Patents

Literature

7822results about "Forging/hammering/pressing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

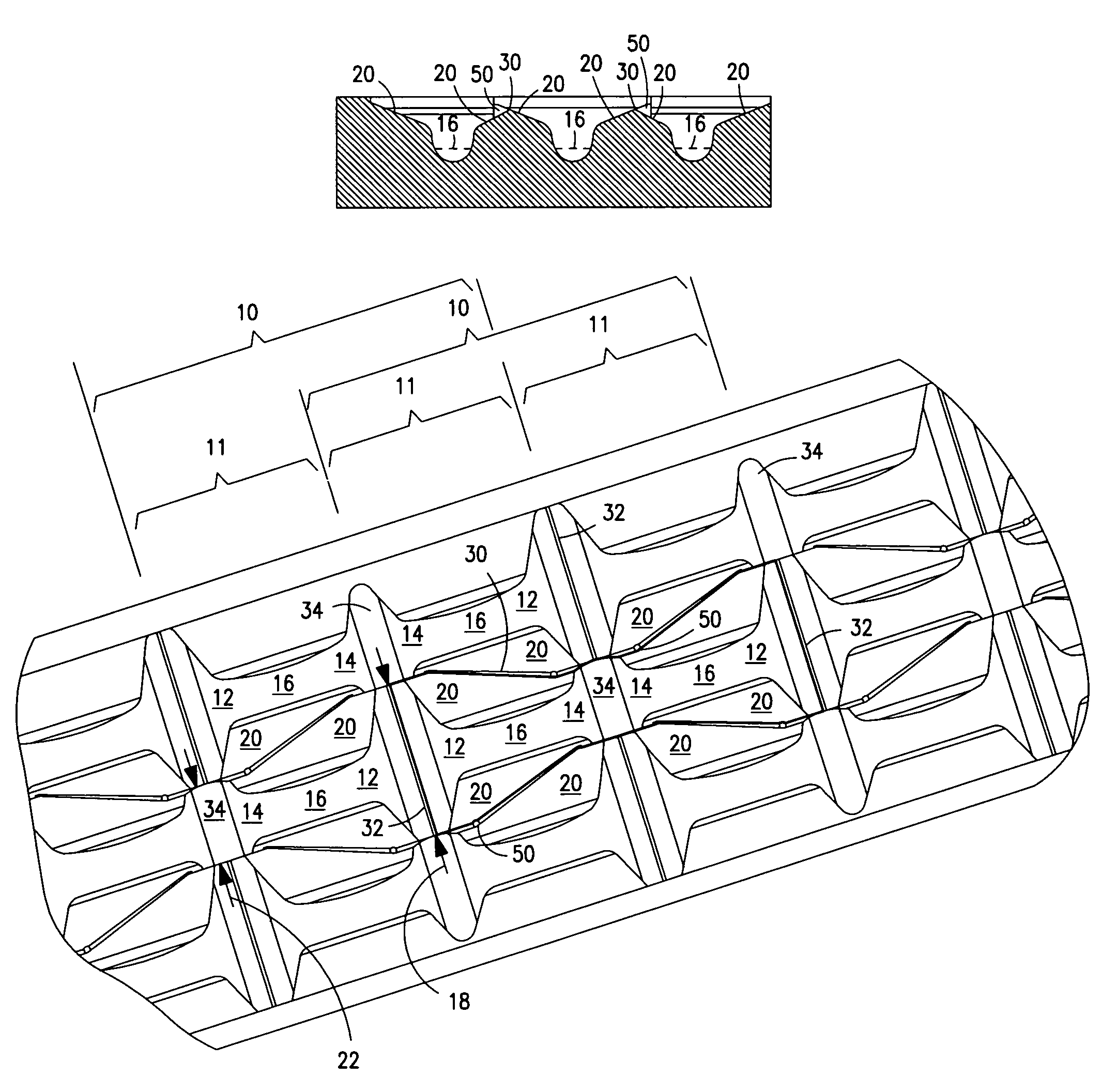

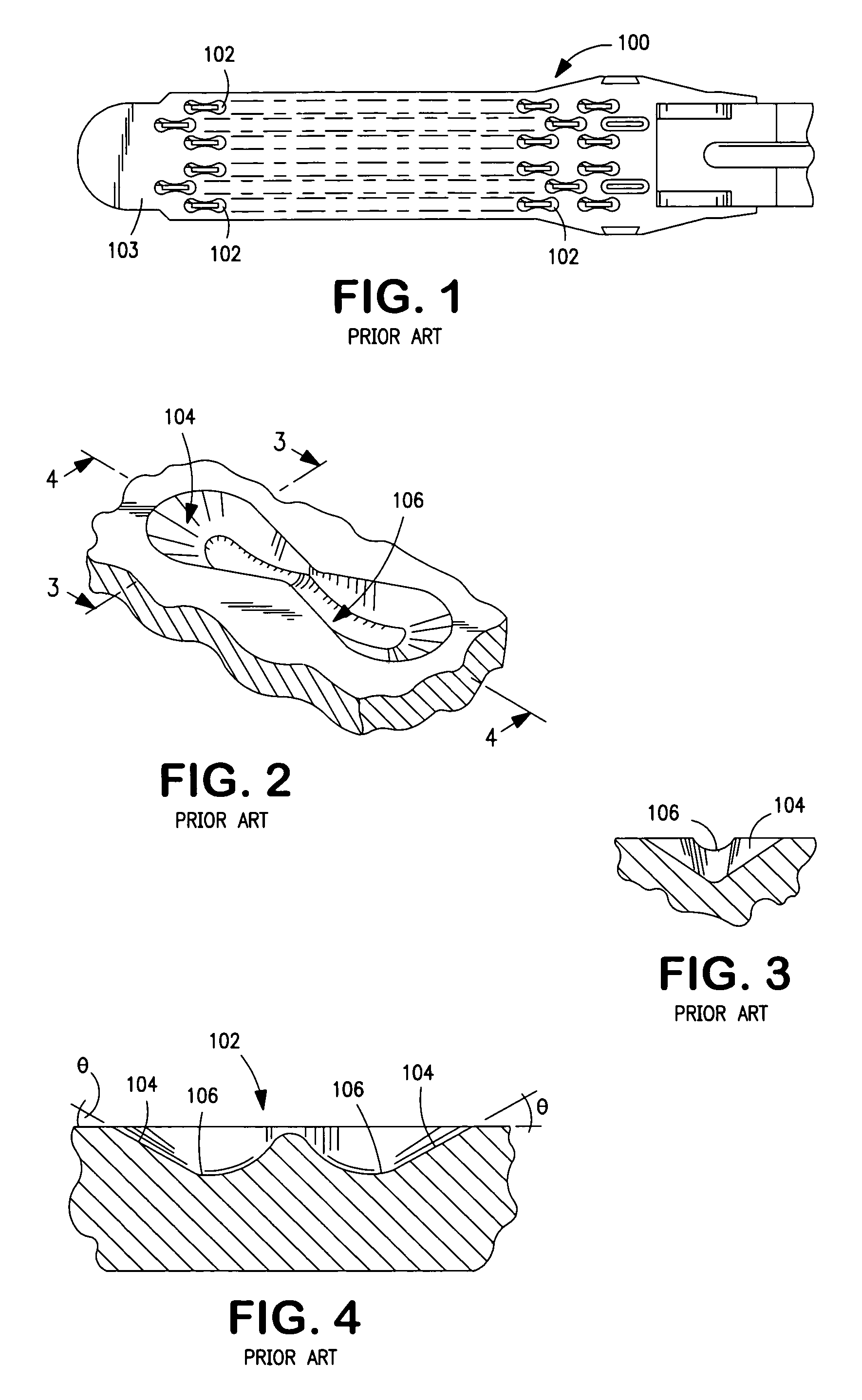

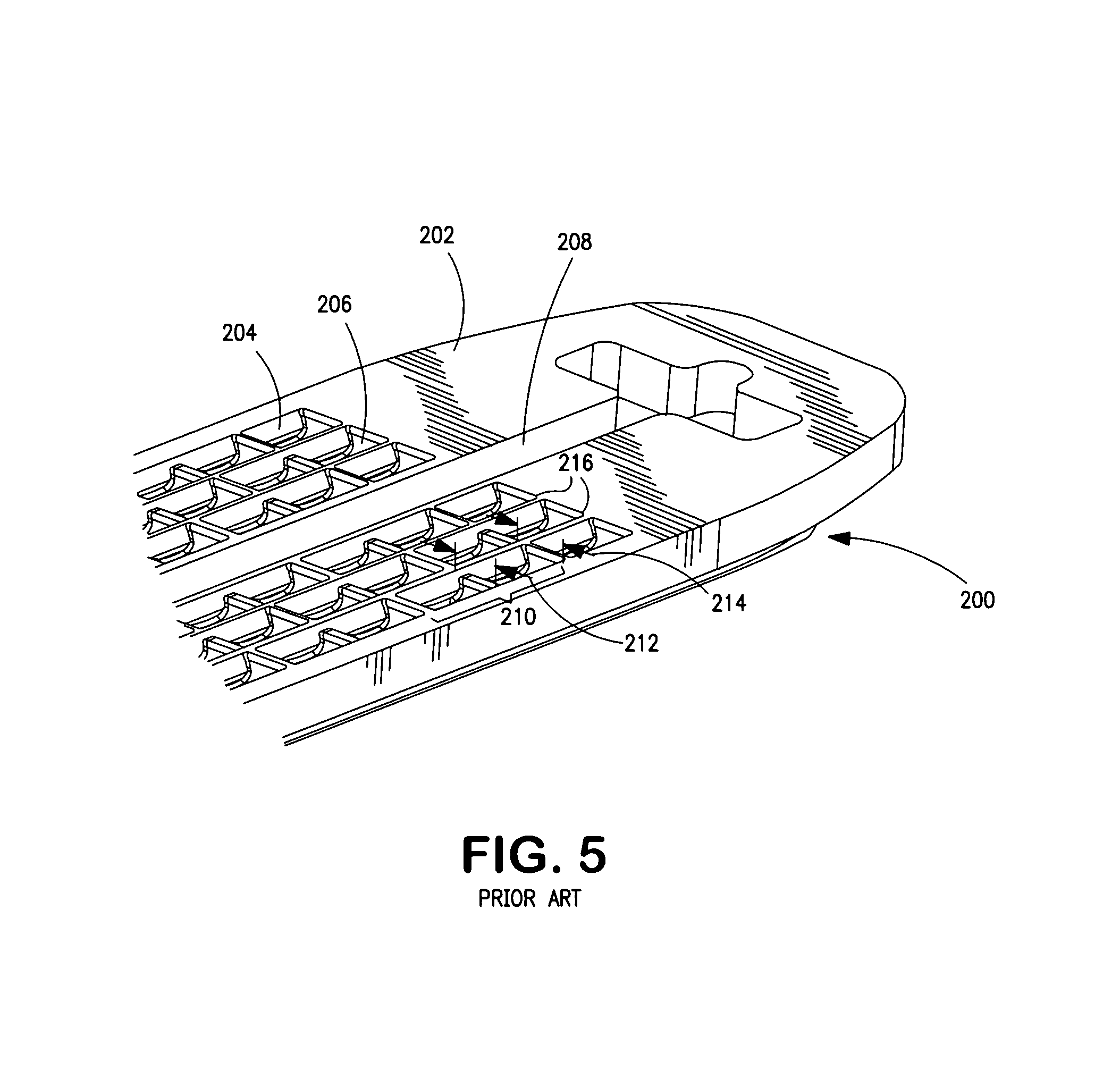

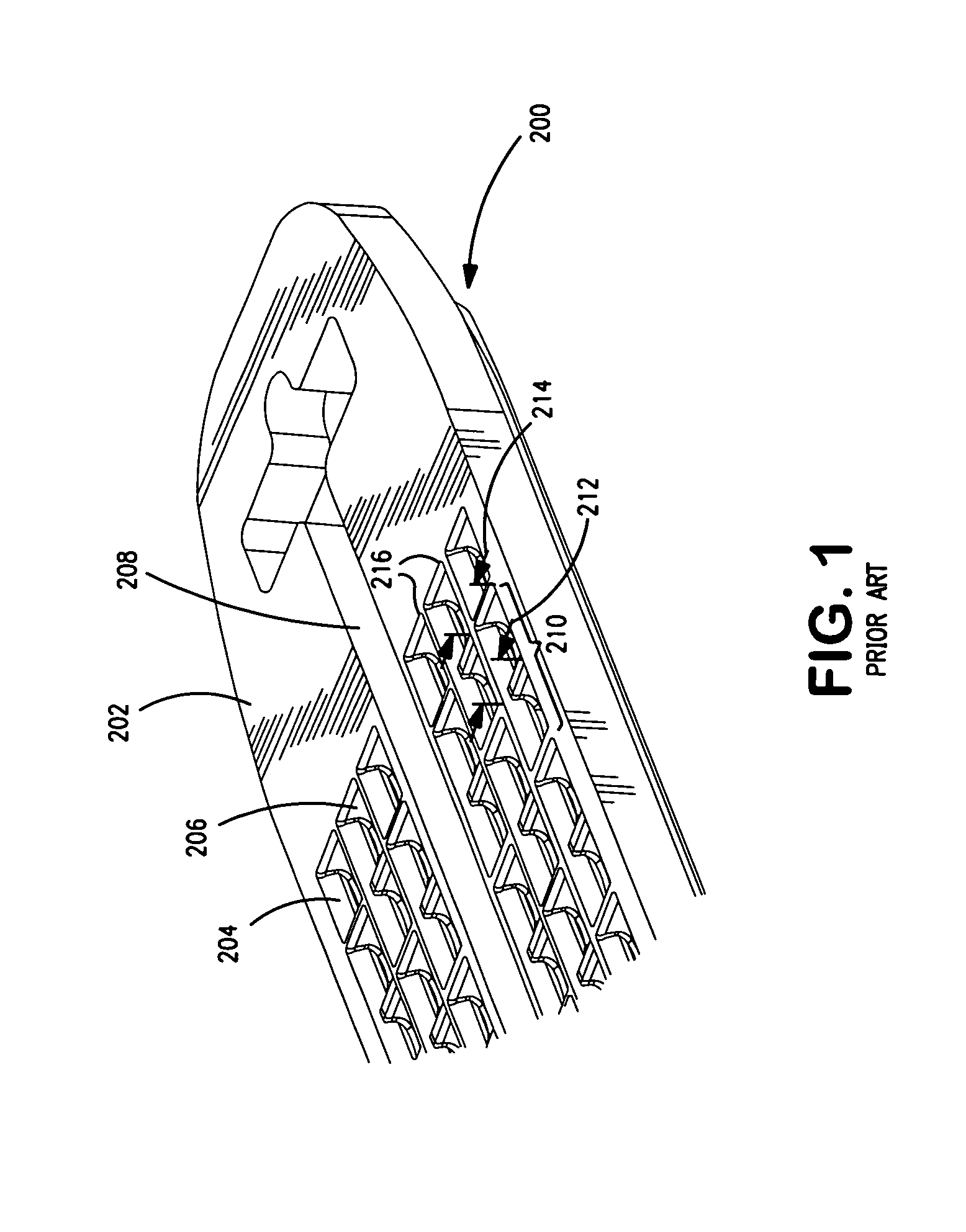

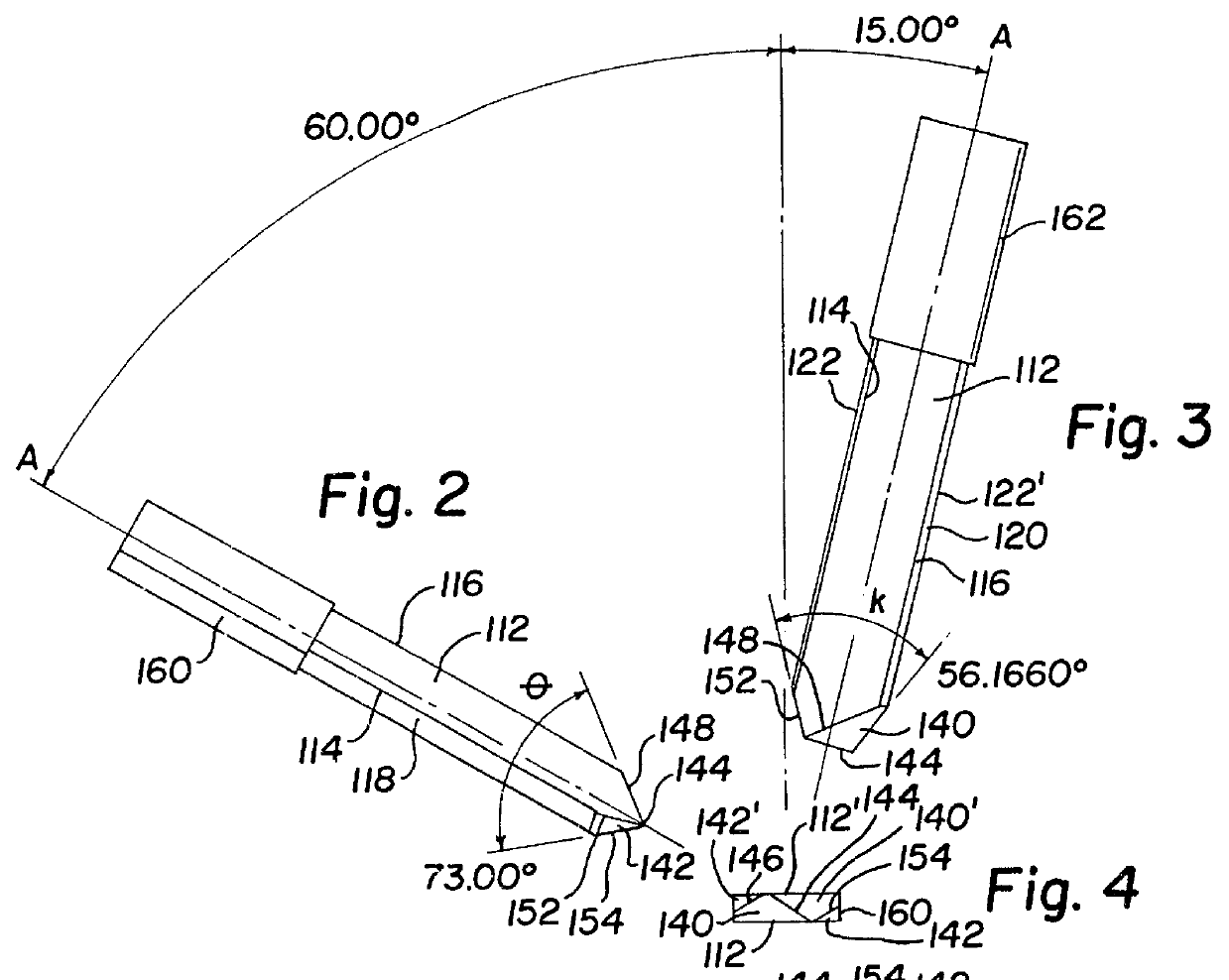

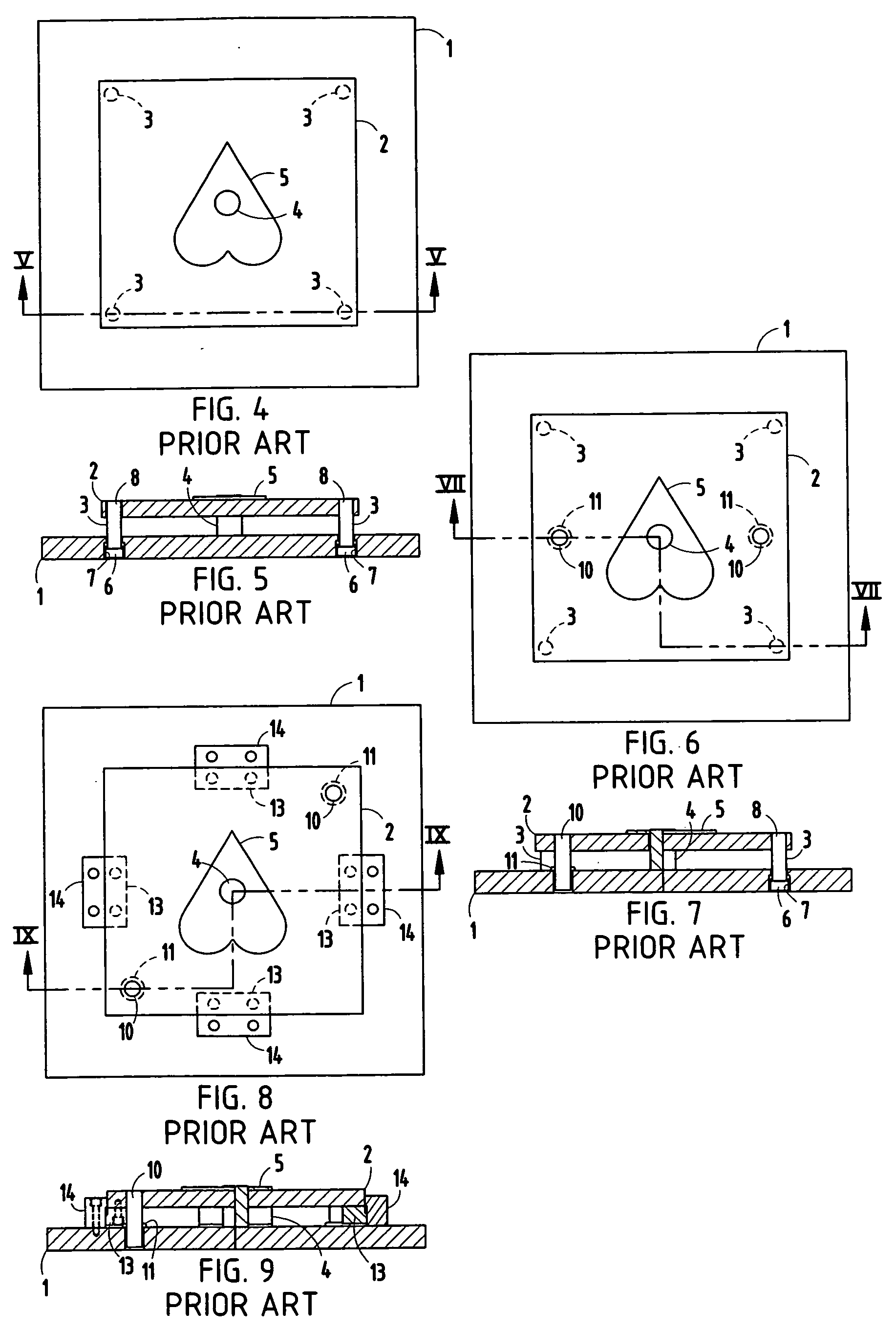

Surgical stapler anvil with nested staple forming pockets

InactiveUS6953138B1Increased lateral widthLittle lateral spaceSuture equipmentsStapling toolsMirror imageBiomedical engineering

A surgical stapler anvil provides an expanded leg-receiving target area for a staple forming pocket in a compact staggered array by narrowing the lateral width of the leg-clinching portion of a laterally adjacent pocket. Advantageously, the lateral spacing between adjacent rows of staple forming pockets can remain small, while the leg-receiving target area for laterally adjacent rows of pockets is significantly expanded. The staple forming pockets include two mirror image leg-forming cups. The cups are longitudinally aligned with their respective ascending leg clinching portions adjoining in the center of the pocket. Laterally spaced guide surfaces extend upwardly and outwardly from the clinching surface at the bottom of the cup to define an expanded leg-receiving target area at the distal ends of the pocket. Substantially planar laterally outward portions of the guide surface intersect with the guide surface of a laterally adjacent pocket to form a non-linear ridge.

Owner:DWORAK FR W

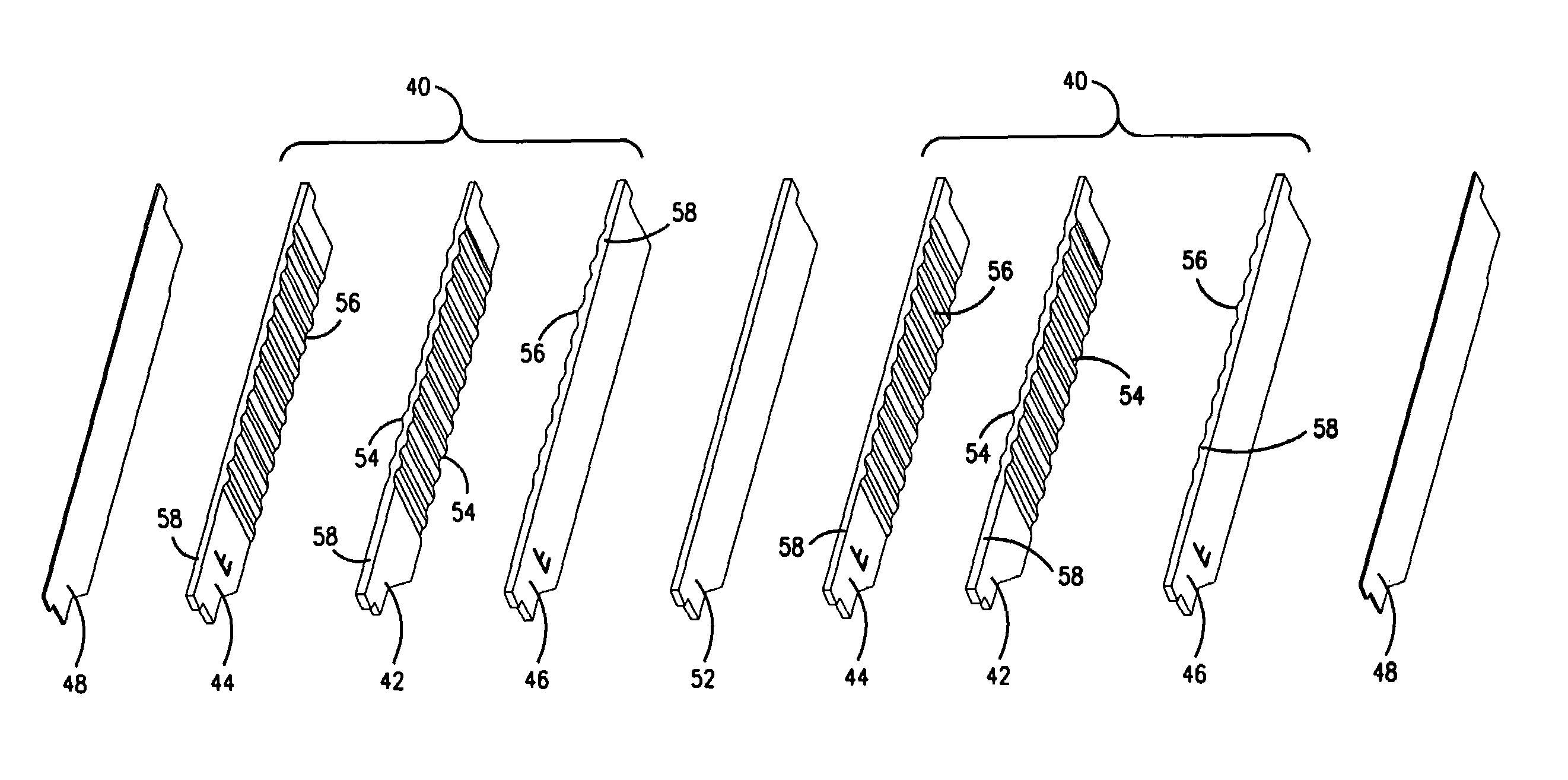

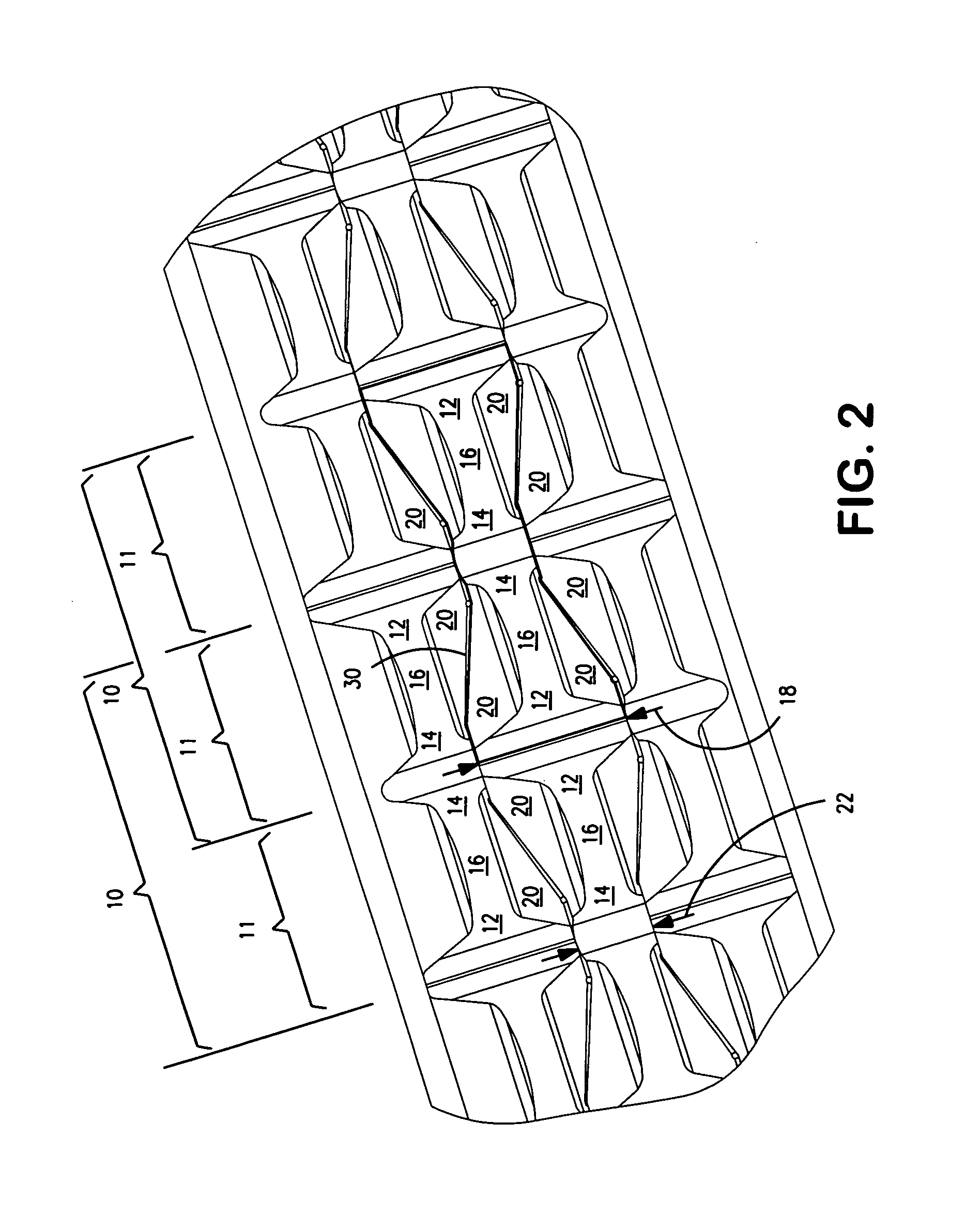

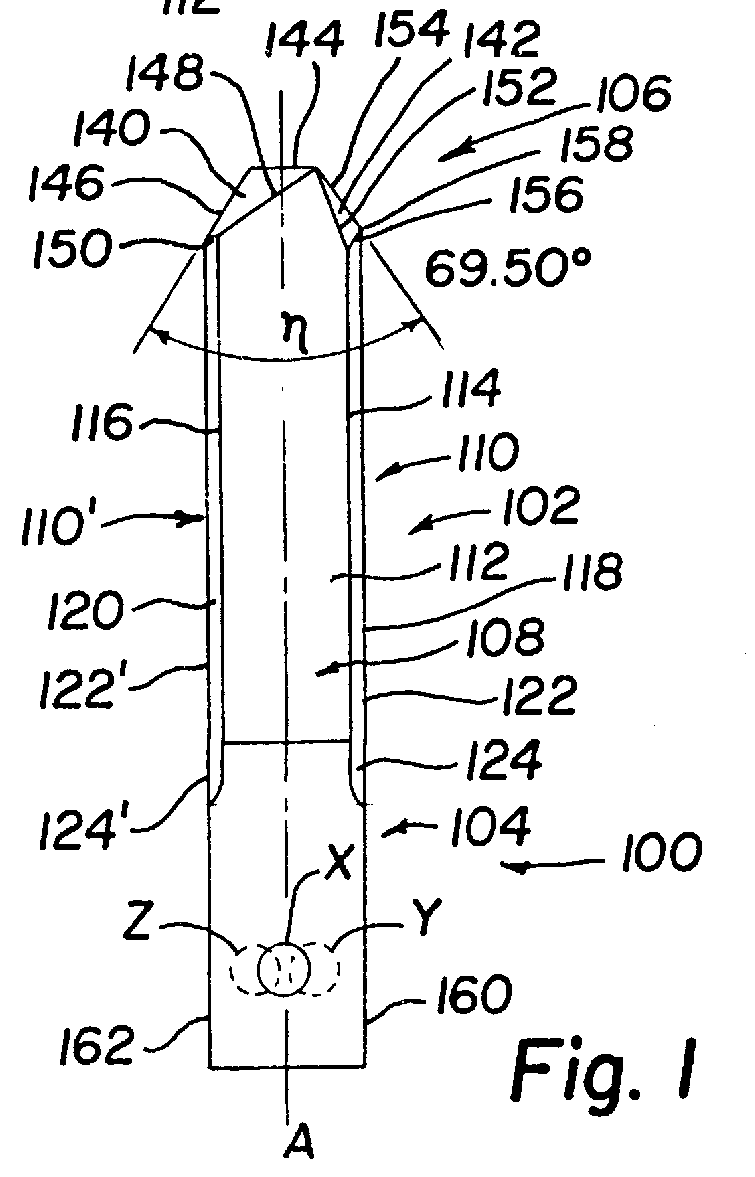

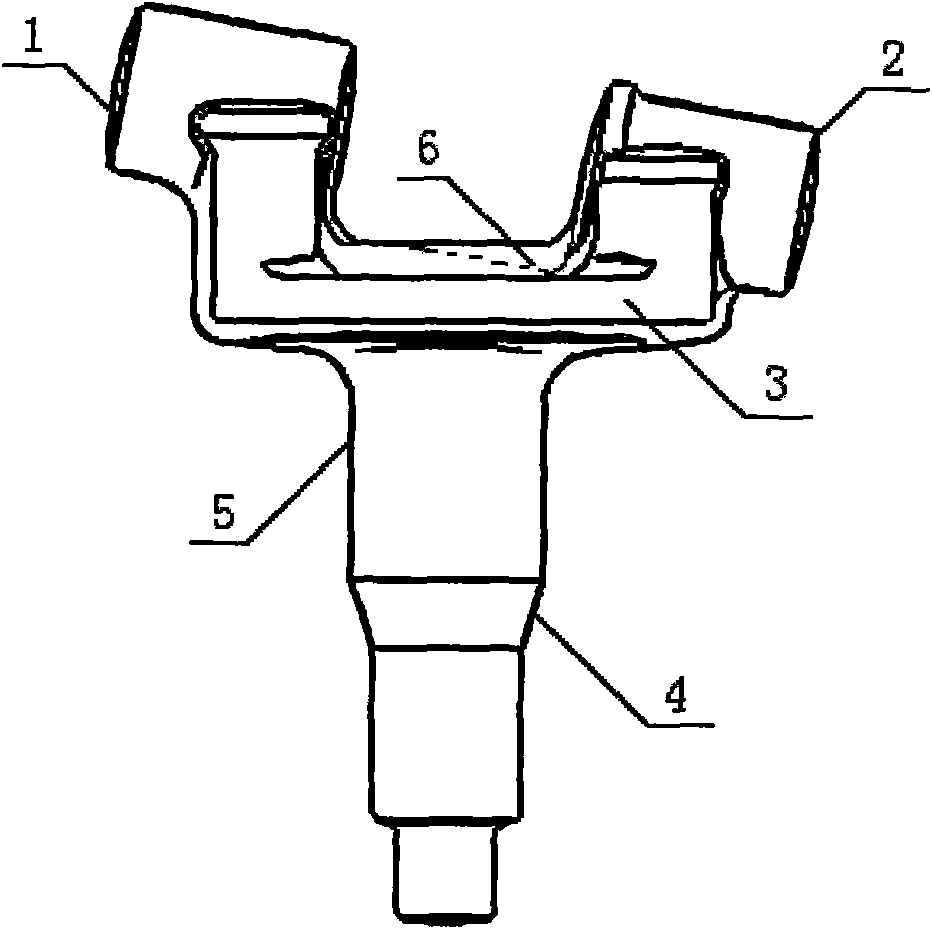

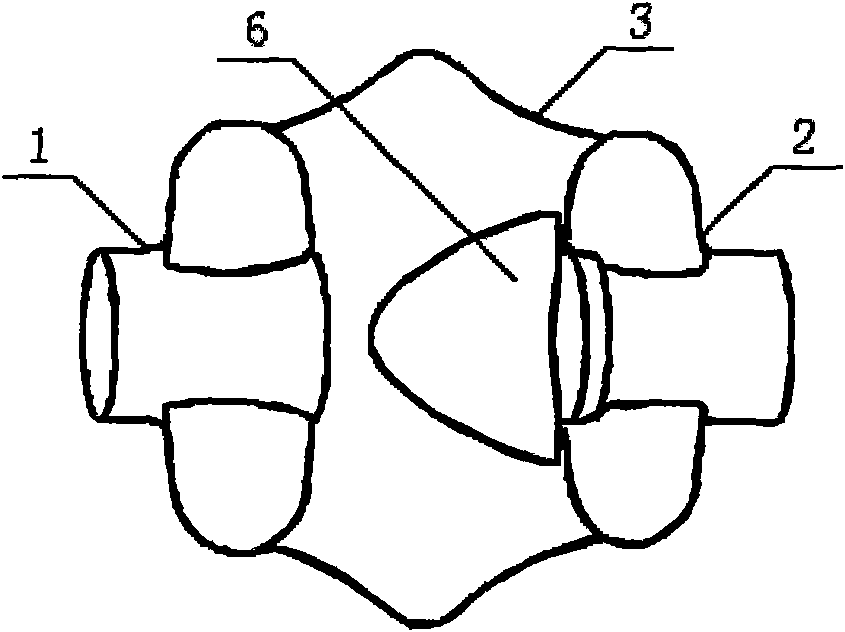

Metal-forming die and method for manufacturing same

InactiveUS7086267B2Good flexibilityIncrease flexibilitySuture equipmentsShaping toolsMetal formingEngineering

A metal-forming die according to the present invention includes die blades with convoluted opposed side surfaces that correspond to variable-width features on the working surface of the die. The convoluted side surfaces and variable-width working surface features permit the impression left by one die blade to fill space taken from an impression made by a laterally adjacent die blade. Such a die permits formation of working surface shapes not possible with flat-sided die components. The die is manufactured in discrete longitudinally extending components, or blades. Dividing the working surface of the die into longitudinally extending portions, each carried by a die blade allows conventional machining processes to be employed in forming the working surface on each die blade. An additional machining process cuts complementary shapes on the sides of the die blades. The die blades and their corresponding working surfaces interfit, or nest together.

