Patents

Literature

615results about "Reclaiming serviceable parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

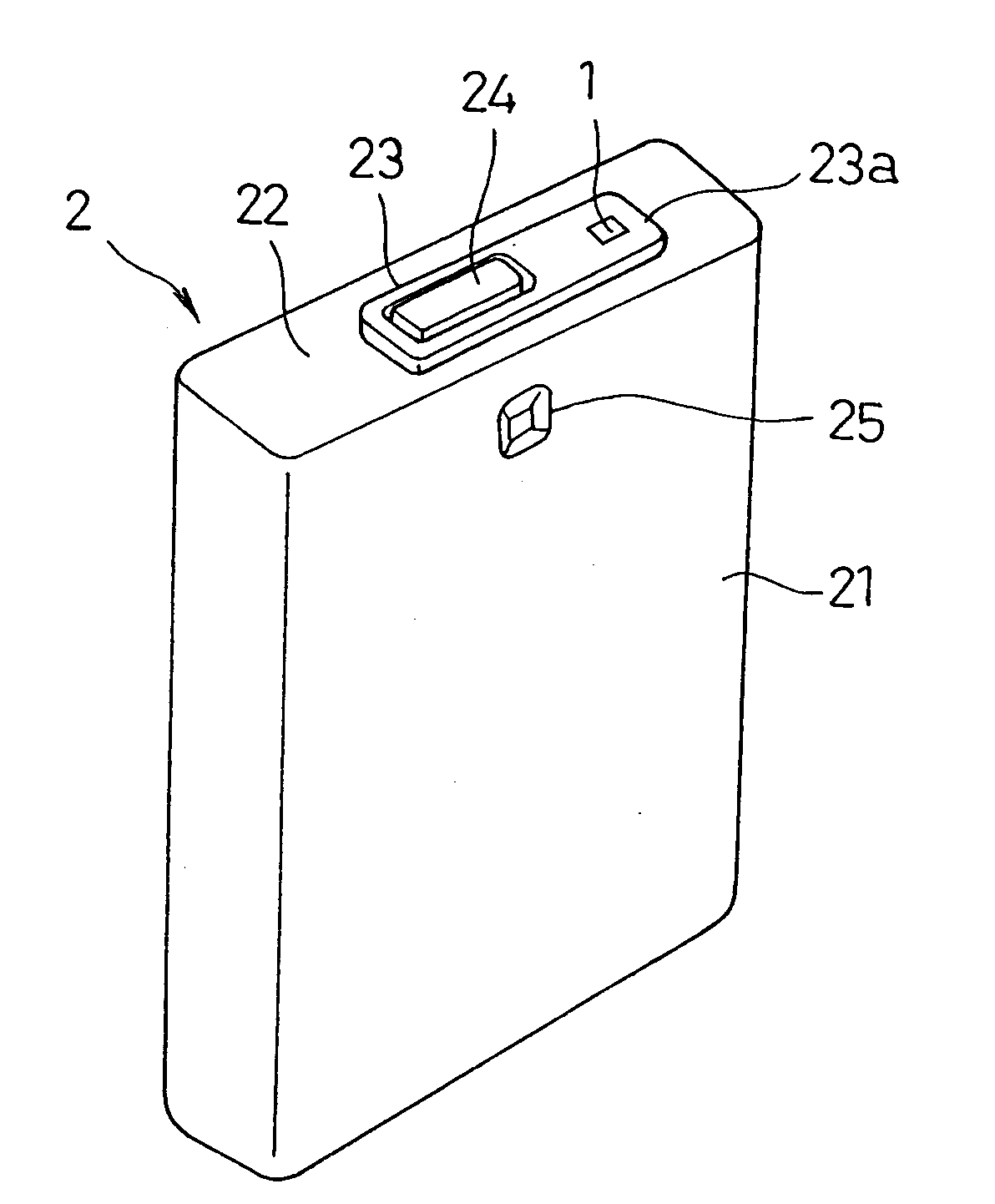

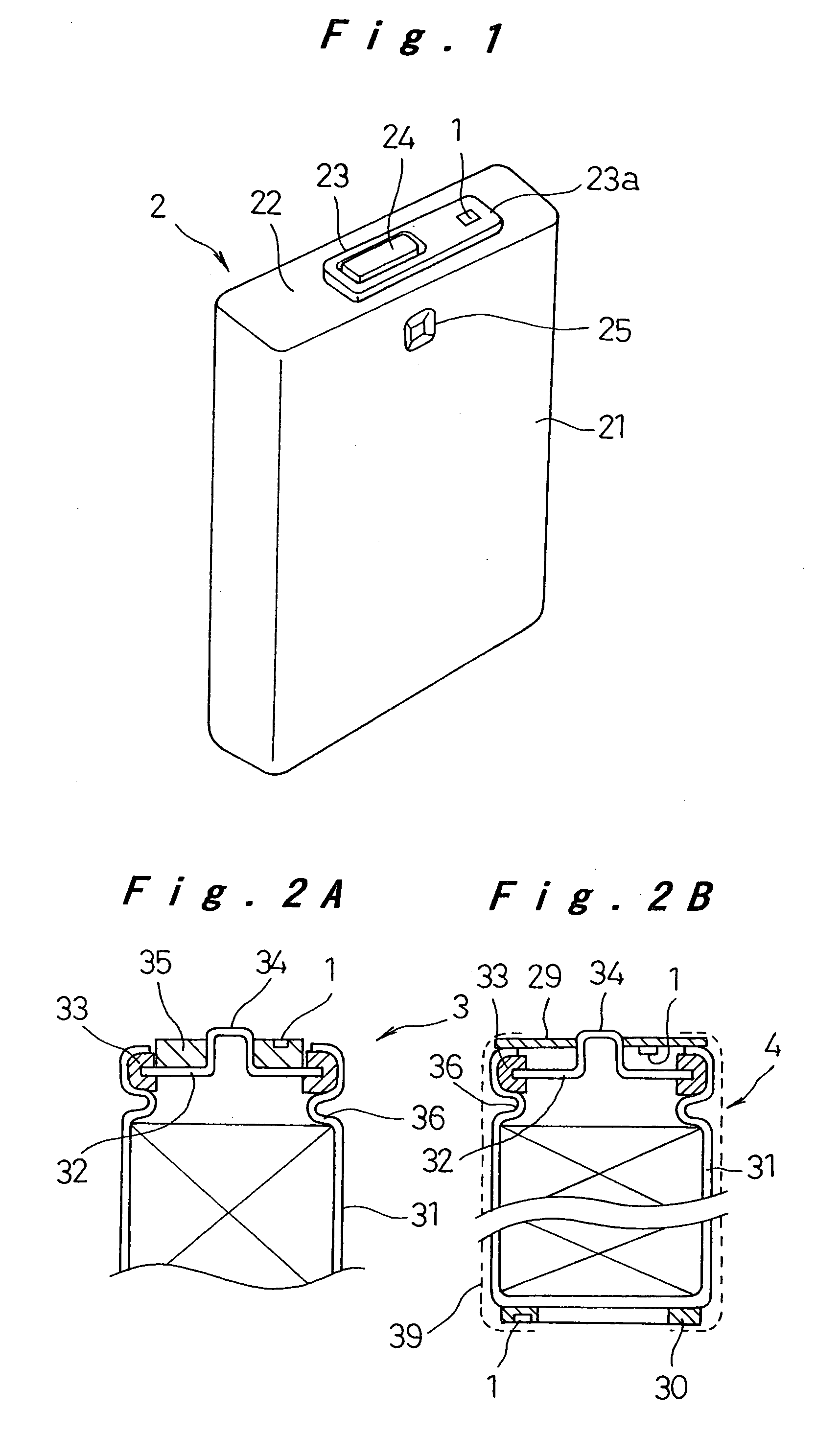

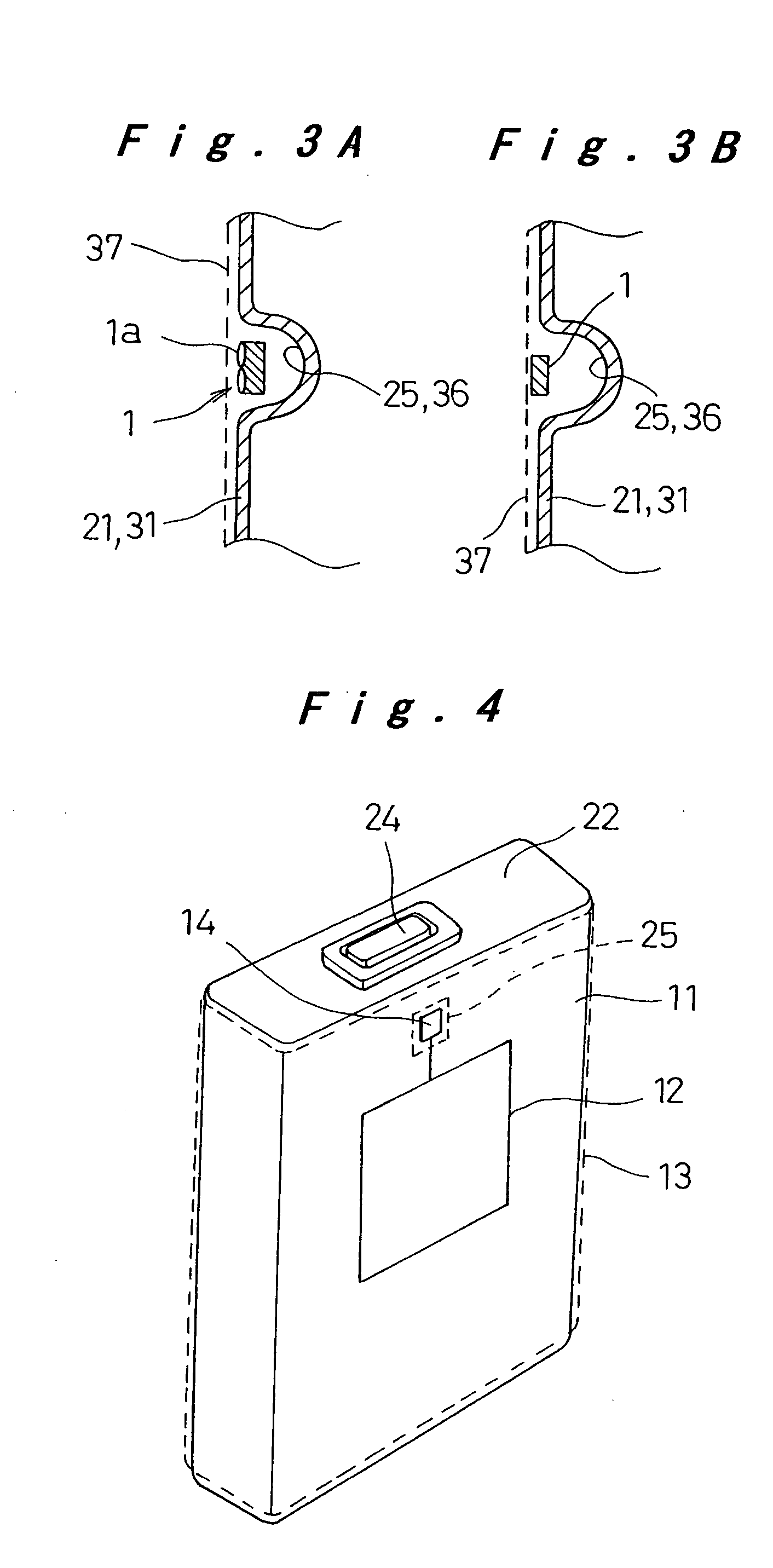

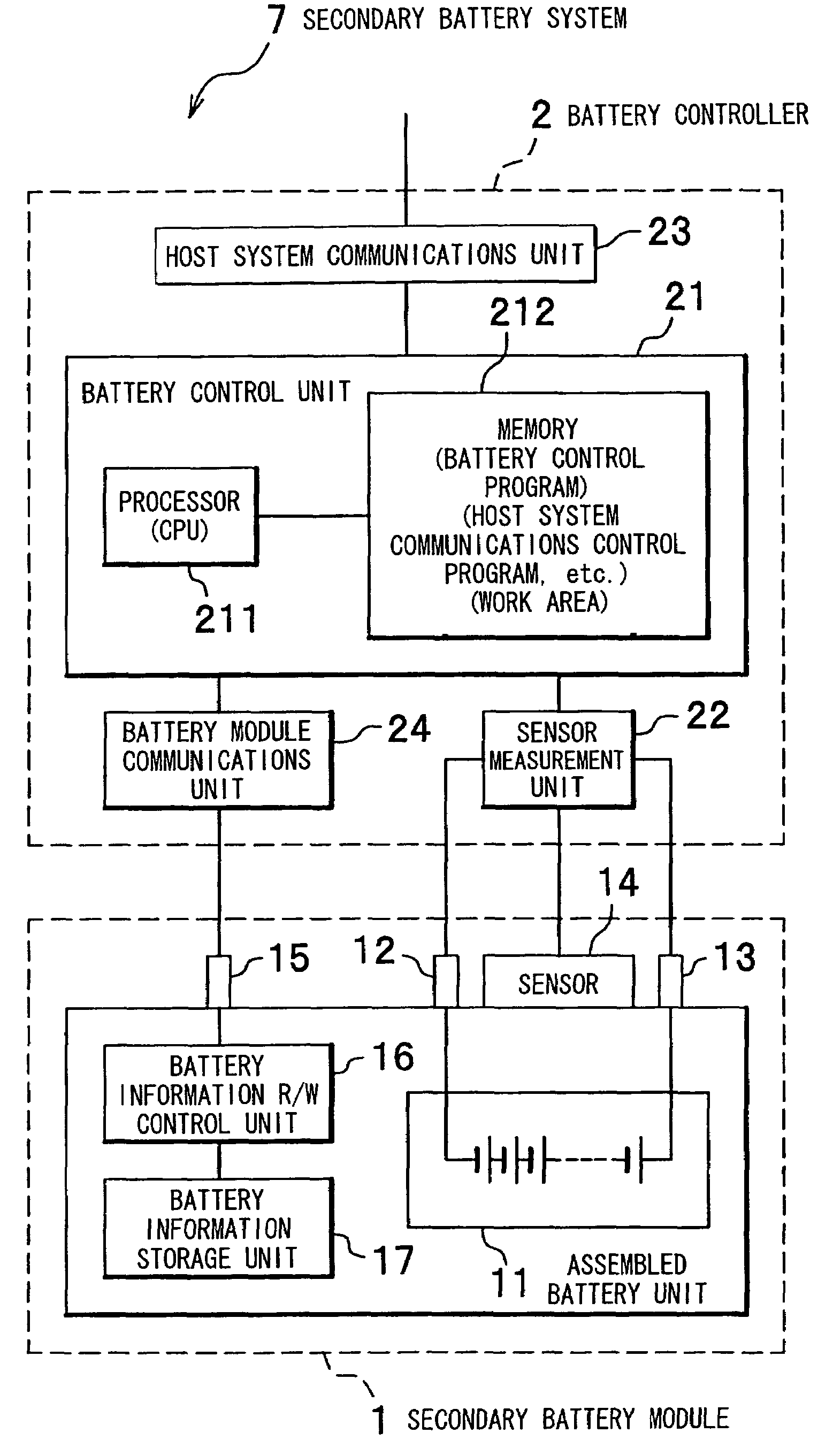

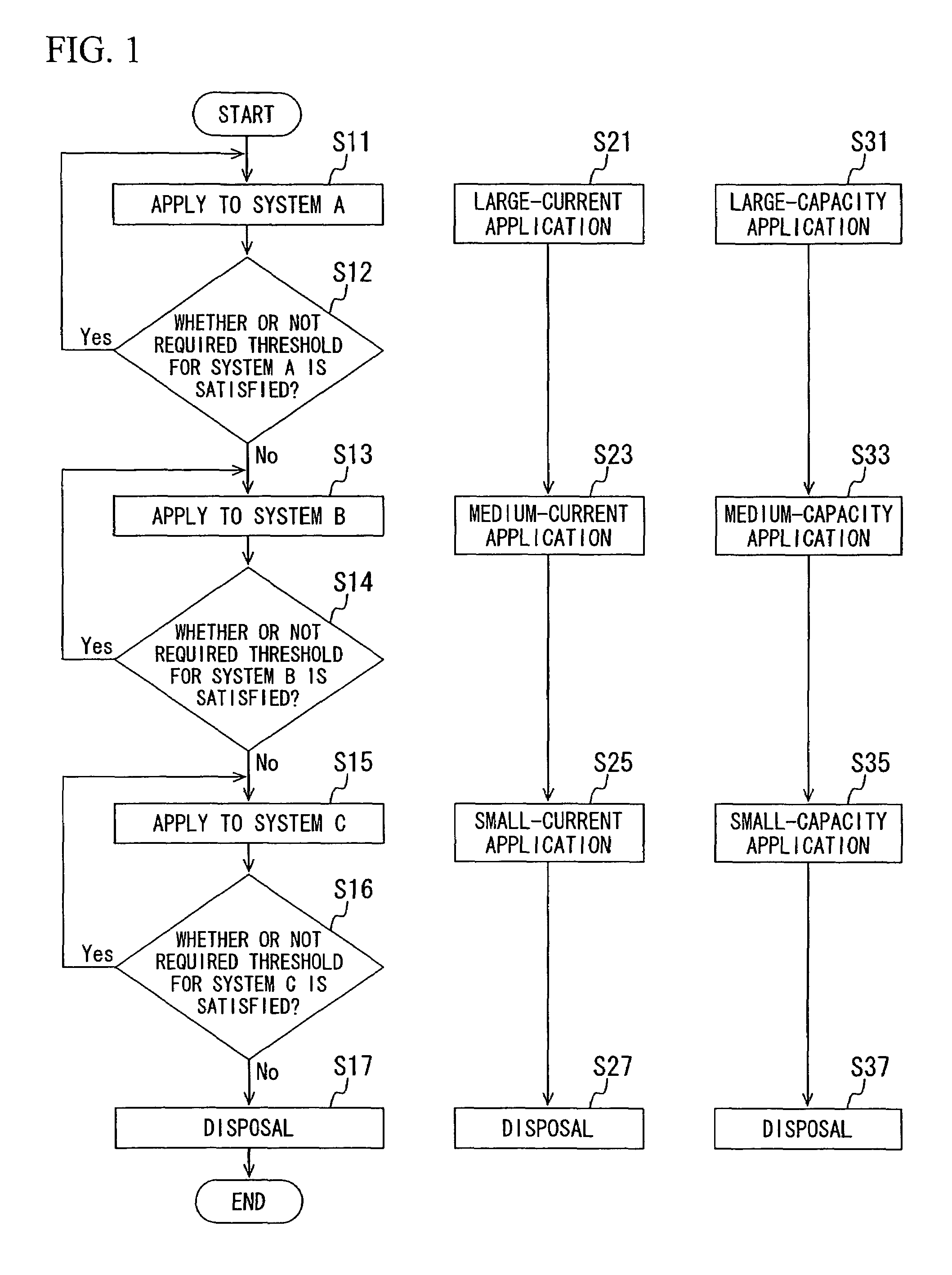

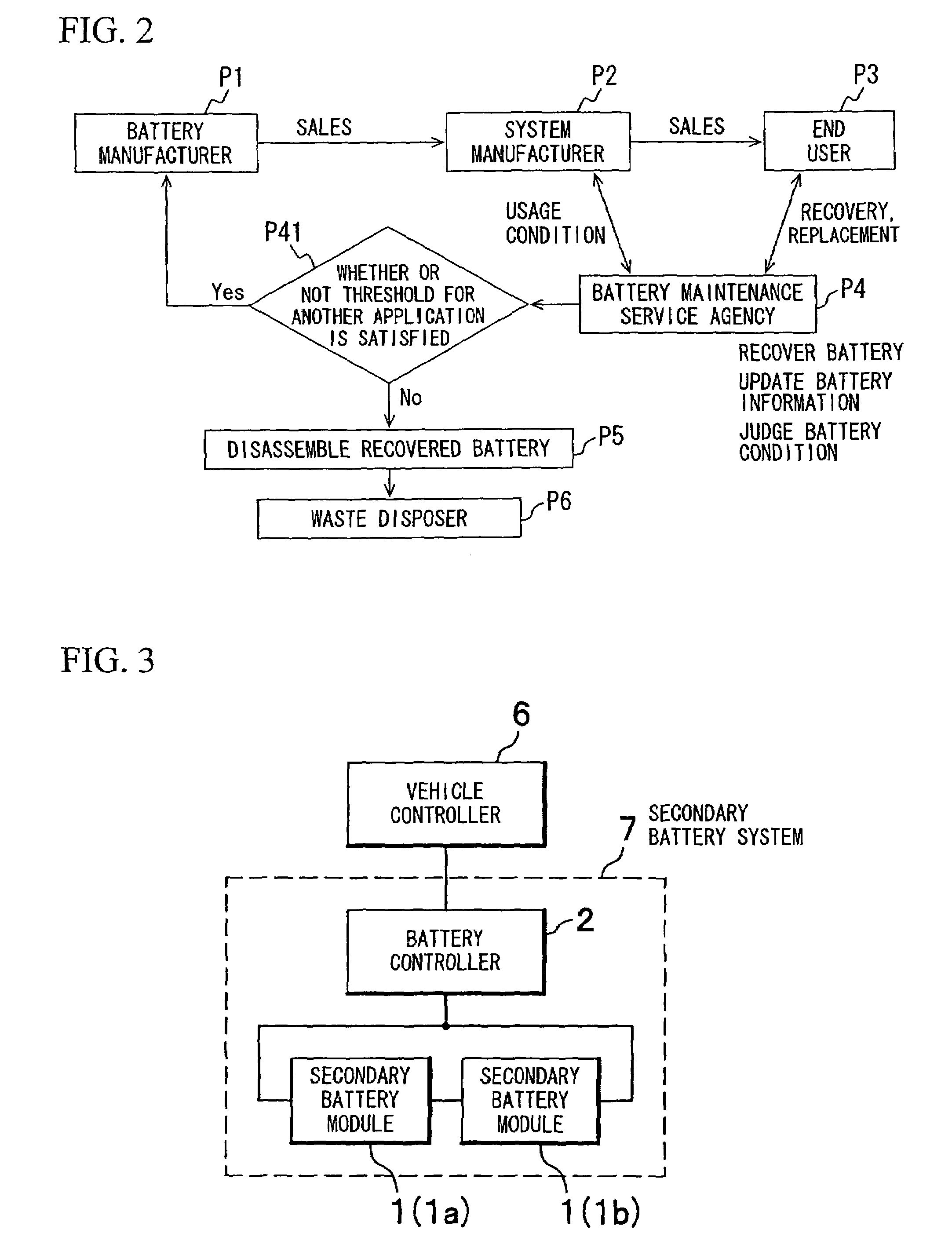

Secondary battery module, battery information management device, battery information management system, secondary battery reuse system, secondary battery recovery and sales system, secondary battery reuse method, and secondary battery recovery and sales method

ActiveUS20070108946A1Reduce processingAddress rising pricesBatteries circuit arrangementsReclaiming serviceable partsElectricityTerminal equipment

