Patents

Literature

5799results about How to "Increase the level of automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air traffic control system and method for four-dimensional (4D)-trajectory-based operation

InactiveCN102509475AReduce disorderImprove airspace safetyAircraft traffic controlTraffic conflictTraffic conditions

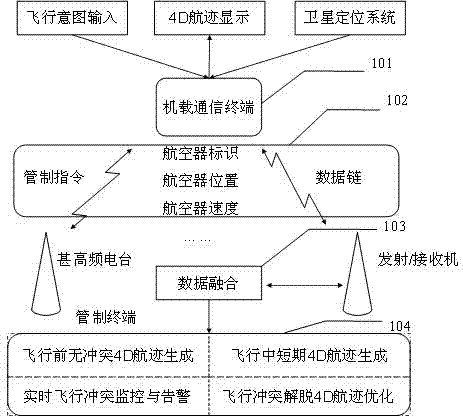

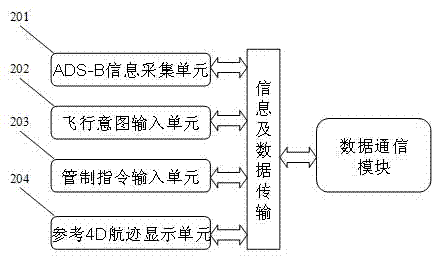

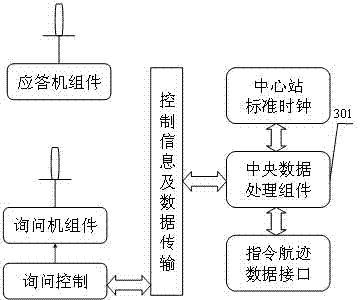

The invention discloses an air traffic control system for four-dimensional (4D)-trajectory-based operation. The air traffic control system comprises a data communication module, a monitoring data fusion module, an airborne terminal module and a control terminal module, wherein the monitoring data fusion module is used for fusing the monitoring data of an air traffic control radar and automatic dependent monitoring data, and providing real-time trajectory information for the control terminal module; and the control terminal module comprises a preflight conflict-free 4D trajectory generation sub-module, an in-flight short-term 4D trajectory generation sub-module, a real-time flight conflict monitoring and alarming sub-module and a flight conflict resolution 4D trajectory optimization sub-module. The invention also discloses an air traffic control method for the system. The control terminal module processes flight plan data, generates 4D trajectories, analyzes potential traffic conflicts of air traffic conditions and provides an optimal resolution scheme. By the system and the method, flight conflicts can be effectively prevented, and the safety of air traffic can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

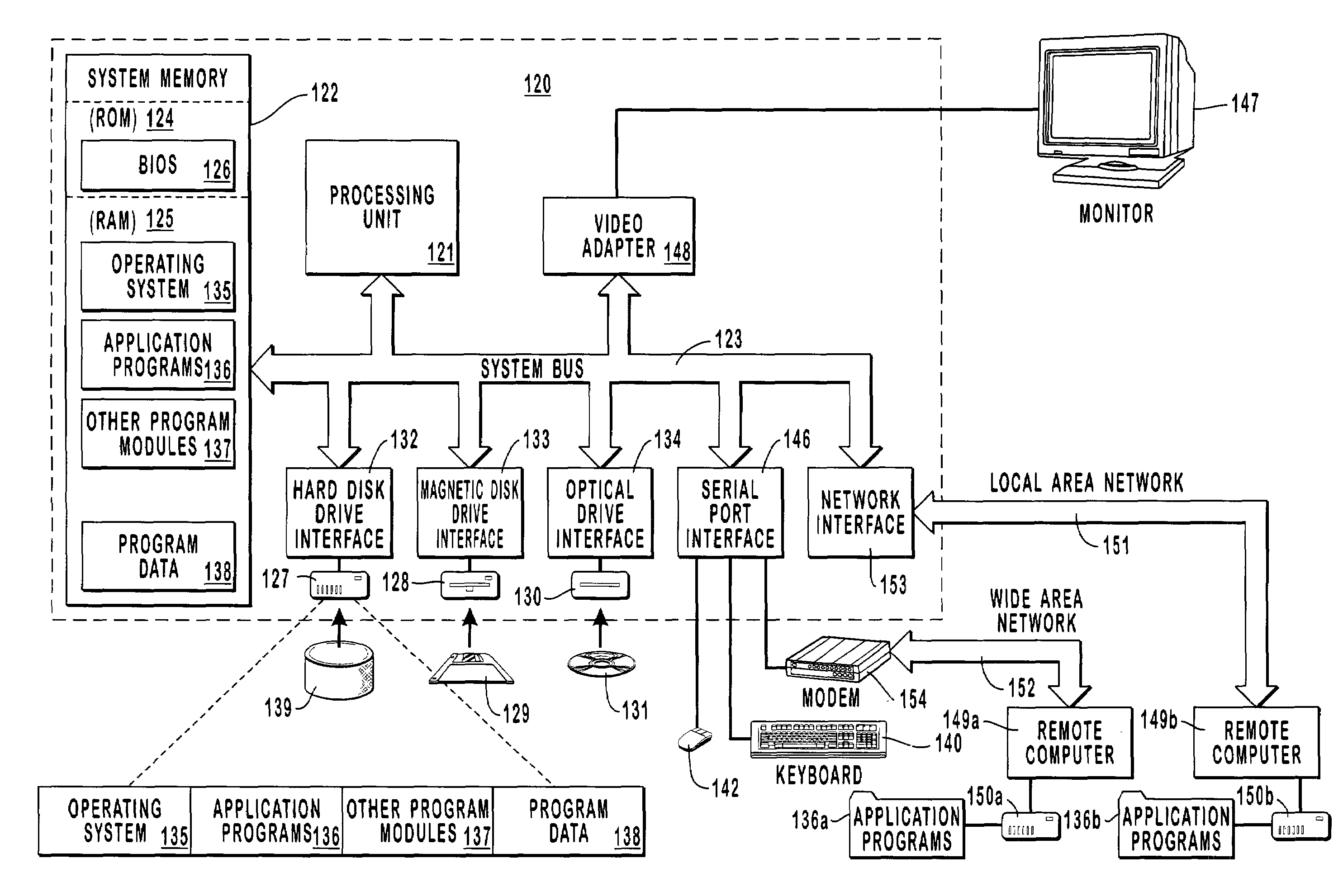

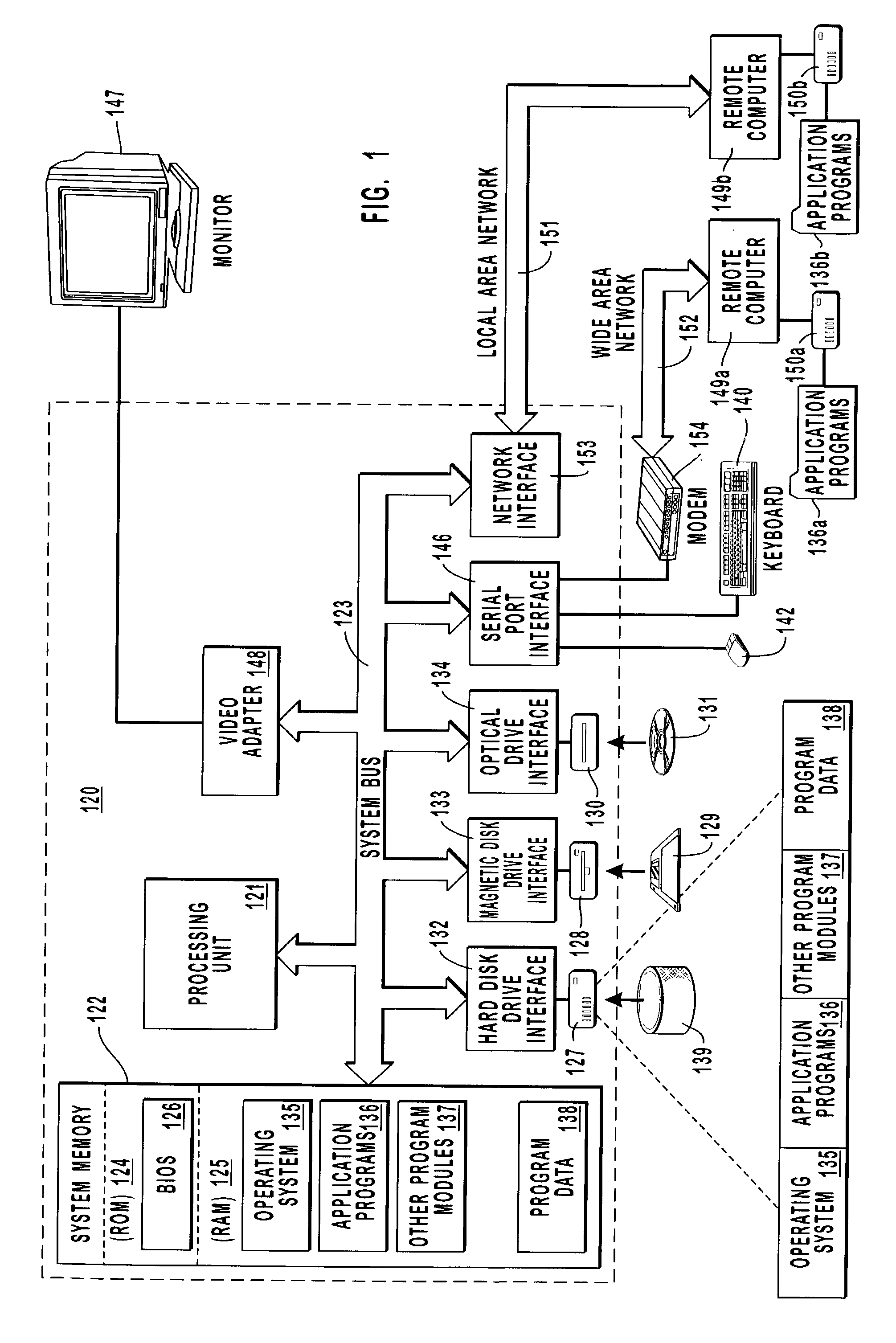

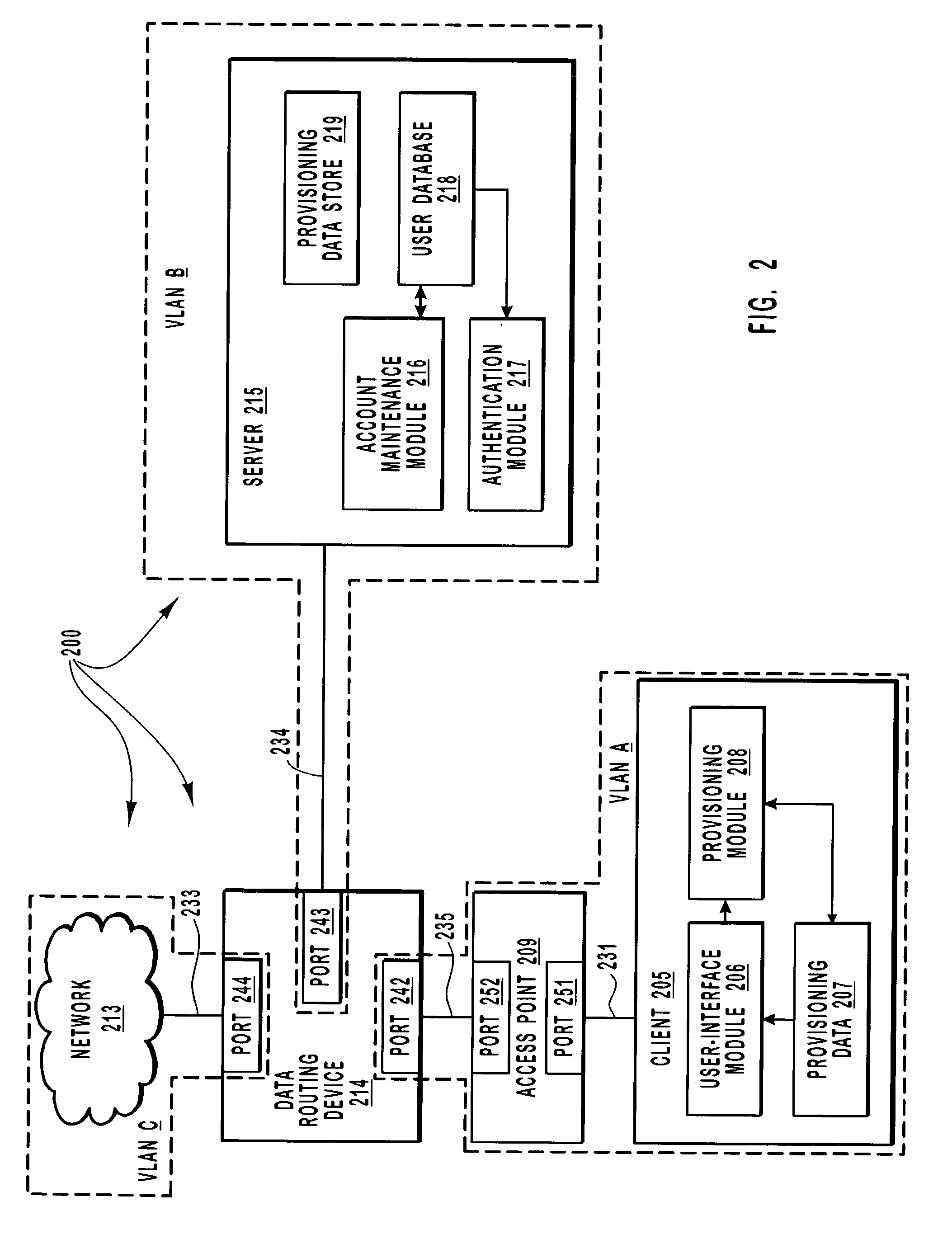

Increasing the level of automation when provisioning a computer system to access a network

ActiveUS7284062B2Increase the level of automationRelieving userData taking preventionUser identity/authority verificationPasswordUser input

A computer system attempts to authenticate with a server to gain authorization to access a first network. It is determined by the server that the computer system is not authorized to access the first network. The computer system is given authorization to access a second network for at least the purpose of downloading files (e.g., signup and configuration files) needed to access the first network. A user-interface for receiving user-entered signup information is automatically presented at the computer system. A first schema-based document including user-entered information is transferred to the server. If the server determines that the user-entered information is appropriate, a second-schema document, which includes an indication of authorization to access the first network (e.g., a user-identifier and password), is received. A third schema-based document is executed at the computer system to compatibly configure the computer system for accessing the first network.

Owner:MICROSOFT TECH LICENSING LLC

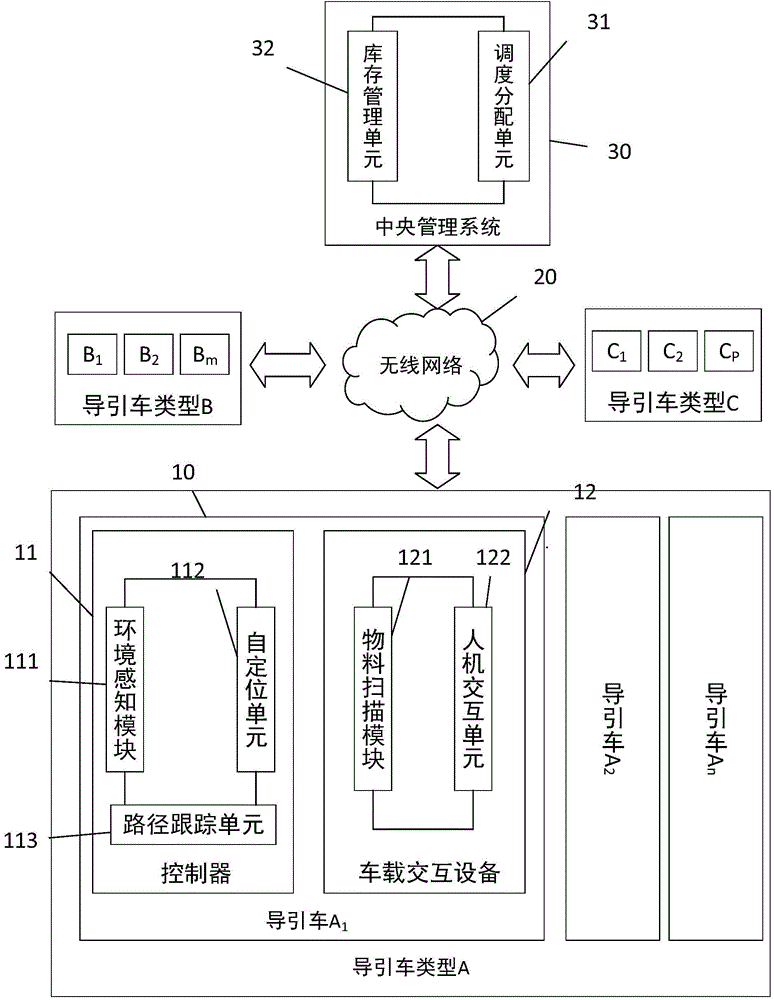

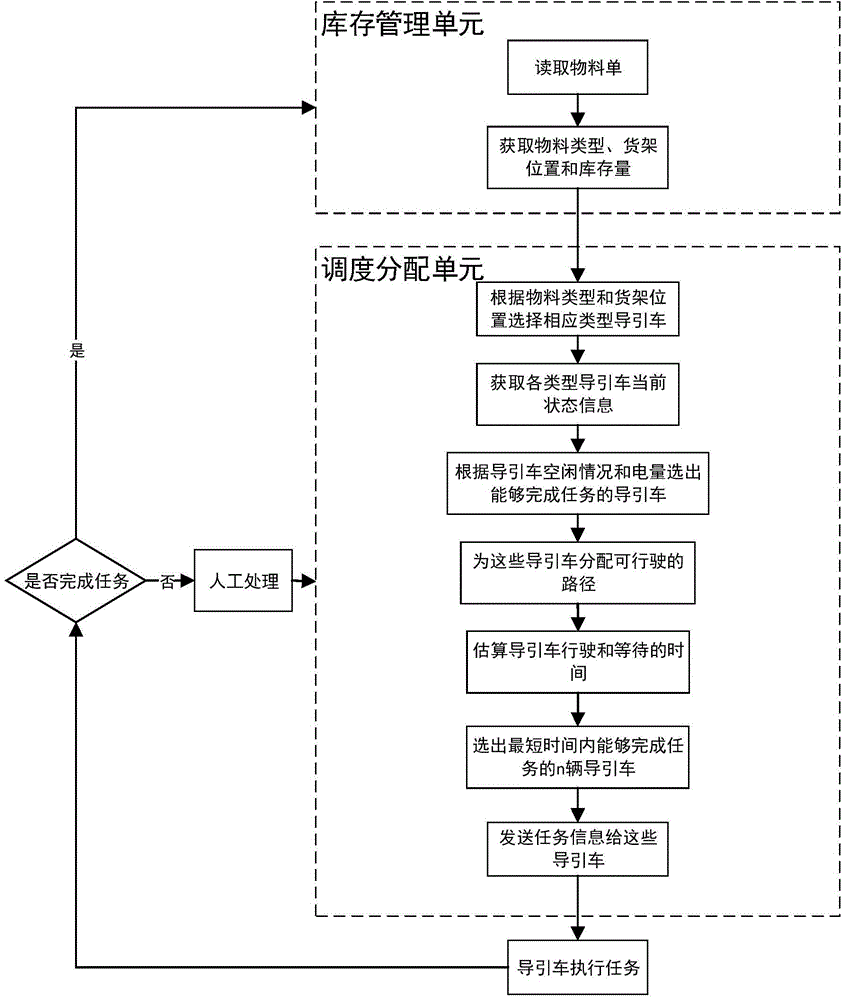

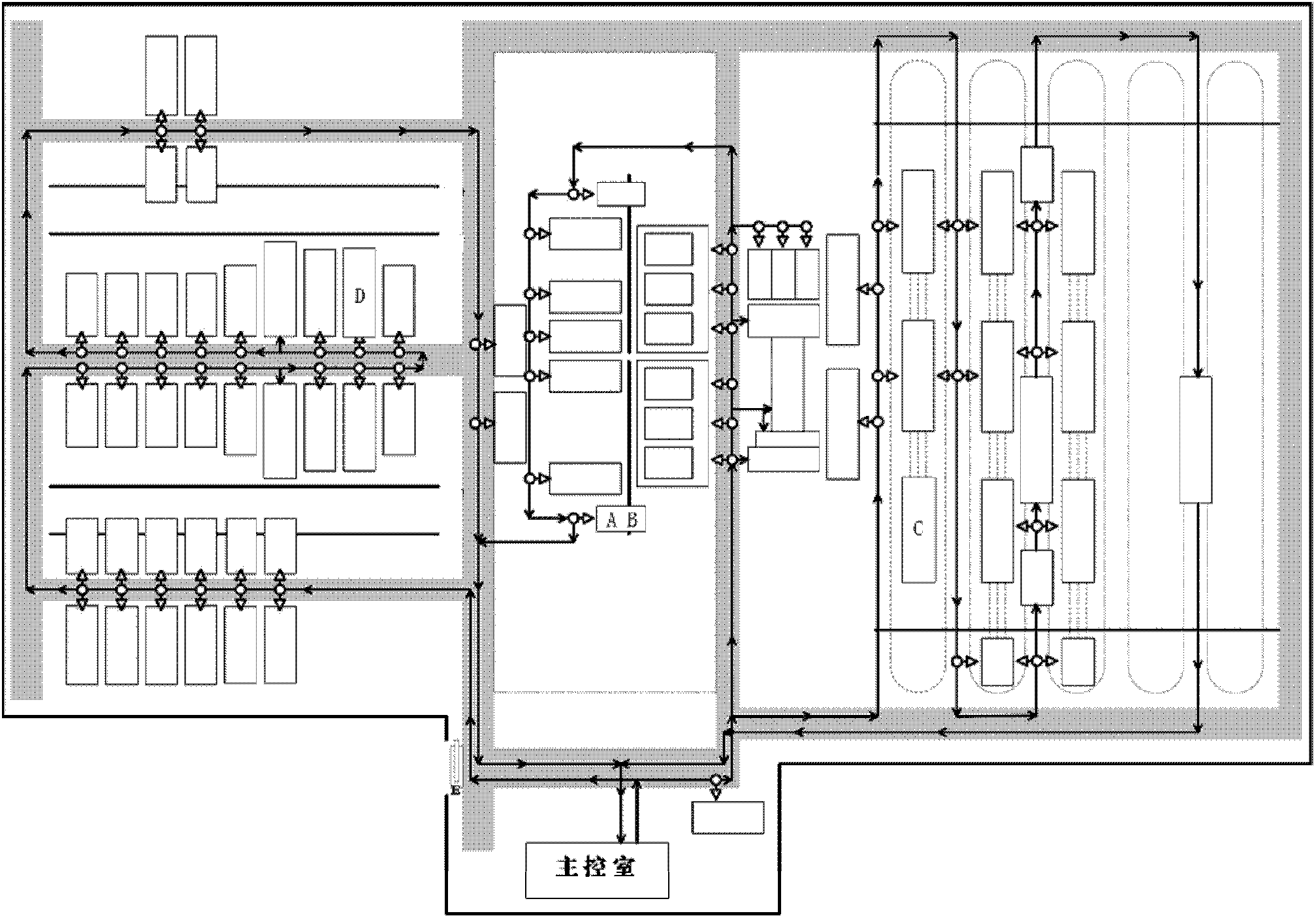

Warehouse management system with multi-guide-vehicle dispatching and distribution function

ActiveCN104809606AEasy way to workIncrease the level of automationLogisticsSelf positioningComputer science

The invention discloses a warehouse management system with a multi-guide-vehicle dispatching and distribution function. The warehouse management system comprises a central management system and guide vehicles. The central management system reads material lists to obtain the inventory and position information of materials, selects appropriate guide vehicle types and number according to task quantity and the material positions, distributes the traveling routes for the guide vehicles, and selects the guide vehicles and distributes material input and output tasks according to the shortest time principle. The guide vehicles travel in a warehouse along the routes distributed by the central management system and have functions of self-positioning and barrier avoiding. The guide vehicles complete material information scanning, map information displaying and task displaying and receiving through vehicular interaction equipment and transmit guide vehicle state information to the central management system. The warehouse management system has the advantages that the guide vehicles are dispatched according to the comprehensive material information and the state information of the guide vehicles, the guide vehicles travel along the distributed routes to target positions to complete material input and output, a traditional warehouse management manner is optimized, and warehouse management efficiency is increased.

Owner:SHANGHAI JIAO TONG UNIV

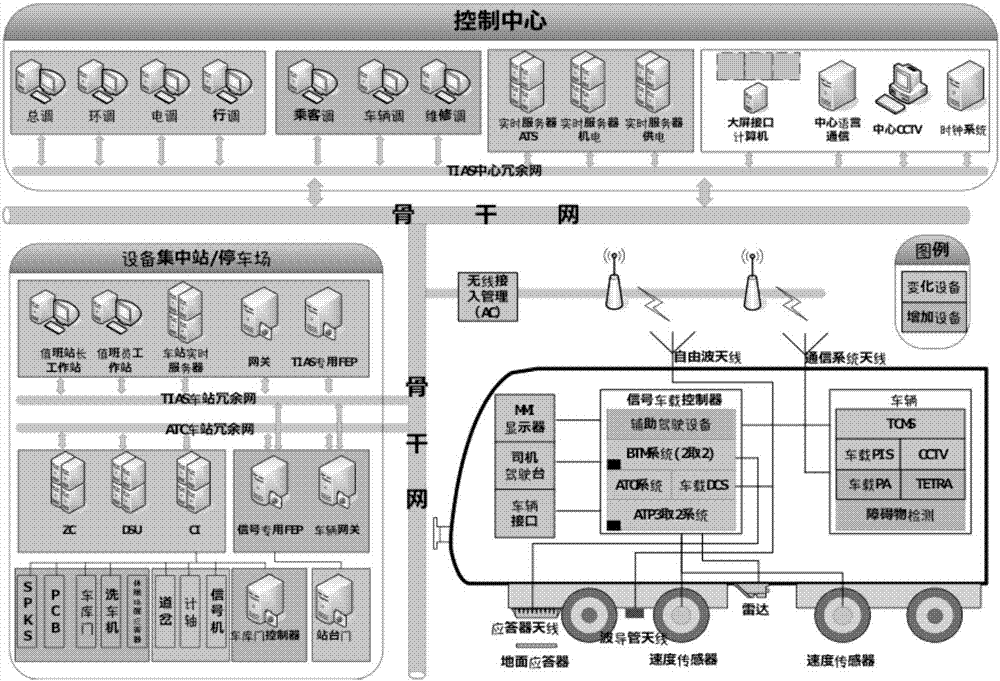

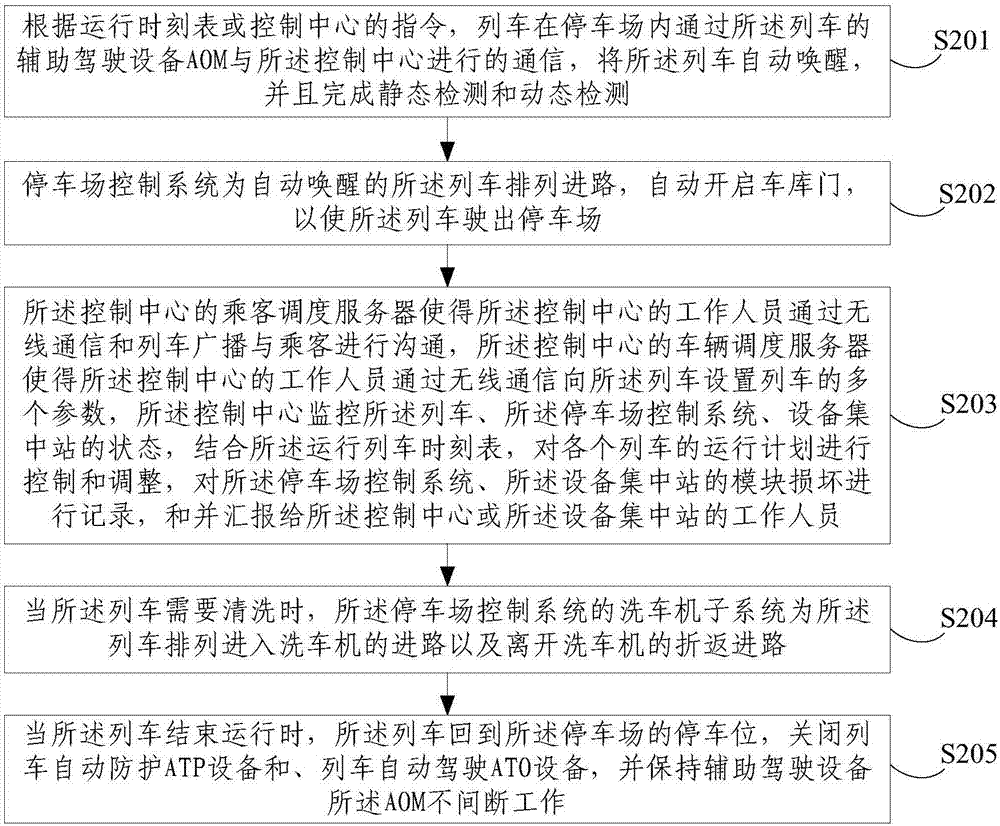

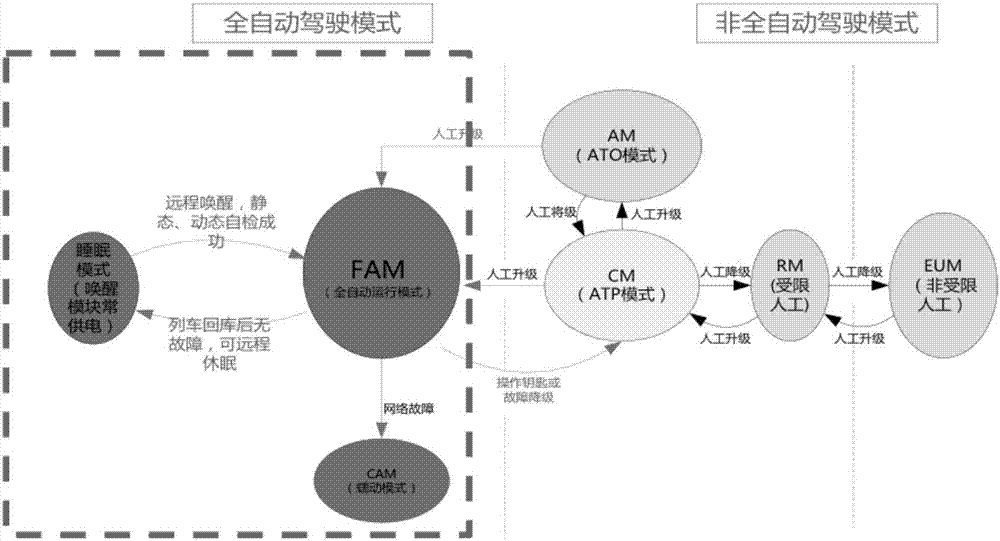

Train full-automatic running method and system

ActiveCN107226099ARealize fully automatic operationImprove reliabilityAutomatic systemsLocomotivesAutomatic train protectionProgram planning

The invention provides a train full-automatic running method and system. The train full-automatic running method comprises the following steps that according to a running schedule or a command of a control center, trains are automatically awakened, and static detection and dynamic detection are completed; a parking lot control system performs route arrangement on the trains which are automatically awakened; the control center monitors the condition of the trains, the condition of the parking lot control system and the condition of an equipment centralization station, and controls and adjusts the running plan of each train combining the running schedule; when the trains need cleaning, a train washing machine sub system of the parking lot control system arranges a route for the trains to enter the train washing machine and a reentrant route for the trains to leave from the train washing machine; and when the trains stop running, automatic train protection ATP equipment and automatic train operation ATO equipment are closed, and AOM is kept working continuously. Compared with a conventional CBTC system, the train full-automatic running method disclosed by the invention realizes full-automatic running, the reliability, the safety, the availability and the maintainability of the train full-automatic running system are further improved, the operating emergency handling level is improved, the automation level is improved, and the labor strength is reduced.

