Preparation method of graphdiyne

A technology of graphdiyne and reaction substrate, which is applied in the field of preparation of graphdiyne, can solve the problems of controllable preparation but not substantively solved, and achieves easy transfer and spreading, simple process, and controllability of reaction temperature and time. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In an argon (purity ≥ 99.999%) gas environment, the substrate (1,3,5-tripynylbenzene) 192mg (1.0mmol) and the catalyst (tris(tert-butoxy)(2,2-di Methpropynyl) tungsten) 47.0mg (0.1mmol) into a Schlenk bottle, 15mL of toluene (anhydrous and anaerobic treatment) dissolved. Heated in an oil bath, slowly raised to 75°C, and reacted for 24 hours; during the process, the solution was vacuumed (6 times, 25s each time) to remove the by-product 2-butyne, and the solvent lost in the vacuum was compensated by adding 3 mL of new solvent; the reaction After the end, a gel-like solid was produced. After repeated washing with toluene, the target product graphyne was obtained by suction filtration. The chemical equation of this reaction is as follows:

[0036]

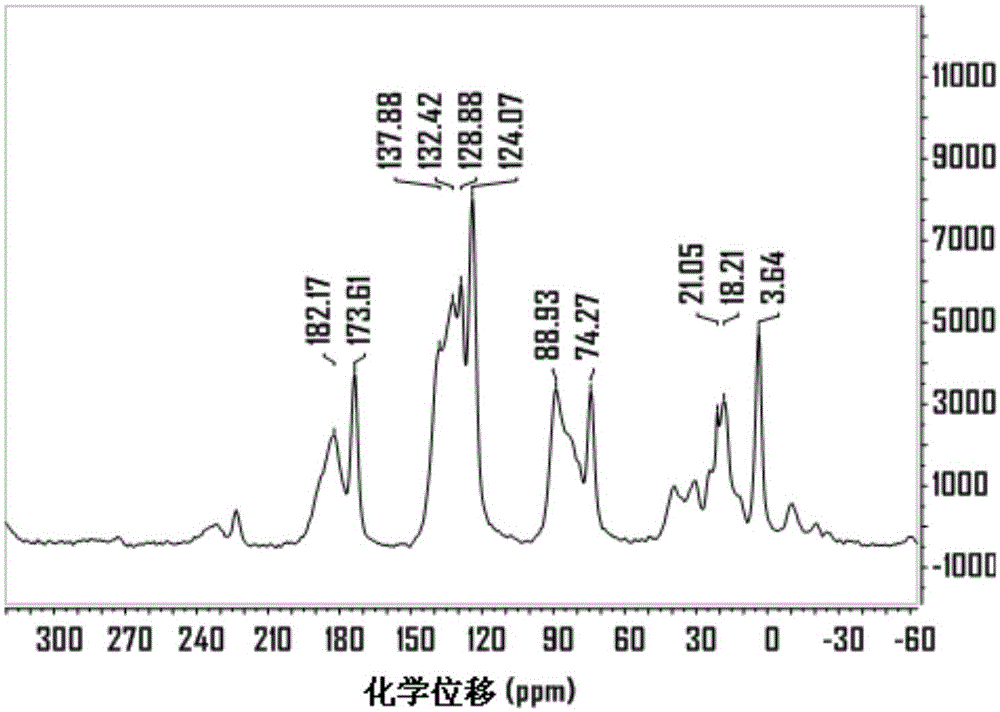

[0037] figure 1 It is the solid carbon-13 NMR spectrum of the graphyne prepared in Example 1, and the test results show that the graphyne has kept the basic characteristic structure of the benzene ring and the alkyne bond;...

Embodiment 2

[0046] Argon (purity ≥ 99.999%) gas environment, 192mg (1.0mmol) substrate (1,3,5-tripynylbenzene) and 23.5mg (0.05mmol) catalyst (tri(tert-butoxy) ( 2,2-Dimethylpropynyl)tungsten) into a Schlenk bottle, and dissolved in 60mL of toluene (anhydrous and oxygen-free). Heated in an oil bath, slowly raised to 75°C, and reacted for 24 hours; during the process, the solution was vacuumed (5 times, 20s each time) to remove the by-product 2-butyne, and the solvent lost in the vacuum was compensated by adding 7.5mL of new solvent; After the reaction, a gel-like solid was produced. After repeated washing with toluene, the target product graphyne was obtained by suction filtration.

Embodiment 3

[0048] Under nitrogen (purity ≥ 99.999%) gaseous environment, 1.92g (10.0mmol) substrate (1,3,5-tripynylbenzene) and 0.705g (1.5mmol) catalyst (three (tert-butoxy) ( 2,2-Dimethylpropynyl)tungsten) into a Schlenk bottle, and dissolved in 15 mL of toluene (anhydrous and oxygen-free). Heat in an oil bath, slowly rise to 50°C, and react for 192h; during the process, the solution is vacuumed (8 times, 30s each time) to remove the by-product 2-butyne, and the solvent lost in vacuum is compensated by adding 4mL of new solvent; After the end, a gel-like solid was produced. After repeated washing with toluene, the target product graphyne was obtained by suction filtration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com