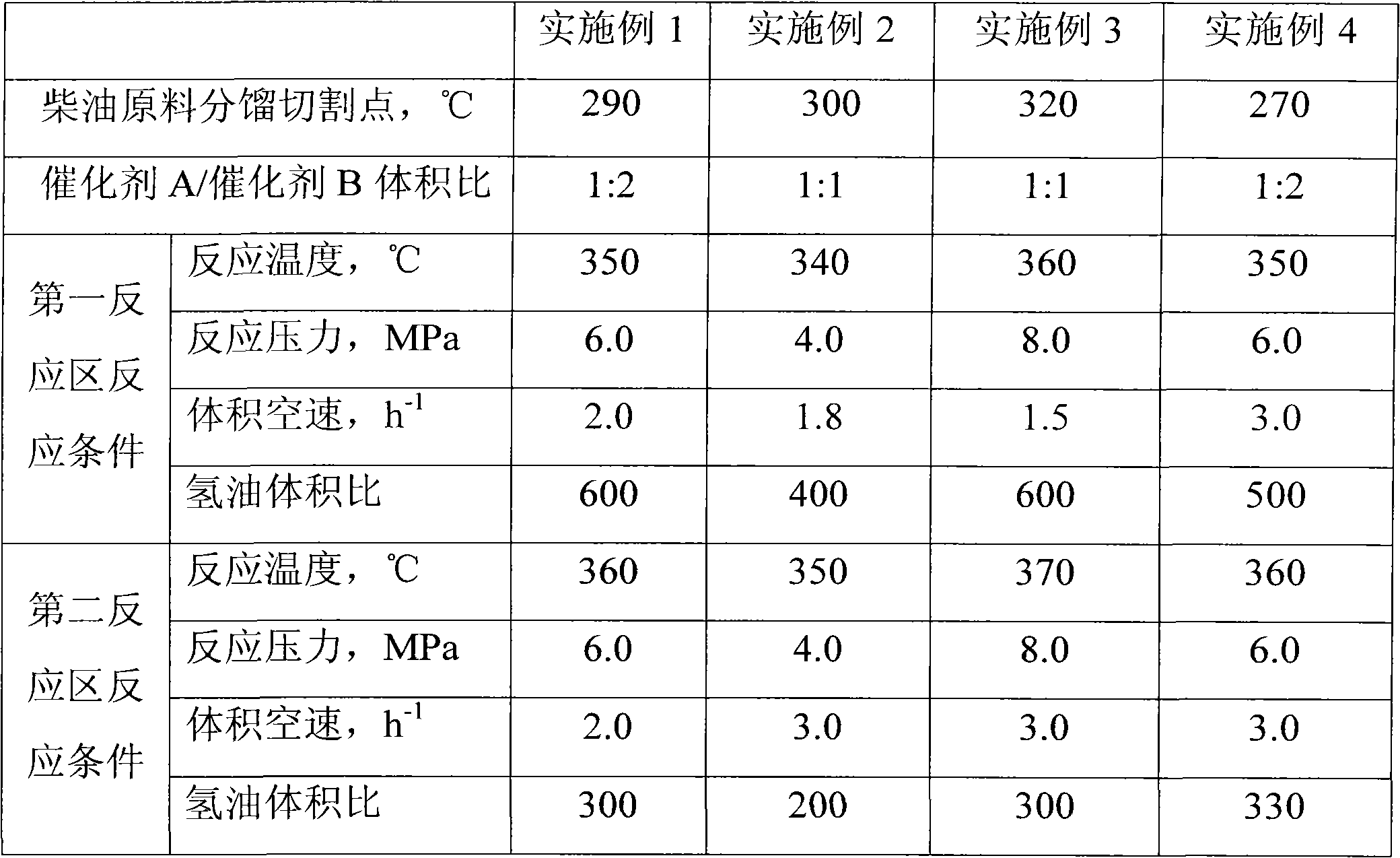

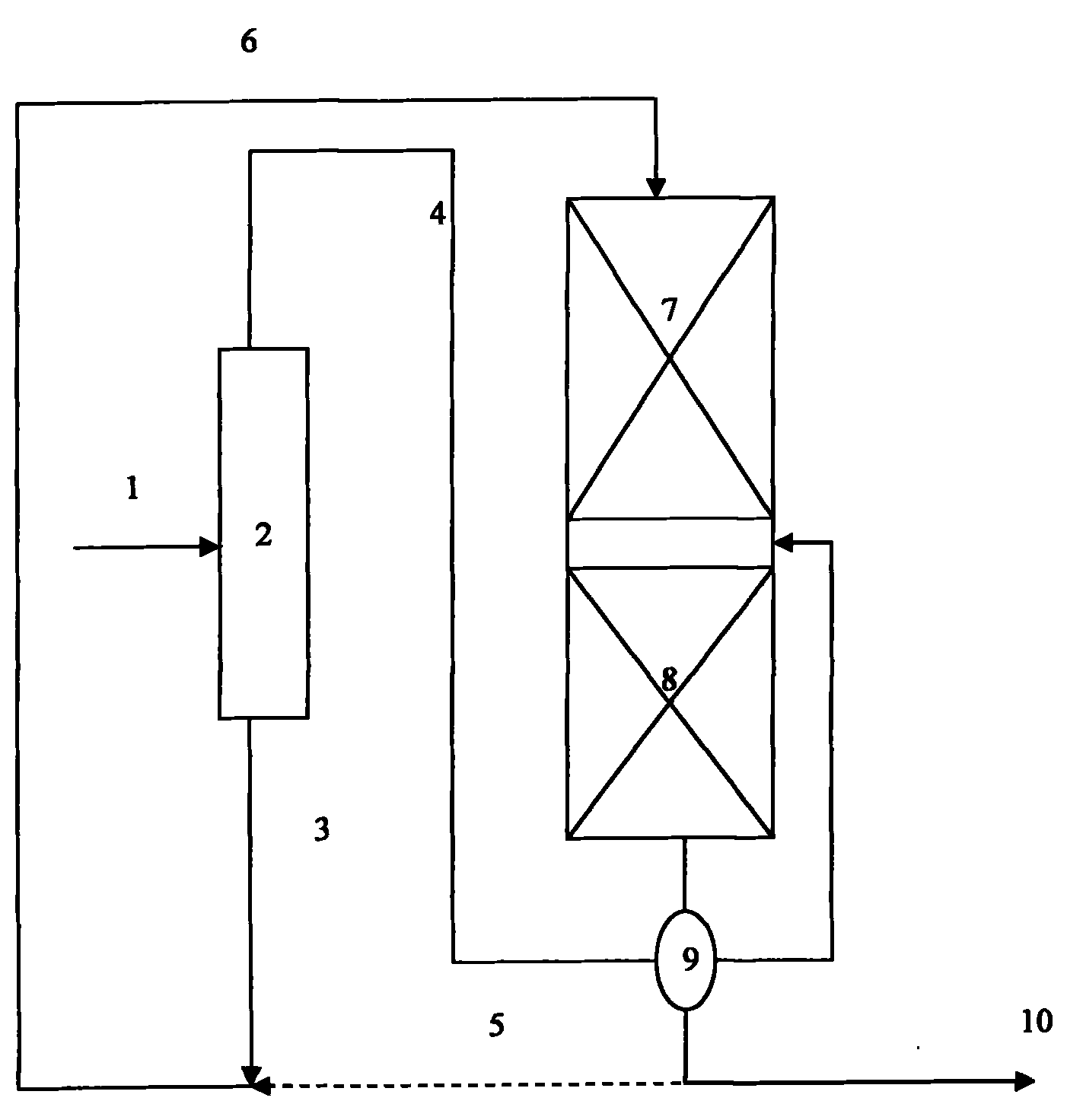

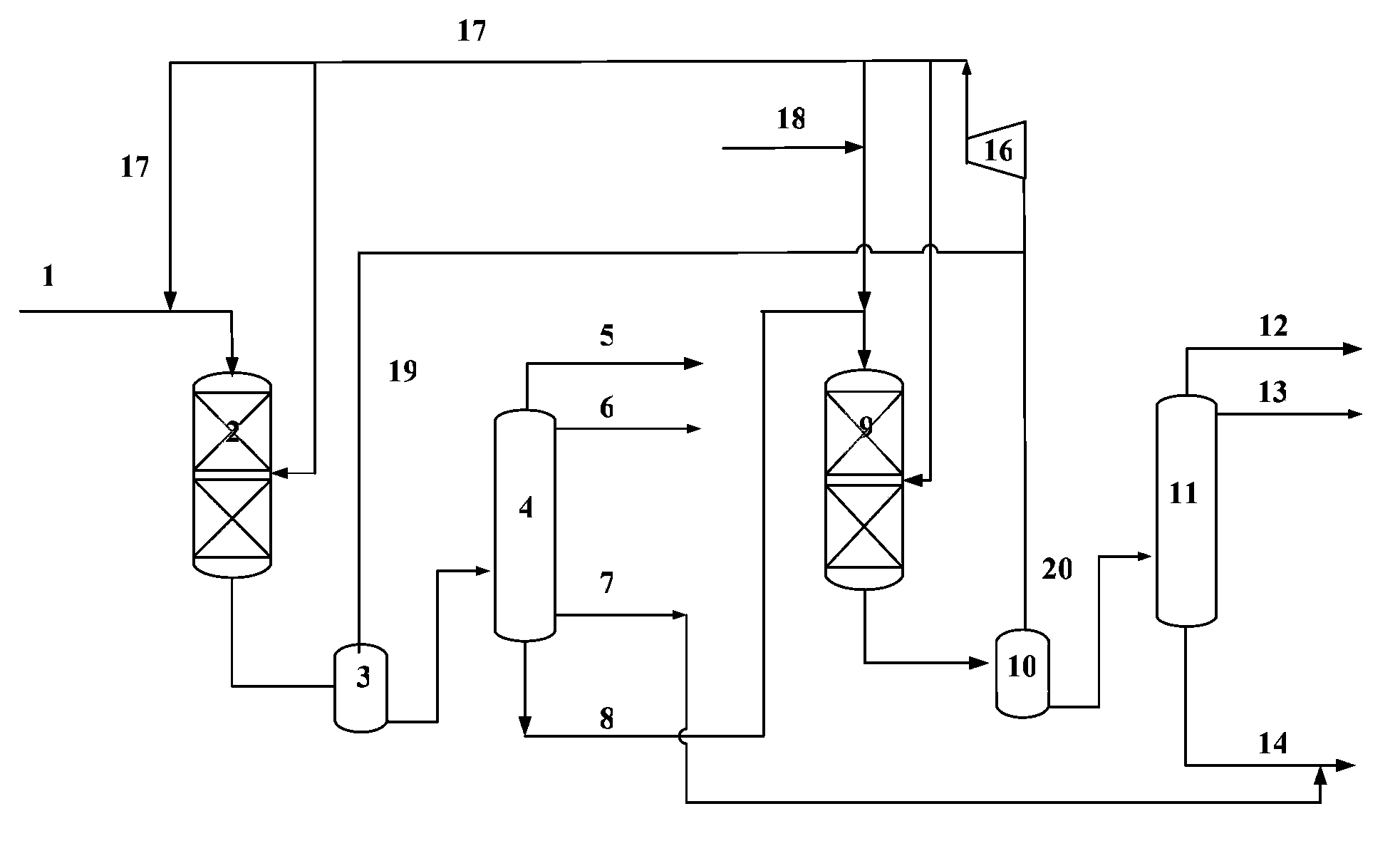

Hydrogenation technology for diesel

ActiveCN102041071AUniform temperature distributionExtended service lifeTreatment with hydrotreatment processesHydrogenNitrogen

The invention discloses a hydrogenation technology for diesel, comprising the following steps: distilling a diesel raw material into light components and heavy components; under the hydrogenation refined condition, carrying out hydrorefining reaction on the heavy components in a first reaction region; mixing effluents at the first reaction region with the light components to enter a second reaction region for the hydrorefining reaction; and carrying out separation treatment on the effluents in the second reaction region. Compared with the prior art, by the technology in the invention, released reaction heat is effectively utilized in the hydrorefining process of the diesel raw material, a great amount of cold hydrogen is not used, and the negative influence of nitrogenous compounds and nuclei aromatics in the heavy components on deep desulfuration reaction of the diesel is overcome; and simultaneously, the technology is simple, energy consumption is reduced, and ultra low sulfur diesel products can be manufactured by using the technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

