Patents

Literature

1044results about How to "Increased dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

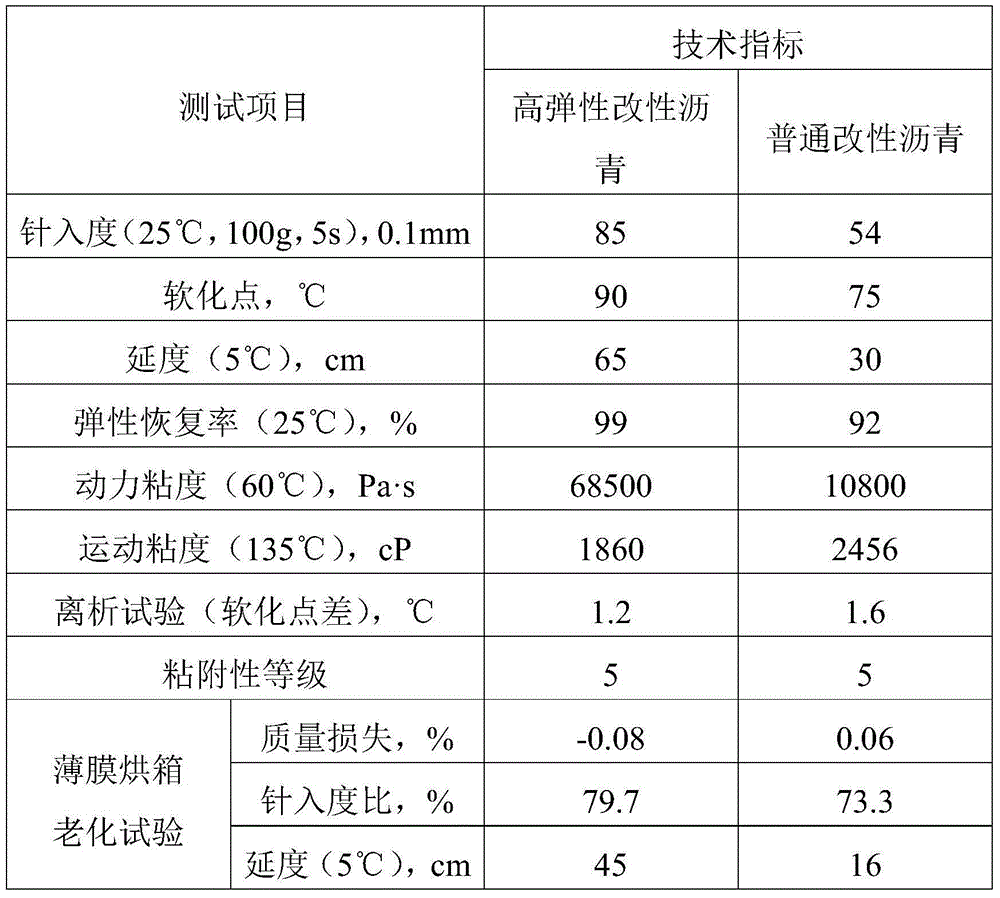

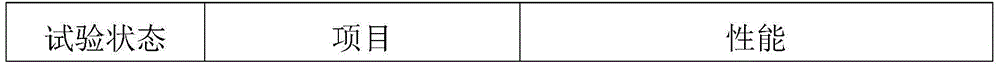

High-elasticity asphalt modified composition, modifier, modified asphalt, modified asphalt mixture and preparation method

ActiveCN104629391AImproved high temperature stability and elastic recoveryReduce melt viscosityBuilding insulationsButadiene-styrene rubberPlasticizer

The invention relates to a high-elasticity asphalt modified composition, a modifier, modified asphalt, a modified asphalt mixture and a preparation method. The modified composition comprises 100 parts of a styrene-butadiene-styrene segmented copolymer, 20-40 parts of a tackifier, 20-40 parts of a softener, 3-8 parts of a warm mixing agent, 15-40 parts of a plasticizer and 2-6 parts of a stabilizer. The preparation method of the modifier comprises the following steps: (1) mixing the styrene-butadiene-styrene segmented copolymer, the tackifier and the warm mixing agent according to a formula to obtain a melt; and (2) mixing the softener, the plasticizer and the stabilizer with the melt, and then extruding, cooling and dicing. The modified asphalt is prepared by doping the modifier into matrix asphalt and uniformly mixing. The modified asphalt mixture is prepared by mixing the modified asphalt and a raw material of a mineral mixture. The modified asphalt provided by the invention has good high-temperature and low-temperature stabilities and anti-fatigue capacity, and the modified asphalt mixture is strong in construction workability and good in pavement performance.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

