Patents

Literature

114results about How to "Reduce coal consumption for power generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

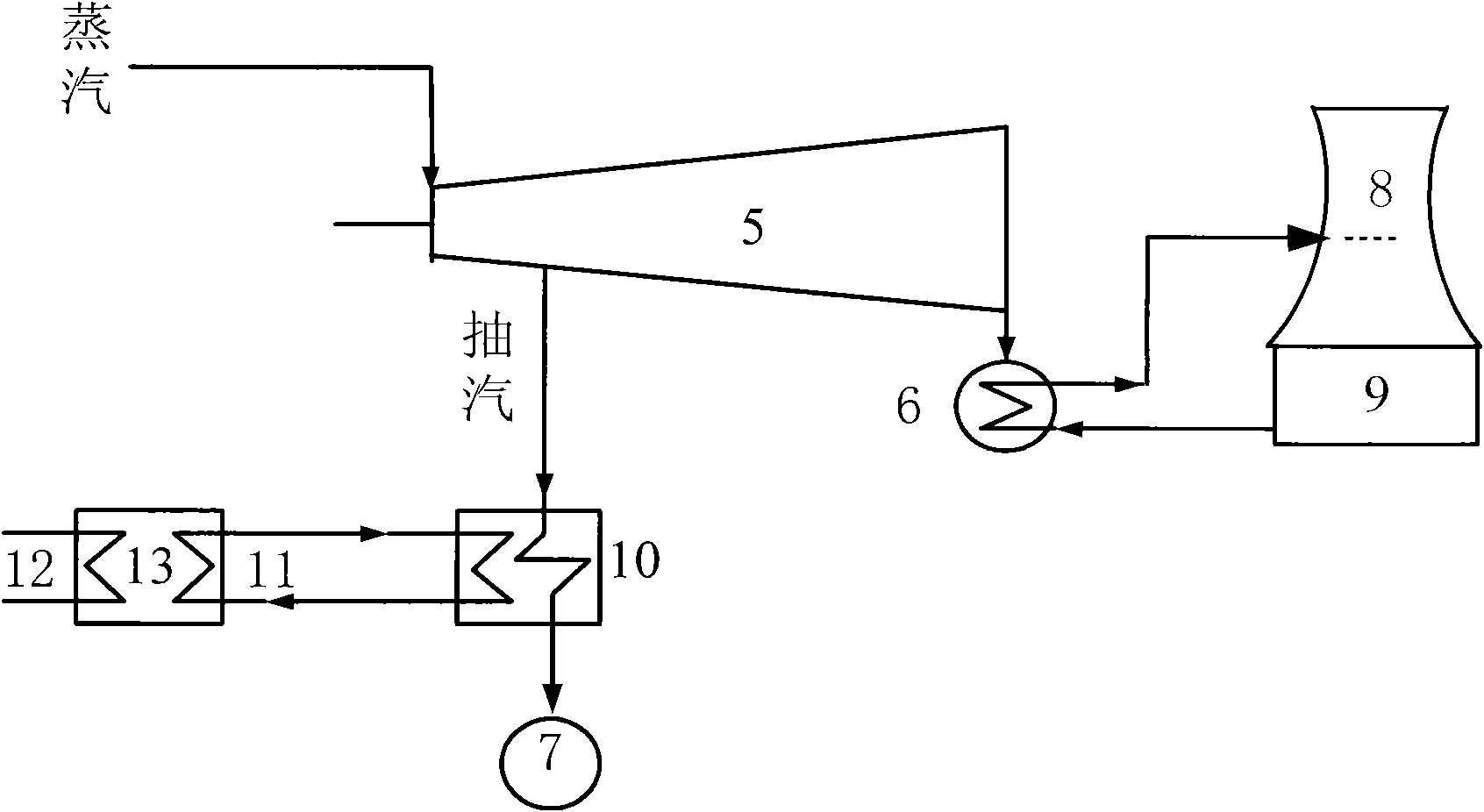

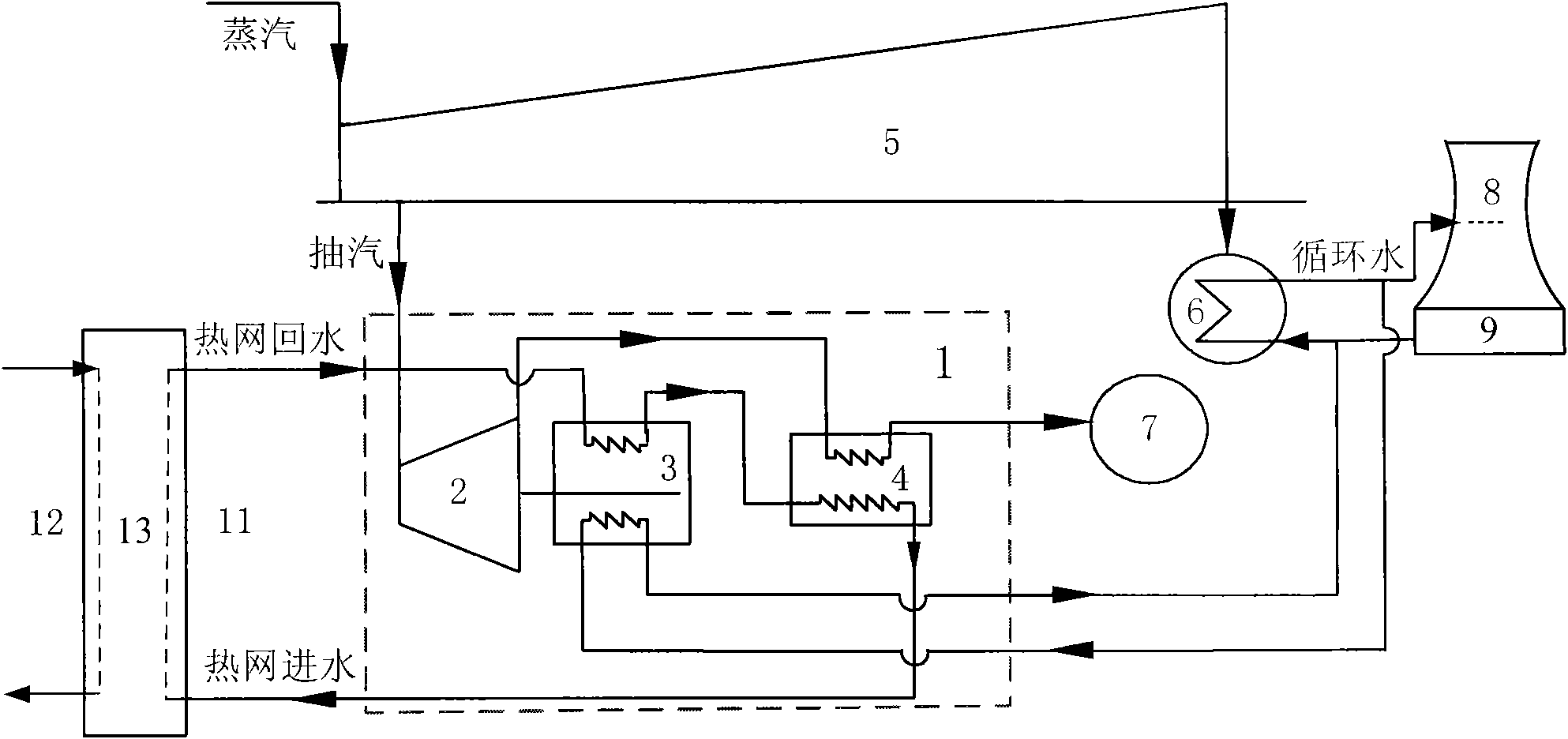

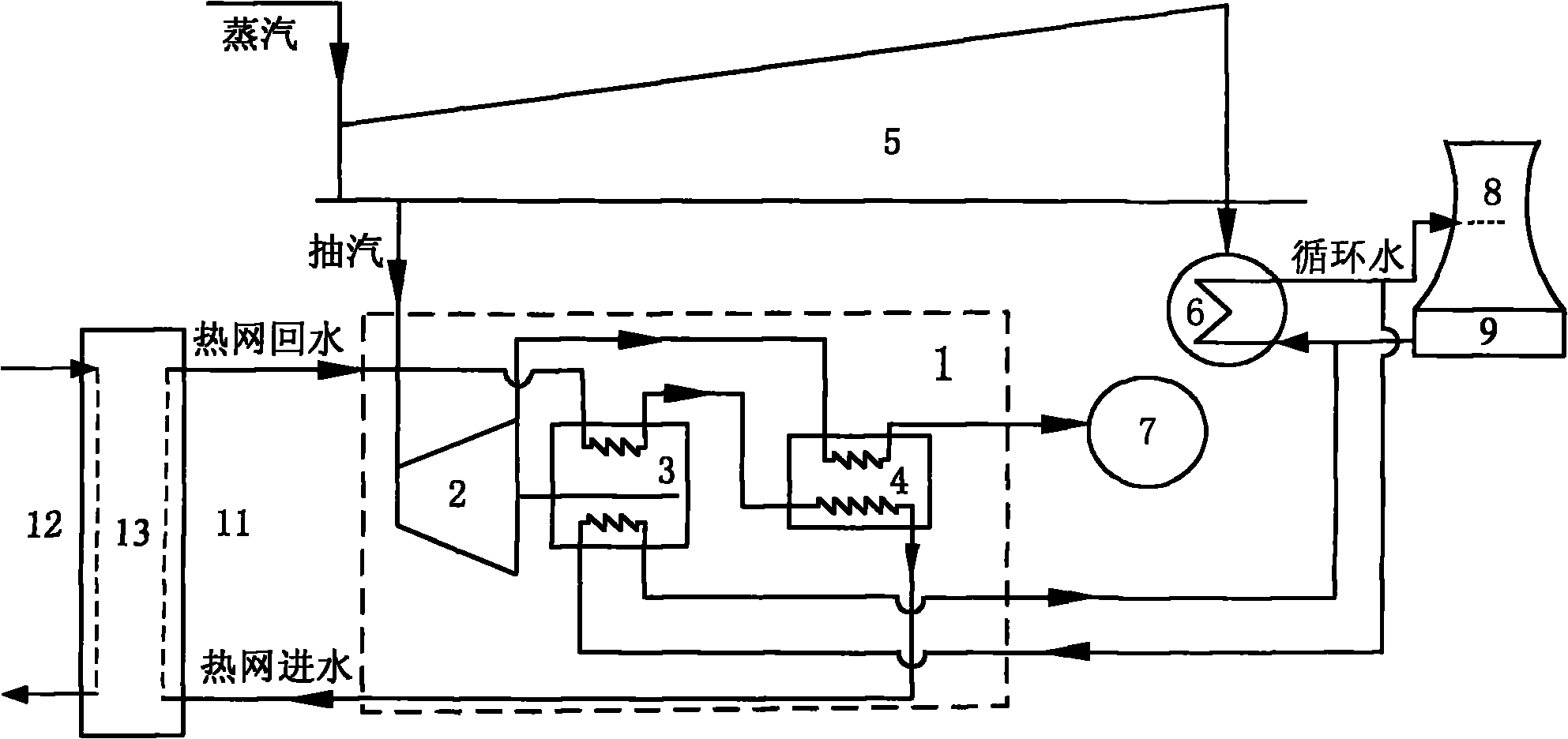

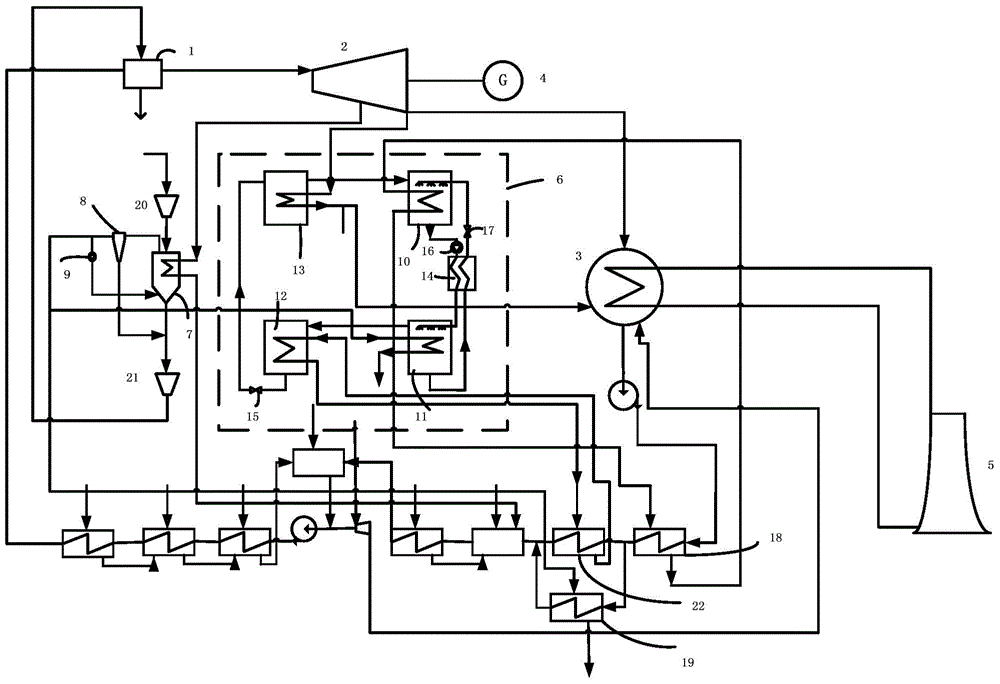

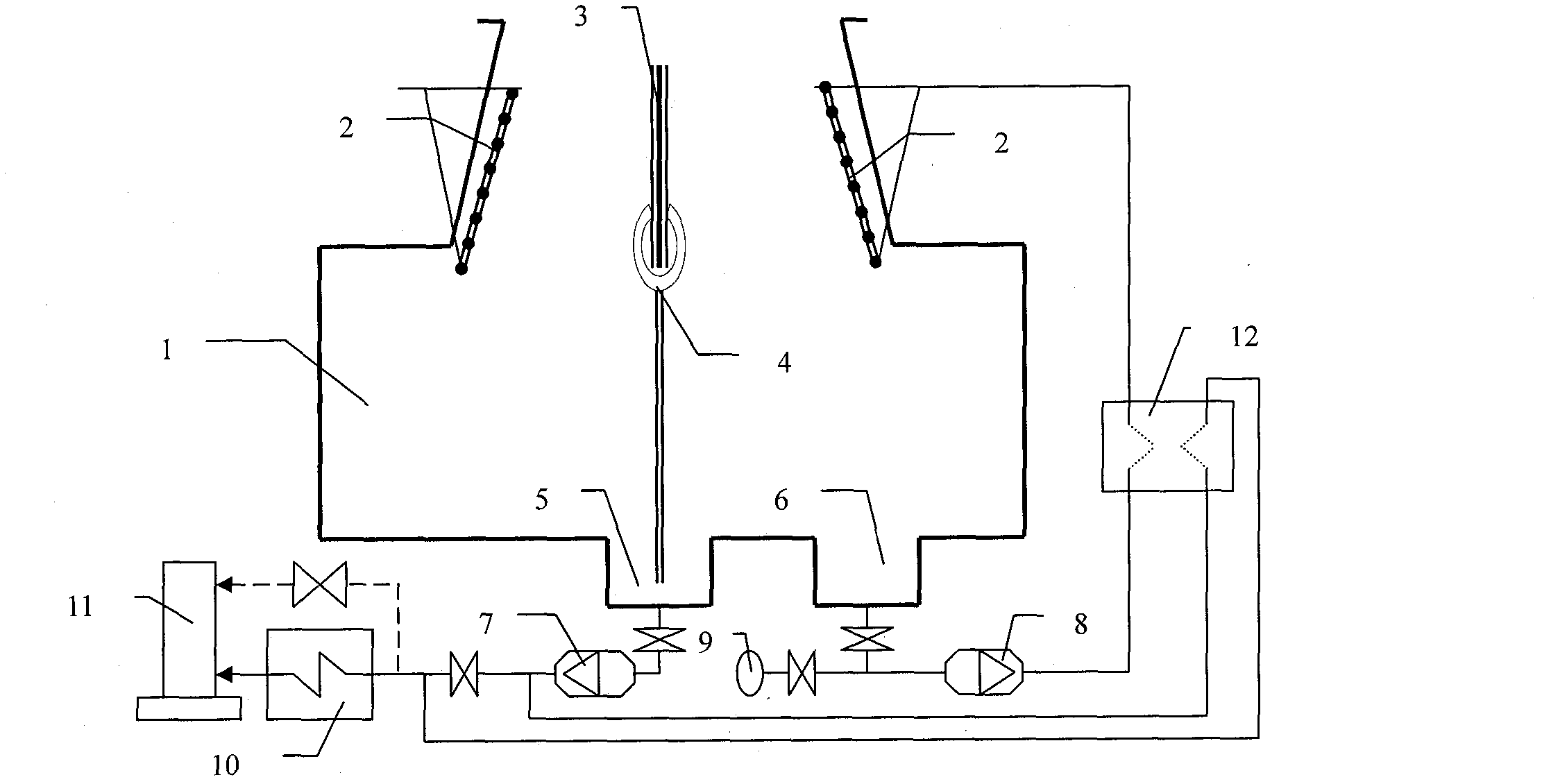

Combined heat and power generation energy saving device using afterheat to supply heat and energy saving method

InactiveCN101967999AIncrease small loopReduce heat transfer irreversible lossLighting and heating apparatusEnergy efficient heating/coolingCooling towerCogeneration

