Patents

Literature

1281 results about "Cell material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

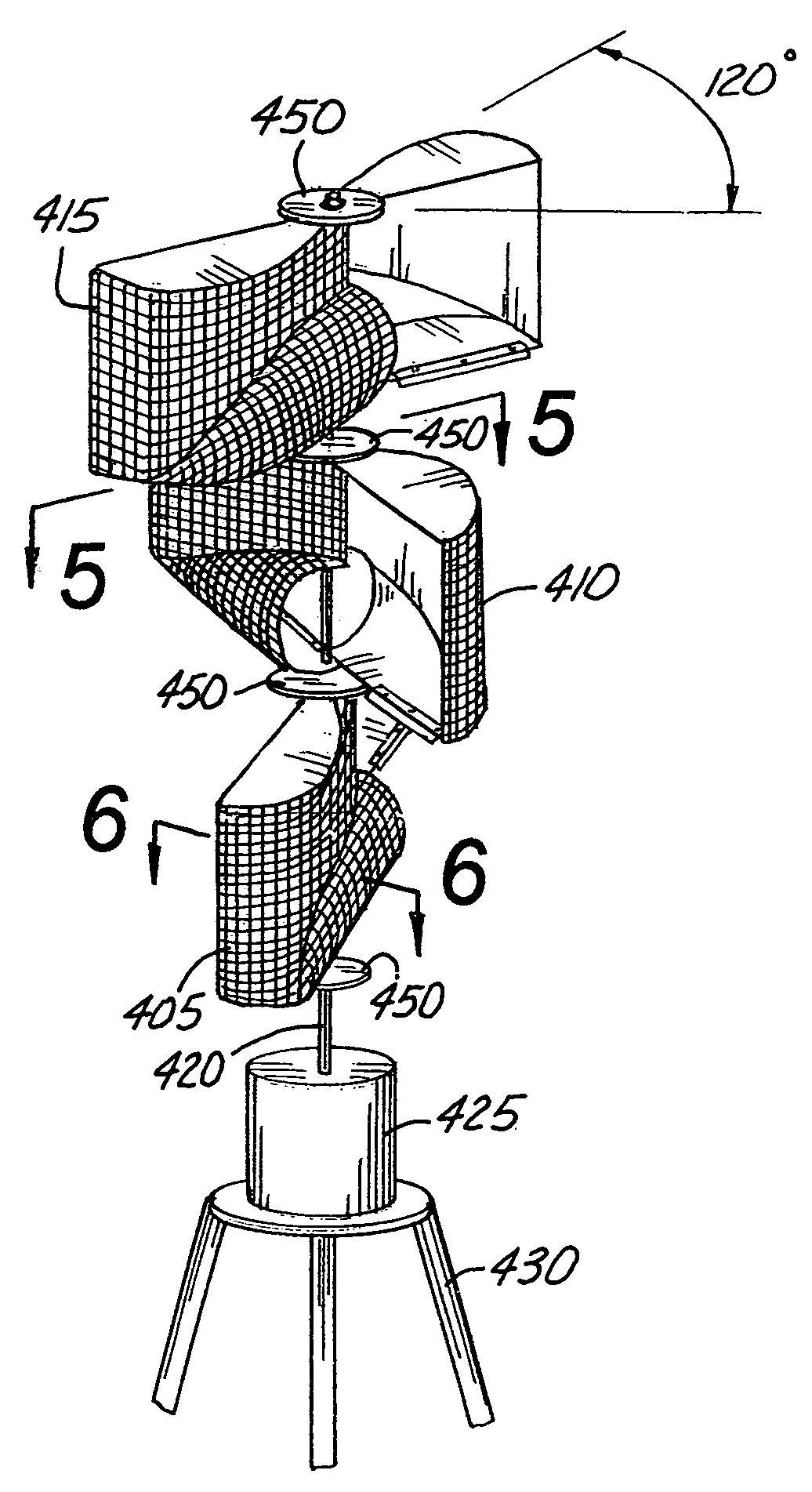

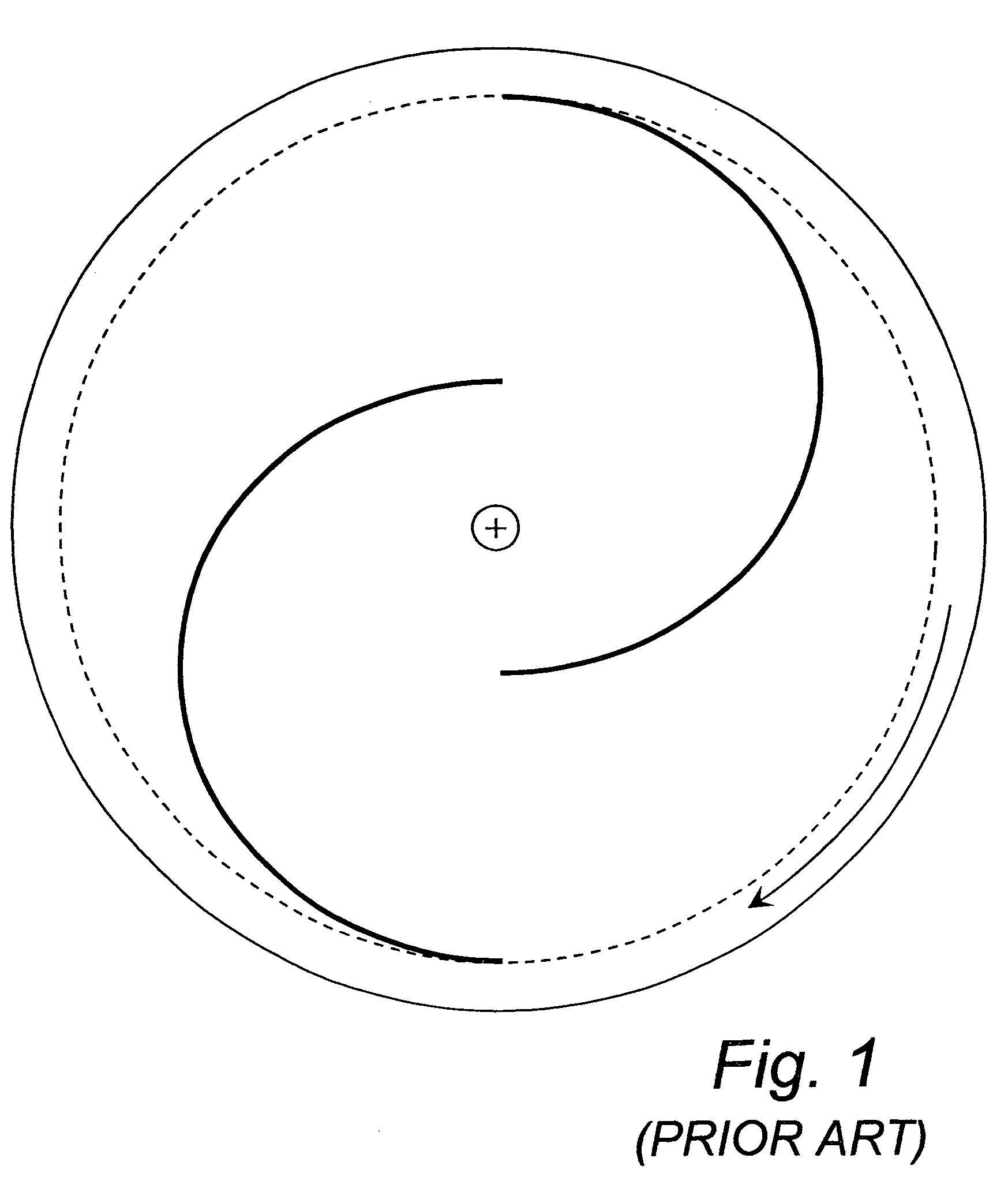

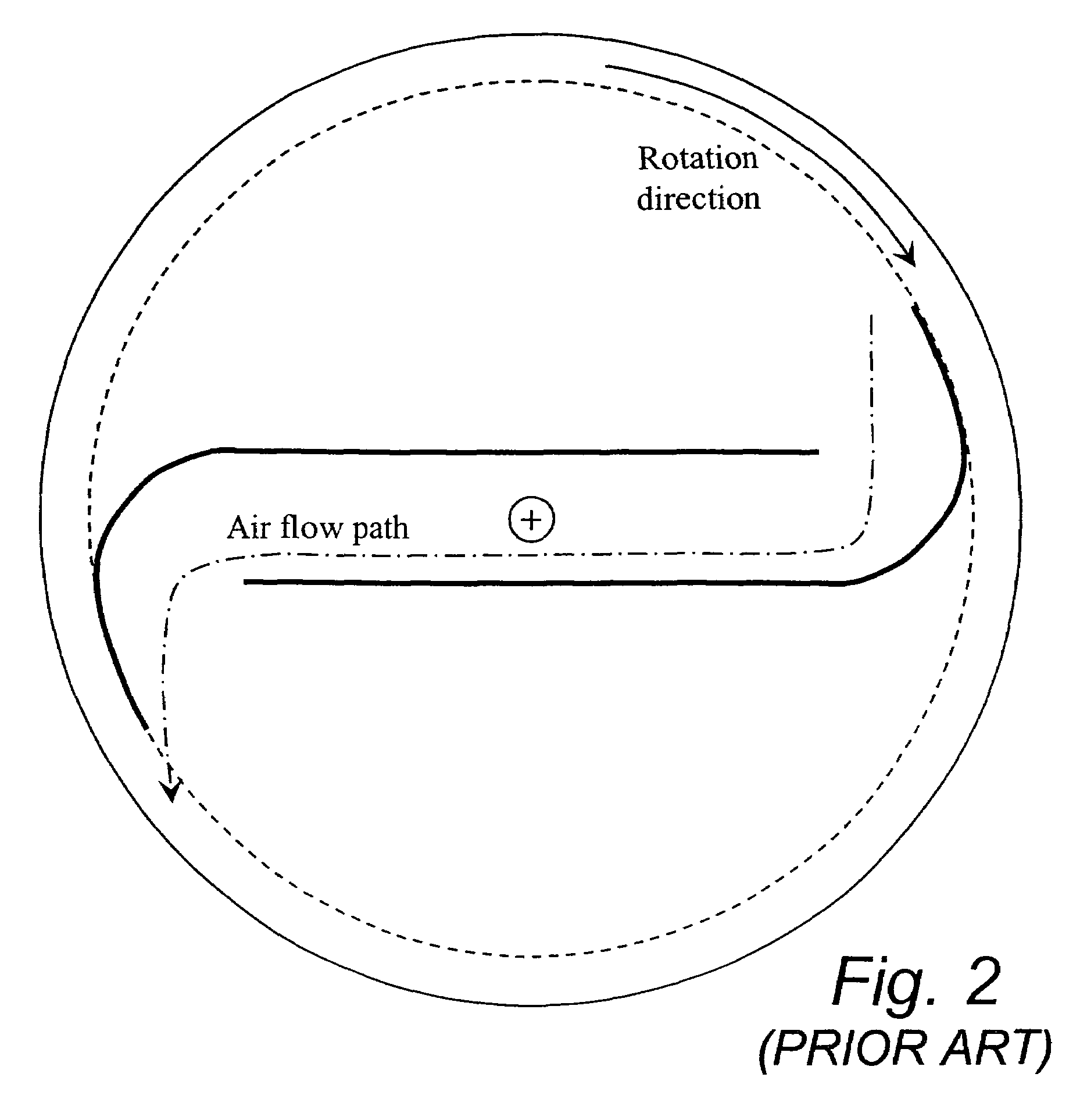

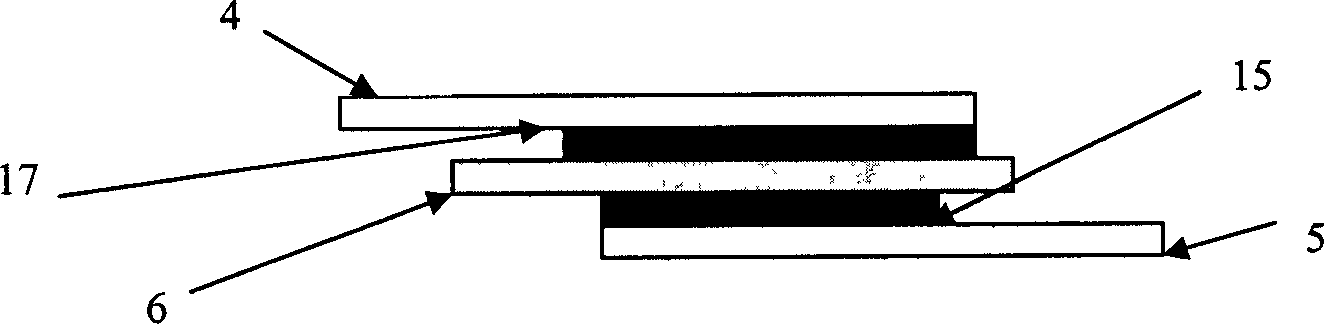

Modified Savonius rotor

A novel modification of a Savonius rotor used as a wind turbine provides an exhaust channel in each vane. The vane of the modified Savonius rotor is formed into an “S” shape. The air that enters a given end of the vane exits that end through the new exhaust channel into the freestream. A plurality of modified Savonius rotors are stacked one on top of the other for self-starting and greater power output. The outer surfaces of the entire assembly may be coated with photo voltaic cell material for additional energy production. In one embodiment of the invention, a cone shaped solar collector is placed on top of the entire modified Savonius rotor assembly.

Owner:CIRCLE WIND CORP

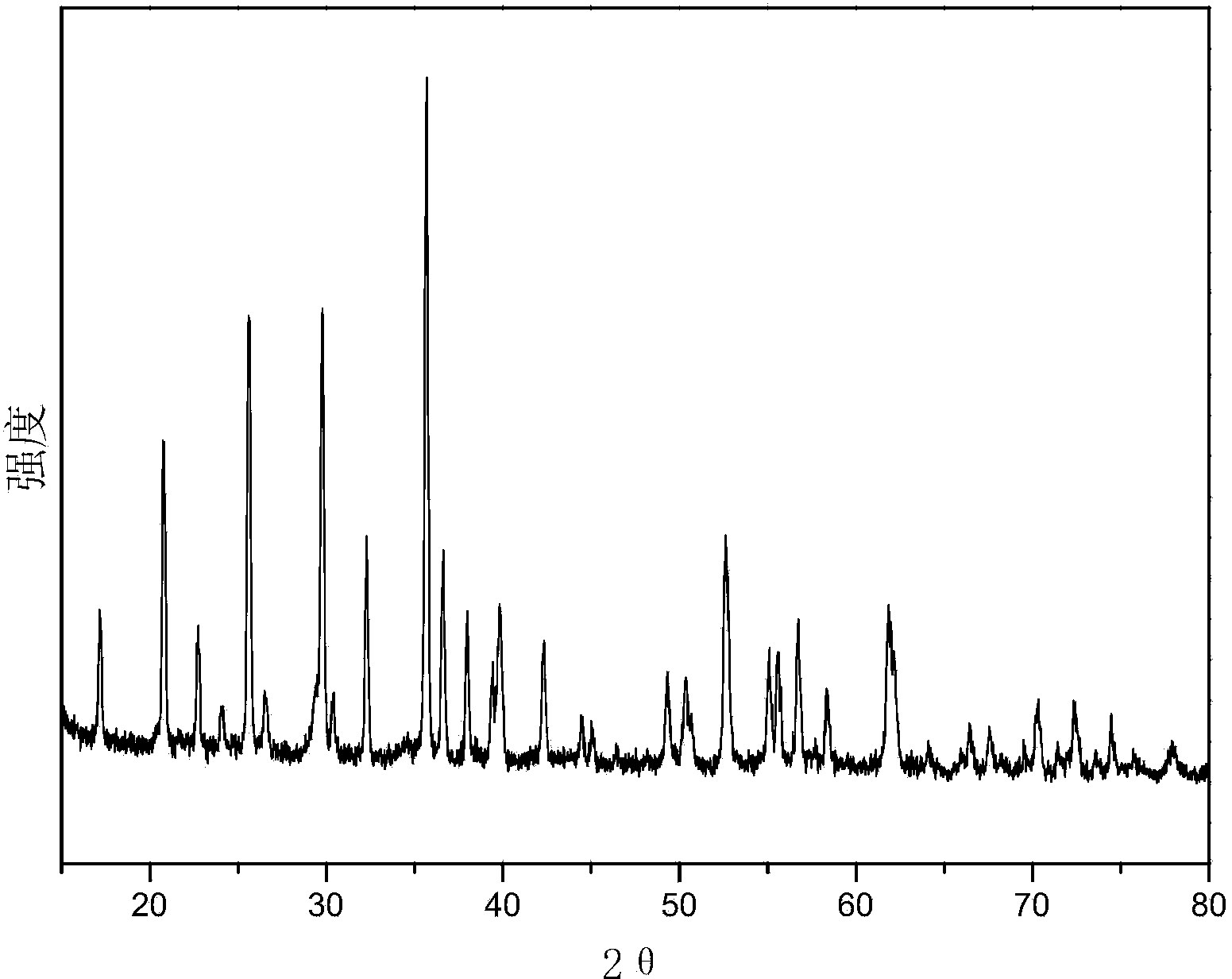

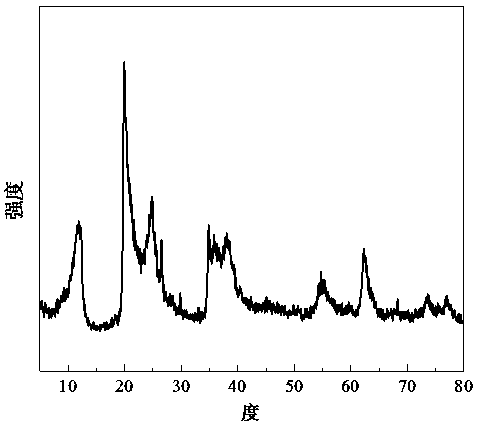

Rare earth doped carbon clad type nanometer anode material iron lithium phosphate and its preparation method

InactiveCN1830764AIncrease capacityImprove cycle lifeCell electrodesPhosphorus compoundsEpoxyRare earth

A carbon-coated RE-doped iron lithium phosphate nano-particle used for positive electrode of battery is prepared from FeC2H4, H2O, Li2CO3, NH4H2PO4, Y2O3, CeO2 and epoxy resin through proportional mixing, ball grinding, baking, sieving, calcining in N2 atmosphere at 350 deg.C and 600-750 deg.C respectively, and keeping the temp for a certain time.

Owner:TSINGHUA UNIV +1

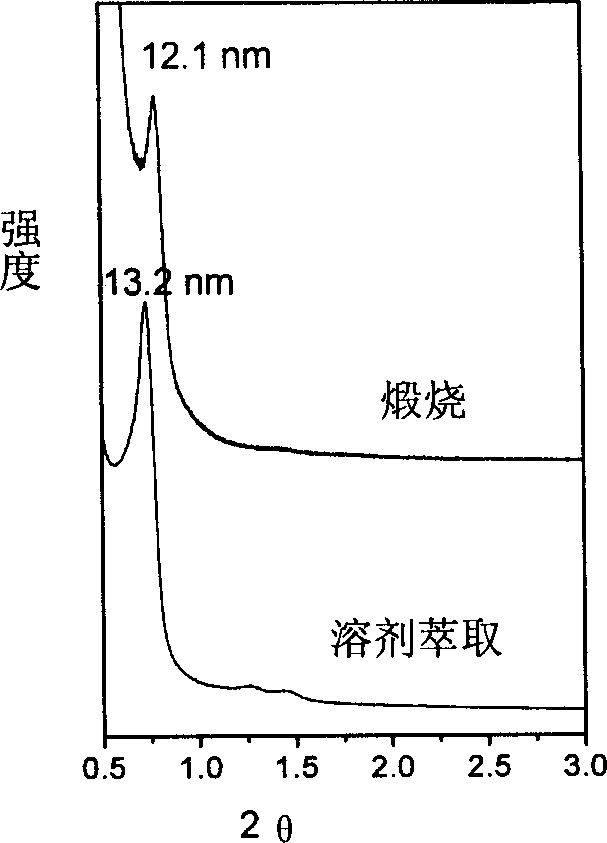

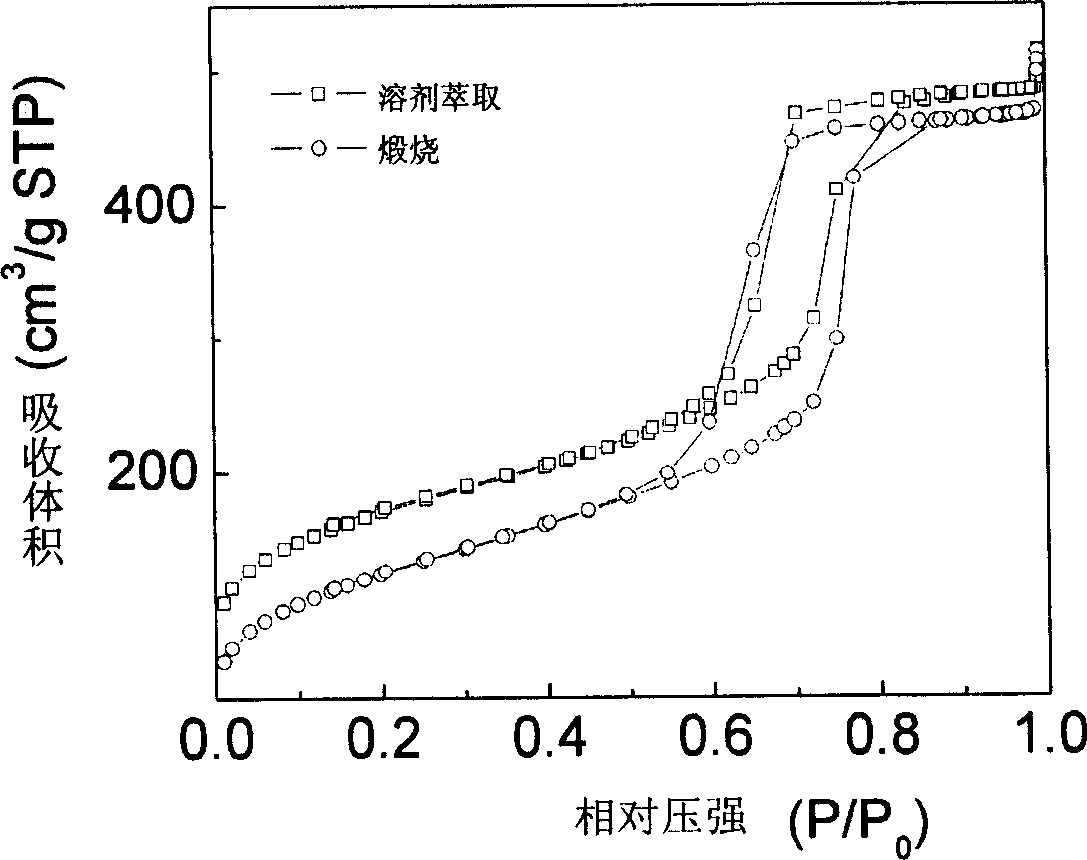

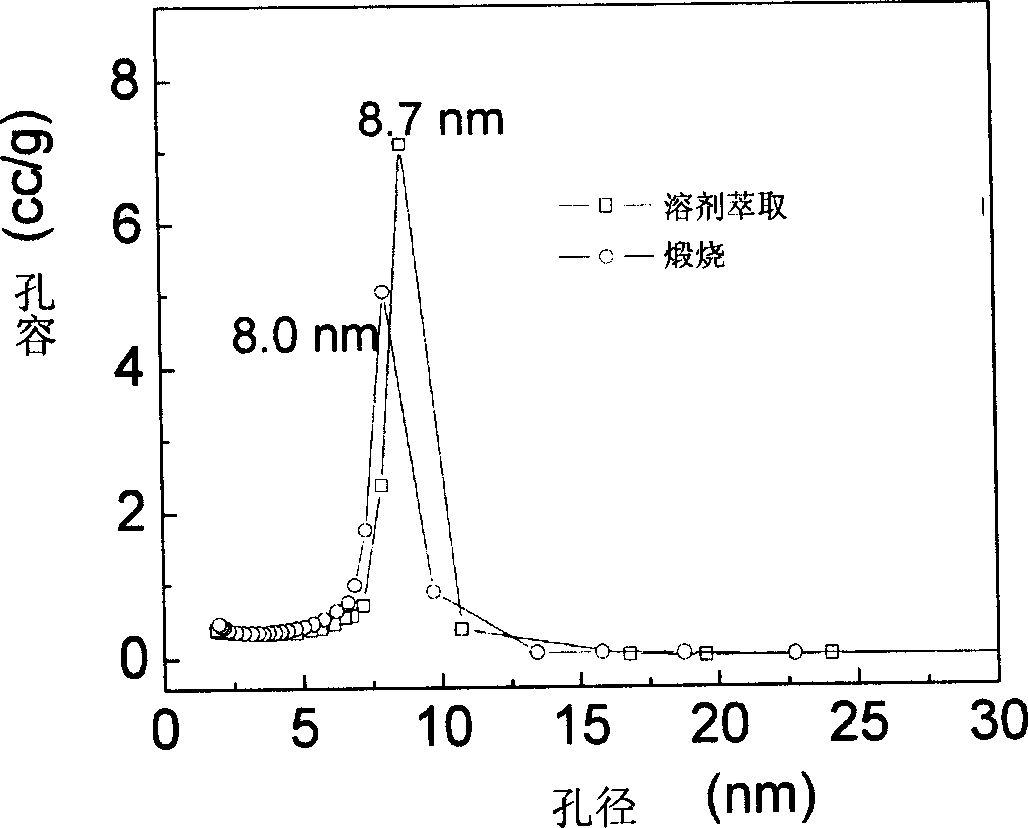

Method for preparing mesoporous carbon material

The present invention belongs to the field of material preparing technology. By means of sol-gel technology, organic high molecule and silicon source are led into a surfactant self-assembling reaction system so as to prepare high ordered mesoporous high molecule / silica and carbon / silica composite material and ordered mesoporous carbon material through organic-organic competition, inorganic-inorganic competition, organic-inorganic competition, cross-linking polymerization coordinate assembling and solvent volatizing self assembling. The prepared mesoporous carbon material has high order property, great specific surface area, great caliber and great porosity, as well as excellent electrochemical properties as super capacitor and cell material. It has also wide application foreground in catalysis, adsorption, biomolecule separation, and other fields.