Owner:TRAFFIC CONTROL TECH CO LTD

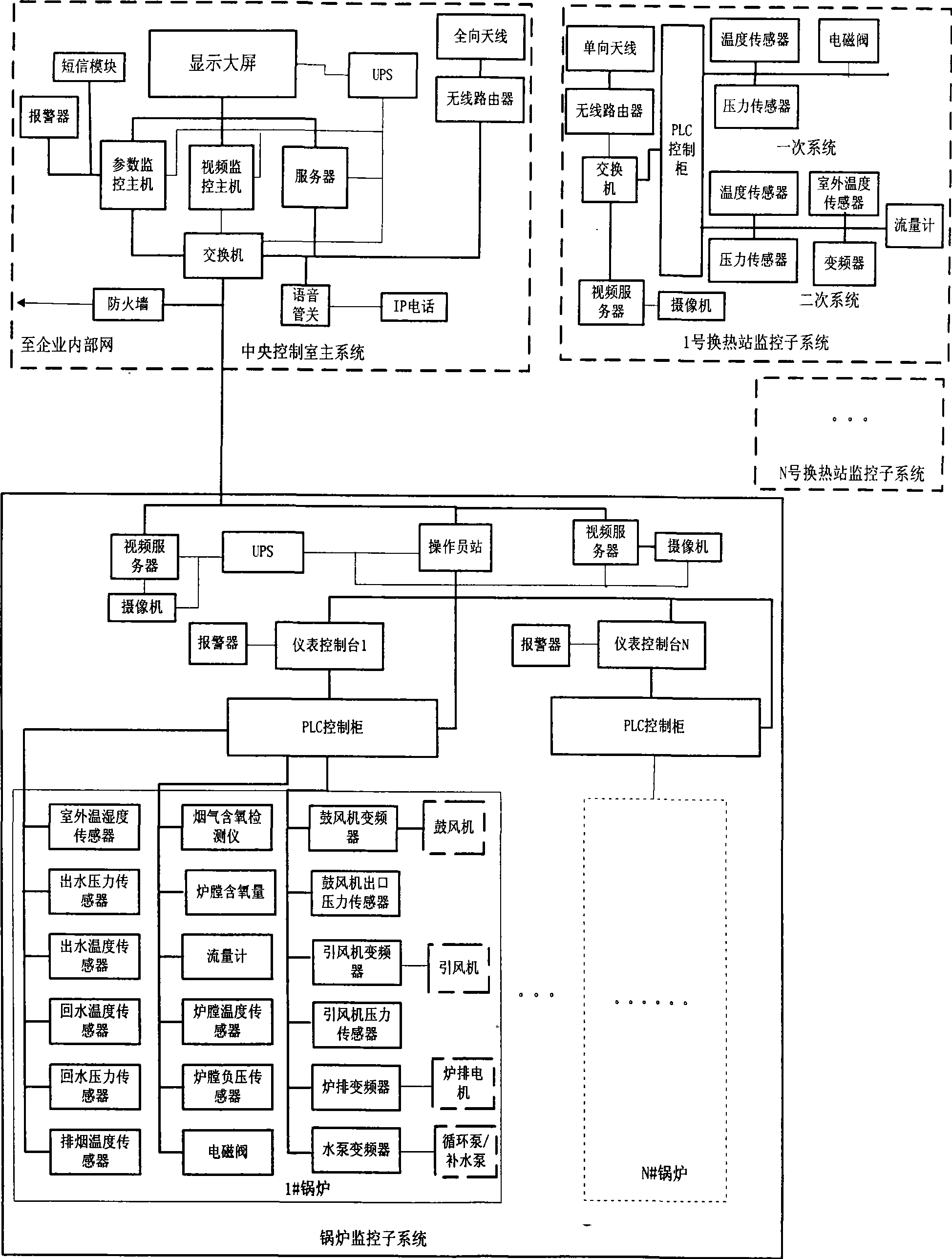

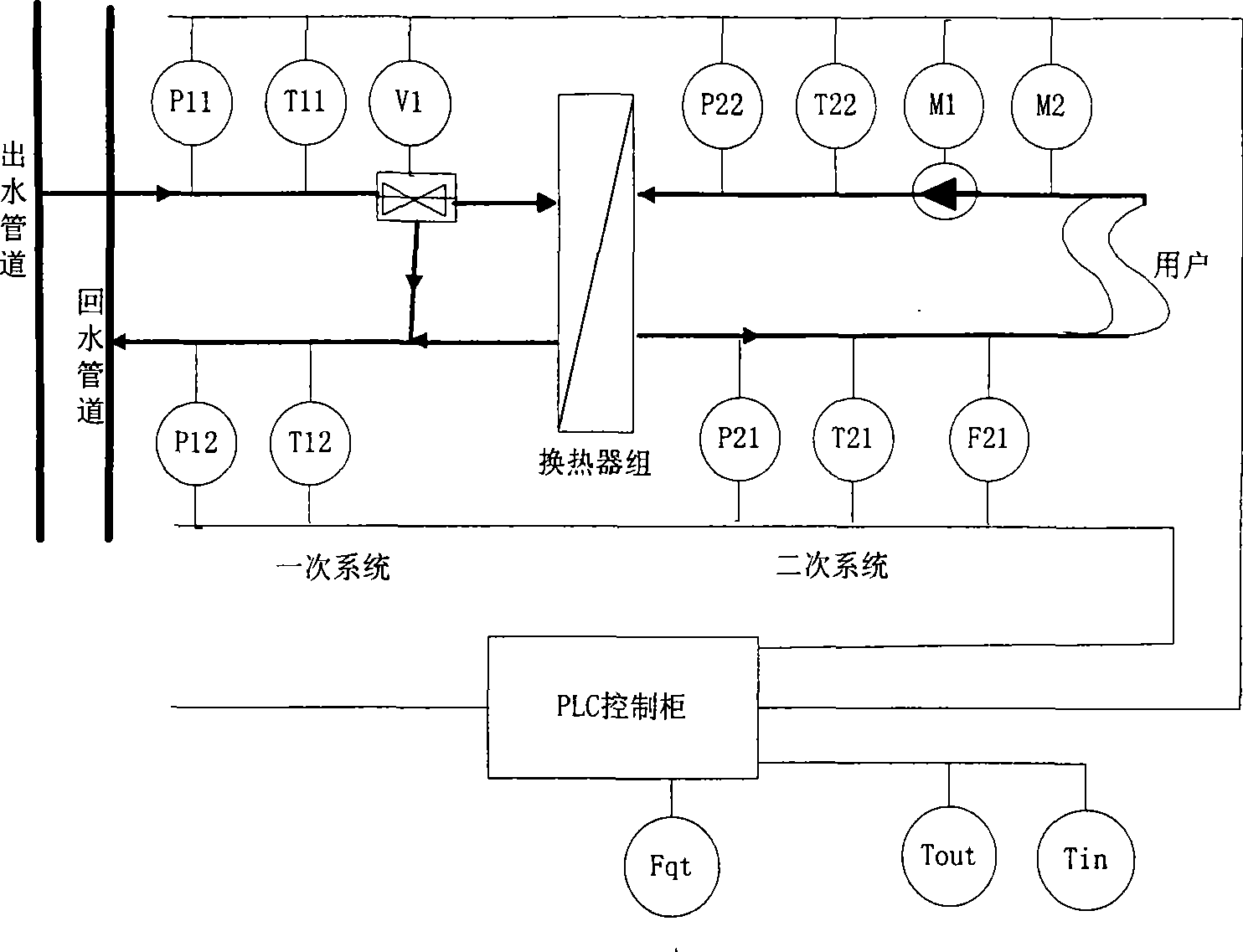

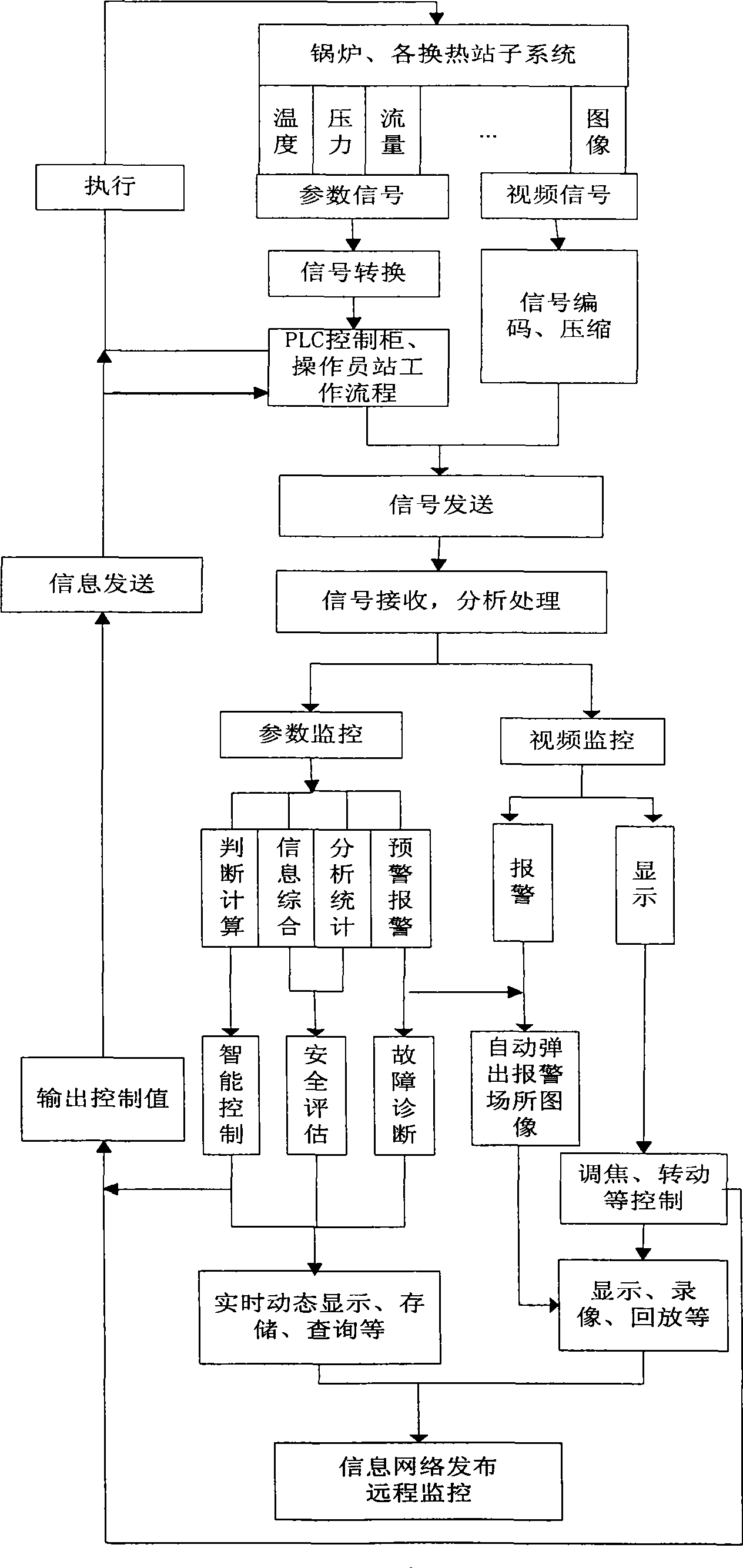

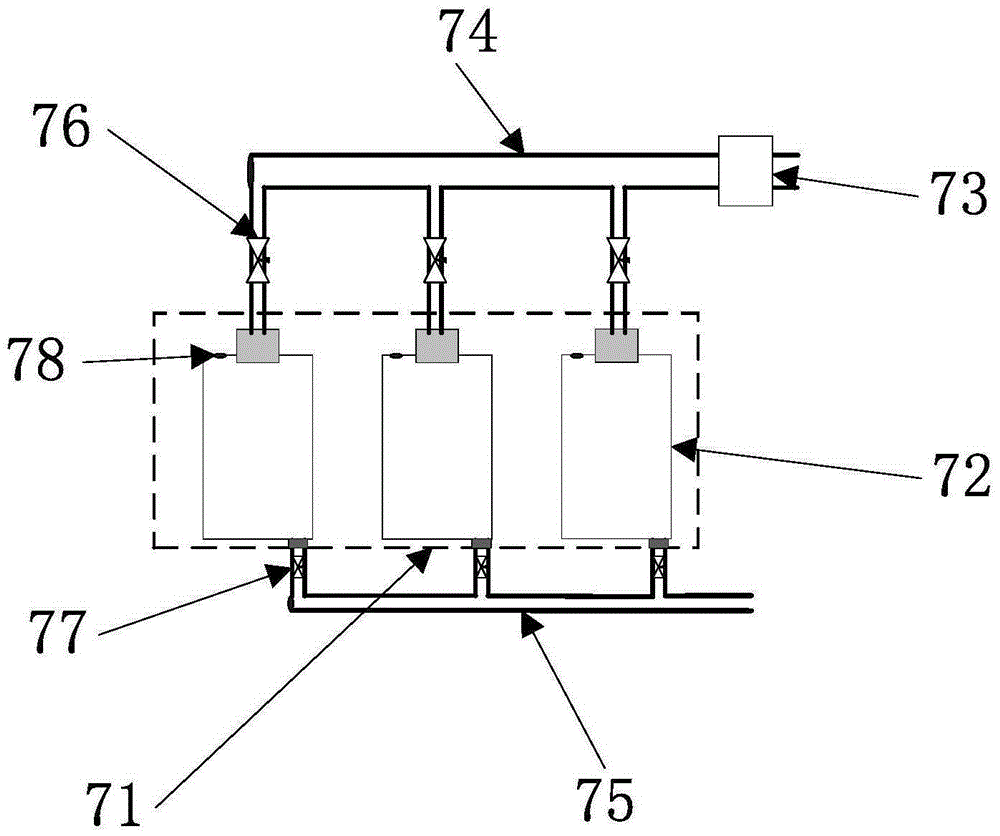

Intelligent monitoring system for boiler and heat exchange station

InactiveCN101498468AImprove operational balance benefitsIncrease the level of automationLighting and heating apparatusSpace heating and ventilation detailsAutomatic controlSignal on

The invention relates to an intelligent monitoring system for a boiler and a heat exchange station and a method thereof, which belong to the technical fields of production monitoring and security management. The system comprises a main system in a central control room, a plurality of boiler monitoring subsystems which are respectively connected with the main system in the central control room and a plurality of heat exchange station monitoring subsystems. The method comprises the following steps: parameters and video signals on site are collected and transmitted in real time and transmitted to a host machine in the central control room after being converted and compressed; the host machine carries out comprehensive processes of intelligent analysis, dynamic display, prewarning and warning and management for the received signals and transmit control commands to the monitoring subsystems to carry out control; and the monitoring subsystems can be cooperated with the central room to carry out monitoring or independently carries out monitoring to realize automatic control. The invention can realize real-time and dynamic intelligent control, prewarning and warning, security management and automatic monitoring for a large boiler or a boiler group and a heating network system and has the advantages of energy saving, consumption reduction, comprehensive analysis, safety, stability and economic operation.

Owner:CHINA ACAD OF SAFETY SCI & TECH

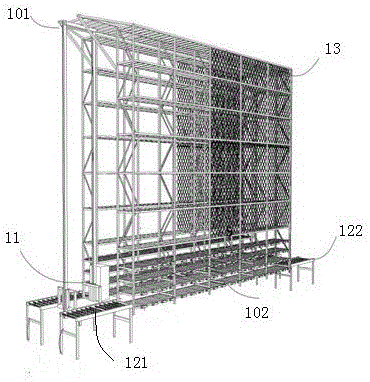

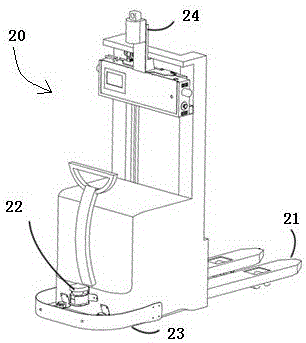

Intelligent warehousing system based on mobile robots

ActiveCN106005866AEasy to sortIncrease the level of automationStorage devicesMobile robotElectronic business

The invention discloses an intelligent warehousing system based on mobile robots. The intelligent warehousing system comprises three-dimensional goods shelves, a gallery stacking machine, an unmanned forklift type mobile robot, a temporary roller storage line, a roller transferring type robot, an automatic sorting type mobile robot and a software system; the temporary roller storage line comprises warehouse-in temporary roller storage lines and warehouse-out temporary roller storage line arranged at the two ends of the three-dimensional goods shelves respectively; the automatic sorting type mobile robot loads sorting baskets bound with orders and moves to sorting area stopping sites corresponding to goods in the orders; the software system comprises an intelligent warehousing management system and an intelligent warehousing control system, the intelligent warehousing management system comprises an information management hierarchy and an intelligent management hierarchy, and the intelligent warehousing control system comprises a dispatching management hierarchy and an execution feedback hierarchy. According to the intelligent warehousing system, especially daily necessity warehousing systems for electronic business retailing, seamless joint from the warehouse-in process to the sorting process can be realized, the automation level is high, the efficiency of the sorting work is improved, and the human cost is lowered.

Owner:苏州海通机器人系统有限公司

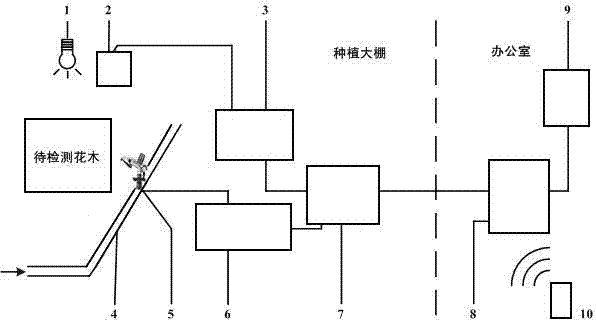

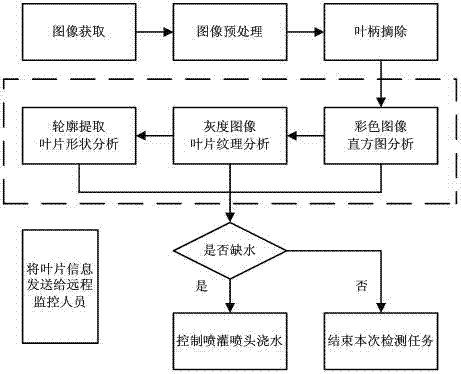

Plant growth condition monitoring system based on compute vision and internet of things

ActiveCN102564593AEasy to monitor remotelyHigh speedColor measuring devicesWatering devicesGrowth plantImaging processing

The invention discloses a plant growth condition monitoring system based on compute vision and internet of things. The plant growth condition monitoring system is characterized by comprising a high speed digital signal processor (DSP) computer vision module for shooting plant leaves and acquiring and analyzing the shot images, a control execution module for watering plants, and an internet of things module for transmitting the plant leaf information to a remote terminal through a remote server and providing the information for workers to consult and operate, wherein the high speed DSP computer vision module, the control execution module and the internet of things module are connected through data. The traditional detection system is improved, a computer vision-based DSP image processing technology and an improved processing algorithm are used for acquiring and processing leaf images of luxurious flowers and trees, the image acquiring and processing speed and accuracy are improved, theautomation level of the system is improved and the production cost is reduced; and the acquired data is timely transmitted to the workers at the terminal through the remote server by the internet of things technology.

Owner:HOHAI UNIV CHANGZHOU

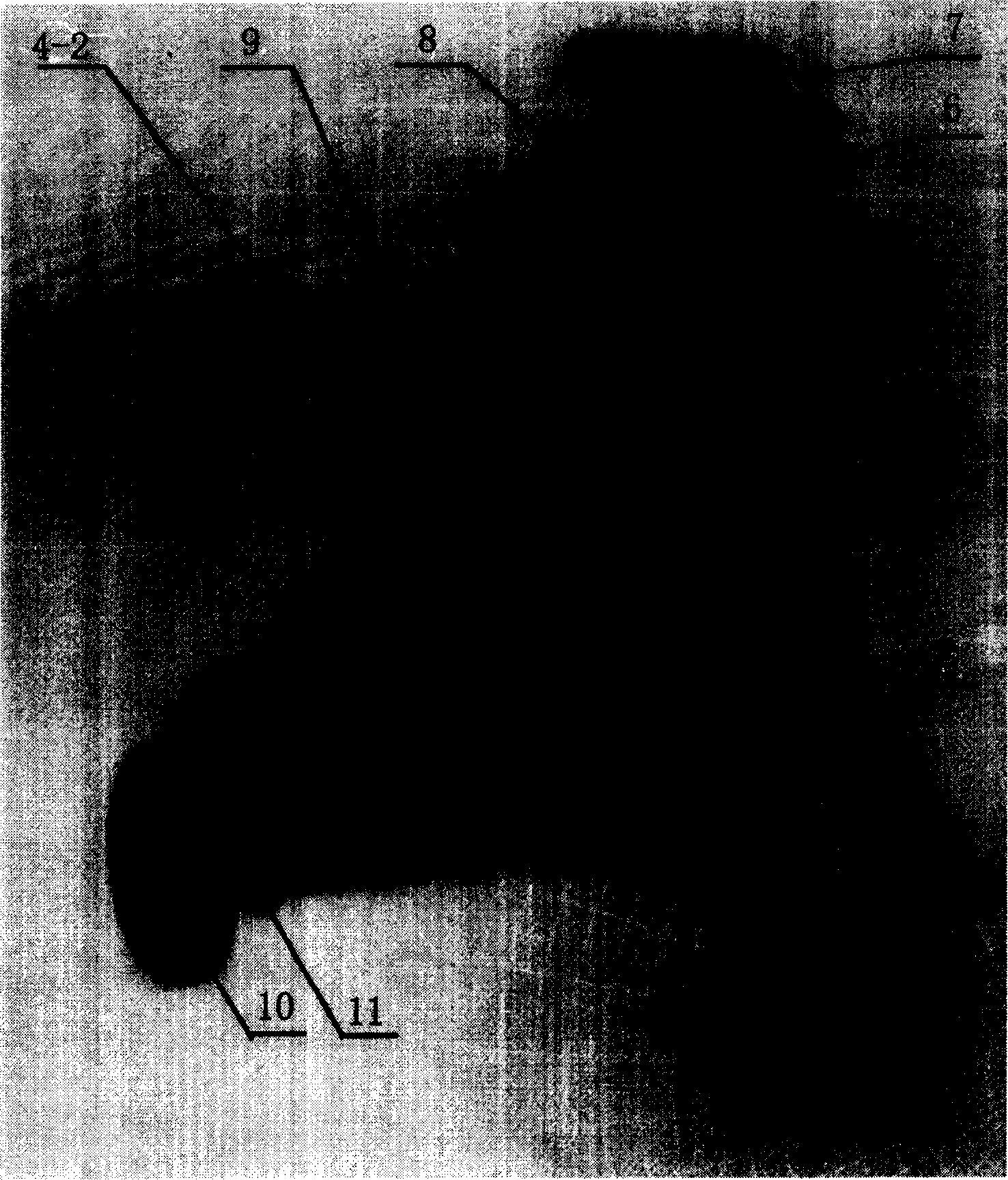

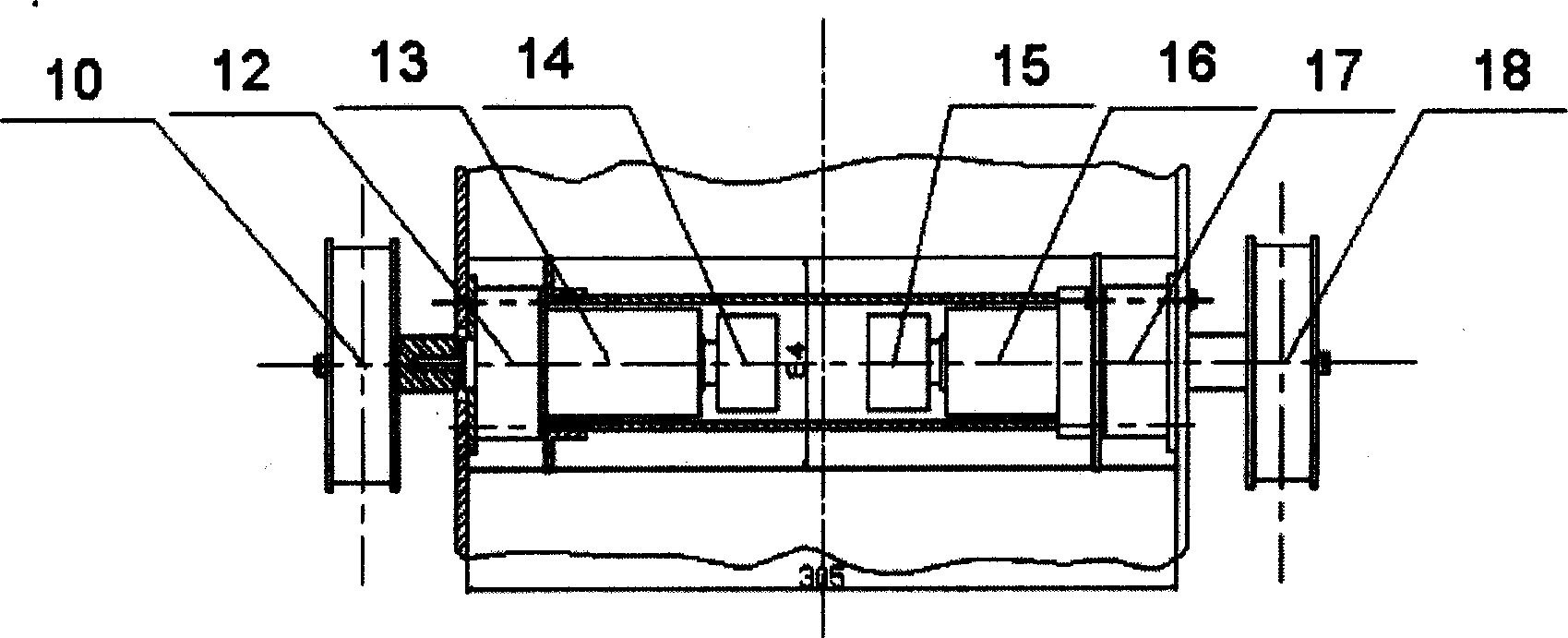

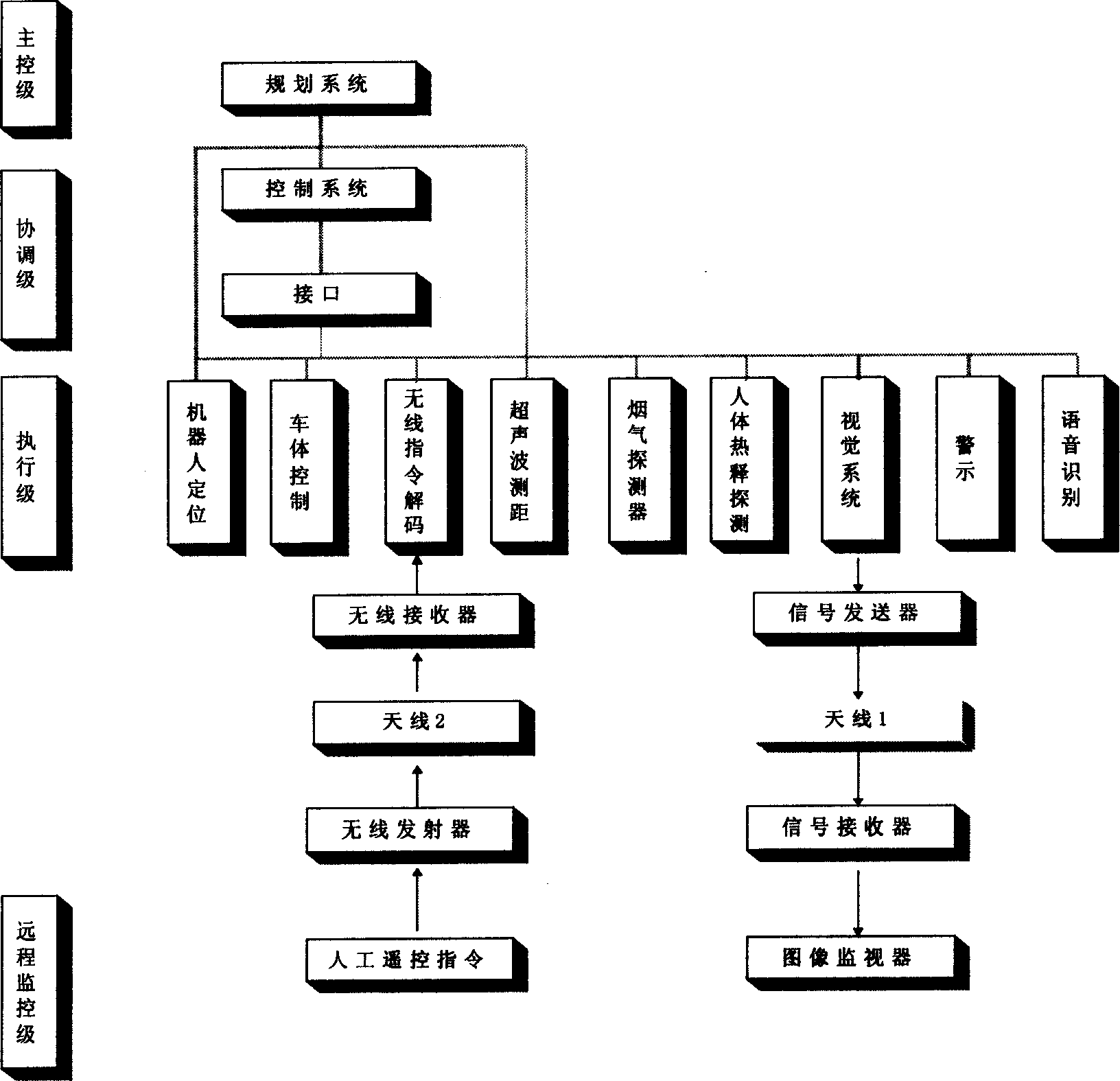

Security ensuring and patrolling robot

InactiveCN1593859AReliable completionStabilize security patrol tasksManipulatorControl systemPatrolBot

The invention relates to a kind of patrolling robot. It consists of robot body, the movable controlling unit and the bearing rack of which is fixed firmly to the outer shell; anti- stakeout system, which consists of infrared temperature sensor, smoking sensor, hot releasing infrared sensor, mini CCD camera eye, signal lamp, buffer, and graphic message wireless conveying module; the controlling system that sends message to control the robot to patrol, move to control and give an alarm automatically within the circumstance; multi-sensor system. The robot can patrol along the scheduled path, and judge the location is at according to the messages from the sensors to avoid the impediment and change the moving path. The invention is more suitable to increasing onerous security task, and improves the atomicity of security work.

Owner:SOUTH CHINA UNIV OF TECH

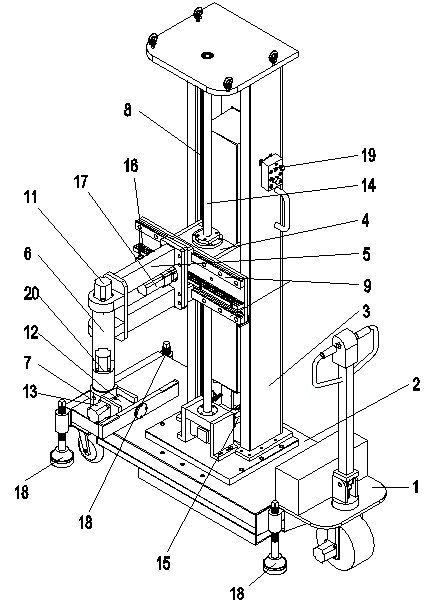

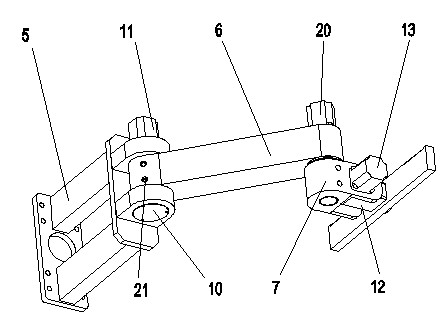

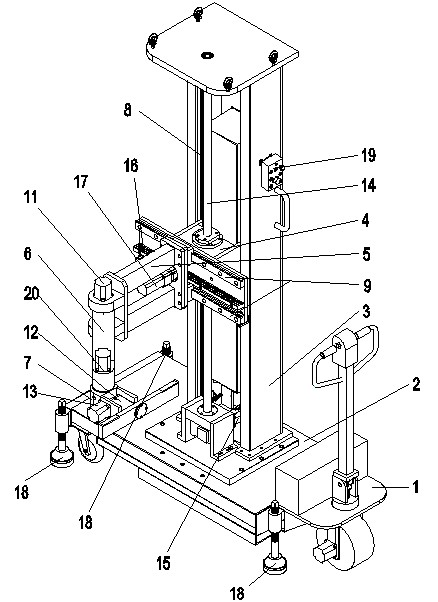

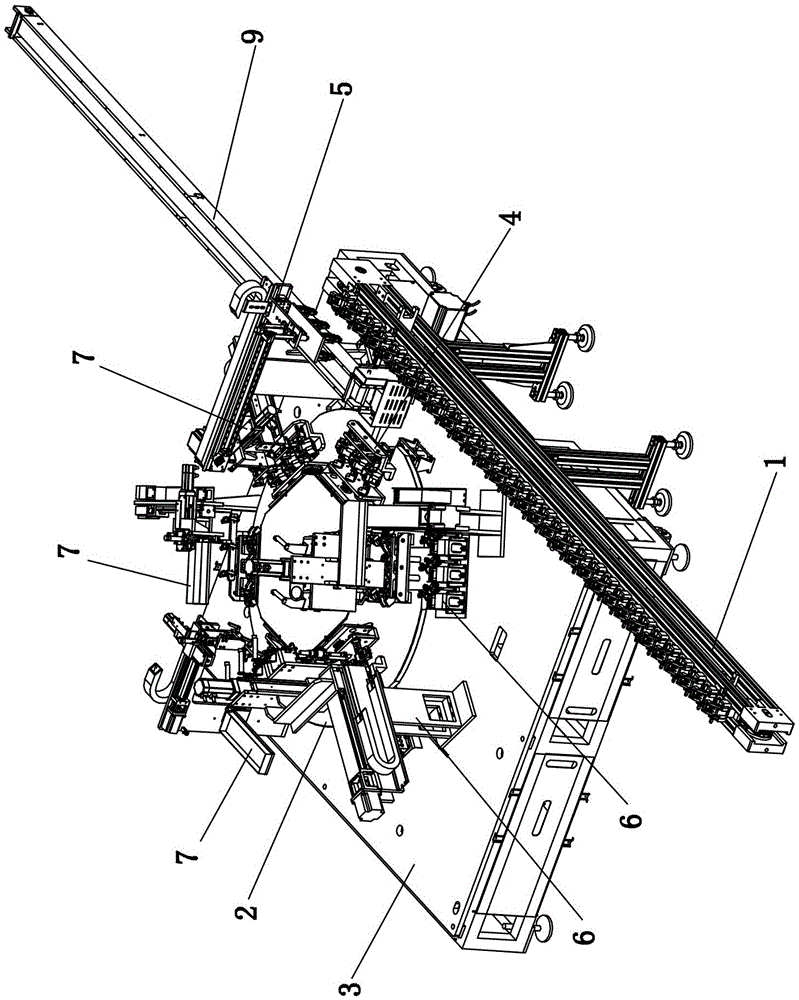

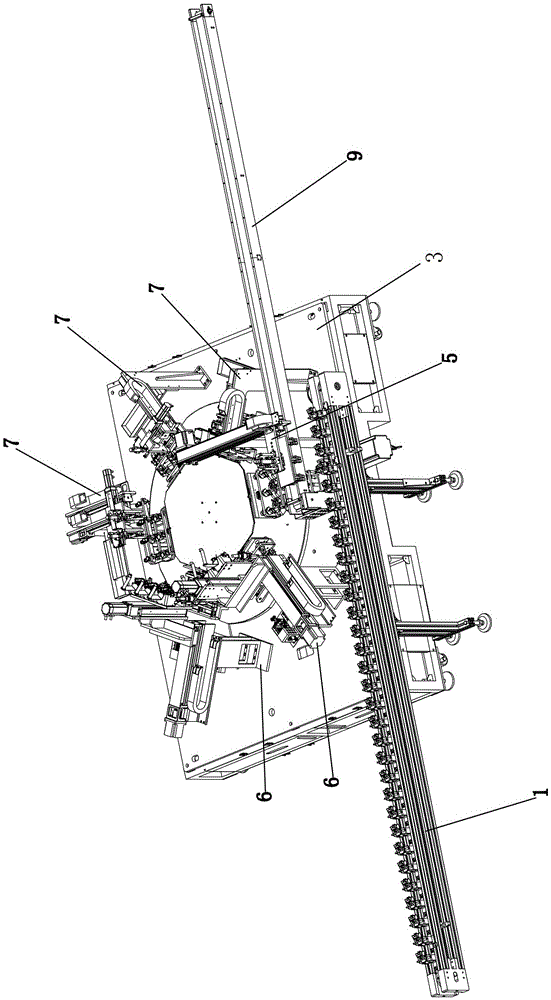

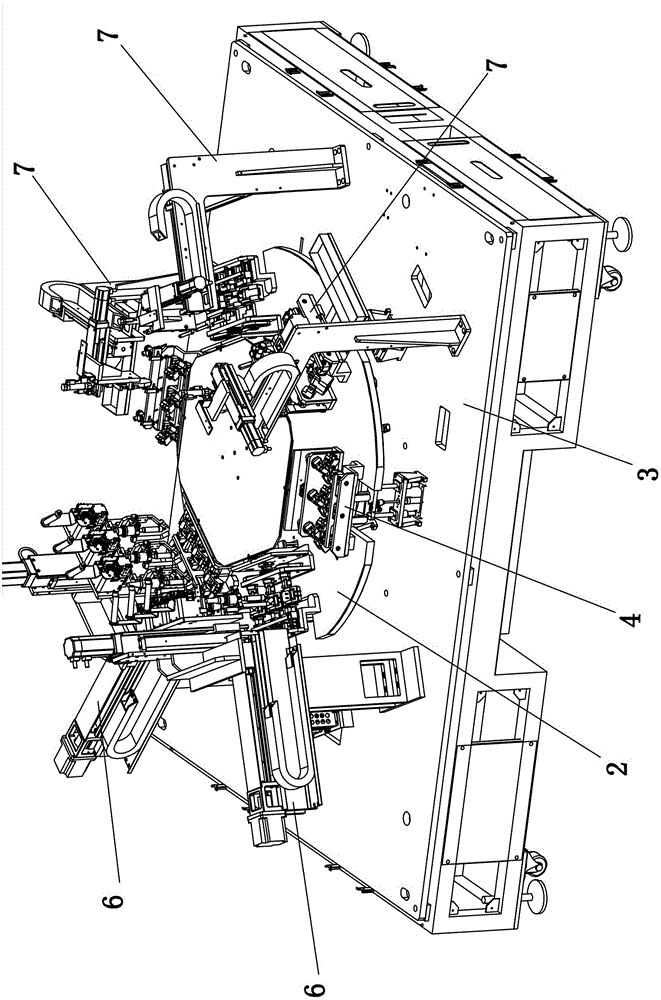

Handling and calibrating manipulator

InactiveCN102020113ASimple structureEasy to operateProgramme-controlled manipulatorConveyor partsDrive motorActuator

The invention discloses a handling calibrating manipulator which comprises an electric table truck (1), a lifting platform (2), a rack (3), an up-and-down movable rack (4), a left-and-right movable rack (5), a rotating arm (6), a front end actuator (7) and the like. The rack (3) and an up-and-down movable guide way (8) are connected by a screw-nut transmission mechanism; the up-and-down movable rack (4) and the left-and-right movable rack (5) are connected by a gear-rack transmission mechanism; the rotating arm (6) rotates around a rotating shaft (10) which is arranged on the front end of the left-and-right movable rack (5); and the front end actuator (7) is installed on the other end of the rotating arm (6) and respectively connected with a deflection driving motor (12) and a pitch driving motor (13). The invention can adjust and calibrate objects (or modules) to be loaded in a multi-pose mode and has the advantages of high positioning accuracy, simple structure, convenient operation and the like.

