Patents

Literature

392results about "Upsetting presses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Swaging technology

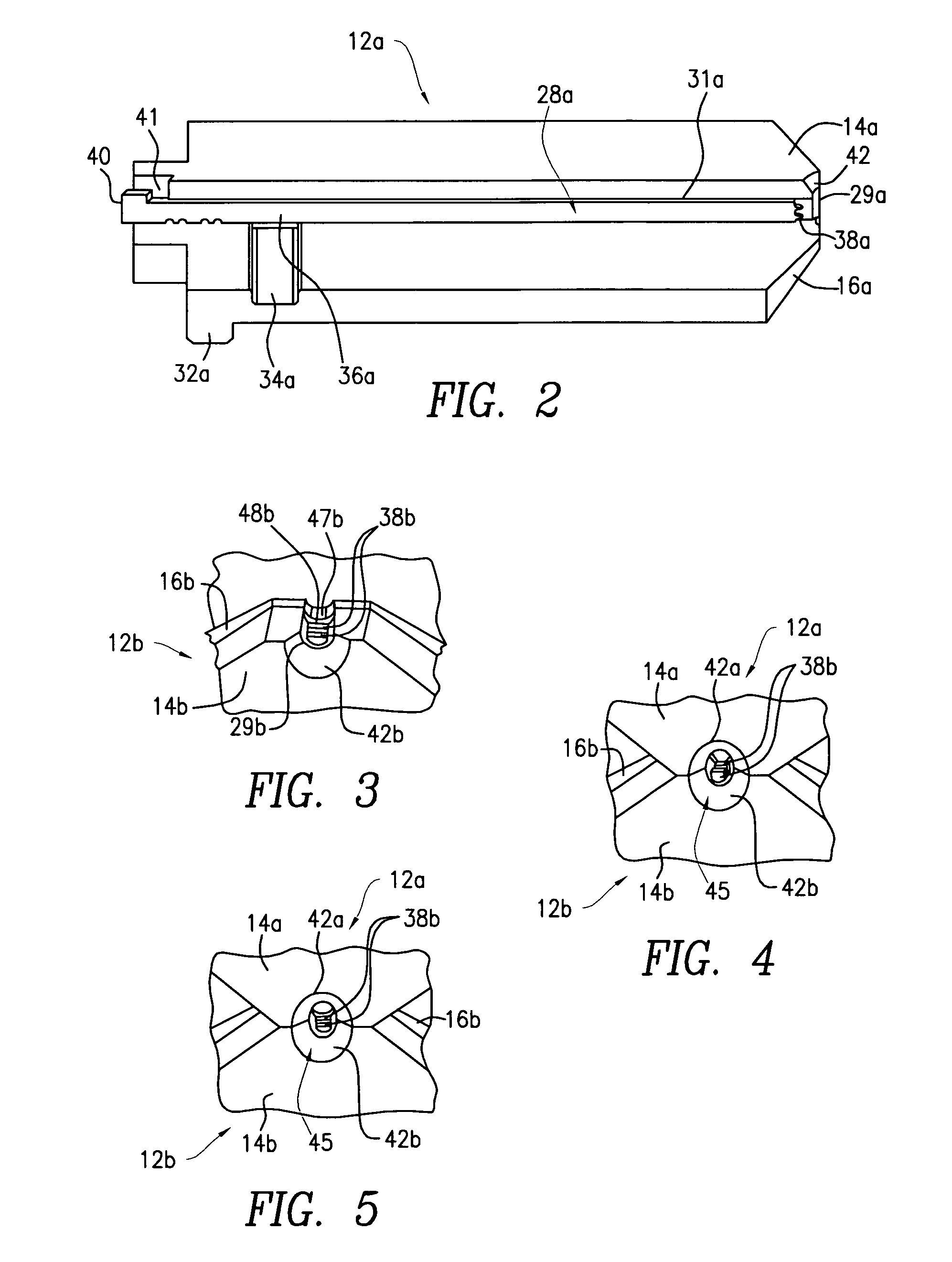

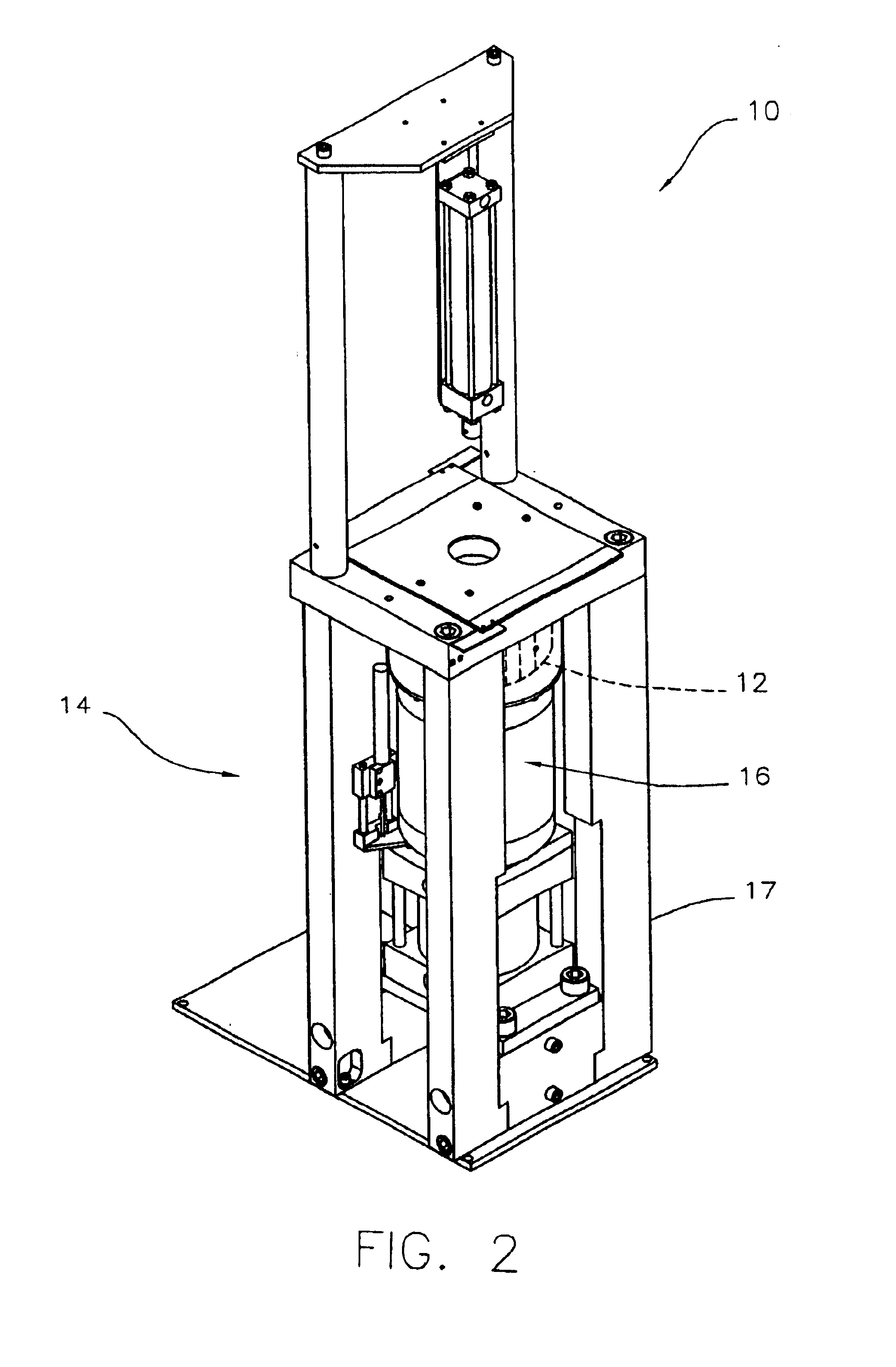

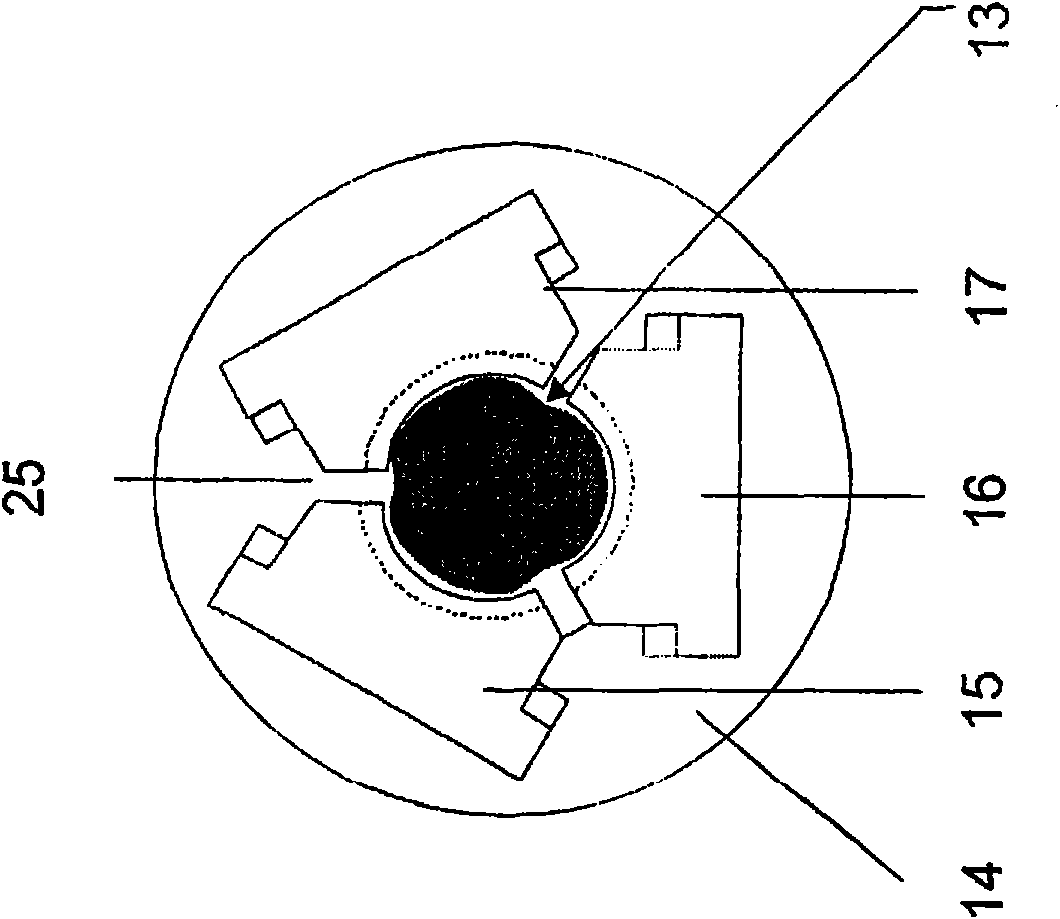

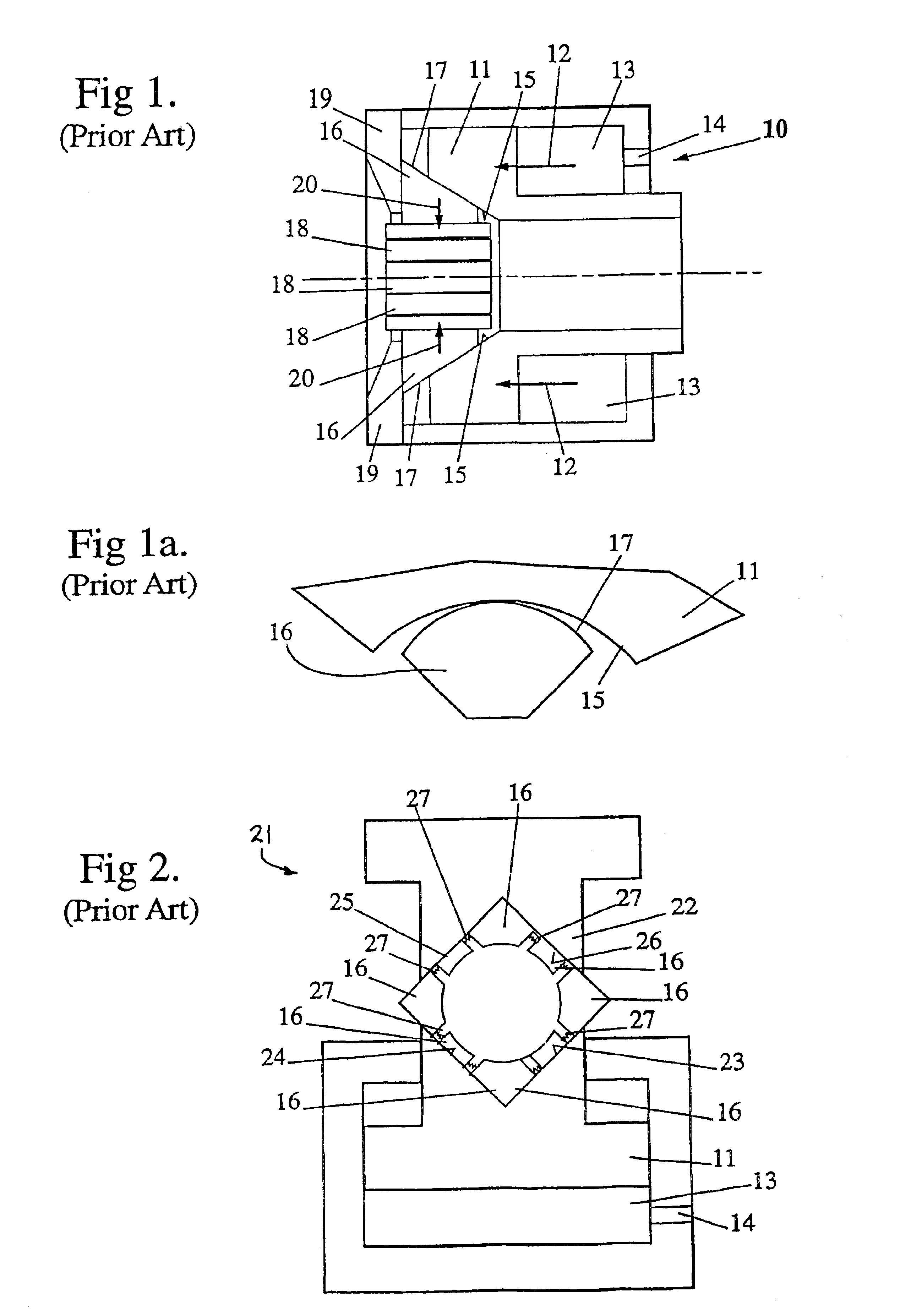

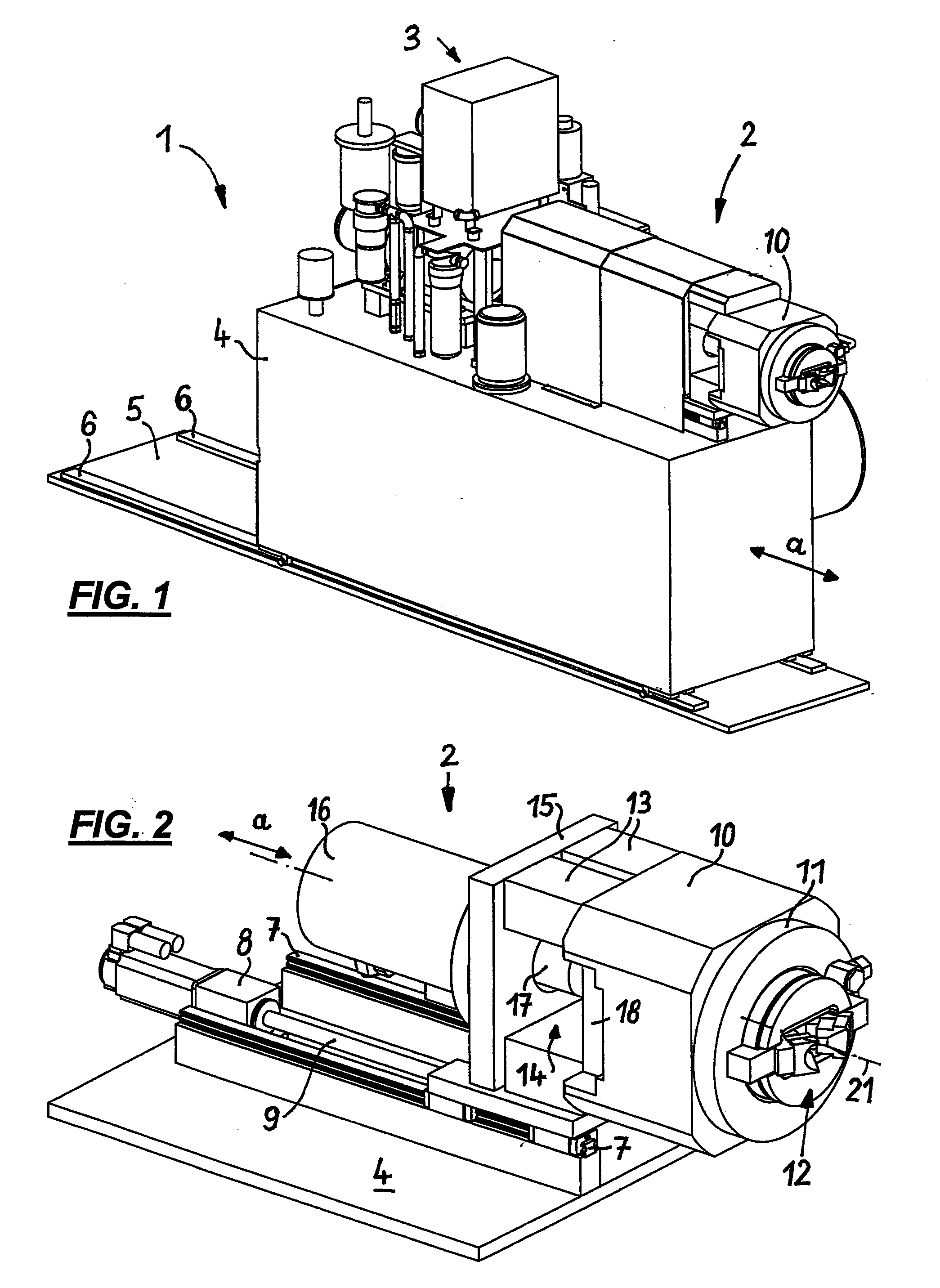

InactiveUS6931899B2Practical and reliable and accurate and efficientForging hammersShaping safety devicesEngineeringCatheter

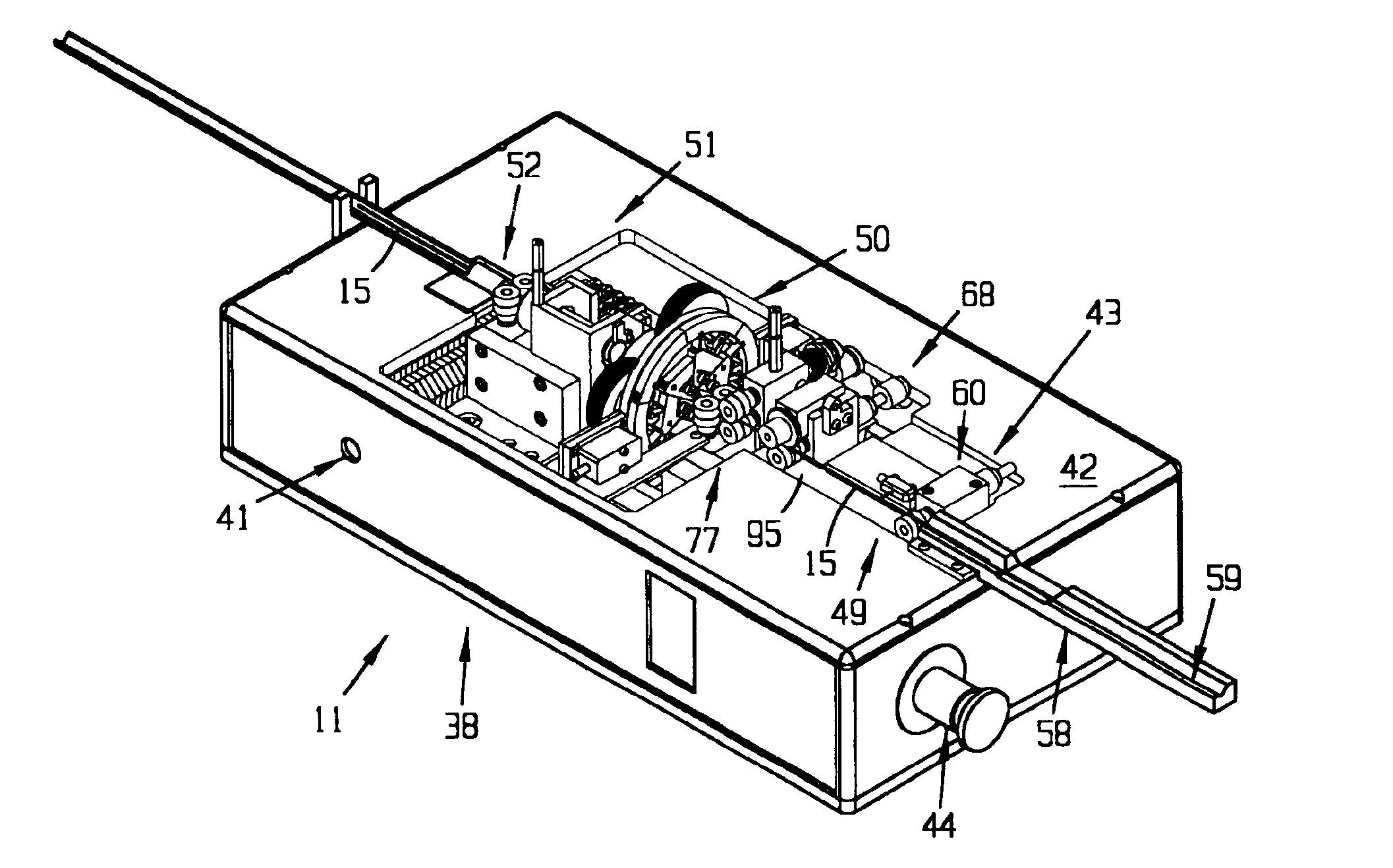

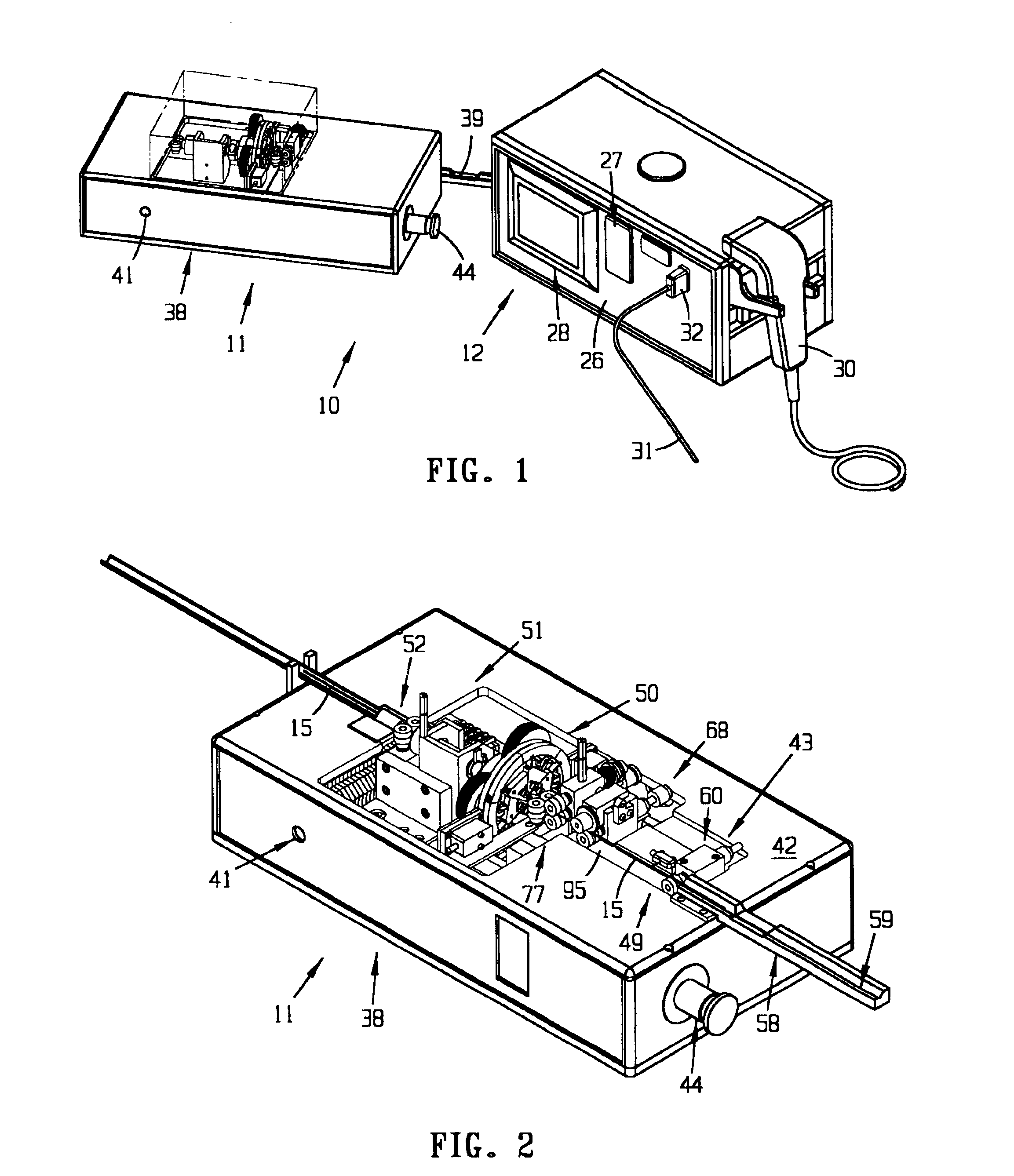

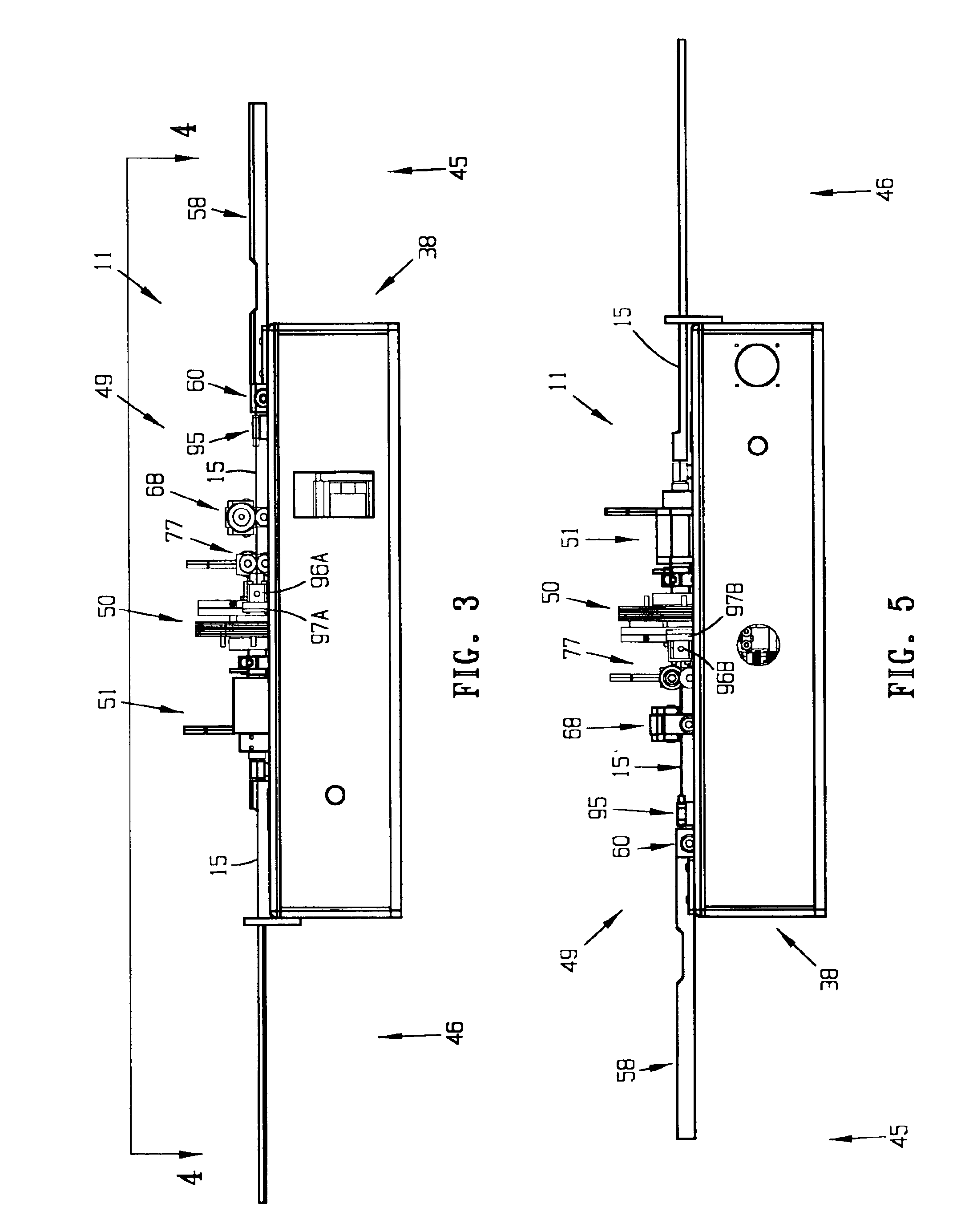

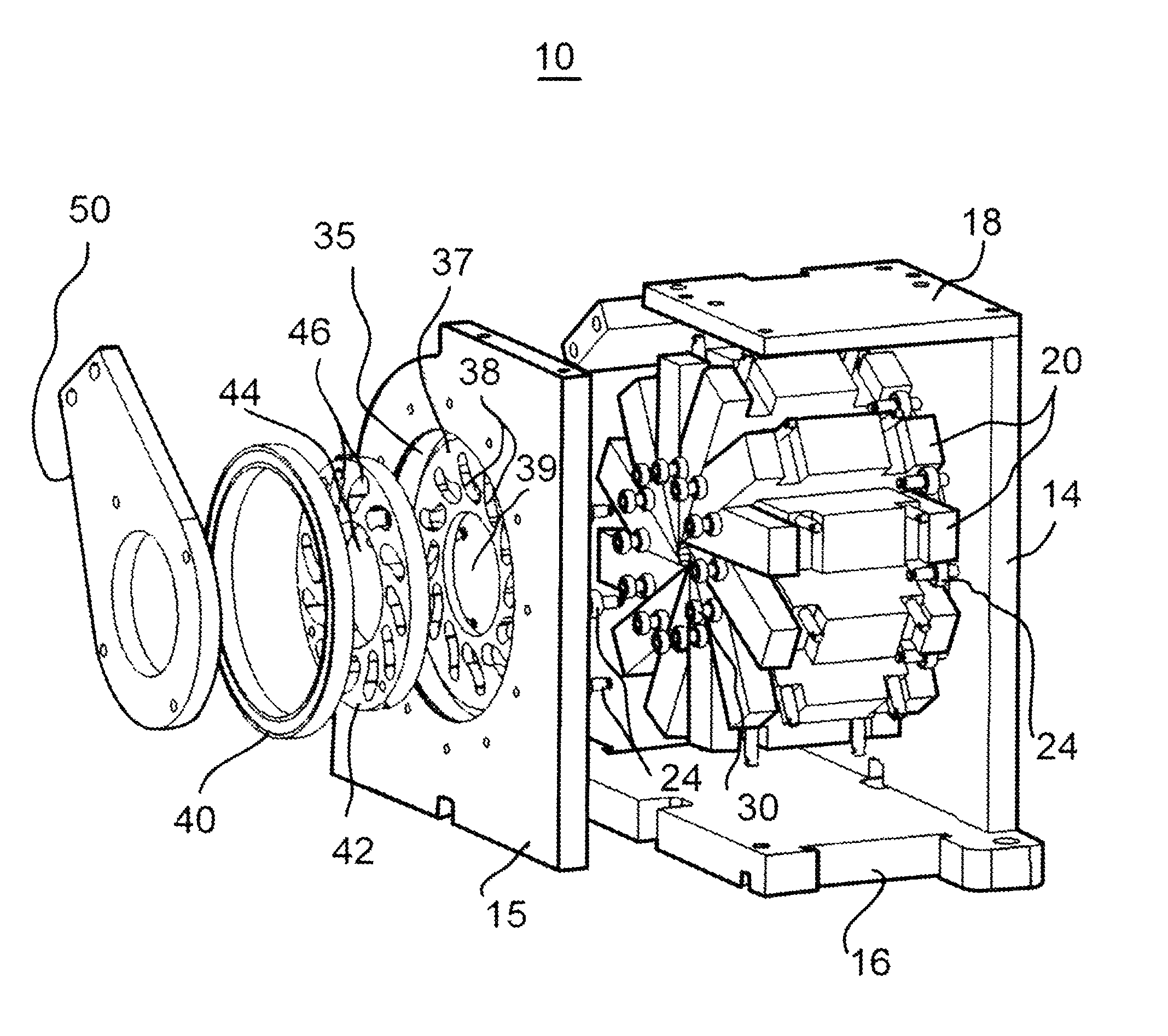

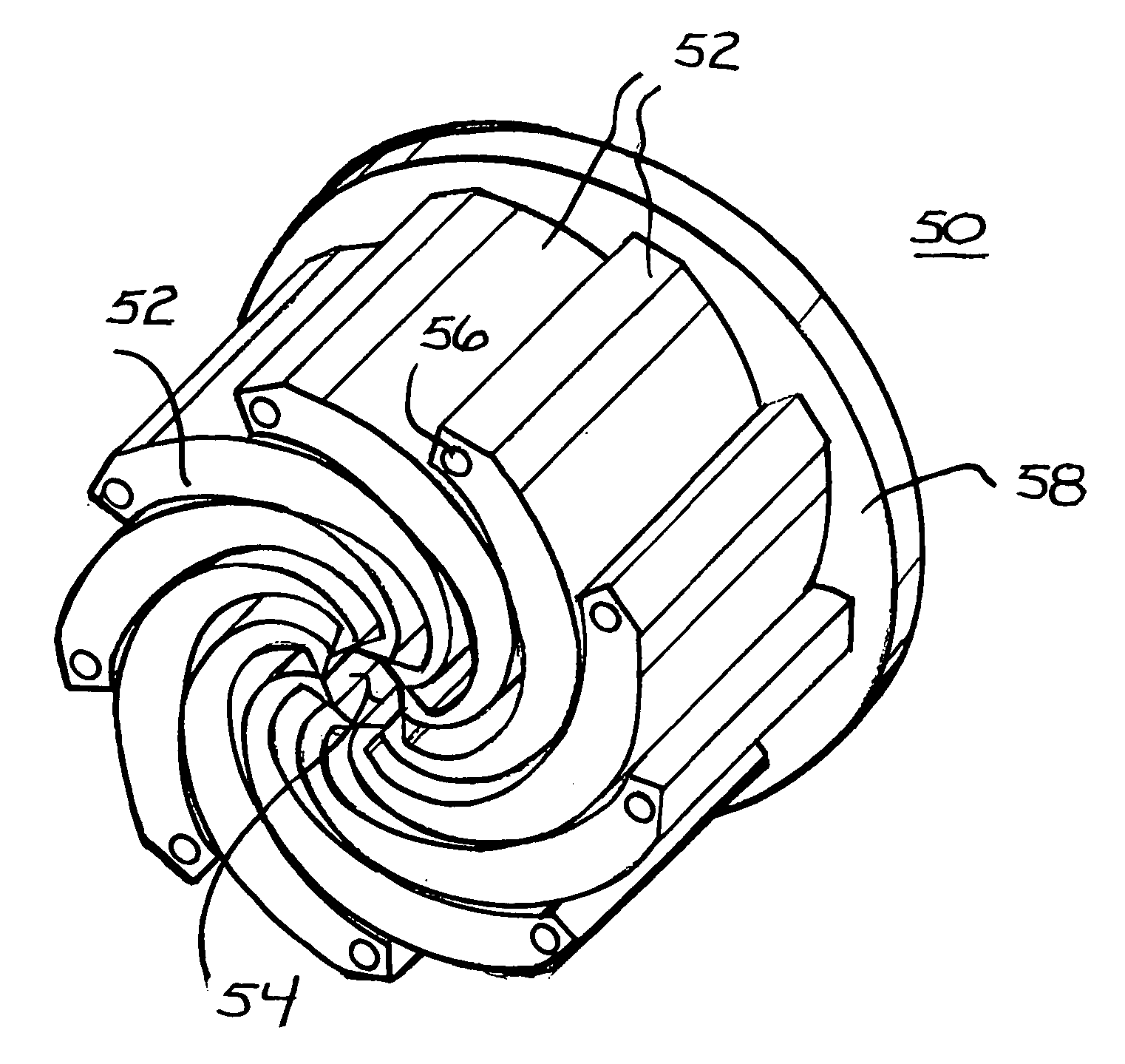

A swager for swaging marker bands to a medical catheter, comprises an article input mechanism, the article input mechanism having a first input roller assembly for receiving and conveying an article, a first sensor for detecting a predetermined aspect of the article, a second input roller assembly for receiving and conveying the article, a positioning roller assembly for precisely aligning the article with respect to the swaging head, and a second sensor all constructed and arranged in a streamwise orientation. The swager also has a radial compression swaging head with a central swaging aperture, the swaging head being aligned and communicatively coupled with the input mechanism to receive an input article from the article input mechanism and to swage the article, the swaging head being rotatable and including (i.) a unitary die plate including a plurality of die segments movably coupled to each other to provide a radial compressive force to the article disposed in the central swaging aperture; and (ii.) a closing plate pivotally coupled with respect to each other. The swager also has an output mechanism aligned and communicatively coupled with the swaging head to receive the swaged article. A swaging head and die are also disclosed.

