Patents

Literature

100results about How to "Low degree of reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

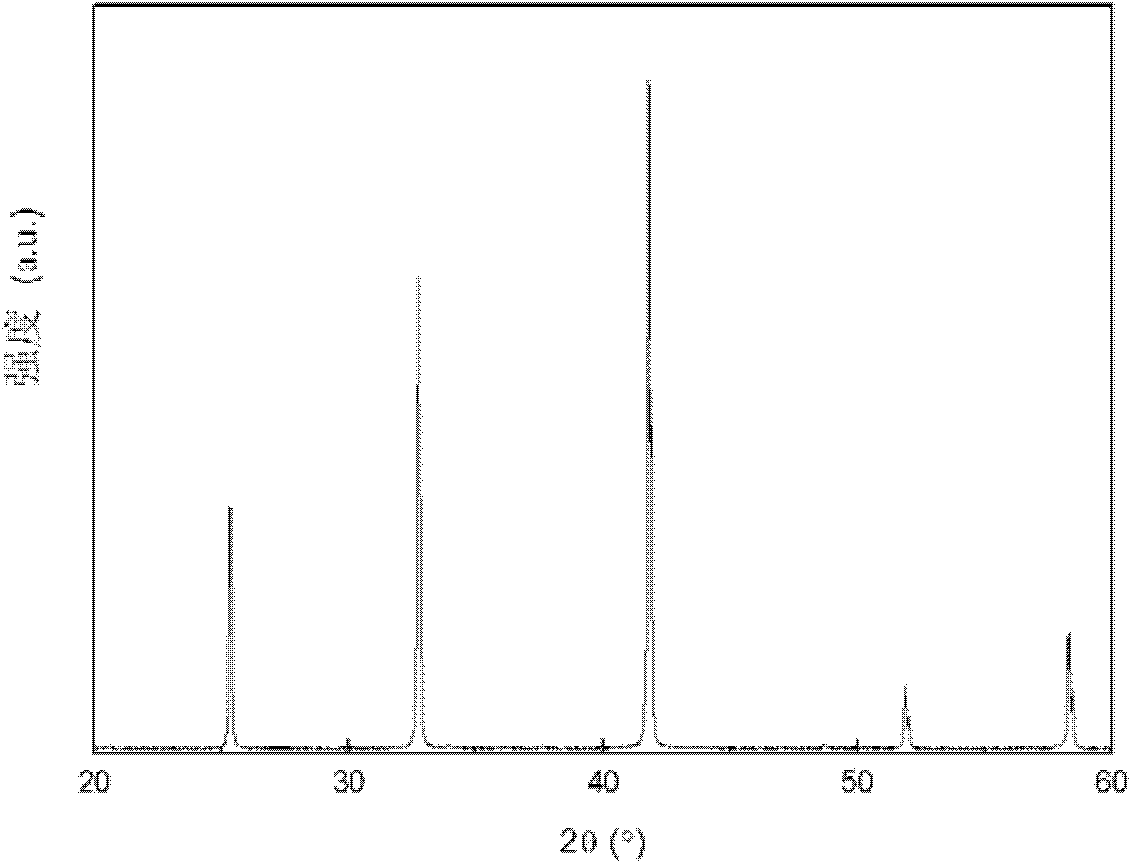

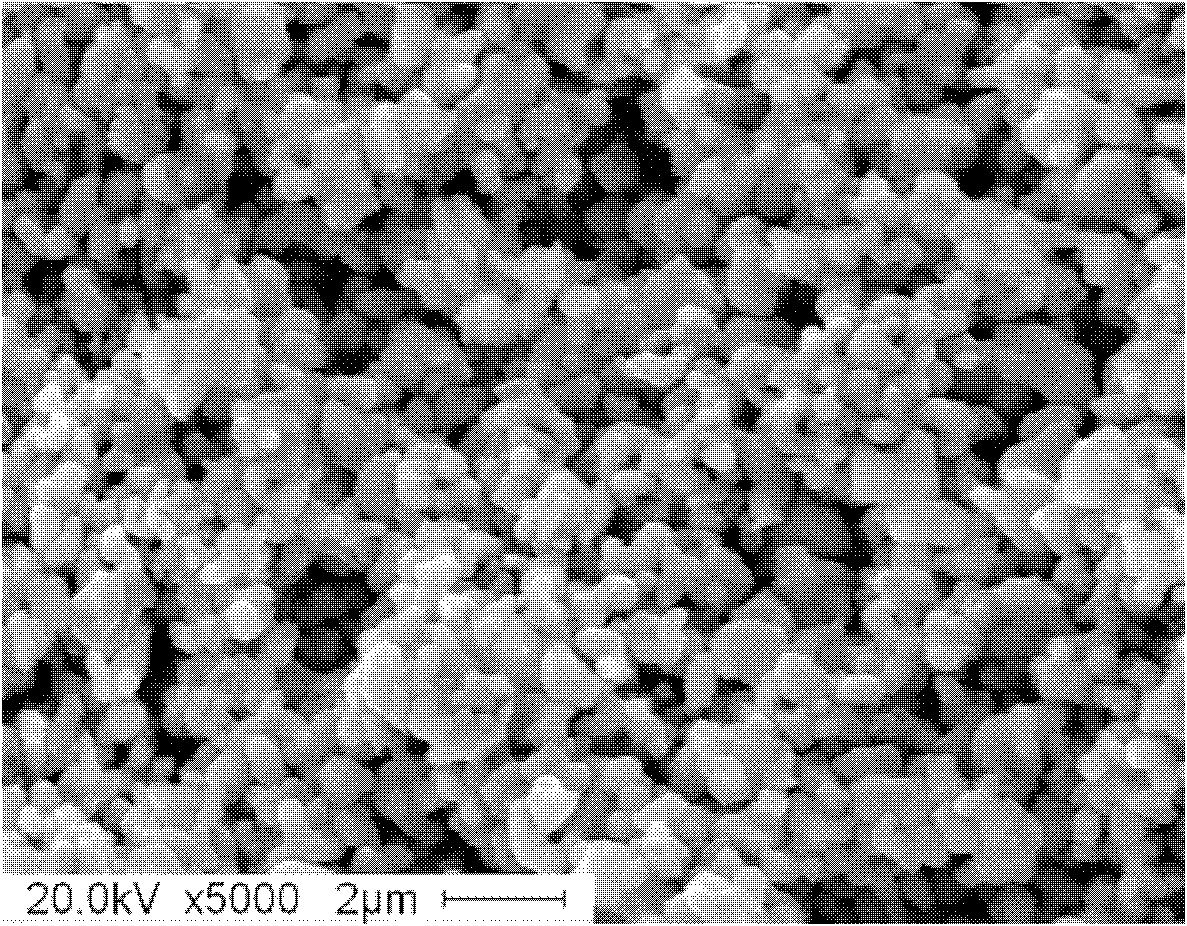

Method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at the low temperature and belongs to the technical field of the preparation of high-temperature structural material. The method respectively uses a homogeneous precipitation method for synthesizing a nanometer coloring agent, and a coprecipitation method for synthesizing nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as a coloring agent. The zirconia powder is not added with any sintering additive, only added with small amount of coloring agent and sintered at the temperature of 1150-1350 DEG C, thus obtaining the black zirconia ceramics with excellent performance and bright color. As the homogeneous precipitation method is adopted for synthesizing coloring agent powder, the monodisperse nanometer particles with uniform powder granules, narrow size distribution and high purity are obtained so that the coloring agent easily colors the particles. As the coprecipitation method is used for synthesizing zirconia powder, nanometer particles with small granularity, big superficial area and high activity are obtained, and can reduce the temperature of the solid-phase reaction, greatly reduce the sintering temperature and solve the problem that the black coloring agent oxide decomposes and volatiles at the high temperature. Simultaneously the method adopts the Fe-Co-Ni-Mn as the coloring agent, thus avoiding the poisonous function of Cr on the human body.

Owner:TSINGHUA UNIV

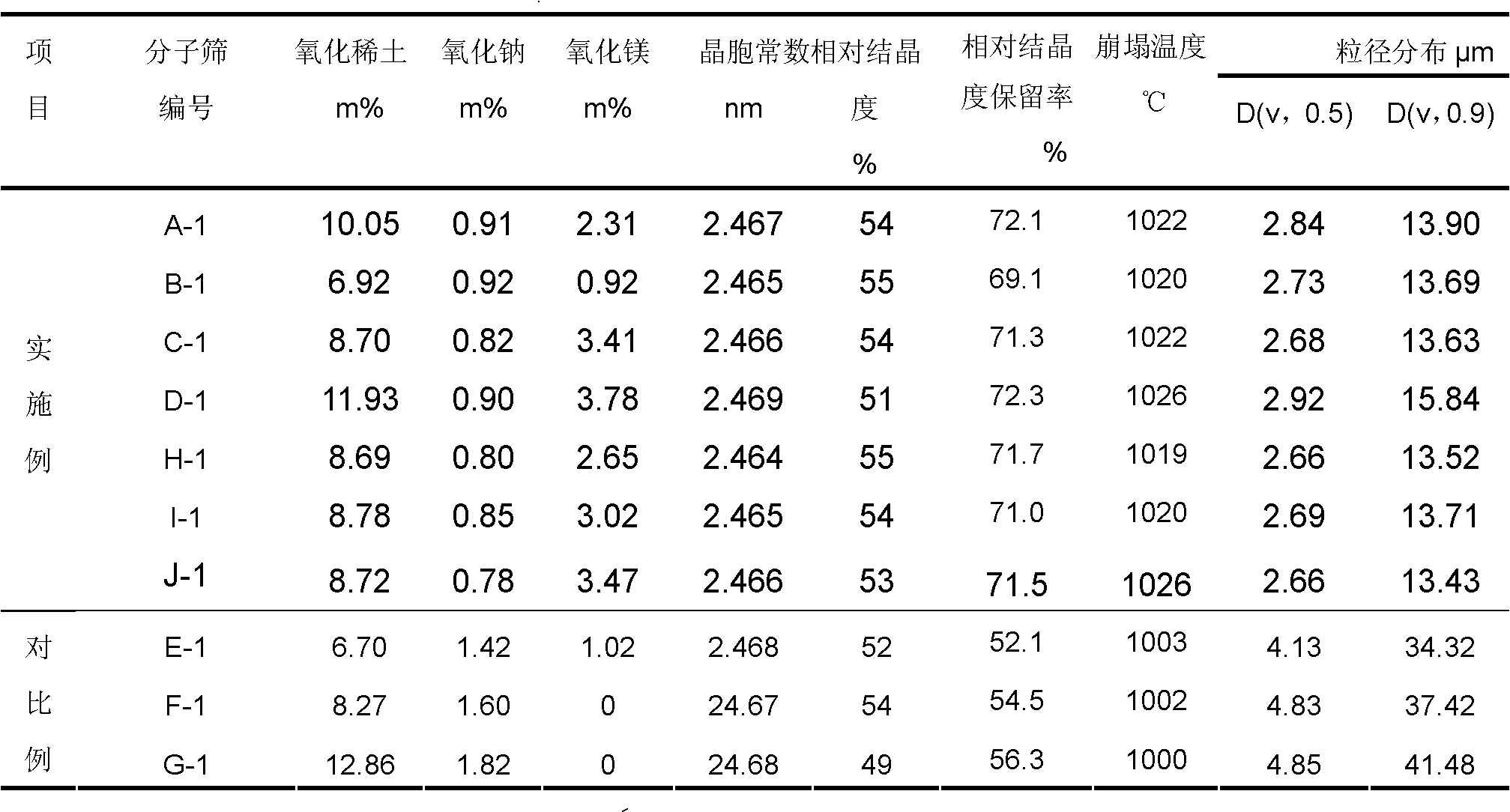

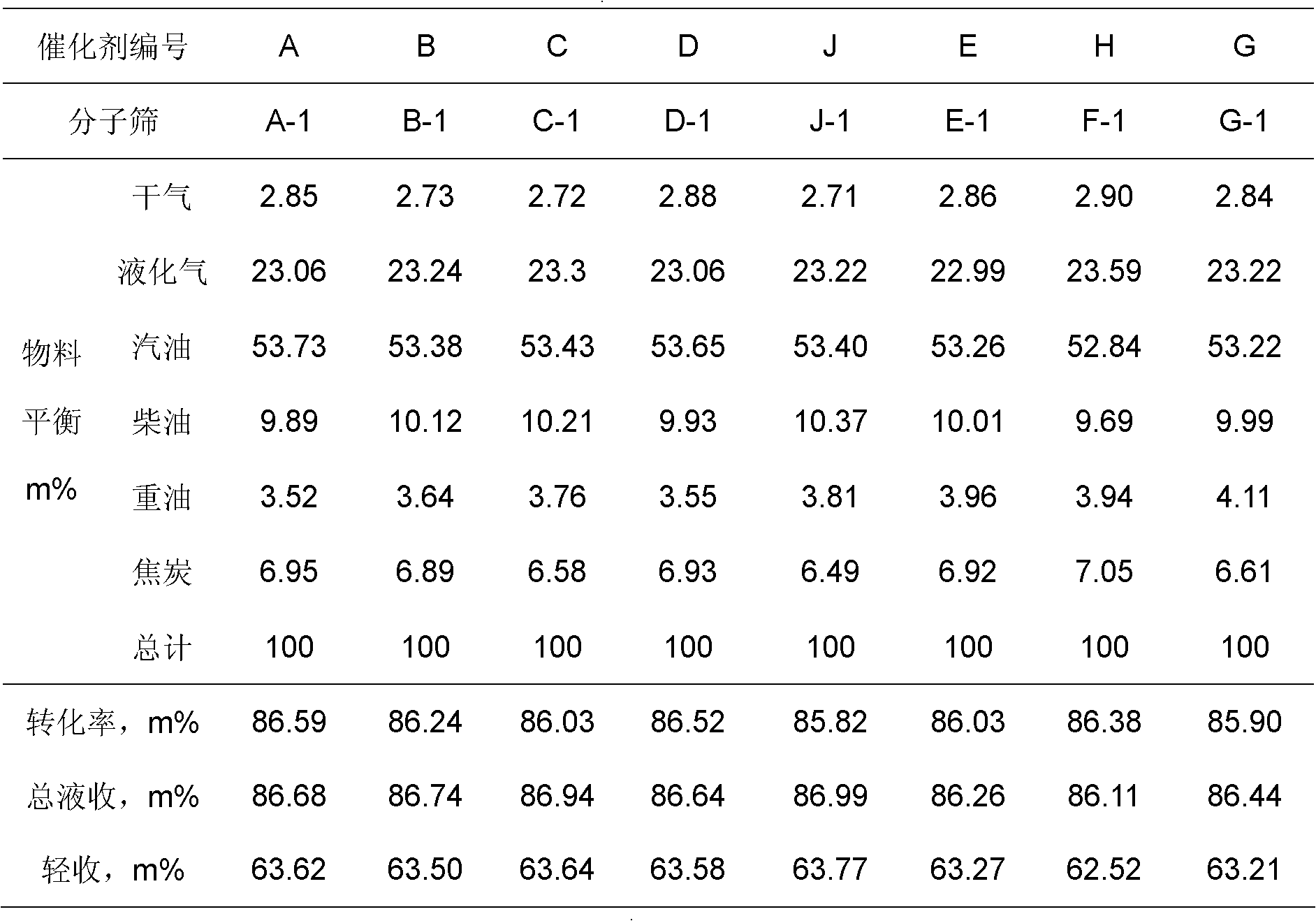

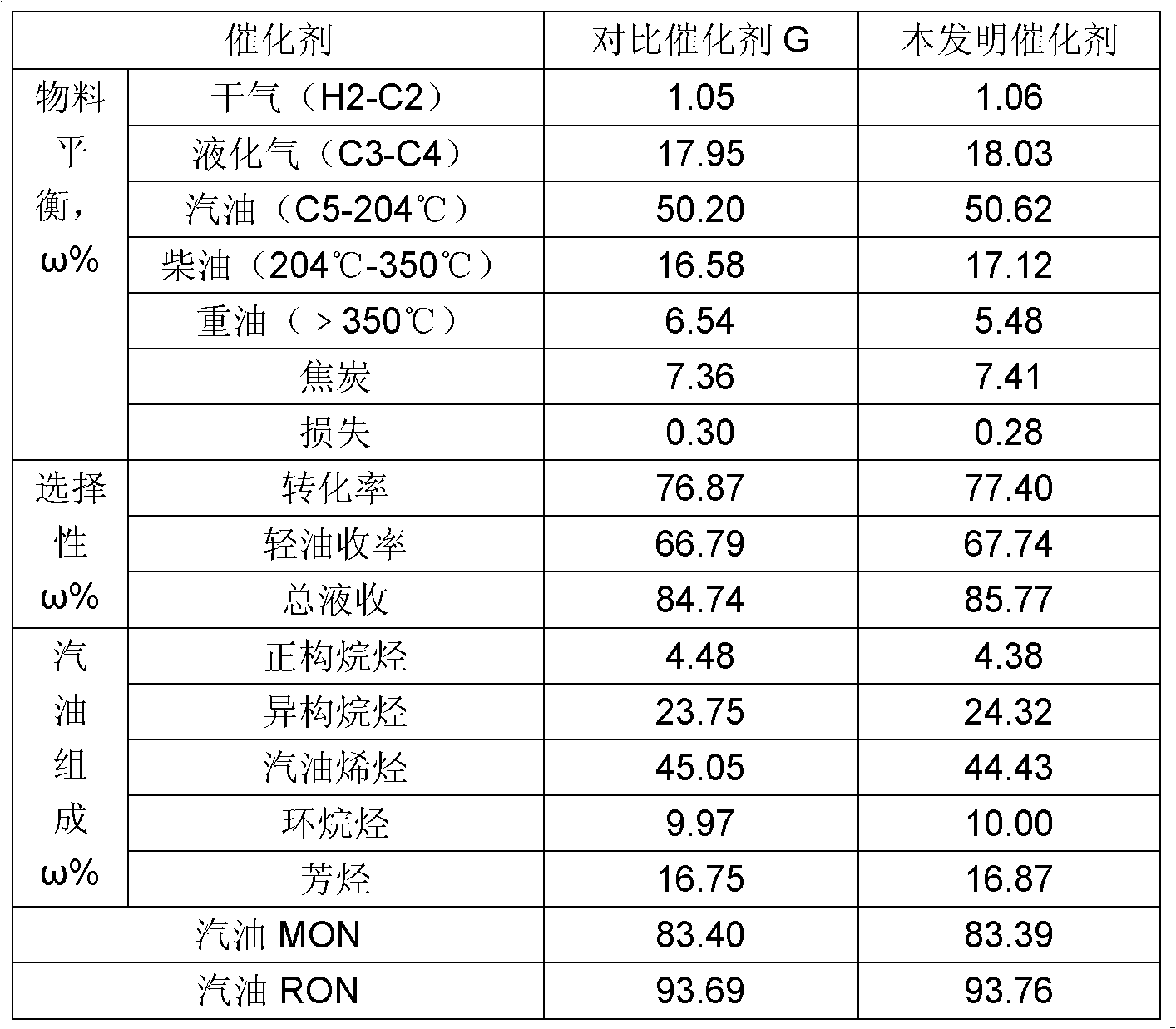

Heavy oil catalytic cracking catalyst with high light oil yield and preparation method thereof

ActiveCN103157506ASolve the problem of selectivityReduce resistanceCatalytic crackingMolecular sieve catalystsMolecular sieveMagnesium salt

The invention relates to a heavy oil catalytic cracking catalyst with high light oil yield and a preparation method thereof. The catalyst contains 2-50 wt% of a magnesium modified ultrastable rare earth Y-type molecular sieve, 0.5-30 wt% of one or several other molecular sieves, 0.5-70 wt% of clay, 1-65 wt% of a refractory inorganic oxide and 0.01-12.5 wt% of rare earth oxide. The magnesium modified ultrastable rare earth Y-type molecular sieve is prepared from a raw material NaY molecular sieve through rare earth exchange, dispersing pre-exchange, magnesium salt exchange modification, ammonium exchange for reducing sodium, and ''two exchanges and two roasting''. The catalyst provided by the invention has characteristics of strong heavy oil conversion ability and high light oil yield.

