Patents

Literature

61903 results about "Exhaust gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exhaust gas or flue gas is emitted as a result of the combustion of fuels such as natural gas, gasoline, petrol, biodiesel blends, diesel fuel, fuel oil, or coal. According to the type of engine, it is discharged into the atmosphere through an exhaust pipe, flue gas stack, or propelling nozzle. It often disperses downwind in a pattern called an exhaust plume.

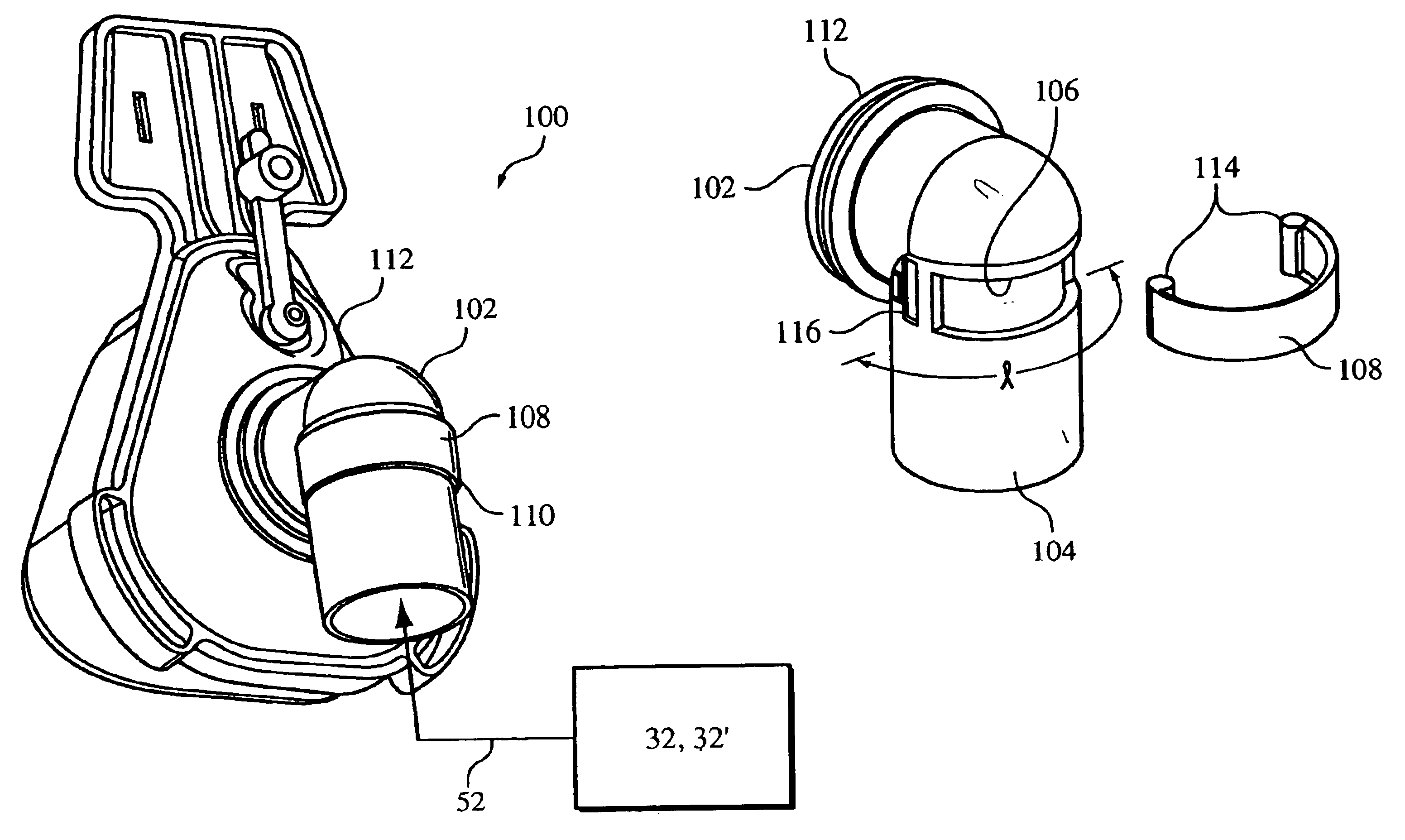

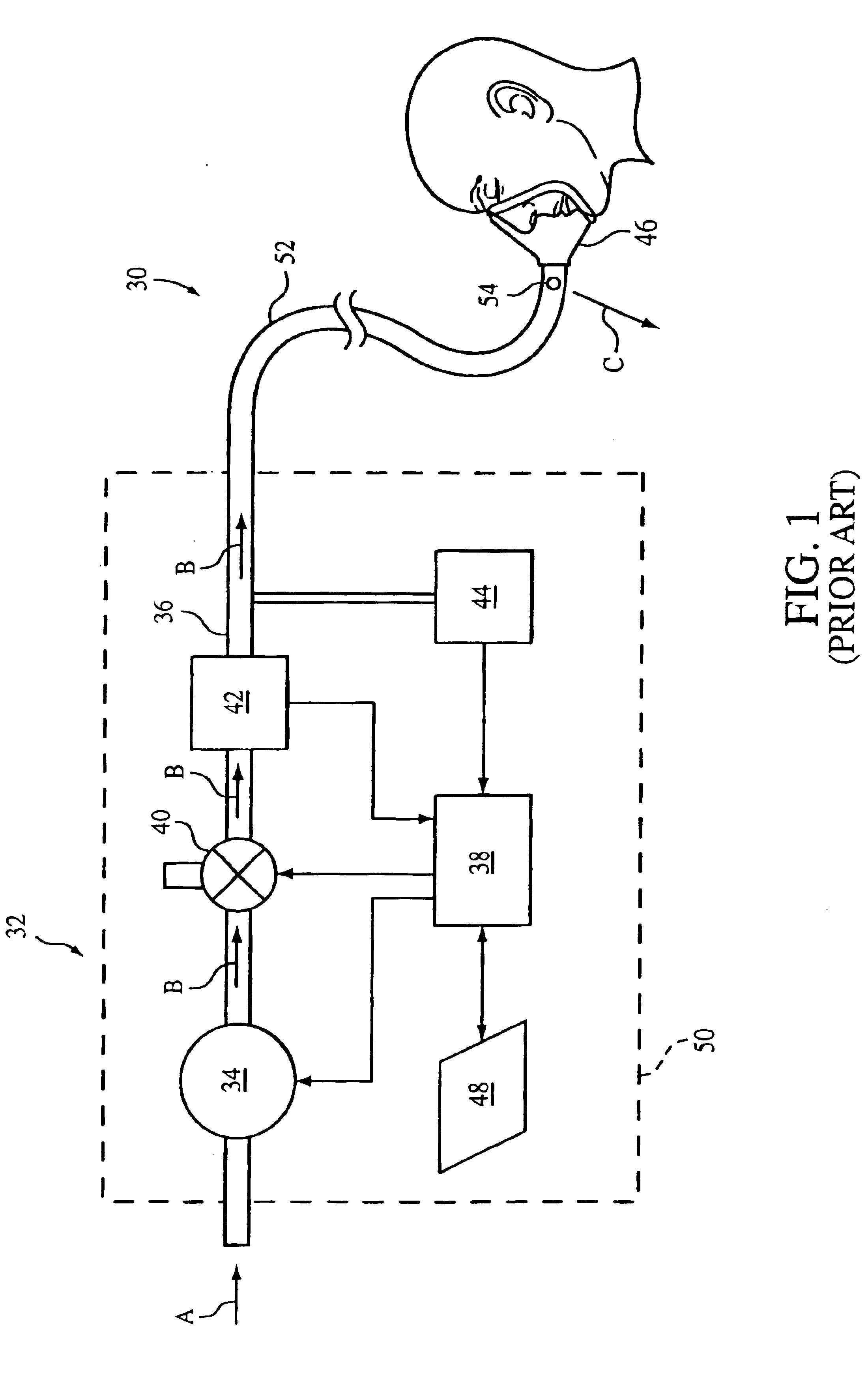

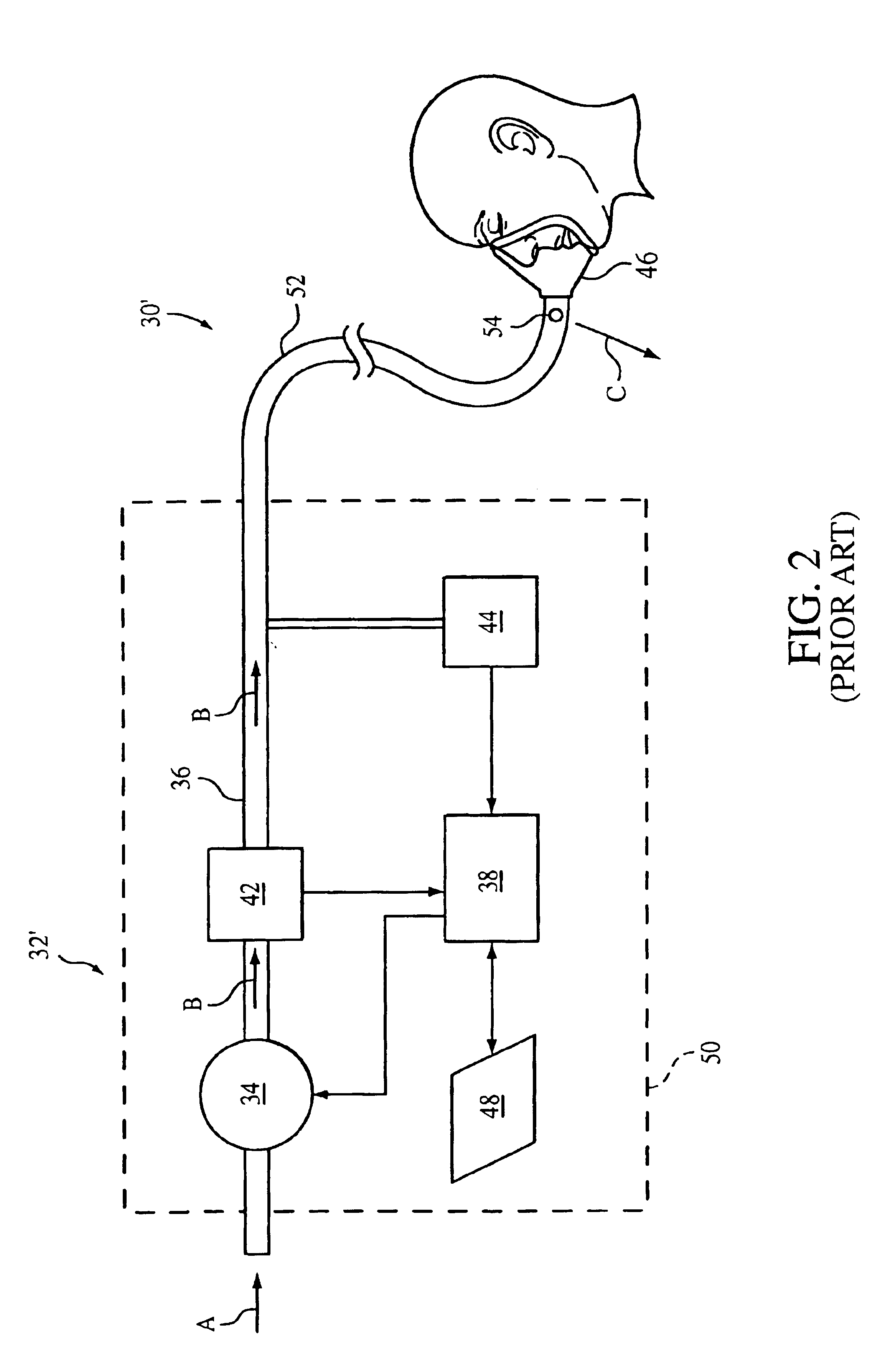

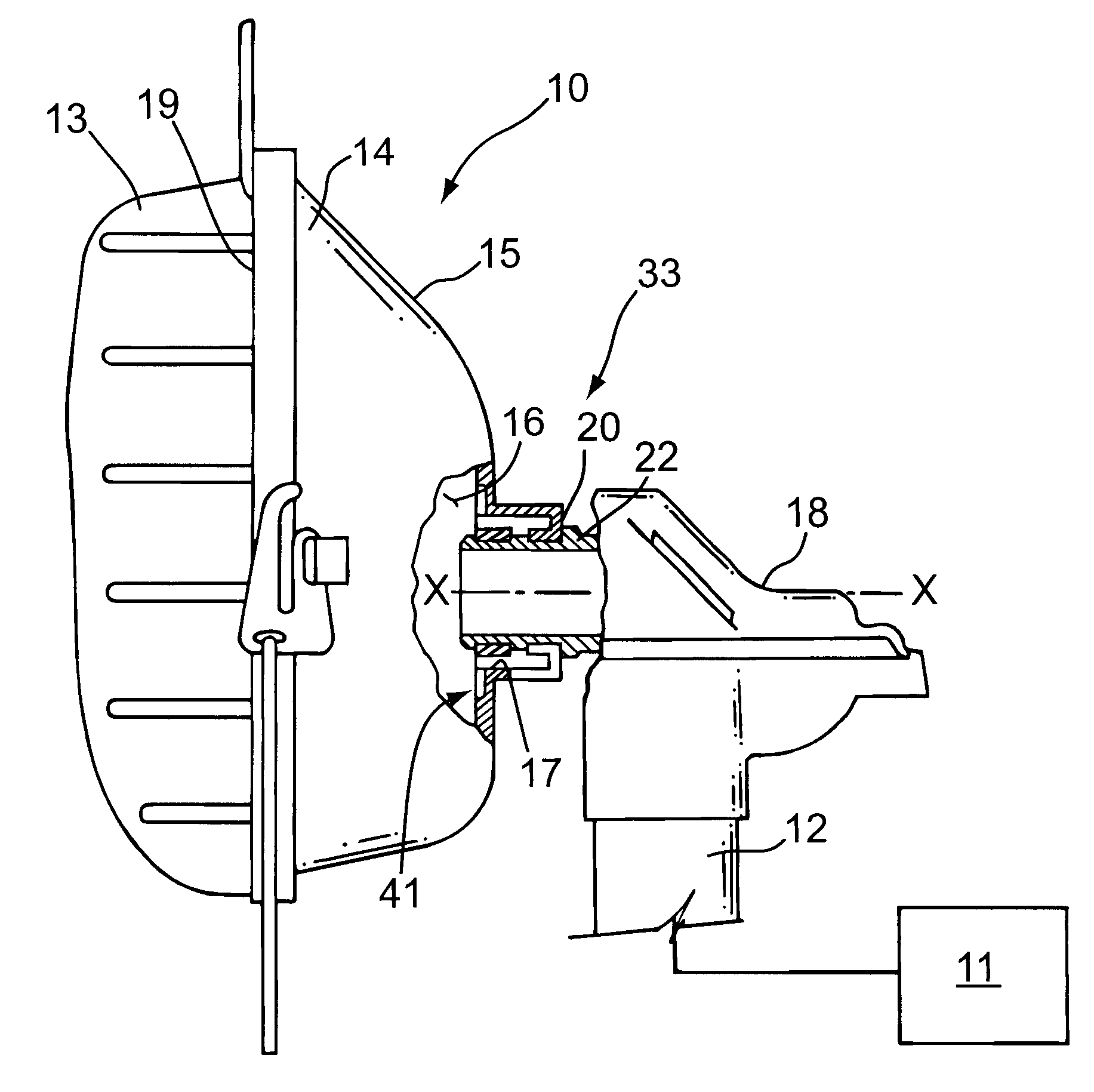

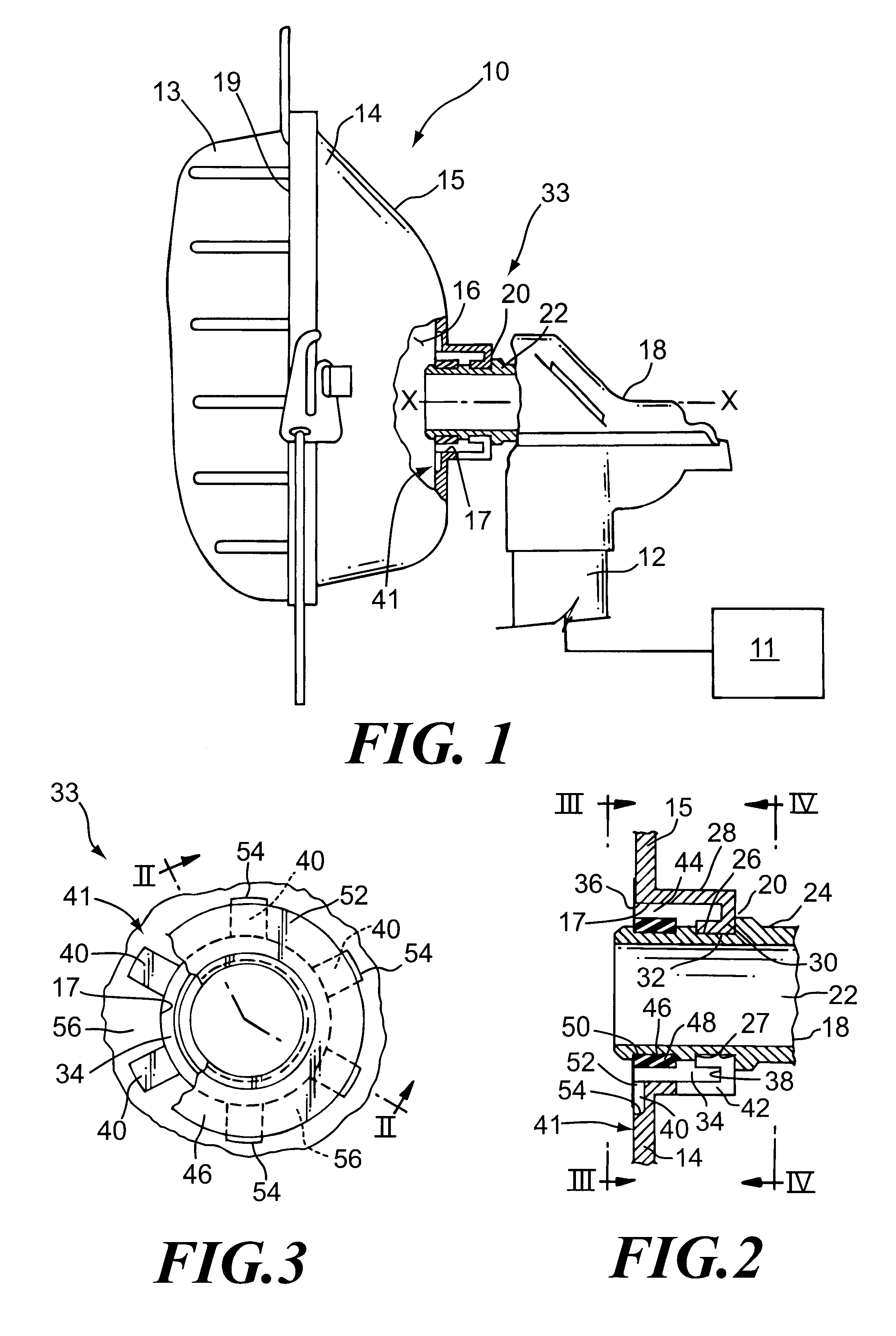

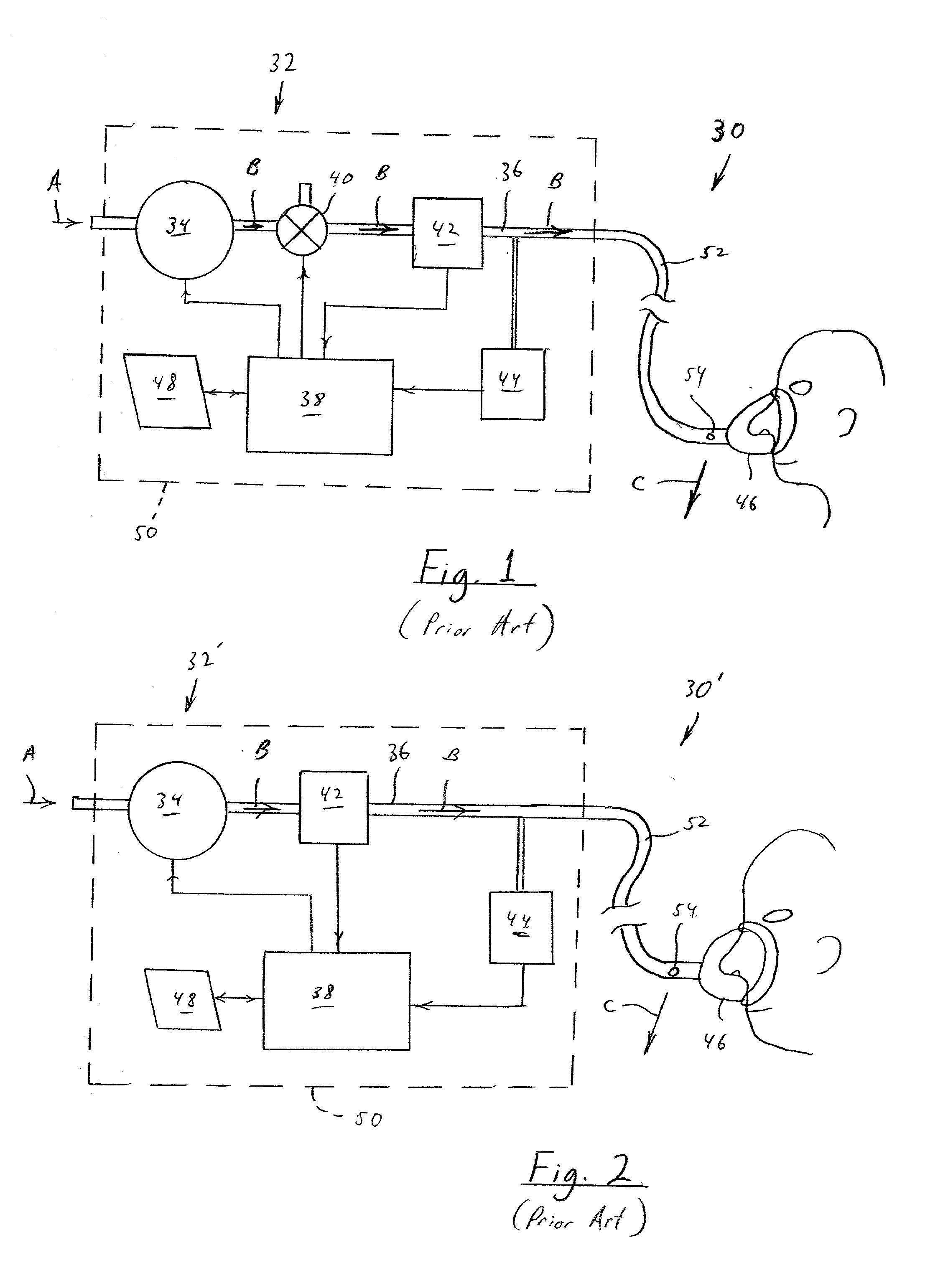

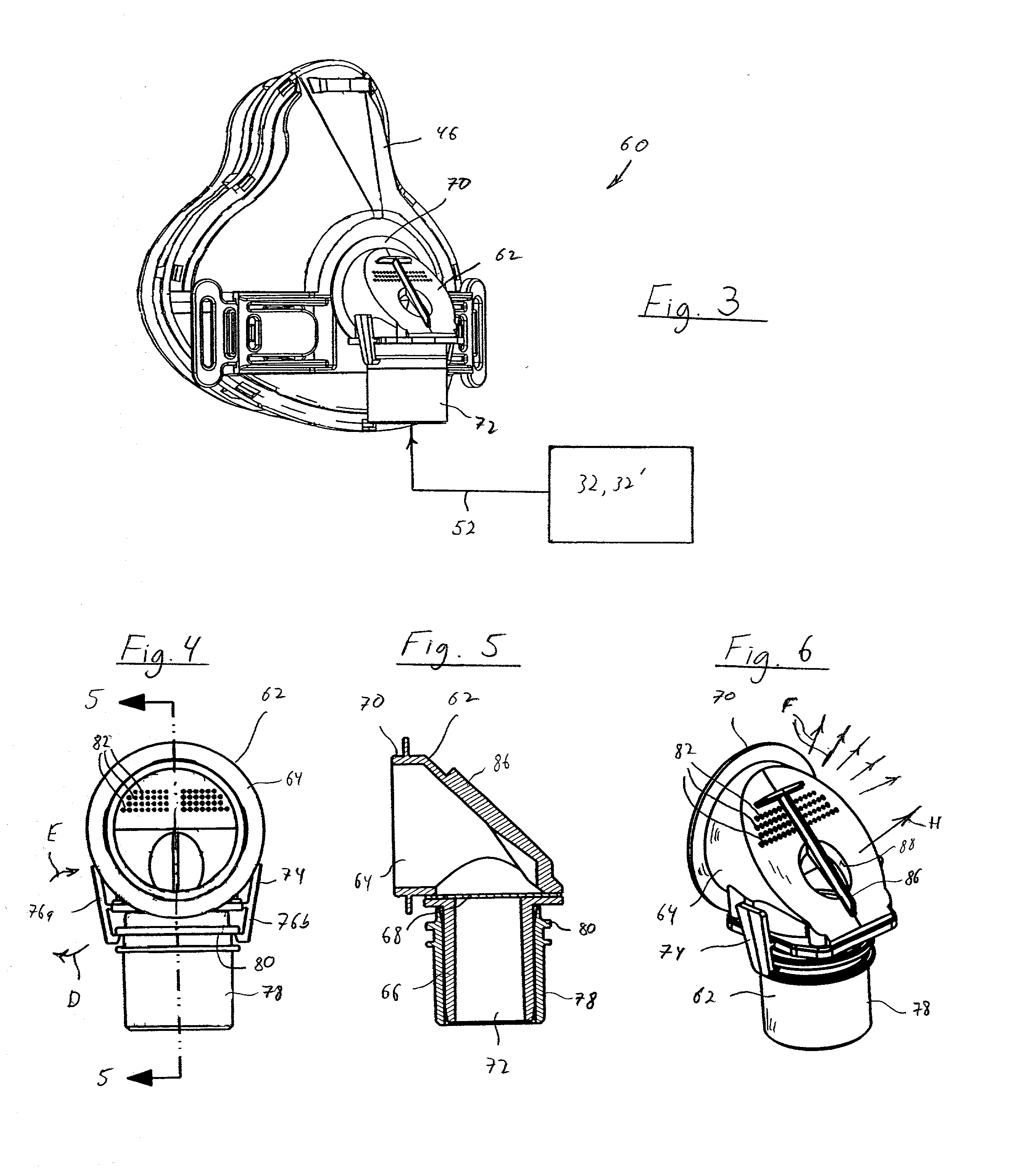

Exhaust port assembly for a pressure support system

InactiveUS6851425B2Noise minimizationArea minimizationBreathing masksRespiratory masksSupporting systemAtmospheric air

An exhaust port assembly comprising a conduit carries a flow of gas. A vent assembly having a fixed exhaust area is provided on the conduit for venting a flow of exhaust gas from within the conduit to ambient atmosphere. The vent assembly is configured so as to minimize noise associated with the flow of exhaust gas passing to atmosphere, diffuse the flow of exhaust gas passing to ambient atmosphere over a relatively large area, and minimize the area occupied by the venting assembly on the conduit.

