Patents

Literature

258 results about "High ozone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ozone levels are generally highest in the hot afternoon hours. The highest ozone levels occur during the summer when strong sunlight, high temperatures, and stagnant meteorological conditions combine to drive the chemical reactions and trap the air in the region for several days.

Apparatus for the purification of water and method therefor

InactiveUS6090294AComprehensive understandingSignificant utilityOther chemical processesIon-exchanger regenerationSolubilityGas phase

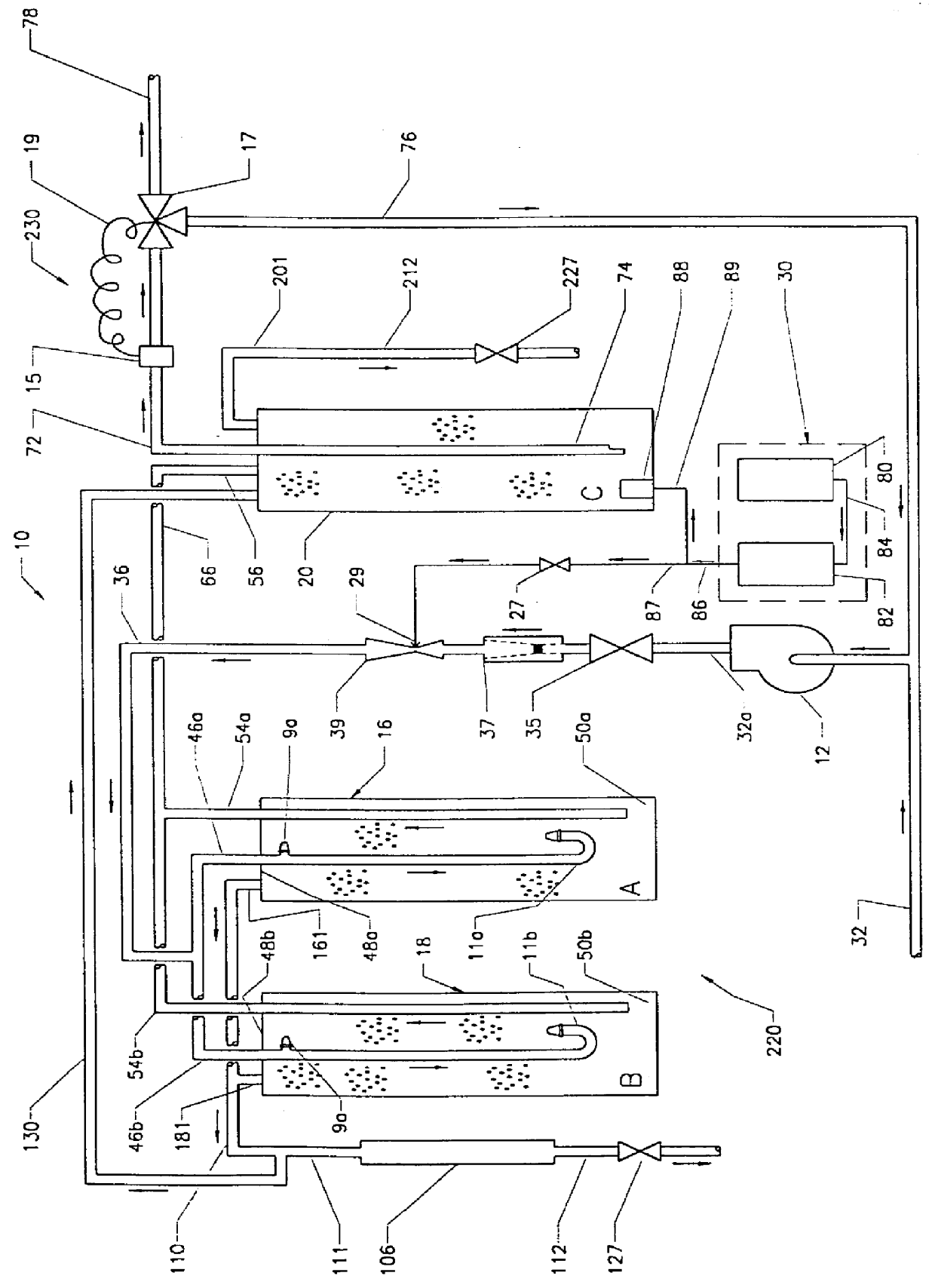

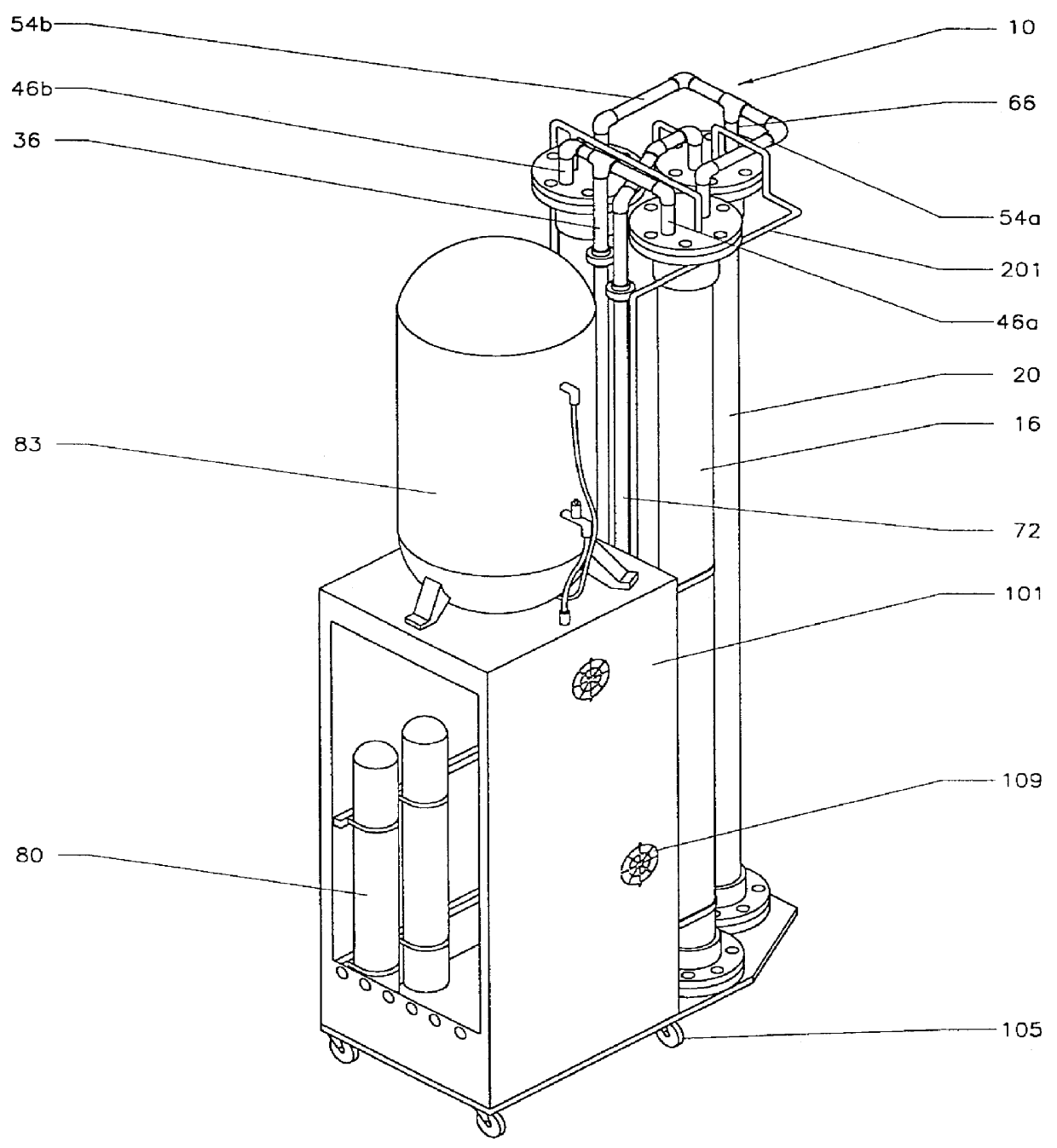

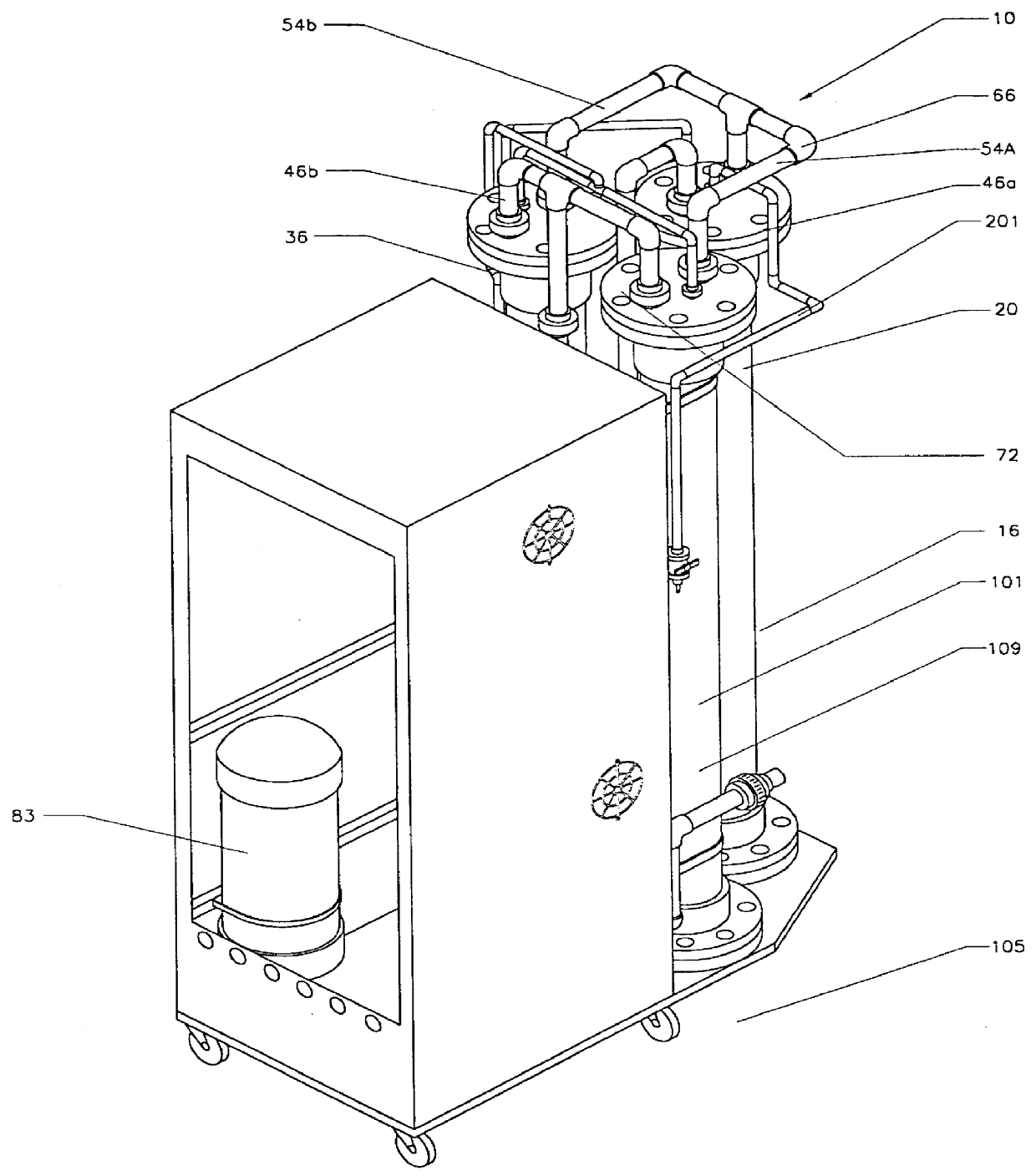

An apparatus and method for the purification of contaminated water whereby the contamination level of the wastewater is automatically monitored and treatment self-adjusted and continued until the desired level of purification is reached. Specifically, if upon treatment a pre-set purification level is not obtained a water recycle control means completely precludes the uptake of additional contaminated water and recycles wastewater within the apparatus until the desired level of purification is obtained. The present invention more particularly pertains to an efficient, turn key, economical, movable, automatic and compact apparatus and method for treating a fluid with ozone comprising multiple pressurized contact columns which are arranged in a hybrid parallel and series column configuration, which utilizes a unique water recycle control system and piping arrangement to improve the efficiency of the mass transfer of ozone into the water and increase its solubility by increasing the contact time between the water phase and the gas phase. The apparatus and method of the present invention has the further advantage that it requires minimal installation and may be used to fulfill the clean and safe water needs of any hotel, resort, restaurant, hospital, light industry, commercial business, apartment complex or small city.

Owner:AGRIMOND USA CORP

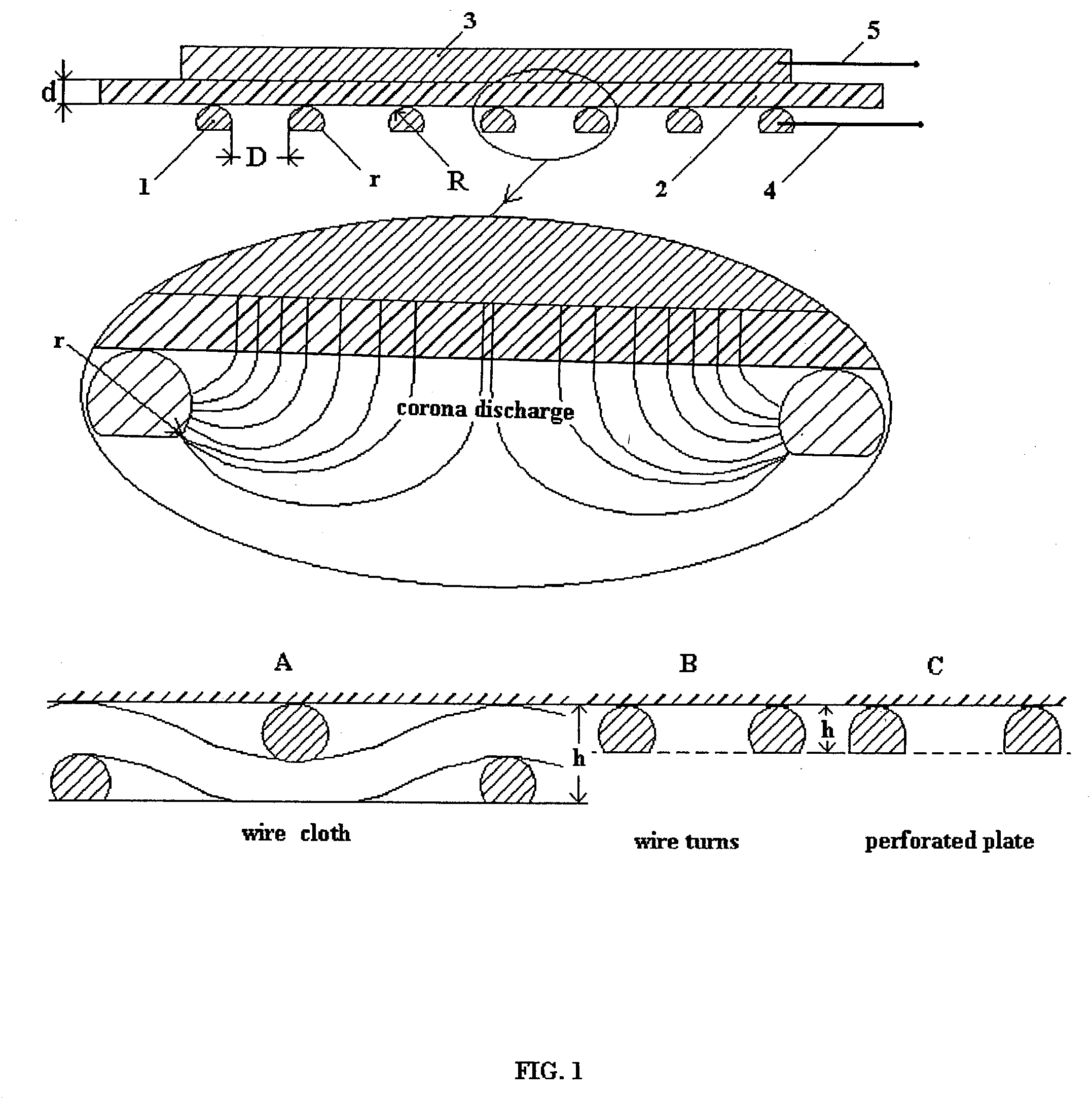

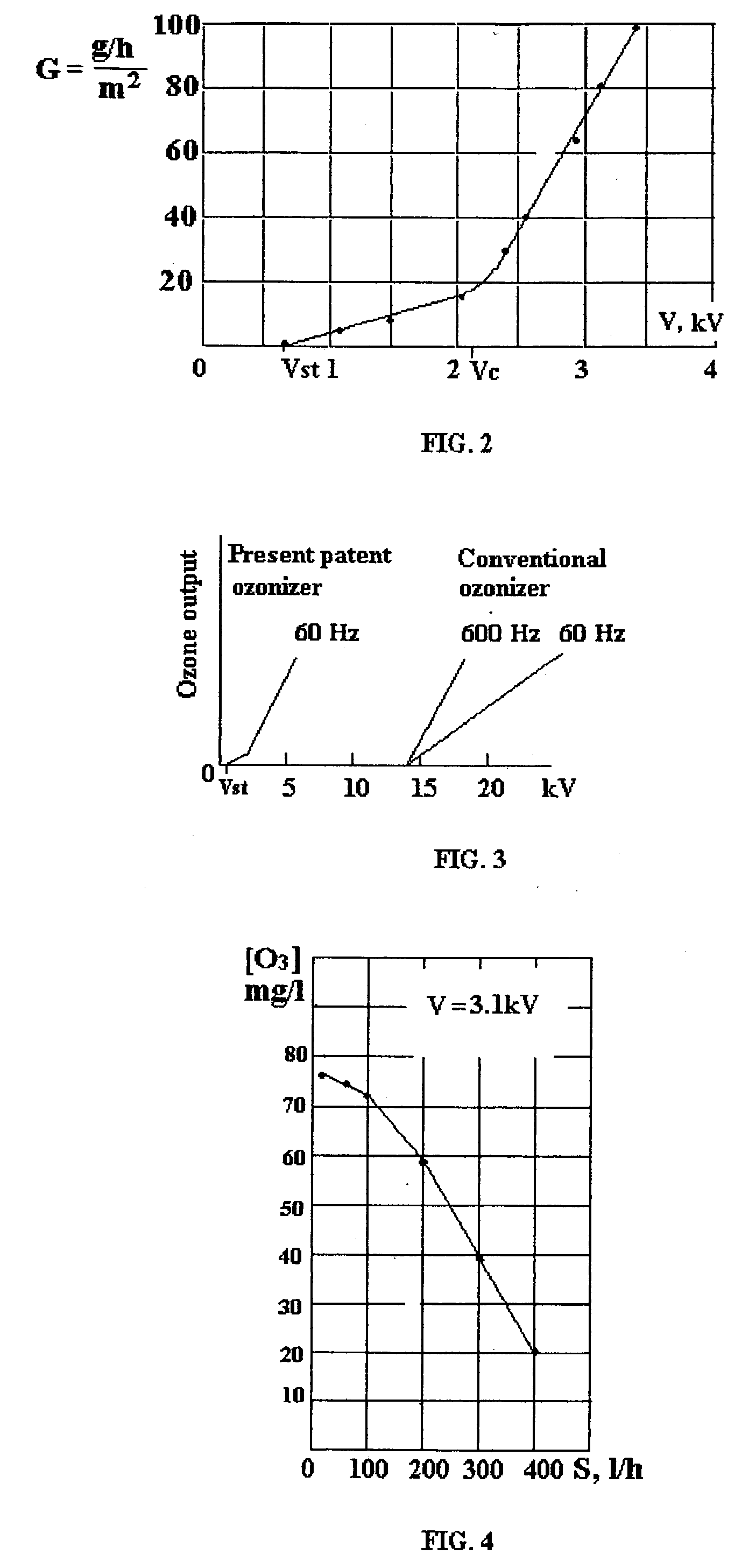

Method for surface corona/ozone making, devices utilizing the same and methods for corona and ozone applications

