Patents

Literature

2571 results about "Honeycomb like" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

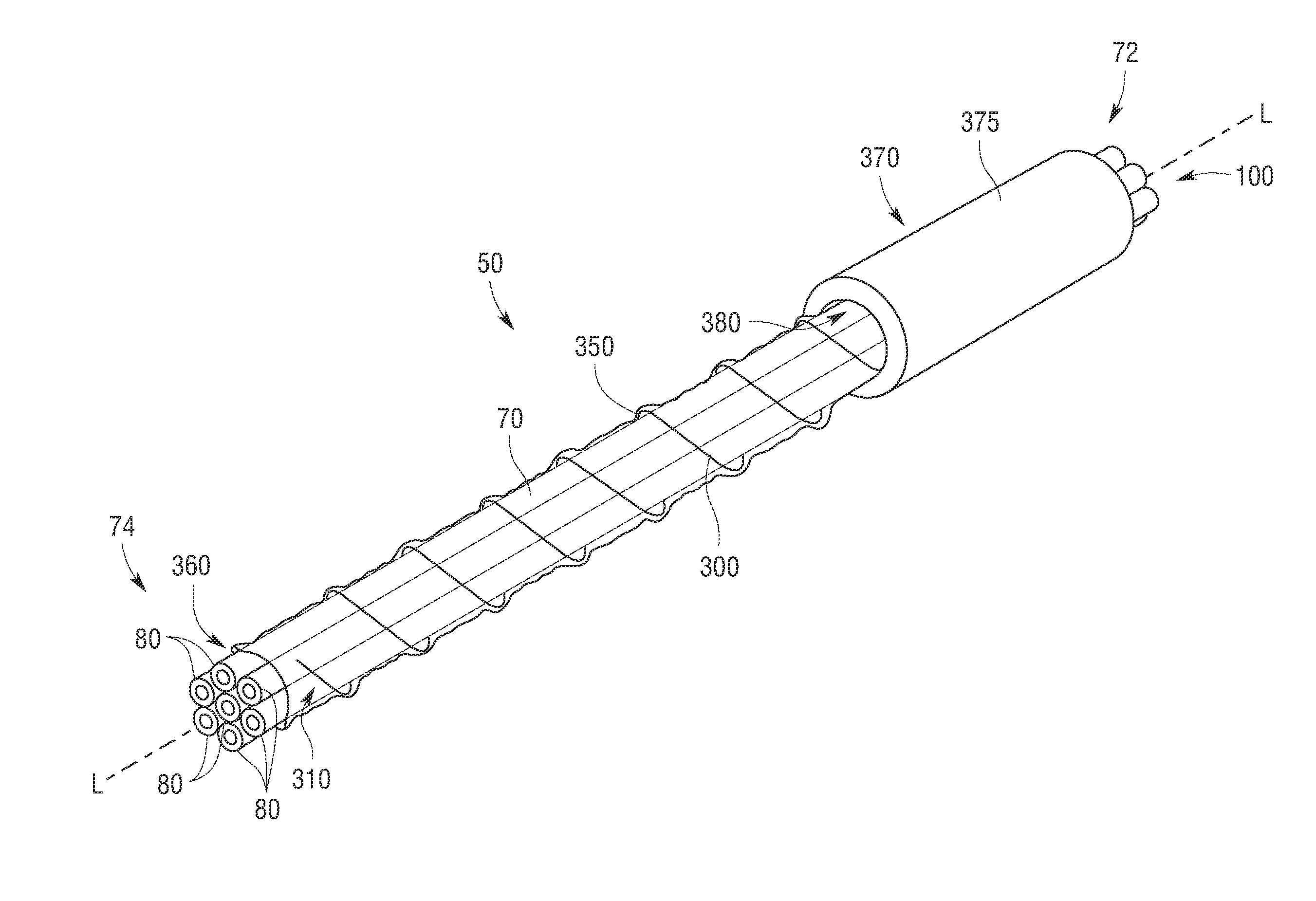

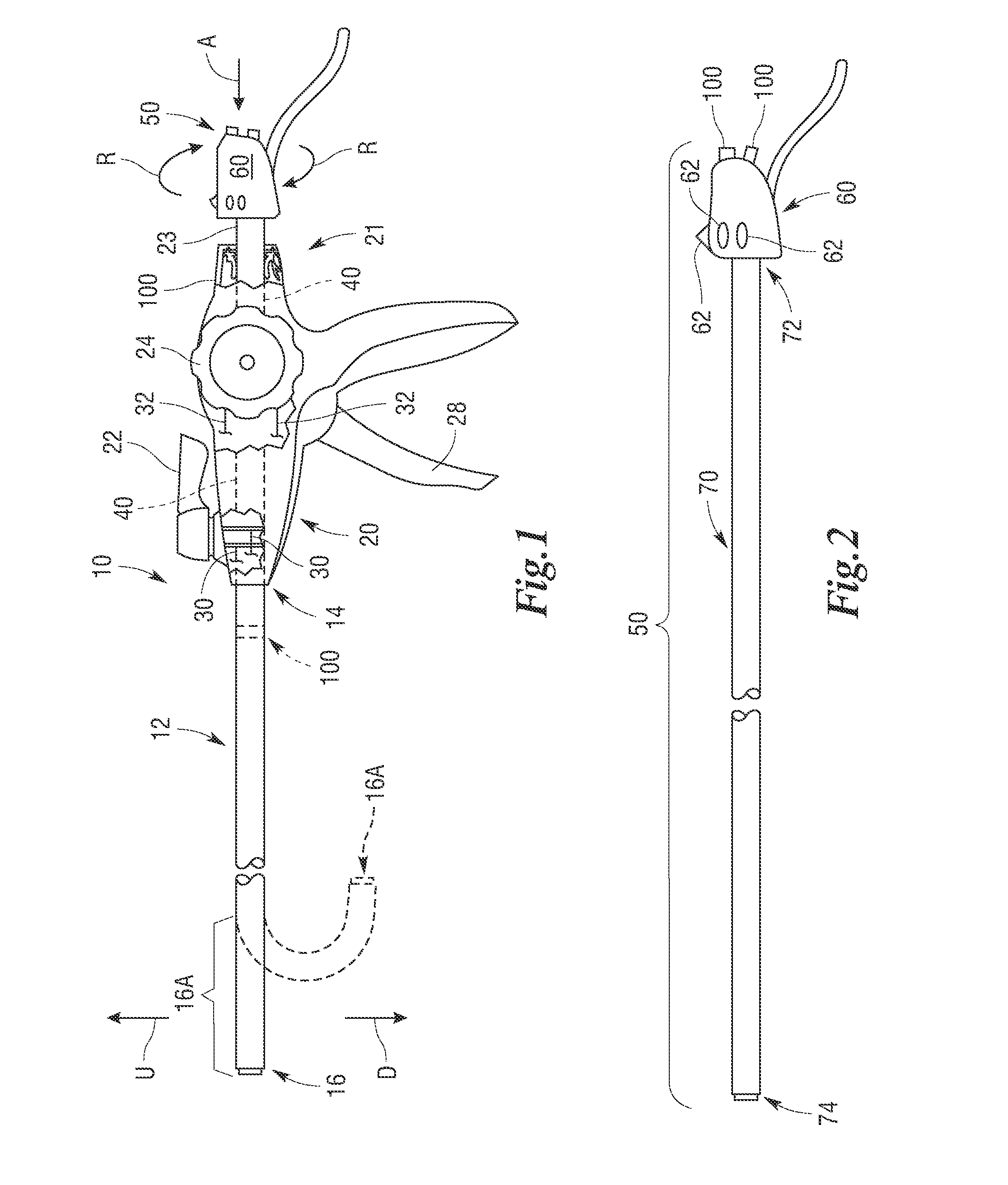

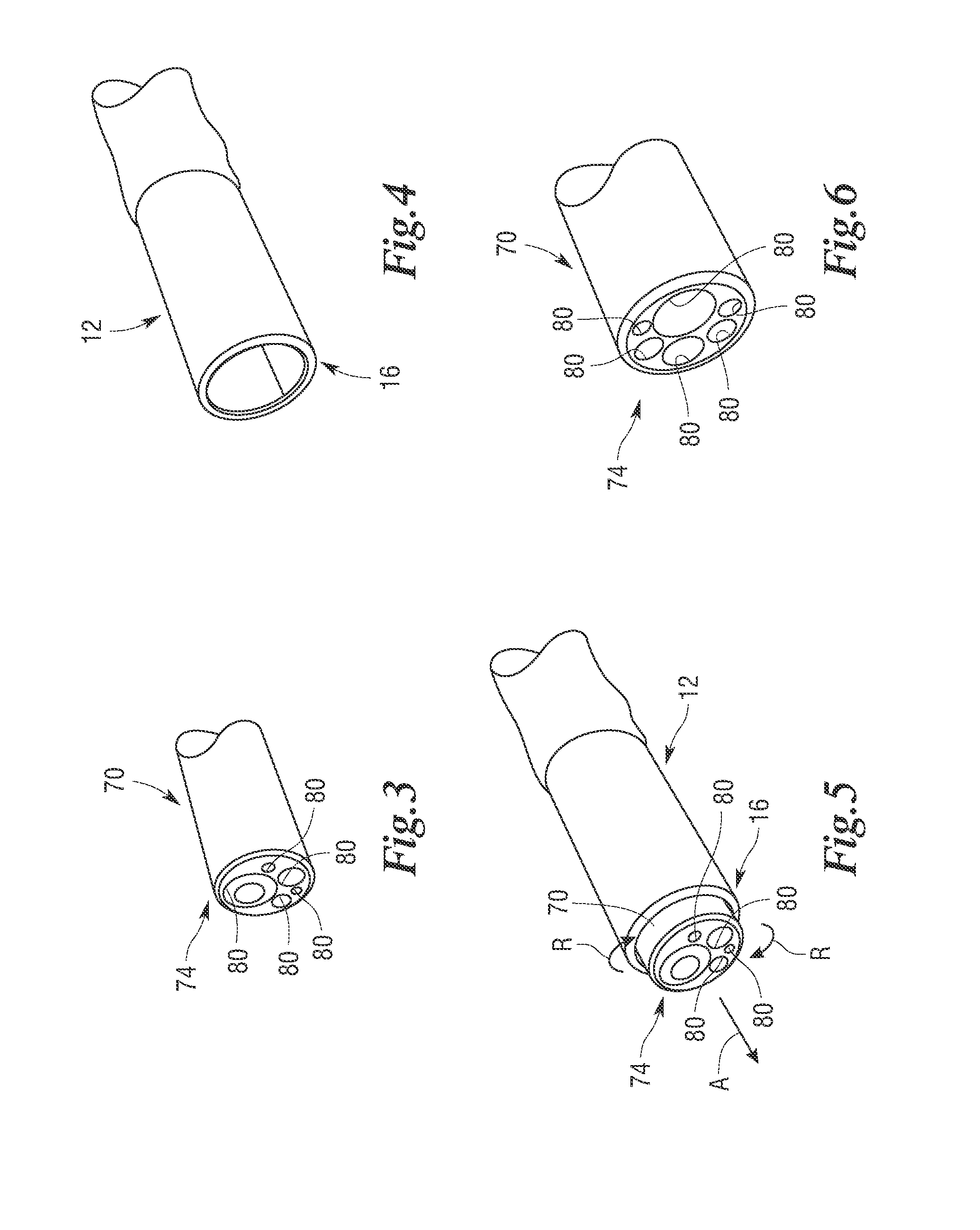

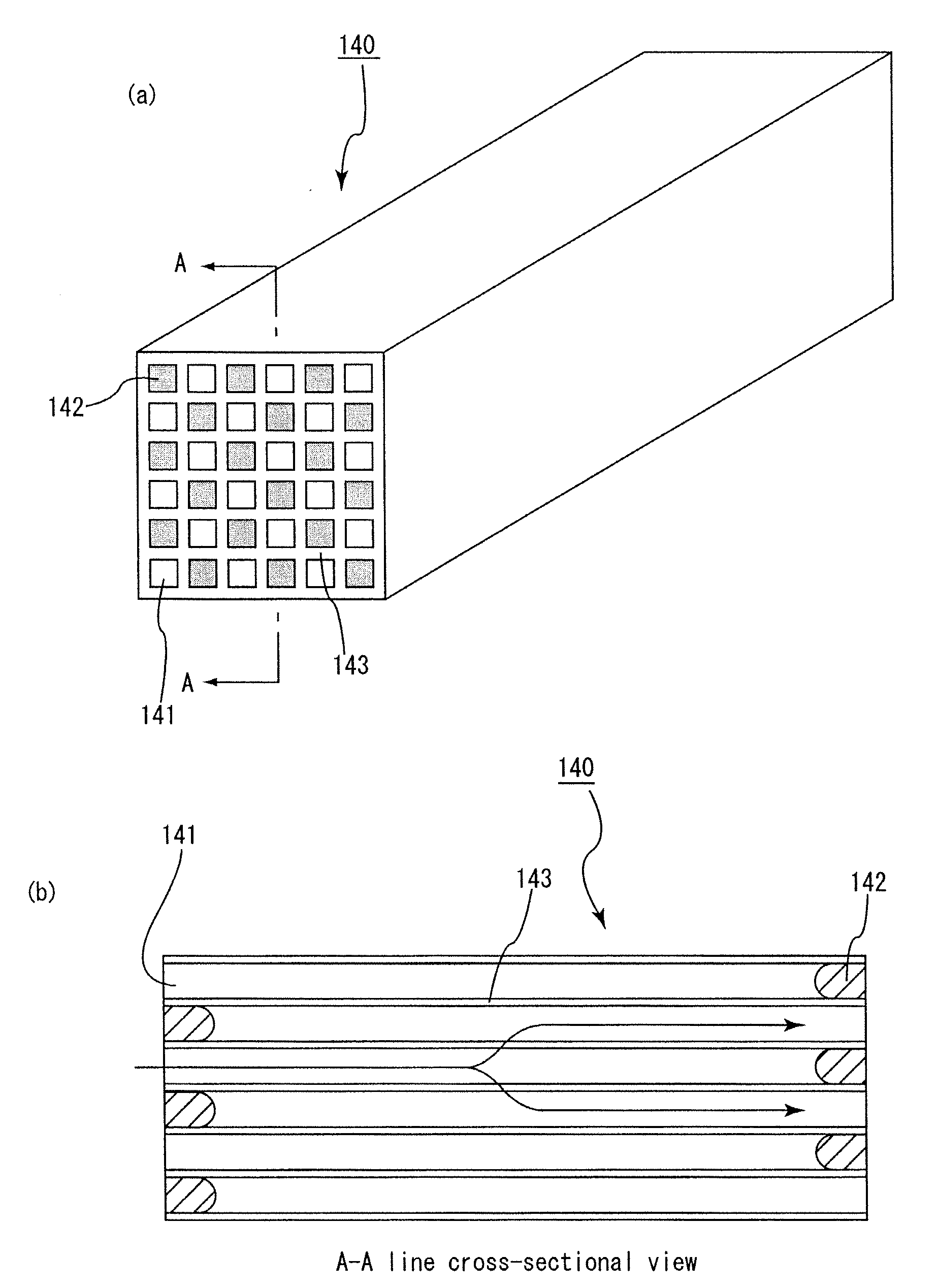

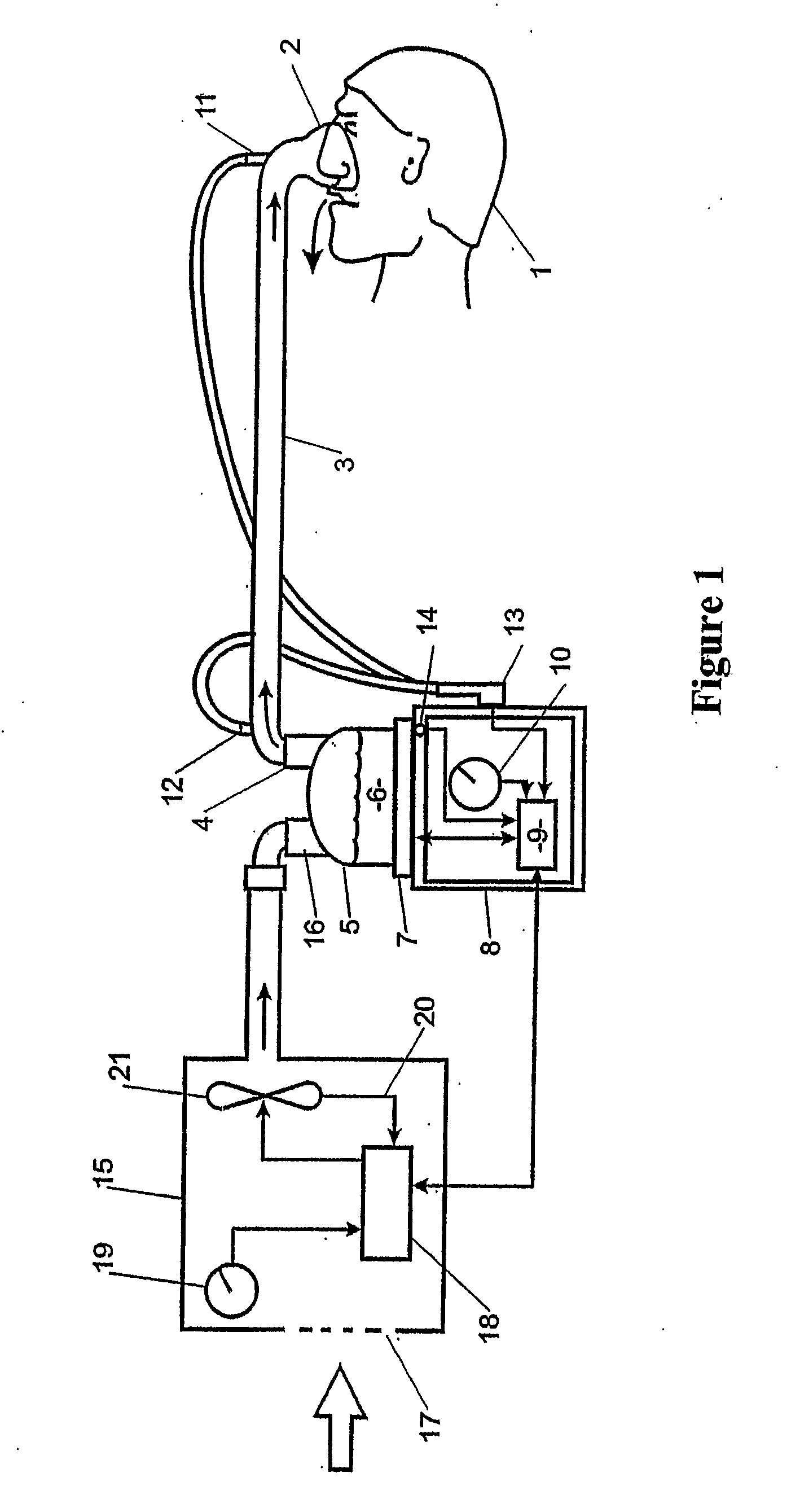

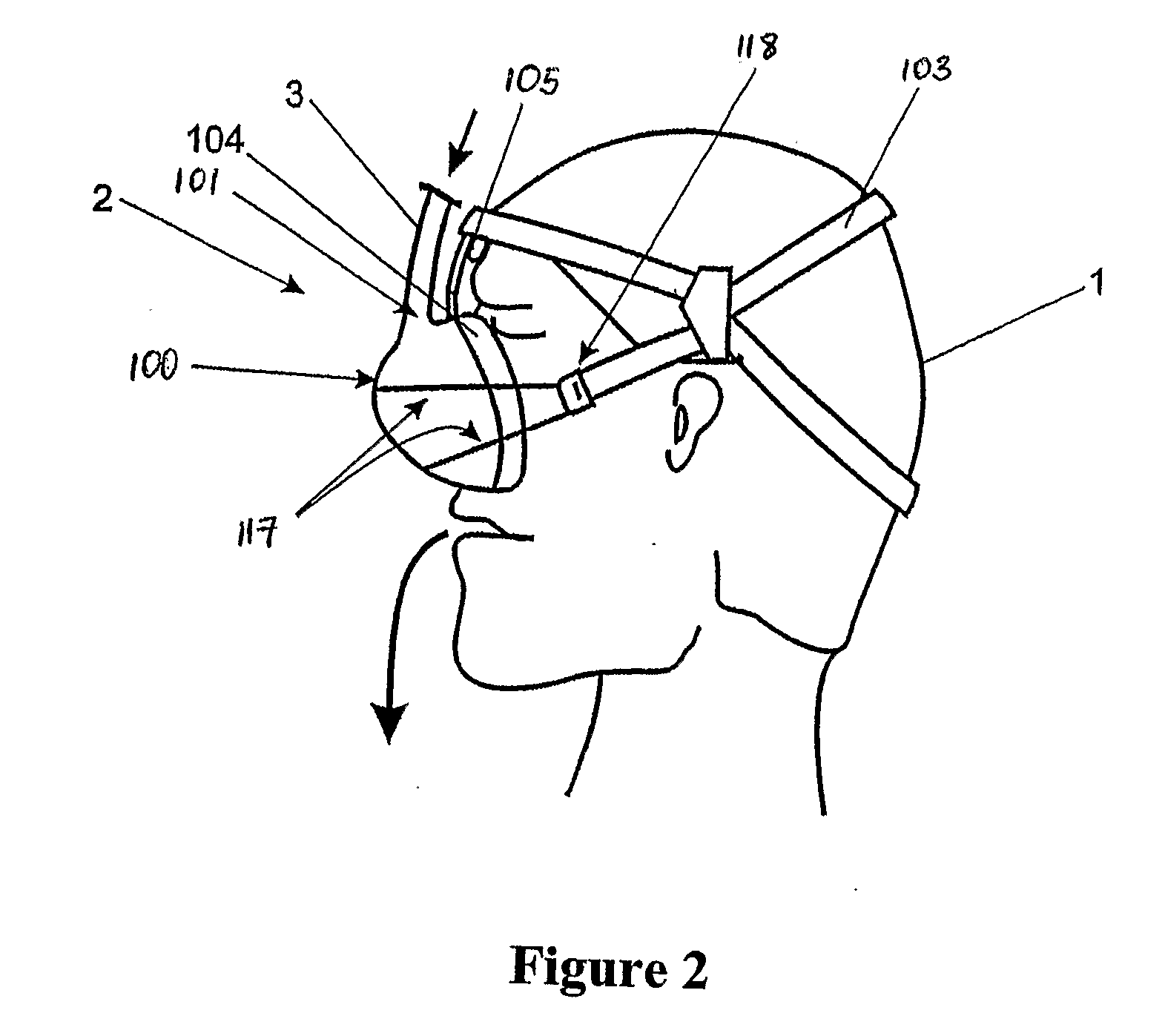

Manipulatable guide system and methods for natural orifice translumenal endoscopic surgery

A guide system for accommodating an endoscopic tool. The guide system comprises a flexible inner sheath and a handle coupled to the inner sheath adjacent a proximal end of the inner sheath. The inner sheath includes a plurality of working channels. The working channels are bundled over a common portion of their respective lengths, and the working channels collectively define a substantially honeycombed cross-sectional area.

Owner:ETHICON ENDO SURGERY INC

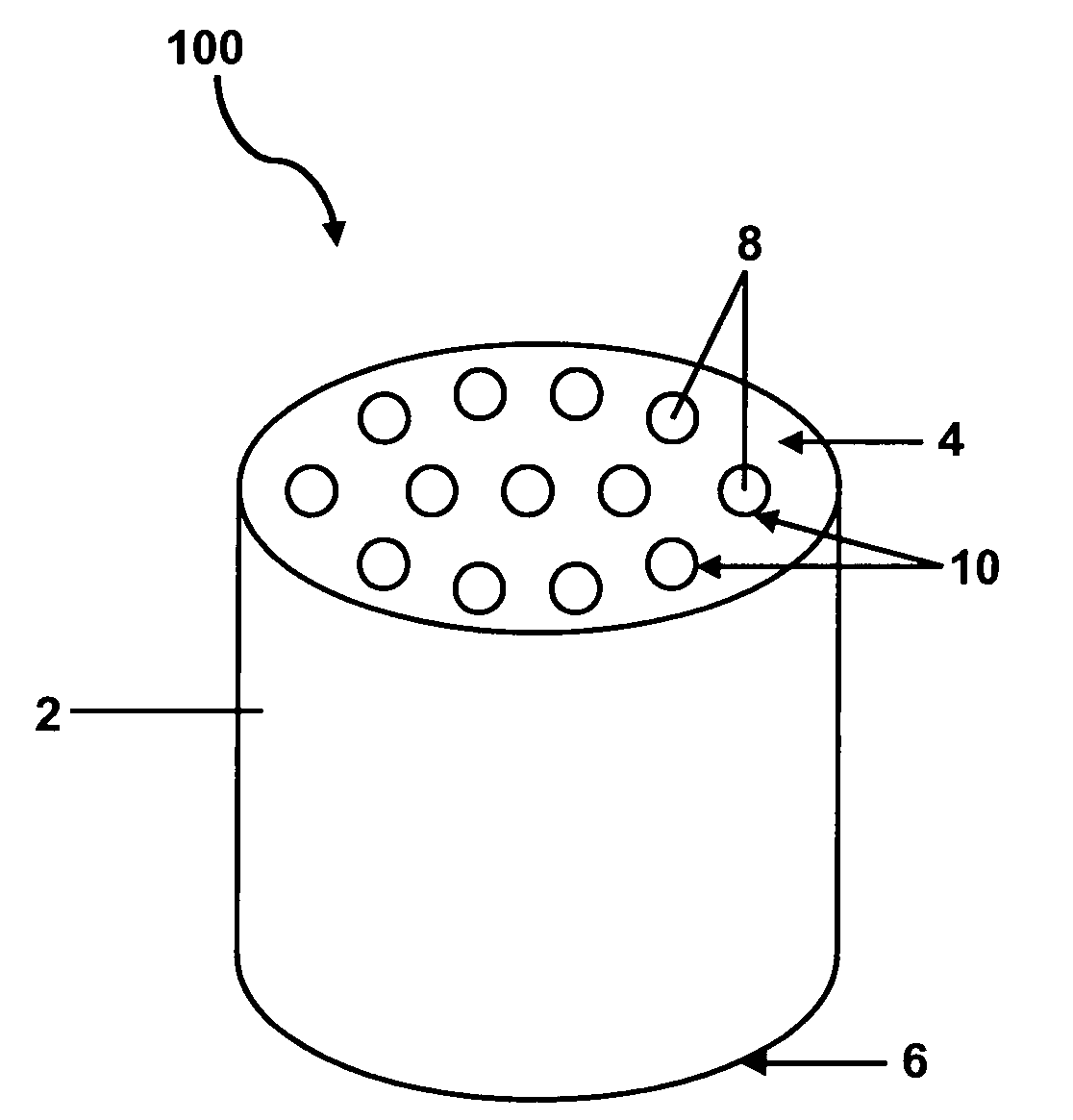

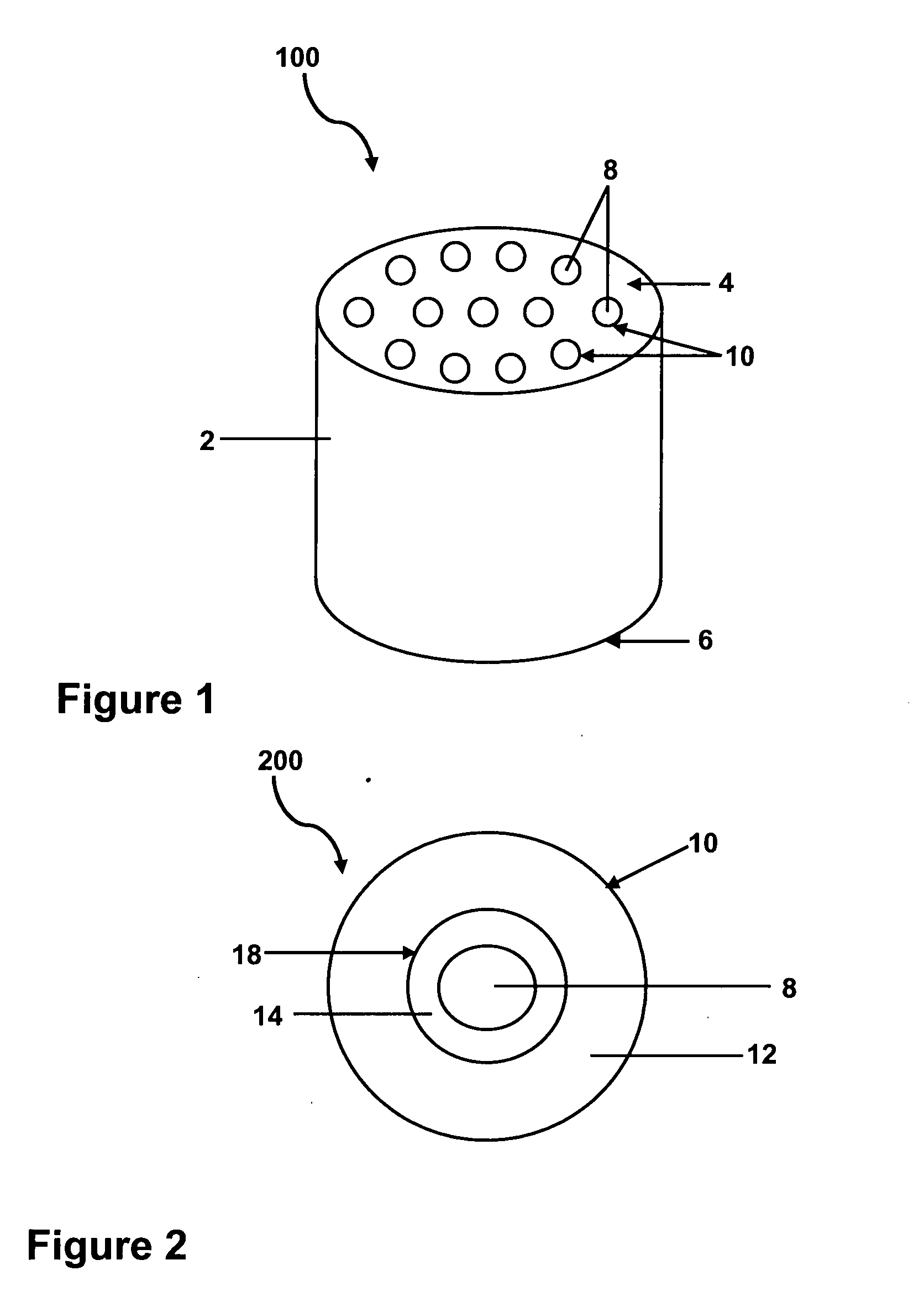

Apparatus suitable for transporting and storing nuclear fuel rods and methods for using the apparatus

InactiveUS6064710ARugged and convenient to handleHighly effectiveReactor fuel elementsPortable shielded containersHoneycombHoneycomb like

Apparatus suitable for transporting and storing nuclear fuel rods comprising a basket having storage cells formed from a honeycomb gridwork of metal plates in a rectilinear configuration, the plates welded to each other at their intersections so that all contiguous corners of the storage cells formed by the gridwork are completely connected so as to allow conduction heat transfer, the metal plates having neutron absorber material positioned in areas which form walls of the storage cells. Method of making an apparatus suitable for transporting and storing nuclear fuel rods comprising a) providing metal plates having slots and having neutron absorber material positioned on sides of the metal plates, b) arranging the plates so that the slots intersect to form a honeycomb gridwork of storage cells having contiguous corners and having the neutron absorbing material on sides of the storage cells, and c) welding the plates to each other at their intersections so that all contiguous corners of the storage cells formed by the gridwork are completely connected so as to allow conduction heat transfer and to provide a rigid structure.