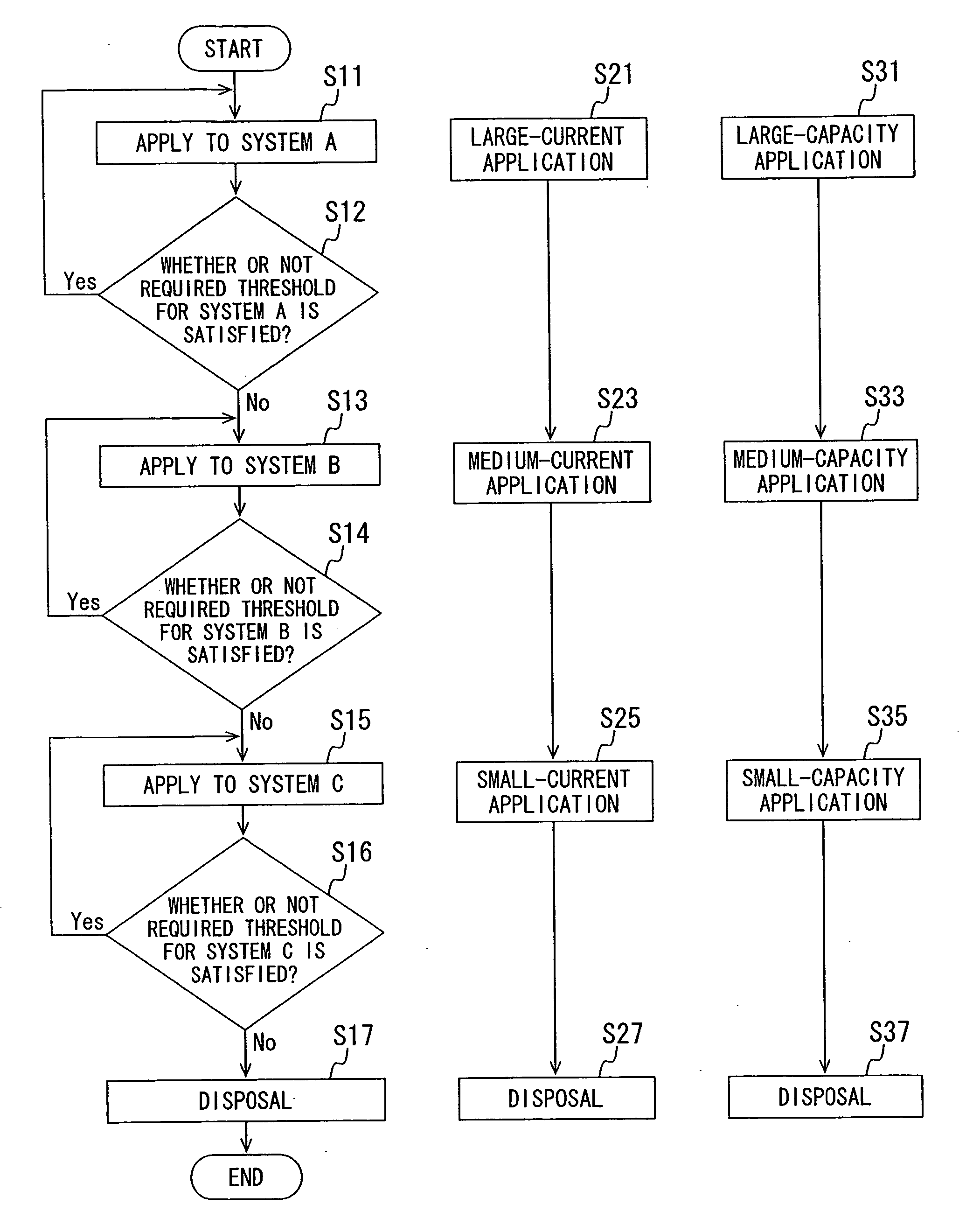

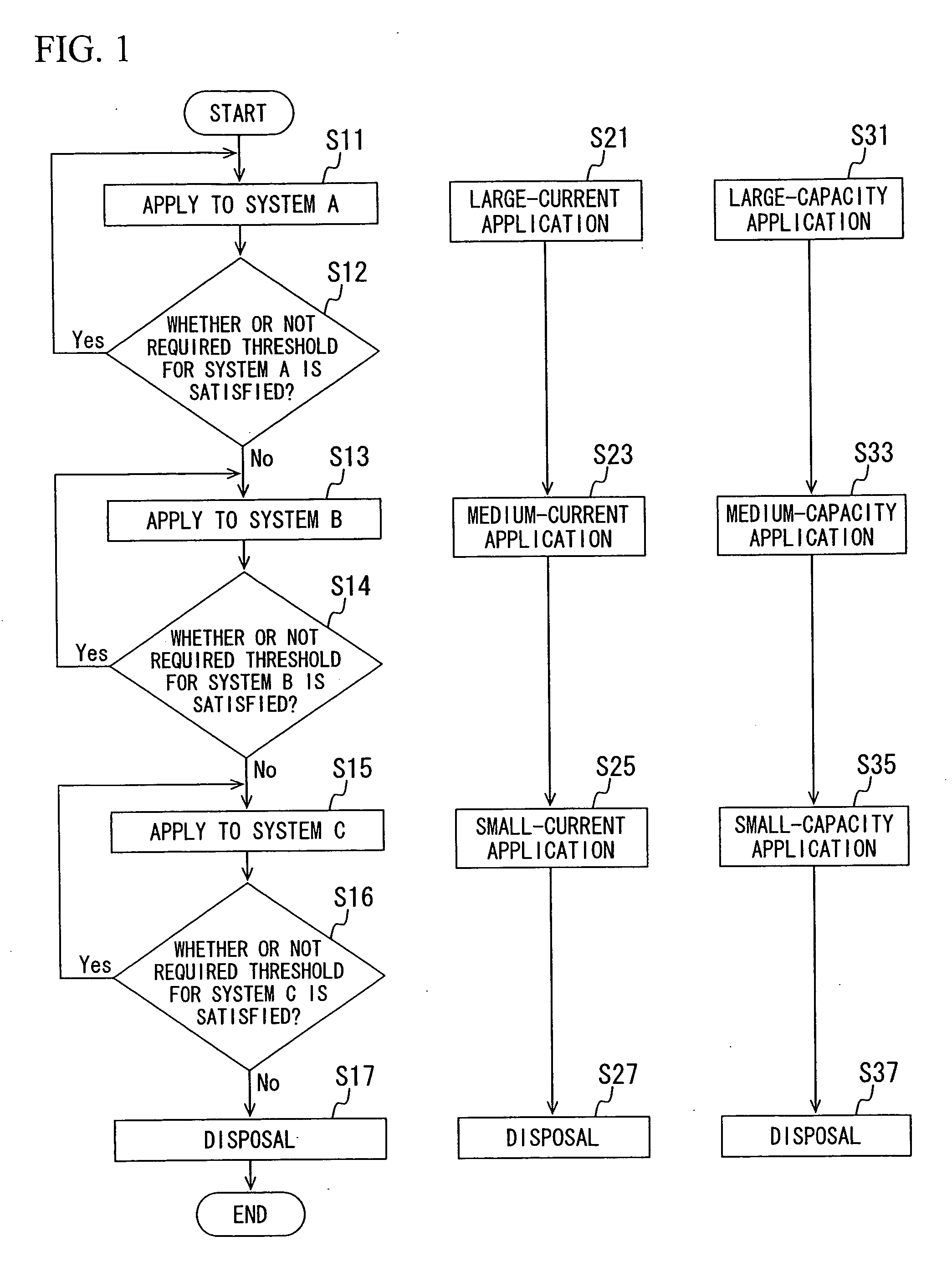

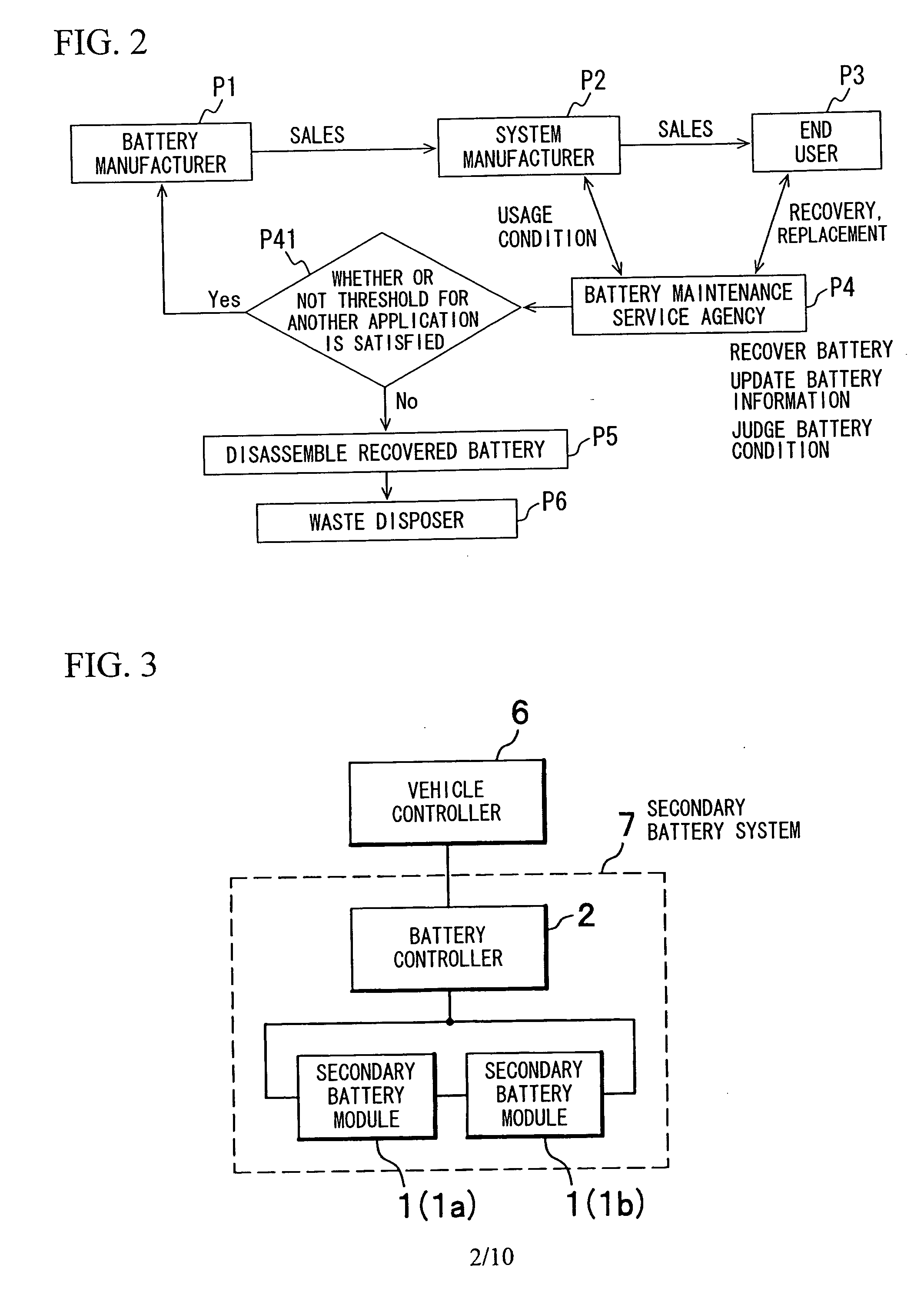

A secondary battery module includes a battery information storage unit for storing electric characteristic information and usage history information of the secondary battery module. A battery information management device and a terminal device respectively include interfaces to be connected to the secondary battery module. The battery information management device is provided with a battery information database. The battery information management device is connected to the terminal device through a communications network. In this way, battery information stored in the battery information storage unit, which is acquired by the battery information management device and the terminal device, is accumulated in the battery information database. Moreover, the battery information management device grades the secondary battery module for reuse based on the battery information and a predetermined threshold.

Owner:HITACHI ASTEMO LTD

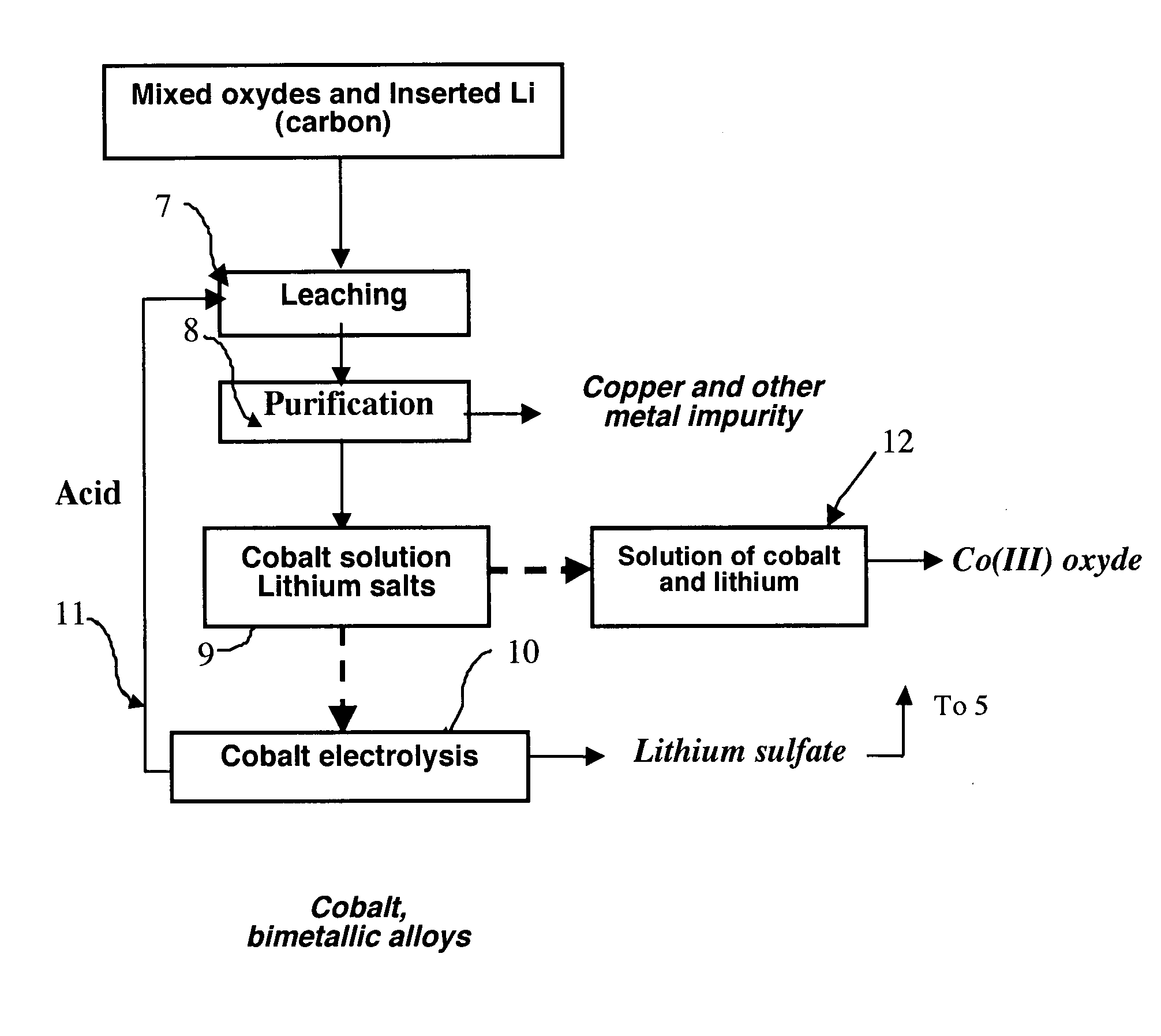

Method for separating and recovering cobalt from waste lithium ion cell

InactiveCN1688065AHigh purityHigh recovery rateReclaiming serviceable partsWaste accumulators reclaimingLithiumOrganic solvent

This invention relates to a method for separating and recovering Co from the positive material lithium cobaltate of waste Li ionic batteries discharging of the battery to get a positive material containing lithium cobaltate to be annealed or dipped by an organic solvent to strip Al plates of the positive material to get a black solid material containing lithium cobaltate to be put under an acid condition and take H2O2 or Na2S2O3 as the reducer to be heated and dissolved to get a solution with Co2+ and Li+, then take NaOH solution as the precipitant to transfer the iron Co2+ to Co(OH)2 to be deposited and filtered after settlement.