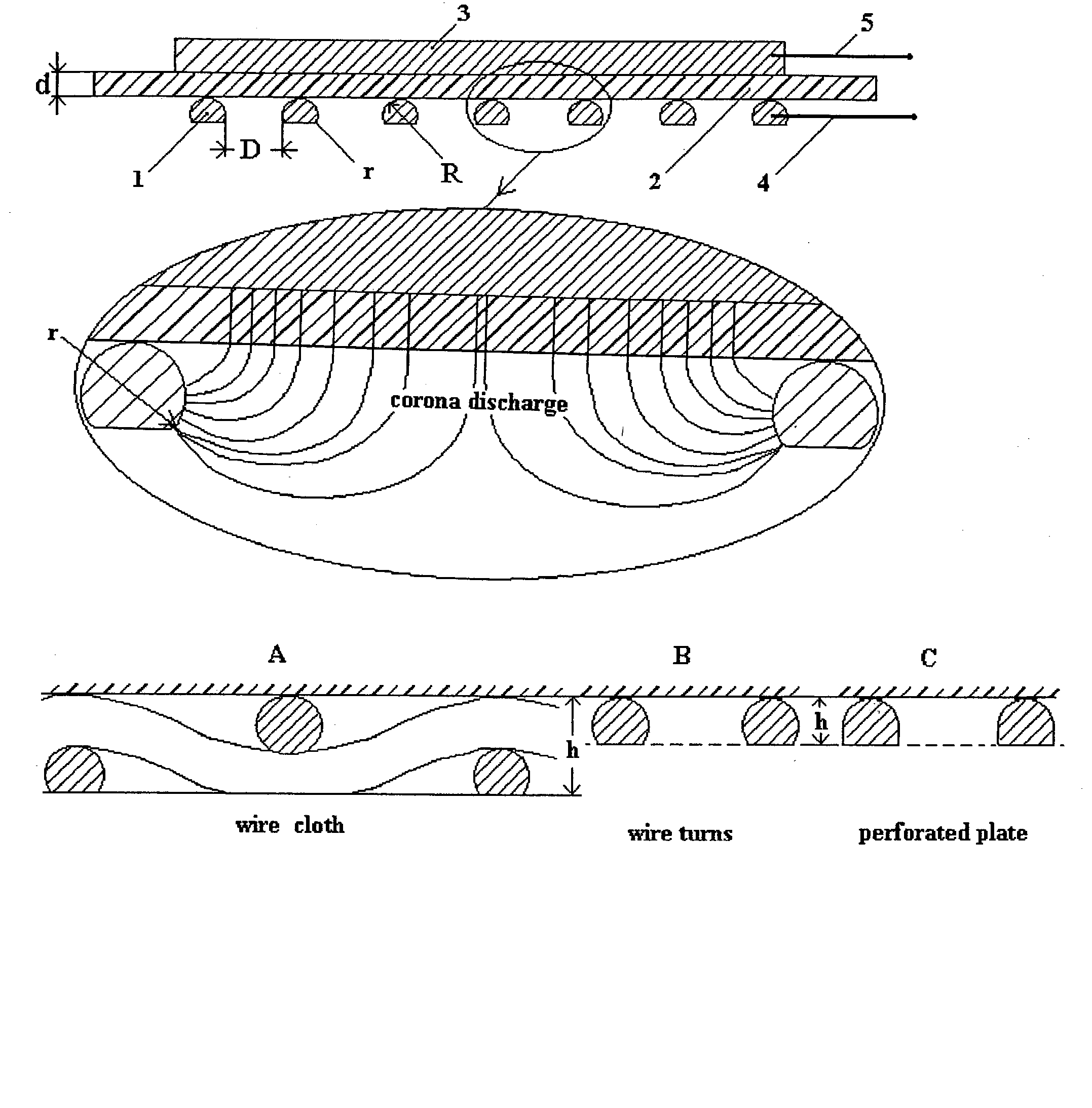

A method for making surface corona discharge, which produces ozone gas and apparatus for producing the same are disclosed, in which a dielectric spacer / film having a specific capacity C' equal to or more than 200 nanofarad per square meter positioned between the base electrode and the net electrode. Said net electrode is a wire net or a perforated metal or a wire winding having an open area not less than about 70%, and a size of hole D equals to or less than about 0.7V / P, where V is a voltage in kilovolts and P is pressure of an ambient air or an oxygen in atmospheres. Net electrode has radius R of wire or radius of an edge of openings in the perforated metal equal to or more than about 1.6d, where d is the thickness of the said dielectric spacer / film, which is determined by a fundamental formula d=9k / C', where d is in millimeters, C' is in nF / m2, and k is dimensionless dielectric constant k of given material. Under disclosed parameters said surface corona is safe for human contact if said net electrode is grounded. Start voltage Vst of ozone production is determined by experimental formula Vst=0.7+60 / C', kV, here C' in nF / m2. The even and high intensity corona surface and high ozone output takes place if the operating voltage is more than about 3Vst. AC power supply is applied to produce ozone gas at "home" voltage 0.7-1.0 kV and produces ozone gas more effectively at 2,5-3.6 kV. A method for disinfection and decontamination of objects by using the direct corona contact and apparatus for making the same is disclosed, in which safe corona surface is placed on said object and is acting by ozone, ultraviolet and ion bombing simultaneously in the unique environment, which takes place inside of the safe corona. A method for ozone disinfection and decontamination and devices for making the same is disclosed, in which said ozone generating element is placed in a closed container / room with or without treated objects and produce a high ozone concentration due to effective ozone dispersion from corona surface without blowing of air / oxygen through said container / room.

Owner:ANDREEV SERGEY I +1

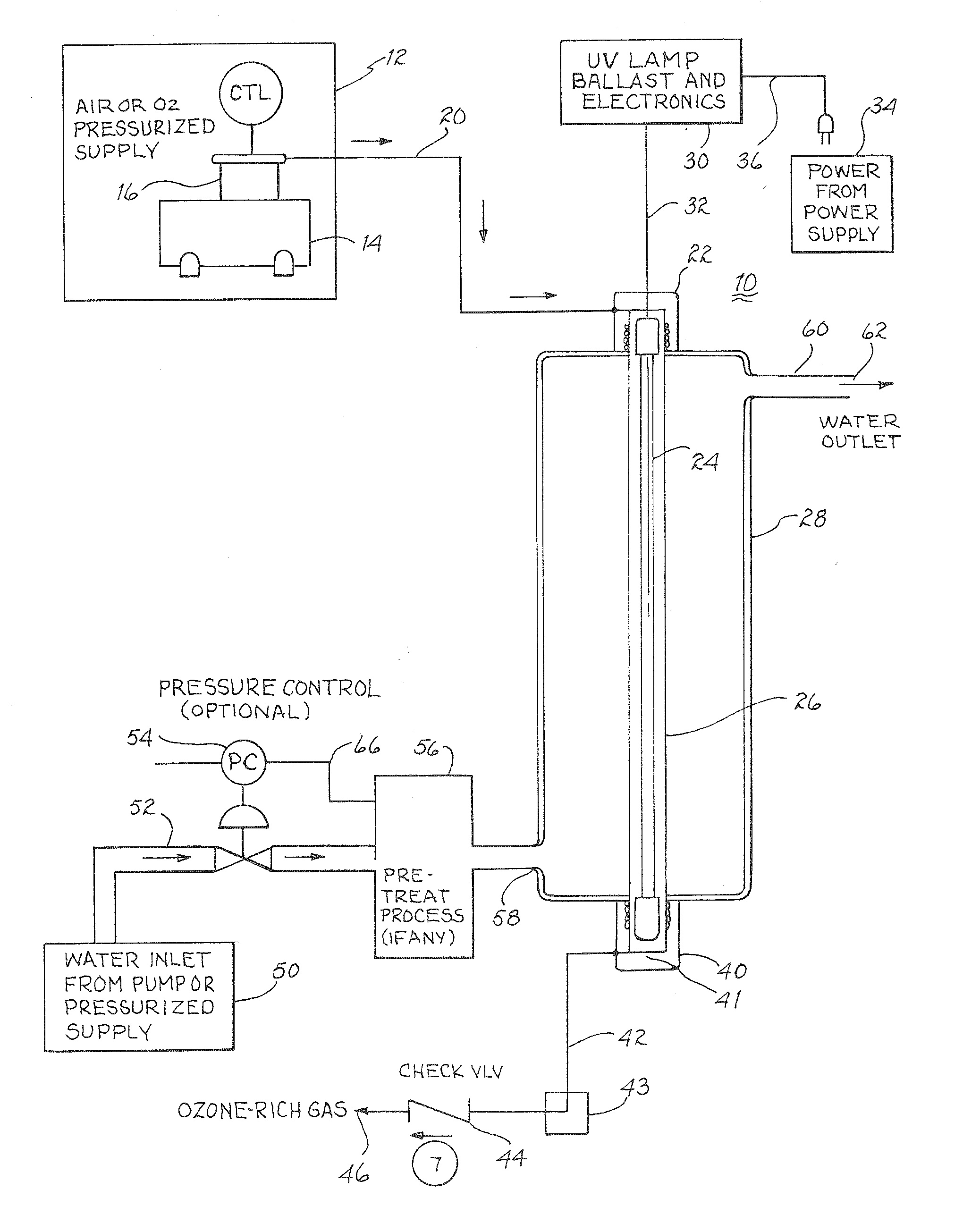

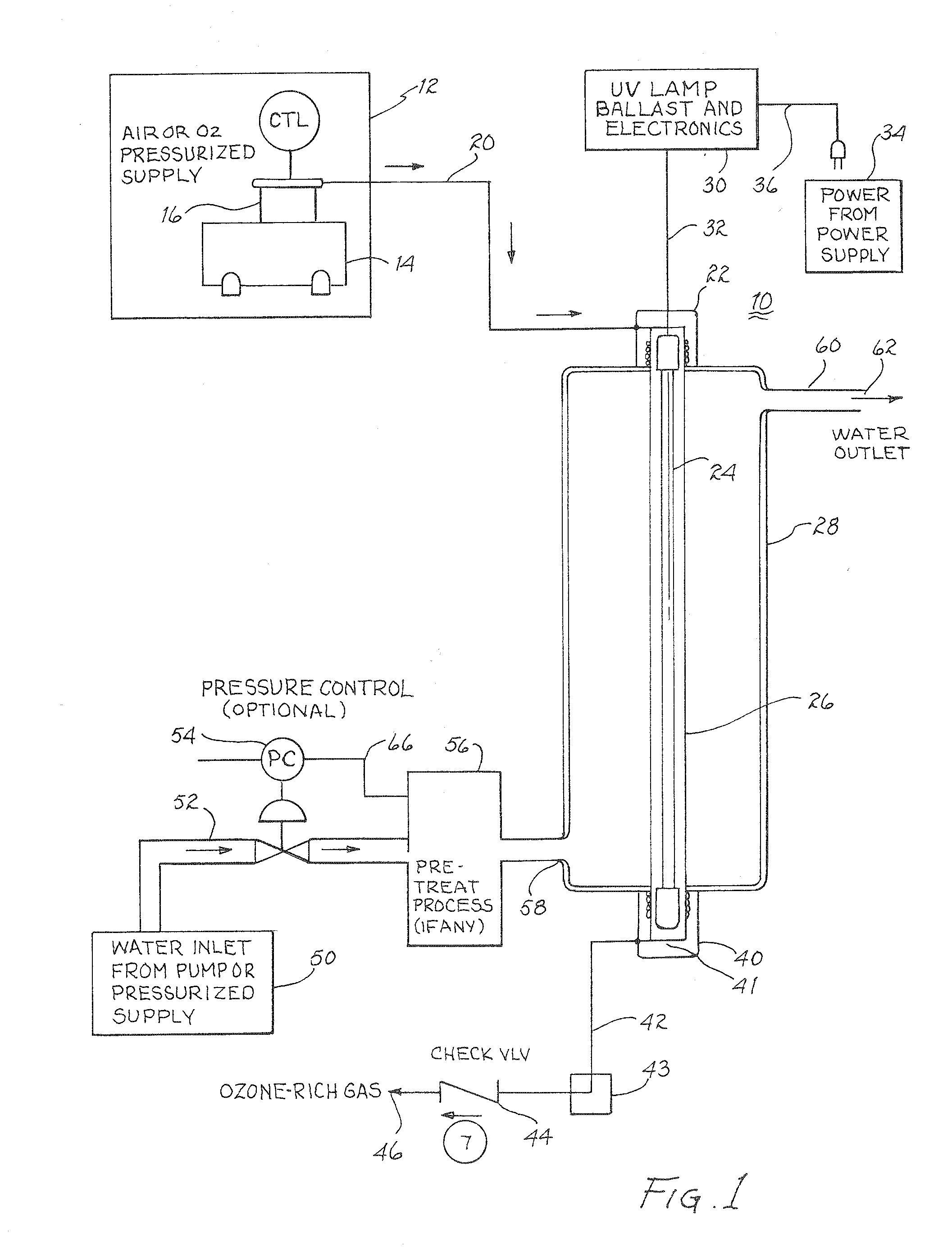

Pressurized uv/o3 water purification system

InactiveUS20080008632A1High ozone concentrationImprove concentrationWater treatment parameter controlWater contaminantsHigh concentrationDifferential pressure

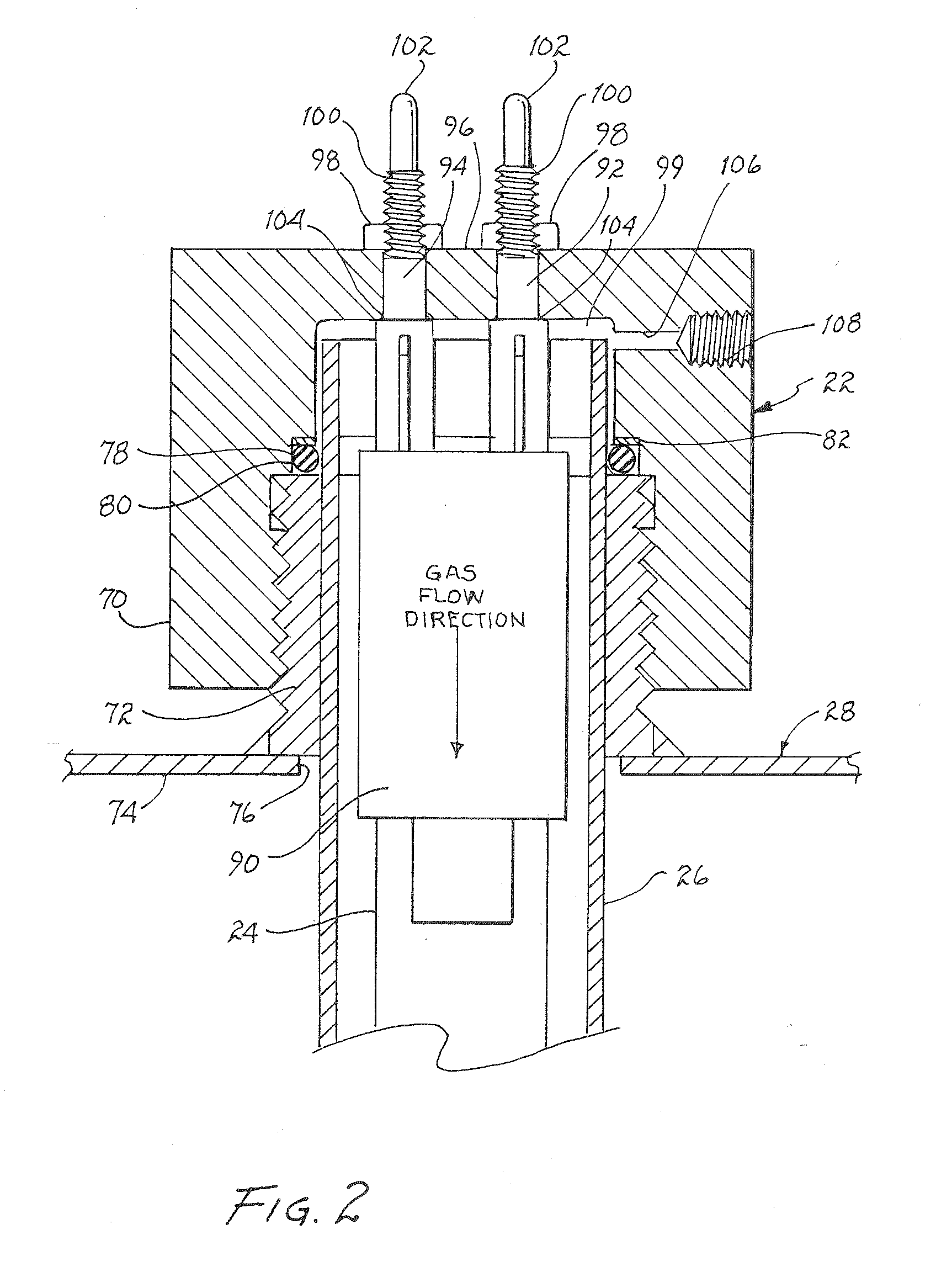

An oxygen containing gas is injected at a pressure in the range of about two (2) to about five (5) atmospheres or more into an ultraviolet transmissive sleeve surrounding an ultraviolet lamp to produce a high concentration of ozone. Simultaneously, the ultraviolet lamp irradiates water to be purified disposed in a container surrounding the sleeve. The ozone enriched gas is entrained into the water flowing into the container resulting in an oxidative reaction with any organic matter present and coming into contact with the ozone. Alternatively, the ozone may be entrained in water in a second container downstream of the container wherein the water has been irradiated with ultraviolet radiation. In a further variant, the ozone may be entrained in water in a container upstream of the container wherein the water has been irradiated with ultraviolet radiation. In a yet further variant, the ozone may be entrained in one or more containers upstream and prior to irradiation of the water with ultraviolet radiation in the downstream most container. The ozone may be extracted from the ozonated water prior to discharge if the oxidative effect of the ozone is not desired for the intended end use. To enhance ozone production a predetermined pressure is maintained within the sleeve. To prevent damage to sleeve in the event of a drop in pressure of the water surrounding the sleeve, a further differential pressure regulator may be used to relieve the pressure within the sleeve by discharging ozonated gas from within the sleeve. By use of specifically configured end caps for the sleeve, certain existing water purification systems may be converted to embody the present invention.