Owner:FUDAN UNIV

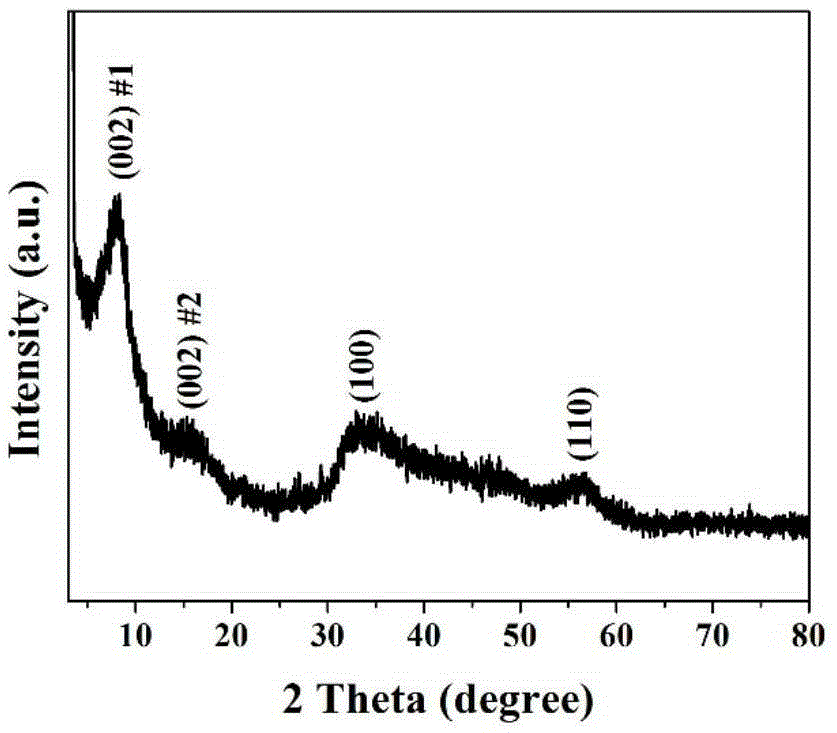

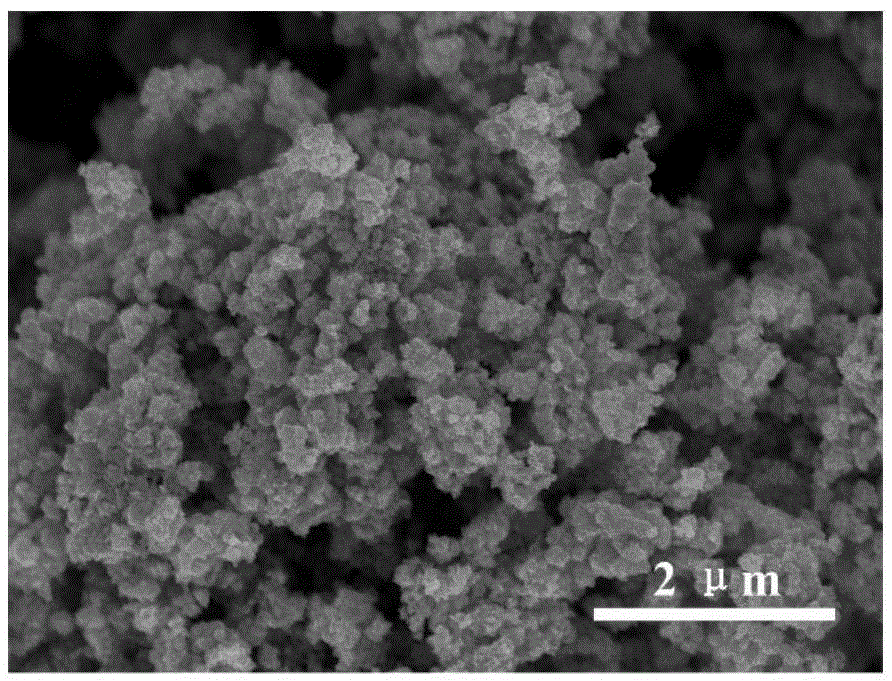

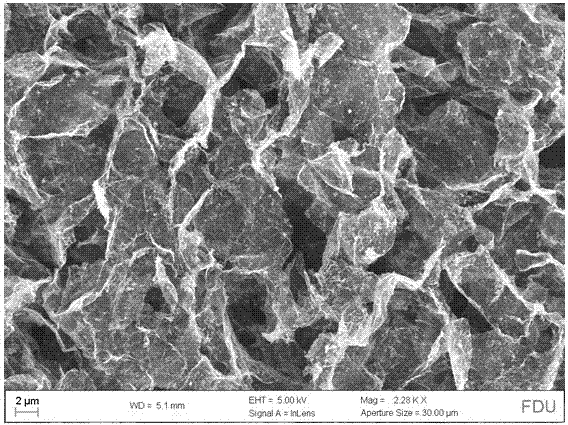

Cobalt-intercalated molybdenum sulfide secondary battery material and preparation method and application thereof

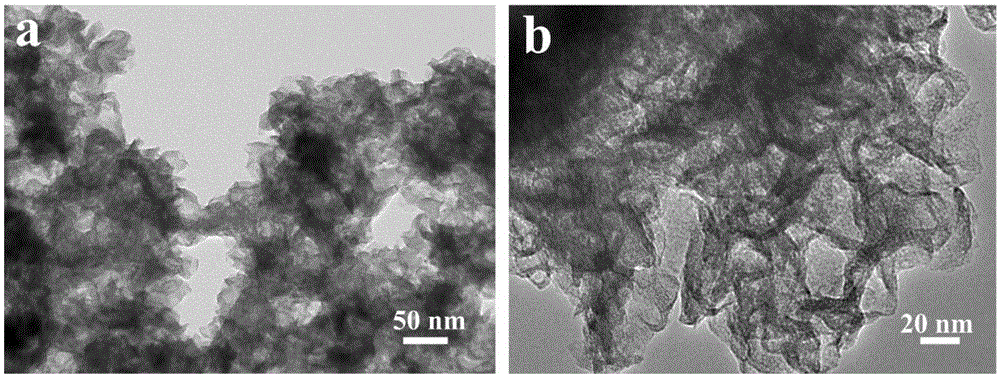

InactiveCN106611837AAvoid reunionAvoid stackingMaterial nanotechnologyHybrid capacitor electrodesLevel structureChemical solution

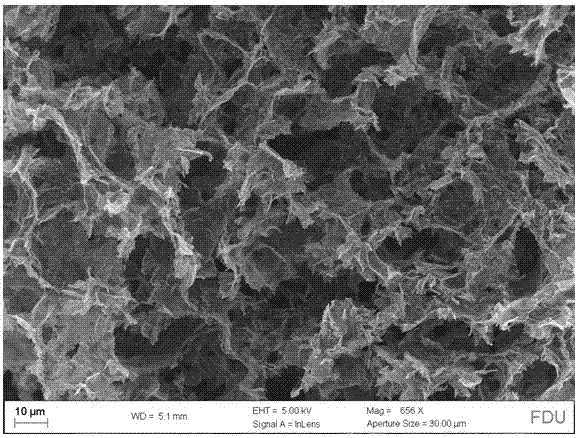

The invention relates to a cobalt-intercalated molybdenum sulfide secondary battery material and a preparation method and an application thereof. A three-dimensional cobalt-intercalated molybdenum sulfide multi-level structure is prepared by adopting a chemical solution method; firstly, a cobalt salt, a molybdenum salt and a sulfur source are dispersed into a solvent to prepare a reaction liquid; and then the prepared reaction liquid is subjected to solvent thermal treatment to obtain the three-dimensional cobalt-uniformly-intercalated molybdenum sulfide multi-level structure which is self-assembled by graphene-like ultra-thin nanosheets, wherein the size of the multi-level structure is about 100nm. The invention also discloses a preparation method for the multi-level structure. The secondary battery material prepared by the method is stable in nanomaterial performance, and long in cycle life when the secondary battery material is used as a negative electrode material of a lithium ion battery and an electrode material of a supercapacitor.

Owner:SHANGHAI JIAO TONG UNIV

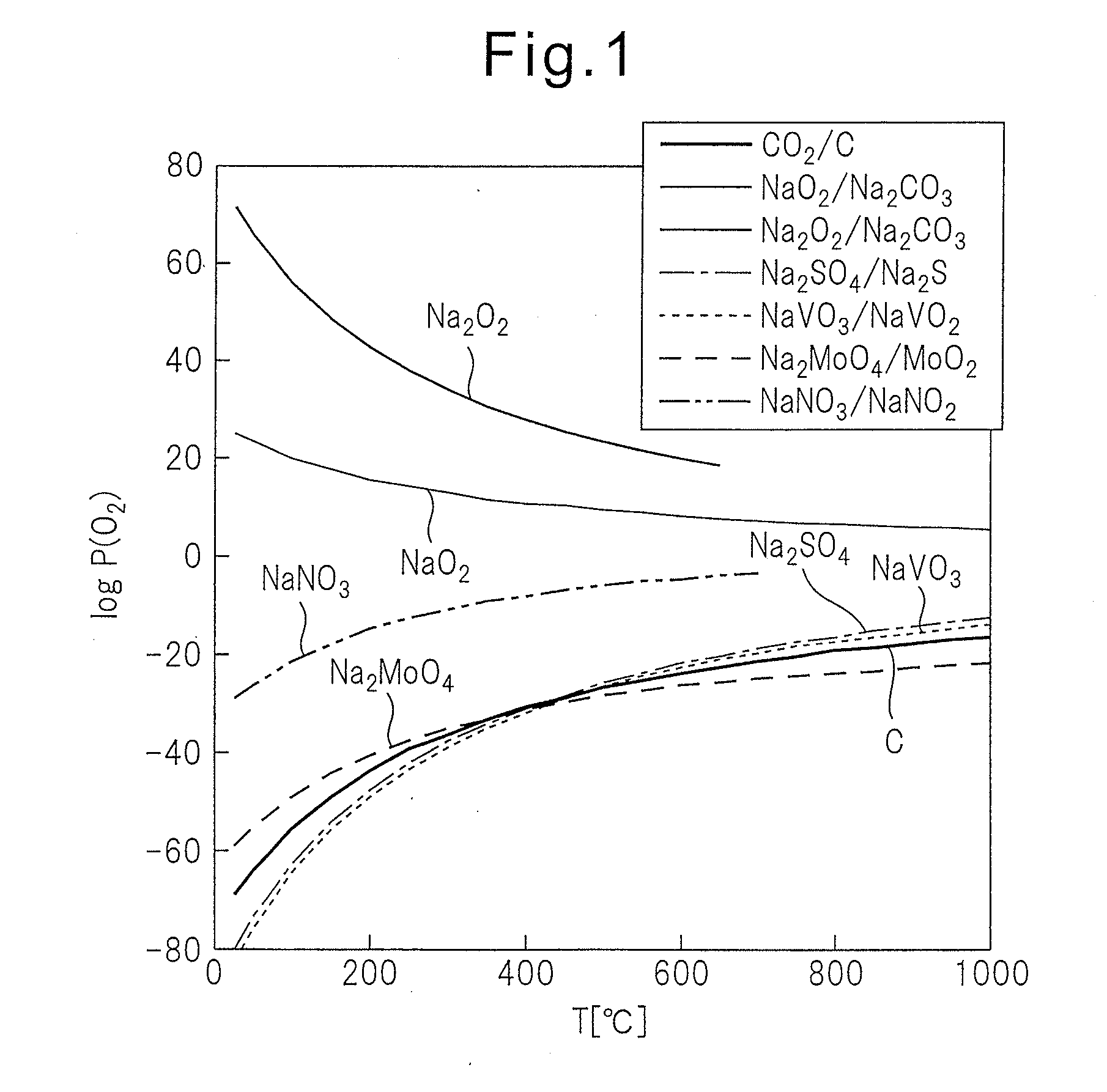

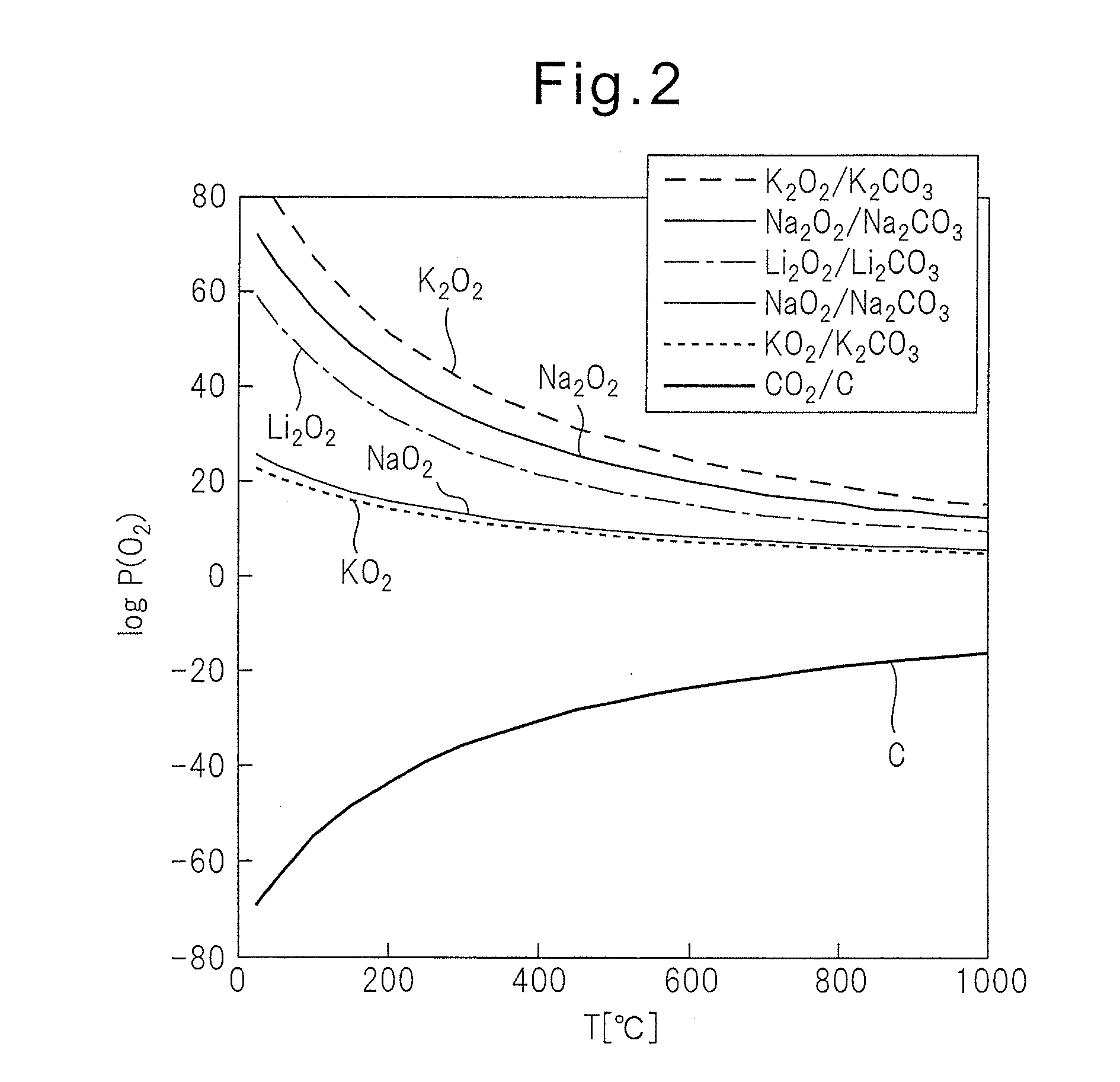

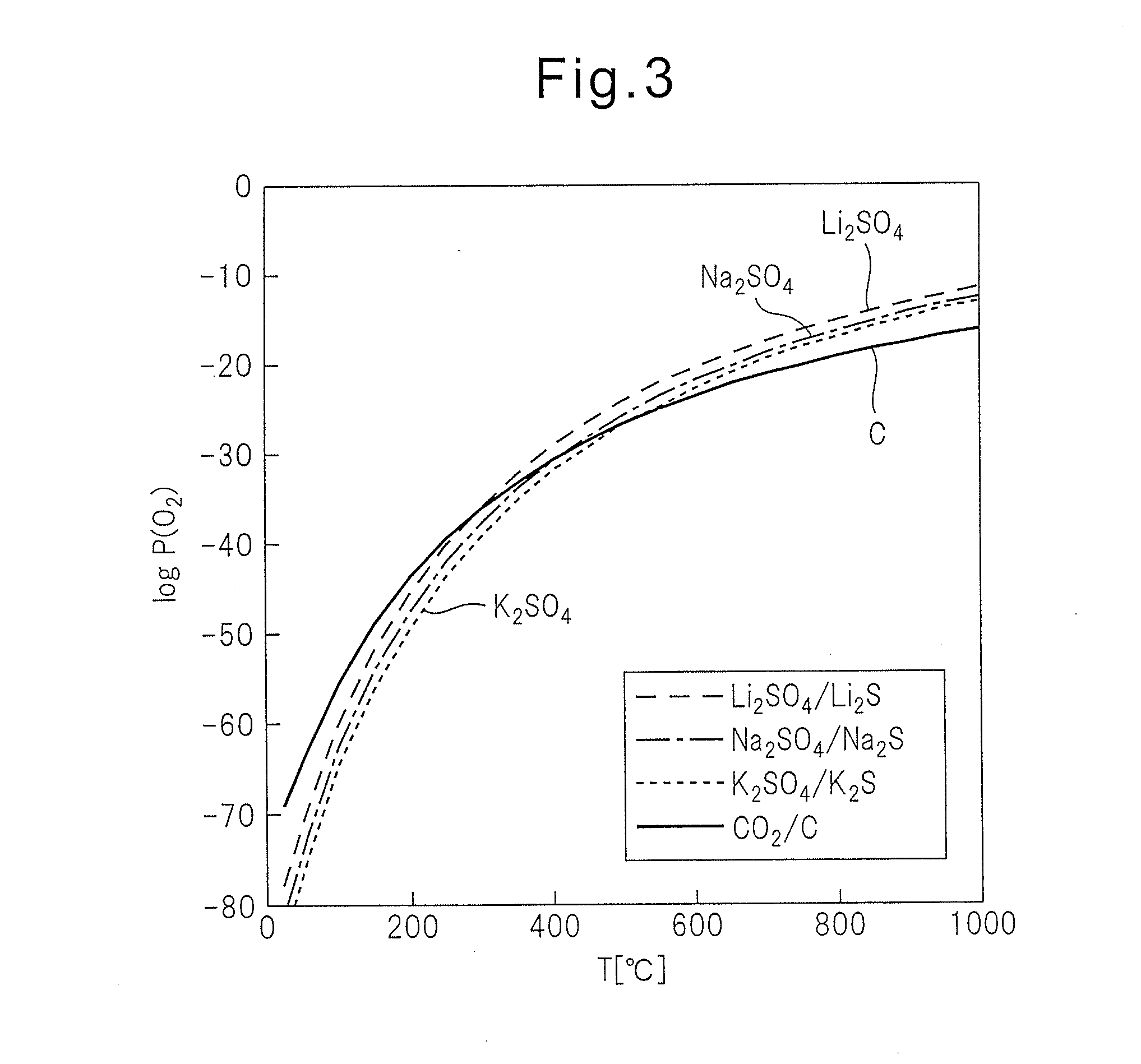

Method for directly roasting and processing spent lithium ion batteries and recycling valuable metals

InactiveCN101519726AImprove leaching rateEasily brokenProcess efficiency improvementCobaltSodium sulfate

The invention relates to a method for directly roasting and treating spent lithium ion batteries and recycling valuable metals, in particular to a method for recycling and treating spent lithium ion batteries using lithium cobalt oxide as an anode material. The method comprises the following steps: firstly, remove organic binder on an organic diaphragm material and an electrode material in the batteries by roasting at a temperature of 500 DEG C to 850 DEG C; crushing and mixing the roasted battery material with sodium sulfate (or potassium sulfate) and concentrated sulfuric acid before size mixing; carrying out secondary heat treatment in an electric stove at a temperature of 350 DEG C to 600 DEG C to convert metals in the spent lithium ion batteries, such as cobalt, copper, lithium, and the like into easily water-soluble sulfate which is leached by water or a dilute sulphuric acid solution; then, using an organic extracting agent to respectively extract the cobalt and the copper from a leaching solution and obtain a cobalt product and a copper product; using sodium carbonate to precipitate the metal lithium from the leaching solution after the cobalt and the copper are removed; and enabling the leaching solution to return treatment heat so as to secondarily treat materials. The invention has a metal leaching rate higher than 99.5 percent and a metal recovery rate higher than 99 percent.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

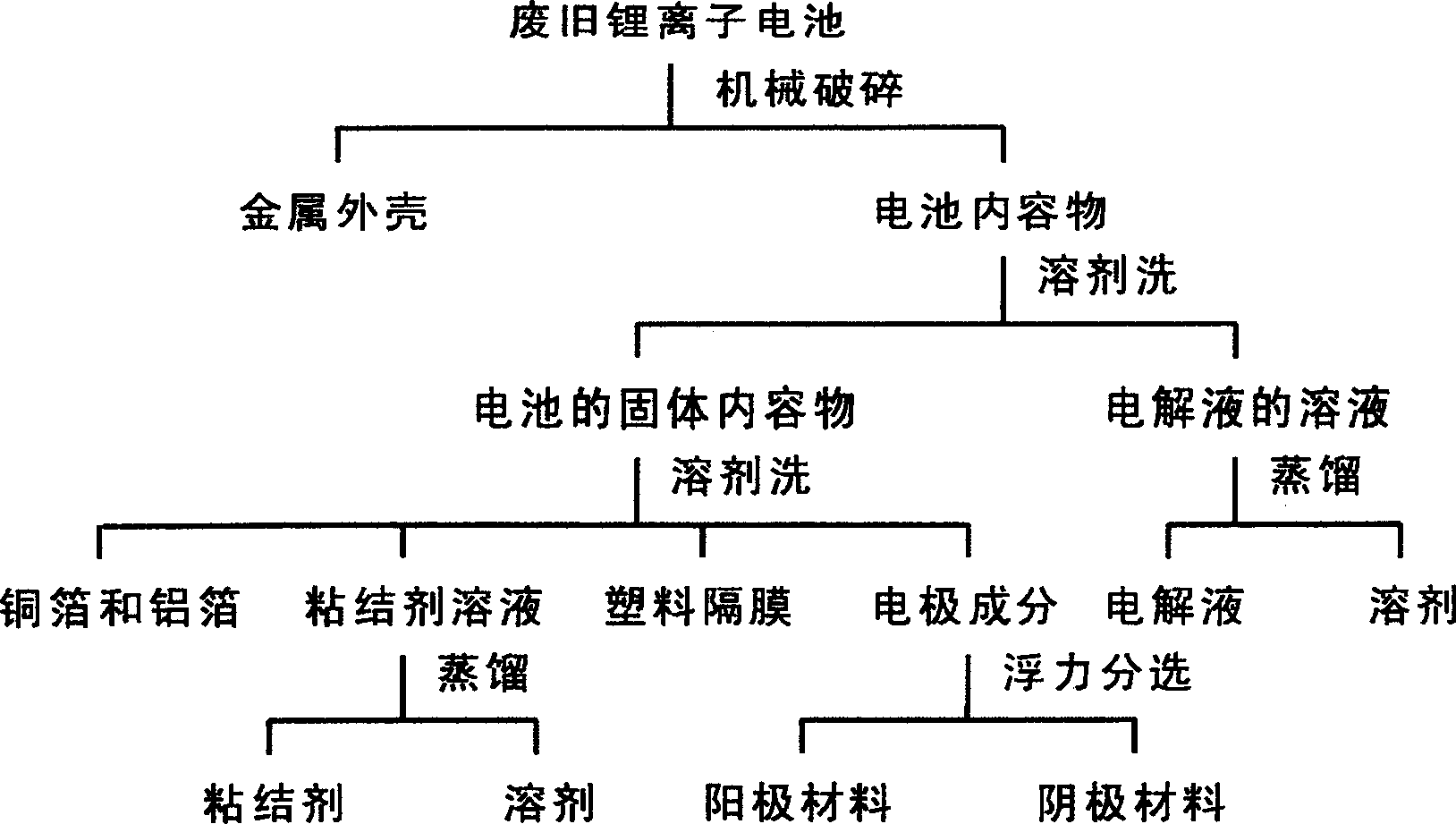

Resource separation of waste lithium ion battery

InactiveCN1819326AReserve availabilityLow added valueReclaiming serviceable partsWaste accumulators reclaimingAdhesiveCopper foil

The invention can make separation for all kinds of components in wasted Li-ion battery such as: case, electrolyte, anode material, cathode material, adhesive, copper foil, and aluminum foil. The process includes: breaking wasted batteries by mechanical process; separating metal case from others; washing out electrolyte using organic solvent, and filtering it from remaining solid; processing the remaining component where the electrolytes are removed using organic solvent to make all electrode active component eluted from current collector, and separated from diaphragm, copper foil, and aluminum foil. The solvent and adhesive can be reused.