Owner:WUHAN UNIV OF TECH

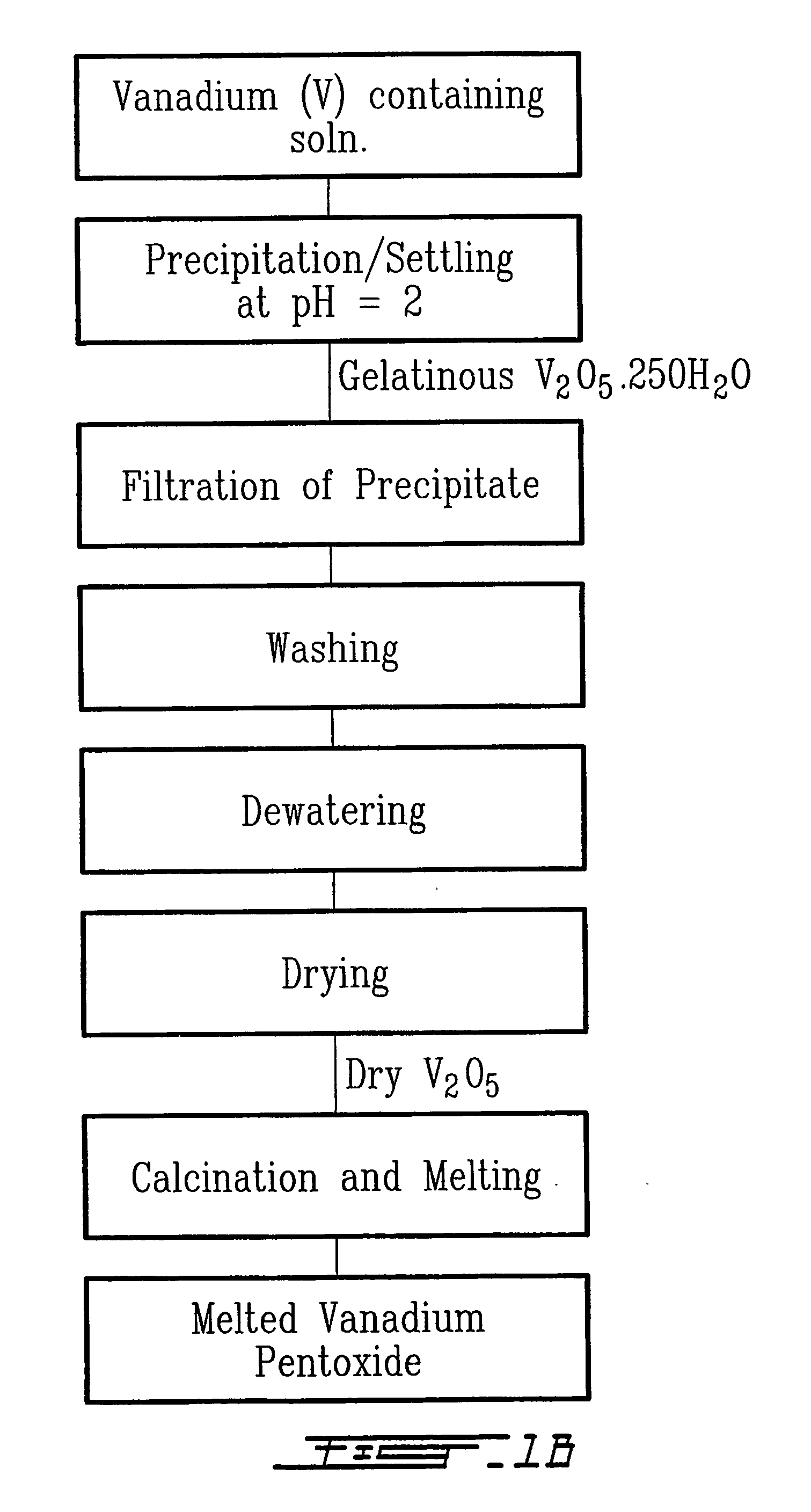

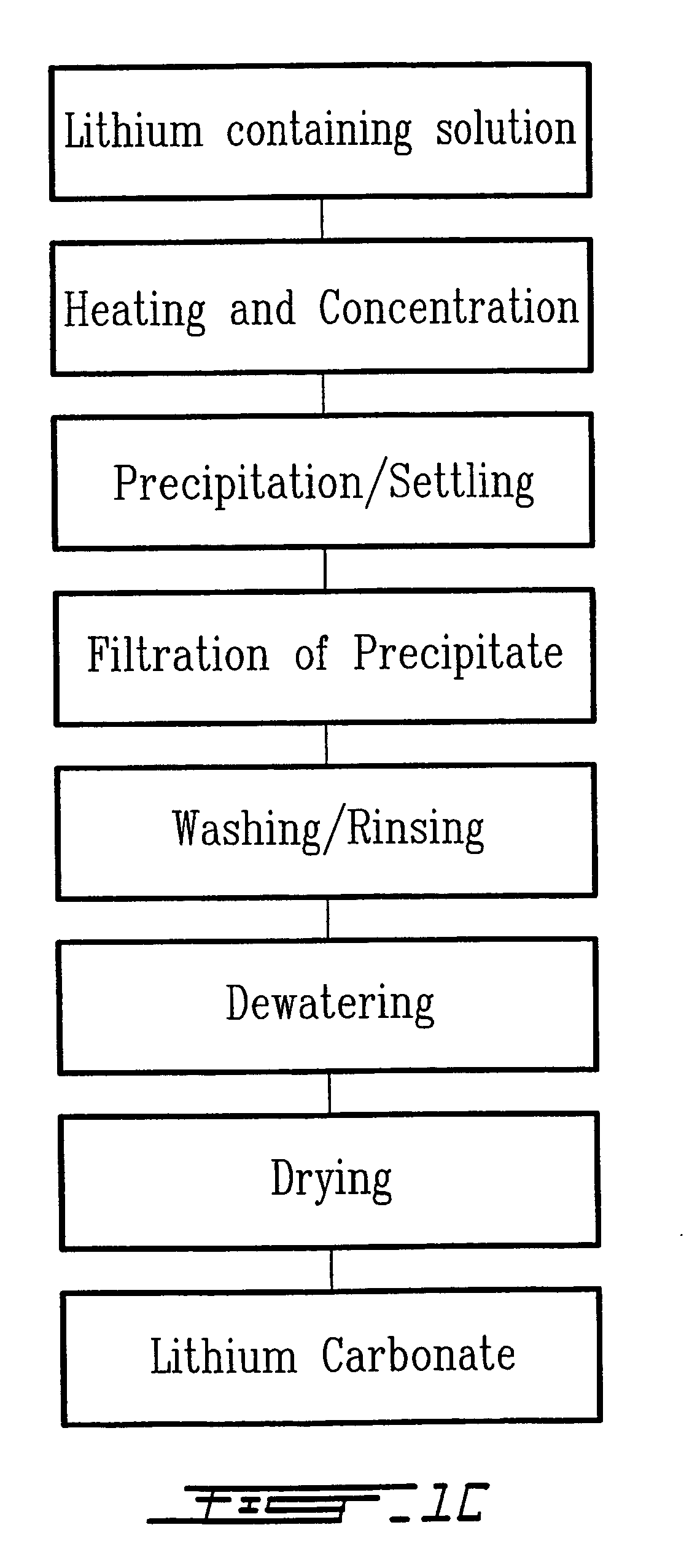

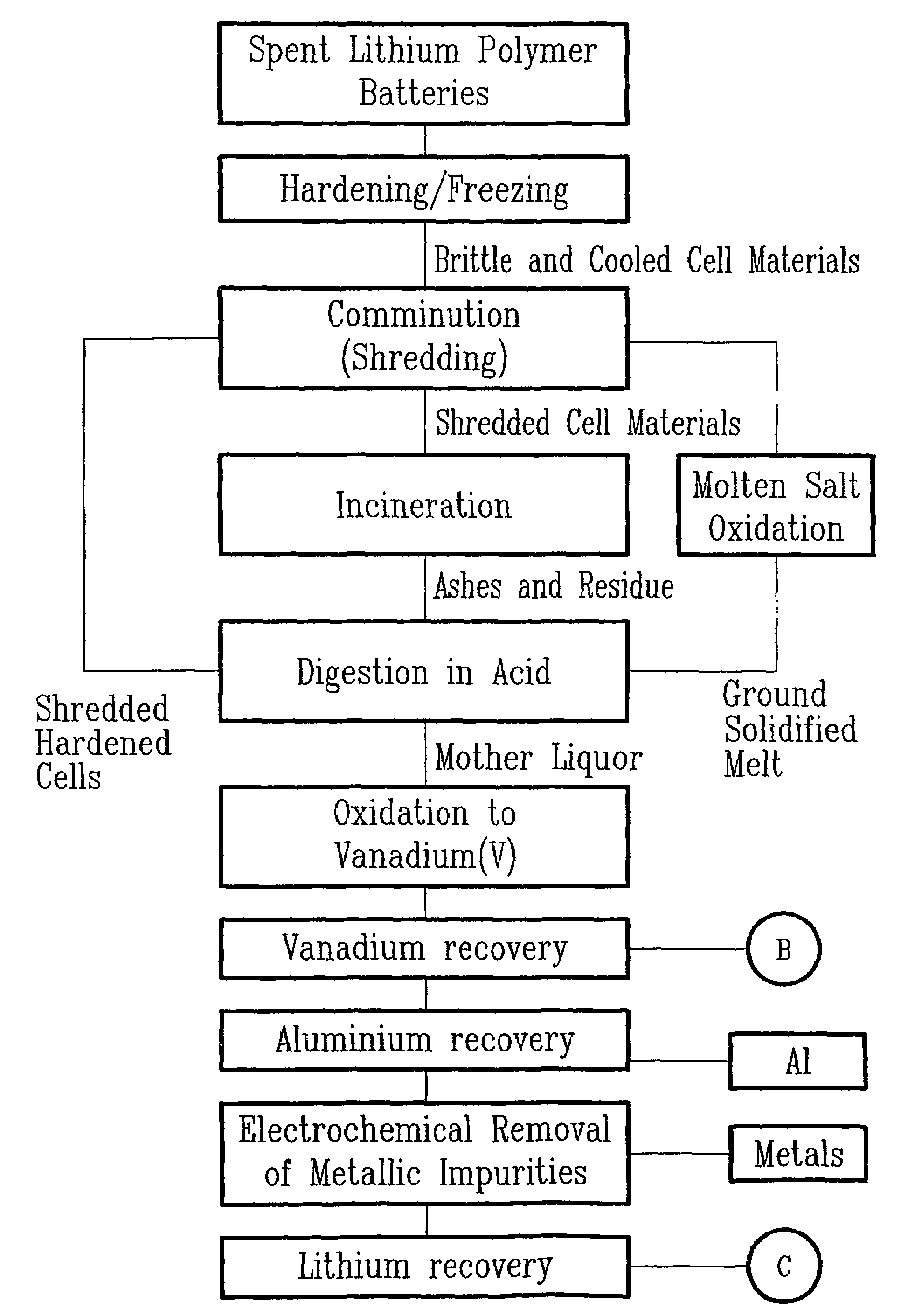

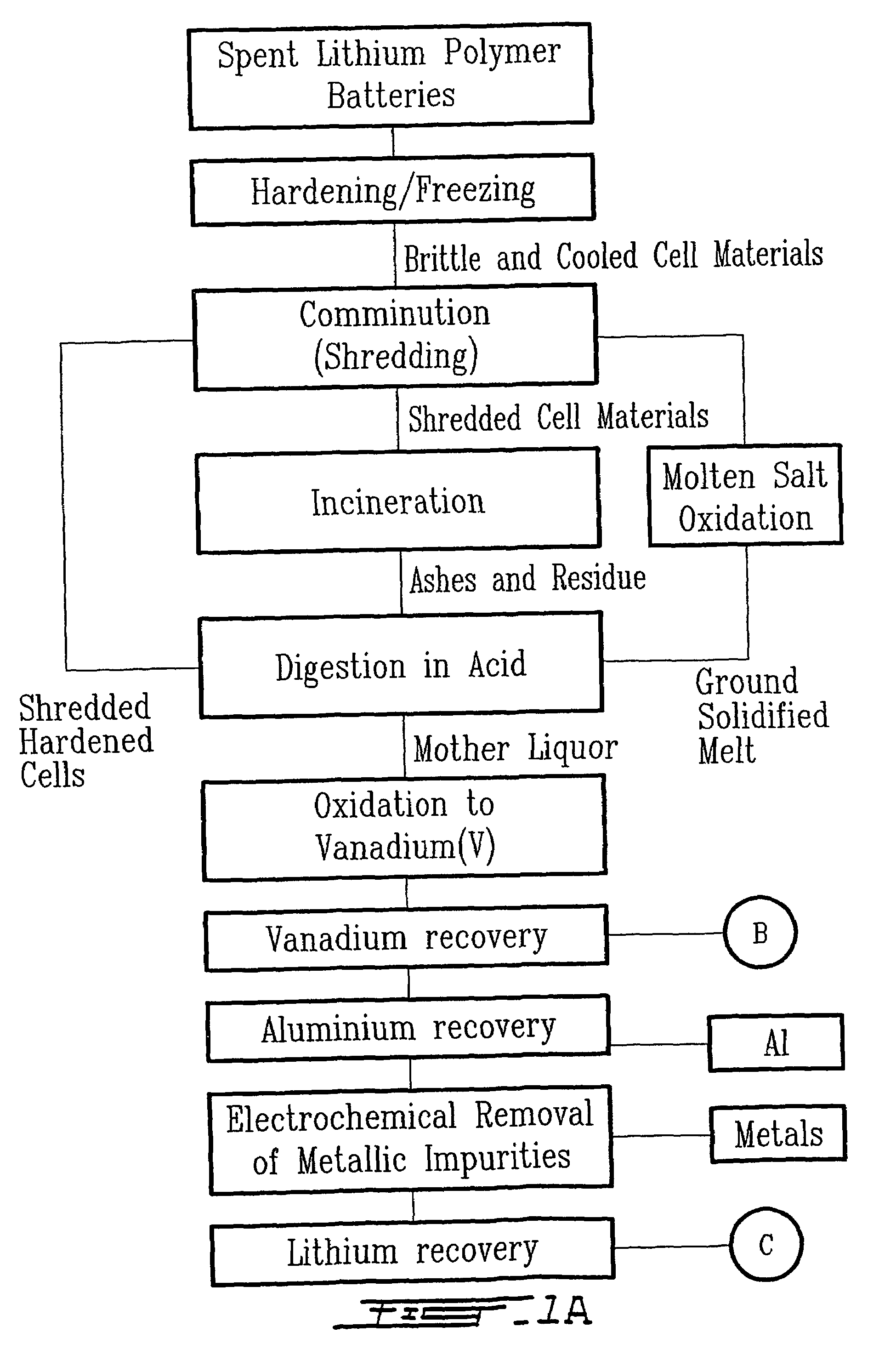

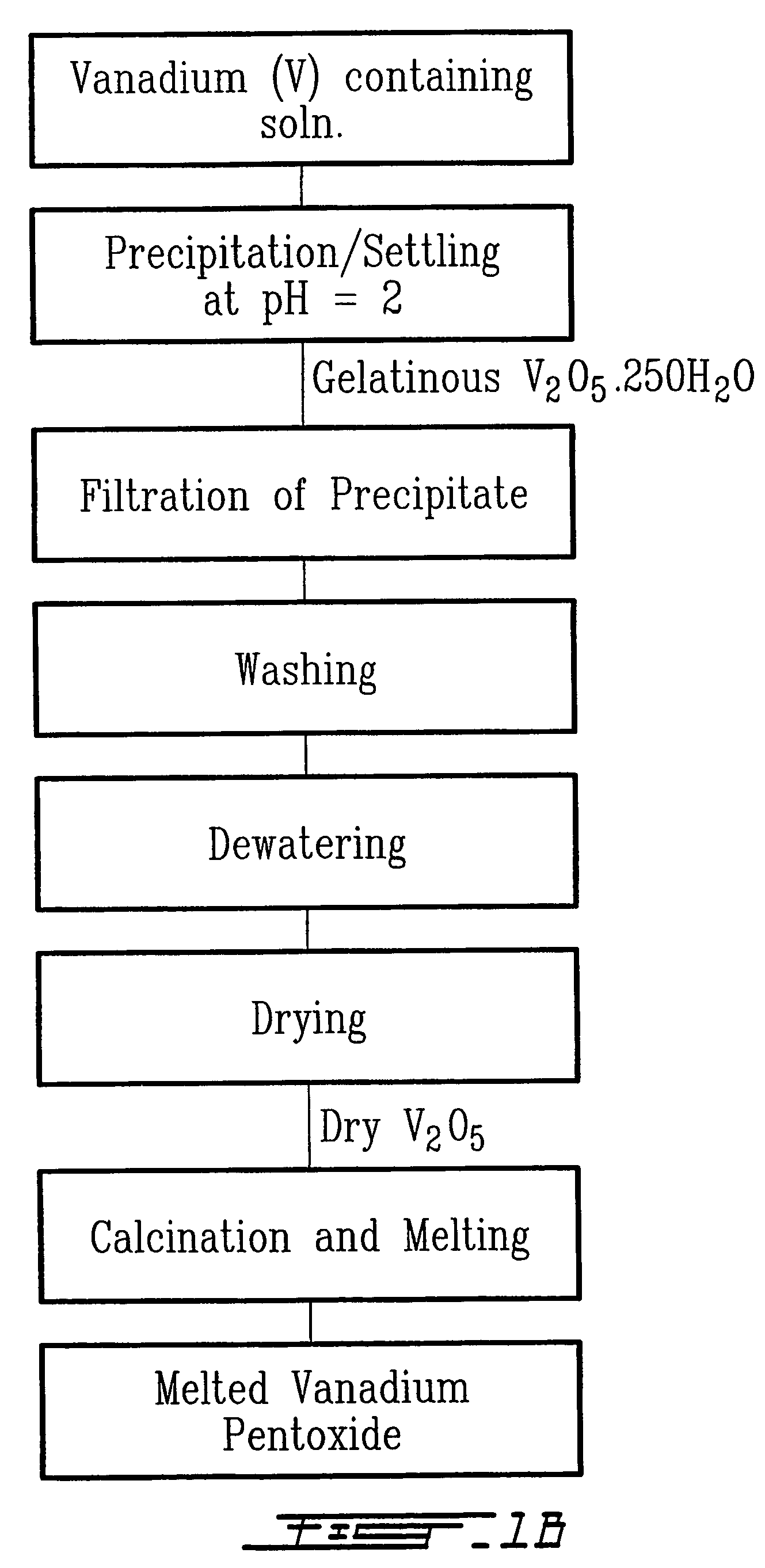

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

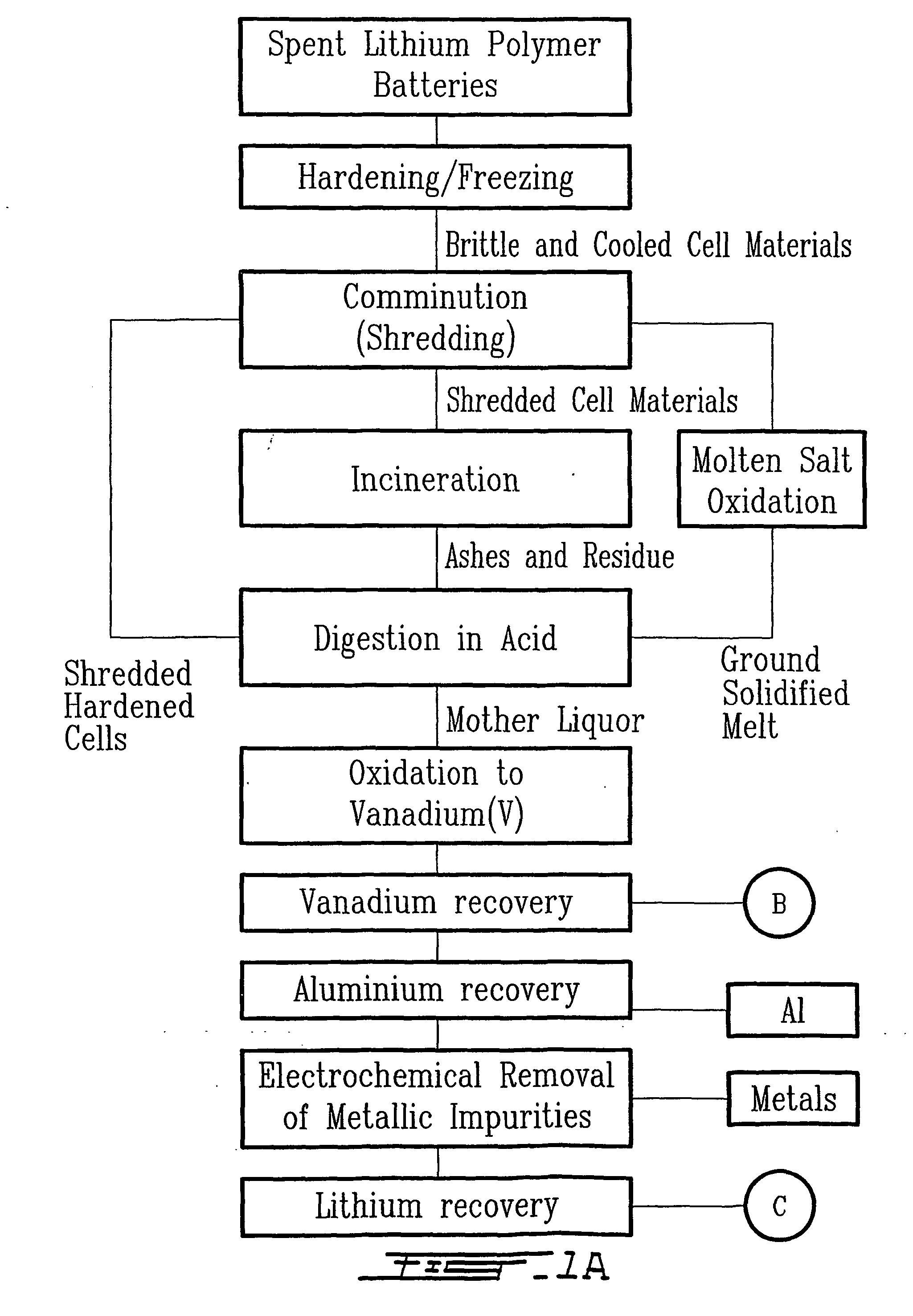

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

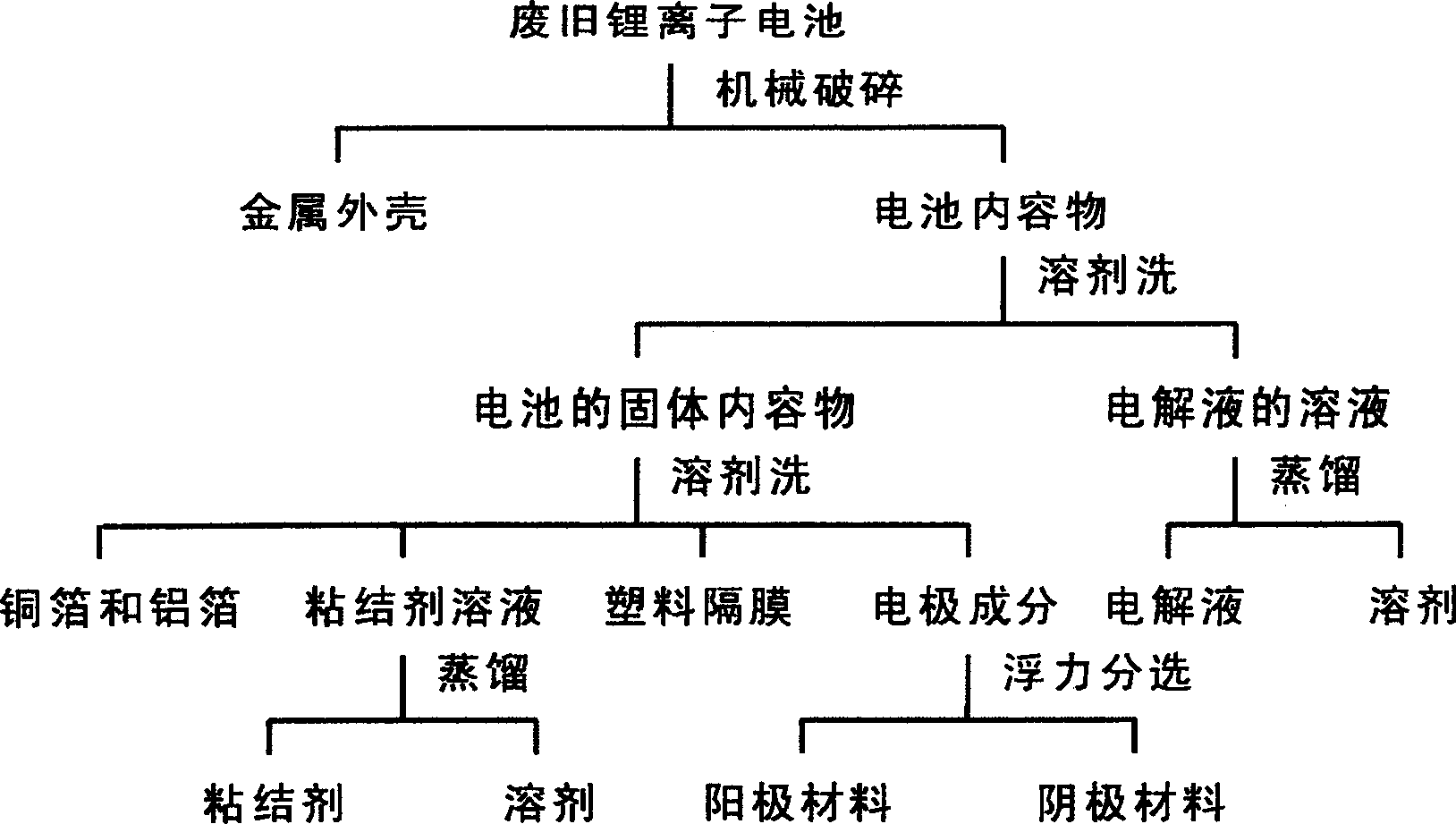

Resource separation of waste lithium ion battery

InactiveCN1819326AReserve availabilityLow added valueReclaiming serviceable partsWaste accumulators reclaimingAdhesiveCopper foil

The invention can make separation for all kinds of components in wasted Li-ion battery such as: case, electrolyte, anode material, cathode material, adhesive, copper foil, and aluminum foil. The process includes: breaking wasted batteries by mechanical process; separating metal case from others; washing out electrolyte using organic solvent, and filtering it from remaining solid; processing the remaining component where the electrolytes are removed using organic solvent to make all electrode active component eluted from current collector, and separated from diaphragm, copper foil, and aluminum foil. The solvent and adhesive can be reused.

Owner:SOUTHEAST UNIV

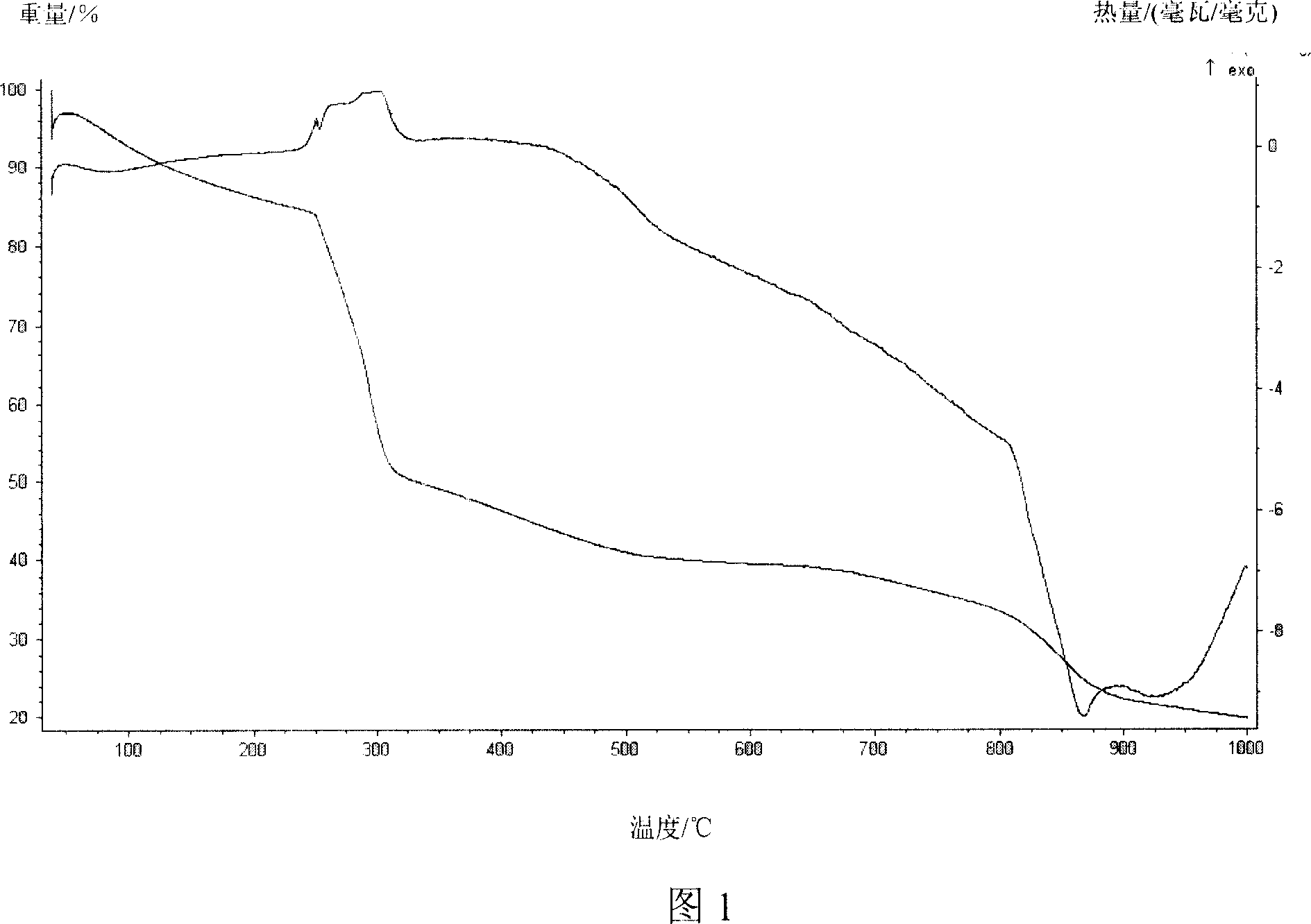

Ultrafine lead oxide prepared by using waste lead plaster and preparation method thereof

InactiveCN103374657AReduce energy consumptionSimple ingredientsReclaiming serviceable partsLead oxidesFiltrationTwo step

The invention discloses an ultrafine lead oxide prepared by using a waste lead plaster and a preparation method thereof. The preparation method comprises the following steps of: carrying out desulphurization process by mixing the waste lead plaster with an aqueous solution containing a composite desulfurizer for reaction; carrying out filtration to remove the desulphurization filtering solution to obtain the desulfurated lead plaster (filter residue); carrying out a leaching and crystal transformation process by adding a citric acid solution and a reducing agent into the desulfurated lead plaster obtained in the process, and carrying out filtration, washing, and drying to obtain the lead citrate after the desulfurated lead plaster reacts with the citric acid solution; carrying out a roasting process by roasting the lead citrate to obtain the ultrafine lead oxide. According to the preparation method disclosed by the invention, the ultrafine lead oxide is prepared from the waste lead storage lead plaster; a two-step leaching process is adopted; the filtering solution is simple in ingredient and can be recycled; a side product is recycled from the desulphurization solution. The preparation method disclosed by the invention is low in energy consumption, simple in equipment, high in lead recycling rate, and high in ultrafine lead product quality, and has the characteristics of good resource recycling effect, environmentally-friendly and pollution-free production process, and capability of clean production.