Owner:MACHINE SOLUTIONS

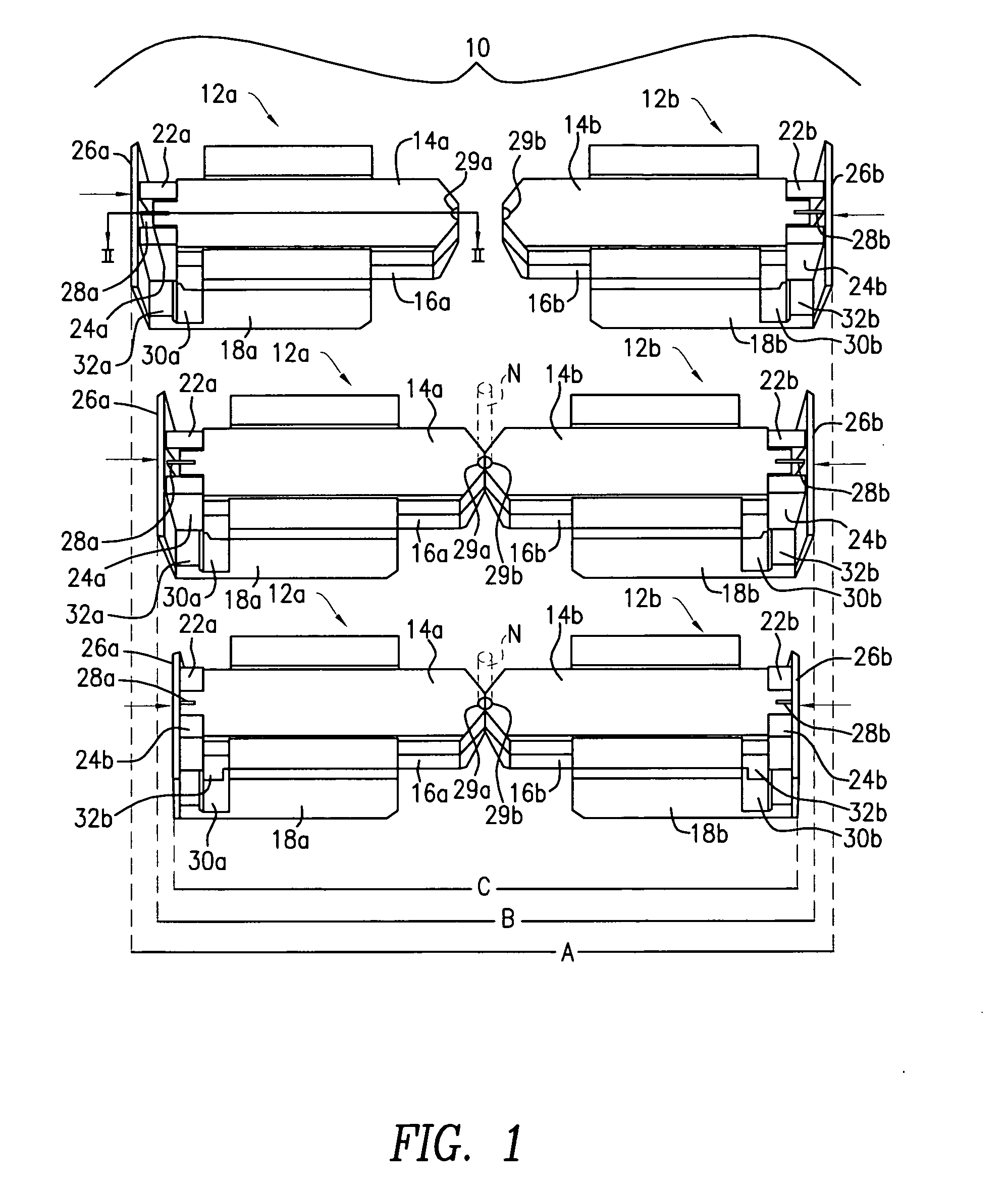

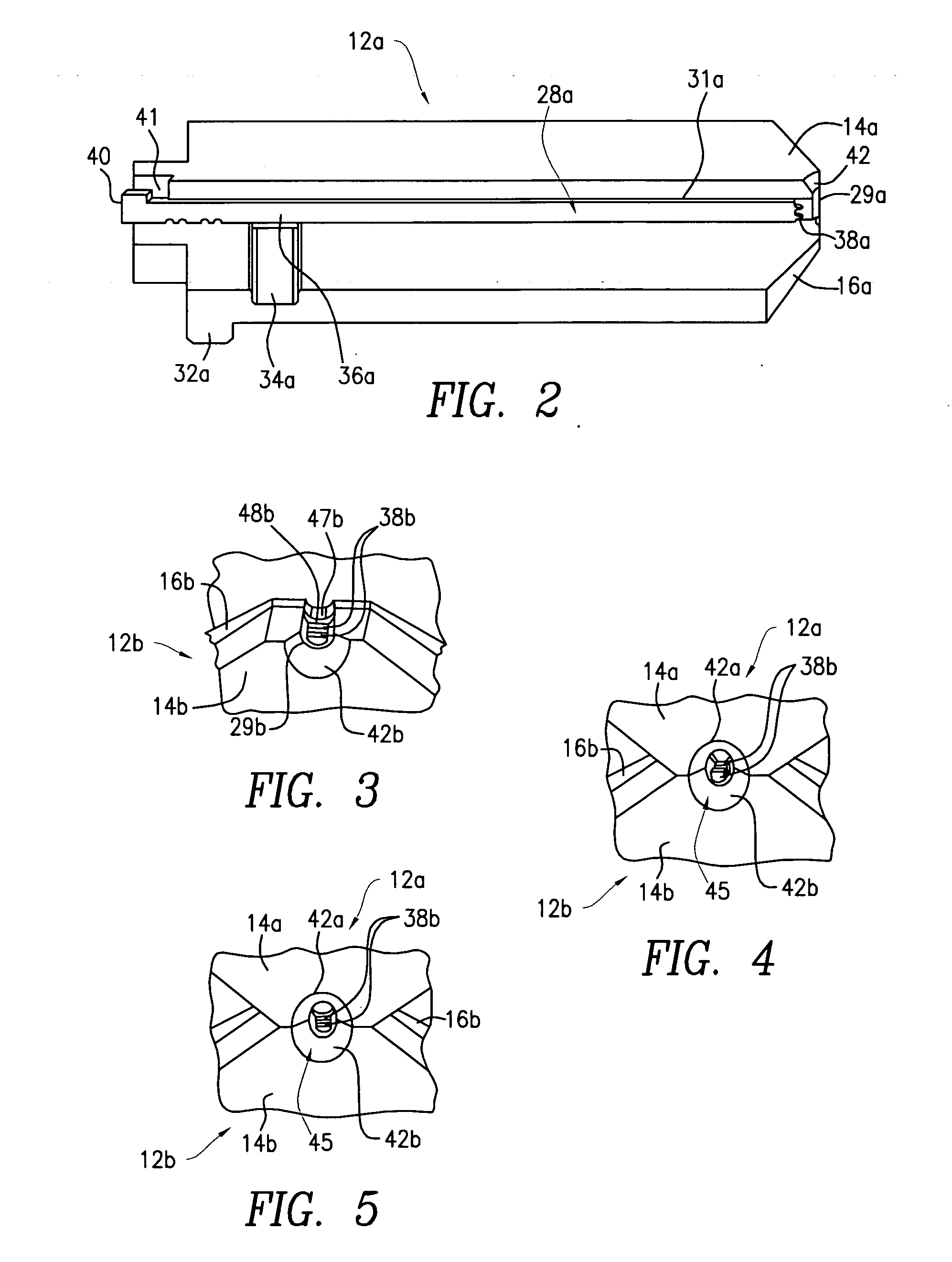

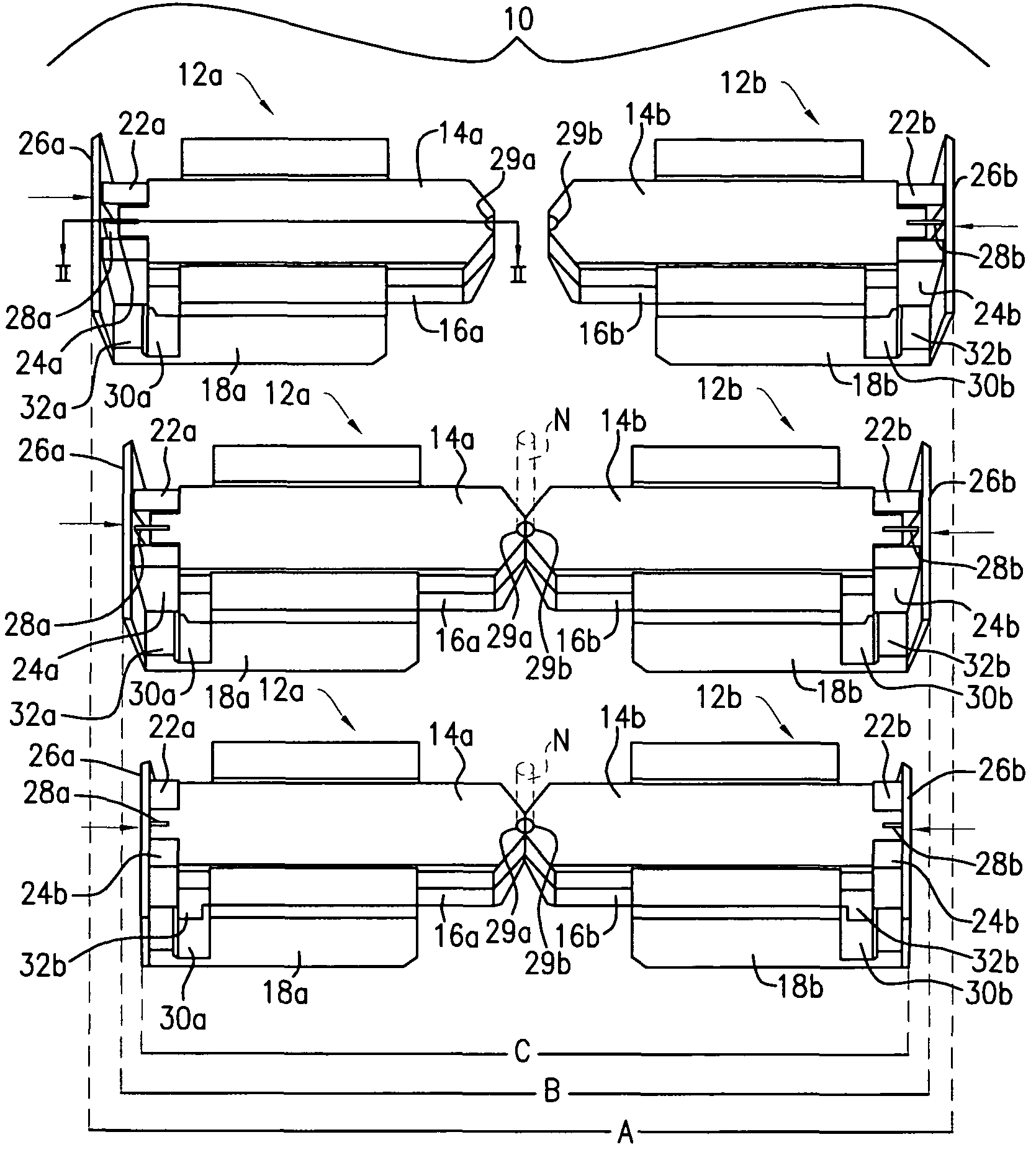

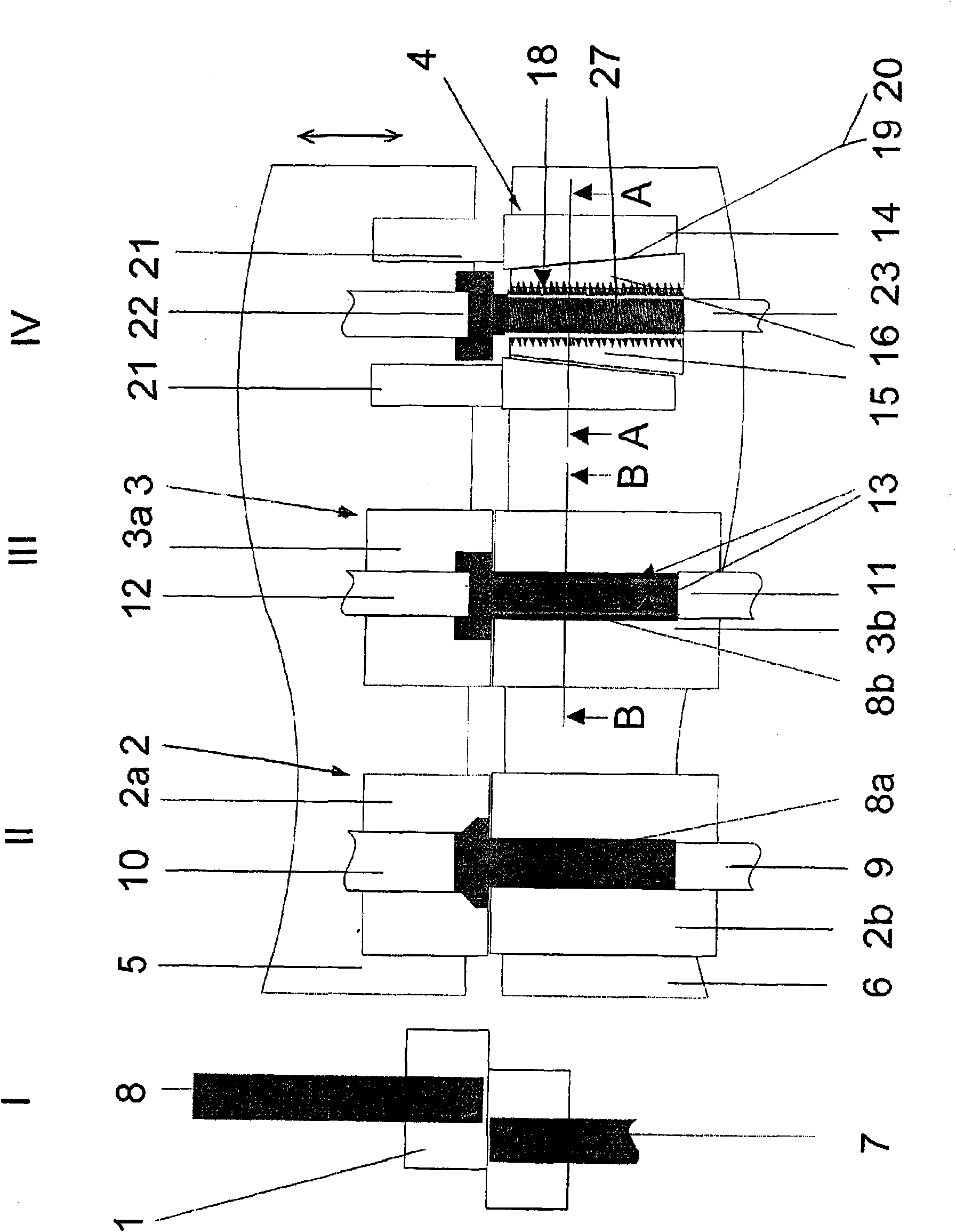

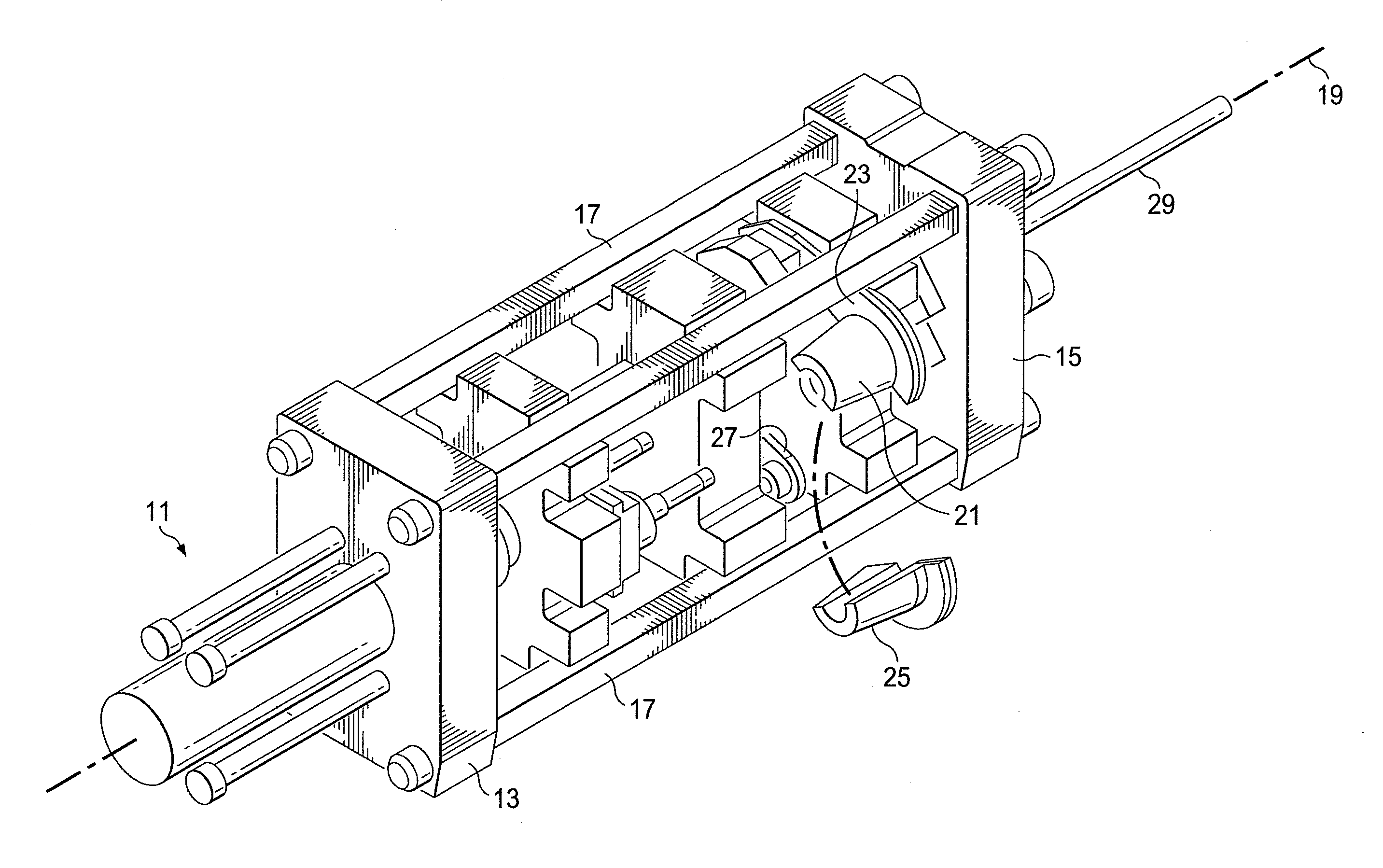

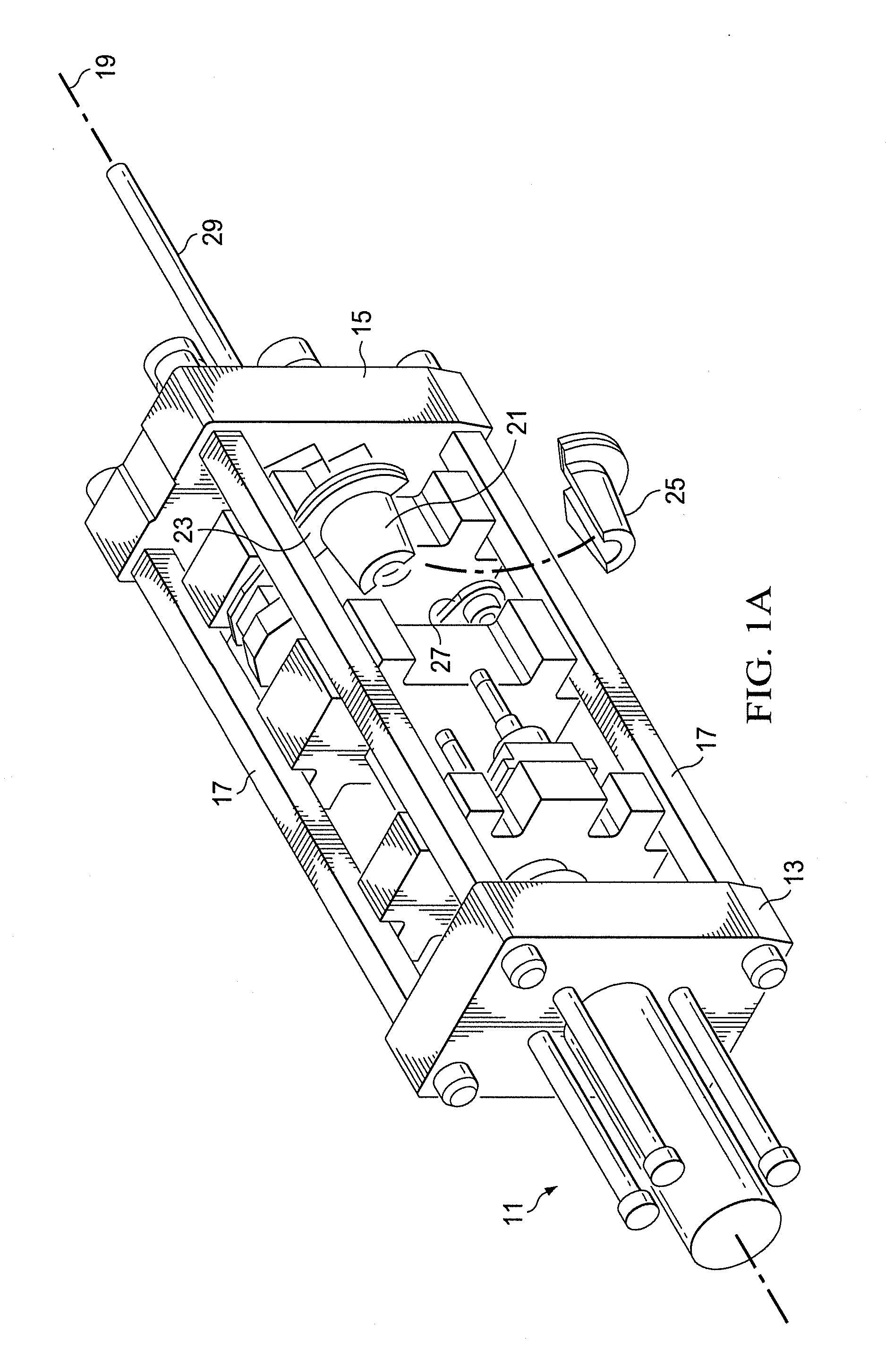

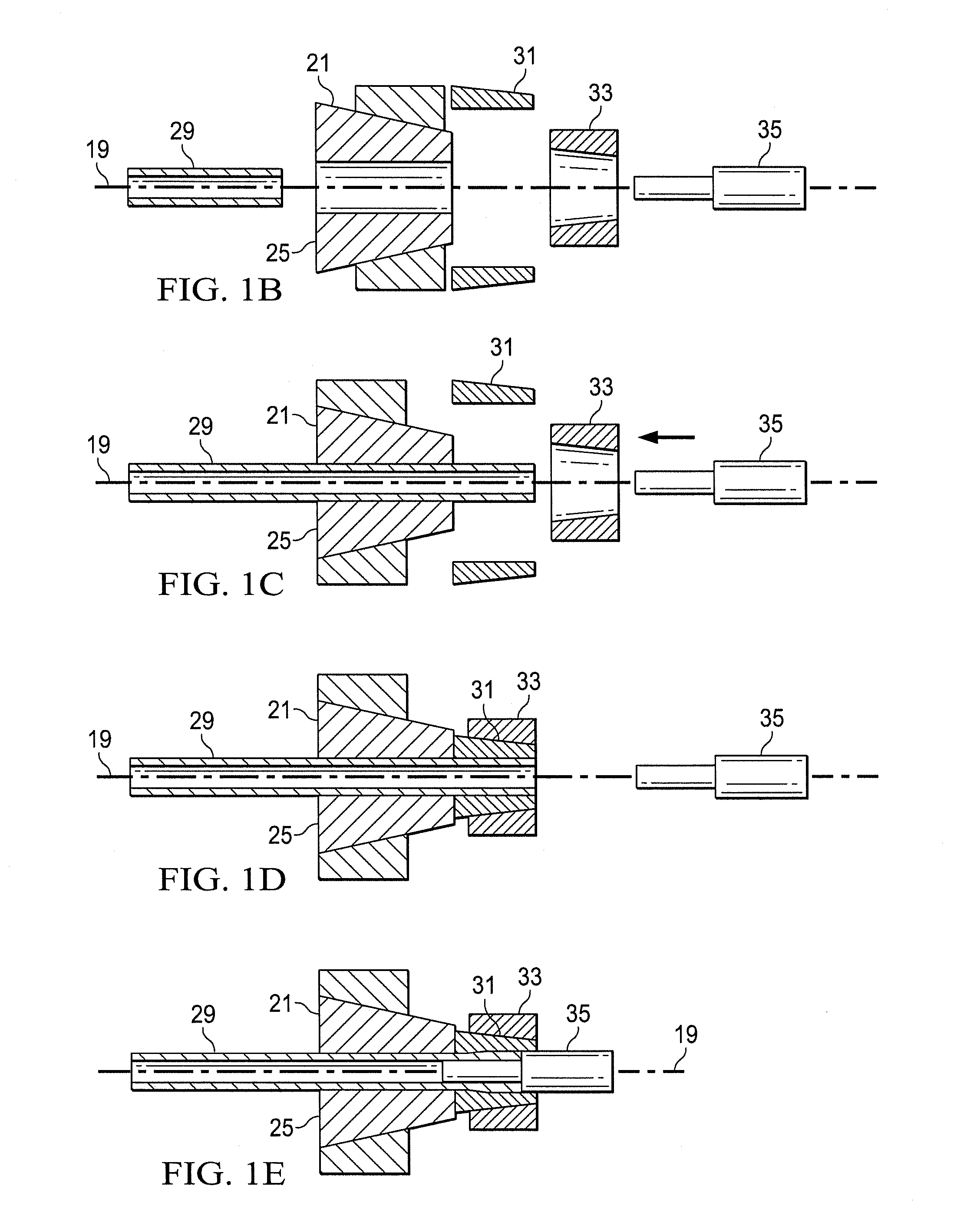

Apparatus and method for swaging needles

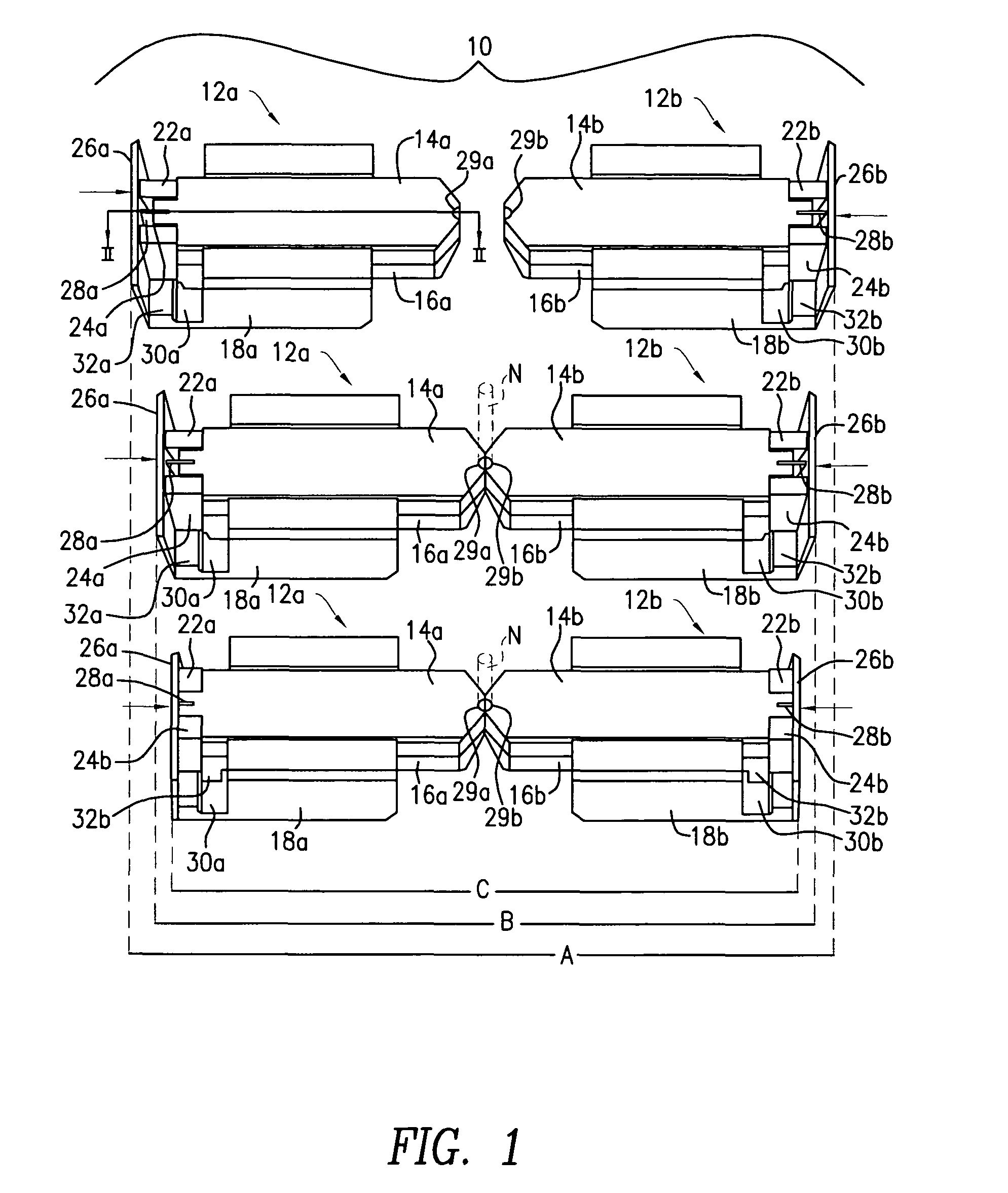

ActiveUS20080119876A1Overcome disadvantagesOvercome problemsSuture equipmentsSurgical needlesSuturing needleEngineering

A method and apparatus for making armed sutures has a pair of opposed die assemblies that may be driven by actuating surfaces of a swaging machine to hold and swage a needle on a suture. The dies grip and confine the needle in the area of the suture receptacle. A pair of opposed swaging elements with offset stakes insert through passageways in the dies and impinge on the captured needle making a plurality of indentations in the needle barrel and gripping the suture in the suture receptacle. The indentations are offset and aligned generally in alternating peak-to-valley relationship, causing the suture receptacle and the contained suture to assume a serpentine configuration. The stakes and the resulting indentations can be dimensioned to result in a converging suture receptacle, which exhibits increasing shear force being exerted on the suture with increasing depth into the suture receptacle. The apparatus and method permit reliable suture-needle attachment over a larger range of tolerances, such that a single die setup can be used on a plurality of needle and suture materials. The resulting product exhibits a serpentine suture / needle attachment interface with reliable attachment and smooth outer dimensions.