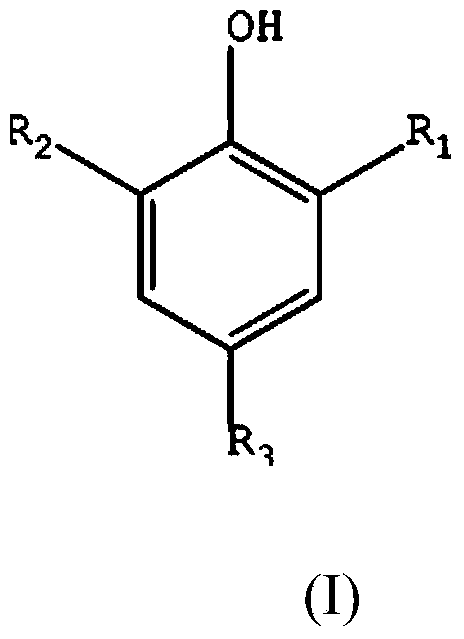

Method for synthesizing phenolic resin

ActiveCN104327227ASynthetic Method AdvantagesReduce volumeChemical/physical/physico-chemical processesCompound (substance)Treatment costs

The invention relates to a method for synthesizing phenolic resin. The method comprises the following steps: mixing raw materials, preparing a catalyst, synthesizing, extracting and distilling. By using a micro-channel reactor, the heat conduction process is intensified, the mass transfer problem is well solved, the material waste is greatly reduced, and the later treatment cost is also reduced. As a parallel 'quantity enlargement' mode is adopted during the industrial enlargement of the micro-channel reactor, direct enlargement from a laboratory to the industrial production process is achieved, and the practical production is relatively flexible. Modern high-efficiency chemical development and production windows are opened, and the modern chemical engineering develops towards environment protection, safety and high efficiency.

