A labor-saving automobile hub forming method and device

An automobile wheel hub and forming technology, which is applied in forging/pressing/hammer devices, metal extrusion, and other manufacturing equipment/tools, etc., can solve the problems of difficulty in forming front and rear rims, large equipment pressure, and large forming force, and achieve simplification. Process and process, reducing mold tooling and equipment, the effect of high dimensional accuracy and surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation will be described in detail below in conjunction with the accompanying drawings (this embodiment is a further description of the present invention, rather than any limitation to the present invention).

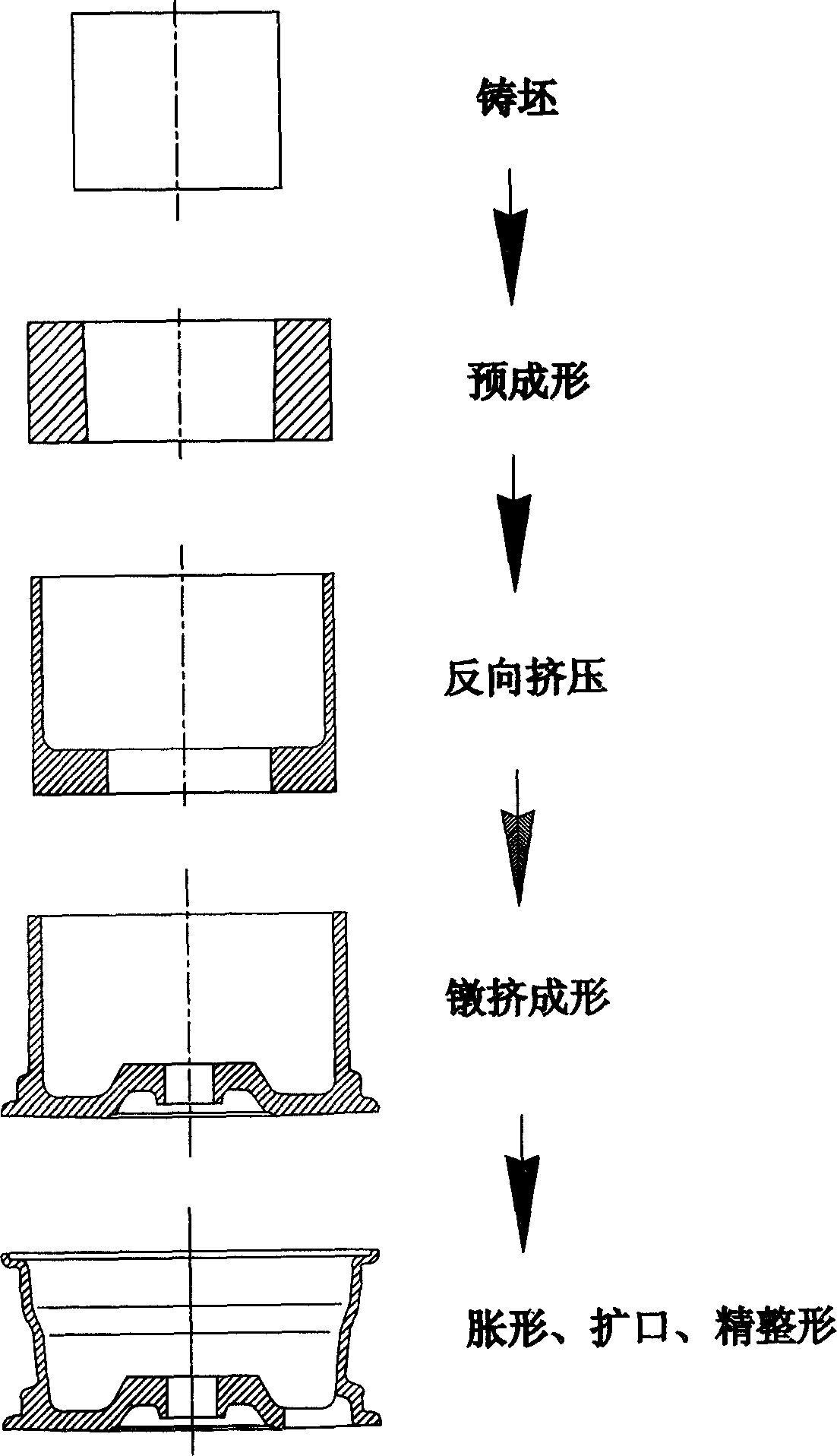

[0039] figure 1 As shown, a process flow chart of an automobile wheel hub labor-saving forming method. A labor-saving forming method for an automobile wheel hub includes casting blanks-homogenization treatment-preforming blanks-extrusion-upsetting the front wheel rim-flaring and flanging rear wheel rim technology, and finishing procedures; wherein the extrusion process adopts reverse extrusion process.