Owner:ETHICON INC

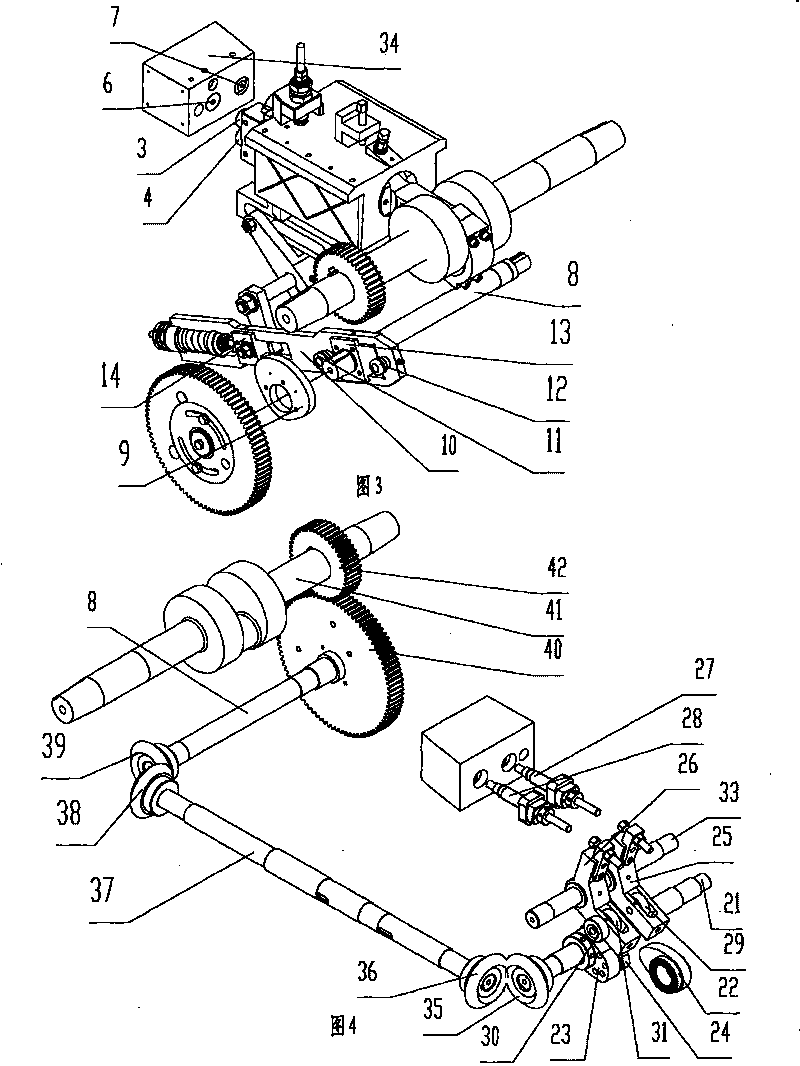

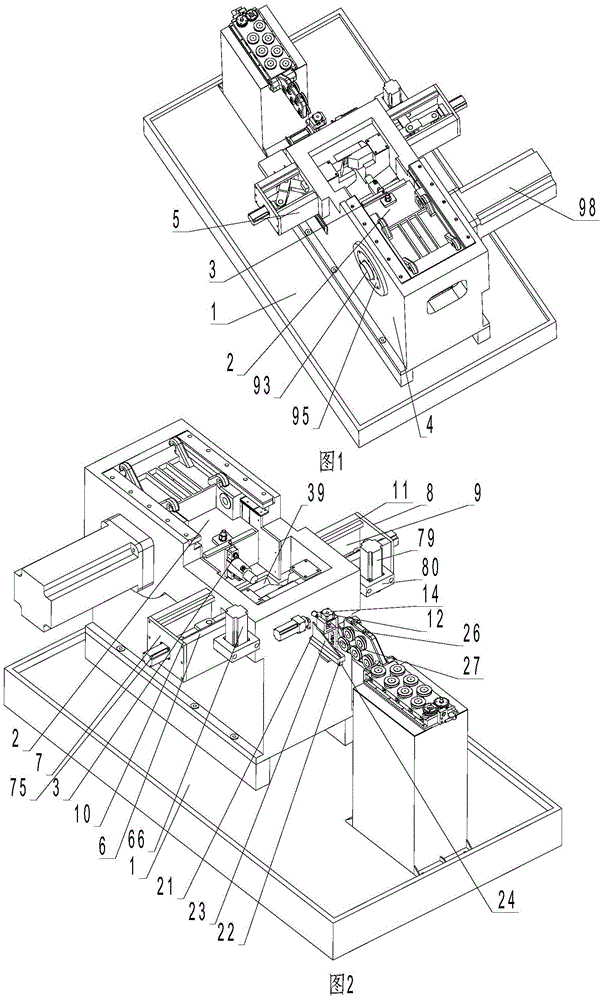

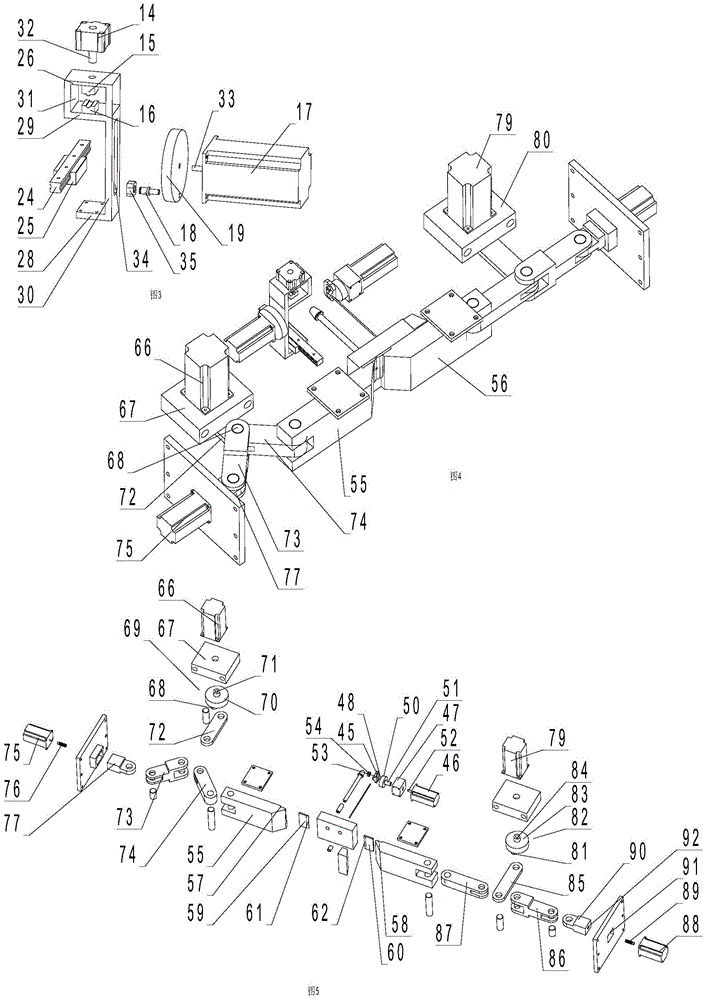

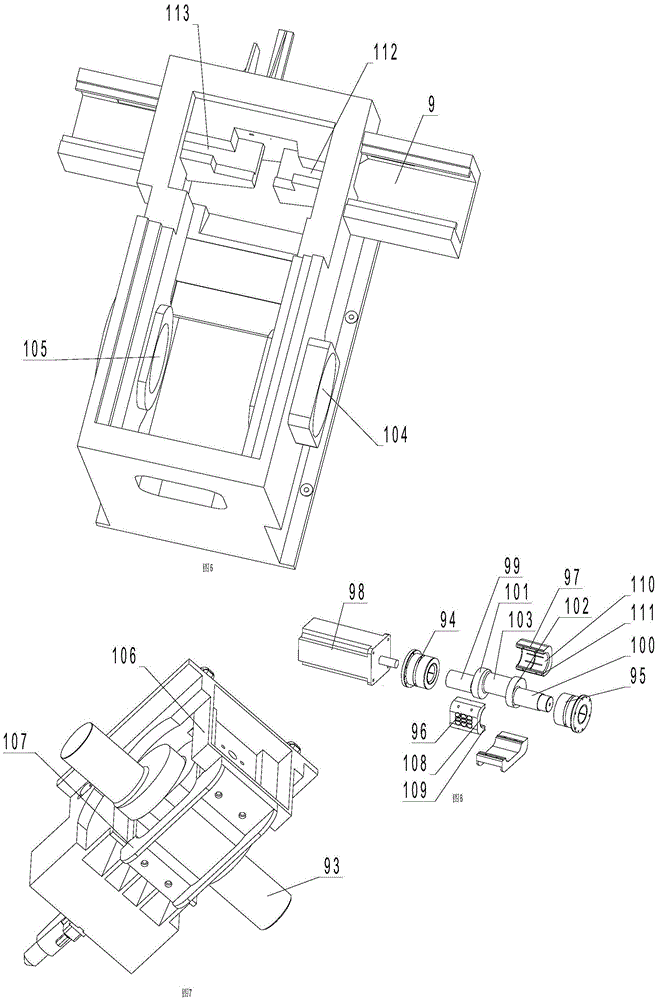

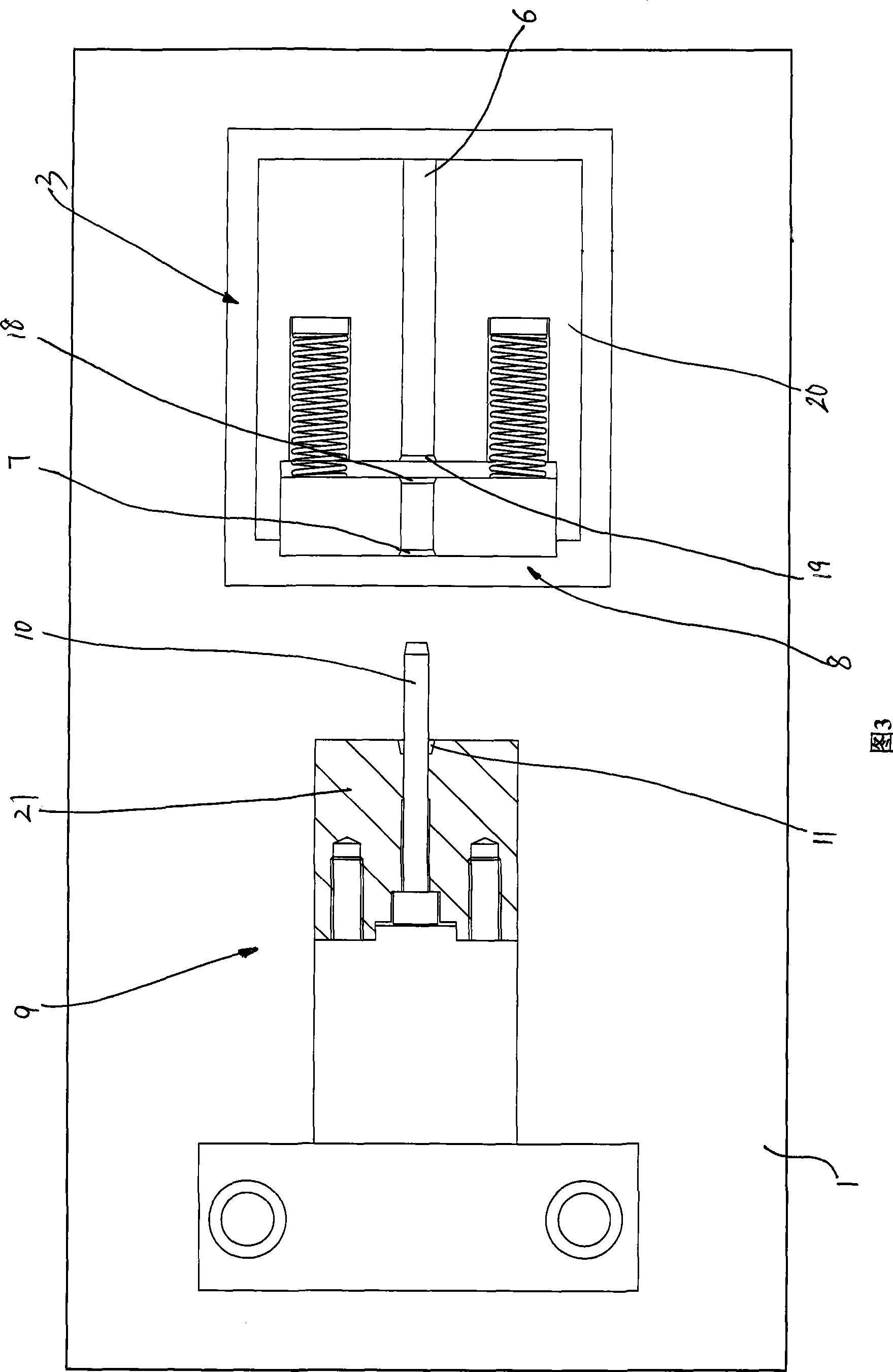

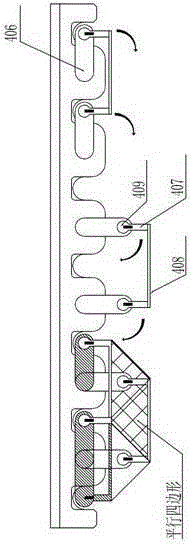

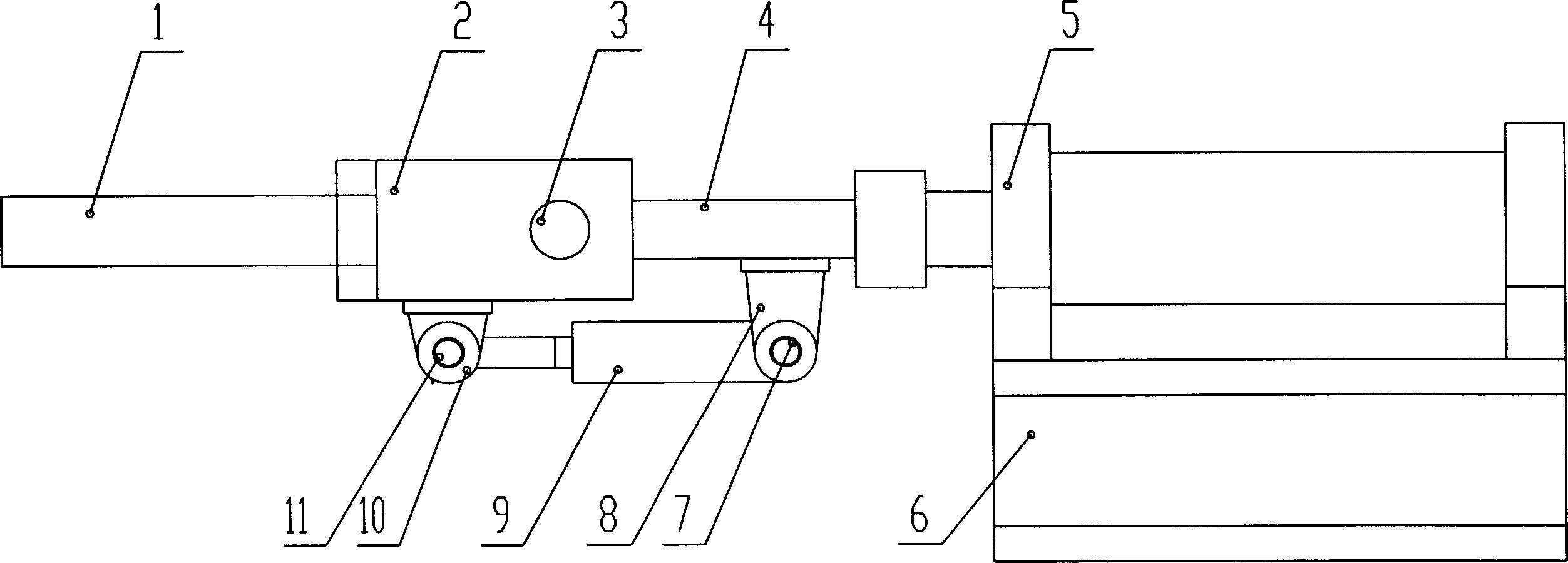

Two-die three-punch upsetter and working method

The invention relates to a two-die three-punch upsetter. A third punch die is a trimming die or a forging and pressing die and is arranged on a large slide block, and a first punch die and a second punch die are arranged on a lifting plate; a first concave die corresponds to the first punch die and the second punch die, and a second concave die corresponds to the third punch die; and axis of the second concave die and the third punch die are oppositely kept on the same straight line all the time. A working method comprises the following steps of: forming a workpiece by rotating a crank shaft twice; when the large slide block is upset for the first time, upsetting a blank into a primary upsetting semi-finished workpiece by the first punch die and preserving the semi-finished workpiece in the first concave die; upsetting a secondary upsetting semi-finished workpiece into a finished workpiece by the third die and ejecting the finished workpiece out; when the large slide block upsets for the second time, upsetting the primary upsetting semi-finished workpiece into the secondary upsetting semi-finished workpiece by the second punch die and ejecting the secondary upsetting semi-finished workpiece out; and air beating by the third punch die. The invention can achieve the functions of various upsetters, such as a one-die two-punch upsetter, an outer hexangular trimming machine, a three-die three-punch upsetter, and the like.

Owner:杨东佐

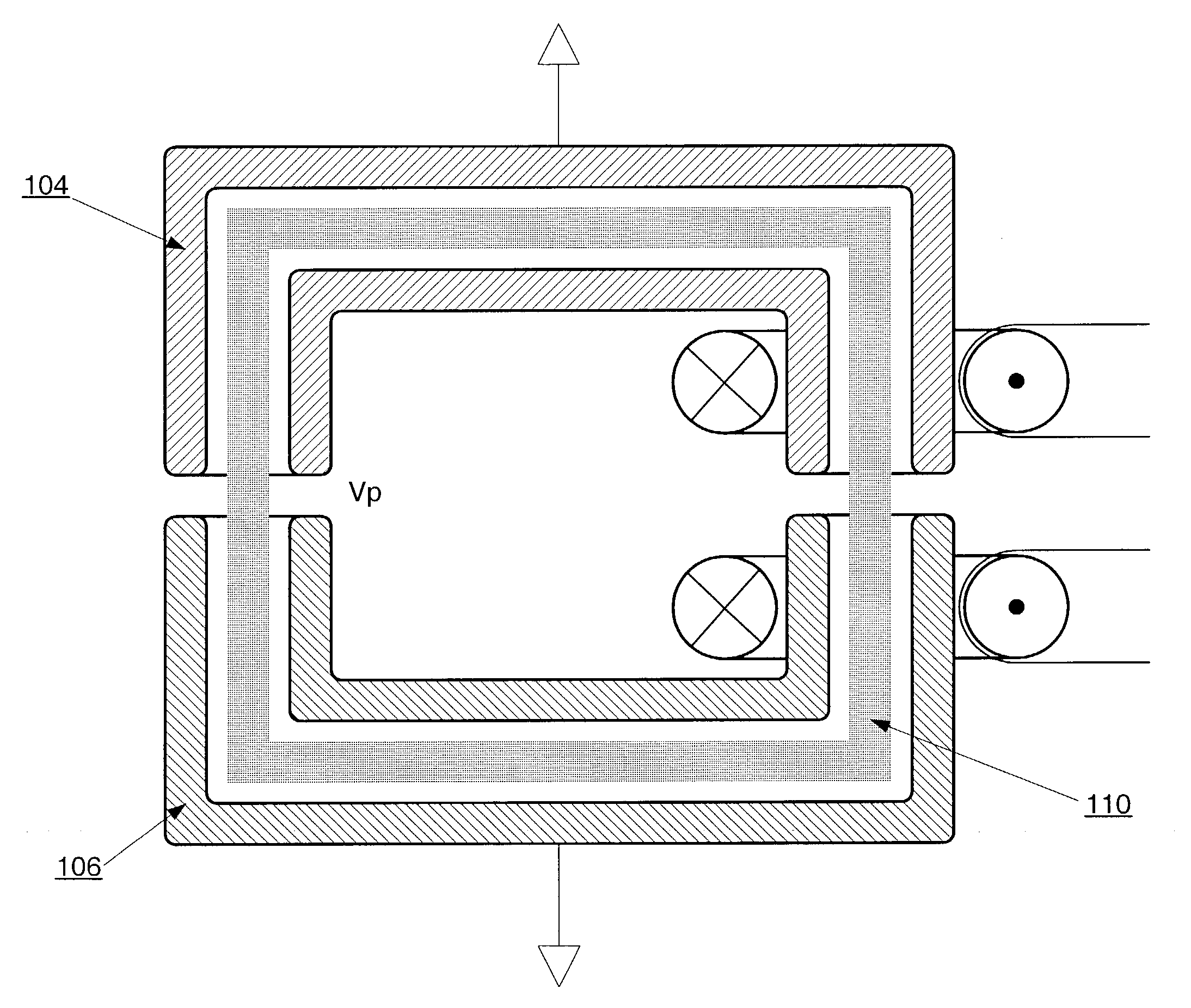

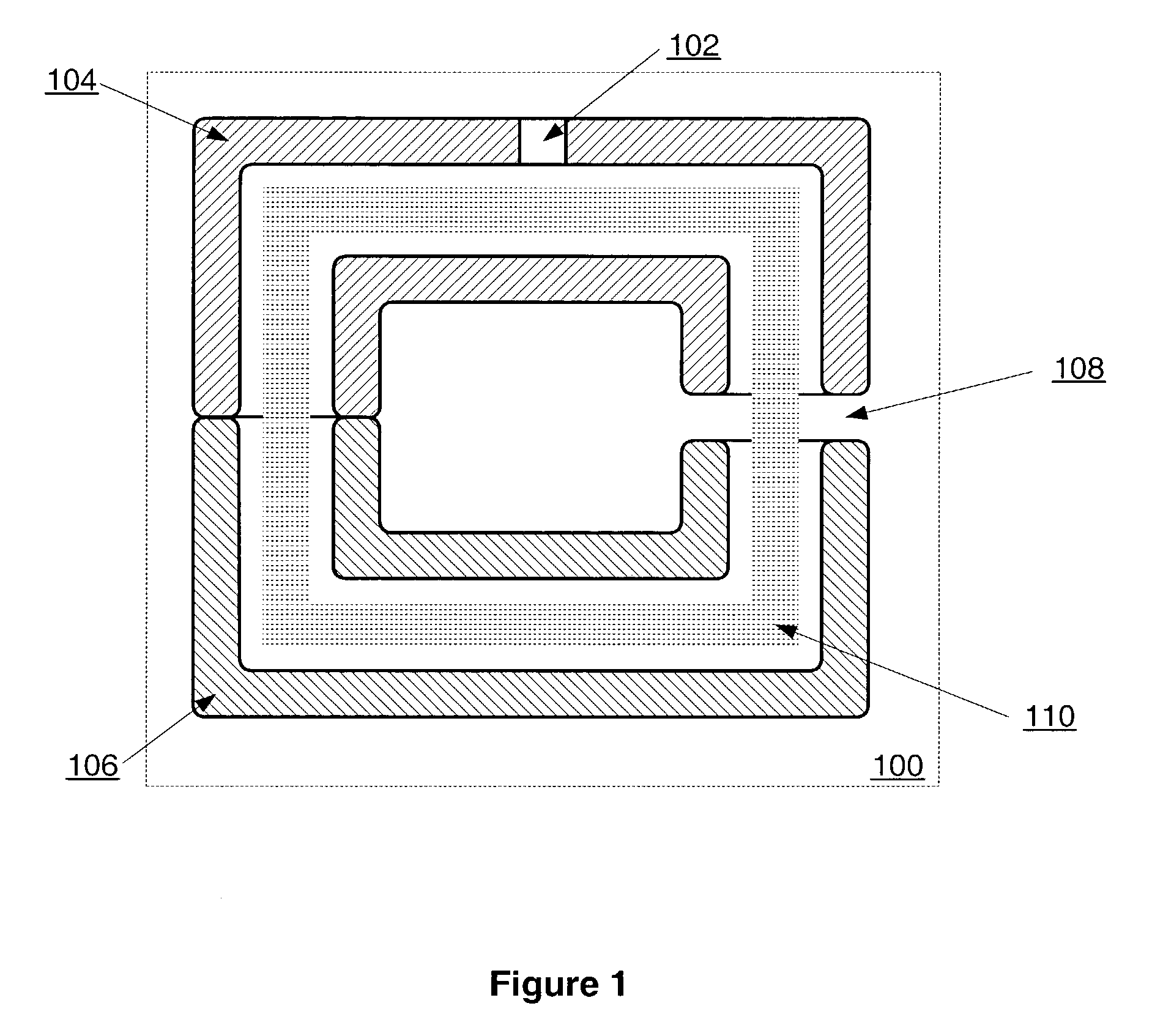

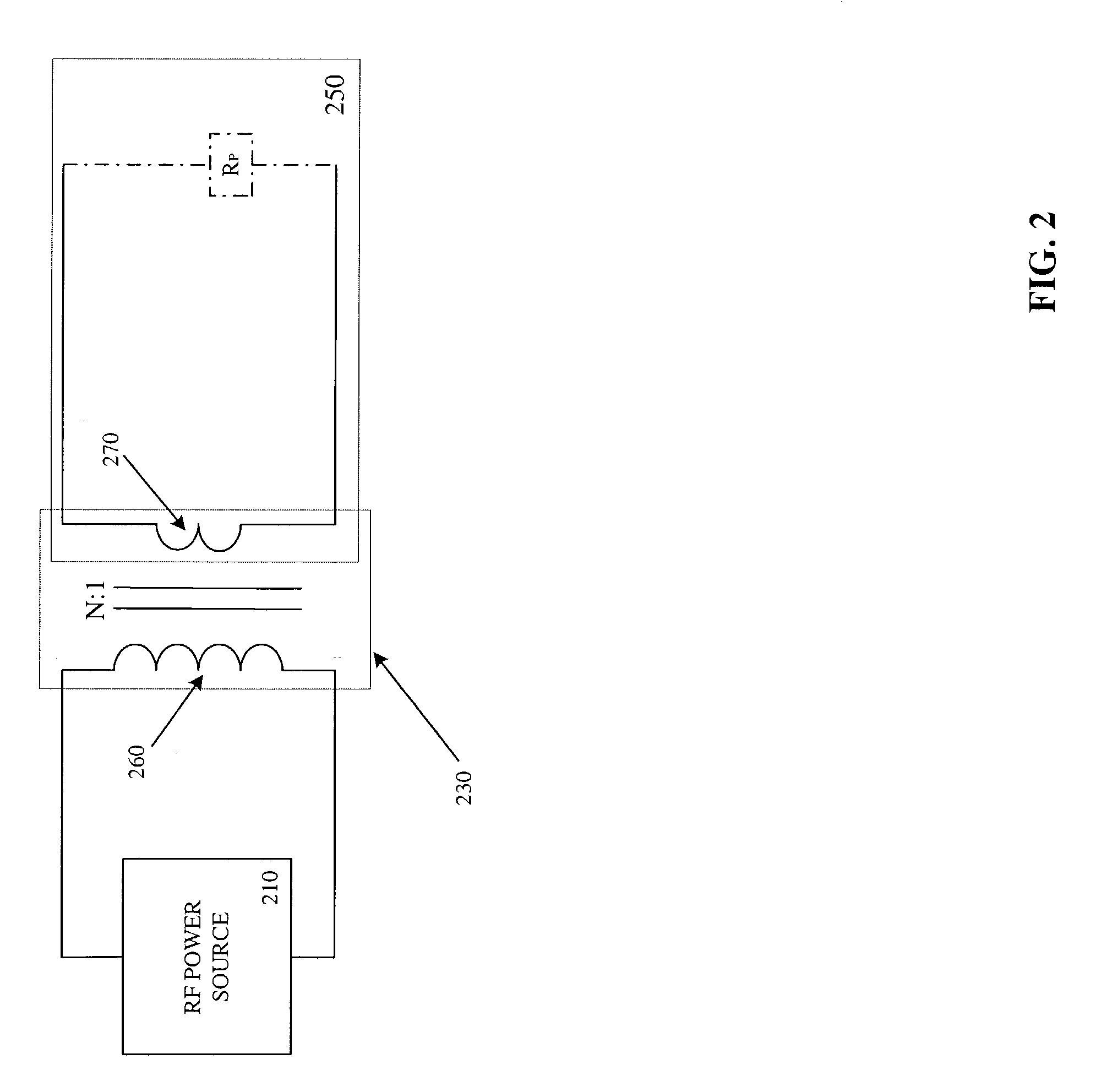

Deterioration resistant chambers for inductively coupled plasma production

InactiveUS6946063B1Improved wall resistanceVacuum evaporation coatingSputtering coatingElectricityIon bombardment

In one aspect of the invention is a method to construct plasma chambers with improved wall resistance to deterioration. In one embodiment of the invention, a chamber is made of an aluminum alloy having low concentrations of elements that form non-soluble, intermetallic particles to address coating / substrate issues, has swaged-in cooling tubes to reduce thermal stress by improving thermal resistance, and has a plurality of dielectric gaps to decrease ion bombardment.

Owner:ADVANCED ENERGY IND INC

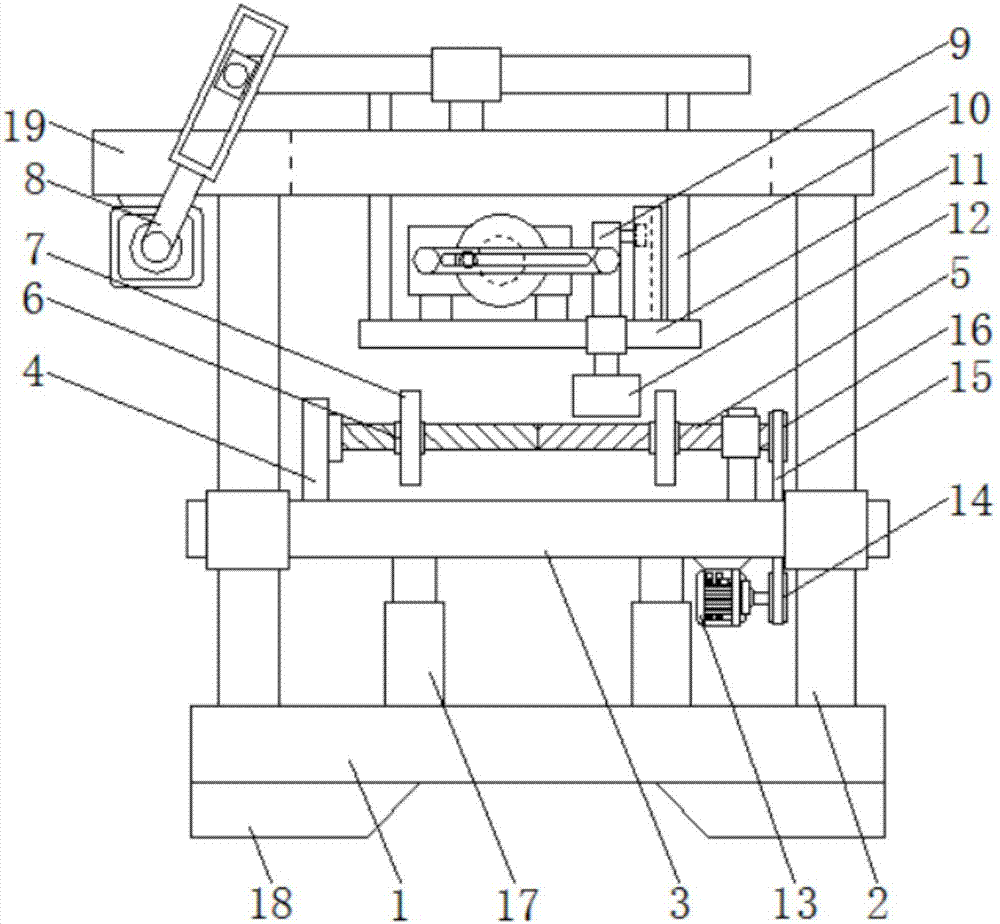

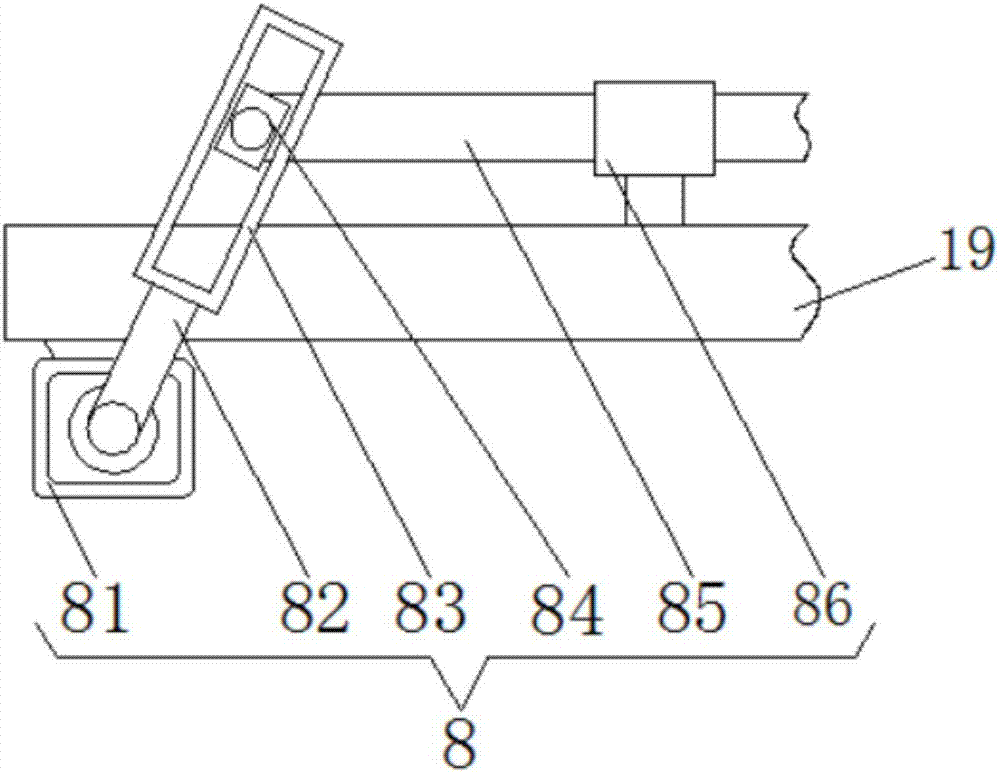

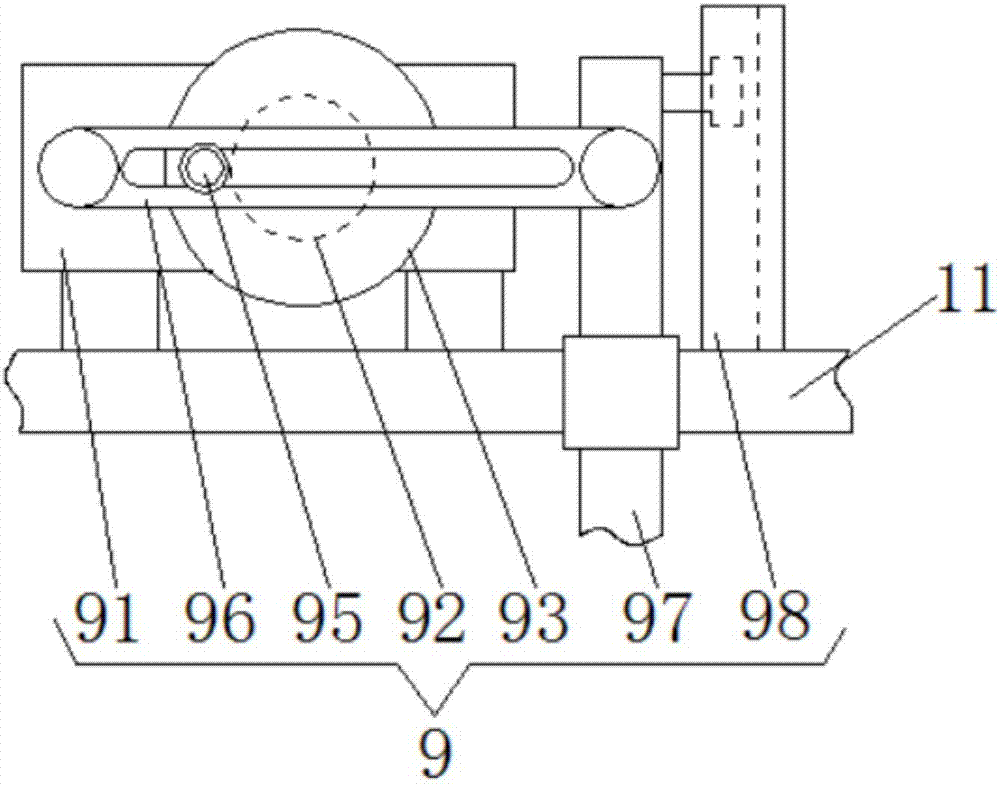

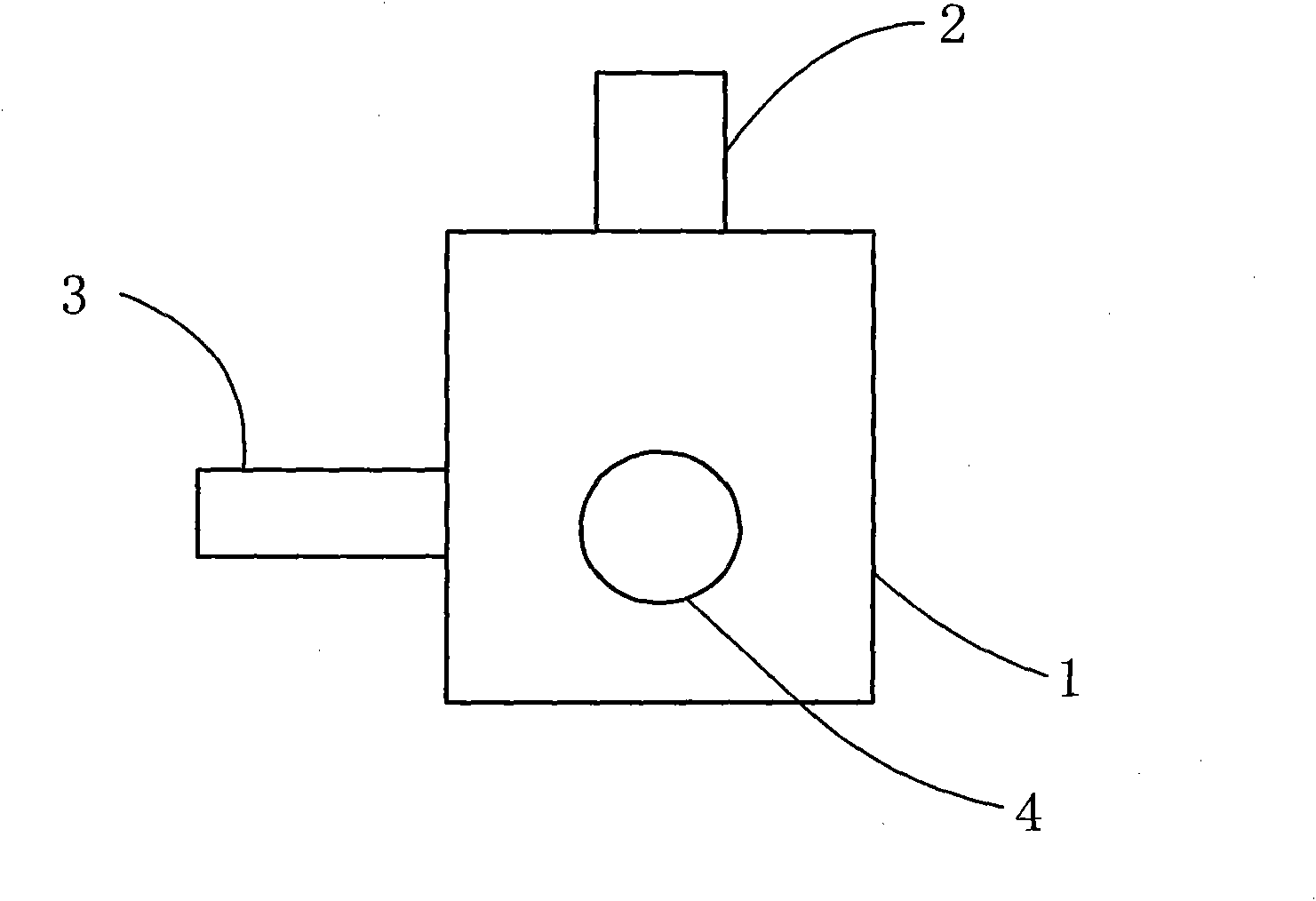

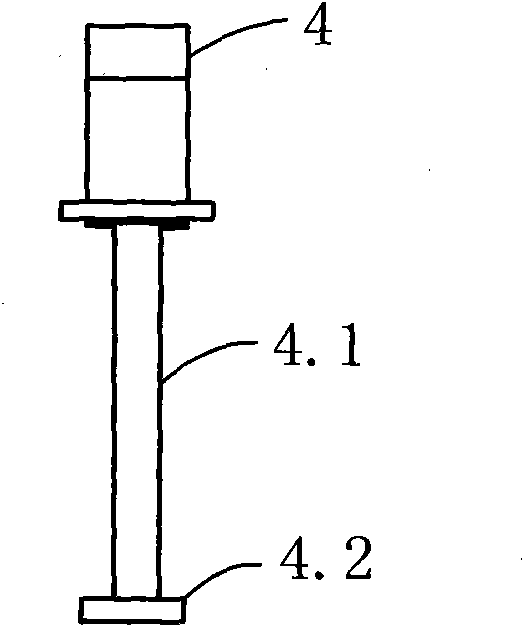

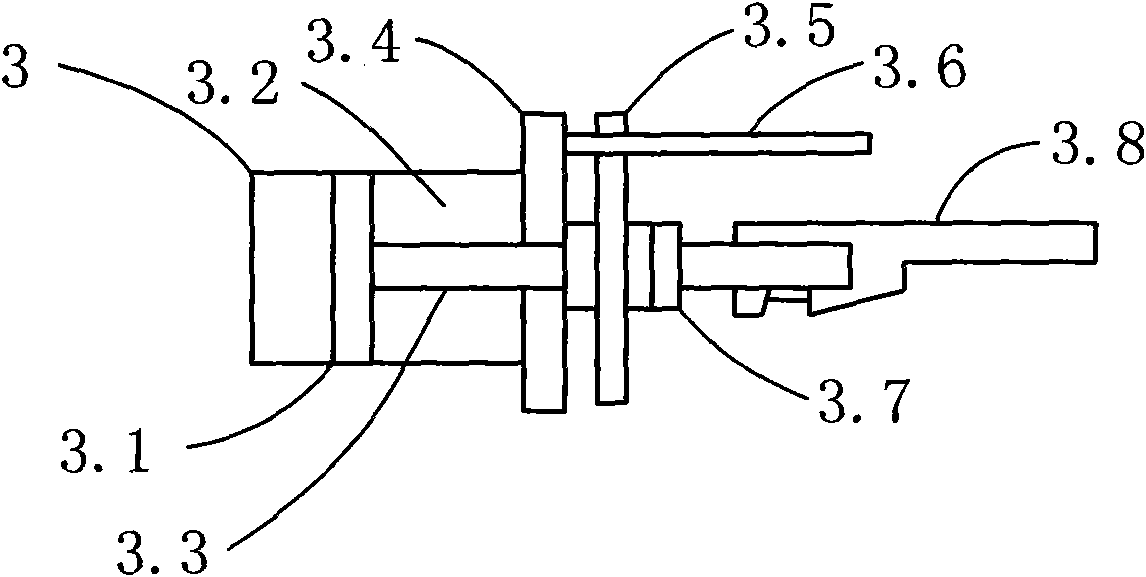

Die assembly upsetting and forging machine and working method thereof

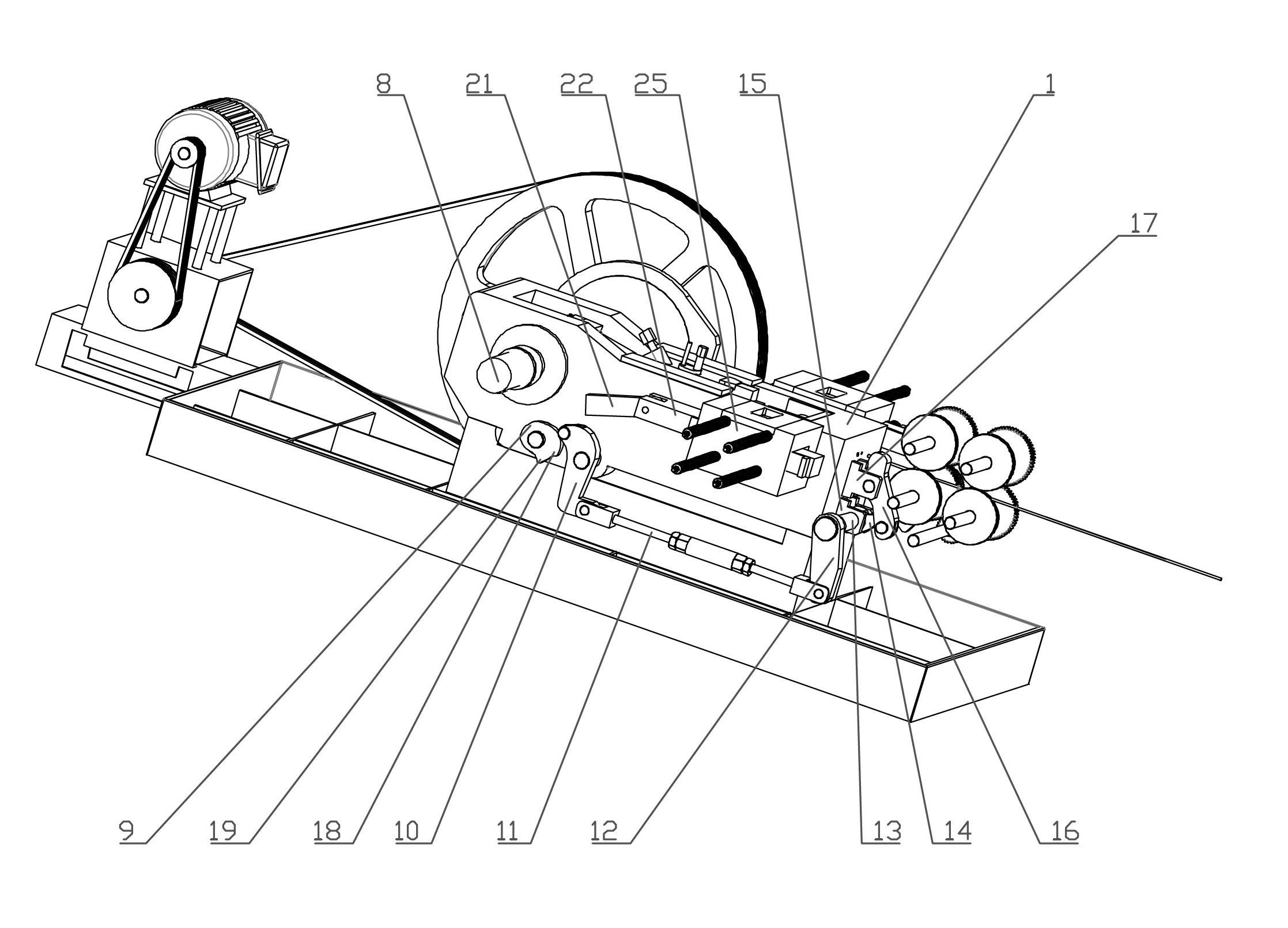

InactiveCN105642807AEasy to installEasy to debugUpsetting pressesSwagging pressesEngineeringMechanical engineering

The invention discloses a die assembly upsetting and forging machine and a working method thereof. The die assembly upsetting and forging machine comprises a machine body, a punch die assembly, a punch die assembly driving mechanism, a feeding mechanism and a material shearing sleeve; the machine body is provided with a die assembly device; the die assembly device comprises a first die assembly base and a second die assembly base; a first installation space is arranged on the side face, close to the second die assembly base, of the first die assembly base; a second installation space is arranged on the side face, close to the first die assembly base, of the second die assembly base; and the die assembly upsetting and forging machine is further provided with a first die assembly driving mechanism for driving the first die assembly base to horizontally move and a second die assembly driving mechanism for driving the second die assembly base to horizontally move. The working method comprises the steps that displacement whole-circle material shearing and material transferring of station parts are achieved through horizontal movement of the die assembly device, and then upsetting and forging are conducted. According to the working method, an independent material shearing mechanism and an independent material clamping and blank transferring mechanism are omitted, and the functions of die assembly material shearing and die assembly upsetting and forging and the function of a clamp are achieved.