Owner:湖北金洋冶金股份有限公司 +1

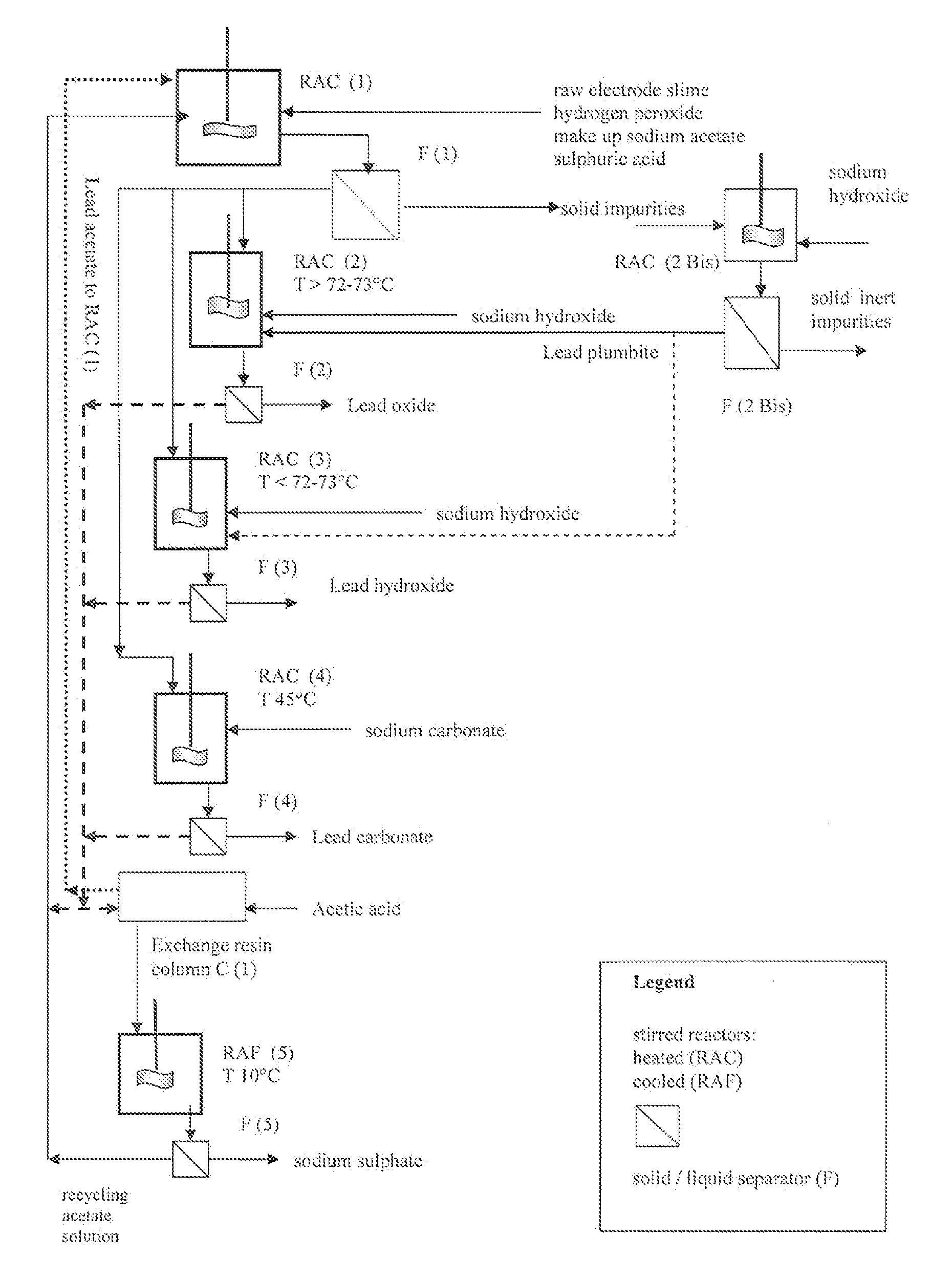

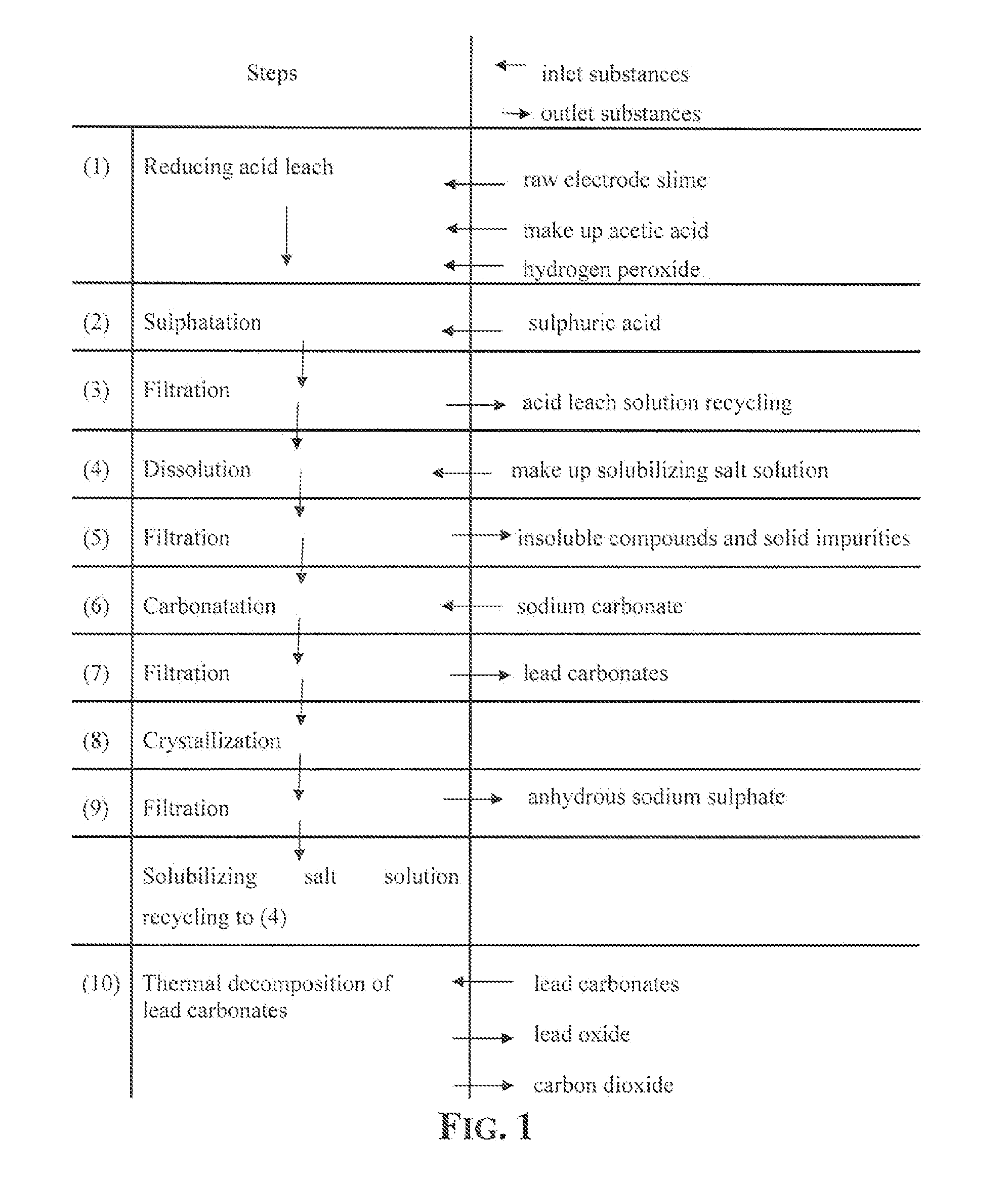

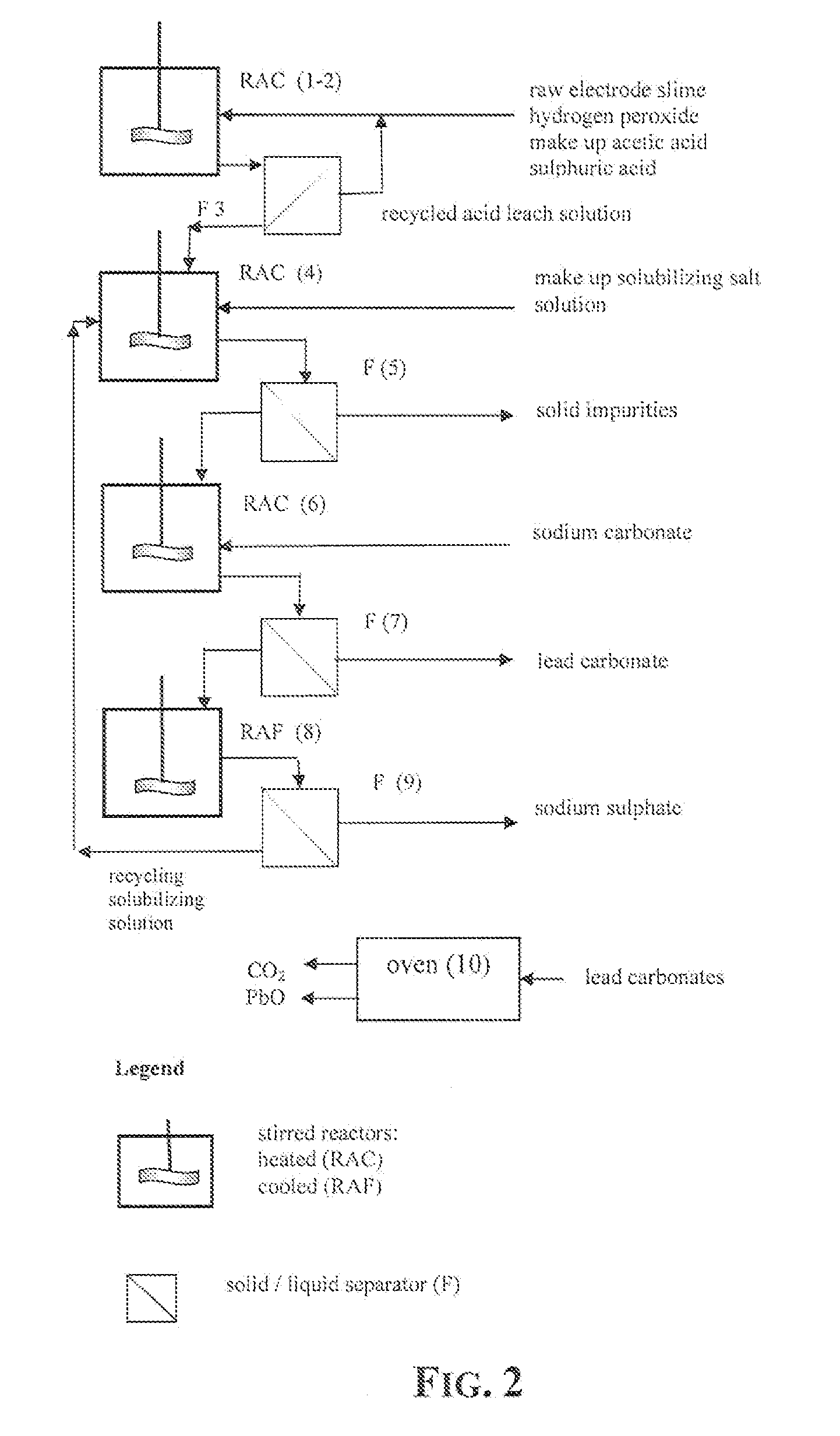

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

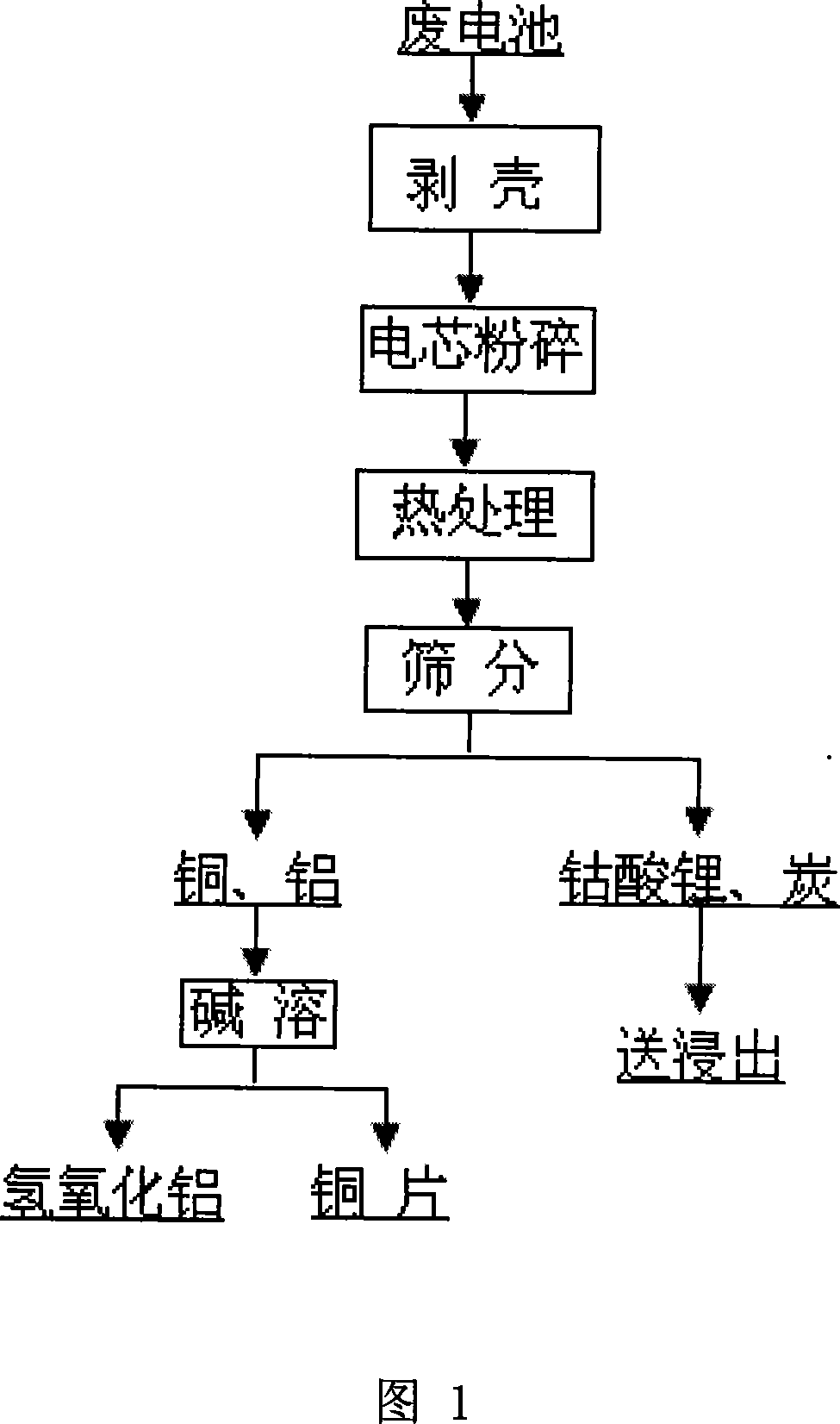

High efficient stripping method of current collector in lithium battery recycling

InactiveCN101217206AAutomatic fall offReduce labor intensitySolid waste disposalReclaiming serviceable partsNegative powerPhysical separation

The invention discloses a high-efficient stripping method for recycling a current collector of a waste lithium battery. An electrical core of the waste lithium battery is mechanically crushed to 1 - 5mm and is treated with thermal treatment at 150 - 600 DEG C, powder material after the thermal treatment is treated with vibration screening, the part below the screen is lithium acid cobalt and carbon powder, and the part above the screen is a copper sheet and an aluminum sheet. The invention can realize the streamlined mechanical automated operation of the stripping procedure of the current collector and the positive and negative power materials; the labor intensity of the physical separation of the waste lithium battery can be reduced by at least 50 percent, the separation efficiency can be improved by 40 - 50 percent; and the invention can lay the foundation for the large-scale recycling of the waste lithium batteries.

Owner:CENT SOUTH UNIV

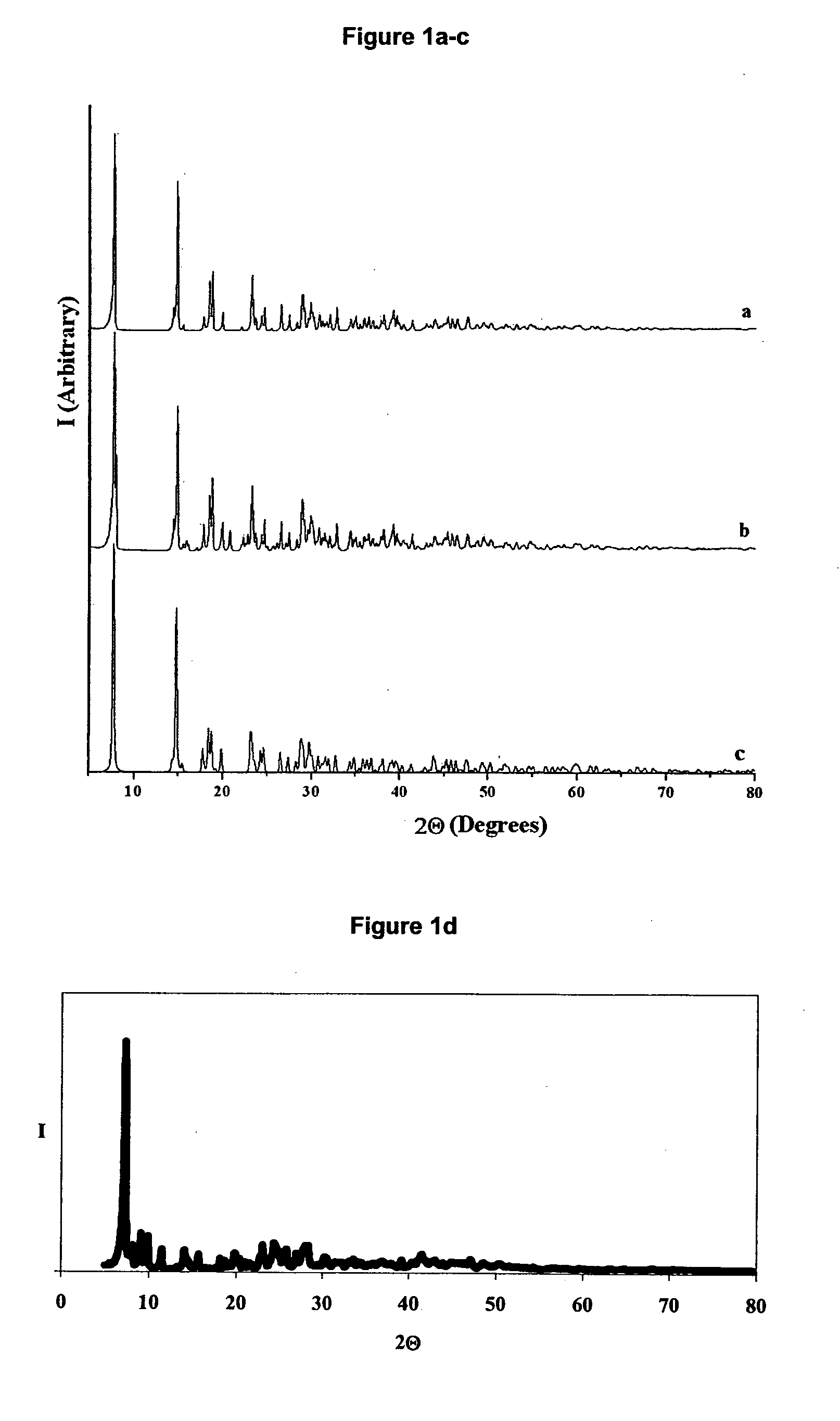

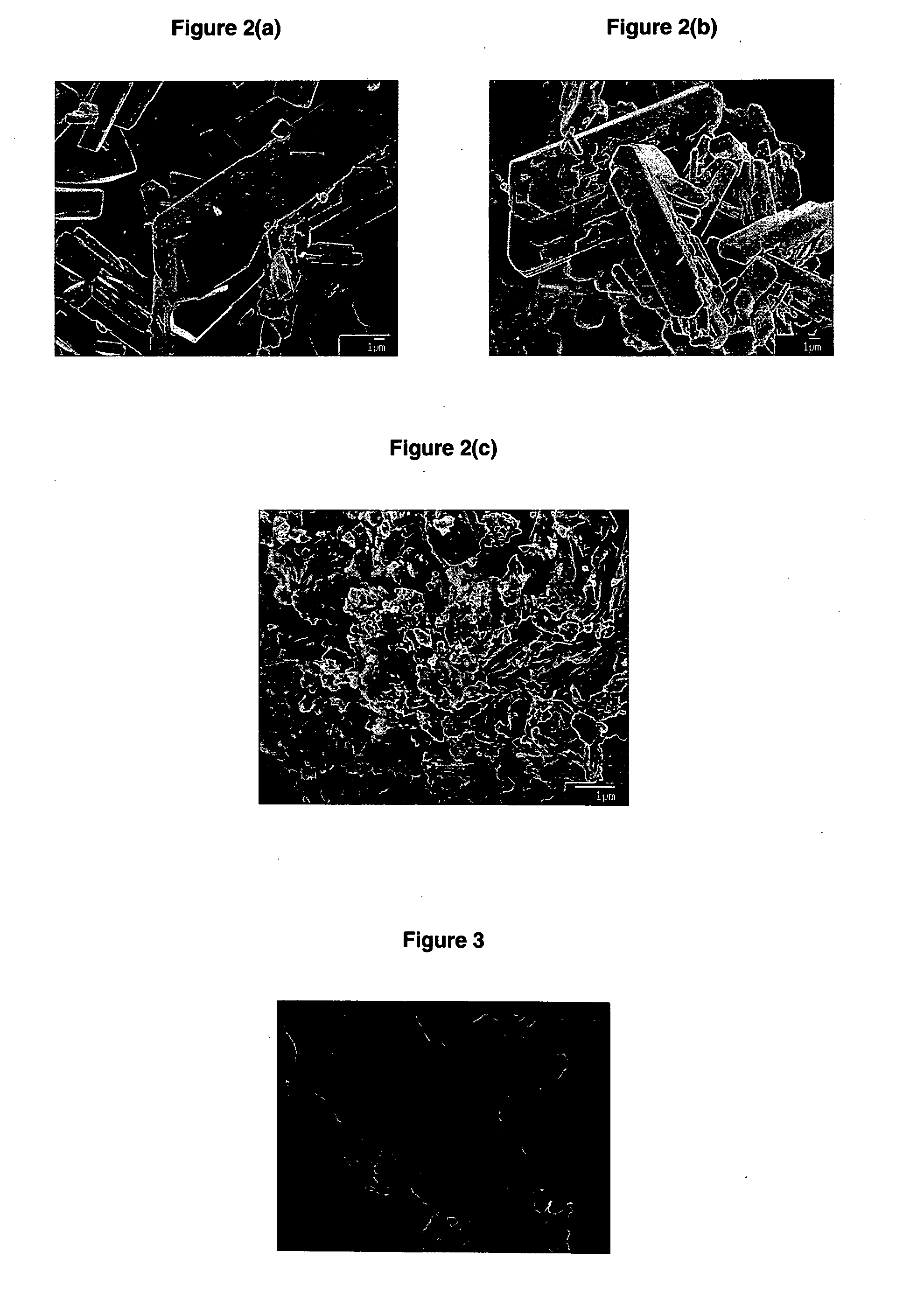

Lead recycling

The present invention describes a method of recycling lead from lead containing waste, the method comprising the steps of mixing the battery paste with aqueous citric acid solution so as to generate lead citrate; isolating lead citrate from the aqueous solution; and converting the lead citrate to lead and / or lead oxide.

Owner:CAMBRIDGE ENTERPRISE LTD

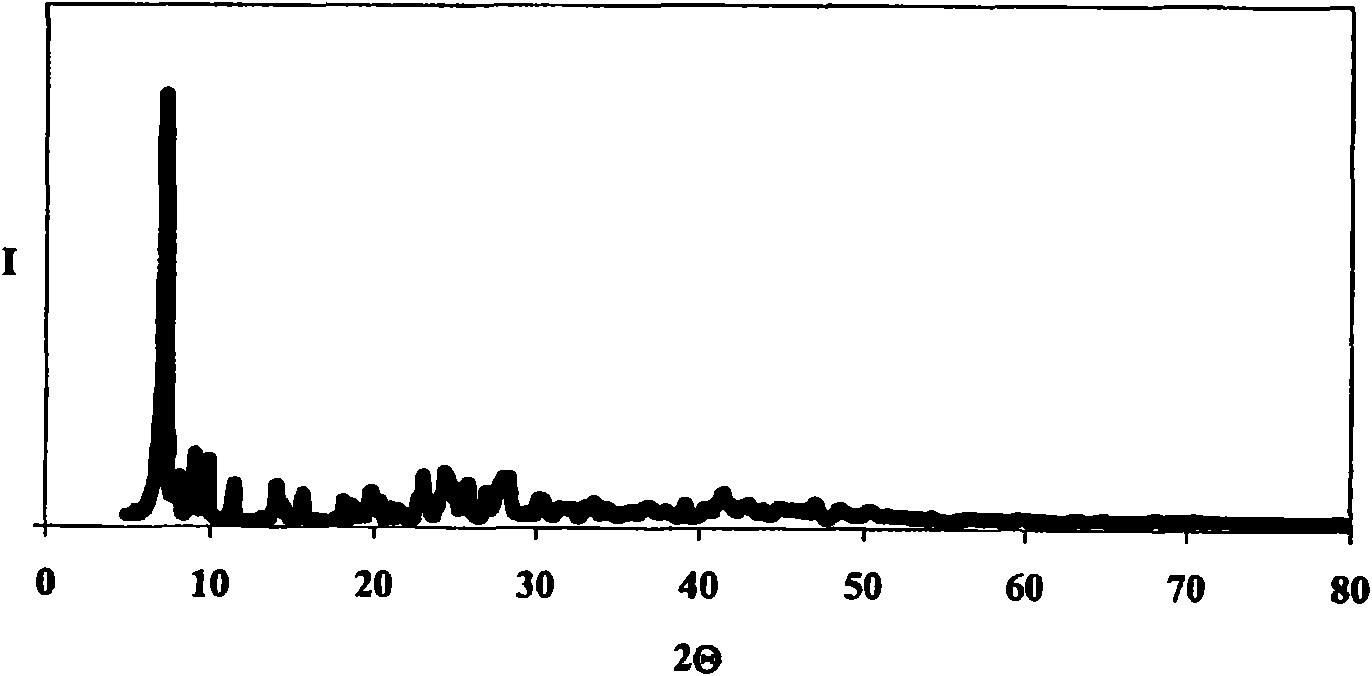

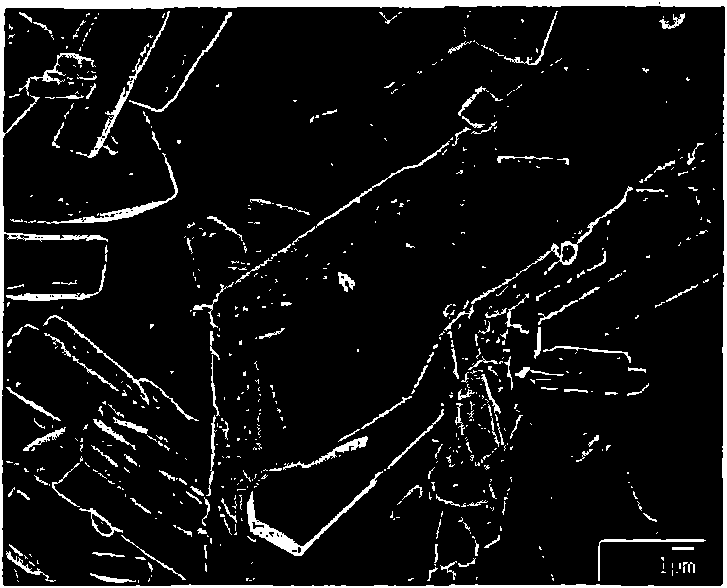

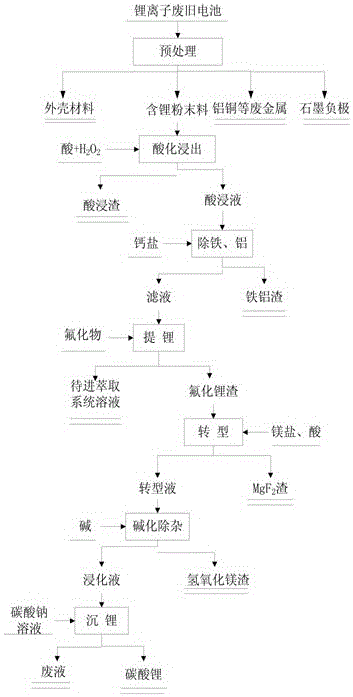

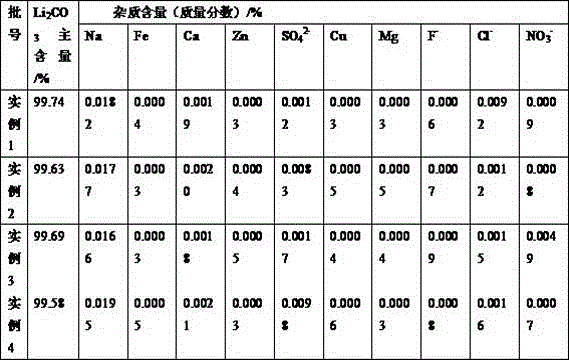

Method for recovering lithium from waste lithium battery to prepare battery grade lithium carbonate

InactiveCN106505225AHigh recovery rateReduce lossesReclaiming serviceable partsWaste accumulators reclaimingMagnesium saltLithium carbonate

The invention discloses a method for recovering lithium from a waste lithium battery to prepare battery grade lithium carbonate. Lithium is extracted from the waste lithium battery as a raw material to prepare the battery grade lithium carbonate. The method mainly comprises the following steps of (1) battery dismantling; (2) acidifying and leaching; (3) iron and aluminum removal; (4) fluorinating lithium deposition; (5) magnesium salt transformation; (6) alkalifying impurity removal; and (7) lithium deposition employing sodium carbonate. The lithium is recovered from the waste lithium battery to prepare the battery grade lithium carbonate, so that the battery grade lithium carbonate has the advantages of being high in lithium recovery rate, small in losses of other metal elements, friendly to environment and high in product purity; the main content of a product exceeds 99.5%; the requirements of battery grade products are met; and the method is simple in process, low in production cost and suitable for industrial production.