Owner:SINGH KRIS

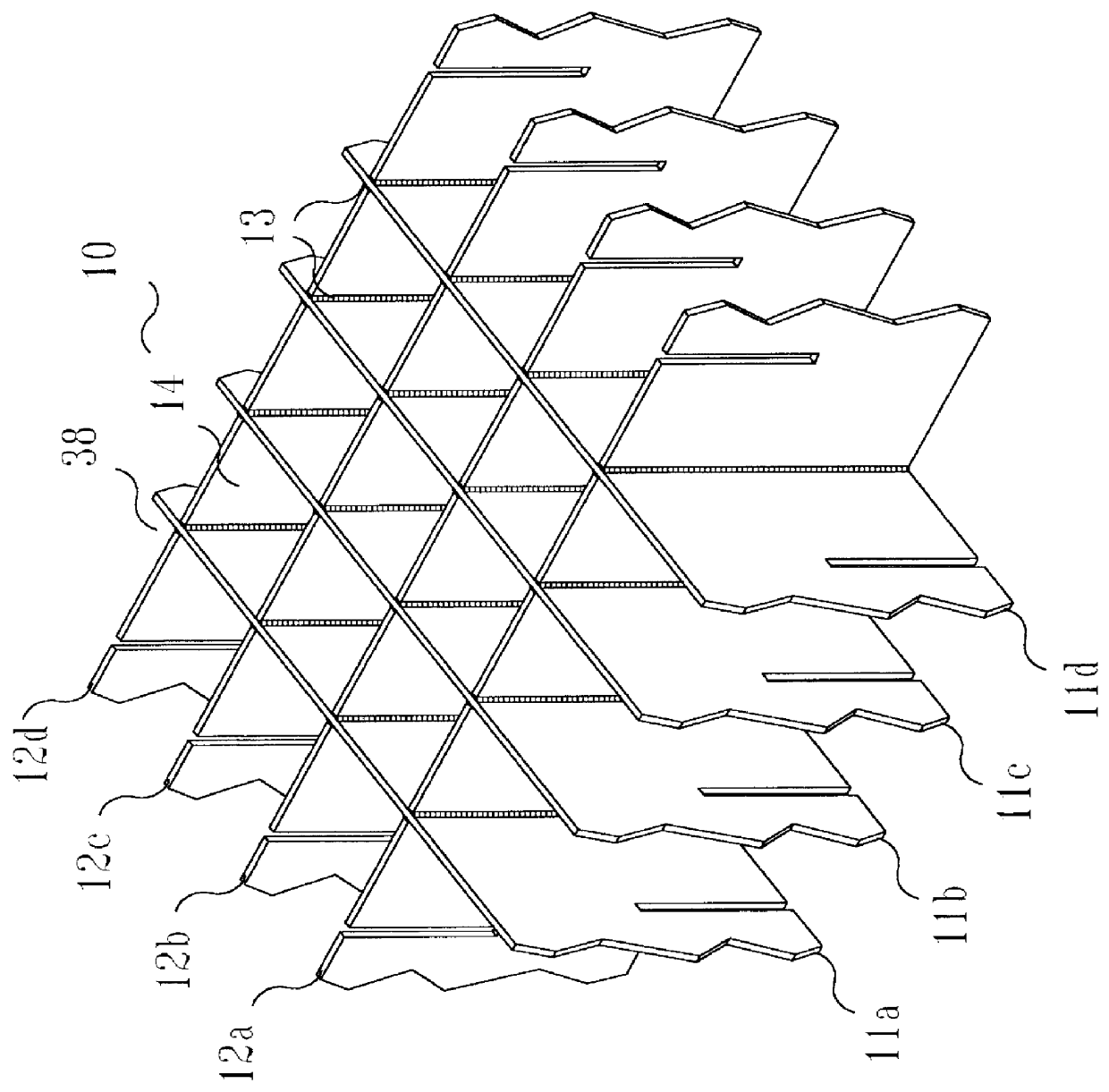

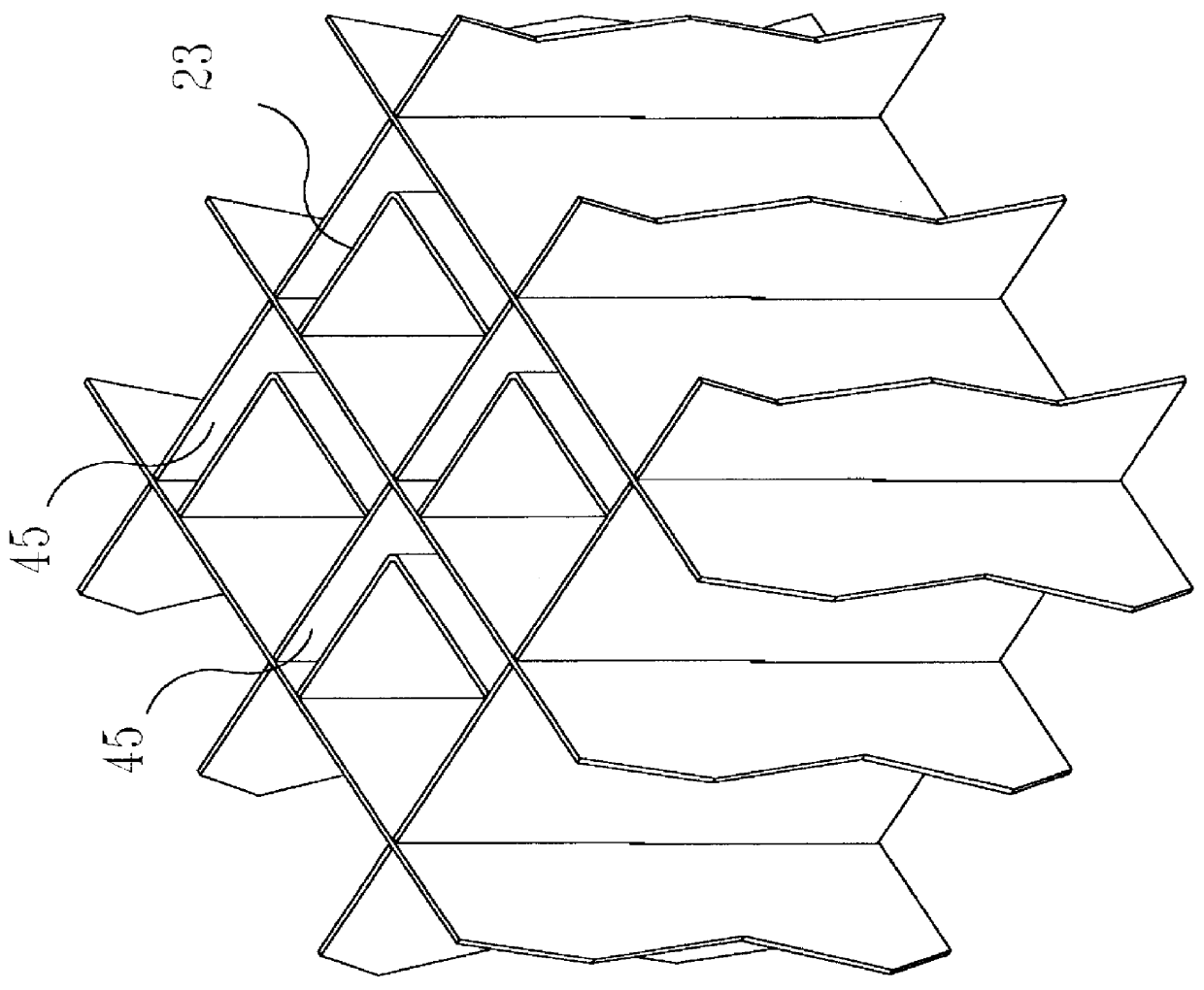

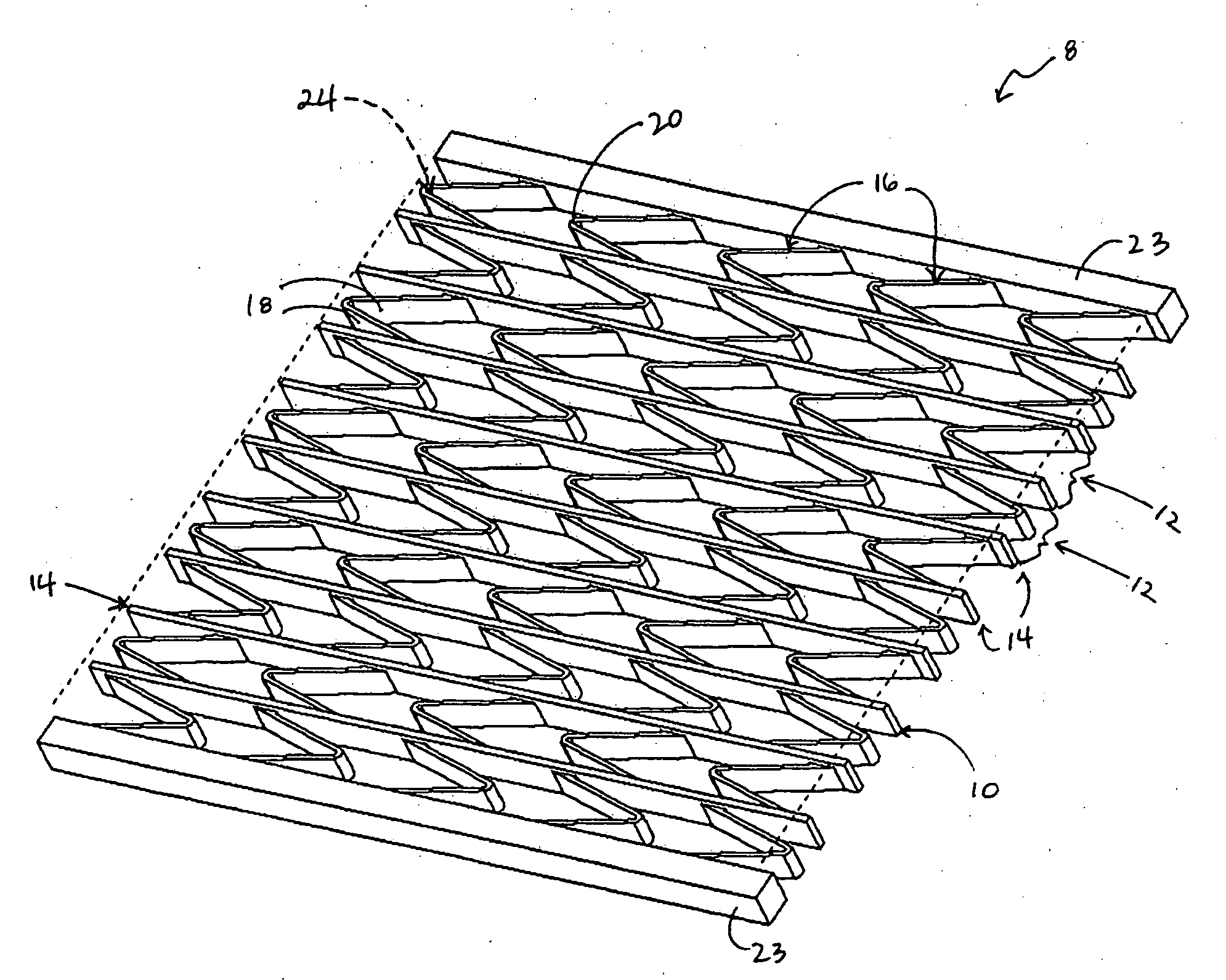

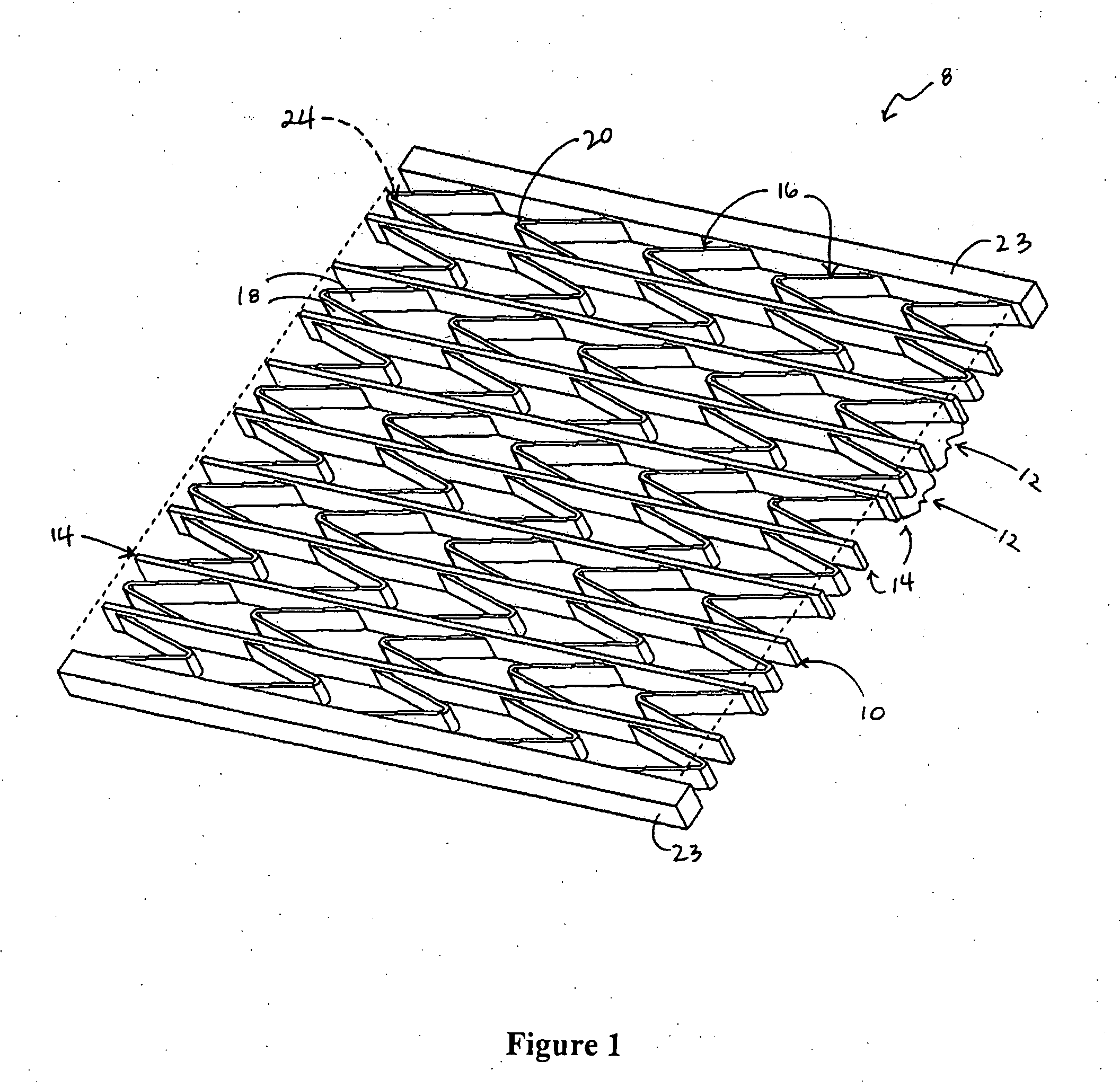

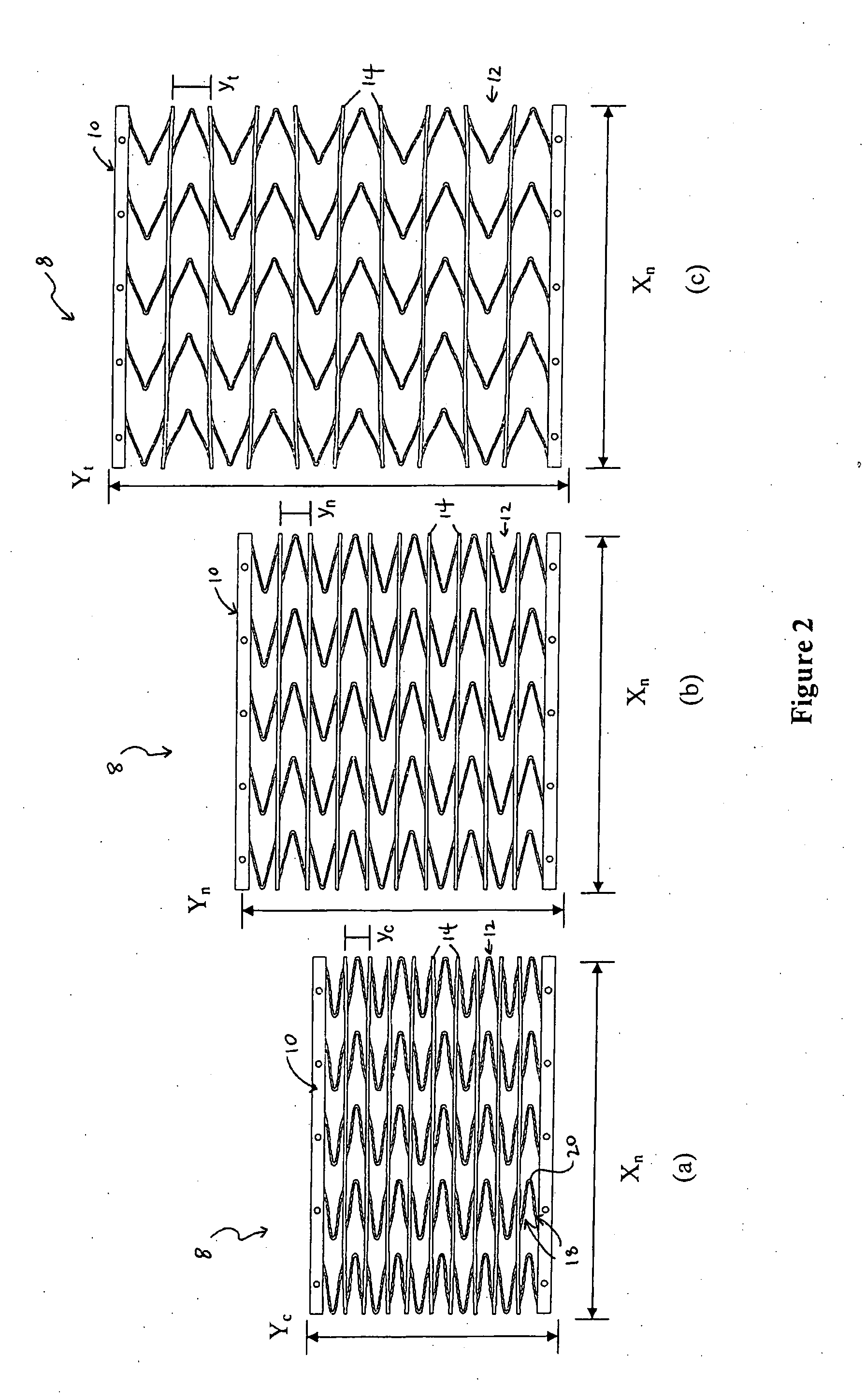

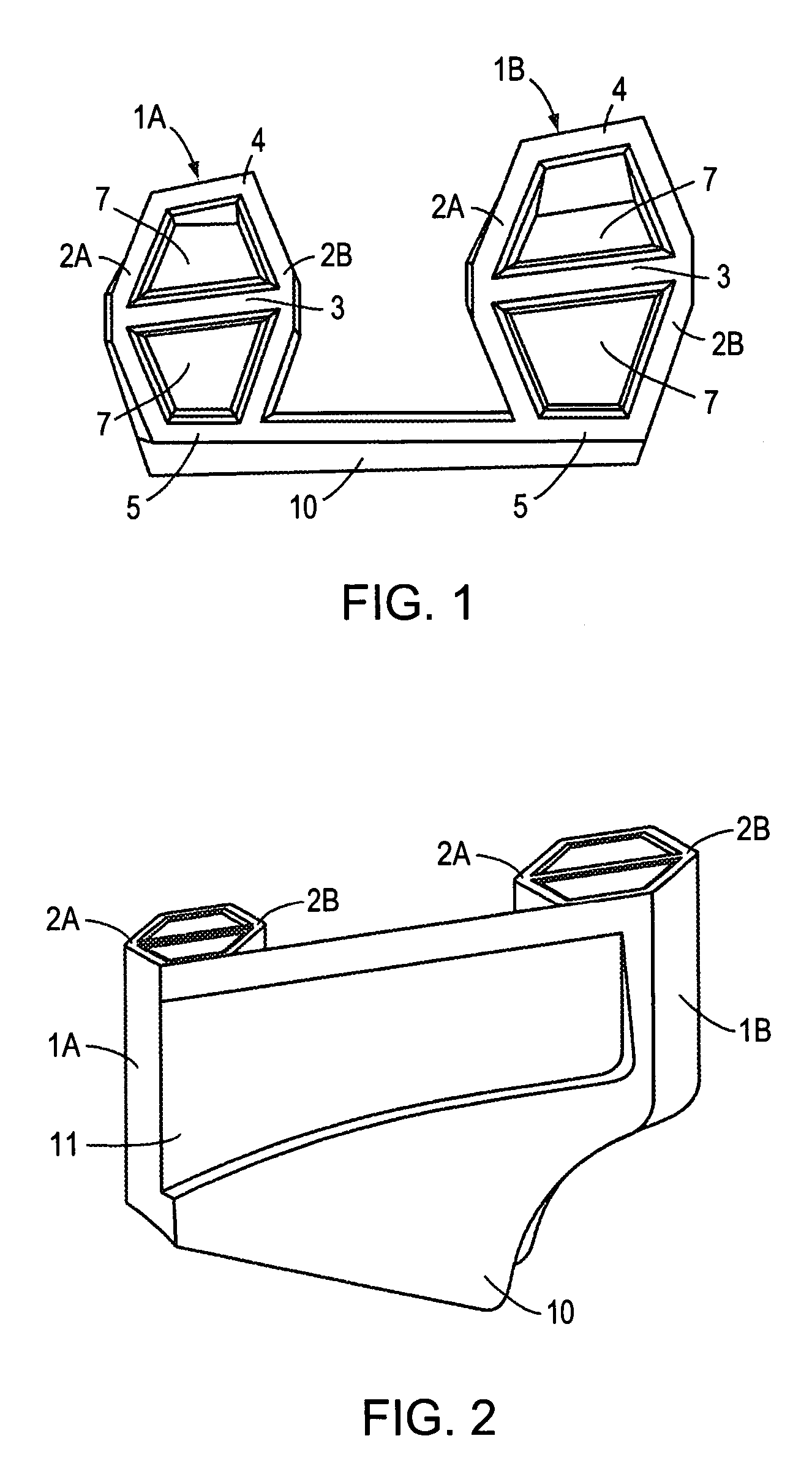

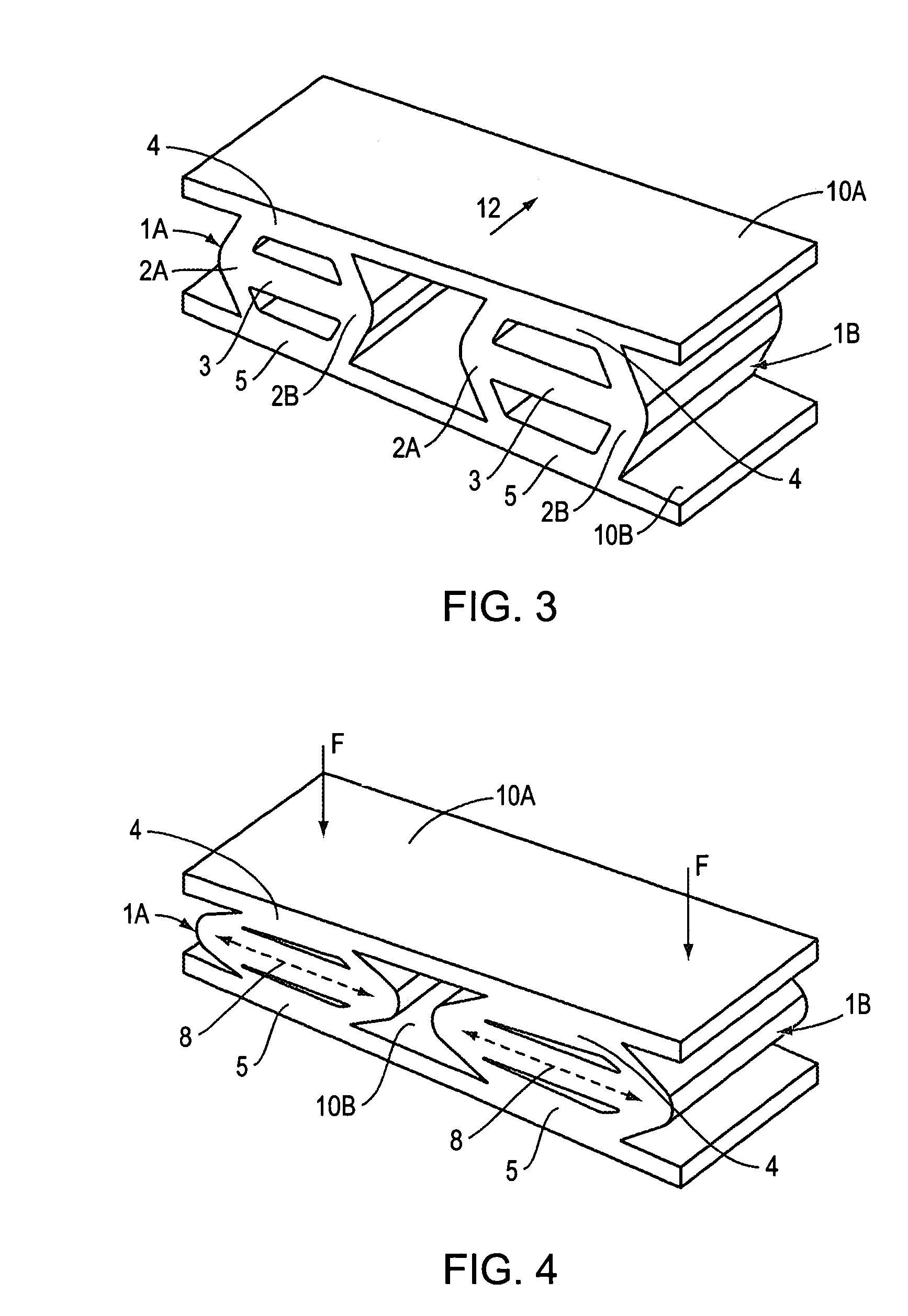

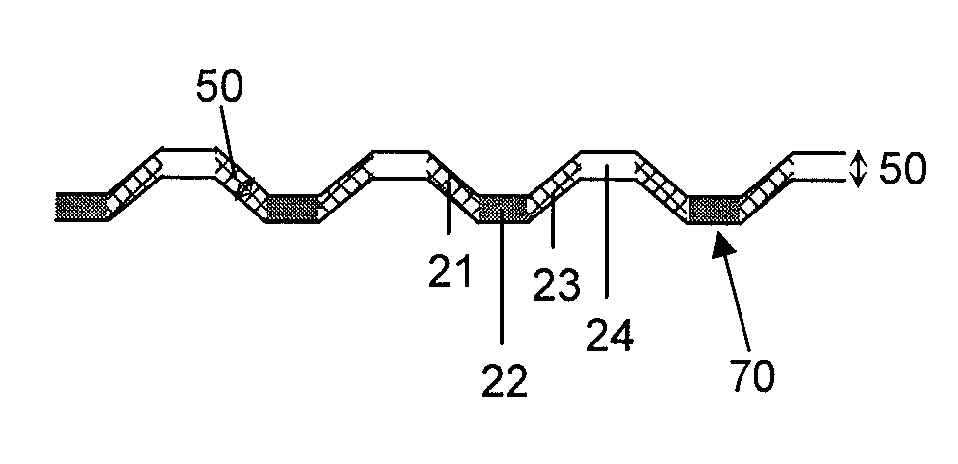

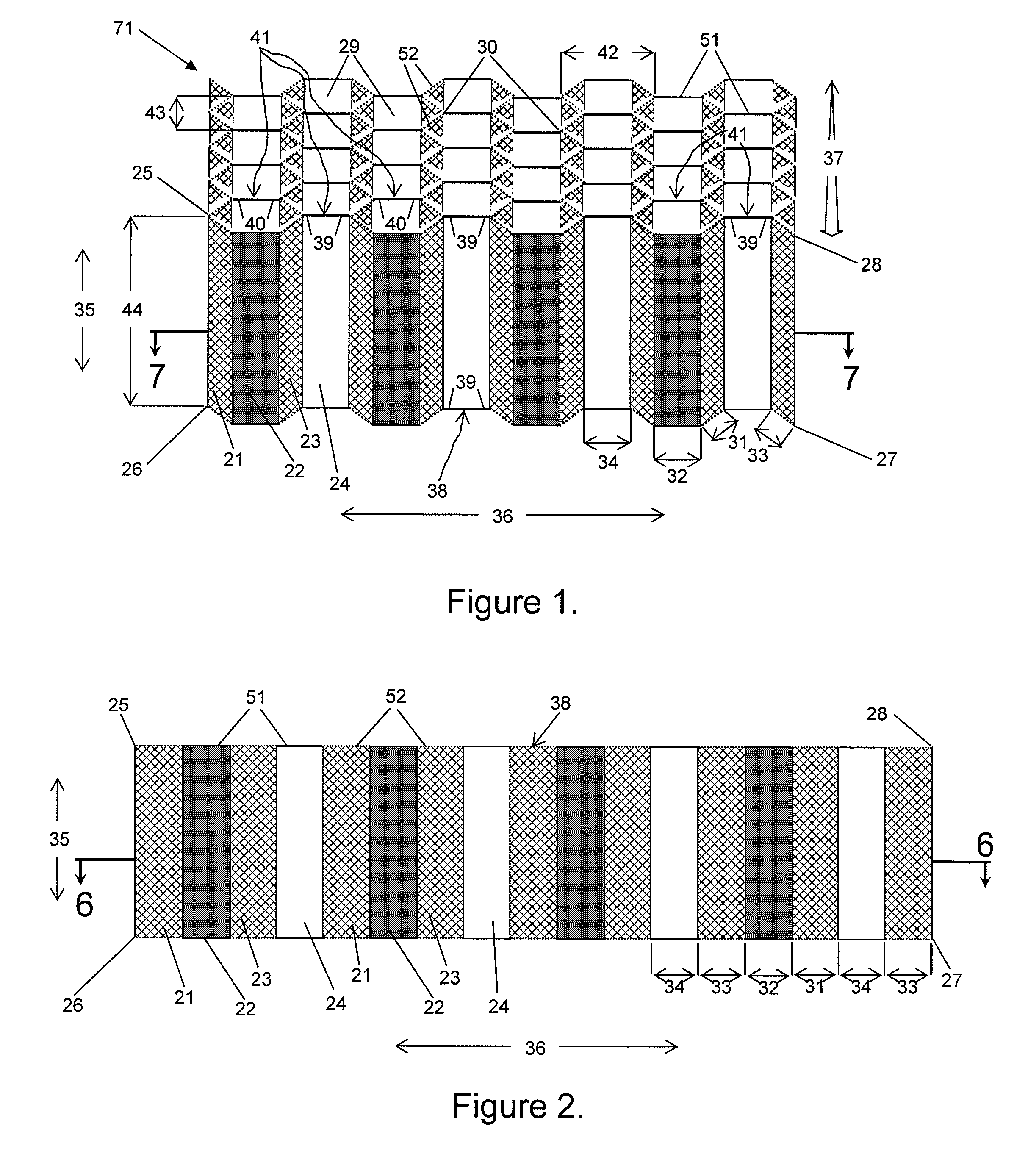

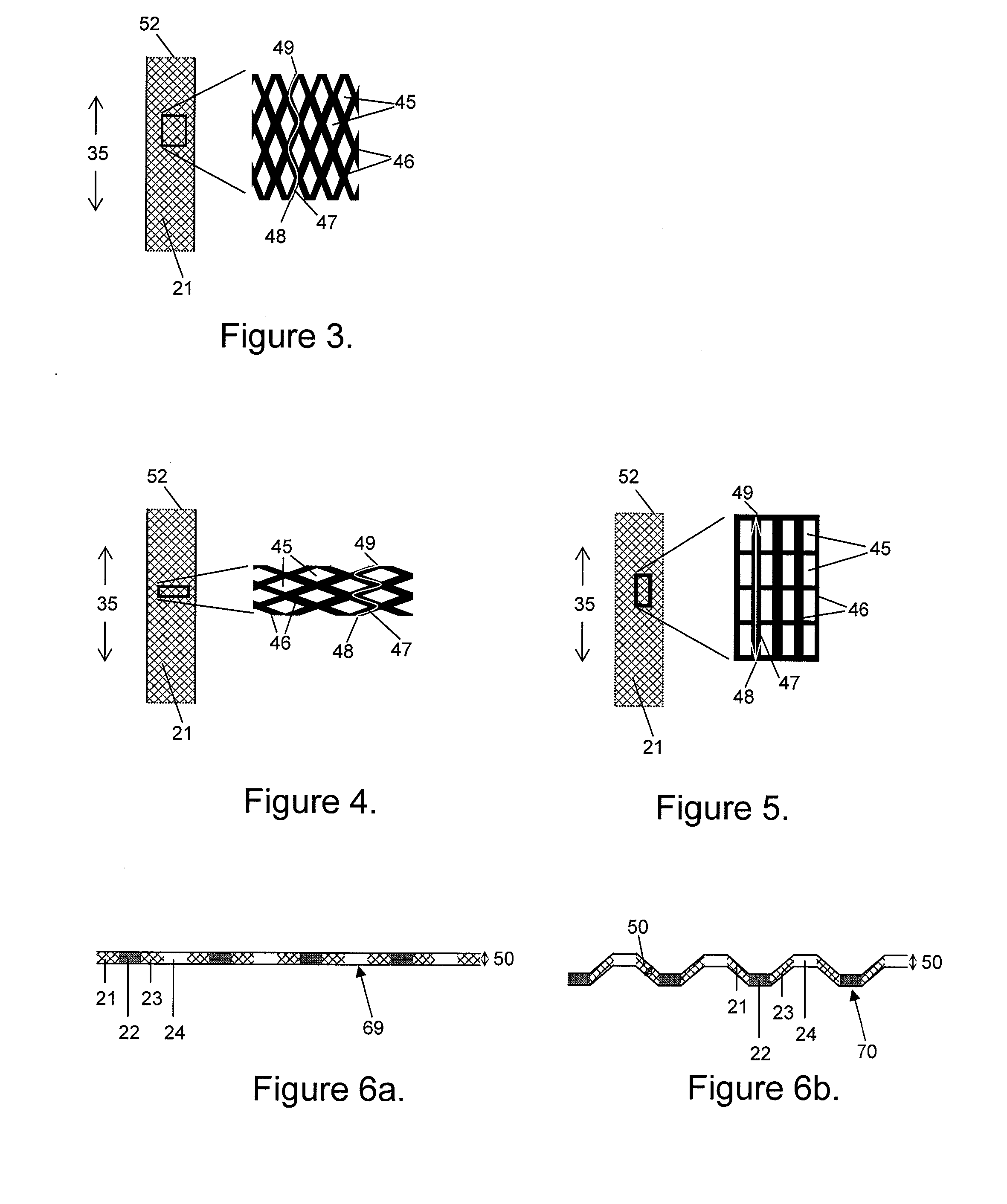

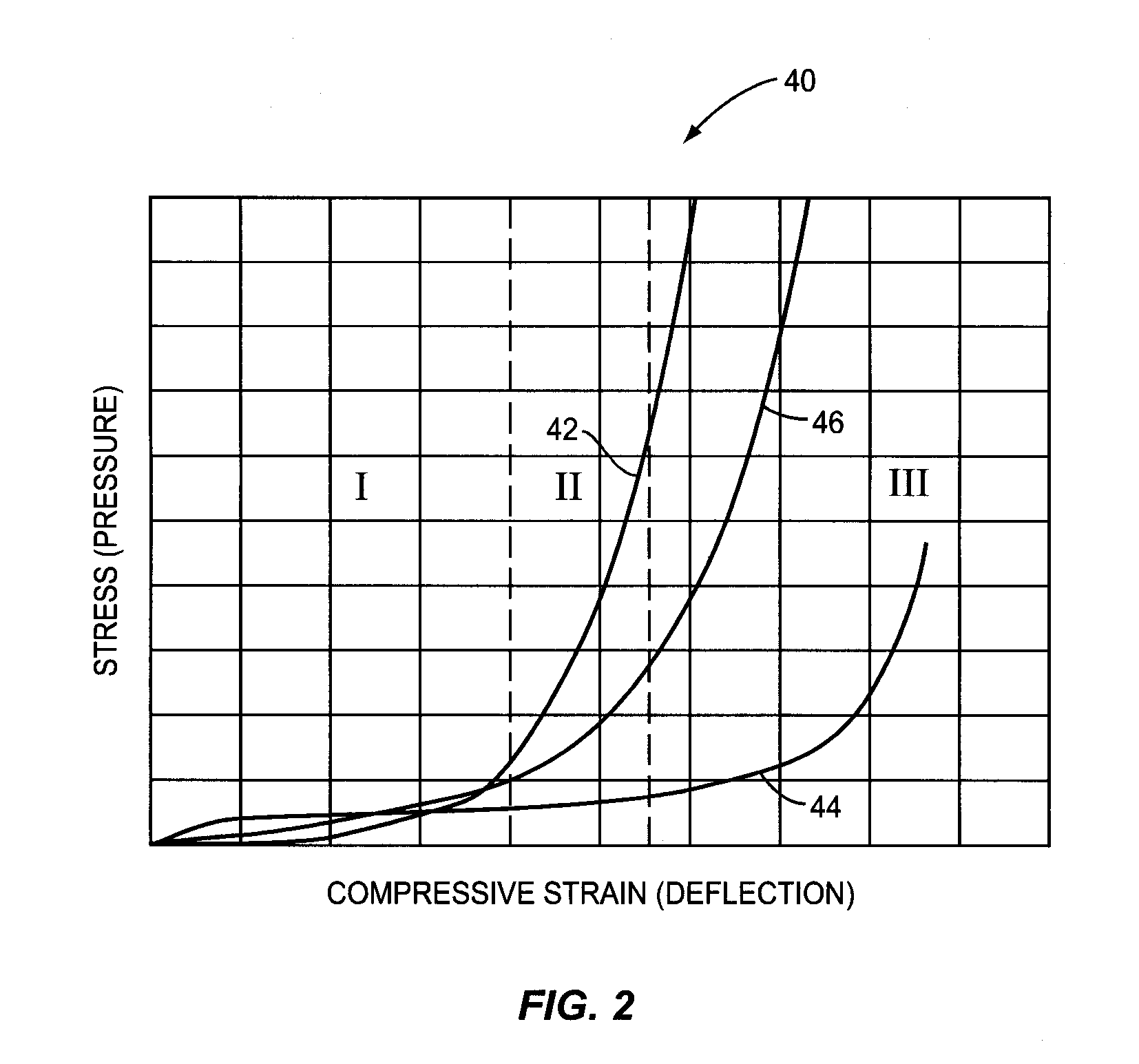

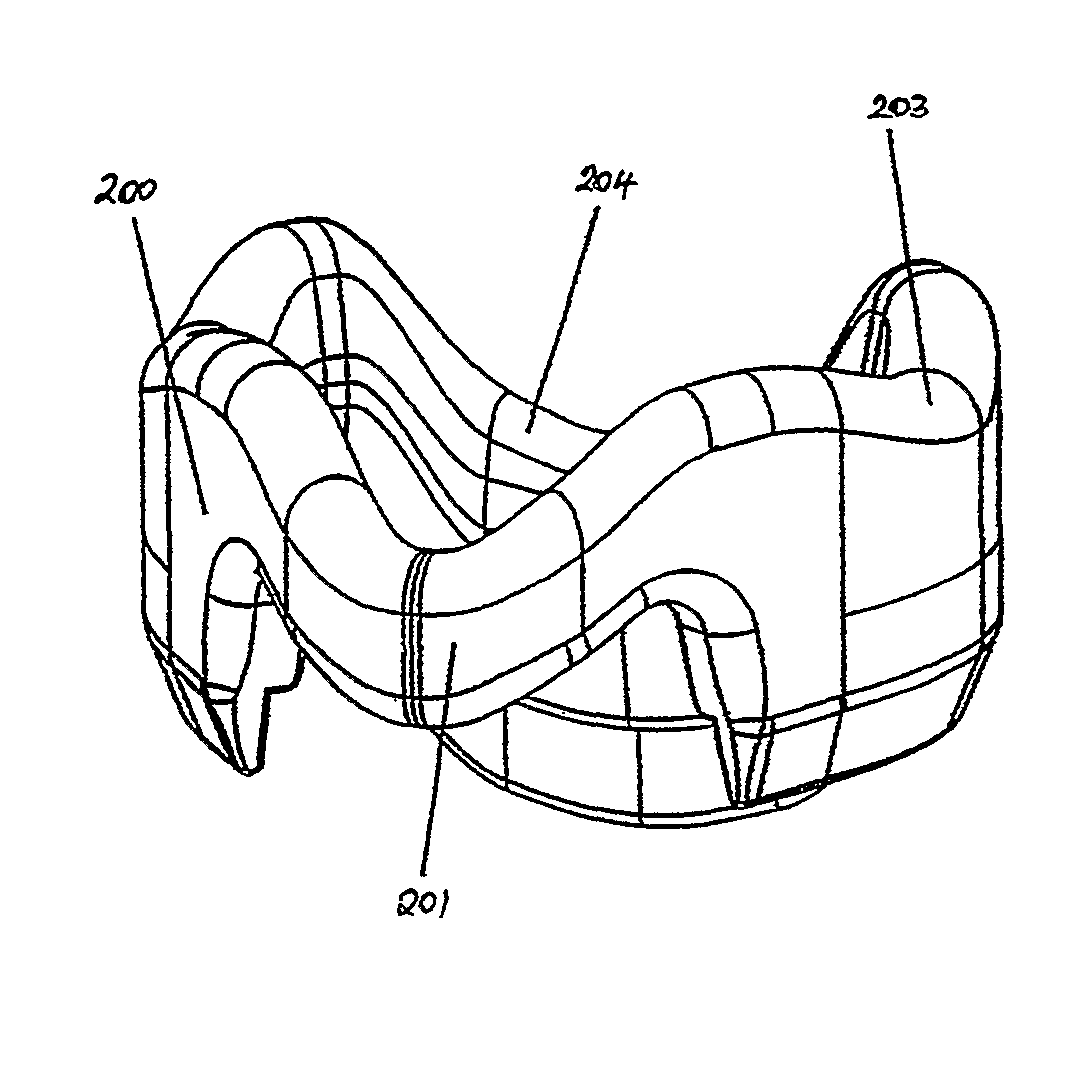

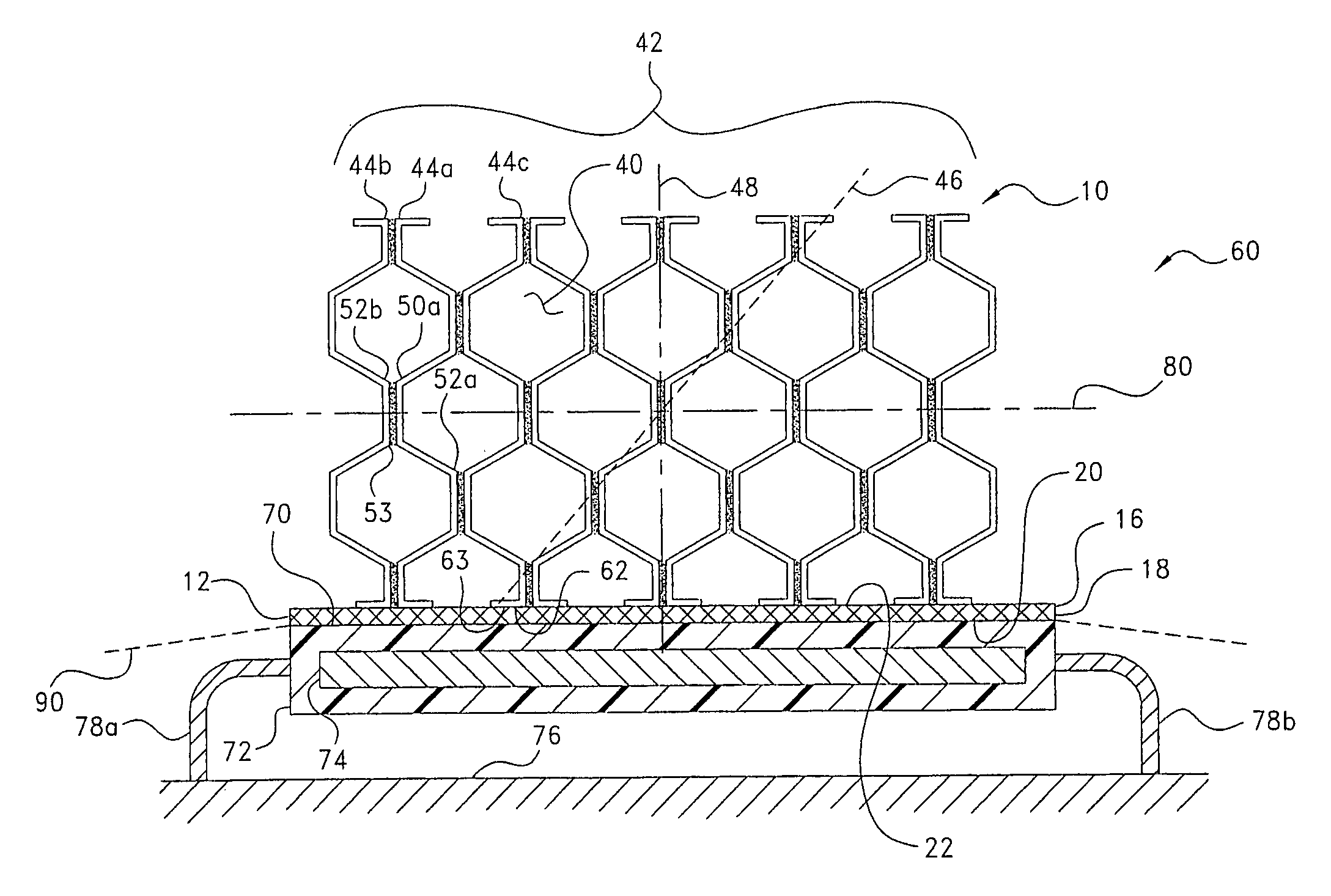

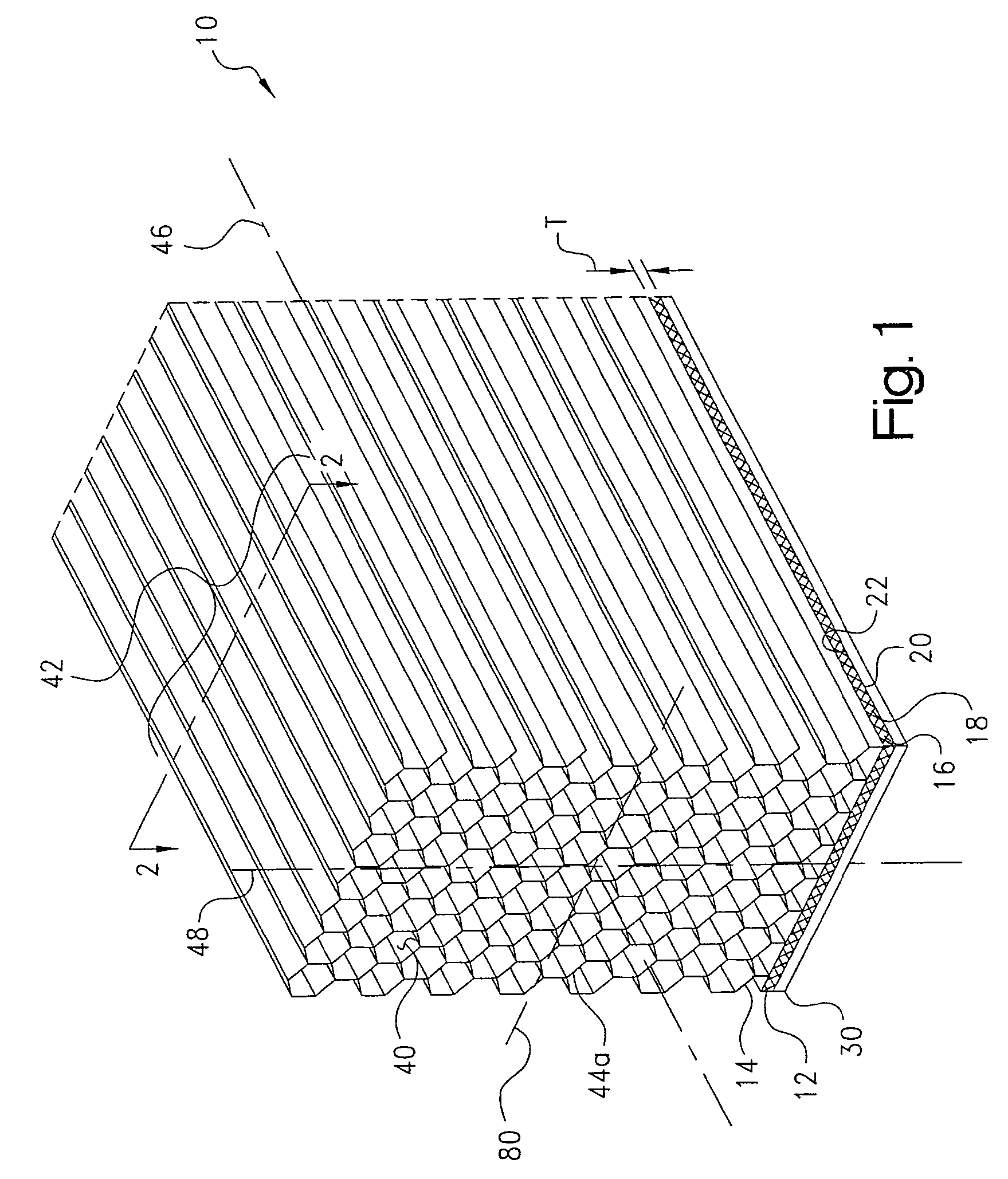

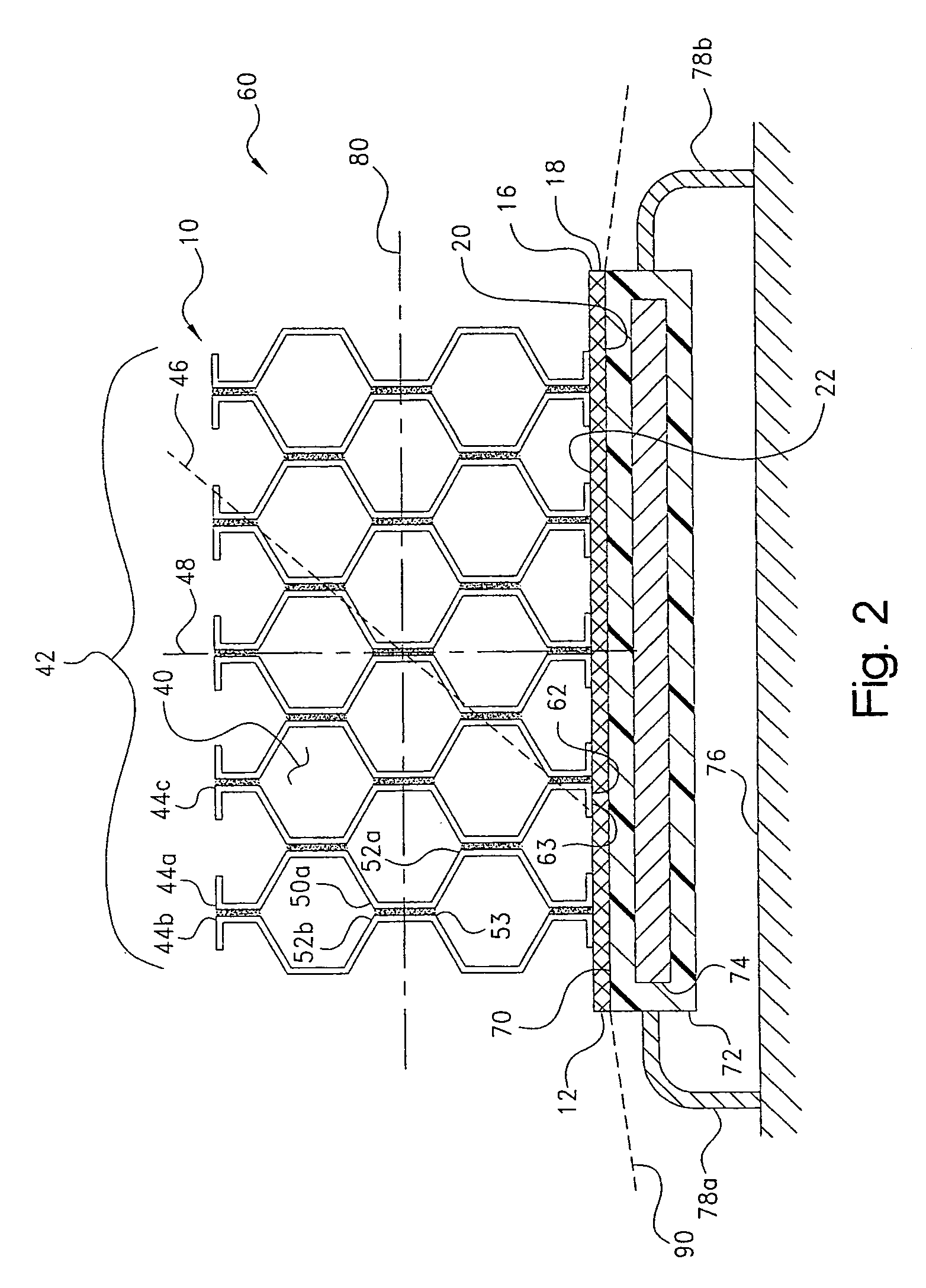

Cellular support structures used for controlled actuation of fluid contact surfaces

InactiveUS20080035788A1Aircraft stabilisationWithout power ampliicationHoneycomb likeBiomedical engineering

An assembly for controlling a vehicle, including a fluid contact surface constructed and arranged to act against a fluid passing over the fluid contact surface; and a support structure coupled to the fluid contact surface. The support structure is constructed and arranged to expand or contract between a first position and a second position, such that a first dimension of the support structure changes during movement of the support structure between the first position and the second position, while a second dimension of the support structure remains substantially constant during the movement of the support structure between the first position and the second position.