Owner:杨东佐

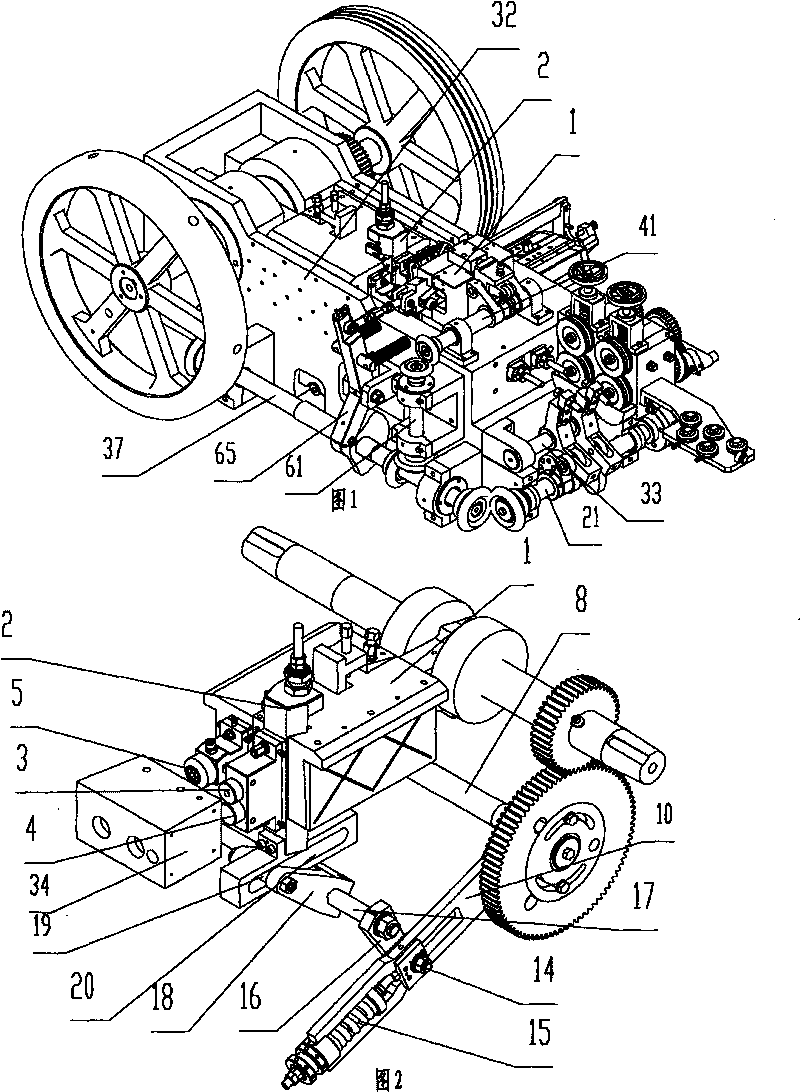

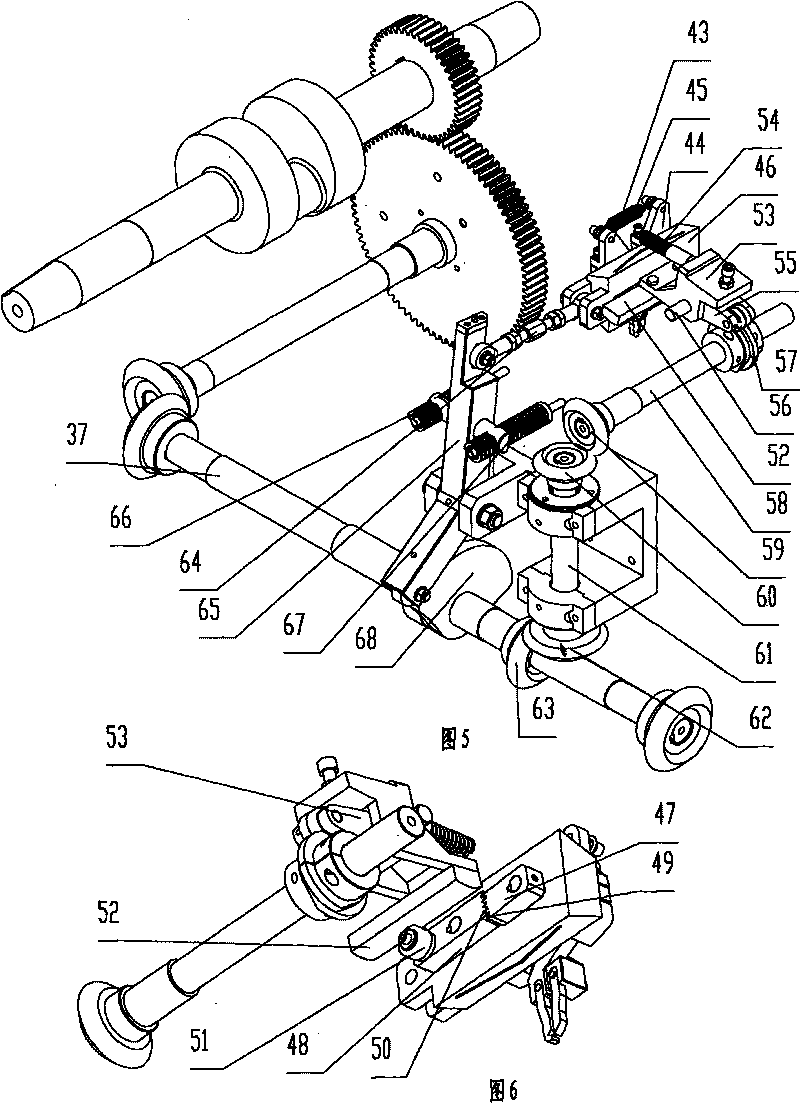

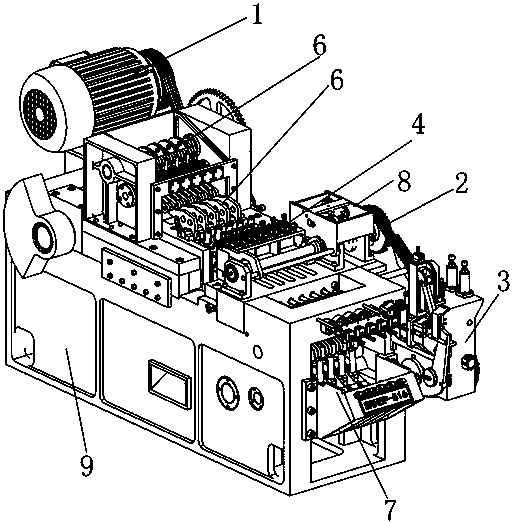

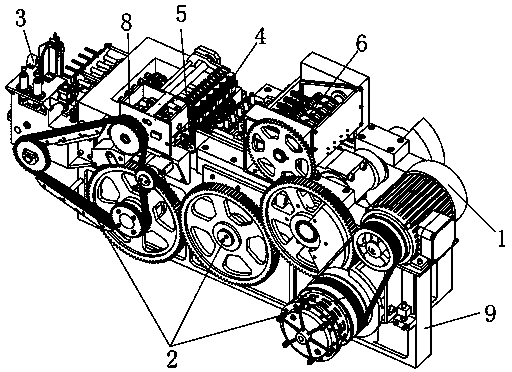

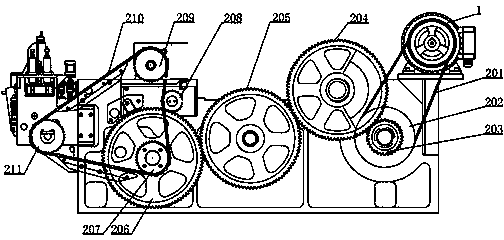

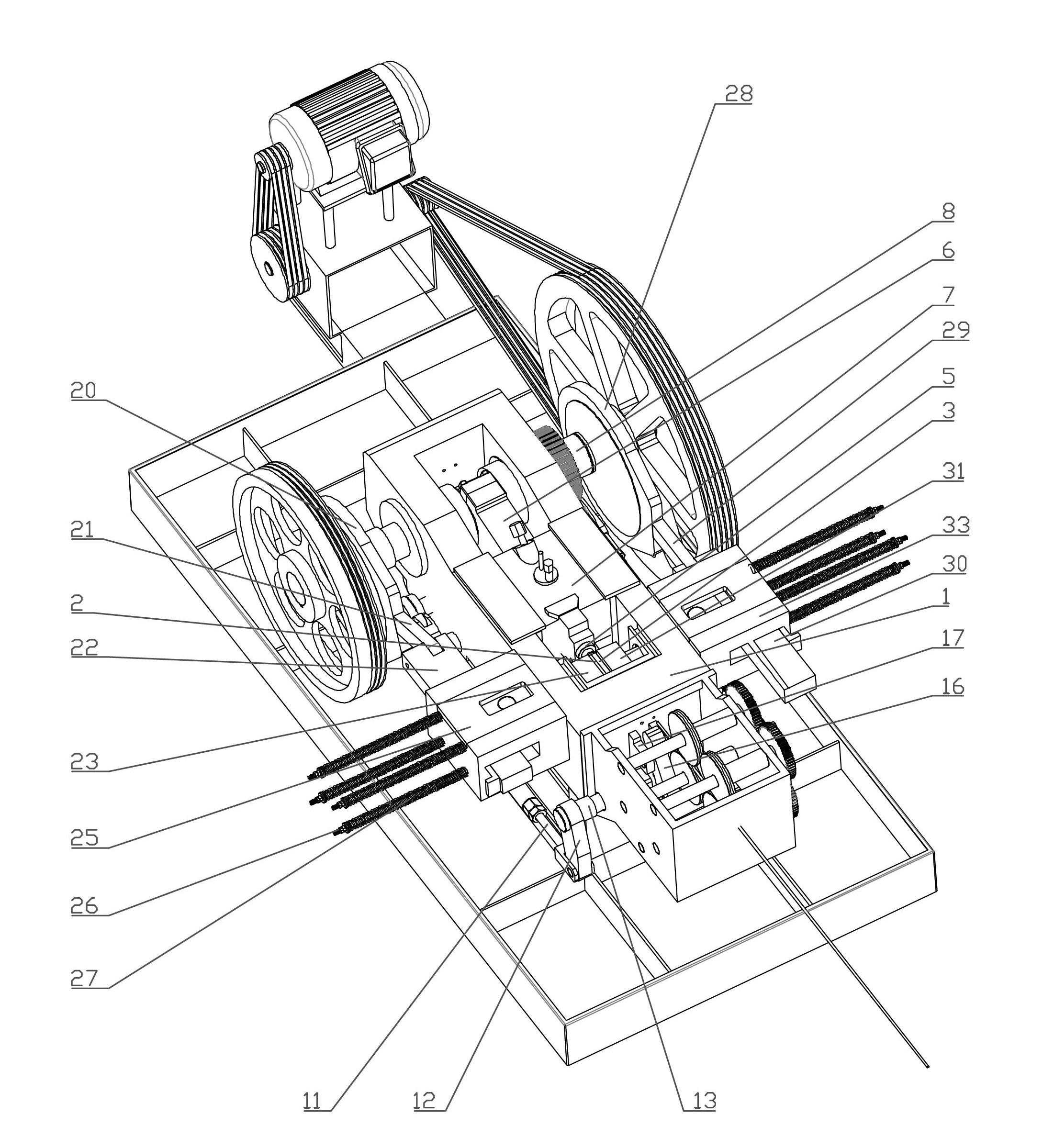

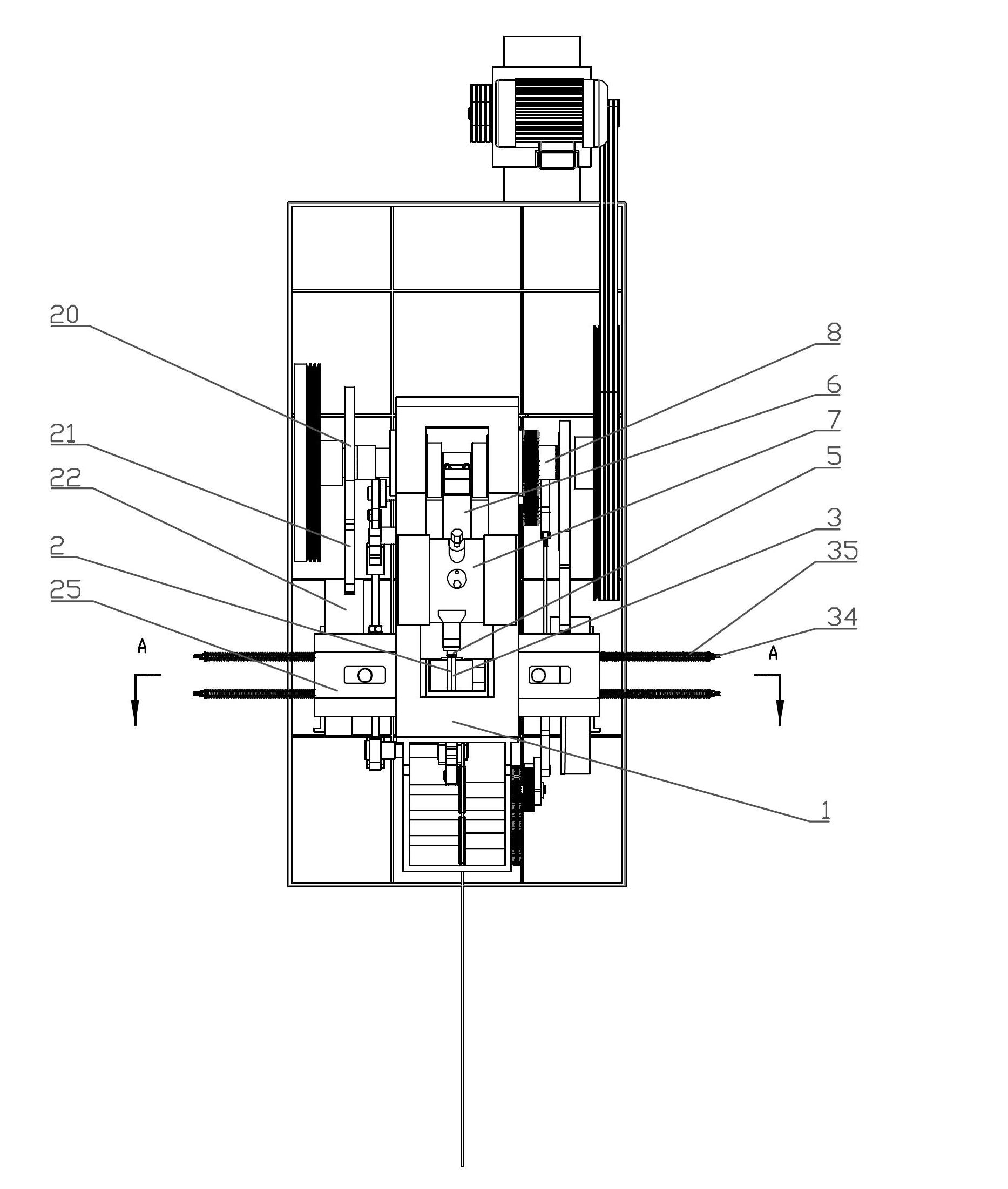

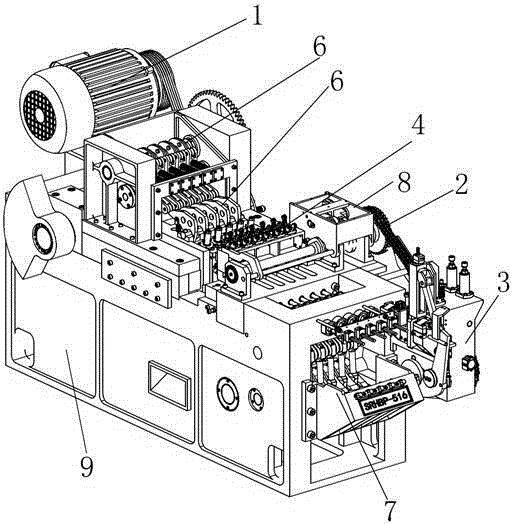

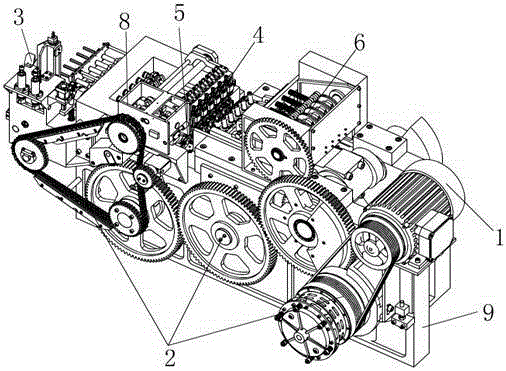

Cold heading machine

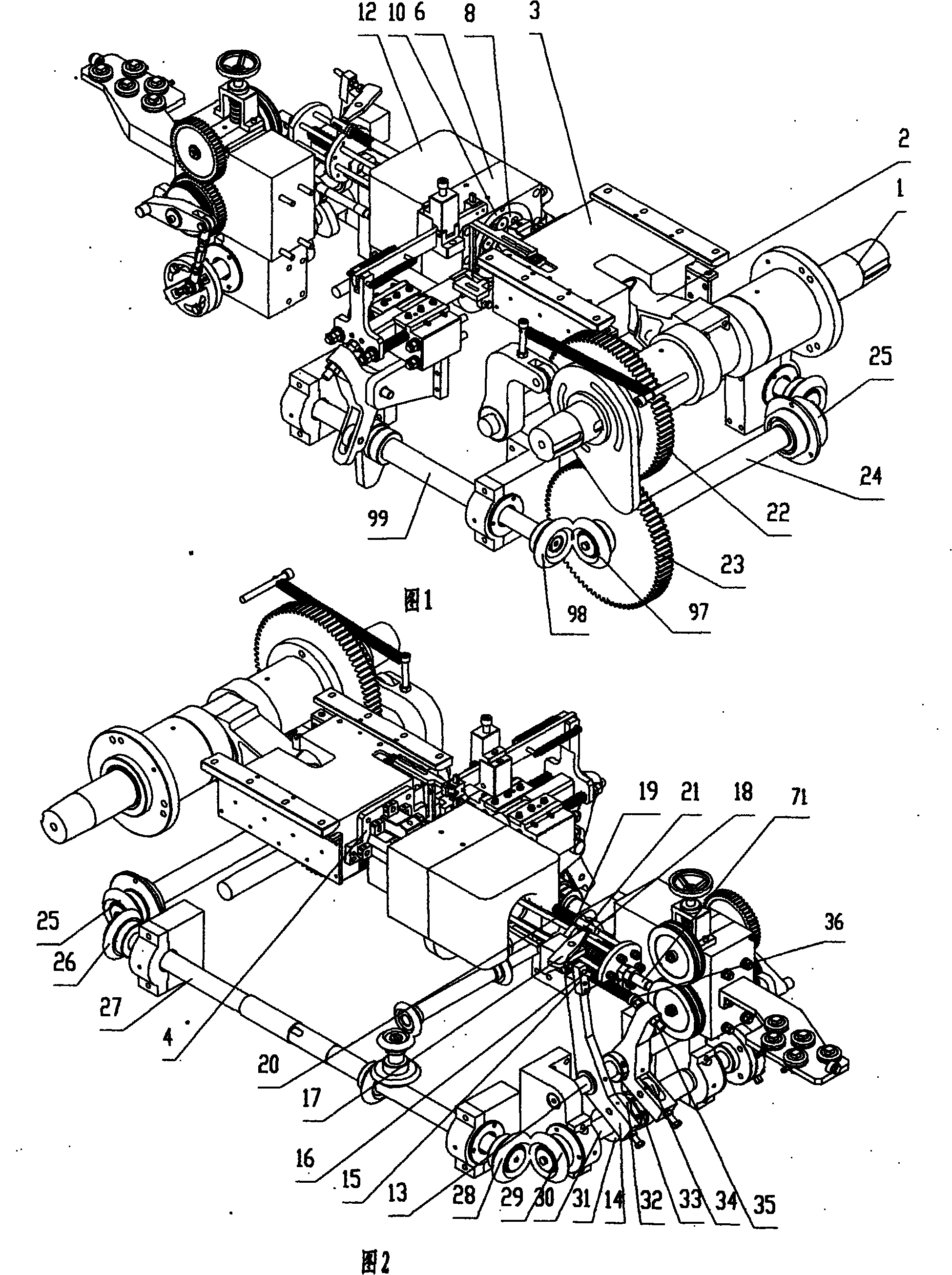

ActiveCN104174802AMeet sporting requirementsNot easy to move at high speedUpsetting pressesSwagging pressesMotor driveBack support

The invention discloses a cold heading machine. The cold heading machine comprises a machine body, wherein a main motor, a drive system, a linear feeding device, a rotary clamp, a cutter system, an adjustable male die ejecting mechanism and a closed back support are arranged on the machine body; the main motor is arranged at a first end of the machine body, and the drive system is arranged at an output end of the main motor; the linear feeding device is arranged at a second end of the machine body, and the closed back support is arranged on one side of the feeding device; the rotary clamp and the male die ejecting mechanism are arranged in the middle of the machine body; and the cutter system is arranged below the rotary clamp. After the main motor of the machine is started, the main motor drives the linear feeding device, the rotary clamp, cutters, the male die ejecting mechanism and the like through the drive system to finish processing steps of feeding, cutting, upsetting, finished product ejecting and the like. The cold heading machine has the advantages that the drive efficiency can be improved, the high-speed driving is realized, the working efficiency and precision of the cold heading machine are improved, and the like.

Owner:HUANGSHAN SHENGRUI HEAVY IND MACHINERY

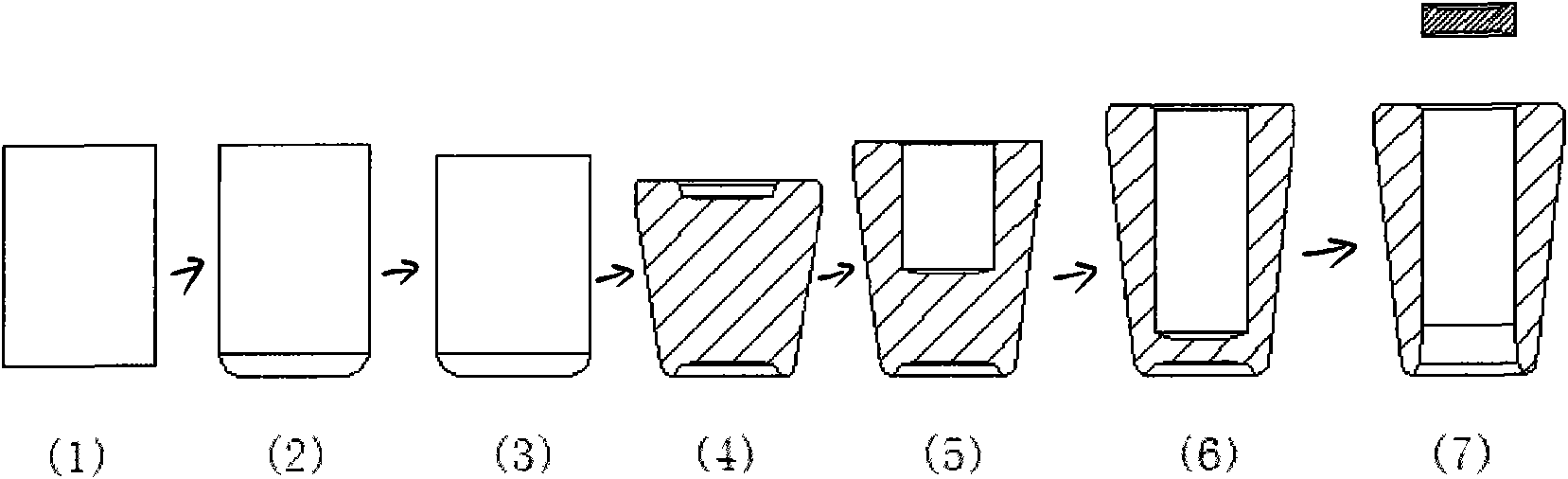

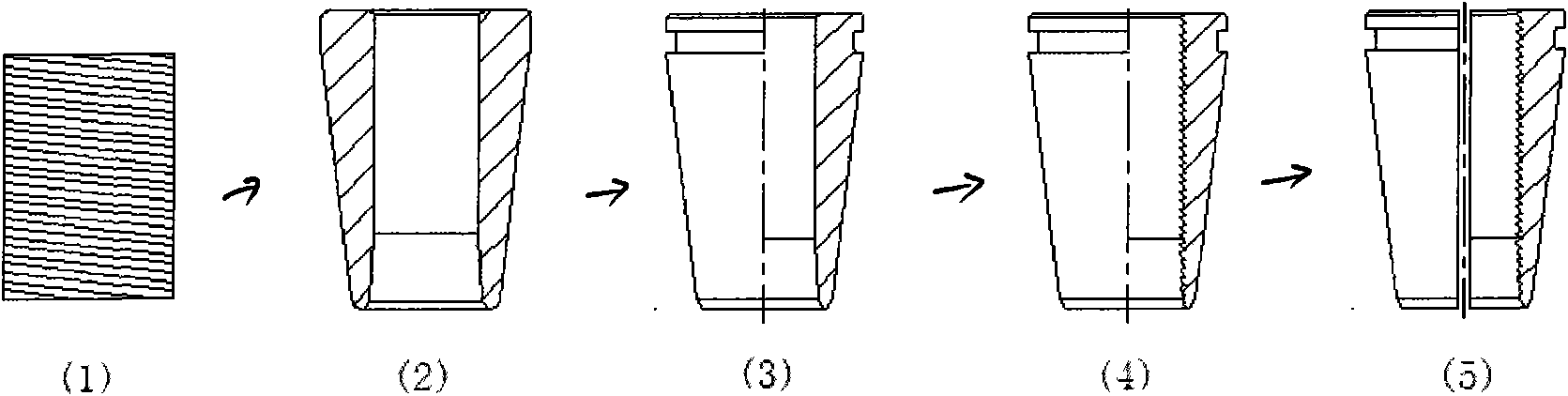

Manufacturing method of internal jacket

The invention discloses a manufacturing method of an internal jacket. The method comprises the following steps: the wire rod blanks are taken as the raw materials, firstly, the spheroidizing annealing is performed to the wire rod blanks of the internal jacket, the phosphating and the fine-drawing and sizing are performed to the blanks after spheroidizing annealing, and then the multi-station cold heading automatic one-time molding and the secondary fine finishing working procedures are carried out, i.e., groove broaching, tapping, piece cutting and finally, packaging and shipment. The invention adopts the wire rod materials to replace straight rods and fracturing materials, can meet the requirement of multi-station cold heading continuous production, reduces the loss of remnants, reduces the large-area of lathe remainder of the exterior conical surface, the inner hole and the end surface after adopting the multi-station cold heading one-time molding and further reduces the loss of the raw material by 30 percent, therefore, the cost is reduced; due to the adoption of the multi-station cold heading continuous molding production, the production speed can reach 60 PCS / minute, the daily output is up to 21,000 PCS in average, the production efficiency is promoted by 7-8 times than before, and the cost of investment of manpower and material resources is greatly reduced.

Owner:NINGBO ANCHOR FASTENERS INDAL

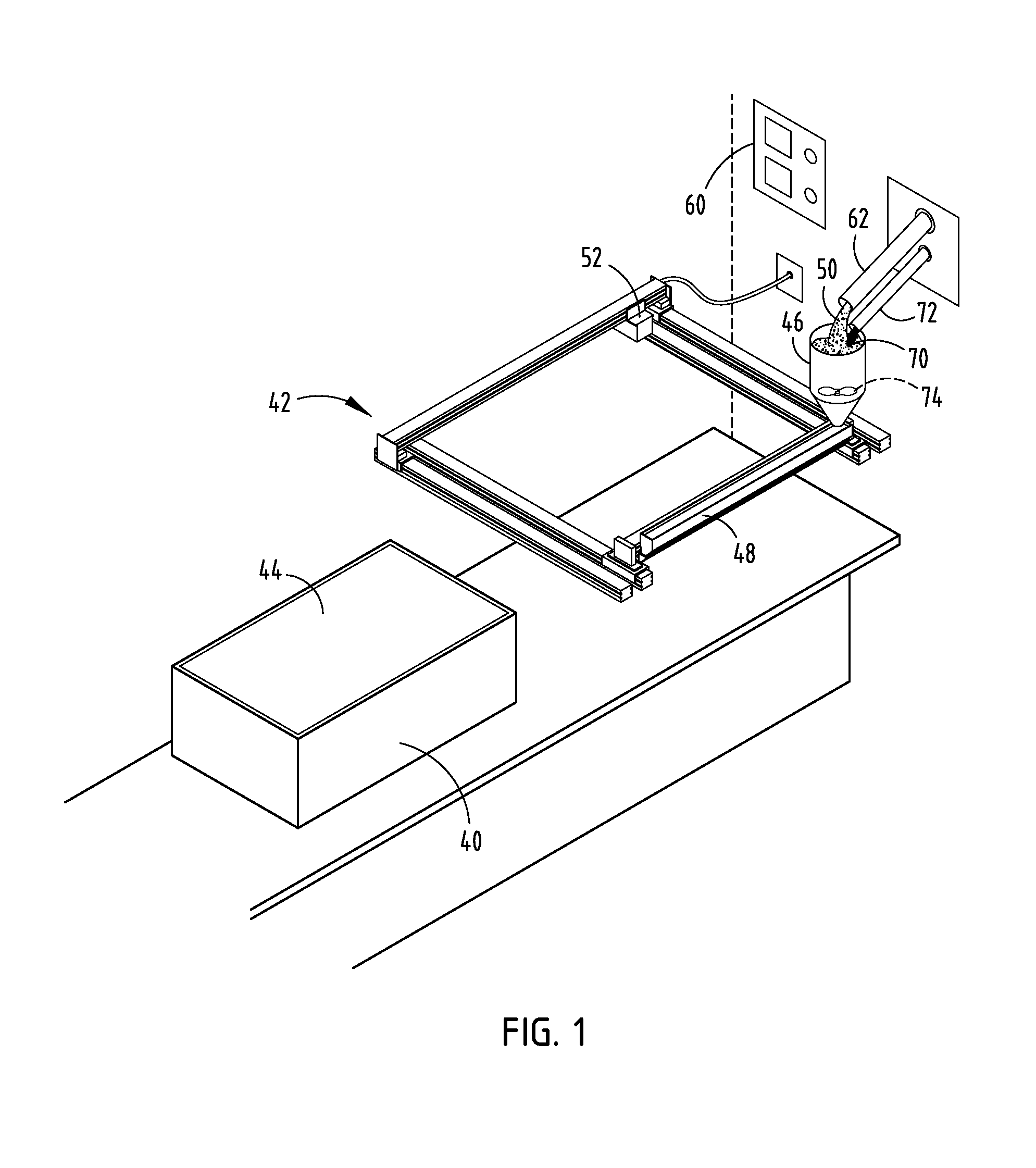

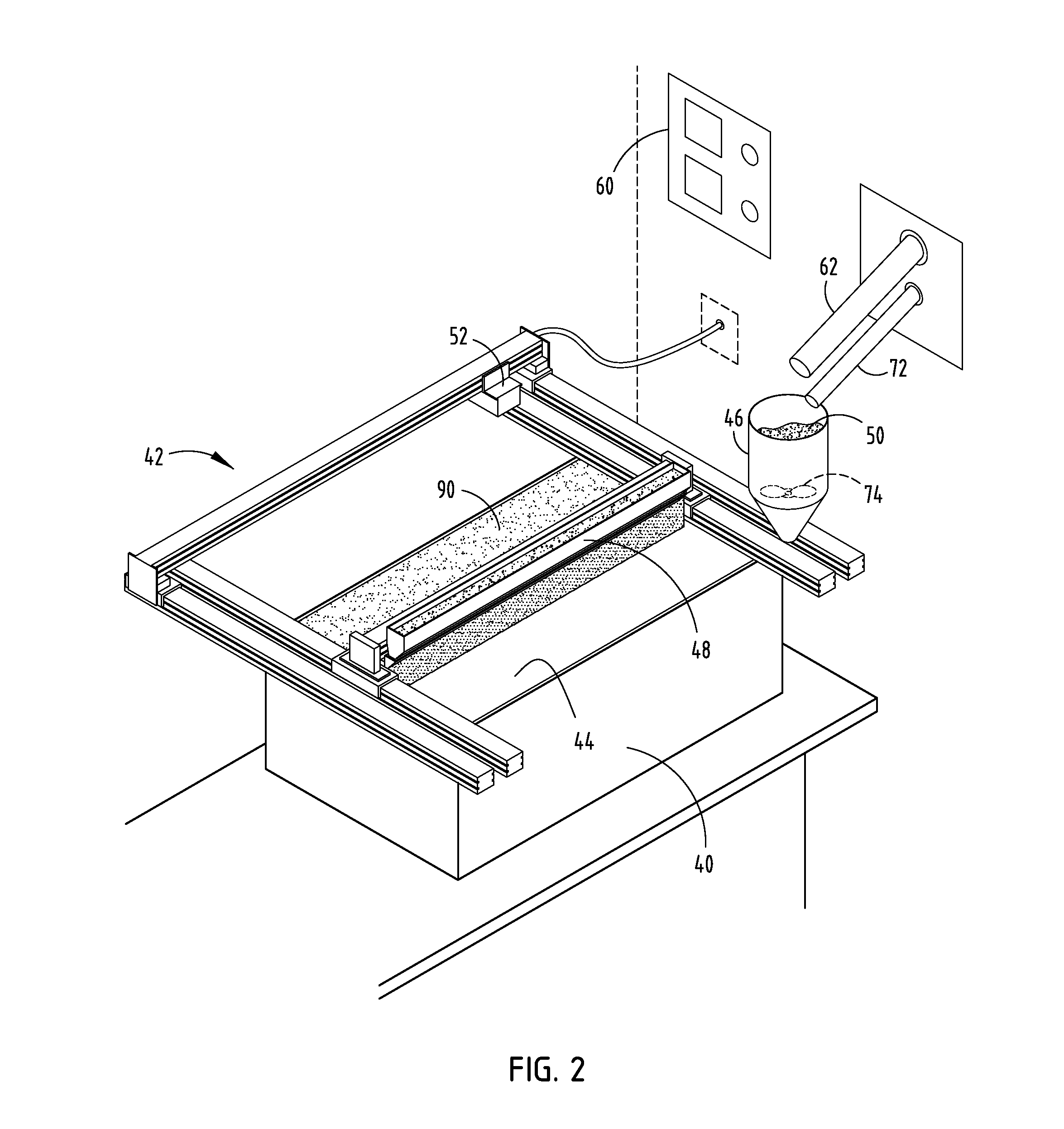

Interchangeable mold inserts

A mold core package for forming a molding tool with a removable insert includes a plurality of stacked particulate layers having a binding agent. The plurality of stacked particulate layers form molding pattern walls that generally define a base mold cavity and an insert mold cavity defining a mold surface. A sacrificial displacement line extends through the insert mold cavity closely following contours of the mold surface.

