Patents

Literature

464 results about "Forming force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

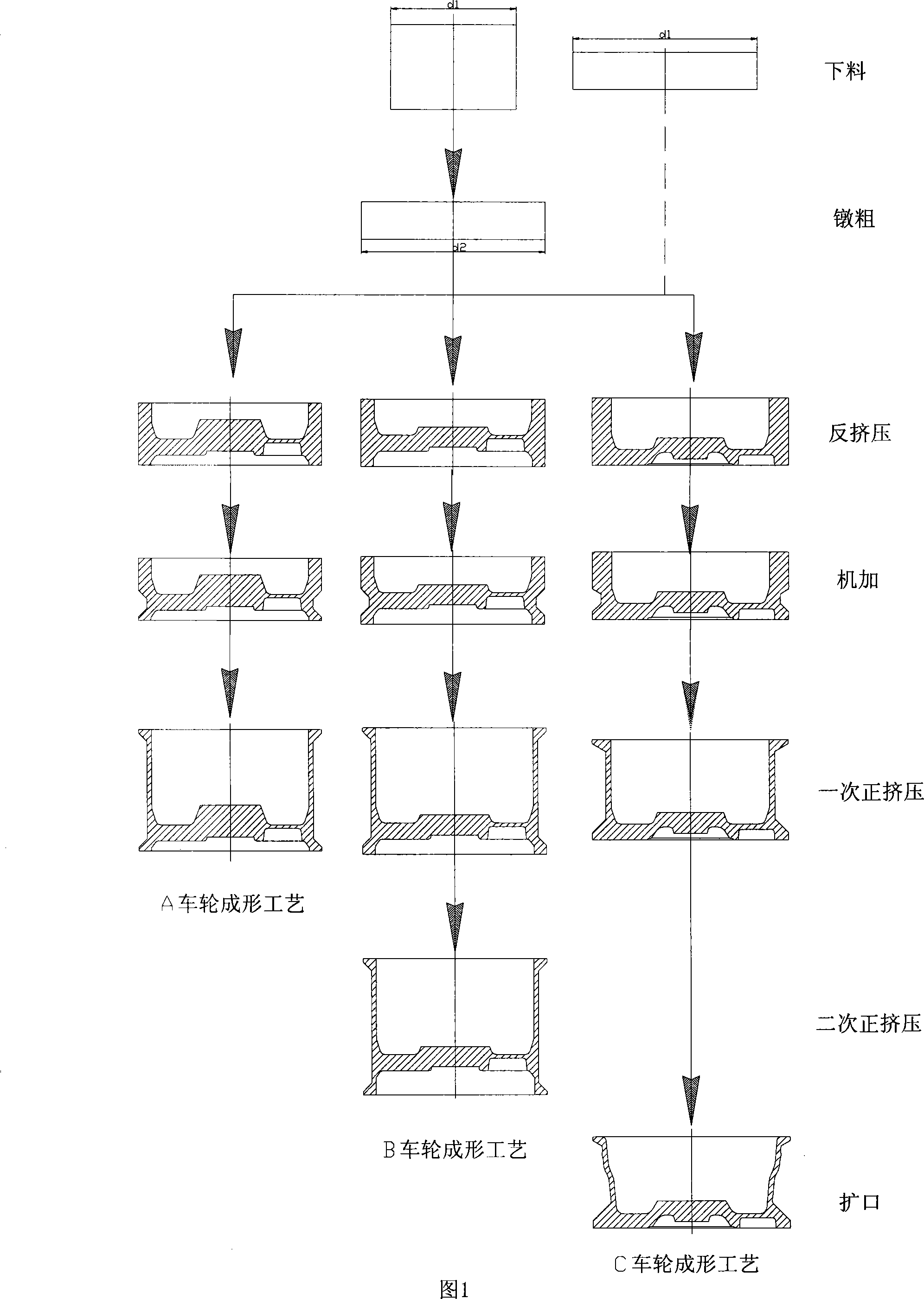

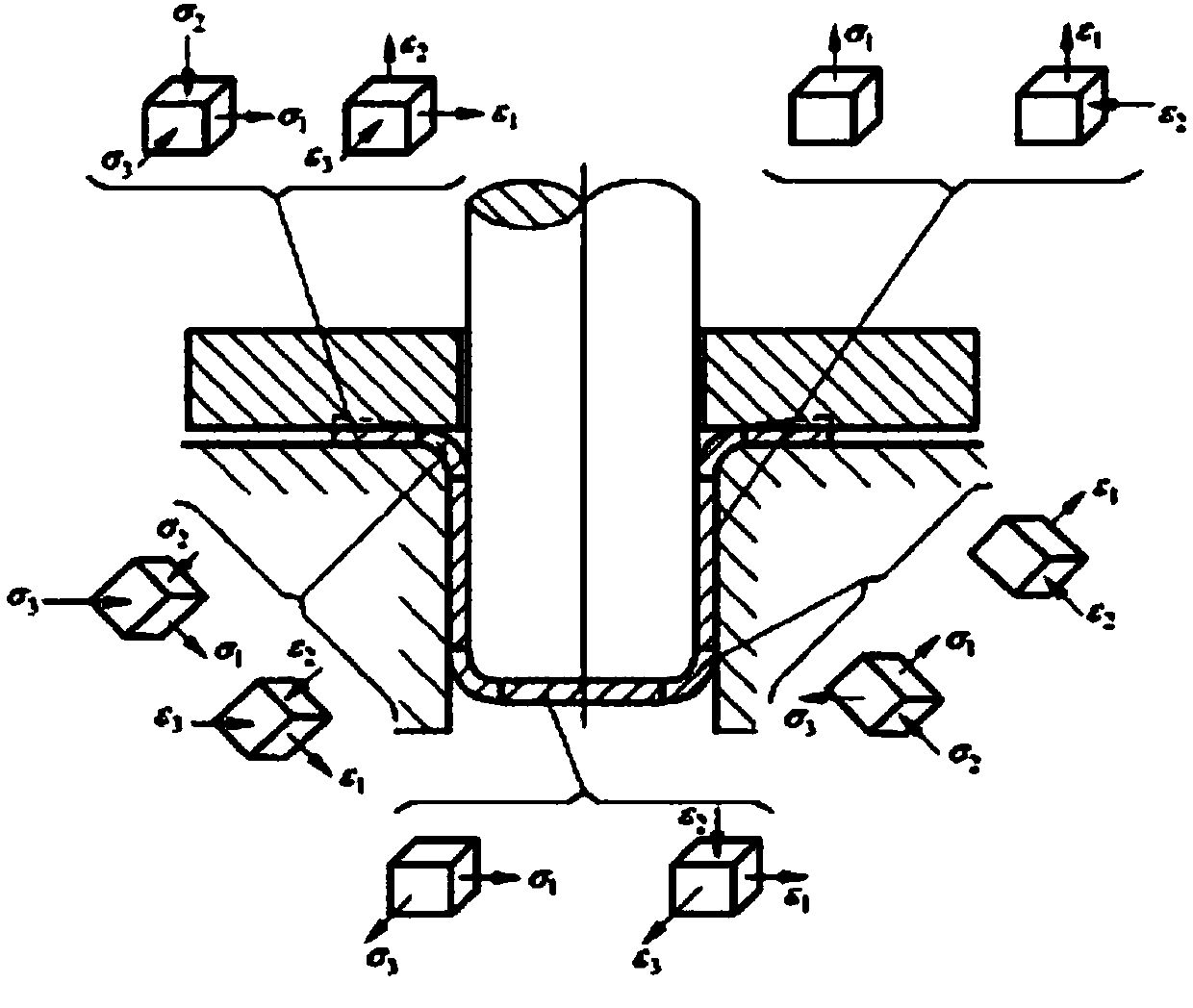

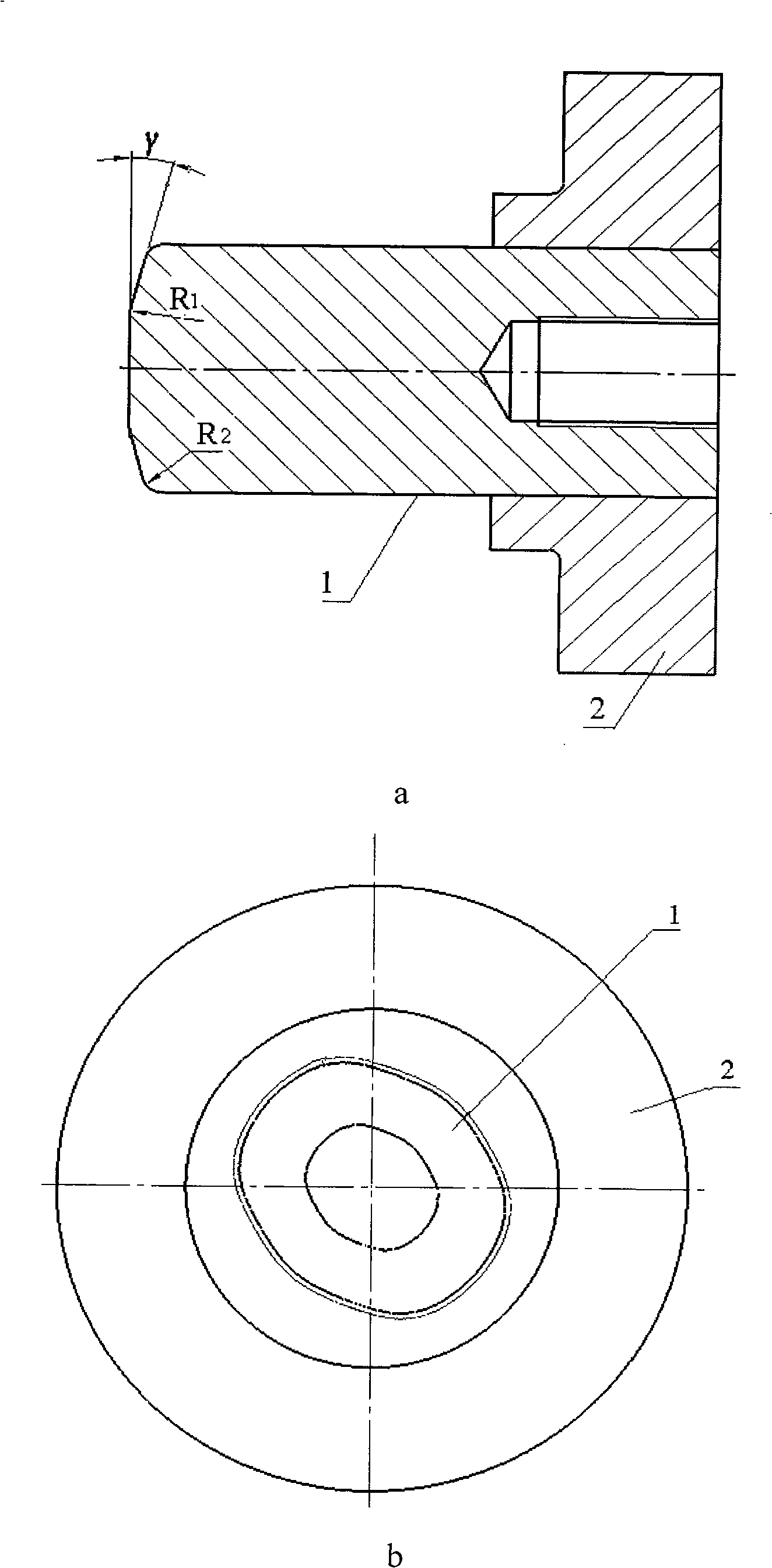

Magnesium alloy automobile wheel extrusion molding method and mold

The invention relates to a press forming method of magnesium alloy automobile wheels and a die thereof, the working procedures of the press forming method comprise: blanking-continuous upsetting-backward extrusion-machinery adding-forward extrusion-flaring-thermal treatment-ultimate machinery adding-superficial treatment; the press forming die comprises: a backward extrusion die, a forward extrusion die and a flaring die; the method of the invention can directly form magnesium alloy or aluminium alloy automobile wheels of various shapes, which solves the problem of hard forming of flanges of wheels and reduces the forming force, which particularly suitable for the magnesium alloy of low plasticity with hexagonal close packed lattice, three-direction compressive stress acquired from forward extrusion is beneficial to improve the plasticity of the material; the formed wheel has the advantages of high size precision and surface precision, good comprehensive mechanical property and simple die structure, which improves the quality of the product, simplifies technical process, decreases die frock and equipment and reduces production cost.

Owner:ZHONGBEI UNIV

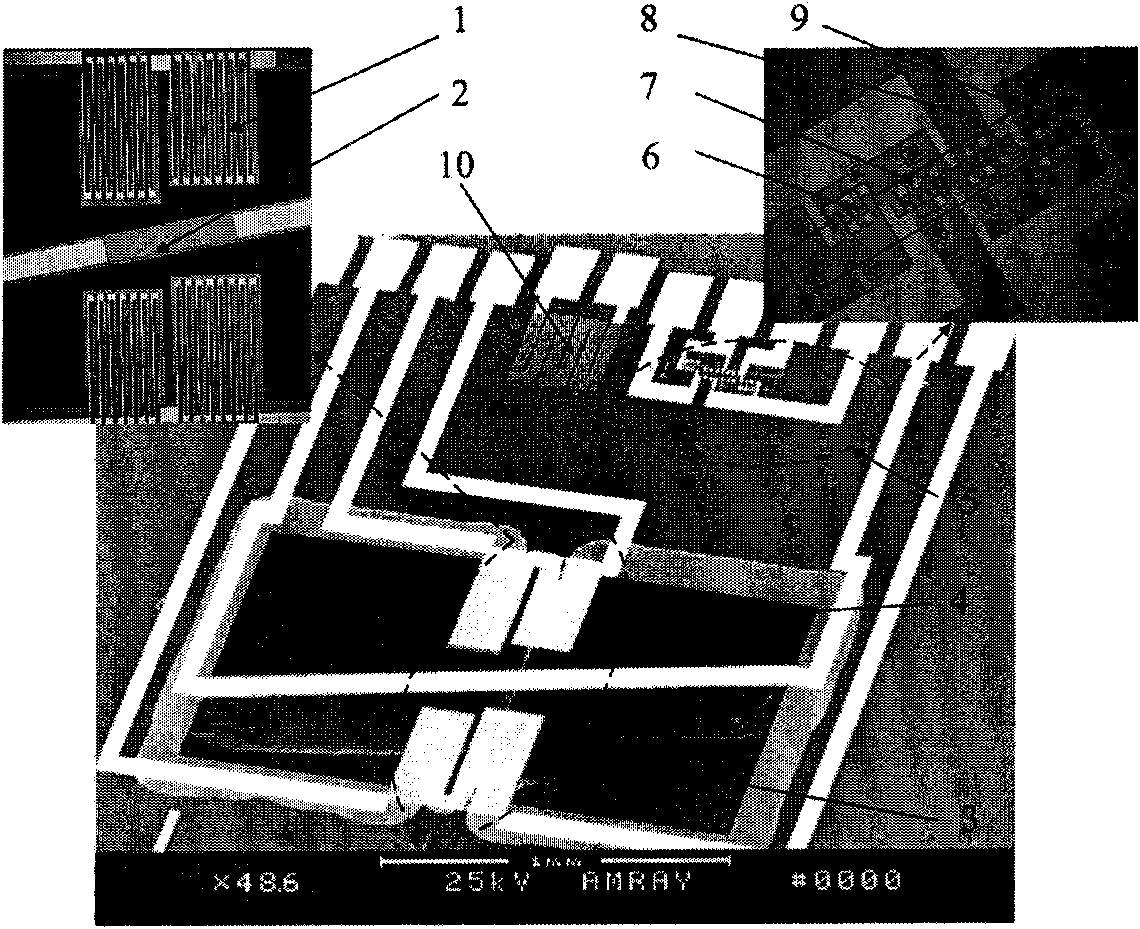

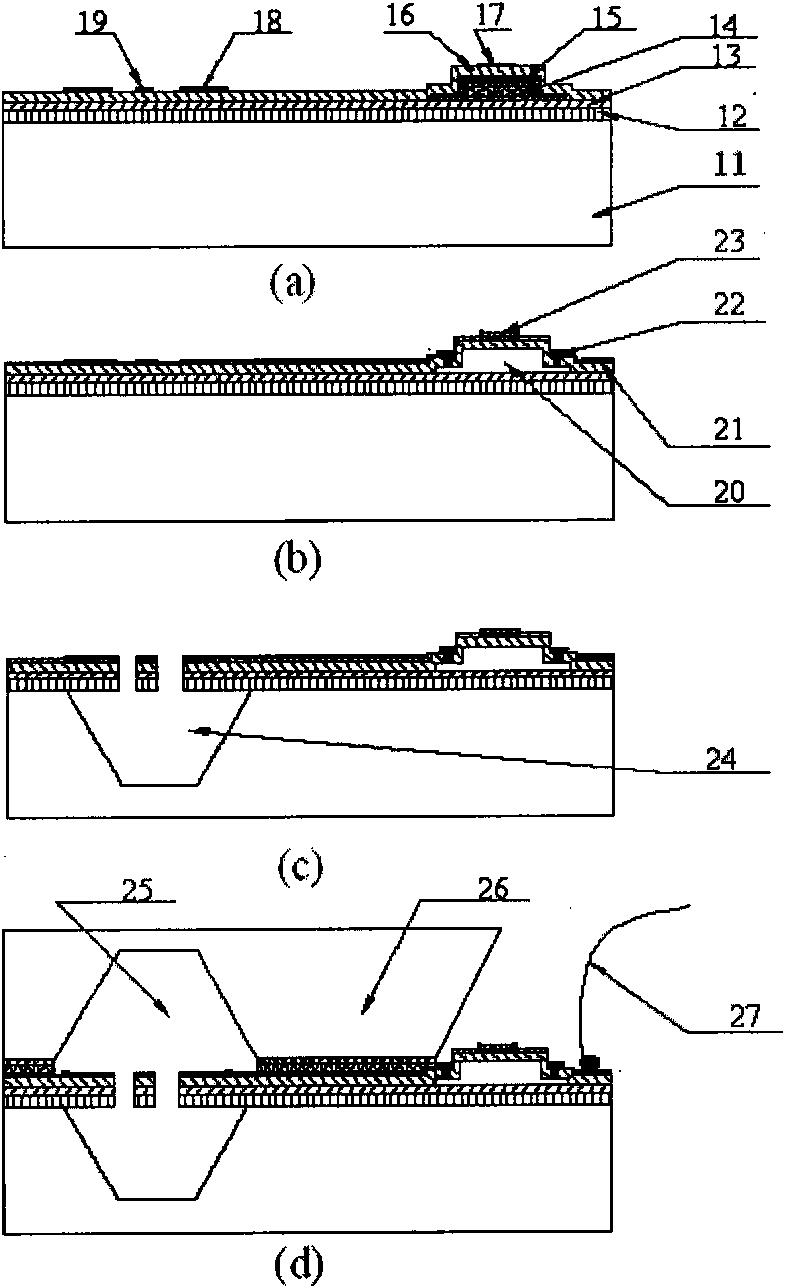

Integrated silicon chip for testing acceleration, pressure and temperature, and manufacturing method thereof

ActiveCN101551403AHigh sensitivityImprove stabilityFluid pressure measurement using ohmic-resistance variationDecorative surface effectsAccelerometerThermopile

The invention relates to an integrated silicon chip for testing acceleration, pressure and temperature, and the manufacturing method thereof. The invention is characterized in manufacturing the pressure sensor, temperature sensor and accelerometers of thermoelectric pile on to one chip by the same micro processing technology. The acceleration is detected by adopting thermal convection type accelerometers, using polysilicon resistor as heater, using a thermoelectric pile composed of two pairs of metals (such as aluminium and tungsten-titanium) and P type or N type polysilicon to detect the temperature difference in the sealed cavity caused by acceleration. The high accurate absolute pressure sensor is manufactured by using silicon nitride film with low stress as the core structure layer of the pressure sensor chip, and forming force sensitive resistor track by polysilicon film, forming vacuum reference cavity by TEOS bolt in LPCVD furnace. At the same time, the temperature sensor is composed by using polysilicon thermistor to detect temperature change. The integrated chip achieves the advantages of microminiaturization, low cost, high precision, high reliability and high stability.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