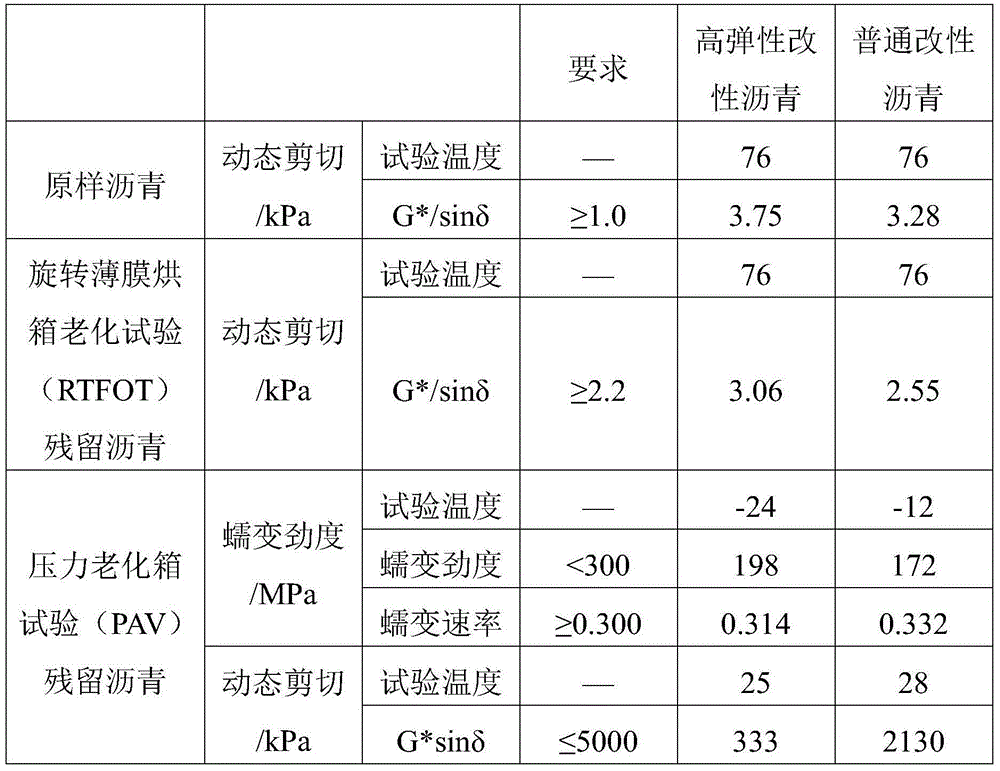

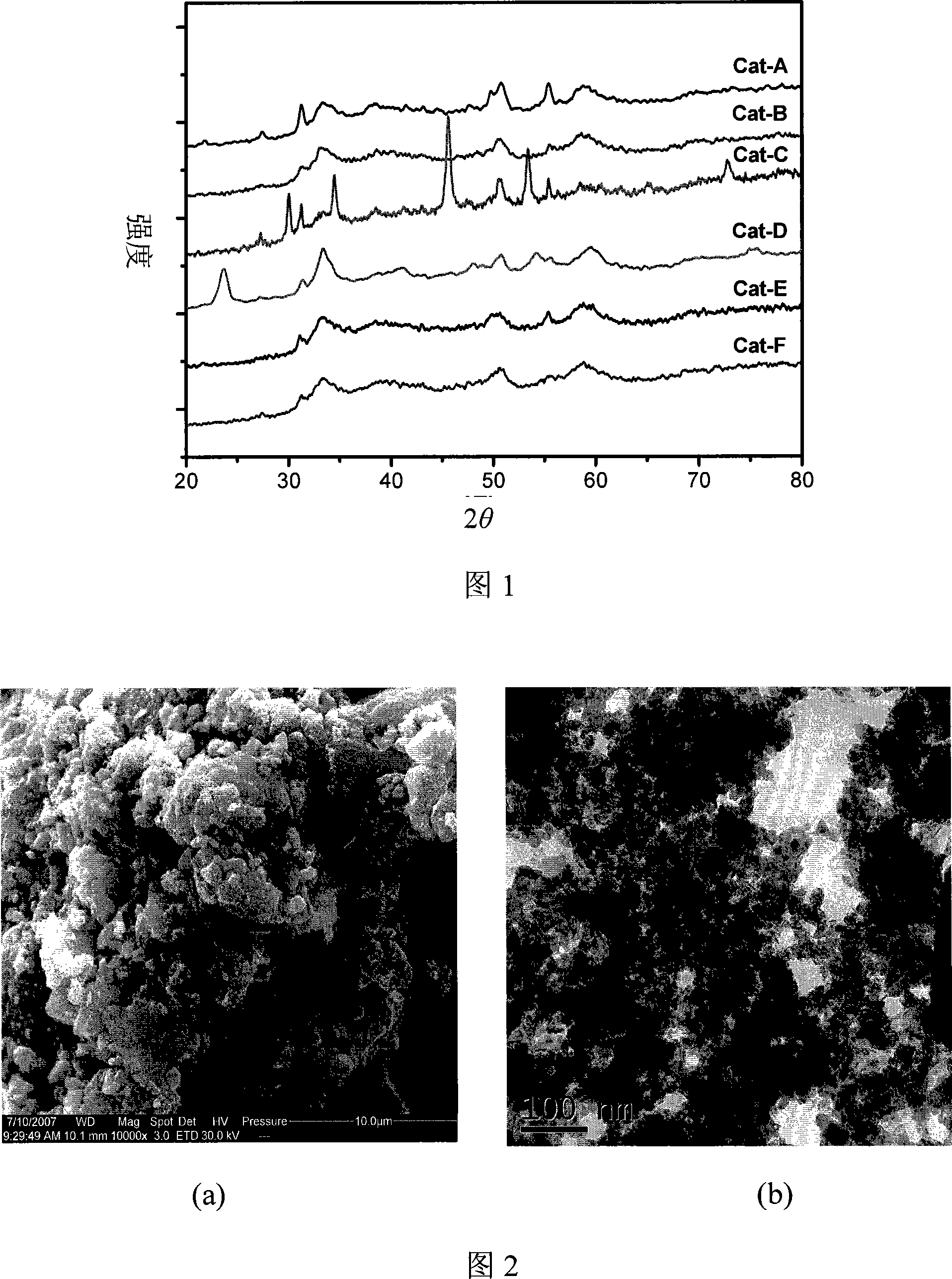

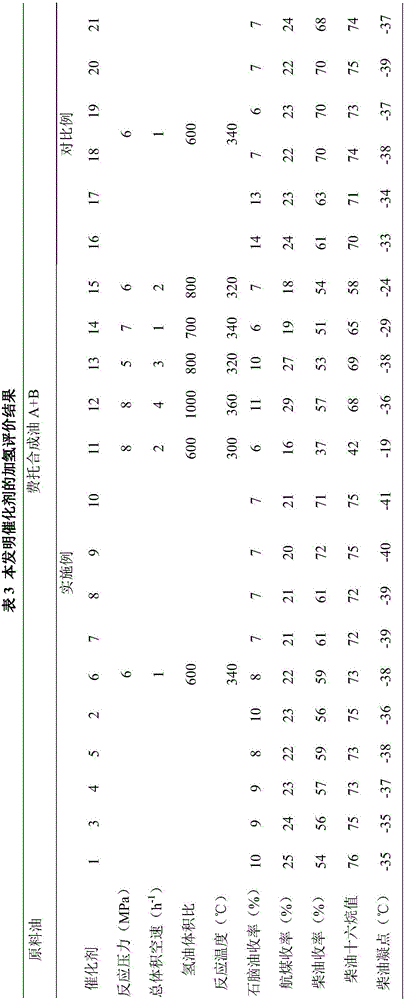

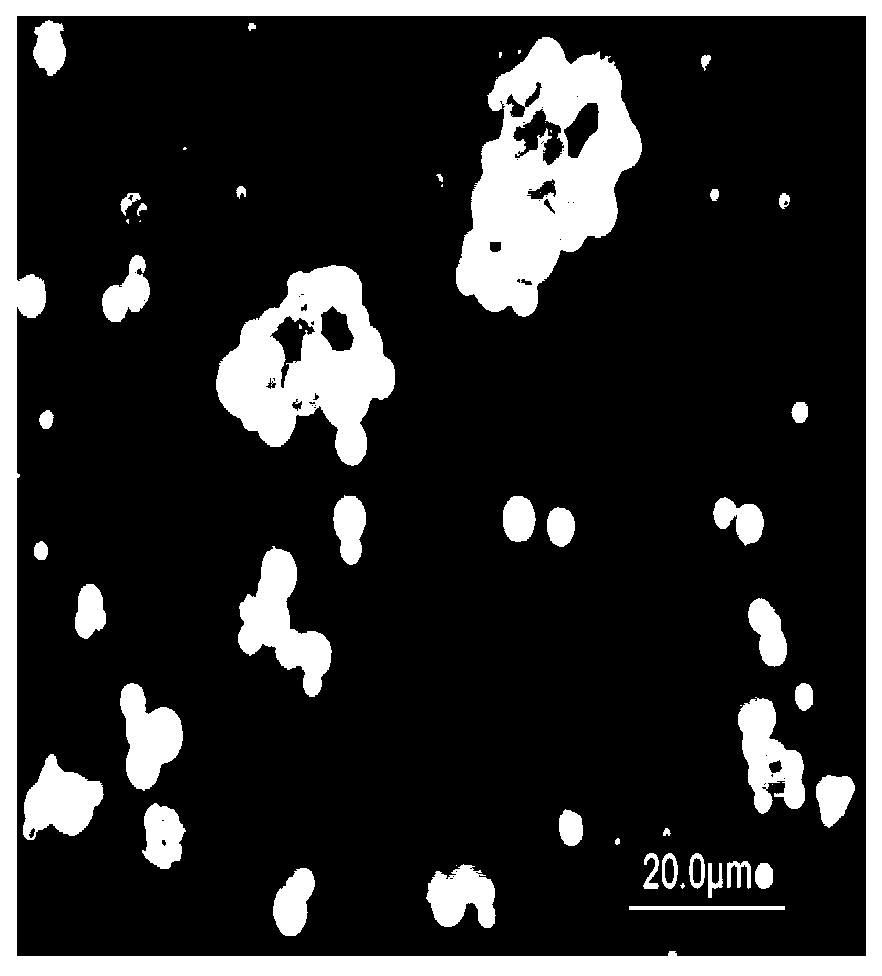

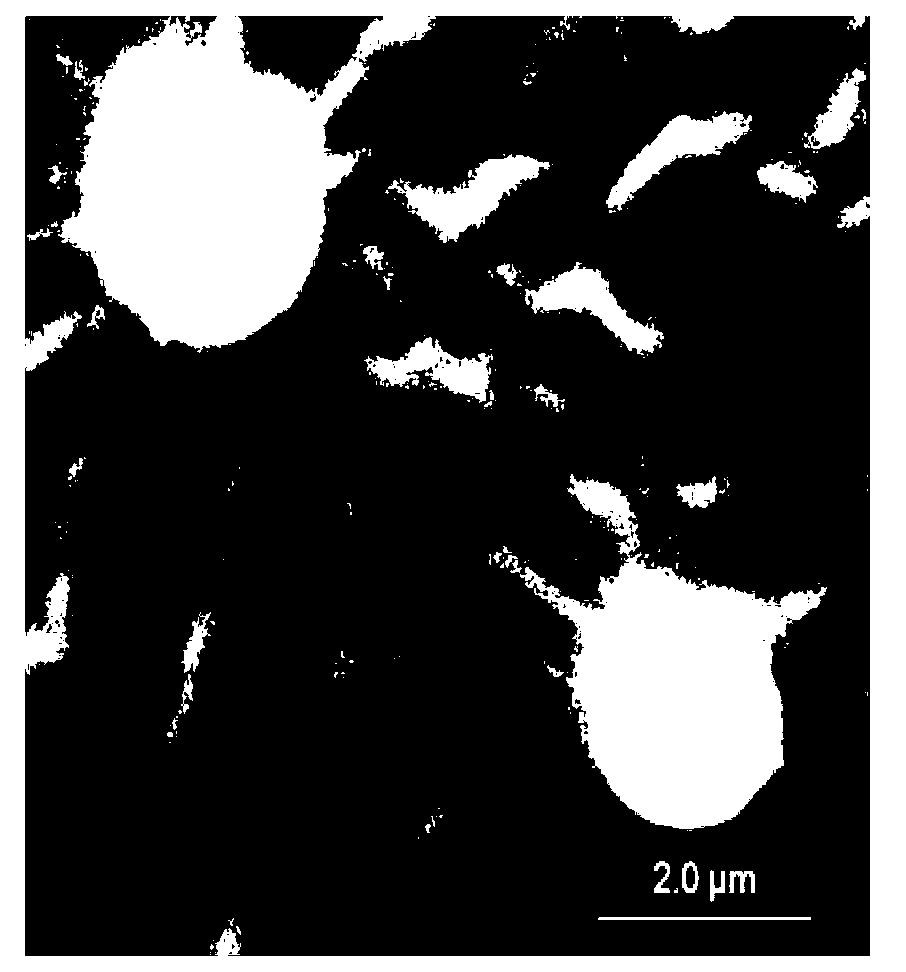

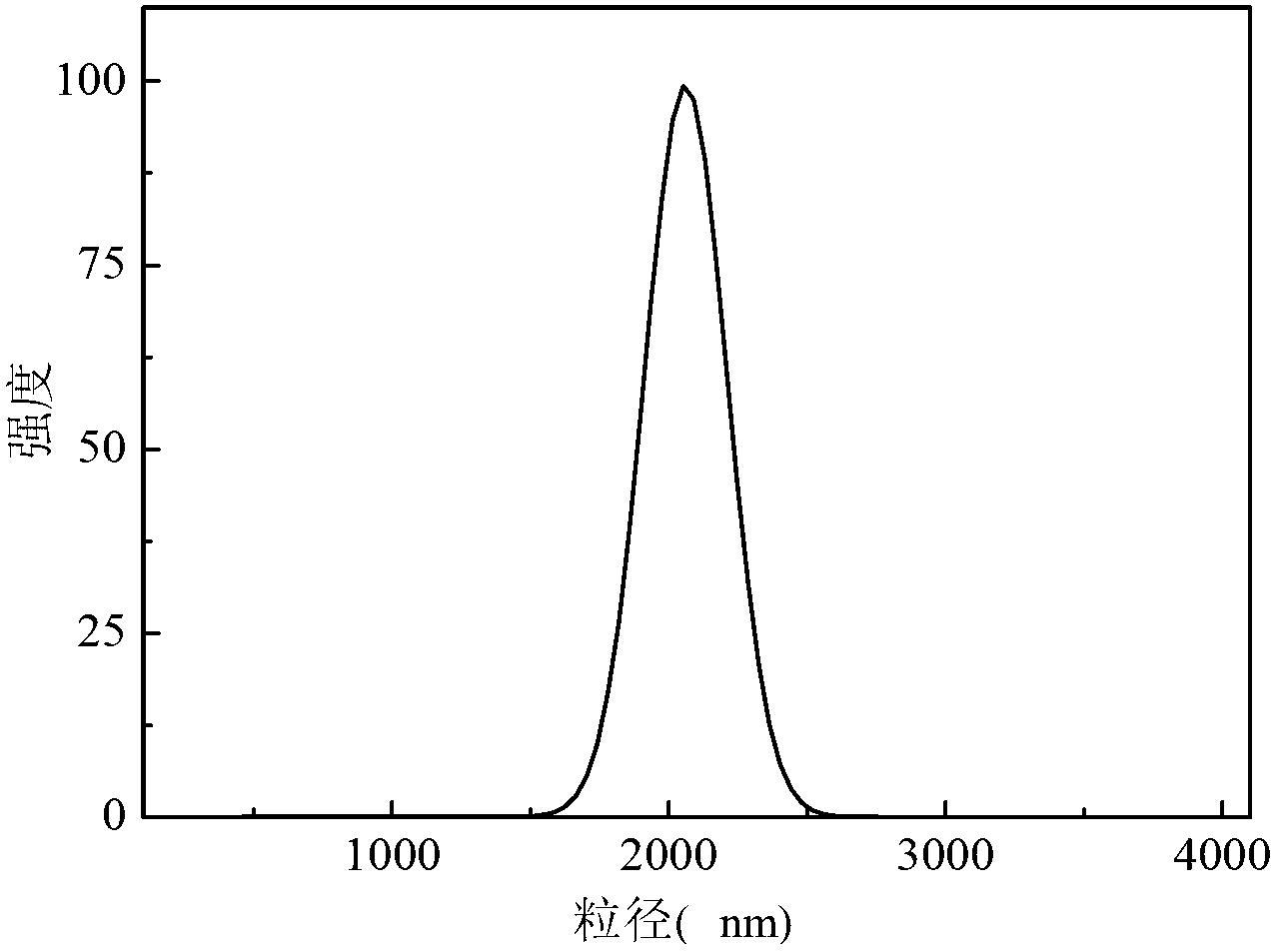

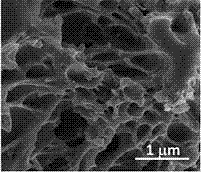

Multi-metal noumenon catalyzer for hydrodesulphurization of diesel oil, producing method and application of the same

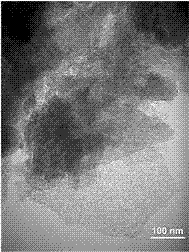

InactiveCN101153228ARaw materials are simple and cheapEasy to operateRefining to eliminate hetero atomsHydrodesulfurizationSolvent

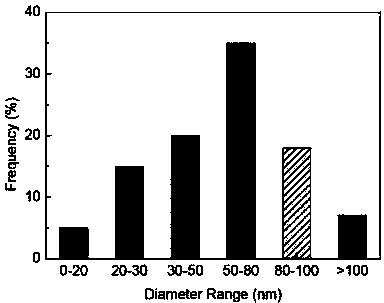

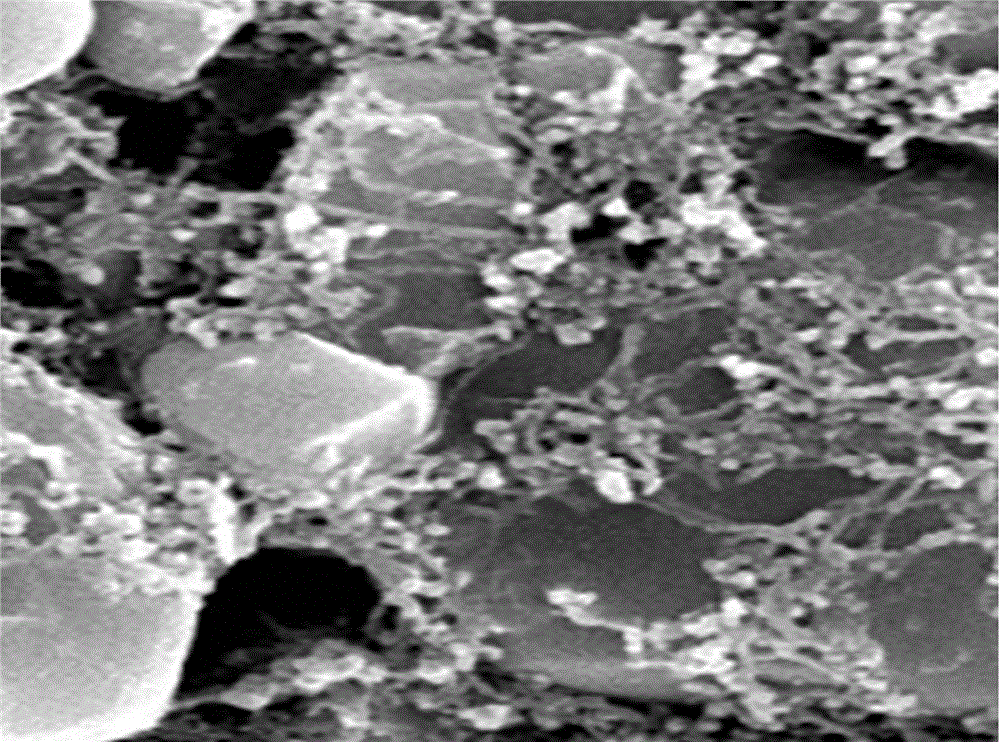

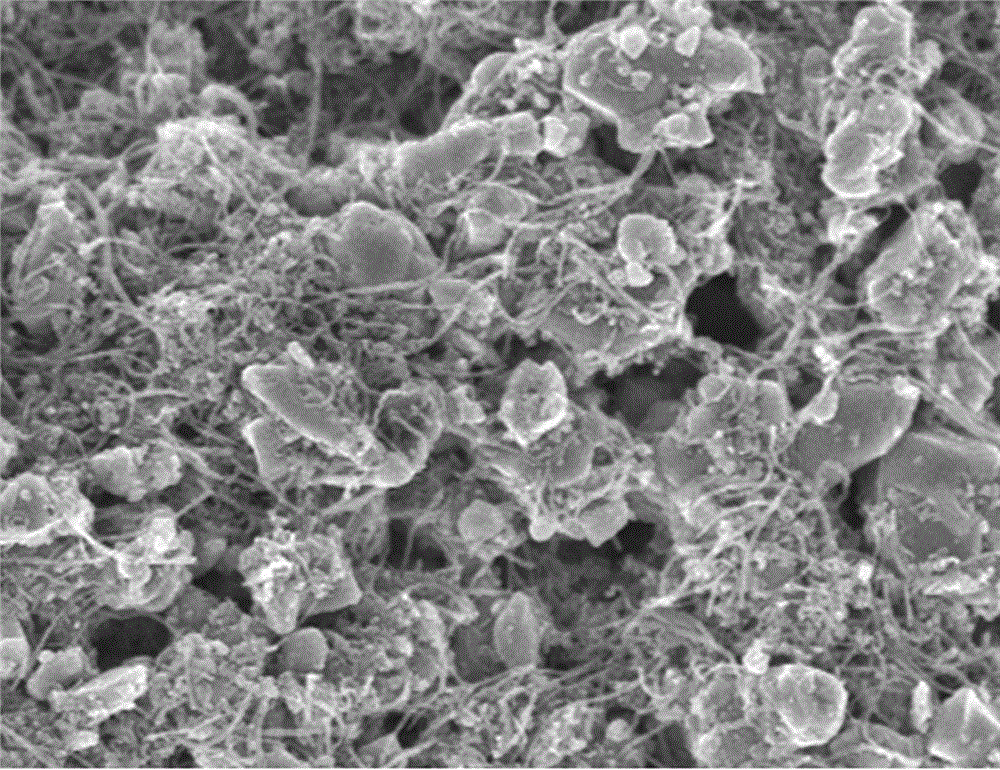

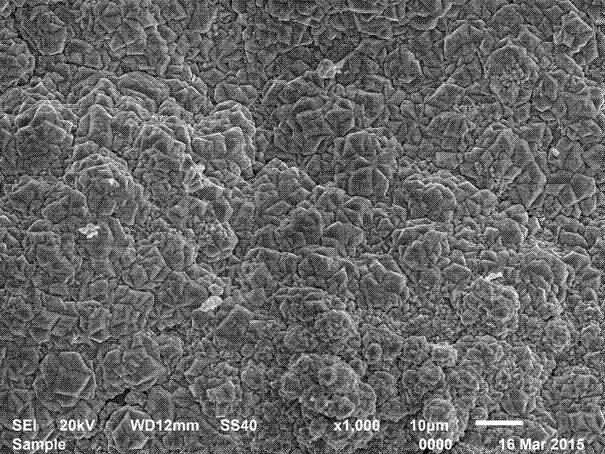

A polymetallic bulk catalyst for diesel oil hydrodesulfurization is provided. The particle diameter of the present invention is 10-100 nm, and the present invention consists of a species of VIII metal and two species of VIB metal, wherein, the mole ratio of the VIII metal and the VIB metal is 1:9-9:1, while the mole ratio of two species of VIB metal is 1:5-5:1. The preparation method is that: a) the basic carbonate of VIII metal is led to dissolve in solvent to form suspension liquid; b) two species of metal salts of the VIB metal are led to dissolve in the solvent, and surfactant is added into the solvent, stirred and heated to 50-250 DEG C; c) the suspension liquid in step a is added into the solvent in step b and led to react in reflux for 4-25 hours under 50-250 DEG C; d) the product obtained in step c is filtered, washed and dried to obtain target product. The catalyst of the present invention is used in the ultra-deep hydrodesulfurization of diesel oil and shows extremely high hydrodesulfurization activity. Under the same operating conditions, the activity of the present invention is 5.9 times as much as industrial reference agent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

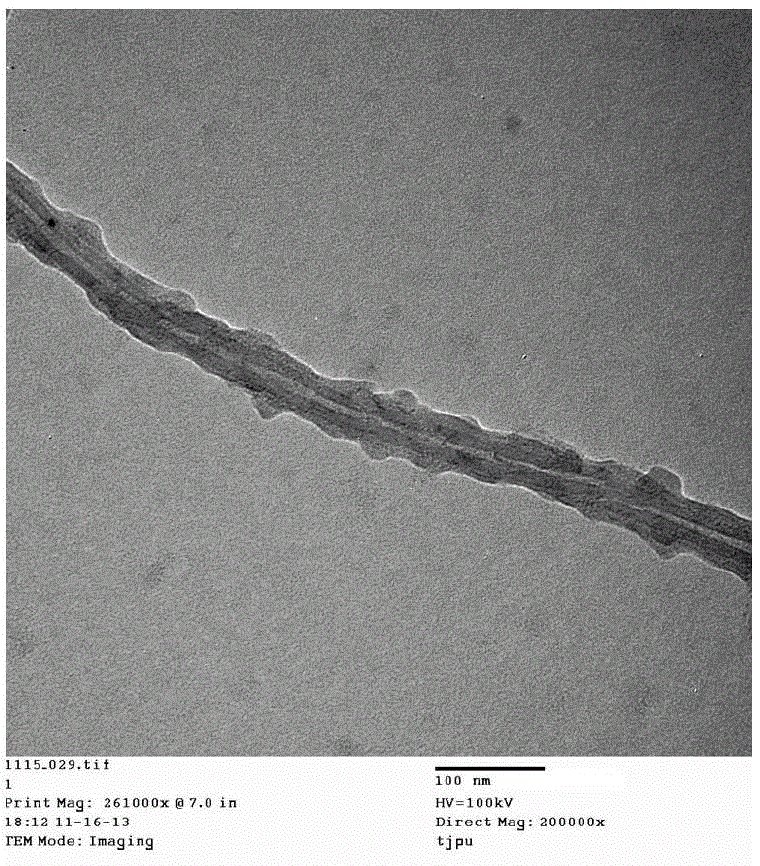

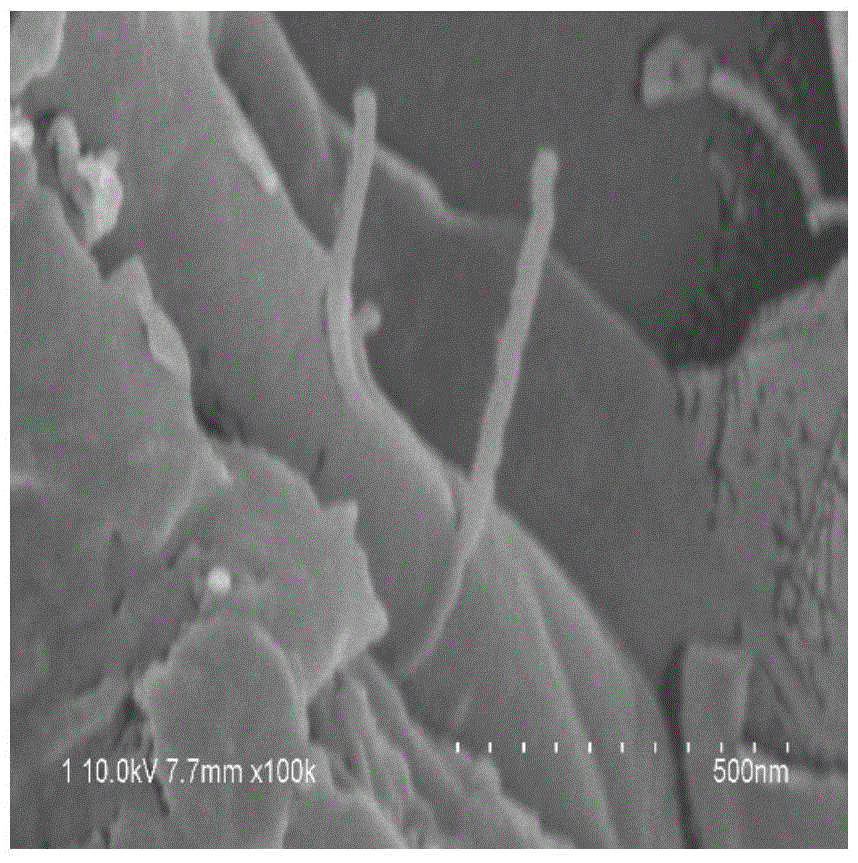

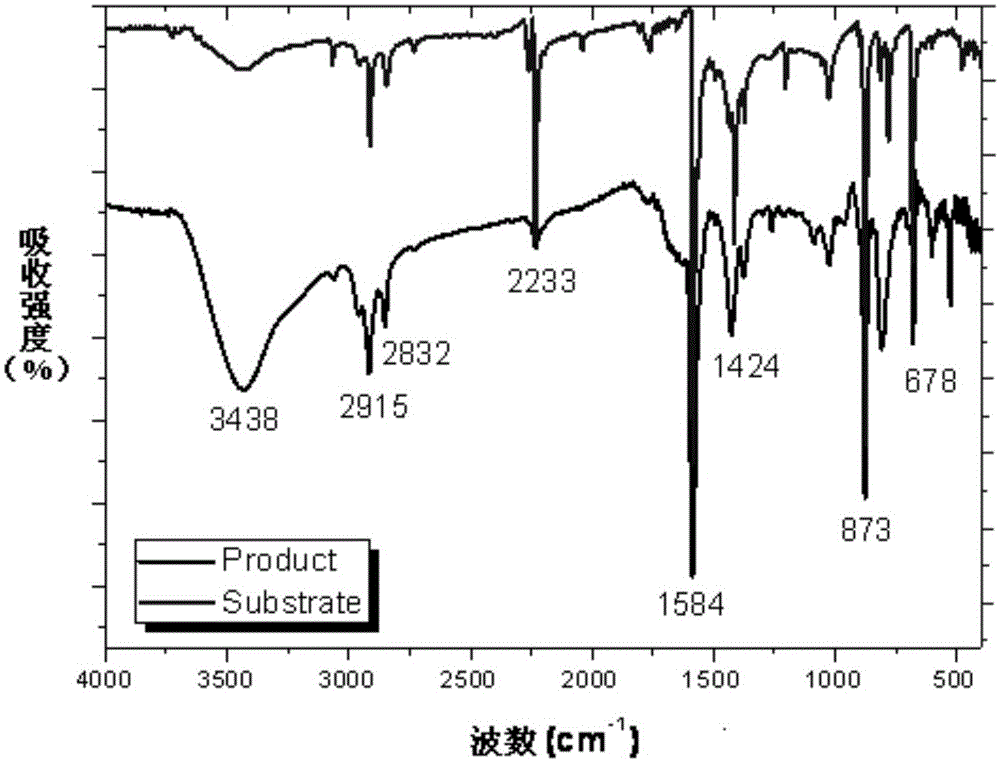

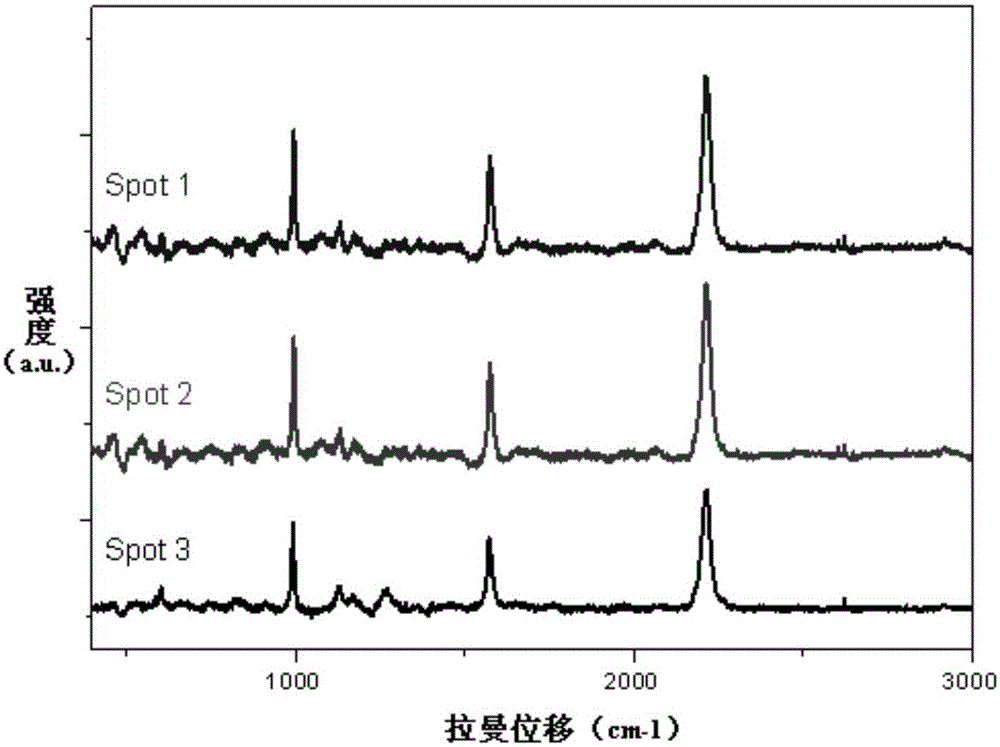

Graphene and multiwalled carbon nanotube synergetic enhanced polymer fiber and preparation method thereof

ActiveCN104357941AHigh mechanical strengthIncreased dispersionArtificial filament heat treatmentMelt spinning methodsFiberMasterbatch

The invention discloses a preparation method for a graphene and multiwalled carbon nanotube synergetic enhanced polymer fiber. The preparation method comprises the following steps: conducting functional processing on oxidized graphene and a hydroxylated multiwalled carbon nanotube to be mixed with a monomer capable of being subjected to condensation polymerization, conducting condensation polymerization to obtain a composite master batch, processing the composite master batch, fusing and squeezing out the processed composite master batch to obtain a nascent fiber, and conducting postprocessing on the nascent fiber so as to obtain the graphene and multiwalled carbon nanotube synergetic enhanced polymer fiber. According to the preparation method, the dispersion degree of carbon material in fiber forming polymer can be obviously improved, and then the mechanical strength of the prepared fiber can be improved.

