Patents

Literature

5024 results about "Temperature treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

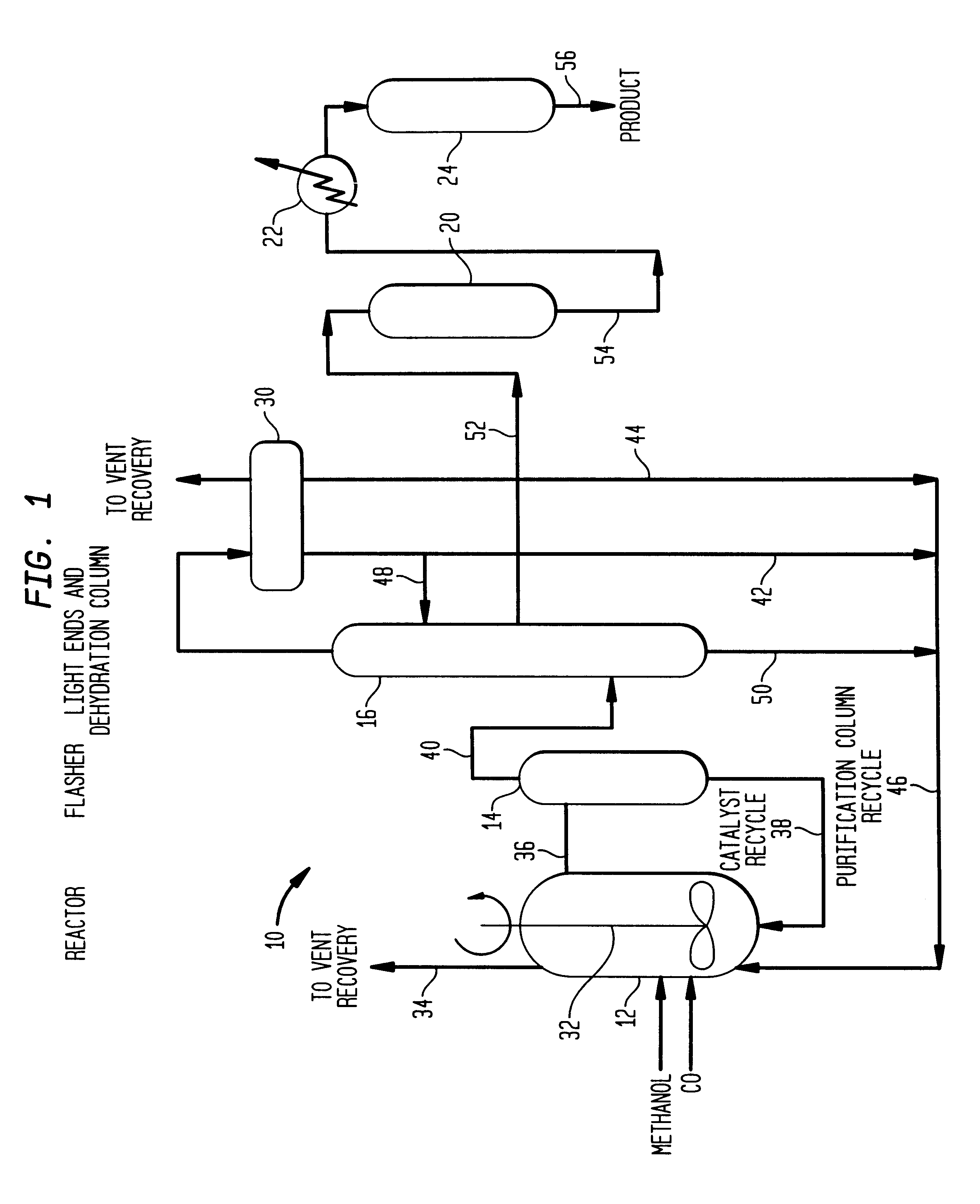

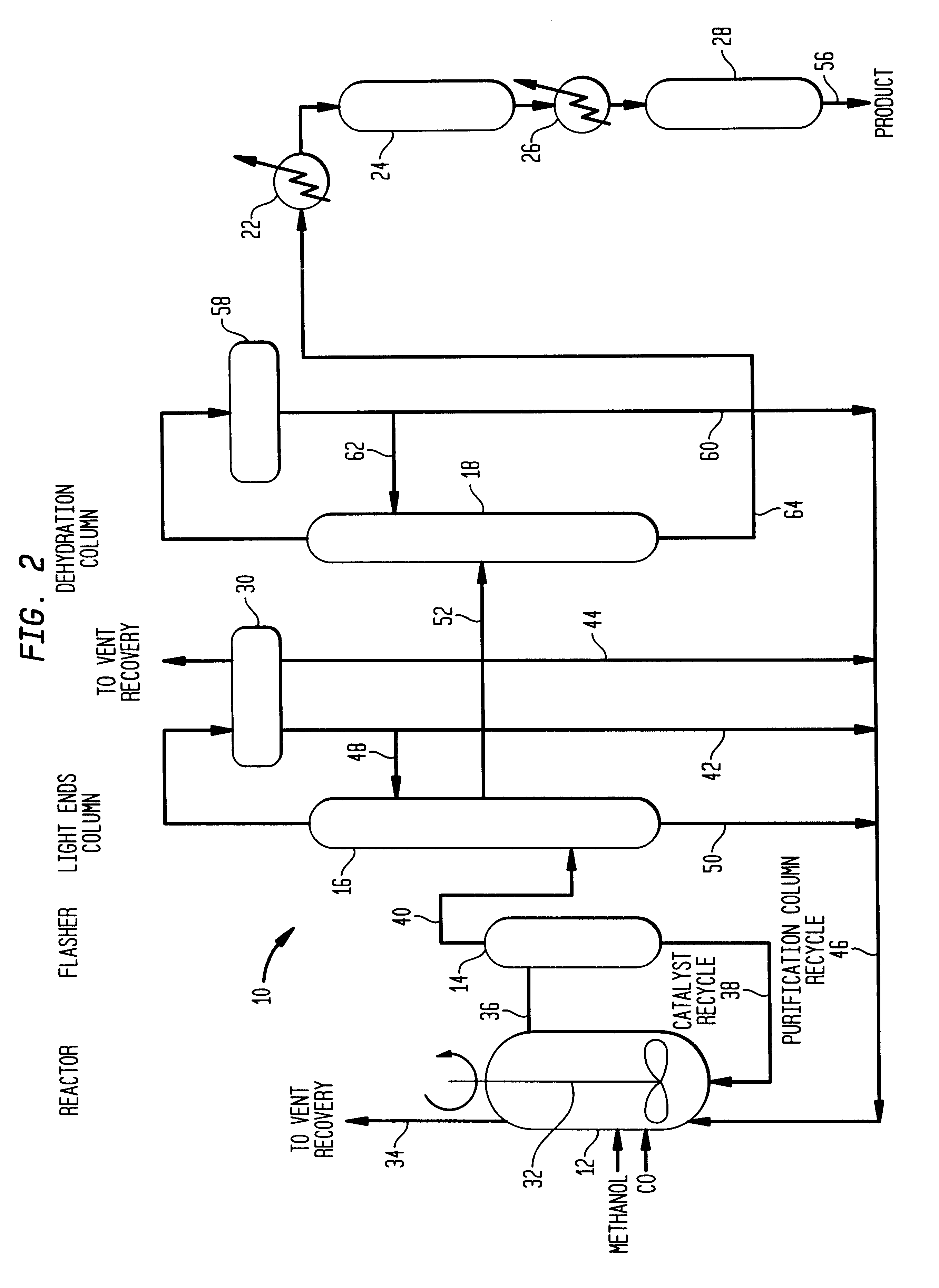

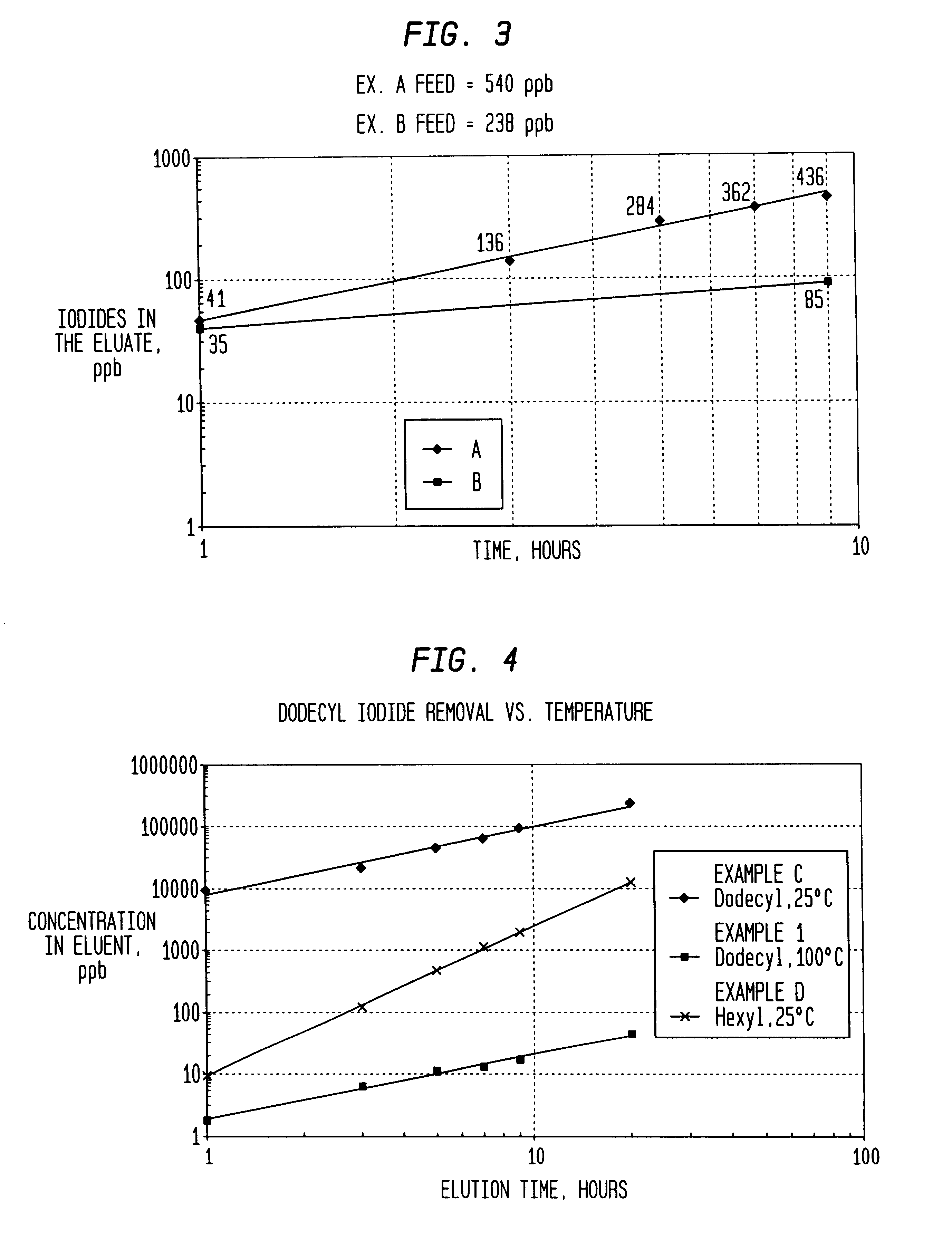

Low energy carbonylation process

InactiveUS6657078B2Weaken energyHigh purityOrganic compound preparationOrganic chemistry methodsPropanoic acidIodide

A low energy process for producing acetic acid by the carbonylation of methanol is disclosed. The process involves a rhodium-catalyzed system operated at less than about 14% water utilizing up to 2 distillation columns. The process is preferably controlled such that the product stream has a low level of propionic acid impurity and the level of aldehyde impurities is minimized by way of aldehyde removal or minimizing aldehyde generation. The level of iodides is controlled by contacting the product, at elevated temperatures, with ion exchange resins. In preferred embodiments, at least one silver or mercury exchanged macroreticular strong acid ion exchange resin is used to purify the product. The high temperature treatment provides the added benefit of controlling the Color Value (Pt-Co units) of the product stream.

Owner:CELANESE INT CORP

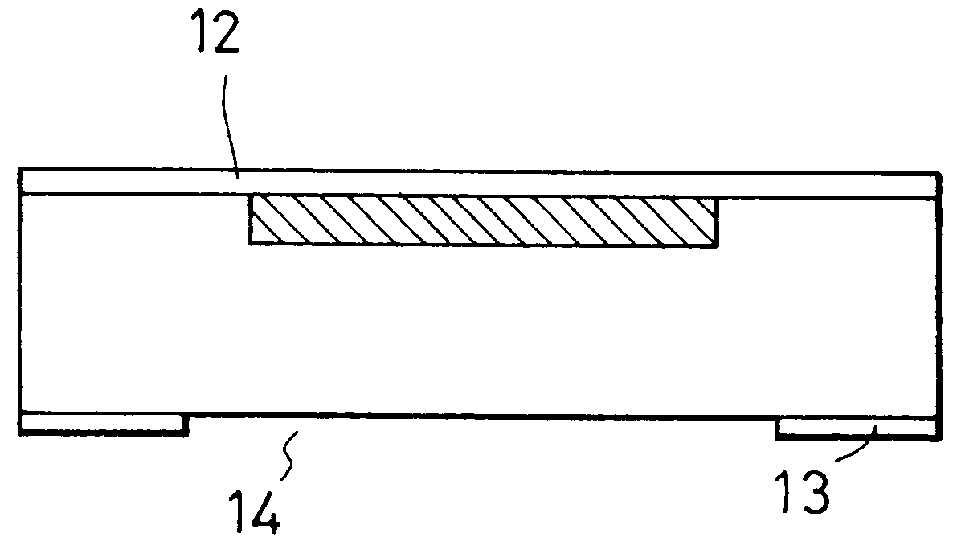

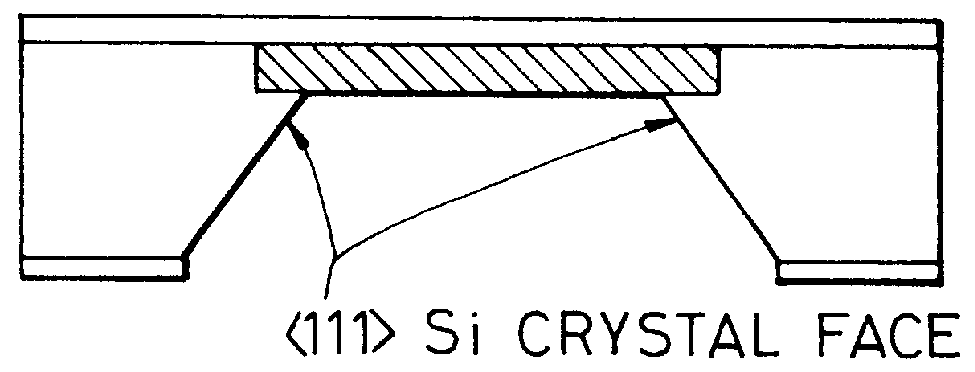

Method of producing a through-hole, silicon substrate having a through-hole, device using such a substrate, method of producing an ink-jet print head, and ink-jet print head

The invention provides a method of producing a through-hole, a substrate used to produce a through-hole, a substrate having a through-hole, and a device using such a through-hole or a substrate having such a through-hole, which are characterized in that: a through-hole can be produced only by etching a silicon substrate from its back side; the opening length d can be precisely controlled to a desired value regardless of the variations in the silicon wafer thickness, and the orientation flat angle, and also regardless of the type of a silicon crystal orientation-dependent anisotropic etchant employed; high productivity, high production reproducibility, and ease of production can be achieved; a high-liberality can be achieved in the shape of the opening end even if temperature treatment is performed at a high temperature for a long time; and a high-precision through-hole can be produced regardless of the shape of a device formed on the surface of a substrate.

Owner:CANON KK

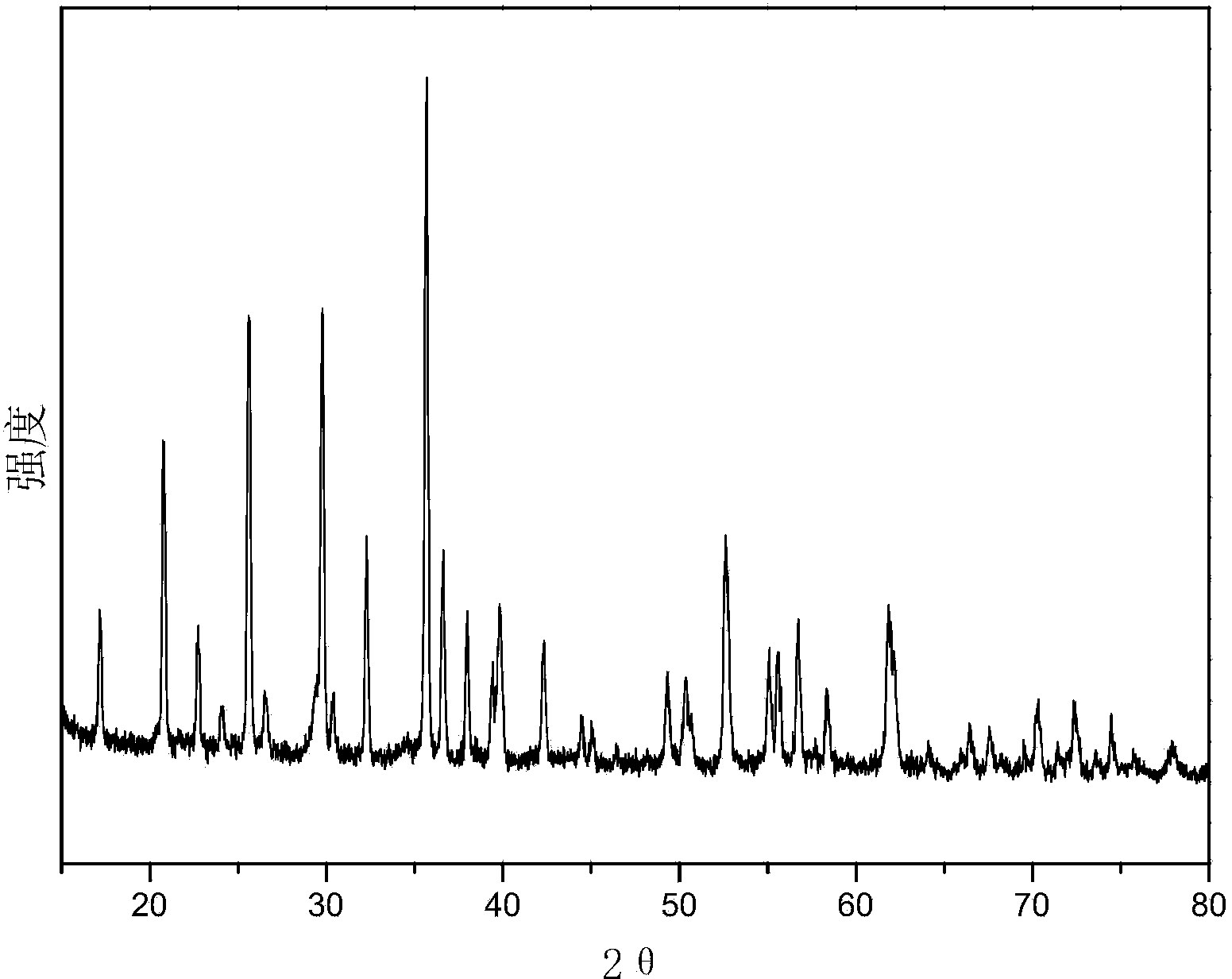

Process for preparing high density spherical nickel-cobalt lithium manganate as anode material of lithium ion cell

InactiveCN1622371AWell mixedImprove performanceElectrode manufacturing processesLithium compoundsNickel saltManganate

The present invention relates to energy source material technology, and is preparation process of high density spherical lithium nickel-cobalt-manganate as positive electrode material for lithium ion cell. The preparation process includes the reaction of nickel salt, cobalt salt, manganese salt, ammonium hydroxide and ammonian in water solution to synthesize spherical or spheroid precursor Ni1 / 3Co1 / 3Mn1 / 3 (OTHER)2, washing, drying and mixing with lithium carbonate; and high temperature treatment in the air at 750-950 deg.c for 8-48 hr to obtain spherical lithium nickel-cobalt-manganate. The spherical lithium nickel-cobalt-manganate has great bulk density reaching 2.25-2.50 g / cu cm after vibration densifying, average grain size of 3-7 microns, and reversible specific capacity up to 172-185 mA.hr / g.