Owner:FORD MOTOR CO

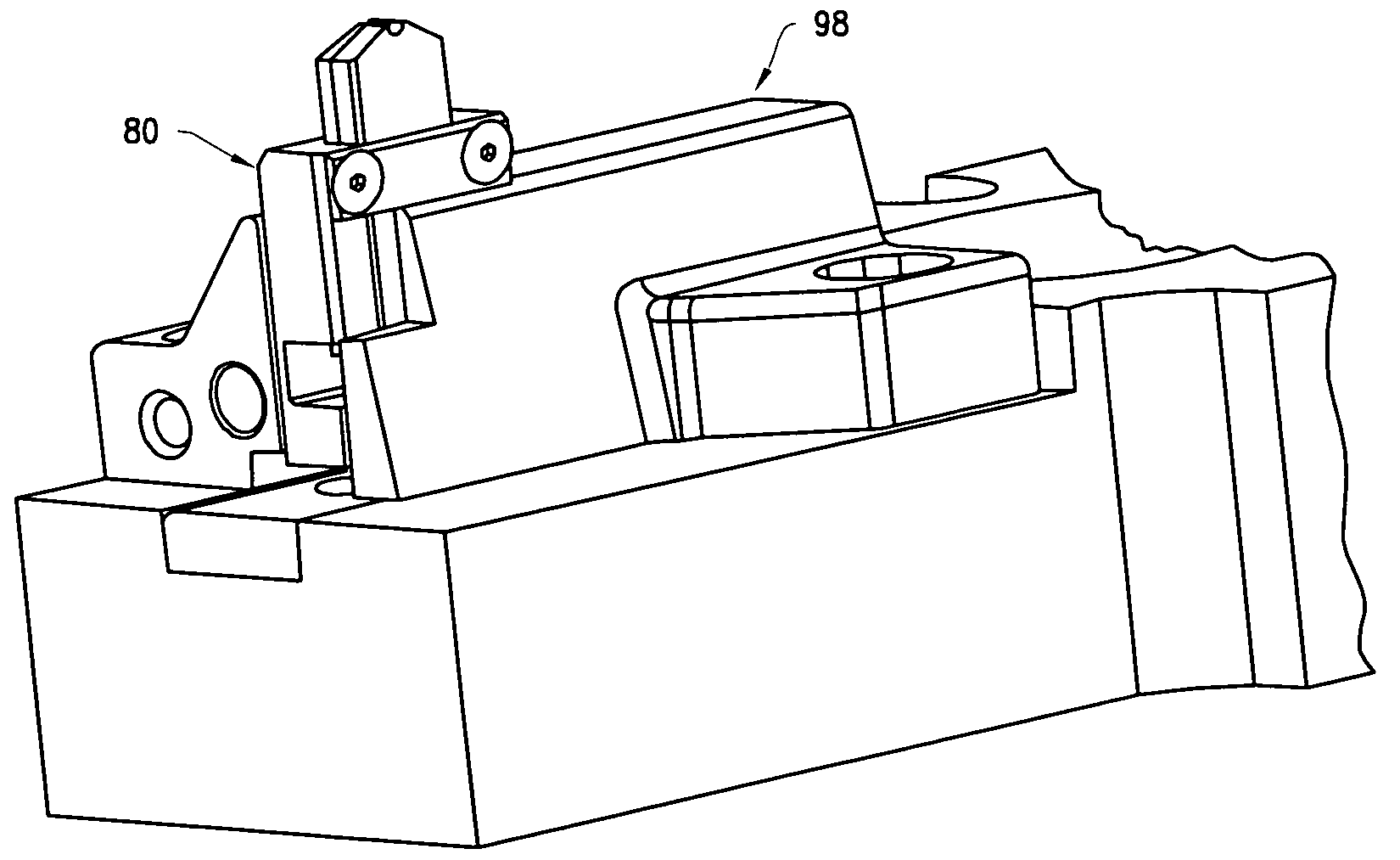

Apparatus and method for swaging needles

A method and apparatus for making armed sutures has a pair of opposed die assemblies that may be driven by actuating surfaces of a swaging machine to hold and swage a needle on a suture. The dies grip and confine the needle in the area of the suture receptacle. A pair of opposed swaging elements with offset stakes insert through passageways in the dies and impinge on the captured needle making a plurality of indentations in the needle barrel and gripping the suture in the suture receptacle. The indentations are offset and aligned generally in alternating peak-to-valley relationship, causing the suture receptacle and the contained suture to assume a serpentine configuration. The stakes and the resulting indentations can be dimensioned to result in a converging suture receptacle, which exhibits increasing shear force being exerted on the suture with increasing depth into the suture receptacle. The apparatus and method permit reliable suture-needle attachment over a larger range of tolerances, such that a single die setup can be used on a plurality of needle and suture materials. The resulting product exhibits a serpentine suture / needle attachment interface with reliable attachment and smooth outer dimensions.