Owner:TIANJIN POLYTECHNIC UNIV

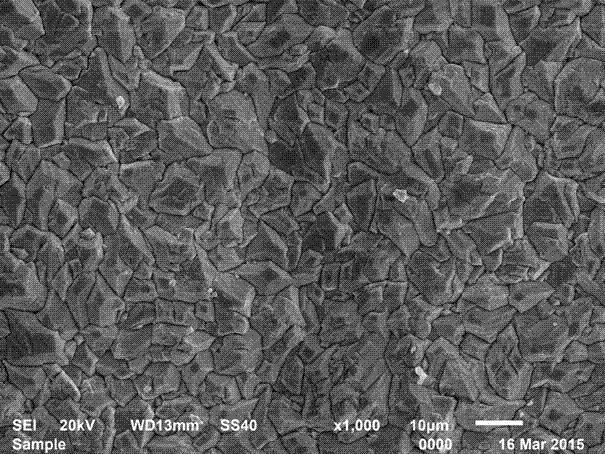

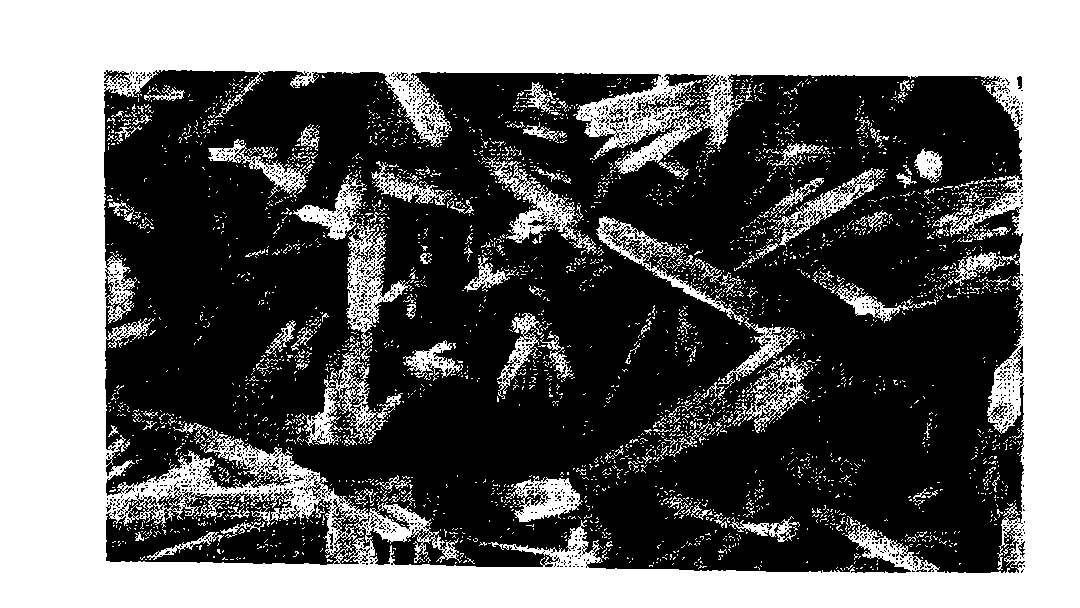

Preparation method of high dispersed white carbon black

ActiveCN102229758AIncreased dispersionReduce forcePigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsDispersityFiltration

The invention discloses a preparation method of high dispersed white carbon black. According to a new method and technology, a synthesis reaction of liquid soluble glass and concentrated sulfuric acid is carried out in two steps by first preparing fine seeds, and then carrying out a synthesis reaction, wherein the synthesis reaction is a precipitation reaction carried out under effects of an organic surfactant SDS and a composite silane coupling agent. The high dispersed precipitated white carbon black specially used in high-performance tyres is obtained through particle surface cladding, modification treatment, press filtration, washing, pulping and pressure drying. The method improves a traditional white carbon black production technology of a precipitation method by optimizing technological parameters and using an optimized auxiliary agent to meet a requirement of enhanced product dispersiveness; besides the method overcomes defects of an ordinary precipitation method, such as crude particles, wide distribution, strong hydrophilism and weak mixing dispersion. A prepared product has characteristics of fine primary particles, low surface hydroxyl content, increased lipophilicity,high bonding force with rubber high molecules and high wettability, and is an ideal reinforcing filling material specially used in high-performance tyres.

Owner:FUJIAN ZHENGSHENG INORGANIC MATERIAL

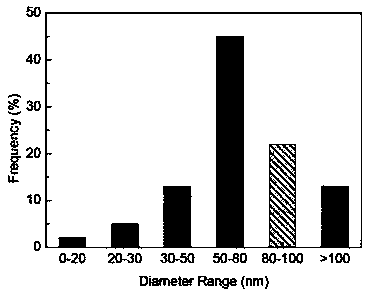

Preparation method for composite material of cellulose nanofiber and reinforced polyurethane

InactiveCN103436002AHigh strengthReduce forcePaper recyclingWaste paper working-upCelluloseChemical treatment

The invention discloses a preparation method for a composite material of cellulose nanofiber and reinforced polyurethane. The method comprises the following steps: 1) pretreating in a chemical method; 2) unfastening fibers in a mechanical method. According to the invention, chemical treatment and mechanical treatment are adopted to separate the cellulose nanofiber, which has a high length diameter ratio and is used for reinforced polyurethane, from newspaper; the transparent nano composite material with high-intensity is prepared; wood meal and newspaper are adopted as raw materials to prepare cellulose nanofiber through the chemical treatment combined with the mechanical treatment; the diameter range of the cellulose nanofiber is 30-100 nm, and the length diameter ratio is higher than 1000.

Owner:NANJING FORESTRY UNIV

Selective catalytic reducing NOx catalyst based on MnOx/TiO2 system at low-temperature and production thereof

InactiveCN1817448AAchieve removalIncreased dispersionDispersed particle separationCatalyst activation/preparationAlcoholProton

A catalyst based on MnOx / TiO2 system for low-temp selective catalytic reduction of NOx is proportionally prepared from alkoxy compound of Ti, alcohol solvent, water, protonic acid, soluble salt of Mn and the soluble salt of transition element through proportional mixing, stirring until sol becomes gel, drying, grinding and high-temp calcining.

Owner:ZHEJIANG UNIV

Carbon nanotube paste for lithium battery and preparation method for carbon nanotube paste

InactiveCN105552375AIncreased dispersionGood dispersionCell electrodesSecondary cellsCarbon nanotubeSolvent

The invention discloses a carbon nanotube paste for a lithium battery and a preparation method for the carbon nanotube paste. The carbon nanotube paste comprises the ingredients of carbon nanotubes, carbon black, a surfactant, a thickening agent and a solvent, wherein the ratio of carbon nanotube: carbon black: surfactant: thickening agent: solvent is (3-10wt%): (0-8wt%): (0.1-1.3wt%): (0-1wt%): (80-96wt%); and the uniformly-dispersed uniform carbon nanotube paste is prepared based on the ratio through a mixing and stirring process. Under the effects of the surfactant and the thickening agent, a high-speed mechanical stirring mode and an ultrasonic stirring mode are combined, so that the dispersion degree of the conductive agent is greatly improved; and pre-fabrication for the paste is carried out for the carbon nanotube conductive agent that is difficult to disperse, so that a relatively good dispersion effect is achieved, the stirring requirement in the next step applied to the battery paste is lowered, and a relatively good mixing effect can be realized.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

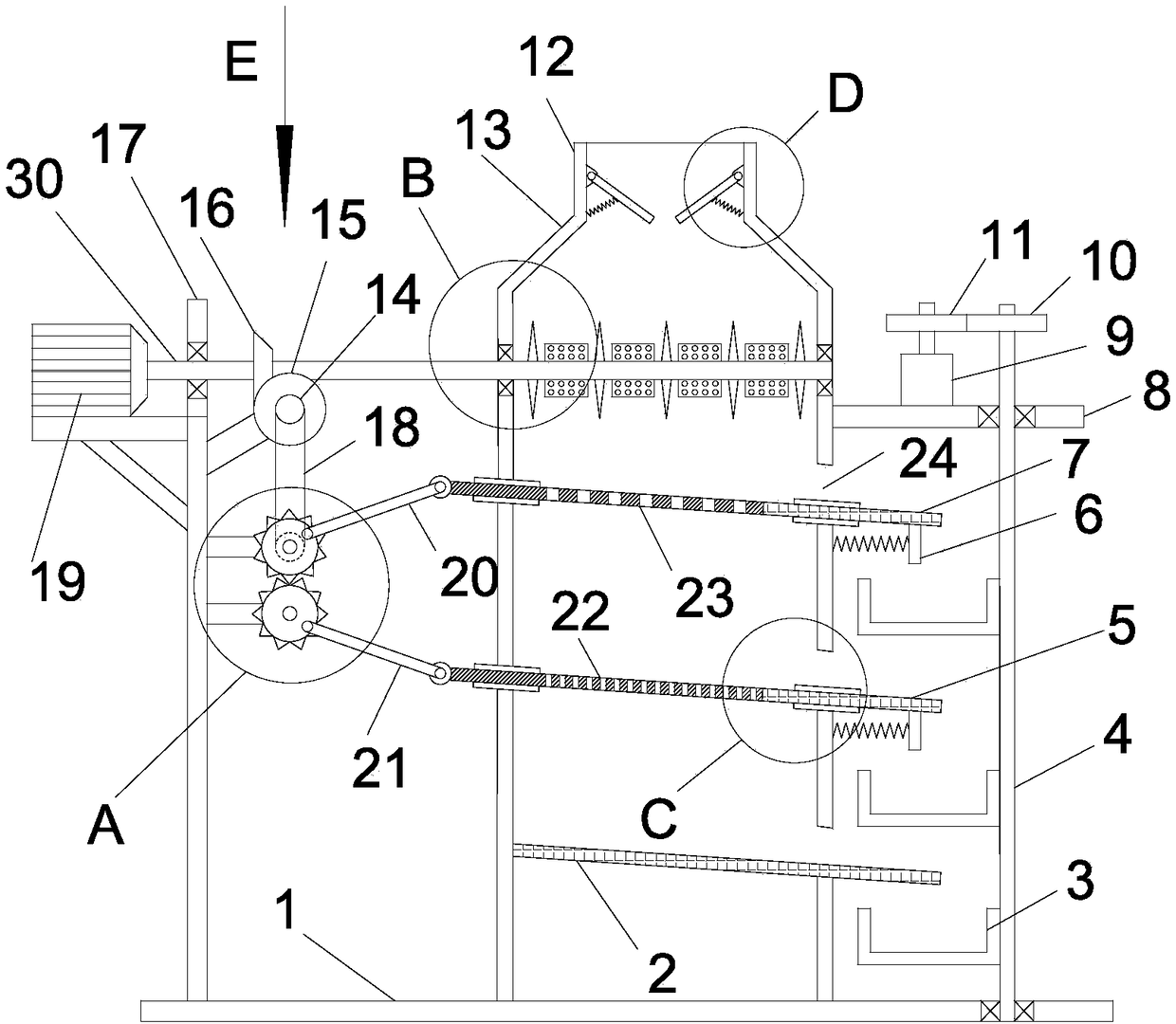

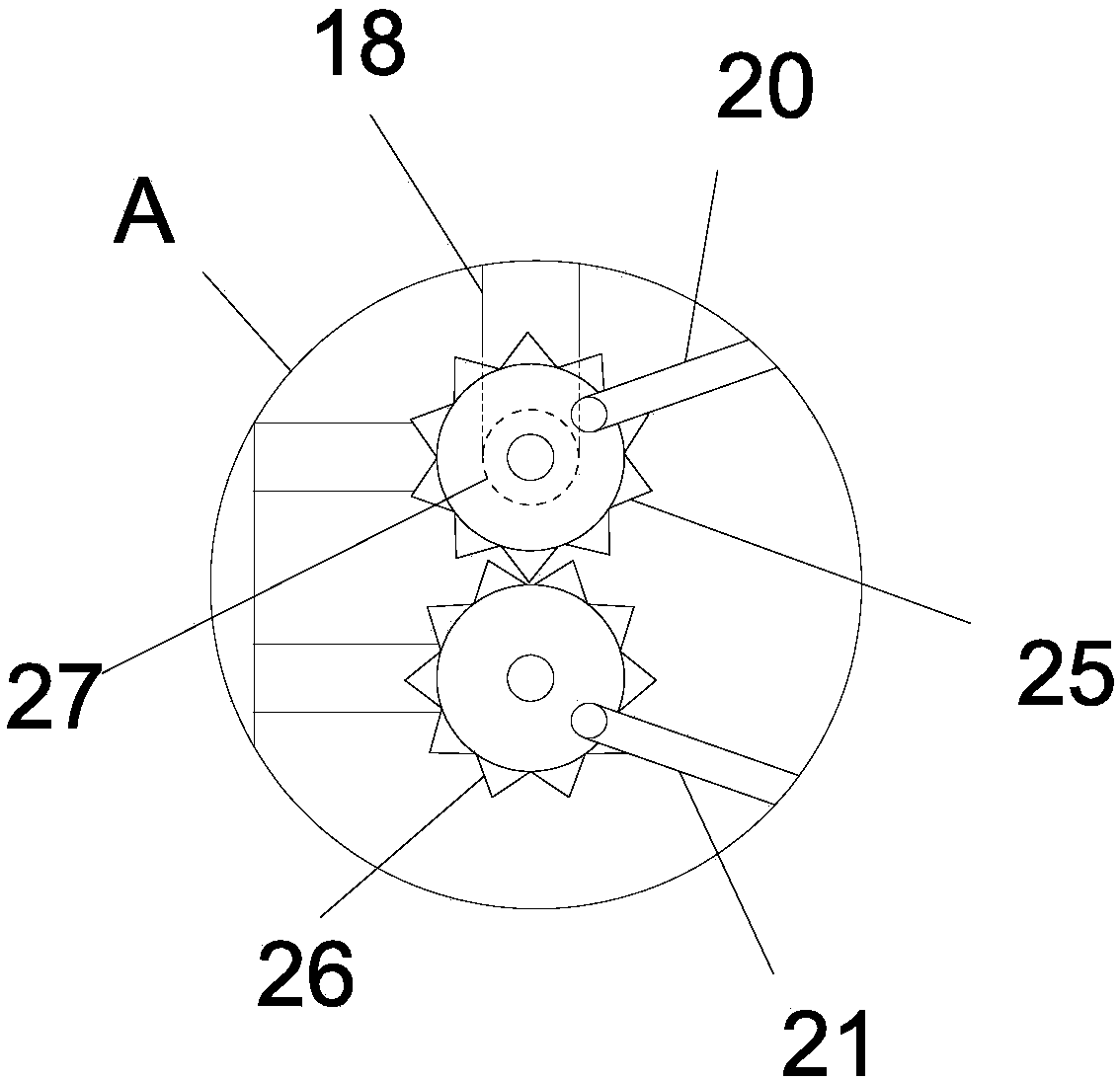

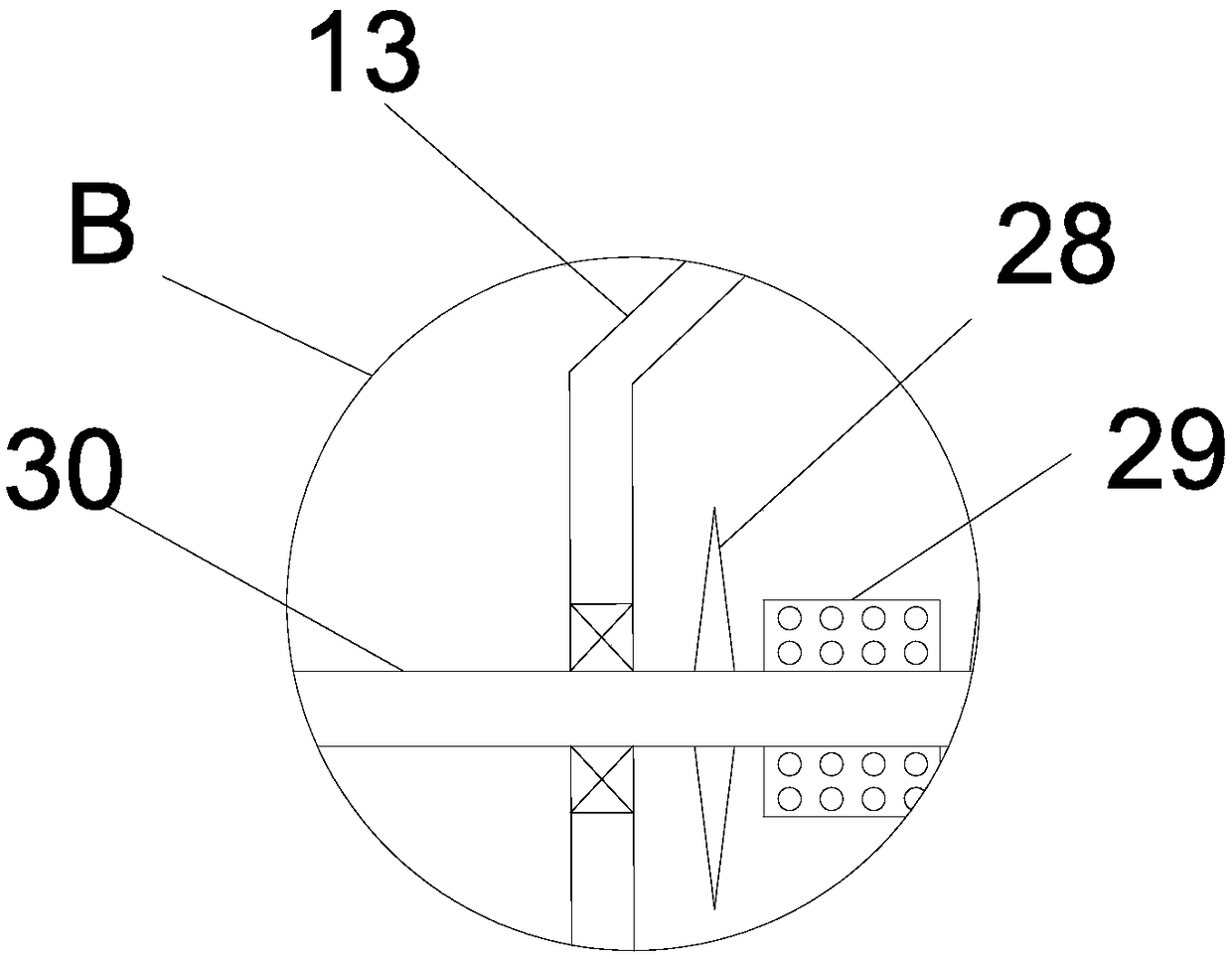

Secondary gravel screening device

InactiveCN108160259AIncreased dispersionImprove screening efficiencySievingScreeningElectric machineryDrive motor