Owner:CHONGQING UNIV

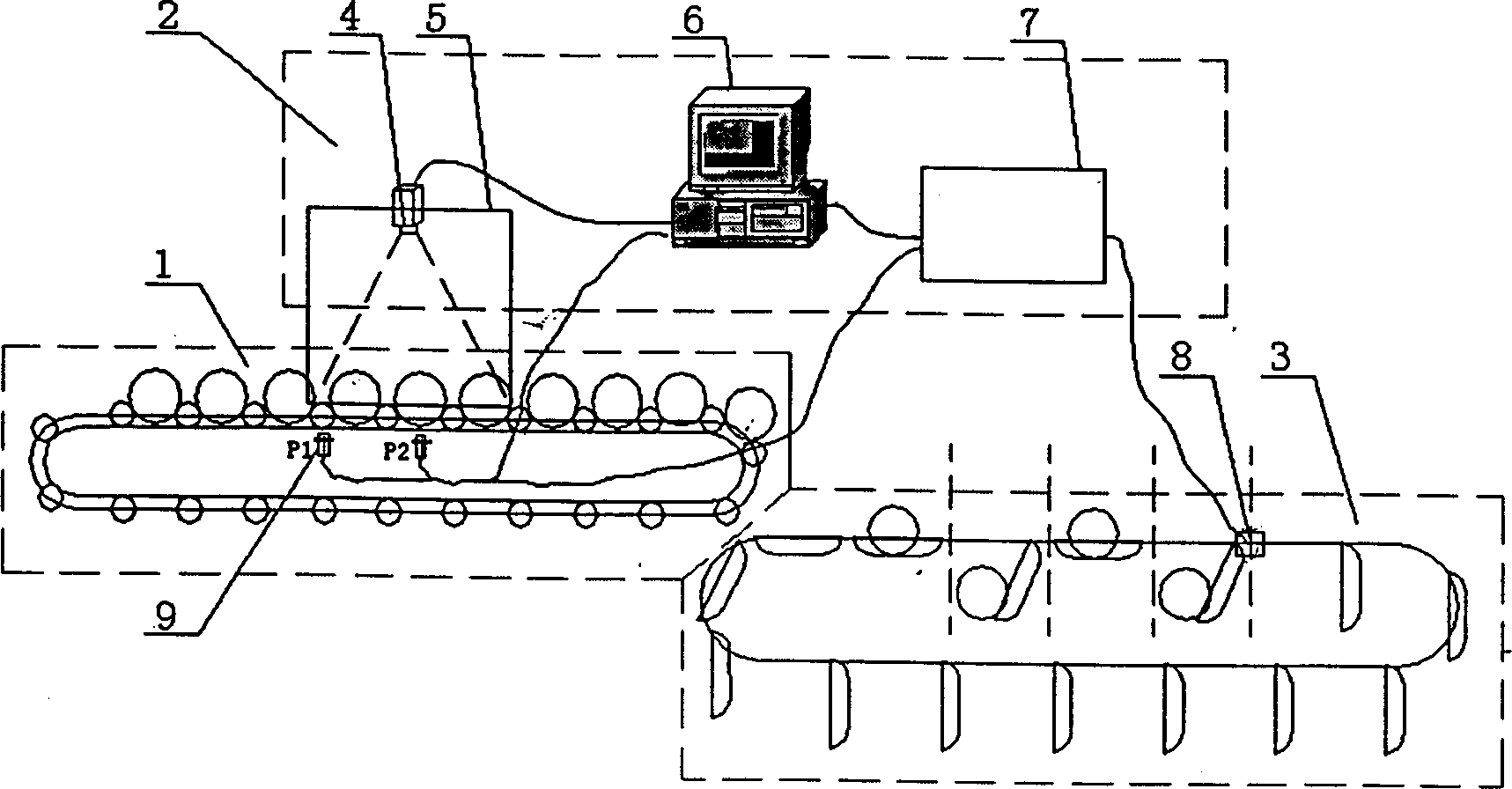

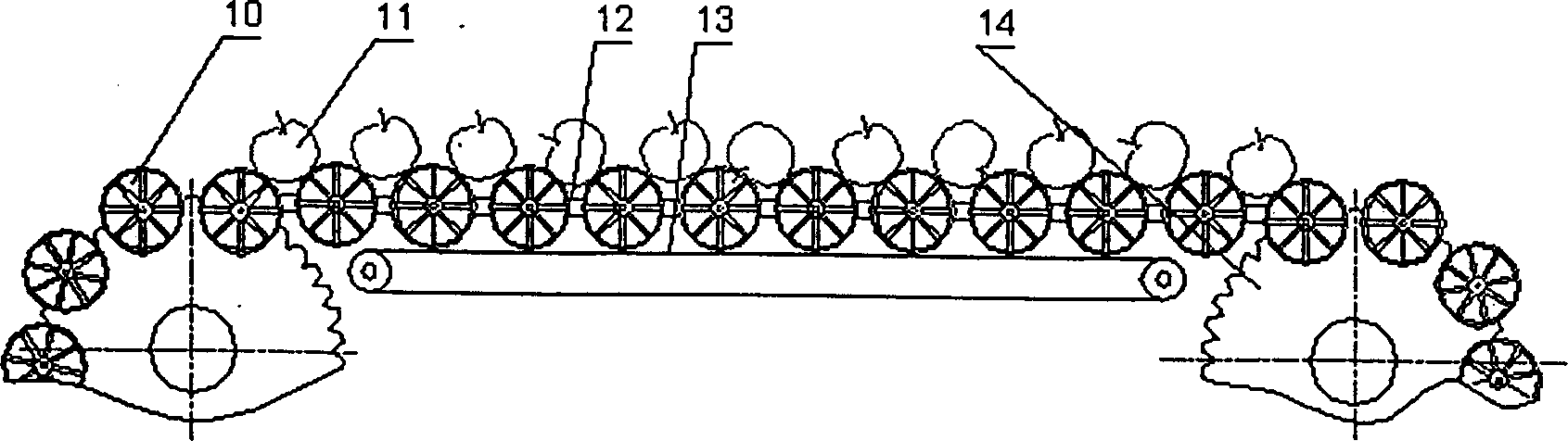

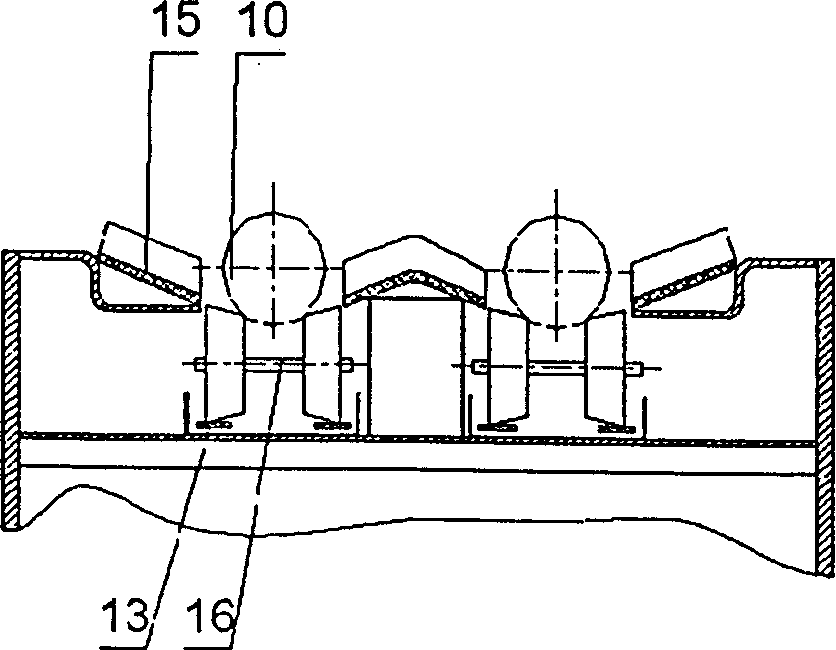

Fruit quality real time detection and grading robot system

The fruit quality real-time detection and sorting robot system is formed from fruit conveying and turning component, computer vision identification component and autoamtic sorting component. The double-cone rollers of fruit conveying and turning component can make fruits, automatically form single line arrangement, and can forward convey fruits at a certain speed, at the same time make the fruits uniformly turn around horizontal small shaft so as to make computer vision identification component detect whole surface of every fruit, including shape, size, colour, surface smoothness and surface defect and injury and obtain quality information of every fruit, and define its grade and position information, said information can be transferred into automatic sorting component to make fruit fall into its correspondent fruit collecting box so as to implement automatic of fruit detection and sorting process.

Owner:ZHEJIANG UNIV

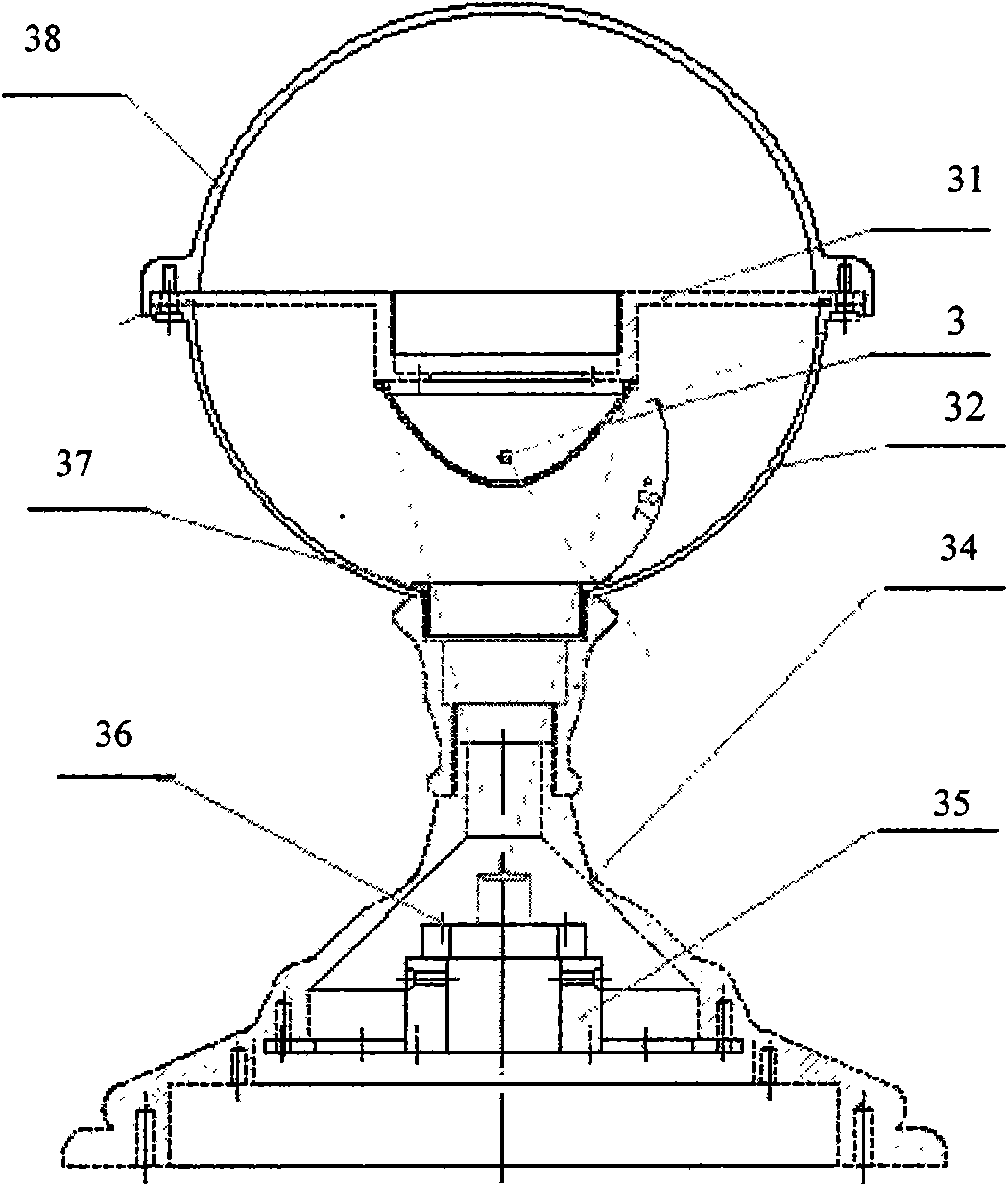

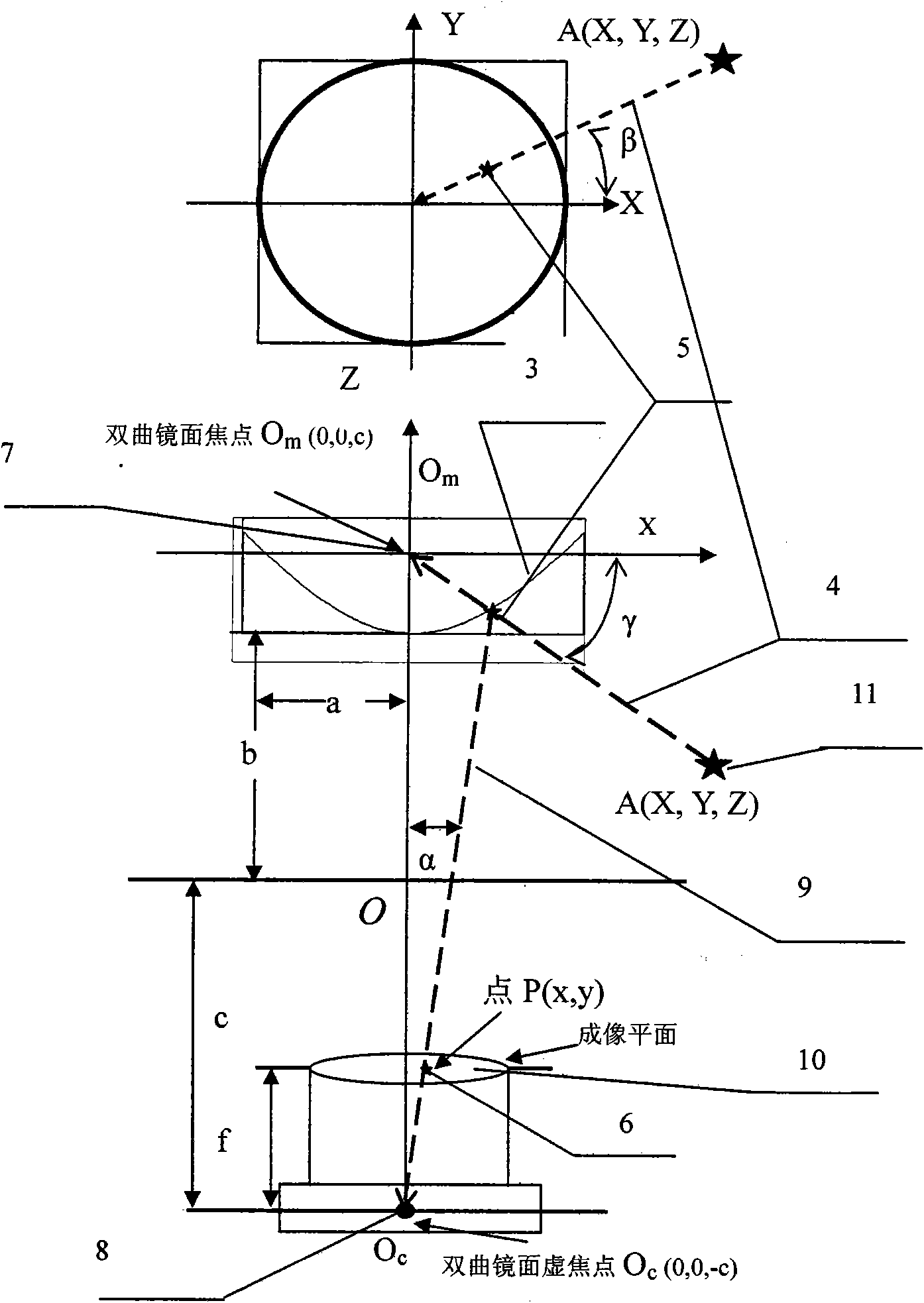

Biometrics-based device for detecting indentity of people and identification

InactiveCN101669824AReduce work intensityReduce error ratePerson identificationCharacter and pattern recognitionFace detectionProcess module

The invention discloses a biometrics-based device for detecting identity of people and identification, which comprises an omni-directional vision sensor used for acquiring the facial image of an ID card holder, an ID card reader used for reading the photograph information in a bulit-in chip of the second-generation ID card and a microprocessor used for comparing whether the facial photograph imagestored in the built-in chip of the second-genration ID card and the facial images acquired by the omni-directional vision sensor are consistent or not, wherein the microprocessor comprises a data module used for reading photograph image in the ID card, a first facial detecting module, a first facial feature extraction module, a panoramicpicture reading module, a second facial detecting module, animage expanding module, a second facial feature extraction module, an identity detecting module for the biological feature of people and the ID card and a decision-layer voting and processing module.The device adopts biometrics identification technology, can greatly improve the efficiency for validating the ID card, and reduce the working strength and error rate of office personnels.