Owner:INNOVITAL LLC +2

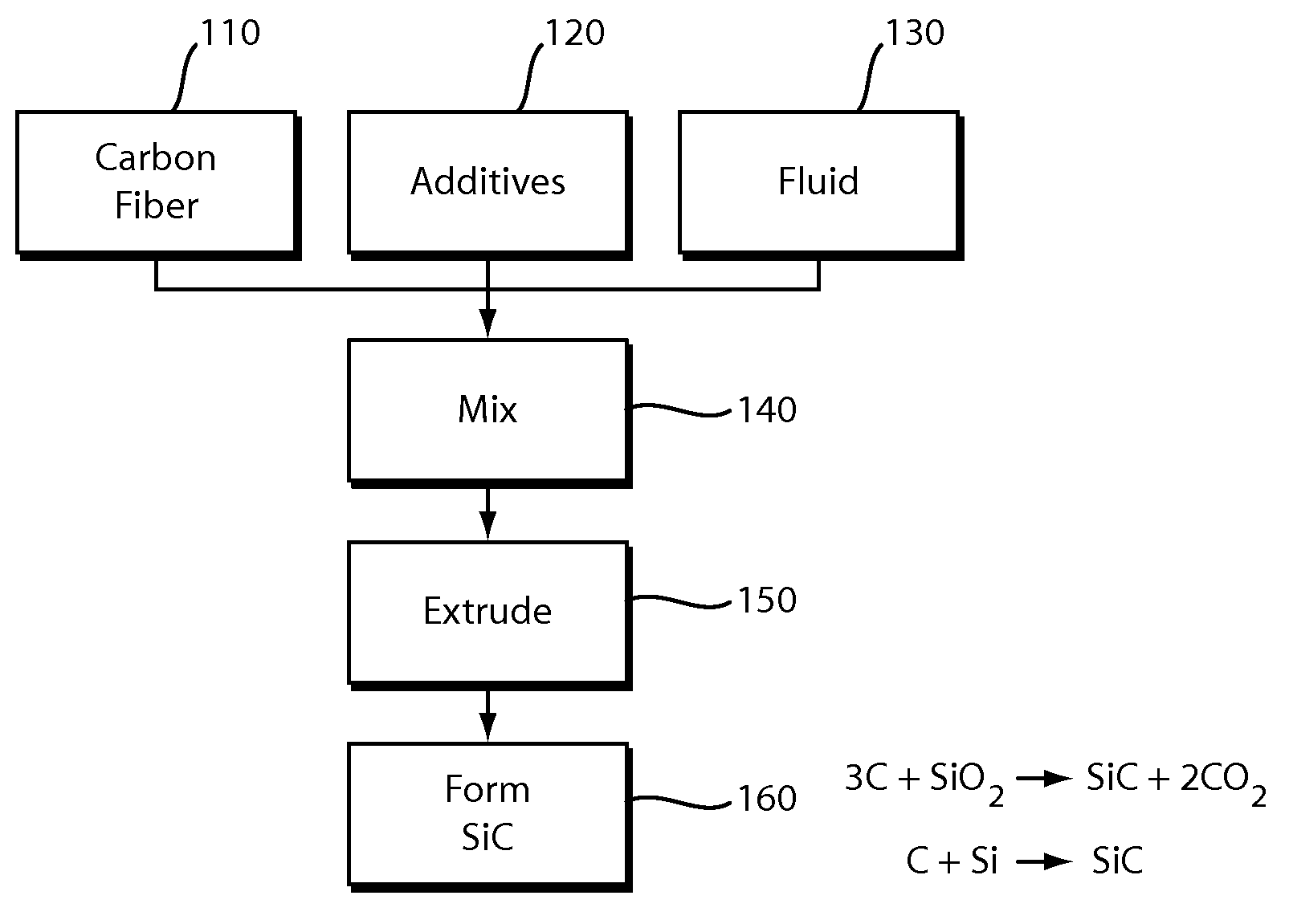

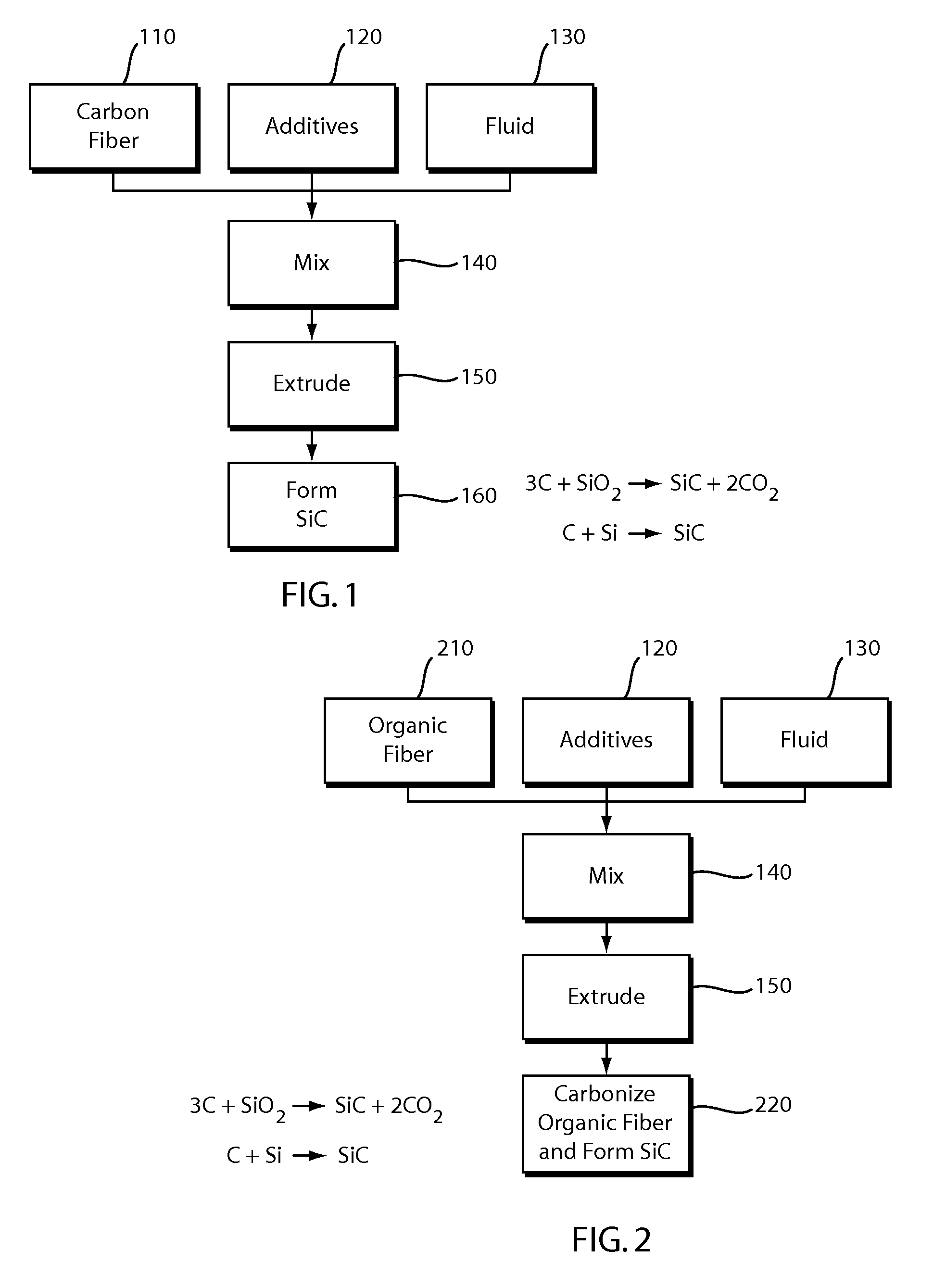

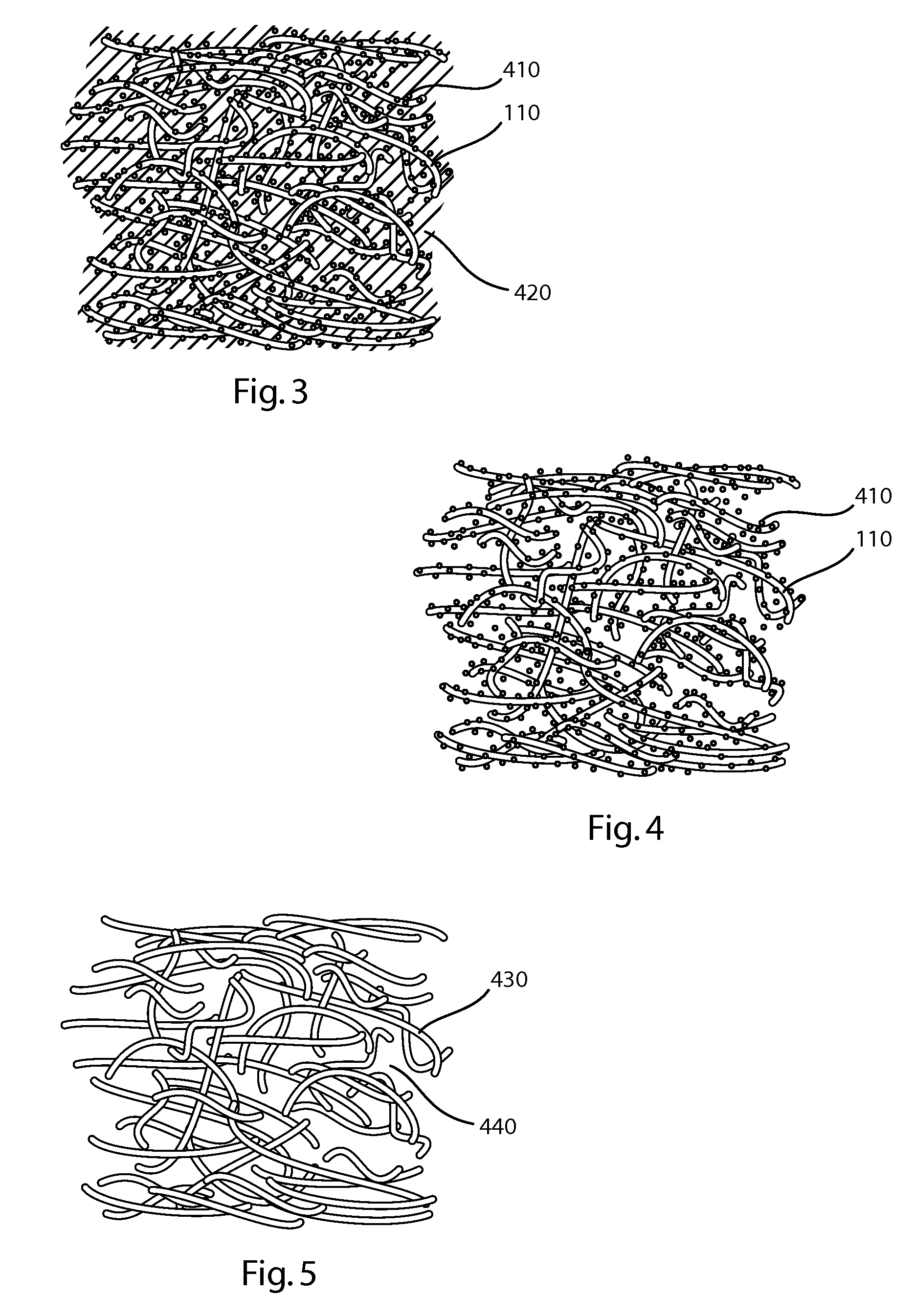

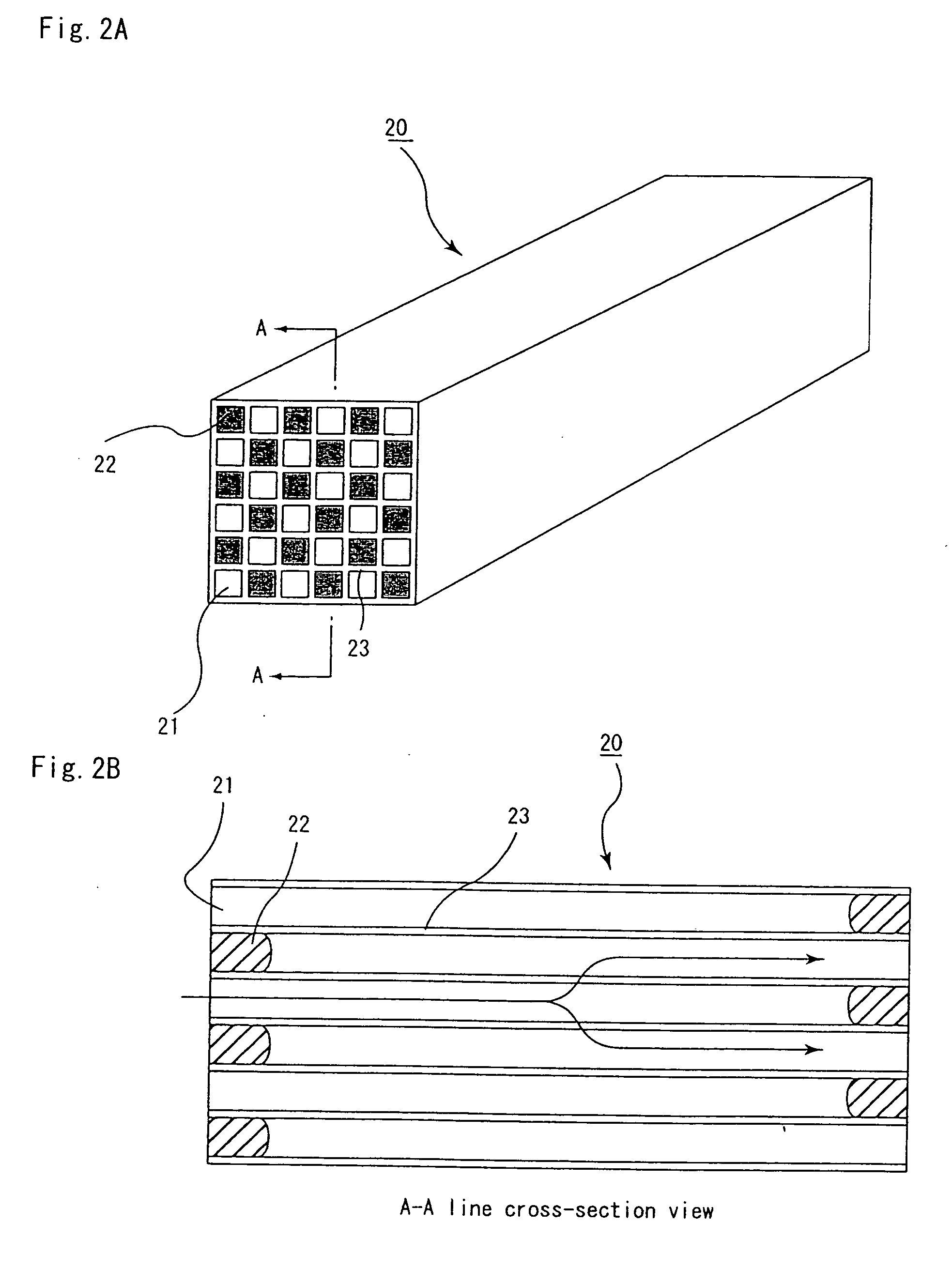

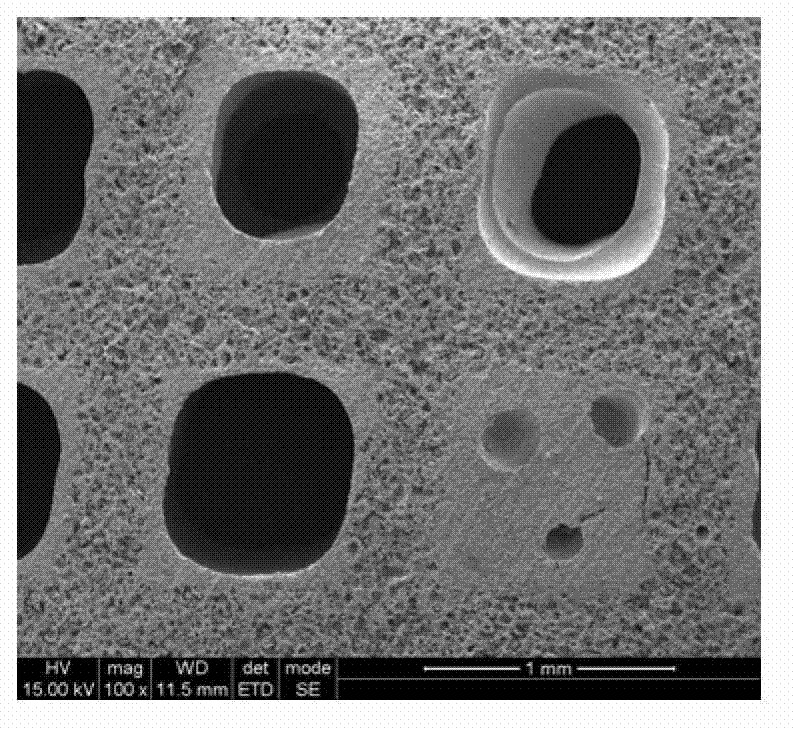

Extruded Fibrous Silicon Carbide Substrate and Methods for Producing the Same

InactiveUS20080179783A1Low costImprove performanceInternal combustion piston enginesExhaust apparatusPorosityHoneycomb

A fibrous silicon carbide substrate is disclosed that provides porosity through an open network of pores resulting from an intertangled arrangement of silicon carbide fibers. The fibrous structure is formed from mixing carbon or organic fibers with silicon based additives, and forming a honeycomb substrate. The carbon or organic fibers are heated in an inert environment to form silicon carbide through a reaction of the carbon in the fibers and the silicon-based additives.

Owner:GE02 TECH INC

Signal light and rear-view mirror arrangement

A signal light and rear-view mirror arrangement is constructed to include a circuit board mounted in the back recess of a vehicle rear-view mirror and adapted to control a set of lamps to flash, and a lens covered on the back side of the vehicle rear-view mirror, the lens having a plurality of raised portions protruded from the inner surface and forming a honeycomb-like condensing area adapted to condense and refract light from the lamps, a transparent area surrounding the honeycomb-like condensing area, and a photomask covered on the outer surface of the lens corresponding to the condensing area.

Owner:HUANG JEAN SAN

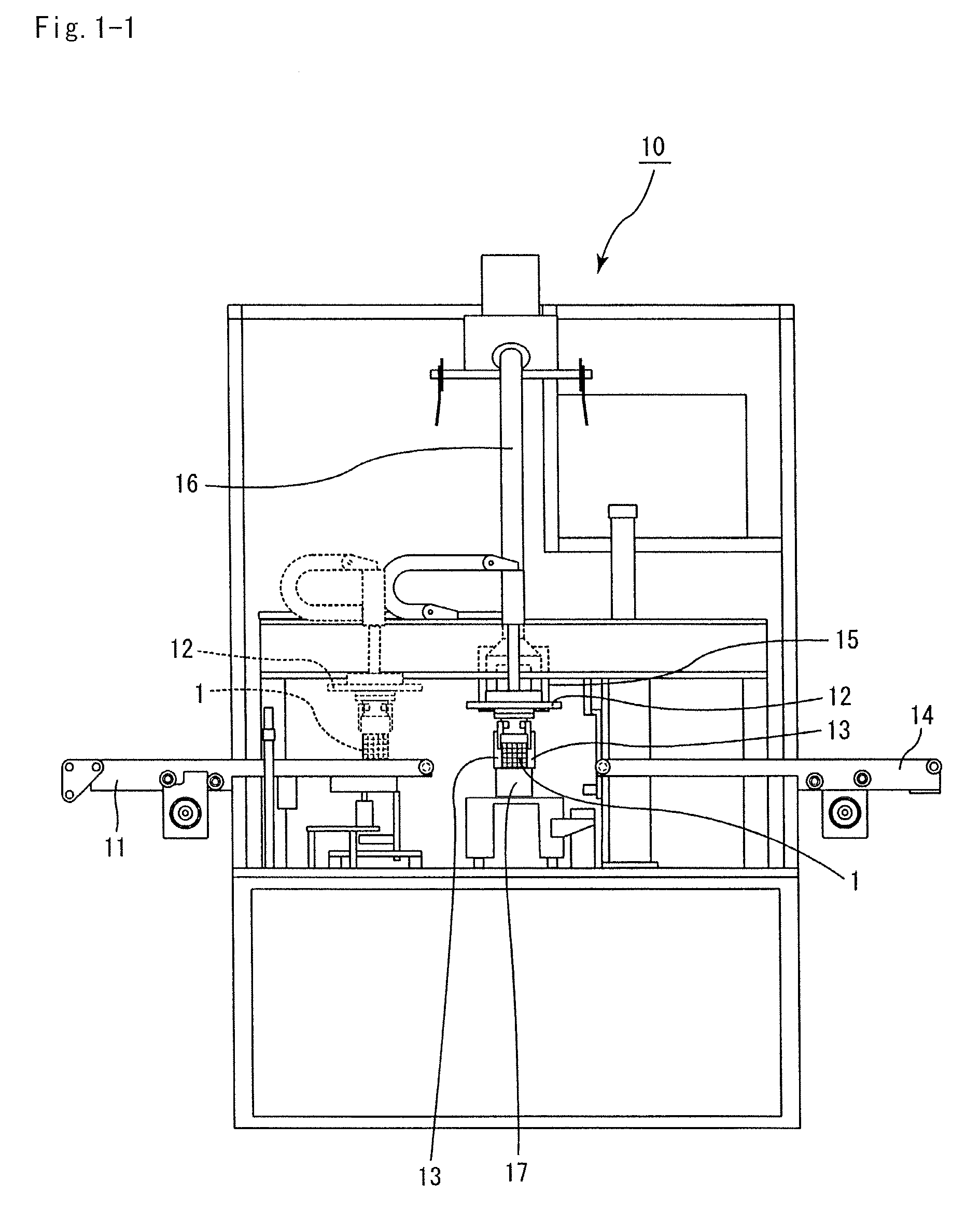

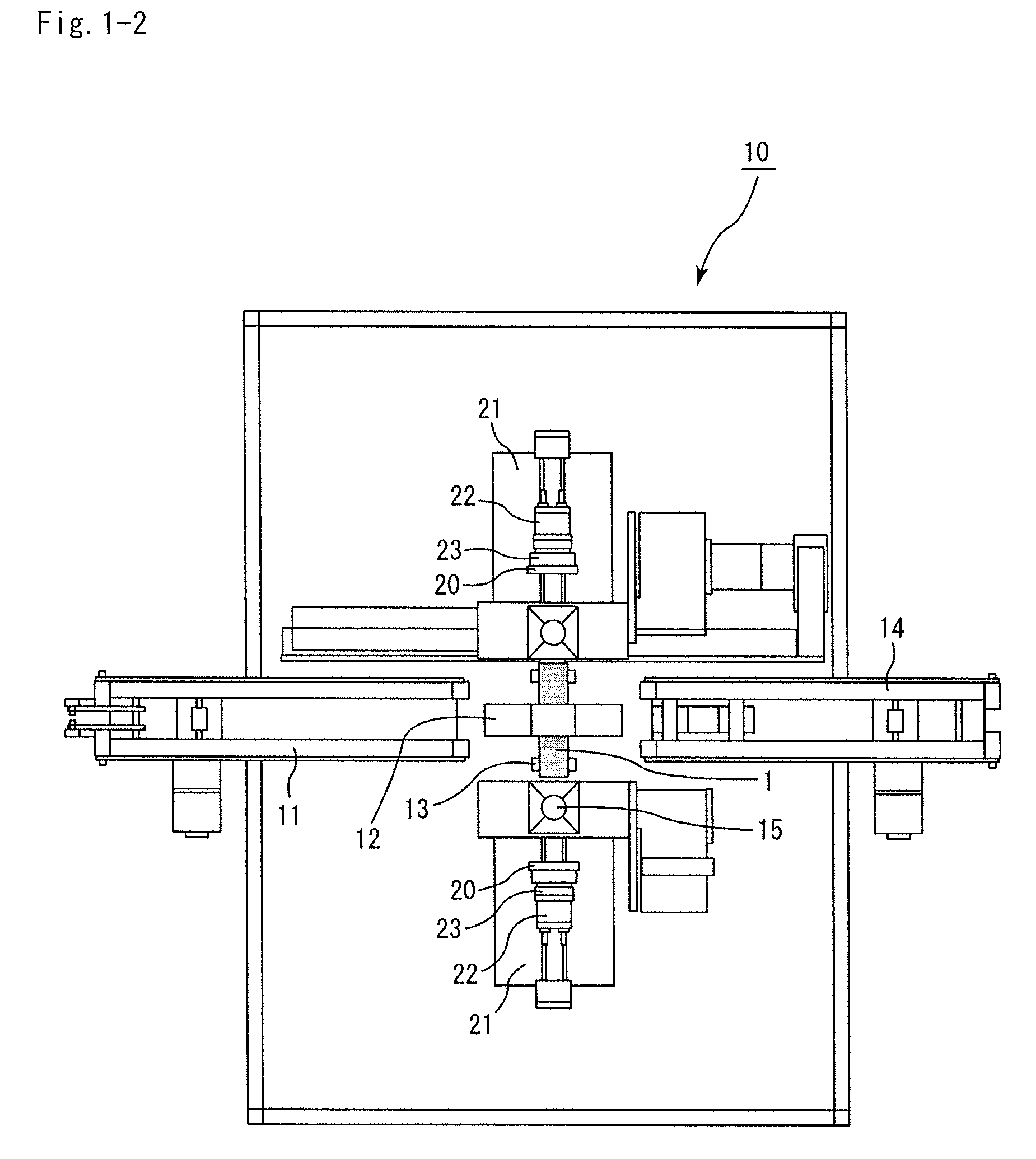

Molded body treating apparatus, sealing method of honeycomb molded body, and method for manufacturing cell-sealed honeycomb fired body

ActiveUS20080116601A1Internal combustion piston enginesDispersed particle filtrationHoneycombEngineering

A molded body treating apparatus includes a support, at least one flat plate and a first movement mechanism. The support is configured to support a honeycomb molded body which has a first end portion and a second end portion in a longitudinal direction of the honeycomb molded body and which includes a plurality of cells each extending along the longitudinal direction from a first end at the first end portion to a second end at the second end portion. Either the first end or the second end of each of the plurality of cells is sealed with a plug material paste. The first movement mechanism is configured to move the at least one flat plate along the longitudinal direction to press the either one of the first and second end portions.

Owner:IBIDEN CO LTD

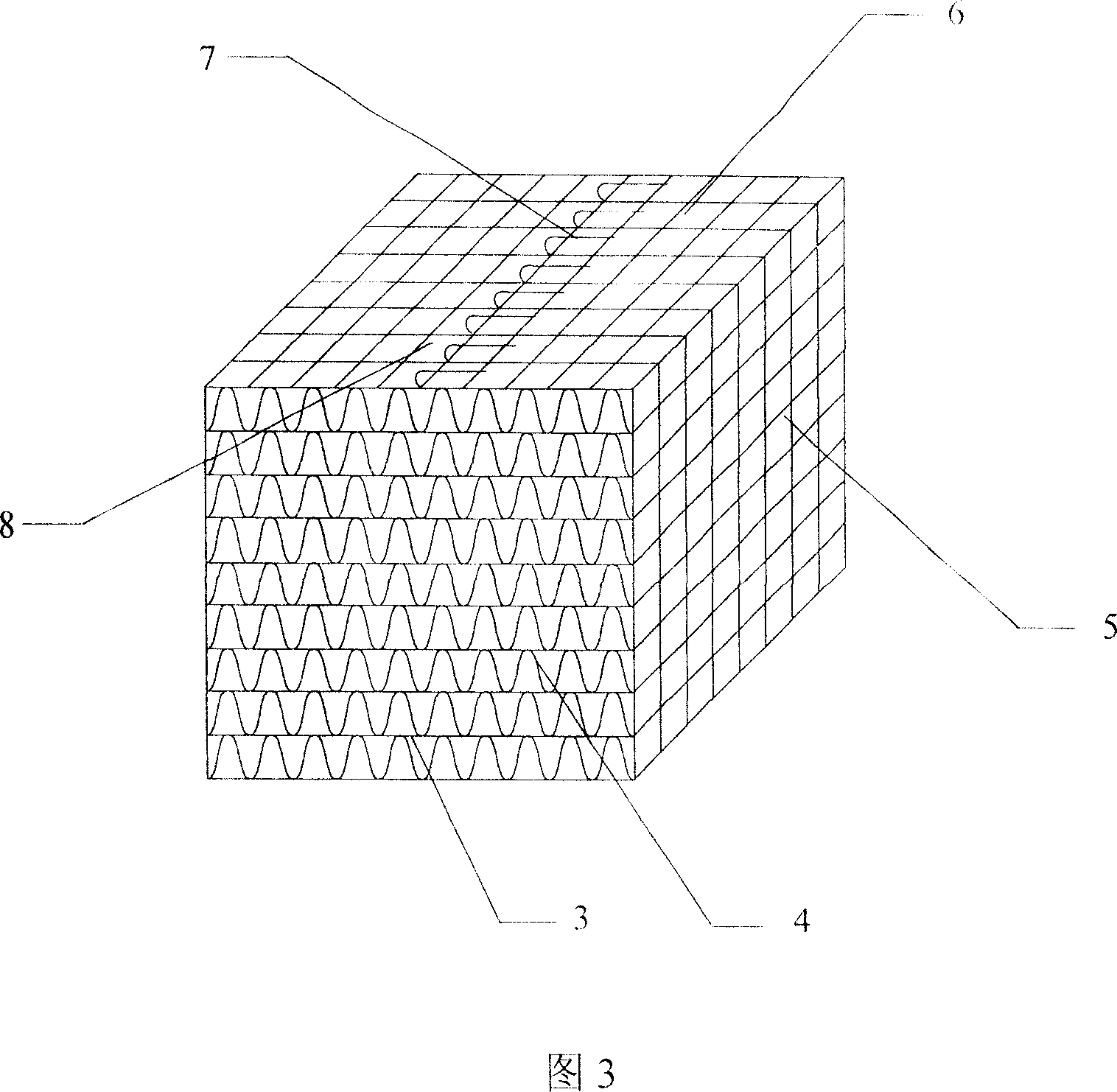

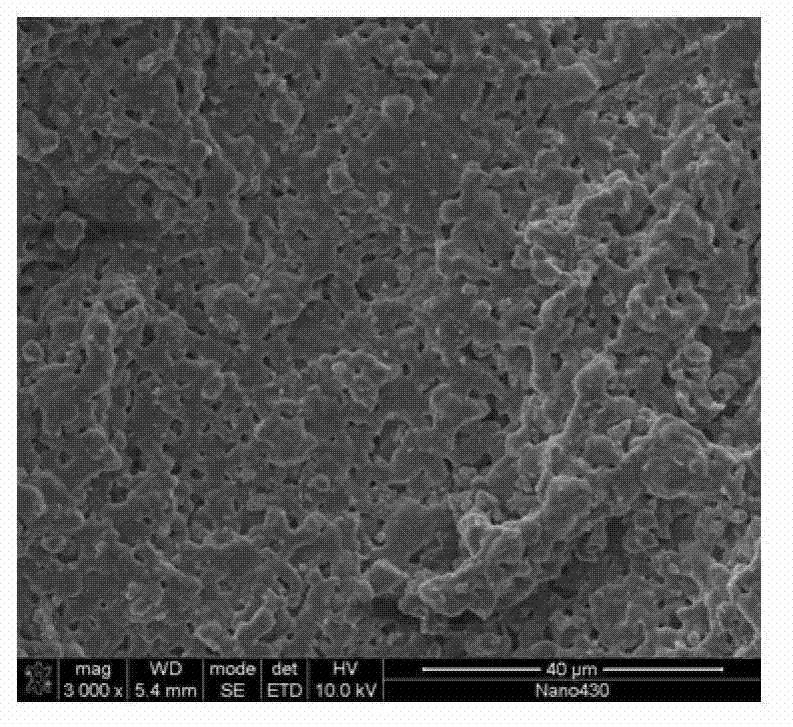

Cellulated wiremesh carrier with alumina coat, and preparation method

InactiveCN101049577AImprove thermal shock resistanceImprove mechanical propertiesCatalyst carriersHoneycomb likeStainless steel wire

A cellular metallic wire net carrier with coated aluminum oxide layer is composed of a metallic carrier and a coated layer and has an internal 3D through structure. Its preparing process includes such steps as preparing the planar metallic wire nets and corrugated metallic wire nets from stainless steel wire, pre-treating, preparing electric depositing liquid from gamma-Al2O3 powder, electric depositing to form a coated aluminum oxide layer on said metallic wire nets, stacking them in stagger mode, and binding them together by the strips of metallic wire net.