Owner:TSINGHUA UNIV

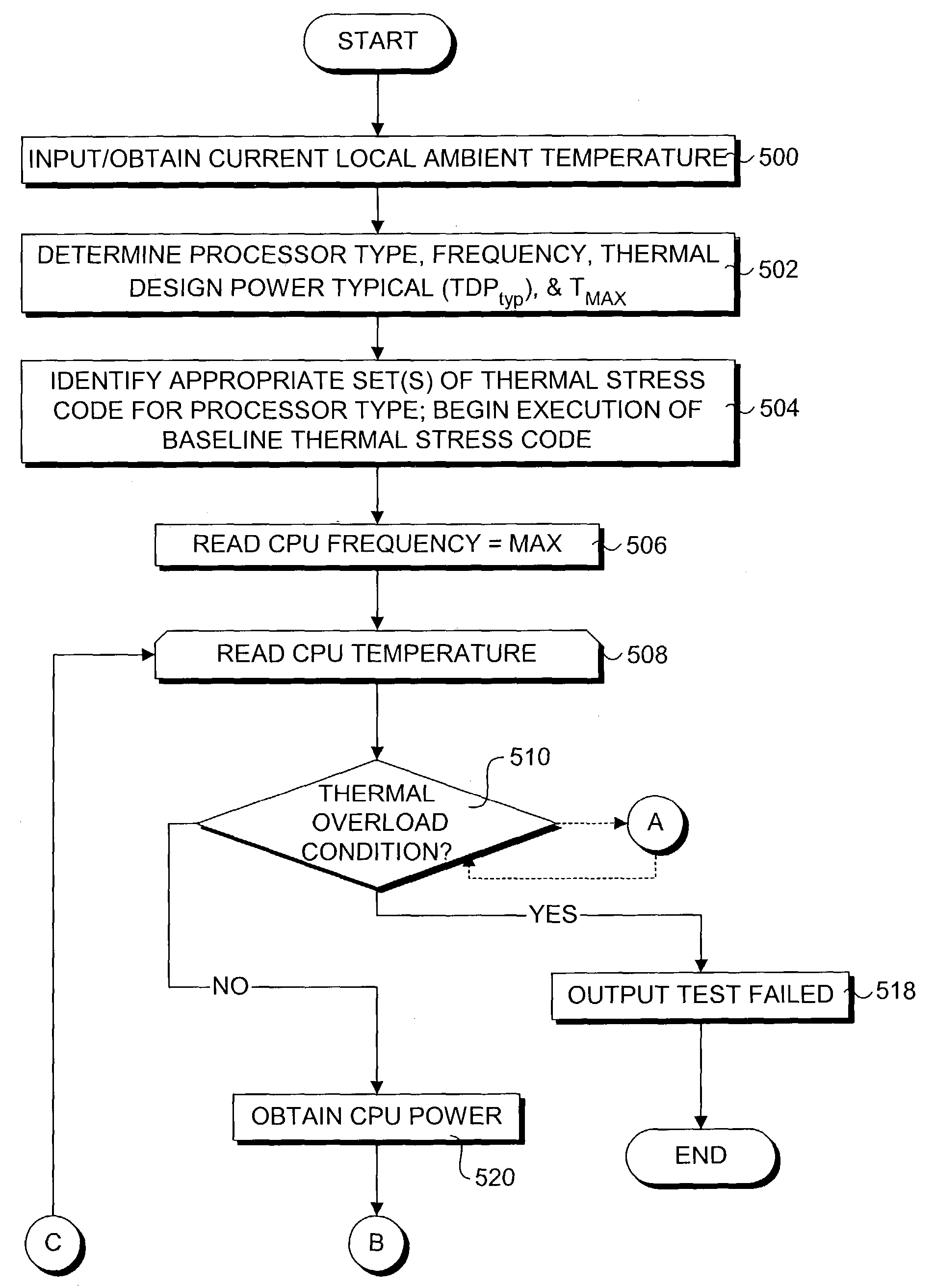

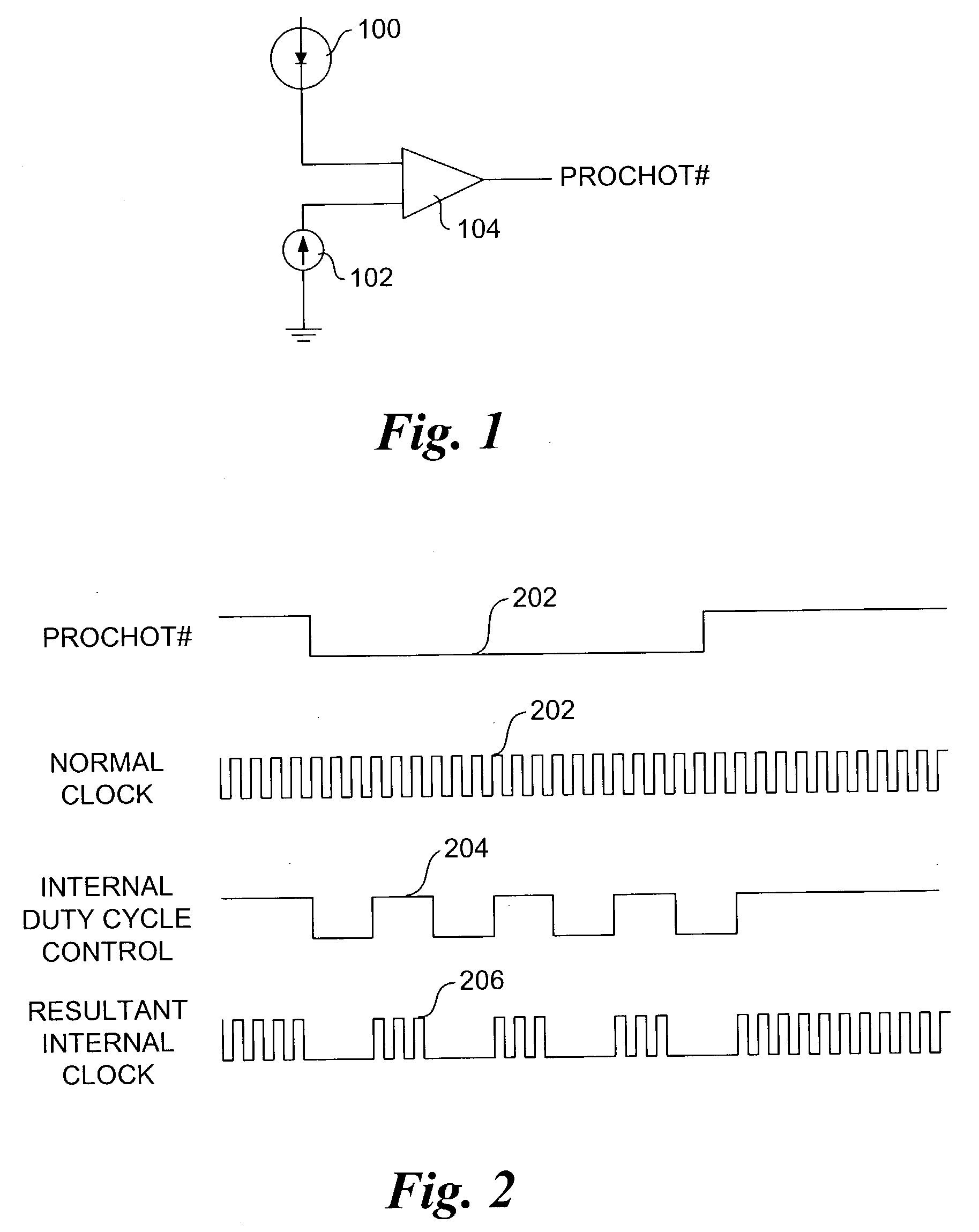

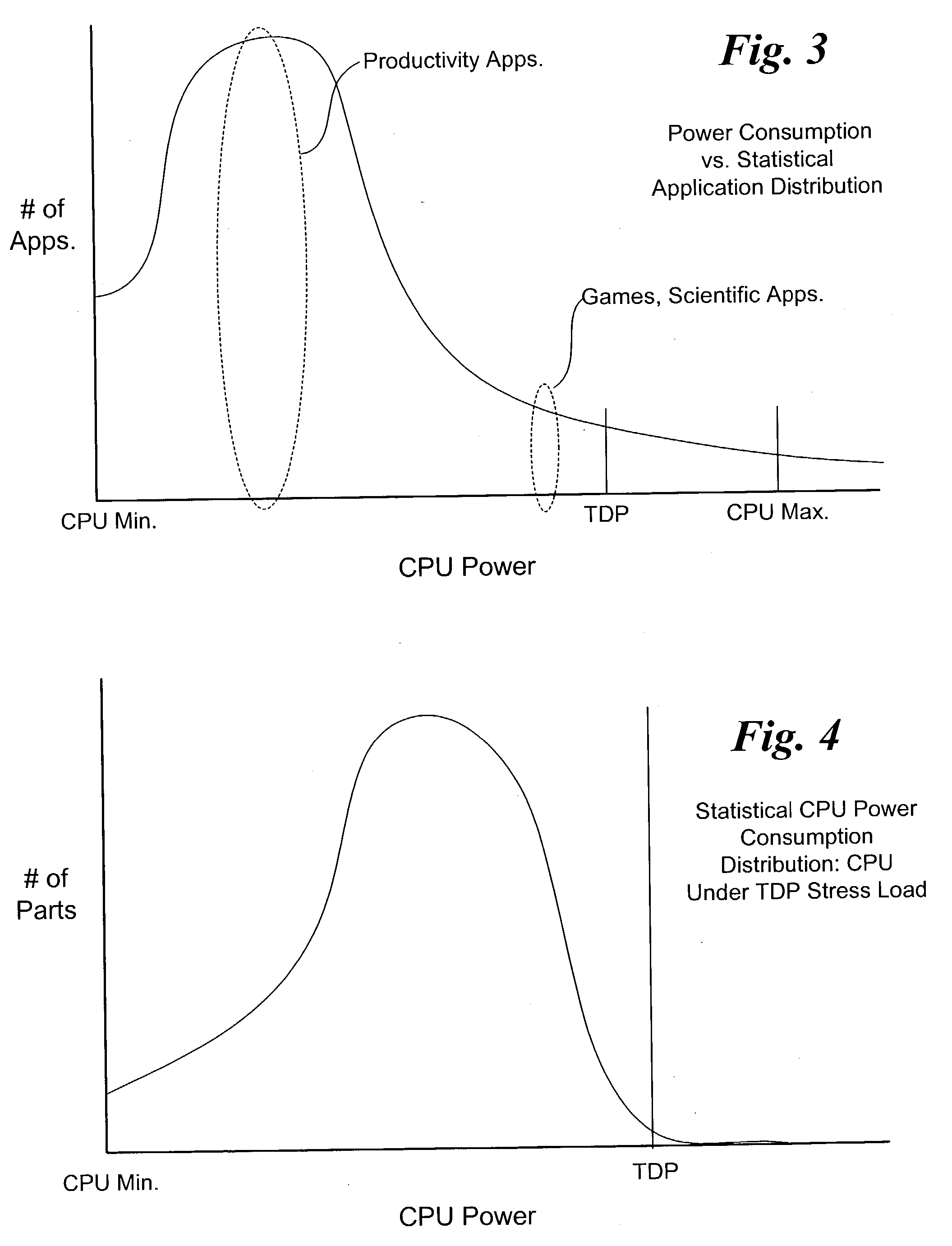

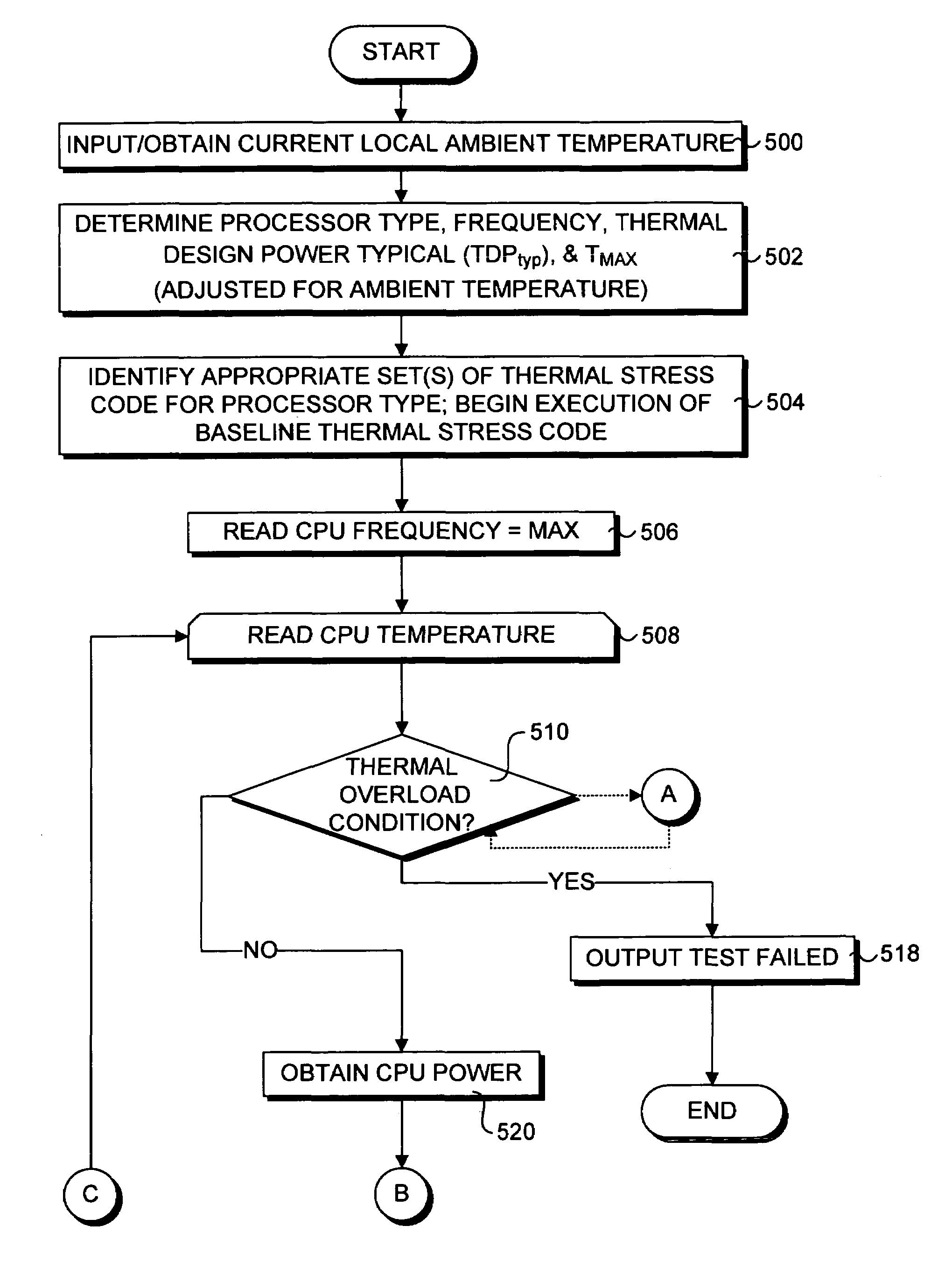

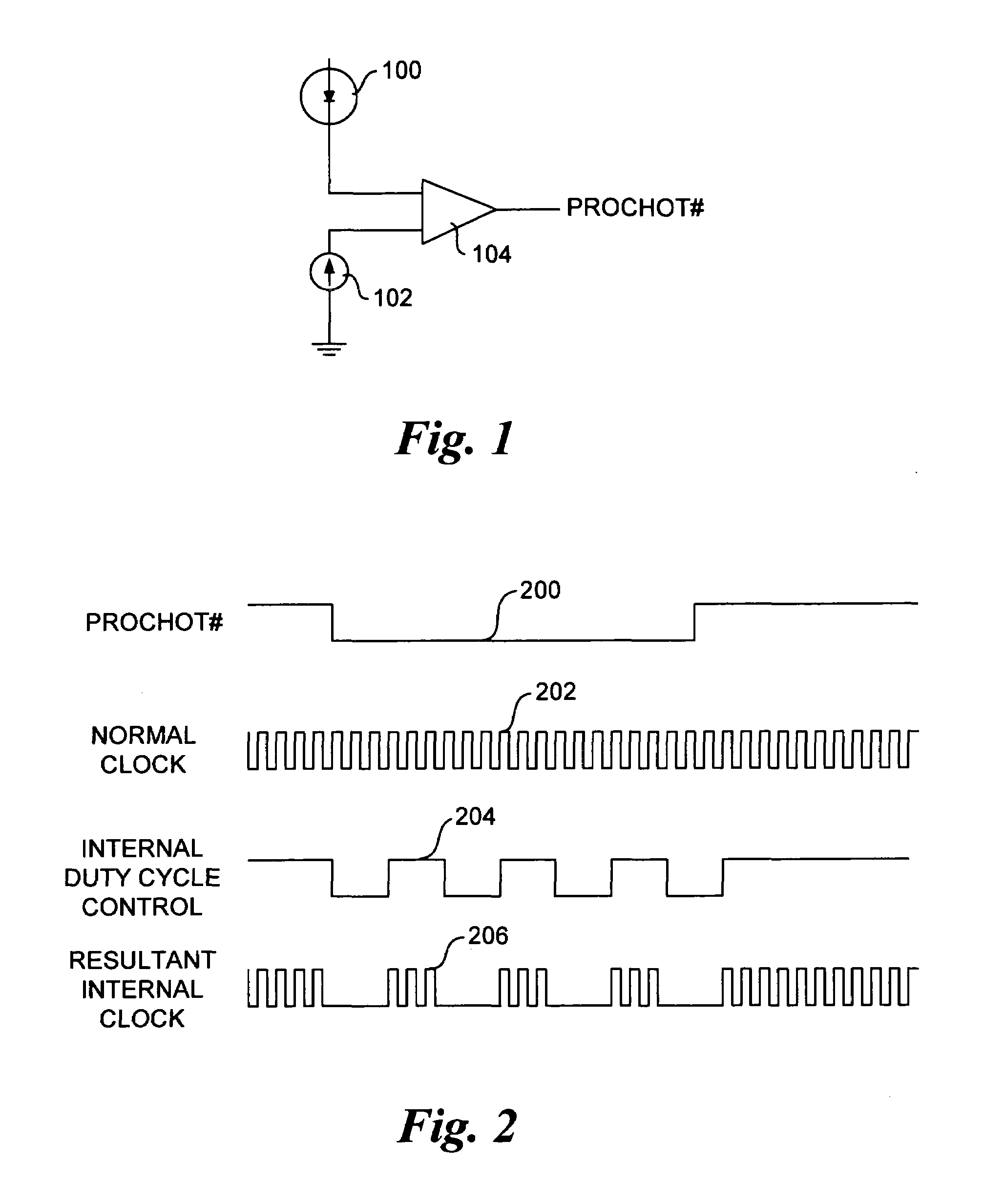

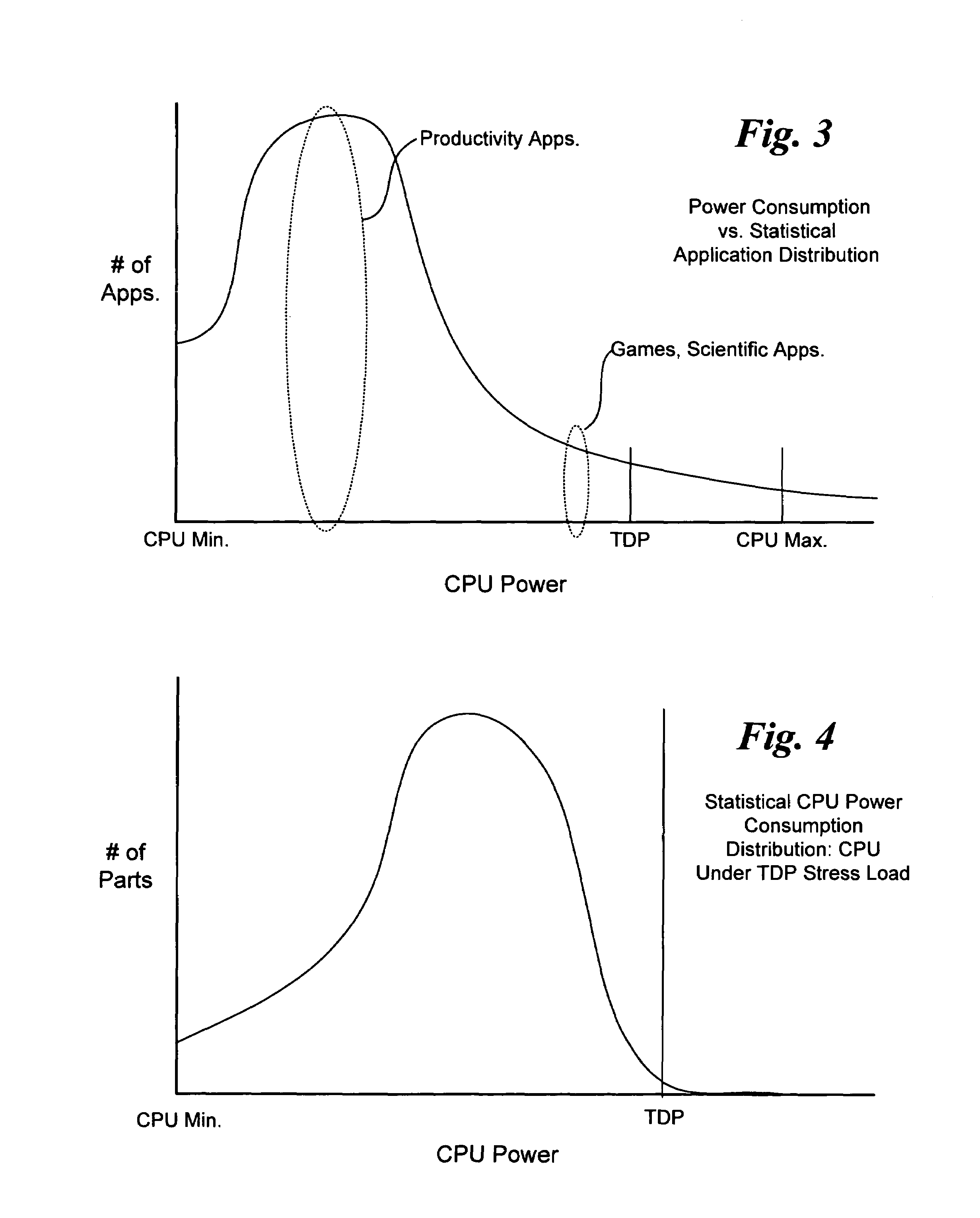

Automated method and apparatus for processor thermal validation

InactiveUS20040128101A1Thermometer detailsDigital data processing detailsThermal solutionAutomated method

A method and corresponding software for automatically validating a computer platform thermal solution. An application program is employed to selectively execute thermal stress code to cause the platform's processor to dissipate an amount of power corresponding to a predetermined value, such as a thermal design power dissipation value specified by the processor's manufacturer. In one embodiment, tests are performed while operating at this power dissipation level to determine if a thermal overload condition exists, which may be determined by the processor's temperature, an indication that the processor is throttled, or a signal provided by the processor indicating the processor has detected a thermal overload condition. In another embodiment, a thermal resistance value is calculated based on the processor power dissipation, the temperature of the processor, and the ambient temperature of the test environment. In one embodiment the entire validation process is automatically performed by the application program without requiring any extraneous test equipment or temperature probes.

Owner:INTEL CORP

Coating material for protecting metals, especially steel, from corrosion and/or scaling, method for coating metals and metal element

InactiveCN101360796AVarious usabilityImprove conductivityPretreated surfacesAnti-corrosive paintsAfter treatmentSpot welding

The invention surprisingly finds that when a suitable binder including a suitable filler is used during the high temperature treatment of a curing process, the coating materials of the invention change in such a manner that electrically conducting reactive layers are formed that allow welding and especially spot welding together with the metal substrate even after treatment at temperatures of more than 800 DEG C.

Owner:NANOX

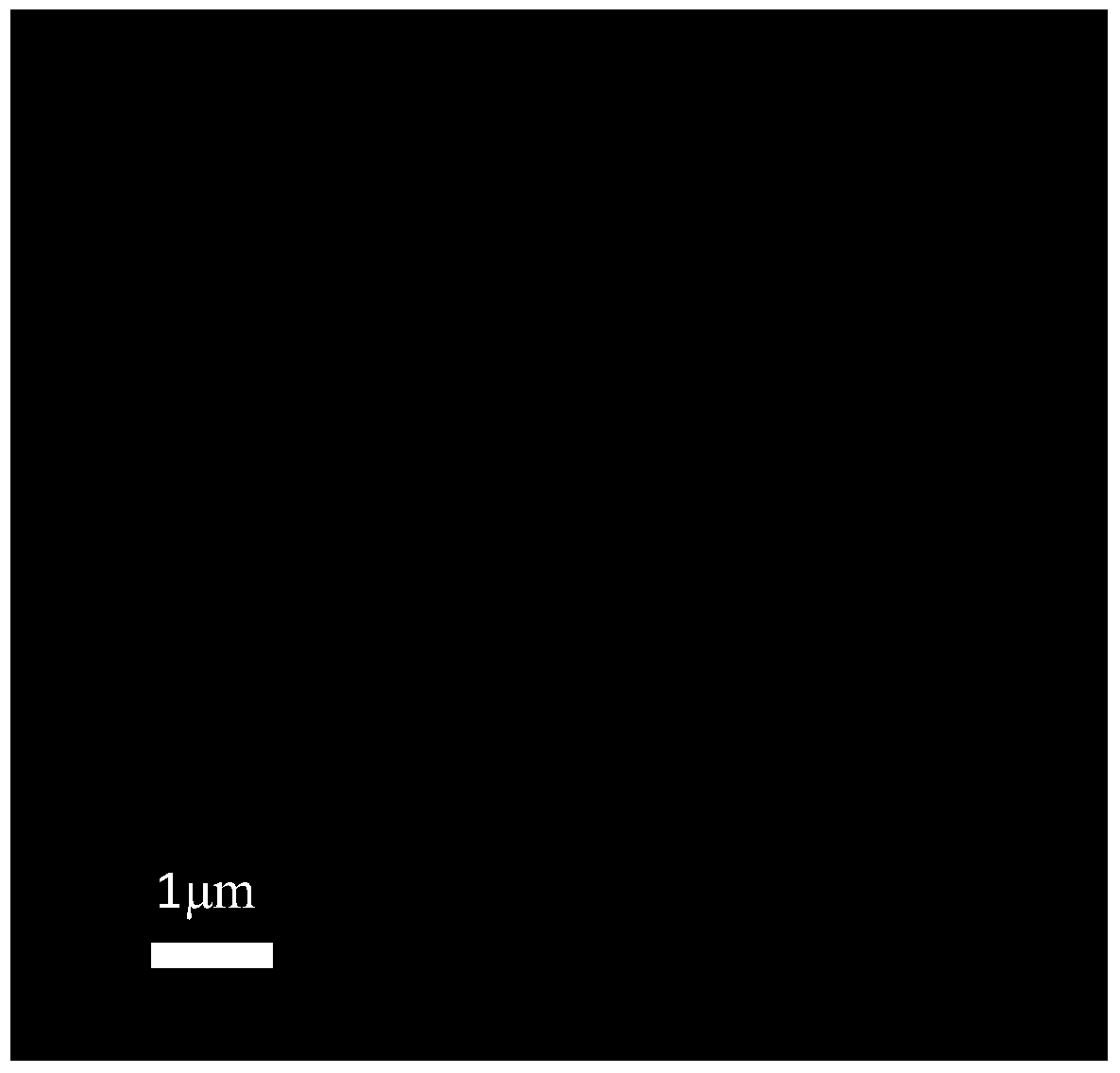

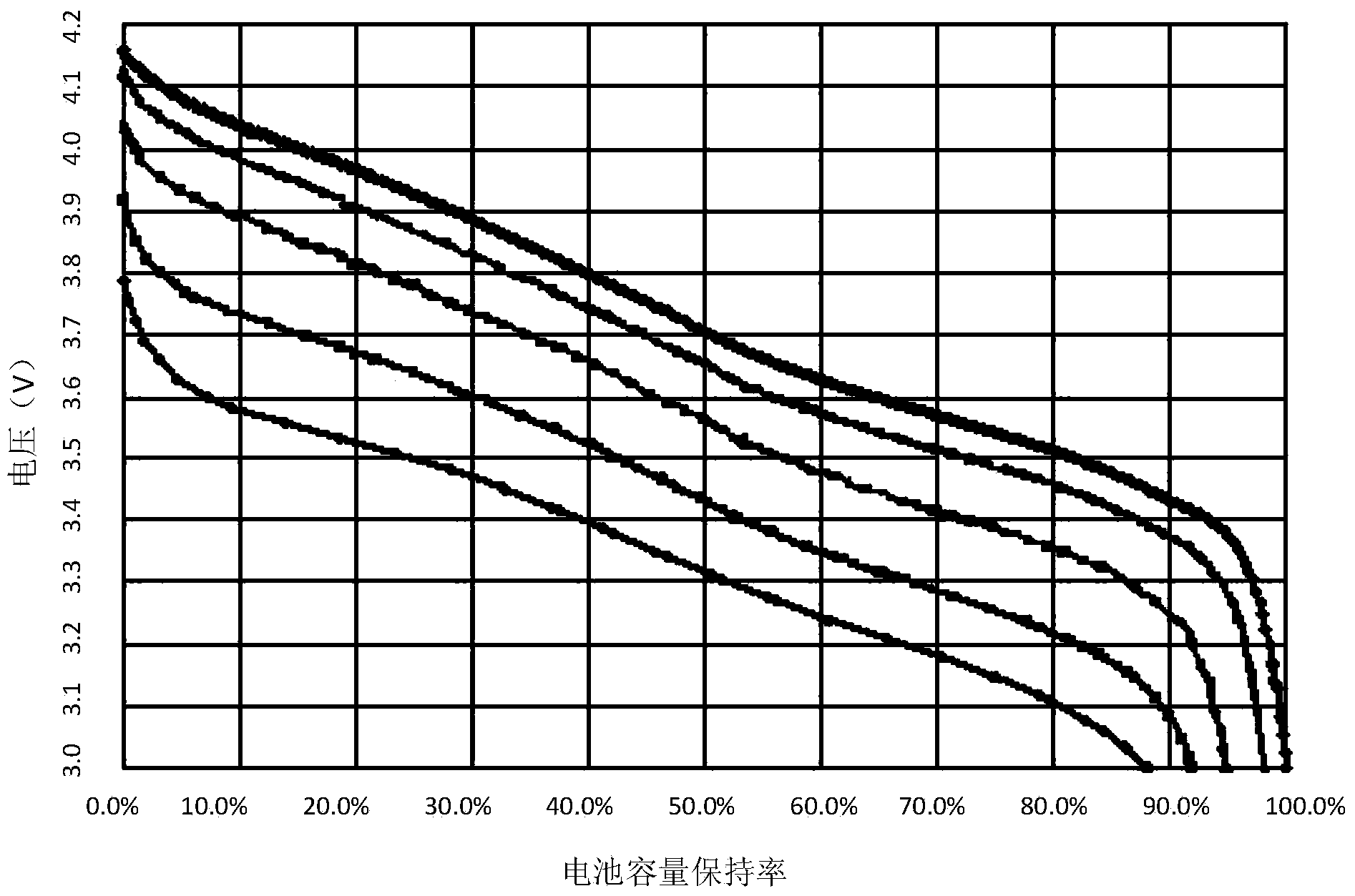

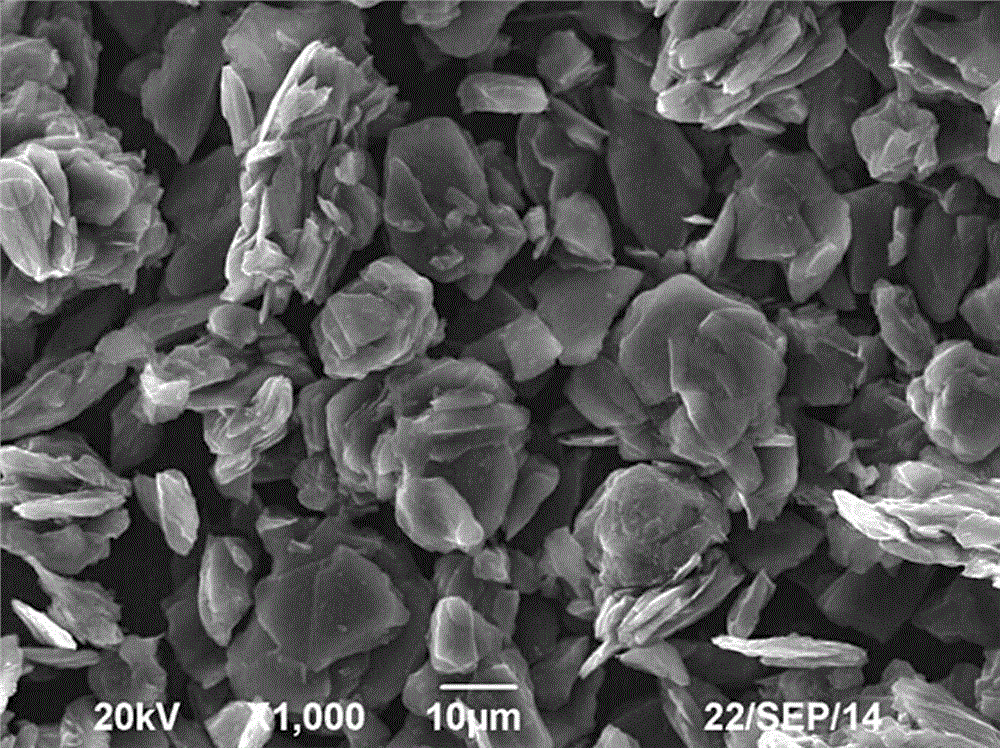

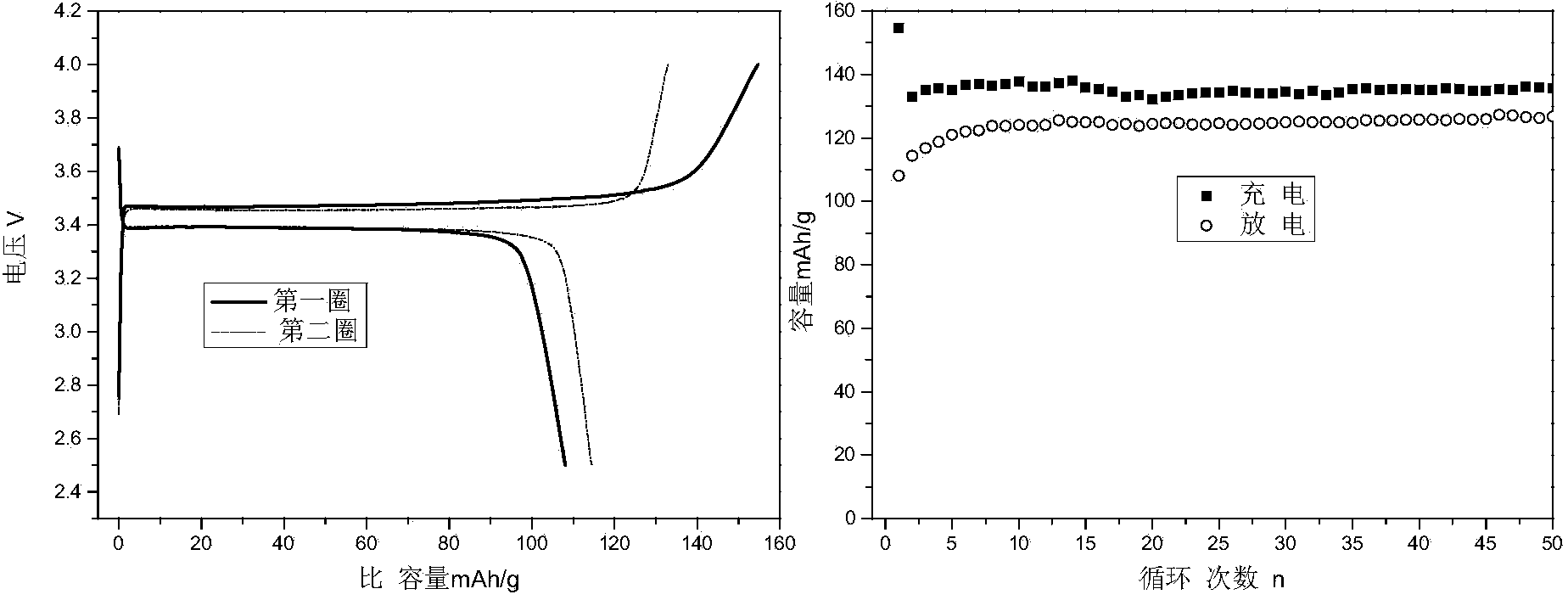

Carbon-coated ternary positive electrode material and preparation method thereof

ActiveCN103474628AImproved magnification performanceImprove conductivityCell electrodesNickel saltManganese

The invention discloses a carbon-coated ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a ternary positive electrode material precursor by taking nickel salt, cobalt salt and manganese salt as raw materials; S2, preparing a conductive carbon dispersion system, wherein conductive carbon is dispersed in water containing an organic carbon source; S3, adding the ternary positive electrode material precursor and a lithium compound into the conductive carbon dispersion system, and mixing uniformly to obtain a mixture; S4, drying the mixture under a vacuum condition; S5, carrying out high temperature treatment on the dried mixture under a closed condition or in an inert gas protection atmosphere so as to obtain the carbon-coated ternary positive electrode material. The carbon-coated ternary positive electrode material is uniform in coating, simple to operate, low in cost and high in efficiency; the conductive carbon and the ternary positive electrode material are simultaneously coated with network-shaped amorphous carbon which serves as a conductive medium or a channel of the conductive carbon and the ternary positive electrode material, thereby greatly improving the rate performance of the ternary positive electrode material.

Owner:SHENZHEN BETTERPOWER BATTERY

Automated method and apparatus for processor thermal validation

InactiveUS7275012B2Thermometer detailsDigital data processing detailsThermal design powerThermal solution

A method and corresponding software for automatically validating a computer platform thermal solution. An application program is employed to selectively execute thermal stress code to cause the platform's processor to dissipate an amount of power corresponding to a predetermined value, such as a thermal design power dissipation value specified by the processor's manufacturer. In one embodiment, tests are performed while operating at this power dissipation level to determine if a thermal overload condition exists, which may be determined by the processor's temperature, an indication that the processor is throttled, or a signal provided by the processor indicating the processor has detected a thermal overload condition. In another embodiment, a thermal resistance value is calculated based on the processor power dissipation, the temperature of the processor, and the ambient temperature of the test environment. In one embodiment the entire validation process is automatically performed by the application program without requiring any extraneous test equipment or temperature probes.