Owner:ZHEJIANG UNIV OF TECH

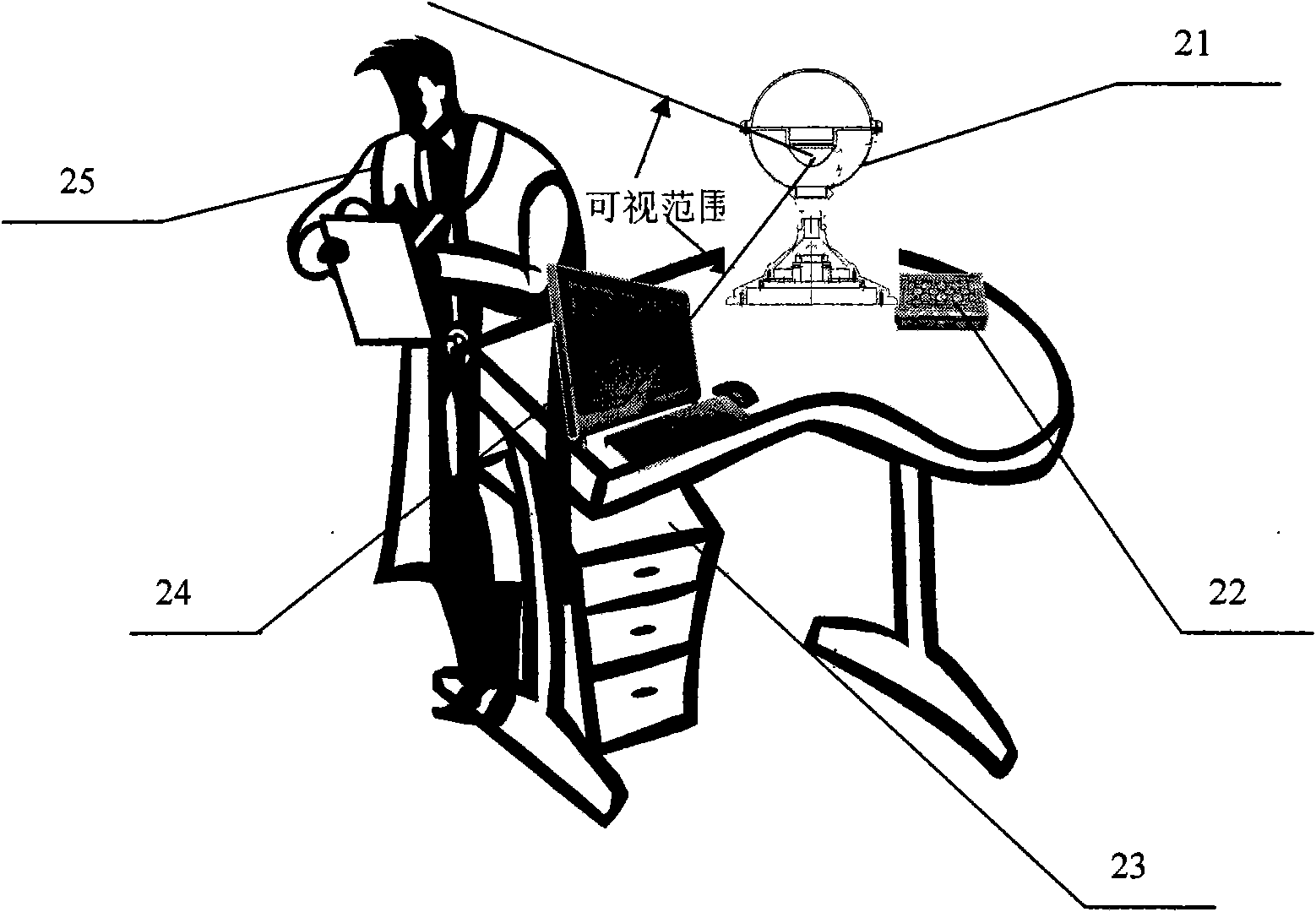

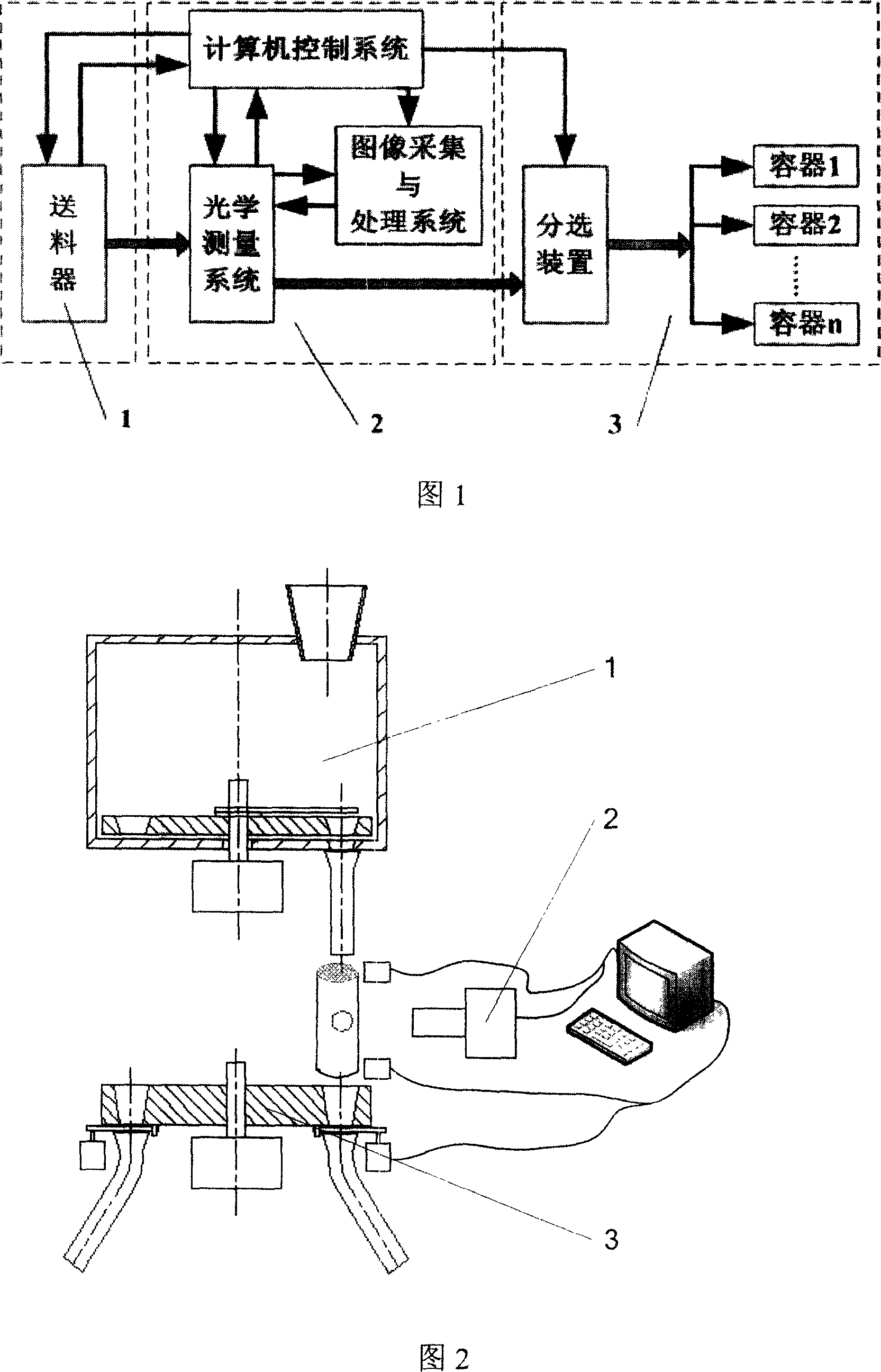

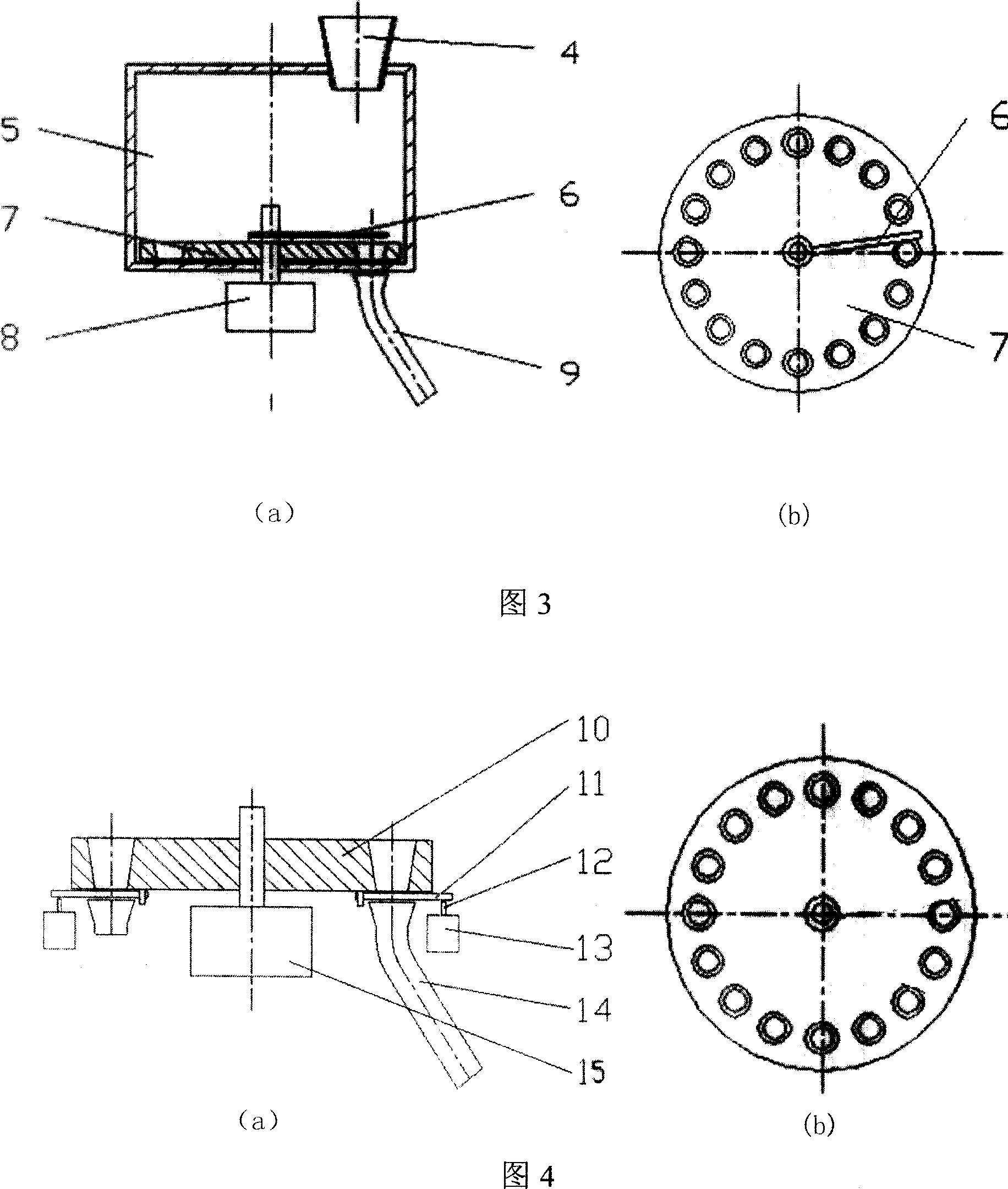

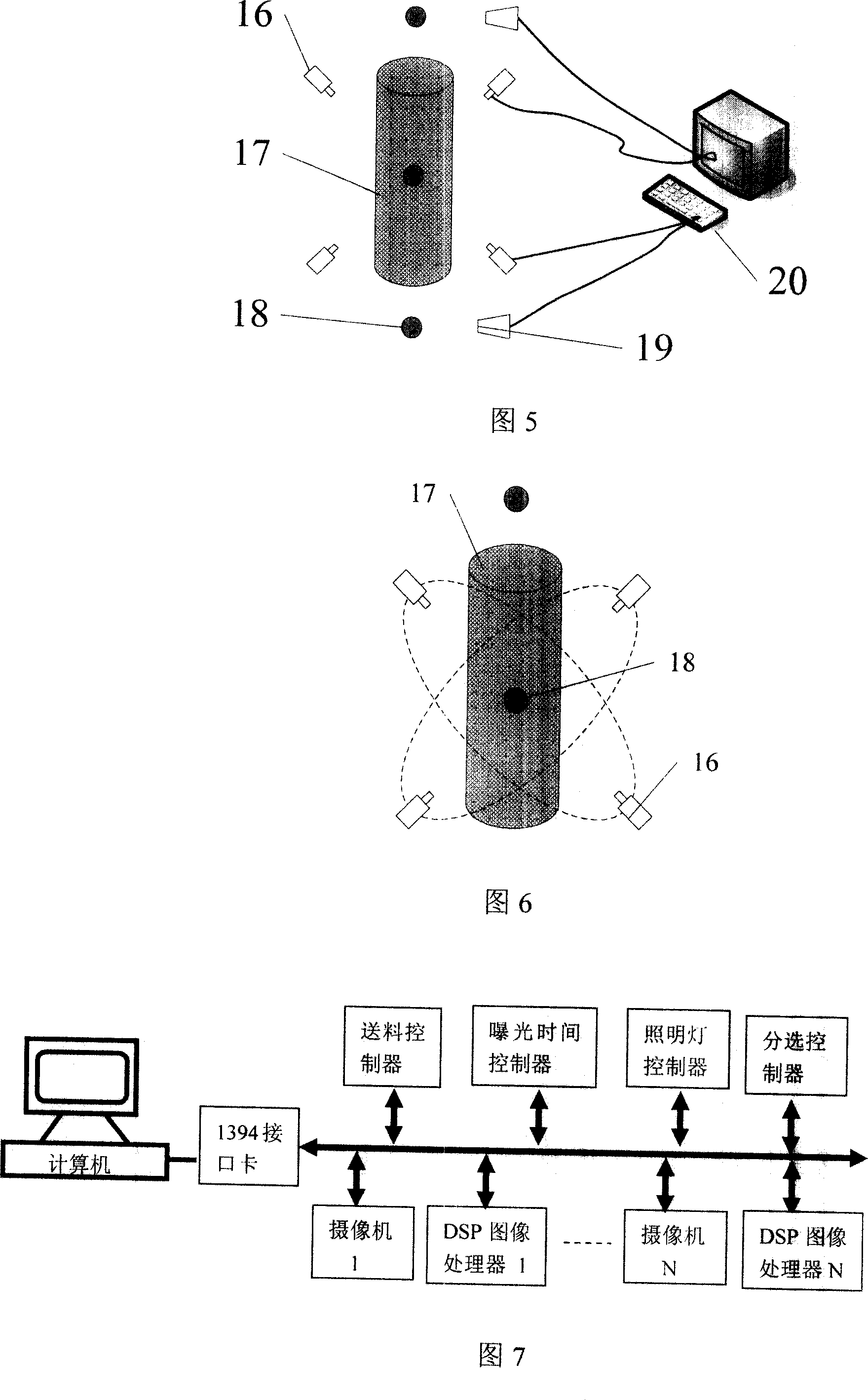

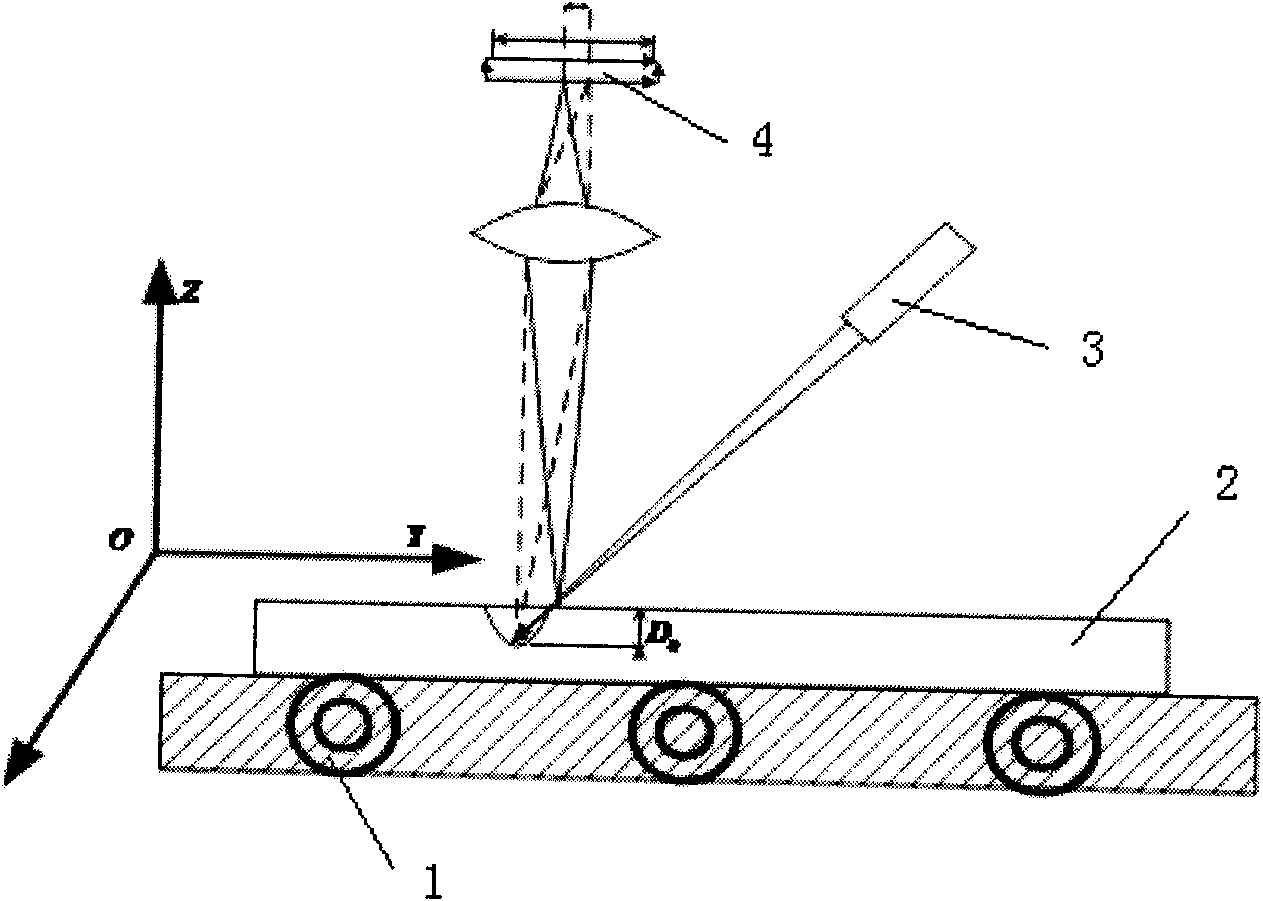

Pearl real time detection and classifying system based on mechanical vision

InactiveCN101007308AAccurate acquisitionEfficient acquisitionPhotogrammetry/videogrammetrySortingFree fallingMachine vision

The invention discloses pearl real-time detection and grading system based on machine vision which includes: computer vision recognition component which is equipped under the charging conduit of pearl charging device, and pearl sorting device is equipped under the computer vision recognition component. Using the computer vision technology, collecting image of sequential free-falling pearl surface, sending the collected image to DSP and computers and other hardware apparatus to dealing, then distinguishing the pearl classification standard instantaneously through the dealing results, last sending the distinguishing information to sorting device to achieving classification of pearl with different characteristics automatically using devices. It can get pearl whole surface image, can complete the testing of whole apparent quality index such as pearl size, shape, smooth, defect and color, etc. simultaneously, achieve the rapid real-time detection and grading. The system can adapt to different classification speed, and the structure is simple, adaptability is strong.

Owner:ZHEJIANG UNIV

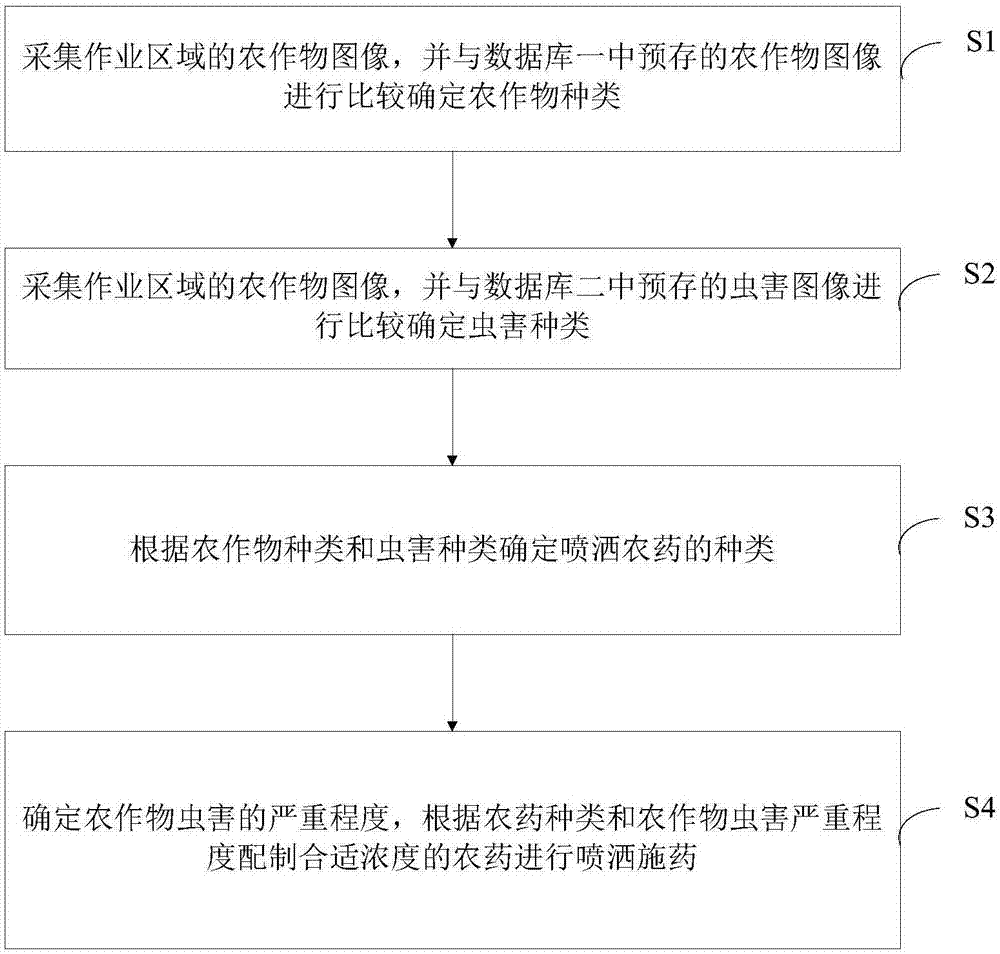

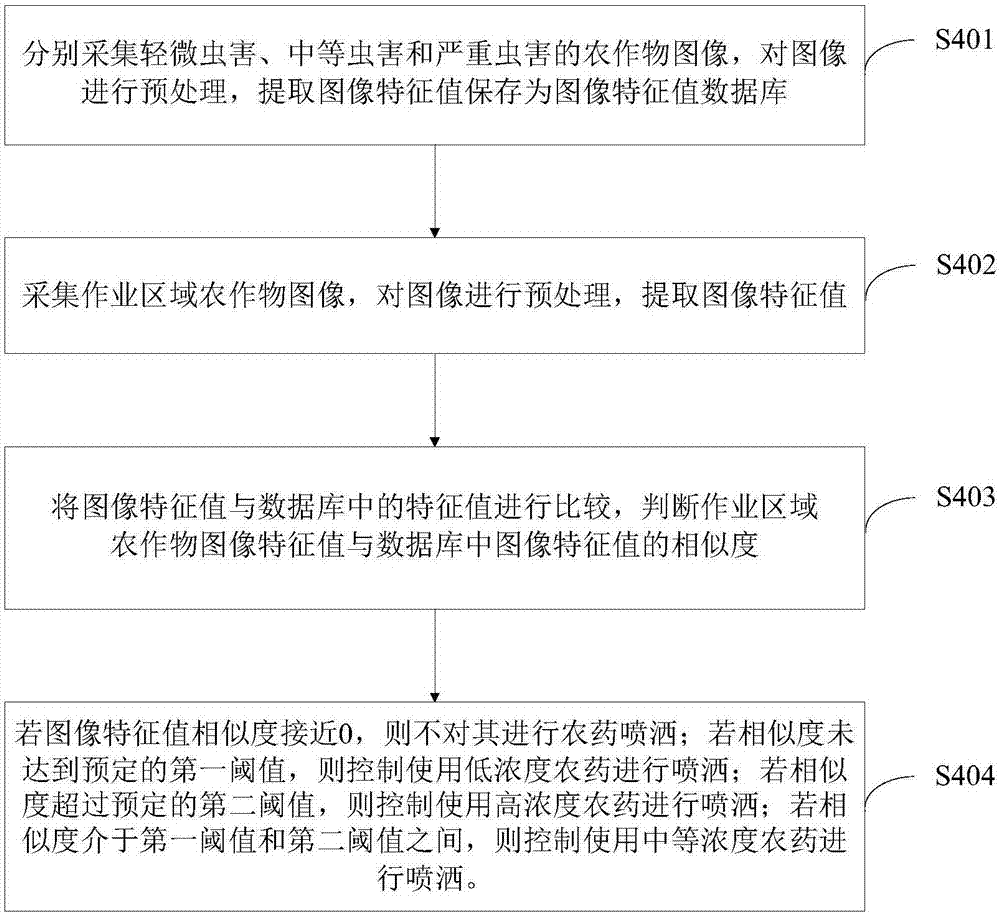

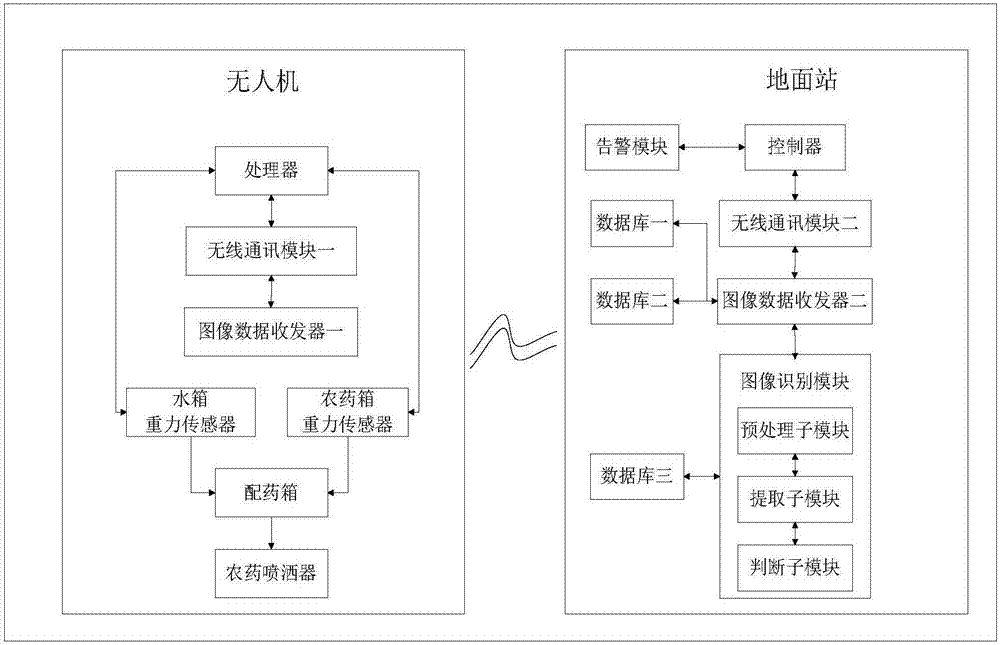

Unmanned aerial vehicle pesticide spraying method and system

InactiveCN106956778AIncrease profitAvoid wastingAircraft componentsTransmission systemsUncrewed vehicleComputer science

The invention relates to the technical field of unmanned aerial vehicles, and provides an unmanned aerial vehicle pesticide spraying method and system. The unmanned aerial vehicle pesticide spraying method comprises the following steps: (1) acquiring crop images of a working area, and comparing the crop images with crop images stored in a databank I in advance so as to confirm types of crops; (2) acquiring crop images of the working area, and comparing the crop images with insect images stored in a databank II in advance so as to confirm types of insects; (3) confirming types of insecticides to be sprayed according to the types of the crops and the types of the insects; (4) confirming the serious degree of crop insects, preparing insecticides of proper concentration according to the types of the insecticides and the serious degree of the crop insects, and spraying the insecticides. As the insecticides are automatically specifically sprayed according to the types of the crops and the crop insects, the insecticide spraying effects and the utilization rates of the insecticides can be improved, insecticide waste can be avoided, the cost can be reduced, and the intelligence and automation levels of the insecticide spraying process are increased.

Owner:GUANGDONG RONGQE INTELLIGENT TECH CO LTD

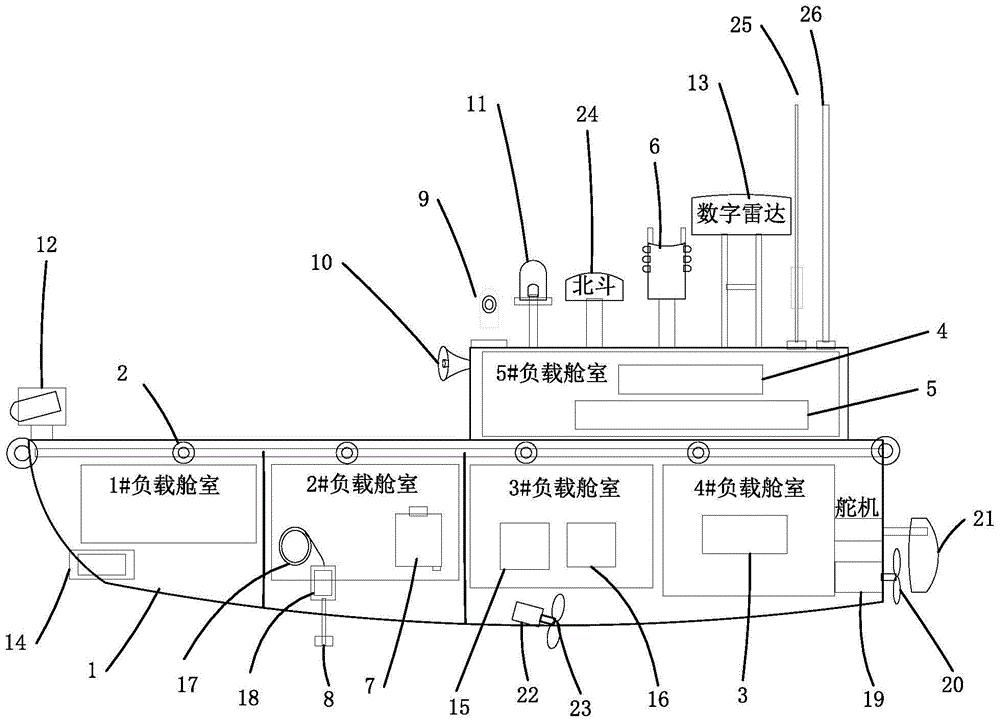

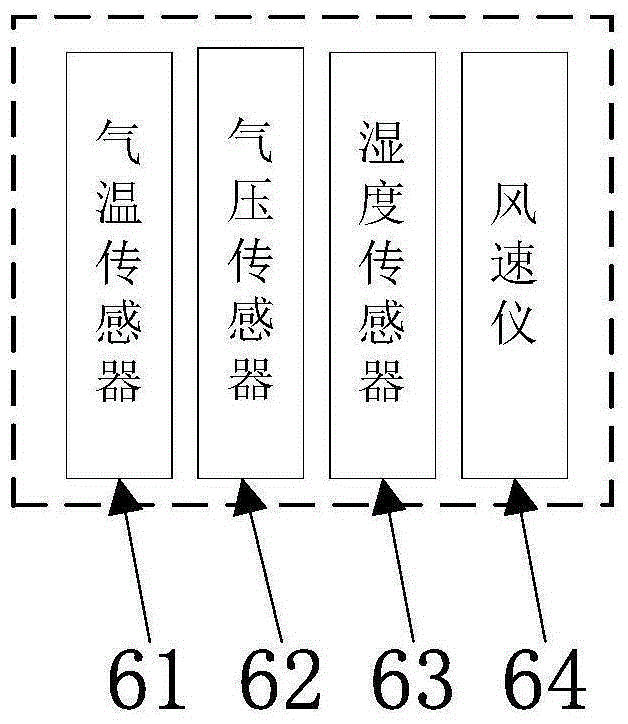

Unmanned ship achieving multi-function monitoring of water area

InactiveCN105242023AIncrease the level of automationCost-effectiveTesting waterPosition/course control in two dimensionsMonitoring dataMultiple function

The invention provides an unmanned ship achieving multi-function monitoring of a water area. The unmanned ship comprises a ship hull and a power device, a control apparatus and an application apparatus which are arranged on the ship hull, and five load compartments are arranged on the ship hull; the control apparatus comprises a programmable controller, a navigation device and a communication device, the programmable controller is connected with the power device, the navigation device, the communication device and the application apparatus through communication interfaces, and the programmable controller is used for receiving monitoring data and operation information of the power device, the navigation device, the communication device and the application apparatus and sending control instructions to the power device, the navigation device, the communication device and the application apparatus through the communication interfaces; the ship hull is further provided with a water quality sampling apparatus. The unmanned ship takes the programmable controller as the core, an internal bus and communication board cards are adopted to uniformly manage other apparatuses. The unmanned ship is high in cost performance, convenient to carry and easy to operate, the functions such as environment monitoring, water quality monitoring, water quality sampling and flow rate monitoring are integrated into a whole, and the water area monitoring operation efficiency is greatly improved.

Owner:SIFANG JIBAO WUHAN SOFTWARE CO LTD

Battery assembling and packaging device

ActiveCN101789525AIncrease the level of automationImprove performanceFinal product manufactureNon-aqueous electrolyte cellsProduction linePunching

The invention relates to a battery assembling and packaging device, comprising an aluminium plastic film forming flaking unit, an assembling and packaging unit, an electrode group charging unit and an auxiliary unit. Aluminium plastic film punching and forming, electrode group feeding and automatic assembly of the two are sequentially realized, then top edge and side edge of packaging bag are sealed and adhered, and test classification is carried out on packaging product, thus automation of batter production line can be effectively improved. The invention has the advantages of convenient operation, high production efficiency, reliable product performance, low production cost and less waste.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

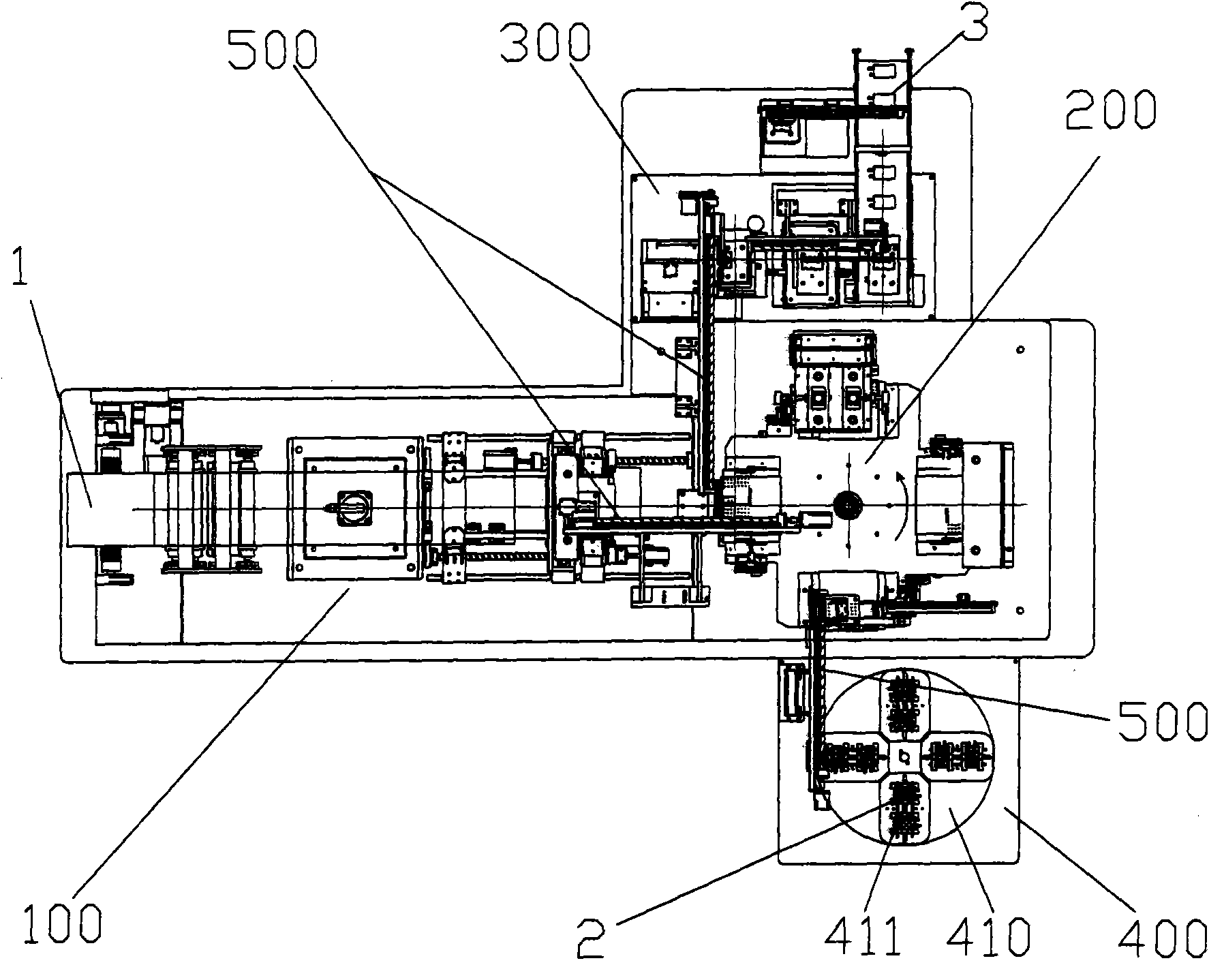

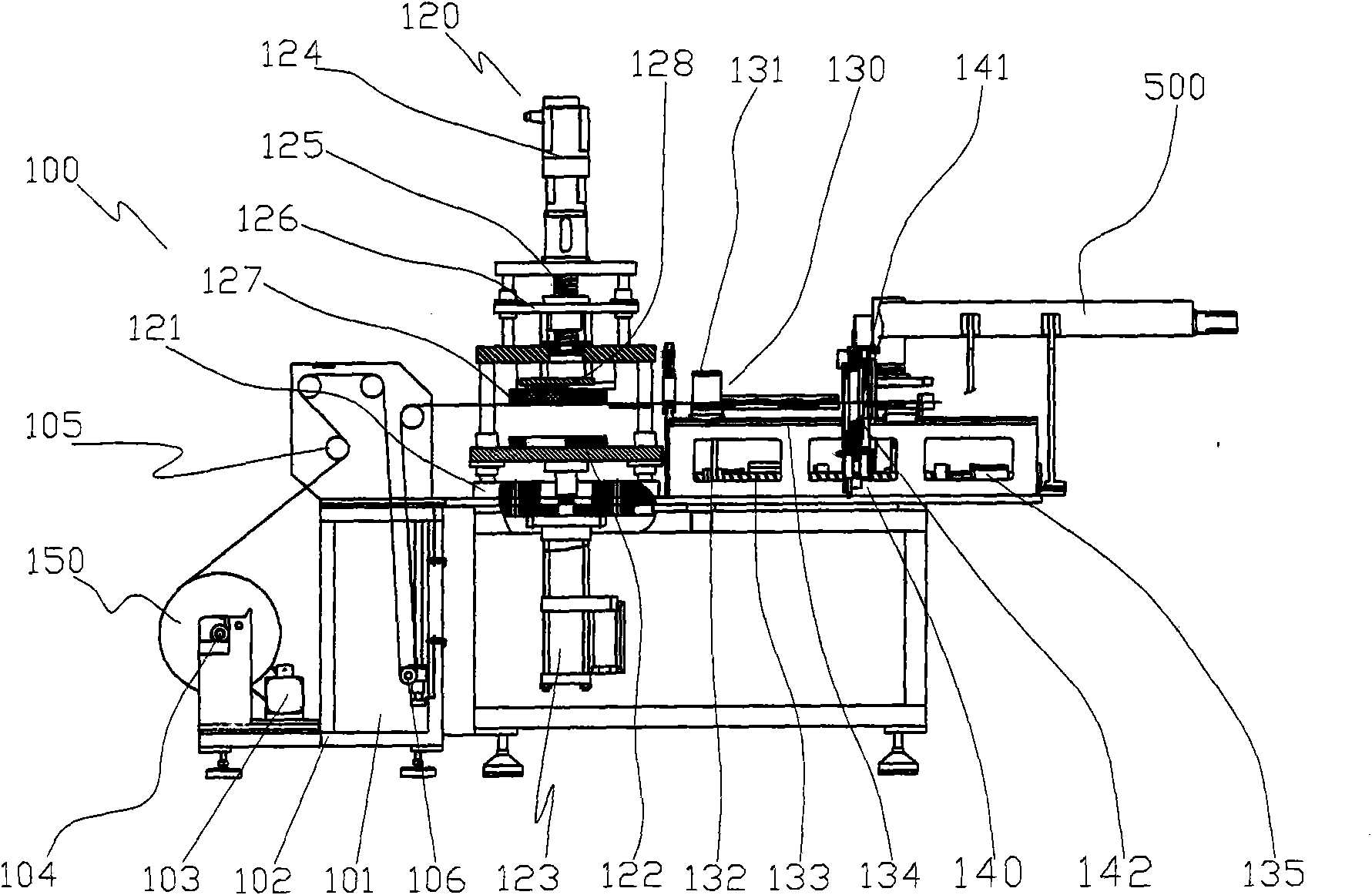

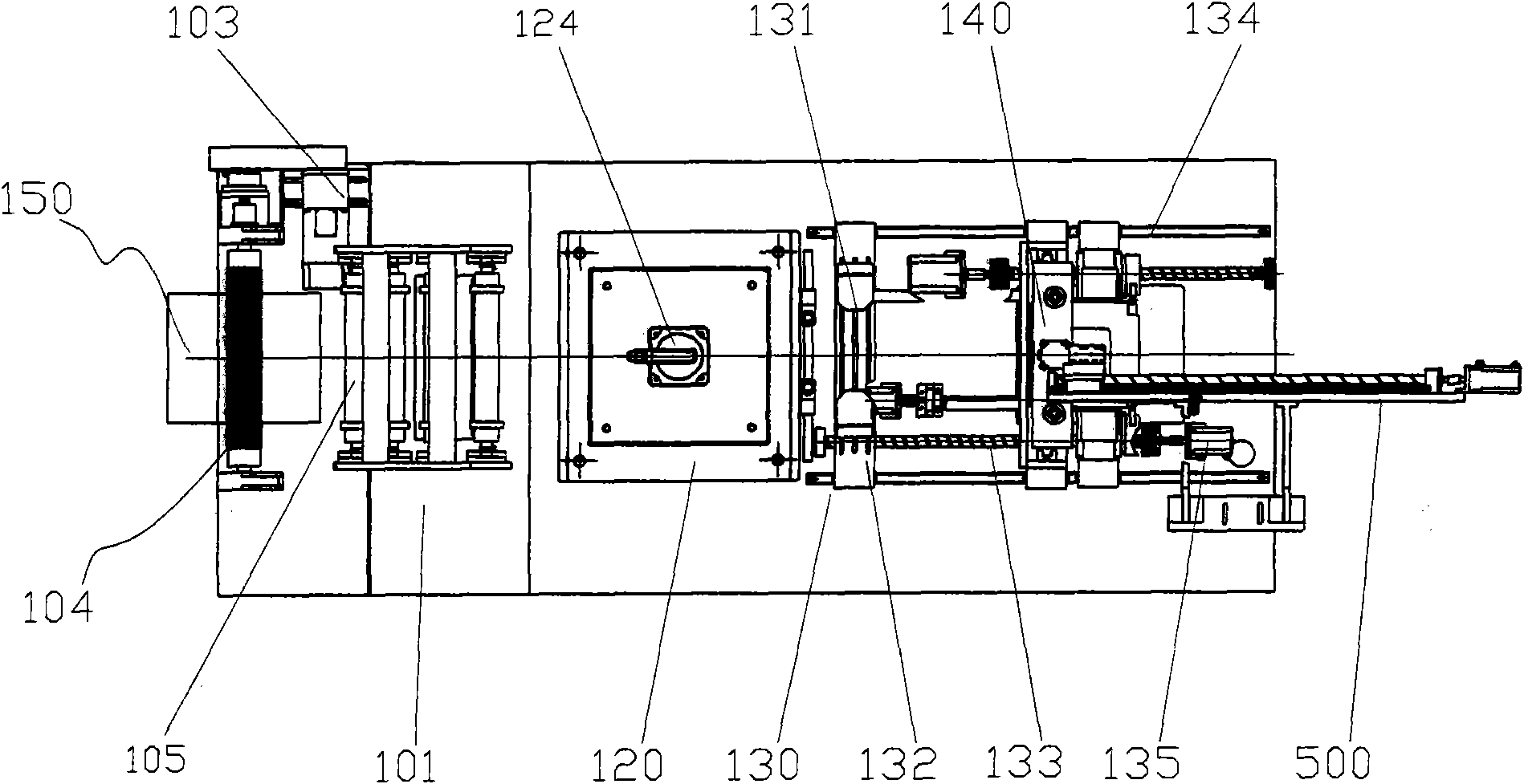

Power source automatic assembly production line and assembly process thereof

ActiveCN105583622ASave space costGuaranteed normal rotationLiquid surface applicatorsAssembly machinesProcess engineeringMachining

The invention discloses a power source automatic assembly production line and an assembly process thereof. The power source automatic assembly production line comprises a feeding mechanism, an assembly platform, a material conveying mechanism, welding mechanisms, adhesive dispensing mechanisms and a discharging mechanism. The feeding mechanism and the discharging mechanism are disposed on the two sides of the assembly platform correspondingly. A rotary plate is disposed in the middle of the assembly platform. Feeding and discharging stations and at least two machining stations are disposed at the edge of the rotary plate at intervals. The material conveying mechanism is disposed on the outer sides of the feeding and discharging stations. The welding mechanisms and the adhesive dispensing mechanisms are disposed on the outer sides of the machining stations. The assembly process of the power source automatic assembly production line includes the following steps that power sources are mounted and fixed inside jigs; jig loading and guiding are performed; feeding is prepared; feeding is conducted; the jigs are transferred to the machining stations; the power sources are machined; and discharging is performed. By means of the power source automatic assembly production line and the assembly process thereof, full-automatic guiding, feeding, machining and discharging are achieved, the multiple stations are combined, the power source assembly efficiency is improved, the machining accuracy is improved, and the reject ratio of products is decreased.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

