Patents

Literature

14483 results about "Honeycomb" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A honeycomb is a mass of hexagonal prismatic wax cells built by honey bees in their nests to contain their larvae and stores of honey and pollen. Beekeepers may remove the entire honeycomb to harvest honey. Honey bees consume about 8.4 lb (3.8 kg) of honey to secrete 1 lb (454 g) of wax, so it makes economic sense to return the wax to the hive after harvesting the honey. The structure of the comb may be left basically intact when honey is extracted from it by uncapping and spinning in a centrifugal machine—the honey extractor. If the honeycomb is too worn out, the wax can be reused in a number of ways, including making sheets of comb foundation with hexagonal pattern. Such foundation sheets allow the bees to build the comb with less effort, and the hexagonal pattern of worker-sized cell bases discourages the bees from building the larger drone cells.

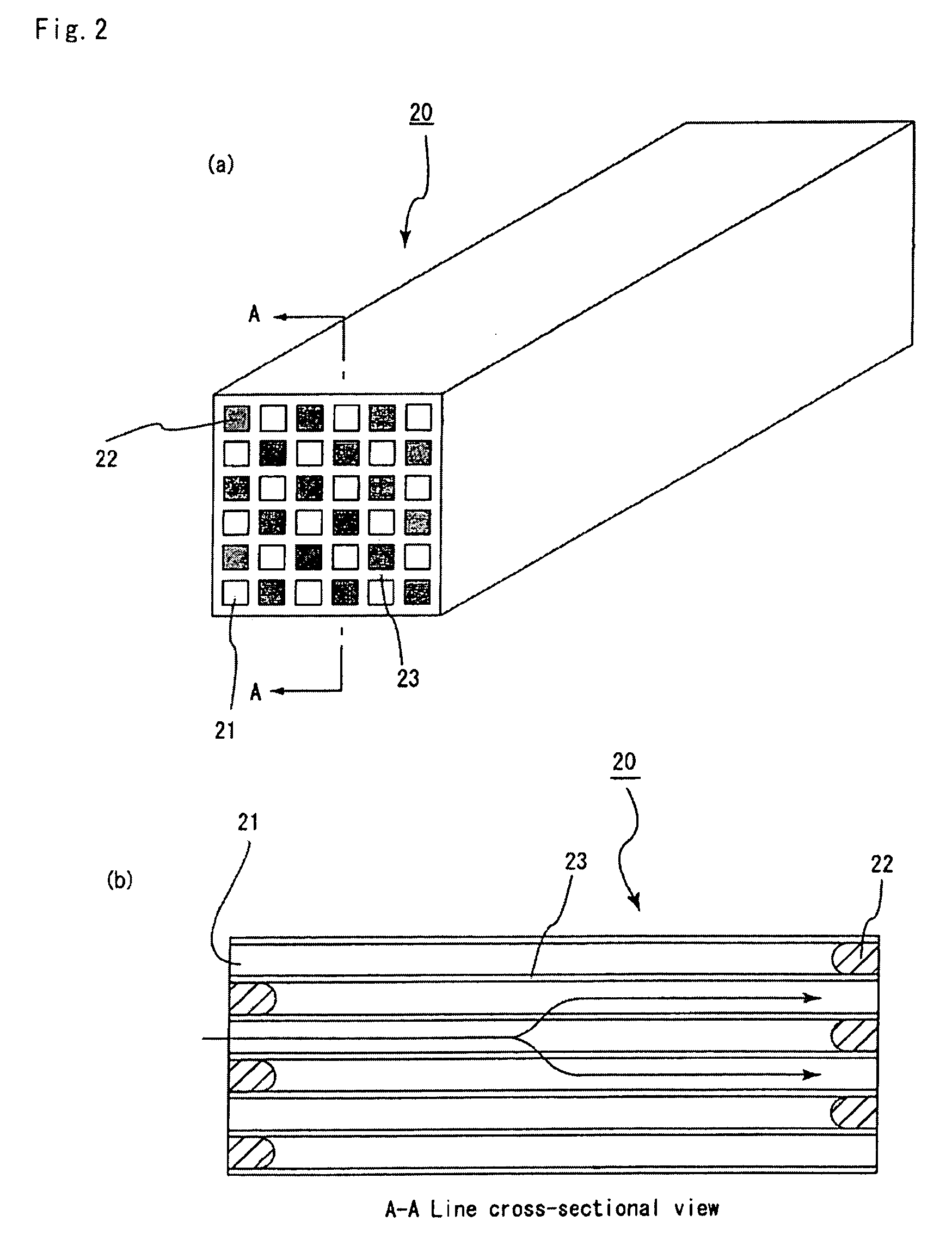

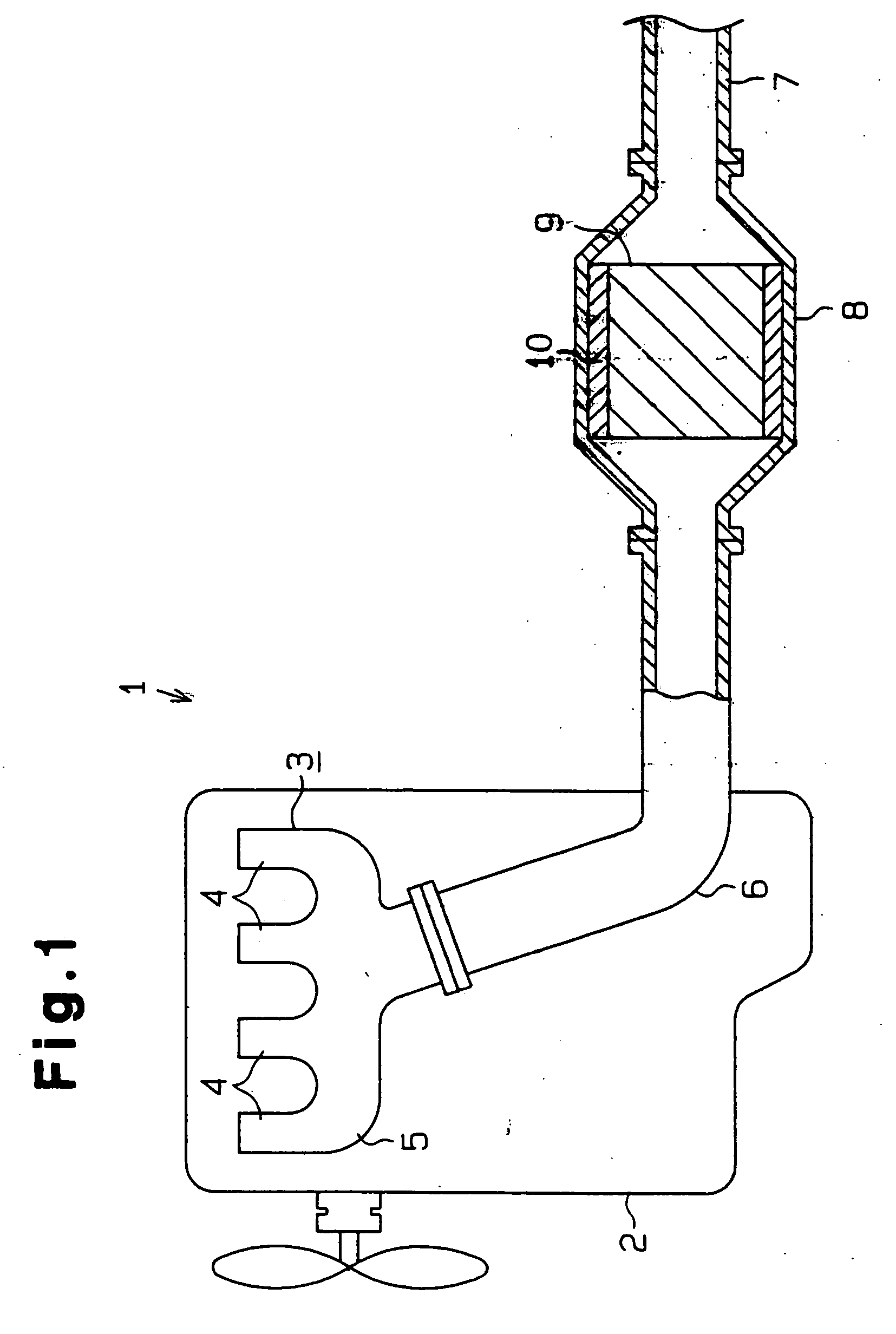

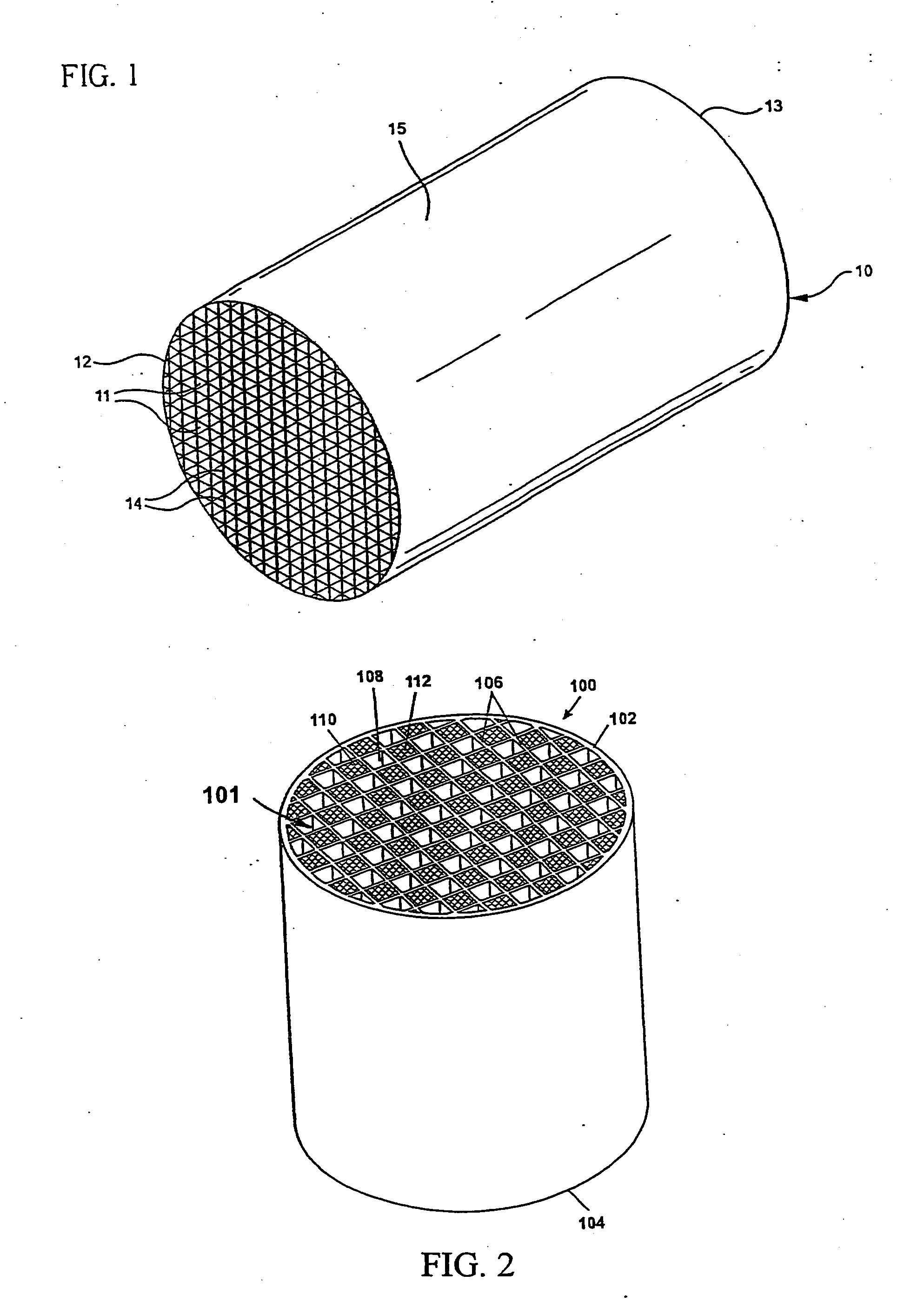

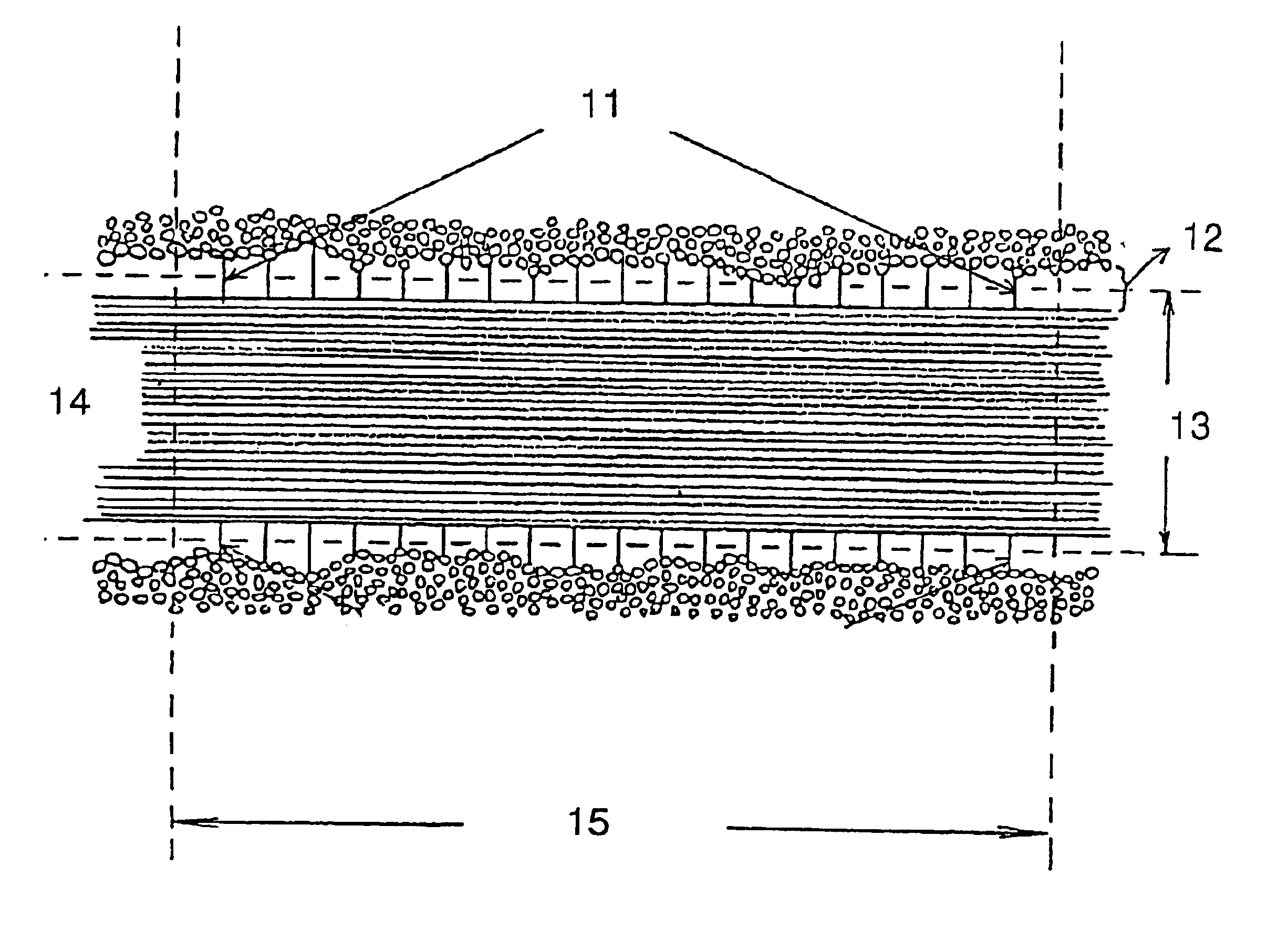

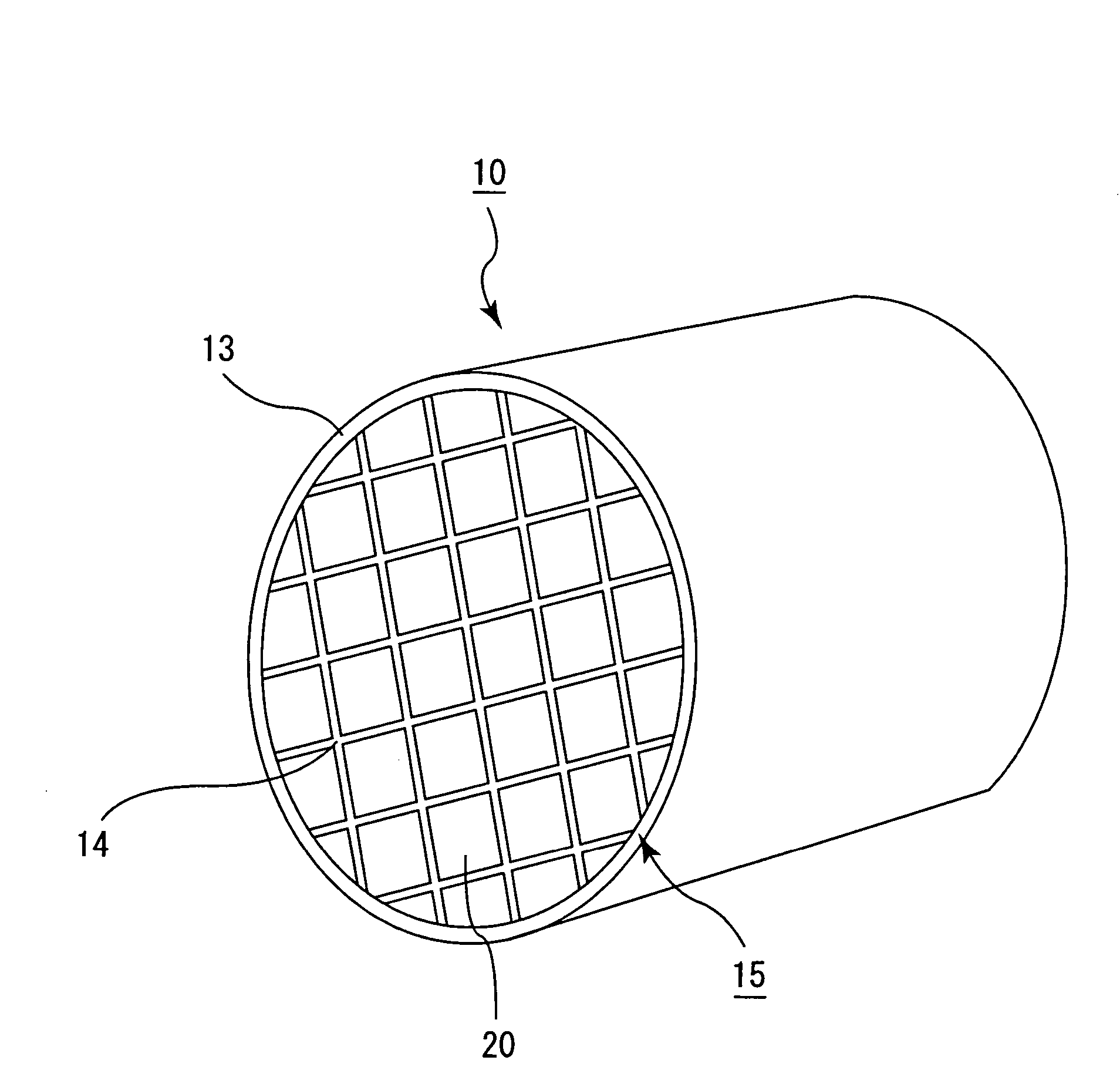

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