Owner:INTEL CORP

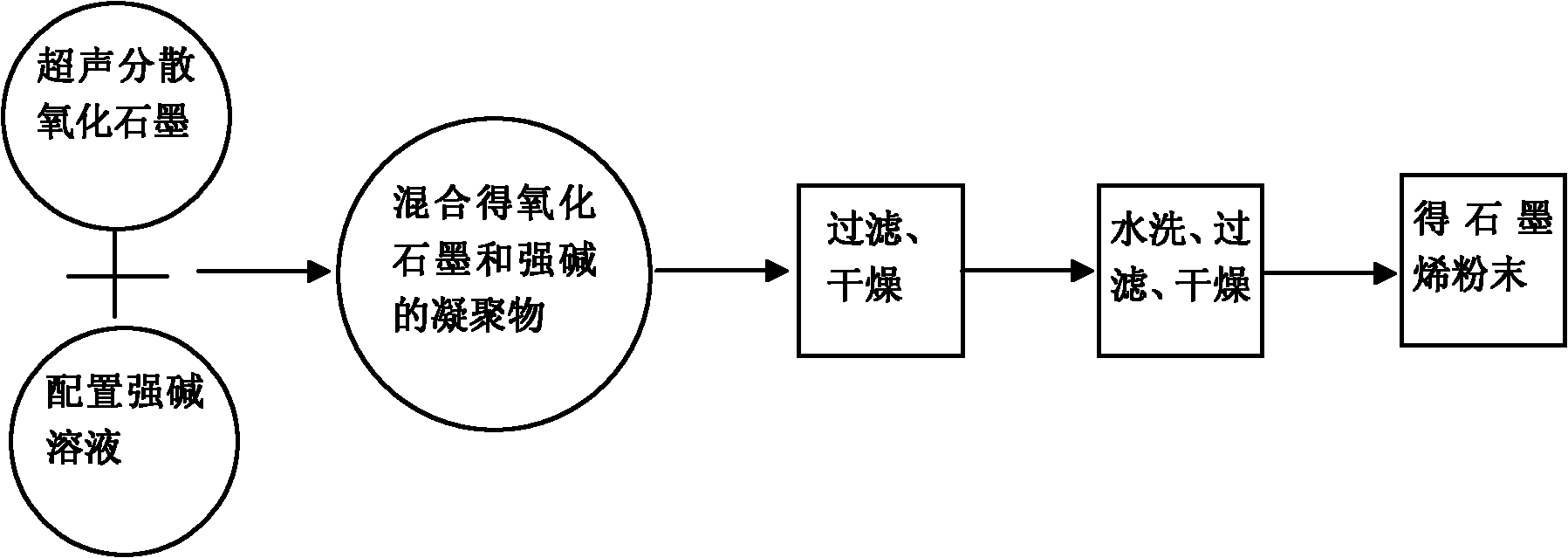

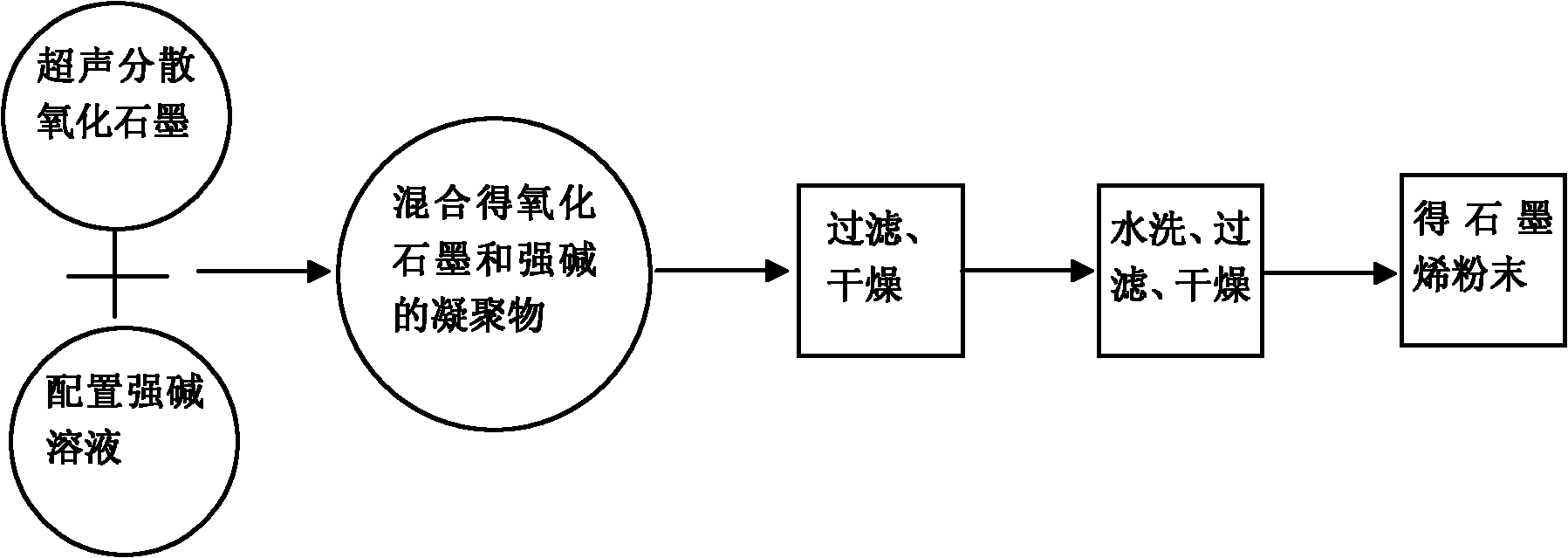

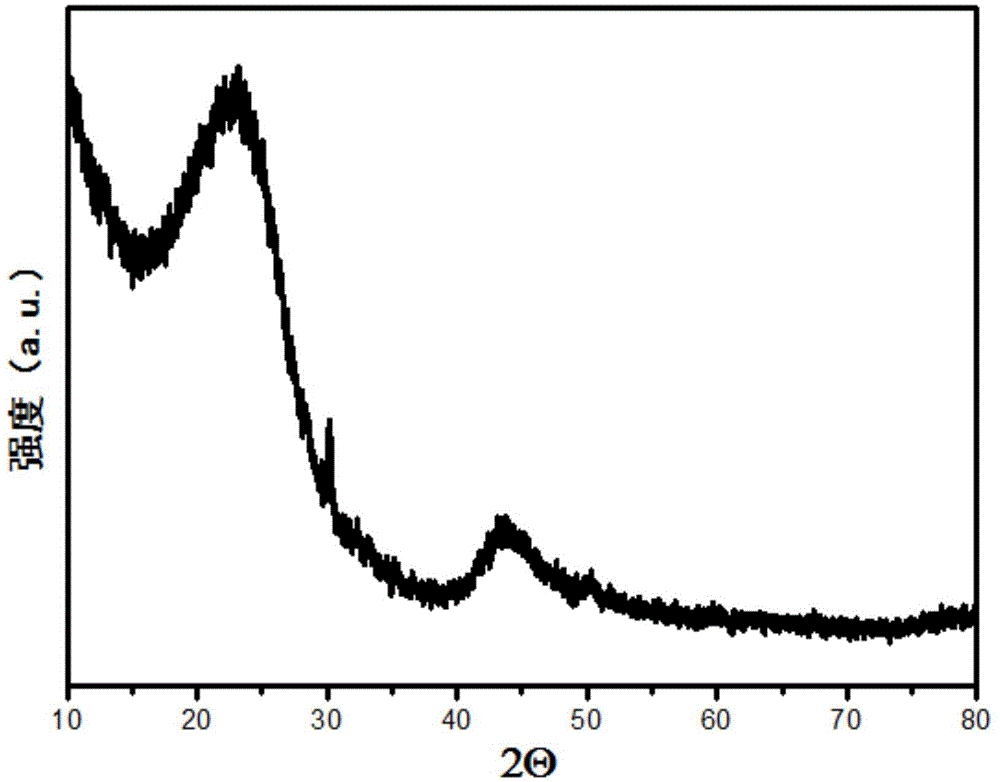

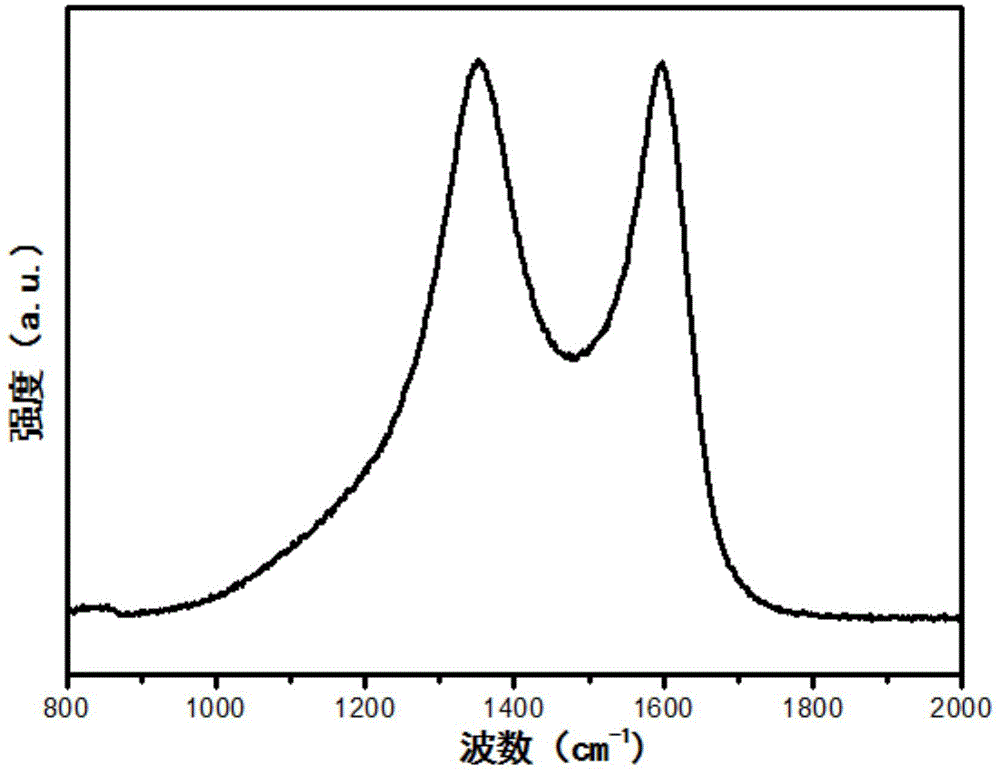

Method for preparing high-specific surface area graphene material by utilizing strong base chemical treatment

ActiveCN102070140AHigh specific surface areaHigh conductanceMaterial nanotechnologyGraphiteChemical treatmentCvd graphene

The invention relates to a method for preparing a high-specific surface area graphene material by utilizing strong base chemical treatment and belongs to the technical field of preparation of graphene materials. By reacting strong base with carbon at high temperature to further perform chemical treatment on graphene powder obtained through thermal treatment or microwave irradiation, nano-scale micropores are rapidly and massively corroded on the surface of graphene, and the specific surface area is greatly improved. Meanwhile, the graphene can be reduced through high-temperature treatment; therefore, high conductivity of the obtained material is guaranteed.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

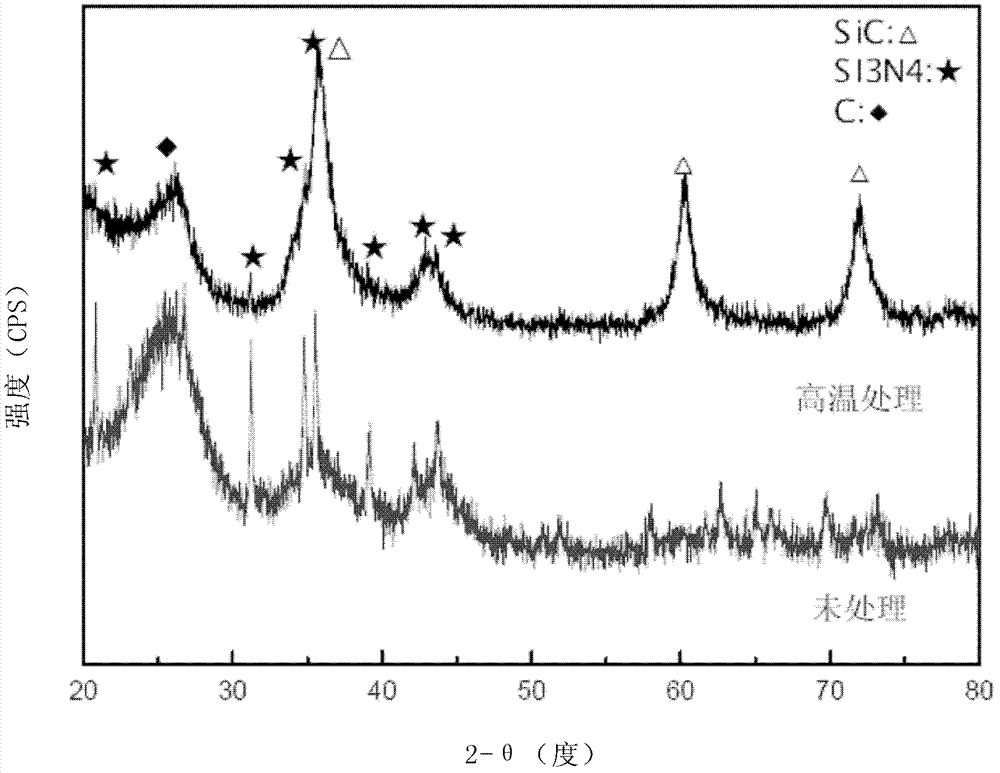

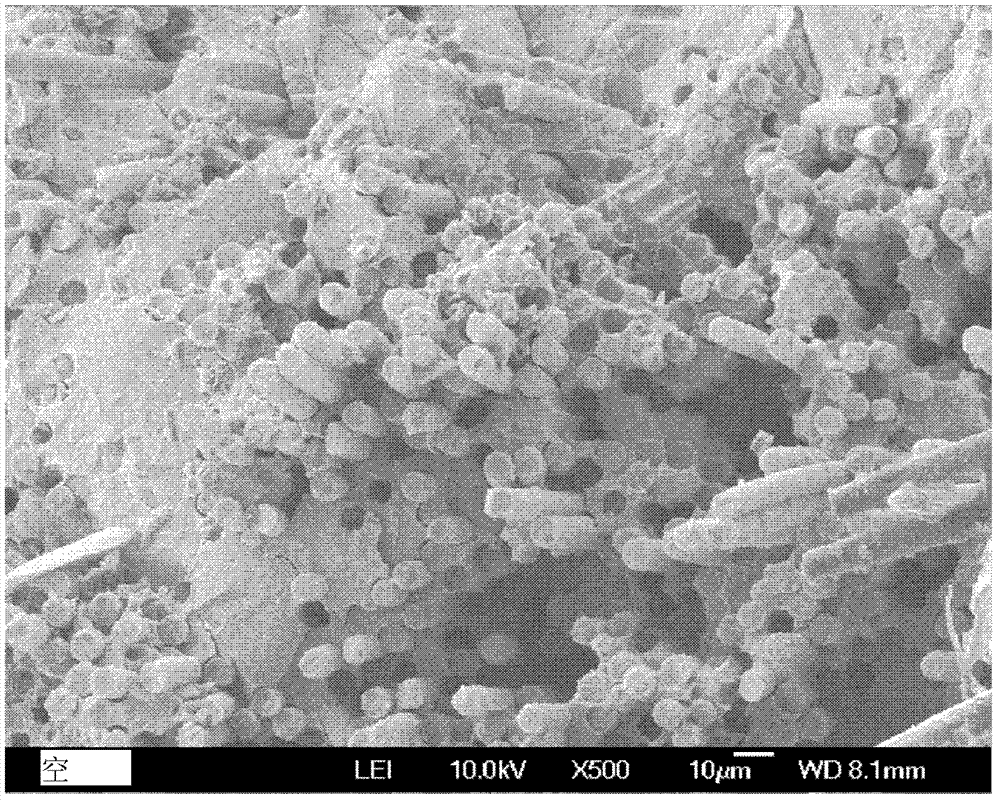

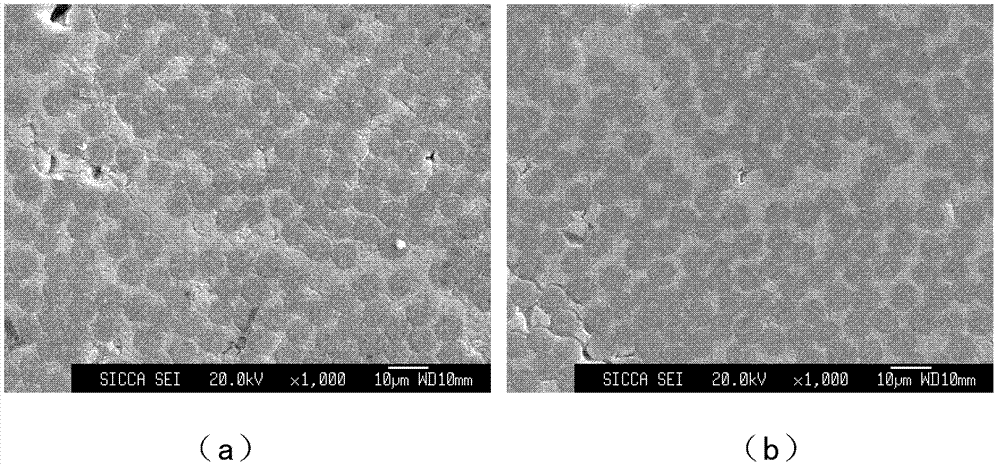

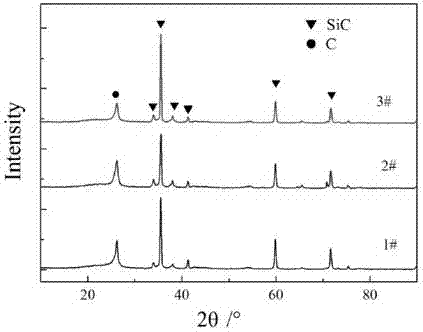

Micro-region in-situ reaction preparation method for high strength fiber-reinforced ceramic matrix composite material

ActiveCN103086731AImprove mechanical propertiesEquivalent mechanical propertiesMaterial nanotechnologyMetallurgyInterface layer

The invention relates to a micro-region in-situ reaction preparation method for a high strength fiber-reinforced ceramic matrix composite material. The method comprises the following steps: (1) depositing an interface layer on the surface of a composite material fiber preform so as to protect fiber reinforcement body, wherein the interface layer comprises a PyC interface, a BN interface, a SiC interface, and a composite interface of the PyC interface, the BN interface and the SiC interface, and a thickness of the interface layer is 10-2000 nm; (2) introducing a Si3N4 ceramic phase to pores of the composite material fiber preform to obtain a composite material pre-molding body; and (3) carrying out a densification treatment on the composite material pre-molding body to obtain the high strength fiber-reinforced ceramic matrix composite material, wherein the densification treatment comprises a high temperature treatment with a temperature of 1200-2300 DEG C, such that the Si3N4 and a carbon-containing phase in the composite material are subjected to a micro-region in-situ reaction through mutual diffusion so as to form the SiC phase.

Owner:嘉兴睿创新材料有限公司

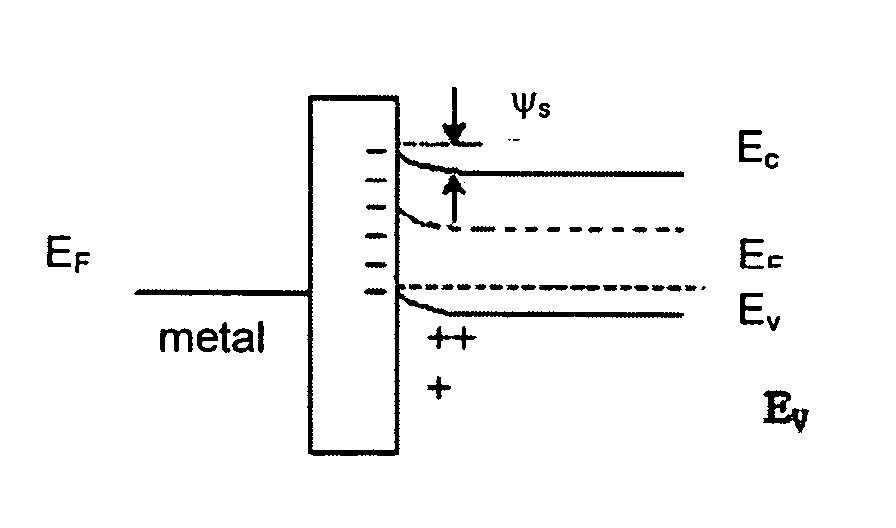

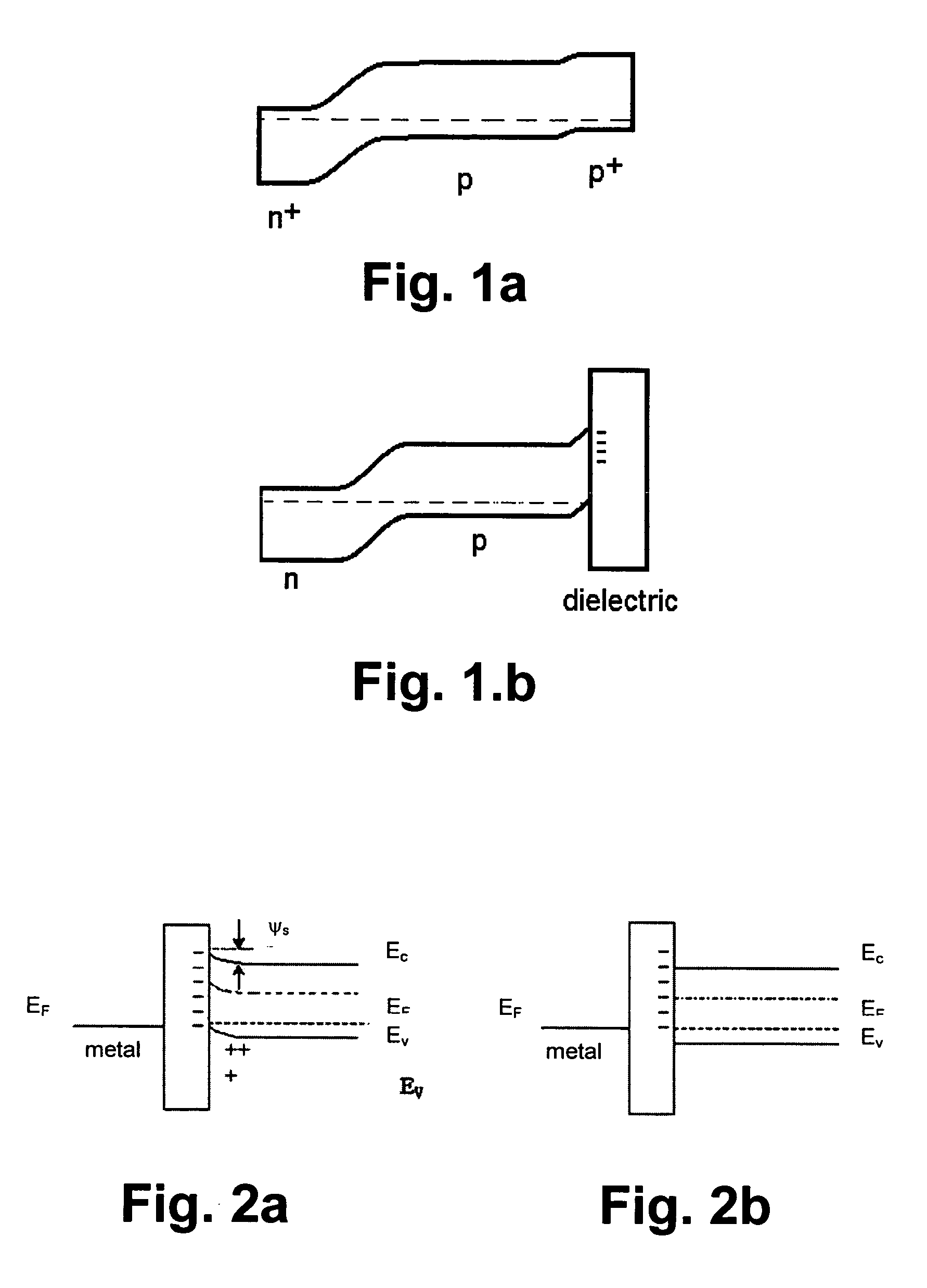

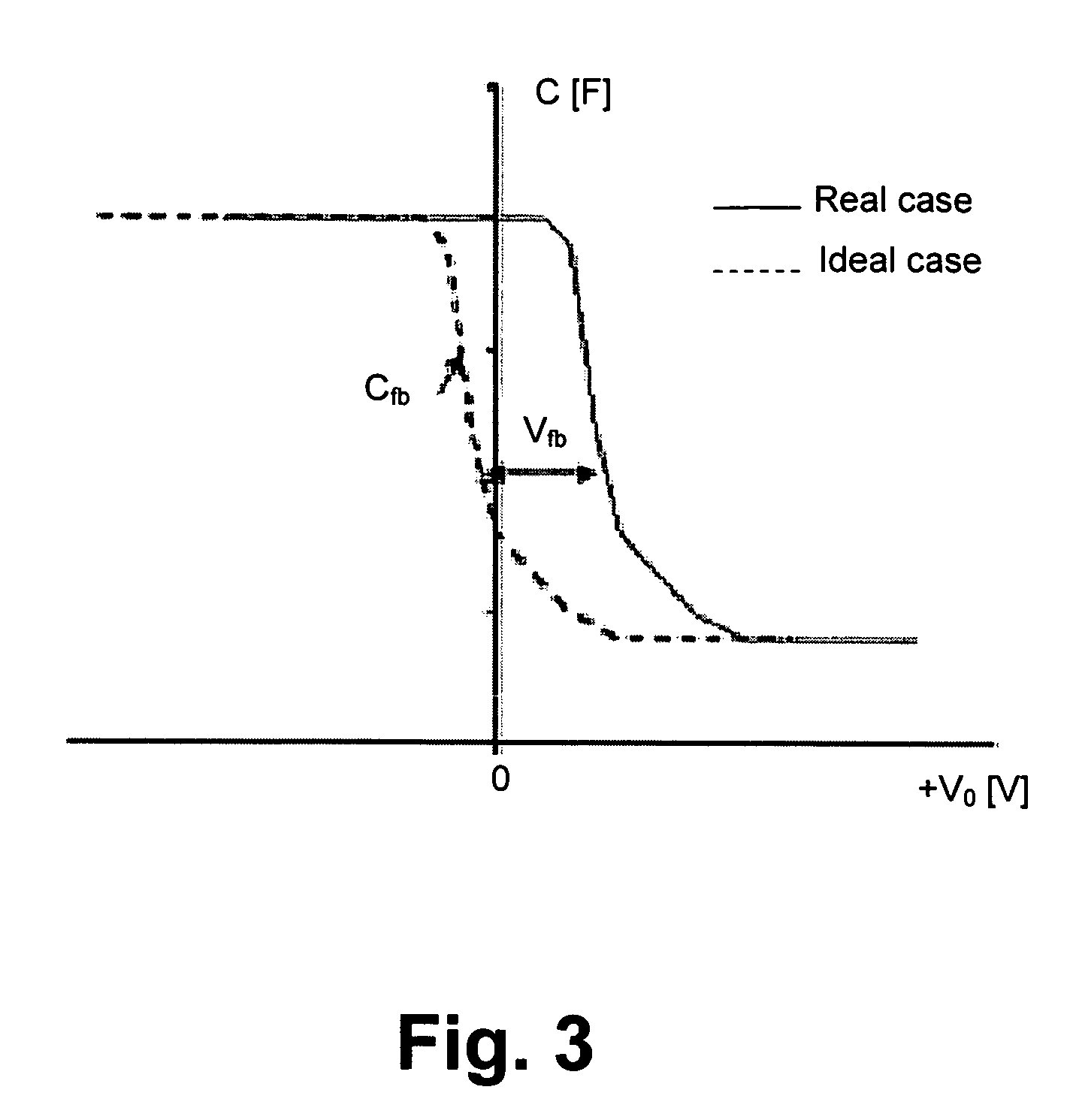

Method for backside surface passivation of solar cells and solar cells with such passivation

InactiveUS20050022863A1Easy to manufactureSimple and cheap to manufacturePV power plantsFinal product manufactureSemiconductor materialsAlloy

The present invention provides a method for dielectric passivating the surface of a solar cell by accumulation of negative fixed charges of a first type at the interface between semiconductor material and a passivating material. According to the invention the passivating material comprises an oxide system, for example a binary oxide system, comprising Al2O3 and at least one metal oxide or metalloid oxide which enhances the tetrahedral structure of Al2O3, for example, an (Al2O3)x(TiO2)1-x alloy. In this way it is possible to combine the desirable properties from at least two different oxides, while eliminating the undesirable properties of each individual material. The oxide system can be deposited onto the semiconductor surface by means of a sol-gel method, comprising the steps of formation of the metal oxide and / or metalloid oxide sol and the aluminum solution and then carefully mixing these together under stirring and ultrasonic treatment. Thin films of the oxide system can then be deposited onto the semiconductor surface by means of spin coating followed by a temperature treatment.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