Owner:RIC INVESTMENTS LLC

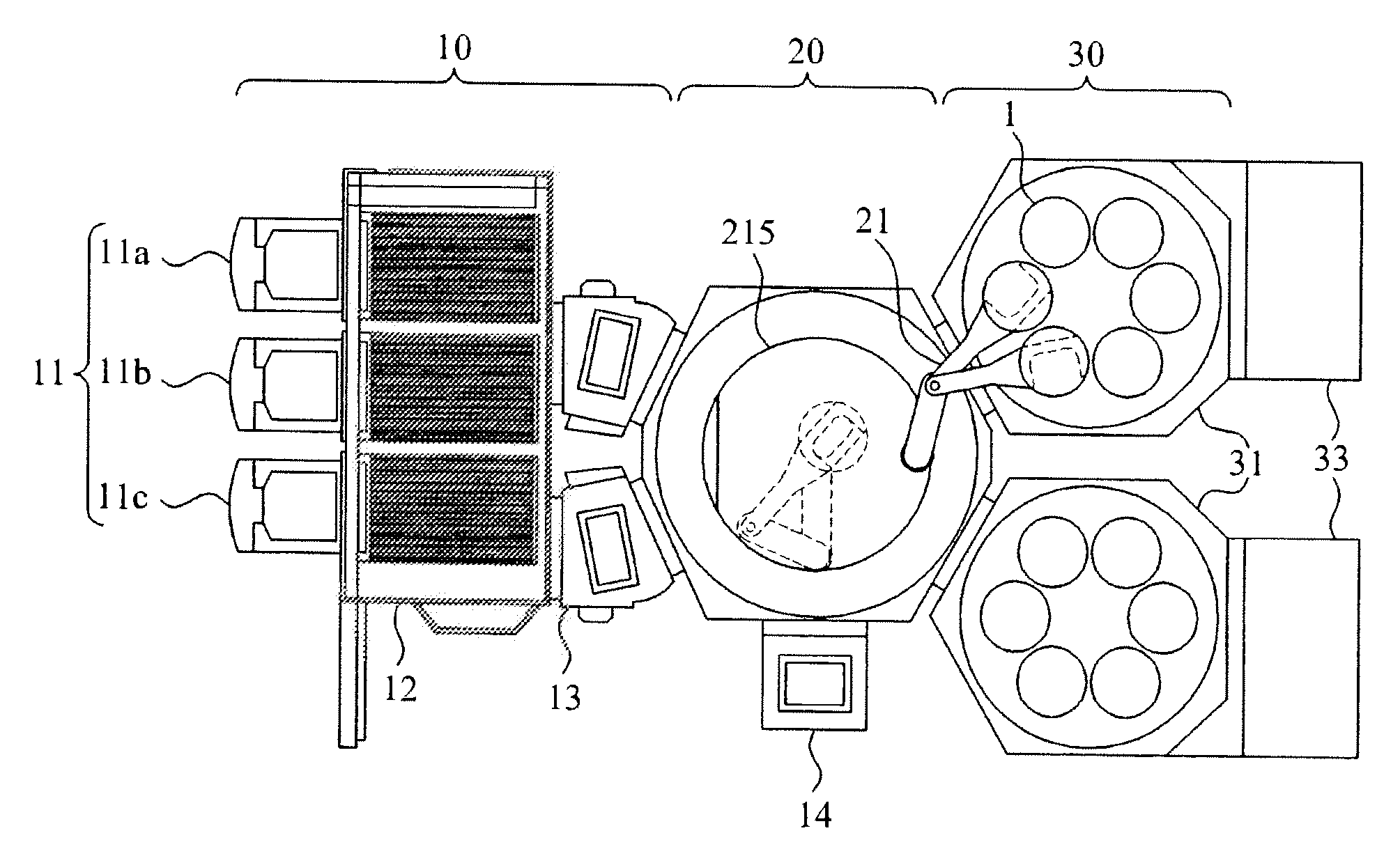

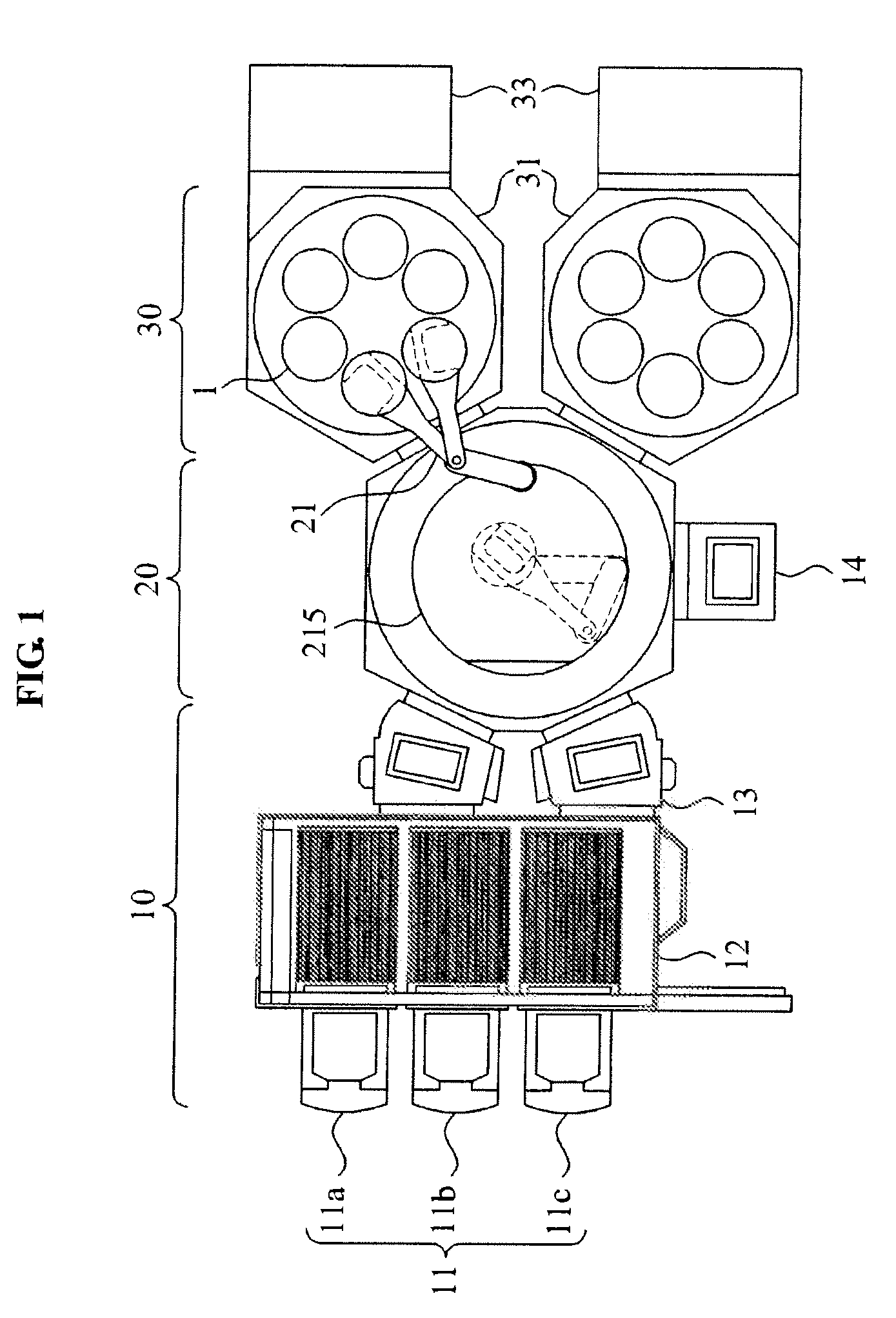

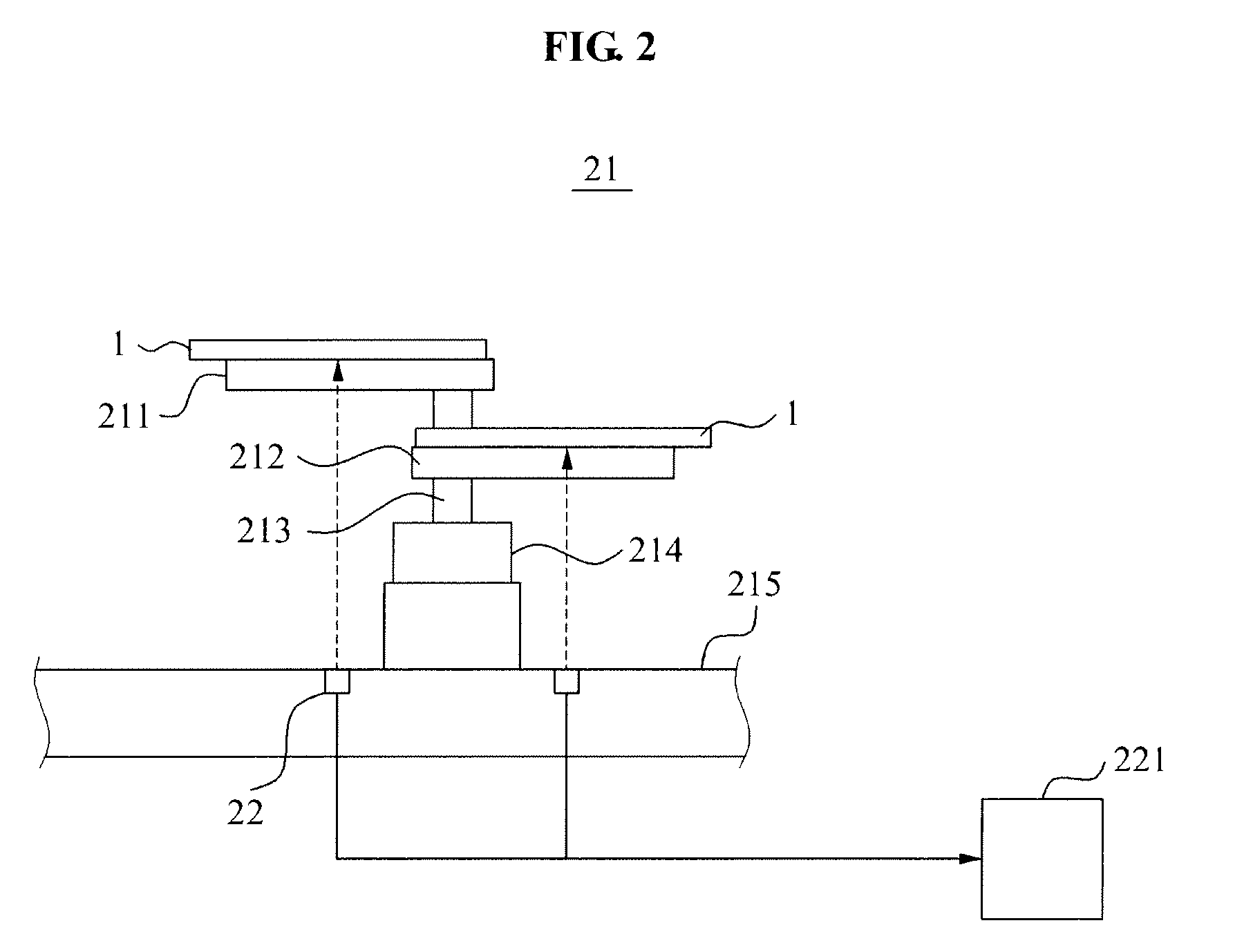

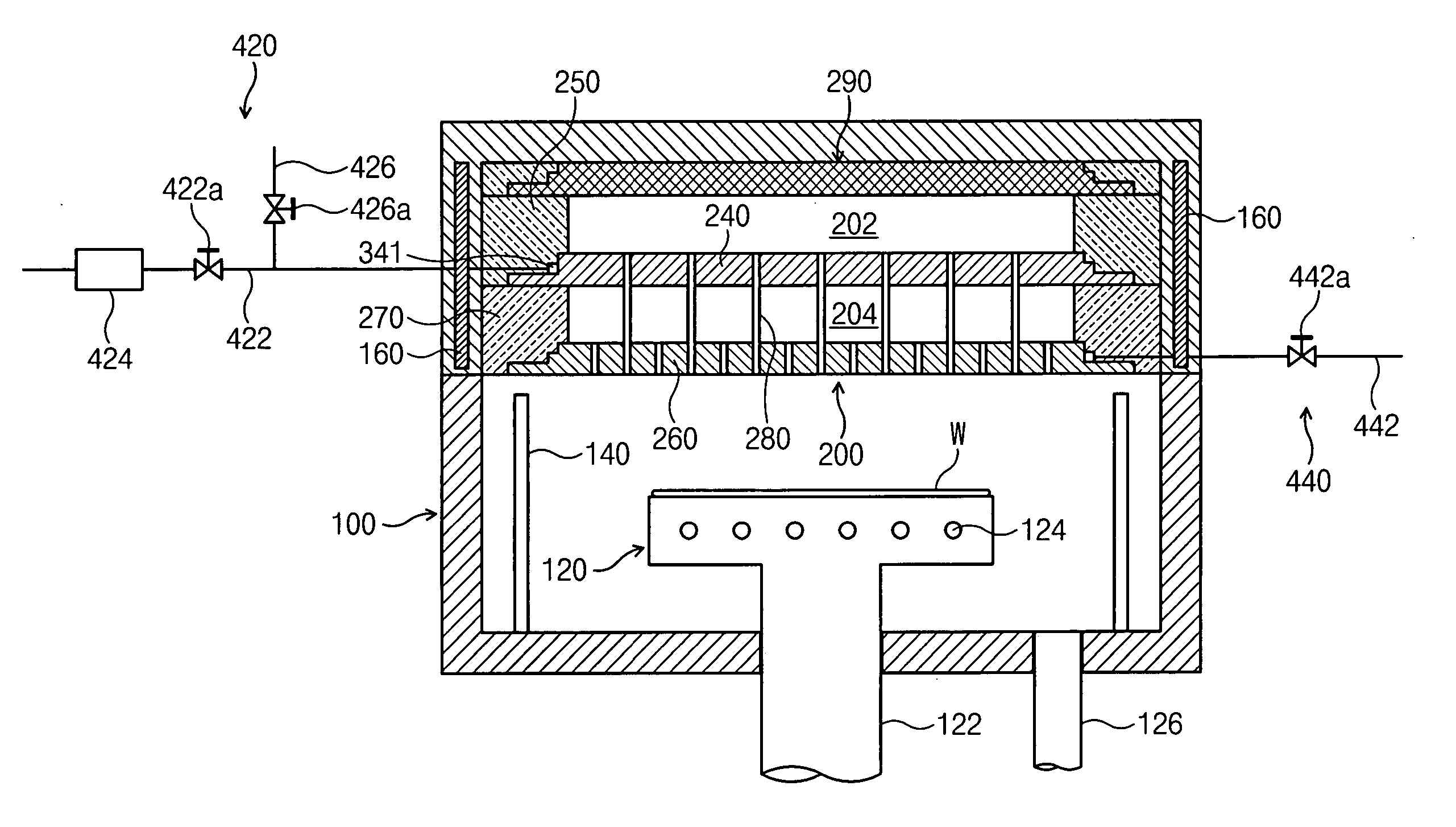

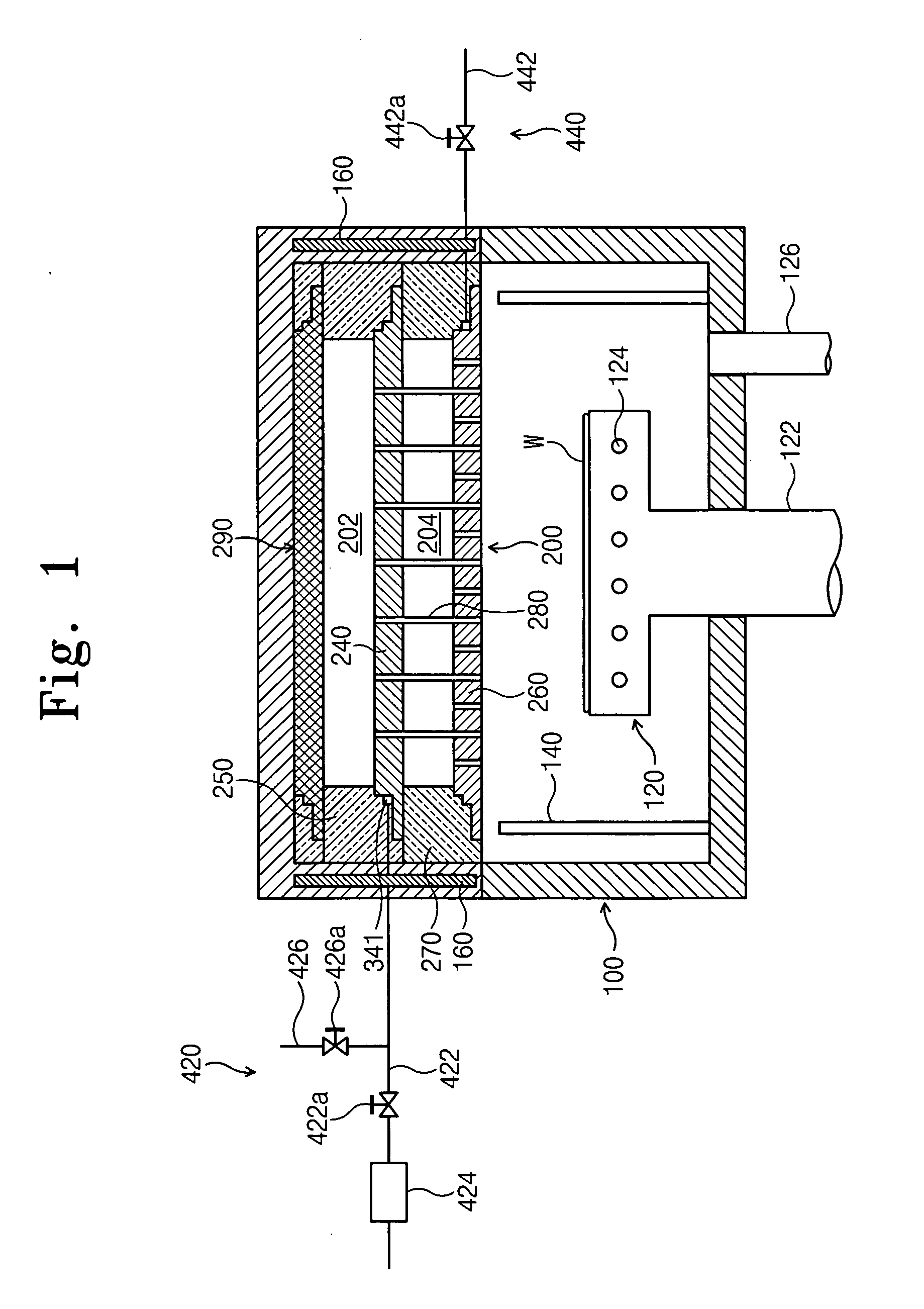

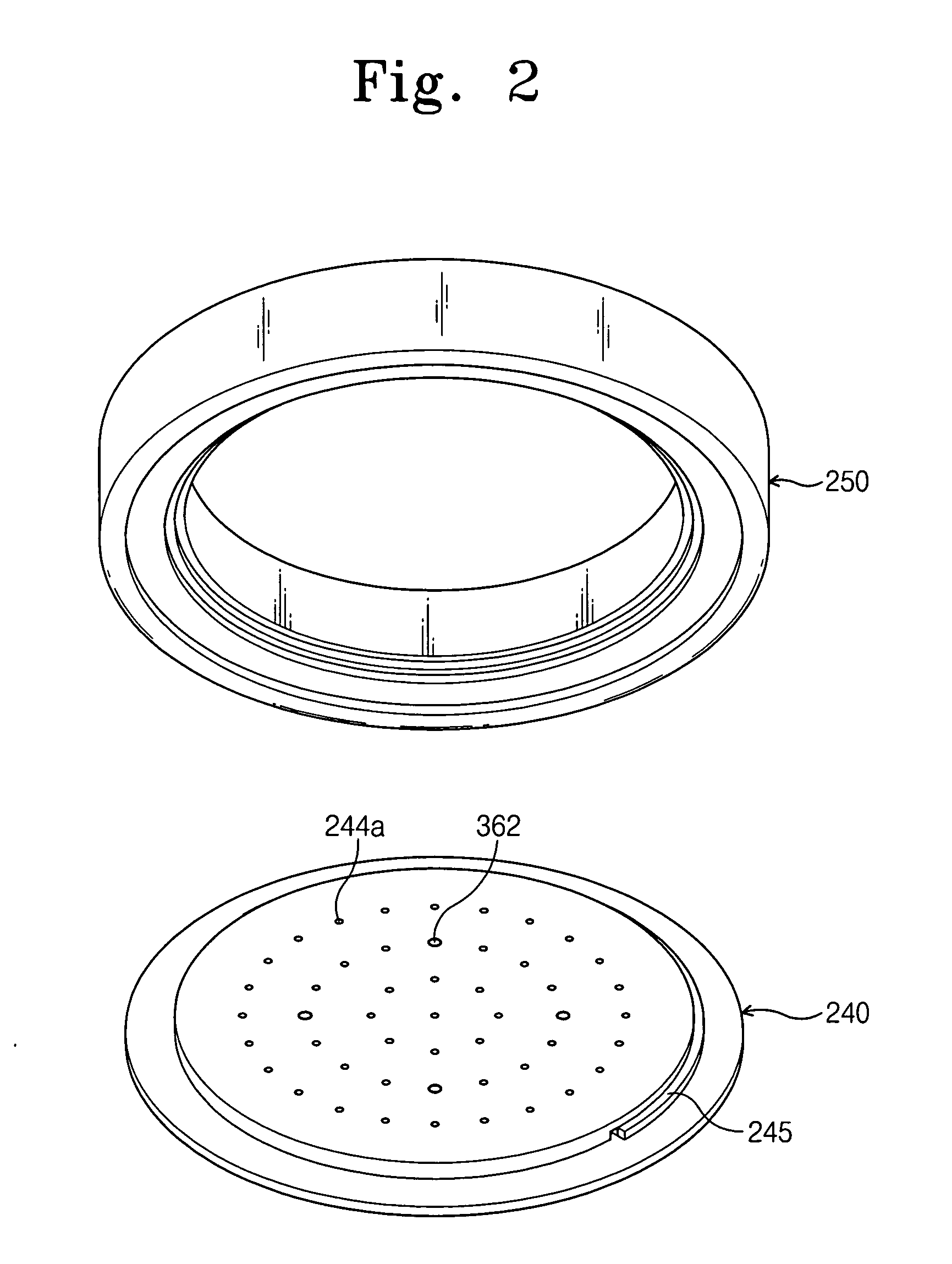

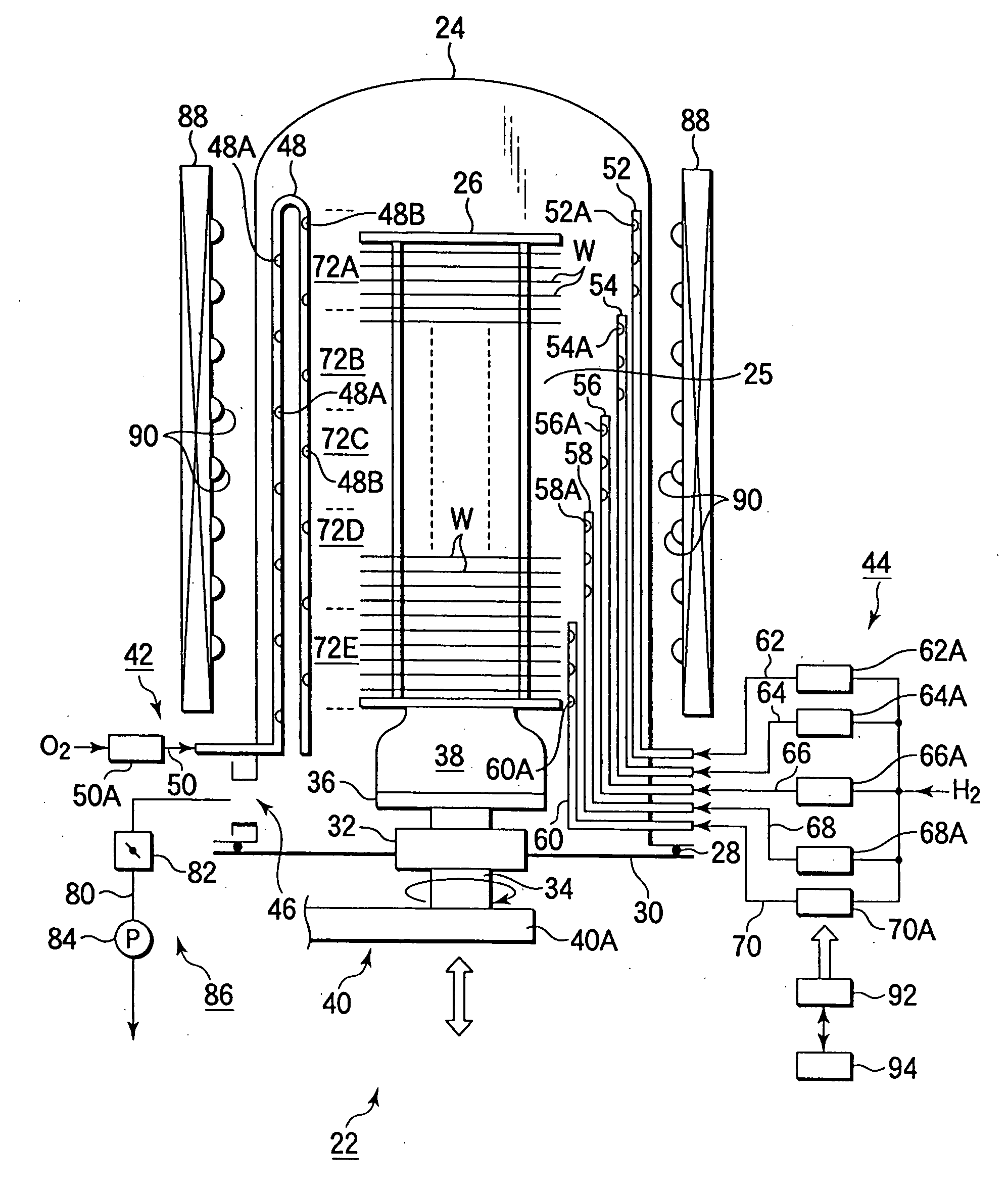

Atomic layer deposition apparatus

ActiveUS20100186669A1Avoid time delayShorten the timeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess moduleEngineering

An atomic deposition apparatus is provided for simultaneously loading / unloading a plurality of substrates. The atomic deposition apparatus which may load / unload the plurality of substrates when transmitting the plurality of substrates to a process module, includes a loading / unloading module for loading / unloading a substrate, a process module including a plurality of process chambers for simultaneously receiving a plurality of substrates and performing a deposition process, each of the plurality of process chambers including a gas spraying unit having an exhaust portion by which an exhaust gas is drawn in from inside the process chamber and the drawn in gas is exhausted above the process chamber, and a transfer module including a transfer robot provided between the loading / unloading module and the process module, the transfer robot being adopted for simultaneously holding the plurality of substrates while transporting the substrate.

Owner:K C TECH

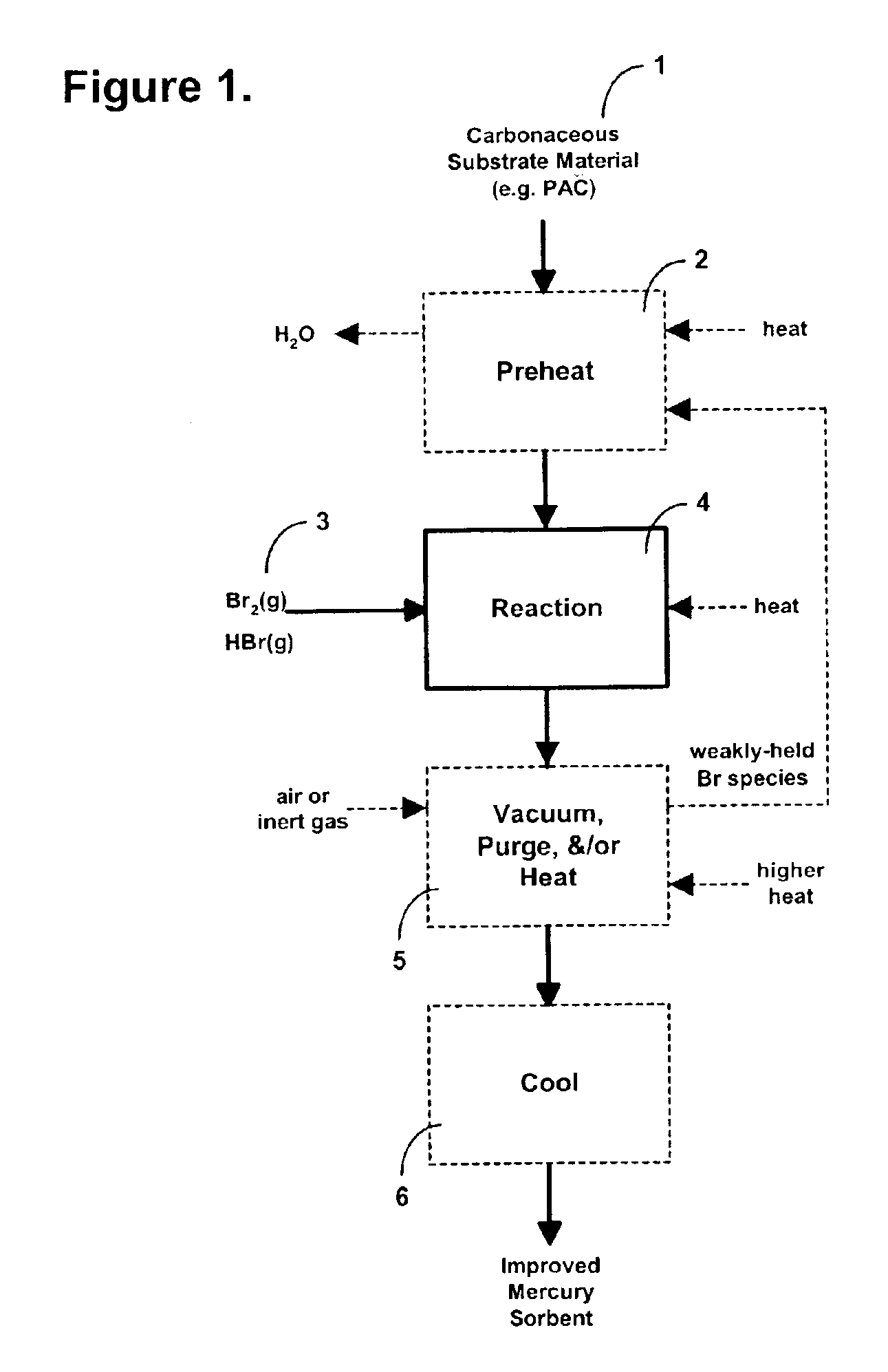

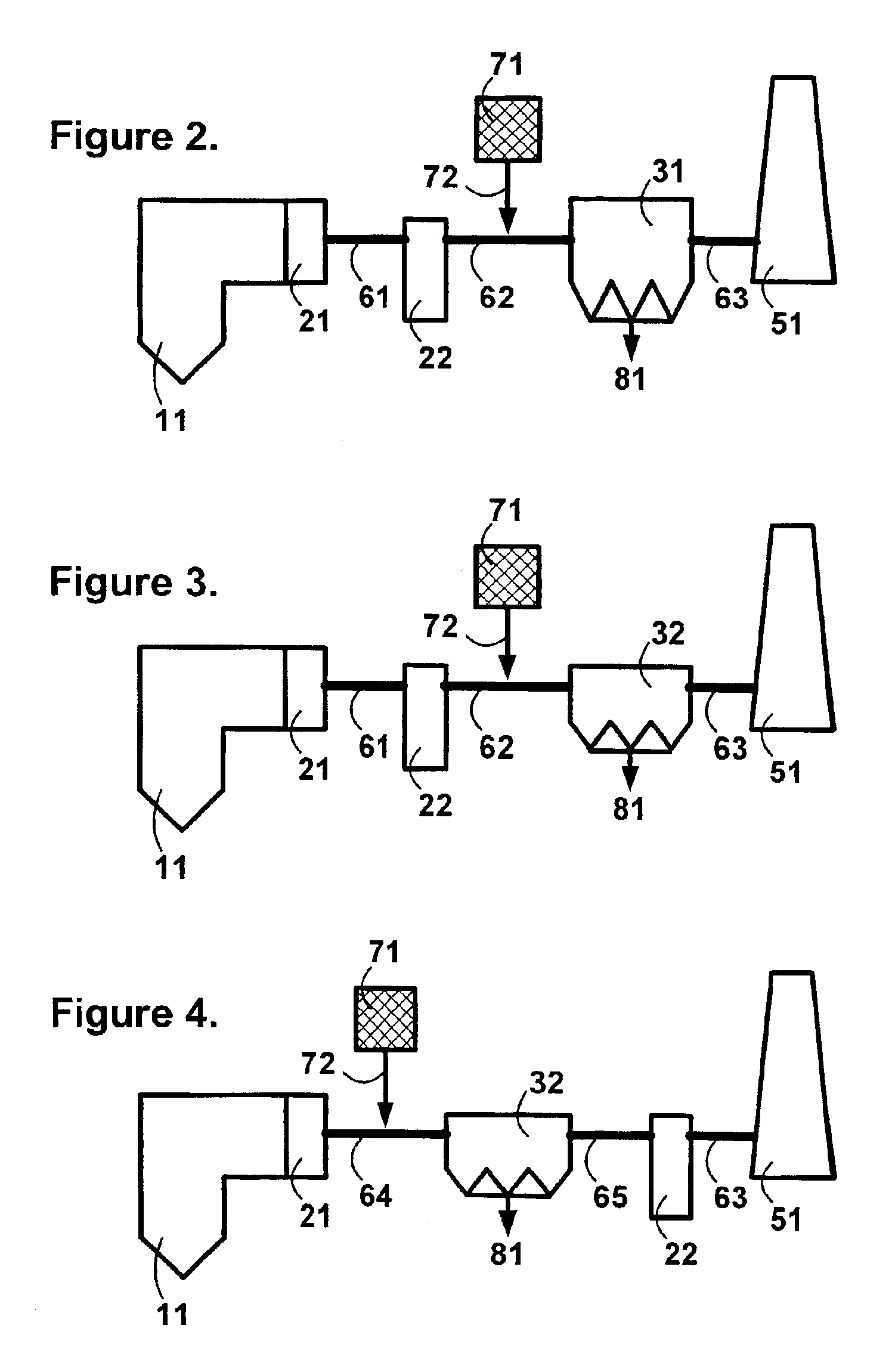

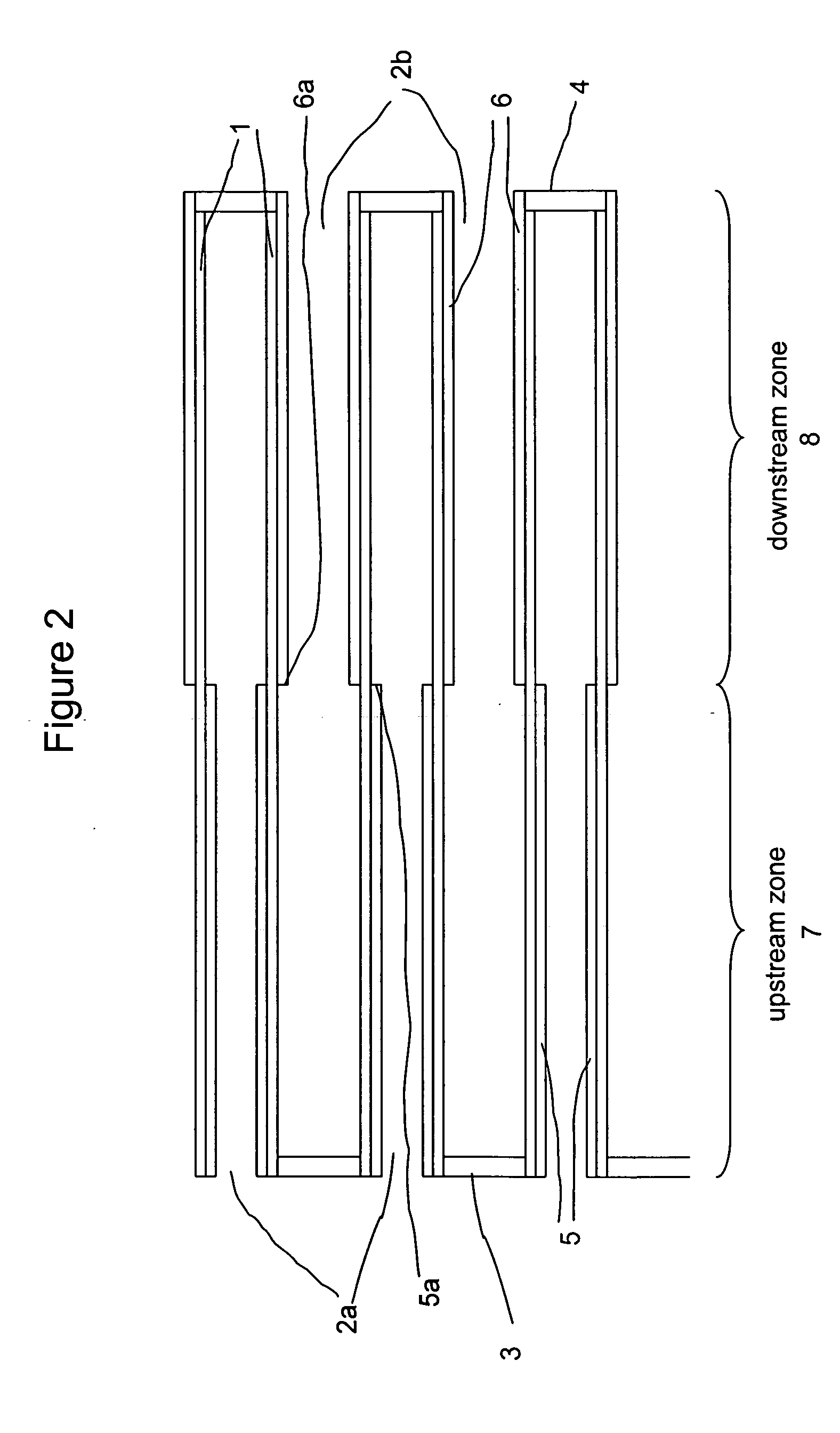

Sorbents and methods for the removal of mercury from combustion gases

InactiveUS6953494B2Improve abilitiesUnified processingGas treatmentOther chemical processesSufficient timeCombustion

A method for removing mercury and mercury-containing compounds from a combustion gas in an exhaust gas system has the steps of providing a mercury sorbent; injecting the mercury sorbent into a stream of the mercury-containing combustion gas for a sufficient time to allow at least an effective amount of the mercury and mercury-containing compounds in the combustion gas to adsorb onto the mercury sorbent, and collecting and removing the mercury sorbent from the combustion gas stream. The mercury sorbent is prepared by treating a carbonaceous substrate with an effective amount of a bromine-containing gas, especially one containing elemental bromine or hydrogen bromide, for a time sufficient to increase the ability of the carbonaceous substrate to adsorb mercury and mercury-containing compounds. The points of injecting and collecting and removing the mercury sorbent may be varied, depending upon the exact configuration of the exhaust gas system.

Owner:SORBENT TECH +1

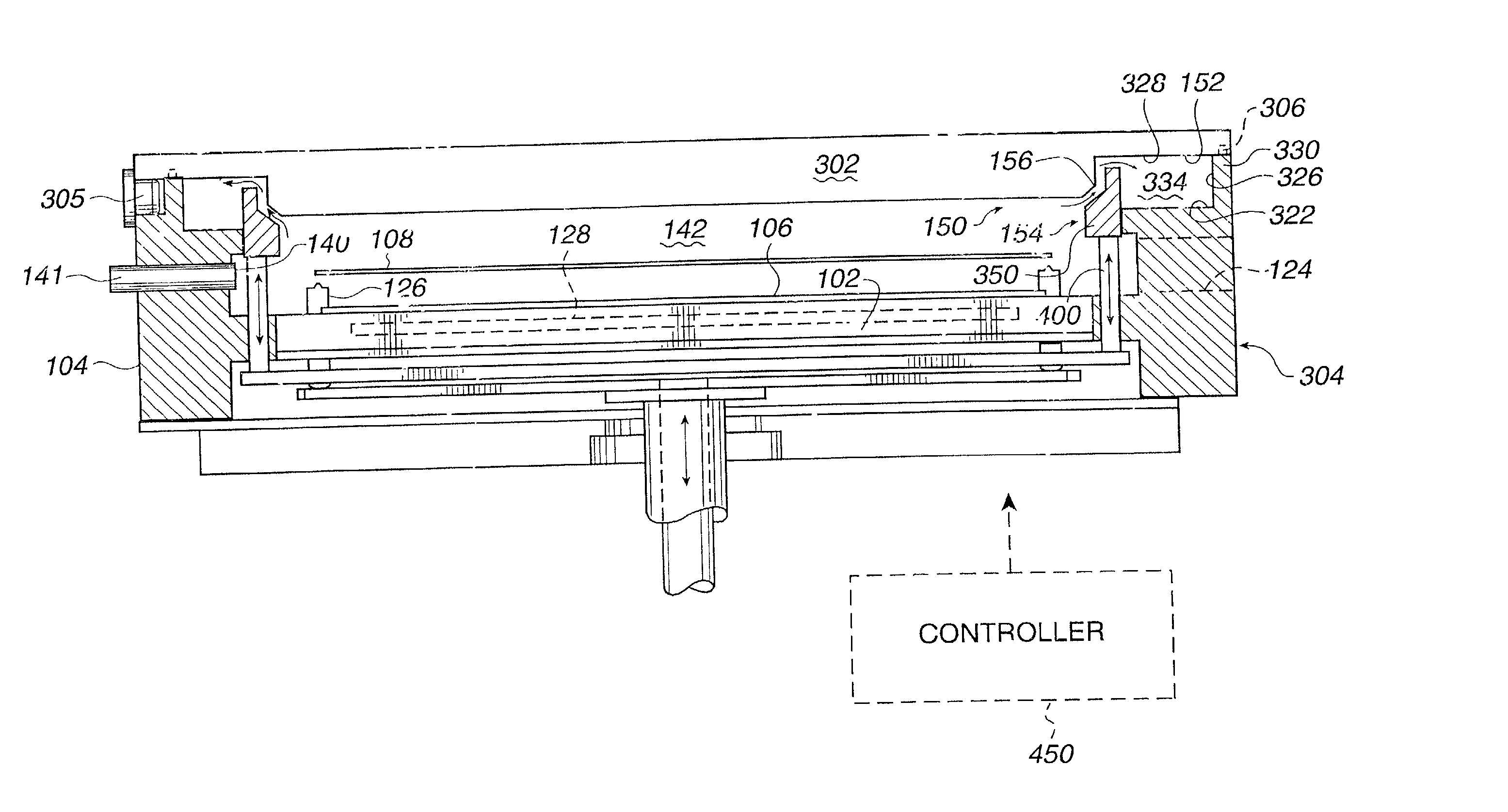

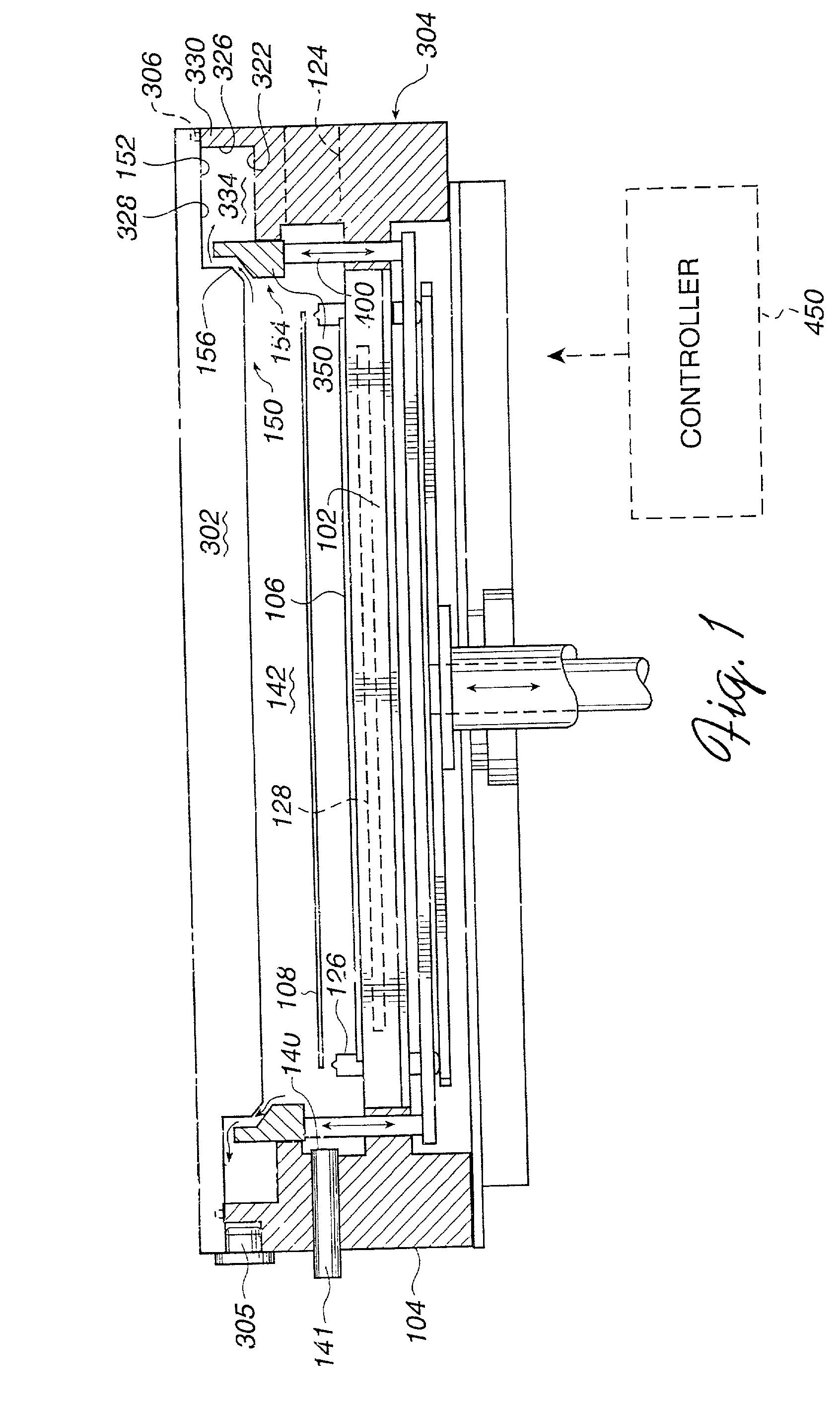

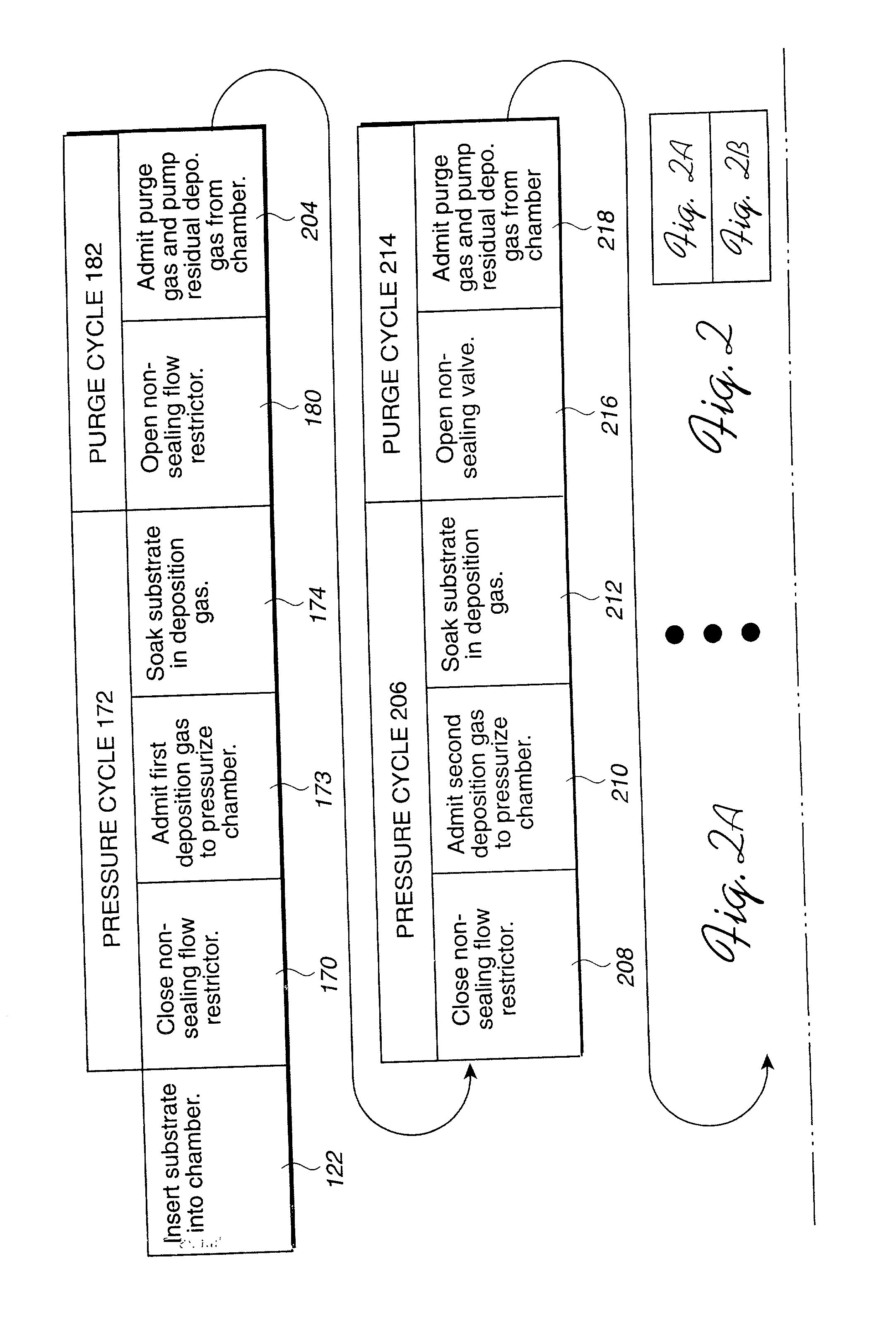

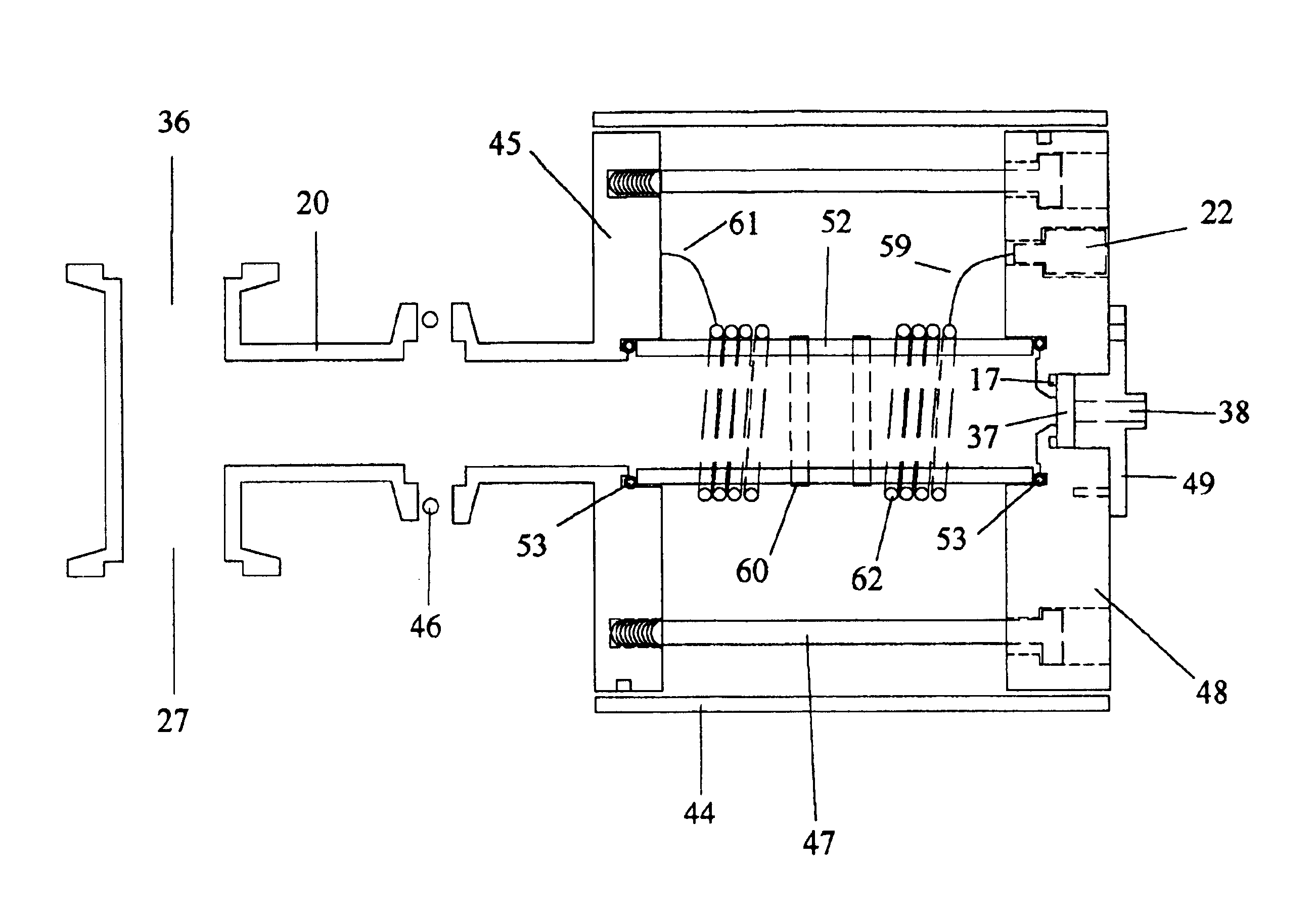

Variable flow deposition apparatus and method in semiconductor substrate processing

InactiveUS20030153177A1Facilitate rapid openingEasy to closeLiquid surface applicatorsVacuum evaporation coatingEngineeringMechanical engineering

In one embodiment of the present inventions, an exhaust outlet in a vacuum processing chamber includes a nonsealing flow restrictor which can facilitate rapid opening and closing of the flow restrictor in some applications. Because the flow restrictor is a nonsealing flow restrictor, the conductance of the flow restrictor in the closed position may not be zero. However, the flow restrictor can restrict the flow of an exhaust gas from the chamber to permit the retention of sufficient processing gas in the chamber to deposit a film on the substrate or otherwise react with the substrate. After a film has been deposited, typically in a thin atomic layer, the exhaust flow restrictor may be opened such that the flow restrictor conductance is significantly increased to a second, higher flow rate to facilitate exhausting residue gas from the chamber. The nonsealing flow restrictor may be closed again to deposit a second layer, typically of a different material onto the substrate. The nonsealing flow restrictor may be rapidly opened and closed to deposit alternating layers of a variety of materials onto the substrate.