Owner:XIAN ORIGIN CHEM TECH

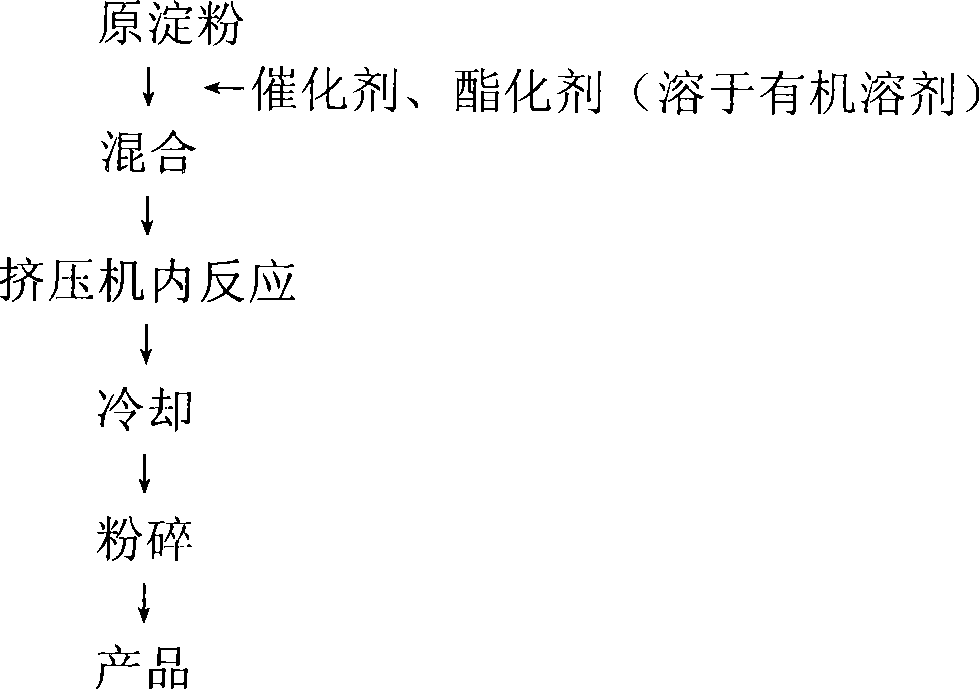

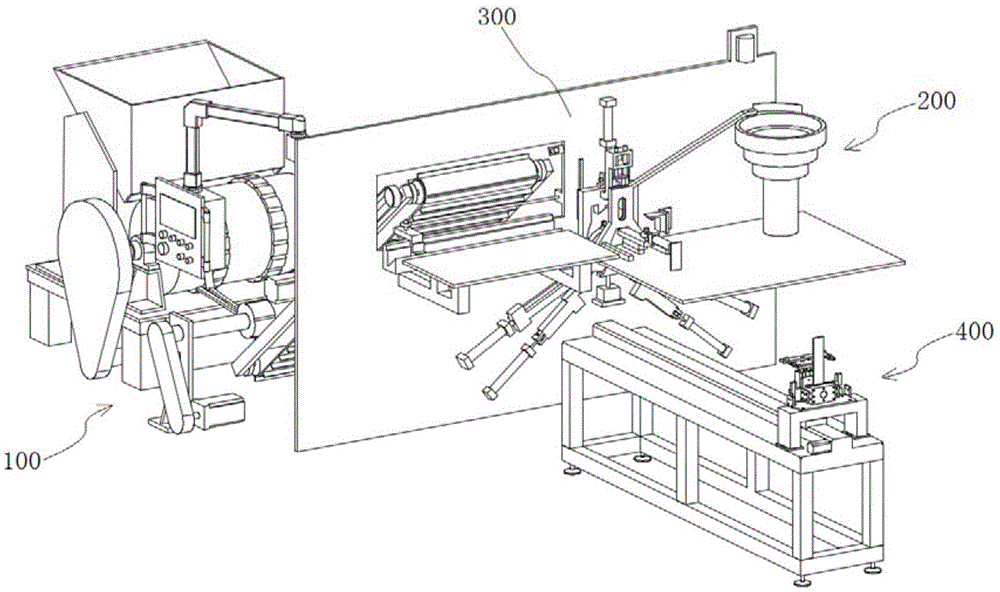

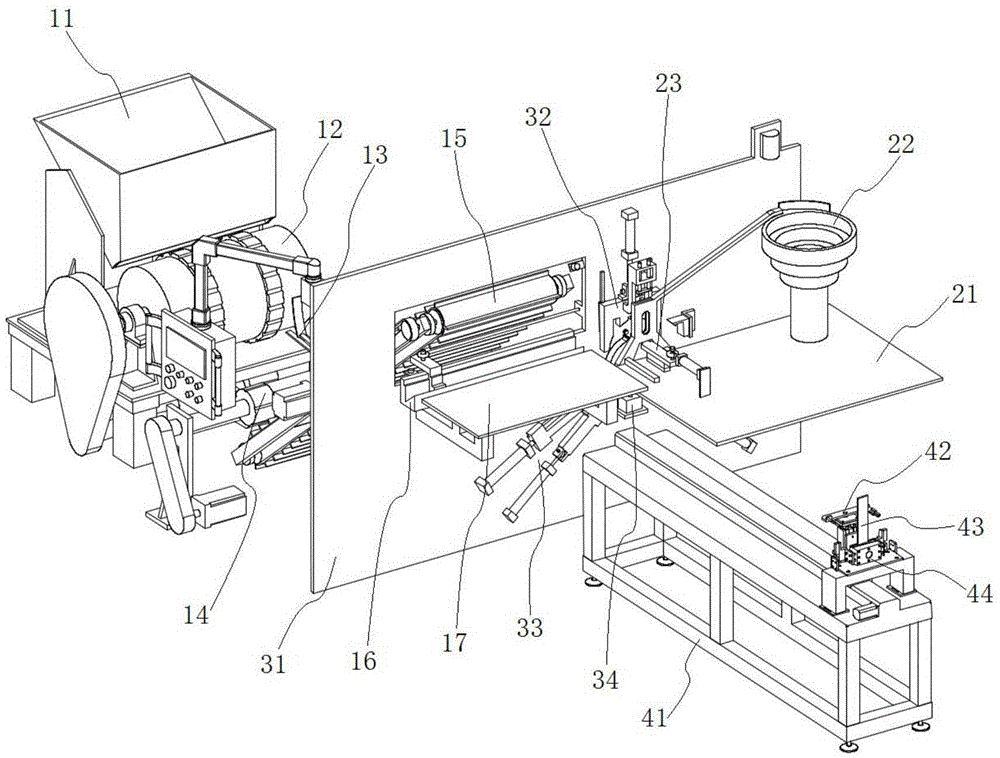

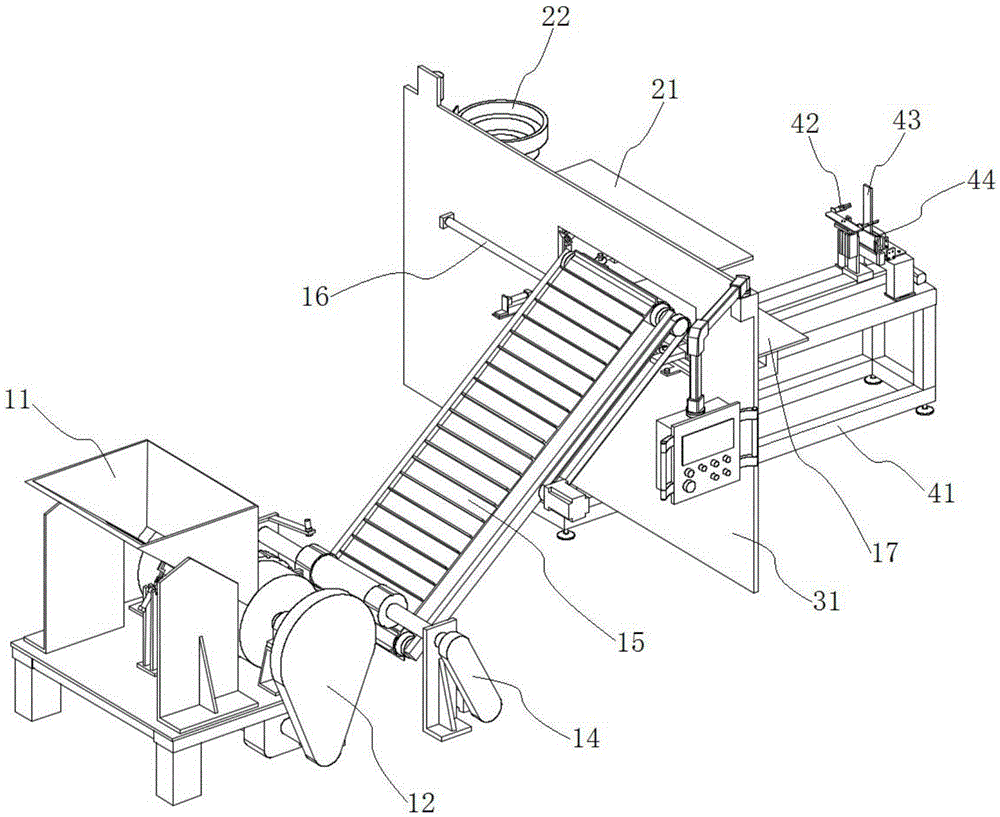

Method for preparing fatty acid starch ester and application

InactiveCN101456916AIncrease choiceImprove freeze-thaw stabilityFood preparationCarbon chainHigh pressure

The invention relates to a preparation method for a fatty acid starch ester and application thereof, which belongs to the technical field of modified starch. According to the invention, starch is adopted as a raw material and fatty acid is taken as an esterification agent; and on the condition of taking an extruder as a chemical reactor, the acidolysis and esterification modification of the starch is carried out to prepare the fatty acid starch ester product with the low substitution degree. The fatty acid which is subjected to the high temperature high pressure high shearing action treatment of the extruder has an esterification reaction with crude starch according to a certain proportion; and due to the introduction of the hydrophobic organic carbon chain, the starch has the lipophilicity and hydrophilicity, and consequently has certain emulsibility. The product can be used as a stabilizer, an emulsifier, a gelling agent, a fat substitute, a microcapsule wall material, and the like in the food industry, and can be applied to the foods such as artificial butter, salad seasoning matter, bakery products, diary products, and the like. The invention has the advantages that the extruder is adopted to prepare the esterified starch; the reaction process is continuous and has simple operation, easy implementation and little environmental pollution; and the obtained product has excellent performance.

Owner:JIANGNAN UNIV

Zinc-aluminum-rare earth middle alloy and its use in hot galvanizing alloy production

The invention relates to a process for producing a hot dip galvanizing alloy and an interalloy thereof. The technical proposal comprises that the interalloy of zinc, aluminum and rare earth consists of the following components in mass percentage: 3 to 5 percent of Al, 6 to 10 percent of RE, and the balance being Zn. The method of producing the hot dip galvanizing alloy comprises the following steps: mixing the zinc, the aluminum and the rare earth according to the following weight ratio: 3 to 5 percent of the Al, 6 to 10 percent of the RE, and the balance being the Zn; melting the materials in an interalloy smelting furnace with smelting temperature of between 500 and 650 DEG C; stirring the materials evenly and casting the materials into the interalloy of the zinc, the aluminum and the rare earth; adding the solid zinc required for the production of the hot dip galvanizing alloy into the smelting furnace made from the hot dip galvanizing alloy to be melted into zinc liquid; adding a slag former to the zinc liquid, stirring the mixture and forming slag at a temperature of between 470 and 480 DEG C; removing the slag in the furnace; adding the alloy of the zinc, the aluminum and the rare earth required according to the mixture ratio of the produced hot dip galvanizing alloy to the zinc liquid; and stirring the mixture to obtain the hot dip galvanizing alloy. The process reduces the temperature for alloy smelting, shortens the smelting and stirring time, prolongs the service life of a core-type induction furnace and is advantageous to uniform the components of the hot dip galvanizing alloy, and has the advantages of low equipment cost and simple and convenient maintenance.

Owner:湖南株冶火炬新材料有限公司

Fully-automatic round-head barrel hook forming machine

ActiveCN105414415AMeet production requirementsFulfill production requirementsWire articlesProduction lineControl system

The invention discloses a fully-automatic round-head barrel hook forming machine belonging to the field of wire bending machines. The fully-automatic round-head barrel hook forming machine comprises a steel wire feeding device, a handle tube feeding device, a forming device, a fetching and shaping device and a control system, wherein the handle tube feeding device is arranged in front of the forming device; the steel wire feeding device is arranged at the rear of the forming device; the fetching and shaping device is arranged in front of the forming device, is located below the handle tube feeding device and is composed of a grabbing mechanism, a locating mechanism and a shaping mechanism; and all the steel wire feeding device, the handle tube feeding device, the forming device and the fetching and shaping device are automatically controlled by the control system to sequentially finish the actions of handle tube feeding, steel wire feeding, barrel hook forming as well as fetching and shaping. By using the fully-automatic round-head barrel hook forming machine, a barrel hook not only can be fully-automatically produced, but also can be corrected and shaped after being formed to make preparation for the next installation of the barrel hook, so that the requirement of an automatic installation production line of the barrel hook is met, and the automatic level and production efficiency of vessels such as barrels and tanks are greatly increased.