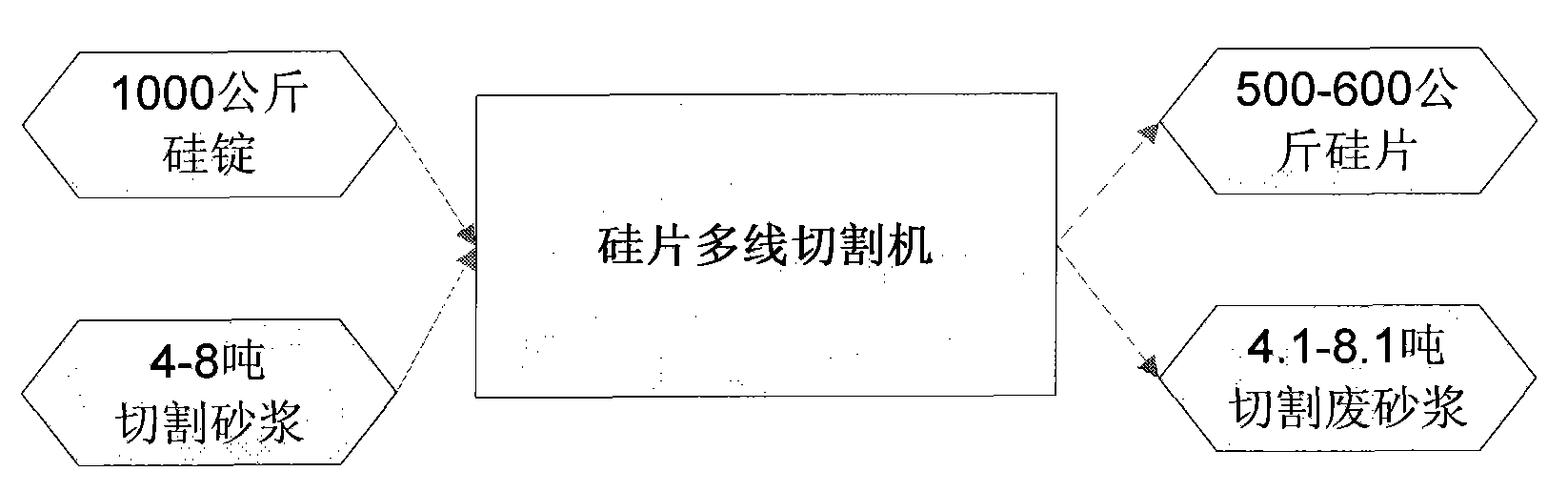

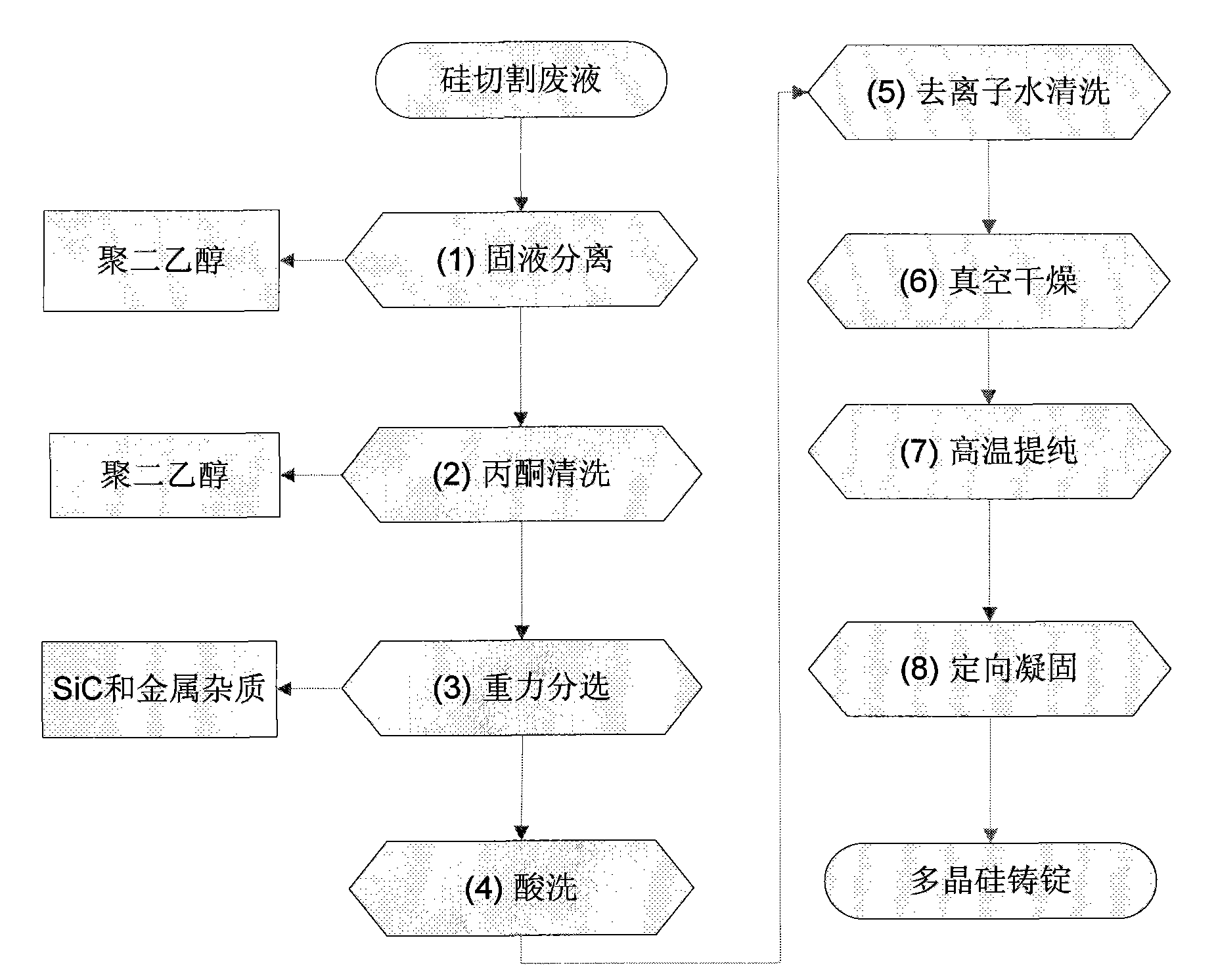

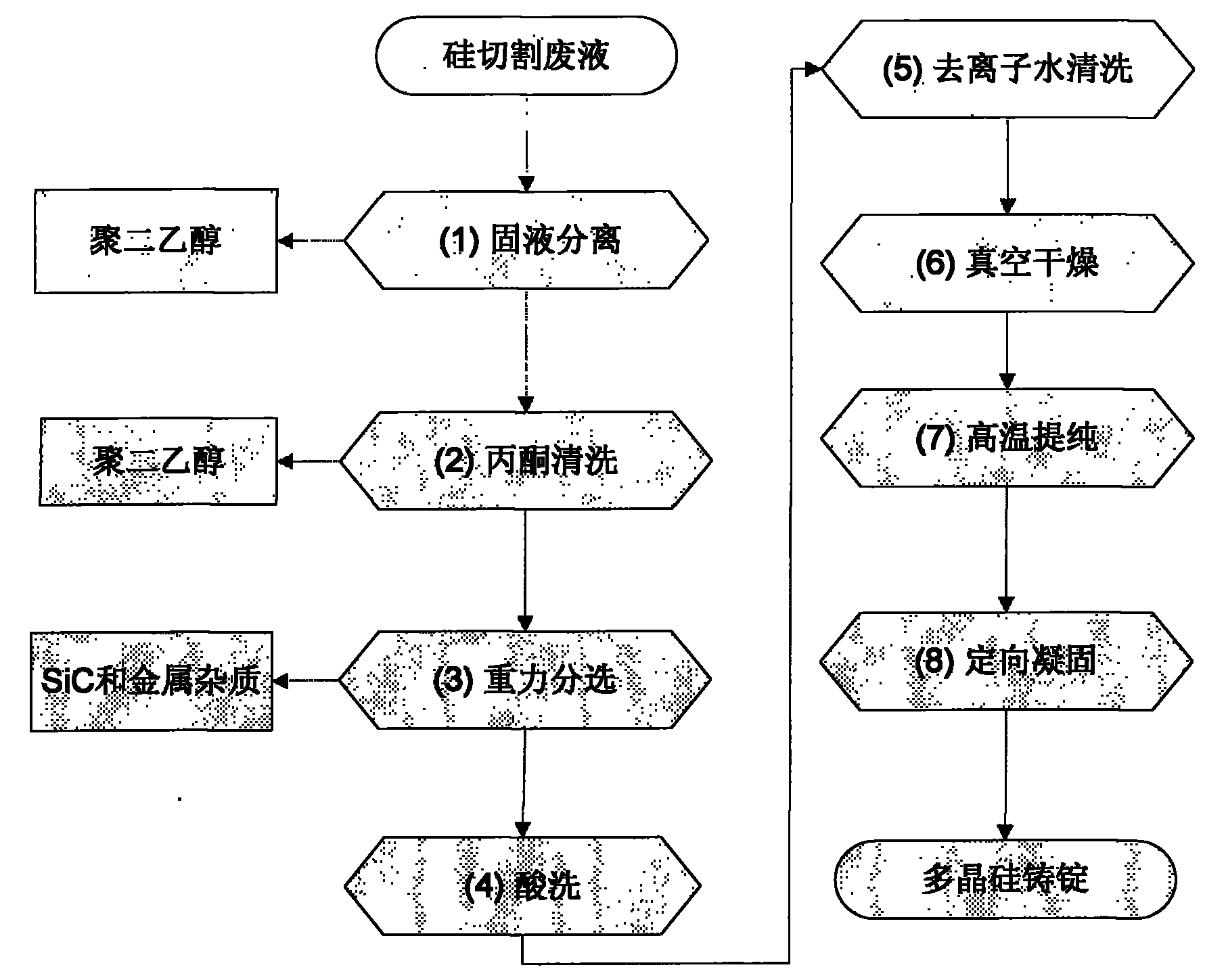

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

Preparation method of silicon/carbon multi-component composite negative electrode material

ActiveCN103545493AGood dispersionDispersion is better than that of materials without surface treatmentMaterial nanotechnologyCell electrodesCarbon nanotubeSilicon oxide

The invention provides a preparation method of a silicon / carbon multi-component composite negative electrode material. The preparation method comprises the following steps: (1) preparing a carboxyl carbon nano-tube by using acid and a carbon nano-tube, or preparing an aminated carbon nano-tube by using the carboxyl carbon nano-tube; (2) oxidizing the surface of nanometer silicon so as to generate a layer of silicon oxide, or aminating slightly oxidized nanometer silicon by using ammonia-containing organosilane under the condition of heating reflux; (3) adding the carboxyl carbon nano-tube and the aminated nanometer silicon, or the carboxyl carbon nano-tube and the slightly oxidized nanometer silicon to an organic carbon source-containing solvent, dispersing and carrying out spray drying-pyrolysis; (4) mixing a material obtained in the step (3) with asphalt, and sequentially carrying out low-temperature, constant temperature and high-temperature heat treatments, thus obtaining a secondary silicon-carbon nano-tube / amorphous carbon composite negative electrode material; and (5) carrying out airflow crushing, grading, adding to the organic carbon source-containing solvent, carrying out spray drying-pyrolysis or spray pyrolysis, and carrying out high-temperature treatment, thus obtaining the silicon / carbon multi-component composite negative electrode material. The silicon / carbon multi-component composite negative electrode material prepared by the method has the advantages of large reversible capacity, designable capacity, good cycle performance, high tap density and the like.

Owner:CENT SOUTH UNIV

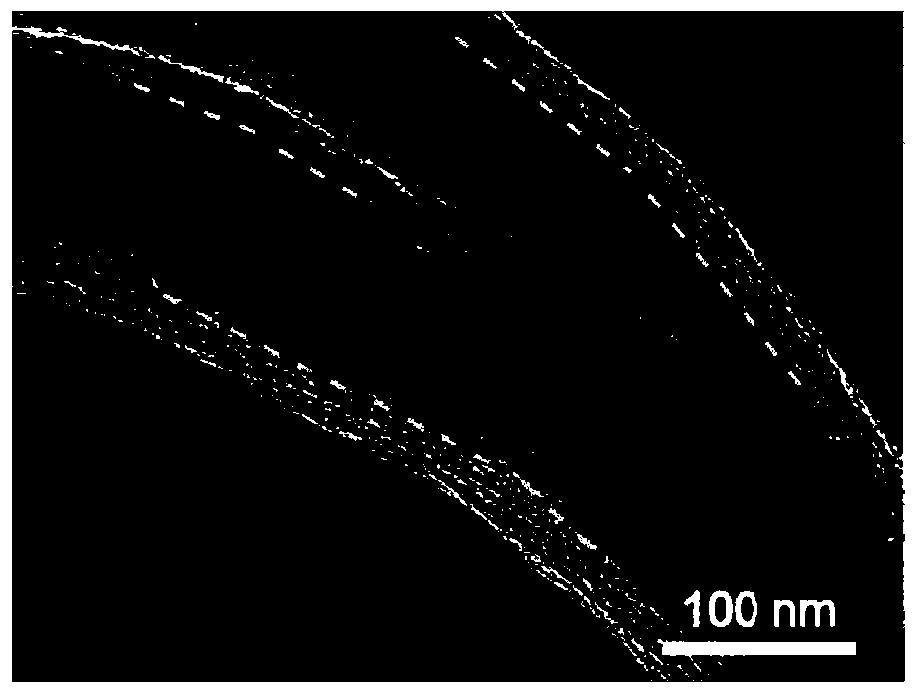

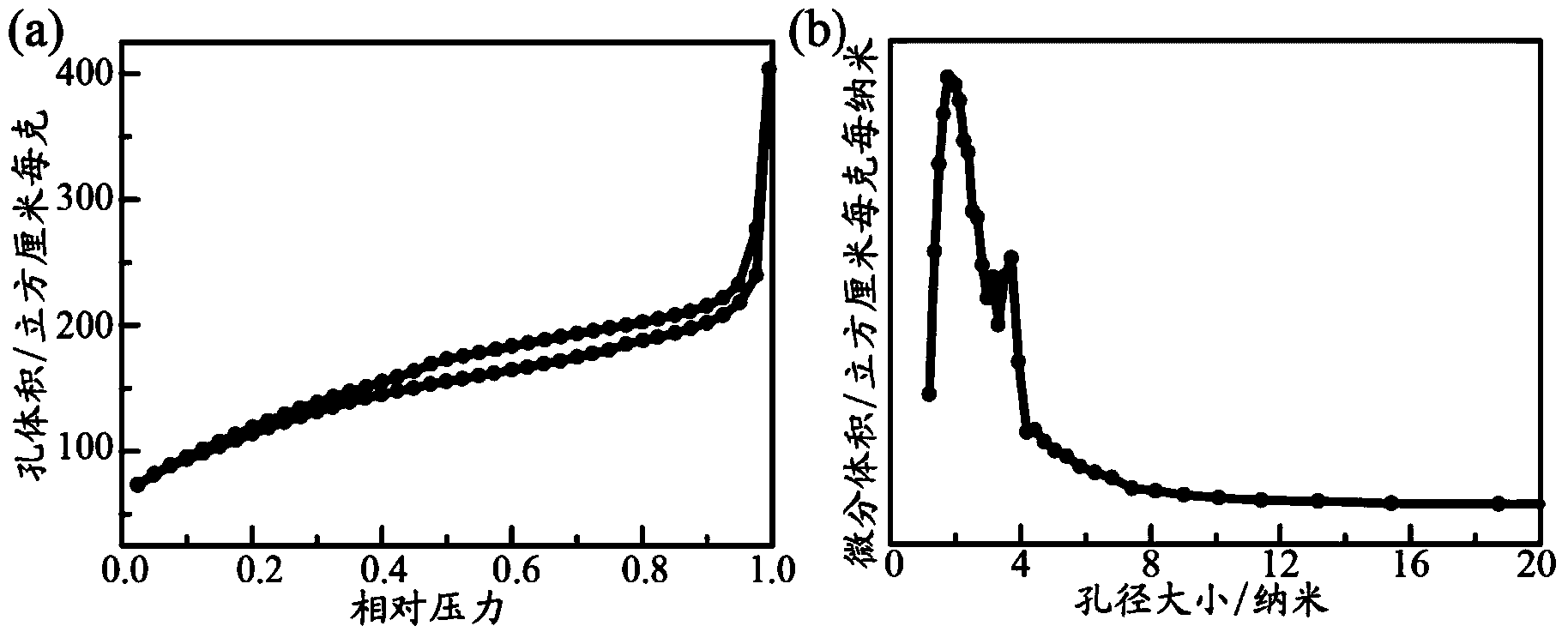

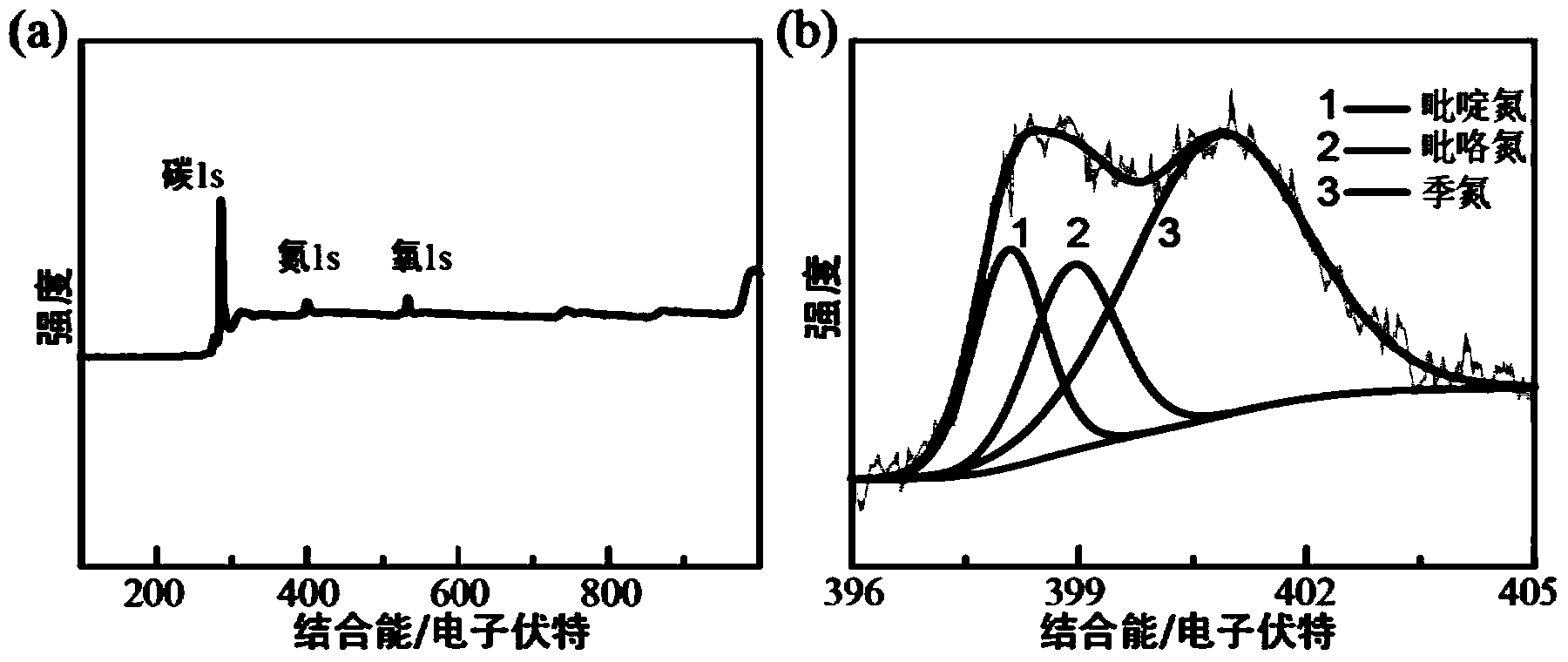

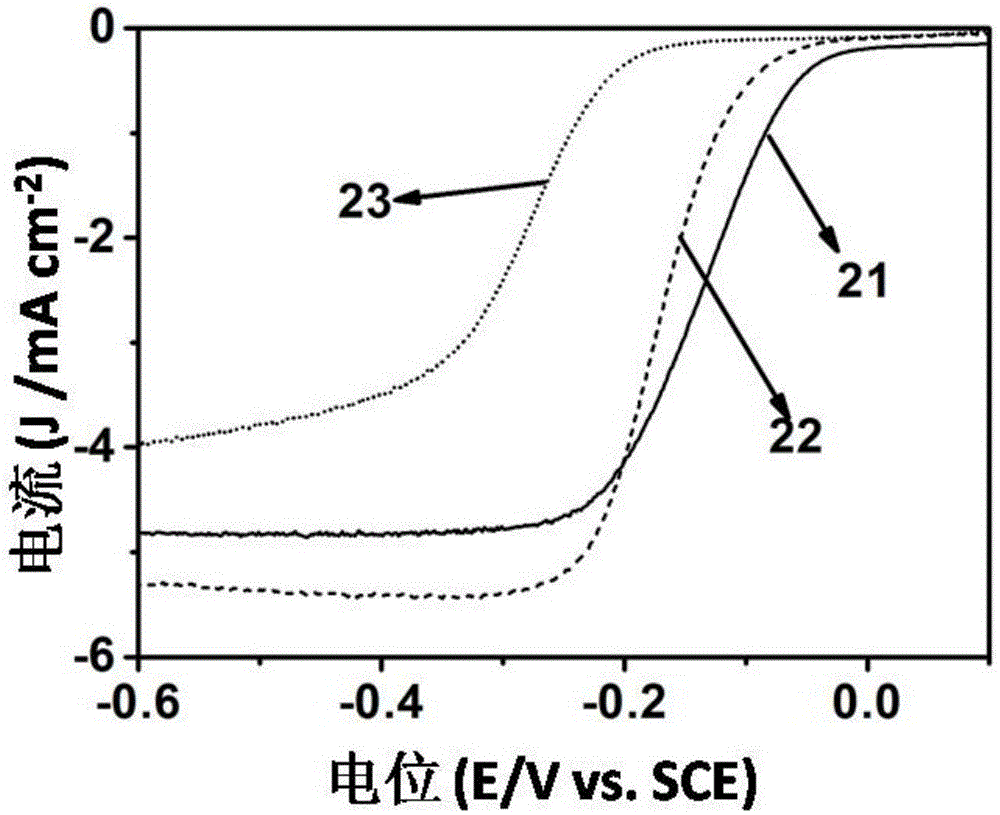

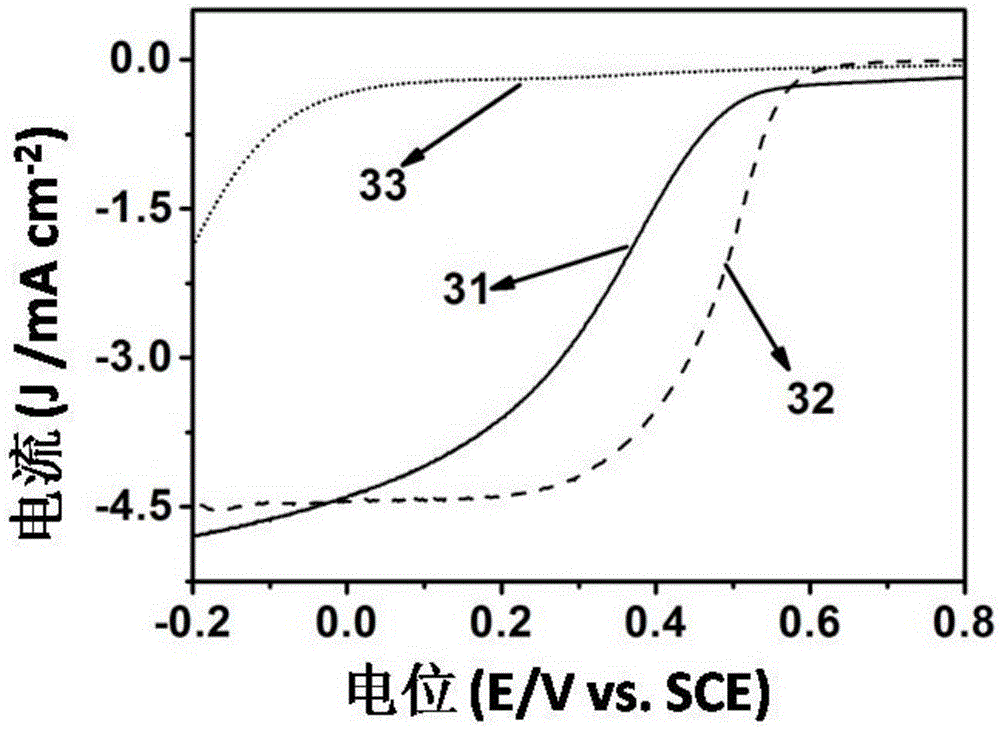

Composite material of nitrogen-doped porous carbon-wrapped carbon nano tube as well as preparation method and application of material

ActiveCN103706388AEasy to prepareEconomical method of preparationMaterial nanotechnologyPhysical/chemical process catalystsCarbon layerPorous carbon

The invention relates to a composite material of a nitrogen-doped porous carbon-wrapped carbon nano tube as well as a preparation method and an application of the composite material. The preparation method comprises the following steps: dispersing the carbon nano tube in water, adding a carbon source to obtain a reaction system, subsequently performing hydrothermal reaction, performing thermal treatment on the carbon nano tube wrapped with a carbon layer on the surface, and a nitrogen source at the high temperature so as to obtain the composite material of the nitrogen-doped porous carbon-wrapped carbon nano tube. According to the preparation method, the carbon source is polymerized under a hydrothermal reaction condition so as to obtain the carbon layer, the outer surface of the carbon nano tube is wrapped with the carbon layer, subsequently the carbon layer is carbonized and decomposed to generate a porous structure under high temperature treatment, and at the same time, the gasified nitrogen source is diffused to the carbon layer through ducts to be subjected to in-situ doping. The composite material provided by the invention can be used as a cathode oxidation reduction catalyst of a fuel battery, is excellent in catalysis, and is high in oxidation activity when being compared with other nitrogen-doped materials reported in documents. The preparation method provided by the invention is simple and economic in process, convenient to operate and easy to achieve the large-scale production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of anode material for power lithium ion battery

InactiveCN104659366AImprove electrochemical performanceIncrease capacityCell electrodesSecondary cellsCarbonizationDischarge rate

The invention discloses a preparation method of an anode material for a power lithium ion battery. The preparation method comprises the following steps: by adopting petroleum coke ground until the grain size is 1-6mu m, calcined petroleum coke or needle coke as a raw material, adding additives, adding a mixture to a reaction kettle to carry out first high-temperature carbonization coating under the protection of the inert atmosphere, then grinding the mixture with a grinder until the grain size is 5-13mu m, then carrying out superhigh-temperature graphitization at a temperature above 3200 DEG C, adding one or a mixture of petroleum asphalt, coal asphalt and resin to a material obtained after graphitization, and then enabling the mixture to enter a carburization furnace to undergo second coating under the protection of the inert atmosphere to obtain the anode material for the power lithium ion battery, namely a spheroidal artificial graphite material which is formed through bonding after being coated with granules and undergoes two-time coating and three-time high-temperature treatment. The preparation method has the advantages that the discharge rate property of the anode material is improved, the low temperature properties of the anode material are improved, and the latest requirements of the market for the product are further met.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

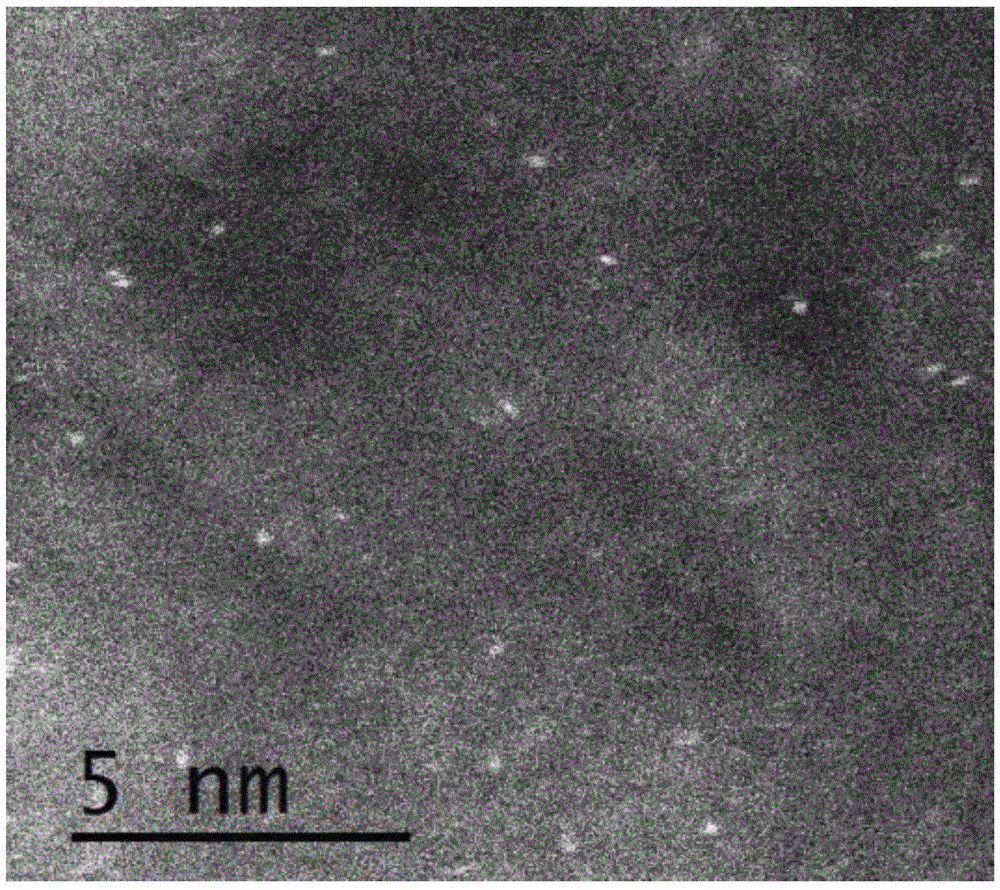

Catalyst with dispersed single platinum atoms and preparation method of catalyst

The invention relates to a catalyst with dispersed single platinum atoms and a preparation method of the catalyst, and aims at solving the technical problems that a precious metal oxygen reduction catalyst is high in preparation cost and low in utilization rate of platinum in the prior art. The catalyst with dispersed single platinum atoms is prepared by stirring, refluxing, evaporating, drying and grinding a carbon support, a nonmetal heteroatom reagent and a platinum compound as raw materials, and carrying out high-temperature treatment and interaction in a sliding rail furnace. A test result shows that the platinum element in the catalyst exists in a form of single atoms platinum; the catalytic activity is high; in acid and alkaline systems, the initial oxygen reduction potential and the half-wave potential are equivalent to those of a commercial carbon-supported platinum catalyst with the platinum content of 20%; other metal impurities are not introduced in the preparation process; and the stability is relatively good. The preparation method of the catalyst provided by the invention is relatively low in cost, simple and feasible. The catalyst is suitable for preparation of a fuel cell; the utilization rate of the platinum is greatly improved; the cost of the catalyst is reduced; and the commercialization process of the fuel cell can be promoted.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing carbon/carbon-silicon carbide composite material for bearings

The invention discloses a method for preparing a carbon / carbon-silicon carbide composite material for bearings. The preparation method comprises the following steps: preparing a carbon fiber integral felt of 0.15-0.30g / cm<3> from polyacrylonitrile preoxidized fibers through puncture carbonization, or preparing a non-woven cloth carbon fiber integral felt of 0.4-0.6g / cm<3> from non-woven cloth and a mesh tyre through puncture carbonization in an alternating lamination manner; preparing C / C porous preform with density of 1.35-1.75g / cm<3> by adopting a chemical vapor infiltration (CVI) and resin precursor infiltration and pyrolysis (PIP) comprehensive process, and performing a high-temperature treatment at 2,250-2,600 DEG C in the Ar gas protective atmosphere; and vacuumizing, then introducing Ar gas, heating to 2,200-2,350 DEG C to perform liquid silicon infiltration, and preserving heat for 1.5 hours. The method is a preparation method of the carbon / carbon-silicon carbide (C / C-SiC) composite material with little residual silicon and low abrasion rate for bearings.

