Method for filling and mining after ore caving

It is a technology of filling mining and mine collapse, which is applied in the direction of filling, ground mining, mining equipment, etc. It can solve the problems of high impact force, high labor intensity, and high consumption of blasting materials in the lower triangular pillar, so as to reduce impact damage, The effect of improving work efficiency and improving the recovery rate of mineral resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

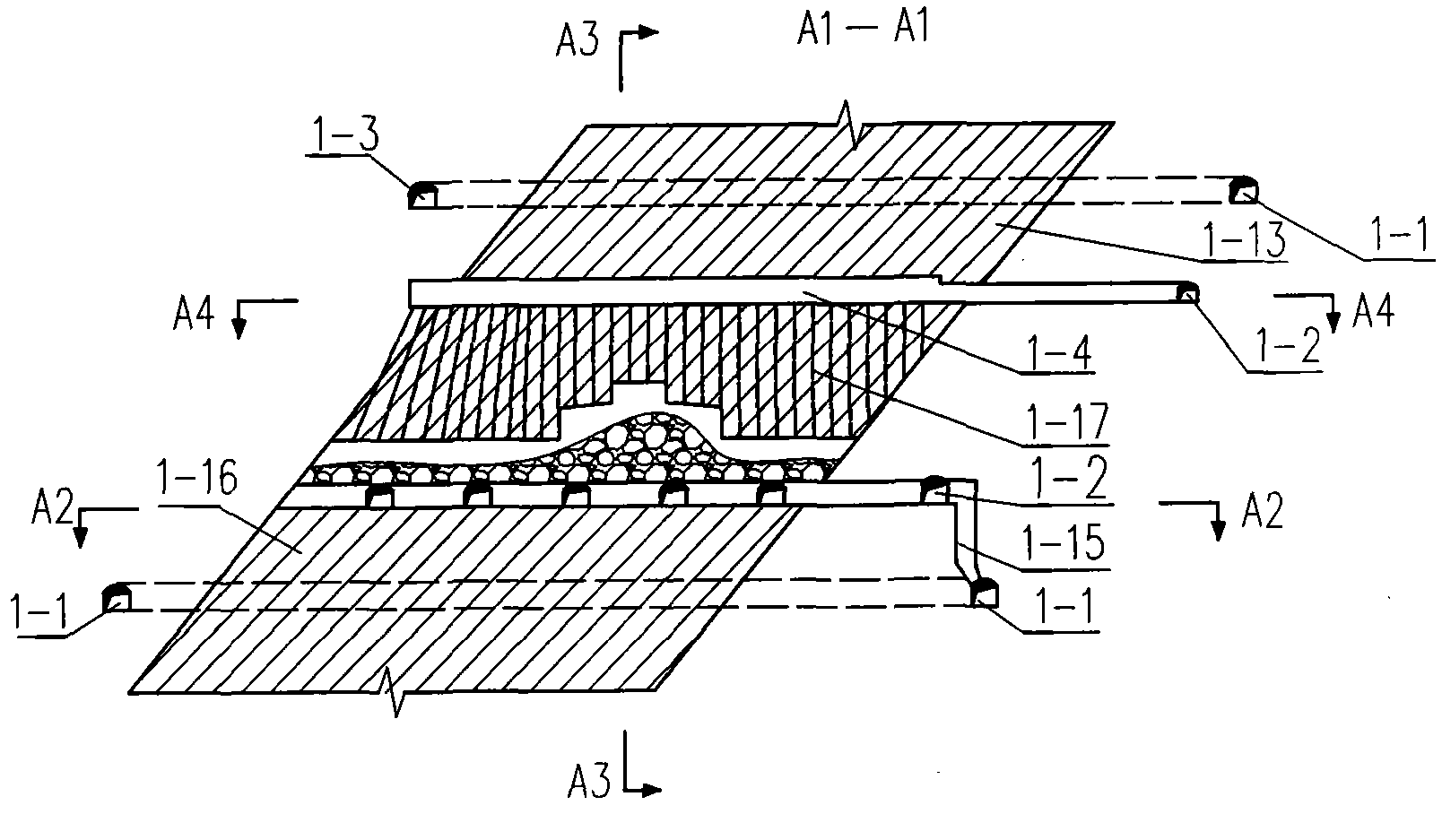