Owner:PETROCHINA CO LTD

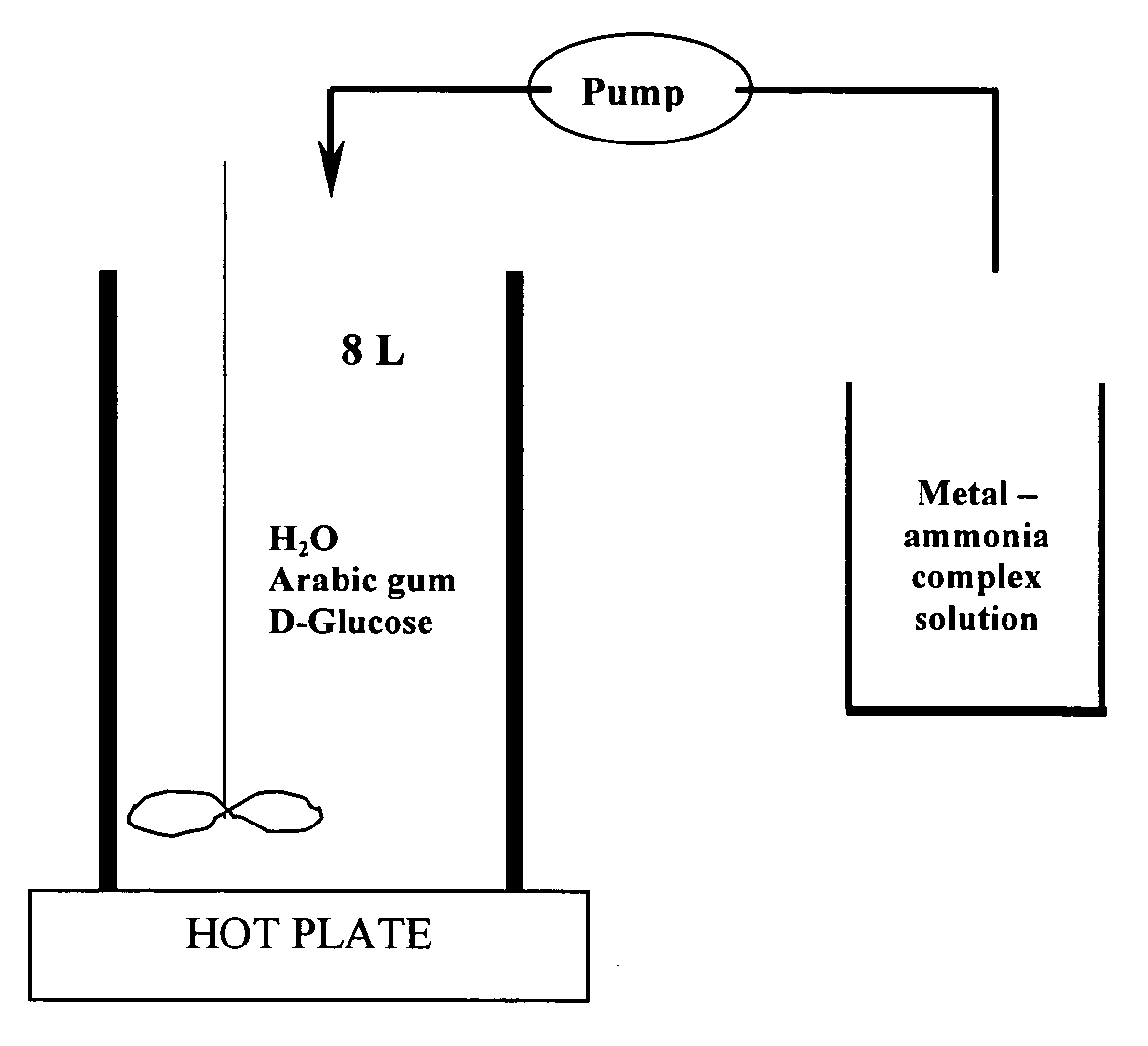

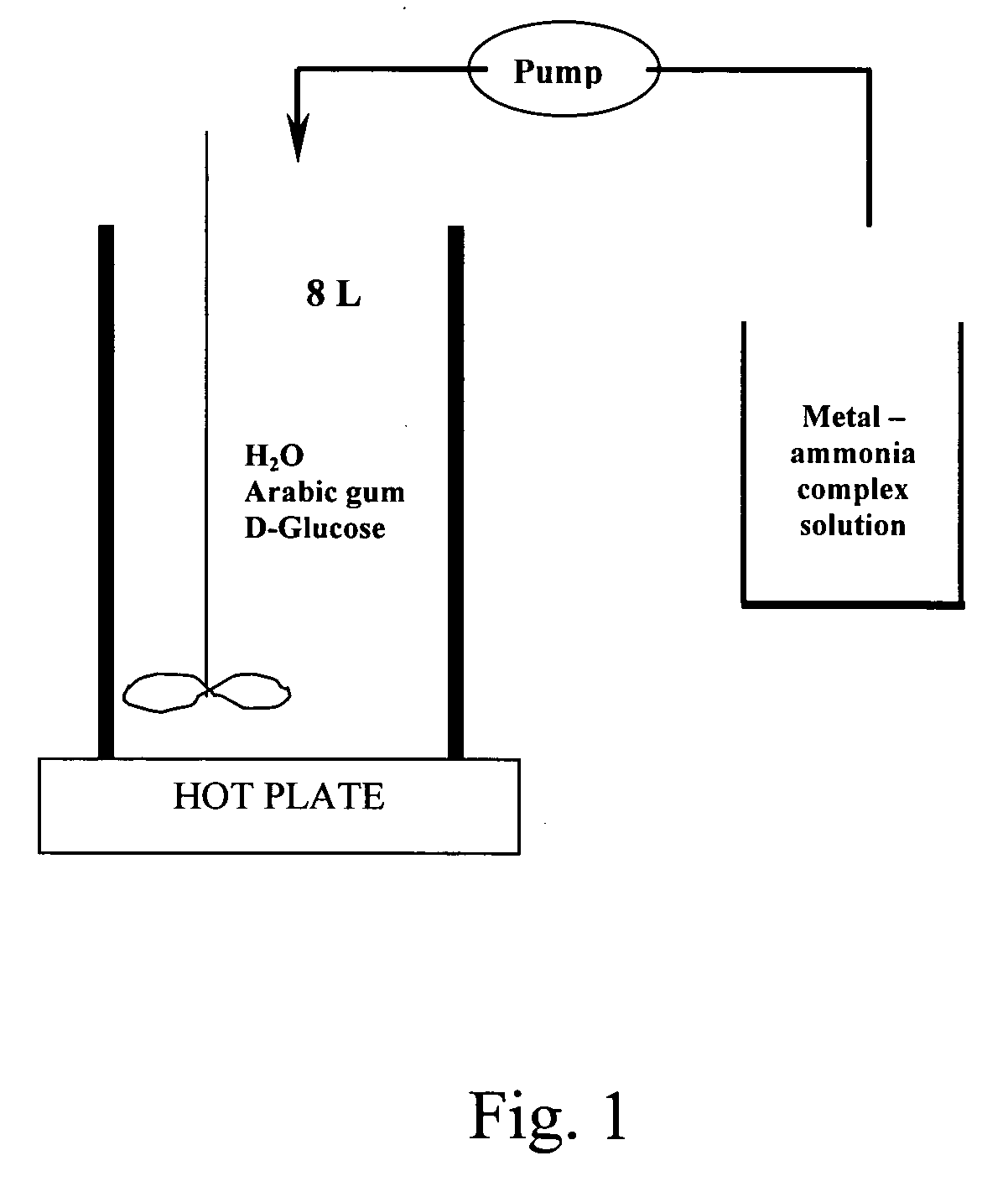

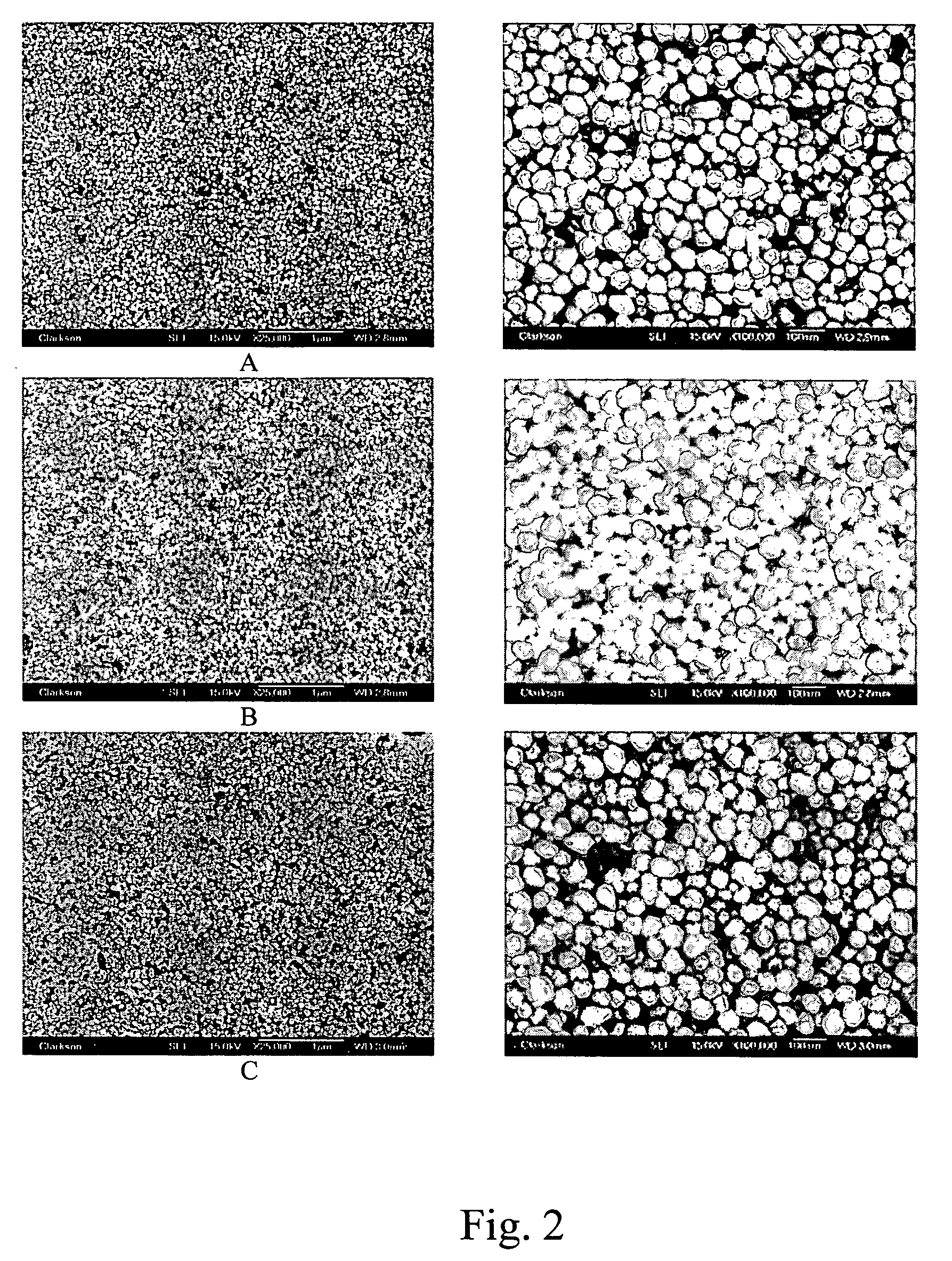

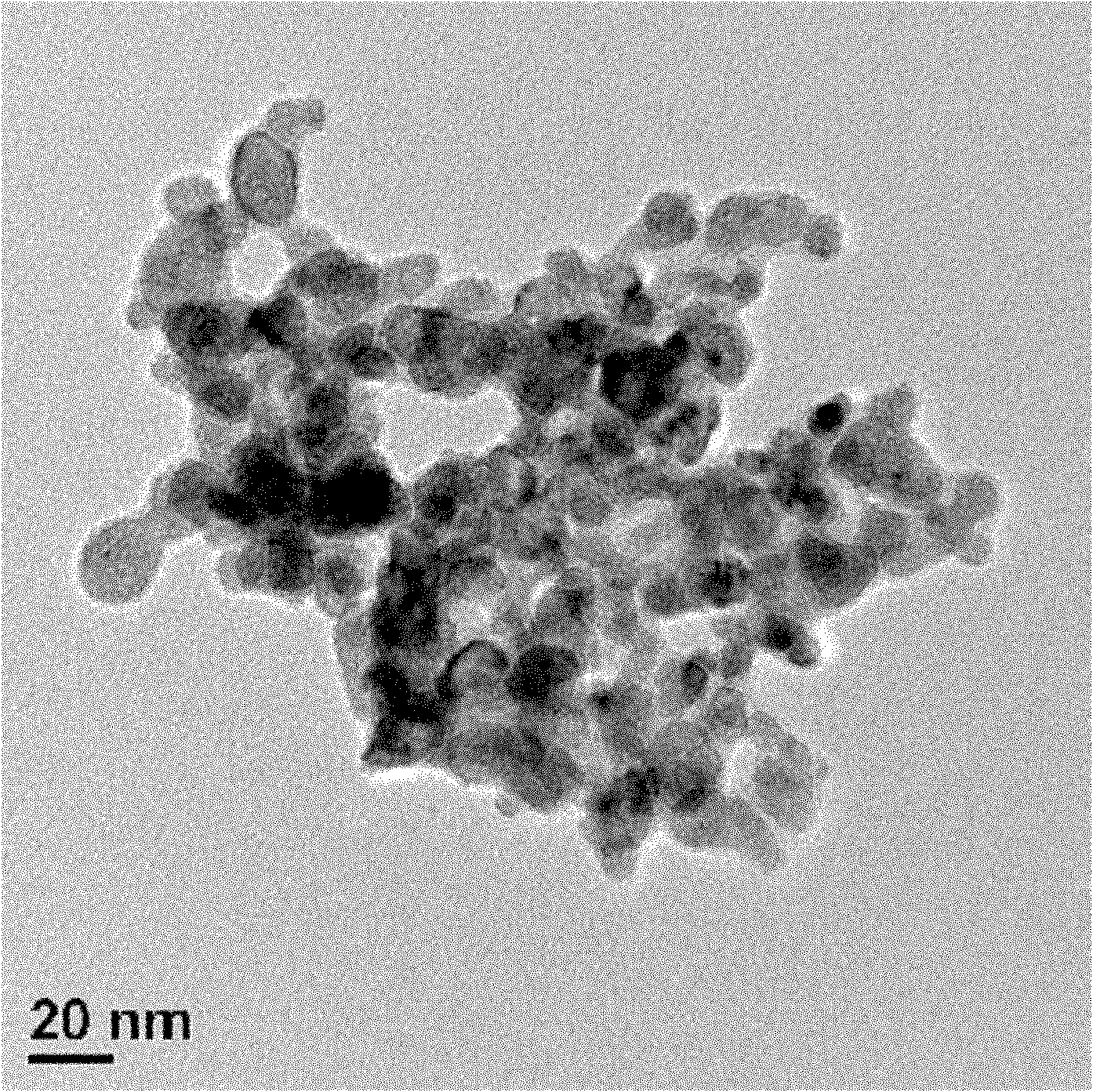

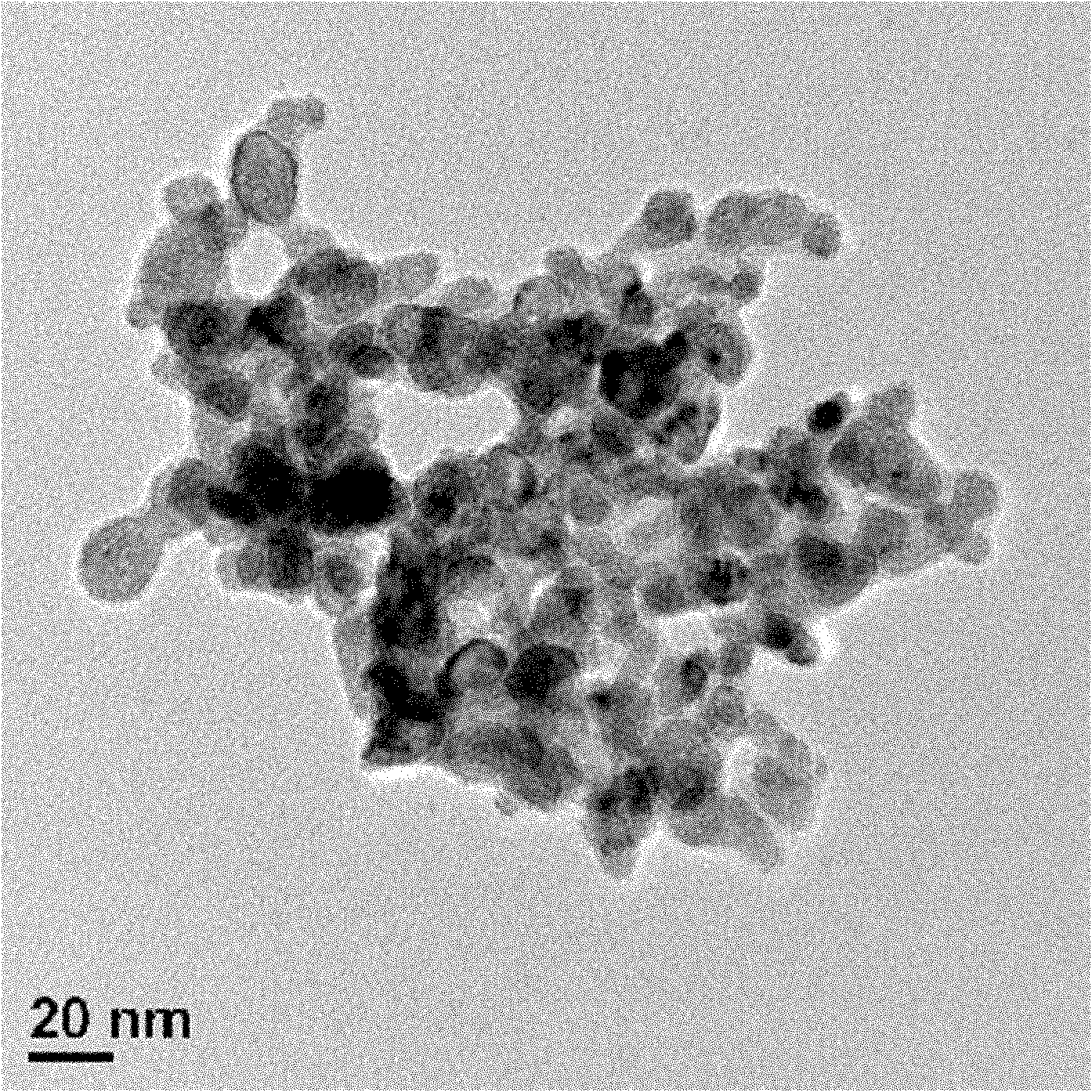

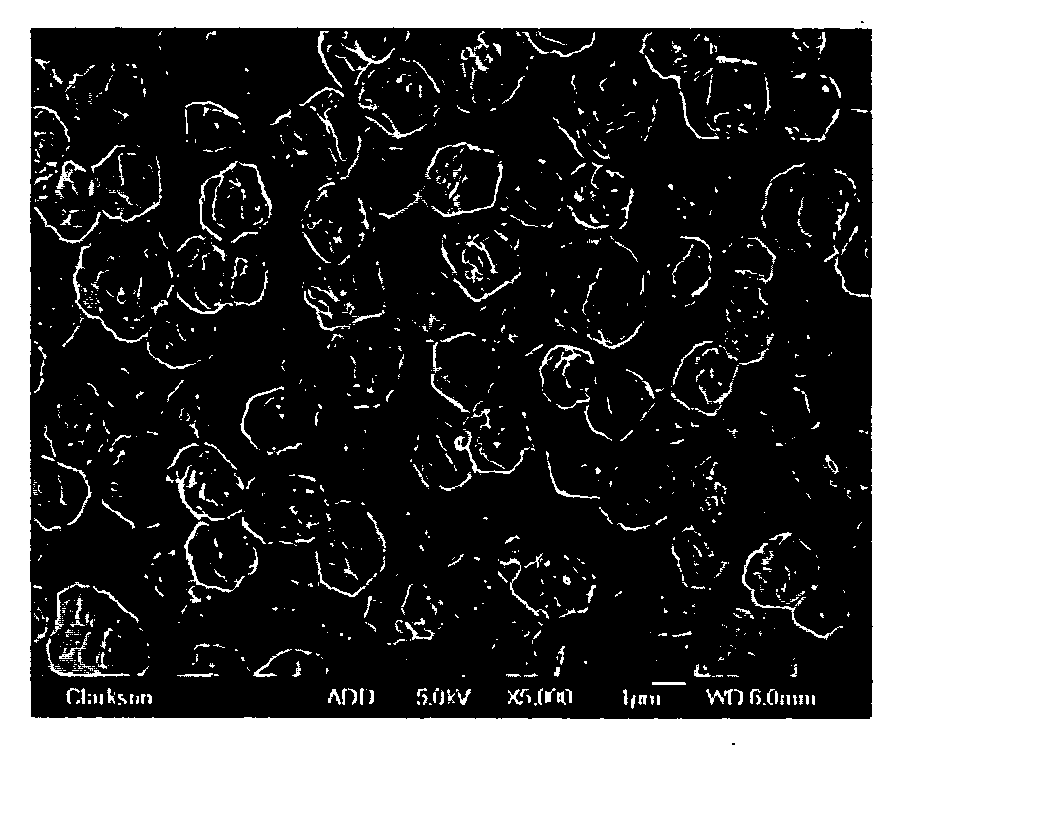

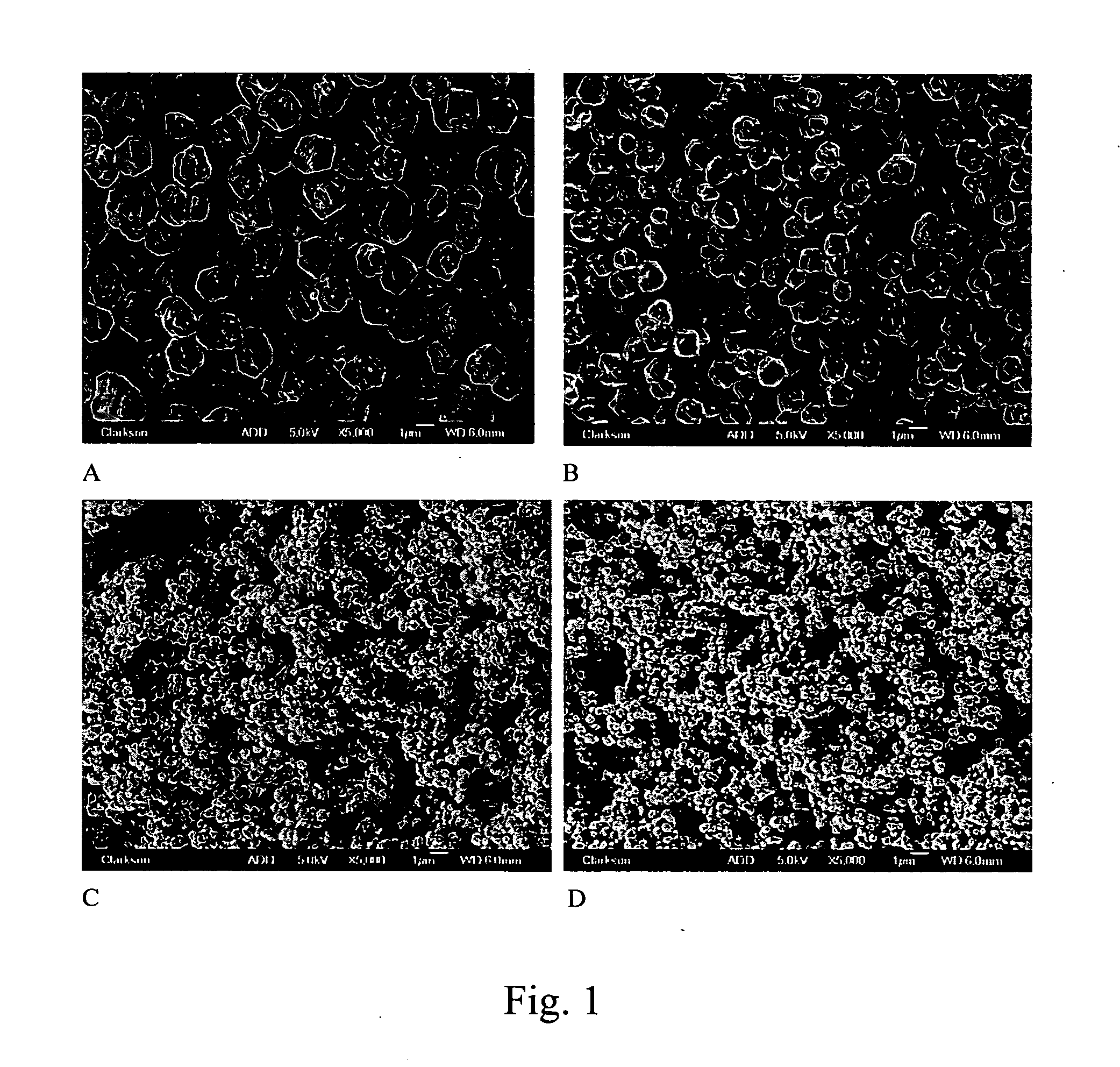

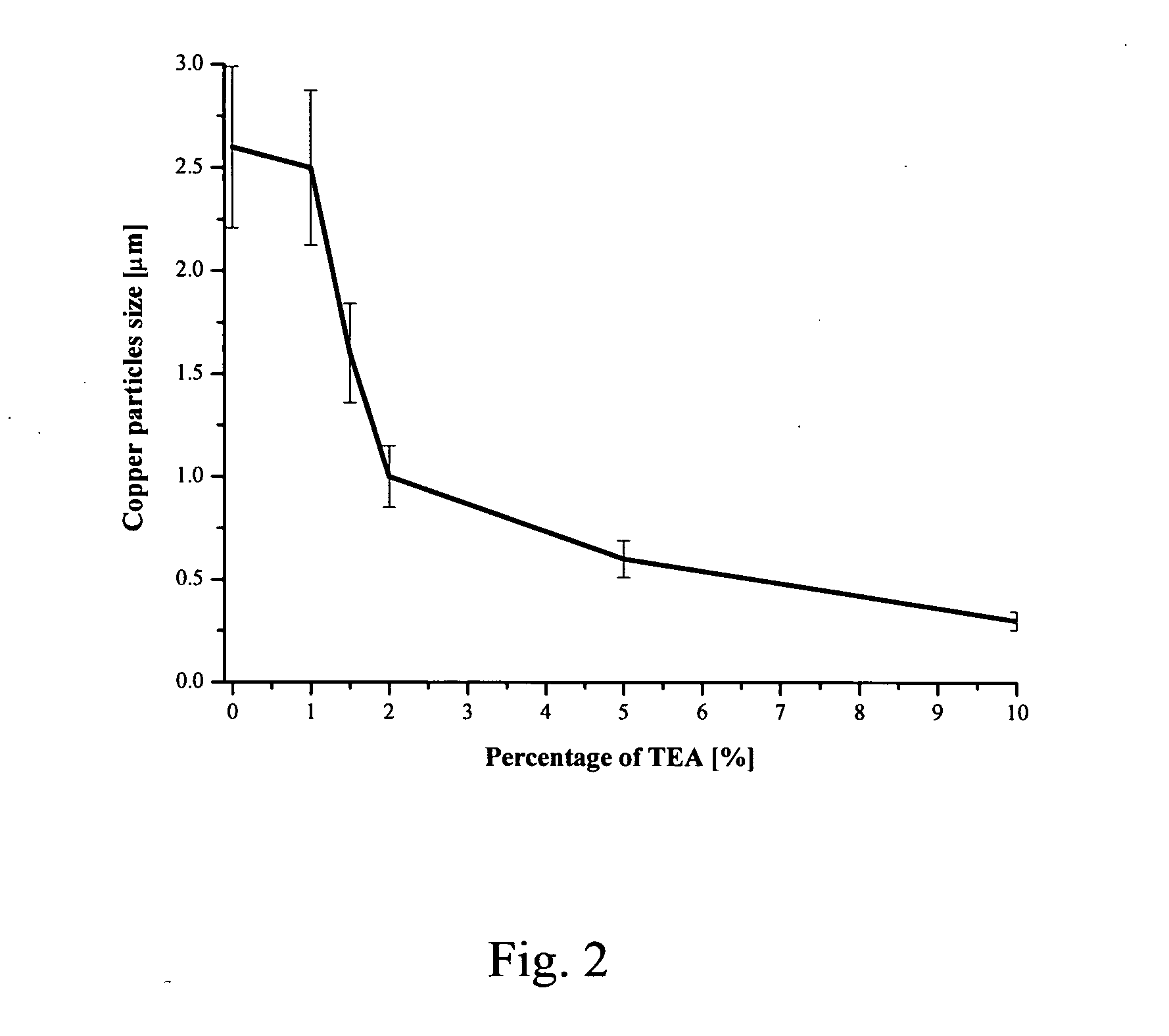