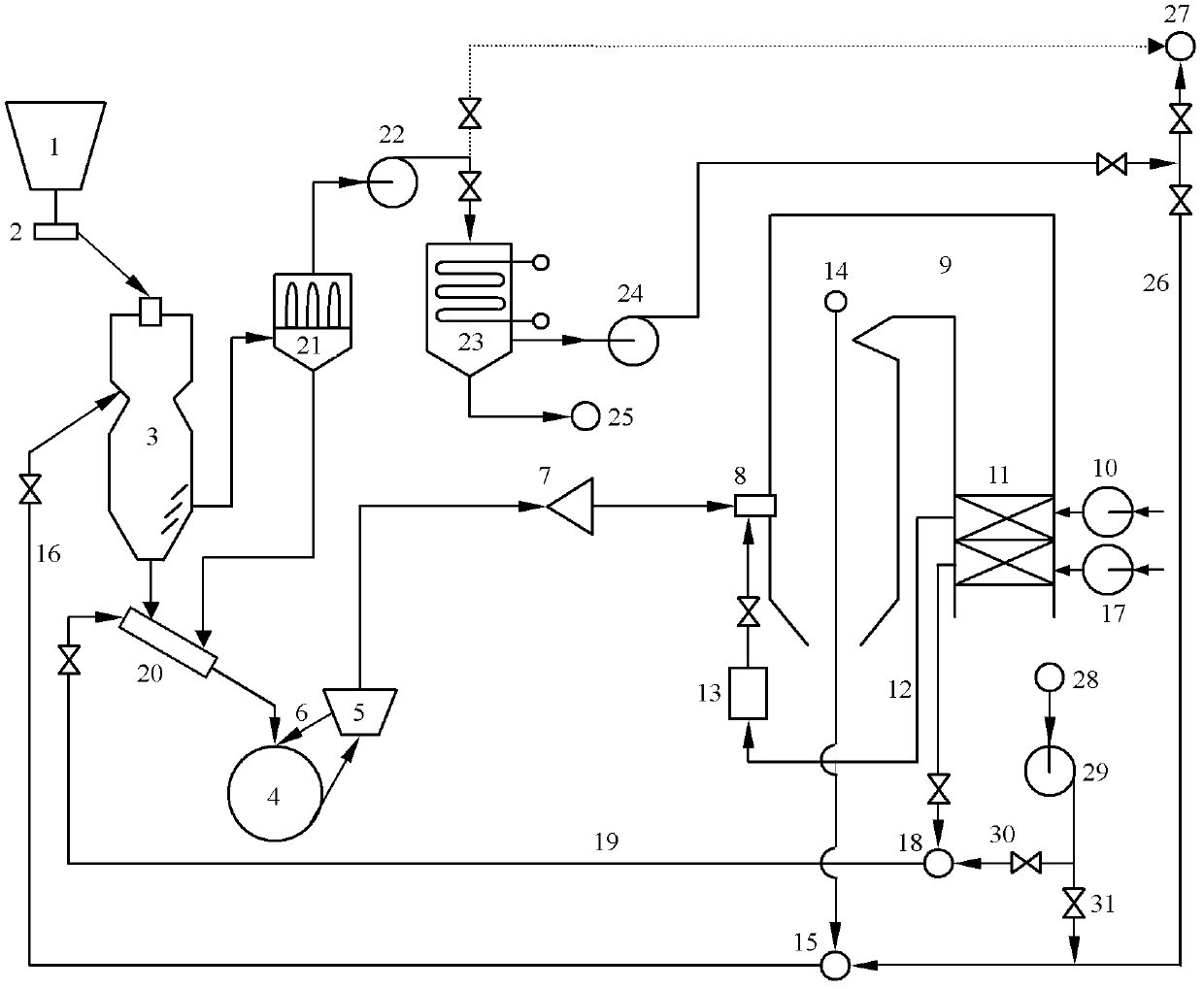

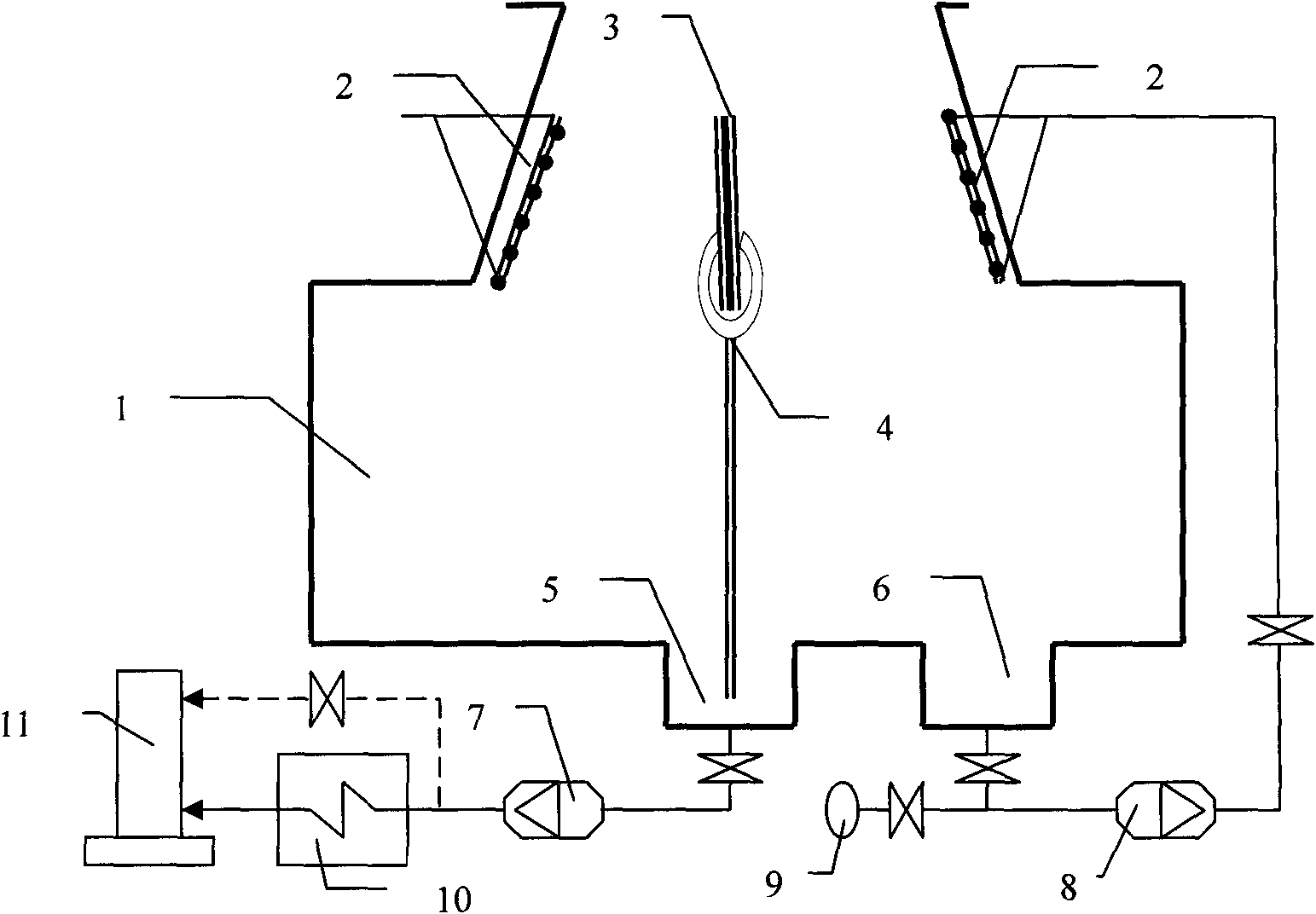

The invention relates to a combined heat and power generation energy saving device using afterheat to supply heat and an energy saving method. The combined heat and power generation energy saving device comprises a steam boiler, a steam extraction condensed type steam turbine, an electric generator, a condenser, a deaerator and a cooling tower, wherein the steam extraction condensed type steam turbine is connected with the condenser by an exhaust steam cylinder, and the condenser is connected with the cooling tower to form large waterway circulation; the combined heat and power generation energy saving device also comprises a backpressure turbine, a compression heat pump and a heat exchanger, wherein a steam inlet of the backpressure turbine is connected with a steam extraction hole of the steam extraction condensed type steam turbine, an exhaust steam hole is connected with a steam inlet of the heat exchanger, the compression heat pump is drawn by the backpressure turbine and is connected with the backwater end of a hot-water pipe network, the condenser and the compression heat pump are connected with the cooling tower to form small waterway circulation, the water inlet end of the heat exchanger is connected with the water outlet end of the compression heat pump, the water outlet end is connected with the water inlet end of the hot-water pipe network, and the drainage end is connected with the deaerator. The invention is capable of reducing cold source loss, increasing comprehensive heat efficiency and electrothermal proportion and reducing unit electric-generation coal consumption.

Owner:联合优发生物质能源徐州有限公司

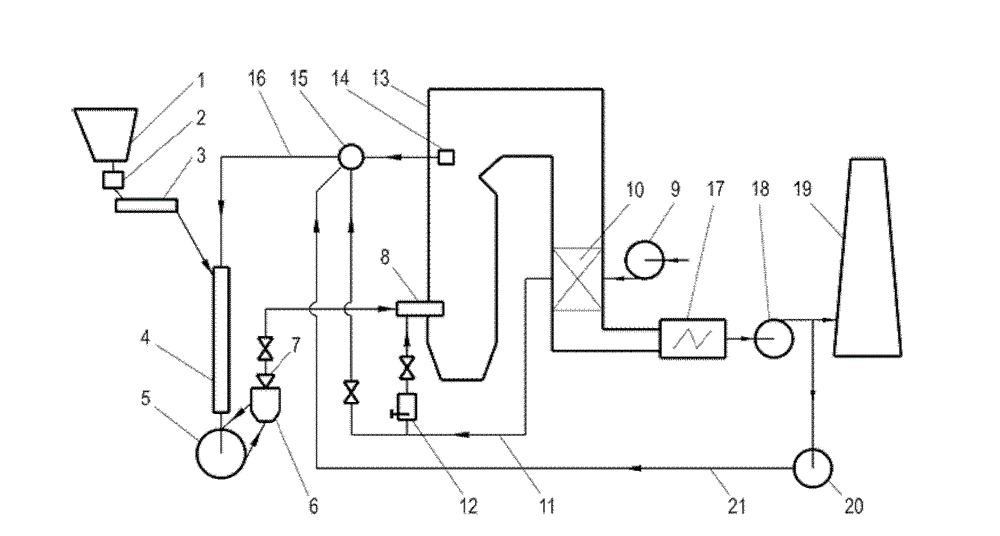

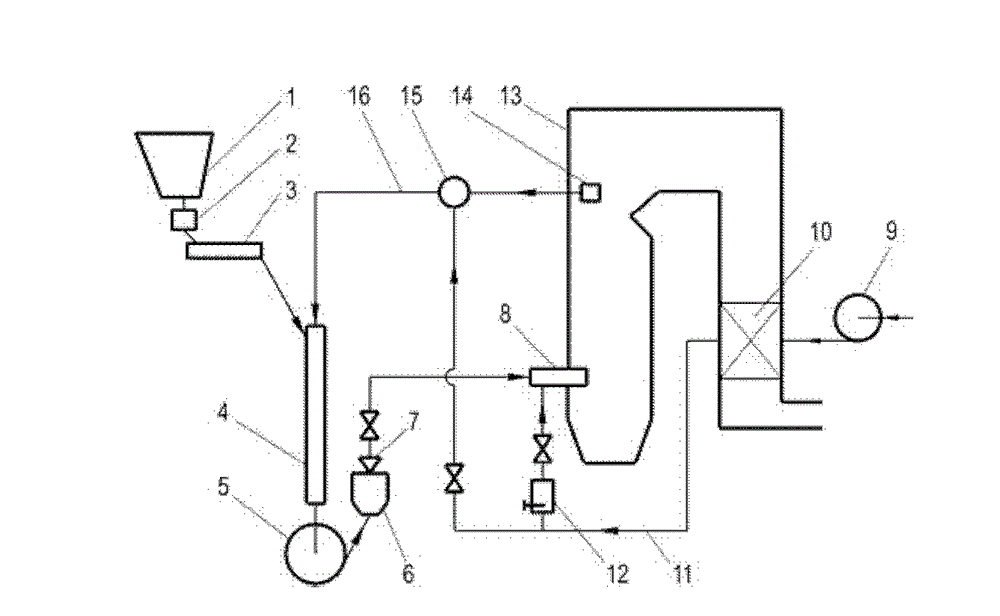

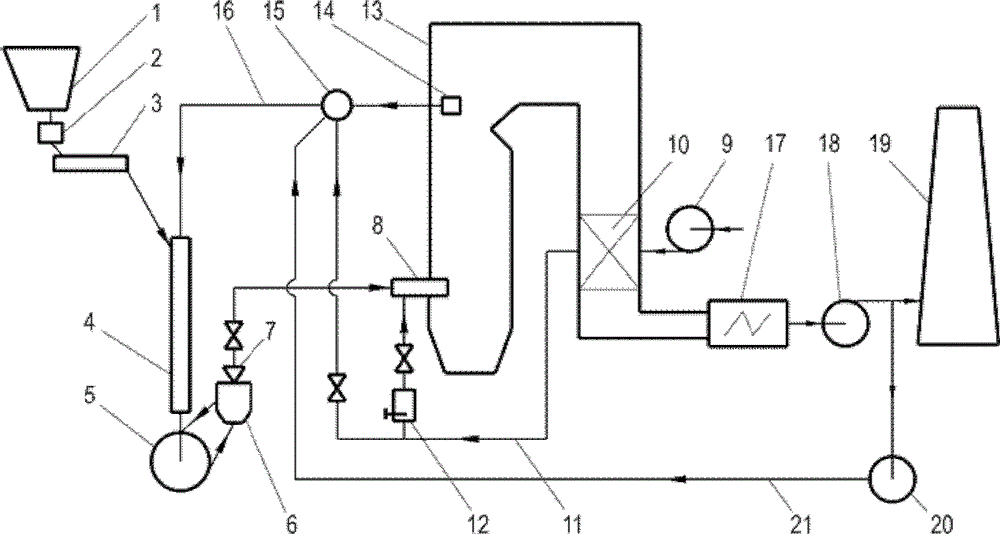

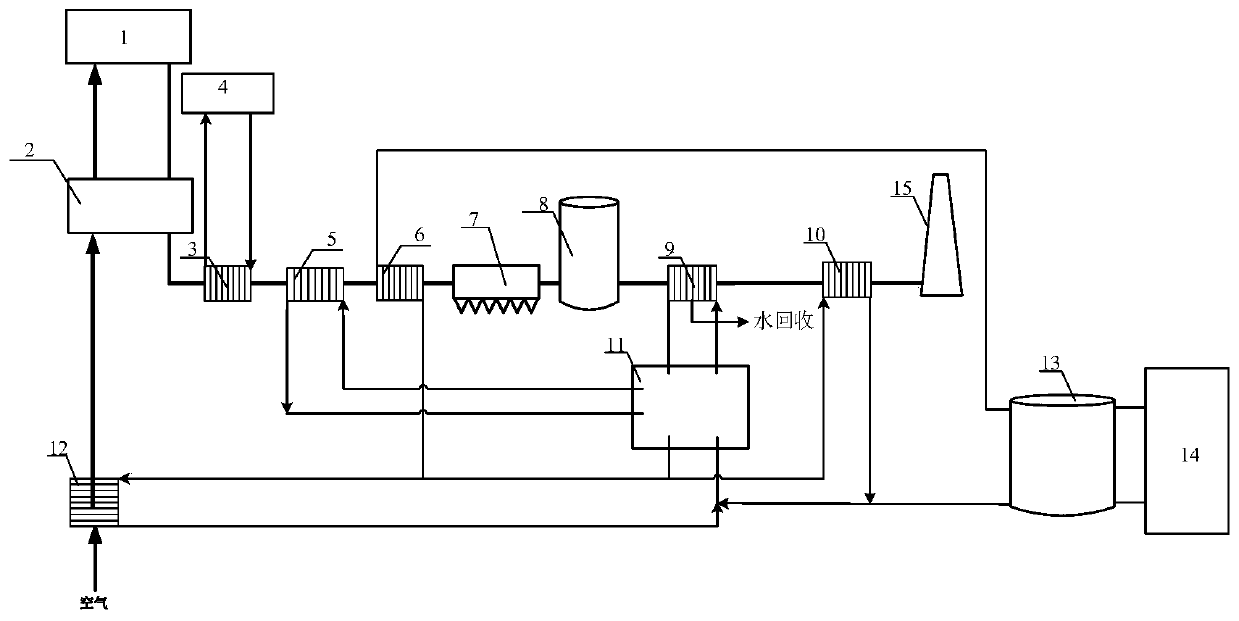

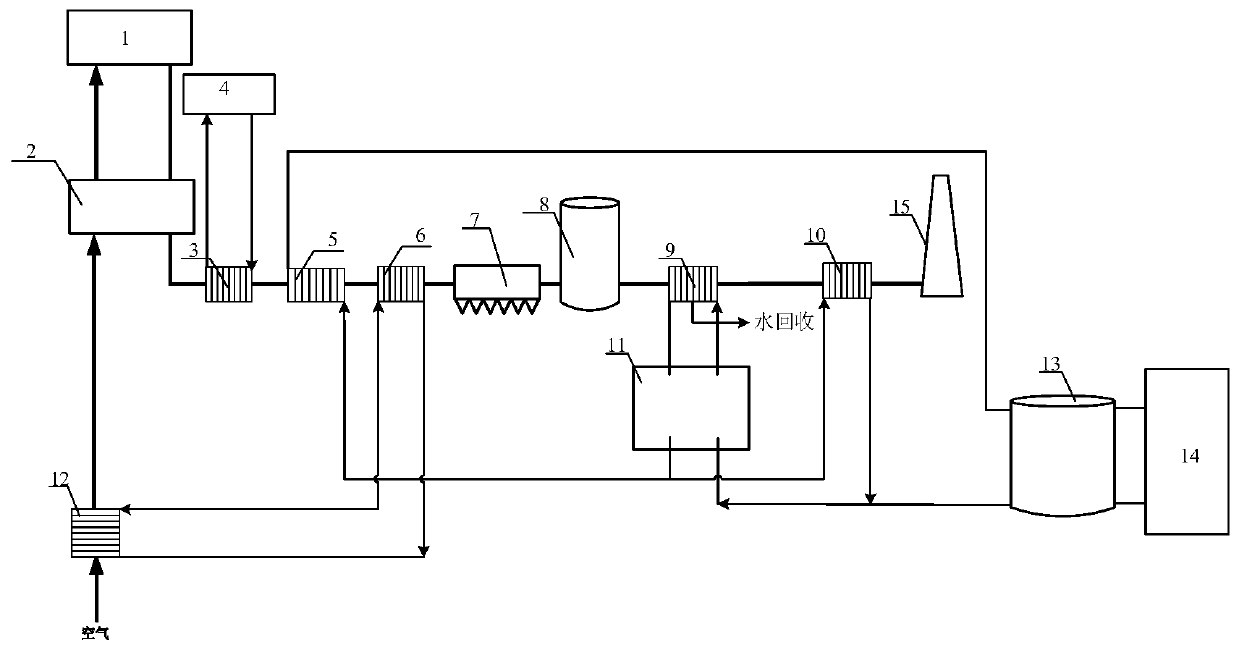

Fan grinding hot blast powder feeding and pulverizing system utilizing flue gas drying and water recycling

ActiveCN102798133AImprove fuel consumption qualityReduce volumeLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationAir preheaterFlue gas

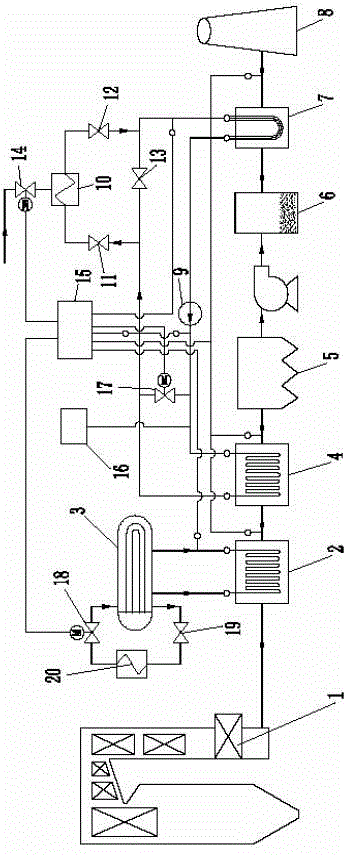

The invention relates to a fan grinding hot blast powder feeding and pulverizing system utilizing flue gas drying and water recycling. The system is further provided with a steam exhaust separator, a pulverized fuel feeder and a coal-dust mixer in sequence between a tailing separator and a coal-dust distributor; the upper part of the steam exhaust separator is provided with a steam exhaust outlet; the steam exhaust outlet is communicated with a steam exhaust filter; the coal outlet of the steam exhaust filter is communicated with the pulverized fuel feeder; the air outlet of the steam exhaust separator is communicated with a steam exhaust fan; the steam exhaust fan is then communicated with a desulfurizing tower; and an air preheater is further communicated with the coal dust mixer. The system has the advantages of improving the burn-up quality of brown coal and the thermal efficiency of fuel coal, and as drying, pulverizing, upgrading, water conservation and storage of the brown coal are combined, the coal consumption of power generation can be reduced, and a large amount of water in the brown coal can be recycled.

Owner:NORTHEAST ELECTRIC POWER DESIGN INST CO LTD OF CHINA POWER ENG CONSULTING GRP +1

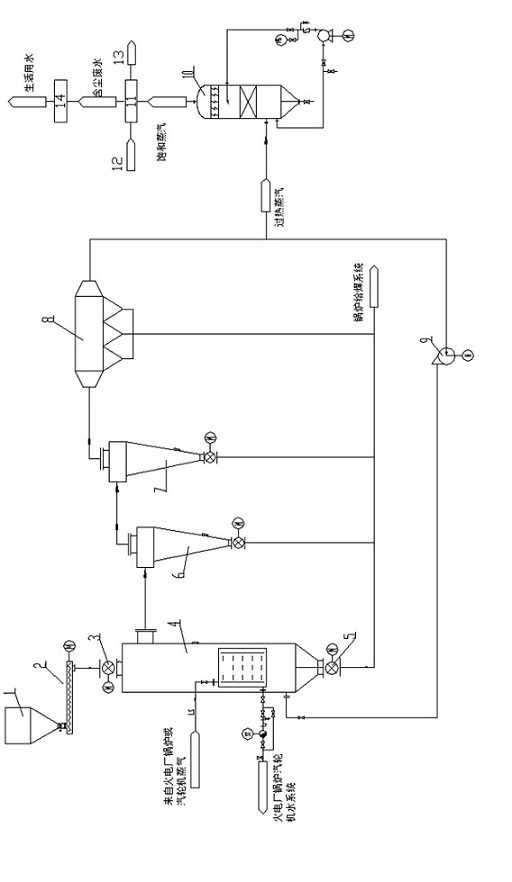

Comprehensive utilization system for drying low-order coal of thermal power plant in steam pumping and indirect heat exchanging way and process thereof

The invention relates to a comprehensive utilization system for drying low-order coal of a thermal power plant in a steam pumping and indirect heat exchanging way and a process thereof. The system comprises an indirect-heat-exchange low-order coal predrying device using a steam pipeline of a boiler or a steam turbine of the thermal power plant as a heat source, wherein tail steam obtained by the drying low-order coal of the device is connected with a secondary steam heat insulating and washing device; the secondary steam heat insulating and washing device is connected with a secondary steam recycling device; and the secondary steam recycling device is connected with a dust-containing waste water purifying and utilizing device. In the invention, the steam pumped by the boiler or the steam turbine is used as the drying heat source, high-moisture low-order coal (brown coal) is dewatered and dried through an indirect-heat-exchange drier, and secondary steam generated by dewatering the low-order coal (brown coal) is butt jointed with a steam-water system of the power plant, thereby the operating condition of the boiler is improved, the CO2 emission and fuel consumption are obviously reduced, the loss of a coal mill and matched systems is reduced, the generating efficiency of the power plant is improved, and the blank of the drying and the comprehensive utilization of the low-order coal (brown coal) of the thermal power plant in China is filled.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

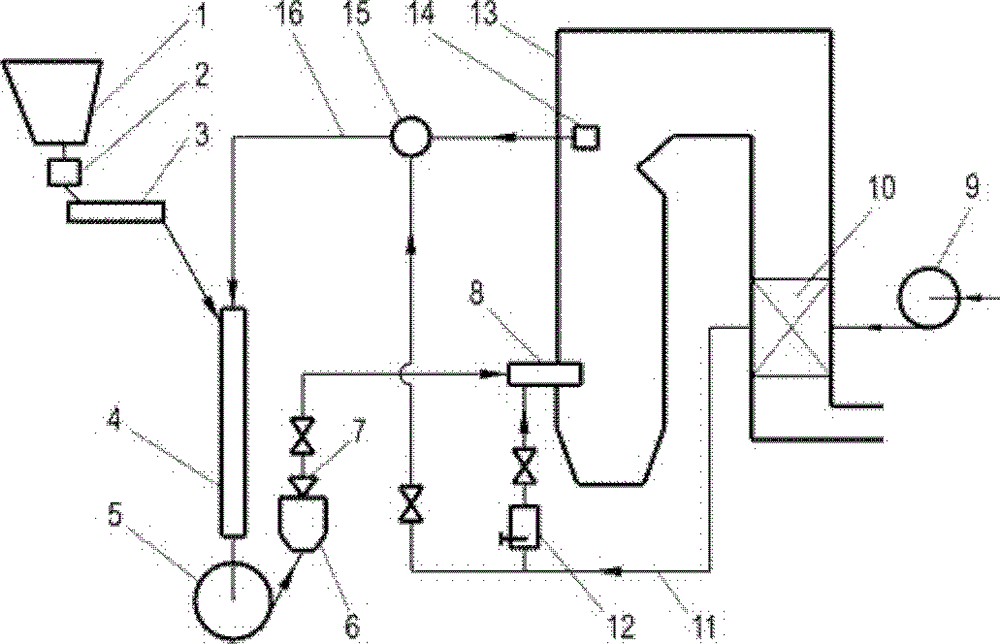

Fan mill front counter flow type furnace-smoke drying dewatering direct blowing pulverization system

ActiveCN102798132AImprove combustion qualityReduce volumeSolid fuelsLump/pulverulent fuel feeder/distributionBrown coalCounter flow

The invention discloses a fan mill front counter flow type furnace-smoke drying dewatering direct blowing pulverization system. A pulverized coal mixer is arranged between a coarse powder separator and a pulverized coal distributor. The upper part of the lower drying pipe is provided with a coal gas outlet which is communicated with a coal gas filter. A coal outlet of the coal gas filter is also communicated with the pulverized coal mixer, a gas outlet of the coal gas separator is communicated with a coal gas fan, the coal gas fan is also communicated with a coal gas cooler, the coal gas cooler is provided with a condensation water outlet and a coal gas outlet, and the coal gas outlet is communicated with a coal gas burner of a boiler. The fan mill front counter flow type furnace-smoke drying dewatering direct blowing pulverization system has advantages of improving the burn-up quality of brown coal so as to enhance the thermal efficiency of the coal, recovering a large quantity of water vapor, obviously reducing the size and the manufacturing cost of the boiler, realizing zero pollution discharge and the like.