Owner:ETHICON INC

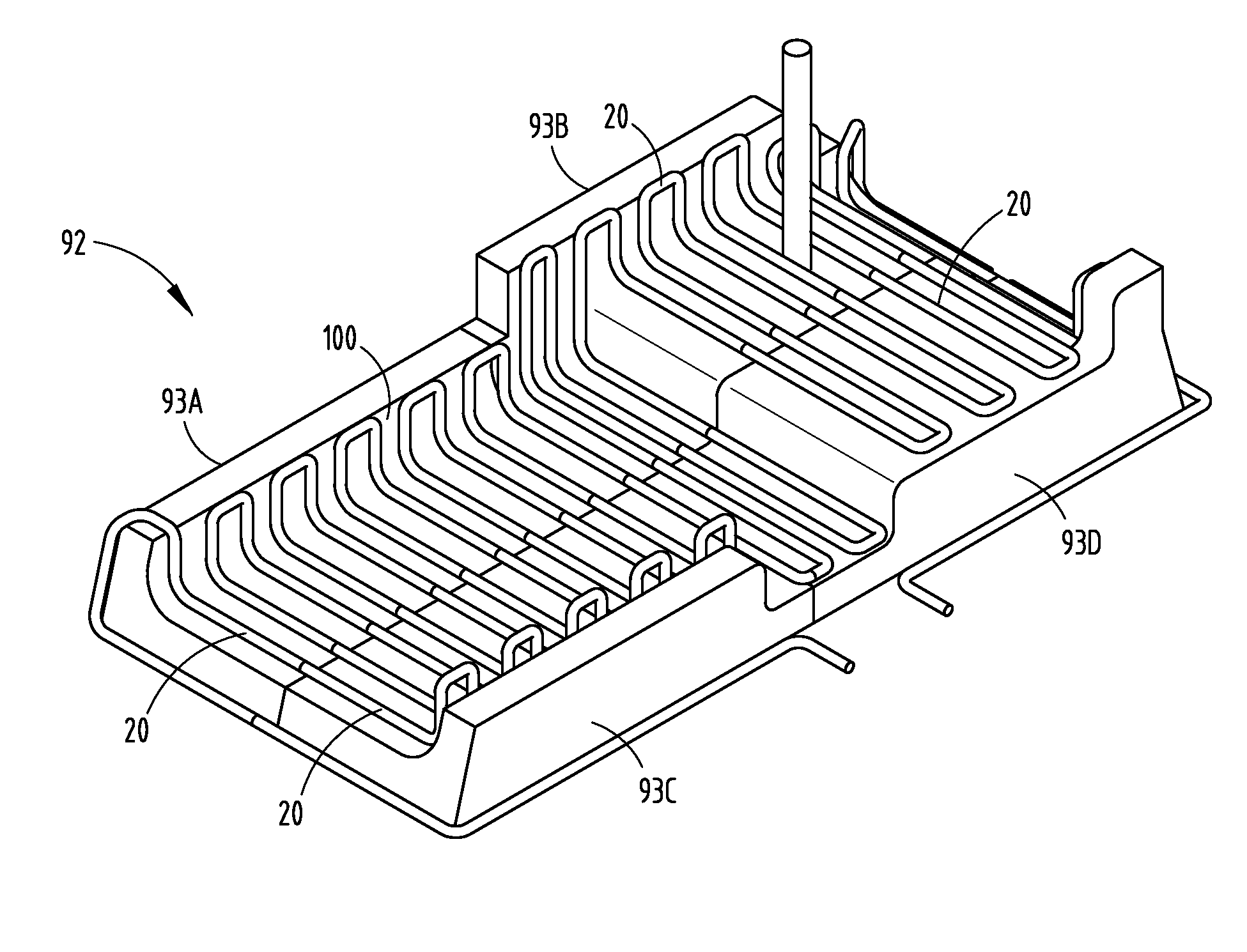

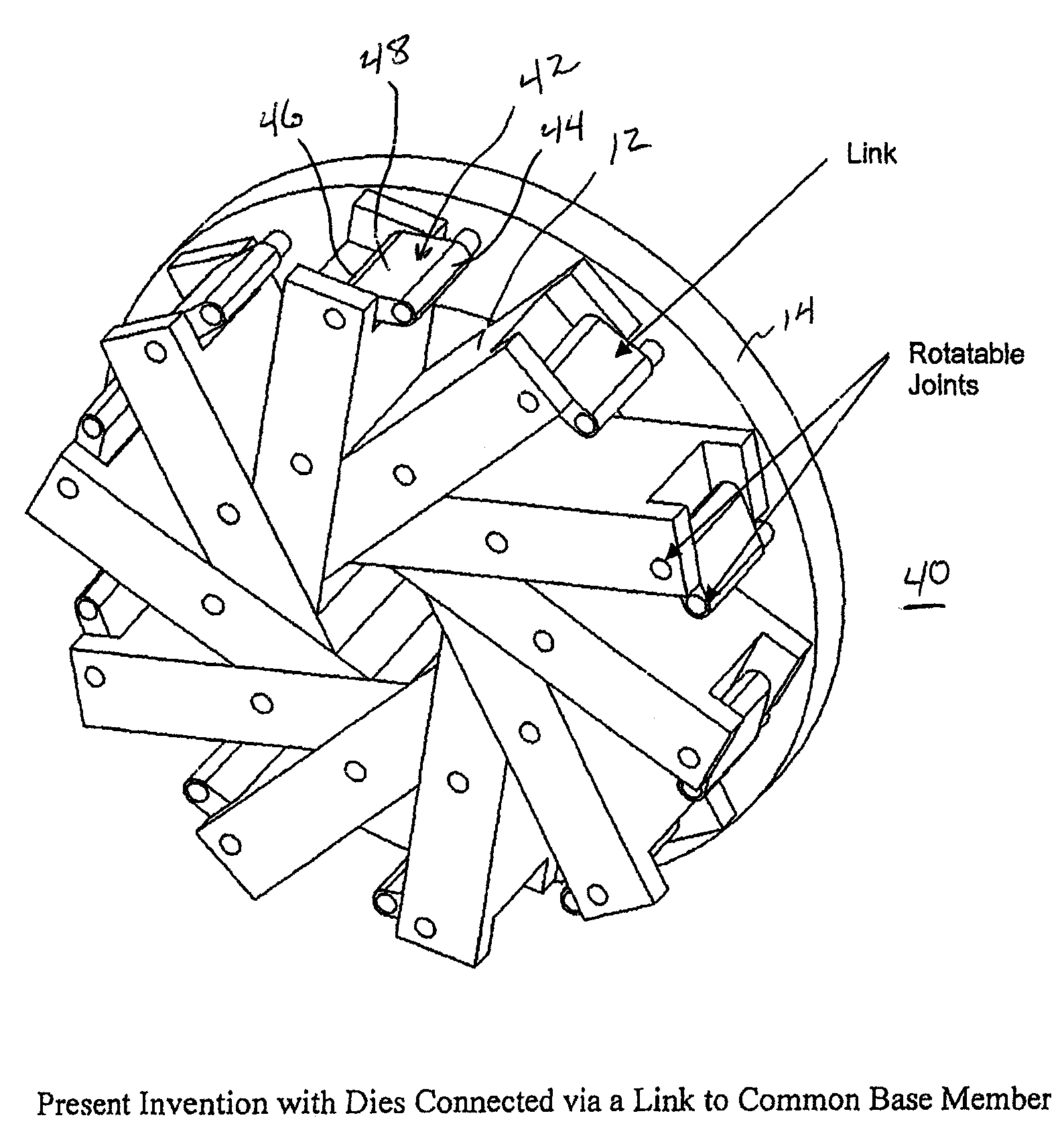

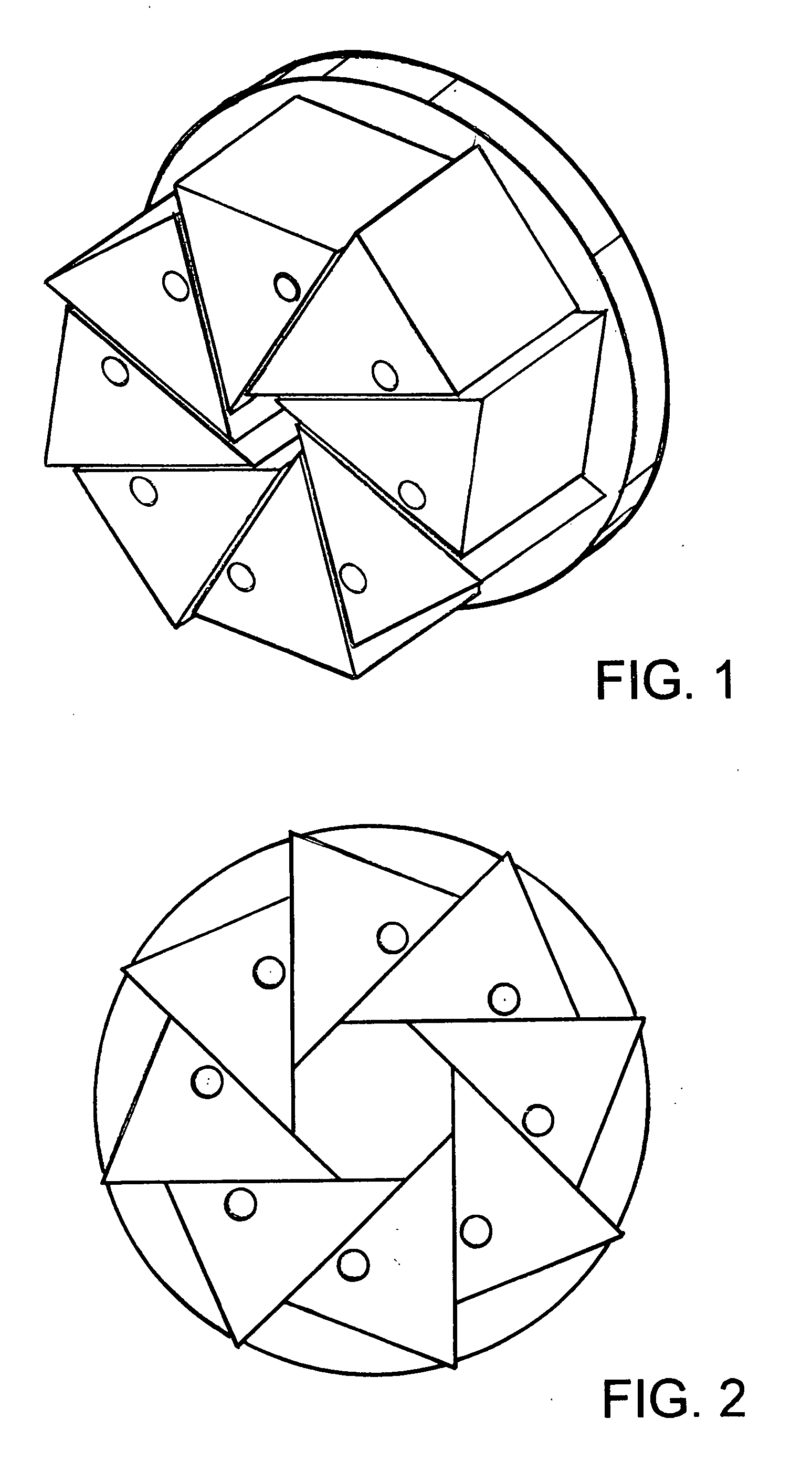

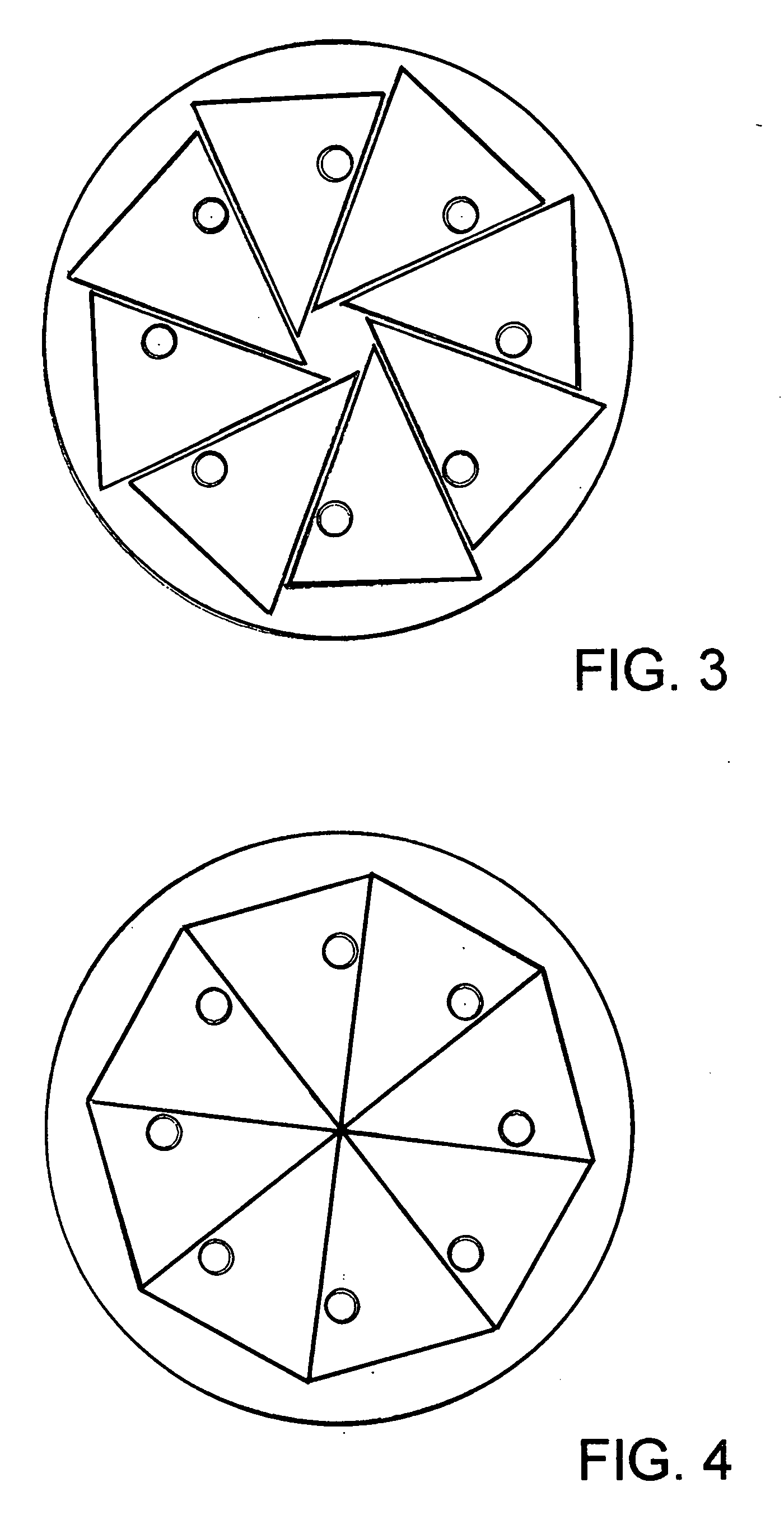

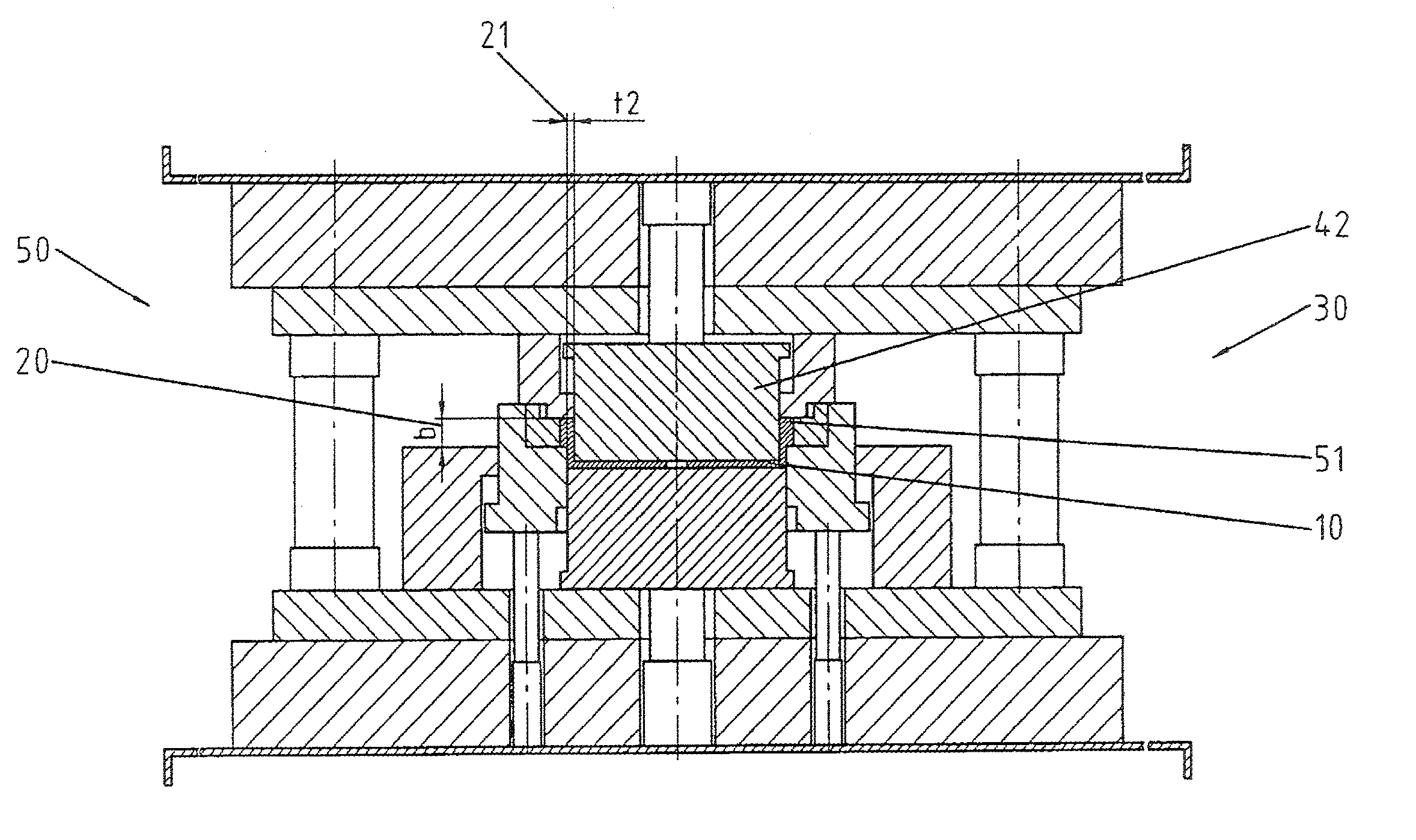

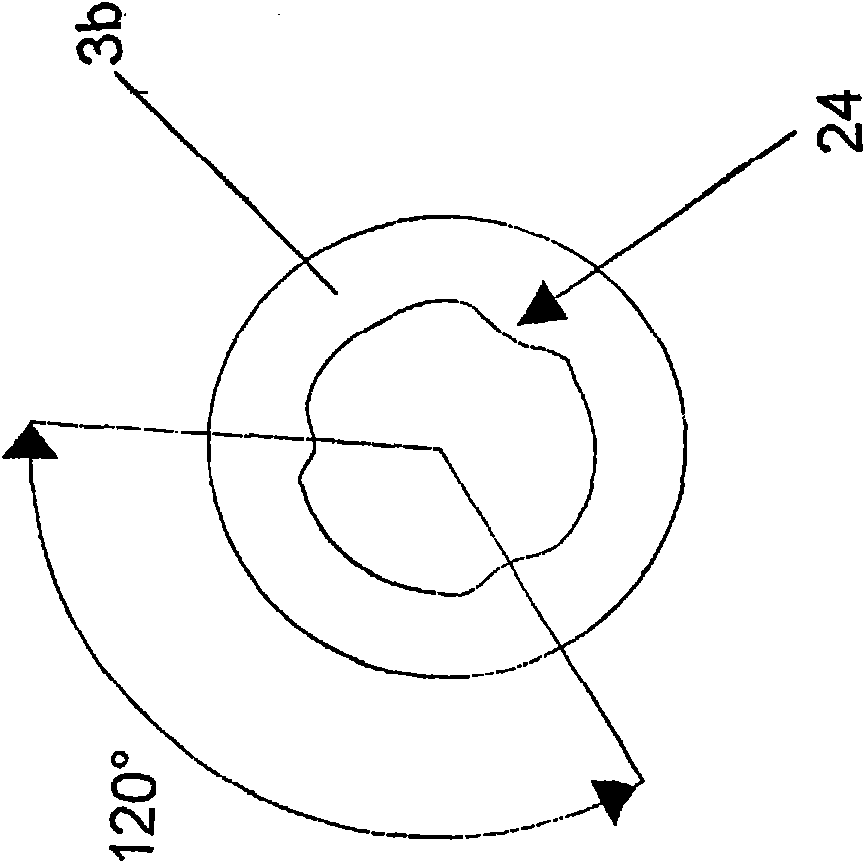

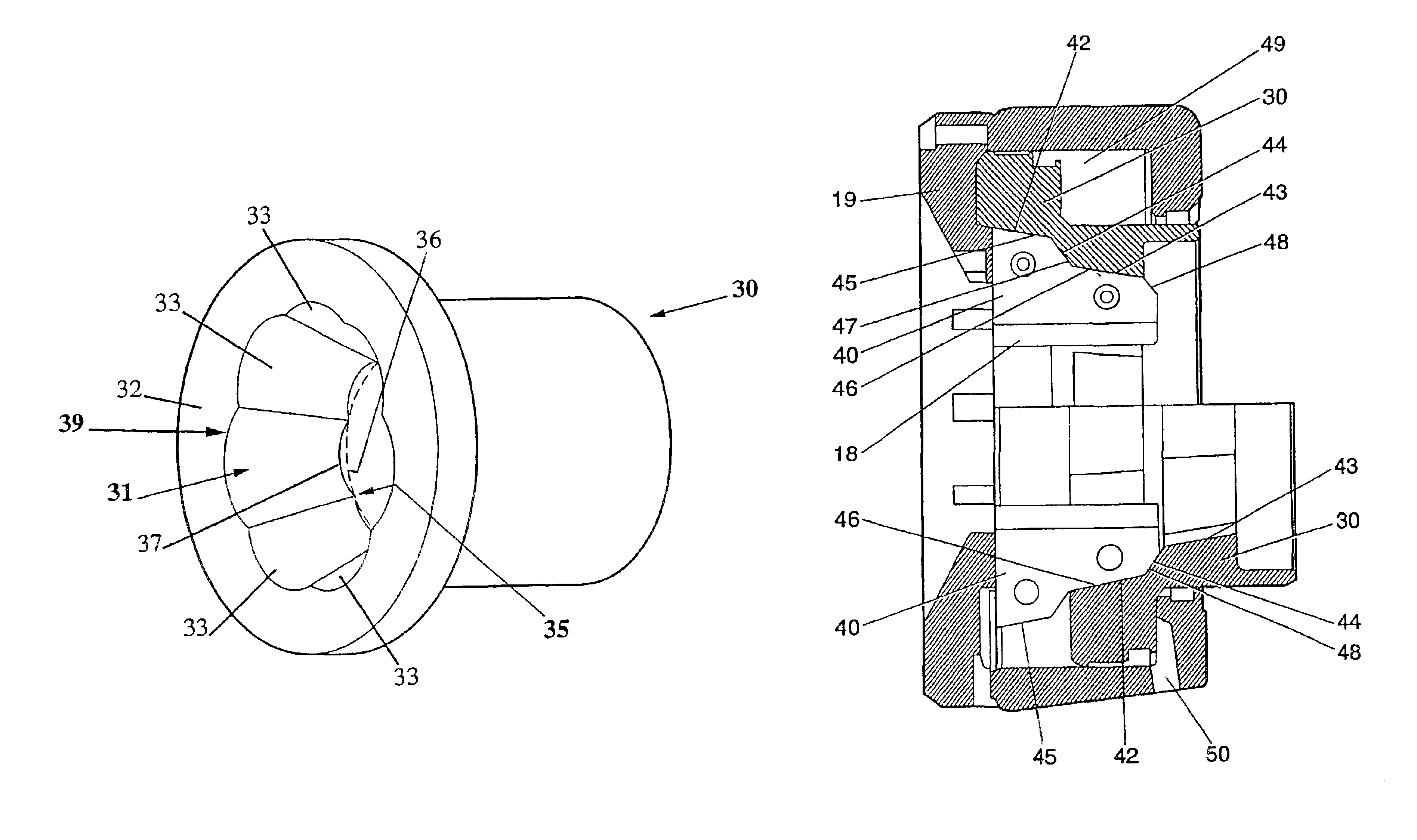

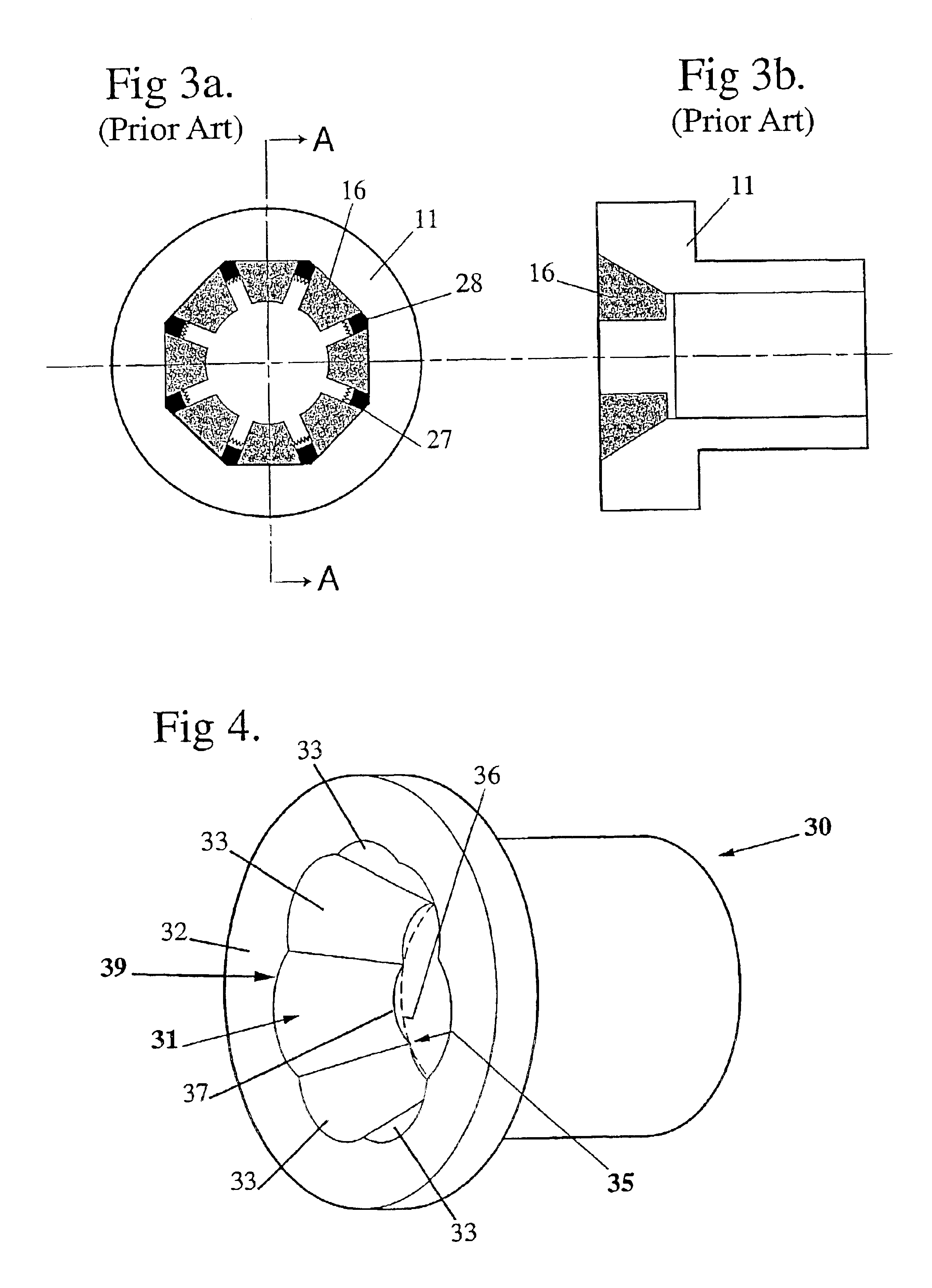

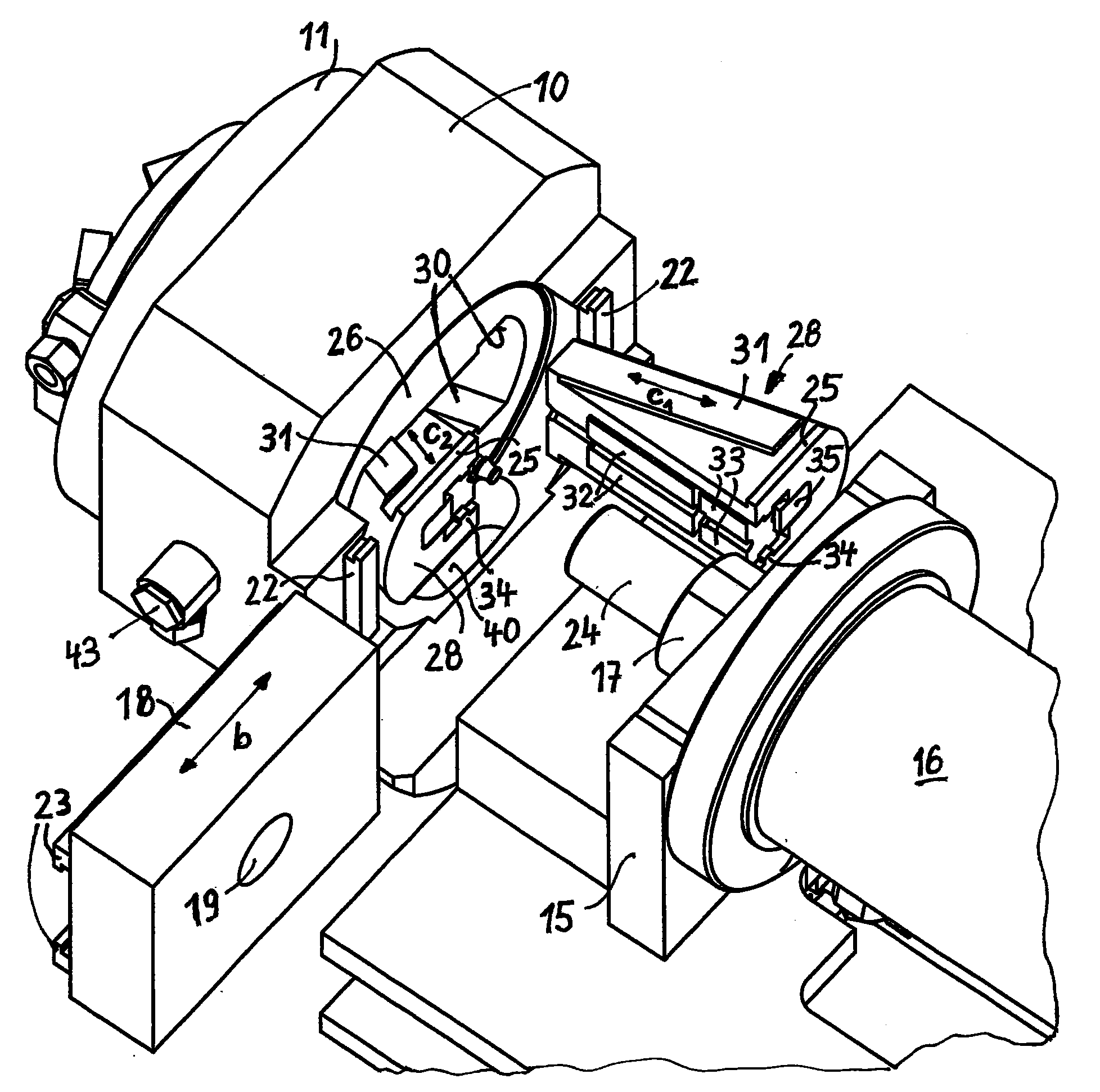

Radial compression mechanism

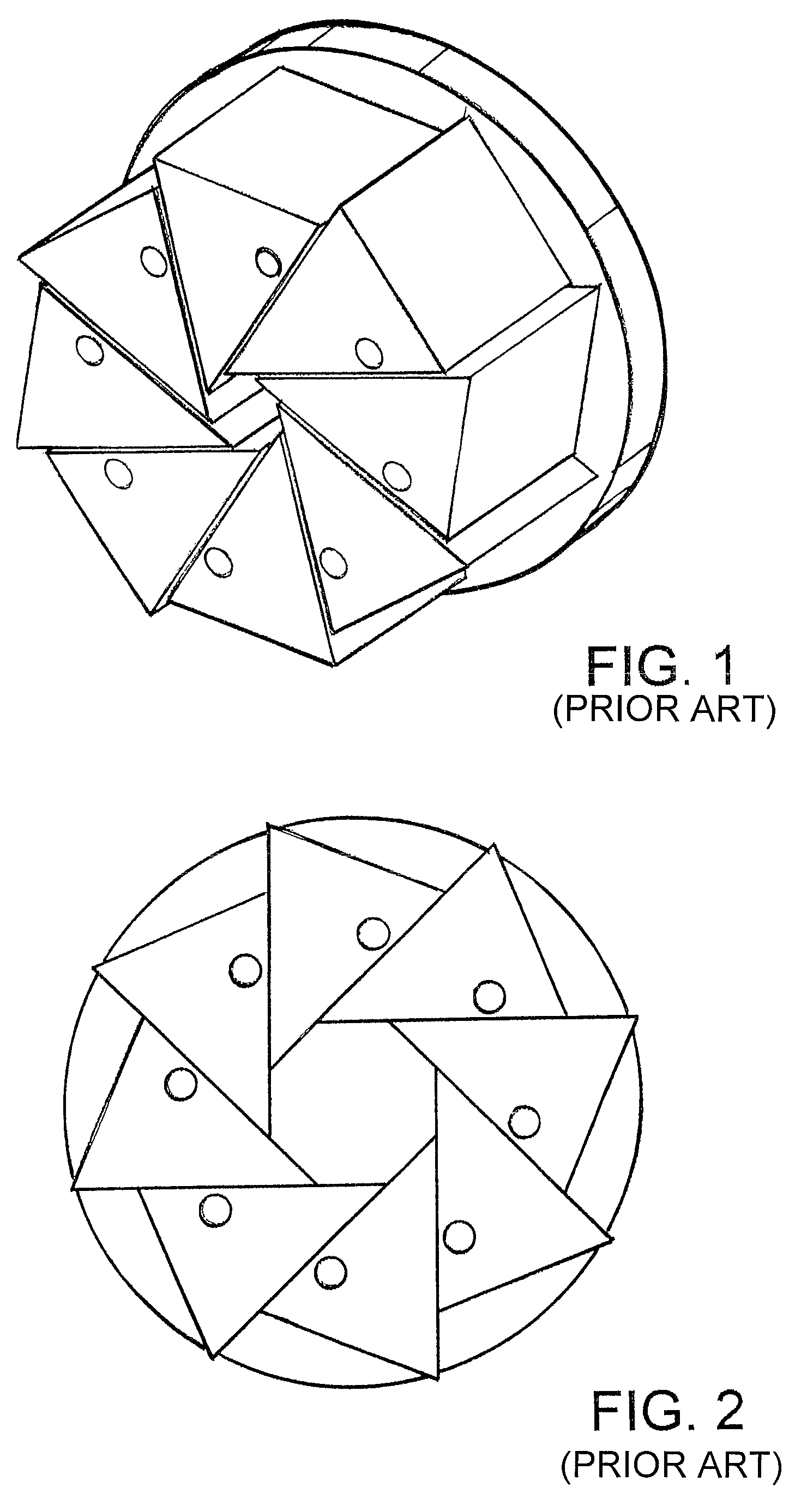

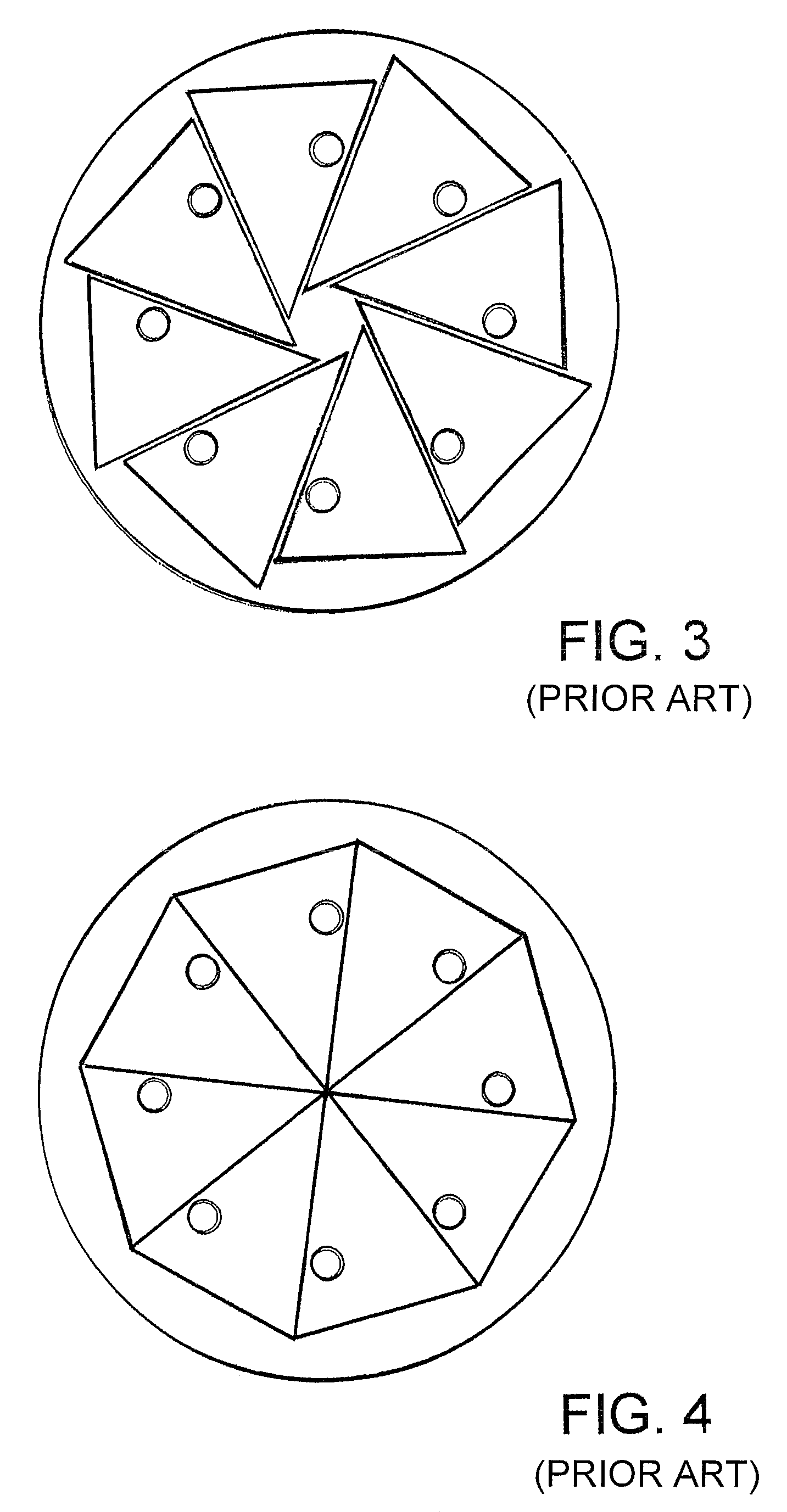

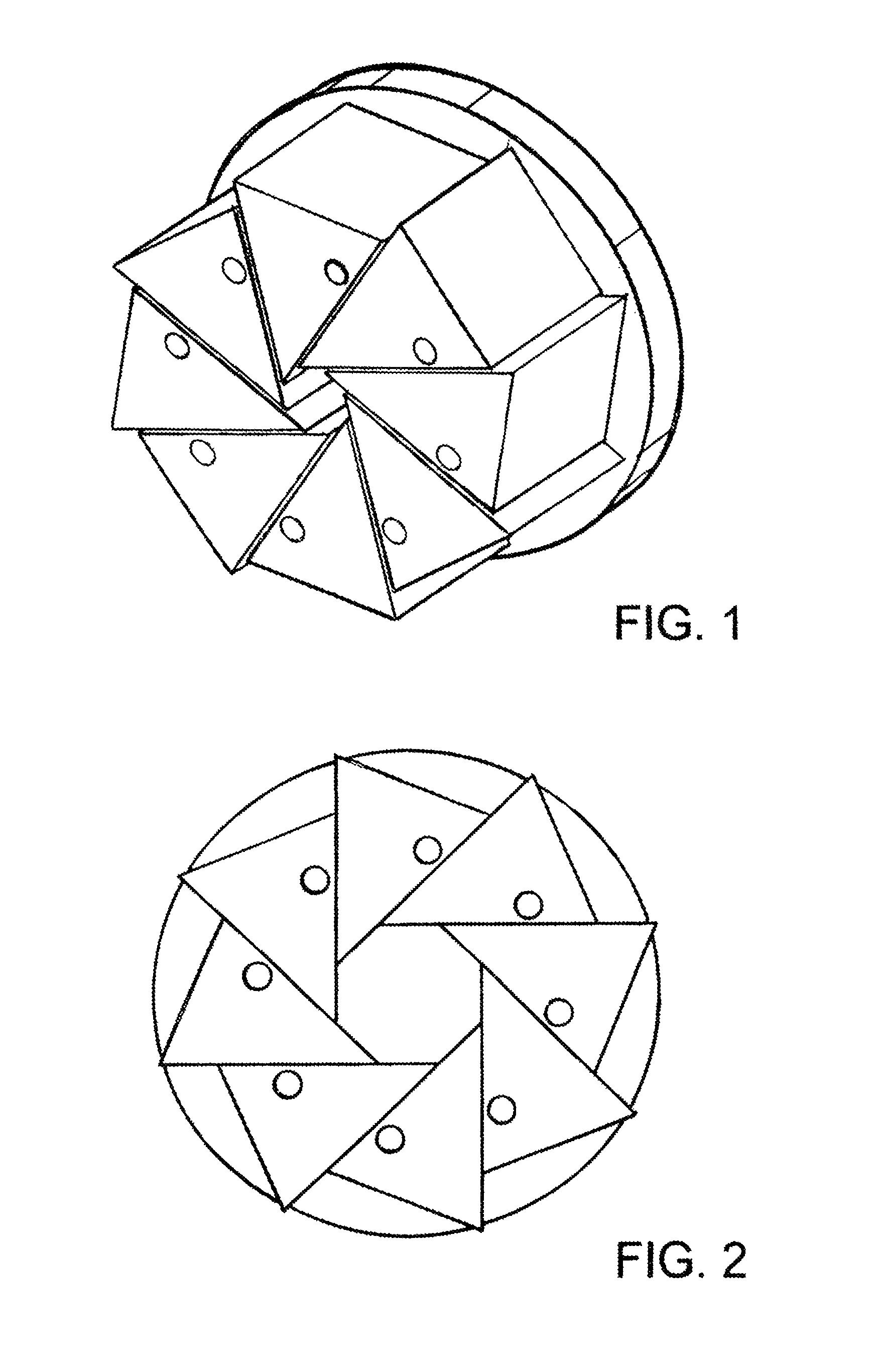

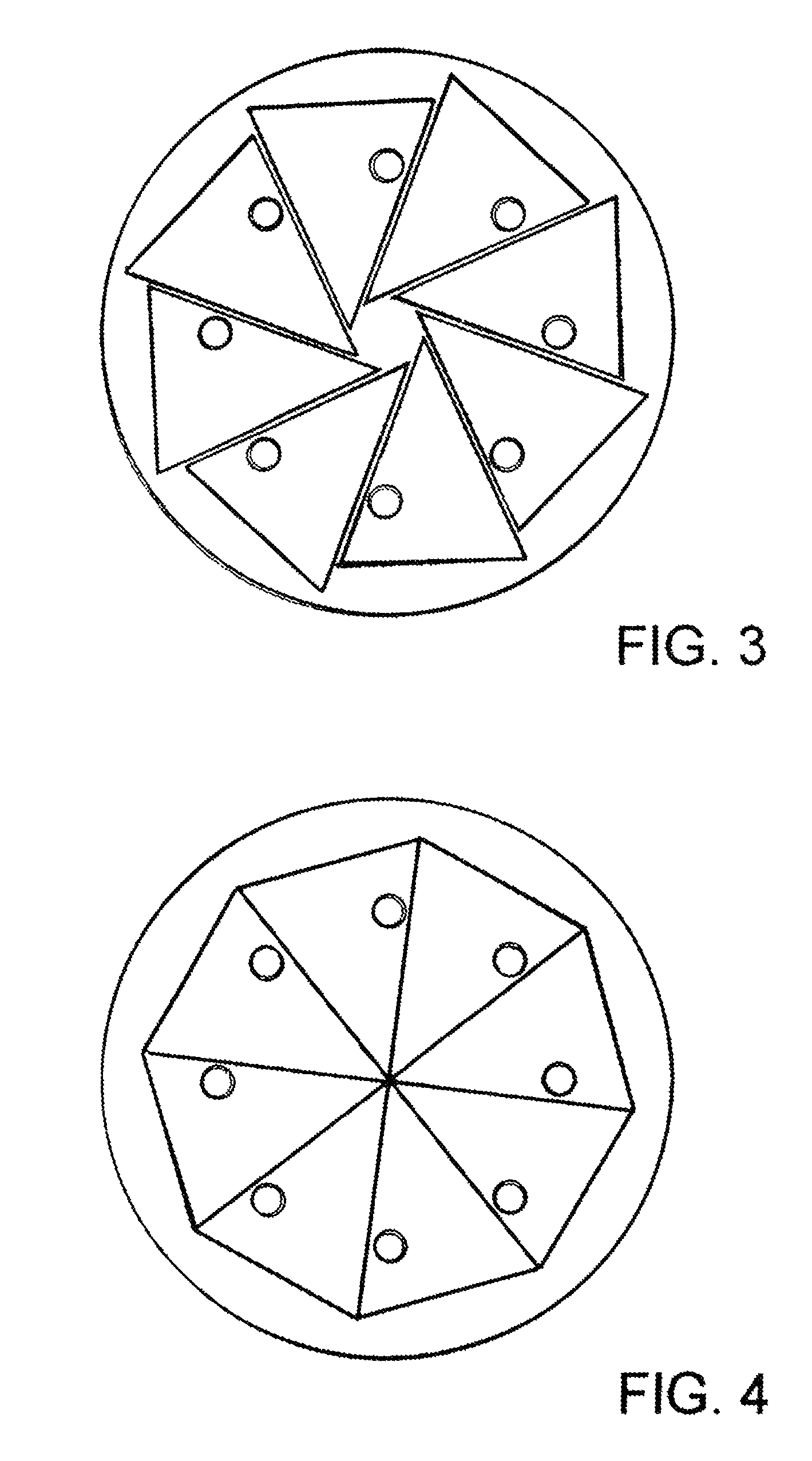

Radial compression mechanism includes a base member and a plurality of elongated compression dies. The dies are arranged in a generally circular orientation on the base member with a contact surface of each die in sliding contact with a base surface of an adjacent die. A portion of each base surface of each die cooperates with portions of base surfaces of adjacent dies to define a generally cylindrical central cavity moved between open and closed positions by a driving mechanism. The dies are cammingly coupled to the base member and to the driving mechanism so that rotation of the driving mechanism about the central axis causes each die to move generally arcuately about a point of camming engagement with the base member.

Owner:GOFF ED +2

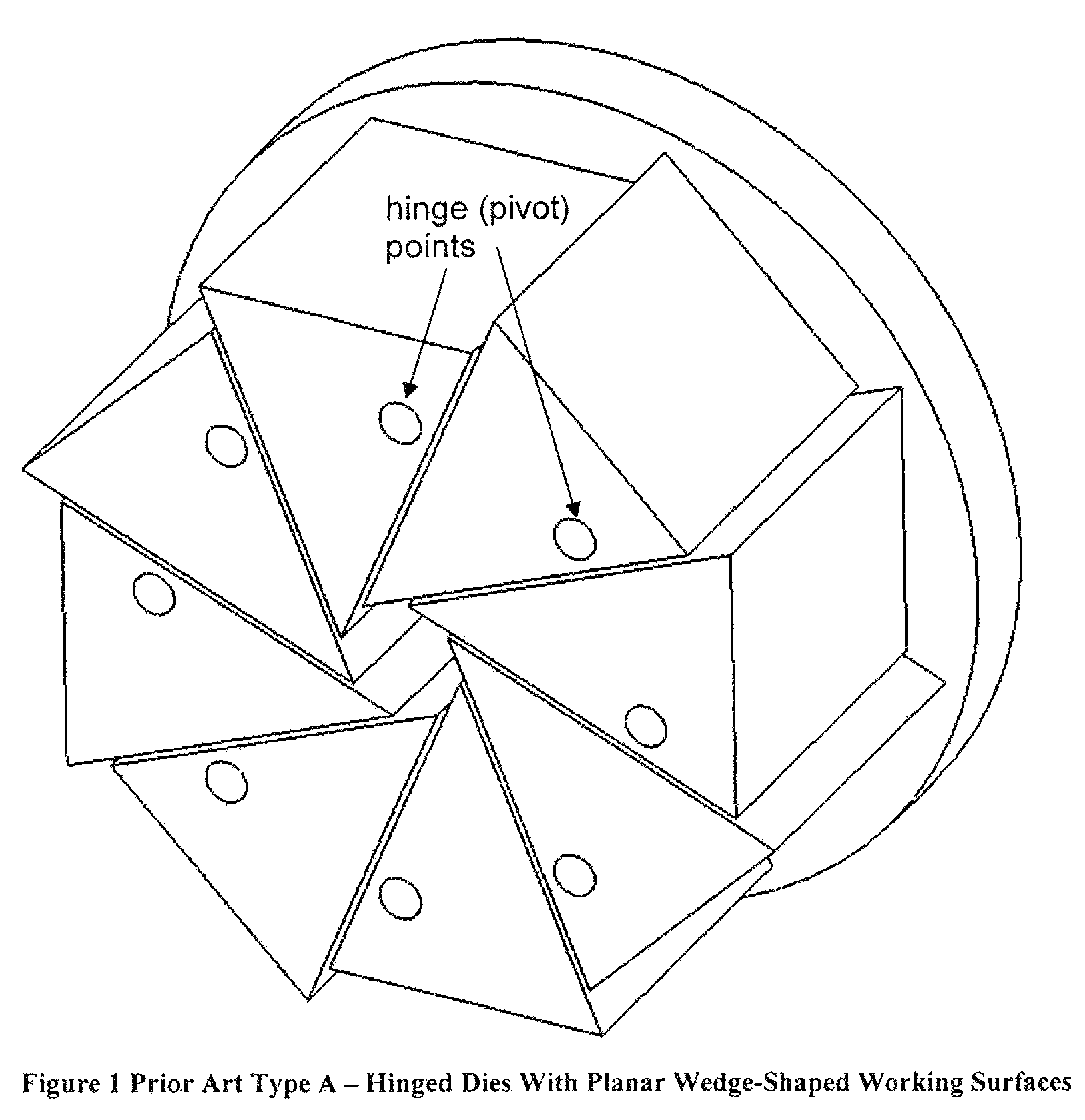

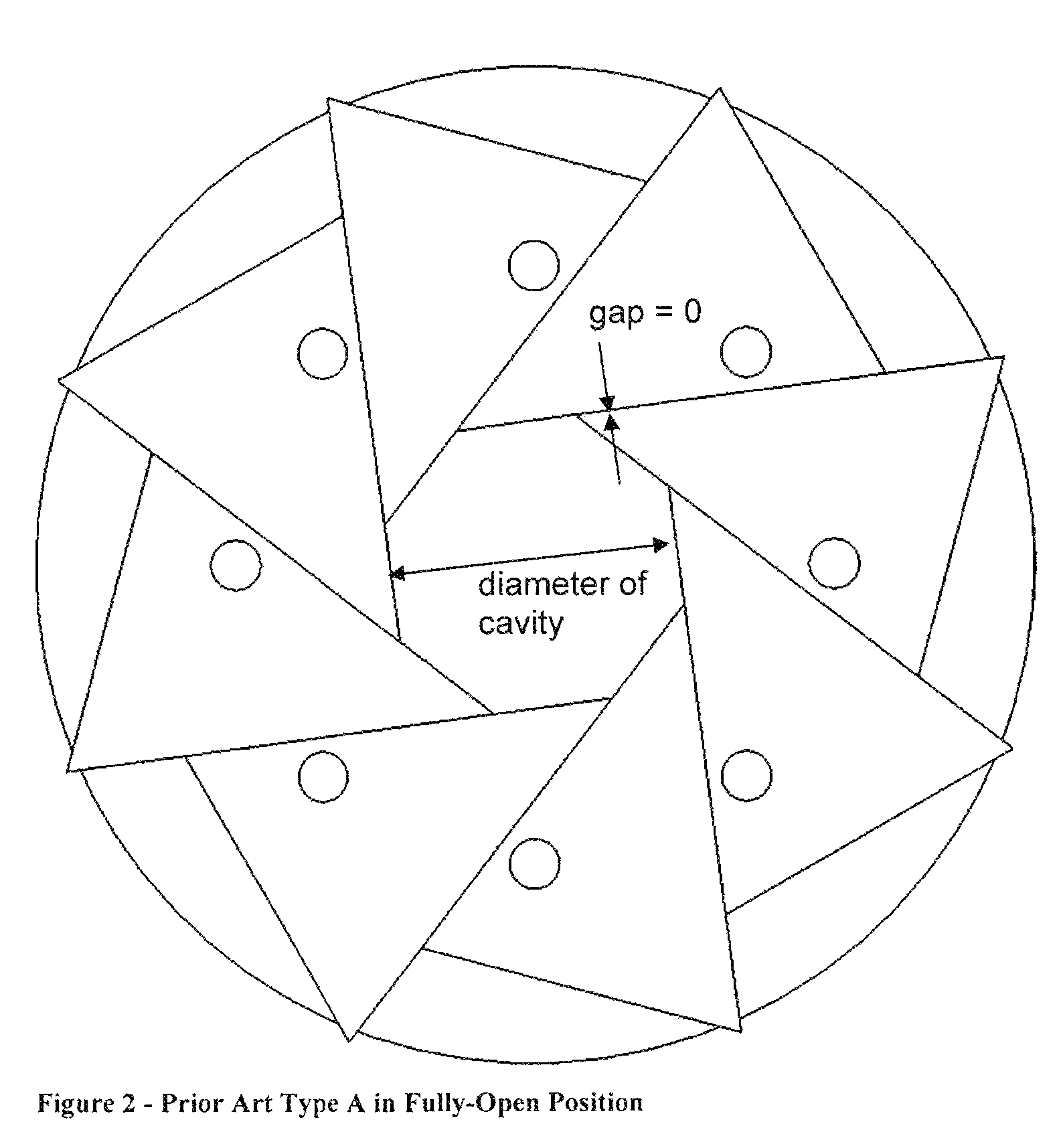

Radial compression mechanism with optimum die-to-die gap

Radial compression mechanism includes a plurality of dies each having an elongated arcuate body with an outer end pivotally attached to a hinge plate and an inner working tip. The dies are mounted on the hinge plate in an inwardly spiraling orientation with the outer ends positioned in a circle and the working tips cooperating to define a central product-receiving cylindrically-shaped cavity. The product-receiving cavity is transitional between an open and a closed orientation. The working tip of each die has a sliding surface and a working surface with the sliding surface positioned in parallel juxtaposition to the working surface of an adjacent die and a constant width gap therebetween. Driving mechanism is coupled to rotatably drive all of the dies in unison to transition between open and closed orientations. The width of the gap remains constant during transition and between the open and closed orientations.

Owner:GOFF ED

Radial compression mechanism with optimum die-to-die gap

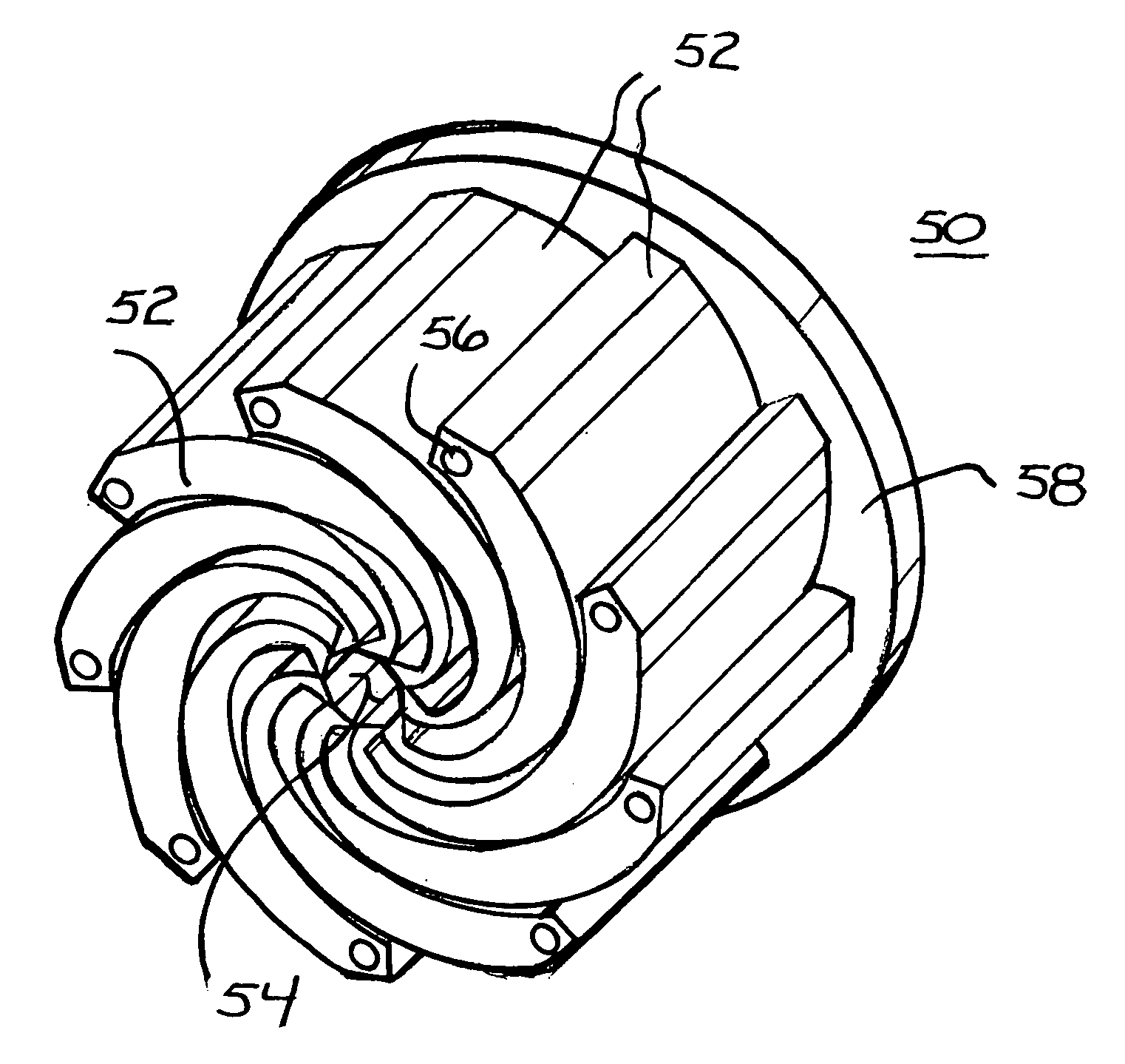

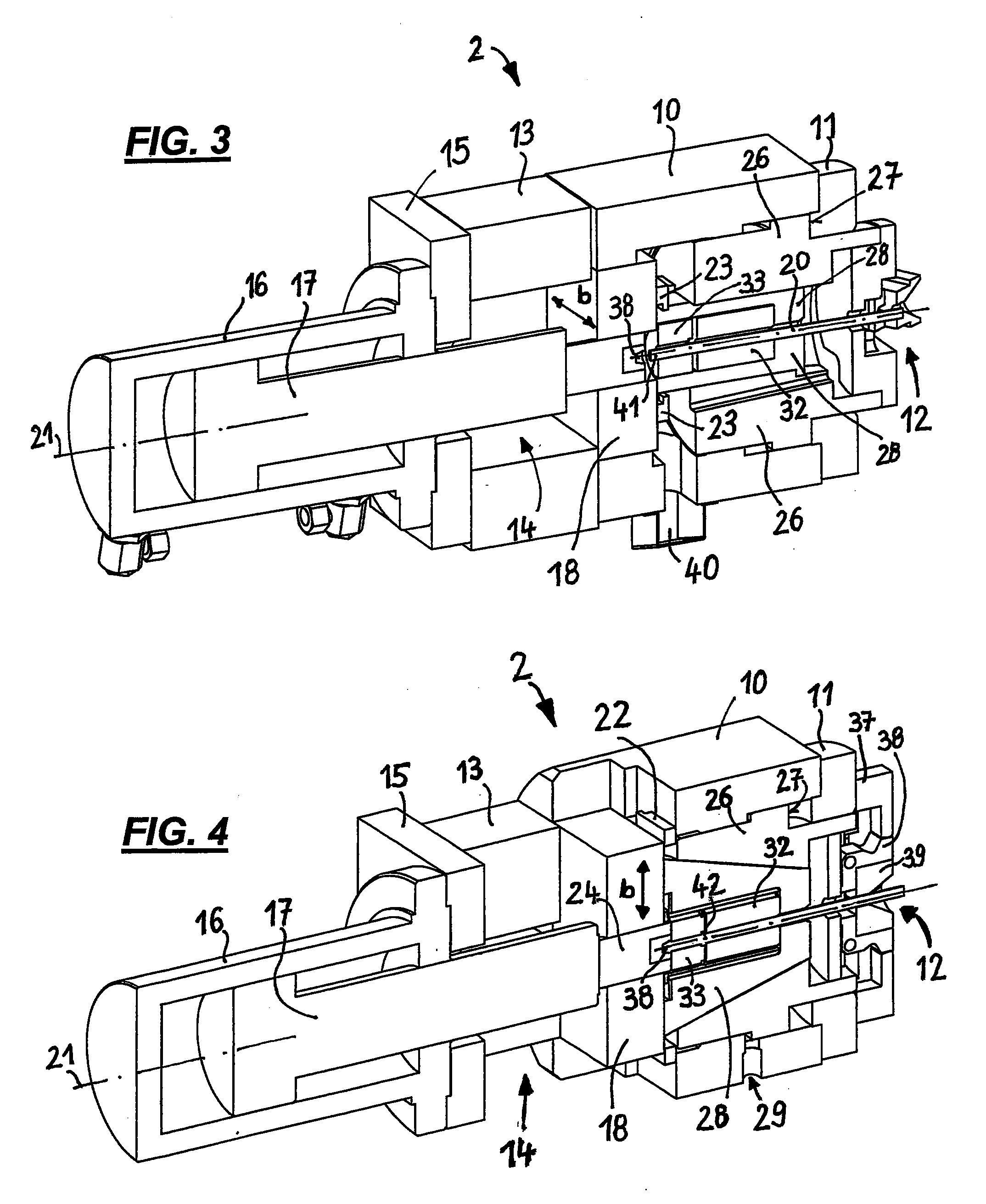

ActiveUS8245559B1Large usable size rangeReduce forceForging hammersUpsetting pressesReciprocating motionRadial compression

Radial compression mechanism includes a housing defining an inner chamber and a central opening for insertion and removal of product. A plurality of elongated compression dies are movably mounted for reciprocal movement within the inner chamber and define a central product receiving cavity coaxial with the axis of the central opening. Cam followers are affixed to the dies. First cam surfaces are affixed relative to the housing and second cam surfaces are movably mounted relative to the housing. Each cam follower engages a first cam surface to define a first position control constraint, and a second cam surface to define a second position control constraint. Each die has a position relative to each adjacent die and the coaxial central cavity that is controlled by the first position control constraint and the second position control constraint.

Owner:WARRINER JEREMIAH J +2

Radial compression mechanism with optimum die-to-die gap

Radial compression mechanism includes a plurality of dies each having an elongated arcuate body with an outer end pivotally attached to a hinge plate and an inner working tip. The dies are mounted on the hinge plate in an inwardly spiraling orientation with the outer ends positioned in a circle and the working tips cooperating to define a central product-receiving cylindrically-shaped cavity. The product-receiving cavity is transitional between an open and a closed orientation. The working tip of each die has a sliding surface and a working surface with the sliding surface positioned in parallel juxtaposition to the working surface of an adjacent die and a constant width gap therebetween. Driving mechanism is coupled to rotatably drive all of the dies in unison to transition between open and closed orientations. The width of the gap remains constant during transition and between the open and closed orientations.

Owner:GOFF ED

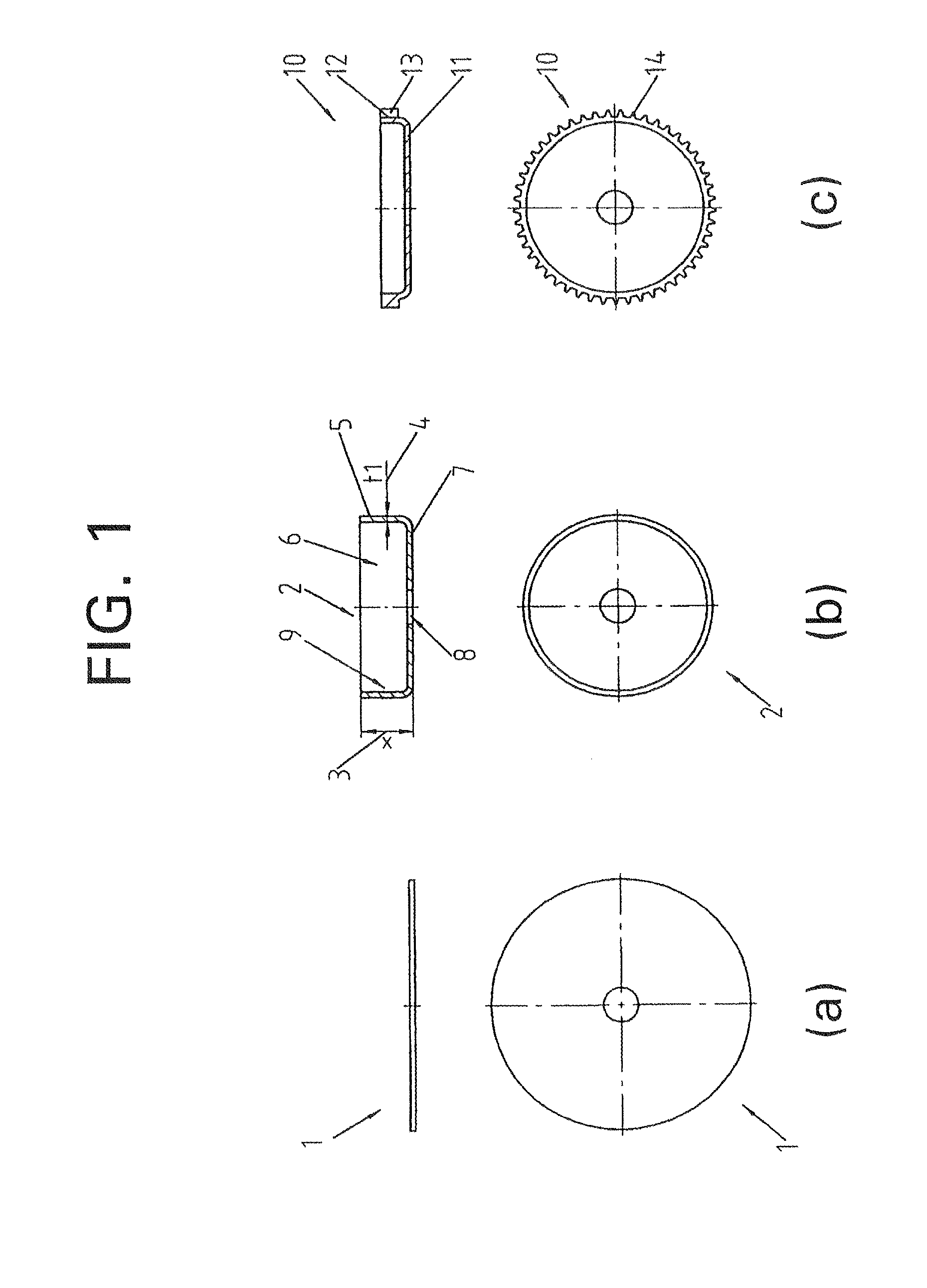

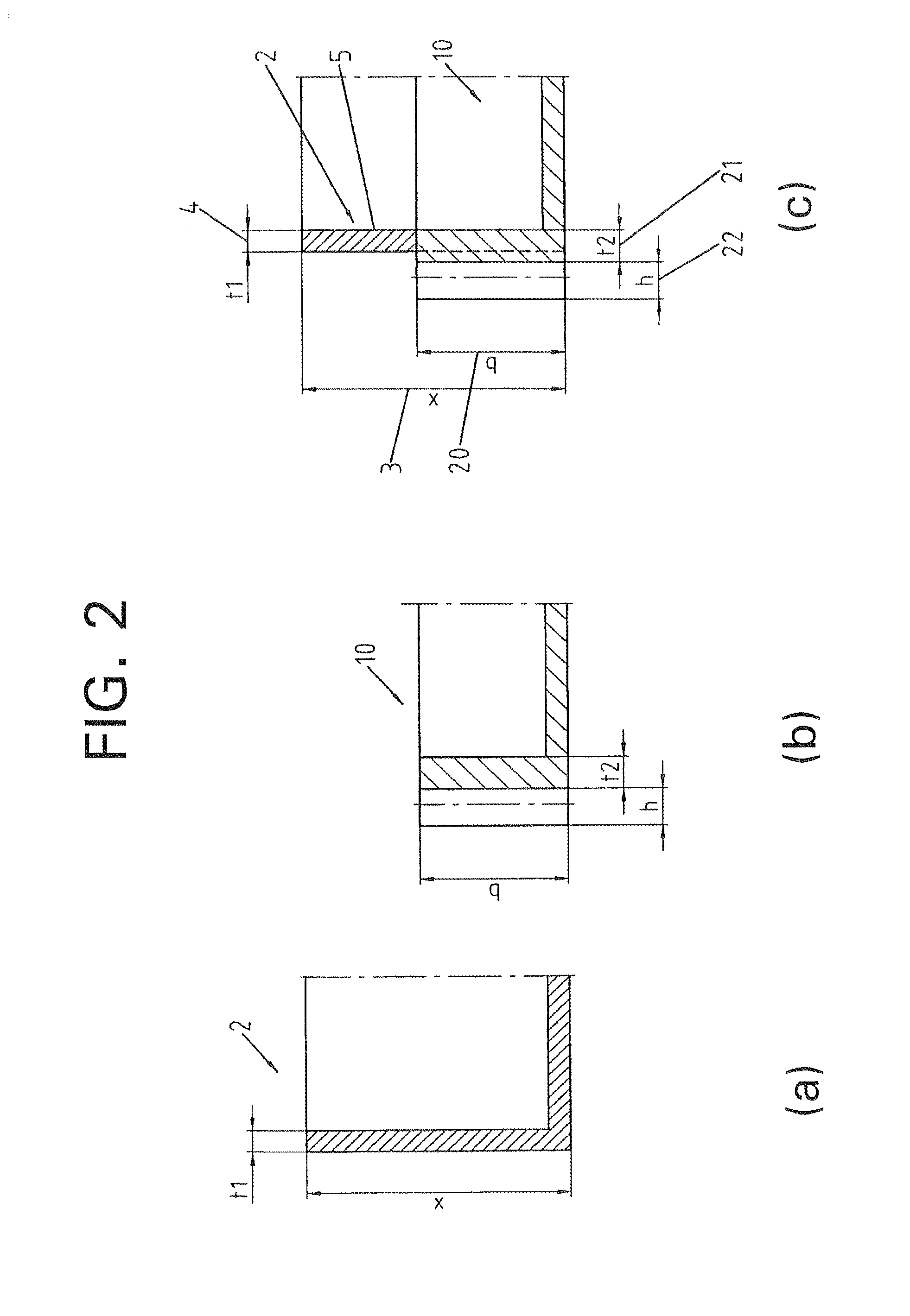

Method and tool for producing a component and a component produced by forming

The invention relates to a component, a method, and a tool for forming, in particular for the lateral extrusion or upsetting of thin-walled preforms to form components having a structure formed thereon, in particular having a toothing, wherein, by carrying out the method according to the invention and by using the tool according to the invention, buckling of the wall of the preform during the forming process to form the component according to the invention is prevented.