Owner:FR W DWORAK

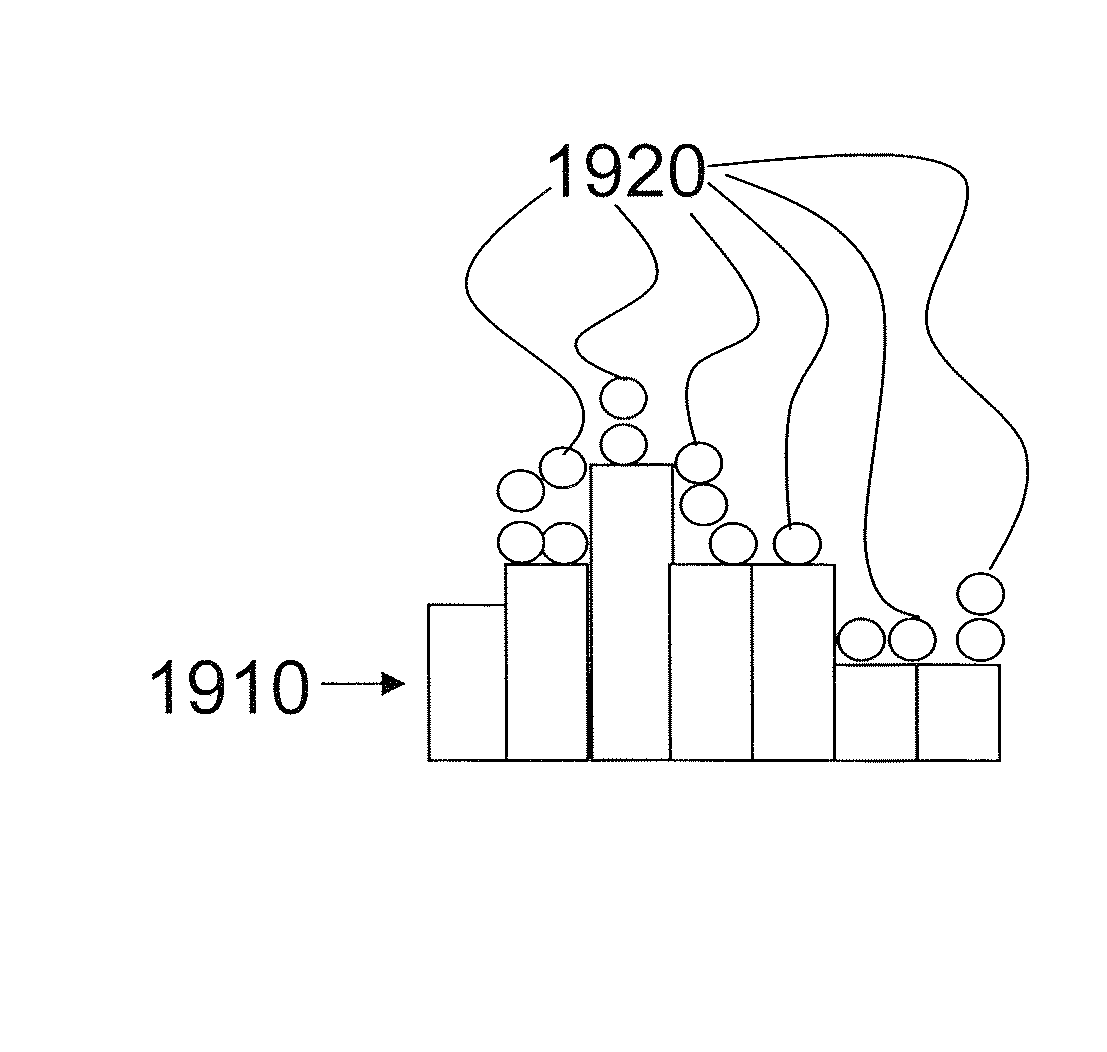

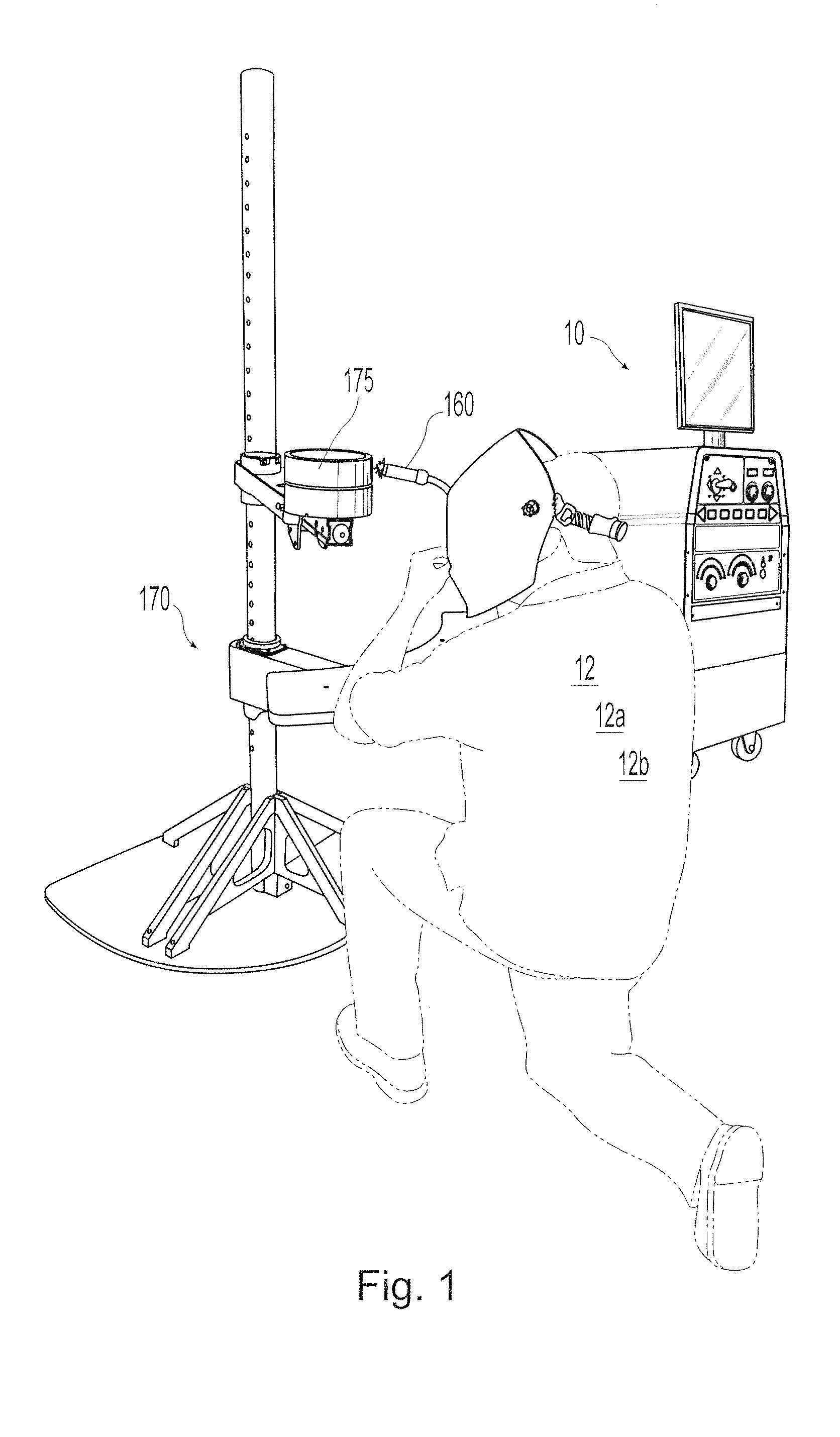

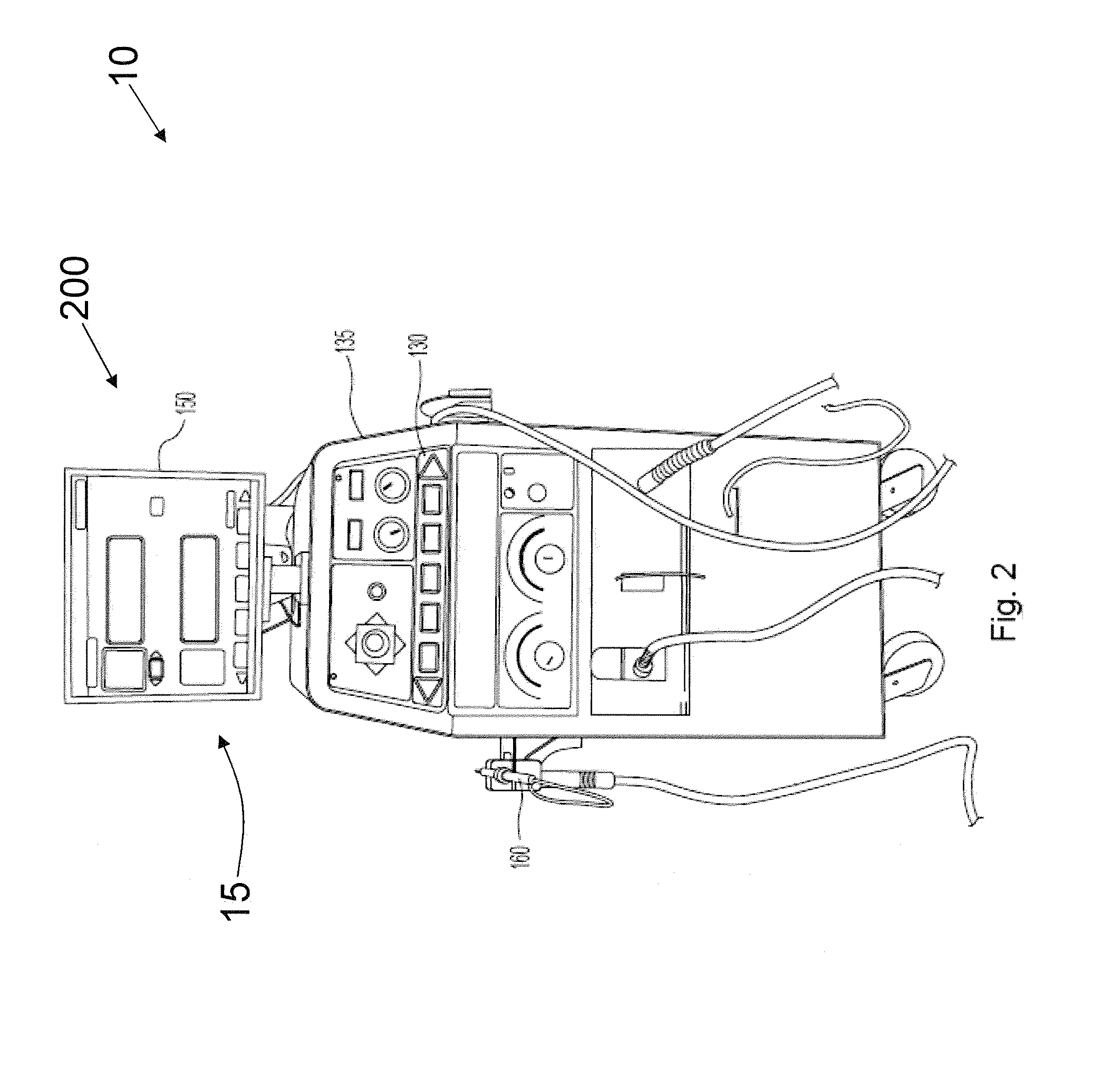

Virtual reality pipe welding simulator

A simulator facilitates virtual welding activity of pipe and open root weld joints. The simulator may include a logic processor based system operable to execute coded instructions for generating an interactive welding environment that emulates welding activity on a section of virtual pipe having at least one virtual weld joint. It also includes a display connected to the logic processor based system for visually depicting the interactive welding environment, wherein the display depicts the section of virtual pipe. A mock welding tool is provided for performing virtual welding activity on the at least one weld joint in real time where one or more sensors are adapted to track movement of the input device in real time for communicating data about the movement of the input device to the logic processor based system.

Owner:LINCOLN GLOBAL INC

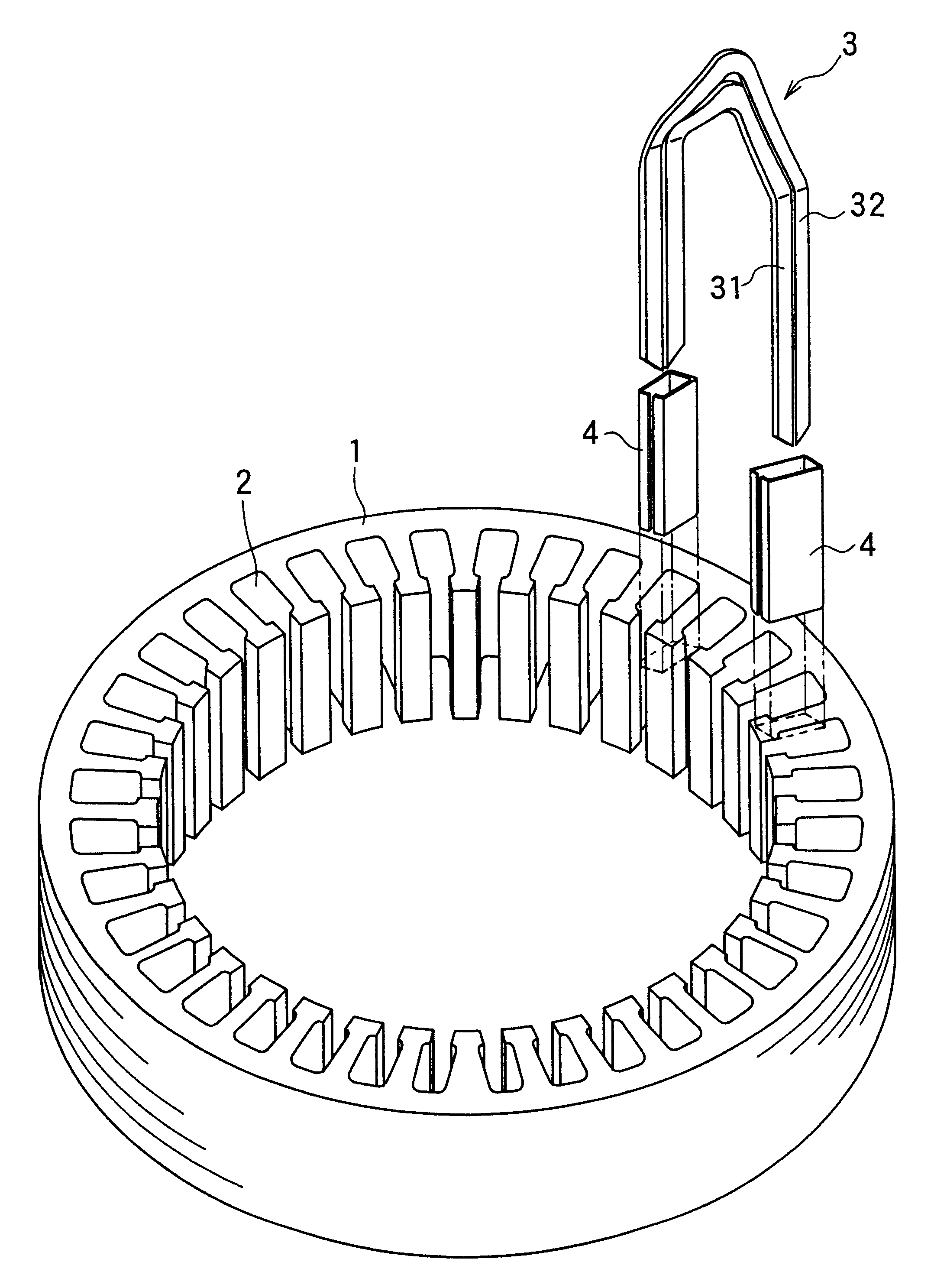

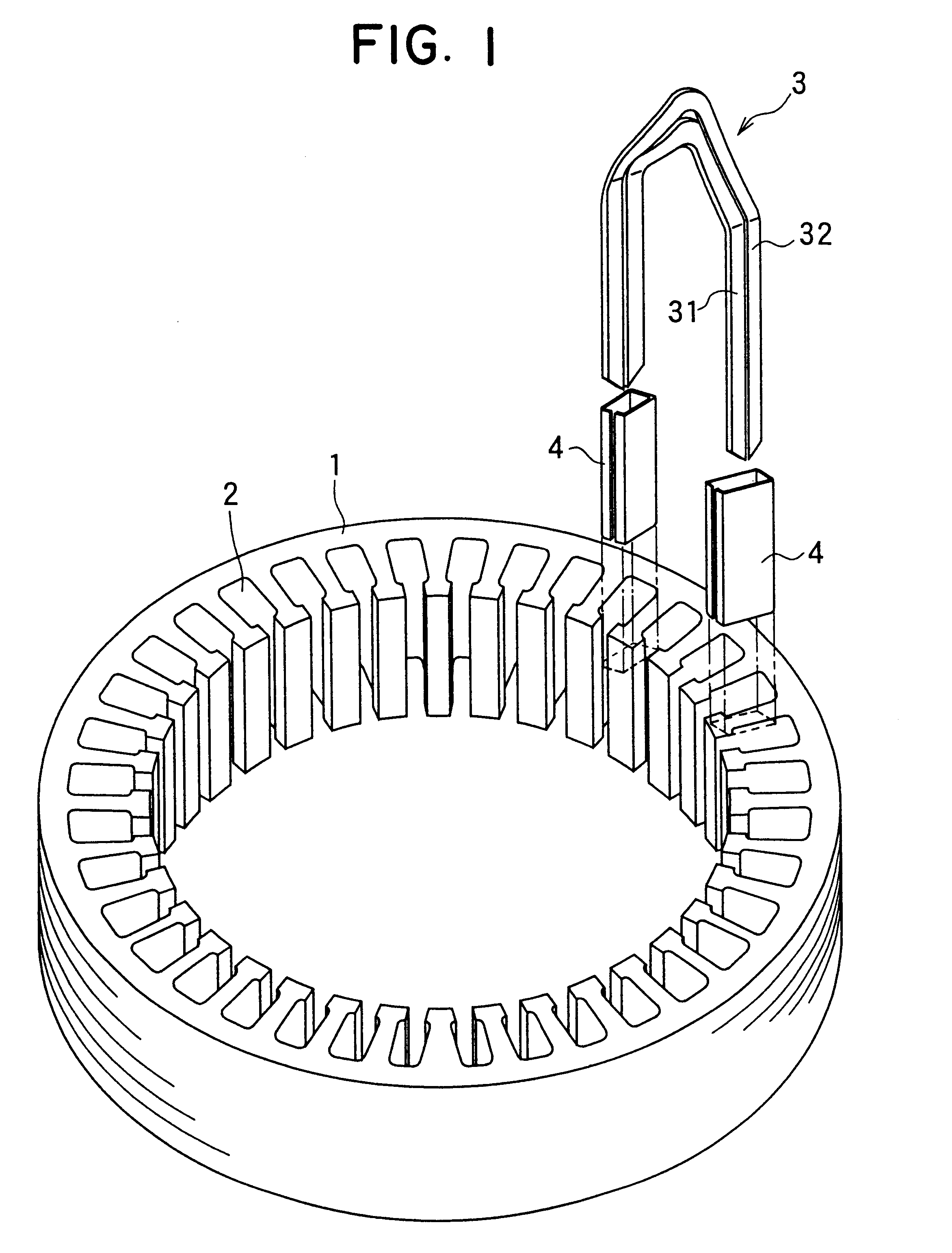

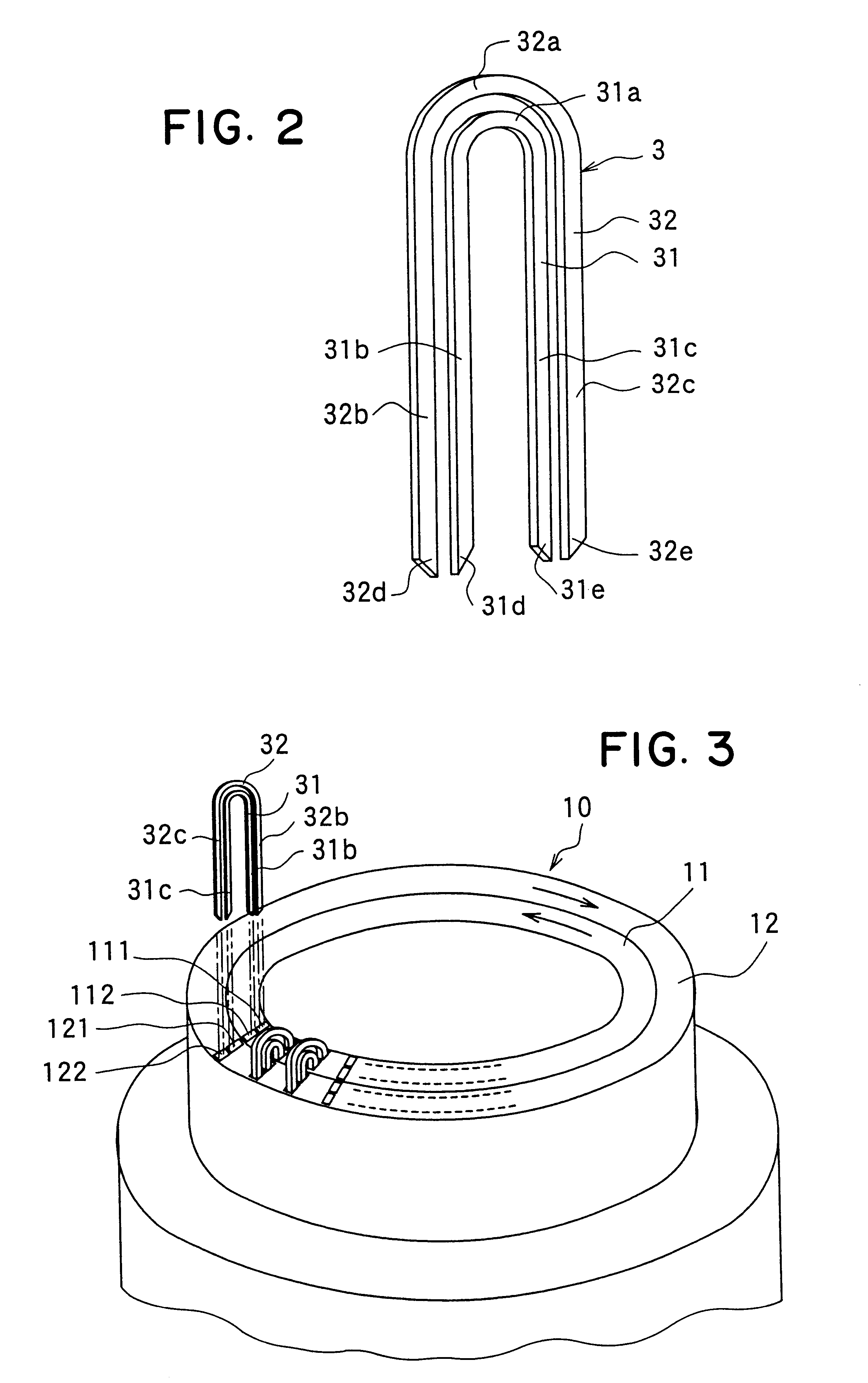

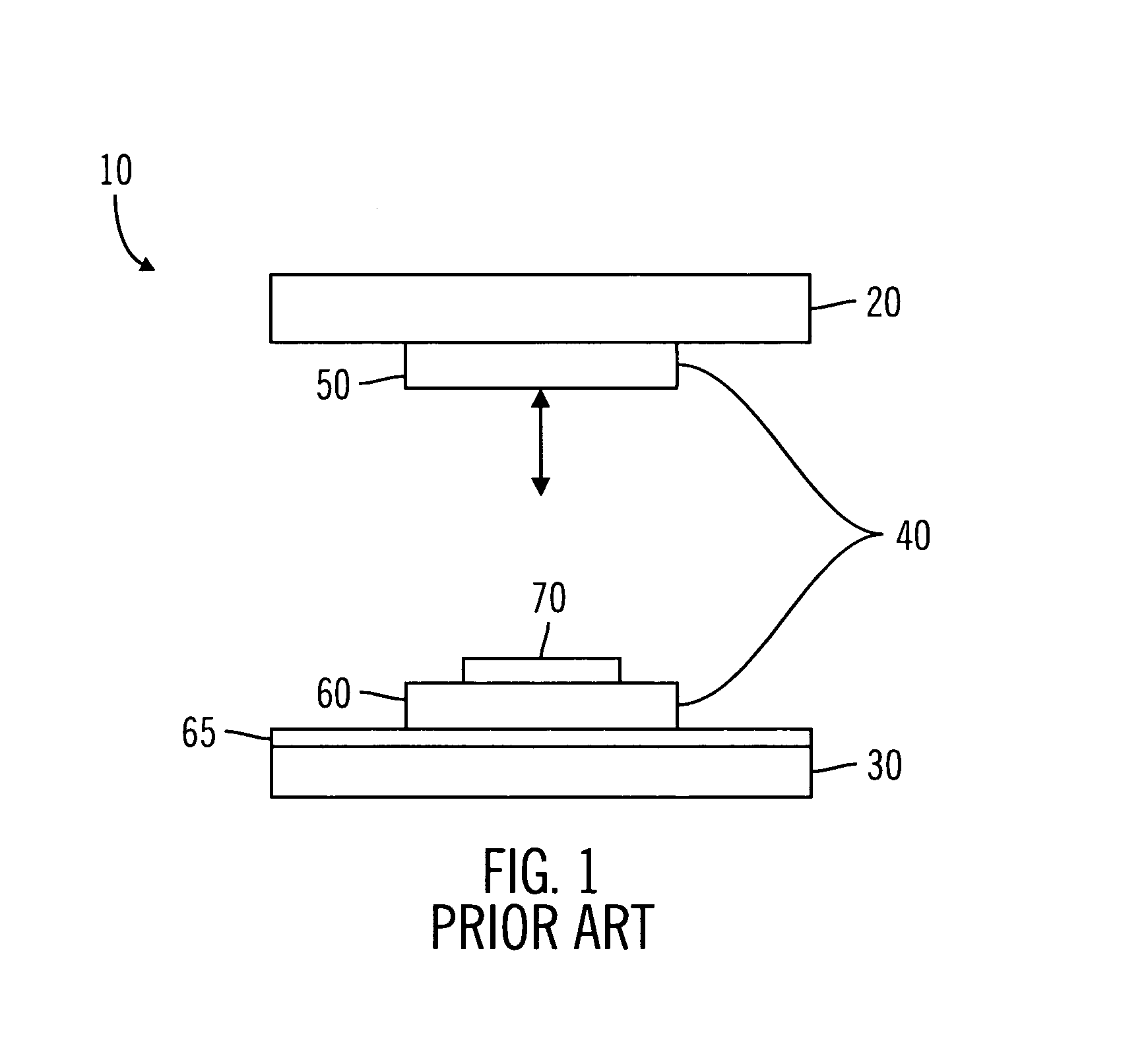

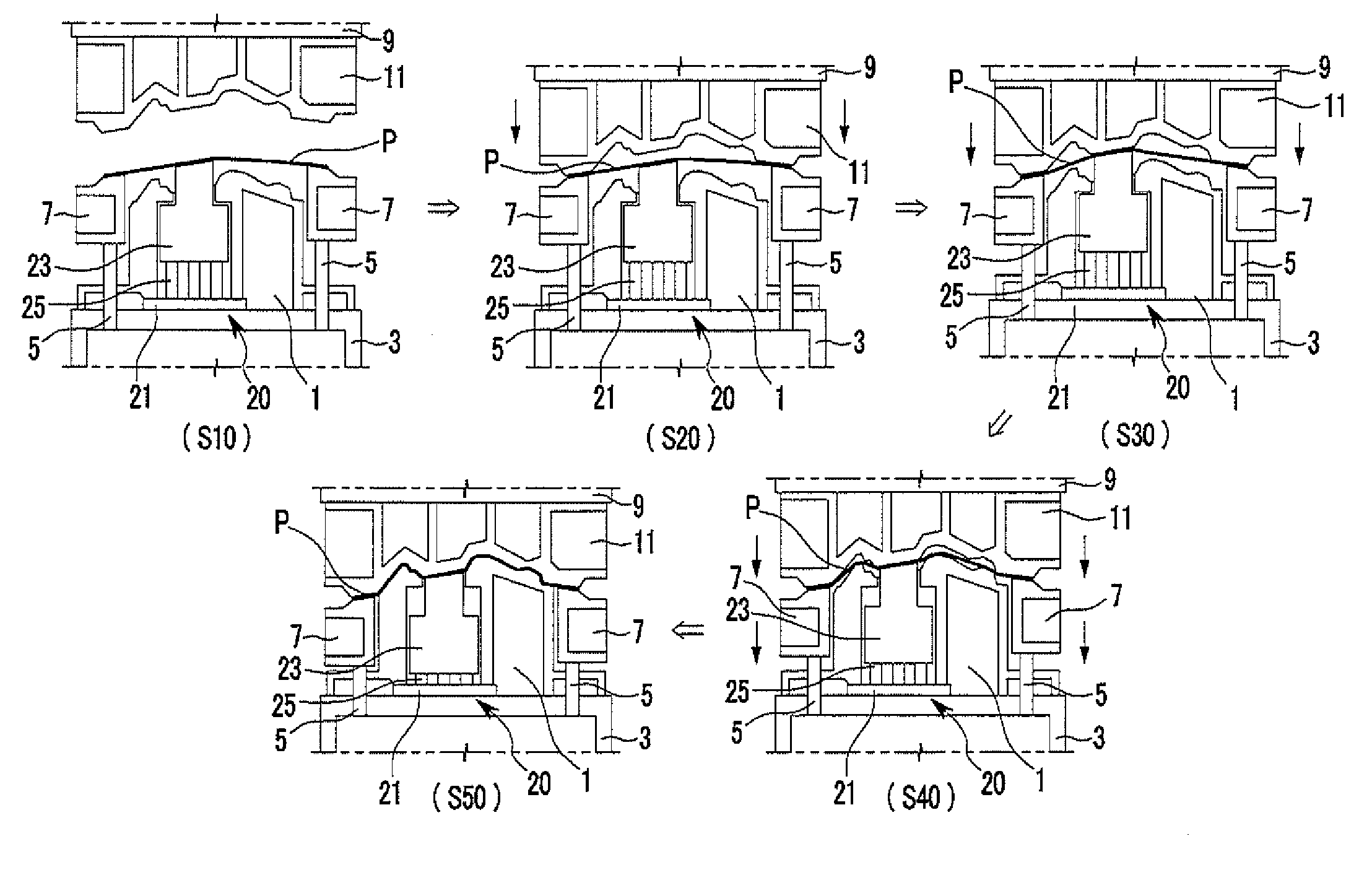

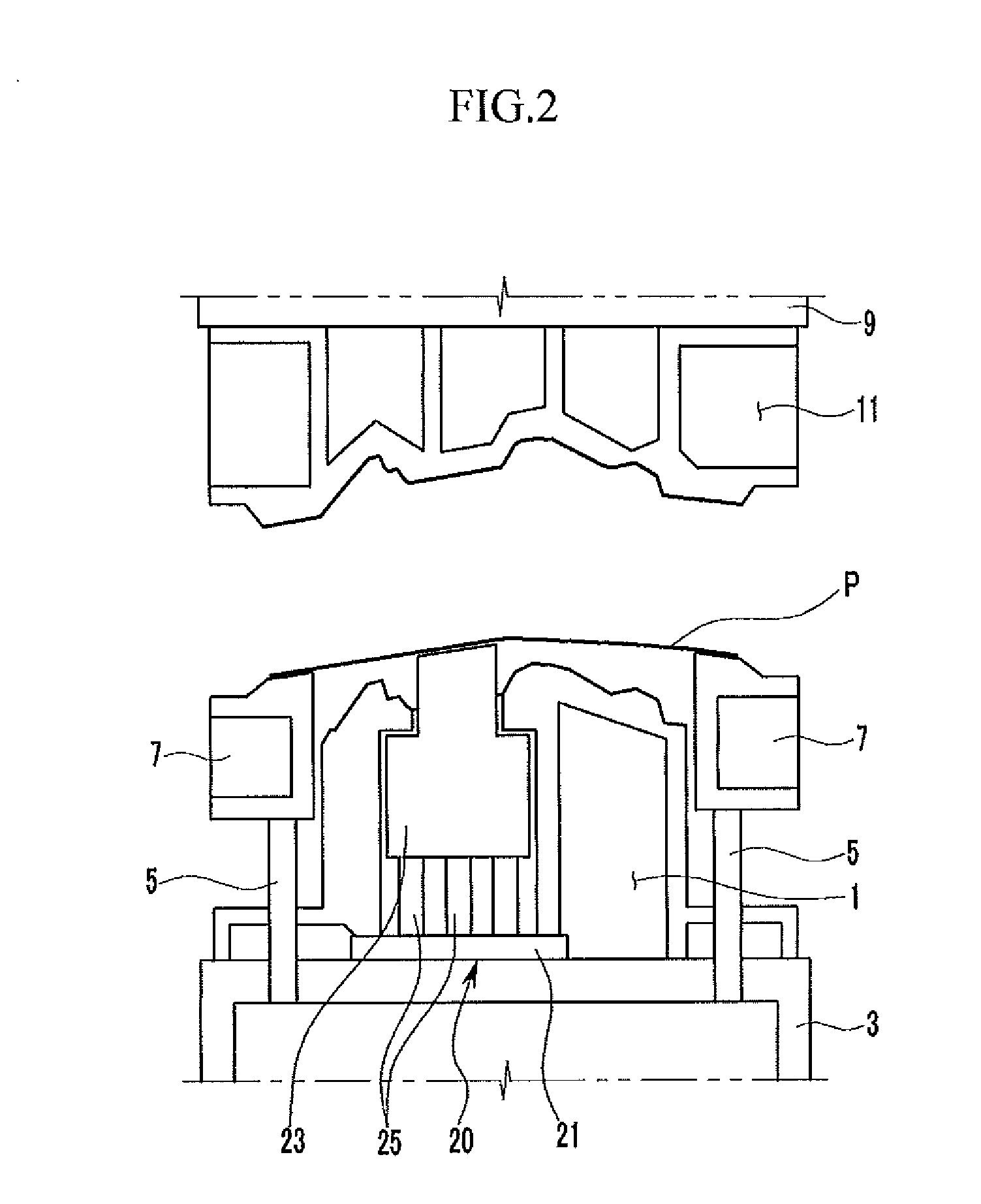

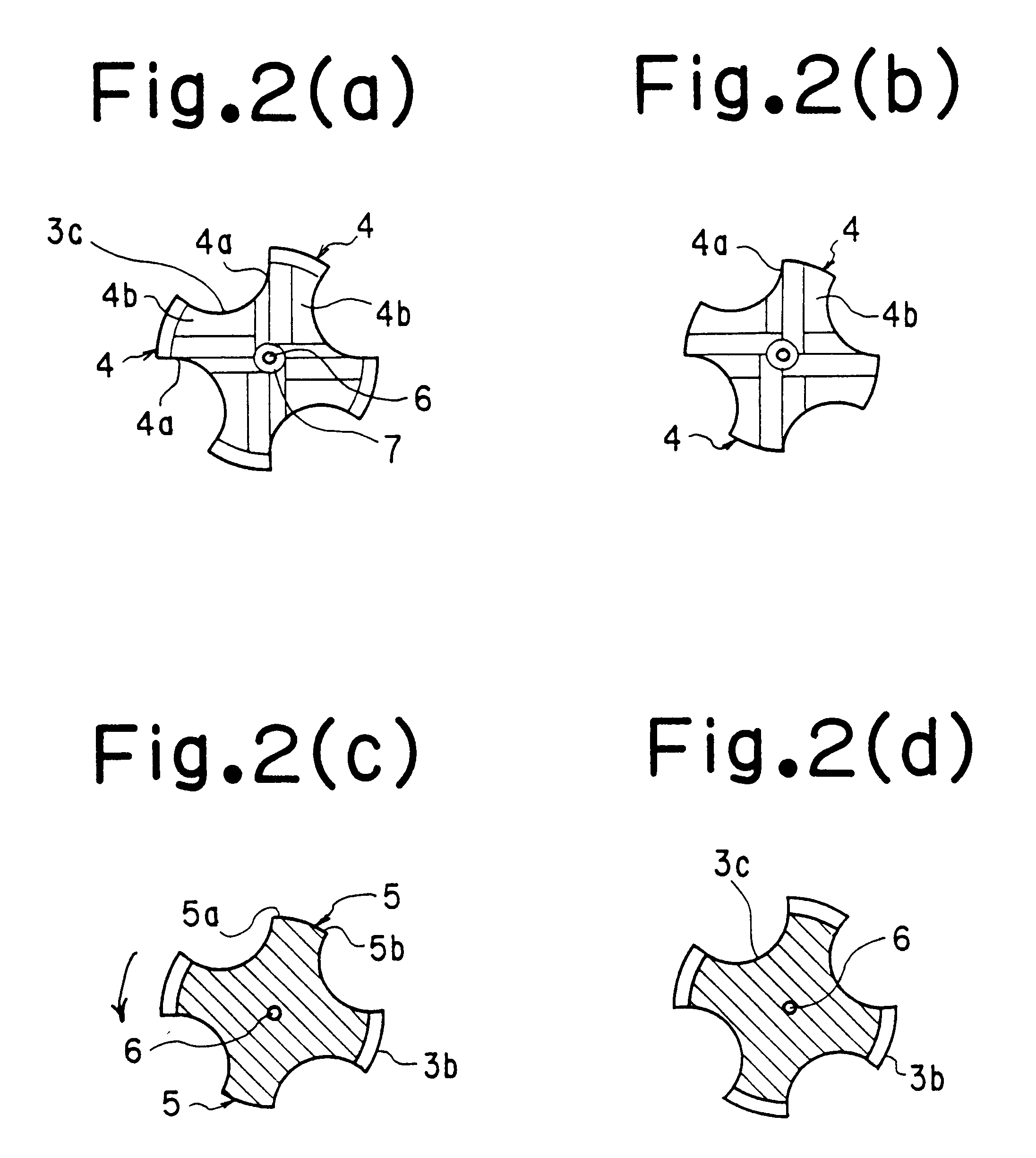

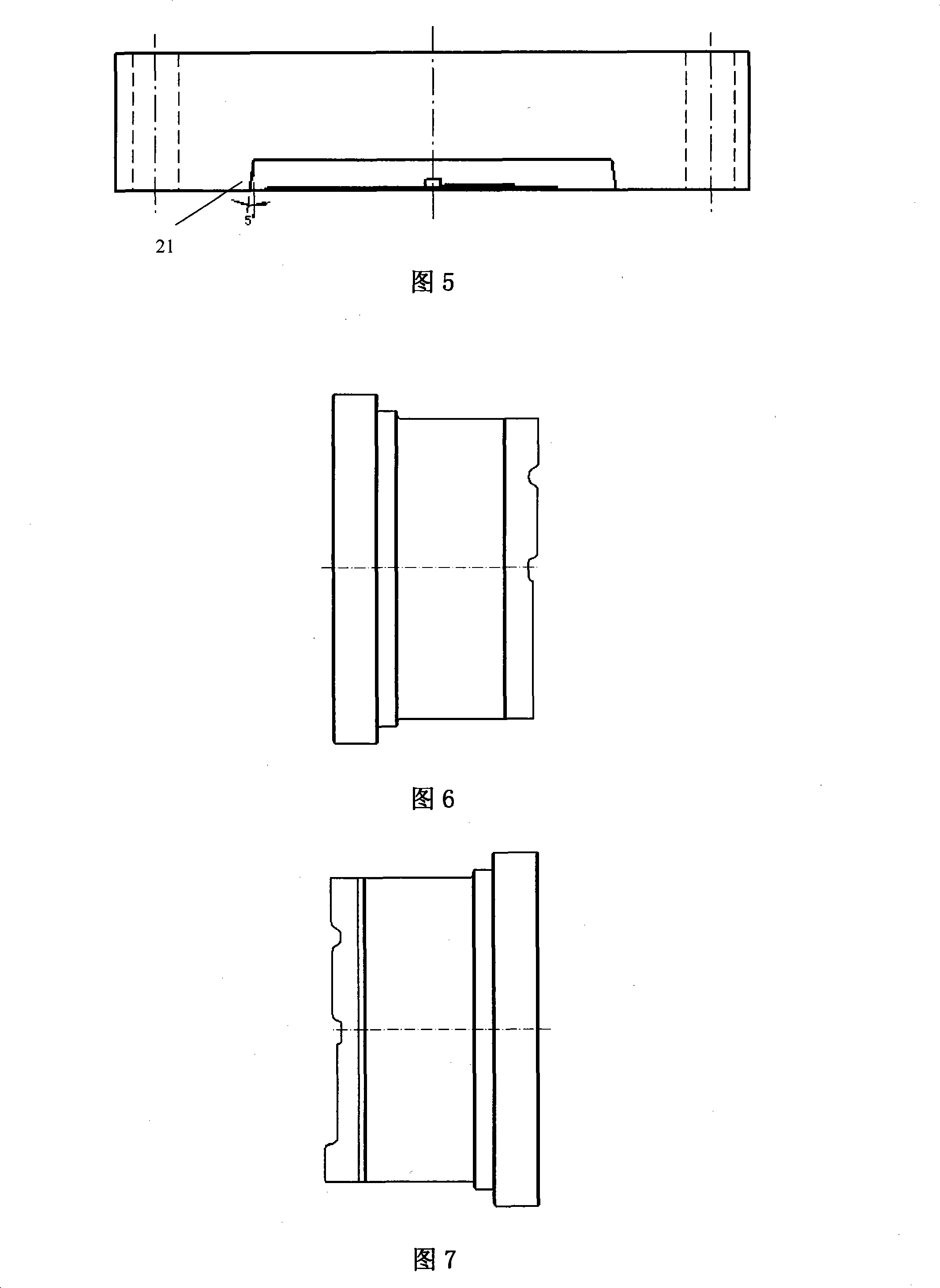

Method and apparatus for manufacturing AC-generator's stator for vehicle

InactiveUS6249956B1Positioning-accuracy can be improvedAvoid damageWire articlesForging/hammering/pressing machinesElectrical conductorEngineering

The object of the present invention is to provide a method and an apparatus for manufacturing a stator to improve accuracy in inserting conductor segments (3, 31, 32) into slots (2). The apparatus according to the present invention comprises a conductor holder (21, 22) holding the conductor segments (3, 31, 32) and an axial-moving-mechanisms (214) moving the conductor holder (21, 22) relative to a stator core (1) in an axial direction. The conductor holder (21, 22) holds straight portions (31b, 31c, 32b, 32c) of the conductor segments (3, 31, 32) to be inserted into the slots (2) from one end of the stator core (1).