Owner:CHANGZHOU PUHE PLASTIC

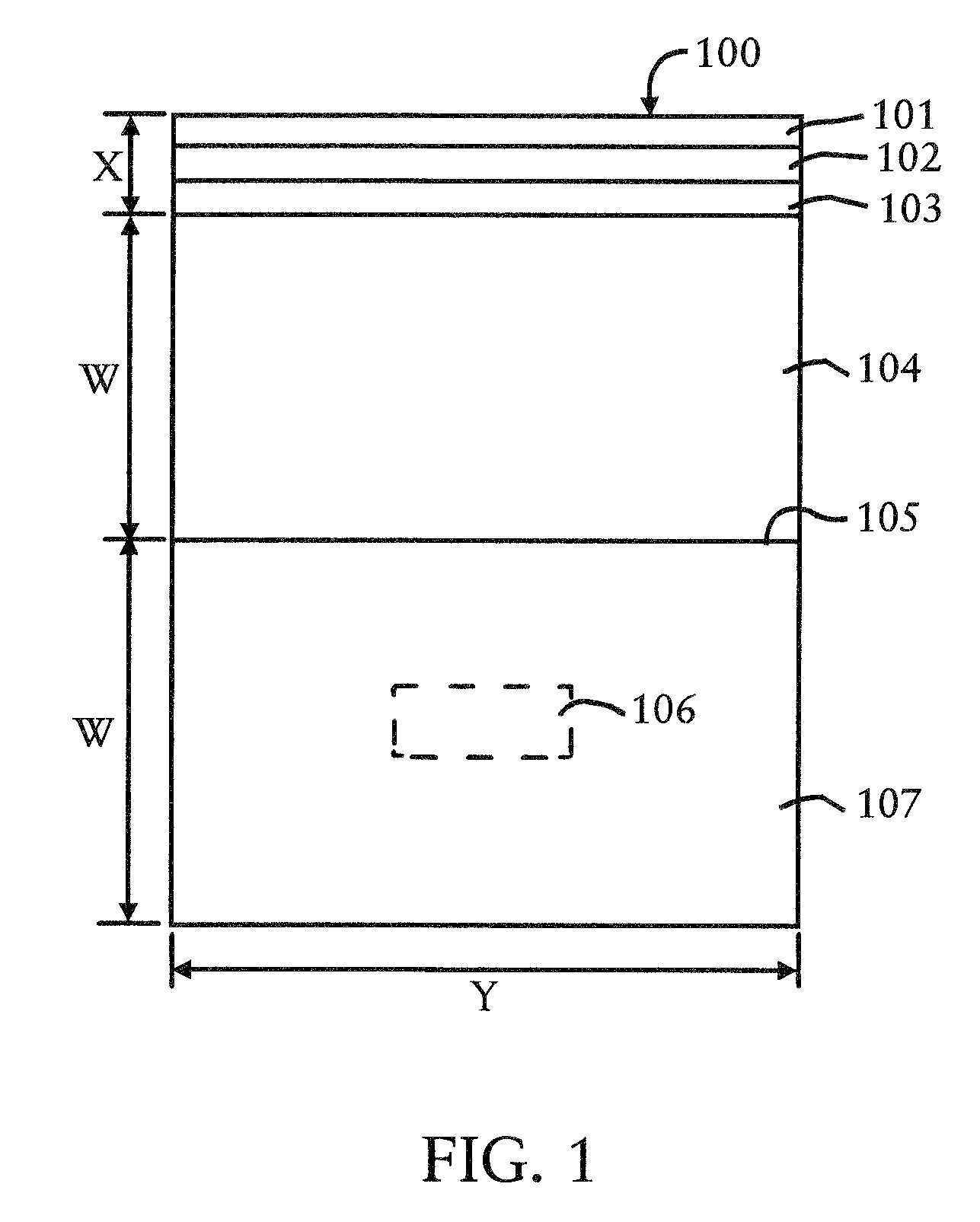

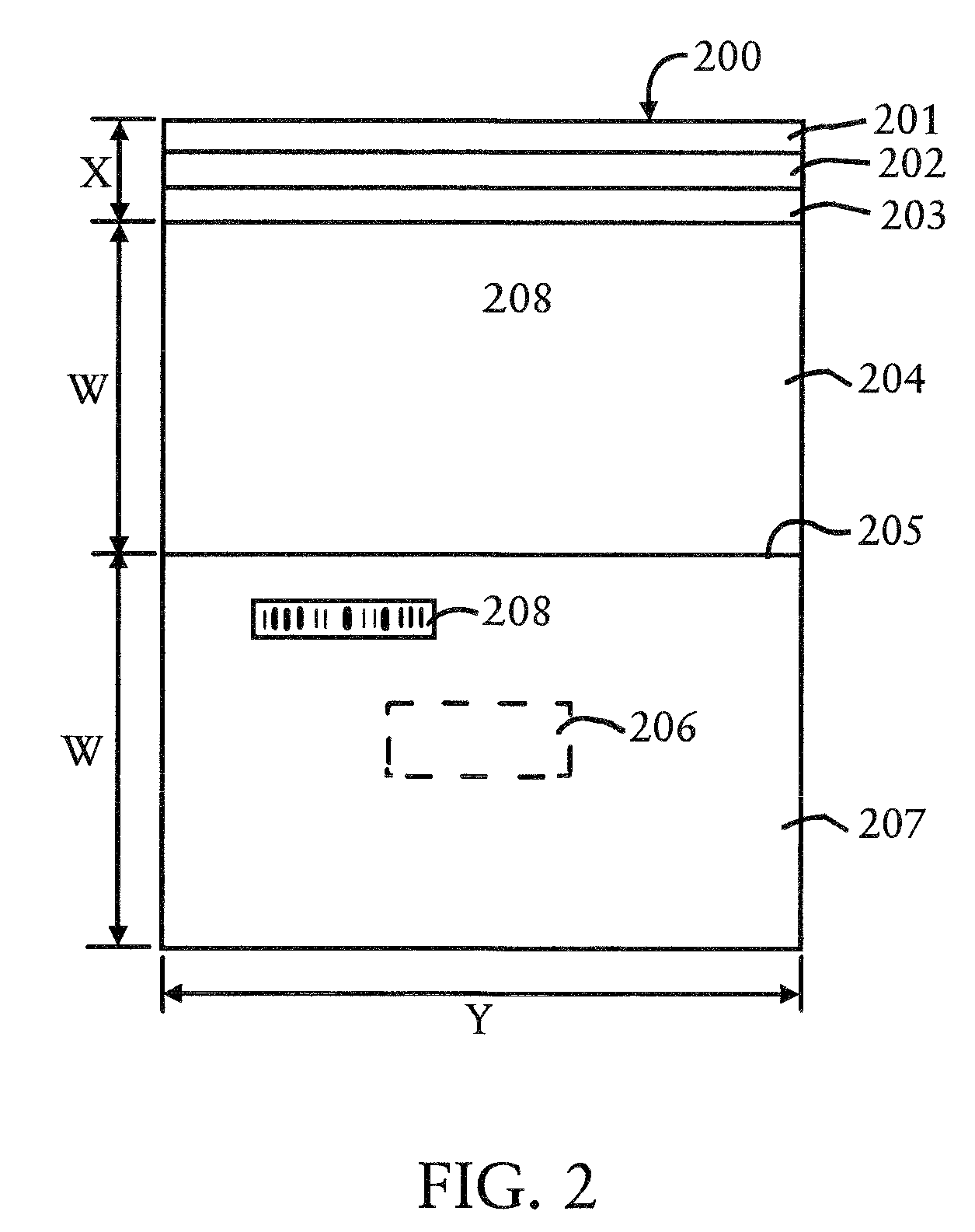

Organic electrofluorescence device and producing mehtod thereof

InactiveCN1472994AExtend your lifeImprove uniformity of light emissionElectrical apparatusElectroluminescent light sourcesOxygenOrganic electroluminescence

The invention relates to an organic electro-luminescence device and the manufacturing method thereof in the technical field of electronic and semiconductor component. A double-layer insulating column is provided for on the pattern of the first electrode (2) of the device, the cross section of the line of the second layer (8) of the insulating column has the shape that its width is decreased from up to down, and its hypotenuse has two sequentially convergent angles alpha,beta, and alpha>beta. Then the organic functioning layer (5) and the second electrode (6) are deposited sequentially. The angle beta of the hypotenuse of the second layer (8) of the insulating column can increase greatly the tolerance of the evaporating angle and the evaporating thickness of the metal back electrode, and the organic functioning layer can be fully covered by the metal back electrode by using the different evaporating angles between the organic functioning layer and the metal back electrode.