Owner:GANFENG LITHIUM CO LTD

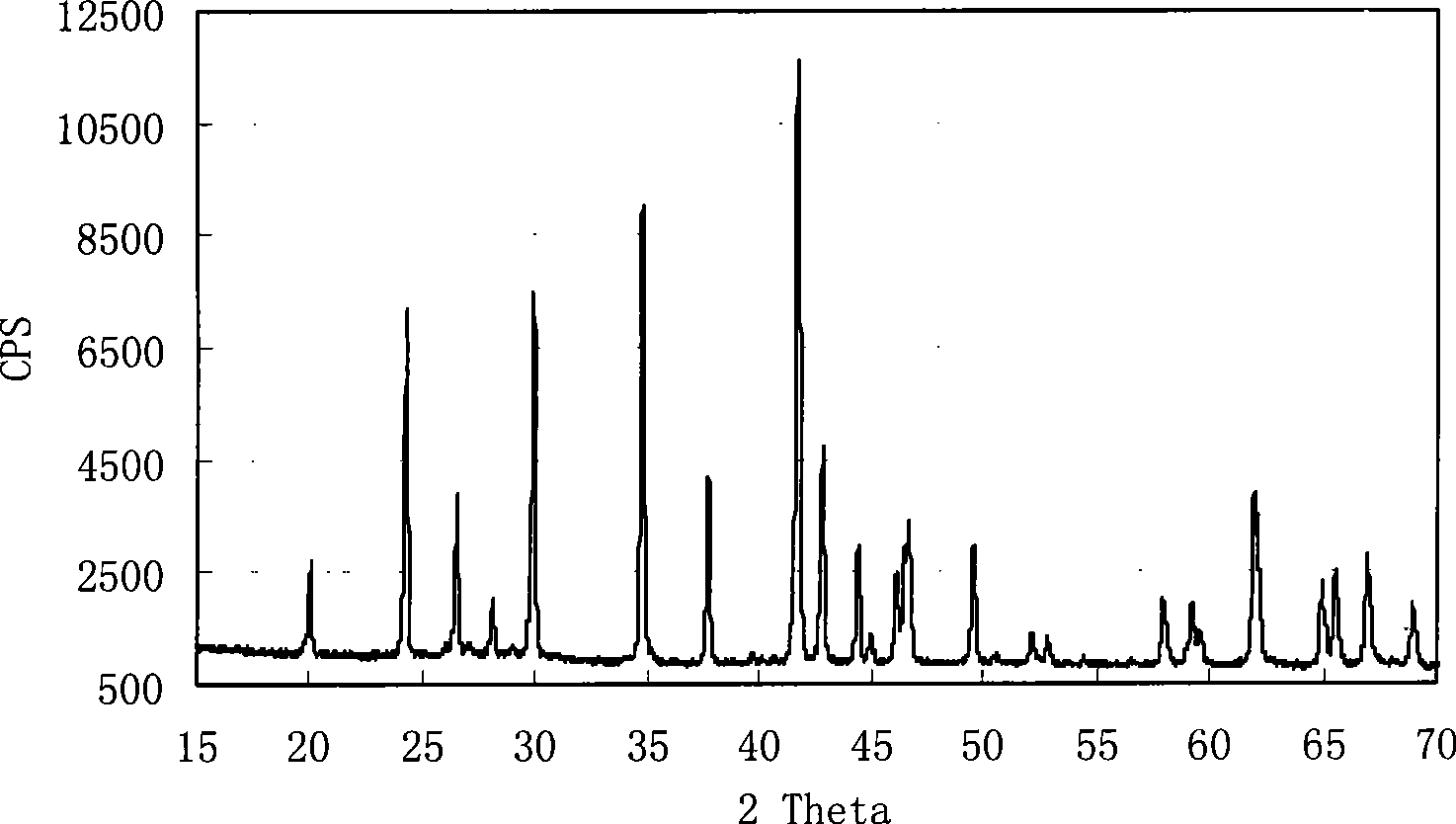

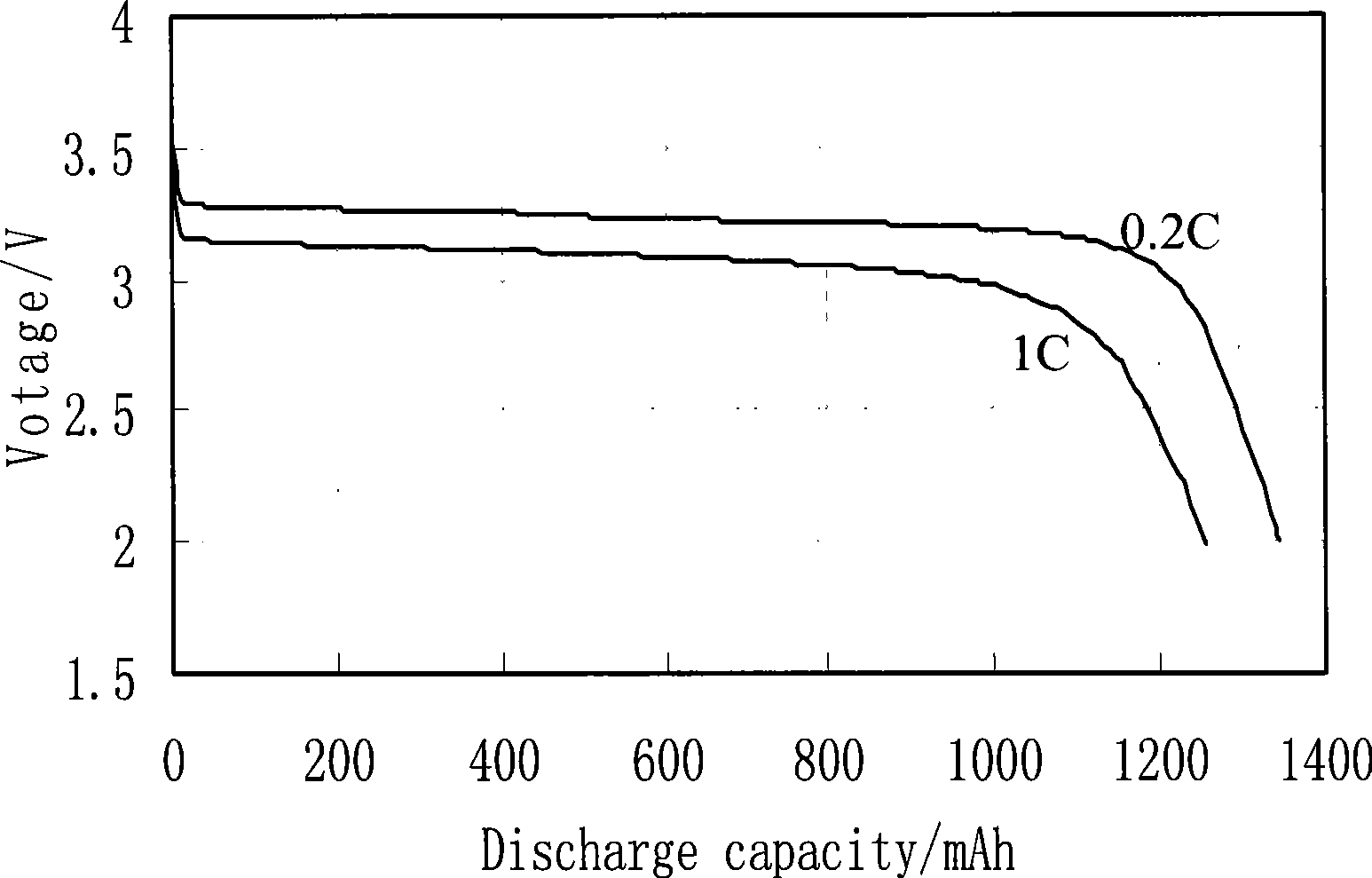

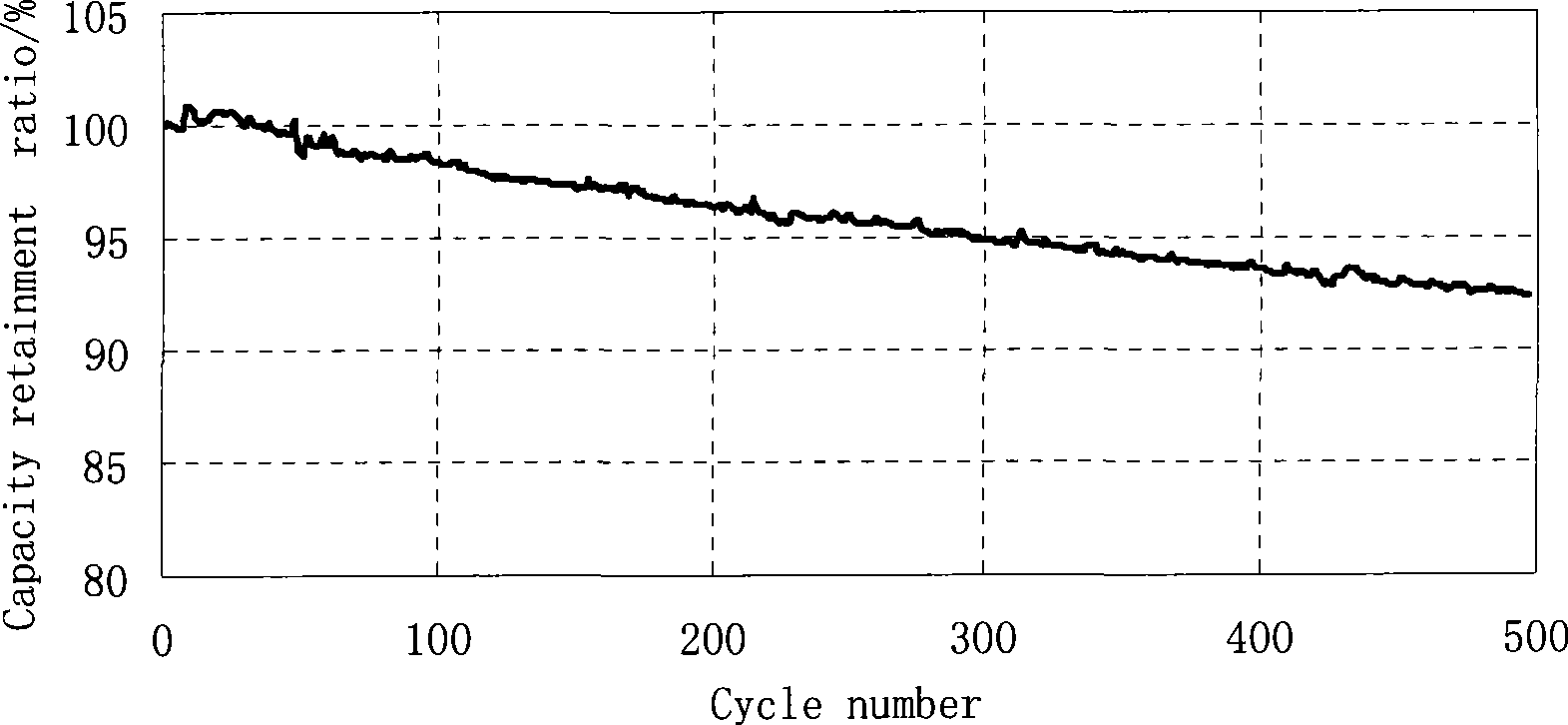

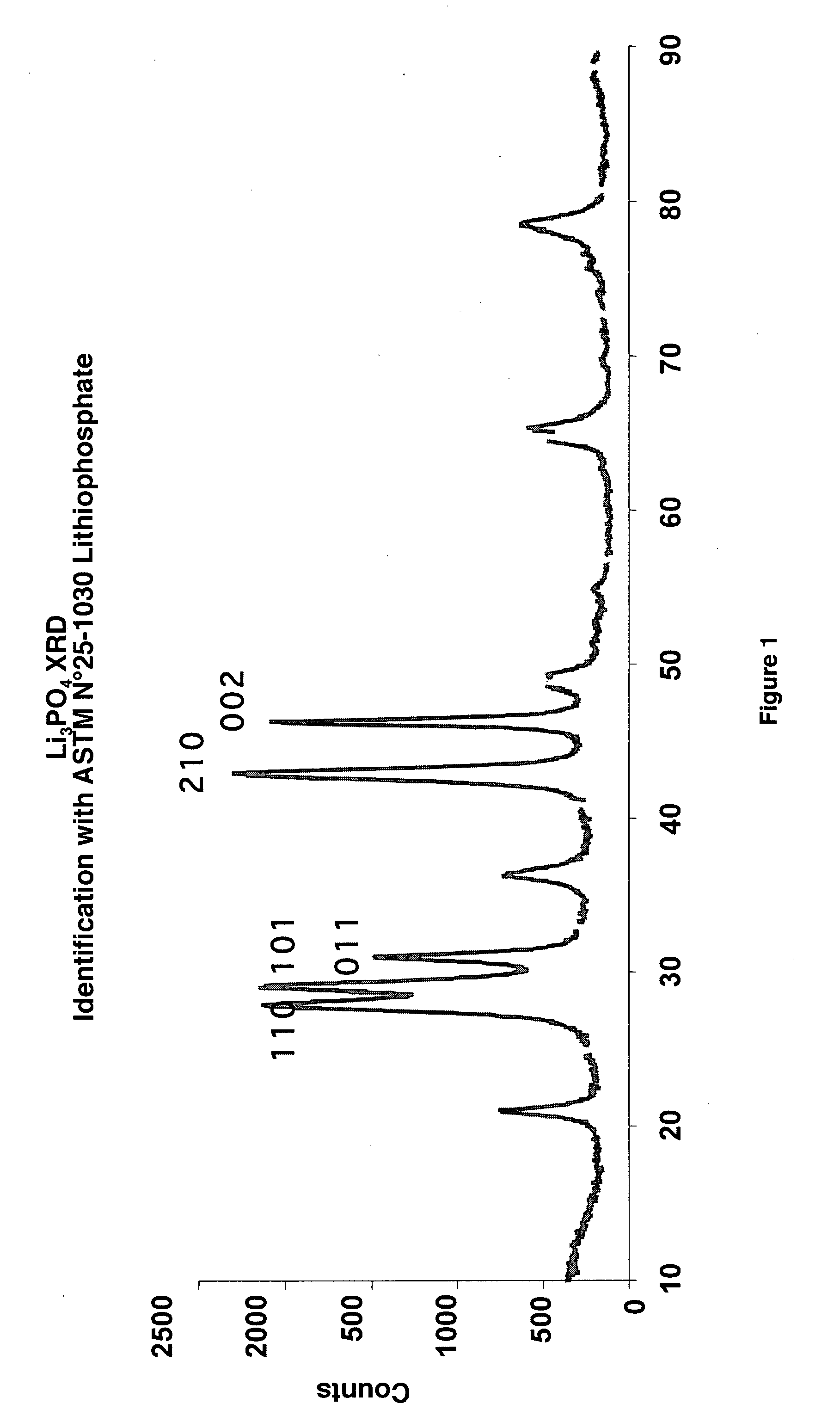

Regeneration method for waste lithium ion phosphate positive pole material

InactiveCN101394015AEx situ recyclingLow costElectrode manufacturing processesSolid waste disposalLithium iron phosphatePhosphate

The invention provides a method for regenerating waste materials of positive materials of ferric phosphate lithium. The method comprises the following steps: firstly, the waste materials of the positive materials of the ferric phosphate lithium are dried for 0.5h to 12.0h at 80 to 200 DEG C; secondly, the dried waste materials of the positive materials of the ferric phosphate lithium are crushed to the extent that the composition of the grain sizes accords with the preparation requirements on a positive sizing agent of the ferric phosphate lithium. Positive regeneration materials of the ferric phosphate lithium processed by using the method have similar electrochemistry performance as normal materials. The method has the advantages that the process is simple, the implementation is convenient, and the cost is low. By adopting the method, the recycling and the reutilization of the waste materials of the positive materials of the ferric phosphate lithium can be easily realized; the overall cost of the battery production is reduced; the environmental pollution caused by improperly processing the waste materials of the positive materials of the ferric phosphate lithium is avoided.

Owner:SHENZHEN BAK BATTERY CO LTD

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

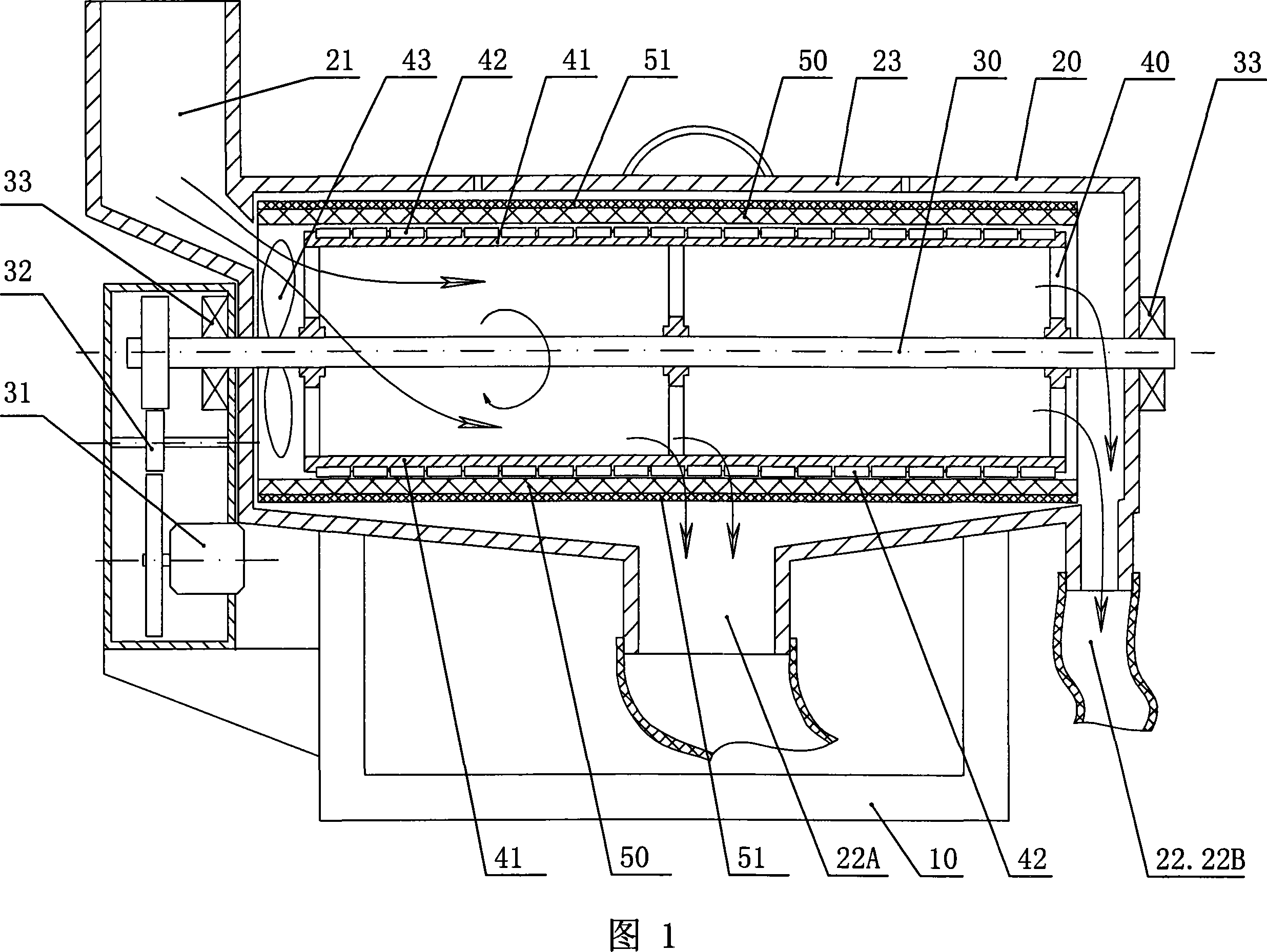

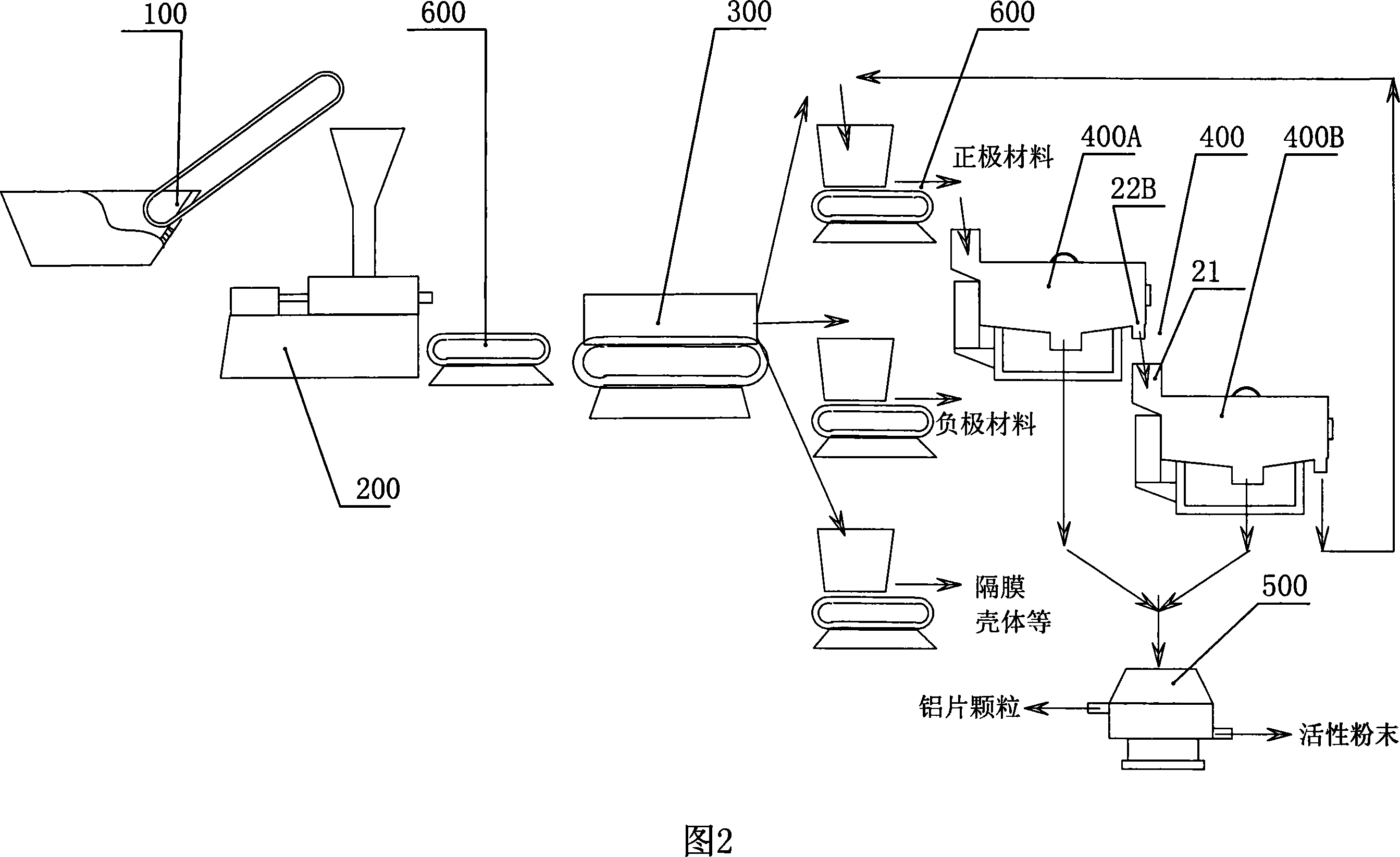

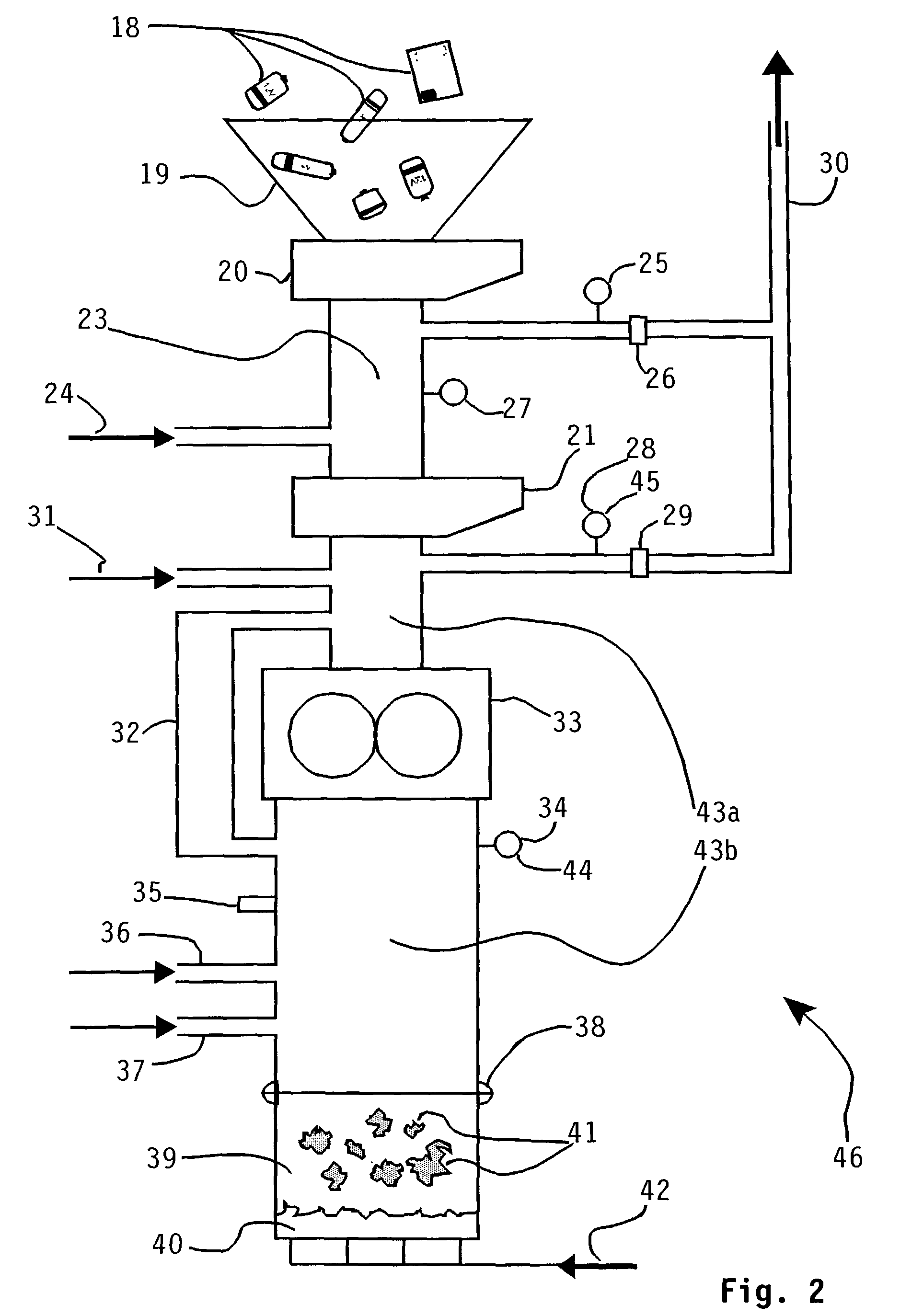

Method of controlling fragmentation and recovery of waste battery and system thereof

ActiveCN101183740AAppropriate spacingReduce pollutionSolid waste disposalReclaiming serviceable partsRecovery methodEngineering

The invention relates to a controllably-crushing recovery method and system of scrap batteries, comprising the following steps that: the scrap batteries are separated and classified to obtain a collection of lithium-ion batteries; the casings of the lithium-ion batteries are shelled by a scrap-battery rejuvenator to obtain a collection of lithium-ion battery content; the collected lithium-ion battery content is physically separated to obtain a collection of aluminium positive plates and positive active coatings on the positive plates; the aluminium positive plates and the positive active coatings on the positive plates are sent into a controllably-crushing device of scrap batteries and processed controllably-crushing to obtain a collection of mixture of aluminium granule and positive powder; the mixture of aluminium granule and positive powder is subtly sieved and separated to respectively obtain the aluminium granule and the positive powder. The invention has the advantages of greatly reducing environmental pollution of recovery process, less material-separating energy consumption, being close to 90% of intrinsic purity for the lithium cobalt oxide powder from recovery and facilitating economic running.

Owner:GEM CO LTD

Information recording method and device for battery

InactiveUS20060261960A1Stable and fastBatteries circuit arrangementsPlastic recyclingElectrical batteryElectrical and Electronics engineering

Owner:PANASONIC CORP

Process for recovering carbon materials of battery cathode

ActiveCN101154757APromote circulationImprove cycle performanceSolid waste disposalReclaiming serviceable partsRecovery methodRoom temperature

The invention discloses a method for recycling cathode carbolic materials of battery, wherein, the cathode carbolic materials are loaded on a current collection body by binding agents, forming a cathode piece of battery; the method includes the following steps that: firstly, according to the solid-liquid weight ratio of 1:3 to 30, the cathode piece of battery is put into the soaking agent with the temperature of 30 to 10 Celsius degrees for complete soaking, until the cathode materials are separated from the current collection body; secondly, the current collection body is taken out and filtered to get the solid materials; thirdly, under the protection of the non-oxidizing gas, the solid materials are heated at the temperature of 400 to 800 Celsius, getting the carbolic materials. The discharging capacity at the normal temperature and the multiplying power discharging performance of the battery of which the carbolic materials are recovered by the method of the invention are very close to those of the battery with the finished product carbolic materials for manufacturing, thereby the carbolic materials are recycled by the method of the invention complies with the production requirement.

Owner:BYD CO LTD

Secondary battery module, battery information management device, battery information management system, secondary battery reuse system, secondary battery recovery and sales system, secondary battery reuse method, and secondary battery recovery and sales method

ActiveUS7710073B2Smoothly and efficientlyLower-cost and environmental cyclingBatteries circuit arrangementsReclaiming serviceable partsElectricityTerminal equipment

A secondary battery module includes a battery information storage unit for storing electric characteristic information and usage history information of the secondary battery module. A battery information management device and a terminal device respectively include interfaces to be connected to the secondary battery module. The battery information management device is provided with a battery information database. The battery information management device is connected to the terminal device through a communications network. In this way, battery information stored in the battery information storage unit, which is acquired by the battery information management device and the terminal device, is accumulated in the battery information database. Moreover, the battery information management device grades the secondary battery module for reuse based on the battery information and a predetermined threshold.