Owner:DALIAN UNIV OF TECH

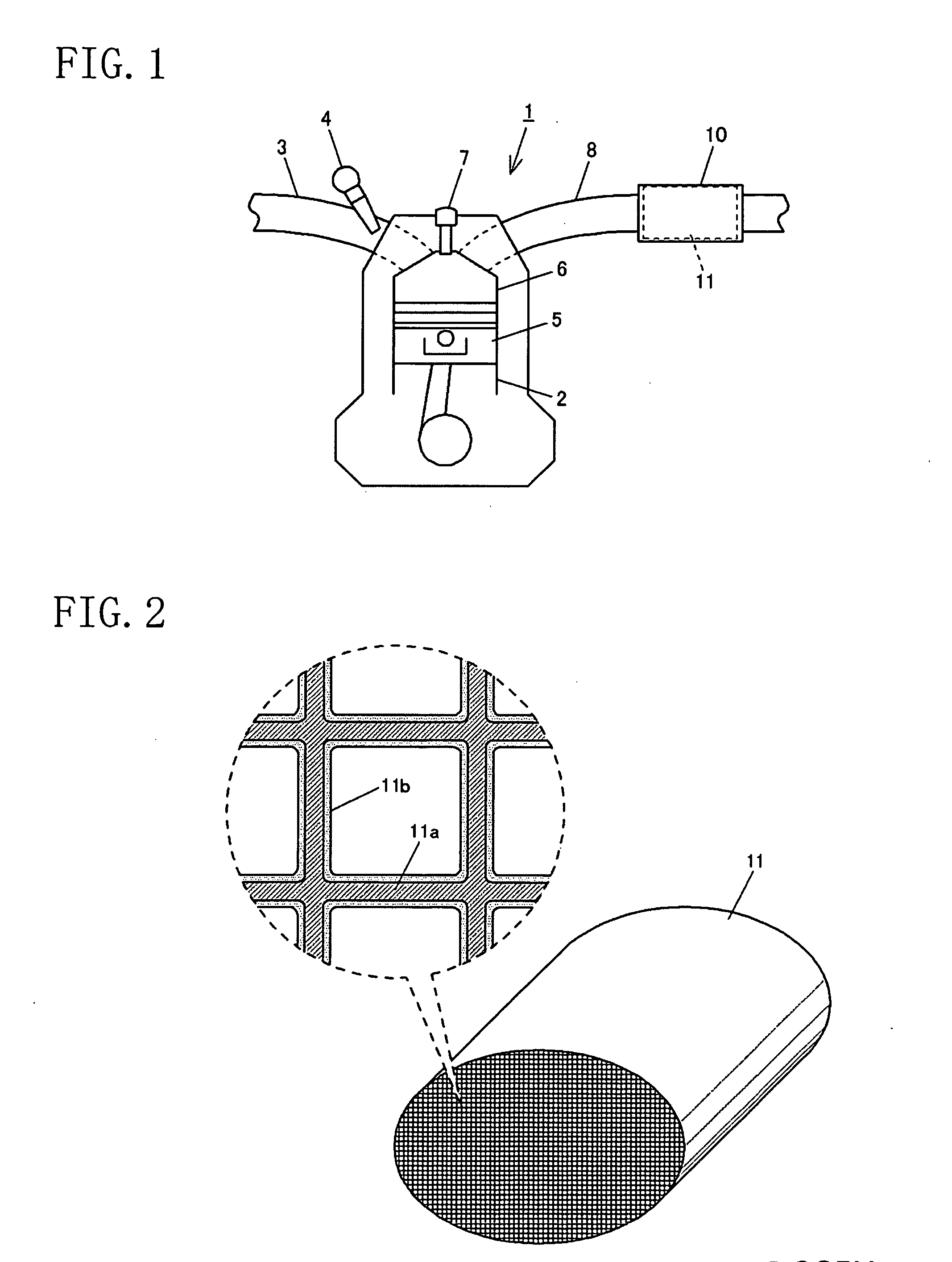

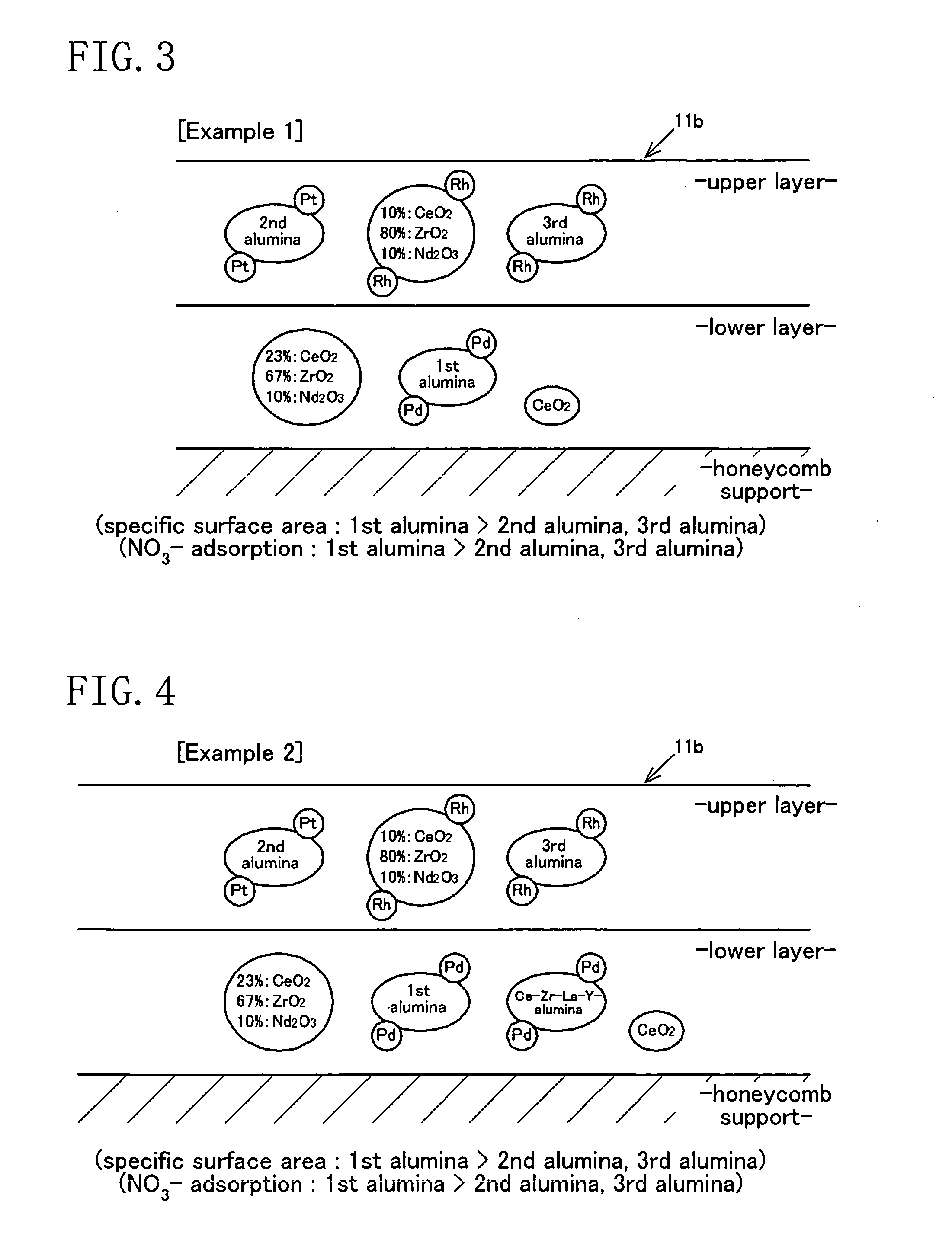

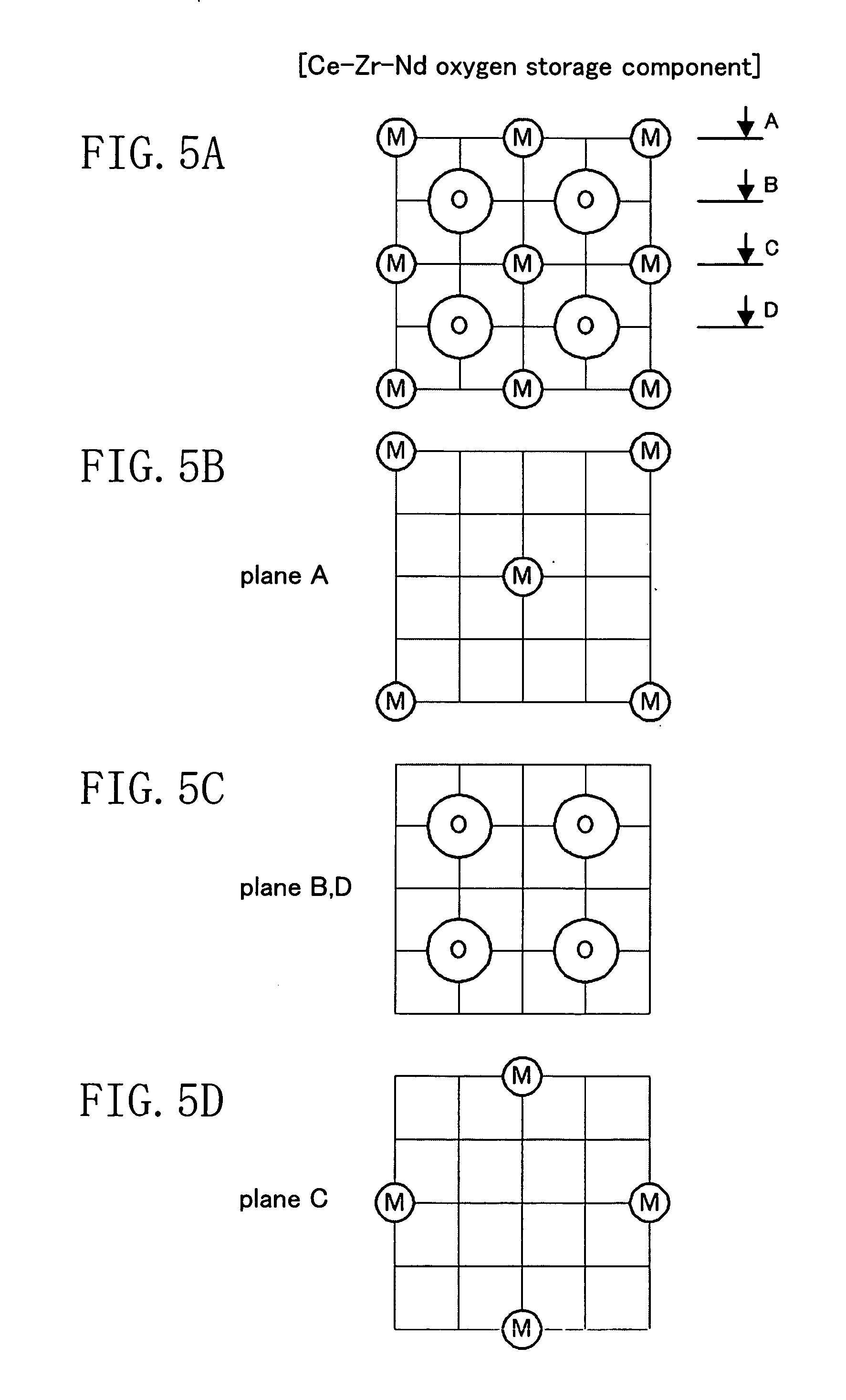

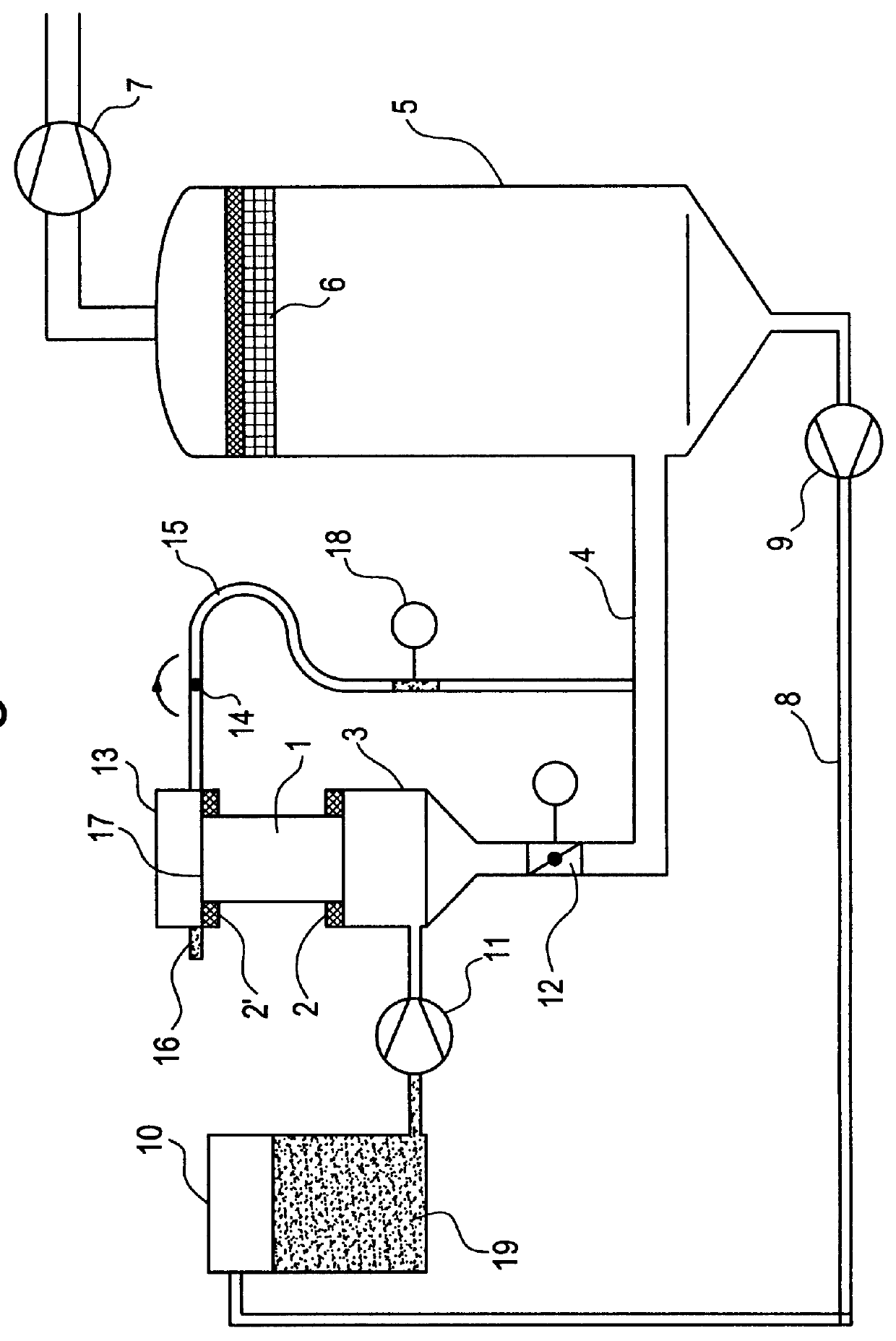

Exhaust gas purification catalyst

InactiveUS20060217263A1Improve catalytic conversion effectImprove heat resistanceInternal combustion piston enginesDispersed particle separationHoneycomb likePt element

In an exhaust gas purification catalyst in which a catalytic coating containing plural kinds of aluminas and plural kinds of oxygen storage components each carrying a catalytic precious metal is coated on a honeycomb support, the catalytic coating is formed of an upper layer and a lower layer, palladium is carried on a first alumina and a Ce—Zr—La—Y-alumina compound having oxygen storage capacity in the lower layer, platinum is carried on a second alumina in the upper layer, and rhodium is carried on a third alumina and a Ce—Zr—Nd mixed oxide having oxygen storage capacity in the upper layer.

Owner:TOKYO ROKI +1

Process for the coating of the flow channels of a honeycomb form catalytic converter carrier with a dispersion coating

A process for the coating of the flow channels of a cylindrical, honeycomb form catalyst carrier with a dispersion coating through filling of the vertically oriented flow channels with a fill quantity of the coating dispersion through the bottom face of the catalyst carrier and subsequent downward emptying and clearance extraction of the flow channels, as well as drying and calcination of the catalyst carrier, by the following steps: a) filling of the flow channels with a fill quantity that is about 10% greater than the empty volume of the flow channels, so that the coating dispersion goes over the upper face of the catalyst carrier after completion of the filling cycle, b) removal of the excess coating dispersion at the top before emptying of the flow channels and c) emptying and clearance extraction of the flow channels through an extraction impulse, which is generated by connection of a vacuum tank with the bottom face of the catalyst carrier, whereby the time between the beginning of the fill cycle and the end of the emptying and clearance extraction amounts to no more than 5 seconds.

Owner:DMC2 DEGUSSA METALS +1

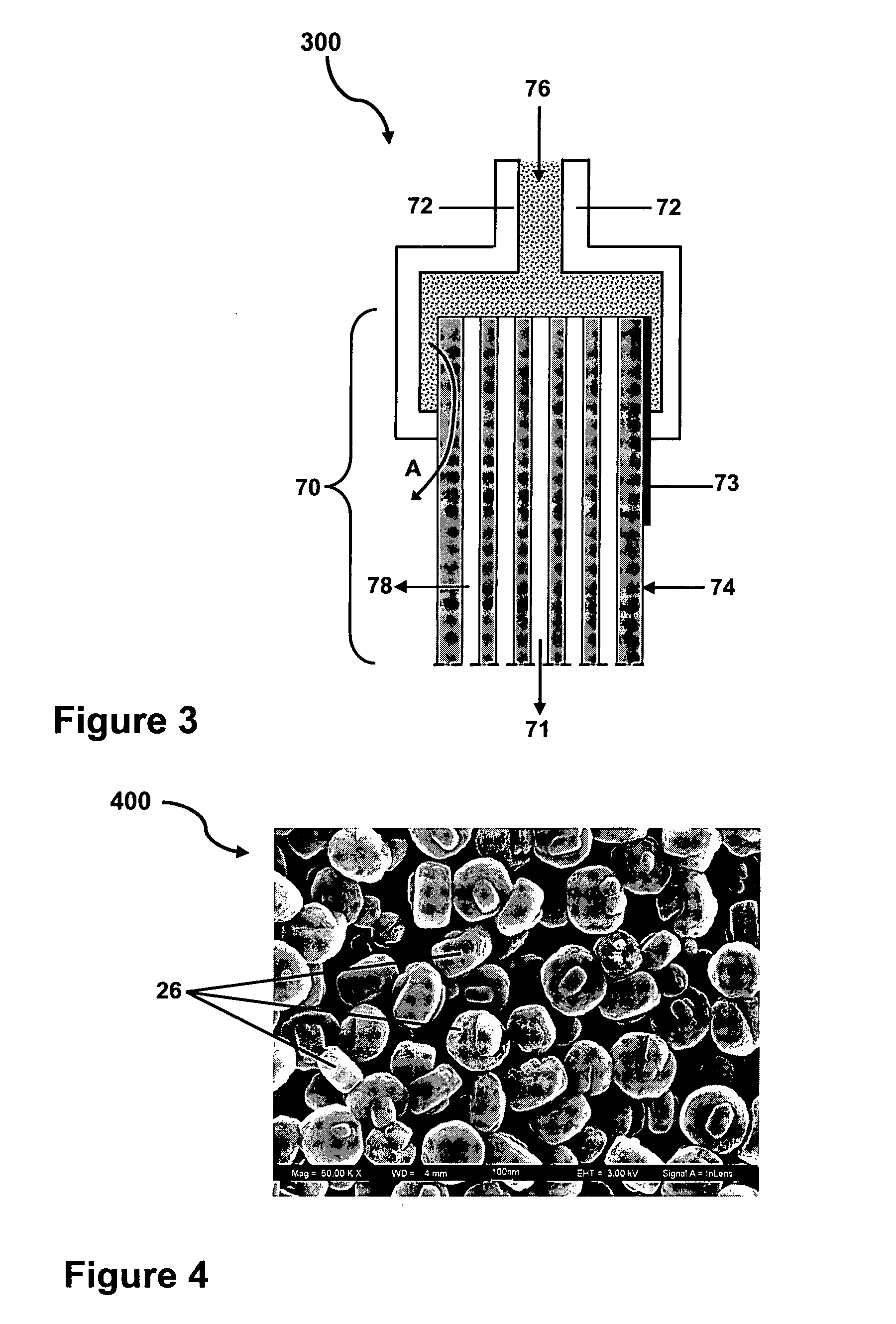

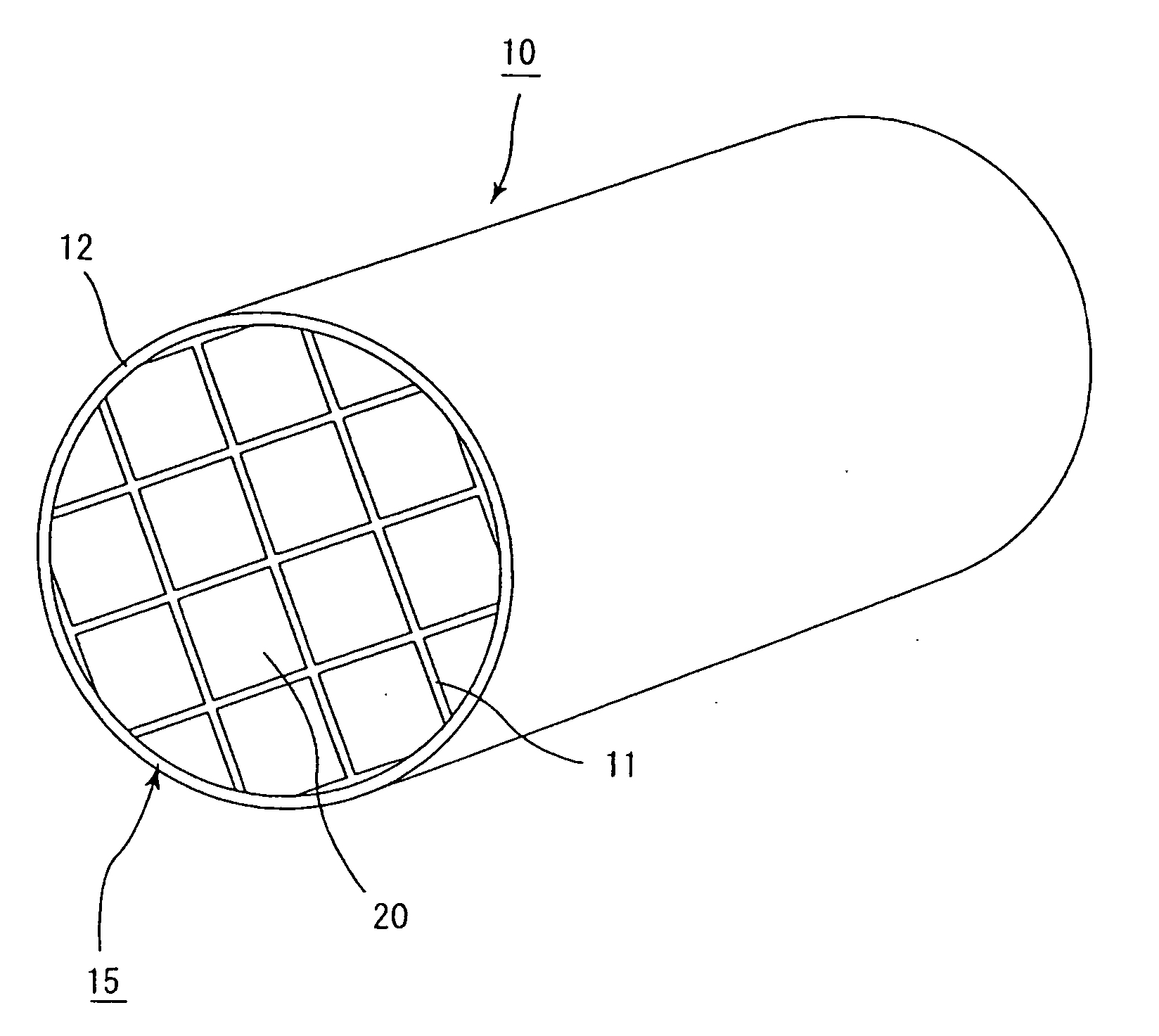

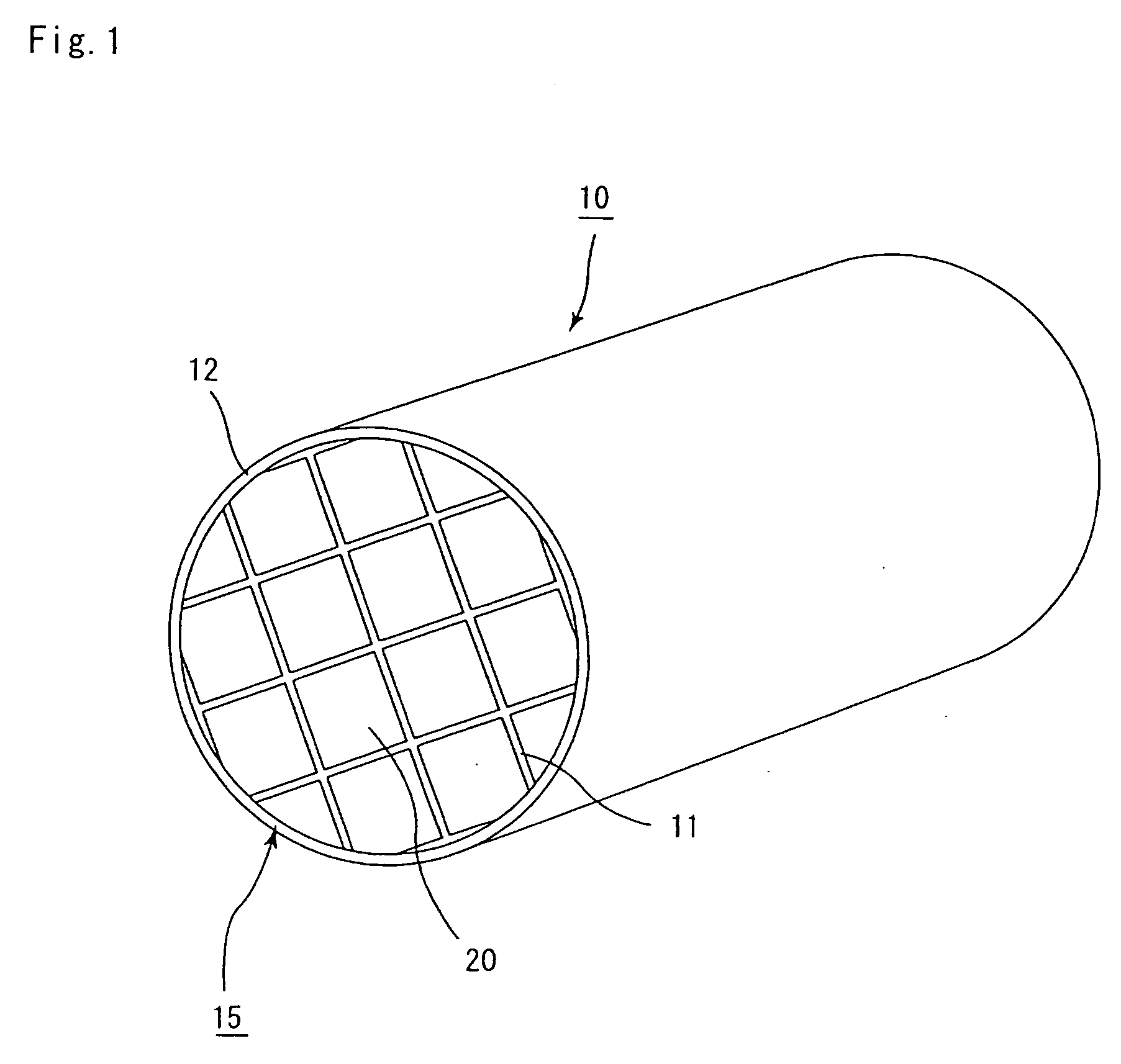

Zeolite membrane structures and methods of making zeolite membrane structures

InactiveUS20090000475A1High energyEnhanced capital efficiencyMembranesSemi-permeable membranesFiltrationHoneycomb

Inorganic membrane structures of high stability, high permeability, and large surface area. Zeolite membranes can be disposed onto an intermediate pore size modification layer which reduces the pore size of the inorganic porous support. The intermediate pore size modification layer minimizes the defects in the zeolite membrane and provides a more continuous and uniform zeolite membrane. The inorganic membrane structure can be in the form of a honeycomb monolith. The applications for the zeolite membranes include, for example, membrane ultra-filtration of gas or liquid fluids, biological assays and cell culture surfaces.

Owner:CORNING INC

Application and design for embedding bionic honeycomb-shaped active safety escape capsule into aircraft

The invention provides the application and design for embedding a bionic honeycomb-shaped active safety escape capsule into an aircraft. The application and design comprise the following related technologies including redesign of a main machine body of the aircraft for the embedded type bionic honeycomb-shaped active safety escape capsule, internal space layout design of the main machine body of the aircraft for the embedded type bionic honeycomb-shaped active safety escape capsule, design of an escape capsule embedded type shell and the shape, analysis of influences of the embedded escape capsule on the overall load of the aircraft, integral analysis and determination of flight aerodynamic load data, selection of an escape capsule material, escape capsule ejection mode analysis and ejection device design, logic design of launch motion of the escape capsule, internal space structure analysis of the escape capsule; active safety design of space landing of the escape capsule, description of flight dynamics influences of the escape capsule on the aircraft during and after separation, and design of an active help seeking system of the escape capsule. In this way, the application and design for researching and manufacturing the bionic honeycomb-shaped active safety escape capsule embedded into the aircraft are achieved.

Owner:王晨

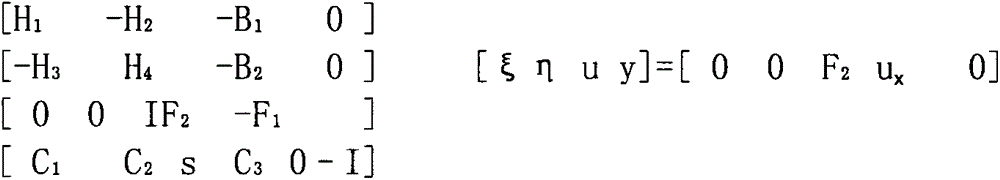

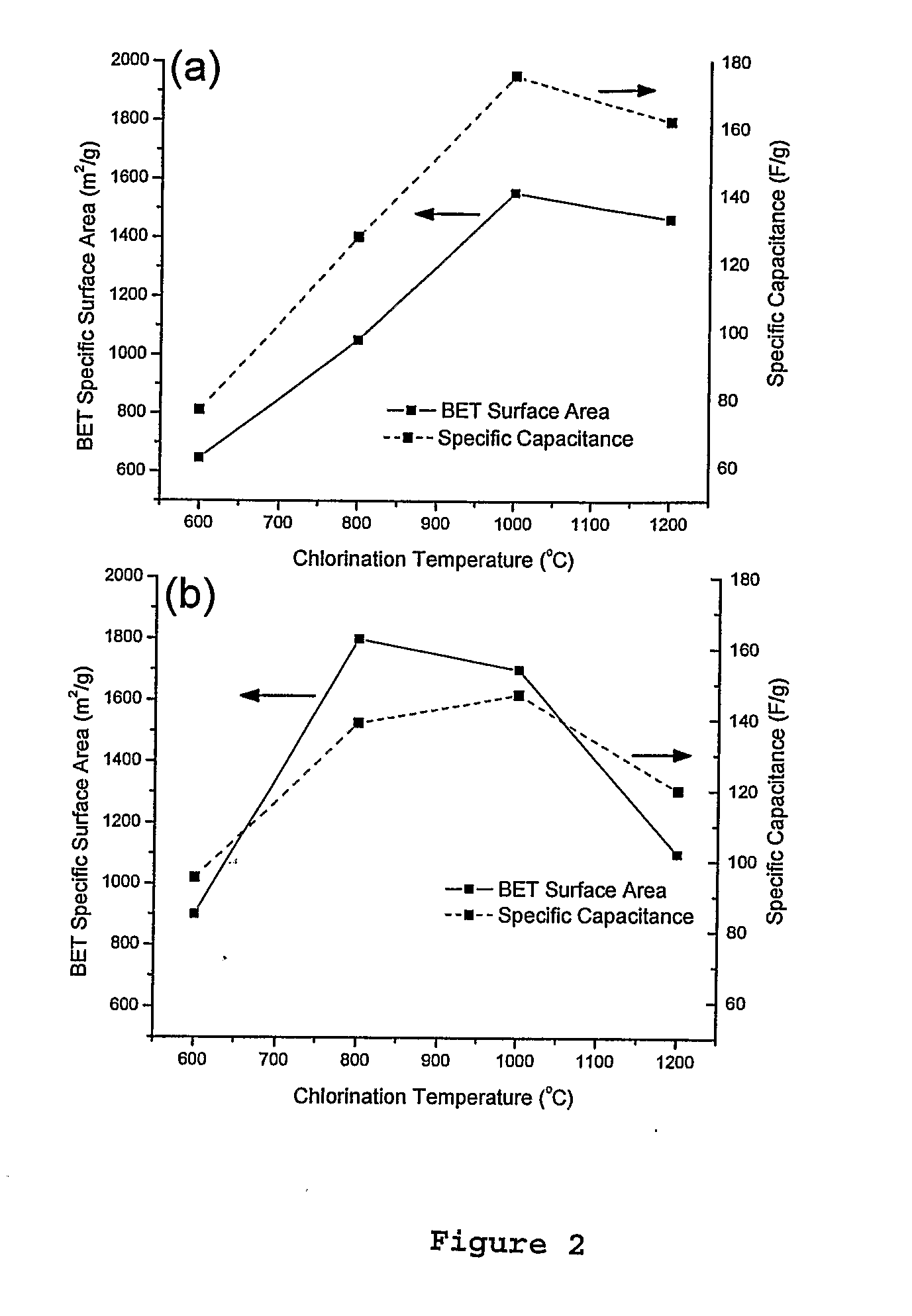

Nanocellular high surface area material and methods for use and production thereof

InactiveUS20090213529A1Improve conductivityHighly structuredElectrolytic capacitorsLayered productsPolymer scienceHoneycomb like

Nanocellular high surface area materials of a carbon material with high surface area that is controllable and which exhibits high conductivity, controllable structure and a precisely controllable pore size and methods for production and use of these materials are provided.

Owner:DREXEL UNIV

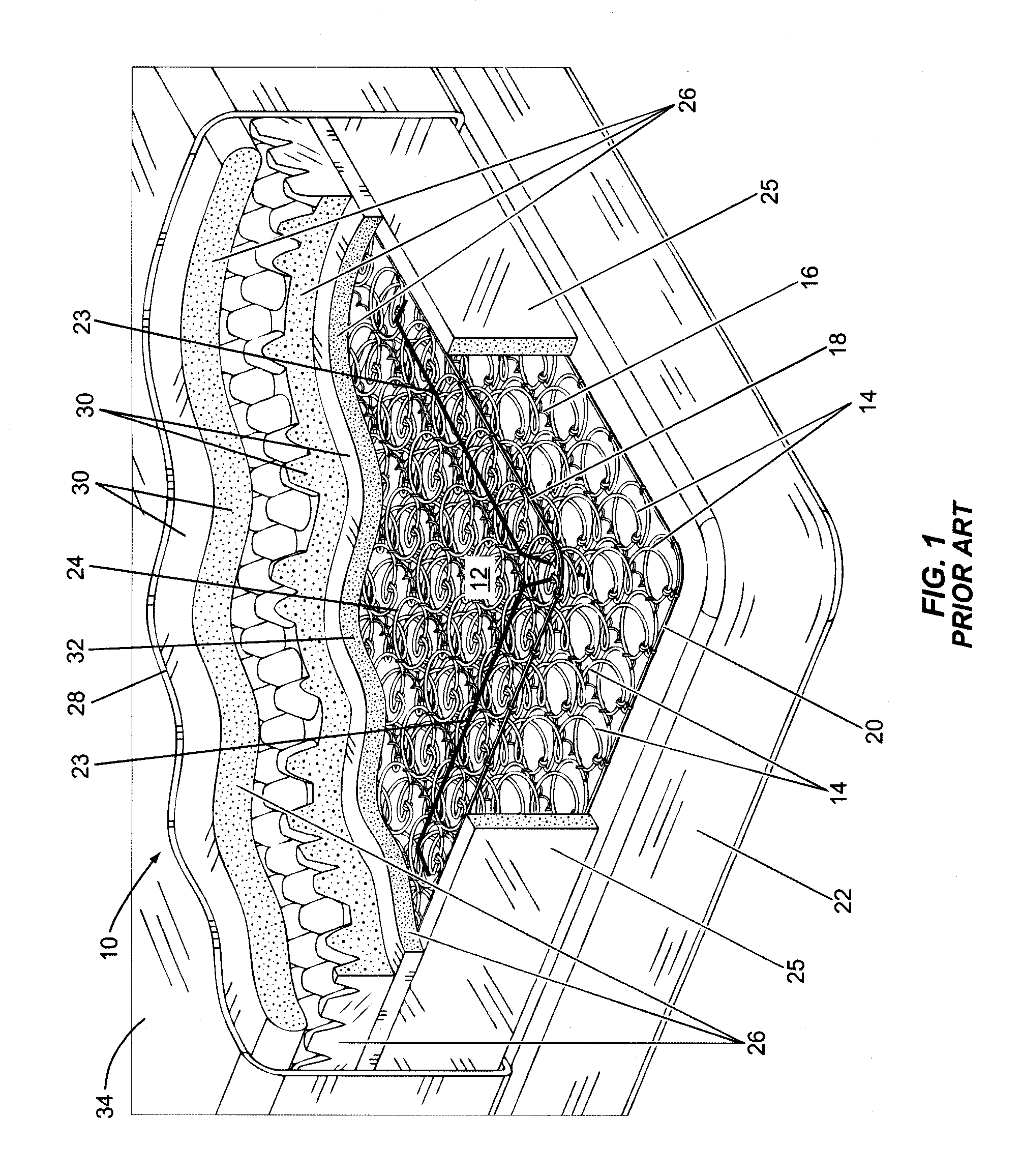

Full length cartridge cushioning system

The invention relates to a shoe sole for an article of footwear, in particular a sports shoe. The sole includes a first area having a first deformation element and a second area having a second deformation element. The first deformation element includes a foamed material and the second deformation element includes an open-walled or honeycomb-like structure that is free from foamed materials.

Owner:ADIDAS

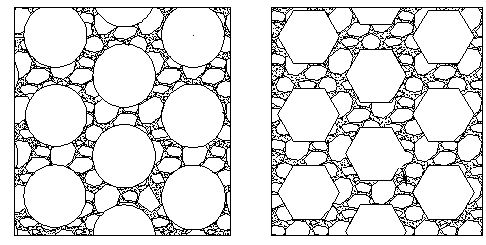

Honeycomb with a fraction of substantially porous cell walls

InactiveUS20080044621A1Large specific surface areaEasy and inexpensiveNatural cellulose pulp/paperSynthetic cellulose/non-cellulose material pulp/paperFiltrationEngineering

An artificial honeycomb structure, and simple constructions therefrom, are provided, wherein at least a portion of at least one of the enclosing honeycomb cell walls is substantially porous, open, or permeable, and wherein at least one of the hollow cells comprises at least one substantially nonporous enclosing wall. The honeycomb and its constructions can be useful in applications that include, but are not limited to, heat exchange and storage, structural support, impact absorption, filtration, acoustic dampening, catalysis, and flow control and distribution.