Owner:APPLIED MATERIALS INC

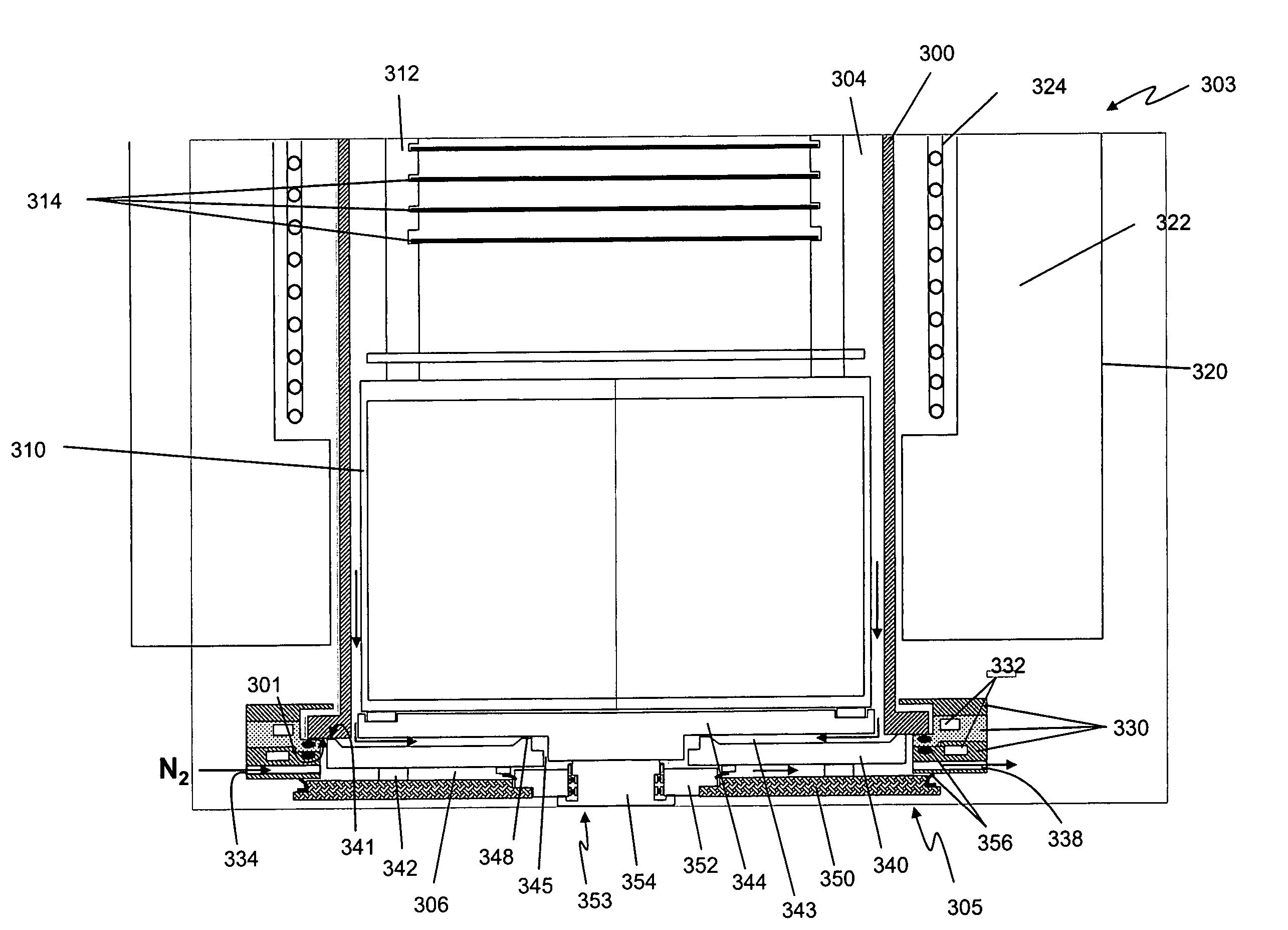

Door plate for furnace

The process chamber of a vertical furnace is provided with a closure, or door, comprising an upper and a lower door plate. The upper door plate has a gas exhaust opening proximate its center, thereby allowing for a symmetrical flow of process gases through the process chamber and into the gas exhaust opening. The upper door plate is spaced from the lower door plate to form a sealing chamber, which is purged with inert gas. Optionally, both the gas exhaust opening and the sealing chamber empty into a gas exhaust channel formed inside the upper door plate. The gas exhaust channel leads to an exhaust which exhausts gases from the furnace and separates the flow path of corrosive process gases from surfaces of the lower door plate, which may be formed of relatively easily-corroded metal.

Owner:ASM INTERNATIONAL

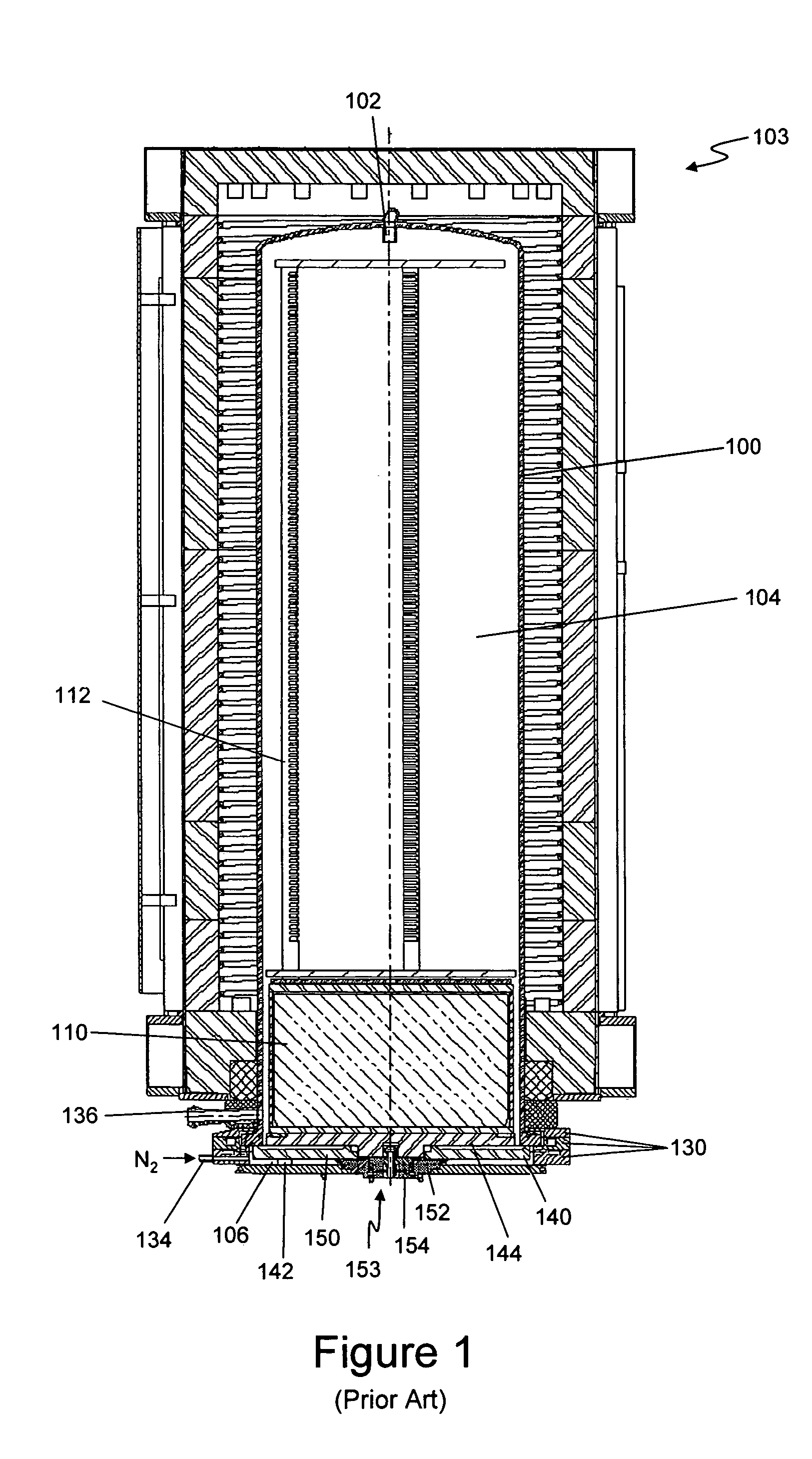

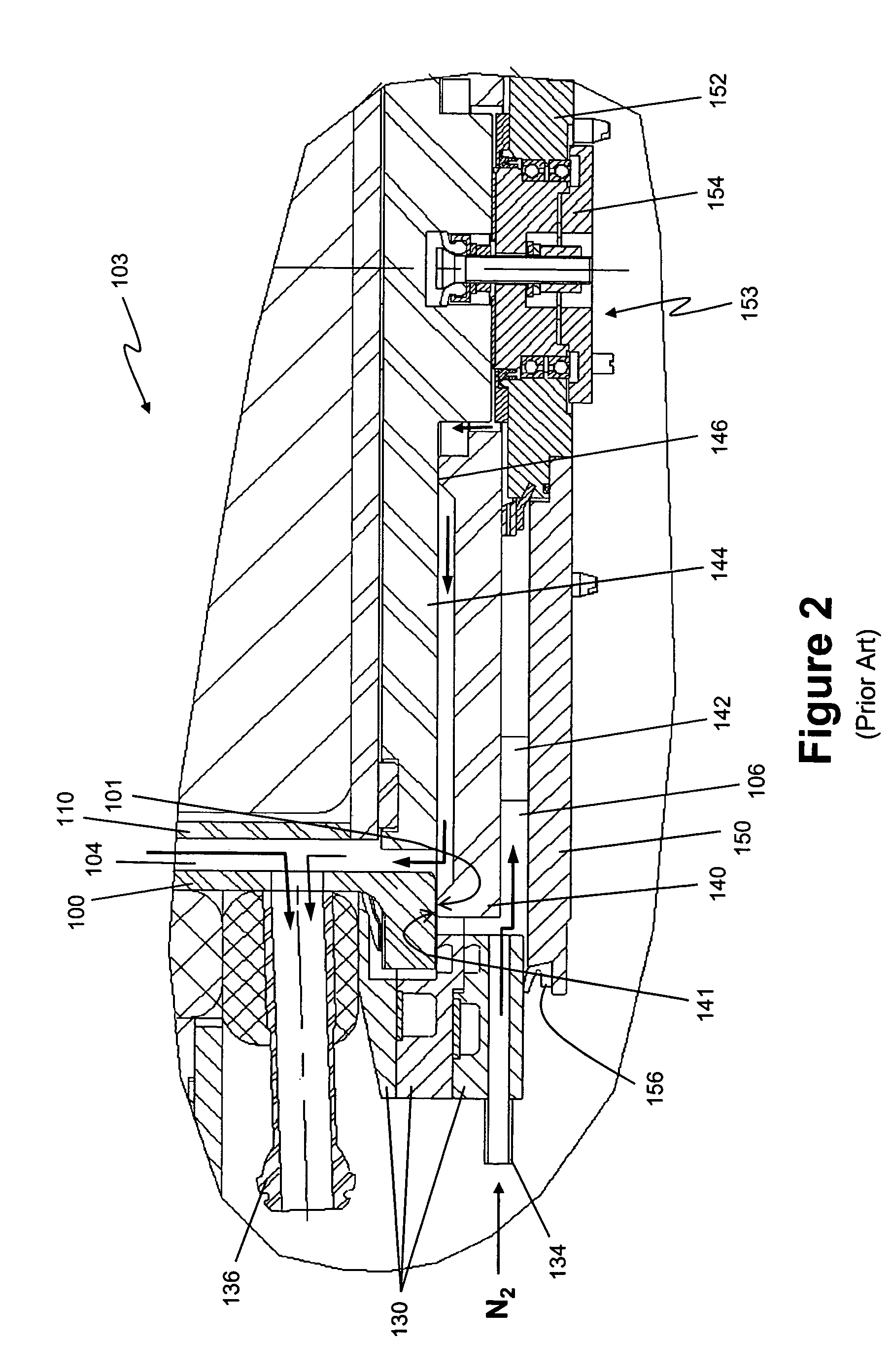

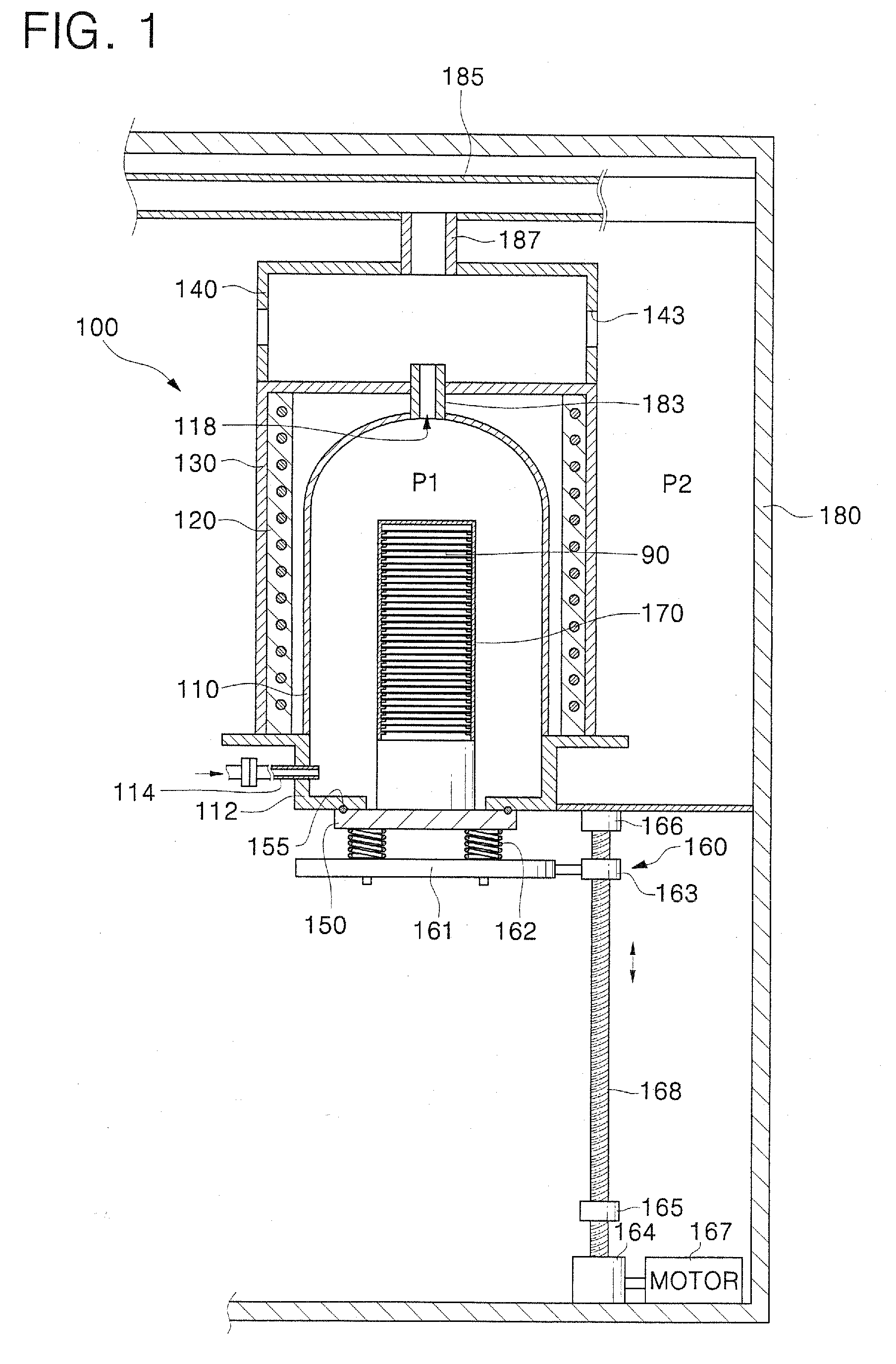

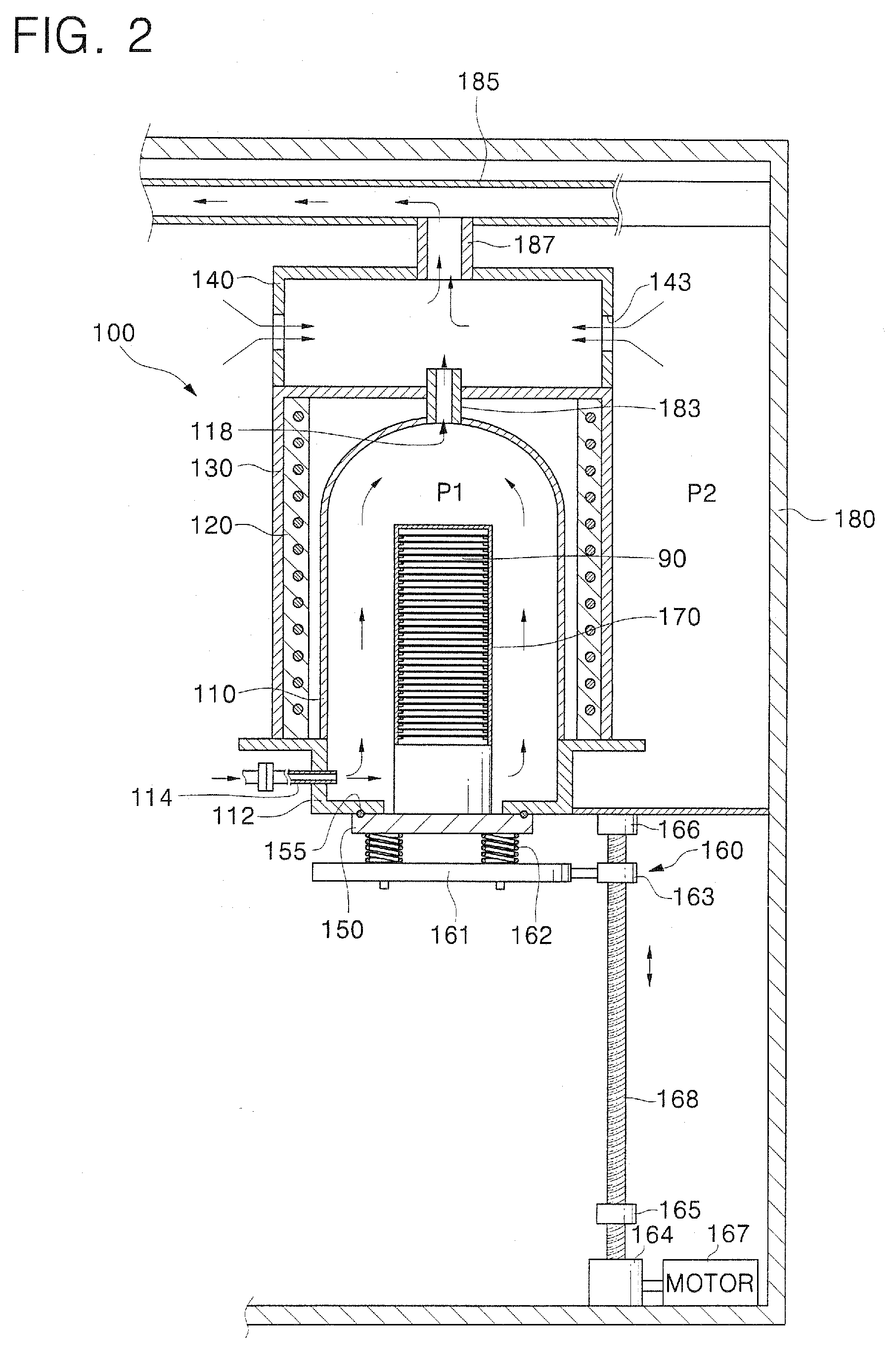

Heat treatment equipment

InactiveUS7850449B2Growth inhibitionReduce processing stepsMuffle furnacesBaking ovenProcess engineeringPressure controlled ventilation

In an embodiment, heat treatment equipment comprises a process tube, an exhaust duct connected to the process tube, and, during operation, exhausting gases present within the process tube. The heat treatment equipment also comprises a hollow pressure control member interposed between the process tube and the exhaust duct, the pressure control member being operatively connected to the process tube and the exhaust duct respectively, and including one or a number of openings. Negative pressure is avoided in the process tube during heat treatment processes so that unwanted gas and impurities cannot enter the process tube from outside.

Owner:SAMSUNG ELECTRONICS CO LTD

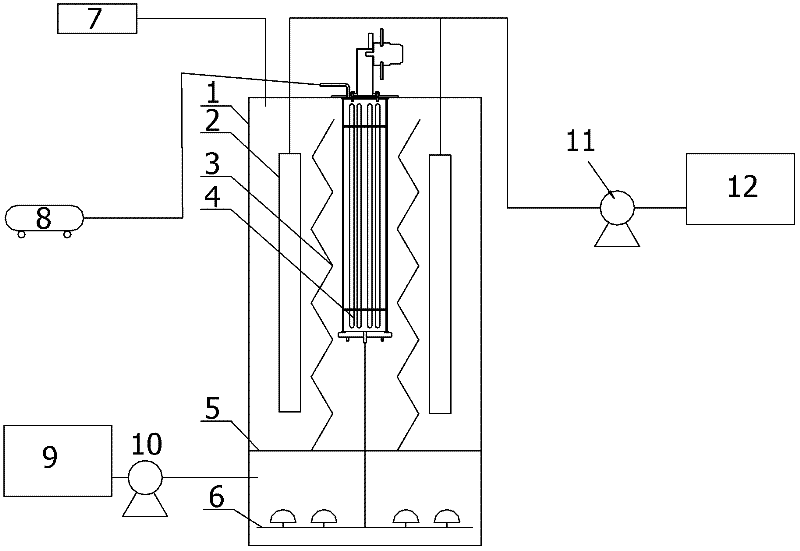

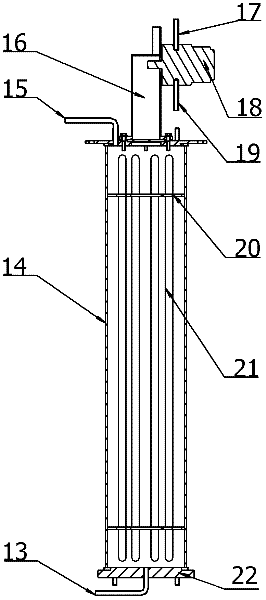

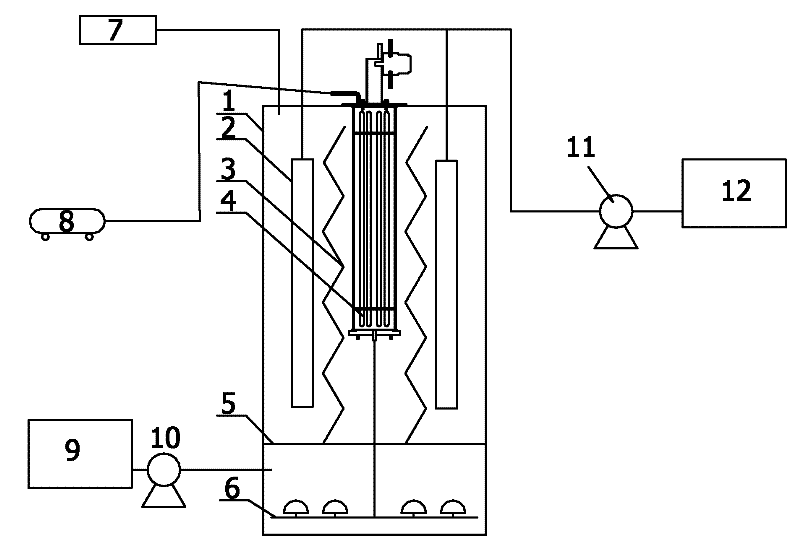

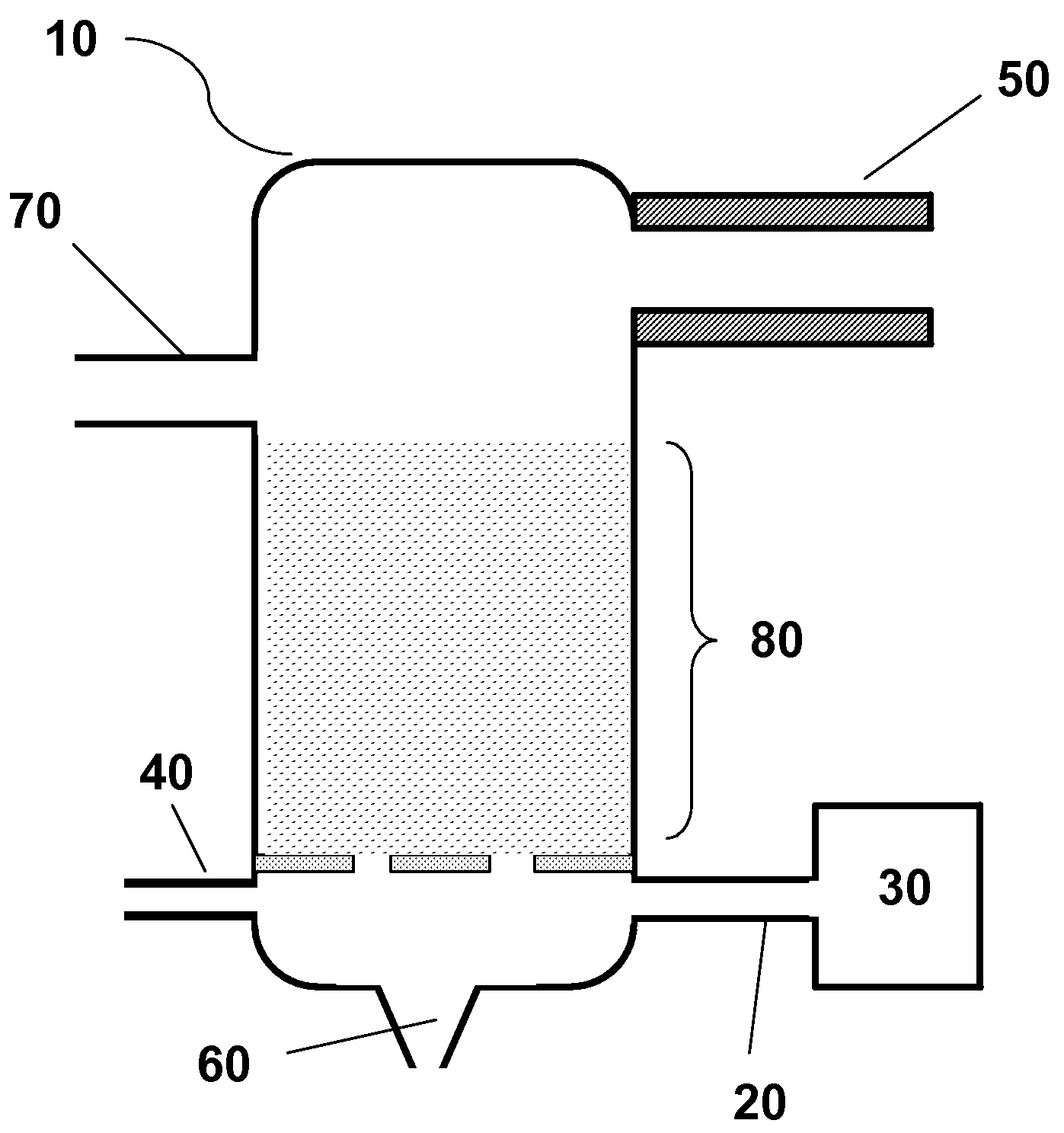

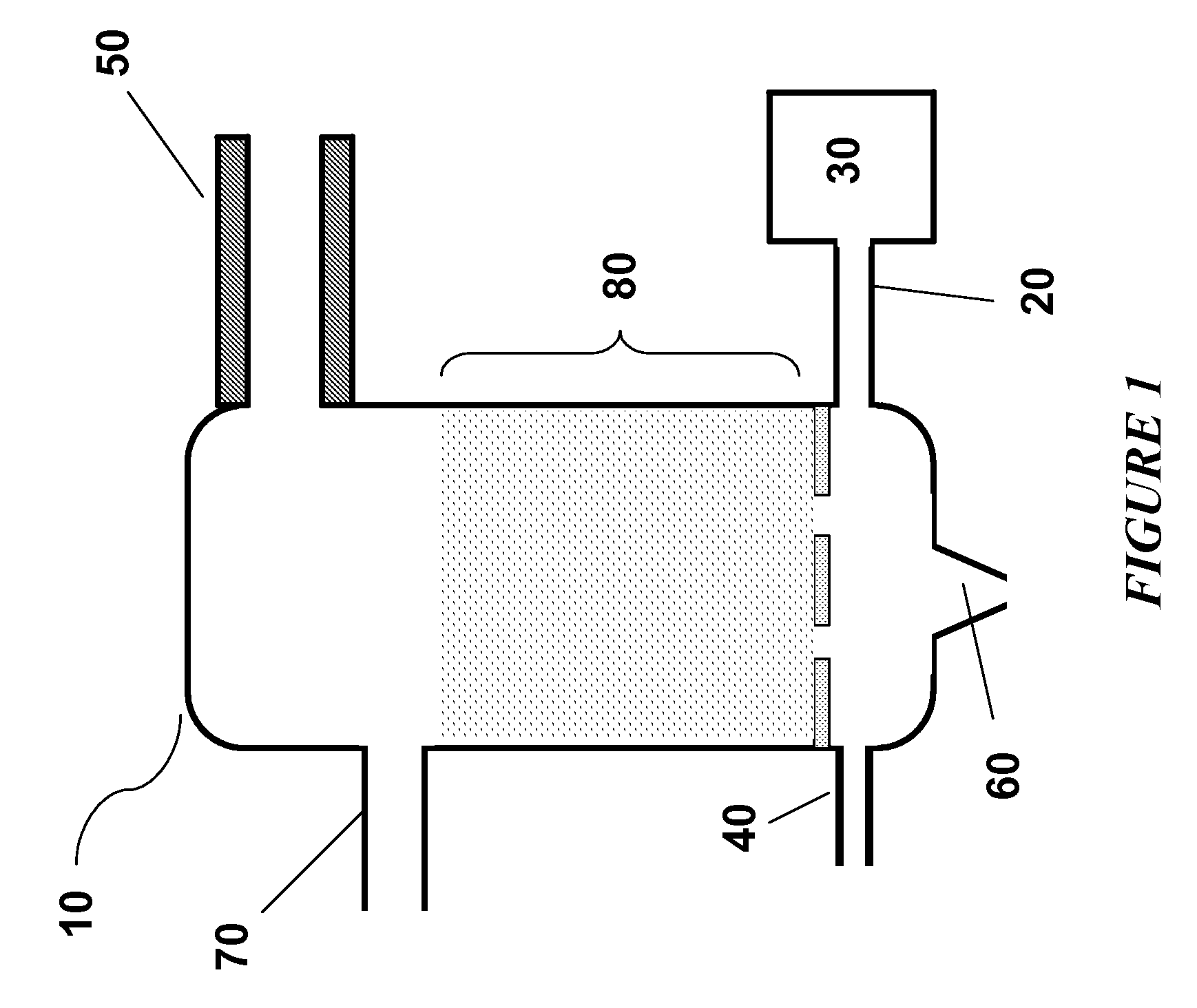

Industrial Wastewater Microwave Electrodeless UV Photocatalysis-Double Membrane Separation Coupling Treatment Device

InactiveCN102260003AAchieve coolingShort wavelengthWater/sewage treatment by irradiationWaste water treatment from animal husbandryIndustrial waste waterDecomposition

The present invention is an industrial waste water microwave electrodeless ultraviolet photocatalysis-dual membrane separation coupling treatment device, the device mainly consists of a reactor (1), a membrane separation system (2), a microwave electrodeless ultraviolet light source system (4), an aeration system, and an ozone tail gas decomposition device (7) connected to the reactor, and an inlet and outlet water system, wherein: the upper and lower parts of the reactor are respectively the reaction zone and the aeration zone, which are separated by a water distribution plate (5); the membrane separation system The microwave electrodeless ultraviolet light source system is located in the reaction zone and is separated by a corrugated partition (3); the aeration system is composed of a microporous aeration head (6) and a blower (8), and the microporous aeration head is located in the aeration At the bottom of the zone, the blower sends air to the aeration zone through the air duct. The invention has the characteristics of high reaction rate, complete degradation of organic matter, long-term operation and the like, and has strong operability and high safety. It is suitable for the treatment of refractory organic industrial wastewater, and it is also suitable for sterilization and disinfection in the field of water supply.

Owner:WUHAN TEXTILE UNIV

Apparatus and method for heating subterranean formations using fuel cells

InactiveUS6684948B1Eliminate needAvoid inefficiencyFuel cell heat exchangeFuel cells groupingElectricityFuel cells

A fuel cell based subterranean heater for mineral extraction, in situ decontamination, or other applications. The fuel cells are preferably stacked within a casing which is then inserted into a hole bored, or otherwise formed, into the formation to be heated. Conduits within the casing, and preferably formed by adjacent, aligned holes formed through the plates of the individual fuel cells supply fuel and air and extract exhaust gases. An optional manifold is used to span the overburden without applying heat to it directly. The manifold may also function as a heat exchanger between incoming and exhaust gases. Preferably the fuel cell is fueled by gases produced by the formation and also generates electricity which is available for use or export.