Owner:DENSO CORP

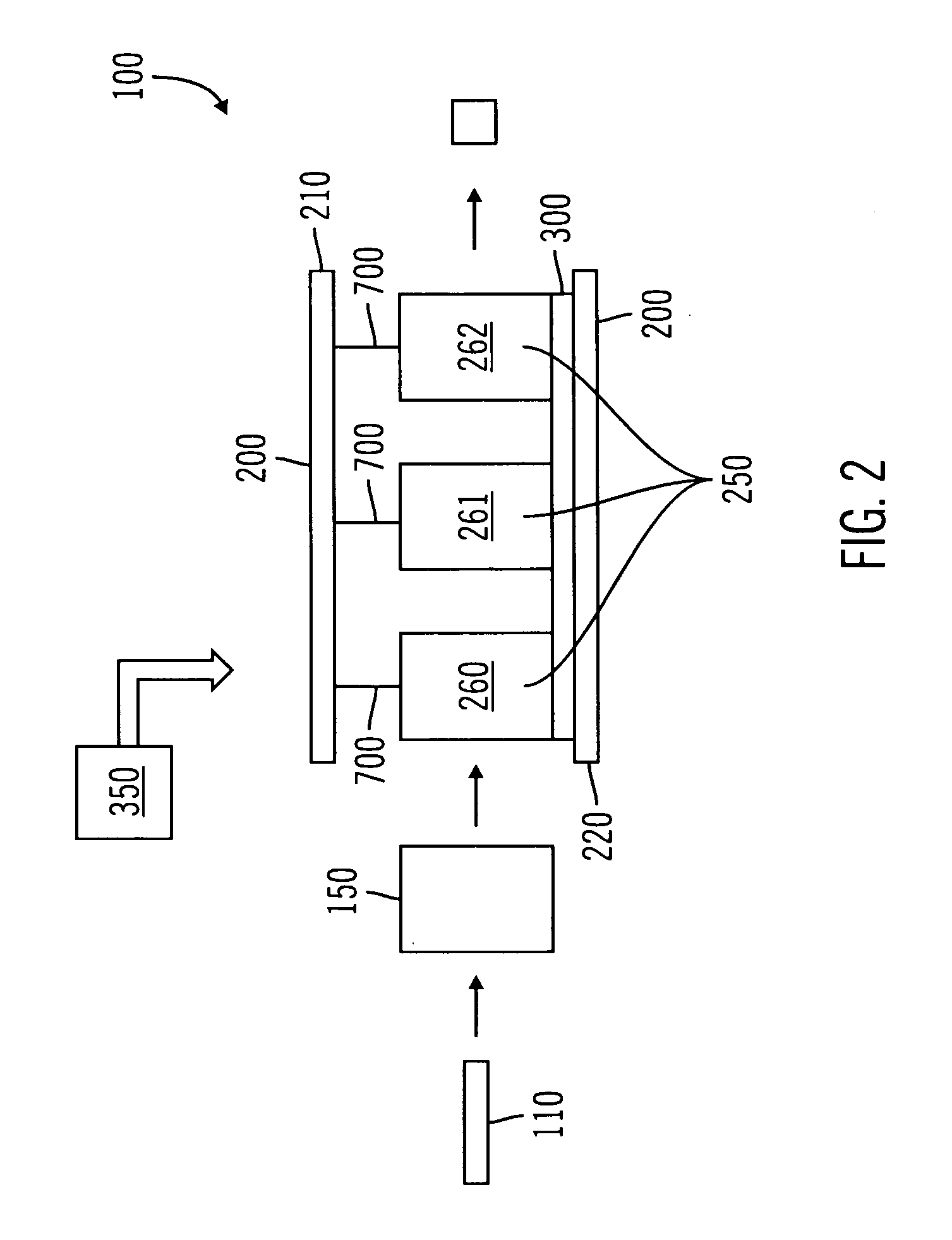

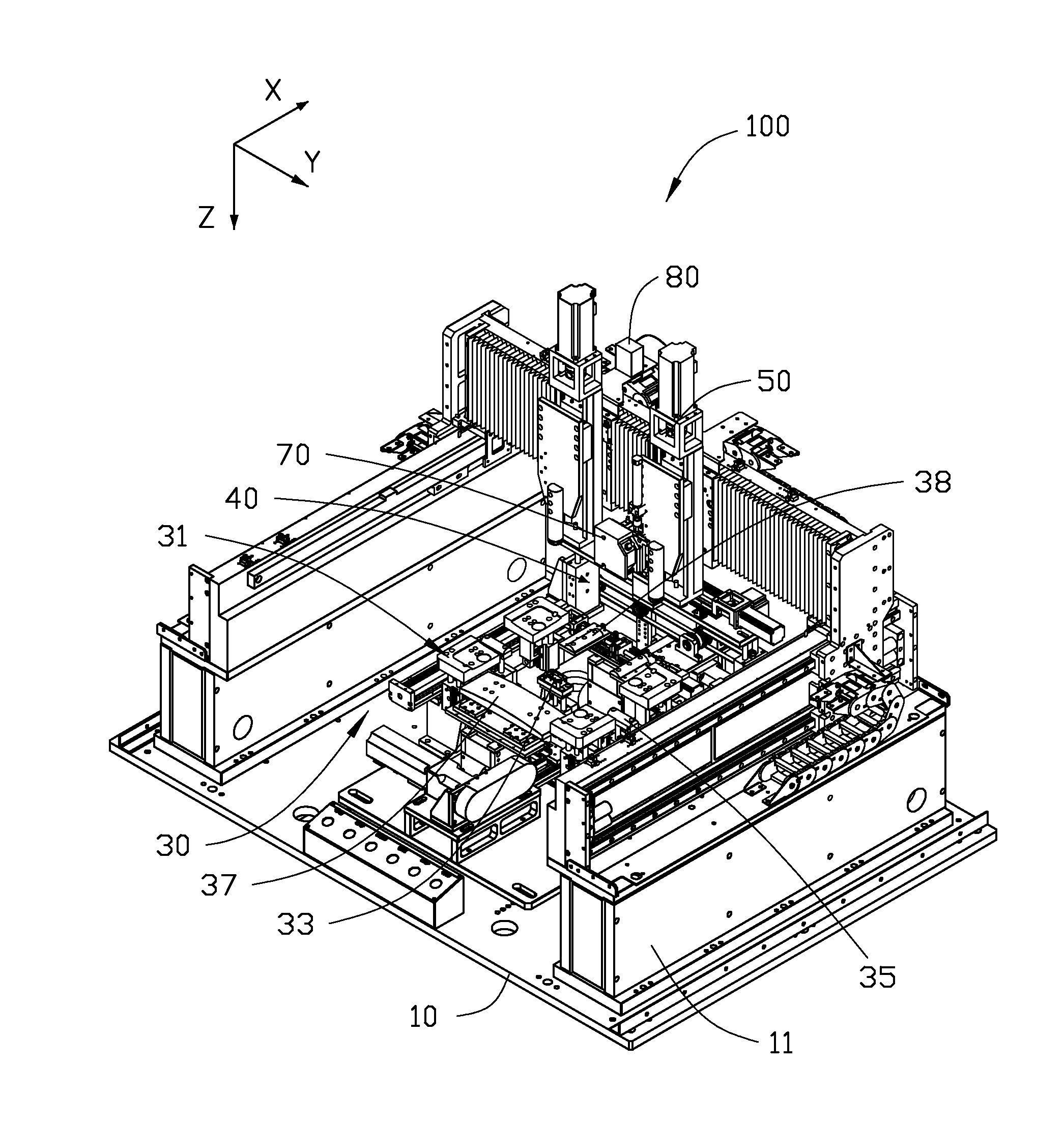

Stamping system for manufacturing high tolerance parts

ActiveUS7343770B2Minimize the numberTight toleranceShaping toolsPerforating toolsMachine pressStamping press

A system and process for stamping parts having tolerances below 1000 nanometers. The inventive system and process is particularly suited for producing optoelectronic parts. The system includes a stamping press and one or a progression of stamping stations for supporting a punch and die. The stamping stations are designed to maintain substantial alignment of the punch and die with minimal moving components. The stamping station includes a shaft for rigidly guiding the punch to the die. The stamping press is capable of providing the punch with the necessary force to perform the stamping operations. The system includes an interface system for interfacing the force of the press with the punch, while simultaneously structurally decoupling the press from the punch. The system also includes a locating sub-plate, for locating the stamping station in alignment relative to each other, and means for in-line machine stock material before entry into the stamping stations.

Owner:SENKO ADVANCED COMPONENTS

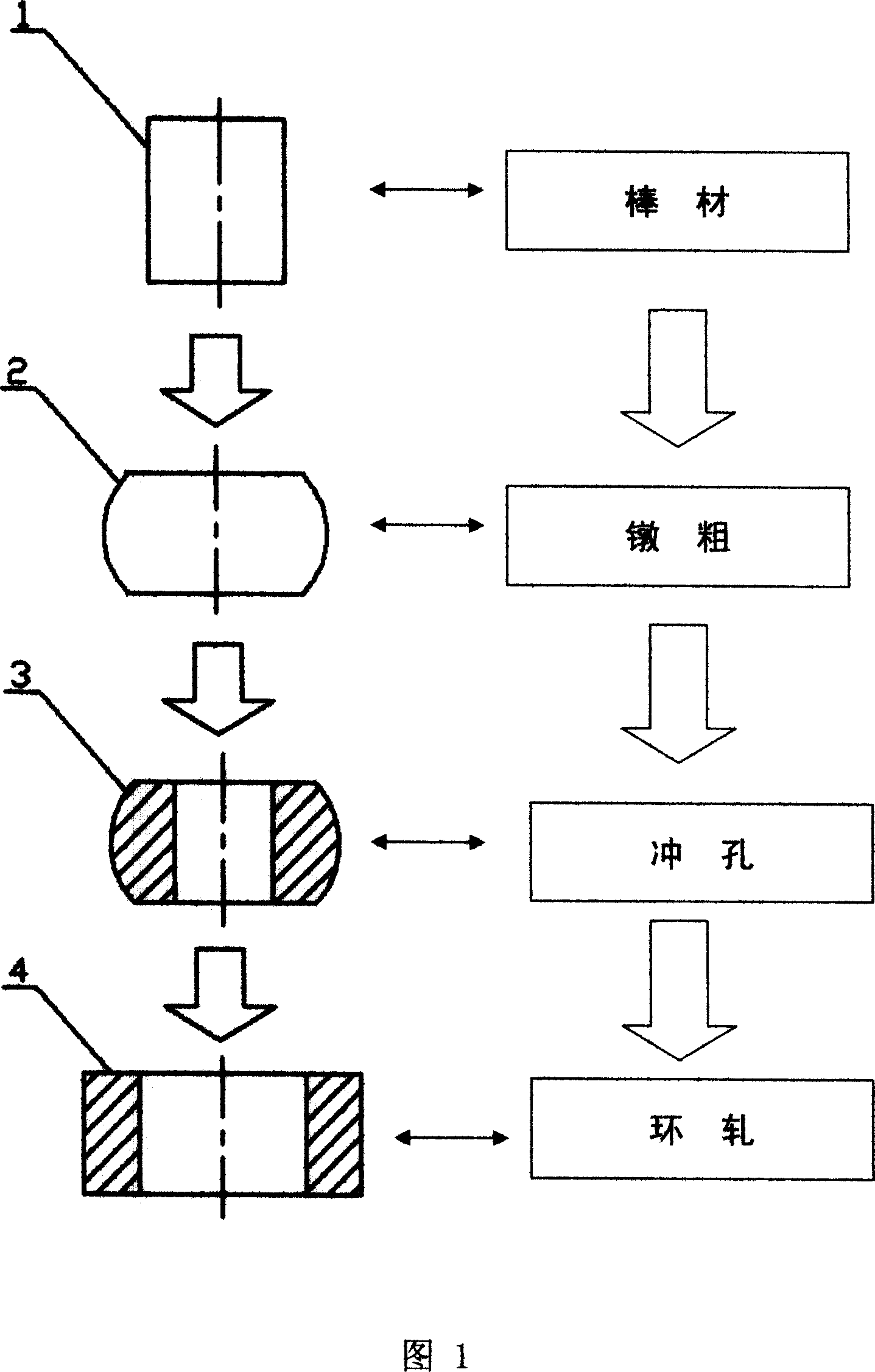

Making process of large irregular ring blank of high temperature alloy

InactiveCN101020284AEasy to achieve billet formingEasy to manufactureForging/hammering/pressing machinesSuperalloy

Owner:GUIZHOU ANDA AVIATION FORGING

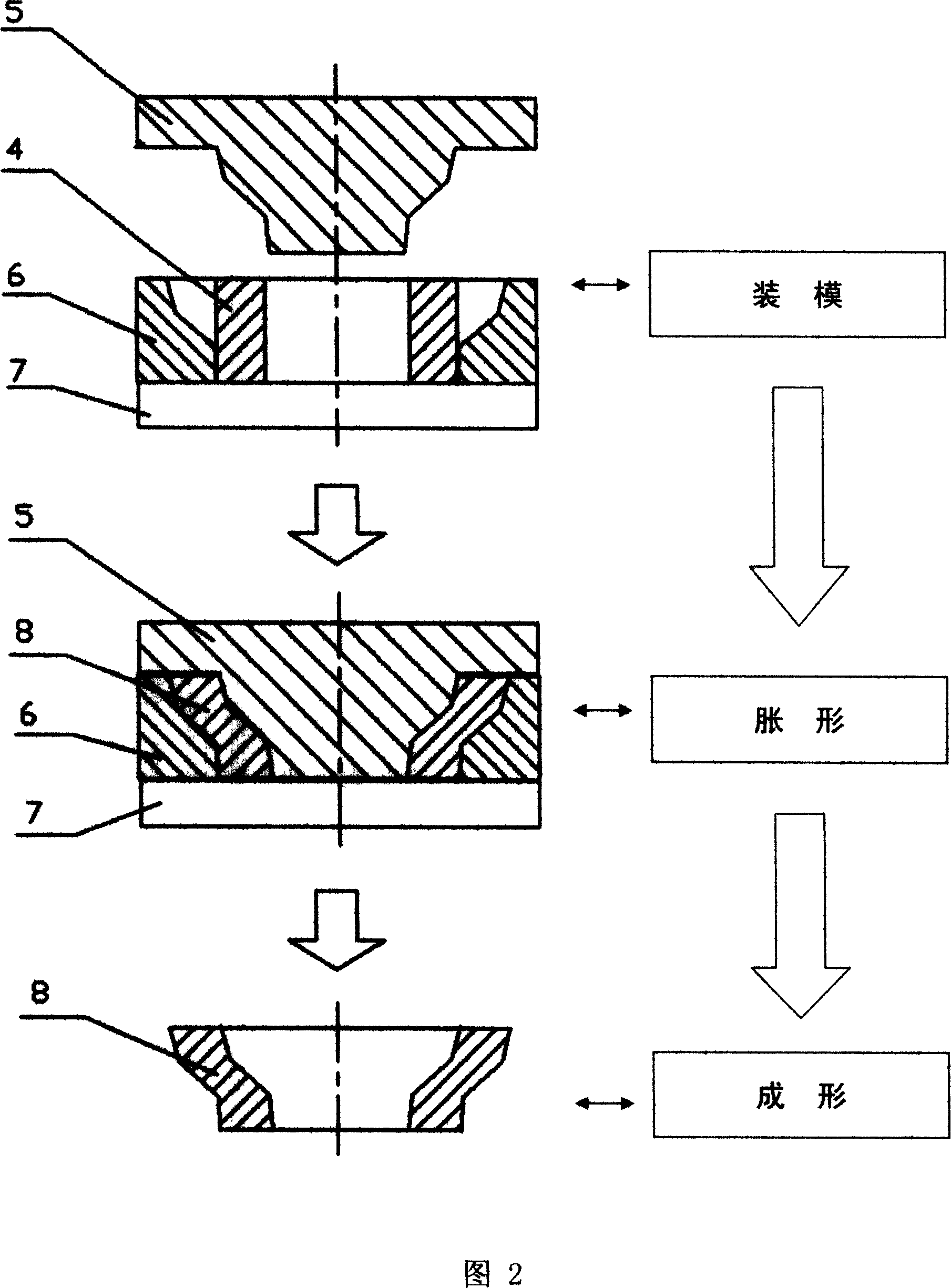

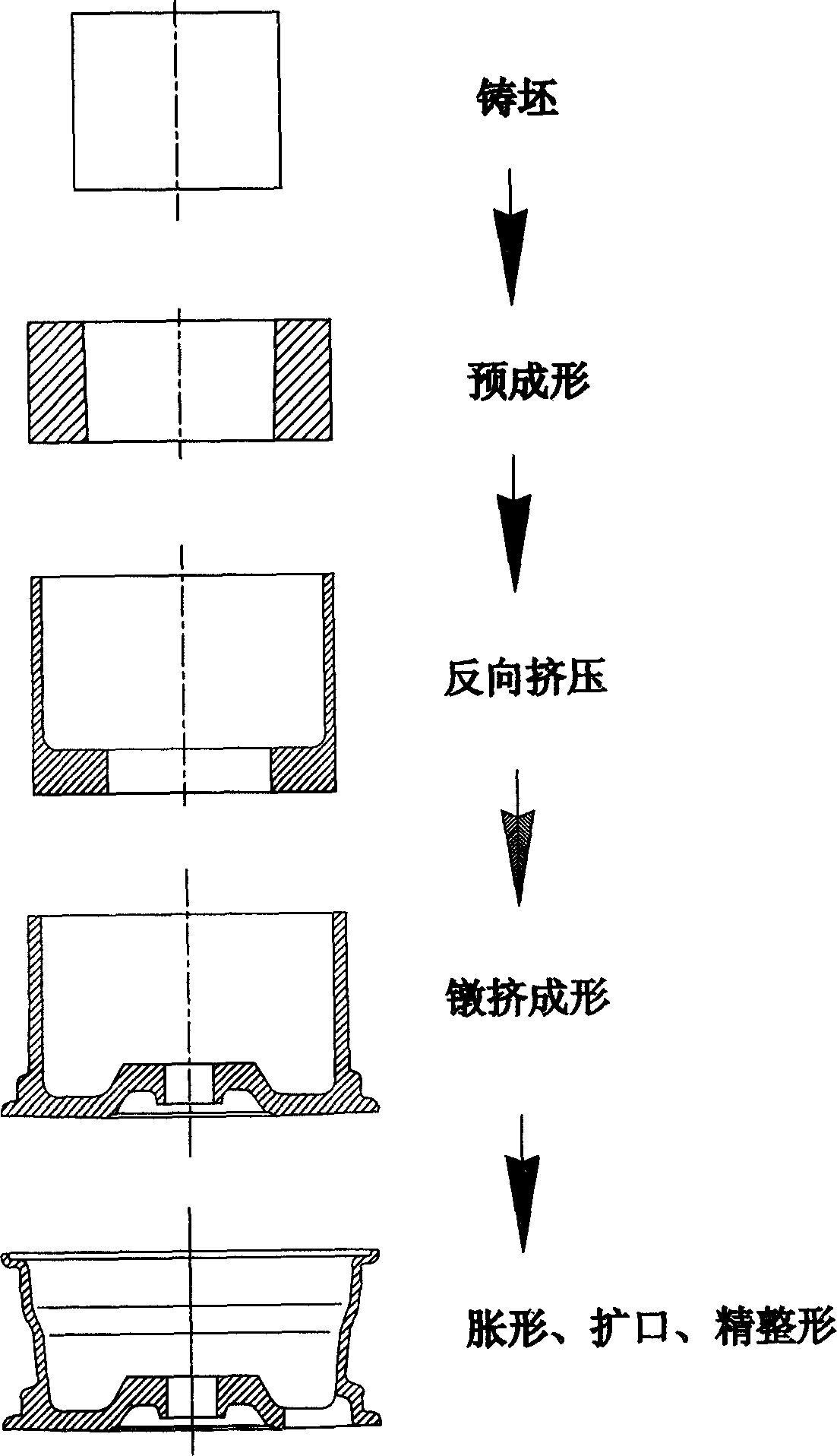

A labor-saving automobile hub forming method and device

InactiveCN1864915AWith substantive technologyReduction toolExtrusion diesExtrusion control devicesEngineeringMechanical engineering

The invention relates to a method for shaping the vehicle hub and relative device. Wherein, it comprises following steps that casting blank; uniform processing; pre-shaping blank; compressing; compressing the front rim; expanding opening and folding the edge at the back rim. The invention is characterized in that: the casting blank via pre-shaping is made into hollow blank; the concave and convex moulds in the compressing step and the compressing front rim step are integrated, while the convex mound contains core axle; the compressing step compresses the hollow blank in the mould via core axle to obtain the cylinder element whose bottom has holes; the step that compressing front rim uses metal diversion to stuff and shape; the step that expanding opening and folding the edge of back rim uses integrated convex mould and separated concave mould to expand opening, fold edge an shape the back rim. The invention can simplify the process, reduce device number, reduce the shaping force, reduce the energy consumption, and reduce the producing cost. The invention is mainly used to produce aluminum and magnesium alloy hub.

Owner:ZHONGBEI UNIV

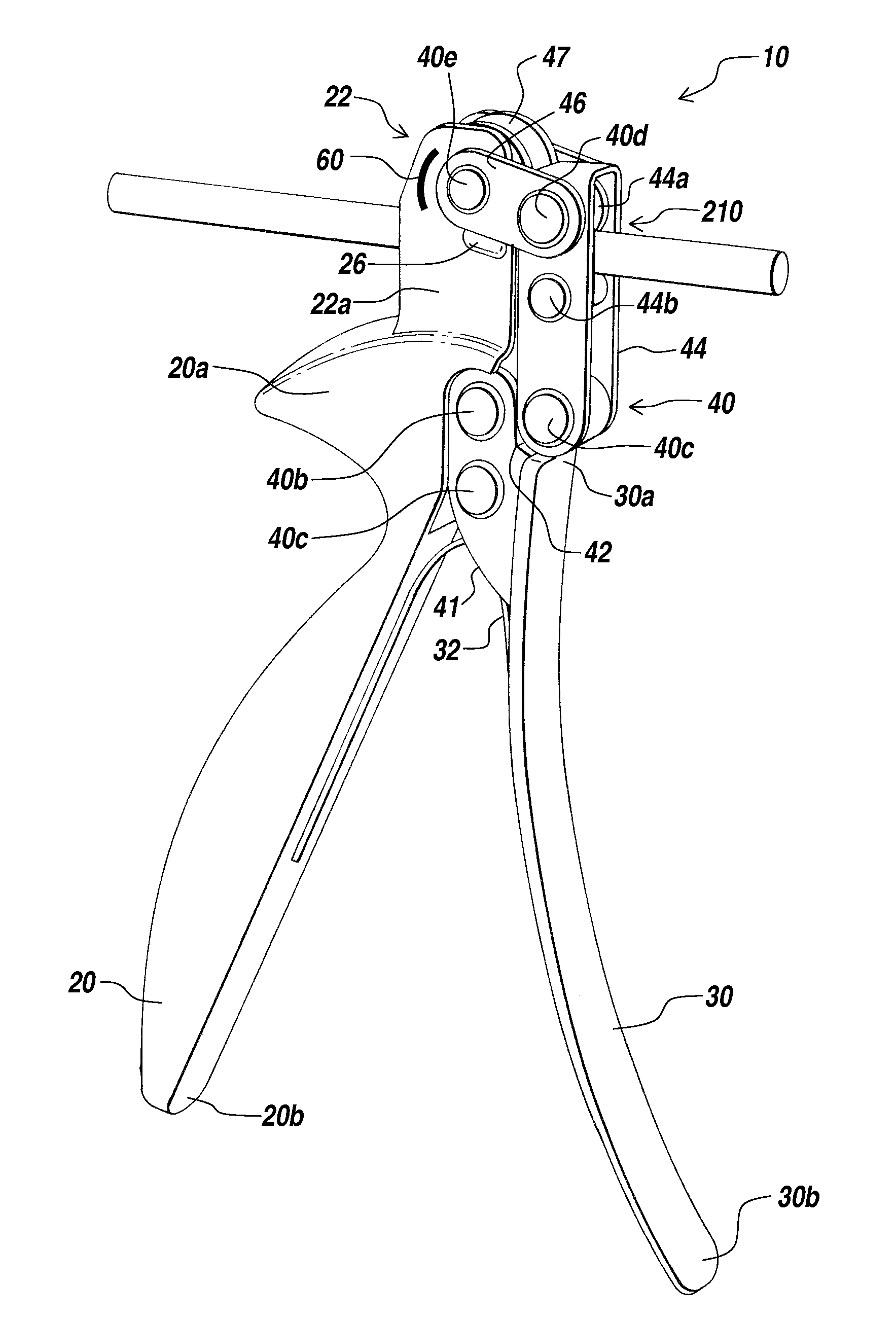

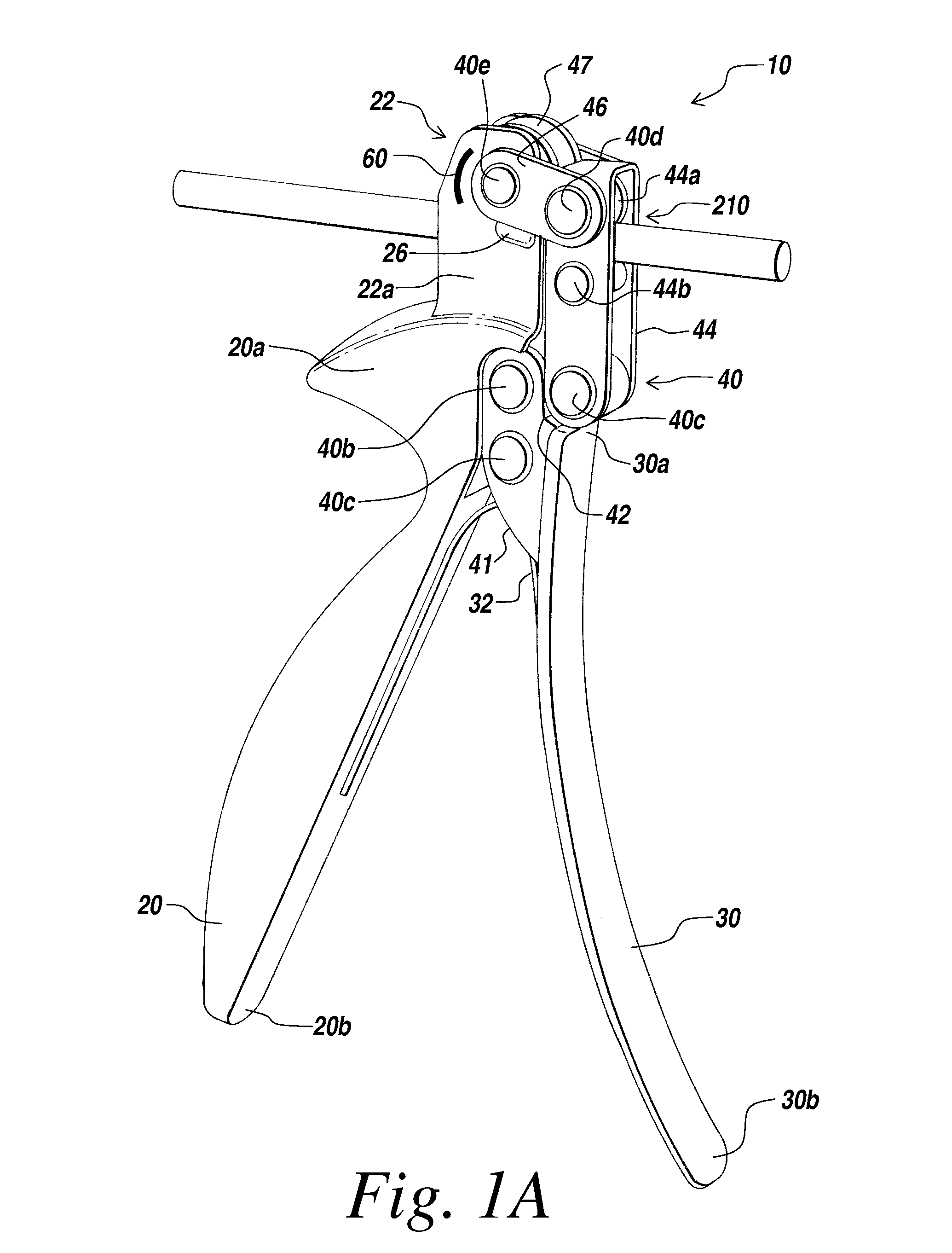

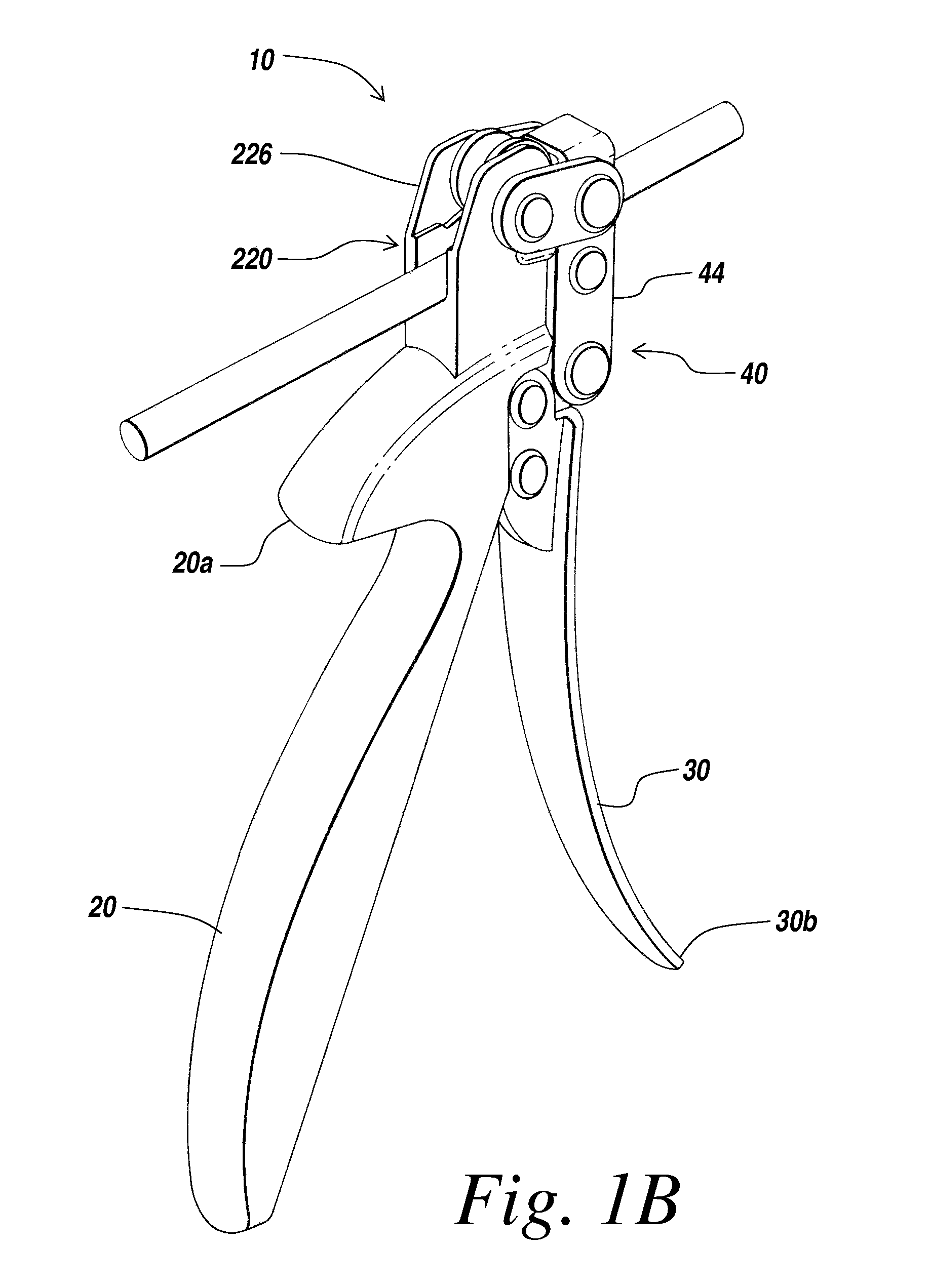

Instrument for bending spinal rods used in a spinal fixation system

InactiveUS7454939B2Easy to operateEasy to controlForging/hammering/pressing machinesOsteosynthesis devicesBearing surfaceFixed position

Owner:DEPUY SPINE INC (US)

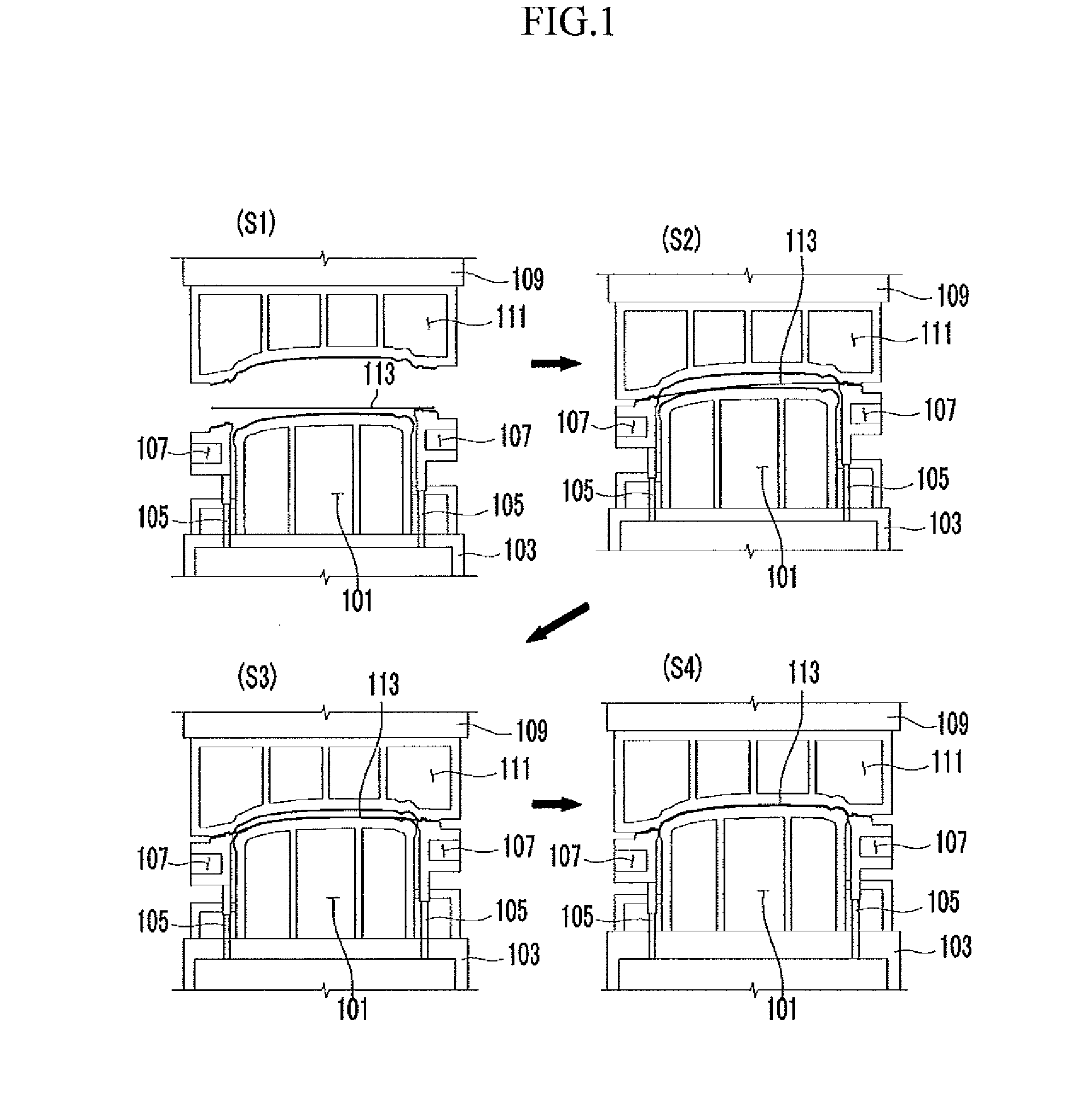

Press system

InactiveUS20120137749A1Good moldabilityImprove marketabilityShaping toolsForging/hammering/pressing machinesEngineeringCushion

Disclosed is a press system having advantages of preventing a molded product panel from bursting or being torn due to a difference in molding depth caused by a protrusion shape to improve the moldability and marketability of the product panel when press molding is performed on a material panel. An illustrative press system comprises: a lower die punch provided on a bolster and having a lower surface shape of a product panel; a blank holder provided on the outside of the lower die punch and mounted on the bolster through cushion pins; an upper die having an upper surface shape of the product panel, mounted on the slider, and pressing a material panel together with the lower die punch to mold the product panel; and a sub blank holder unit provided inside the lower die punch by performing the molding while holding a portion of the material panel to be molded into a protrusion shape together with the upper die such that a difference in molding depth is compensated when molding is performed.