Owner:ZUCO WATER LLC

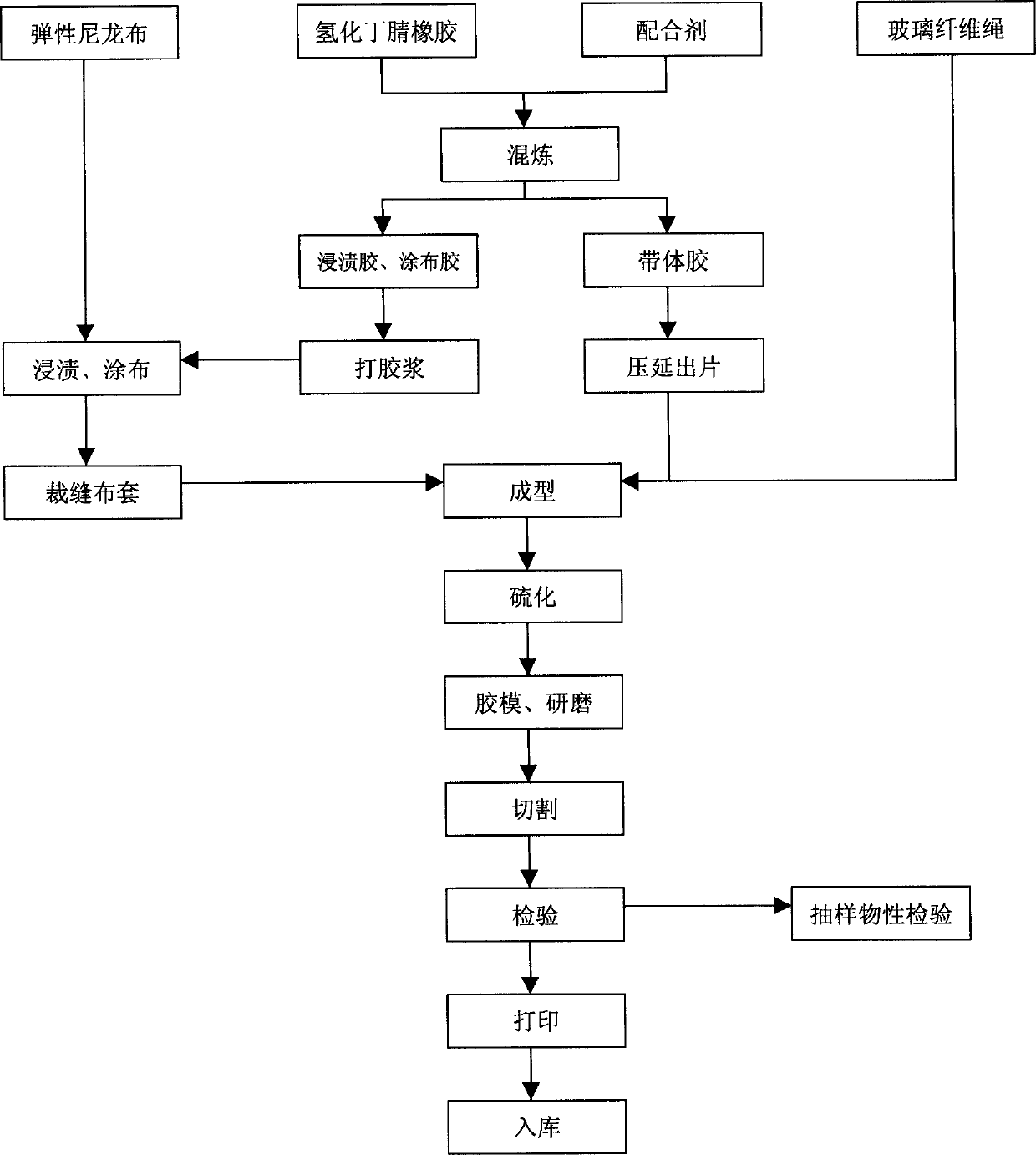

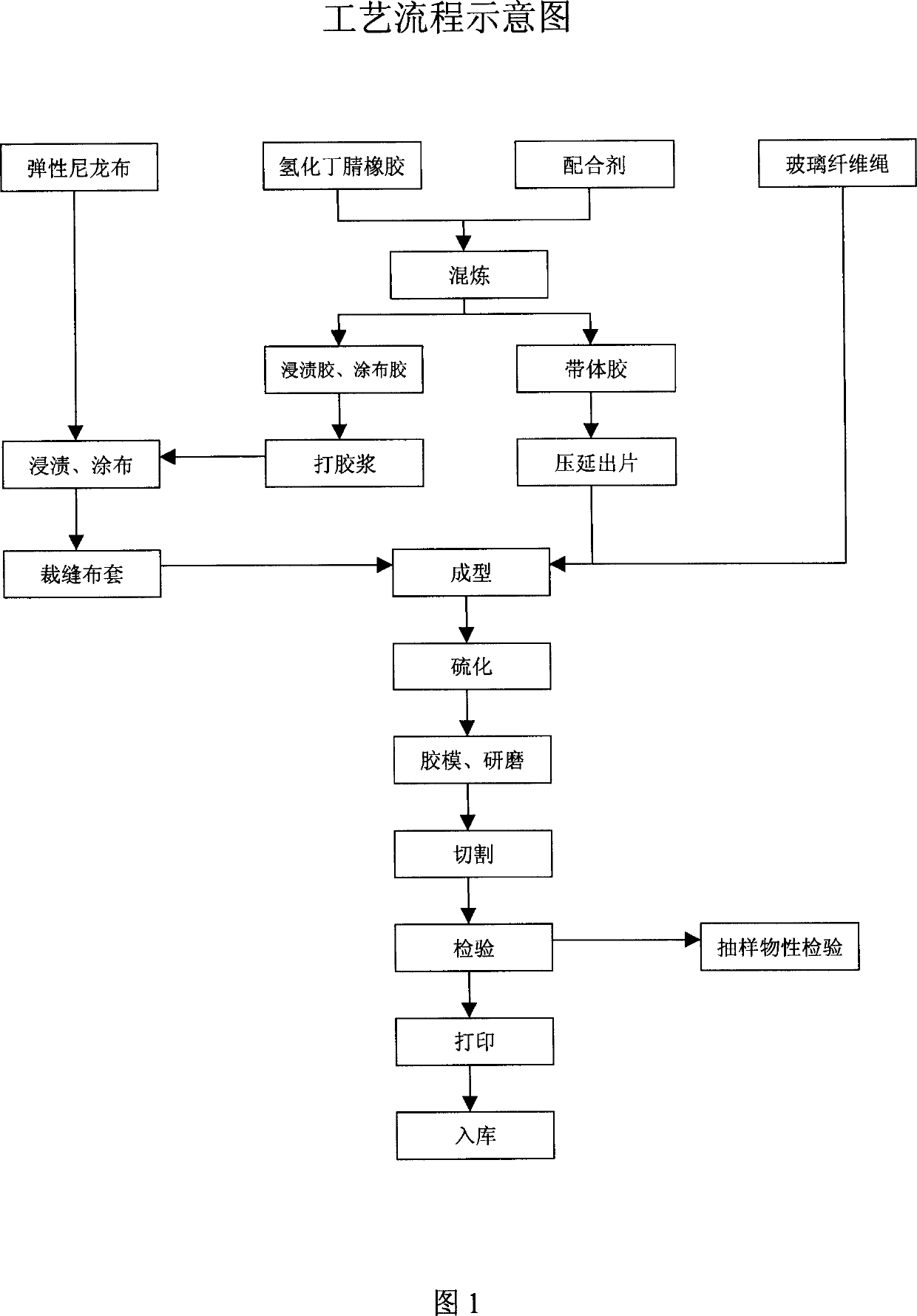

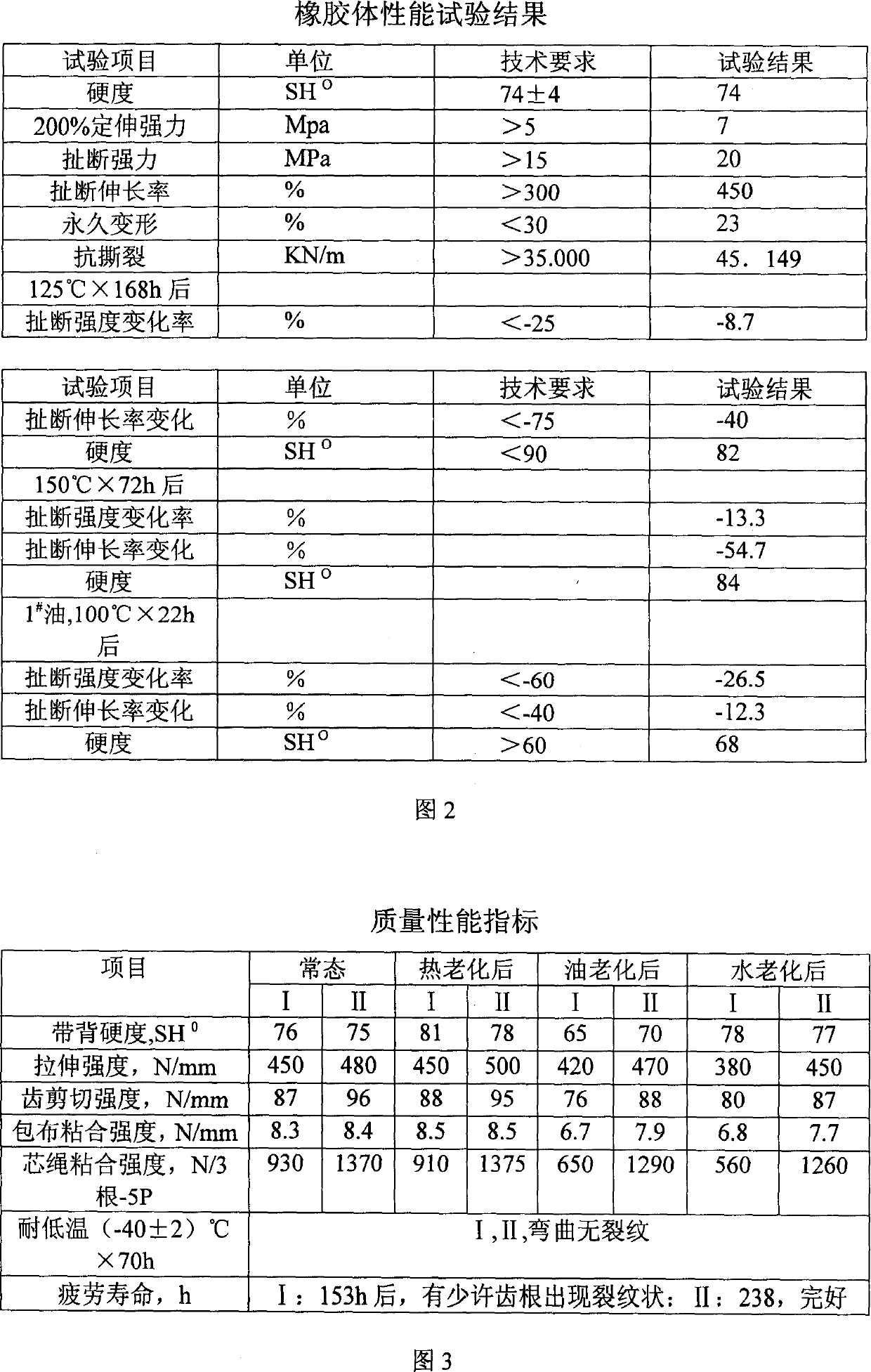

Rubber automobile synchronous belt and its producing method

The rubber holding belt is key part of automobile engine, and used for the timing ignition and gas distribution of cam shaft automobile engine. The materials including elastic nylon cloth as toothed coating cloth, hydrogenated butadiene-acrylonitrile rubber and auxiliary materials are produced through mixing to form the rubber belt, calendering to form sheet, shaping, sulfurizing, demolding, grinding, cutting, packing and other steps into the rubber holding belt. The product s high strength, high wear resistance, high ozone resistance, high rebound elasticity, less deformation, low cost, simple production process, long service life and capacity of operation in 130 deg.c environment.

Owner:朱国有 +3

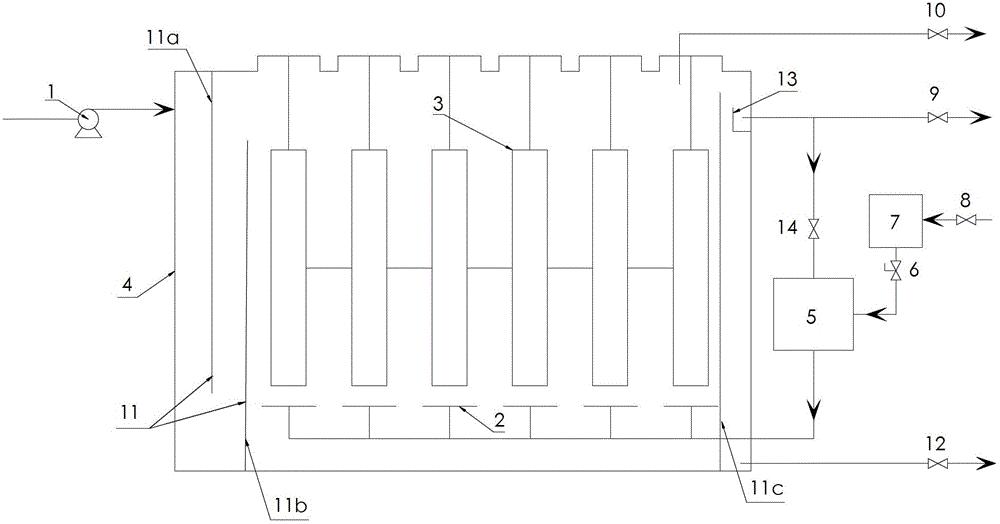

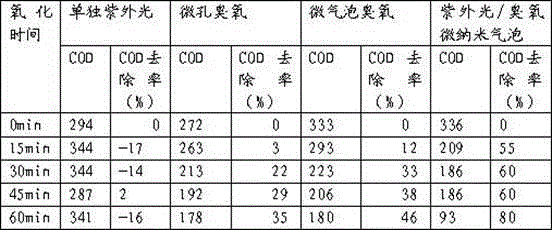

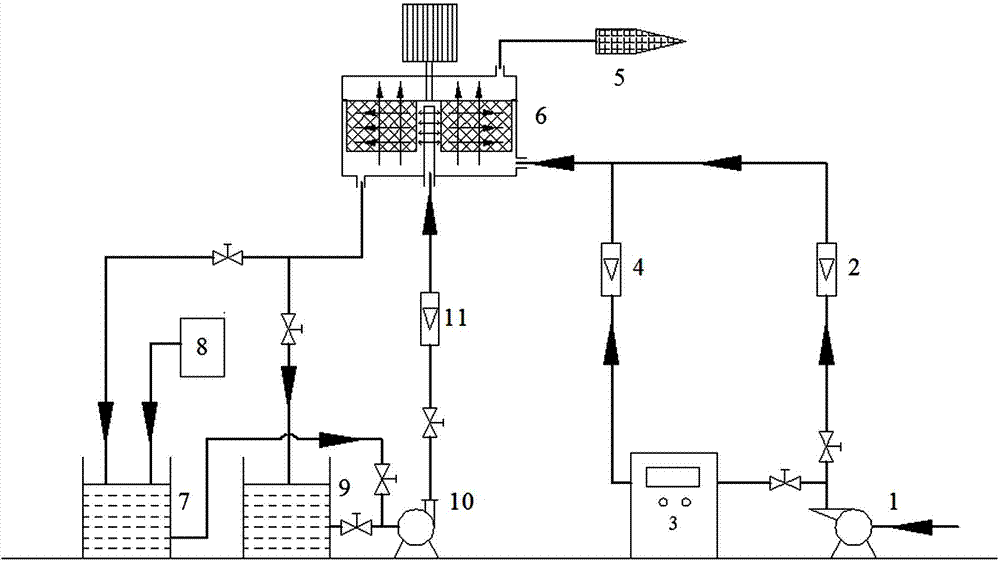

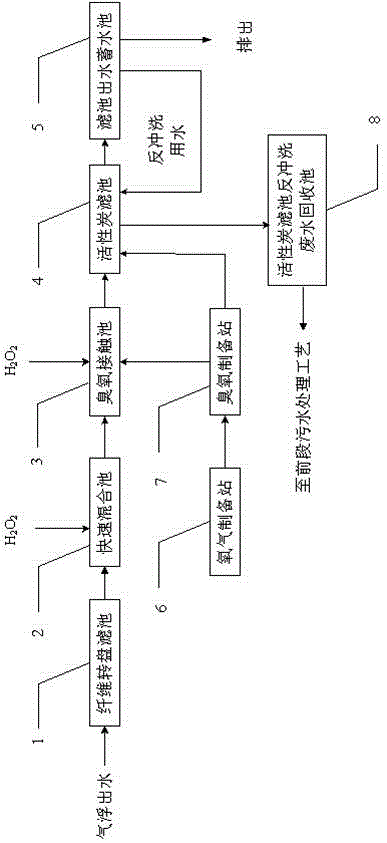

Waste water treatment system of ultraviolet light and ozone micro/nanobubbles and method

ActiveCN102910772AImprove biodegradabilityExtended stayWater/sewage treatment by irradiationMultistage water/sewage treatmentWater treatment systemUltraviolet lights

The invention relates to a waste water treatment system of ultraviolet light and ozone micro / nanobubbles, which comprises a raw water lifting pump, a reaction tank, an ultraviolet lamp casing pipe group, a micro / nanobubble generator and an ozone generator. The water inlet of the reaction tank is positioned at the upper part of the water inlet end of the reaction tank; a water outlet overflow weir is arranged at the upper part of the water outlet end of the reaction tank; the ultraviolet lamp casing pipe group is hung on an upper cover of the reaction tank; the water outlet overflow weir is respectively communicated with a water outlet valve of the reaction tank and the water inlet of the micro / nanobubble generator; the air inlet of the micro / nanobubble generator is connected with the ozone generator; and the micro / nanobubble generator leads produced air-water mixture into the reaction tank. The waste water treatment system adopts ultraviolet light and ozone micro / nanobubbles, improves the mass transfer performance of ozone, greatly improves the utilization rate of ozone, and reduces the output of tail gas. The particle size of ozone micro / nanobubble is small, the quantity of the ozone micro / nanobubbles is large, the retention time of the ozone micro / nanobubbles is long, and the ozone micro / nanobubbles can scrub the surface of an ultraviolet lamp casing pipe while being spread in water to prevent the adhesion or scaling of organic or inorganic pollutant.

Owner:UNIV OF SCI & TECH BEIJING +1

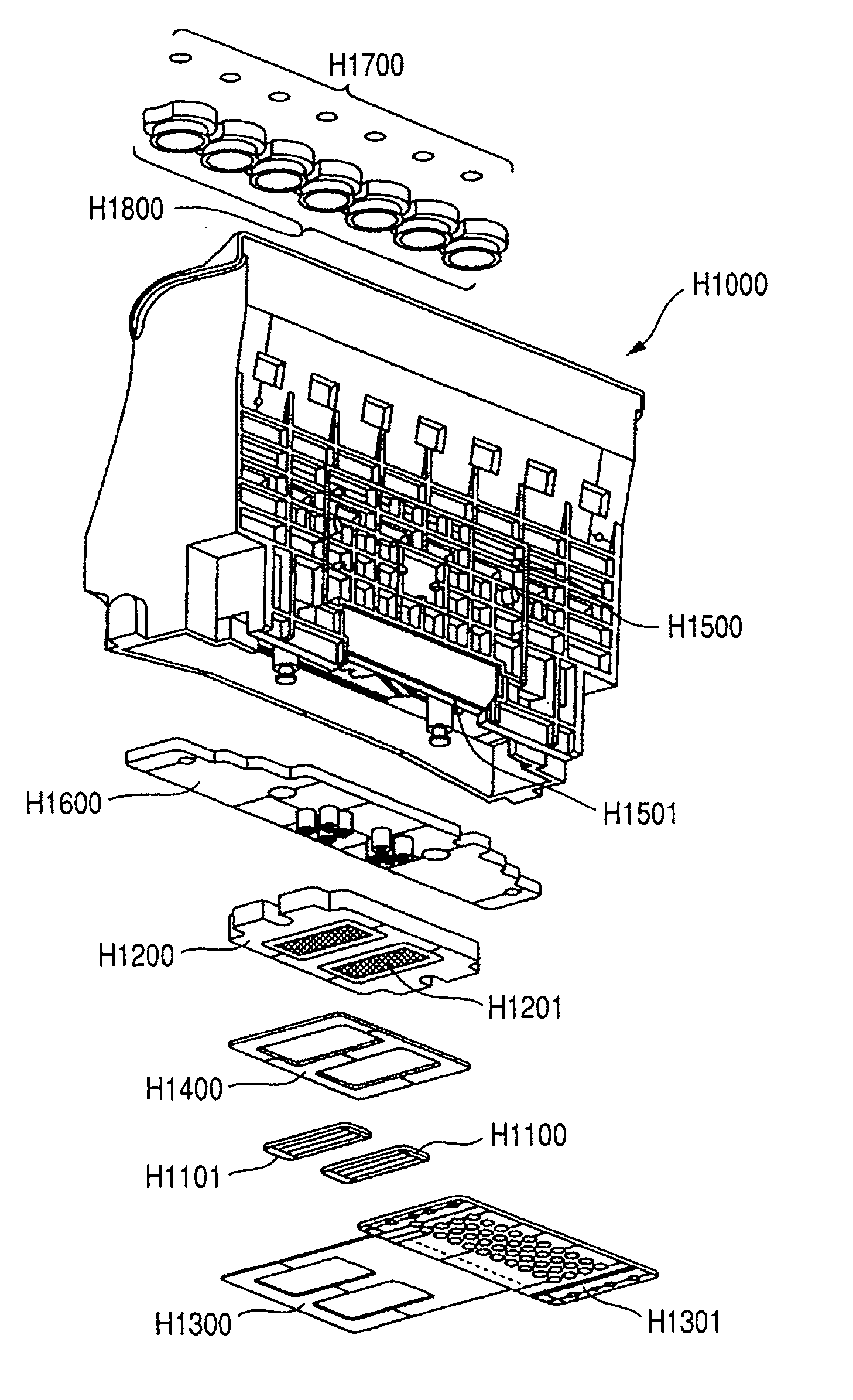

Ink jet black ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

InactiveUS20060146108A1Good storage stabilityHigh sticking recovery propertyMeasurement apparatus componentsDuplicating/marking methodsDecompositionDiethylene glycol

To provide an ink jet black ink which has a favorable tint for ink jet black ink, provides high ozone fastness, a high image density, and high sticking recovery property, and is capable of suppressing the decomposition of a compound represented by the following general formula (I) or a salt thereof at the time of storage for a long time period. The ink jet black ink is an ink jet black ink comprising at least a compound represented by the following general formula (I) or a salt thereof as a coloring material, and ethylene glycol or diethylene glycol, wherein the content of ethylene glycol or diethylene glycol is 15 mass % or more and 30 mass % or less with respect to the total mass of the ink jet black ink. General formula (I)