Owner:SHANGHAI UNIV +2

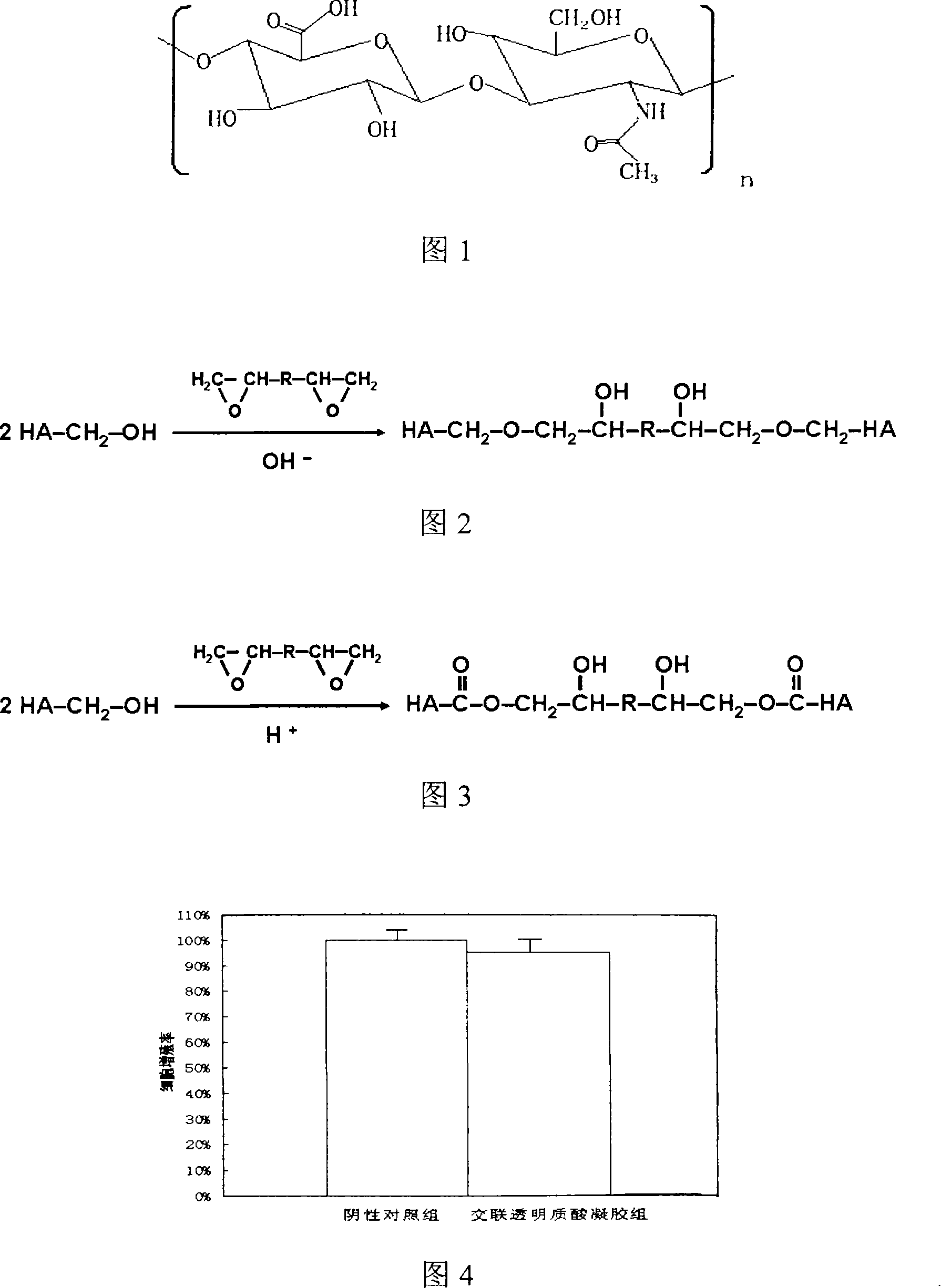

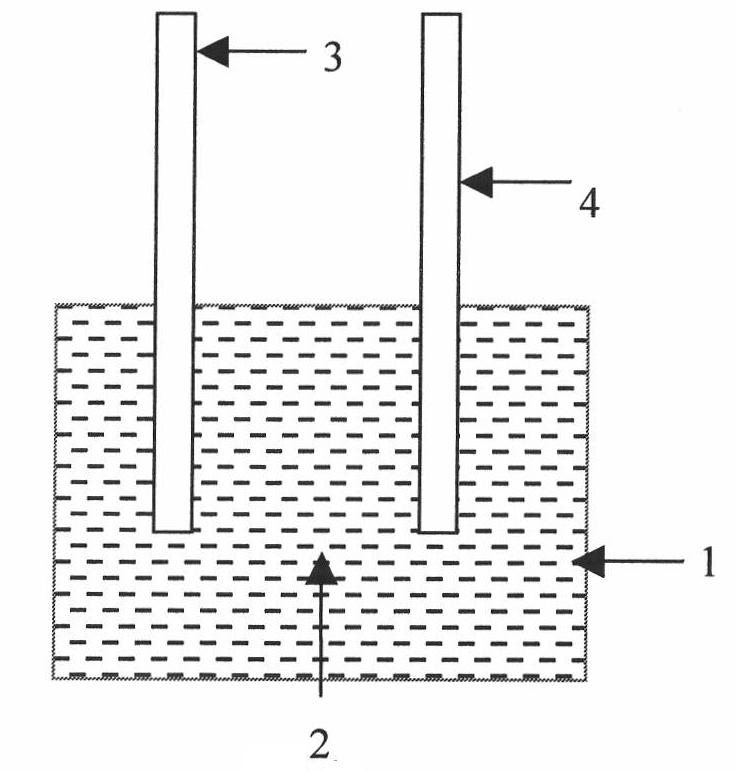

Method for preparing crosslinked hyaluronic acid microgel for tissue filling

The invention relates to a preparation method of cross-linking hyaluronic acid microgel for tissue filler; wherein, the monolithic gel is generated by the cross-linking reaction of the hyaluronic acid and the di-epoxide in the certain mold and processed by acid solution; the purification and dialysis by physiological balanced solution are processed; the microgel is made by extrusion of mechanical equipment. The cross-linking hyaluronic acid microgel has the advantages of (1) specific physical properties that the storage modulus (G') is 500-2000Pa, the loss modulus (G'') is 50-200Pa, the phase angle (Delta) is below 20 and the complex viscosity (Eta*) is 10-3500Pa x s as described by the dynamic viscoelasticity at frequency of 0.05-10Hz, (2) good stability that the performance of gel is independent of high pressure-high temperature treatment and the enzymolysis-resistant performance is excellent, (3) injectable property that the size of fine particle is 50-1000Mum, (4) good biocompatibility of no cytotoxicity, (5) biodegradability of being fully degraded by hyaluronidase, and (6) being suitable for tissue filler and bio-medical treatment.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

Preparation method of neodymium iron boron magnet

ActiveCN102103916AReduce usageUniformity controllableInductances/transformers/magnets manufactureMagnetic materialsRare earthImpurity

A preparation method of neodymium iron boron magnet is disclosed. The composition general formula of the magnet provided by the invention is R1R2FeMB, wherein R1 is at least one element selected from the group consisting of Nd, Pr, La, Ce, Sm, Sc, Y and Eu, having a content of 23 to 35 wt%; R2 is at least one element selected from the group consisting of Tb, Dy, Gd, and Ho, having a content of 0.1 to 5 wt%; M represents transition group metal with the exception of Fe, having the content of 0.01 to 5 wt%; B represents simple substance boron, having the content of 0.8 to 1.2 wt%; the balance isFe and the other inevitable impurities. The preparation method of neodymium iron boron magnet provided by the invention works in such a manner that: one or more elements in the R2 are plated to the surface of the magnet, the metal R2 is diffused into the interior of the magnet by primary high temperature heat treatment, and imbalance organization and internal stress brought by the high temperature treatment are eliminated through secondary low temperature tempering. Low temperature molten salt electrodeposition method is employed to plate films. The present invention is advantageous in greatly improving the production efficiency, reducing the dosage of the heavy rare earth during preparation process of magnet, saving rare earth resource, and obtaining high coercivity without reducing remanent magnetism and magnetic energy product of a magnet.

Owner:GRIREM ADVANCED MATERIALS CO LTD

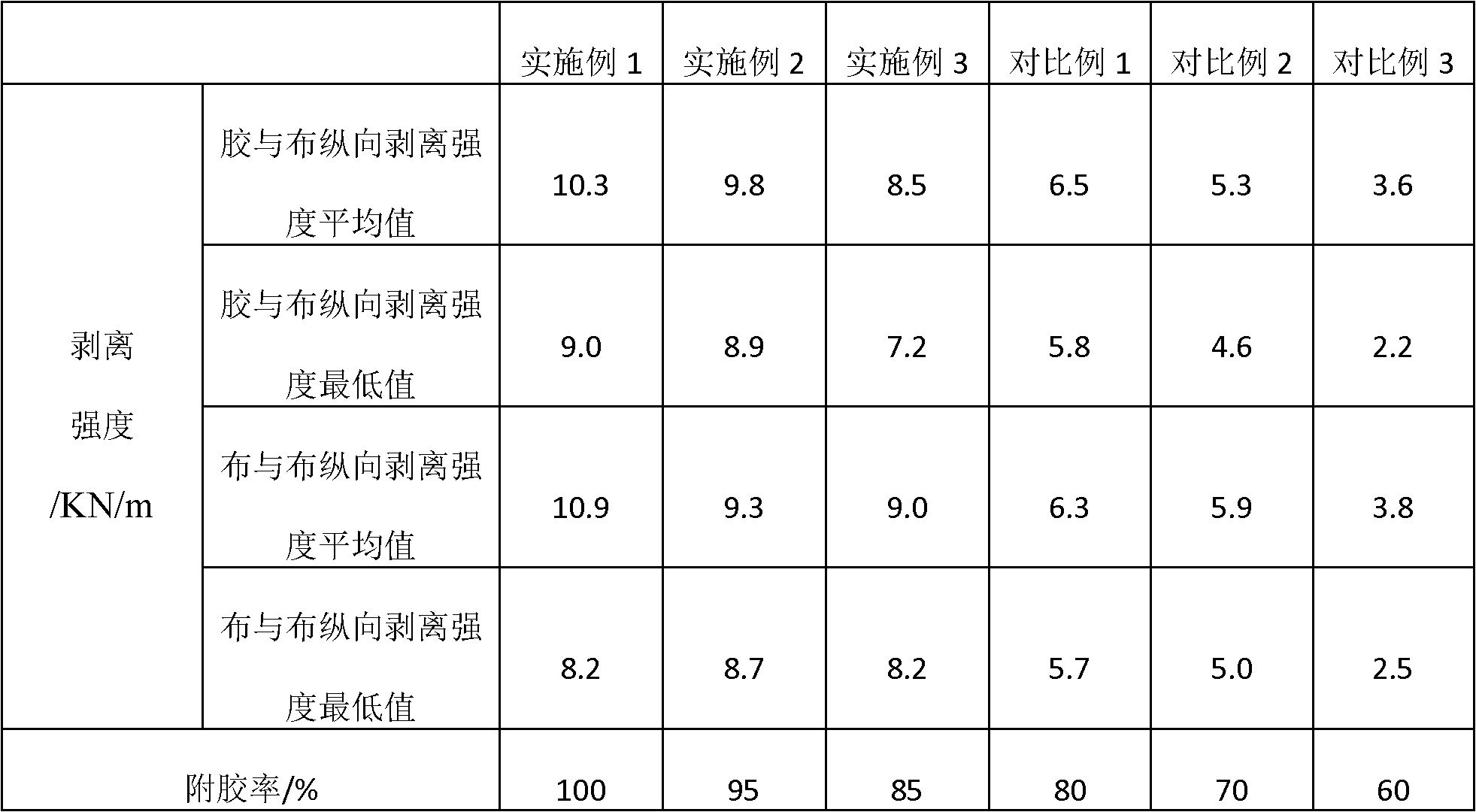

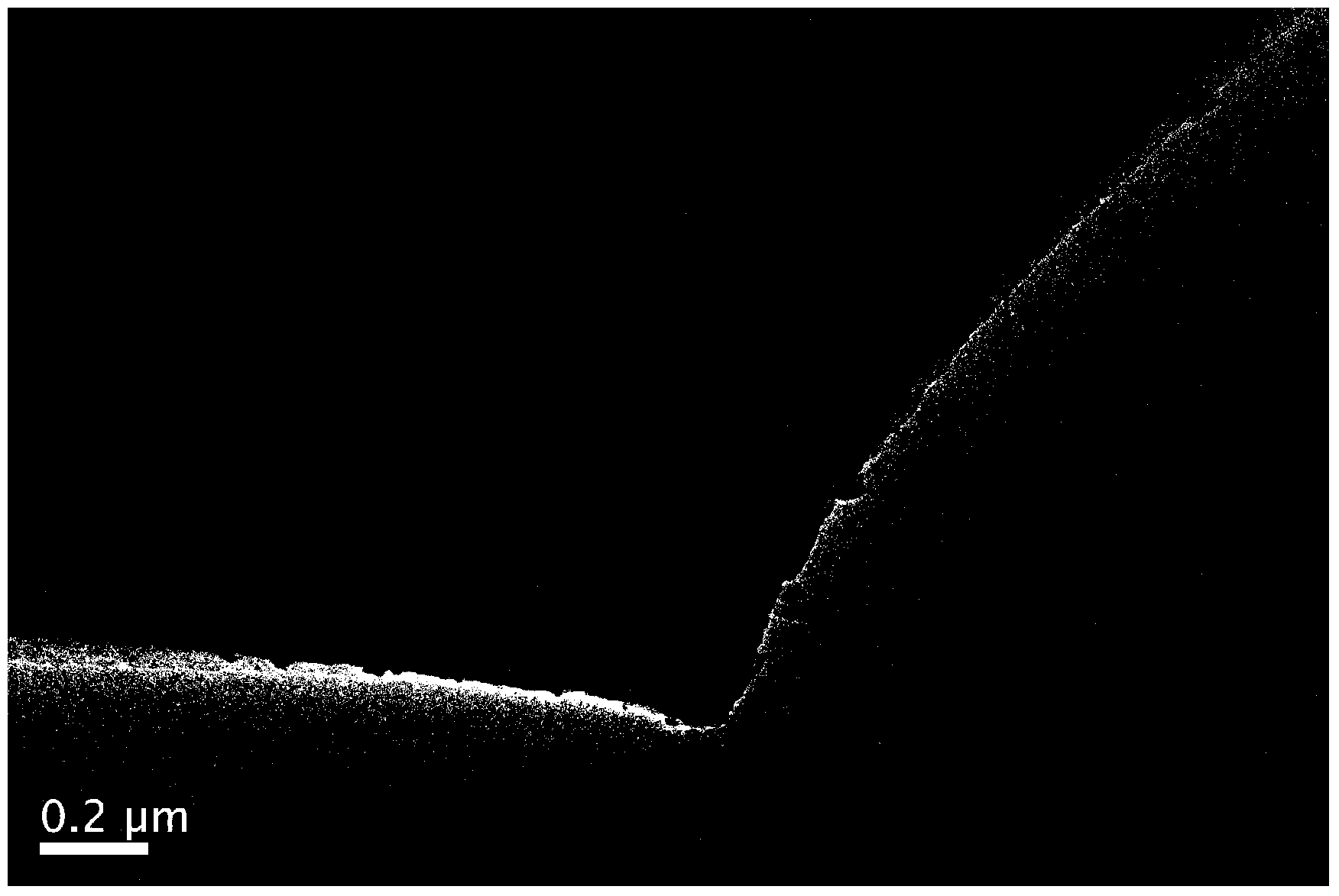

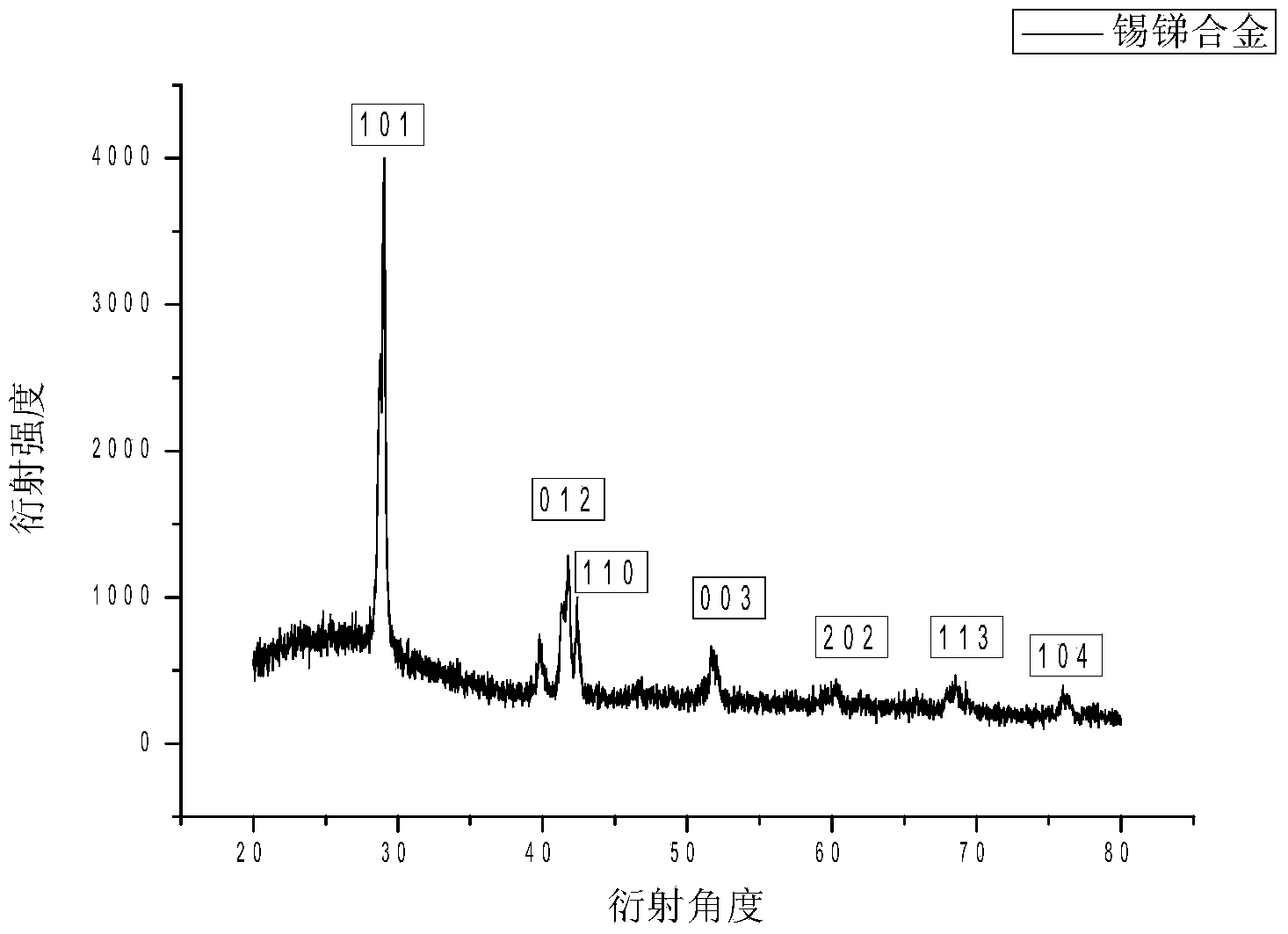

Method for pretreating fibers

The invention relates to a method for pretreating fibers, comprising the following steps of: performing surface activation on fibers by a dopamine hydrochloride biomimetic modification method, and then performing impregnation treatment on the fibers by using impregnation solution composed of rubber latex and phenolic resin, aiming to improve the interface adhesion property of the fibers with rubber so that the fibers are more suitable for tyres, conveyor belts, high-pressure rubber tubes and transmission belts. The method solves the experimental problem caused by high toxicity of isocyanate and avoids damage on the fibers caused by high-temperature treatment; and the process flow is simplified and the production cost is reduced.

Owner:BEIJING UNIV OF CHEM TECH

Method for loading nanocrystalline metal oxide or nanocrystalline metal materials by porous carbon

The invention belongs to the technical field of nanometer material preparation, and relates to a method for loading nanocrystalline metal oxide or nanocrystalline metal materials by porous carbon. Urea derivatives, saccharides and metal salt can form the characteristics of even mixed solutions at certain temperature, the porous carbon is formed in situ after dehydration and carbonization, and then the nanocrystalline metal oxide or the nanocrystalline metal materials loaded by the porous carbon are prepared through high temperature treatment. According to the method, the raw material ratio, response time, heat treatment temperature and other synthesis condition are changed, and carrying type nanometer materials with the carrying amount, the size of the particle diameter, the crystalline phase and components simultaneously controllable can be obtained. The whole process has the advantages of being easy to operate, environmentally friendly, low in cost and the like, the obtained nanocrystalline metal oxide or nanocrystalline metal materials loaded by the porous carbon have wide application prospects in industrial catalysis, water treatment, electrochemistry and other aspects.

Owner:CHANGZHOU UNIV

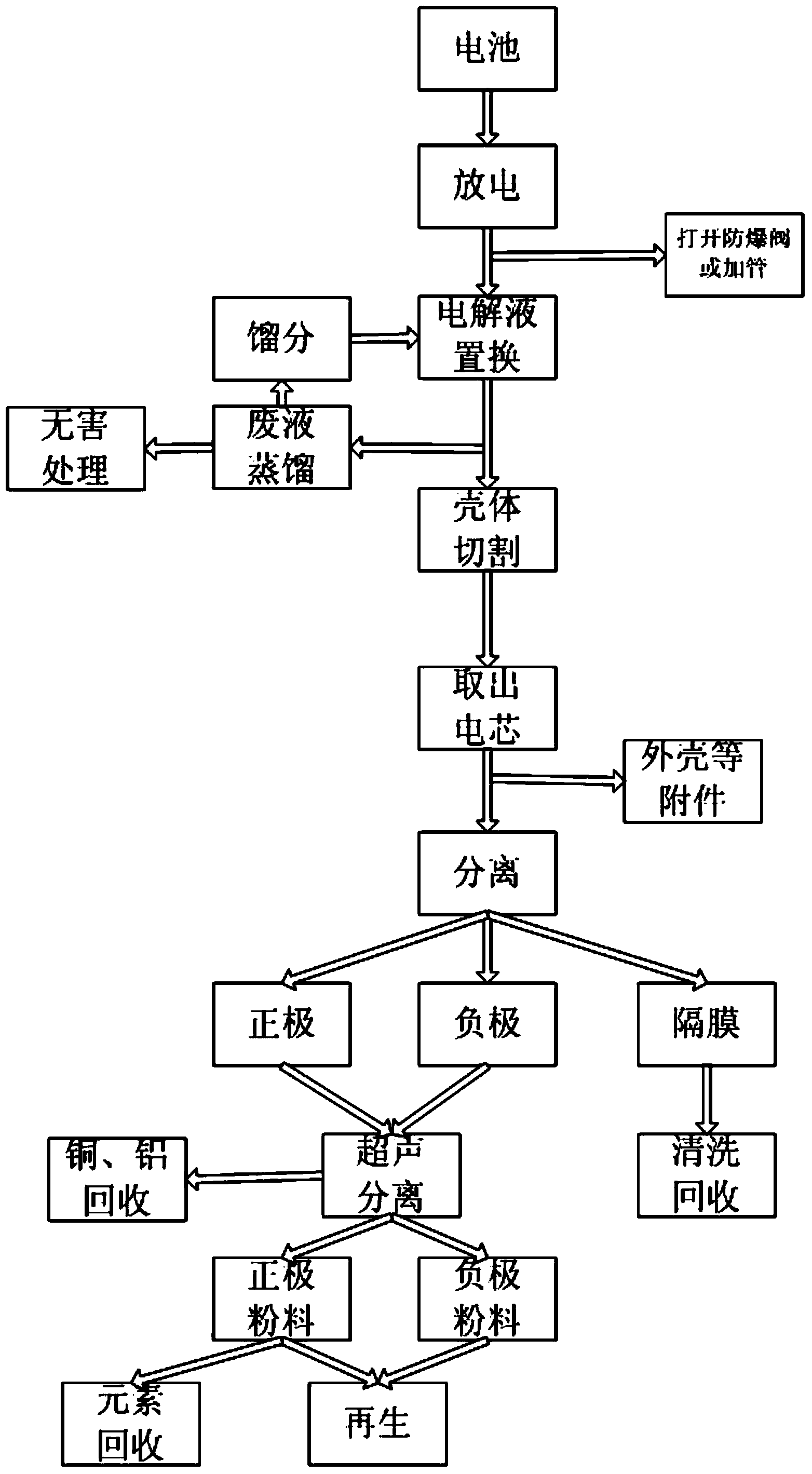

Demonstration process for recovering waste and old dynamic lithium iron phosphate cell in environmental protection mode

InactiveCN103825064AHarm reductionAvoid it happening againWaste accumulators reclaimingCell component detailsLithium iron phosphateSolvent

The invention relates to a demonstration process for recovering a waste and old dynamic lithium iron phosphate cell in an environmental protection mode, which belongs to the technical field of recovery of the power lithium iron phosphate cell. The method comprises the following steps: completely discharging the cell, extracting an electrolyte in the cell, adding a certain amount of solvent or displacement liquid, standing for 30 minutes and extracting the inner liquid of the cell, and distilling the extracted electrolyte to obtain the liquid for cycle usage when the electrolyte is displaced. According to the invention, the cell is cut by 1cm at the position along the cell top through a water jet, an electrical core is taken, wherein the steel casing, or aluminium casing or a PP plate can be directly recovered for usage. The anode, the cathode and a diaphragm are separated, and the diaphragm can be directly recovered through cleaning by ethanol. After the anode and the cathode are separated through physical methods such as ultrasound, a copper foil and an aluminium foil can be directly recovered, anode and cathode powder can be reused to be a cell material through high temperature treatment, and the purposes of no waste and no pollution can be reached by recovering the elements through a chemical method.

Owner:BEIJING UNIV OF TECH +1

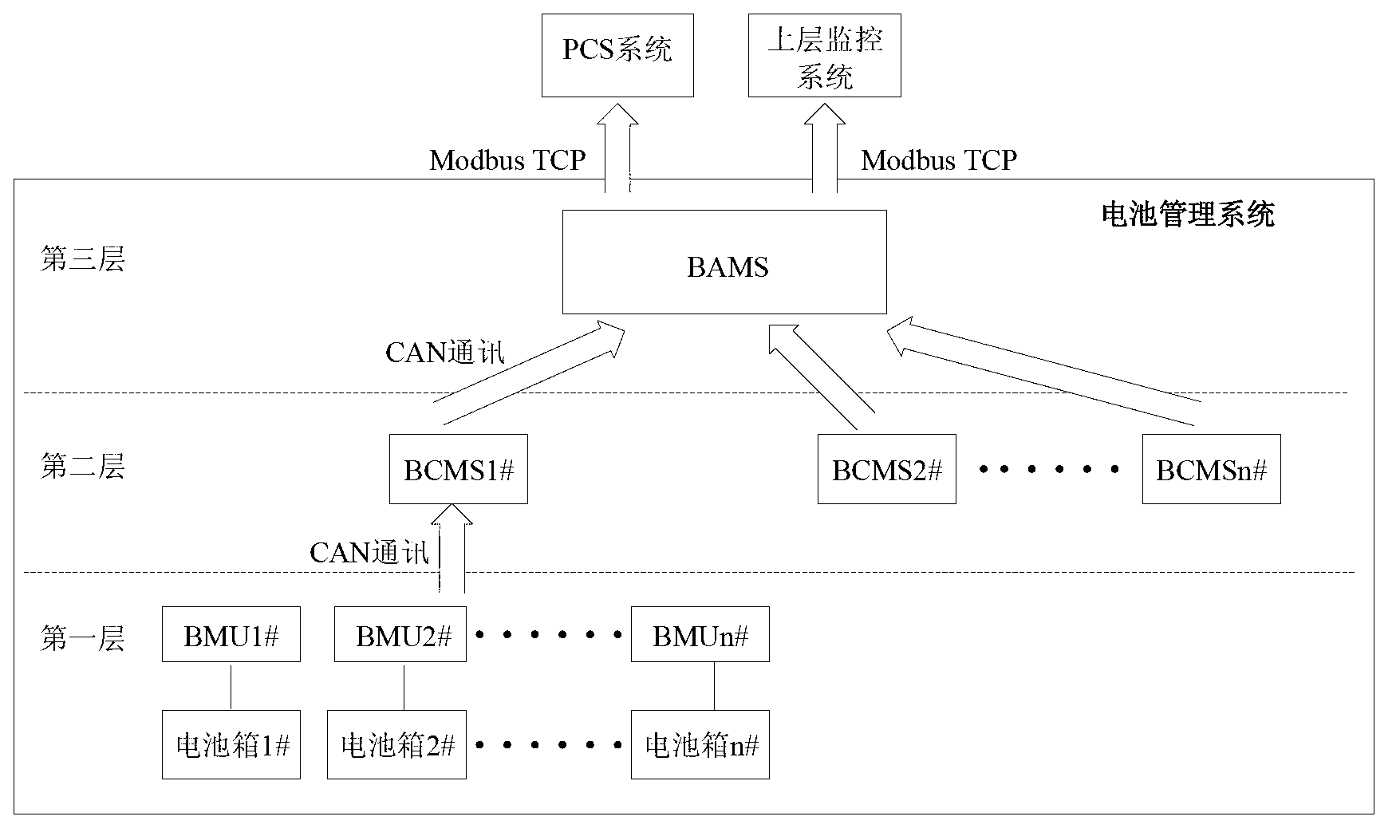

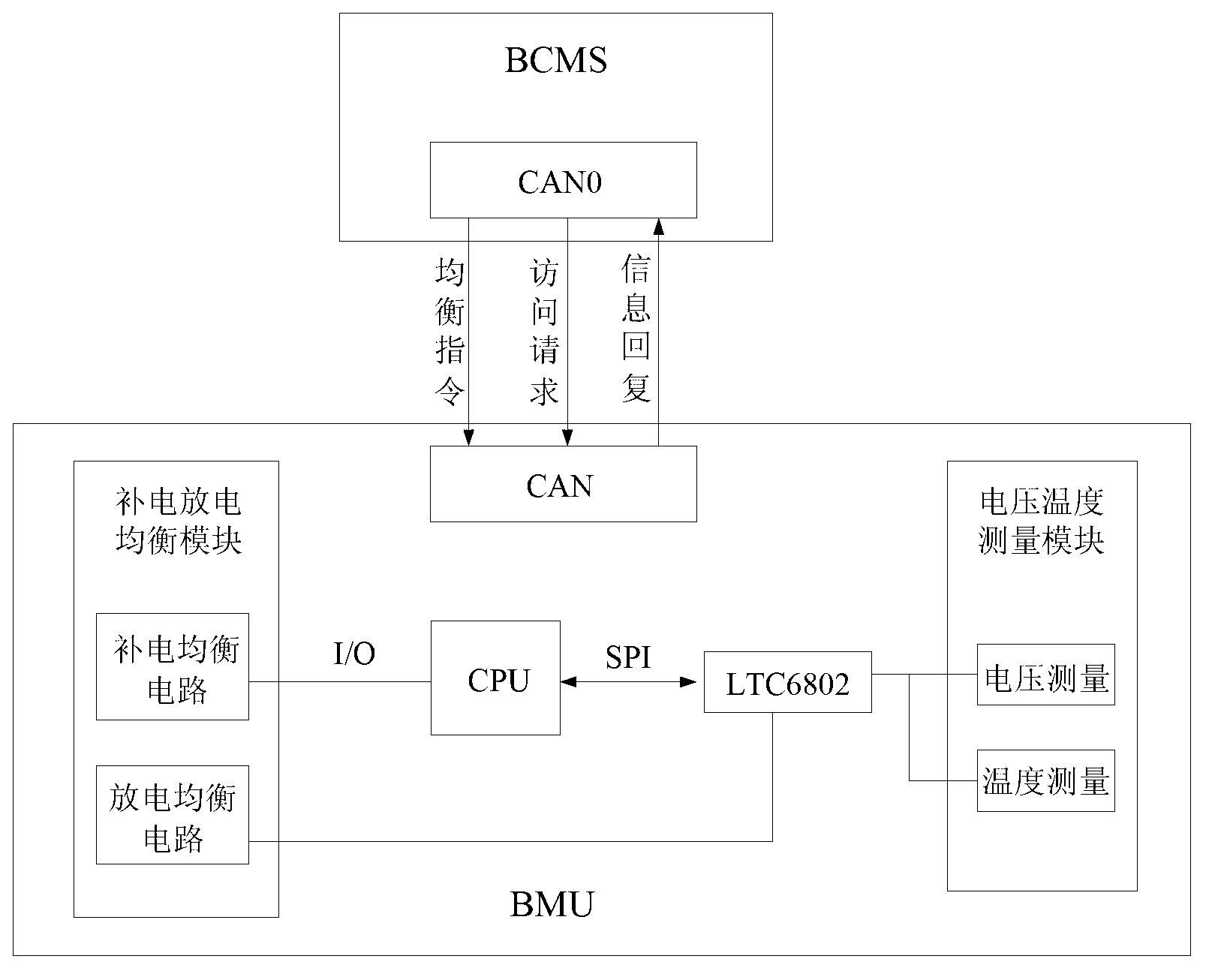

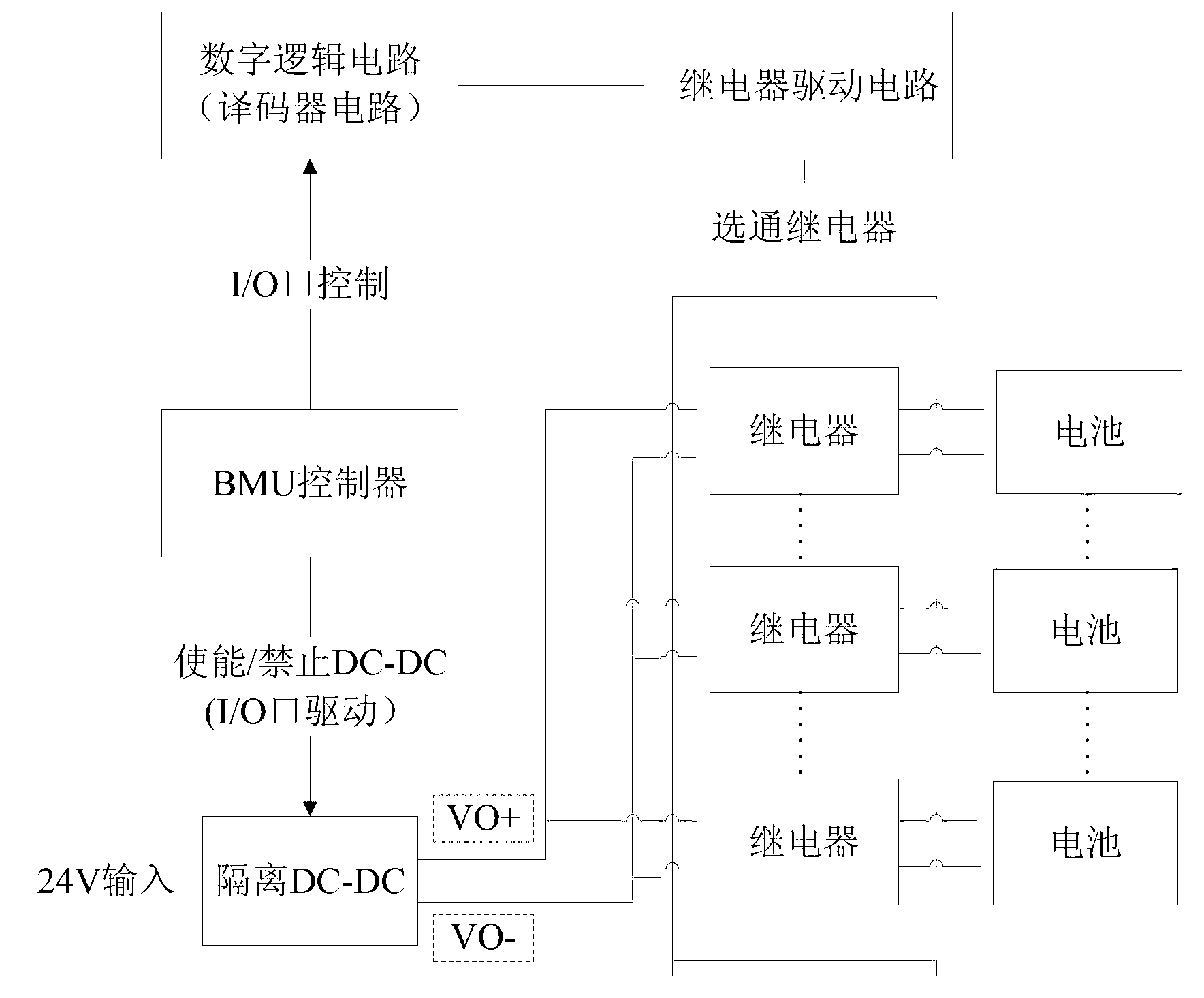

Energy storage battery management system

ActiveCN103227494AImprove reliabilityVersatileBatteries circuit arrangementsElectric powerModbusElectricity

The invention discloses an energy storage battery management system. A distributed three-layer management system is adopted in the system, wherein the management system comprises a bottom BMU (Battery Measurement Unit), a middle BCMS (Battery Cluster Management System) and a top BAMS (Battery Array Management System). The bottom BMU comprises a voltage and temperature measuring module and a charging / discharging balancing module; the middle BCMS is the core of the battery management system and comprises a voltage temperature treatment module, a balance control module, a relay control module, an AD (Analog and Digital) collecting module and a core parameter calculating module; and the top BAMS comprises a battery information gathering module, a system alarm information treatment module, a BAMS-PCS (Battery Array Management System-Process Control System) communicating module and a BAMS-PCS-upper monitoring system communicating module. Information transmission in the three layers of structures in the system is realized by using a CAN2.0B communication protocol; and the communication between the BAMS and an energy conversion PCS system and an upper monitoring system is realized by using a Modbus TCP (Transmission Control Protocol). On account of the special requirement on the battery management system in the field of energy storage, the invention provides the energy storage battery management system which is high in reliability, complete in function, real-time and stable in communication and relatively complete in management system structure.