Owner:HYUNDAI MOTOR CO LTD

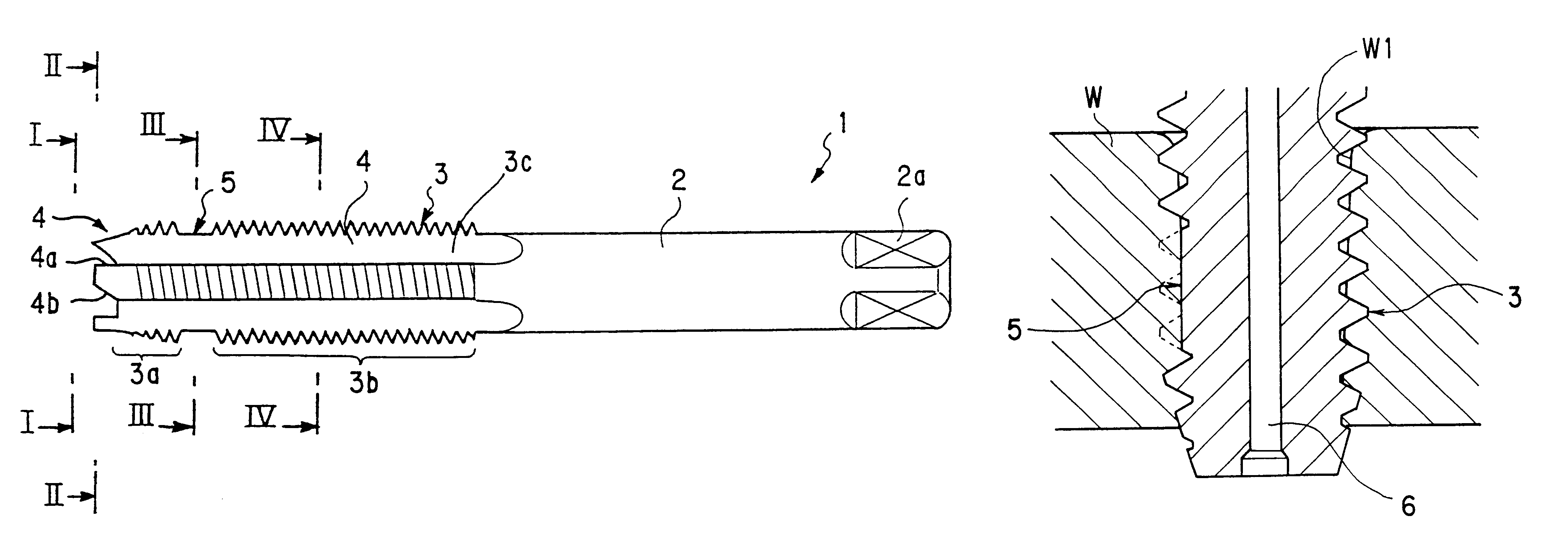

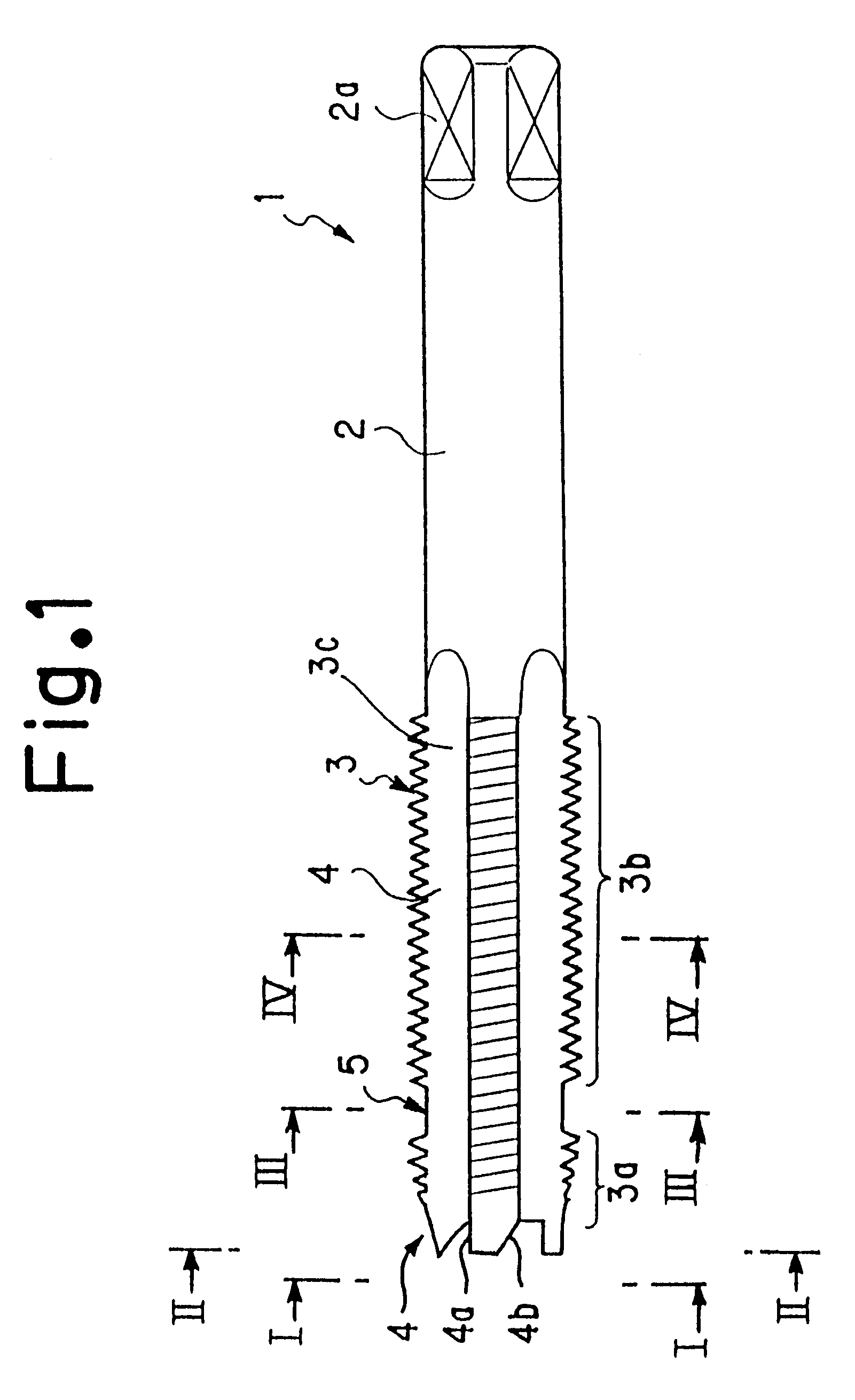

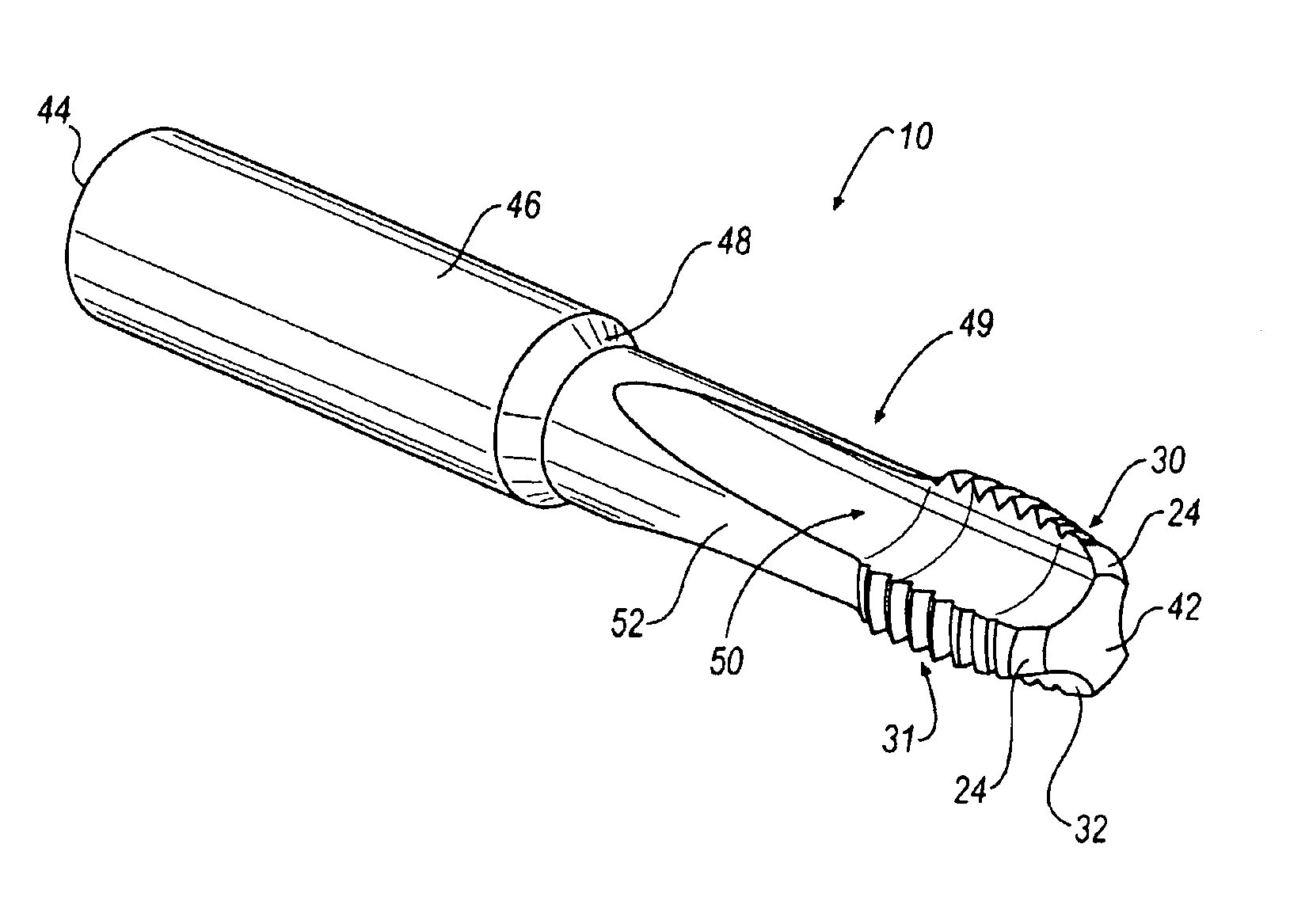

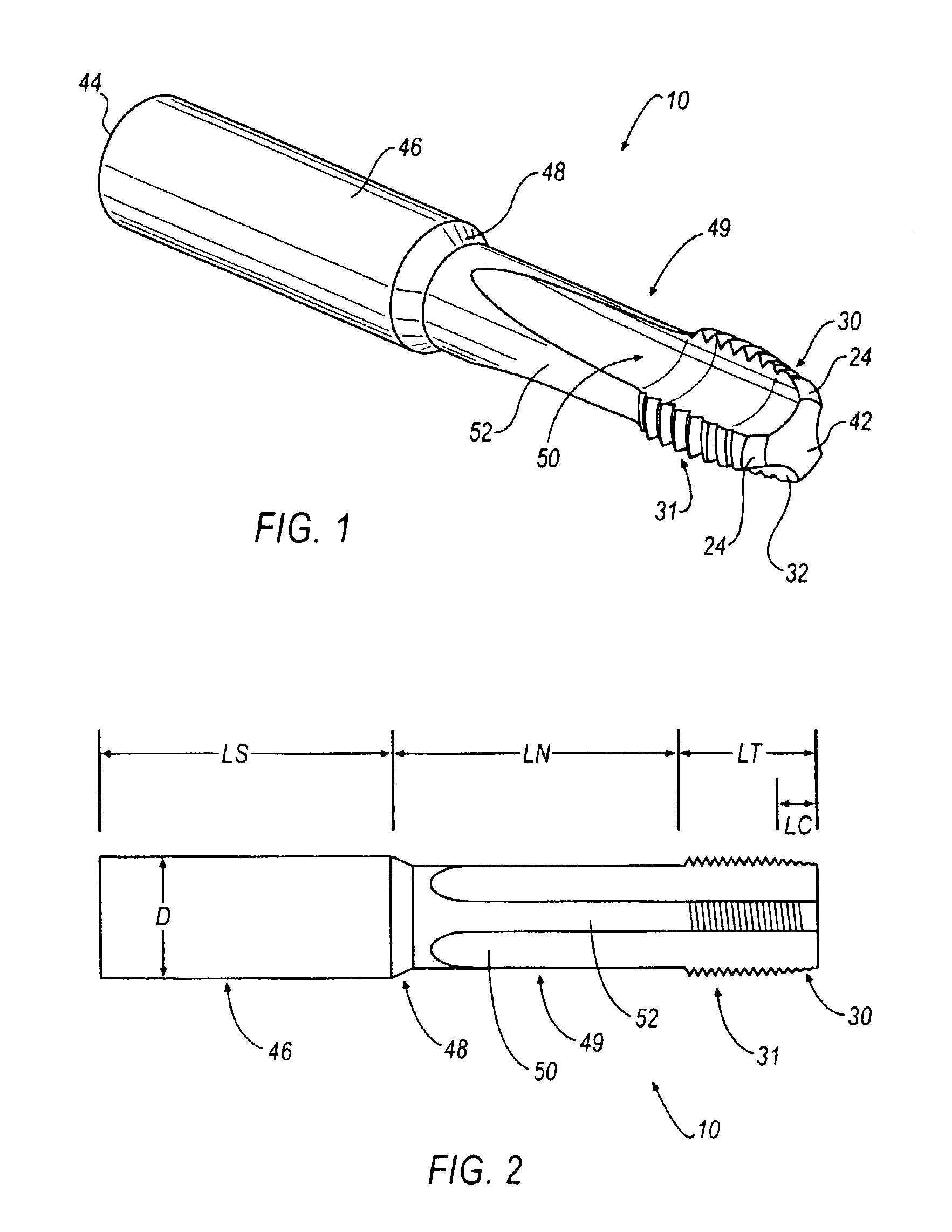

Tap

InactiveUS6499920B2Reduce processing timeImprove productivityThread cutting toolsWood turning toolsFluteEngineering

A cutting tap comprises a threaded portion including a lead whose thread diameter gradually decreases toward a front end of the lead, a complete thread portion continued from the lead, and four flutes arranged at equal intervals in a circumferential direction. In the cutting tap, a first cutting edge portion for processing a prepared hole is formed at a front end surface of the lead, and a second cutting edge portion for finishing a minor diameter of an internal thread is formed in a part of an outer periphery of the complete thread portion, the second cutting edge portion being one or more pitches long. The cutting tap can perform processing of a prepared hole, tapping, and finishing of a minor diameter by a single step, and can also perform tapping even if a prepared hole for an internal thread is a blind hole or the like and does not have enough space.

Owner:TANOI MFG CO LTD

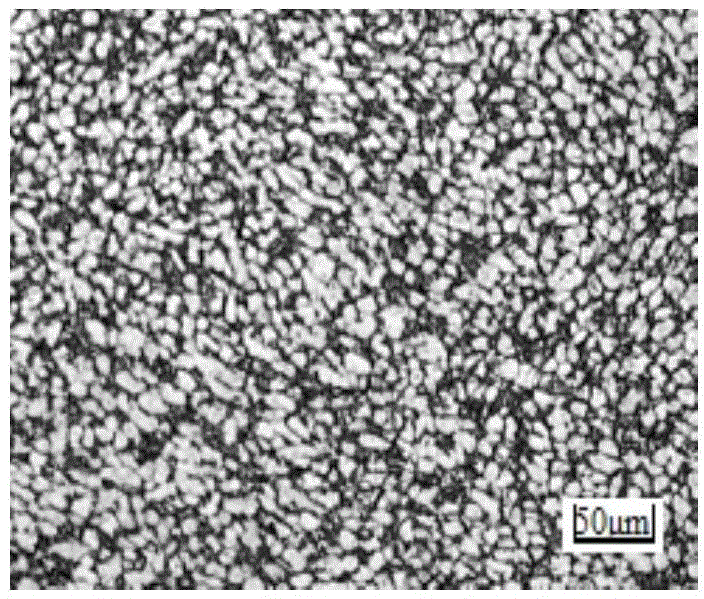

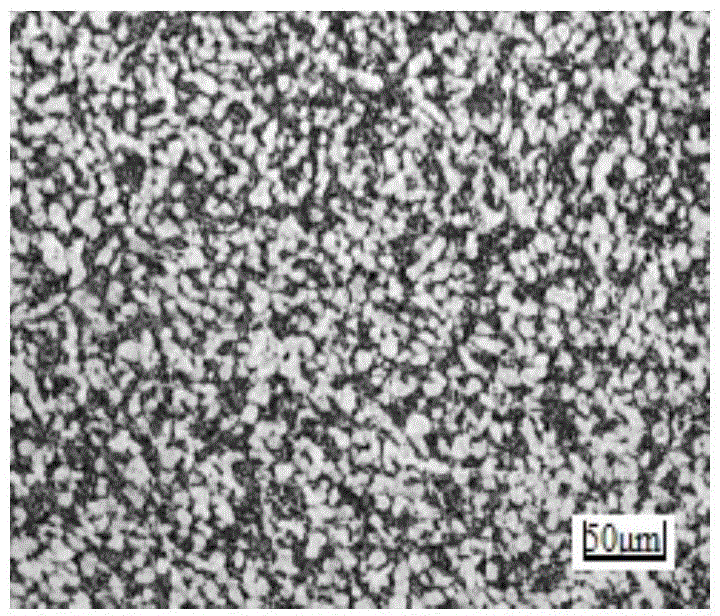

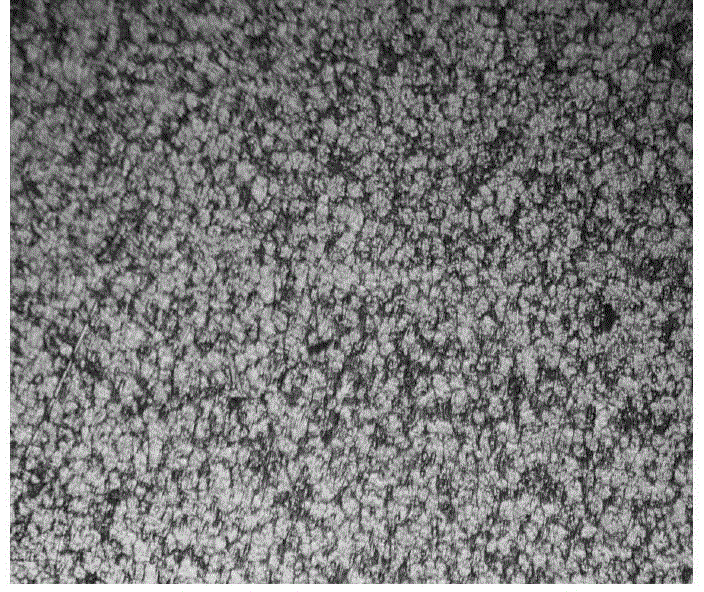

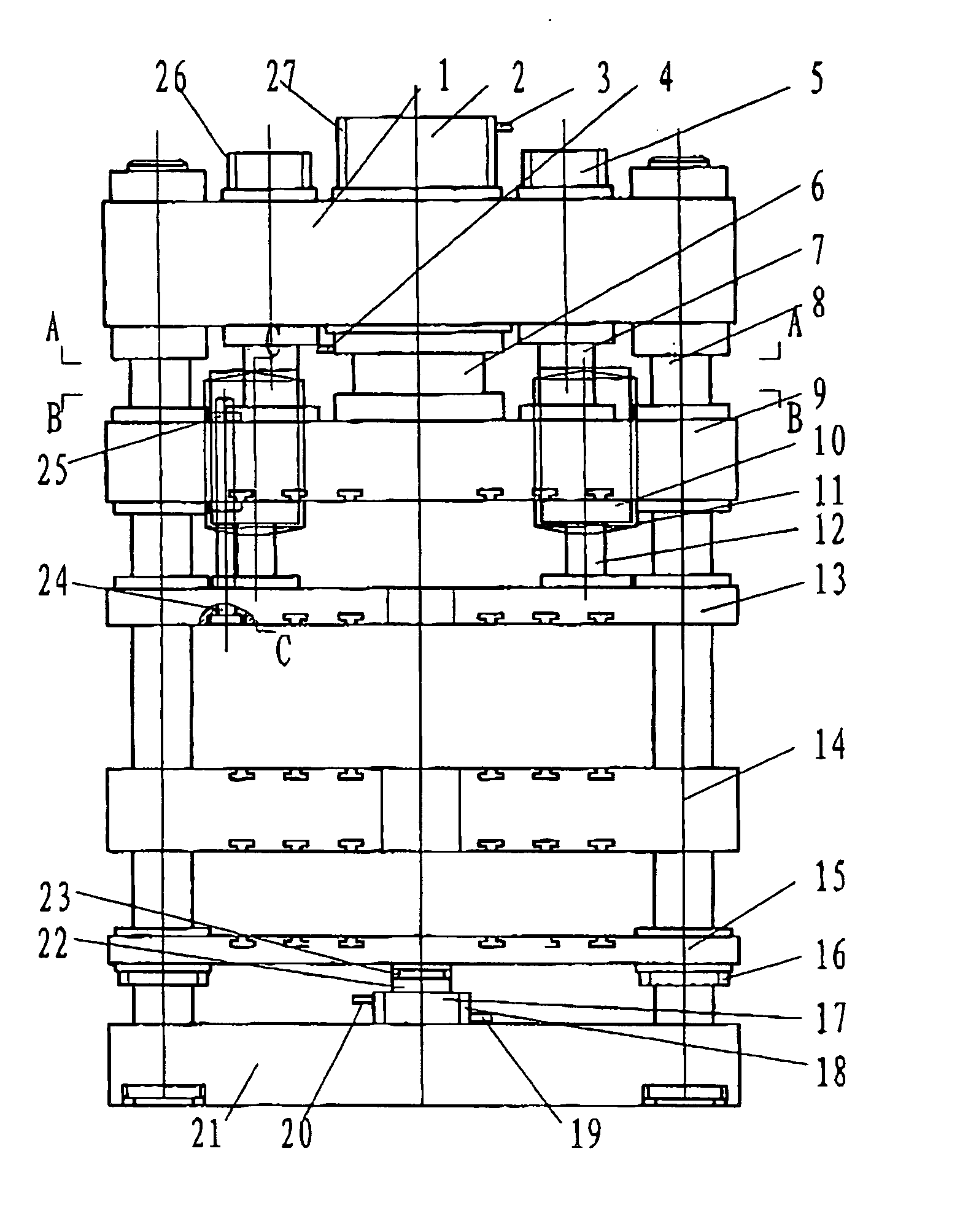

Forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy

InactiveCN104070125ALess investmentSave energyForging/hammering/pressing machinesElectric arc furnaceIngot casting

The invention relates to bar material forging machining method of titanium alloy, particularly to a forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy. The forging machining method is characterized by comprising the following steps of step 1, performing cogging forging, step 2, performing intermediate forging above a phase transformation point, step 3, performing intermediate forging below the phase transformation point, step 4 and step 5, performing finished product forging and obtaining the phi 200 to 300 mm and 2000 to 3000 mm length of large-sized bar materials of the TC4 titanium alloy finally. Compared with the prior art, a large-sized ingot casting and a large-tonnage forging device are not required and the industrialized production can be achieved through an ordinary industrial 3 ton ingot and a small-tonnage forging press and the equipment investment is small, only a 3 tons of electric arc furnace and a 3000 tons of forming oil press which is matched with the electric arc furnace need to be invested in the phi 600 of 3 ton ingot, the small-tonnage forging press such as a 1600 tons of forging press needs to be invested in the forging process, and accordingly the equipment investment is significantly reduced.

Owner:宁夏中色金航钛业有限公司

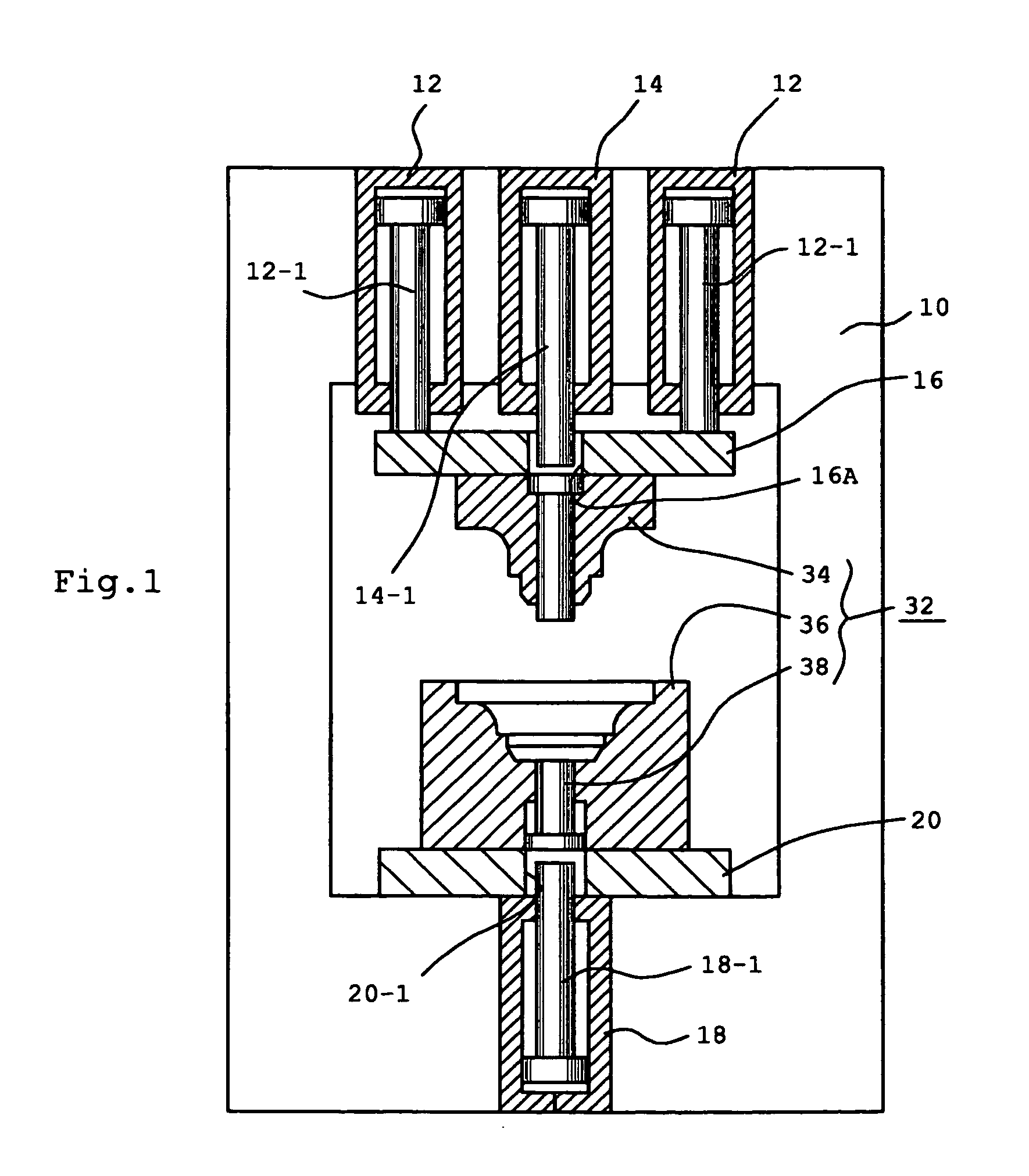

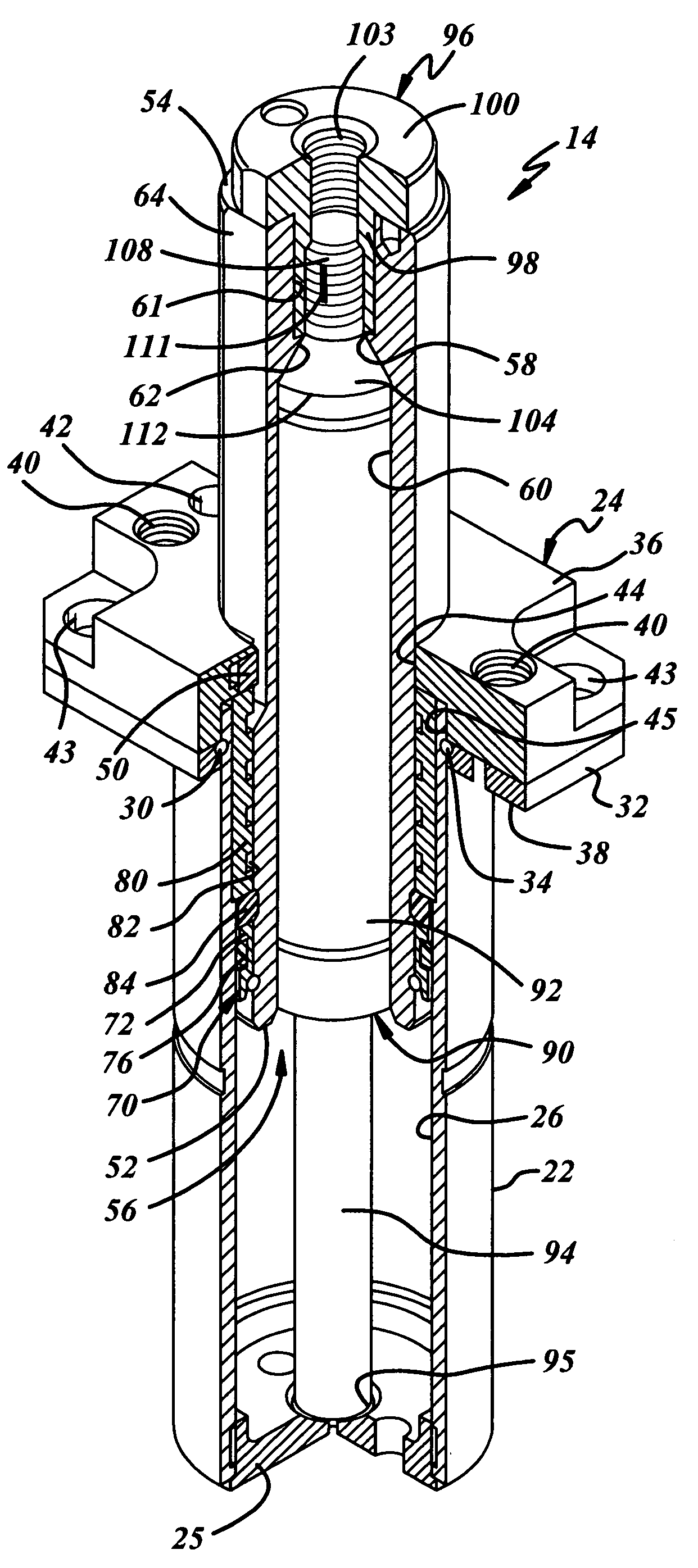

Method and apparatus for producing thin walled tubular product with thick walled flange