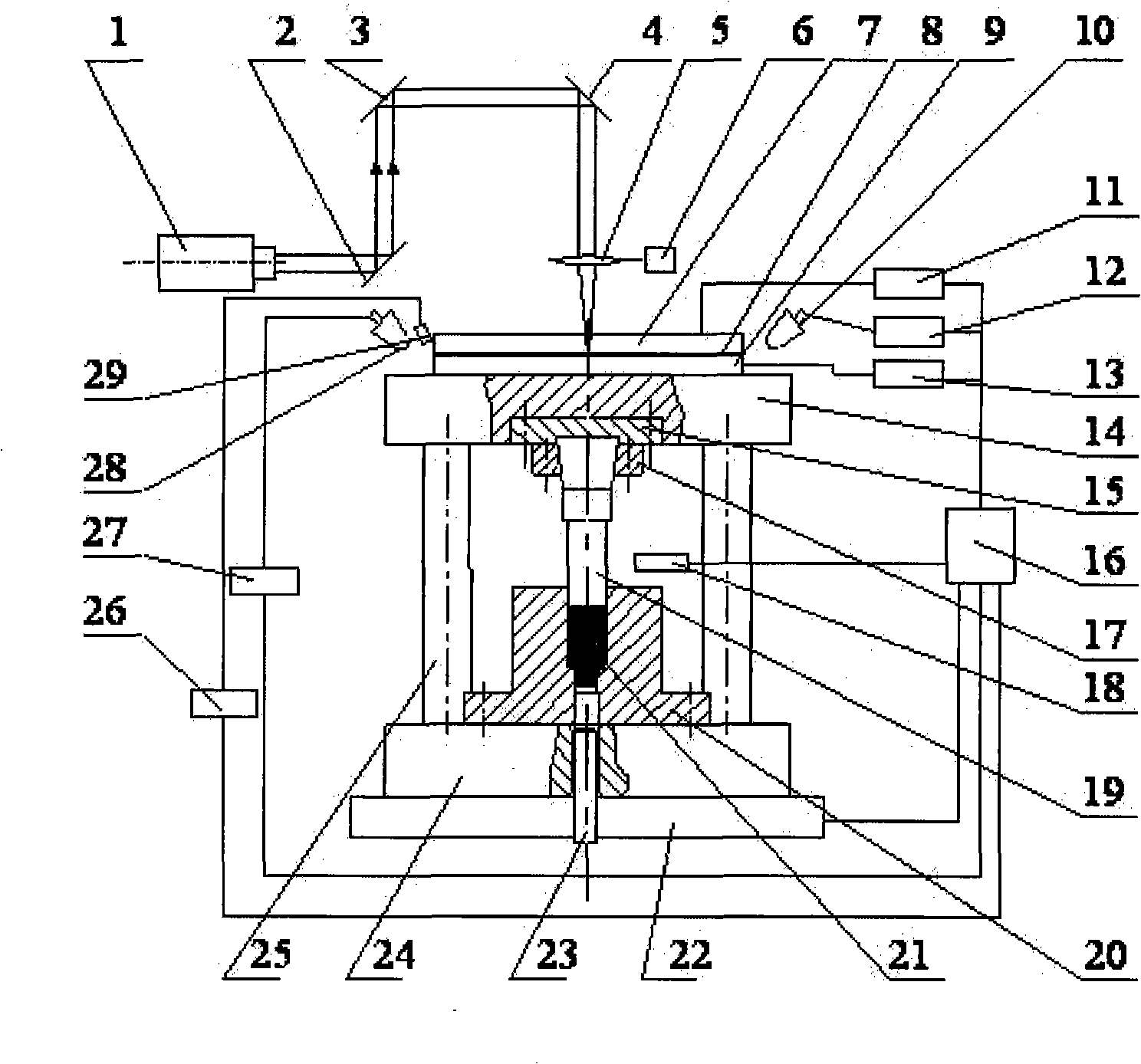

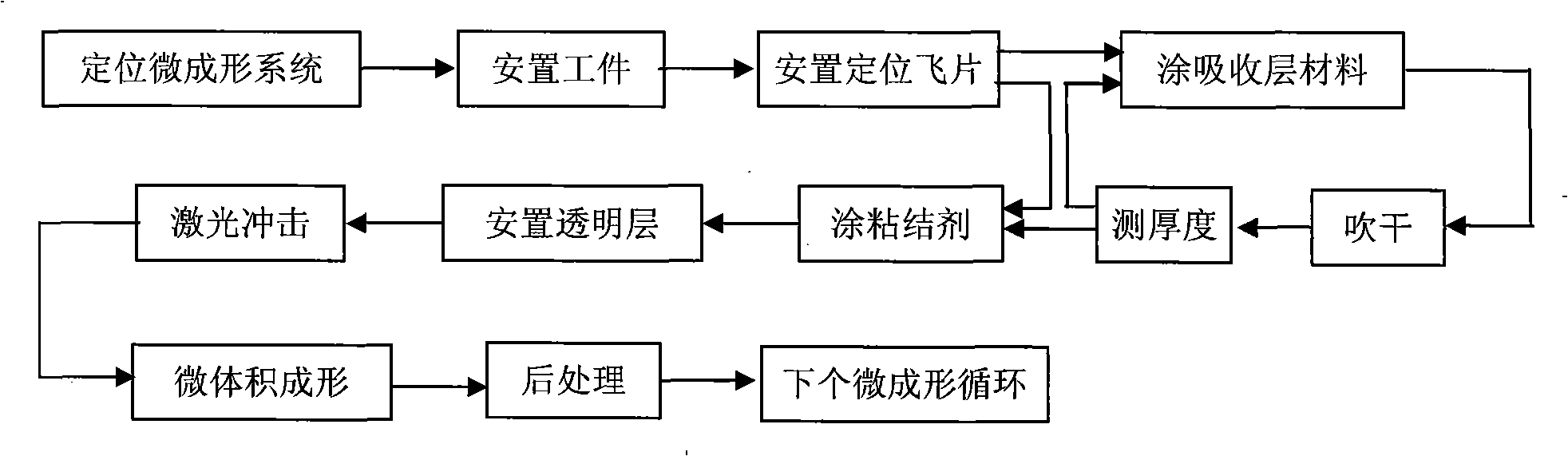

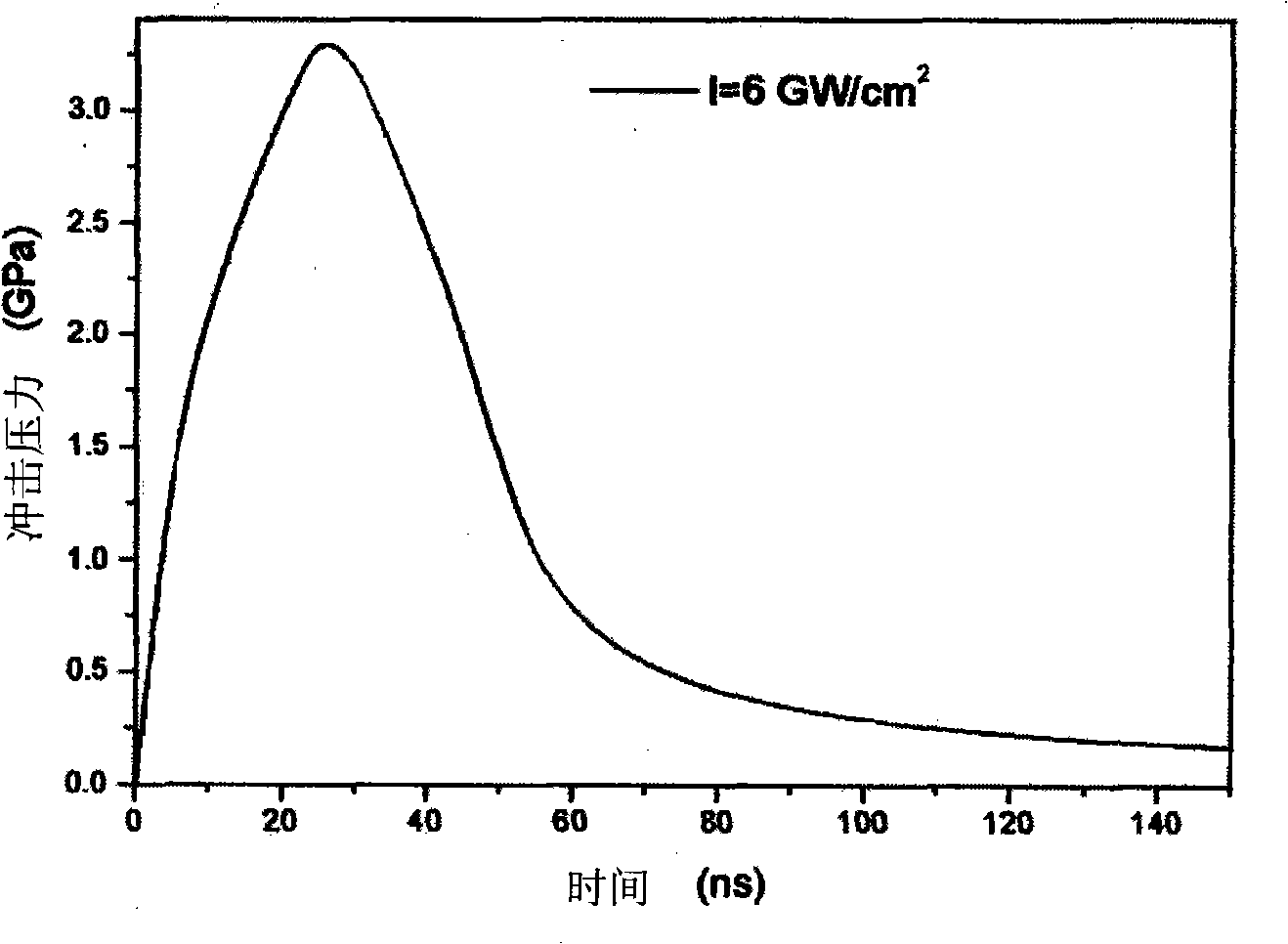

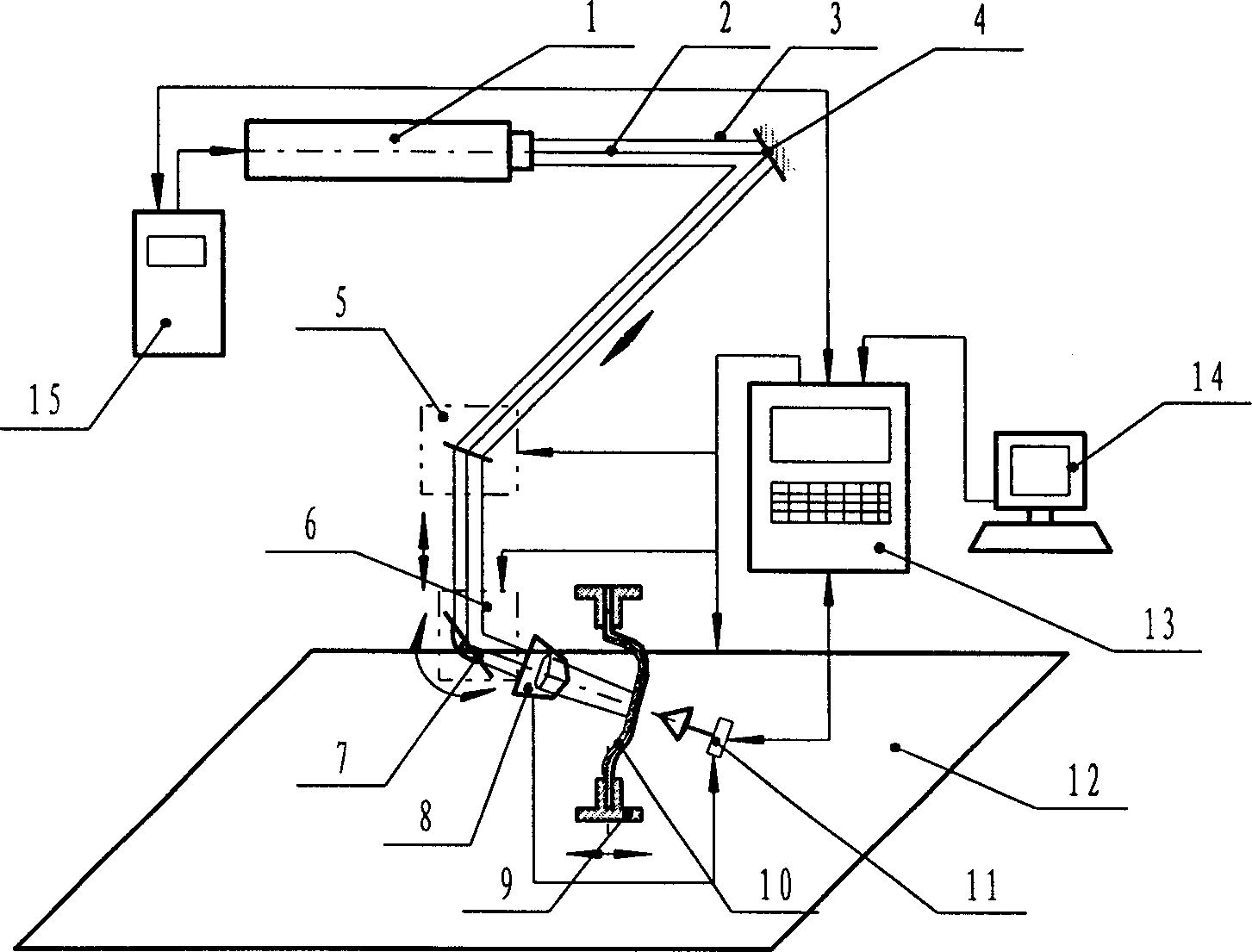

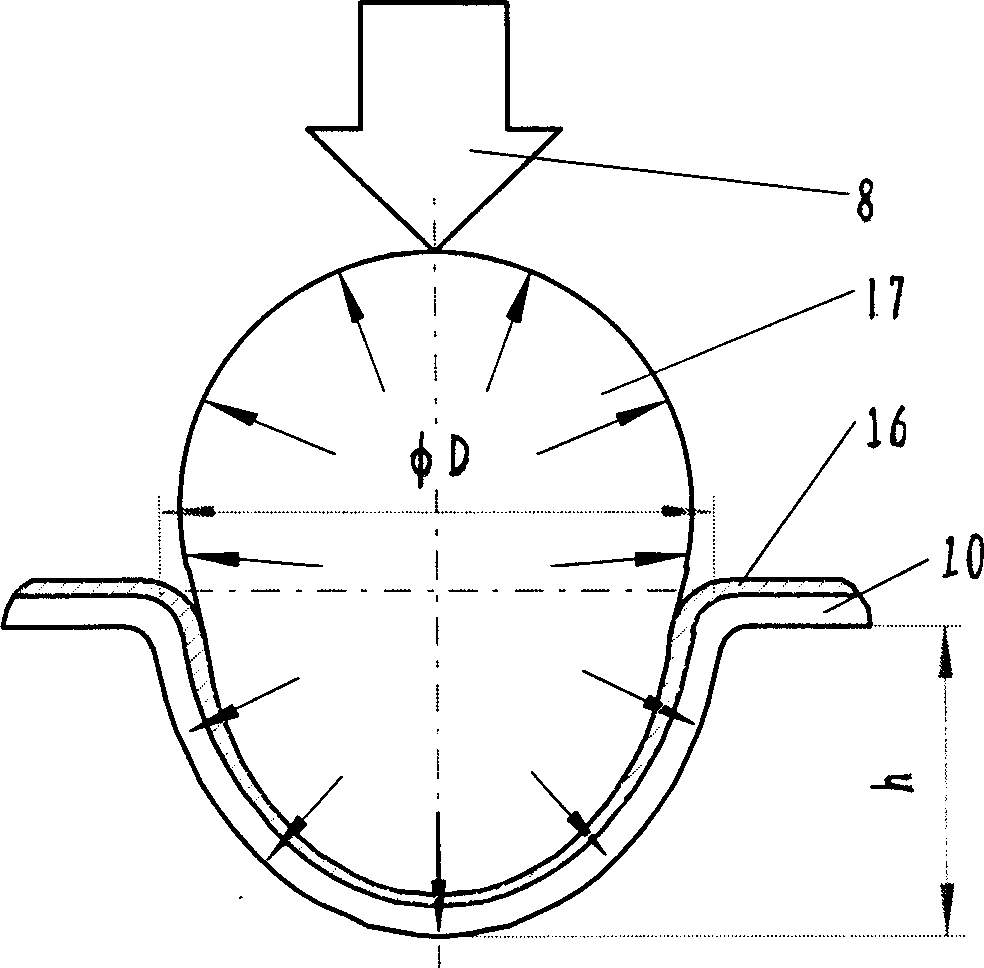

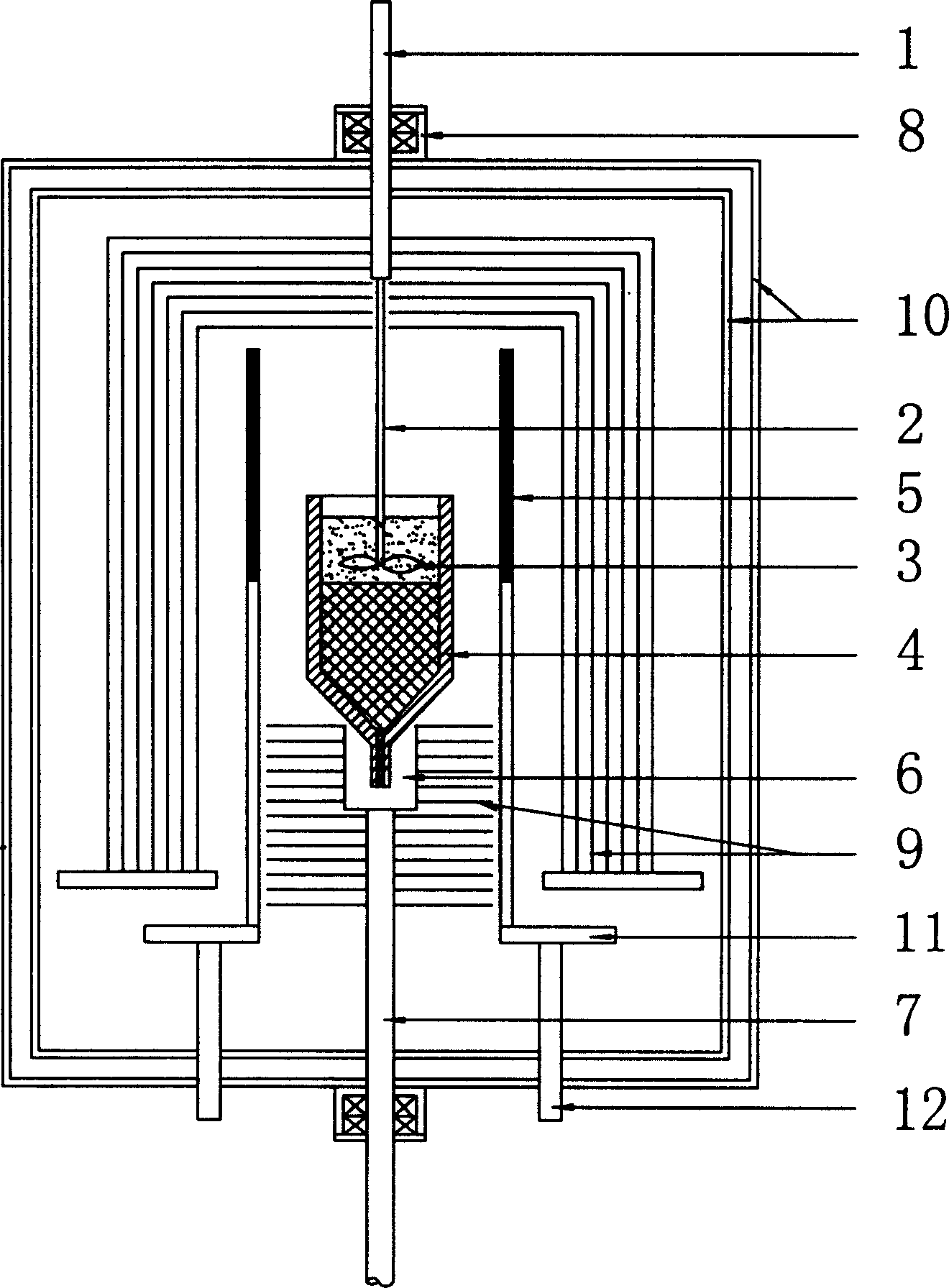

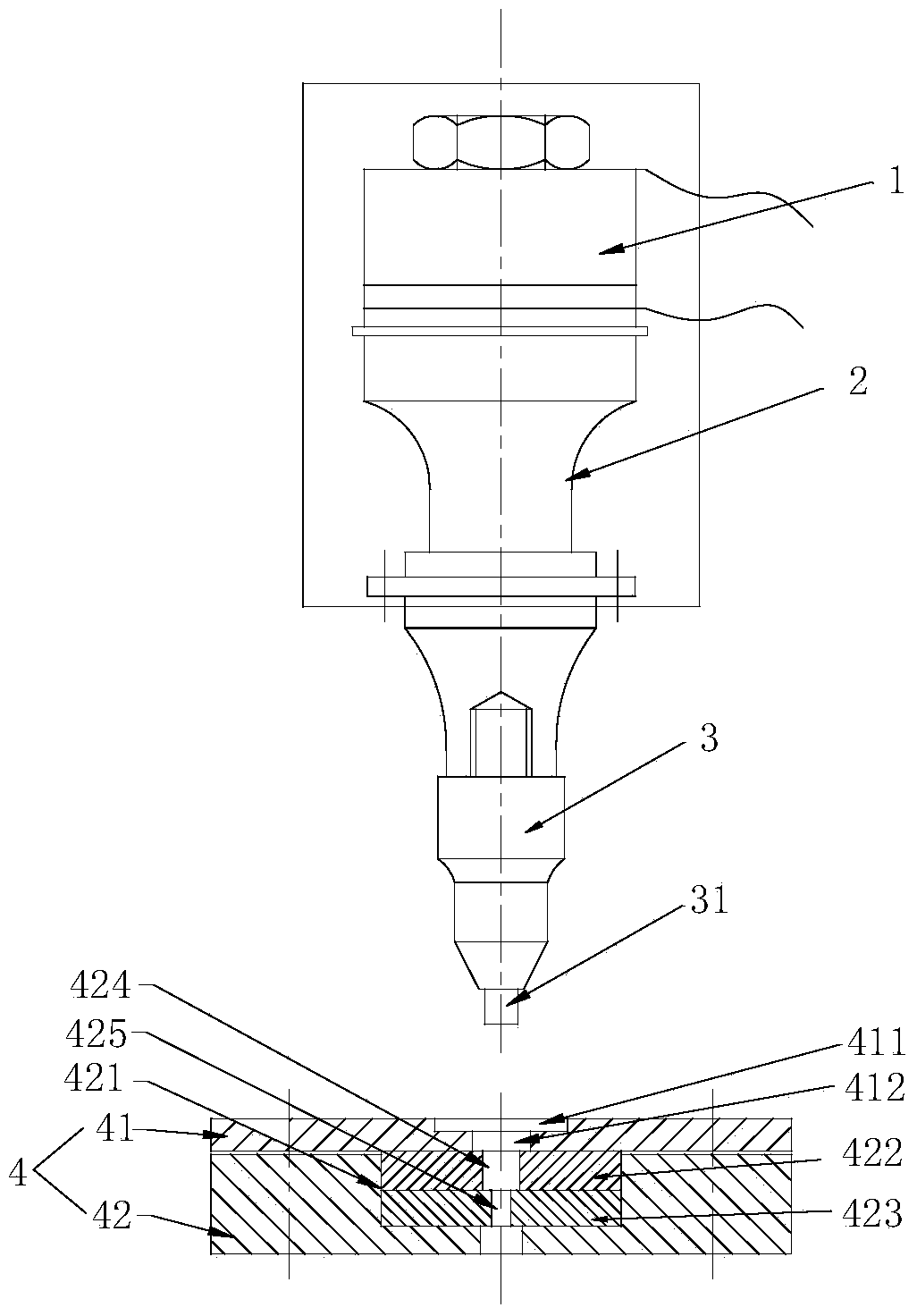

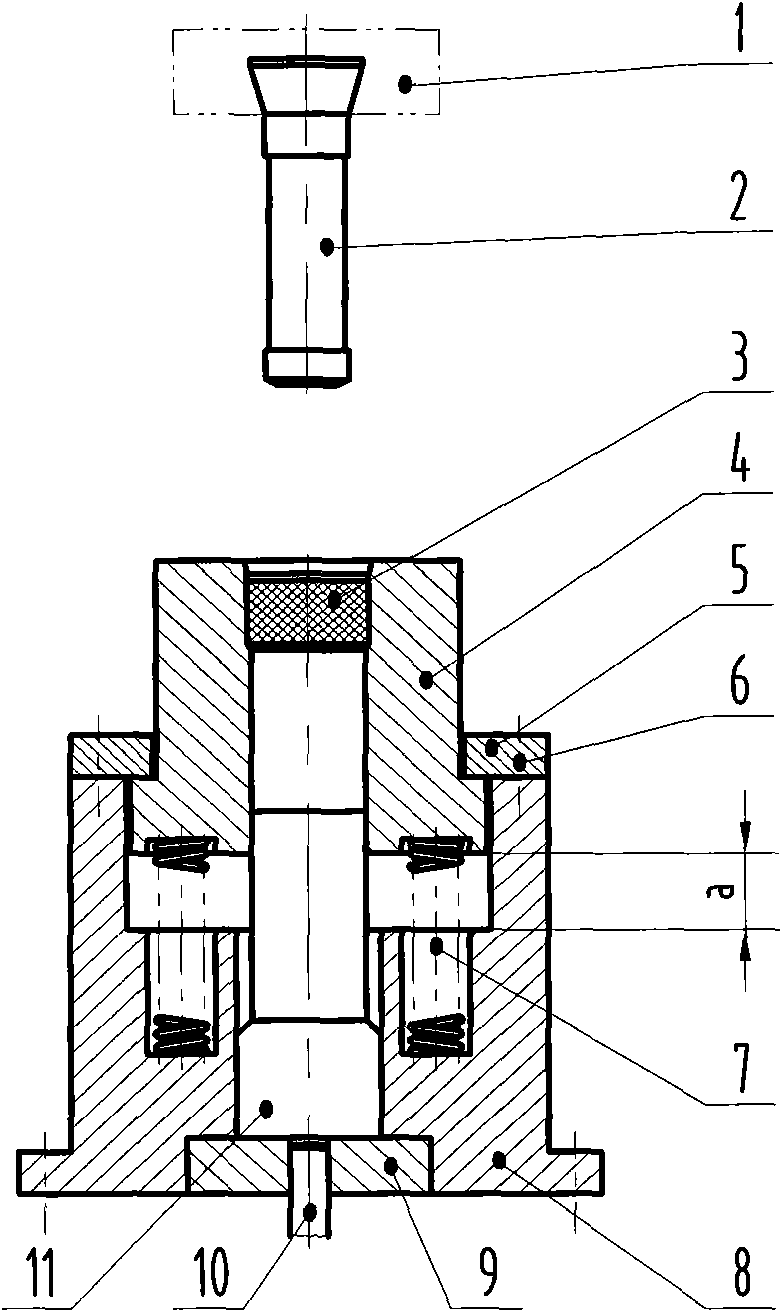

Laser impact tiny bulk forming method and apparatus for tiny apparatus

InactiveCN101269440AEasy to achieve microplastic formingImprove absorption rateLaser beam welding apparatusOptical pathForming force