Owner:TSINGHUA UNIV +1

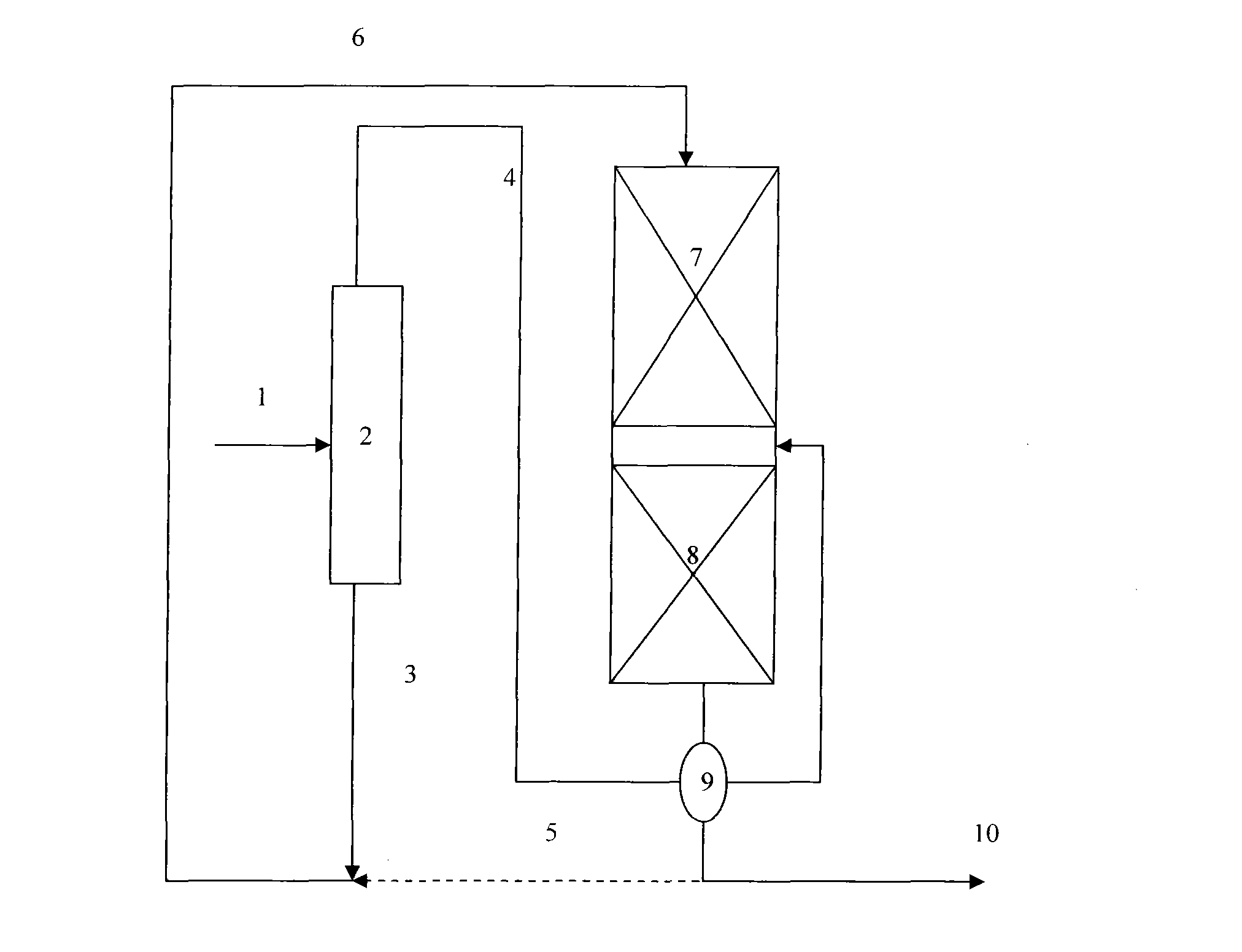

Hydrogenation method for reducing condensation point of diesel

ActiveCN103773488AHigh yieldHigh selectivityTreatment with hydrotreatment processesNaphthaPtru catalyst

A hydrogenation method for reducing the condensation point of diesel comprises the following steps: raw oil is in contact with a hydrofining catalyst in a first reaction area for reaction, effluents in the first reaction area are subjected to separation and fractionation to obtain gases, naphtha fractions, low-condensation-point diesel fractions I and high-condensation-point heavy diesel fractions; the obtained high-condensation-point heavy diesel fractions enter a second reaction area, and are in contact with a hydro-upgrading condensation point reducing catalyst to carry out an isocracking condensation point reducing reaction; effluents in the second reaction area are subjected to separation and fractionation to obtain low-condensation-point diesel fractions II; the low-condensation-point diesel fractions and the low-condensation-point diesel fractions II are mixed to obtain low-condensation-point diesel. According to the invention, the process selectivity is improved, so that the low-condensation-point diesel yield is improved remarkably. Through the adoption of the hydrogenation method, No.-10 to No.-50 low-condensation-point diesel can be produced flexibly, the cetane number is increased as compared with that of the raw material, the content of impurities such as sulfur and nitrogen is reduced greatly, and the Europe IV diesel standard and the Europe V diesel standard can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

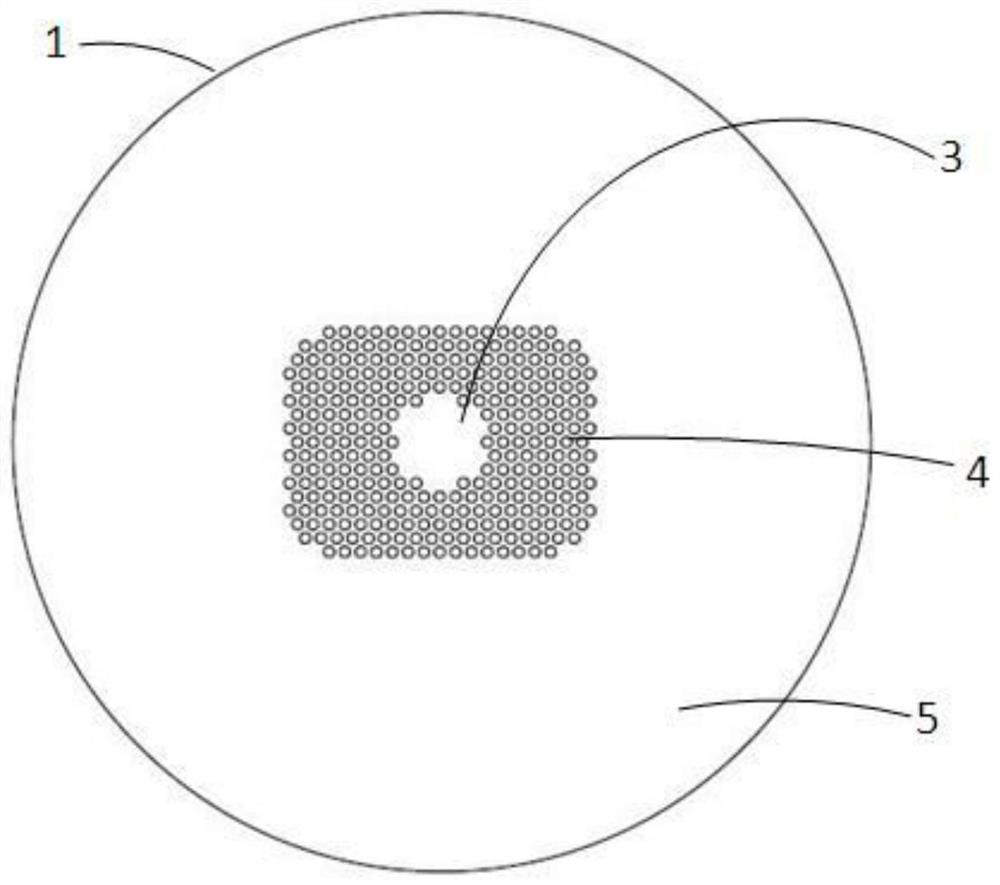

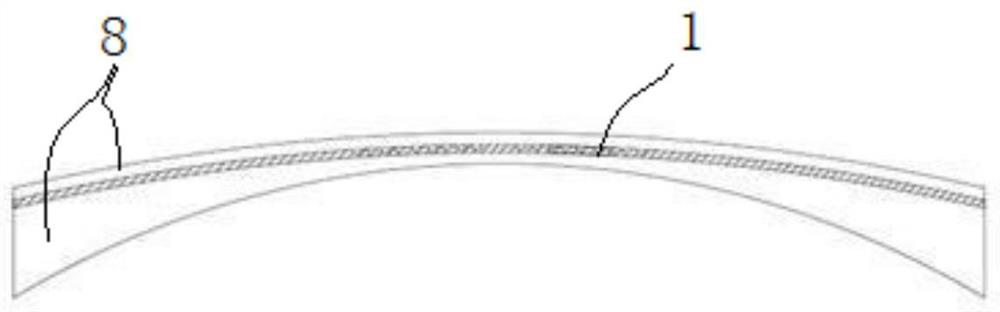

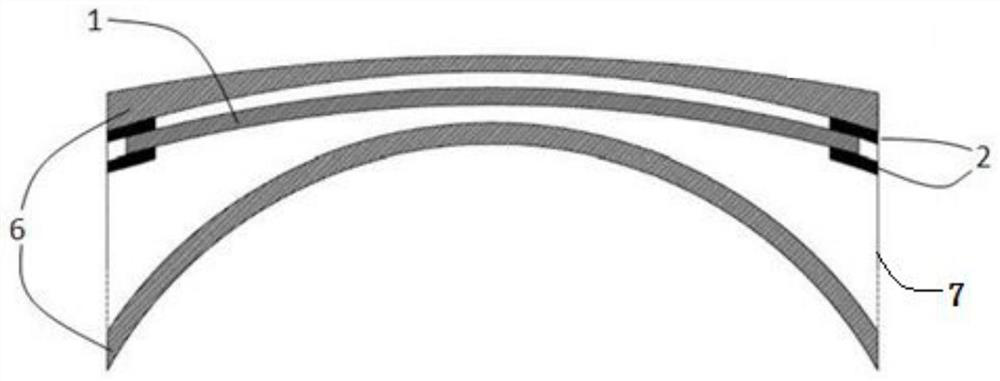

Lens for slowing down myopia deepening and preparation method thereof

PendingCN111796436APlay the role of myopia prevention and controlDoes not affect uniformitySpectales/gogglesOptical articlesOphthalmologyPlastic film

The invention relates to a lens for slowing down myopia deepening. The lens comprises two layers of resin monomers and an optical plastic film arranged between the two layers of resin monomers, wherein the optical plastic film sequentially comprises a central flat light area, an out-of-focus refraction area and an external flat light area from inside to outside, and the out-of-focus refraction area is a discontinuous out-of-focus refraction area. According to the invention, the optical plastic film is used for preparing the functional film with the defocusing effect; the functional film is arranged in the middle of the resin lens, so that the lens can still play a role in myopia prevention and control; in addition, tiny bulges do not exist on the surface of the lens, the uniformity of hardening and film coating is not influenced in the subsequent hardening and film coating processes, and the lens is simpler and more thorough to clean when being worn in daily life.