Owner:SOUTHEAST UNIV

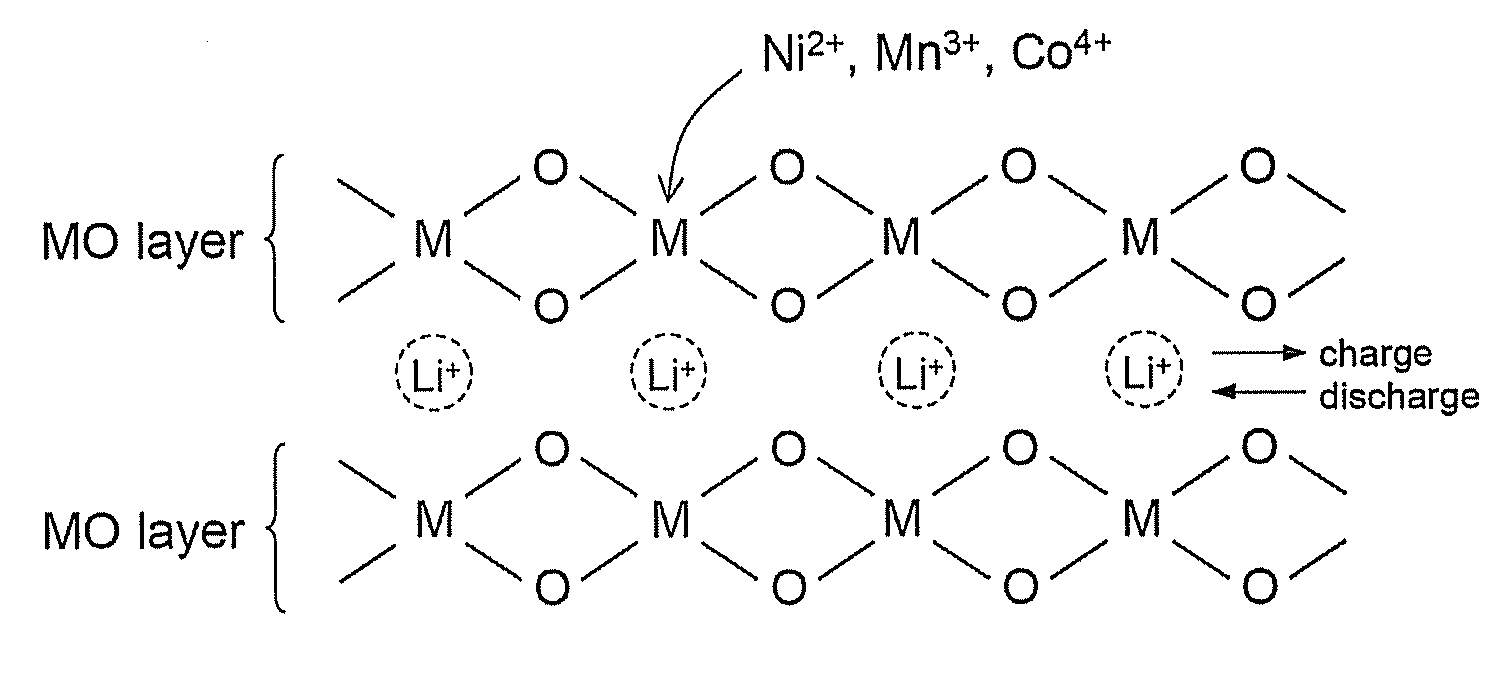

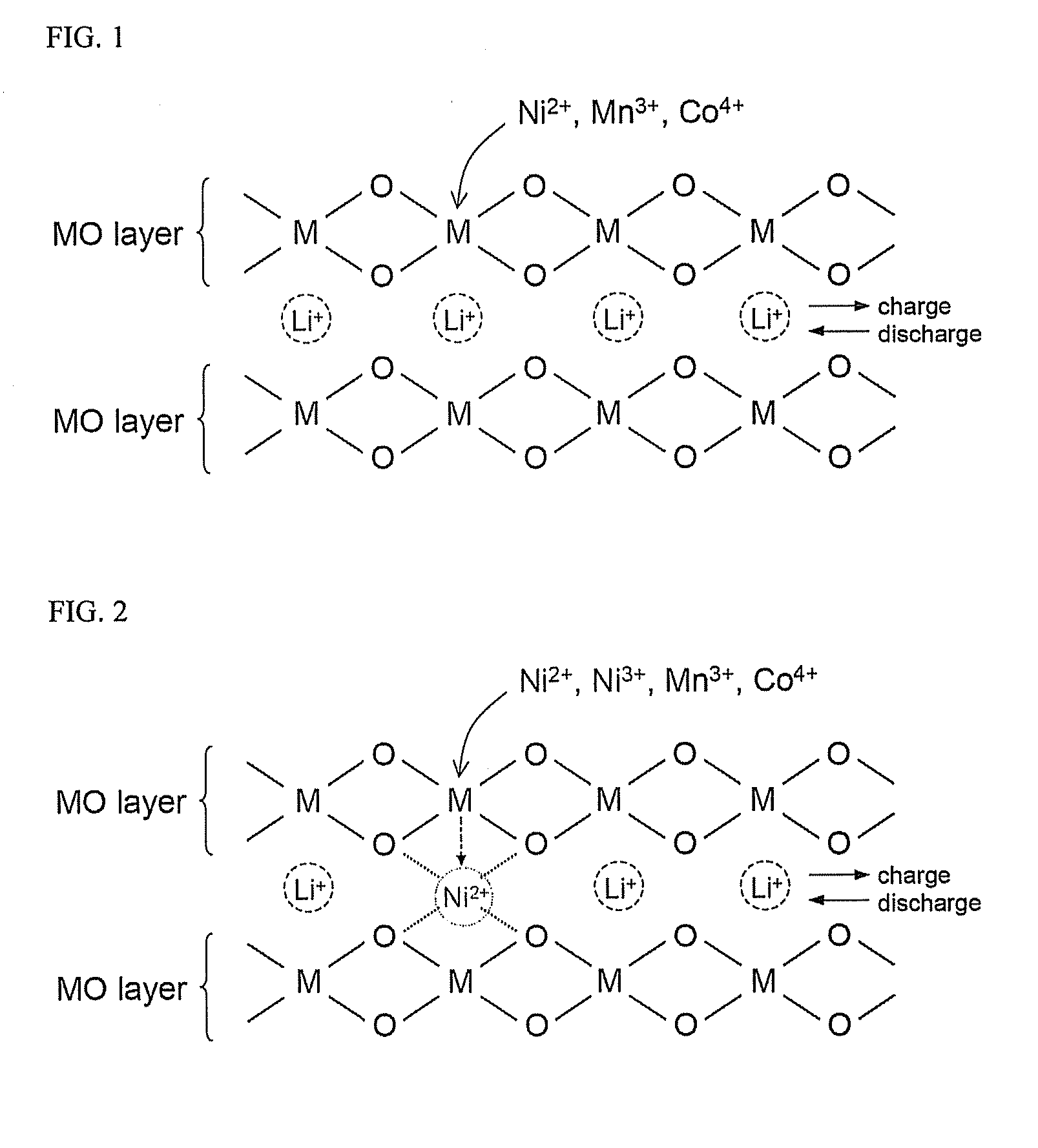

Material for lithium secondary battery of high performance

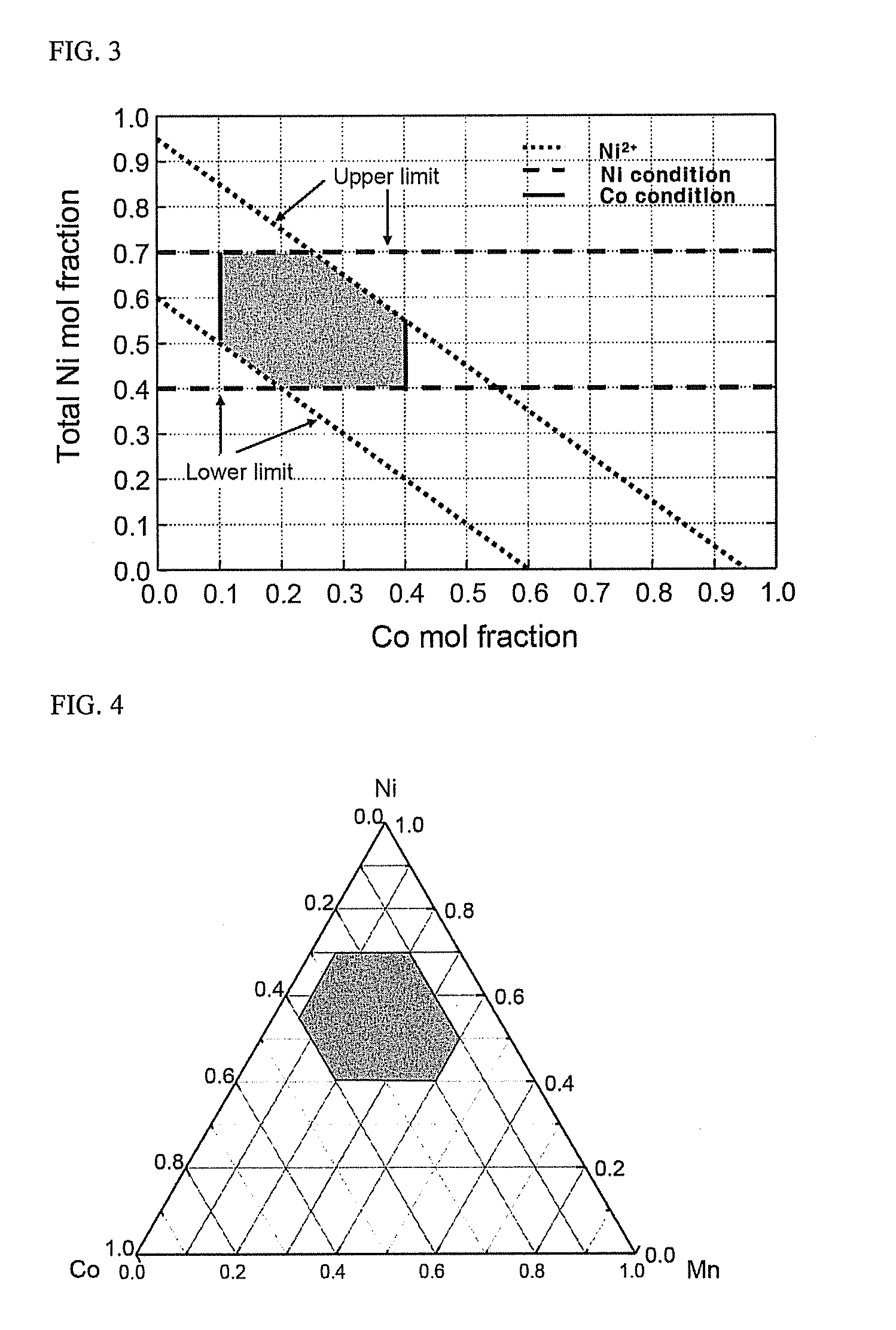

InactiveUS20070292761A1Improve thermal stabilityImprove cycle stabilityFinal product manufacturePositive electrodesElectrical batteryLayered structure

Provided is a lithium mixed transition metal oxide having a composition represented by Formula I of LixMyO2 (M, x and y are as defined in the specification) having mixed transition metal oxide layers (“MO layers”) comprising Ni ions and lithium ions, wherein lithium ions intercalate into and deintercalate from the MO layers and a portion of MO layer-derived Ni ions are inserted into intercalation / deintercalation layers of lithium ions (“reversible lithium layers”) thereby resulting in the interconnection between the MO layers. The lithium mixed transition metal oxide of the present invention has a stable layered structure and therefore exhibits improved stability of the crystal structure upon charge / discharge. In addition, a battery comprising such a cathode active material can exhibit a high capacity and a high cycle stability. Further, such a lithium mixed transition metal oxide is substantially free of water-soluble bases, and thereby can provide excellent storage stability, decreased gas evolution and consequently superior high-temperature stability with the feasibility of low-cost mass production.

Owner:LG ENERGY SOLUTION LTD

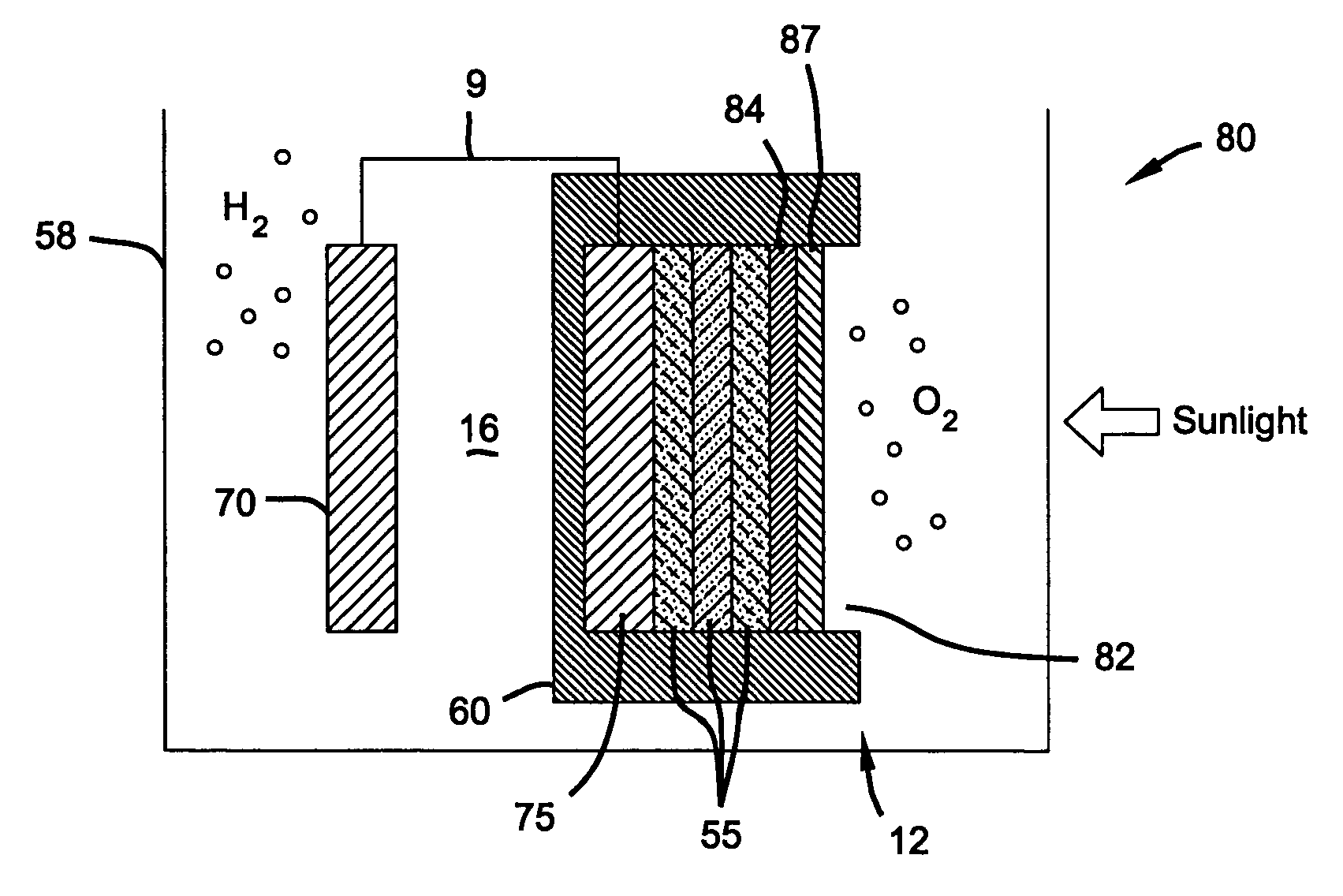

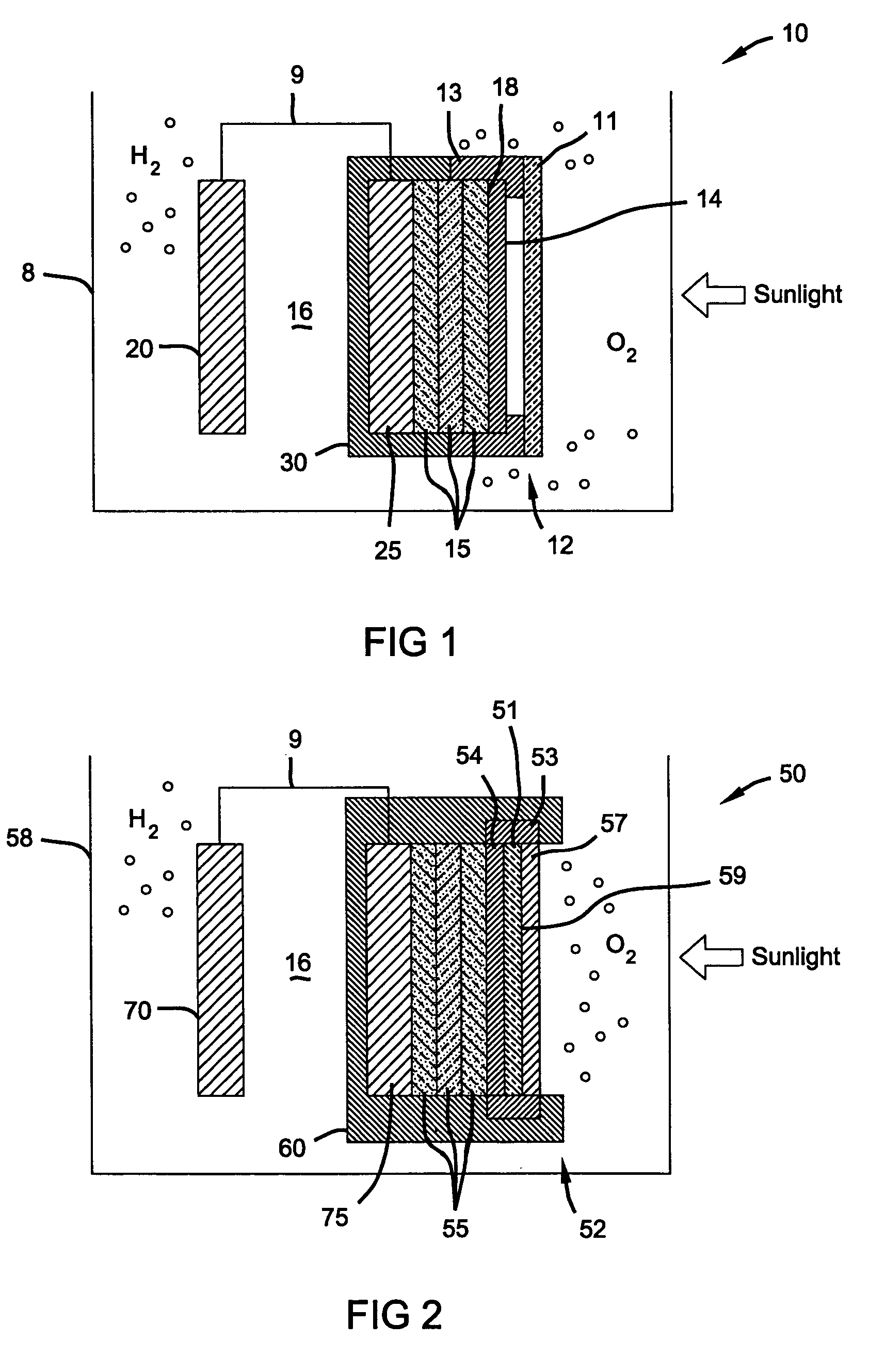

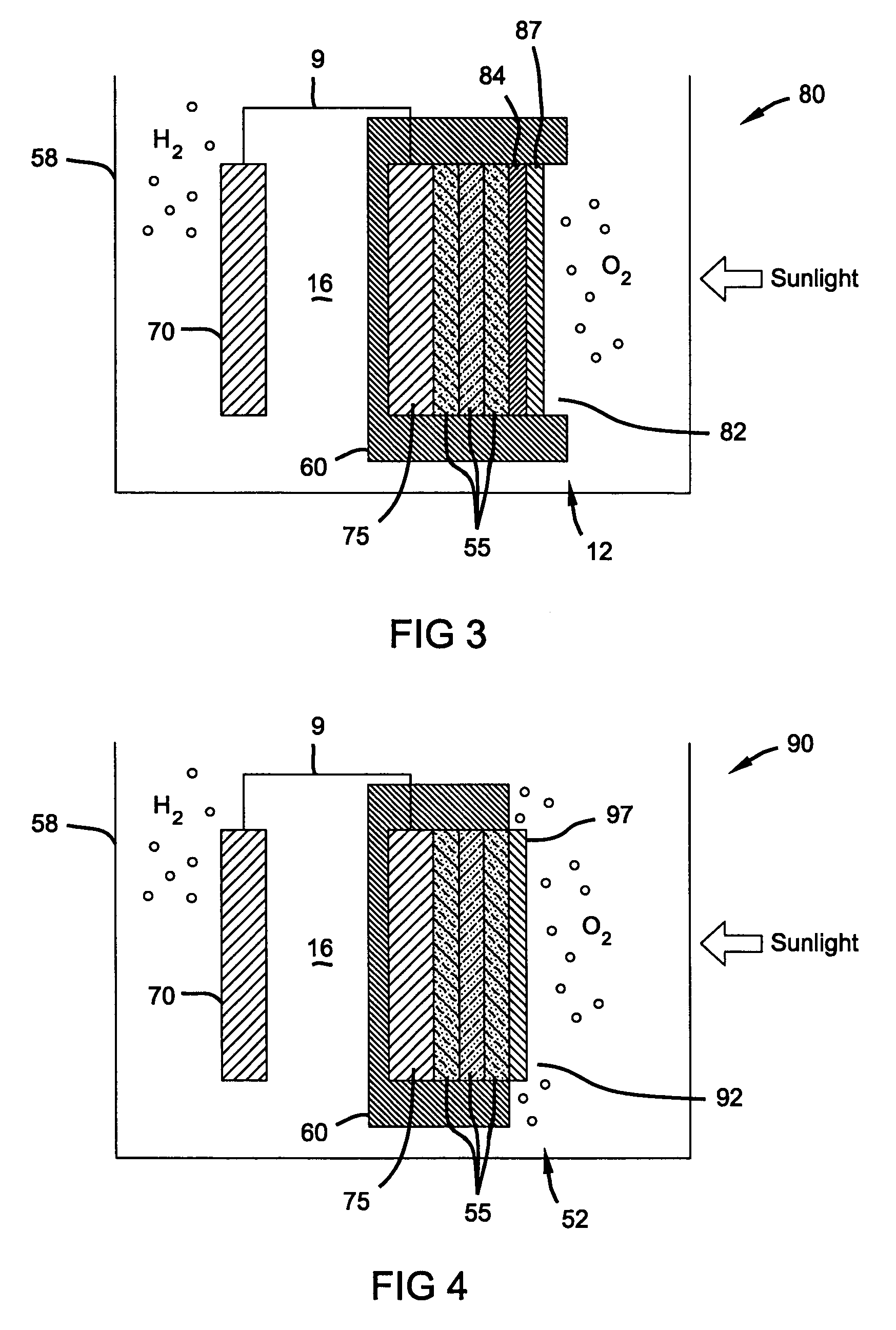

Photoelectrochemical device and electrode

In one aspect, the invention provides a photoelectrochemical (PEC) electrode or photoelectrode for use in splitting water by electrolysis. The photoelectrode has an electrically conductive surface in contact with an electrolyte solution. This surface is a doped tin oxide layer, which is in electrical contact with the semiconductor solar cell material of the PEC photoelectrode. In a variation of the present invention, another layer of metal oxide having transparent, anti-reflective, and conductive properties is disposed between the doped tin oxide layer and the semiconductor material.

Owner:GM GLOBAL TECH OPERATIONS LLC

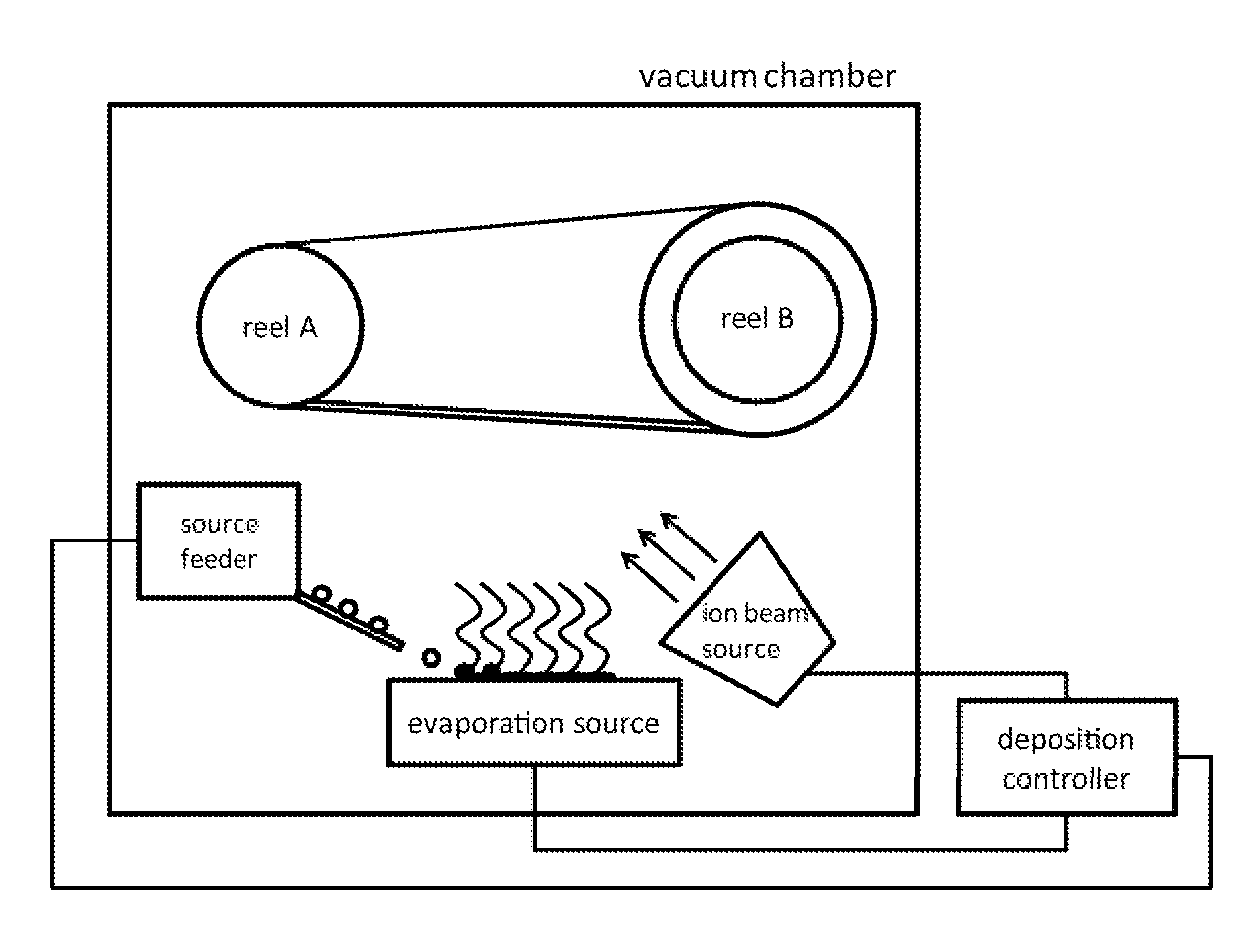

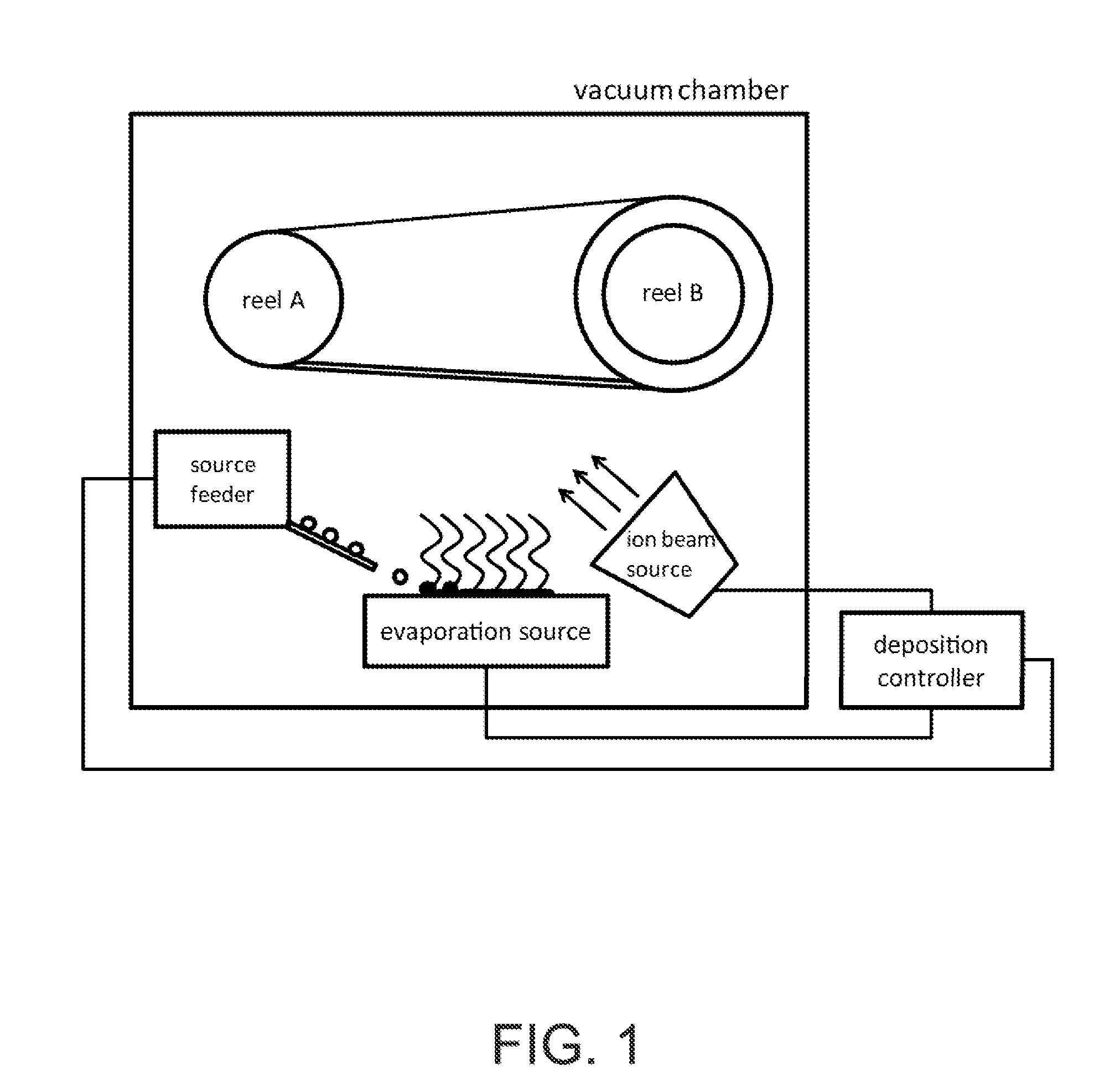

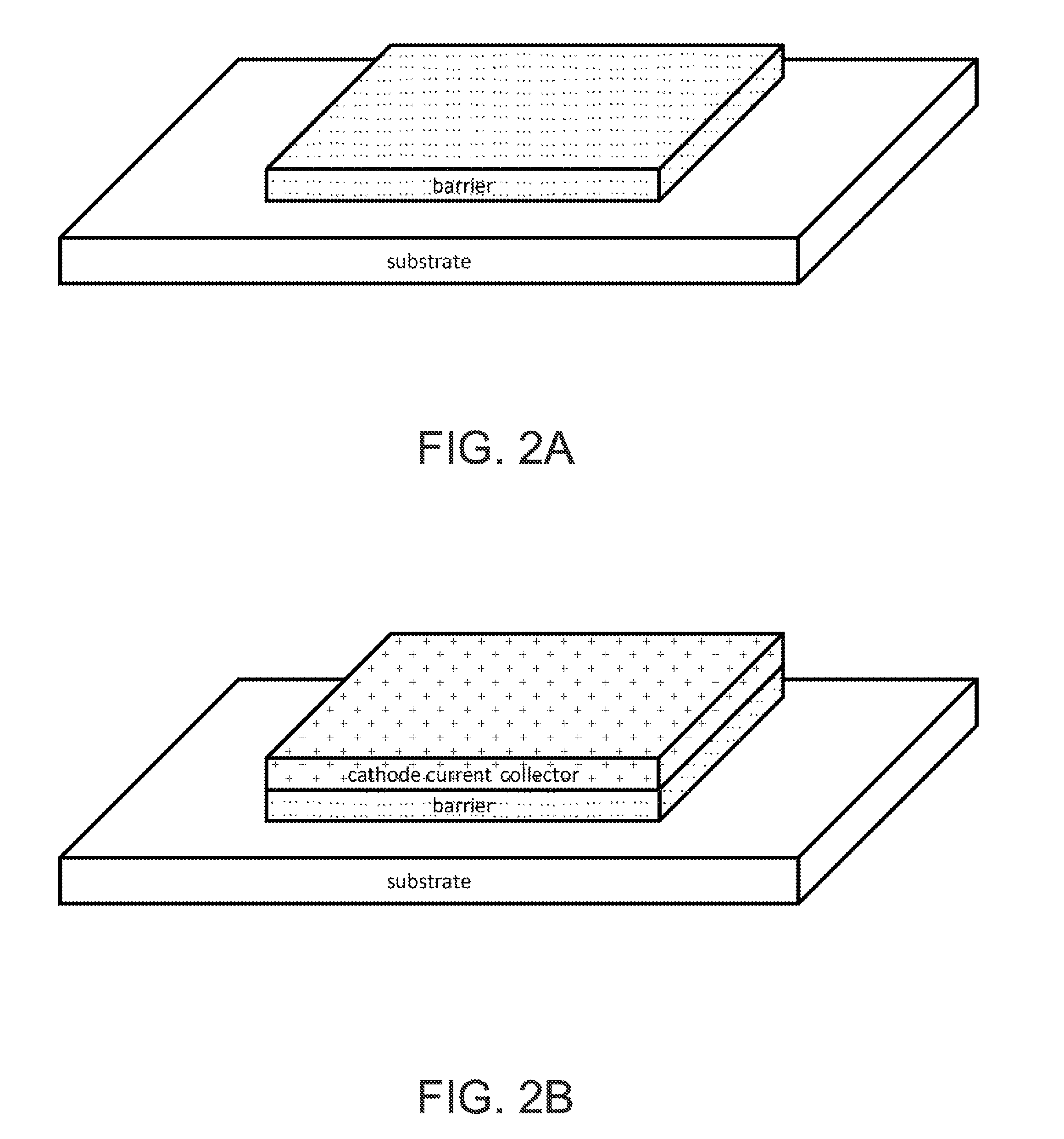

Thermal evaporation process for manufacture of solid state battery devices

ActiveUS20120058280A1Easy to implementEfficient and cost-effectiveFinal product manufactureVacuum evaporation coatingThermal energySource material

A method for manufacturing a solid-state battery device. The method can include providing a substrate within a process region of an apparatus. A cathode source and an anode source can be subjected to one or more energy sources to transfer thermal energy into a portion of the source materials to evaporate into a vapor phase. An ionic species from an ion source can be introduced and a thickness of solid-state battery materials can be formed overlying the surface region by interacting the gaseous species derived from the plurality of electrons and the ionic species. During formation of the thickness of the solid-state battery materials, the surface region can be maintained in a vacuum environment from about 10-6 to 10-4 Torr. Active materials comprising cathode, electrolyte, and anode with non-reactive species can be deposited for the formation of modified modulus layers, such a void or voided porous like materials.