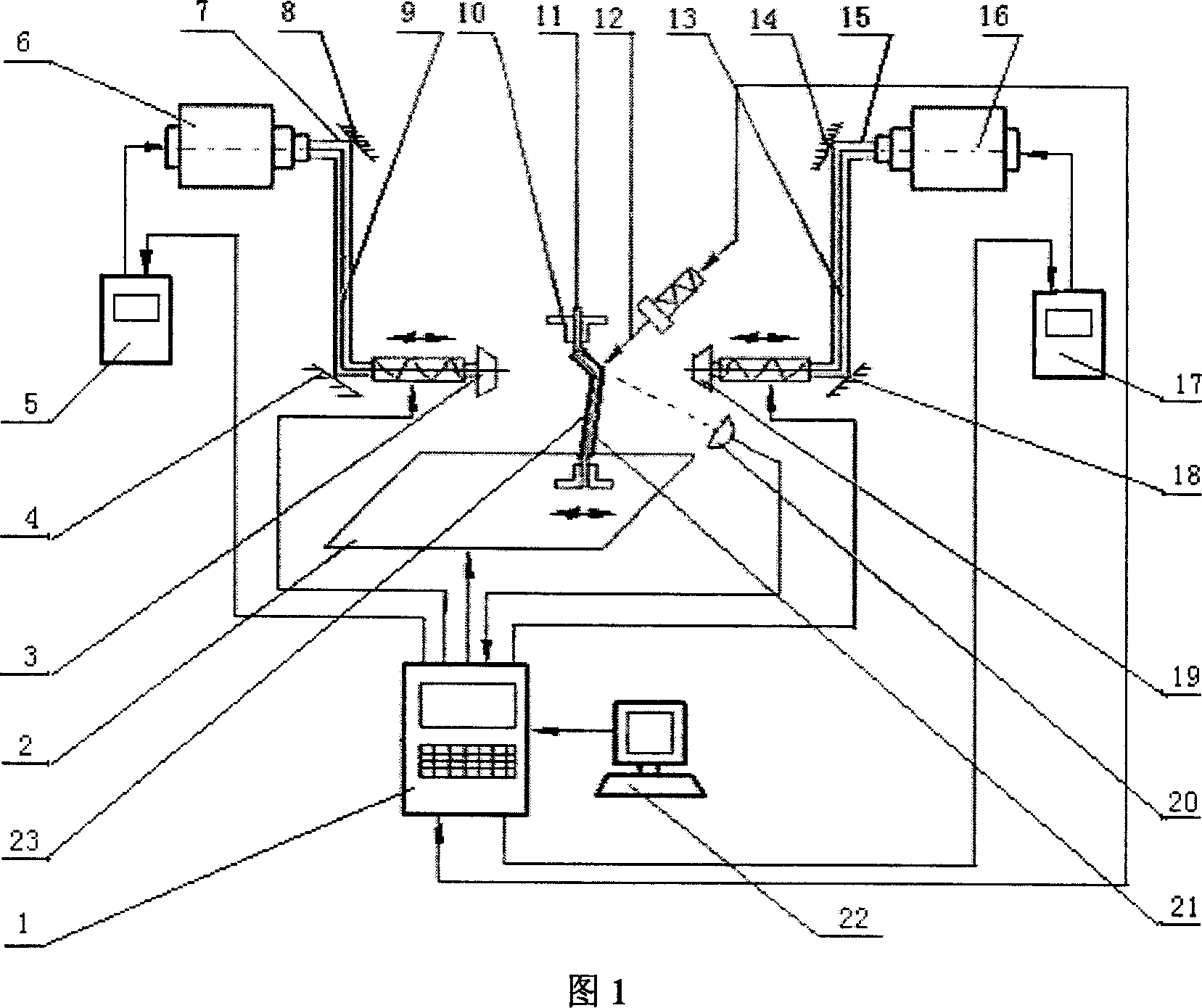

The invention provides a laser impulse micro-bulk forming method and a device thereof, being suitable for the micro-bulk forming of a planchet and belonging to the laser micro-processing field and micro-bulk forming field. The forming method is as follows: impulse wave induced by laser is used as a forming force source for micro-device micro-bulk forming; laser burst generated by a laser generator according to requirements is irradiated at a flying-piece surface layer passing through a transparent restraint layer through an external light path system; a high temperature and high pressure plasma body is generated and the impulse wave is formed; overhigh pressure of the impulse wave is used for driving the flying-piece and a micro-plastic forming system connected with a flying piece; a micro-workpiece is pressed; the micro-bulk forming of the workpiece is finished. The device applied to the method comprises six parts of the laser generator, an external light path system, an induction impulse wave generation system, a micro-plastic forming system, a control system and an operating platform. The laser impulse micro-bulk forming method can be used for realizing the micro-bulk forming of any complex shaped micro-devices, and can be repeatedly impacted and loaded on, and has good repeatability and easy realization of automatic production.

Owner:JIANGSU UNIV

Plate forming process and apparatus

InactiveCN1931467APrecise Local FormingAccurate shapeShaping toolsComputer controlShock waveLaser processing

The plate forming process and apparatus belongs to the field of laser processing technology. The present invention has CO2 laser for pre-heating plate, infrared thermometer for measuring and controlling the plate heating temperature, neodymium glass laser for providing powerful short laser pulse to induce the generation of laser shock wave as the forming force source in processing plate and plate deformation measuring feedback device. The present invention is superior to laser thermal stress forming process, which has inferior formed surface quality, and laser shock forming process, which has small deformation amount, and can form plate directly in relatively great deformation amount, relatively high size precision and relatively high surface quality.

Owner:JIANGSU UNIV

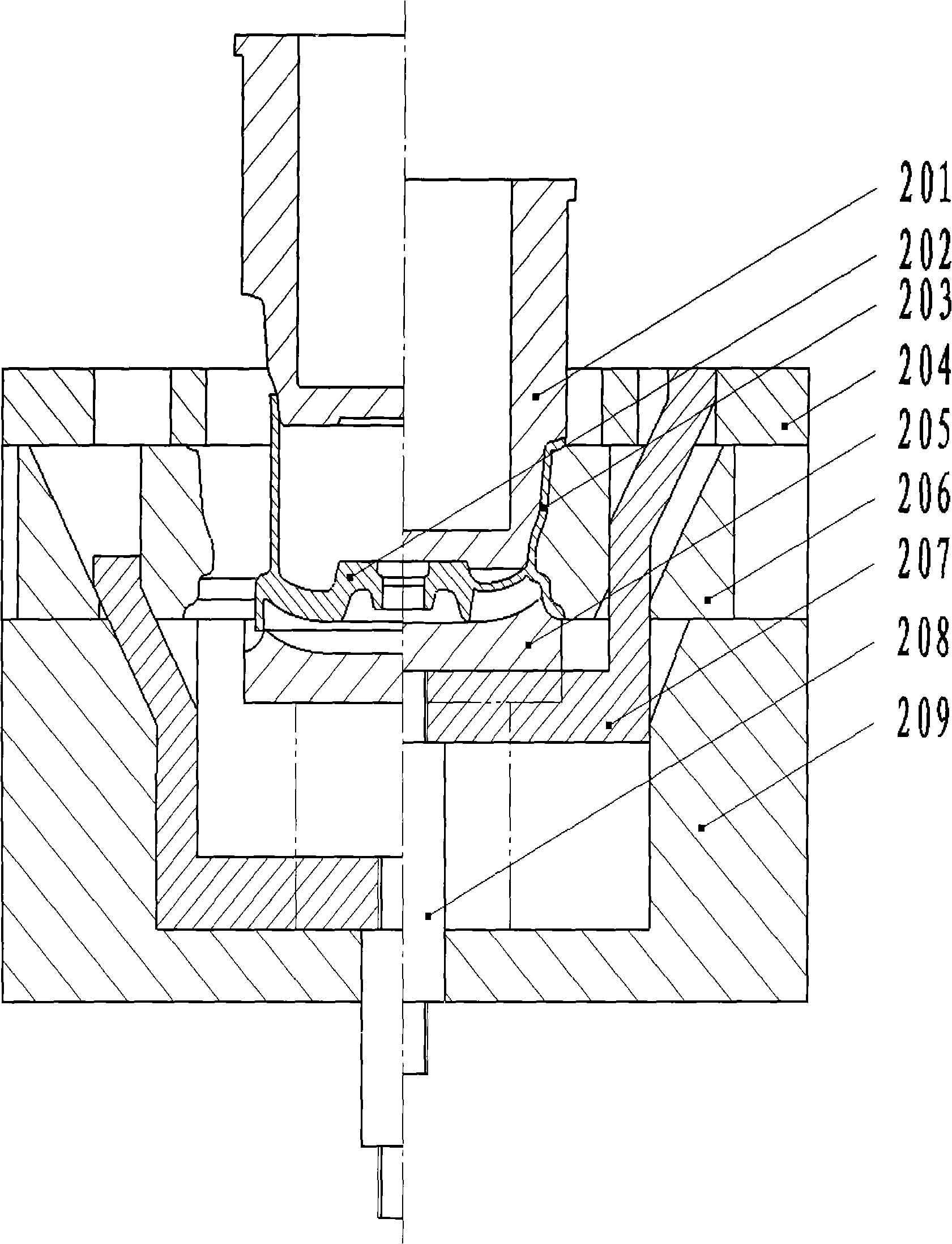

Gear-box planetary gear shaping die

InactiveCN101284299AHigh strengthImprove mechanical propertiesForging/hammering/pressing machinesWheelsGear wheelEngineering

The invention relates to a forming die of a gearbox planet gear, belongs to the processing dies of car automatic gearbox planet gears, solves the problems in prior forging die, including big forging force, rigorous requirement for blanks, and short service life of the die, and satisfies the forming requirement of a car automatic gearbox planet gear. The forming die comprises an upper die and a lower die arranged symmetrically and vertically; the end faces of both an upper punch and a lower punch are bosses; a diffluent trough is formed on the boss of the lower punch; the shoulders of both the upper punch and the lower punch extend into a tooth-shaped cavity die by 1-2mm in the final extrusion state; a rotary ejection mechanism can also be arranged; the lower punch can rotate when being ejected; and a helical cylindrical gear with a bigger helix angle can be forged. The forming die has the advantages of simple structure, easy manufacture and installation, small forming force and low requirement for blanking precision. Furthermore, the forming die can realize single punch extrusion according to different die carriers and equipment, double punch extrusion in opposite directions, as well as the extrusion of the helical cylindrical gear with big helix angle.

Owner:HUAZHONG UNIV OF SCI & TECH +1

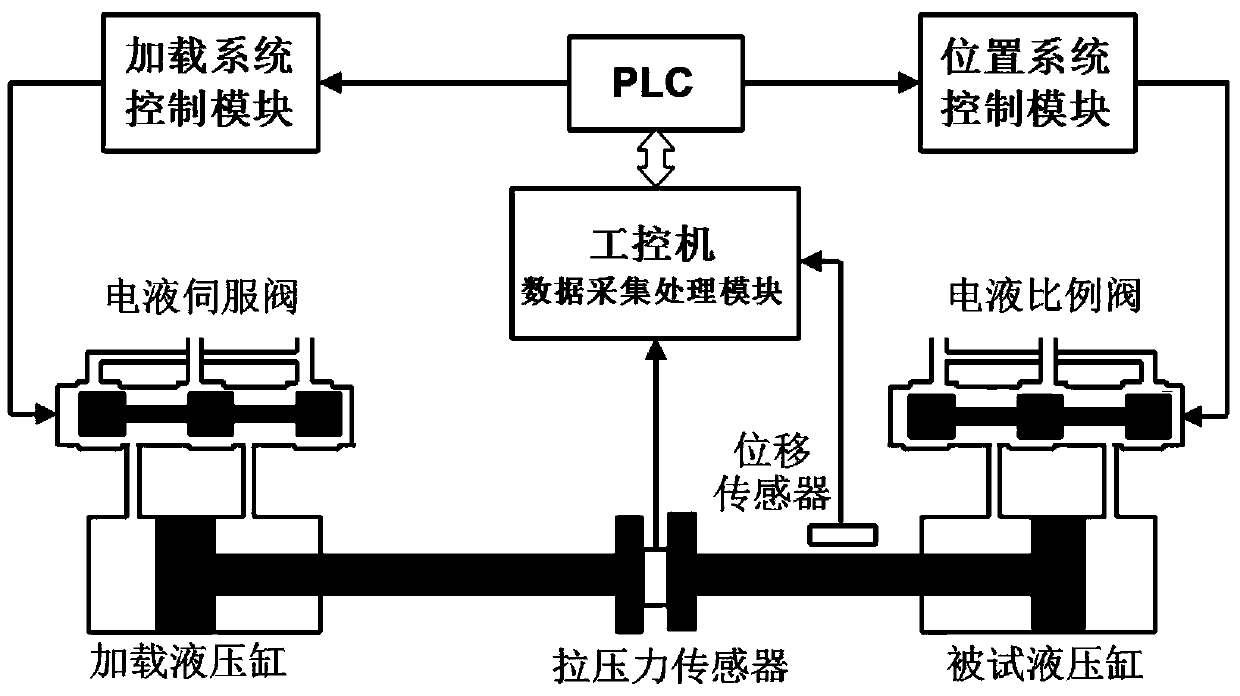

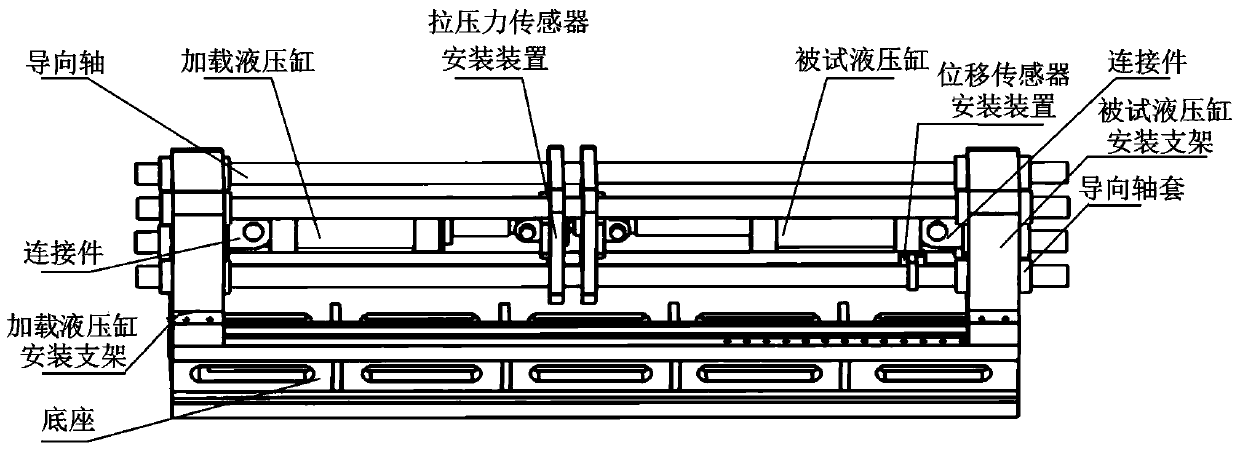

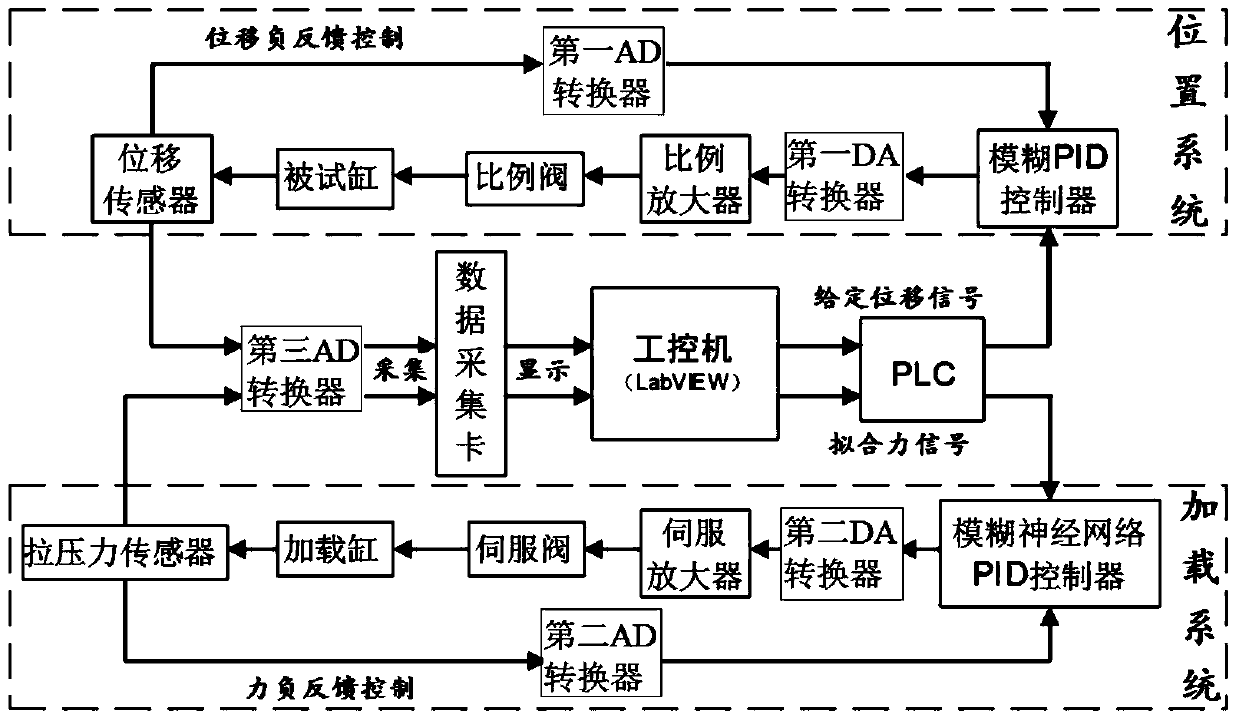

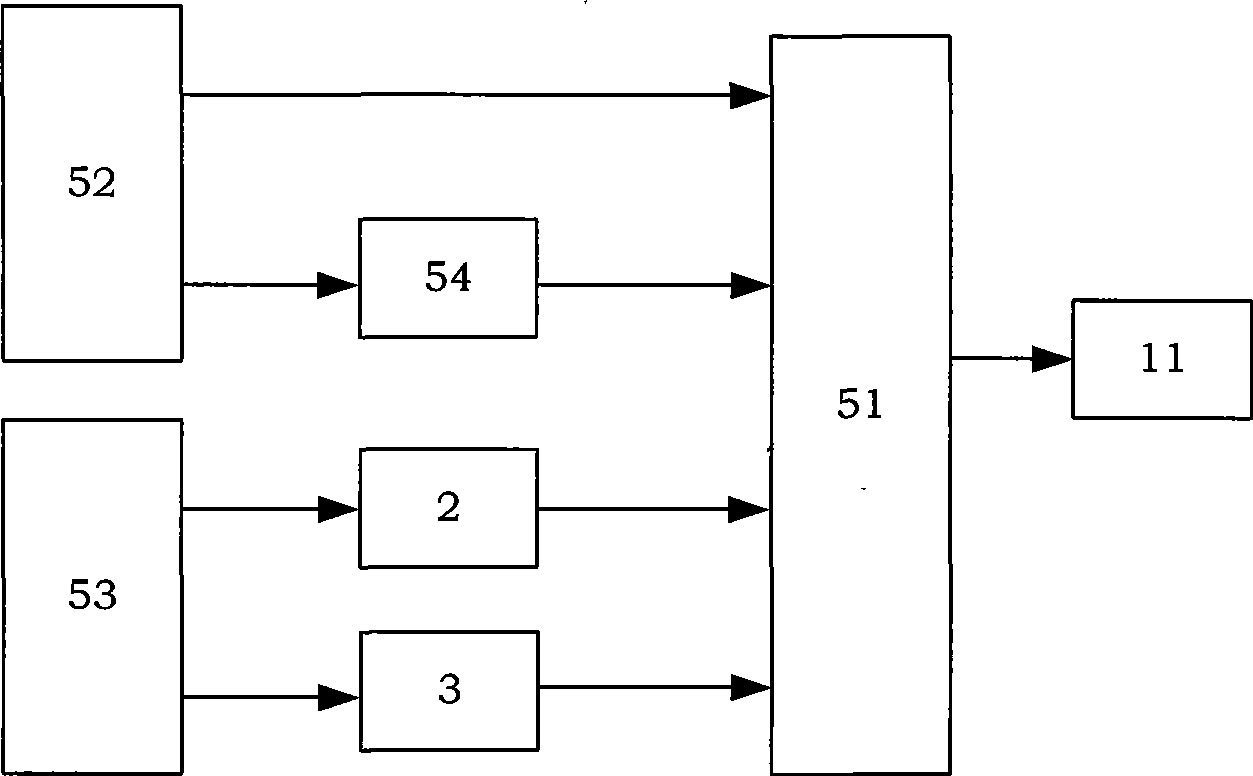

Hydraulic cylinder test bench load simulation device and control method thereof

ActiveCN103775437ARealize online controlRealize fault alarmFluid-pressure actuator testingHydraulic cylinderNegative feedback

The invention discloses a hydraulic cylinder test bench load simulation device and a control method thereof. The hydraulic cylinder test bench load simulation device comprises a test bench frame, a control system, a loading hydraulic cylinder and a tested hydraulic cylinder, wherein the control system comprises an industrial personal computer, a PLC (programmable logic controller), a positional system control module and a loading system control module, the industrial personal computer sends a displacement signal to the PLC to drive the tested hydraulic cylinder to run, a displacement sensor detects the displacement signal of the tested hydraulic cylinder, the displacement sensor feeds the displacement signal back to the positional system control module so as to adjust displacement of the tested hydraulic cylinder on the one hand, and sends the displacement signal to the industrial personal computer on the other hand, the industrial personal computer converts the displacement signal into a simulation resultant force signal, and sends the simulation resultant force signal to the loading system control module so as to drive the loading hydraulic cylinder to perform opposite vertex loading on the tested hydraulic cylinder, and simultaneously a pull pressure sensor detects a pull pressure signal, and feeds the pull pressure signal back to the loading system control module after comparing the pull pressure signal with the simulation resultant force signal so as to form force negative feedback control. The hydraulic cylinder test bench load simulation device and the control method thereof achieve high automation of the hydraulic cylinder test bench load simulation device, and is high in accuracy and strong in practicability.