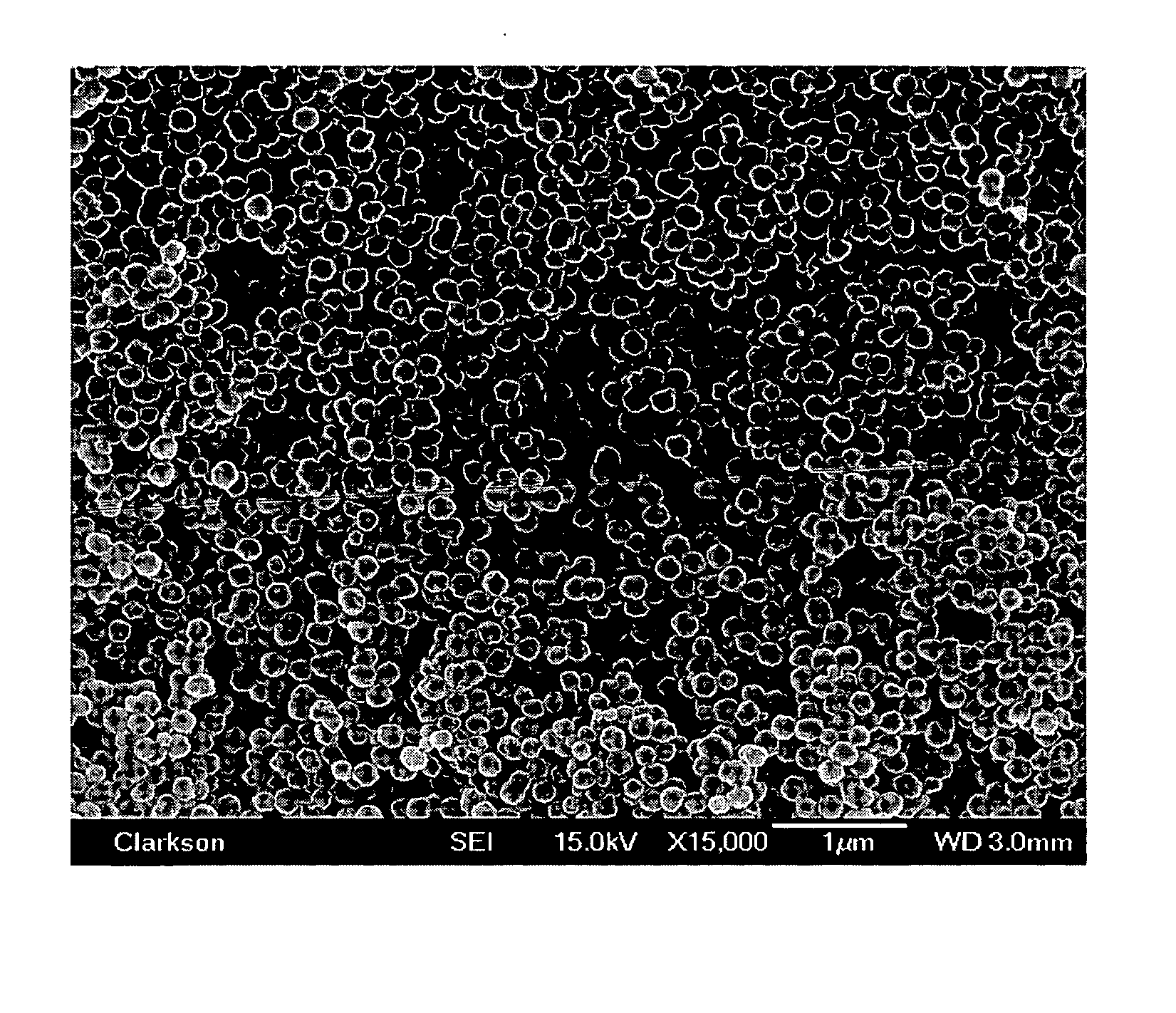

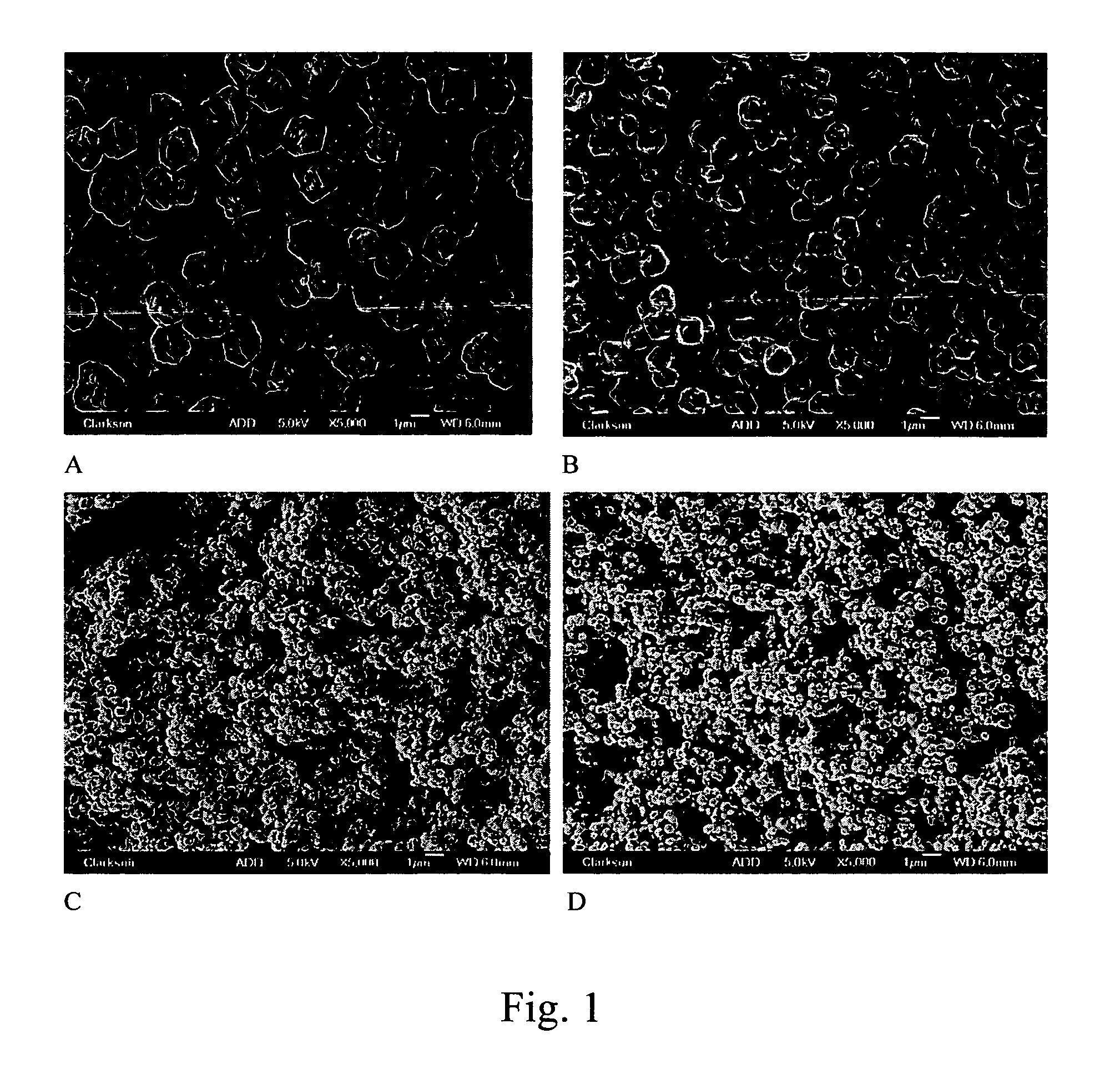

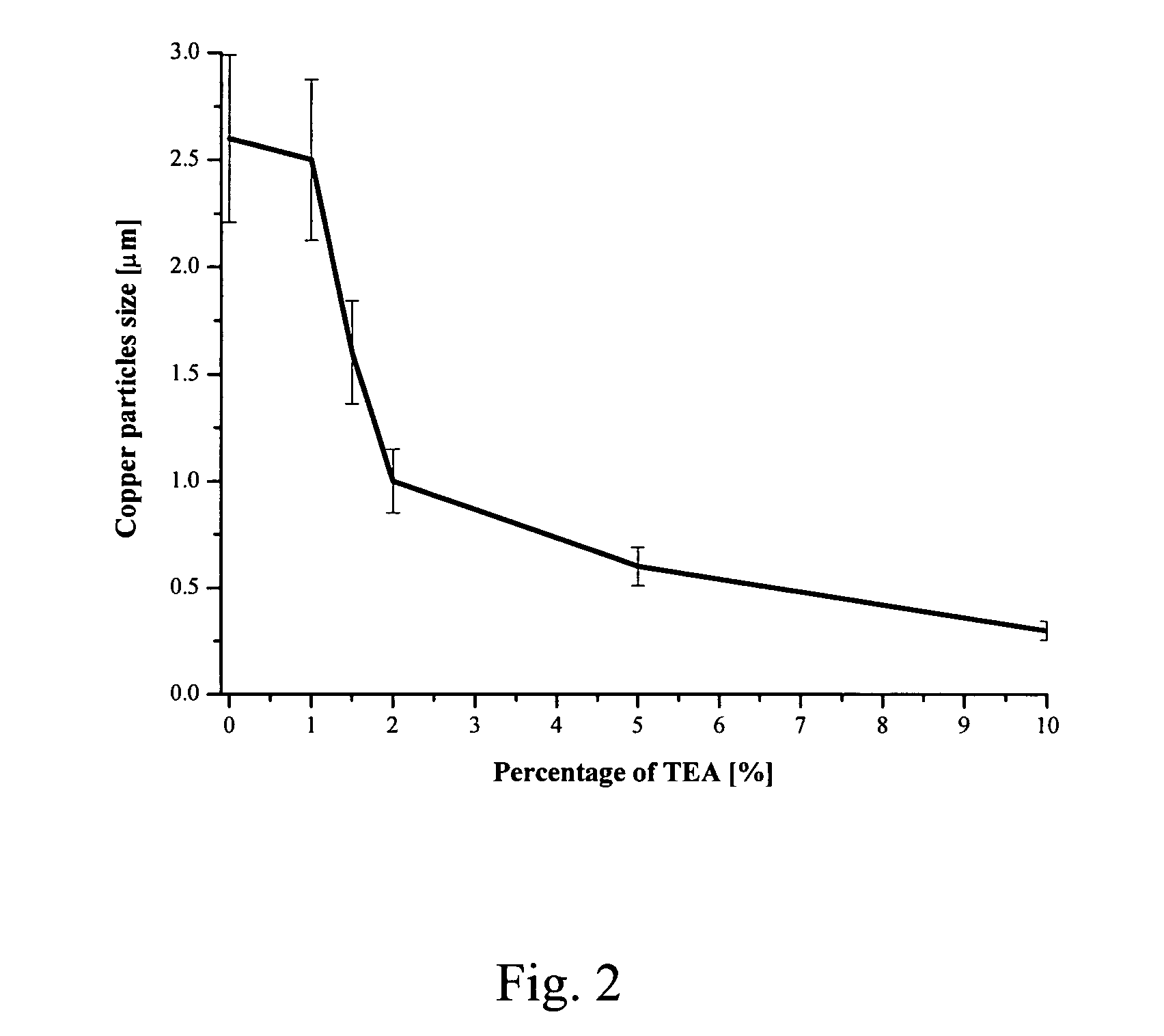

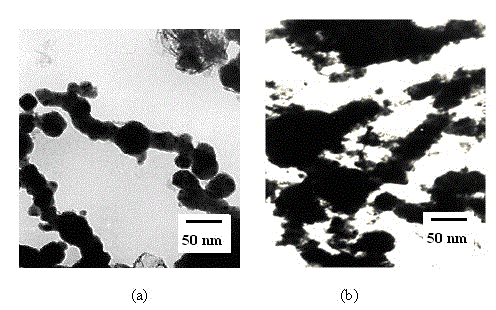

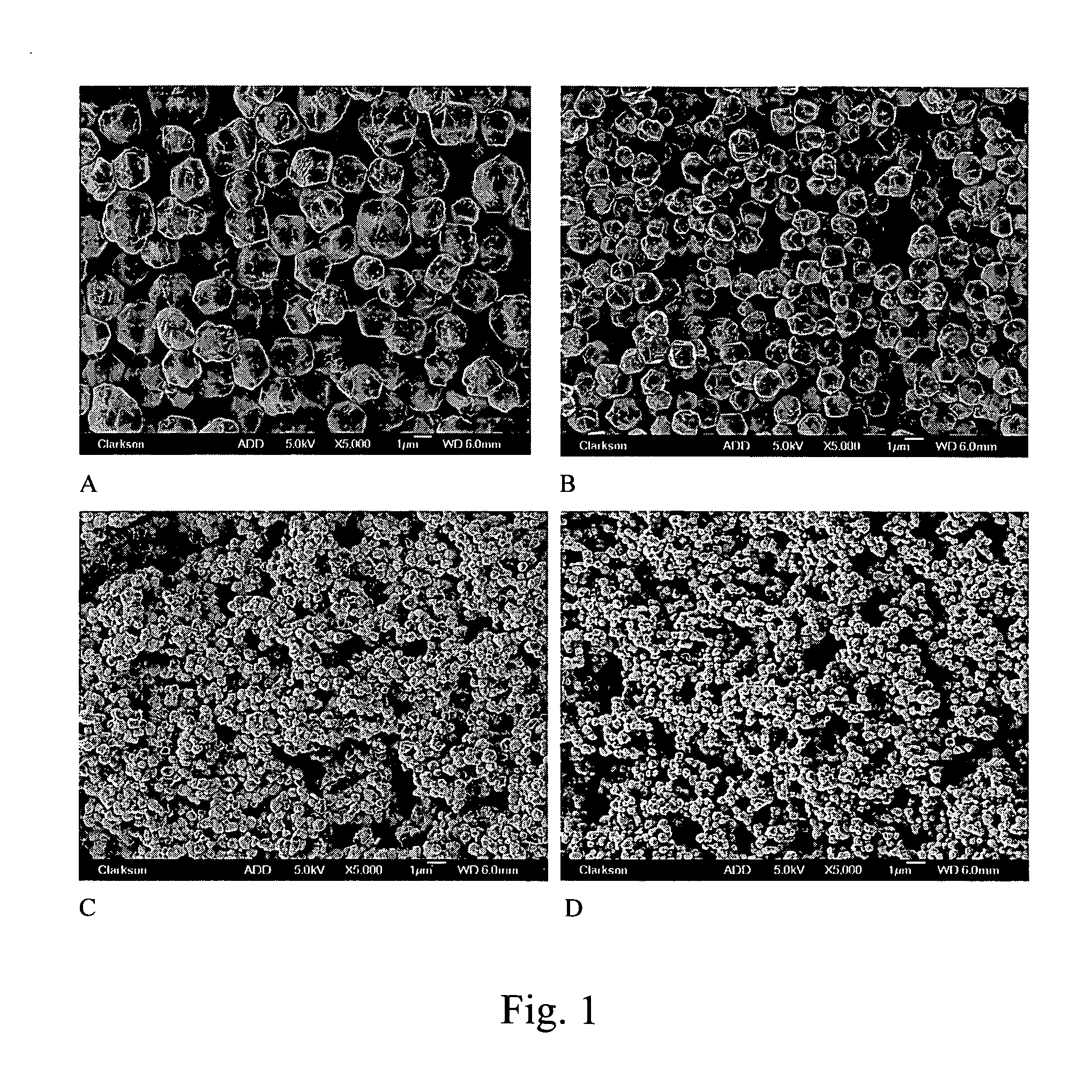

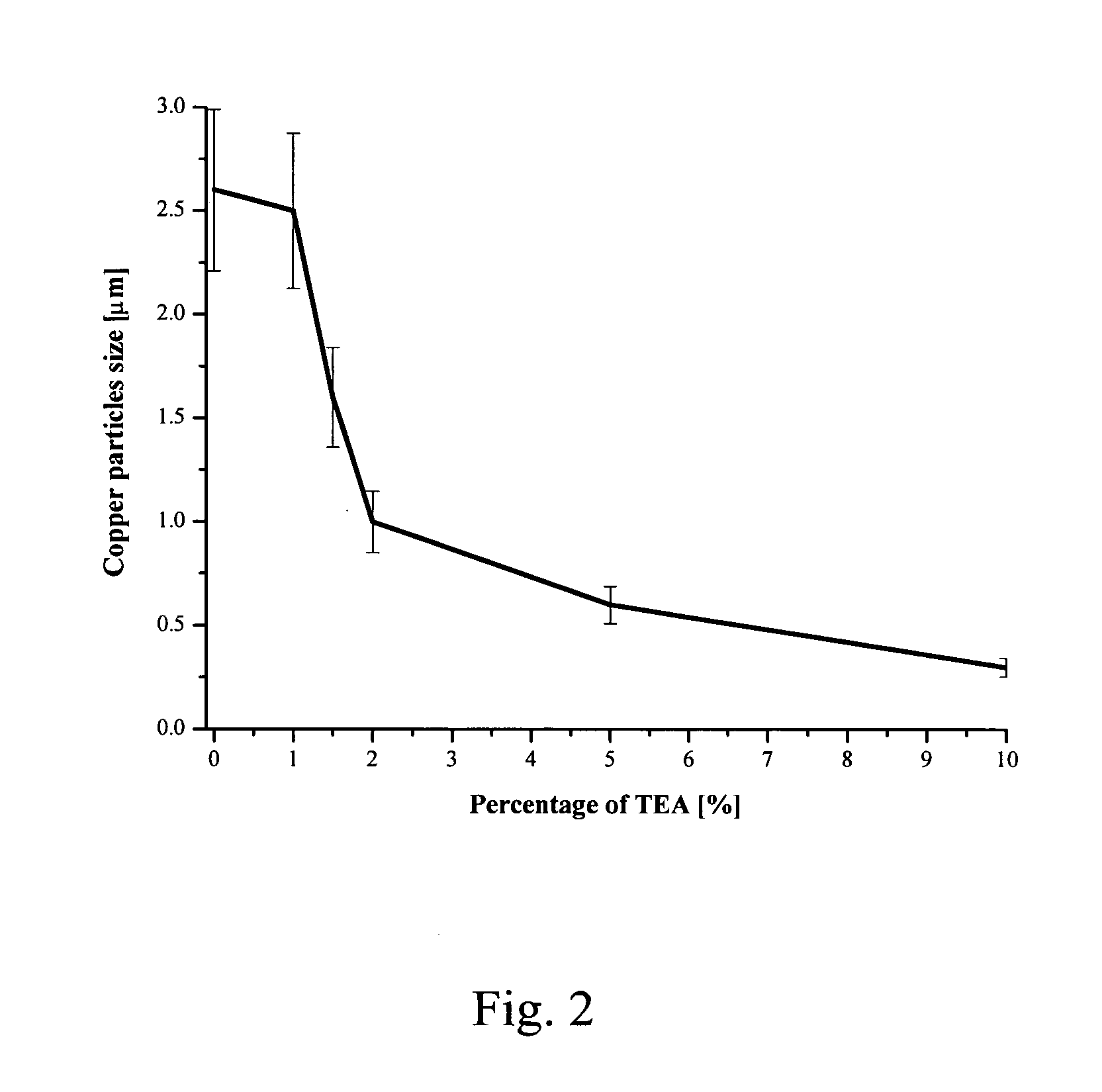

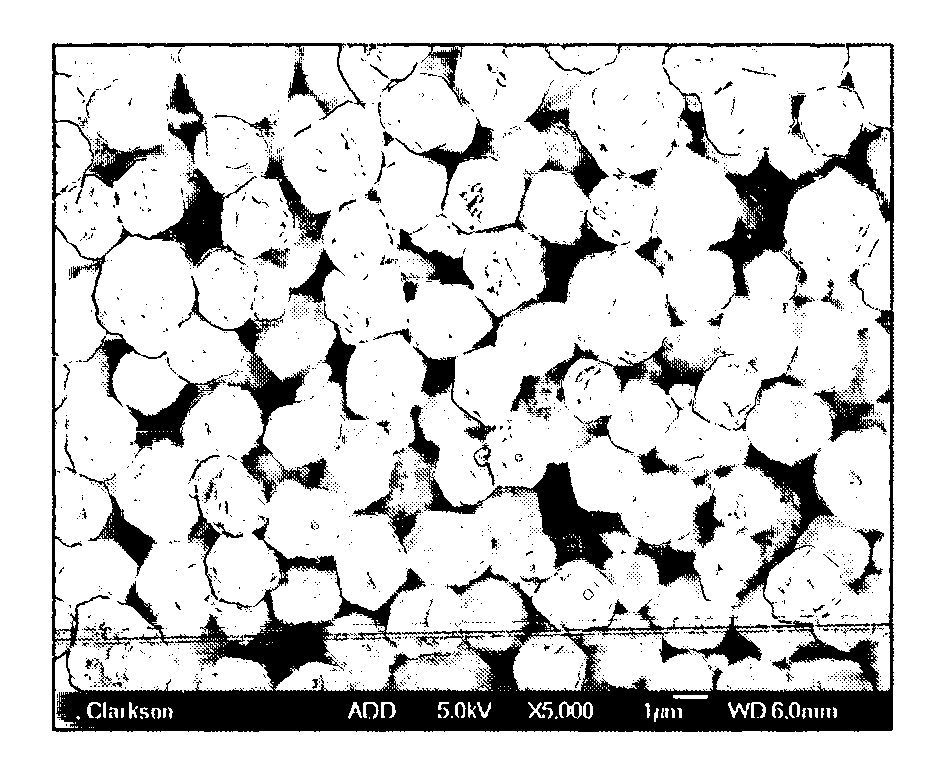

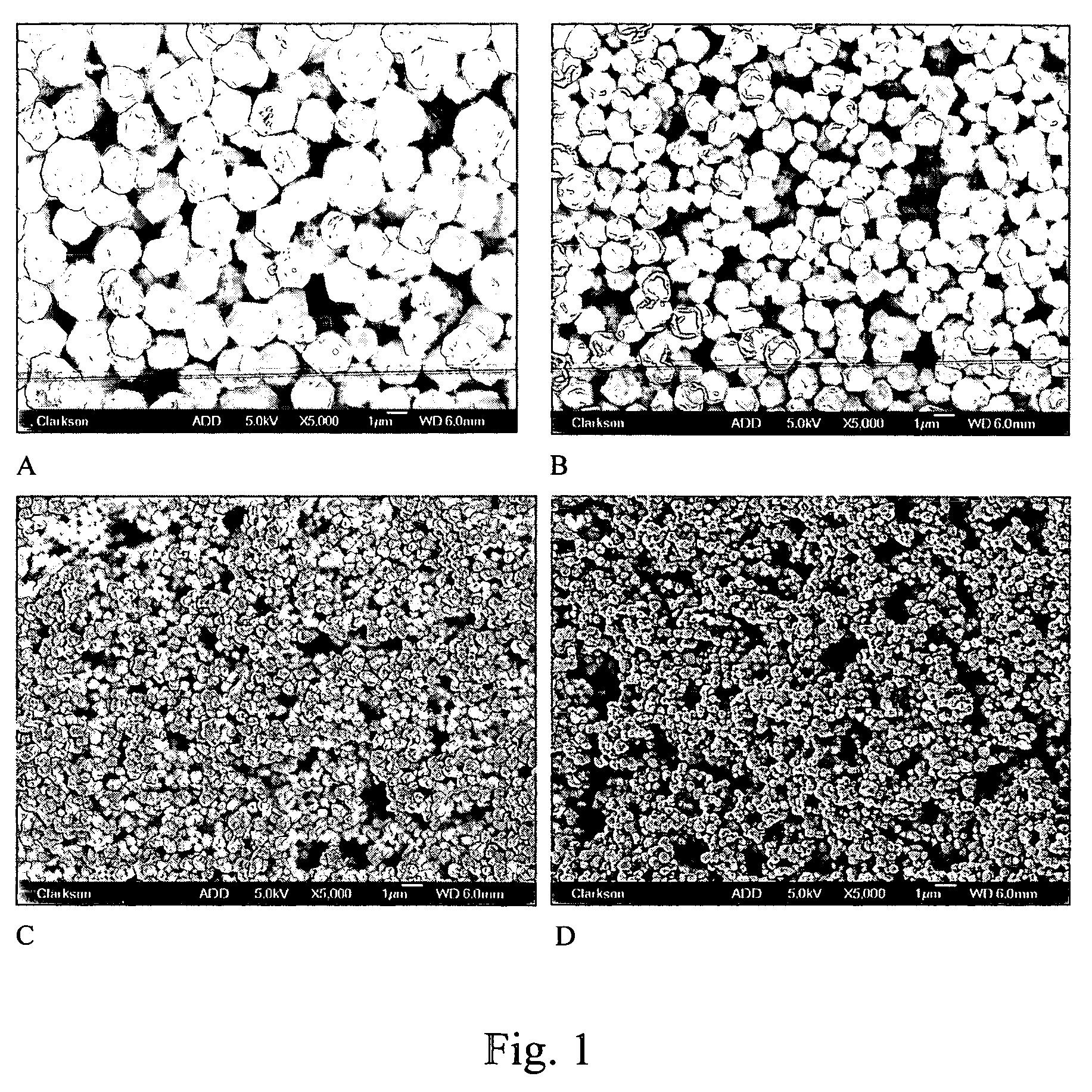

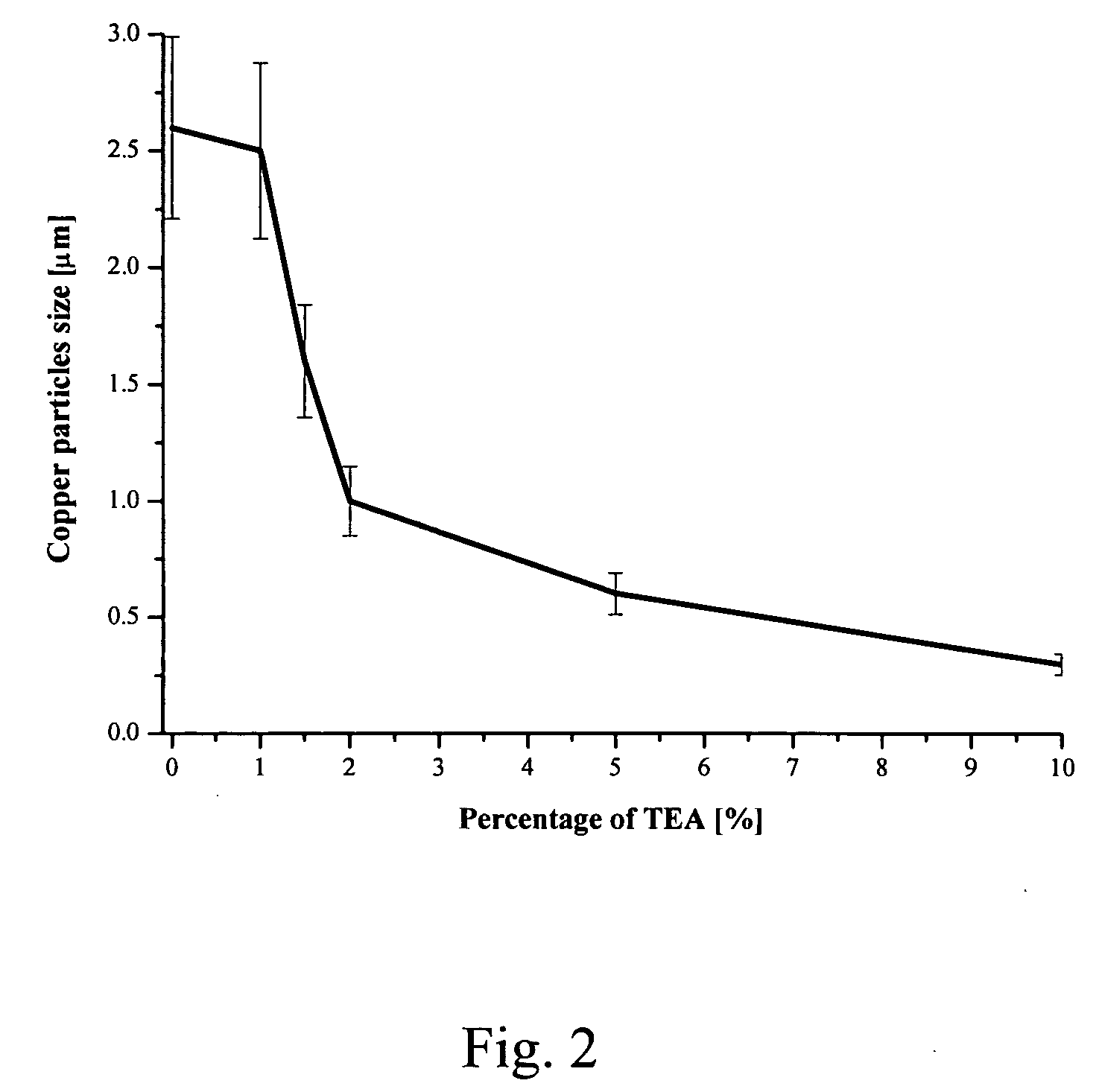