Owner:BEIJING HUADIAN TIANREN ELECTRIC POWER CONTROL TECH +1

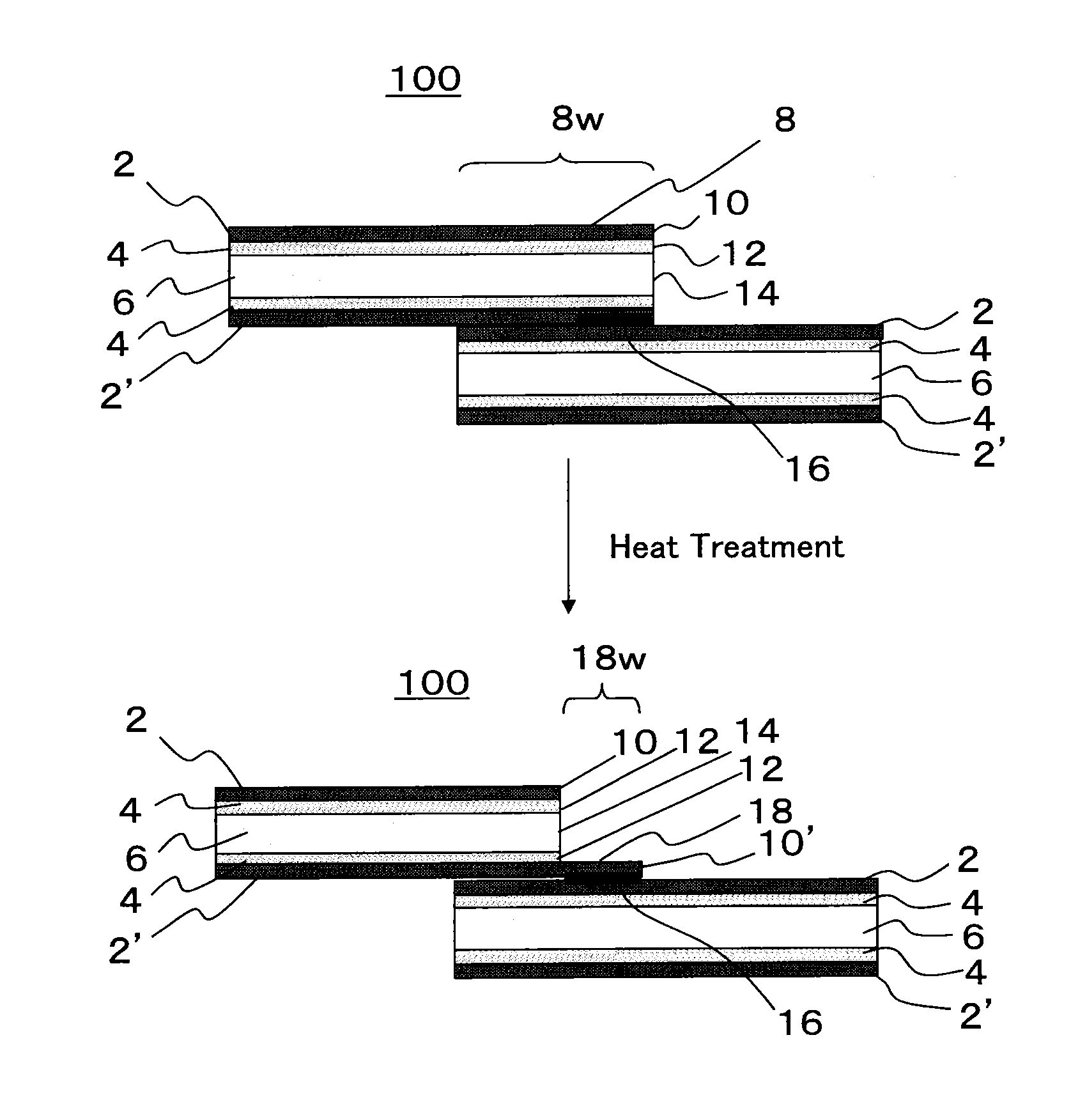

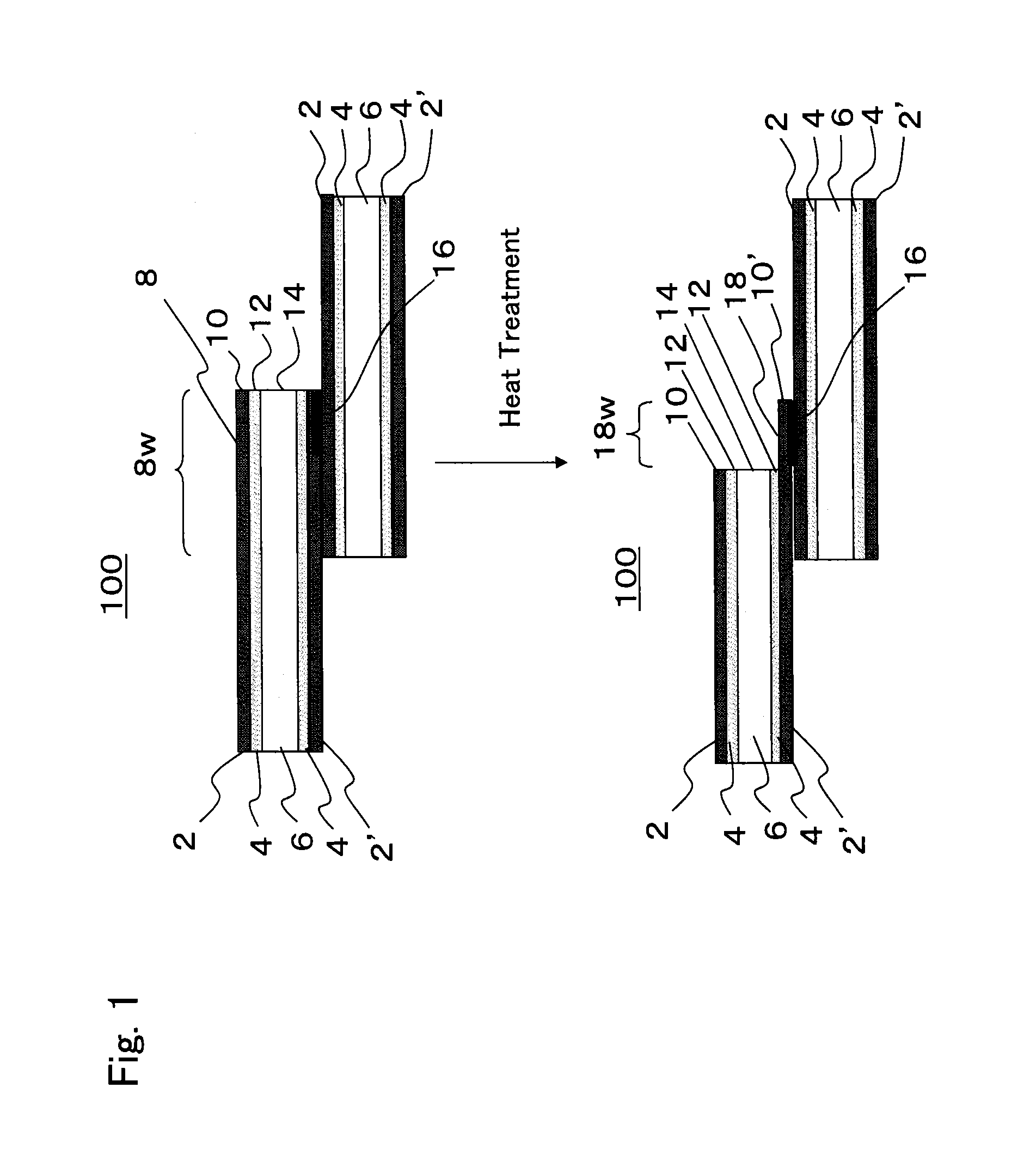

Heat-shrinkable laminated film, molded product and heat-shrinkable label comprising the film, and container

ActiveUS20130224412A1Good heat shrinkabilitySolve easy peelingBottlesSynthetic resin layered productsPolyesterRoom temperature

A heat-shrinkable laminated film having: (A) layer mainly having a polyester series resin; (C) layer mainly having a polystyrene series resin or mixture of polyester series and polystyrene series resins; and (B) layer mainly having polyester series and polystyrene series resins and disposed between (A) and (C) layers, the film having excellent heat-shrinkability, transparency, and interlayer-adhesiveness at room temperature, not easily peeled in a high-temperature treatment, inhibited from whitening when bent during processing, and suitable for shrinkage-packaging, shrink-bond-packaging, etc., with (B) layer having: a hard polyester series resin or mixture of hard polyester series and soft polyester series resins; and soft styrene series resin, hard styrene series resin, or mixture thereof, or with a content of the (B) layer polyester series resin smaller than that of the (A) layer one, and a content of the (C) layer polyester series resin smaller than that of the (B) layer one.

Owner:MITSUBISHI CHEM CORP

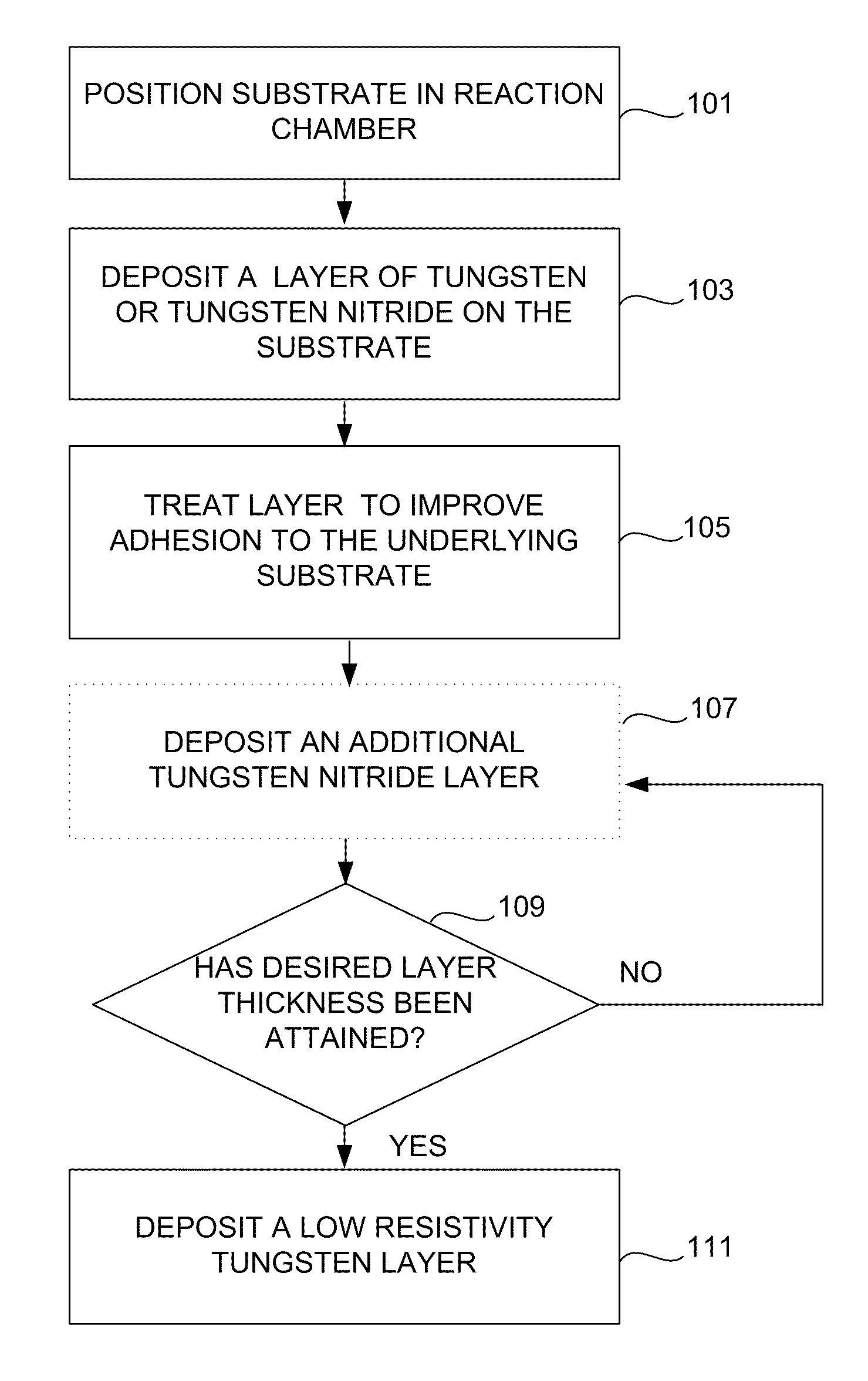

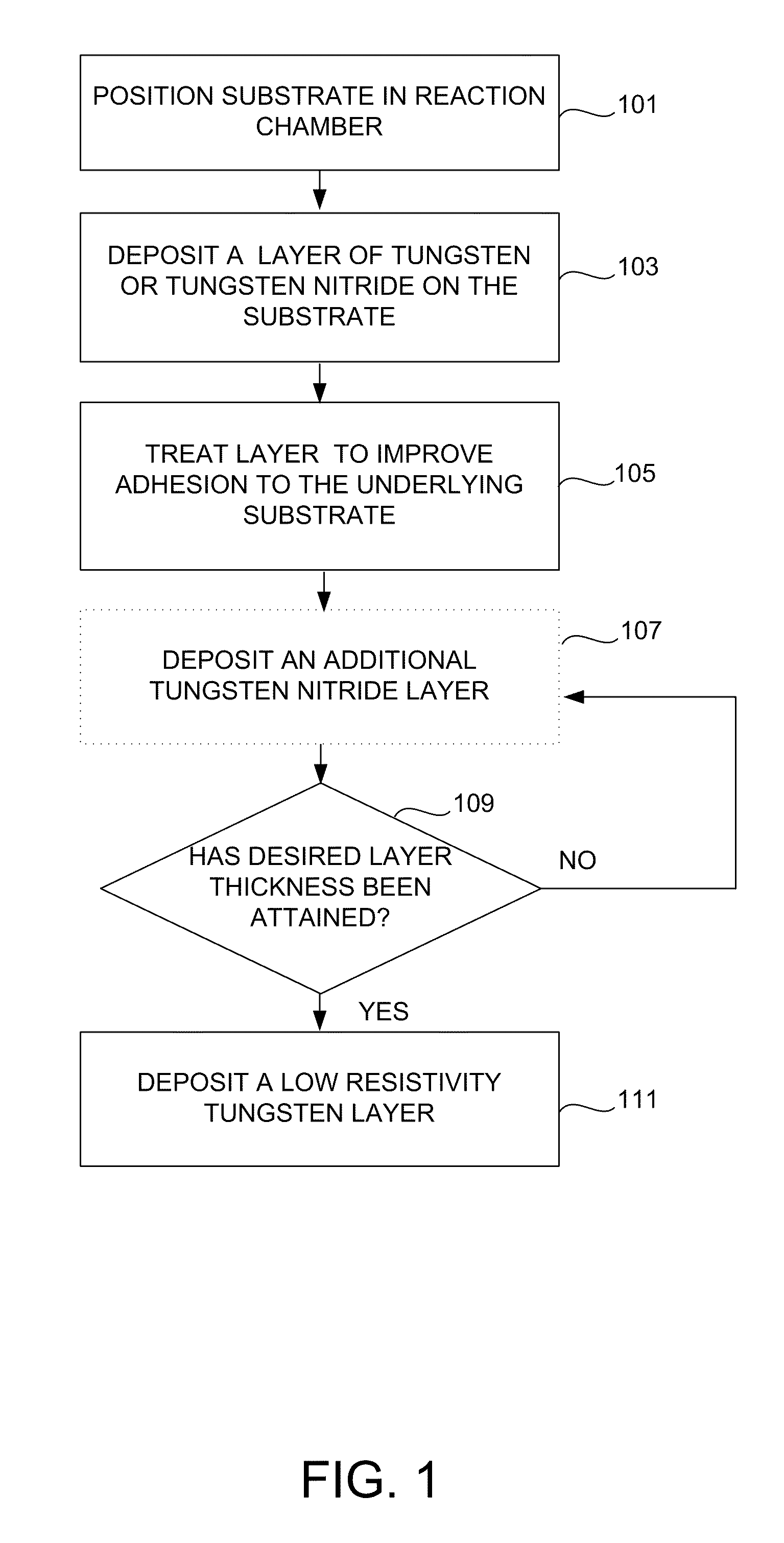

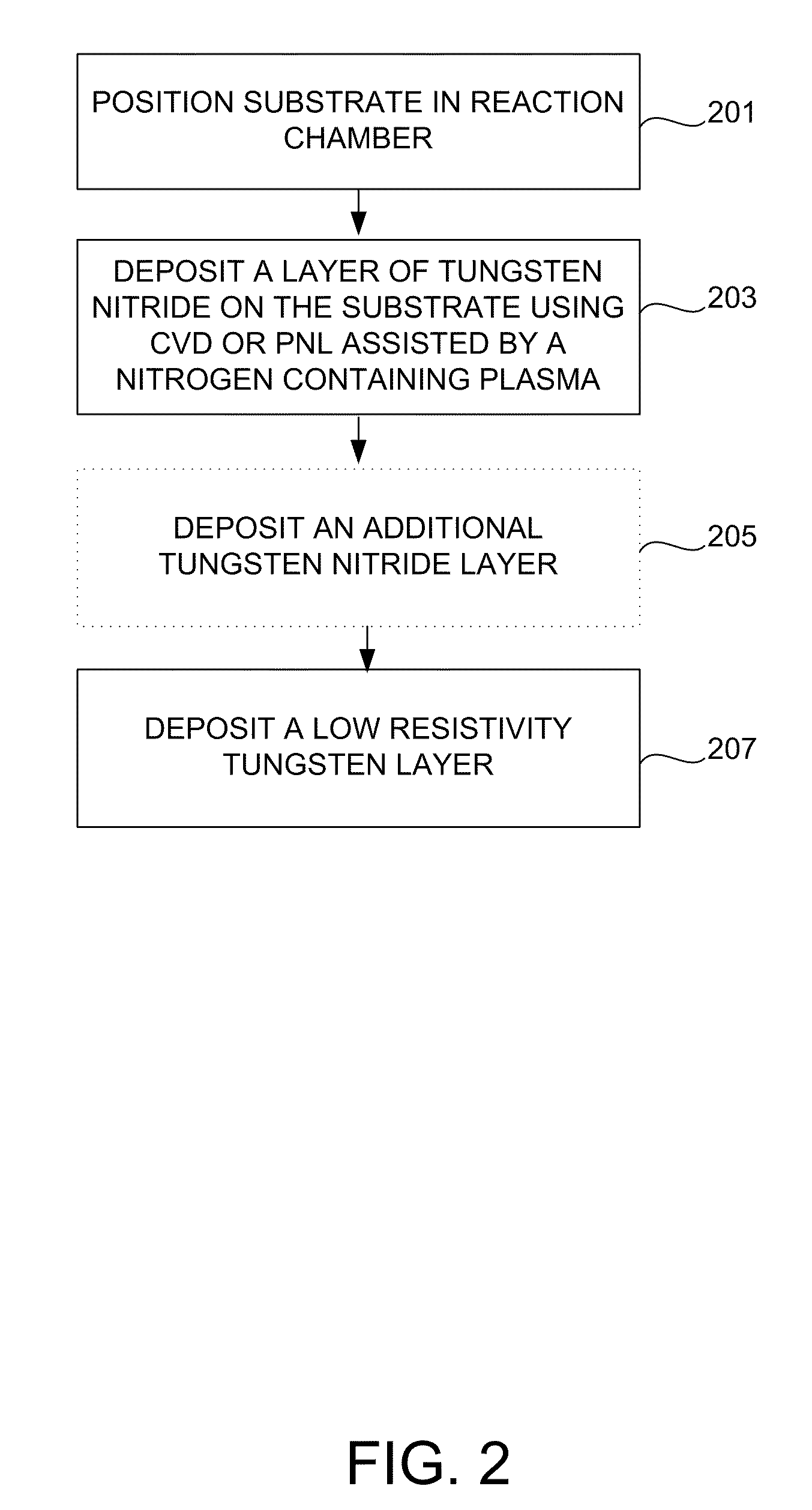

Method for improving adhesion of low resistivity tungsten/tungsten nitride layers

ActiveUS20110059608A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTungsten nitrideGaseous atmosphere

Methods of improving the adhesion of low resistivity tungsten / tungsten nitride layers are provided. Low resistivity tungsten / tungsten nitride layers with good adhesion are formed by treating a tungsten or tungsten nitride layer before depositing low resistivity tungsten. Treatments include a plasma treatment and a temperature treatment. According to various embodiments, the treatment methods involve different gaseous atmospheres and plasma conditions.