Owner:NANJING UNIV OF SCI & TECH +1

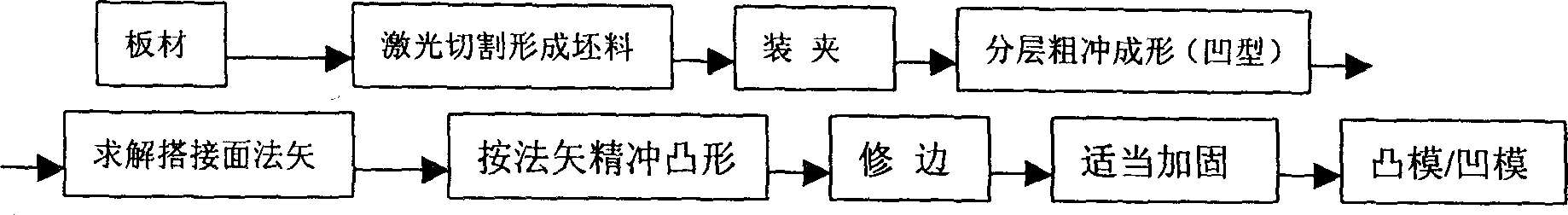

Fast die machining method and apparatus based on laser shock wave technology

The present invention relates to die machining and is especially the machining of stretching die and bending die with thick metal board. Laser shock wave is used as the forming force source in machining steel board die. The machining process includes rough shocking course and fine shocking course and in-situ detector with laser displacement probe is used. The equipment incldues laser generator, laser guide system, shocking head, workpiece fixture system and control system. Owing to that the laser parameters are precise and controllable, the present invention has high repeatability and is suitable for automatic production. The present invention can form large complciated die and die with precise fine part.