[0040] Preforming billet making process: upsetting preformed hollow billets in the free state of casting billets.

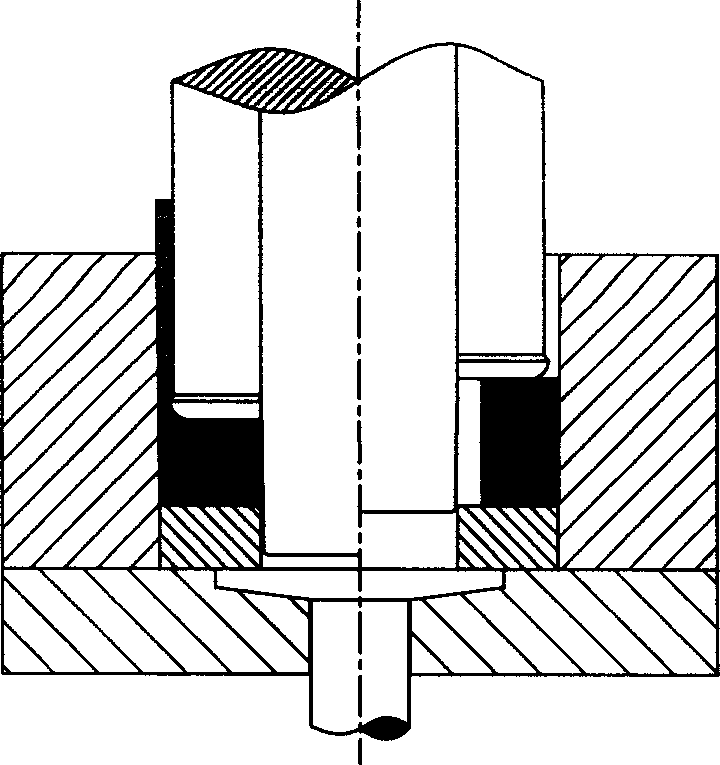

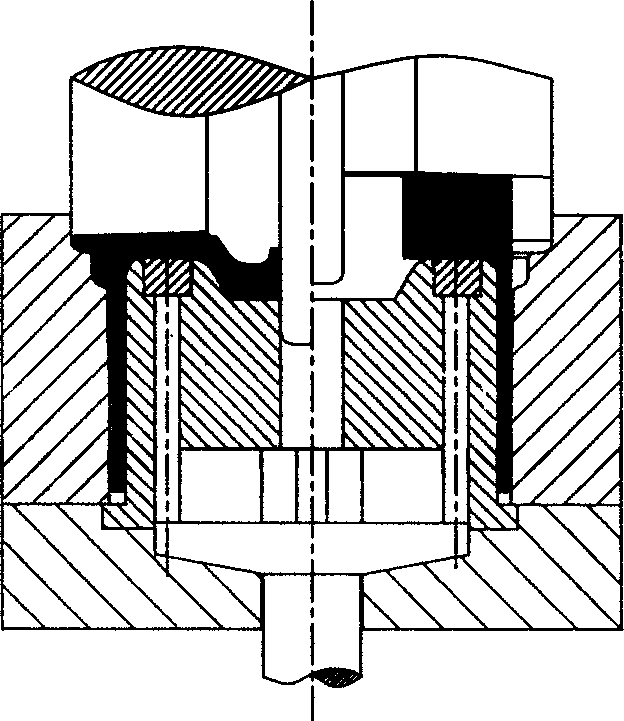

[0041] figure 2As shown, it is called "hollow billet, mandrel extrusion" method. Back-extrusion process: use a punch with a mandrel, which is an integral mold. The back-extrusion process uses a mandrel to extrude a hollow b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com