Method for reinforcing drop shaft in underground mine producing area

A technology of chute and mining area, which is applied in the field of reinforcement of chute in underground mine mining area, can solve the problems of short service life, low impact resistance, low support strength, etc., and achieve good wear resistance, good elasticity and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

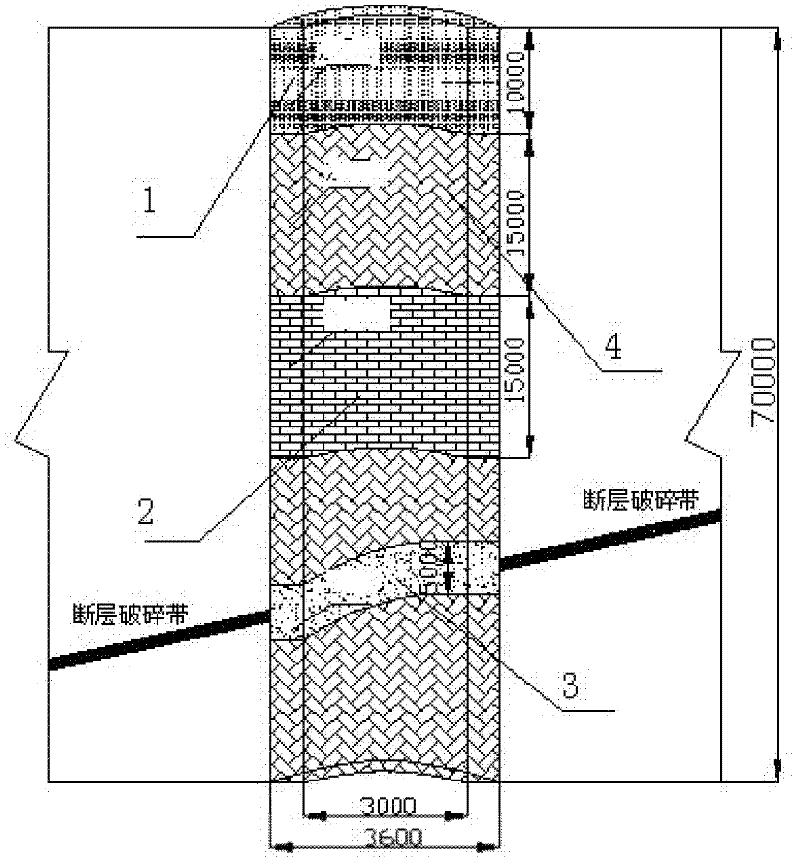

[0032] Implementation 1: Reinforcement of the 70-meter-deep underground mining area chute

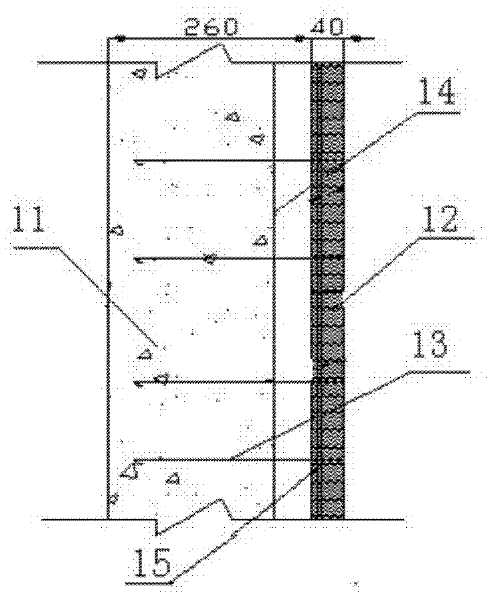

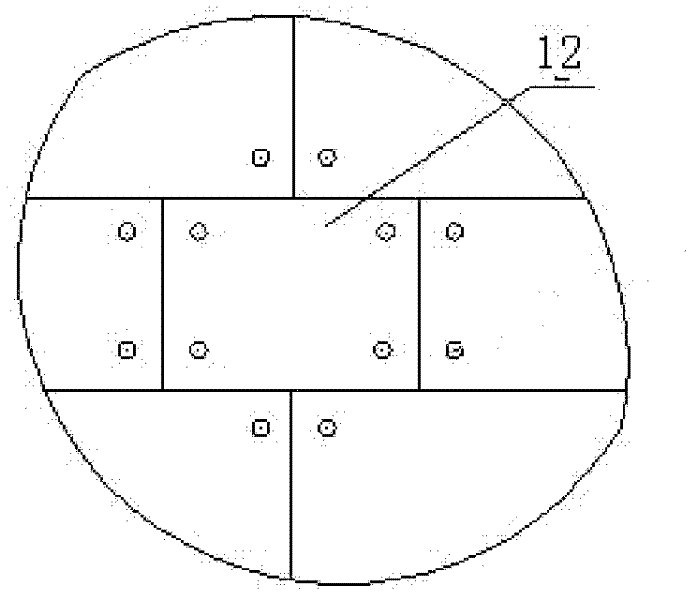

[0033] Firstly, the first impact damage area is within 10m under the ore unloading. The impact damage in this area is mainly affected by the impact of normal loads, and the reinforcement method of rubber plates is adopted; the first lining plate 15 is fixed on the concrete through the first anchor claw 13 On the well wall 11, the first steel bar 14 is arranged between the first anchor claws 13 for reinforcement, and then the rubber liner with a size of 600mm×400mm and a thickness of 40mm is fixed on the first liner 15 by bolts. An impact zone is reinforced (e.g. figure 2 shown);

[0034] Secondly, the range of 25m to 40m below the ore discharge port is the second impact damage. The impact damage in this area is mainly affected by the tangential impact load. The specific parameters of the reinforcement method using high manganese steel plates are as follows:

[0035] First, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com