Owner:NORTHEAST ELECTRIC POWER DESIGN INST CO LTD OF CHINA POWER ENG CONSULTING GRP +1

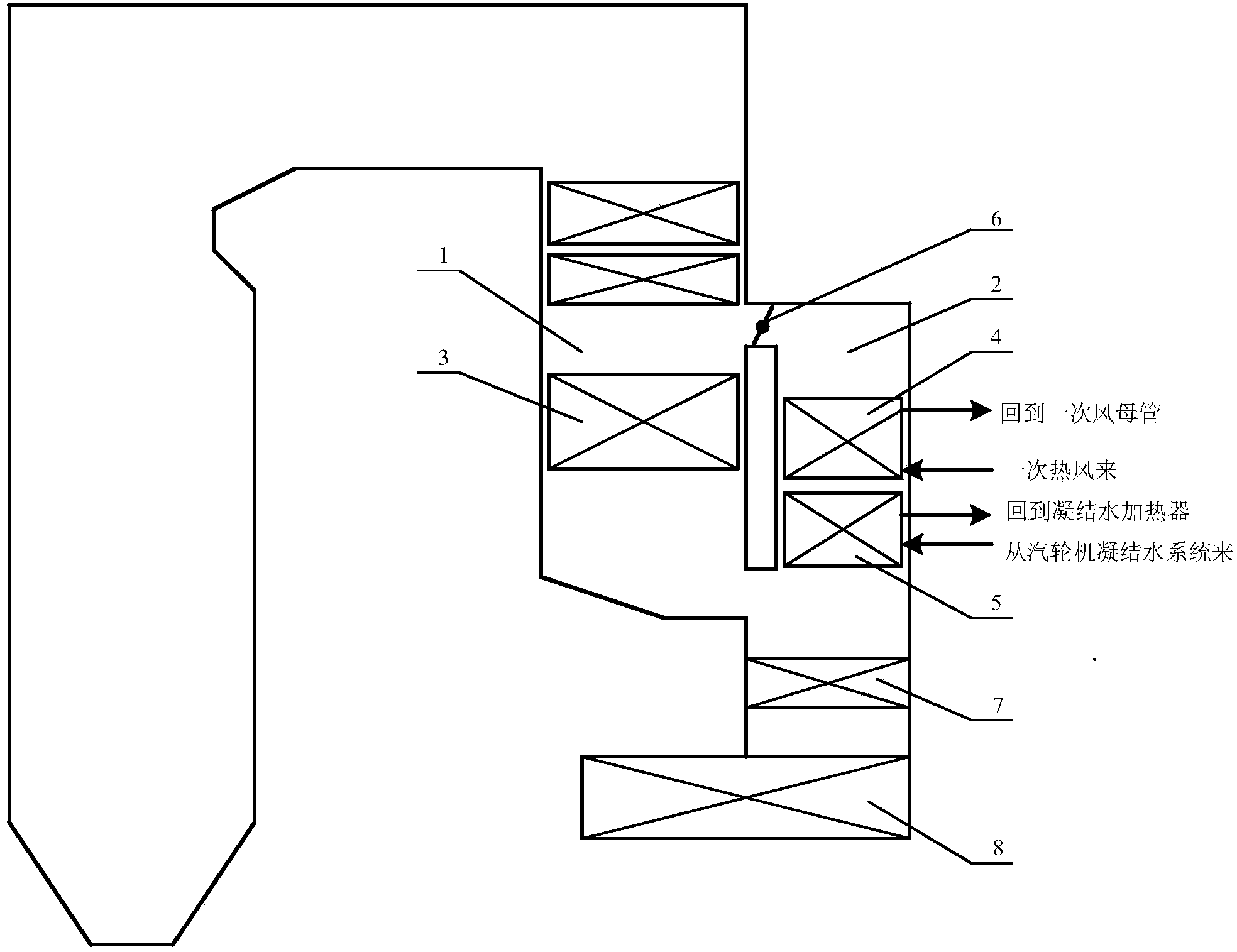

Air preheating system and method performing steam extraction by utilizing steam turbine

InactiveCN103244944AReduce running power consumptionReduce power consumptionFeed-water heatersEngineeringAir temperature

The invention relates to an air preheating system of a thermal power generator set, in particular to an air pre-heating system and method performing steam extraction by utilizing a steam turbine. In the system, a primary air preheating subsystem and a secondary air preheating subsystem are coupled with a boiler system and a steam turbine system of the thermal power generator set to form a novel boil feed water preheating system. Primary air is heated by a four-stage air heater and a first-stage drain water cooler to reach primary air rated temperature. Secondary air is heated by a five-stage air heater to reach a secondary air rated temperature. The air preheating system effectively solves the air leakage problem, reduces operation power consumption of a primary fan, a forced draught blower and an induced draft fan and improves the generating efficiency of a coal-fired power plant. In addition, the primary air temperature and the secondary air temperature can be flexibly adjusted by adjusting steam extraction volume of the air heaters and opening degree of a drain water by-pass valve.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

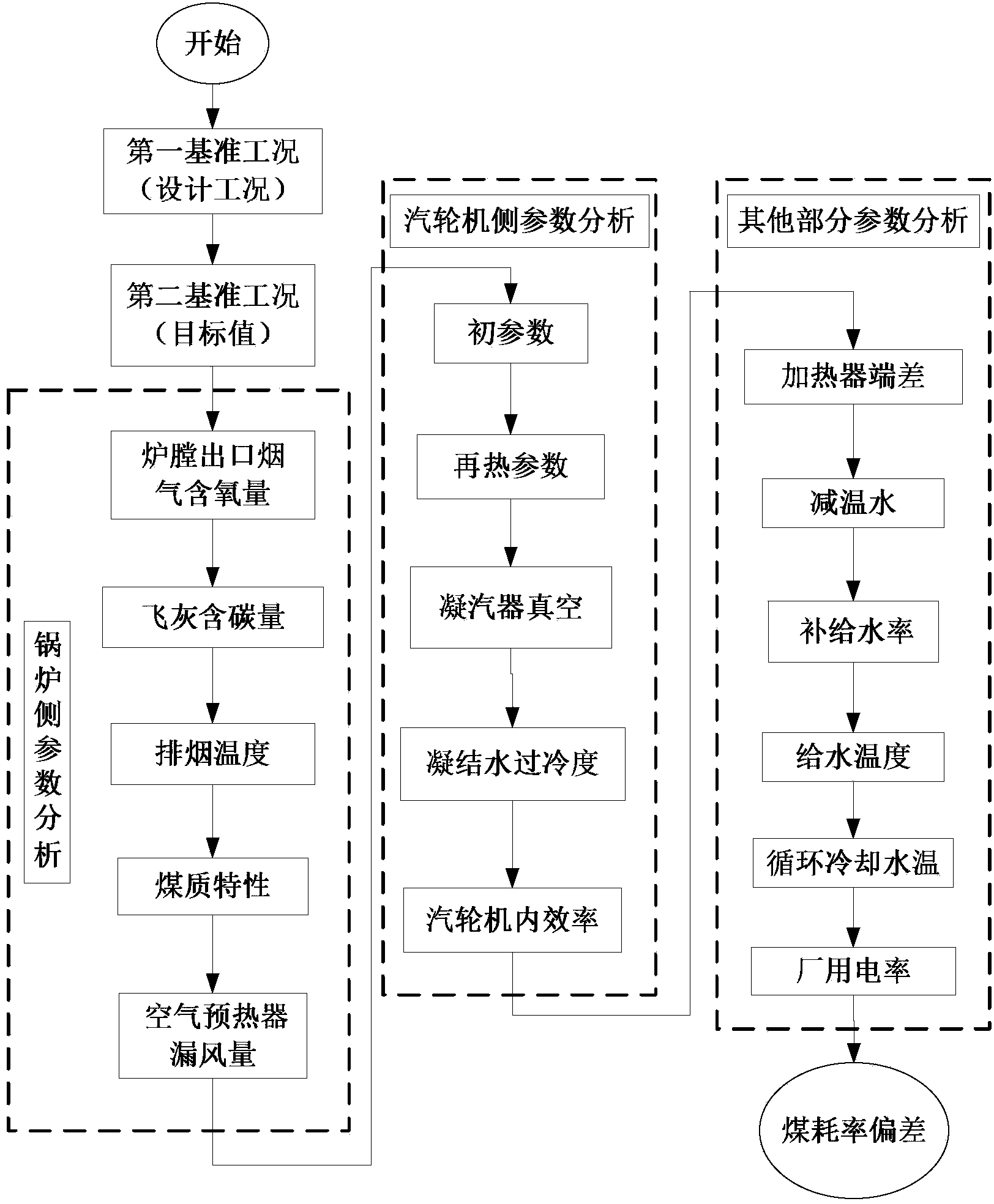

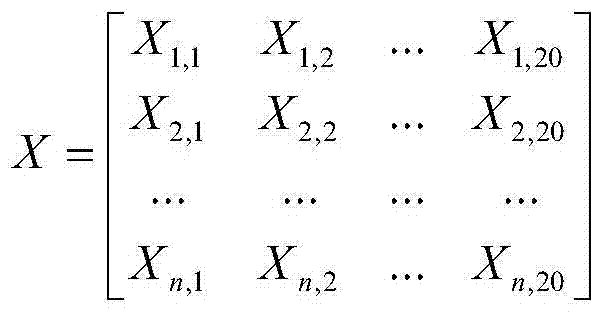

Thermal power plant generator set varying duty energy consumption analysis method based on approach method

InactiveCN103678915AReduce coal consumption for power generationSave coal resourcesSpecial data processing applicationsProcess engineeringAnalysis method

The invention discloses a thermal power plant generator set varying duty energy consumption analysis method based on an approach method. According to the method, 18 operating parameters with large influence on economical efficiency of generator sets are selected as analyzing objects according to long-tern operation experience, an operation statistic optimum value is used as an operation reference value, a series of working conditions is hypothesized between a stable operation condition and an actual operation condition, the 18 operating parameters are made to approach an actual operation value from the operation reference value one by one, energy consumption analysis of varying duty is carried out according to coal consumption difference values in the approaching process, parameters having large influences on coal consumption levels in the varying duty process are obtained through ranking, guide bases are provided for the determination of duty varying speed, duty varying scope and the time of a stabilization section in varying duty operation of a million-level set, the purpose of reducing coal consumption for electricity generation in the duty varying operation of a power plant is achieved, the task of duty varying is completed, and coal resources are saved at the same time.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