Owner:SAKTI3

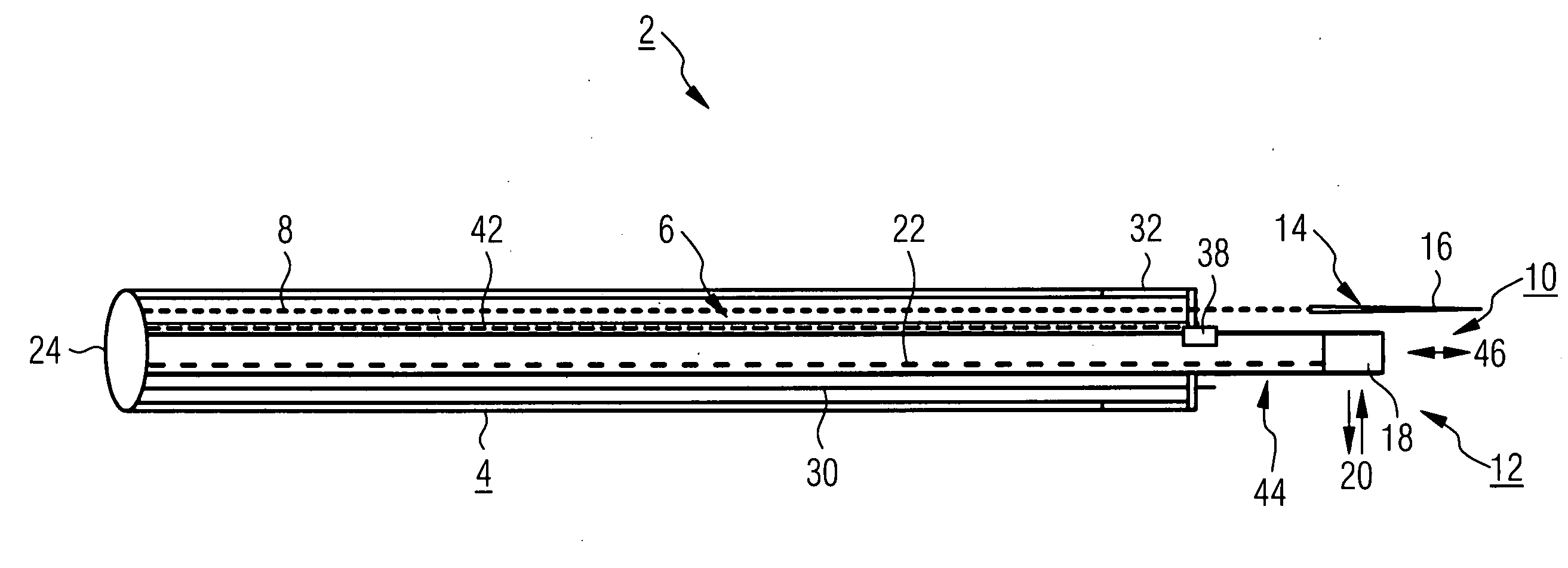

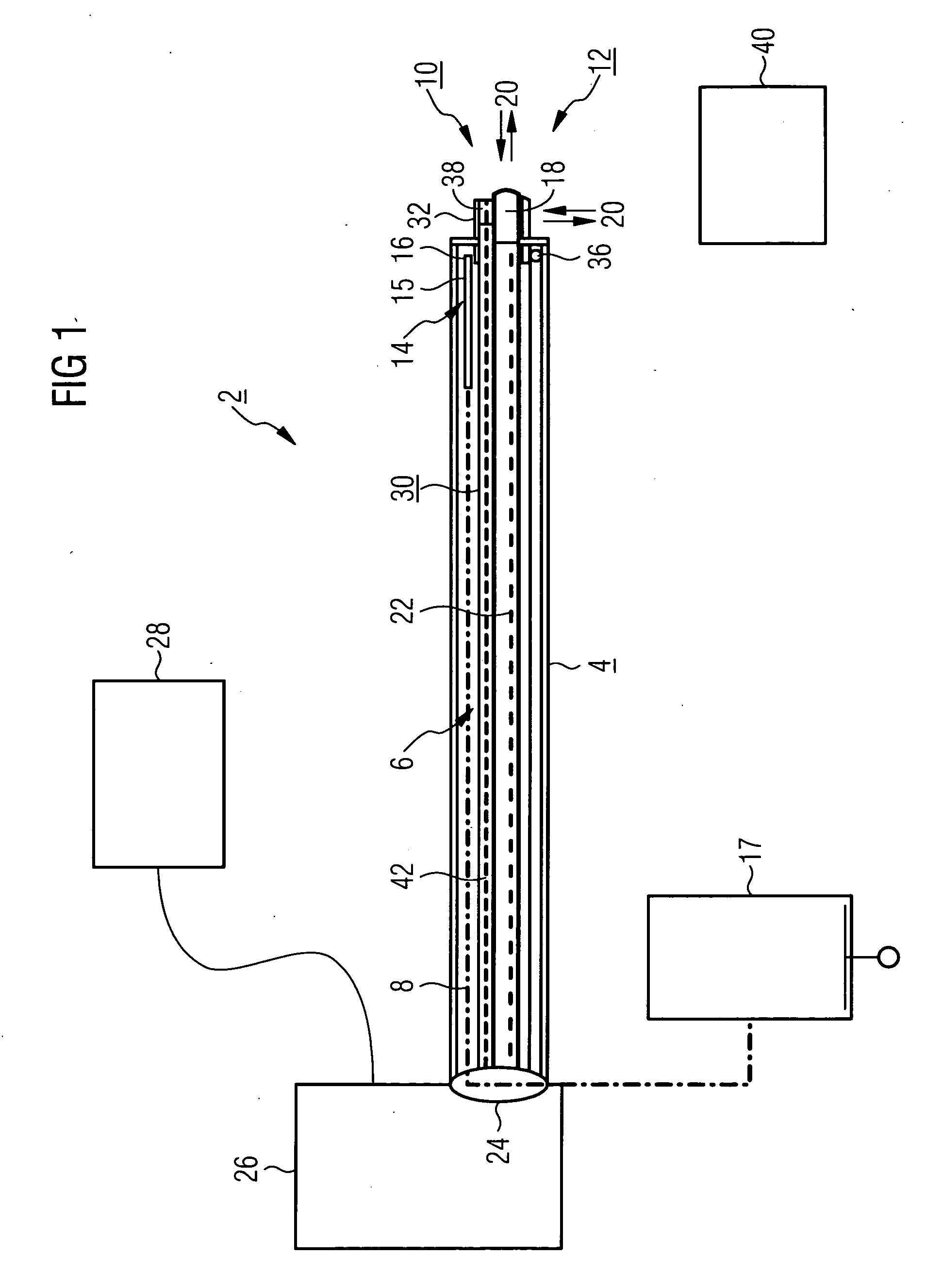

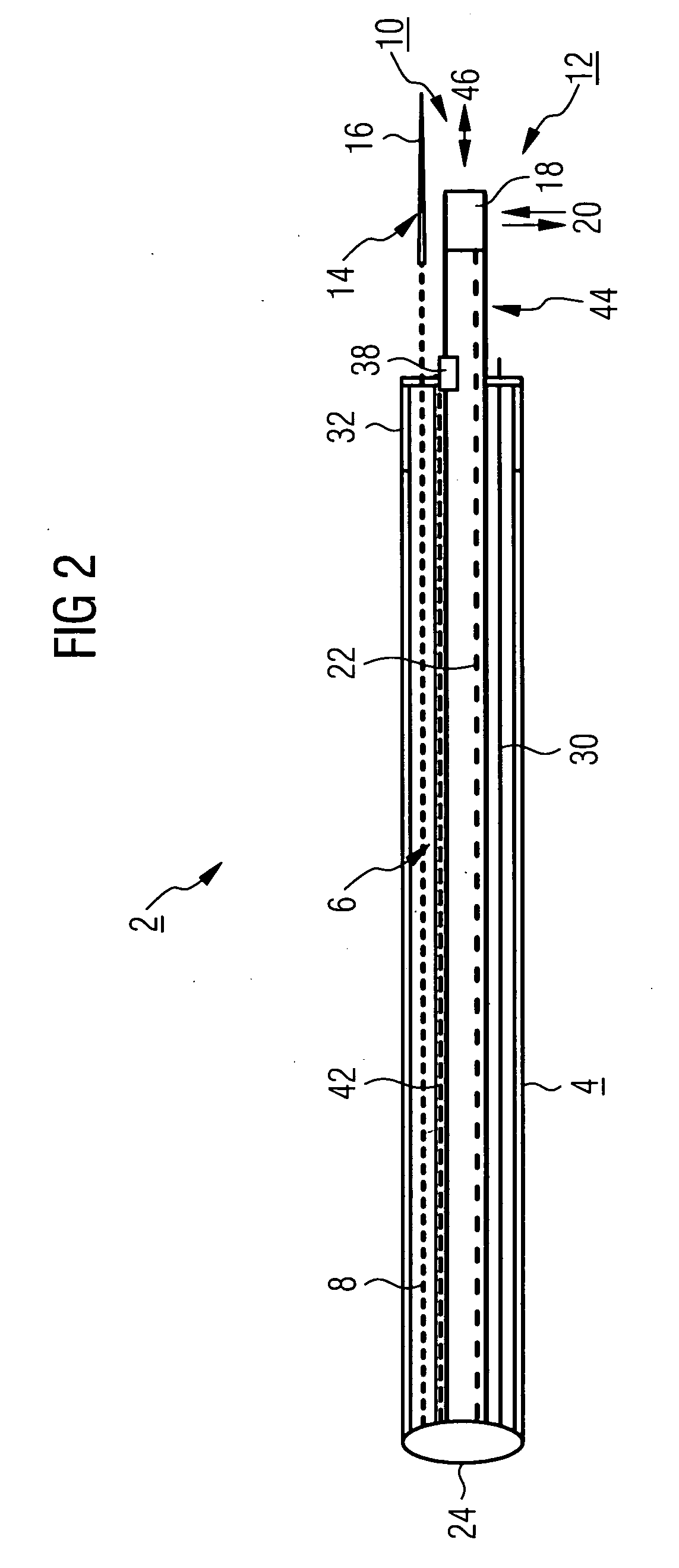

Catheter and associated medical examination and treatment device

InactiveUS20090234220A1Reduce riskRaise the possibilityGuide needlesSurgical navigation systemsTherapeutic DevicesInjection device

A catheter for treatment of the heart with a flexible catheter sheath surrounding a catheter lumen and with an apparatus for implanting cell material, which comprises an injection apparatus arranged in an area of the catheter tip, is to be created such that the risk of such an intervention is reduced in relation to previously known and practiced concepts. To this end there is inventive provision for at least one imaging sensor to be arranged in the area of the catheter tip.

Owner:SIEMENS AG

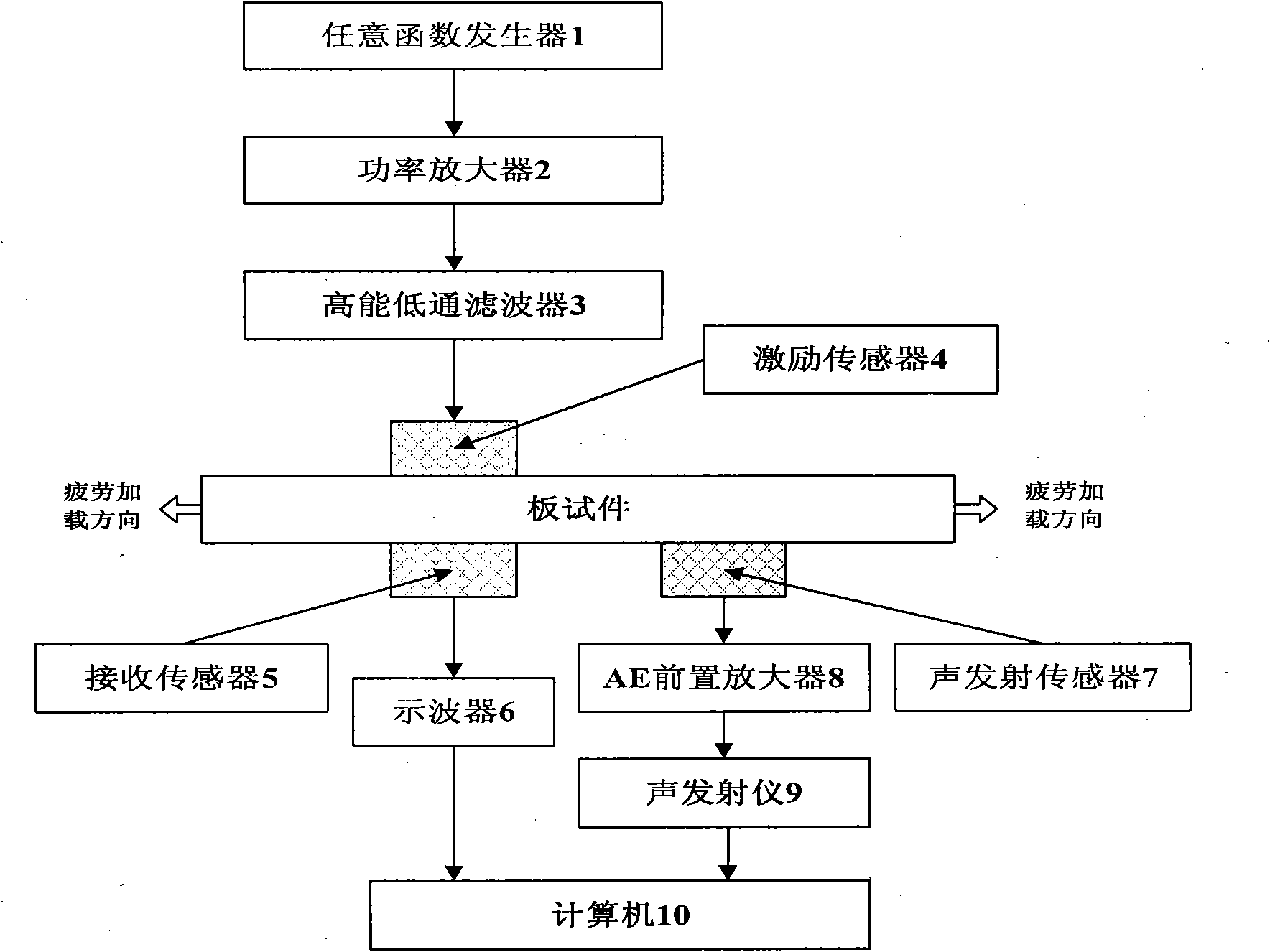

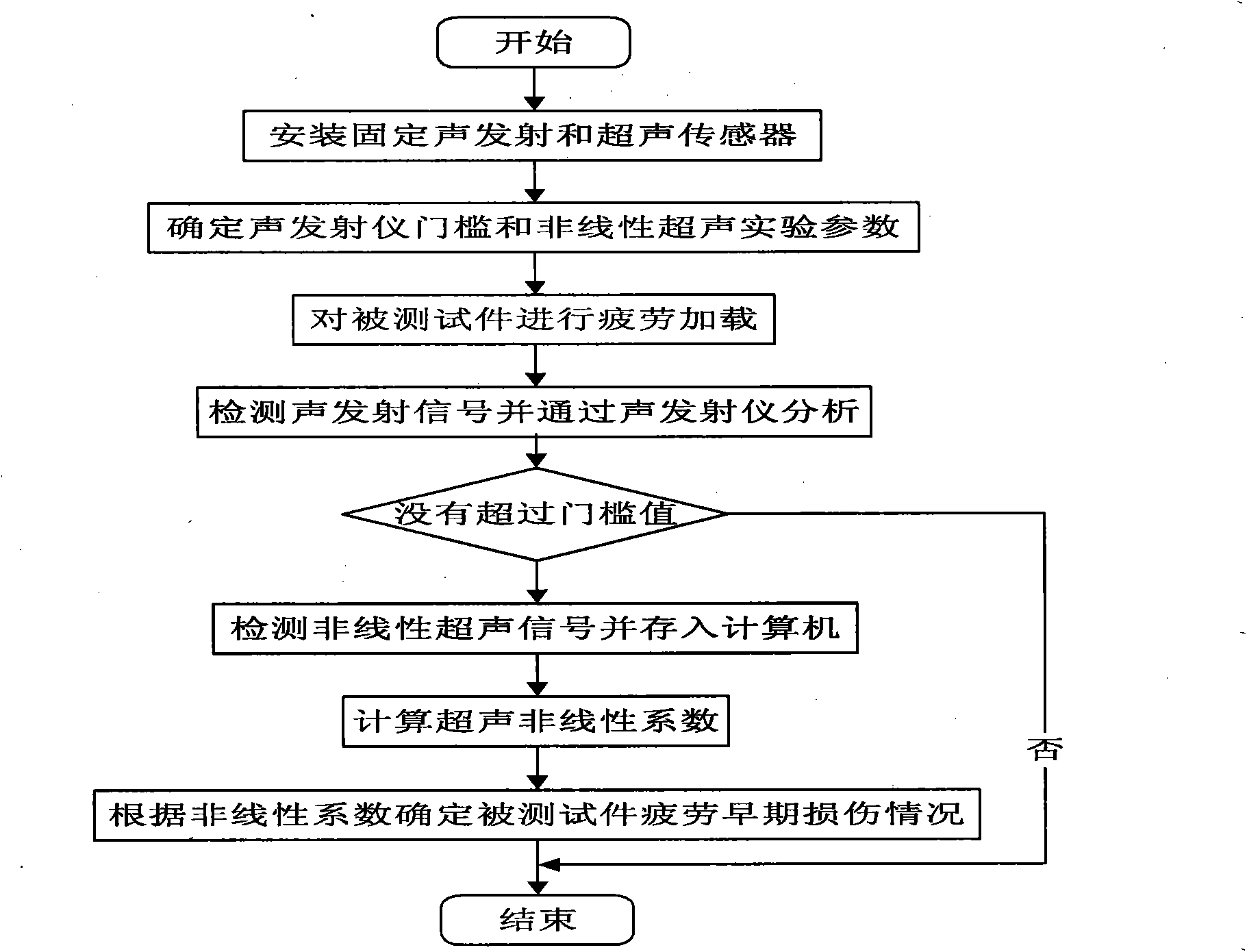

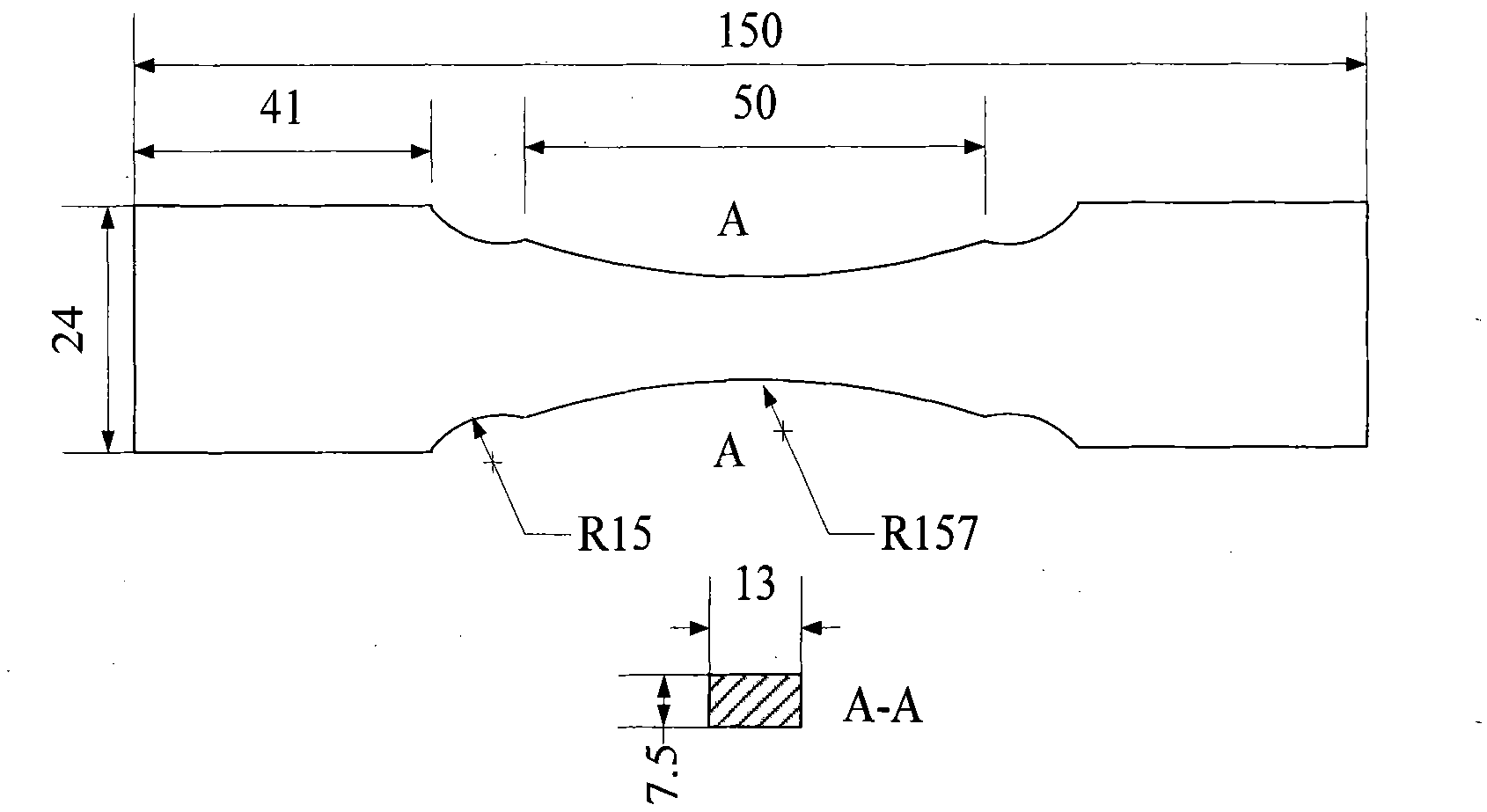

Method for non-linear ultrasonic online detection of early fatigue damage to metal material

InactiveCN101806778ARealize the whole process of fatigue detectionSolve misjudgmentMaterial analysis using acoustic emission techniquesFatigue damageSonification

A method for the non-linear ultrasonic online detection of early fatigue damage to a metal material belongs to the field of nondestructive detection. The method comprises the following steps: determining an excitation signal parameter according to the thickness of a tested piece and inputting the parameter to an arbitrary function generator to generate a sound signal; determining a threshold value of an acoustic emission instrument according to the amplitude of a no-load noise signal; performing fatigue loading on the tested piece, continuously detecting an acoustic emission signal in real time with an acoustic emission sensor, amplifying the acoustic emission signal, inputting the acoustic emission signal into the acoustic emission instrument, and judging ring with the acoustic emission instrument when the amplitude of the acoustic emission signal exceeds the preset the threshold value of the acoustic emission instrument; detecting a non-linear ultrasonic signal at equal time interval if the acoustic emission instrument does not display the ring or the times of the continuous ring is not more than an empirical value; and stopping detection if the displayed ring times is more than the empirical value, because fatigue cracks are generated and develop. On the basis of non-linear ultrasonic nondestructive detection, the method of the invention introduces acoustic emission technique, so the method does not make incorrect judgment when detecting the early fatigue damage to the metal material and realizes continuous online detection.