Owner:JIANGSU MINGYUE PHOTOELECTRICS TECH

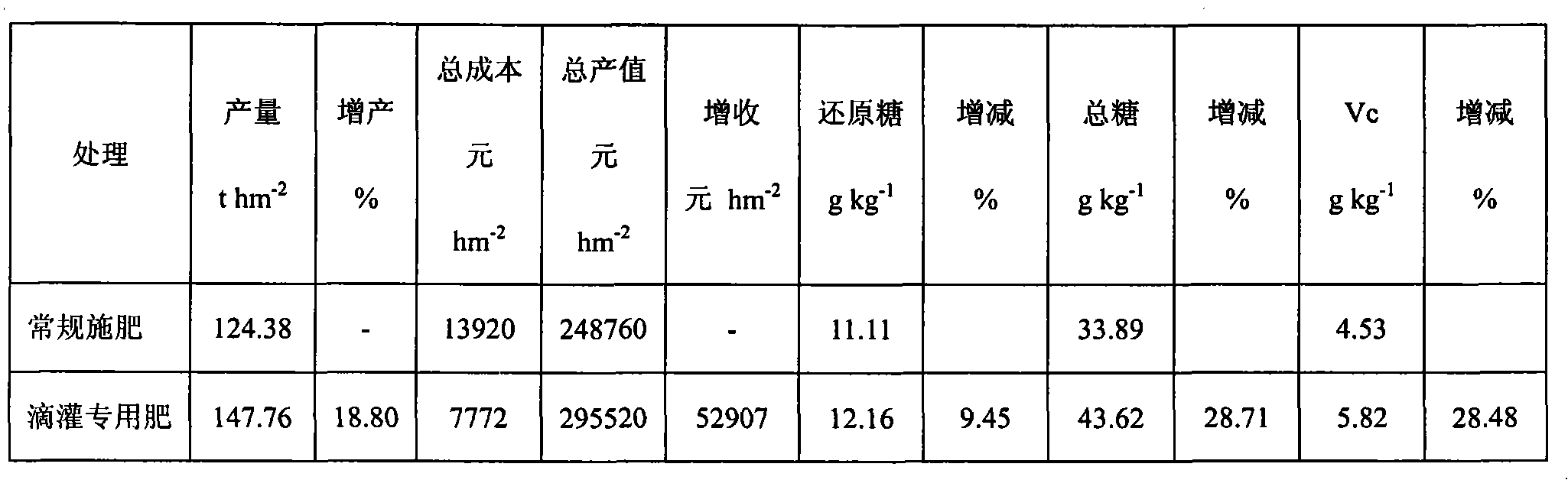

Compound fertilizer special for drip irrigation of cucumber in greenhouse and preparation method thereof

InactiveCN101913935AThere are few types of solutionsSolve solubilityFertilizer mixturesAgricultural scienceGreenhouse

The invention discloses a compound fertilizer special for drip irrigation of cucumber in a greenhouse, which comprises the following nutritive elements in each hm<-2>: 391.41 kg of N, 255.43 kg of P2O5, 416.91 kg of K2O, 65.25 kg of CaO, 46.50 kg of MgO, 26.46 kg of Fe, 17.60 kg of Mn, 9.70 kg of Cu, 6.46 kg of Zn, 3.00 kg of B and 1.50 kg of Mo. The compound fertilizer special for the drip irrigation of the cucumber in the greenhouse with high applicability is prepared by a physical method through field trails and verification research based on a nutrient preserving capability and a water requirement principle and a nutrient requirement principle of the cucumber.

Owner:NINGXIA UNIVERSITY

Method for producing milk product

ActiveCN101258880AFlexible productionIncrease productivityMilk preparationMilk preservationProduction rateChemistry

The invention relates to a method for producing dairy products, which comprises steps of mixing cow milk and functional particle substances which are pre-sterilized and then sterilizing the mixture. The method of the invention ensures that: the production of the dairy products is more flexible; the production rate is higher; the quality of the products is better and choosing range of the raw materials of the products is greatly expanded; the product types are enriched, thus the method has wide market prospect.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

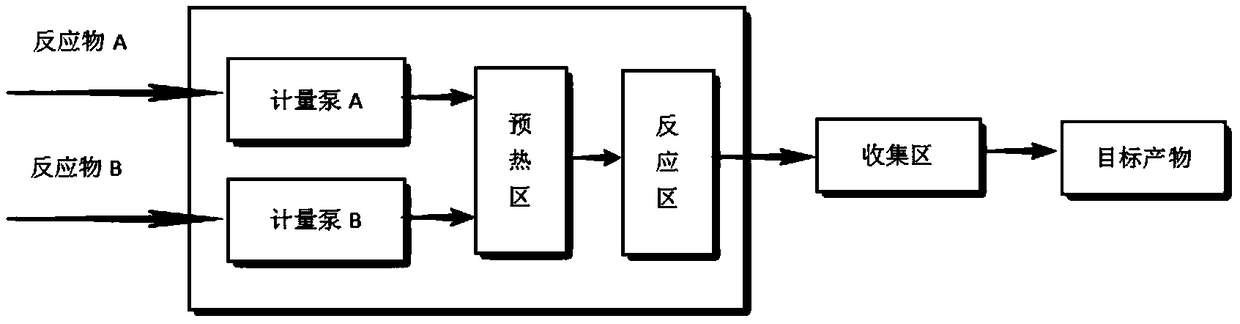

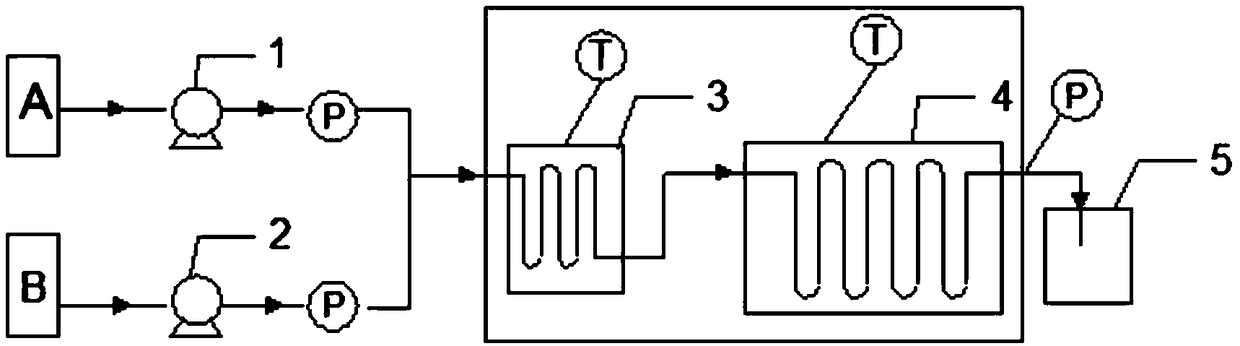

Method for continuous synthesis of dialkyl phosphite in micro-channel reactor

InactiveCN108840884AShort reaction timeIncrease temperatureGroup 5/15 element organic compoundsChemical industryAlcoholDolichyl phosphate

The invention discloses a method for continuous synthesis of dialkyl phosphite in a micro-channel reactor and belongs to the technical field of organic synthesis technologies. The method is used for generating the dialkyl phosphite through continuous reaction in the micro-channel continuous-flow reactor by using alcohol and phosphorus trichloride as substrates. Phosphorus trichloride is used as the material A, an alcohol solution is used as the material B, and the material A and the material B enter a micro-channel simultaneously through a metering pump for the continuous esterification reaction. According to the technological method, the high mass and heat transfer efficiency of the micro-channel reactor is utilized, the mass transfer rate between the two phase materials is effectively increased, and the safety and the operability of a test are greatly improved.

Owner:CHANGZHOU UNIV

Special root-inducing slow release high-efficiency fertilizer for double cropping rice and preparation method thereof

InactiveCN102153416AInhibition of urease activitySupplementary needsFertilizer mixturesRoot growthPotassium

The invention discloses a special root-inducing slow release high-efficiency fertilizer for double cropping rice and a preparation and application method thereof. The preparation method comprises the following steps: mixing and blending nitrogen fertilizer and compound synergist in a blender for 3-5 minutes to obtain root-inducing slow release high-efficiency nitrogen fertilizer; and then, continuing to mix with phosphorus fertilizer and potassium fertilizer for about 5 minutes to obtain the finished fertilizer, wherein the compound synergist is prepared by uniformly mixing the following materials in percentage by weight: 3.4-3.8% of borax (B), 2-2.5% of hydroquinone (HQ), 0.9-1.4% of dicyandiamide (DCD), 33-36% of silicon fertilizer (SiO2), 9-14% of polyaspartic acid (PASP), 31-38% of humic acid (HA) and 9-12% of phosphorus activator. The finished fertilizer is used as basal fertilizer to be completely applied after rice soaking and in the early rice transplanting stage, and no additional fertilizer is required for the later stage; the amount of applied fertilizer for early rice is 40-45 kg / mu; and the amount of applied fertilizer for late rice is 50-55 kg / mu. The fertilizer disclosed by the invention has the dual effects of promoting root growth and delaying nutrient release, can greatly improve the nutrient utilization ratio and rice yield, is convenient to produce and use, and has the advantages of high technical compatibility, low cost, environment friendliness and the like.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