The invention discloses a secondary gravel screening device which comprises a base plate. A supporting frame is vertically and fixedly installed on the base plate. A drive motor is fixedly installed at the left side of the supporting frame. The right side wall of the supporting frame is provided with a driven bevel gear in meshing connection with a driving bevel gear in a rotary mode. A feeding pipe is arranged at the upper end of a screening box. A horizontal plate is horizontally and fixedly installed on the outer wall of the right side of the screening box. A stepping motor is fixedly installed on the horizontal plate. A driven gear in meshing connection with a driving gear is fixedly installed at the upper end of a rotating shaft. According to the secondary gravel screening device, gravel can be scattered in a rotating mode through rotation of blades and a shifting plate with through holes, the scattering degree of the gravel before screening is increased, and the gravel screeningefficiency is improved. A second sieve plate and a first sieve plate make left-right reciprocating motion under the driving action of a second connecting rod and a first connecting rod correspondingly, the fast screening effect on the gravel is achieved, the gravel, obtained after passing the second sieve plate and the first sieve plate, of different grain diameters enters a collecting groove to be collected, and discharging is convenient and rapid.

Owner:长沙双合盛企业管理有限公司

Graphene modified fluorine-contained lead dioxide electrode and preparation method thereof

ActiveCN106868509AImprove conductivityFast transferElectrolytic coatingsWater contaminantsLead dioxideMaterials science

The invention provides a graphene modified fluorine-contained lead dioxide electrode and a preparation method thereof. A tin antimony oxide bottom layer, an alpha-PbO2 middle layer and a beta-PbO2 active layer of the electrode all contain graphene. The preparation method comprises the steps of titanium plate pretreatment, thermal deposition of the tin antimony oxide bottom layer containing the graphene, acoustoelectric deposition of the alpha-PbO2 middle layer containing the graphene, and acoustoelectric deposition of the beta-PbO2 active layer containing the graphene. The graphene modified fluorine-contained lead dioxide electrode has the following advantages: the prepared graphene modified fluorine-contained lead dioxide electrode greatly is improved in electrocatalytic oxidation activity and largely prolonged in service life compared with a general fluorine-contained lead dioxide electrode, and is an anode material with development potential and suitable for electrocatalytic oxidation and degradation of organic pollutants in waste water.

Owner:JILIN NORMAL UNIV

Cross-blending material between polythene in high density and polythene in superhigh molecular weight

This invention discloses a method for preparing a blend of high-density polyethylene and ultrahigh molecular weight polyethylene, and its application. The method comprises: modifying ultrahigh molecular weight polyethylene with composite dispersant (resin with low melting point and low viscosity, and lubricant), blending with high-density polyethylene, and extruding. The blend comprises: ultrahigh molecular weight polyethylene 10-30 wt. %, composite dispersant 2-15 wt. %, and high-density polyethylene 5-10 wt. %. The obtained blend has a melt flow index of 0.1-0.3 g / 10 min (190 deg.C, 2.16 kg), and can be processed into thin film of 20-100 mum by blow molding or tape casting. The thin film prepared by blow molding has higher tensile and tearing strength than neat high-density polyethylene thin film, and fewer crystal spots on the surface than that prepared by simple blending.

Owner:广州广化塑料管道有限公司

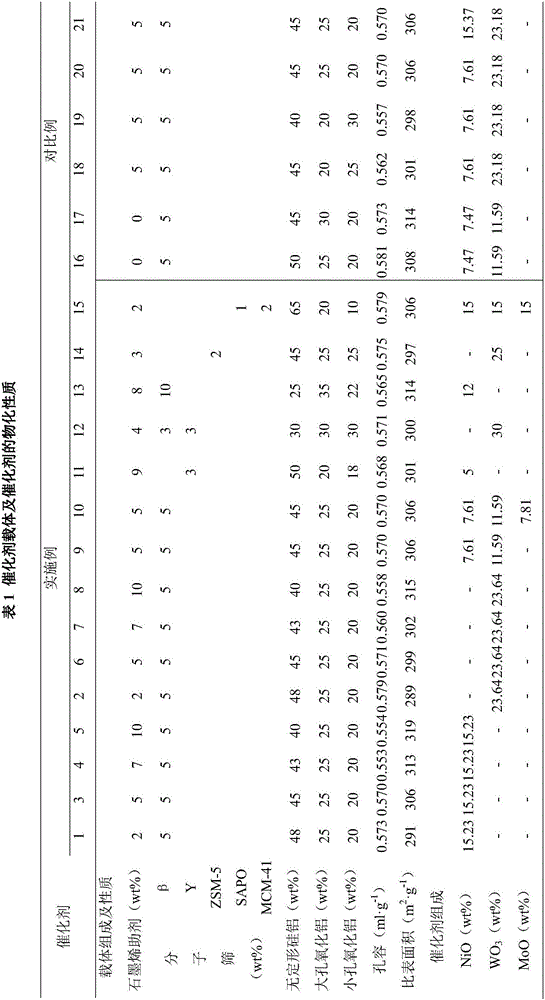

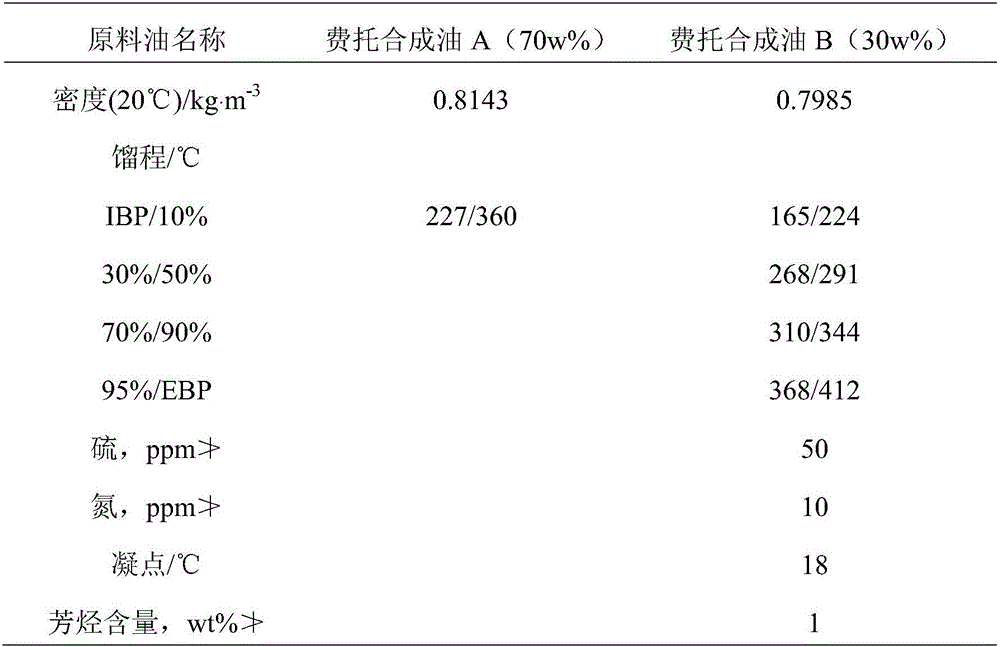

Selective hydrogenation catalyst for producing biodiesel and preparation method and application of selective hydrogenation catalyst

InactiveCN105903488AImprove thermal conductivityUniform temperature distributionMolecular sieve catalystsHydrocarbon oils refiningBiodieselFreeze-drying

The invention discloses a selective hydrogenation catalyst for producing biodiesel and a preparation method and application of the selective hydrogenation catalyst. The selective hydrogenation catalyst comprises a carrier and a main metal active ingredient loaded on the carrier, the main metal active ingredient accounts for 5-30% of the catalyst in weight and is one of or a combination of oxides containing Co, Mo, Ni and W, and the carrier is composed of, by weight, 1-8% of a molecular sieved, 25-65% of amorphous sial, 30-65% of alumina and 2-10% of a graphene auxiliary. The preparation method includes: disposing the carrier in a metal salt solution containing Co, Mo, Ni or / and W for soaking for 4-20 h to obtain a soaked carrier; freeze-drying and then calcining the soaked carrier to obtain the selective hydrogenation catalyst. With same carrying capacity of the carrier, active surface area represented by the carrier is large, the selective hydrogenation catalyst has more active sites, reaction temperature is lowered, and hydrogenation performance is improved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Fog seal modified emulsified asphalt and preparation method thereof

ActiveCN102702760AGood stabilityEasy to applyIn situ pavingsBuilding insulationsColloid millAqueous solution

The invention relates to fog seal modified emulsified asphalt which comprises the following components by weight: 18-35% of asphalt, 8-18% of an asphalt modifying agent, 5-12% of an asphalt regenerating agent, 1-4% of a compound emulsifying agent and 50% of water. The preparation method comprises the following steps: directly adding the asphalt modifying agent and the asphalt regenerating agent to hot melt asphalt for mixing to prepare modified asphalt; mixing and emulsifying the modified asphalt and an aqueous solution of the compound emulsifying agent through a colloid mill; and mechanically stirring to prepare the fog seal modified emulsified asphalt. The prepared fog seal modified emulsified asphalt has the advantages of good storage stability, good water dilutability, environmental protection in use, good surface consolidation performance after construction, good abrasion resistance, difficult sticking off by wheels, short traffic close time, improvement of construction conditions, improvement of construction efficiency, good water seal function, asphalt pavement water damage prevention, pavement structure protection and extension of pavement service life.

Owner:云南交投公路建设第四工程有限公司

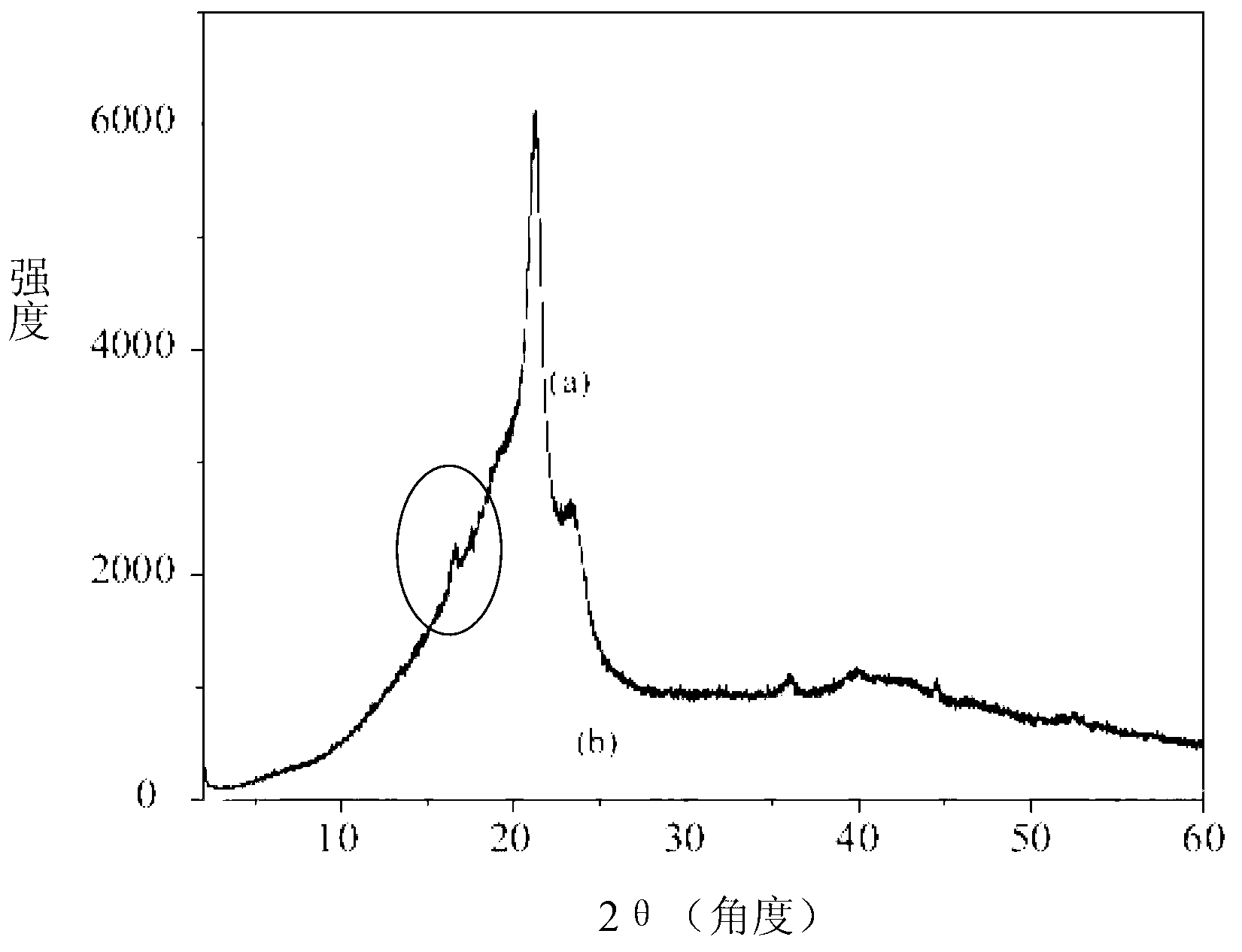

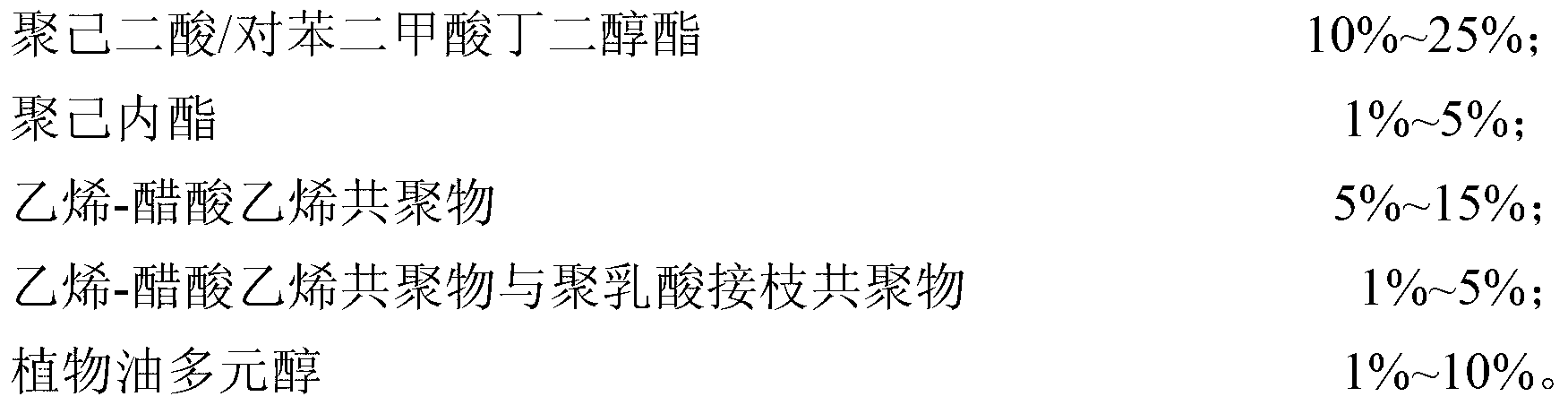

PLA/PBAT biodegradable composite material and preparation method thereof

The invention discloses a PLA / PBAT biodegradable composite material, which is prepared from the following components in percentage by weight: 60-75% of a polylactic acid, 60-75% of poly(adipic acid) / butylene terephthalate, 1-5% of poly (caprolactone), 5-15% of an ethylene-vinyl acetate copolymer, 1-5% of an ethylene-vinyl acetate copolymer and polylactic acid graft copolymer, and 1-10% of vegetable oil polyols. The PLA / PBAT biodegradable composite material disclosed by the invention is excellent in tensile strength and toughness, good in chemical stability, and easy to process, and in addition, the material is biodegradable. The invention also discloses a preparation method of the PLA / PBAT biodegradable composite material, which can be implemented through the existing equipment twin-screw extruder, therefore, the method is easy to implement, strong in maneuverability, and easy to realize industrialized mass production, and has good economic benefits and broad application prospects.