Owner:CANON KK

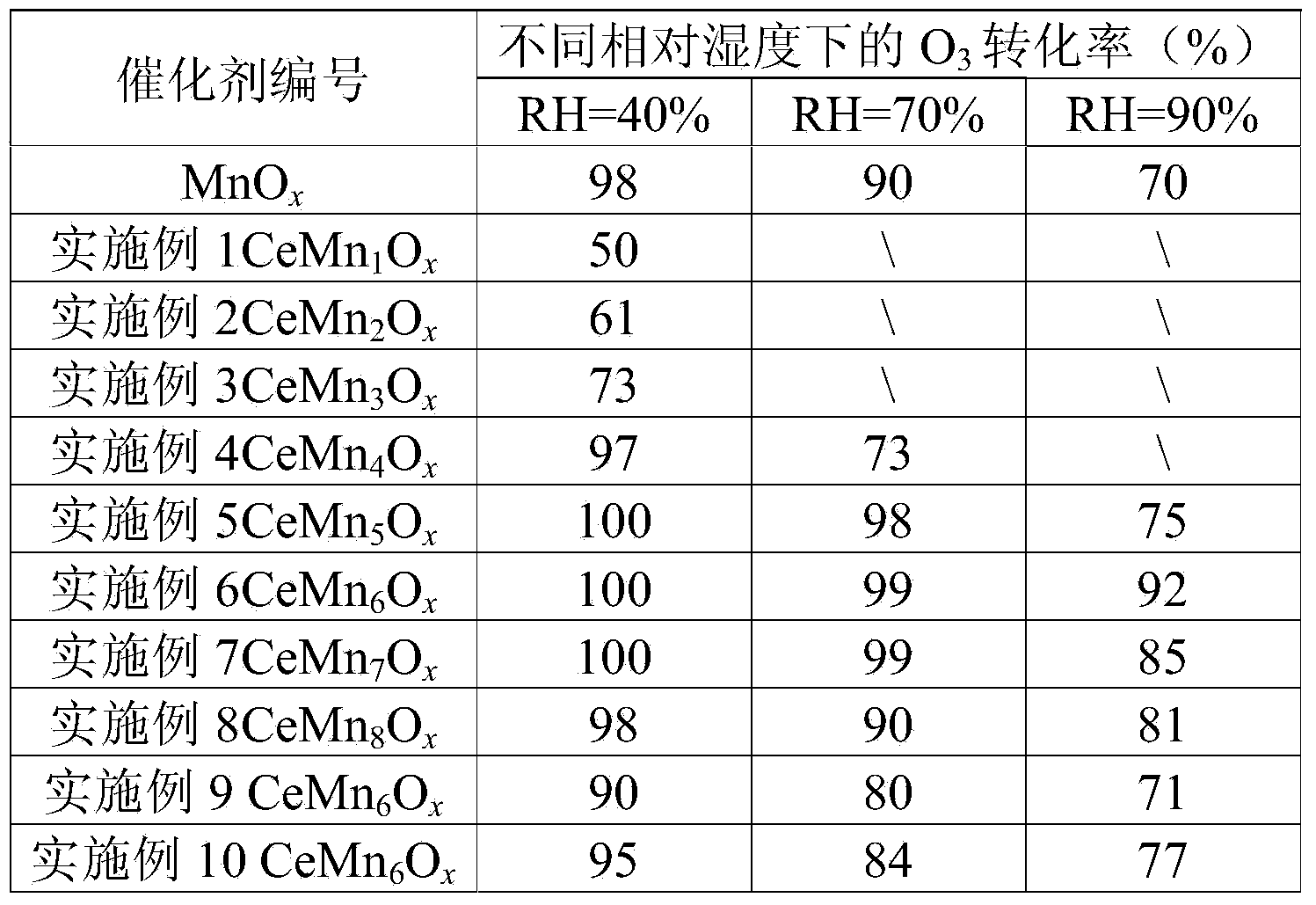

Cerium-manganese catalyst for decomposing ozone at room temperature in high humidity as well as preparation method and application of cerium-manganese catalyst

ActiveCN104001502AImprove moisture resistanceImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDecompositionCerium

The invention discloses a cerium-manganese catalyst for decomposing ozone at room temperature in high humidity as well as a preparation method and an application of the cerium-manganese catalyst. The cerium-manganese catalyst comprises the following chemical composition: CeMnaOx, wherein a is a natural number being 1 to 8. The method comprises the following steps: (1) dissolving a divalent manganese source into deionized water, sufficiently stirring till the divalent manganese source is completely dissolved, and subsequently adjusting the pH value to be 4-5; (2) adding a cerium source into the solution obtained in the step (1), sufficiently stirring till the solid is completely dissolved, then slowly dropping a potassium permanganate solution, stirring, and subsequently moving the solution into a high pressure hydrothermal kettle, and performing hydrothermal reaction for 24 hours at 100 DEG C; and (3) cooling, performing centrifugal washing, and drying, thereby obtaining the cerium-manganese catalyst for decomposing ozone at room temperature in high humidity. The cerium-manganese catalyst shows relatively high ozone catalysis and decomposition activity when the relative humidity is 90%, and can be applied to ozone decomposition at room temperature in high humidity.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

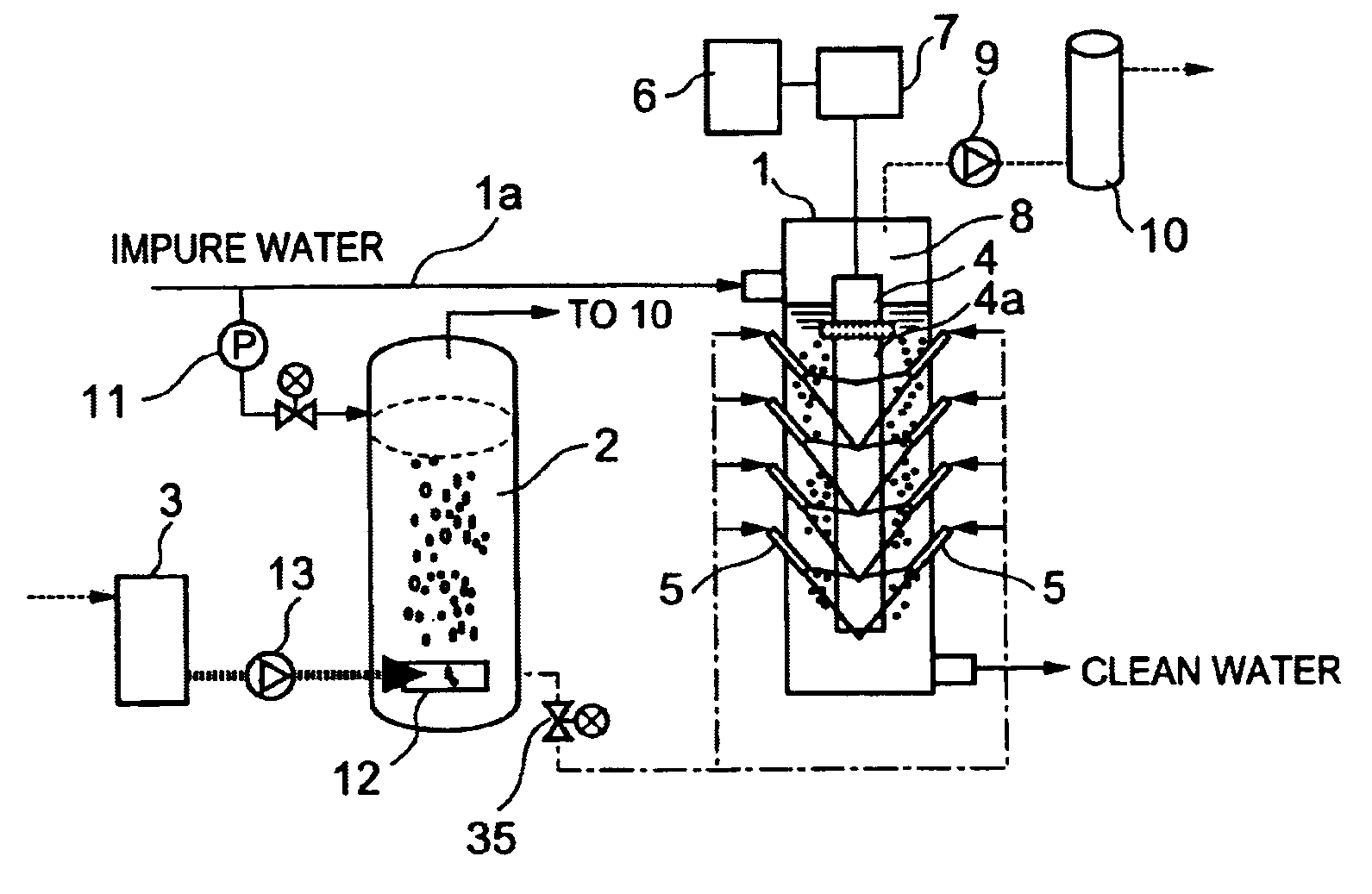

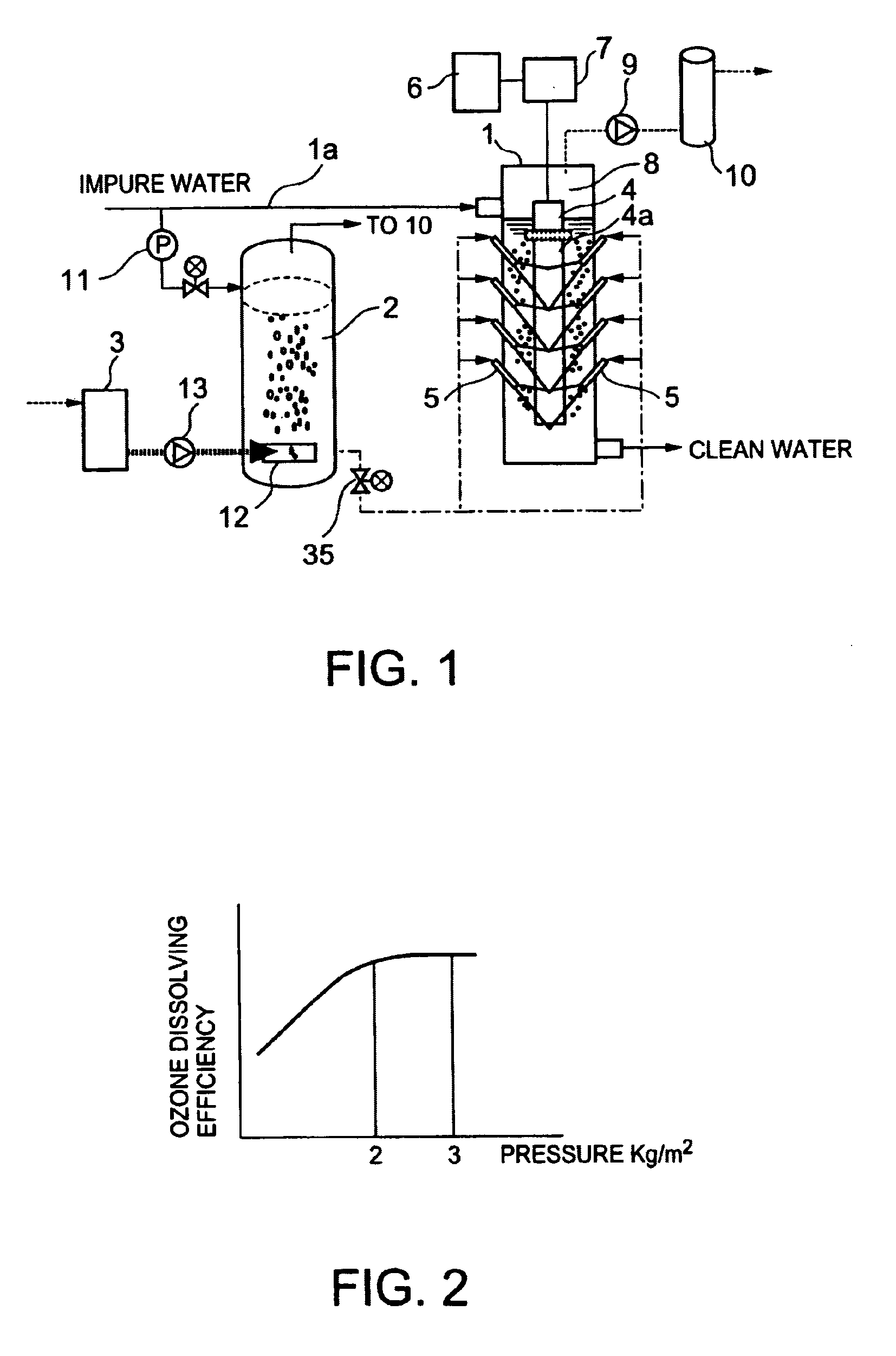

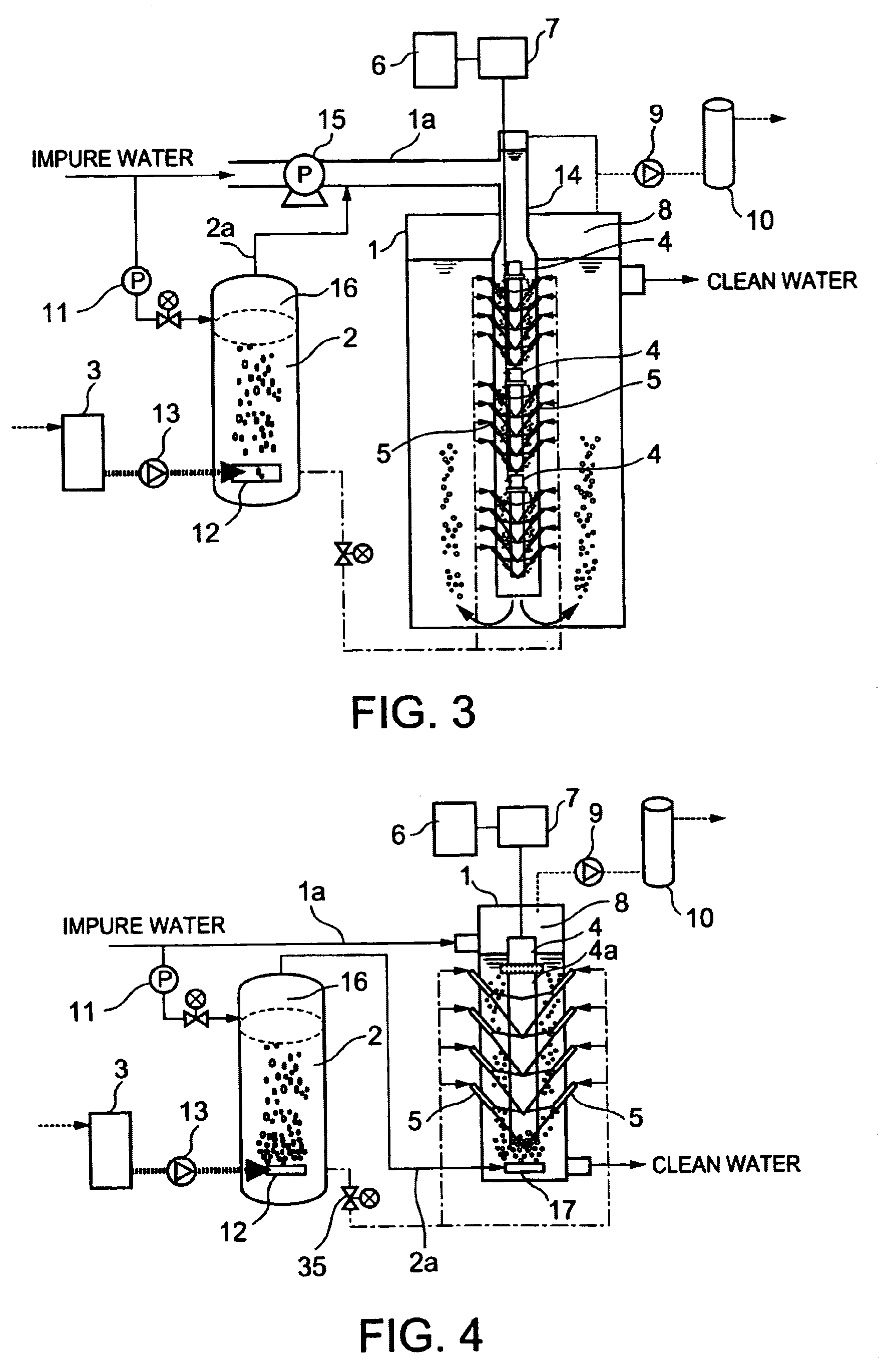

UV-assisted advanced-ozonation water treatment system and advanced-ozonation module

InactiveUS6921476B2Reduce maintenanceImprove decomposition efficiencyWater treatment parameter controlWater/sewage treatment by irradiationWater treatment systemHandling system

A UV-assisted advanced-ozonation water treatment system comprises a water treating tank 1, an ozonic water tank 2, an ozonized gas generator 3, and a UV light source 4 disposed in the water treating tank 1 and having a UV-radiating surface 4a, and an ozonic water jetting device including jetting nozzles 5 for jetting the ozonic water onto the UV-radiating surface of the UV light source. An ozonized gas diffusing device 12 is placed in the ozonic water tank 2. An ozonized gas generated by the ozonized gas generator 3 and compressed by a compressor 13 at a pressure in the range of about 2 to about 3 kg / cm2 is diffused into the ozonic water tank 2 by the ozonized gas diffusing device 12. A high-pressure, a high-ozone-concentration ozonic water produced in the ozonized water tank 2 is jetted through the jetting nozzles 5 onto the UV-radiating surface 4a.

Owner:KK TOSHIBA

Method for removing organic pollutants in water by ferrate reinforced ozone oxidation

ActiveCN105036293AIncrease the effective concentrationImprove removal efficiencyWater contaminantsWater/sewage treatment by oxidationWater sourcePotassium ferrate

The invention relates to a water treatment method, particularly a method for removing organic pollutants in water by ferrate reinforced ozone oxidation, which aims to solve the problem of high ozone addition amount due to great influence by background components and low effective concentrations of ozone and hydroxy free radicals in the existing ozone-oxidation-process exposed water. The treatment method comprises the following steps: adding ferrate into source water containing organic pollutants to perform preoxidation treatment, stirring to react, introducing ozone, and continuing stirring to react, thereby removing the organic pollutants in water by ferrate reinforced ozone oxidation, wherein the ferrate is one or mixture of potassium ferrate and sodium ferrate. The ferrate is used as a strong oxidant, has a co-oxidation action with ozone, and reduces the trapping consumption of the background component for ozone and hydroxy free radicals. Compared with the oxidation by single ozone, the pollutant removal rate is enhanced by 30-50%, and the ozone addition amount is decreased by 20-50%.

Owner:HARBIN INST OF TECH

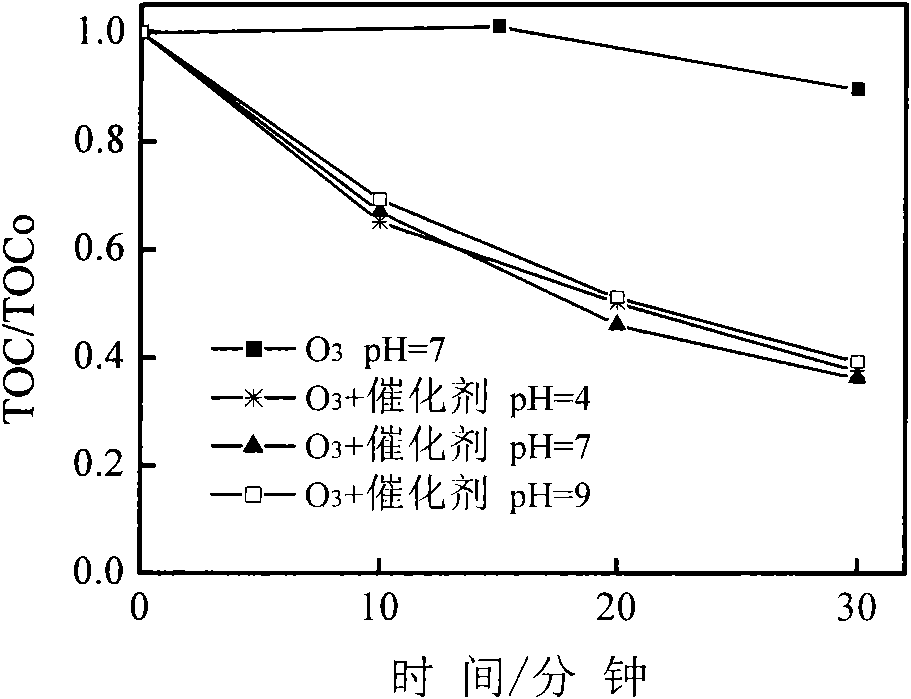

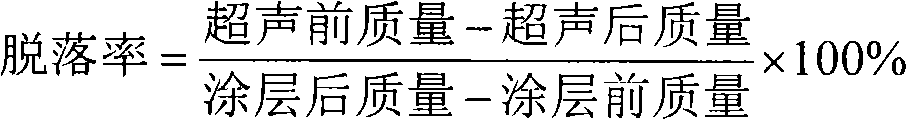

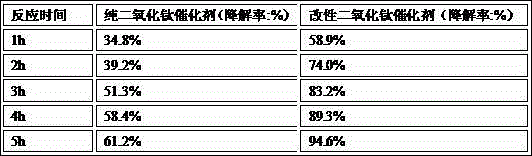

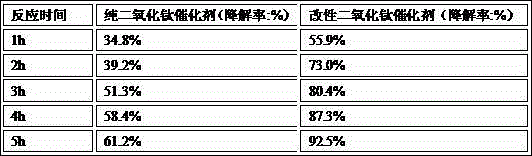

Method for preparing honeycomb ceramic catalyst for catalytically ozonizing organic matters in water

ActiveCN101811049AMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationFixed bedHigh ozone

The invention relates to a method for preparing honeycomb ceramic catalyst for multi-phase catalytic ozonization fixed bed reactors. Honeycomb ceramic is soaked in dilute hydrochloric acid solution, the honeycomb ceramic is then taken out and washed by deionized water, the honeycomb ceramic is immersed into alumina sol for 1 to 5 minutes, and is then taken out and dried under the room temperature, and the honeycomb ceramic is then dried under the temperature of 80 DEG C to 120 DEG C for 2 to 8 hours, and is calcined under the temperature of 400 DEG C to 600 DEG C for 2 to 6 hours, so that primary-coated honeycomb ceramic carrier is obtained. The coating steps are repeated, so that the content of alumina coating is 5 wt percent to 15 wt percent. The coated ceramic carrier is soaked in Co(NO3)2 solution for 0.5 to 2 hours, and is then taken out and dried under the temperature of 80 DEG C to 120 DEG C for 1 to 6 hours, the coated ceramic carrier is washed by deionized water, and is then dried again under the temperature of 80 DEG C to 120 DEG C for 1 to 6 hours, finally, the coated ceramic carrier is calcined under the temperature of 300 DEG C to 600 DEG C for 2 to 6 hours, and the loading of cobalt oxide in the obtained sample is 1 wt percent to 10 wt percent. Compared with ozonation, the catalyst shows high ozone catalytic activity, has excellent durability and catalytic stability, and can greatly increase the mineralization rate of 2,4-dichlorphenoxyacetic acid within the pH range between 4 and 9.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

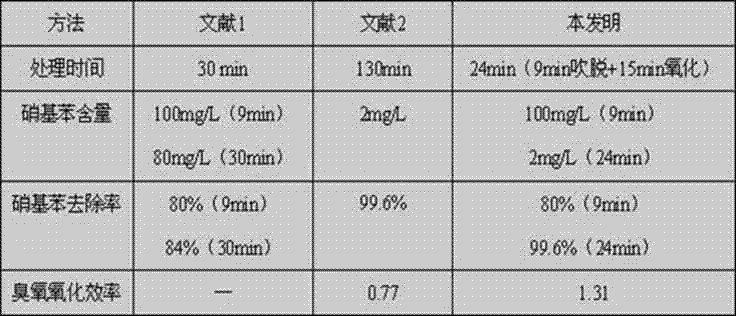

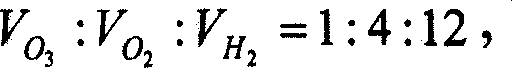

Method and device for stripping, oxidizing and degrading high-concentration nitrobenzene-containing wastewater

ActiveCN104724852AReduce processing timeImprove oxidation efficiencyWater contaminantsMultistage water/sewage treatmentAdvanced oxidation processNitrobenzene

The invention belongs to the technical field of high-concentration nitrobenzene-containing wastewater treatment and provides a method and a device for stripping, oxidizing and degrading a high-concentration nitrobenzene-containing wastewater for solving the high cost problem of the high-concentration nitrobenzene-containing wastewater treatment through the ozone advanced oxidation process. The method comprises the steps of contacting the high-concentration nitrobenzene-containing wastewater with fresh air in a supergravity device to finish a stripping mass transfer process; sending the wastewater into a liquid storage groove after finishing mass transfer process and mixing with hydrogen peroxide, performing contact reaction with an ozone gas in a supergravity device, and degrading the residual organic matter in the wastewater under the synergistic effect of ozone and H2O2. By adopting the method, the ozone oxidation efficiency is increased, the processing time is shortened, the pollutant content in the wastewater is reduced through a blow-off method and the oxidation reaction is performed, the water quality change of the wastewater is furthest reduced, the intermediate product production is reduced, the ozone and the hydroxyl radical depleting substance production is reduced, the ozone oxidation efficiency is increased by 65-75%, the processing time is shortened by 80%, the ozone use amount is reduced by 70% and the processing cost is saved by about 50%.