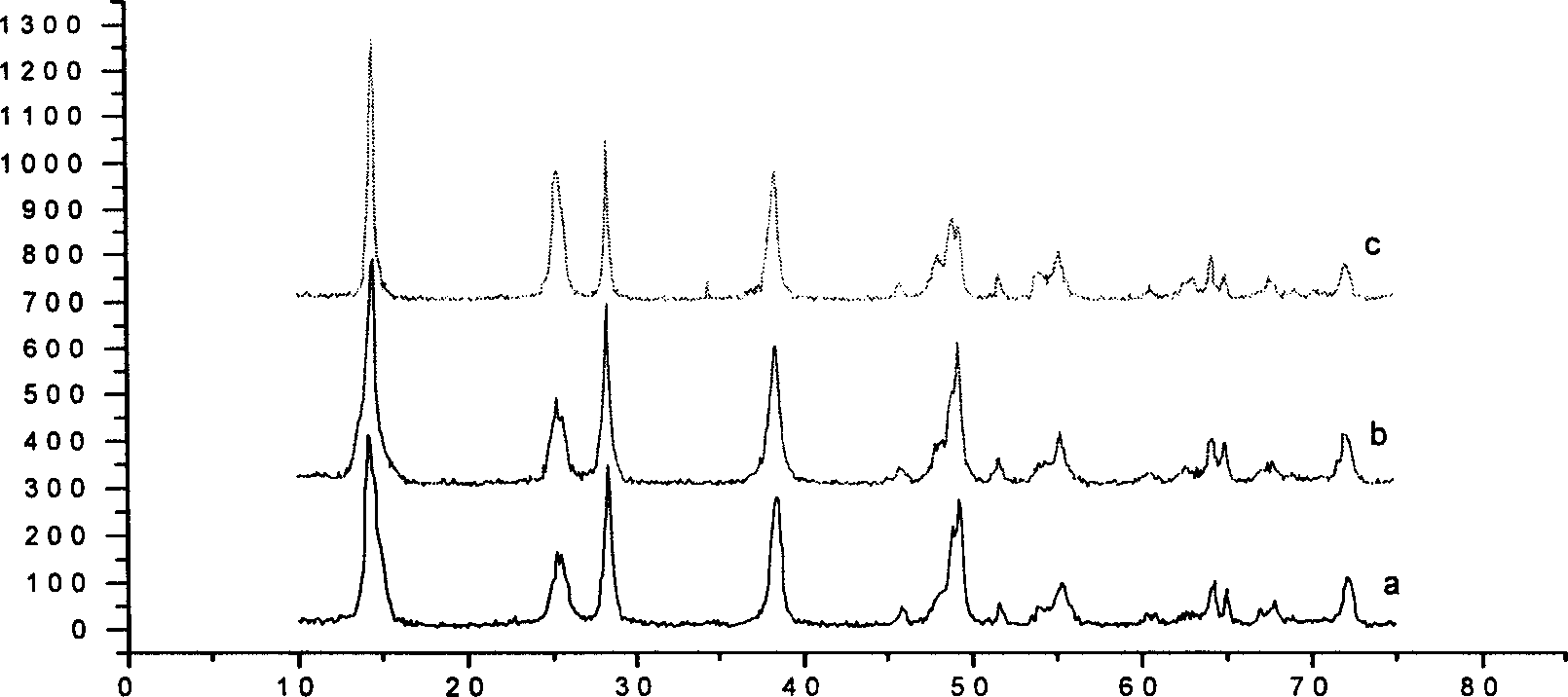

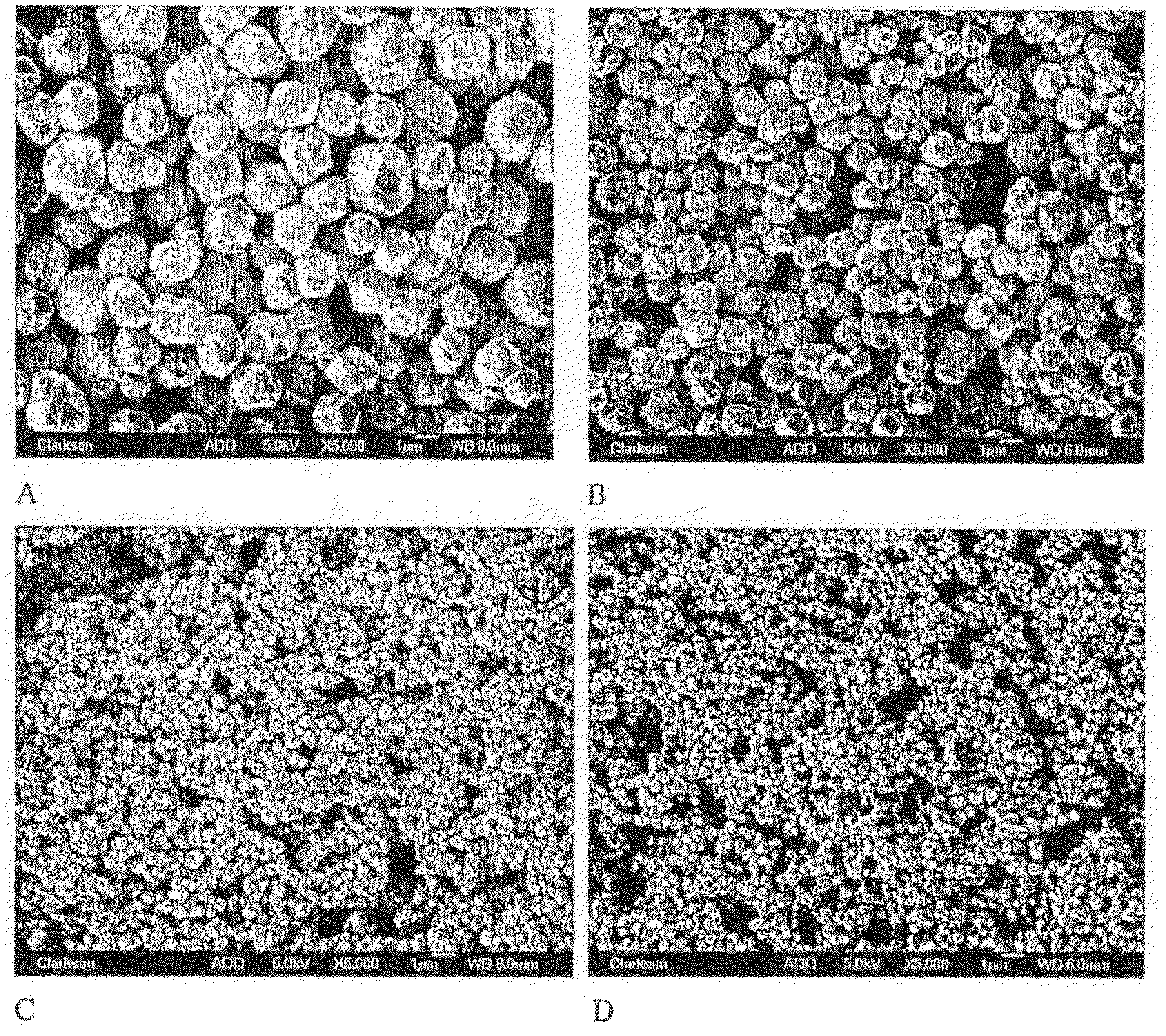

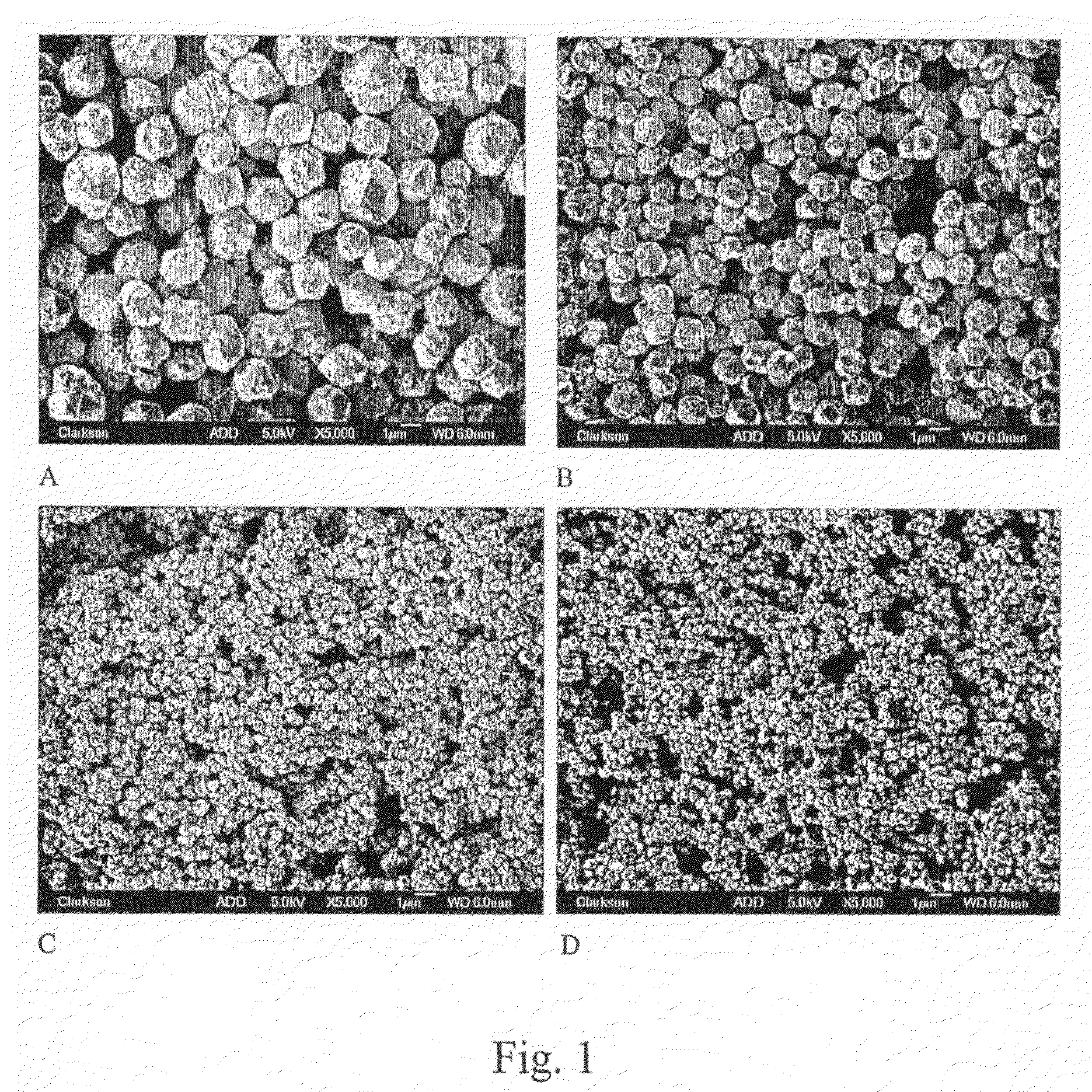

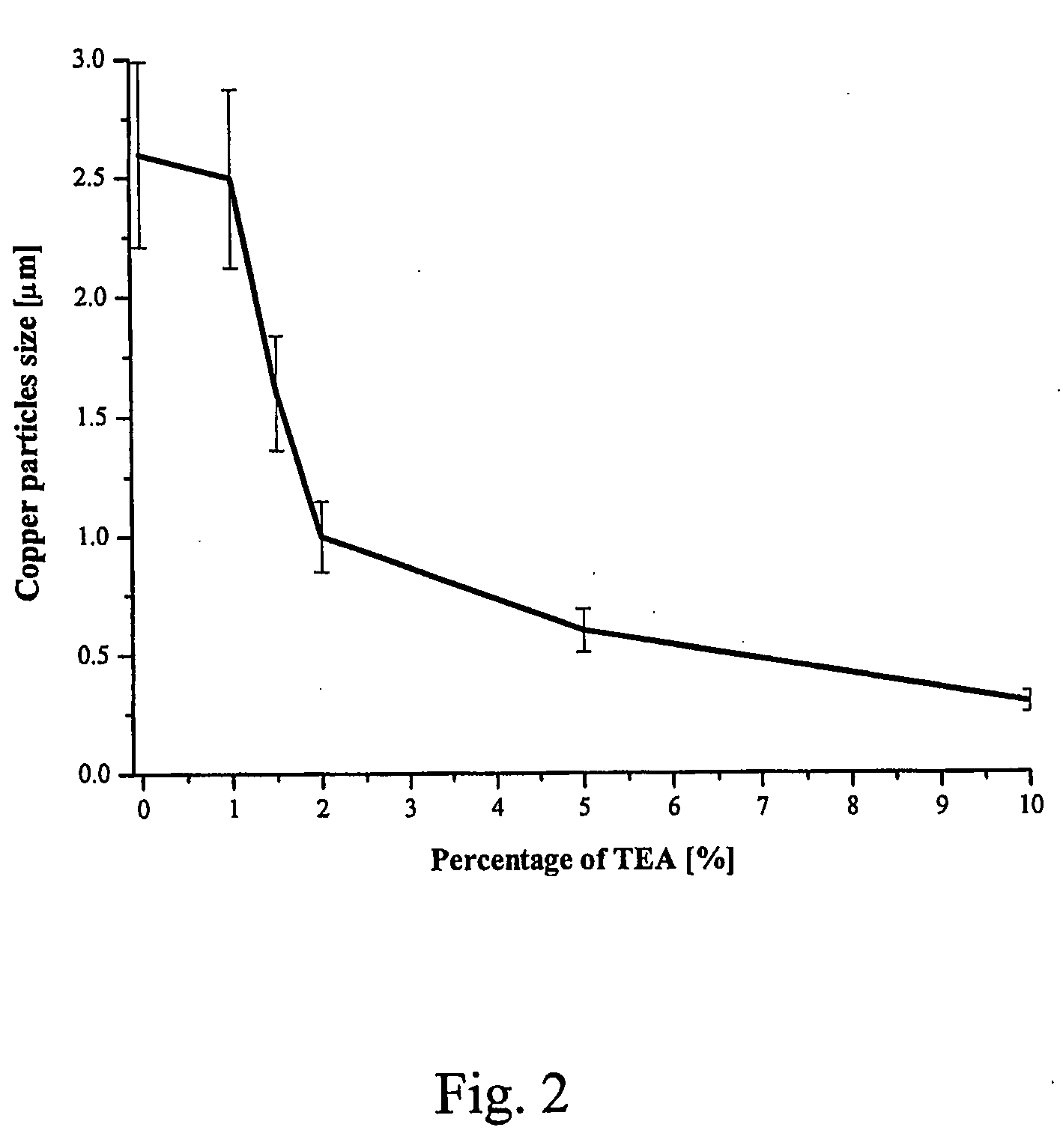

Aqueous-based method for producing ultra-fine metal powders

ActiveUS20060090596A1Tight size distributionLow degree of reunionMaterial nanotechnologyMetal-working apparatusUltra fineMetal powder