TRIP (Transformation-Induced Plasticity) steel and production method thereof

Owner:SHOUGANG CORPORATION

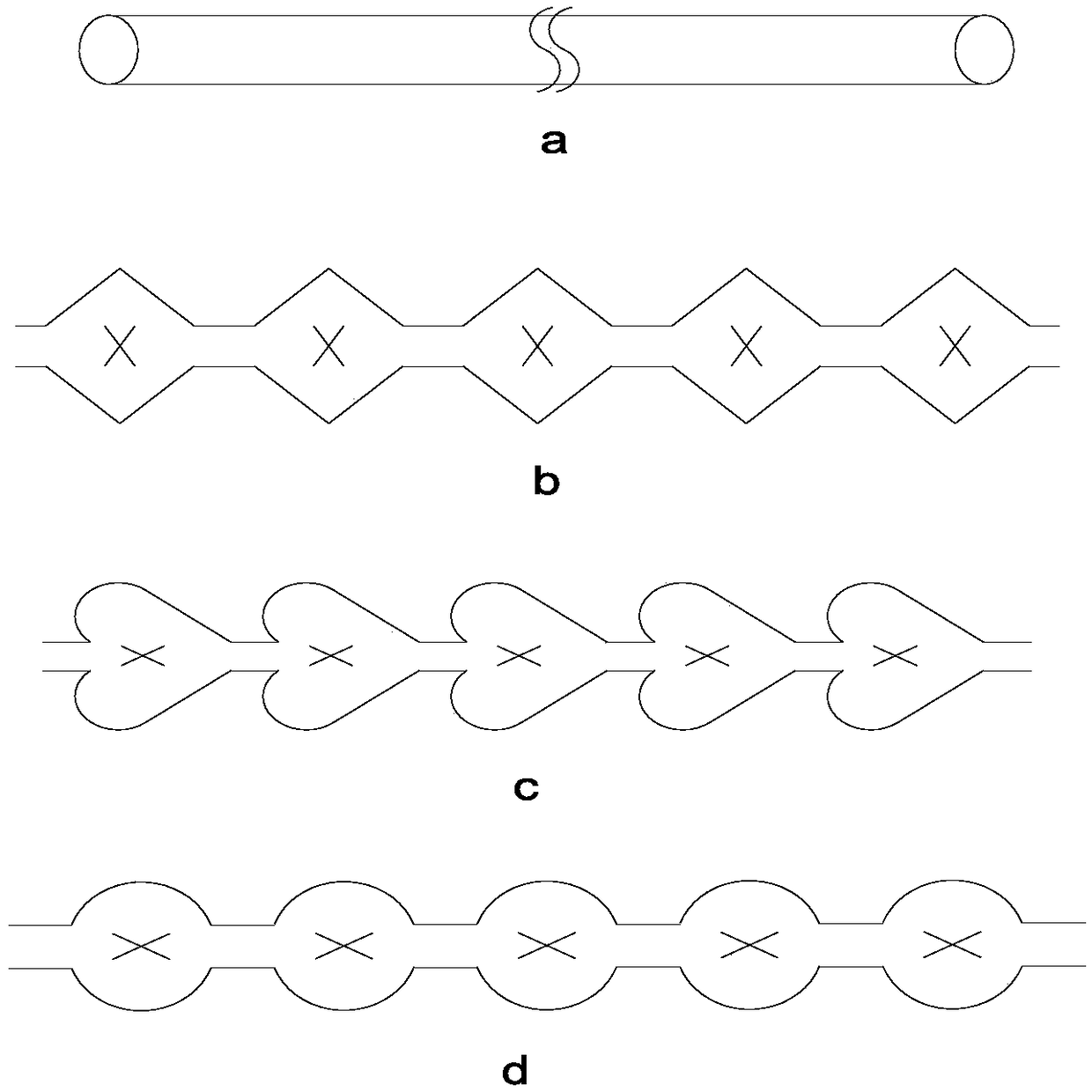

Method for performing extraction separation on cobalt and nickel by using microfluid technology

The invention provides a method for performing extraction separation on cobalt and nickel by using a microfluid technology. The method comprises the following steps of: uniformly mixing an extraction agent and diluent which are subjected to homogeneous phase saponification by using a mixed material liquid of Co<2+> and Ni<2+>, using 2-ethyl cthylhexyl phosphonate mono 2-ethyl cthylhexyl ester as the extraction agent and using No.260 solvent oil and using the extraction agent and the diluent as an oil phase; introducing the water phase and the oil phase into a micro-reactor by virtue of two flow pumps; mixing the two phases in the micro-reactor and performing extraction reaction at 25-50 DEG C; and collecting a product at an outlet of the micro-reactor and standing for separating the phases to ensure that Co<2+> enters the oil phase and Ni<2+> stays in the water phase so as to realize extraction separation of cobalt and nickel. According to the method, continuous flow micro-reactor with an enhanced hybrid channel structure is adopted, the extraction separation of cobalt and nickel is carried out, and the reaction time is shortened to be within a micro-second level range, so that single-level cobalt extraction efficiency is obviously improved, and the extraction levels are reduced; and moreover, standing layering on the water phase and the oil phase can be quickly carried out without any emulsion phenomenon.