Owner:SCHULER CARTEC

Forging press used for metal machining

InactiveCN107999676AEasy to clamp and fixAvoid affecting the effect of processingUpsetting pressesSwagging pressesMetal machiningEngineering

The invention discloses a forging press used for metal machining, and relates to the technical field of metal forging. The forging press used for metal machining comprises a base plate. Fixed columnsare fixedly connected to the two sides of the top of the base plate correspondingly, and a workbench is movably connected to the surfaces of the two fixed columns. A vertical plate is fixedly connected to the left side of the top of the workbench. A lead screw is rotatably connected to the right side of the vertical plate. Movable blocks are connected to the two sides of the surface of the lead screw in a threaded mode, and clamping plates are fixedly connected to the surfaces of the movable blocks. A transverse plate is fixedly connected to the top ends of the fixed columns. A moving device is fixedly connected to the top of the transverse plate. According to the forging press for metal machining, a workpiece can be clamped and fixed conveniently, the situation that the machining effect is affected due to deviation of the workpiece in the machining process is avoided, and the safety in the machining process is improved; and the position of a forging device can be changed convenientlyso that different positions of the workpiece can be forged, the operating mode is flexible, manual operation is facilitated, and working efficiency is improved.

Owner:王传忠

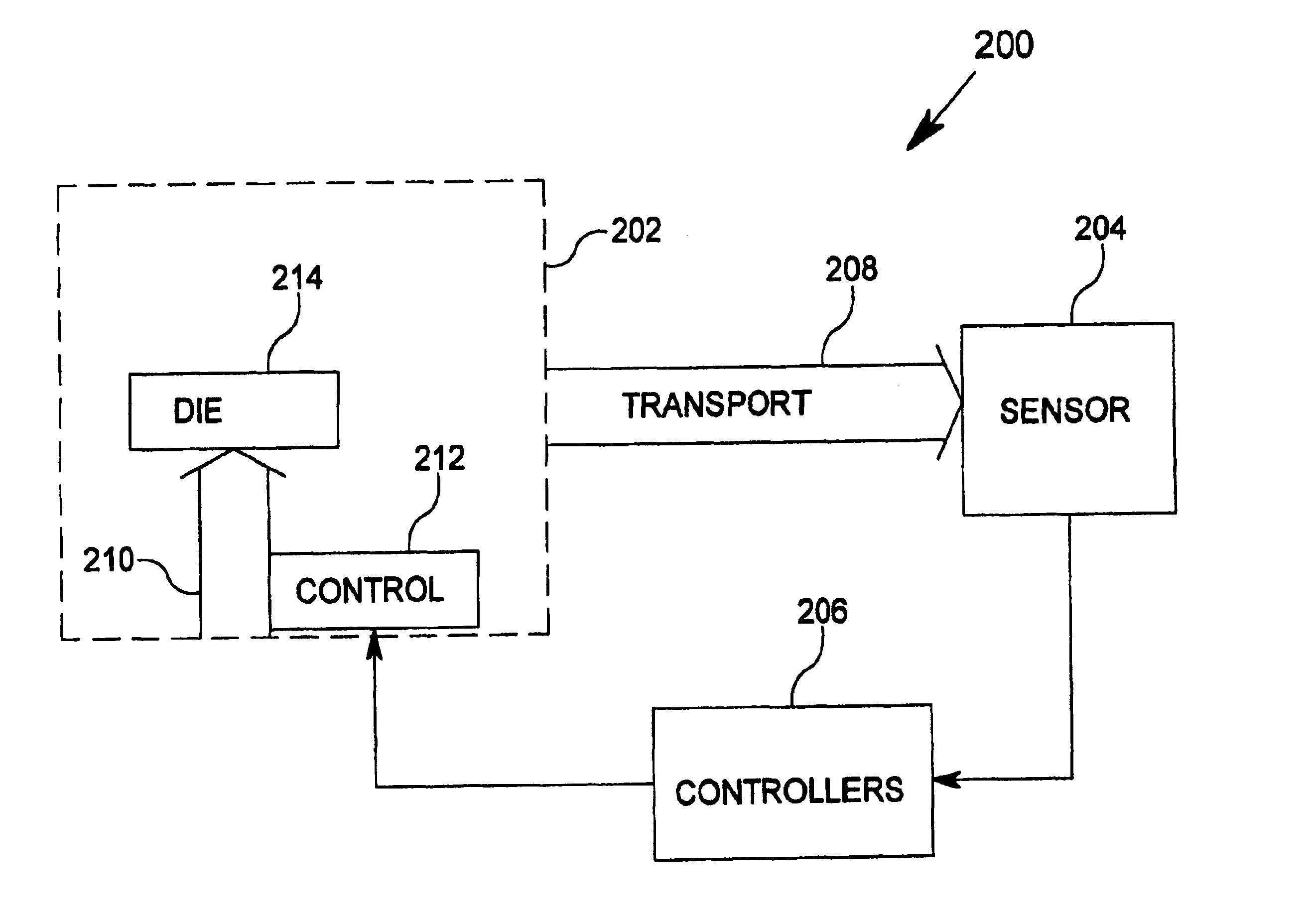

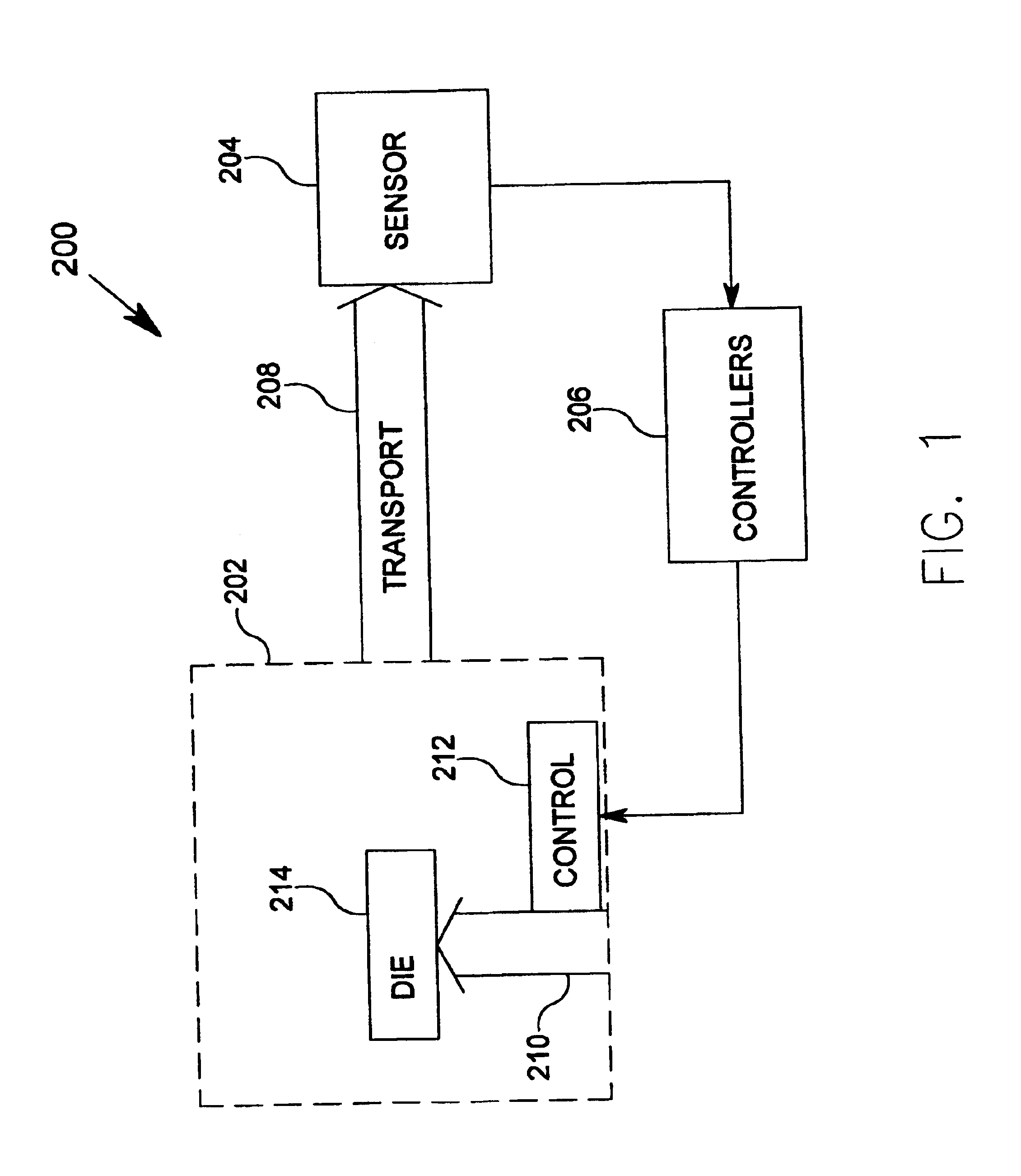

Swaging feedback control method and apparatus

A swaging system includes a swaging assembly, a sensor, and a controller. The swaging assembly includes a movable tool, the movable tool operate to exert force on a die. The die is configured to reduce a dimension of a work piece responsive to the exerted force, the dimension reduction having a relationship to a stroke of the movable tool. The sensor is operable to obtain information including a measurement of the reduced dimension of the work piece. The sensor is operable to generate a measurement signal representative of the obtained information. The controller is operably coupled to receive the measurement signal from the sensor, and is operable to cause adjustment the stroke of the movable tool responsive to the measurement signal.

Owner:BARTROM MICHAEL A +1

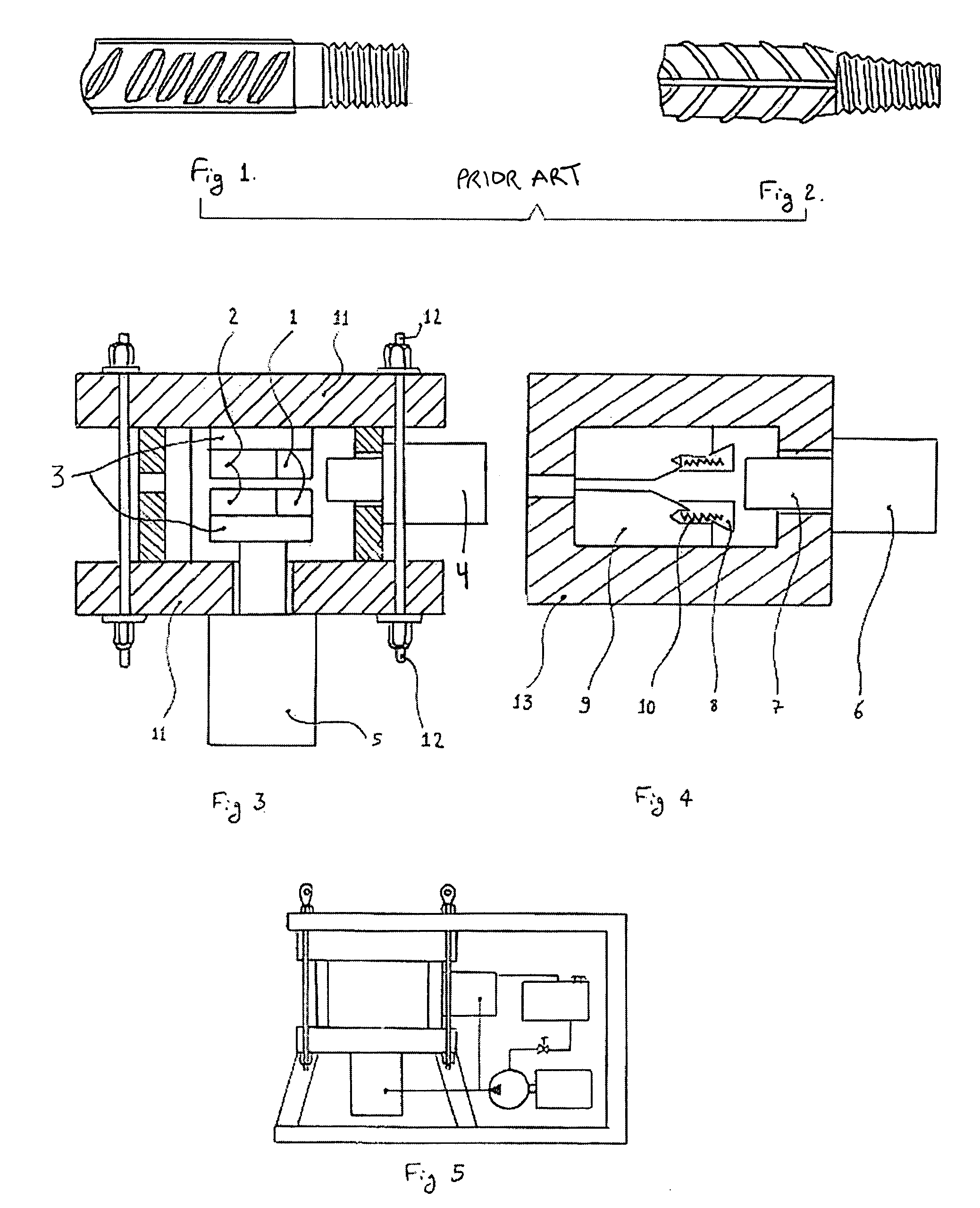

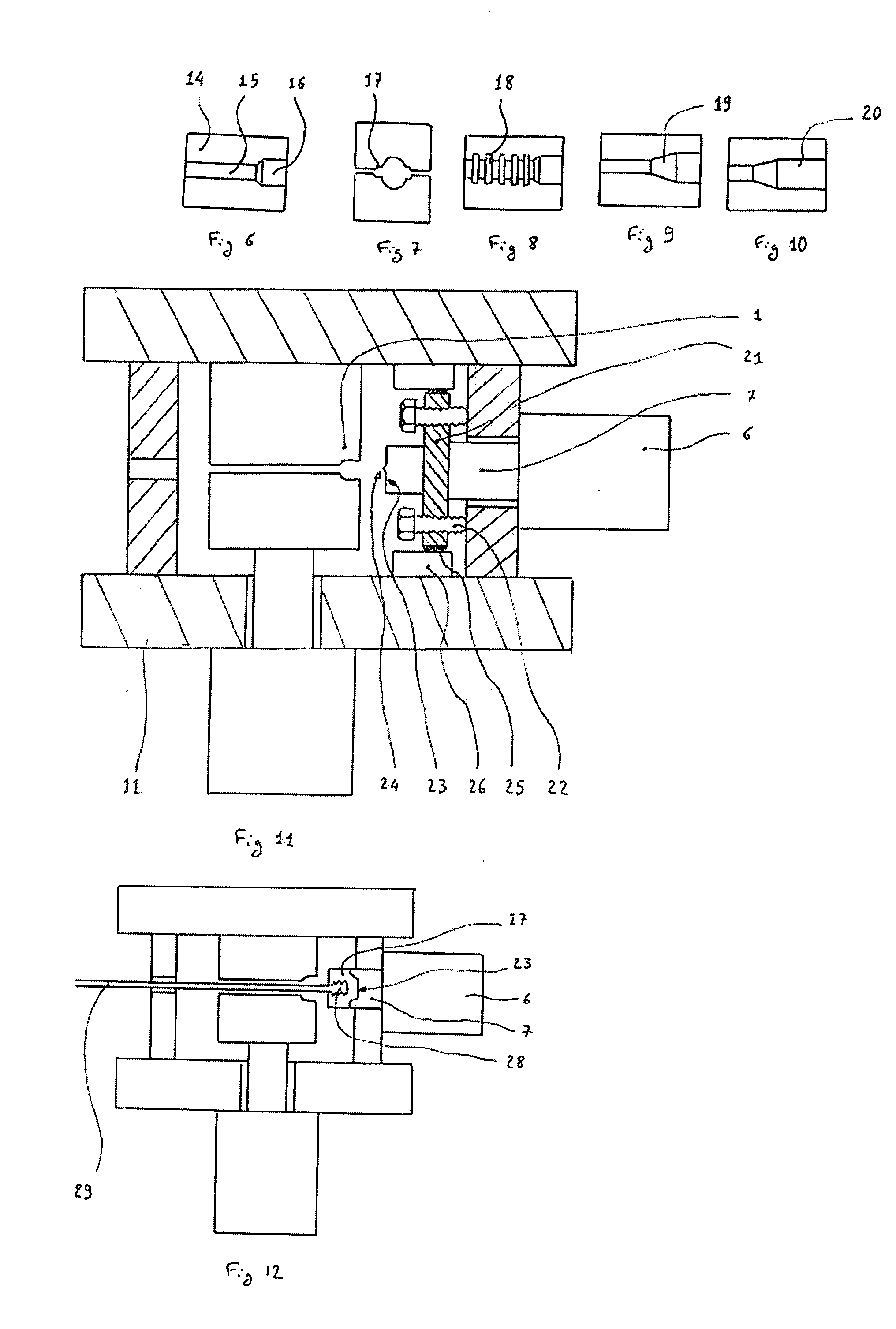

Method and device for producing fixing or connection components with radial outer contours, in particular screws or threaded bolts

InactiveCN101658894AHigh mechanical load capacityBoltsUpsetting pressesEngineeringMechanical engineering

A method of manufacturing fastenings or fasteners with radial outer contours, especially screws or threaded bolts, made of solid metal is performed by a device. The method manufactures the fasteningsor fasteners preferably on a multi-stage press. Several recesses running in an axial direction at a fixed radial distance are formed in the shank-shaped section of a blank. The prefabricated blank with the recesses is inserted into a multi-part split mold within a multi-stage press, whose die stocks have an inner profiling forming the outer contour, and are opened in the starting position, that atthe places where the die stocks are opened, there are the recesses. During the closing movement of the die stocks, at least one radial outer contour is pressed on the shank-shaped section of the blank by radial action of forces, with the recesses preventing material from getting between the die stocks during the pressing process.

Owner:SIEBER FORMING SOLUTIONS

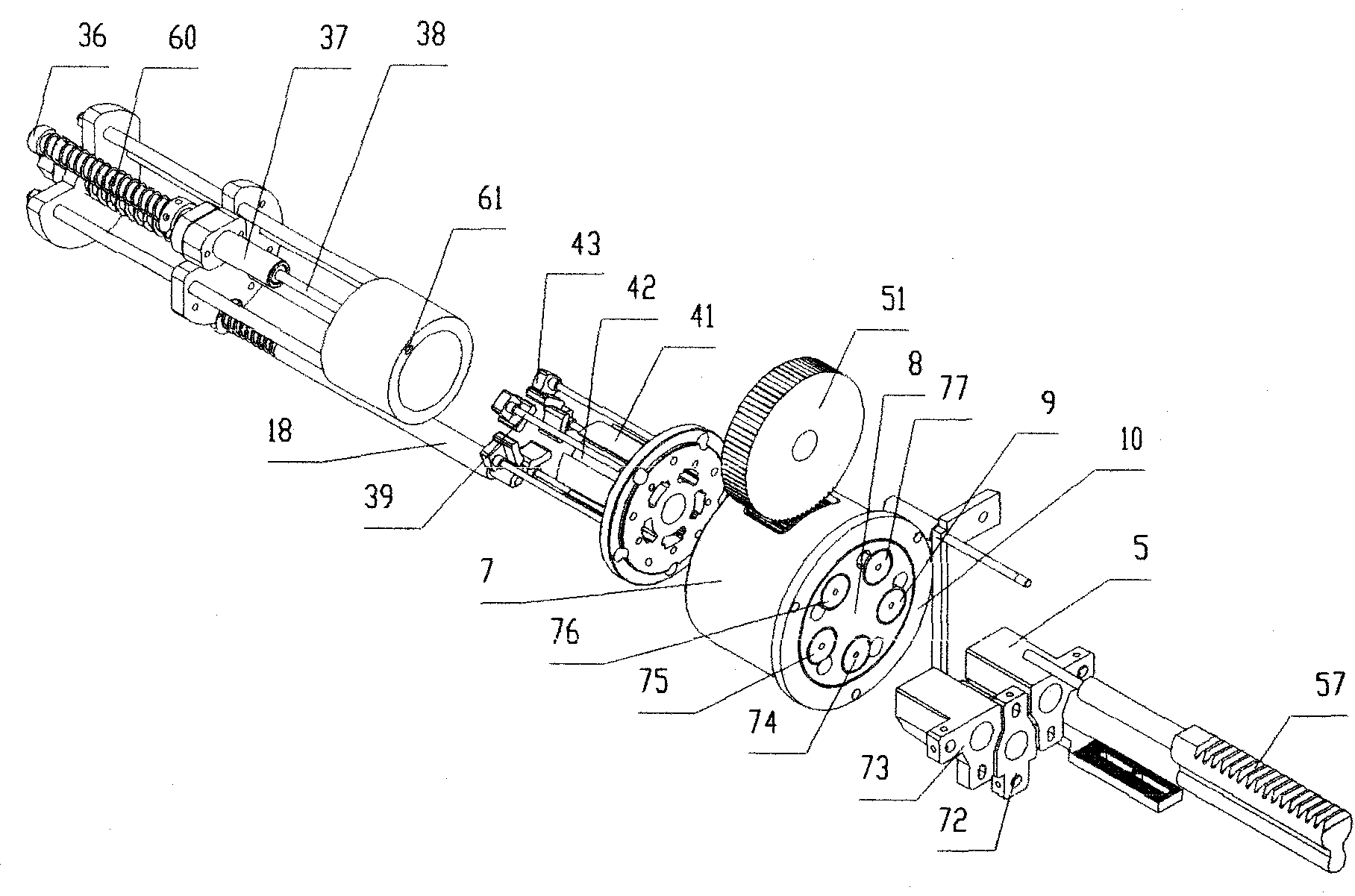

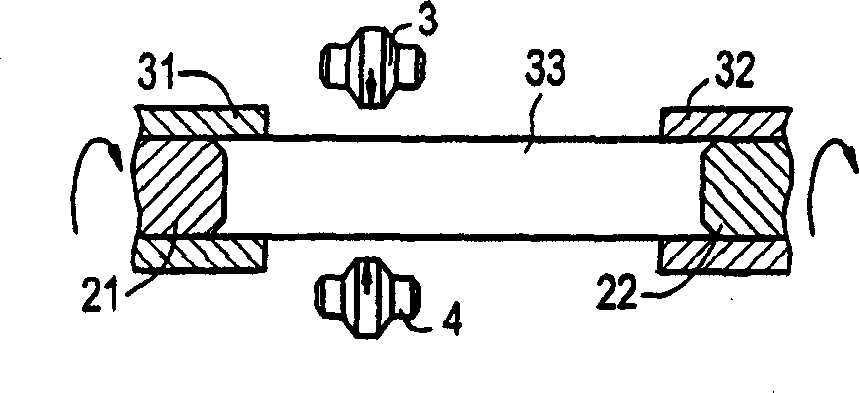

Cold forging machine capable of forging two ends

ActiveCN102641979AUpsetting forming effect is goodUpsetting pressesSwagging pressesEngineeringReciprocating motion

The invention relates to a cold forging machine capable of forging two ends, which mainly solves the problem that the existing cold forging machine cannot realize the technology of completing the even upsetting of both ends of a blank at one time. The cold forging machine capable of forging two ends comprises a rack, a material delivering mechanism, an upset head mould, a first stamping mechanism and a drive mechanism, wherein a feed hole for allowing the blank to extend into is arranged on the rack, the material delivering mechanism consists of a first pushing mechanism and a second pushing mechanism, the cold forging machine capable of forging two ends further comprises a mould core and a second stamping mechanism, the mould core consists of a left half mould core and a right half mould core and is used for clamping the blank, a linear reciprocating movable end of the first pushing mechanism is fixedly connected with the left half mould core, the linear reciprocating movable end of the second pushing mechanism is fixedly connected with the right half mould core, and the second stamping mechanism is used for driving a lower mould to do linearly reciprocating movement; and the first stamping mechanism and the second stamping mechanism are matched and simultaneously form first top press fit with both the end parts of the blank, and the second stamping mechanism is also used for forming the second top press of the lower mould and the blank, so that the blank is separated from the lower mould.

Owner:ZHEJIANG JINRUI HARDWARE RIGGING

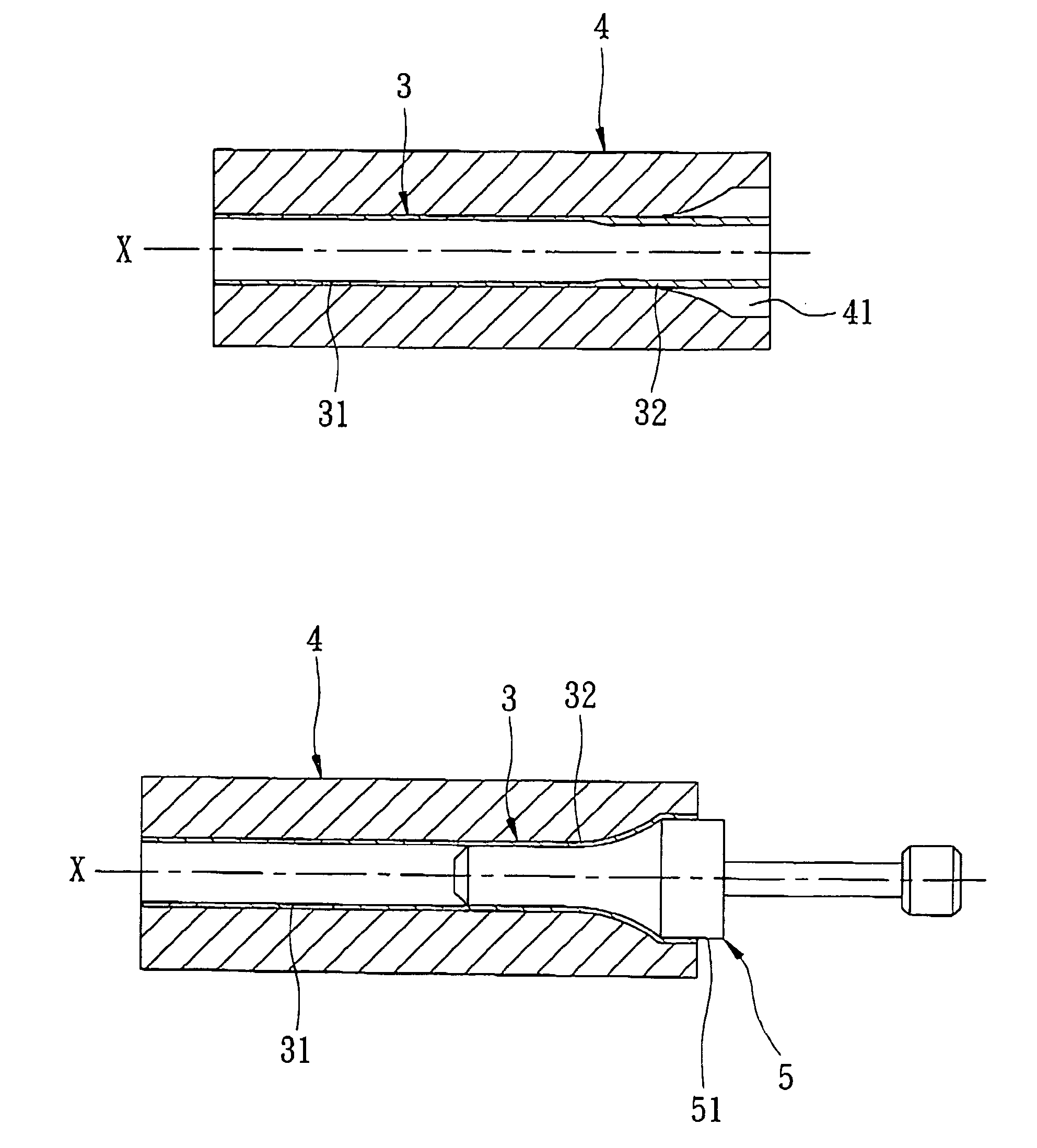

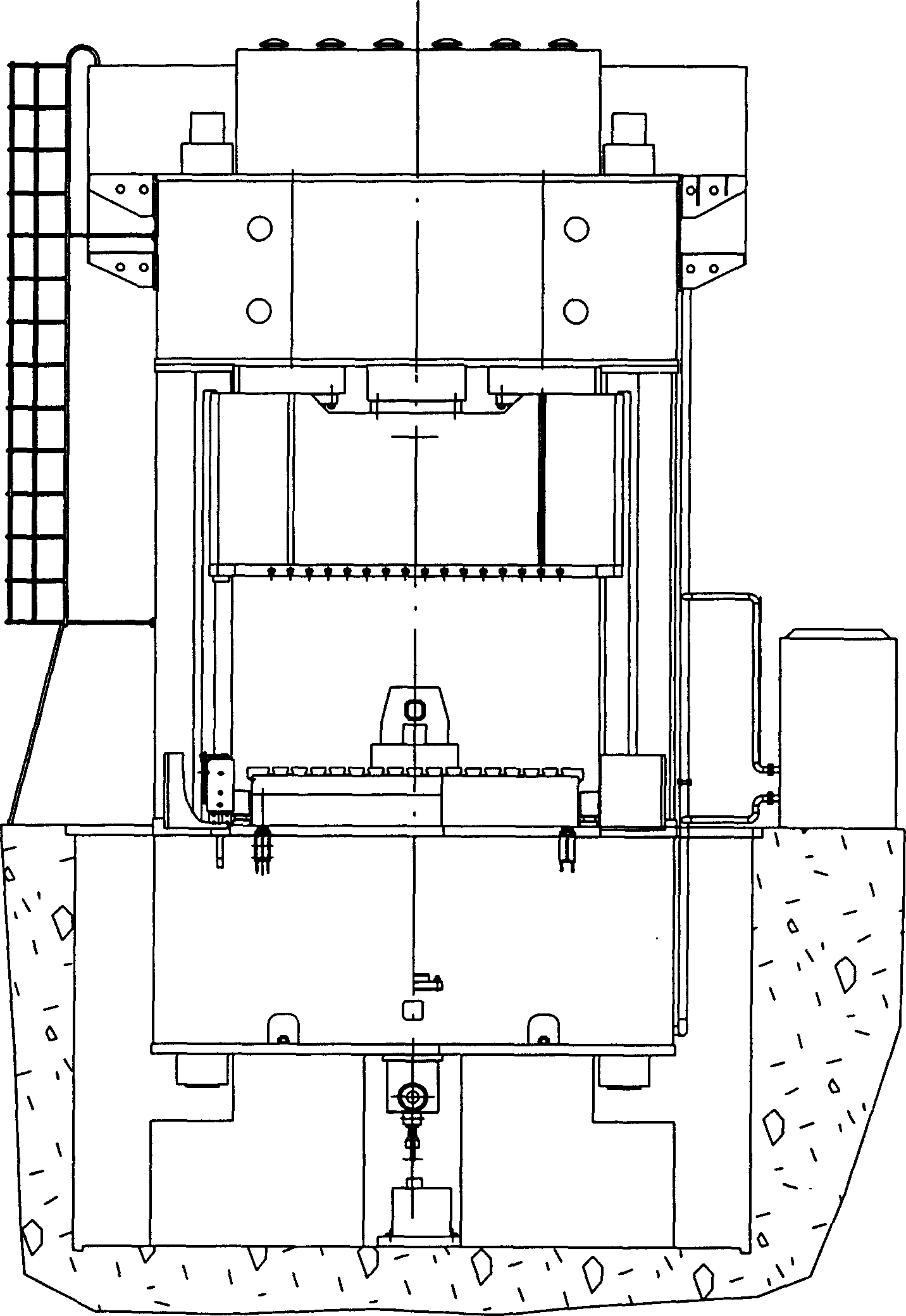

Process for Upset Forging of Drill Pipe and Articles Produced Thereby

ActiveUS20150096346A1Thicker upsetSmall inner diameterShaping toolsDrilling rodsEngineeringUpset forging

Shown is a method for manufacturing horizontal directional drilling pipe having internally and externally upset pipe ends. The forging is done by heating the green tube ends and applying pressure using a closed die hydraulic forging press to form the upsets. One end of a steel tube is worked by upsetting and pressing to form an external upset portion having an outer taper being shaped by upset forging. That portion is then pressed by an internal upset die so as to displace the outer taper to an internal upset portion having an inner taper. Internal upset forging is then carried out by an internal upset die to produce the finished part. The process allows the manufacturer to produce a thicker upset horizontal directional drilling pipe, where the ratio of the outside diameter to the inside diameter of the upset can be on the order of 3.5, or even greater.