Owner:BEIJING UNIV OF TECH

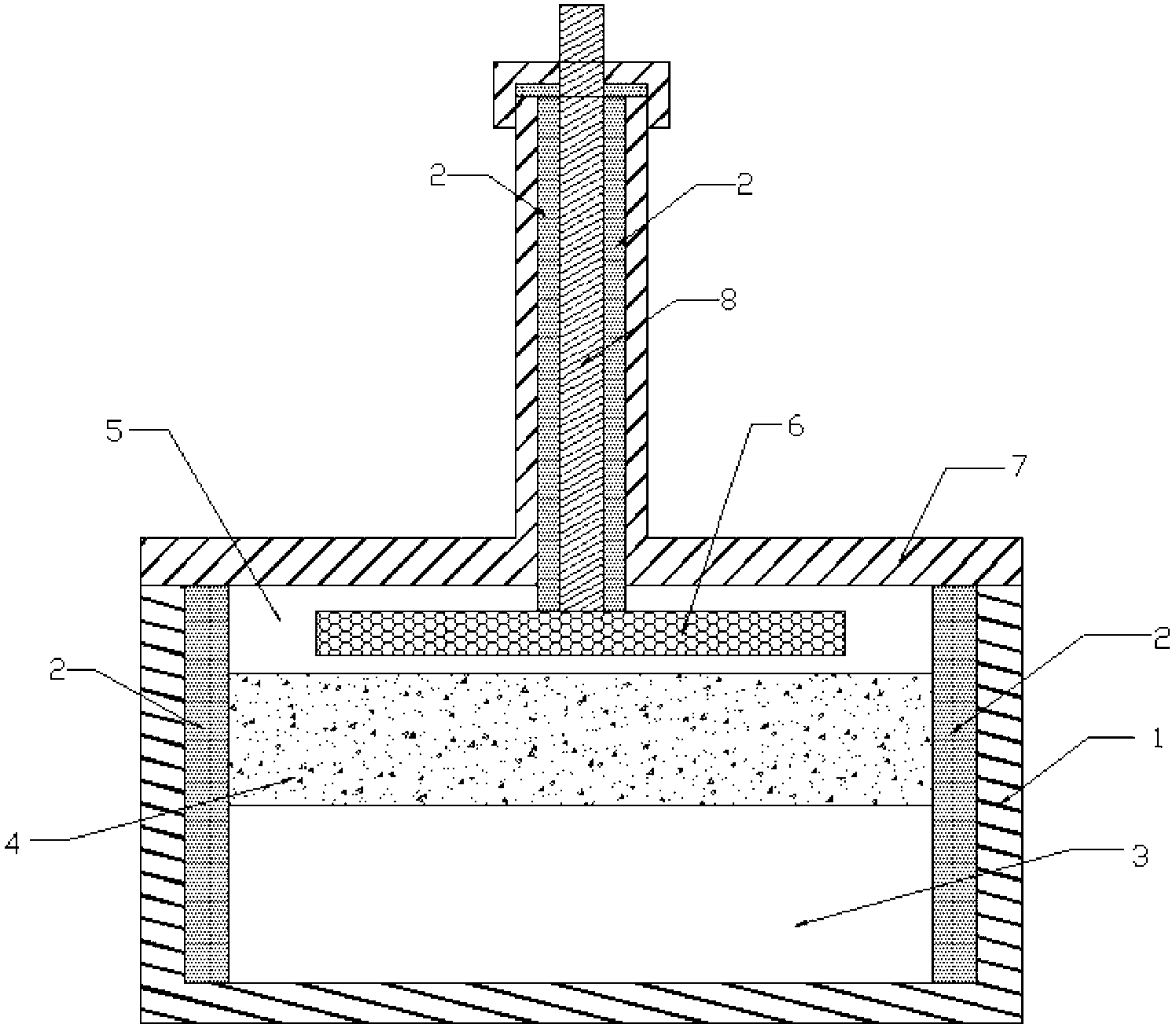

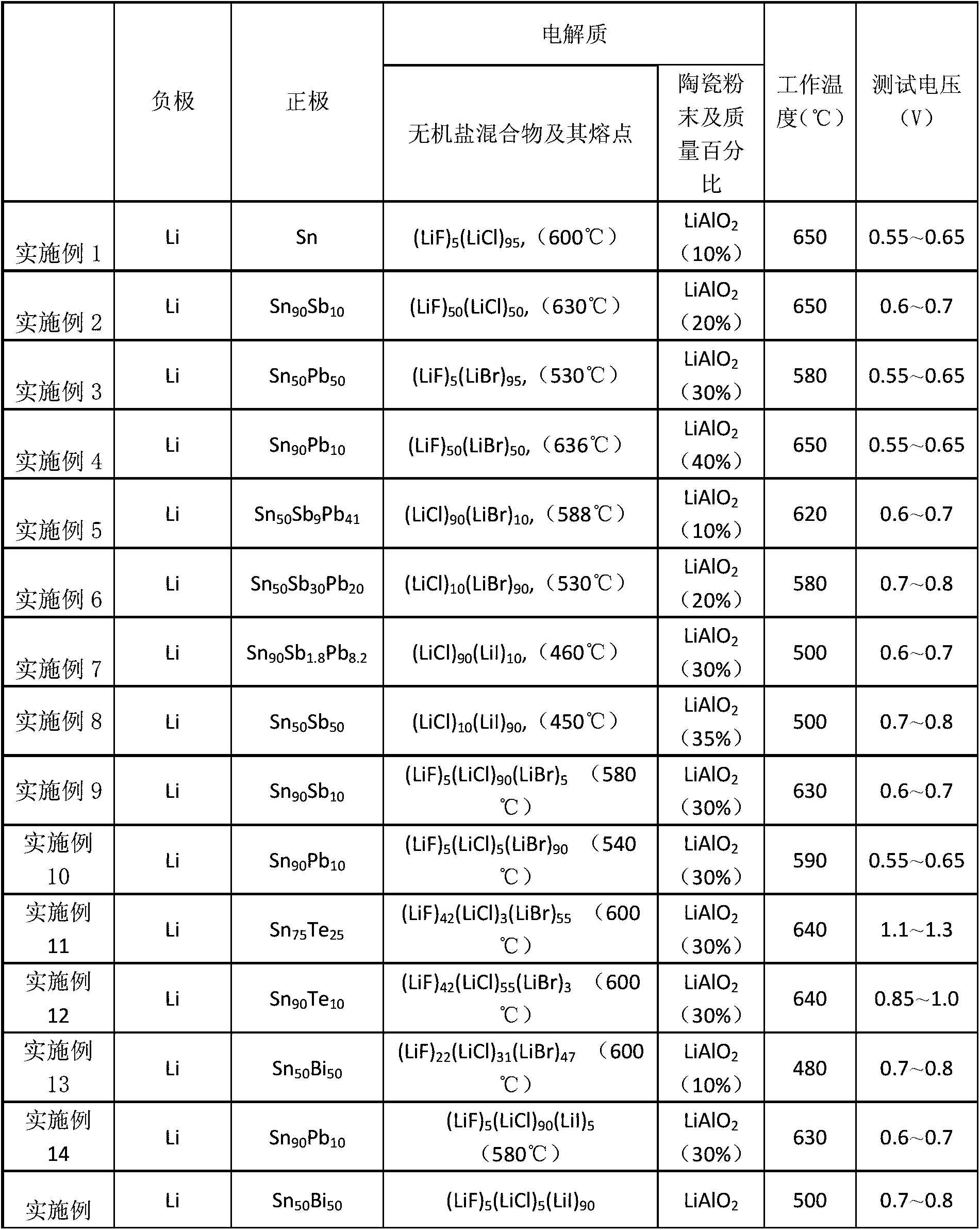

Semi-liquid metal electrode energy storage battery

ActiveCN103259033AAvoid short circuitIncrease profitCell electrodesFused electrolyte fuel cellsElectric power systemWorking temperature

The invention relates to a semi-liquid metal electrode energy storage battery, belonging to the field of an energy storage battery, and aiming at solving the problems that the all-liquid metal battery is narrow in battery material selection range and high in running temperature, and has potential safety problem. The semi-liquid metal electrode energy storage battery comprises a shell, a positive pole, electrolyte, a negative pole and a collector, wherein the positive pole is alloy made from one or more of Sn, Sb, Pb, Bi and Te; the negative pole is alloy made from one or more of Li, Na, Mg and Ca; and the electrolyte is a mixture of inorganic salt mixture and ceramic powder. When the semi-liquid metal electrode energy storage battery runs, the positive pole is in a semi-liquid state structure with alloy solid phase distributed in liquid phase, and the electrolyte is melted into semi-liquid state paste, so that the short circuit of the positive pole and the negative pole can be effectively prevented, the energy storage cost is lowered, the working temperature of the battery is reduced, the corrosion speed of the shell is slowed down, the service life of the battery is prolonged, the safety and the reliability of running can be improved, and the semi-liquid metal electrode energy storage battery is suitable for storing energy for new energy power generation grid-connection, frequency modulation and peak-load regulation of an electrical power system as well as smart power grid construction.

Owner:HUAZHONG UNIV OF SCI & TECH

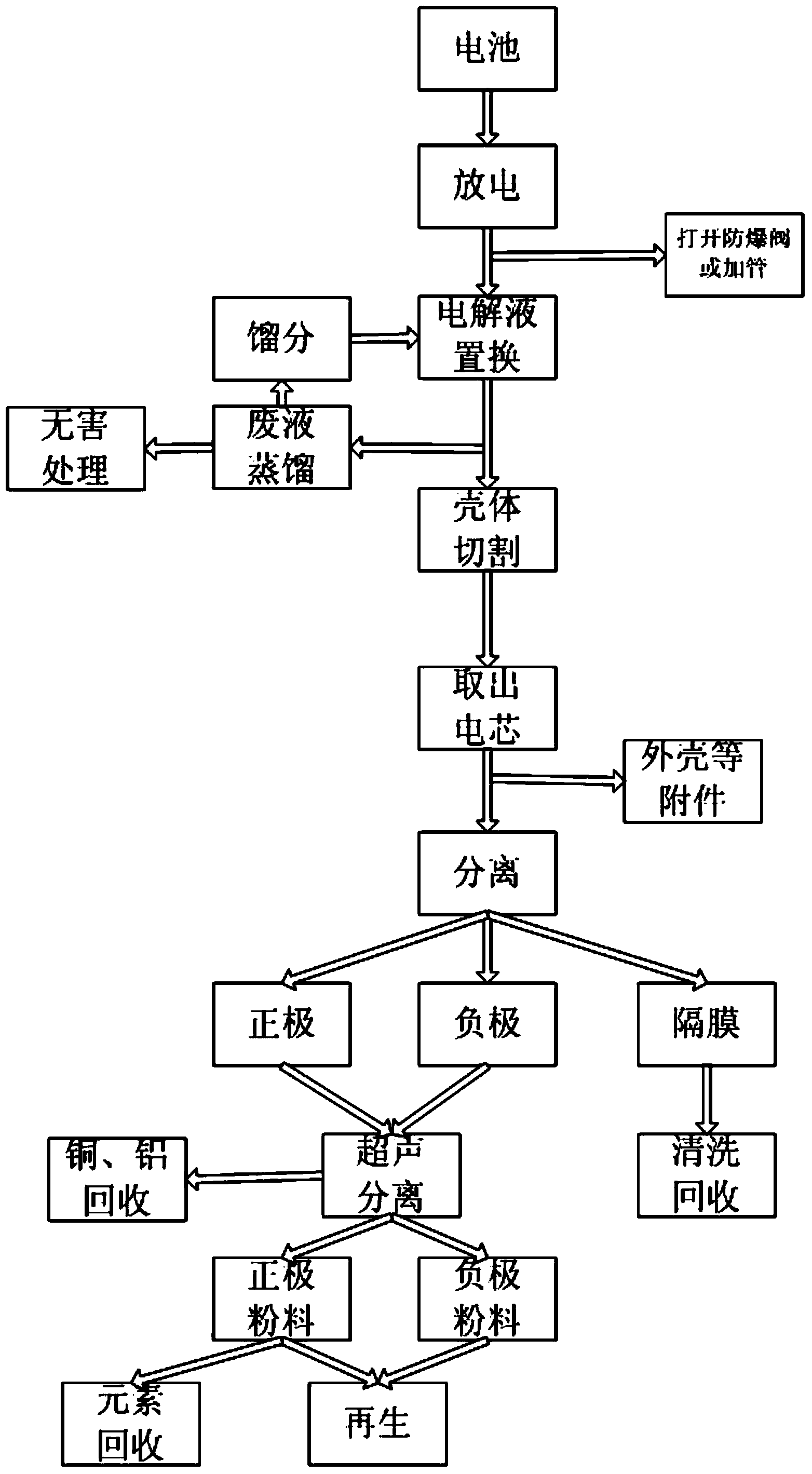

Demonstration process for recovering waste and old dynamic lithium iron phosphate cell in environmental protection mode

InactiveCN103825064AHarm reductionAvoid it happening againWaste accumulators reclaimingCell component detailsLithium iron phosphateSolvent

The invention relates to a demonstration process for recovering a waste and old dynamic lithium iron phosphate cell in an environmental protection mode, which belongs to the technical field of recovery of the power lithium iron phosphate cell. The method comprises the following steps: completely discharging the cell, extracting an electrolyte in the cell, adding a certain amount of solvent or displacement liquid, standing for 30 minutes and extracting the inner liquid of the cell, and distilling the extracted electrolyte to obtain the liquid for cycle usage when the electrolyte is displaced. According to the invention, the cell is cut by 1cm at the position along the cell top through a water jet, an electrical core is taken, wherein the steel casing, or aluminium casing or a PP plate can be directly recovered for usage. The anode, the cathode and a diaphragm are separated, and the diaphragm can be directly recovered through cleaning by ethanol. After the anode and the cathode are separated through physical methods such as ultrasound, a copper foil and an aluminium foil can be directly recovered, anode and cathode powder can be reused to be a cell material through high temperature treatment, and the purposes of no waste and no pollution can be reached by recovering the elements through a chemical method.

Owner:BEIJING UNIV OF TECH +1

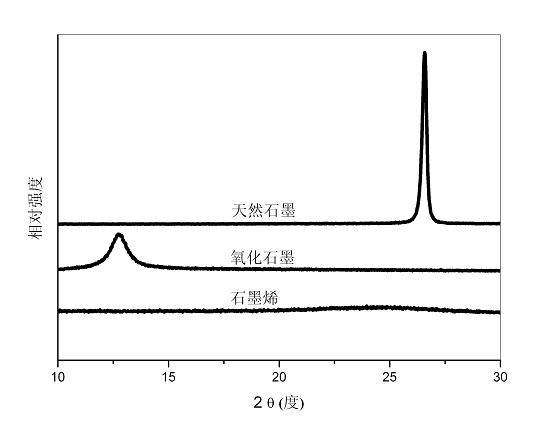

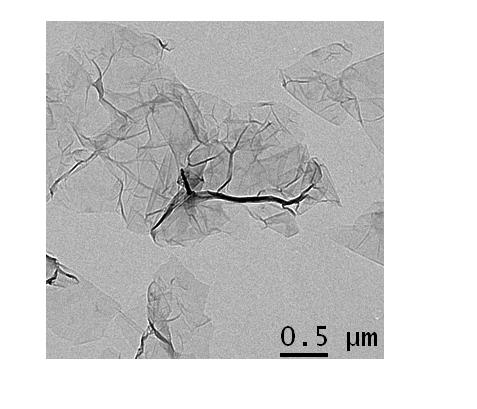

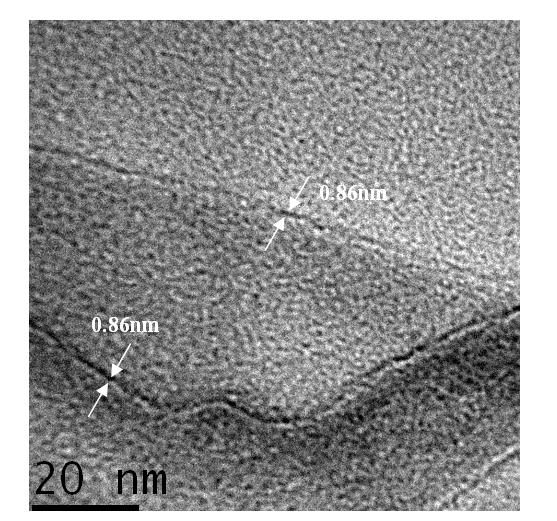

Single-layer graphene capable of dispersing stably and preparation method thereof

ActiveCN102398900AAvoid it happening againMethod environmentally friendlyOrganosolvConductive materials

The invention discloses a single-layer graphene capable of dispersing stably and a preparation method thereof, belonging to the field of nanometer graphite conductive materials. The single-layer graphene capable of dispersing stably in water or in an organic solvent is prepared through reduction of single-layer graphene oxide by phenolic aminated compounds. According to the method, the single-layer grapheme is prepared by employing a phenolic aminated green environment-friendly reducing agent, using graphite as a raw material and carrying out the three steps of oxidation, peeling and reduction. The method enables extreme toxicity of hydrazine reducing agents to be avoided, is green and environment-friendly and is applicable to mass production. The single-layer graphene prepared in the invention has the characteristics of stable dispersion in a water phase and / or an organic phase without addition of any stabilizing agents and good conductivity, and can be used in the fields of battery materials, energy storage materials, electronic devices, current-conducting and heat-conducting polymer composite materials, etc.

Owner:TORAY IND INC

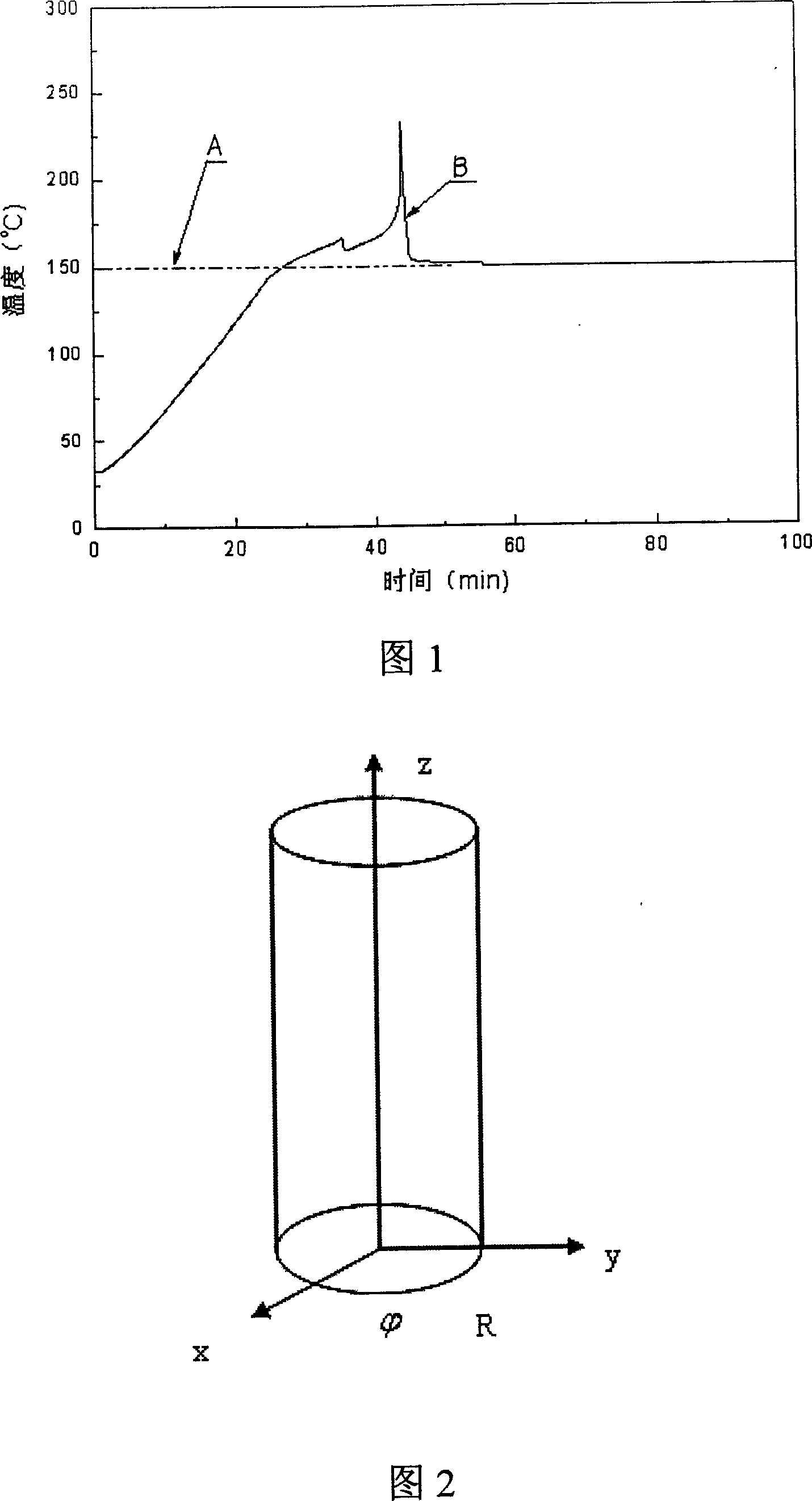

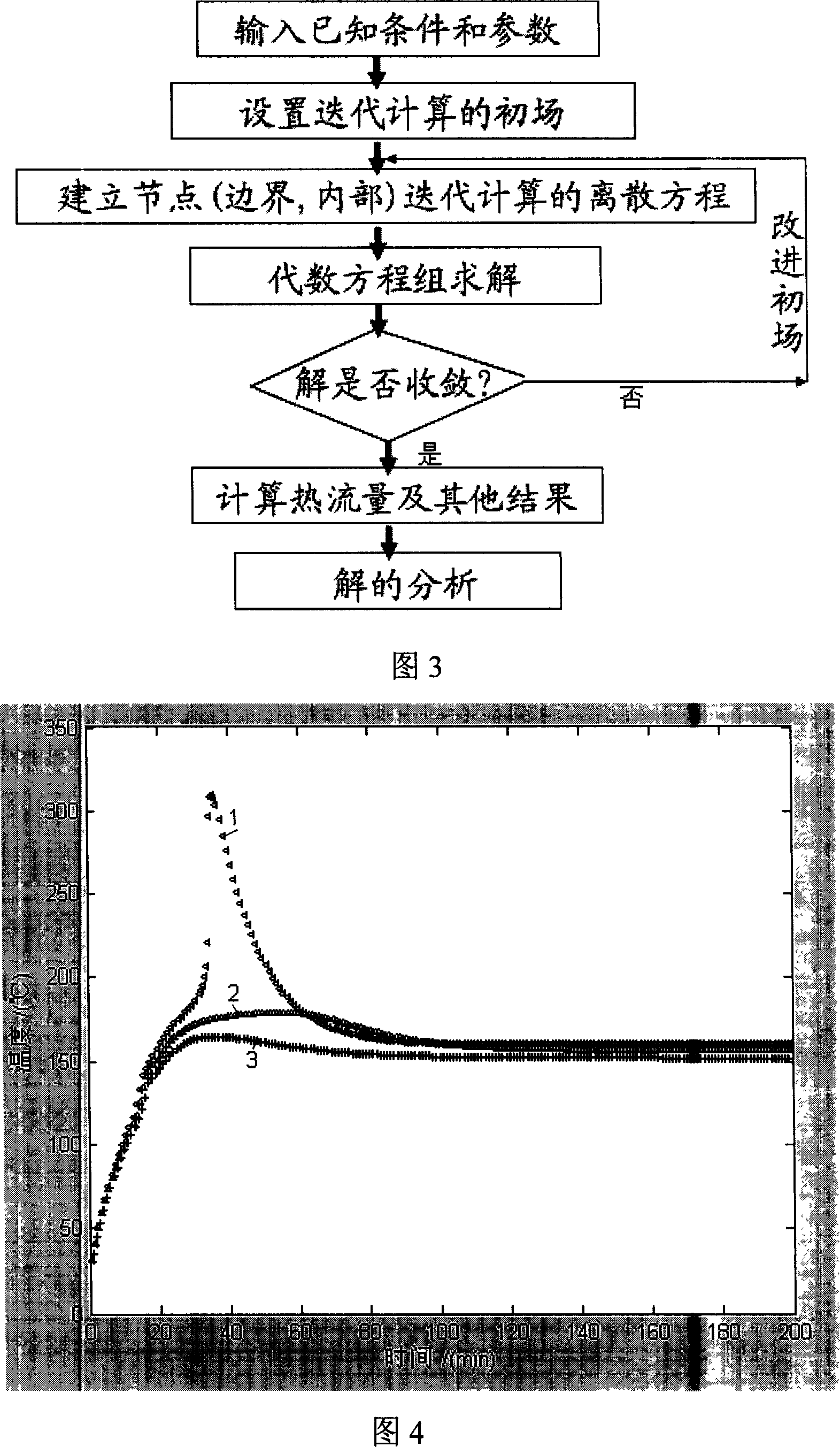

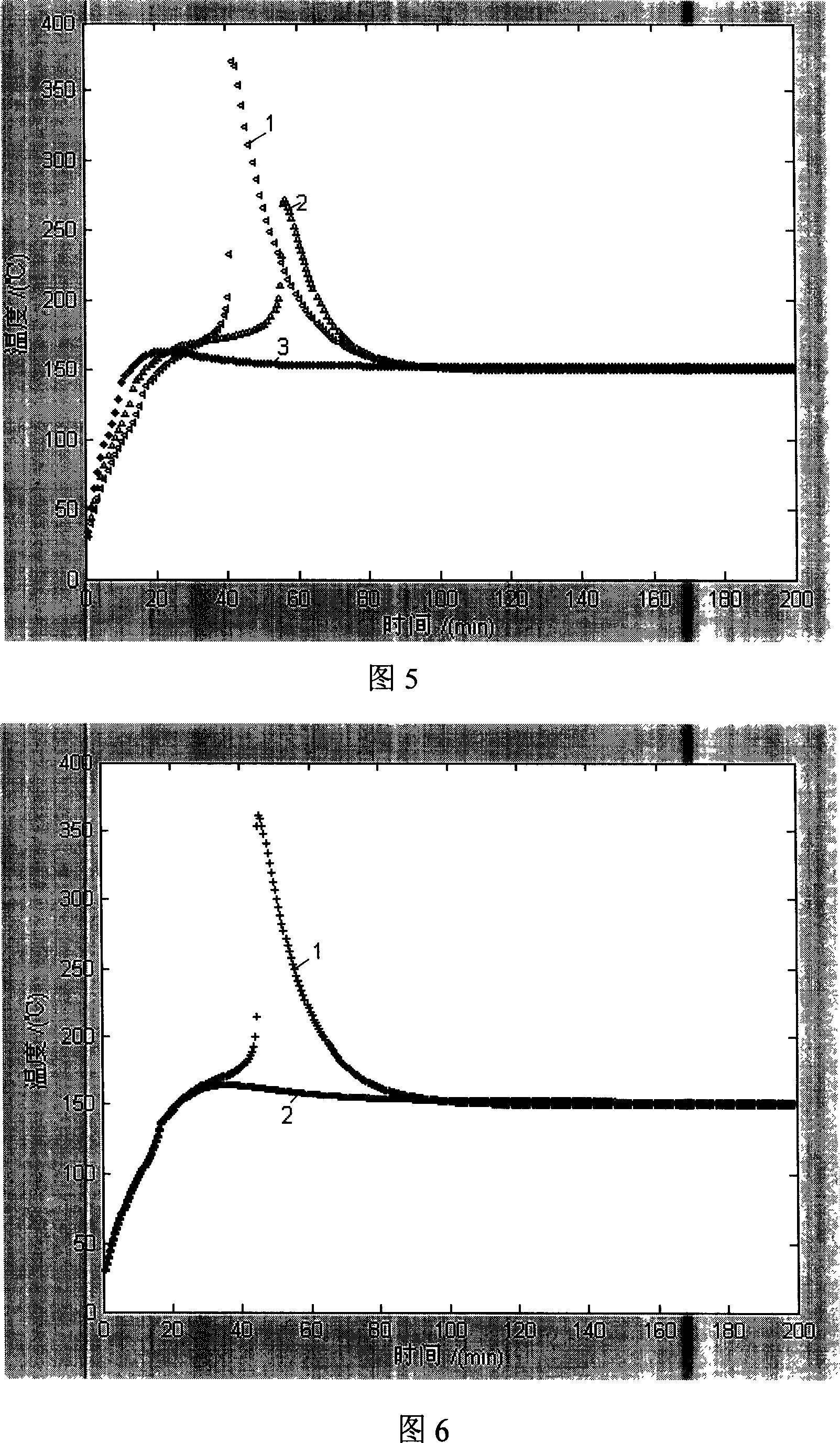

Predicting method for lithiumion cell heat safety performance

The core of the technique is that the method builds thermal model of lithium ion battery under condition of abuse (for ex. hot box, short circuit, and overcharge) based on law of conservation of energy and Fourier law. Using thermal insulation technique for measuring heat determines kinetic parameter of internal heat source item in model; and other parameters come from documents and experiments. Using the model can forecast safety performance of battery under condition of abuse. Modifying model parameter obtains thermo-safety factors influencing lithium ion battery so as to provide theory basis of predicting safety critical value including size of battery, application temperature and material of battery for safety design of battery. The method reduces fussy working procedures for estimating safety performance of material and new battery by making actual battery and carrying out performance test. Advantages are: avoiding waste of resources and time, quick test speed, and low cost.