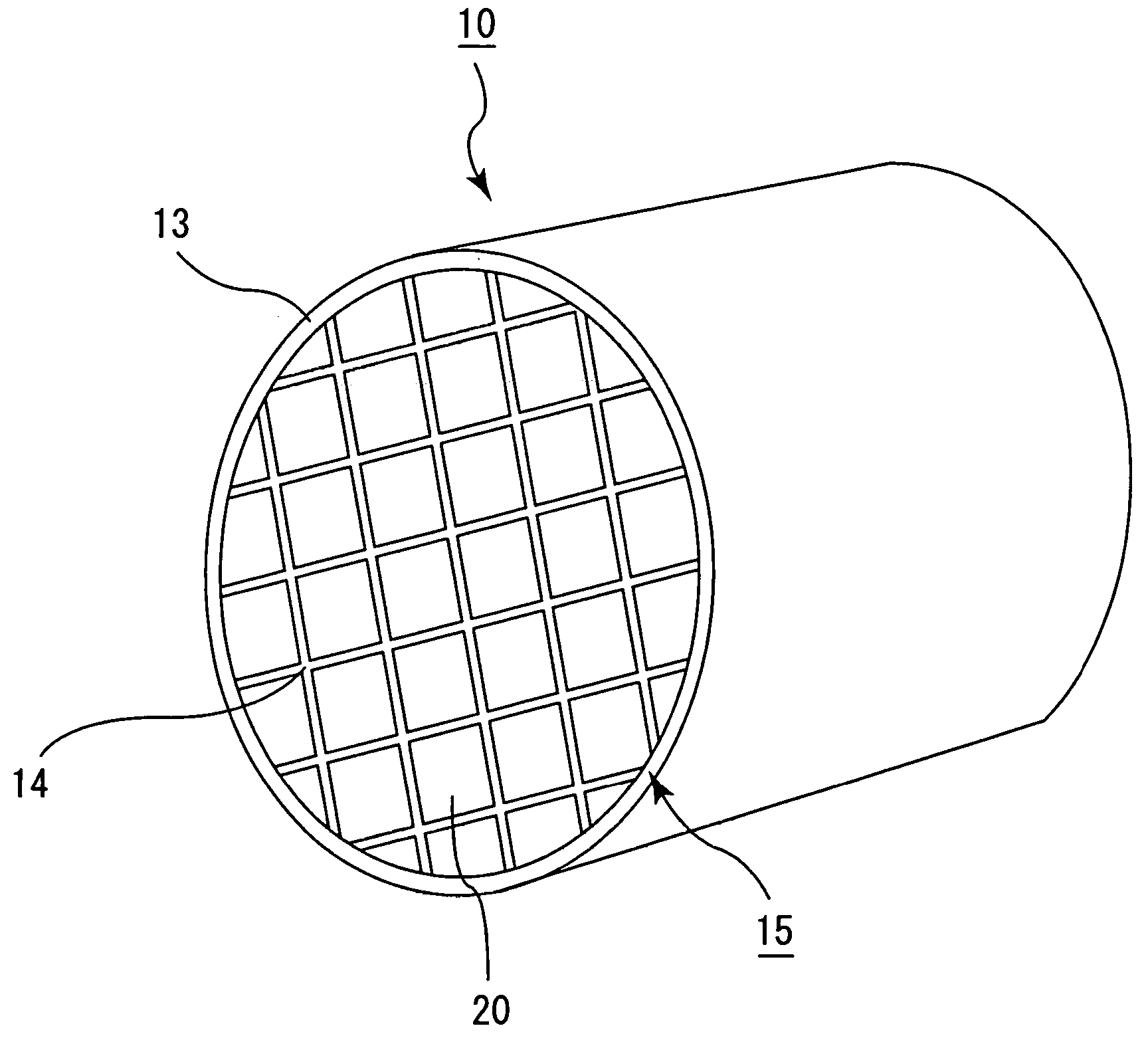

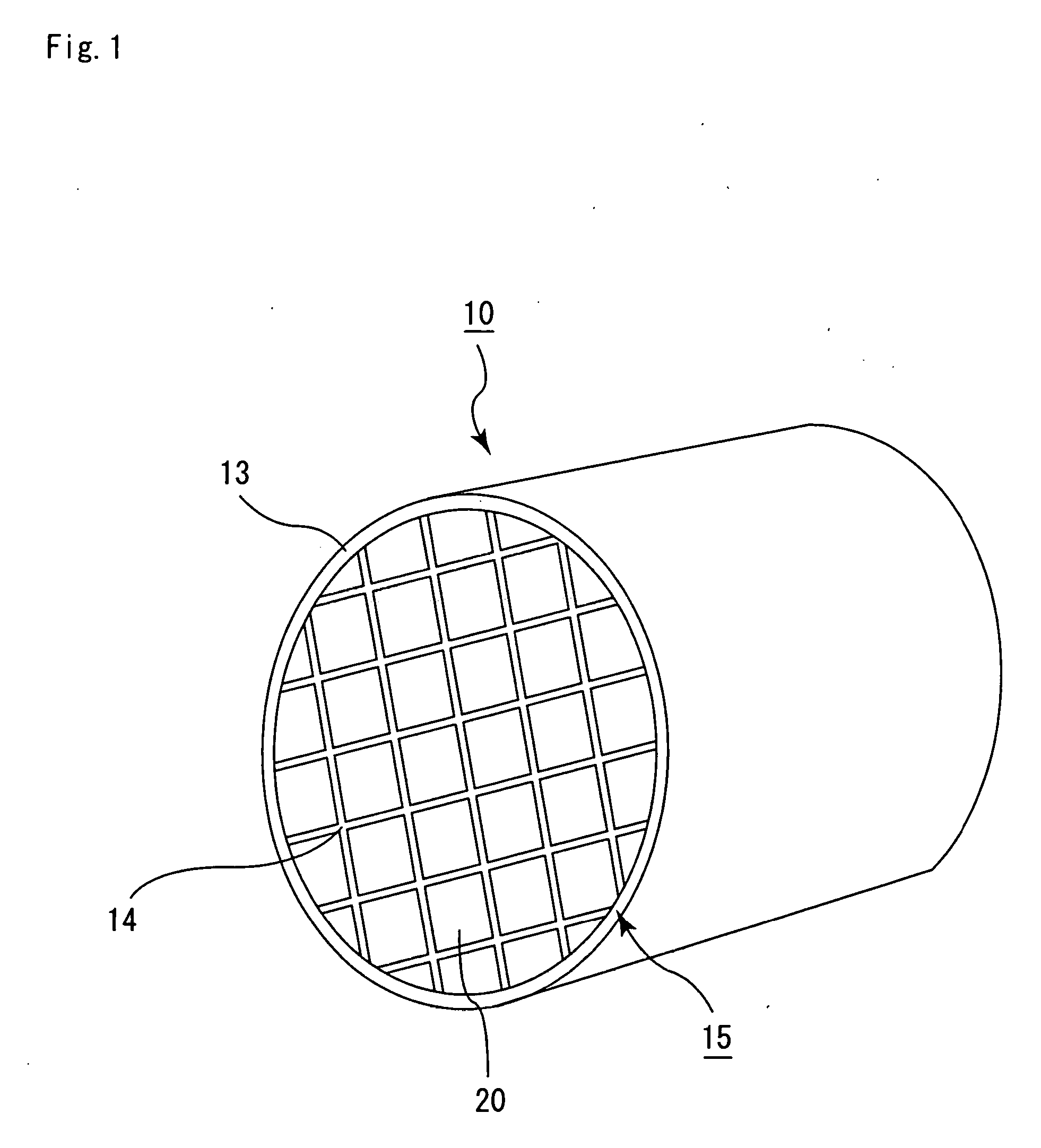

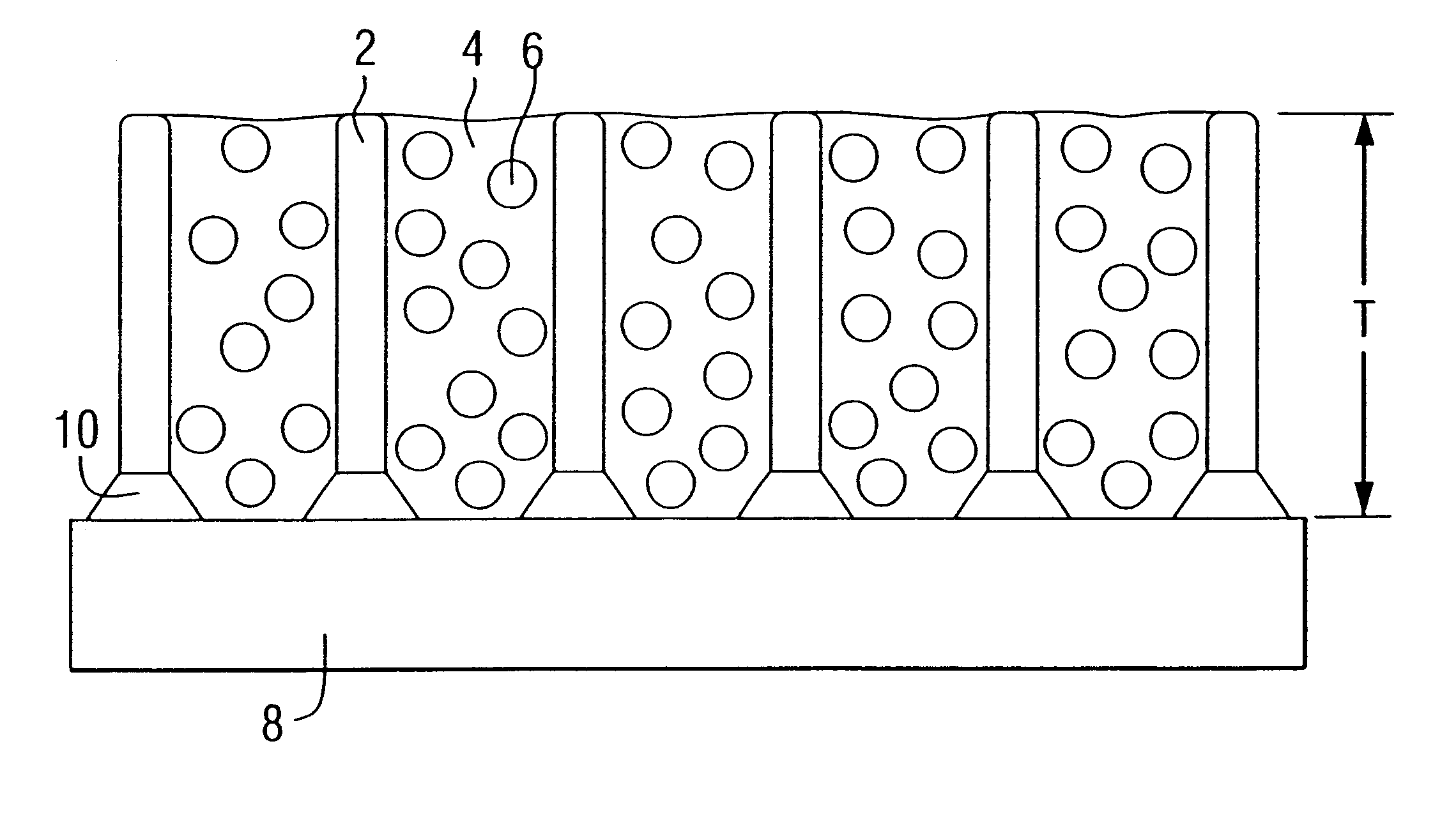

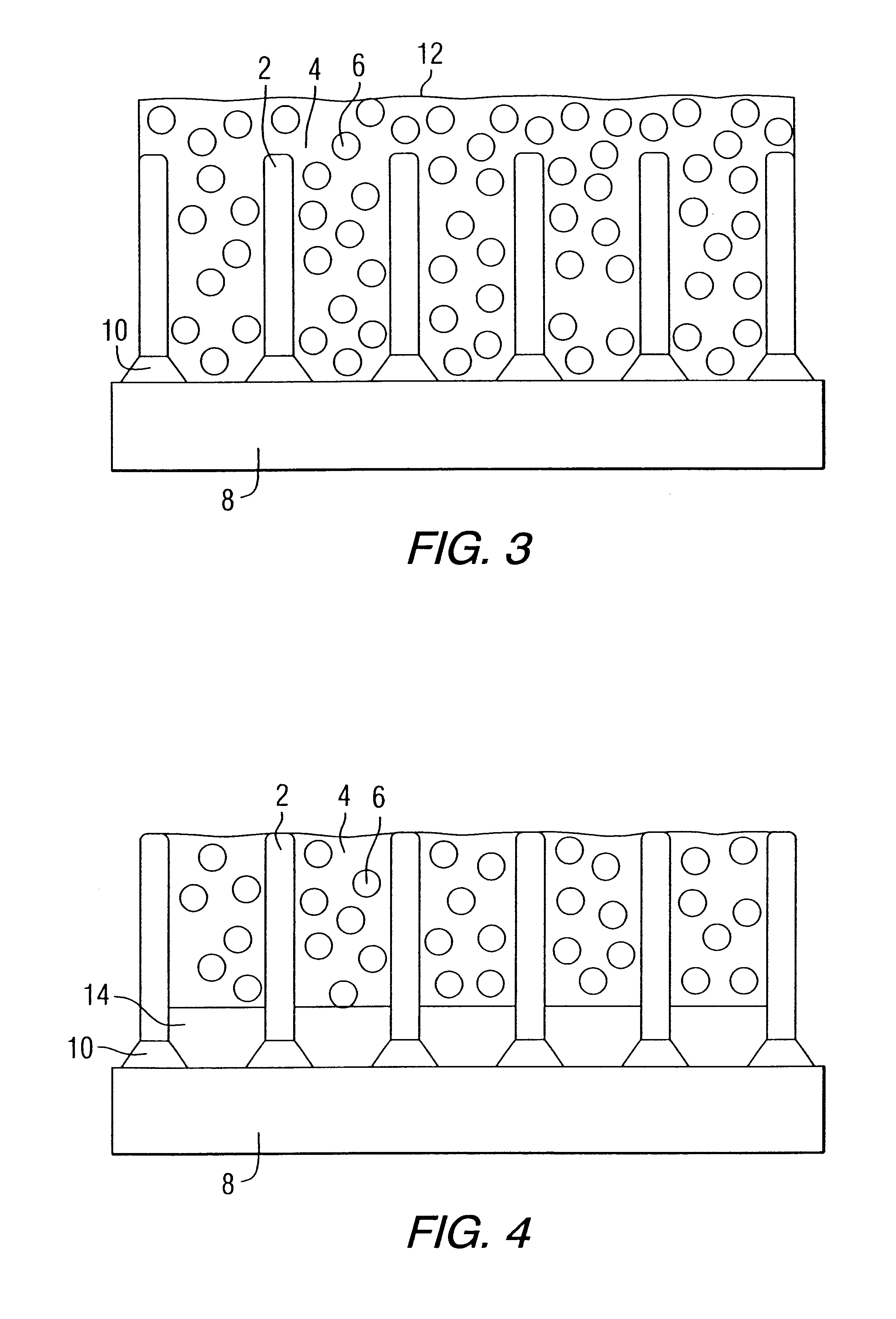

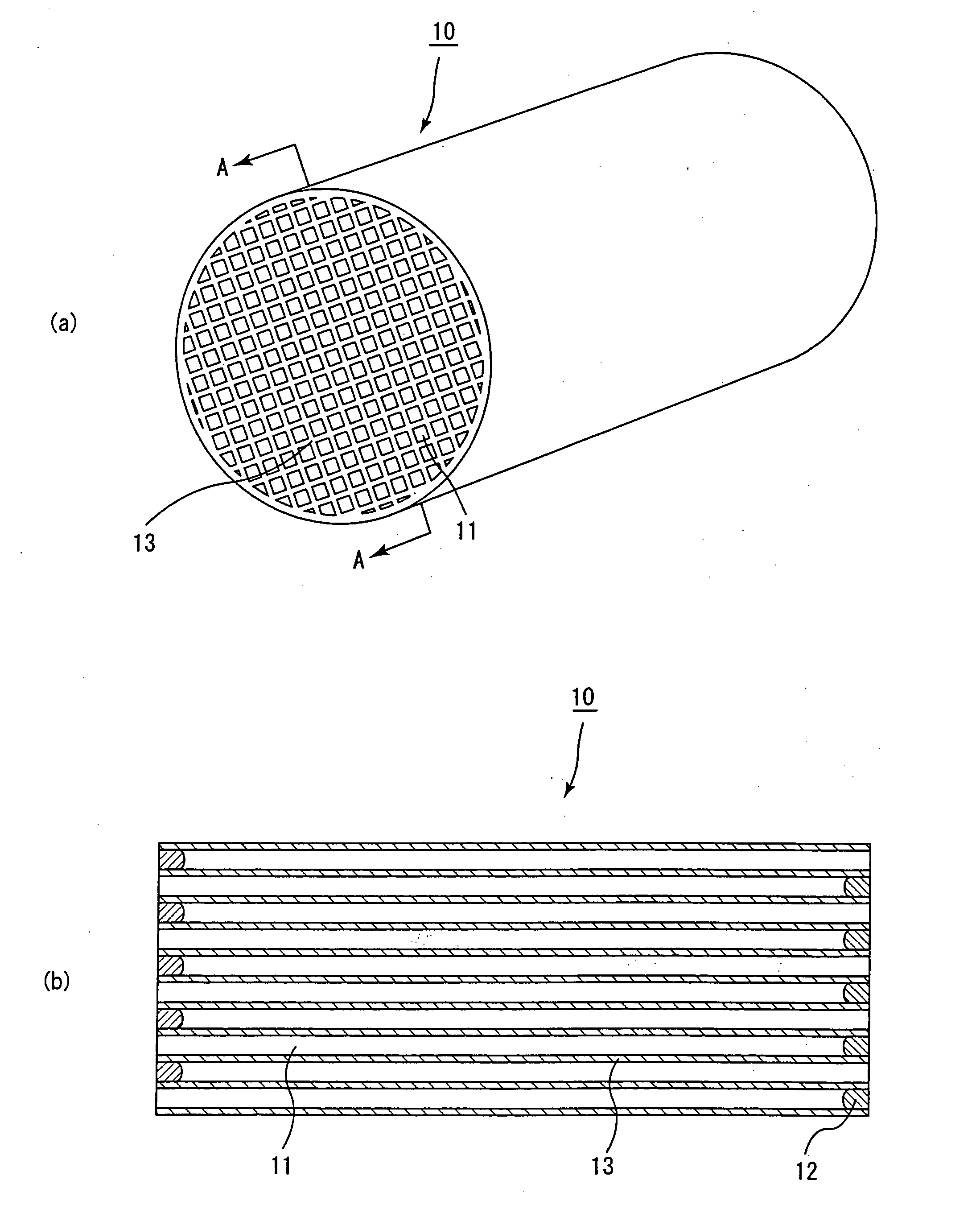

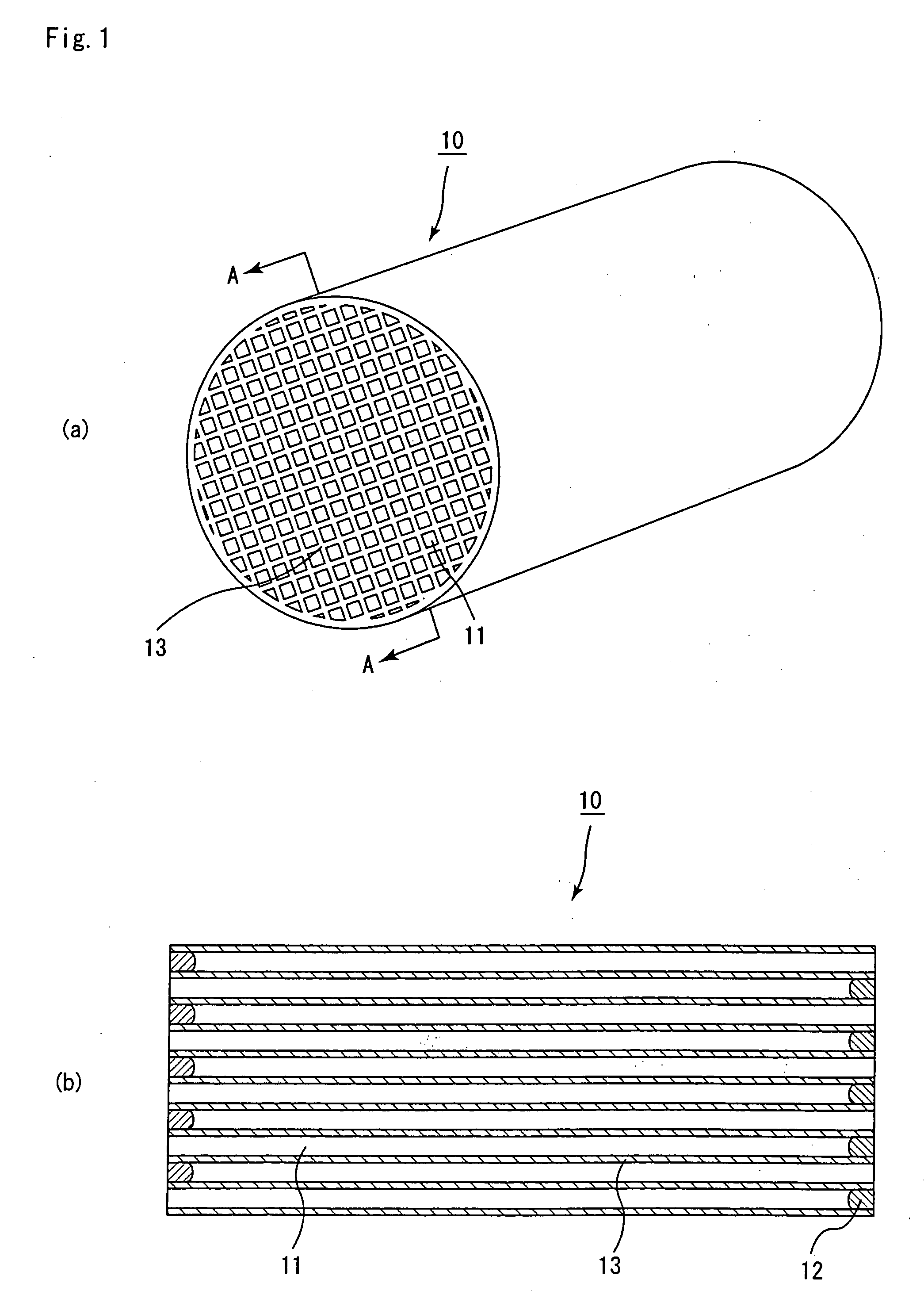

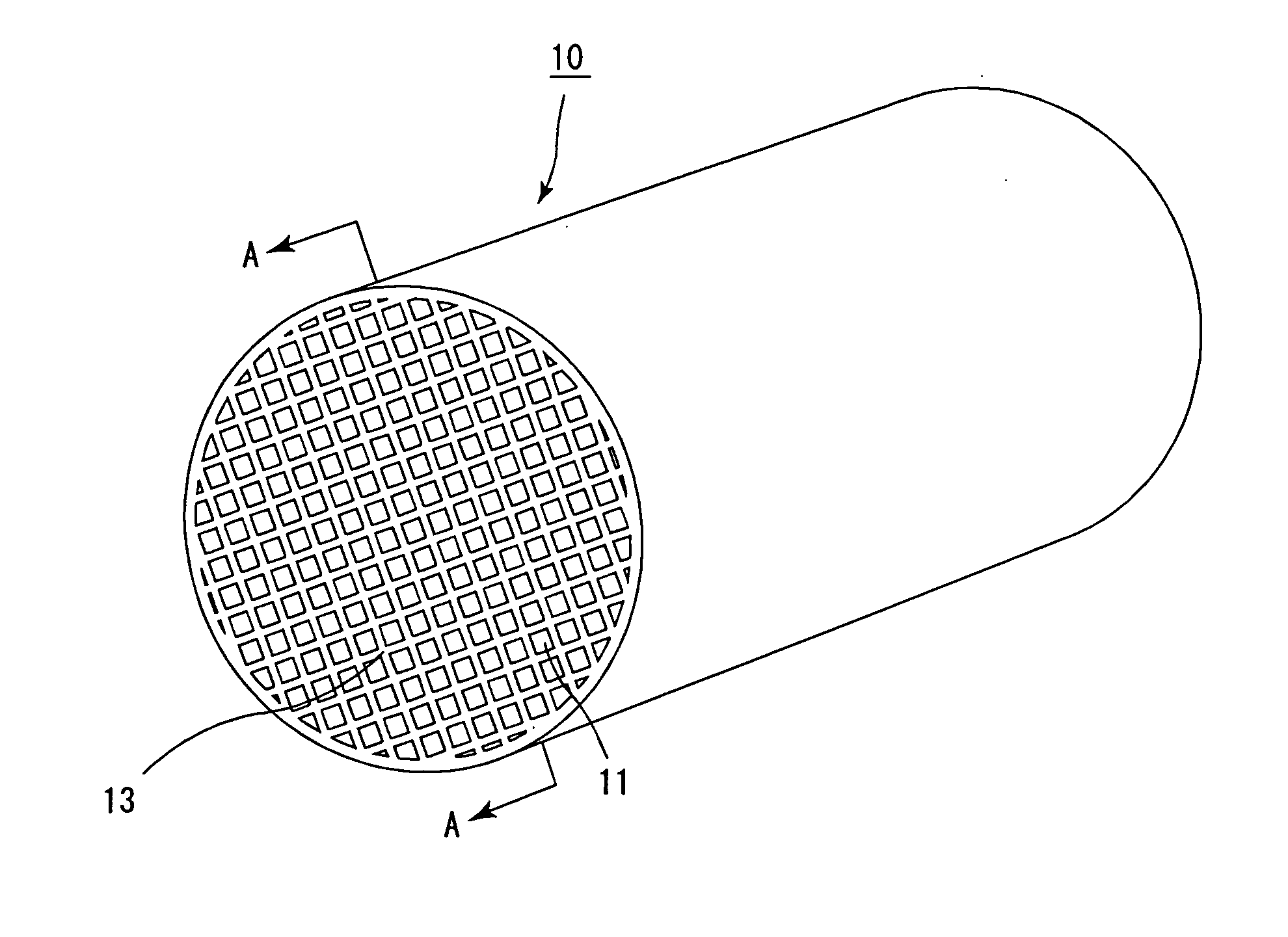

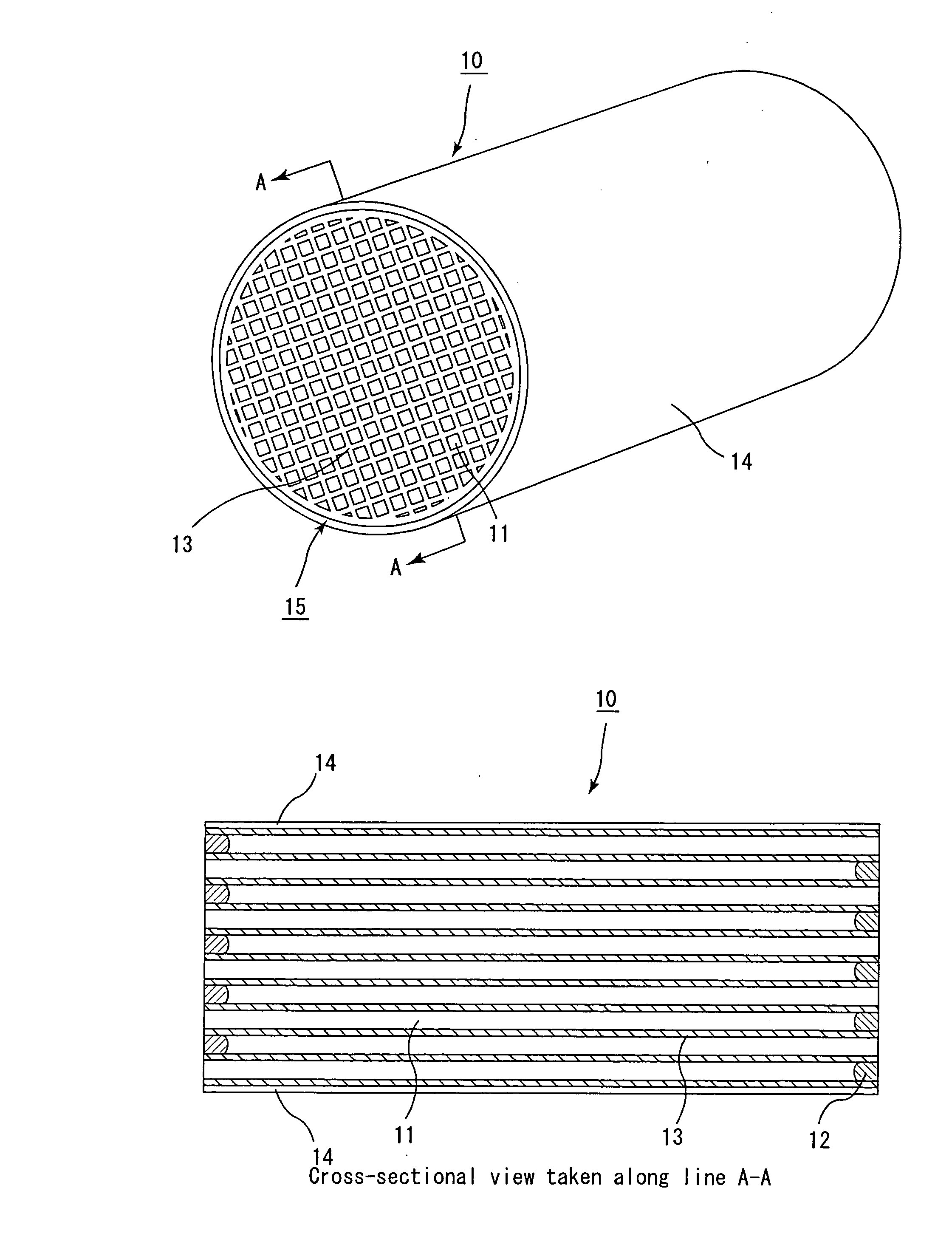

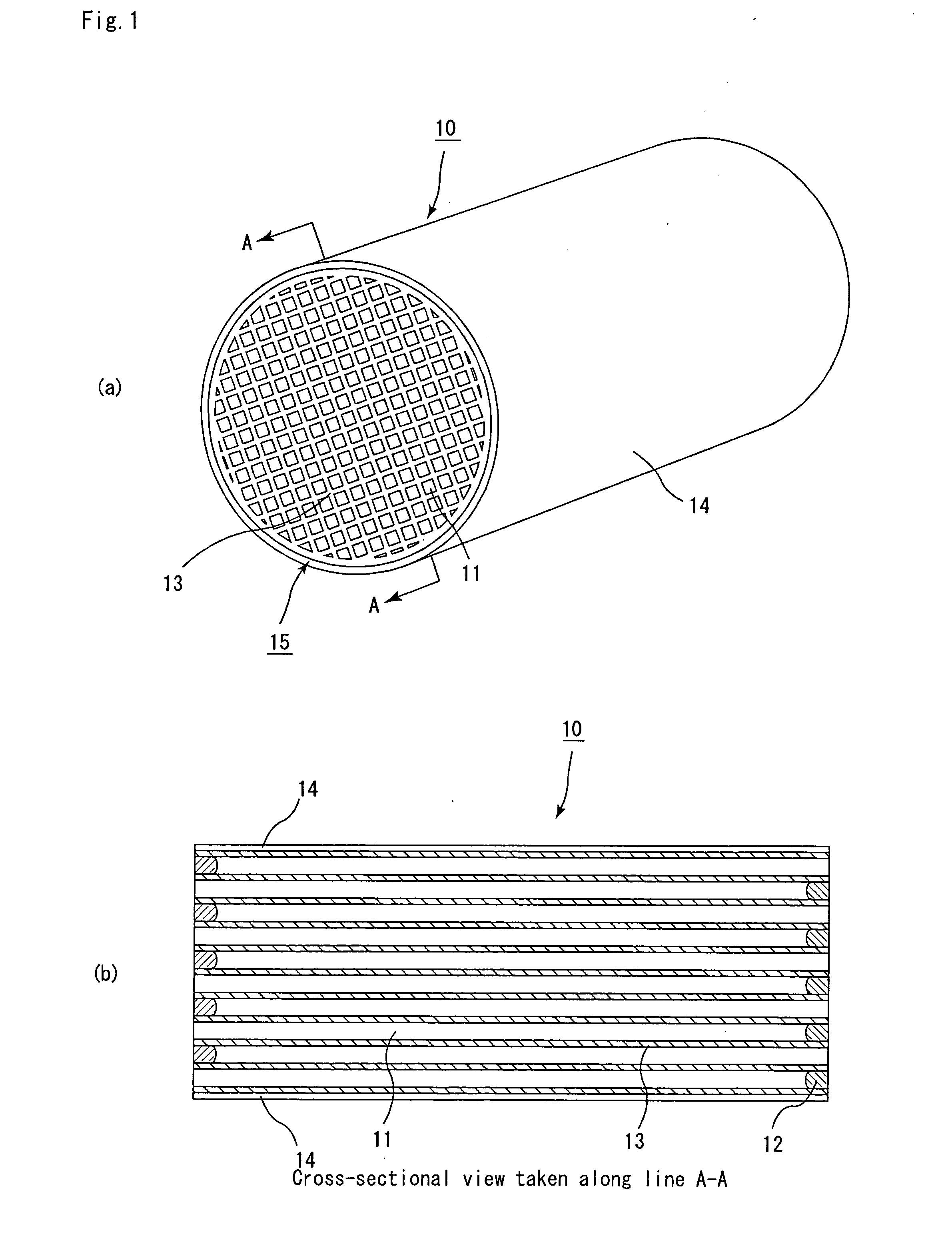

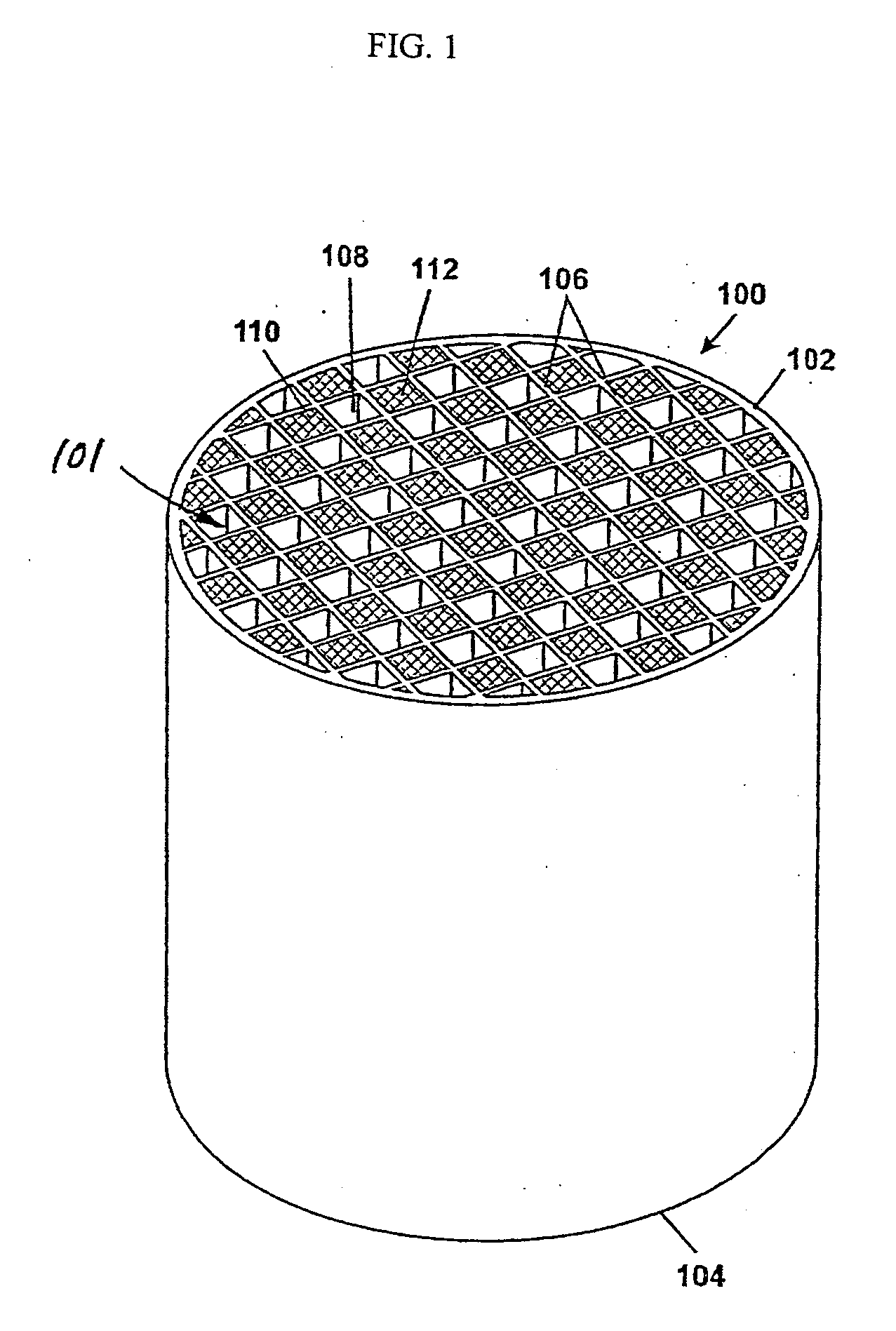

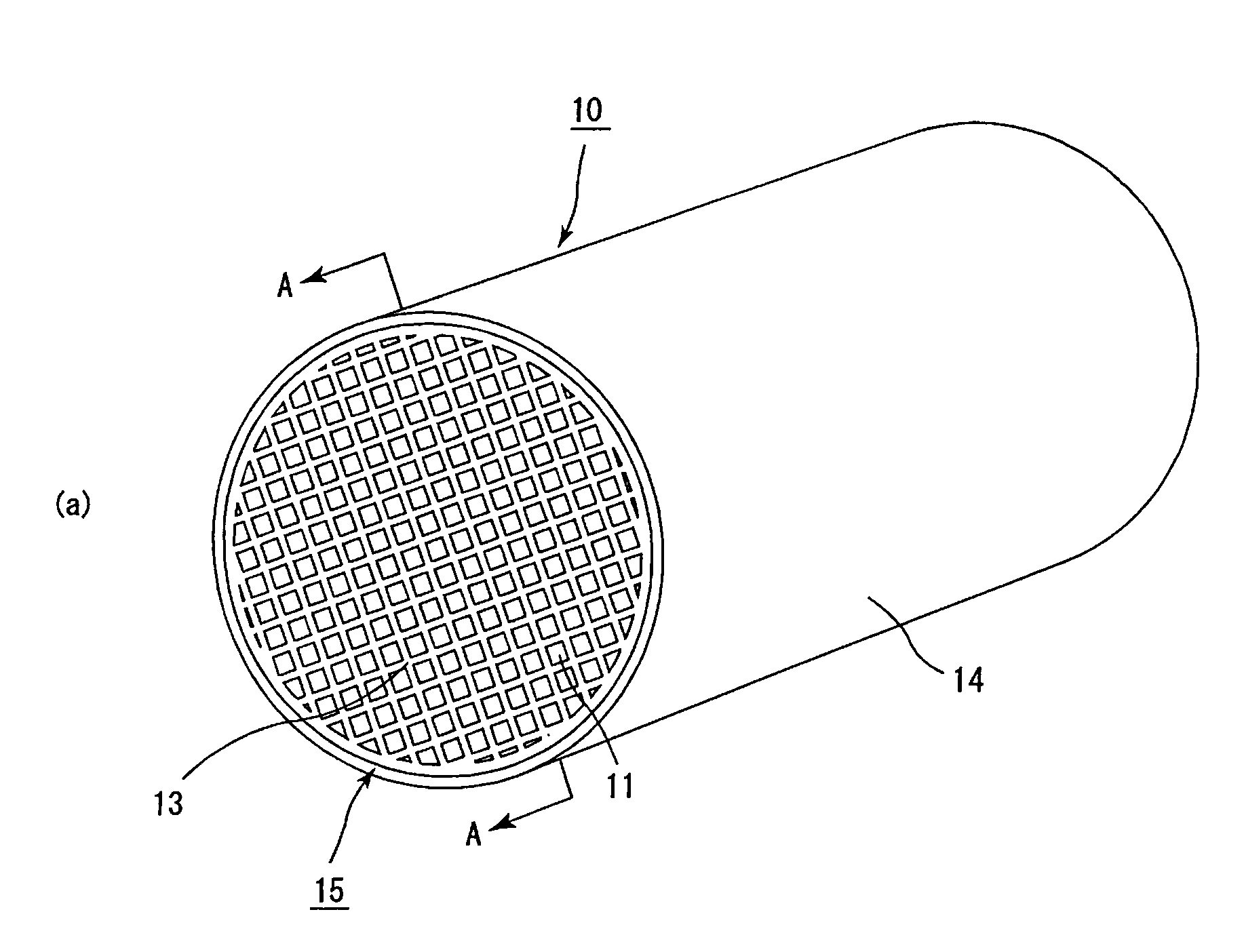

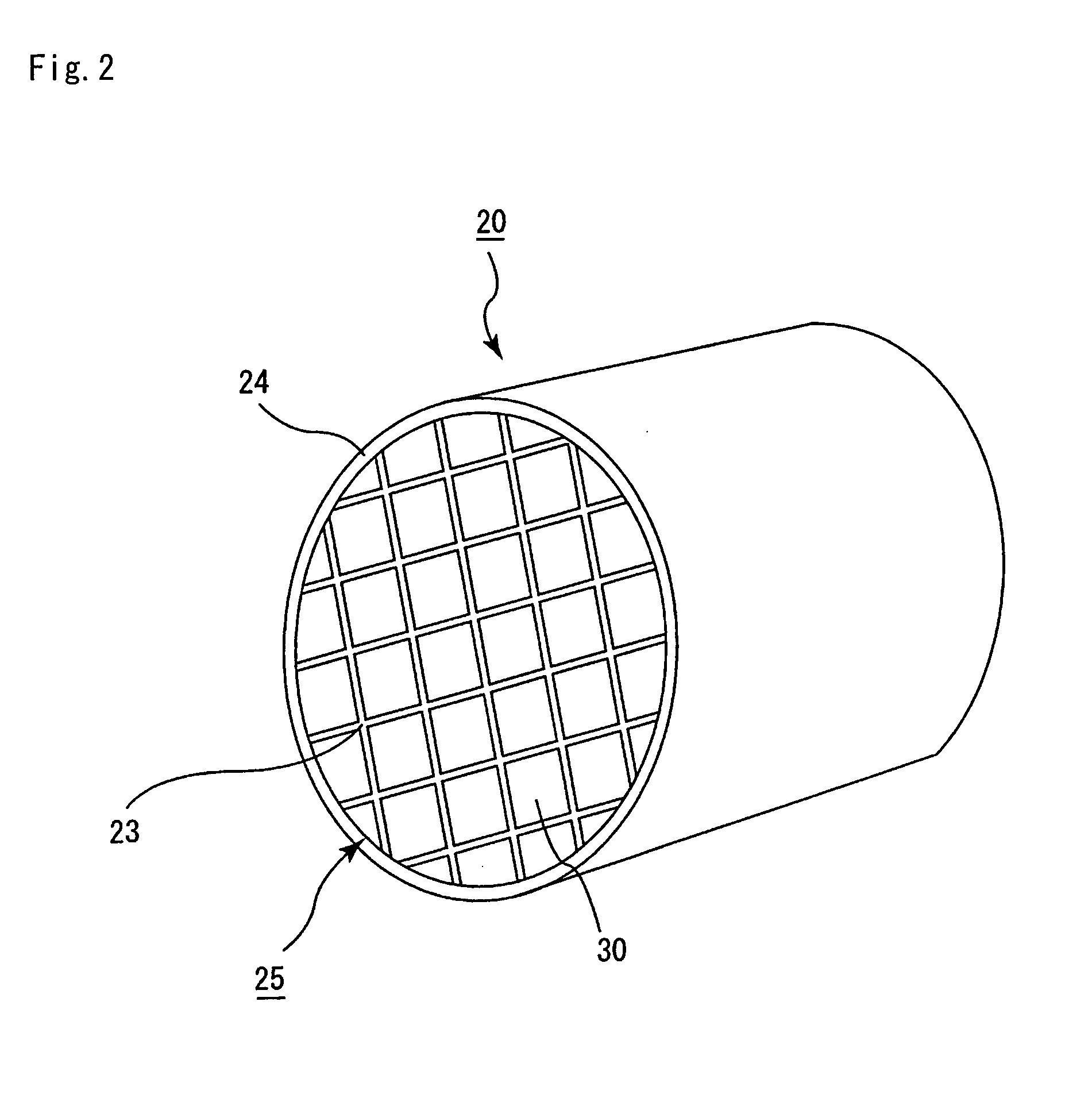

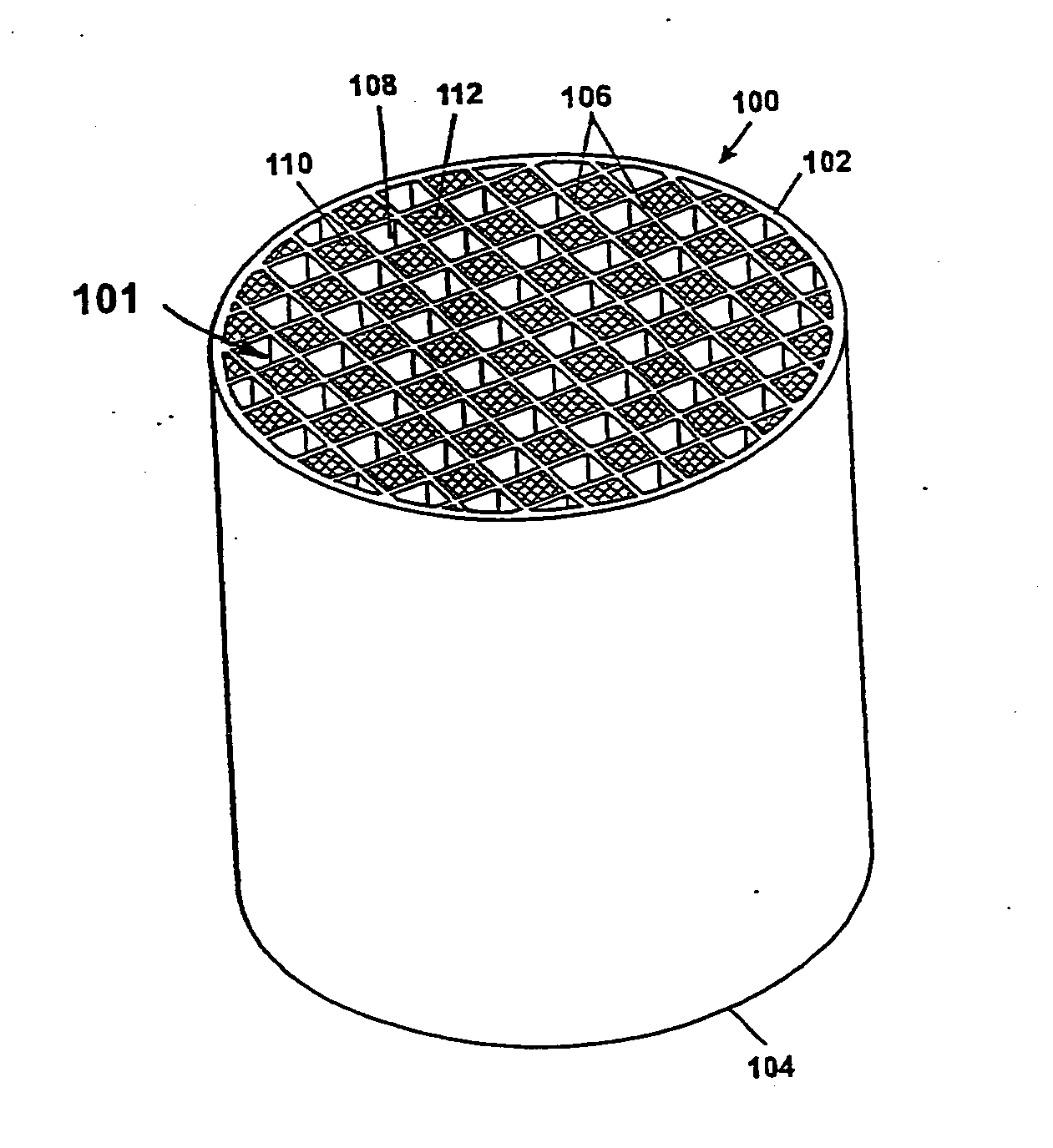

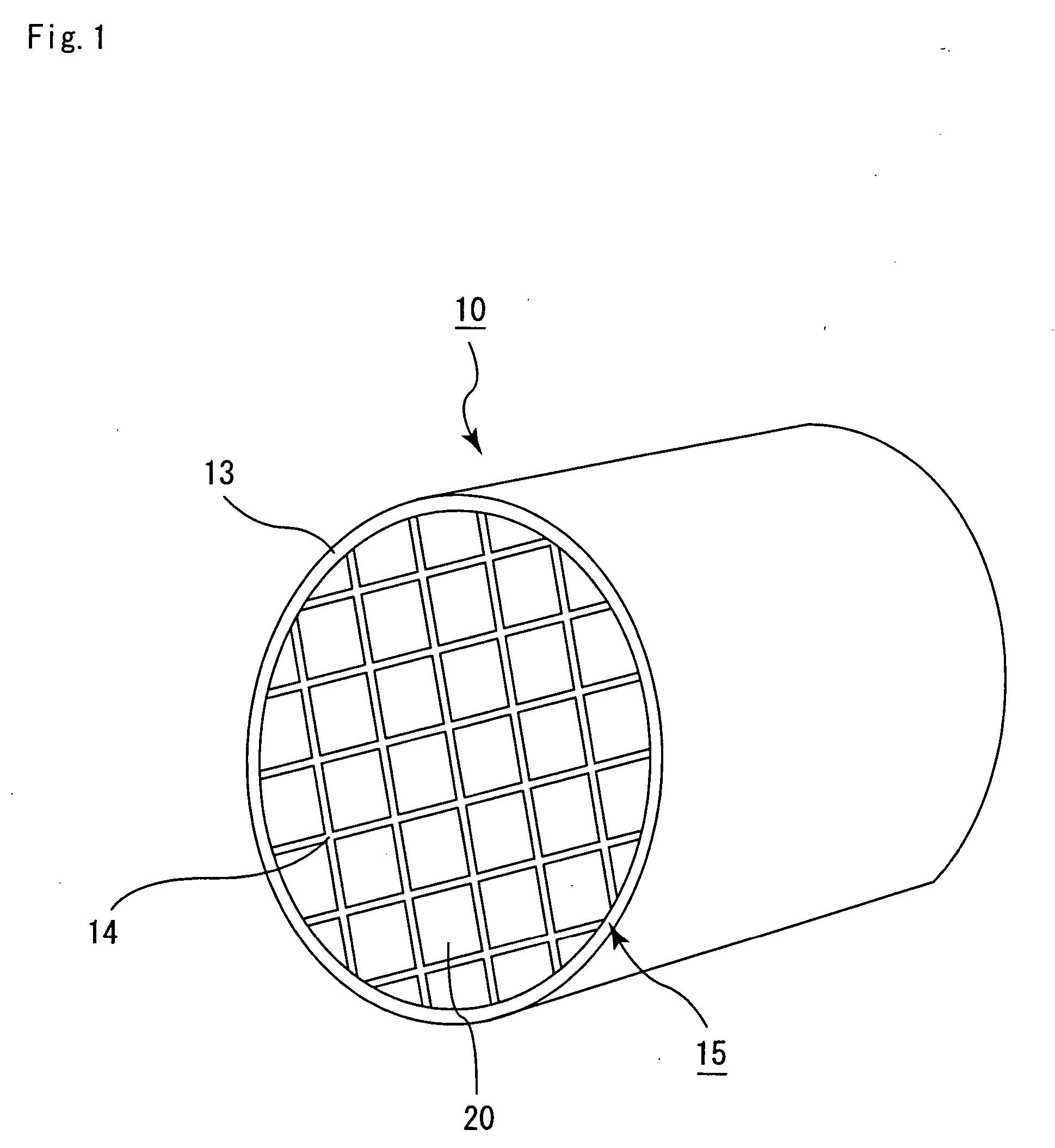

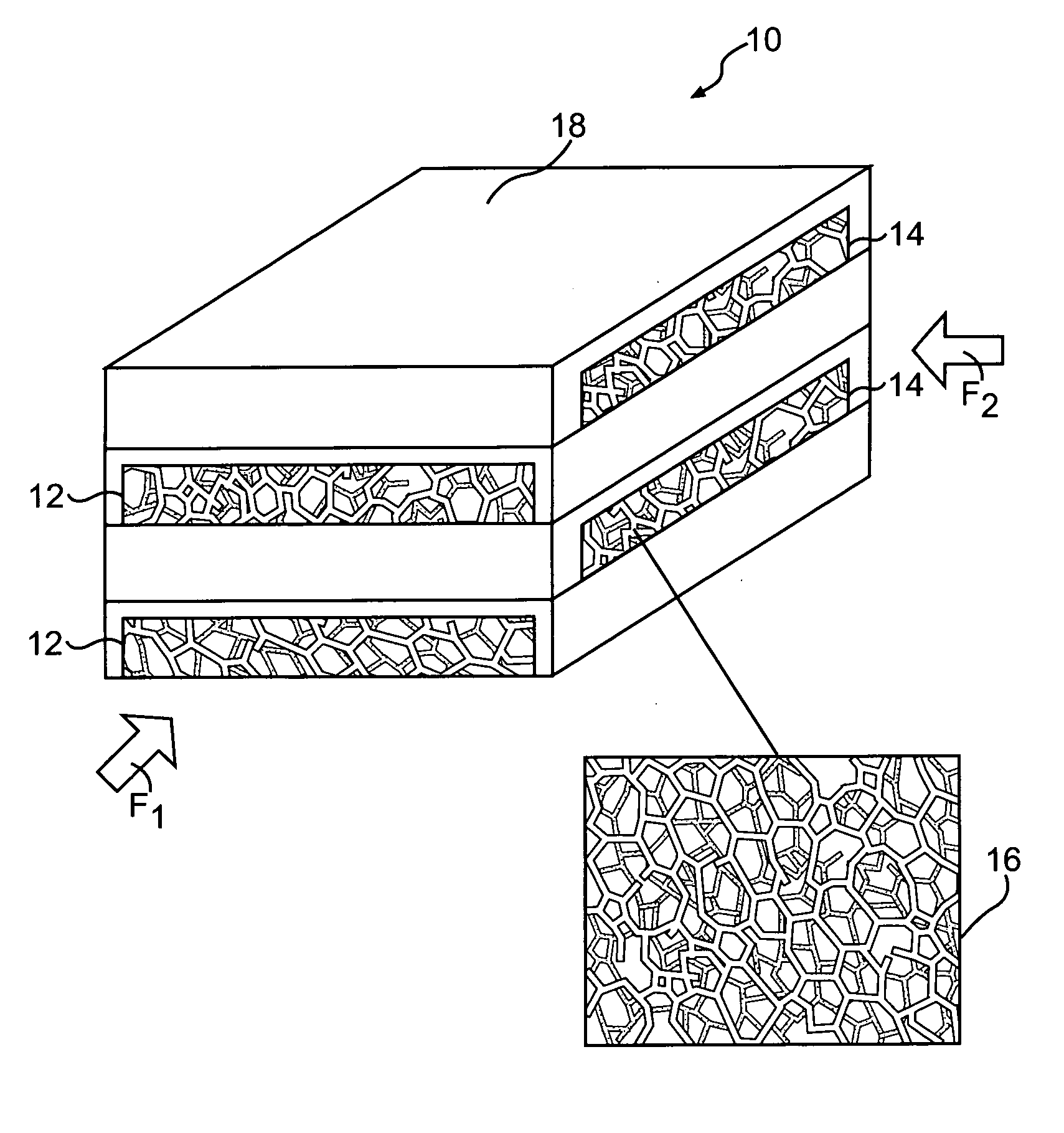

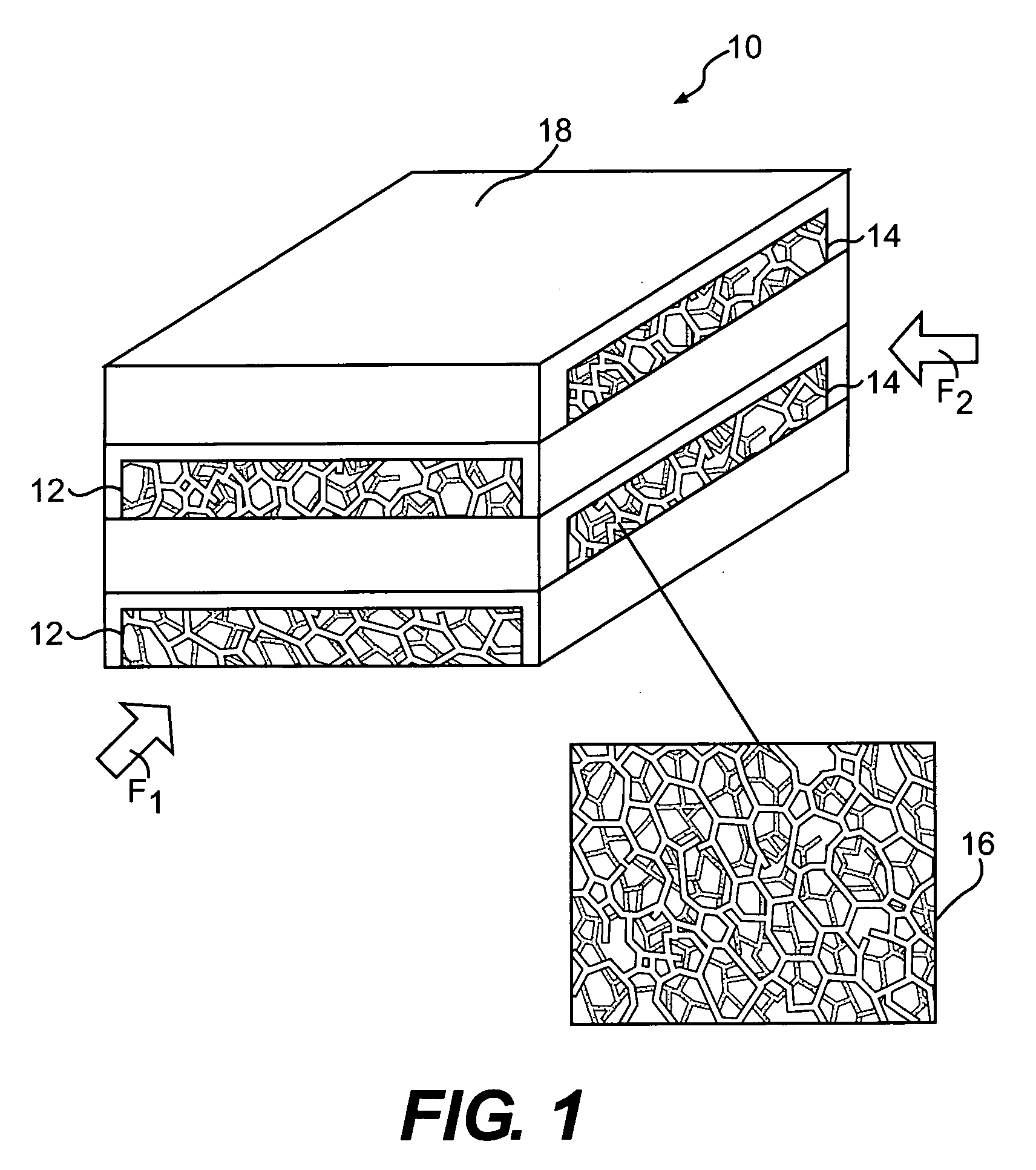

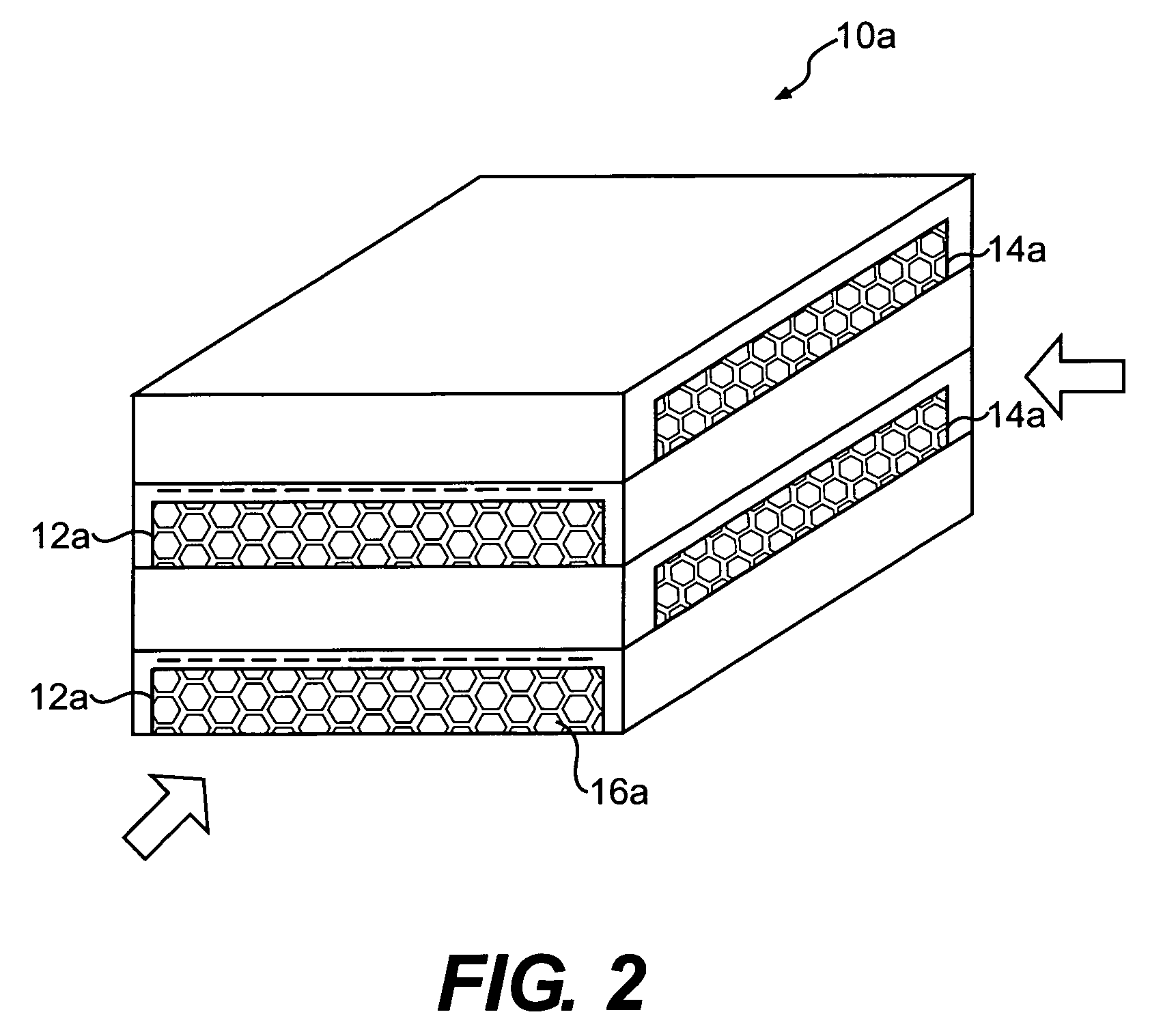

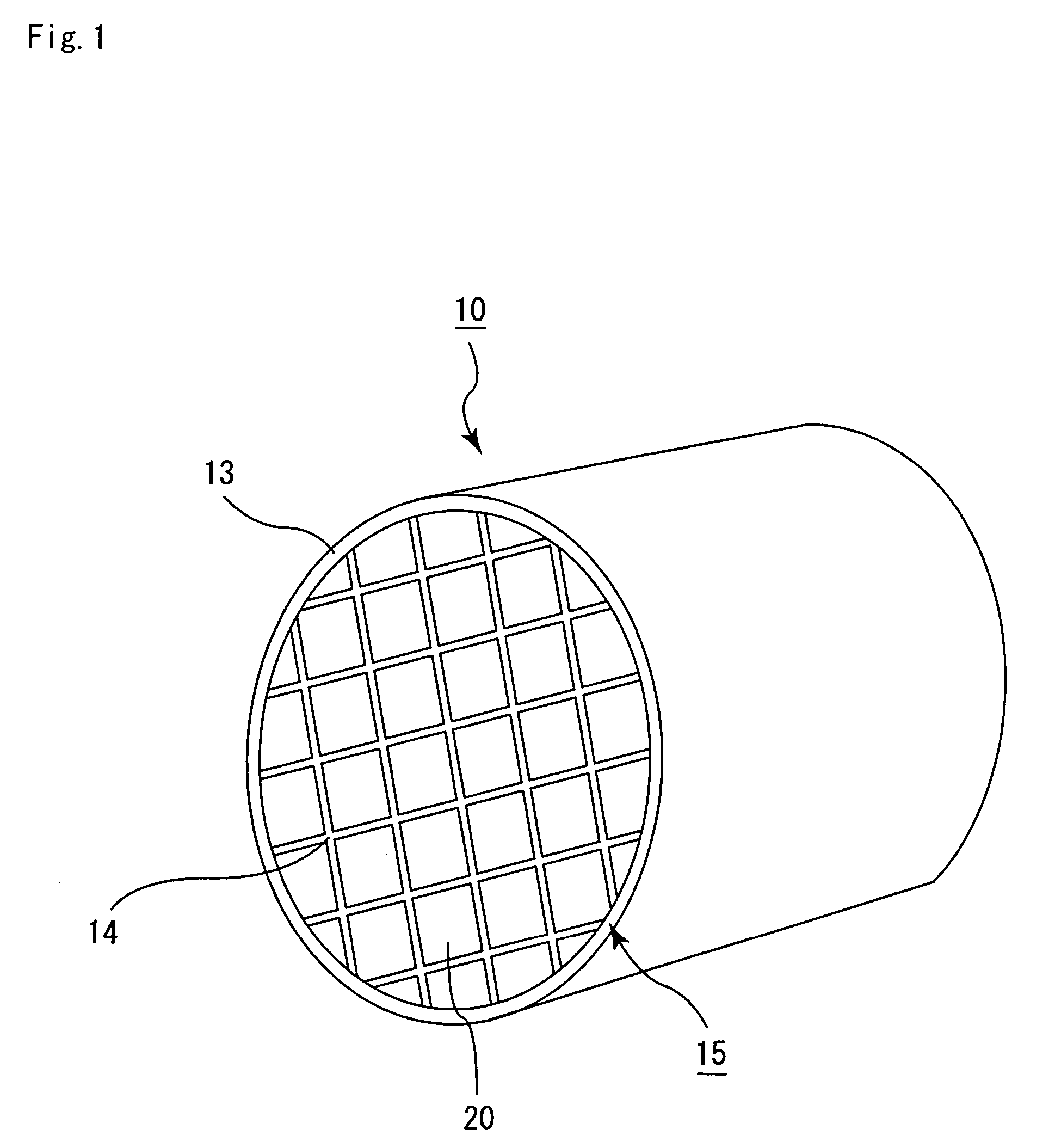

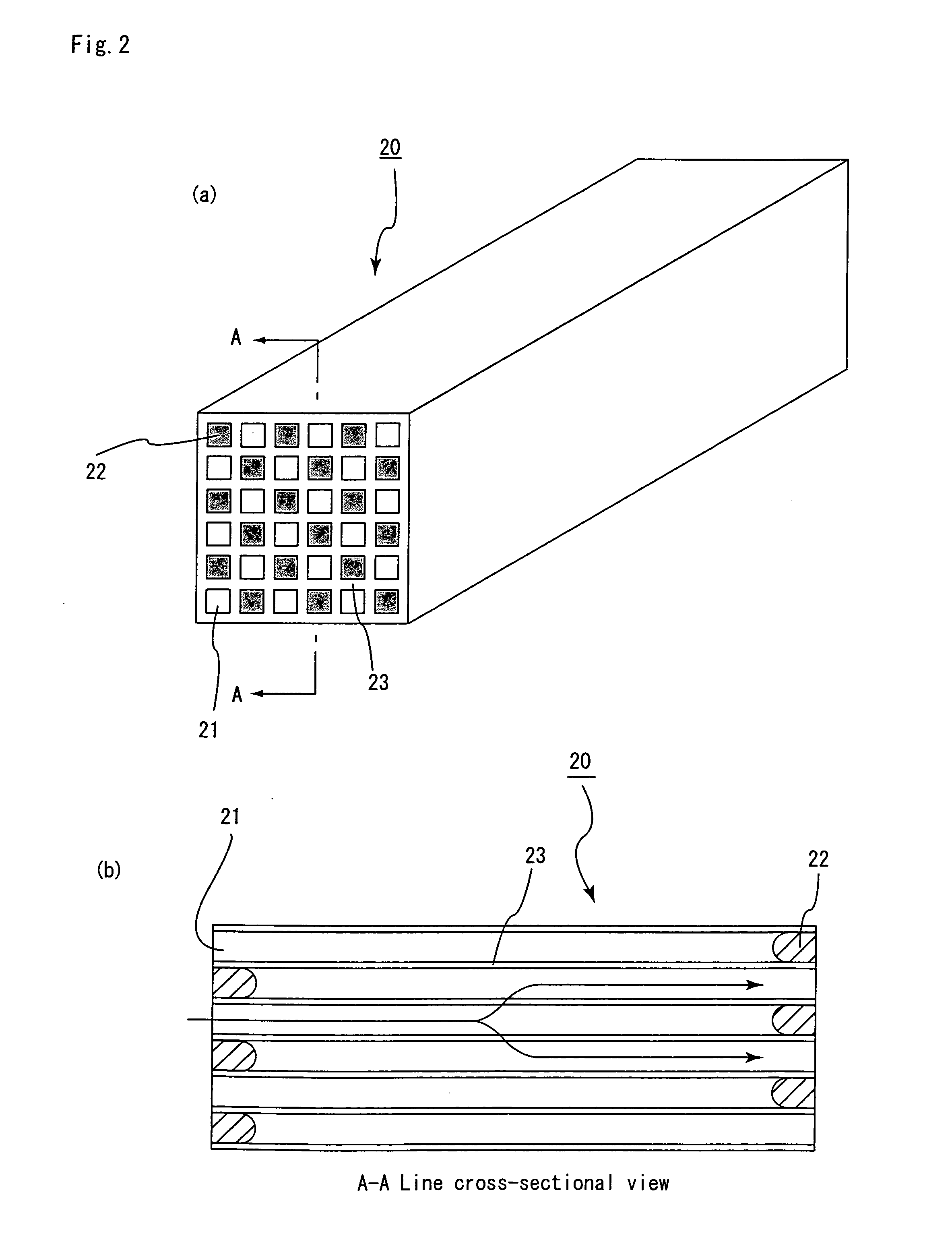

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

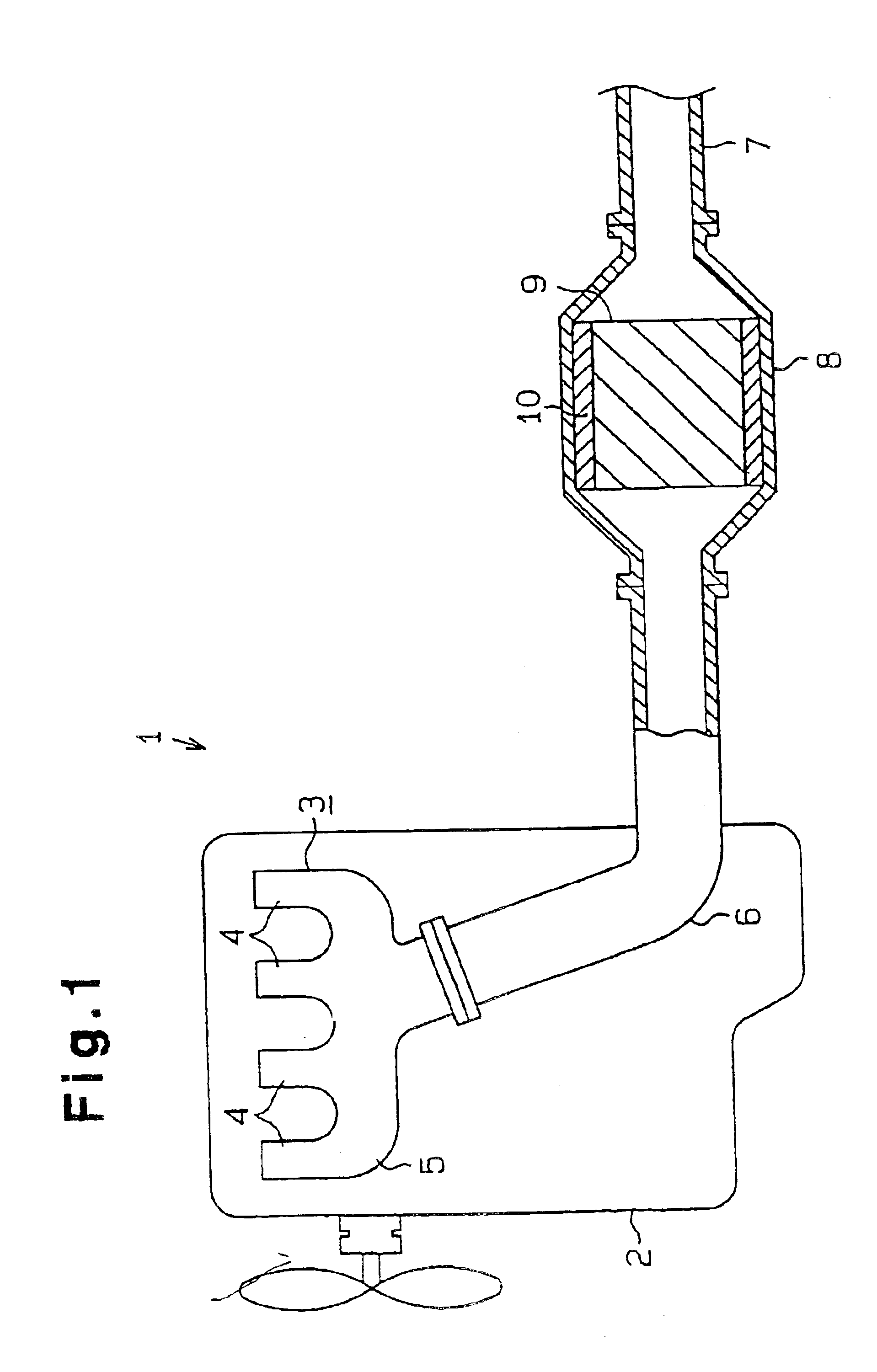

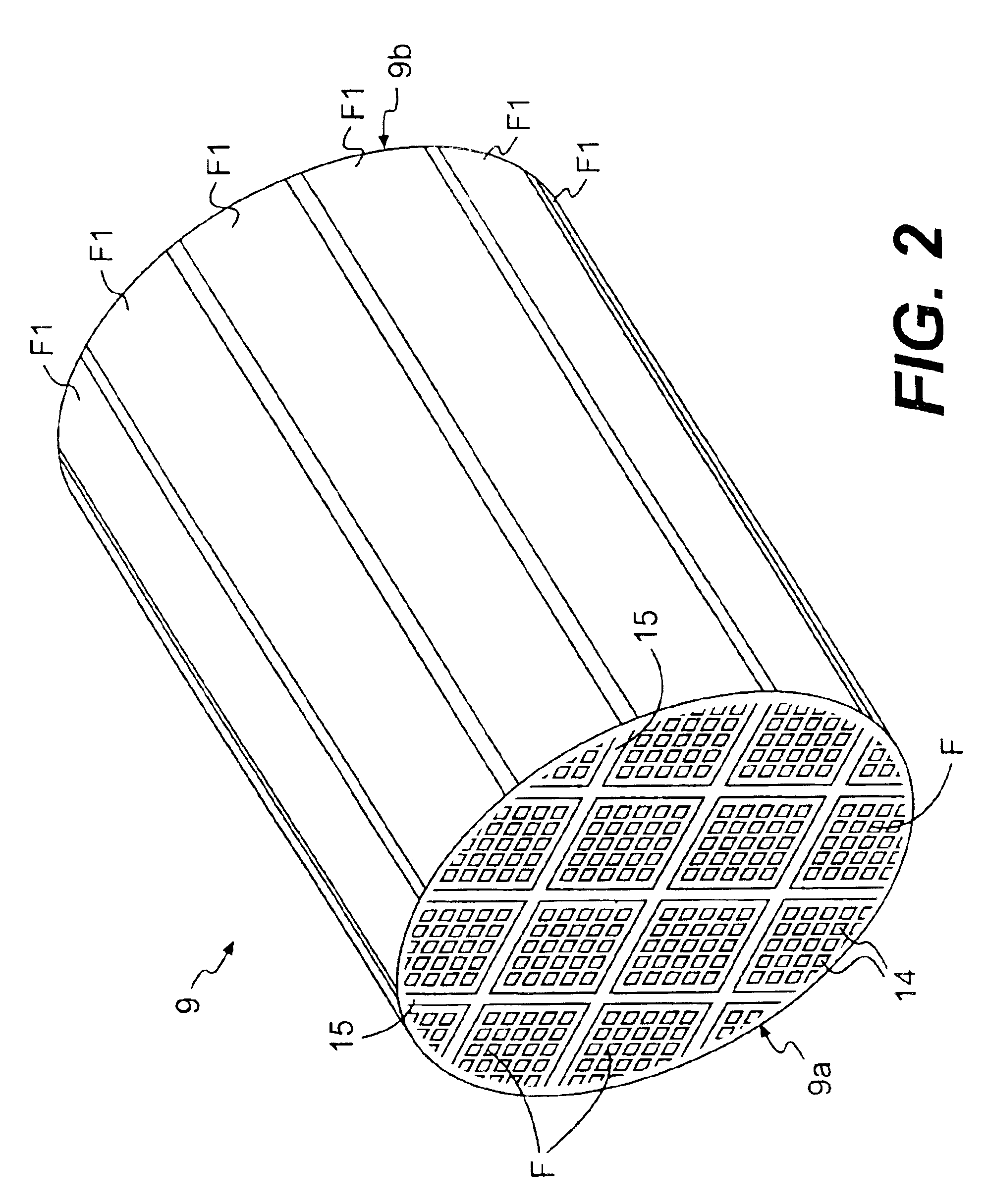

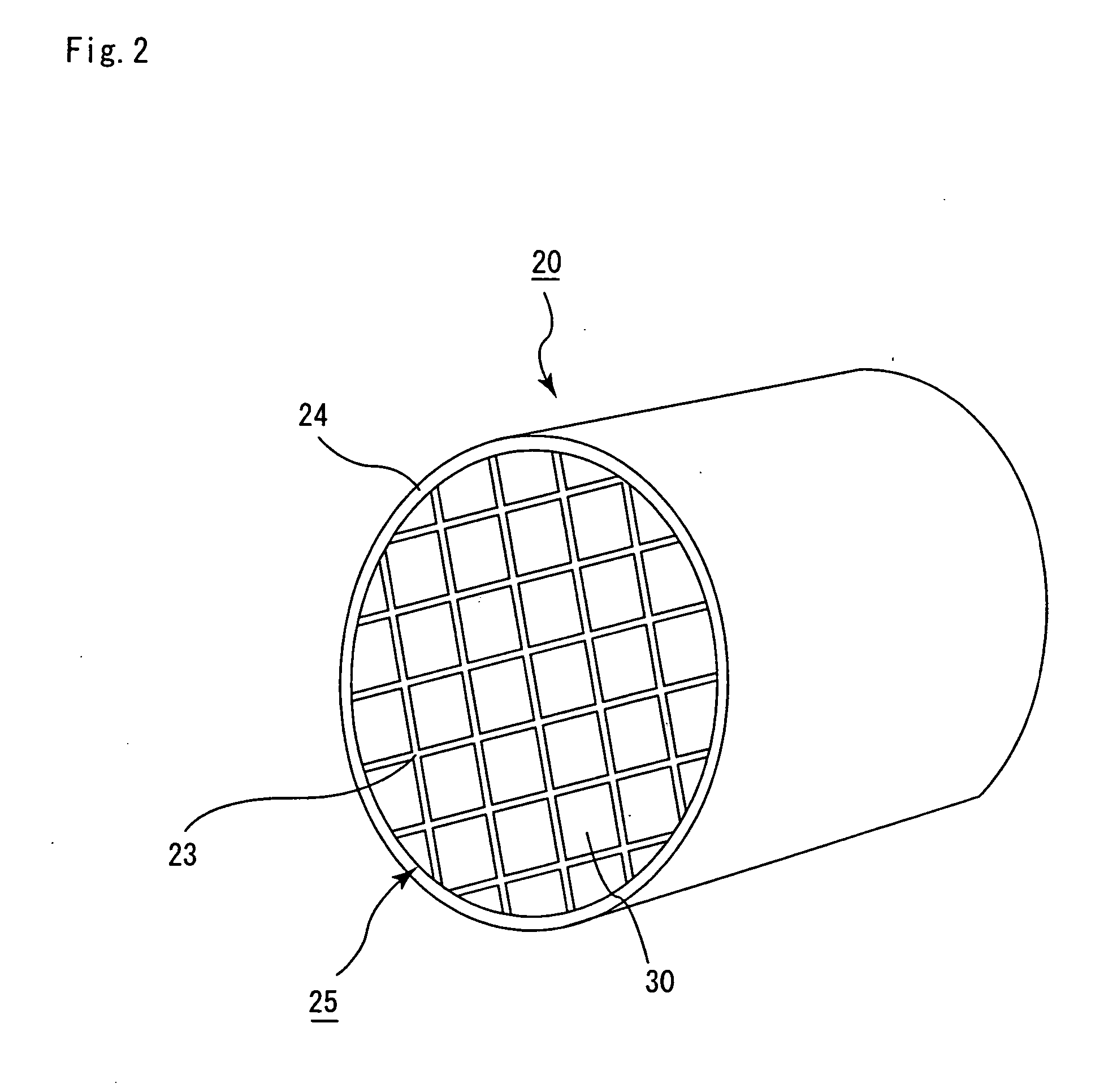

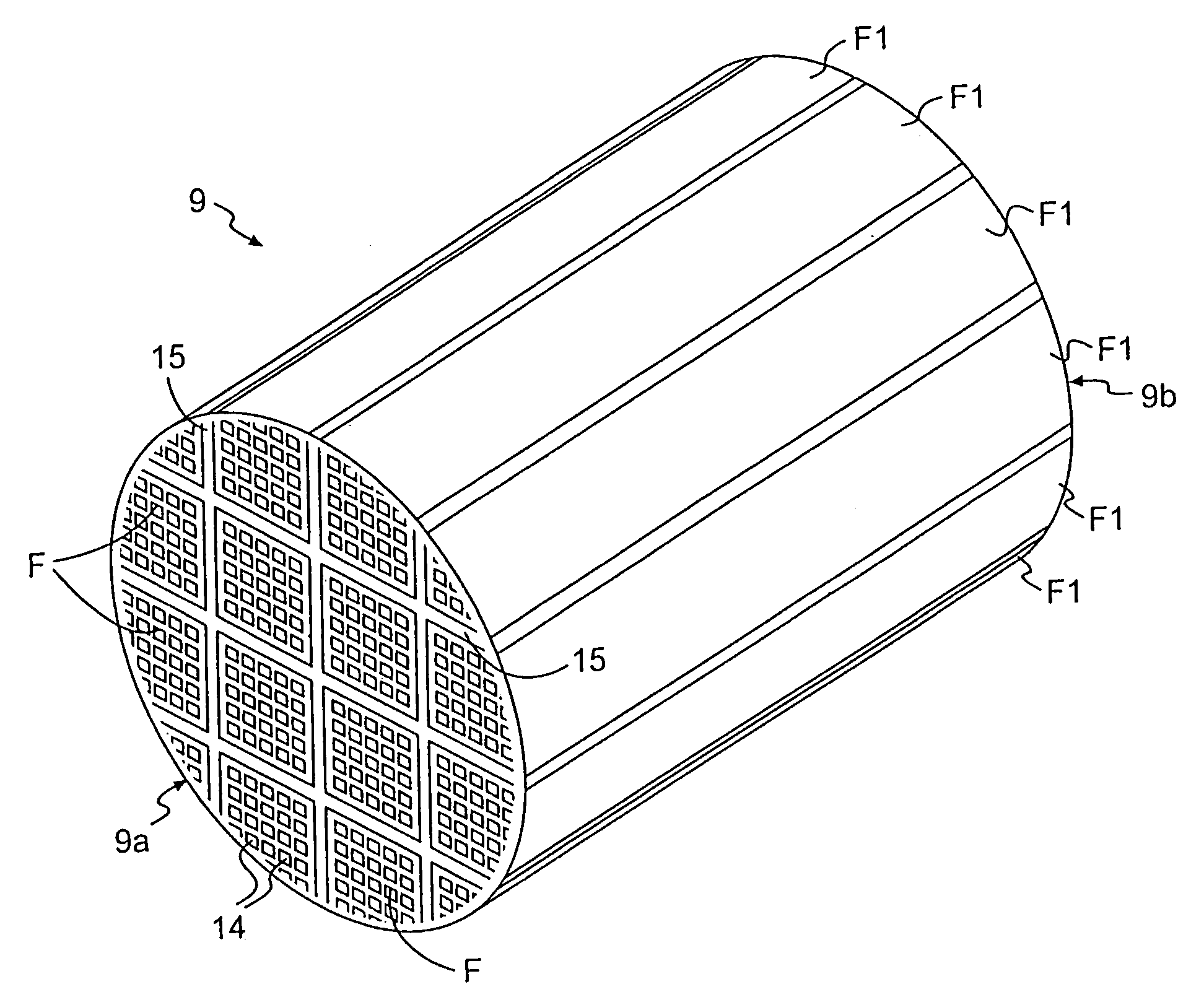

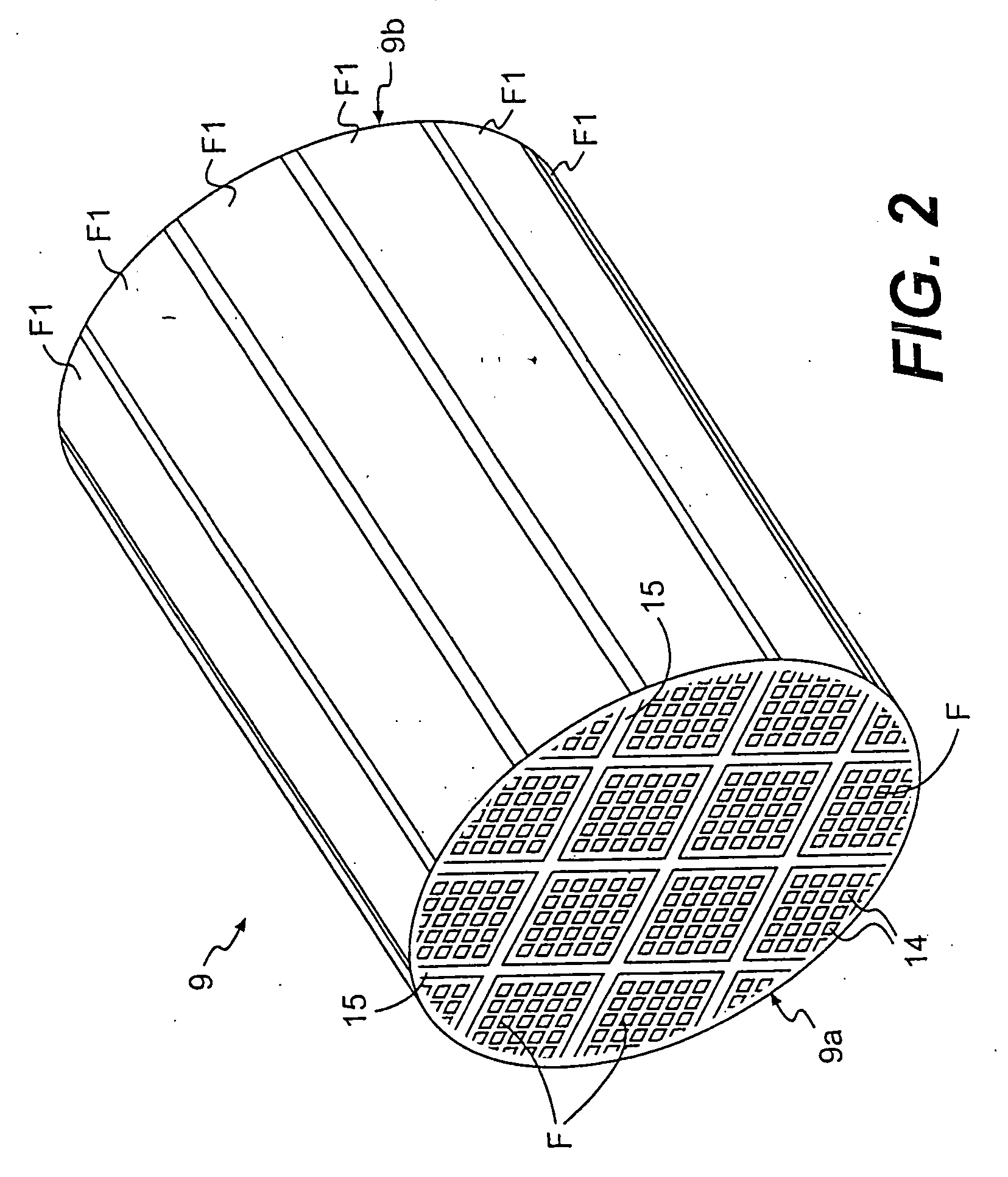

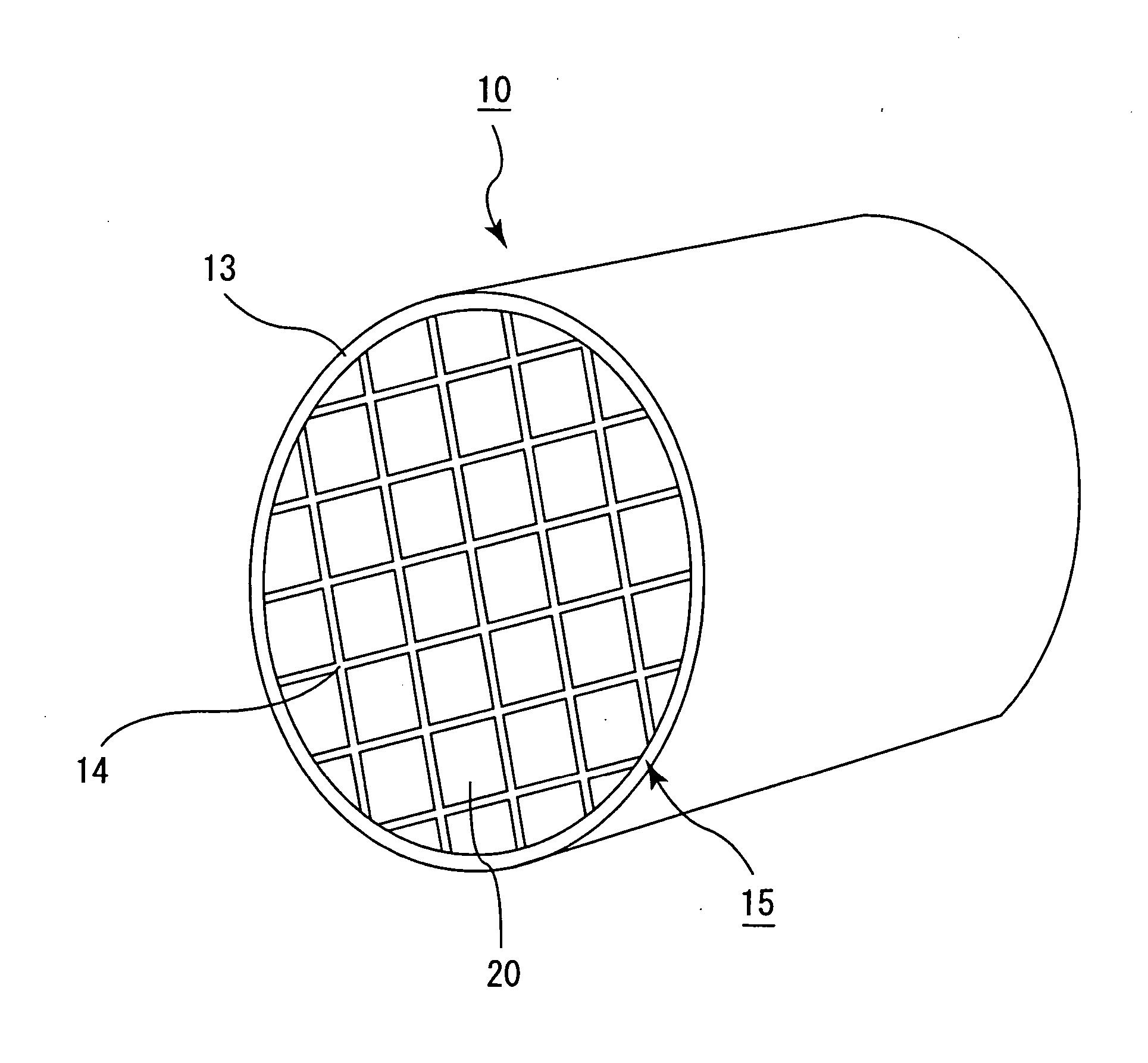

Honeycomb filter and ceramic filter assembly

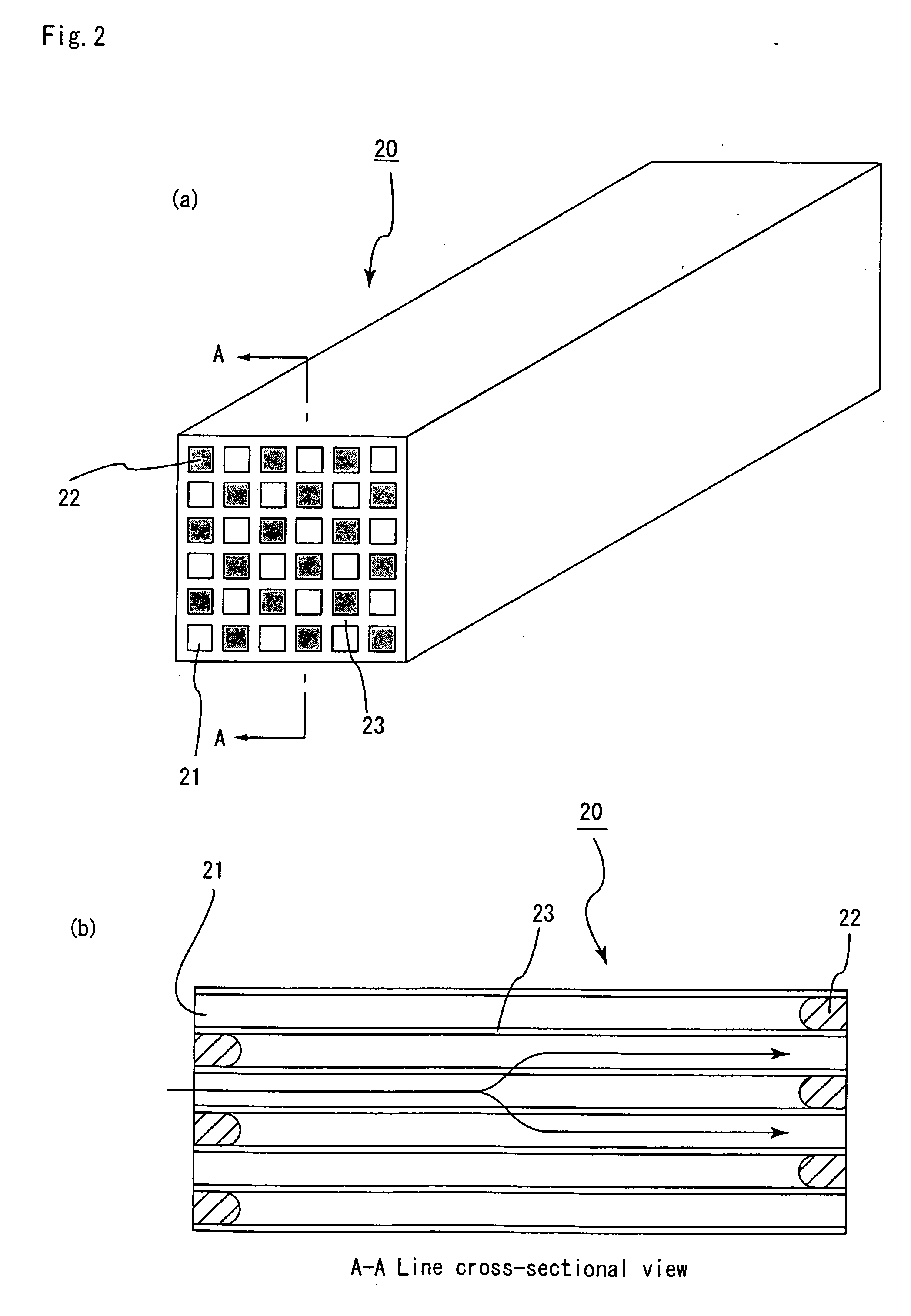

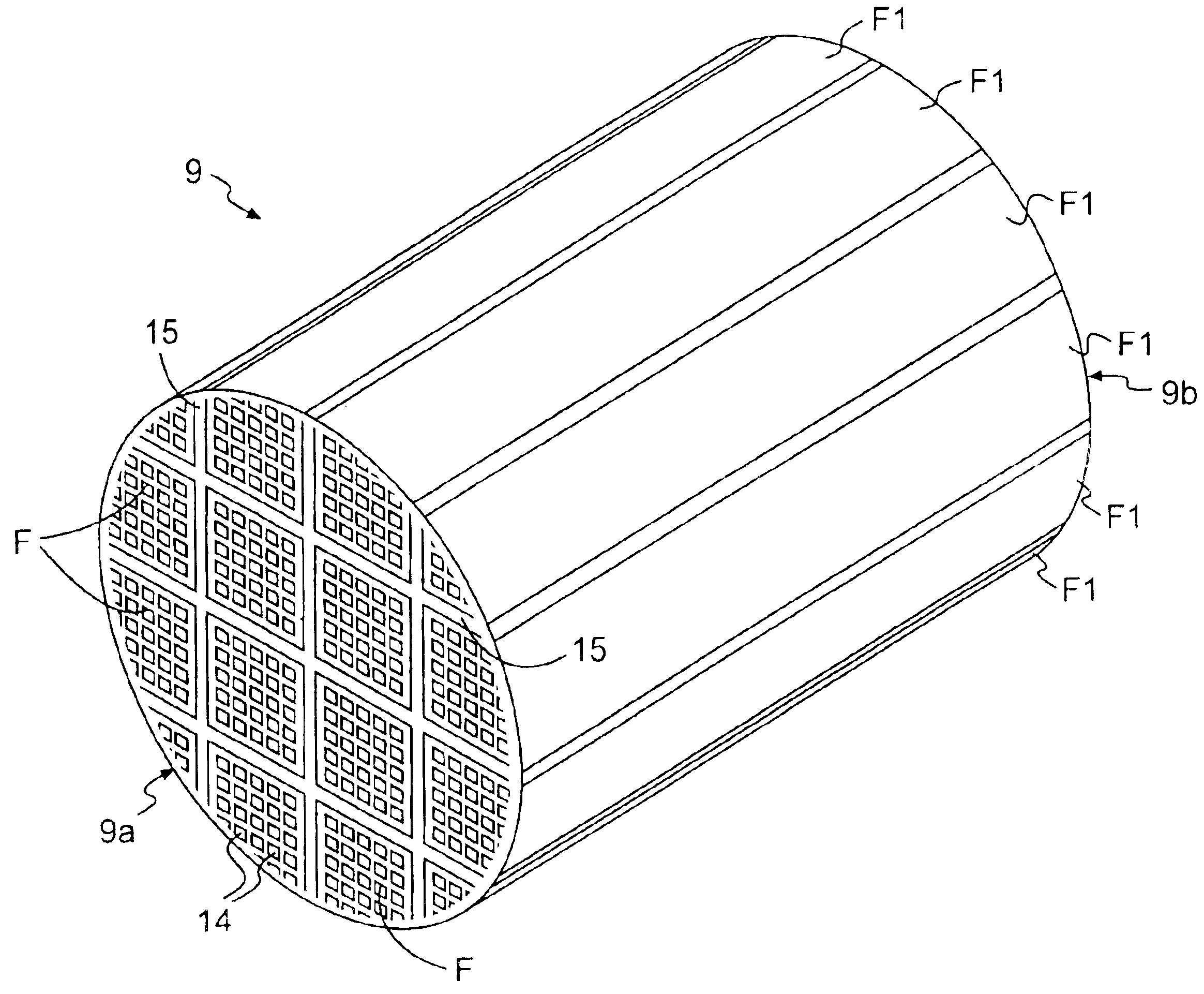