Owner:CLARKSON UNIVERSITY

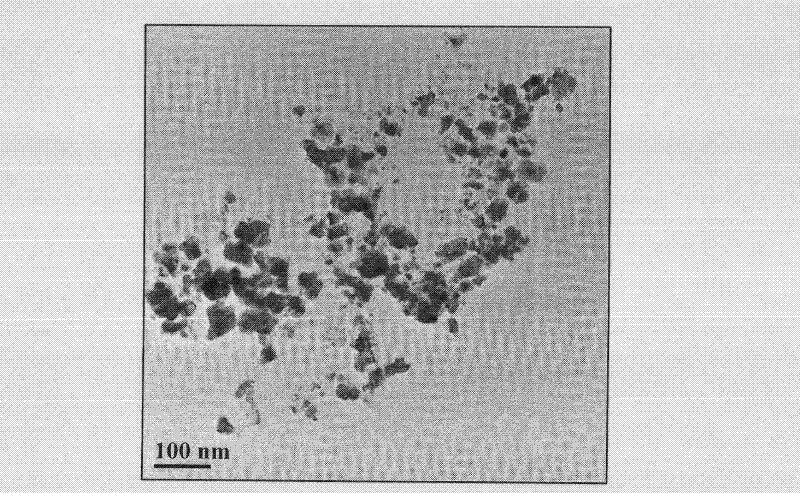

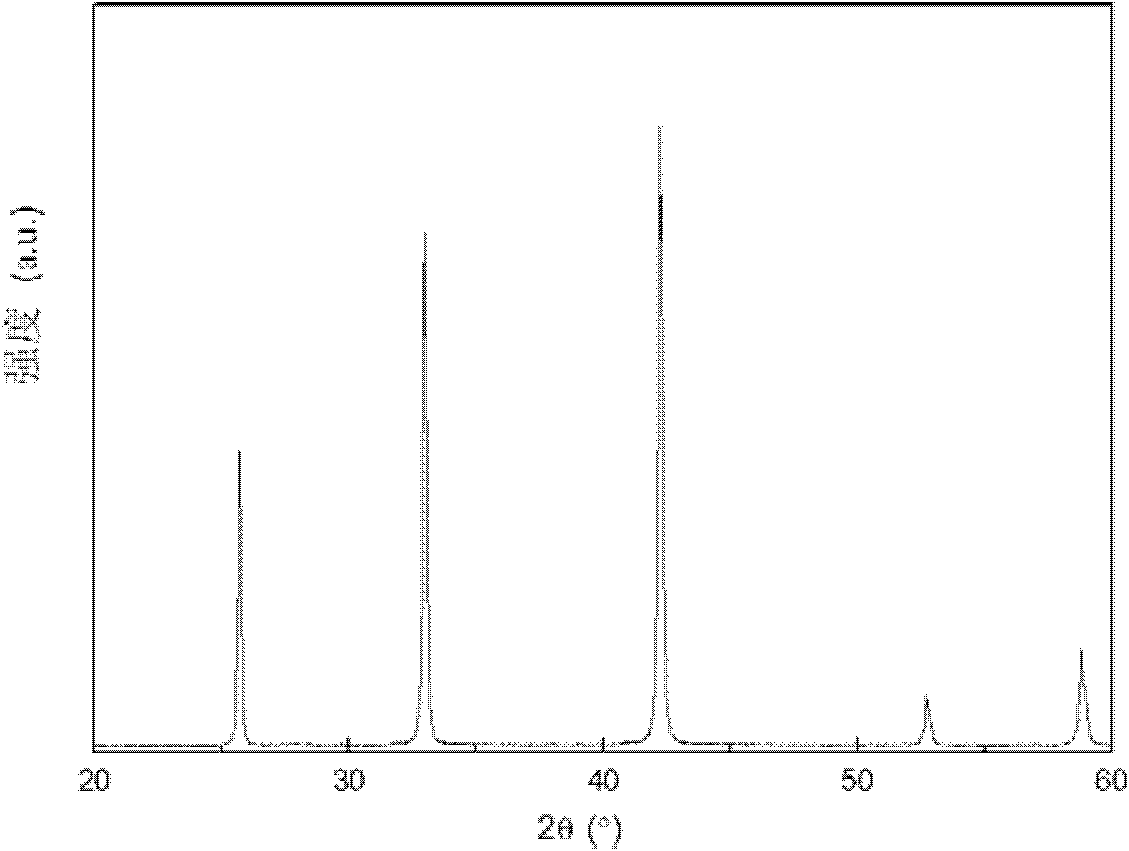

Preparation method of nano-tungsten powder

InactiveCN102019429ASimple preparation processThe preparation process is practicalAir atmosphereAmmonium metatungstate

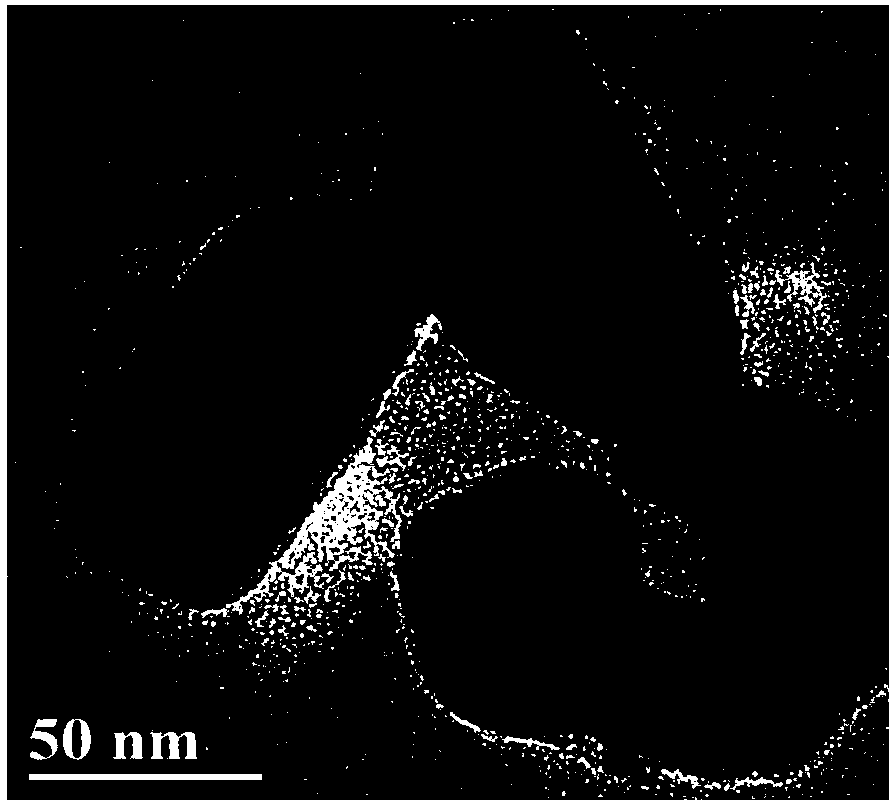

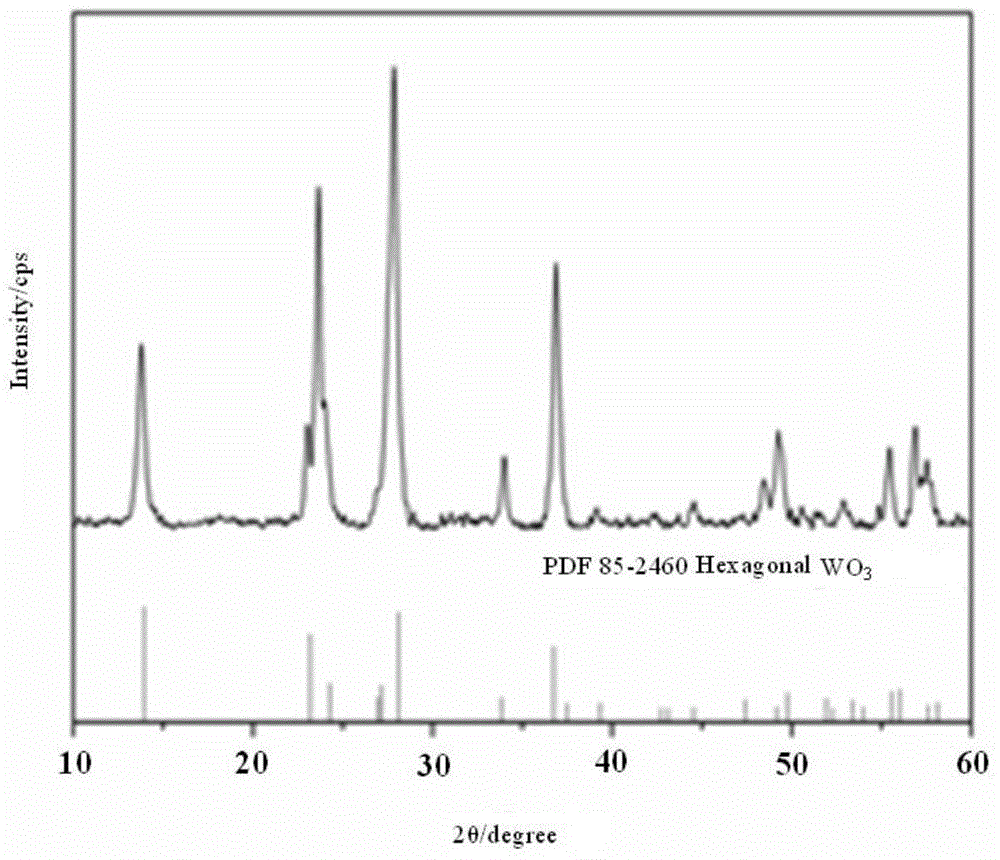

The invention discloses a preparation method of nano-tungsten powder. The preparation method comprises the following steps: preparing ammonium metatungstate and citric acid into clear mixed aqueous solution; performing complex reaction at the temperature of 60 to 90 DEG C; filtering and drying to obtain the precursor of tungsten oxide; calcining in air to obtain tungsten oxide (WO3) powder; introducing ammonia gas to the tungsten oxide powder for nitridation to obtain tungsten nitride (W2N) powder; and finally performing thermal treatment on the tungsten nitride powder to obtain the nano-tungsten powder. The preparation process disclosed by the invention is simple and practical and has the high operability and is easy in implementation of scale production; the prepared powder has small particle size of which the average particle size is 20-50 nm; the particle size distribution is uniform; and the degree of aggregation is low and high sintering activity is realized. The technology disclosed by the invention can promote the progress of high-quality tungsten material in China and the performance level, and provide means for transforming advantages in tungsten ore resources into industrial and economical advantages.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of tungsten carbide nanopowder

InactiveCN102190299AHigh purityReduce the introductionNanostructure manufactureTungsten/molybdenum carbideOrganic acidResidual carbon

The invention provides a preparation method of tungsten carbide nanopowder. The preparation method comprises the following steps of: preparing a tungsten-carbon precursor by using soluble tungsten salt and organic acid as raw materials through a sol-gel method, and then carrying out heat treatment on the tungsten-carbon precursor to obtain the tungsten carbide nanopowder. The preparation method provided by the invention is simple and practical, avoids the multistep control mode of the traditional preparation methods, saves energy, and is suitable for industrial production; and the tungsten carbide nanopowder prepared by the invention has the advantages of uniform and small particle size (smaller than 50 nm), low aggregation degree, low impurity content and low residual carbon content (lower than 0.5wt%).

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing ZrO2-CeO2/CNTs composite nanotube by hydrothermal method

InactiveCN101767770AGood dispersionLarge specific surface areaNanostructure manufactureCatalyst activation/preparationCarbon nanotubeSurface-active agents

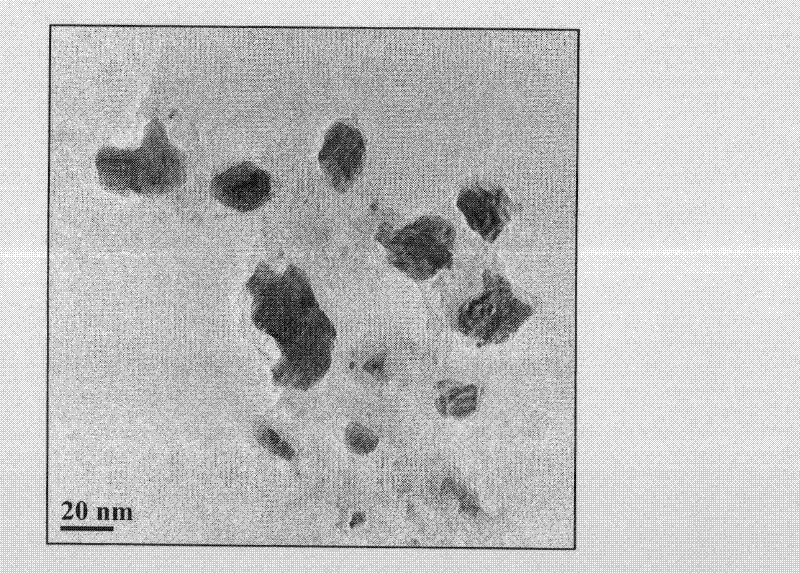

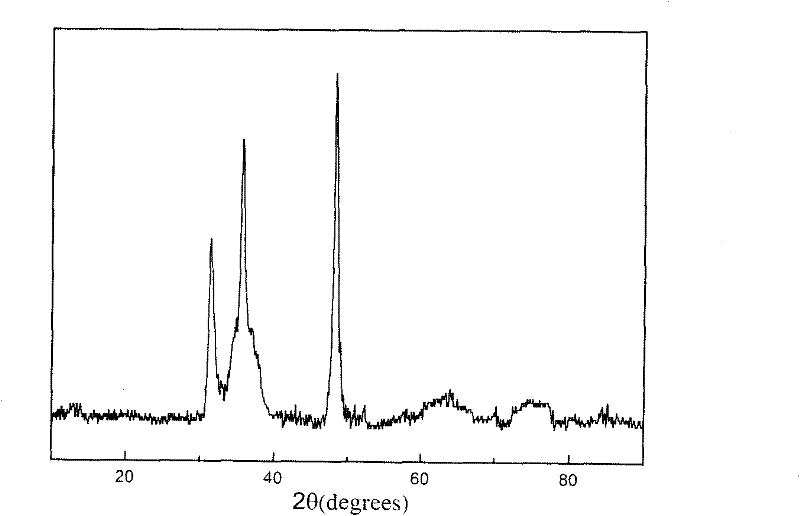

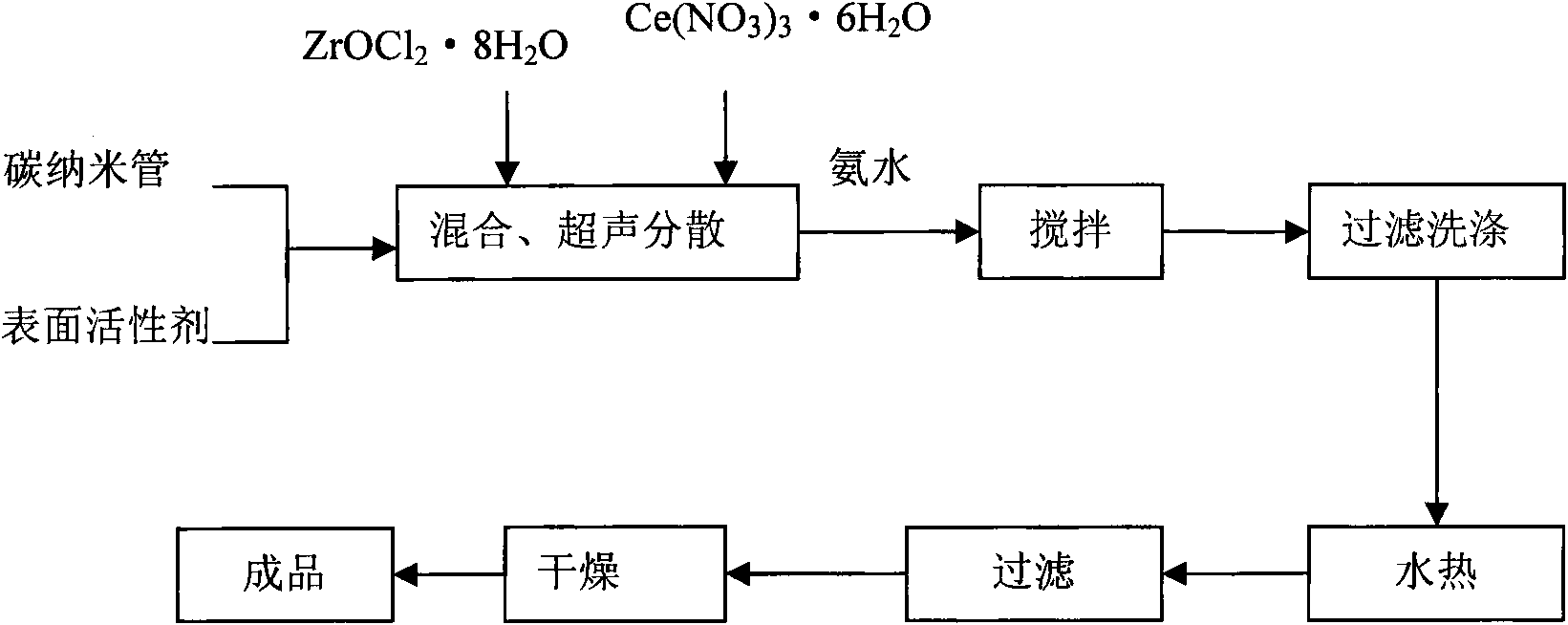

The invention discloses a method for preparing a ZrO2-CeO2 / CNTs composite nanotube by a hydrothermal method, which is a method for preparing a composite carbon nano tube based on nanoscale cerium oxide, nanoscale zirconia and a carbon nano tube. The preparation method comprises the steps of: sequentially adding the carbon nano tube, a surface active agent, zirconium oxychloride, cerous nitrate and deionized water which serve as raw materials according to stoichiometric ratio; performing ultrasonic dispersion to uniformly mix the raw materials; dripping ammonia water into the mixed raw materials until the pH value is 9.5; and performing hydro-thermal treatment to prepare a product, wherein the tube diameter of the prepared ZrO2-CeO2 / CNTs composite nanotube is between 50 and 80 nanometers, and a specific surface area reaches 70-150 m<2> / g; and the ZrO2-CeO2 / CNTs composite nanotube exists in the form of complete solid solution of a square / cubic system, the crystallinity reaches over 75 percent, and the ZrO2-CeO2 / CNTs composite nanotube is uniform in loading and has no agglomeration phenomenon. The method has the advantages of simple process, no need of high-temperature calcination, low energy consumption and the like.

Owner:GUANGDONG UNIV OF TECH

Polyol-based method for producing ultra-fine silver powders

InactiveUS20060090599A1Tight size distributionLow degree of reunionMaterial nanotechnologyMetal-working apparatusSilver particlesUltra fine

The present invention provides a metallic composition, which contains a plurality of ultra-fine metallic particles (e.g., ultra-fine copper, nickel, or silver particles) having at least one desirable feature, such as, tight size distribution, low degree of agglomeration, and high degree of crystallinity and oxidation resistance. The present invention further provides a method for forming the ultra-fine metallic particles. Also provided are a substance or substrate coated with the ultra-fine metallic particles and a method of coating a substance or substrate with the ultra-fine metallic particles. Furthermore, the present invention provides a method of controlling the size of ultra-fine metal particles formed in a reducing reaction in a liquid. Also provided is a method for producing ultra-fine metallic particles, which utilizes a concentrated reaction system.

Owner:CLARKSON UNIVERSITY

Polyol-based method for producing ultra-fine nickel powders

InactiveUS20060090601A1Tight size distributionLow degree of reunionTransportation and packagingMetal-working apparatusPolyolUltra fine

The present invention provides a metallic composition, which contains a plurality of ultra-fine metallic particles (e.g., ultra-fine copper, nickel, or silver particles) having at least one desirable feature, such as, tight size distribution, low degree of agglomeration, and high degree of crystallinity and oxidation resistance. The present invention further provides a method for forming the ultra-fine metallic particles. Also provided are a substance or substrate coated with the ultra-fine metallic particles and a method of coating a substance or substrate with the ultra-fine metallic particles. Furthermore, the present invention provides a method of controlling the size of ultra-fine metal particles formed in a reducing reaction in a liquid. Also provided is a method for producing ultra-fine metallic particles, which utilizes a concentrated reaction system.

Owner:CLARKSON UNIVERSITY

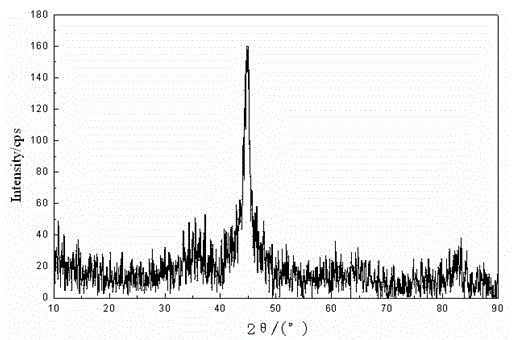

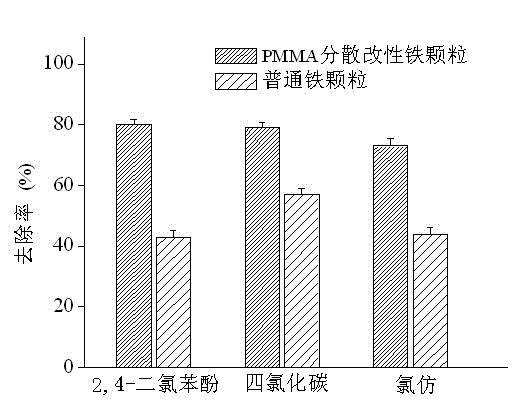

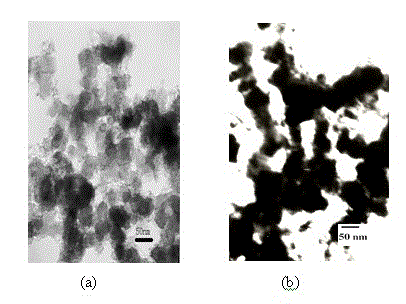

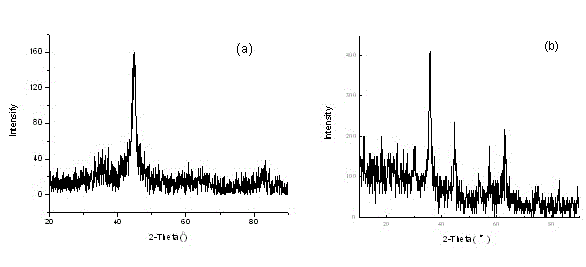

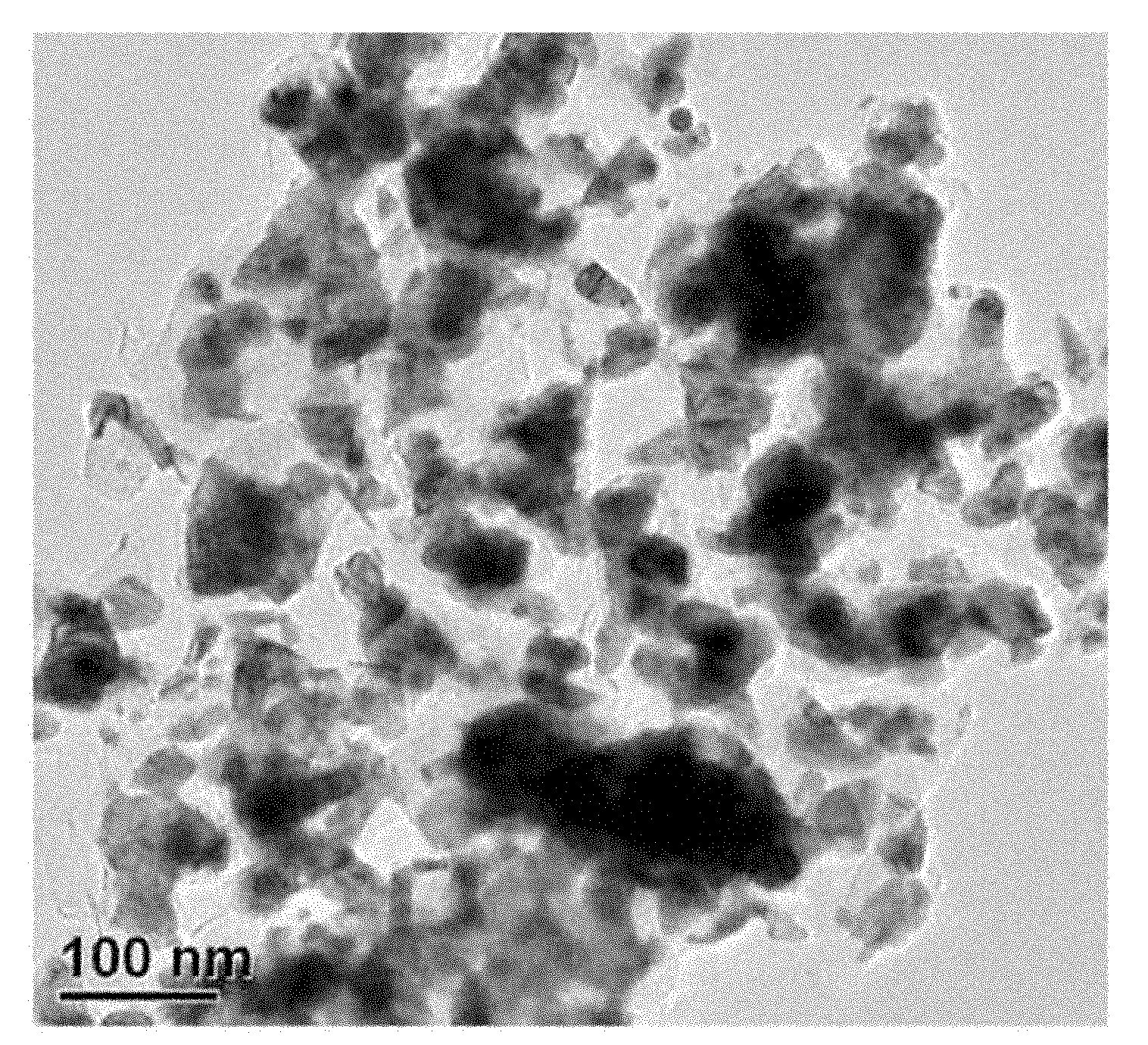

Preparation method of dispersant modified iron nanoparticles

InactiveCN102614918AImprove stabilityLow degree of reunionOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsEnvironmental mediaOrganic compound

The invention discloses a preparation method of dispersant modified iron nanoparticles. According to the preparation method, high polymer, a cationic surfactant or anionic polymer electrolyte is used as a dispersant to perform surface modification on particles in a preparation process of the iron nanoparticles so as to prepare the dispersant modified iron nanoparticles. The iron nanoparticles prepared by the method have good dispersion stability; the hard agglomeration of the iron nanoparticles in an aqueous medium is reduced; the dispersion degree of the iron nanoparticles is increased; the method can also be used for performing dispersion modification on iron base bimetallic particles; and the method can be applied to pollution remediation of chlorinated organic compounds in an environmental medium and has broad application prospect.