Owner:LINONGFENG TECH

Catalyst used for preparing isobutene through isobutane dehydrogenation and preparation method and application thereof

ActiveCN104525195AInhibition formationIncreased dispersionHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalActive component

The invention provides a catalyst used for preparing isobutene through isobutane dehydrogenation and a preparation method and application of the catalyst. According to the catalyst, magnesium aluminate spinels serve as carriers, platinum nanoparticles serve as active components, tin serves as a first addition agent, and alkaline metal or alkaline-earth metal serves as a second addition agent; by weight of the magnesium aluminate spinel carriers, the capacity of the platinum nanoparticles is 0.2-0.6 wt%, the capacity of the first addition agent is 0.01-2 wt%, and the capacity of the second addition agent is 0.5-2 wt%. The invention further provides the preparation method of the catalyst and application of the catalyst in the field of preparing isobutene through isobutane dehydrogenation. The catalyst used for preparing the isobutene through isobutane dehydrogenation has high isobutane conversion rate and high isobutene selectivity; moreover the catalyst has good high-temperature stability; meanwhile the catalyst can inhibit deposited carbon from forming, and therefore side reactions can be effectively inhibited.

Owner:PETROCHINA CO LTD +1

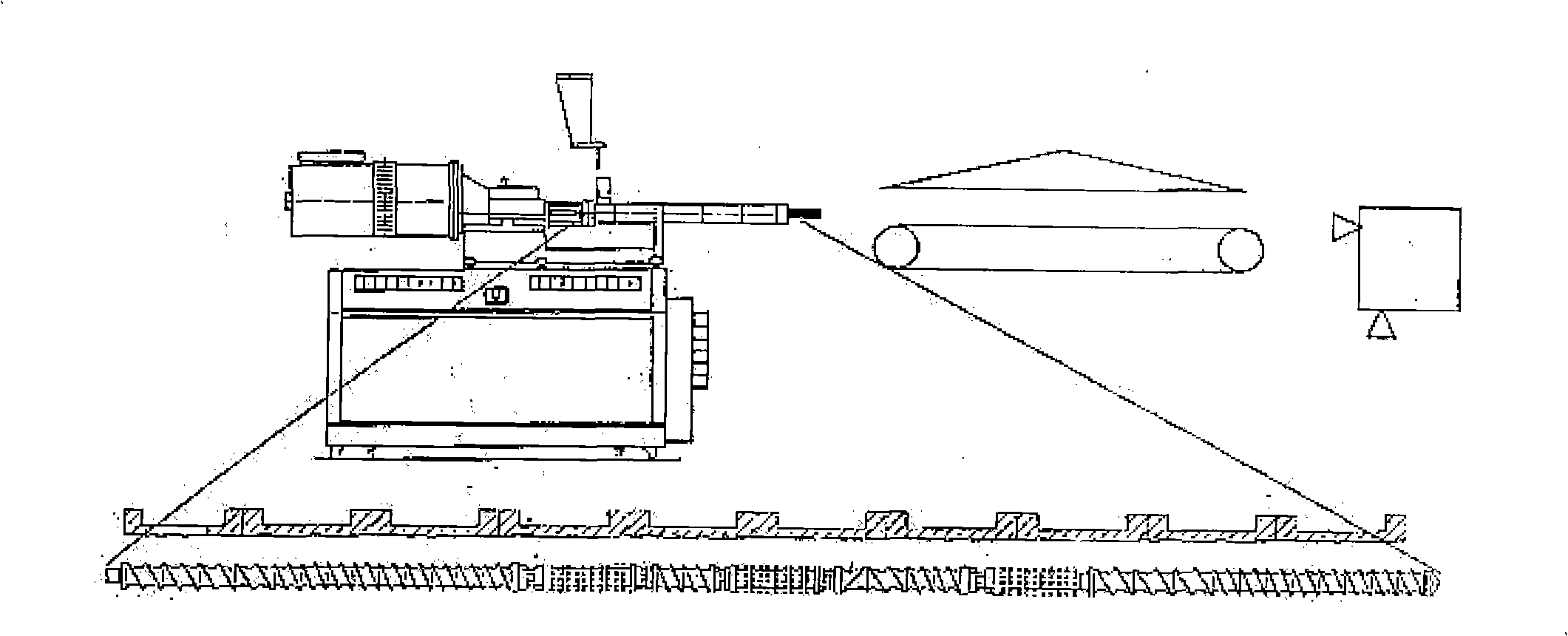

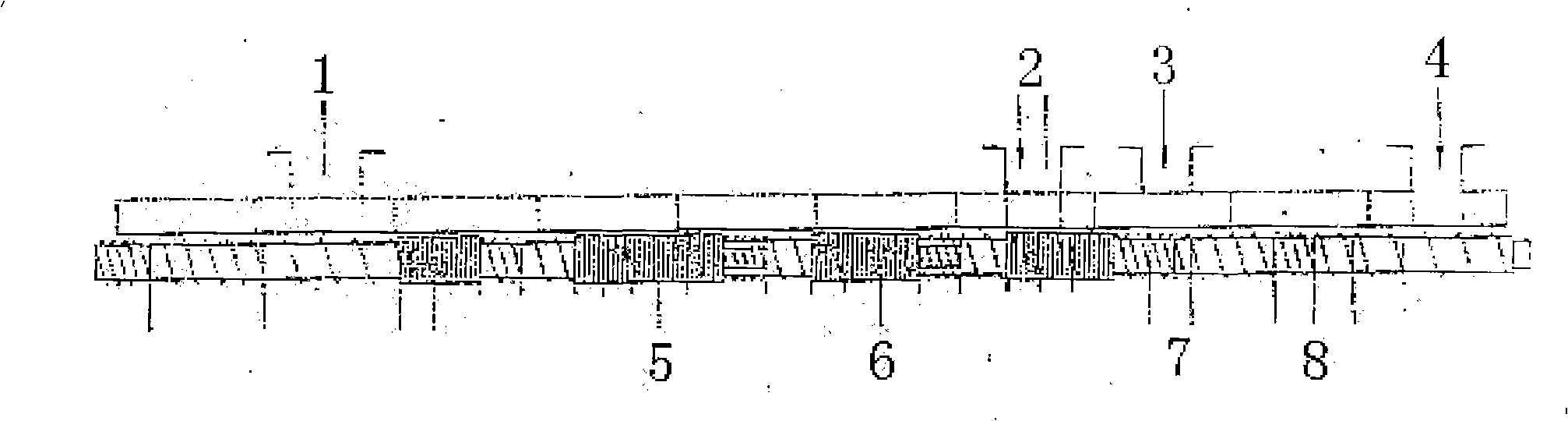

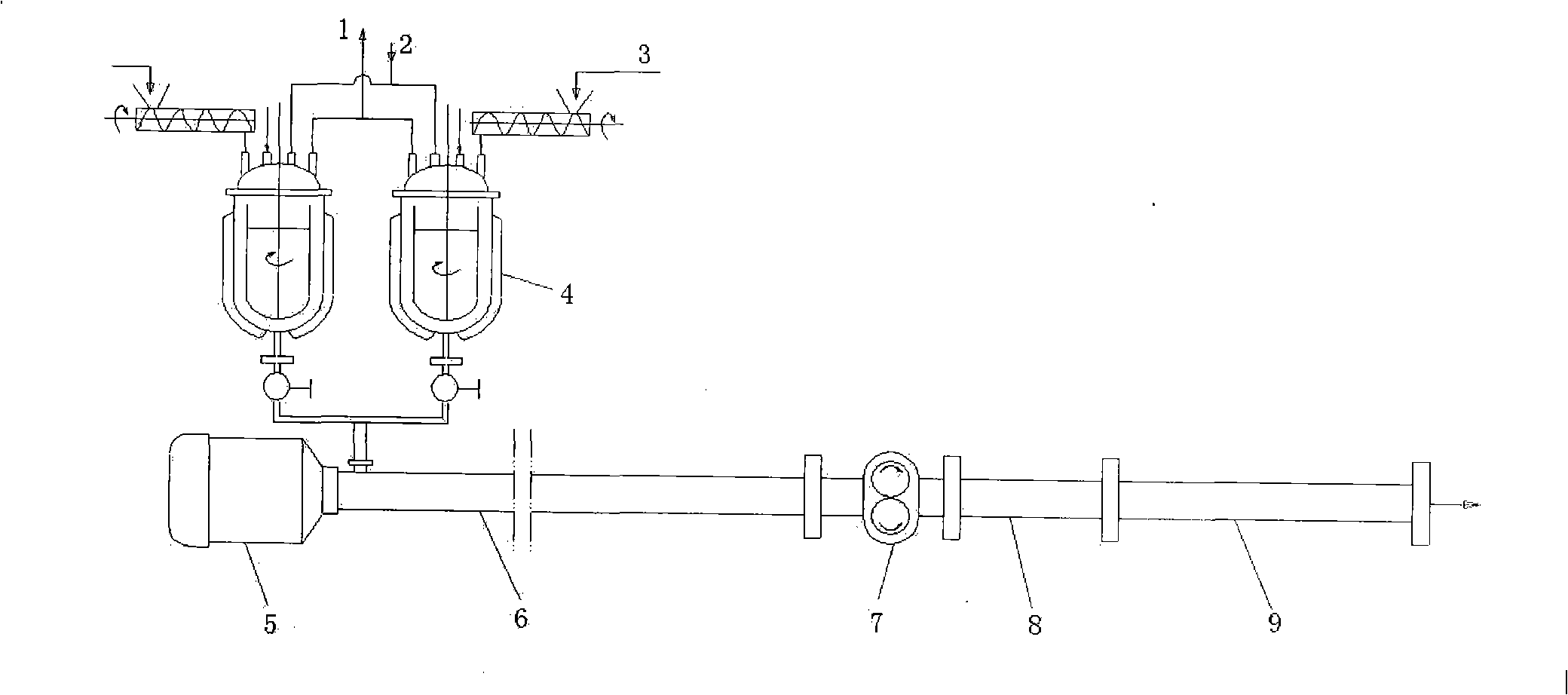

Multistage reaction continuous polymerization unit for synthesizing polylactic acid material with lactides monomer

The invention provides a multi-grade continuous polyplant of polylactic acid materials, which is synthesized by the ring-opening polymerization of a lactide monomer. The multi-grade continuous polyplant consists of a polyplant device and a feed device with different characteristics, including a prepolymer reaction kettle set, a double-screw reaction squeezer, a fused mass feed pump, a static mixer and a tubular reactor. Compared with the plant for adopting a single double-screw reaction squeezer to synthesize the polylactic acid materials, the multi-grade continuous polyplant disperses and lightens the load of the reaction devices of each grade as a multi-grade plant is used for replacing a single-grade reaction plant, thus leading the control on the conversion rate of the lactide monomer to be easier and more stable; as the fused mass feed pump is connected in series in the middle, the floating speed of the materials and the pressure of the squeezer and a subsequence device can be stabilized, the reaction condition can be better controlled; as the back section of the plant is provided with the static mixer and the tubular reactor, the final conversion rate of the lactide monomer can be further improved, thus being beneficial to improving and adjusting the molecular weight and the molecular weight distribution of the polylactic acid materials.

Owner:四川琢新生物材料研究有限公司

Method for synthesizing mullite whiskers by normal pressure sintering

InactiveCN101935877ASimple processIncreased dispersionPolycrystalline material growthFrom solid stateDiameter ratioWhiskers

The invention relates to a method for synthesizing mullite whiskers by normal pressure sintering. A second phase whisker material capable of enhancing and toughening a metal or ceramic matrix at the temperature of over 1,200 DEG C is prepared by using the high-temperature creep resistance of the mullite whiskers. The method for synthesizing the mullite whiskers by the normal pressure powder sintering has simple process; and the synthesized mullite whiskers have the advantages of high dispersion degree, uniform granule size distribution and high length-diameter ratio and purity, and can be used as enhancing and toughening whiskers for metal and ceramic materials.

Owner:KUNMING UNIV OF SCI & TECH

Aqueous polypyrrole/attapulgite electrically-conducting paint and its preparation method

ActiveCN102311703ALow costGood value for moneyPolyurea/polyurethane coatingsElectrically-conductive paintsEmulsionPolypyrrole

The invention relates to an electrically-conducting paint, more specifically to a two-component aqueous polyurethane electrically-conducting paint and its preparation method. The electrically-conducting paint is prepared by the following steps of: firstly, preparing a polypyrrole / attapulgite nanometer conducting composite material; then, dispersing the obtained conducting composite material into an aqueous hydroxyl acrylic emulsion; and finally adding various auxiliary agents and hydrophilic modified polyisocyanates to obtain the two-component aqueous polyurethane electrically-conducting paint. The preparation method provided by the invention has a simple process; in addition, the product has high cost performance and is environmentally friendly.

Owner:溧阳常大技术转移中心有限公司

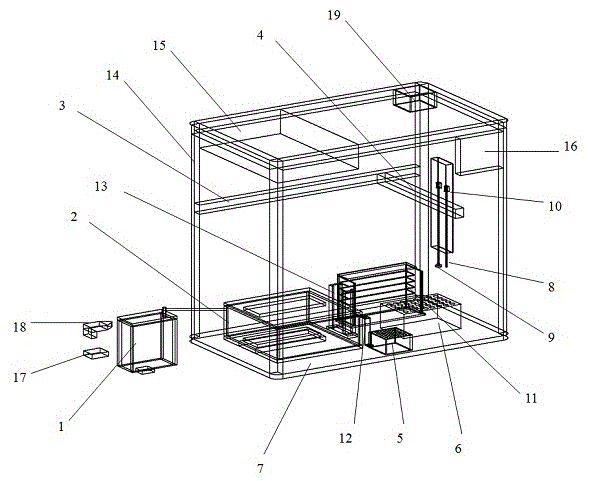

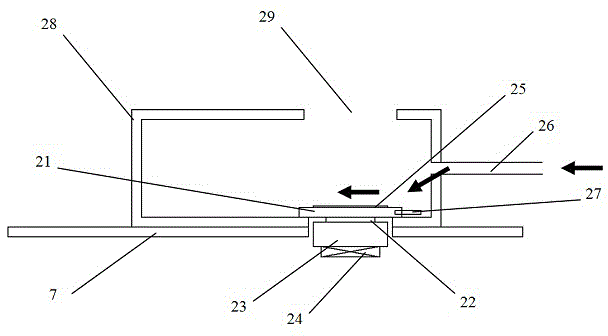

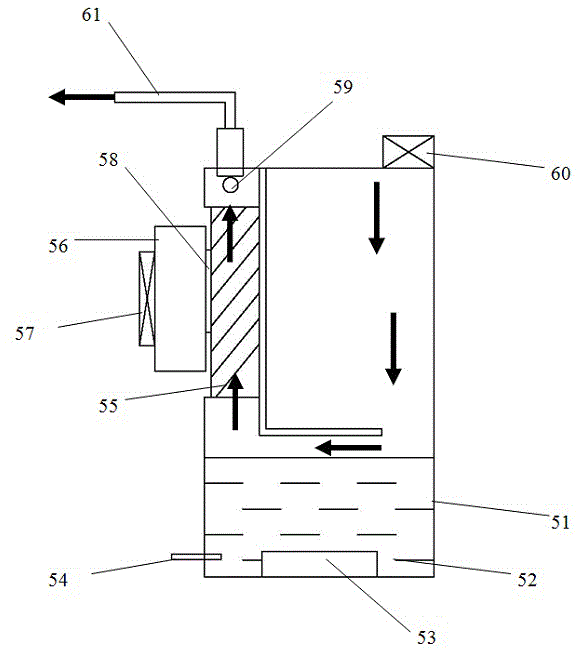

Biological sample processing system

ActiveCN104089804AReduce humidityControl the dispersion processPreparing sample for investigationHuman–machine interfaceControl system

The invention discloses a biological sample processing system which comprises a system base plate, a glass slide placing platform, a sample cell, a biological sample dropping device, a sample processing cavity body, a control system and a human-computer interface, wherein the biological sample dropping device comprises a space motion mechanism, a pipetting device and a glass slide taking and putting device, and the space motion mechanism is controlled by the control system, so that a preset moving track is output by a moving part of the space motion mechanism, a glass slide is automatically arranged at the beginning of an experiment, a biological sample is automatically sucked and transferred onto the surface of the glass slide by the pipetting device, the glass slide is automatically removed after the completion of the experiment, and the temperature of the biological sample cell can be adjusted. According to the biological sample processing system disclosed by the invention, the automatic dropping operation of chromosomes can be performed in a high-throughput mode; the biological sample processing system has the advantages of small size, low production cost, convenience in installation and maintenance and low energy consumption and is especially suitable for analyzing cytogenetics; the dropping process automation of the chromosomes is realized, the analysis efficiency is improved, and the biological sample processing quality is guaranteed.

Owner:SHANGHAI LECHEN BIOLOGICAL SCI & TECH

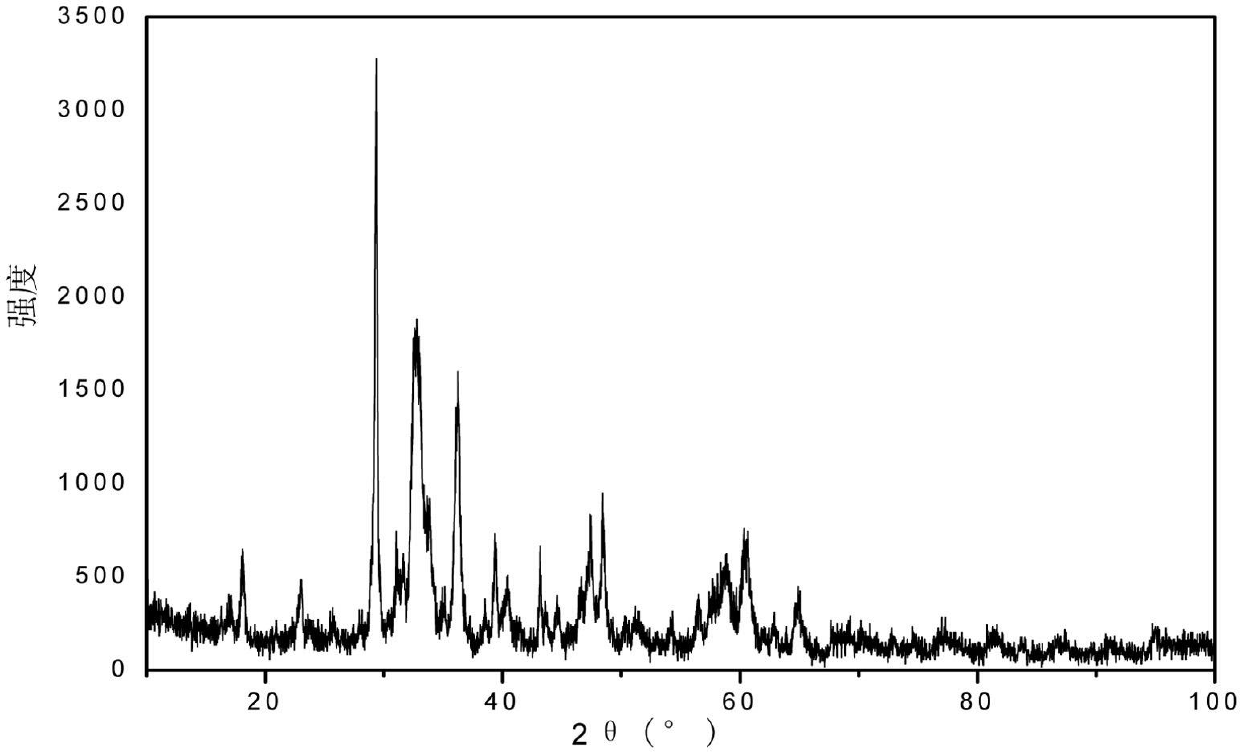

Boron and nitrogen co-doping chitosan-base activated carbon and method for preparing same

ActiveCN102951637AHigh nitrogen contentHigh specific capacitanceCarbon compoundsProtonationStrong acids

The invention provides a boron and nitrogen co-doping activated carbon which is prepared through utilizing biomass. The boron and nitrogen co-doping chitosan-base activated carbon takes chitosan and boric acid as raw materials, wherein boron in the activated carbon accounts for 1-3wt%, nitrogen in the activated carbon accounts for 4.1-9.2wt%, the specific surface area is 500-1000m<2> / g, and the pore size distribution is 0.46-2nm. The boron and nitrogen co-doping chitosan-base activated carbon takes the chitosan and the boric acid as raw materials and is prepared through co-pyrolysis. According to a method, the combining quantity of the boron in a carbon source and the dispersion degree of the boron in the carbon source are increased under the mutual action of the protonated chitosan and the boric acid, and the boron and nitrogen co-doping chitosan-base activated carbon is obtained through the co-pyrolysis. An environmental-friendly technology for preparing the activated carbon without consuming strong acid and strong alkali is realized, so that a costly and non-environmental-friendly process which consumes a great deal of activating agent and water during the traditional process for preparing the activated carbon is avoided. Moreover, the boron and nitrogen co-doping chitosan-base activated carbon has the advantages of short time consumption, simplicity in preparation technology, simplicity and easiness in equipment and the like.