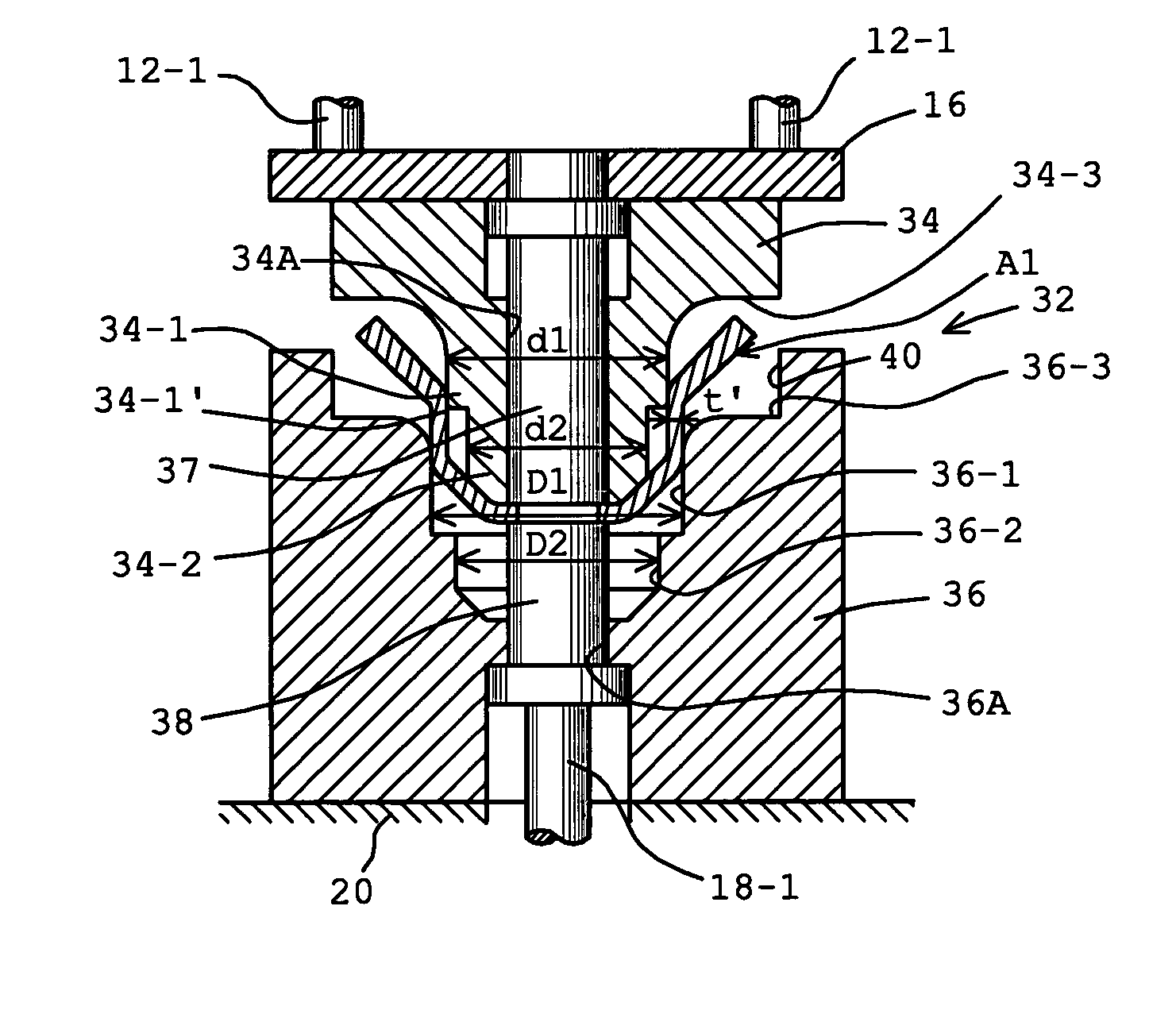

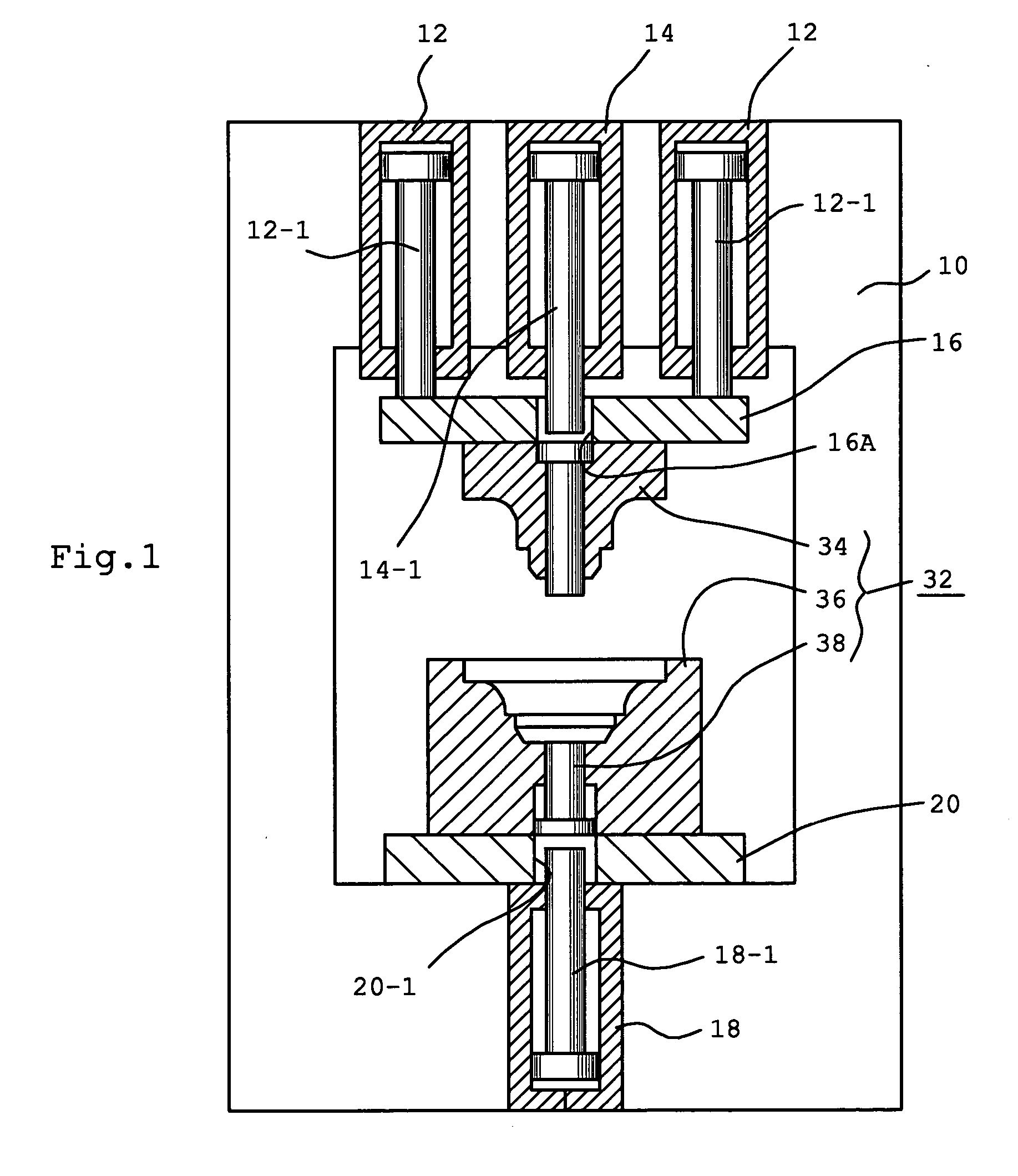

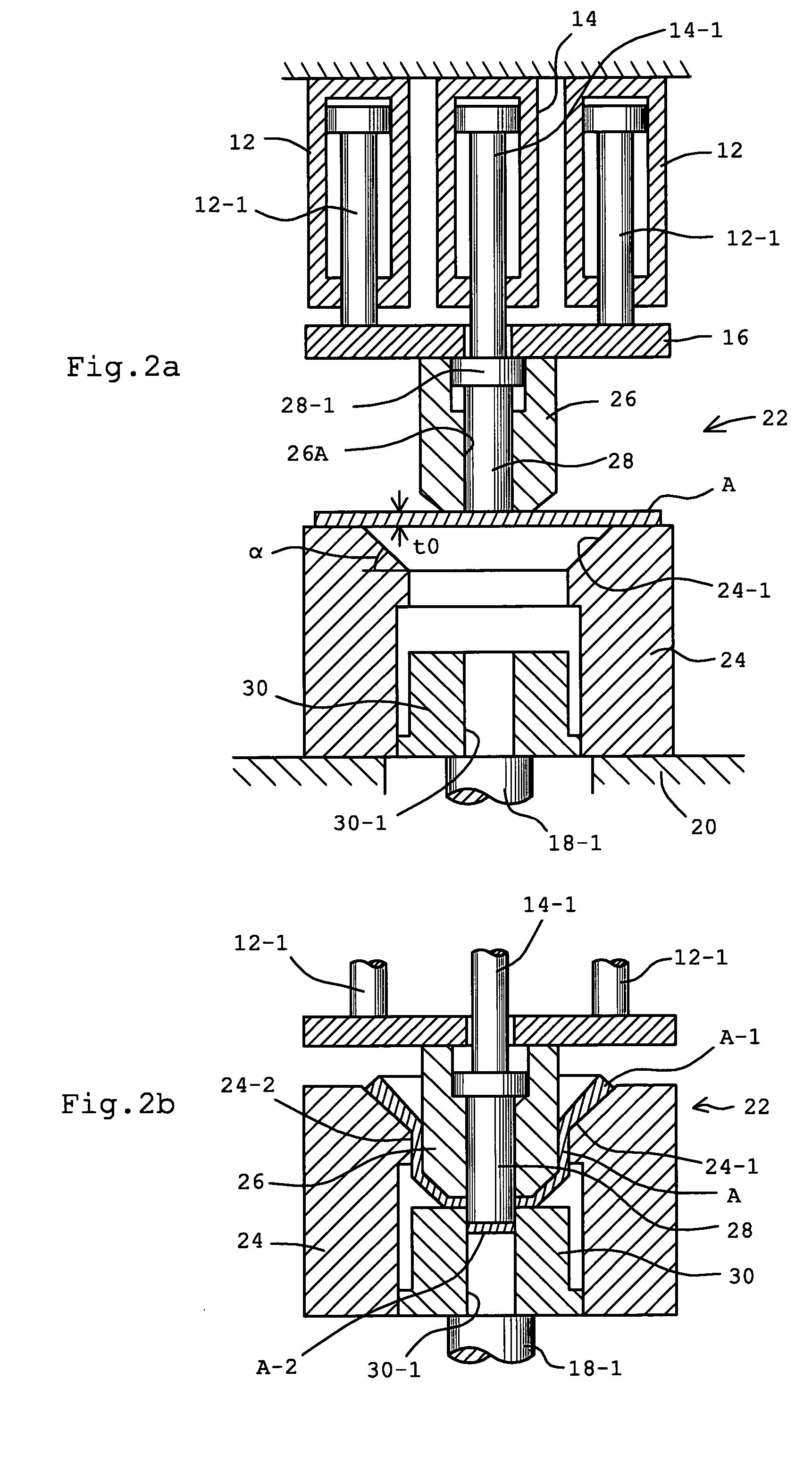

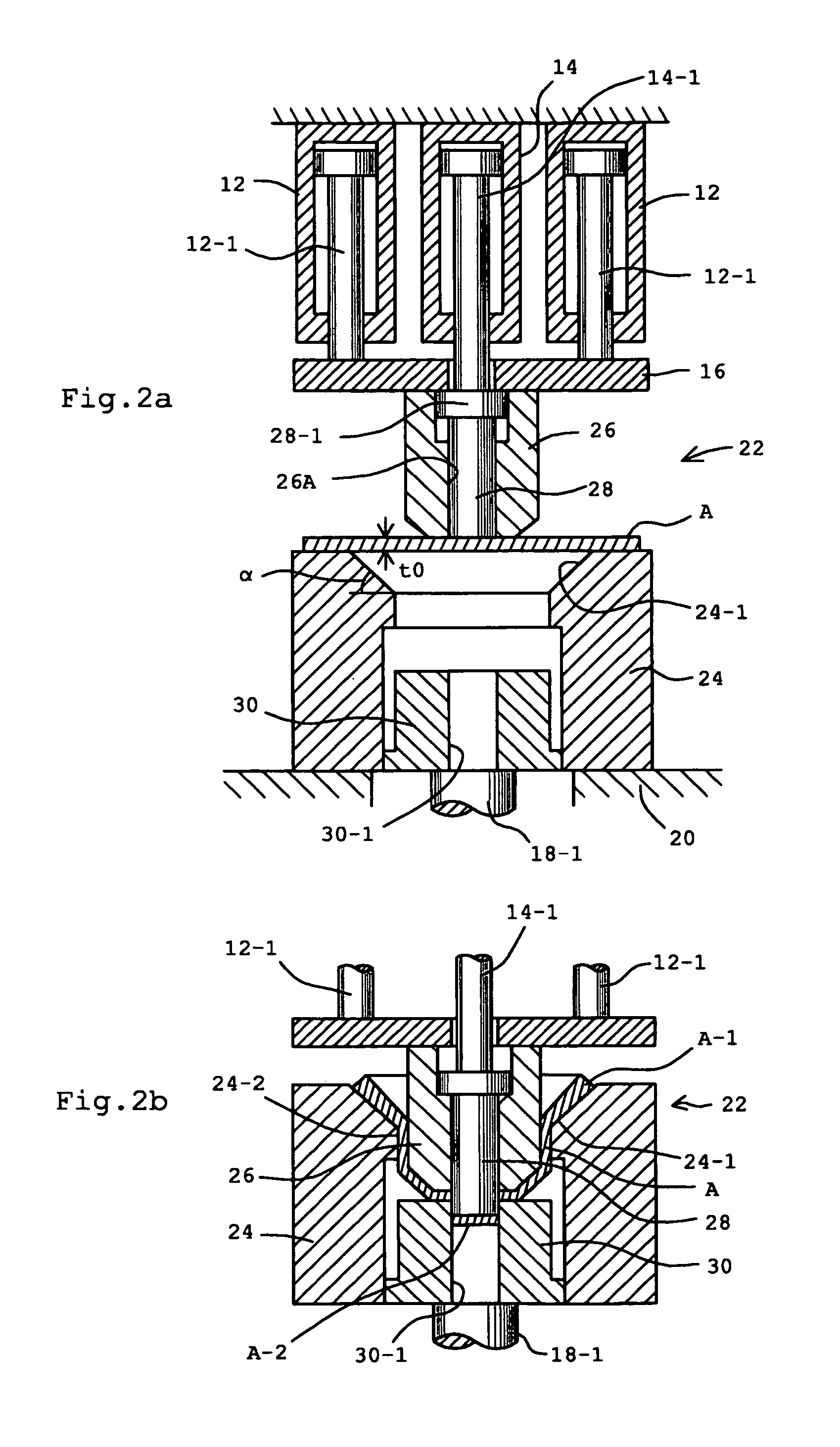

InactiveUS20040244459A1Forging/hammering/pressing machinesDomestic articlesMetalworkingWork in process

Method and apparatus for producing a thin walled tubular product with thickened flange. A first stage metalworking (drawing) of a circular plate material A is done by using a first die set 22 having a conical die 24 and a drawing punch 26 is done in a manner that the end of the blank plate is remained on the conical surface 24-1 of the die, so that a semi-finished tubular product A1 with a inclined flange A1-1 is obtained. Then, a second stage metalworking (drawing) of the semi-finished tubular product A1 is done by a second die set 32 having a shaping punch 34 and a restraint die 36. The semi-finished tubular product A1 is held by the restraint die 36 and the shaping punch 34 is introduced into the semi-finished tubular product A1 for effecting a wall thickness reduction under ironing principle while forming a stepped portion. Simultaneous with the execution of the second stage drawing, a flattening of the flange is done while restriction diameter expansion by a wall 40, thereby obtaining a thickened flattened flange A2-3.

Owner:MATSUOKA MINAKO +2

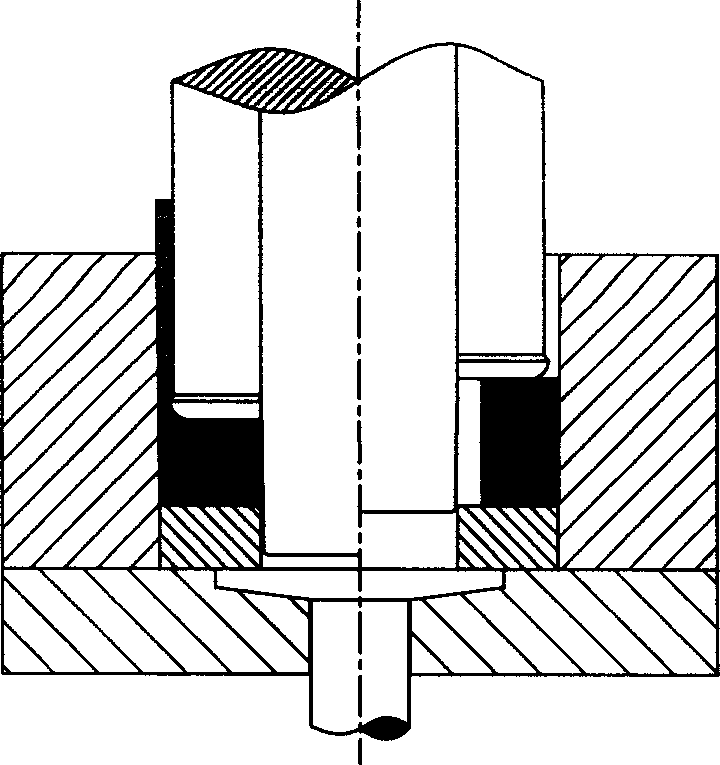

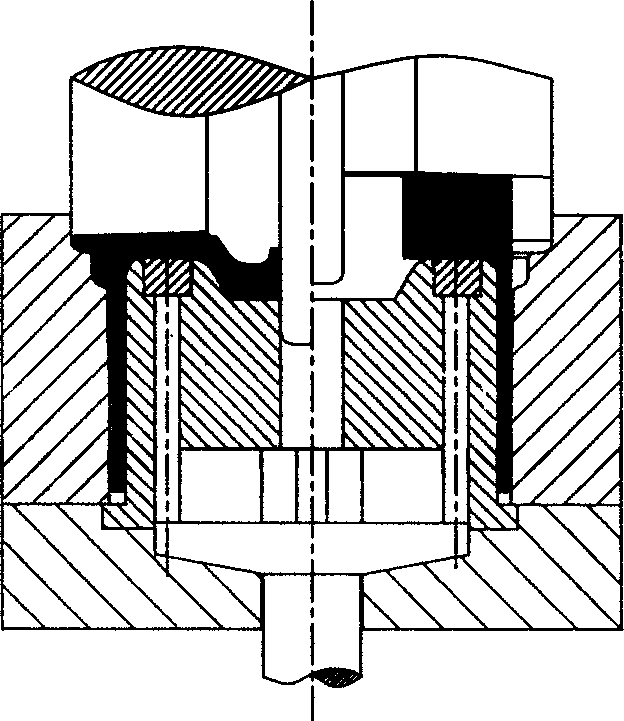

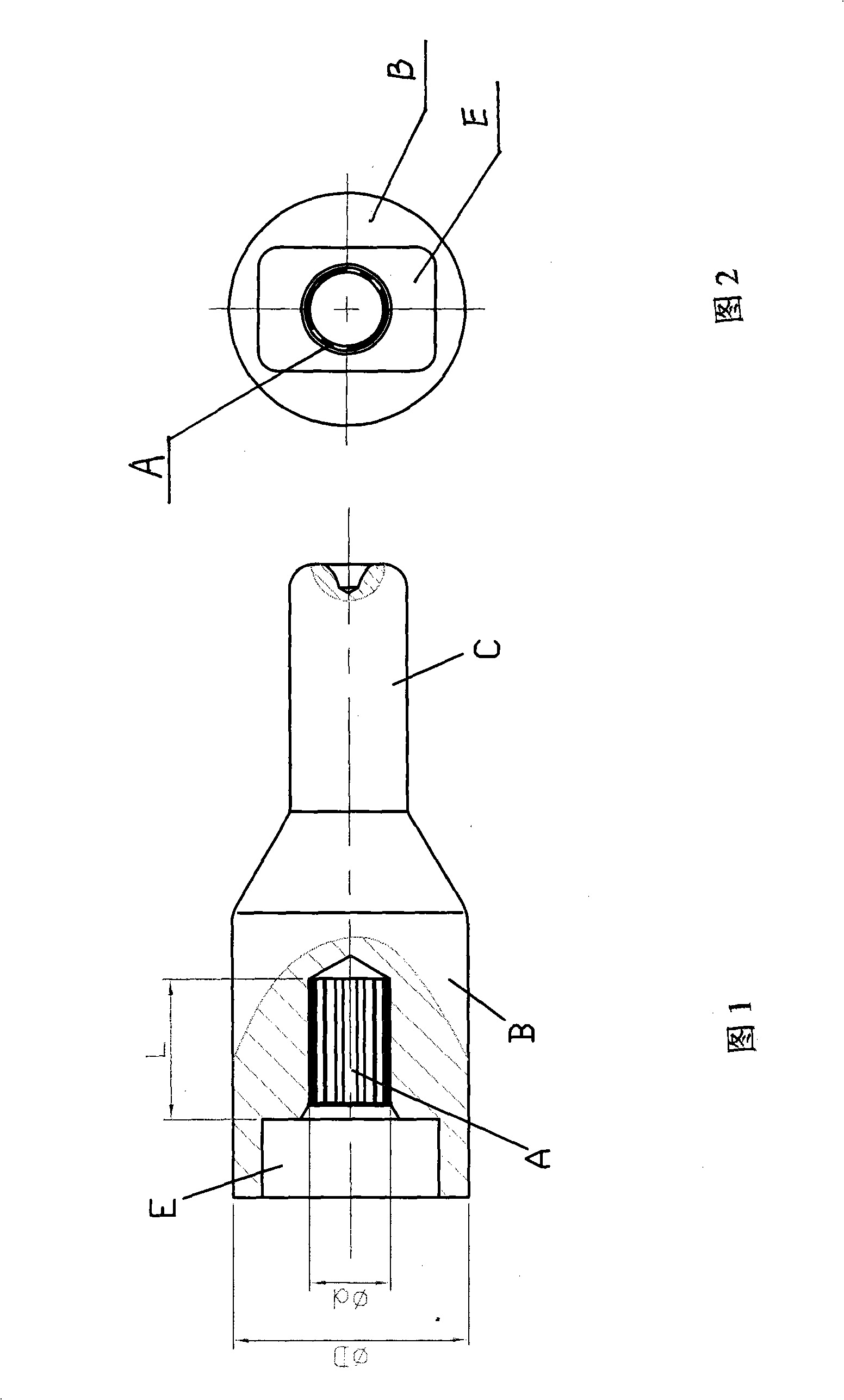

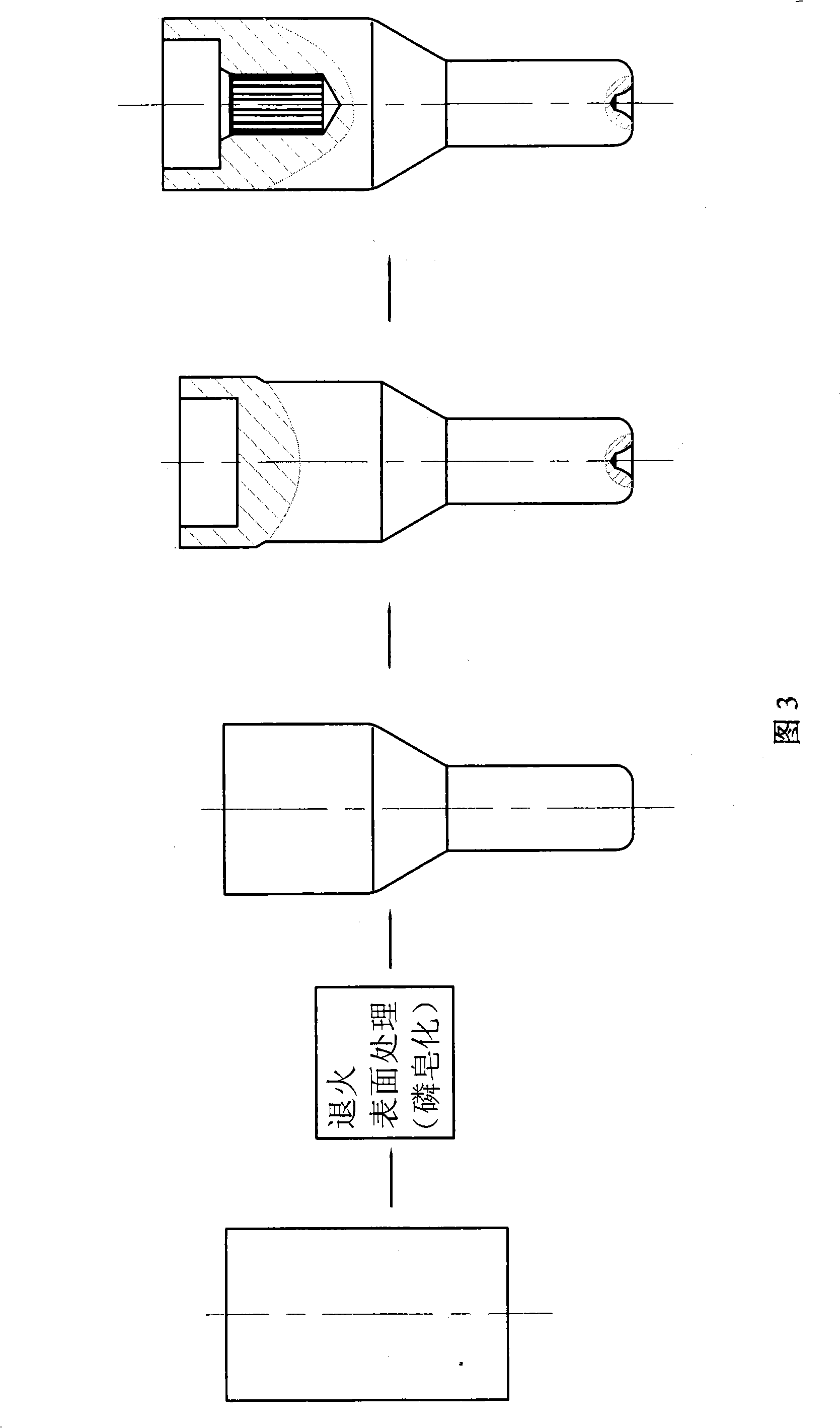

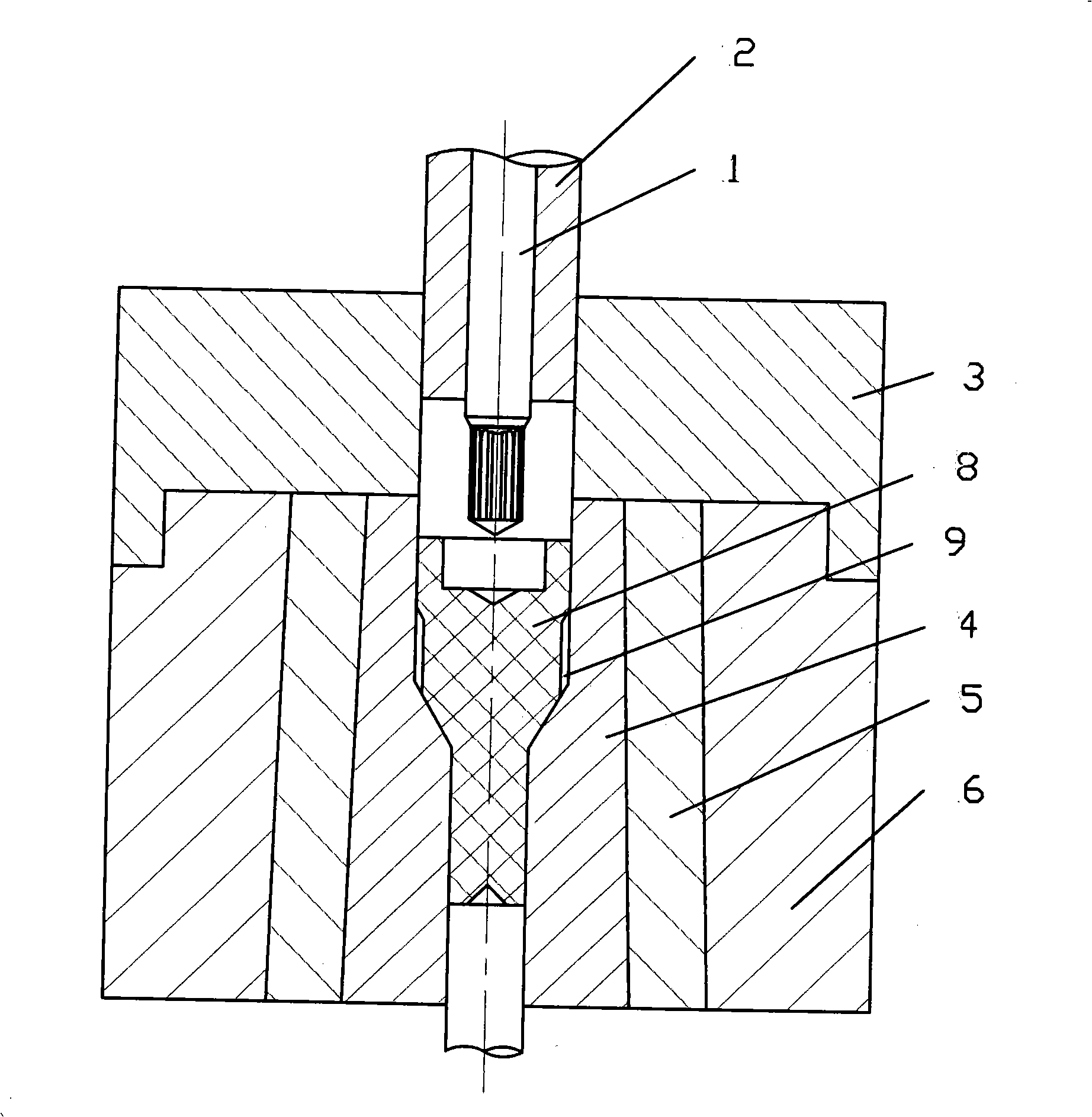

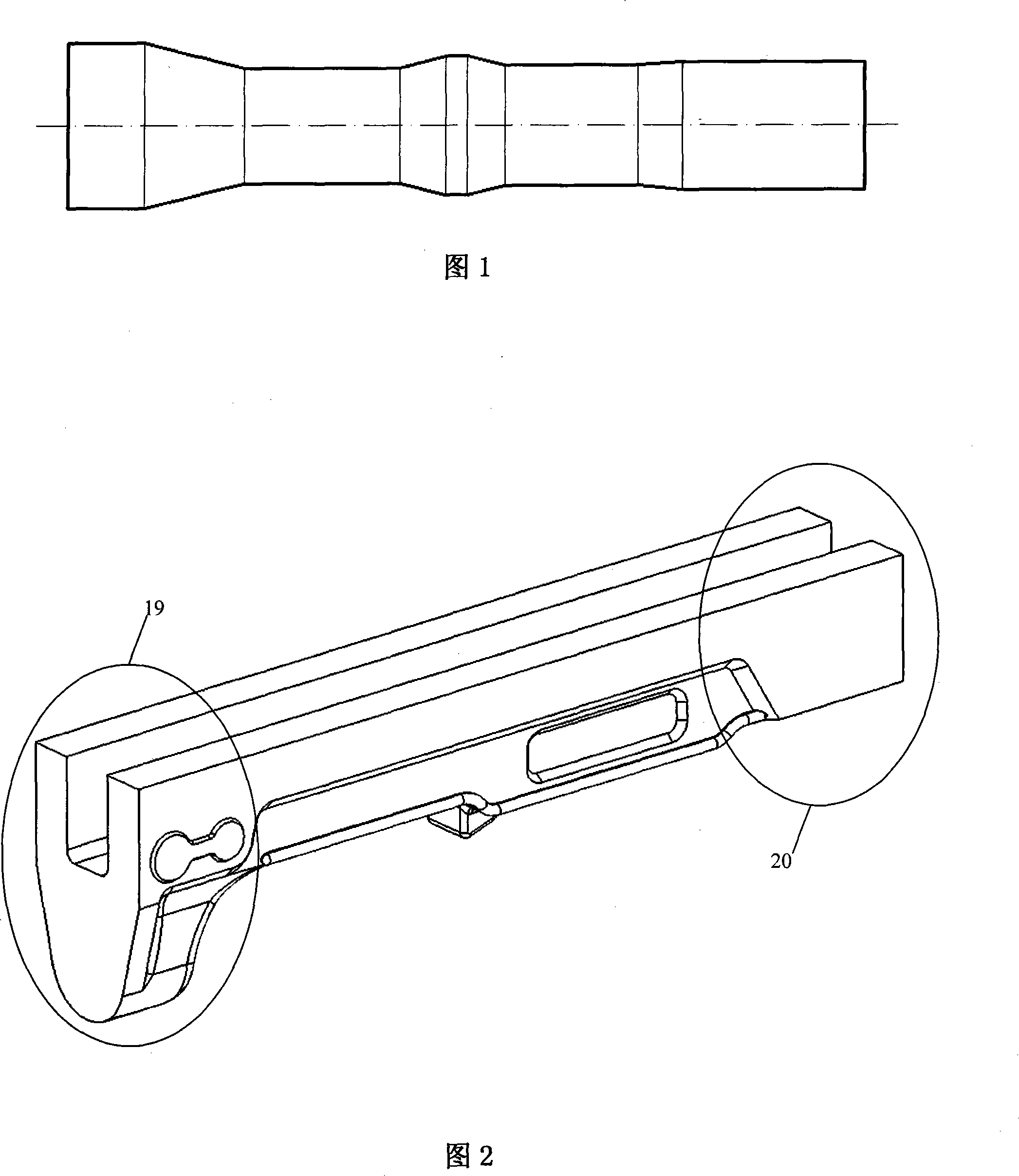

Cold-forging technique of gear shaft

InactiveCN101332488ALow flow resistanceReduce the bearing unit extrusion forceForging/hammering/pressing machinesMetallic material coating processesGear wheelPre stress

The invention relates to a cold forging technology for a gear shaft; the cold forging technology is characterized in that a new technology of the cold forging forming of the inside and outside and split flow forging, a volume split flow space is arranged between the gear shaft diameter and a concave die, the metal flow resistance is reduced and the unit extruding force carried by the die is lowered by split flow; high-strength die steel and split structure are adopted to produce a gear hole forming die; the concave die is produced by adopting three-layer sleeve prestressed structure so as to improve the compression resistance of the die; a punch is made from an alloy steel material and used for the cold forging and precision forming of a complex gear form blind hole, which improves the forming quality and production efficiency of the gear hole, and lowers the consumption of the raw materials markedly. The cold forging technology of the invention has the advantages of achieving the smooth forming of the gear form blind hole, improving the production efficiency greatly, and improving the quality of the gear hole and the qualification rate of the product markedly.

Owner:SHANGHAI DONGFU COLD FORGING MFG

Precision cemented carbide threading tap

InactiveUS7147413B2Improve accuracyIncrease speedThread cutting toolsWood turning toolsEngineeringCemented carbide

A precision cemented carbide threading tap is designed for use in precision tool holders in synchronous high speed tapping. The precision tap includes a fully cylindrical shank without the aid of squares, flats or other notches. The precision tap further includes a threaded body portion and a threaded cutting chamfer portion. The threaded body portion and the threaded cutting chamfer portion of the precision tap are concentric to the cylindrical shank of the tap within a runout of 10 microns. The precision cemented carbide threading tap improves the accuracy, life and speed by which internal screw threads are produced.

Owner:KENNAMETAL INC +1

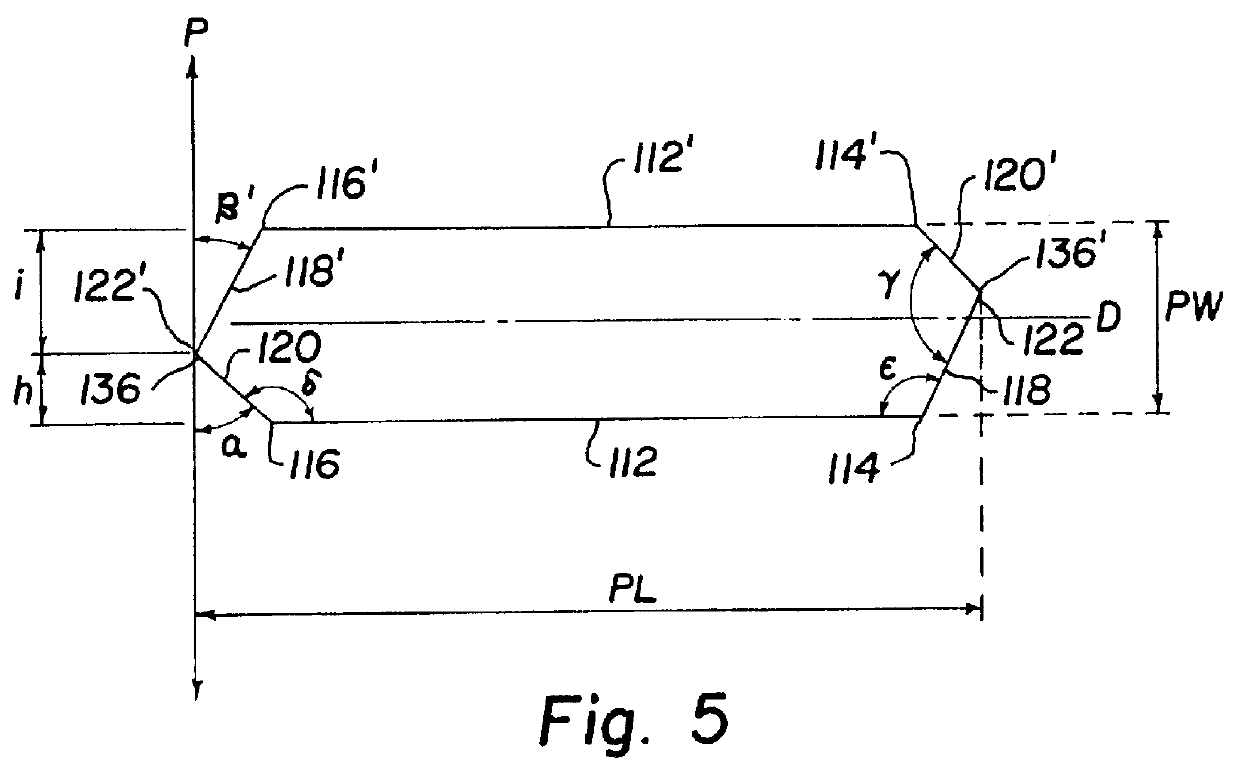

Punch and die for producing connector plates

A blade punch for forming teeth in a connector plate, the blade punch comprising an elongated blade having a metal working tip at one end and a shank at the other end. The blade has an elongated cross-section defined by opposing parallel spaced planar side walls and opposing ends. Each end comprises a major end wall and a minor end wall which converge to end wall intersections, where the end wall intersections are eccentric to a plane parallel to and midway between said side walls. Each end wall intersects a side wall at an obtuse angle. The metal working tip has opposed air cut faces abutting one another along an air cut edge and opposed first and second forming faces, each of the forming faces abutting one of the air cut faces along an exterior edge. Each of the air cut faces is bordered by a portion of one of the minor end walls, a portion of one of the side walls, the air cut edge, and one of the exterior edges. Each of the forming faces is bordered by a portion of one of the major end walls, a portion of one of the minor end walls, a portion of one of the side walls, and one of the exterior edges. A forming angle between 50 DEG and 60 DEG is formed between the first forming face and the exterior edge bordering the second forming face in a plane normal to the first forming face.

Owner:ILLINOIS TOOL WORKS INC

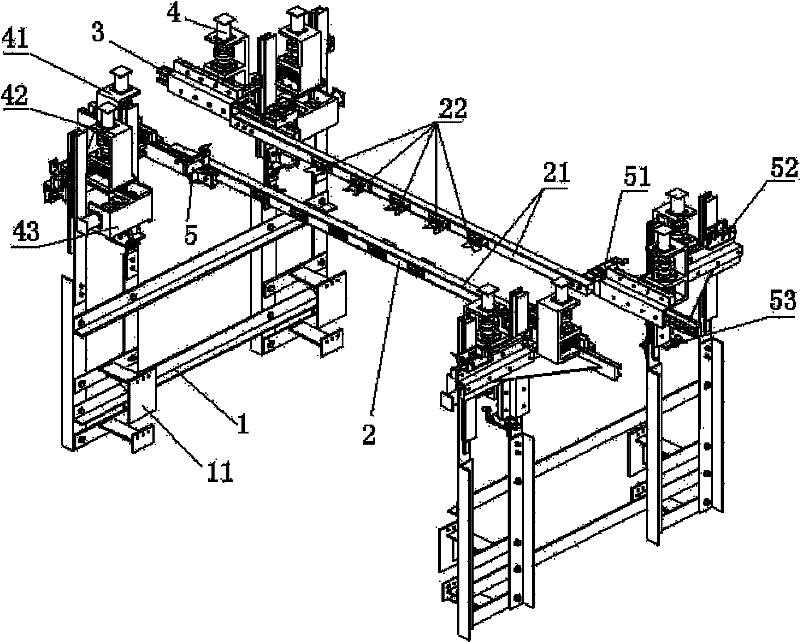

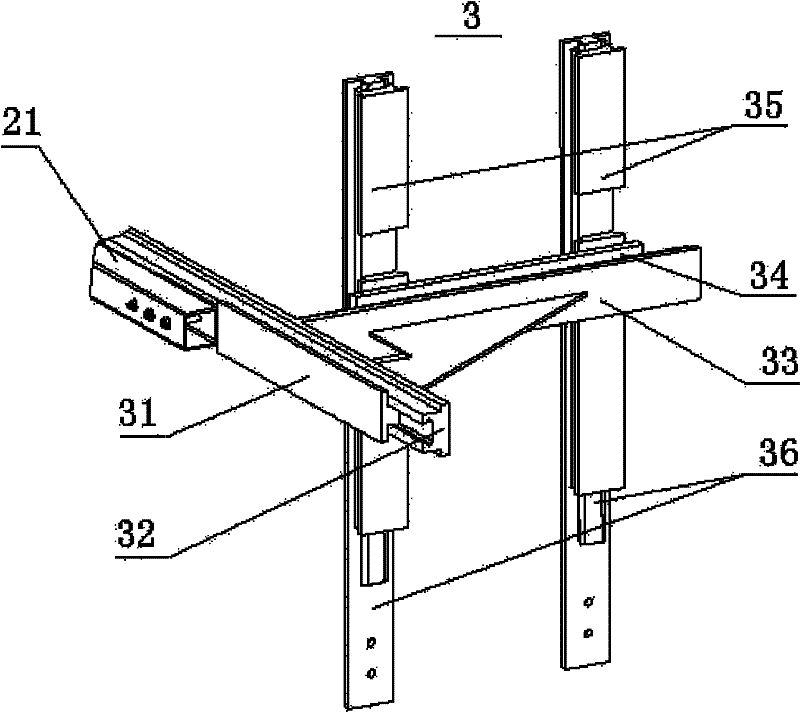

Multi-station automatic feeding method and device

InactiveCN102173097ARealize continuous automatic feedingAccurate clamping forceMetal-working feeding devicesForging/hammering/pressing machinesControl systemFeed drive

The invention relates to a multi-station automatic feeding method and device. The feeding device is characterized by comprising an execution mechanism, a guiding mechanism, a driving device, a sensing limiting device and a control system, wherein the execution mechanism, the guiding mechanism, the driving device and the sensing limiting device are arranged on a frame; the execution mechanism comprises two walking beams which are arranged in parallel; a plurality of pairs of clamping devices are alternately arranged on the two walking beams; the guiding mechanism comprises feeding guide rails and feeding guide grooves, which are respectively arranged at two ends of the walking beams; a clamping guide groove which slides along one clamping guiderail is vertically fixedly arranged in the middle of each feeding guide groove; two ends of the clamping guide rails are respectively fixedly arranged on lifting guide grooves which slide along lifting guide rails; the bottom ends of the two lifting guide rails are respectively fixedly arranged on the frame; the driving device comprises a feeding driving device, a clamping driving device and a lifting driving device; the sensing limiting device comprises a feeding sensing limiting device, a clamping sensing limiting device and a lifting sensing limiting device; and the output end of the control system is connected with the sensing limiting device while the output end is connected with the driving device.