Owner:KUNMING UNIV OF SCI & TECH

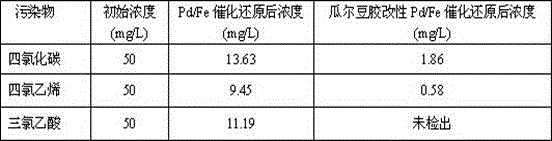

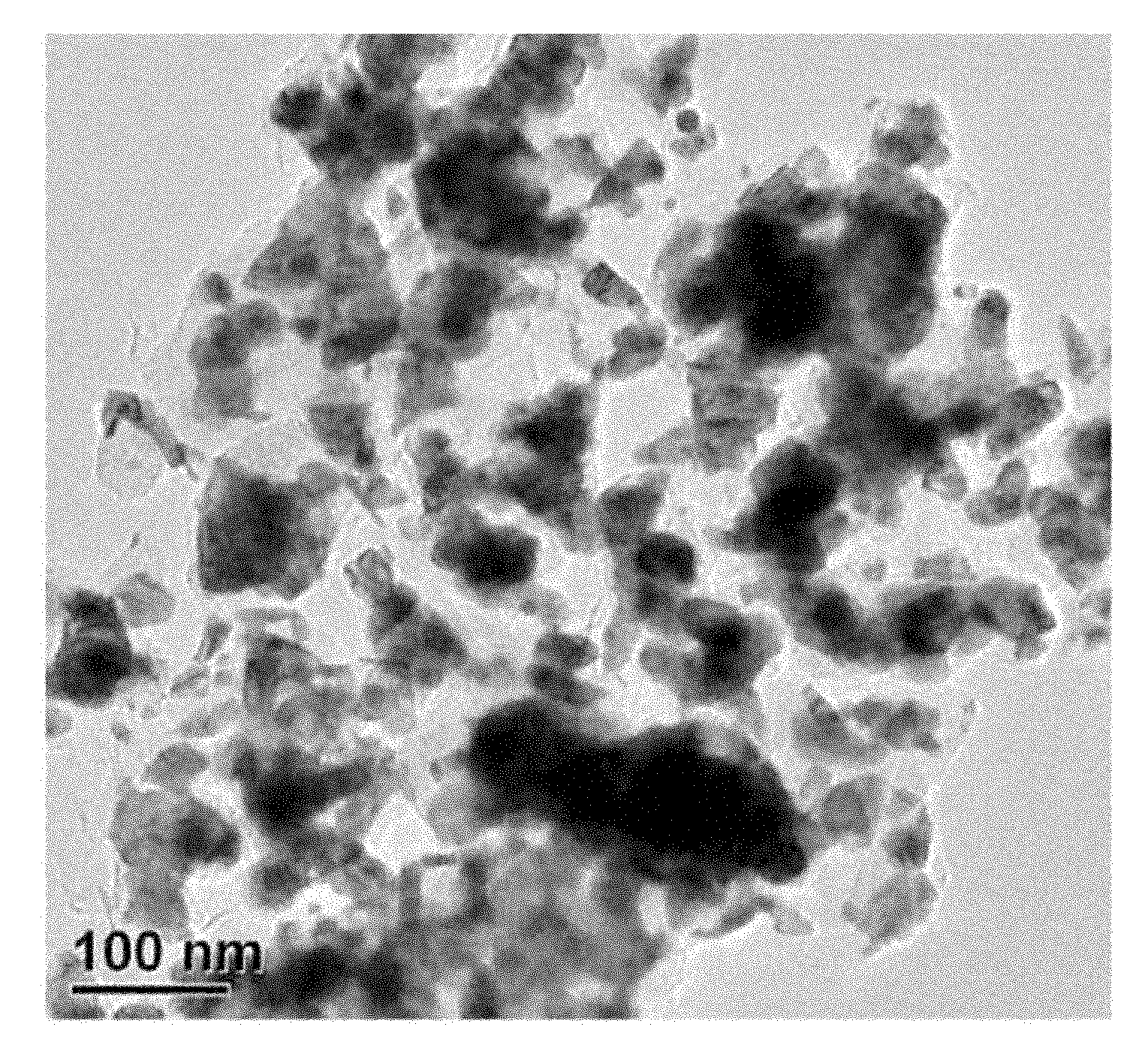

Preparation method of surface modified nano palladium/iron catalytic reducing agent

InactiveCN102614896AIncreased dispersionImprove stabilityWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsFlocculationOrganic compound

The invention relates to a preparation method of a surface modified nano palladium / iron catalytic reducing agent. The nano palladium / iron catalytic reducing agent is prepared by using a liquid-phase deposition method; and by adding a surface modifier and coating the surface modifier on the outer layer of the catalytic reducing agent, hard agglomeration of the nano palladium / iron catalytic reducing agent in water is reduced. The nano palladium / iron catalytic reducing agent modified by the surface modifier has no flocculation phenomenon in water and higher dispersion degree. Compared with the normal nano palladium / iron catalytic reducing agent, the modified nano palladium / iron catalytic reducing agent prepared by the invention has the advantages of high particle purity, no oxidative inactivation phenomenon, small particle size, high catalytic reduction reaction activity and capability of increasing the removal rate for various chlorinated organic compounds in water by 9-24 percent compared with the unmodified nano palladium / iron catalytic reducing agent.

Owner:KUNMING UNIV OF SCI & TECH

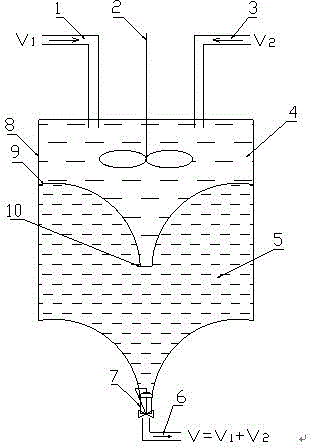

Production method and device of fine-grained low-chloride rare earth carbonate

ActiveCN104310456AAchieve spatial separationPromote formationRare earth metal compoundsChlorideReaction zone

The invention relates to a production method and device of fine-grained low-chloride rare earth carbonate. The production method is mainly characterized in that rare earth chloride and a carbonate solution are added in a concurrent flow feeding way on a designed special precipitation reaction device, the spatial separation of a reaction zone and a crystallization zone is realized by controlling the feeding speed and discharging speed and controlling the aging time of rare earth carbonate, and thus the double purposes of directly obtaining a fine-grained low-chloride rare earth carbonate product from a hydrochloric acid medium by precipitation and realizing continuous production are achieved. By adopting the production method and device provided by the invention, the fine-grained rare earth carbonate product with the chloride content of less than 50ppm can be directly obtained from the hydrochloric acid medium by using cheap ammonium bicarbonate, the precipitation reaction device has a simple structure, and the continuous production can be realized.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

Method for preparing WC-Co (tungsten carbide-cobalt) nano-powder

InactiveCN102078965ASimple preparation processThe preparation process is practicalNanotechnologyCarbonizationMixed gas

The invention discloses a method for preparing WC-Co (tungsten carbide-cobalt) nano-powder, which comprises the following steps of: firstly, preparing tungsten oxide-cobalt oxide powder by adopting a citrate or package method; secondly, introducing ammonia gas into the obtained tungsten oxide-cobalt oxide powder for nitridation to obtain tungsten nitride-cobalt nitride powder; and thirdly, mixing the obtained tungsten nitride-cobalt nitride powder with carbon black, performing ball milling, and performing heat treatment under a vacuum or inert atmosphere with the air pressure of less than 200Pa to obtain the WC-Co nano-powder; or directly charging the obtained tungsten nitride-cobalt nitride powder into a tube furnace, and introducing mixed gas of methane and hydrogen gas into the tube furnace for carbonization to obtain the WC-Co nano-powder. The preparation process disclosed by the invention has the advantages of simplicity and practicality, strong maneuverability, and easiness of large-scale production. Moreover, the prepared powder has the advantages of small particle diameter, uniform particle size distribution and good sintering activity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

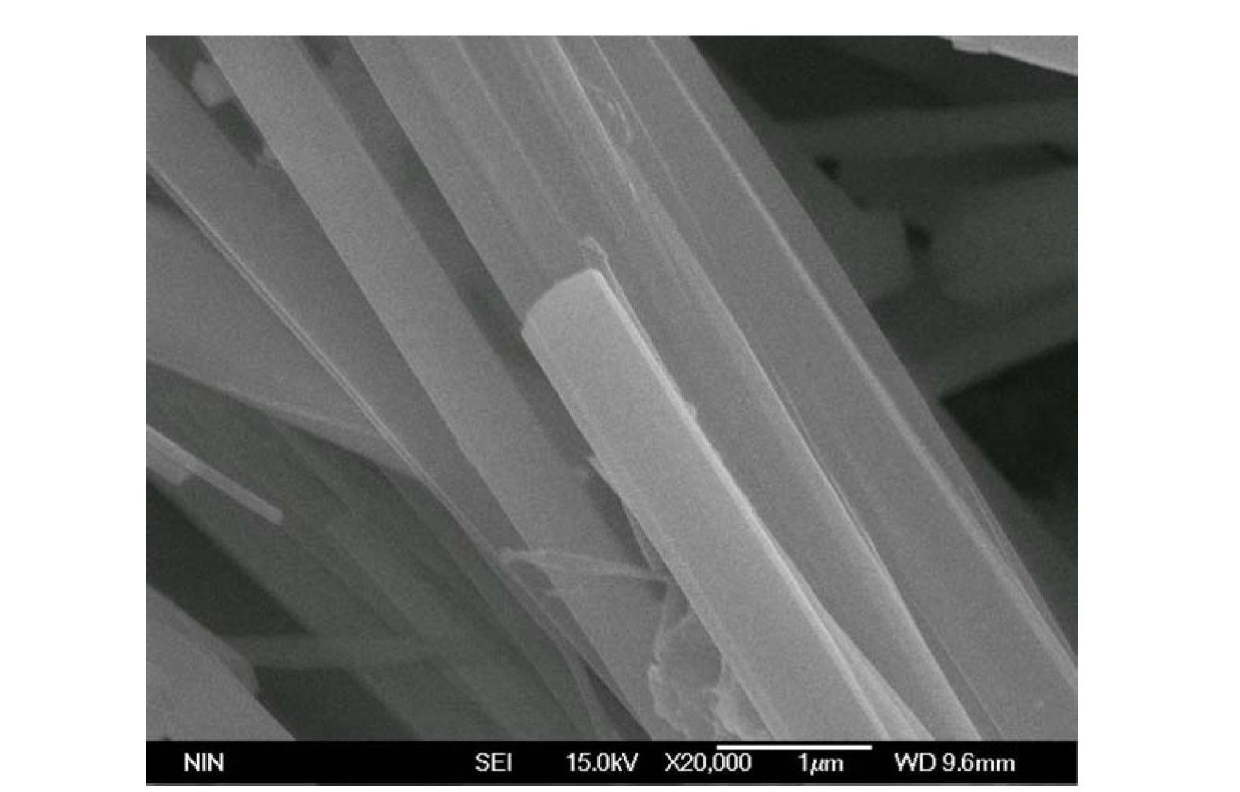

Preparation method of Y2SiO5 crystal whiskers

ActiveCN102677144ANarrow particle size distributionSimple processPolycrystalline material growthFrom normal temperature solutionsFully developedSolvent

The invention relates to a preparation method of Y2SiO5 crystal whiskers, which comprises the steps of: dissolving Y (NO)3.6H2O and Na2SiO3.9H2O in anhydrous ethanol to obtain solution A; adding citric acid in the solution A and magnetically stirring at room temperature to obtain solution B; and placing the solution B in a hydrothermal reaction kettle for constant-temperature reaction, conducting centrifugal separation after a reaction system is naturally cooled to room temperature, successively washing with distilled water and anhydrous ethanol and finally drying to obtain the Y2SiO5 crystal whiskers. Compared with the traditional method, the preparation method of the Y2SiO5 crystal whiskers has the advantages that the purity of the Y2SiO5 crystal whiskers prepared through a solvent hydrothermal synthesis method is high, the fineness is ultrahigh, the grain size distribution range is narrow, the extent of particle aggregation is low, the crystal is fully developed, the process is relatively simple, the appearance and the size are controllable, the process is simple and high-efficiency, the cost is lower, the preparation temperature is low, the later-stage crystallization is not required, the possible defects that the crystal grains grow up, are coarsened or are curled and the like in the later-stage heat treatment process are avoided to some extent, and the like. By adopting the solvent hydrothermal synthesis method, high-purity Y2SiO5 crystal whiskers with controllable appearance are prepared under low-temperature condition.

Owner:李建伟

Polyol-based method for producing ultra-fine metal powders

InactiveUS20060090597A1Tight size distributionLow degree of reunionMaterial nanotechnologyMetal-working apparatusPolyolUltra fine

The present invention provides a metallic composition, which contains a plurality of ultra-fine metallic particles (e.g., ultra-fine copper, nickel, or silver particles) having at least one desirable feature, such as, tight size distribution, low degree of agglomeration, and high degree of crystallinity and oxidation resistance. The present invention further provides a method for forming the ultra-fine metallic particles. Also provided are a substance or substrate coated with the ultra-fine metallic particles and a method of coating a substance or substrate with the ultra-fine metallic particles. Furthermore, the present invention provides a method of controlling the size of ultra-fine metal particles formed in a reducing reaction in a liquid. Also provided is a method for producing ultra-fine metallic particles, which utilizes a concentrated reaction system.

Owner:CLARKSON UNIVERSITY

Polyol-based method for producing ultra-fine copper powders

InactiveUS20060090600A1Tight size distributionLow degree of reunionMaterial nanotechnologyMetal-working apparatusPolyolUltra fine

The present invention provides a metallic composition, which contains a plurality of ultra-fine metallic particles (e.g., ultra-fine copper, nickel, or silver particles) having at least one desirable feature, such as, tight size distribution, low degree of agglomeration, and high degree of crystallinity and oxidation resistance. The present invention further provides a method for forming the ultra-fine metallic particles. Also provided are a substance or substrate coated with the ultra-fine metallic particles and a method of coating a substance or substrate with the ultra-fine metallic particles. Furthermore, the present invention provides a method of controlling the size of ultra-fine metal particles formed in a reducing reaction in a liquid. Also provided is a method for producing ultra-fine metallic particles, which utilizes a concentrated reaction system.

Owner:CLARKSON UNIVERSITY

Preparation method for synthesizing nucleocapsid TiO2/Al2O3 nano powder by one-step hydrothermal process

This invention discloses one step hydrothermal method synthesizing nucleocapsid style TiO2 / Al2O3 nm powder body preparation method. It includes following procedures first ammonia water is added into material TiC14 solution to control pH value between 8.5 and 9.0 to fully deposit Ti4+ in the solution to make predecessor Ti(OH)4 of Ti02, then AlCl3 solution is added to Ti(OH)4, and ammonia water is added to Ti(OH)4 at the same time, pH value is adjusted to 8.8-9.5, then Al(OH)3 envelope is formed on surface of Ti(OH)4 to get predecessor. The predecessor is filled into high pressure tank as Ti(OH)4 / Al(OH)3 style to take part in hydrothermal reaction, then it is filtrated after the reaction, and then it is alcohol water exchanged by absolute ethyl alcohol, finally TiO2 / Al2O3 nm powder body is got after dried. There is no need to prepare nm level Ti02 core, and then enveloping in this method. Because water heat method is used in this invention, complex powder particles are uniform, envelope is integrated, agglomeration is few, and its preparation cost is reduced, technological line is facilitated, so it has wide industrial application prospect.

Owner:GUANGDONG UNIV OF TECH

Preparation method of submicron transition metal boride powder with low oxygen content

The invention discloses a preparation method of a submicron transition metal boride powder with low oxygen content. The method comprises the following steps: first carrying out ball milling mixing and drying on a transition metal oxide and elementary substance boron to obtain a MO2 / B mixed powder carrying out heat treatment on the MO2 / B mixed powder to obtain a MB2 / B2O3 powder; adding the obtained MB2 / B2O3 powder into water, heating and stirring to dissolve out B2O3 therein and centrifuging to obtain a MB2 powder; carrying out heat treatment on the obtained MB2 powder again. Compared with a prior art, the transition metal boride powder prepared by the method of the invention has advantages of a small particle size of 200-700 nm, low degree of aggregation and an oxygen content about 0.01-1.0wt%; besides the process of the preparation method of the present invention is simple and practical, has strong controllability and is easy for realization of large scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of tin antimony oxide organic nano paste

ActiveCN104263056AQuality improvementLow degree of reunionCoatingsPigment treatment with organosilicon compoundsOrganic solventEnergy consumption

The invention discloses a preparation method of a tin antimony oxide organic nano paste, which comprises the following steps: mixing ATO nano powder with an organic solvent, adding tetraethoxysilane for carrying out a heat preservation reaction, cooling, adding the organic solvent again and polyethylene imine, adjusting the pH value of the obtained mixture, and grinding the obtained product so as to obtain an ATO organic nano paste. The method disclosed by the invention is simple in process, low in energy consumption and low in cost; and due to the adoption of an efficient composite dispersant and a unique dispersion technology, a stable ATO organic nano paste can be prepared in a relatively short time.

Owner:GUANGXI UNIV

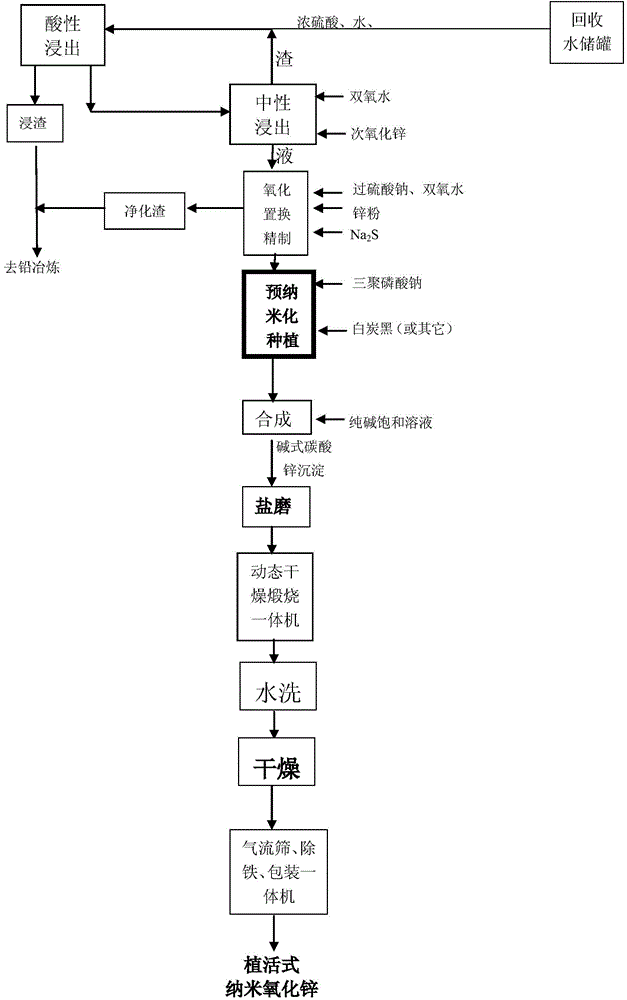

Engraftment type nano-zinc oxide and production process thereof

ActiveCN104591259AReduce contentHigh purityMaterial nanotechnologyZinc oxides/hydroxidesZno nanoparticlesPetrochemical

The invention relates to the technical field of the petrochemical and chemical fine chemicals and particularly relates to an engraftment type nano-zinc oxide and a production process thereof. According to the production process, a leaching purification process is changed to reduce the contents of the heavy metal impurities such as lead, cadmium, copper, arsenic so as to increase the purity and the quality of the product; the concentration of the reactant zinc is changed to increase the yield of the nano-zinc oxide; the catalyst is changed to eliminate the polarity of the zinc oxide and reduce the aggregation degree of the nano-zinc oxide; a salt-milling process is added to reduce the grain size, increase the specific surface area and improve the activity; at the same time, the types of the disperser are added to enrich the types of the product, adapt to various uses and expand the market adaptability of the product.

Owner:黄有余

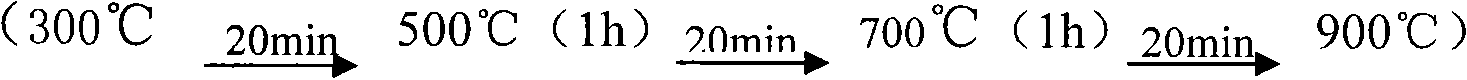

Method for preparing ultra-high rare earth composite oxide ultraviolet screening agent

The invention relates to a method for preparing ultra-high rare earth composite oxide ultraviolet screening agent, which is characterized by comprising the steps of: formulating raw materials, including salt solution of the rare earth and oxides of two elements in IIIB-IIB, into mixed solution with the rare earth ion concentration of 0.05mol / L to 2mol / L, wherein the rare earth salt in the mixed solution accounts for 40%-80% by mass percent, adding surface dispersant for dissolution, wherein the adding amount of the surface dispersant accounts for 0.1-3% of the mixed solution by mass percent, then adding precipitating agent with the concentration of 0.1mol / L to 4mol / L to react under vigorous stirring at 50 DEG C to 90 DEG C until pH value reaches 6.5 to 7, filtering and washing the reactant, drying the reactant for 6 to 24 hours at 70 DEG C to 110 DEG C, converting the dried reactant to precursor powder with the particle size lower than 2 microns, and heating the precursor powder to 900 DEG C in a gradient manner through 300 DEG C and then preserving heat for 30 to 180 minutes to obtain the ultra-high rare earth composite oxide ultraviolet screening agent with the particle size of 20 to 300nm. The method has the advantages of: low cost, excellent quality, high efficiency, great easiness for industrial production, strong screening within the ultraviolet range from 100nm to 400nm, high thermal and chemical stability, no toxicity, no odor and great solvent resistance.