Owner:DALIAN UNIV OF TECH

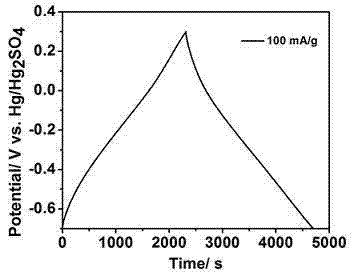

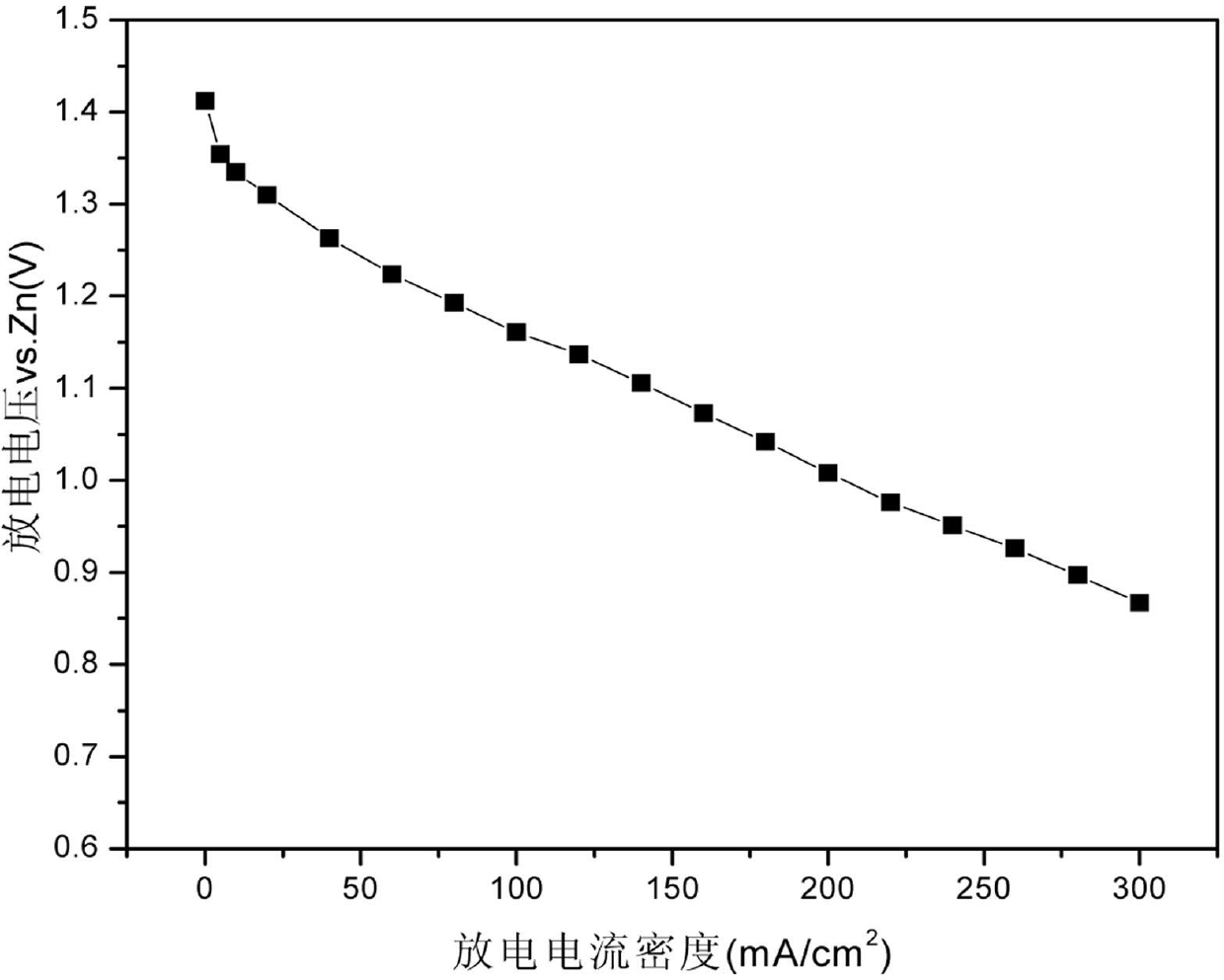

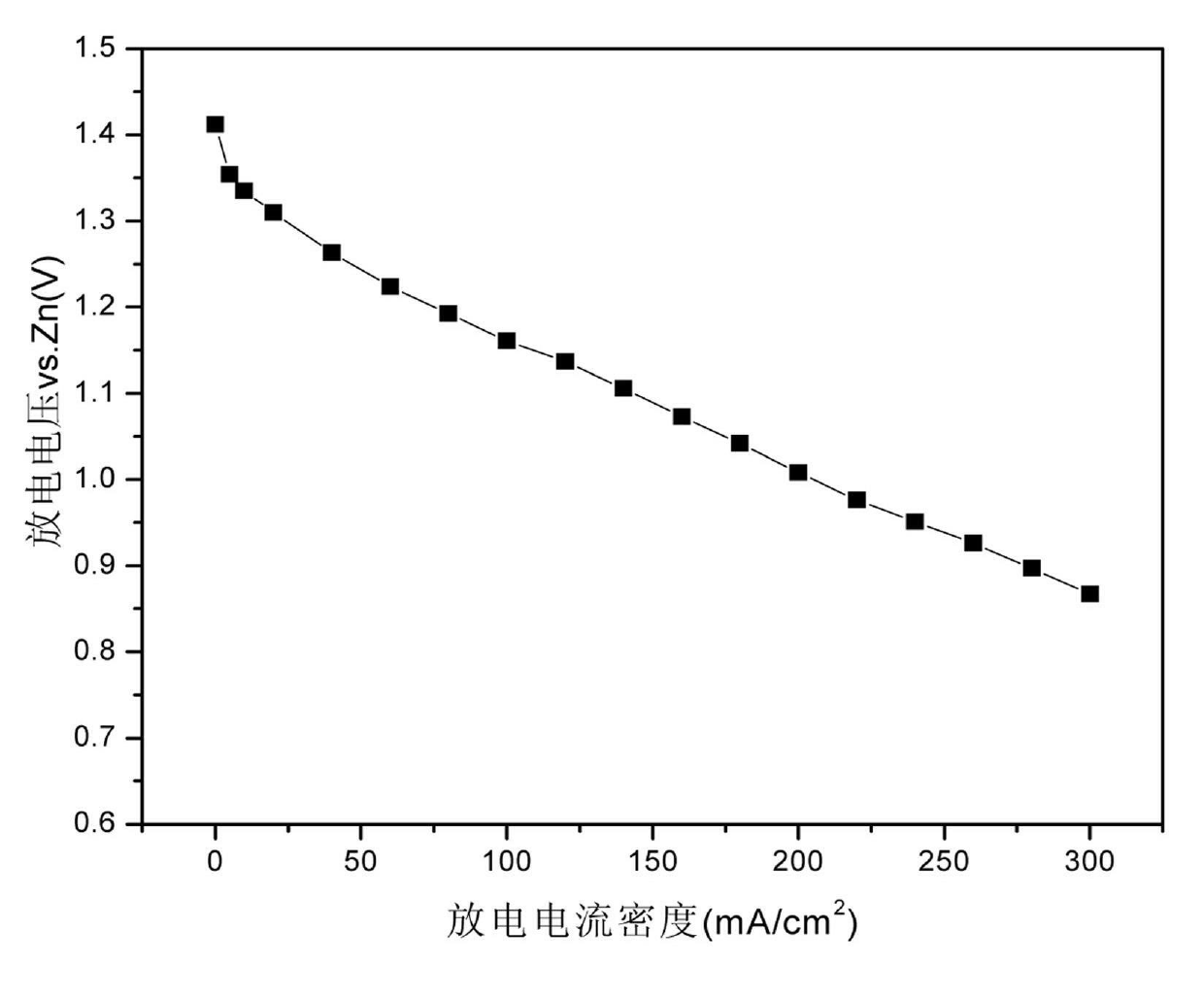

Preparation method and application of perovskite type composite oxide catalyst

InactiveCN102166517AIncreased dispersionHigh catalytic activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention discloses a preparation method and application of a perovskite type composite oxide catalyst. The perovskite type composite oxide catalyst is an A-position substituted perovskite type composite oxide. The structural formula of the catalyst is A1-xA'xBO3, wherein x is larger than 0 and smaller than 1; A is La or Nd element; the A'-position substitution ion is one of Ca, Sr, Ba, Ce and the like; and the B-position ion is one of Mn, Co, Ni, Fe and the like. The preparation method comprises the following steps of: according to a chemical metering ratio, weighing a water-soluble salt which contains the A-position, A'-position and B-position elements; mixing the salt and deionized water to obtain 5 to 20 percent salt solution; adding the solution into a beaker; adding activated carbon of which the mass is 0.1 to 1.5 times of the salt into the solution; completely soaking the activated carbon and standing; heating and stirring the mixture, continuously heating until the water content is completely evaporated, wherein the co-crystallized solid mixture is uniformly carried on the activated carbon, and after drying the mixture, grinding the mixture into powder; and sintering the powder in a muffle furnace, cooling the sintered powder with the furnace to room temperature, and grinding the cooled powder to obtain the powder of the perovskite type composite oxide mixed catalyst. The preparation method is suitable for production; and the electrode activity of the perovskite type catalyst can be greatly improved in a zinc air cell structure.

Owner:BEIJING CHANGLI UNION ENERGY TECH CO

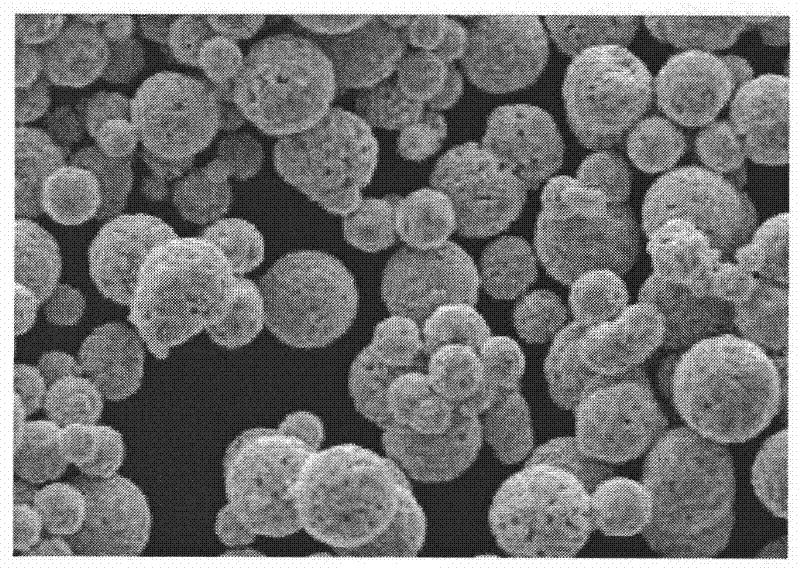

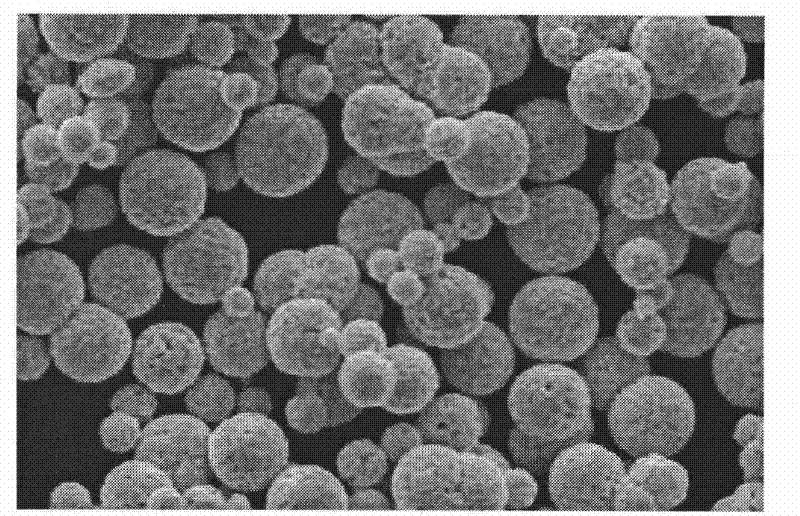

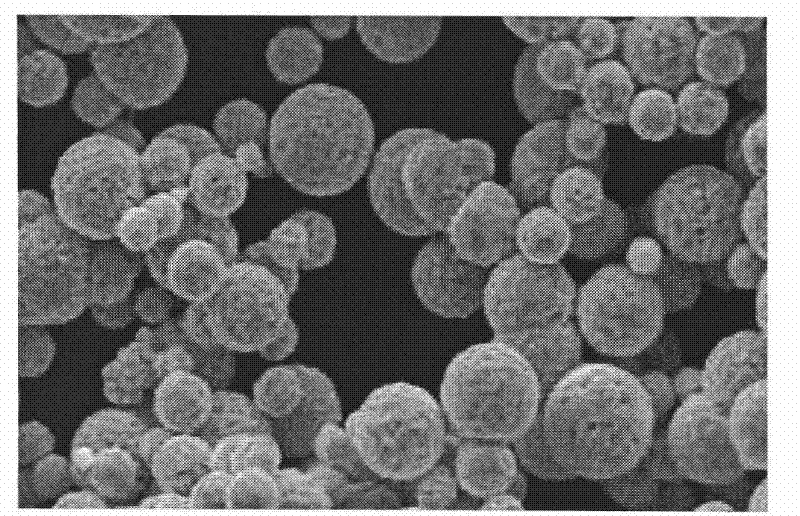

Preparation method for silver powder

The invention provides a preparation method for silver powder, which comprises a step of contacting a silver nitrate solution with a reducing agent solution, thereby preparing the silver powder, wherein the silver nitrate solution contains a dispersing agent; the reducing agent solution contains a dispersing agent and a neutralizing agent; the silver nitrate solution and / or the reducing agent solution contain / contains a thickening agent; and a reducing agent in the reducing agent solution contains a strong reducing agent and a weak reducing agent and contains a medium strong reducing agent or medium reducing agent at the same time. According to the preparation method provided by the invention, the thickening agent is used for adjusting a viscosity of a reaction system, thus the aggregation of the silver powder is efficiently prevented; the method of using different reducing agents together is adopted for realizing the stability of the acidic and basic properties and the reaction rate of the reaction system, thereby preparing the silver powder with basically consistent appearance and excellent dispersing property; and the grain size adjustment and the appearance adjustment for the silver power can be realized by selecting different reducing agents in proportions, and the stability of the reaction rate also can be controlled.