Owner:HITACHI ASTEMO LTD

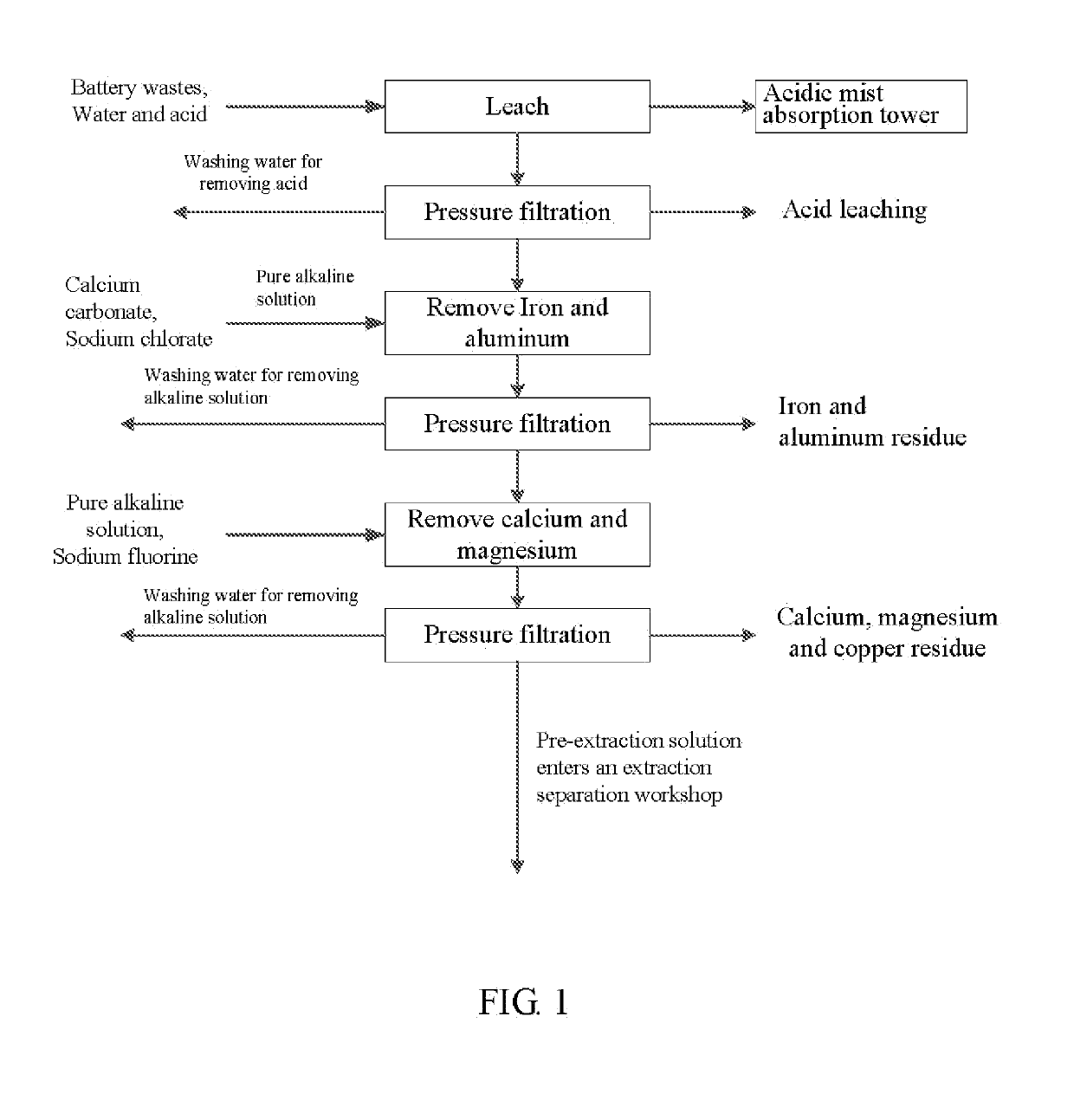

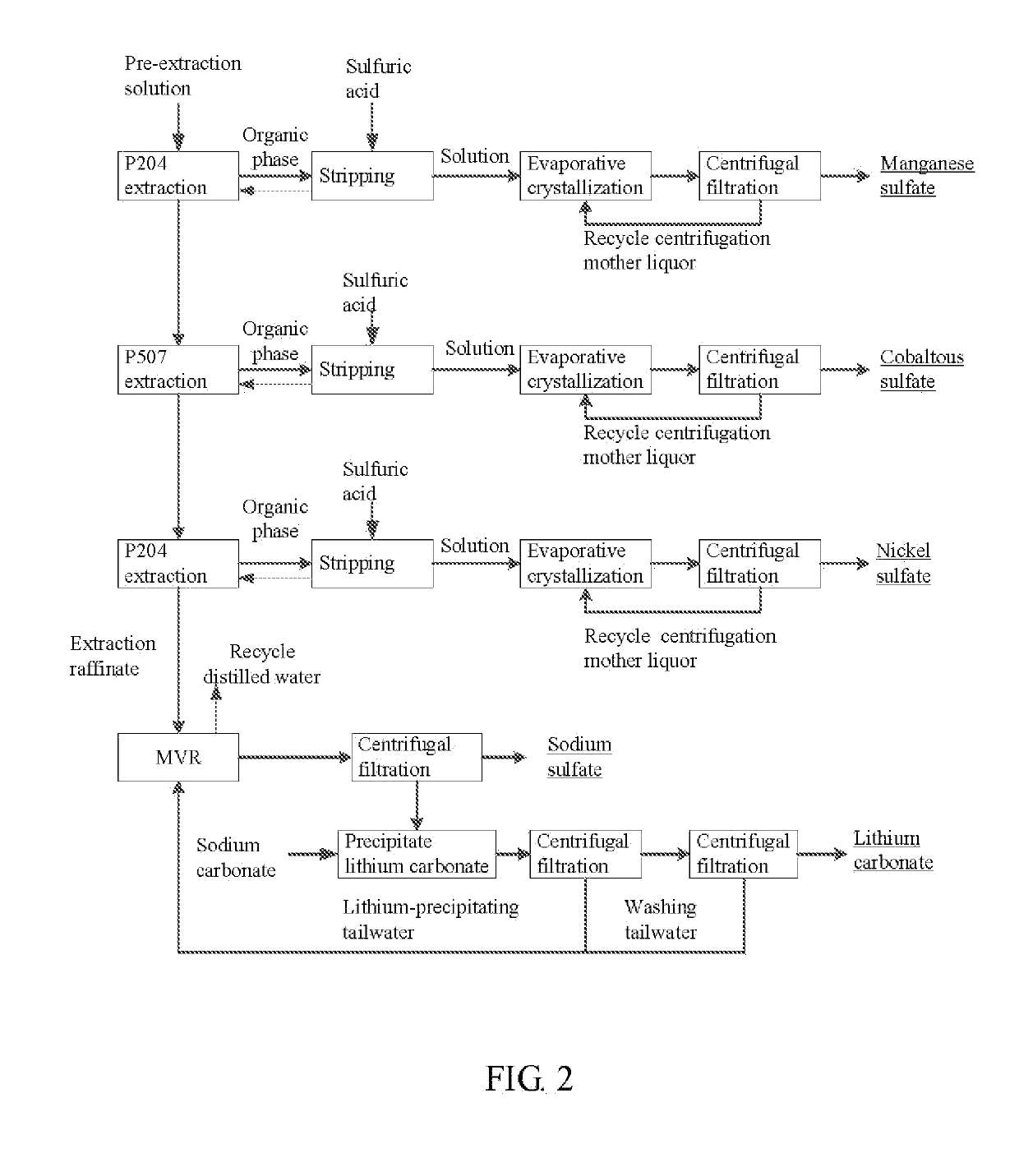

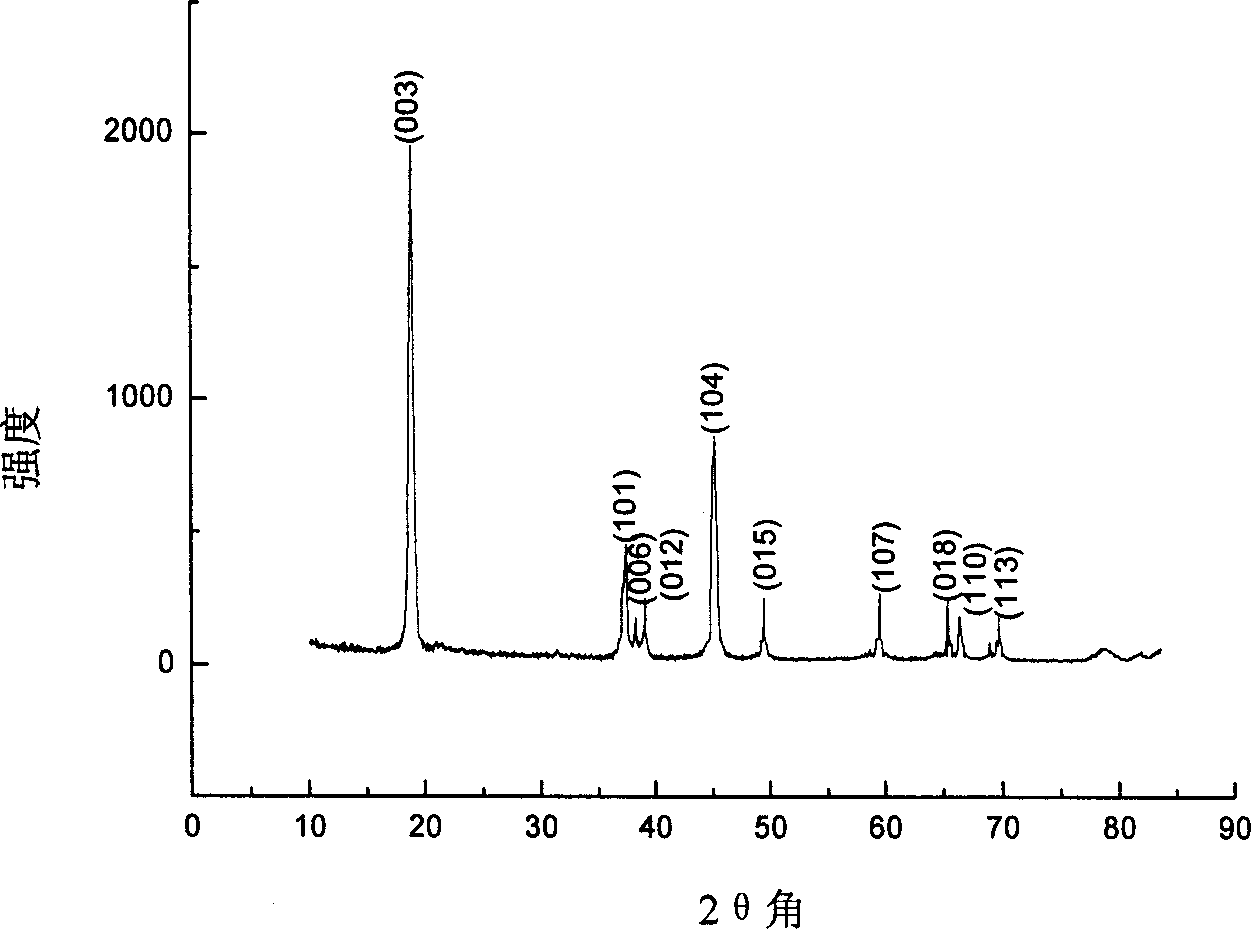

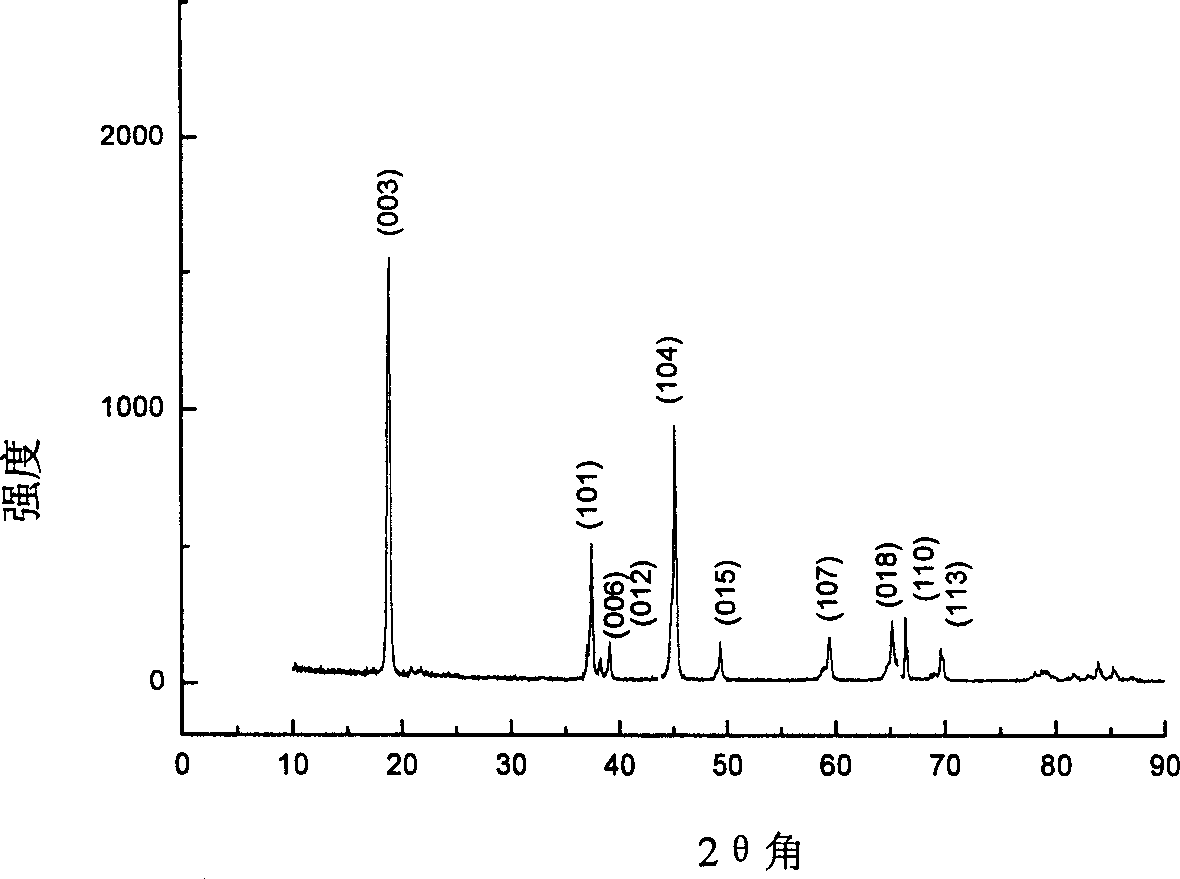

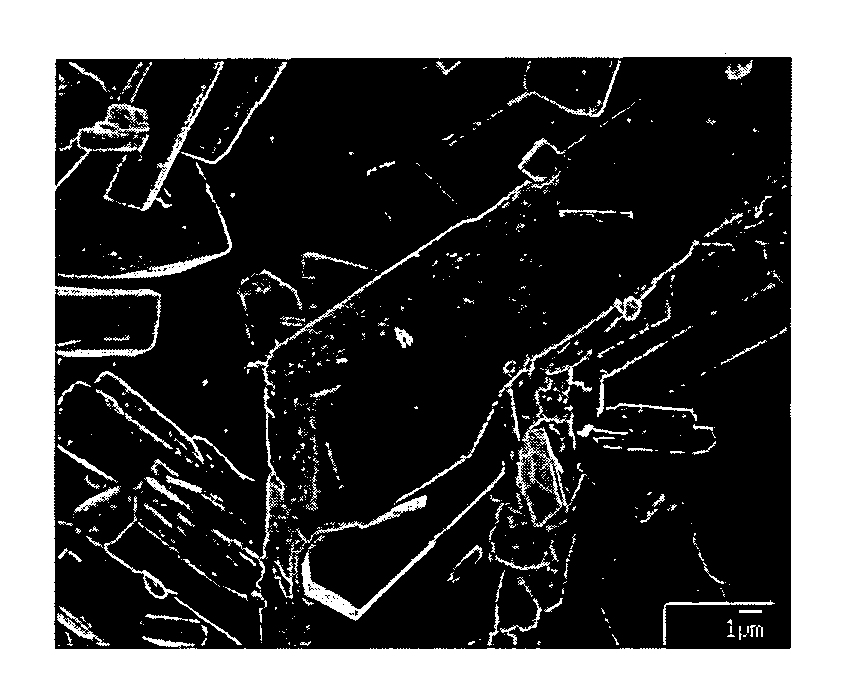

Method for preparing nickel/manganese/lithium/cobalt sulfate and tricobalt tetraoxide from battery wastes

ActiveUS20190152797A1Reduce productionHigh puritySolvent extractionCobalt sulfatesManganeseCobalt Sulfate

A method for preparing nickel / manganese / lithium / cobalt sulfate and tricobalt tetraoxide from battery wastes adopts the following process: dissolving battery wastes with acid, removing iron and aluminum, removing calcium, magnesium and copper, carrying extraction separation, and carrying out evaporative crystallization to prepare nickel sulfate, manganese sulfate, lithium sulfate, cobalt sulfate or / and tricobalt tetraoxide. By using the method, multiple metal elements, such as nickel, manganese, lithium and cobalt, can be simultaneously recovered from the battery wastes, the recovered products are high in purity and can reach battery grade, battery-grade tricobalt tetraoxide can also be directly produced. The method is simple in process, low in, energy consumption and free in exhaust gas pollution, and can realize zero release of wastewater.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

Method for recycling valuable metals in manganese series waste batteries

ActiveCN102569838AEfficient recyclingStrong ability to useReclaiming serviceable partsProcess efficiency improvementResource utilizationLithium metal

The invention discloses a method for recycling valuable metals in manganese series waste batteries. In the method, the manganese, iron, zinc and lithium metal resources in a waste zinc-manganese dry battery, a waste alkaline-manganese battery and a waste lithium-manganese primary battery and a waste lithium ion battery taking lithium manganate or lithium manganate derivative as a positive electrode material are comprehensively utilized by pyrometallurgy and made into products such as manganese-iron alloy and zinc oxide, wherein the total mass of manganese and iron in the prepared manganese-iron alloy reaches over 90%, and the manganese-iron alloy can be applied to steel enterprises and stainless steel enterprises; and the total mass of zinc and lithium in zinc oxide reaches over 40%, and zinc oxide can be applied to wet refining of zinc and lithium. The method disclosed by the invention has the characteristics of high resource utilization and recovery rate, simple technology and high recovery value.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

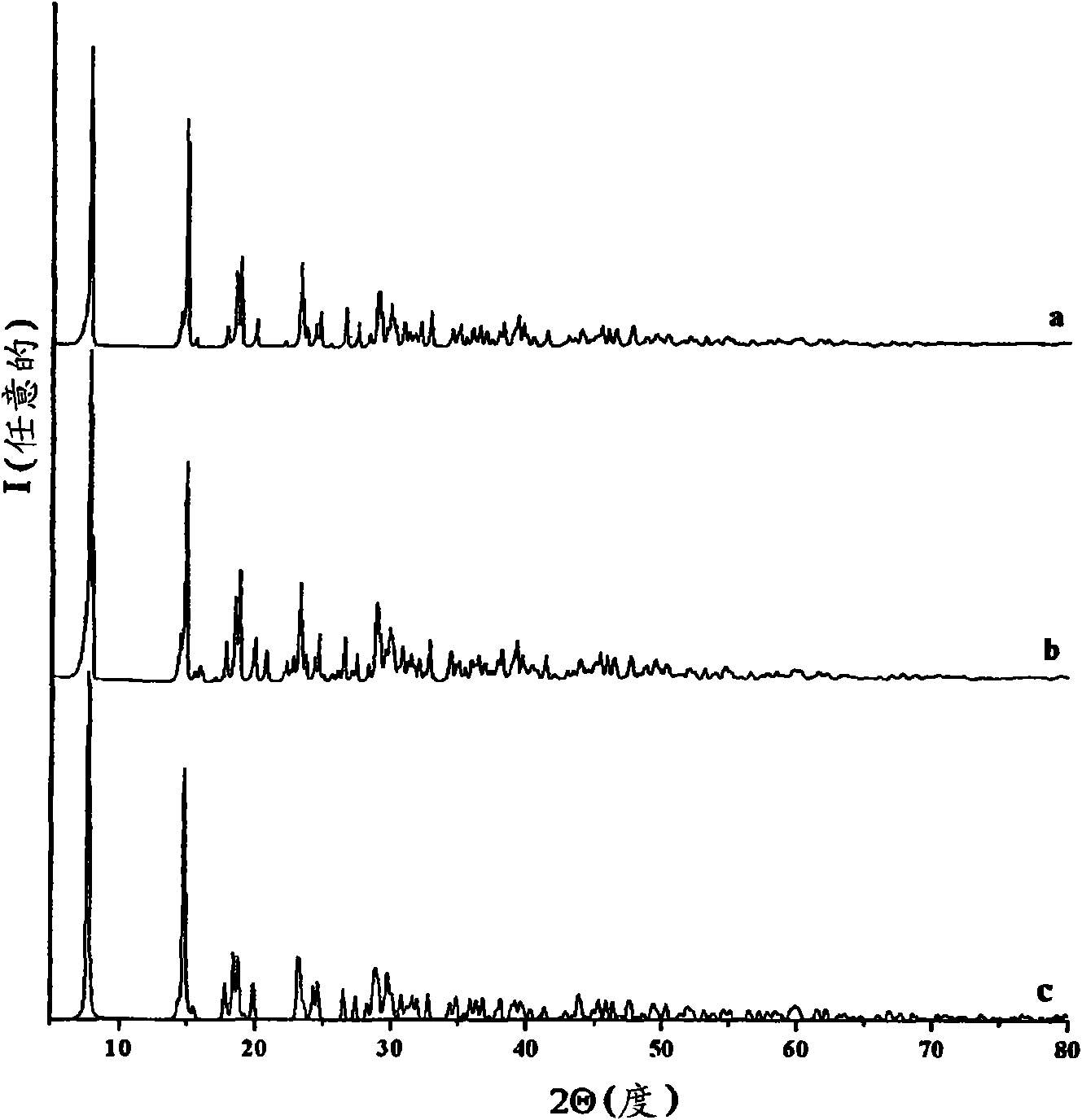

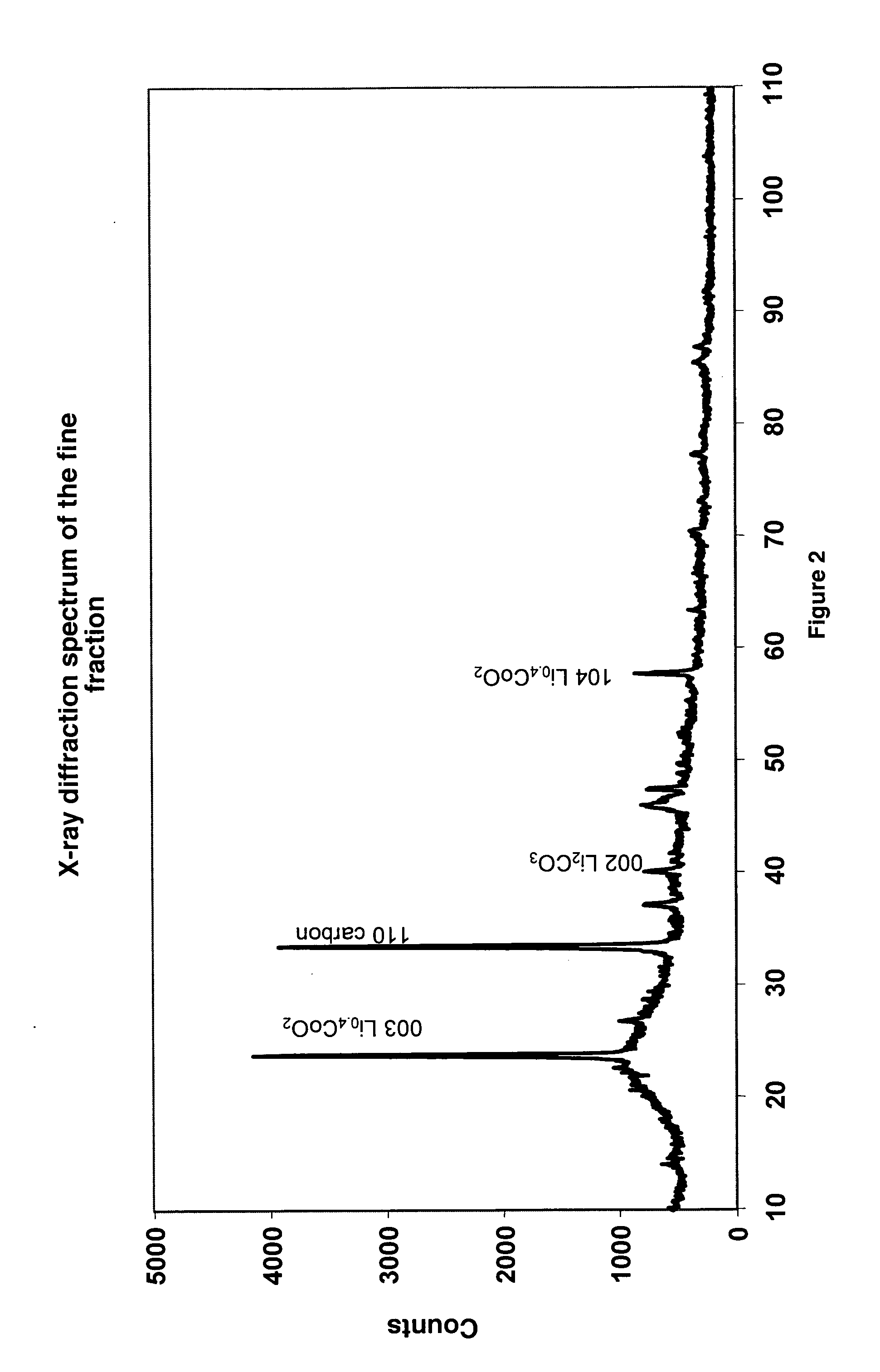

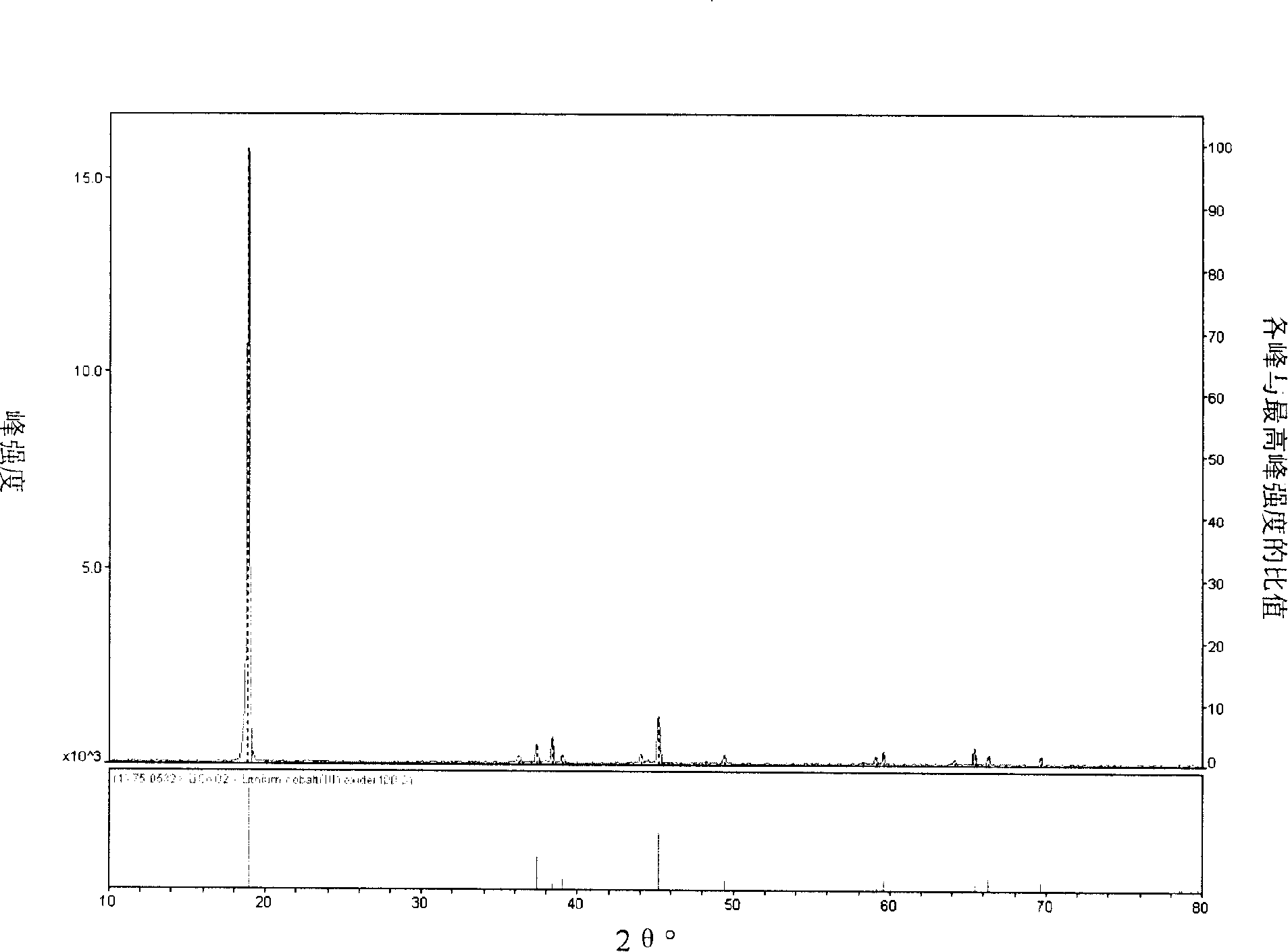

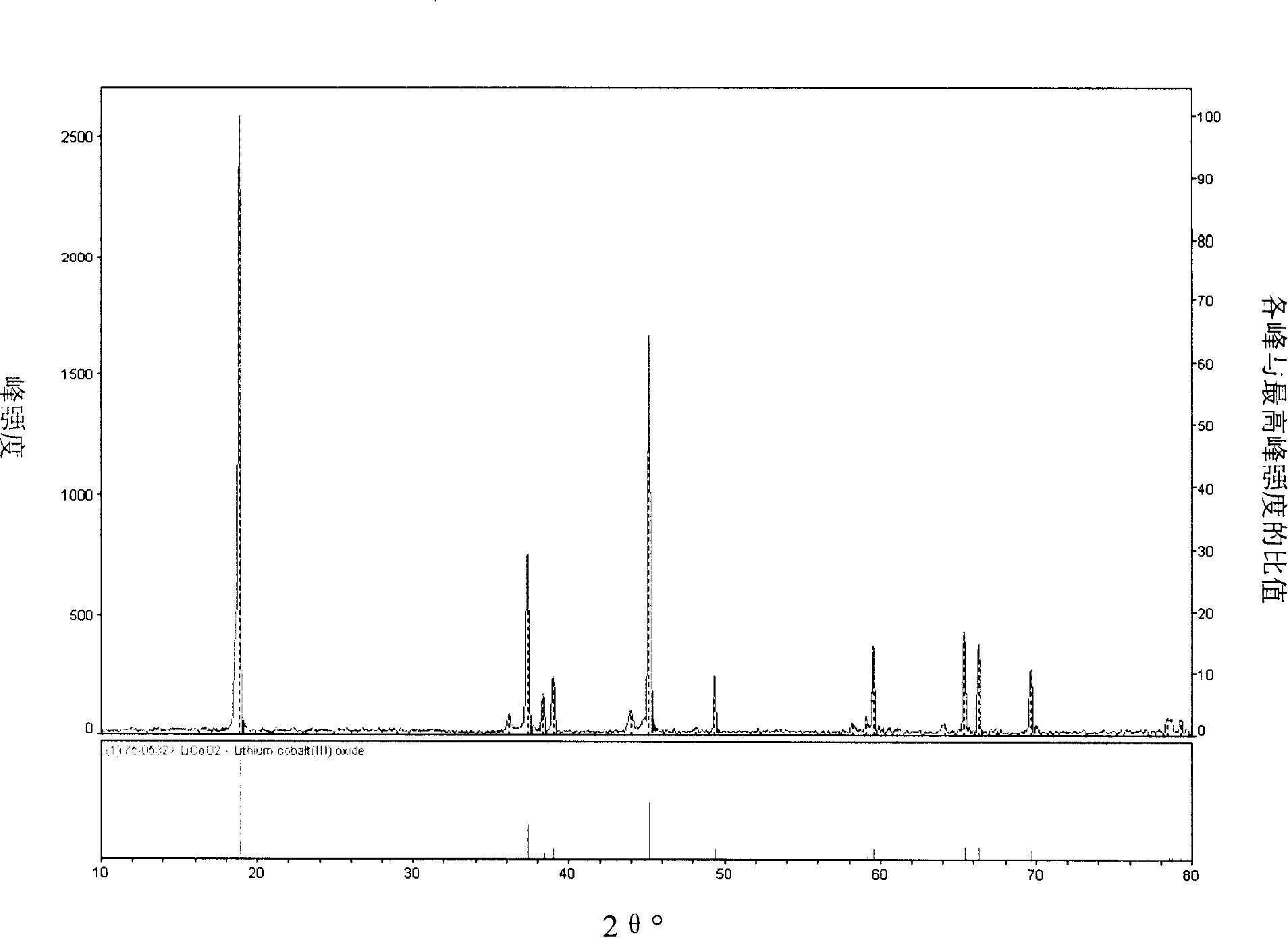

Production of LixCoO2 from recovering waste lithium ionic battery

InactiveCN1747224AHigh specific surface area of powderLarge specific surface areaReclaiming serviceable partsWaste accumulators reclaimingNitrateChloride

The method includes following steps: cut off batteries; separate anode materials, and cut the anode material into pieces; the anode pieces are steeped into N-Methyl-2-Pyrrolidone liquor, and are heated to separate activating material LiCoO2, and then acquire black powder. The black powder is putted into nitric acid solution or spirit of salt, and after filtering the nitric acid solution or chloride solution containing Co2+,Li+ ion is acquired. NH3íñN2O is added into Co2+,Li+ ion acidic solution, and meanwhile add surfactant; LiOH is added into suspension to adjust concentration of Li+ in suspension; the suspension is filtered and dried, then is sintered at 600-900 Deg C. to acquire LixCoO2 powder.

