Combined heat and power generation energy saving device using afterheat to supply heat and energy saving method

A technology of combined heat and power generation and energy-saving devices, applied in the energy field, can solve problems such as waste of water resources, and achieve the effects of increasing power generation, increasing power generation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

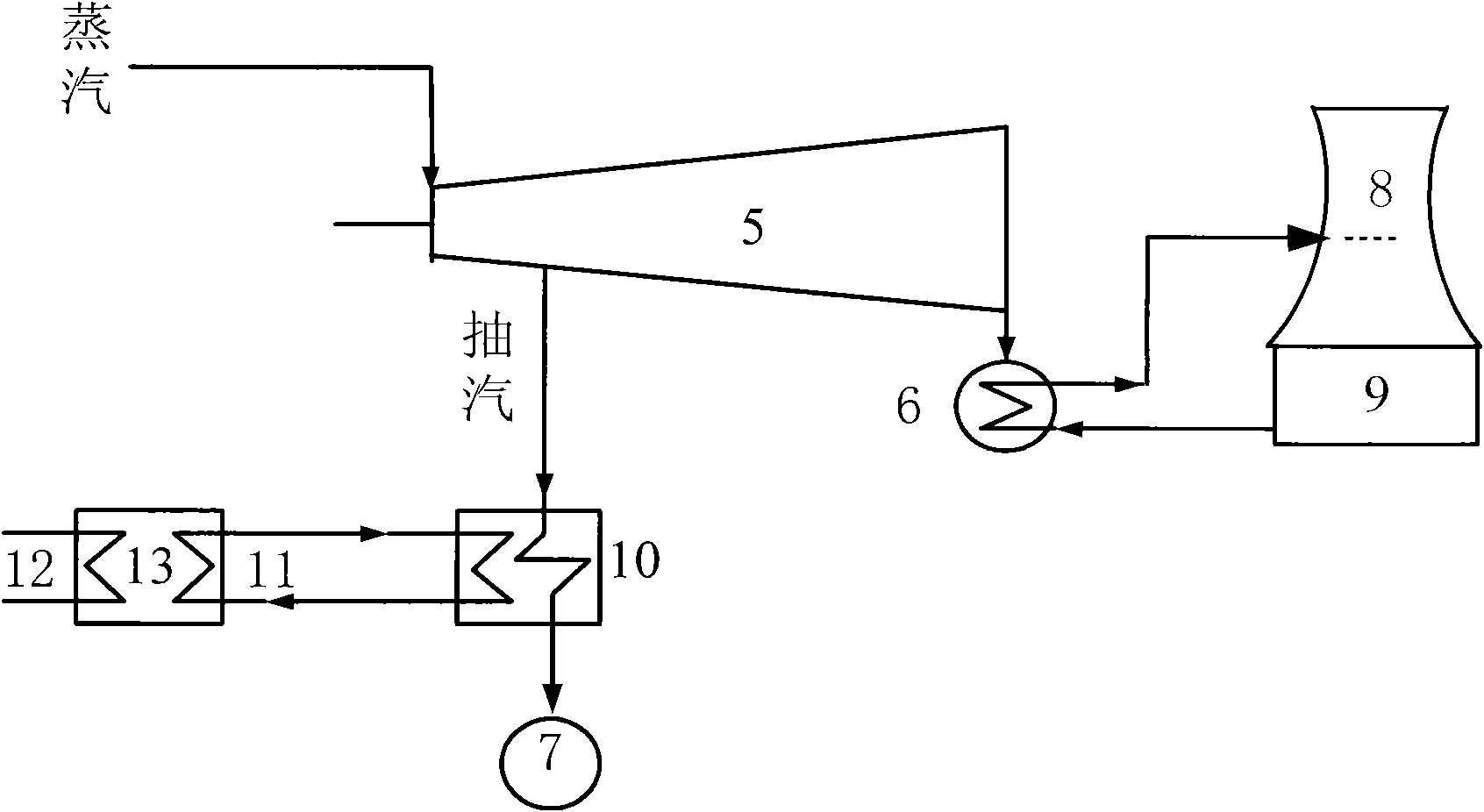

[0029] Such as figure 1 As shown, the typical features of the prior art are: the primary heating network heater is a surface heating network heater 10, which uses the steam extracted by the steam extraction and condensing steam turbine 5 to send to the heating pipe network (also called the hot water pipe network) The incoming return water is heated.