Owner:BYD CO LTD

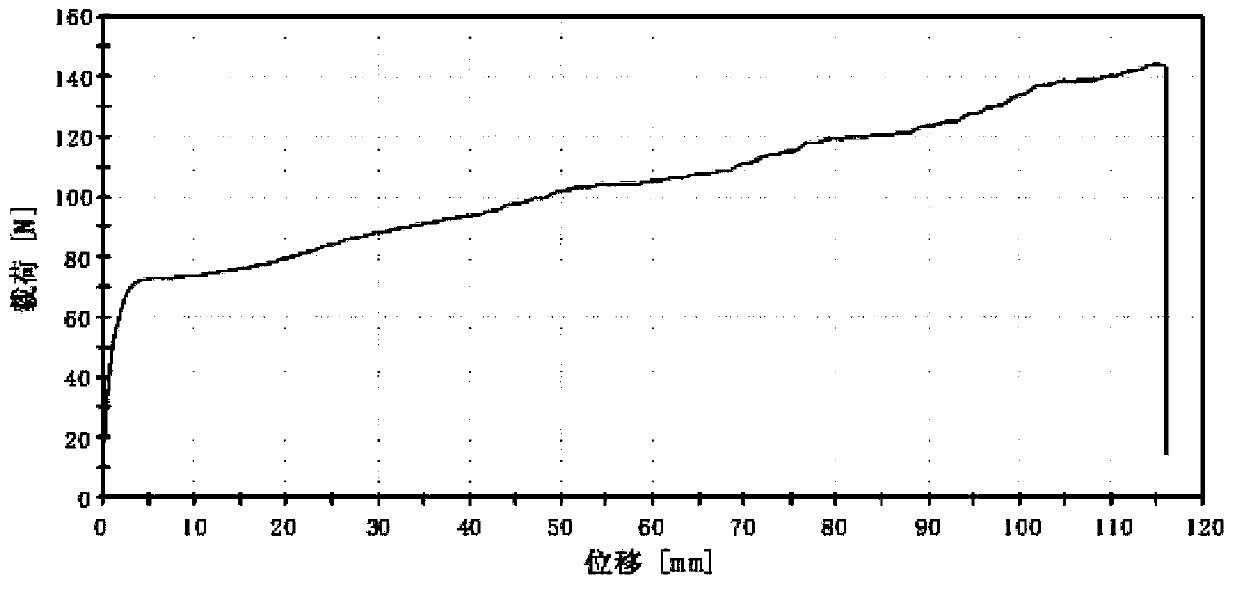

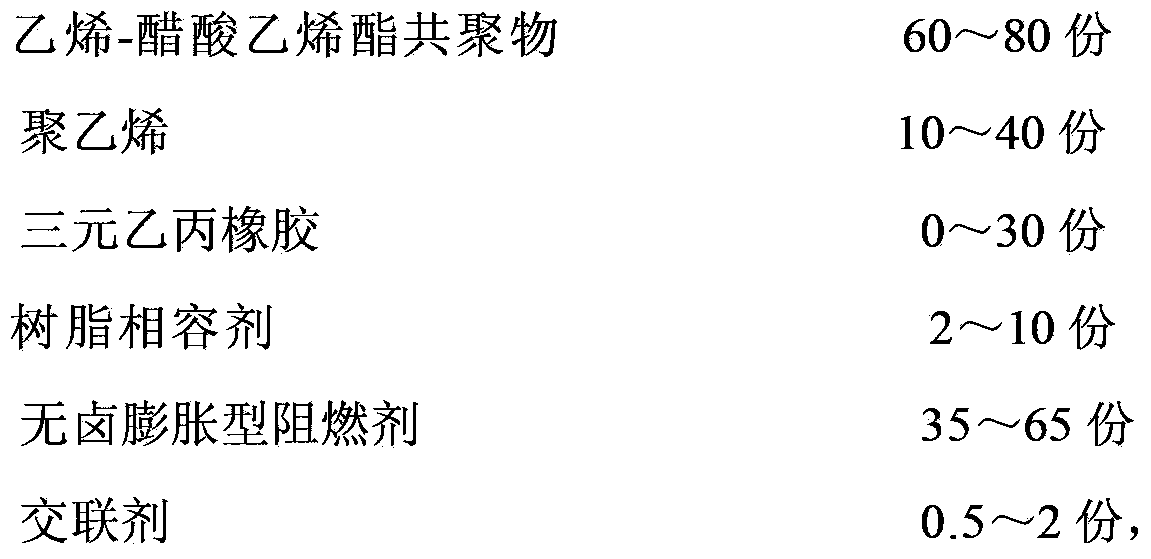

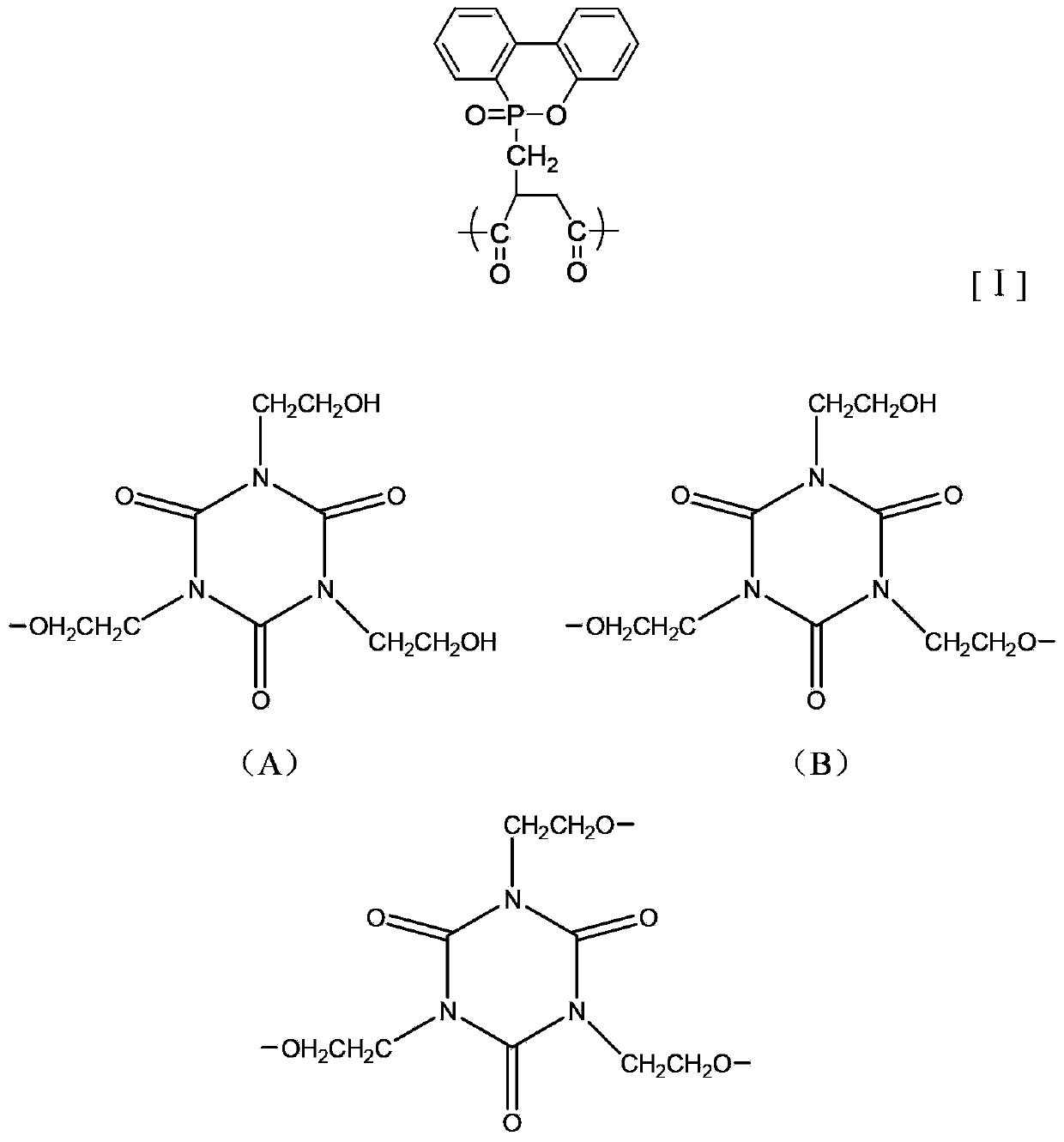

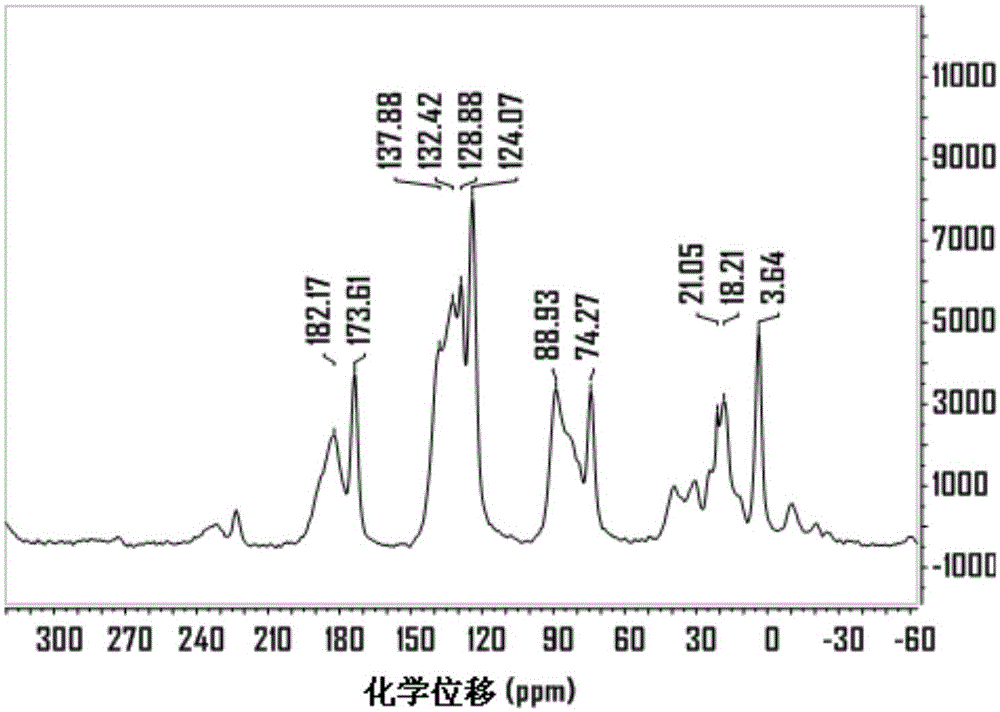

Low temperature-resistant flexible crosslinkable halogen-free flame retardant cable material and preparation method thereof

ActiveCN103467832AGood mechanical propertiesIncreased dispersionPlastic/resin/waxes insulatorsPolymer scienceCarvacryl acetate

The invention discloses a low temperature-resistant flexible crosslinkable halogen-free flame retardant cable material. The low temperature-resistant flexible crosslinkable halogen-free flame retardant cable material is obtained through mixing 60-80 parts of an ethylene-vinyl acetate copolymer, 10-40 parts of polyethylene, 0-30 parts of ternary ethylene propylene rubber, 2-10 parts of a resin compatilizer, 35-65 parts of a halogen-free expanded flame retardant and 0.5-2 parts of a crosslinking agent, wherein at least one charring agent component in the halogen-free expanded flame retardant has a melting point of 155DEG C or less and an initial pyrolysis temperature of 245DEG C or less. The invention also discloses a preparation method of the cable material. The processing temperature of the introduced low-melting-point high-initial-pyrolysis-temperature charring agent component has a wide window and is matched with the processing temperature of a cable material matrix resin, so the charring agent component can be fused and well dispersed in the processing process, thereby the flame retardation efficiency is improved, the influences on the mechanical performances of the matrix resin are reduced, and the cable material has an excellent flame retardation performance and excellent mechanical performances. The preparation method has the advantages of simplicity, convenient operation, easy control and easy industrial production.

Owner:应急管理部四川消防研究所

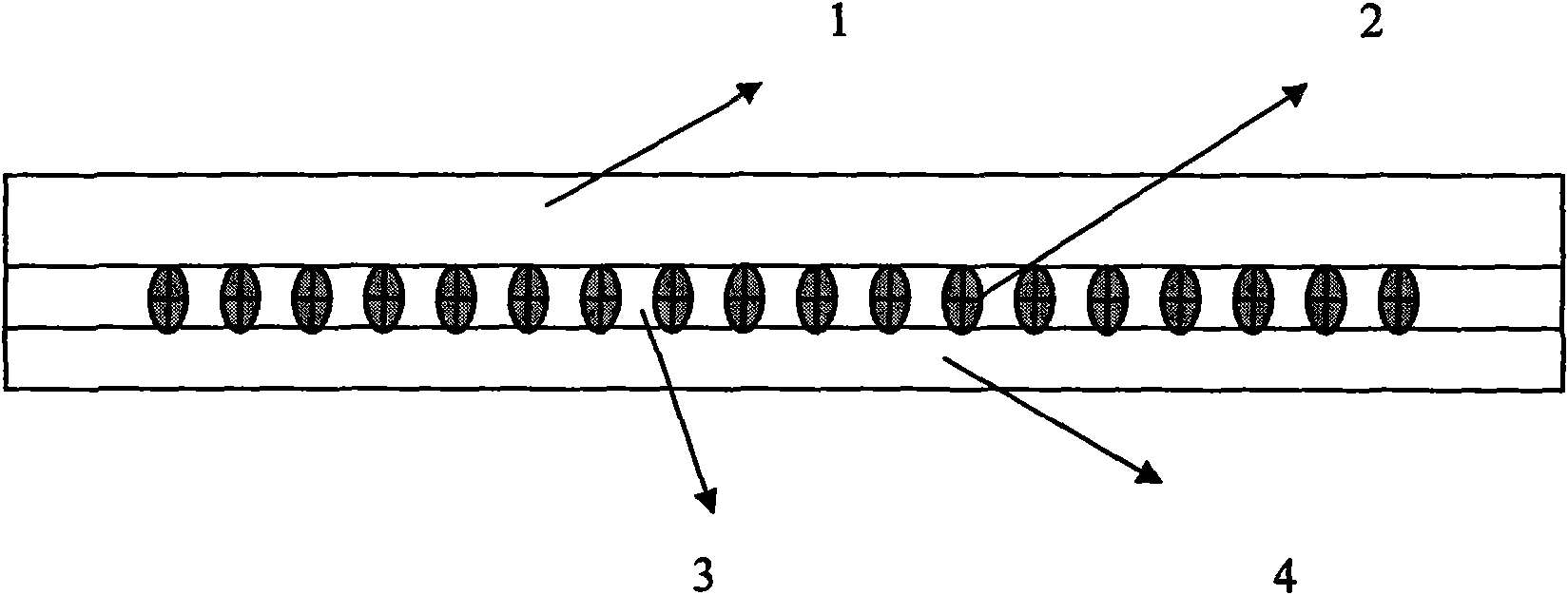

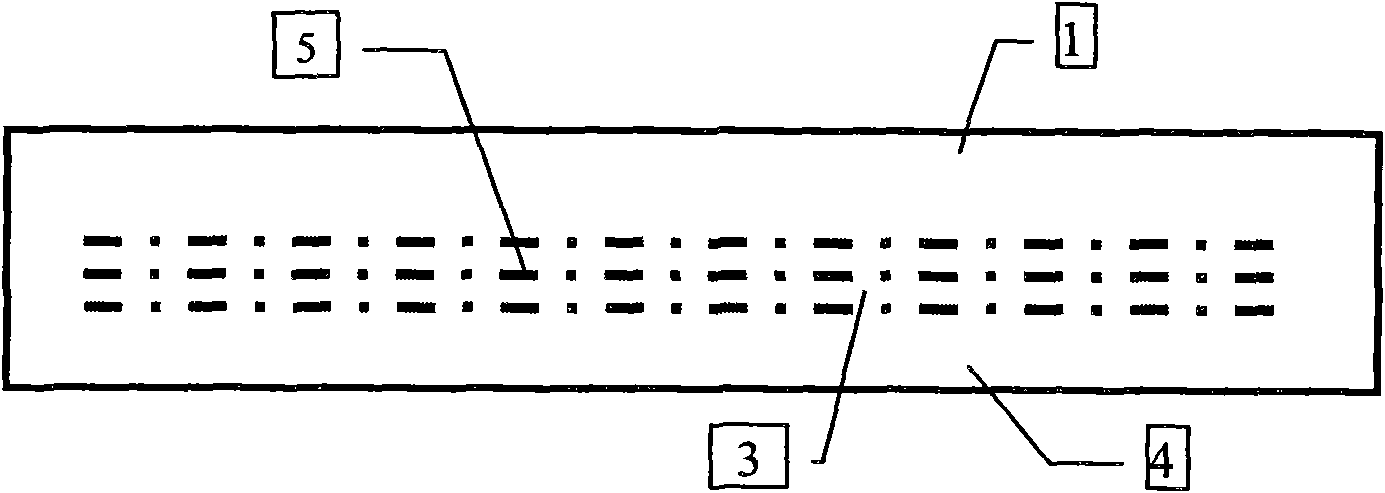

Preparation method of graphdiyne

ActiveCN105016962APromote formationEasy to assembleHydrocarbonsHydrocarbon preparationVacuum pumpingNitrogen

The invention relates to a preparation method of graphdiyne. The preparation method comprises that 1, in a nitrogen or argon protective atmosphere, a reaction substrate 1,3,5-tripropargylbenzene and a catalyst are put into a reaction container, a solvent is added into the reaction container to dissolve the materials in the reaction container, and the solution undergoes a heating reaction, 2, in the reaction process in the step 1, the solution is subjected to vacuum pumping process multiple times so that a reaction side product 2-butyne is removed and a solvent is supplied to make up for a loss of the solvent, and 3, after the reaction, the reaction product is purified so that the product graphdiyne is obtained. Compared with the prior art, the preparation method has simple processes. The prepared graphdiyne has the uniform surface and a low oxidation degree and can stably exist in air.