Owner:KUNMING UNIV OF SCI & TECH

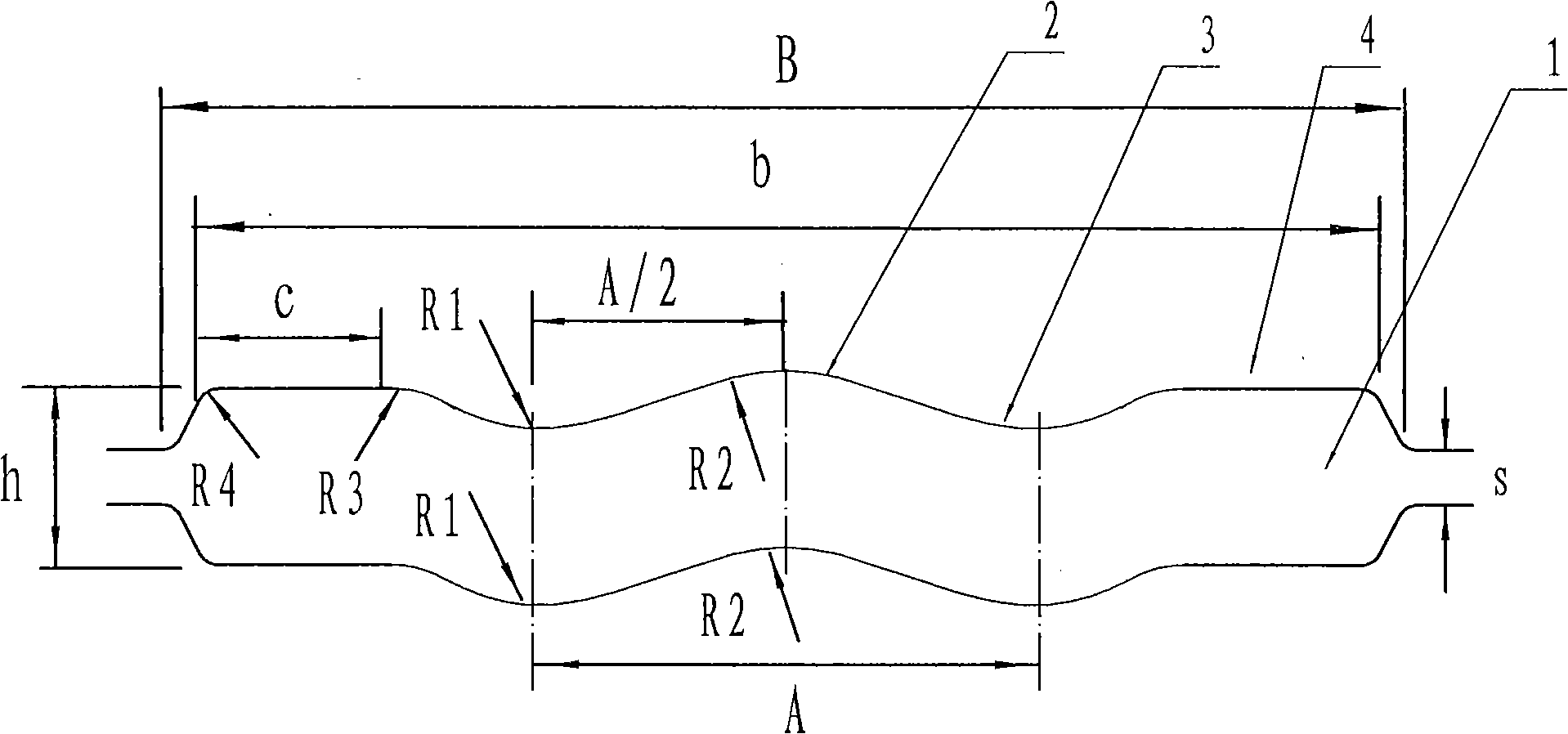

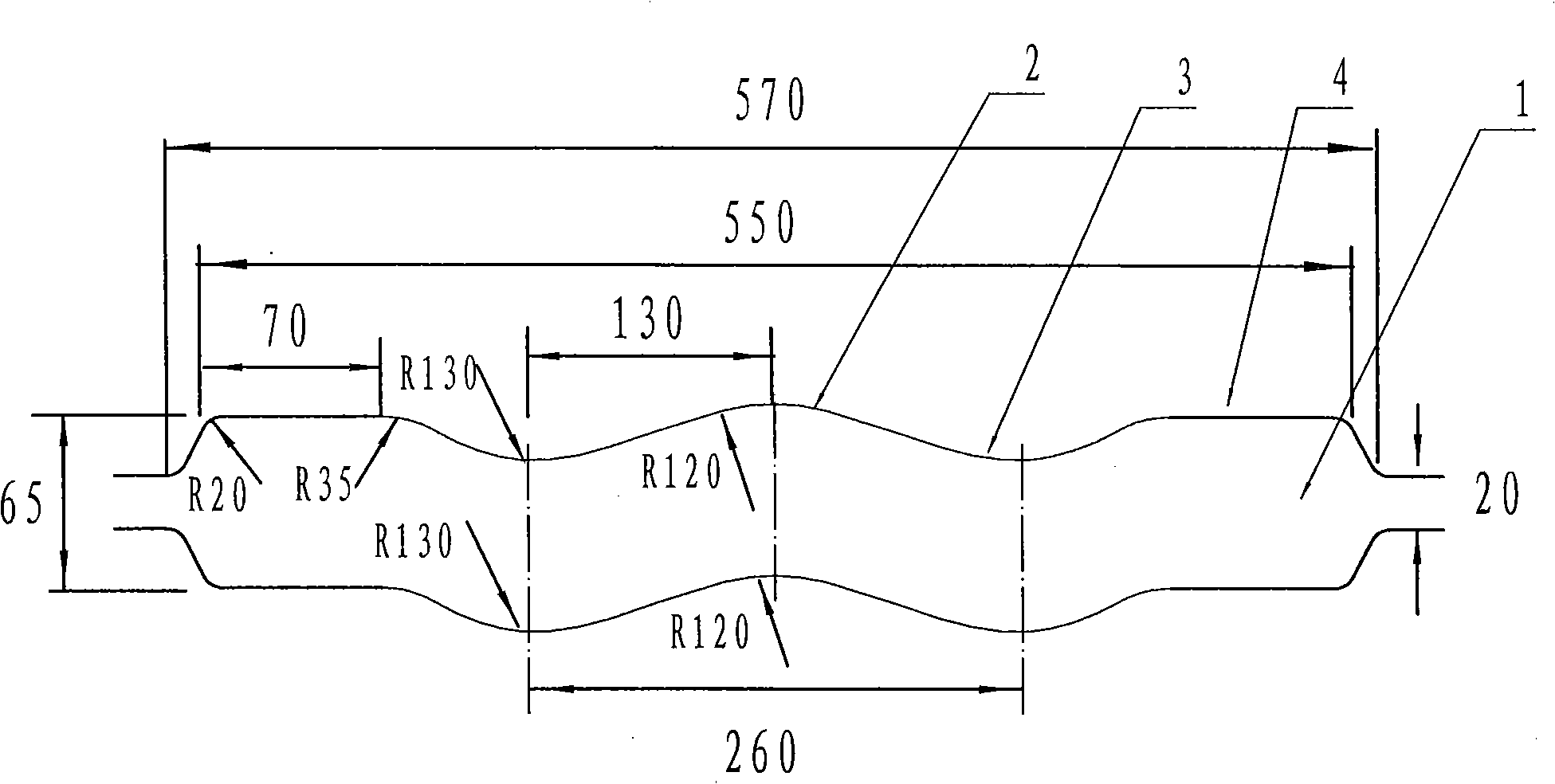

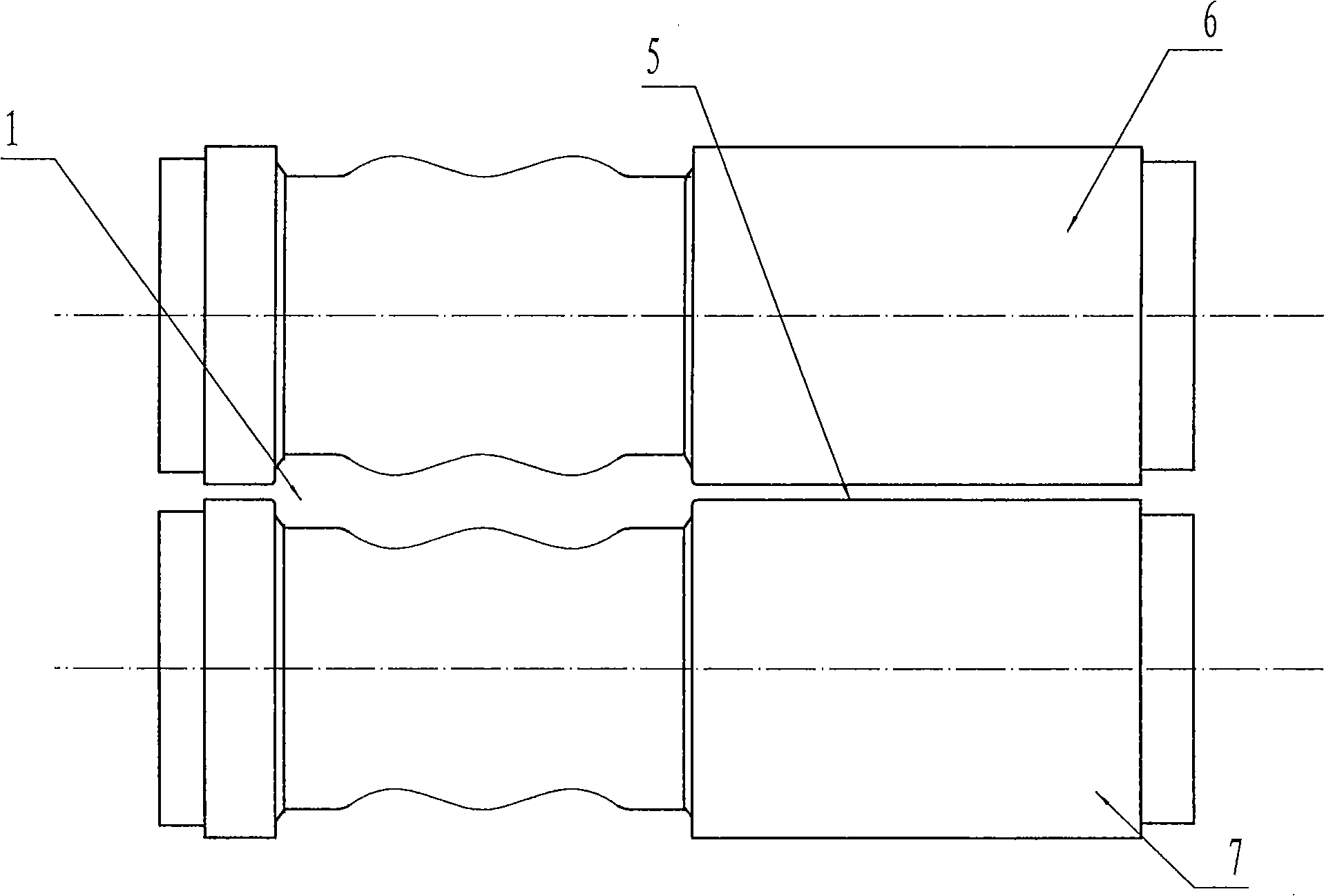

Forcedly stretching hole structure and stretching rolling method for rolling strip steel

InactiveCN101318197AImprove efficiencyFlexible productionRollsMetal rolling arrangementsStrip steelMaterials science

The invention discloses a force broadening pass structure used for strip rolling and a broadening rolling method thereof, and belongs to the technical field of steel rolling; the invention is used for solving the problem of increasing the broadening degree of the strip rolling. After improvement, the pass is composed of a wave curve outline part and a linear outline part of an upper roll and a lower roll, the wave curve camber of the upper and the lower rolls are uniformly corresponding to each other, and the linear outline part is positioned at the two ends of the wave curve. The broadening rolling method of the invention includes that a rolled piece is firstly broadened and rolled on the force broadening pass, then goes through flat rolling pass or flat roll rolling, the first pass of the flat rolling pass or the flat roll rolling is broadening rolling, and broadening rolling reduction is matched with the wave bending amplitude of the rolled piece in the first pass. By adopting the force broadening pass structure of the invention, the broadening degree can reach 100-150mm, thus achieving the aim of significantly increasing the broadening, degree and realizing that a wider strip steel can be rolled by a relatively narrow continuous casting slab. The force broadening pass structure of the invention is beneficial for widening products, increasing the efficiency of a mill, and leading strip production to be more flexible.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of packaging financial transaction instruments, particularly stored value cards

ActiveUS8613389B2Flexible productionFinanceSensing record carriersFinancial transactionStored-value card

A method of packaging financial transaction instruments includes preparing a batch of cards, where each card is provided with a first piece of machine readable information, and where the cards in the batch are in an order. A batch of packaging blanks is prepared, where each packaging blank is provided with a second piece of machine readable information. Each packaging blank is provided with a third piece of machine readable information, which is recorded onto a magnetic stripe carried by the packaging blank. A card is picked from a first ordinal position in the batch of prepared cards. A packaging blank is picked from a position, corresponding to the first ordinal position, in the batch of prepared packaging blanks. The picked card in the picked packaging blank is enclosed if and only if a matching condition is verified between the first and second pieces of information is verified.

Owner:IDEMIA FRANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com