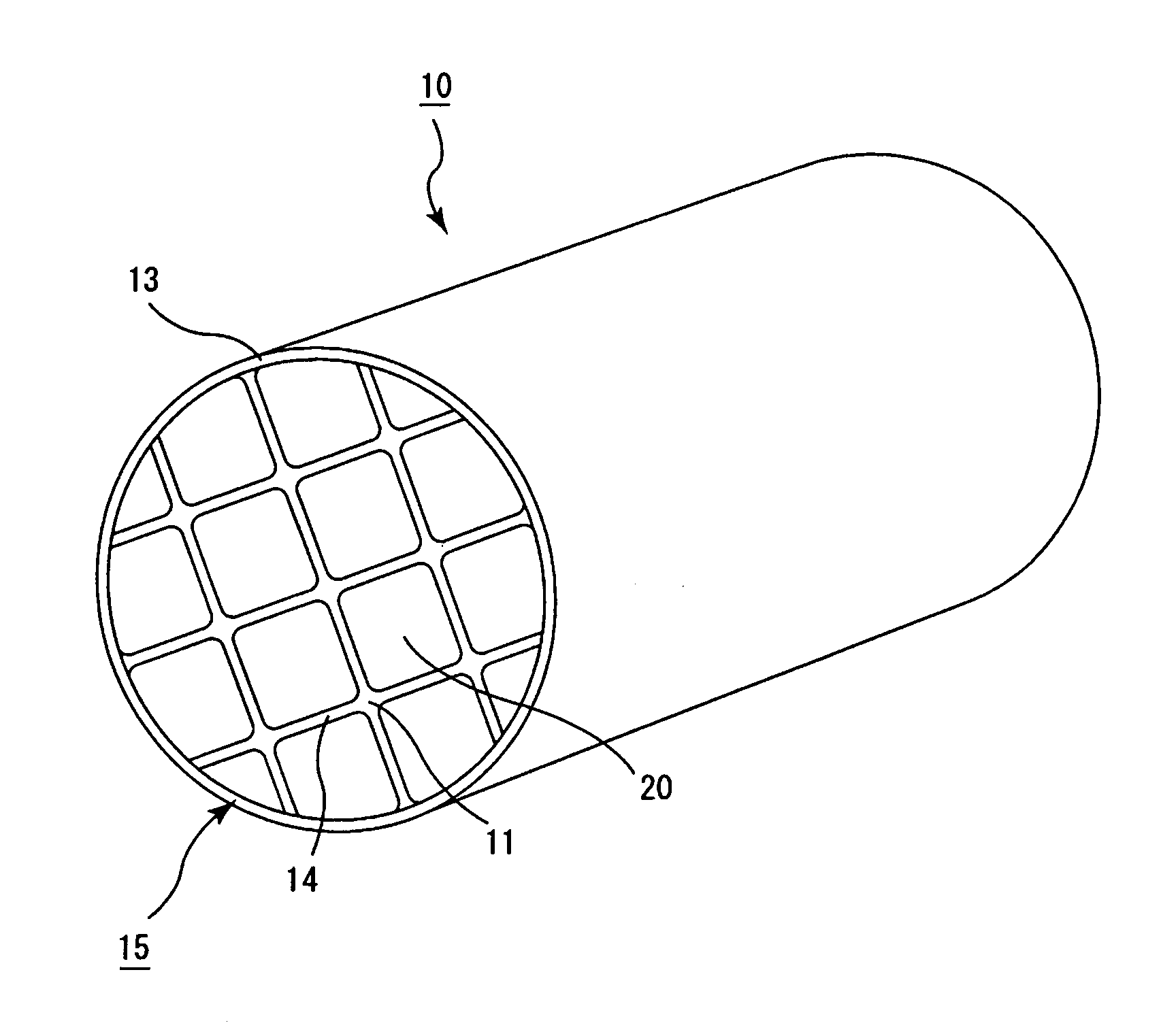

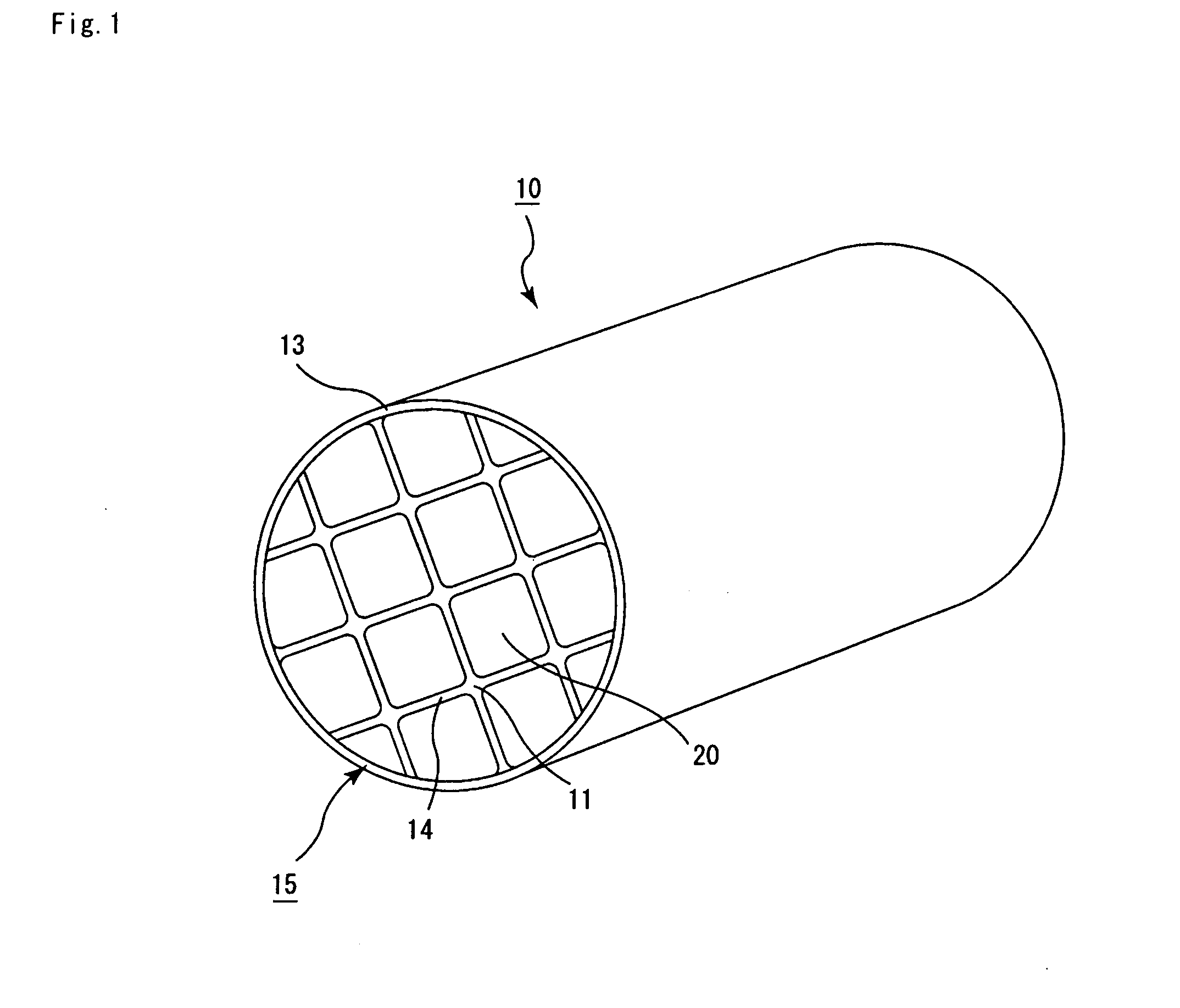

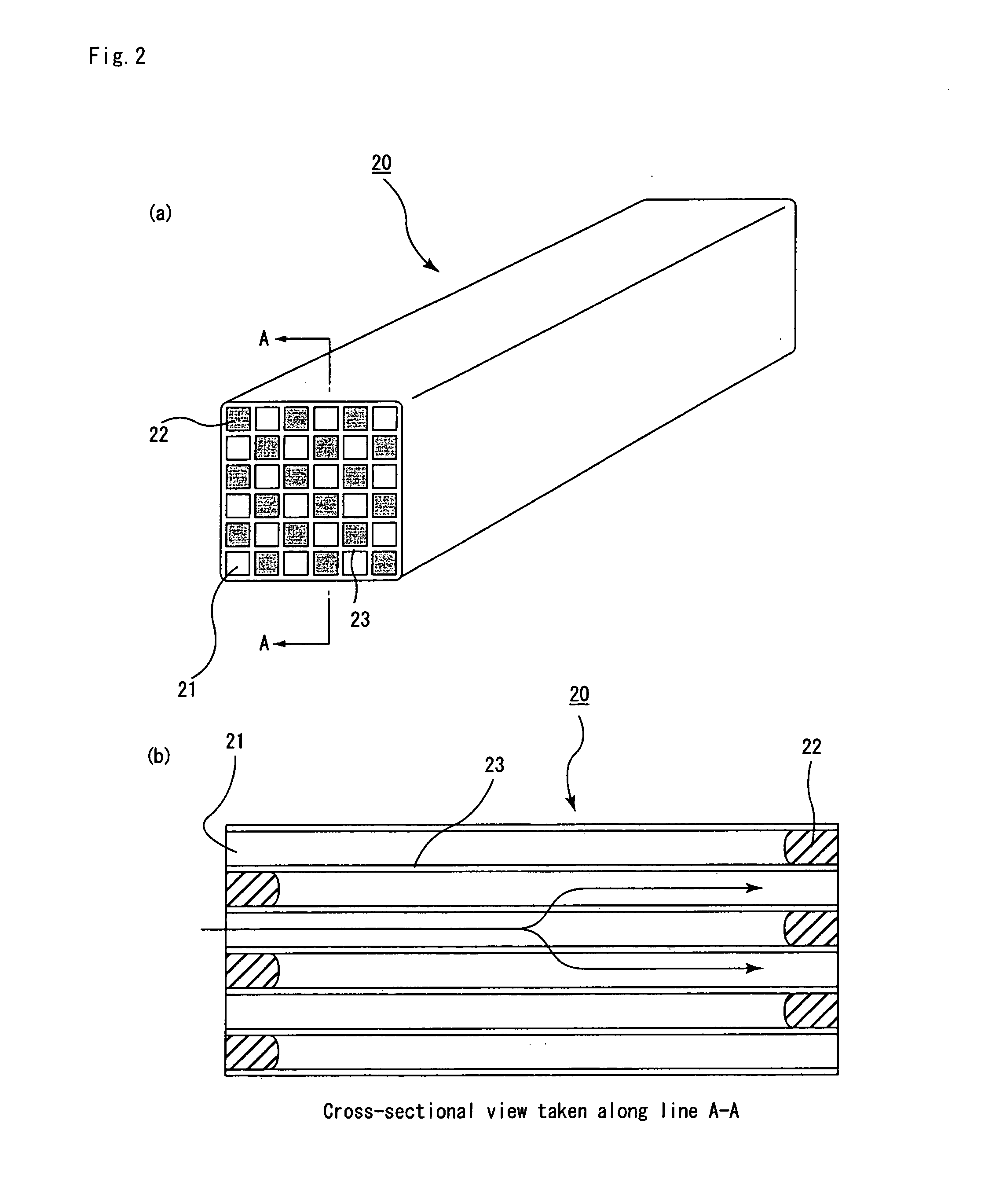

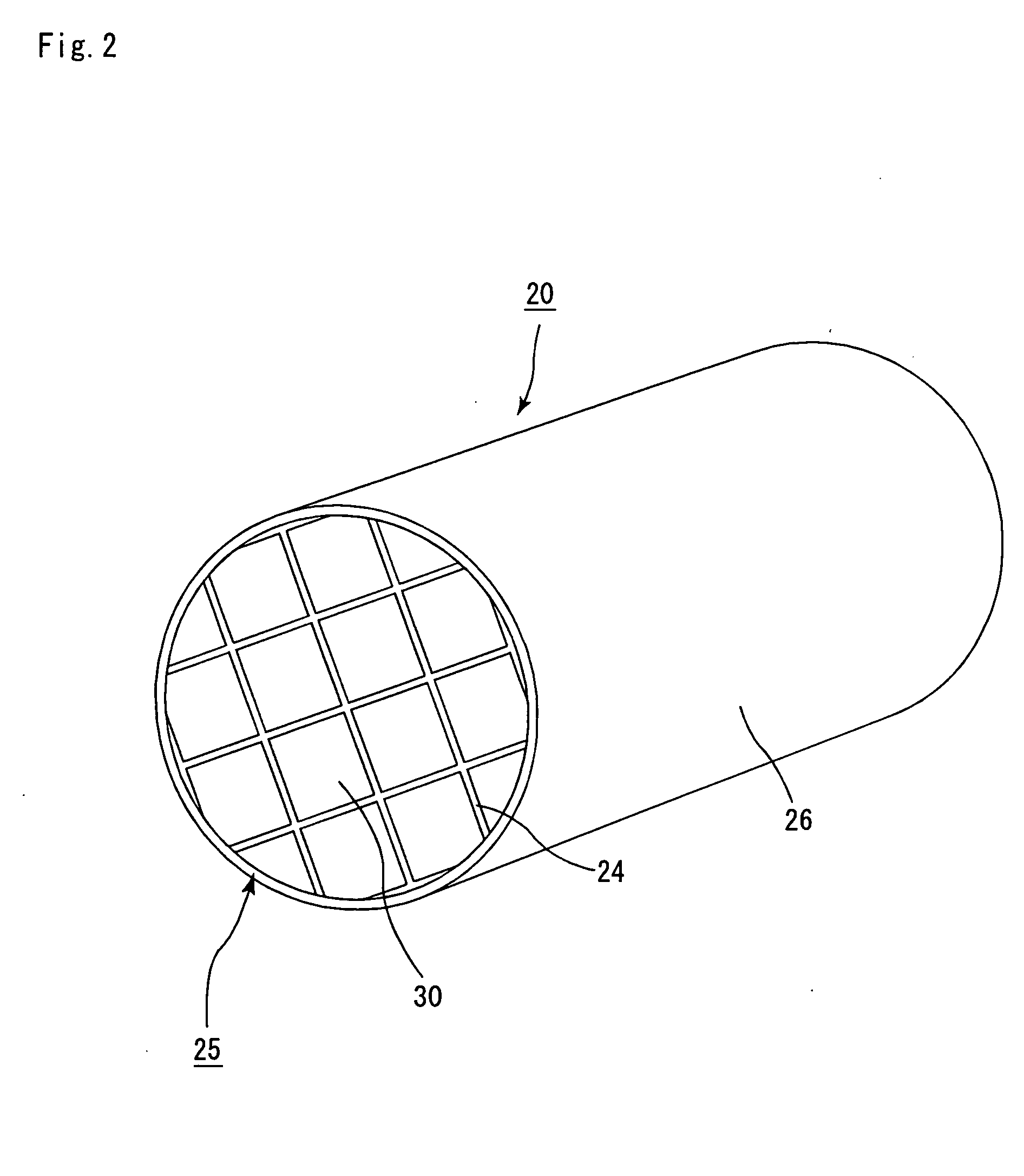

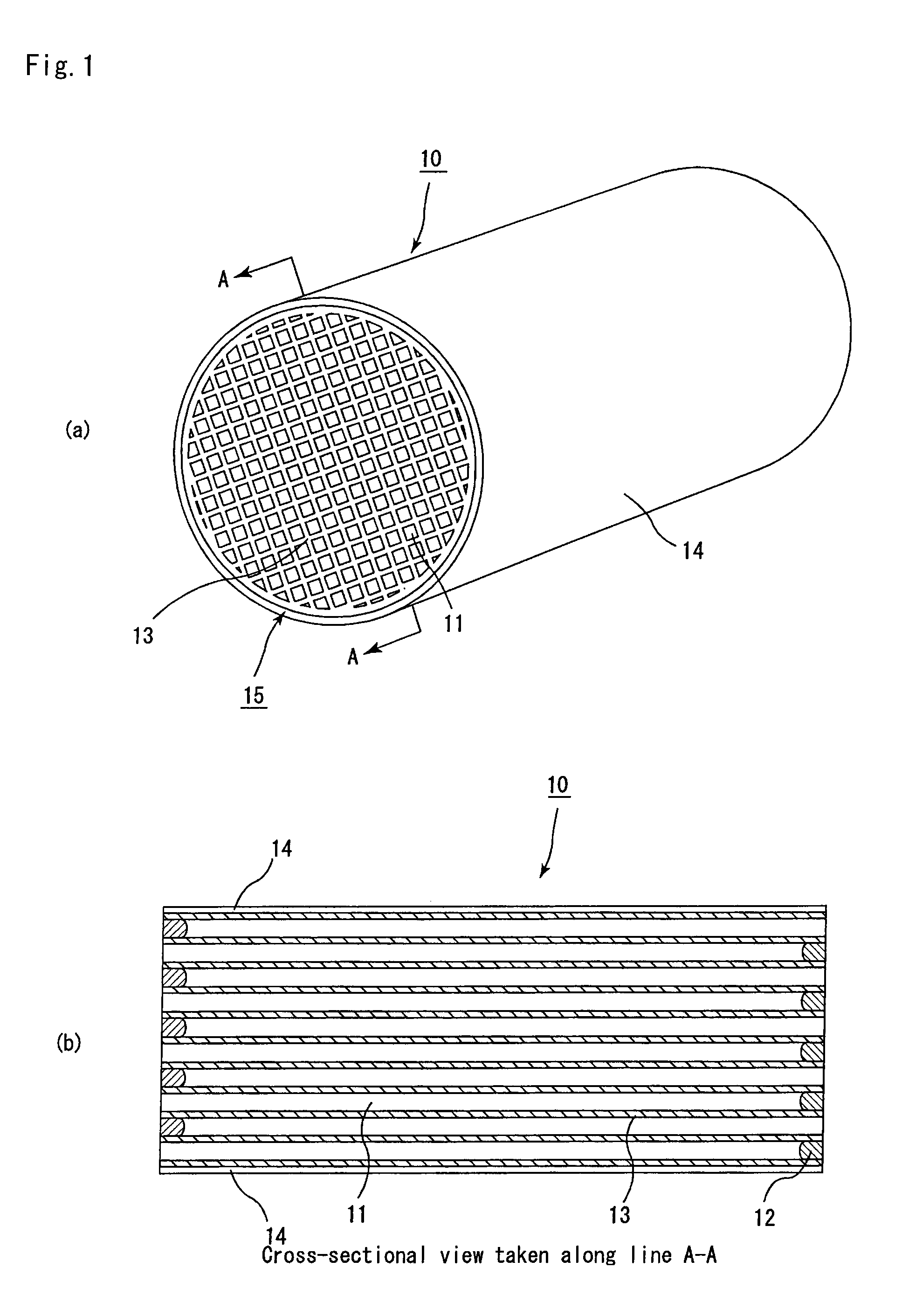

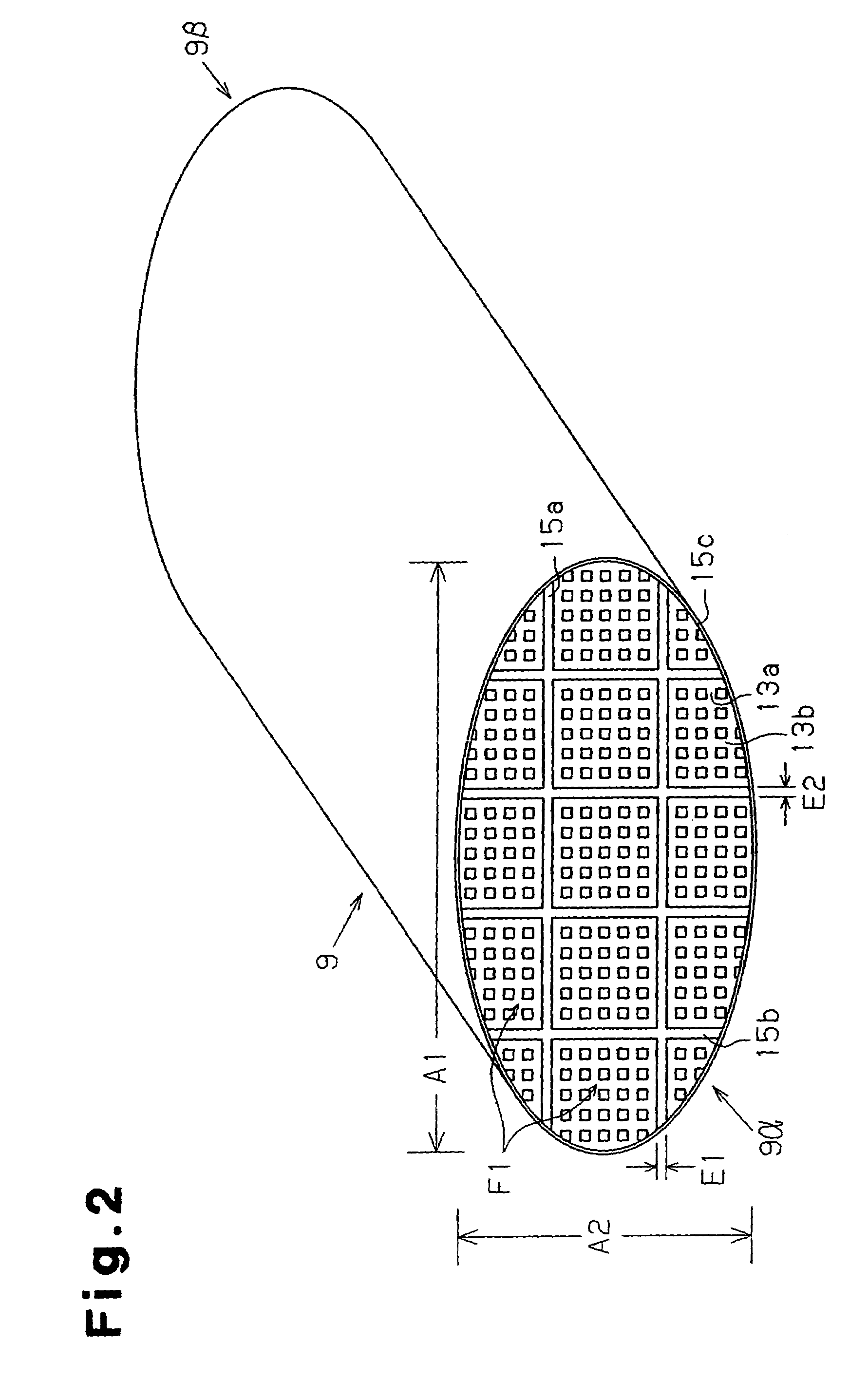

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

High temperature erosion resistant, abradable thermal barrier composite coating

InactiveUS6235370B1Improve wear resistanceImprove adhesionMolten spray coatingPump componentsCombustorHoneycomb

A composite thermal barrier coating system includes a honeycomb metallic structure filled with high thermal expansion ceramic hollow spheres in a phosphate bonded matrix. The composite thermal barrier coating system may be manufactured to thicknesses in excess of current thermal barrier coating systems, thereby imparting greater thermal protection. Superior erosion resistance and abrasion properties are also achieved. The composite thermal barrier coating is useful on combustion turbine components such as ring seal segments, vane segment shrouds, transitions and combustors.

Owner:SIEMENS ENERGY INC

Honeycomb filter for clarification of exhaust gas

InactiveUS20050180898A1Increased durabilityReduce crackingCombination devicesInternal combustion piston enginesParticulatesHoneycomb