Owner:JIANGSU UNIV

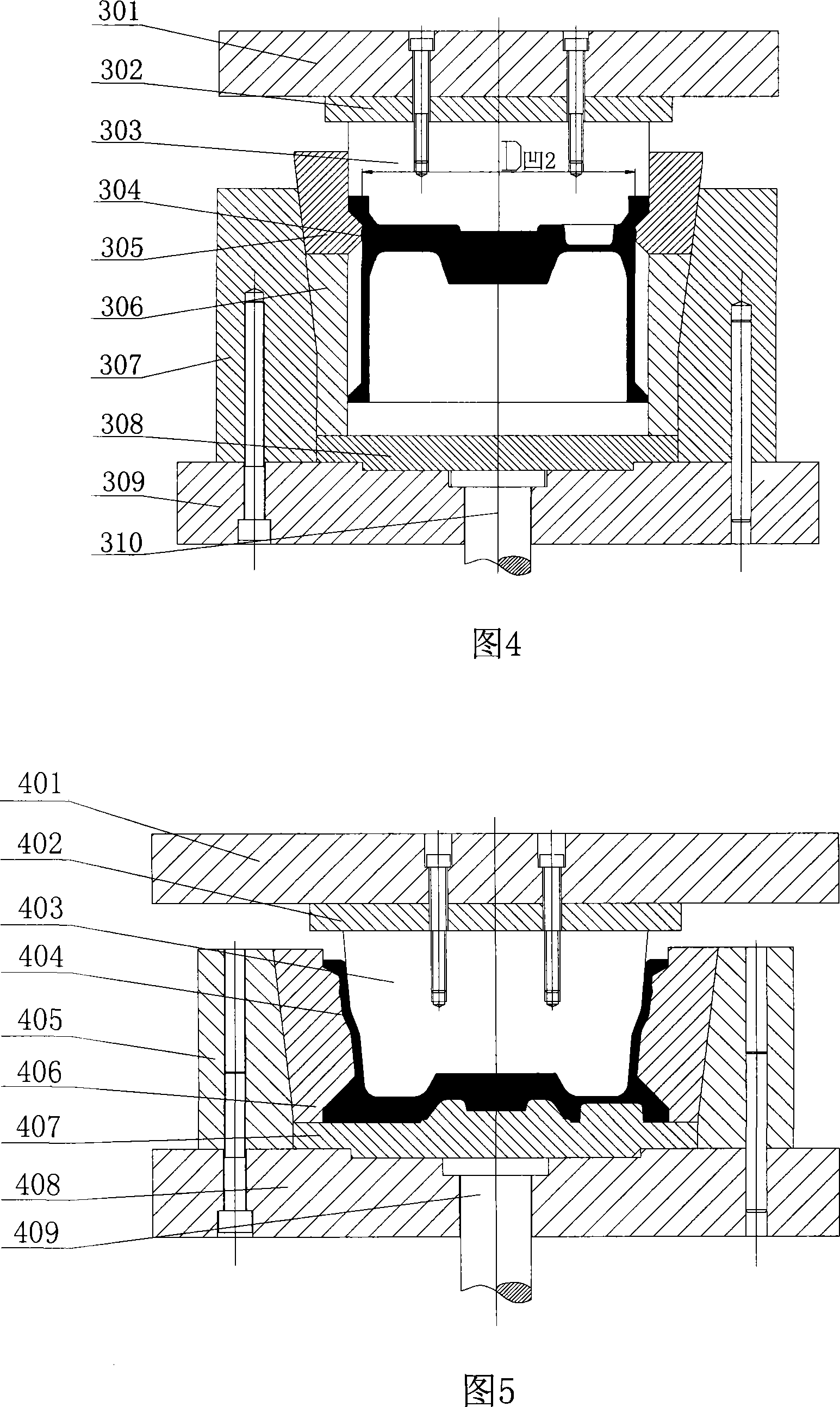

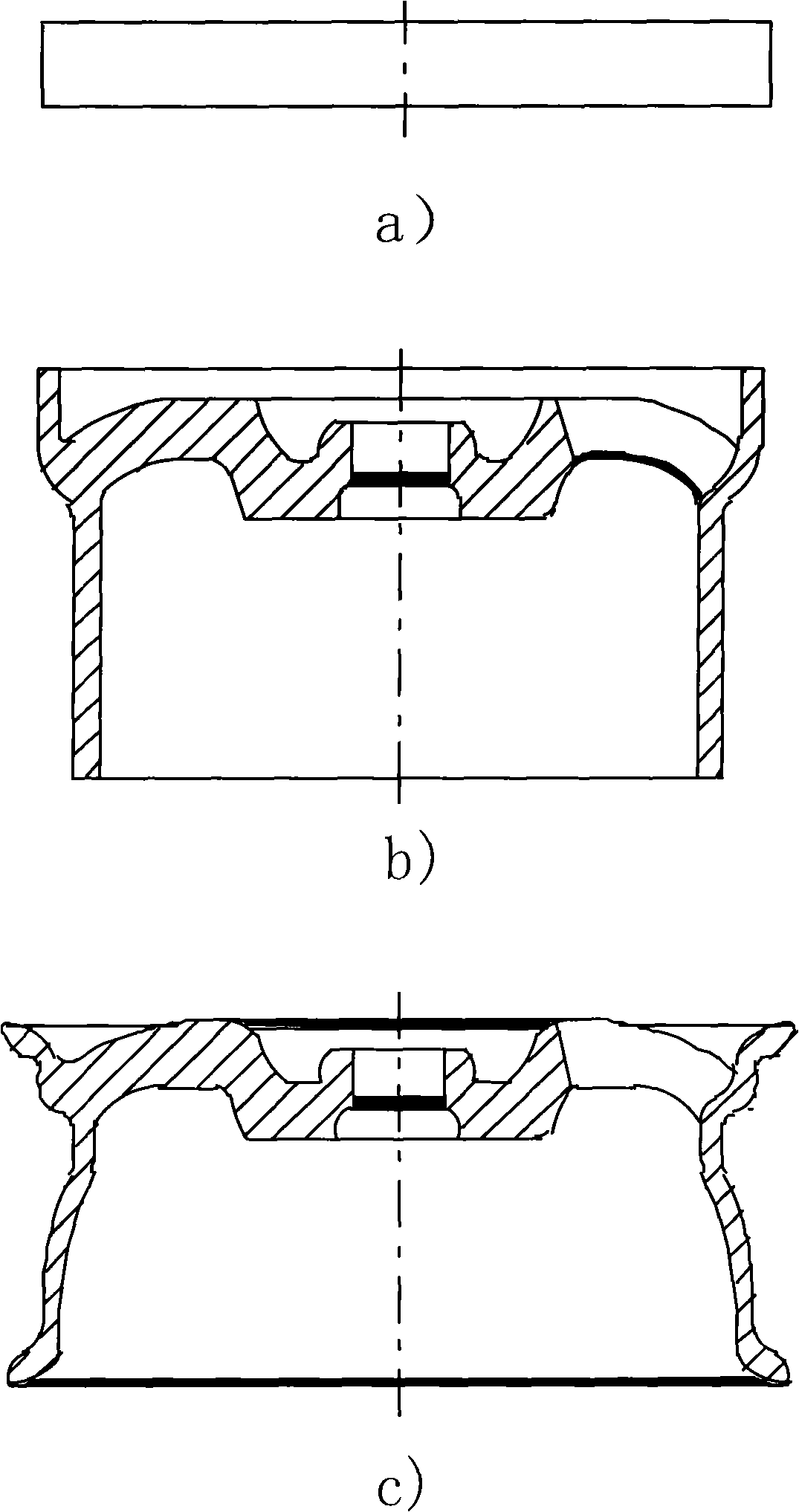

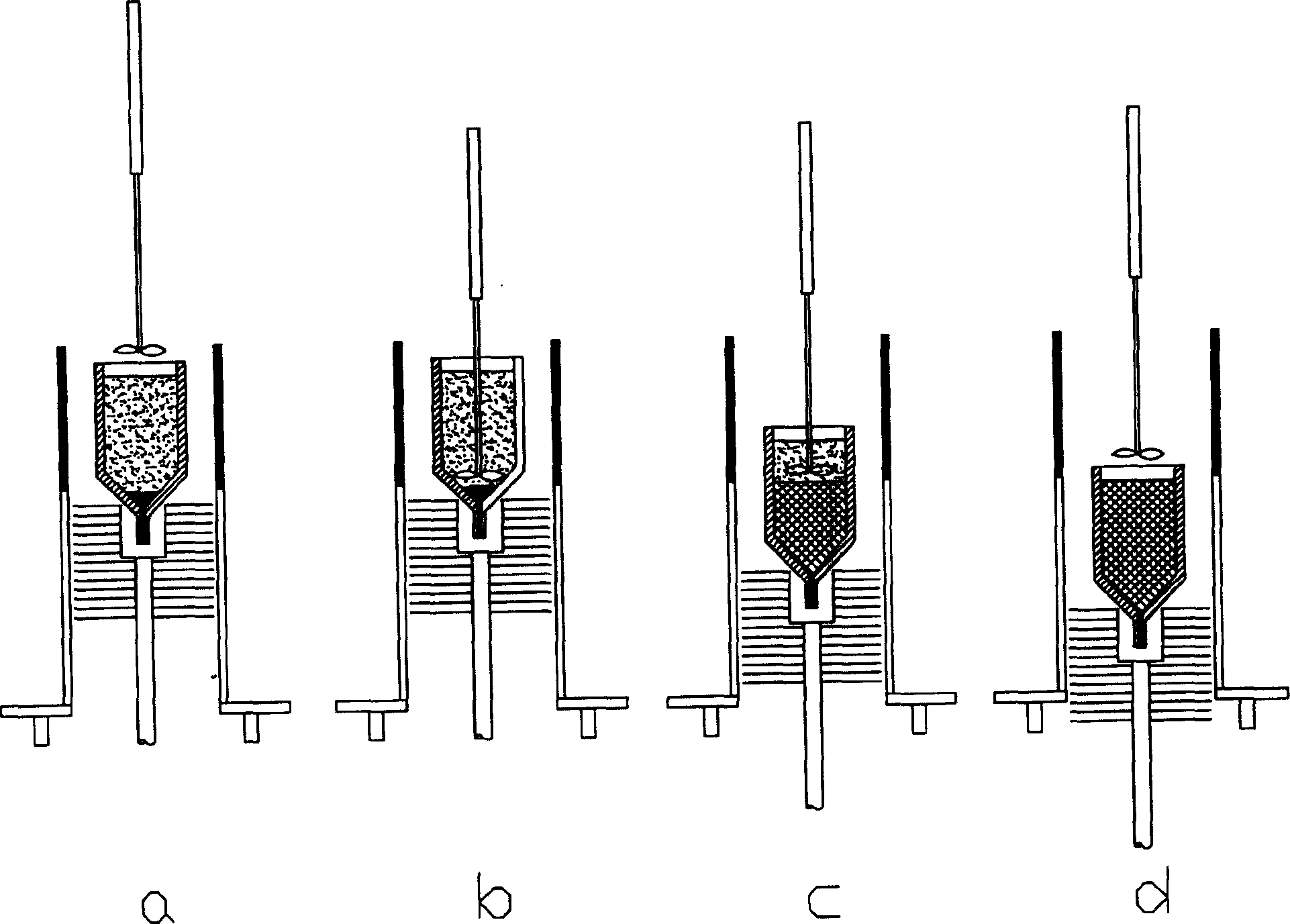

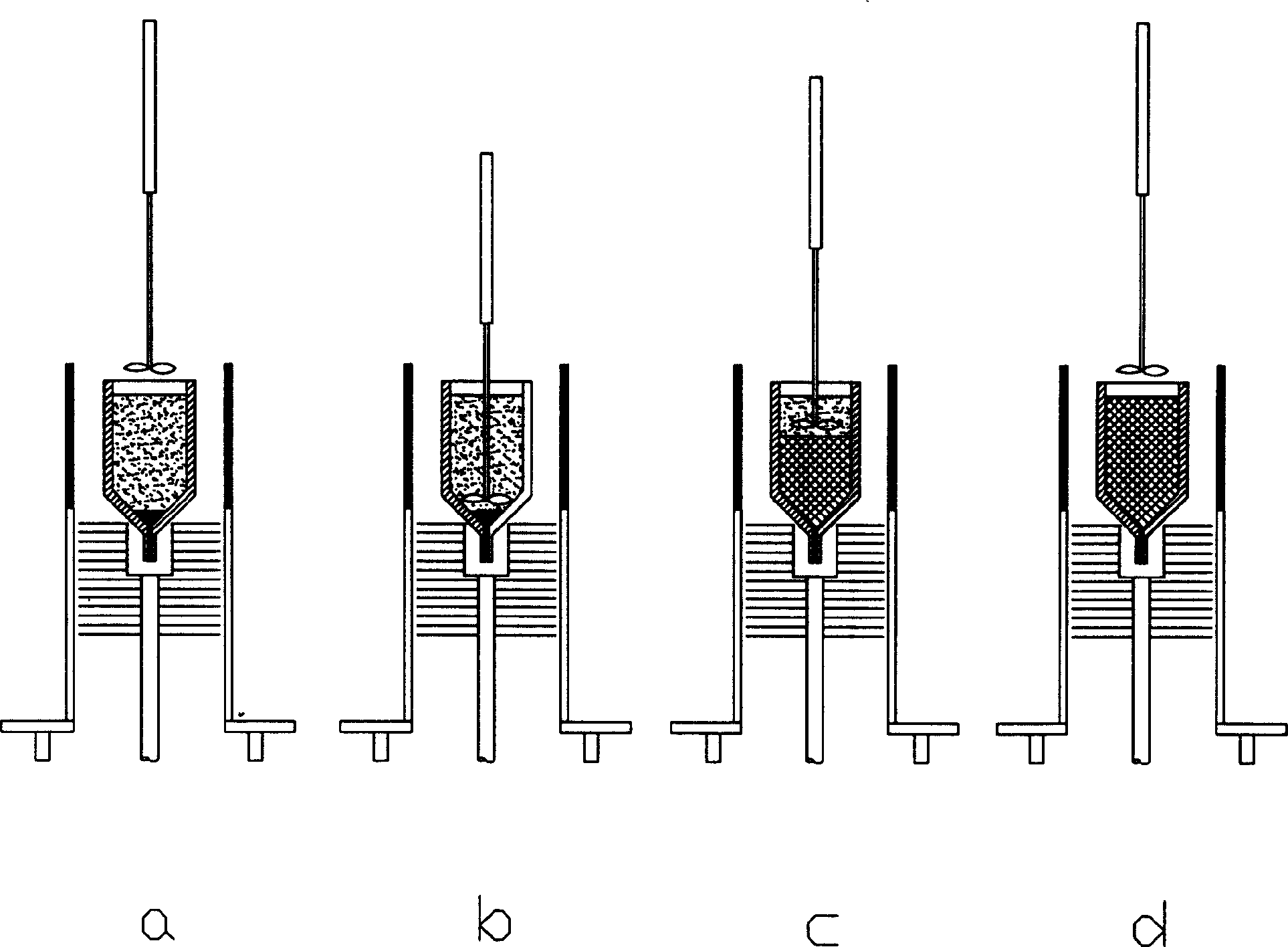

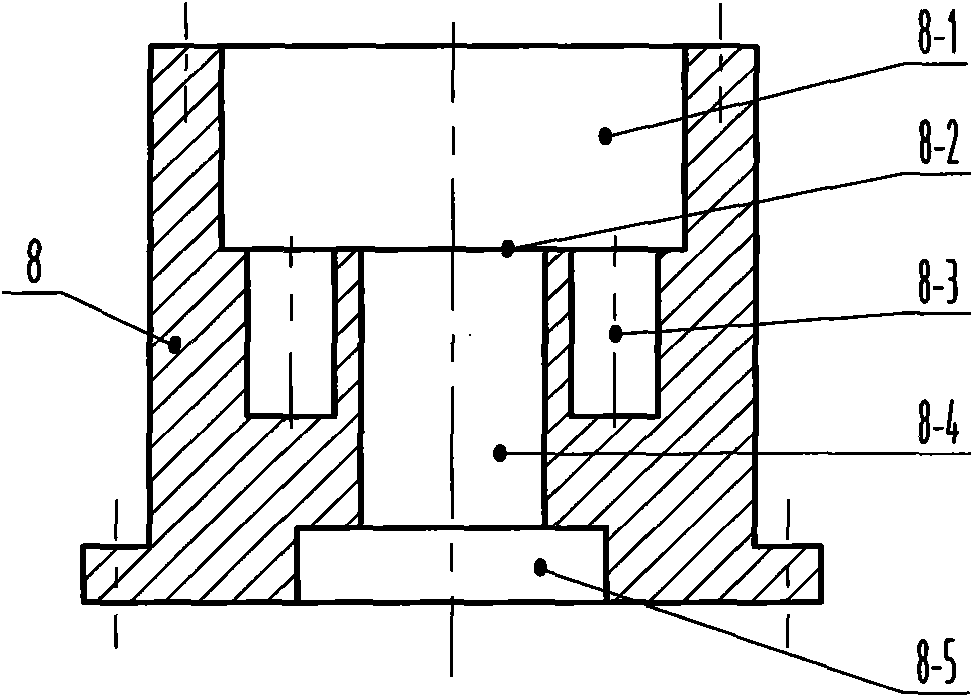

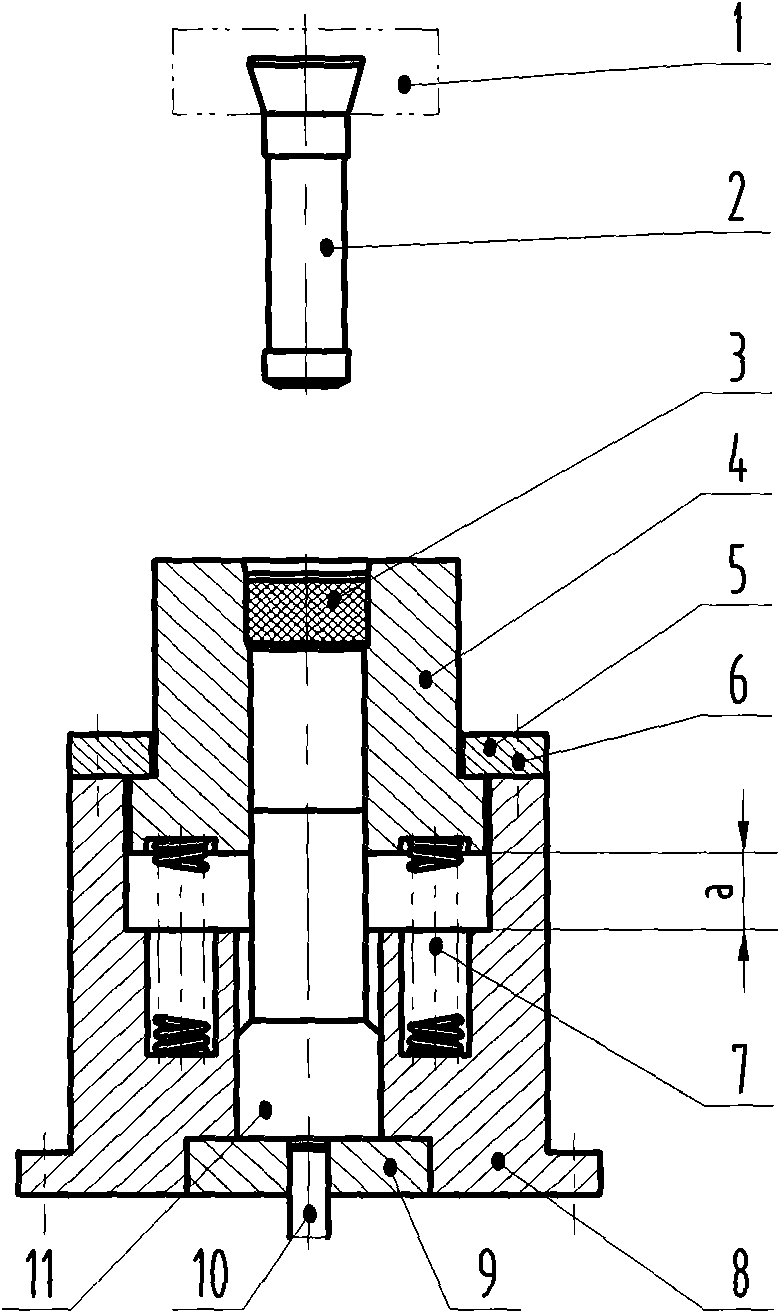

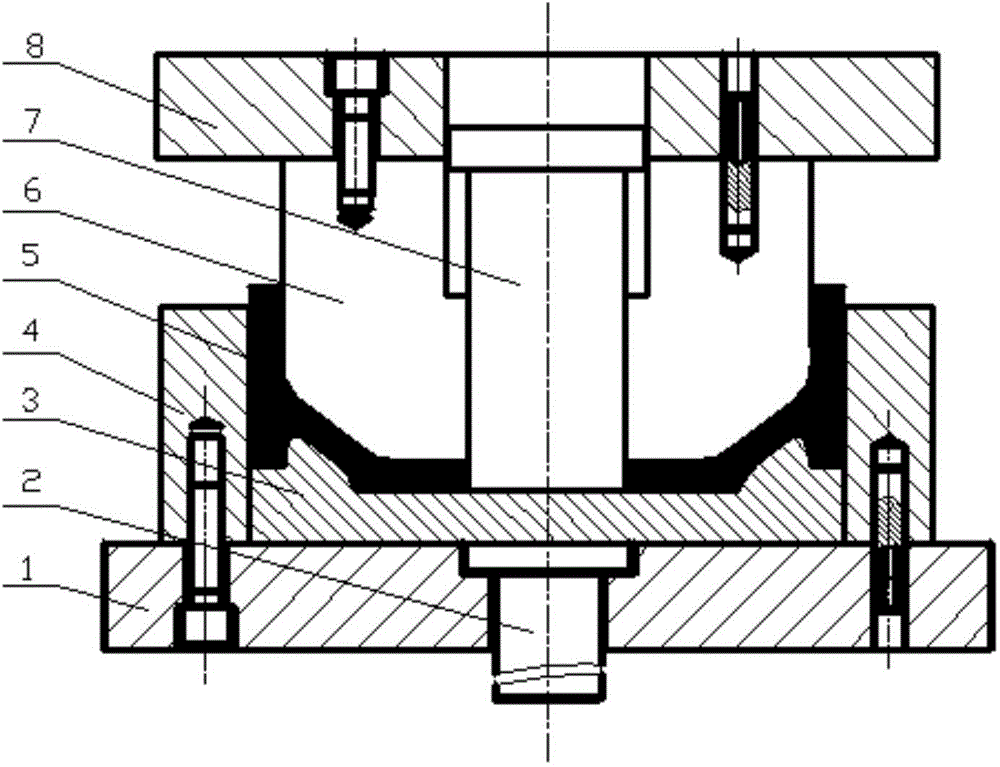

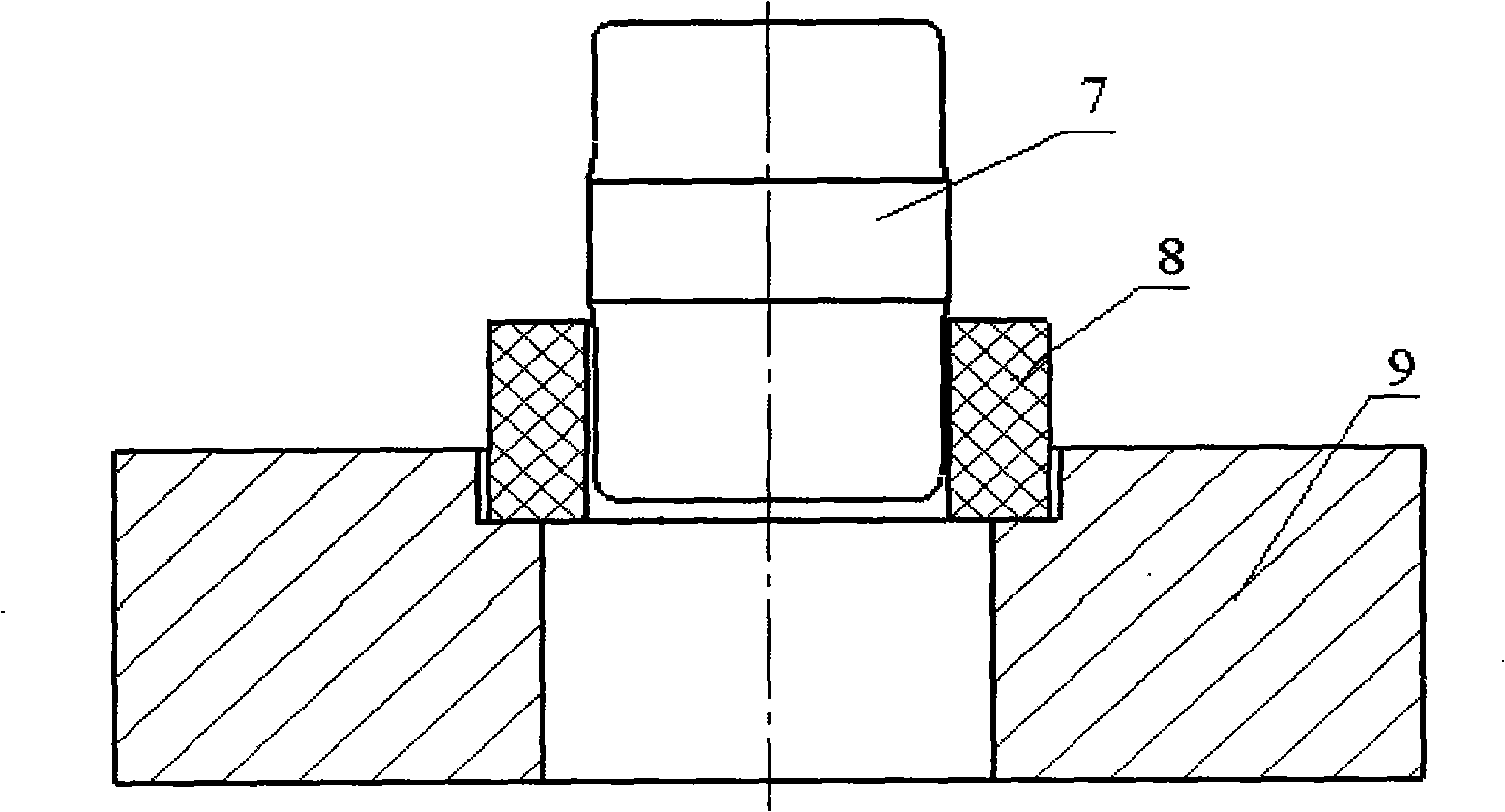

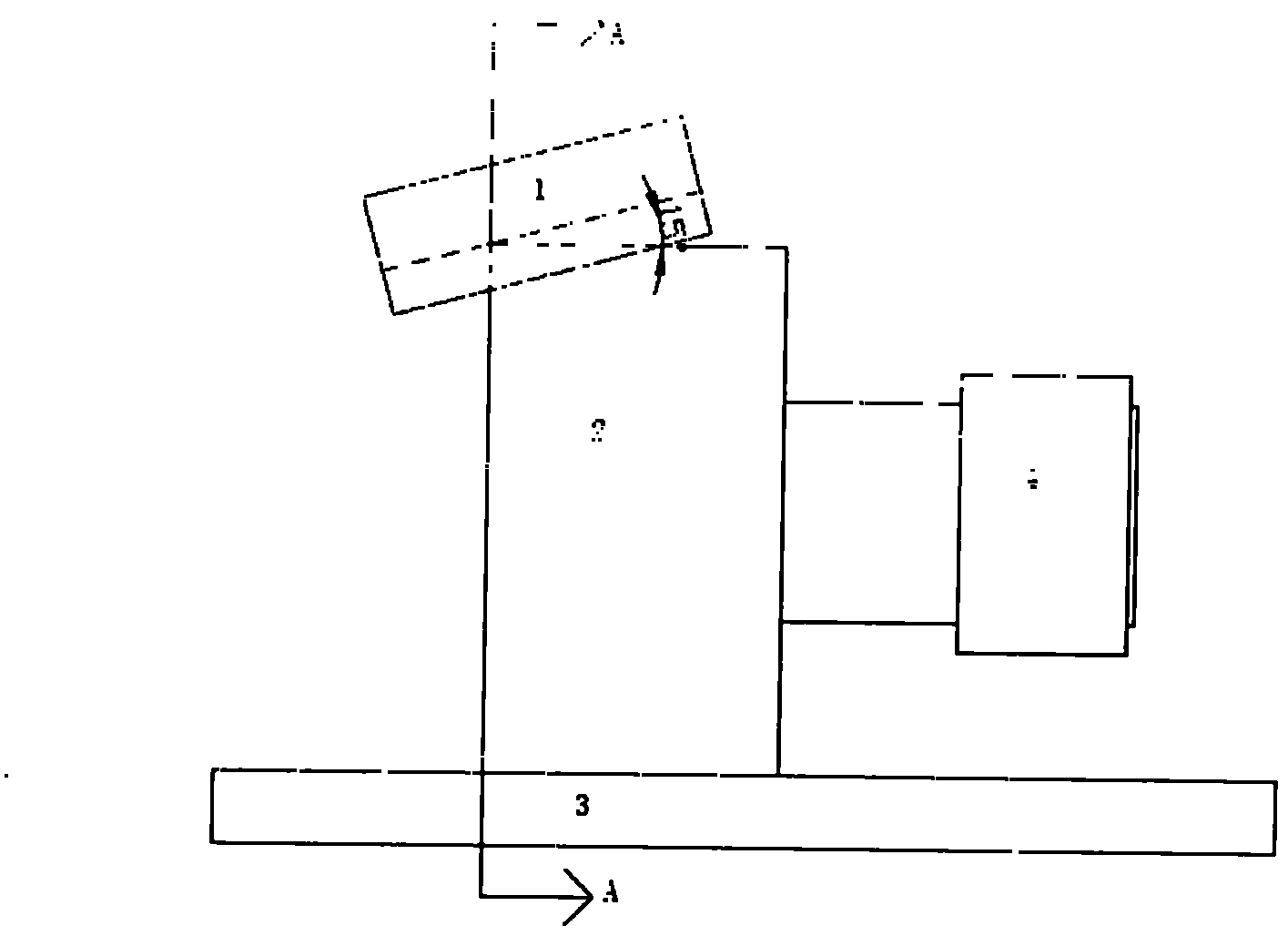

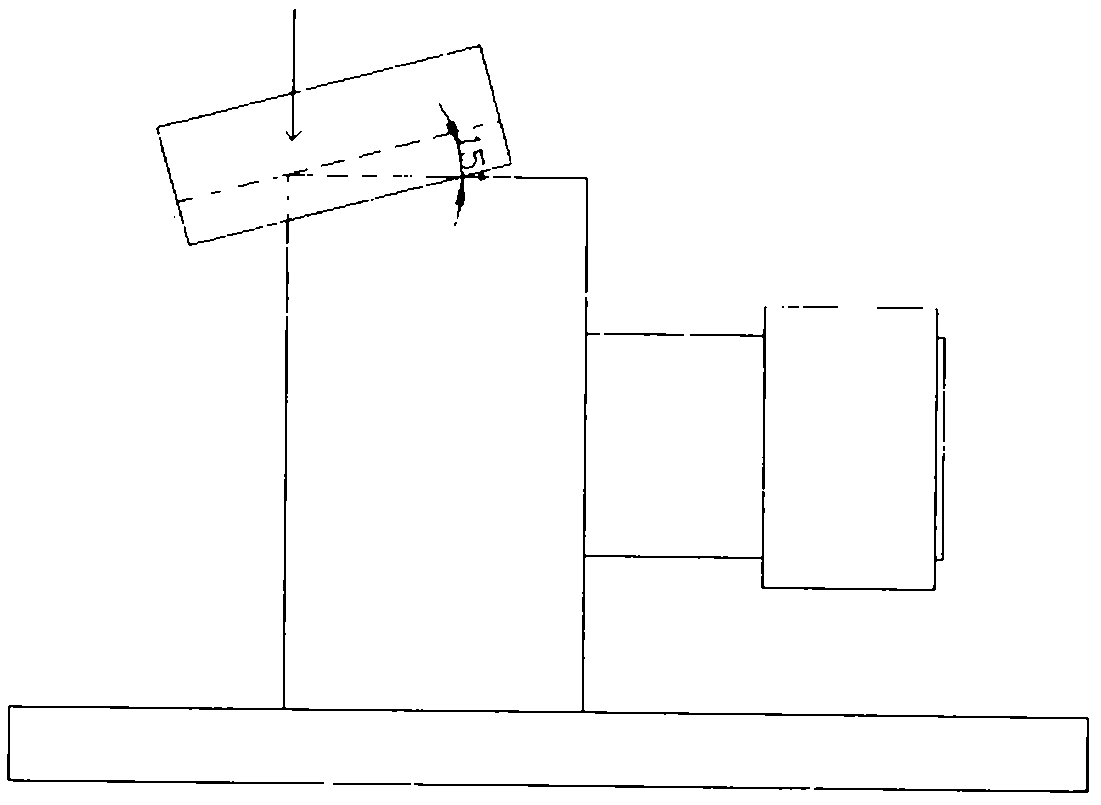

Two-step plasticity forming method of vehicle wheel hub and mated forming die

InactiveCN101491873AReduce investmentOptimizing the forming processExtrusion diesExtrusion control devicesEngineeringMechanical engineering

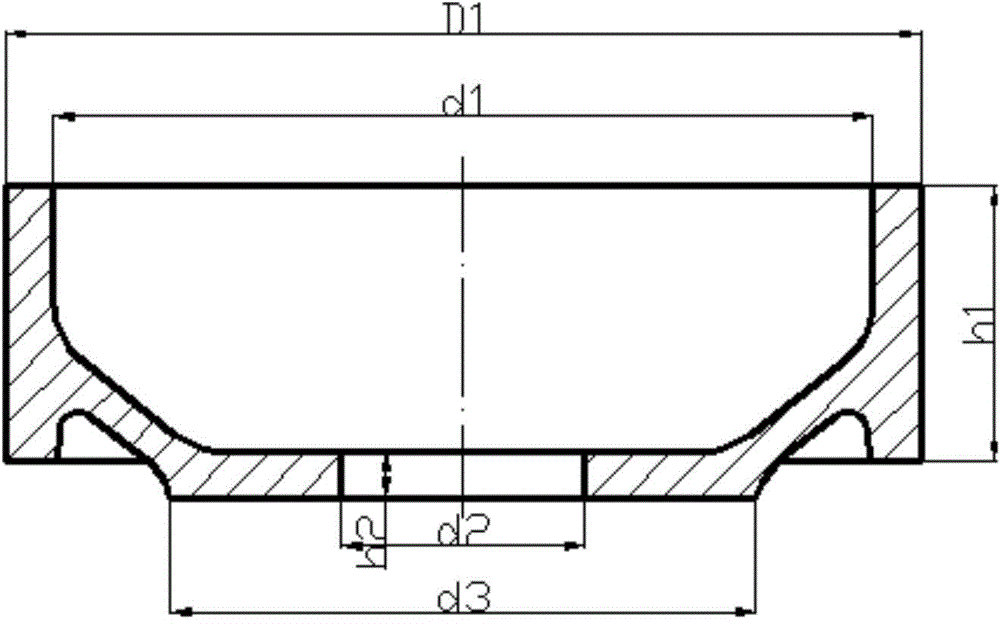

The invention discloses a two-step plastic forming method for a wheel hub of an automobile. The method adopts two sets of molds to perform extrusion forming on a blank in two steps under isothermal conditions, and comprises the following steps: 1, placing the blank into a extrusion forming mold, and forming a wheel spoke part firstly and pre-forming front and rear wheel rim parts of a wheel felloe at the same time by adopting an extrusion mode; and 2, placing a preformed part into a flaring mold to perform one-time flaring forming on the front and rear wheel rim parts of the wheel felloe. Compared with the prior art, the method has the characteristics of low forming force, less equipment investment, low production cost, high forming quality, and the like. At the same time, the invention also discloses the extrusion forming mold and the flaring mold which are matched with the method.