Owner:IEP TECH INC

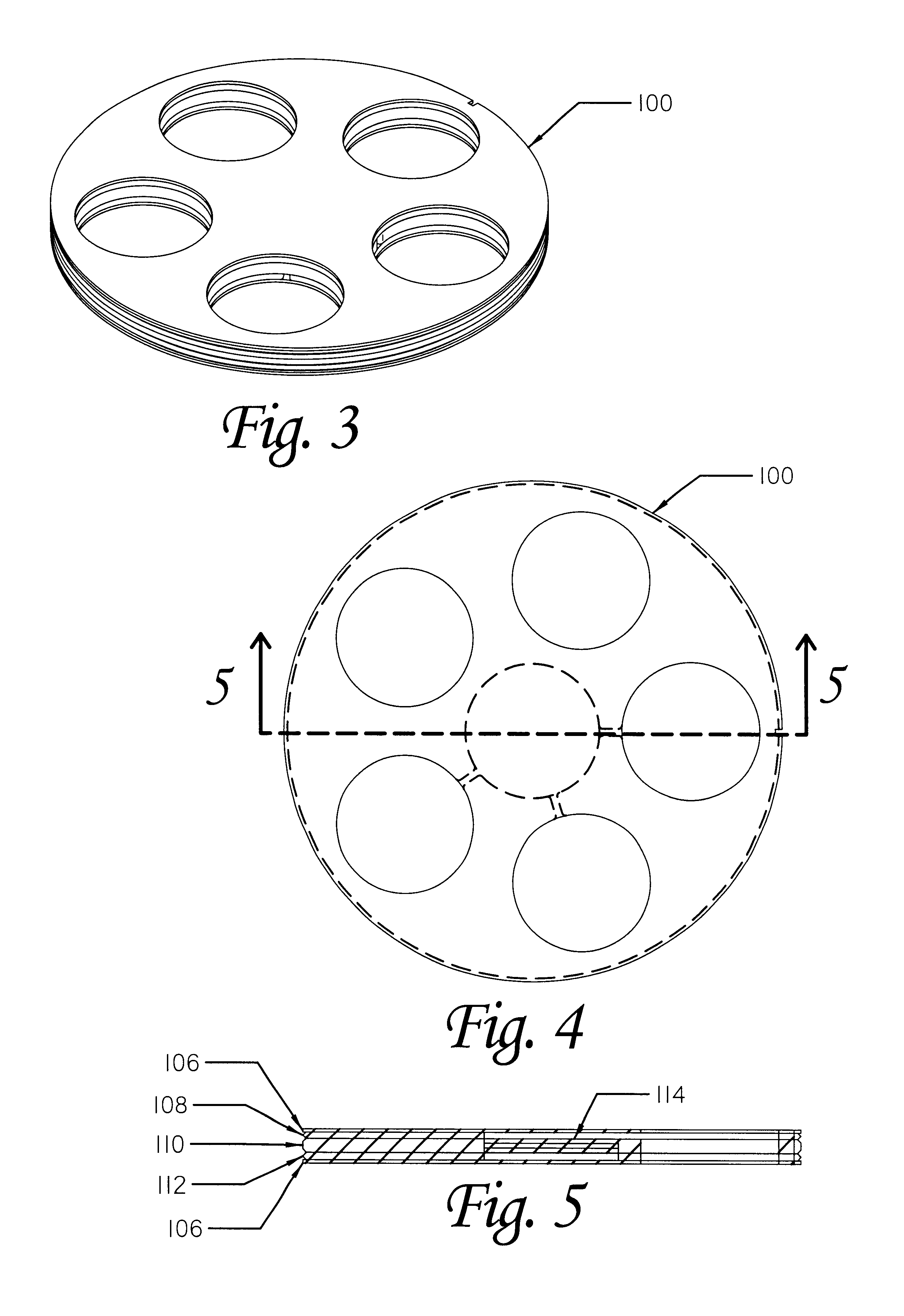

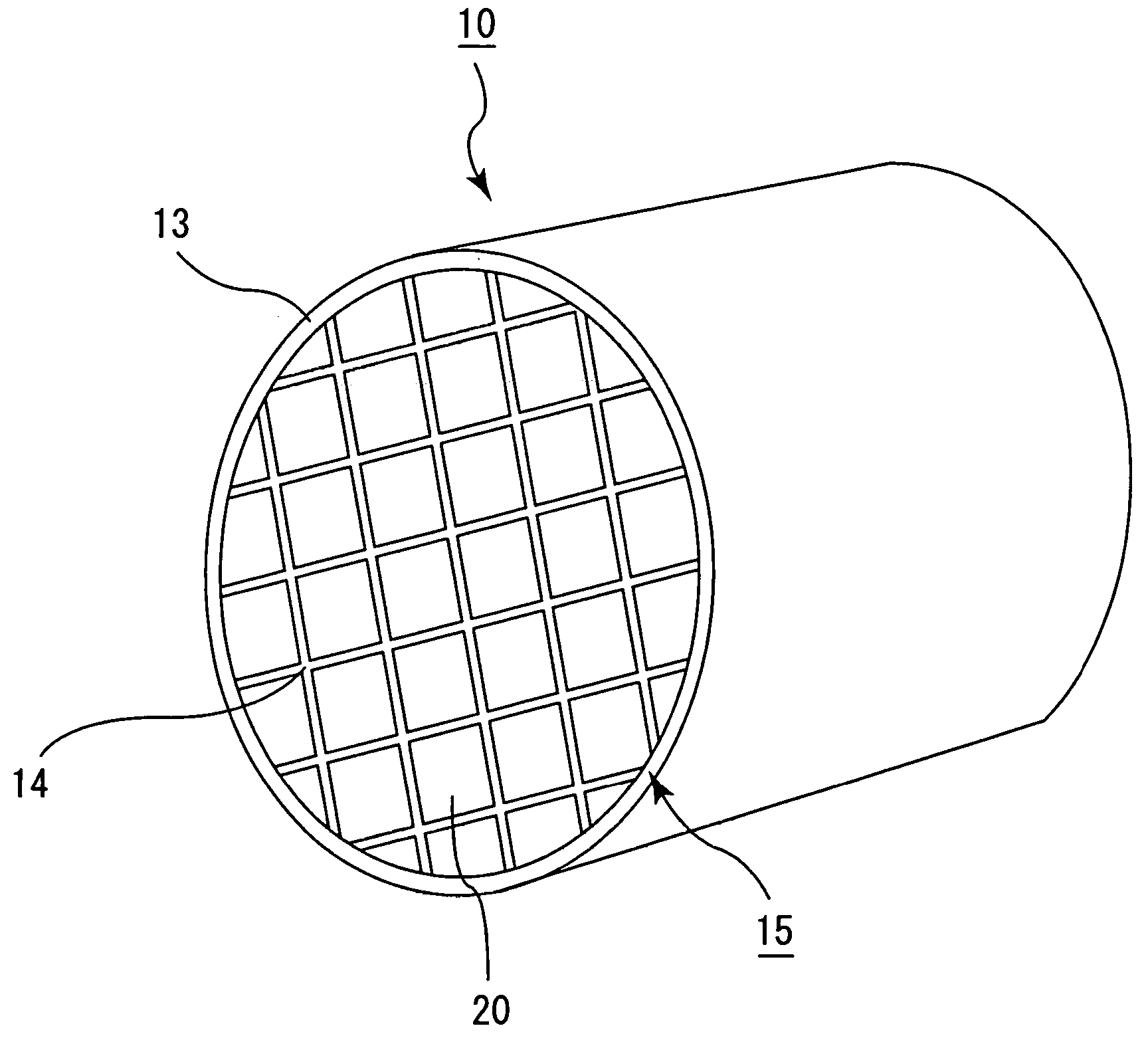

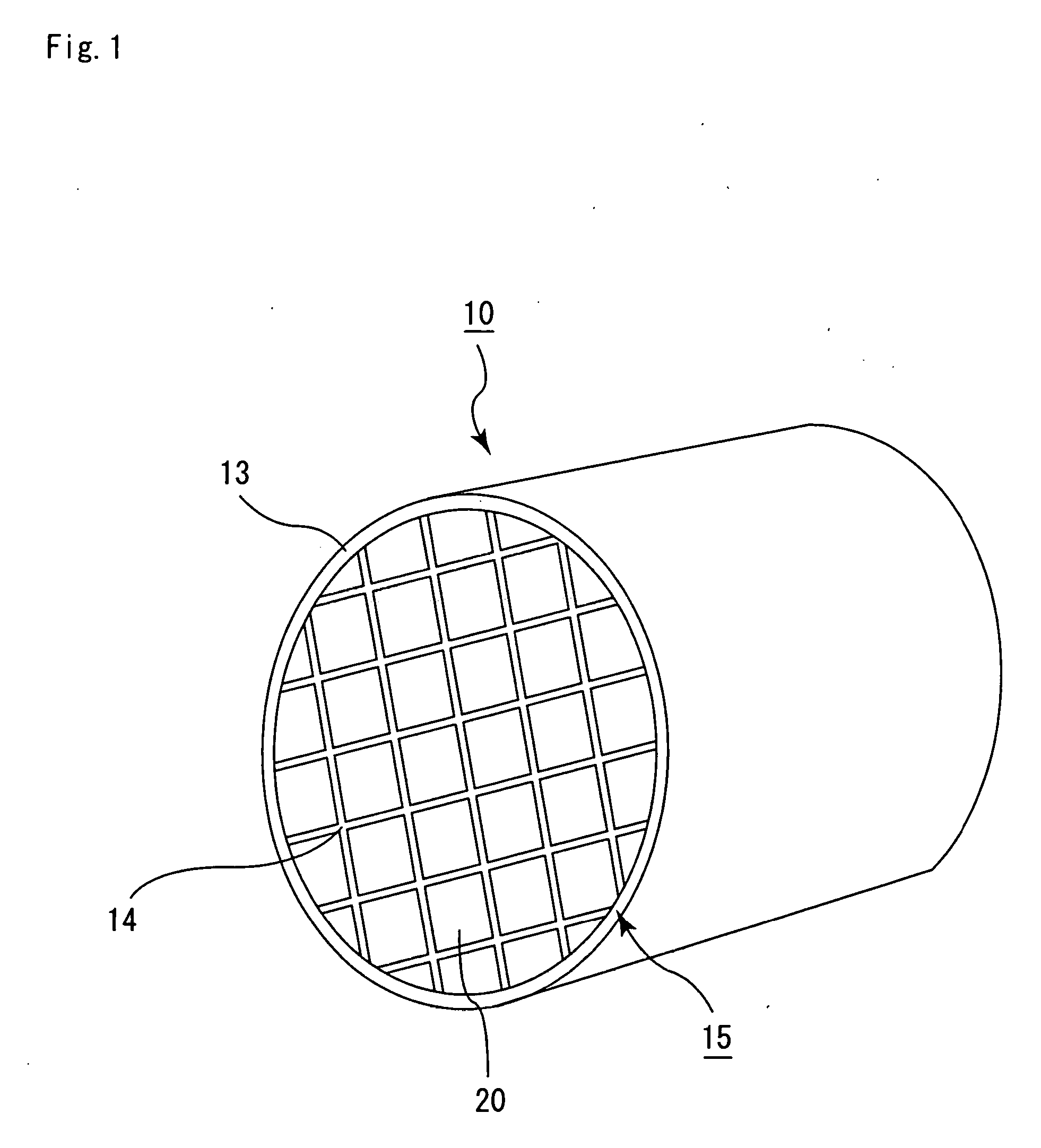

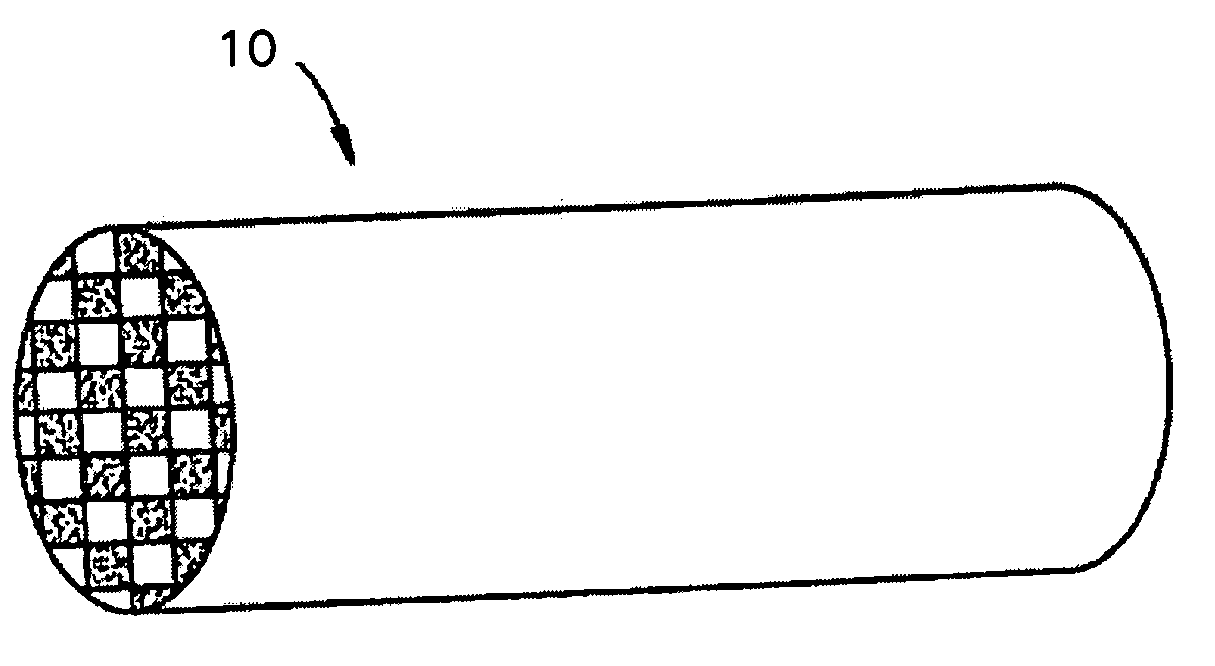

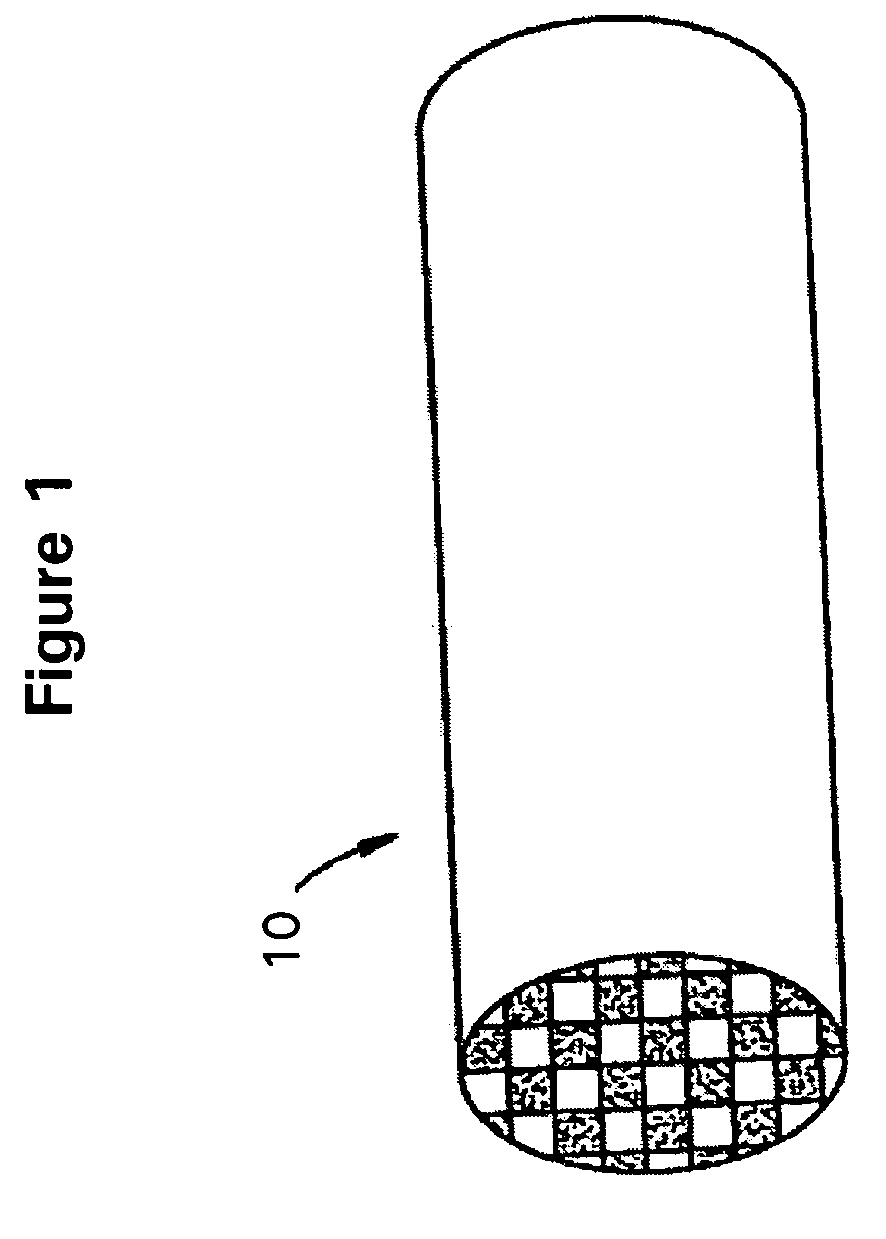

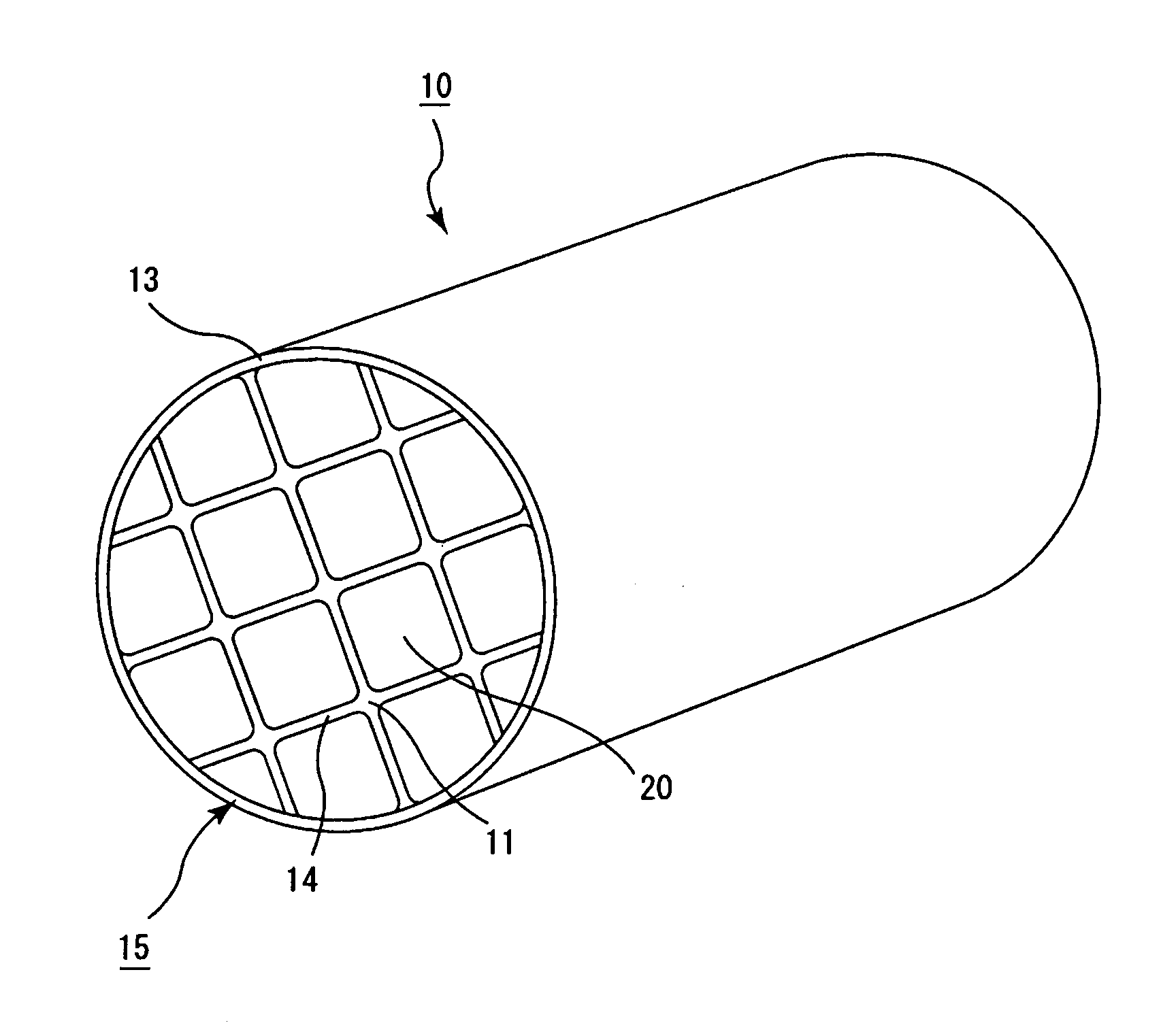

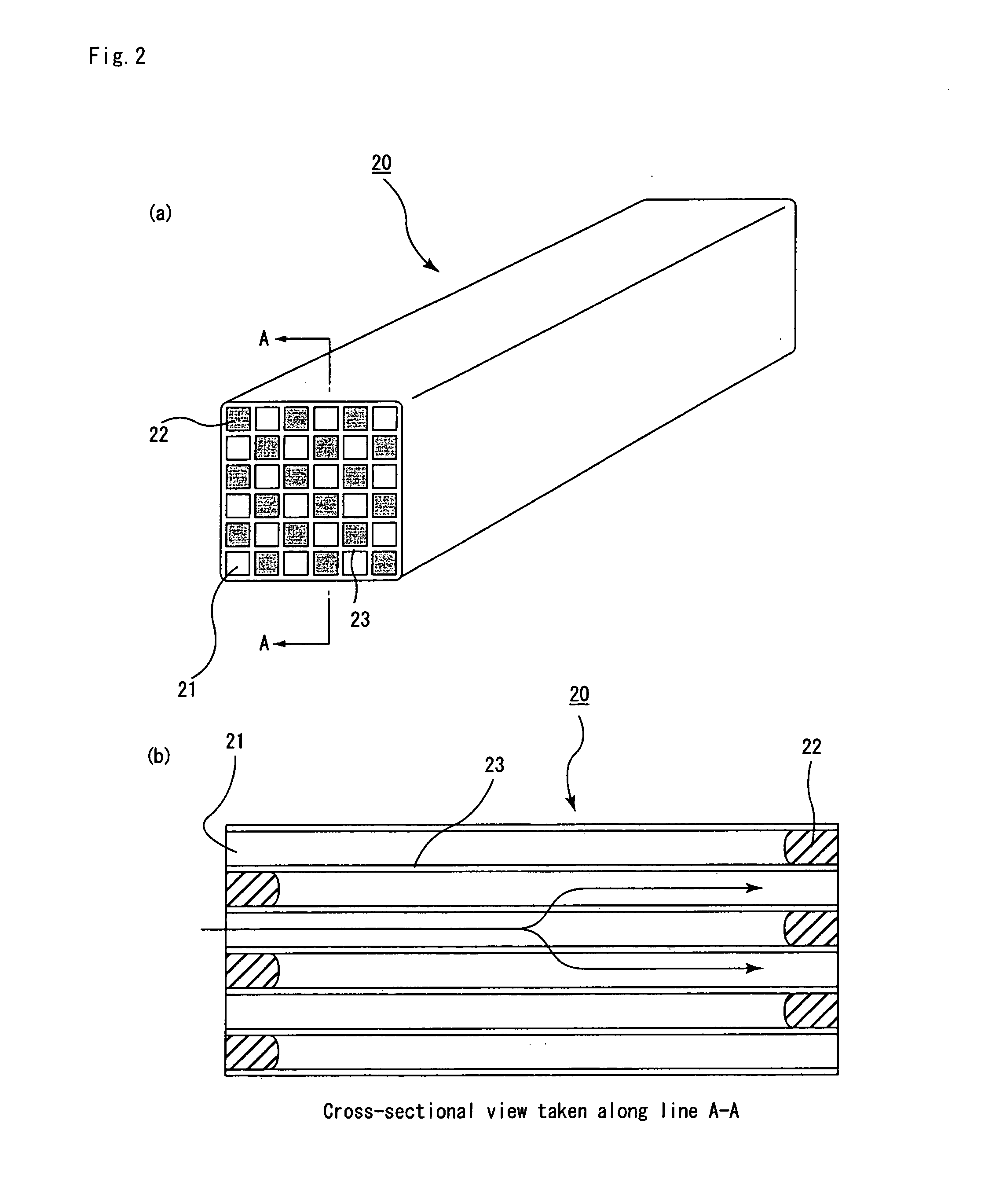

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

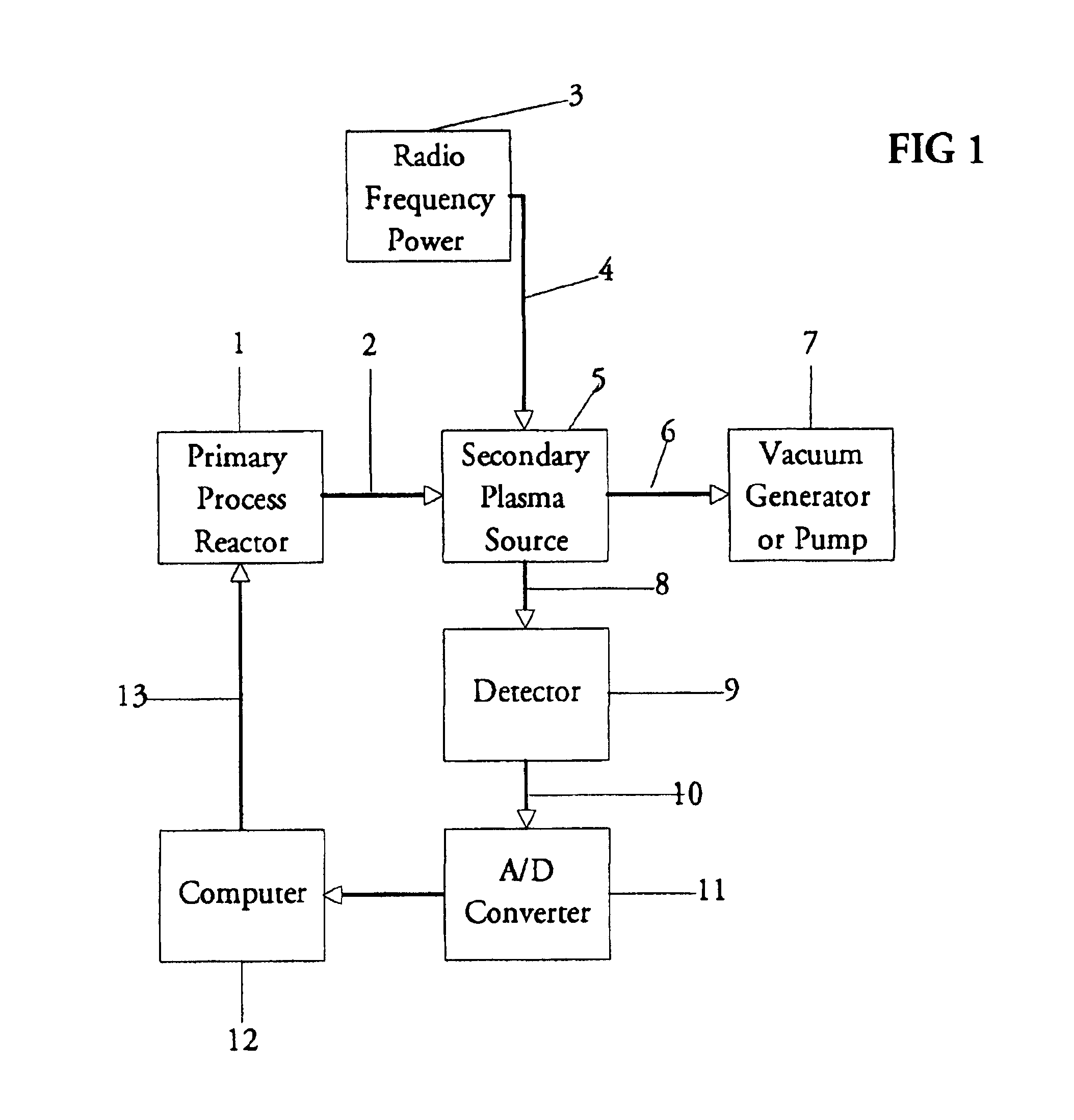

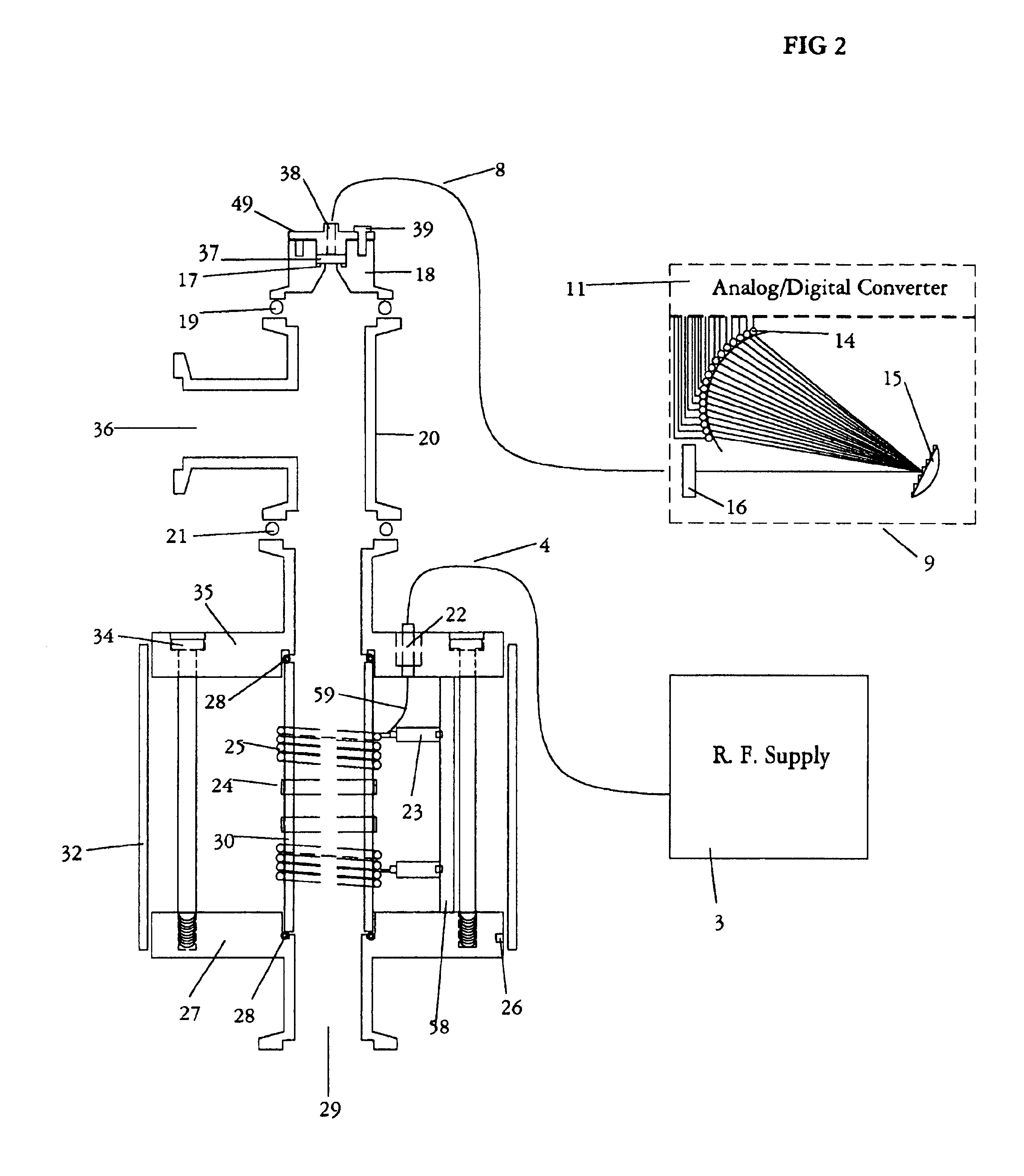

Inductively coupled plasma spectrometer for process diagnostics and control

InactiveUS6867859B1High sensitivitySimple reactor designEmission spectroscopyRadiation pyrometryOptical radiationInductively coupled plasma

The present invention relates to an apparatus and method for forming a plasma in the exhaust line of a primary process reactor. The plasma is generated in an inductive source (5) to examine the chemical concentrations of the waste or exhaust gas in vacuum lines that are below atmospheric pressure. The optical radiation emitted by the plasma is analyzed by an optical spectrometer (9) and the resulting information is used to diagnose, monitor, or control operating states in the main vacuum vessel.

Owner:LIGHTWIND CORP

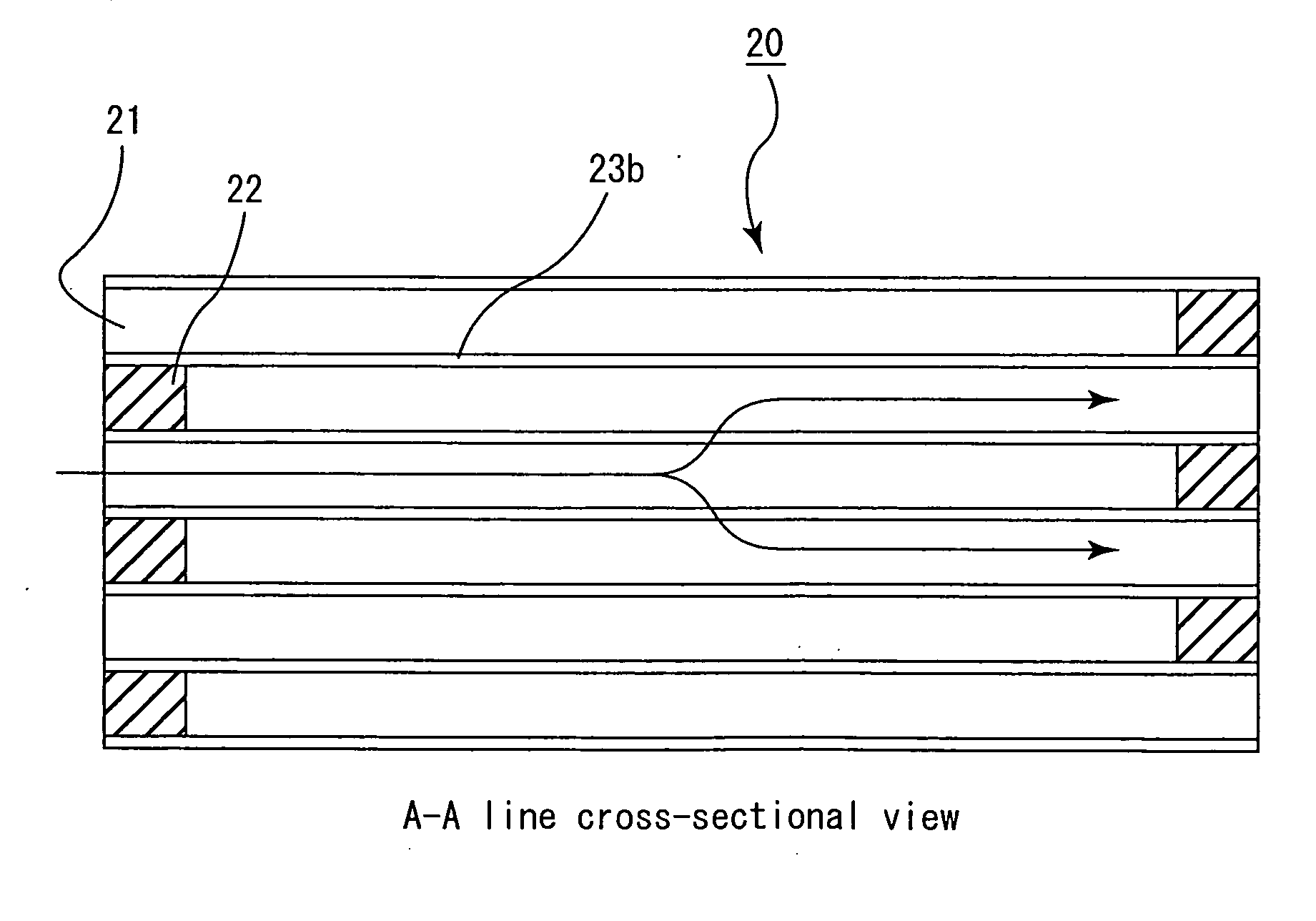

Showerhead with branched gas receiving channel and apparatus including the same for use in manufacturing semiconductor substrates

InactiveUS20060011298A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductorExhaust gas

Showerheads for use in an apparatus for manufacturing a semiconductor substrate include an injection plate defining a bottom face of a gas receiving space in the showerhead and a gas receiving channel extending within the injection plate. A plurality of exhausting holes in the injection plate are coupled to the gas receiving channel. The exhausting holes are configured to exhaust gas from the gas receiving channel to the bottom face of the gas receiving space. A plurality of channels extend through the injection plate from the bottom face of the gas receiving space configured to flow gas from the bottom face of the gas receiving space out of the space.

Owner:SAMSUNG ELECTRONICS CO LTD

Pressure-balanced, catalyzed soot filter

ActiveUS20060057046A1Minimal overall platinum group metal component material costSpeed up the conversion processCombination devicesMolecular sieve catalystsParticulatesCatalytic function

The invention provides a catalyzed soot filter formed on a wall flow substrate having internal walls coated with catalyst compositions. The soot filter maintains a homogeneous flow of the exhaust gases through the internal walls of the substrate along the length of the filter due to the coating design. Both the efficiency and the durability of the catalytic function are increased over conventionally designed catalyzed soot filters. The catalyzed soot filter provides an integrated function for simultaneously treating the gaseous components of the exhaust (e.g., CO and HC) and the particulate matter deposited in the filter.

Owner:BASF CATALYSTS LLC

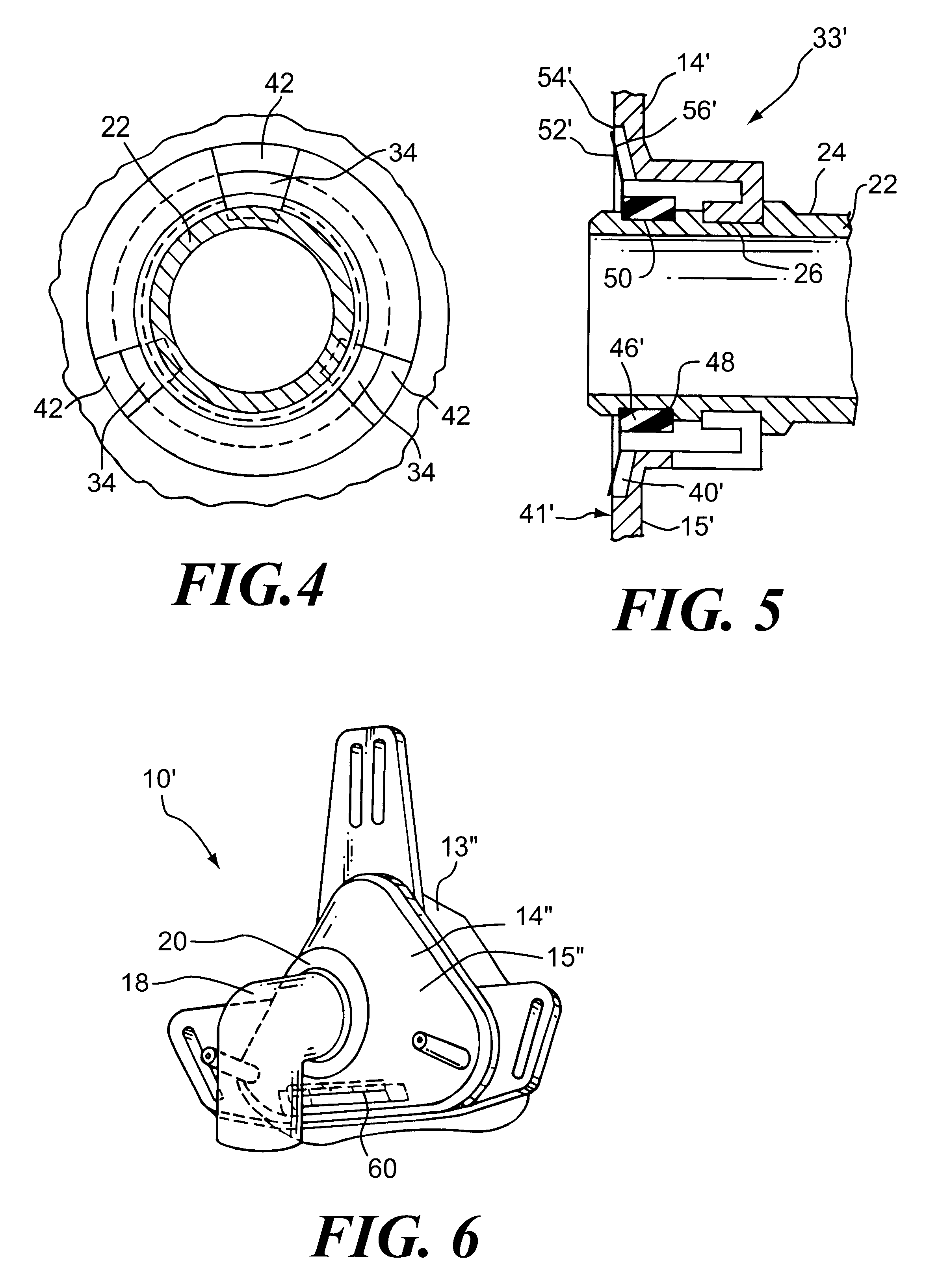

Combined patient interface and exhaust assembly

InactiveUS6584977B1Narrowing the exhaust pathReduce the effective cross-sectional areaBreathing masksRespiratory masksMedicineMechanical engineering

A combined patient interface and integrated exhaust assembly that passes a controlled flow of gas from an interior of a patient interface to ambient atmosphere at a predetermined flow rate irrespective of variations of pressure in the interior of the patient interface device relative to ambient atmosphere. Control of the flow of exhaust gas is achieved by varying the effective cross sectional area of the exhaust path communicating the interior of the patient interface with ambient atmosphere based on the pressure in the interior of the patient interface relative to ambient atmospheric pressure.