Owner:ZHONGBEI UNIV

Method for processing organic waste gas through optical microwave catalytic oxidation

InactiveCN103977678AEasy to handleEfficient decompositionDispersed particle separationRadiationChemical reactionHigh energy

The invention discloses a method for processing organic waste gas through optical microwave catalytic oxidation. The method comprises the following steps: spraying an alkaline solution to a corrugated plate to form a liquid membrane, contacting the organic waste gas with the liquid membrane to carry out physical dissolution and chemical reactions to complete a pretreatment; screen-filtering the pretreated organic waste gas, then carrying out microwave radiation on the organic waste gas so as to break down the molecular chains of the organic waste gas for the first time; utilizing high-energy C-wave band ultraviolet lights to radiate the organic waste gas to break down the molecular chains of the organic waste gas for the second time; carrying out first oxidation on the organic waste gas by hydroxyl free radicals; then carrying out second oxidation on the organic waste gas by ozone which is generated by high-ozone HV ultraviolet light beams; and finally making the deodorized and sterilized organic waste gas go through a rare-earth oxide catalyst taking titanium dioxide as the honeycomb carrier to carry out third catalytic oxidation. The method can effectively completely decompose and crack the high-molecular pollutants and high-molecular pollutant molecular chains, and then catalytically oxidizes and converts the high-molecular pollutants into low-molecular harmless substances. Moreover, the catalytic oxidation speed is accelerated, the processing time is shortened, and the electric energy is saved.

Owner:JIANGXI NAIKE CHEM IND EQUIP PACKINGCO

Method of preparing ozone by low-voltage electrolysis method

InactiveCN101054679AReduce energy consumptionLow costElectrolysis componentsOrganic synthesisHigh ozone

The present invention relates to a process for preparing ozone through a low pressure electrolytic method. In an electrolytic tank of diaphragm type or non-diaphragm type, a neutral or acidic electrolysing solution is added, a non-corrodible steel electrode, a nickel alloy electrode, a lead alloy electrode or a graphitic electrode is selected as the cathode, a fluorine-containing lead dioxide electrode is selected as the anode, an electric current density of 100-2000 A / m2 and a tank voltage of 3.0-6.0 V are adopted, and the temperature of the electrolysing solution is controlled at 5-35 DEG C, then ozone is obtained after energization for an electroanalysis. The substrate of said fluorine-containing lead dioxide electrode is titanium, graphite or ceramics. Said ozone generating device for preparing ozone in accordance with the present invention is characterized by its simple structure, convenient operations, superior performances, capability of operations at normal temperature and pressure, low energy consumption, high ozone concentration generated, and avoidance to generate oxynitrides harmful to persons and entironment during electrolysises, and then is a green environmental protection equipment. According to actual needs, said method is capable of being extensively used for generating ozone in fields such as disinfection, sterilization, odor treatment, fresh-keeping, air purification, preparation of pure water, wastewater treatment, organic synthesis and the like.

Owner:ZHEJIANG UNIV OF TECH

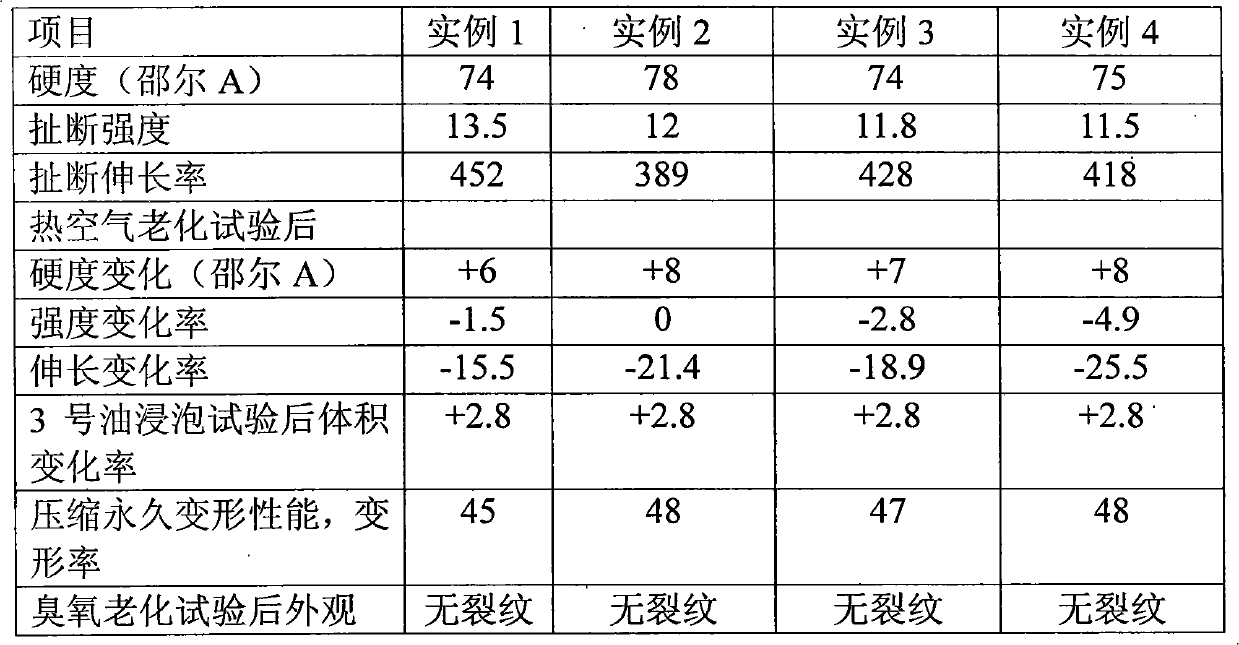

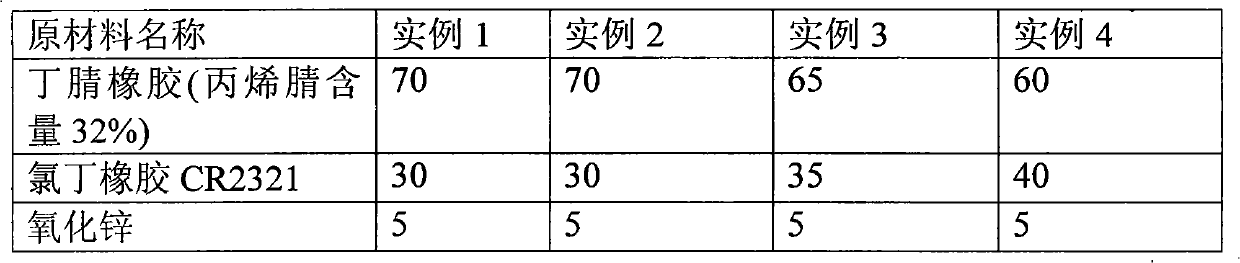

Anti-cracking and anti-aging blend material for oil pipe of automobile

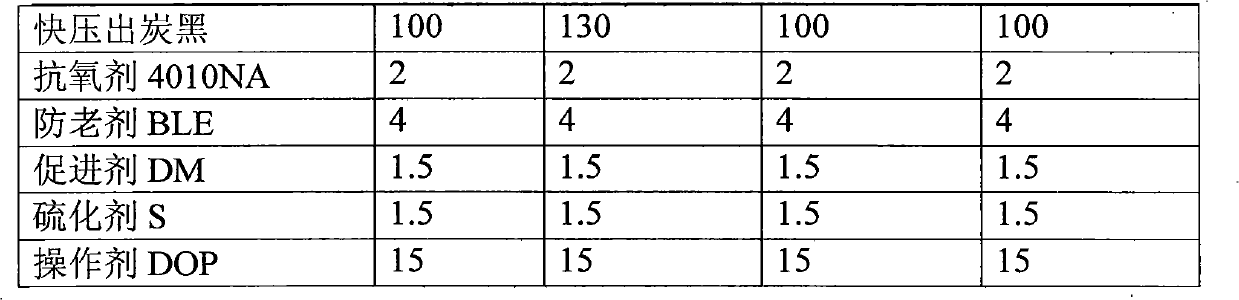

InactiveCN101948576AProtection against thermo-oxidative agingExtended service lifeFlexible pipesNitrile rubberVulcanization

The invention provides an anti-cracking and anti-aging blend material for an oil pipe of an automobile. The blend material is obtained by blending most readily available materials such as nitrile rubber and chloroprene rubber, particularly the nitrile rubber, the chloroprene rubber, a vulcanizing agent, an accelerating agent, an active agent, an anti-aging agent, an antioxidant and a filler; and a finished product is obtained by performing rubber mixing, extrusion and vulcanization on an operating agent under a certain temperature environment. The blend material has the advantages of low cost, usability in the preparation of the oil pipe with comprehensive performance such as ozone resistance, oil resistance and the like, high material compatibility, uniform dispersion of a compounding agent, no island phase structure, easy processing, high anti-aging performance, high ozone resistance, excellent physical and mechanical performance such as hardness, intensity and the like, good extrusion manufacturability and vulcanization manufacturability, capability of prolonging the service life of the product and particular suitability for oil-resistance rubber pipe products.

Owner:SHIYAN YINSEN IND & TRADE

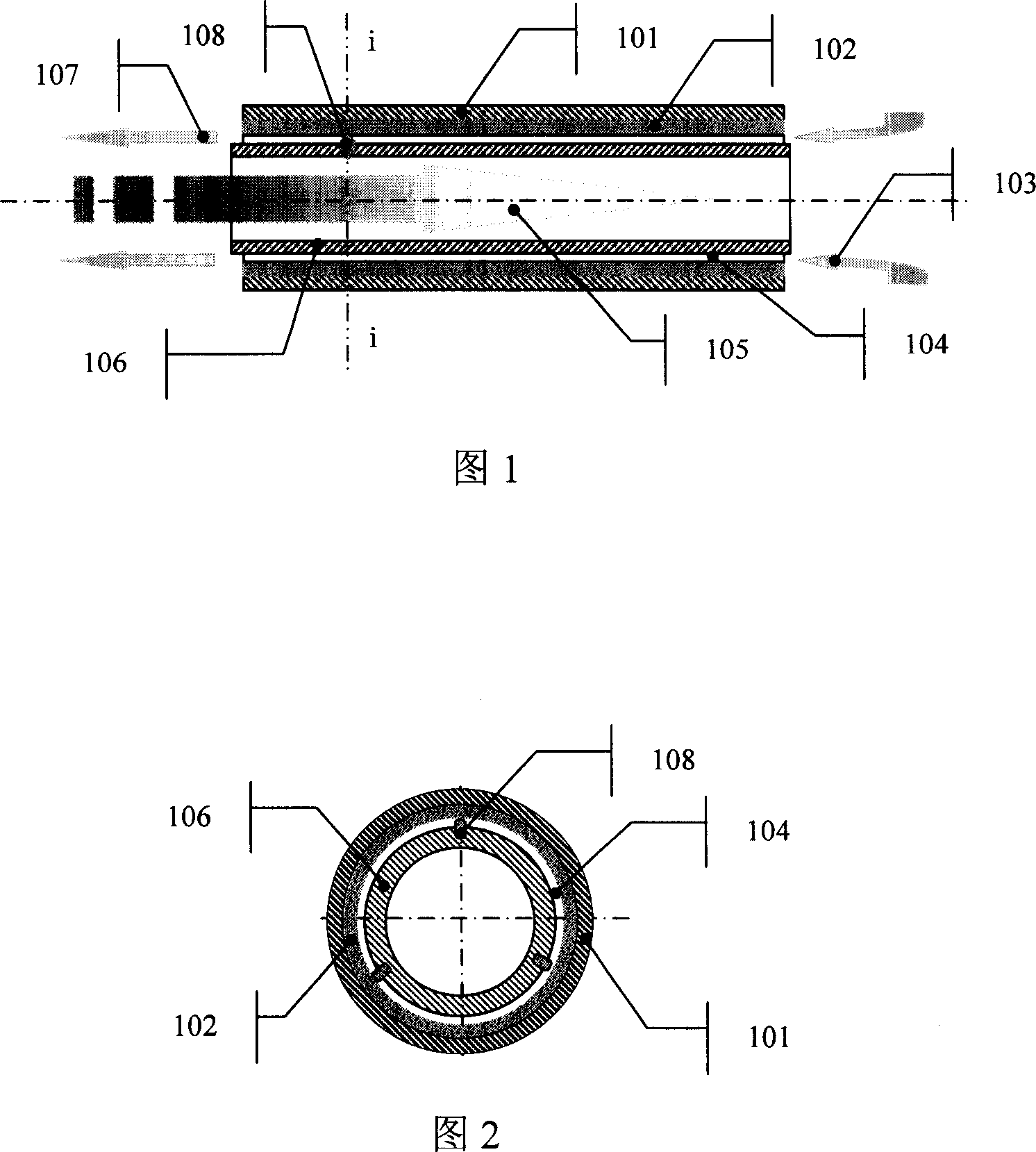

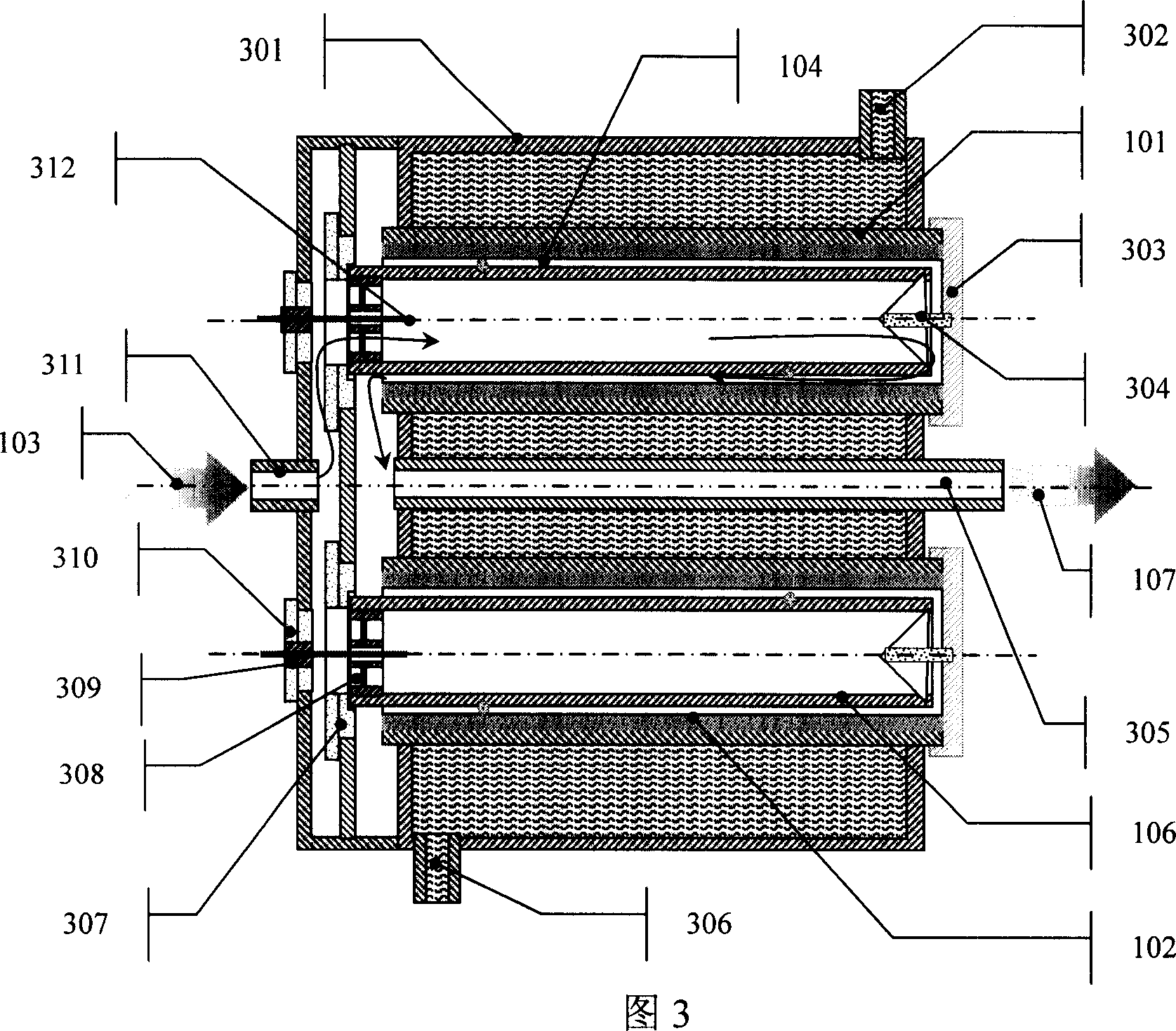

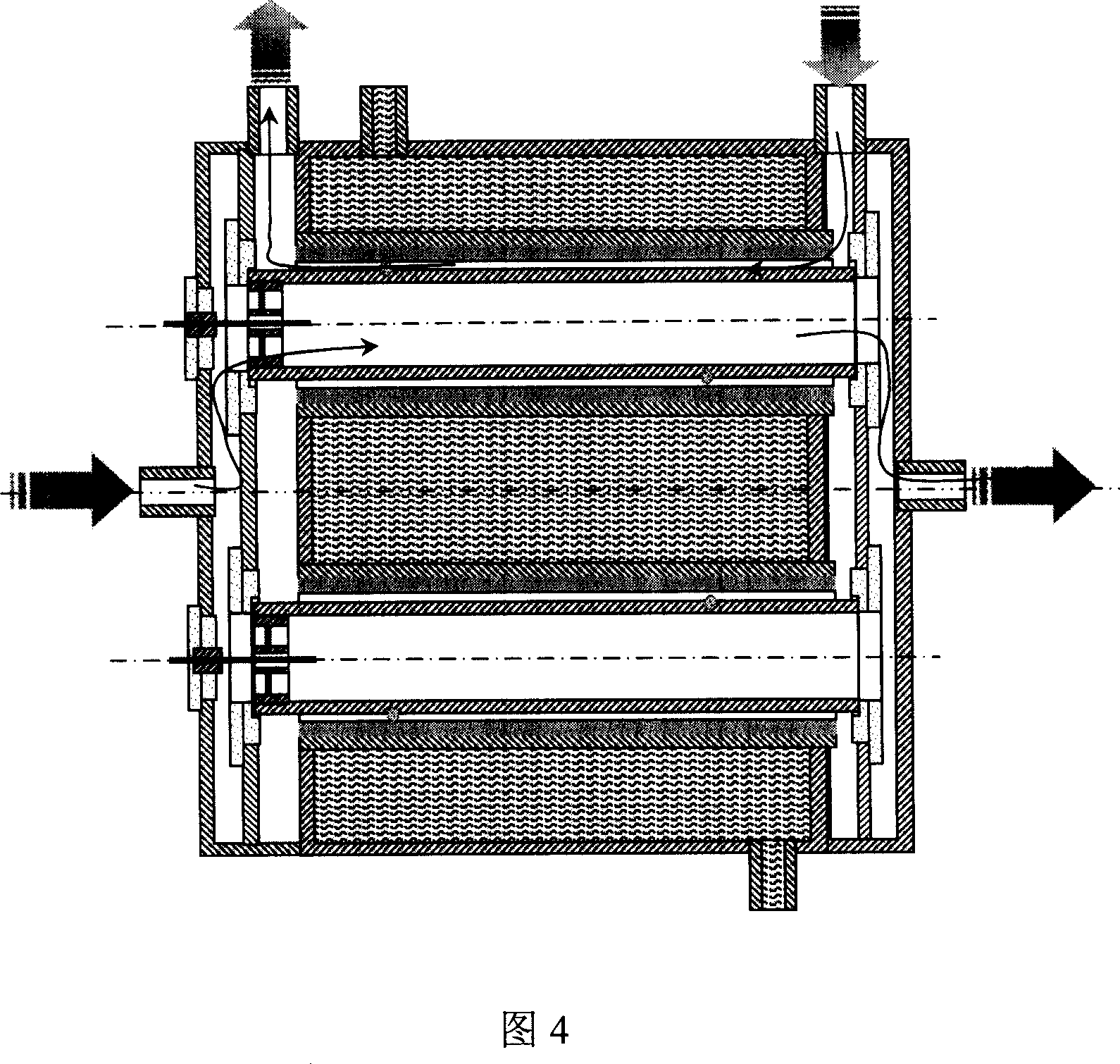

Double cooled ozone discharging tube

InactiveCN101003363AUniform and dense materialIncreased ozone yieldOzone preparationOzone generatorTitanium

This invention discloses a double-cooling ozone discharge tube for producing ozone. The discharge tube comprises a high-voltage electrode made of metal tube, and a ground electrode. A titanium layer is coated on the high-voltage electrode and the ground electrode. A dielectric layer is used as the inner lining of the ground electrode. A discharge tube assembly is placed at the outer wall of the high-voltage electrode, which forms a sliding concentric circle with the gap convex block supported by the dielectric layer, and has a discharge chamber air gap. The material for the dielectric layer is ceramic, enamel, glaze, glass, or their composite. Compared with the present technique, the discharge tube in this invention has such advantages as simple structure, high ozone generation efficiency, rapid assembly / disassembly, and easy cleaning. The discharge tube can be integrated into large power ozone generator.