Owner:HENAN UNIV OF SCI & TECH

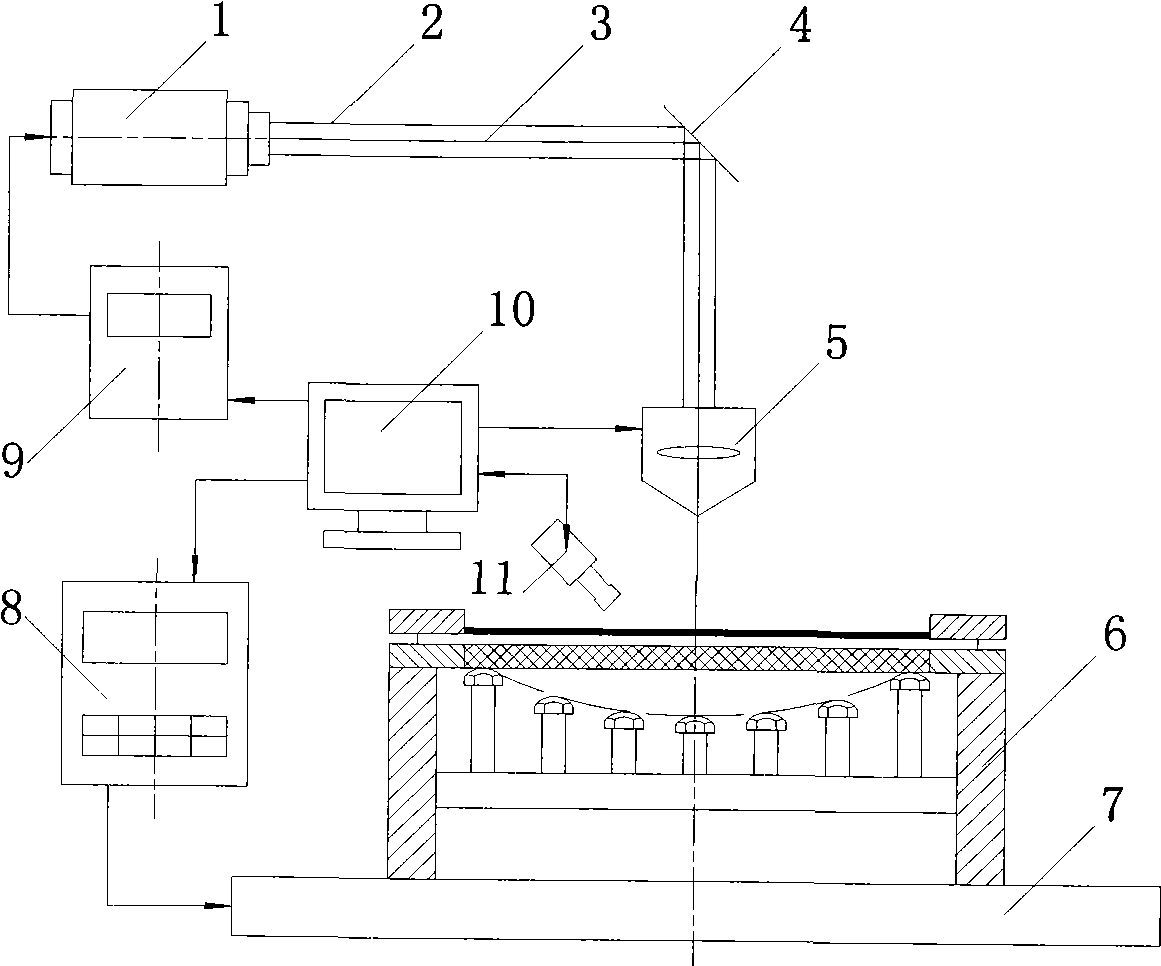

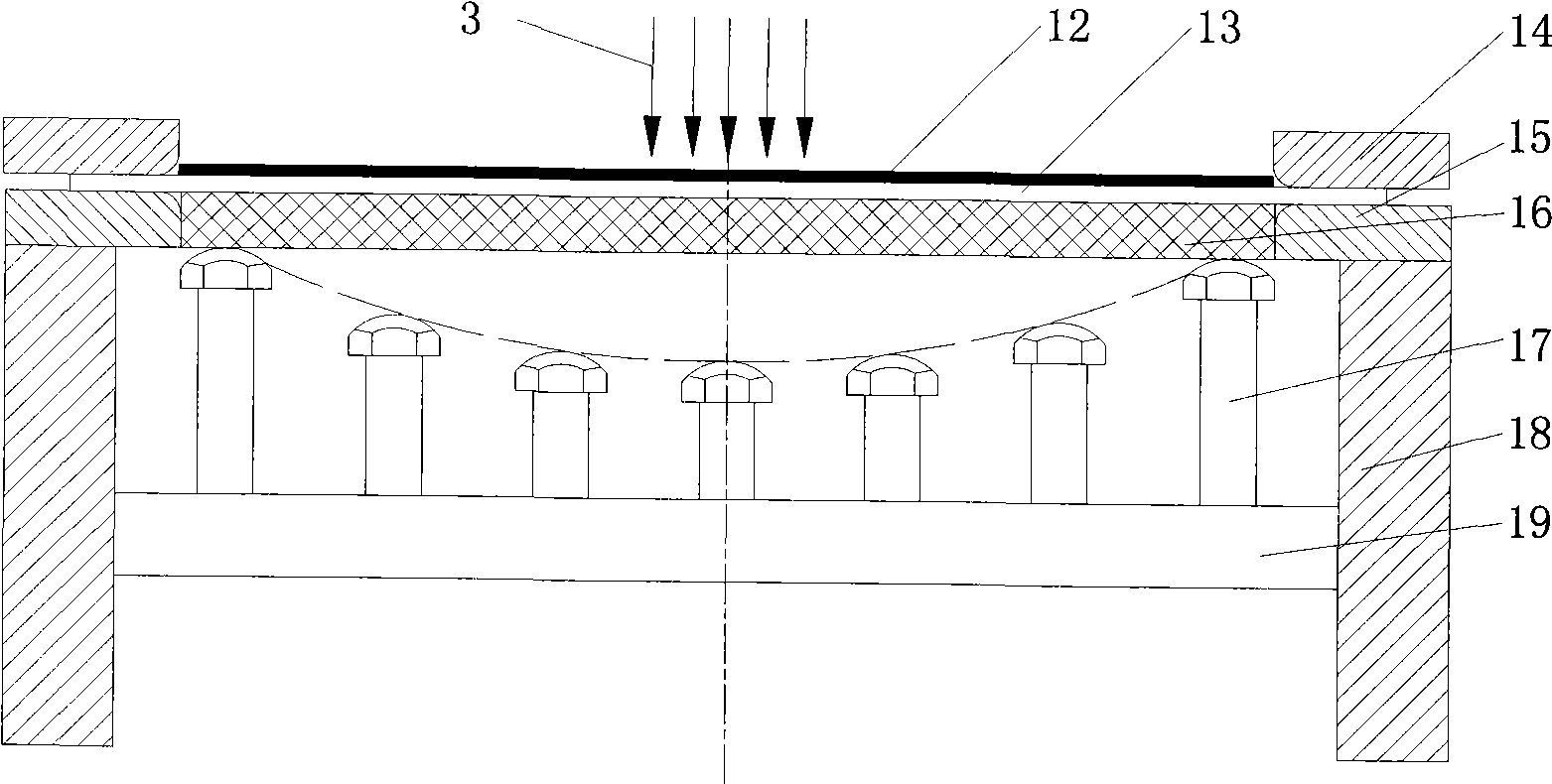

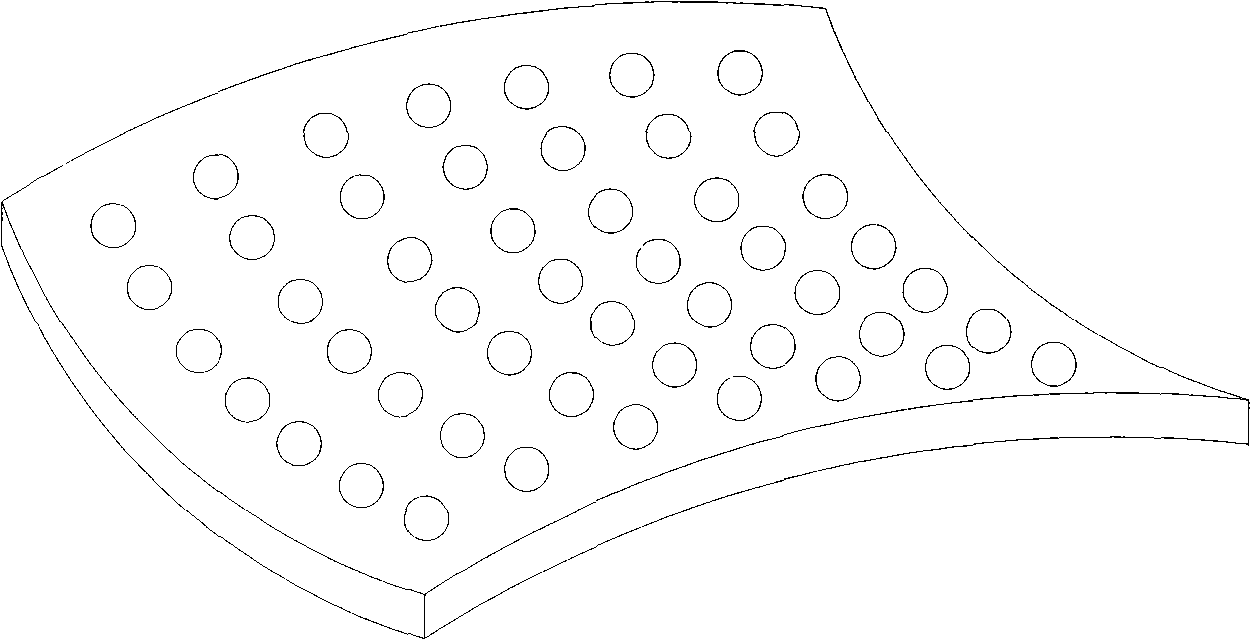

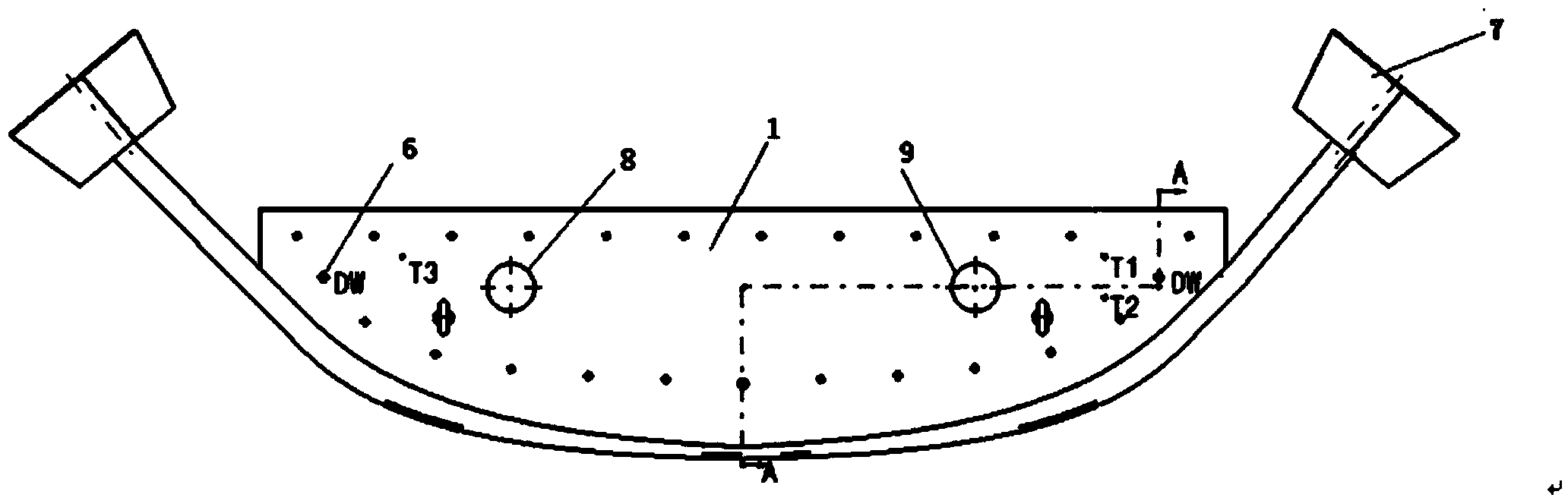

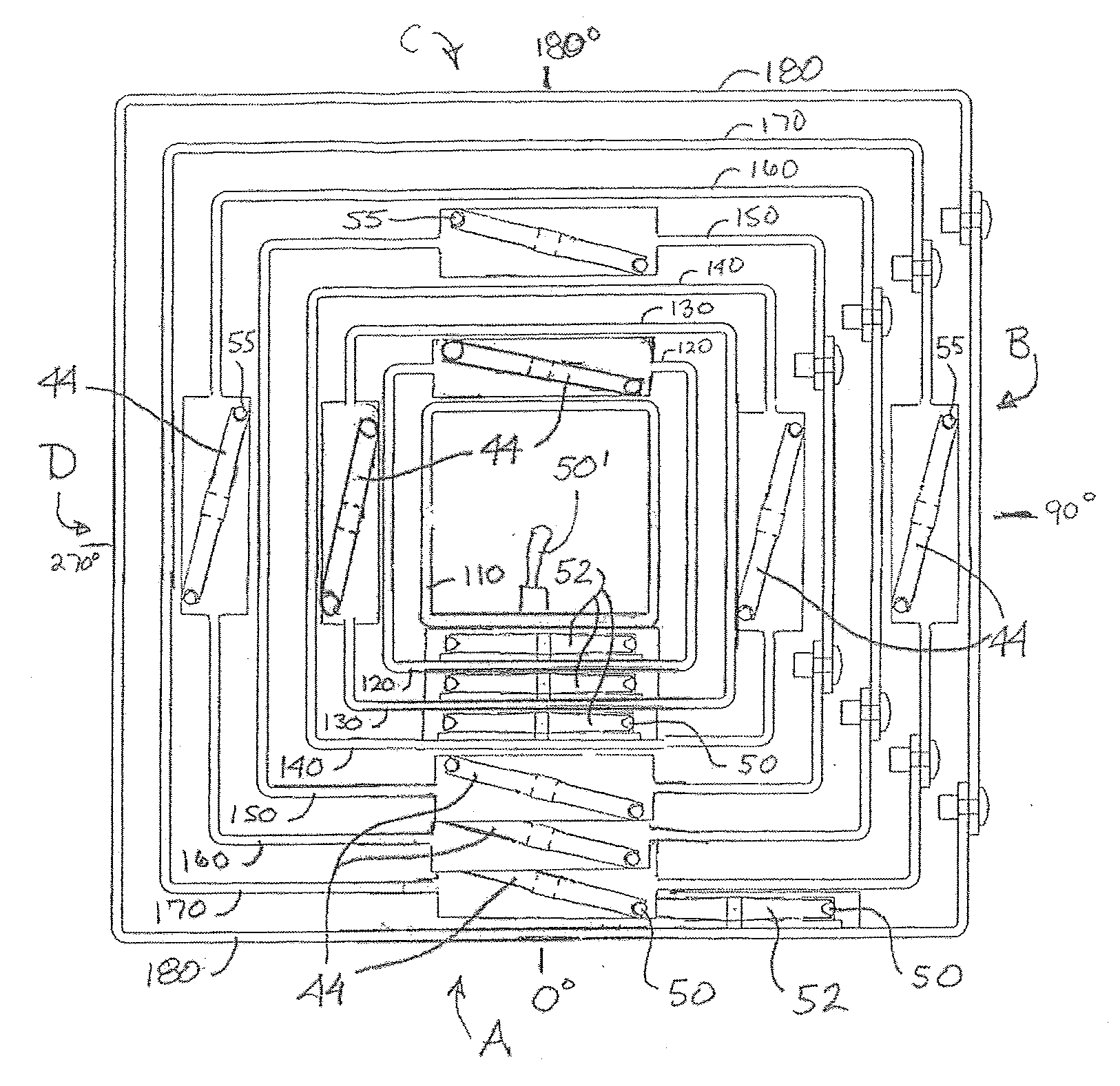

Method and device based on laser shock multi-point compound forming

InactiveCN101518852APrecise Local FormingShock wave pressure optimizationShaping toolsLaser beam welding apparatusShock waveLight guide

The invention relates to the field of machinery manufacturing, in particular to a method and a device for laser shock multi-point compound forming. The method utilizes shock waves induced by laser as a forming force source, and adopts a discrete multi-point die as a female die or a male die to realize laser shock female die profile modeling or prestress shock forming. The device comprises a laser generator, a light guide system, a laser shocking head, a multi-point die system and a control system, and is provided with a detection feedback system with a displacement measuring device. According to a curved surface shape of a plate and the requirement of a forming rule, laser shock process parameters are optimized, the height of an element group of the multi-point die is adjusted, and the plate is deformed under the combined action of the shock waves and the multi-point die. The method and the device are particularly suitable for precision shock forming of metal plates with large deformation and large area, especially the forming of plates with complicated curved surface shapes.

Owner:JIANGSU UNIV

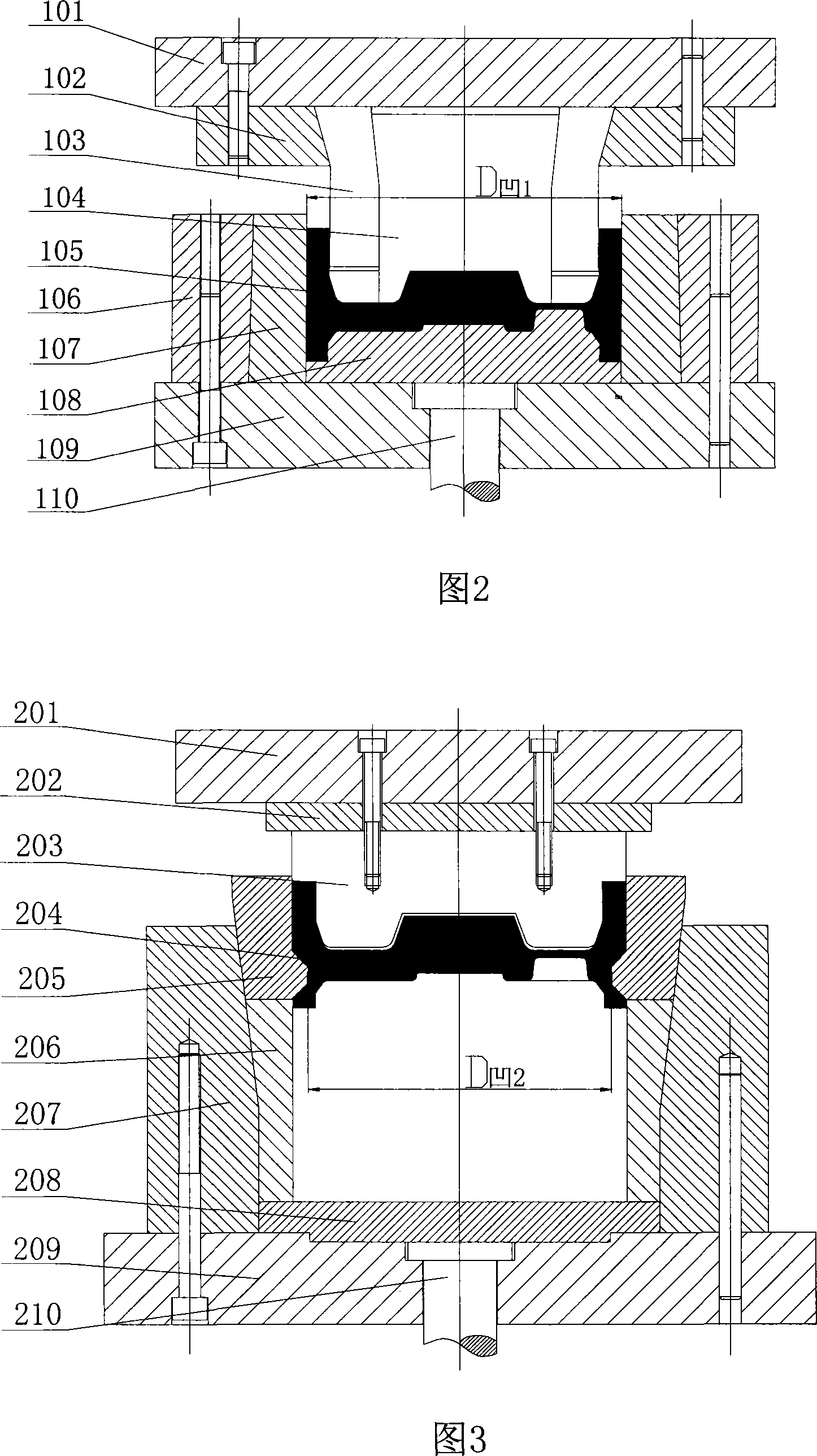

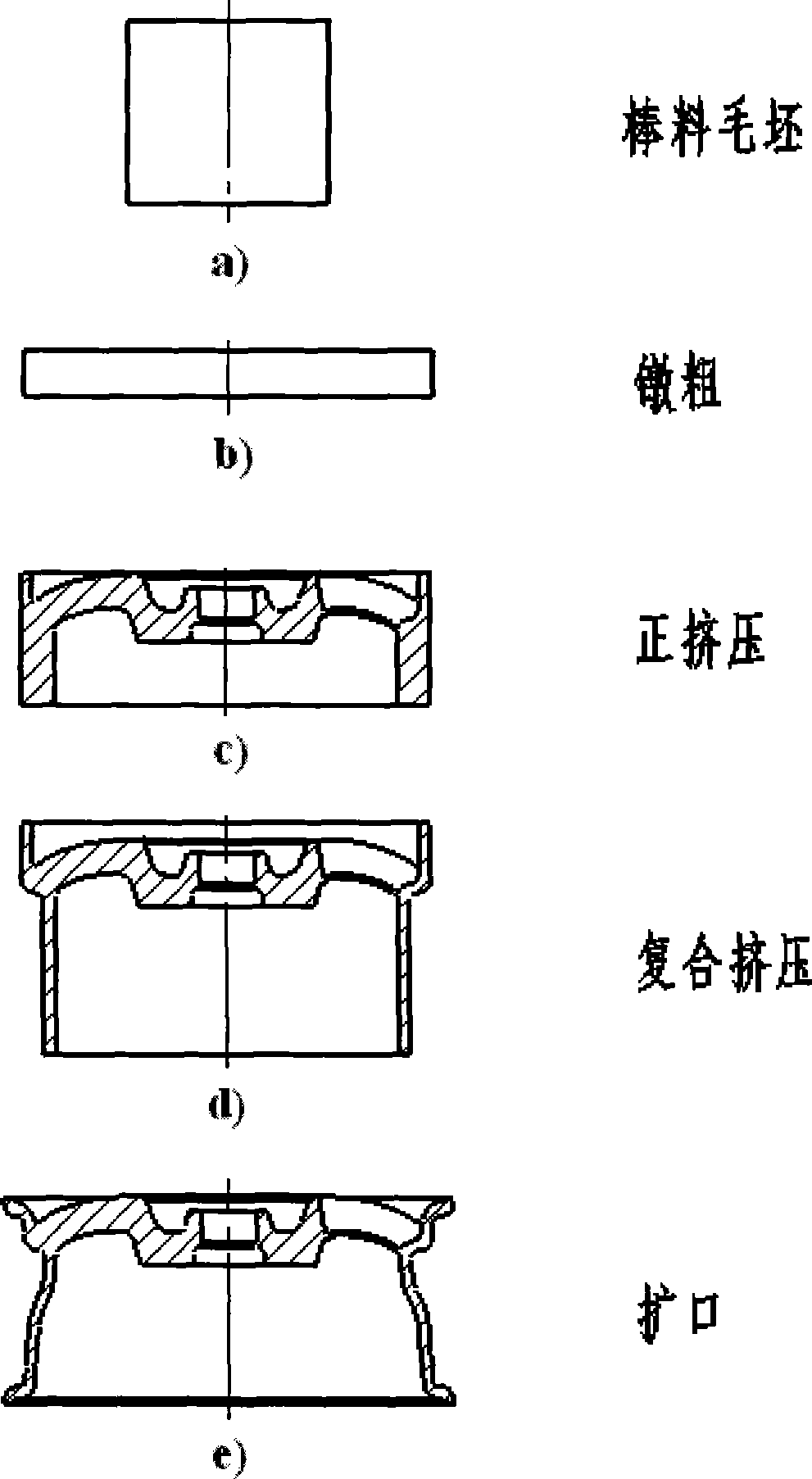

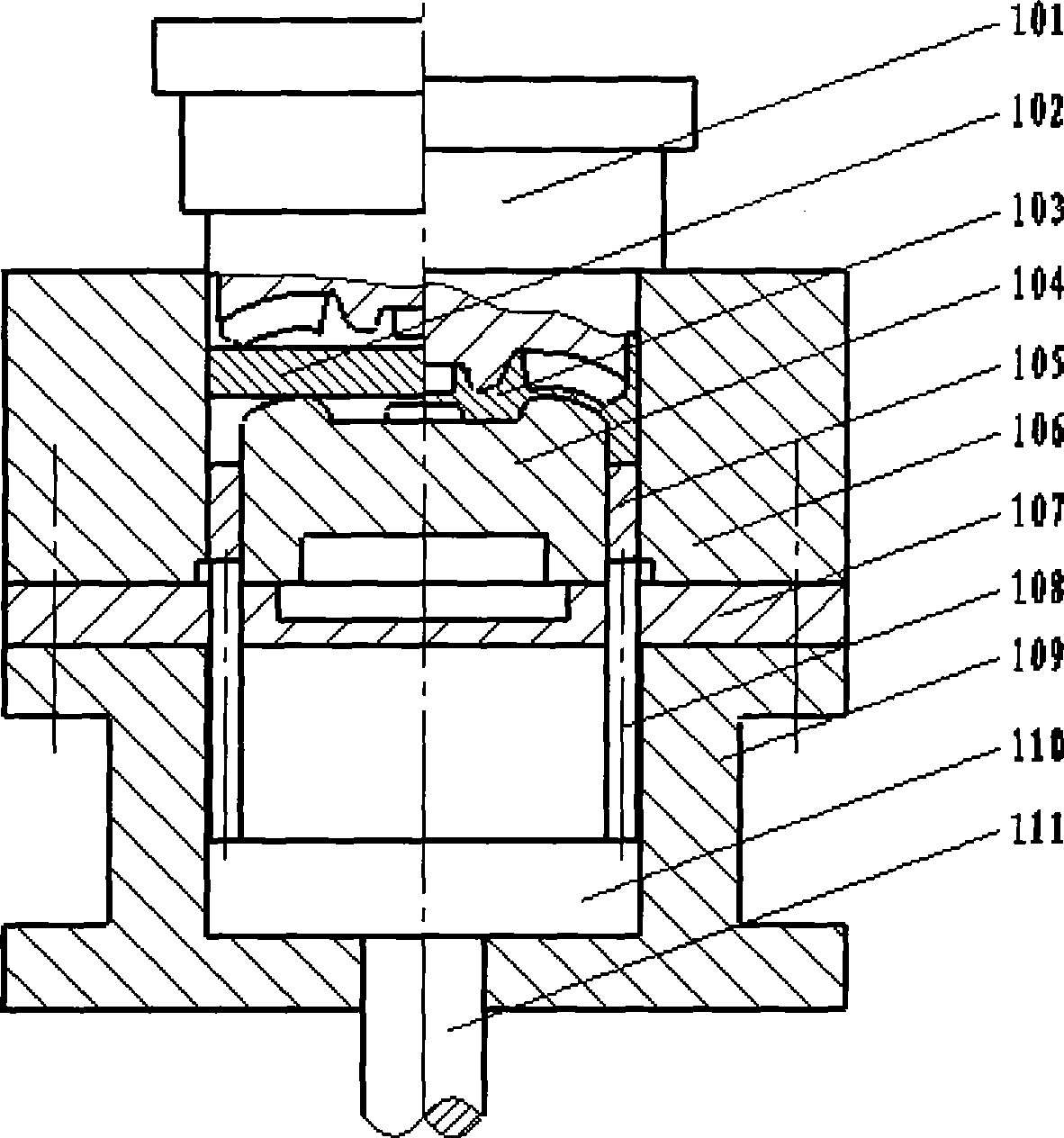

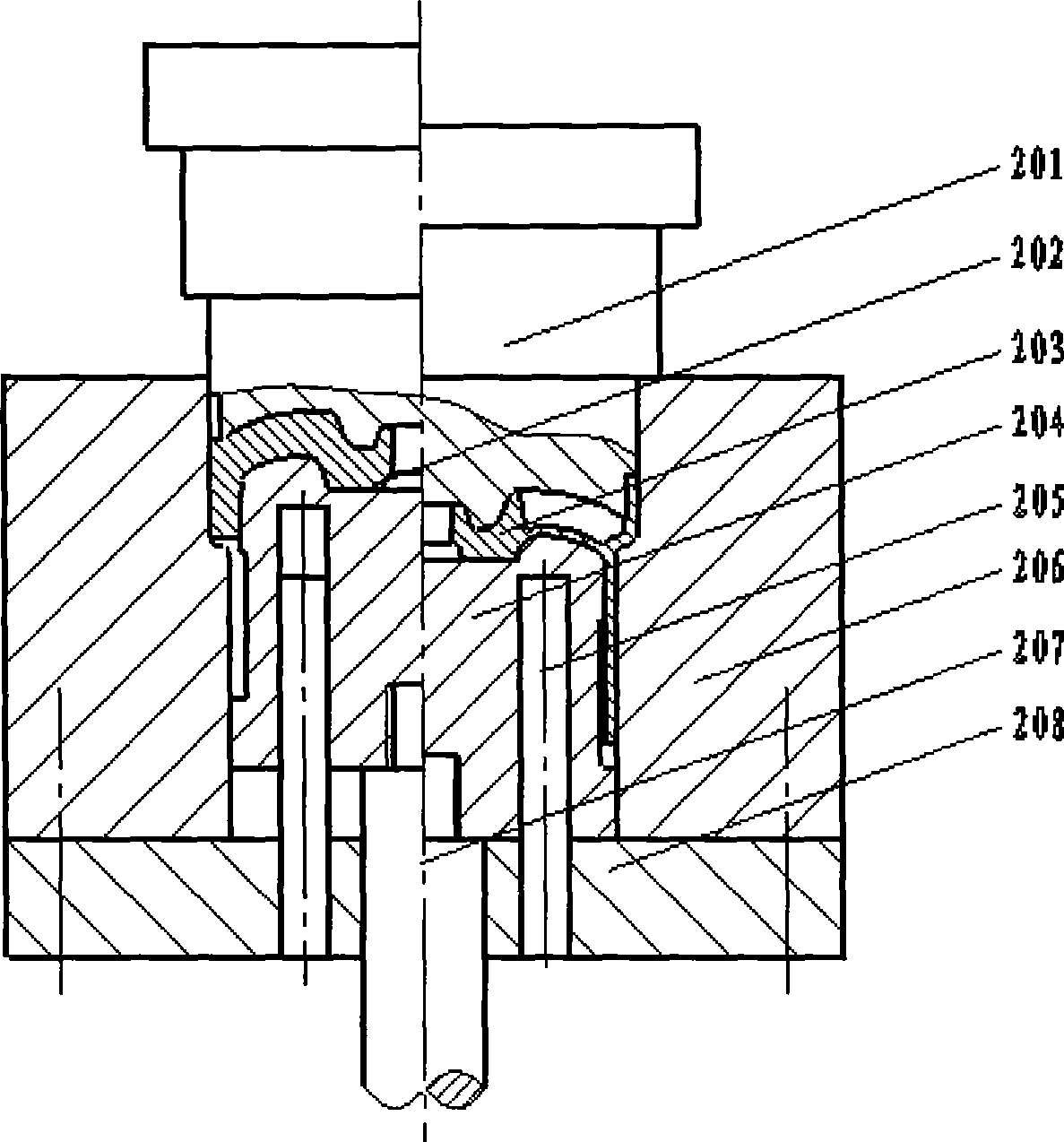

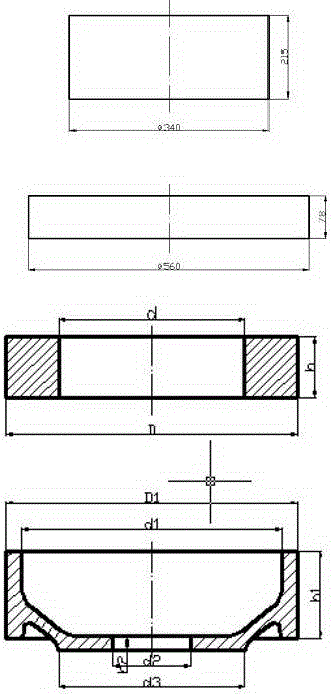

Press forming method of automobile hub and matched forming mold thereof

The invention relates to an extrusion forming method for a wheel hub of an automobile, and an extrusion piece for the wheel hub is formed by adopting work division procedures isothermally. The method comprises the following steps: a biscuit which has the same outside dimension as the outside dimension of the wheel hub to be formed is taken, and is subjected to processing and forming through forward extrusion, combined extrusion and a flaring procedure in sequence, wherein the forward extrusion forms a wheel arm and enables the rest metal to be gathered evenly in the peripheral positions of the wheel arm preliminarily; the combined extrusion pre-forms a barrel-shaped wheel rim and the upper and the lower wheel flanges of the wheel rim; and the flaring process enables the wheel rim to be formed. The invention further relates to three sets of moulds, which include a forward extrusion and forming mould, a combined extrusion and forming mould and a wheel rim flaring mould. The technical proposal of the invention can reduce the forming force, save the investment of the equipment and the mould, lower the production cost, and improve the quality of forming products.