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of crop straw dye adsorption material

InactiveCN103881033ANo pollution in the processSimple methodOther chemical processesWaste water treatment from textile industryItaconic acidPyrrolidinones

The invention relates to a preparation method of a crop straw dye adsorption material. The preparation method is characterized by comprising the process steps of adding straw powder into N, N-dimethylformamide, putting into an ultrasonic cleaning tank to perform ultrasonic treatment for 20-60 minutes at 30-50 DEG C, then adding phytic acid and urea into the system, heating to 50-90 DEG C, reacting for 2-6 hours, then cooling a product to the room temperature, precipitating, washing, drying and crushing to obtain phytic acid modified straw; neutralizing itaconic acid by using NaOH, then adding the phytic acid modified straw, acrylamide, vinyl pyrrolidone and a crosslinking agent, fully stirring for 30 minutes, then gradually heating to 50-60 DEG C, and finally slowly dropwise adding a redox initiator into a polymerization system to initiate a polymerization reaction for 3-5 hours; and after polymerization, precipitating, washing and drying to obtain the crop straw dye adsorption material. The adsorption capacity of the crop straw dye adsorption material to a cationic dye aqueous solution with the initial concentration of 200-2000mg / L is 195-1400mg / g, the decolorization rate of the crop straw dye adsorption material is 55-90%, and the crop straw dye adsorption material can reach adsorption equilibrium after 100-200 minutes of room temperature adsorption, and can be widely applied to the adsorption, separation and purification of cationic dyes, the environmental pollution control of cationic dye wastewater, and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

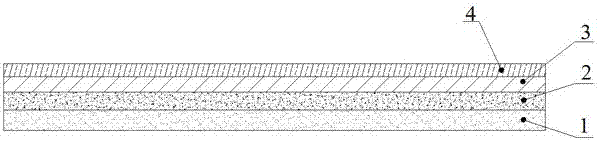

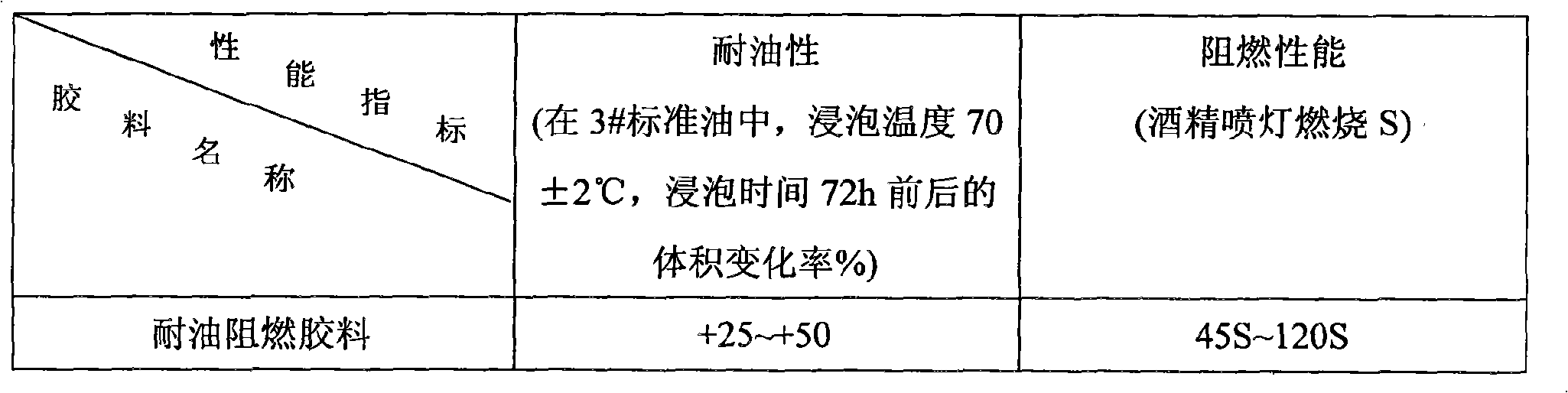

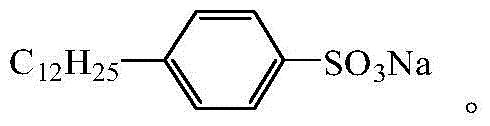

Oilproof flame retardant conveyor belt

ActiveCN101559874AGood oil resistanceImprove featuresConveyorsRubber layered productsNitrile rubberSulfur

The invention discloses an oilproof and flame retardant conveyor belt, belonging to the technical field of conveying materials. Cover rubbers and middle bonding rubber masses of the conveyor belt comprise the following components based on weight proportions: 20-40 parts of neoprene, 60-80 parts of nitrile rubbers containing propylene, 15-20 parts of chlorinated polyethylene, 50-70 parts of compound flame retardant, 3-5 parts of combined dispersant, 3-5 parts of zinc oxide, 1-2 parts of stearic acid, 1.0-1.5 parts of accelerators, 3-5 parts of age inhibitors, 40-50 parts of carbon black and 2.0-3.0 parts of sulfur. The oilproof and flame retardant properties of the conveyor belt are greatly improved; the oilproof property reaches related national standard (HG / T3714-2003) and the flame retardant property also meets the national security requirement (GB / T10082-2003).

Owner:SHANDONG ANENG CONVEYOR BELT & RUBBER

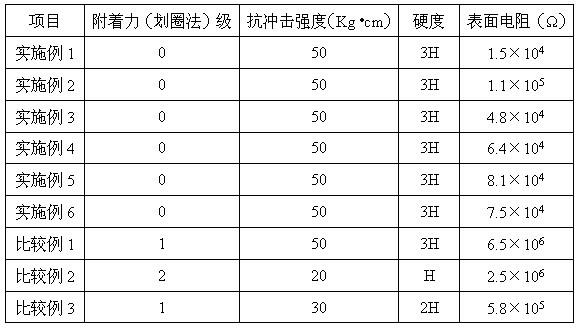

Anti-static non-woven fabric and preparation method thereof

InactiveCN104695137ALarge specific surface areaHigh porosityElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsPorosityPolyester

The invention relates to an anti-static non-woven fabric and a preparation method thereof. The anti-static non-woven fabric is prepared from the following components in parts by weight: 85-98 parts of polyester, 2-10 parts of a polyamide polymer, and 0.5-5 parts of an antistatic agent. The non-woven fabric prepared by adopting the preparation method is smaller in diameter of fibers; the obtained non-woven fabric has the advantages of large specific surface area, high porosity, excellent filtering efficiency, good softness, strong comfortable feeling and the like. The non-woven fabric can be widely applied to fields such as medical and industrial masks, thermal insulation materials, filtering materials, medical and health materials, oil absorption materials, wiping cloth, battery separators and sound insulation materials.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

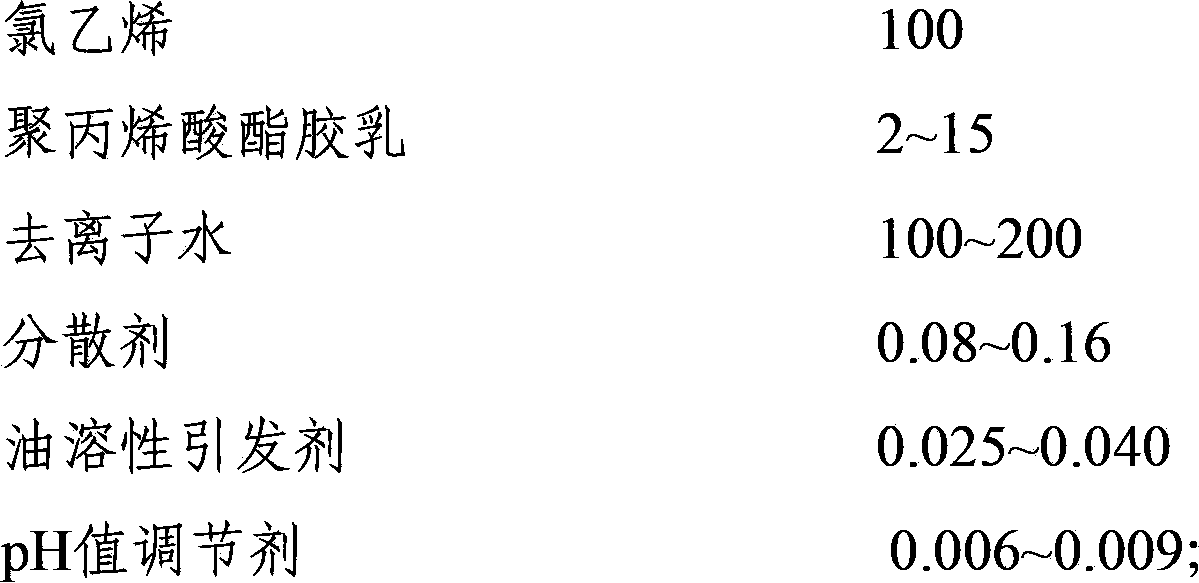

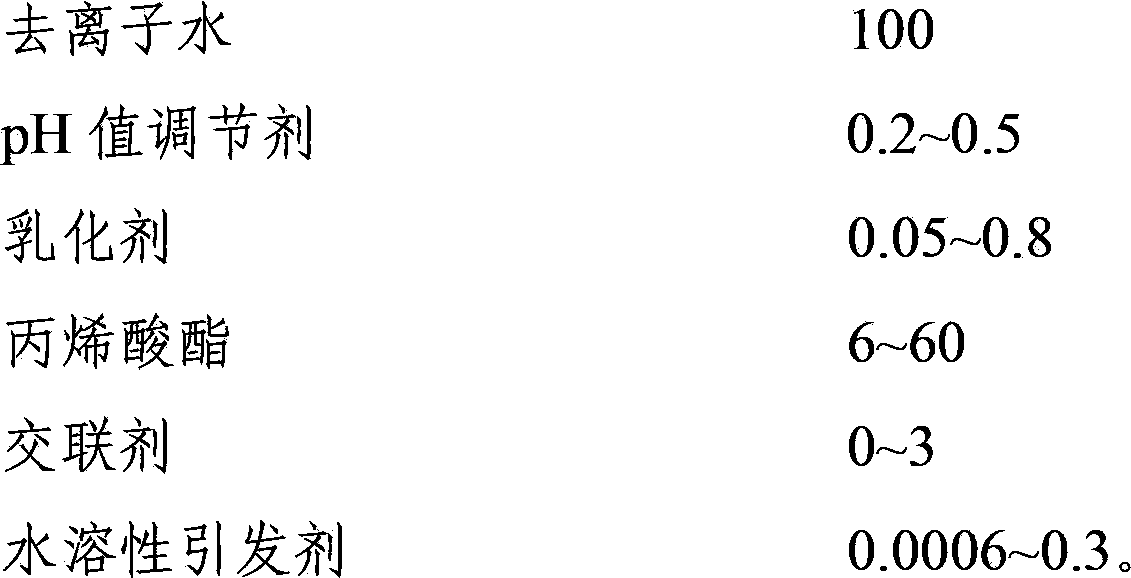

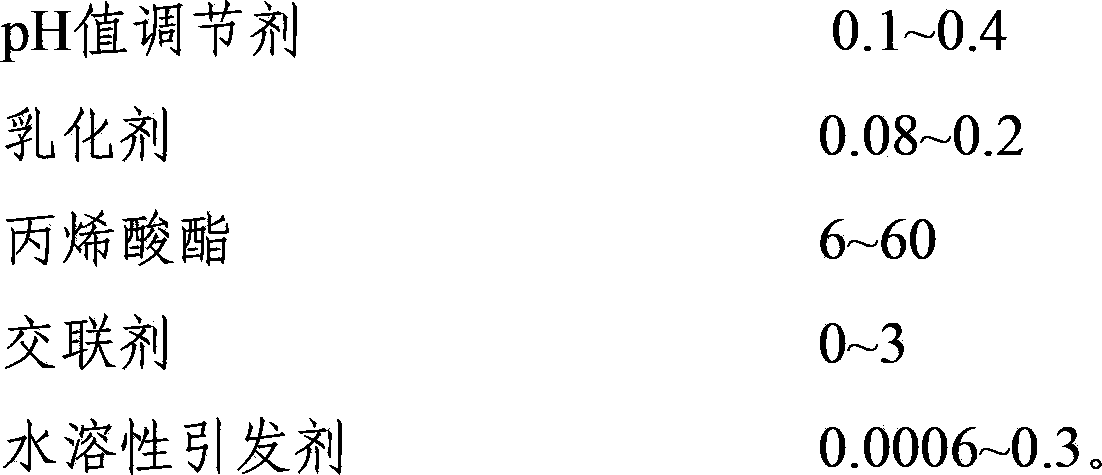

Polyacrylate grafted vinyl chloride composite resin and preparation method thereof

The invention relates to a polyacrylate grafted vinyl chloride composite resin and a preparation method thereof. The polyacrylate grafted vinyl chloride composite resin is prepared from the following components in parts by weight: 100 parts of vinyl chloride, 2-15 parts of polyacrylate latex (calculating by solid content), 100-200 parts of deionized water, 0.08-0.16 part of a dispersant, 0.025-0.040 part of an oil-soluble initiator and 0.006-0.009 part of a pH value adjusting agent. Polyacrylate latex is prepared by: continuing to dropwise add or not add acrylate into the system after acrylate is subjected to a polymerization reaction at 65-95 DEG C. The prepared polyacrylate grafted vinyl chloride composite resin is good in impact resistance, short in plasticizing time and excellent in processing fluidity.

Owner:河北盛华化工有限公司 +1

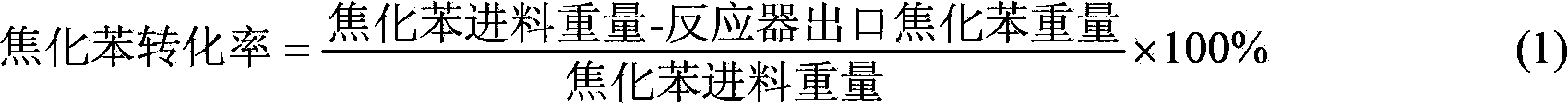

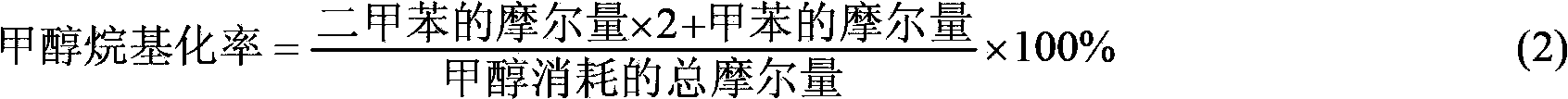

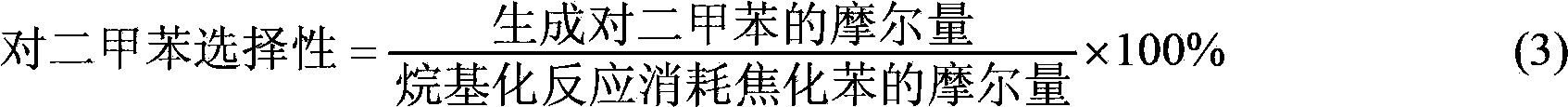

Catalyst used for synthesis of paraxylene through alkylation reactions between coking benzene and methanol and preparation method thereof

ActiveCN103418421AHigh activityIncrease surface areaMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveWater vapor

The invention discloses a catalyst used for synthesis of paraxylene through alkylation reactions between coking benzene and methanol and a preparation method thereof. The catalyst comprises carriers and active components, the carriers are HZSM-5 molecular sieves or SAPO-11 molecular sieves which have been subjected to a water steam heating treatment, and the active components are metal oxides. The molecular sieves are subjected to a high-temperature water steam heating treatment, thus active centers and acid-base properties of the molecular sieves are evenly distributed, and the acidity of the molecular sieves is reduced, so active components can be evenly loaded on the carriers, the catalyst is not easy to be poisoned or lose activity when the catalyst is catalyzing the alkylation reactions of coking benzene, the conversion rate of the alkylation of coking benzene is increased, and the service life of the catalyst is prolonged at the same time.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

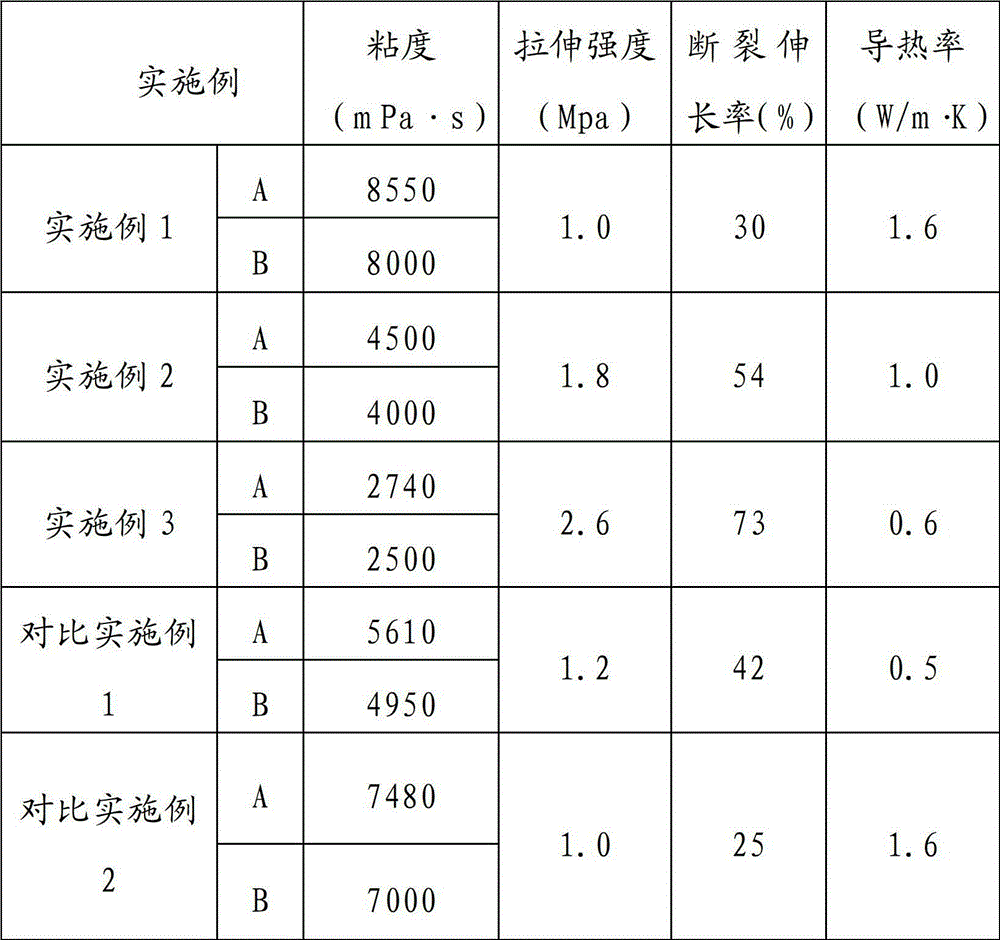

Heat-conduction electronic potting adhesive and preparation method thereof

InactiveCN102942895AMeet potting requirementsEffective protectionNon-macromolecular adhesive additivesAdhesiveUltimate tensile strength

The invention relates to the field of a potting adhesive and particularly relates to a low-viscosity heat-conduction electronic potting adhesive applicable to each electronic element and a preparation method thereof. The heat-conduction electronic potting adhesive is formed by a component A and a component B in a weight ratio from 100: 90 to 100: 110; the component A comprises the following raw materials in weight percentage of 39.20-79.60% of heat-conduction inflaming retarding powder, 0.80-2.00% of color matching agent, 0.40-1.00% of silane coupling agent, 16.20-43.80% of liquid silicon oil and 3.00-14.50% of silane cross-linking agent; and the component B comprises the following raw materials in weight percentage of 39.20-79.60% of heat-conduction inflaming retarding powder, 18.00-57.80% of liquid silicon oil, 0.20-1.00% of silane coupling agent, 1.00-1.96% of color matching agent and 0.04-1.00% of catalyst. The low-viscosity heat-conduction electronic potting adhesive has lower viscosity, excellent mobility, good heat-conduction performance and high inflaming retarding grade; the potting requirement of a seam less than 0.02 mm can be met and the construction is convenient; and after the heat-conduction electronic potting adhesive is cured, the strength is good, and the dustproof, moisture-proof and vibration-proof performances are good, the electronic element can be effectively protected and the service life of the electronic element is prolonged.

Owner:YANTAI DARBOND TECH

Method for adding carbon nano tube into metal bath

The invention relates to a method for adding carbon nano tube into metal bath, which is characterized in mixing carbon nano tube, metal powder and stearic acid according to a weight ratio between the carbon nano tube and metal powder of 1:10-2, and a weight ratio between stearic acid, carbon nano tube and metal powder of 1:15-20, putting into a ball mill for ball milling, sieving with a 50-80 mesh stainless steel sieve to obtain a uniform mixture, adding the mixture into the mold, pressing for molding to obtain carbon nano tube / metal composite press block; adding the carbon nano tube / metal composite press block into a metallic or alloy solution, regulating temperature of fused mass to a casting temperature, casting the article.

Owner:NANCHANG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com