Owner:TSINGHUA TONGFANG CO LTD

Natural benzaldehyde preparation method

The invention discloses a natural benzaldehyde preparation method, which comprises the following steps of: taking cinnamaldehyde as raw material; adding 0.5-10% of activated carbon catalyst modified by 0.1-1.0mol / L of hydrochloric acid; at the temperature of below-10-30DEG C, introducing in 0.05-1.0g of ozone at the rate of 1g of cinnamaldehyde per hour; carrying out ozonization reaction for 0.5-10 hours; under the condition of keeping the low temperature, dipping an ozonide intermediate into thiourea aqueous solution for reduction reaction; carrying out centrifugal separation; and finally carrying out molecular distillation at the temperature of 60DEG C and the pressure of 100Pa by a molecular distillation device to obtain the natural benzaldehyde with higher purity. The natural benzaldehyde preparation method disclosed by the invention has the advantages of simple technology, simplicity in operation, high reaction rate, high ozone use ratio, green and environmental-friendly reaction process, efficient catalyst, and is cheap and non-toxic and easy to separate from a product, the natural degree of the benzaldehyde can be kept, the selectivity of the benzaldehyde is good, and the purity and yield of the benzaldehyde are high.

Owner:GUANGXI UNIV

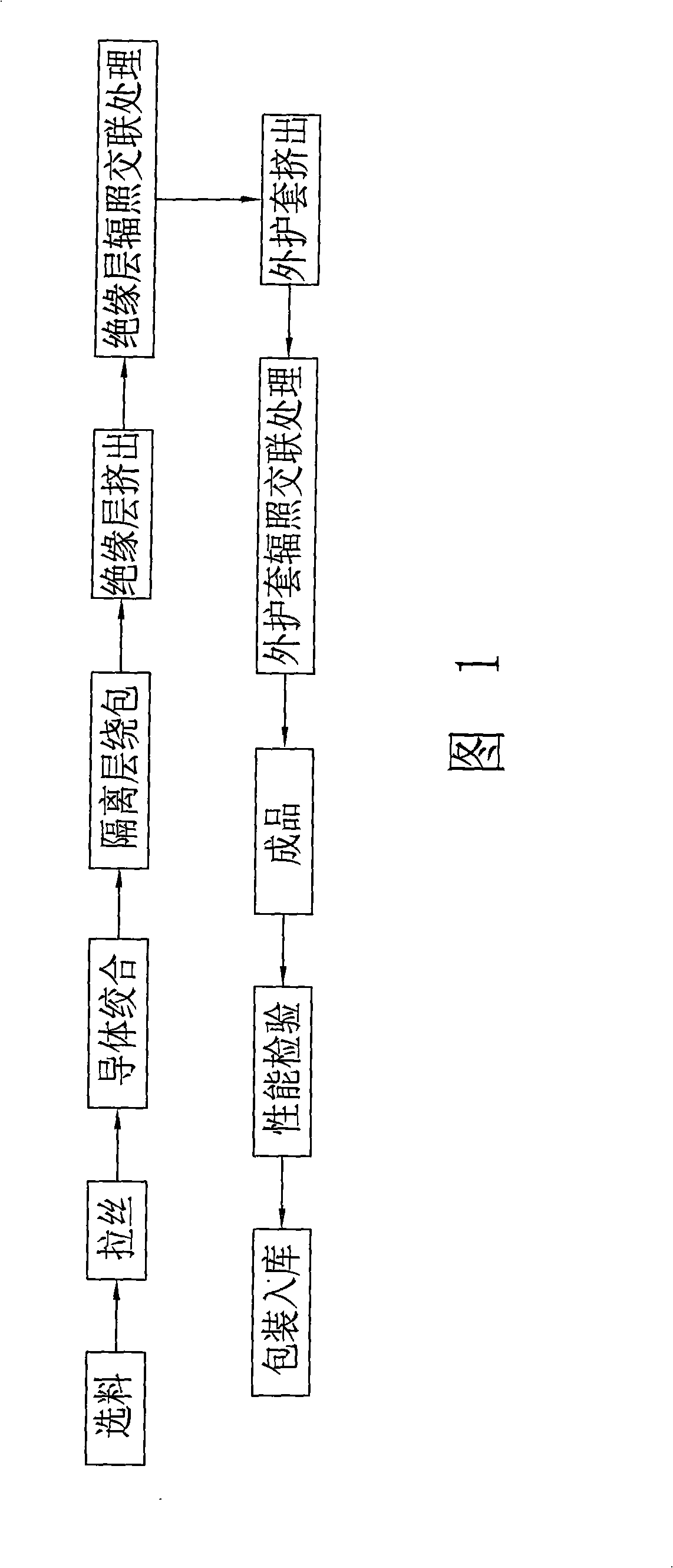

Production method of power cable for solar photovoltaic power generation assembly

ActiveCN101295562AGood weather resistanceGood UV resistanceInsulating conductors/cablesCross-linkInsulation layer

The invention discloses a manufacturing method for power cables used for solar energy photovoltaic power-generating equipment. The method is characterized in that the manufacturing process has the following steps: material selection, wire drawing, conductor twisting, isolated-layer wrapping, insulation-layer extrusion, insulation-layer radiation cross-linking processing, jacket extrusion, jacket radiation cross-linking processing and finished-product. The cable manufactured by the method has high weather resistance, high UV radiation resistance and high ozone corrosion resistance. Moreover, the resisted high temperature can reach 120 DEG C. The cable can resist atrocious weathers and mechanical impacts so as to dramatically enhance the safety and service life of the solar energy photovoltaic power-generating equipment.

Owner:SICHUAN MINGXING CABLE

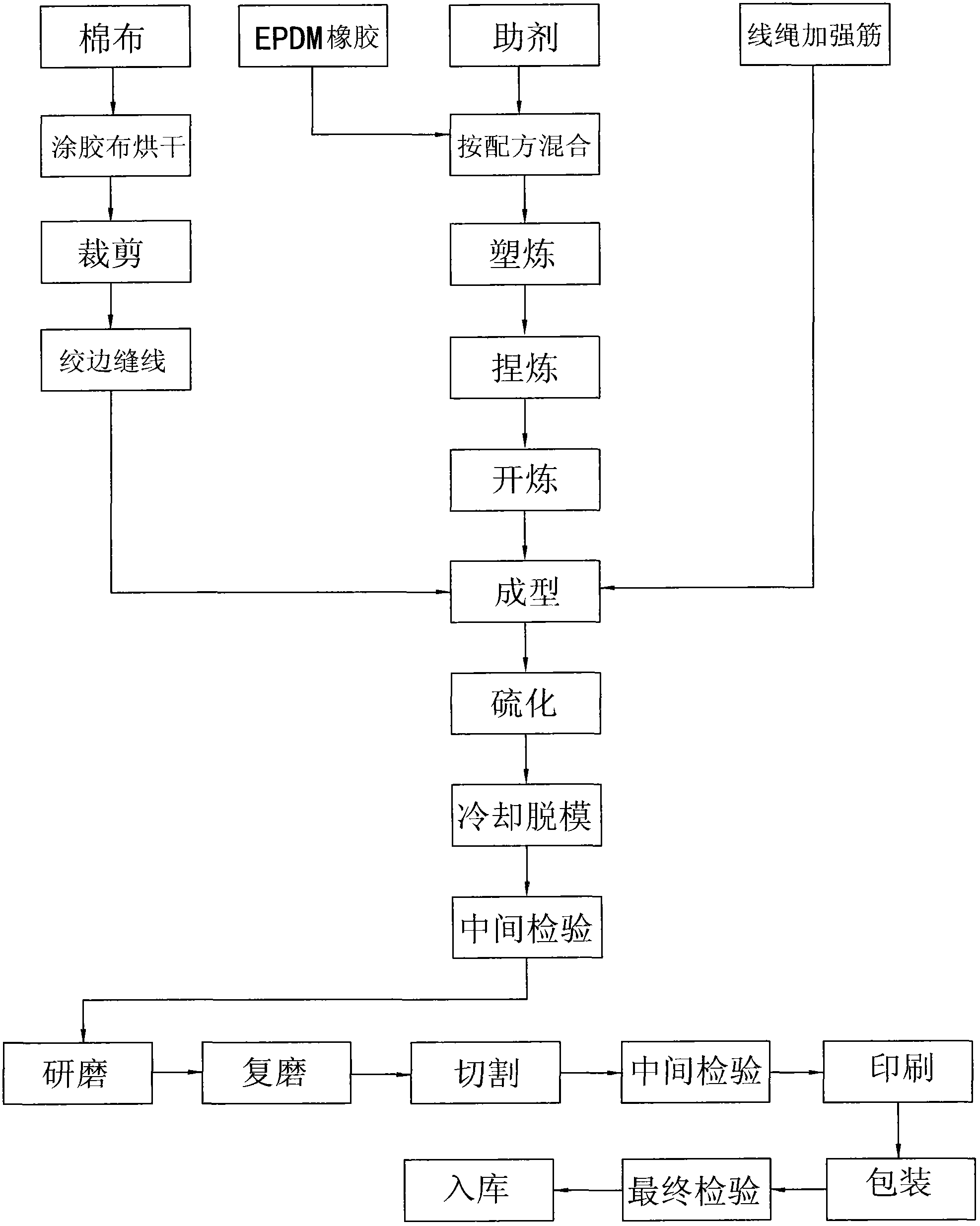

Driving belt and manufacturing method thereof

InactiveCN102705439AAvoid poor materialImprove temperature resistanceDriving beltsBeltsLow noiseVulcanization

The invention discloses a driving belt and a manufacturing method thereof. A formula for the driving belt is that: 1.3 to 1.6 weight parts of anti-aging agent, 1.3 to 1.6 weight parts of polyethylene glycol, 4 to 6 weight parts of phenolic resin, 3.5 to 4.5 weight parts of resorcinol, 49 to 51 weight parts of paraffin oil, 20 to 50 weight parts of carbon black, 5 to 6 weight parts of reinforcing rib made from aramid fibers, 29 to 31 weight parts of reinforcing agent 6851 and 24 to 26 weight parts of industrial cloth are added into every 100 weight parts of ethylene-propylene-diene monomer rubber. The manufacturing method for the driving belt comprises the steps of plastication, forming, vulcanization, cutting, grinding, printing and formation of a finished product. The conventional chloroprene rubber is replaced by the ethylene-propylene-diene monomer rubber, various auxiliaries for different uses are added, and a gum structure compounded by short fibers and a thin tape body process are introduced, so that the formed product has the advantages of high temperature resistance, abrasion resistance, small elongation for use, low noise, high driving efficiency, high flexibility, long service life and the like, has higher ageing resistance, particularly higher ozone aging resistance, higher weather resistance and higher thermal aging resistance, and also has a higher electric insulation property, higher chemical corrosion resistance and higher impact elasticity.

Owner:DAISHAN HEINER RUBBER BELT

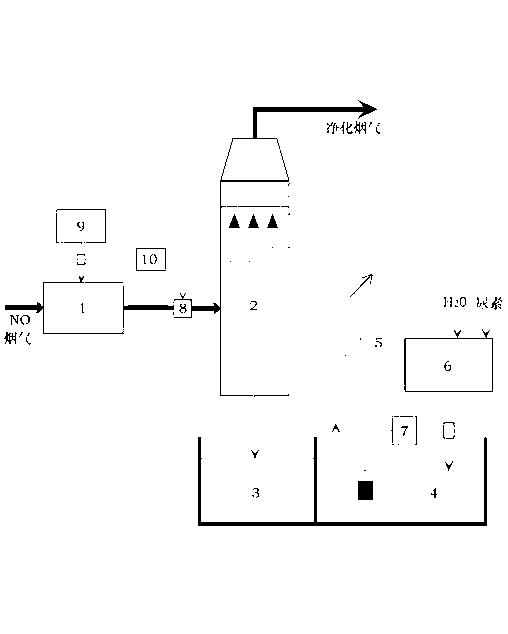

Two-step oxidation-reduction flue gas denitration method

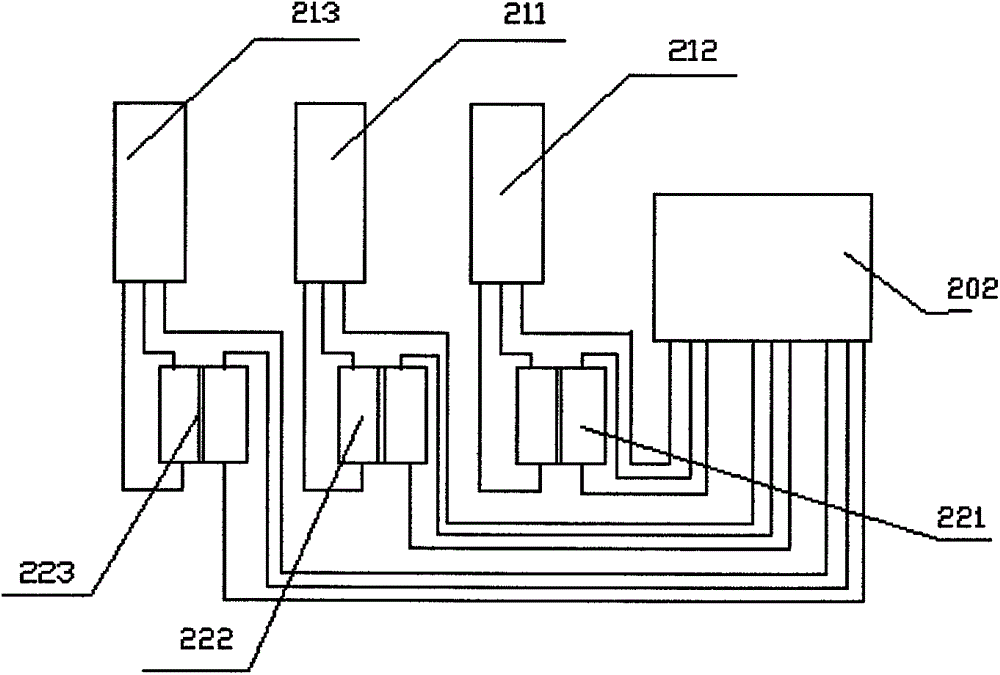

InactiveCN103055672AImprove ozone utilizationSimple processDispersed particle separationPartial oxidationFlue gas

The invention discloses a two-step oxidation-reduction flue gas denitration method which comprises an ozone oxidation device 1, an ozone generator 9, an ozone adding control system 10, an NO / NOx sensor 8, a reduction reaction tower 2, an absorption liquid recovery pool 3, a reducing agent absorption liquid circulation pool, a reducing agent solution preparation device 6, a reducing agent solution adding device 7 and a circulating pump system 5. Firstly, flue gas to be treated enters the ozone oxidation device; under the action of ozone, part of NO in the flue gas is oxidated into NO2; afterwards, the flue gas is conveyed into the reduction reaction tower to be in contact with reducing agent solution; and under the action of reducing agents, most of NO and NO2 in the flue gas are reduced into N2, so that the purpose of denitration and purification of the flue gas can be achieved. Waste water generated after flue gas denitration reaction can be reclaimed and reused. The method provided by the invention accomplishes flue gas denitration in two steps, and has the advantages of high ozone utilization ratio, good denitration effect, recyclability of solution, low investment and treatment cost and broad application prospect.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

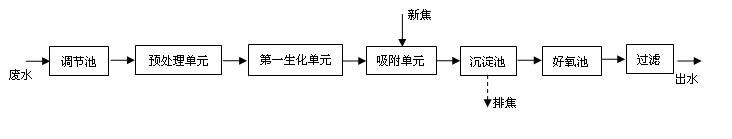

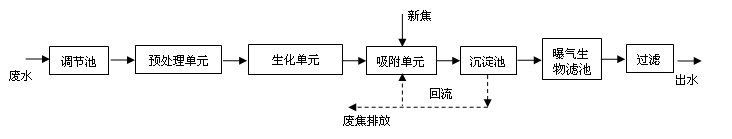

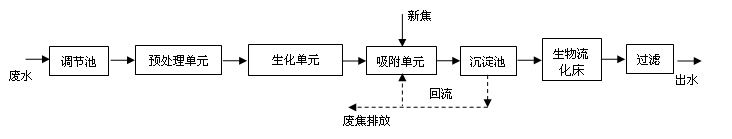

Method for treating coal chemical wastewater

InactiveCN102211839AEfficient treatment processHandling process safetyMultistage water/sewage treatmentWastewaterWater quality

The invention relates to a method for treating coal chemical wastewater, which comprises the following steps in turn: pretreatment, biochemical treatment with a first biochemical unit, adsorption treatment with an adsorption unit, sedimentation treatment with a sedimentation tank, and advanced biochemical treatment. The method solves the technical problems of high ozone electric power consumption, high cost and influence on yielding water quality because ozone is used for performing advanced treatment in the method for treating the coal chemical wastewater in the prior art. In the method for treating the coal chemical wastewater, the ozone is not used, resources are saved, and the yielding water quality can be well guaranteed, so the method is particularly suitable for treating the coal chemical wastewater.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

Device for treating volatile organic gaseous contamination

InactiveCN101468285AImprove washing effectResidue reductionGas treatmentDispersed particle separationWater storage tankCatalytic oxidation

The invention relates to a device for the treatment of the pollution caused by a volatile organic gas, which comprises a washing tower, a catalytic oxidation tank, a liquid storage tank and an ozone generator, wherein the middle part of the space in the washing tower is provided with a plurality of washing solution nozzles, the lower part of the space in the washing tower is provided with a plurality of layers of sieve plates, the upper part of the space in the washing tower is provided with a gas-liquid separator, an air inlet of the washing tower is connected with the space on the lower part the sieve plates in the tower, and the air outlet is connected with the air outlet end of the gas-liquid separator; the catalytic oxidation tank is filled with photocatalyst particles, the air inlet of the catalytic oxidation tank is positioned on the bottom thereof, and the air outlet is positioned on the top thereof; the ozone generator is provided with an ozone contact device for dissolving the ozone into water; a nozzle pipeline of the washing tower is connected with the water storage tank; and a bottom water outlet and the water inlet on the bottom of the catalytic oxidation tank are connected with the liquid storage tank. The device has the advantages of good washing effect, less residue of volatile gas molecules in the gas, little washing solution carried by the discharged gas, fast oxidization rate, high ozone effective utilization rate, low cost for investment and running, less pollution in the washing solution, and less circulating use of water, and is applicable to the treatment of various gas pollutants which can be dissolved in water.