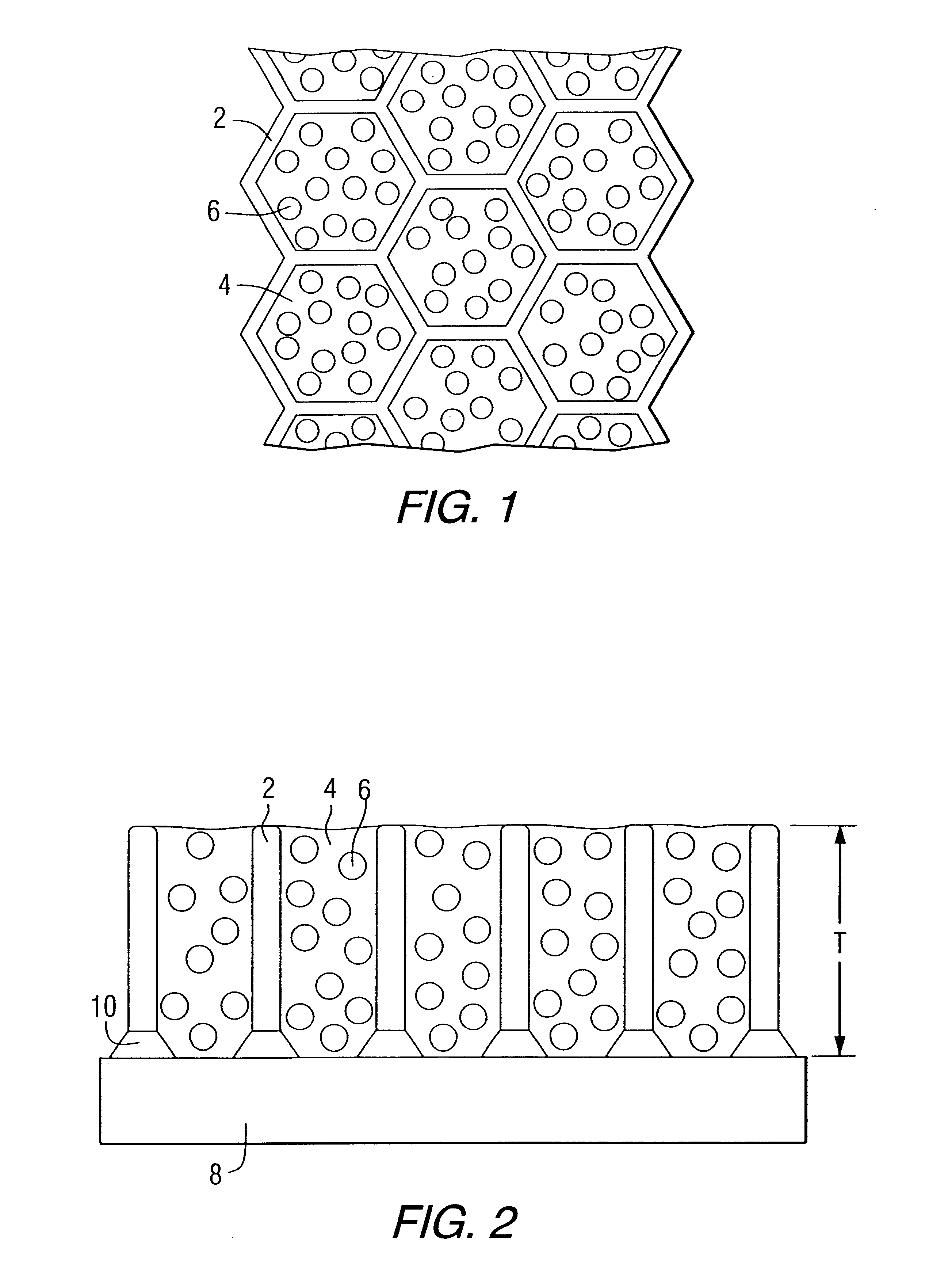

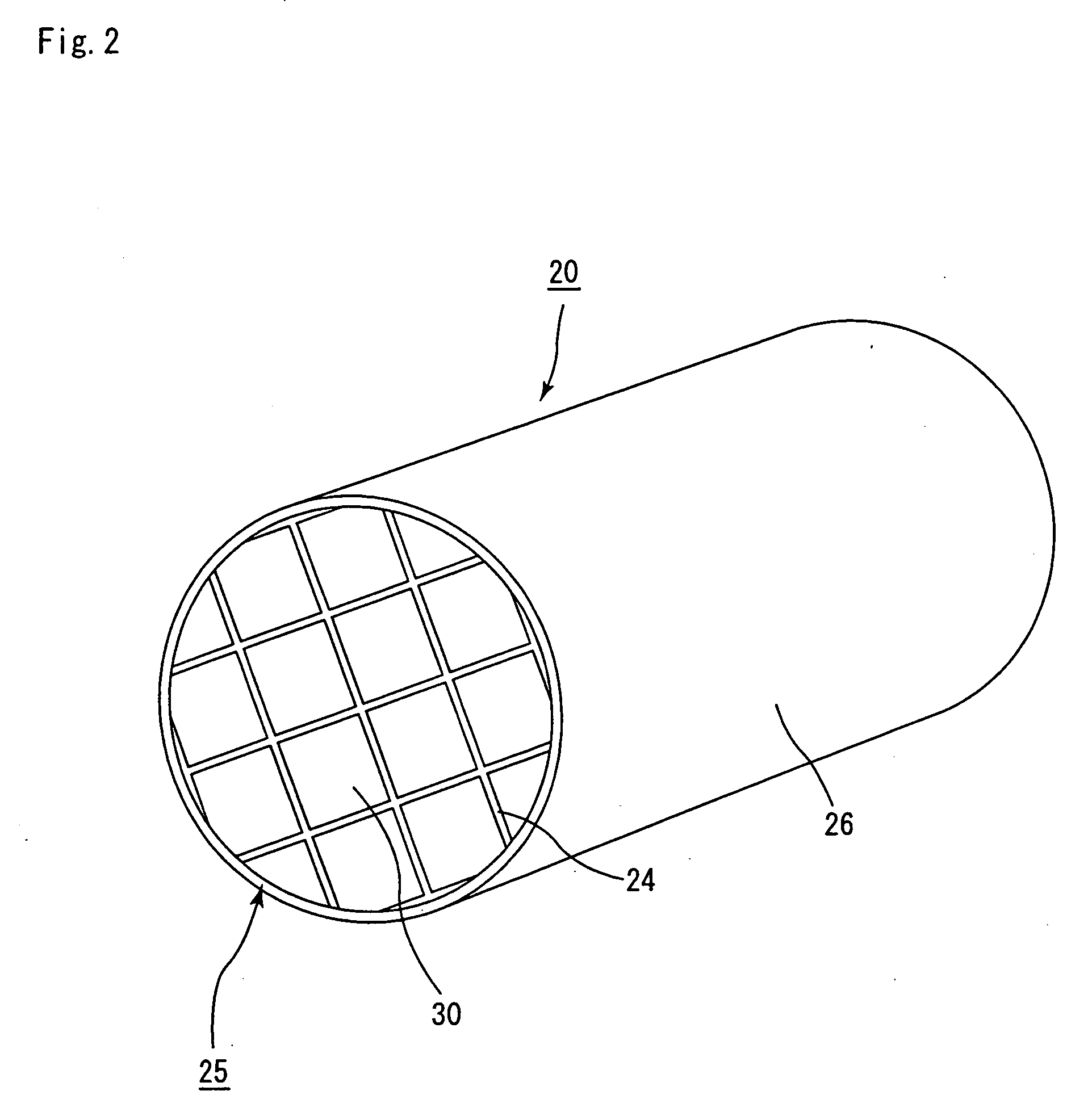

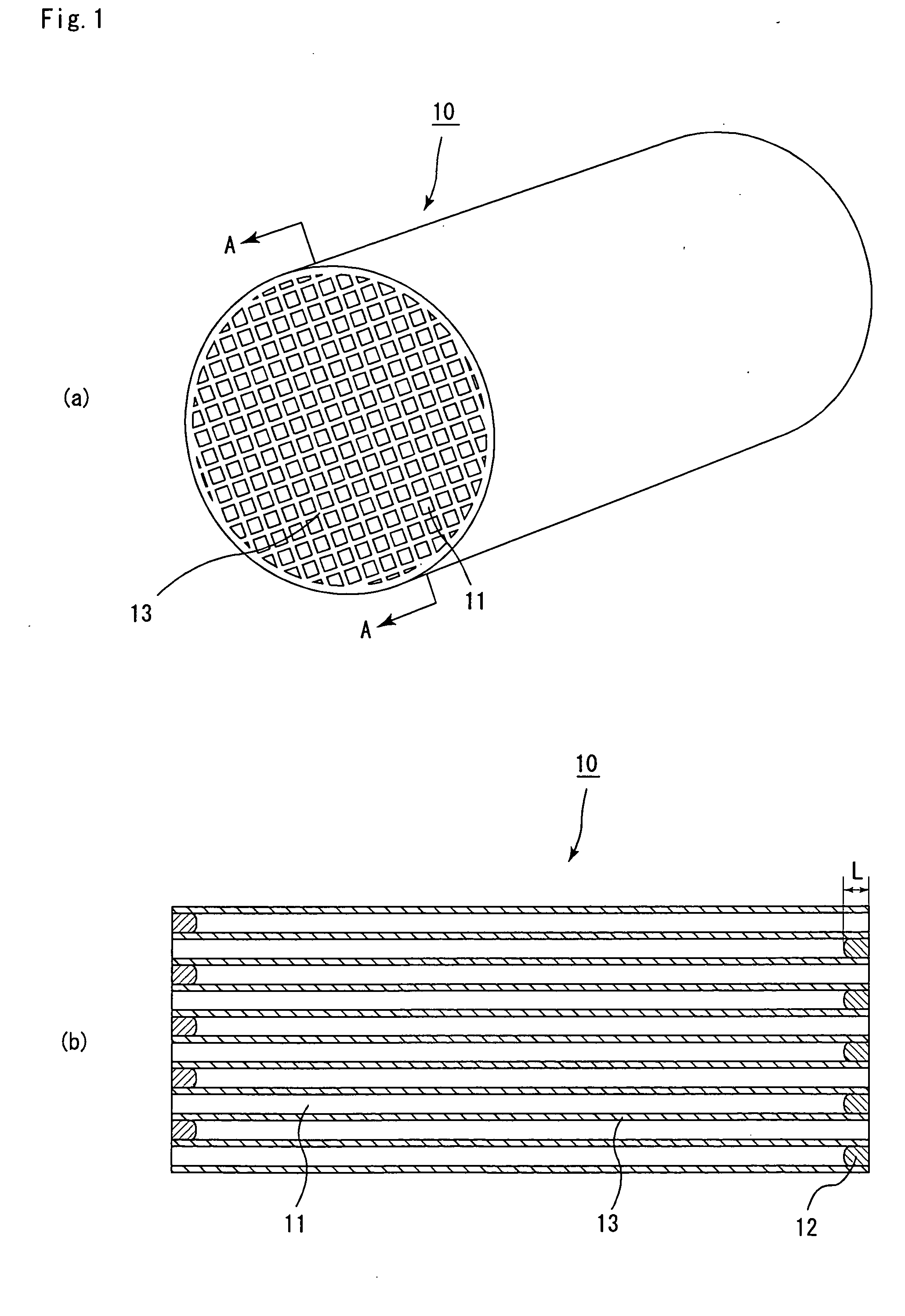

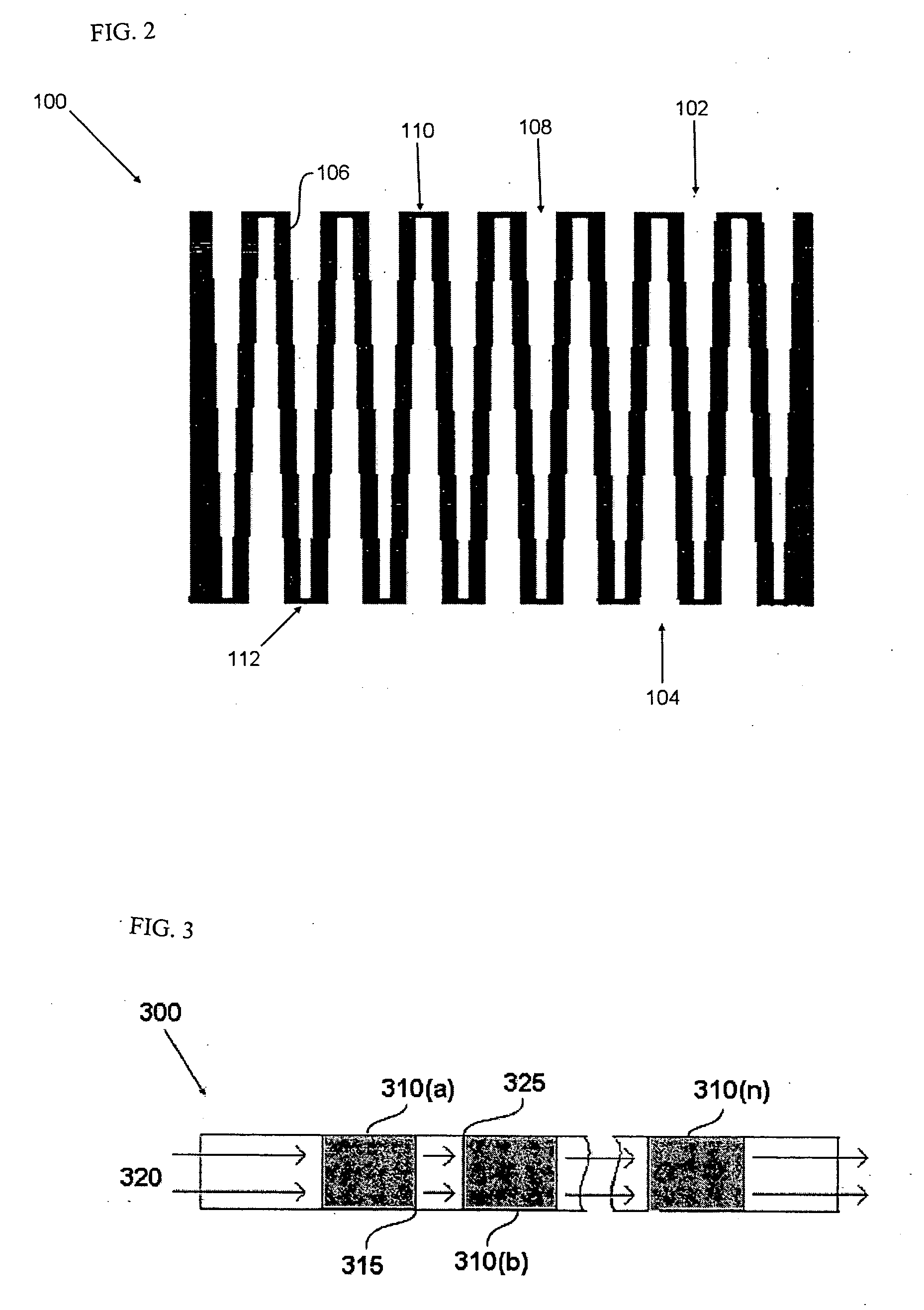

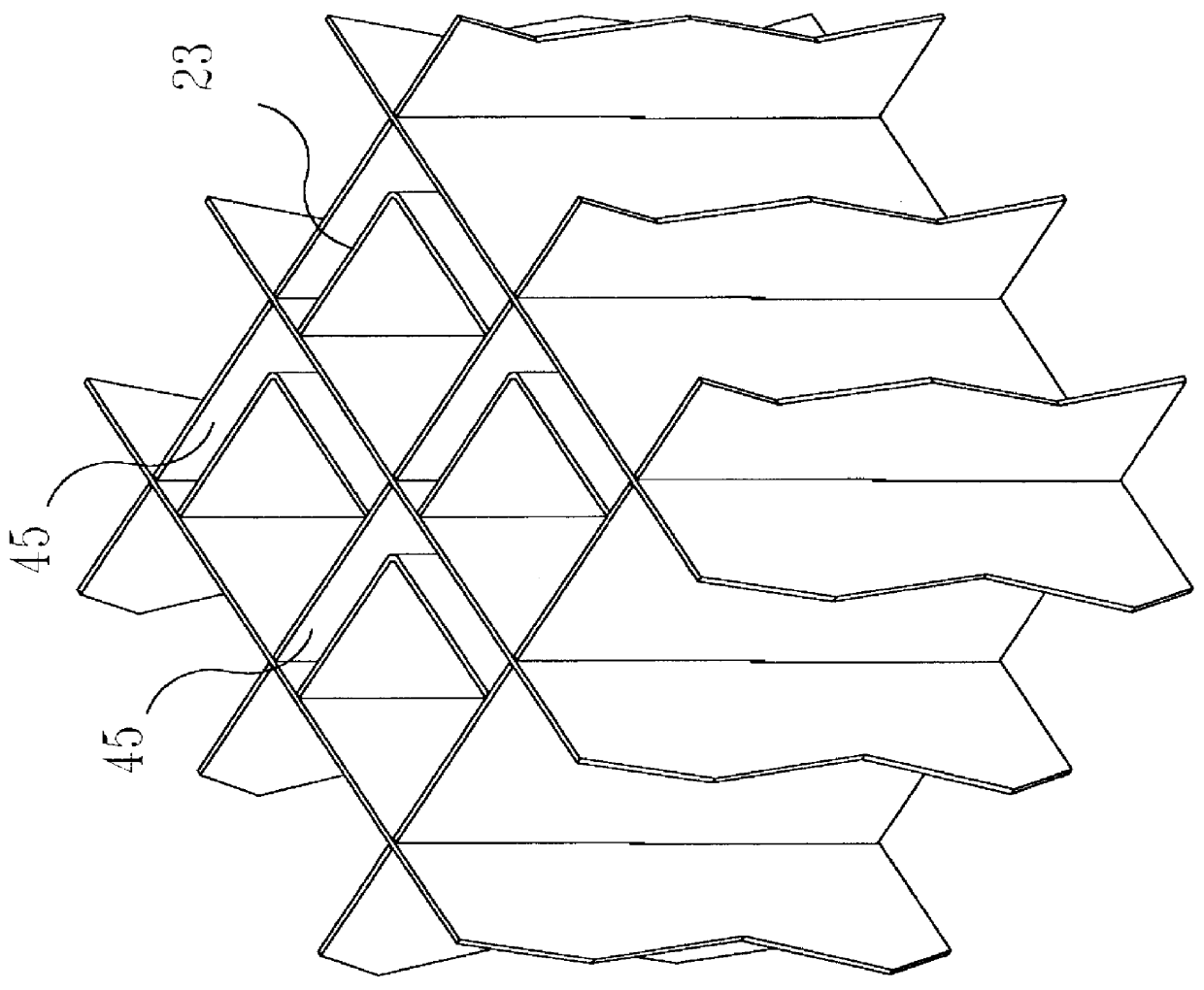

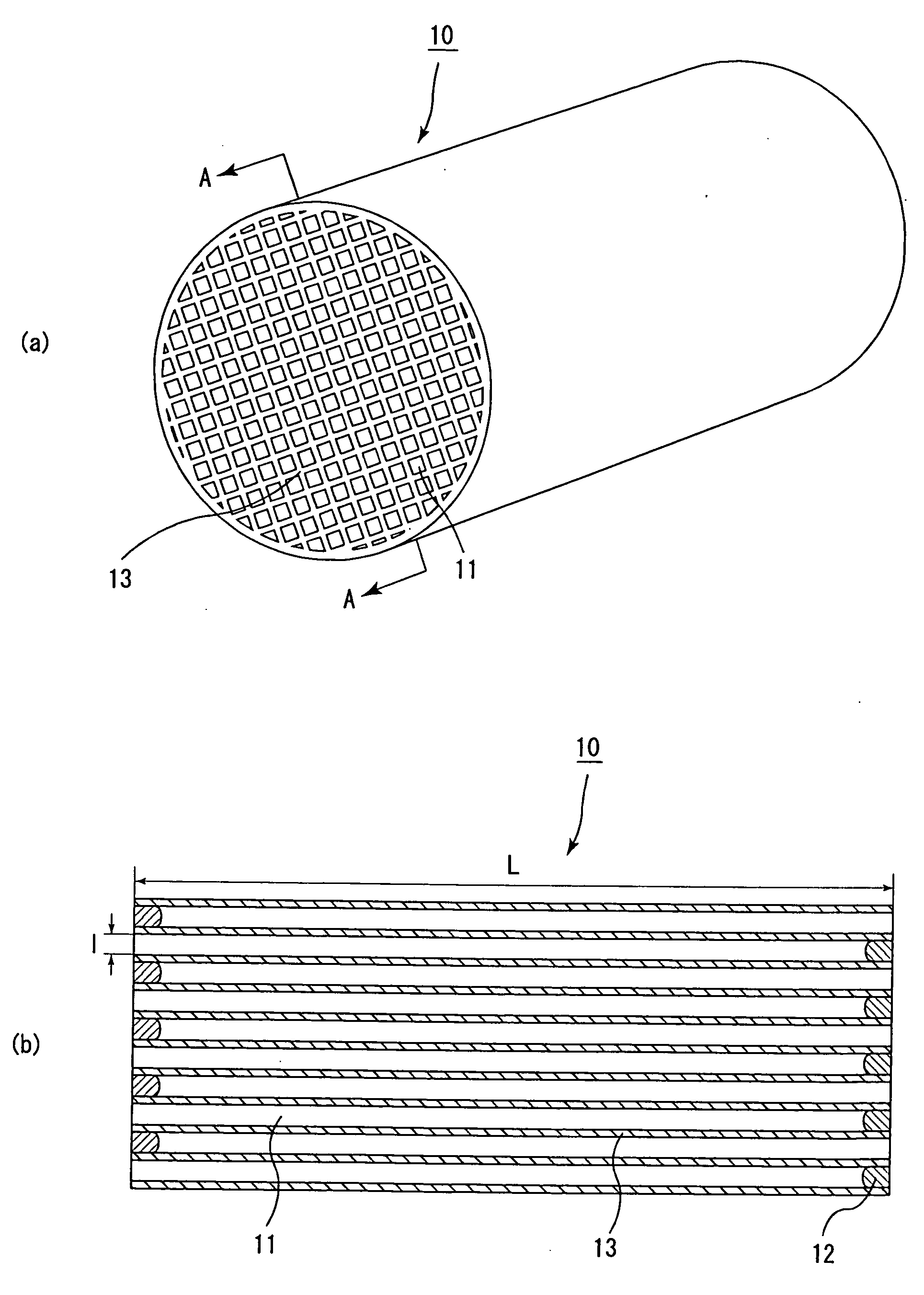

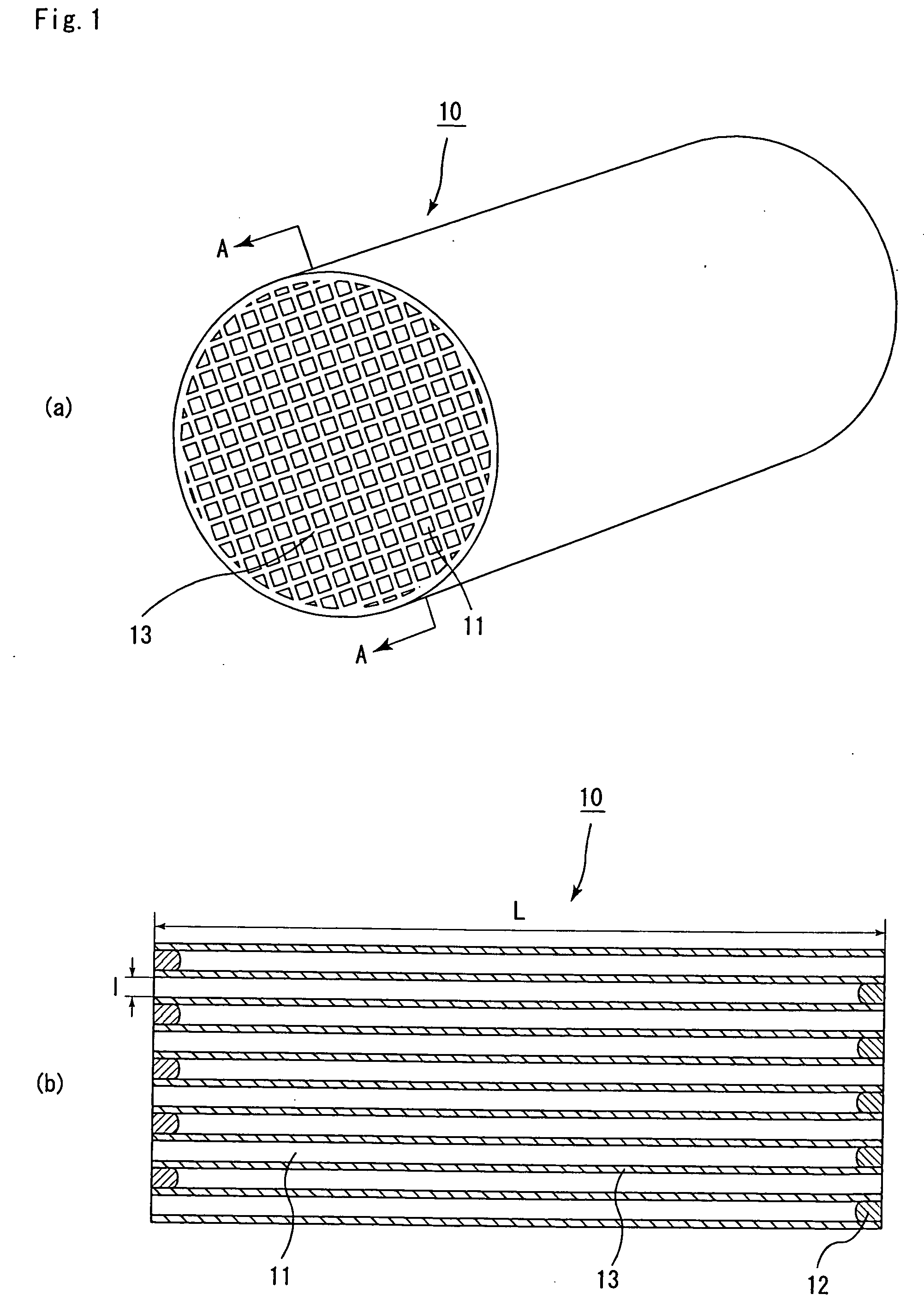

A honeycomb filter for purifying exhaust gases. A plurality of rectangular columnar porous ceramic members are combined with one another through a sealing material layer to constitute a ceramic block, each of the rectangular columnar porous ceramic member including a number of through holes that are placed in parallel with one another in the length direction with a partition wall interposed therebetween. A sealing material layer is also formed on a circumference portion of the ceramic block, and the partition wall that separates the through holes functions as a filter for collecting particulates. On a cross section perpendicular to the length direction of the porous ceramic member of the ceramic block, the maximum width L (mm) of the crisscross portion of the sealing material layer is 1.5 to 3 times greater than the minimum width I (mm) of the sealing material layer.