Owner:NOVELLUS SYSTEMS

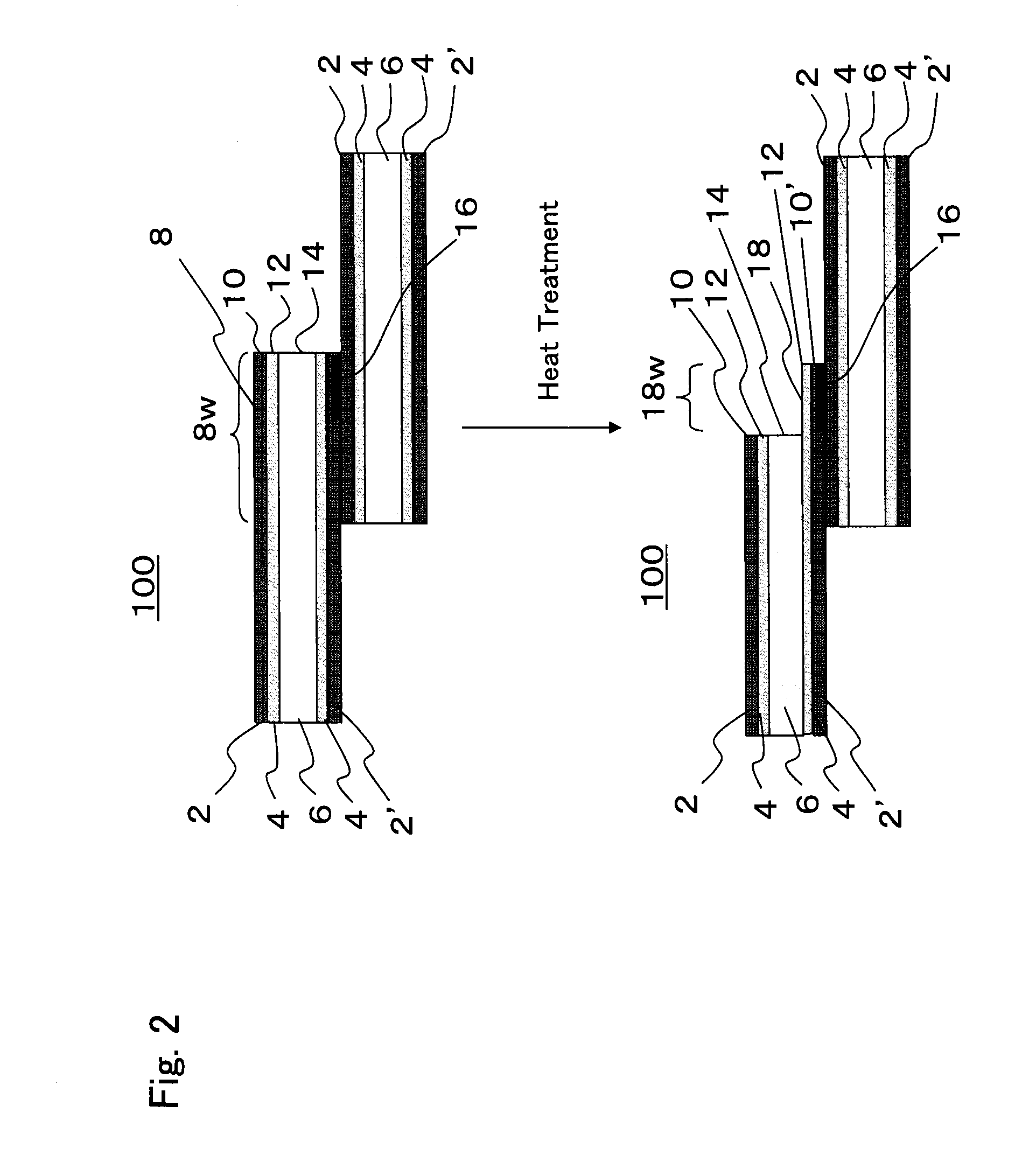

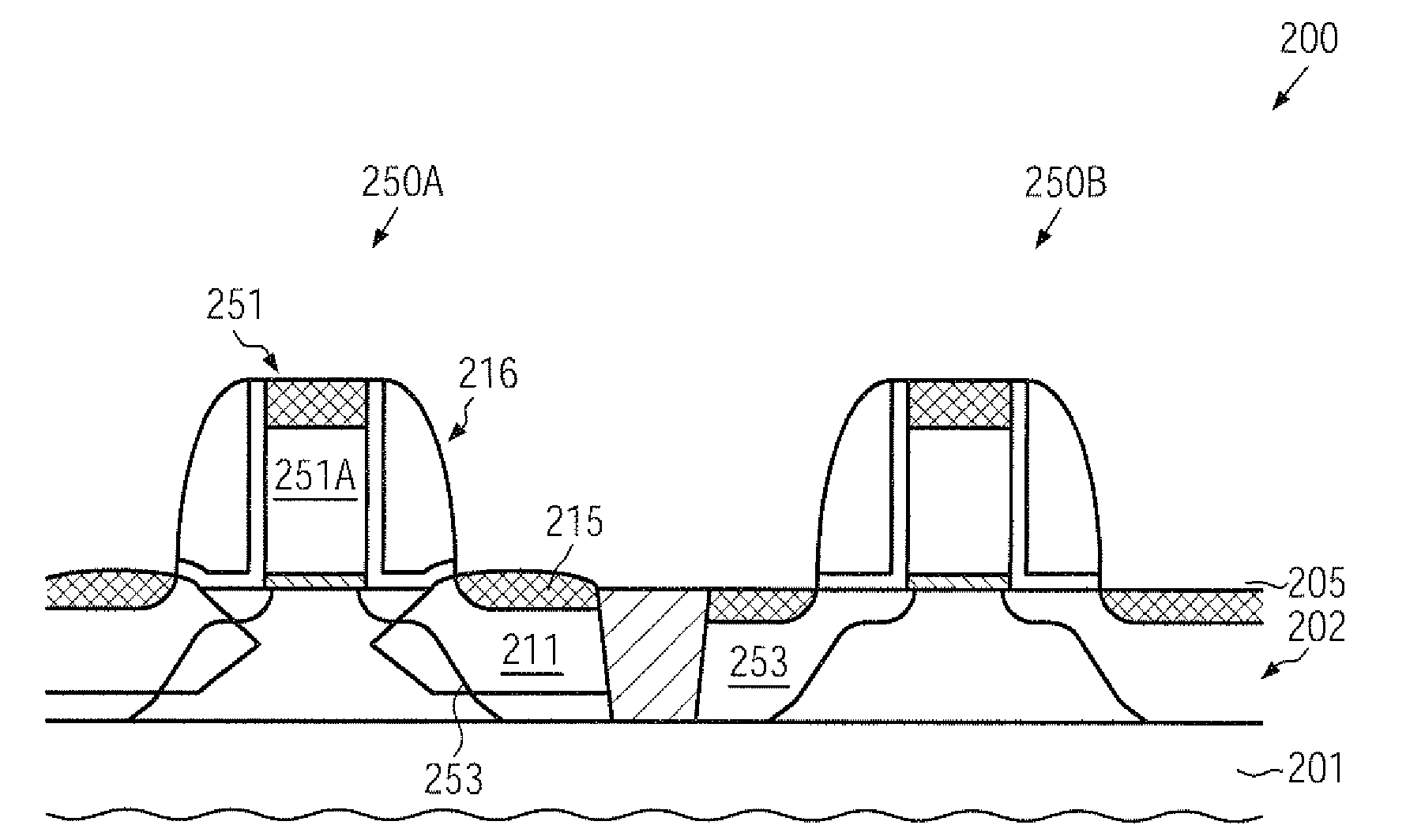

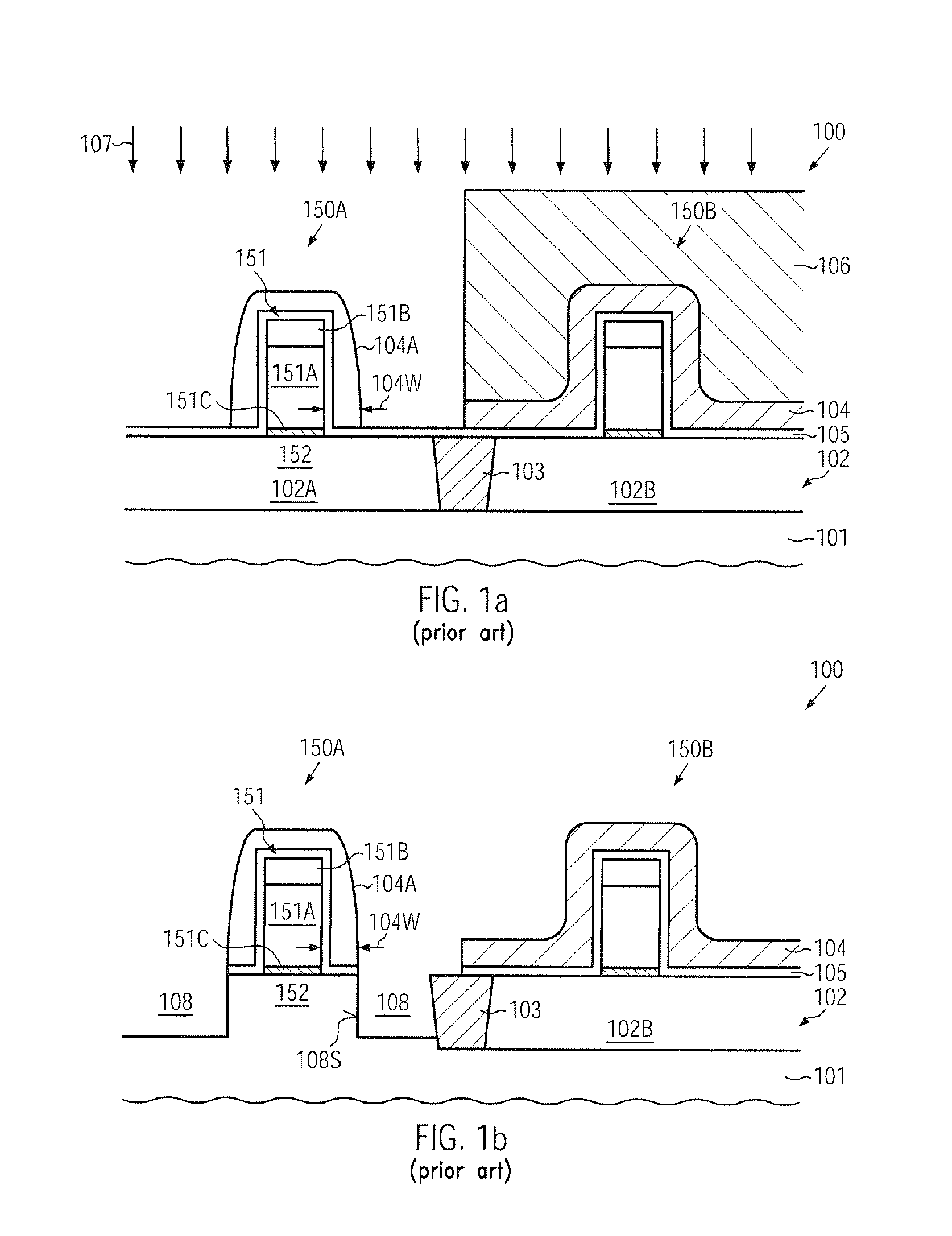

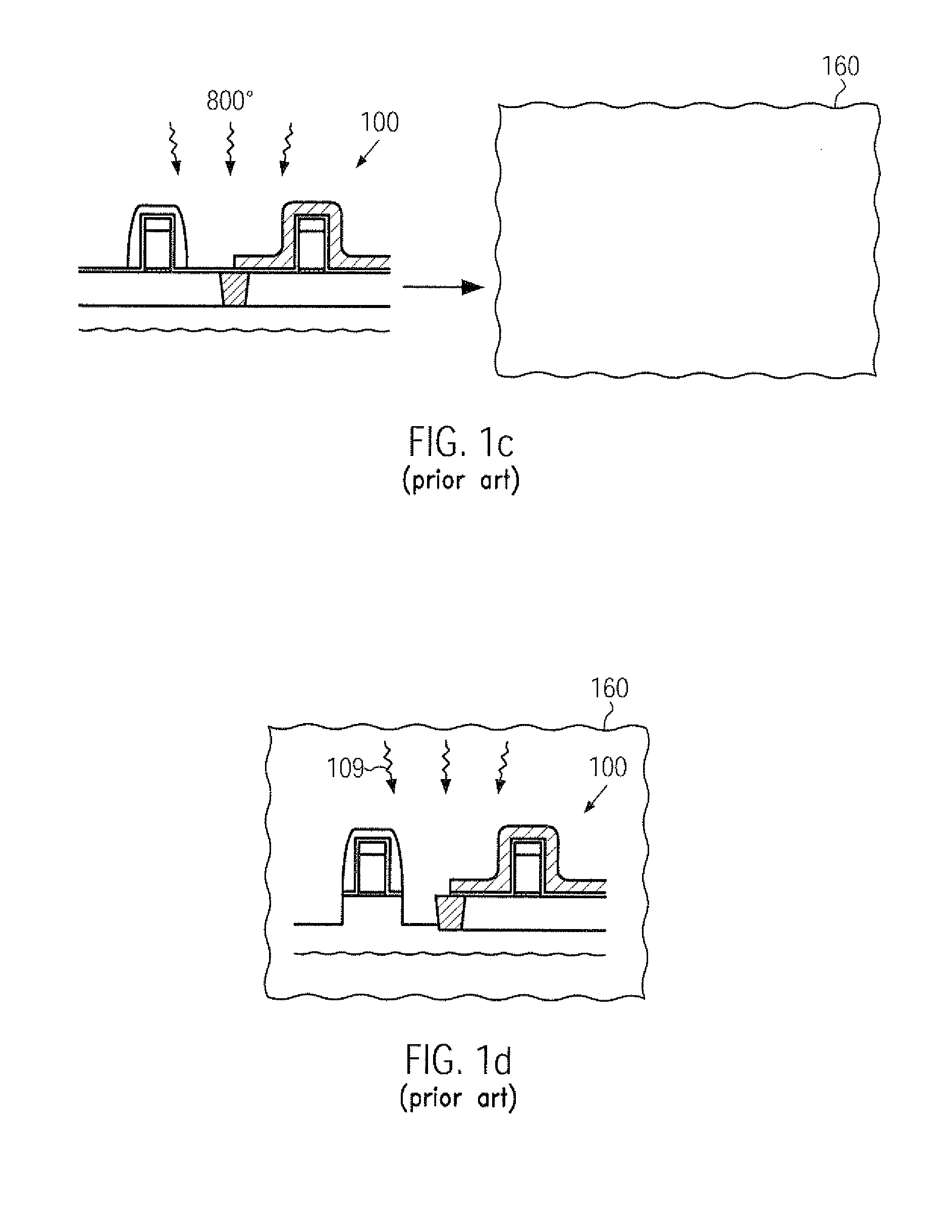

Transistor with embedded si/ge material having reduced offset to the channel region

ActiveUS20100078689A1Prevent backflowIncrease flexibilitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor alloys

A strain-inducing semiconductor alloy may be formed on the basis of cavities which may have a non-rectangular shape, which may be maintained even during corresponding high temperature treatments by providing an appropriate protection layer, such as a silicon dioxide material. Consequently, a lateral offset of the strain-inducing semiconductor material may be reduced, while nevertheless providing a sufficient thickness of corresponding offset spacers during the cavity etch process, thereby preserving gate electrode integrity. For instance, P-channel transistors may have a silicon / germanium alloy with a hexagonal shape, thereby significantly enhancing the overall strain transfer efficiency.

Owner:ADVANCED MICRO DEVICES INC

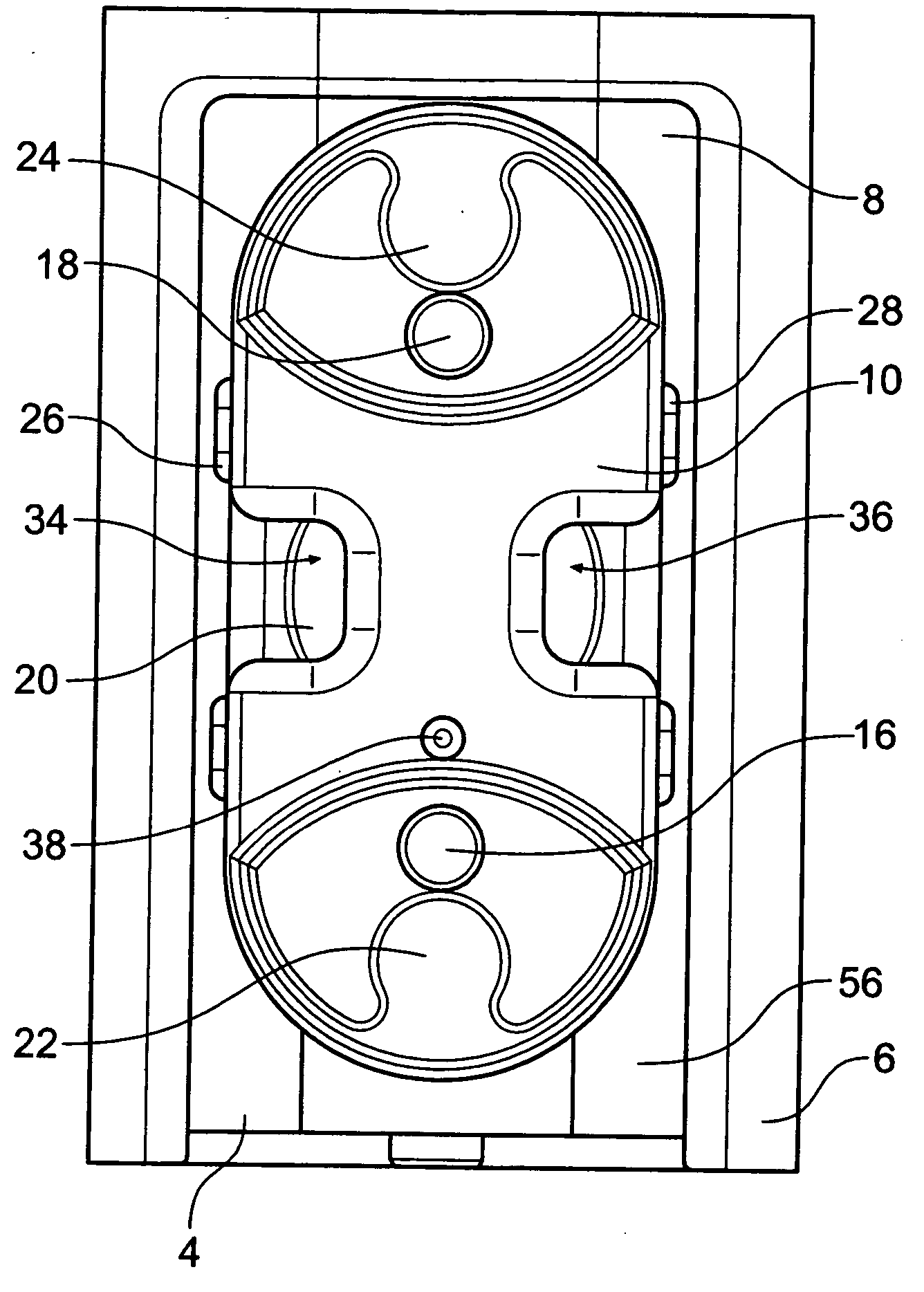

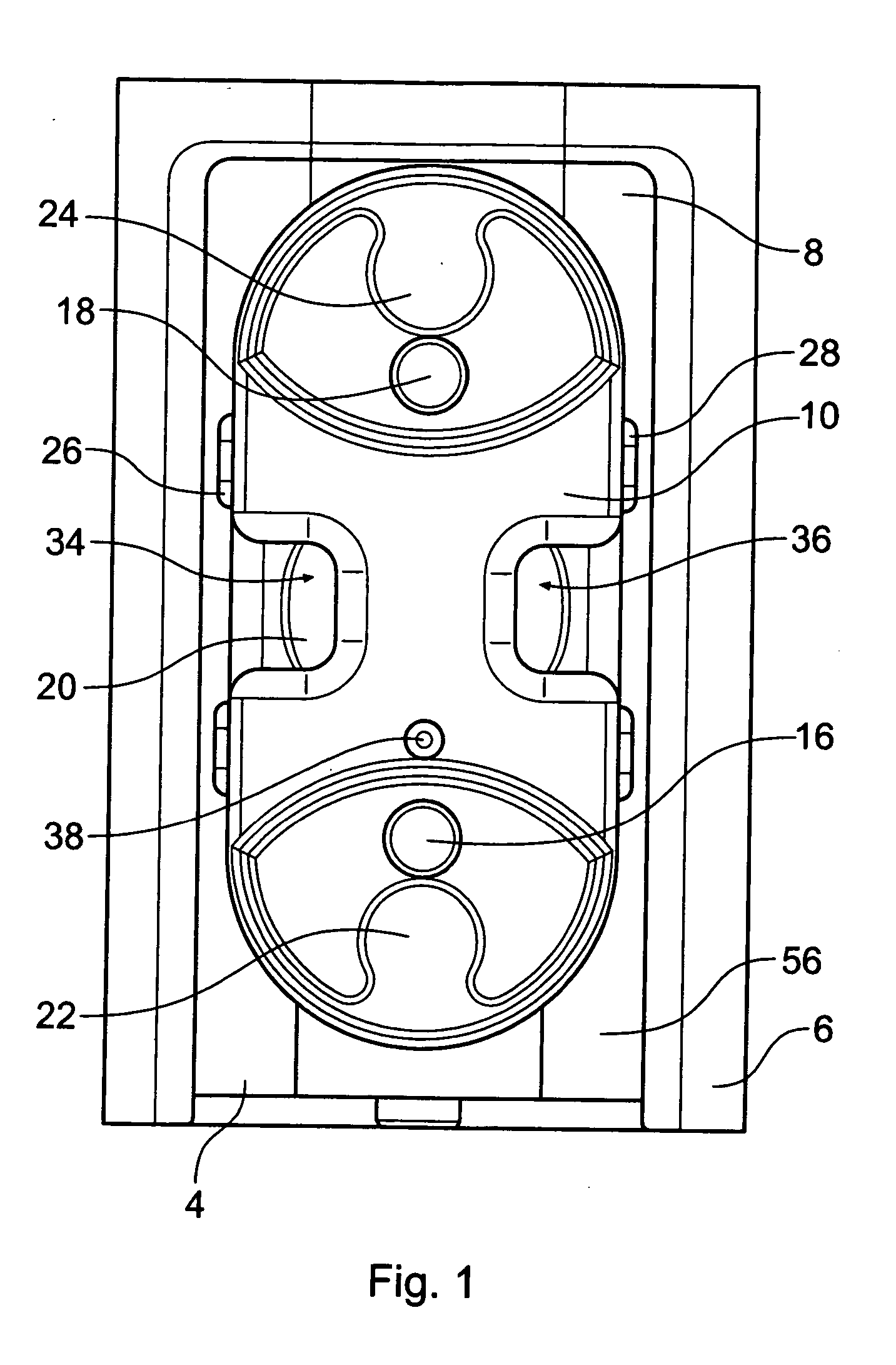

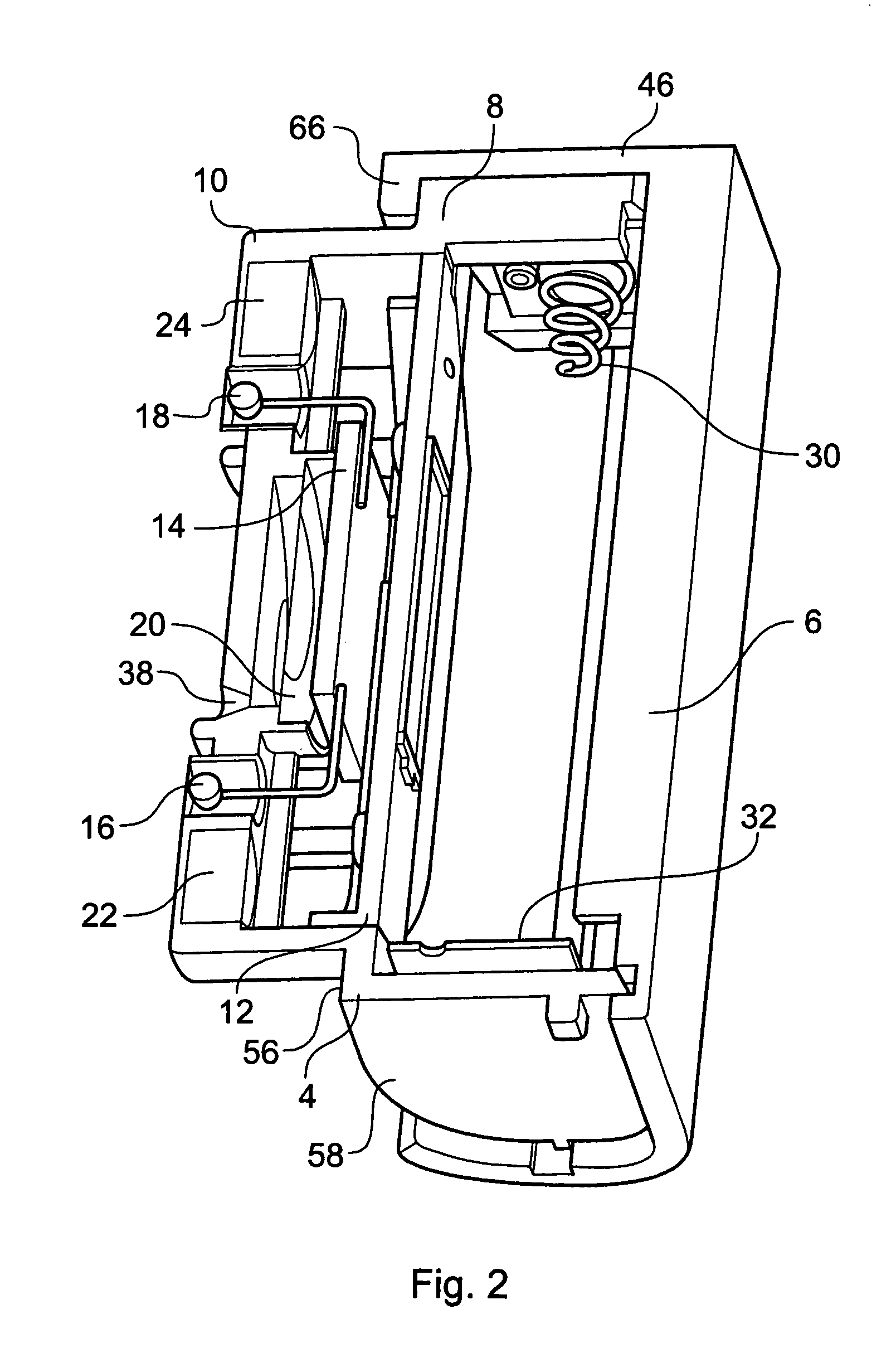

Liquid level indicators

InactiveUS20050081623A1Provide protectionEfficiently formedMachines/enginesLubrication indication devicesEngineeringTemperature treatment

A liquid level indicator, suitable for determining the level of a volatile liquid within a container, includes temperature sensors spaced vertically apart from each other. A processor processes the outputs of the temperature sensors and produces an indication, such as an audible indication by an audible alert device, when liquid level is detected. The determination of liquid level can be by one or more of various temperature processing techniques, including difference in temperature between temperature sensors, and / or difference in temperature over time at one or more of the temperature sensors.

Owner:PROD INNOVATION

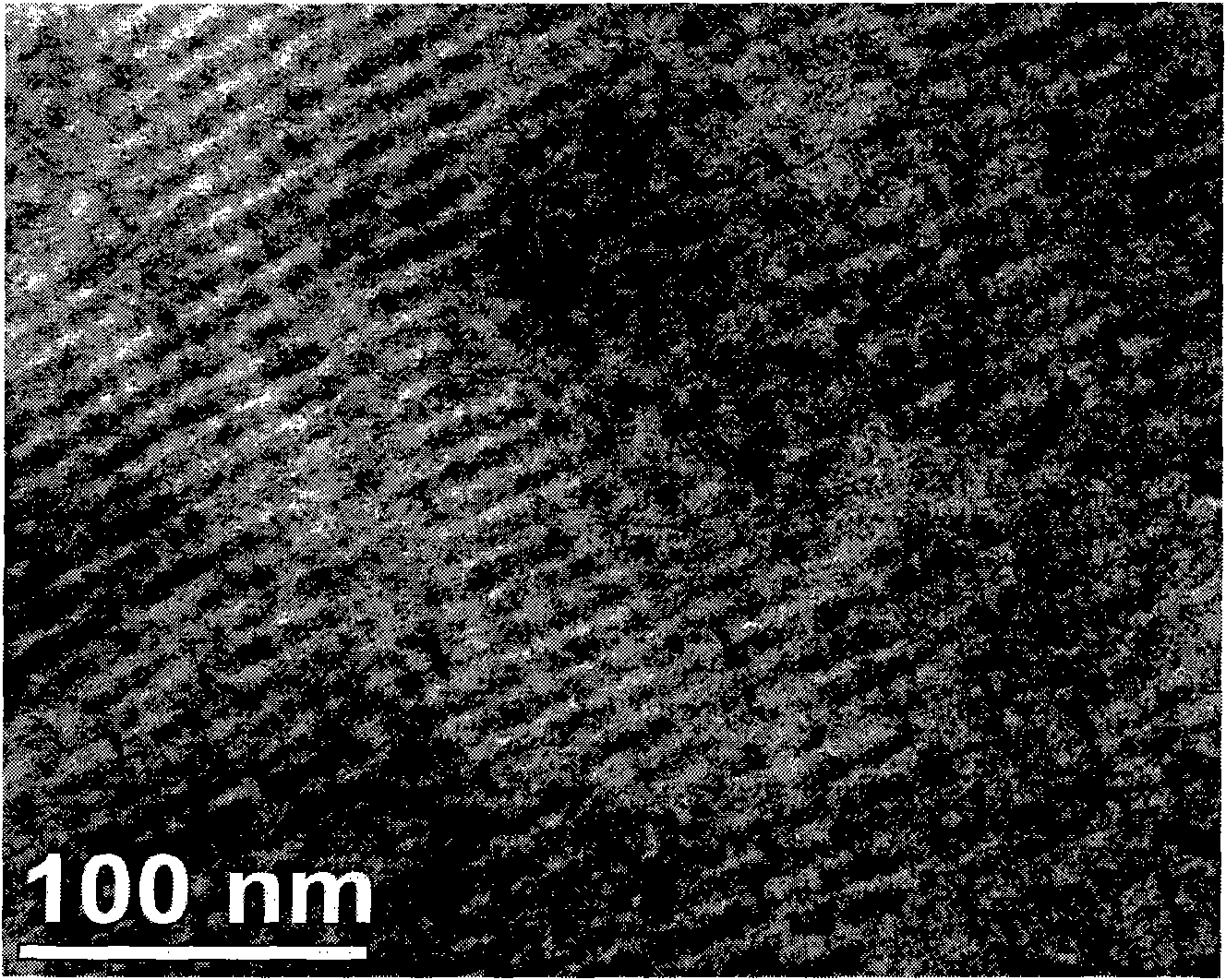

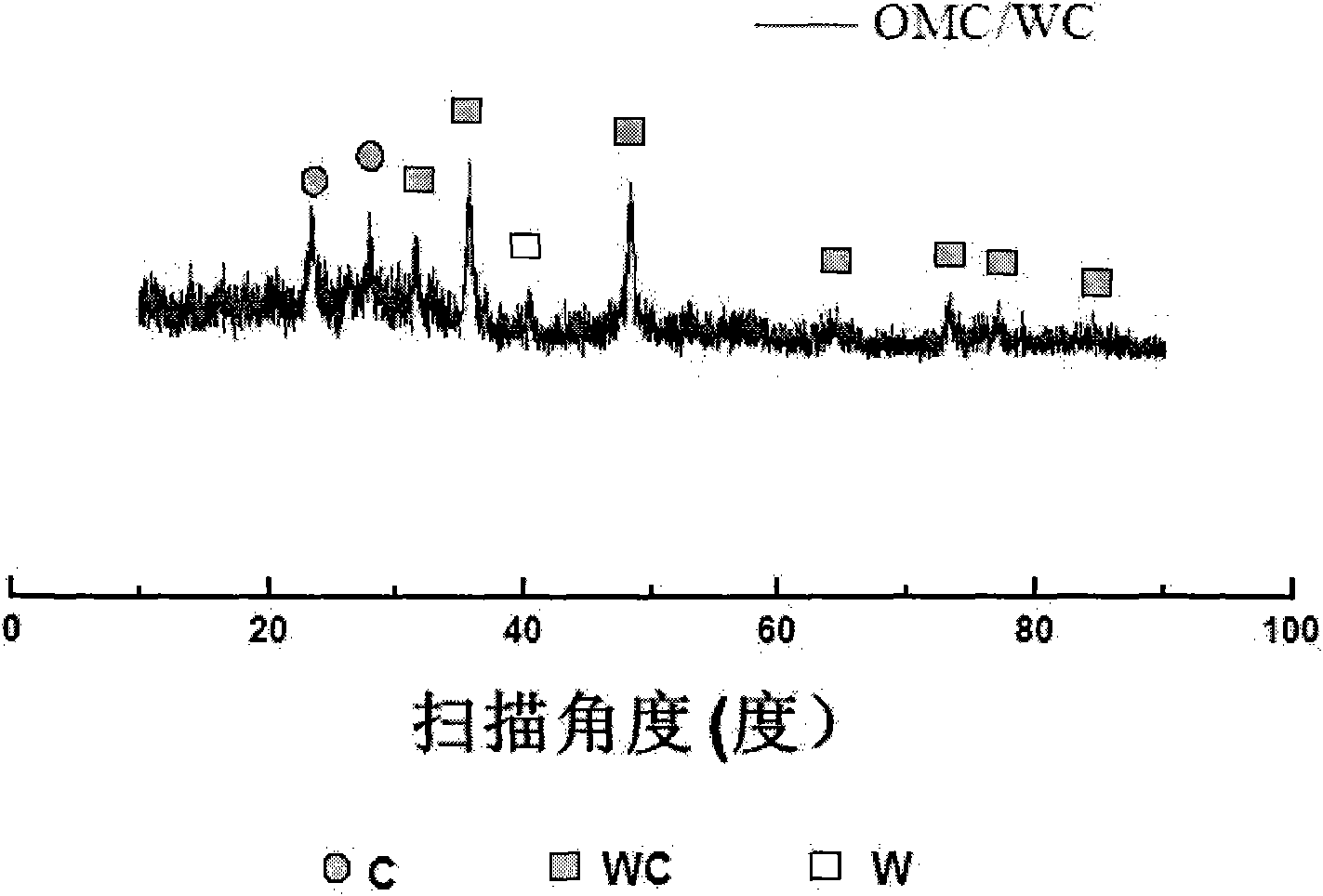

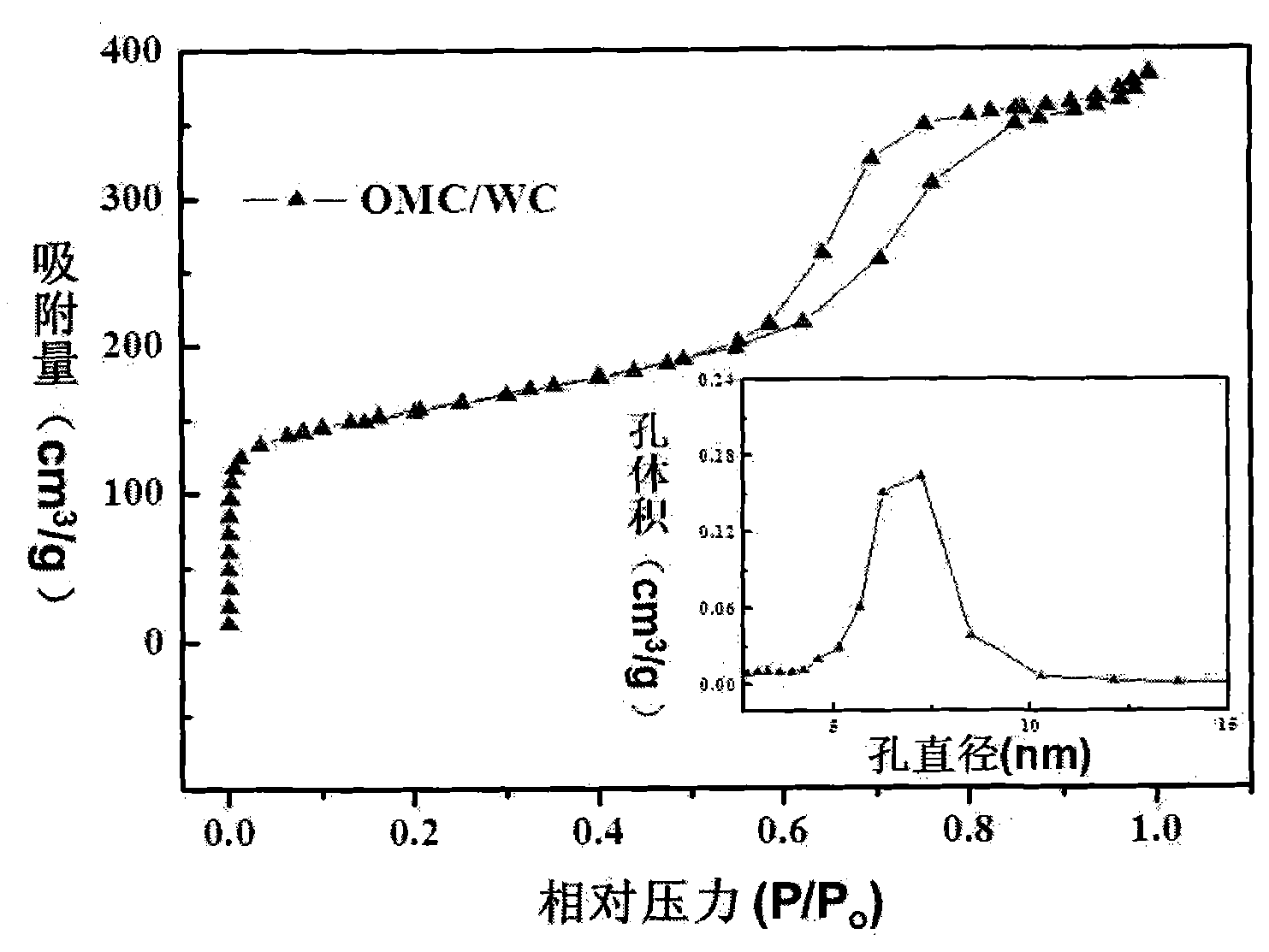

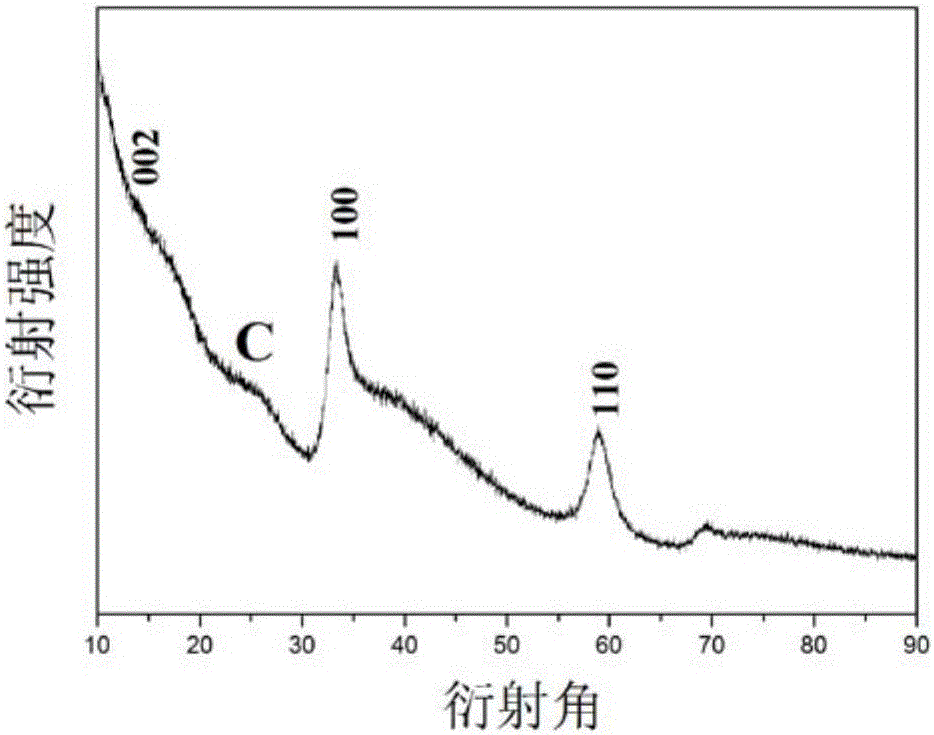

Ordered mesoporous carbon/tungsten carbide composite material and supported catalyst thereof and preparation method thereof

