Comprehensive utilization system for drying low-order coal of thermal power plant in steam pumping and indirect heat exchanging way and process thereof

A low-rank coal, thermal drying technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of no actual deployment, and achieve the effects of saving energy consumption, improving boiler efficiency, and reducing coal consumption for power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

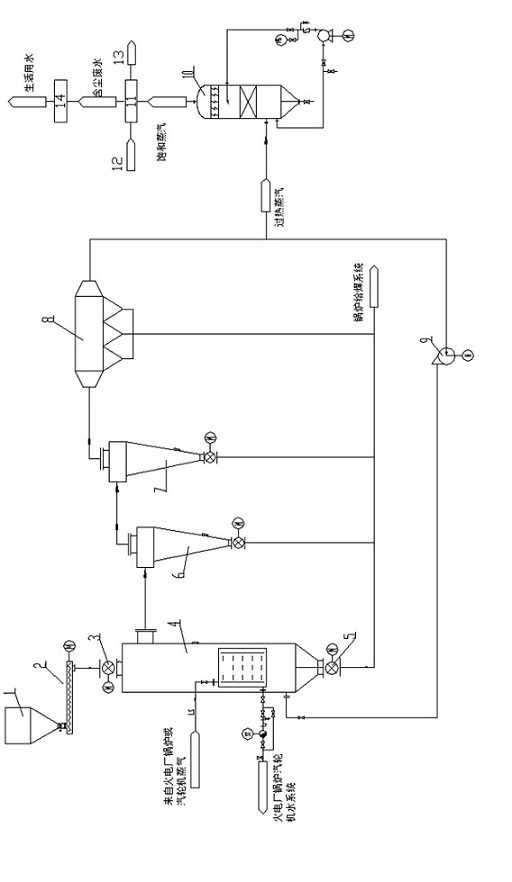

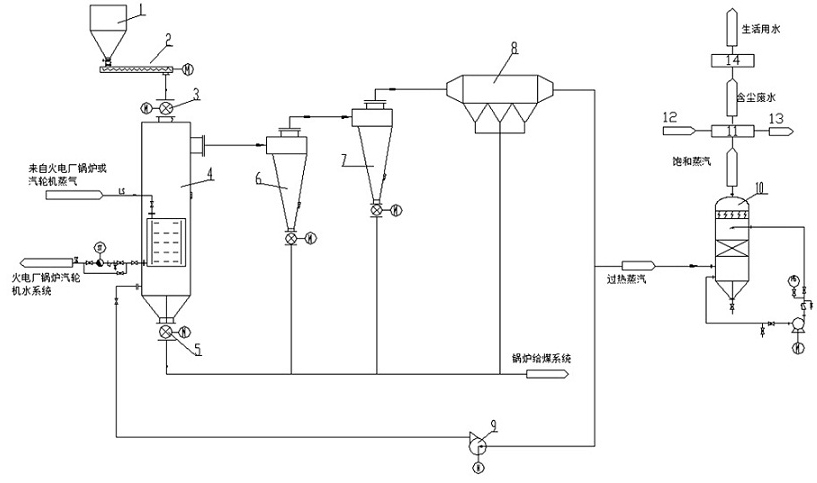

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] figure 1 Among them, the comprehensive utilization system for indirect heat exchange and drying of low-rank coal by pumping steam in thermal power plants includes an indirect heat-exchange low-rank coal pre-drying device using the steam pipeline of a thermal power plant boiler or steam turbine as a heat source. The steam tail gas is connected to the secondary steam adiabatic scrubbing device, the secondary steam adiabatic scrubbing device is connected to the secondary steam recovery and utilization device, and the secondary steam recovery and utilization device is connected to the dusty wastewater purification and utilization device.

[0021] The indirect heat exchange low-rank coal pre-drying device includes at least one drying host 4 with a built-in heat exchanger, the inlet end of the built-in heat exchanger communicates with the steam pipeline of the ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com