Cerium-manganese catalyst for decomposing ozone at room temperature in high humidity as well as preparation method and application of cerium-manganese catalyst

A high-humidity, catalyst technology, applied in the direction of separation methods, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low ozone decomposition rate, complicated preparation process, and limited wide application, etc. Achieve low cost, reduce hazards, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

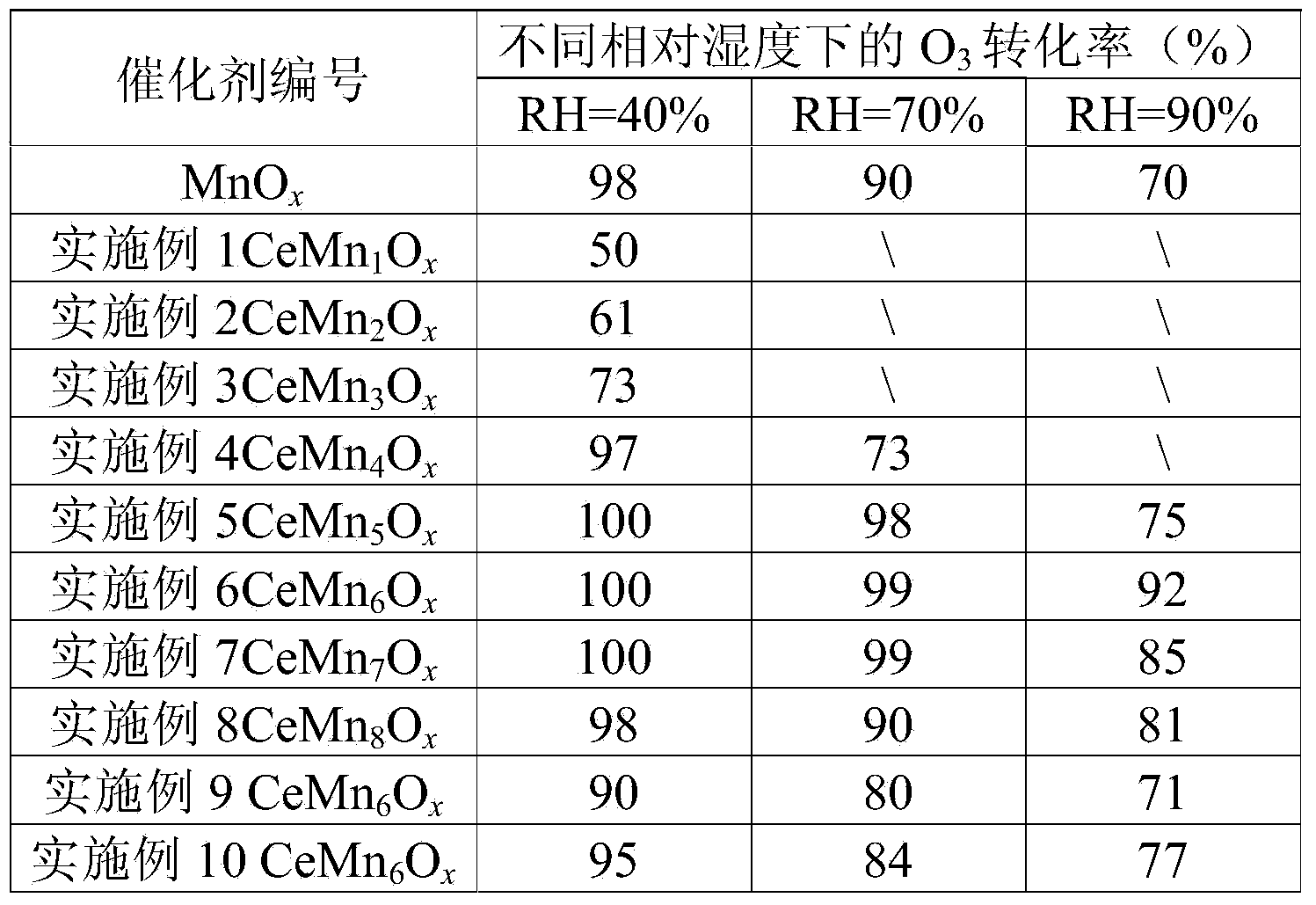

Examples

Embodiment 1

[0043] A preparation method of a cerium-manganese catalyst decomposing ozone at room temperature and high humidity, the cerium-manganese catalyst has the following chemical composition: CeMn 1 o x , the method includes the steps of:

[0044] (1) Dissolve manganese acetate in deionized water, stir until completely dissolved, then add acetic acid to adjust the pH to 4-5;

[0045] (2) Add cerium nitrate to the solution obtained in step (1), stir well until the solid is completely dissolved, then slowly add potassium permanganate aqueous solution dropwise, and finally add water until the mixed volume of the solution is about 80ml, and after stirring for a period of time, transfer 100ml In a high-pressure hydrothermal kettle, hydrothermally react at 100°C for 24 hours;

[0046] (3) After cooling to room temperature, centrifuge washing to neutrality, and dry at 100° C. for 12 hours to obtain a cerium-manganese catalyst that decomposes ozone at room temperature and high humidity. ...

Embodiment 2

[0048] All the other are identical with embodiment 1, except that the cerium-manganese catalyst that obtains has following chemical composition: CeMn 2 o x .

Embodiment 3

[0050] All the other are identical with embodiment 1, except that the cerium-manganese catalyst that obtains has following chemical composition: CeMn 3 o x .

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com