Method for recovering lithium from waste lithium battery to prepare battery grade lithium carbonate

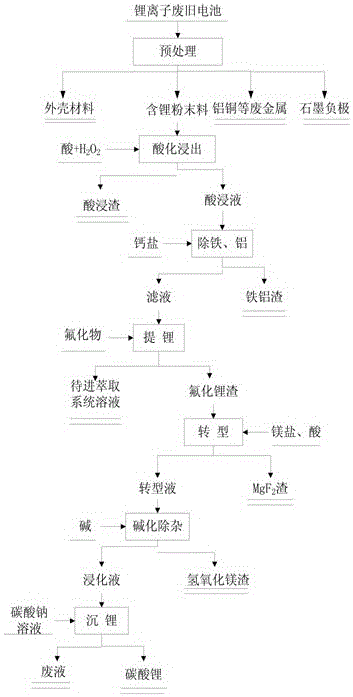

A waste battery and battery-level technology, applied in battery recycling, waste collector recycling, lithium carbonate; The problem of high impurities in the product can achieve the effect of main lithium concentration, small loss of other metal elements, and high lithium recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

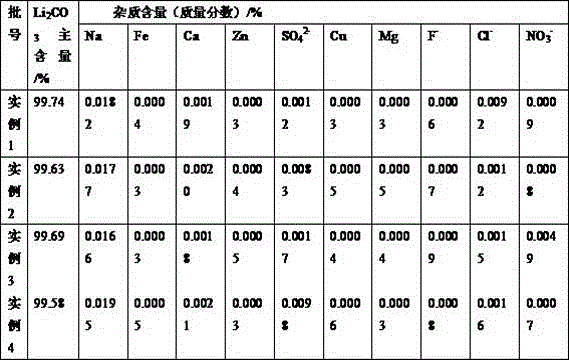

Examples

Embodiment 1

[0055] A. Battery dismantling: Lithium-containing powder is separated from waste lithium batteries through discharge, dismantling, sorting, crushing and other processes;

[0056] B. Acidizing leaching: 100Kg of lithium-containing powder (Li% 7.1%) obtained in step A was adjusted into a slurry with 200Kg of pure water, and then 357Kg of 31% hydrochloric acid and 35Kg of 50% hydrogen peroxide were added to the slurry, and then the Leach for 30 minutes, obtain leachate and acid leaching residue after pressure filtration;

[0057] C. Remove iron and aluminum: add calcium carbonate to the leaching solution obtained in step B, adjust the pH of the solution to 4.5, obtain 550.0L iron and aluminum filtrate after pressure filtration (the analysis of Li in the filtrate is 12.7g / l);

[0058] D. Lithium fluoride precipitation: Add 42.7kg of 98.0% (wt%) sodium fluoride to the iron-removing aluminum filtrate obtained in step C, stir and react at room temperature for 30min, control the pH ...

Embodiment 2

[0063] A. Battery dismantling: Lithium-containing powder is separated from waste lithium batteries through discharge, dismantling, sorting, crushing and other processes;

[0064] B. Acidizing leaching: adjust 100Kg of lithium-containing powder (Li% 6.5%) obtained in step A into a slurry with 500Kg of pure water, then add 163Kg of 98% sulfuric acid and 42Kg of 50% hydrogen peroxide to the slurry, and then Leach for 30 minutes, obtain leachate and acid leaching residue after pressure filtration;

[0065] C. Iron and aluminum removal: Add unslaked lime to the leaching solution obtained in step B, adjust the pH of the solution to 5.0, and obtain 600.0L of iron and aluminum filtrate after pressure filtration (the Li in the analysis filtrate is 10.6 g / l);

[0066] D. Lithium fluoride precipitation: Add 36.5kg of 55.0% (wt%) hydrofluoric acid to the iron-removing aluminum filtrate obtained in step C, stir and react at room temperature for 60min, control the pH of the reaction syste...

Embodiment 3

[0071] A. Battery dismantling: Lithium-containing powder is separated from waste lithium batteries through discharge, dismantling, sorting, crushing and other processes;

[0072] B. Acidizing leaching: 100Kg of lithium-containing powder (Li% 6.8%) obtained in step A was adjusted into a slurry with 400Kg of pure water, and then 377Kg of 65% nitric acid and 66Kg of 50% hydrogen peroxide were added to the slurry, and then the Leach for 45min, obtain leachate and acid leaching residue after pressure filtration;

[0073] C. Iron removal and aluminum removal: add calcium hydroxide to the leaching solution obtained in step B, adjust the pH of the solution to 6.0, obtain 800.0L iron and aluminum filtrate after pressure filtration (the Li in the analysis filtrate is 8.3g / l);

[0074] D. Lithium fluoride precipitation: Add 67.4kg of 98.0% (wt%) potassium fluoride to the iron-removing aluminum filtrate obtained in step C, stir and react at room temperature for 30min, control the pH of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com