Owner:BAOTOU RES INST OF RARE EARTHS

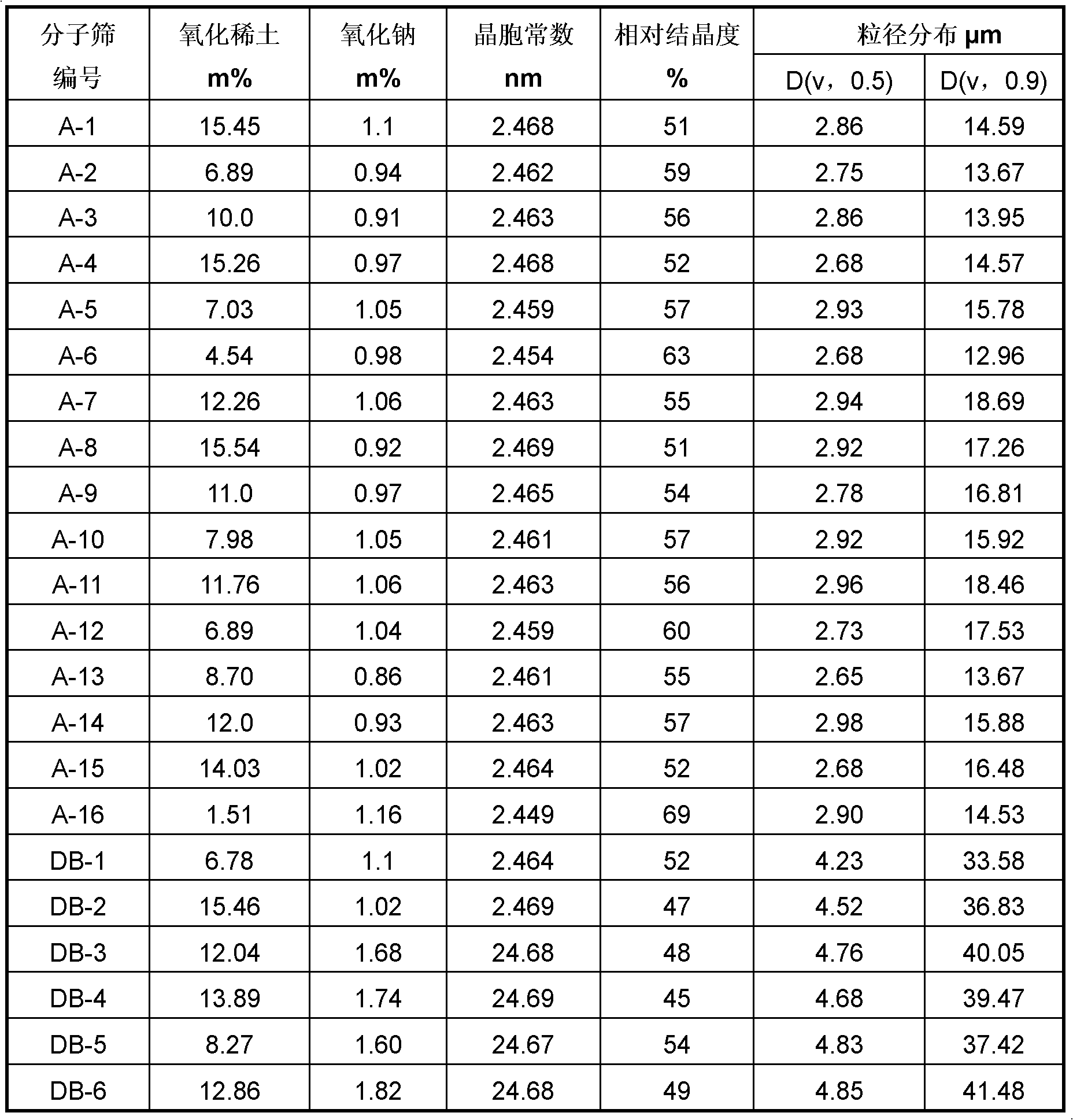

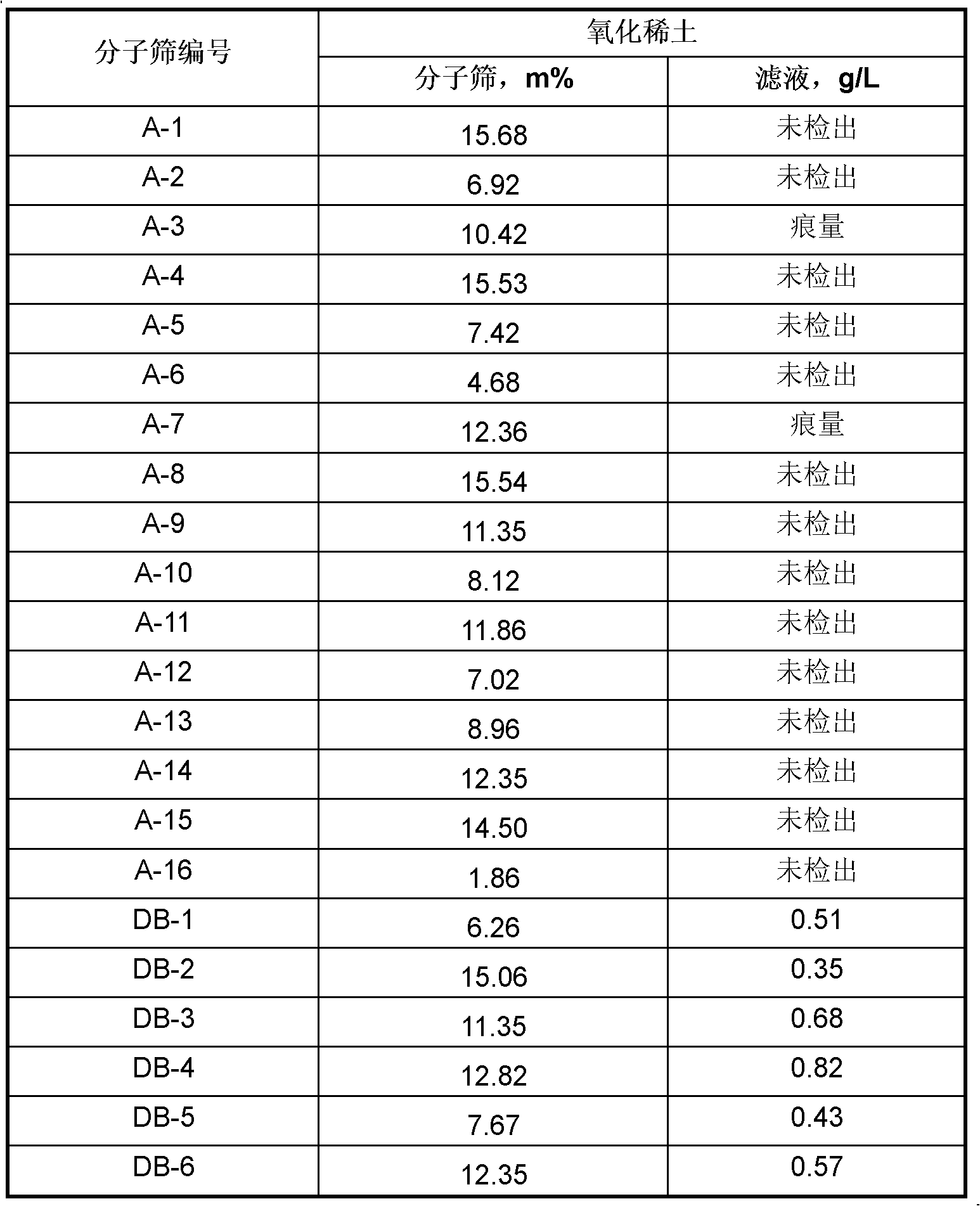

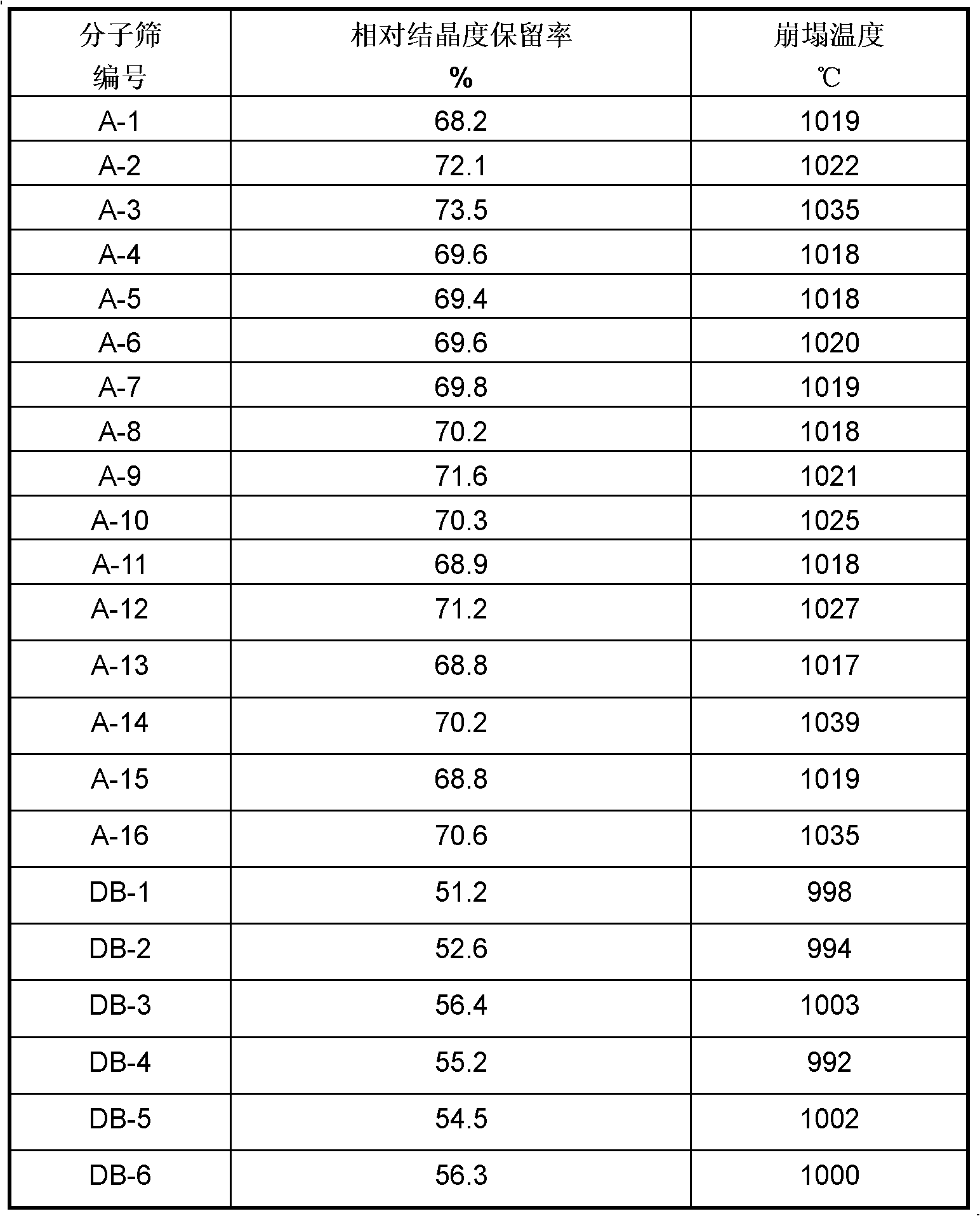

Ultra-stable rare earth Y-type molecular sieve and preparation method thereof

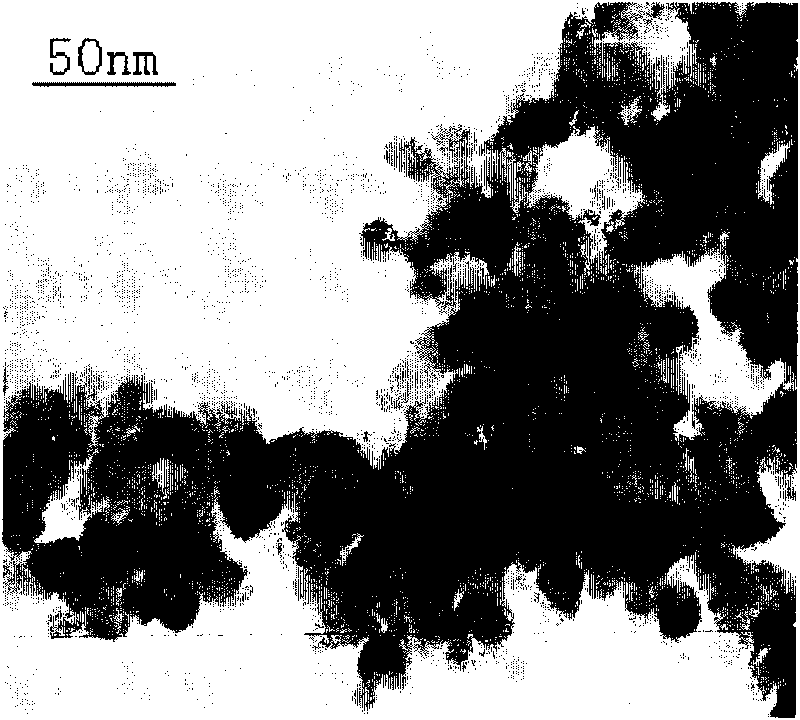

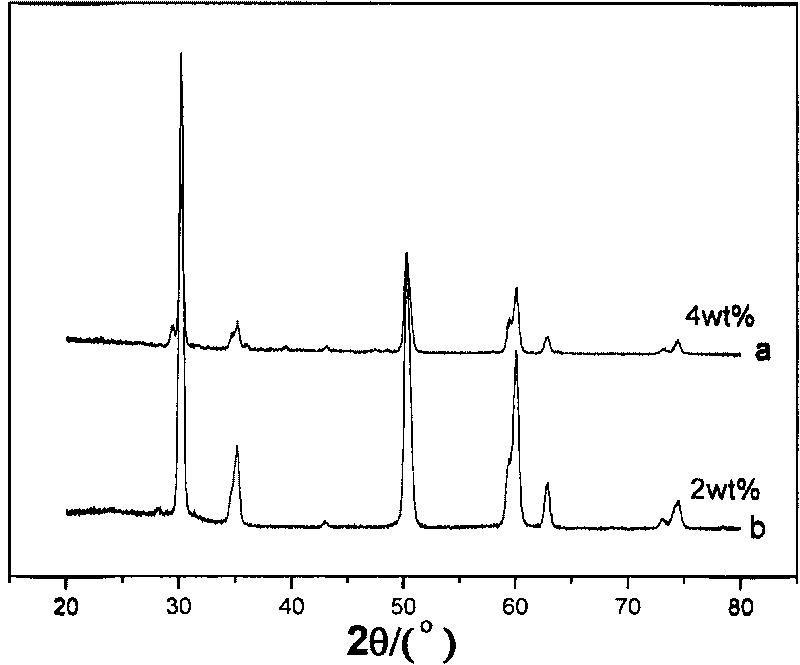

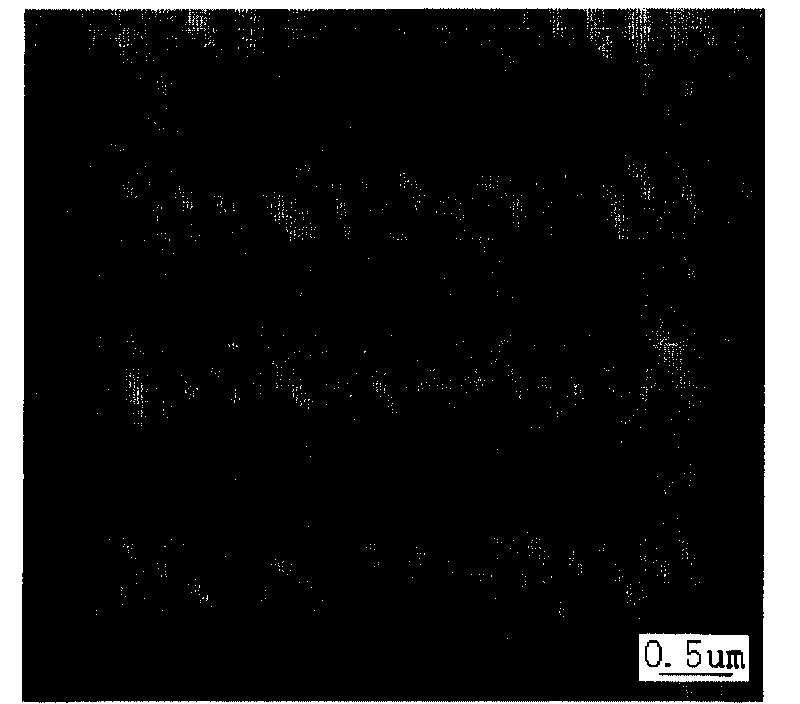

ActiveCN103159228ALow degree of reunionReduce the amount of ammonium saltCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth ions

The invention provides an ultra-stable rare earth Y-type molecular sieve and a preparation method thereof. According to the method, a NaY molecular sieve is used as a raw material, then a rare earth exchange reaction and a dispersion pre-exchange reaction are carried out, and finally, ultra-stable roasting is carried out. The molecular sieve contains 1 to 20 wt% of rare earth oxide and no more than 1.2 wt% of sodium oxide, has a degree of crystallization of 51 to 69% and a cell parameter of 2.451 to 2.469 nm. Compared with the prior art, a rare earth ion of the molecular sieve prepared by using the method is positioned in a sodalite cage, which is embodied by no loss of the rare earth ion in the process of reverse exchange; meanwhile, the molecular sieve prepared by using the method has a particle size D (v, 0.5) of no more than 3.0 mu m and a particle size D (v, 0.9) of no more than 20 mu m. The molecular sieve is used as an active component of a catalytic cracking catalyst and has the characteristics of high heavy oil conversion capability and high yield of a high-value target product.

Owner:PETROCHINA CO LTD

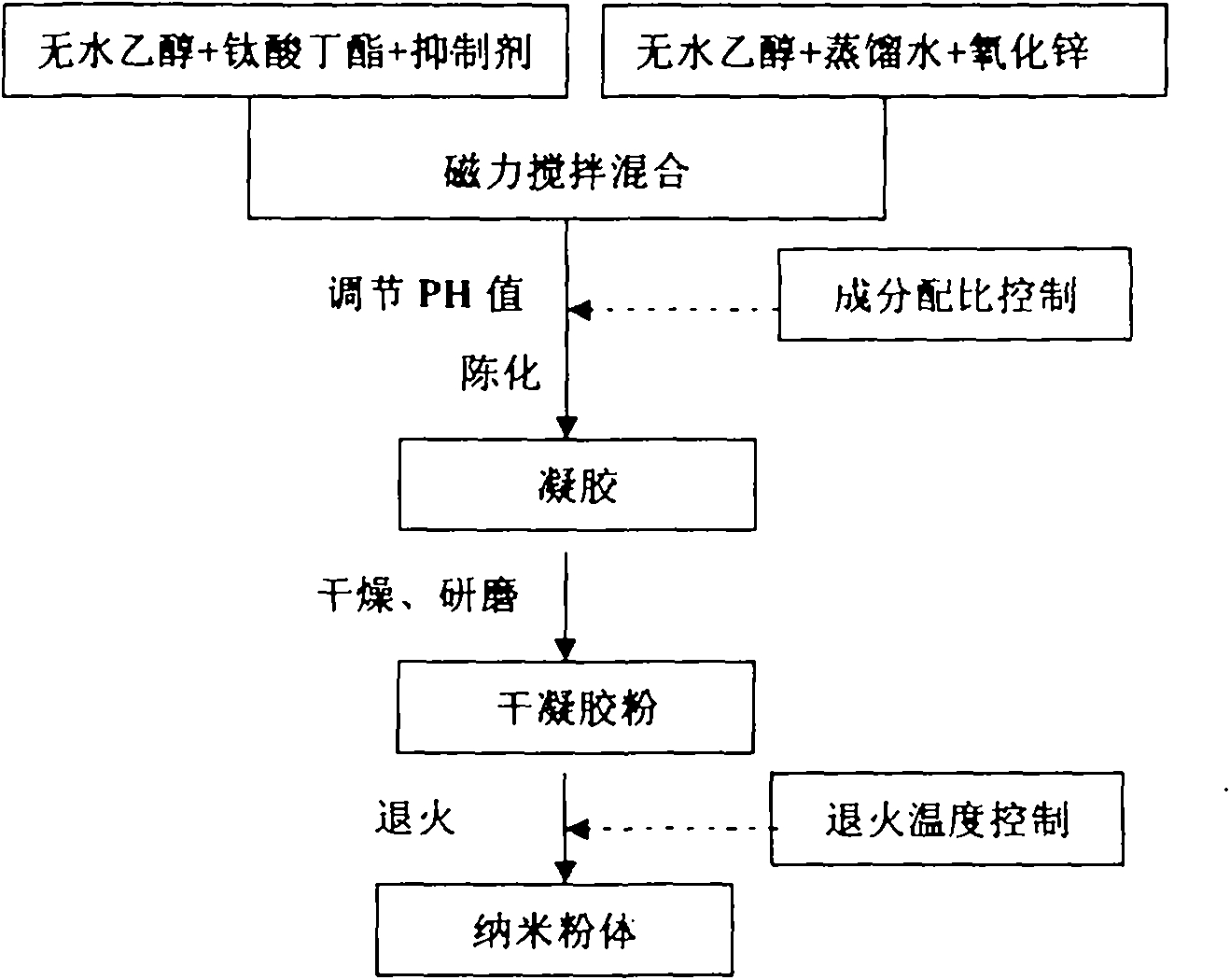

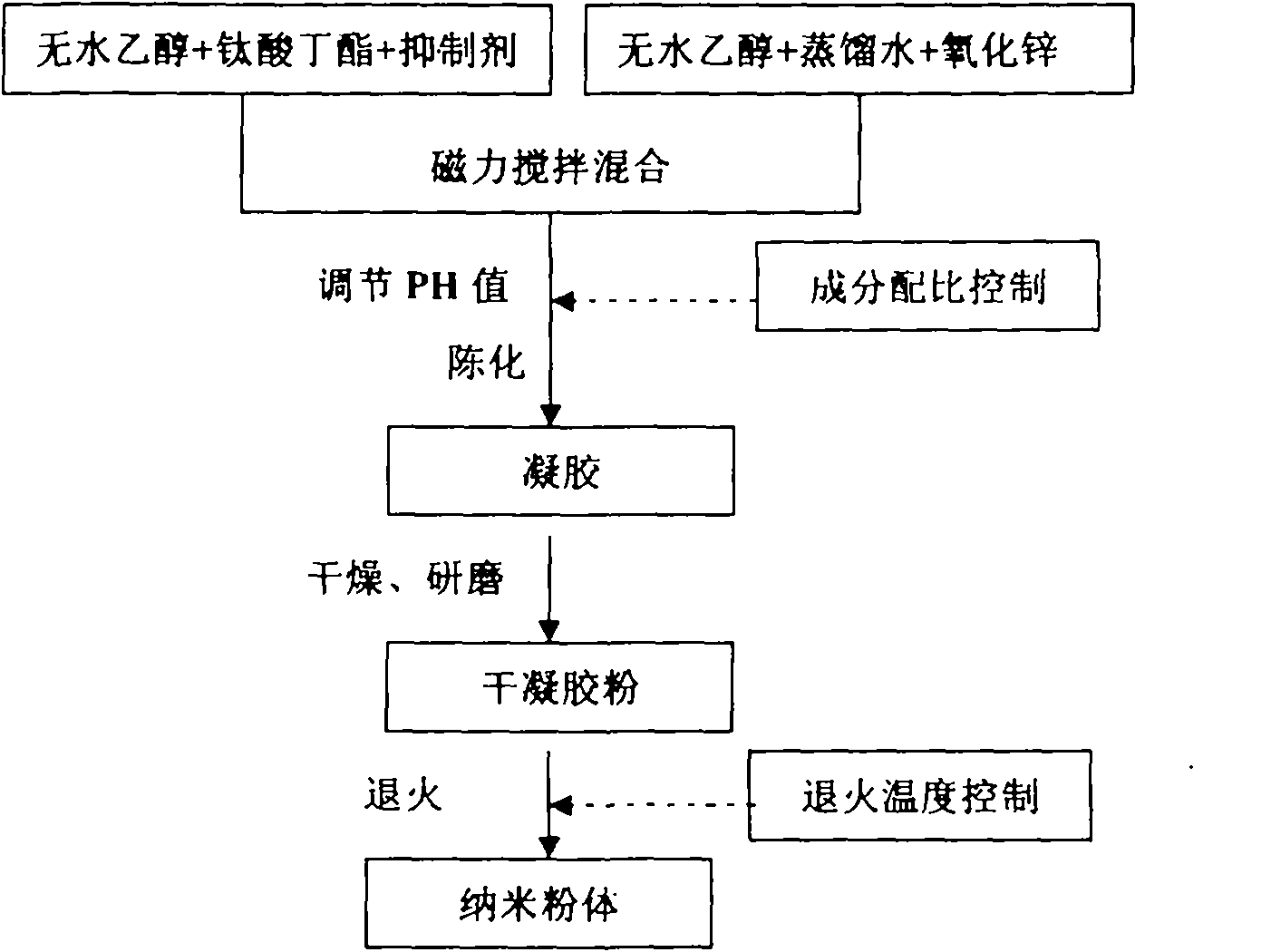

Composite photocatalyst for degrading pesticide residues

InactiveCN101822975AHigh purityNarrow particle size distributionNanostructure manufactureMetal/metal-oxides/metal-hydroxide catalystsPesticide residueSolvent

The invention relates to a preparation method of a nanometer-level photocatalyst, in particular to water solution which is convenient to use for degrading pesticide residues and a preparation method thereof. The preparation method comprises the following steps of: firstly, mixing tetrabutyl titanate as a precursor of TiO2, anhydrous alcohol as a solvent and a certain amount of glacial acetic acid together, magnetically stirring for a period of time at room temperature for adequately mixing solution to obtain solution A; meanwhile, taking a certain amount of distilled water and anhydrous alcohol, adding different dosages of doping salts in percentage by mass and magnetically stirring for a period of time to obtain solution B; then slowly adding the obtained solution B to the solution A, adding concentrated hydrochloric acid to adjust pH value to be a proper value and stirring for a period of time to obtain a stable, uniform and transparent TiO2 sol; placing the sol into a vacuum drying box and baking the sol into a dried gel at 80 DEG C; grinding the dried gel by using an agate mortar to obtain powder; placing the powder into a muffle furnace and carrying out heat treatments on the powder at different temperatures to obtain nanometer TiO2 powder; carrying out hydrophilic modification on the obtained nanometer TiO2 powder to prepare nanometer TiO2 water solution with a certain concentration under the condition of a certain pH value, and finally bottling for being directly sprayed. The prepared nanometer photocatalyst has favorable transmission of light, low production cost, simple technological line and industrial application prospect.