[0030] The heating pipe network has two levels: the primary heating network 11 and the secondary heating network 12 . The primary heating network 11 is connected to the surface heating network heater 10 through pipelines, and the secondary heating network 12 is used to supply heat to the outside.

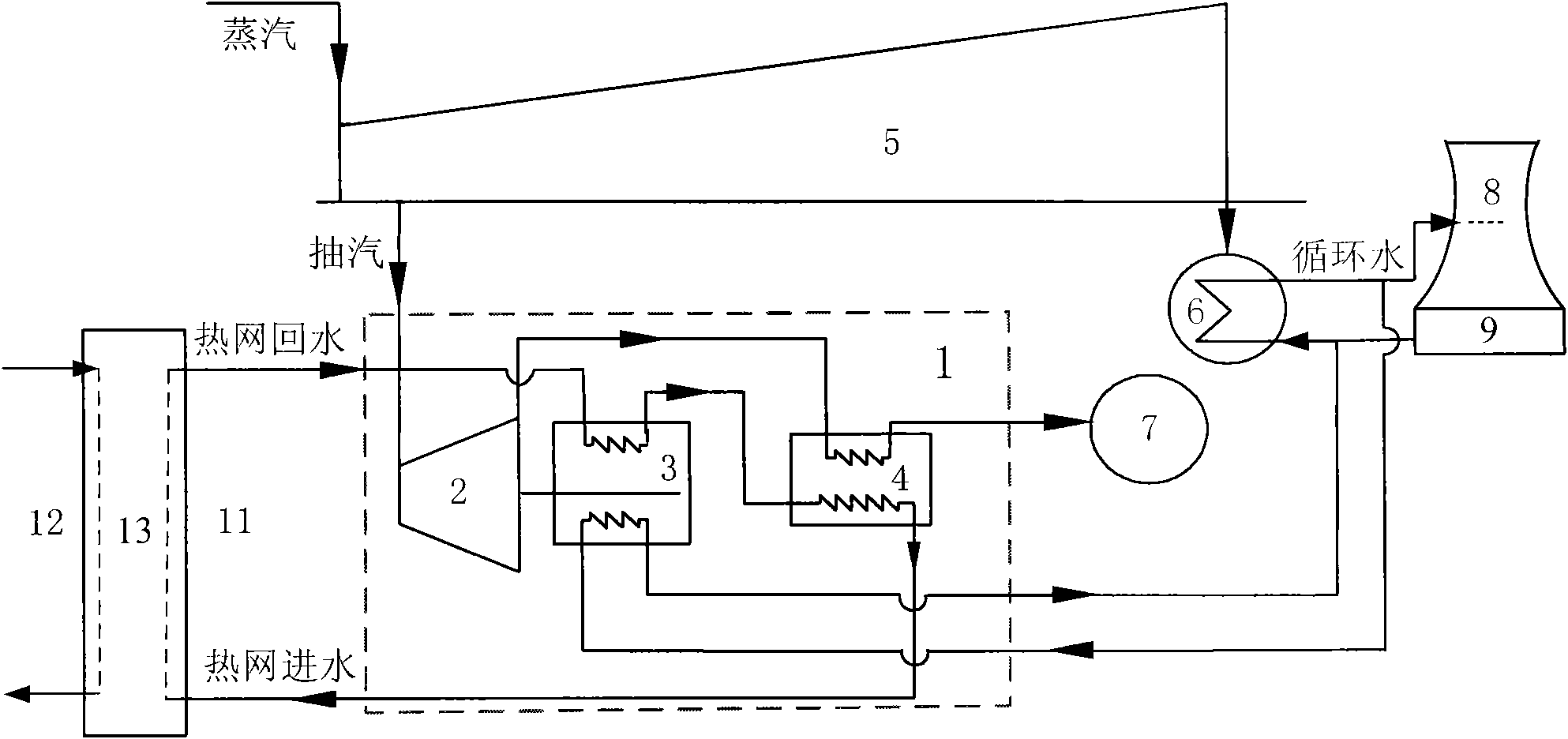