Owner:TIANJIN UNIV +1

Lead recycling

ActiveUS20100040938A1Simple methodOrganic chemistryPrimary cell maintainance/servicingCITRATE ESTERLead oxide

The present invention describes a method of recycling lead from lead containing waste, the method comprising the steps of mixing the battery paste with aqueous citric acid solution so as to generate lead citrate; isolating lead citrate from the aqueous solution; and converting the lead citrate to lead and / or lead oxide.

Owner:CAMBRIDGE ENTERPRISE LTD

Method for preparing ternary positive electrode material precursor by virtue of waste batteries

ActiveCN104659438AAchieve recyclingAvoid pollutionReclaiming serviceable partsWaste accumulators reclaimingPhysical chemistryManganese

The invention discloses a method for preparing a ternary positive electrode material precursor by virtue of waste batteries. The method comprises the steps of detaching waste batteries, roasting the detached waste batteries and carrying out sulfuric acid dissolving to obtain a waste battery positive electrode material, then separating and removing metal impurities in the waste battery positive electrode material by virtue of an extraction method to obtain a sulfate solution, supplementing manganese or aluminum to prepare a mixed solution for preparing the ternary positive electrode material precursor, then sequentially adding ammonia water and a sodium hydroxide solution, reacting to generate ternary positive electrode material precursor precipitates, and finally washing and drying to obtain the ternary positive electrode material precursor. According to the method, the cyclic utilization of resources of nickel and cobalt in waste batteries is realized, and the environmental pollution caused by heavy metals is avoided; furthermore, a nickel-cobalt-aluminum precursor and a nickel-cobalt-manganese precursor are produced from the recycled waste batteries, so that the requirements on primary mineral resources are lowered, and the purchase costs of nickel and cobalt are lowered; the method adopts a simple technological process and is applicable to industrial large-scale production.

Owner:广东芳源新材料集团股份有限公司

Ultrafine lead oxide prepared from desulfurated lead plaster by means of three-stage process and method thereof

InactiveCN103374658ALead volatility is smallReduce soot rateReclaiming serviceable partsLead oxidesLead carbonateLead oxide

The invention discloses ultrafine lead oxide prepared from desulfurated lead plaster by means of three-stage process and a method for preparing the ultrafine lead oxide. The method comprises the following steps of: carrying out a desulfurization and lead plaster acid leaching process by causing the desulfurated lead plaster to react with acid, simultaneously adding a reducing agent, and carrying out solid-liquid separation after the reaction is ended to obtain a plumbic acid containing solution; carrying out a lead carbonate preparation process by causing the plumbic acid containing solution to react with sodium carbonate, carrying out solid-liquid separation, washing and drying to obtain the lead carbonate; carrying out a roasting process by preparing the ultrafine lead carbonate by roasting the lead carbonate, wherein the ultrafine lead oxide can be PbO, Pb3O4, or the mixture of the PbO and the Pb3O4, the mean particle granularity of the ultrafine lead oxide is less than 2 mu m, and the nanocrystalline grain size is less than 500nm. Compared with the prior art, the preparation method of the ultrafine lead oxide disclosed by the invention has the following beneficial effects: the active material of the ultrafine lead oxide powder compound for the production of a storage battery enterprise can be directly prepared, lead volatilize quantity is small, the ash rate is low, the direct lead yield is high, the energy consumption is low, pollutants of sulfur dioxide and the like are not generated, and the like.

Owner:湖北金洋冶金股份有限公司 +1

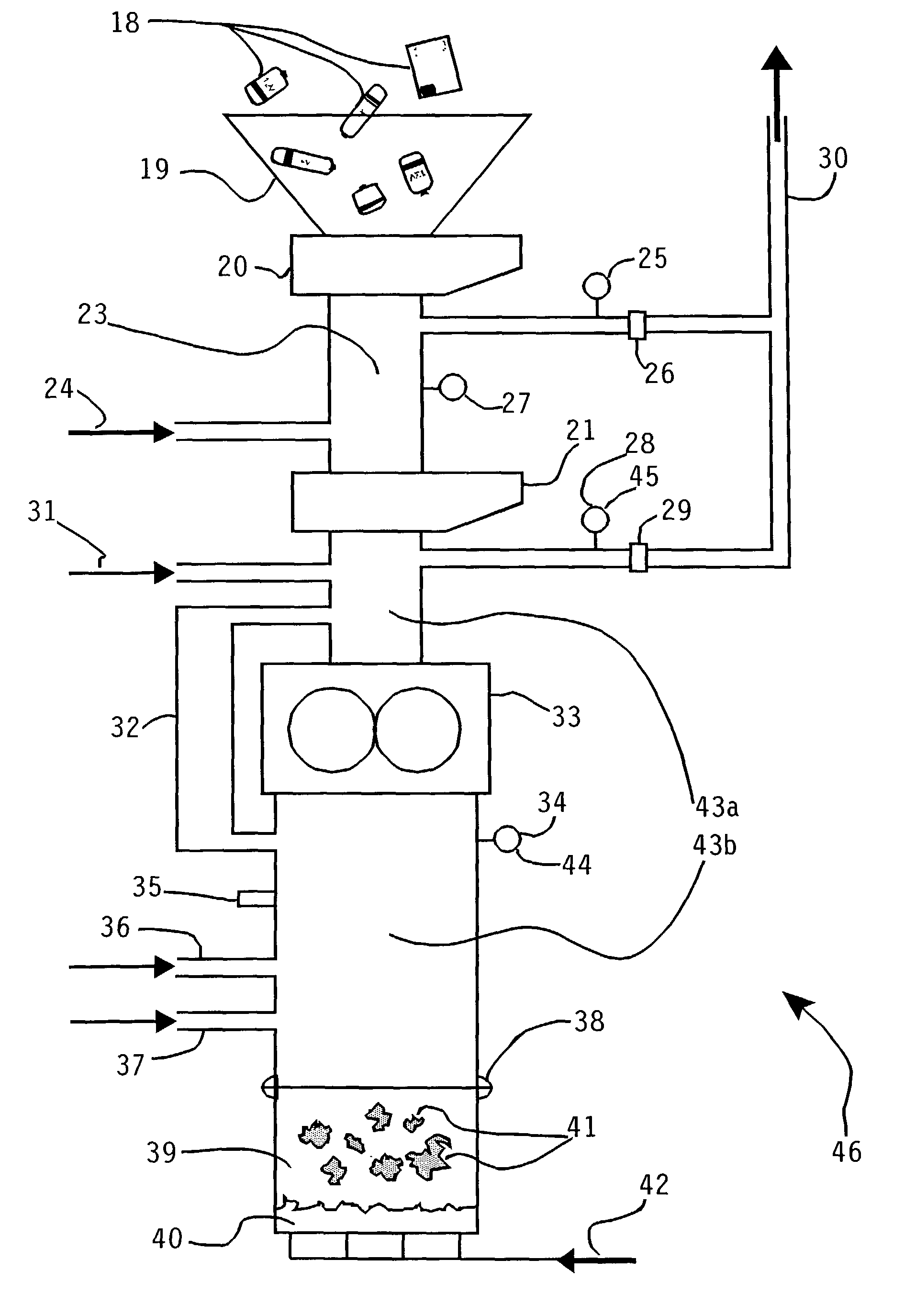

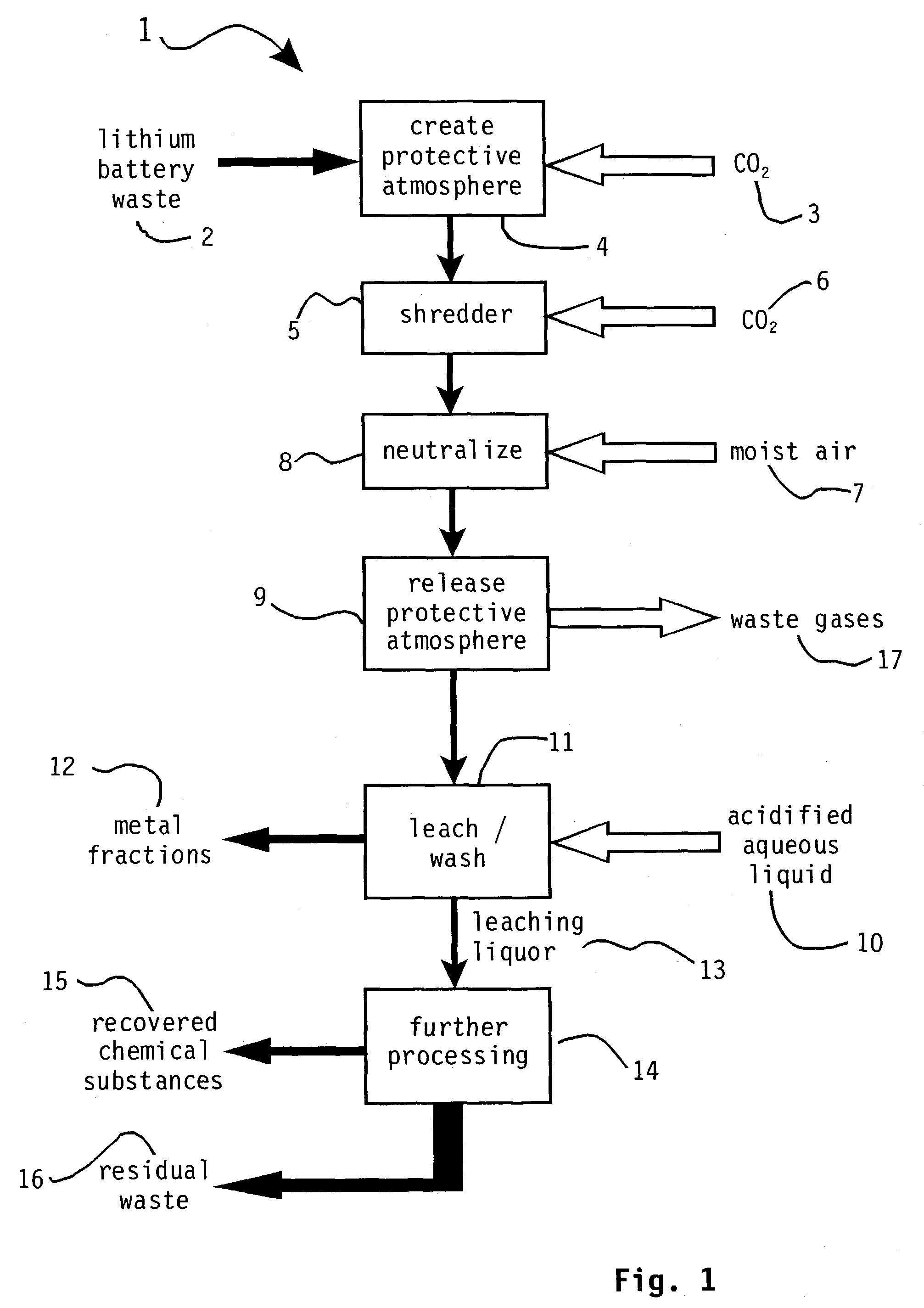

Method of and apparatus for dismantling and storage of objects comprising alkali metals, such as alkali metal containing batteries

InactiveUS7833646B2Cost effectiveEasy to separateNon-aqueous electrolyte accumulatorsArtificial filament recoveryProduct gasMetal

There is disclosed a method of and an arrangement for dismantling and storage of objects comprising alkali metal containing substances, in particular lithium containing batteries, in the presence of a protective atmosphere, wherein the protective atmosphere is carbon dioxide. The arrangement comprises a gas-tight chamber for bringing the objects under a protective environment, and a gas-tight chamber for dismantling the objects within the protective atmosphere of carbon dioxide gas.

Owner:BATREC IND

Method for recovery plus-negative plate material from waste and old electrode plate

InactiveCN1758478AImprove adhesionImprove ductilityReclaiming serviceable partsWaste accumulators reclaimingMaterials scienceNickel–metal hydride battery

This invention relates to a method for recovering positive and negative materials from waste pole plates including a high temperature method and a specific gravity method, in which, the high temperature method includes putting the waste positive and negative pole plates under high temperature to dissolve the PVDF and break the positive and negative materials from the matrix and separate them from the conduction agent, then separating the PVDF with water, which applies a physical method to recover the materials and does not change the physical and chemical targets of the materials.

Owner:朱明明

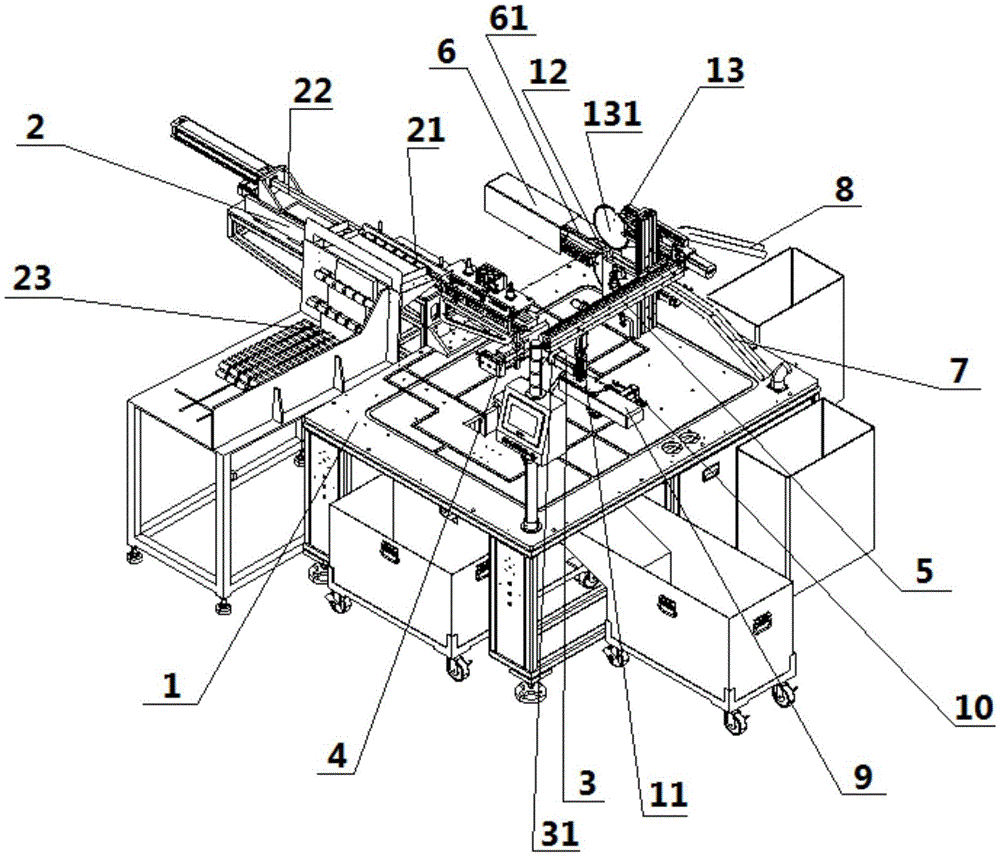

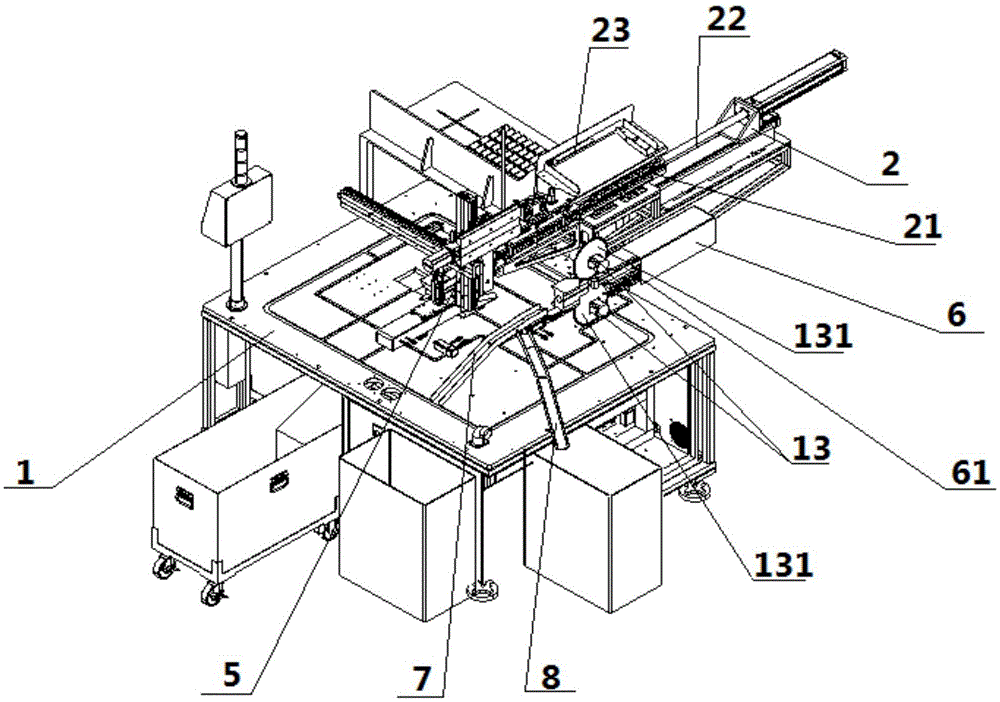

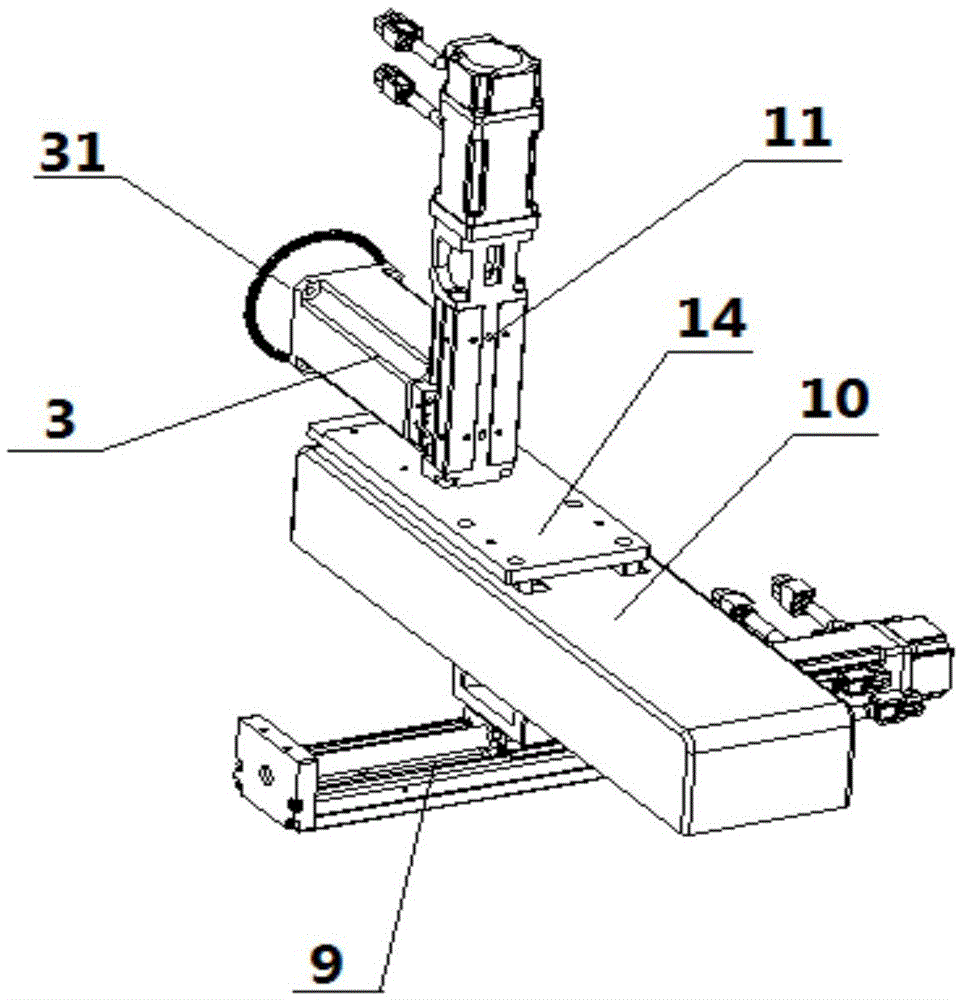

Battery shell breaking disassembling apparatus

ActiveCN105655660AShort tripReduce wearSolid waste disposalReclaiming serviceable partsEngineeringAutomation

The invention provides a battery shell breaking disassembling apparatus. The apparatus comprises a feeding device, a vertical annular cutting device, a rotatable telescopic clamping device, a separating device, a core pushing device, an electrical core discharging groove and a shell discharging groove which are arranged on a frame, the vertical annular cutting device is placed behind a feeding groove, the vertical cutting tool of the vertical annular cutting device is vertical to the direction of the feeding groove, the rotatable telescopic clamping device is arranged at one side between the feeding groove and the vertical annular cutting device, one side opposite to the rotatable telescopic clamping device is sequentially provided with the separating device and the core pushing device from inside to outside, and the electrical core discharging groove and the shell discharging groove are arranged at the rear end of the core pushing device. The battery shell breaking disassembling apparatus realizes automation from feeding, cutting and separation to collection, reduces the wearing degree of the cutting tool and improves the working efficiency.

Owner:先进储能材料国家工程研究中心有限责任公司

Method for the mixed recycling of lithium-based anode batteries and cells

InactiveUS20070196725A1Fuel cells disposal/recyclingPrimary cell maintainance/servicingMetallic lithiumRoom temperature

The invention relates to a method for treating all types of lithium anode cells and batteries by means of a hydrometallurgical process at room temperature. The treatment method enables cells and batteries comprising a metallic lithium-based anode or an anode containing lithium incorporated in an anodic insertion compound to be treated under safe conditions, thus enabling the metallic casings, electrode contacts, cathode metal oxides and lithium salts to be separated and recovered.