Owner:WUYI UNIV

Preparation method of transparent rare earth composite oxide ultraviolet screener

InactiveCN103130261AHigh transparencyReduce manufacturing costOther chemical processesZinc oxides/hydroxidesHeat stabilityChemical stability

The invention relates to a preparation method of a transparent rare earth composite oxide ultraviolet screener. The method is characterized in that the method comprises the following steps: processing raw materials comprising a rare earth salt solution and salts of tin and zinc to prepare a mixed solution having a rare earth ion concentration of 0.05-2mol / L and having a rare earth salt mass fraction of 40-80%, adding a dispersant for dissolving, adding a precipitating agent in a dropwise manner, reacting under stirring at 50-90DEG C until the pH value reaches 7-8, carrying out filtration washing, drying at 70-110DEG C for 6-24h for converting to precursor powder, heating the precursor powder to 900DEG C in a 300DEG C temperature gradient manner, and carrying out heat insulation for 30-180min to obtain the transparent rare earth composite oxide ultraviolet screener having an average particle size of below 500nm. The ultraviolet screener has the advantages of transparency, cheapness, high quality, easy industrialized production, strong shielding of ultraviolet ray in a wavelength range of 100-400nm, permeation of visible light in a wavelength range of 400-780nm, high heat stability, high chemical stability, non-toxicity, odorlessness and solvent resistance.

Owner:BAOTOU RES INST OF RARE EARTHS

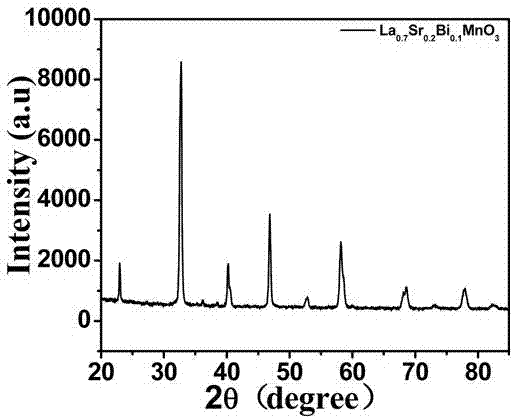

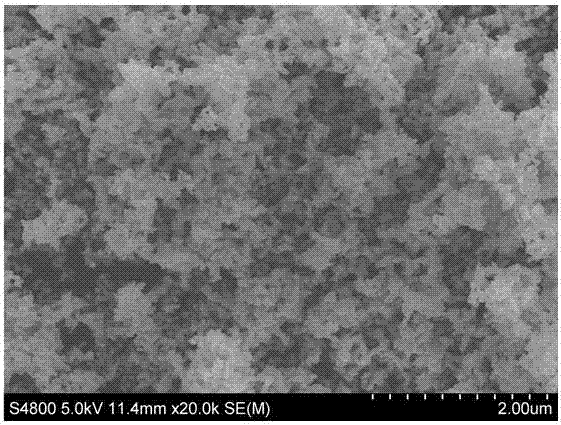

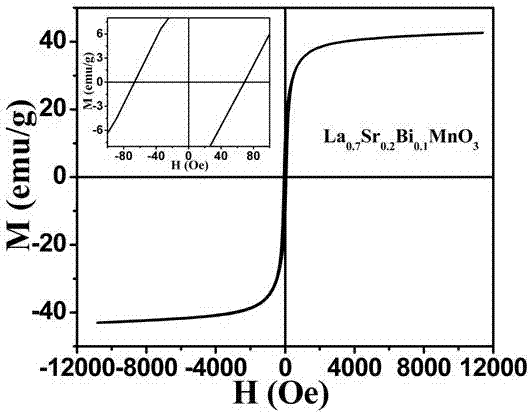

Magnetic nanoparticle, preparation method and application of magnetic nanoparticle

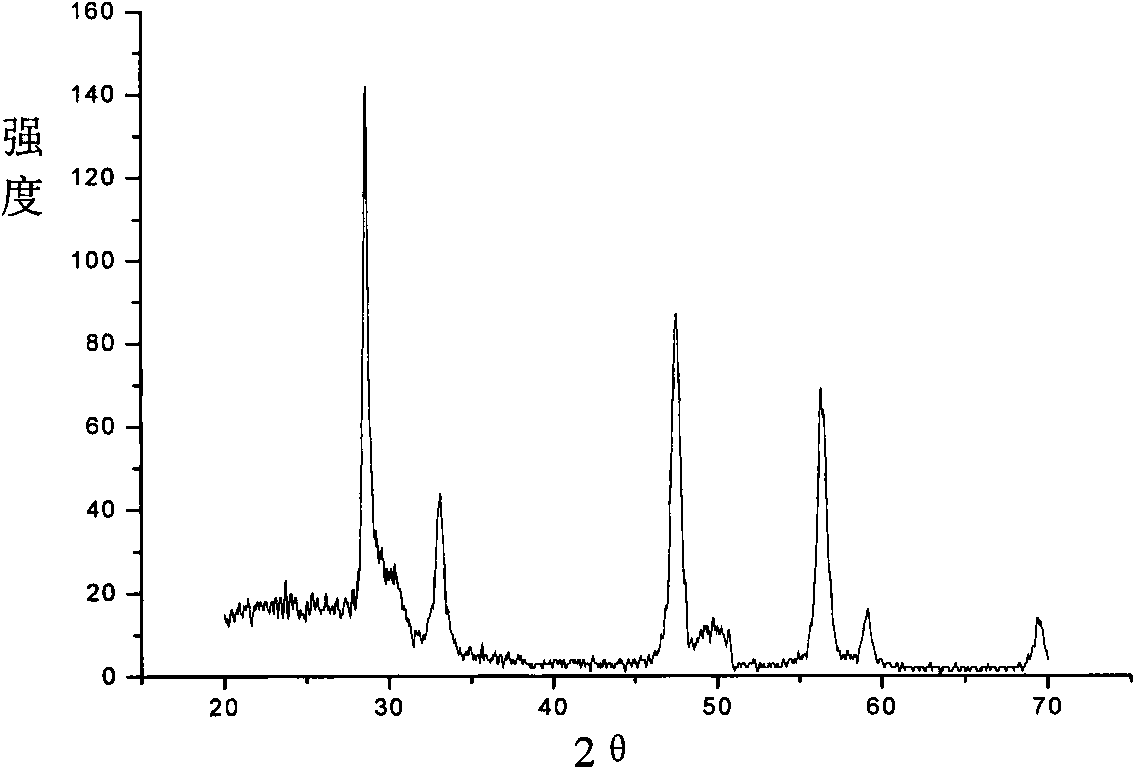

InactiveCN107452457AImprove performanceHigh purityEnergy modified materialsPharmaceutical non-active ingredientsMagnetic heatingCancer cell

The invention belongs to the field of biomedical materials, and particularly relates to a La0.7Sr0.2Bi0.1MnO3 magnetic nanoparticle, a preparation method and an application of the magnetic nanoparticle. The sodium hyaluronate modified La0.7Sr0.2Bi0.1MnO3 magnetic nanoparticle serves as a magnetic thermal therapy medium, a magnetic fluid takes the La0.7Sr0.2Bi0.1MnO3 magnetic nanoparticle as a core, and the surface of the magnetic nanoparticle is modified by the sodium hyaluronate to form stable magnetic hydrosol. The magnetic thermal therapy medium has good biocompatibility and chemical stability and high magnetic heating performance, can effectively kill cancer cells and has a wide application prospect in magnetic thermal therapy and thermo-chemotherapy combination and anti-tumor diagnosis and treatment integration.

Owner:LANZHOU UNIVERSITY

High performance computer cable sheathing compound

InactiveCN105199263AImprove flame retardant performanceGood mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesFiberPolyvinyl butyral

The invention discloses a high performance computer cable sheathing compound, which comprises raw materials with parts by weight: polypropylene 20-40 parts, polyvinyl chloride 30-50 parts, ethylene propylene terpolymer 20-40 parts, succinic acid peroxide 0.5-0.9 part, tert-butyl hydrogen phthalate 0.8-1.5 parts, sodium dichromate ammoniums 2-5 parts, accelerants DM 0.2-0.8 part, carbon fibers 26-34 parts, silica 20-50 parts, hard clays 30-50 parts, modified cotton short fibers 25-45 parts, anti-aging agents 1-2 parts, polyvinyl butyral 1.2-1.8 parts, stearic acids 1-3 parts, trioctyl phosphates 0.5-1.8 parts and aromatic hydrocarbon oil 1.2-2.3 parts. The high performance computer cable sheathing compound is excellent in flame retardant efficiency, and is extremely excellent in mechanical property.

Owner:ANHUI LAND GRP

Polyol-based method for producing ultra-fine metal powders

InactiveUS20100136358A1Tight size distributionLow degree of reunionMaterial nanotechnologyMetal-working apparatusPolyolUltra fine

The invention provides monodisperse ultra-fine metallic particles having a low degree of agglomeration and a high degree of crystallinity and oxidation resistance, and methods for forming such particles. The invention provides a method of controlling the size and size distribution of ultra-fine metal particles by regulating the pH of a polyol-type process. The methods of the invention make it possible to increase the metal loading in a polyol-type process without increasing particle size, enabling the production of ultra-fine metallic particles in high yield.

Owner:NANODYNAMICS INC

Superfine transition metal boride powder as well as preparation method and application thereof

InactiveCN108455623APrevent high temperature (>1800°C) growthSmall particle sizeMaterial nanotechnologyMetal boridesThermal insulationAtmospheric pressure

The invention belongs to the technical field of superfine powders and discloses a superfine transition metal boride powder as well as a preparation method and the application thereof. The superfine transition metal boride powder is a MO2-Ta2O5-B mixed power obtained by ball-milling and mixing MO2, Ta2O5 and B and then drying; then the MO2-Ta2O5-B mixed power is subjected to first-step thermal insulation under an air pressure of less than 200 Pa or an inert atmosphere to obtain a M1-xTaxB2-B2O3 powder; the M1-xTaxB2-B2O3 powder is continuously heated up under an air pressure of less than 200 Paor an inert atmosphere and is subjected to second-step thermal insulation to prepare a M1-xTaxB2 powder, wherein M is equal to Zr or Hf, and x is 0.005-0.2. The powder is low in degree of aggregation, has good high temperature resistance and still does not grow at a high temperature above 1800 DEG C. The superfine transition metal boride powder as well as the preparation method and the application thereof disclosed by the invention have the benefits that the cost is significantly reduced, and the preparation process is simple and low in cost.

Owner:GUANGDONG UNIV OF TECH

Spherical organic polymer-silicon compound composite particles, hollow particles and their production methods

InactiveUS20100204342A1Improve roundnessLow degree of reunionBiocideLiquid surface applicatorsDecompositionCarbide

The present invention is to provide hollow particles with a low degree of agglomeration and having a high roundness, and a process for producing them.Hollow particles comprising a silicon compound, having an average particle size of from 5 to 65 nm and an average roundness of at least 0.90, and having a shell comprising the silicon compound and having a thickness of from 1 to 20 nm. Further, a method for producing hollow particles, which comprises adding sulfuric acid to a liquid containing spherical organic polymer-silicon compound composite particles having a core comprising an organic polymer and a shell comprising a silicon compound in a medium containing at least 95 mass % of water, followed by heating to carbonize the organic polymer thereby to convert it to a carbide, and subjecting the carbide to decomposition using a liquid oxidizing agent other than sulfuric acid.

Owner:DENKA CO LTD

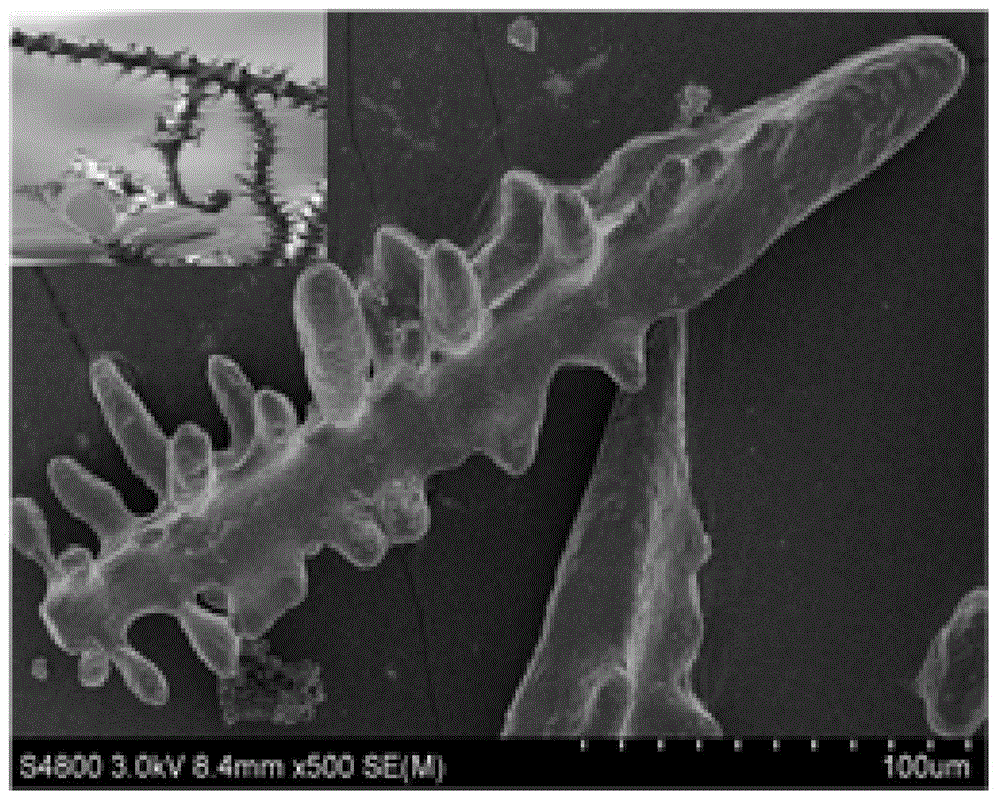

Preparation method of one-dimensional Euphorbia-milii-shaped WO3 microcrystal

ActiveCN104909409AAchieving controllable synthesisUniform shapeTungsten oxides/hydroxidesDispersityDistilled water

The invention provides a preparation method of a one-dimensional Euphorbia-milii-shaped WO3 microcrystal, which comprises the following steps: adding WCl6 into an isopropanol-distilled water mixed solvent, adding a polyoxyethylene-polyoxypropylene block copolymer into the solution to obtain a precursor solution, pouring the precursor solution into a hydrothermal kettle, and reacting while controlling the temperature at 80-240 DEG C under the pressure of 2-16 MPa for 4-36 hours, wherein the hydrothermal kettle is fixed in an homogeneous reaction instrument, and rotates around a fixed axis at the rate of 20-70 r / min in the insulating process; and taking out the product, washing and drying. The prepared one-dimensional Euphorbia-milii-shaped WO3 microcrystal has the advantages of high purity, favorable crystallinity, favorable dispersity, uniform size, uniform shape and obvious oriented growth.

Owner:安徽翰邦科技咨询有限公司

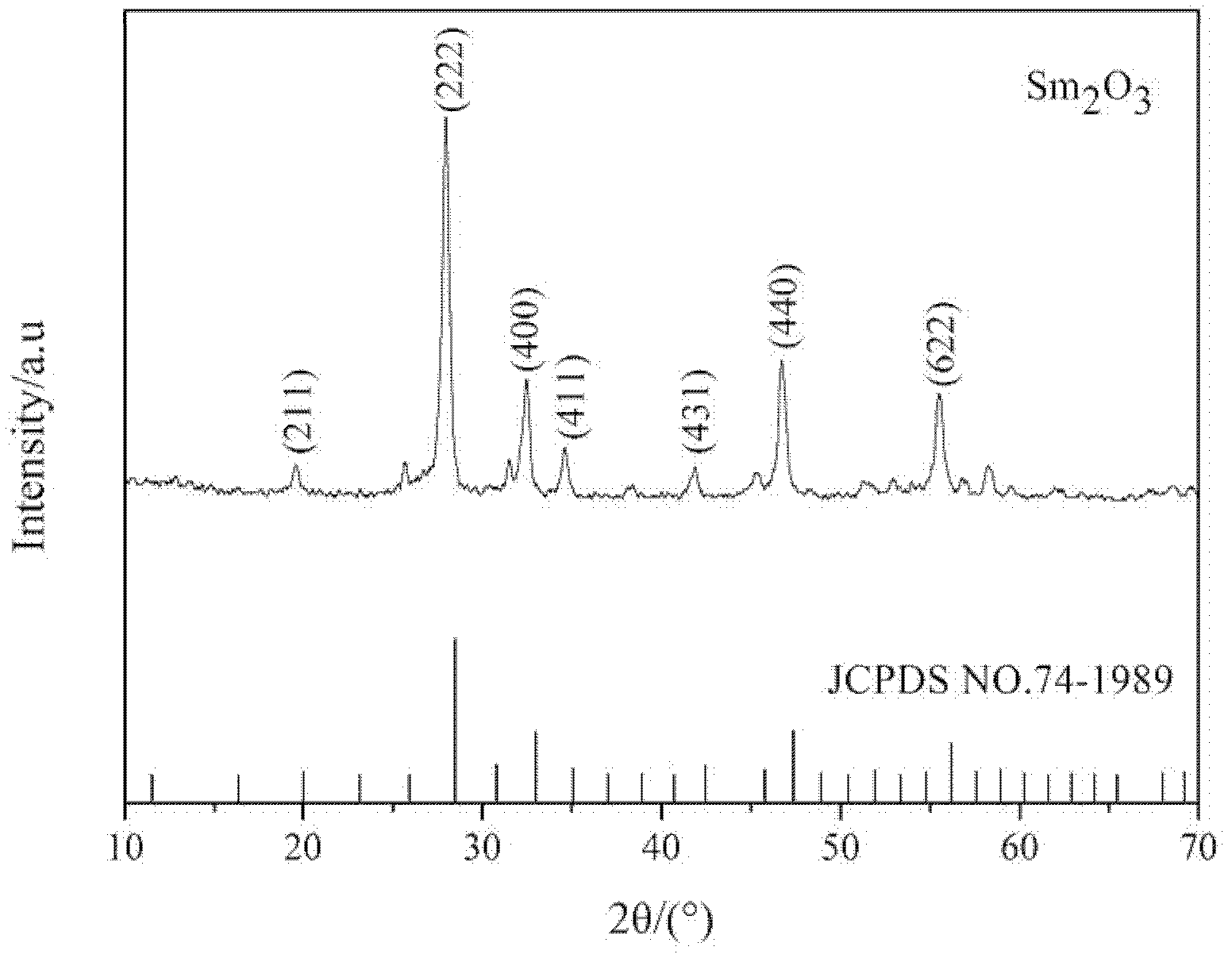

Method for preparing Sm2O3 nano crystals by solvent thermal method

InactiveCN102432056ASimple developmentFully developedNanotechnologyRare earth metal compoundsSolventVacuum drying

The invention discloses a method for preparing Sm2O3 nano crystals by a solvent thermal method. The method comprises the following steps of: adding analytically pure SmCl3.6H2O into isopropyl alcohol or a mixed solvent of the isopropyl alcohol and water to obtain a solution A; adjusting the pH value of the solution A by using NaOH to form a precursor solution; pouring the precursor solution into a hydrothermal kettle, sealing the hydrothermal kettle, putting into an electric heating vacuum drying oven, and naturally cooling to room temperature after a solvent thermal reaction; and taking a product out, washing by using deionized water, performing centrifugal separation, washing by using absolute ethanol, performing centrifugal separation, repeatedly washing, drying under vacuum, and thus obtaining the Sm2O3 nano crystals. The Sm2O3 nano crystals prepared by the method react in a liquid phase at a time without later-stage crystallization thermal treatment, so that the defects of agglomeration and crystal grain coarsening possibly caused during thermal treatment of the Sm2O3 nano crystals, impurity introduction in an atmosphere reaction and the like are overcome, and process equipment is simple. Agglomeration degrees are relatively low, so that an appropriate chemical measurement ratio and a crystal grain state are easy to obtain; cheaper raw materials can be used; and high-temperature calcination and ball-milling processes are eliminated, so that an impurity introduction defect and a structural defect are overcome.

Owner:江苏润辉物流有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com