Owner:CHINA AGRI UNIV

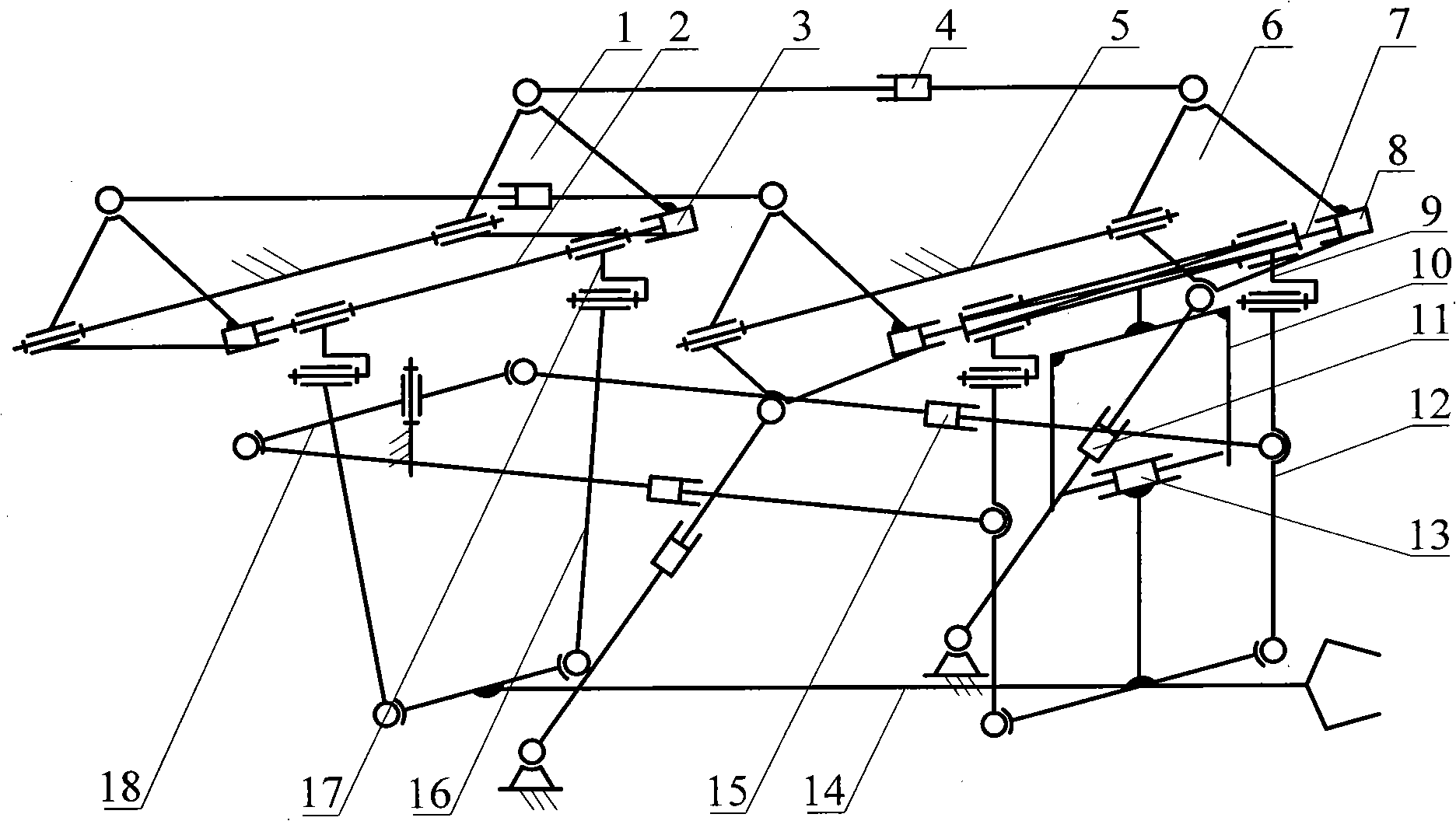

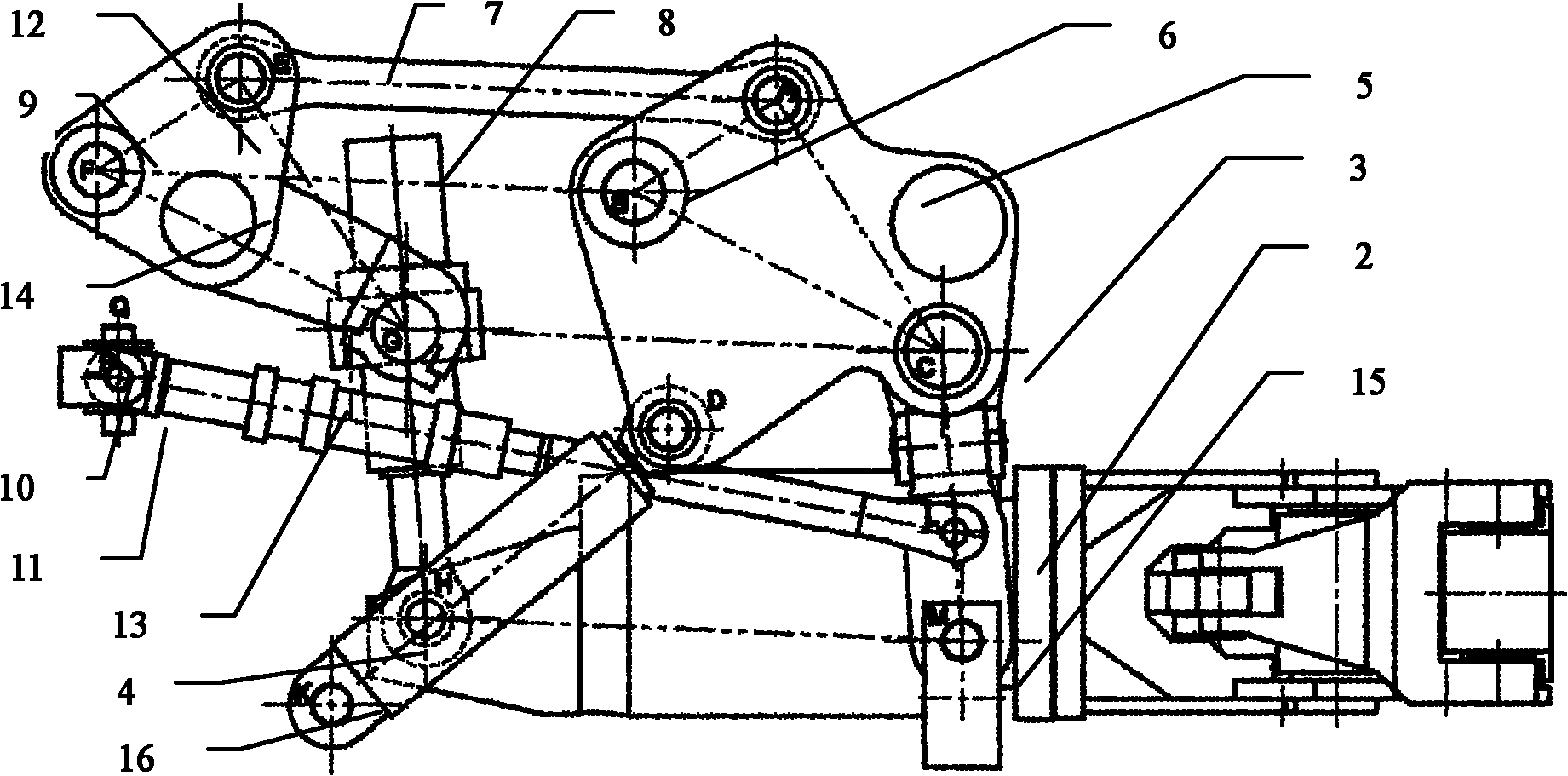

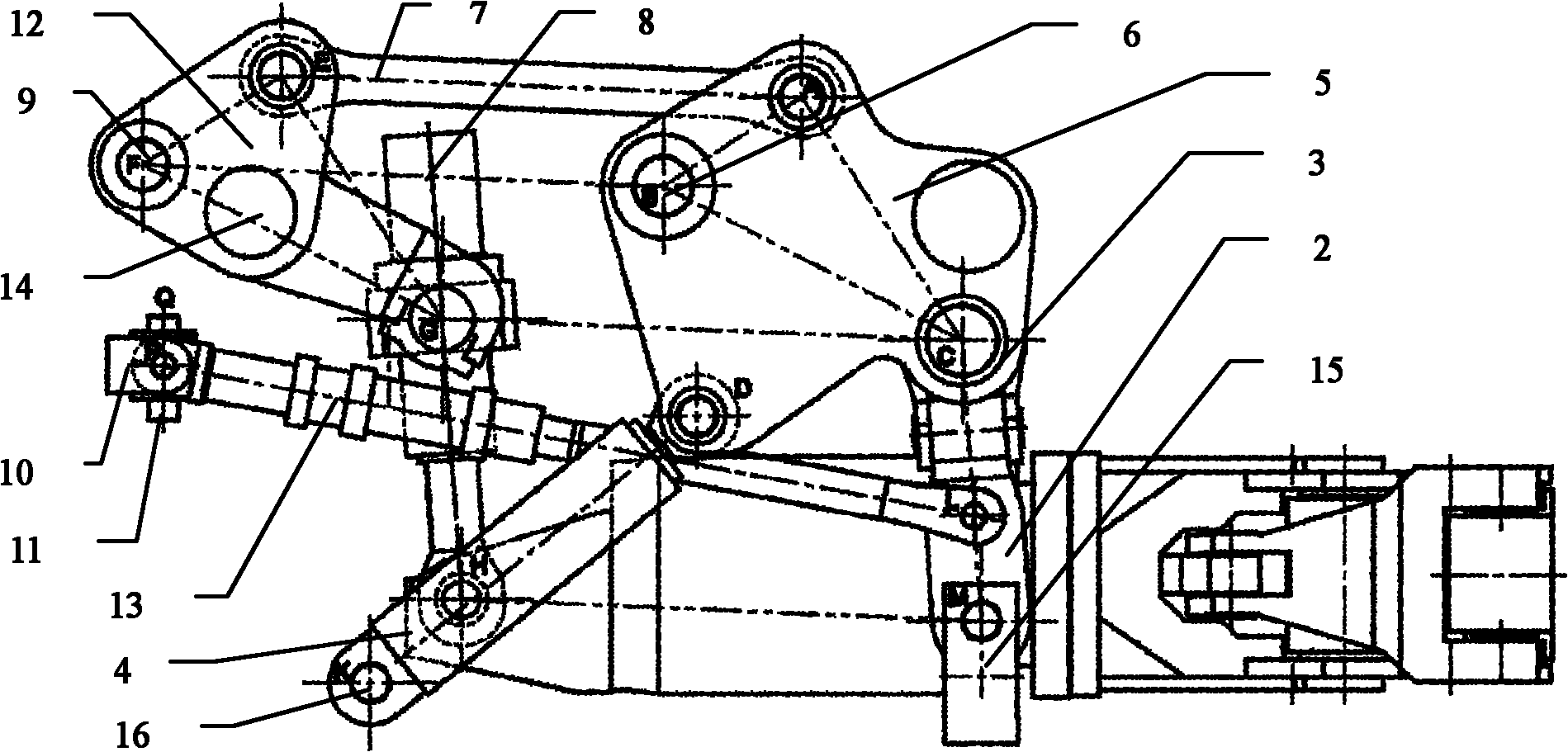

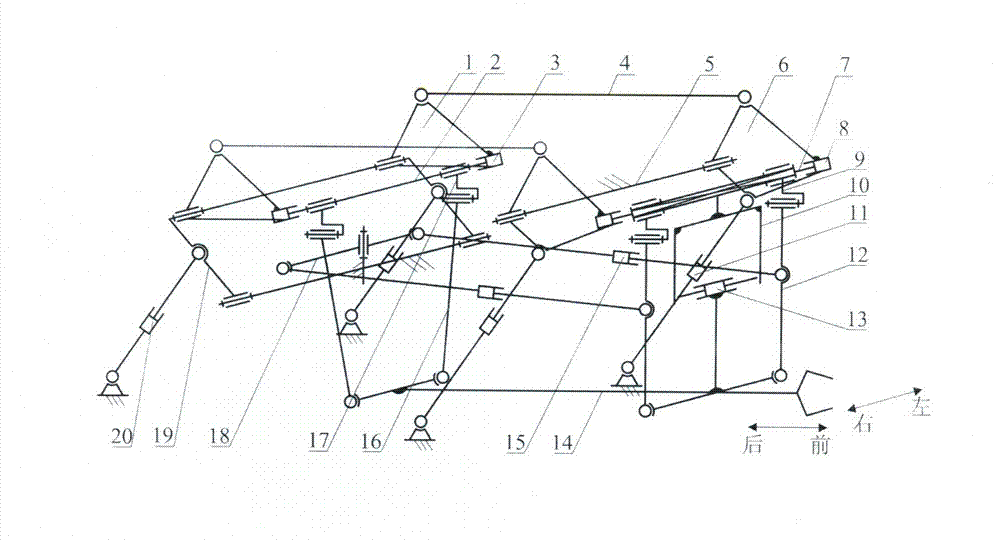

Forging manipulator lifting mechanism with inclined rear suspension rods

InactiveCN101879571AImprove carrying capacityReduce stressForging/hammering/pressing machinesForging manipulatorMechanical engineering technology

The invention relates to a forging manipulator lifting mechanism with inclined rear suspension rods in the technical field of the mechanical engineering, which is characterized in that the upper ends of two front suspension rods (12) are respectively connected at the lower ends of two front connecting pieces (9) by rotating hinges; the upper ends of the two front connecting pieces (9) are respectively connected on both sides of a movable frame (10) by rotating hinges; the movable frame (10) can move left and right on a front sliding rod (7); two rear suspension rods (16) are arranged symmetrically right and left in an inclined mode; the upper ends of the two rear suspension rods (16) are respectively connected at the lower ends of two rear connecting pieces (17) by rotating hinges; the upper ends of the two rear connecting pieces (17) are respectively connected on both sides of a rear sliding rod (2) by rotating hinges; two pitching linear drivers (4) are horizontally arranged on the top of a lifting arm front and back; and the front ends of the two pitching linear drivers (4) are respectively connected on both sides of a front lifting arm (6) by spherical hinges, while the rear ends thereof are respectively connected on both sides of a rear lifting arm (1) by spherical hinges. The forging manipulator lifting mechanism with the inclined rear suspension rods has the characteristics of high bearing capability, easy installation, long service life and the like and is suitable for forging operation of large-scale / ultra large forgings.

Owner:YANSHAN UNIV

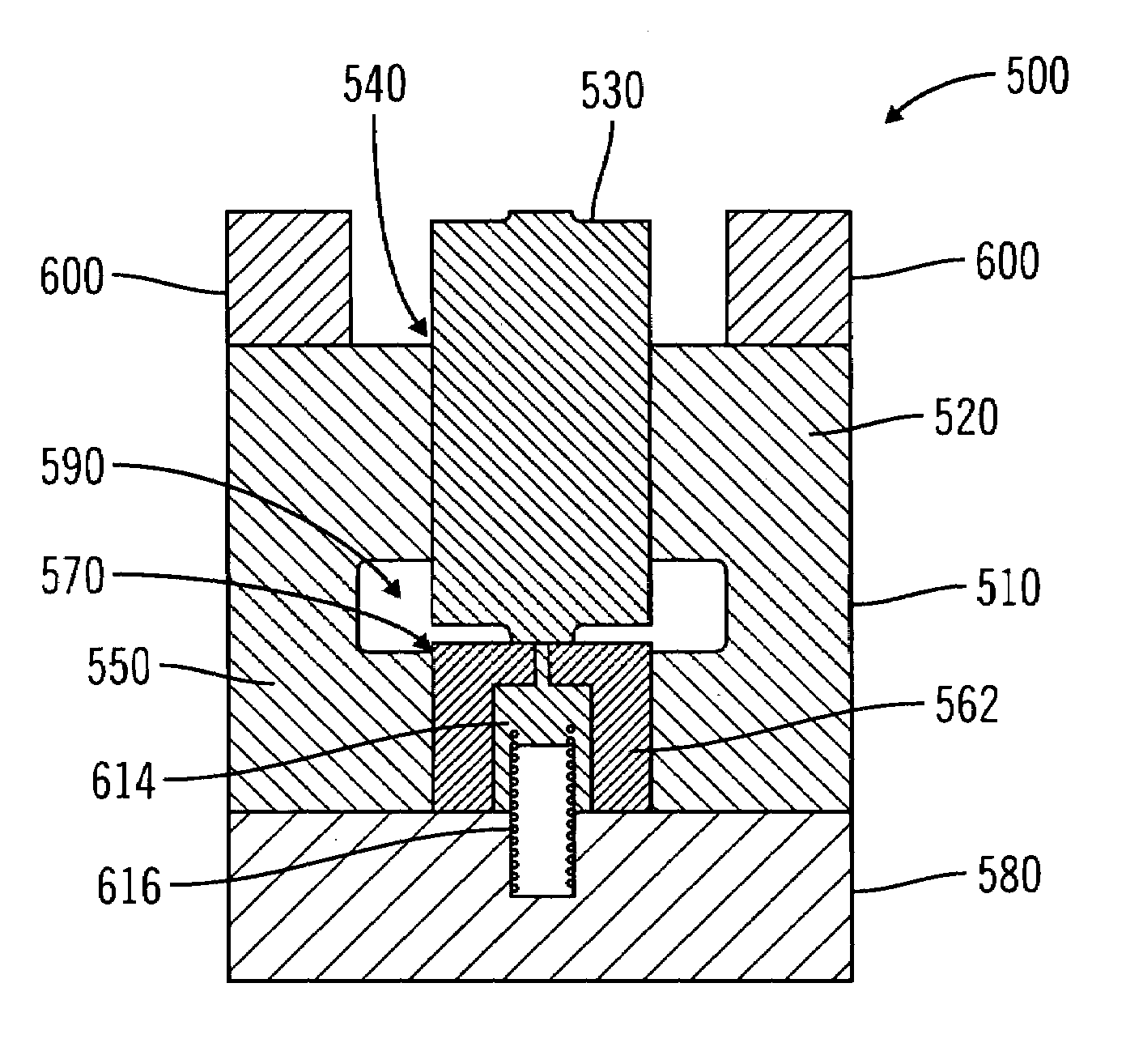

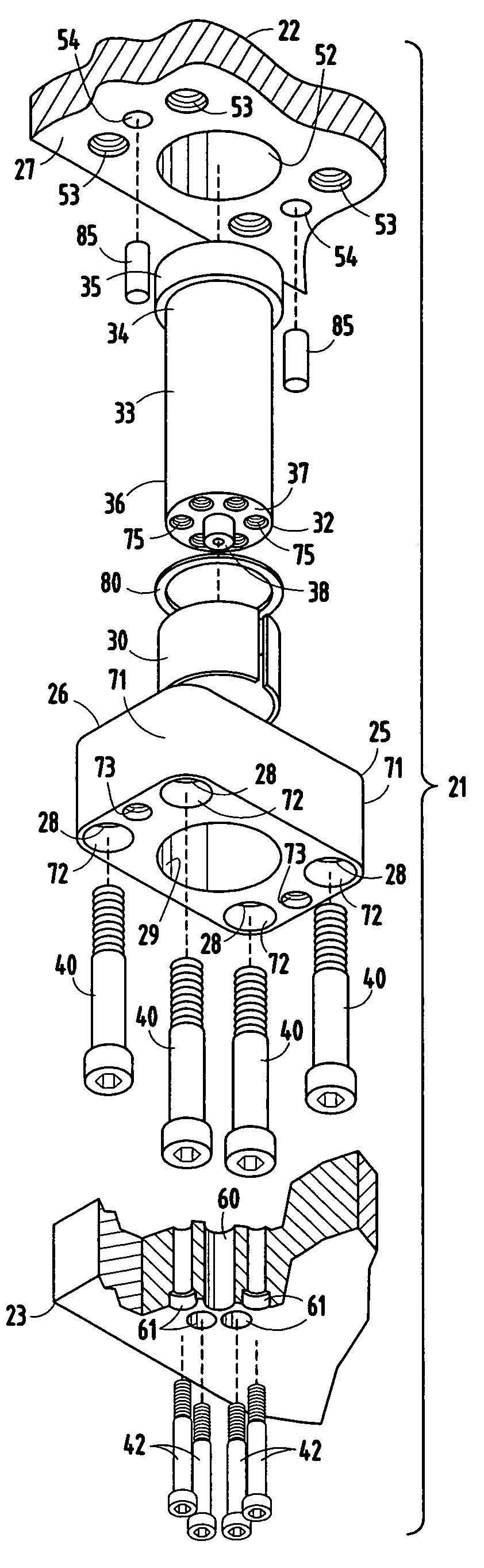

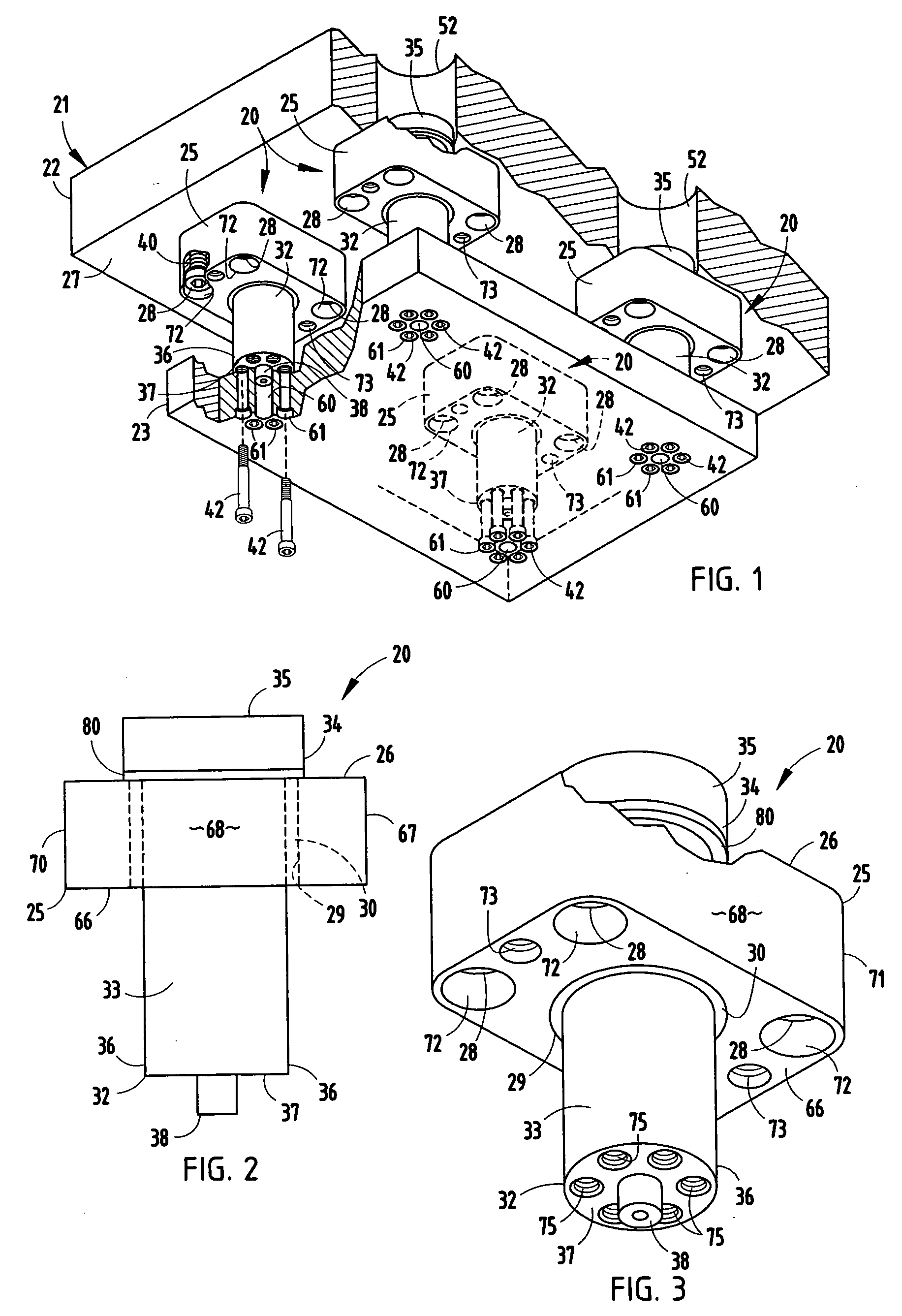

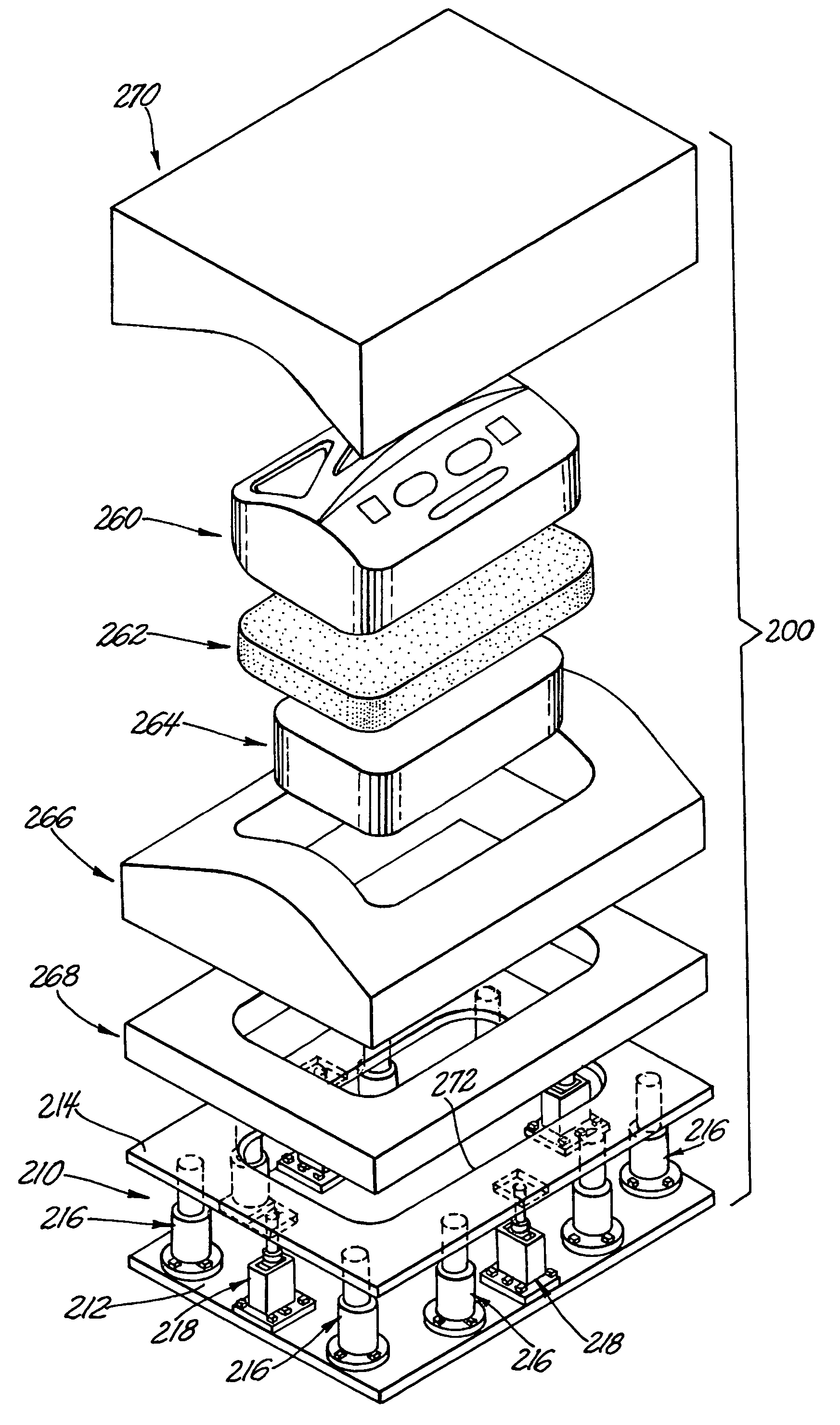

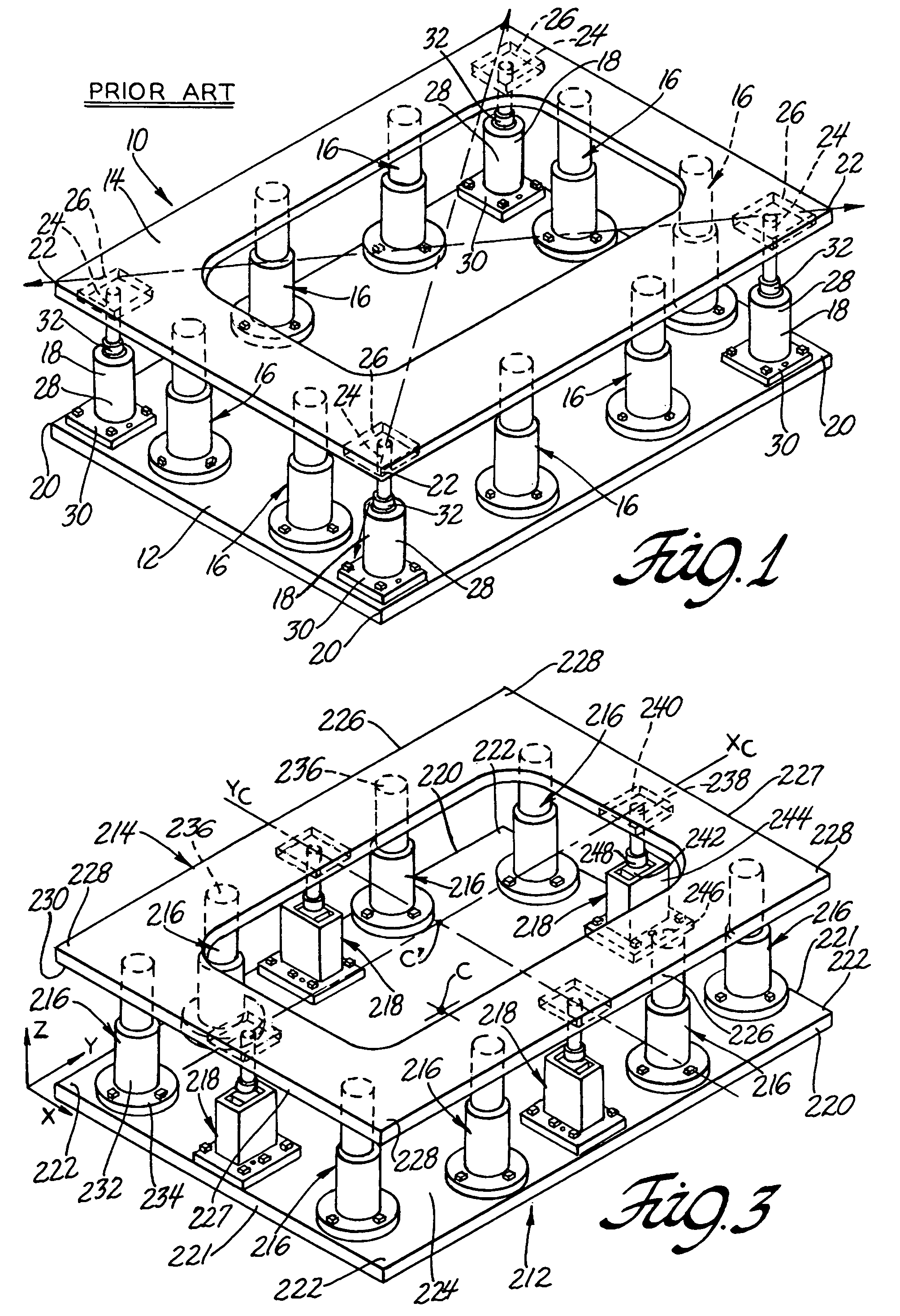

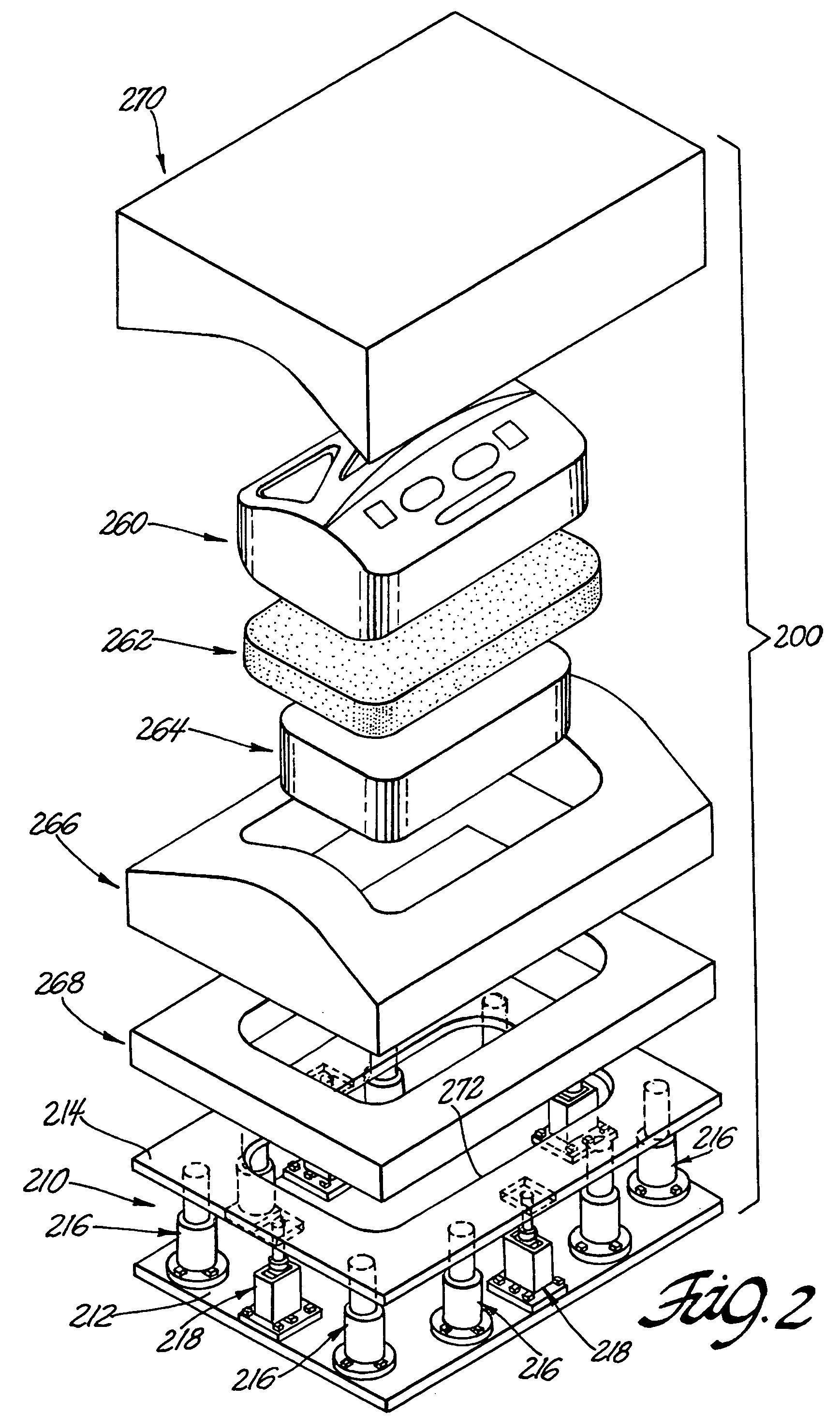

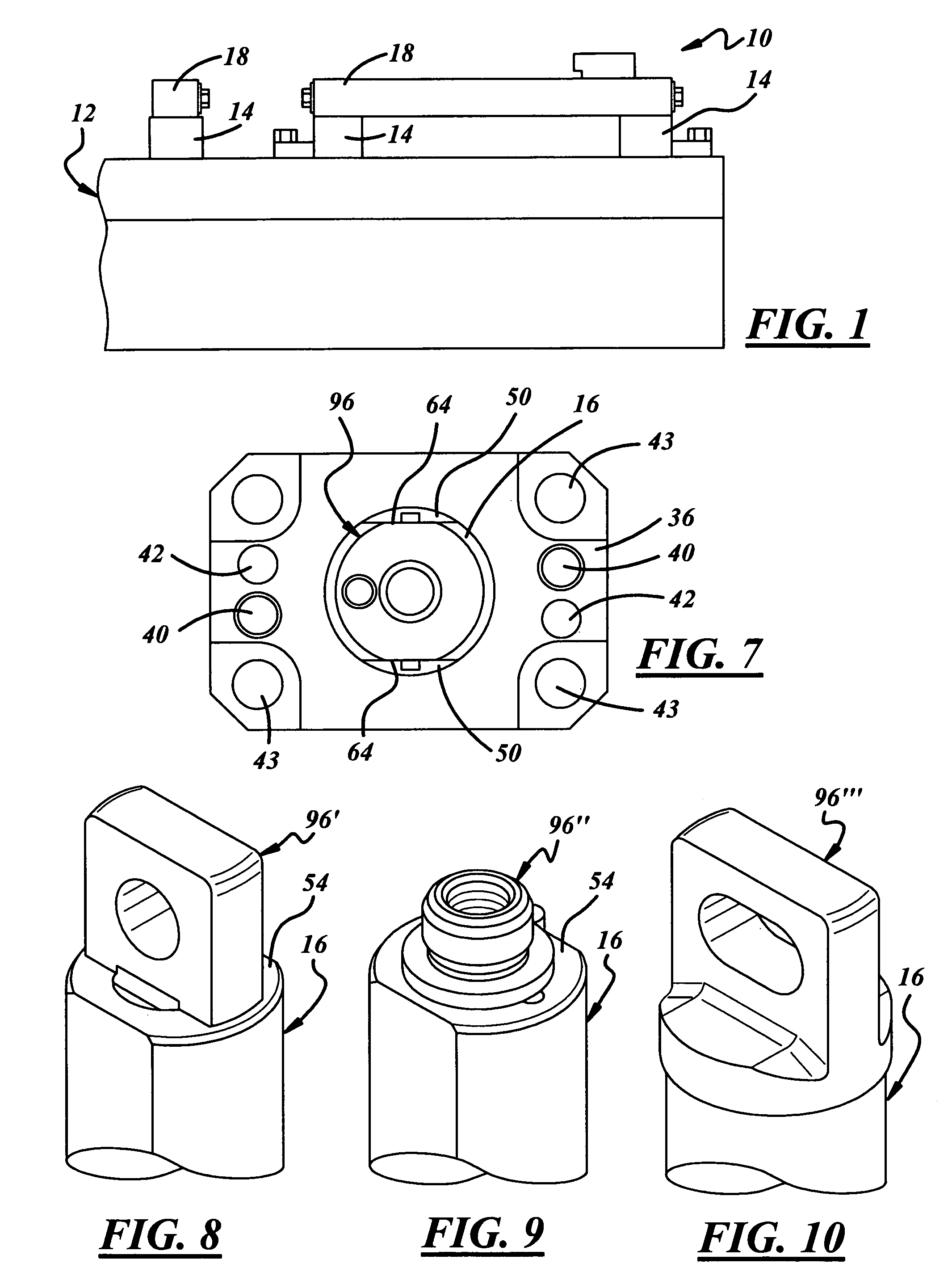

Guided keeper assembly and method for metal forming dies

ActiveUS20090193865A1Facilitate transport and mountingEasy to installShaping toolsStripping-off devicesMetal formingReciprocating motion

A guided keeper assembly and method for metal forming dies includes a base having a mounting face, a connector portion and a central aperture. A guide pin has a cylindrical center portion closely received in the central aperture of the base for reciprocation, an enlarged first end with an alignment member, and an outwardly opening circumferential groove. A retainer ring is removably mounted in and protrudes radially outwardly of the groove to securely, yet detachably, retain the base on the guide pin between the enlarged head and the retainer ring in an assembled condition to facilitate transport and mounting of the guided keeper assembly.