Owner:STRAUSS BEN

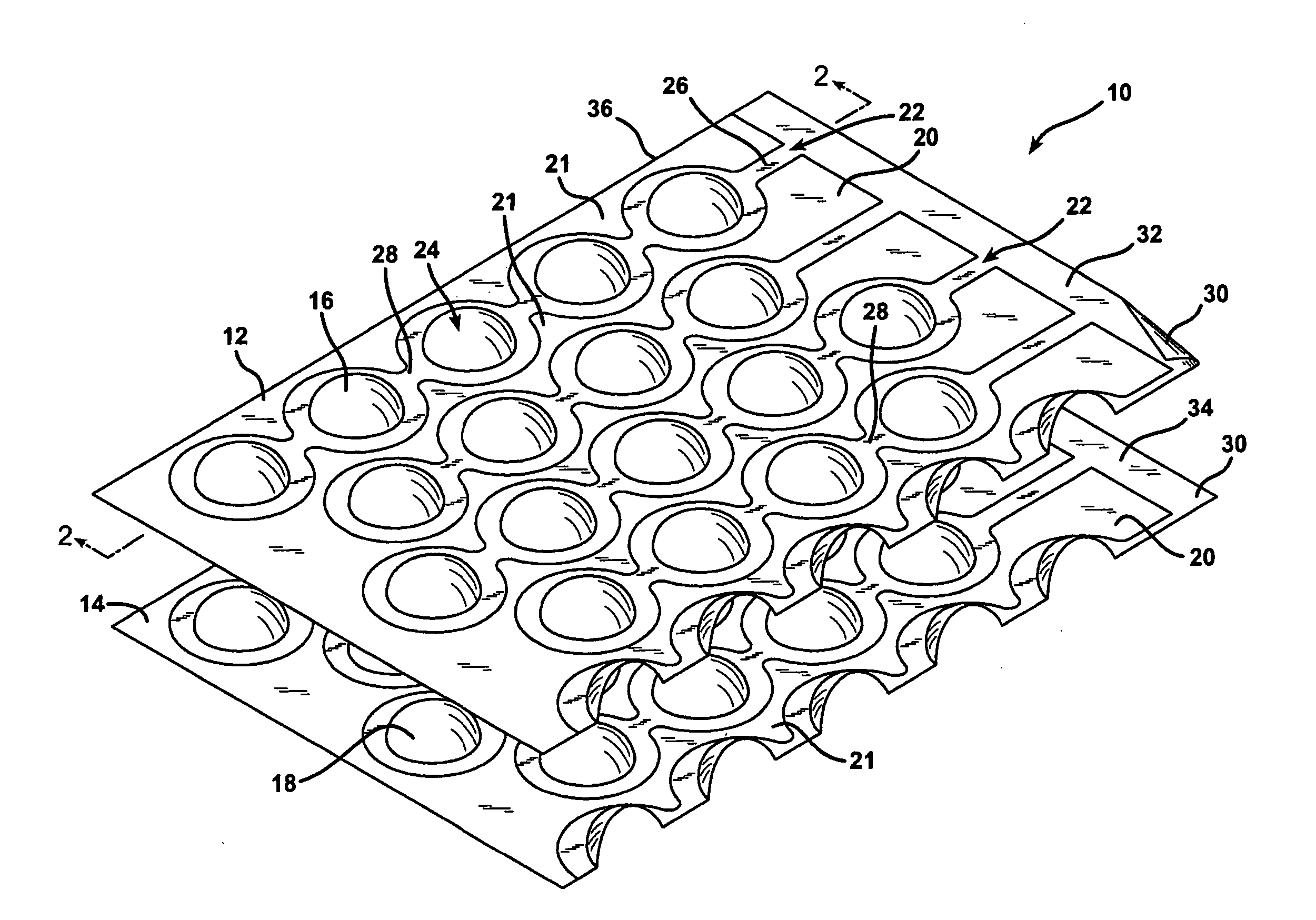

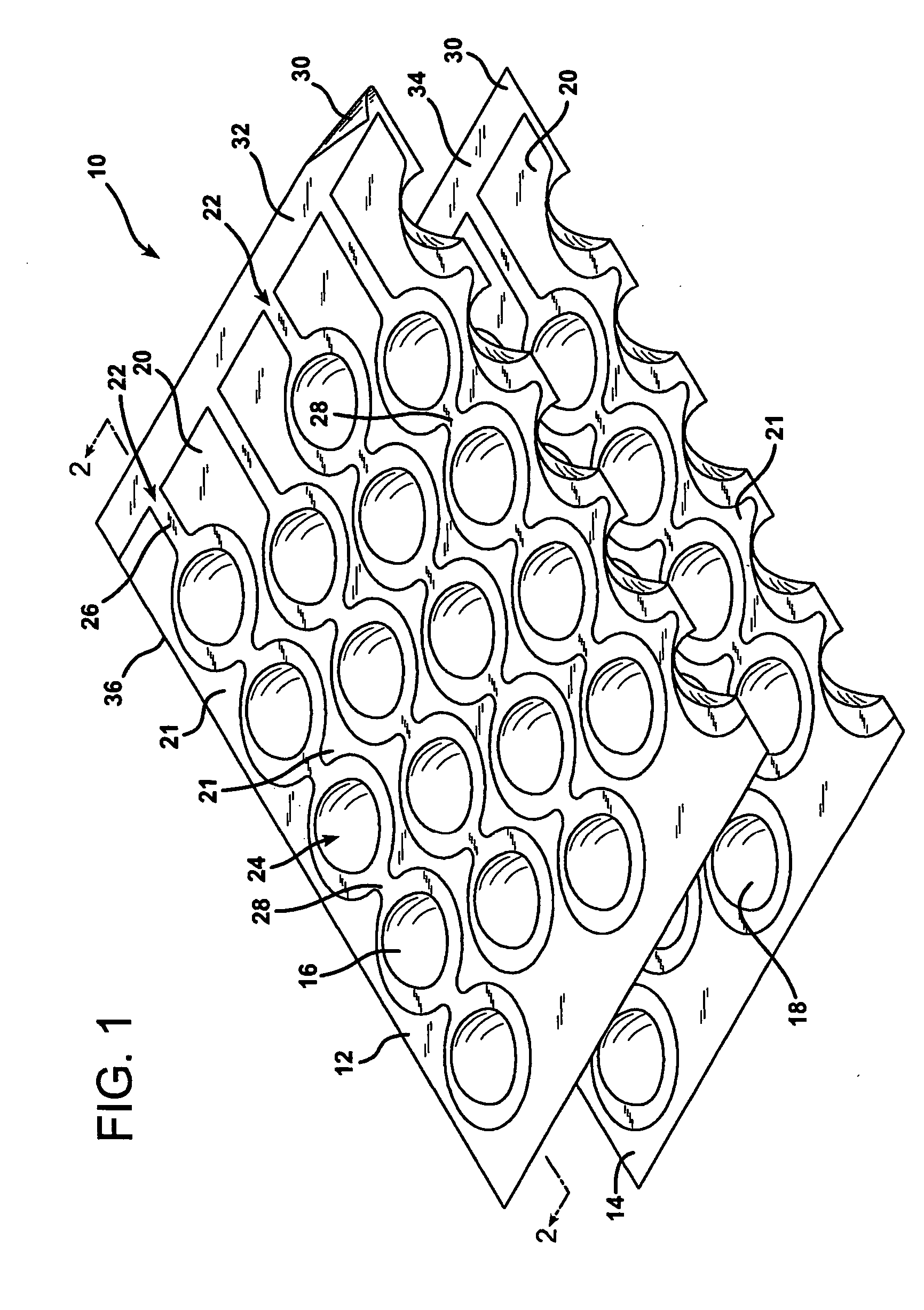

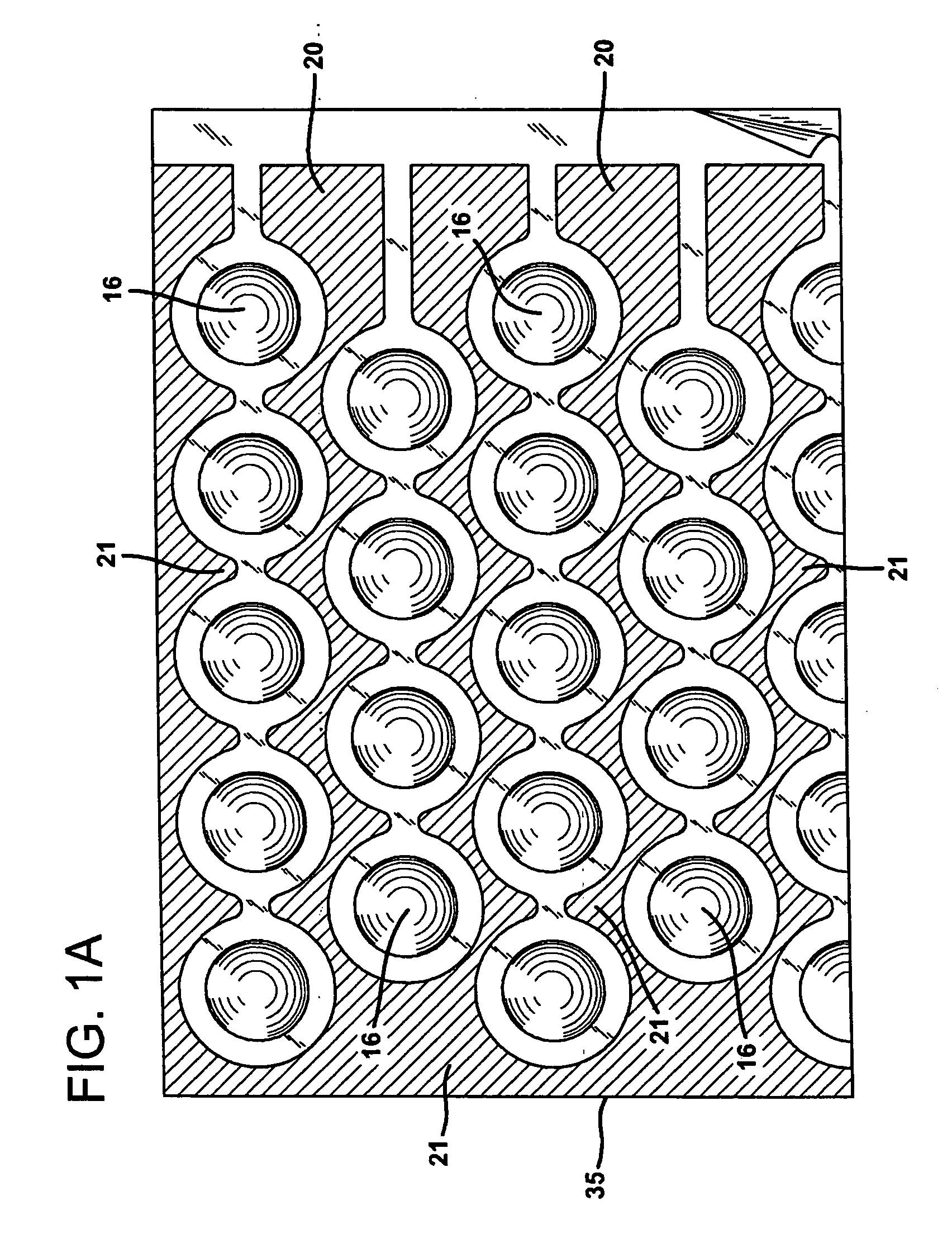

Formed inflatable cellular cushioning article and method of making same

InactiveUS20060210773A1Reduced lateral contractionCell height can be increasedLabelling non-rigid containersPaper/cardboard articlesCushioningHoneycomb like

An inflatable article has a first film bonded to a second film so as to provide between the first film and the second film a plurality of inflatable chambers, each of the inflatable chambers containing a plurality of cells. Each of the cells is connected to at least one adjacent cell by an inflatable connecting channel. The first film is bonded to the second film between adjacent inflatable chambers. The first film and the second film each have at least one formed region corresponding with a location of a cell, with the at least one formed region of the second film being nested into the at least one formed region of the first film. Also disclosed are processes of making the inflatable article.

Owner:SEALED AIR U S

Honeycomb structured body

The honeycomb structured body of the present invention is a honeycomb structured body in which a plurality of porous ceramic members are combined with one another through an adhesive layer, each of the porous ceramic members having a plurality of cells which are allowed to penetrate in a longitudinal direction with a wall portion therebetween and either one end of which is sealed, with a catalyst supporting layer being adhered to the wall portion, wherein an average pore diameter of the porous ceramic member is larger than an average particle diameter of particles constituting the catalyst supporting layer, and when a pore diameter distribution of the porous ceramic member and a particle diameter distribution of particles constituting the catalyst supporting layer are drawn with the pore diameter and the particle diameter being on the same axis, a pore volume in an overlapped area of both the distributions is about 10% or less to the entire pore volume of the porous ceramic member.

Owner:IBIDEN CO LTD

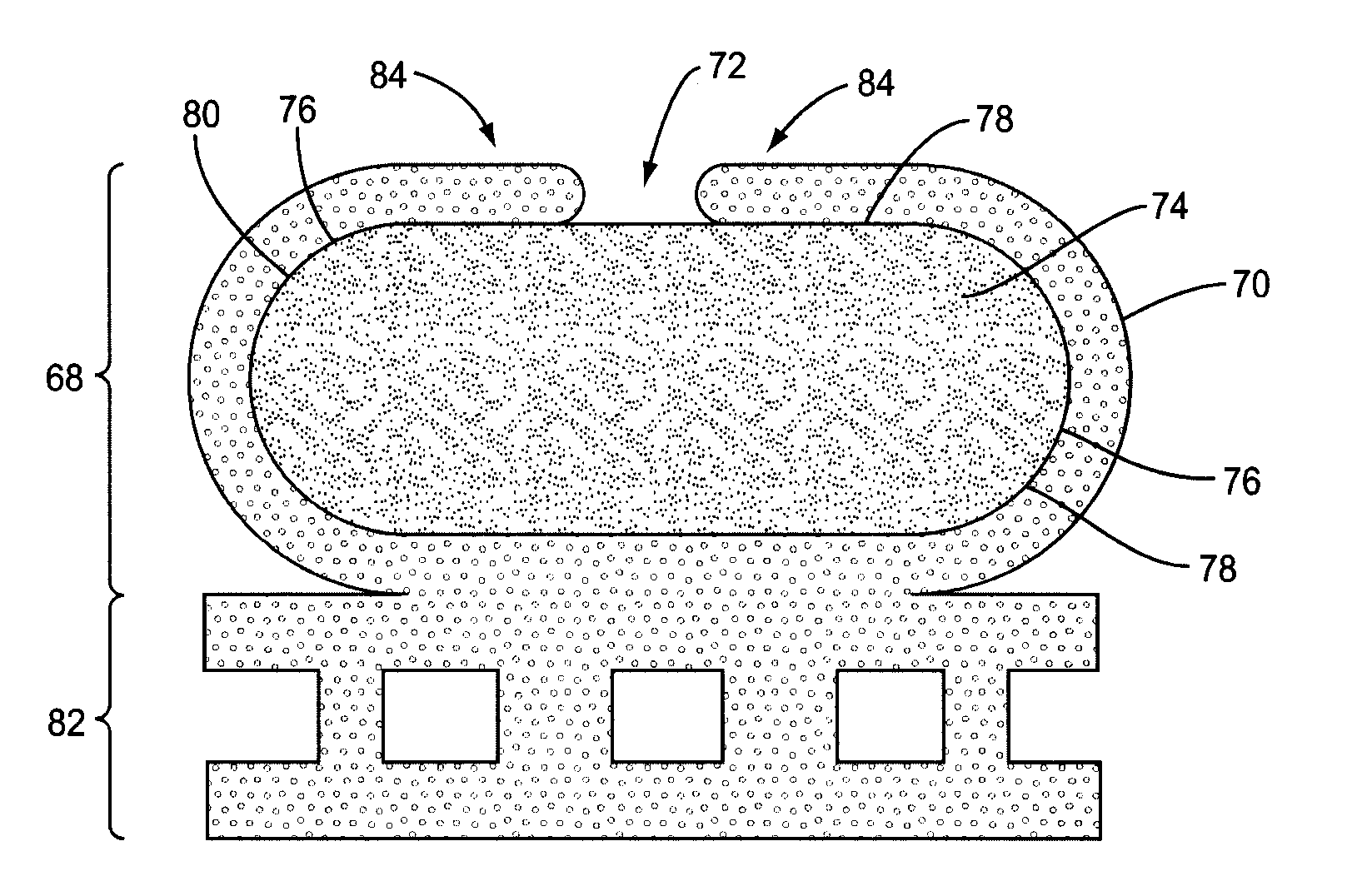

Unitary composite/hybrid cushioning structure(s) and profile(s) comprised of a thermoplastic foam(s) and a thermoset material(s)

InactiveUS20100223732A1Improved compression setLow costStuffed mattressesSpring mattressesCushioningThermoplastic

Embodiments disclosed in the detailed description include a unitary or monolithic composite or hybrid cushioning structure(s) and profile(s) comprised of a cellular thermoplastic foam and a thermoset material. The thermoset material may also be provided as cellular foam as well. In one embodiment disclosed herein, the unitary composite cushioning structure is formed from a cellular thermoplastic foam and a thermoset material. The cellular thermoplastic foam provides support characteristics to the unitary composite cushioning structure. The thermoset material provides a resilient structure with cushioning characteristics to the cushioning structure. A stratum is disposed between at least a portion of the cellular thermoplastic foam and at least a portion of the thermoset material to secure the at least a portion of the thermoset material to the at least a portion of the cellular thermoplastic foam to provide a unitary composite cushioning structure.

Owner:NOMACO

Preparation method and application of hierarchical porous bioactive ceramic

InactiveCN103113129AHigh degree of automationHigh degree of mechanical formingProsthesisCeramicwareViscous liquidSolvent

The invention discloses a preparation method and application of hierarchical porous bioactive ceramic. The preparation method comprises the following steps: mixing a binding agent, plasticizer and solvent to obtain an additive emulsion; adding a pore forming agent into the additive emulsion, and mixing to obtain a pore forming agent viscous liquid; adding bioactive powder into the pore forming agent viscous liquid, compounding, and aging to obtain high-plasticity mud pies; and performing extrusion molding on the mud pies, drying, sintering to obtain honeycombed hierarchical porous bioactive ceramic, grouting with a bioactive powder suspension to regulate the size and shape of pores, drying again, and firing to finally obtain the bioactive ceramic having a hierarchical pore size structure and a non-acute pore shape. According to the invention, the preparation method is simple; industrial production can be realized; and the hierarchical porous bioactive ceramic having the advantages of high porosity, favorable mechanical property, satisfactory connectivity and the like can be prepared and is an ideal bone defect repair material.

Owner:SOUTH CHINA UNIV OF TECH

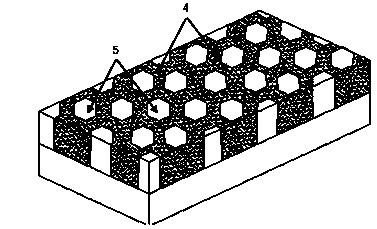

Lightweight ceramic tile and production method

The invention discloses a light-weight ceramic brick, which is a light-weight ceramic brick fired at high temperature and has a honeycomb-like internal structure of closed pores. The invention also discloses a preparation method of the above-mentioned lightweight ceramic tiles, which is formed by dry pressing after wet ball milling, sieving, iron removal, spraying drying tower and powder spraying on the vitrified brick polishing waste produced in large quantities in the ceramic industry at present. Method forming, or kneading using wet extrusion molding, and then firing products in continuous or batch kilns. Manufacture a kind of lighter quality ceramic tiles, aiming at the insufficient use of waste materials in the past, more effectively utilize industrial waste residues in large quantities, and because of its light structure, it can be used in the decoration of high-rise building walls, It has good properties such as light weight, high strength, heat preservation, and sound absorption, and it can significantly reduce the weight of the wall structure. At the same time, it also has the characteristics of easy transportation, easy construction, and fast speed. It has great advantages in saving energy and reducing the weight of buildings. The outstanding advantage is that it is an environment-friendly building ceramic decoration material.

Owner:FOSHAN OCEANO CERAMICS

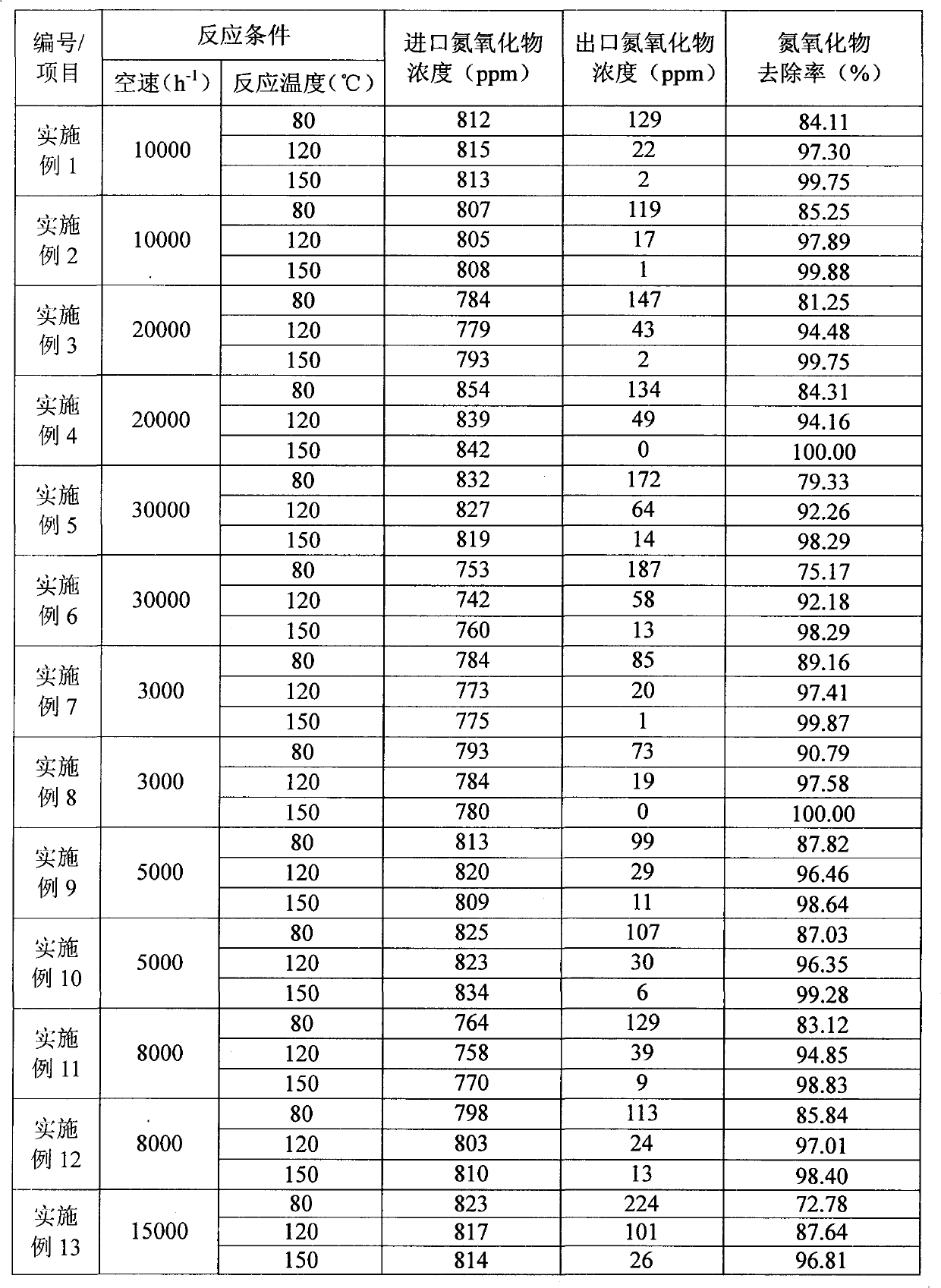

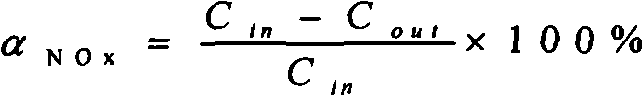

Cellular Mn-Ti-based catalyst for low-temperature selective catalytic reduction denitration reaction and preparation method and using method

InactiveCN101947443AAvoid hard clumpingAvoid the disadvantages of self-growth of crystal grainsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurFlue gas

The invention discloses a cellular Mn-Ti-based catalyst for low-temperature selective catalytic reduction (SCR) denitration reaction, and a preparation method and a using method. The catalyst comprises the following components in molar percent: 40 to 60 percent of TiO2, 5 to 16 percent of MnO2, 3 to 7 percent of Mn2O3, 2 to 4 percent of Mn3O4, 2 to 8 percent of CeO2, 1 to 3 percent of V2O5, 0.5 to 1 percent of Se, 0.5 to 1 percent of Sb, and 0.15 to 1.5 percent of Bi. The preparation method comprises the following steps of: first preparing Mn-Ti catalyst powder by a hydrothermal method, and then preparing modified cellular Mn-Ti-based catalyst by processes such as extrusion forming, soaking and the like so as to improve the low temperature SCR activity and the sulfur poisoning resisting capability of the catalyst. Furthermore, the catalyst prepared by the method has the advantages of high mechanical strength, high dispersibility of active substances and difficult sintering, can be applied to the low temperature SCR denitration reaction of flue gas, is directly arranged behind a dust removing device even a desulfurizing device, can greatly reduce the operational temperature and operation cost of the traditional SCR process, and has high nitrogen oxide removing rate at the temperature of about 100 DEG C.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

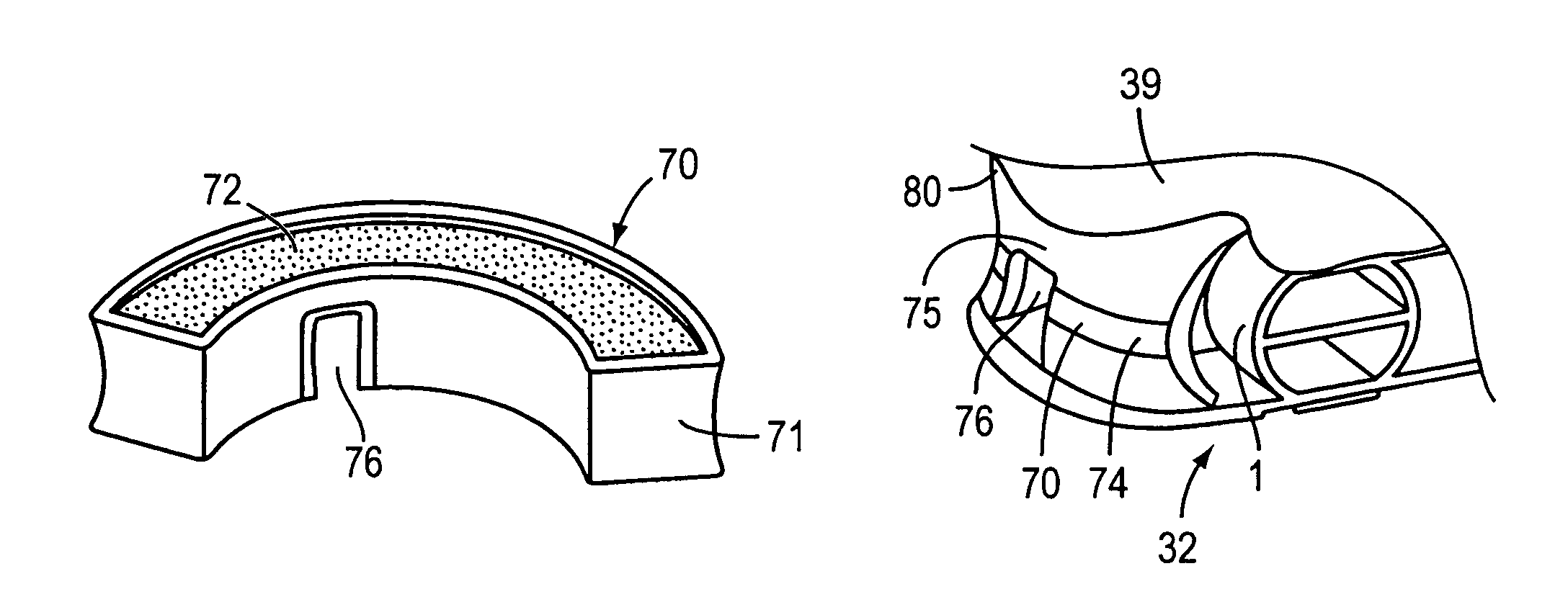

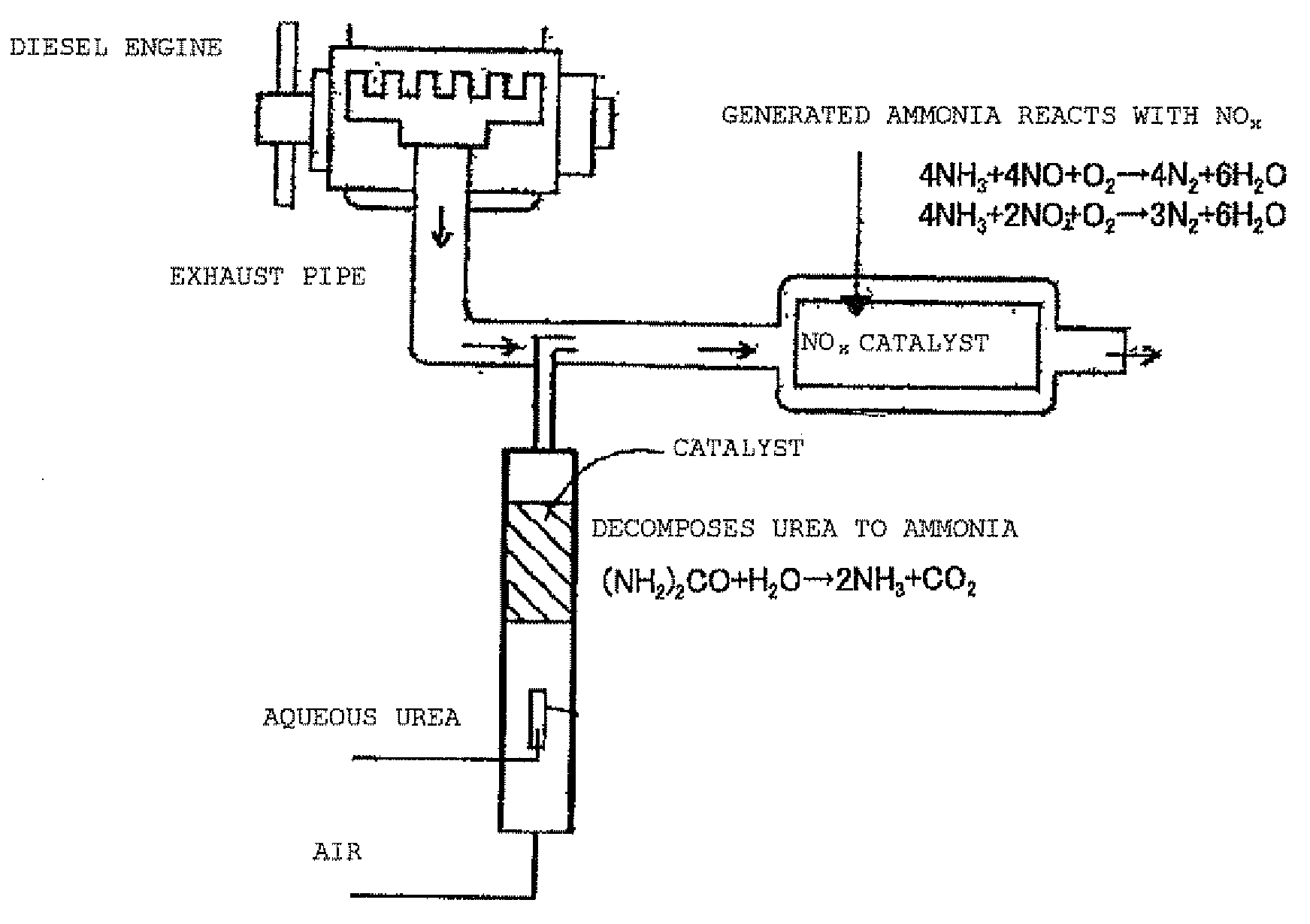

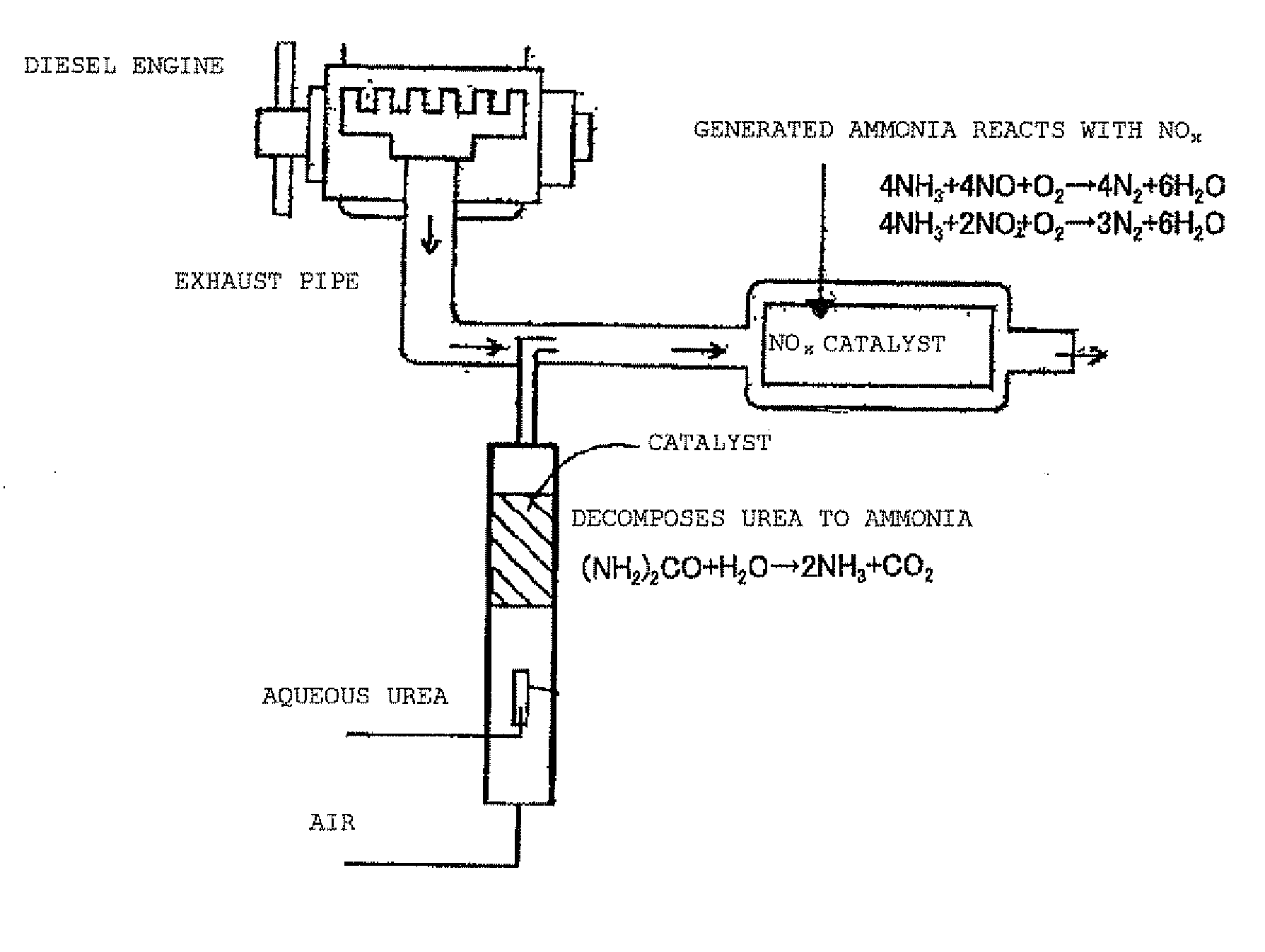

Exhaust Gas Treatment Apparatus

InactiveUS20090214397A1Improve adhesionIncrease resistanceCombination devicesGas treatmentParticulatesHoneycomb

An exhaust gas treatment apparatus includes a device (A) which is provided in an exhaust system and which selectively reduces NOx in an exhaust gas and a device (B) which is disposed upstream of the device (A) and which decomposes urea and supplies ammonia as a NOx reducing gas, the device (B) including a urea decomposition catalyst. The catalyst is [1] a zeolite catalyst which is composed of granular molded bodies including zeolite particles or which includes a catalyst layer composed of zeolite particles disposed on a support, or [2] a honeycomb catalyst or a membranous catalyst in which metal oxide particulates adhere to a conductive honeycomb substrate or netlike support, and the metal oxide particulates are composed of at least one oxide of a metal selected from the group consisting of Na, Mg, Ca, Ba, La, Ce, Ti, Zr, V, Cr, Mo, W, Mn, Zn, Al, Si, P, Sb, Cu, Fe, Ru, Co, and Re.