Owner:IBIDEN CO LTD

Honeycomb filter for clarifying exhaust gases

InactiveUS20050153099A1Increased durabilityPhysical/chemical process catalystsInternal combustion piston enginesParticulatesHoneycomb

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases that is free from a gap formed between a plug and a partition wall and cracks generated in the plug and a portion of the partition wall contacting the plug, and is superior in durability. The present invention provides a honeycomb filter for purifying exhaust gases which has a structure in which: a columnar body made of porous ceramic comprises a number of through holes, said through holes being placed in parallel with one another in the length direction with a wall portion interposed therebetween; predetermined through holes of said through holes are filled with plugs at one end of said columnar body, while the through holes that have not been filled with said plugs at said one end are filled with plugs at the other end of said columnar body; and a part or all of said wall portion functions as a filter for collecting particulates, wherein the porosity of the columnar body is in a range from 20 to 80%, and the porosity of the plug is 90% or less and is also set to 0.15 to 4.0 times as much as the porosity of the columnar body.

Owner:IBIDEN CO LTD

Honeycomb filter for clarifying exhaust gas

ActiveUS20050175514A1Increased durabilityCombination devicesPhysical/chemical process catalystsHoneycombFlexural strength

A honeycomb filter for purifying exhaust gases that is free from occurrence of cracks and coming-off of plugs and is superior in durability upon its use. The honeycomb filter includes a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, designed so that predetermined of the through holes are filled with plugs at one end of the columnar body, while the through holes not filled with the plugs at the one end are filled with plugs at the other end of the columnar body, and part of or the entire wall portion functions as a plug for collecting particles. A bending strength Fα (MPa) of the honeycomb filter and a length L (mm) of the plug in the length direction of the through hole satisfy the relationship of Fα×L≧30.

Owner:IBIDEN CO LTD

Honeycomb filter for purifying exhaust gas

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases having a structure in that, even when comparatively large sealing material layer is included therein, there is hardly any increase in the amount of organic components contained in exhaust gases to be discharged. The present invention provides a honeycomb filter for purifying exhaust gases, having a structure in that a sealing material layer is formed on a circumference of a columnar body made of porous ceramics, which has a number of through holes placed in parallel with one another in the length direction with wall portion interposed therebetween, and the wall portion which separate the through holes from each other functions as a filter for collecting particulates, wherein the rate Sα of an area occupied by the sealing material layers to the total area of a cross-section including the through holes in the direction perpendicular to the through holes is set to 0.5% or more, and the rate Vα of organic components to the honeycomb filter for purifying exhaust gases is set to 0.5% by weight or less.

Owner:IBIDEN CO LTD

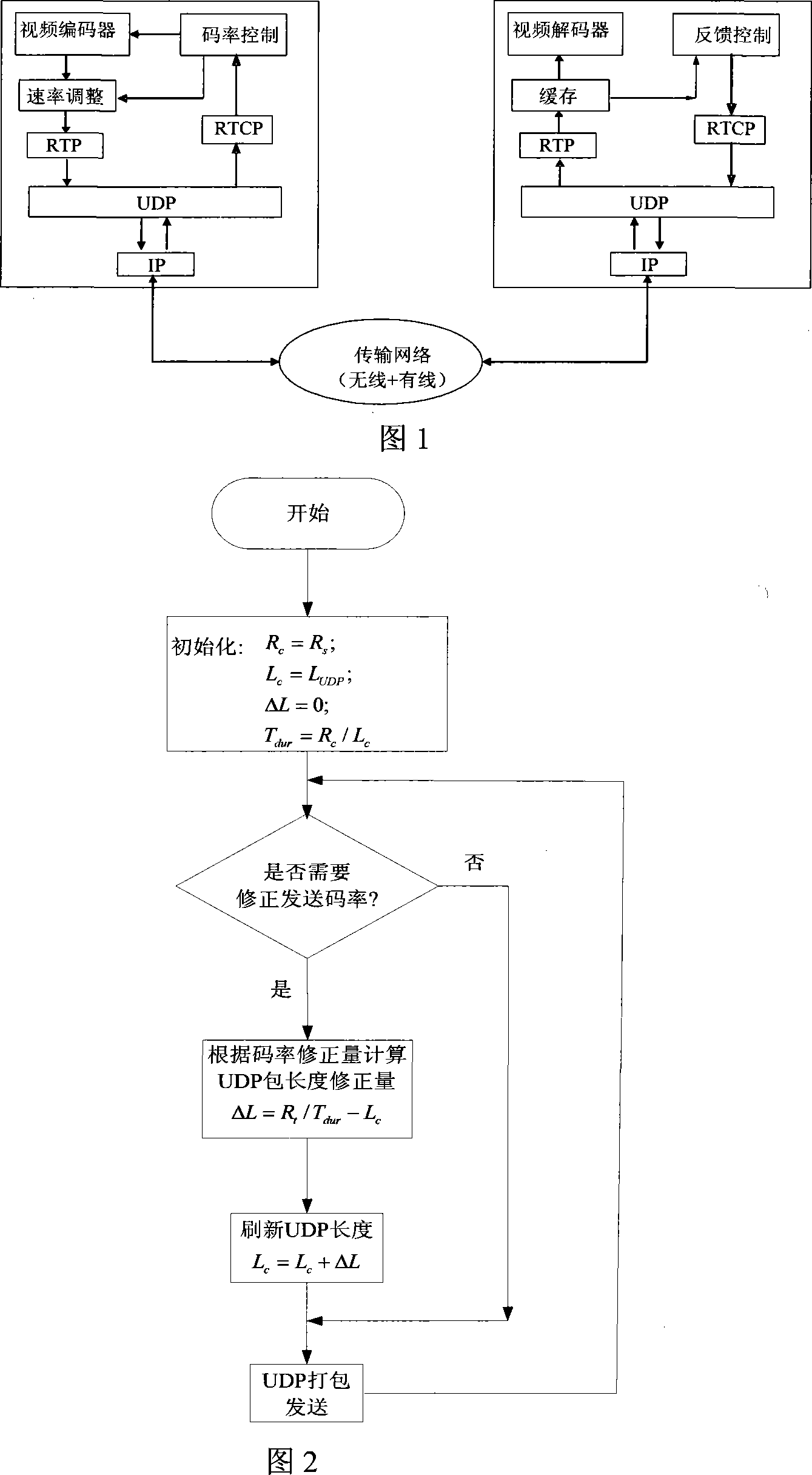

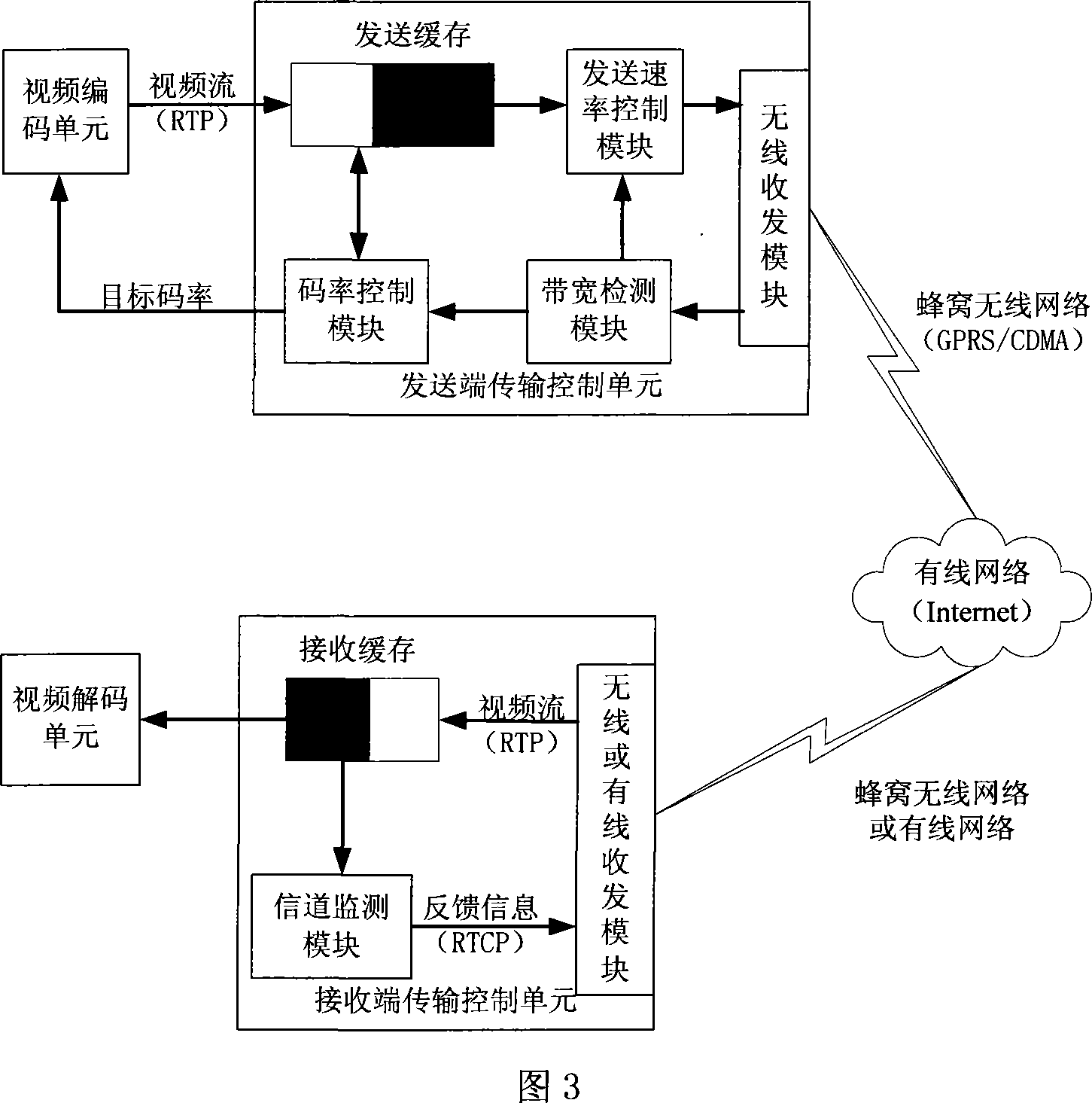

Self-adapting transmission method and system in ascending honeycomb video communication

InactiveCN101222296AImprove playback qualityReduce packet loss eventsError preventionData streamPacket loss

The invention discloses a self-adaptive transmission method and a self-adaptive transmission system in the uplink cellular video communication of the wireless multimedia communication technical field. The method is that: a feedback-based channel effectively transmits bandwidth perceiving; the sending speed of a data flow is adjusted according to the perceived effective transmission bandwidth, the adjustment of the sending rate is realized by changing the packet length of the data flow; two-stage information resource rate control based on cache cleaning and rate control of an encoder is used. The device comprises a sending end, a transmission network and a receiving end, wherein the sending end comprises a video encoding unit and a transmission control unit, the receiving end comprises a transmission control unit and a video decoding unit, the sending end and the receiving end transmit messages through the transmission network. The sending rate of the invention can automatically adapt to the change of the channel bandwidth, decreases the probability of packet loss caused by the fluctuation of the wireless channel bandwidth, and realizes that the customer side can obtain the best possible playing quality under the condition of constant change of network operation conditions.

Owner:SHANGHAI JIAO TONG UNIV

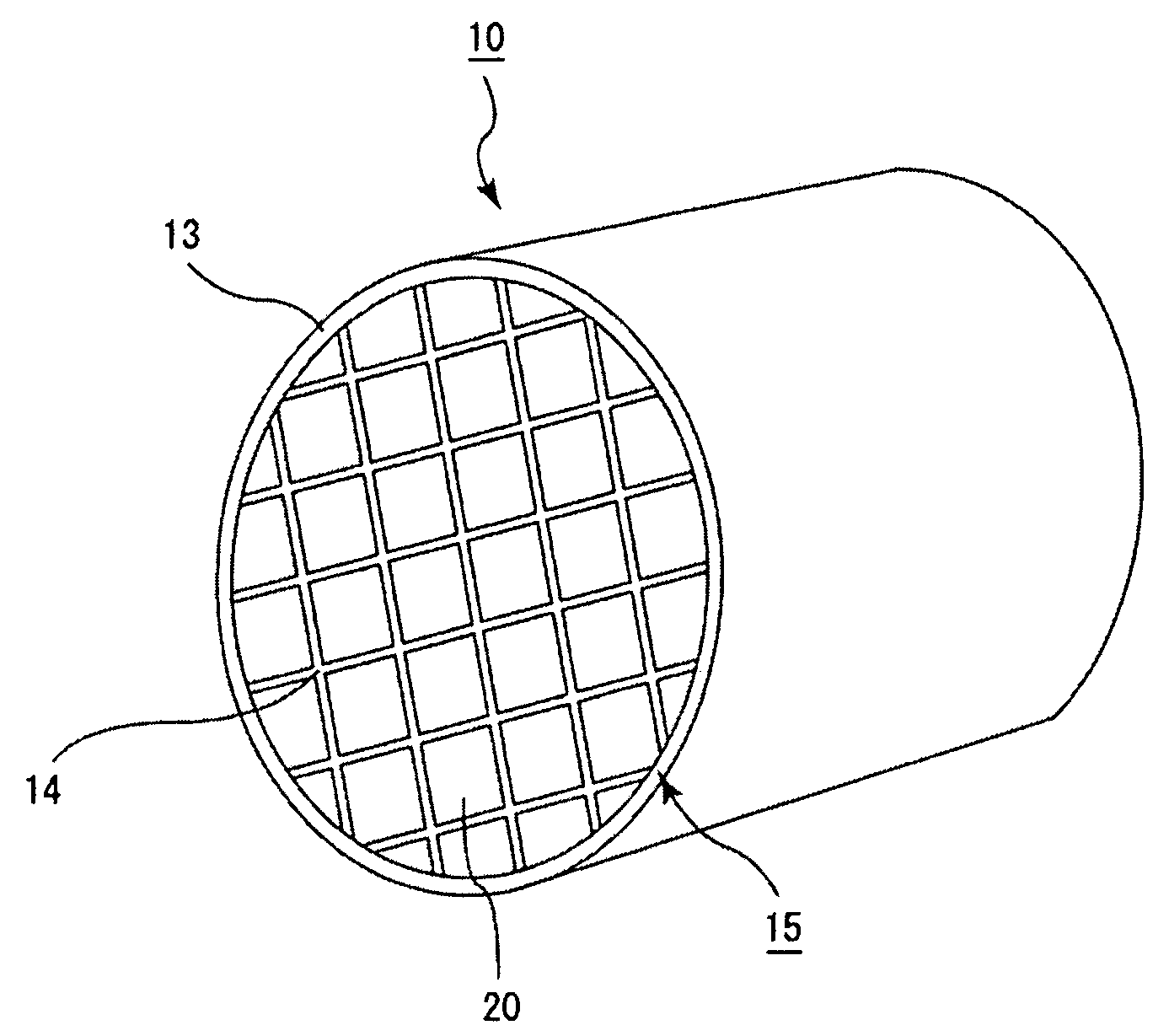

Activated carbon honeycomb catalyst beds and methods for the use thereof

InactiveUS20070261557A1Simple designLow costGas treatmentCarbon compoundsActivated carbonCombustion system

Disclosed herein, without limitation, are activated carbon honeycomb catalyst beds and systems for removing mercury and other toxic metals from a process stream, i.e, from flue gas of a coal combustion system. The activated carbon honeycomb can for example remove greater than 90% mercury from flue gas with a simple design and without adding material to the flue gas. Also disclosed herein, and without limitation, are methods for manufacturing and using the disclosed honeycomb catalyst beds and systems.

Owner:CORNING INC

Honeycomb filter for purifying exhaust gases, adhesive, coating material, and manufacturing method of honeycomb filter for purifying exhaust gases

InactiveUS20080241015A1Increased durabilityHigh strengthCombination devicesPhysical/chemical process catalystsParticulatesAdhesive

Owner:IBIDEN CO LTD

Honeycomb filter and ceramic filter assembly

InactiveUS20060021310A1Internal combustion piston enginesDispersed particle filtrationMetallurgyHoneycomb

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

Method for manufacturing honeycomb filter for purifying exhaust gases

InactiveUS20080213485A1Dispersed particle filtrationTransportation and packagingExhaust fumesHoneycomb

A method for manufacturing a honeycomb filter for purifying exhaust gas, including: providing a columnar body including porous ceramic and having a wall portion and through holes partitioned by the wall portion, the through holes extending in a length direction of the columnar body, coating a sealing material including one or more organic components over a circumferential surface of the columnar body to form a sealing material layer; and heating the columnar body having the sealing material layer on the circumferential surface of the columnar body at a temperature sufficient to lower a total weight of the organic component with respect to a total weight of the honeycomb filter, Vα.

Owner:IBIDEN CO LTD

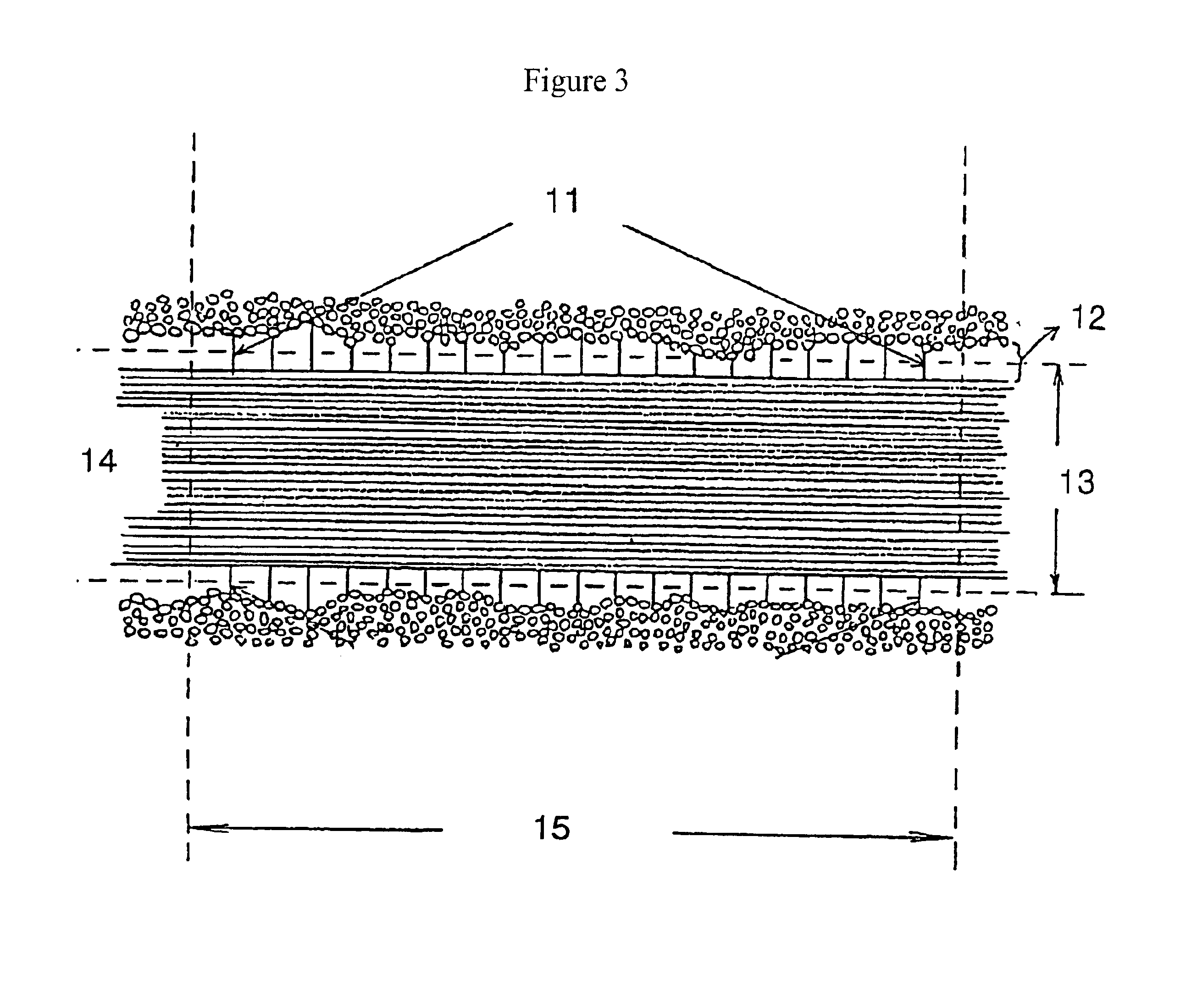

Prepreg fabric and honeycomb sandwich panel

InactiveUS6429157B1Good self-adhesiveReduce porositySynthetic resin layered productsPaper/cardboard layered productsPorosityHoneycomb

A woven fabric prepreg comprising at least [A] a woven fabric as reinforcing fibers, [B] a thermosetting resin or thermosetting resin composition and [C] fine particles of a resin and having a cover factor of 95% or more, and a honeycomb sandwich panel, comprising skin panels fabricated by said woven fabric prepreg and [D] a honeycomb core can be obtained. The woven fabric prepreg little changes in tackiness with the lapse of time and has moderate drapability, being excellent in self adhesiveness to the honeycomb core when used as skin panels of a honeycomb sandwich panel. Furthermore, the honeycomb sandwich panel obtained has a small porosity in the skin panels fabricated by the cured prepreg and has excellent surface smoothness with few pits and depressions on the surfaces of the skin panels.

Owner:TORAY IND INC

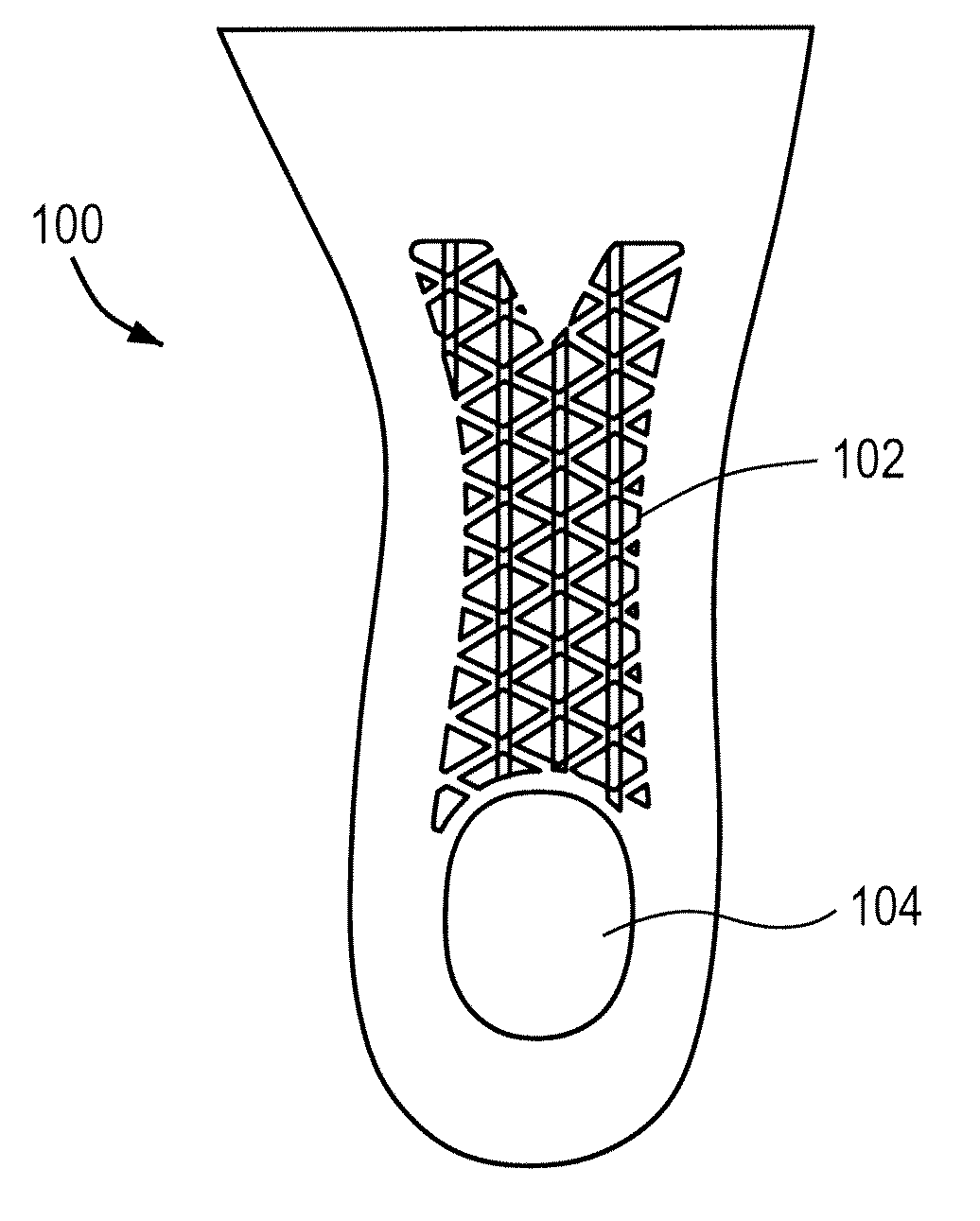

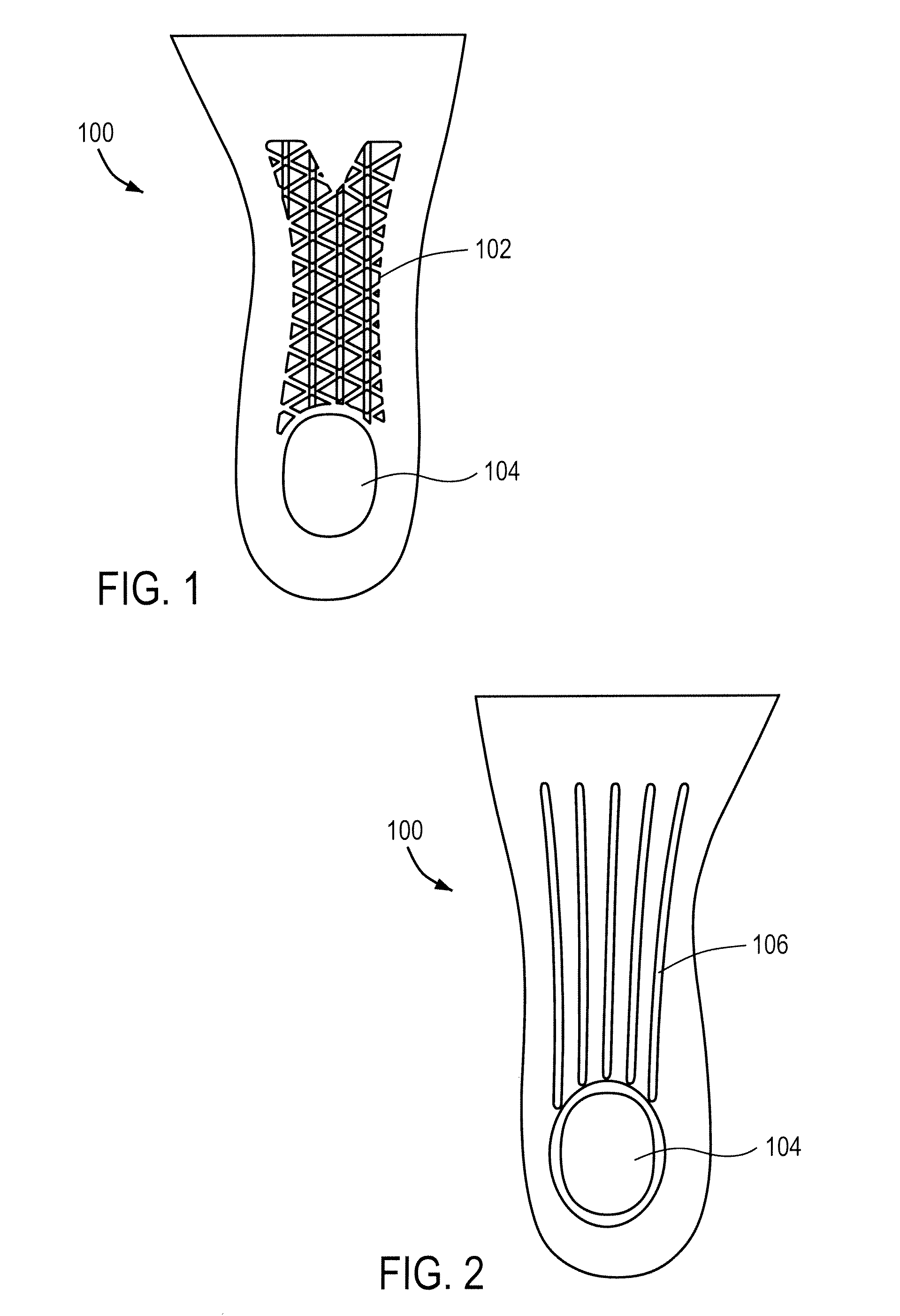

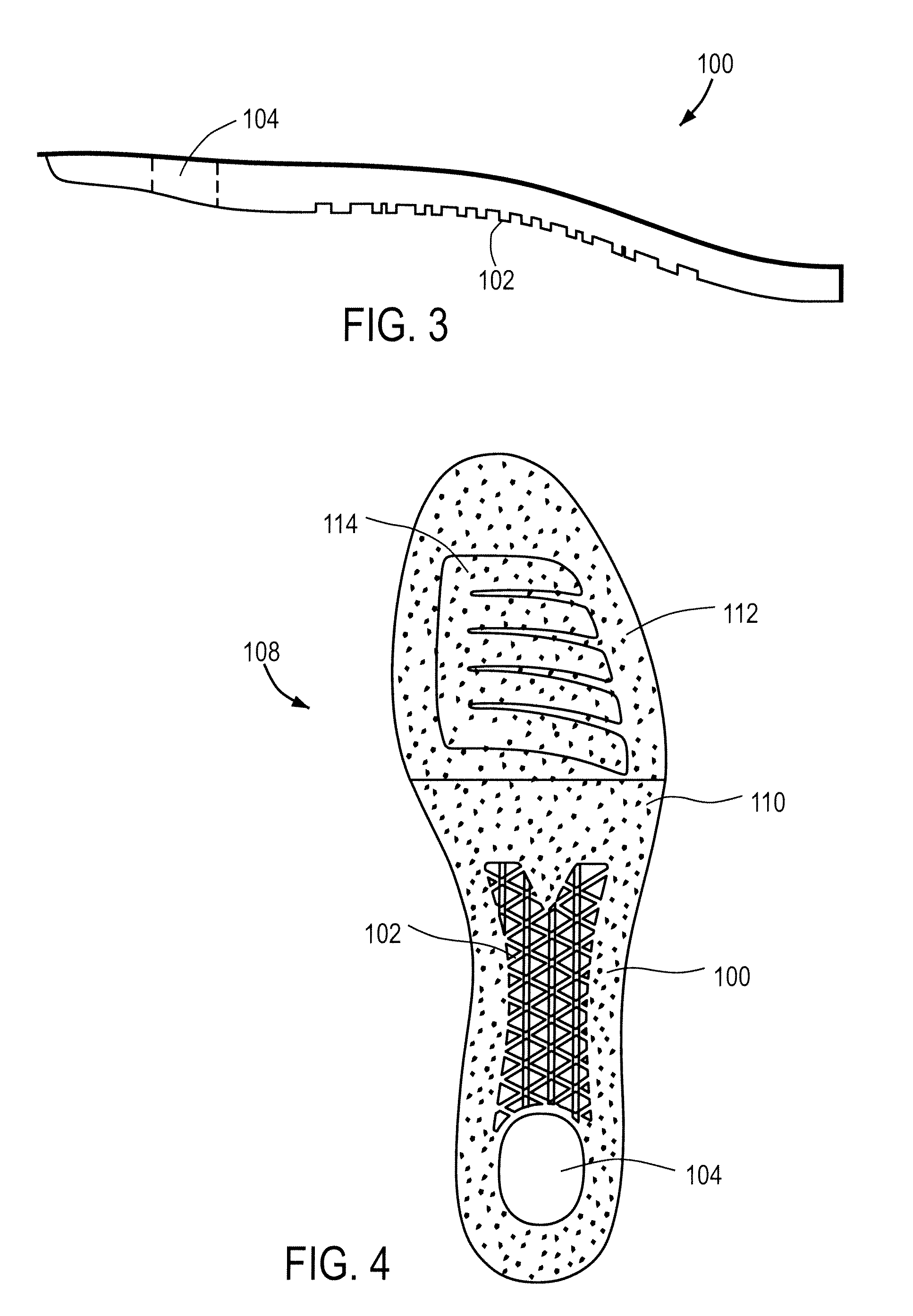

Footwear Sole with Honeycomb Reinforcement Shank, Fabric Layer, and Polymer Components

A footwear sole includes a shank with a honeycomb reinforcement structure, heel aperture and rib receptacle in the bottom side of a front region of the shank. A fabric sheath surrounds the shank. Polymers are formed in the rib receptacle, in the heel aperture and on the top side of the shank. A foot bed insert is used with the shank. The foot bed insert includes a fabric upper layer, a foam forefoot component, a foam matrix connected to the foam forefoot component, a heel cradle and a heel strike region.