Owner:RIC INVESTMENTS LLC

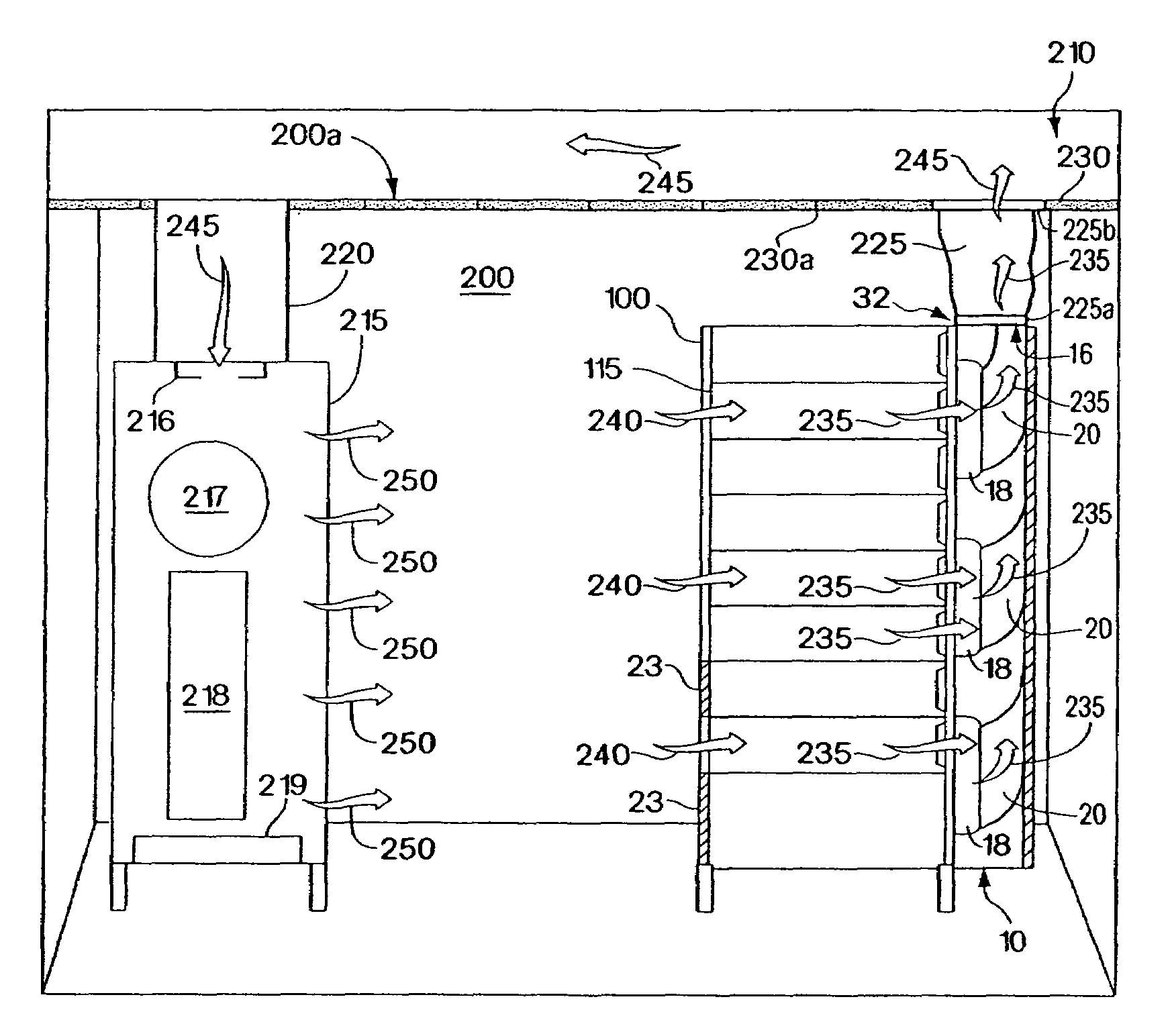

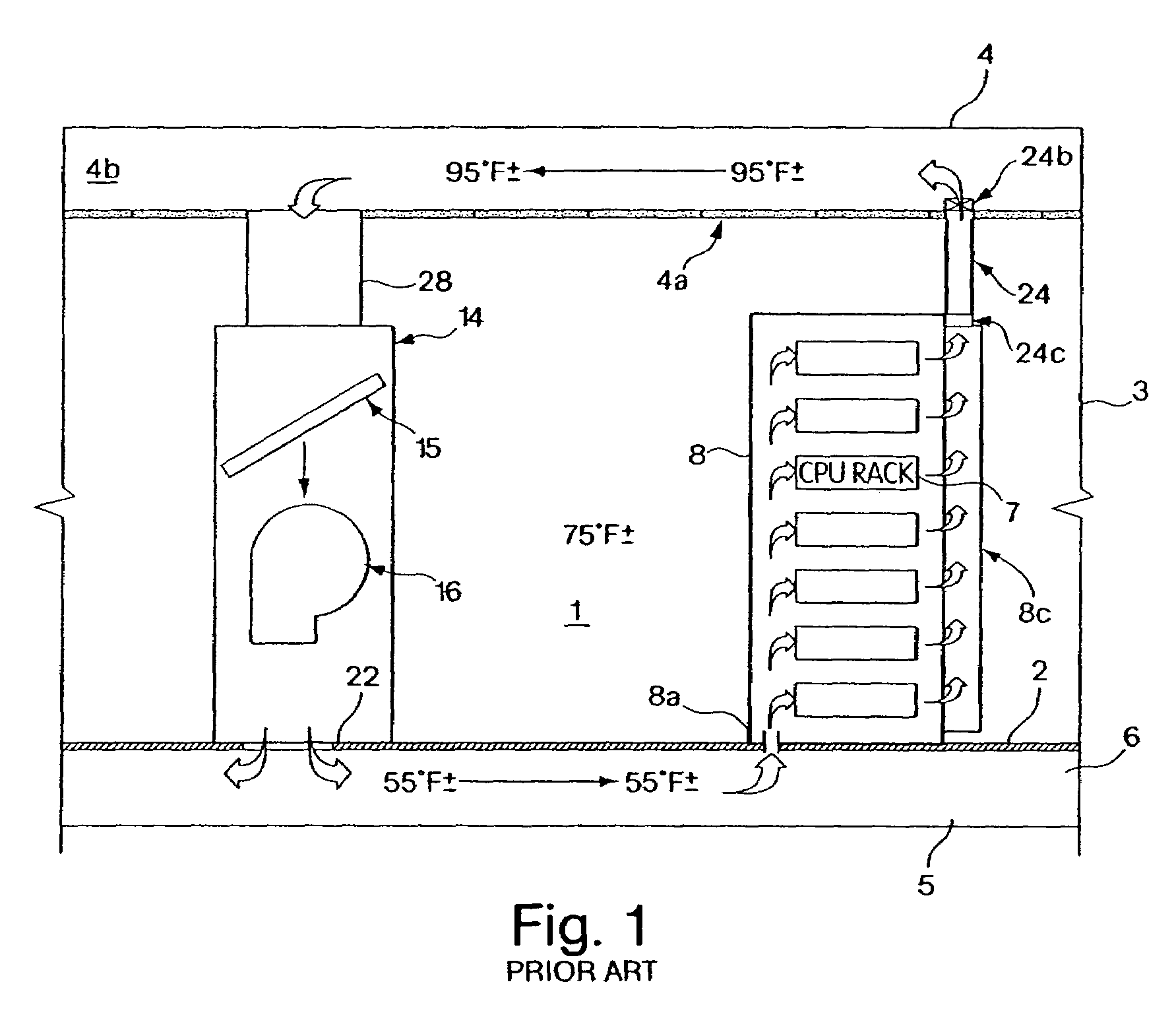

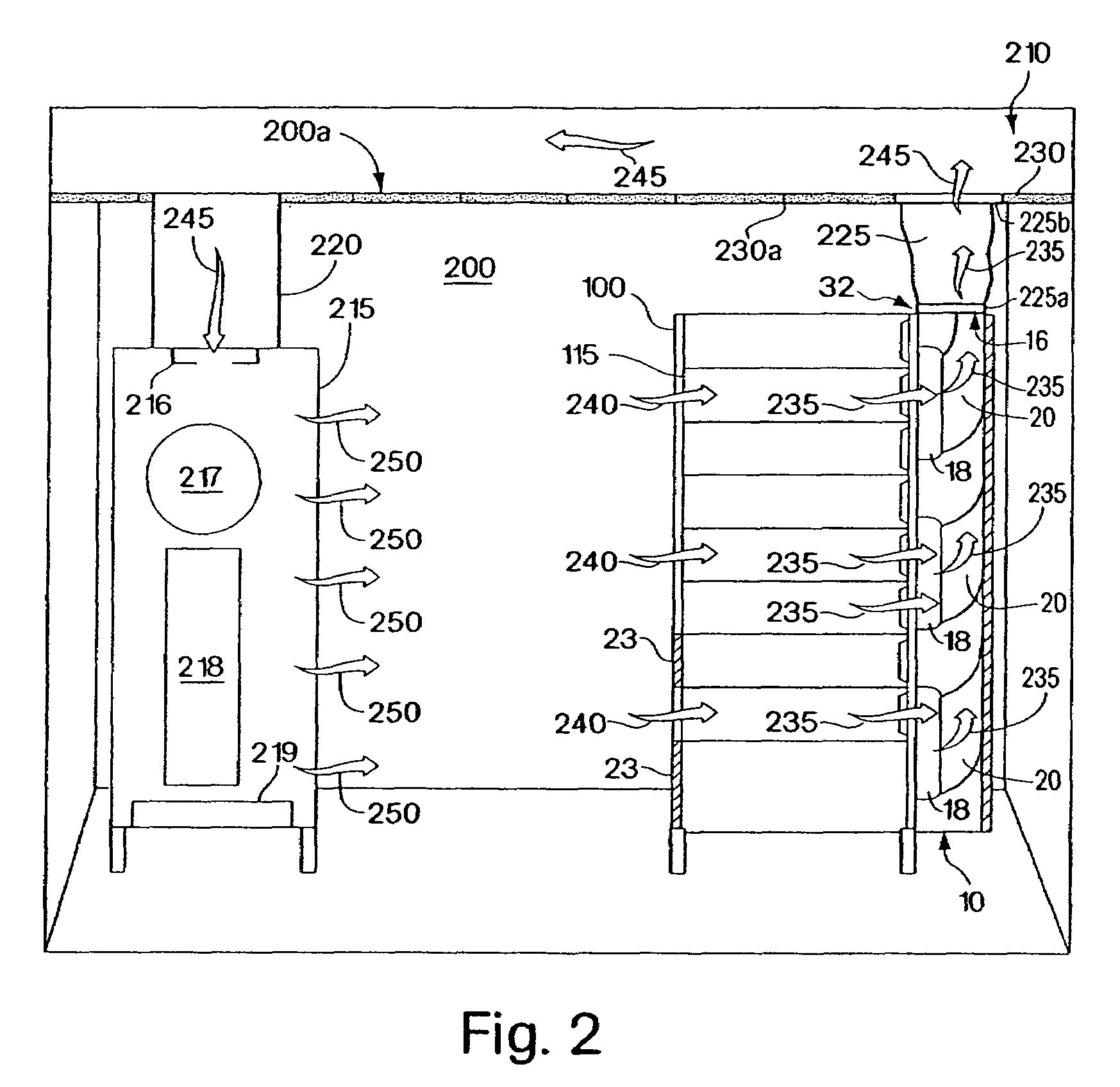

Exhaust air removal system

InactiveUS7500911B2Avoid heat buildupIndirect heat exchangersCooling/ventilation/heating modificationsExhaust fumesBack door

An exhaust air removal system and method for use with a rack or enclosure containing equipment is provided. The system and method are configured for removal of exhaust air vented from equipment during operation to thereby remove heat from the equipment. In one aspect, the system includes a fan unit preferably configured to serve as a back door of an equipment rack or enclosure and configured to provide access to an interior of the rack or enclosure. The fan unit provides multiple fans coupled to internal exhaust ducts that are arranged to draw and to remove exhaust air vented from rack-mounted equipment. The fan unit is further configured to vent exhaust air to an area external to a rack or enclosure, such as an external exhaust duct or plenum. Removal of hot and warm exhaust air vented from rack-mounted equipment enables the equipment to operate effectively, drawing sufficient amounts of cooling air to meet its cooling requirements. The fan unit is constructed for portability and for easy attachment to and removal from a rack or enclosure, providing flexibility in handling equipment exhaust needs.

Owner:SCHNEIDER ELECTRIC IT CORP

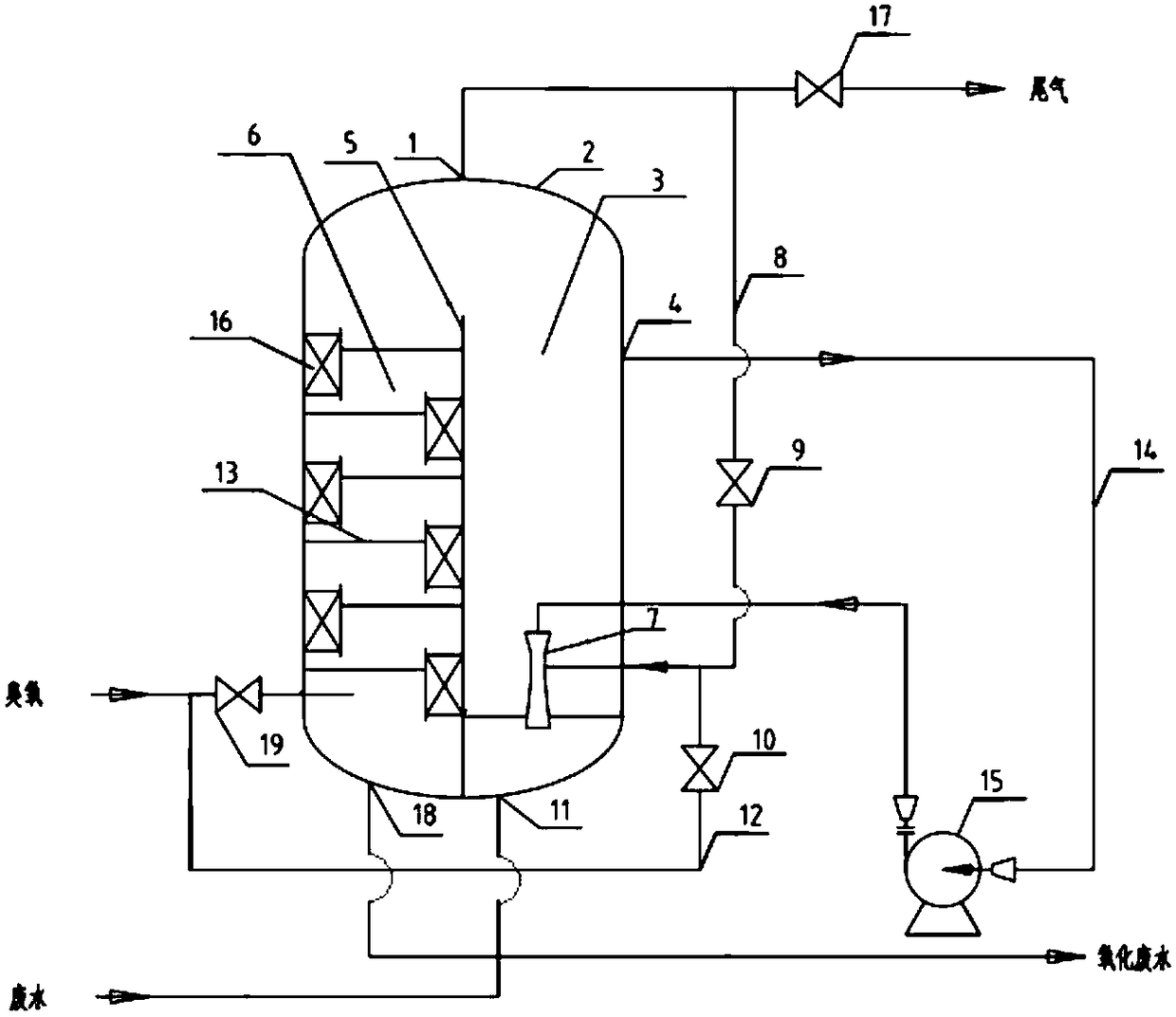

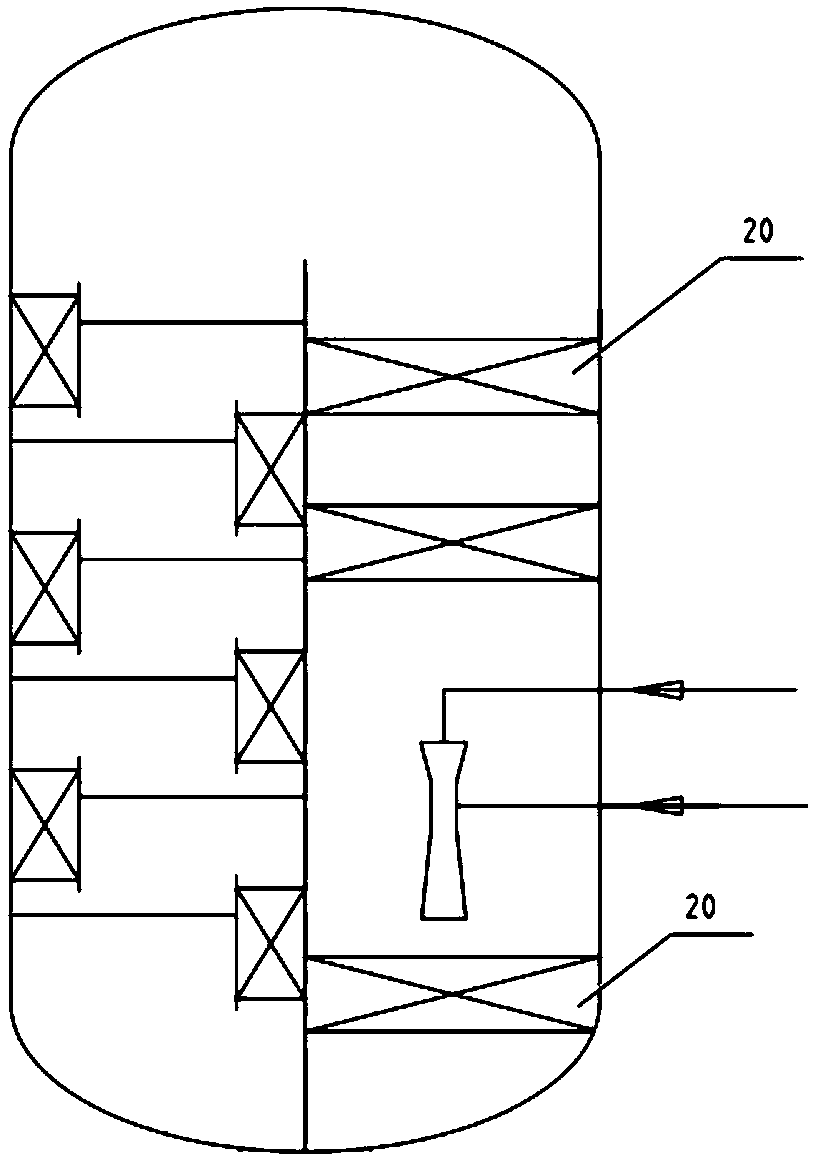

Reactor for catalytically oxidizing wastewater through ozone and application method thereof

PendingCN109437390AEnhanced mass transferReduce backmixingWater/sewage treatment by oxidationWorking fluidChemical oxygen demand

The invention discloses a reactor for catalytically oxidizing wastewater through ozone and an application method thereof. The reactor comprises a reaction chamber, a water inlet, a water outlet, a gasoutlet and a circulating water outlet, wherein a separation plate in the reaction chamber is used for separating the lower part of the reaction chamber into a jet flow reaction chamber and a tower type reaction chamber; the jet flow reaction chamber is internally provided with a first catalysis bed layer and an ejector; the circulating water outlet is connected with a working fluid inlet of the ejector; the gas outlet is connected with a sucked liquid inlet of the ejector through a gas circulating pipe; the water inlet is arranged at the bottom of the jet flow reaction chamber; the tower typereaction chamber is internally provided with a tower plate and a second catalysis bed layer; the water outlet is arranged at the bottom of the tower type reaction chamber; a gas inlet is communicatedwith the lower side of the tower plate and the gas circulating pipe; the gas circulating pipe is connected with a tail gas outlet. The reactor has the advantages of high mass transfer efficiency, rapid reaction speed, high ozone utilization rate, high COD (Chemical Oxygen Demand) removal rate and the like.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

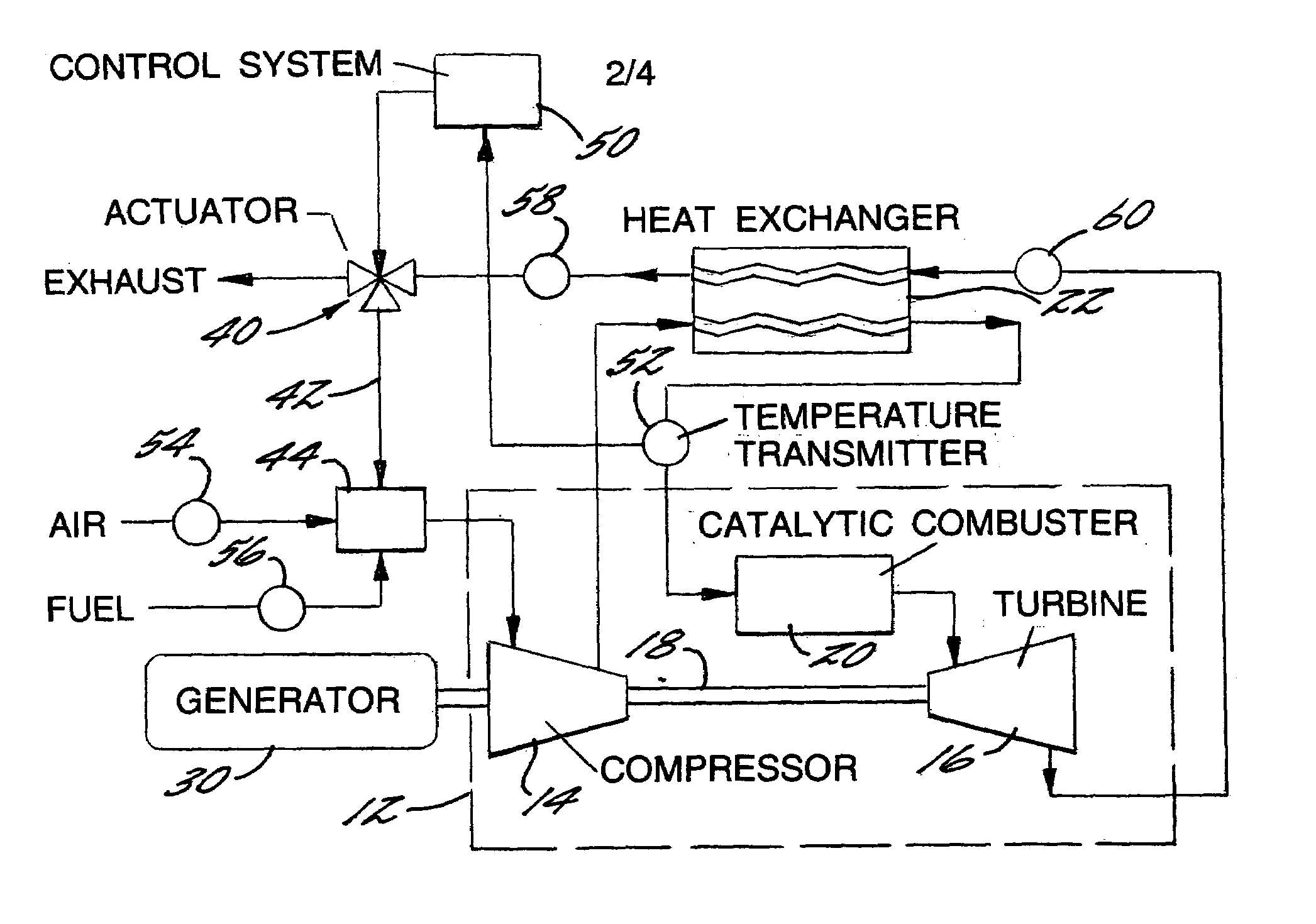

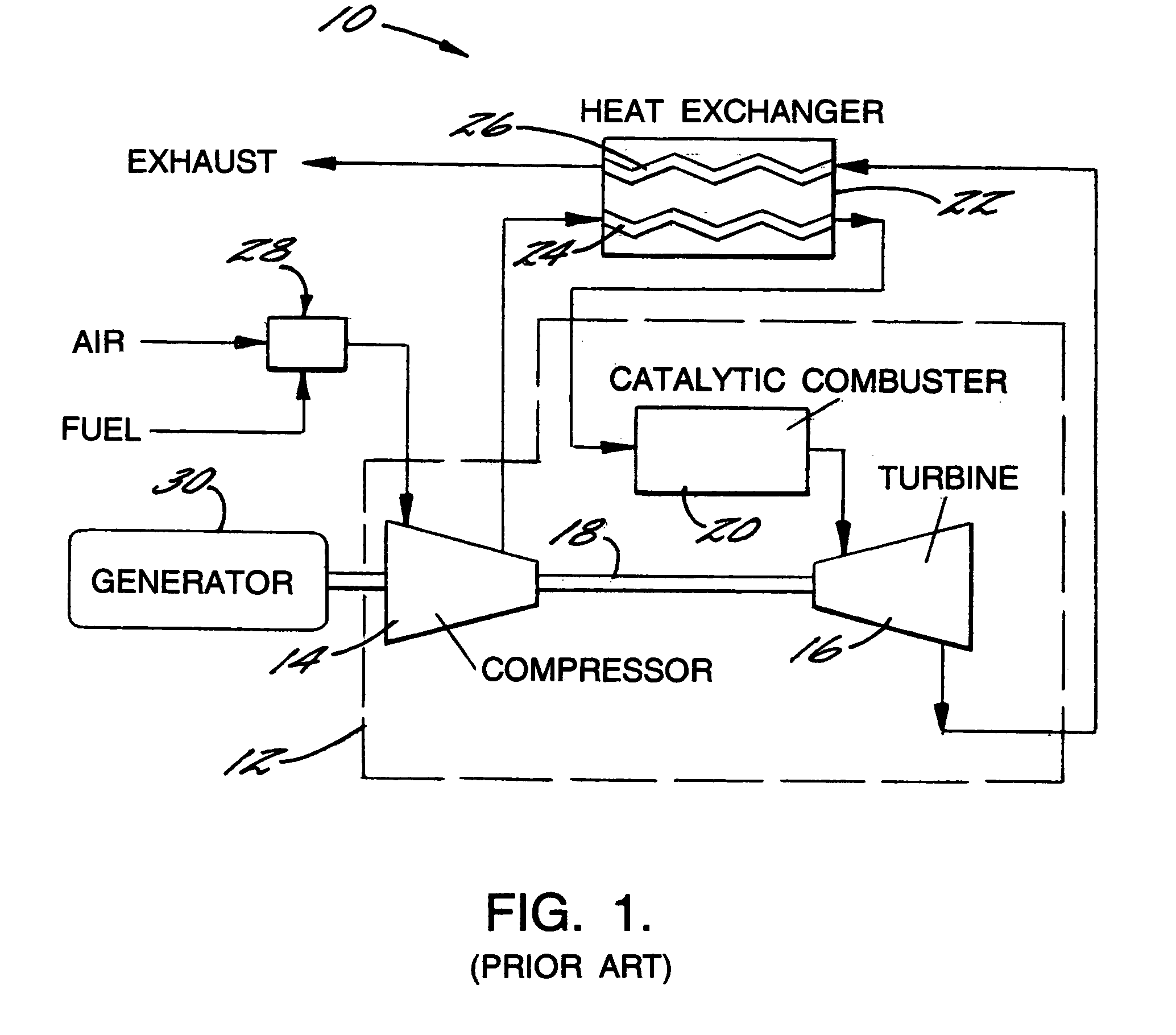

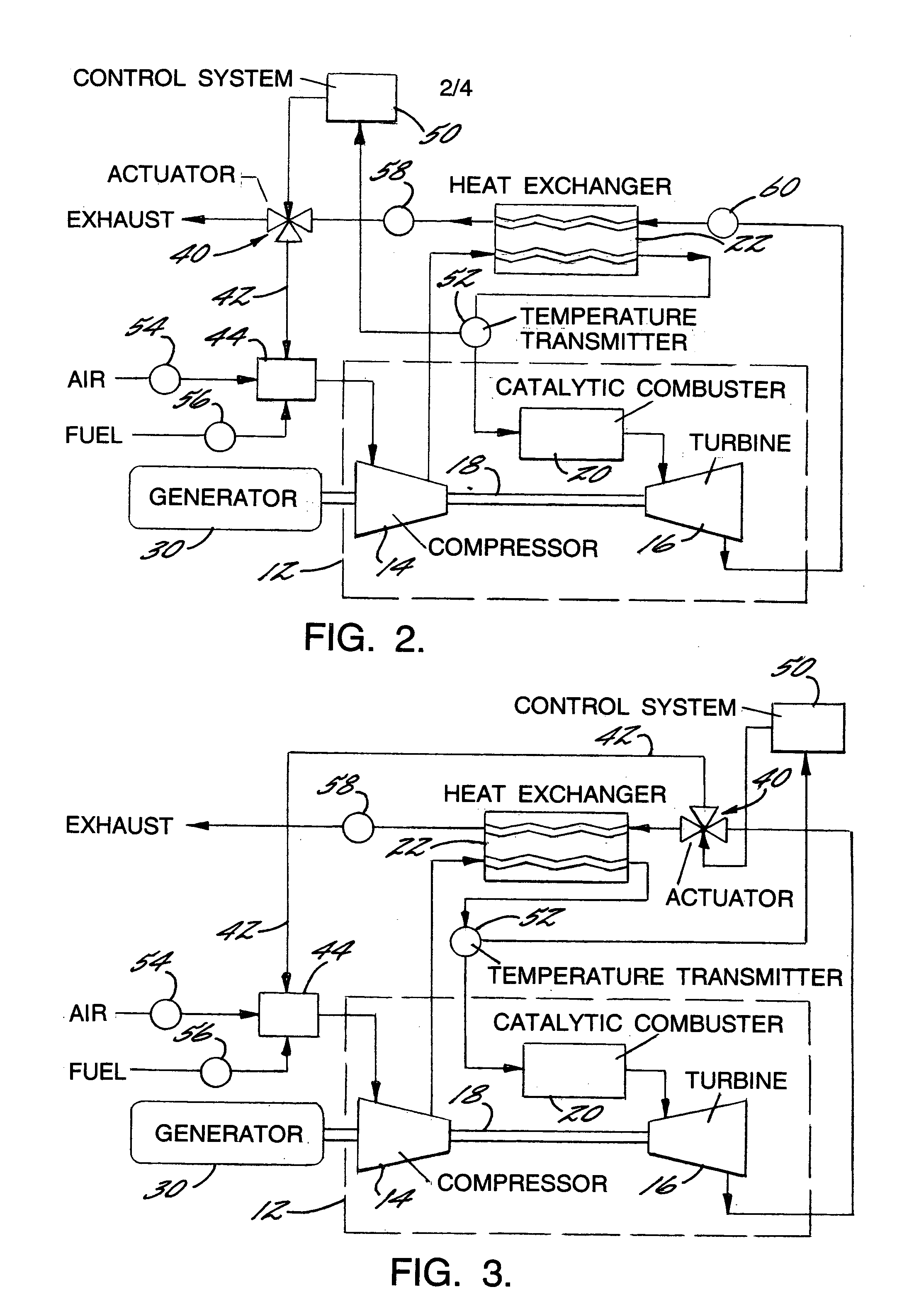

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

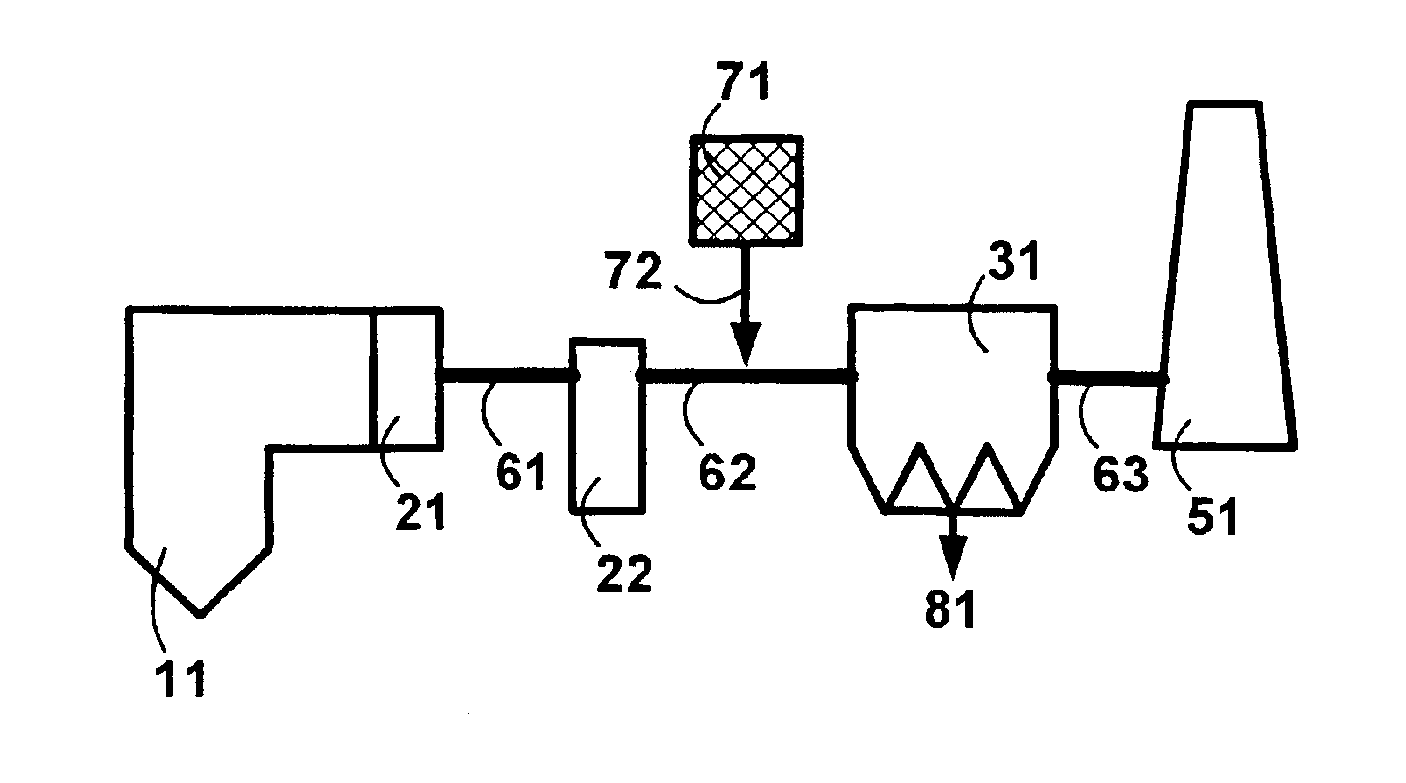

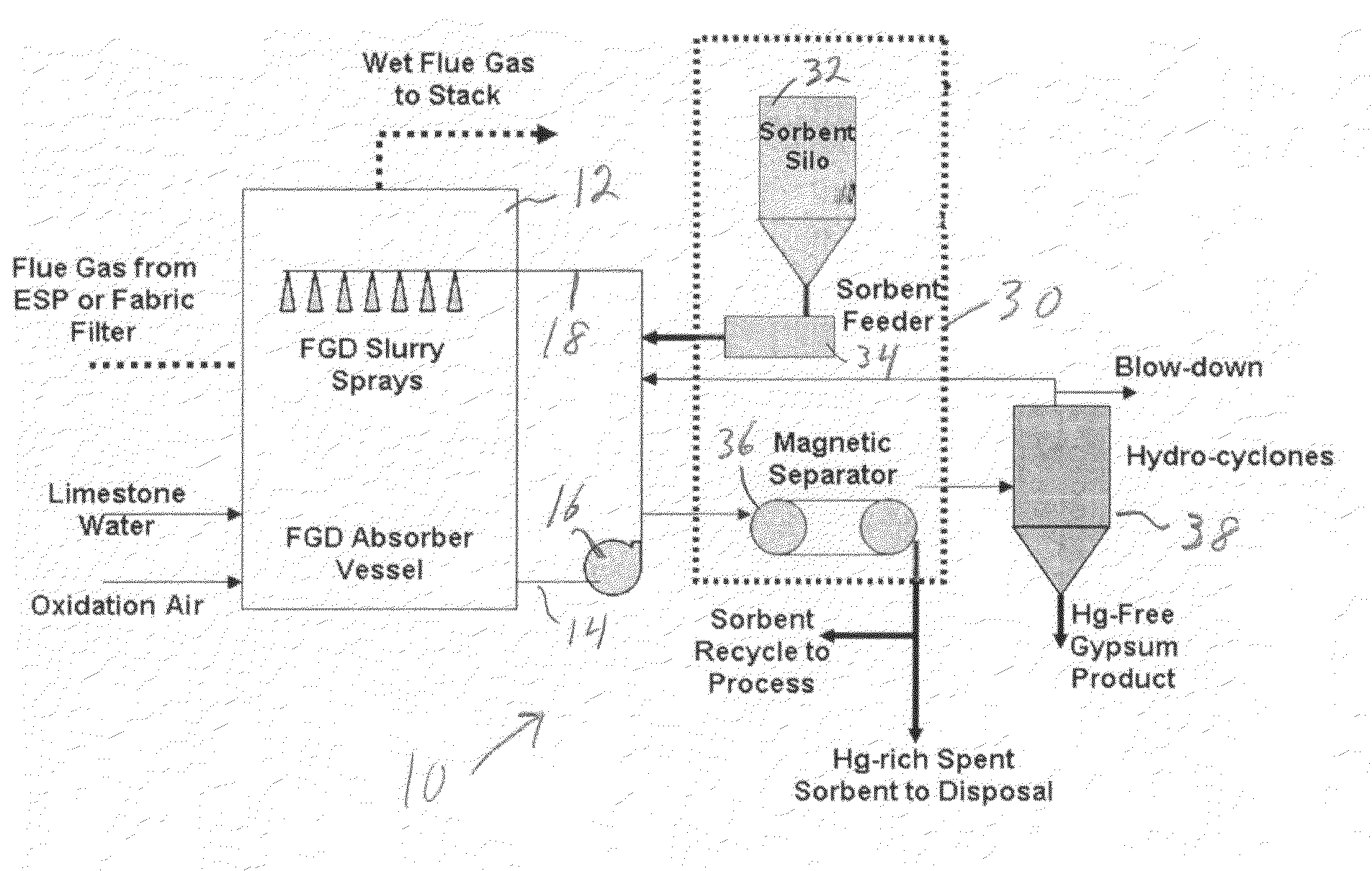

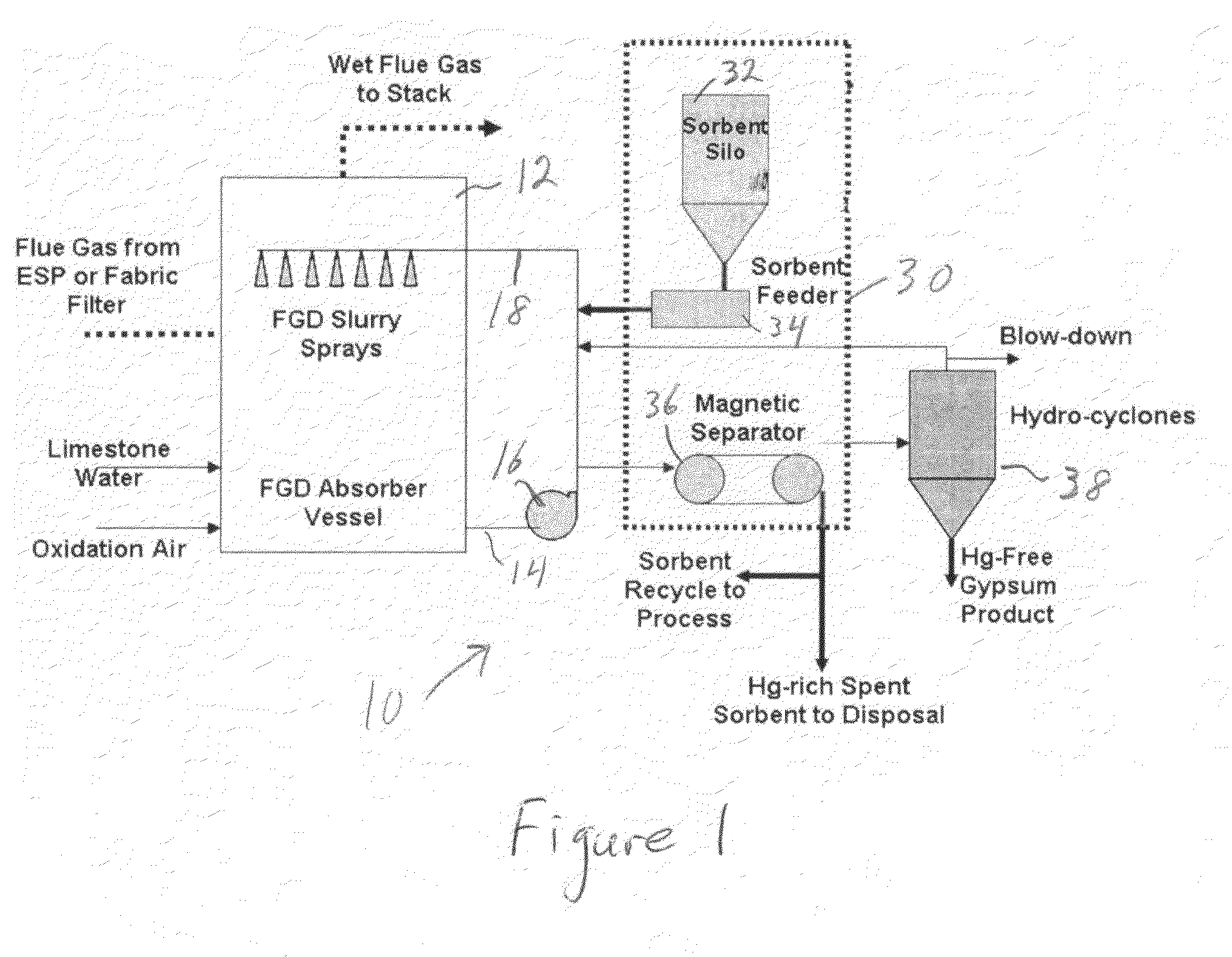

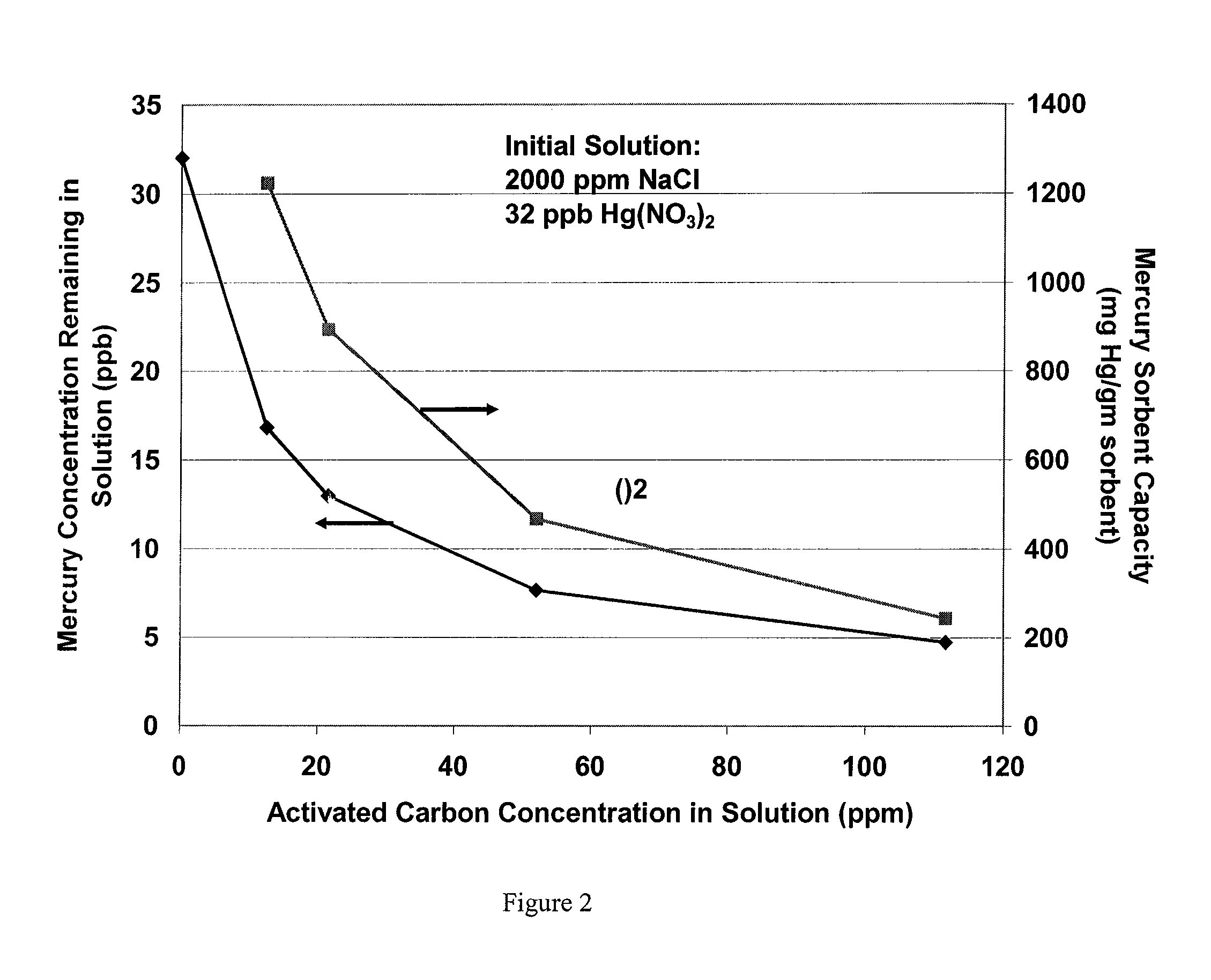

System and method for sequestration and separation of mercury in combustion exhaust gas aqueous scrubber systems

ActiveUS7722843B1Emission reductionMinimize re-emissionCombination devicesExhaust apparatusCombustionSorbent

A process, system and sorbent for removal of mercury from a combustion exhaust gas stream in a combustion exhaust gas purification scheme that includes a combustion exhaust scrubber system that uses an aqueous liquid to remove acid gases from the combustion exhaust gas. A powdered mercury sorbent is used. The sorbent is introduced into the aqueous scrubber liquid in the scrubber system. After introduction of the mercury sorbent into the scrubber liquid, at least some of the mercury sorbent is separated from the scrubber liquid.