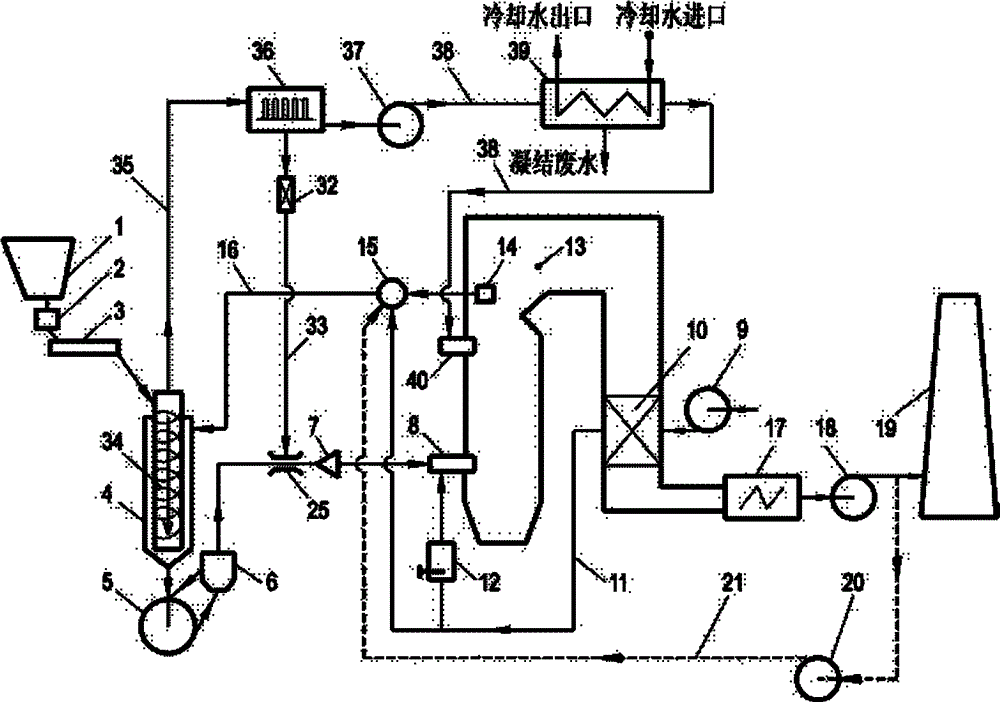

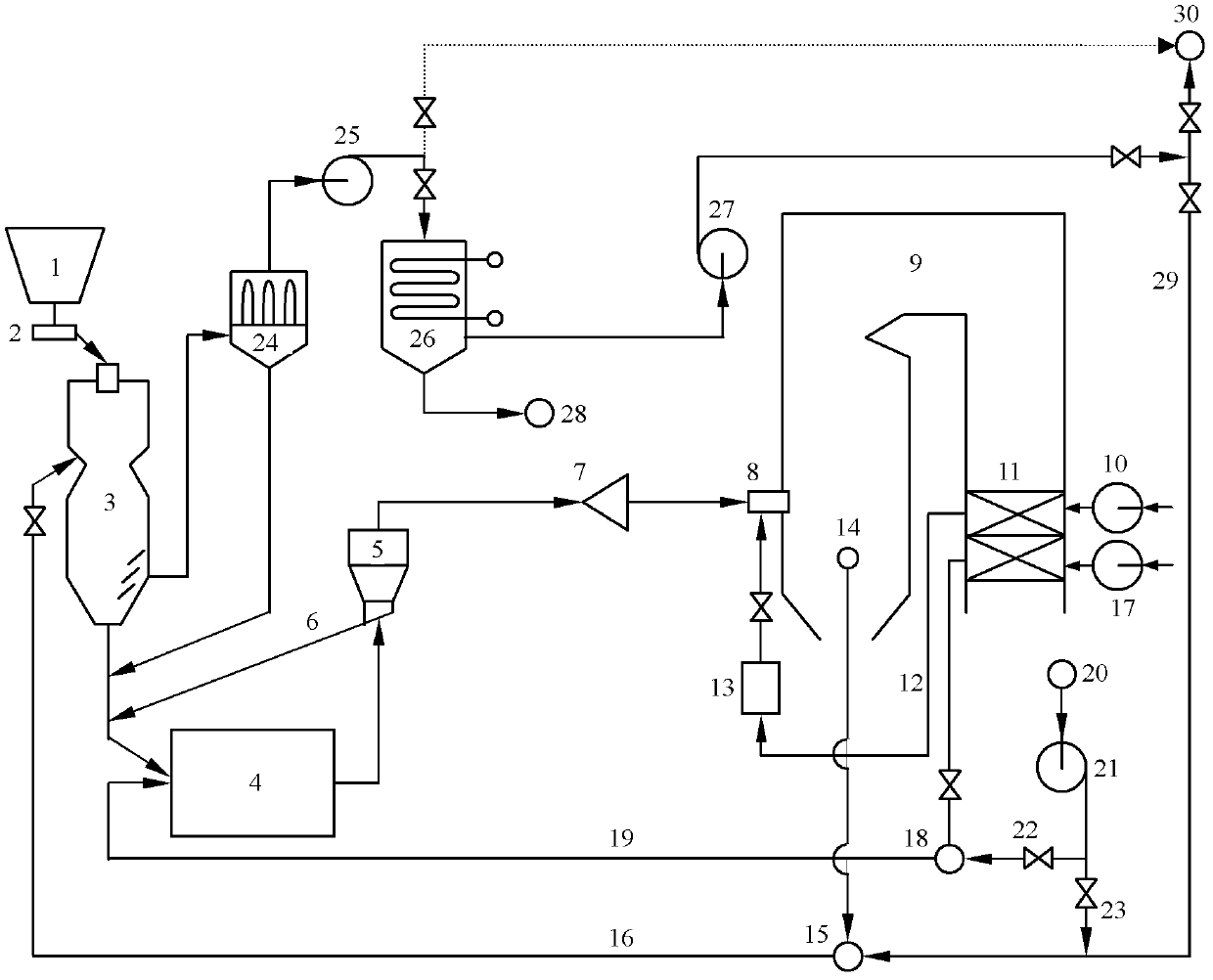

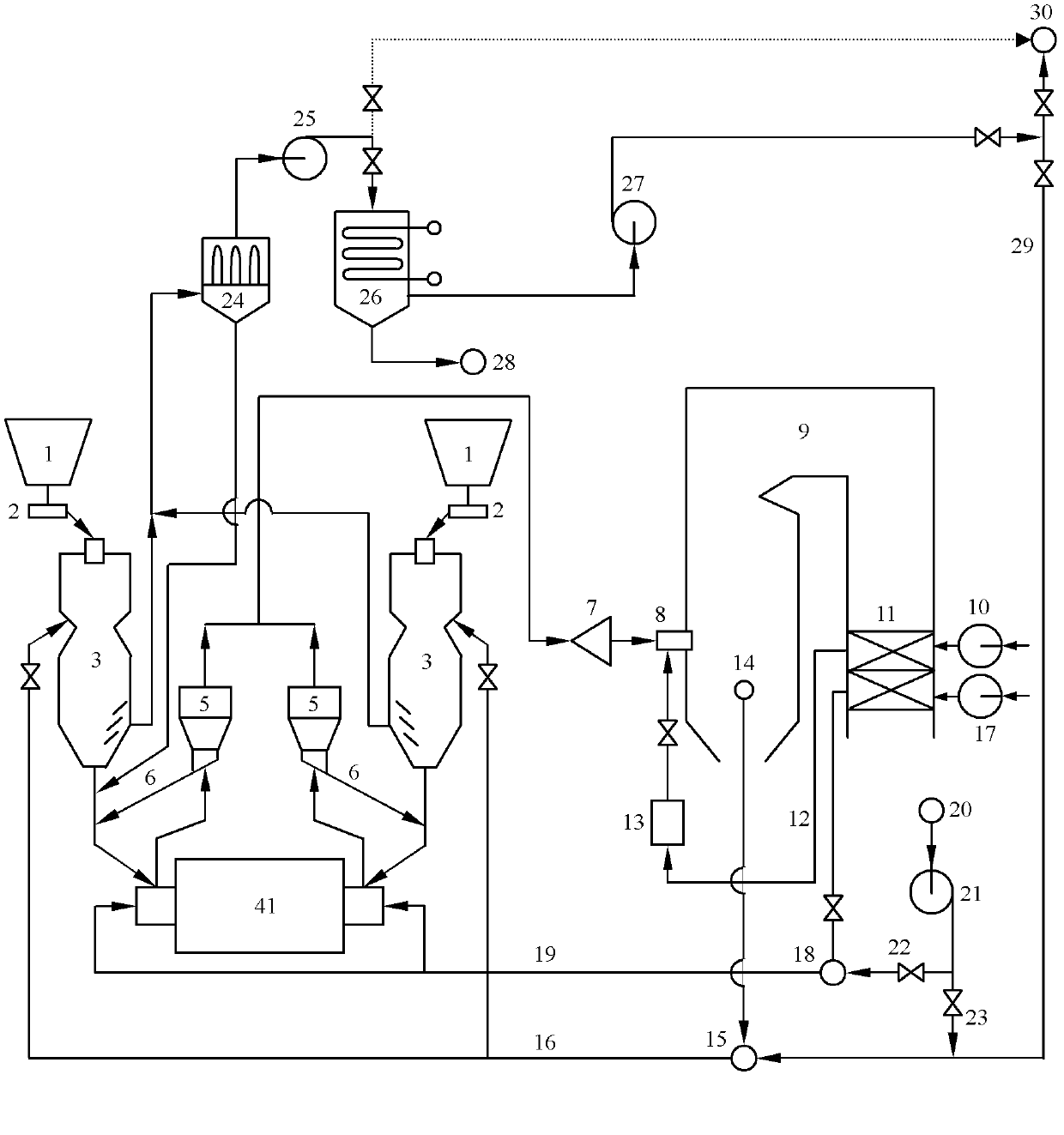

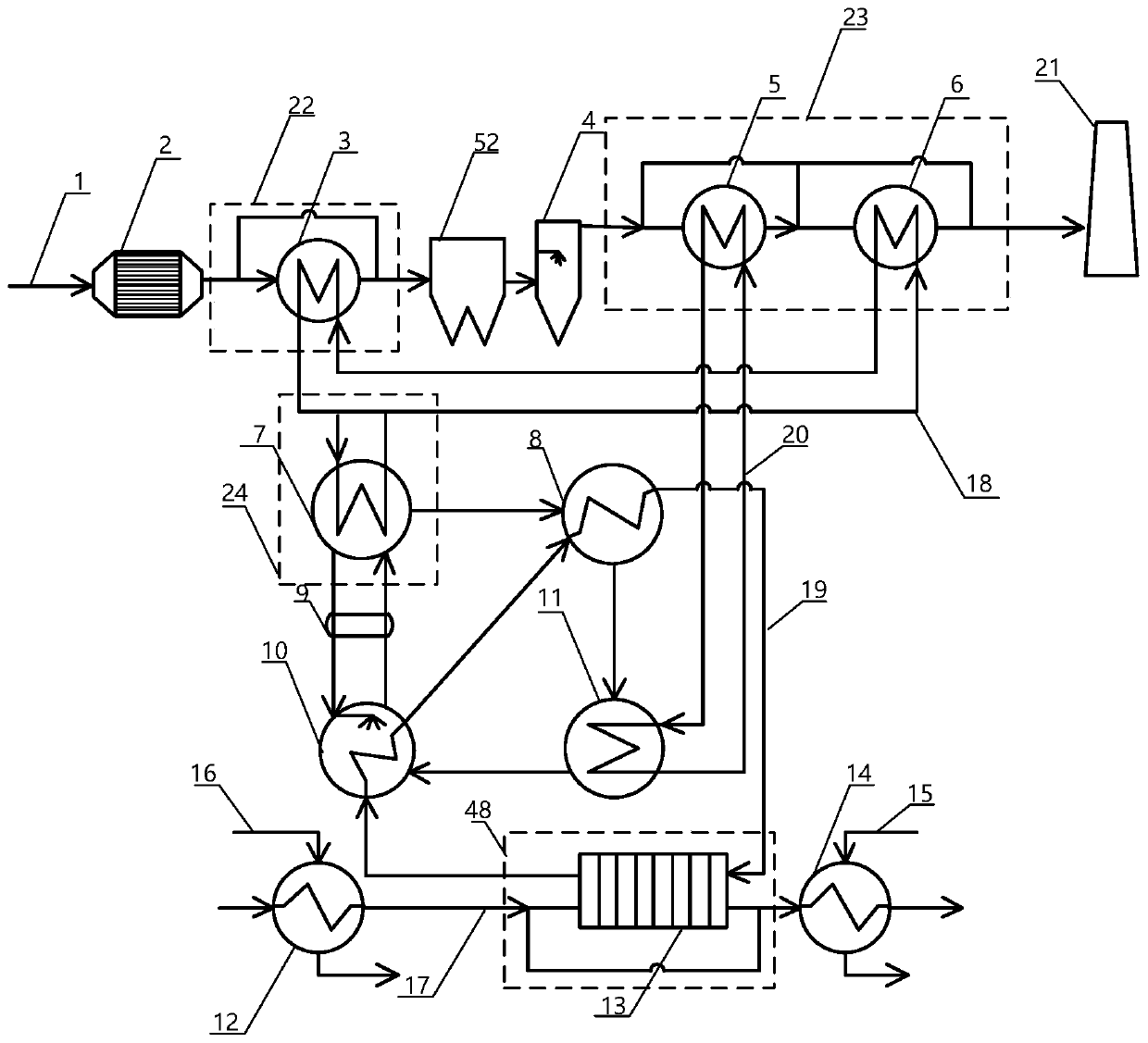

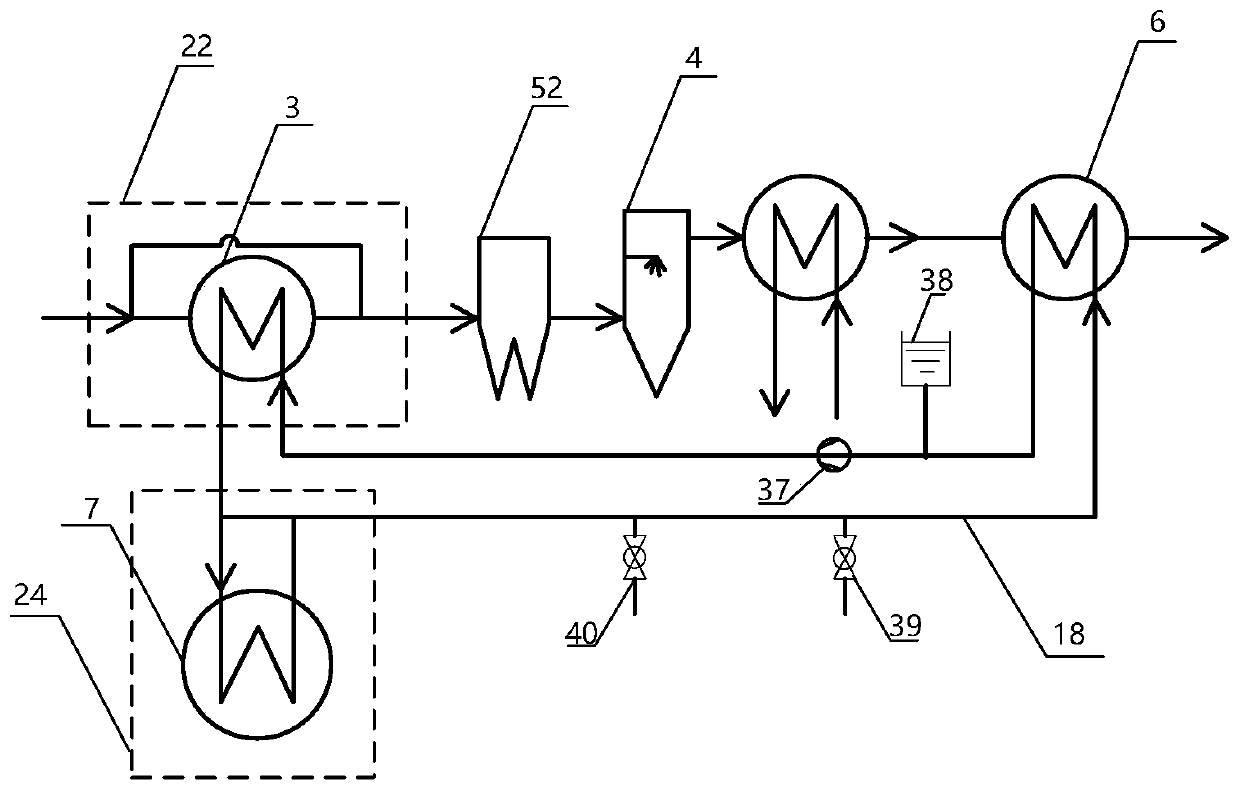

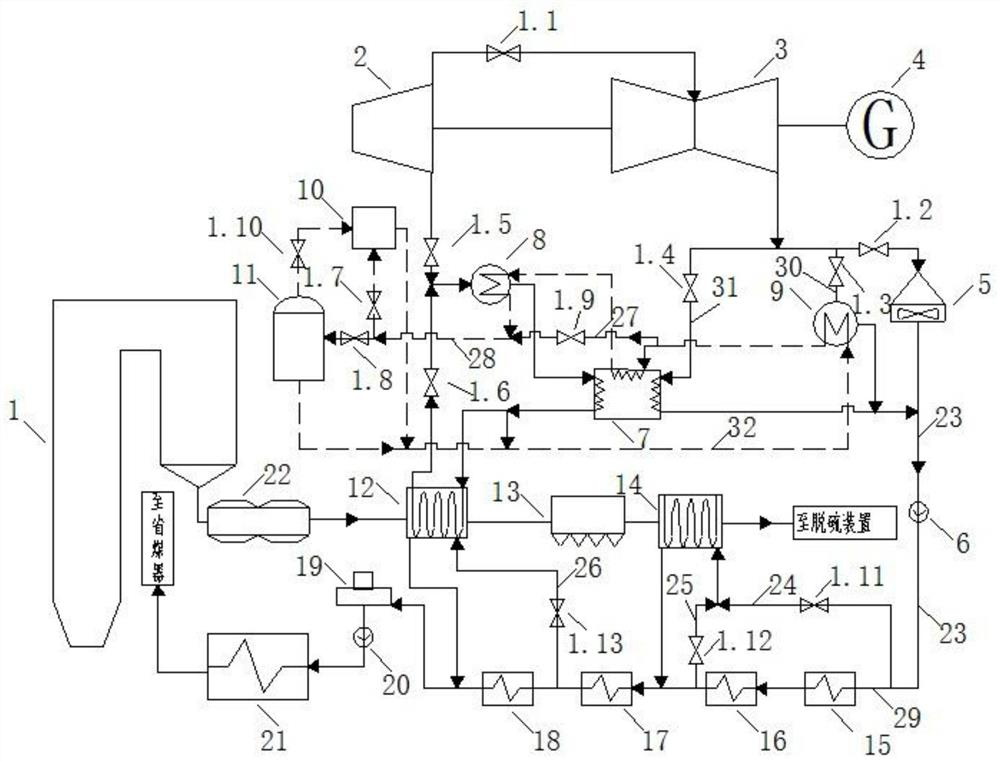

Pre-drying brown coal power generation system integrated with first-class absorption heat pump and pre-drying brown coal power generation method

ActiveCN105179023AReduce steam extractionImprove system efficiencyDrying solid materials with heatSteam useFluidized bed dryingEngineering

The invention discloses a pre-drying brown coal power generation system integrated with a first-class absorption heat pump and a pre-drying brown coal power generation method. The system mainly comprises such apparatuses as a traditional coal-fired power generation system, a steam fluidized-bed dryer with a built-in heater and the first-class absorption heat pump. According to the method, dry tail gas is used as a fluidizing and drying medium in the fluidized-bed dryer. The extracted steam of one stage of a steam turbine low-pressure cylinder flows through the built-in heater of the dryer to provide heat needed by evaporating moisture in brown coal. The dry tail gas serves as a high-temperature heat source for the heat pump, and turbine steam exhaust serves as a low-temperature heat source for the heat pump to generate low-temperature steam at a temperature between the temperatures of the dry tail gas and the turbine steam exhaust for heating the condensed water of the power generation system. The system is capable of reducing the steam extraction amount of a heat regenerative system, reducing the amount of waste heat emitted by the power generation system to the environment, realizing the utilization of the waste heat of the dry tail gas and the turbine steam exhaust and improving the efficiency of the power generation system.

Owner:XI AN JIAOTONG UNIV

Waste heat utilization system capable of guaranteeing lignite boiler dry output and SCR safe flue gas temperature

InactiveCN103486566AReduce coal consumptionIncrease workLiquid degasificationFeed-water heatersFlueProcess engineering

The invention discloses a bootstrap system capable of guaranteeing lignite boiler dry output and SCR safe flue gas temperature. The bootstrap system comprises a boiler tail flue and a flue gas denitrification SCR which is arranged at the tail end of the boil tail flue. A bypass flue communicated with the boil tail flue is further parallelly connected between a flue gas inlet of an economizer and a flue gas inlet of the flue gas denitrification SCR. The bypass flue is internally and sequentially provided with a primary-air tubular heater and a low-pressure economizer which are used for lowering temperature of flue gas entering the flue gas denitrification SCR. Due to the arrangement that the bypass flue is additionally arranged on the tail portion of a boiler, and the primary-air heater is arranged on the upper portion of the bypass flue, primary-air temperature is ensured to meet requirements of a coal pulverizing system. The amount of flue gas passing through the economizer can be regulated by the bypass flue, so that flue gas temperature at the exit of the economizer can be regulated. The primary air is heated to the temperature as required by the high-temperature flue gas at the inlet of the economizer, and meanwhile, the flue gas temperature in the bypass flue is lowered through the low-pressure economizer, so that the flue gas temperature at the inlet of the SCR can meet the requirements of catalyst.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

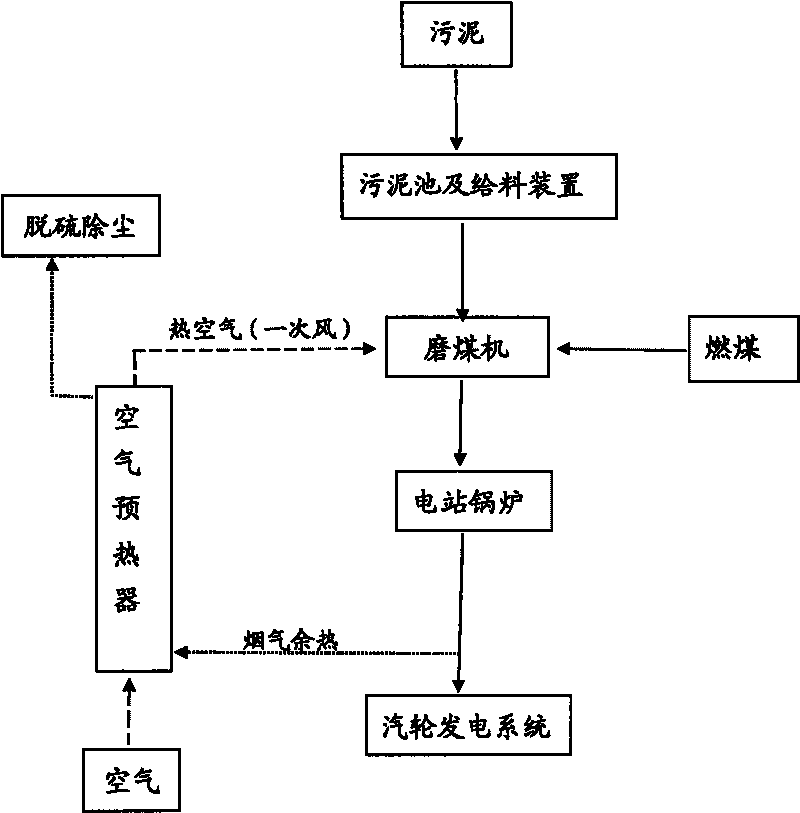

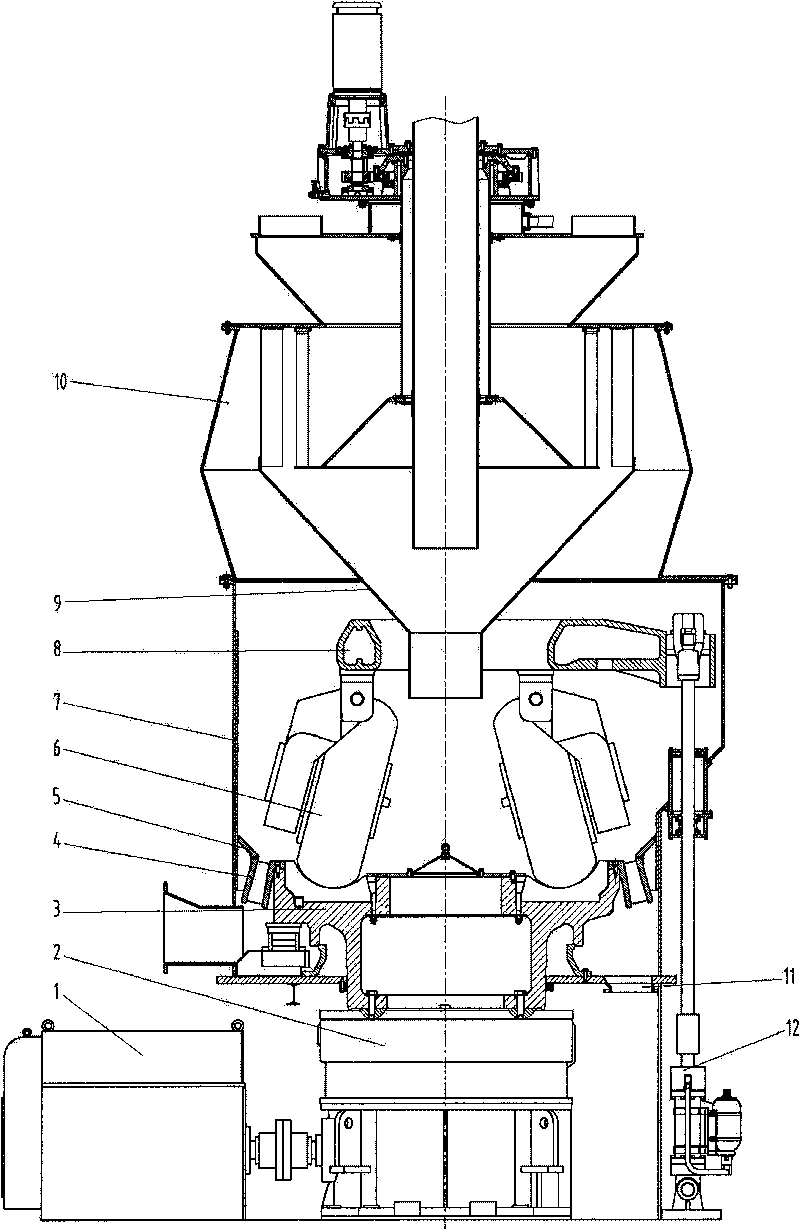

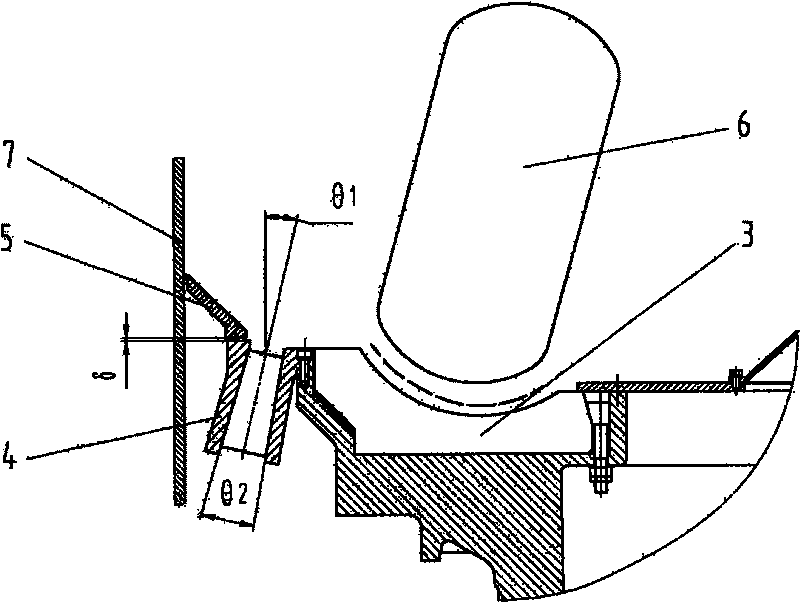

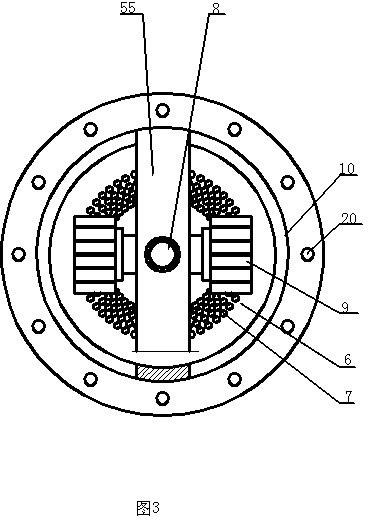

Sludge treatment method for drying sludge by using coal grinding machine and using sludge for electricity generation

InactiveCN101723570ALess investmentSave spaceSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationElectricityReflux

The invention discloses a sludge treatment method for drying sludge by using a coal grinding machine and using the sludge for electricity generation. The method comprises the following steps of: 1) directly introducing wet sludge with the moisture content of 70 to 90 percent into the coal grinding machine, wherein the ratio of the wet sludge is 2 to 10 percent of a fuel coal; 2) performing heat exchange between the waste heat of a utility boiler flue gas and air to generate primary air blown into the coal grinding machine, mixing the sludge with the fuel coal in the coal grinding machine, and performing grinding while drying; and 3) spraying the coal powder containing the dried sludge into the utility boiler for burning and generating electricity. The coal grinding machine which is also used as sludge drying equipment is characterized in that a hot air introduction device is a rotary type hot air nozzle ring, a powder reflux device is a through-type flow-guiding powder reflux cone, and a separating device is a rotary separator with a first separate stationary blade. The sludge treatment method makes full use of the original process of an electric power plant, makes full use of the waste heat of the flue gas and the heat value of the sludge, and acquires no additional hot resource or device for drying the sludge, and has the advantages of investment saving, low operation cost, no secondary pollution and the like.

Owner:ZHEJIANG UNIV

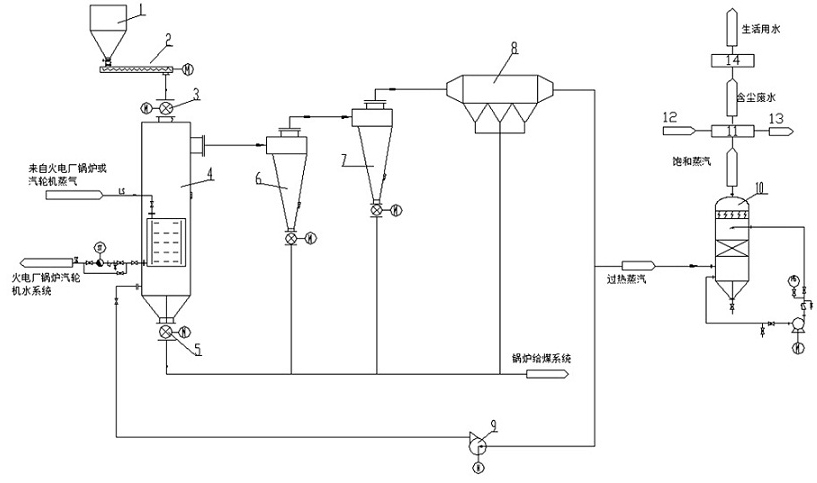

Direct fired pulverizing system of smoke pre-drying lignite steel ball mill

InactiveCN102889606AImprove combustion effectReduce coal consumption for power generationDrying gas arrangementsLump/pulverulent fuel preparationFlueBoiler furnace

The invention discloses a direct fired pulverizing system of a smoke pre-drying lignite steel ball mill. A coal inlet of the steel ball coal mill is connected with a pre-drying device; a coal inlet and a high-temperature smoke dryer inlet are arranged on the upper part of the pre-drying device; an exhaust port is arranged on a side of the bottom and connected with a dust remover; an exhaust outlet of the dust remover is connected with an exhaust fan; a powder outlet of the dust remover is connected with a coal inlet of the steel ball coal mill; and the high-temperature smoke dryer inlet of the pre-drying device is connected with a smoke mixing chamber that has two smoke inlets, wherein the first smoke inlet is connected with a hot smoke pumping port of a boiler furnace, while the second smoke inlet is connected with a cool smoke pumping port of the boiler furnace. The direct fired pulverizing system has a series of advantages such as good drying effect, safety in operation, and capability in improving combustion performance of pulverized coal and lowering coal consumption for power generation. The direct fired pulverizing system can be used for transformation of steel ball mill pulverizing systems of the in-service lignite generator units, or lately built lignite generator units and has great promotion and application prospect.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