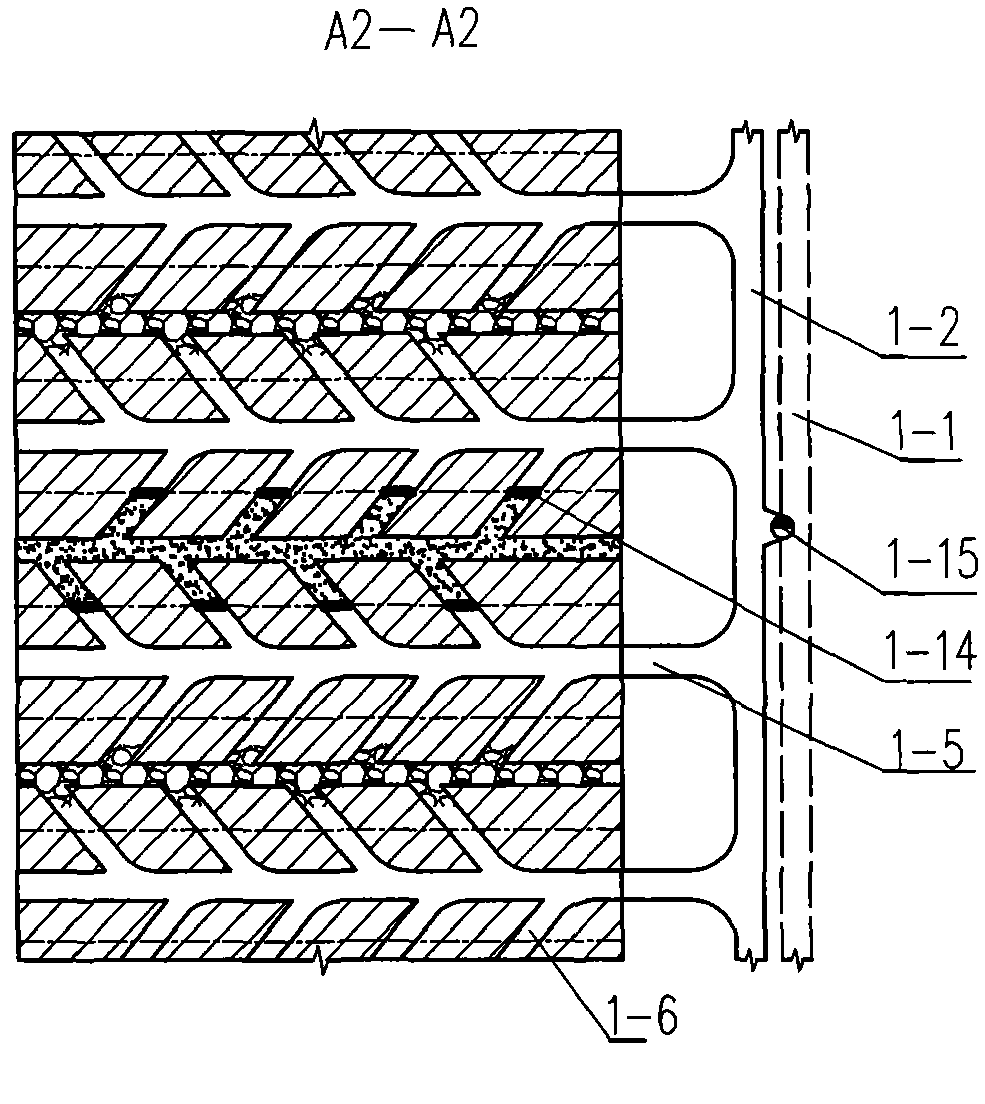

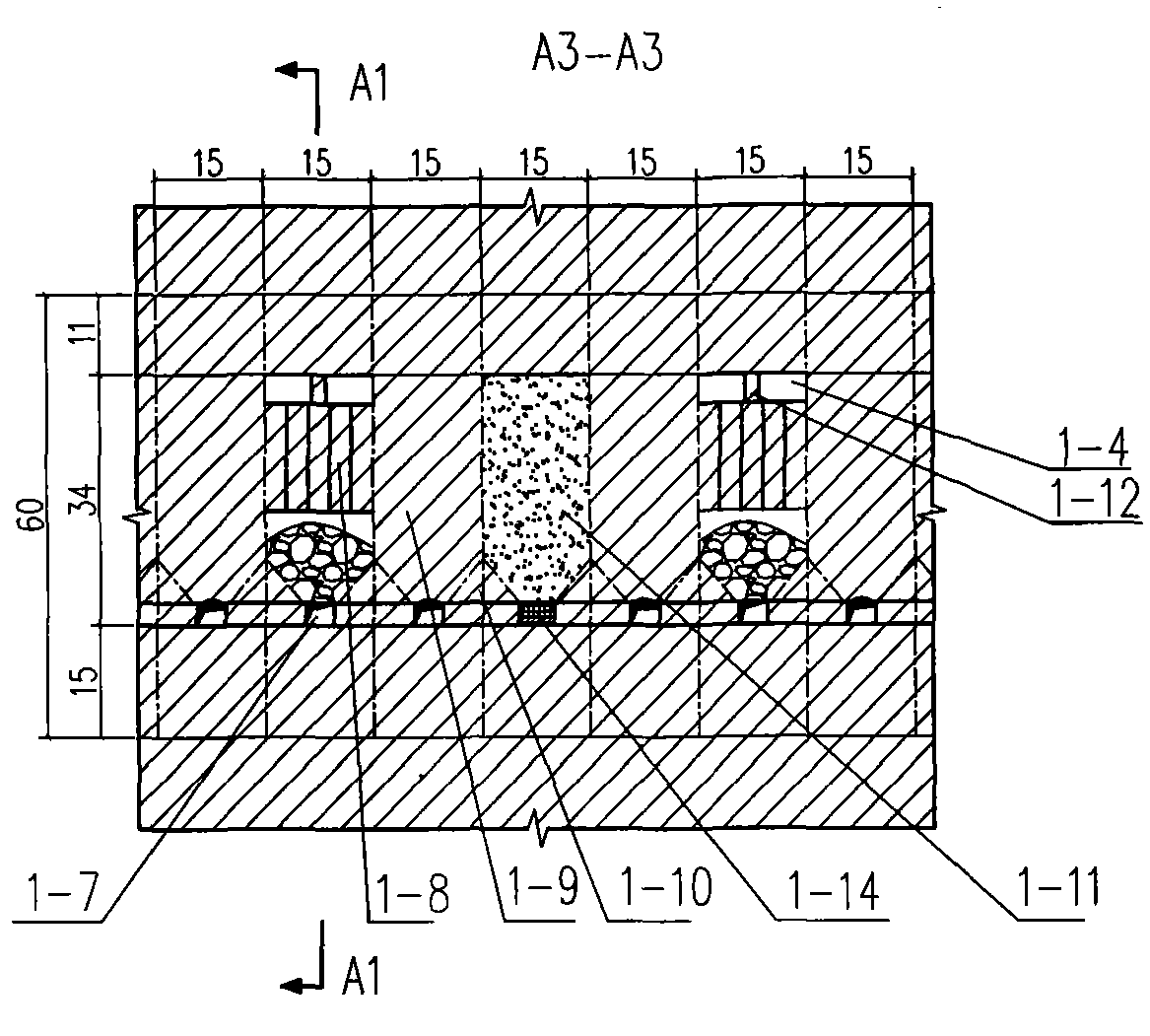

[0084] Below in conjunction with accompanying drawing, take an iron ore as embodiment, describe in detail.

[0085] The ore block layout and structural parameters of this embodiment:

[0086] Stage height: 120 meters, including the upper and lower rock drilling levels;

[0087] Ore block length: The average thickness of the ore body is 70 meters, that is, the vertical distance of the mine house:

[0088] The width of the ore block: 36 meters. The ore block is divided into mine room and ore pillar. When mining, it is mined in two steps, each with a width of 18 meters;

[0089] Pillar thickness: 0 meters;

[0090] Bottom column height: 15 meters.

[0091] Embodiment The main mining object of iron ore is the part between -170 and -410 meters level within the scope of mining rights.

[0092] EXAMPLES The iron ore mines are exploited using shafts. A total of seven vertical shafts are arranged, namely the main shaft, No. 1 auxiliary shaft, No. 2 auxiliary shaft, south auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com