Owner:JGC CATALYSTS & CHEM LTD

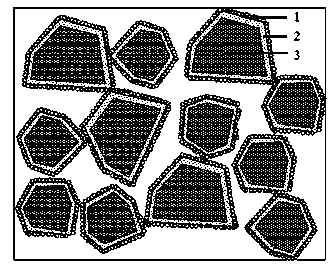

Preparation method and application of ceramic preform

The invention discloses a preparation method and application of a ceramic preform, belonging to the field of metal matrix composite. The preparation method comprises steps of mixing adhesive with ceramic particles, fully mixing powder of carbide such as silicon carbide and boron carbide with powder of oxide, then adding into adhesive coated ceramic particles to be mixed, filling the mixed material into a die so as to prepare the cellular porous ceramic preform, wherein a coating layer well wetted by molten metal is formed on the surface of the ceramic particle. The ceramic particles prepared by the method allow the ceramic particles of the metal matrix composite to be distributed more uniformly in the metal matrix, the composite layer is thick, the coated surface of the ceramic particle is easy to be wetted by molten metal, the bonding strength of the metal and the ceramic is greatly improved, and the service life of the composite is prolonged.

Owner:KUNMING UNIV OF SCI & TECH

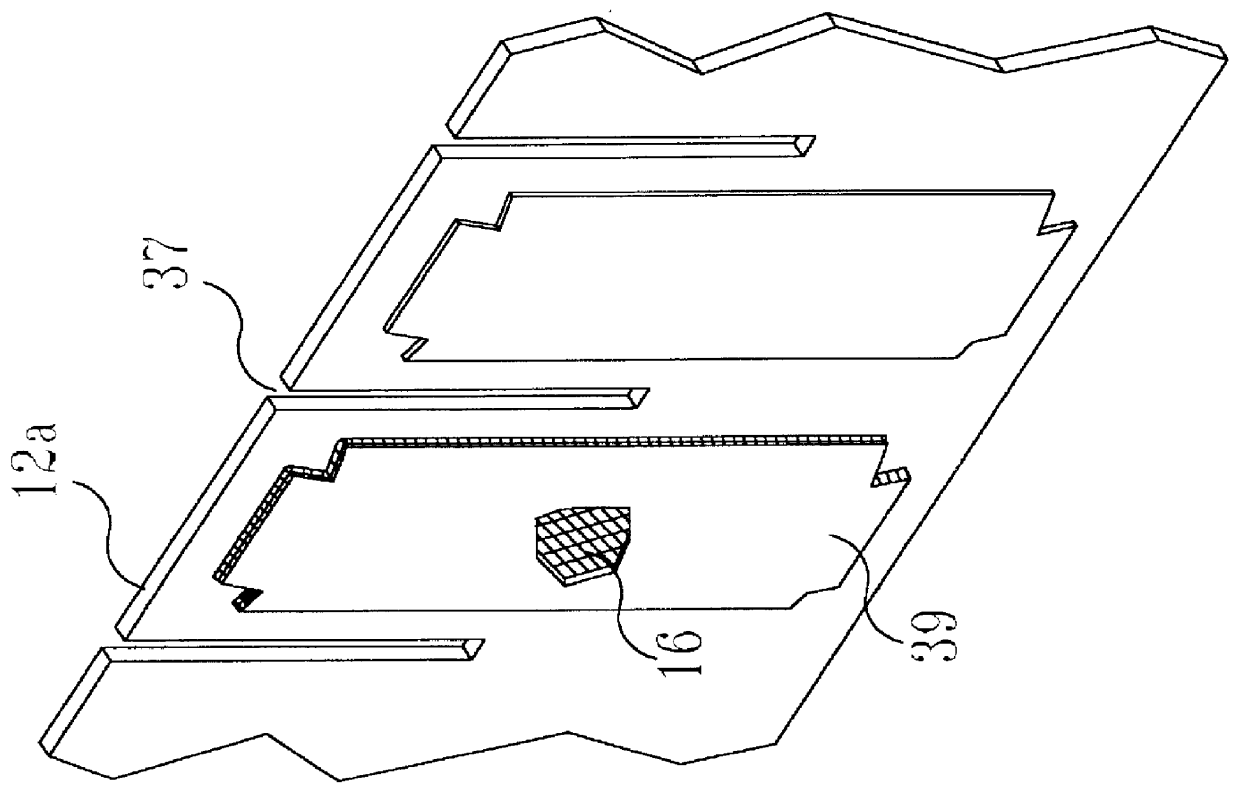

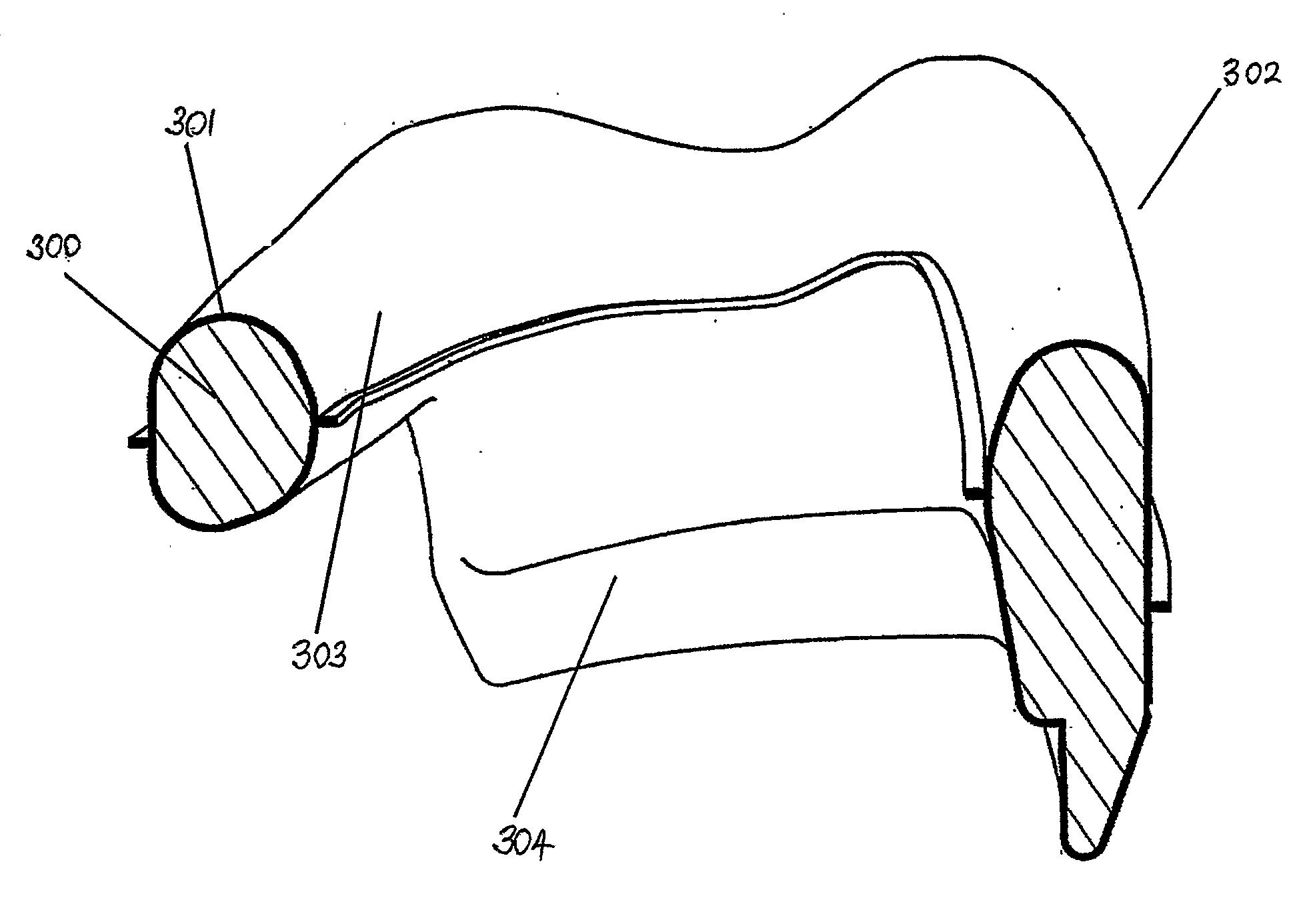

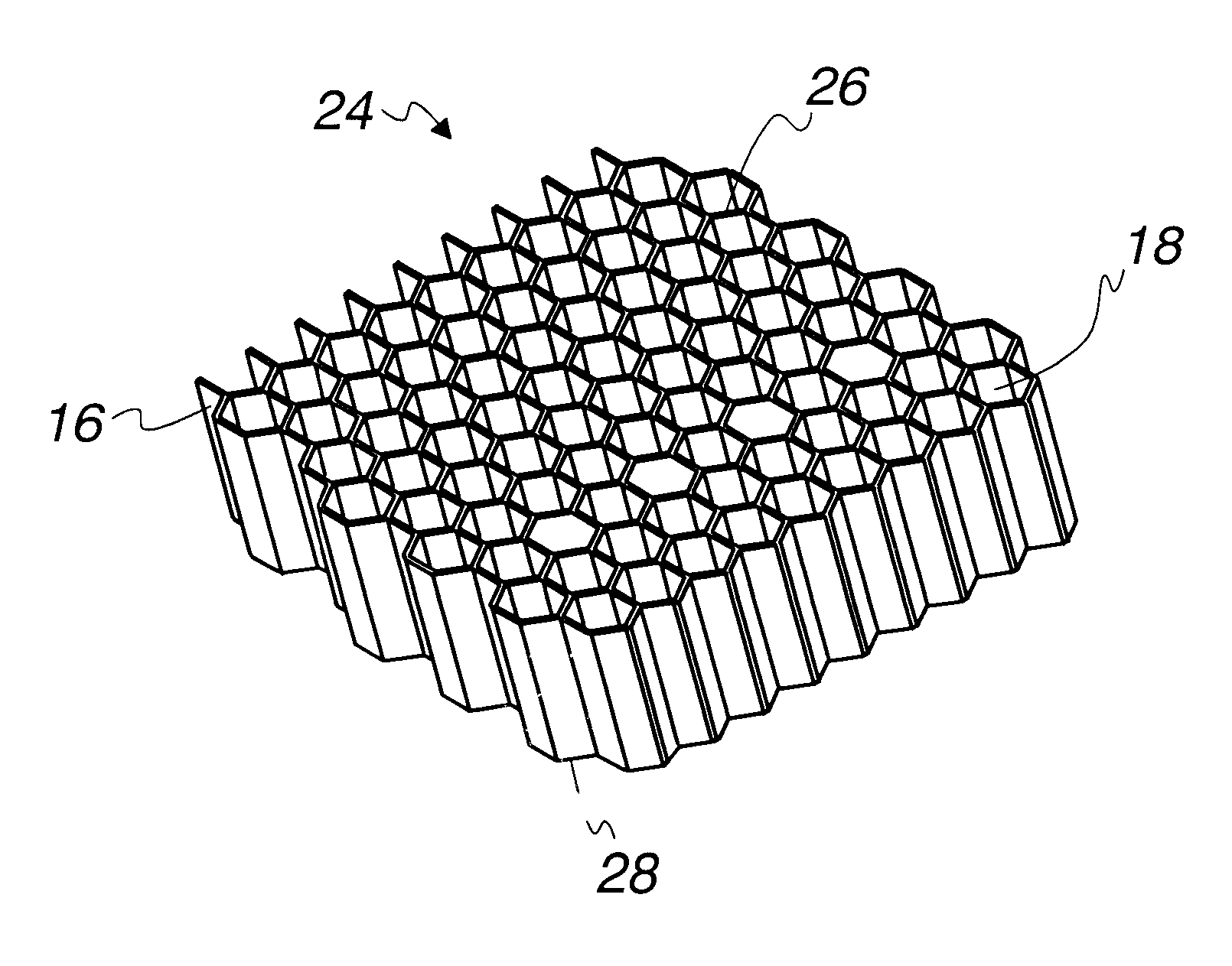

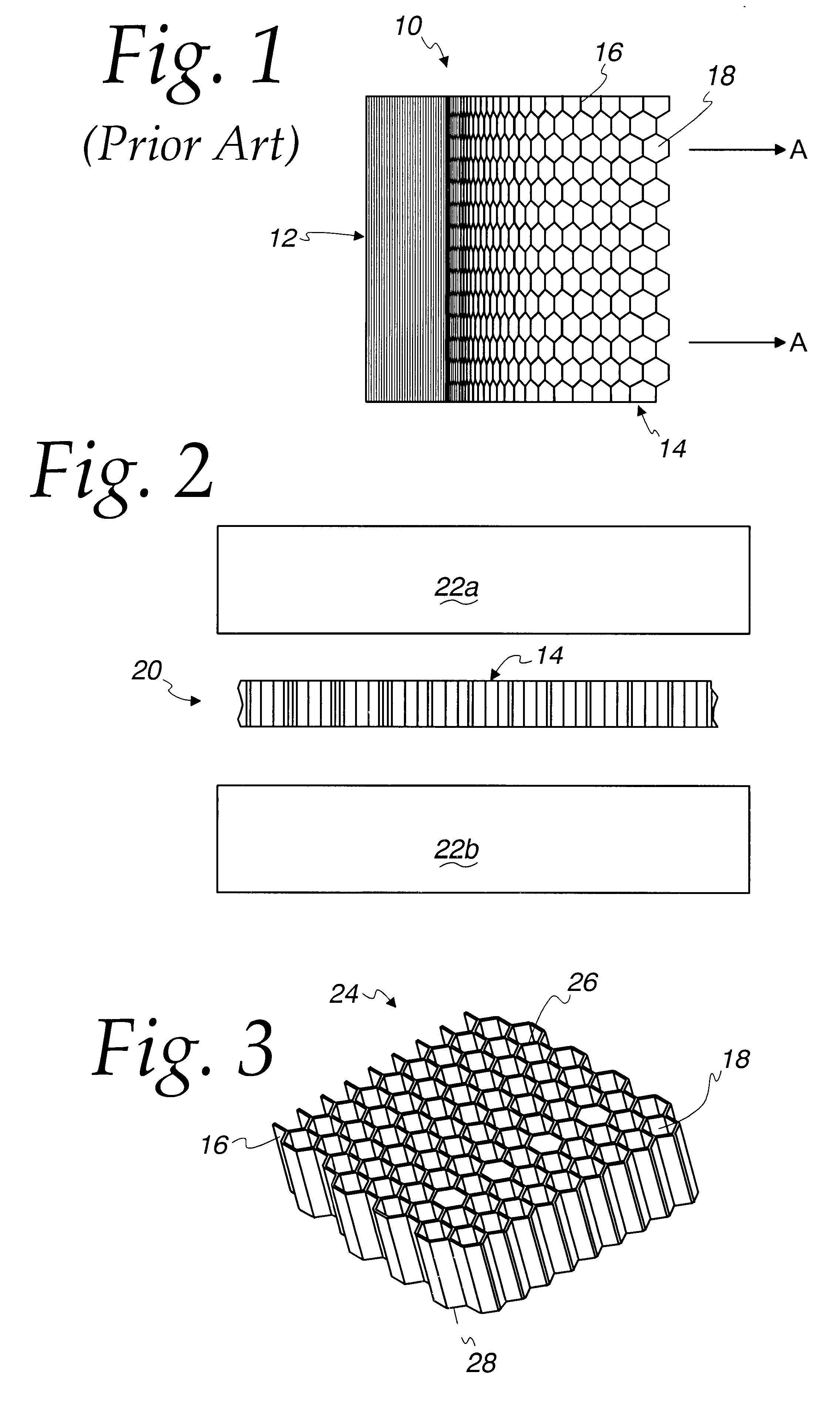

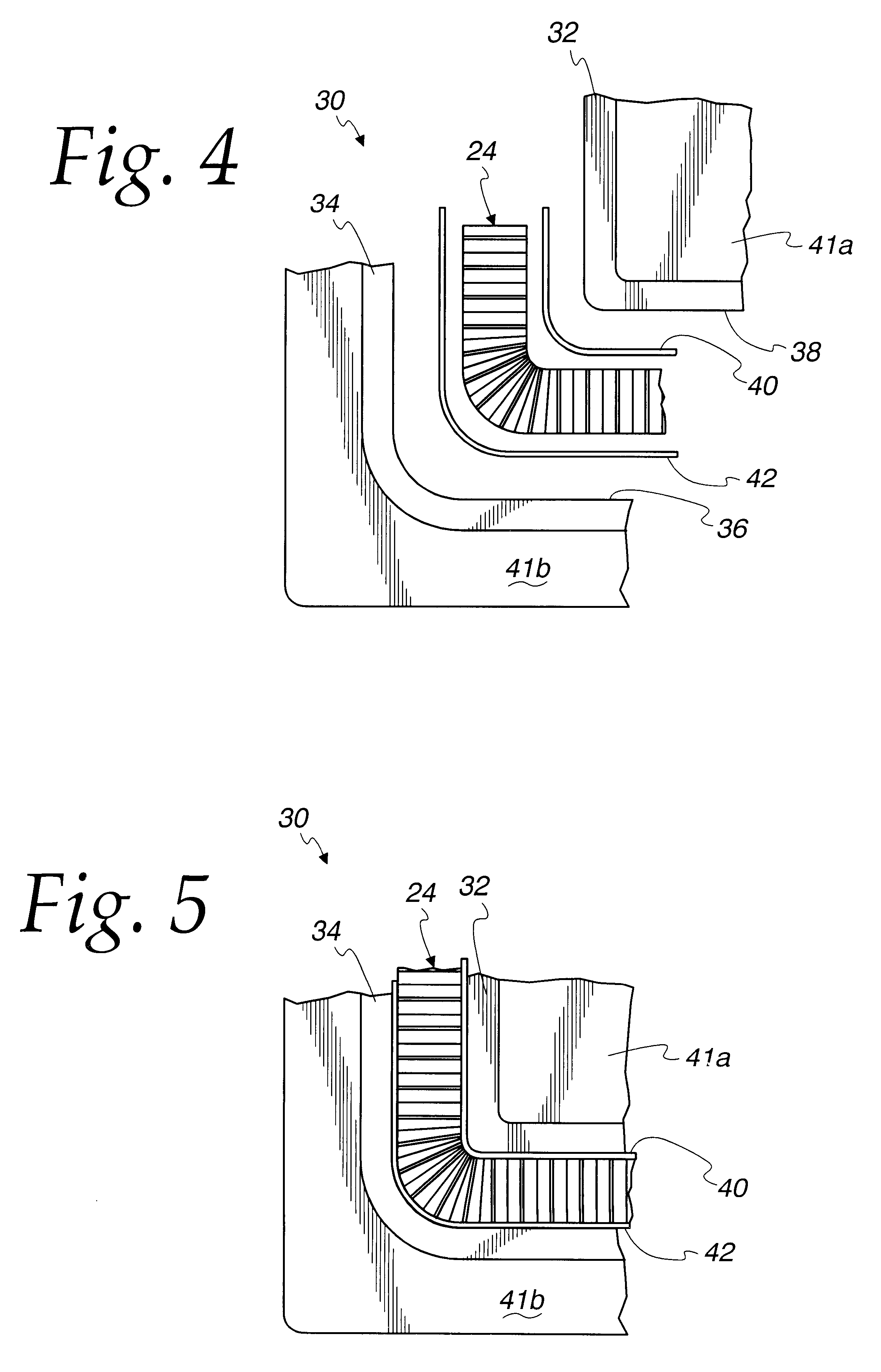

Shaped honeycomb structures and method and apparatus for making shaped honeycomb structures

InactiveUS6372322B1Paper/cardboard articlesSynthetic resin layered productsHoneycomb likeHoneycomb structure

A shaped honeycomb structure having a permanently fixed fold portion. The shaped honeycomb structure has a honeycomb core with a plurality of abutting partition walls defining a plurality of abutting hollow cell faces on a top side and a bottom side of the honeycomb core. The fold portion defines a first panel portion converging with a second panel portion. At the fold portion, the partition walls are generally not vertically deformed. The shaped honeycomb structure may be made by a method comprising expanding an unexpanded honeycomb core to form an expanded honeycomb core comprising a plurality of abutting partition walls forming a plurality of cells defining a plurality of abutting hollow cell faces on a top side and a bottom side of the expanded honeycomb core. The expanded honeycomb core is impregnated with a resin. The fold portion is formed in the expanded honeycomb core such that the partition walls are generally not vertically deformed at the fold portion. The resin impregnated folded honeycomb core is then completely cured to permanently rigidly fix the plurality of abutting partition walls into the plurality of abutting hollow cell faces with the fold portion.

Owner:HEXACOMB

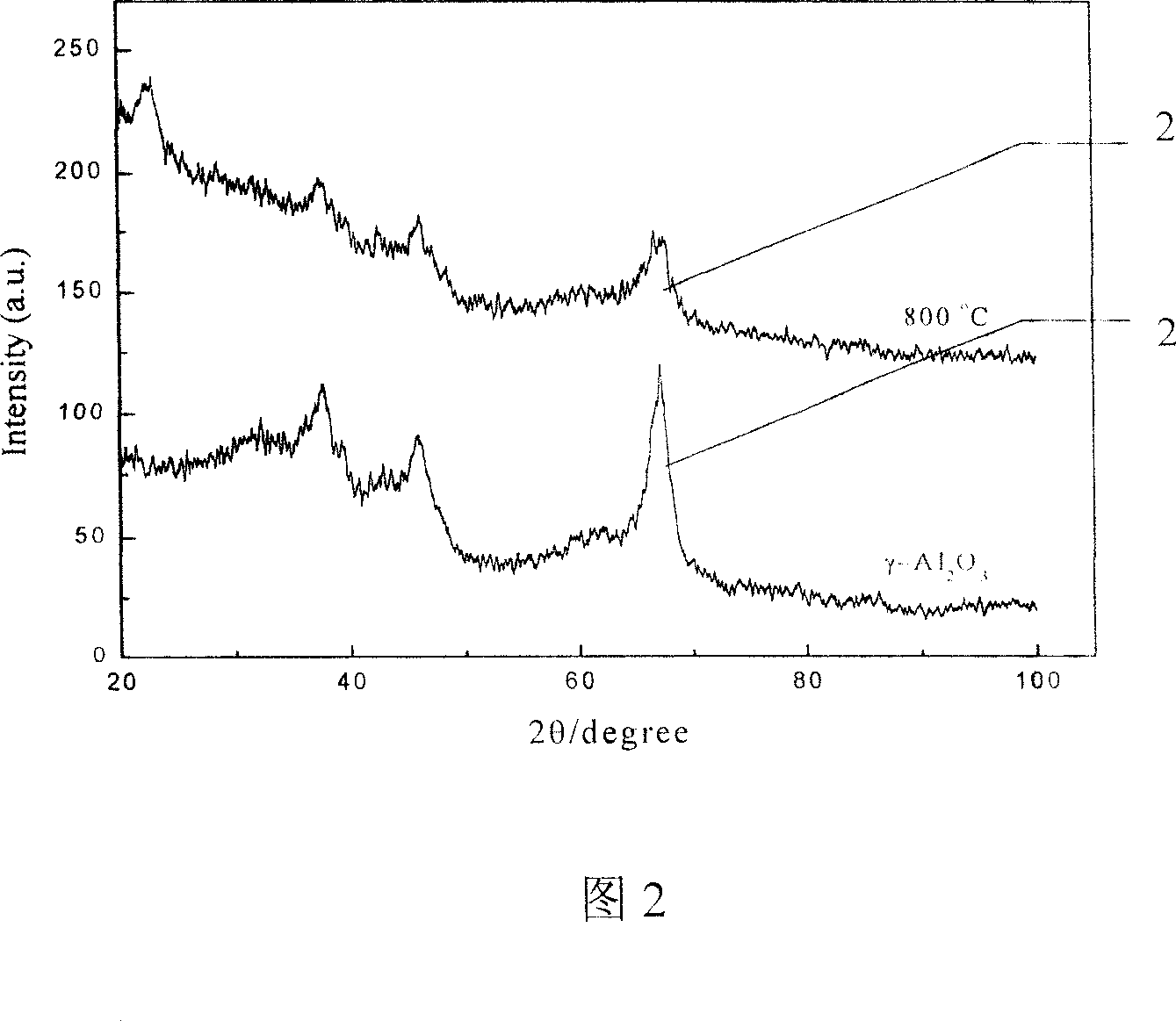

Honeycomb metal wire net carrier catalyst for catalytically reducing nitrogen oxide and preparing method thereof

InactiveCN101015800AHigh activityGood dispersionDispersed particle separationCatalyst activation/preparationCeriumHoneycomb like

The invention relates to a honeycomb metal network carrier catalyst for catalyzing and reducing nitrogen oxide, and relative preparation, used in vehicle tail gas purification technique. The invention comprises metal carrier and catalyst, characterized in that the catalyst is load-type catalyst, the catalyst carrier is honeycomb metal network carrier carrying gamma-Al2O3 coat, referring coat mass, the content of TiO2 is 14.0-20.0wt% and the content of CeZrO is 3.0-6.0wt%, and referring to catalyst mass, the content of active component palladium is 0.1-1.0wt%, and the preparation comprises that preparing TiO2 gel, preparing TiO2 coat at the face of carrier, loading cerium zirconium oxide on carrier, leading in catalyst active component palladium. The invention has the advantages that the invention can improve mass transfer and heat transfer in catalyst, the catalyst has higher catalysis activity in low-temperature oxygen-abundant condition, wide active temperature window, simple preparation and low cost.