Owner:RECUPYL

Recovery method for active matter from waste material containing lithium ionic cell anode active matter

InactiveCN101192693AAvoid stickingAvoid separabilitySolid waste disposalReclaiming serviceable partsRecovery methodActive matter

Owner:BYD CO LTD

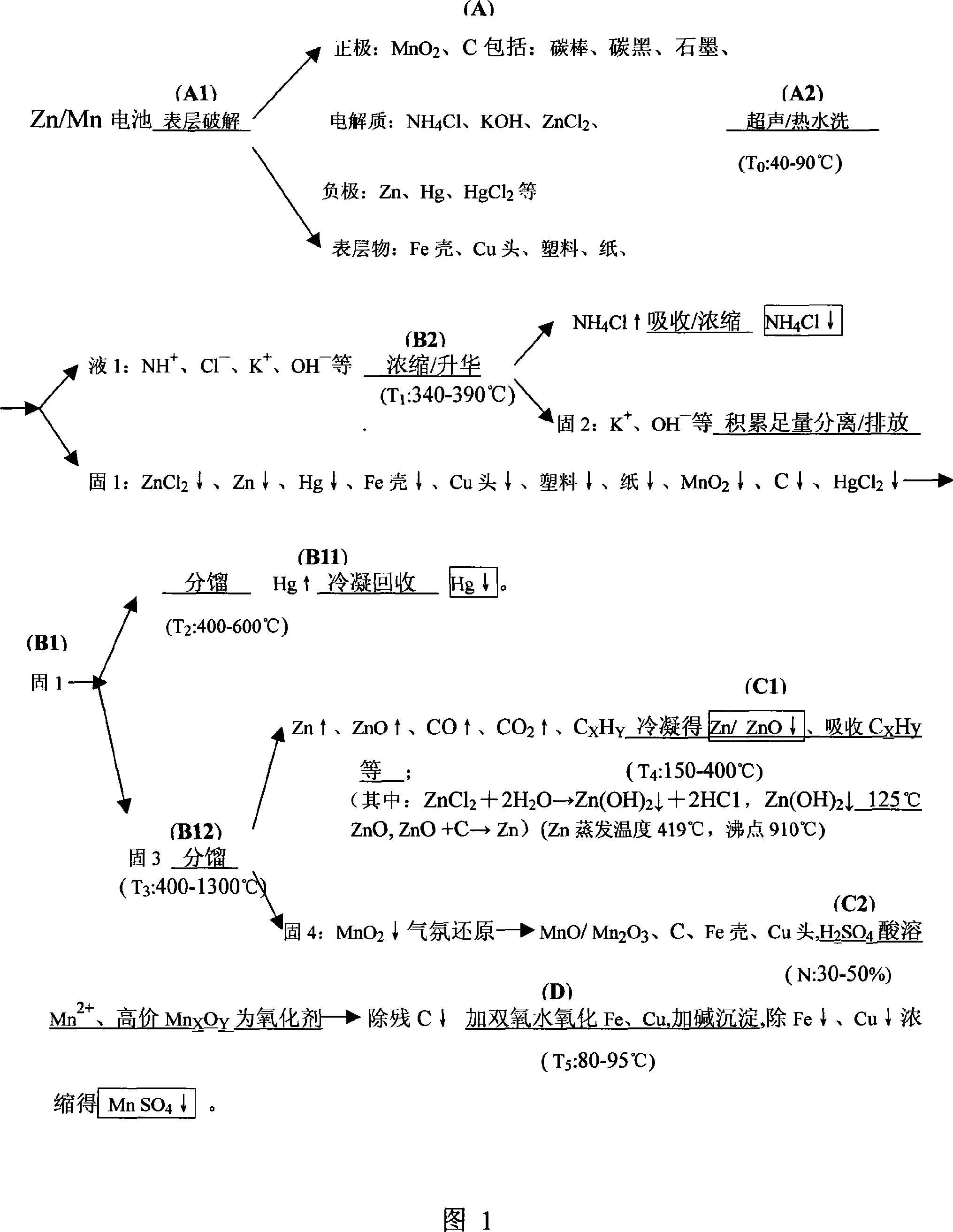

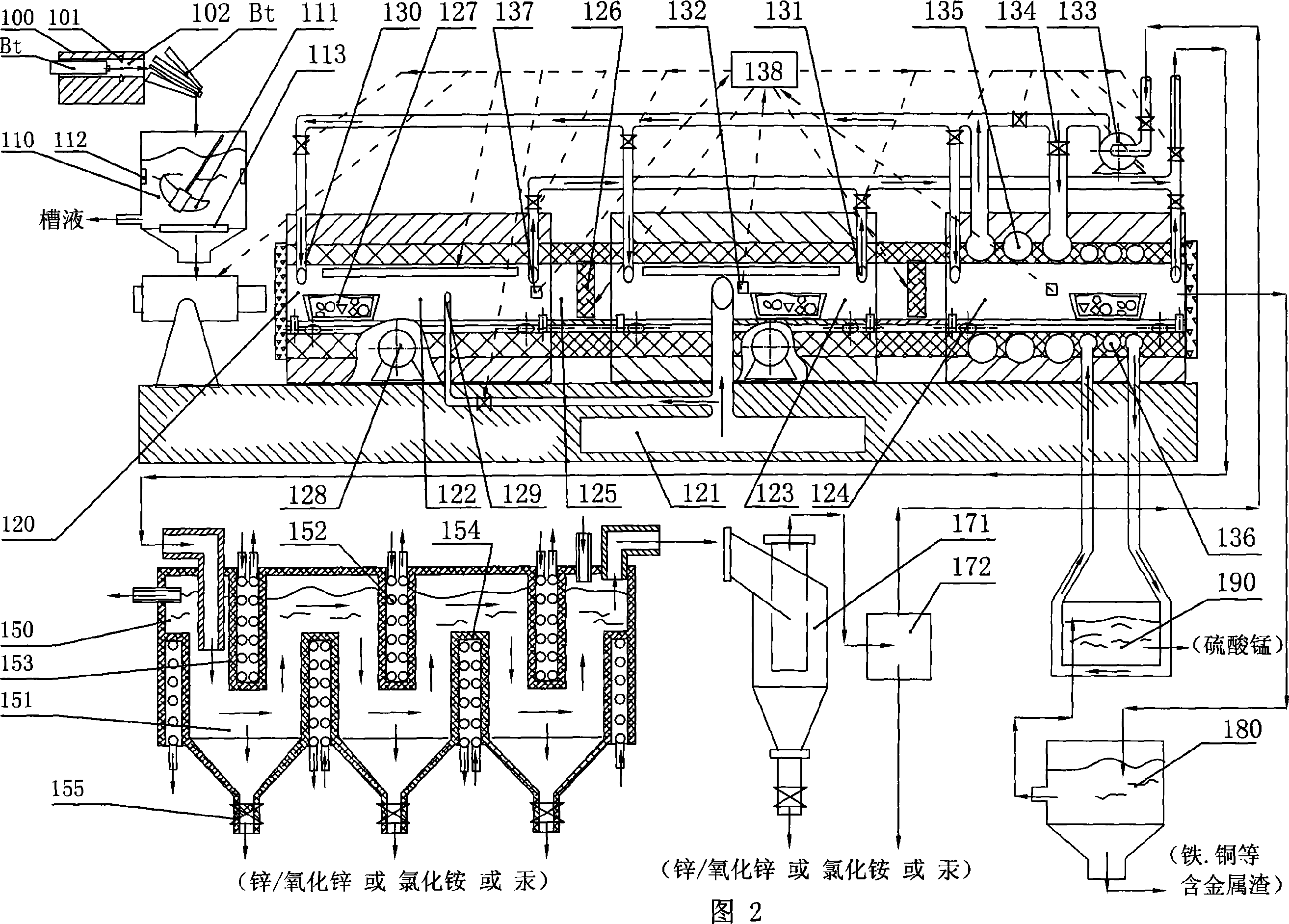

Selectivity volatilization reclaiming technique for waste zinc-manganese battery and reclaiming system thereof

ActiveCN101054187AGood for acid soluble recoveryFull recoveryZinc oxides/hydroxidesReclaiming serviceable partsSurface layerSulfate

The present invention relates to a selective volatilization recovery technology for abandoned zinc-manganese battery, which comprises the steps of that: the surface layer of the battery is broken and scrubbed, thereby the tank liquor, washed up surface layer matter and contained matter are obtained; then the remaining solid containing manganese / ferric oxide and high pure gas are obtained by high temperature carbonization in a properly closed roaster, wherein the temperature inside of the roaster is controlled; the multiple scrubbed tank liquor is heated and concentrated to obtain concentrate which is further heated and cooled to obtain ammonium chloride with a high purity; the distilled off hot gas is guided into a condensation and recovery container and is cooled to be separated and collected thereof, thereby the powder containing zinc and / or zinc oxide is obtained; the remaining solid is subjected to acid soluble to obtain the manganese sulfate primordial solution which is then subjected to oxidation, alkali-settling and separation so as to obtain the purified manganese sulfate solution. In the present invention, the bulk inclusion in the zinc-manganese battery can be completely recovered, the recovered product has a higher purity, the recovery operation and the equipment thereof is simple, and secondary pollution will not occur basically.

Owner:GEM CO LTD

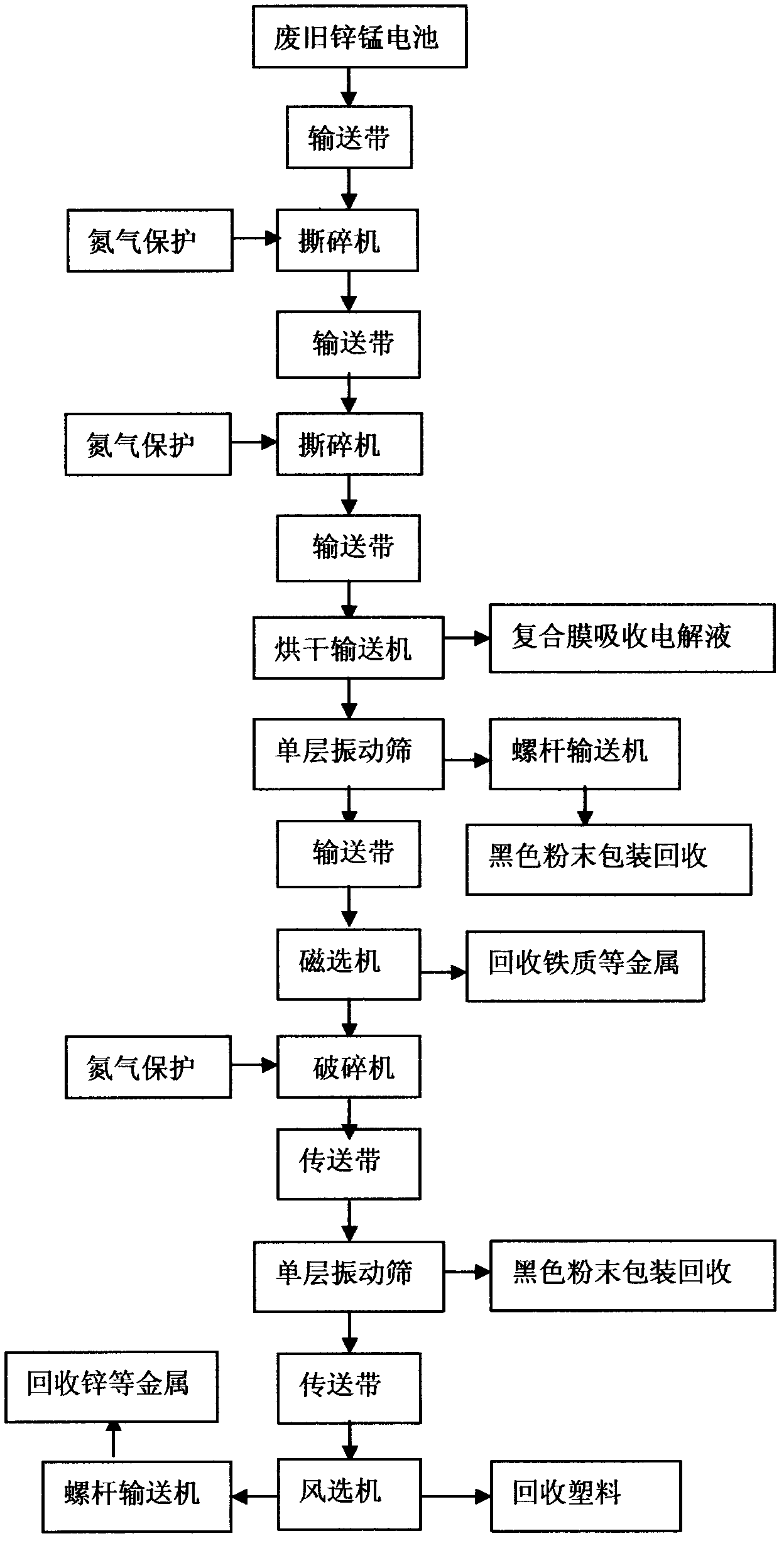

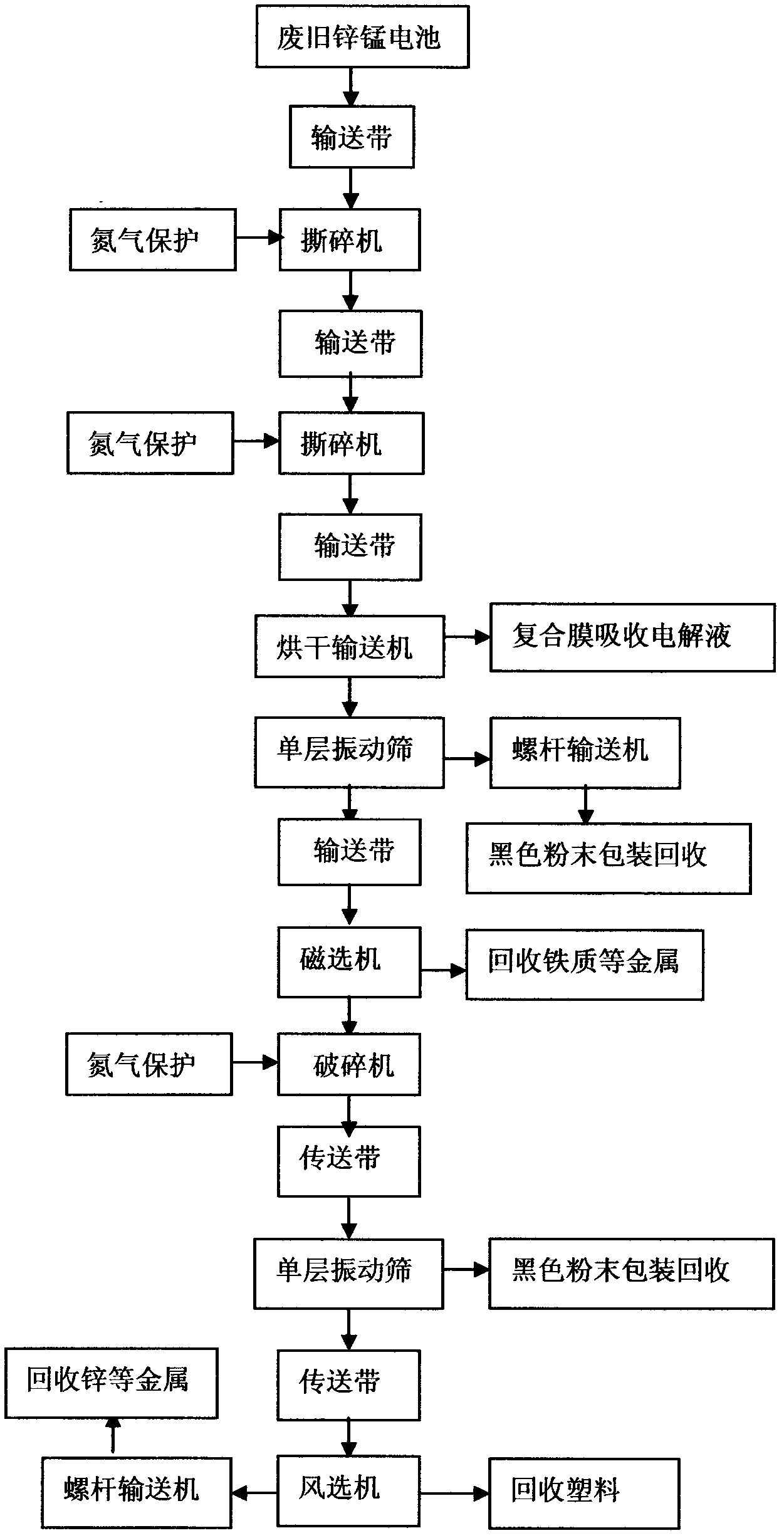

Method for industrializedly recovering zinc and manganese in waste dry cells

ActiveCN102509807AWill not cause secondary pollutionSimple processSolid waste disposalReclaiming serviceable partsThree levelManganese

The invention discloses a method for industrializedly recovering zinc and manganese in waste dry cells. The method comprises the following steps of: primarily shredding cells and secondarily shredding the cells; drying, screening and recovering partial black carbon powder, and recovering irony metal by magnetic separation; carrying out three-level crushing on broken fragments of the cells; and screening and recovering rest black powder, and winnowing to separate metal powder such as plastics and zinc. The method is a mechanical processing method, so that the waste cell recovery process cannot result in three wastes and secondary pollution and is operated in a full-automatic assembly line manner, the method is simple in process and low in production cost, is used for adsorbing and recovering through a self-made film and favorable for solving the problems that mercury easily volatilizes and is difficult to control and the like, and ensures high recovery rate of various valuable constituents.

Owner:深圳市泰力废旧电池回收技术有限公司

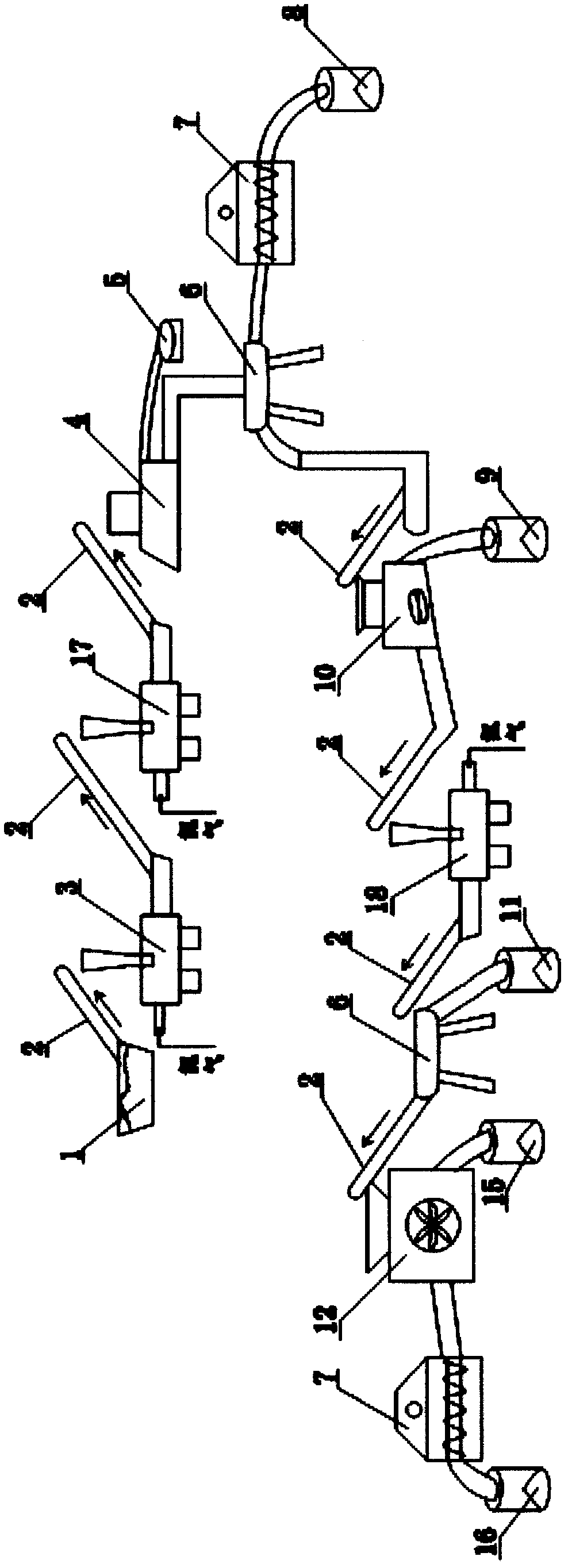

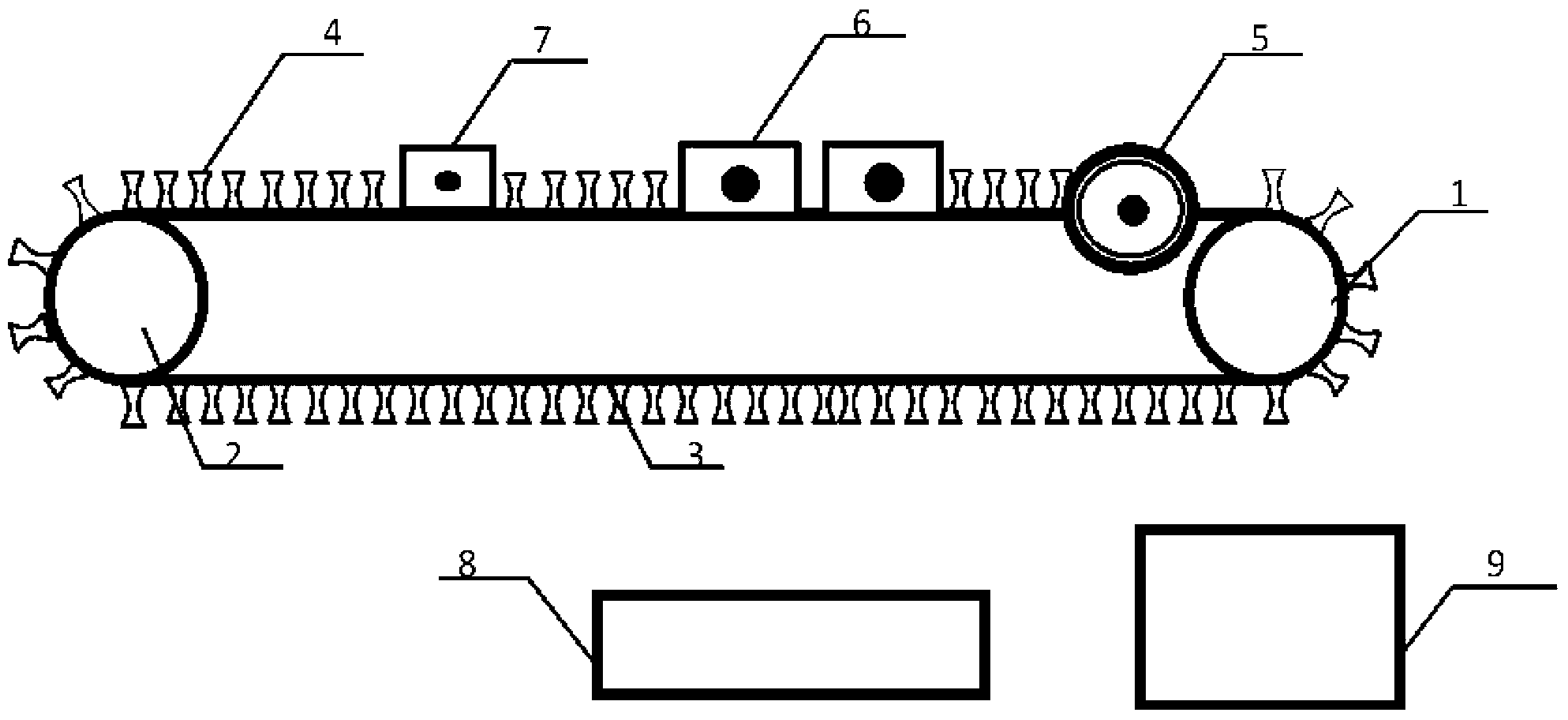

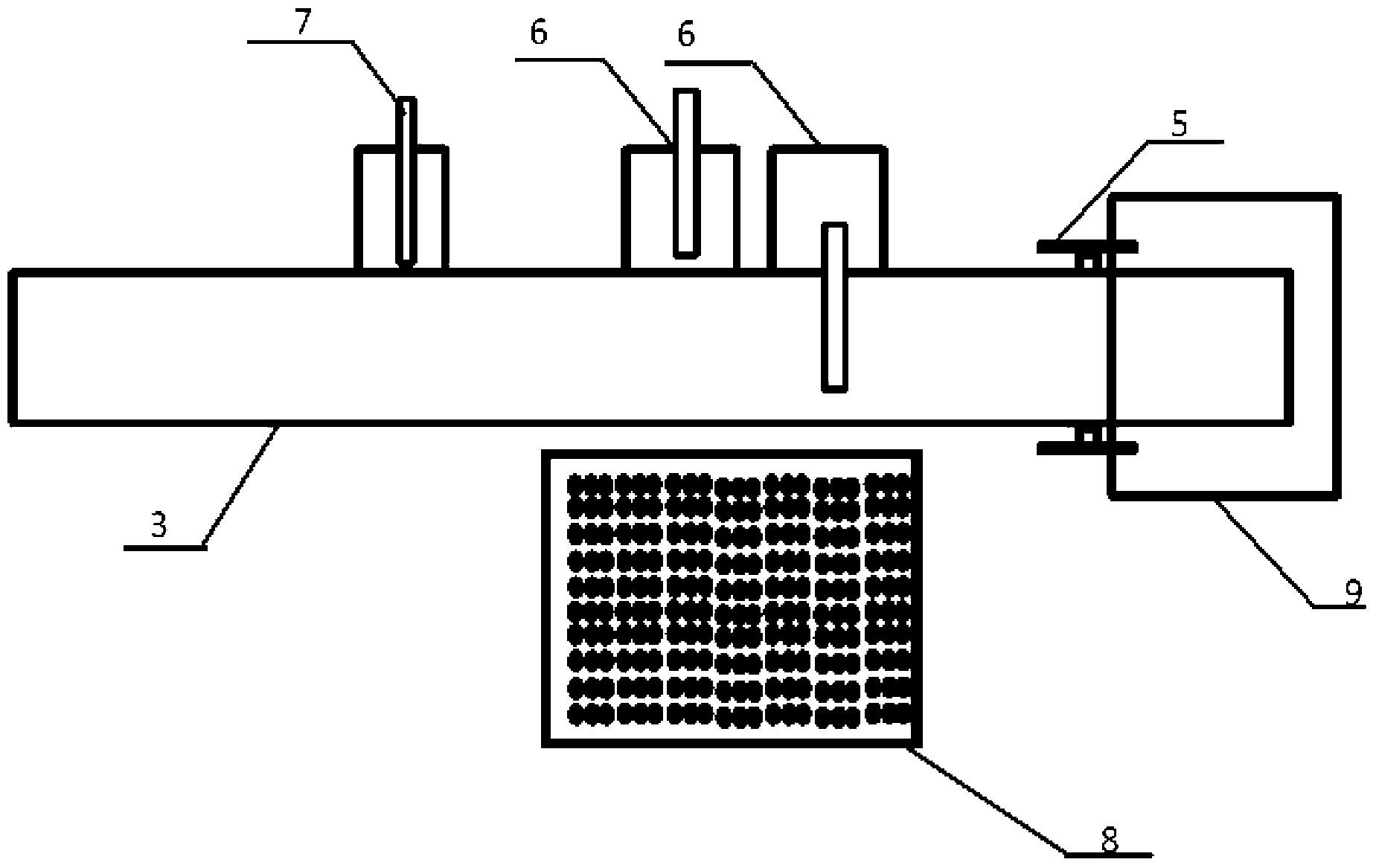

Automatic dismantling and separating device for waste dry cell and dismantling and separating method

InactiveCN103296294AAvoid processing inefficienciesSolve follow-up processing difficultiesSolid waste disposalReclaiming serviceable partsProcess engineeringConveyor belt

The invention discloses an automatic dismantling and separating device for a waste dry cell and a dismantling and separating method, The automatic dismantling and separating device comprises a roller, a belt, a grinding wheel group, a firing pin, a cutter and a vibrating screen, wherein the conveyor belt is provided with a plurality of rubber partition plates; the grinding wheel group is arranged on the conveyor belt; the first side of the conveyor belt is provided with the cutter and the firing pin; the second side of the conveyor belt is provided with the vibrating screen. A first roller, a grinding wheel, the cutter and the firing pin are powered on; the waste dry cells are fixedly arranged between two adjacent partition plates of the belt one by one. Along with the movement of the belt, two ends of each waste dry cell are cut off by the grinding wheel rotating at high speed, paste and a carbon bar of the dry cell are pushed out of a shell of the dry cell through the firing pin, and a zinc skin is separated from a plastic skin through the cutter. The automatic dismantling and separating device and dismantling and separating method for the waste dry cell have the advantages that a paste electrolyte, a zinc drum and the carbon bar can be comprehensively recycled, and the processing working efficiency and a separation effect of the waste dry cell can be improved.

Owner:ANHUI UNIV OF SCI & TECH

Comprehensive waste cell utilizing treamtent process

InactiveCN1349271ANo secondary pollutionSimple methodSolid waste disposalReclaiming serviceable partsCadmium sulfateSulfate

The invention is to process various kinds of waste battery in classifications and uses chemical or physical method to extract zinc salt, chalcanthite, carbon black, manganese bioxide and mercury etc.from zinc-manganese battery, ferrisulphas, potion and nickel sulfate etc. from ferronickel battery, potion, cadmium sulfate and nickel sulfate etc. from cadmium-nickel battery, potion, silver salf and white copperas etc. from silver-zinc battery. Said technology can be used to proces waste battery and make the resource obtd. fully utilization. The advantages are: simple and reasonable processing technology and low cost, no three waste problem, no secondary pollution.

Owner:王宗良 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com