Cold forging machine capable of forging two ends

A technology of cold pier machine and two ends, which is applied in the direction of swage forging press, upsetting forging press, forging/pressing/hammering machinery, etc., which can solve the problem of not being able to reach the blank and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

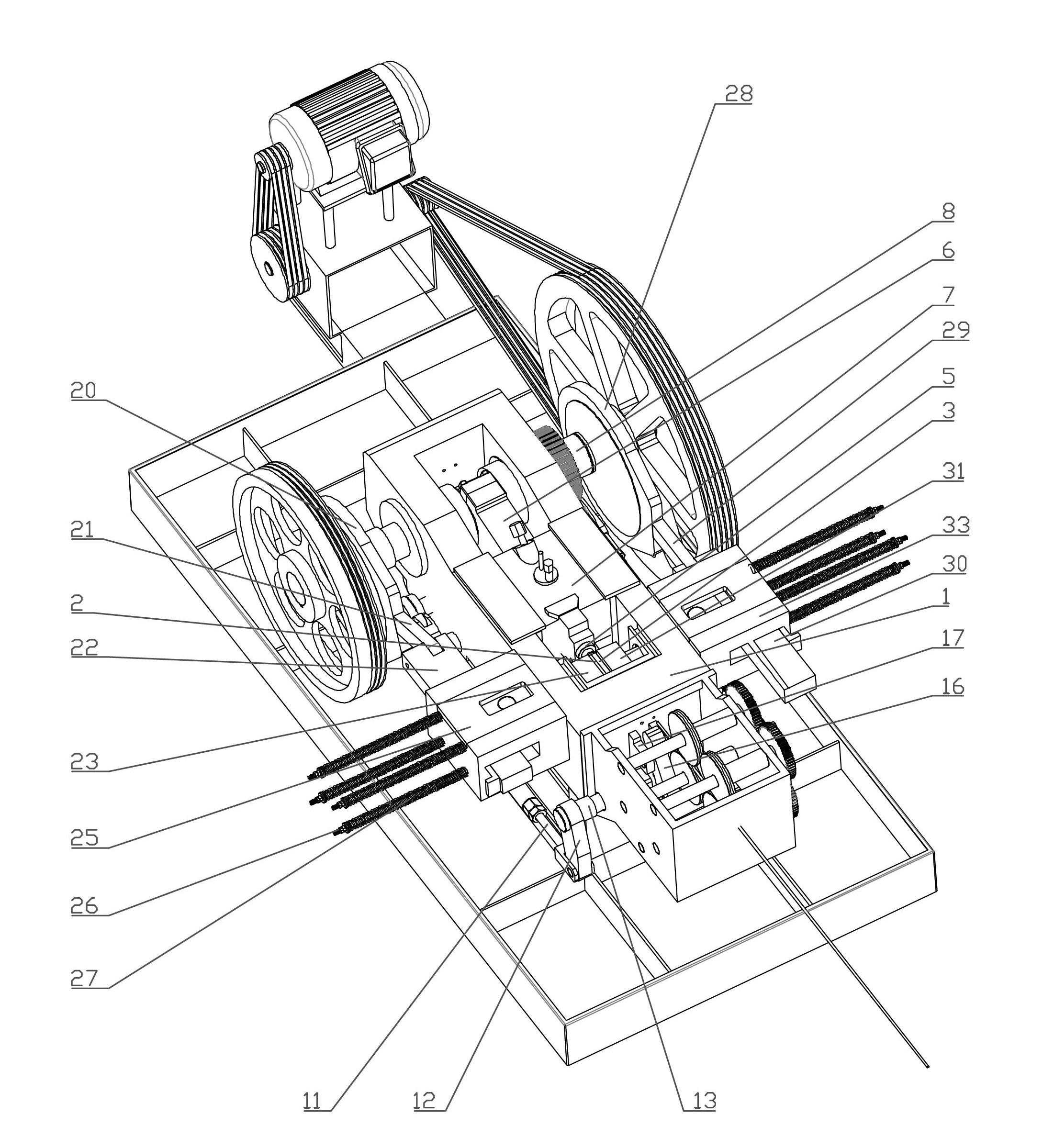

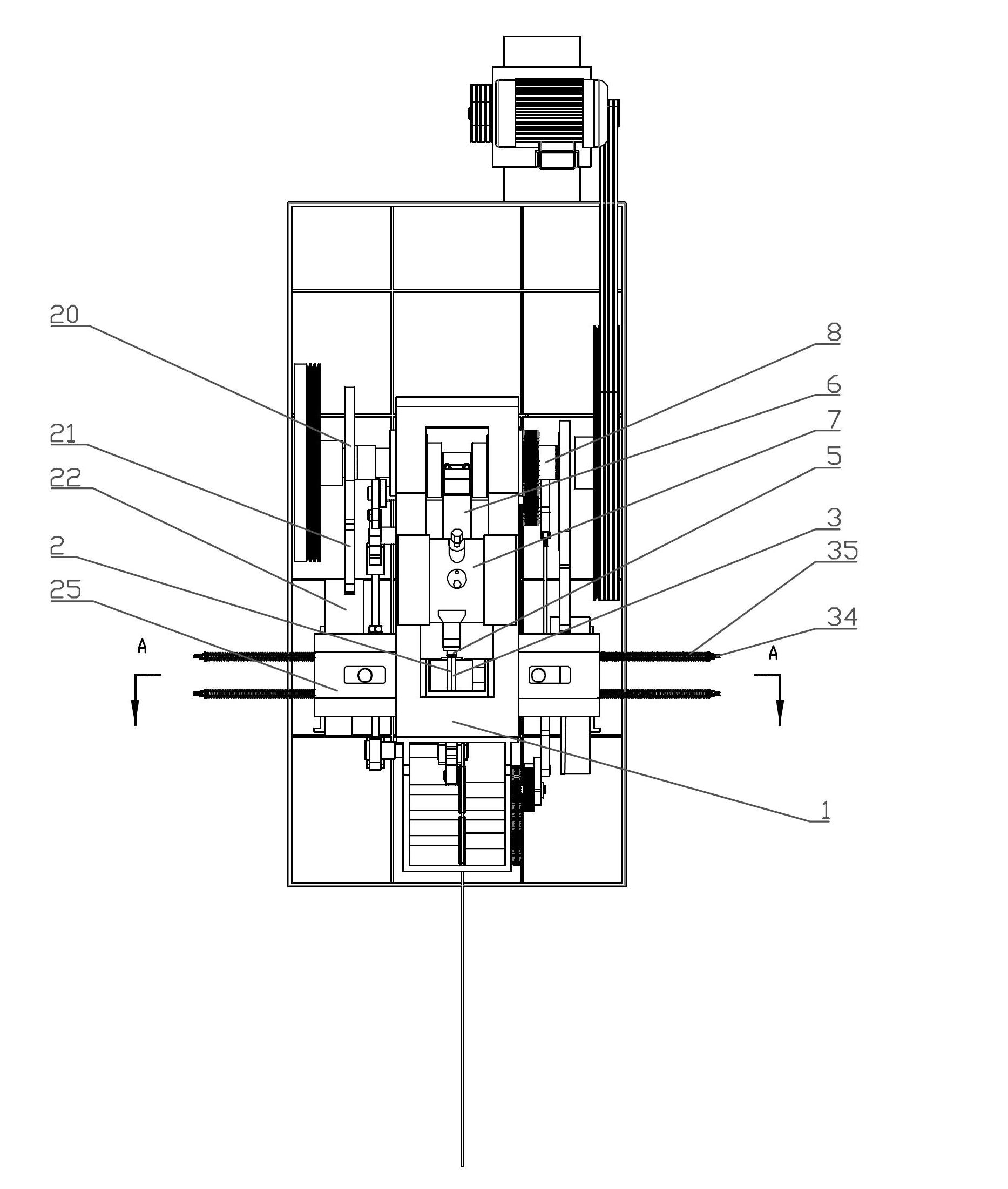

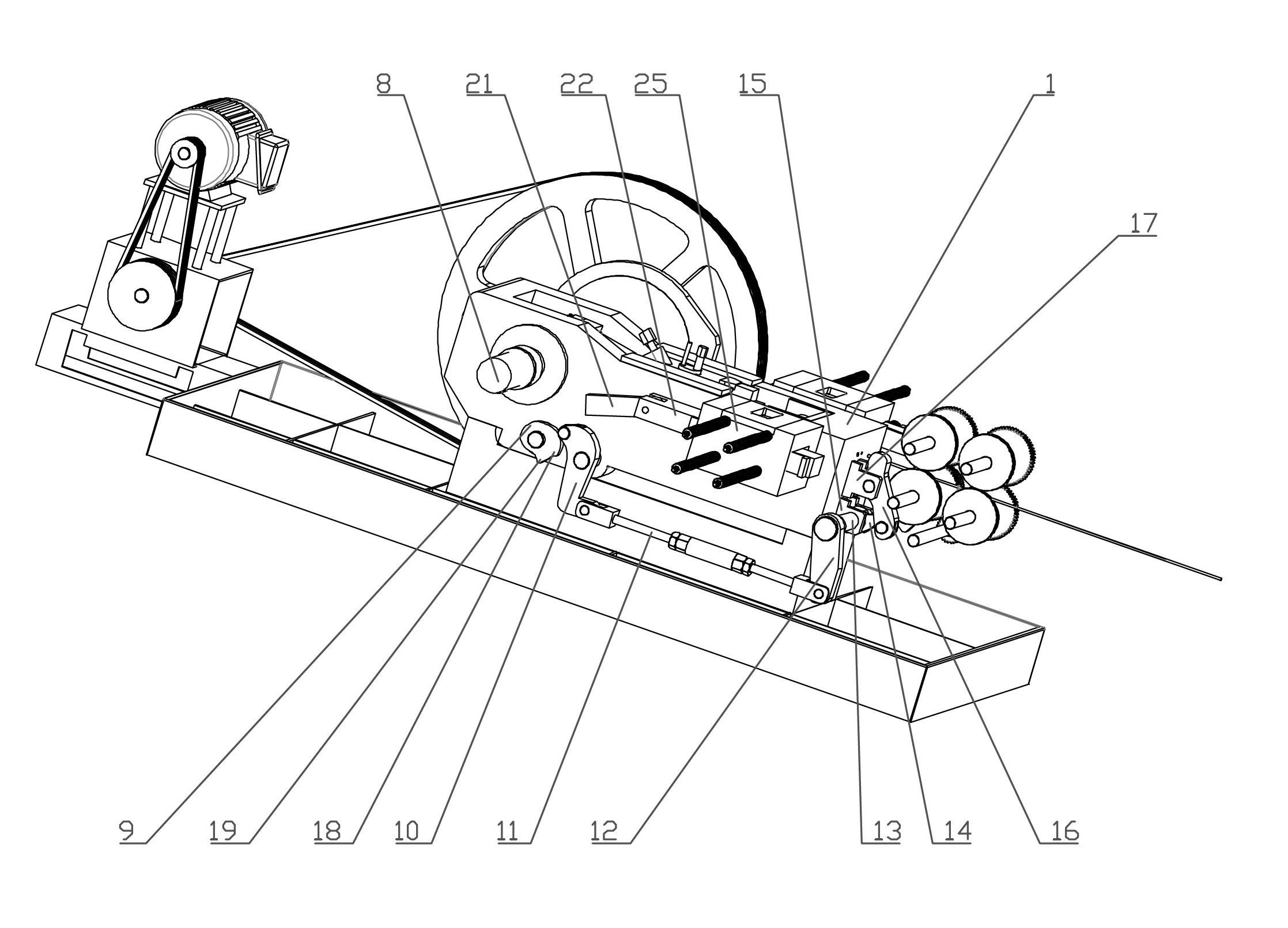

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0018] The present invention can pier two cold pier machines, comprising a frame 1, a die mechanism, a material transfer mechanism, a heading die, and a drive mechanism, and the frame is provided with a feed hole for the blank to extend into, and the material transfer mechanism consists of The first push mechanism and the second push mechanism are composed, and the die mechanism is composed of the first die mechanism and the second die mechanism, and also includes a mold core, and the mold core is composed of a left half mold core 2 and a right half mold core 3, so Described left half-mold core and described right half-mold core all offset against frame, are all provided with semicircular groove 4 on described left half-mold core, described right half-mold core, described left half-mold core and The right half core cooperates to clamp the blank, the linear recipro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com