Owner:ARIAT INT

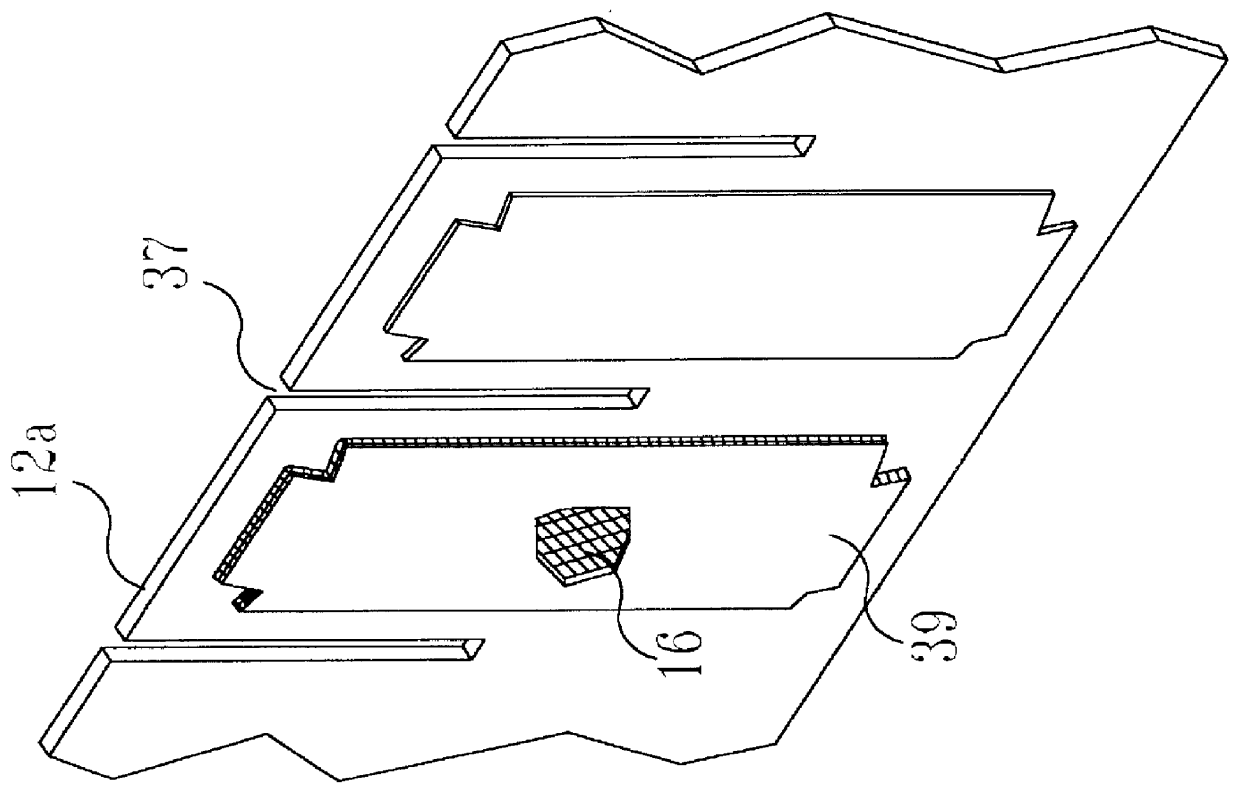

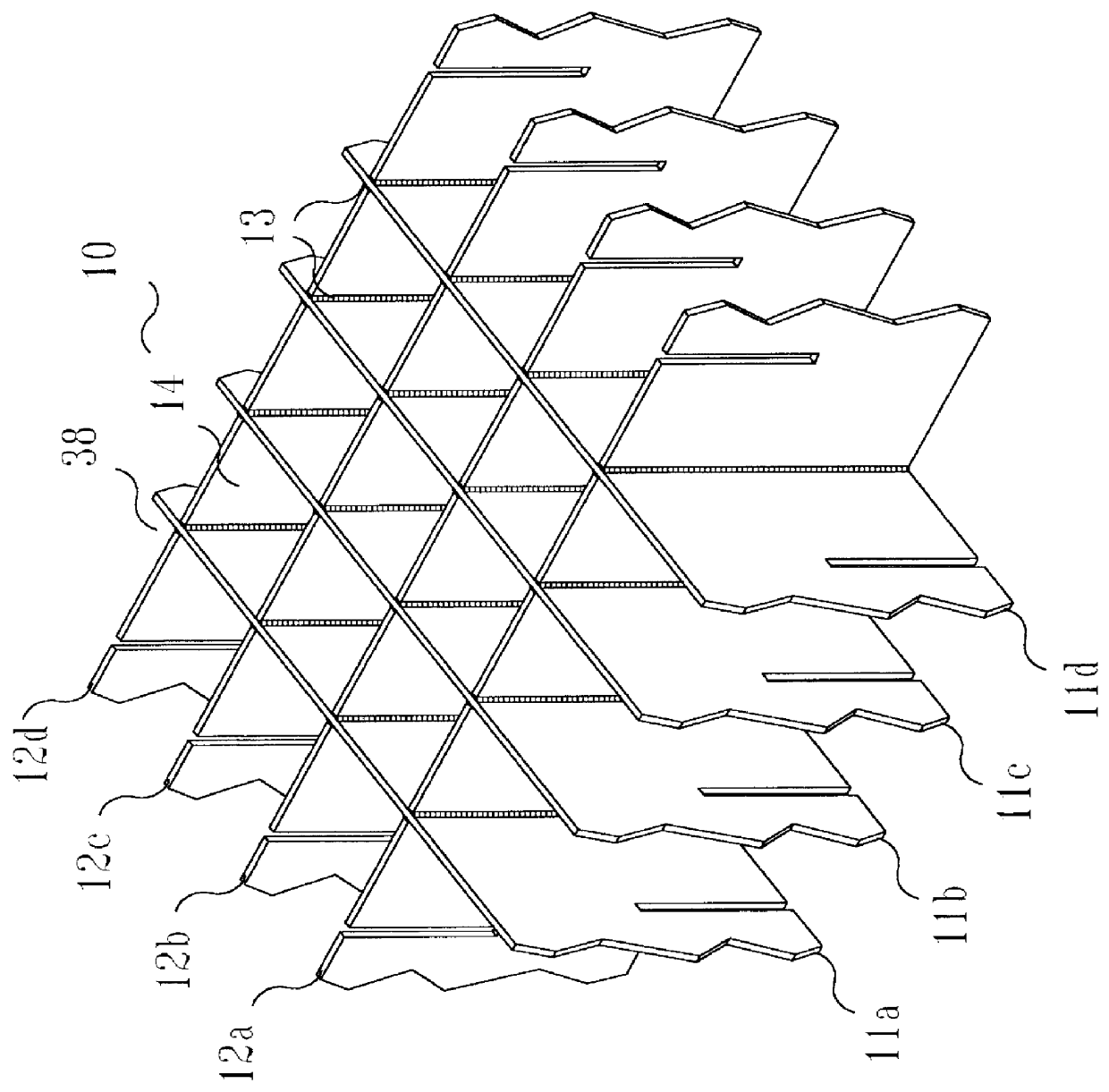

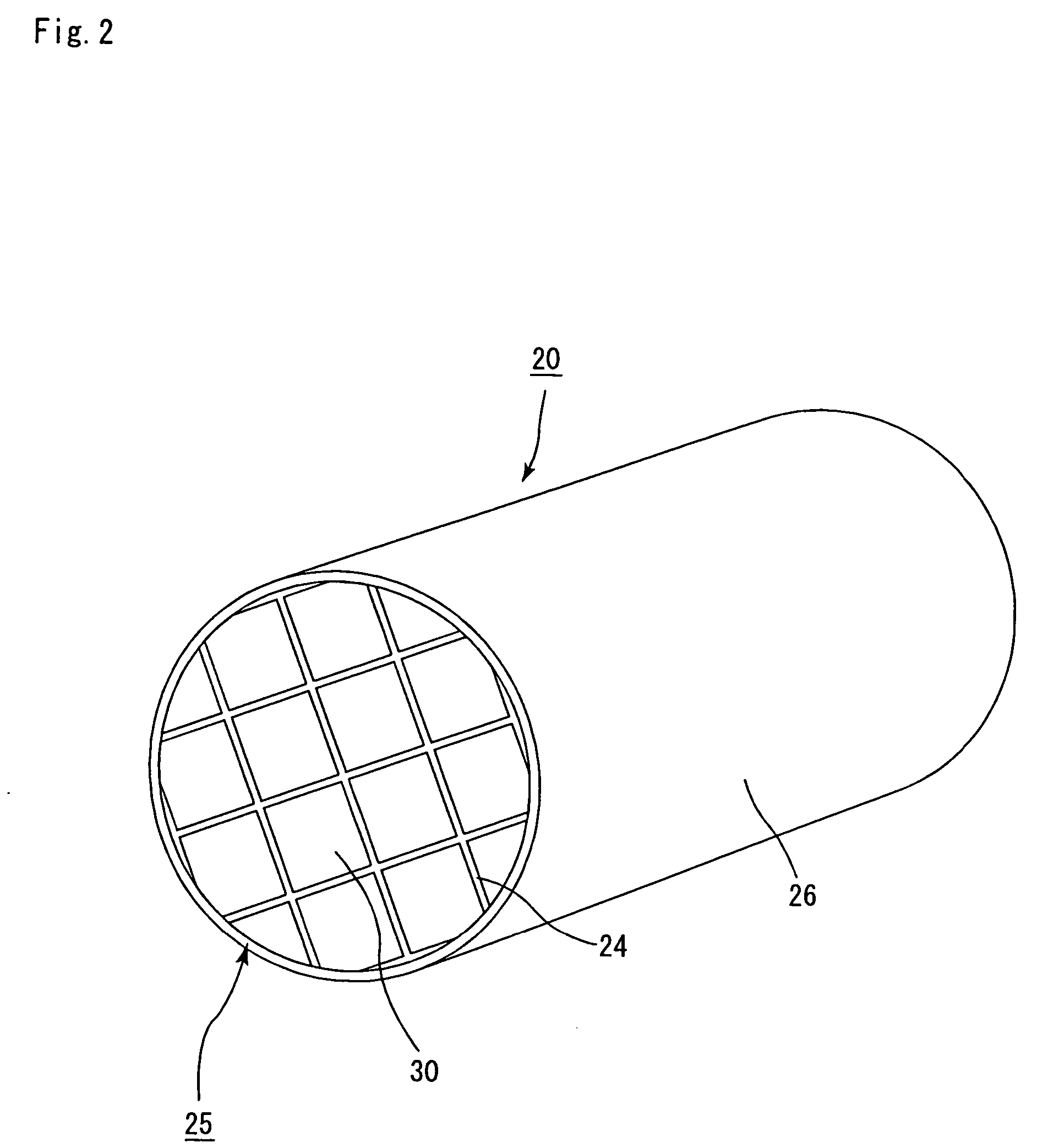

Apparatus suitable for transporting and storing nuclear fuel rods and methods for using the apparatus

InactiveUS6064710ARugged and convenient to handleHighly effectiveReactor fuel elementsPortable shielded containersHoneycombHoneycomb like

Apparatus suitable for transporting and storing nuclear fuel rods comprising a basket having storage cells formed from a honeycomb gridwork of metal plates in a rectilinear configuration, the plates welded to each other at their intersections so that all contiguous corners of the storage cells formed by the gridwork are completely connected so as to allow conduction heat transfer, the metal plates having neutron absorber material positioned in areas which form walls of the storage cells. Method of making an apparatus suitable for transporting and storing nuclear fuel rods comprising a) providing metal plates having slots and having neutron absorber material positioned on sides of the metal plates, b) arranging the plates so that the slots intersect to form a honeycomb gridwork of storage cells having contiguous corners and having the neutron absorbing material on sides of the storage cells, and c) welding the plates to each other at their intersections so that all contiguous corners of the storage cells formed by the gridwork are completely connected so as to allow conduction heat transfer and to provide a rigid structure.

Owner:SINGH KRIS

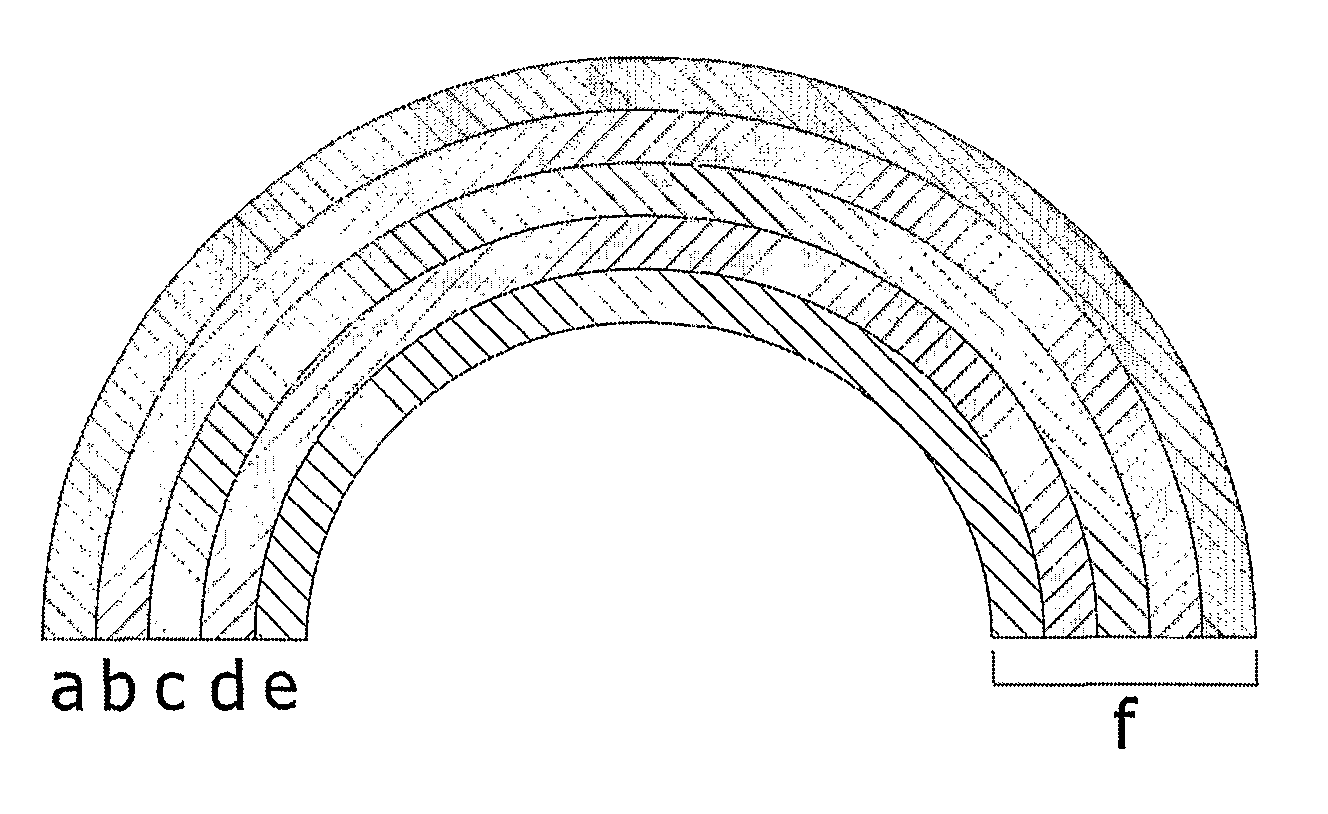

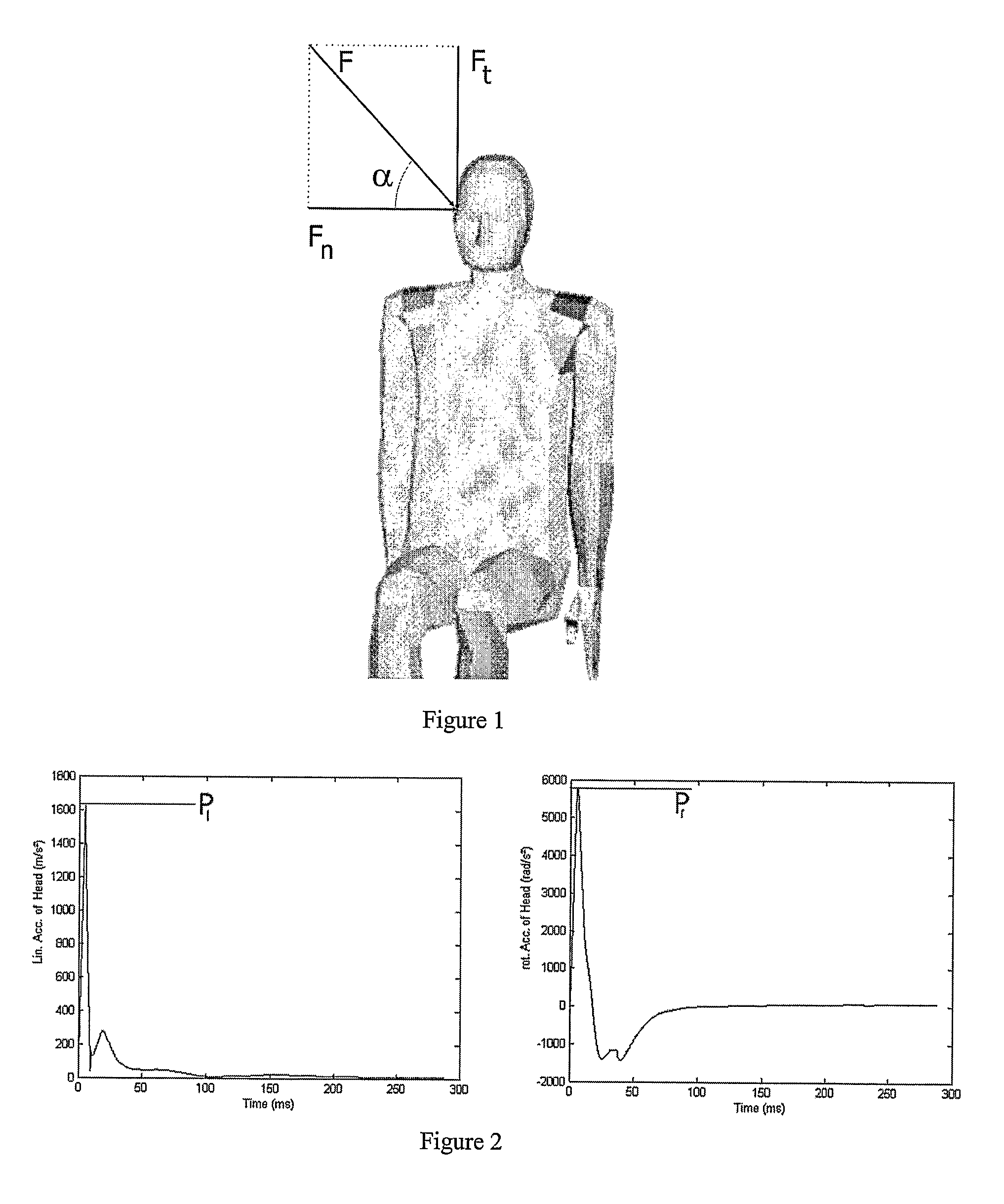

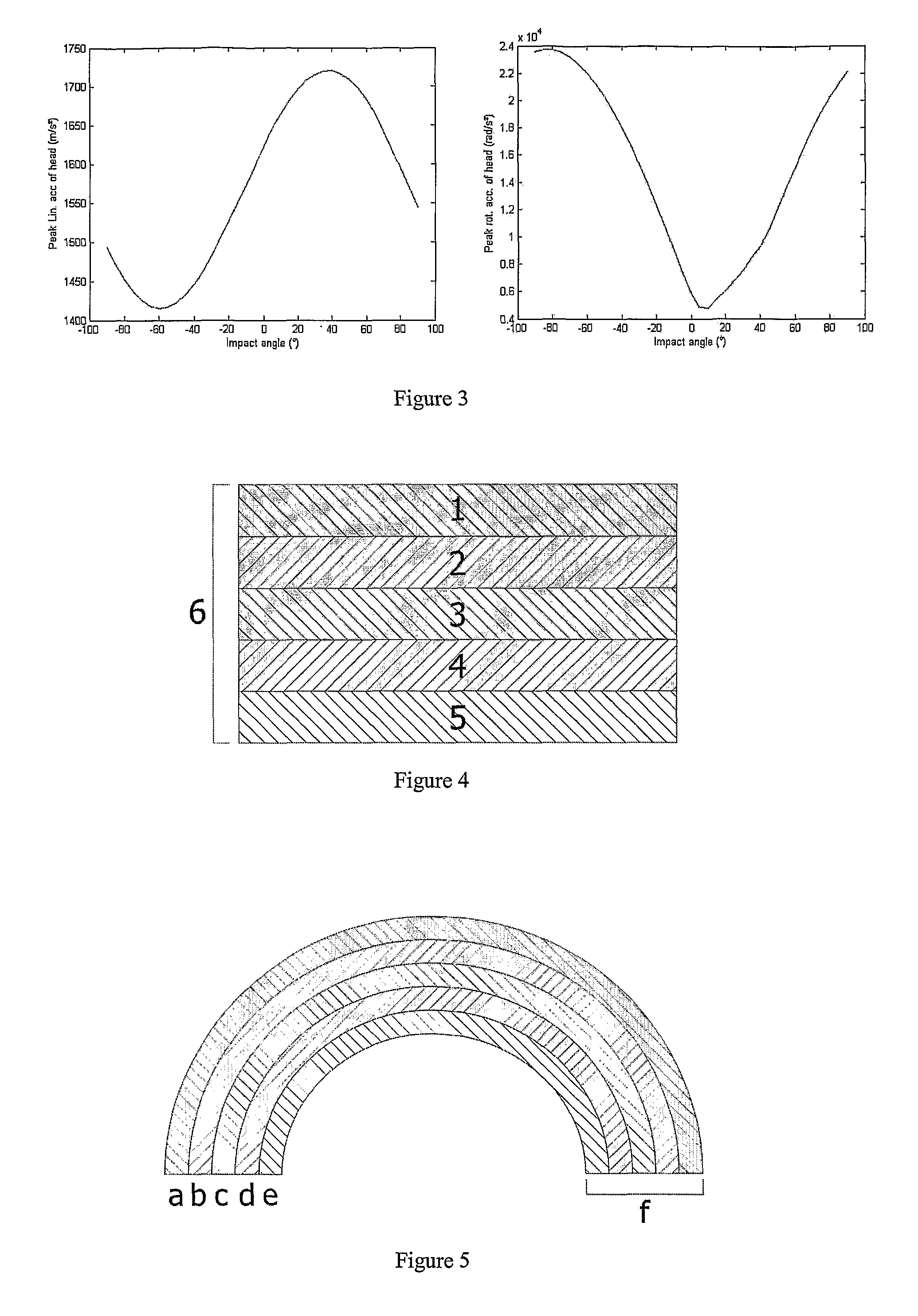

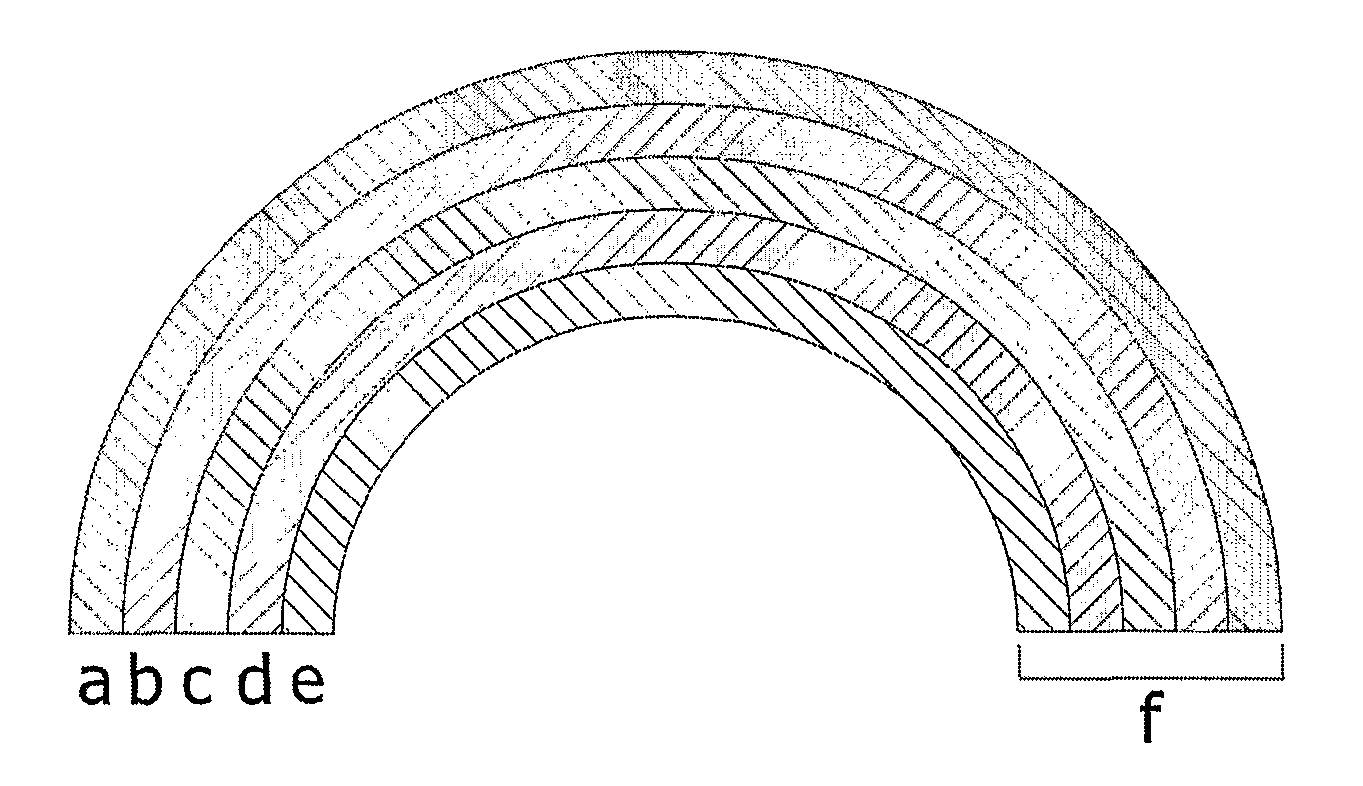

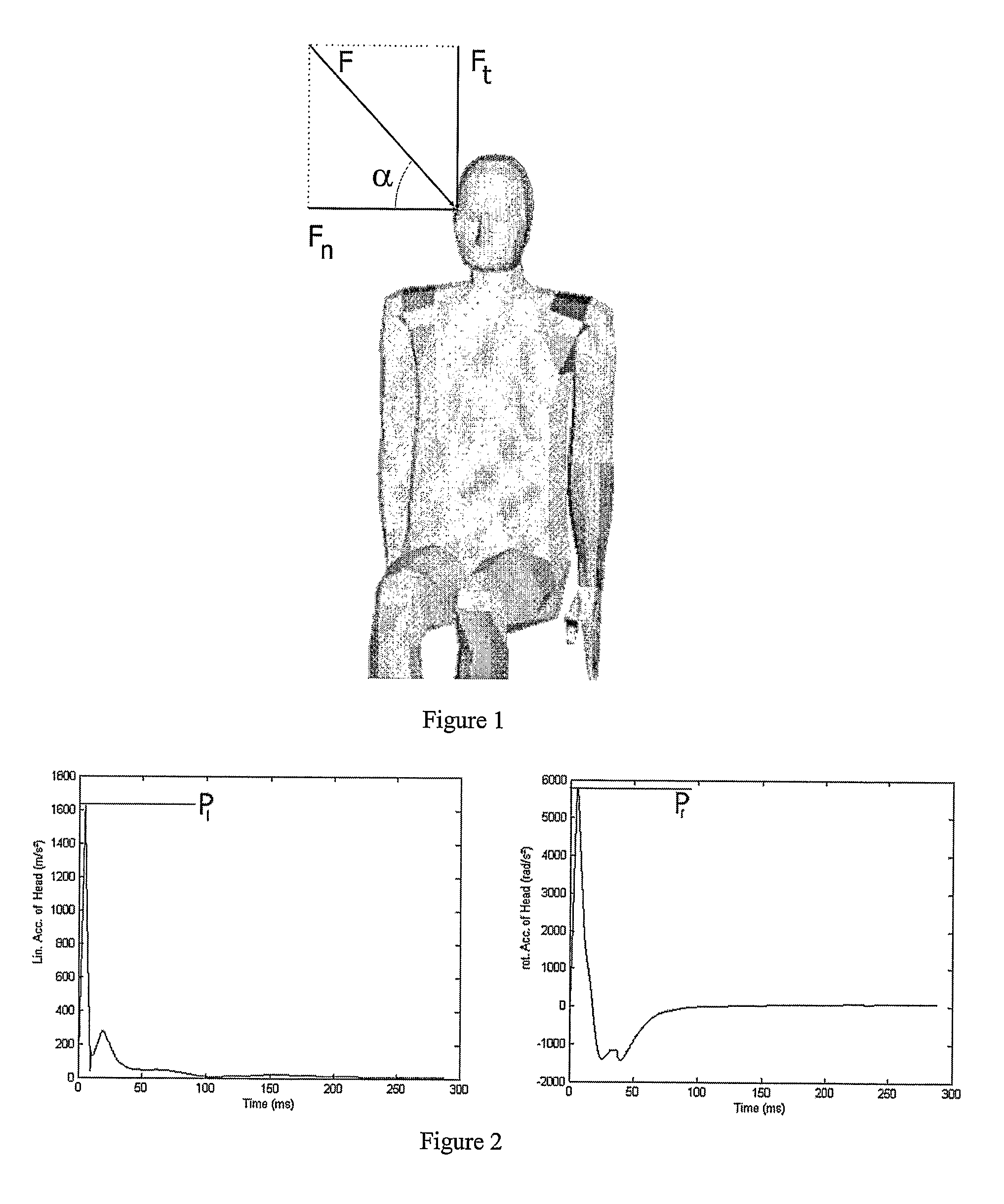

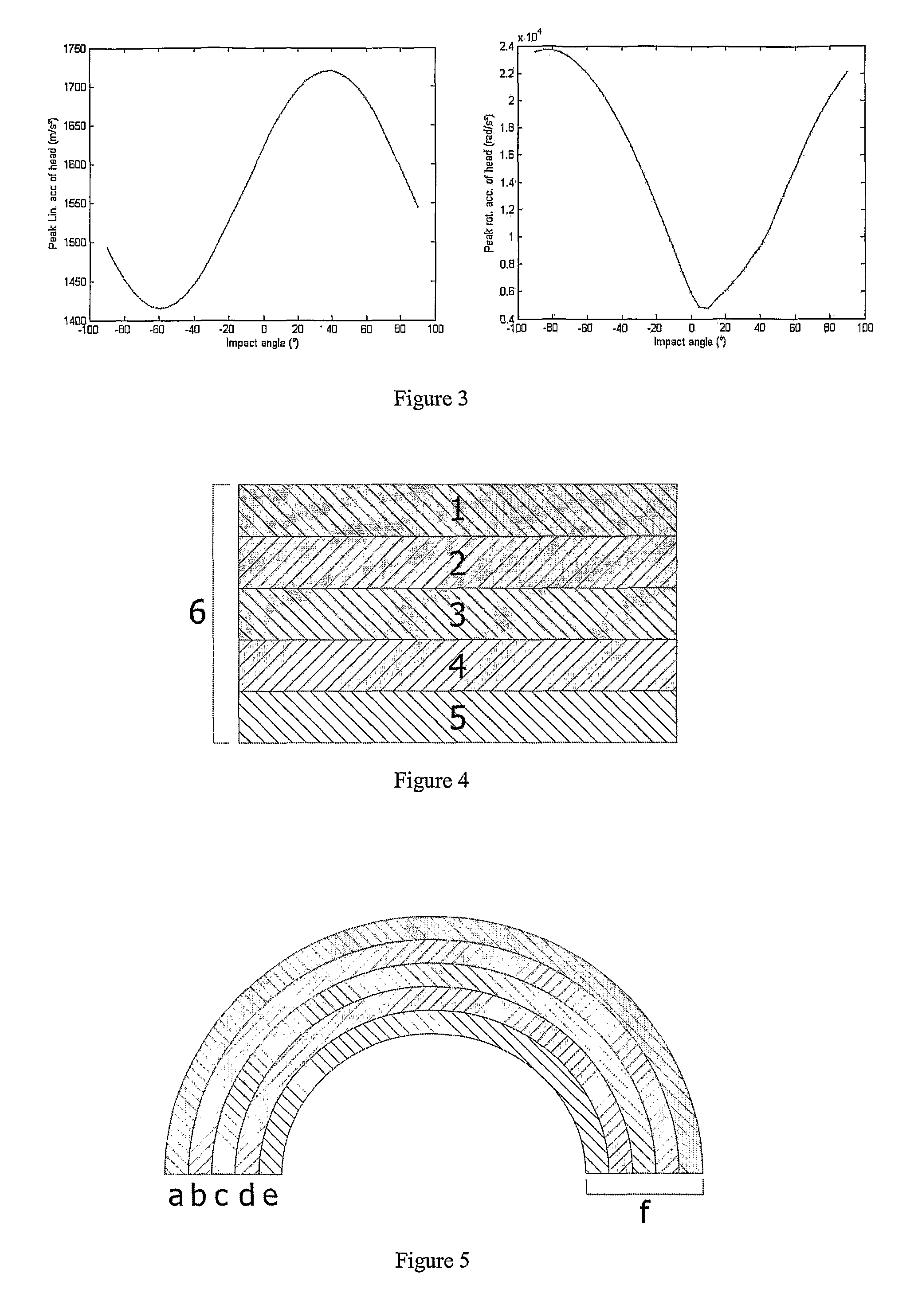

Protective helmet

InactiveUS7930771B2Improve protectionReduce the risk of injuryHatsHeadwear capsTangential forceCell wall

A protective helmet is described comprising: an outer layer (1); an inner layer (5) for contact with a head of a wearer; and an intermediate layer (3, 4) comprising an anisotropic cellular material comprising cells having cell walls, the anisotropic cellular material having a relatively low resistance against deformation resulting from tangential forces on the helmet. The anisotropic material can be a foam or honeycomb material. The foam is preferably a closed cell foam. The helmet allows tangential impacts to the helmet which cause less rotational acceleration or deceleration of the head of the wearer compared to helmets using isotropic foams while still absorbing a significant amount of rotational energy.

Owner:K U LEUVEN RES & DEV

Monolayer and/or Few-Layer Graphene On Metal or Metal-Coated Substrates

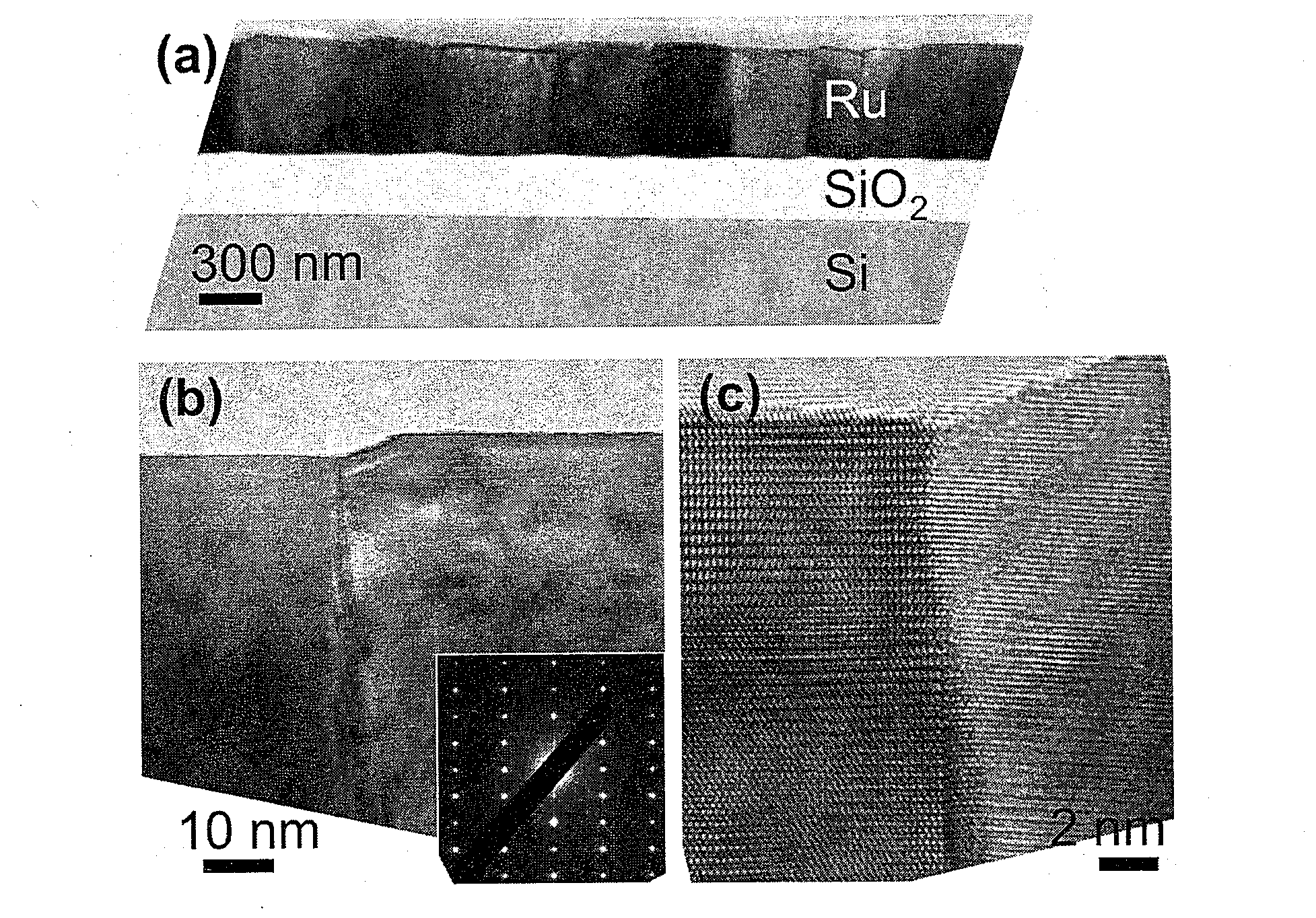

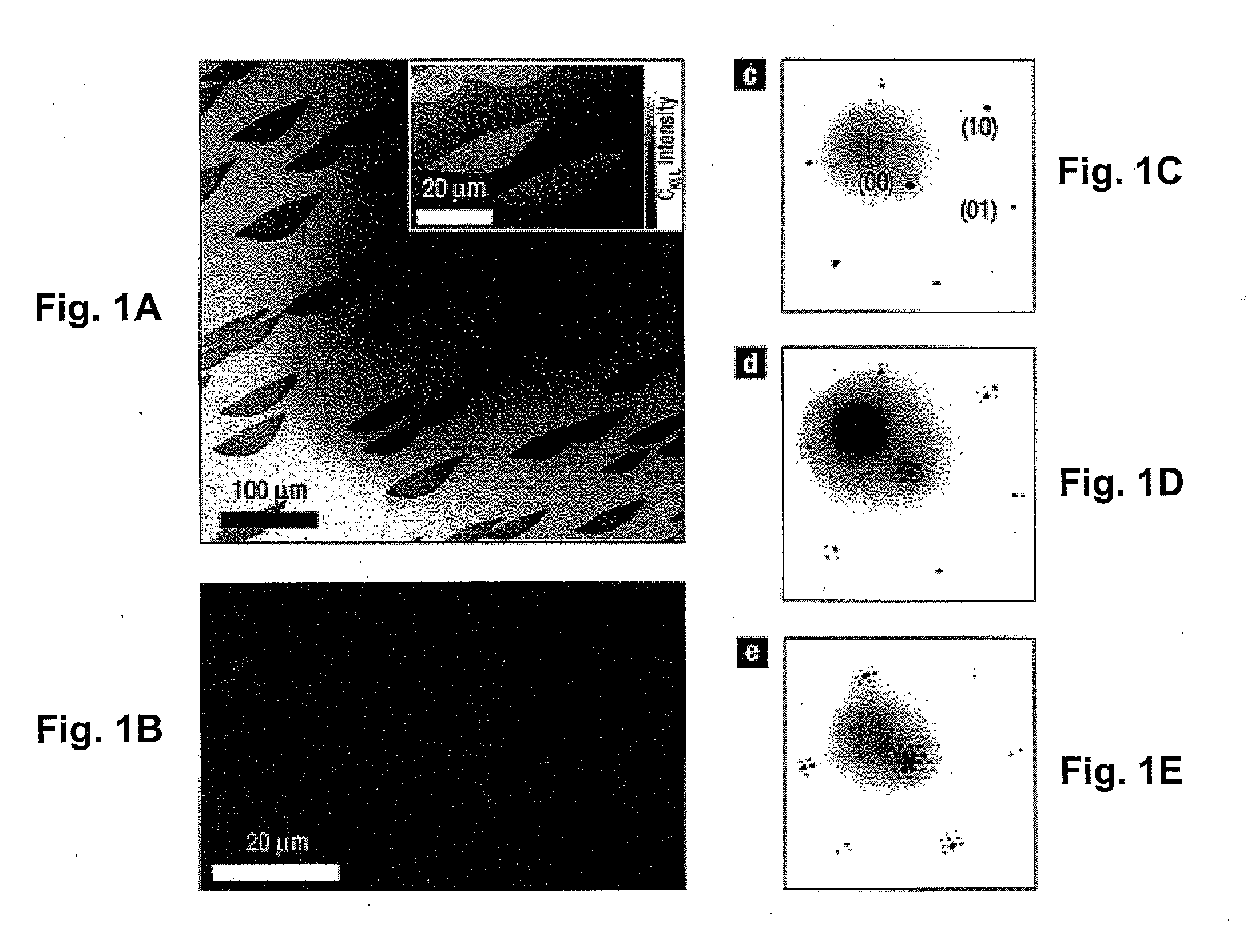

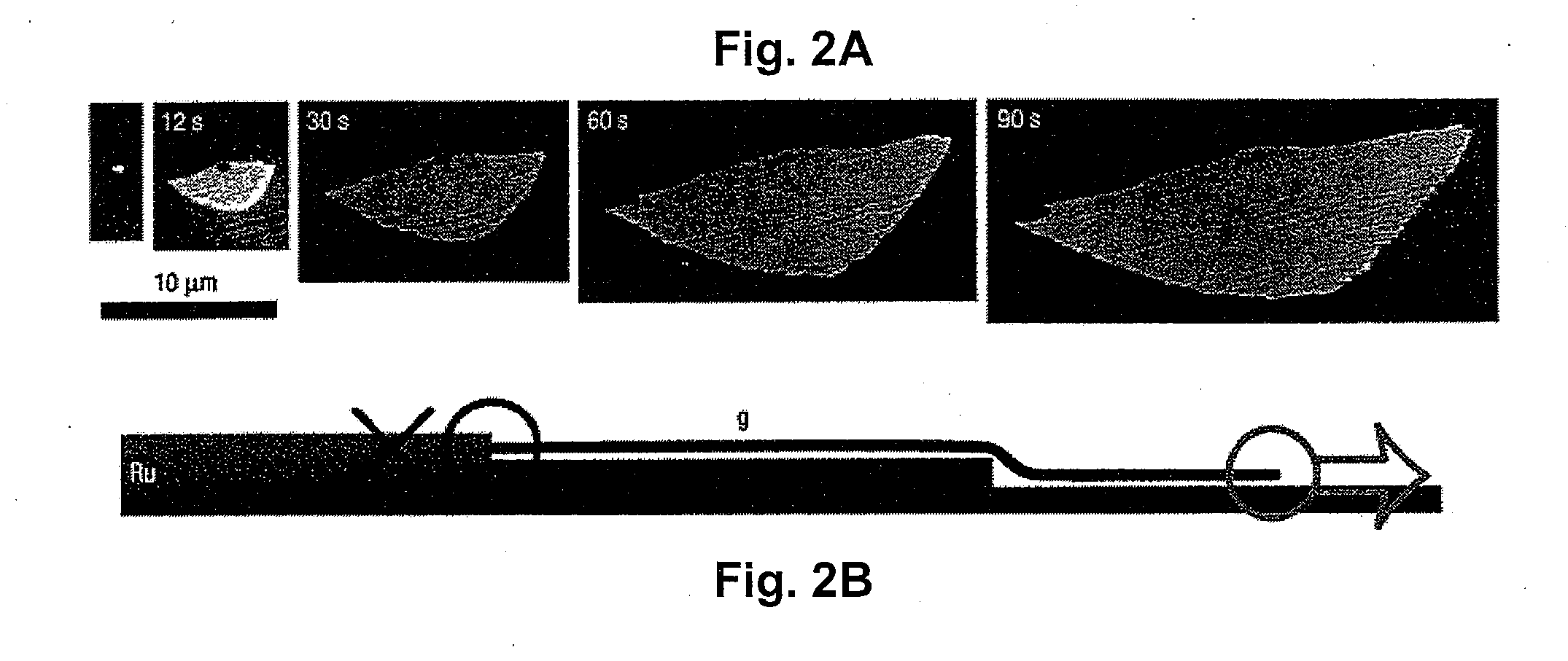

InactiveUS20100255984A1Easy to disassembleMaterial nanotechnologyParticle separator tubesHigh concentrationIn plane

Graphene is a single atomic layer of sp2-bonded C atoms densely packed into a two-dimensional honeycomb crystal lattice. A method of forming structurally perfect and defect-free graphene films comprising individual mono crystalline domains with in-plane lateral dimensions of up to 200 μm or more is presented. This is accomplished by controlling the temperature-dependent solubility of interstitial C of a transition metal substrate having a suitable surface structure. At elevated temperatures, C is incorporated into the bulk at higher concentrations. As the substrate is cooled, a lowering of the interstitial C solubility drives a significant amount of C atoms to the surface where graphene islands nucleate and gradually increase in size with continued cooling. Ru(0001) is selected as a model system and electron microscopy is used to observe graphene growth during cooling from elevated temperatures. With controlled cooling, large arrays of macroscopic single-crystalline graphene domains covering the entire transition metal surface are produced. As the graphene domains coalesce to a complete layer, a second graphene layer is formed, etc. By controlling the interstitial C concentration and the cooling rate, graphene layers with thickness up to 10 atomic layers or more are formed in a controlled, layer-by-layer fashion.