Owner:SRINIVASACHAR SRIVATS

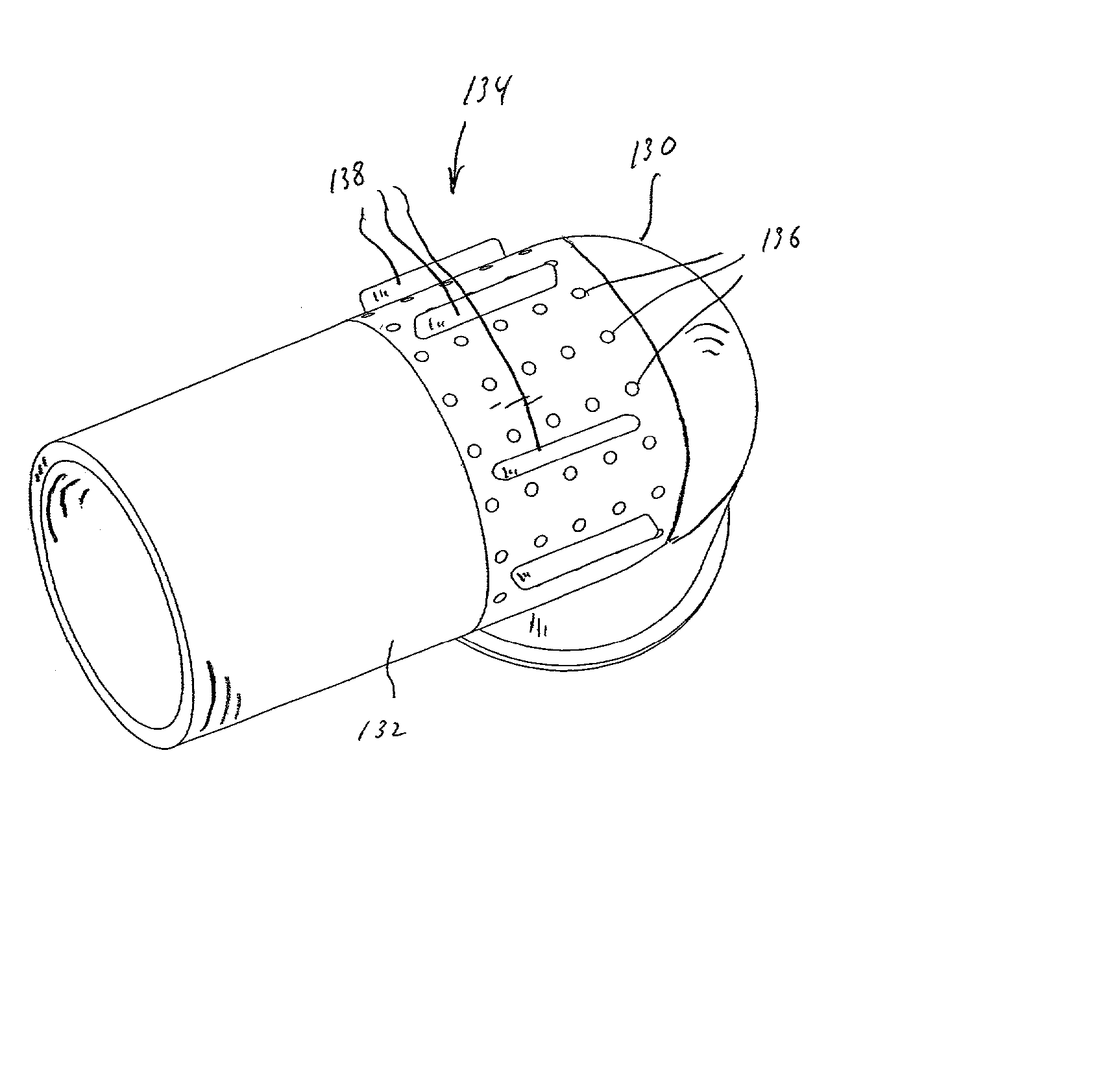

Exhaust port assembly for a pressure support system

An exhaust port assembly comprising a conduit carries a flow of gas. A vent assembly having a fixed exhaust area is provided on the conduit for venting a flow of exhaust gas from within the conduit to ambient atmosphere. The vent assembly is configured so as to minimize noise associated with the flow of exhaust gas passing to atmosphere, diffuse the flow of exhaust gas passing to ambient atmosphere over a relatively large area, and minimize the area occupied by the venting assembly on the conduit.

Owner:RIC INVESTMENTS LLC

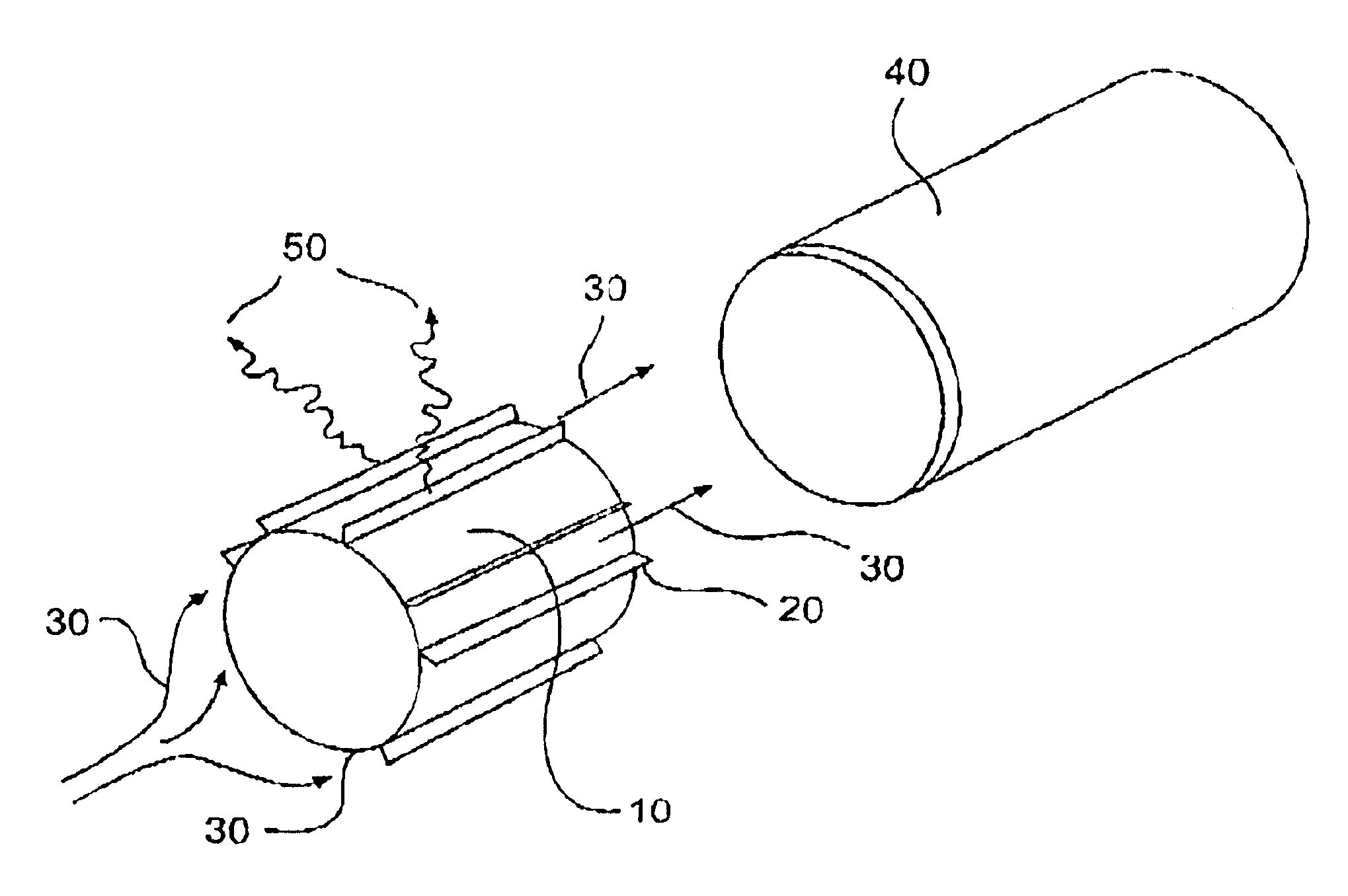

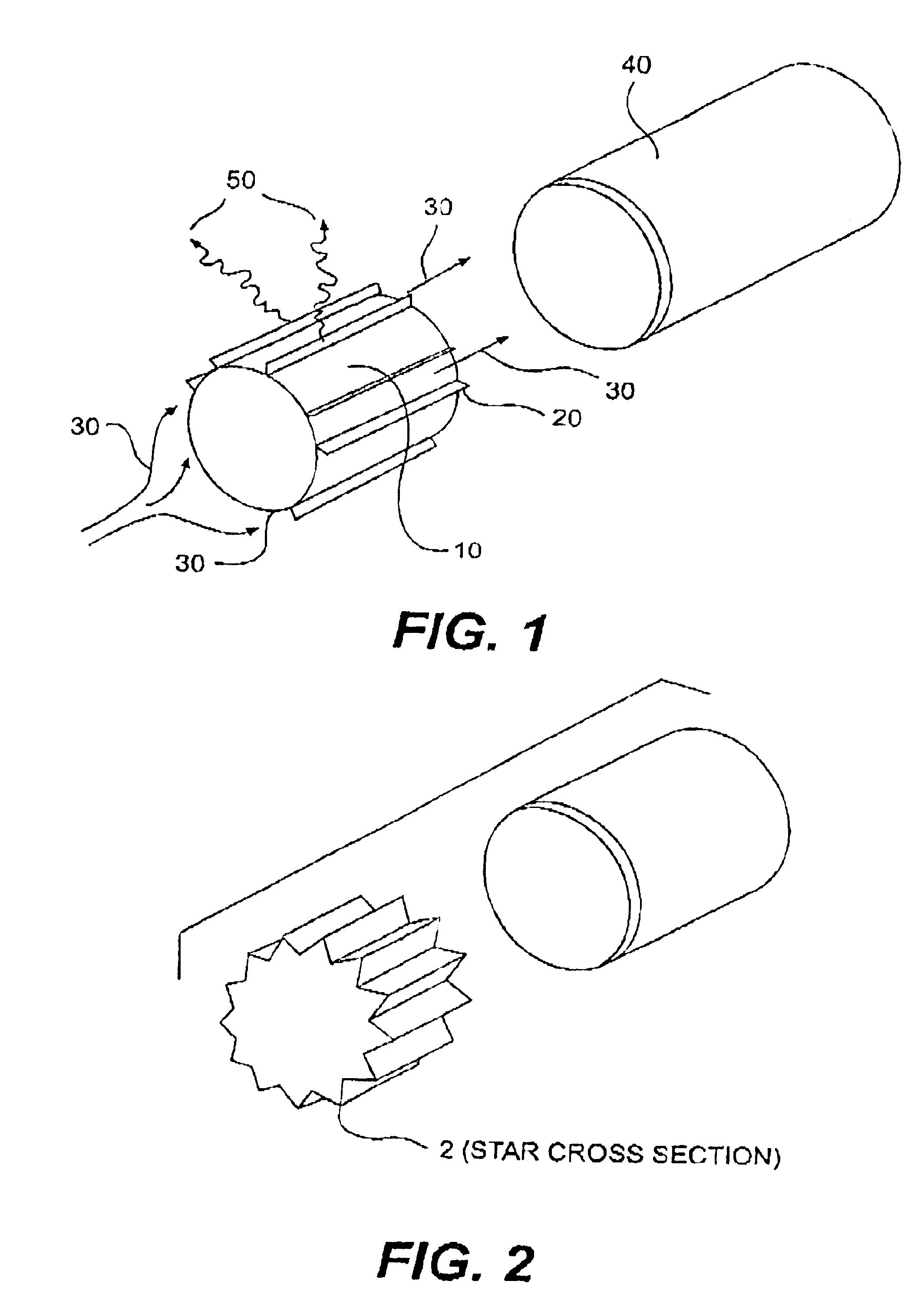

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS6851413B1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

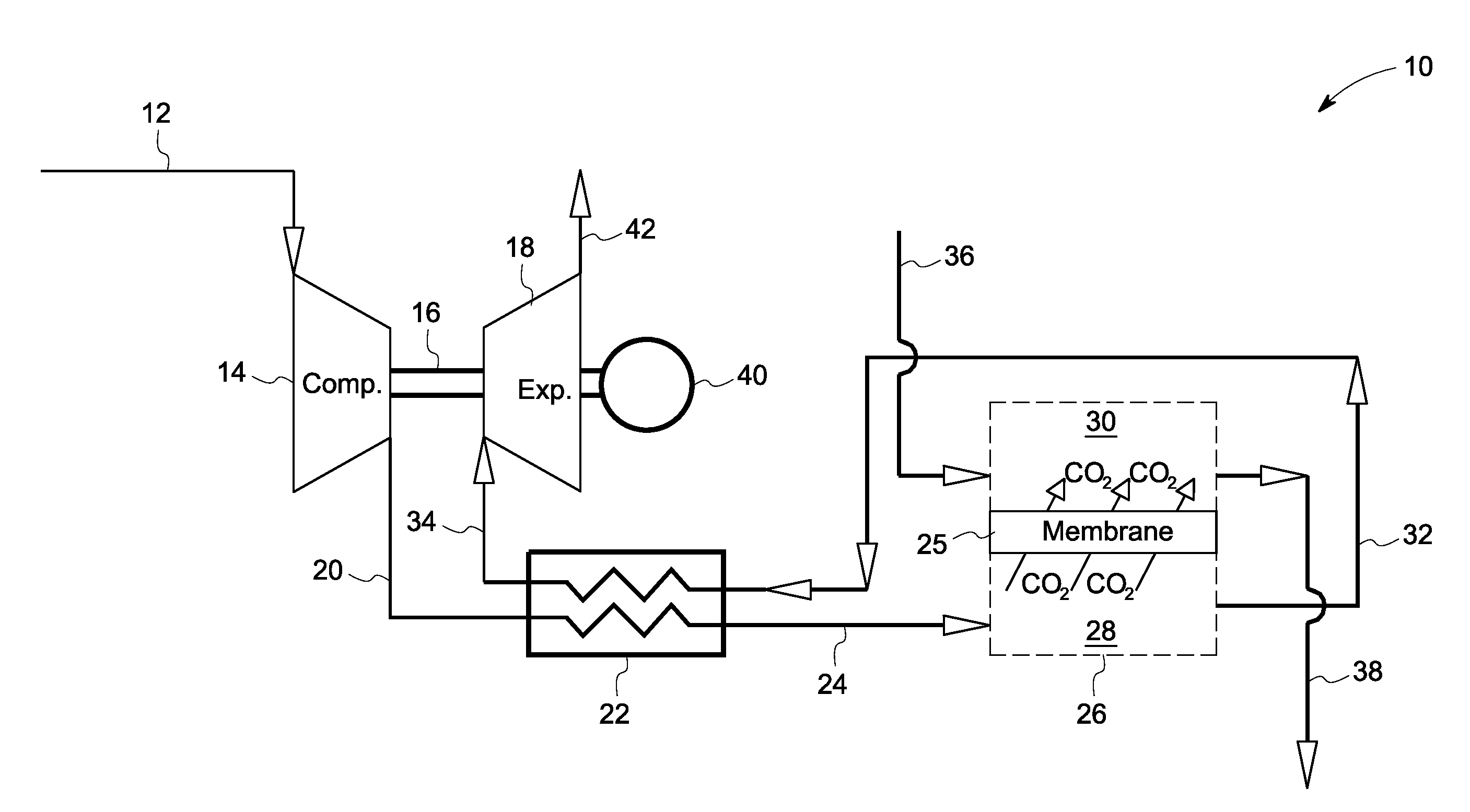

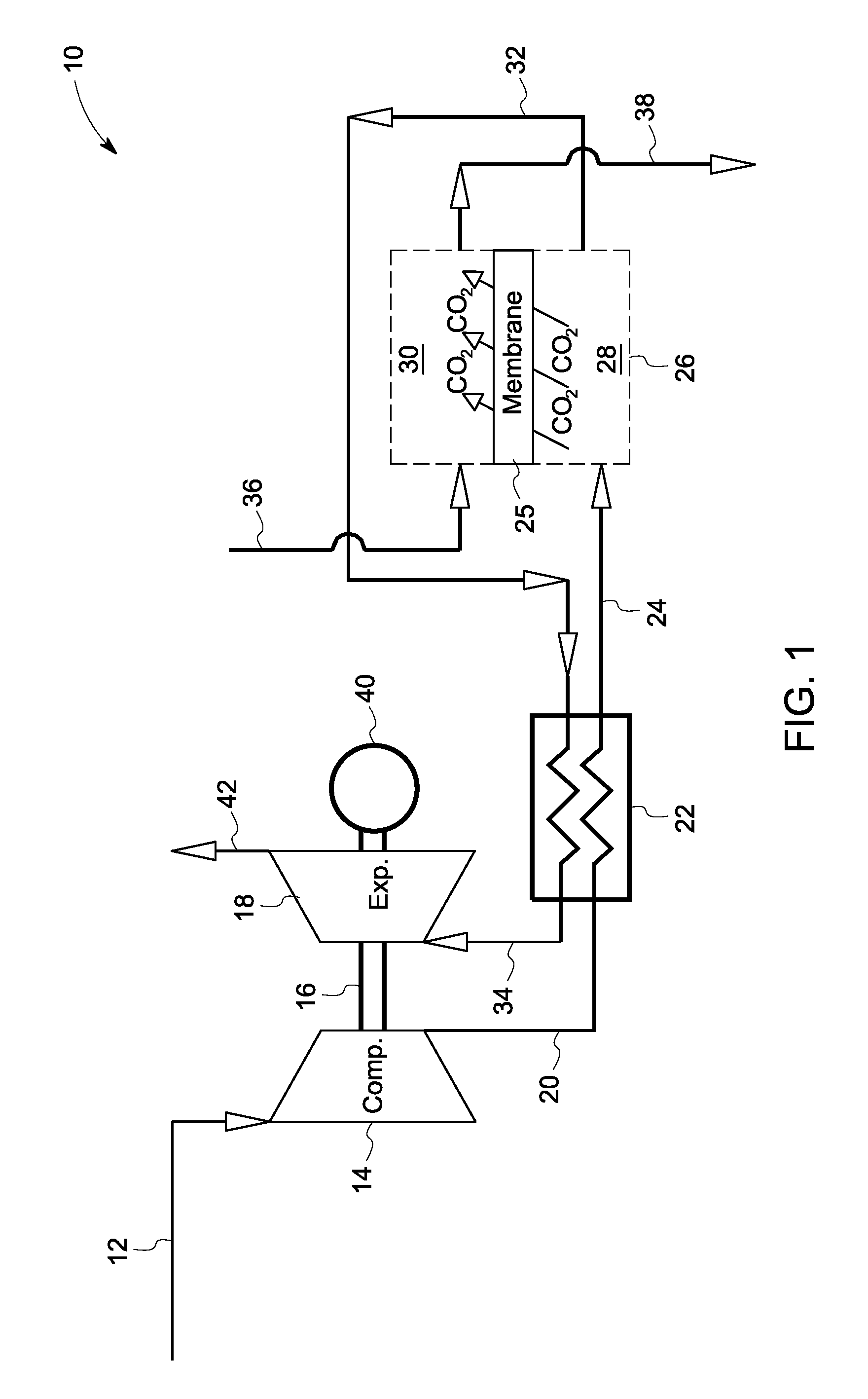

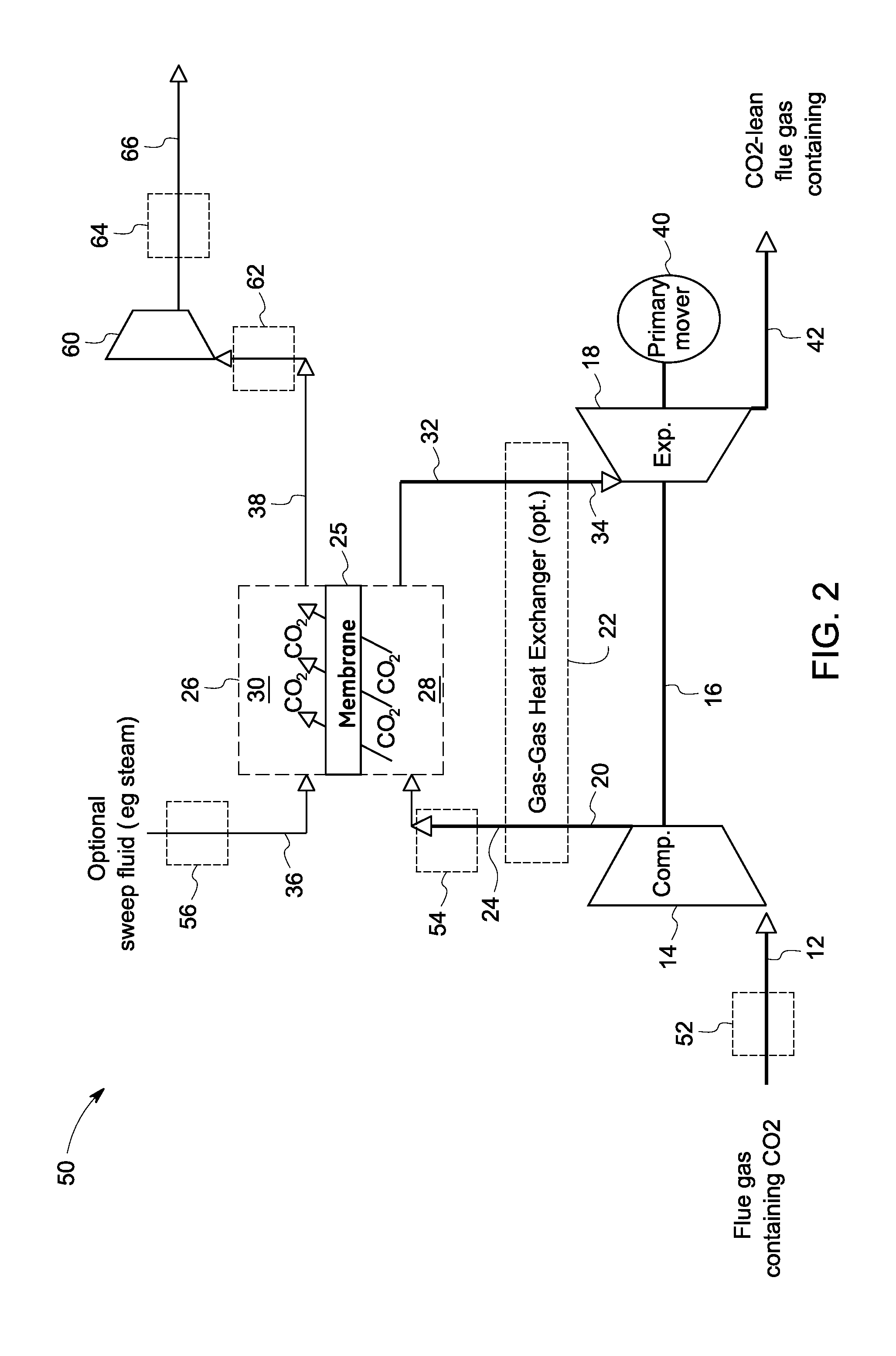

Carbon dioxide capture systems and methods

InactiveUS20080127632A1More cost-effectivelyEasy and cost-effectiveGas treatmentExhaust apparatusCarbon dioxide transportProcess engineering

A carbon dioxide separation system includes a compressor for receiving an exhaust gas comprising CO2 and generate a compressed exhaust gas and a separator configured to receive the compressed exhaust gas and generate a CO2 lean stream. The separator includes a first flow path for receiving the compressed exhaust gas, a second flow path for directing a sweep fluid therethrough, and a material with selective permeability of carbon dioxide for separating the first and the second flow paths and for promoting carbon dioxide transport therebetween. The system further includes an expander coupled to the compressor for receiving and expanding the CO2 lean stream to generate power and an expanded CO2 lean stream.

Owner:GENERAL ELECTRIC CO

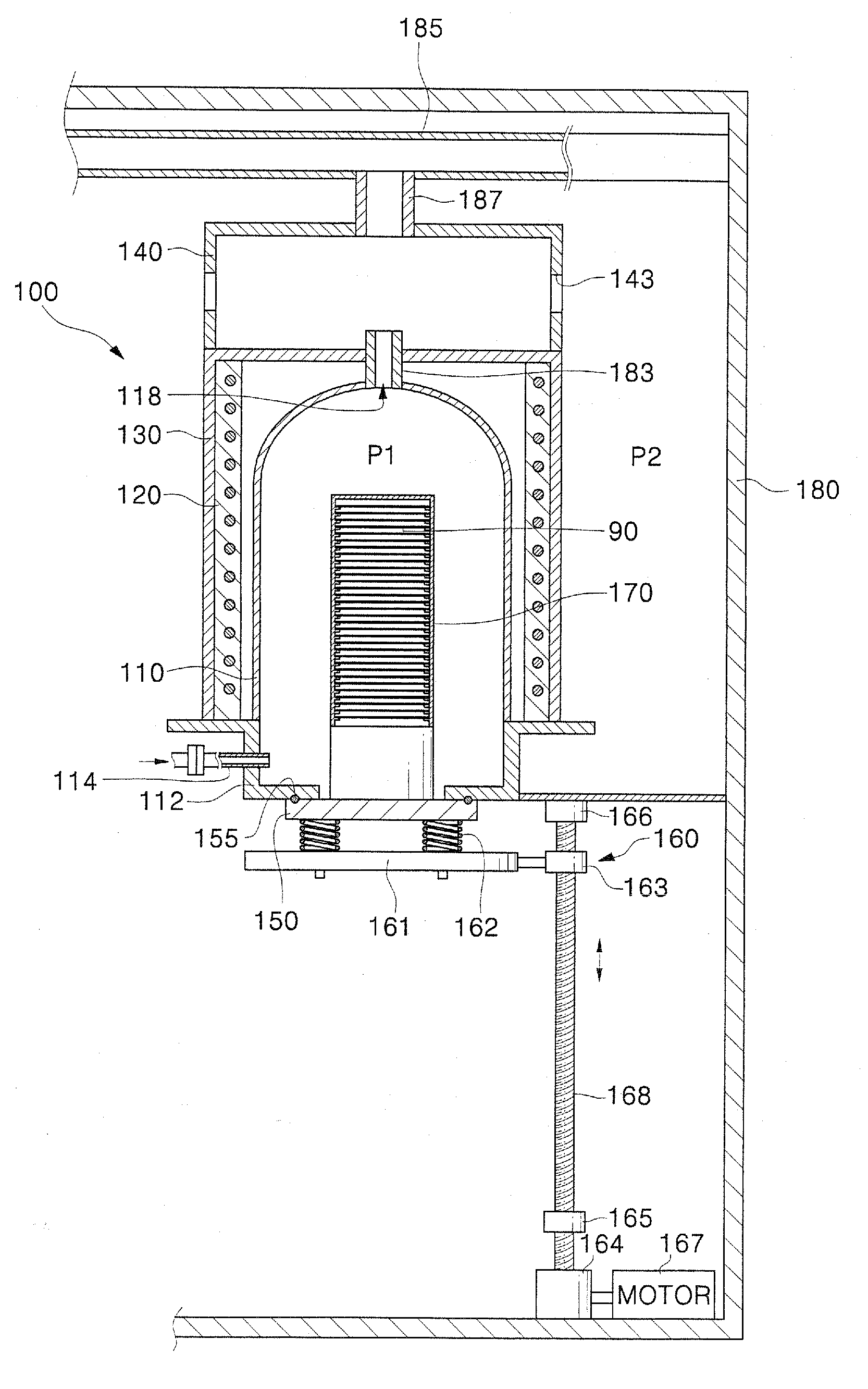

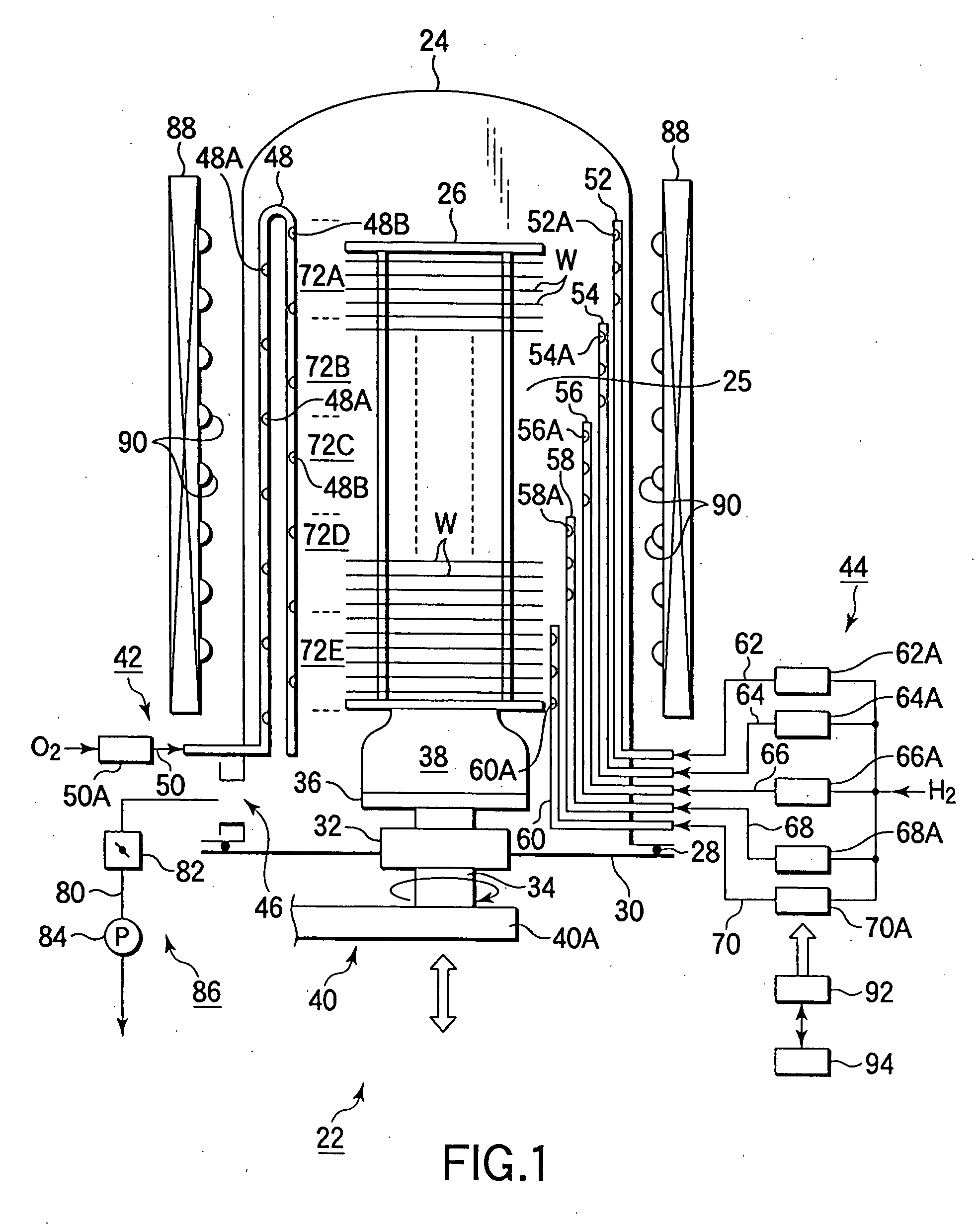

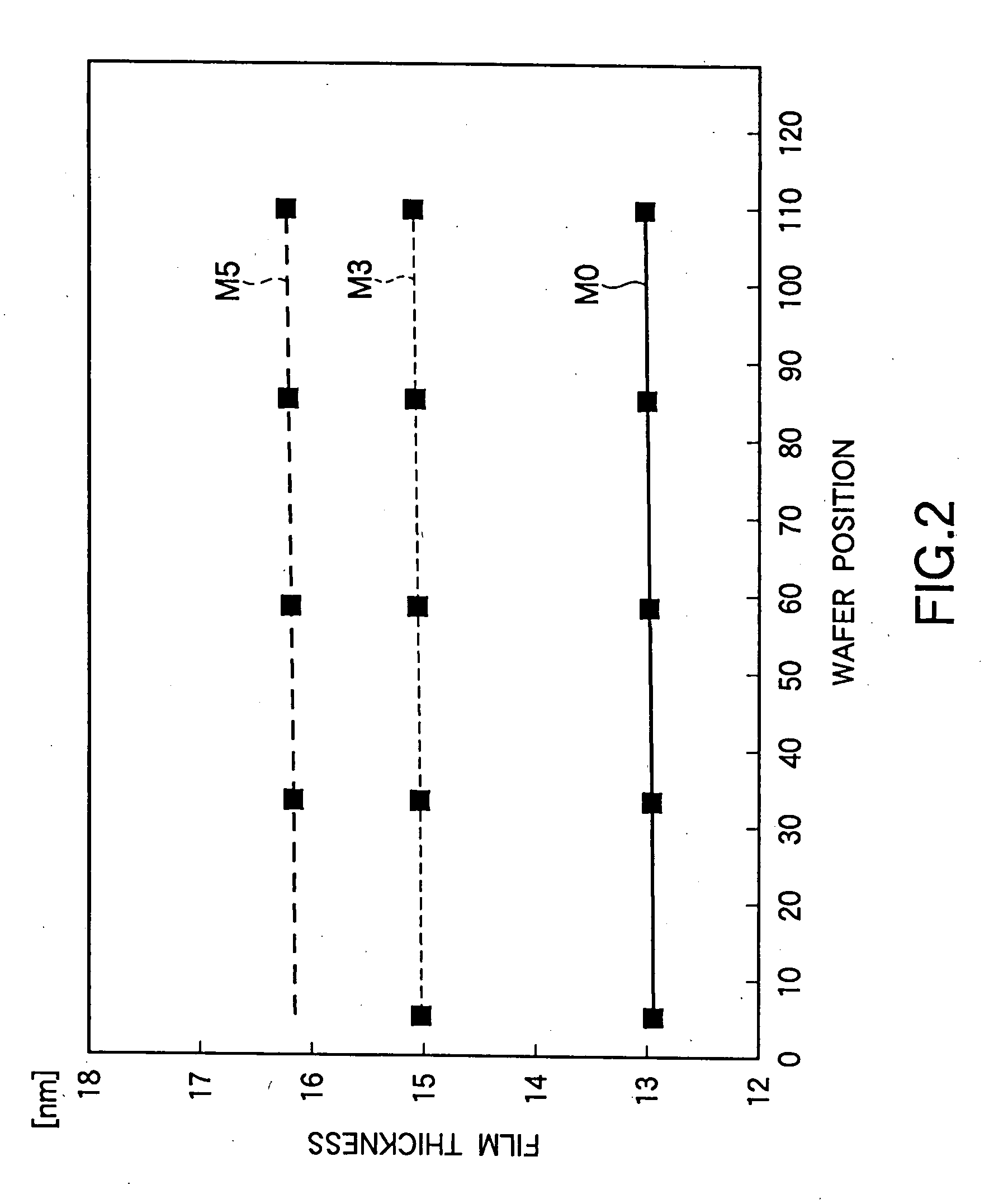

Oxidation apparatus and method for semiconductor process

InactiveUS20080075838A1Easy to operateSemiconductor/solid-state device manufacturingSolid state diffusion coatingProduct gasProcess engineering

An oxidation apparatus for a semiconductor process includes a process container having a process field configured to accommodate target substrates at intervals vertically, a heater configured to heat the process field; an exhaust system configured to exhaust gas from inside the process field; an oxidizing gas supply circuit configured to supply an oxidizing gas to the process field; and a deoxidizing gas supply circuit configured to supply a deoxidizing gas to the process field. The oxidizing gas supply circuit includes an oxidizing gas nozzle extending over a vertical length corresponding to the process field, and having gas spouting holes arrayed over the vertical length corresponding to the process field. The deoxidizing gas supply circuit includes deoxidizing gas nozzles having different heights respectively corresponding to zones of the process field arrayed vertically, and each having a gas spouting hole formed at height of a corresponding zone.

Owner:TOKYO ELECTRON LTD

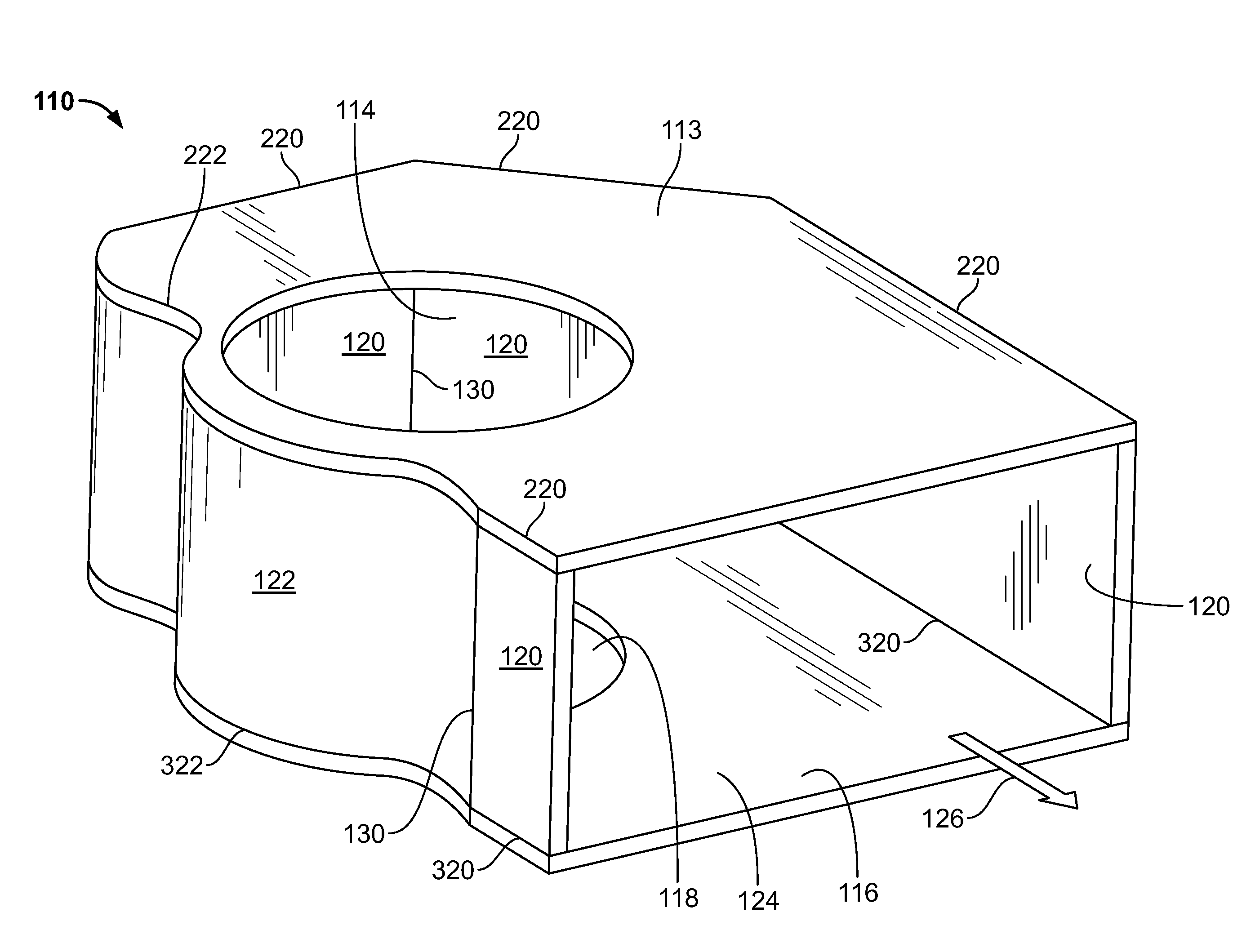

Method and apparatus for radial exhaust gas turbine

A radial exhaust gas turbine apparatus has a gas turbine engine that includes a radial exhaust diffuser section and a casing apparatus consisting essentially of polygonal walls, substantially straight plates, and substantially straight sidewalls. The casing apparatus encloses the radial exhaust diffuser section and is configured to direct at least a substantial portion of the gas exiting the radial exhaust diffuser section to an exit in the casing apparatus via an approximately involute path.