Owner:STANDARD LIFTERS INC

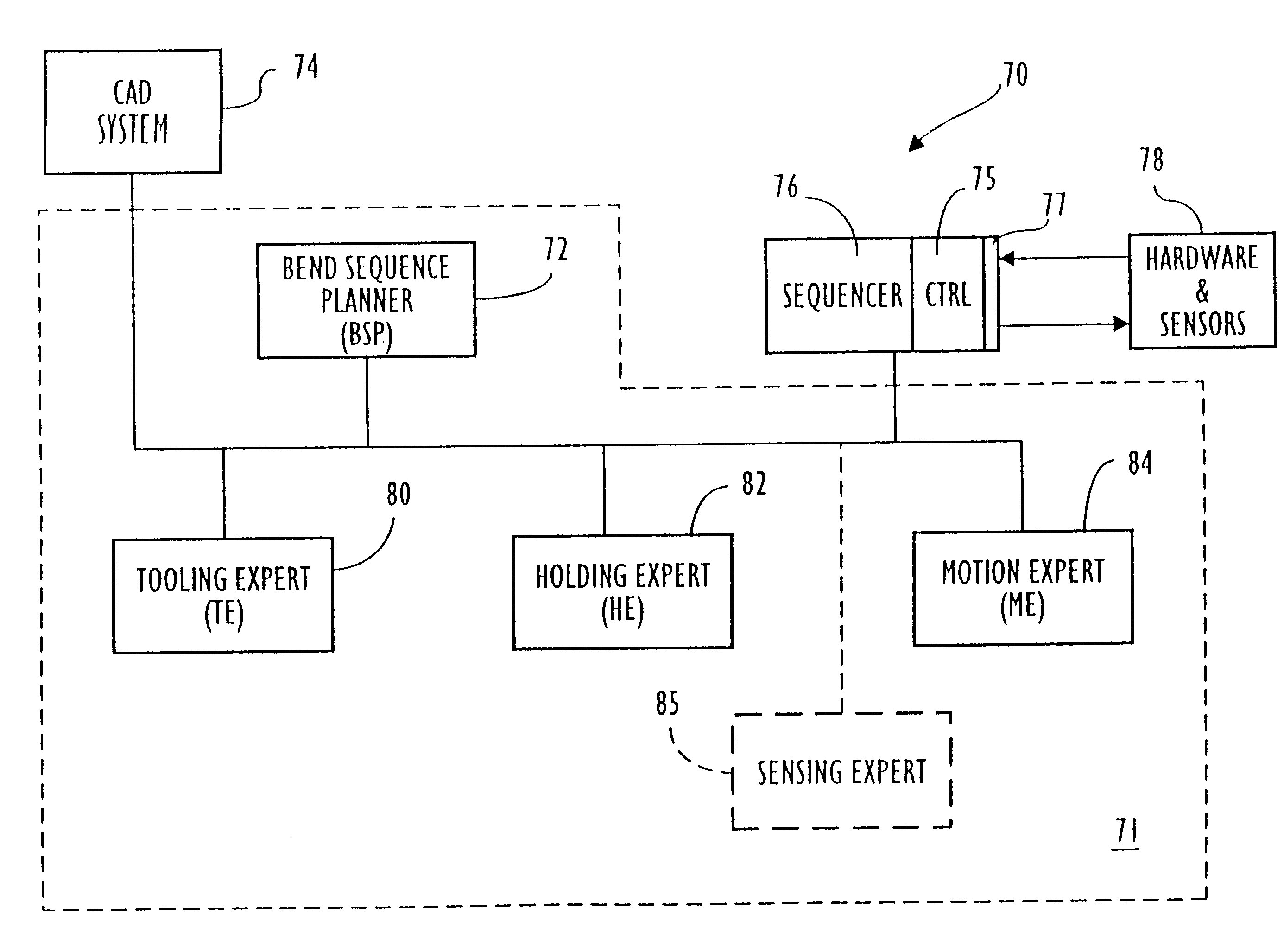

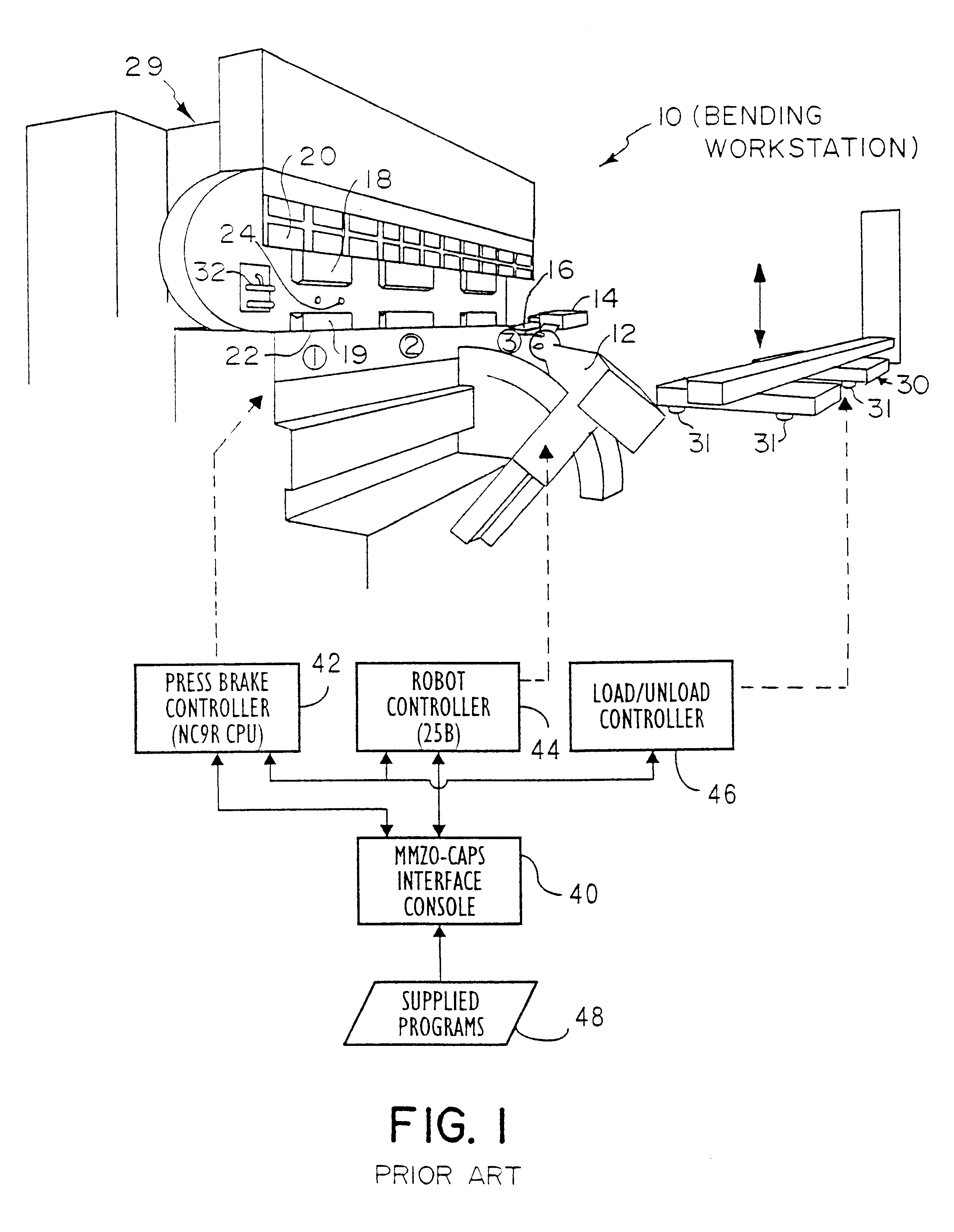

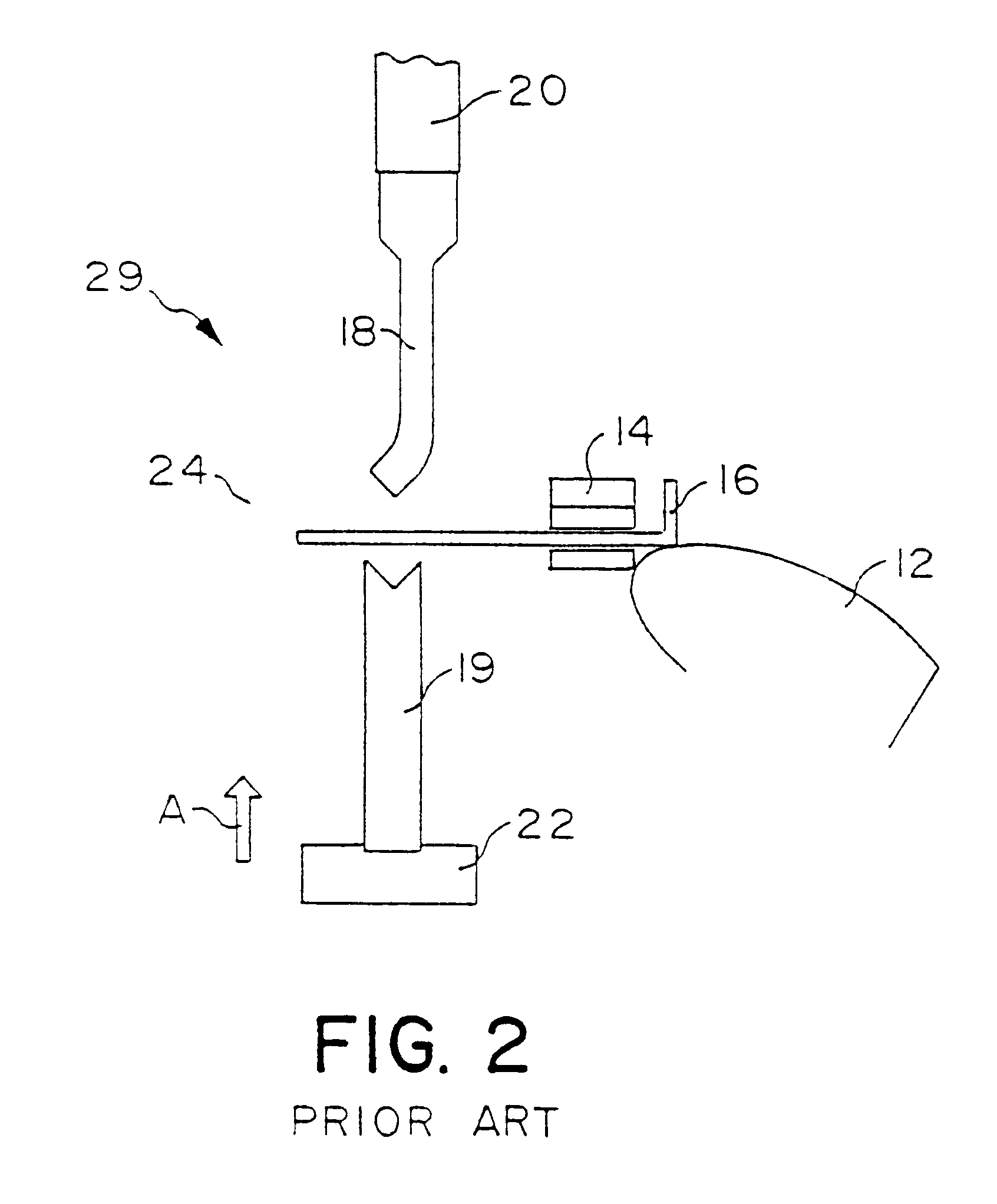

Intelligent system for generating and executing a sheet metal bending plan

An intelligent sheet metal bending system is disclosed, having a cooperative generative planning system. A planning module interacts with several expert modules to develop a bending plan. The planning module utilizes a state-space search algorithm. Computerized methods are provided for selecting a robot gripper and a repo gripper, and for determining the optimal placement of such grippers as they are holding a workpiece being formed by the bending apparatus. Computerized methods are provided for selecting tooling to be used by the bending apparatus, and for determining a tooling stage layout. An operations planning method is provided which allows the bending apparatus to be set up concurrently while time-consuming calculations, such as motion planning, are performed. An additional method or system is provided for positioning tooling stages by using a backgage guide member which guides placement of a tooling stage along the die rail the bending apparatus. A method is provided for learning motion control offset values, and for eliminating the need for superfluous sensor-based control operations once the motion control offset values are known. The planning system may be used for facilitating functions such as design and assembly system, which may perform designing, costing, scheduling and / or manufacture and assembly.

Owner:U S AMADA +1

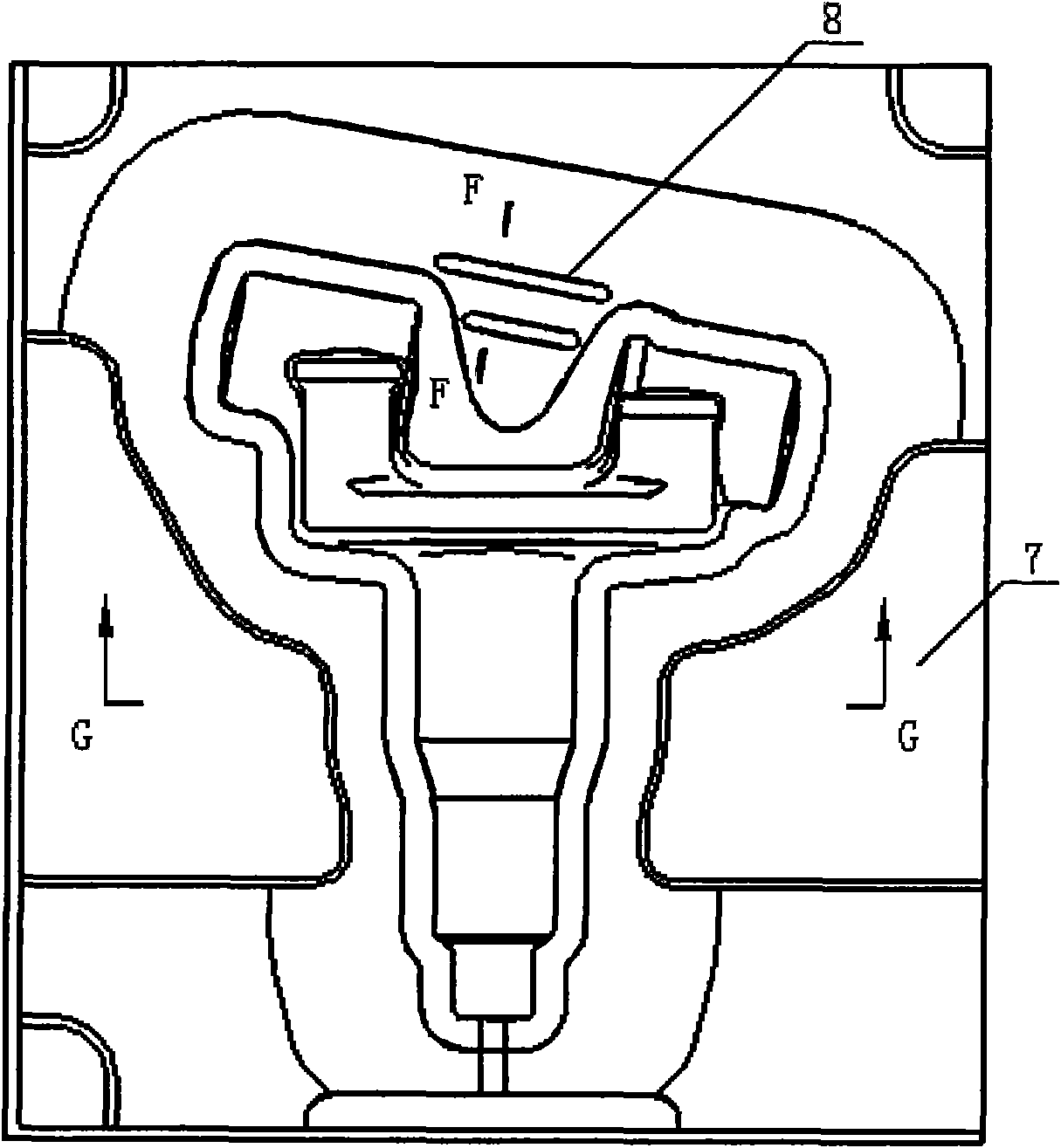

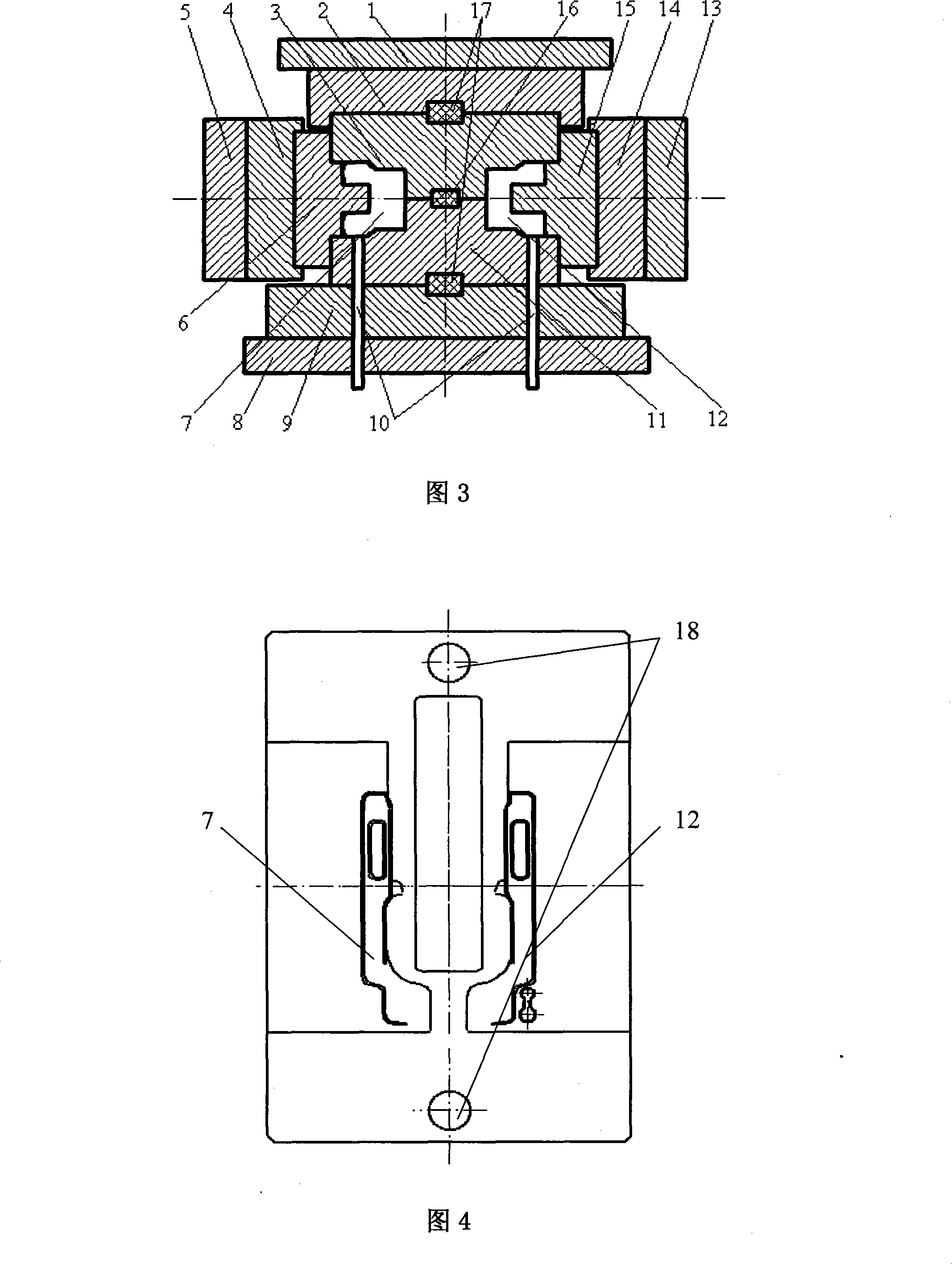

Middle-duty and heavy-duty automobile knuckle stamp forging extruding compound technology

ActiveCN101607294AShort preparation cycleIncrease profitForging/hammering/pressing machinesProduction rateHeavy duty

A middle-duty and heavy-duty automobile knuckle stamp forging extruding compound technology overcomes the disadvantages of low material utilization and large device investment of the traditional production technology, utilizes flexibility of preforming by a stamping hammer and structure characteristic of a press extrusion die and adopts stamping hammer production technology and press extrusion compound technology. The main technical scheme includes a series of technical measures of vertically splitting of blank material by mould with V-shaped cutting edge and locally enclosed structure, preforging of cavity damping stripe, finish forging of locally enclosed structure, hot extrusion forming of steering space and the like, parameter requirements and corresponding moulds and devices. The invention has the characteristics that device investment of stamping hammer production technology is small, structure is simple, and equipment manufacturing period is short; production technological flow is reasonable and processing is easy; and the invention also has the characteristics that product quality is good and productivity is high; and material utilization is obviously higher than that of any original knuckle processing technology and production cost is greatly reduced.

Owner:HUBEI TRI RING FORGING

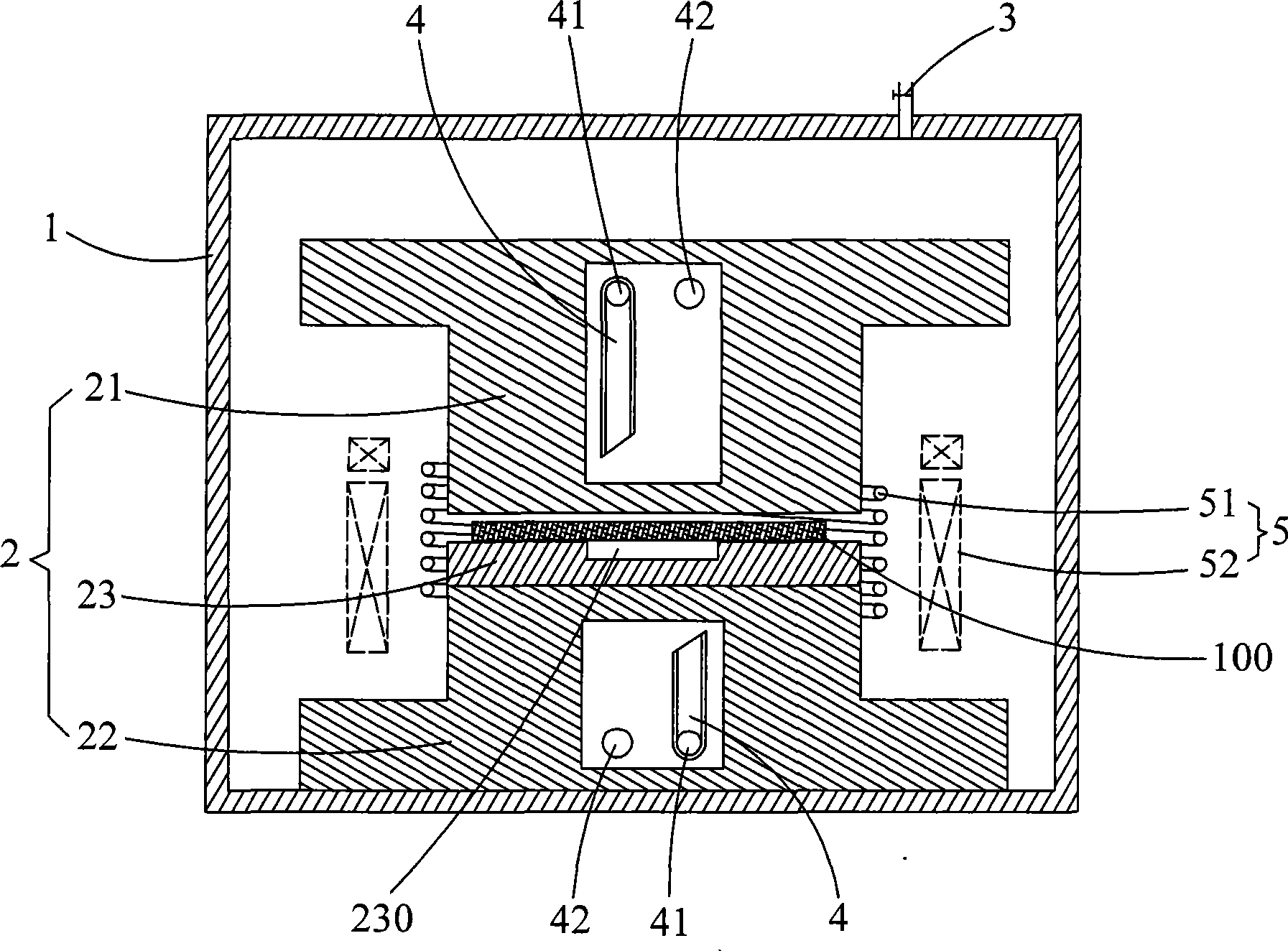

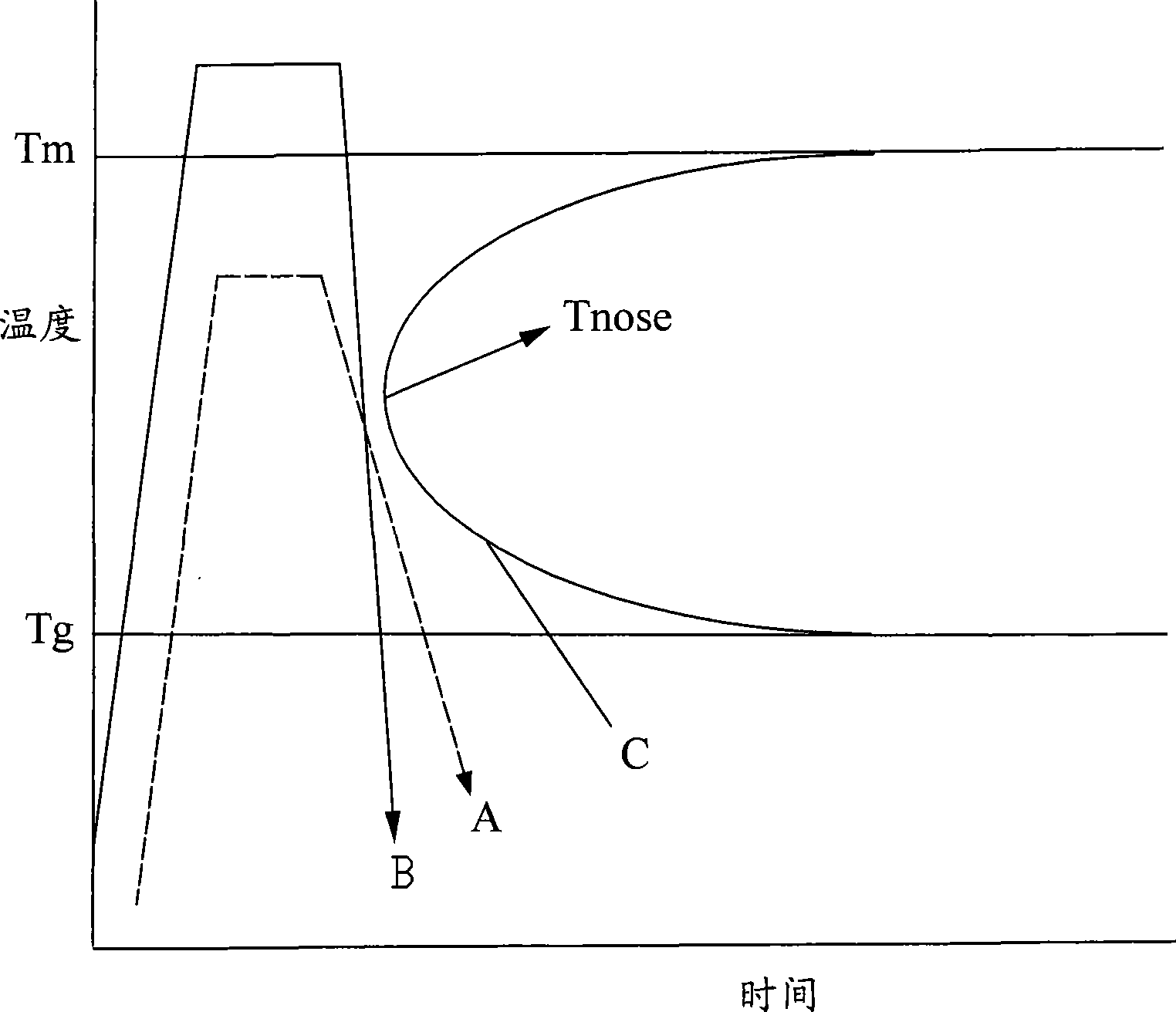

Amorphous alloy thermoforming apparatus and technique

ActiveCN101468370APrevent crystallizationImprove processing efficiencyShaping toolsForging/hammering/pressing machinesNitrogen gasAmorphous metal

The invention provides a device and a process for the hot pressing and molding of an amorphous alloy. The device is provided with a vacuum, inert gas or nitrogen gas protective environment, and a mould set and an induction heating coil positioned in the environment; the mould set comprises an upper mould, a lower mould and a molding mould; the induction heating coil is at least wound in a peripheral space of the molding mould and is not contacted with the molding mould; and the process sequentially comprises the following steps in the vacuum, inert gas or nitrogen gas protective environment: blank placement, induction heating, hot pressing and molding, cooling, and mould extraction. By adopting an induction heating mode, the process can rapidly concentrate on heating a molded blank to Tg temperature above, and carry out the hot pressing and molding within the temperature range between Tg and Tm or the Tm temperature above; a molding strain rate can reach between 10 and 10S; and the process has high processing efficiency and can effectively prevent crystallization of the amorphous alloy in the molding process within shorter temperature rise time.

Owner:BYD CO LTD

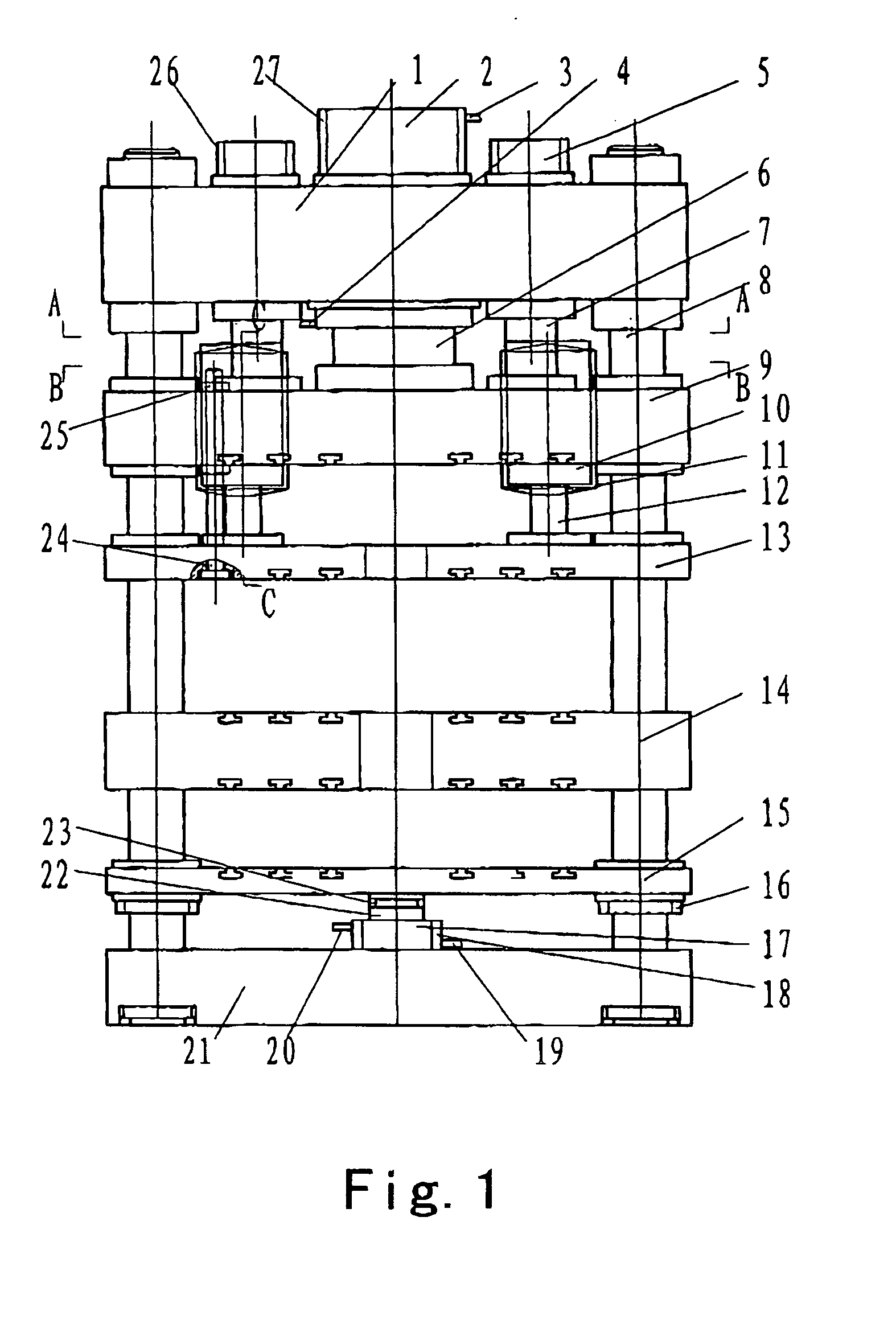

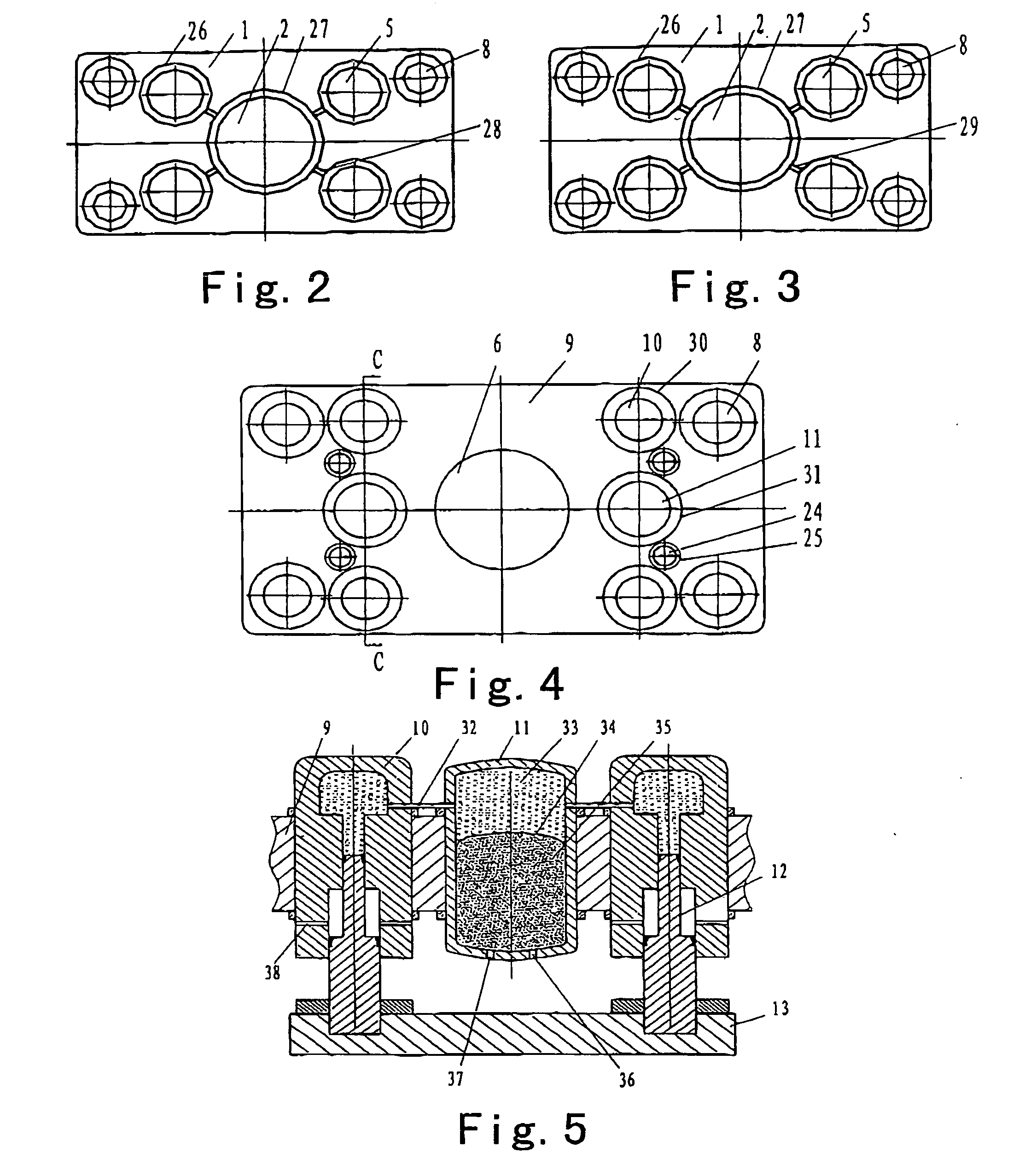

Adjustable Hydraulic Press With Both Upper And Lower Double Action

ActiveUS20080098908A1Innovative designSimple structureShaping toolsForging/hammering/pressing machinesMetal formingGear wheel

The present invention discloses an adjustable hydraulic press with both upper and lower double action, specially suitable for the cylindrical gear formed by stamping or expanding, closed forging and the metal cold forming or metal hot forming of punching, finishing, flanging and drawing of sheet materials. The press comprises four columns, an upper beam, a main slide block, a hold down slide block, a fixing worktable, a floating worktable and a lower beam. The hydraulic chamber of master cylinder fixed in the upper beam communicates to the hydraulic chamber of the auxiliary cylinder, the plunger of master cylinder is connected to the main slide block and drives it. The hydraulic chamber of gas-liquid power accumulator fixed in the main slide block communicates to the hydraulic chamber of hold down cylinder, the plunger of hold down cylinder is connected to the hold down slide block and drives it. The plunger of ejecting cylinder fixed in the lower beam is connected to the floating worktable and drives it. The hydraulic press of the invention simplifies the hydraulic system of the existing hydraulic, improves utilization rate of energy, production efficiency and working accuracy of workpiece.

Owner:JILIN UNIV

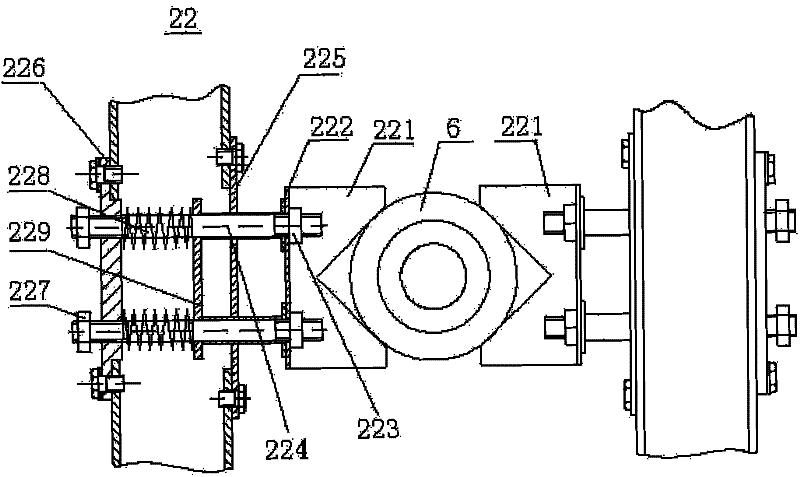

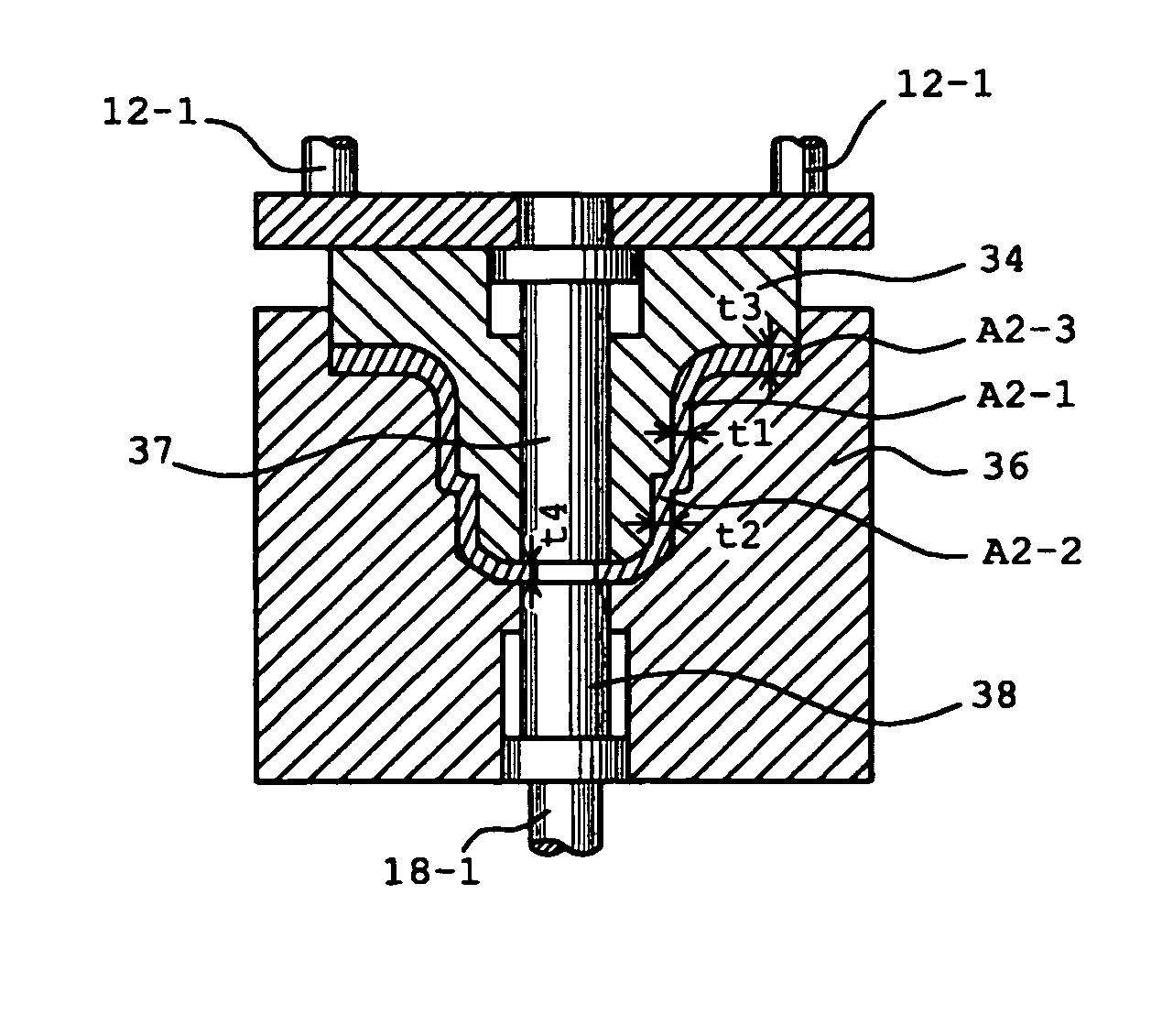

Method and apparatus for producing thin walled tubular product with thick walled flange

InactiveUS7171838B2Increasing the thicknessThickening the flange portionForging/hammering/pressing machinesDomestic articlesWork in processEngineering

Method and apparatus for producing a thin walled tubular product with thickened flange. A first stage metalworking (drawing) of a circular plate material A is done by using a first die set 22 having a conical die 24 and a drawing punch 26 is done in a manner that the end of the blank plate is remained on the conical surface 24-1 of the die, so that a semi-finished tubular product A1 with a inclined flange A1-1 is obtained. Then, a second stage metalworking (drawing) of the semi-finished tubular product A1 is done by a second die set 32 having a shaping punch 34 and a restraint die 36. The semi-finished tubular product A1 is held by the restraint die 36 and the shaping punch 34 is introduced into the semi-finished tubular product A1 for effecting a wall thickness reduction under ironing principle while forming a stepped portion. Simultaneous with the execution of the second stage drawing, a flattening of the flange is done while restriction diameter expansion by a wall 40, thereby obtaining a thickened flattened flange A2-3.