Owner:BROOKHAVEN SCI ASSOCS

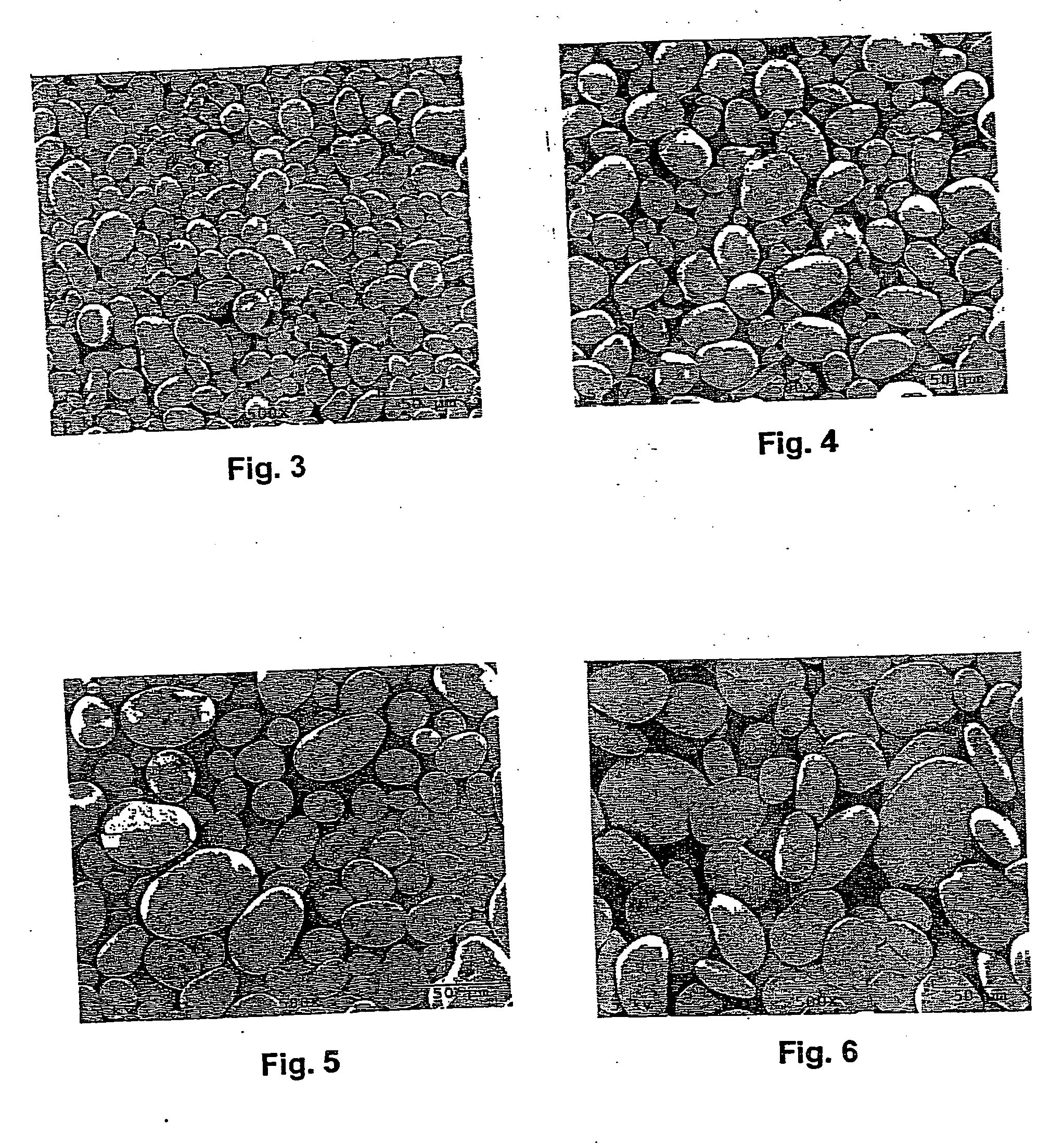

Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor

ActiveUS20070119135A1Lower wash-coated pressure dropQuantity minimizationCombination devicesExhaust apparatusSago palmSource material

A porous ceramic honeycomb filter manufactured from an oxide-based ceramic material having a pore size distribution with d1≧7.0 microns. Preferably, the oxide-based material is cordierite or aluminum titanate. Alternatively, the filter contains a cordierite-containing ceramic body with a narrow pore size distribution with db≦1.00, wherein db=(d90−d10) / d50. Also disclosed is a batch mixture, method and honeycomb green body made from mixture of inorganic source materials selected from the group of magnesia sources, alumina sources, and silica sources, and a pore former having a narrow particle size distribution with dps≦0.90, wherein dps={(dp90−dp10) / dp50}. The pore former is preferably selected from a group consisting of canna starch, sago palm starch, green mung bean starch, and single-mode potato starch.

Owner:CORNING INC

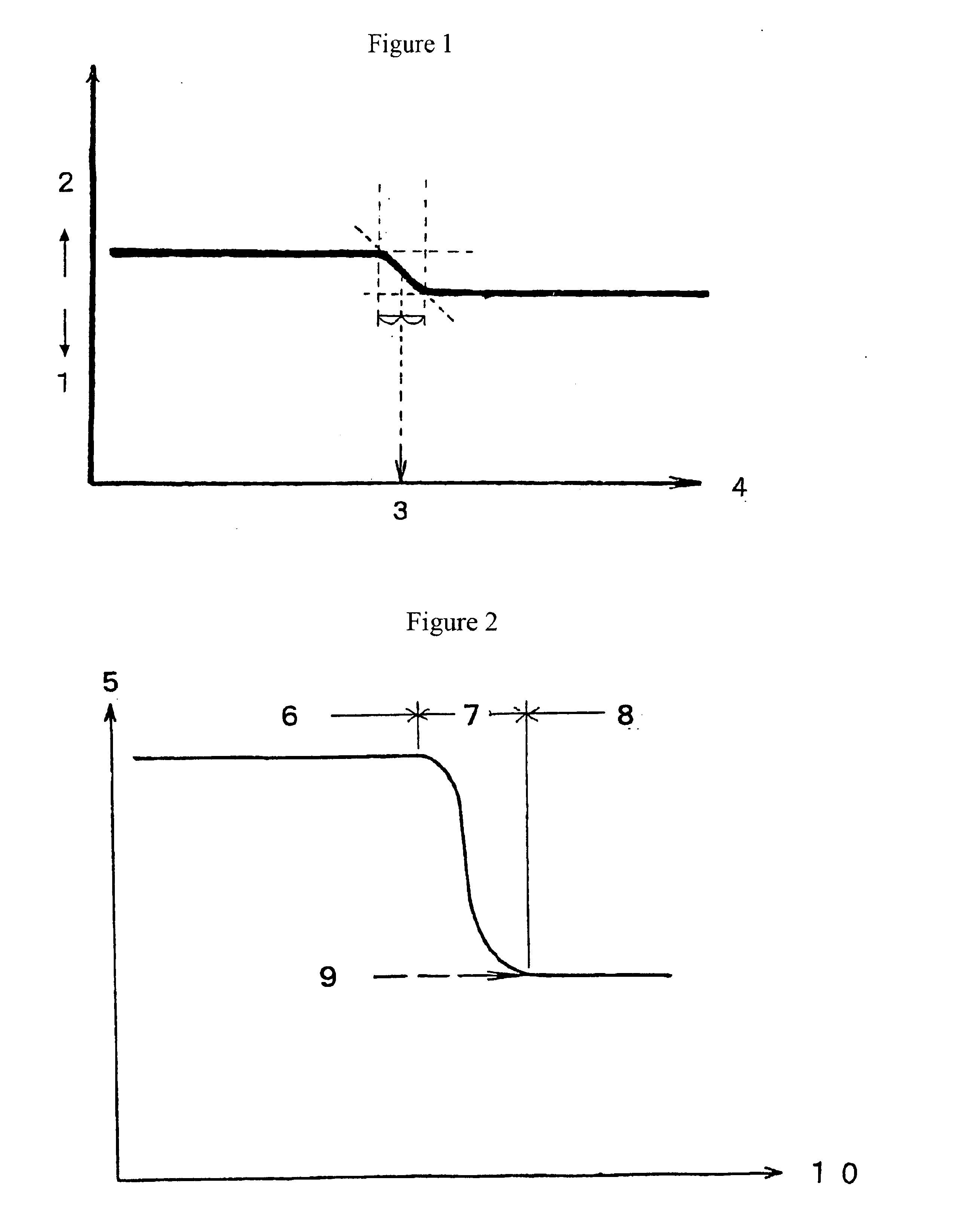

Epoxy resin composition for fiber-reinforced composite material prepreg, and fiber-reinforced composite material

The present invention relates to an epoxy resin composition for a fibre reinforced composite material, which is thermosetting resin composition where the glass transition temperature Tg of the cured material obtained by heating for 2 hours at 180° C. is at least 150° C., and the modulus of rigidity G'R in the rubbery plateau in the temperature region above the aforesaid Tg is no more than 10 MPa. In accordance with the present invention, it is possible to provide a fibre-reinforced composite material which is outstanding in its resistance to hot-wet environmental condition, impact resistance, and strength characteristics such as tensile strength and compression strength, and furthermore it is possible to provide a thermosetting resin composition and a prepreg outstanding in terms of their peel strength to a honeycomb core.

Owner:TORAY IND INC

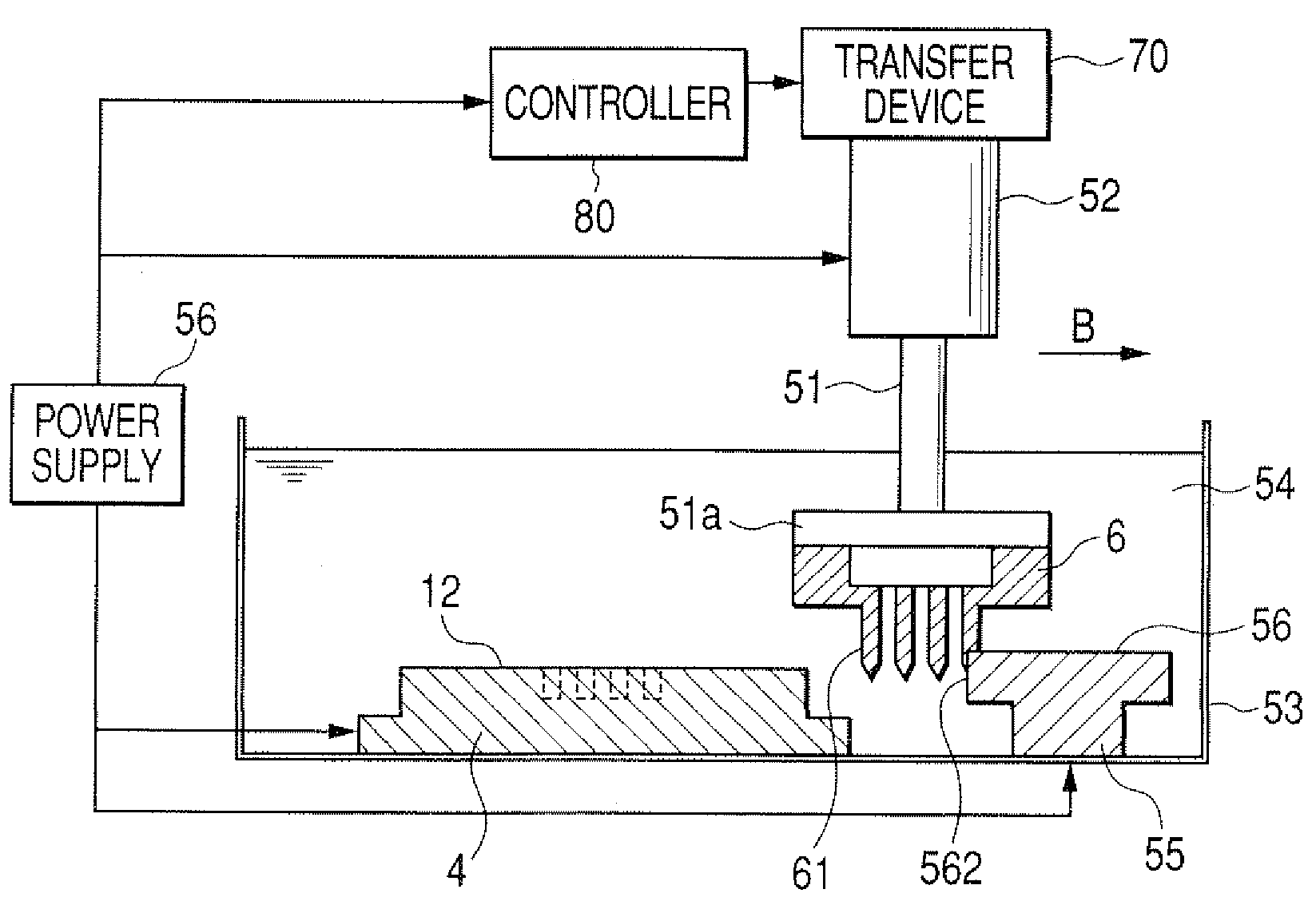

Method and apparatus for manufacturing honeycomb compact-body molding die

InactiveUS20080196237A1InhibitionFinely small sizeExtrusion diesArc welding apparatusShell moldingHoneycomb

A method and apparatus for manufacturing a honeycomb compact-body molding die having material feed bores for supplying material therethrough and slit recesses formed in a polygonal lattice pattern to mold the material in a compact body with a honeycomb shape are disclosed. The slit recesses are formed on a recess forming surface of the molding die using an electrode having electrode segments, formed in a lattice pattern corresponding to shapes of the slit recesses each of which has a wall thickness of 0.1 mm or less, to generate an electrical discharge between the molding die and the electrode to form the slit recess on the molding die. When the electrode is worn by a given amount, an apical end cut-off processing step is executed to cut off an apical end of the electrode using a dress plate to expose a new apical end formed with an electrical discharge surface.

Owner:DENSO CORP

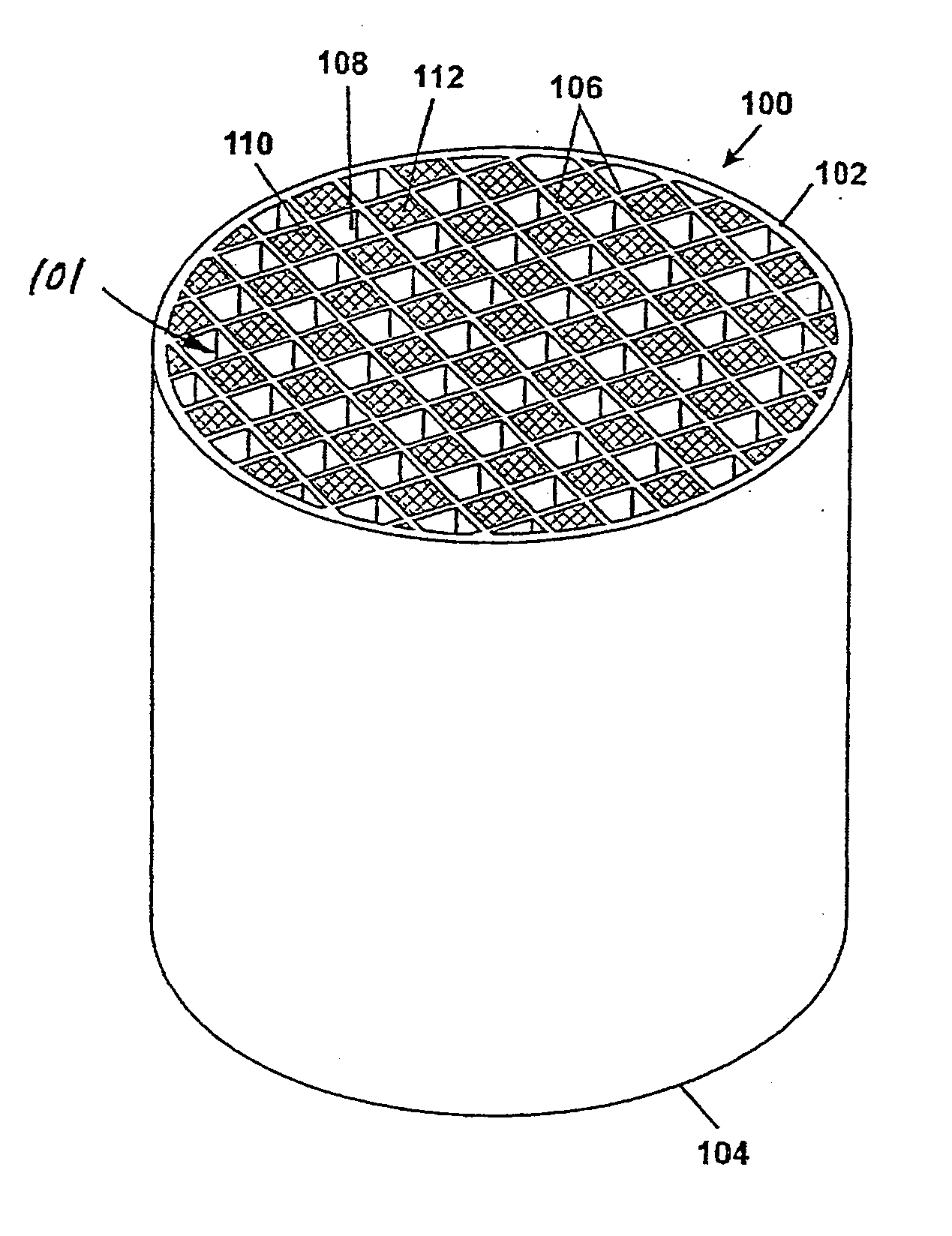

Honeycomb filter for exhaust gas decontamination

ActiveUS20050076626A1Reduce thermal stressHigh strengthCombination devicesAuxillary pretreatmentParticulatesHoneycomb

A honeycomb filter for purifying exhaust gases, which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change, is less likely to generate cracks, and is excellent in strength and durability. The honeycomb filter has a structure in which a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with a partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separates the through holes are allowed to function as a filter for collecting particulates. A thermal expansion coefficient αL of the adhesive layer and a thermal expansion coefficient αF of the porous ceramic member is as follows: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

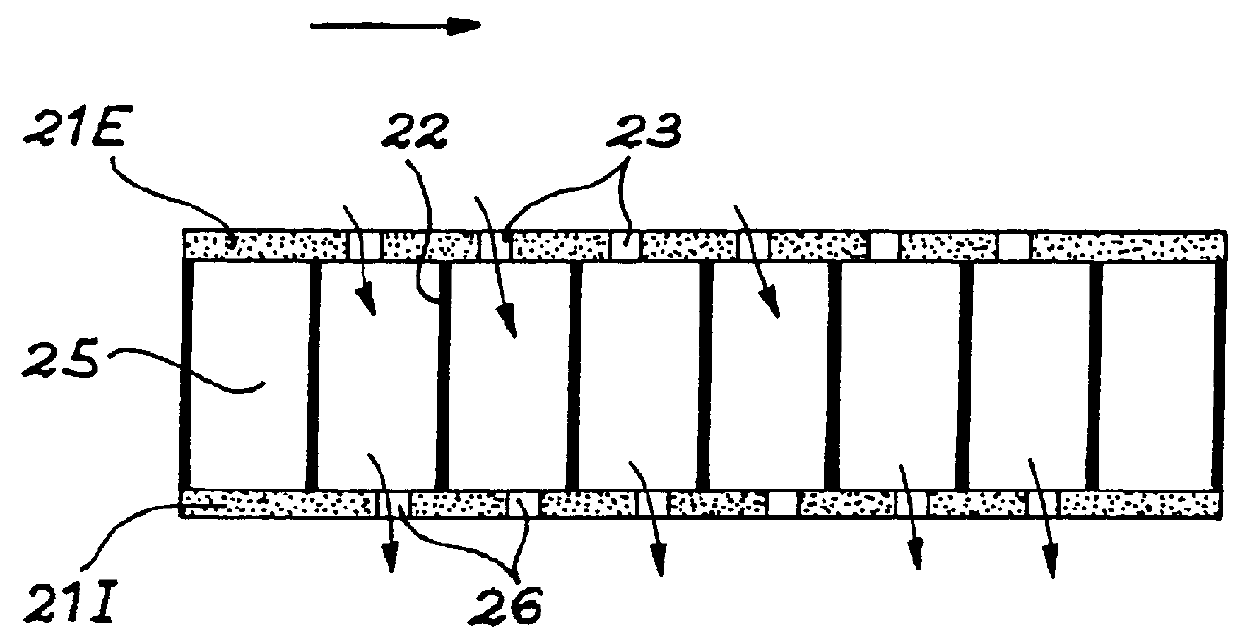

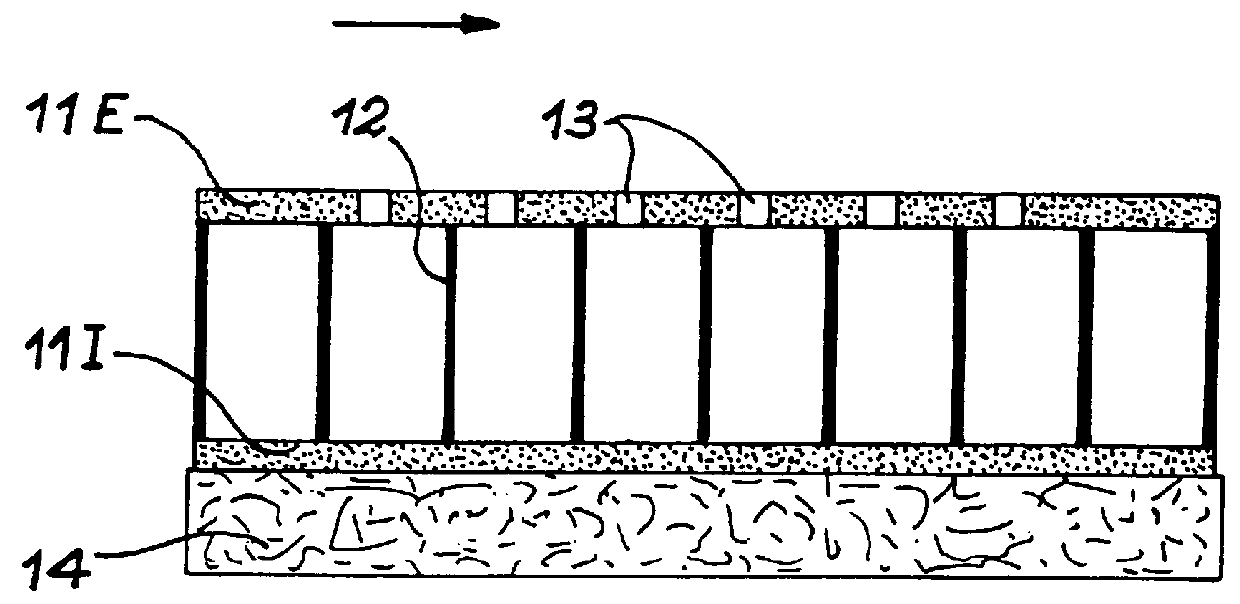

Ventilated honeycomb cell sandwich panel and ventilation process for such a panel

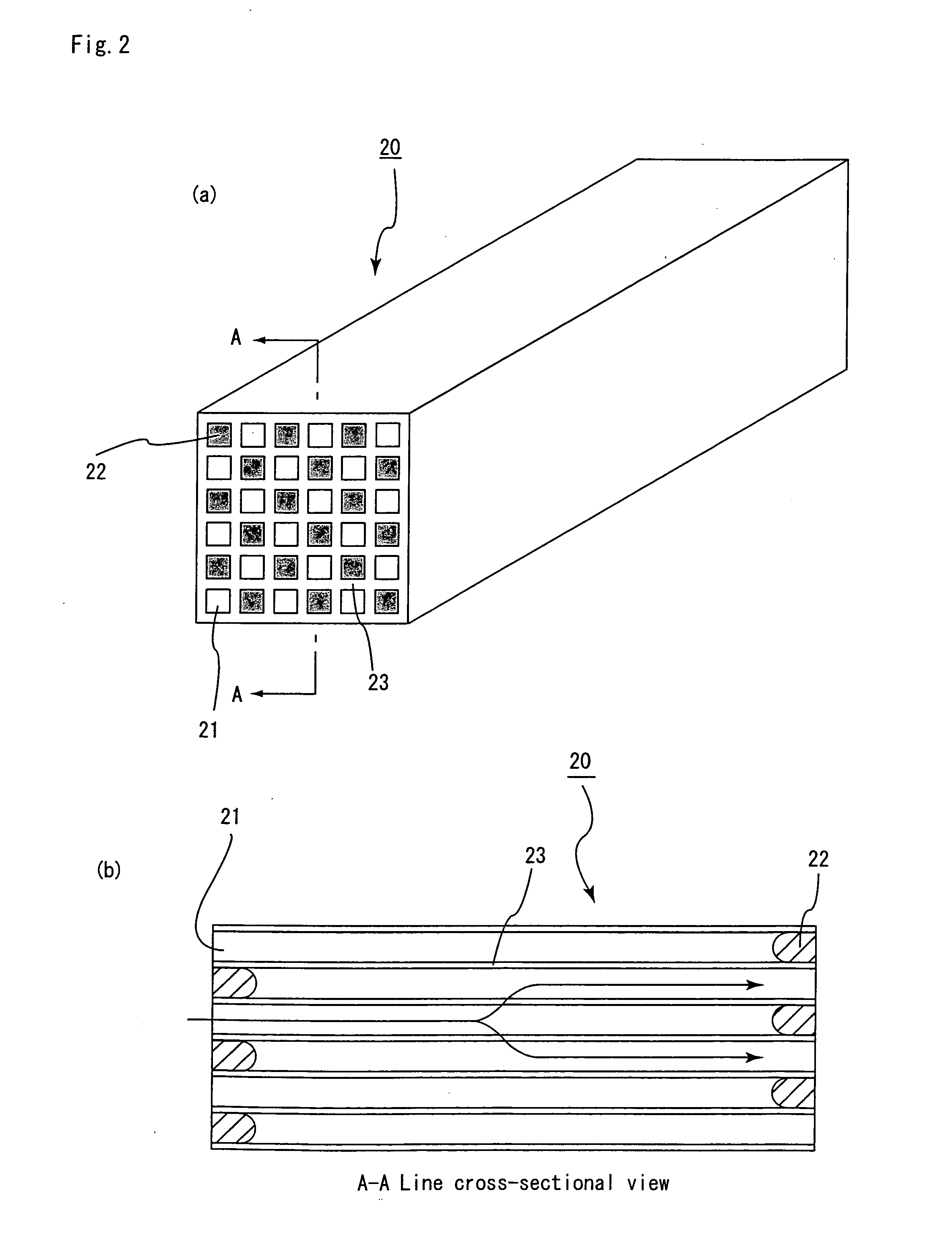

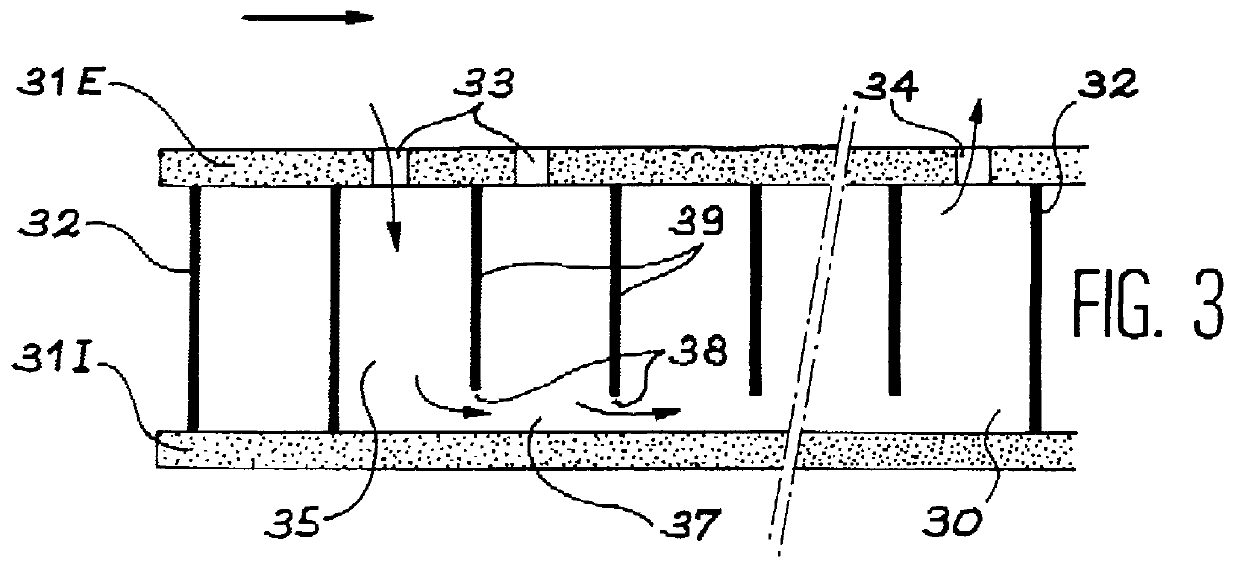

InactiveUS6122892AEasy to shapeSpeed up the flowEngine manufactureLayered productsCells panelHoneycomb

A cell panel for thermal ventilation including a first wall having raised portions which define openings; a second wall; partition walls connected to the first and second walls and that define cells. The openings in the first wall are located upstream of an air flow flowing outside the first wall. The first wall may further include raised portions which define other openings located downstream of the air flow. The second wall may also include raised portions which define openings located downstream of the air flow. The partition walls may define communication holes between adjacent cells.

Owner:SOC HISPANO SUIZA AEROSTRUCTURES

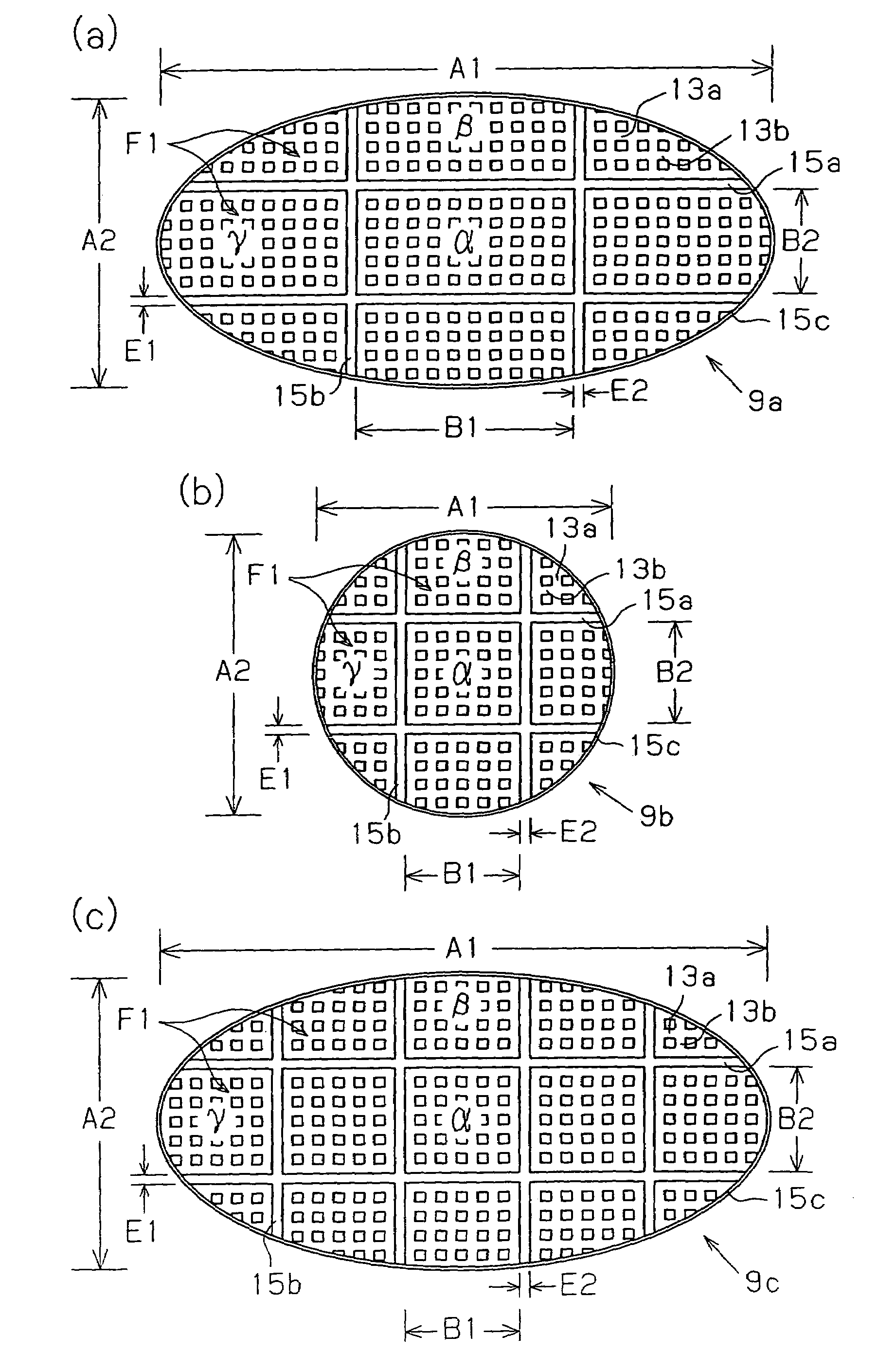

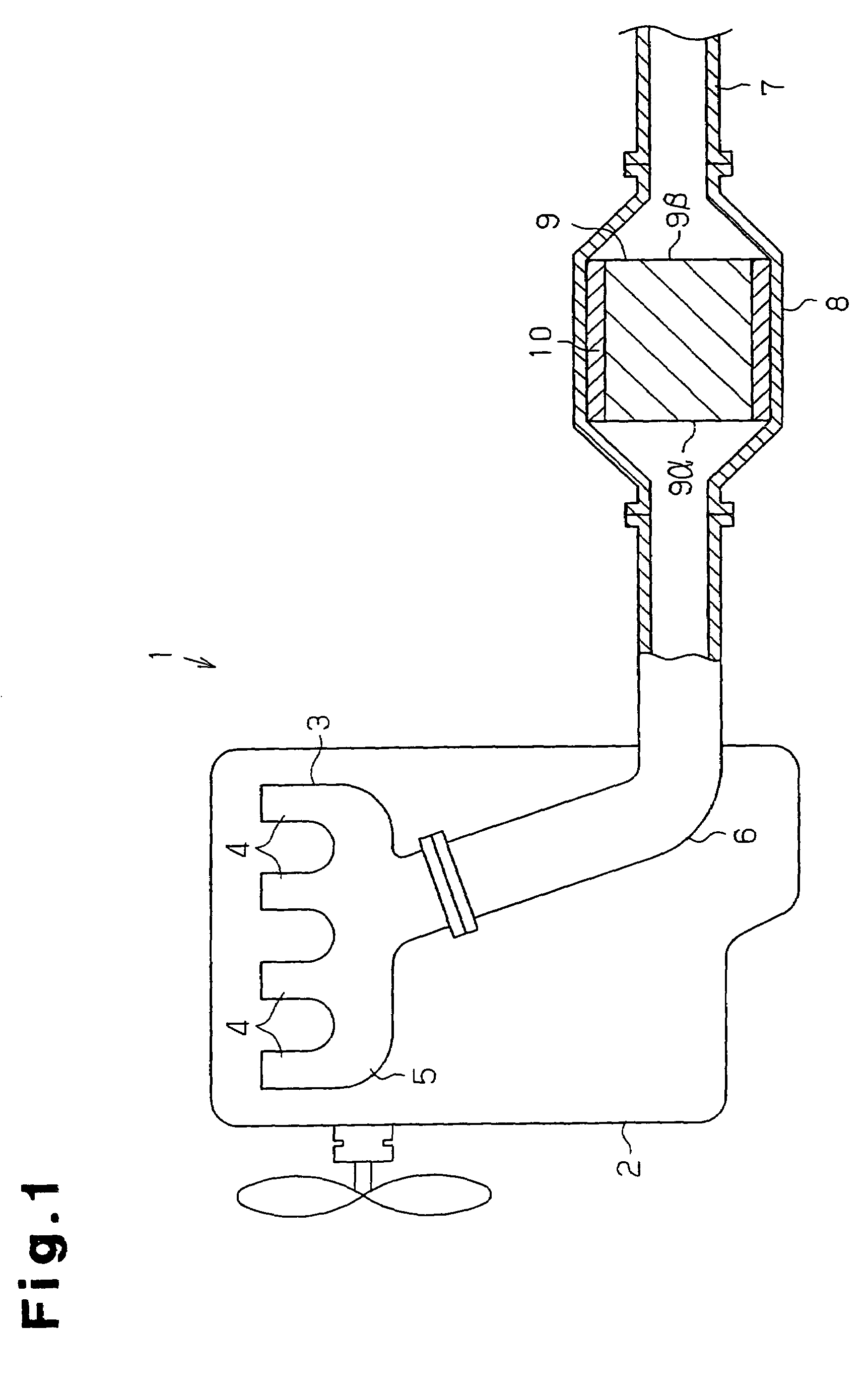

Ceramic filter for exhaust gas emission control

ActiveUS7393376B2High strengthSuitable for manufactureCombination devicesAuxillary pretreatmentMetallurgyExhaust gas emissions

A ceramic filter assembly that resists cracking. The ceramic filter assembly is formed by integrating a plurality of columnar honeycomb filters made of a porous ceramic sintered material with a ceramic sealing material layer and formed to have a substantially elliptical cross sectional shape. The honeycomb filters includes square columnar honeycomb filters in which the ratio between the lengths of their long sides and short sides is between 1.1 and 3.0. The honeycomb filters are arranged so that the long sides and the short sides are respectively parallel to the major axis and the minor axis of the assembly.

Owner:IBIDEN CO LTD

Micro heat exchanger with thermally conductive porous network

ActiveUS20060245987A1Inexpensive and efficient to manufactureGaseous chemical processesAdditive manufacturing apparatusThermal energyReticulated foam

A micro heat exchanger system includes a first flow path and a second flow path transverse thereto for transferring thermal energy between a first fluid flowing through the first flow path and a second fluid flowing through the second flow path. The first flow path and the second flow path are filled with a thermally conductive porous network which incorporate unique structures, such as tubes, honeycomb, corrugated metal, reticulated foams, woven meshes or nonwoven mats or felts, engineered lattice structures, or a combination of these structures. In another embodiment, the thermally conductive porous network is coated with catalyst to provide an integrated heat exchanger and catalytic reactors.