Owner:TIANJIN LISHEN BATTERY

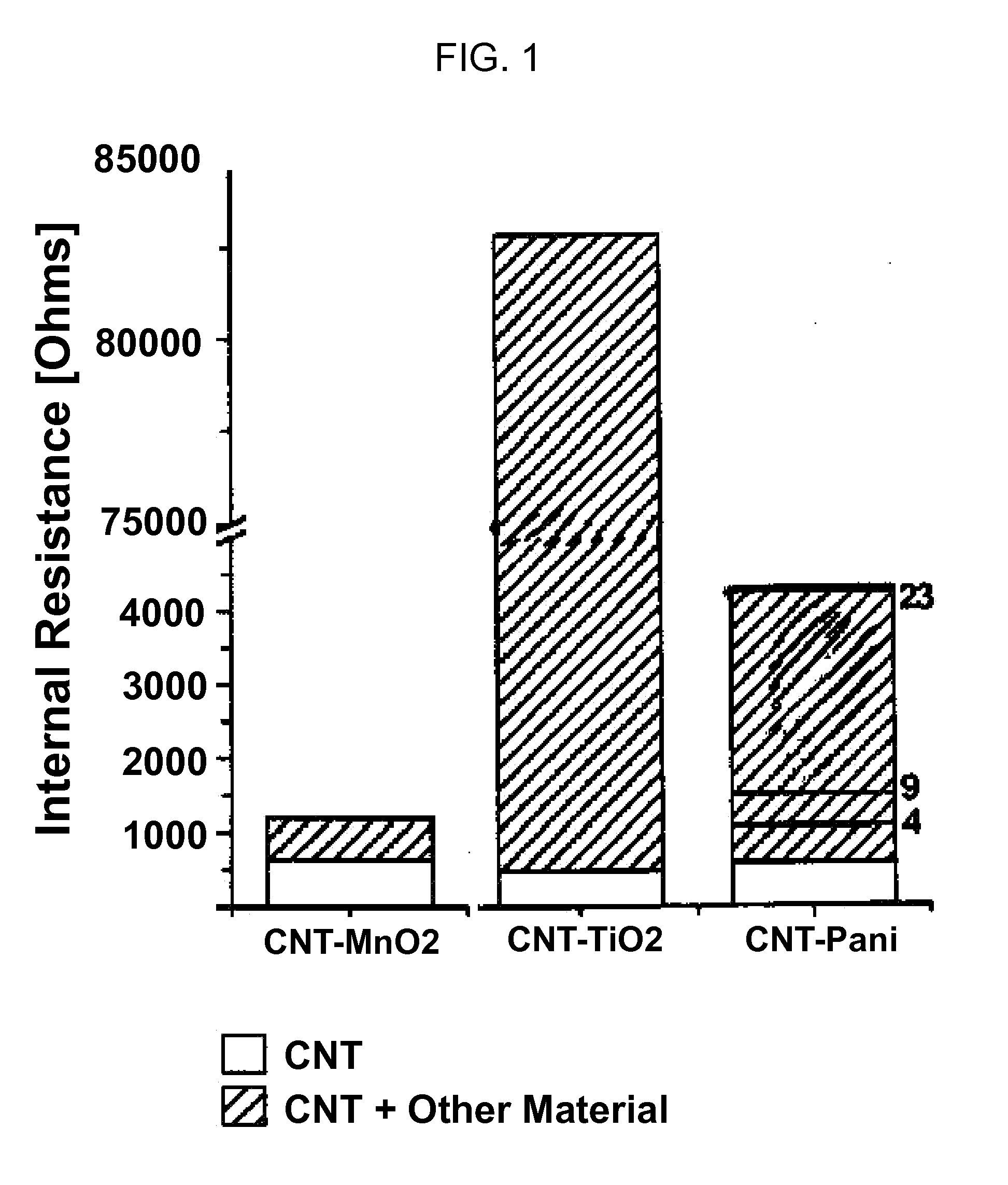

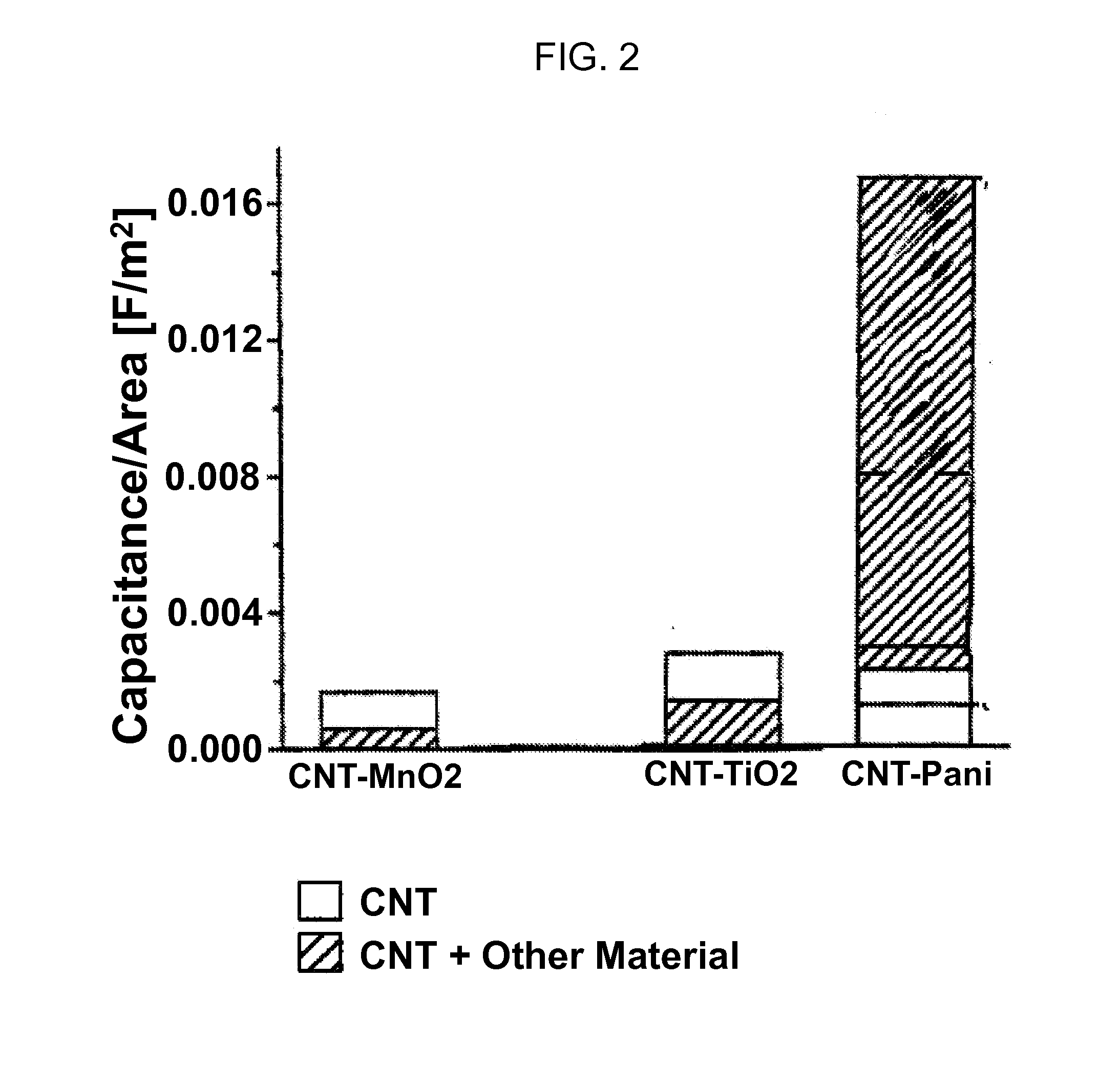

Charge storage device architecture for increasing energy and power density

InactiveUS20110261502A1Fuel and primary cellsHybrid capacitor electrodesEngineeringVolumetric Mass Density

Provided is a new charge storage device structure, incorporating a double layer supercapacitor (DLS) material, electrochemical supercapacitor (ECS) material and / or battery material. More specifically, the DLS material, ECS material and / or battery material may form multilayer electrode structures. Additionally or alternatively, the DLS material, ECS material and / or battery material may form electrode structures in which the DLS material, ECS material and / or battery material are in contact with both a common current collector and electrolyte. The present invention can be generalized towards other energy storage devices, opening a new avenue for a large spectrum of device applications.

Owner:RGT UNIV OF CALIFORNIA

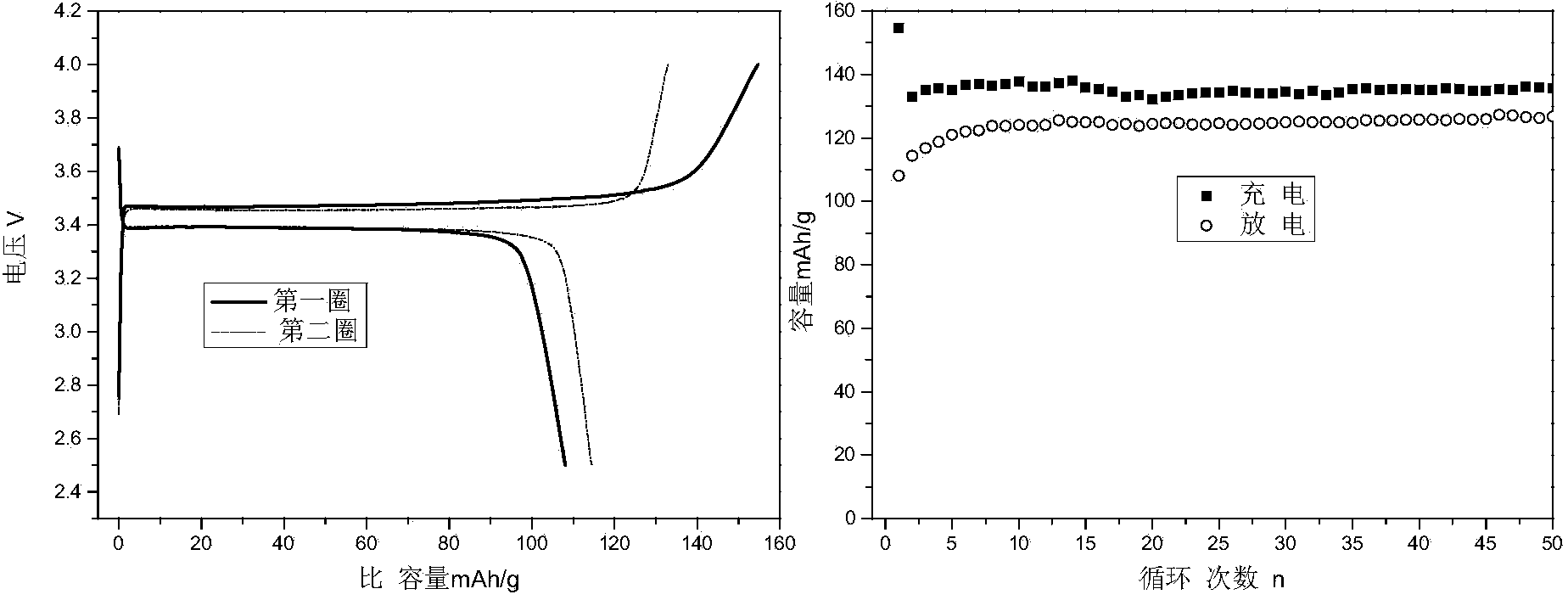

Non-water body electrochemical mixed capacitor with lithium ion battery material as positive pole

InactiveCN1773639AAvoid separationIncrease specific energyElectrochemical generatorsElectrolytic capacitorsEngineeringLithium-ion battery

A nonaqueous system electrochemical mixed capacitor using lithium cell material as positive electrode is prepared as combining ion embedding ¿C deembedding mechanism of lithium cell with double electric layer mechanism in a power accumulator, using LiMn2 ¿C x MxO4 material as positive electrode and using active carbon with high specific surface area as negative electrode to form asymmetric electrochemical capacitor.

Owner:FUDAN UNIV

Resource recycling method of waste battery cathode materials

InactiveCN106328927ALow costIncrease capacityCell electrodesWaste accumulators reclaimingRecovery methodElectric capacity

The invention relates to a resource recycling method of waste battery cathode materials. The resource recycling method comprises the following steps: performing high-temperature calcinating to the waste battery cathode materials so as to separate active powder in the cathode materials from aluminum foil; dissolving the obtained active powder into acid solution, and then filtering to obtain filtrate; determining the concentration of metal ions in the filtrate, and correspondingly supplementing nickel and / or cobalt and / or manganese ions into the solution, so that the molar concentration ratio of nickel, cobalt and manganese ions is 1:1:1; adding sodium hydroxide into the prepared nickel, cobalt and manganese mixture solution, and heating to lead the nickel, cobalt and manganese ions to be co-precipitated, then filtering the precipitate and washing and drying to obtain a nickel-cobalt-manganese precursor; adding sodium carbonate into the filtrate obtained in the step IV, and reacting to obtain lithium carbonate precipitate, filtering, washing and drying the lithium carbonate precipitate, to obtain lithium carbonate powder; and mixing the nickel-cobalt-manganese precursor with the lithium carbonate powder, and calcinating to obtain the lithium nickel cobalt manganese cathode materials. A ternary cathode material is prepared by resource recycling ofvarious battery materials, and batteries produced from the ternary cathode material are lower in cost, higher in electric capacity and better in performance compared with single cobalt-lithium batteries, manganese-lithium batteries and nickel-lithium batteries.

Owner:王剑

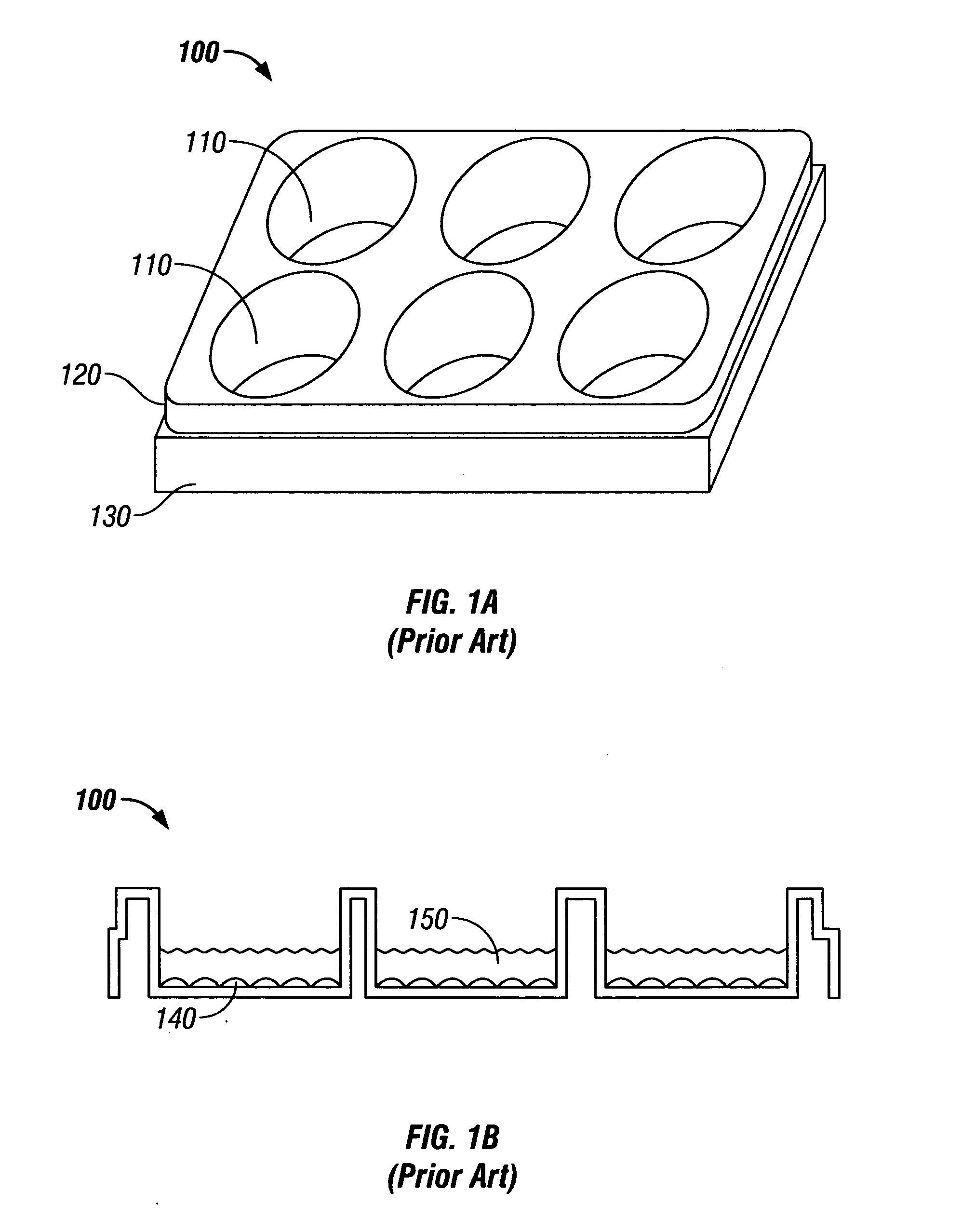

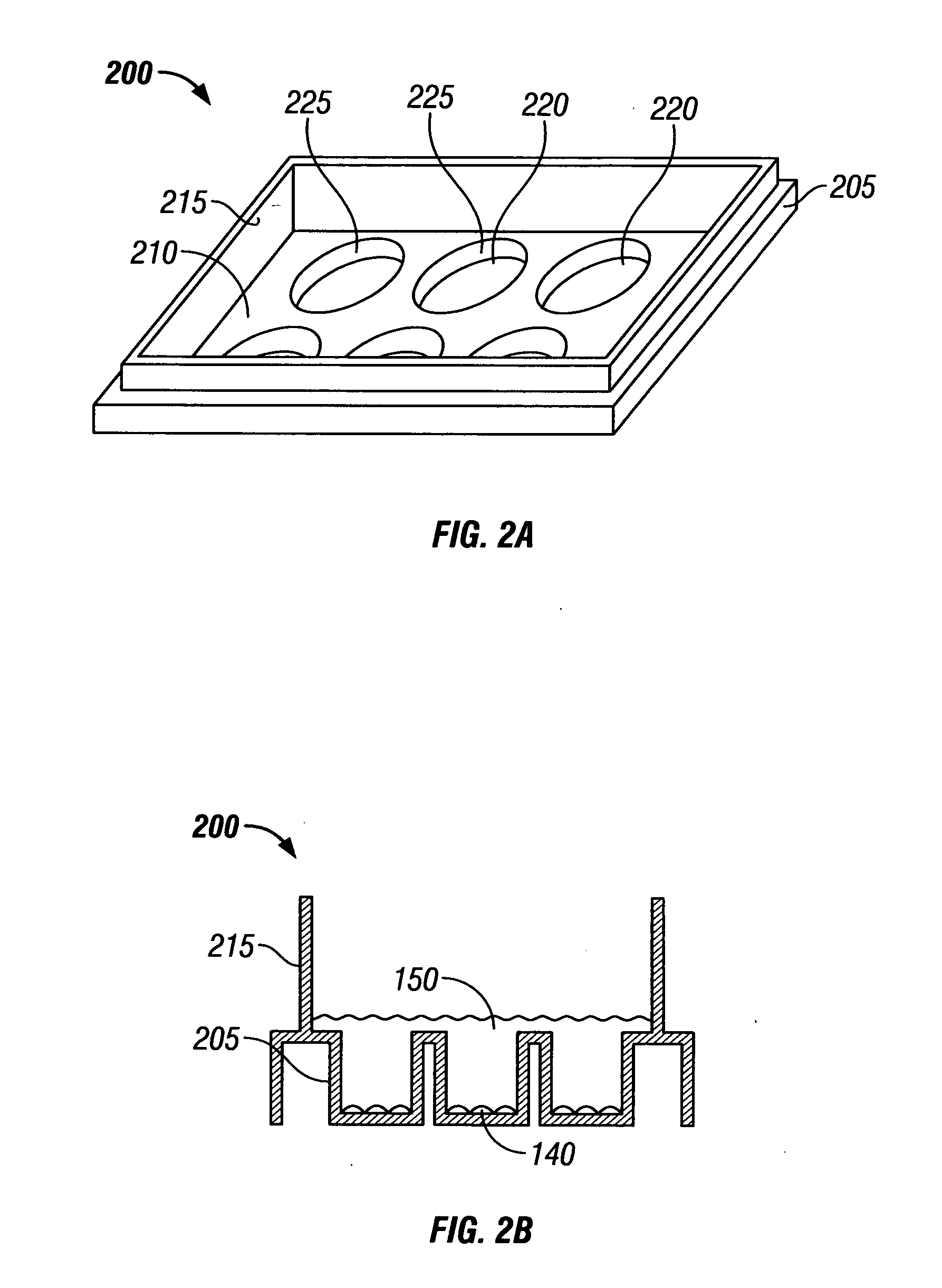

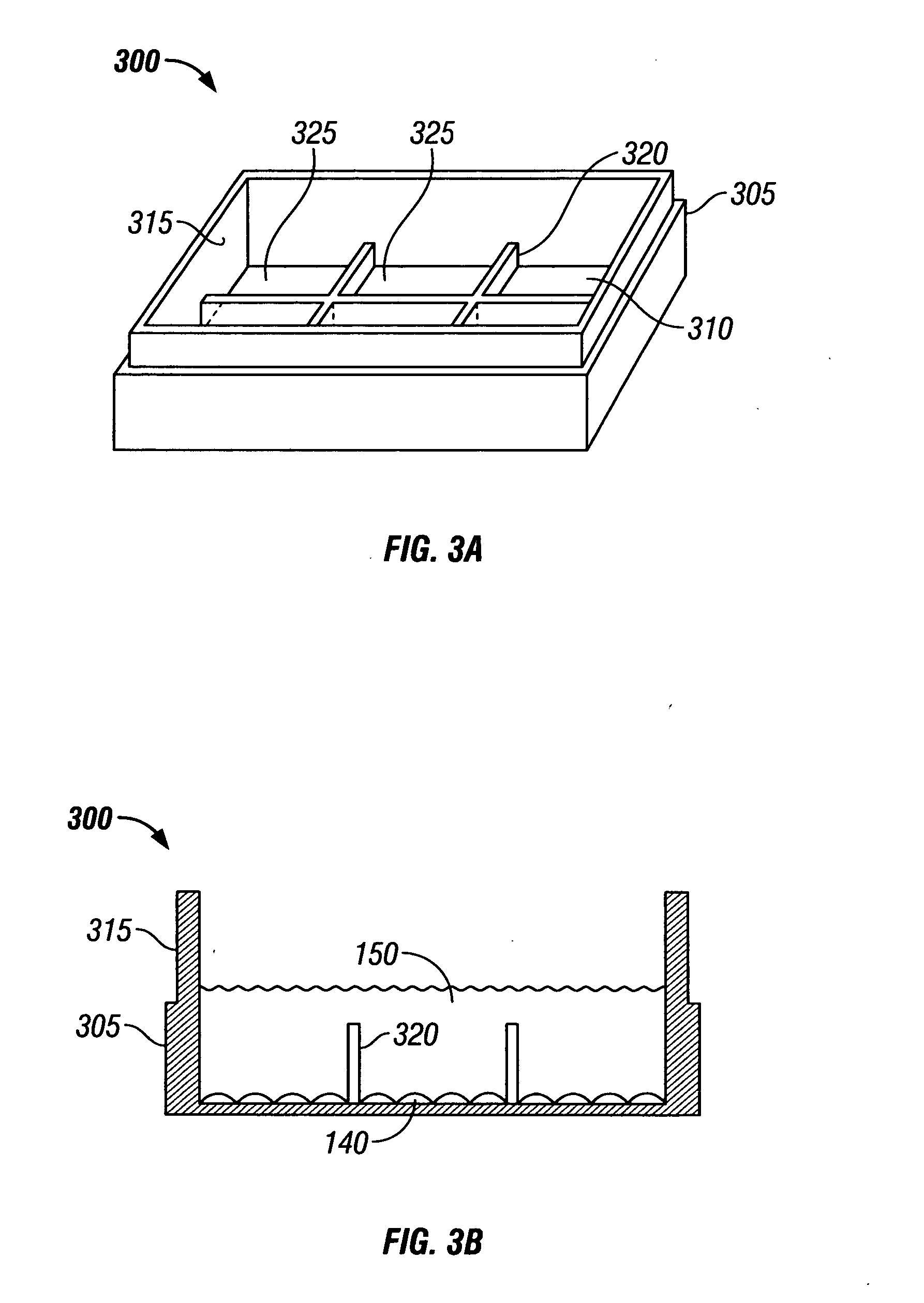

Cell culture tool and method

ActiveUS20050101010A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiologyCell material

A cell co-culture tool includes a body, an outer wall surrounding the body, and more than one vessel within the perimeter of the outer wall. Each vessel has a top edge below a rim of the outer wall. A method of interacting a substance with more than one type of cell material in a culture dish having a plurality of wells includes depositing a different type of the cell material in separate wells of the culture dish, interconnecting the wells with a fluid medium, and adding the substance to the fluid medium.

Owner:DISCOVERY LIFE SCI LLC

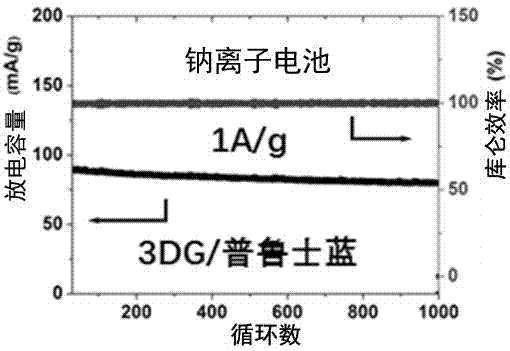

Three-dimensional graphene-coated metal-organic framework (MOF) composite electrode material and preparation method thereof

ActiveCN107195875AImprove electrochemical performanceLarge capacityCell electrodesSecondary cellsCyclic processMetal-organic framework

The invention belongs to the technical field of a battery material, and particularly discloses a three-dimensional graphene-coated metal-organic framework MOF composite electrode material and a preparation method thereof. In order to solve the problems of relatively large volume expansion, limited ion transmission, poor conductivity and the like of an MOF and a derivative thereof during the circulation process, the MOF material is wrapped in three-dimensional graphene by employing an Ostwald curing theory to form three-dimensional graphene-coated MOF aerogel, three-dimensional graphene-coated MOF derivative gel is synthesized by thermal conversion, and the aerogel is compacted to form a flexible thin film and is directly used as a battery electrode material. The preparation method is simple, the raw material resource is rich, the MOF composite electrode material is low in cost, the electrode is high in specific capacity, high in rapid charge-discharge capacity and long in cycle lifetime, and a high-performance flexible electronic device is expected to be produced on a large scale.