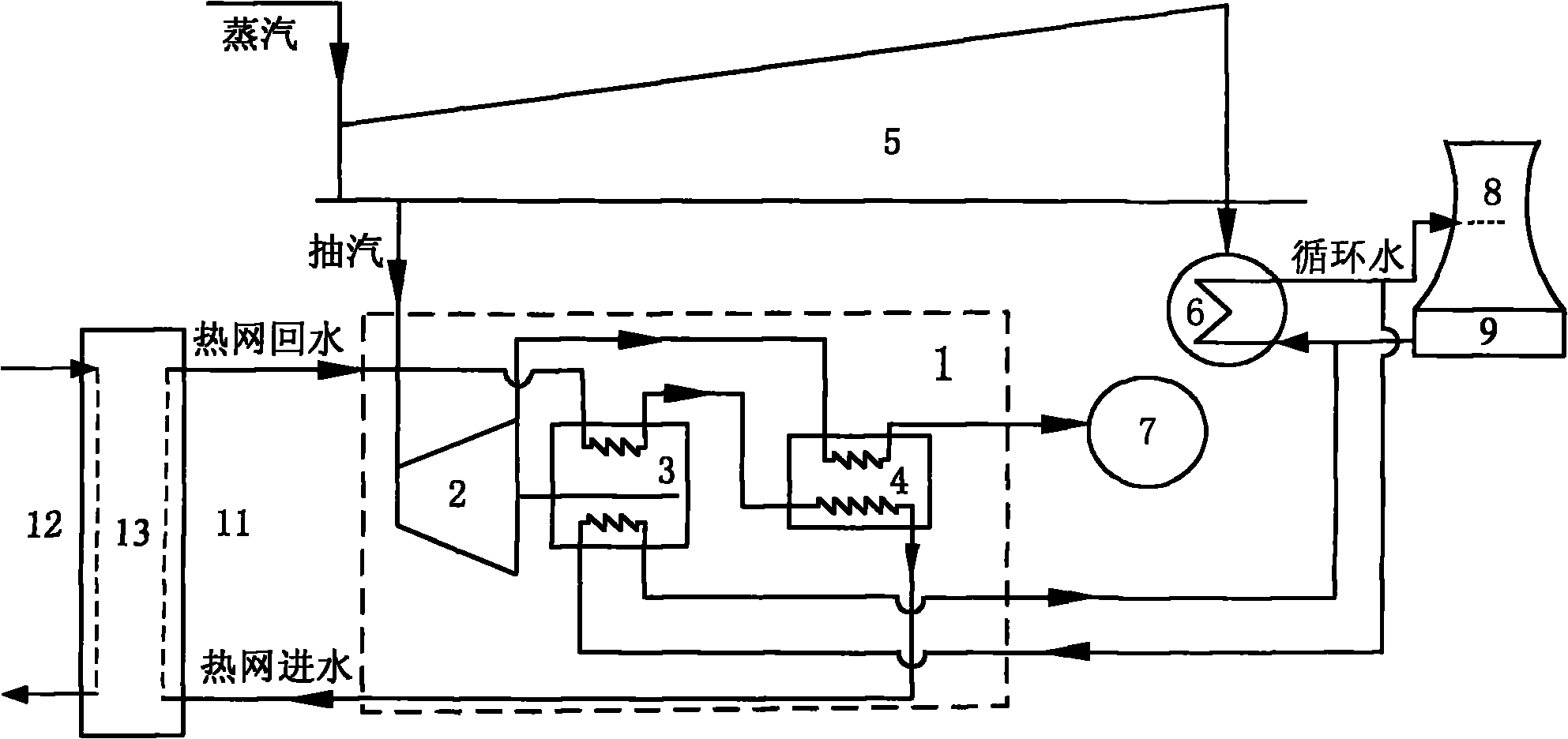

[0031] Such as figure 2As shown, the cogeneration energy-saving device utilizing waste heat for heating according to the present invention includes a steam boiler, a steam extraction condensing turbine 5, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com