Owner:RTX CORP

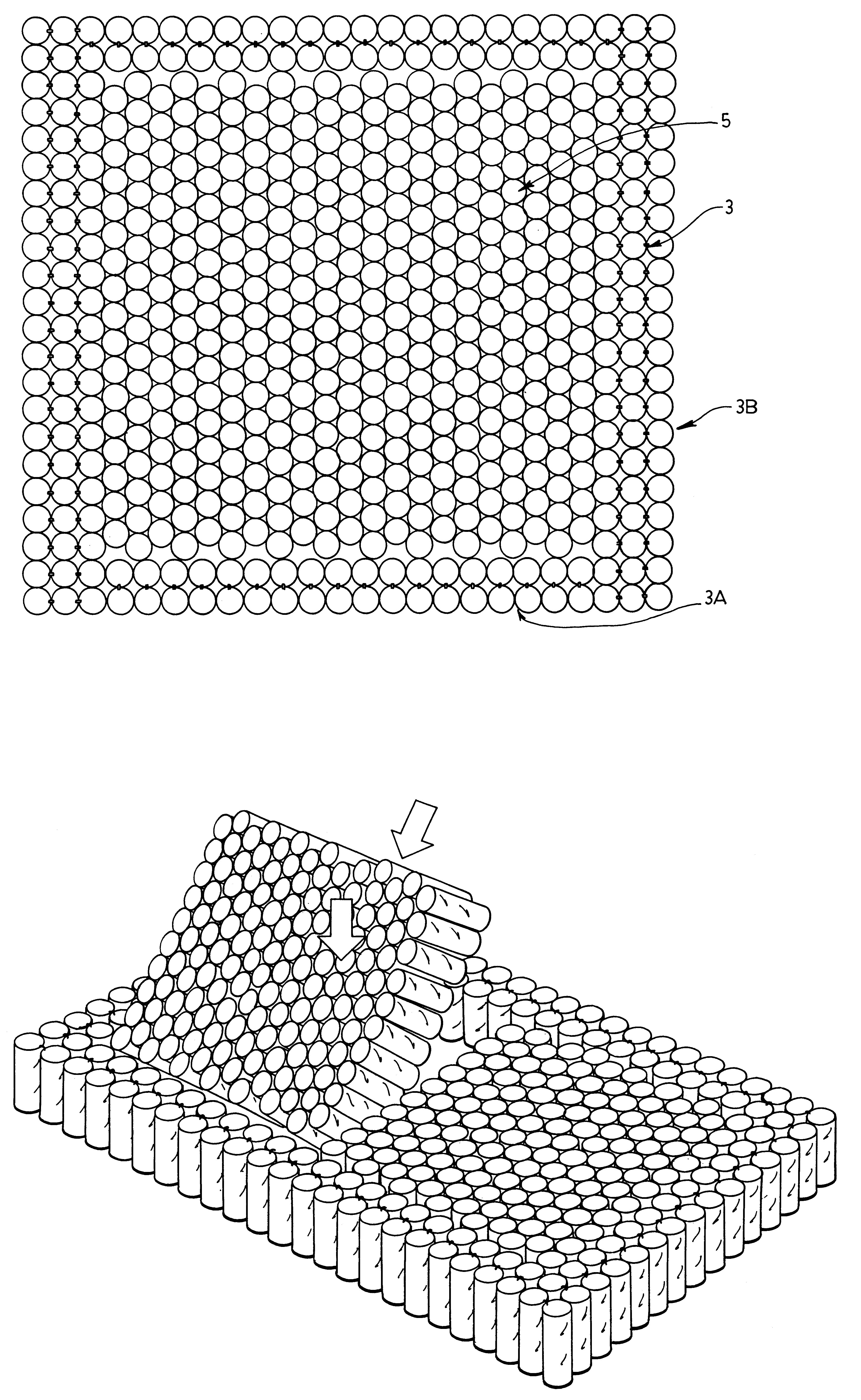

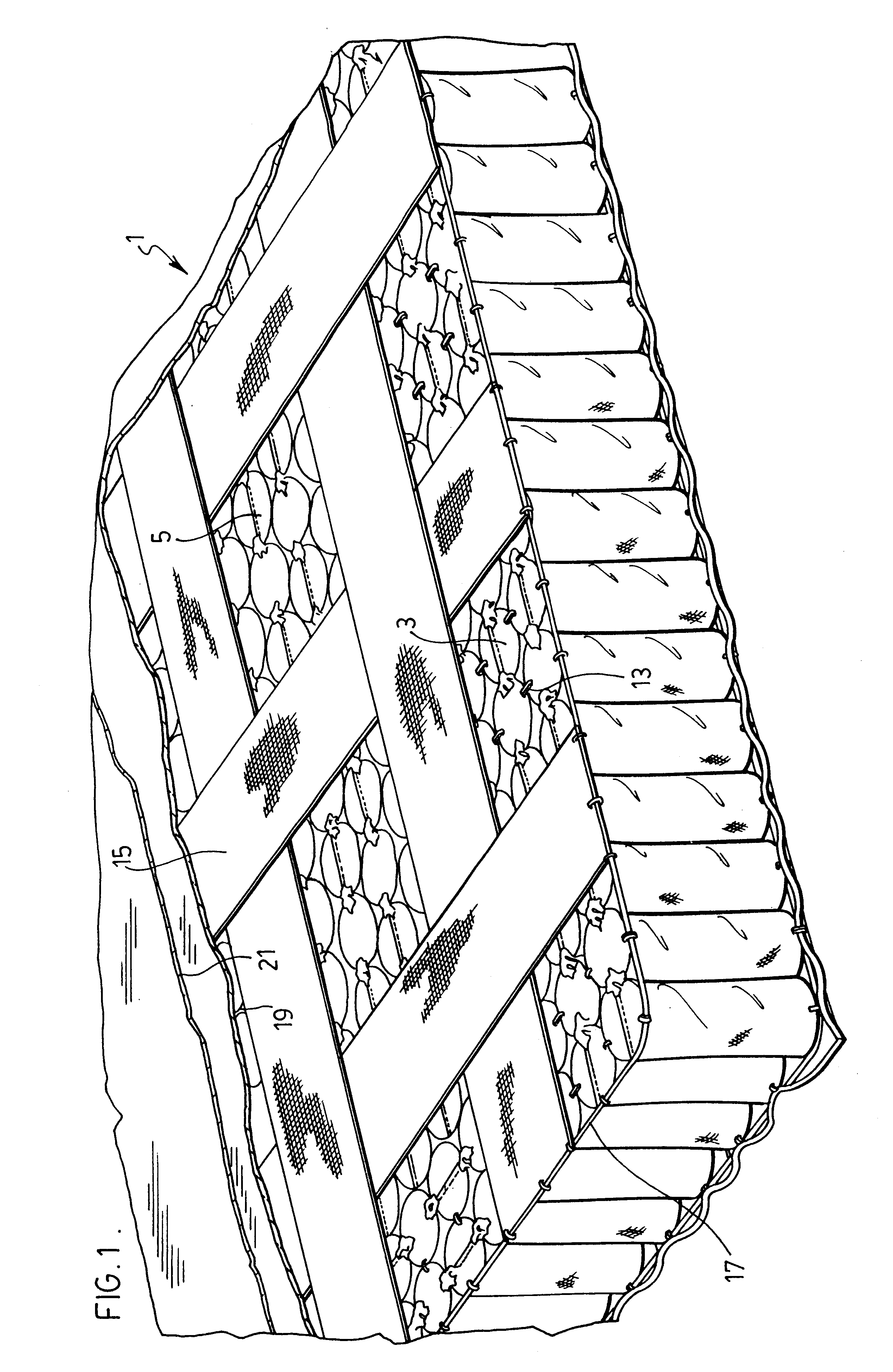

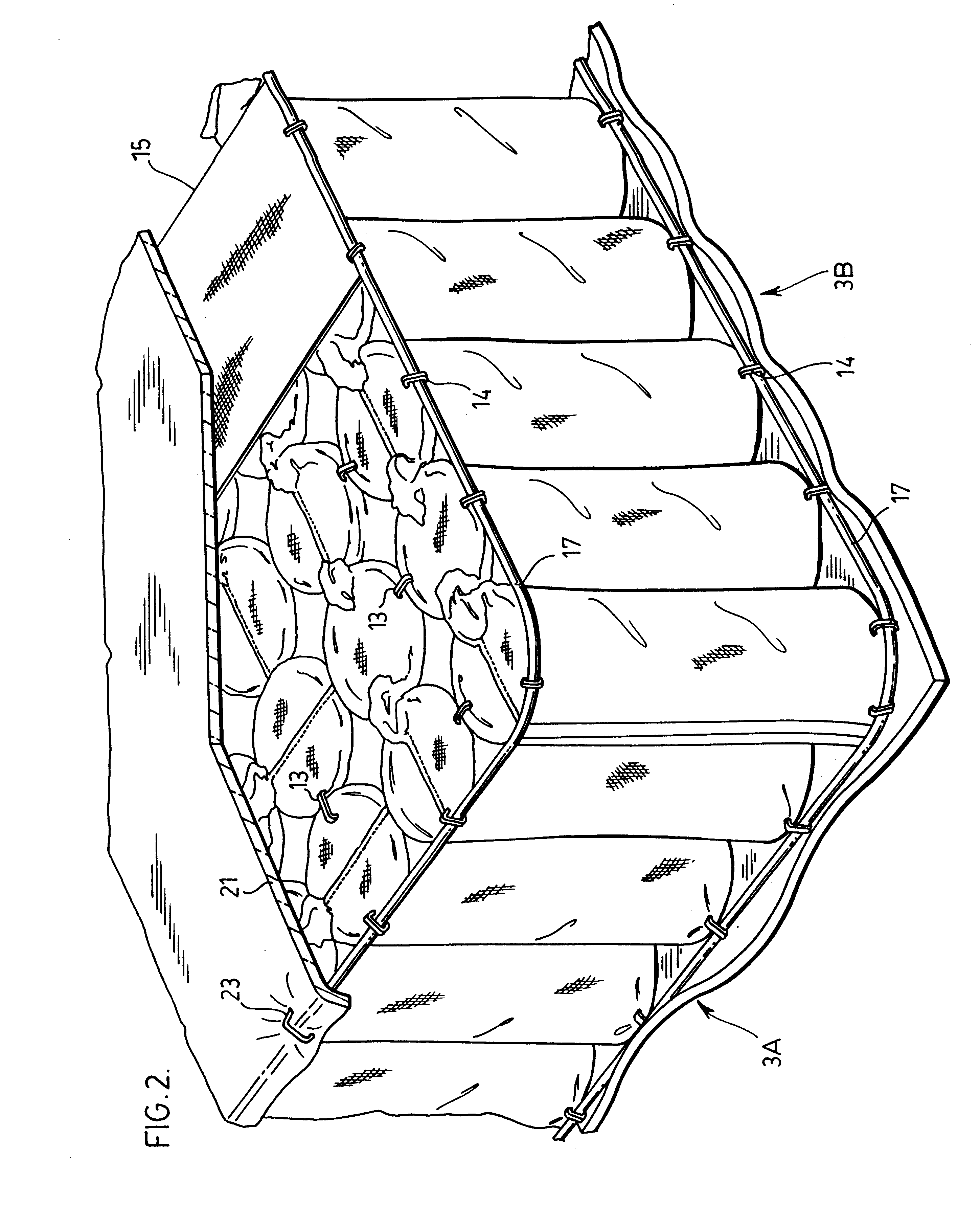

Mattress construction

InactiveUS6295676B1Characteristic is differentReinforces the perimeter trimStuffed mattressesSpring mattressesHoneycombSoft materials

A mattress has a main sleep area surrounded by a perimeter trim. Both the main sleep area and the perimeter trim are formed from wire springs contained within pockets of soft material. The wire springs in the sleep area are arranged in honeycomb nested rows. The wire springs of the perimeter trim, which are of different wire construction with different flex characteristic from the wire springs in the main sleep area, are arranged in side by side rows which are not honeycomb nested. In addition, the wire springs of the perimeter trim are pivotally linked directly to one another across the perimeter trim, both widthwise and lengthwise of the mattress which produces an essentially non-feelable flex transition between the perimeter trim and the main sleep area of the mattress.

Owner:WARNER BRADLEY

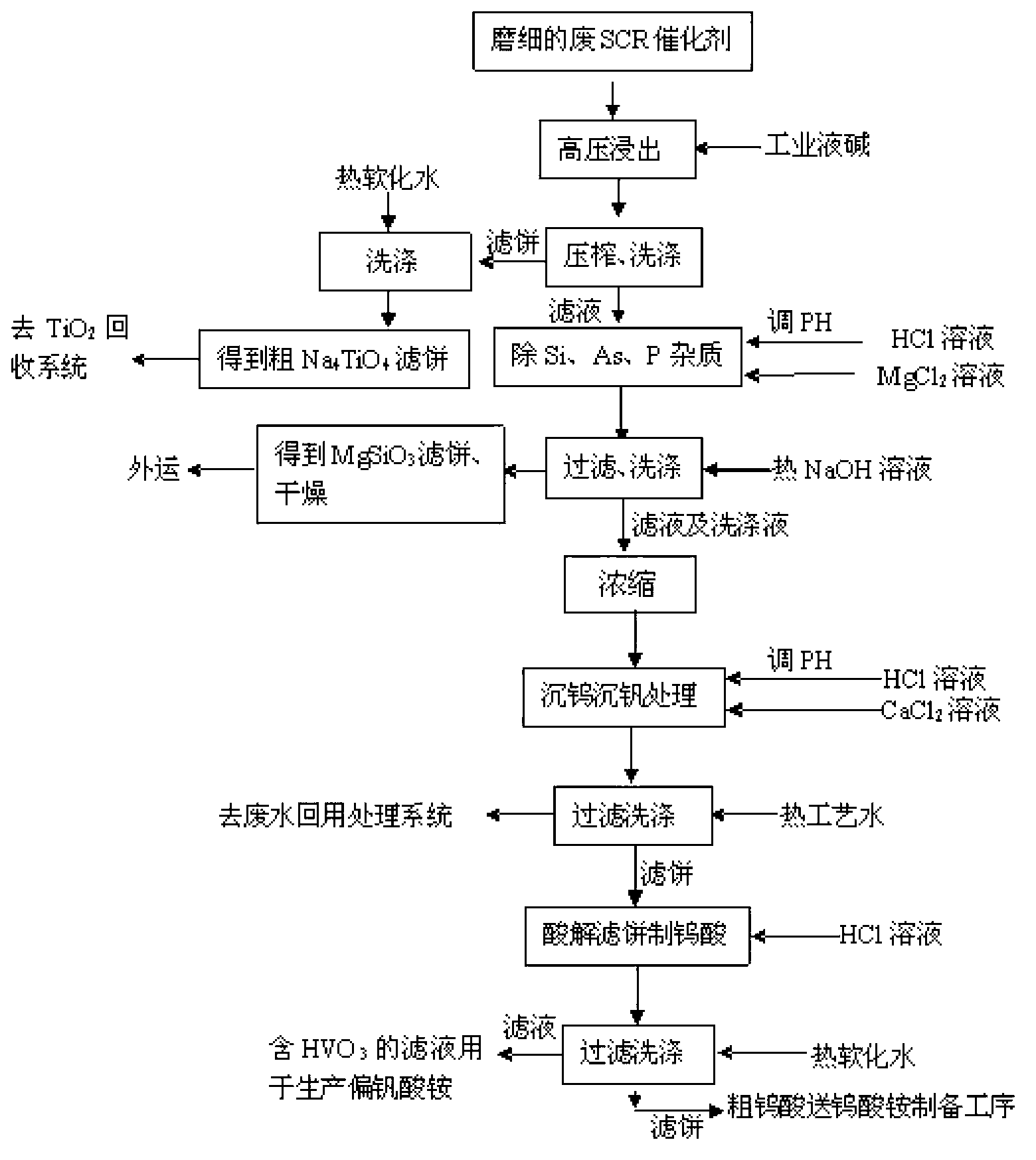

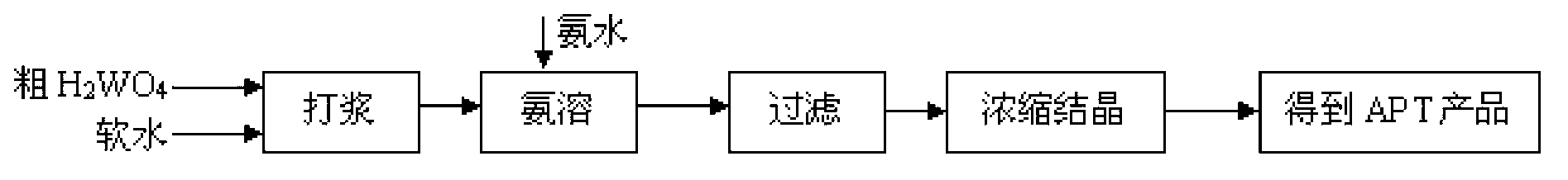

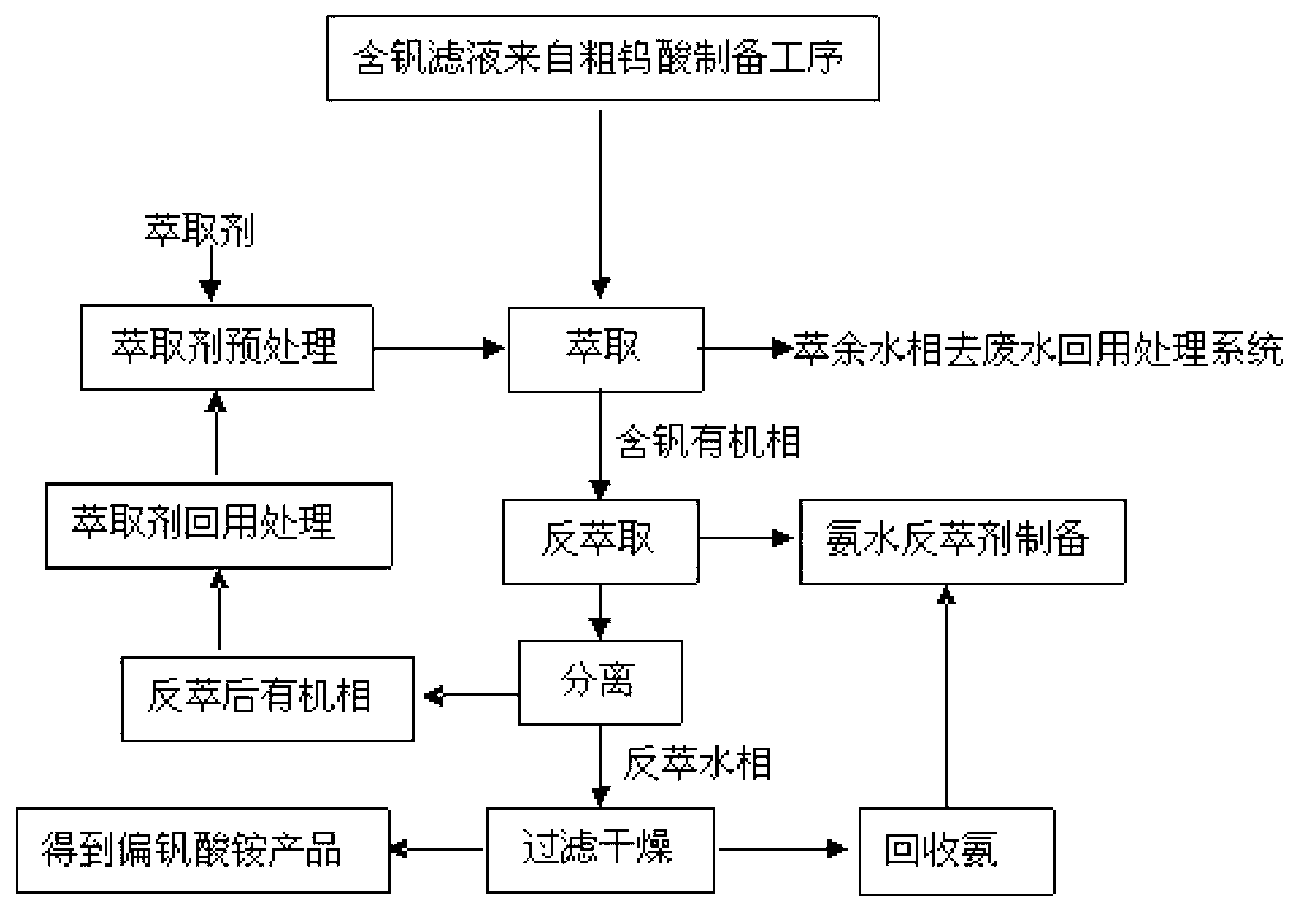

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

Honeycomb filter for exhaust gas decontamination and exhaust gas decontamination apparatus

ActiveUS20050160710A1Less susceptible to high initial pressure lossGuaranteed continuous useCombination devicesPhysical/chemical process catalystsParticulatesHoneycomb

A honeycomb filter for purifying exhaust gases that can almost completely burn and remove particulates accumulated on a wall portion by a regenerating process allowing residual ashes on the wall portion to easily move inside a through hole because the ashes are easily separated from the wall portion. In the honeycomb filter a columnar body made of porous ceramics, having parallel through holes in the length direction with a wall portion interposed therebetween, is designed so that part or all of the wall portion that separates the through holes from each other functions as a filter collecting particulates, wherein a length l of the longest side in a cross section perpendicular to the length direction of the through hole and a length L in the length direction of the columnar body satisfy: 60≦L / l≦500, and a surface roughness Ra (according to JIS B 0601) of the through hole inner wall satisfies: Ra≦100 μm.

Owner:IBIDEN CO LTD

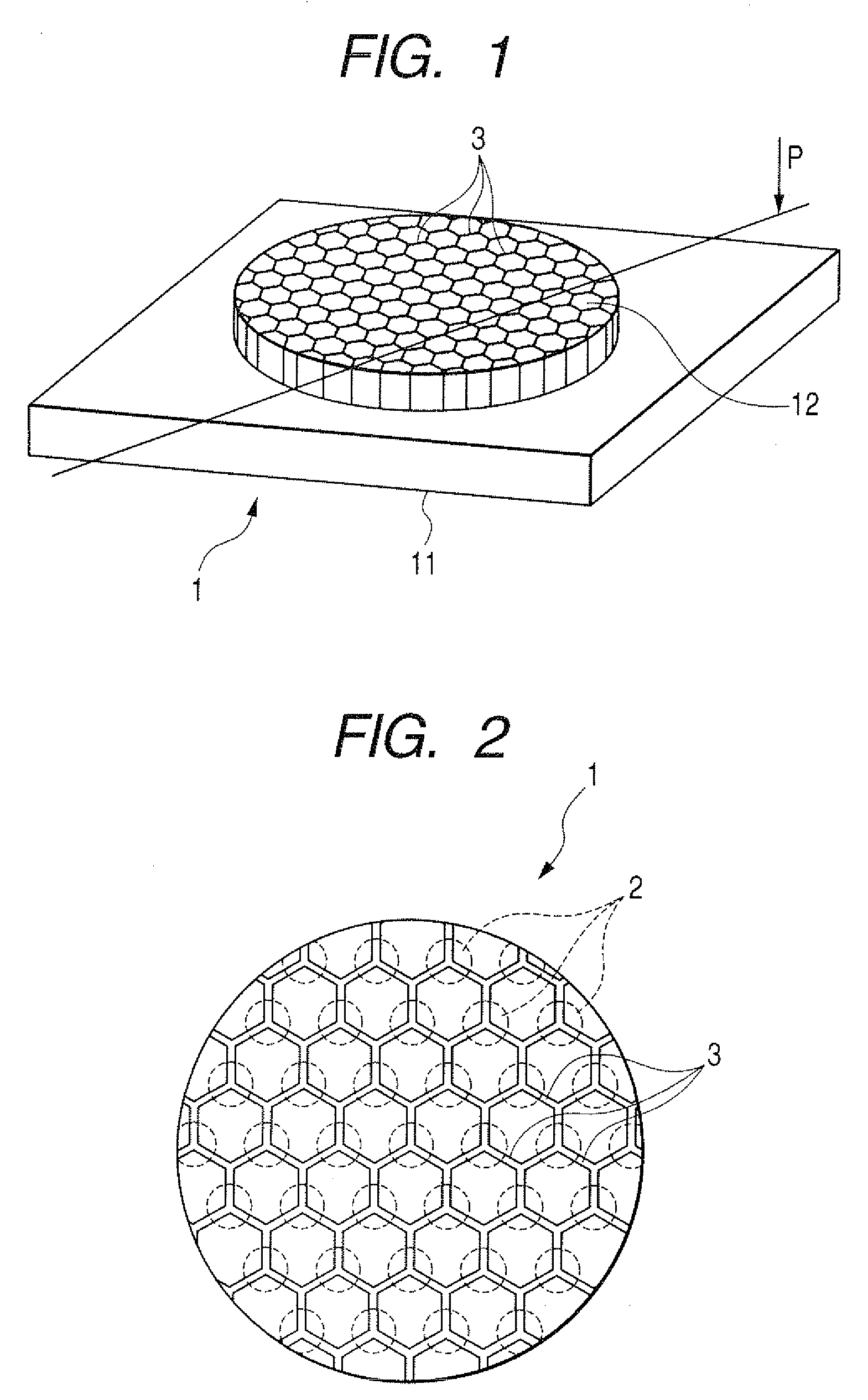

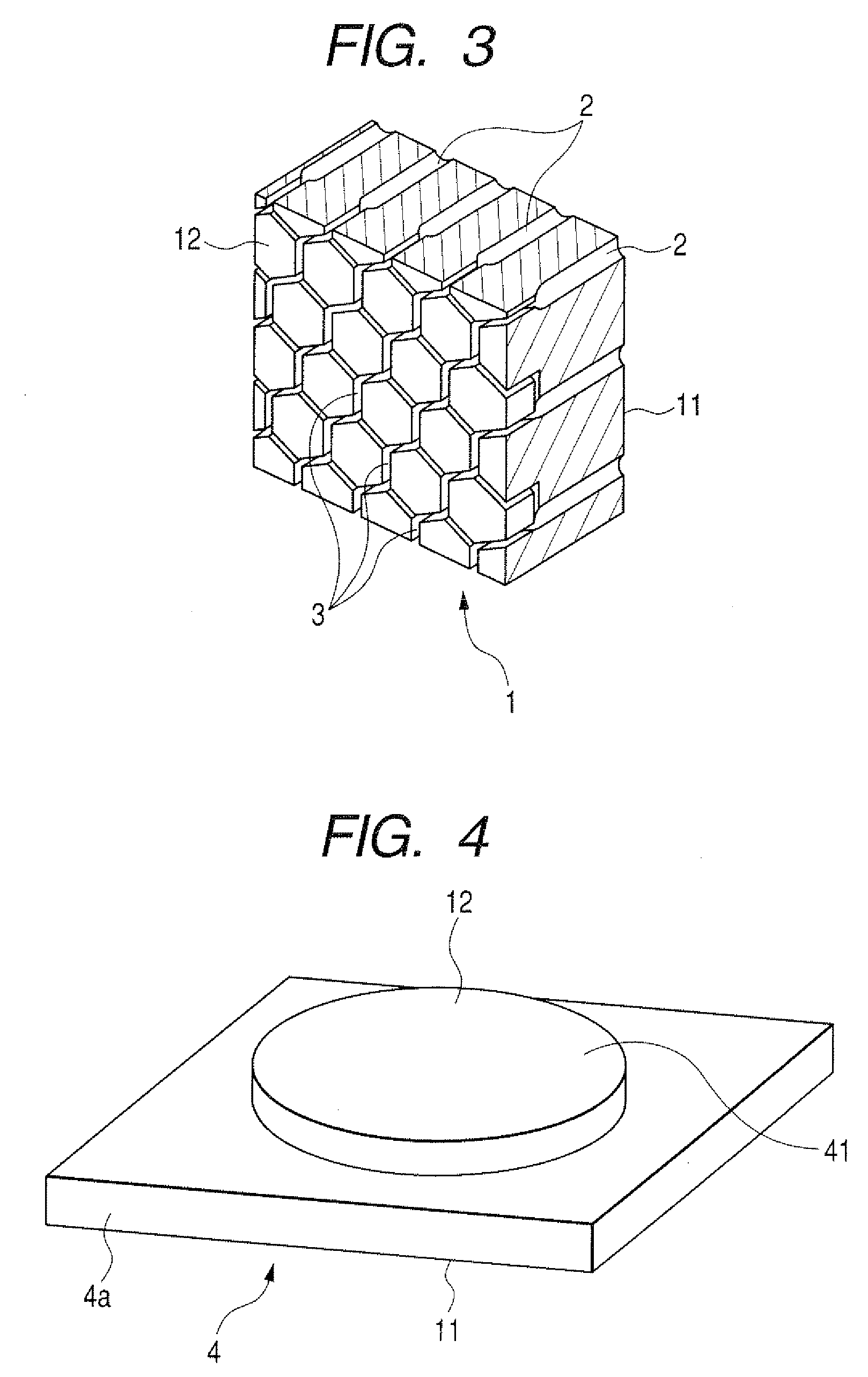

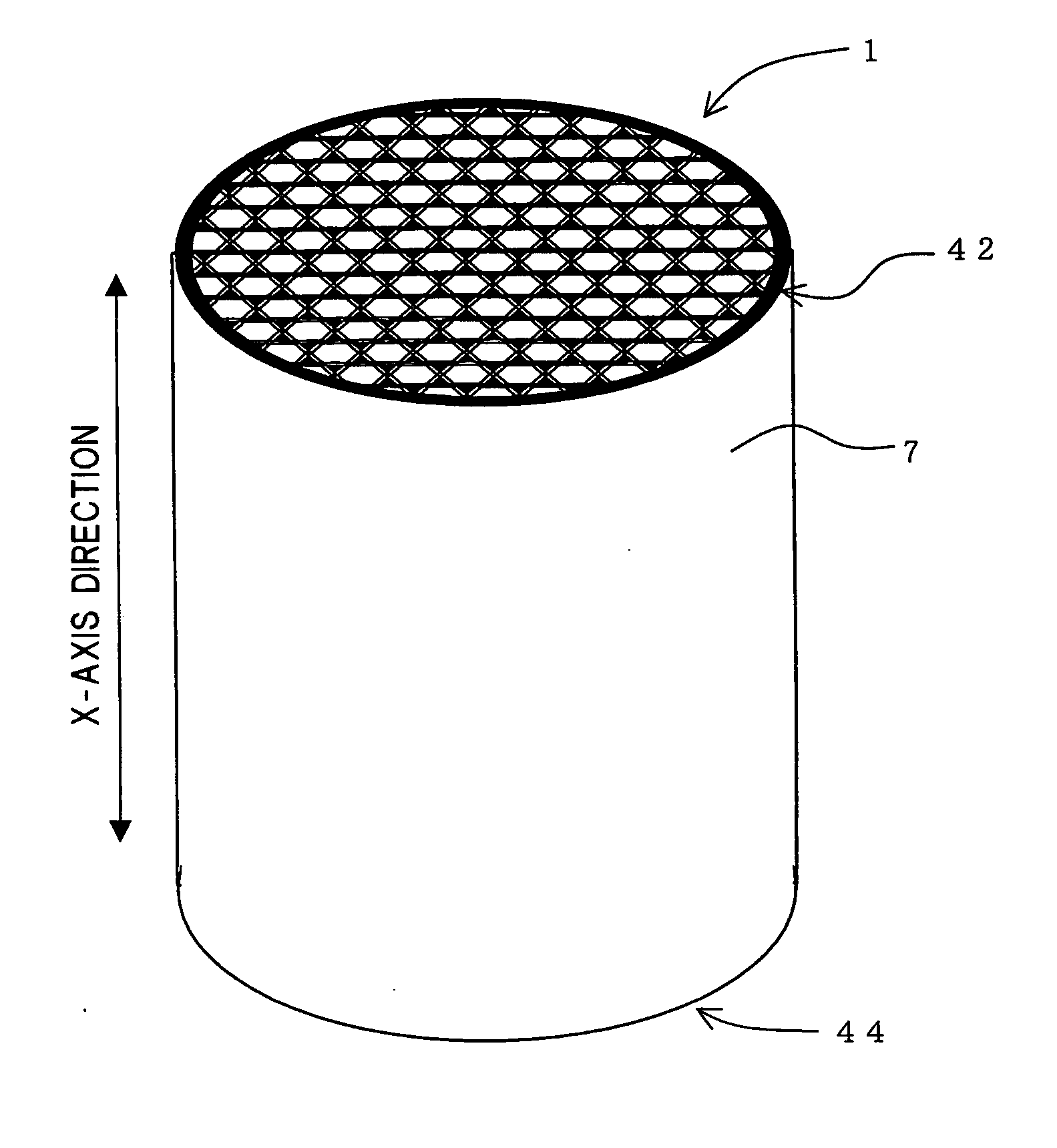

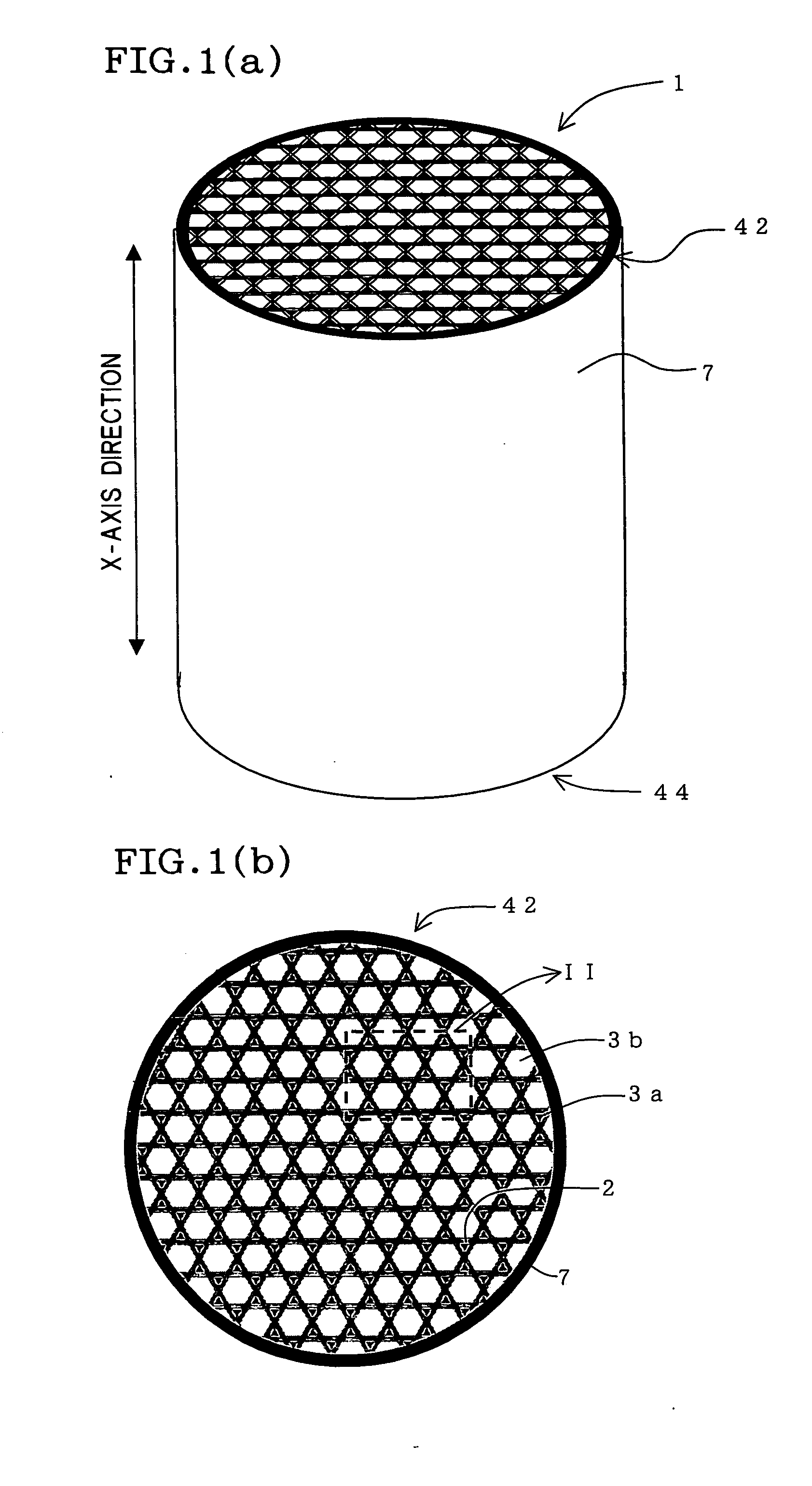

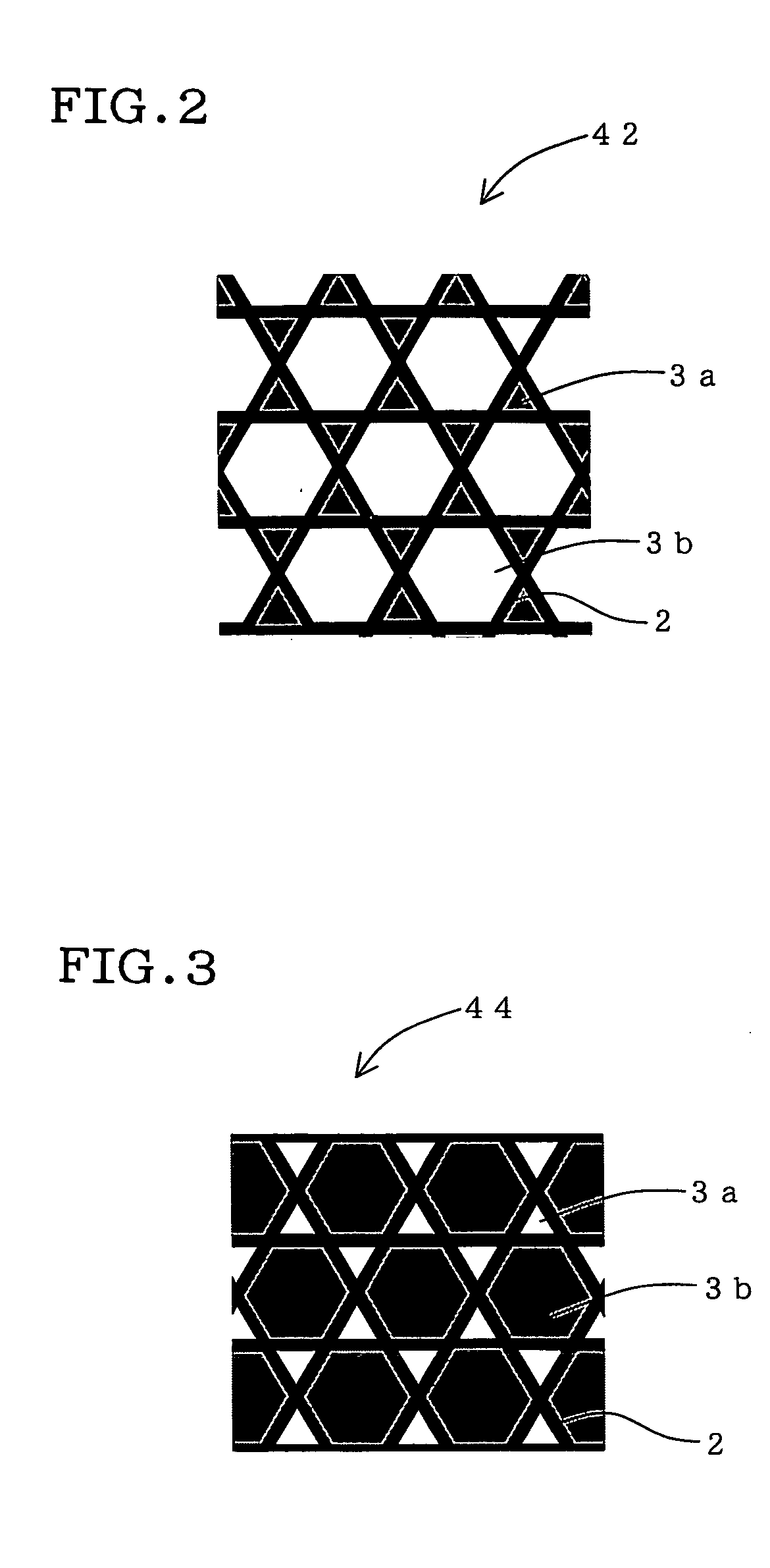

Honeycomb filter

InactiveUS20050076627A1Loss of pressure increasePhysical/chemical process catalystsDispersed particle filtrationHoneycombBiomedical engineering

There is disclosed a honeycomb filter 1 having: an inflow end face 42 and an outflow end face 44 of a fluid to be treated; porous partition walls 2 extending to the outflow end face 44 from the inflow end face 42; and a large number of through channels 3a and 3b partitioned by the partition walls 2 and extending through the outflow end face 44 from the inflow end face 42, predetermined through channels 3a are sealed in the inflow end face, and the remaining predetermined through channels 3b are sealed in the outflow end face 44. In a case where a total of sectional areas of the through channels 3a sealed in the inflow end face 42 is A (mm2), and a total of sectional areas of the through channels sealed 3b in the outflow end face is B (mm2), a relation is A<B in the honeycomb filter 1. The honeycomb filter has only slight increase of a pressure loss with an elapse of time by the use.

Owner:NGK INSULATORS LTD

Honeycomb filter for exhaust gas decontamination

ActiveUS7309370B2High strengthIncreased durabilityCombination devicesAuxillary pretreatmentParticulatesHoneycomb

A honeycomb filter for purifying exhaust gases, which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change, is less likely to generate cracks, and is excellent in strength and durability. The honeycomb filter has a structure in which a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with a partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separates the through holes are allowed to function as a filter for collecting particulates. A thermal expansion coefficient αL of the adhesive layer and a thermal expansion coefficient αF of the porous ceramic member is as follows:0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

Protective Helmet

InactiveUS20080066217A1Improve protectionReduce the risk of injuryHatsSport apparatusHoneycombTangential force

A protective helmet is described comprising: an outer layer (1); an inner layer (5) for contact with a head of a wearer; and an intermediate layer (3, 4) comprising an anisotropic cellular material comprising cells having cell walls, the anisotropic cellular material having a relatively low resistance against deformation resulting from tangential forces on the helmet. The anisotropic material can be a foam or honeycomb material. The foam is preferably a closed cell foam. The helmet allows tangential impacts to the helmet which cause less rotational acceleration or deceleration of the head of the wearer compared to helmets using isotropic foams while still absorbing a significant amount of rotational energy.

Owner:K U LEUVEN RES & DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com