Owner:FUDAN UNIV

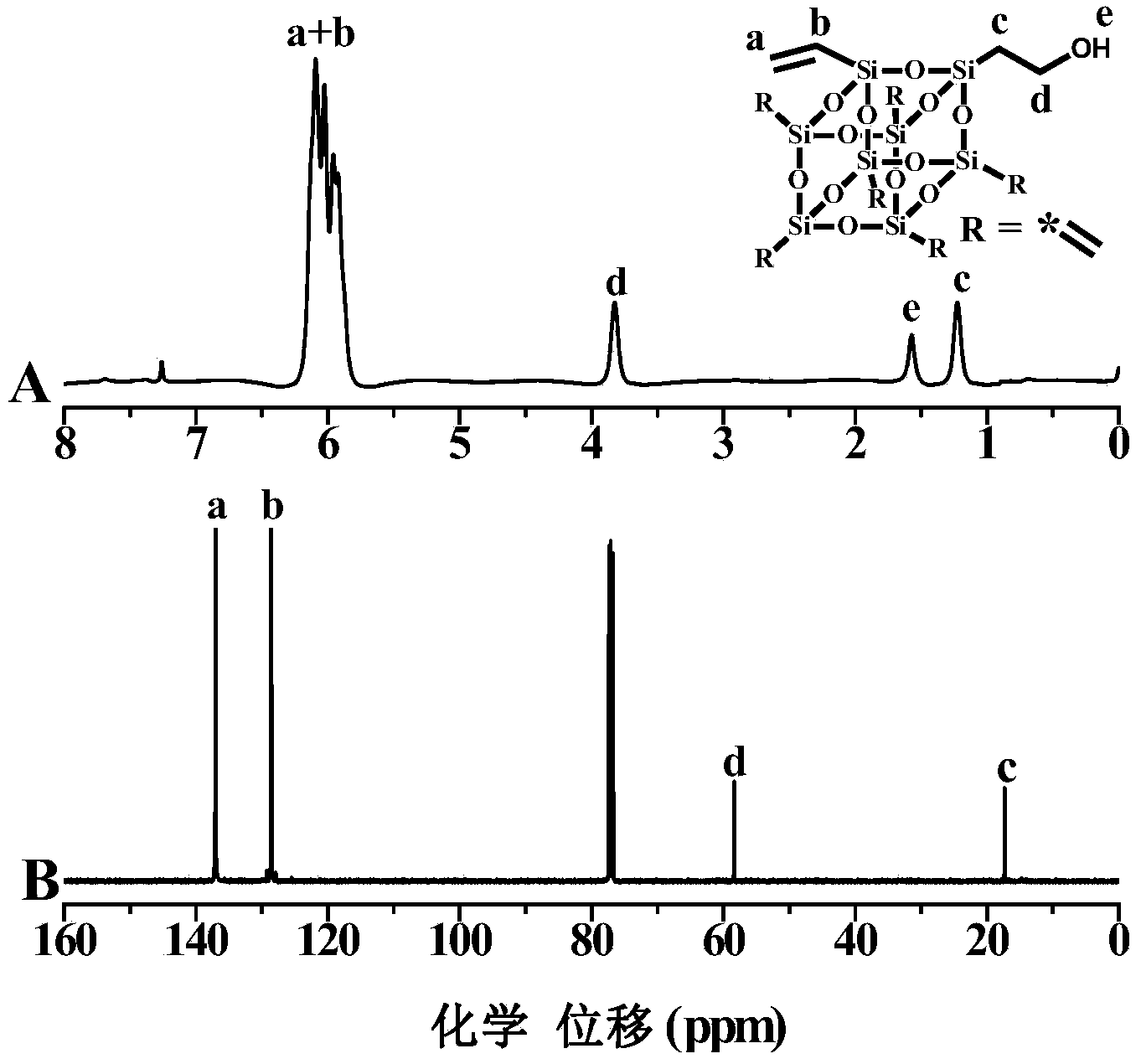

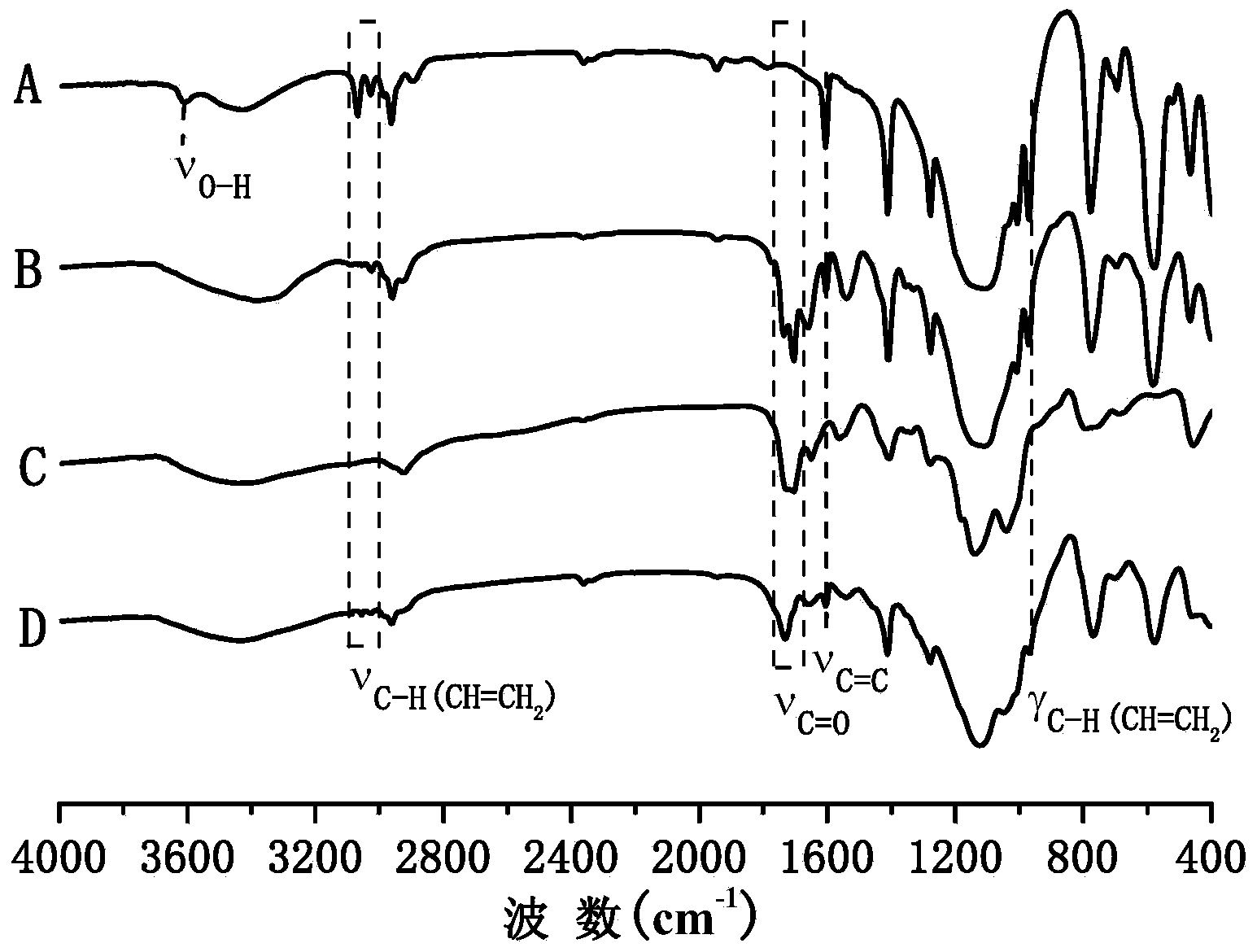

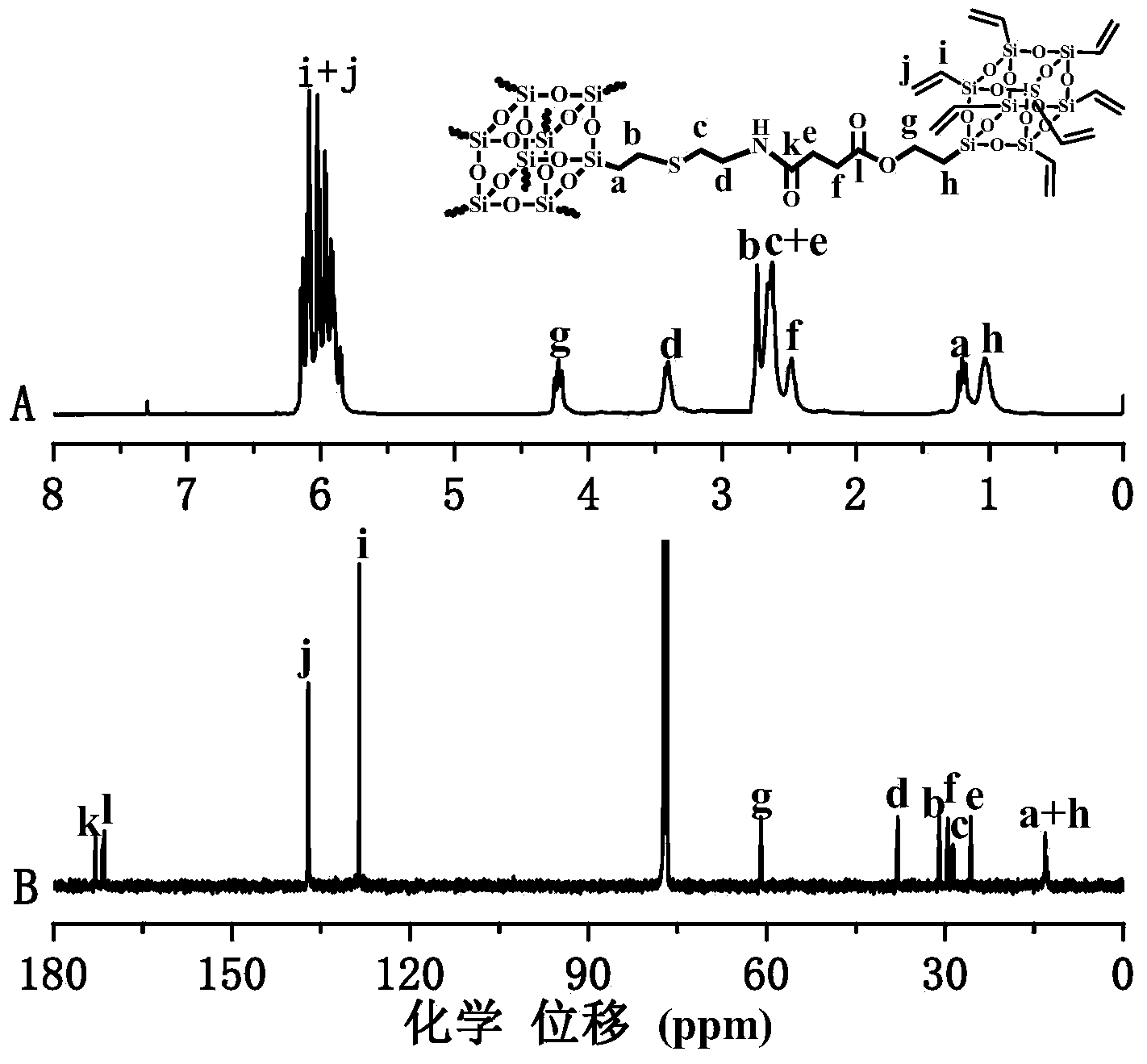

Dendritic polymer with POSS group and preparation method thereof

ActiveCN103642050AWide variety of sourcesRich varietySilicon organic compoundsChemical synthesisCrystallography

The invention relates to a dendritic polymer with POSS group and preparation method thereof. The preparation of the product comprises the following steps: designing a POSS group intermediate R2-POSS-(R1)n-1 (n=6, 8, 10, 12) with asymmetric structure, and then using a chemical synthetic method, and obtaining a dendritic polymer (containing derivatives thereof) containing POSS group and a lot of end functional groups. The product has the advantages of unique structure design and diversified selections, thereby the product has latent application prospects for the aspects of surfactant, biological medicine carrier, catalyst, photon crystallization, optical material, anti-corrosion material, electronic material, information recording material, printing material, battery material, magnetic material, electronic luminescent device, etc.

Owner:INST OF CHEM CHINESE ACAD OF SCI

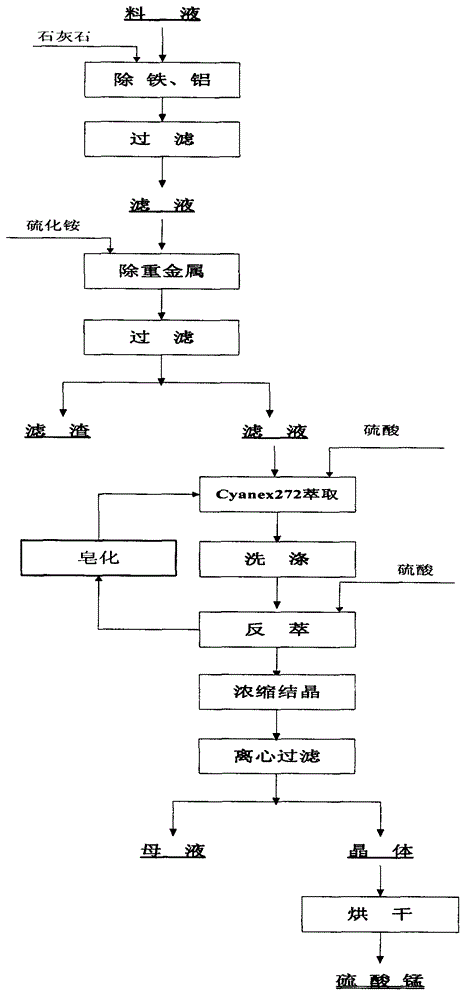

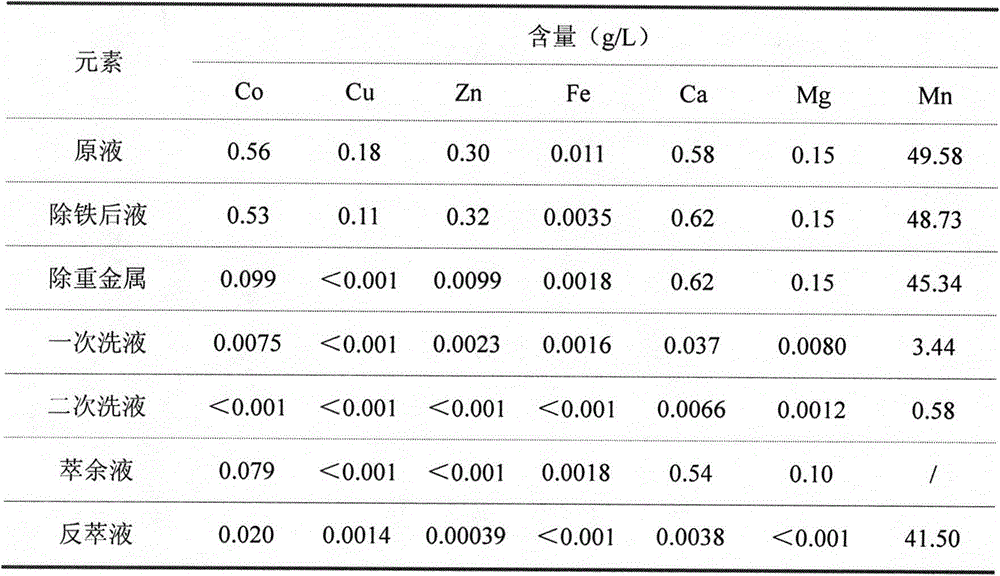

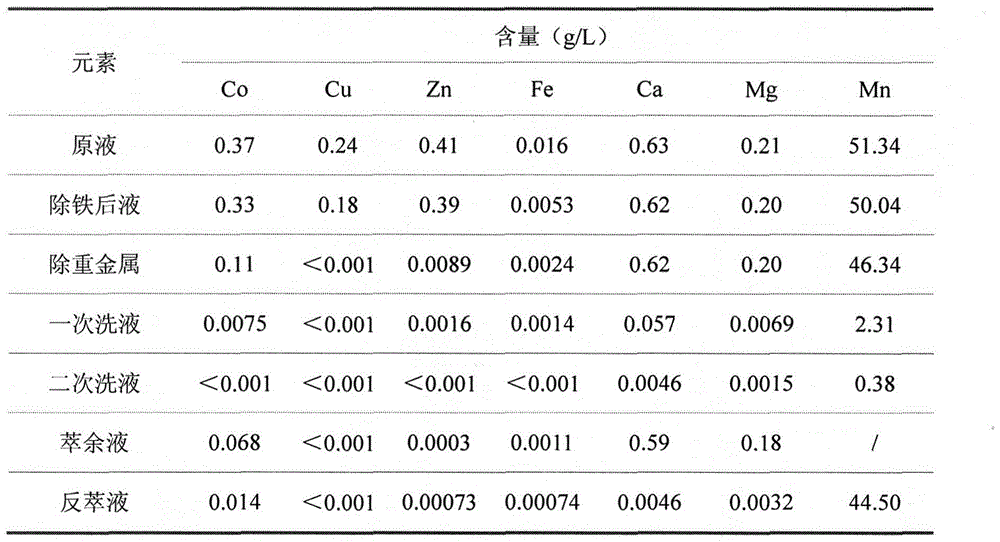

Method for preparing high-purity manganese sulfate from manganese-containing waste liquid

The invention relates to a method for preparing high-purity manganese sulfate from a manganese-containing waste liquid. The existing method for treating the high-manganese-containing waste liquid generated in the wet production of cobalt salts mainly comprises a lime precipitation method and a method for preparing manganese sulfate by removing calcium and magnesium via fluoride and adopting a P204 or P507 extracting agent and has the respective problems that the utilization value of prepared manganese hydroxide is low, the fluoride-containing wastewater is polluted and the like. According to the method, heavy metals are removed by virtue of sulfide, manganese is extracted through a Cyanex272 extracting agent, calcium and magnesium are thrown and the reverse extraction is performed to obtain the high-purity manganese sulfate product which can meet the requirement of a ternary cell material on manganese sulfate; and the method has the advantages of short process flow, no fluoride pollution and the like.

Owner:ZHEJIANG HUAYOU COBALT

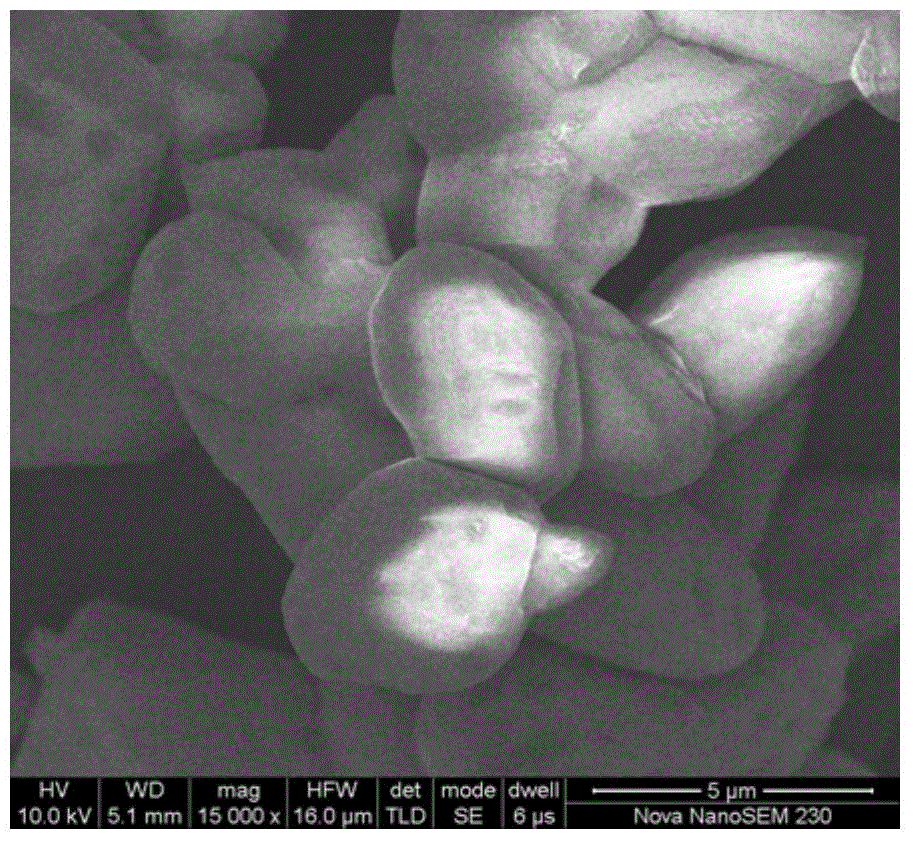

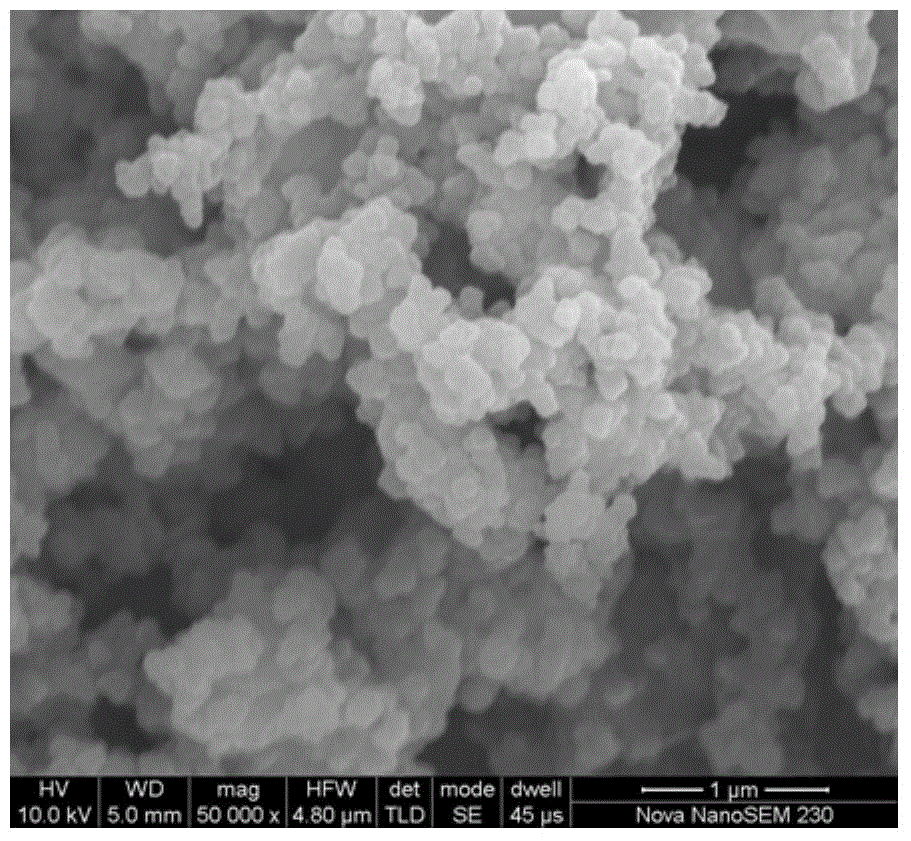

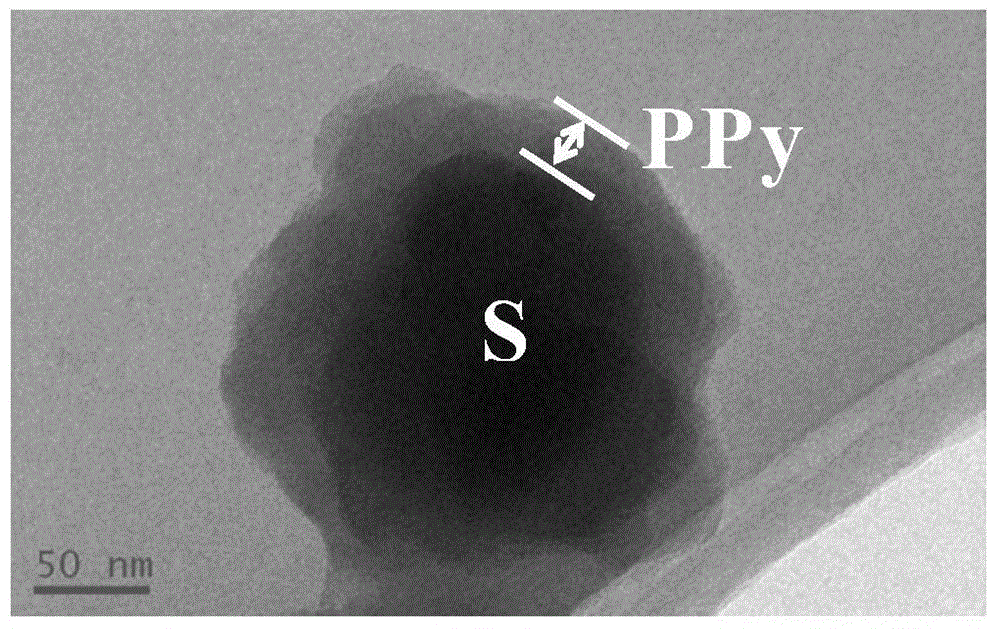

Nanometer sulfur-based positive electrode composite material for lithium sulfur batteries, and preparation method thereof

ActiveCN104900856AHigh yield and controllableShorten the transmission pathMaterial nanotechnologyCell electrodesConductive polymerIn situ polymerization

The invention discloses a nanometer sulfur-based positive electrode composite material for lithium sulfur batteries, and a preparation method thereof. The positive composite material is prepared through compounding a core-shell structure with reduced graphene oxide, the core-shell structure is formed by nanometer elemental sulfur and a conductive polymer nanoparticle, and the sulfur-conductive polymer nanoparticle core-shell structure is uniformly inlaid between graphene sheets to form a sandwiched three-dimensional conductive network. The preparation method of the positive electrode composite material comprises the following steps: forming the core-shell structure through in situ polymerization of the conductive polymer nanoparticle on the surface of the nanometer elemental sulfur core prepared through a low temperature liquid phase technology, and coating the surface of the core-shell structure with the reduced graphene oxide to obtain the positive electrode composite material for lithium sulfur batteries. The positive electrode composite material has the advantages of simple preparation process, low cost, small energy consumption, controllable sulfur content, strong repeatability and easy large-scale production. The positive electrode composite material can improve the discharge specific capacity of a battery material and the active substance utilization rate as a lithium sulfur battery positive electrode material in order to greatly improve the cycle performances of the battery.