Owner:MATSUOKA MINAKO +2

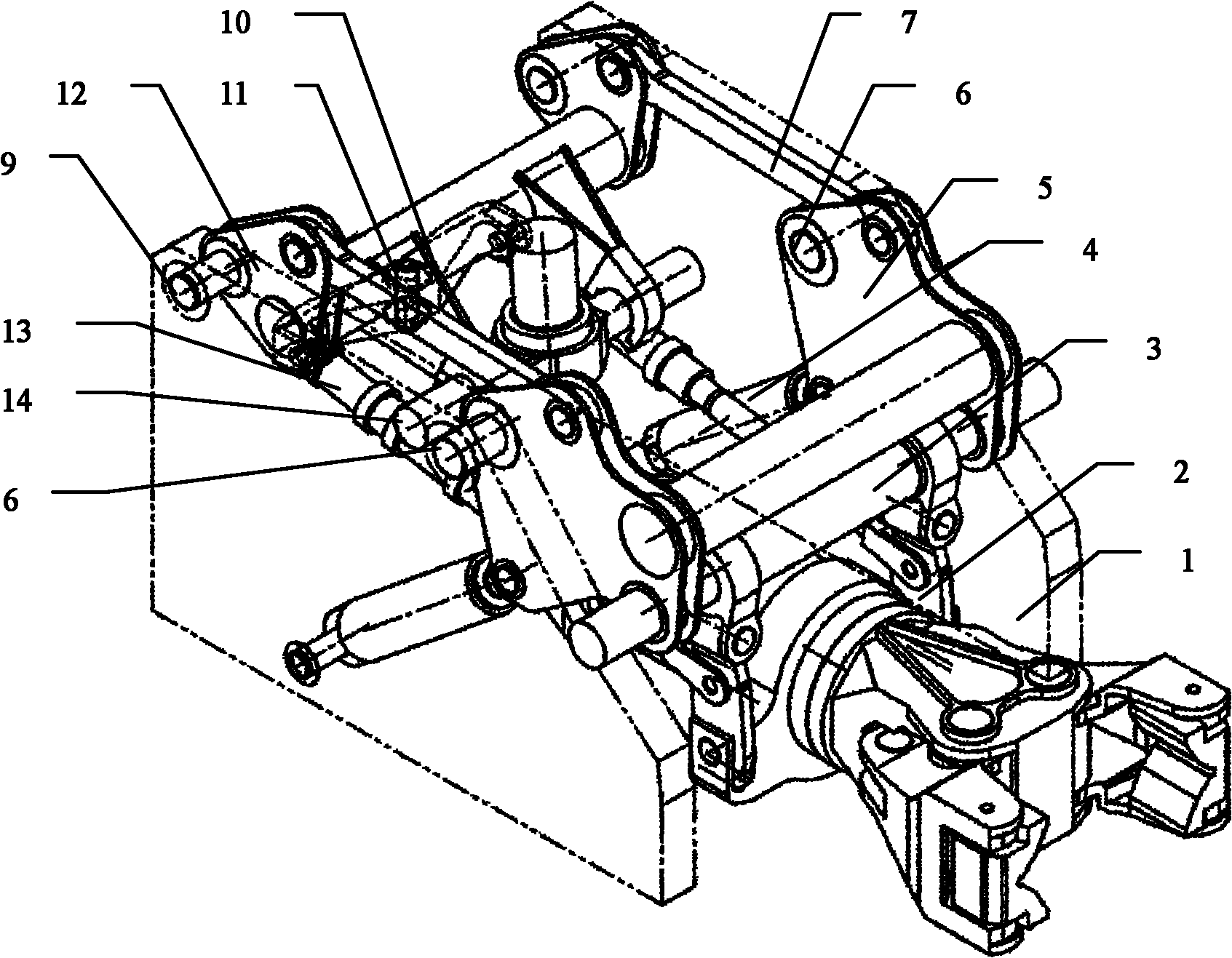

Claw beam lifting mechanism for forging manipulator

InactiveCN102019340AHigh movement precisionGuaranteed motion accuracyForging/hammering/pressing machinesVehicle frameRange of motion

The invention discloses a claw beam lifting mechanism for a forging manipulator, applied to forging industry. The claw beam lifting mechanism mainly comprises a front lifting part, a rear lifting part, a synchronous connector rod, a lifting cylinder, a pitching cylinder and a buffering part, a front fixing shaft in the front lifting part, a rear fixing shaft in the rear lifting part and the lower end of the lifting cylinder are respectively connected with a large machine frame through hinges, the synchronous connecting rod is arranged overhead and always moves in a range above a connecting line of a front fixing hinge point and a rear fixing hinge point of a claw beam lifting and pitching mechanism and the large machine frame, front ends of two buffering cylinders are respectively connected with tow front lifting connecting rods through hinges, the rear ends of the two buffering cylinders are respectively articulated with two ends of a compensating beam, and the middle part of the compensating beam is connected with the middle part of the large machine frame by a hinge through a beam fixing shaft. The claw beam lifting mechanism has novel and scientific design concept, reasonable stress application, high movement precision, simple structure, low manufacturing cost and is convenient to install, adjust and maintain. The invention not only reduces the manufacturing cost of the lifting mechanism under the condition of ensuring the movement precision, but also thoroughly solves the problems that the front fixing shaft and a shaft sleeve matched with the front fixing shaft are worn easily and a side plate of a machine needs to be thickened specifically.

Owner:SHENYANG HEAVY MACHINERY GROUP

Die cushion apparatus for hot stretch-forming

ActiveUS7004007B2Accurate locationInhibit bindingShaping toolsPlywood pressesRelative displacementThermal expansion

A self-contained die cushion assembly for use in a stretch-forming process involving heated tooling. A lower plate is mounted below an upper plate that undergoes different thermal expansion than the lower plate. Guidance devices are mounted between the upper and lower plates and include a guide post, a bearing sleeve circumscribing the guide post, and a cylinder circumscribing the bearing sleeve. The guide post is mounted in fixed relation to the upper plate, and the cylinder is mounted in laterally translatable relation to the lower plate to accommodate lateral relative displacement between the upper and lower plates due to different thermal expansion thereof, thereby preventing binding of the guidance devices.

Owner:GM GLOBAL TECH OPERATIONS LLC

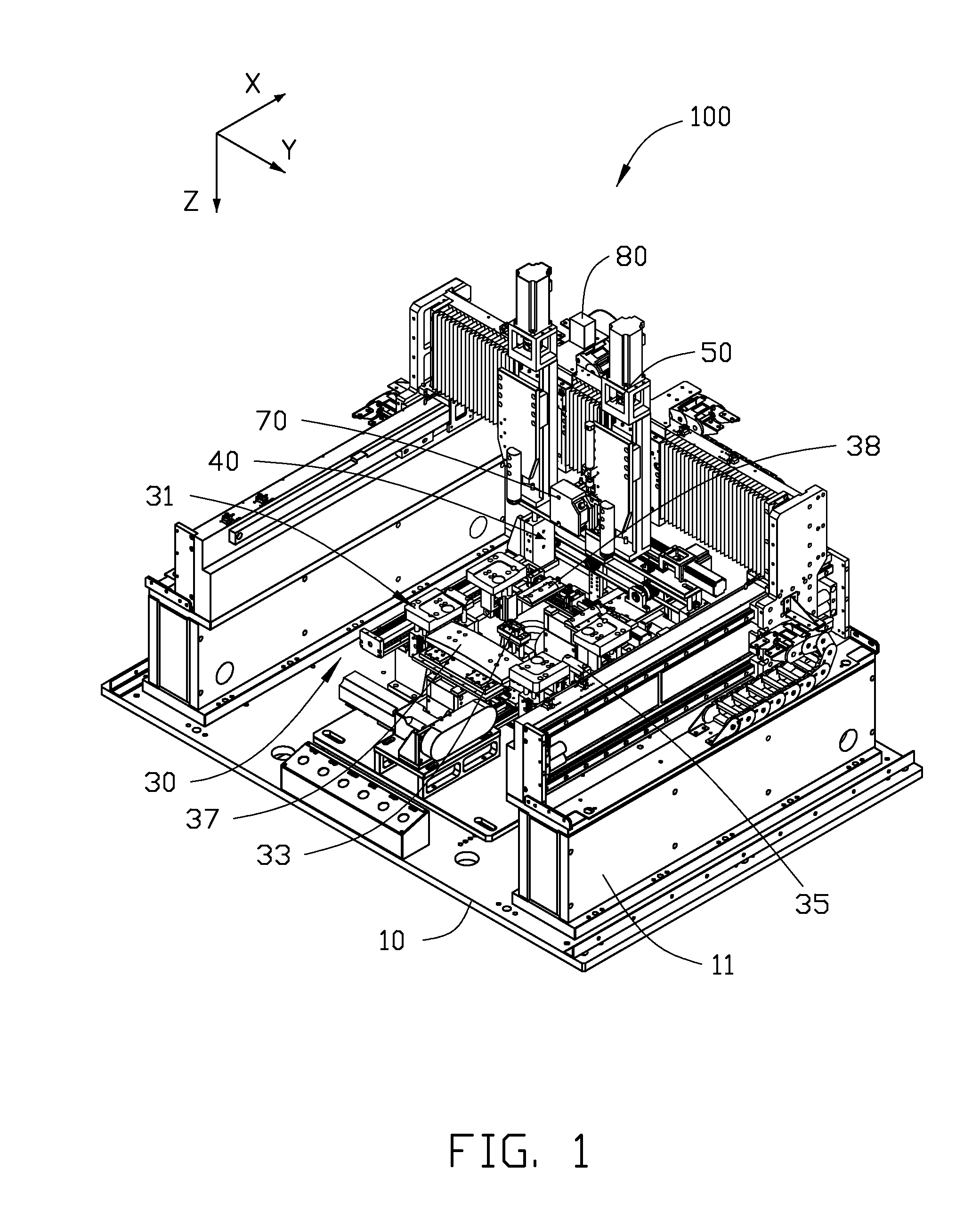

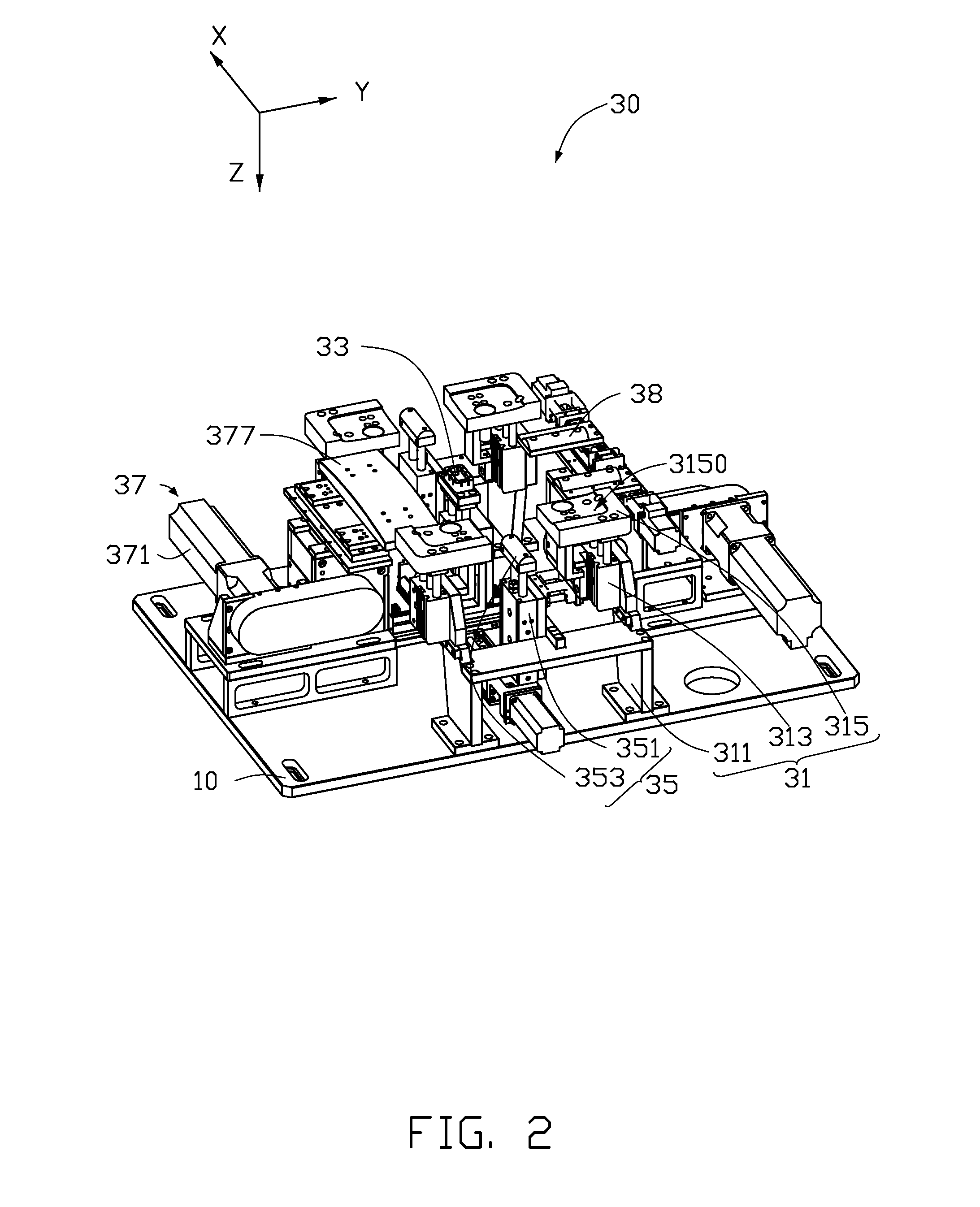

Reshaping device and positioning assembly thereof

InactiveUS20140250964A1Metal-working feeding devicesShaping safety devicesEngineeringElectrical and Electronics engineering

A reshaping device for reshaping a workpiece, includes a worktable, a reshaping assembly, a measuring unit, a positioning assembly, and a controller electrically connected to the reshaping assembly, the measuring unit, and the positioning assembly. The positioning assembly includes a pair of positioning subassemblies and a movable supporting subassembly. Each positioning subassembly comprises a supporting bracket and two positioning members, the two supporting brackets are distributed on the worktable, spaced from each other, for holding the workpiece. The movable supporting subassembly comprises two transmission members and two driving members. The two transmission members are laminated together and disposed on the worktable. The two driving members are respectively assembled to the two transmission members and drive the two transmission members to slide along different directions, thereby supporting the workpiece. The present disclosure further discloses a positioning assembly.

Owner:FU DING ELECTRONICSAL TECH JIASHAN +1

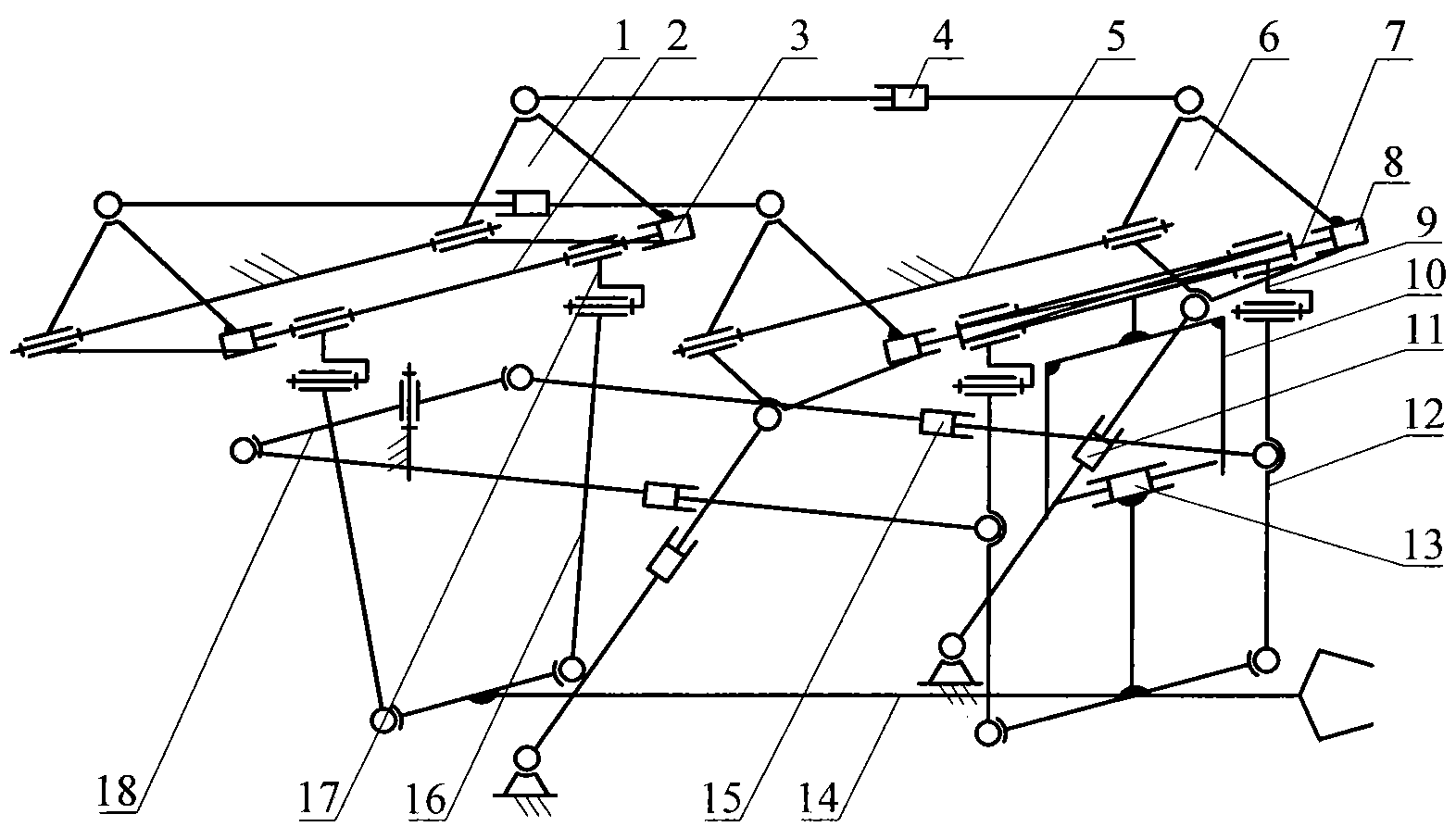

Lifting mechanism of parallel connecting lever type large-tonnage forging manipulator

InactiveCN102728764AImprove carrying capacityReduce stressForging/hammering/pressing machinesForging manipulatorEngineering

A lifting mechanism of a parallel connecting lever type large-tonnage forging manipulator is mainly characterized in that the front part and the rear part of a nipping lever are respectively connected with the lower ends of a front suspension lever and a rear suspension lever, the upper ends of the front and rear suspension levers are respectively connected on front and rear sliding levers by connecting pieces, left and right linear drivers are arranged at two ends of the front and rear sliding levers and are connected with front and rear lifting arms, and the other end of the lifting arm is connected with a rack. The lower arms of the two front lifting arms are connected with the upper ends of the two linear lifting drivers, the upper arms of the front lifting arms are connected with the front end of a horizontal synchronous lever, the rear end of the synchronous lever is connected with the upper arms of the rear lifting arms, the other ends of the two rear lifting arms are connected with one end of a pitching arm, and the other end of the pitching arm is connected with the rack. The middle parts of the two pitching arms are also connected with the upper ends of linear pitching drivers. The lifting mechanism reduces the stress at the connection part of the rack hinges, greatly improves the whole bearing capacity and transmission efficiency of the manipulator, is applicable to forging operation of large-tonnage forged pieces, and can also ensure the lifting parallelism of the nipping lever.

Owner:YANSHAN UNIV

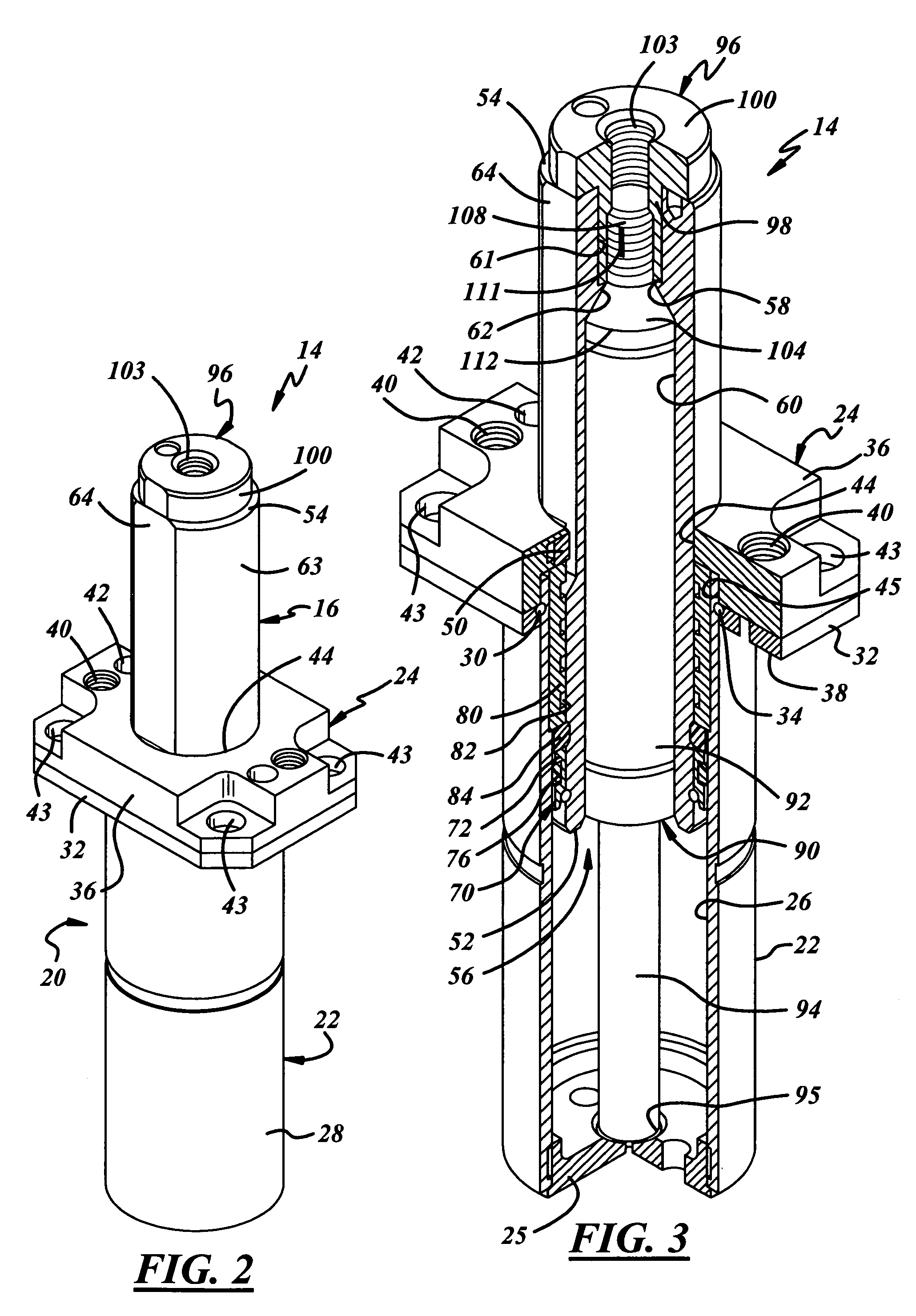

Reaction device for forming equipment

ActiveUS7152451B1Easy to useEasy maintenanceSpringsStripping-off devicesEngineeringMechanical engineering

A reaction device for forming equipment includes a housing having a mount adapted to be connected to a forming die and a casing carried by the mount. A lift rod is disposed at least partially on the housing for movement relative to the house between extended and retracted positions. The lift rod has a first end disposed in the housing, a second end and a passage extending through the lift rod between its ends. An adapter is connected to the lift rod within the passage and is adapted to be coupled to a lift bar of the forming equipment. A biasing member is disposed between the lift rod and the housing to yieldably bias the lift rod to its extended position.

Owner:DIEBOLT INT

7A04 aluminum alloy casing body parts multi-functional die forging technique and mold

InactiveCN101214526ANo lossImprove plastic forming abilityForging/hammering/pressing machinesMetallic materialsForge

A multi-direction forging technique and die for a 7A04 aluminum alloy cartridge receiver body part belongs to the technical field of metal material plastic forming and aims at effectively overcoming the problems of the existing opening-die forging technique and isothermal-die forging technique. The order of the multi-direction forging technique of the invention includes the steps of baiting, heating, rough making, reheating and multi-direction forging. The multi-direction forging relates to (1) using a multi-direction die forging die to pre-forge and form a heated 7A04 aluminum alloy roll forging rough;(2) then suing the multi-direction die forging die to realize finally forge to forge a die forging element. The invention multi-direction forging die includes symmetrical upper half and lower half concave model, a pre-forging convex model, a final-forging convex model, a fixing plate for the pre-forging convex model, a fixing plate for the final-forging convex model and a model frame consisting of an upper model seat and a lower model seat. The invention has the advantages of reasonable technique flow, stable technique parameter and performance, simple structure of the die, convenient manufacture, mounting and use, reliable work. And the invention can greatly reduce the friction resistance between a forging element and a die chamber, improve the surface quality of the forging element and remarkably improve the service life of the die.

Owner:HUAZHONG UNIV OF SCI & TECH

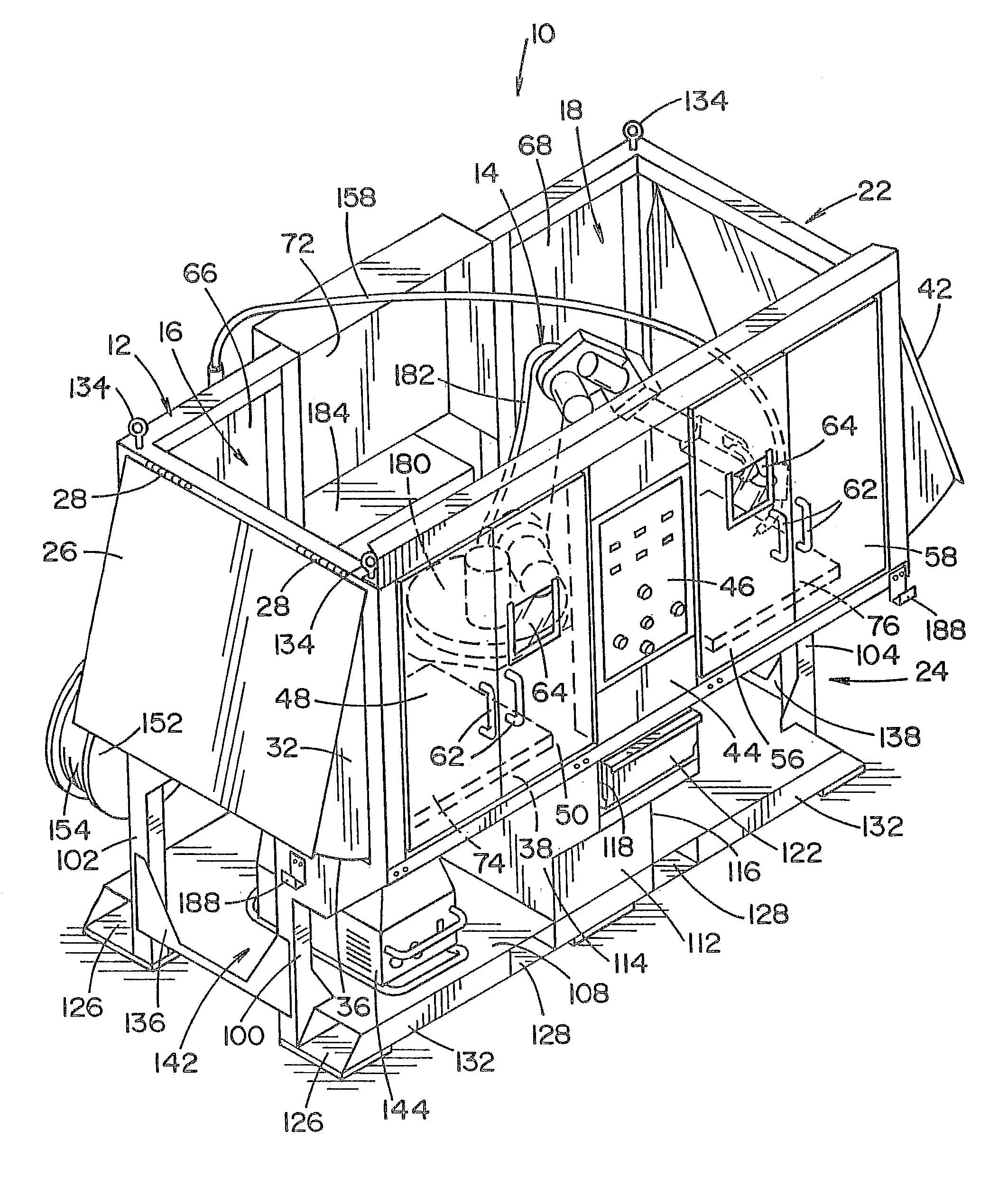

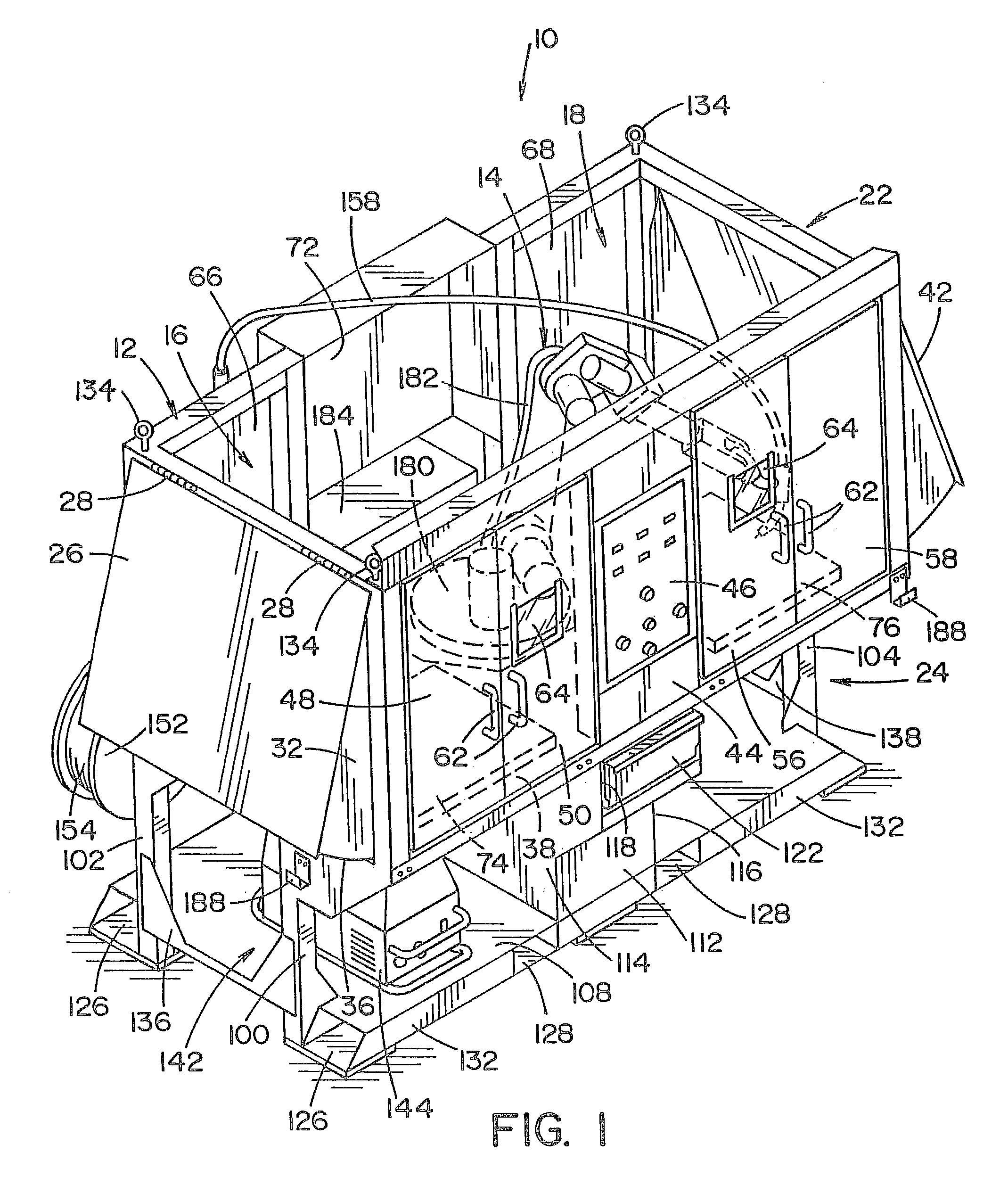

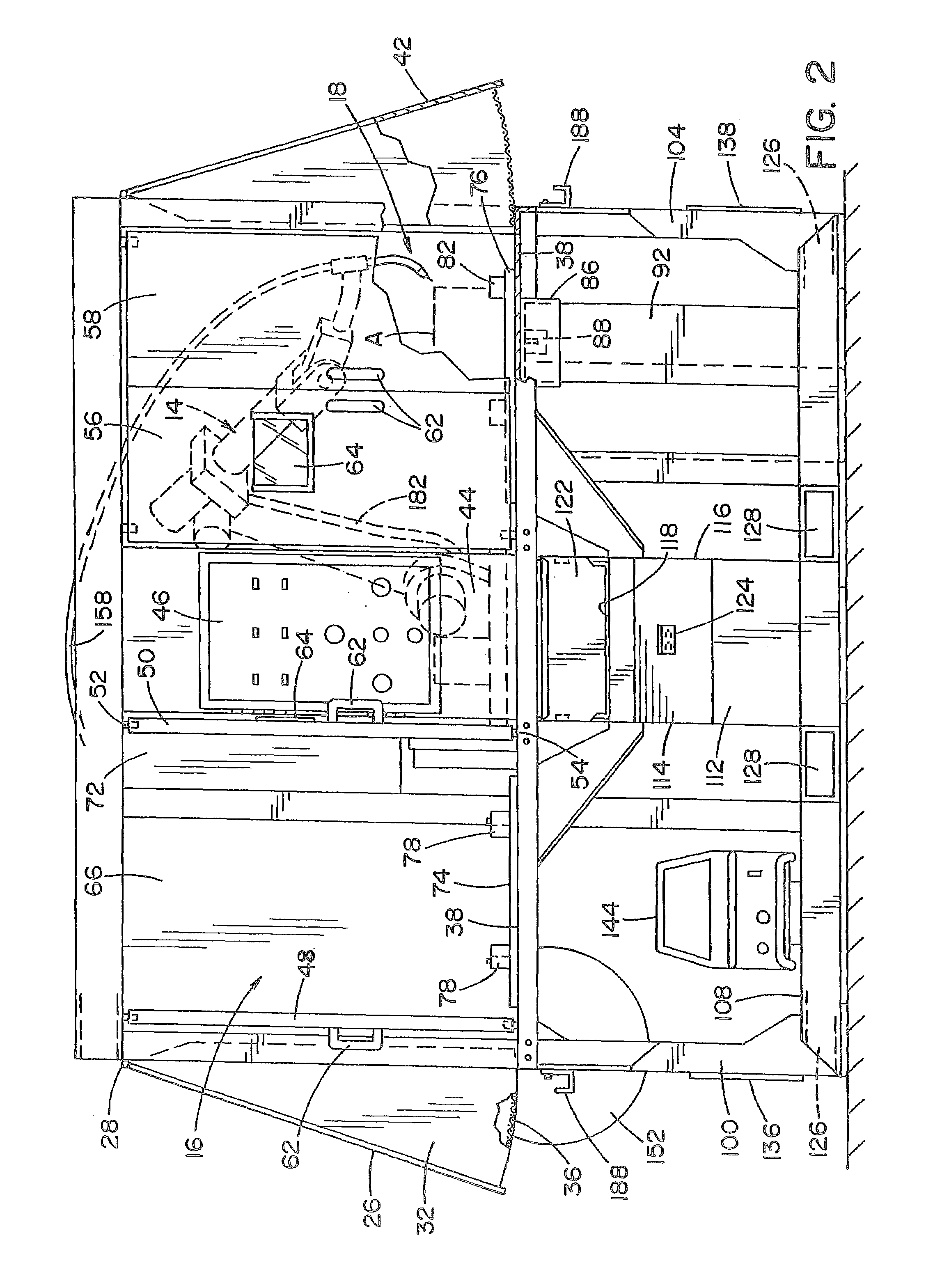

Robotic welding cell unit

InactiveUS7238916B2Easily fitted into bedMore freedom of movementElectric heatingForging/hammering/pressing machinesRobot weldingEngineering

Owner:LINCOLN GLOBAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com