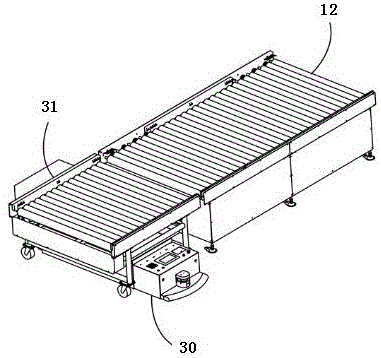

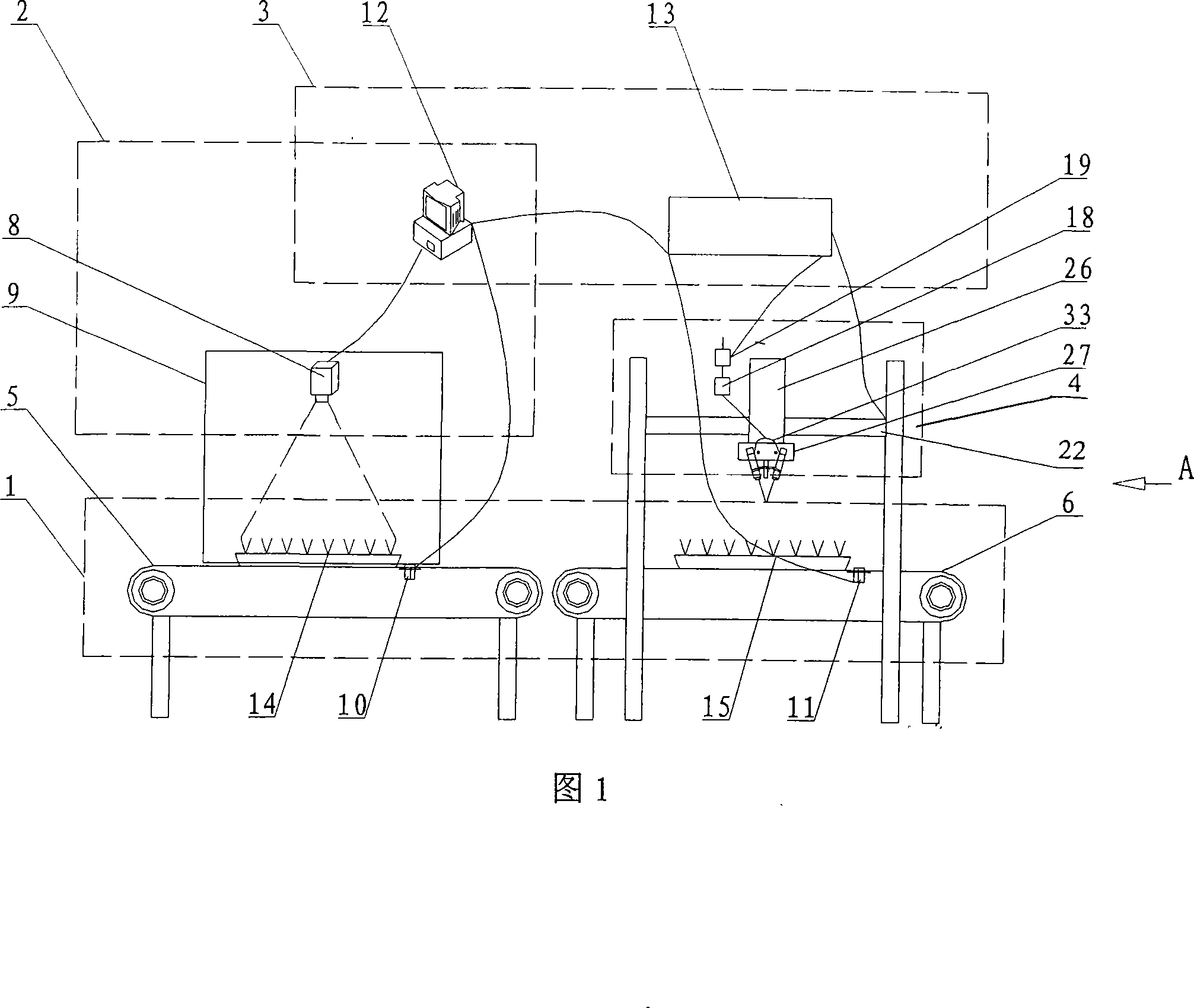

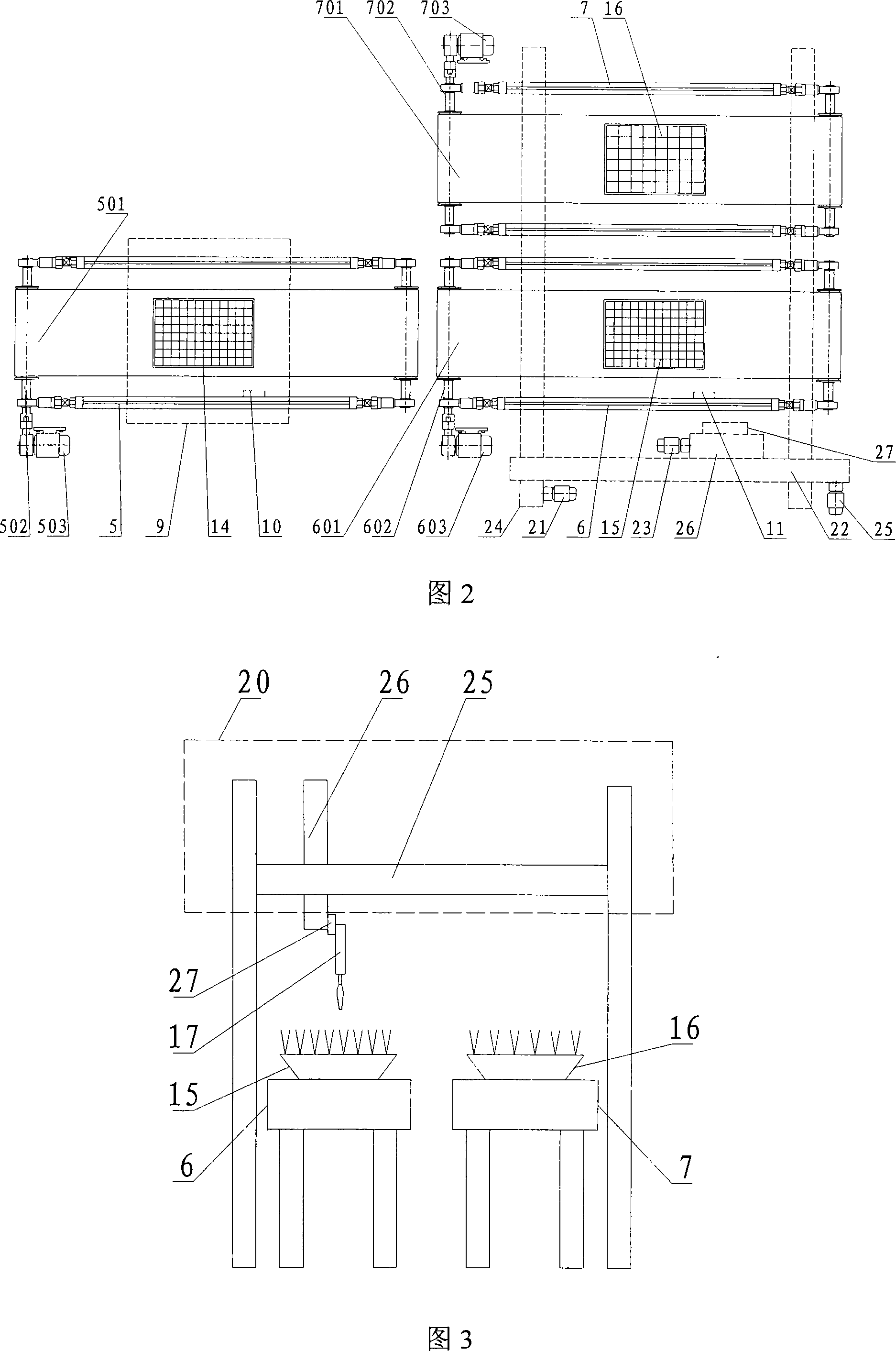

Seedling replanting system based on machine vision

InactiveCN101180928ARealize automatic transplantingIncrease the level of automationProgramme-controlled manipulatorTransplantingColor imageRelevant information

The invention discloses a seedling transplanting system based on machine vision and consists of components of seedling transportation, machine vision identification, control and transplanting. A conveyor belt of the seedling transportation component can convey seedling plates to the transplanting positions and automatically convey after the completion of the transplanting; color images obtained from the machine vision system are used for detecting a plurality of appearance growth indicators such as the size, the number of leaves of the seedlings so as to comprehensively judge whether the seedlings are suitable for transplanting and meanwhile determine the location information of the seedlings to be transferred to the control system by a computer through a serial communication interface RS-232; then the PLC of the control system sends commands to an end effector to realize automatic transplantation of the seedlings through the control system; the end effector adopts shovel-shaped fingers driven by a linear cylinder and meets the seedling transplanting demand for seedling plates with different sizes through regulating the angle of fingers. The invention utilizes the vision system to obtain the growth and location information of the seedlings and realizes the transplantation through the control of the computer and the PLC.

Owner:ZHEJIANG UNIV

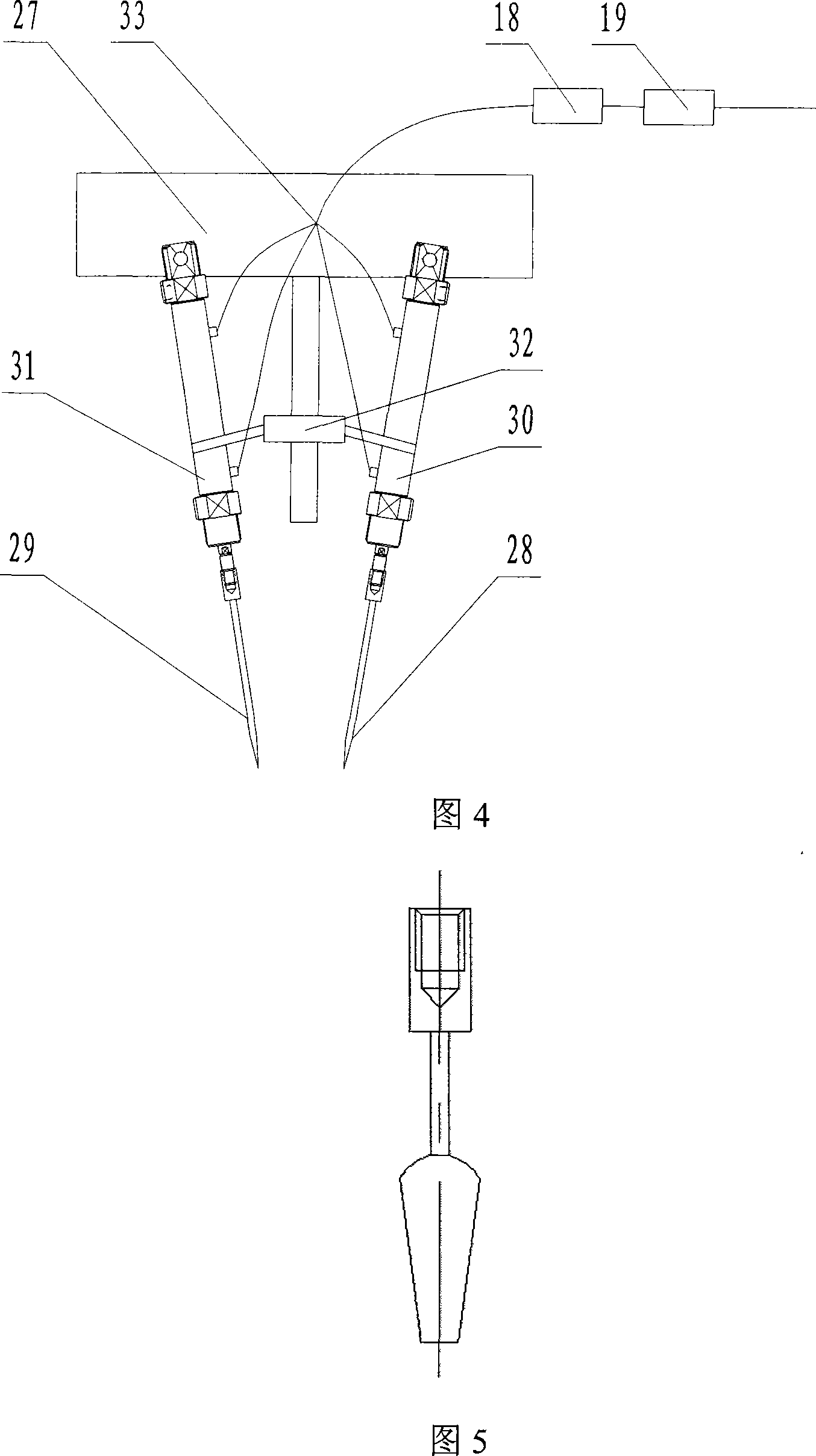

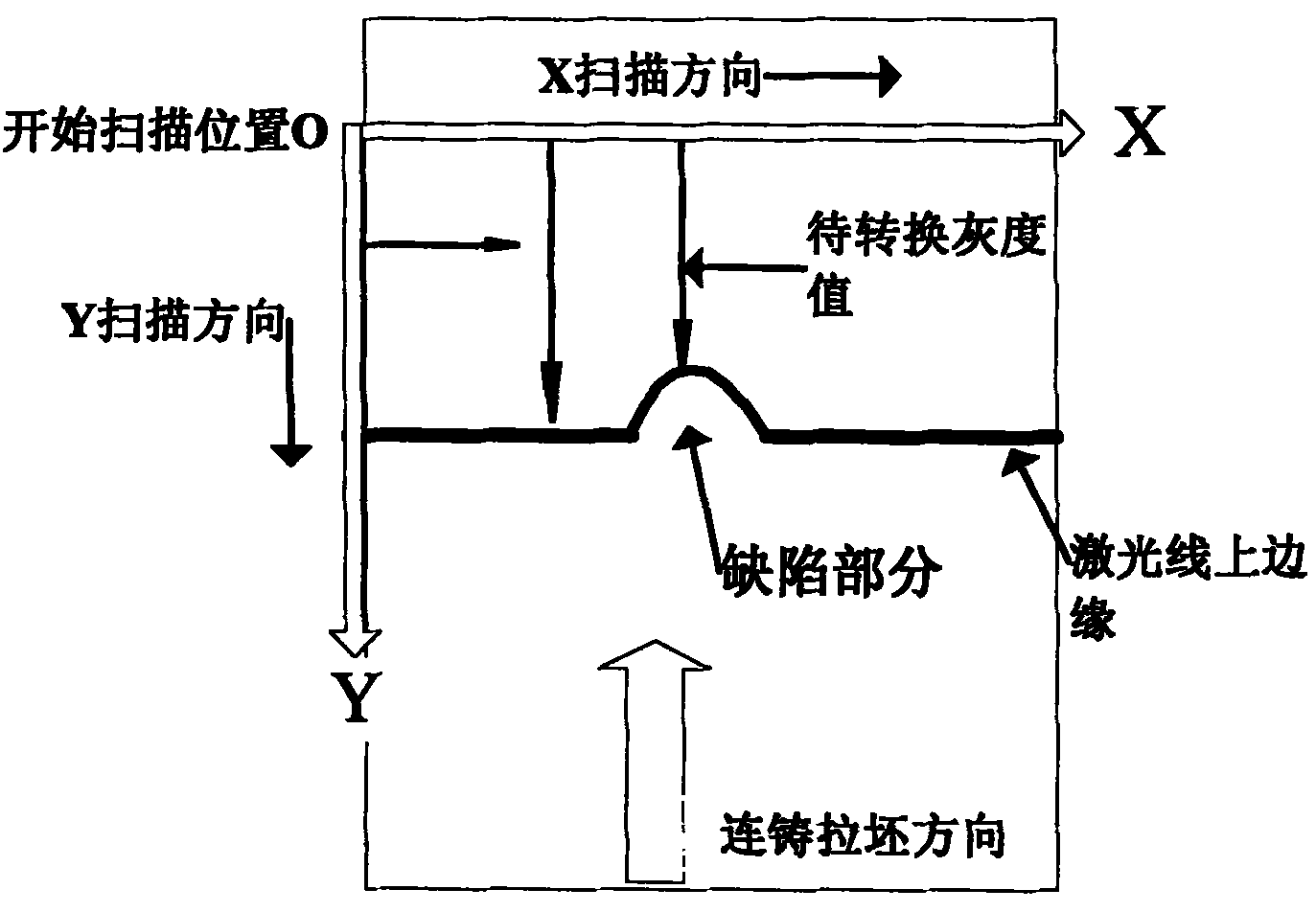

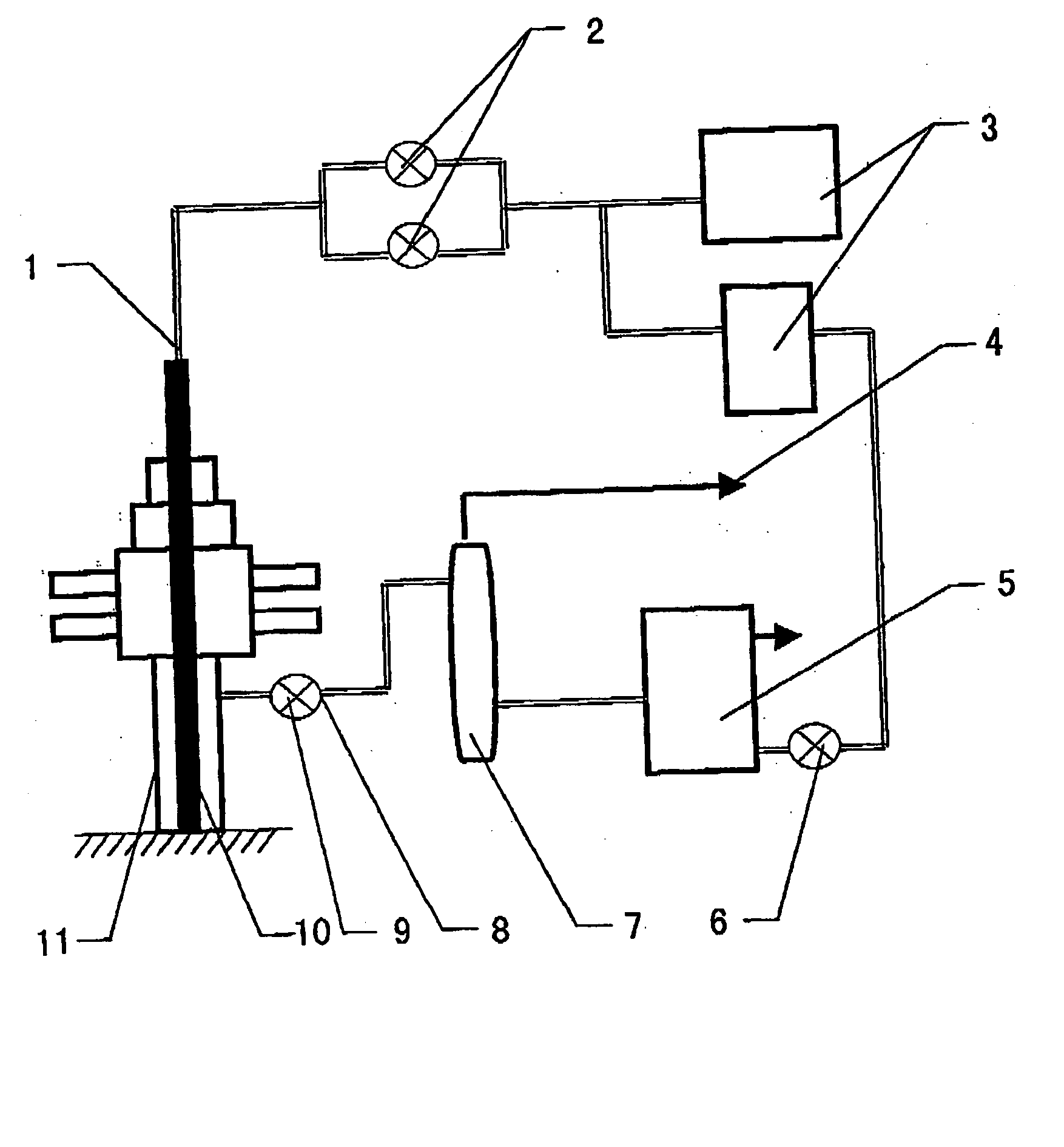

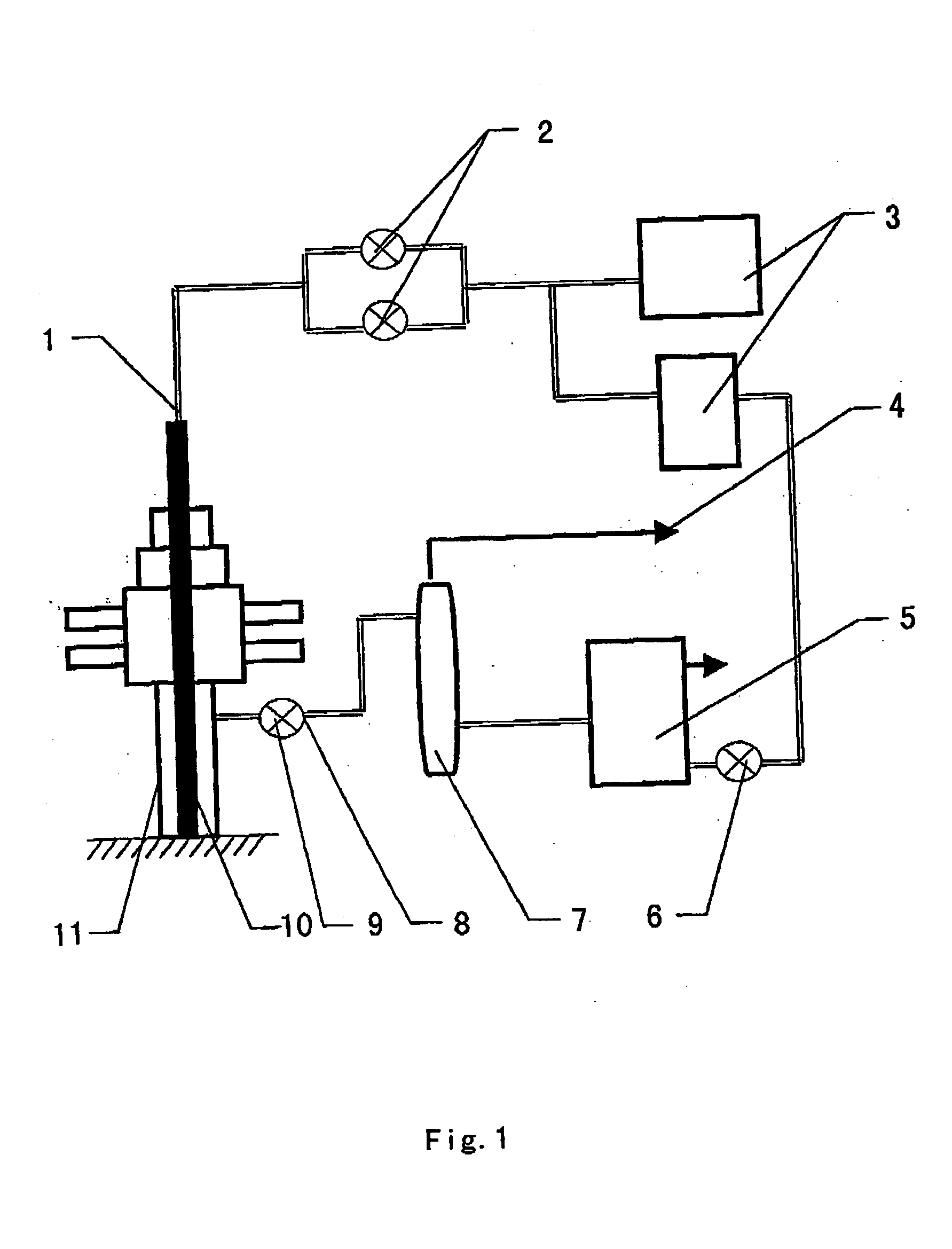

Laser scanning imaging nondestructive inspection method for hot continuous casting blank surface defects

InactiveCN101871895ASuppress interferenceAccurate identificationMaterial analysis by optical meansUsing optical meansLaser transmitterDot matrix

The invention discloses a laser scanning imaging nondestructive inspection method for hot continuous casting blank surface defects, comprising the following steps: 1) transversely irradiating a casting blank by a laser emitter to obtain a laser line; 2) scanning the laser line by utilizing an area array CCD image sensor; 3) extracting information representing the defect depths from the laser line so as to obtain a one-dimensional distance dot matrix formed by assembling the defect depths of the casting blank at the transverse position; and 4) mapping the one-dimensional distance dot matrix into gray level images with different gray levels; 5) splicing the gray level images at different transverse positions of a hot blank so as to obtain a whole gray level image; and 6) identifying the defects on the surface of the casting blank and reconstructing a casting blank surface tri-dimensional topographic image. The intention can effectively inhibit interference from a flaky scale on the high temperature casting blank surface which is not a defect but presents a defect state and water films so as to avoid the pseudo-defects from influencing detection precision, accurately identify defect target images and realize quantized detection of the defect depths, thereby realizing online detection of the defect states and depths of the surface of the casting blank under a high temperature state.

Owner:CHONGQING UNIV

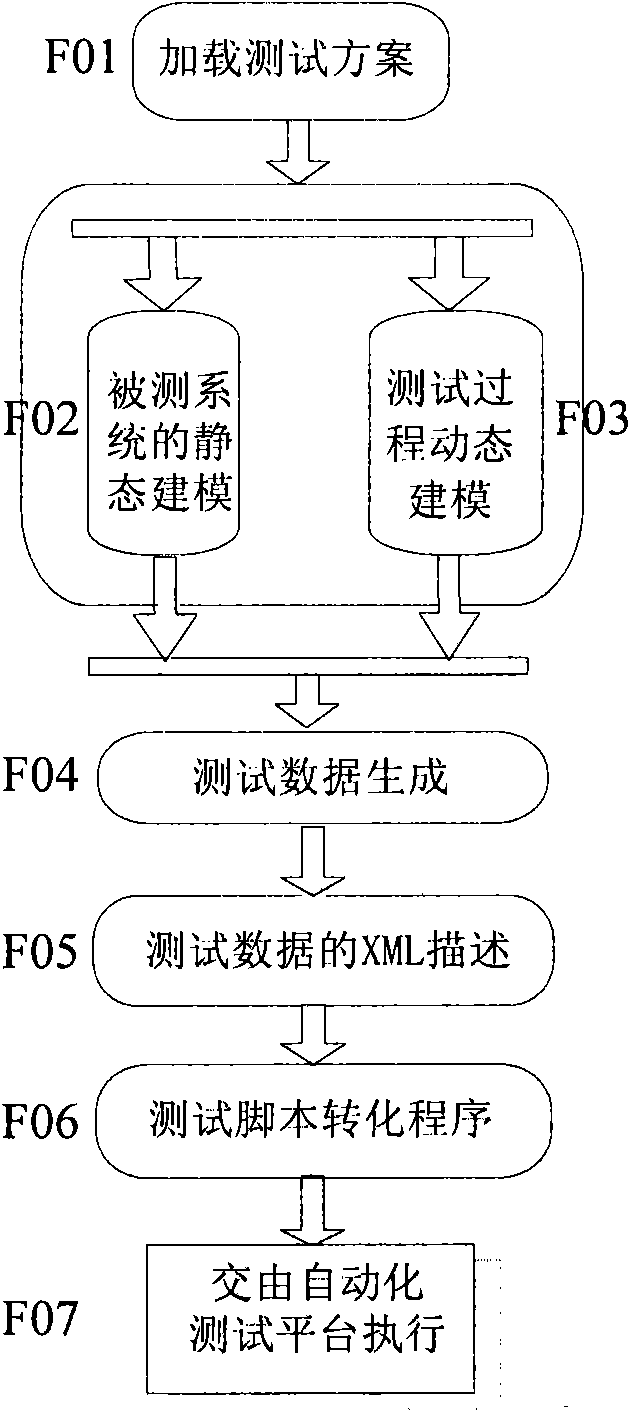

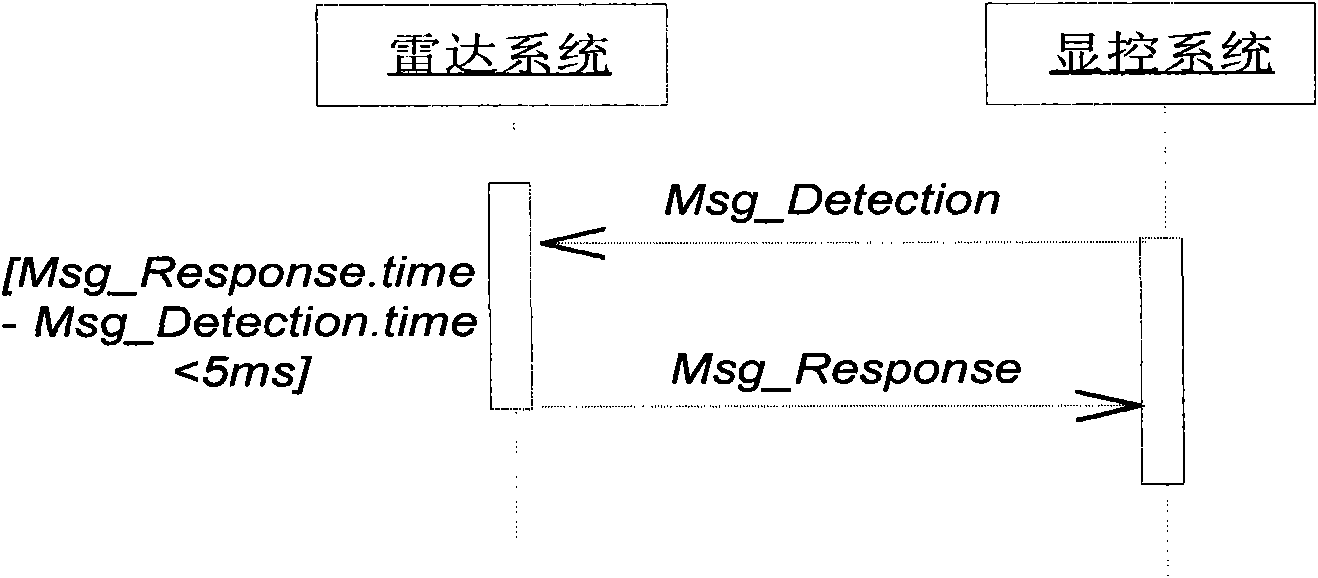

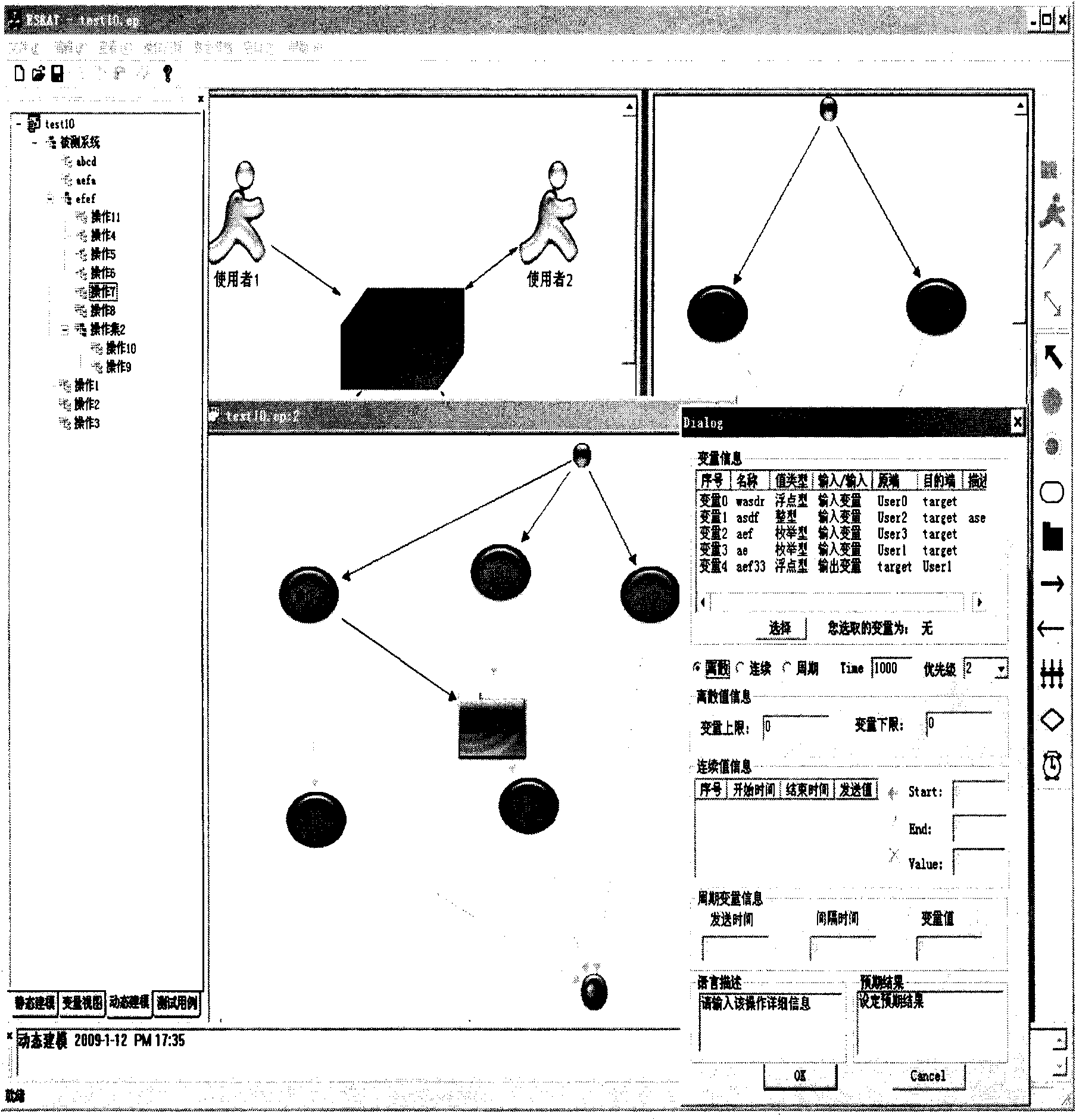

Visualization automatic generation method of embedded software test data and system thereof

InactiveCN101571802AIncrease the level of automationTime consumingSoftware testing/debuggingSpecific program execution arrangementsSpecific testTest script

The invention relates to a visualization automatic generation method of embedded software test data and a system thereof. The method comprises the following steps: adopting a de facto industrial standard--universality and flexibility of a unified modeling language (UML), performing real-time expansion on the UML, and introducing a scene technology to realize automatic generation of the embedded software test data in a visualization manner. The developed automatic test data generation system can automatically transform the test data into a test script required for a specific test platform, and running of the test script can drive the test for running to realize automatic testing for the embedded software.