Owner:GENERAL ELECTRIC CO

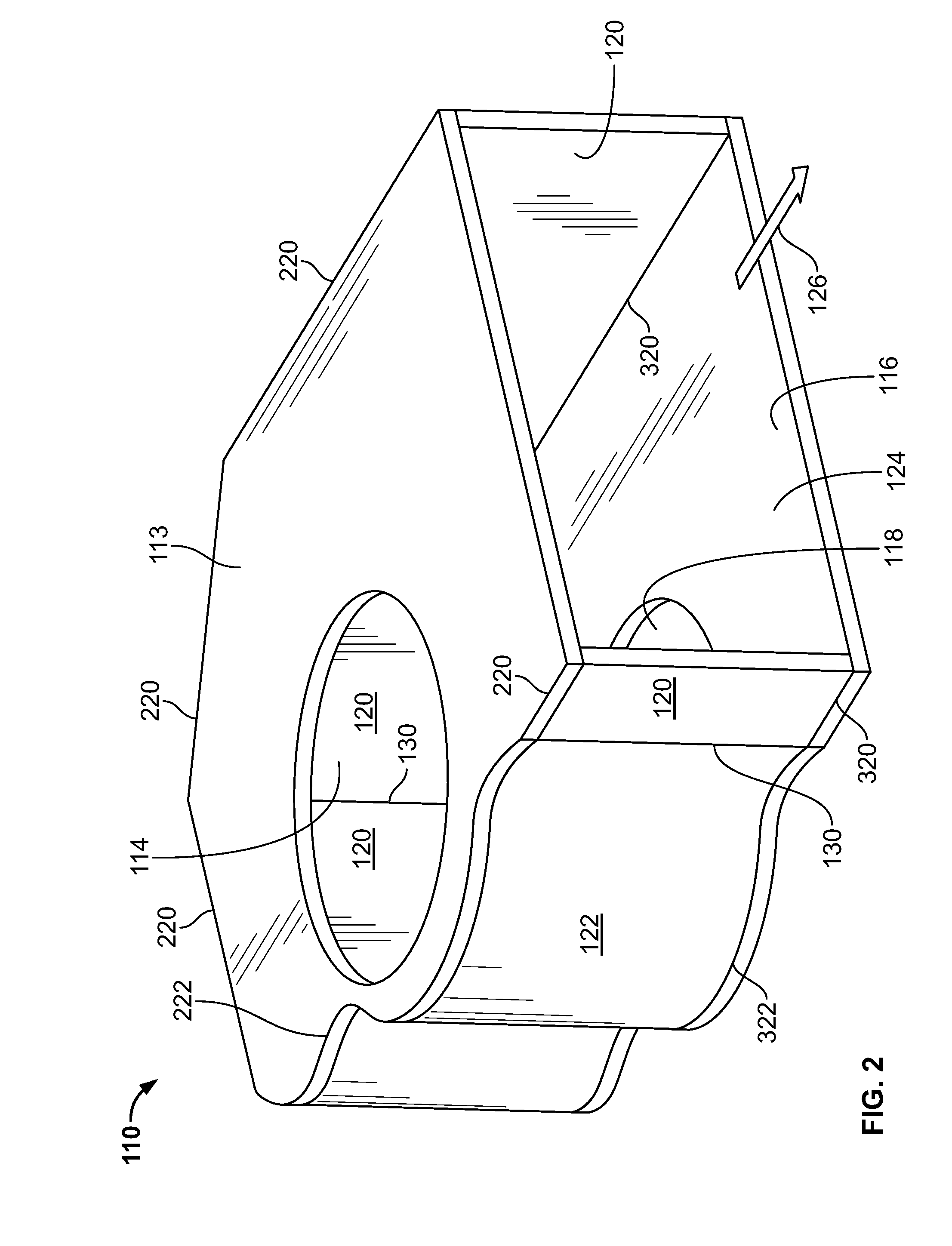

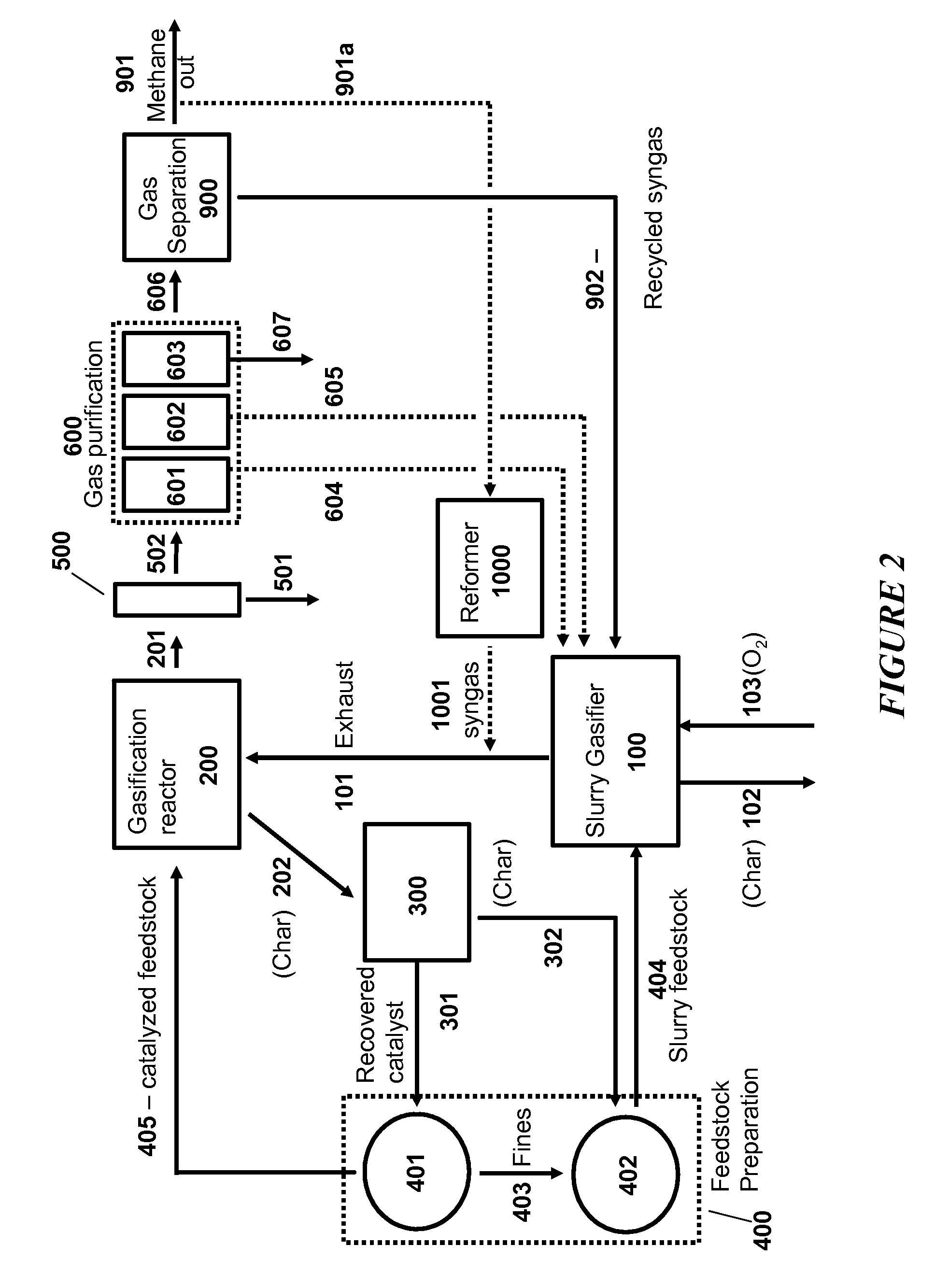

Steam Generating Slurry Gasifier for the Catalytic Gasification of a Carbonaceous Feedstock

Steam generating gasification reactors for providing high-pressure and high-temperature steam for catalytic gasification of a carbonaceous feedstock can be based on oxygen blown gasification reactors adapted for processing a slurry feedstock comprising at least 40% water. The exhaust from the slurry gasifier comprises at least steam, carbon monoxide and hydrogen. The slurry composition and the oxygen to fuel ratio can be varied to control the ratio of carbonaceous gases in the generator exhaust. By directing substantially all of exhaust gases produced from the slurry gasification reactor through the catalytic gasifier and subsequent gas separation and sequestration processes, a greatly higher energy efficiency and decreased carbon footprint can be realized.