Owner:HENAN UNIV OF SCI & TECH

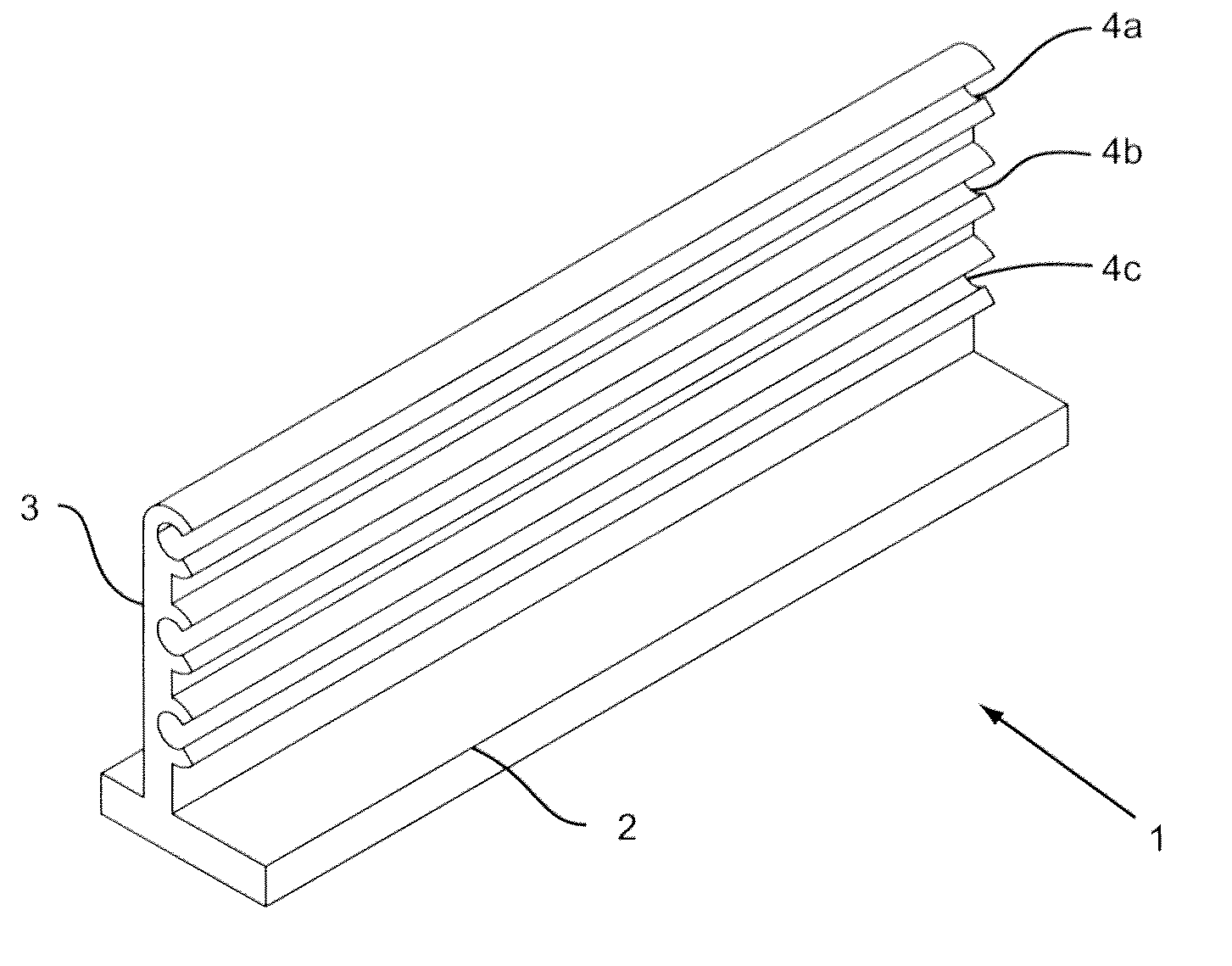

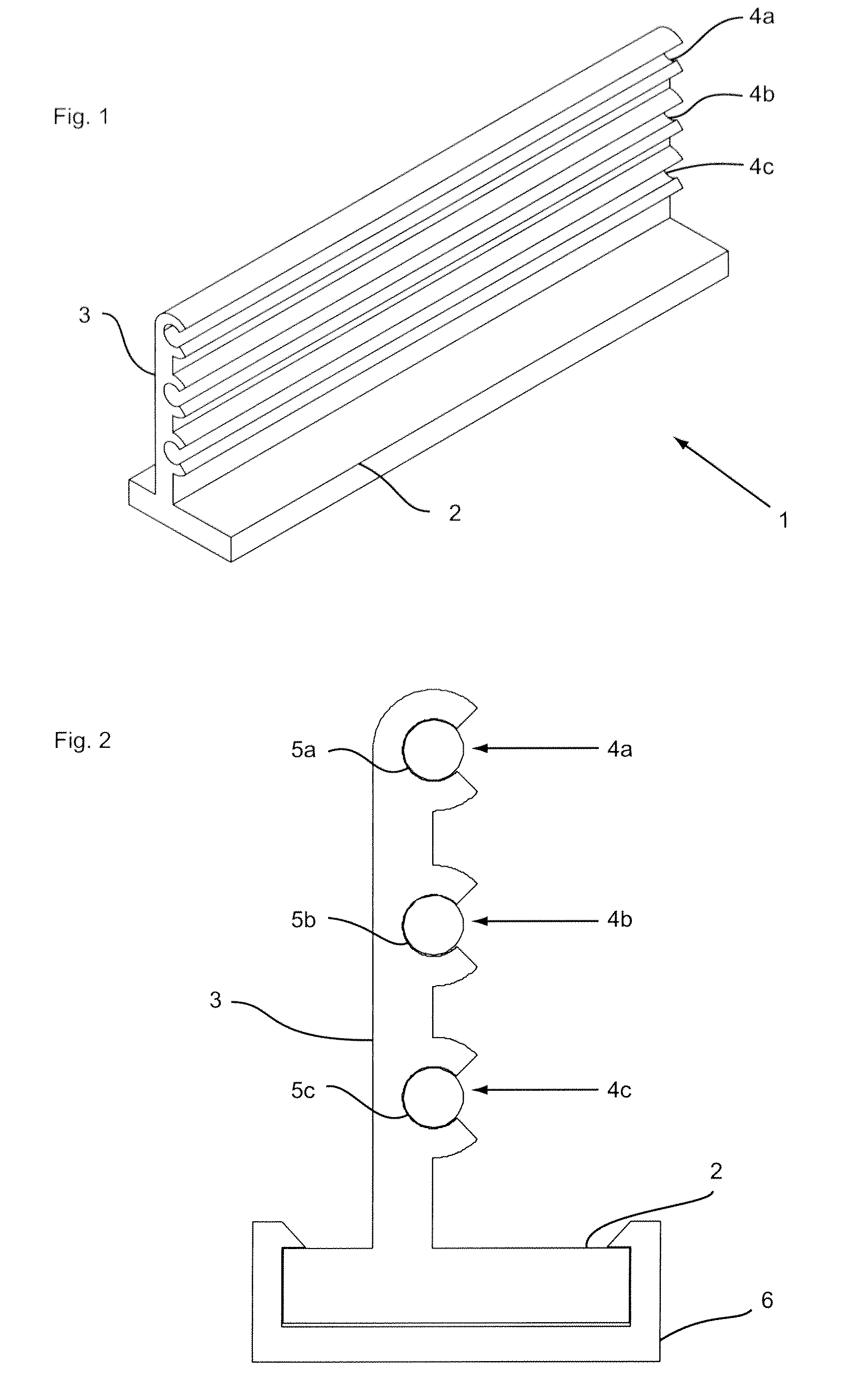

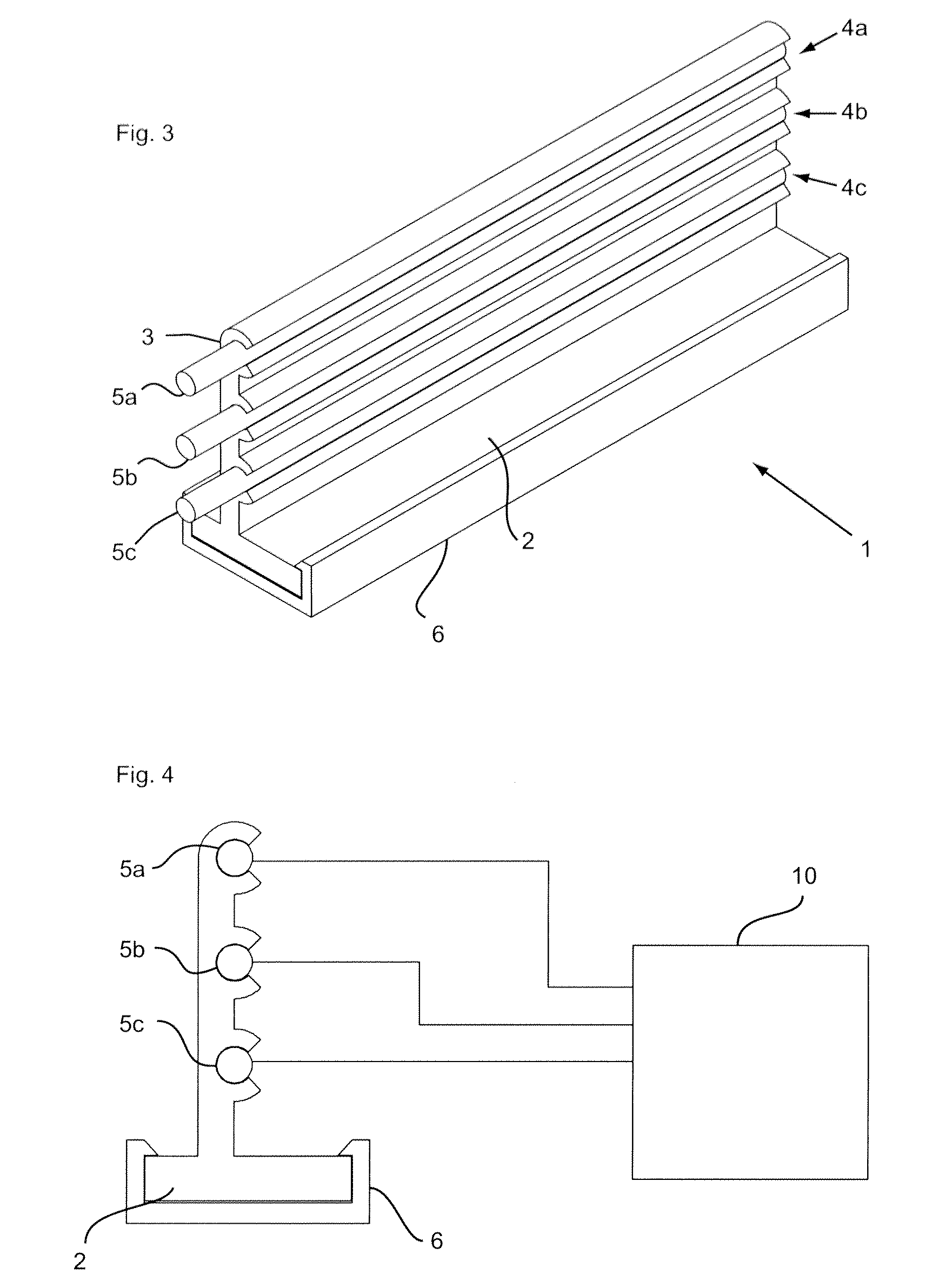

Sensor module

InactiveUS20110012624A1Efficient productionEasy maintenanceResistance/reactance/impedenceElectronic switchingAuxiliary electrodeBiomedical engineering

A capacitive sensor module with a sensor electrode which is used to detect the entry of an object into a space ahead of the sensor electrode, wherein the sensor electrode is formed from a wire. Parallel to the sensor electrode, auxiliary electrodes extend within a plastic carrier that possesses recesses to receive the sensor electrode and the auxiliary electrodes and partially surrounds them along their circumference. The sensor electrodes can be pressed into the plastic carrier by overcoming an elastic forming force and are held within their recesses by the elastic reshaping process.

Owner:HUF HULSBECK & FURST GMBH & CO KG

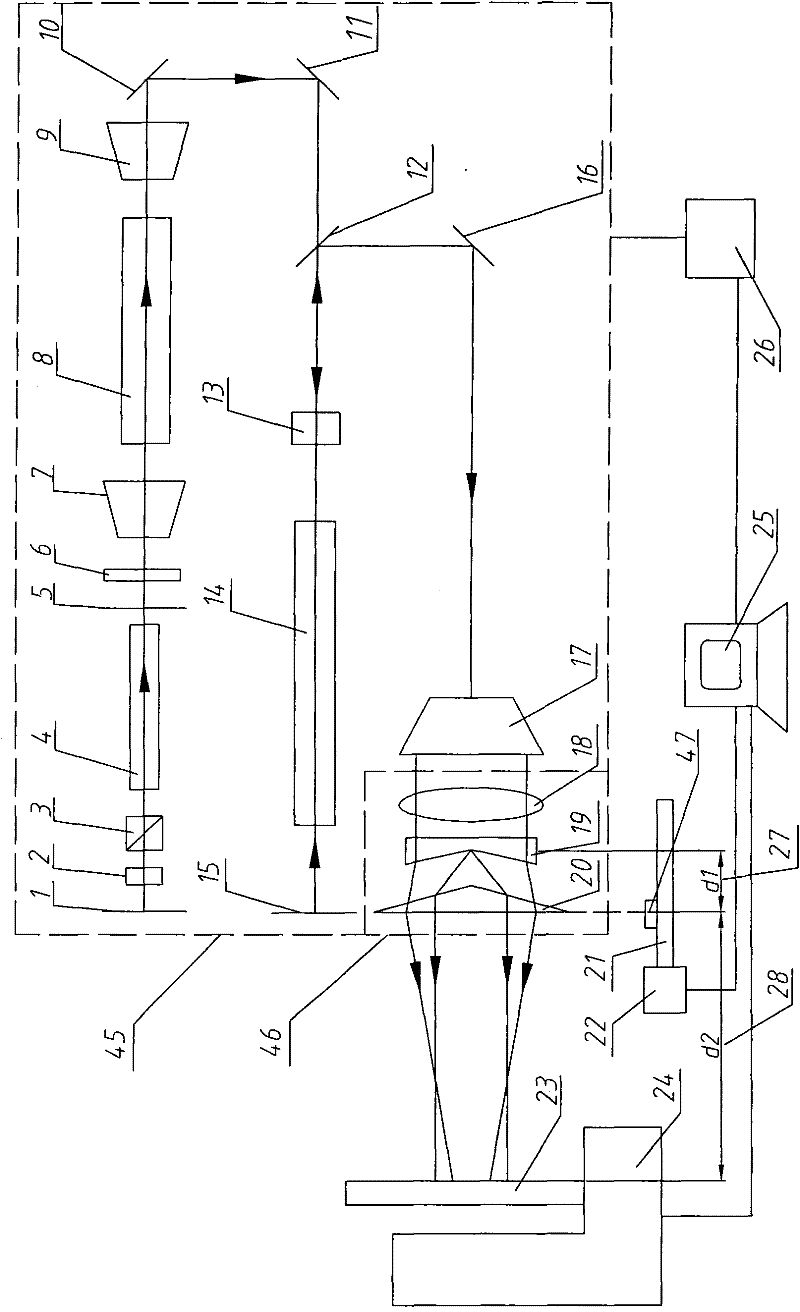

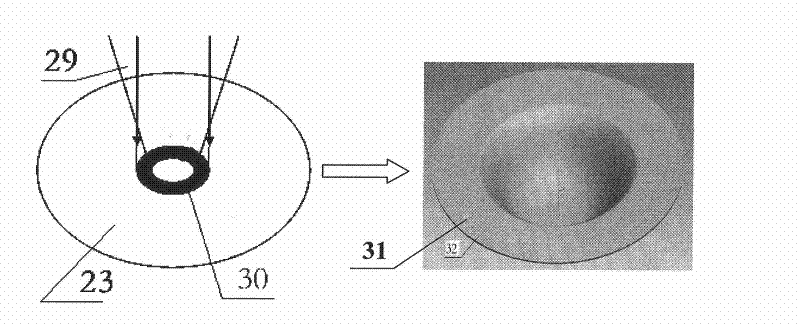

Metal plate material ring-shaped light spot laser impact forming method and device

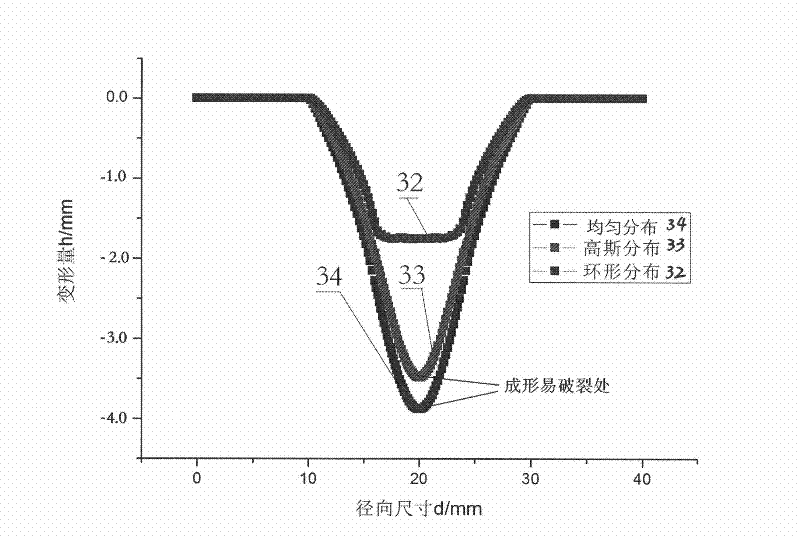

The invention provides a metal plate material ring-shaped light spot laser impact forming method and a device. The method is characterized in that a ring-shaped laser light spot is adopted to act on the surface of a work-piece system and then quick plastic deformation occurs on the surface of a work-piece under the function of impact wave induced by laser. The device is mainly composed of a lasergenerator power supply (26), a control device (25), a machine tool (24), a stepping motor (22), a guide rail (21) and a laser generating system (45). The laser generating system (45) interacts with acone lens set to generate a hollow light beam, and the hollow light beam is irradiated on the surface of the work-piece to form the ring-shaped light spot. The invention is beneficial for changing the distribution of the laser impact forming force, so as to prevent the cracking in the forming process, thereby improving the laser impact forming property and limit of a plate material, and increasing the finished product rate and the processing speed.

Owner:JIANGSU UNIV

Three-dimensional multi-curvature part bending method

InactiveCN104281725ALower requirementReduce the cost of updatesSpecial data processing applications3D modellingNumerical controlComputer Aided Design

The invention discloses a three-dimensional multi-curvature part bending method. According to the method, the structural form of a section bending die and a suitable section bending machine are determined by analyzing the shape, size, bending angle and forming force of a part to be bent; a digital model of the part to be bent is subjected to curvature analysis through a computer; bending springback theoretical analysis is adopted, and a die profile springback compensation design is performed by a numerical simulation method through computer aided design. The bending of a section requires matched bending chuck, bending die and machine tool. The die is processed by a numerical control technology. A measuring machine is used for detecting and correcting the die to be processed, and an error between theory and actuality is reduced, so that the part manufacturing accuracy is improved. Dies for three-dimensional complicated parts can be formed on a two-dimensional bending machine, the bending pass is reduced, and repair or scraping of the bending dies is reduced, so that the part manufacturing cost is effectively reduced; moreover, the production efficiency is high.