Owner:BEIHANG UNIV

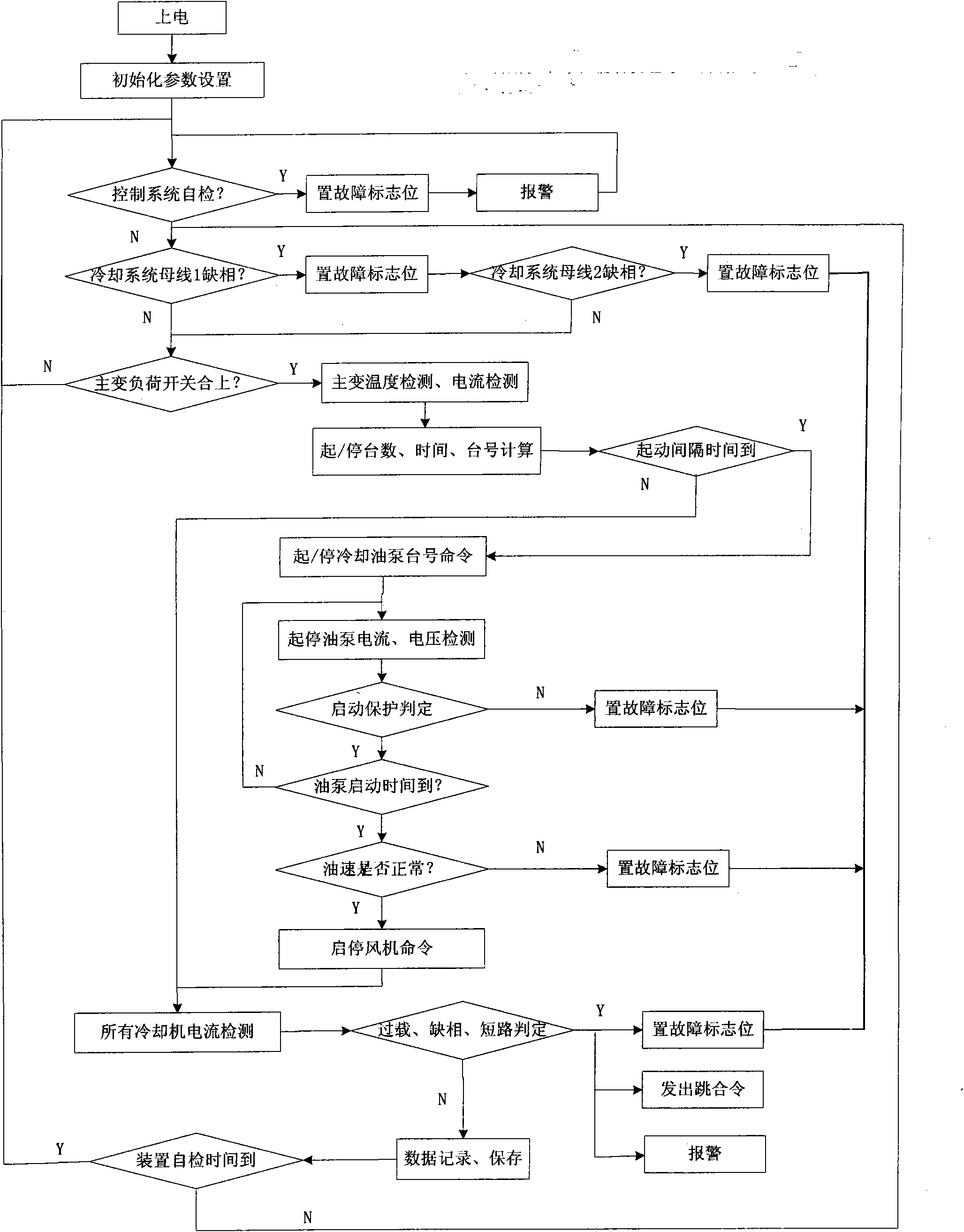

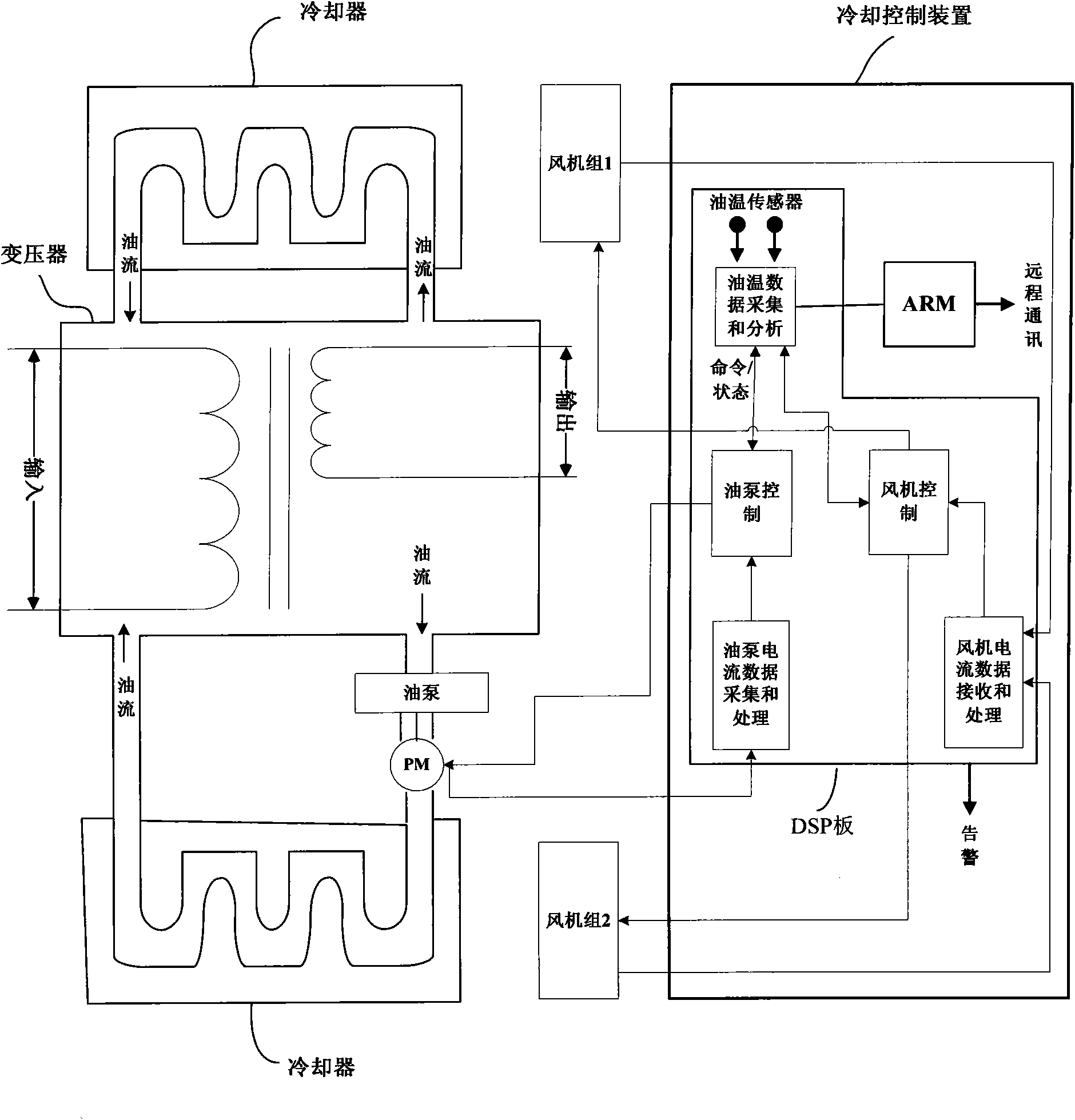

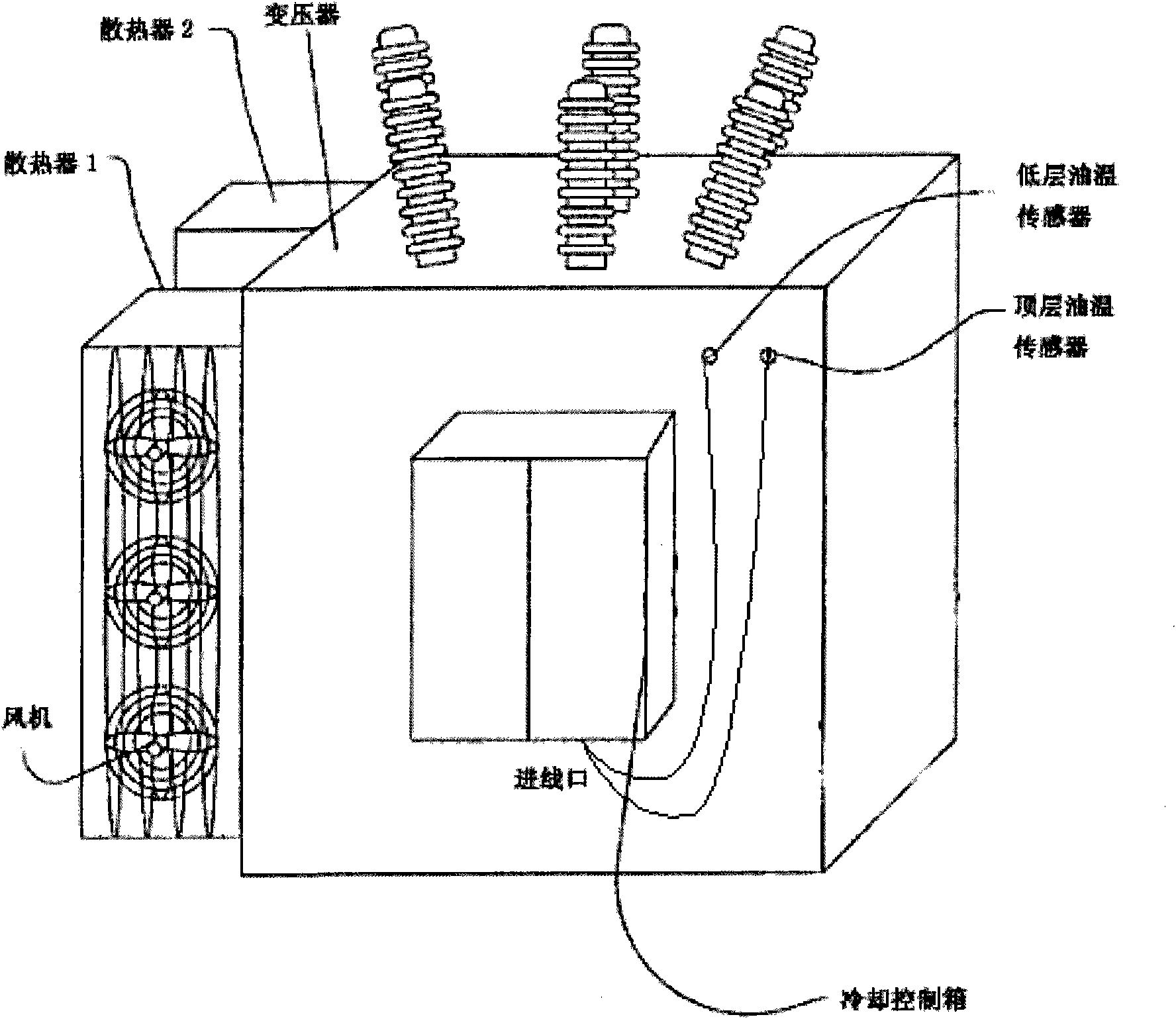

Intelligent control method and intelligent control device of transformer cooling system

ActiveCN101943921AIncrease the level of automationIntelligent online real-time controlTransformers/inductances coolingPower network operation systems integrationTransformerDual core

The invention discloses an intelligent control method and an intelligent control device of a transformer cooling system. The method comprises the following steps: detecting the cooling oil temperature and the load current value of the upper layer and the lower layer of a transformer; determining the group number, the table number and the time of a start / stop cooler; starting / stopping at least one oil pump; starting / stopping at least one fan in a delay mode; detecting the current of the oil pump and the fan; entering a device debug mode; and recording events. The device comprises a DSP and ARM double-core hardware platform, wherein a DSP plate comprises a cooling oil temperature data acquisition and analysis module, an oil pump motor current data acquisition and processing module, an oil pump motor control module, a fan motor current data acquisition and processing module and a fan motor control module; and the ARM plate comprises a user interface, a communication module and a data storage module. The invention combines control, relay protection, real-time monitoring and diagnosis as a whole, has more intelligent on-line real-time control, can define and configure the parameter of the transformer cooling system, improves the production efficiency and saves the operation and maintenance cost of the transformer.

Owner:XIAN SHUANGHE SOFTWARE ENG +1

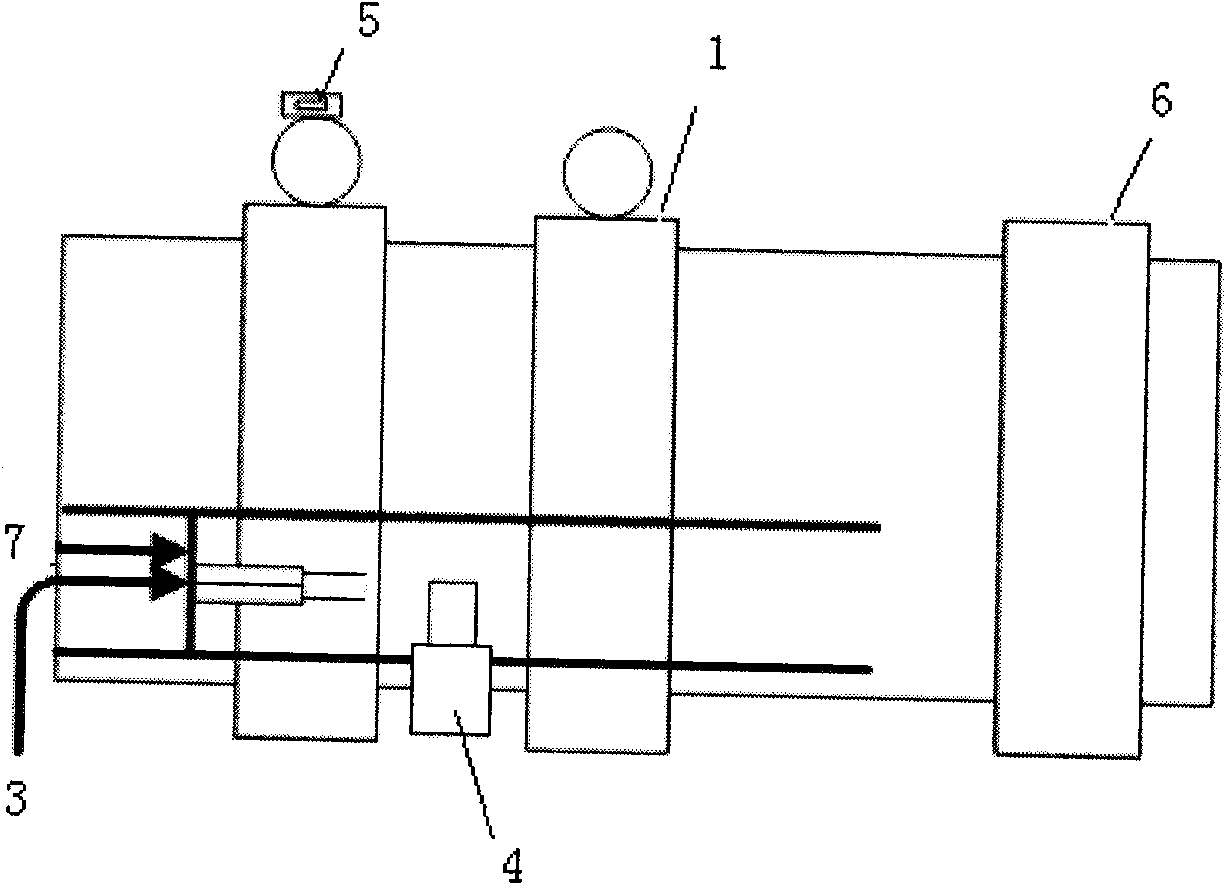

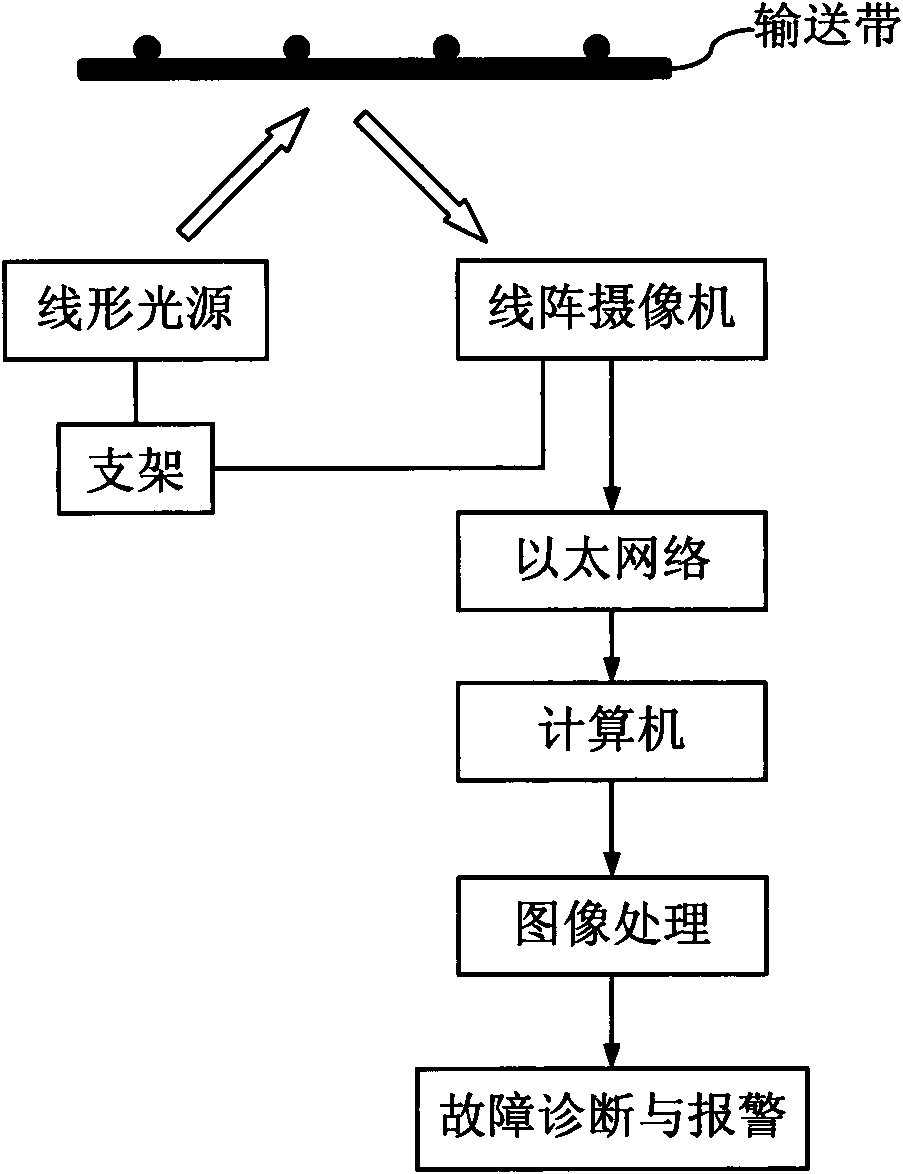

A Conveyor Belt Online Monitoring System and Method Based on Machine Vision

InactiveCN102275723AGuaranteed uptimeRaising the Level of Condition MonitoringControl devices for conveyorsImage transferConveyor belt

The invention discloses a conveyor belt online monitoring system based on machine vision, which is used for real-time detection of conveyor belt deviation, surface damage and longitudinal tear faults. Image information; image transmission module, used to transmit the conveyor belt image collected by the image acquisition module to the computer through Ethernet; image processing module, used for real-time processing of the conveyor belt image transmitted to the computer; fault diagnosis and alarm module, used for identification The running state of the conveyor belt, if the deviation, surface damage and longitudinal tear fault are diagnosed, the alarm will be reported in time; the bracket is used to fix the image acquisition module to the appropriate position of the conveyor belt. The monitoring system provided by the present invention can improve the monitoring level of the conveyer belt state, and achieve the purpose of reducing the manpower and increasing the efficiency of the enterprise. The invention also discloses an online monitoring method for the conveyor belt comprising the monitoring system.

Owner:TIANJIN POLYTECHNIC UNIV +1

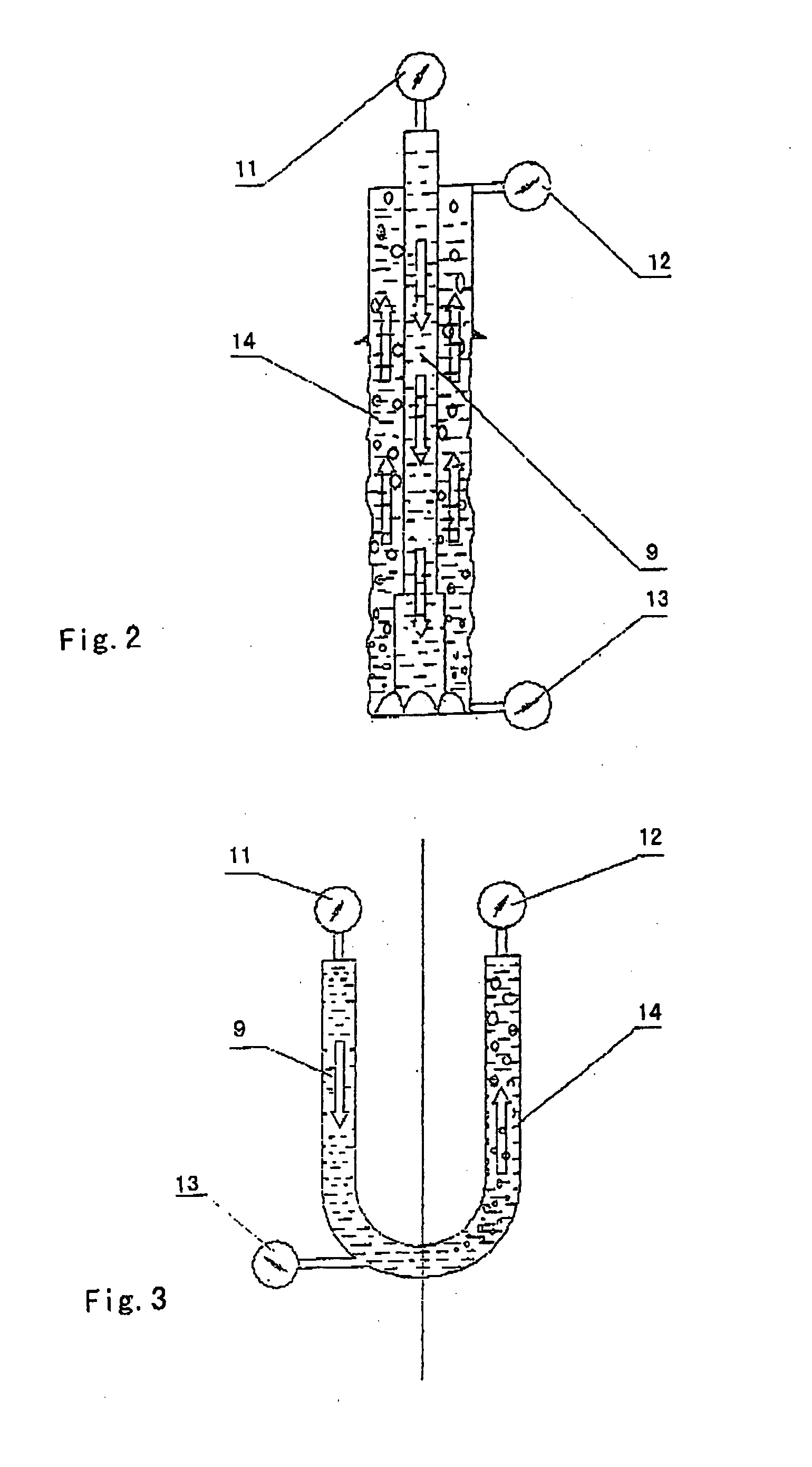

Automatic control system and method for bottom hole pressure in the underbalance drilling

ActiveUS20050096848A1Easy to controlHigh adjustment accuracyElectric/magnetic detection for well-loggingConstructionsAutomatic controlEngineering

This invention provides an automatic control system and method for bottom hole pressure (BHP) in the underbalance drilling. It relates to a computer automatic control technology. The automatic control system according to the invention includes a processing module for the BHP based on the mechanisms of hydraulics. The BHP in the underbalance drilling is calculated from the acquired standpipe pressure (SPP), the calculated circulating pressure loss in the drilling tools, drill bit pressure drop and the fluid column pressure in the drill string. The resulting BHP is then compared with the set pressure value of the system. In case that the BHP is higher or lower than the set pressure, an instruction to regulate throttle valve opening will be issued in order to bring the BHP back to the set pressure range and complete BHP monitoring and control. The automatic control system and method according to the invention enable real-time tracking of the changes in BHP and achieve accurate and timely adjustment and control of BHP. The automatic control system and method improve the level of automation in the underbalance drilling process, and also enhance the reliability and safety in the underbalance drilling operation, which have wide foreground for application.

Owner:CHINA PETROCHEMICAL CORP +1

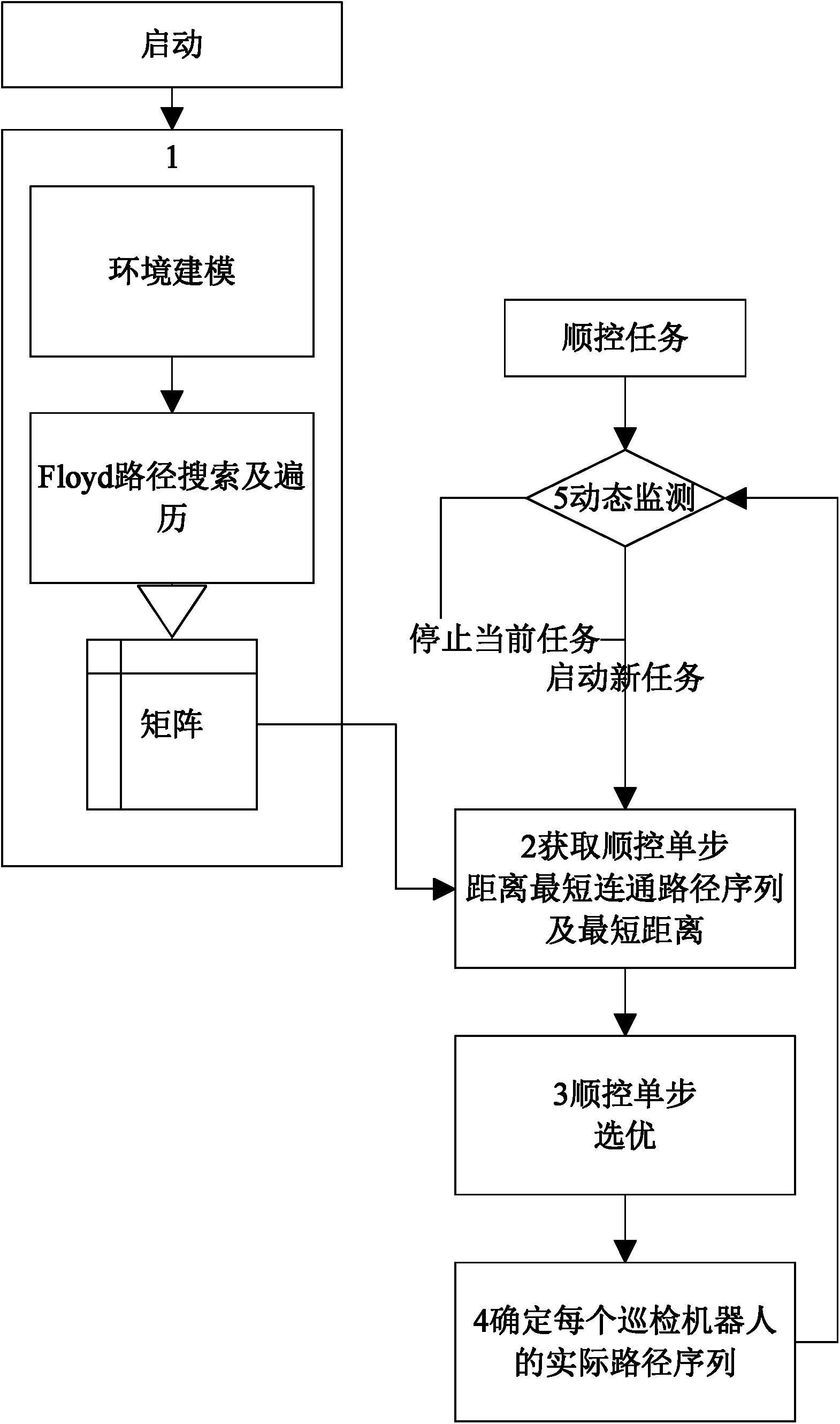

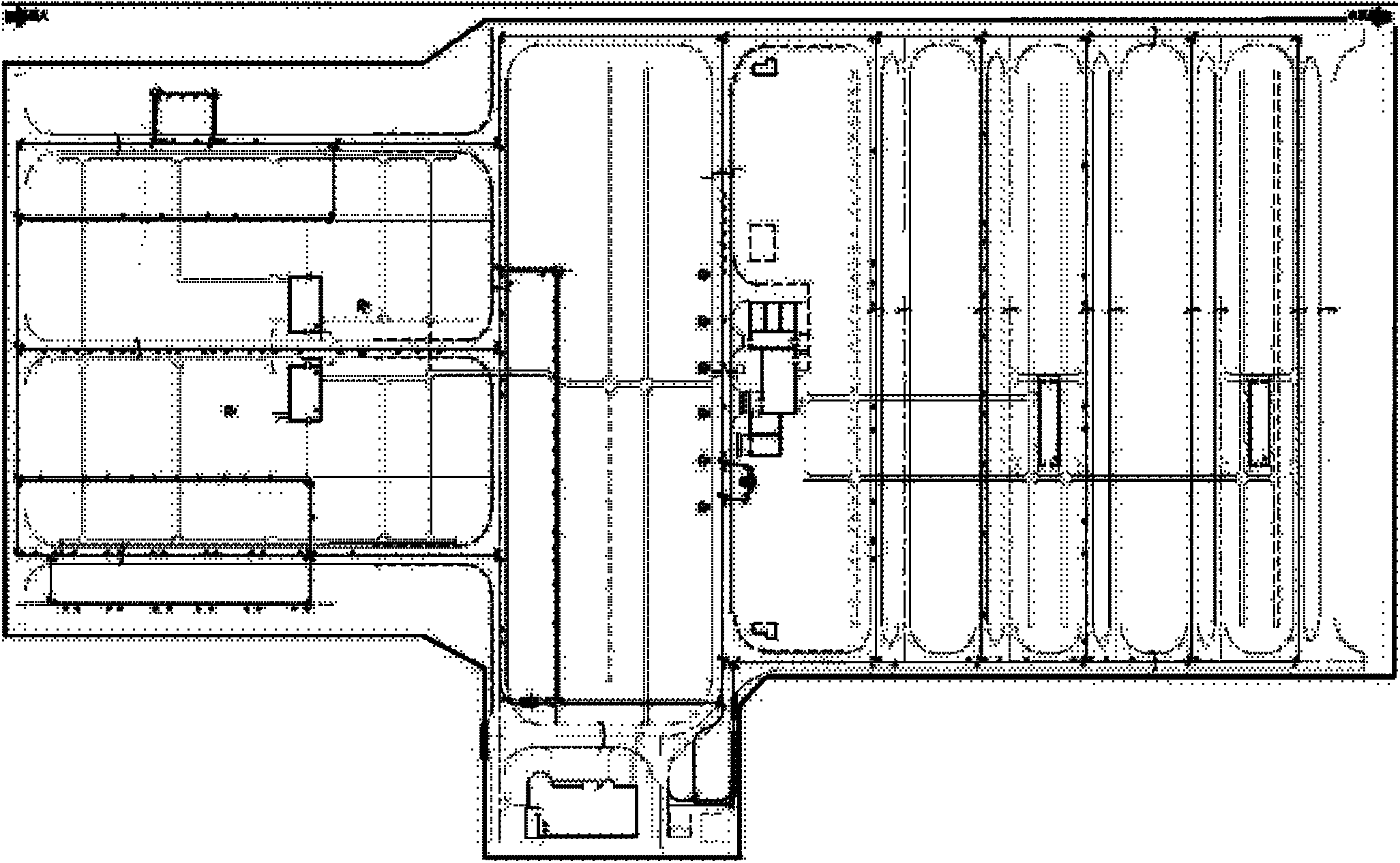

Multiple inspection robot cooperative operation method for substation sequence control system

ActiveCN102566576AShort driving routeIn place detection time is fastPosition/course control in two dimensionsSequence controlLoop control

The invention discloses a multiple inspection robot cooperative operation method for a substation sequence control system. When the closed-loop control and the state visualization of the intelligent substation sequence control system are implemented, the executing and checking time of the sequence control system can be effectively saved by adopting the method. The invention provides the multiple inspection robot cooperative operation method which comprises the following steps: modeling by adopting a topological method on the basis of the substation environment, forming a topological network chart and a communication relation matrix according to walking routes of inspection robots, and carrying out search and traversal of paths to output a discharge matrix and a shortest path matrix; in the single-step sequence control process, determining a shortest communication path sequence of each inspection robot from a current position to a target point according to the distance matrix and the shortest path matrix; carrying out excellence selection of single-step sequence control, i.e. selecting the inspection robot with the optimal performance under the condition of considering comprehensive indexes of journey, time, safety and maneuverability; determining an operation path sequence of each inspection robot and a corresponding activation event; and carrying out on-line monitoring, wherein if the environment is changed, the on-line monitoring takes charge of debugging and recovering operation.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