Owner:SURE CHAMPION INVESTMENT LTD

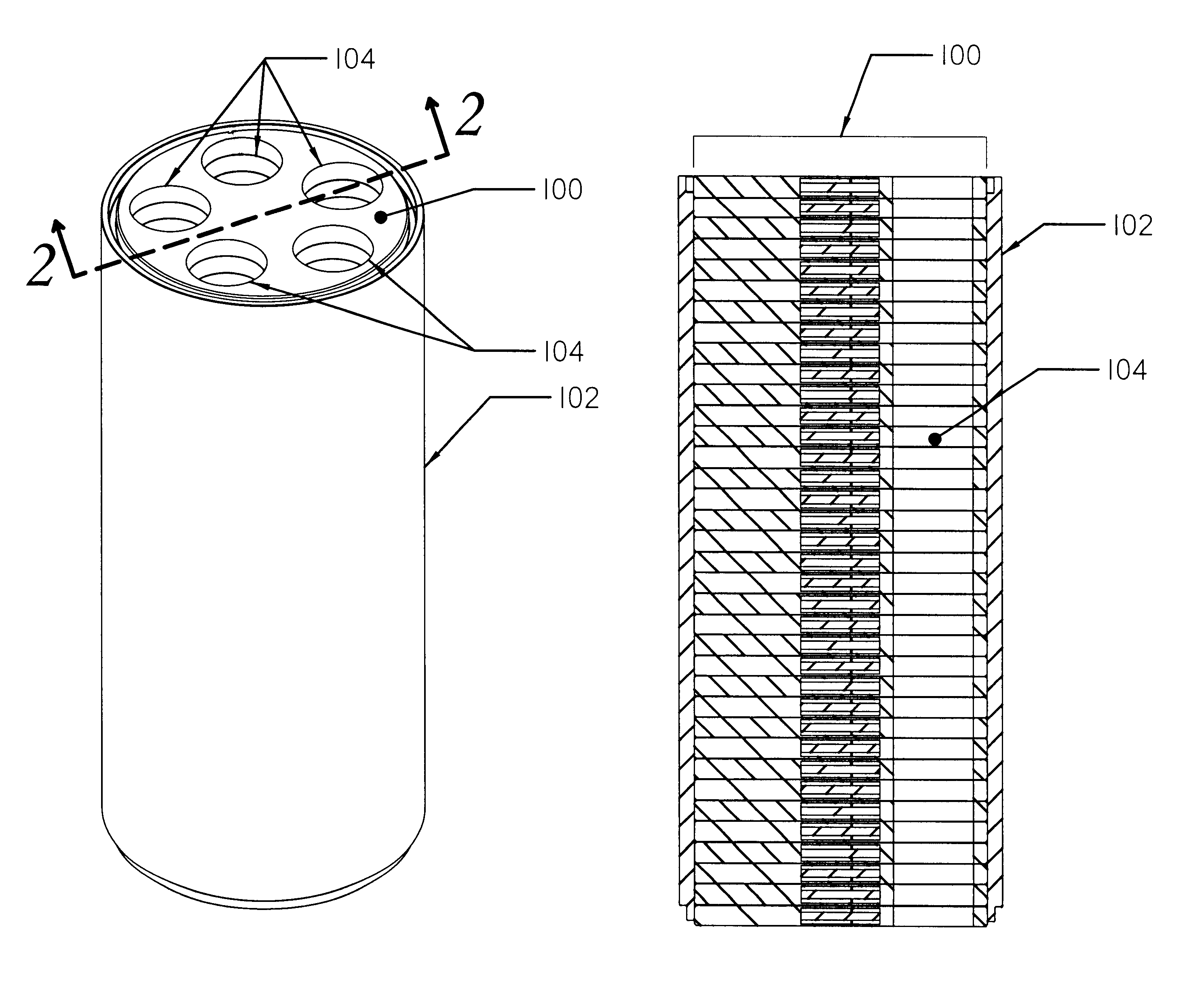

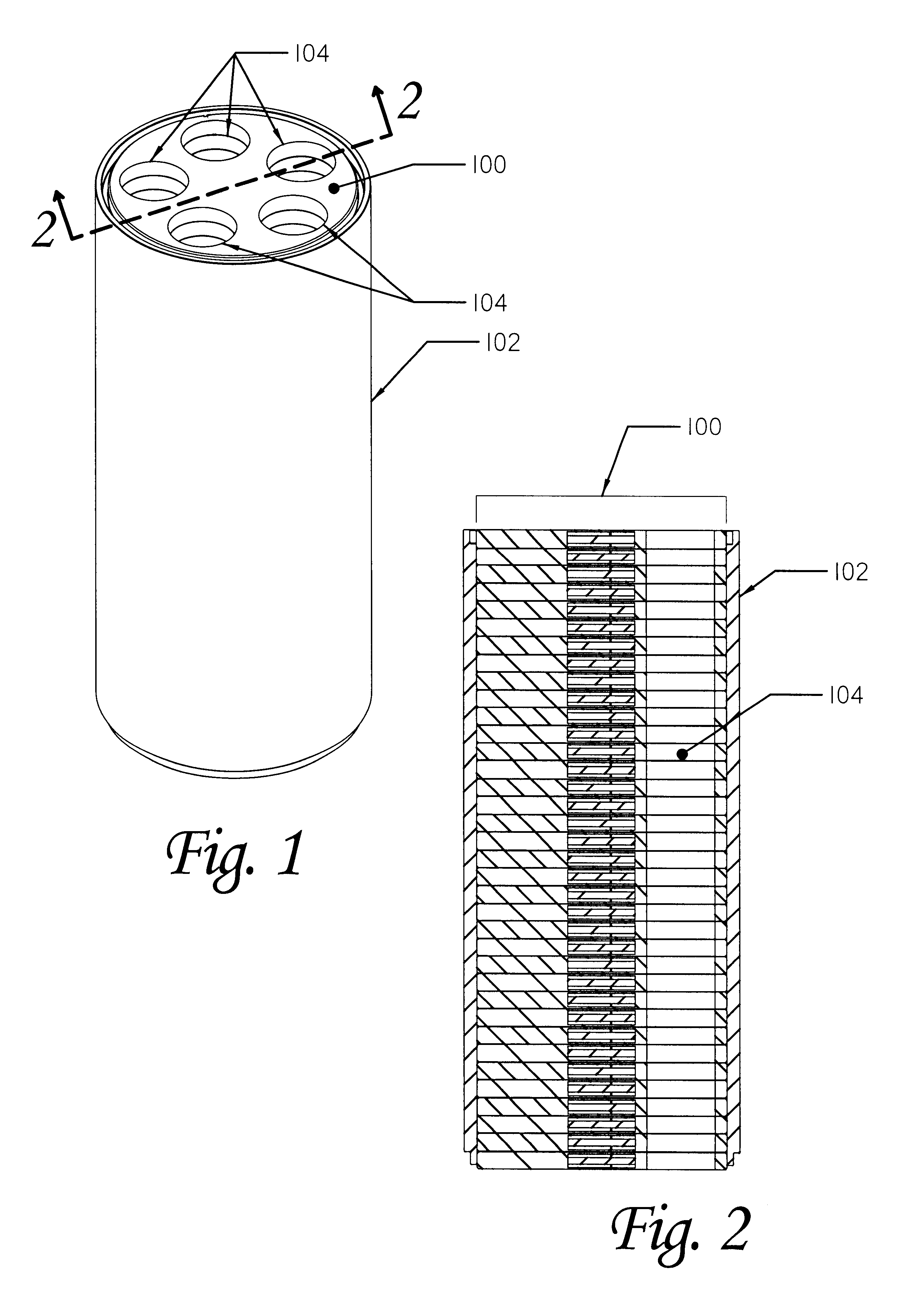

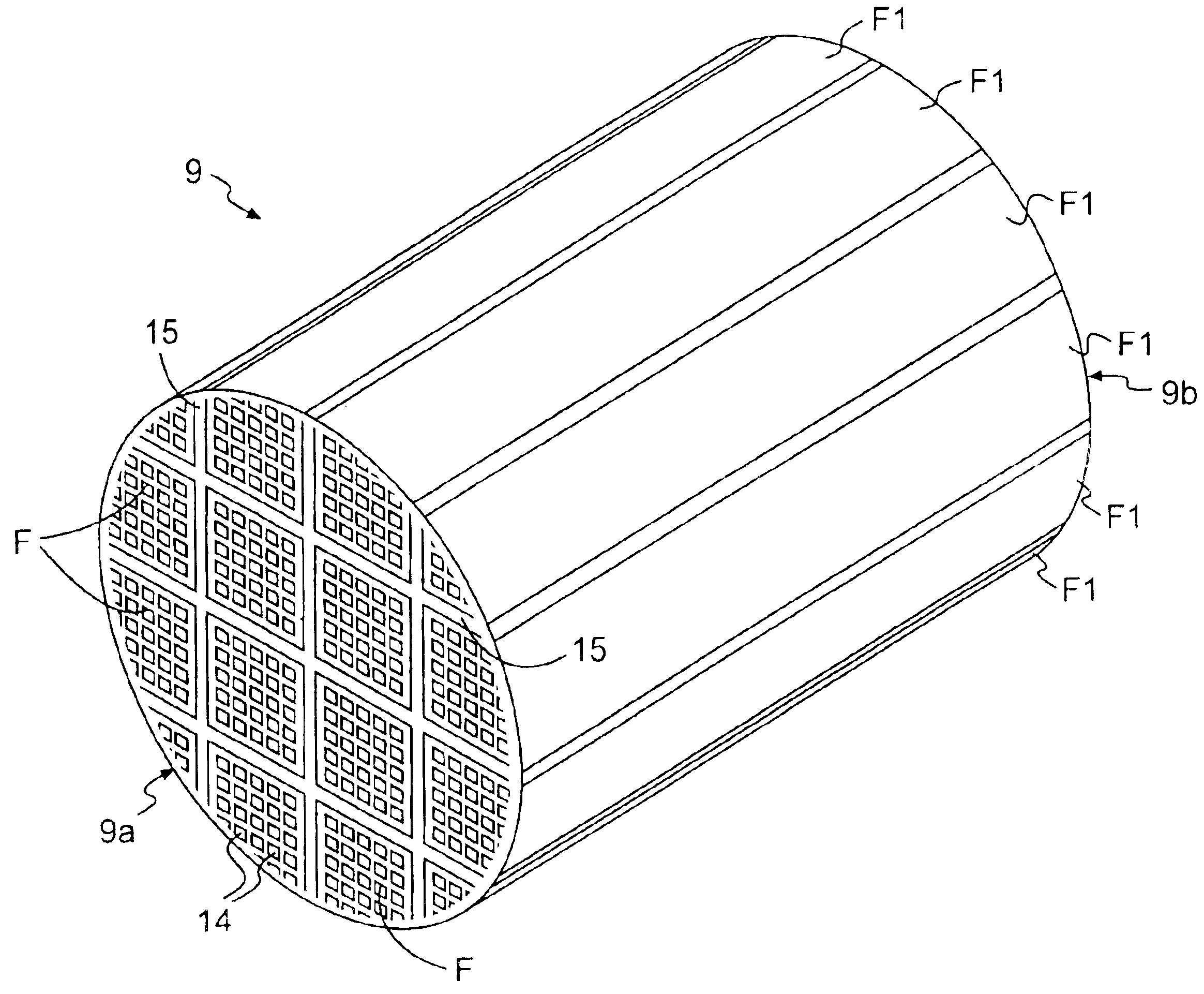

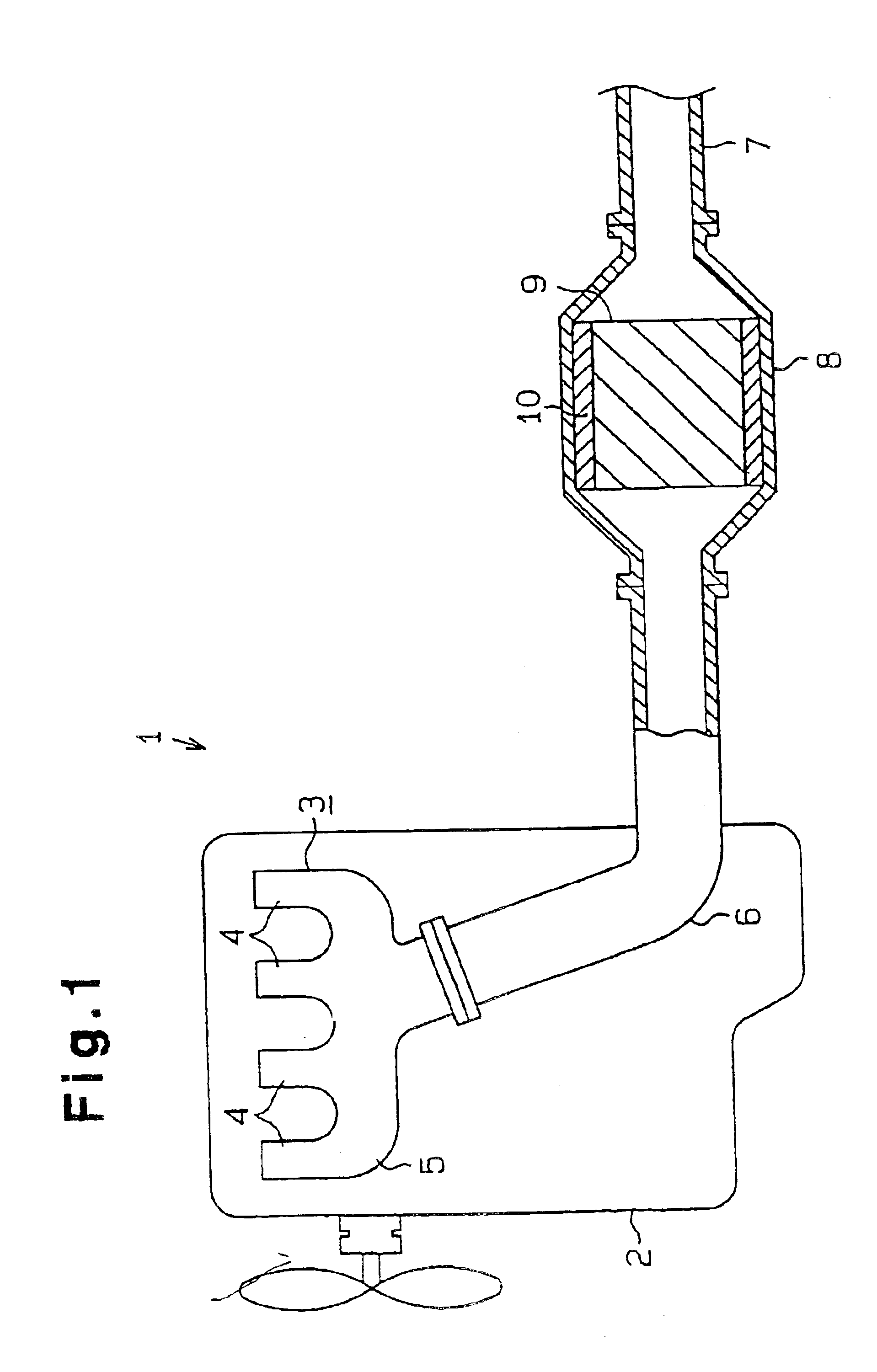

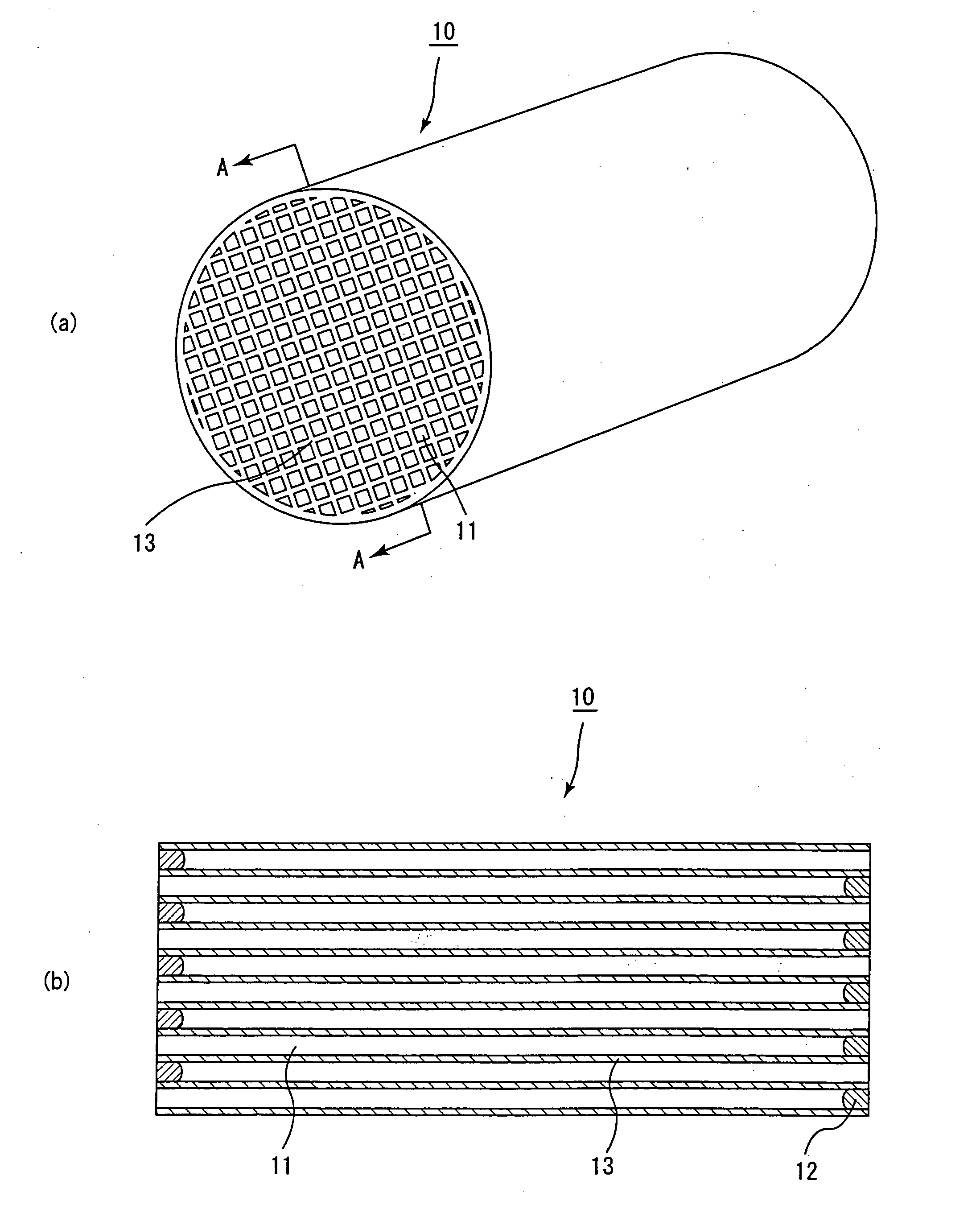

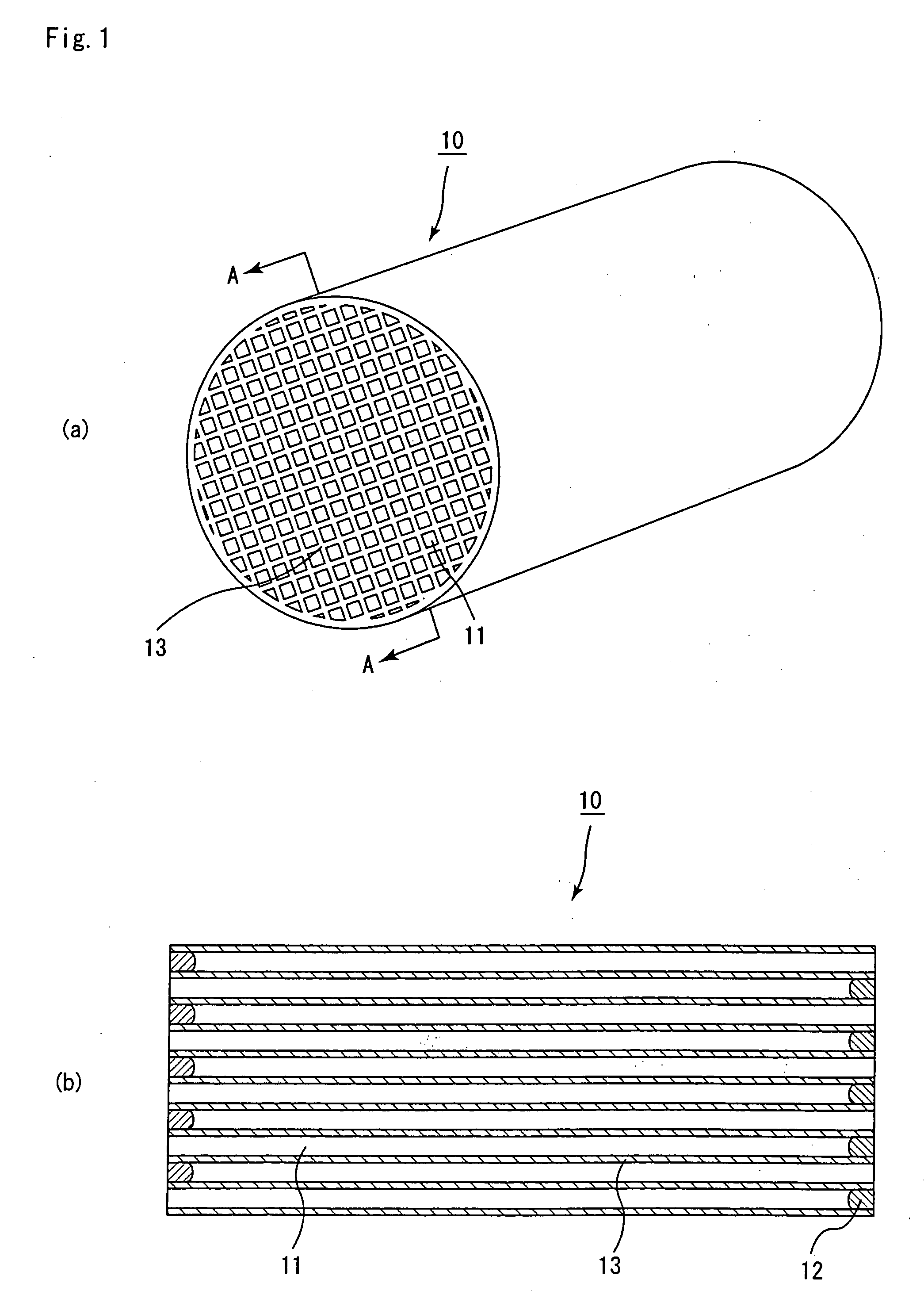

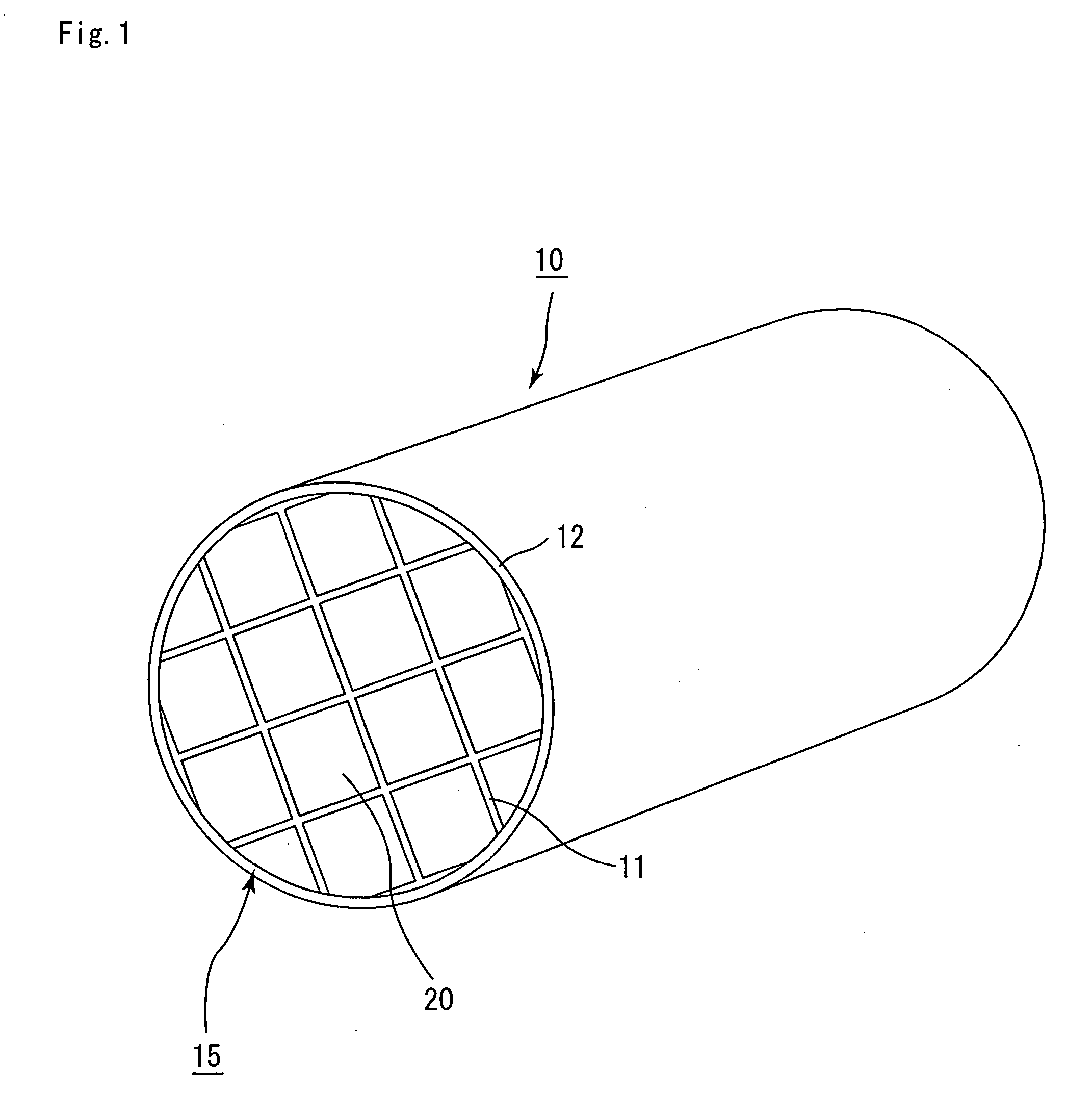

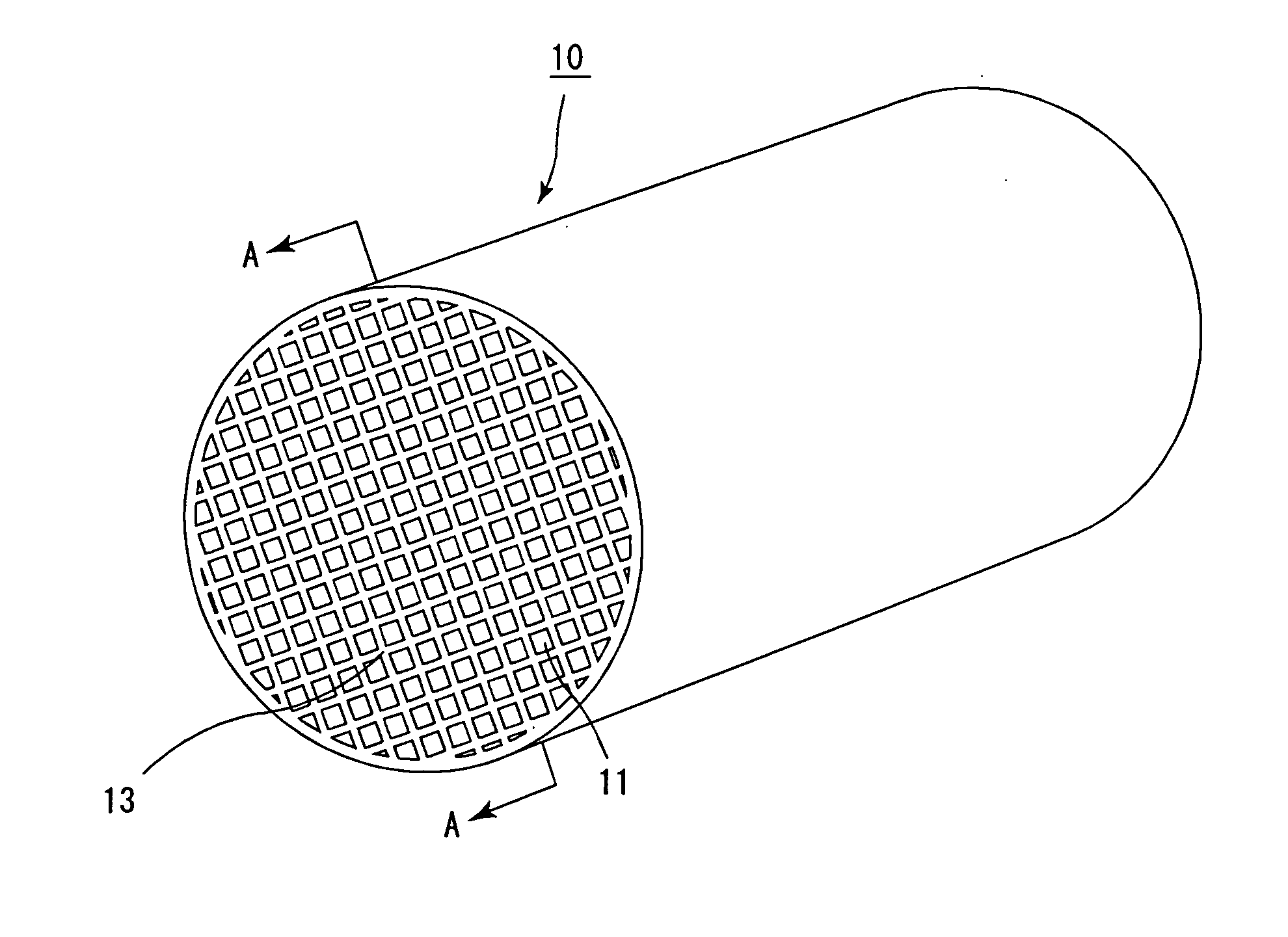

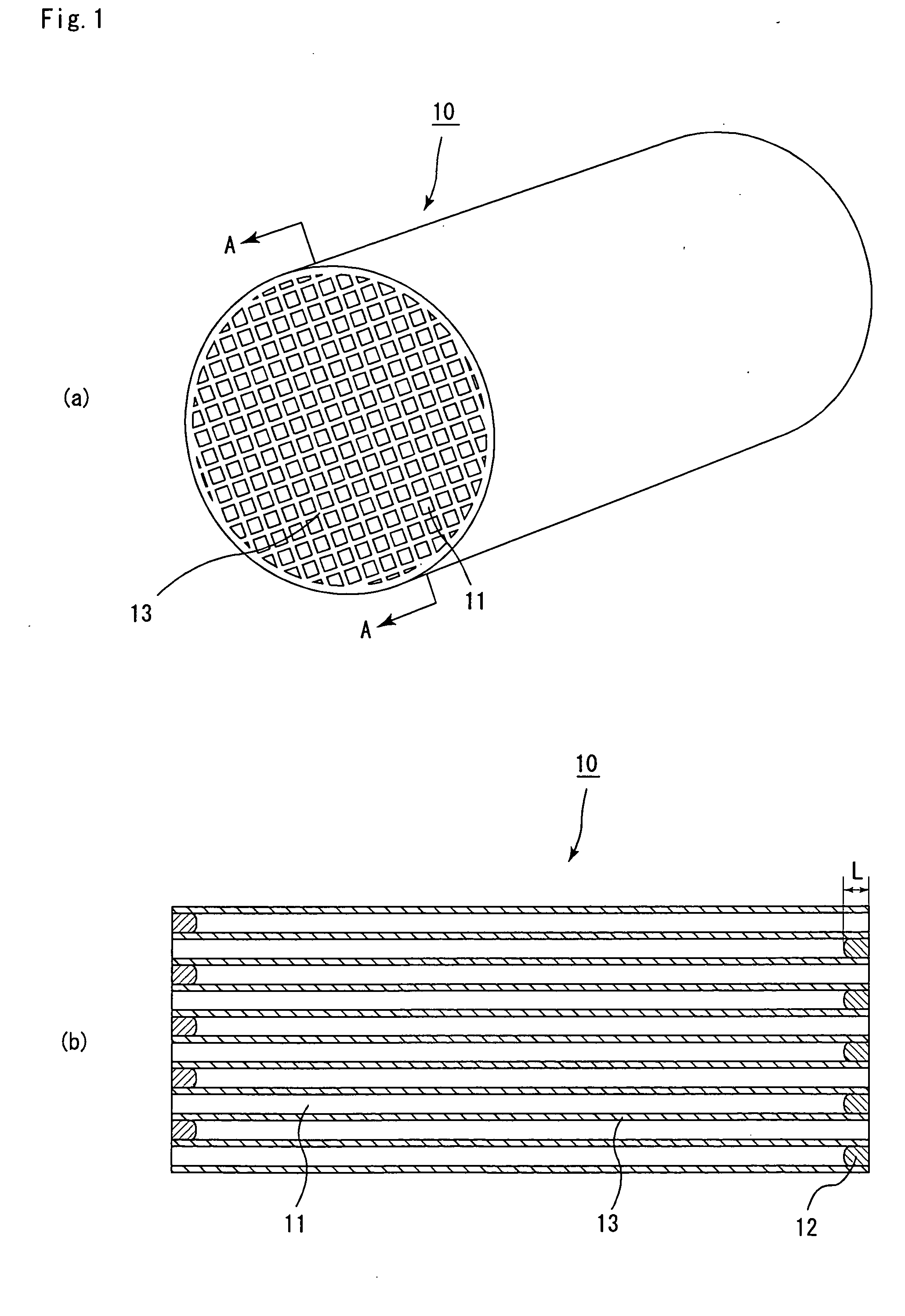

Honeycomb filter and ceramic filter assembly

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

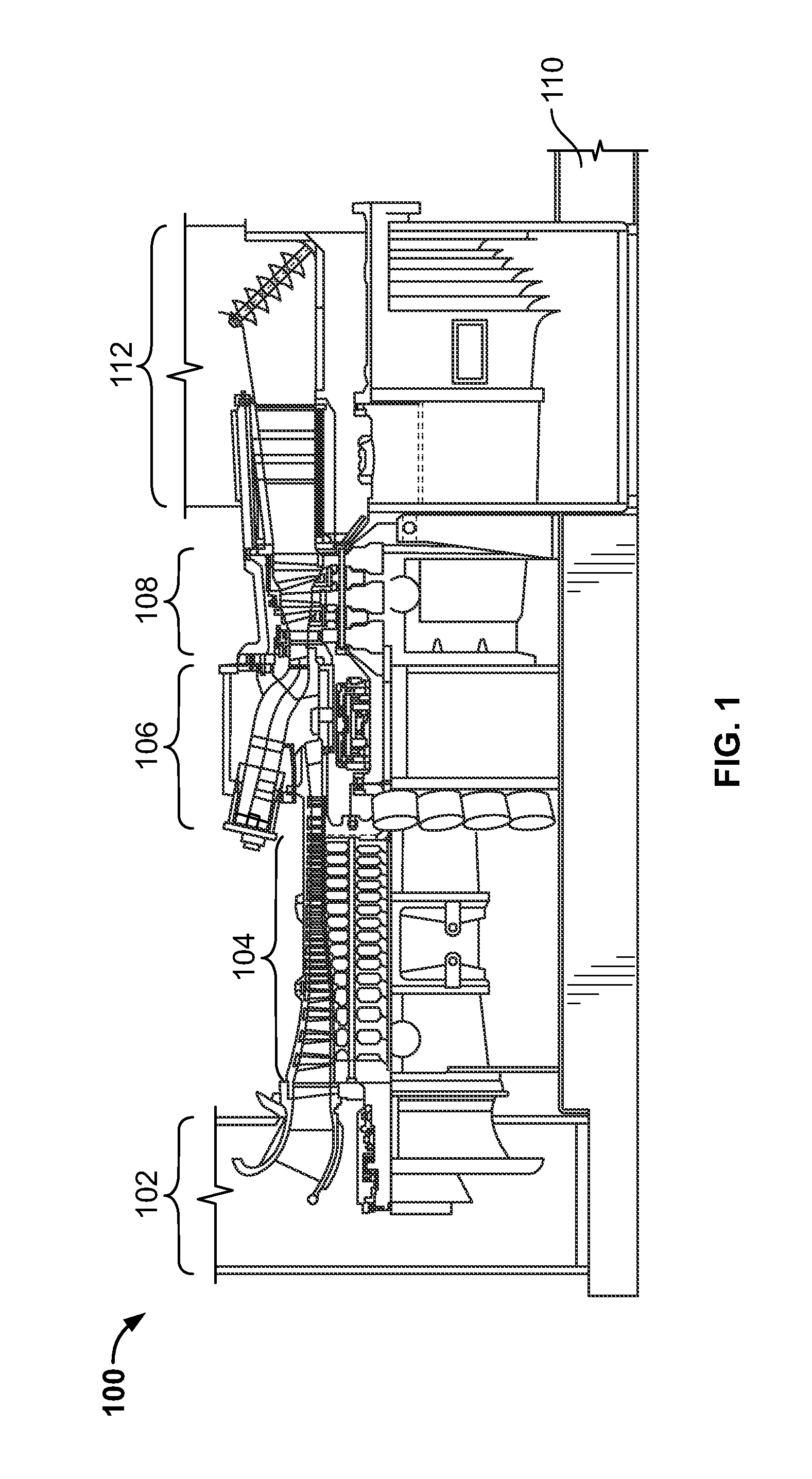

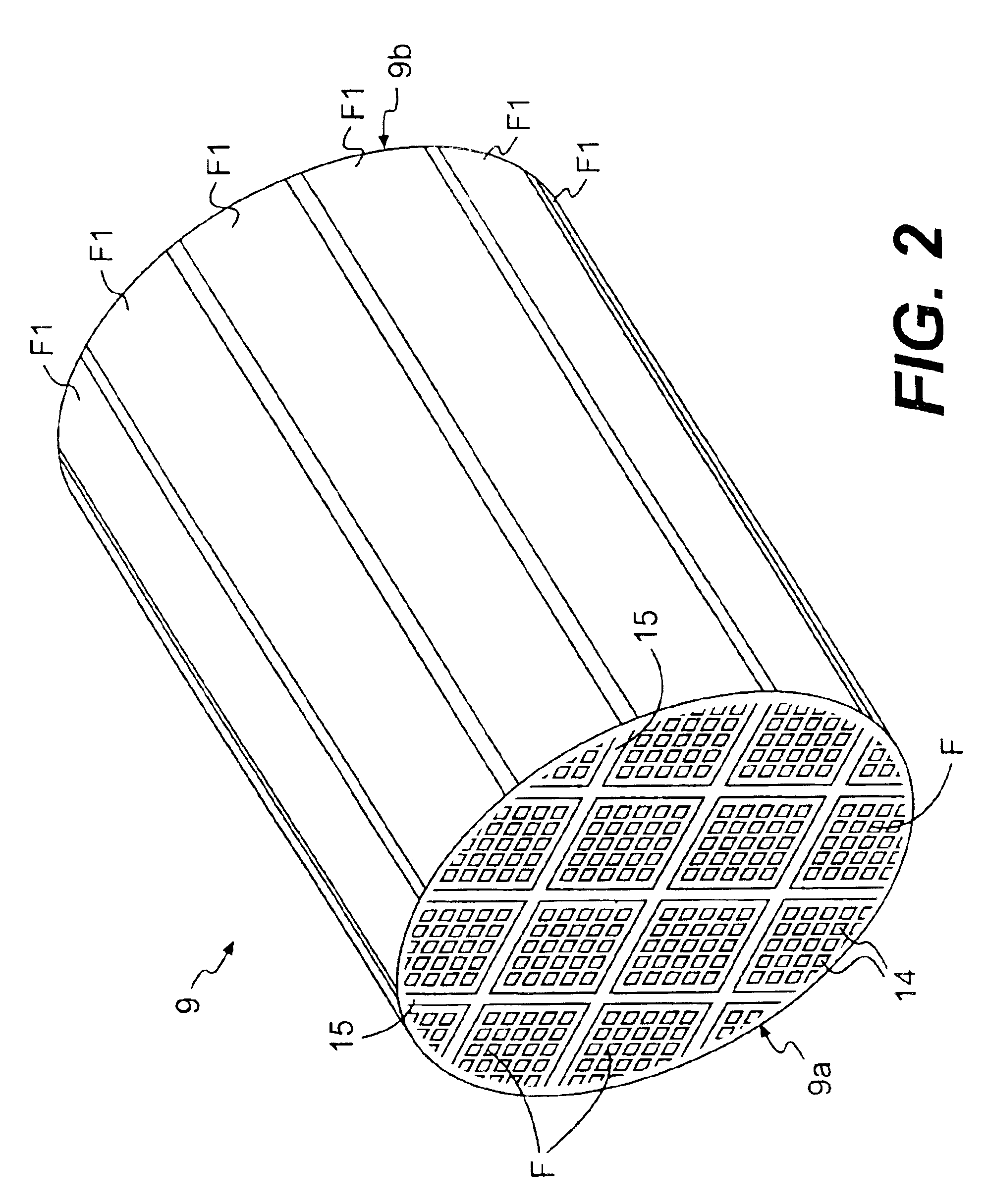

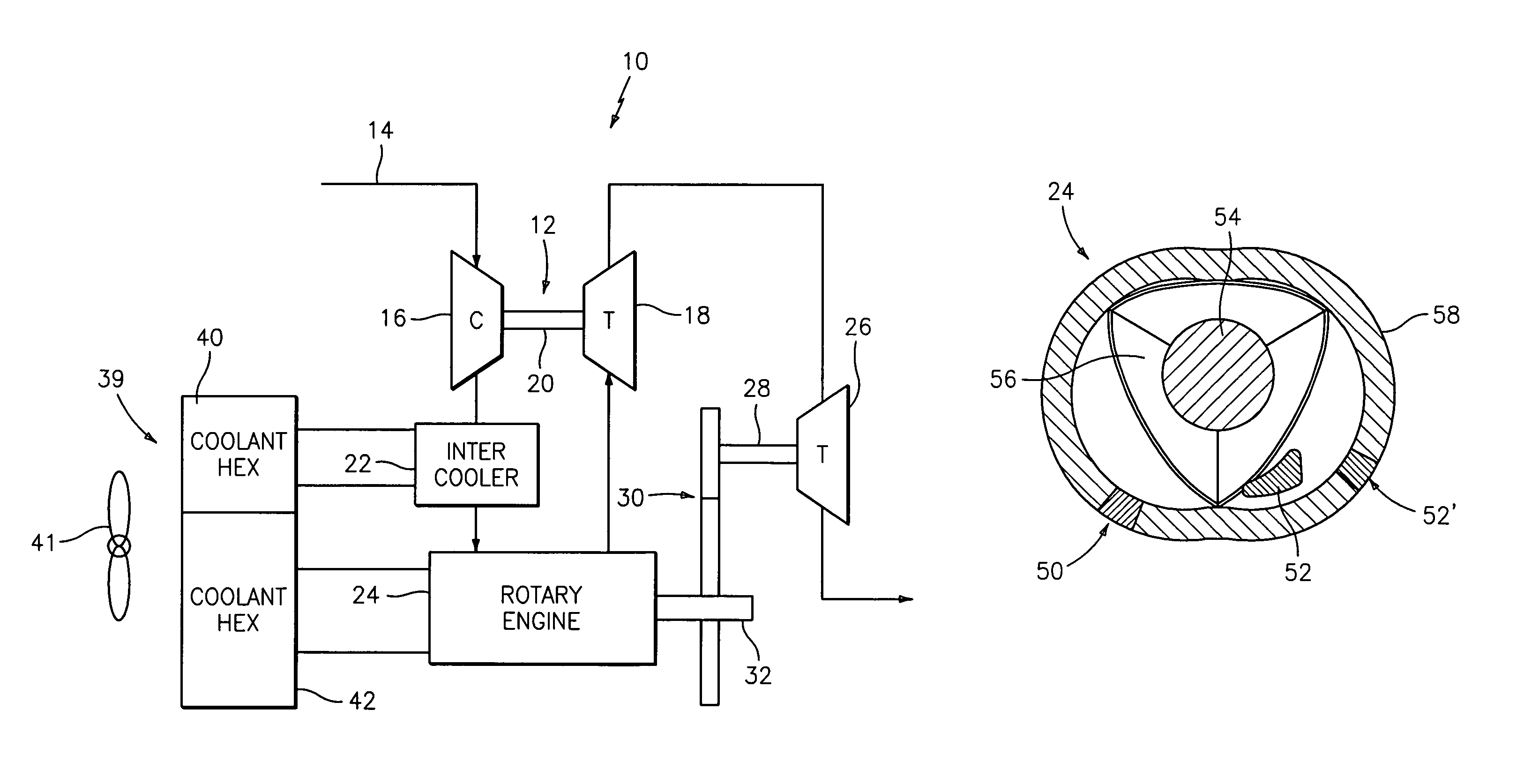

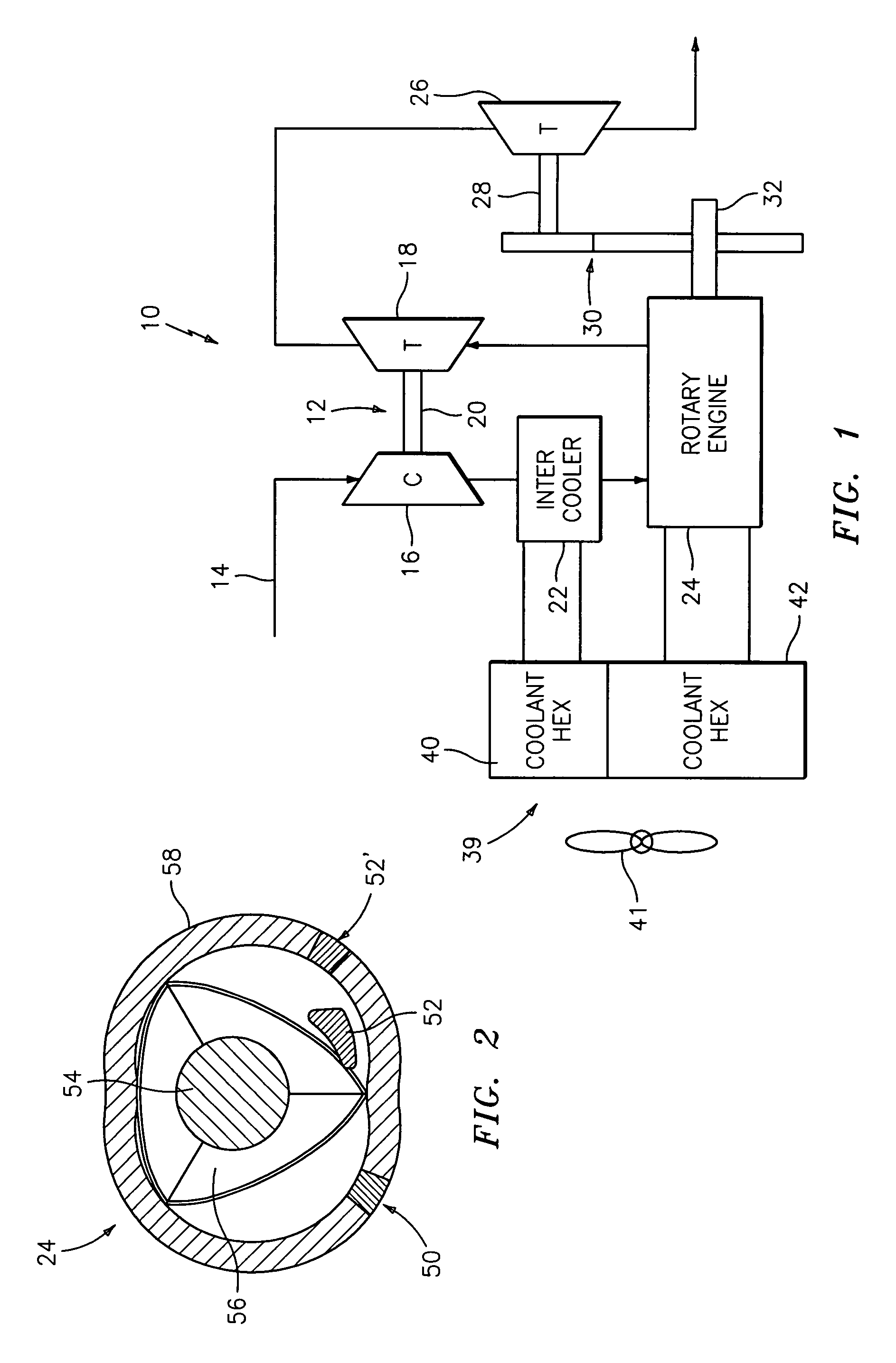

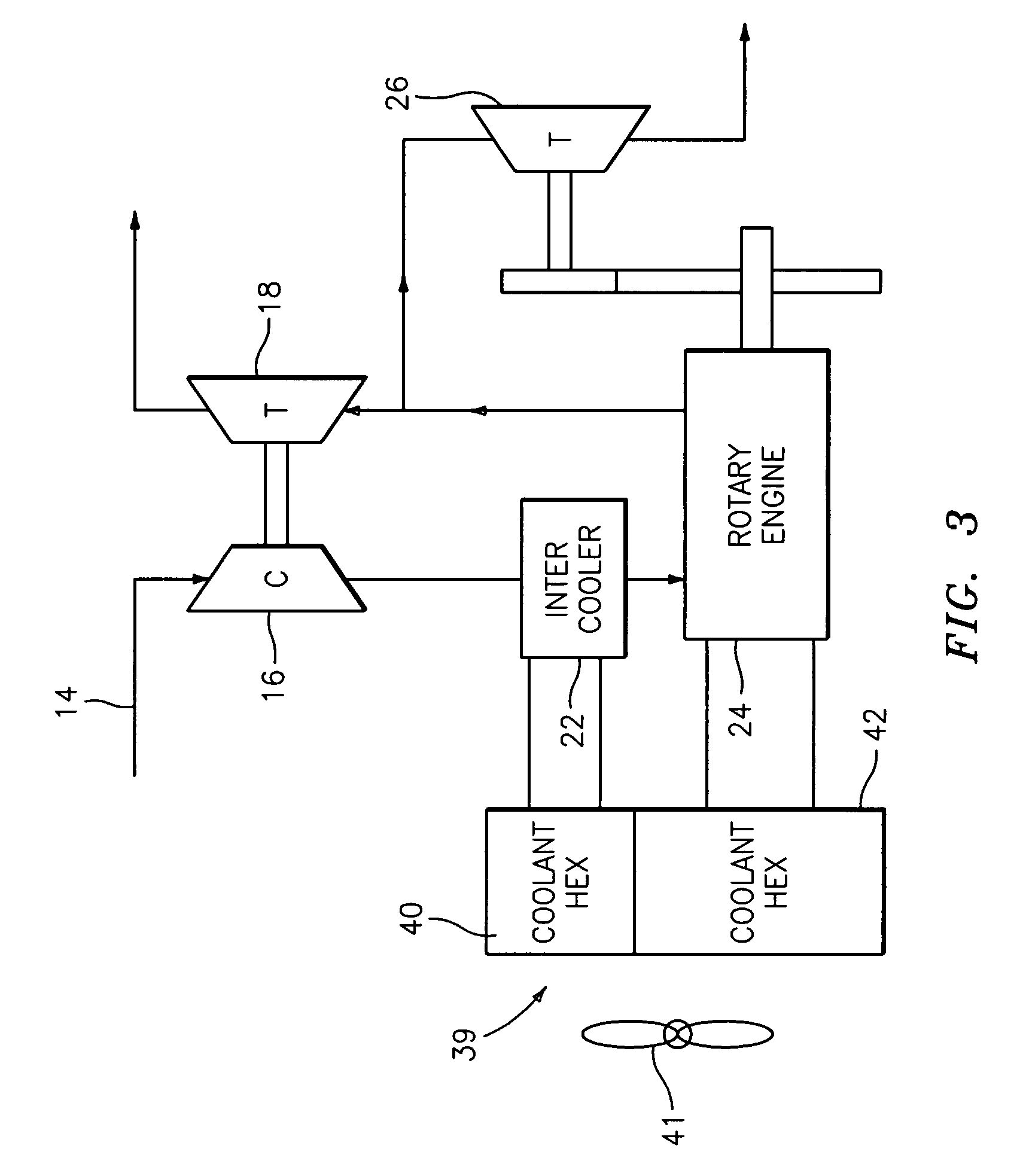

Compound cycle rotary engine

ActiveUS7753036B2High power to weightReduce fuel consumptionInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

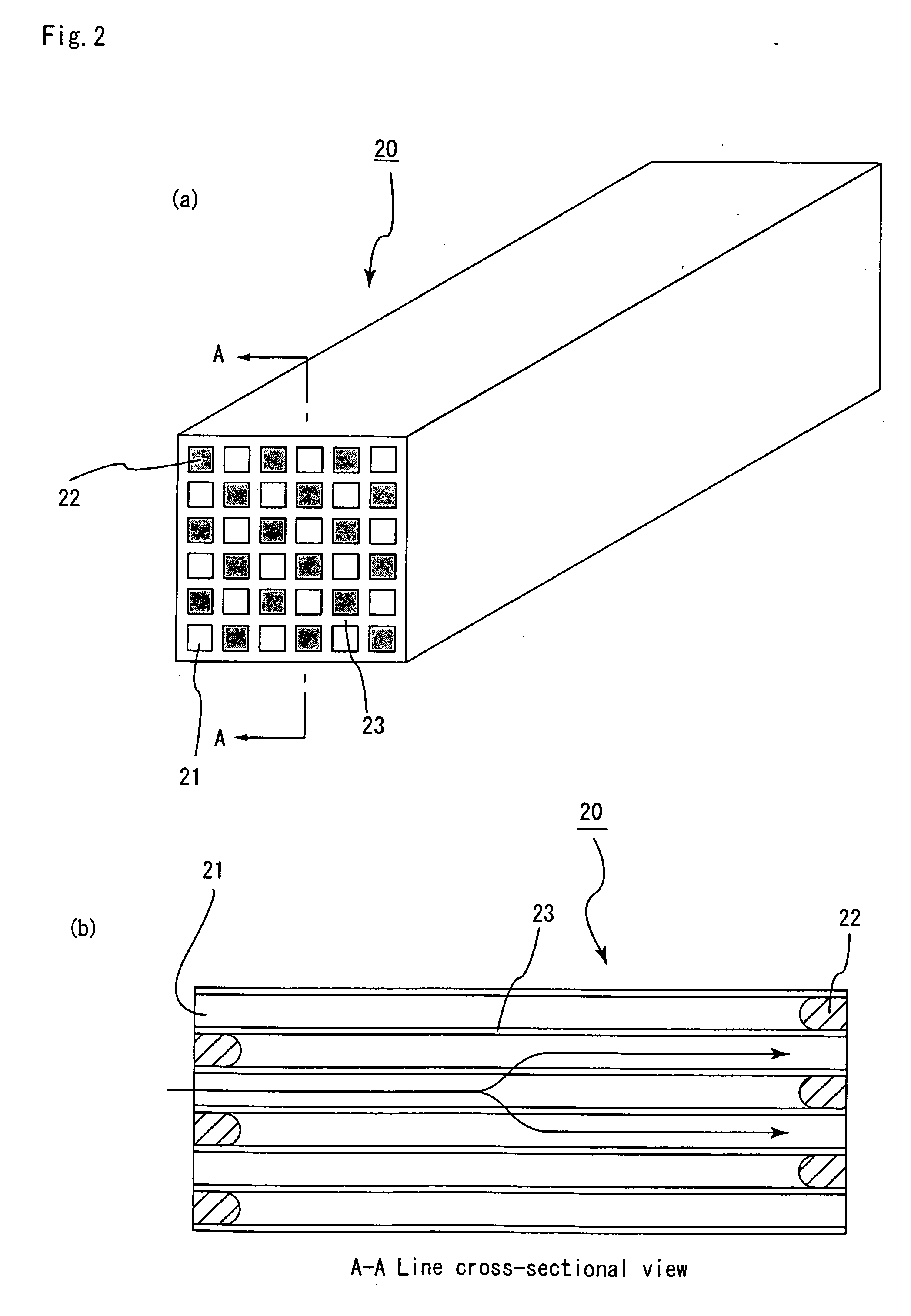

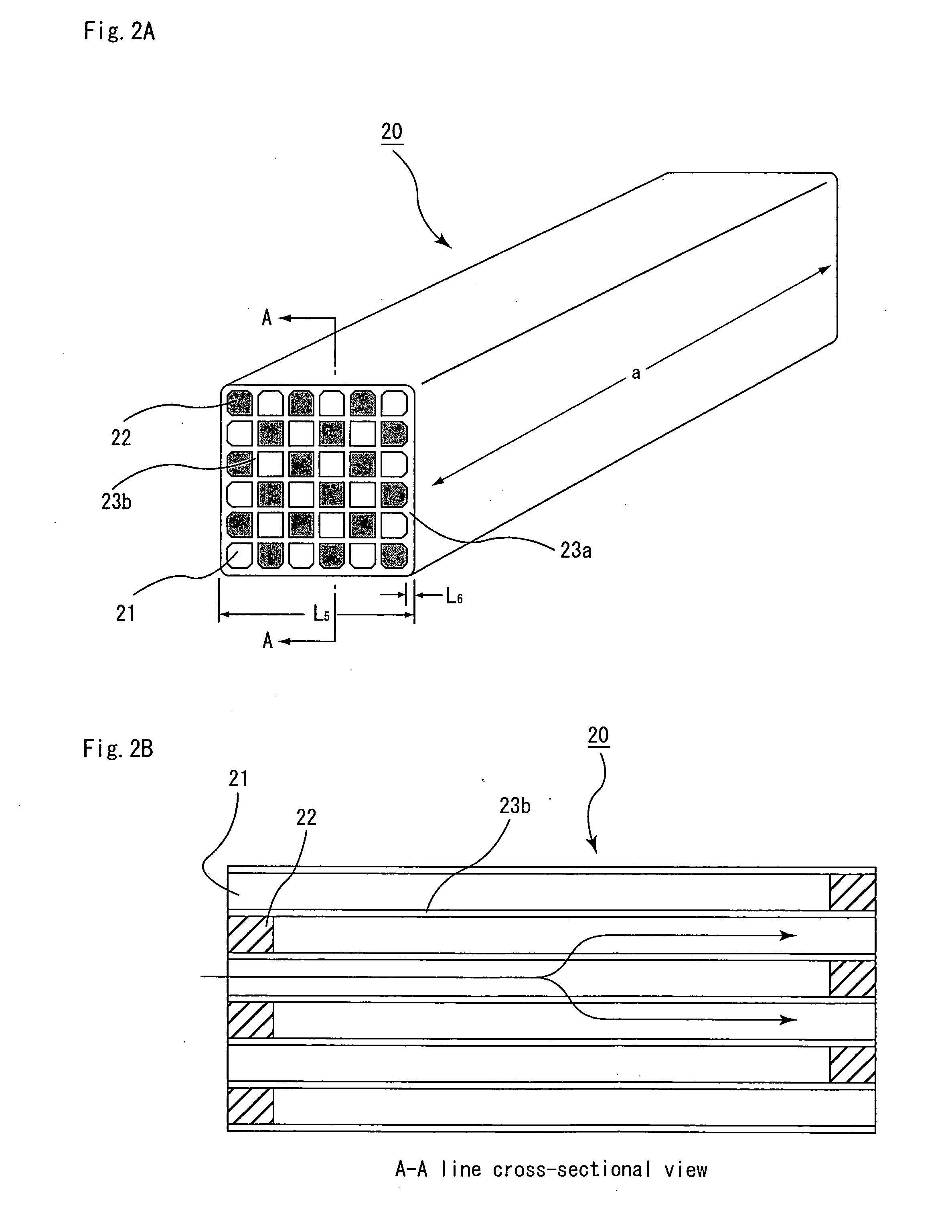

Honeycomb filter for clarification of exhaust gas

InactiveUS20050180898A1Increased durabilityReduce crackingCombination devicesInternal combustion piston enginesParticulatesHoneycomb

A honeycomb filter for purifying exhaust gases. A plurality of rectangular columnar porous ceramic members are combined with one another through a sealing material layer to constitute a ceramic block, each of the rectangular columnar porous ceramic member including a number of through holes that are placed in parallel with one another in the length direction with a partition wall interposed therebetween. A sealing material layer is also formed on a circumference portion of the ceramic block, and the partition wall that separates the through holes functions as a filter for collecting particulates. On a cross section perpendicular to the length direction of the porous ceramic member of the ceramic block, the maximum width L (mm) of the crisscross portion of the sealing material layer is 1.5 to 3 times greater than the minimum width I (mm) of the sealing material layer.

Owner:IBIDEN CO LTD

Honeycomb filter for clarifying exhaust gases

InactiveUS20050153099A1Increased durabilityPhysical/chemical process catalystsInternal combustion piston enginesParticulatesHoneycomb

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases that is free from a gap formed between a plug and a partition wall and cracks generated in the plug and a portion of the partition wall contacting the plug, and is superior in durability. The present invention provides a honeycomb filter for purifying exhaust gases which has a structure in which: a columnar body made of porous ceramic comprises a number of through holes, said through holes being placed in parallel with one another in the length direction with a wall portion interposed therebetween; predetermined through holes of said through holes are filled with plugs at one end of said columnar body, while the through holes that have not been filled with said plugs at said one end are filled with plugs at the other end of said columnar body; and a part or all of said wall portion functions as a filter for collecting particulates, wherein the porosity of the columnar body is in a range from 20 to 80%, and the porosity of the plug is 90% or less and is also set to 0.15 to 4.0 times as much as the porosity of the columnar body.

Owner:IBIDEN CO LTD

Layered noble metal-containing exhaust gas catalyst and its preparation

InactiveUS6294140B1Shorten recovery timeImprove conversion efficiencyOrganic chemistryNitrogen compoundsCerium(IV) oxideEngineering

A catalyst for treating exhaust gas from an internal combustion engine includes a carrier body coated with an inner layer and an outer layer. The inner layer includes platinum deposited on a first support material and on a first oxygen storage component, and the outer layer includes platinum and rhodium deposited on a second support material and on a second oxygen storage component. The first and second support materials may be the same or different, and may be selected from the group of: silica, alumina, titania, zirconia, mixed oxides or mixtures thereof, and zirconia-rich zirconia / ceria mixed oxide. The first and second oxygen storage components may include ceria-rich ceria / zirconia mixed oxide compounds, optionally including praseodymia, yttria, neodymia, lanthana or mixtures thereof.

Owner:DMC2 DEGUSSA METALS +1

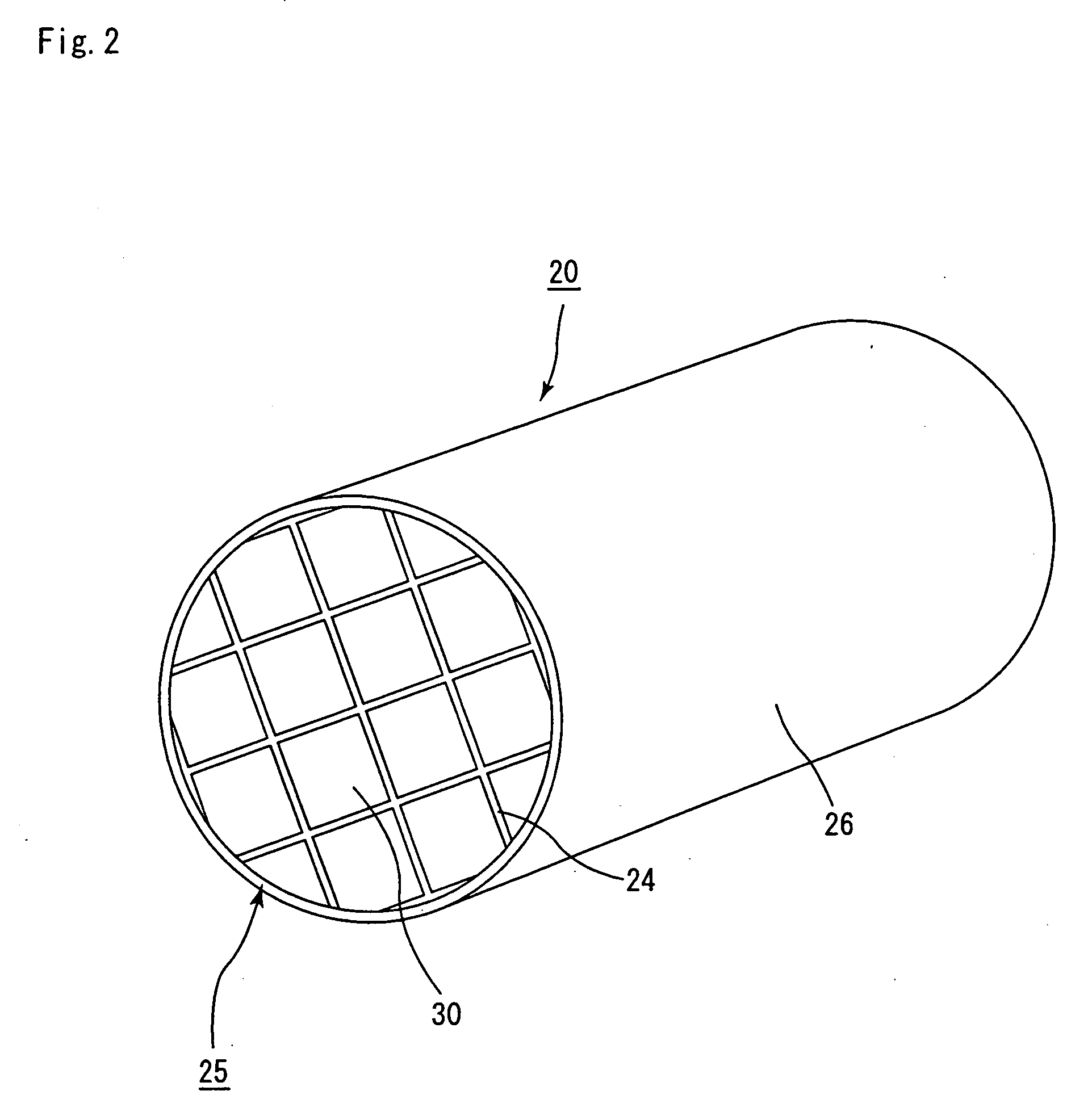

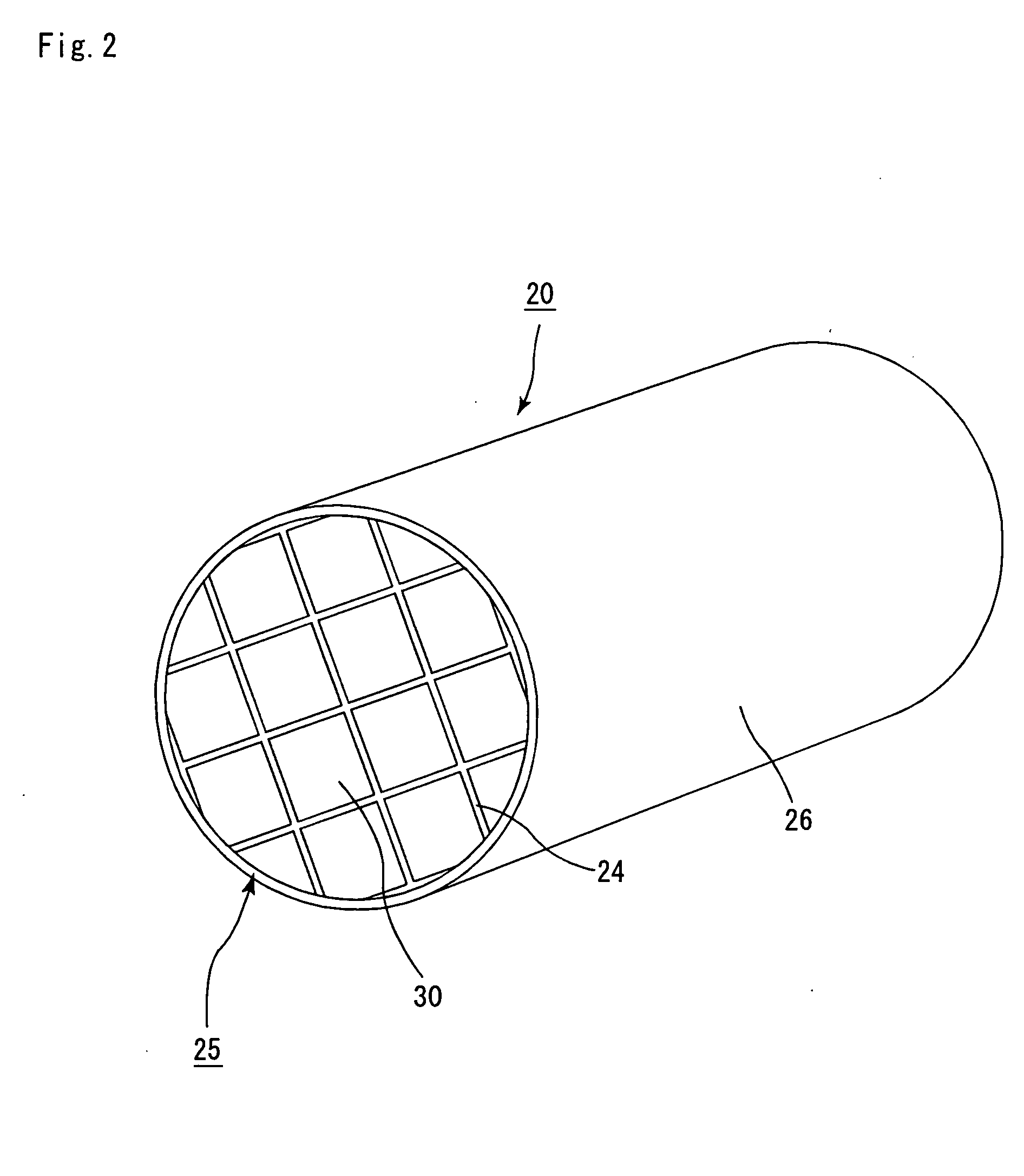

Honeycomb structured body, method for manufacturing honeycomb structured body and exhaust gas purifying device

ActiveUS20070128405A1Secure strengthLoss levelingPhysical/chemical process catalystsInternal combustion piston enginesRight triangleEdge surface

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and having an outer edge wall on the outer edge surface thereof, wherein each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members, a cross-sectional shape of the outermost cell at the face orthogonal to the longitudinal direction of the cells is an almost tetragon, and a cross-sectional shape of the filling body at the face orthogonal to the longitudinal direction of the cells is an almost right triangle.

Owner:IBIDEN CO LTD

Honeycomb filter for clarifying exhaust gas

ActiveUS20050175514A1Increased durabilityCombination devicesPhysical/chemical process catalystsHoneycombFlexural strength

A honeycomb filter for purifying exhaust gases that is free from occurrence of cracks and coming-off of plugs and is superior in durability upon its use. The honeycomb filter includes a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, designed so that predetermined of the through holes are filled with plugs at one end of the columnar body, while the through holes not filled with the plugs at the one end are filled with plugs at the other end of the columnar body, and part of or the entire wall portion functions as a plug for collecting particles. A bending strength Fα (MPa) of the honeycomb filter and a length L (mm) of the plug in the length direction of the through hole satisfy the relationship of Fα×L≧30.

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com