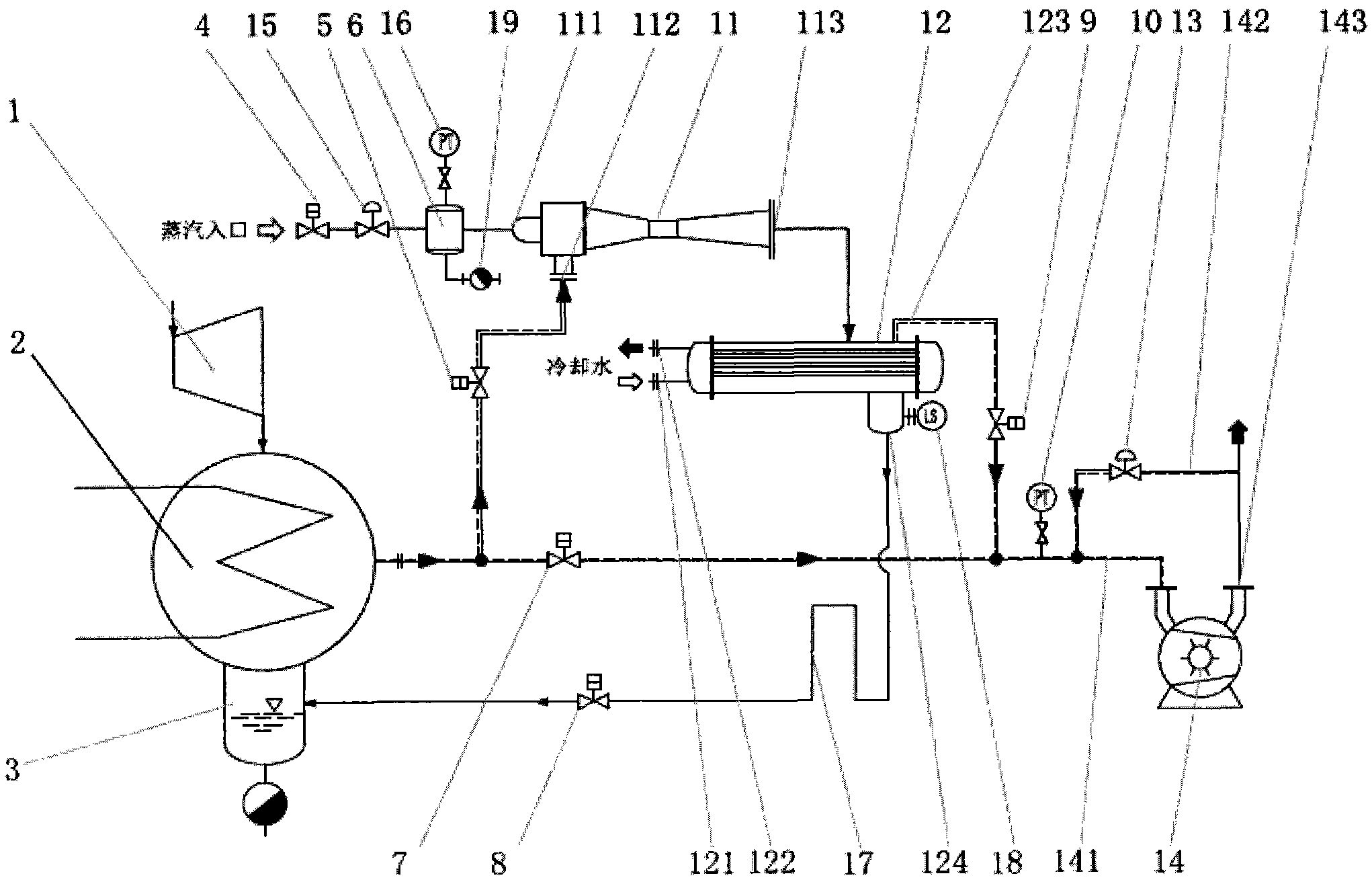

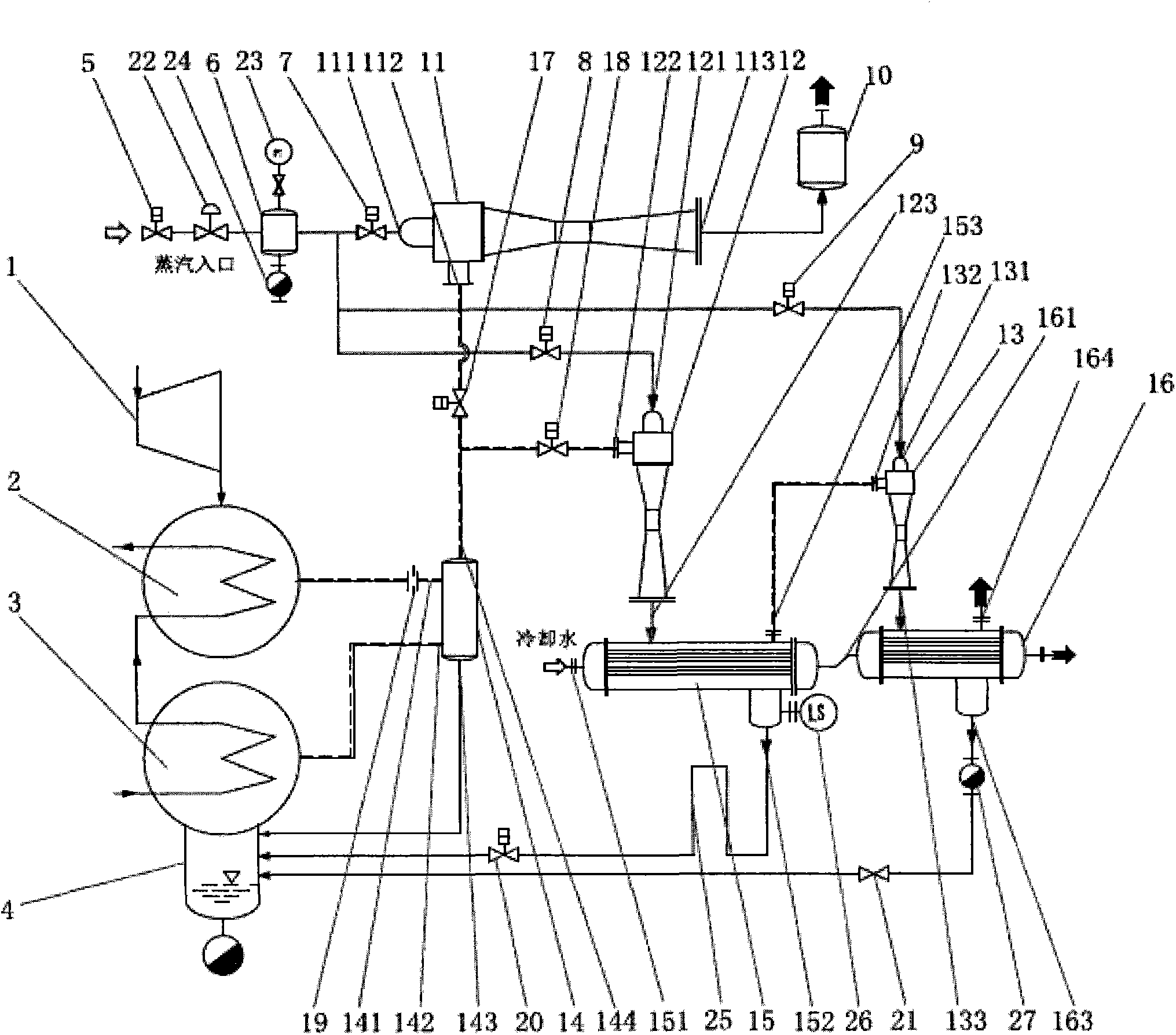

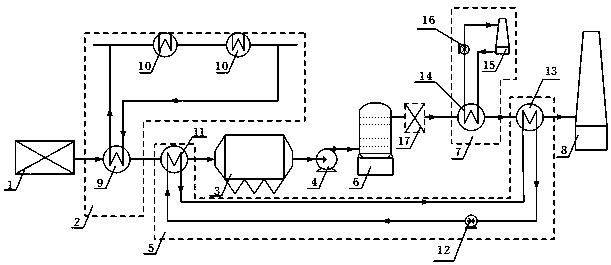

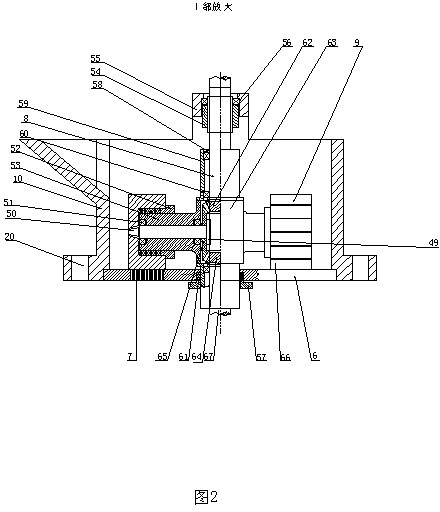

Power plant condenser steam jet and vacuumizing system with pressure control function

The invention provides a power plant condenser steam jet and vacuumizing system with a pressure control function. The system comprises a steam turbine (1), a condenser (2), a condenser hot well (3), a power steam pressurizer (6), a steam ejector (11), a steam condenser (12), a water ring vacuum pump (14), a condensate discharge valve (8) of the steam condenser, a condensate drain pipeline water seal (17), a condensate pipeline liquid level switch (18), a pressure adjusting valve (13) on the inlet of the water ring vacuum pump, multiple control valves and pipelines, wherein the control valves and the pipelines are arranged among the parts. Due to the fact that pressure control of power steam, control of the liquid level after condensates flow back to the condenser hot well and inlet pressure control of the water ring vacuum pump are adopted, the vacuumizing system can maintain the maximum vacuum degree of the condenser, force of the condenser is improved, the vacuum degree of the condenser is improved, the heat consumption rate of the steam turbine is lowered, and coal consumption for unit power generation is lowered. The system is safe and free of maintenance, guarantees 100% of force and can operate stably for a long time. A pressure backflow adjusting system is arranged on the final-stage exhaust device, namely the water ring vacuum pump, so that it is guaranteed that the cavitation phenomenon of the water ring vacuum pump does not happen.

Owner:浦江瑞尔科技有限公司

Deep recovery device for flue gas heat of power station boiler and method of deep recovery device

PendingCN109855109AImprove COPIncrease temperatureHeat pumpsEnergy efficient heating/coolingLithium bromideEvaporator

The invention discloses a deep recovery device for flue gas heat of a power station boiler and a method of the deep recovery device. The recovery device comprises an air preheater, a sensible heat exchanger, a desulfurization tower, a latent heat exchanger, a flue gas heater, a plate heat exchanger, a lithium bromide absorption heat pump generator, a lithium bromide absorption heat pump condenser,a lithium bromide absorption heat pump evaporator and a lithium bromide absorption heat pump absorber. Compared with an existing thermal power plant flue gas heat recovery system, by the adoption ofthe deep recovery device and the method, on the premise of satisfying the user load, by adopting the coupling use of the lithium bromide absorption heat pump and a low-pressure heater, sensible heat of flue gas after the air preheater in a thermal power plant can be recycled, and latent heat of vaporization of moisture in flue gas after the desulfurization tower can be also recycled, so that the coal consumption for power generation is reduced, meanwhile moisture carried by flue gas is reduced, colored smoke plume is eliminated, and the device and the method better respond to the policy requirements on energy saving and emission reduction in China.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

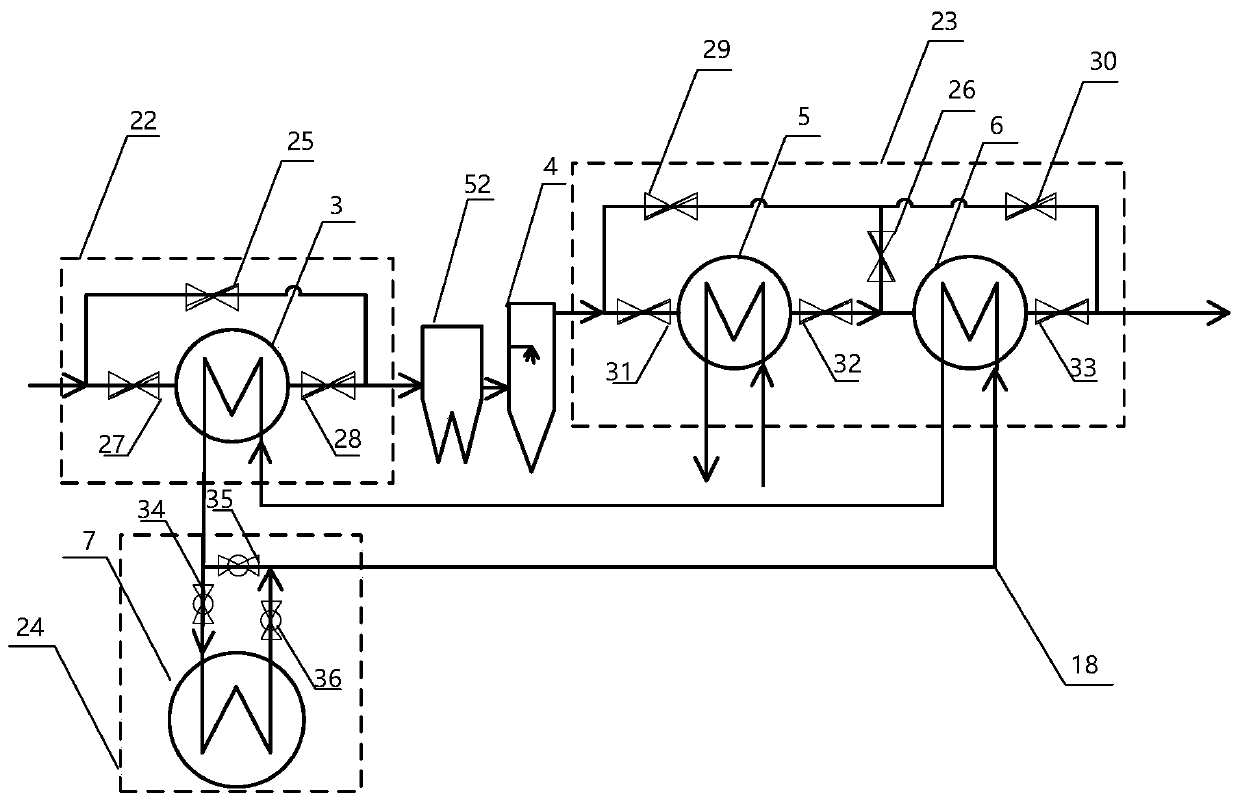

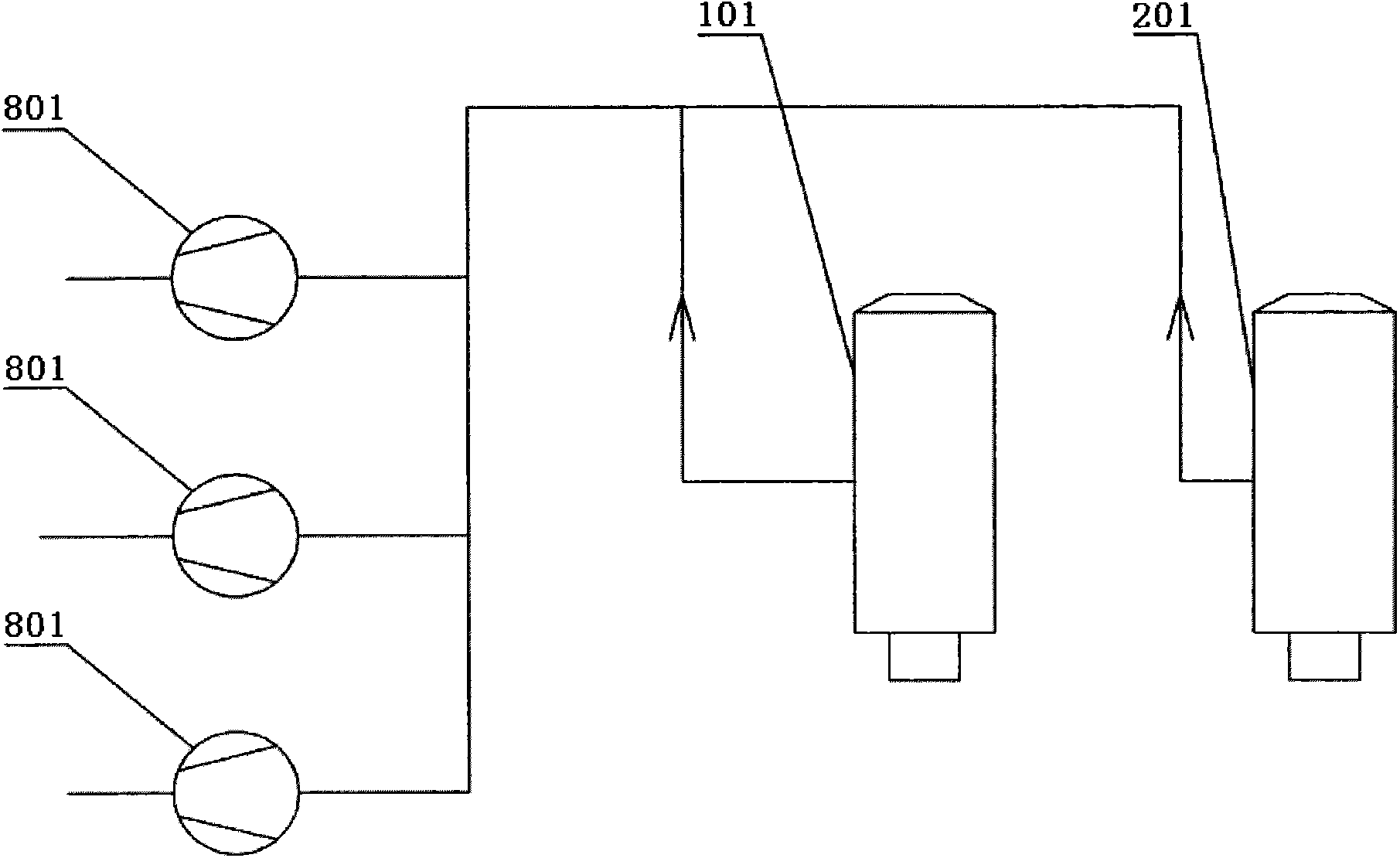

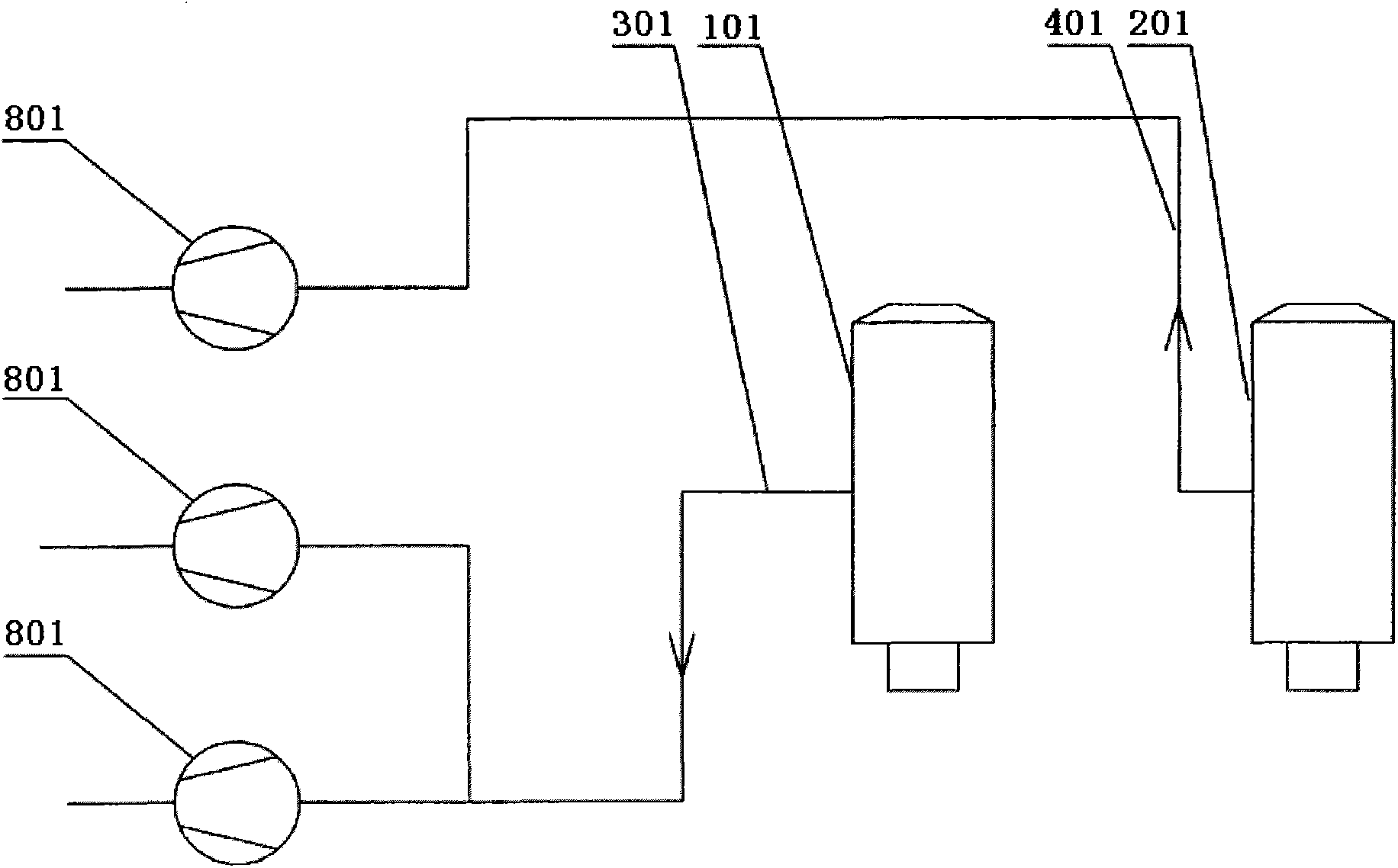

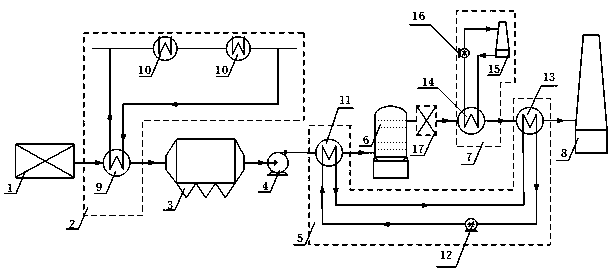

Multistage steam jet vacuum-pumping system with double backpressure steam condensers

The invention provides a multistage steam jet vacuum-pumping system with double backpressure steam condensers. The multistage steam jet vacuum-pumping system comprises a turbine (1), the first steam condenser (2), the second steam condenser (3), a power steam pressure stabilization tank (6), an exhaust silencer (10), a first steam jet device (11), a second steam jet device (12), a third steam jet device (3), a vacuum buffer tank (14), a first condenser (15), a second condenser (16), a high-pressure side air exhaust pipeline restriction orifice (19), and a plurality of control valves and a plurality of pipelines arranged between all the parts mentioned above. Due to the fact that the restriction orifice is arranged on the high-pressure side and the vacuum buffer tank is arranged in the position where the high-pressure side and the low-pressure side are communicated, the pressure difference between the high-pressure side and the low-pressure side is kept. High-temperature steam serves as power for the steam jet devices, output is stable, and the optimal vacuum can be kept for the steam condensers. High-pressure steam serves as power for the steam jet devices, no house supply is needed, the steam jet devices are static devices and almost free of maintenance, and maintenance cost can be reduced.