Owner:CENT SOUTH UNIV

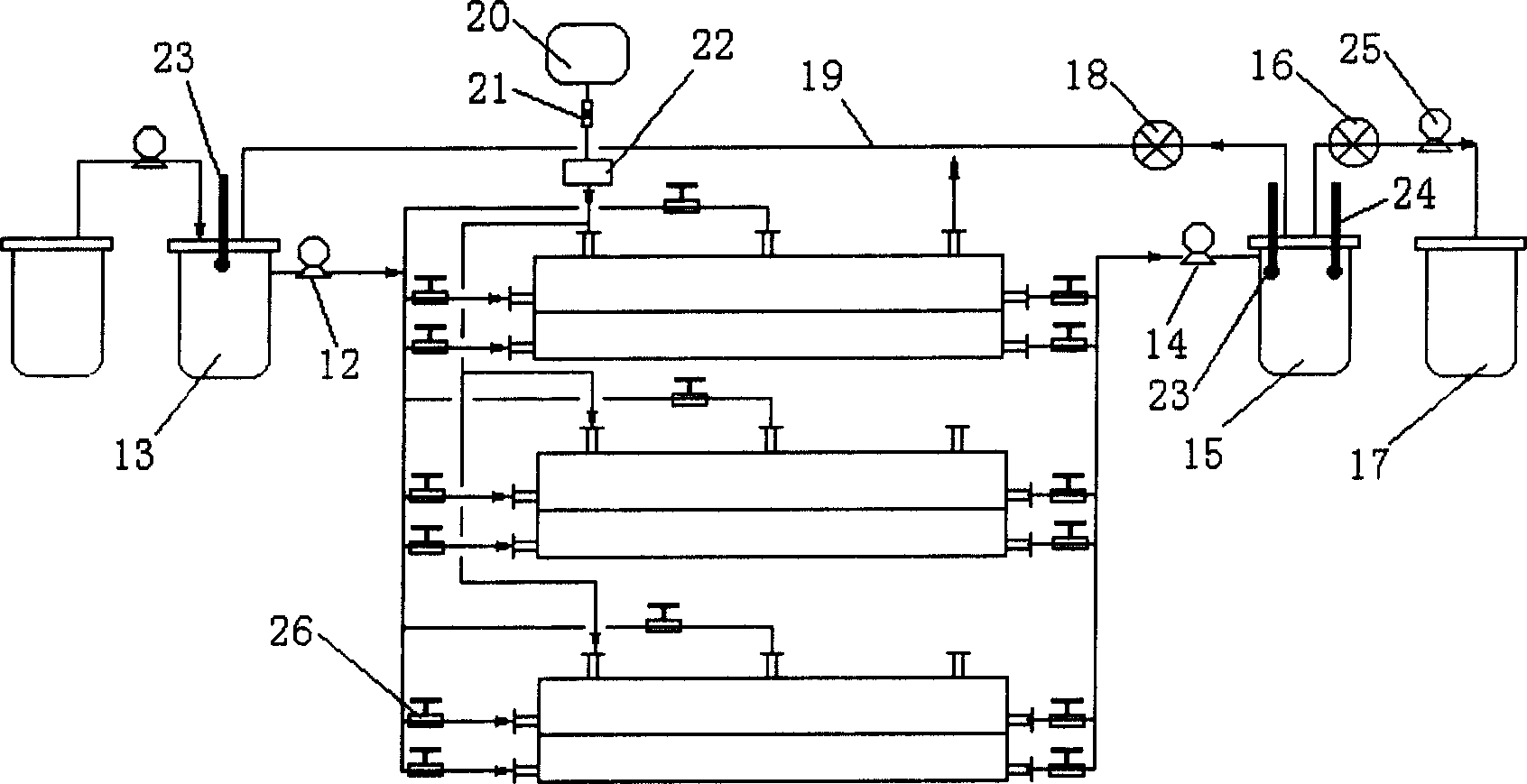

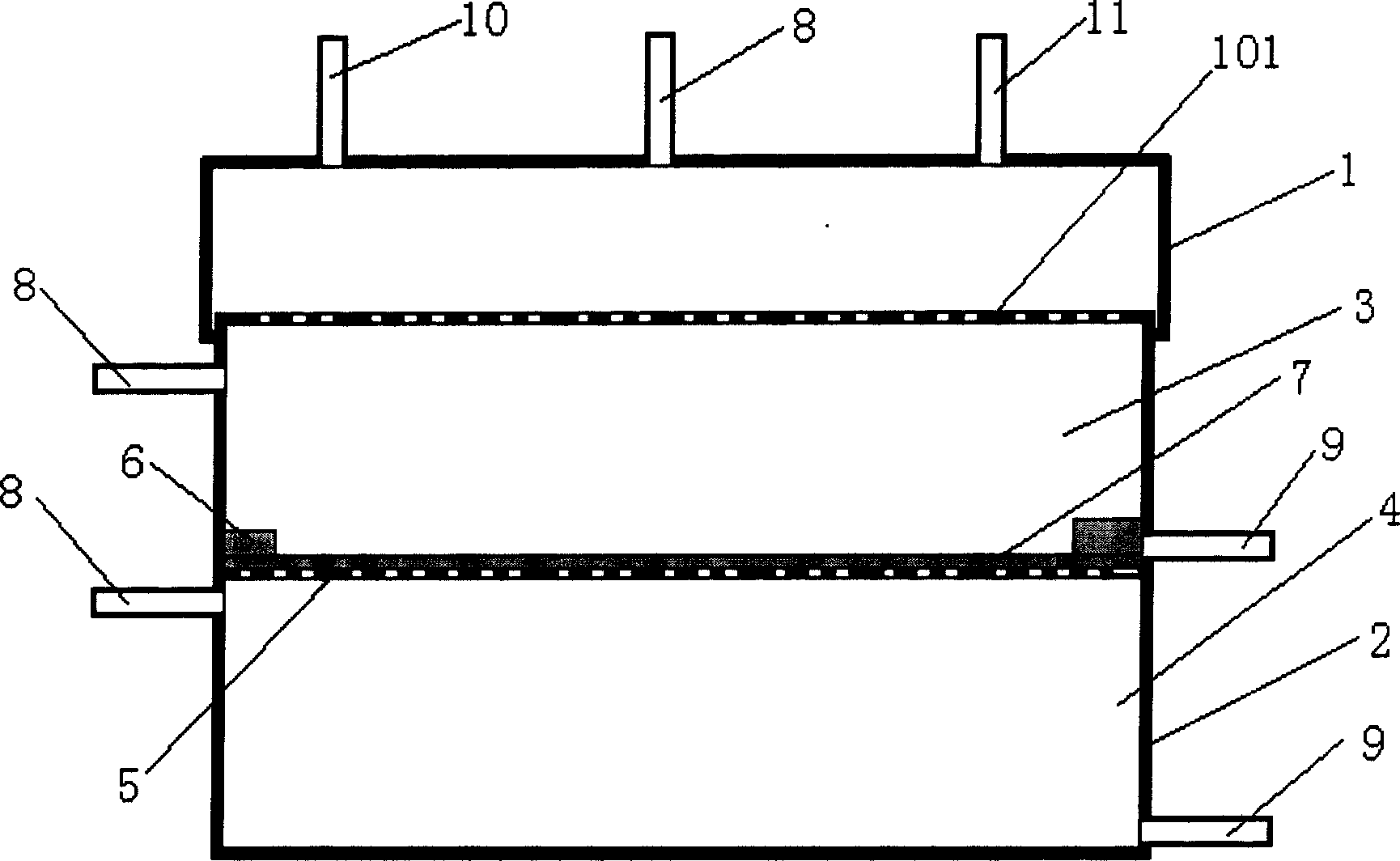

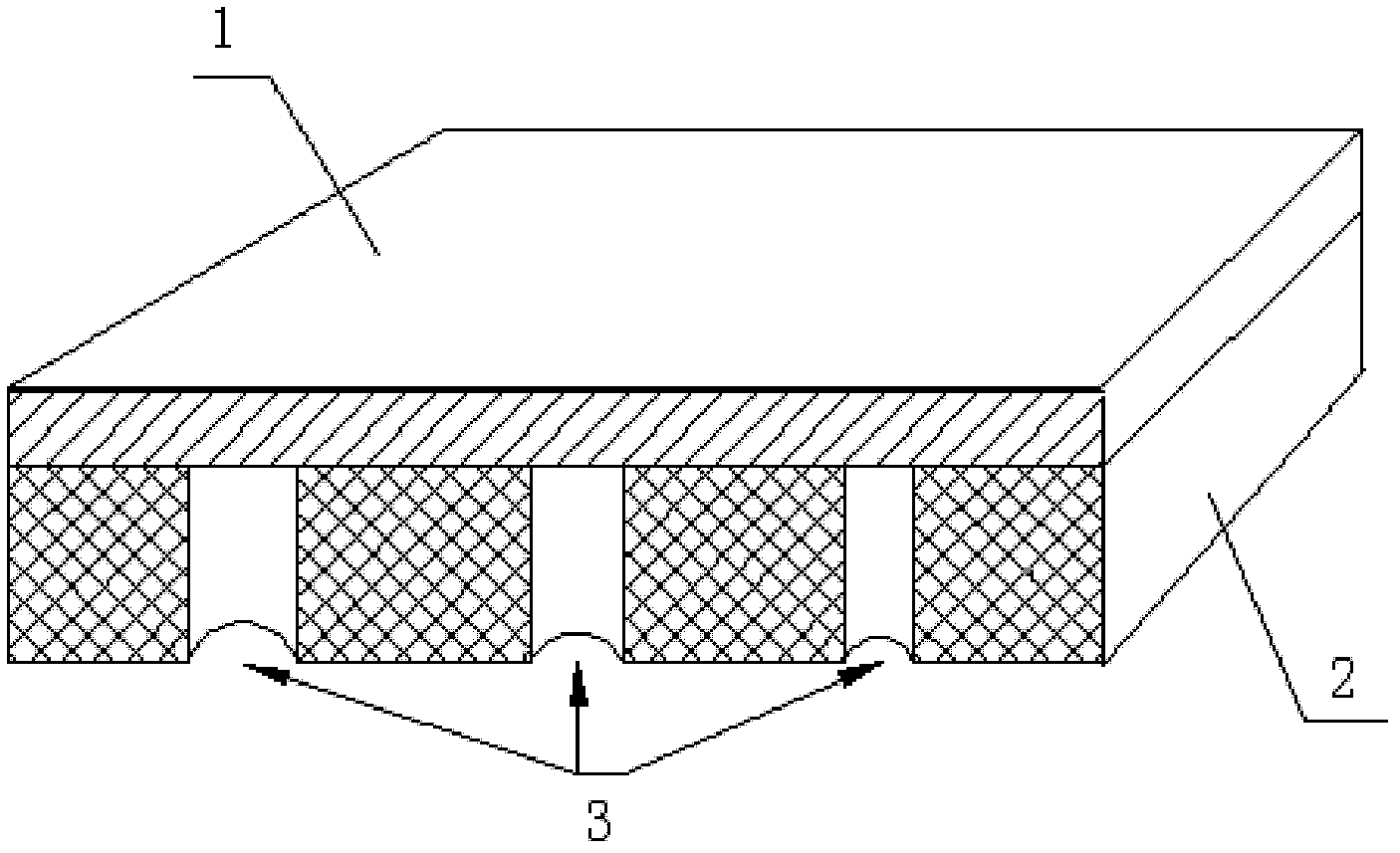

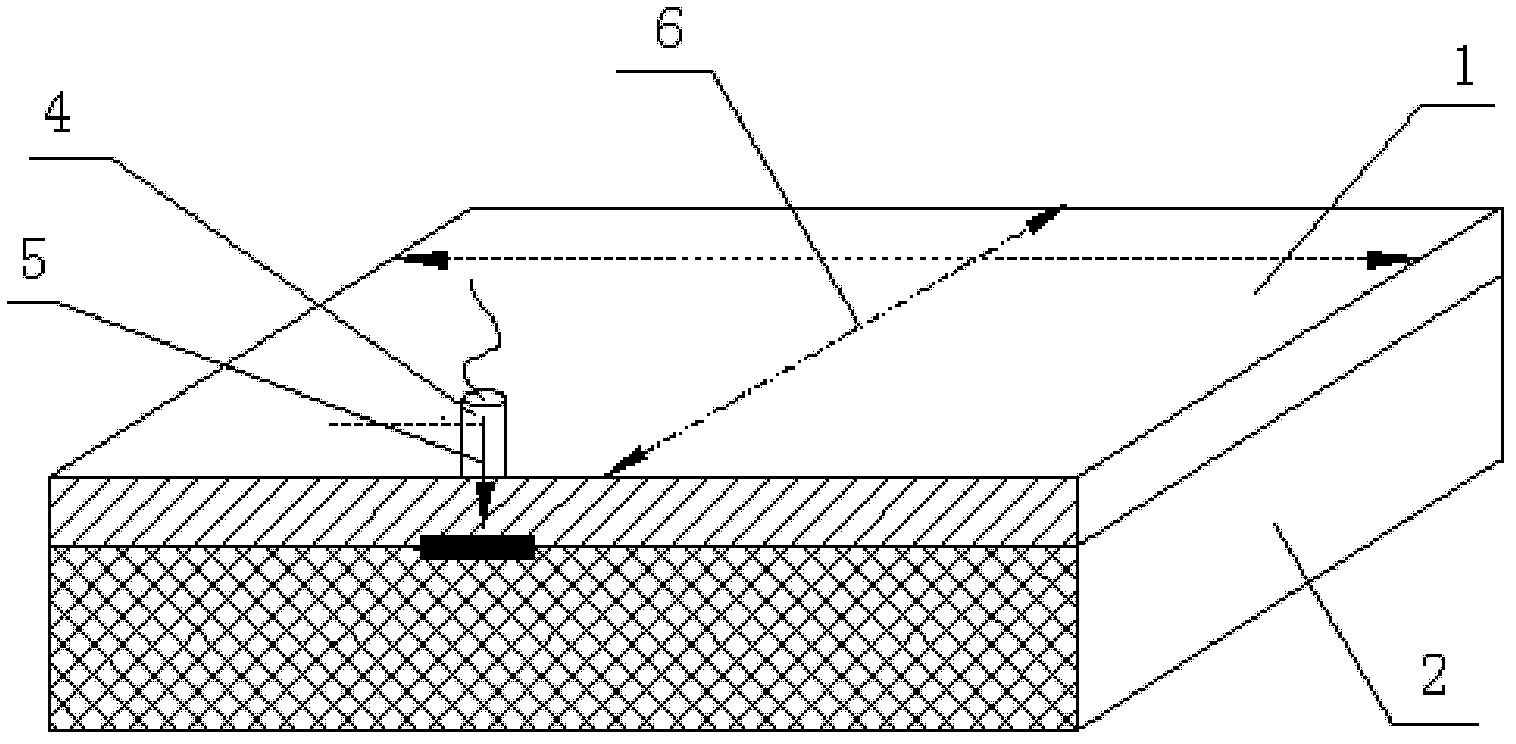

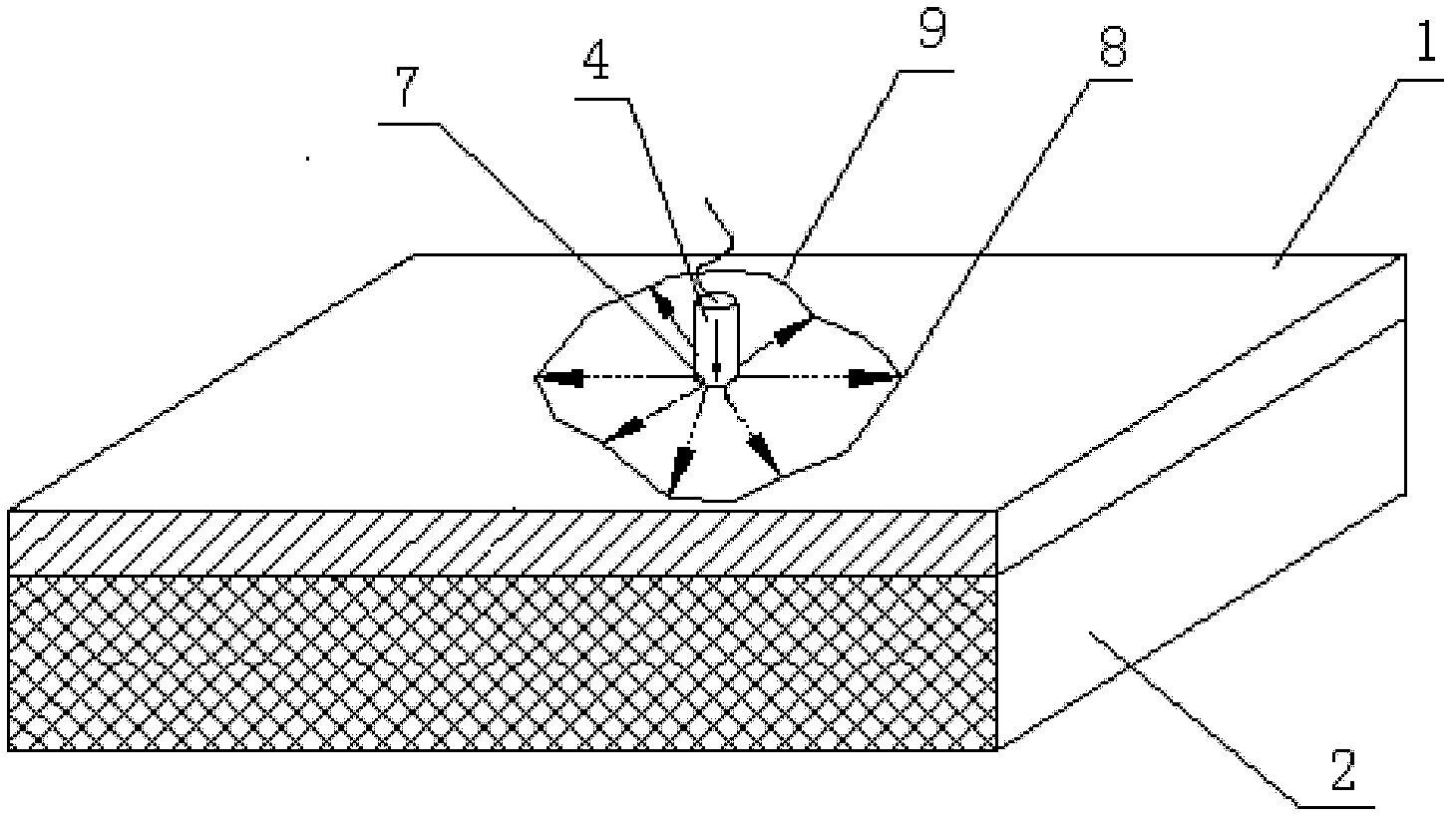

Pouring type biologic reactor system in vitro constructure of dual active skin

InactiveCN1560225AIncrease the areaEvenly distributedTissue cultureTissue/virus culture apparatusRefluxReactor system

The invention is a double-layer active skin-composed in vitro pouring bioreactor system, including a liquid-adding device, a pouring bioreactor, a liquid-collecting device, a liquid reflux and a gas supply device; the liquid-adding device is connected with a liquid inlet of the pouring bioreactor, the liquid-collecting device is connected with a liquid outlet of the pouring bioreactor to collect the culture medium after culture, the liquid reflux is connected with the liquid -adding and -collecting devices through pipelines, and the gas supply device is connected with a gas inlet of the pouring bioreactor through pipeline; the bracket or cell material compound for composing the skin is smoothed out on a multiporous supporting plate of the pouring bioreactor. It has simple structure, easy to enlarge and can make wet-hot sterilization, maintain axenic environment for a long time and primely simulate in vivo growth environment, implementing the course from vaccinating to derma composing to the entire double-layer active skin composing in vitro by pidermis.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for ultrasonic detection of bonding quality of thin-walled metal and non-metal material

InactiveCN102608204AImprove quality reliabilityImprove the safety of useAnalysing solids using sonic/ultrasonic/infrasonic wavesOscillographyBond quality

The invention discloses a method for ultrasonic detection of the bonding quality of thin-walled metal and a non-metal material, wherein an ultrasonic instrument is adopted for detection. The method comprises the steps of: firstly, making a comparative sample, and calibrating the sensitivity of the ultrasonic instrument according to a debonding defect testing hole in the comparative sample; then performing defect position testing on a product: detecting the bonding quality of the thin-waled metal and the non-metal material by adopting the calibrated ultrasonic instrument, placing an output port of a longitudinal wave probe of the ultrasonic instrument on an outer metal surface of the material product, and performing 100% scanning on a bonding face by adopting a moving scanning manner; and if the height of multiple pulse echoes of longitudinal waves at cells 6 to 10 of a horizontal baseline on a oscillography screen of the instrument is found to reach or exceed initial sensitivity during moving scanning, judging that a part below the probe has a debonding defect position or an adverse bonding defect, and if a height envelope curve of the multiple pulse echoes of the longitudinal waves at cells 6 to 10 of the horizontal baseline on the oscillography screen is lower than 50% and gradually decreases to 20% or no reflected waves exist, judging that the bonding quality is intact.

Owner:湖北三江航天江北机械工程有限公司

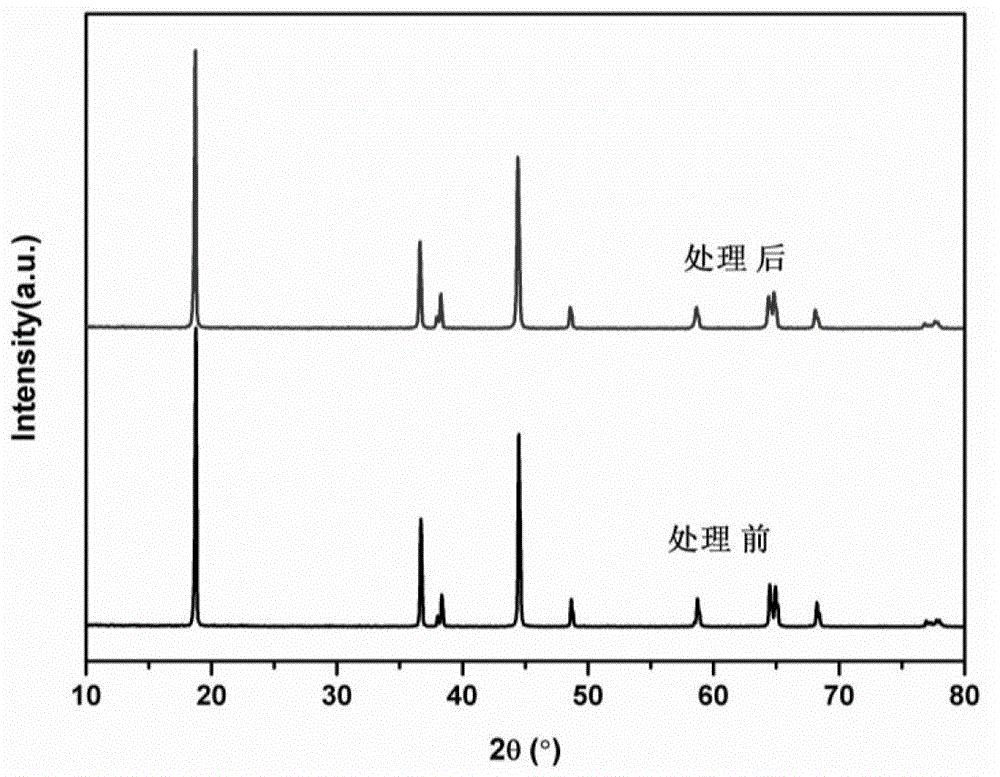

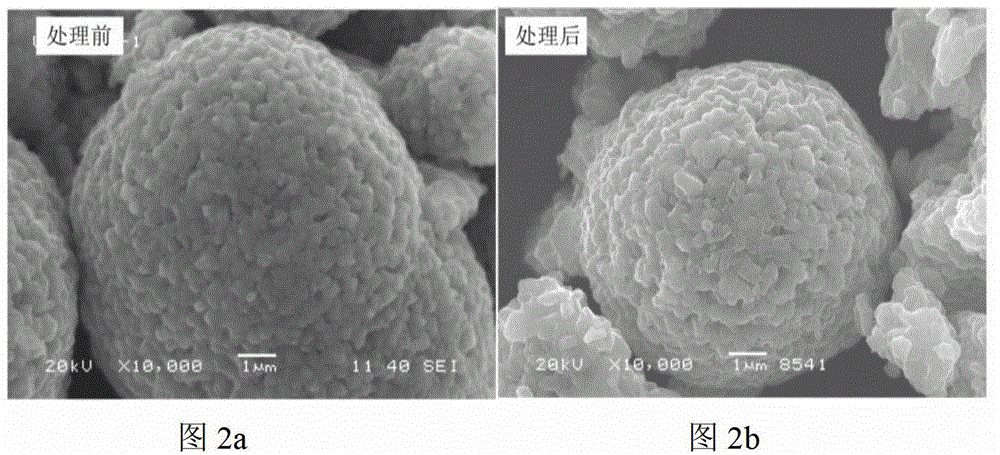

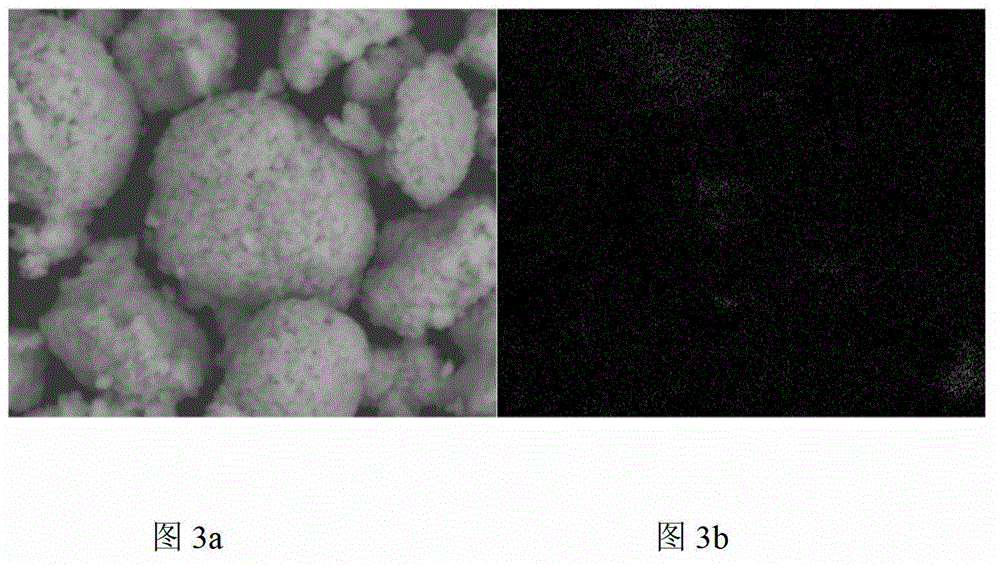

Method for removing lithium ion battery nickel-rich material surface lithium residues by liquid phase precipitation method

ActiveCN102881911ALow hygroscopicityGood hygroscopicityCell electrodesMoisture absorptionMaterial physics

The invention discloses a method for removing lithium ion battery nickel-rich material surface lithium residues by a liquid phase precipitation method. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method includes the steps: dispersing lithium ion battery nickel-rich materials into phosphate solution, combining the nickel-rich material surface lithium residues with phosphate radical ions so as to form precipitation, nucleating on the material surface, and calcining so that a material with the surface wrapped with a compact Li3PO4 layer is obtained. The wrapping layer prepared by the method is more uniform and compact than a traditional wrapping layer, and storage performance of the material in air is obviously improved; and the moisture absorption performance of the nickel-rich materials can be improved while water brought into electrolyte by electrode materials is reduced, and structural stability of the material is enhanced. Moreover, Li3PO4 is better in stability in the electrolyte than in the battery materials, so that the comprehensive electrochemical performance of a positive electrode material can be effectively improved. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method is simple in preparation process, short in flow path and low in production cost, and the prepared positive electrode material is excellent in physical performance and electrochemical performance.

Owner:CENT SOUTH UNIV

Method for recovering active material from waste battery material

ActiveUS20130323142A1Electrode thermal treatmentWaste accumulators reclaimingConductive materialsBiological activation

Method of recovering active material from waste battery materials comprises: (1) an electrode material mixture recovery step of separating an electrode from the waste battery material to recover an electrode material mixture including the active material, a conductive material, and a binder from the electrode; (2) an activation agent mixing step of mixing an activation agent including one or more alkali metal compounds with the recovered electrode material mixture; (3) an activation step of heating the obtained mixture to a retention temperature not less than a melting start temperature of the activation agent to activate the active material included in the mixture; and (4) an active material recovery step of recovering the activated active material from a mixture obtained as a result of cooling after the activation step.

Owner:SUMITOMO CHEM CO LTD

Preparation method of porous silicon/graphite/carbon composite negative electrode material for lithium-ion secondary battery

ActiveCN108199030AAlleviate volume expansionEasy to makeNegative electrodesSecondary cellsCarbon compositesHigh energy

The invention relates to a preparation method of a porous silicon / graphite / carbon composite negative electrode material for a lithium-ion secondary battery. A silicon source of the composite materialis natural mineral soil: namely kaolinite, montmorillonite, mica powder, wollastonite, vermiculite powder, pumice powder and coal gangue. The silicon source is reduced into elemental silicon by usinga metal element or alloy powder and anhydrous metal chloride under a mild condition, and the reduced porous silicon, graphite and an organic carbon source are subjected to high-energy ball mill mixing. The reduction temperature is low, the inherent pore structure of the natural mineral soil is effectively reserved and the prepared silicon material has relatively high specific surface area and abundant pores and has excellent electrochemical properties. Volume expansion can be effectively relieved through the inherent pore characteristic of the natural mineral soil; and the prepared composite material has higher charge-discharge capacity and stability. Especially the kaolinite is wide in source and low in price, so that the preparation cost of the battery material is greatly reduced. The porous silicon / graphite / carbon composite negative electrode material is friendly to environment, simple in preparation method, instrument and equipment and suitable for industrial production.

Owner:NANKAI UNIV

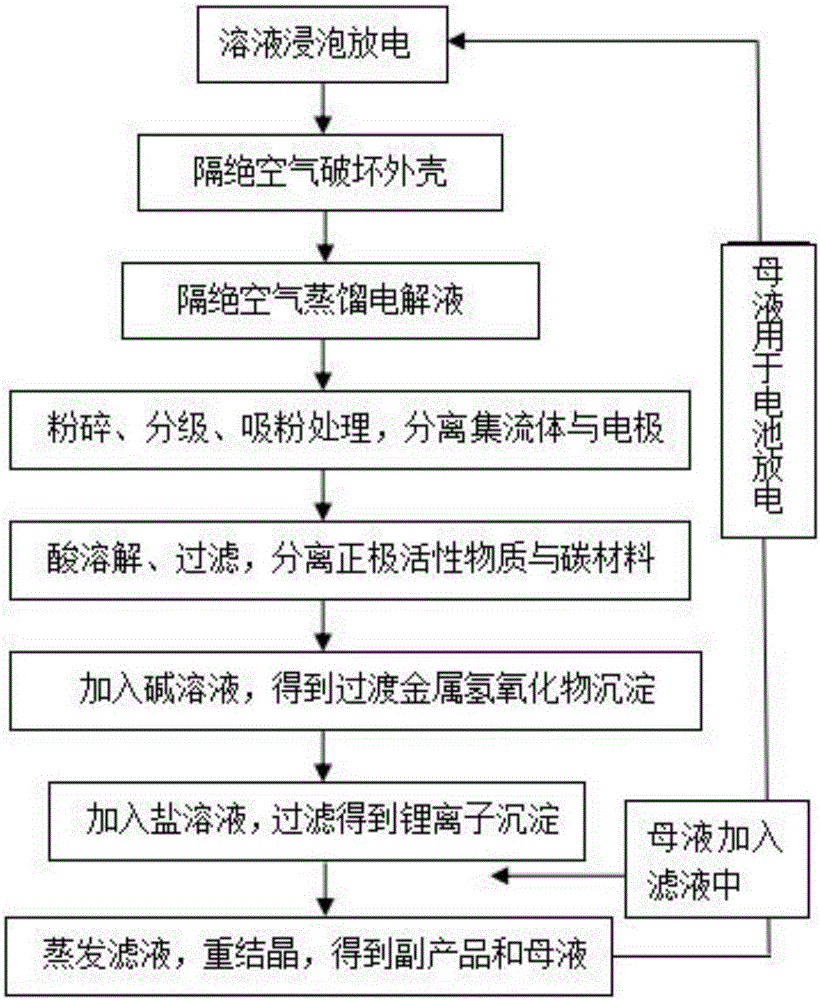

Resource recycling method for waste lithium batteries

InactiveCN105932351ARealize separation and recoveryReduce usageWaste accumulators reclaimingBattery recyclingEvaporationPollution

The invention discloses a resource recycling method for waste lithium batteries. The resource recycling method comprises the following steps: soaking in a solution for discharging, breaking shells and distilling an electrolyte under a vacuum condition or an inert atmosphere protection condition, mechanically smashing, separating current collectors and electrode materials by using difference of density, adding acid to dissolve filtered and separated carbon material, adding base to recycle transition metal elements in cathodes, adding salt to recycle lithium element, and carrying out evaporation-recrystallization to recycle byproducts. The manner that a dry method is combined with a wet chemical technology realizes separation recycling of battery materials, the method is low in invested cost and few in energy consumption, a recycling method for environmentally hazardous lithium hexafluorophate and inflammable carbonic ester is highlighted particularly, and secondary pollution cannot be caused in the recycling process; and moreover, no organic solvent is used in the process, zero emission of waste liquid is realized, and the method is suitable for large-scale recycling production.

Owner:上海赛特康新能源科技股份有限公司

Detecting method and device for lithium ion cell material

This invention relates to a test method for Li ionic battery materials, which utilizes a test device including a battery-like device, a sampling system and a computer control analysis system and includes the following steps: 1, assembling and connecting the battery-like device, the sampling system and the computer control analysis system, in which, the sampling system can collect voltage and current variance data between the positive and negative, the voltage variance data between the positive, negative and the assistant poles, the computer analysis system can control the charge / discharge between the positive and the negative and analyze data got by the sampling system, 2, the computer system controls the operation of the charge and discharge, 3, the sampling system collects several test data and the computer system stops charging and discharging when the data reach to the close condition of the test, 4, the computer system analyzes data of the sampling system to get the necessary result.

Owner:王宏栋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com