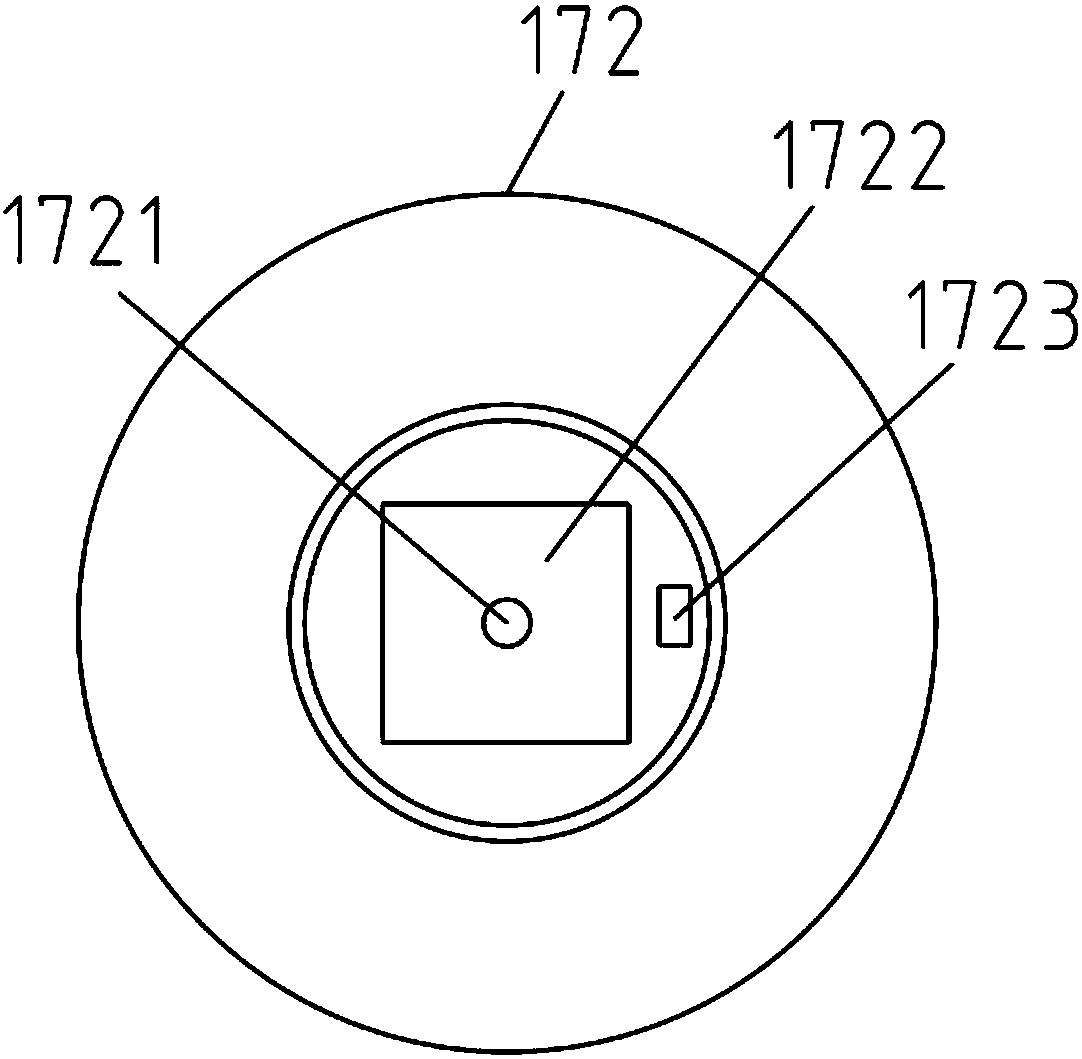

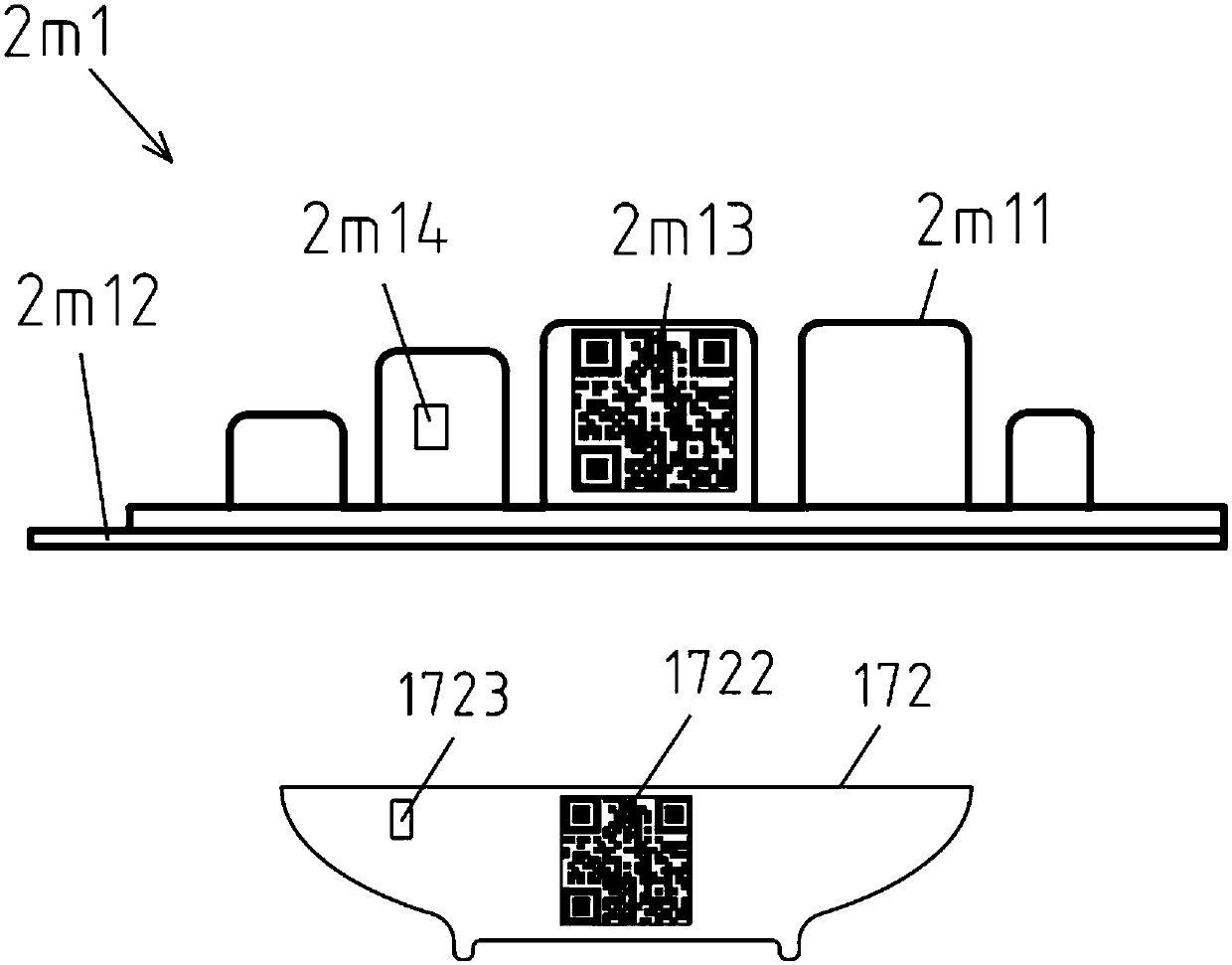

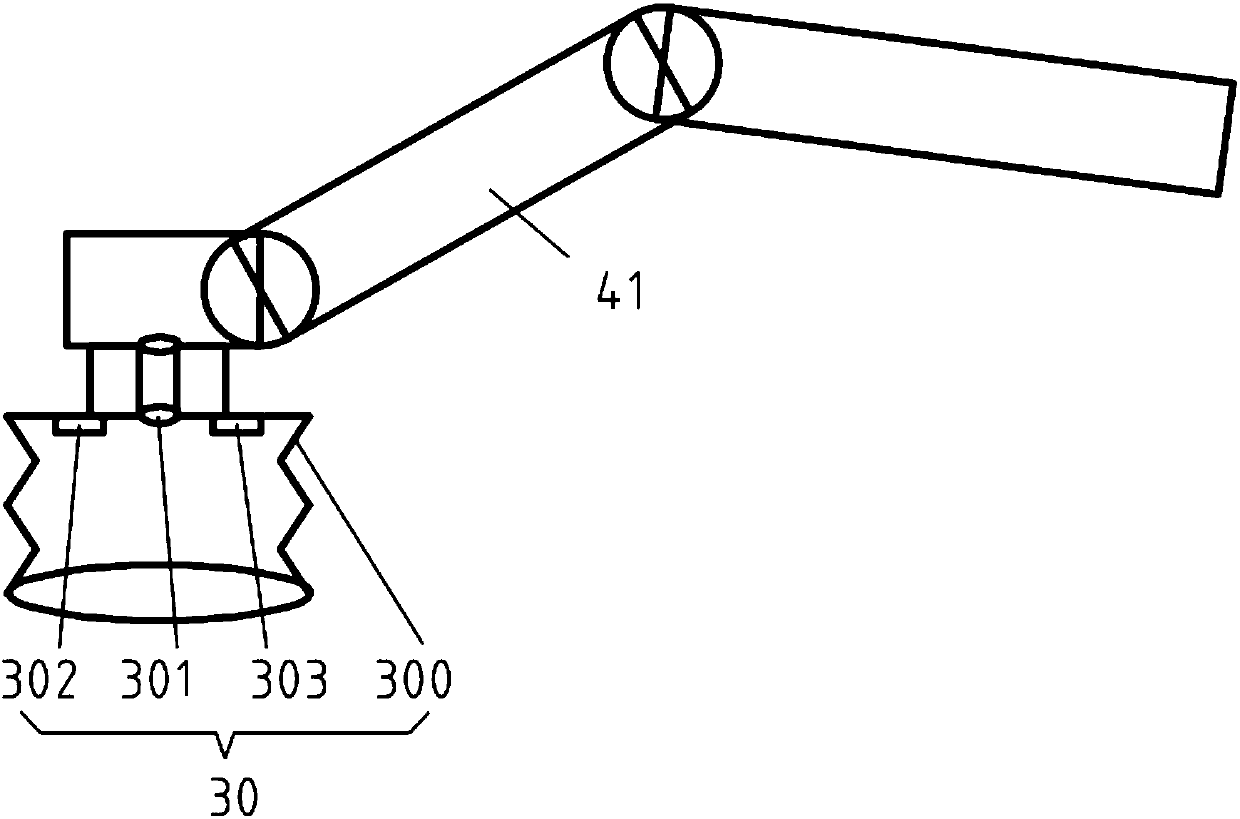

Intelligent dishing up device and cooking machine thereof

PendingCN110097151AIncrease the level of automationImprove cooking efficiencyTableware washing/rinsing machine detailsCooking-vessel lids/coversEngineeringAutomation

The invention relates to the technical field of smart home and discloses an intelligent dishing up system which is applied to an intelligent cooking machine, wherein the cooking machine comprises a pot body and a bowl, and a dishing up device comprises an intelligent dish taking device and an intelligent dish loading device. The bowl is provided with an identification code and / or an electronic identification device. The cooking machine obtains the bowl information to be loaded according to the dishes, the intelligent dish taking device picks up the corresponding bowl according to the bowl information and places the bowl into the intelligent dish loading device, and the intelligent dish loading device is matched with the pot body and pours the food in the pot body into the bowl of the intelligent dish loading device. By means of the intelligent dishing up system, the intelligent dishing up can be achieved without manual intervention, the automation level of the intelligent home is improved, and the cooking efficiency is greatly improved.

Owner:李亚锐

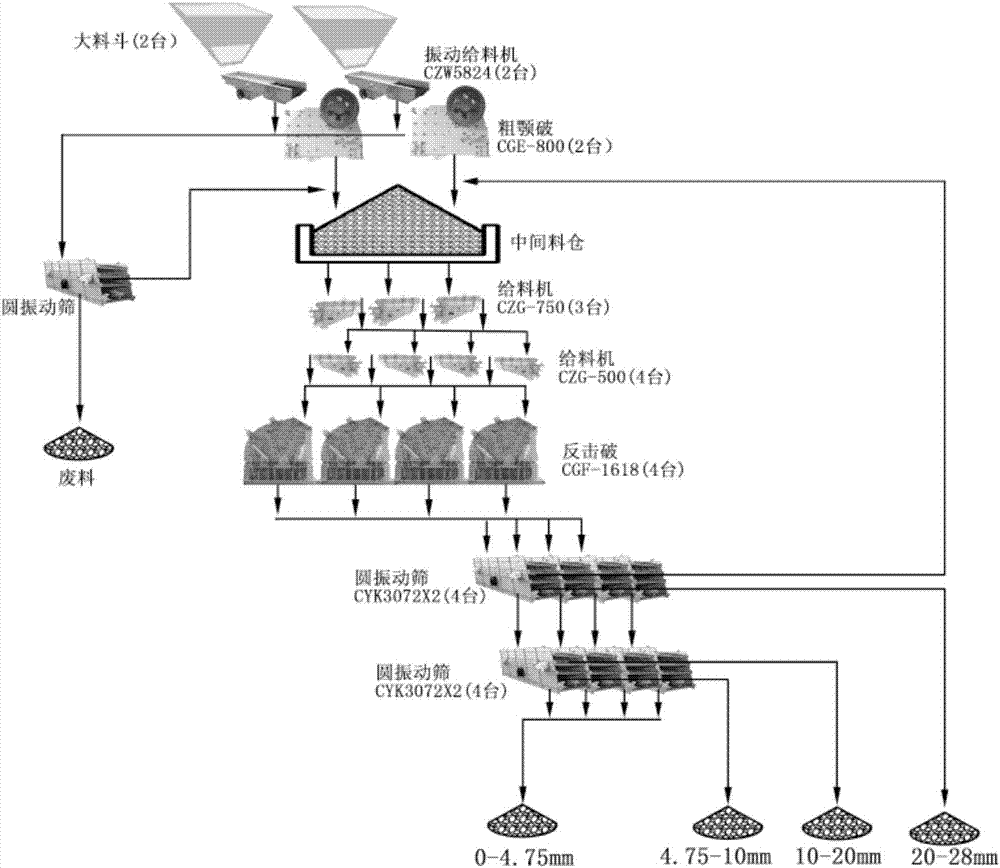

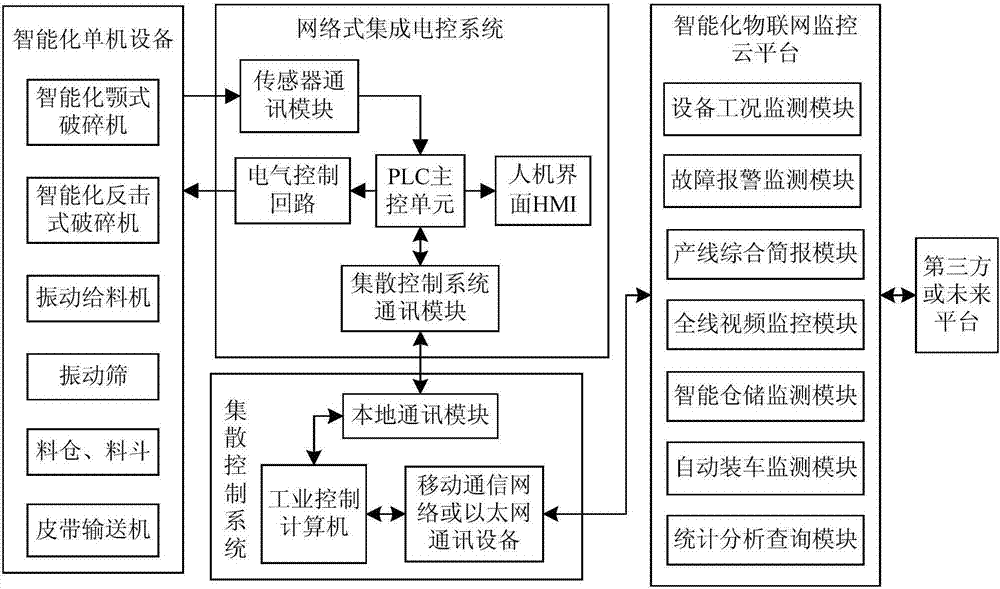

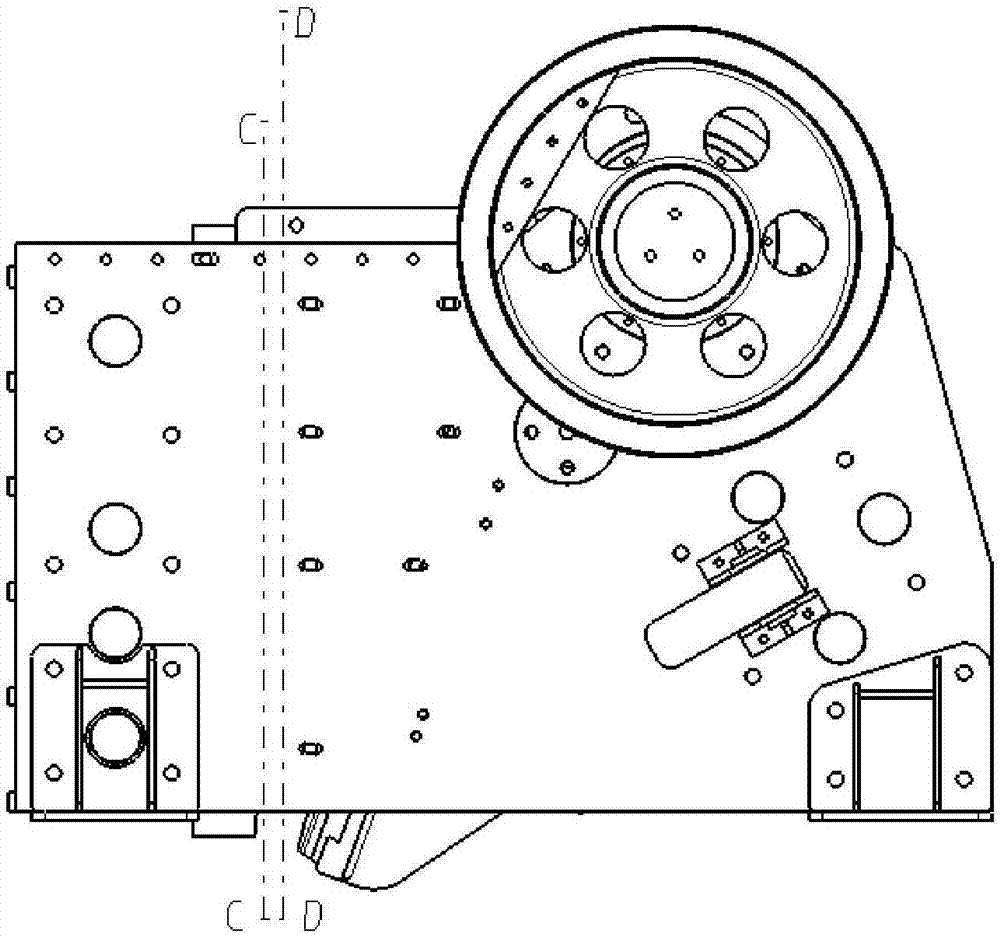

Intelligent gravel aggregate production line

ActiveCN107153410AIncrease the level of automationReduce work intensityTotal factory controlProgramme total factory controlProduction lineDowntime

The invention provides an intelligent gravel aggregate production line, and relates to the technical field of gravel aggregate production. The intelligent gravel aggregate production line comprises an intelligent jaw type crusher, an intelligent impact type crusher, a vibrating screen, a vibrating feeder, a material bin, a hopper, a belt conveyor, a control-related network type integrated electric control system, a distributed control system and an intelligent internet of things monitoring cloud platform, wherein various sensors are additionally arranged on the basis of an original crushing screening production line; sensor information is transmitted to the distributed control system through the network type integrated electric control system, so that automatic regulation and control on the production process is realized, and therefore, the sensor information is transmitted to the intelligent internet of things monitoring cloud platform; and production data storage and safety are managed in a unified mode on the basis of classifying and combing through cloud computation. The intelligent gravel aggregate production line has a fault early-warning function and a real-time alarm function, and quickly increases response speed; internet of things intelligent control and remote monitoring are introduced, the production process is automatically regulated and control, operation is performed with optimal load, the yield is increased, and downtime maintenance is reduced.

Owner:SHANGHAI UNITRUSTON INTELLIGENT TECH CO LTD

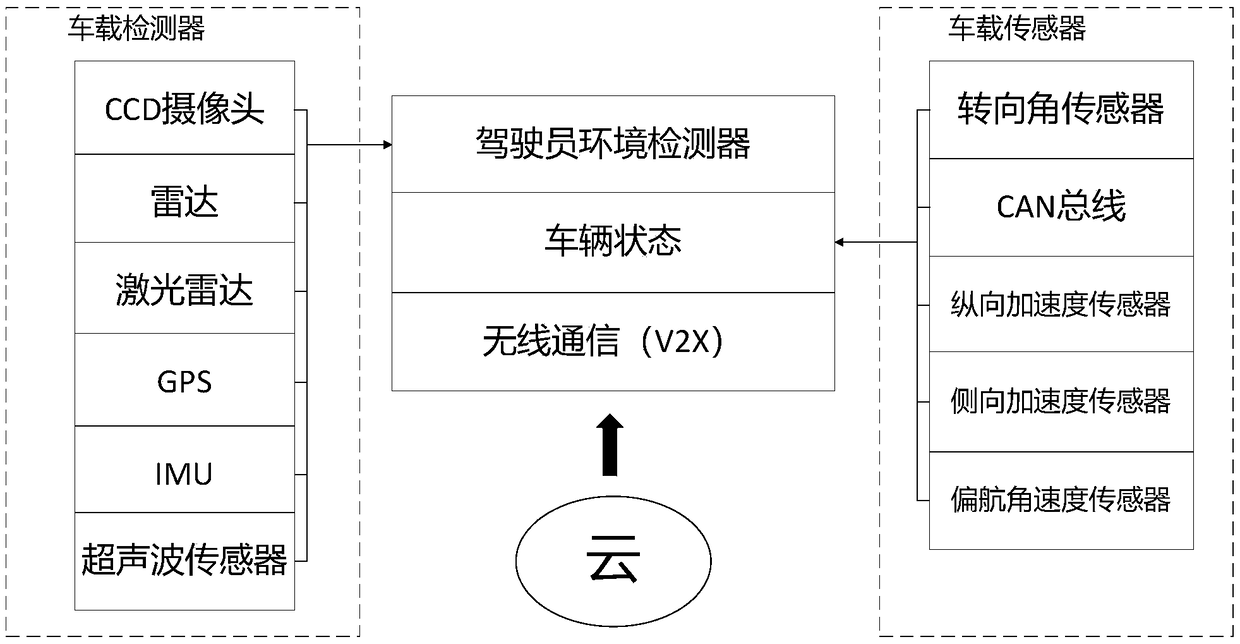

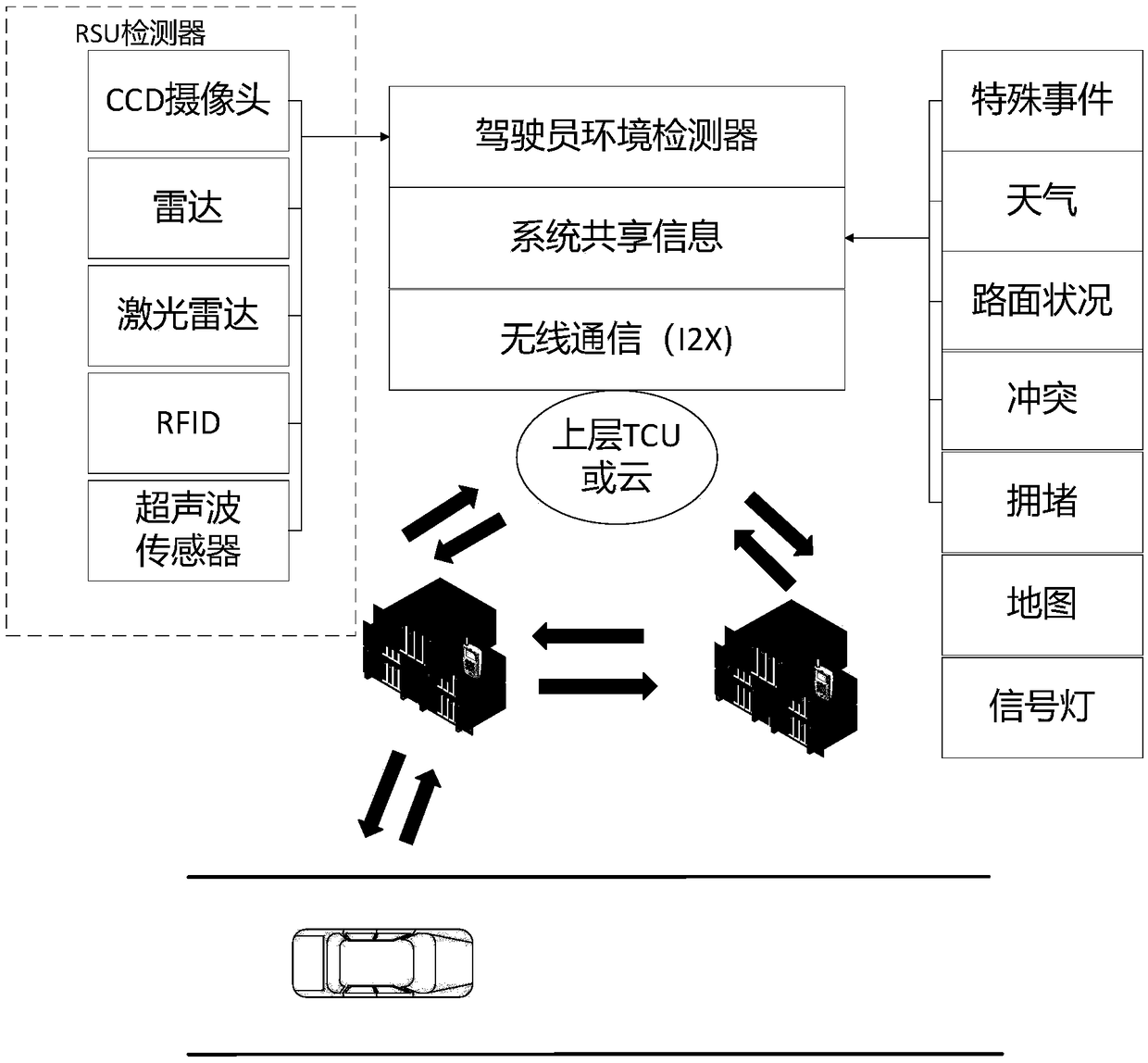

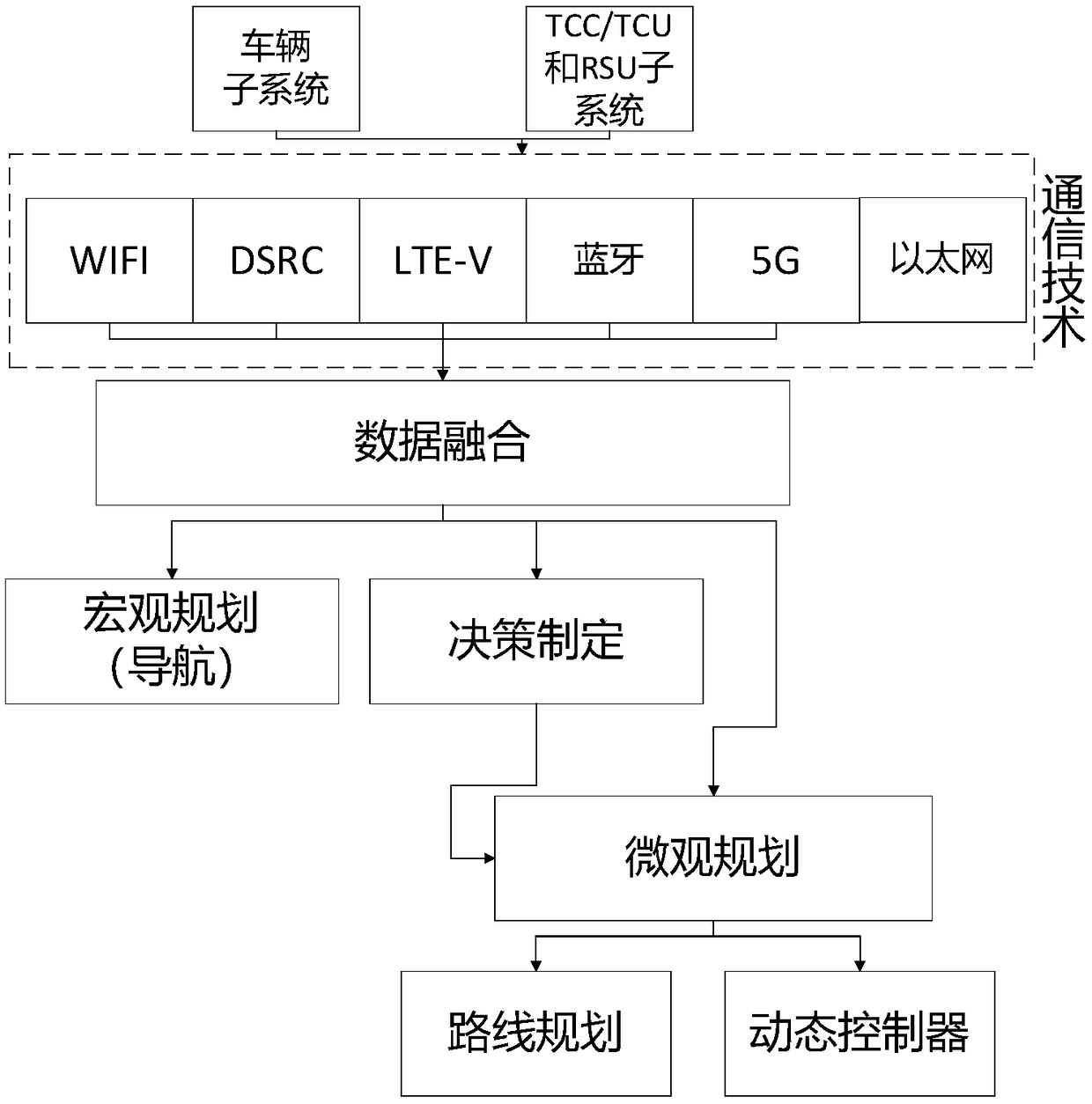

Intelligent network connection traffic management system facing mobile sharing

ActiveCN109118758AIncrease the level of automationRealize personalized autonomous drivingParticular environment based servicesDetection of traffic movementPersonalizationRate control

The invention discloses an intelligent network connection traffic management system facing mobile sharing. The system is used to realize the automatic driving, operation and control of an intelligentnetwork connection vehicle on a road for a shared mobile service provider. The system provides specific personalized information and a time-sensitive control command to the intelligent network connection vehicle to assist the vehicle to complete an automatic driving task, and simultaneously, provides operations and maintenance services to a vehicle owner and / or the shared mobile service provider of the vehicle. The vehicle is a full time control or partial time control vehicle. The driving task comprises one or more of the following contents: vehicle following, lane changing, and path navigation.