Owner:DALIAN UNIV OF TECH

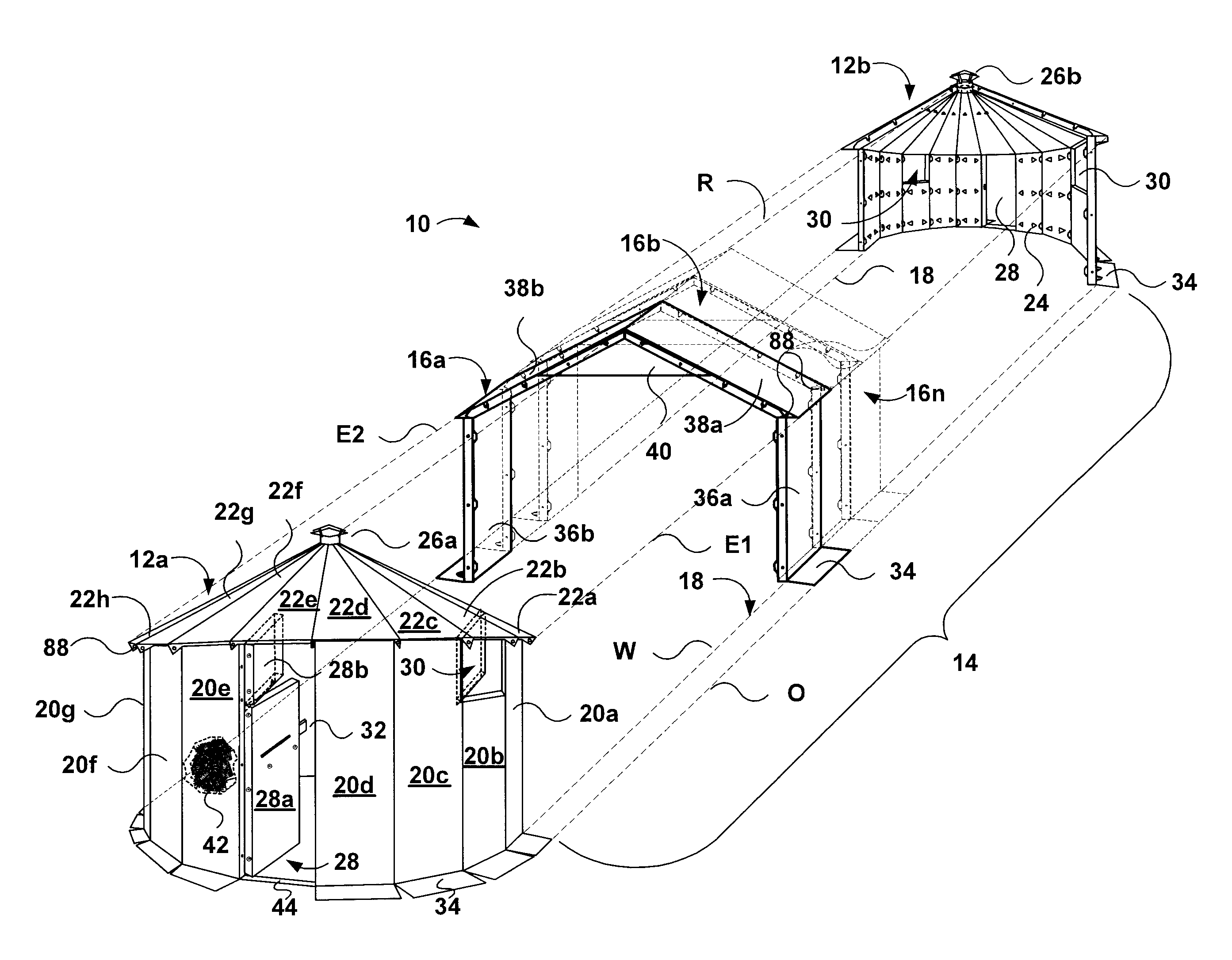

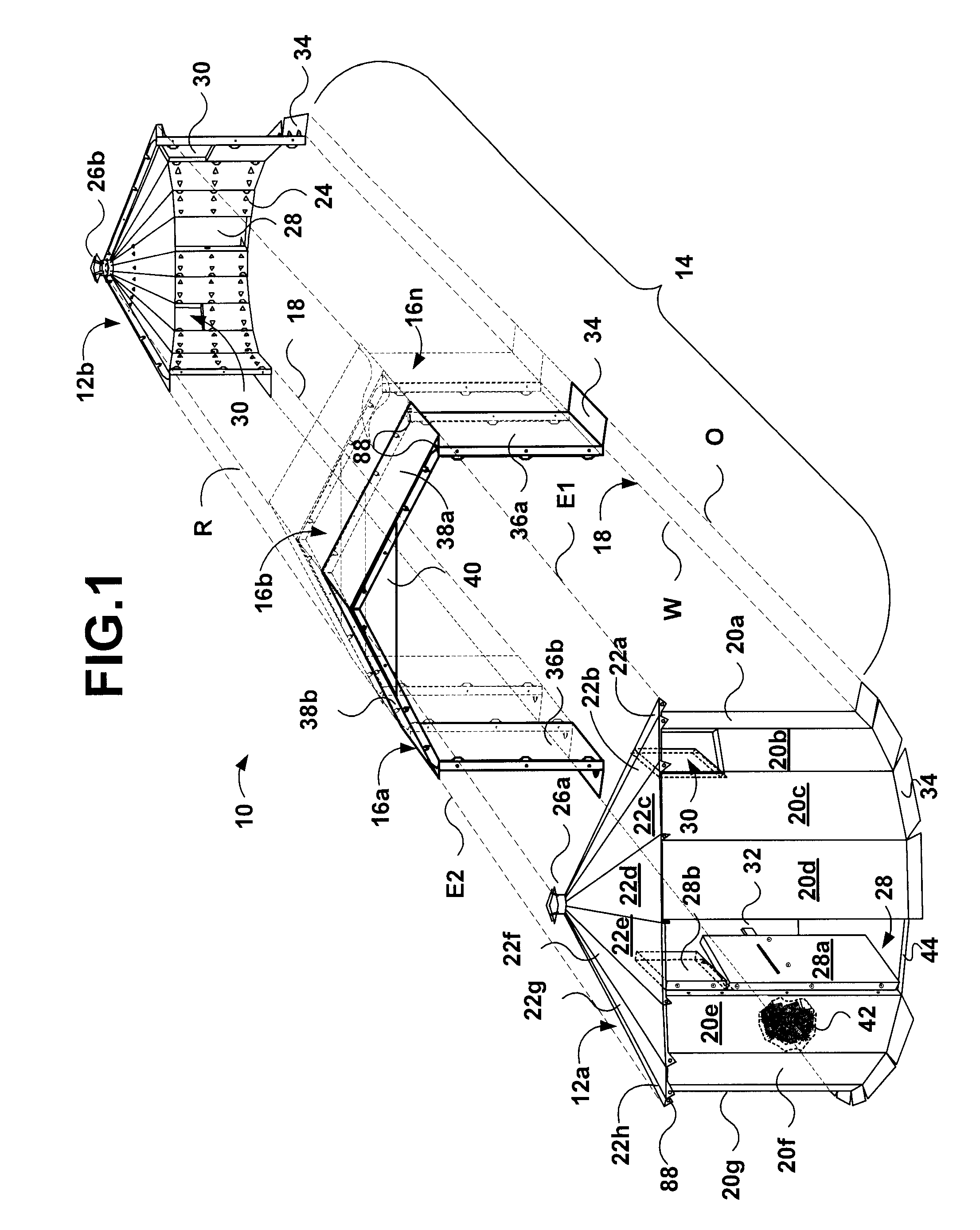

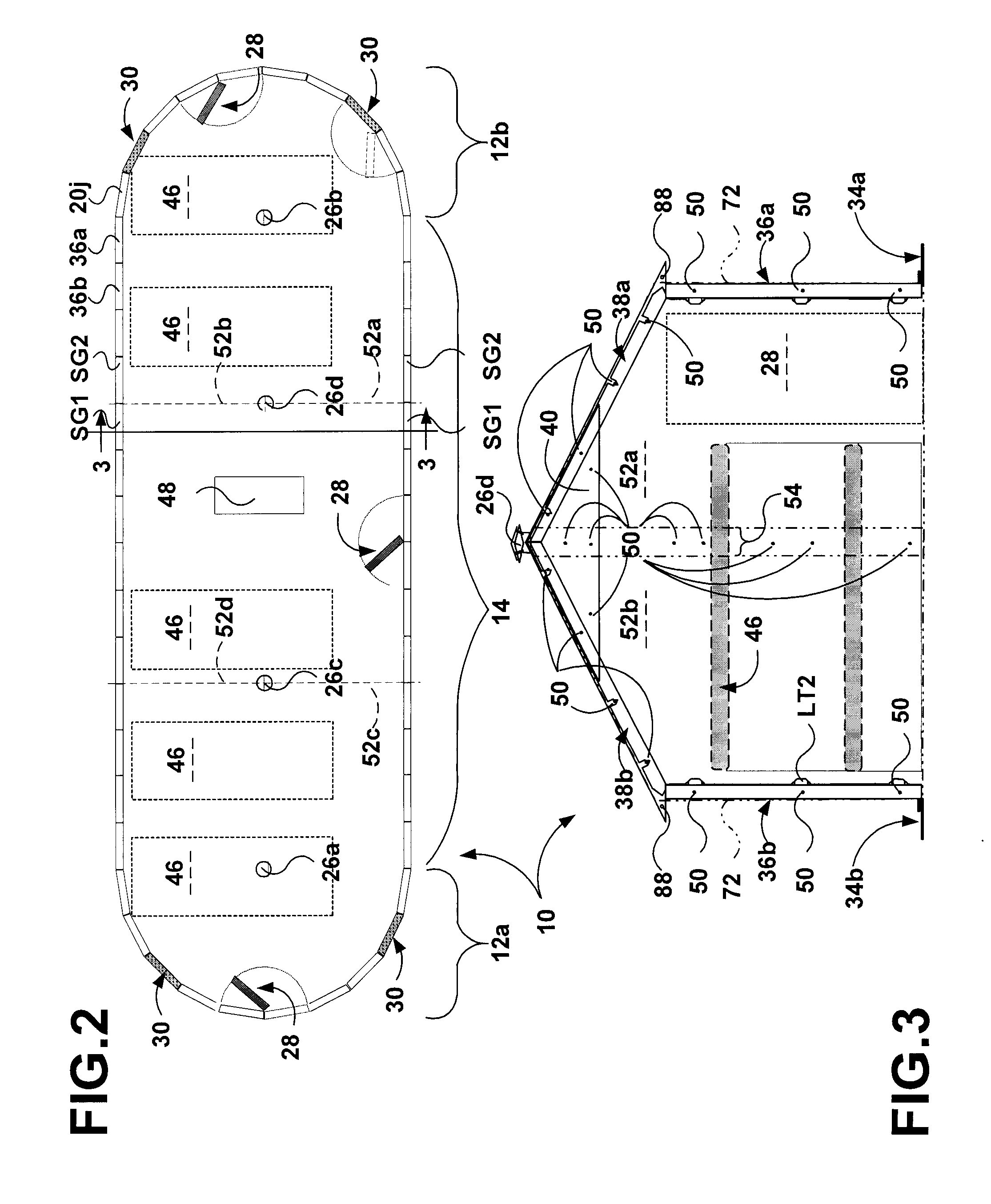

Segmented, elongated, expandable, 4-season, double-walled, low-cost, rigid extruded plastic panel structures

InactiveUS8381454B1Easy to die cutImprove structural stabilityTents/canopiesHospitalsDouble wallRigid wall

Low-cost, semi-permanent rigid-wall modular longhouse-type, peaked-roof structures, stadium-shaped (in plan view), made of light-weight, water-proof cellular extruded plastic sheet material die cut into blanks that are easily portable, quickly field erectable and dismountable by unskilled workers for a wide variety of uses. Two semi-circular end portions are spaced apart and joined by multiple segments of straight wall and roof modules, the length depending only on the number of intermediate segments. Blanks are easily folded on site into double-walled, bolt-together, modular wall and roof panels. Only four basic panel configurations are needed to form all structural elements. Multiple modular structures may be grouped to form larger compound structures with individual ones assigned to individual persons or dedicated work space usages: disaster shelters, sleeping, gathering, storage, hygiene, medical treatment, schooling, entertainment, goods manufacture, cooking, eating, herding, etc. Double-wall modules provide inter-stitial space for cold-weather insulation and passive ventilation in hot environments.

Owner:INNOVATION LAW GROUP

Preparation method of cellular V-Ti low-temperature smoke denitration catalyst

ActiveCN102974340AImprove stabilityGuaranteed service lifeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentHoneycomb like

The invention discloses a preparation method of a cellular V-Ti low-temperature smoke denitration catalyst. The catalyst takes nano-grade TiO2 as a carrier and occupies 70-90% of the mass of the catalyst; an active component is V2O5 and occupies 5-15% of the mass of the catalyst; and a metal oxide auxiliary is one or more of oxides of Cr, Mn, Cu, Ce, W and Mo and occupies 4-16% of the mass of the catalyst. A preparation process of the catalyst is formed by a material mixing process and a molding process; the material mixing process comprises a secondary material mixing step and a calcining step; the NOx removing rate is more than 95% by using the activity of the catalyst at a temperature of 140-260 DEG C; the suitable service life and the mechanical service life of the catalyst are greatly prolonged; and the preparation method is applicable to industrial production and the application of a low-temperature smoke SCR (Selective Catalytic Reduction) denitration system.

Owner:CECEP L&T ENVIRONMENTAL TECH

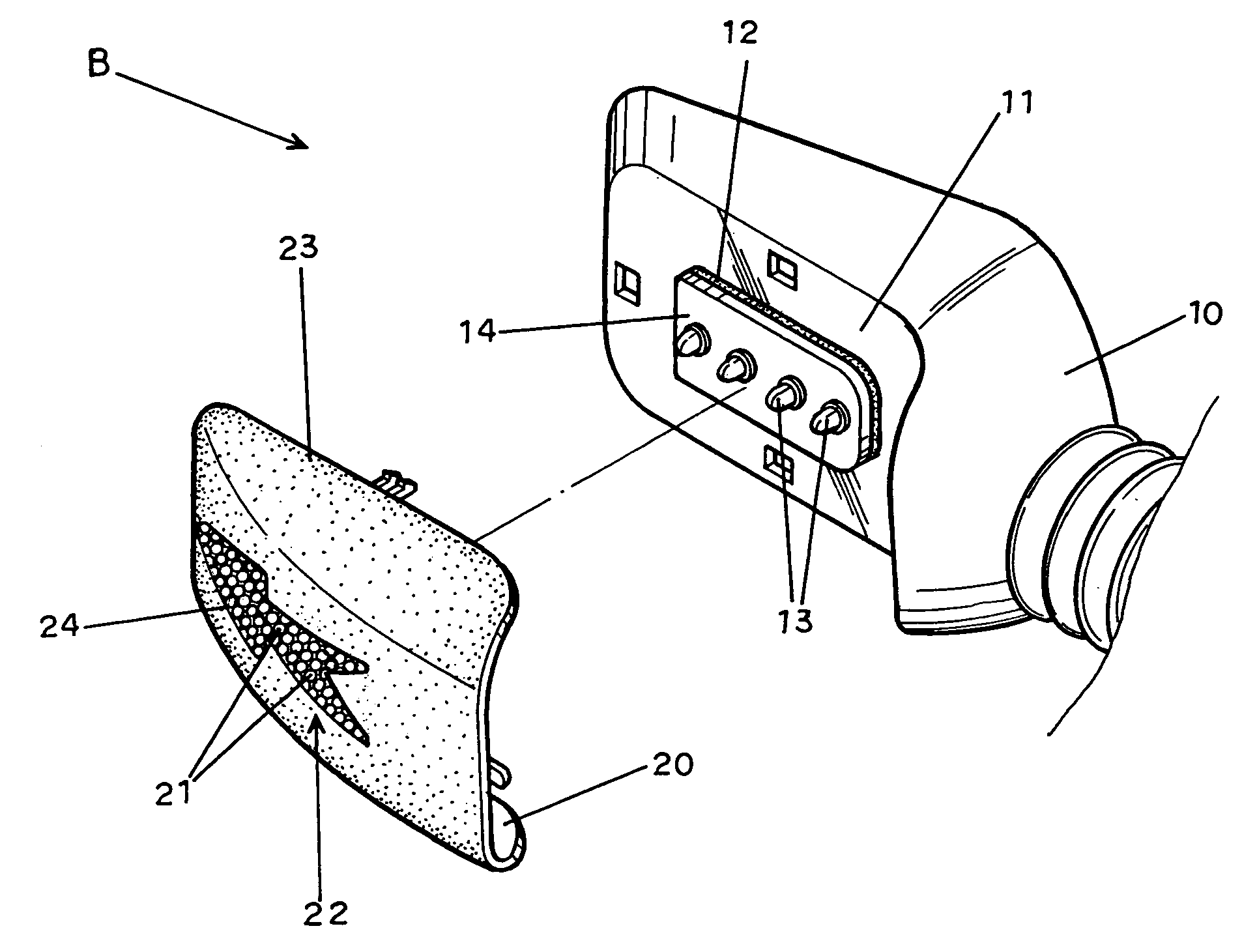

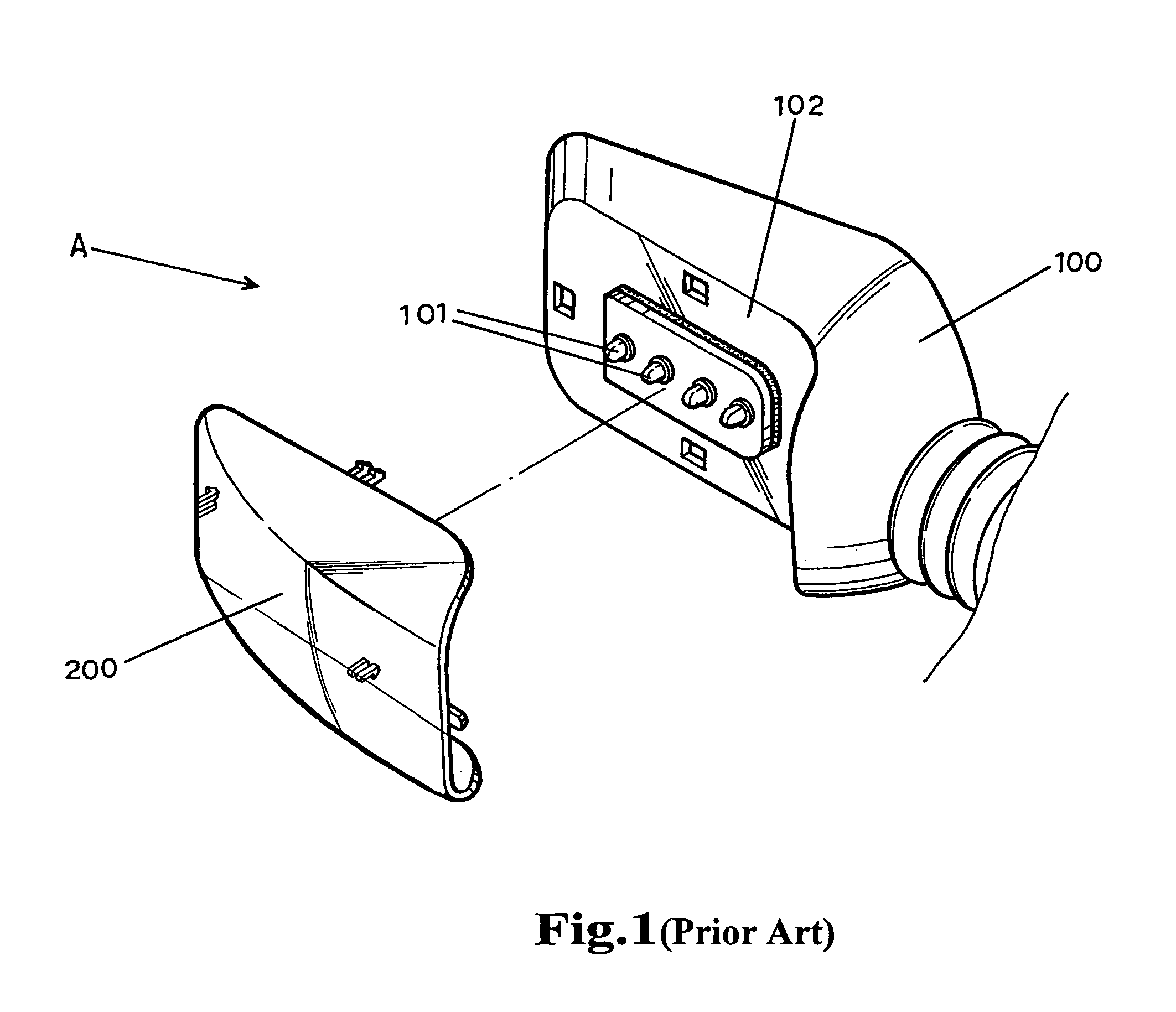

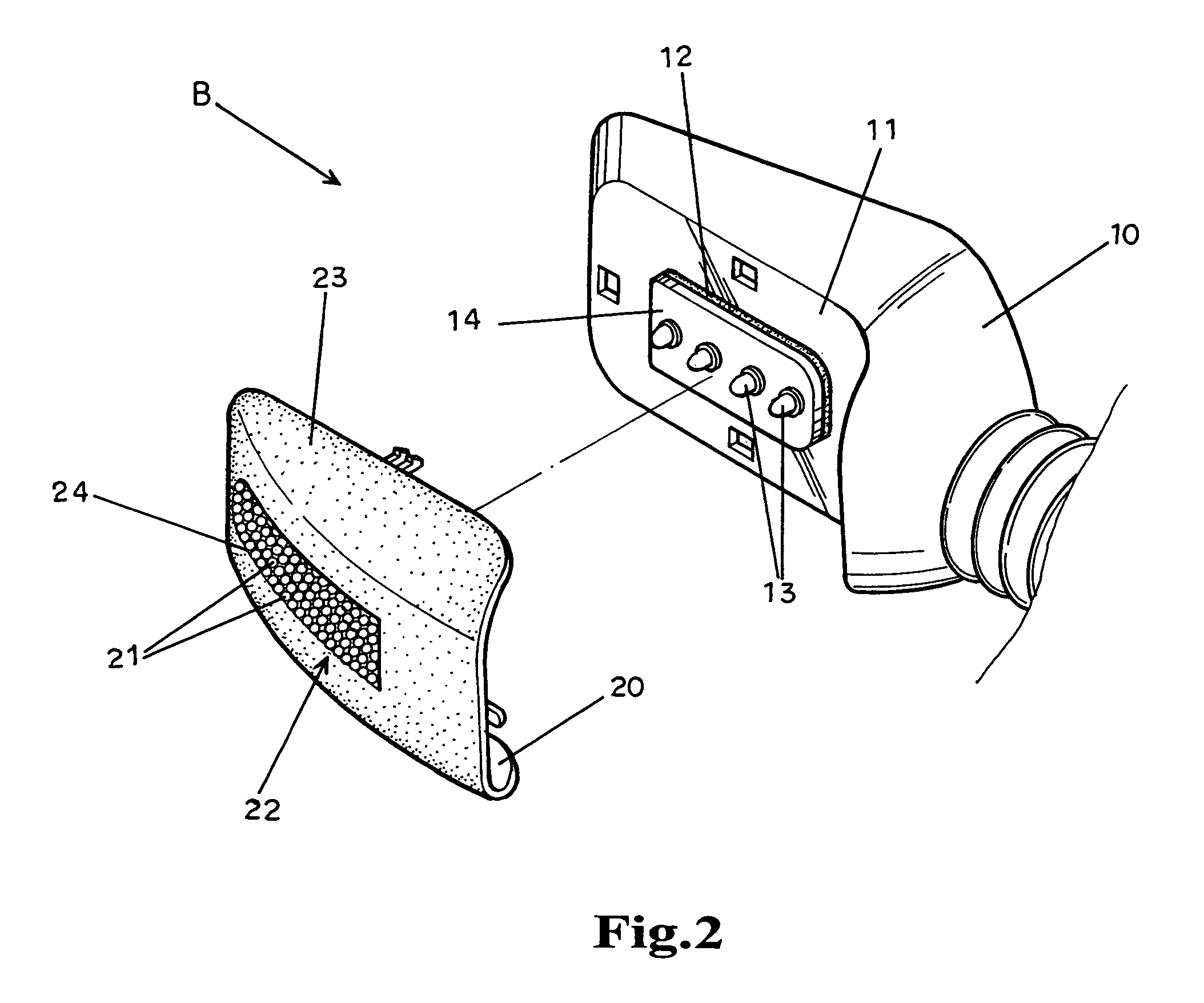

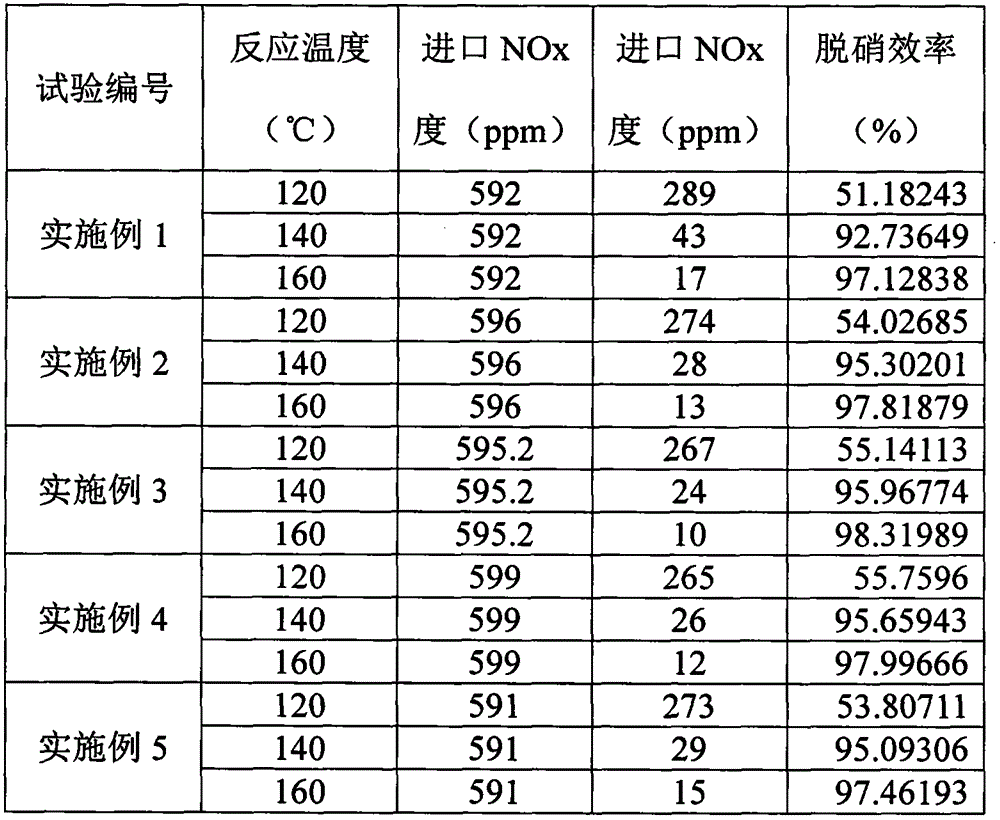

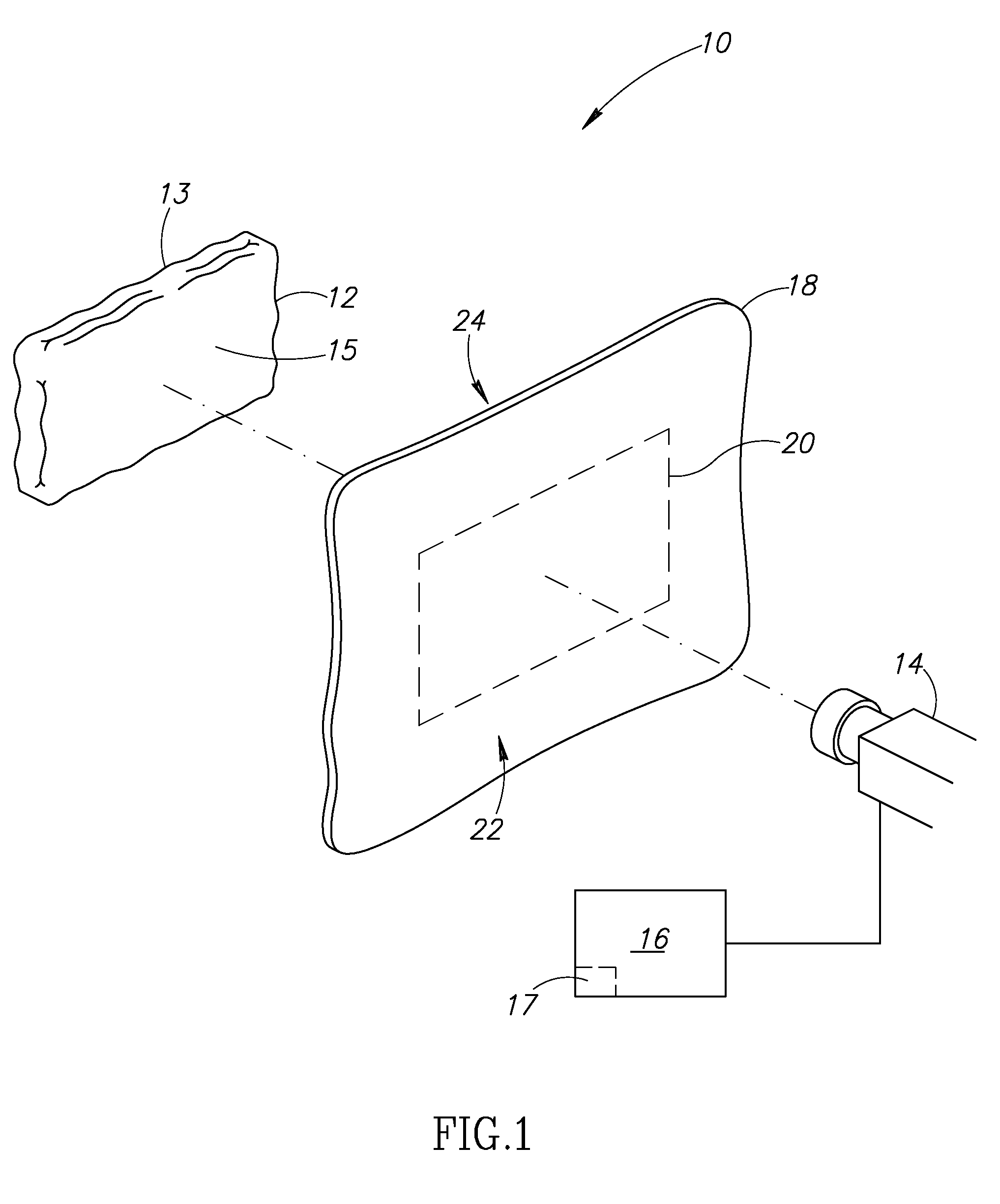

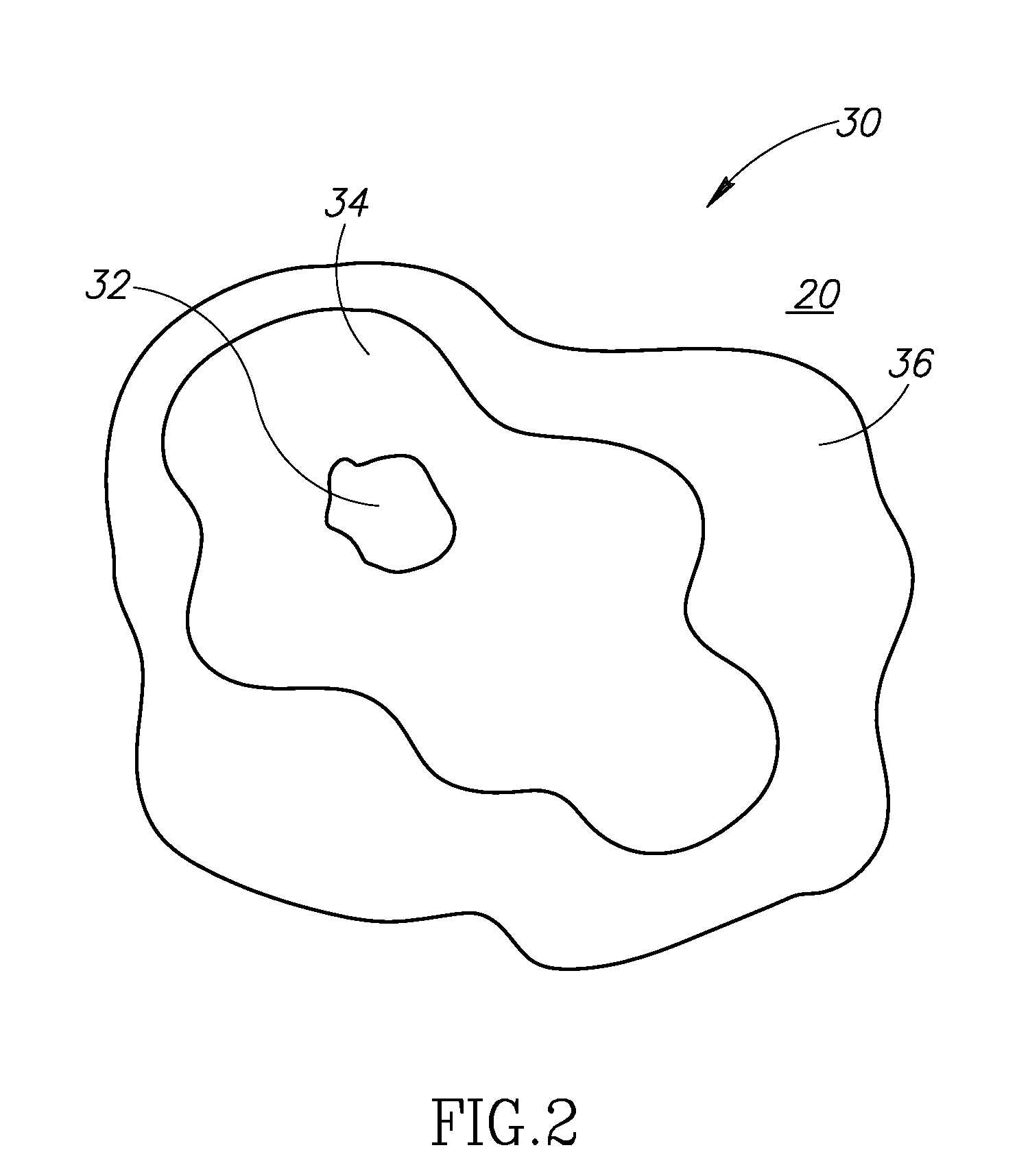

Systems and methods for thermographic inspection of composite structures

Systems and methods for thermographically inspecting a composite material or honeycombed type structures are disclosed. In one embodiment, a system includes a thermal heat source configured to be either removably coupled to or positioned proximate to the composite material to generate a localized thermal field in a selected area of the composite material. A thermal imaging device generates a visible image of the generated thermal field.

Owner:THE BOEING CO

Lightweight heat sink

A heat sink disposable on a heat transfer surface of a heat-generating source such as an electronic component. The heat sink includes a base portion and a body portion. The base portion has a first surface disposable on the heat transfer surface, and a second surface opposite the first surface. The body portion is joined to the second surface of the base portion and is formed of a stack of corrugated sheets of one or more metal foils arranged to form a cellular, honeycomb-like structure.

Owner:PARKER INTANGIBLES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com