Owner:普瑞森能源科技(北京)股份有限公司

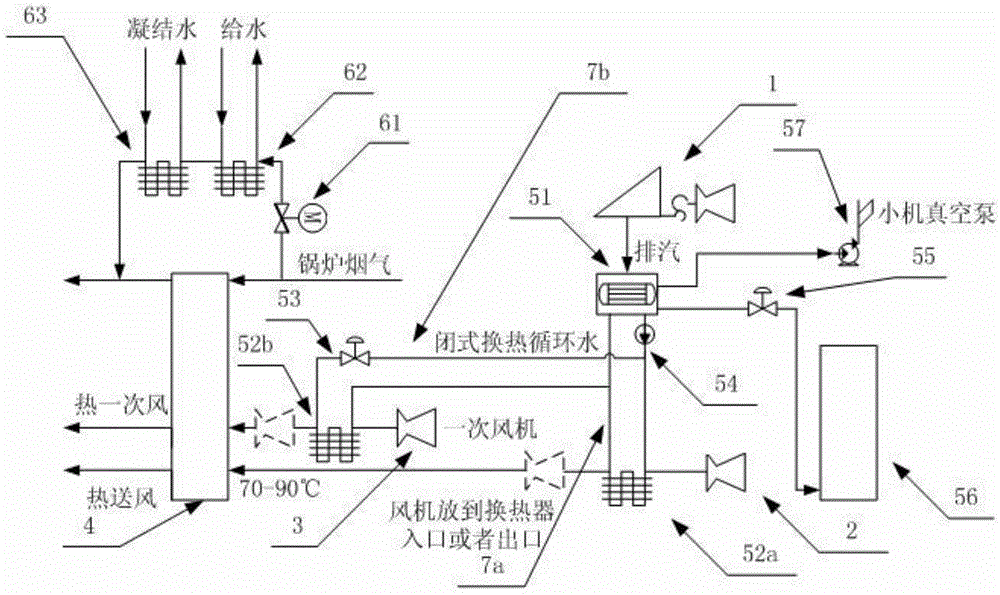

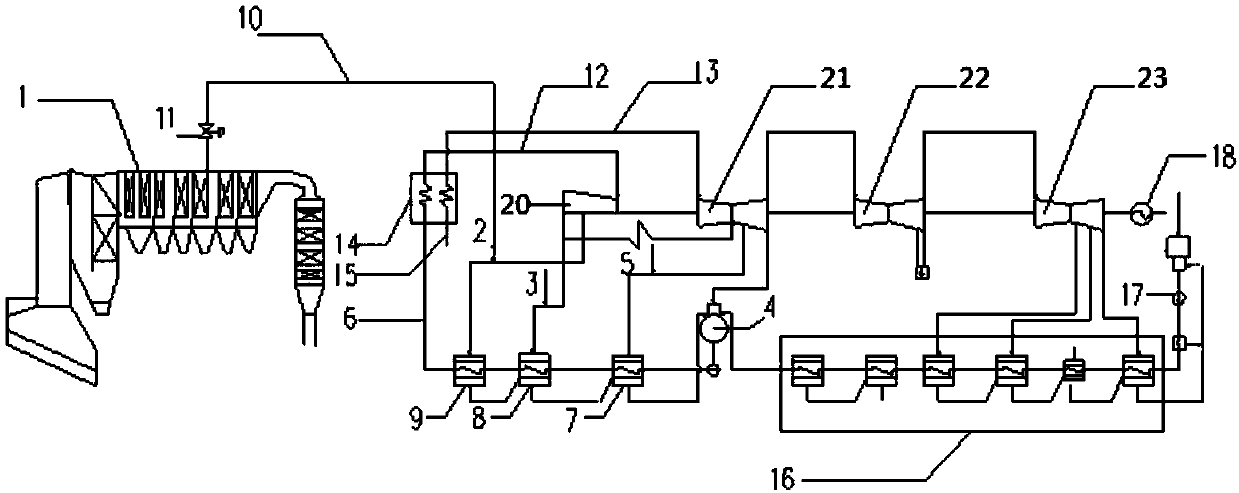

Exhaust steam waste heat recycling system for small steam turbine of induced draft fan through circulating water based on steam turbine driving

InactiveCN104948240ALower the altitudeReduce the amount of civil worksCombustion processSteam useExhaust gasCondensed water

The invention discloses an exhaust steam waste heat recycling system for a small steam turbine of an induced draft fan through circulating water based on steam turbine driving. An indirect cooling and heat exchange system of the exhaust steam waste heat recycling system is composed of a small turbine condenser, a heat exchanger, a primary air heat exchanger regulating valve, a circulating pump and a main machine condenser. An air pre-heater part exhaust gas heat recycling system is composed of an air pre-heater bypass system, a water supply system and a condensed water system. The small steam turbine exhausts steam into the small turbine condenser, and condensed water generated through condensation of the circulating water which is subjected to indirect cooling and heat exchange is discharged into the main machine condenser. The indirect cooling and heat exchange circulating water absorbs the steam exhaust heat of the small turbine condenser, the circulating pump is used for conducting forced circulation, and the heat exchanger is used for heating primary air and supply air. The circulating pump provides circulating power. An air supply system absorbs most of the steam exhaust heat of the small steam turbine. The primary air system can regulate the heat exchange amount by regulating the opening degree of a baffle according to the actual demand of the system. The exhaust steam waste heat recycling system can replace a primary air and air supply steam air heater which is generally arranged in a north power plant, and the circulating water is used for recycling the exhaust steam waste heat of the small steam turbine of the induced draft fan driven by the steam turbine.

Owner:宋子琛

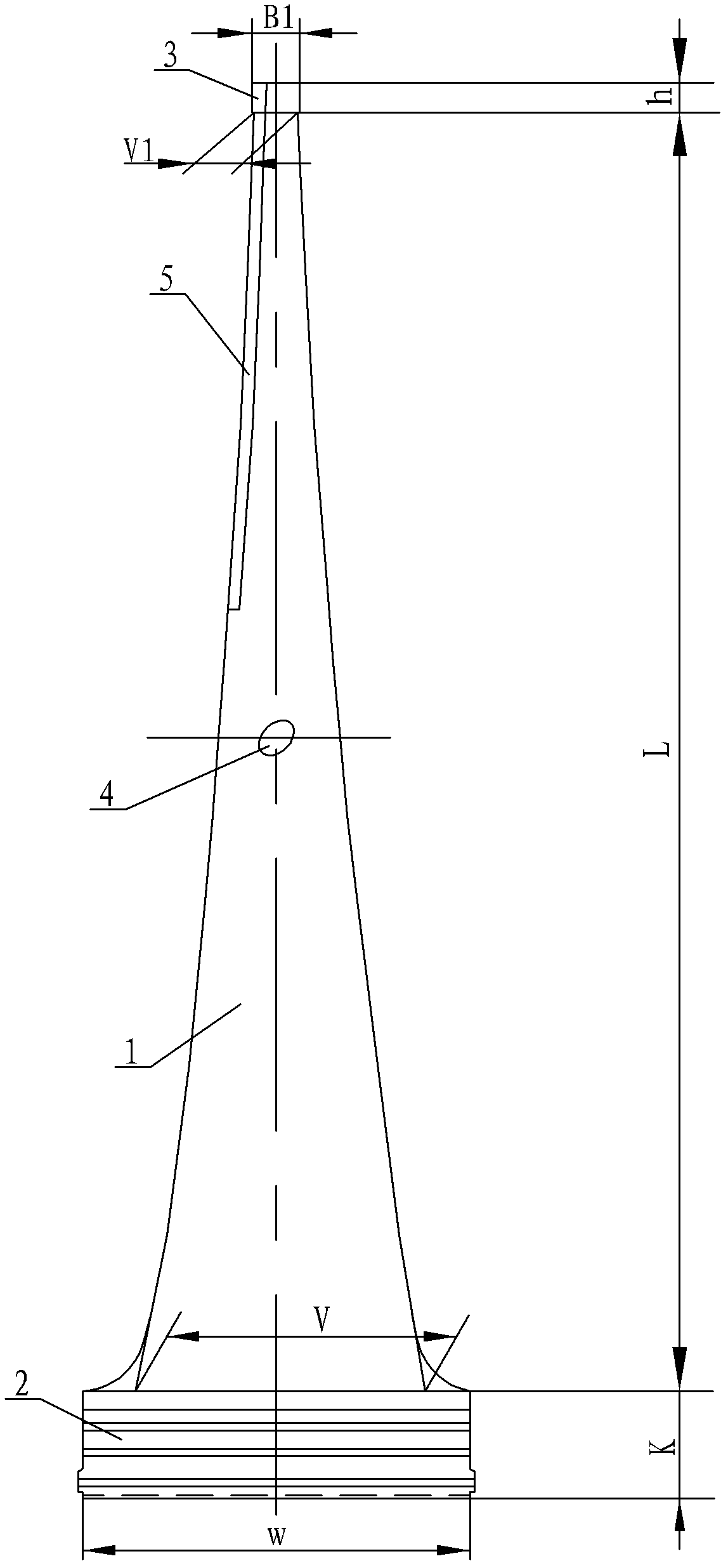

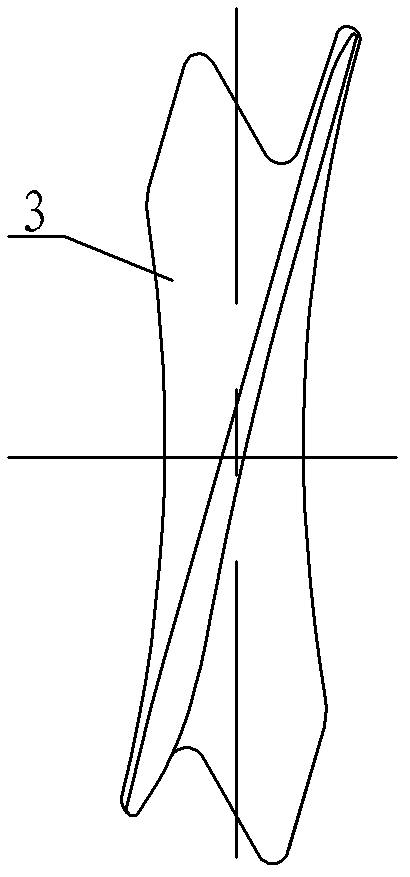

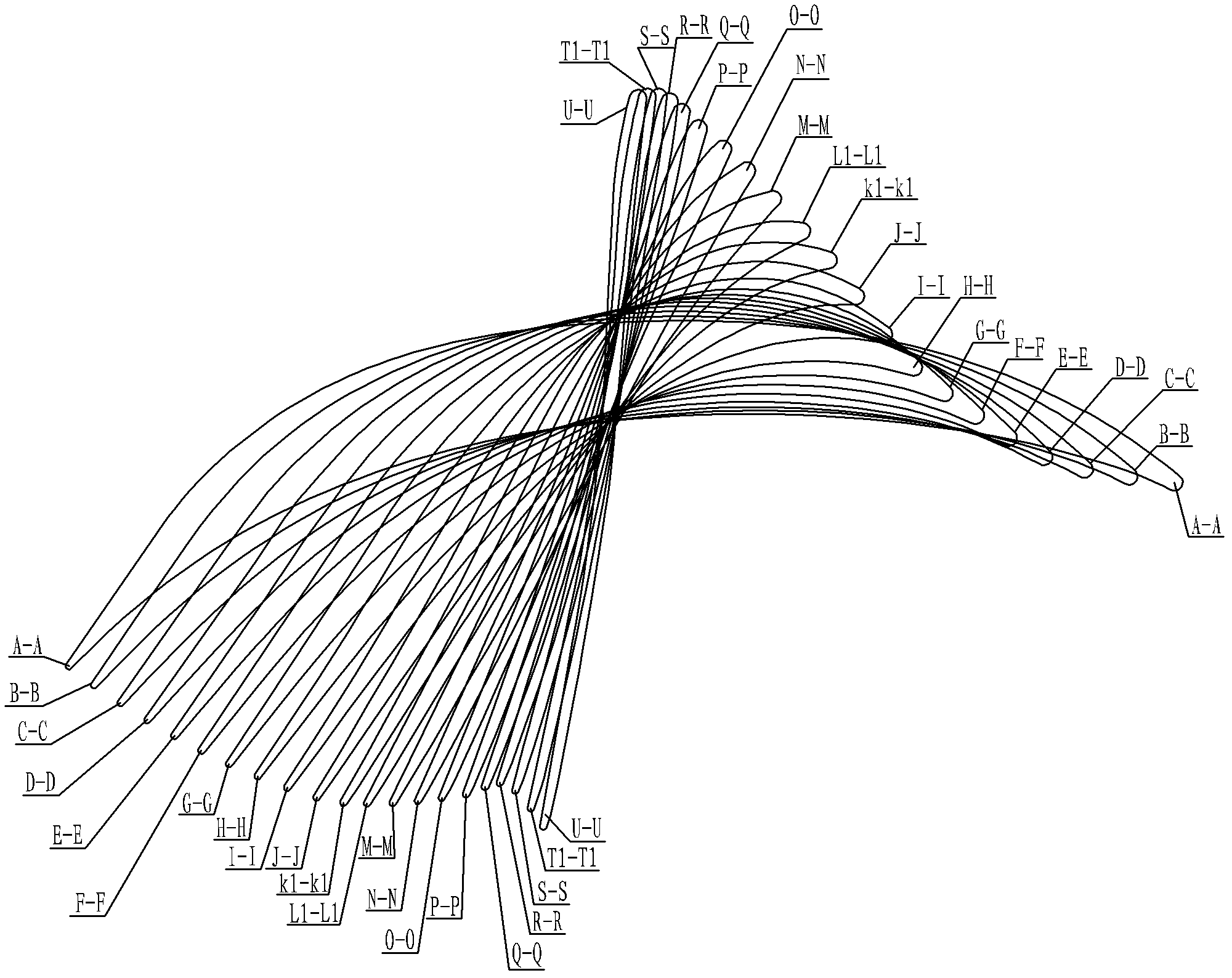

1300mm moving blade of final stage for full-rotary-speed steam turbine

ActiveCN102359397AIncrease stand-alone capacityImprove economyBlade accessoriesMachines/enginesAlloyEngineering

The invention discloses a 1300mm moving blade of the final stage for a full-rotary-speed steam turbine, and relates to a moving blade of the final stage for a full-rotary-speed steam turbine, and the moving blade is used for solving the problems of less length, small steam exhaust discharge area, great energy source consumption of the moving blade of the final stage for the full-rotary-speed steam turbine, and incapability of reaching higher economy requirement. A shroud, a blade operation part and a blade root are subjected to die forging integrally from top to bottom; a boss tie piece is positioned at the middle part of the blade operation part, and is integrated with the blade operation part; a stelite alloy sheet is sticked to the steam inlet side at the upper part of the blade operation part; the height of the blade operation part is 1300mm, the axial width of the root part is 346.62mm, the diameter of the root part is 1850mm, the steam exhaust area of the blade operation part is 12.86m<2>, and the axial width of the blade root is 400mm. The moving blade of the final stage provided by the invention is used for the full-rotary-speed steam turbine with the power between 600MW and 1000MW.

Owner:HARBIN TURBINE +1

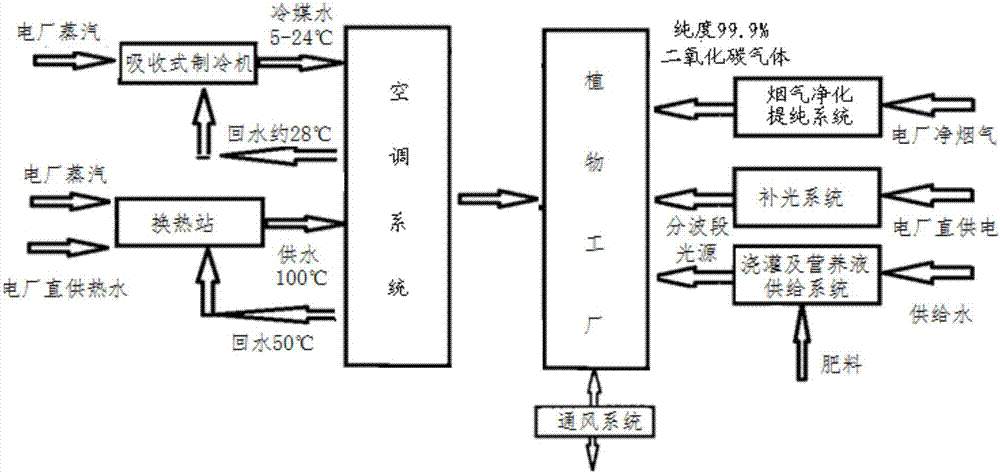

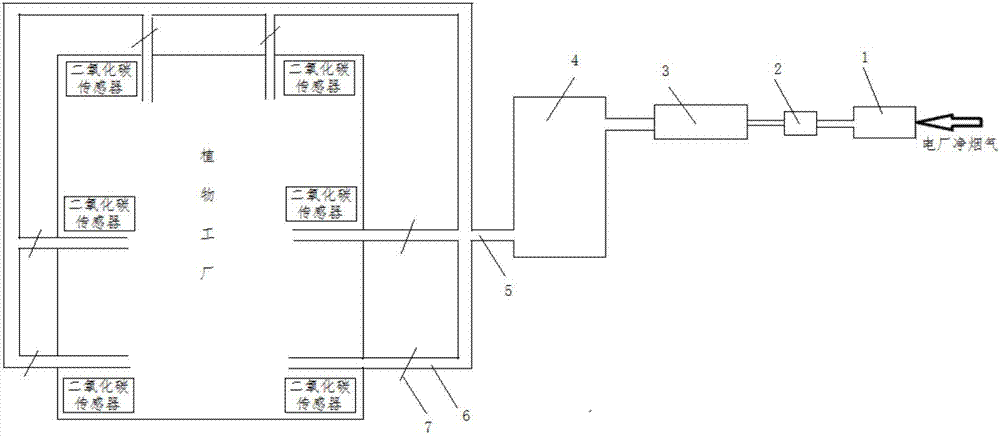

Method and system for utilizing carbon dioxide and energy of thermal power plant based on plant factory

InactiveCN107027554AReduce coal consumption for power generationImprove growing conditionsElectric circuit arrangementsClimate change adaptationPlant factoryFlue gas

The invention discloses a method and a system for utilizing carbon dioxide in exhaust flue gas and energy of a thermal power plant based on a plant factory. The method includes the steps that the plant factory is built near the thermal power plant; low quality heat from the thermal power plant, such as hot water or steam, can be used for supplying heating to the plant factory, and the steam also can be used for driving chillers to produce chilled water to cool the plant factory; the carbon dioxide in the flue gas of the thermal power plant is inlet into the plant factory and used for absorption and utilization as gas fertilizer; the thermal power plant can also be used for directly supplying power to lighting system of the plant factory. The method integrates the thermal system of the thermal power plant and the air conditioning system of the plant factory, thereby providing a new scheme for the energy saving and emission reduction of the thermal power plant.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD +2

Flue gas grading waste heat recovery condensing water collection white flue gas eliminating device and work method thereof

PendingCN109237505AEfficient recyclingAchieve recyclingEmission preventionCombustion technology mitigationAir preheaterEngineering

The invention relates to a flue gas grading waste heat recovery condensing water collection white flue eliminating device and a work method thereof. In order to solve the problem in the prior art thatan existing environment protection alteration technology cannot achieve energy conservation, emission reduction and white flue gas elimination synchronously, the device is provided. The device comprises an air preheater, a high-temperature flue gas waste heat recovery system, an efficient dust removing system, an induced draft fan, a flue gas secondary waste heat recovery and reheating system, adesulfurization system, a flues gas condensing water collection system and a chimney; the air preheater, the high-temperature flue gas waste heat recovery system, the efficient dust removing system, the induced draft fan, the desulfurization system, the flues gas condensing water collection system and the chimney are successively arranged in the flowing direction of flue gas. According to the device, high-temperature flue gas heat is effectively recycled, the thermal efficiency of a boiler is improved, the coal consumption of the boiler is reduced, secondary waste heat recovery of flue gas isconducted to heat purified flue gas, therefore the visual pollution of white flue plume of the flue gas is effectively eliminated, through flue gas condensing dehydration, moisture in the flue gas isrecycled, and the purposes of water collection and white flue gas elimination are achieved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

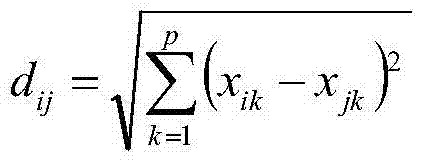

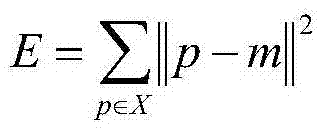

Energy consumption difference analysis method for load varying of ultra-supercritical generating unit of thermal power plant

ActiveCN103699786AReduce coal consumption for power generationSave coal resourcesTechnology managementSystems intergating technologiesCoalProcess engineering

The invention discloses an energy consumption difference analysis method for load varying of an ultra-supercritical generating unit of a thermal power plant. The method comprises the steps of selecting eighteen operation parameters having a greater influence on the economy of the unit as analysis objects; applying a clustering method to the eighteen operation parameters to obtain an operation optimum condition: taking the operation optimum condition as a stable operation standard working condition, and selecting eighteen actual working conditions from a load varying range; taking eighteen parameter influencing factors as independent variables: establishing eighteen equations by taking the energy consumption difference between a single influencing parameter change value and a stable operation standard value as a coefficient of the parameter influencing factor and taking the energy consumption difference between an actual working condition and the stable operation standard working condition as a dependent variable, and finally solving to obtain eighteen parameter influencing factors; finally sequencing the eighteen parameter influencing factors to obtain a parameter having the greatest influence on the coal consumption level in a load varying process. Guidance basis is provided for determination of load varying velocity, load varying amplitude and stable stage time in the load varying operation of million of units, so that the aim of reducing the coal consumption in electricity generation in the load varying operation of the power plant is achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

