Cellular Mn-Ti-based catalyst for low-temperature selective catalytic reduction denitration reaction and preparation method and using method

A catalyst and selective technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of reducing denitrification efficiency and catalyst deactivation, and achieve high Catalytic activity, good dispersion, lower operating temperature and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Catalyst preparation: use n-butyl titanate, ethanol, water and manganese nitrate as raw materials, and the molar ratio of each raw material is 1:5:1:0.4. After the components are fully mixed, they are stirred rapidly, and after stirring for two hours, they are poured into polyfour In a high-pressure reaction kettle lined with vinyl fluoride, put it in a muffle furnace for hydrothermal reaction at 120°C for 12 hours, then put the suspension in the reaction kettle into a centrifuge for high-speed centrifugation, and remove the upper layer after the centrifugation The clear liquid is cleaned with ethanol, centrifuged and filtered again after cleaning, and then the milky substance is put into an oven for drying to obtain a solid powder Mn-Ti catalyst.

[0046] Get 1000g of the catalyst powder prepared above, add 10g polyethylene oxide, 10mL glycerin, 600mL titanium tetrachloride aqueous solution (containing TiO 2 60g), 5g rod-shaped glass fibers, kneaded in a kneader for 4...

Embodiment 2

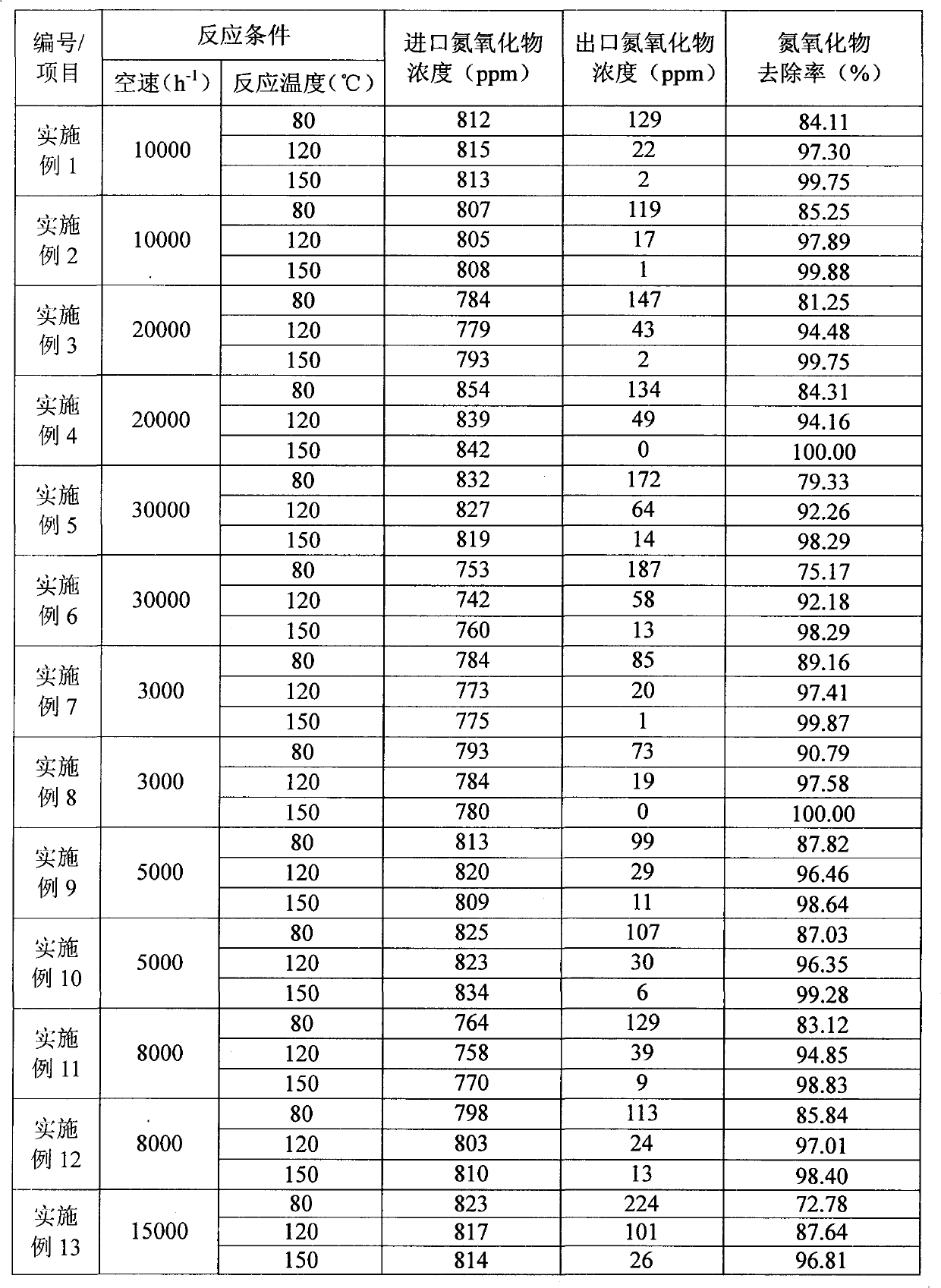

[0050] The preparation was carried out according to the steps of Example 1, except that the molding binder was changed to 800 mL of titanium gel solution, and the molar ratio of Ce:V:Se:Sb:Bi in the precursor solution was changed to 8:1:1:0.5:1.5. Other reagents, addition amount and operation are all according to Example 1, and the obtained catalyst is used for low-temperature SCR denitration reaction, and the results of reaction conditions and activity are shown in Table 1.

Embodiment 3

[0052] Prepare according to the steps of Example 1, except that when preparing the powder catalyst, manganese nitrate is replaced by manganese acetate, the lubricant is changed into 7mL polyacrylate, the reinforcing agent is changed into 5g carbon fiber, and the Ce in the precursor solution: V: Se :Sb:Bi molar ratio was changed to 5:2:0.7:0.6:0.5. Other reagents, addition amount and operation are all according to Example 1, and the obtained catalyst is used for low-temperature SCR denitration reaction, and the results of reaction conditions and activity are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com