InactiveCN101869853AHigh degree of aperture orderNarrow pore size distributionCatalyst carriersCell electrodesSolventPt element

The invention discloses a preparation method for an ordered mesoporous carbon / tungsten carbide composite material and a supported catalyst thereof. In the method, an organic matter and a tungsten salt are separately used as a carbon source and a tungsten source, and the carbon source and the tungsten source are mixed with a surfactant; and a precursor of the ordered mesoporous carbon / tungsten carbide is synthesized by a solvent-evaporation induced self-assembly method, and then the precursor is subject to high-temperature treatment in the inert atmosphere to form the ordered mesoporous carbon / tungsten carbide composite material. The ordered mesoporous carbon / tungsten carbide composite material prepared by the method has the characteristics of high degree of order, narrow aperture distribution, large specific surface area (greater than 500 m<2> / g) and the like. The invention further comprises a supported catalyst prepared by supporting active components on the ordered mesoporous carbon / tungsten carbide composite material which is prepared by the method; and because of the synergistic effect and the structure effect of the ordered mesoporous carbon / tungsten carbide composite material, the catalyst has higher methanol electro-oxidation catalytic activity than a commercial carbon platinum-ruthenium catalyst.

Owner:SUN YAT SEN UNIV

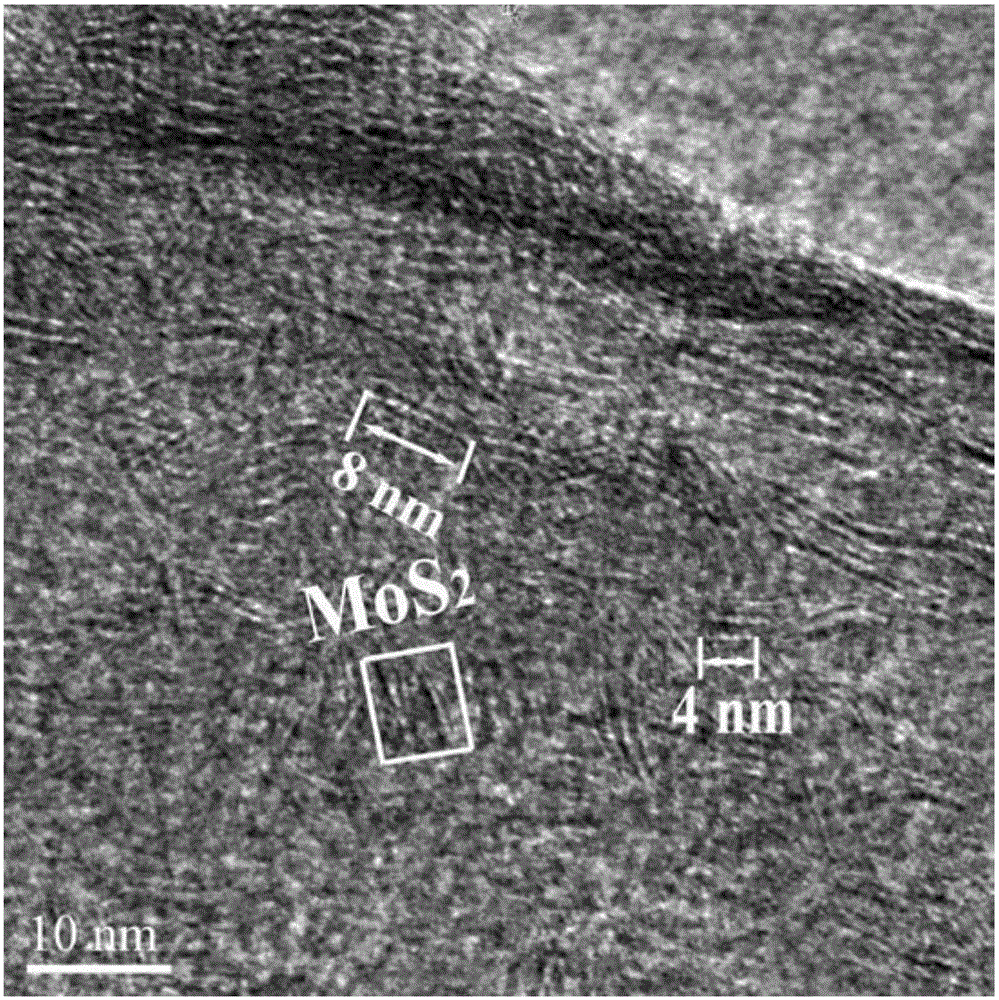

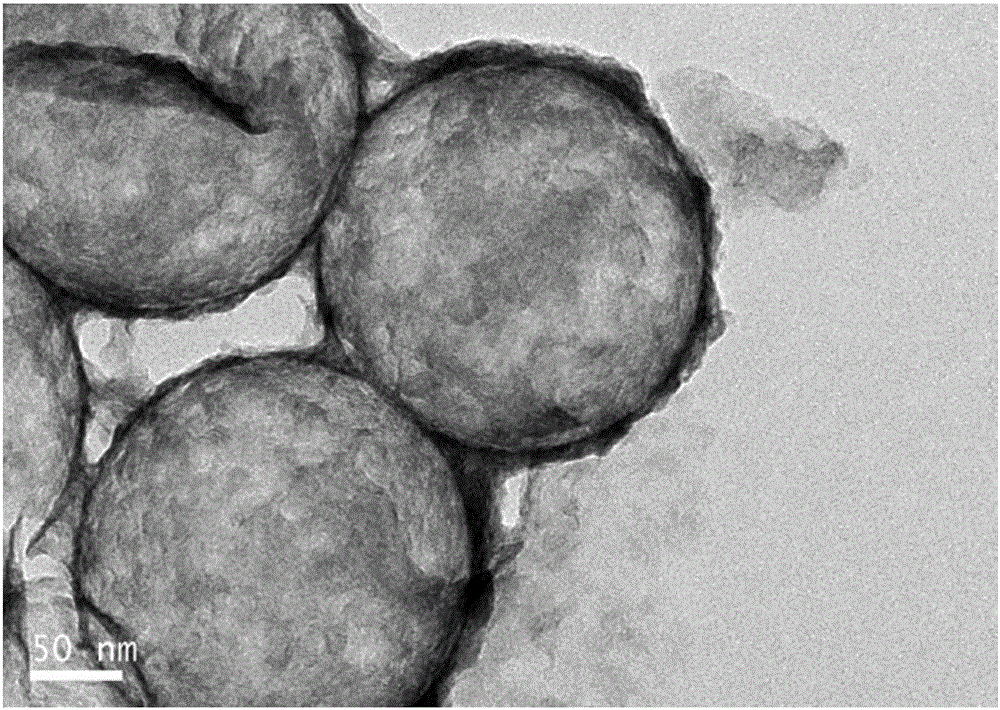

Molybdenum disulfide-carbon hollow ball hybrid material and preparation method thereof

InactiveCN105098151AShorten the transmission distanceImproved magnification performanceCell electrodesSecondary cellsSolventSilicon dioxide

The invention discloses a molybdenum disulfide-carbon hollow ball hybrid material. The molybdenum disulfide-carbon hollow ball hybrid material has a hollow ball structure; and the hybrid material formed by embedding a single layer of molybdenum disulfide nanosheet or a few of layers of molybdenum disulfide nanosheets into a carbon material is a shell layer of the hollow ball. The invention further discloses a preparation method of the molybdenum disulfide-carbon hollow ball hybrid material. The method comprises the following steps: with amino-modified silica particles as a template, coating the template with an organic pyrolytic carbon material and ammonium tetrathiomolybdate through solvothermal reaction; carrying out high-temperature treatment in an inert atmosphere; and finally removing a silicon dioxide template, so as to obtain the molybdenum disulfide-carbon hollow ball hybrid material disclosed by the invention. The initial lithium insertion capacity of the molybdenum disulfide-carbon hollow ball hybrid material disclosed by the invention is close to 1010mAh / g; and the specific capacity can still be kept at 662mAh / g after 40 repeated charge and discharge cycles.

Owner:SHANGHAI JIAO TONG UNIV

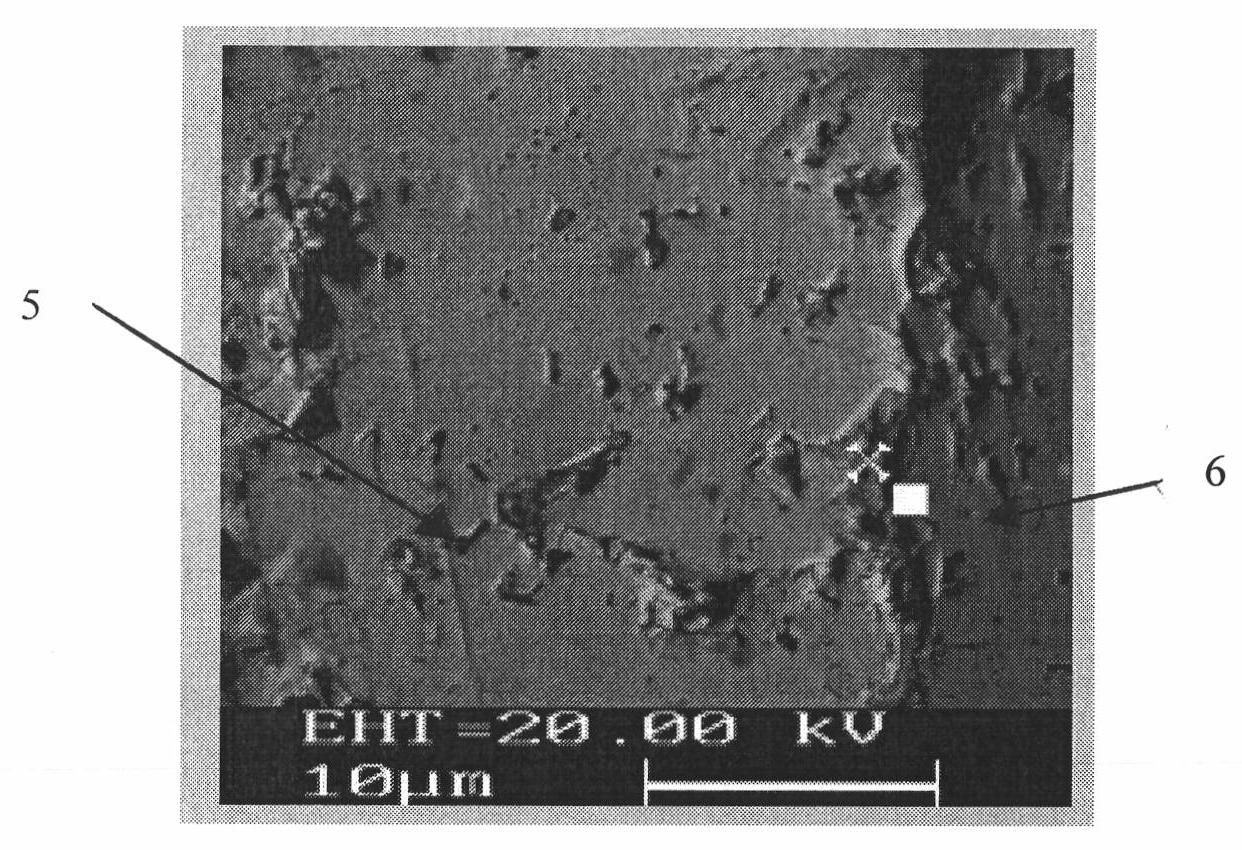

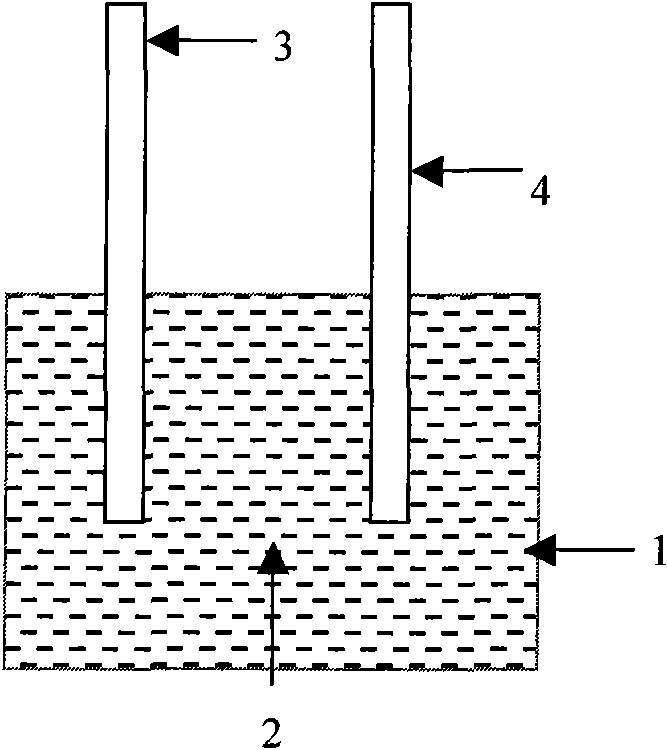

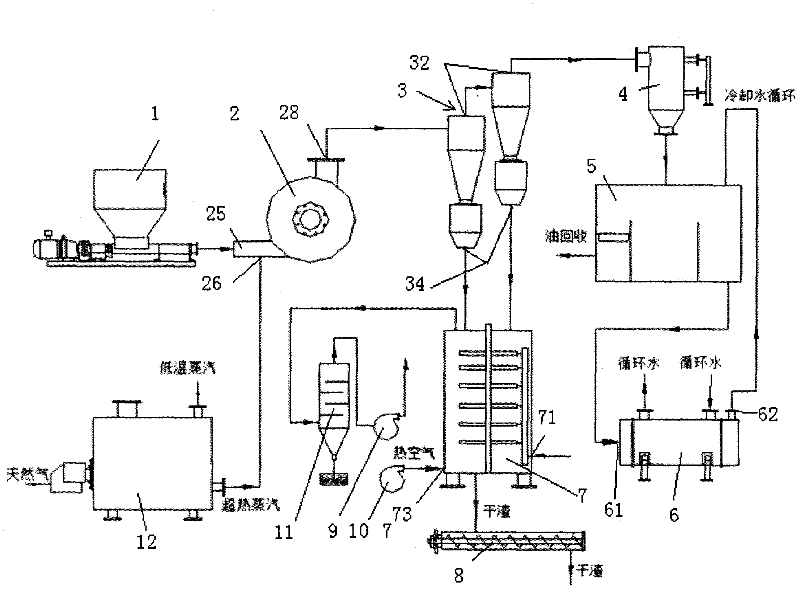

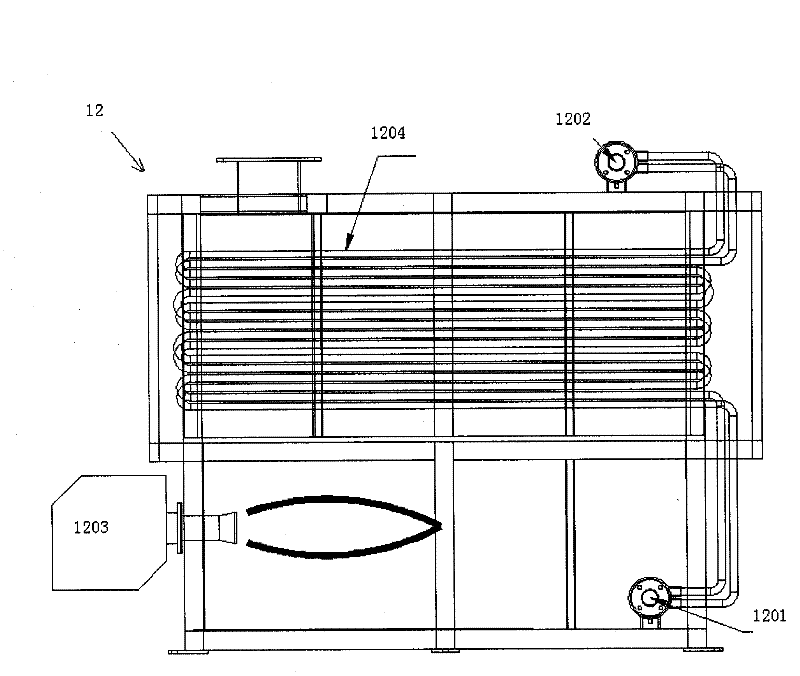

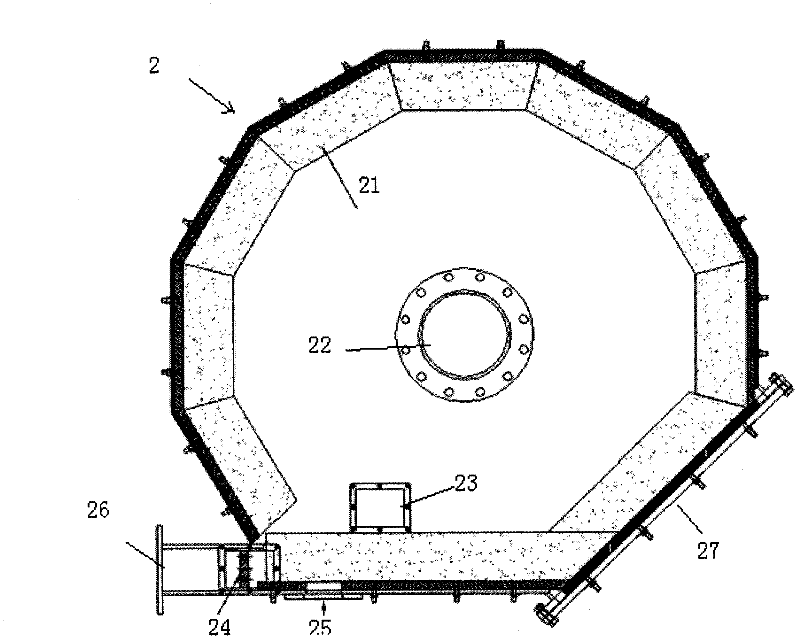

Treatment method and treatment apparatus of oily sludge

InactiveCN102503055AHigh recovery rateReduce moisture contentSludge treatment by thermal conditioningSludgeLiquid state

The invention provides a treatment method of oily sludge, which comprises the steps of: introducing overheated vapor into a high temperature treatment groove to roast the oily sludge so as to evaporate the liquid containing oil and water in the oily sludge to gas; separating the solid granules from the oily sludge and contained in the gas in a gas-solid separator, and conveying the solid granules to a drying machine to be dried and burnt so as to be discharged; condensing the gas separated from the gas-solid separator to liquid state oil and water, separating the liquid state oil and water in an oil-water separator to be respectively recycled, wherein the oily sludge is introduced into the high temperature treatment groove in a pumping manner, the overheated vapor is introduced into the high temperature treatment groove by supersonic jet flow and is vertically collided with the oily sludge. The invention further provides a treatment apparatus of oily sludge for executing the method; the treatment method and treatment apparatus provided by the invention have the advantages of guaranteeing high crude oil recovery, and small water content and oil content of finally generated dry residues.

Owner:河北海清大地环保科技有限公司

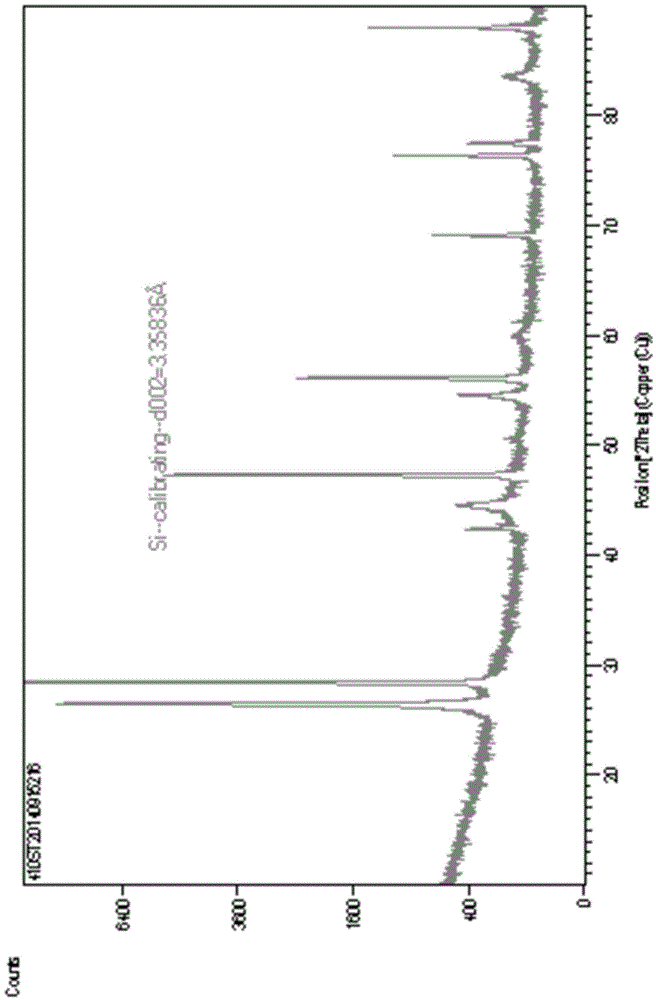

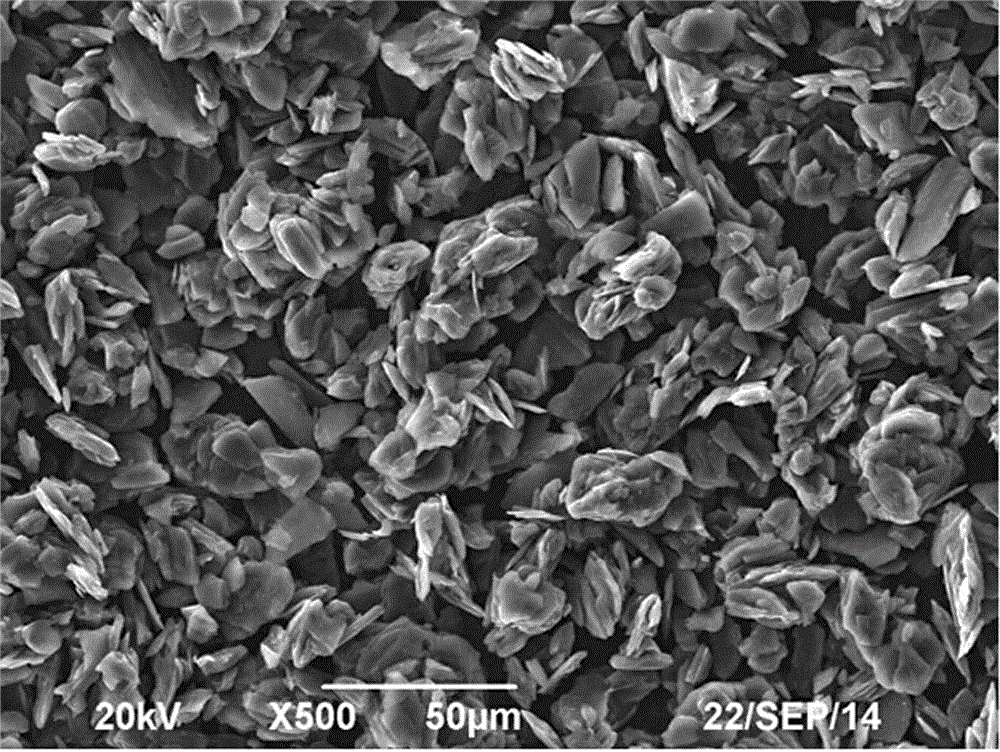

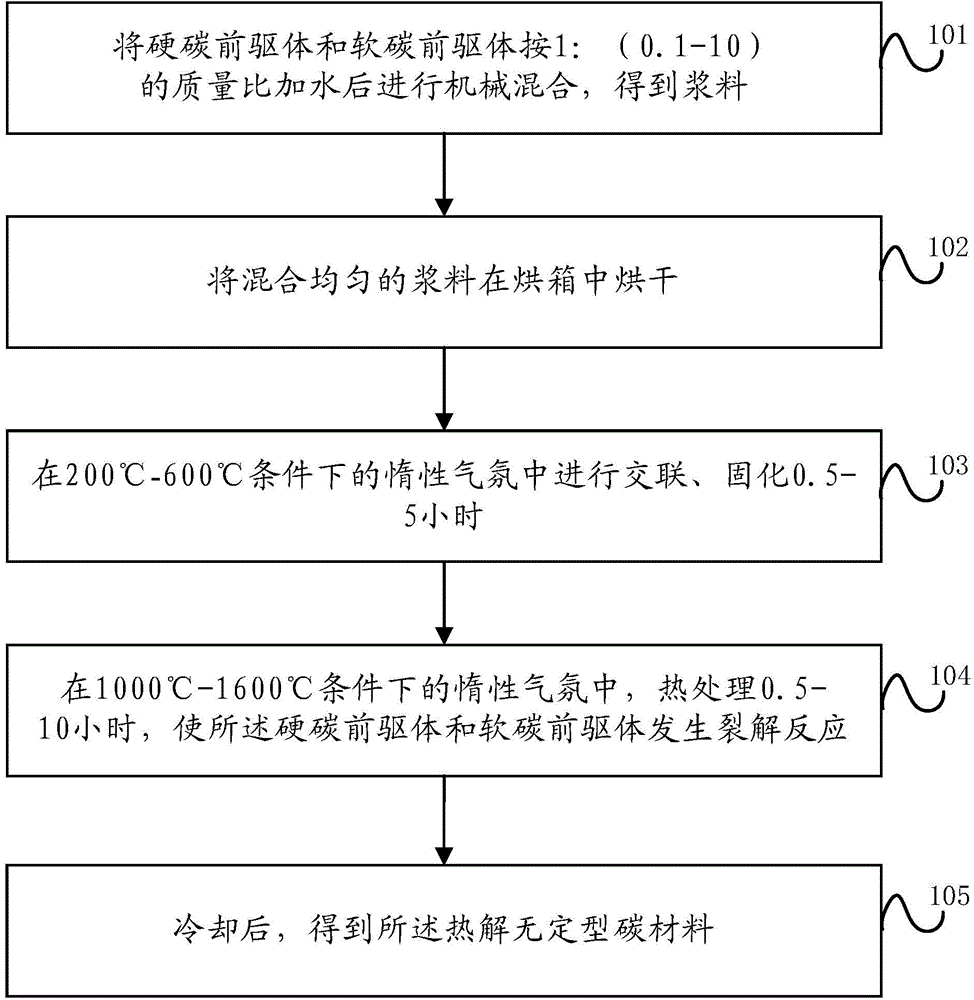

Pyrolysis amorphous carbon material and preparation method and application thereof

The invention discloses a pyrolysis amorphous carbon material and a preparation method and application thereof. The pyrolysis amorphous carbon material is shaped as particles, the average grain size of the particles is 1-100 micrometers, a d<002> value is between 0.35 nanometer and 0.44 nanometer, an L<c> value is between 0.5 nanometer and 4 nanometers, and an L value is between 3 nanometers and 5 nanometers. The preparation method comprises the following steps of: adding a hard carbon precursor and a soft carbon precursor into a solvent and fully mixing to obtain a slurry; drying the slurry and crosslinking and curing the slurry for 0.5 to 5 hours in an inert atmosphere with a condition of 200-600 DEG C; carrying out high-temperature treatment for 0.5 to 10 hours in the inert atmosphere with a condition of 1,000-1,600 DEG C; and cooling to obtain the pyrolysis amorphous carbon material. The material is wide in application, and particularly serves as an anode material of a sodium ion secondary battery or a lithium ion secondary battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com