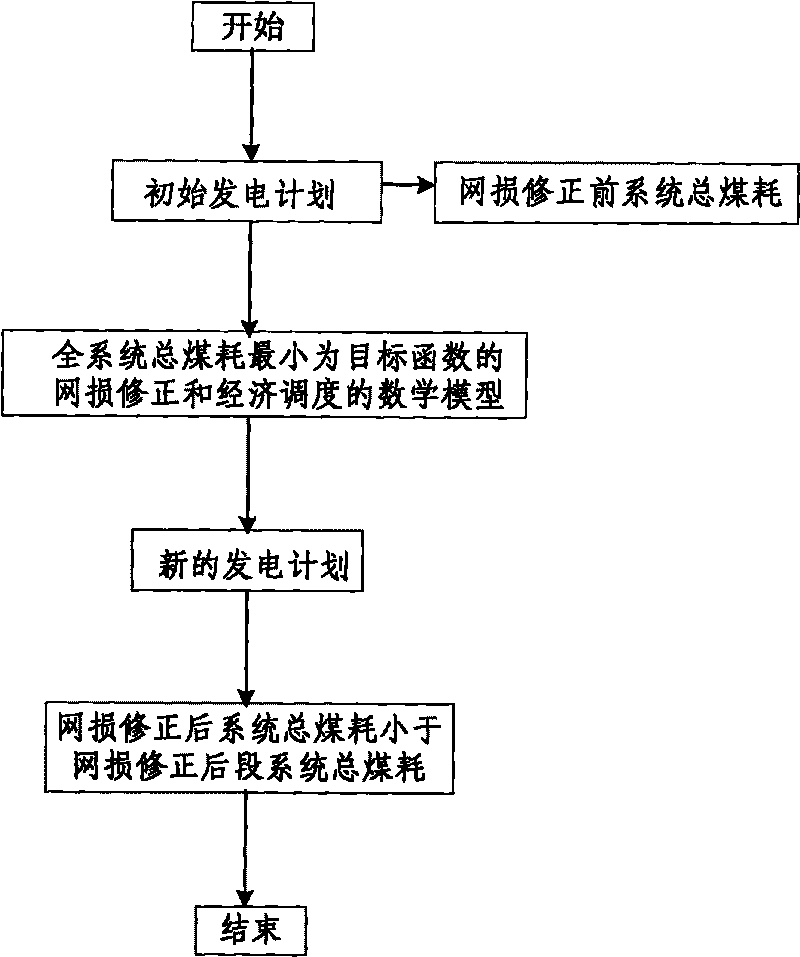

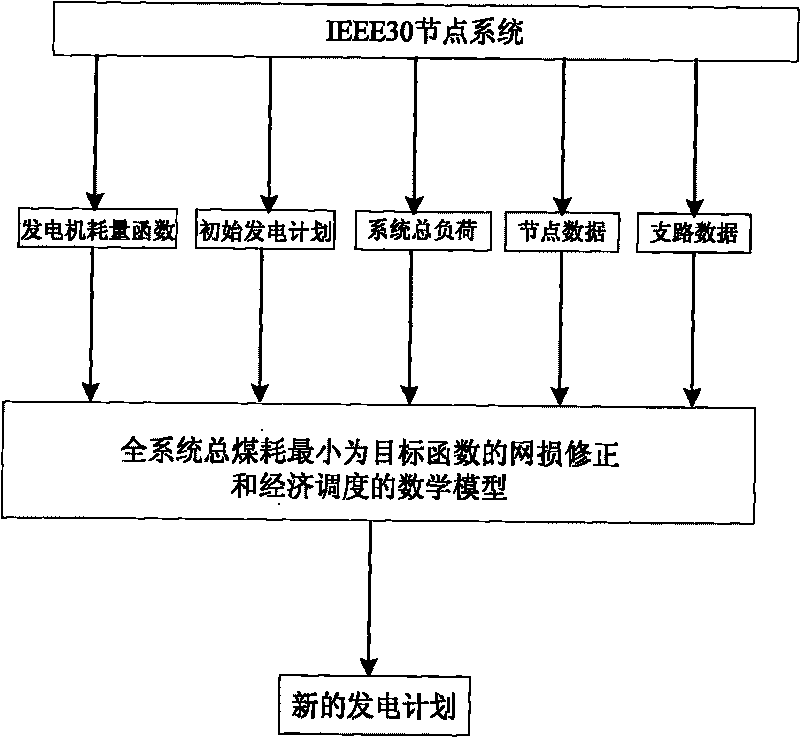

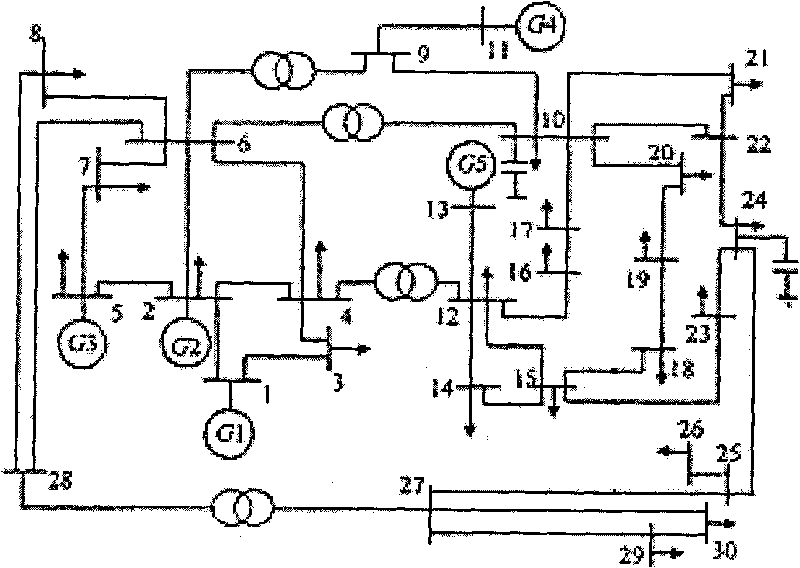

Energy-saving power generation dispatching method considering security constraint and network loss modification

InactiveCN101719668AReduce pollutionReduce coal consumption for power generationSingle network parallel feeding arrangementsComplex mathematical operationsMathematical modelPower system scheduling

The invention belongs to the technical field of power system dispatching automation, and in particular relates to an energy-saving power generation method considering security constraint and network loss modification in the power system. The method comprises the following steps of: a, firstly, providing a mathematical model of the network loss modification and economic dispatch taking minimum total consumption of coal of the whole system as an objective function, wherein the mathematical model is min; b, converting the mathematical model of the energy-saving dispatch into the min, and then acquiring an optimized generation schedule; c, linearizing a constraint condition of the energy-saving dispatch; and d, solving the model of the energy-saving dispatch, and then adjusting the consumption of coal of a corresponding automatic generation control unit according to the solved result of the model. The method can obviously reduce the consumption of coal for power generation, and plays an important role in improving economic growth and benefits, reducing environmental pollution, and ensuring sustainable and rapid economic growth.

Owner:CHONGQING UNIV +1

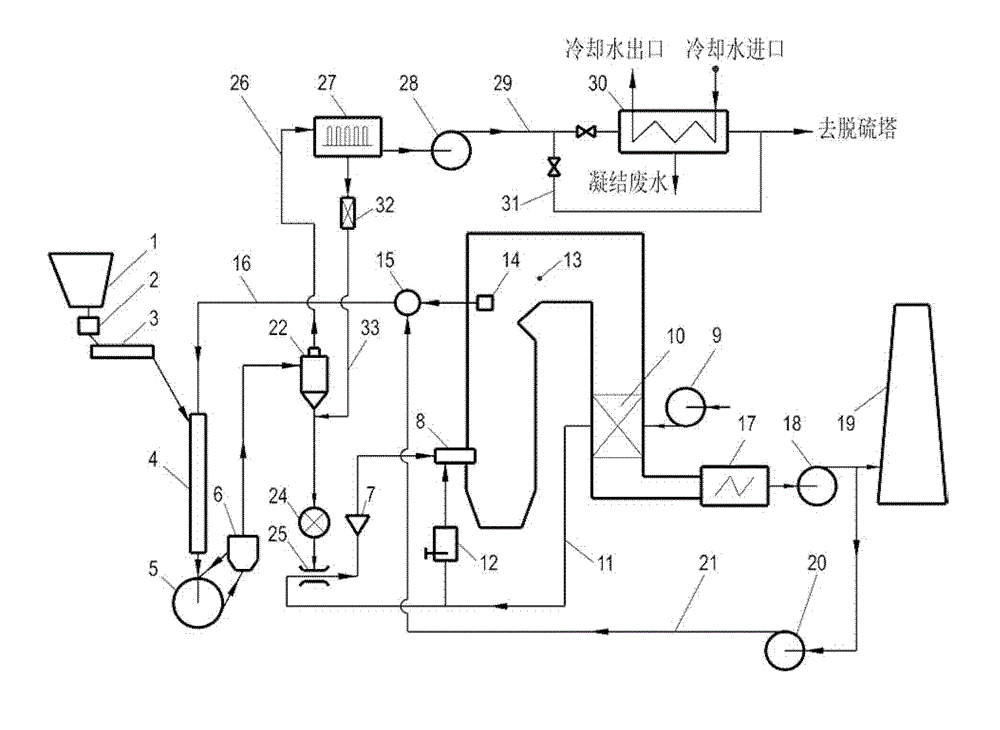

Direct fired pulverizing system of smoke pre-drying lignite fan mill

ActiveCN102889608AImprove combustion effectReduce coal consumption for power generationDrying gas arrangementsLump/pulverulent fuel preparationFlueBoiler furnace

The invention discloses a direct fired pulverizing system of a smoke pre-drying lignite fan mill. A coal dropping port of a coal delivery pipe is connected with a pre-drying device; a coal inlet and a high-temperature smoke dryer inlet are arranged on the upper part of the pre-drying device; an exhaust port is arranged on the side of the bottom and connected with a dust remover; an exhaust outlet of the dust remover is connected with an exhaust fan; a powder outlet of the dust remover is connected with a powder dropping port of the coal delivery pipe; the high-temperature smoke dryer inlet of the pre-drying device is connected with a smoke mixing chamber that is provided with two smoke inlets; and the first smoke inlet is connected with a hot smoke pumping port of a boiler furnace, while the second smoke inlet is connected with a cool smoke pumping port of the boiler furnace. The direct fired pulverizing system has a series of advantages such as good drying effect, safety in operation, and capability in improving combustion performance of pulverized coal and lowering coal consumption for power generation. The direct fired pulverizing system can be used for transformation of steel ball mill pulverizing system of the in-service lignite generator units, or lately built combustible high-moisture lignite generator units and has great promotion and application prospect.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

Energy-saving emission reduction system and energy-saving emission reduction method of horizontal type phase change heat exchanger and front-arrangement type water medium type GGH combined

ActiveCN104964265AImprove economic efficiencyReduce coal consumption for power generationAir heatersCombustion technology mitigationWater pipeSteam condensation

The invention relates to an energy-saving emission reduction system and an energy-saving emission reduction method of a horizontal type phase change heat exchanger and a front-arrangement type water medium type GGH combined. At present, no systems and methods which are reasonable in design, save energy and reduce emissions exist. The energy-saving emission reduction system is characterized in that a phase change heat exchange steam pocket is located above the phase change heat exchanger, and is connected with the phase change heat exchanger through an ascending pipe and a descending pipe, and a water steam condensation cavity is formed in a shell side of the phase change heat exchange steam pocket; and a pipe side inlet and a pipe side outlet of the phase change heat exchange steam pocket are connected with a condensate water leading-out pipe and a condensate water leading-in pipe of a low-pressure heater. The energy-saving emission reduction method is characterized in that smoke obtained after dust removal is heated to 80 DEG C through a smoke purification reheater, enters a chimney and is exhausted to air, and the problem of white smoke emitting of a power plant chimney is solved. The system and the method can efficiently treat the smoke of the boiler, the smoke exhaust temperature is reduced, the portion of the low-pressure heater is heated, and therefore water is condensed, and the energy-saving effect is achieved.

Owner:HANGZHOU HUADIAN ENERGY ENG

Waste heat recovery system and method for coal-fired power plant

PendingCN111486468AAvoid Low Temperature CorrosionLow temperature corrosion achievedCombustion processClimate change adaptationAir preheaterElectrolysis

The invention provides a waste heat recovery system for a coal-fired power plant. The waste heat recovery system involves a boiler, an air preheater, a plurality of coolers, a dust remover, a desulfurizing tower, a flue gas condensation heat exchanger, a flue gas reheater and a chimney which are sequentially arranged; the plurality of coolers are sequentially connected in series, the outlet temperatures of heat exchange media of the plurality of coolers are sequentially reduced, and the plurality of coolers correspond to different heat using devices; the system involves an absorption heat pump, a thermocline heat storage tank and a heat supply network, and the hot water output end of the thermocline heat storage tank communicates with the heat supply network; and heat generated by part ofthe coolers is used for driving the absorption heat pump to recover heat released in the flue gas condensation process, part of the heat generated by the heat pump is conveyed to the flue gas reheaterto be used for reheating flue gas, part of the heat is used for preheating air, and the rest part of the heat is continuously heated in part of coolers and stored in the thermocline heat storage tankto supply heat loads needed by the heat supply network. Gradient utilization of energy is achieved, energy conservation, water recovery and thermoelectric decoupling can be achieved simultaneously, and the unit waste heat and water recovery capacity and the power station operation flexibility are improved.

Owner:DATANG ENVIRONMENT IND GRP +1

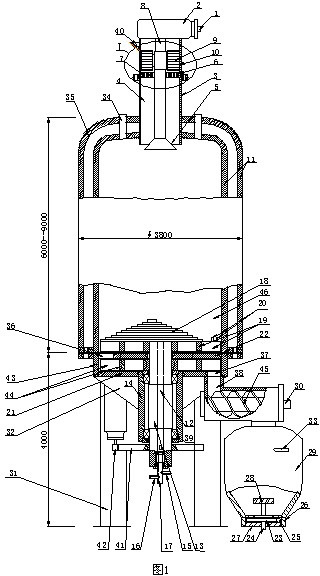

Equipment for preparing fuel gas for gas turbine-steam turbine combined circulating power generation

ActiveCN102634374AInto a stableSolve the problem of easy to reduce the pressure in the furnaceBiofuelsSolid fuelsDrive shaftEngineering

The invention provides equipment for preparing fuel gas for gas turbine-steam turbine combined circulating power generation, comprising a furnace body. An idler wheel extruder is installed at the upper end of the furnace body and is provided with a material receiving barrel, and the material receiving barrel is connected with the furnace body in an airtight mode. A transmission shaft is installed in the material receiving barrel, and two idler wheels are installed on the transmission shaft. A round steel disc is installed on the inner wall of the material receiving barrel below the idler wheels, and a through hole is arranged on the round steel disc. A feed port is arranged at the upper end of the material receiving barrel, the lower end of the material receiving barrel is an opening which is positioned in a fuel gas producer. A fire grate is installed at the lower end of the furnace body, and is connected with a second transmission shaft, and a slagging pipe is installed at one side of the bottom end of the furnace body. An air inlet is arranged in the second transmission shaft and is communicated with a gas mixing pipe, and the gas mixing pipe is respectively connected with a steam pipe and an air pipe. A power transmission piece is installed on the second transmission shaft and is connected with a motor. According to the invention, fuel gas prepared by adopting the equipment has high yield, high cleanliness and high calorific value, and the fuel gas is directly supplied for gas turbine-steam turbine combined circulating power generation.

Owner:孔令增 +1

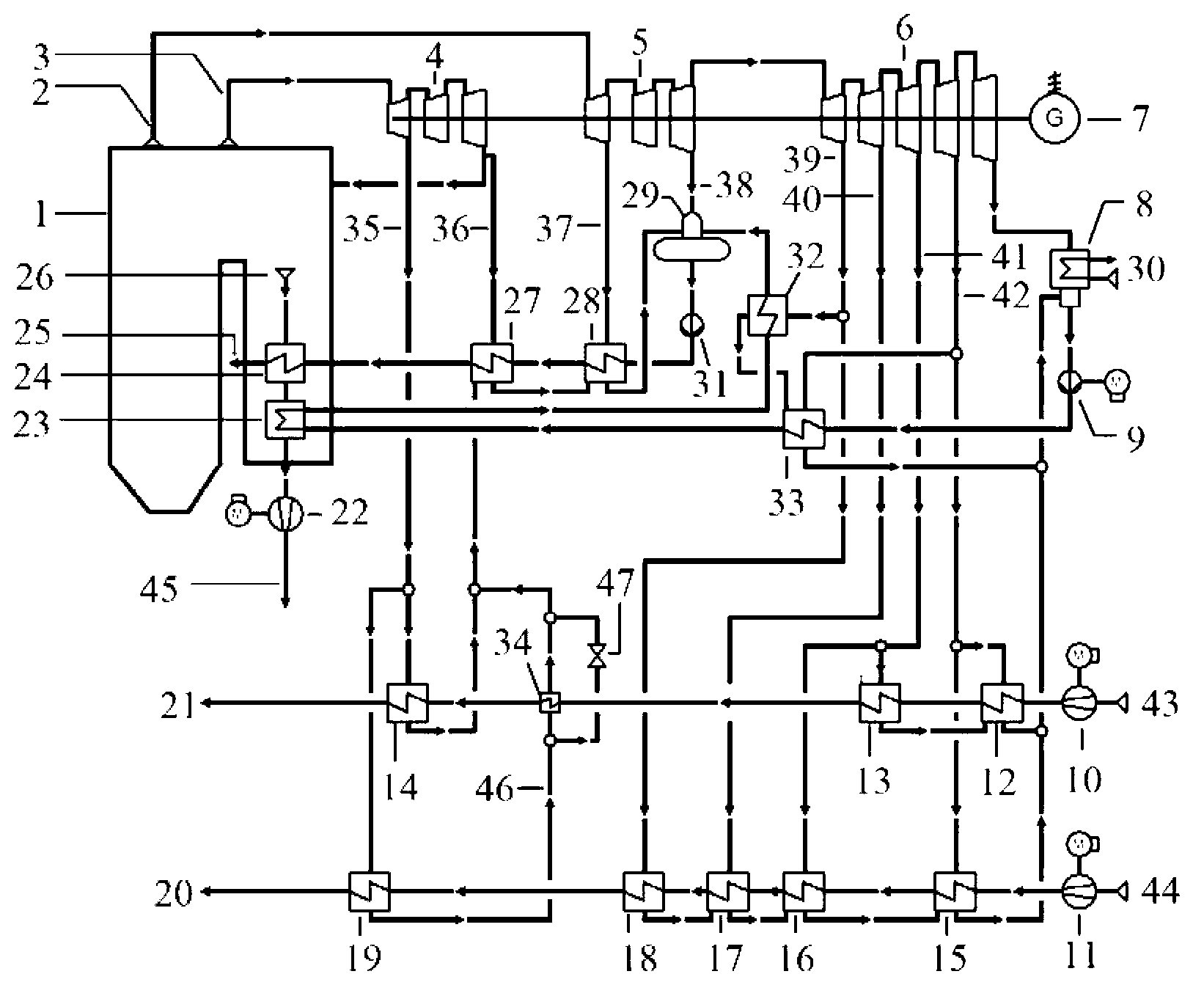

Thermal coupling power generation system of garbage incinerator medium pressure steam and coal-fired unit

ActiveCN107559058AIncrease temperatureIncrease feed water temperatureLiquid degasificationSteam engine plantsEngineeringDeaerator

The invention discloses a thermal coupling power generation system of a garbage incinerator medium pressure steam and coal-fired unit. The thermal coupling power generation system is technically characterized in that a garbage incinerator body and a coal-fired unit are included; a high-pressure heater comprises a first-stage high-pressure heater body and a second-stage high-pressure heater body which communicate with each other; an ultrahigh-pressure cylinder is connected with a high-pressure cylinder; a water feed pump is connected with a low-pressure heater through a pipeline and is connected with a deaerator through a pipeline; the deaerator is connected with the high-pressure heater through a pipeline; the high-pressure heater is connected with the coal-fired unit through a water feedpipeline; the coal-fired unit is connected with a main steam pipeline; the main steam pipeline is connected with the ultrahigh-pressure cylinder; the ultrahigh-pressure cylinder is connected with a third-stage high-pressure heater body through a first-stage steam extraction pipeline; the ultrahigh-pressure cylinder is connected with the second-stage high-pressure heater body through a second-stagesteam extraction pipeline; the coal-fired unit is connected with the high-pressure cylinder through a reheater pipeline; and the high-pressure cylinder is connected with a condenser. According to thethermal coupling power generation system, by means of steam generated by a waste heat boiler for incinerating garbage, the steam is guided into a coal-fired unit thermal system, the efficiency of garbage incineration power generation is improved, and thermal consumption and power generation consumption are reduced.

Owner:HARBIN BOILER

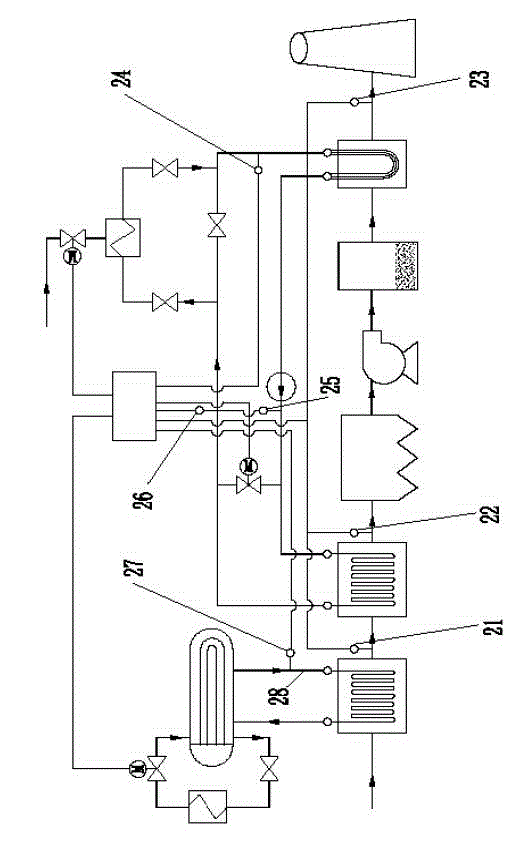

Machine-boiler coupled heat supply waste heat utilization system

PendingCN111623402AGood effectSolve the problem of waste, which is not conducive to energy conservation and environmental protectionEmission preventionSteam useElectrolysisBoiler (power generation)

The invention provides a machine-boiler coupled heat supply waste heat utilization system. The system comprises a boiler smoke waste heat reuse system, a steam turbine power generating system, a condensate water reheating system and a heating system. The boiler smoke waste heat reuse system comprises smoke-water heat exchangers. The steam turbine power generating system comprises an intermediate-pressure cylinder and a low-pressure cylinder communicating with the intermediate-pressure cylinder. The intermediate-pressure cylinder and the low-pressure cylinder further communicate with the heating system. The condensate water reheating system is used for reheating condensate water obtained after heat of steam used as a heat network circulating water heat source is released and / or condensate water obtained after condensation of a condensation device. The heating system is used for supplying heat to a user side. By means of the system, boiler waste heat and low-grade energy for steam turbine power generation are fully used for heating, and waste of low-grade and high-grade heat energy is reduced; a heat storage tank is arranged, the heat energy can be stored in the power generating high-load period, and the effect of thermoelectric decoupling is achieved; and the temperature of exhaust temperature of a boiler is reduced, the amount of water used for smoke desulfuration is reduced, and the system achieves energy saving and environmental protection and has good economic benefits.

Owner:GUODIAN LONGYUAN POWER TECH ENG

Energy-saving heat exchange system with direct vapor-water mixing

InactiveCN102878824AGreat effortImprove heat transfer effectFeed water supplySteam/vapor condensersWater storageWater vapor

The invention discloses an energy-saving heat exchange system with direct vapor-water mixing, namely, a spray atomization heat exchange water collection device is arranged in the high temperature end in the laryngeal portion of a condenser so as to perform high-low temperature condensed water shunting and further to achieve heat exchange cooling circulation and heating circulation of condensed water. The energy-saving heat exchange system is characterized in that cross-cooling circulation and heating circulation are utilized to solve the conflict between the vacuum degree of the unit and the too low temperature of the condensed water. Low-temperature condensed water vapor is directly mixed for heat exchange and cooling circulation to improve the vacuum degree. Condensed water heating circulation is utilized, which avoids the problem that the condensed water becomes too cold, so that backheating economy is improved. Water-water heat exchange and low-temperature water storage are used to improve the vacuum degree of the unit. Furthermore, a water collection device is used for separating the vapor discharging whirlpool at the laryngeal portion to improve the flowing effect. The energy-saving heat exchange system is remarkable in energy-saving effect and easy to implemente and can be massively and widely generalized.