Owner:上海丰豹商务咨询有限公司

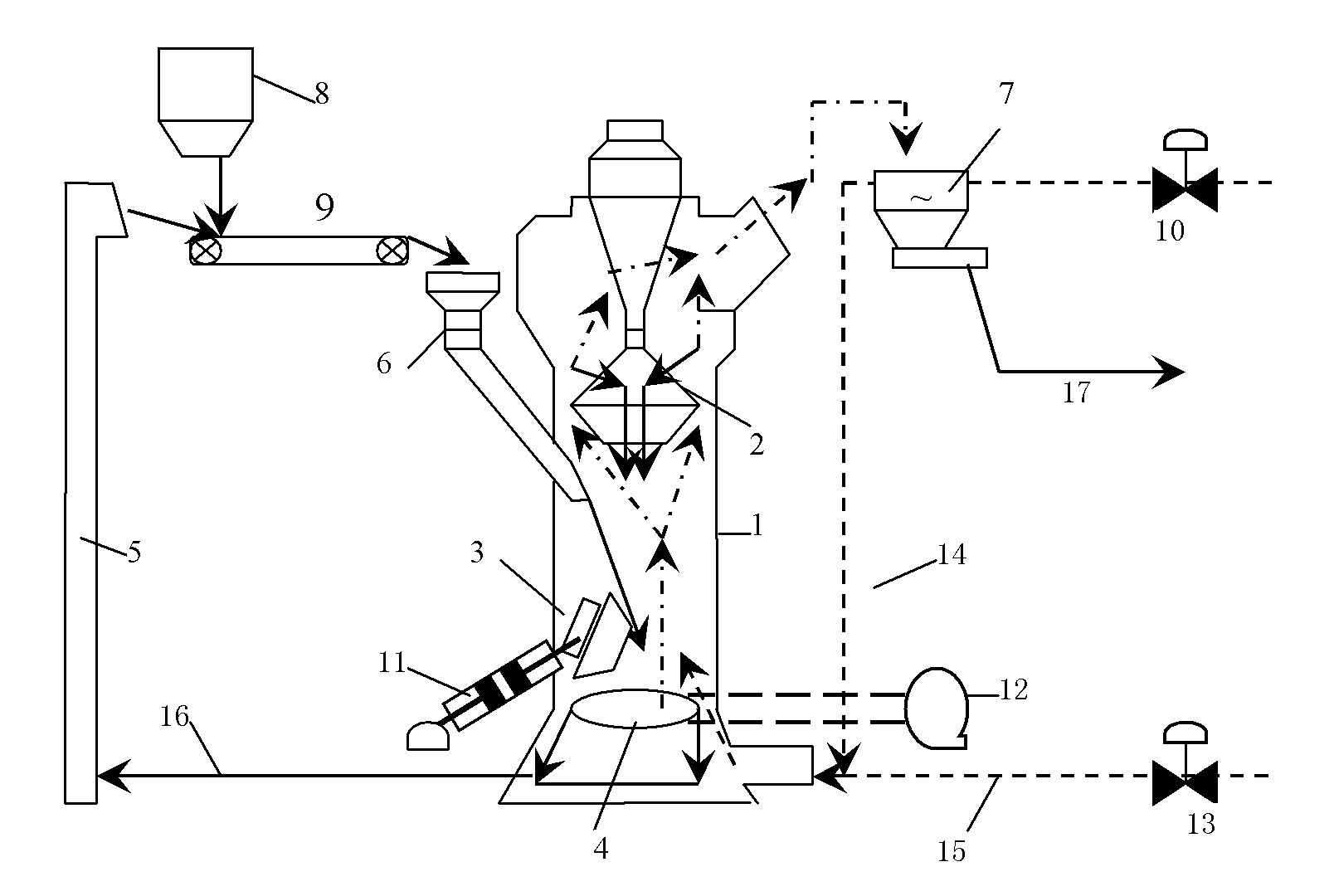

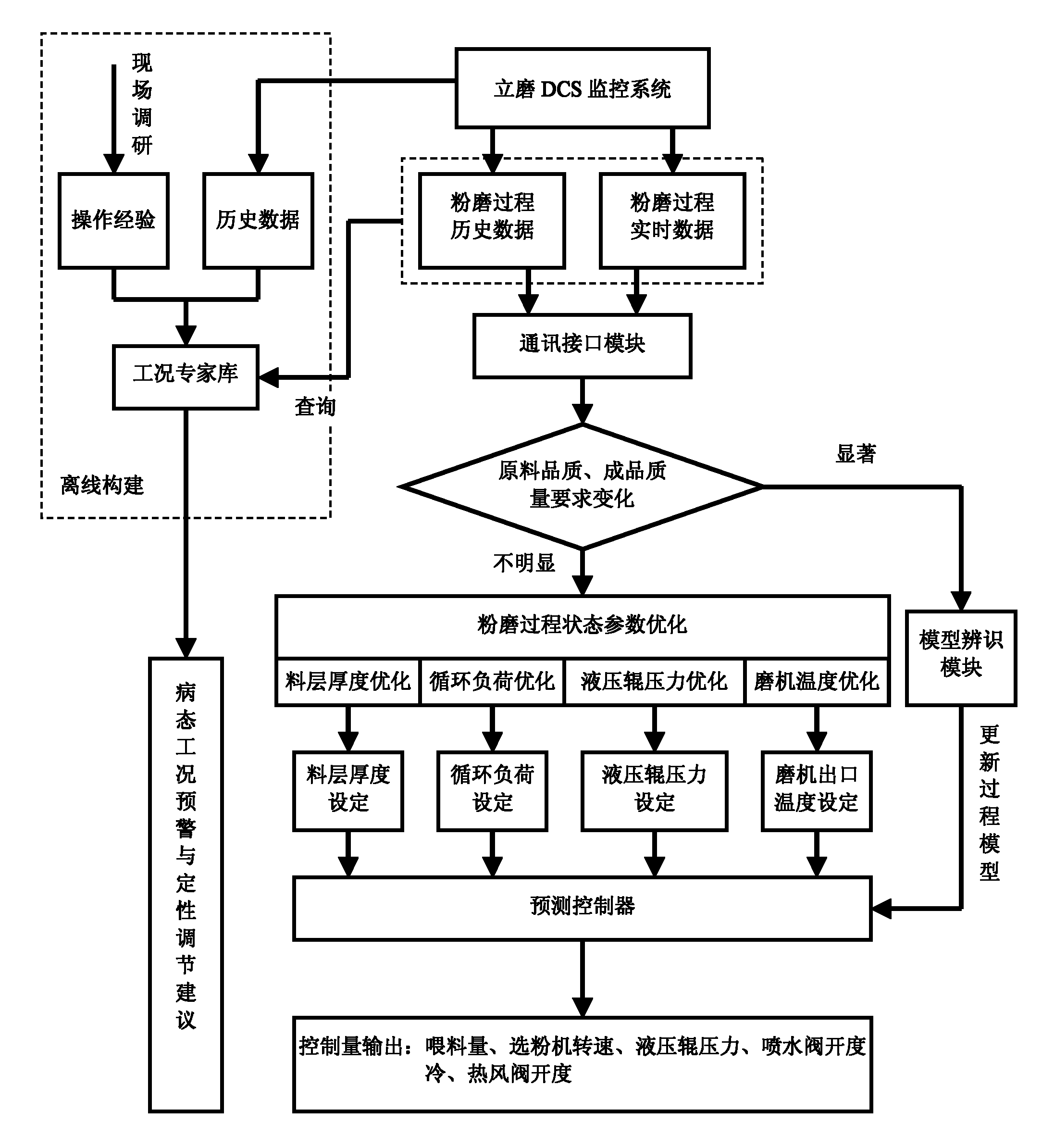

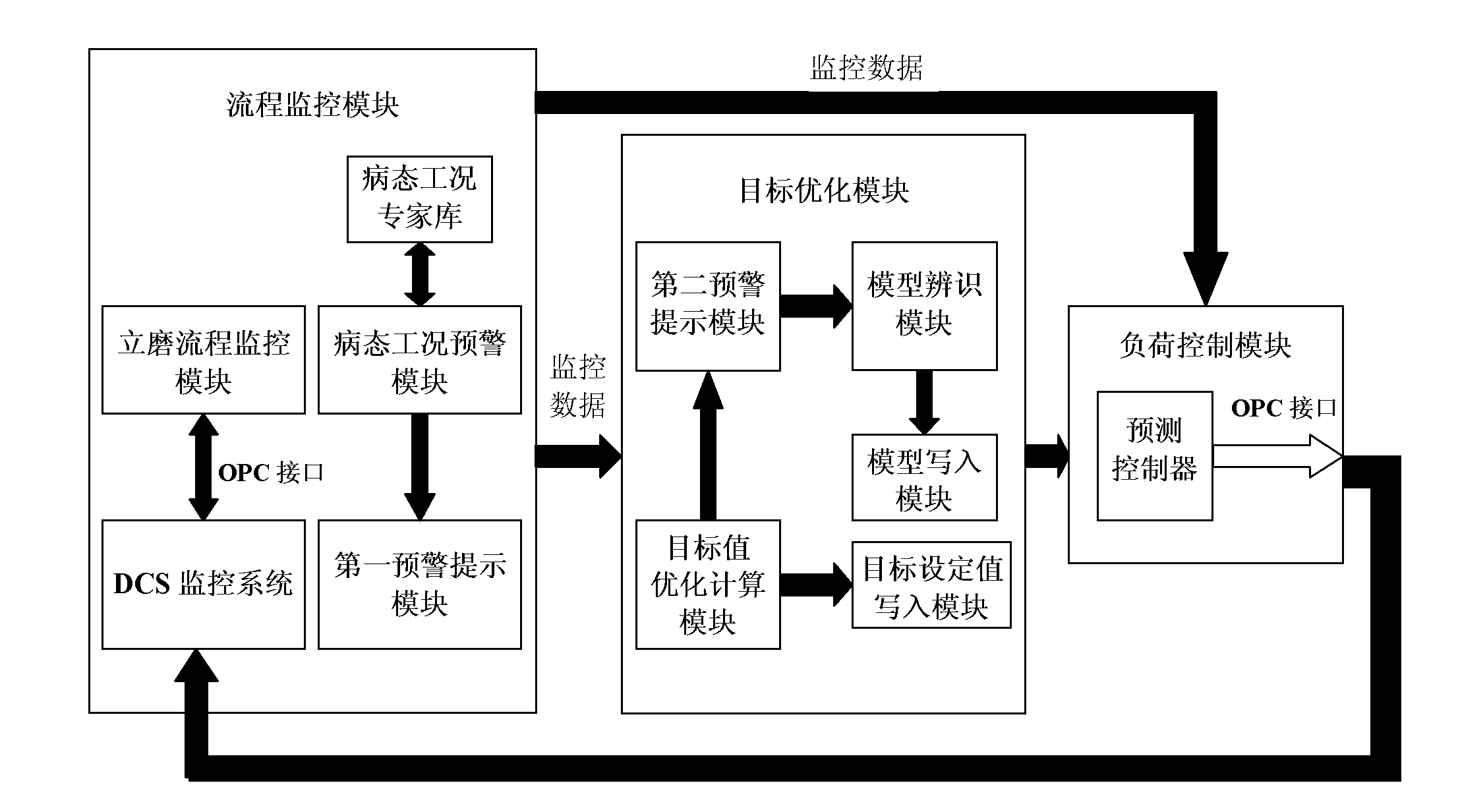

Advanced control method and system for vertical mill based on model identification and predictive control

InactiveCN102151605AIncrease the level of automationQuality improvementCement grindingCement productionMathematical modelOptimal control

The invention relates to raw material grinding in the field of cement process industries, and aims to provide an advanced control method and system for a vertical mill based on model identification and predictive control. The method comprises the following steps of: acquiring real-time data from a distributed control system (DCS) monitoring system; analyzing a variation trend of the operation and technology parameters, and then invoking a pathological working condition expert database for performing trend matching; if a pathological working condition appears, issuing early warning display and giving qualitative adjustment suggestion remind; giving an optimal target set value according to the basic operation condition of the vertical mill and the variation situation of the product quality requirement, and writing into a predictive controller; setting an optimal controlled quantity output according to the optimal target set value, and outputting to the DCS monitoring system to control a field actuator to take action. By adopting the invention, the qualitative adjustment suggestion can be precisely given; a mathematical model of the grinding process of the vertical mill is established and updated in real time; the steady-state error of the control system is reduced; and the grinding process of the vertical mill is instructed, so that the mill can operate stably for long term at a maximum efficiency point, and stable margin is maintained.

Owner:ZHEJIANG UNIV

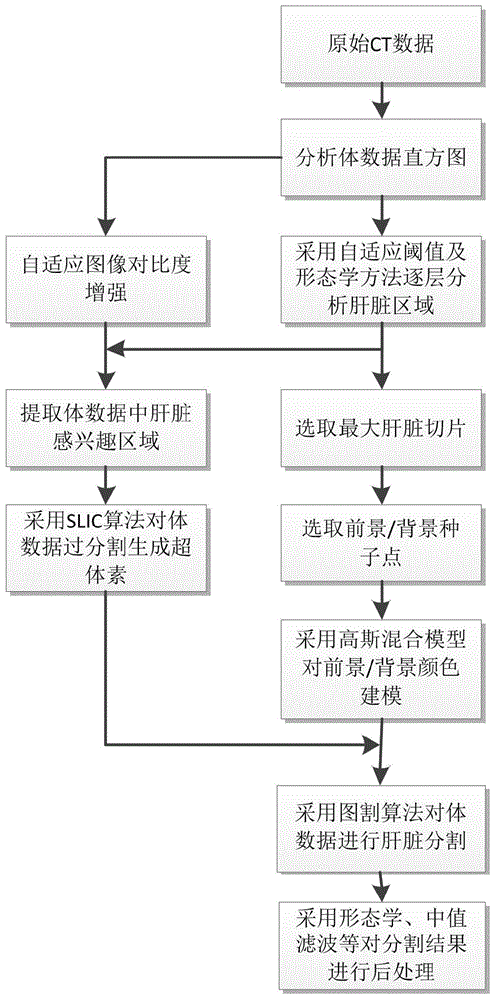

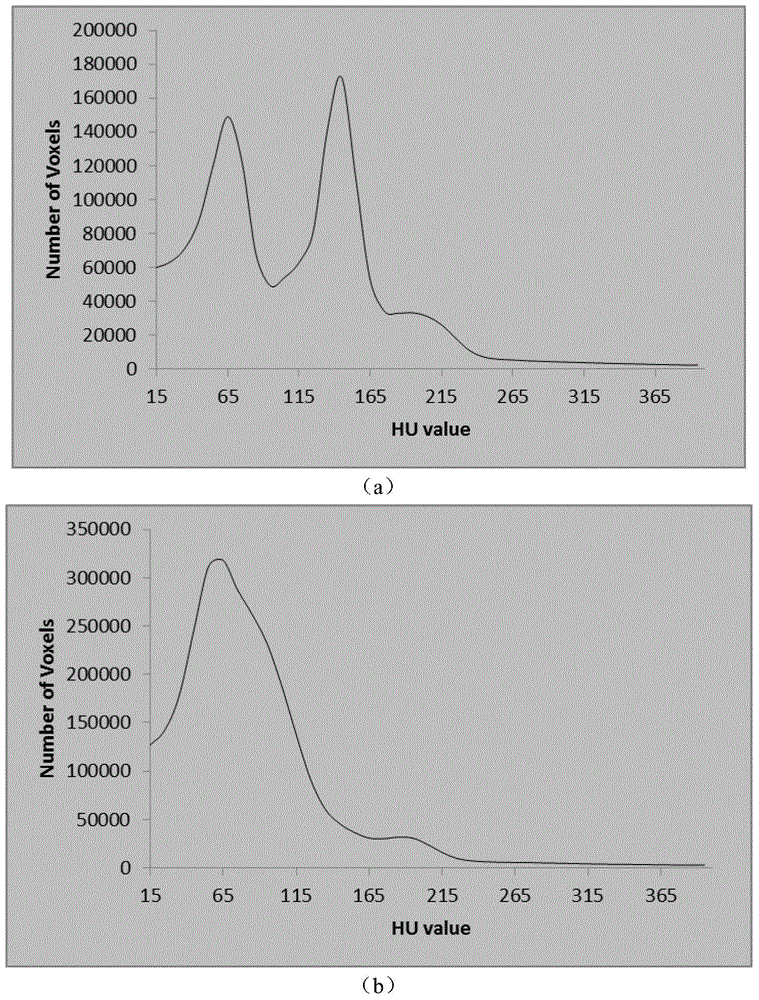

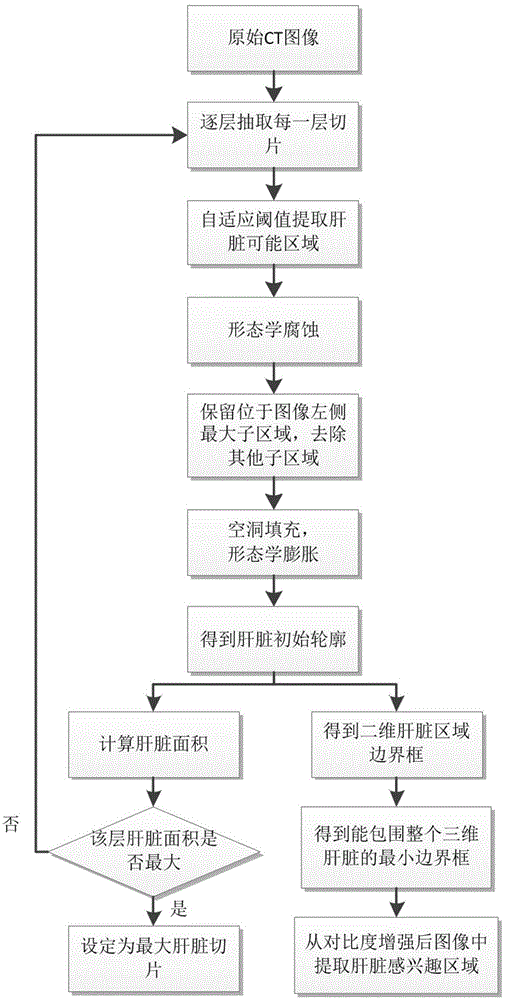

Three-dimensional liver CT (computed tomography) image automatically segmenting method based on hyper voxels and graph cut algorithm

InactiveCN104809723AAvoid robustness effectsIncrease the level of automationImage analysisImage contrastComputed tomography

Disclosed is a three-dimensional liver CT image automatically segmenting method based on hyper voxels and the graph cut algorithm. The method comprises analyzing a volume data histogram to adaptively enhance the image contrast; performing primary liver contour segmentation layer by layer through an adaptive threshold and an morphological method, selecting the largest liver segment to compute and extract a liver interest area; selecting seed points on the largest liver segment according to a primary liver contour, modelling foreground and background colors through a Gaussian mixed model; generating hyper voxels on the contrast-enhanced liver interest area through an SLIC (simple linear iterative clustering) algorithm, structuring an undirected weighted graph by taking the hyper voxels as the vertex, and segmenting the undirected weighted graph through the graph cut algorithm; performing postprocessing on segmentation results through a morphological algorithm. The three-dimensional liver CT image automatically segmenting method based on the hyper voxels and the graph cut algorithm can achieve rapid and accurate automatic segmentation of the liver in a three-dimensional abdominal CT image.

Owner:BEIJING UNIV OF TECH

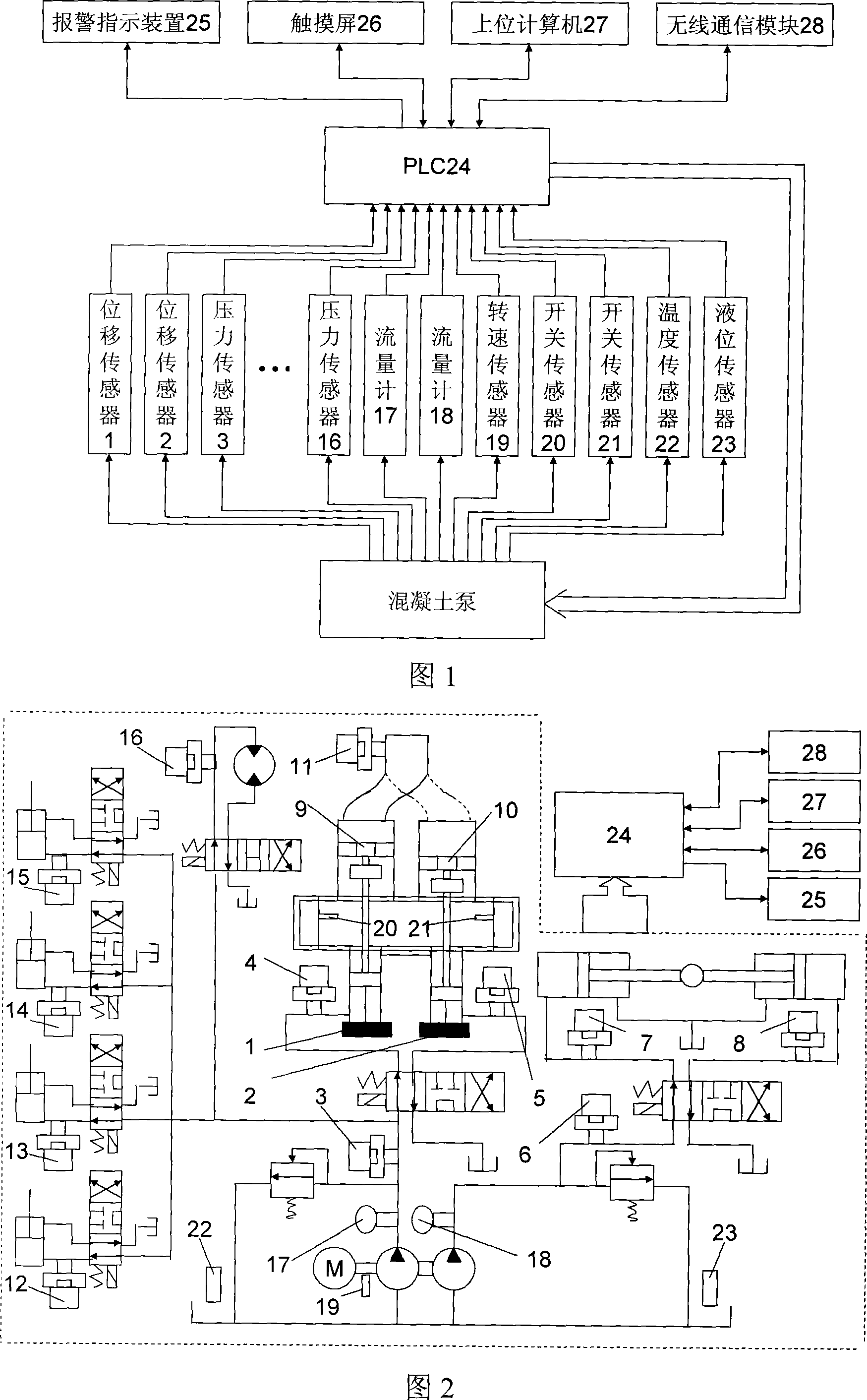

Concrete pump intelligent monitoring and control system

InactiveCN101178061AImprove performanceRealize intelligencePump controlBuilding material handlingElectric machineControl system

The invention discloses a concrete pump intelligent monitoring and control system. A magnetic telescopic displacement sensor is respectively arranged on the piston rod of the main cylinder of a concrete pump; pressure sensors are respectively arranged on a main pump hydraulic system, a concrete pump main cylinder, a swing hydraulic system, a swing cylinder, a concrete conveying cylinder piston, a concrete pump outlet, a concrete pump supporting leg hydraulic system, and a mixed hydraulic system; the outlet of the main cylinder and the outlet of an auxiliary pump are respectively provided with flowmeters; a rotation speed sensor is arranged on a motor mainshaft; a switch sensor is respectively arranged at the position of a concrete water tank; a temperature sensor and a liquid level sensor are arranged at the position of a concrete pump oil tank; all parts are respectively connected with the concrete pump and a PLC; the PLC is respectively connected with an alarm indicator device, a contact screen, an upper bit computer, and a wireless communication module. The invention can implement timely, online and remote state monitoring, malfunction diagnosing and intelligent control, so as to improve the integration performance of the concrete pump.

Owner:ZHEJIANG UNIV

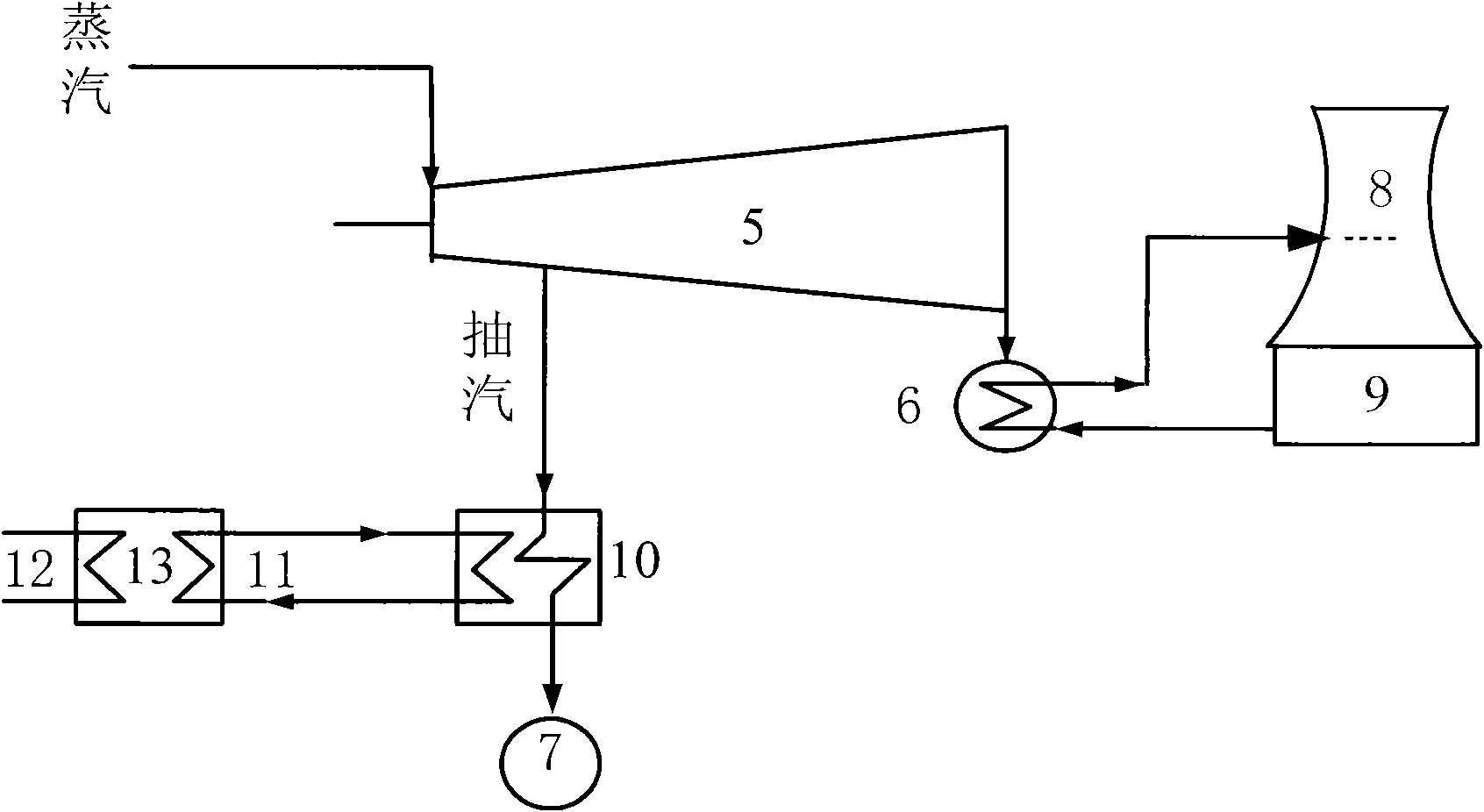

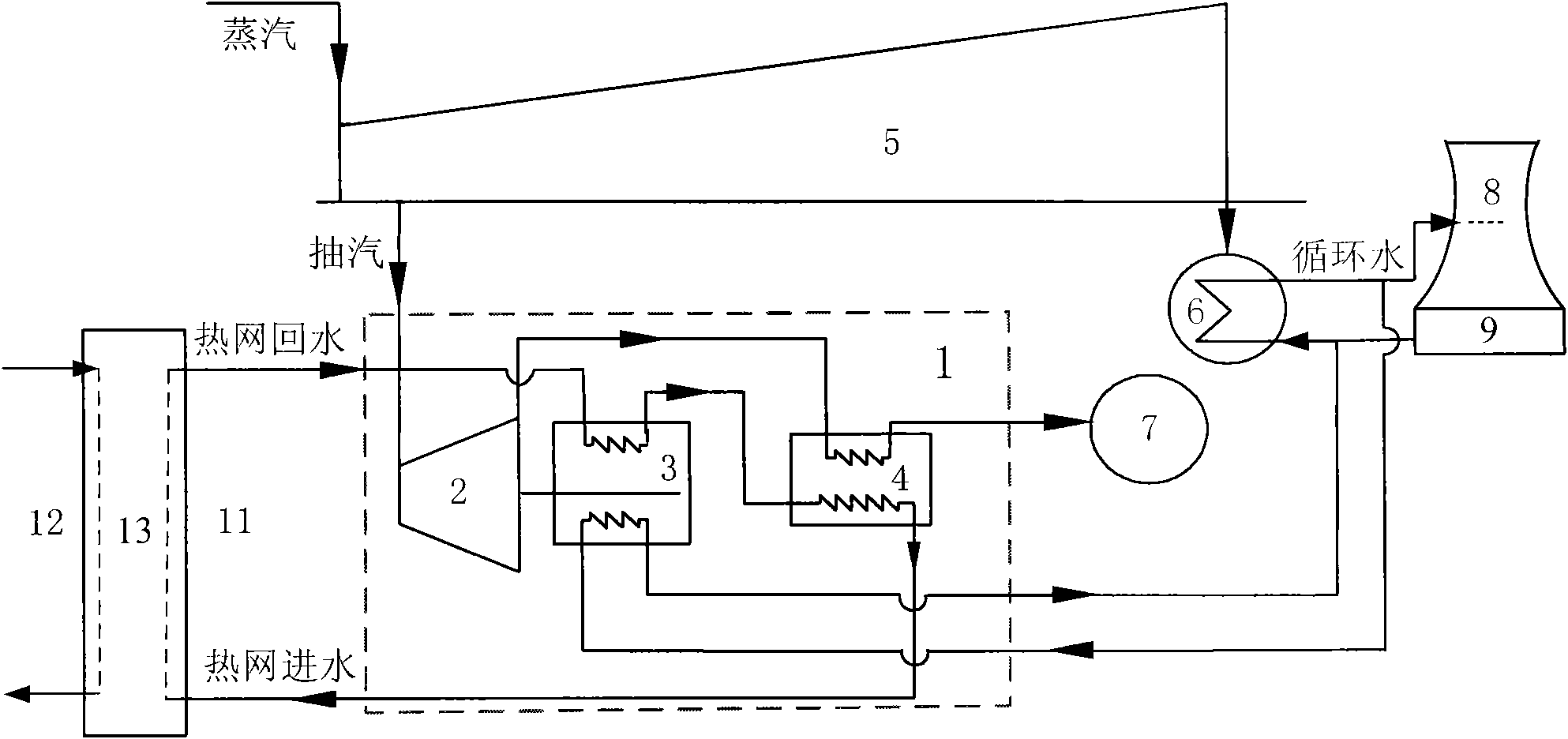

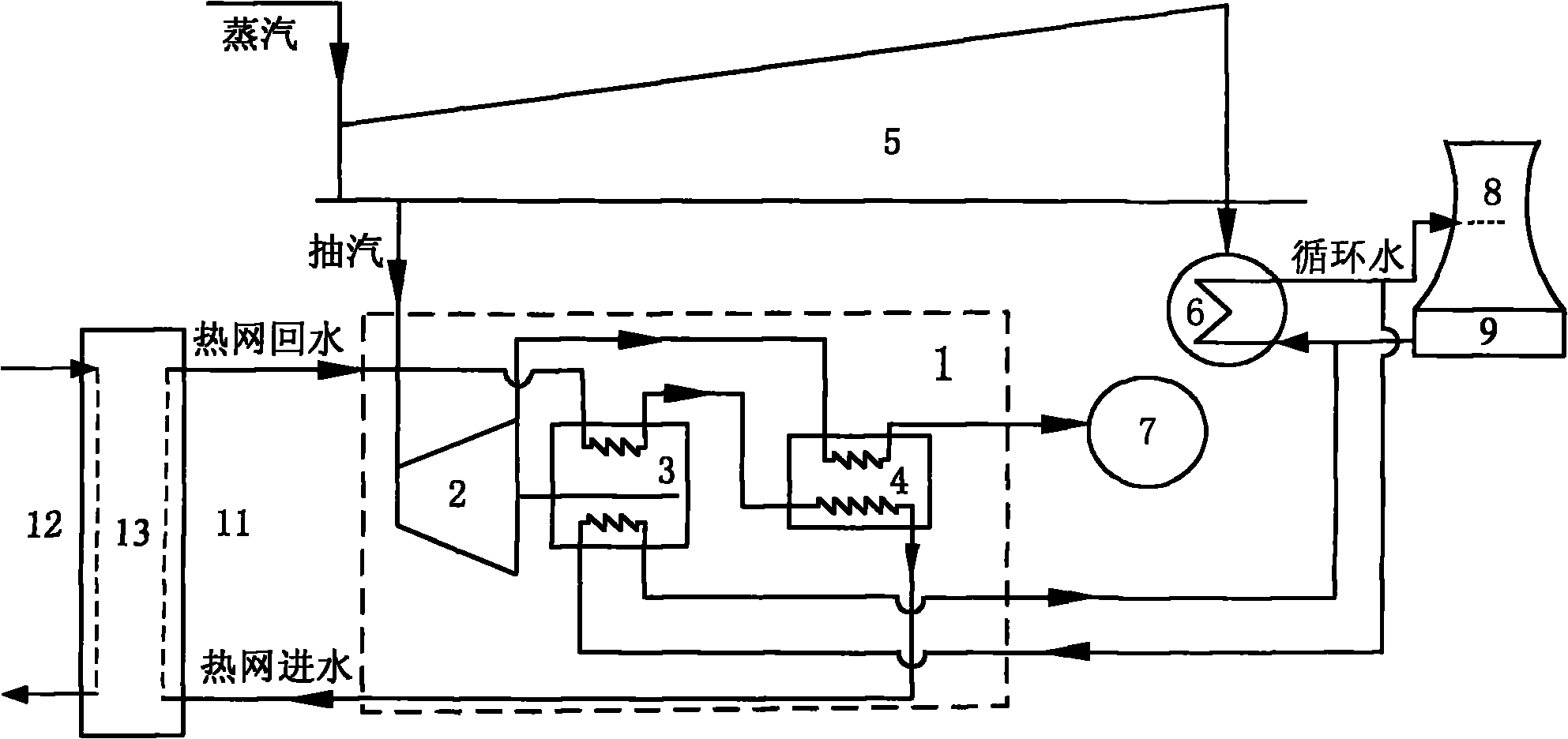

Combined heat and power generation energy saving device using afterheat to supply heat and energy saving method

InactiveCN101967999AIncrease small loopReduce heat transfer irreversible lossLighting and heating apparatusEnergy efficient heating/coolingCooling towerCogeneration

The invention relates to a combined heat and power generation energy saving device using afterheat to supply heat and an energy saving method. The combined heat and power generation energy saving device comprises a steam boiler, a steam extraction condensed type steam turbine, an electric generator, a condenser, a deaerator and a cooling tower, wherein the steam extraction condensed type steam turbine is connected with the condenser by an exhaust steam cylinder, and the condenser is connected with the cooling tower to form large waterway circulation; the combined heat and power generation energy saving device also comprises a backpressure turbine, a compression heat pump and a heat exchanger, wherein a steam inlet of the backpressure turbine is connected with a steam extraction hole of the steam extraction condensed type steam turbine, an exhaust steam hole is connected with a steam inlet of the heat exchanger, the compression heat pump is drawn by the backpressure turbine and is connected with the backwater end of a hot-water pipe network, the condenser and the compression heat pump are connected with the cooling tower to form small waterway circulation, the water inlet end of the heat exchanger is connected with the water outlet end of the compression heat pump, the water outlet end is connected with the water inlet end of the hot-water pipe network, and the drainage end is connected with the deaerator. The invention is capable of reducing cold source loss, increasing comprehensive heat efficiency and electrothermal proportion and reducing unit electric-generation coal consumption.

Owner:联合优发生物质能源徐州有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com