Owner:HAISIBOTE BEIJING SCIENE & TECH

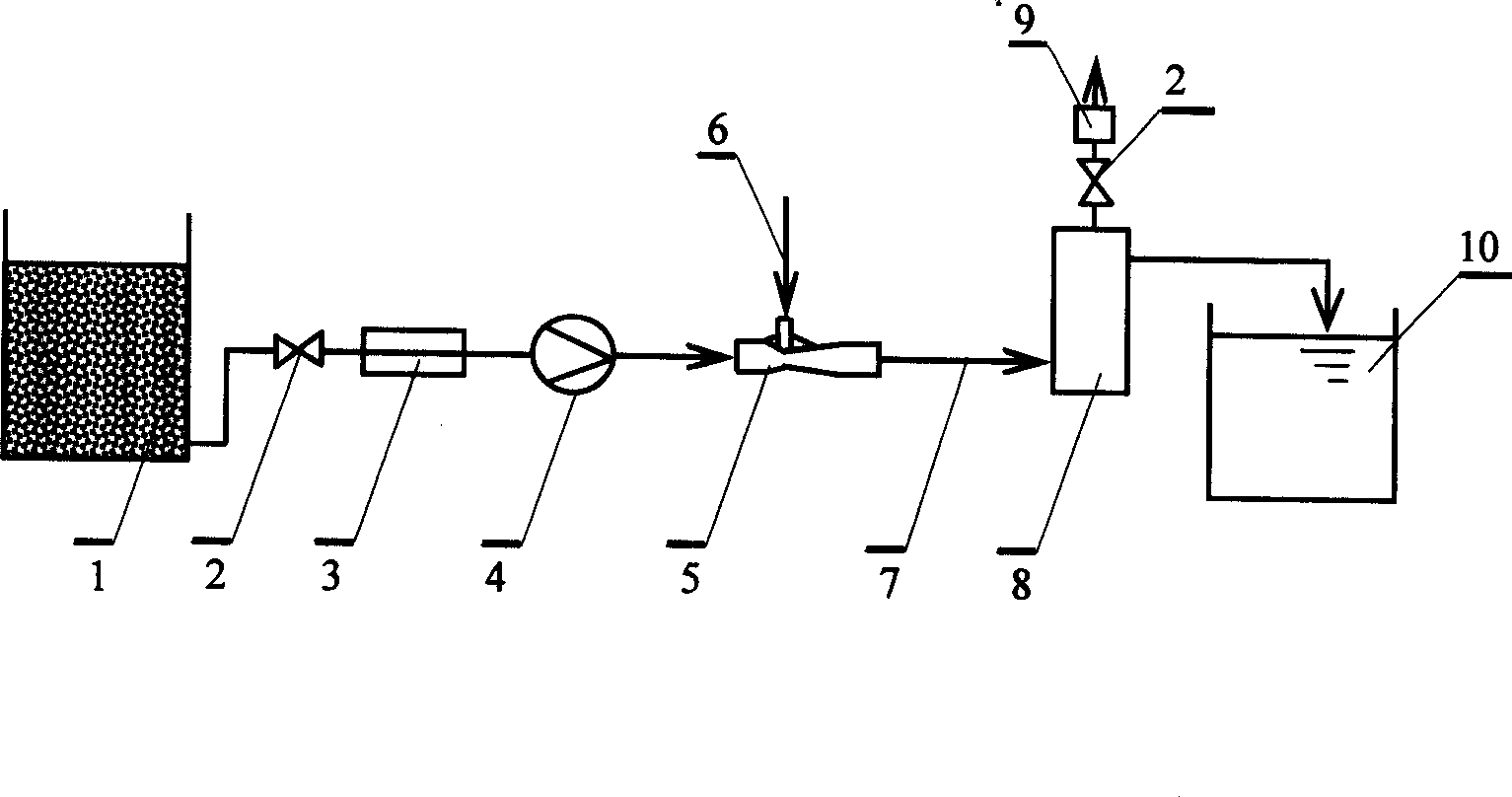

Novel agricultural ozone water generator

ActiveCN104801211ANo secondary pollutionNo power hazardElectrolysis componentsMixing methodsOzone generatorLow voltage

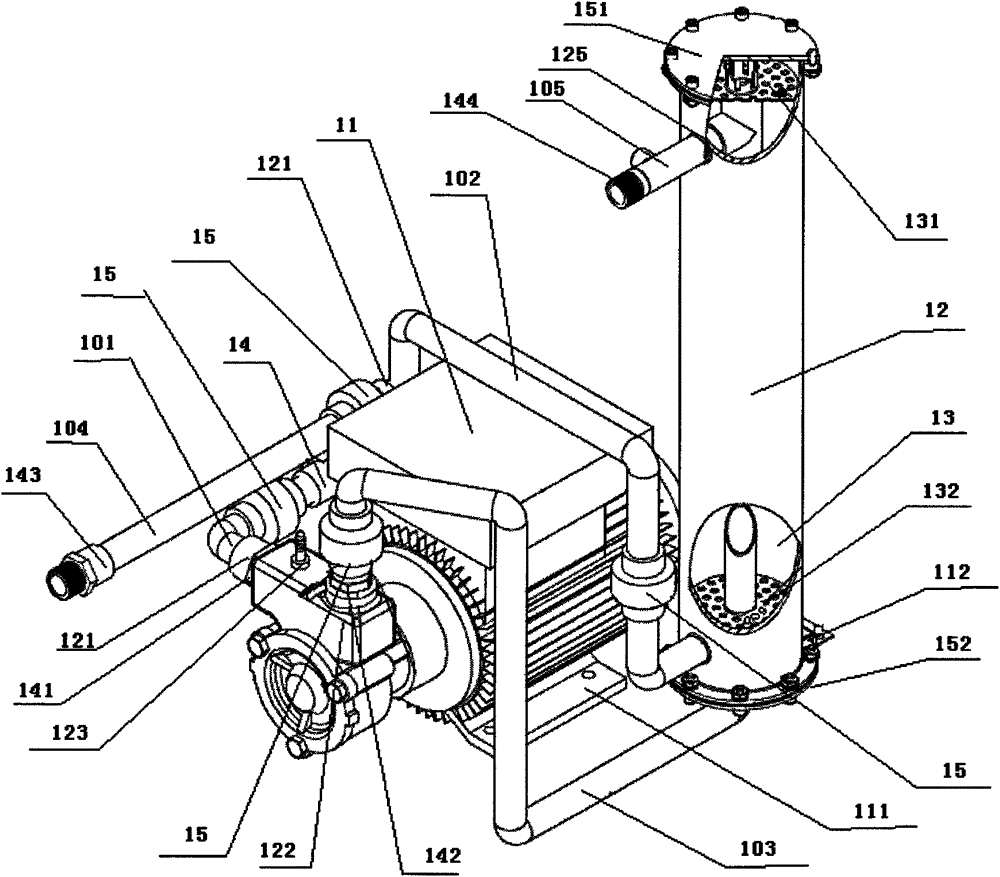

A novel agricultural ozone water generator comprises a connecting pipe 1, a connecting pipe 2, a connecting pipe 3, a connecting pipe 4, a connecting pipe 5, a water pump power driving device, a hybrid power driving device, a first fixed pedestal for arranging the water pump power driving device, and a second fixed pedestal for arranging the hybrid power driving device, the water pump power driving device is provided with an interface 1, an interface 2 and an interface 3, the outside of the interface 3 of the water pump power driving device is connected with a low-voltage electrolytic ozone generator, the hybrid power driving device is filled with a hybrid material, the upper end and the lower end of the hybrid power driving device are provided with water distribution plates respectively, the hybrid material is added between the two water distribution plates, the bottom of the hybrid power driving device is provided with a first seal head, and the top of the hybrid power driving device is provided with a second seal head. Ozone is prepared from pure water in a low-voltage electrolytic mode, auxiliary materials and additives are not needed, and nitrogen oxides and any secondary pollution are not generated; and the novel agricultural ozone water generator has the advantages of high ozone hybrid efficiency, small size, great cost reduction and energy consumption saving.

Owner:金华市广源环保科技有限公司

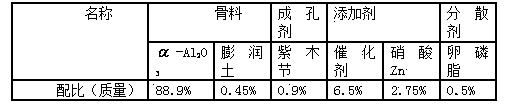

Inorganic film for treating organic waste water under catalysis of ozone and preparation method of film

InactiveCN103736401AImprove oxidation efficiencyOrganic Pollution SuppressionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPtru catalystChemical composition

The invention discloses an inorganic film for treating organic waste water under catalysis of ozone and a preparation method of the film. The preparation method mainly comprises preparation and modification treatment of a supporting body and a separation layer of the film, and is characterized by comprising the step of respectively loading different types of catalysts on the surfaces of the modified supporting body of the inorganic film and the modified film separation layer so as to form a multi-level three-dimensional catalysis composite. The three-dimensional catalysis composite prepared by the method not only can be used for achieving a solid-liquid separation function of an ordinary inorganic film, but also has the function of catalyzing ozone decomposition, so that the oxidation efficiency and the degradation efficiency of ozone on organic pollutants in waste water can be improved. Furthermore, the chemical components of the supporting body and the film separation layer are modified, so that film holes are smooth, the pressure drop is small, the blocking rate of pollutants is reduced, and the service life of a film assembly is prolonged.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

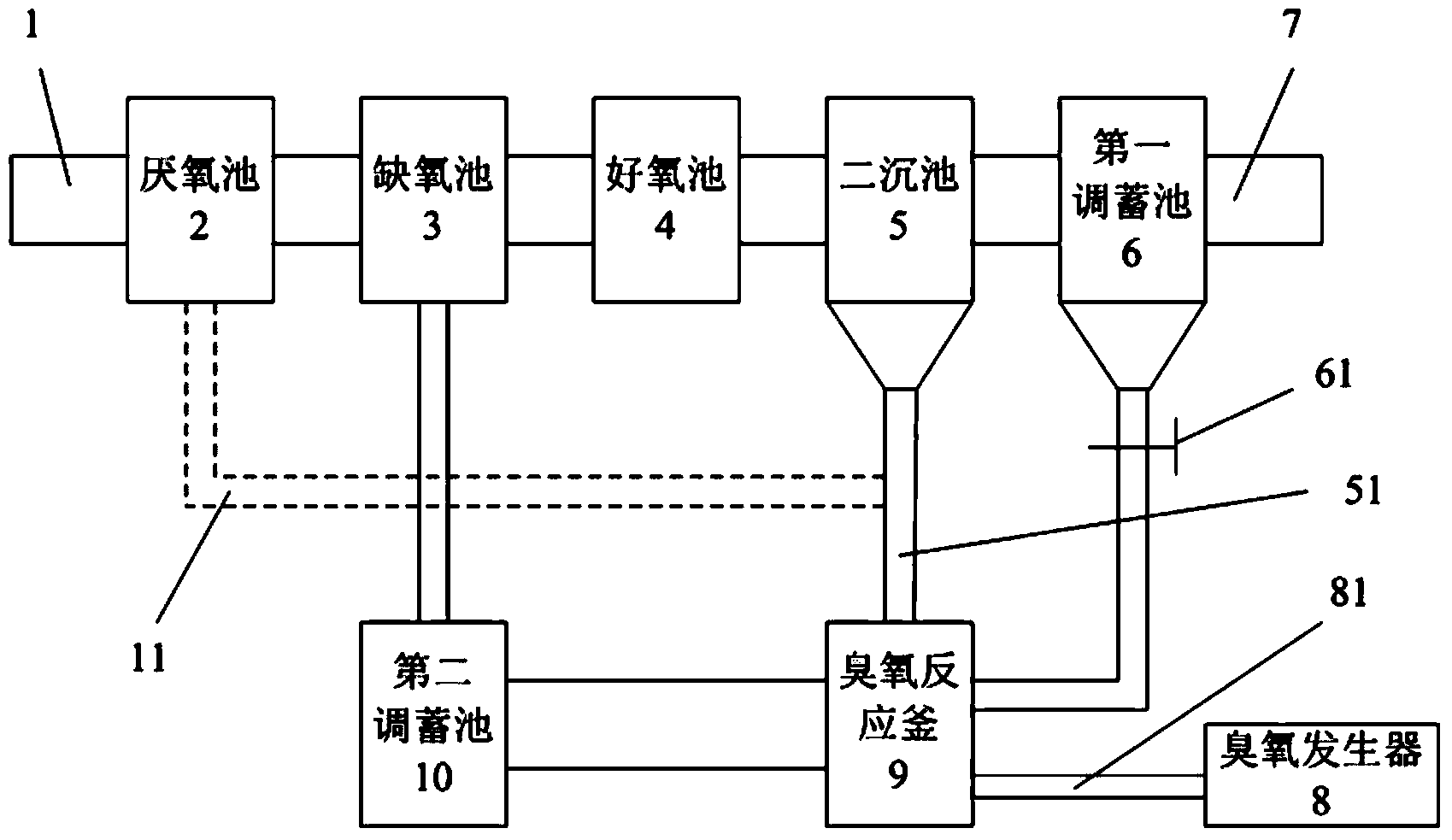

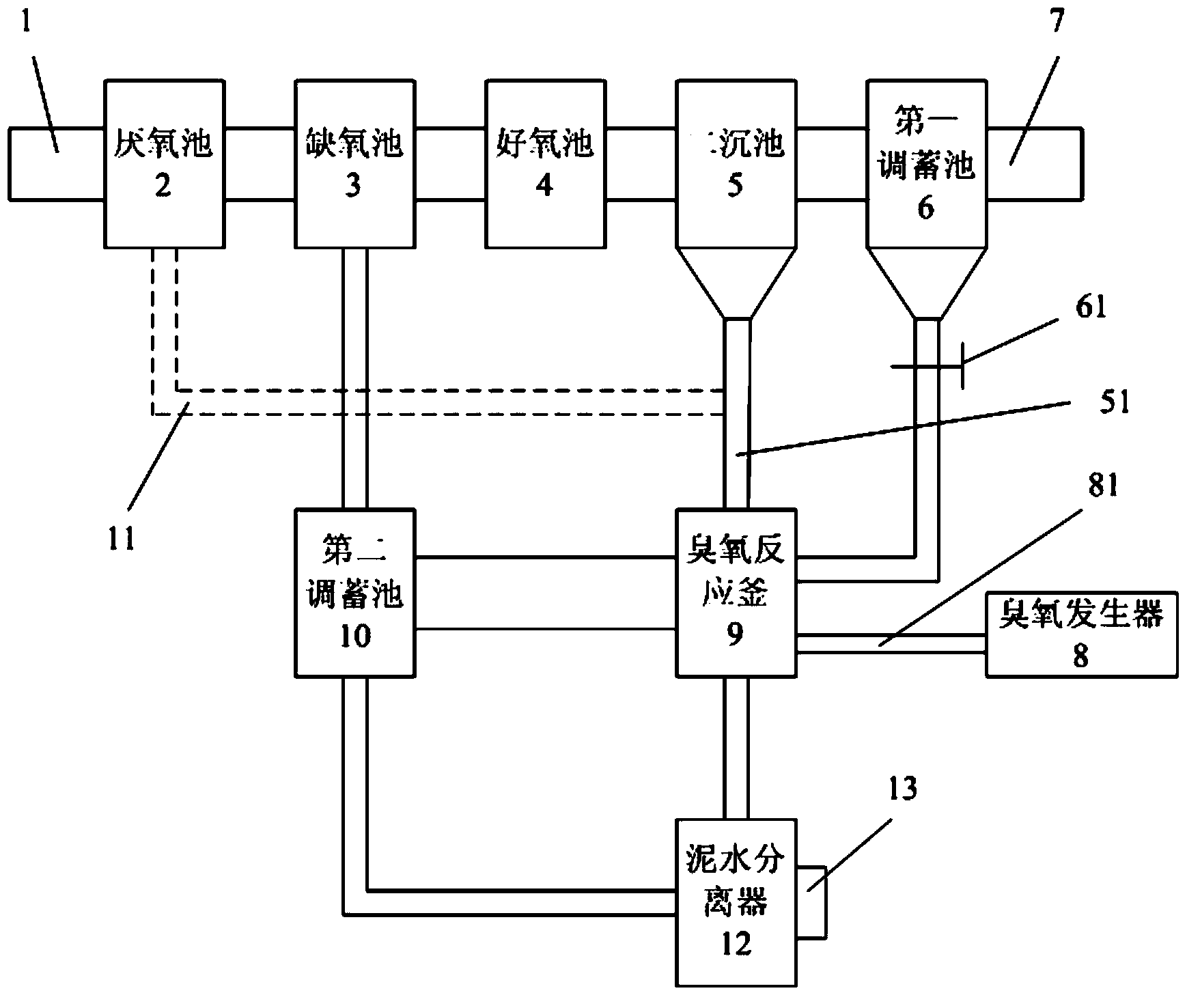

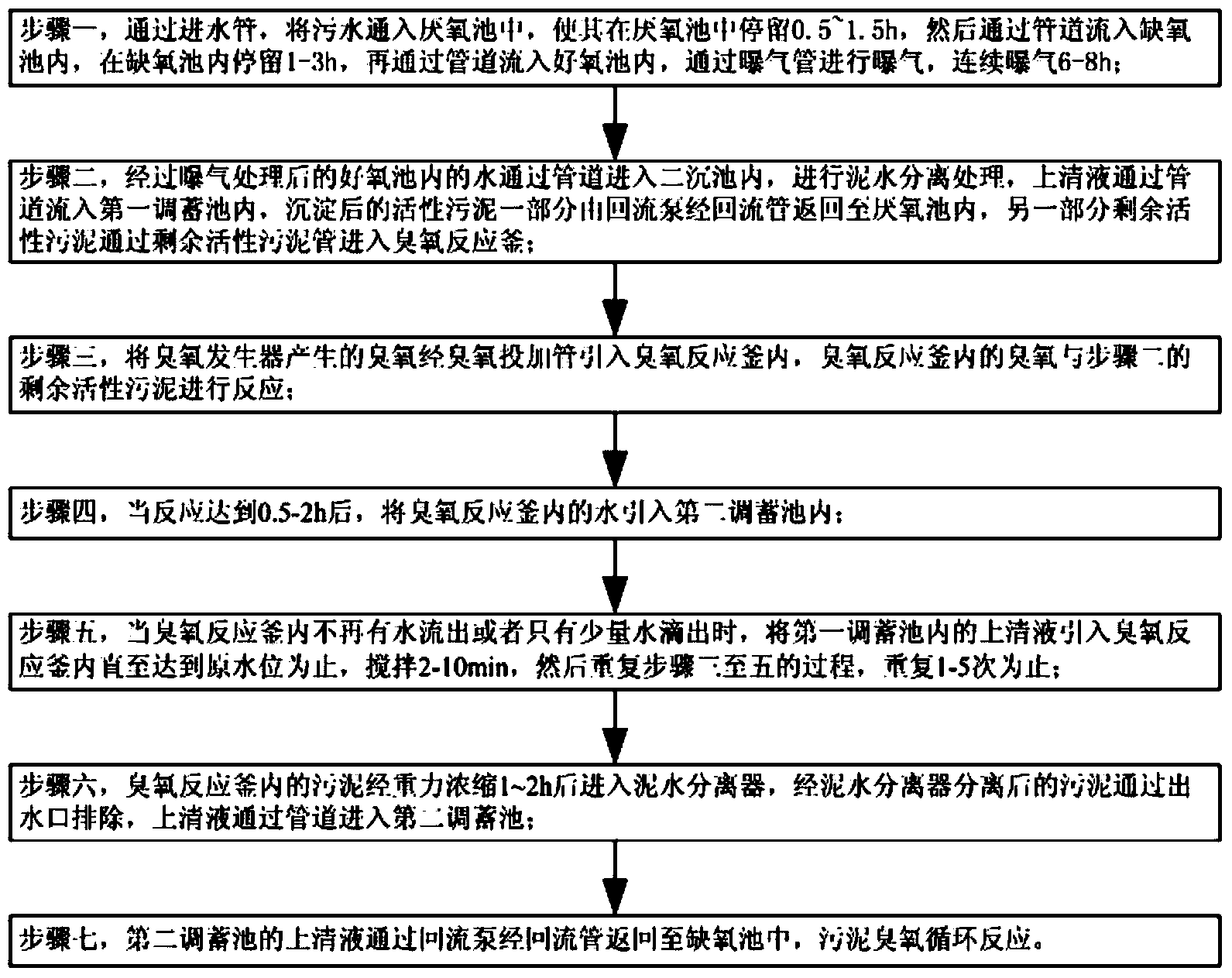

Sludge ozone oxidation and reduction device and use method thereof

ActiveCN104230111ALow costEasy to operateSludge treatment by oxidationMultistage water/sewage treatmentActivated sludgeOzone generator

The invention belongs to the technical field of environmental engineering sludge treatment, and provides a sludge ozone oxidation and reduction device and a use method thereof. The sludge ozone oxidation and reduction device comprises a water inlet pipe, an anaerobic tank, an anoxic tank, an aerobic tank and a secondary settling tank, and further comprises a first regulating and storage tank, an ozone reaction kettle, a second regulating and storage tank and a backflow pipe, wherein an automatic control switch is arranged below the first regulating and storage tank, the first regulating and storage tank is connected with the ozone reaction kettle through the automatic control switch and a pipeline, one side of the first regulating and storage tank is connected with the secondary settling tank through the pipeline, and the other side of the first storage tank is connected with a water outlet pipe; a stirrer is arranged inside the ozone reaction kettle, one side of the ozone reaction kettle is connected with the second regulating and storage tank through a residual activated sludge pipe, and the other side of the ozone reaction kettle is connected with an ozone generator through an ozone dosing pipe; the second regulating and storage tank is respectively connected with the anaerobic tank and the ozone reaction kettle through the pipeline; the backflow pipe is provided with a backflow pump, one end of the backflow pipe is connected with the anaerobic tank, and the other end of the backflow pipe is connected with the residual activated sludge pipe. The sludge ozone oxidation and reduction device and the use method thereof have the advantages of full reaction between ozone and sludge, easiness in process control, small sludge dosage, low cost, high ozone utilization rate and maximum utilization of resources.