Owner:张贵祥

Online pipe anti-blocking method for utility boiler primary air pipe

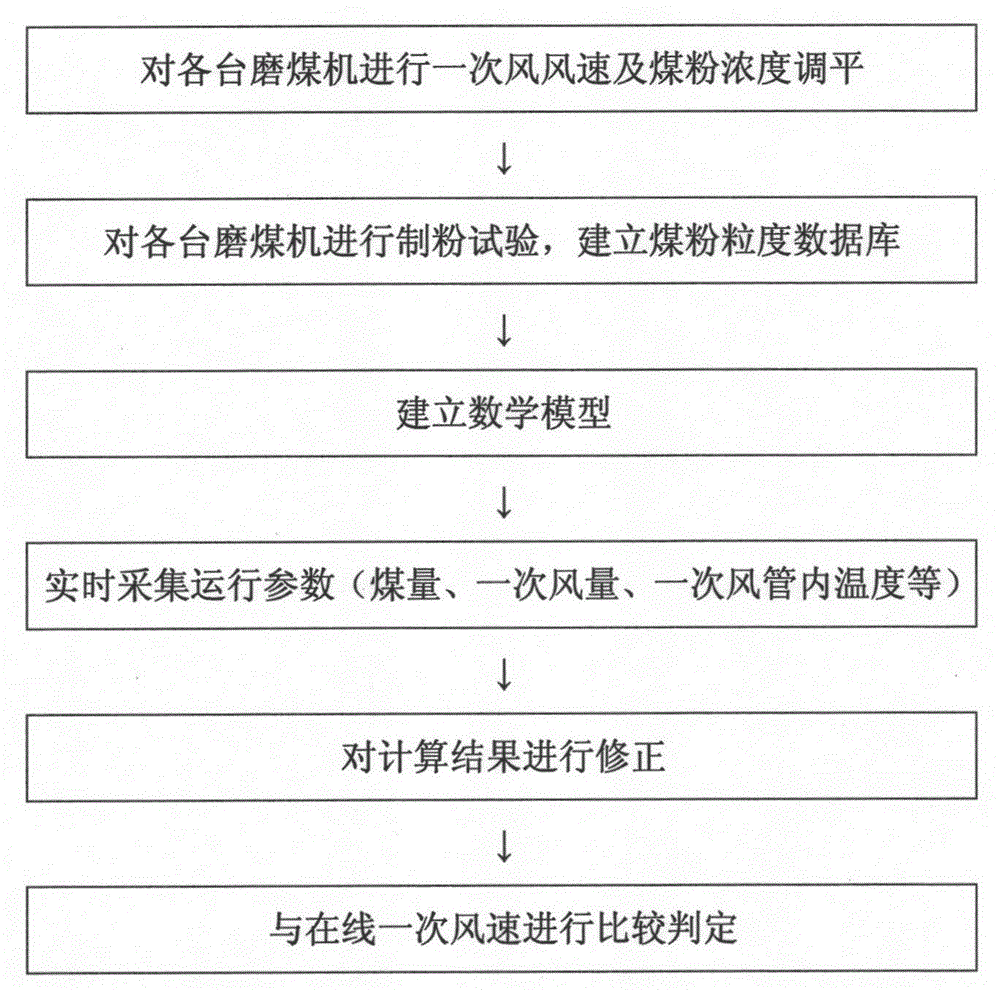

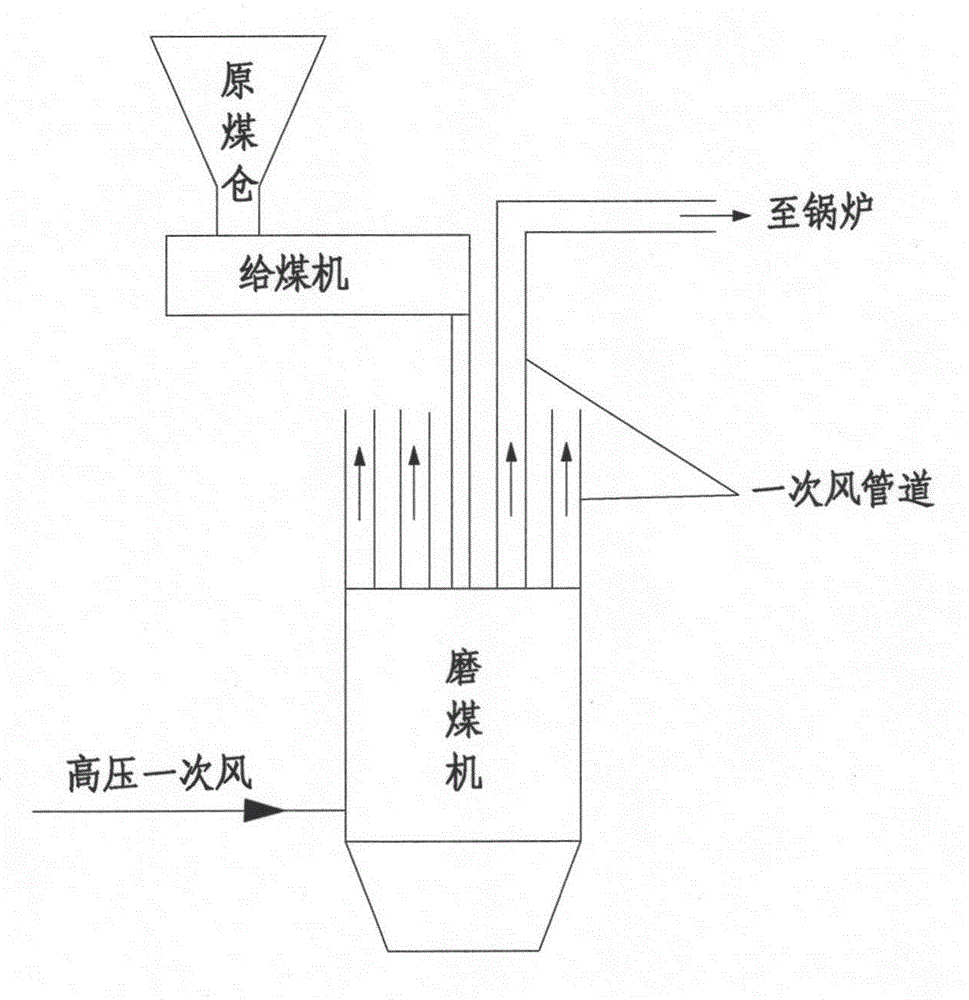

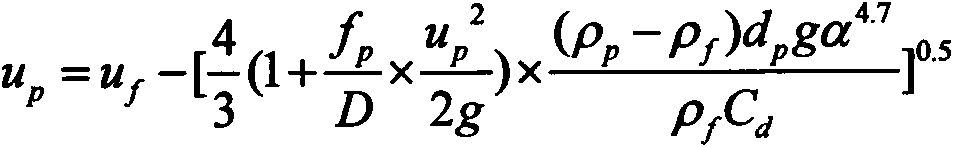

The invention discloses an online pipe anti-blocking method for a utility boiler primary air pipe. The method comprises the steps that firstly, leveling is carried out on the air speed of primary air and pulverized coal concentration of each coal mill; secondly, a coal pulverizing system test is carried out on the coal mill, and a pulverized coal grain size database is established; thirdly, a mathematic model is established, according to parameters in operation collected in real time and the pulverized coal grain size database, the minimum fluidizing velocity of pulverized coal conveying under the theory state is calculated, a theoretical value is corrected according to the actual operation condition, the corrected minimum fluidizing air velocity is compared with the primary air speed measured online, and guiding opinions of the primary air speed are given. The online pipe anti-blocking method for the utility boiler primary air pipe can avoid the defects brought by too high primary air speed that pulverized coal ignition is delayed, the electric current of a primary air fan is too large, and air leakage of an air preheater is increased, and achieve energy saving and consumption reducing under the condition that the primary air pipe is not blocked.

Owner:SHANGHAI POWER EQUIP RES INST

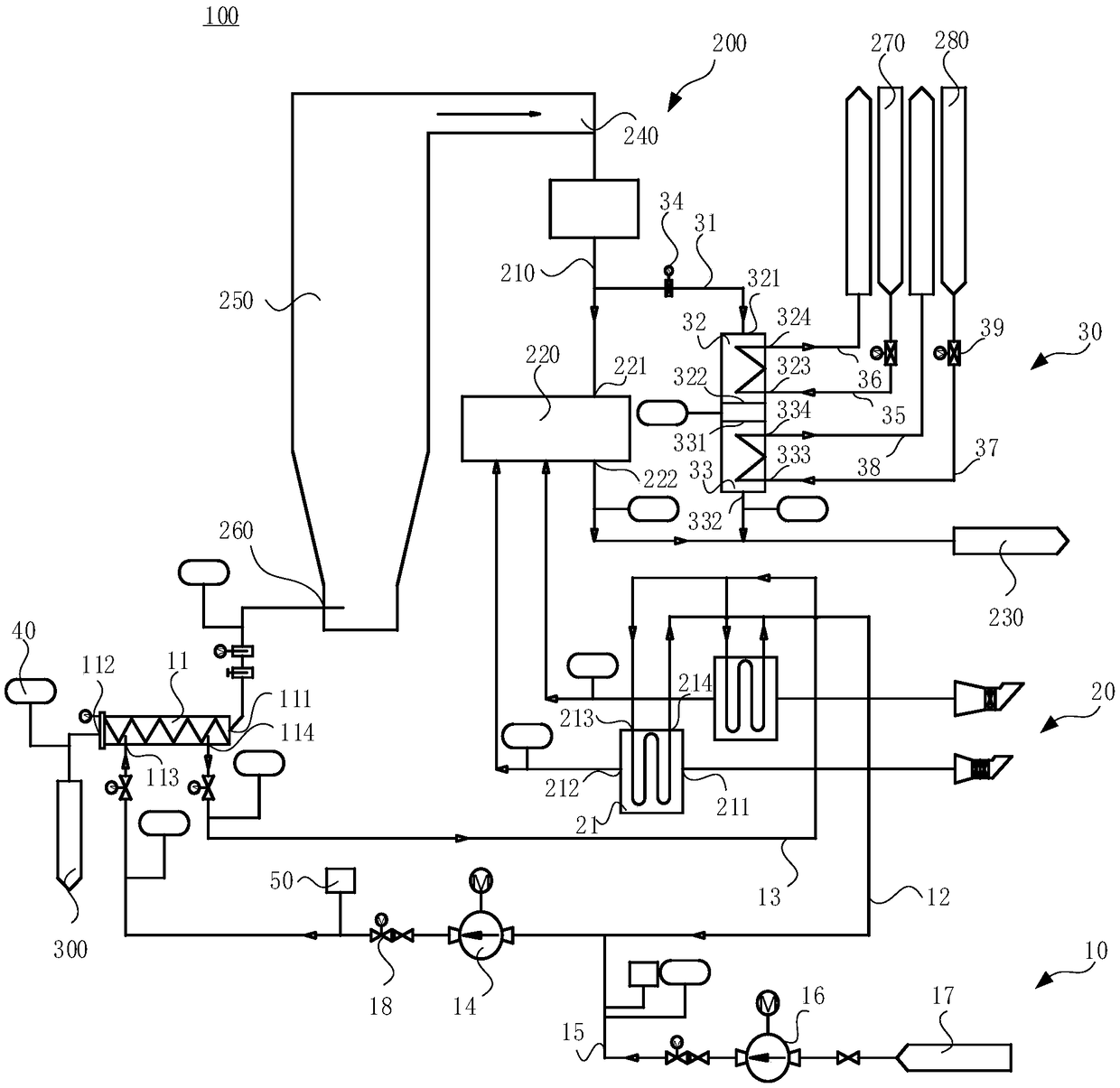

Wind-water combined recovery system for slag heat in circulating fluidized bed boiler, and control method thereof

InactiveCN109282280AImprove recycling ratesThe main disadvantage of avoiding large irreversible lossesFluidized bed combustionIndirect carbon-dioxide mitigationAir preheaterSlag

The invention relates to a wind-water combined recovery system for slag heat in a circulating fluidized bed boiler, and a control method thereof. The wind-water combined recovery system for slag heatcomprises a closed circulating sub-system, a cold air heating sub-system and an air preheater bypass sub-system, wherein the closed circulating sub-system enables a circulating medium to reciprocate between a slag cooler and an air heater of the cold air heating sub-system through a circulating device, so that slag continuously carries out heat exchange with cold air; the heated cold air is conveyed into an air preheater and continues to absorb smoke heat coming from a smoke discharge port of the boiler; and the redundant smoke heat is sequentially transferred and conveyed to a feed water heatexchanger and a condensed heat exchanger in the air preheater bypass sub-system, so that the smoke heat carries out heat exchange with feed water and condensed water. According to the wind-water combined recovery system for slag heat in the circulating fluidized bed boiler, and the control method thereof, high recovery and utilization rate for the slag heat is achieved, so that the efficiency ofthe circulating fluidized bed boiler is increased, and the power generation coal consumption of a unit is reduced.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

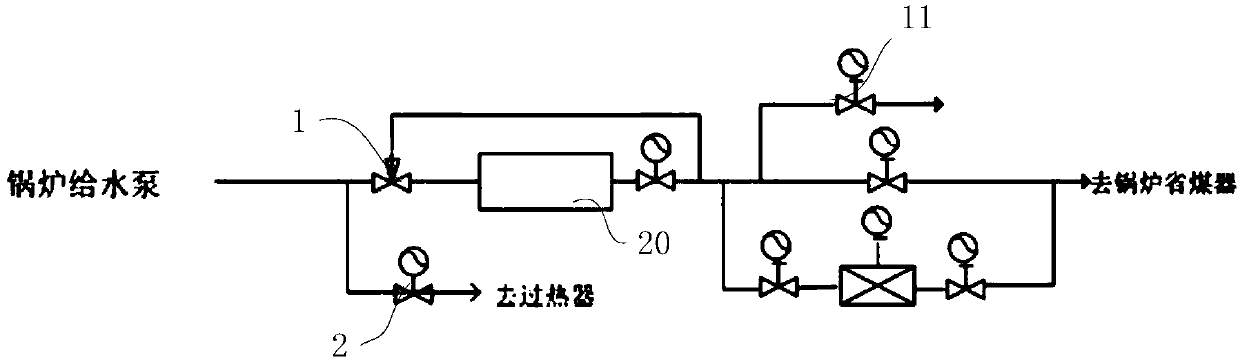

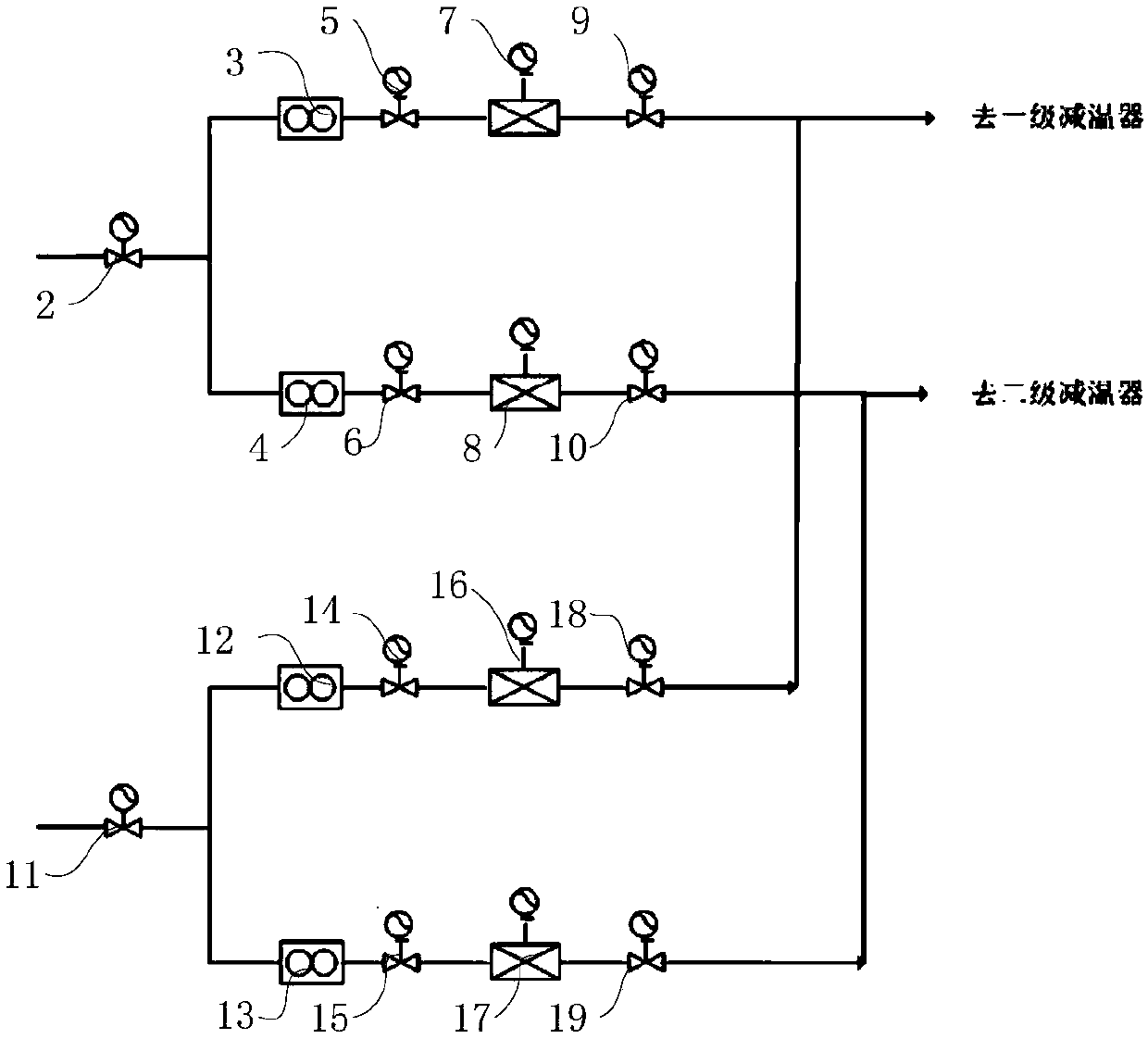

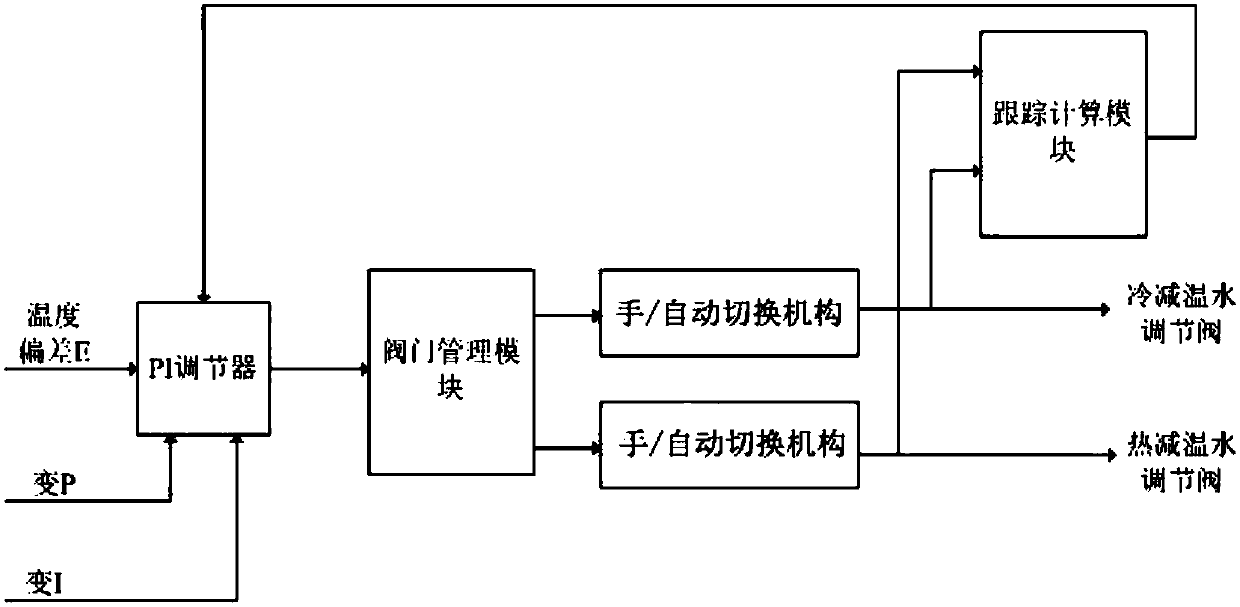

Superheater temperature lowering water supplying system

ActiveCN107620947AImprove efficiencyReduce coal consumption for power generationBoiler controlSteam superheatersSuperheaterCoal

The invention relates to the technical field of superheater temperature lowering for main steam temperature control, in particular to a superheater temperature lowering water supplying system. The superheater temperature lowering water supplying system comprises a high-pressure heater, a superheater and a boiler coal economizer; an inlet of the high-pressure heater is connected with an outlet of aboiler water feeding pump through a first water inlet pipeline; the outlet of the boiler water feeding pump communicates with a water inlet of the superheater through a second water inlet pipeline, and therefore the cold temperature lowering water adjusting process is achieved; an outlet of the high-pressure heater communicates with a water inlet of the boiler coal economizer through a first communicating pipeline; and the outlet of the high-pressure heater further communicates with the water inlet of the superheater through a second communicating pipeline, and therefore the hot temperature lowering water adjusting process is achieved.

Owner:ZHEJIANG OCEAN UNIV

Coal-fired thermal power plant waste heat and water recovery system and method with heat storage function

PendingCN111486469ARaise the temperature of high temperature working fluidImprove efficiencyCombustion processClimate change adaptationAir preheaterElectrolysis

The invention provides a coal-fired thermal power plant waste heat and water recovery system with a heat storage function. The system involves a boiler, an air preheater, multiple coolers, a dust remover, a desulfurizing tower, a flue gas condensation heat exchanger and a chimney which are sequentially arranged in the flue gas circulation direction; the multiple coolers are sequentially connectedin series, the heat exchange medium outlet temperature of the multiple coolers are sequentially reduced in the flue gas circulation direction, and the multiple coolers correspond to different heat using devices; and the system further comprises a thermocline heat storage tank and a heat supply network, wherein the hot water output end of the thermocline heat storage tank communicates with the heatsupply network, and the hot water input end of the thermocline heat storage tank directly or indirectly communicates with a heat exchange medium pipeline of the flue gas condensation heat exchanger and heat exchange medium pipelines of part of the coolers. According to the system, the gradient utilization on energy is achieved, the energy conservation, the water recovery and thermoelectric decoupling can be achieved at the same time, the unit waste heat and water recovery system efficiency is improved, and meanwhile the unit operation flexibility is improved.

Owner:DATANG ENVIRONMENT IND GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com