Owner:HUNTING ENERGY SERVICES LLC

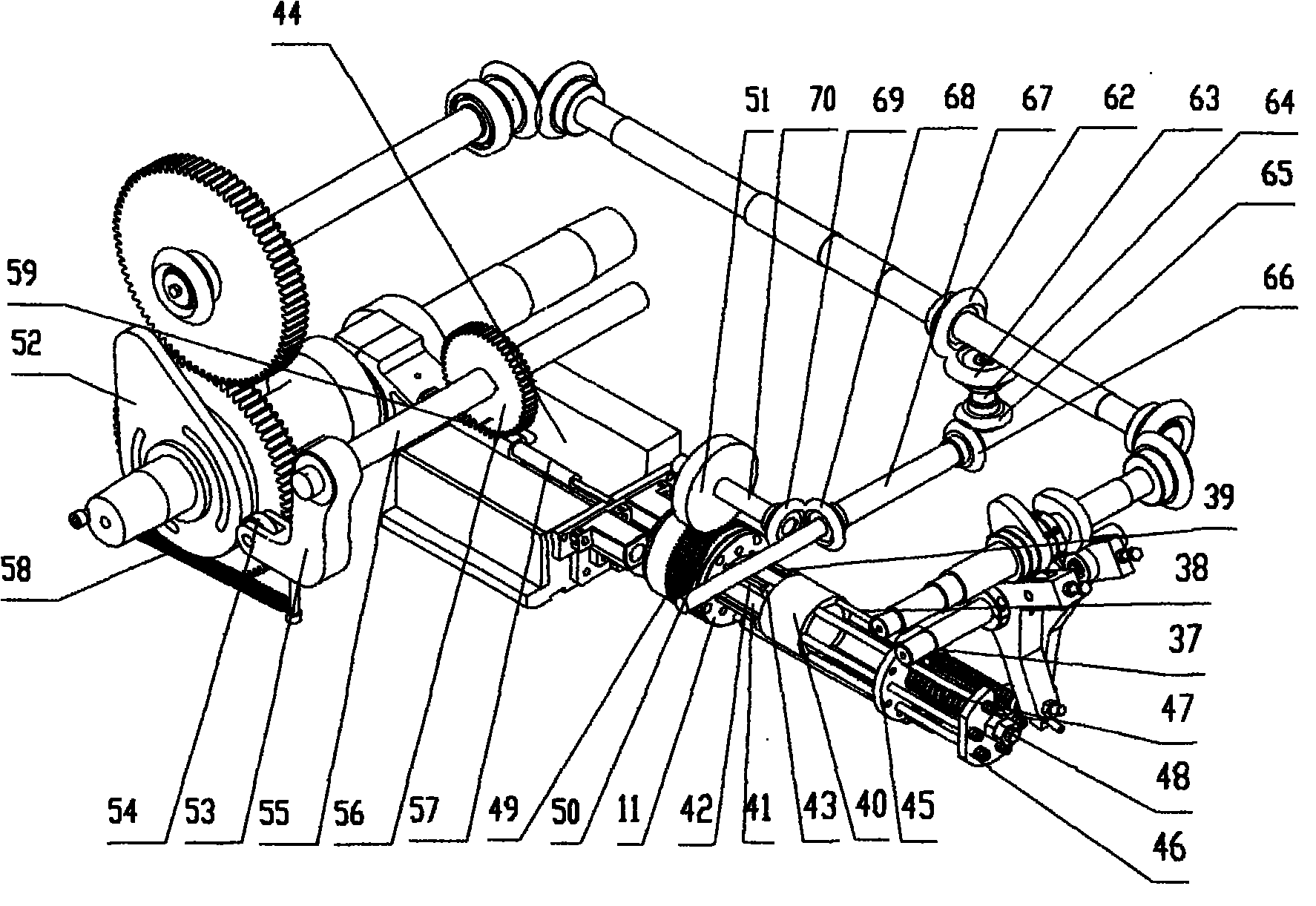

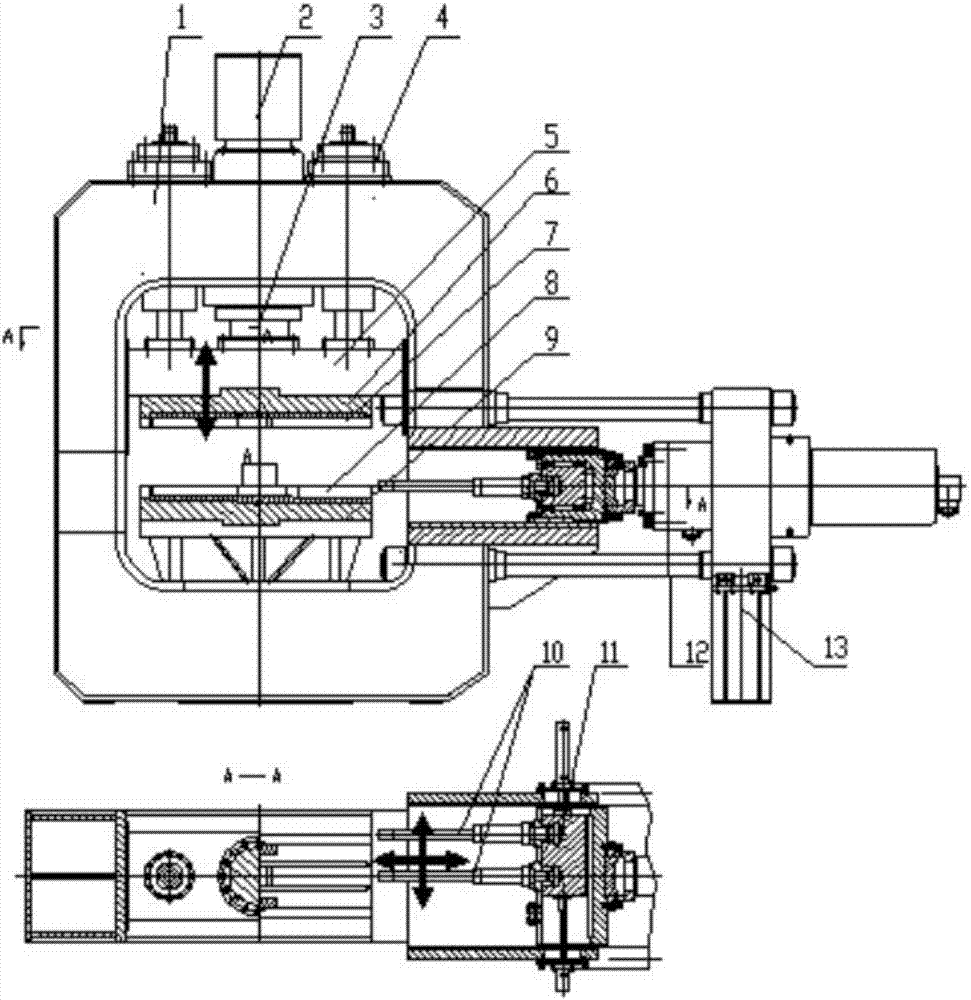

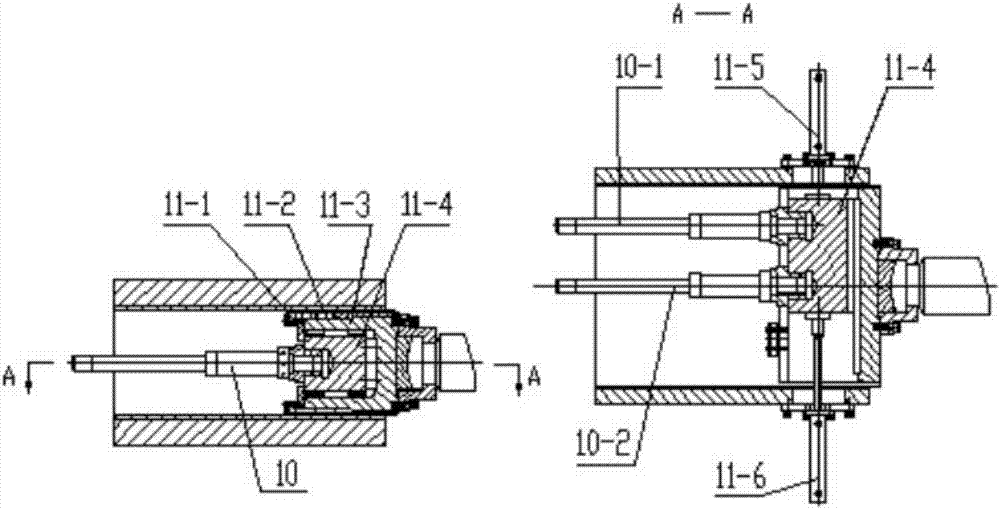

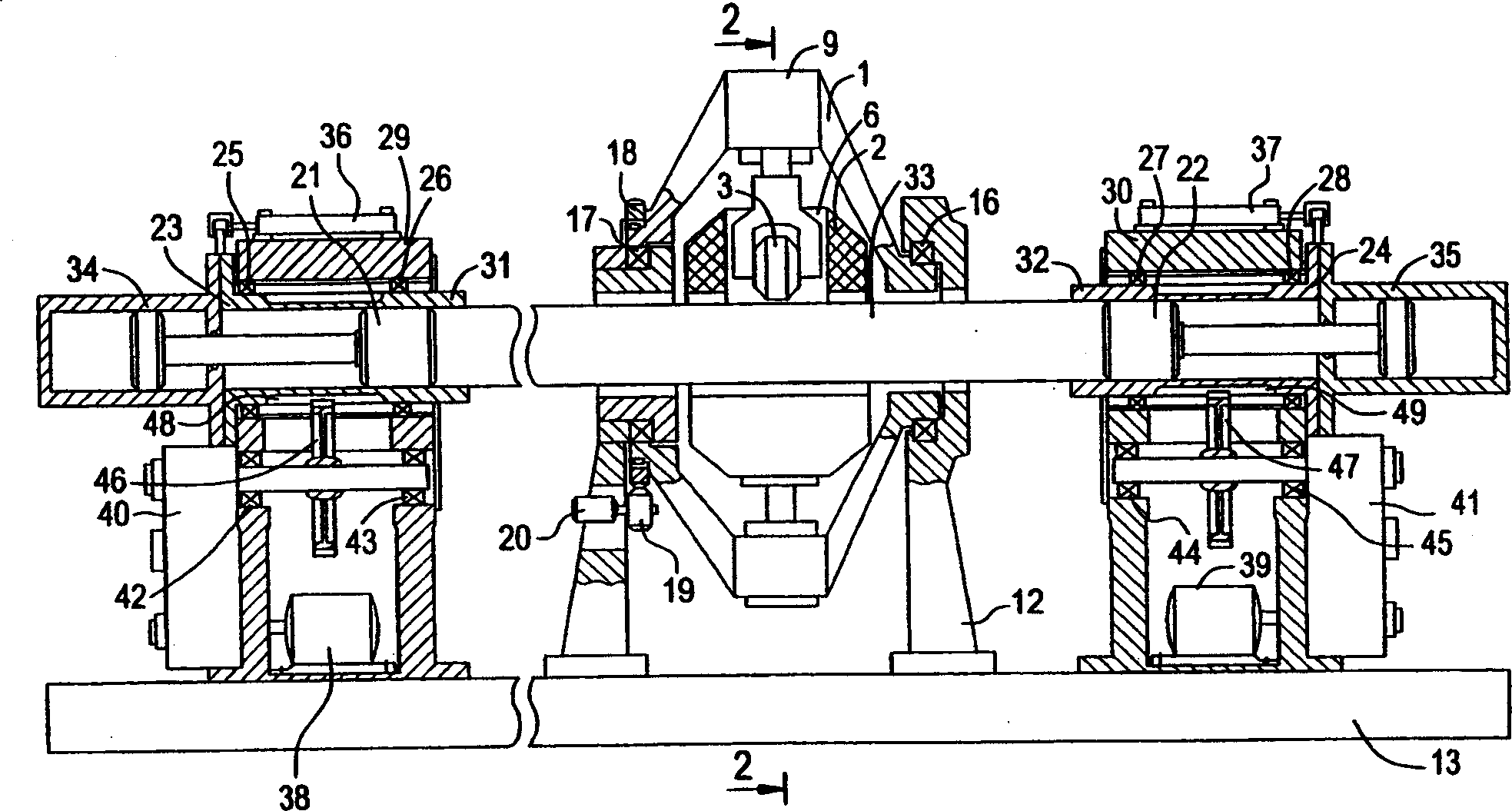

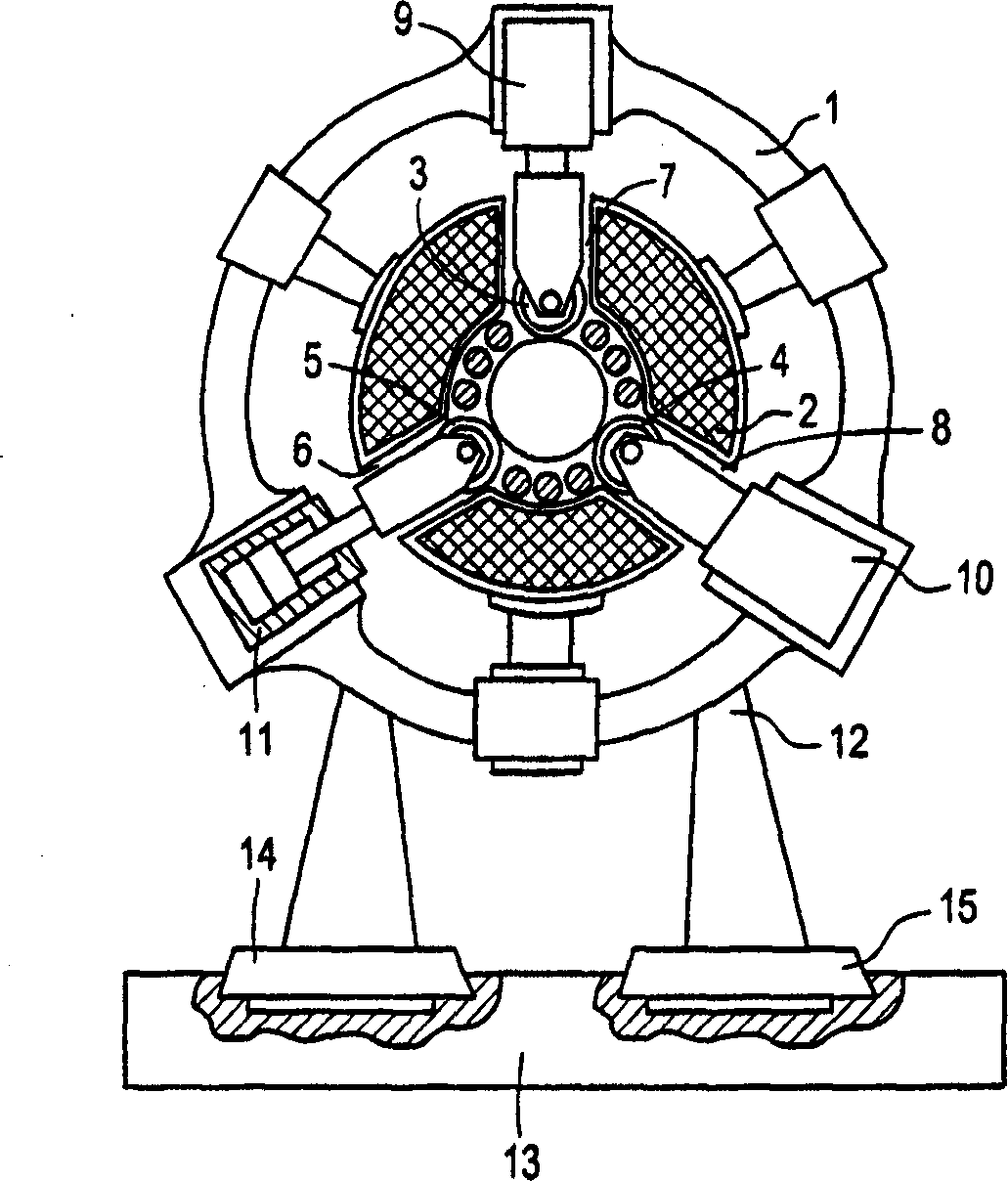

Cavity die rotating upsetter and operating method thereof

InactiveCN101817054ARapid UpsettingImprove work efficiencyPinsUpsetting pressesMechanical engineering

Owner:杨东佐

Machine for processing head of pipe fitting

InactiveCN101376157AUniform wall thicknessEasy to processUpsetting pressesSwagging pressesPipe fittingUltimate tensile strength

The invention relates to a pier head machine for pipe fittings which comprises a stander, a first moulding die, a second moulding die and a pier head. Grooves are formed on the opposite side surfaces of the first moulding die and the second moulding die; a flaring groove part is formed at the rear end of the groove; the pier head is composed of a pier part and a piercing pole; a flaring groove is formed on the pier part. When the pier machine of pipe fittings is in a first working state, the first moulding die is bonded with the second moulding die; the front end surface of the pier part is propped against the back end surface of the first moulding die and the second moulding die; a pair of grooves are butted to form a cavity used for placing the pipe pieces; the piercing pole is inserted in the pipe fittings; the flaring groove part is butted with the flaring groove to form a space used for entering into the pipe wall. Compared with the prior art, the heading machine has the advantages of convenient and quick processing and easy operation; in addition, the pipe wall of the joint pipe processed by using the pier head machine has even thickness, thereby meeting higher strength requirements and having longer service life.

Owner:庄添财

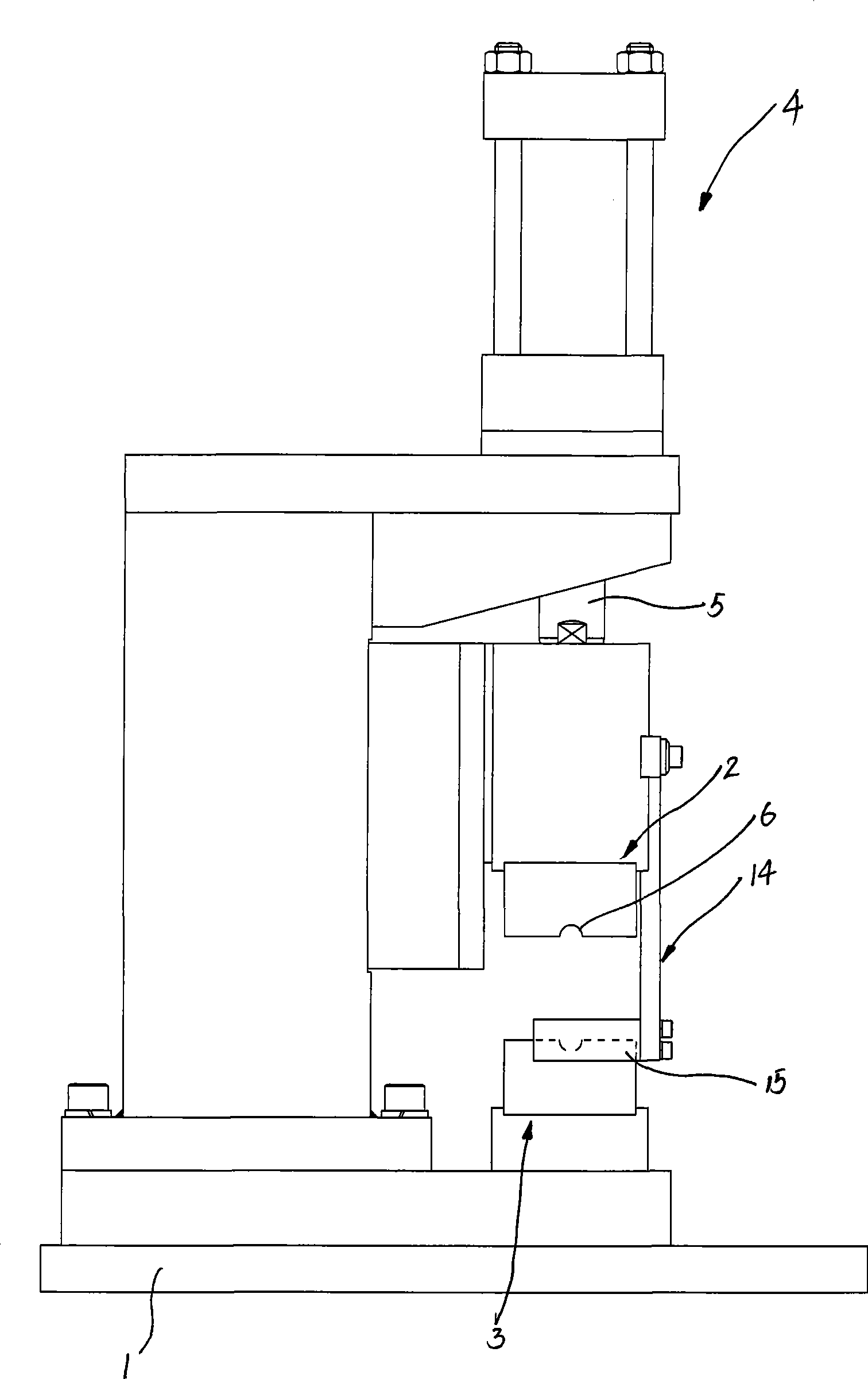

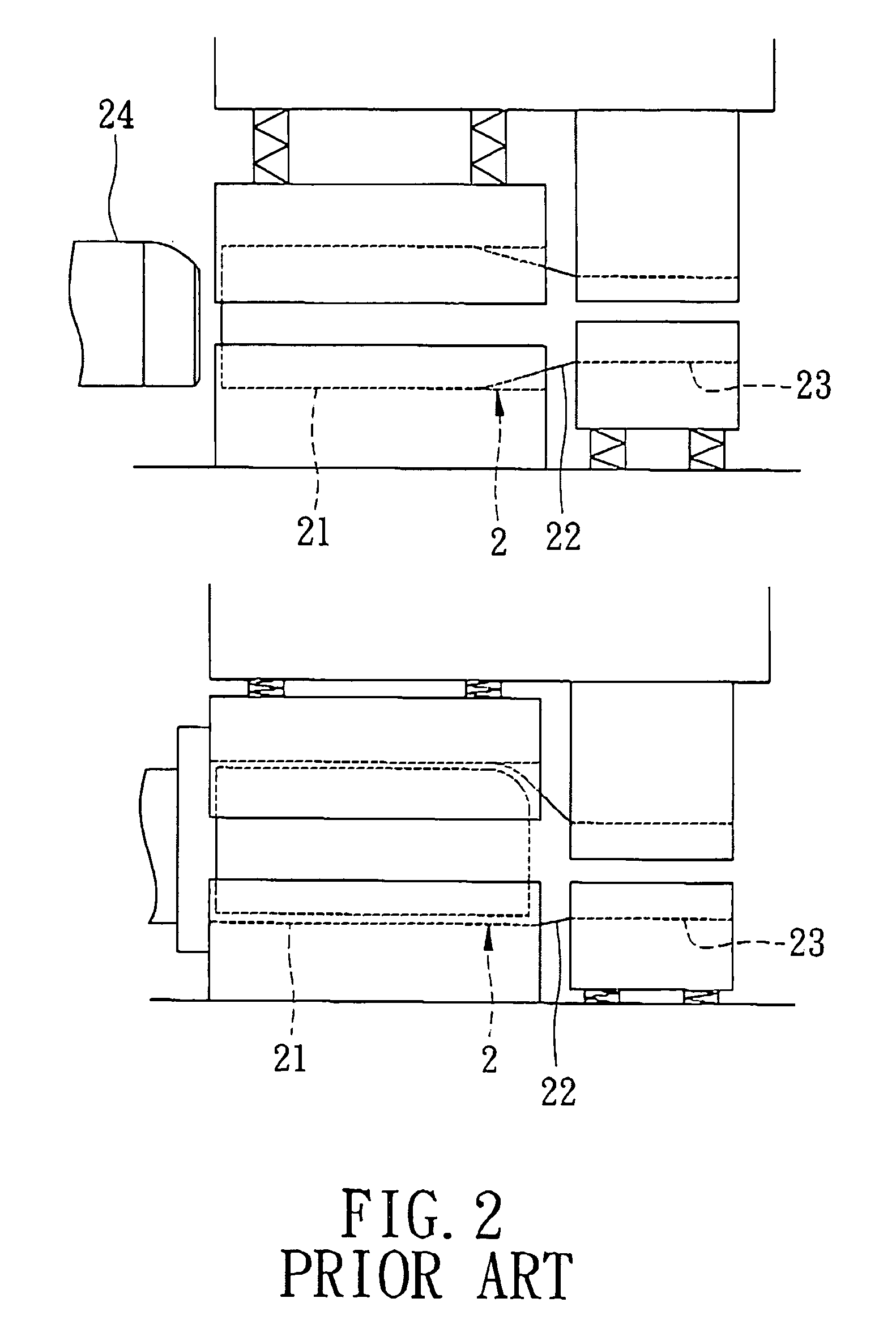

Double-punch upsetting machine

The invention discloses a double-punch upsetting machine which comprises a rack. A charging oil tank is installed at the upper portion of the rack. The charging oil tank communicates with a main cylinder fixed to the rack. A piston rod of the main cylinder is connected with a movable beam. The movable beam is connected with a return cylinder fixed to the rack. The lower portion of the movable beam is connected with an upper die seat, and an upper female die is installed on the upper die seat. A lower female die matched with the upper female die is installed on a lower die seat. The lower die seat is connected with a rack worktable. A punch lateral-moving device is connected to the position, on the side of the rack worktable, on the rack. Two punches installed on the punch lateral-moving device are matched with the rack worktable. The punch lateral-moving device is connected with a piston rod of an upsetting cylinder. The first pass of punch and the second pass of punch can be alternately pushed into a work station through the punch lateral-moving device, and two passes of upsetting can be completed. The double-punch upsetting machine is equivalent to two single-punch upsetting machines, and the equipment cost, the occupied area and the running cost are saved nearly by a half.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Hydraulic upsetter

ActiveCN101890467ALarge upsetting forceFast actionUpsetting pressesSwagging pressesEngineeringMachining

The invention provides a hydraulic upsetter, wherein a die oil cylinder is arranged above a rack, an upset-extruding oil cylinder is installed at one side of the rack, and a push-wedge oil cylinder is installed at a position 90-degree adjacent to the rack; and the oil cylinders respectively and jointly locate, lock and extrude a workpiece in an upset-extruding mould to realize upset-extrusion processing on the workpiece. The hydraulic upsetter of the invention compresses the mould through the die oil cylinder, fixes the mould through the push-wedge oil cylinder and carries out upsetting process on the workpiece through the upset-extruding oil cylinder, and realizes coordinated control and operation through an electromagnetic controller. The hydraulic upsetter has the advantages of large upsetting extrusion force, quick movement speed, good processing quality, energy conservation and wide application range, and is suitable for being applied in upsetting extrusion process on workpieces in the filed of machining.

Owner:葫芦岛龙源采油配套设备有限公司

Method for processing billets out of metals and alloys and article

This method refers to a method by which the physical and mechanical properties intrinsic to a fine-grain structure may be formed in metal billets using pressure treatment. The method is designed to treat rods, bars and other particularly long billets. This method is designed to lower the cost of deformational treatment for long rods and large diameter billets and creates a pre-specified microstructure, including micro-crystal structure, and specific physical and mechanical properties. This may be achieved using various treatment techniques, one of which includes the deformation of at least a part of the billet through reduction of the billets cross-section. In this method, a long rod shaped billet is used. Reduction of the cross-section is achieved using tools that permit movement along and across the billet's axis as well as being rolled about its surface, for example, a roller. In this case at least one support stand is employed for correct placement of the billet. Additionally, a pre-specified strain level is achieved using at least one of the techniques of deformation: torsion, settling and extension using tools, for example the above-mentioned stand. The stand is designed to apply a specified scheme of deformation to the billet at the deformed (strained) section and at a specified temperature. This obtains specified structure with intrinsic physical and mechanical properties.

Owner:GENERAL ELECTRIC CO +1

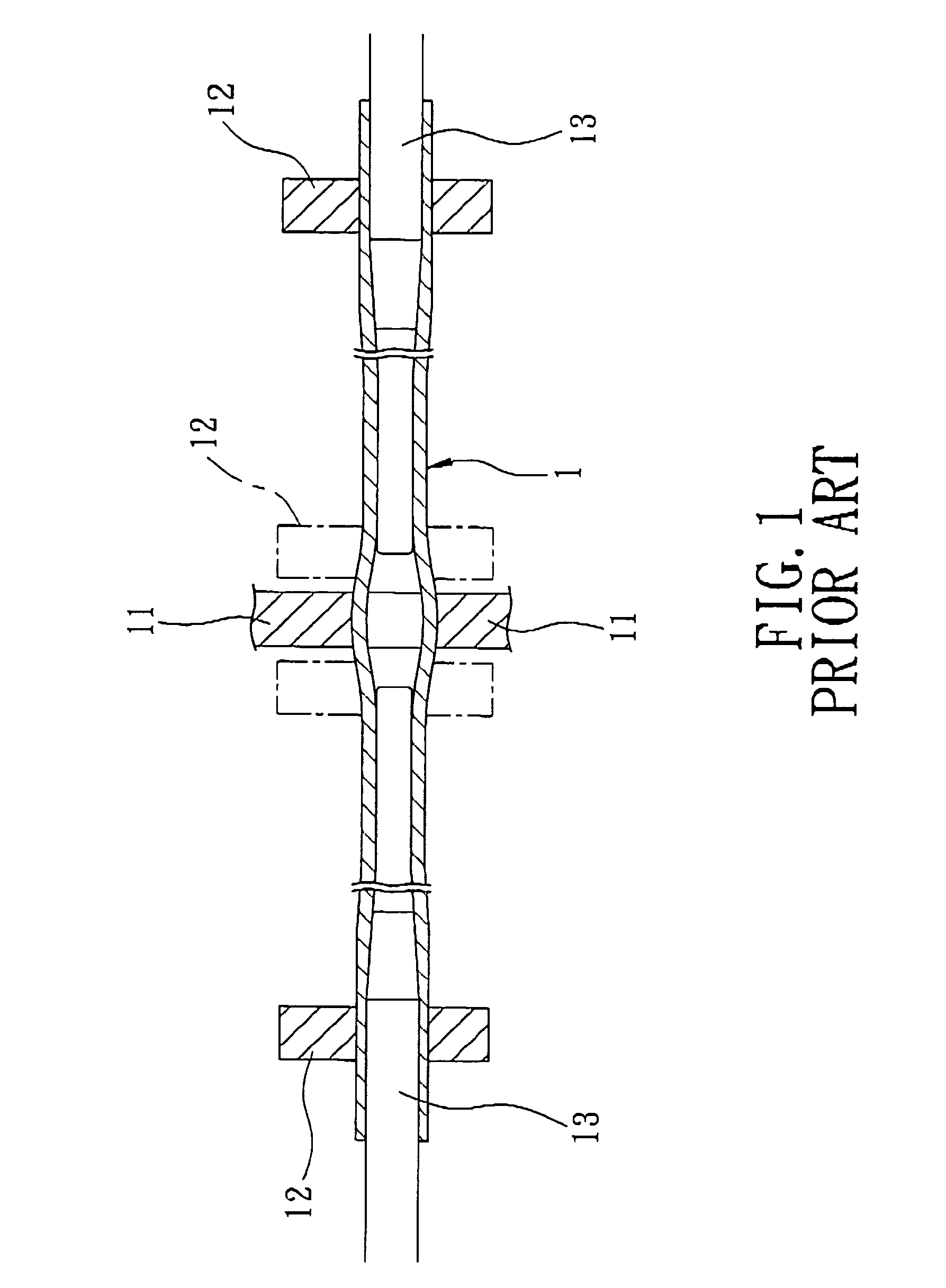

Forging machine for the upsetting of deformed reinforcement bars

ActiveUS20050262914A1Economical and convenient to useForging hammersUpsetting pressesEngineeringSteel bar

Owner:DEXTRA ASIA CO LTD

Methods for making a bicycle frame part having a disproportionally enlarged end section

A bicycle frame part having a disproportionally enlarged end section and a method for making the same. The method may include disproportionally enlarging an end section of an aluminum alloy tube of a bicycle frame part includes the steps of (a) drawing the tube to form a thin section and a thick end section, (b) radially and proportionally enlarging the cross-section of the thick end section of the tube by forging the tube in such a manner that the wall thickness of the thick end section after being enlarged is substantially the same as that of the thin section, and (c) disproportionally varying the cross-section of the thick end section of the tube by forging the tube obtained in step (b).

Owner:GIANT MFG

Cold heading machine

ActiveCN104174802BNot easy to move at high speedImprove stabilityUpsetting pressesSwagging pressesMotor driveEngineering

The invention discloses a cold heading machine. The cold heading machine comprises a machine body, wherein a main motor, a drive system, a linear feeding device, a rotary clamp, a cutter system, an adjustable male die ejecting mechanism and a closed back support are arranged on the machine body; the main motor is arranged at a first end of the machine body, and the drive system is arranged at an output end of the main motor; the linear feeding device is arranged at a second end of the machine body, and the closed back support is arranged on one side of the feeding device; the rotary clamp and the male die ejecting mechanism are arranged in the middle of the machine body; and the cutter system is arranged below the rotary clamp. After the main motor of the machine is started, the main motor drives the linear feeding device, the rotary clamp, cutters, the male die ejecting mechanism and the like through the drive system to finish processing steps of feeding, cutting, upsetting, finished product ejecting and the like. The cold heading machine has the advantages that the drive efficiency can be improved, the high-speed driving is realized, the working efficiency and precision of the cold heading machine are improved, and the like.

Owner:HUANGSHAN SHENGRUI HEAVY IND MACHINERY

Hydraulic swage press

The present specification discloses a swaging press including a piston member co-operable with a plurality of die shoes to drive the die shoes inwardly upon axial movement of the piston member during a swaging operation, the piston member having a frusto-conical recessed region divided into a plurality of circumferentially disposed bearing surface zone of a defined axial length, each of the bearing surface zones having an inner axial end with a numerical radius of curvature less than or equal to the radius of curvature of a circular line forming the lateral edges of each of the bearing surface zones at the inner axial end whereby at least 50% of the outer bearing surface of each said die shoe remains in bearing engagement with the adjacent said bearing surface zone over the axial movement of the piston member during a swaging operation.

Owner:BETASWAGE

Large-sized liquid-state die forging hydraulic press production line

InactiveCN1775410ARealize forming processEasy to replaceUpsetting pressesSwagging pressesProduction lineAutomatic control

The present invention relates to a heavy-duty liquid forging hydraulic press production line, belonging to the field of hydraulic automatic control technology. Said production line is formed from four portions of casting robot, liquid forging hydraulic press, material-taking robot and workpiece band conveyer. Said invention also provides their concrete mounting mode and its concrete operation method and steps.

Owner:TIANJIN TIANDUAN PRESS CO LTD

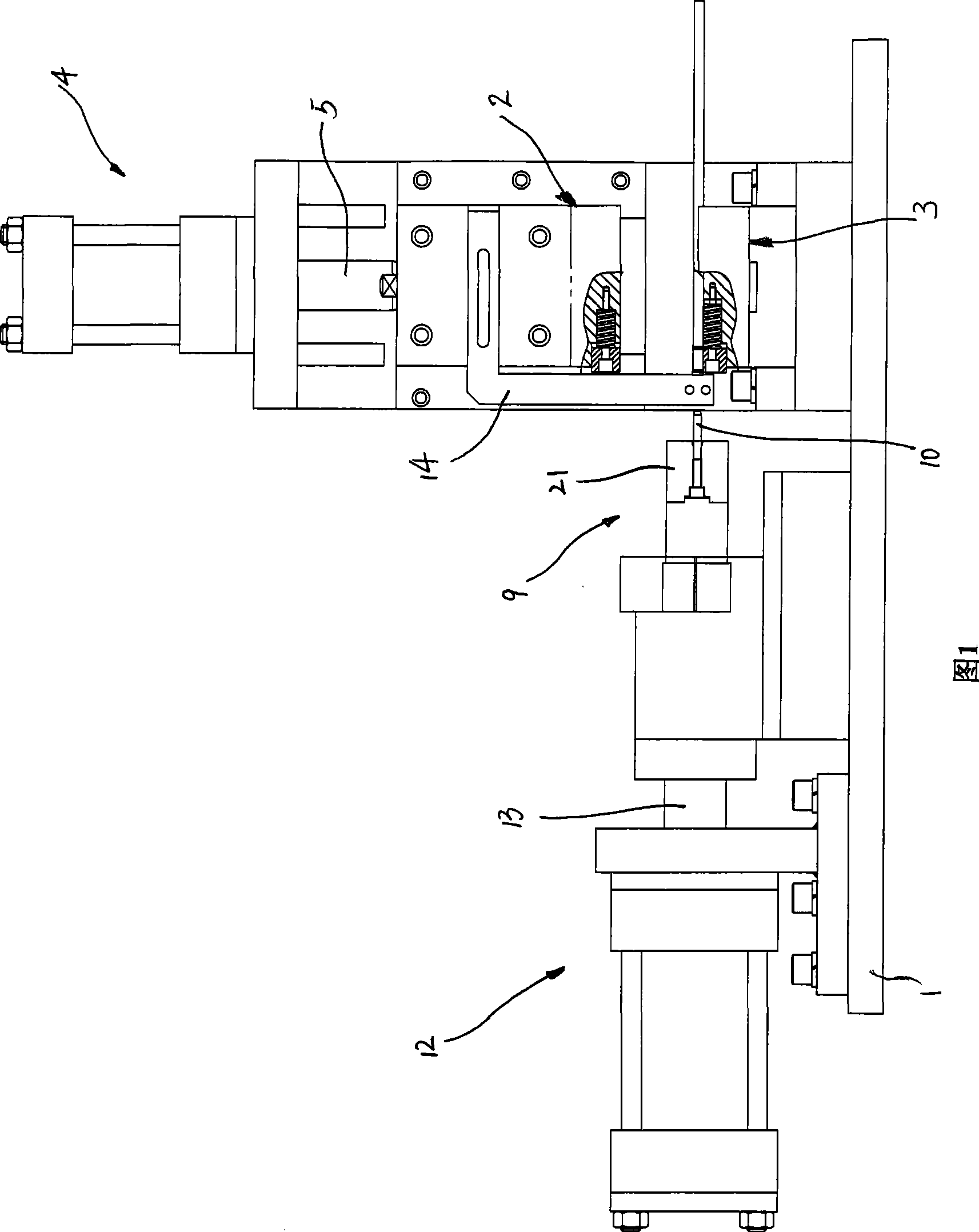

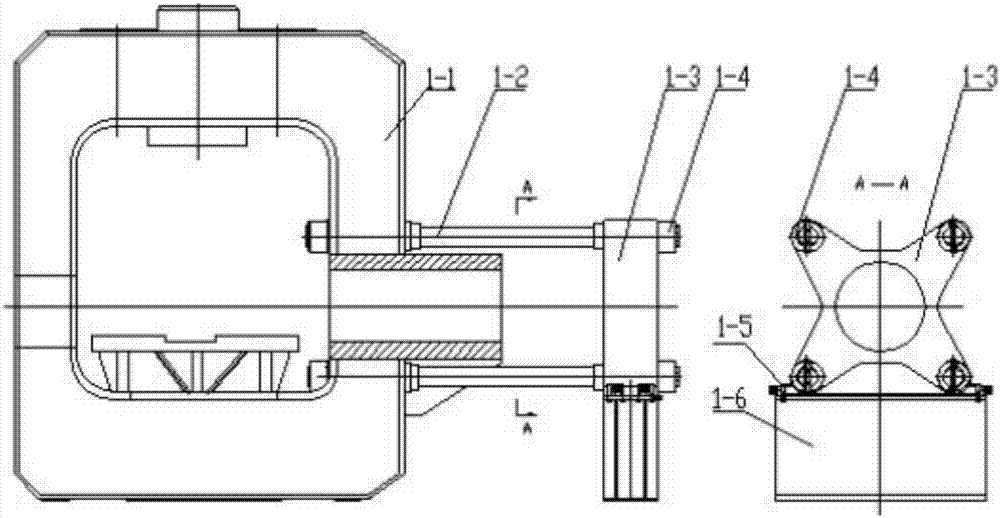

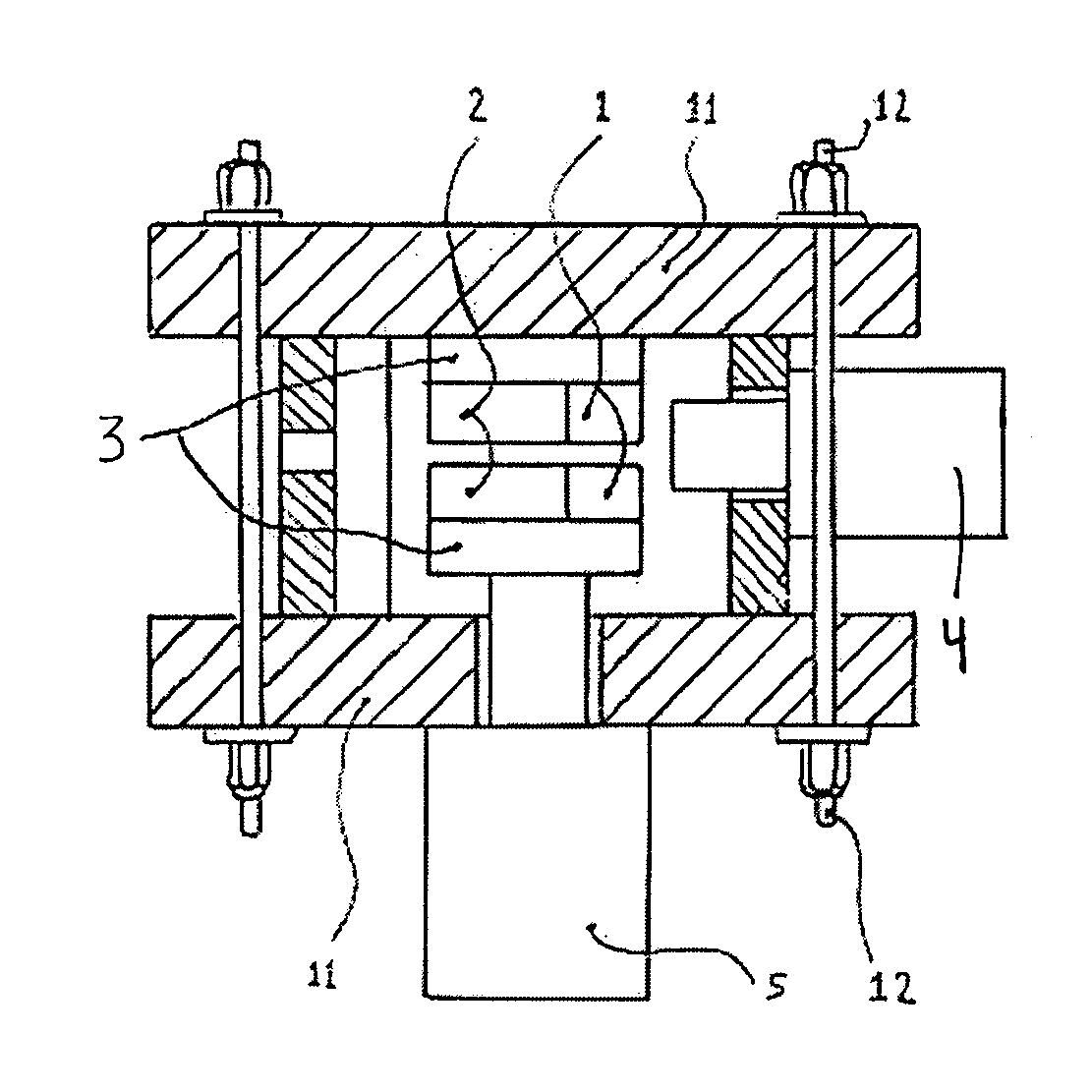

Heading device

ActiveUS20100300173A1Good flexibilityBig free spaceUpsetting pressesSwagging pressesEngineeringLocking plate

In a heading device for elongate workpieces having a hydraulic chucking unit and an shaping ram, which is movable axially from a retracted idle position against the workpiece, the chucking unit comprises a housing having a sliding body which is hydraulically displaceable in the axial direction of the workpiece from a starting position into a clamping position (and vice versa), in which at least two chucking segments which are situated uniformly around the workpiece are inserted, which, on their side facing toward the shaping ram, press against a locking plate which is inserted into the housing and can be fixed therein, are movable radially against the workpiece by a displacement of the sliding body in its clamping position, and each receive at least one clamping jaw, which can be pressed by the chucking segment holding it radially against the workpiece for its clamping. The shaping ram carries a forming tool for upsetting the workpiece on the extension side, using which it can be pressed against the head of the workpiece protruding axially from the clamping jaws upon extension through an opening provided in the locking plate, and is moved completely out of the opening in the locking plate with its forming tool in its retracted idle position.

Owner:WAFIOS AKTIENGES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com