Fully-automatic round-head barrel hook forming machine

A hook forming machine, fully automatic technology, applied in the field of fully automatic round head barrel hook forming machine, can solve the unfavorable application of steel wire handle forming machine, the difficulty of guaranteeing the degree of bending consistency, and the inability to meet the automatic installation of barrel hooks, etc., to achieve The effect of meeting the requirements of automatic installation production line, improving automation level and production efficiency, and reducing the number of times workers load materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

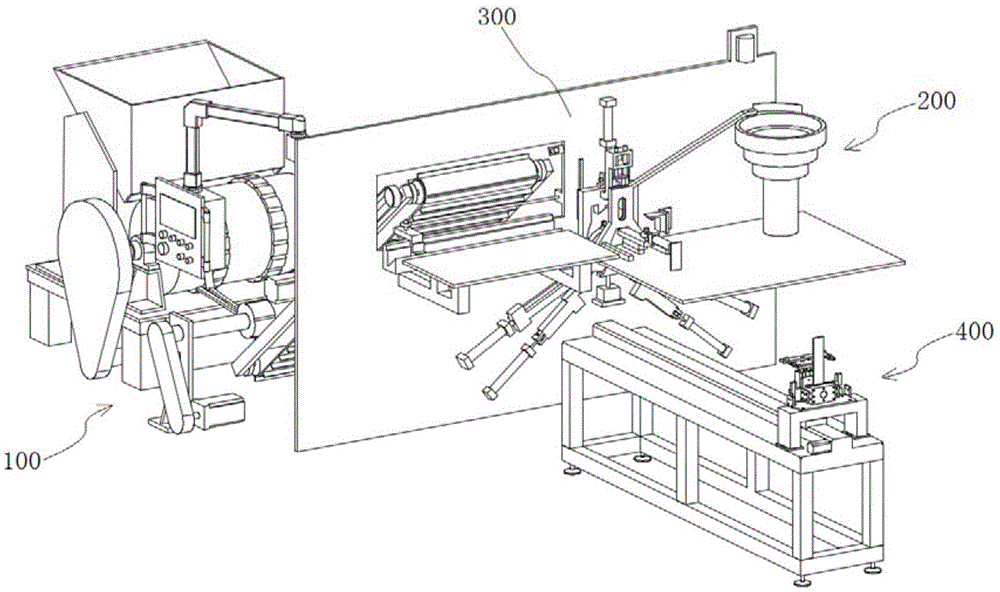

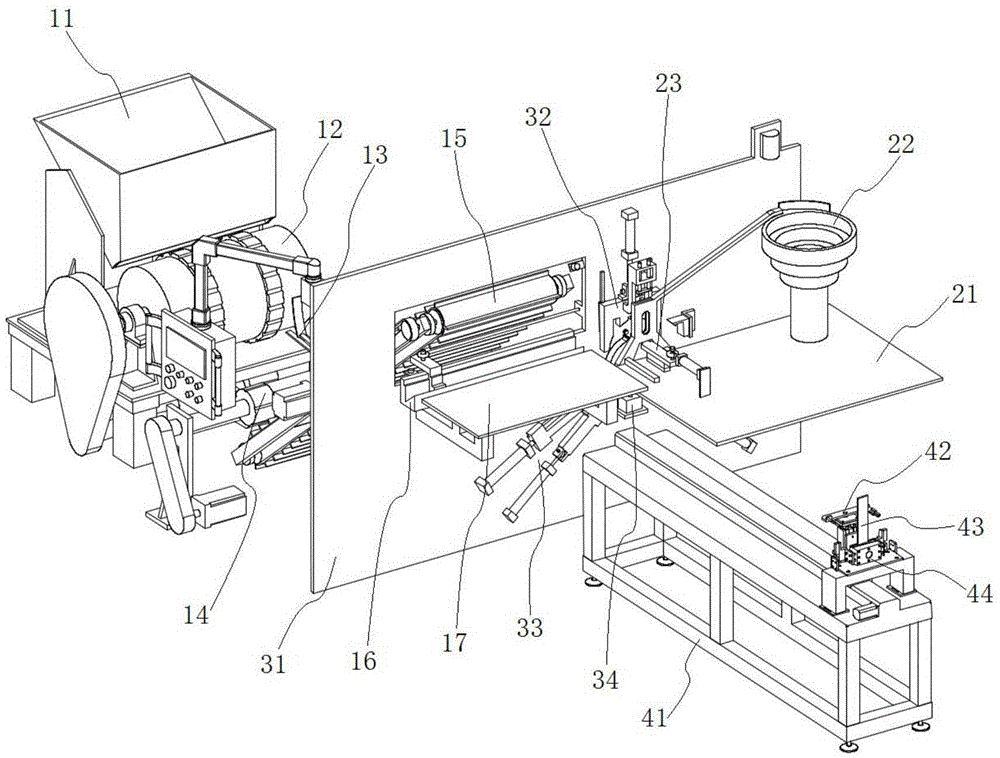

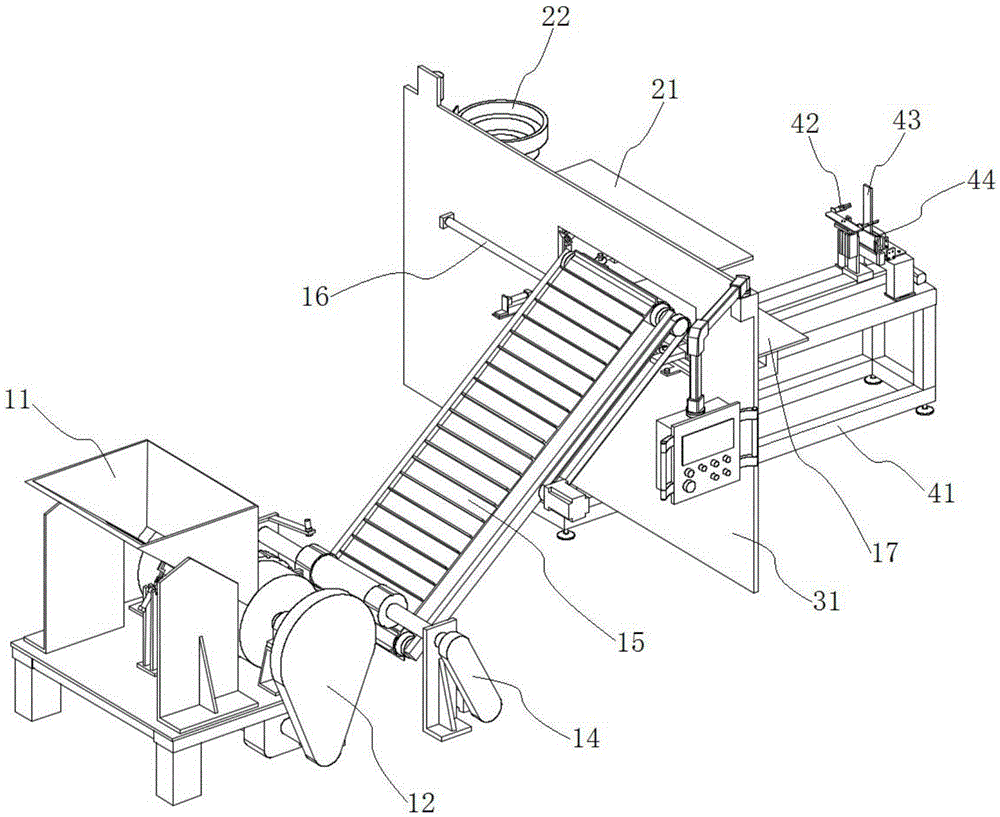

[0052] combine figure 1 , figure 2 and image 3 As shown, a fully automatic round head bucket hook forming machine in this embodiment includes a steel wire feeding device 100, a handle tube feeding device 200, a forming device 300, a retrieving and shaping device 400 and a control system, wherein,

[0053] The handle tube feeding device 200 is arranged in front of the forming device 300, and is used to push the handle tube onto the forming device 300, which includes a workbench 21, a handle tube material selection and storage mechanism 22 and a handle tube feeding mechanism 23, The handle tube material selection and storage mechanism 22 and the handle tube feeding mechanism 23 are installed on the workbench 21, and the handle tube feeding mechanism 23 is used to push the handle tube in the handle tube material selection and storage mechanism 22 to the forming device 300;

[0054] Steel wire feeding device 100 is located at the rear of forming device 300, and it comprises s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com