Owner:SHANGHAI MUNICIPAL WATER RESOURCES DEV & UTILIZATION NAT ENG CENT

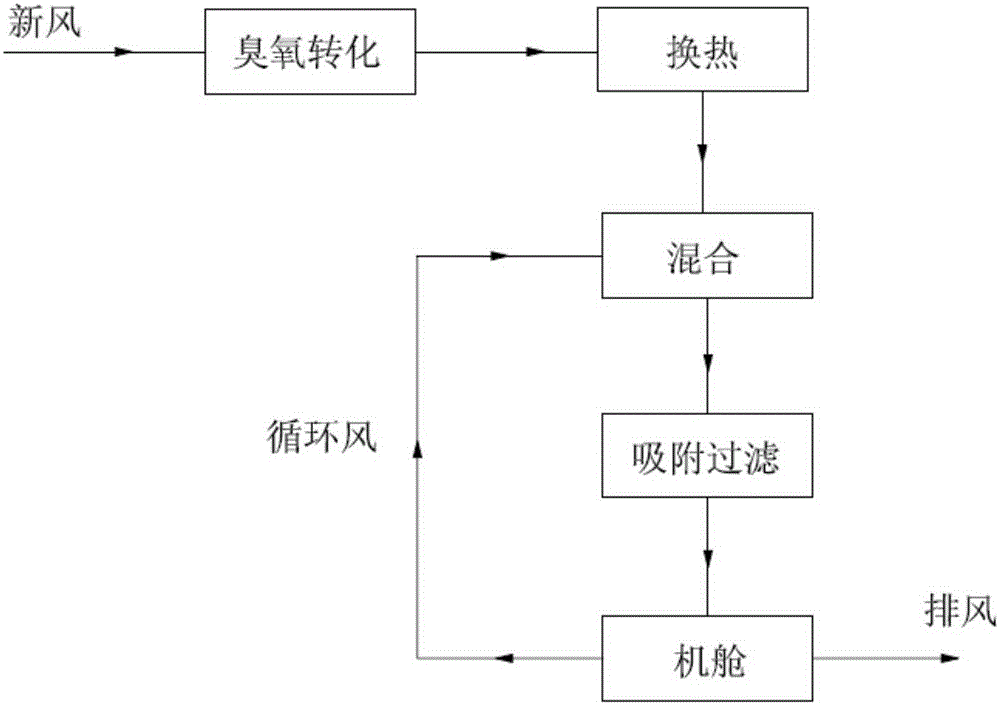

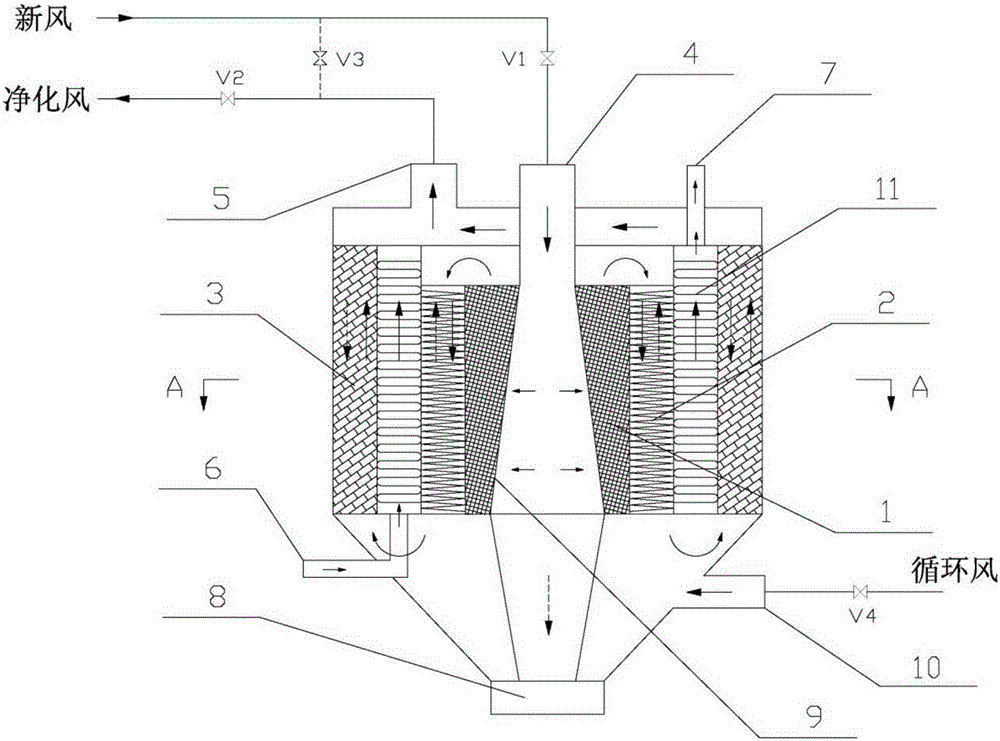

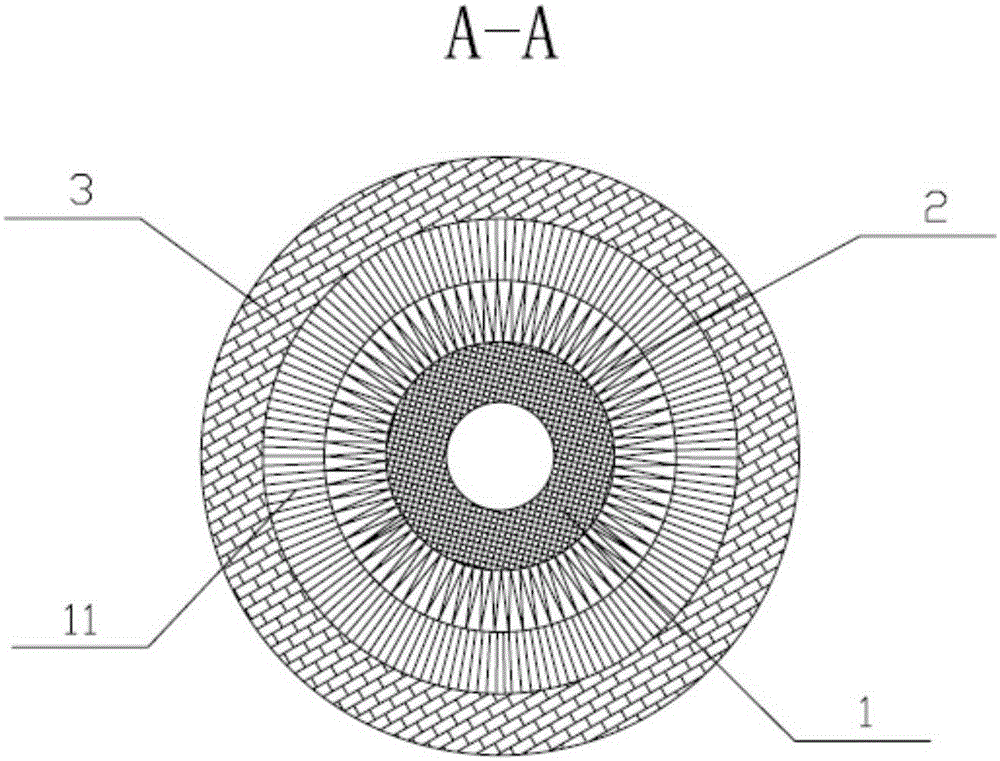

Method and system for ozone removal and gas purification of cabin of aircraft

ActiveCN106512715AEfficient removalWide temperature operating rangeDispersed particle filtrationAir-treatment apparatus arrangementsParticulatesNacelle

The invention discloses a method and system for ozone removal and gas purification of a cabin of an aircraft. The method comprises the steps of introducing fresh air outside the cabin, filtering out microbes and particulate matters in the fresh air, catalytically converting ozone in the fresh air into oxygen gas through a catalyst, cooling the oxygen gas, then, mixing the cooled oxygen gas with recirculated air in the cabin, carrying out adsorptive filtration on the gas mixture so as to further reduce incompletely-removed ozone, microbes and solid particles in the gas mixture, discharging the gas mixture, which is subjected to adsorptive filtration, from a system, and enabling the gas mixture to enter the cabin. The system comprises a catalytic ozone removal reactor, a heat exchanger, an adsorption purifier and a desorption blowback system, or the unit plants are integrated into one reactor. The desorption blowback system is further used for purging the interior of the gas purification system so as to prolong the service life of the system. The system employs a radial reactor structure and has high ozone removal efficiency; and in purified air exhausted from the gas purification system disclosed by the invention, the ozone concentration can be controlled to 0.1mg / m<3> or below.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

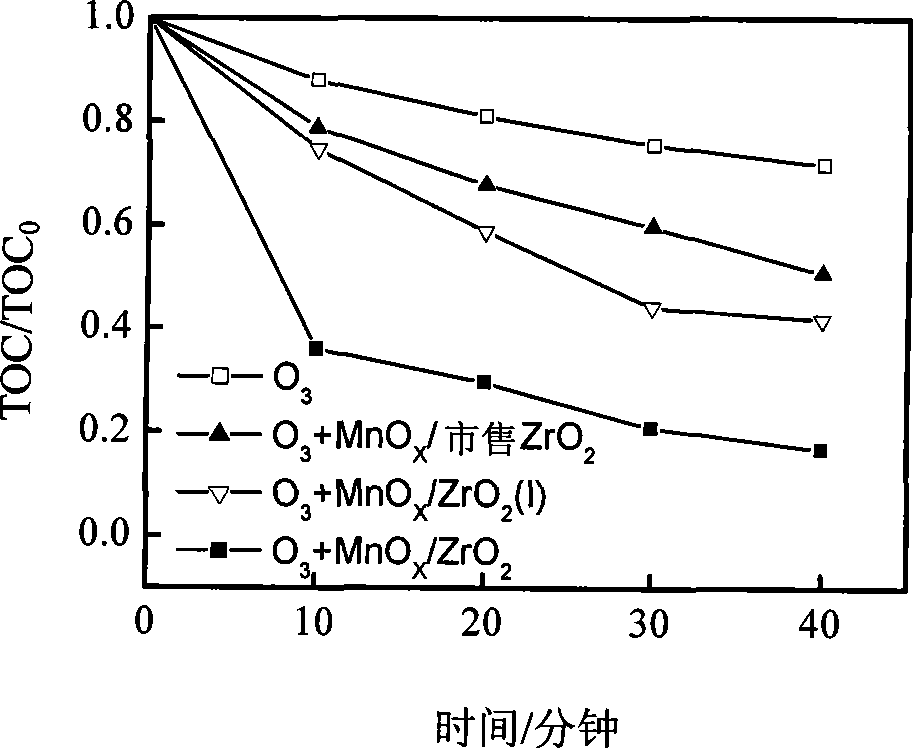

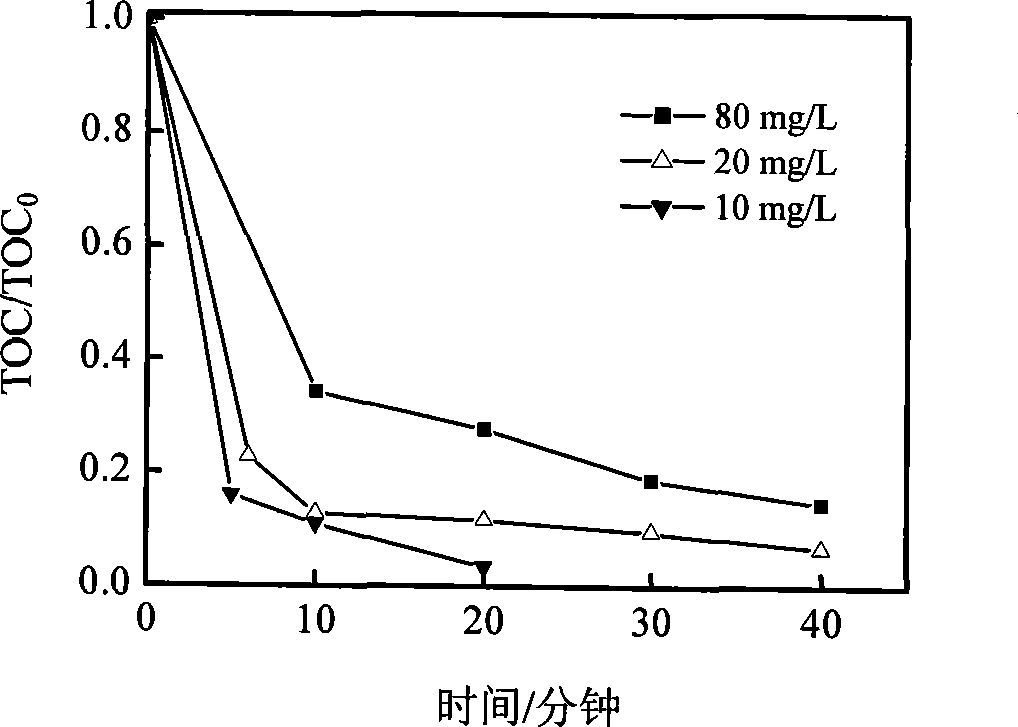

Catalyst preparation method for efficiently catalyzing organic pollutant in ozone oxidation water

InactiveCN101385971AMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationAcetic acidRoom temperature

The invention provides a preparation method used for catalyzing ozone oxidation catalyst MnO / ZrO2; the preparation of the catalyst adopts an isovolumetric impregnation method and adds manganous acetate of a certain quantity into a deioned water; subsequently, mesopore zirconia is added into the solution so as to lead the weight percentage of Mn in Mn / ZrO2 (measured by MnO2) is 1-15wt% and dipped for 0.5-6 hours under room temperature, thus gaining a system which is subsequently dried for 1-6 hours in an oven at the temperature of 100-140 DEG C; subsequently, the system is washed by the deioned water and dried for 1-6 hours at the temperature of 100-140 DEG C so as to gain the powder; the power is calcined for 2-6 hours at the temperature of 300-500 DEG C so as to gain sample MnOX / ZrO2, thus gaining highly dispersed nanometer manganese oxides. The catalyst has extremely high ozone catalysis activity under acid and neutral conditions and can completely mineralize 2, 4-Dichlorophenoxyethanoic acid.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Dyeing wastewater advanced treatment method and device by using ozone, oxydol and activated carbon

InactiveCN105858950AImprove catalytic performanceImprove ozone utilizationTreatment involving filtrationMultistage water/sewage treatmentFiberActivated carbon

The invention relates to a dyeing wastewater advanced treatment method and device by using ozone, oxydol and activated carbon. The method comprises the following steps: floatation effluent water passes through a fiber rotary table filter tank to remove suspended substances and enters a quick mixing tank, H2O2 is added into the quick mixing tank, the effluent water enters an ozone contact tank, H2O2 and O3 are simultaneously added into the tank to degrade nondegradable organic matters, the effluent water enters an activated carbon filter tank, and ozone is added into the activated carbon filter tank; the effluent water of the activated carbon filter tank enters a filter tank effluent water storage tank, and is discharged by a pump; and by using the filter tank effluent water storage tank as a back flushing water tank, back flushing wastewater is discharged into the activated carbon filter tank to perform back flushing on a wastewater recovery tank. By using the H2O2 and the activated carbon which carries the Fe2O3-CuO-MnO2-CeO2 catalyst and adding the ozone in different stages, the method has the characteristics of high catalytic efficiency, high ozone utilization ratio, favorable COD (chemical oxygen demand) removal effect, low cost and the like, so that the device has the characteristics of high treatment efficiency, high economy, high stability, high reliability, low carbon and environment friendliness.

Owner:SHAOXING HEQIAO JIANGBIN WATER TREATMENT

Fluororubber and epichlorophdrin rubber formulation

ActiveCN101081916AHigh electronegativityGood fuel resistanceSynthetic resin layered productsPolymer scienceLead(II,IV) oxide

The present invention is one kind of rubber pipe comprising one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber. The fluororubber consists of polyfluoroprene, thermal black N990, 2, 5-dimethyl-2, 5-dihexane, triallyl cyanourate and carnauba wax; and the chlorohydrin rubber consists of chlorohydrin rubber C, chlorohydrin rubber H, black N550, anti-ager NBC, processing aid R-300, stearic acid, plasticizer RS-107, red lead, ethylene thiourea NA-22, plasticizer W-305ELS and scorch retarder CTP-80. The rubber pipe with one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber has high heat resistance, high oil tolerance, high ozone tolerance and high fuel oil osmosis resistance.

Owner:TIANJIN PENGYI GRP CO LTD

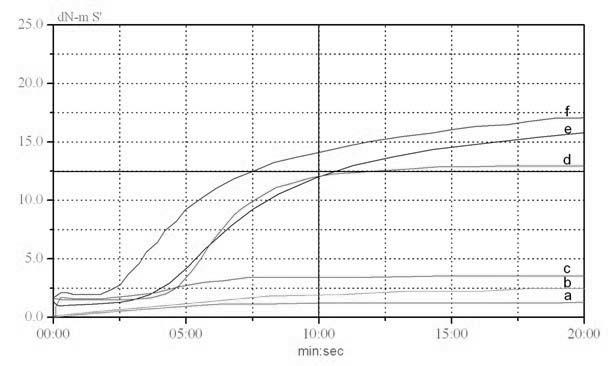

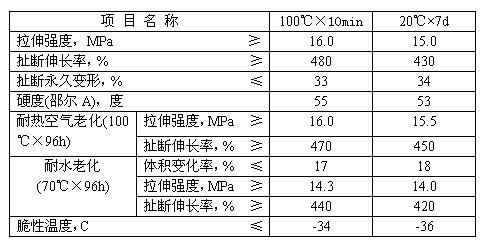

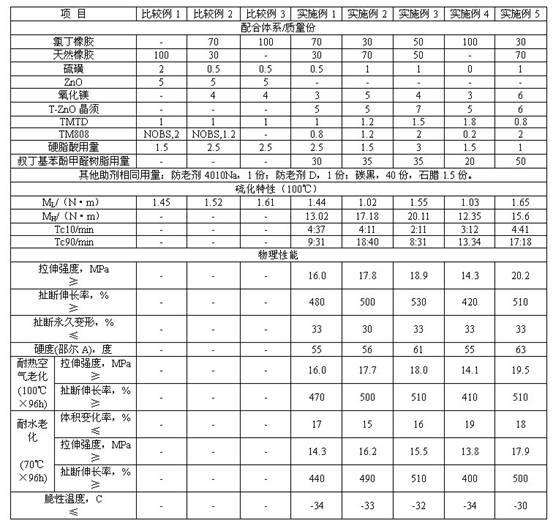

Room temperature/low temperature vulcanized chloroprene rubber sizing material

ActiveCN102115553AStable room temperature/low temperature vulcanization performanceImproved scorch performancePolymer scienceTert butyl phenol

The invention discloses a room temperature / low temperature vulcanized chloroprene rubber sizing material, which relates to rubber. The rubber sizing material is obtained by mixing and processing the following components in parts by mass: 100-30 parts of chloroprene rubber, 0-70 parts of natural rubber, 0-1 part of sulfur S, 4-7 parts of T-ZnO crystal whiskers, 1-6 parts of magnesium oxide, 0-3 parts of TM808, 0.5-1.5 parts of accelerating agent TMTD (Tetramethylthiuram Disulfide), 20-50 parts of tert-butyl phenol formaldehyde resin, 1-6 parts of stearic acid and the balance of compound anti-ageing system consisting of 4010Na and D, carbon black and a paraffin aid, wherein the sulfur S, the T-ZnO crystal whiskers and the magnesium oxide jointly serve as a dual vulcanizing agent, and the TM808 and the accelerating agent TMTD jointly serve as a compound accelerating agent. The chloroprene rubber sizing material obtained by the invention can be vulcanized at room temperature / low temperature, has high scorching property, high adhesion on a framework material and the advantages of ageing resistance, high physical and mechanical performance, high ozone resistance, high oxidation resistance, combustion resistance and the like, and is particularly suitable for the production of large-sized rubber products or the construction of field vulcanization.

Owner:陈尔凡

Method for treating dyeing wastewater in transfer piping by ozone

InactiveCN101050016AImprove utilization efficiencyStrong oxidation abilityWater/sewage treatment by oxidationHigh concentrationWater quality

This invention relates to a method for deeply treating printing and dyeing wastewater with ozone in transportation pipeline with a length of 3-10 m. In the transportation pipeline, the printing and dyeing wastewater is contacted and mixed with ozone via an injector to react for 1-5 s. The mass transfer efficiency of ozone is higher than 98%. The decolorization rate is higher than 98%. The removal rate of COD is higher than 95%. The method has such advantages as high water quality, saved water resources, high ozone mass-transfer efficiency, high ozone utility, no need for high-volume bubbling column, and no secondary pollution, and is suitable for deep treatment of industrial printing and dyeing wastewater, especially high-concentration printing and dyeing wastewater.

Owner:DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com