Owner:XIAN JIAYE AVIATION TECH

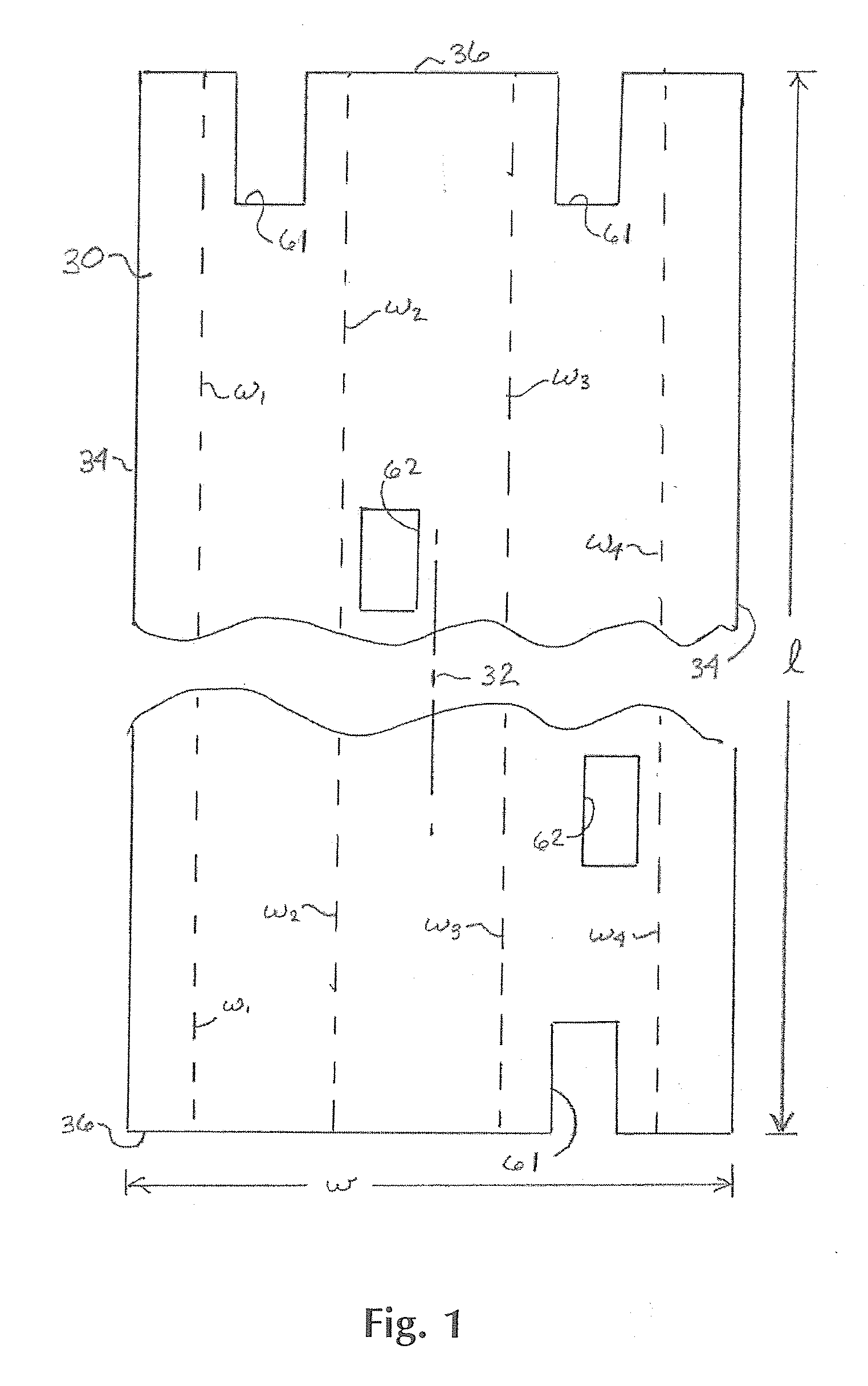

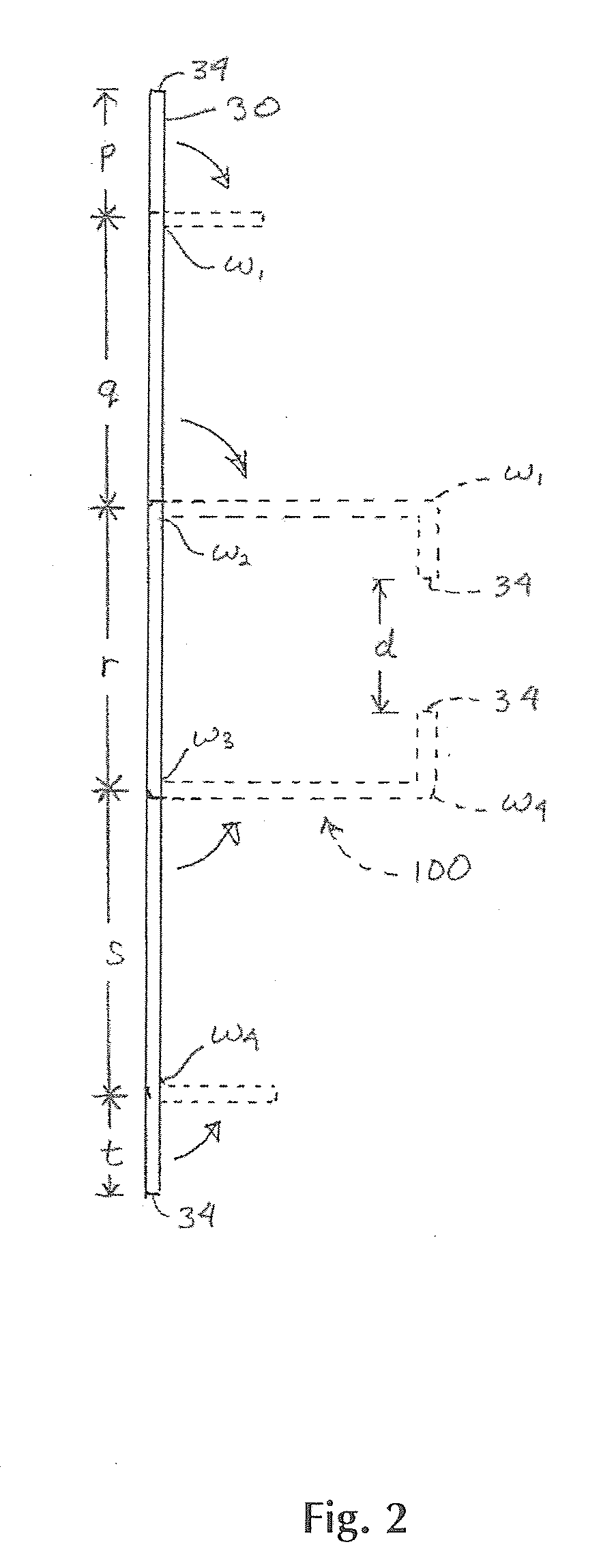

Telescoping tower and method of manufacture

InactiveUS20080236060A1High dimensional accuracyReduce manufacturing costTowersCranesAcute angleMetal sheet

A mast section for a telescoping tower system is made by aligning press brake tools along the length of the metal sheet at spaced width locations and forming the corners of the tube. After forming of the last corner, an opening remains along the length of the tube. The press brake male tool axis is offset sufficiently to permit the tool to apply forming force to the last corner of the tube through the opening, and is sized to remove the tool from the opening. At least three mast sections are nested to form the tower system. Pulleys for a cable extension system are mounted near the upper and lower ends of a wall of an intermediate mast section, with one of the pulleys being oriented at an acute angle to the mast section wall to permit routing of the cable.

Owner:BATTAGLIA VINCENT P

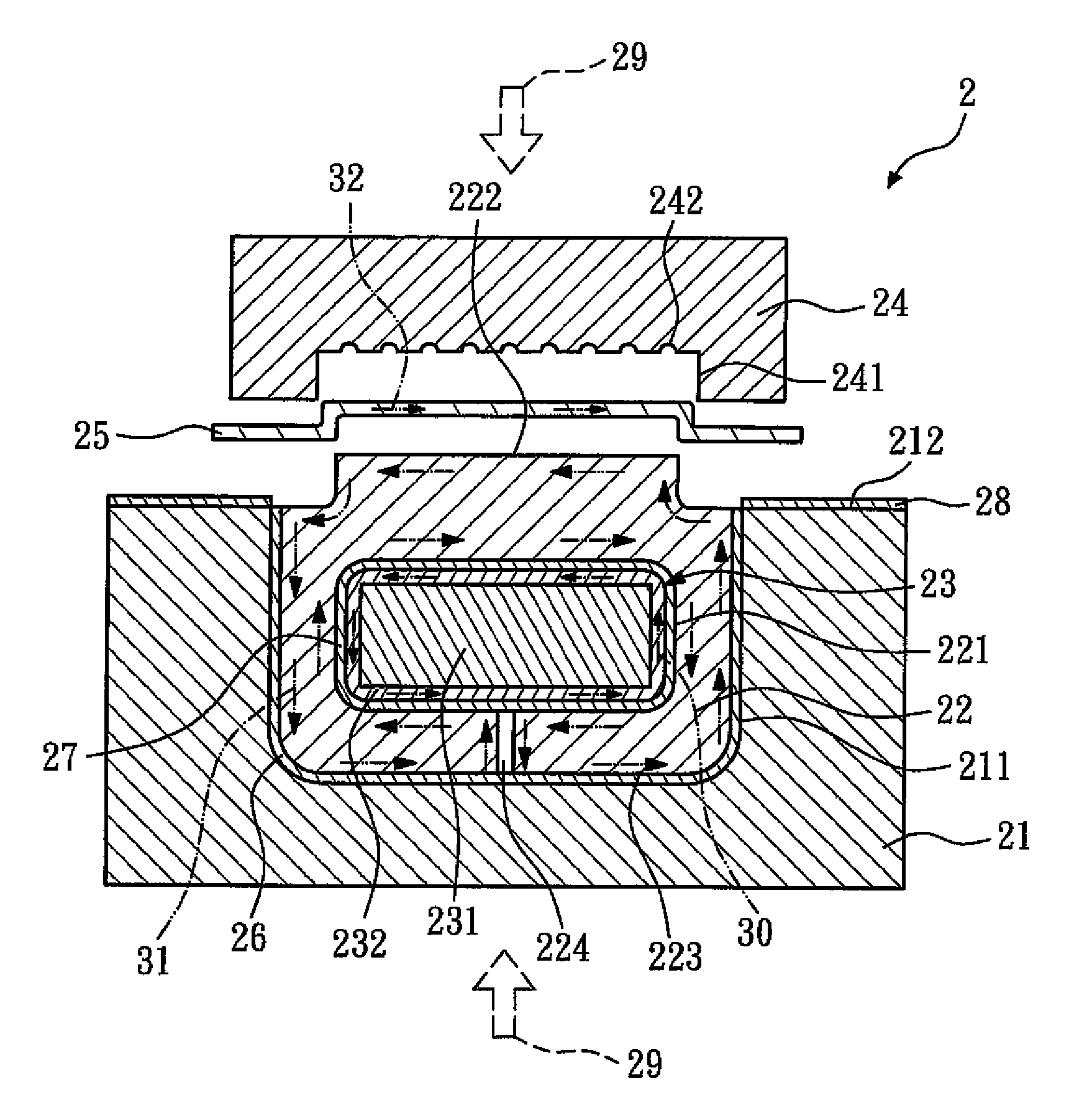

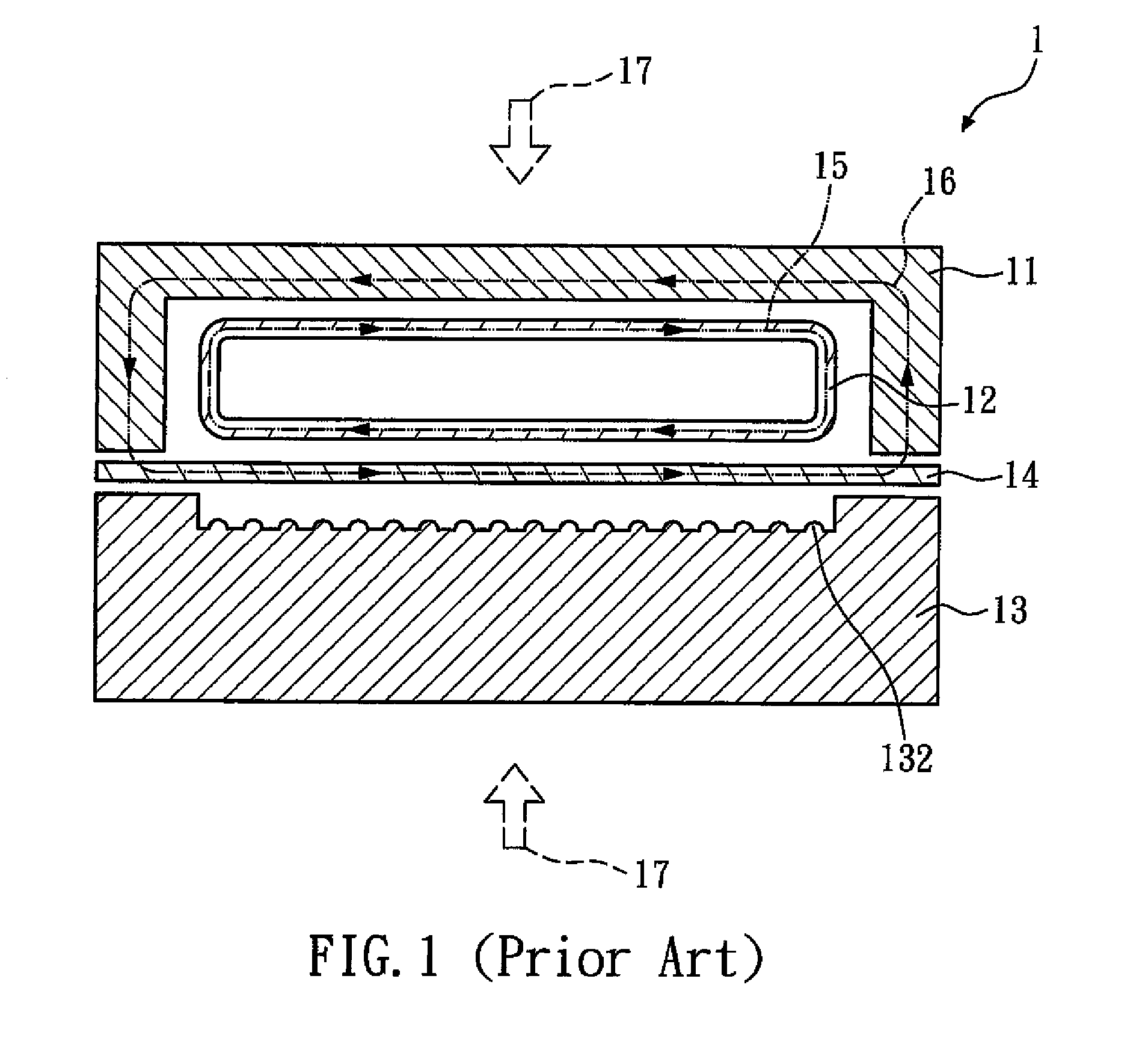

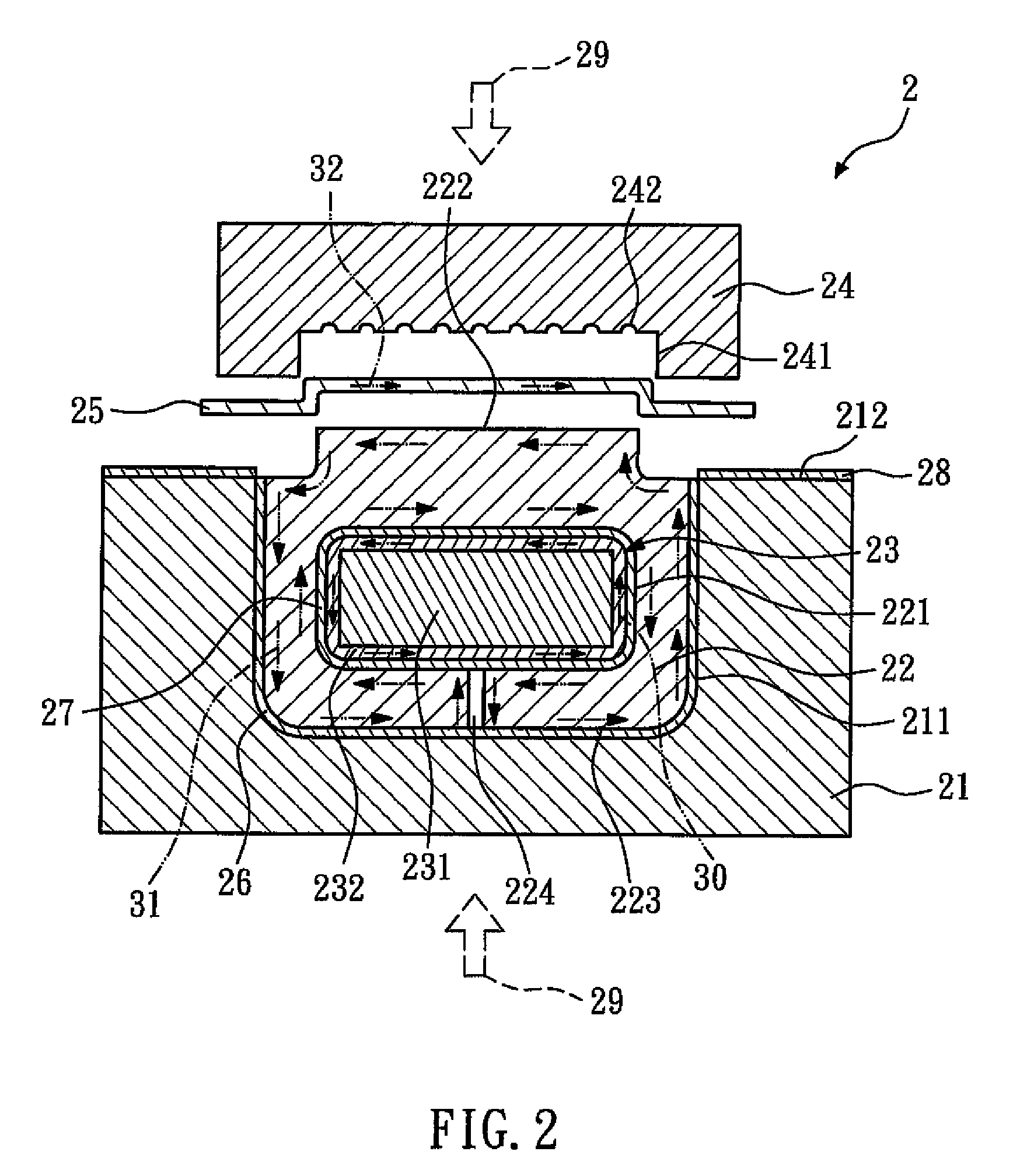

Electromagnetic forming device for sheet of material

ActiveUS7389664B1Reduce manufacturing costMetal-working apparatusForming forceElectromagnetic forming

An electromagnetic forming device for a sheet of material is provided. The electromagnetic forming device includes a fixing base, a magnetic concentration block, an electromagnetic actuator, and a die. The fixing base has a groove. The magnetic concentration block is disposed in the groove of the fixing base, and has an accommodating space therein, which is in communication with a surface of the magnetic concentration block via a slit. The electromagnetic actuator, used to generate a magnetic field, is disposed in the accommodating space of the magnetic concentration block, but does not contact the magnetic concentration block. The die and the magnetic concentration block are separated by a gap, and a sheet of material can be disposed in the gap. As the magnetic concentration block is a block, eddy currents in the magnetic concentration block are distributed uniformly, so the generated magnetic field is also distributed uniformly, thus exerting a uniform forming force on the sheet of material.

Owner:METAL INDS RES & DEV CENT

Sapphire (Al2O3 single crystal) growing technology

The present invention discloses a kind of alumina monocrystal growing process capable of growing alumina monocrystal with high quality and suitable for industrial production. On the basis of available crucible descending method or heat exchange method, one stirrer is added. After heating to melt the alumina material inside crucible and forming one solid-liquid interface between seed crystal and melt, the stirrer is set over the solid-liquid interface and made to rotate so as to form forced convection inside the melt, eliminate bubbles the residual gas forms and raise the quality of the produced monocrystal.

Owner:YUNNAN CRYSTALAND

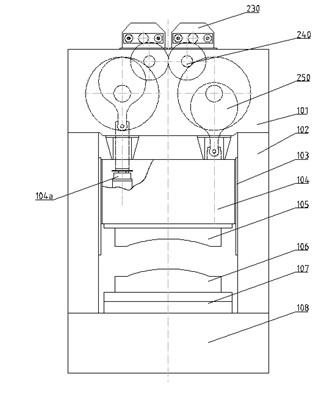

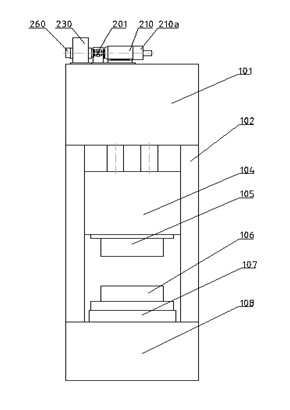

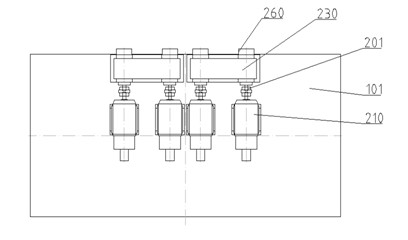

Mechanical pipe fitting bulging device

The invention discloses a mechanical pipe fitting bulging device which comprises a stand main body, a main pressure oil cylinder, an upper die block, a lower die block, closed hydraulic plungers, a hydraulic system, a clamping control switch and an electric control system. The closed hydraulic plungers are arranged on both sides of the upper die block and the lower die block. The mechanical pipe fitting bulging device is characterized by also comprising a crank arm link mechanism and a guide mechanism, the crank arm link mechanism is hinged with the main pressure oil cylinder, the stand main body and the upper die block respectively. One end of the guide mechanism is fixedly connected with the stand main body, and the other end is fixedly connected with the upper die block. The mechanical device can increase the forming force of equipment and has the same effect on high pressure bulging in pipe fittings as big tonnage hydraulic equipment, so that the purchase cost of the equipment is reduced; and the production efficiency is improved due to the mechanical device. Compared with similar equipment, the mechanical pipe fitting bulging device has the advantages of small size and low energy consumption; and the performance conforms to production requirements, and the cost is reduced to 10-20% that of the similar equipment.

Owner:上海交运集团股份有限公司

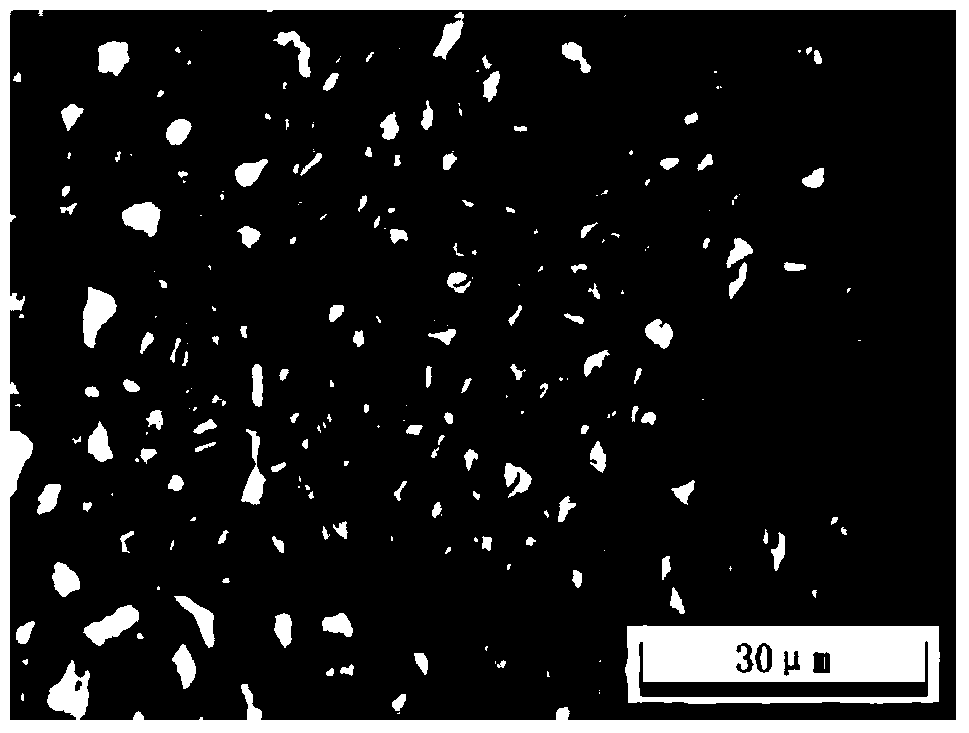

Magnesium alloy ultrasonic wave micro extrusion formed refined grain technology at normal temperature

ActiveCN104174677AImprove surface qualityIncrease productivityExtrusion diesRams/plungersRefined grainsUltrasonic generator

The invention provides a magnesium alloy ultrasonic wave micro extrusion formed refined grain technology at normal temperature. The technology comprises the following steps of manufacturing a male die and a female die, placing magnesium alloy parts into a cavity of the female die, performing die assembly extrusion on the magnesium alloy parts, performing separating die sinking, and taking out a formed part. According to the first step, an amplitude-change pole and an amplitude-change pole are sequentially connected to the tail end of the male die and can be touched by an ultrasonic generator. The magnesium alloy ultrasonic wave micro extrusion formed refined grain technology at the normal temperature can reduce forming force of metal, reduces friction between materials and the dies, expands the machining range of metal material plastic forming, and improves plastic forming capability of the metal materials, and the good product surface quality and the higher size precision can be further obtained.

Owner:SHENZHEN UNIV +1

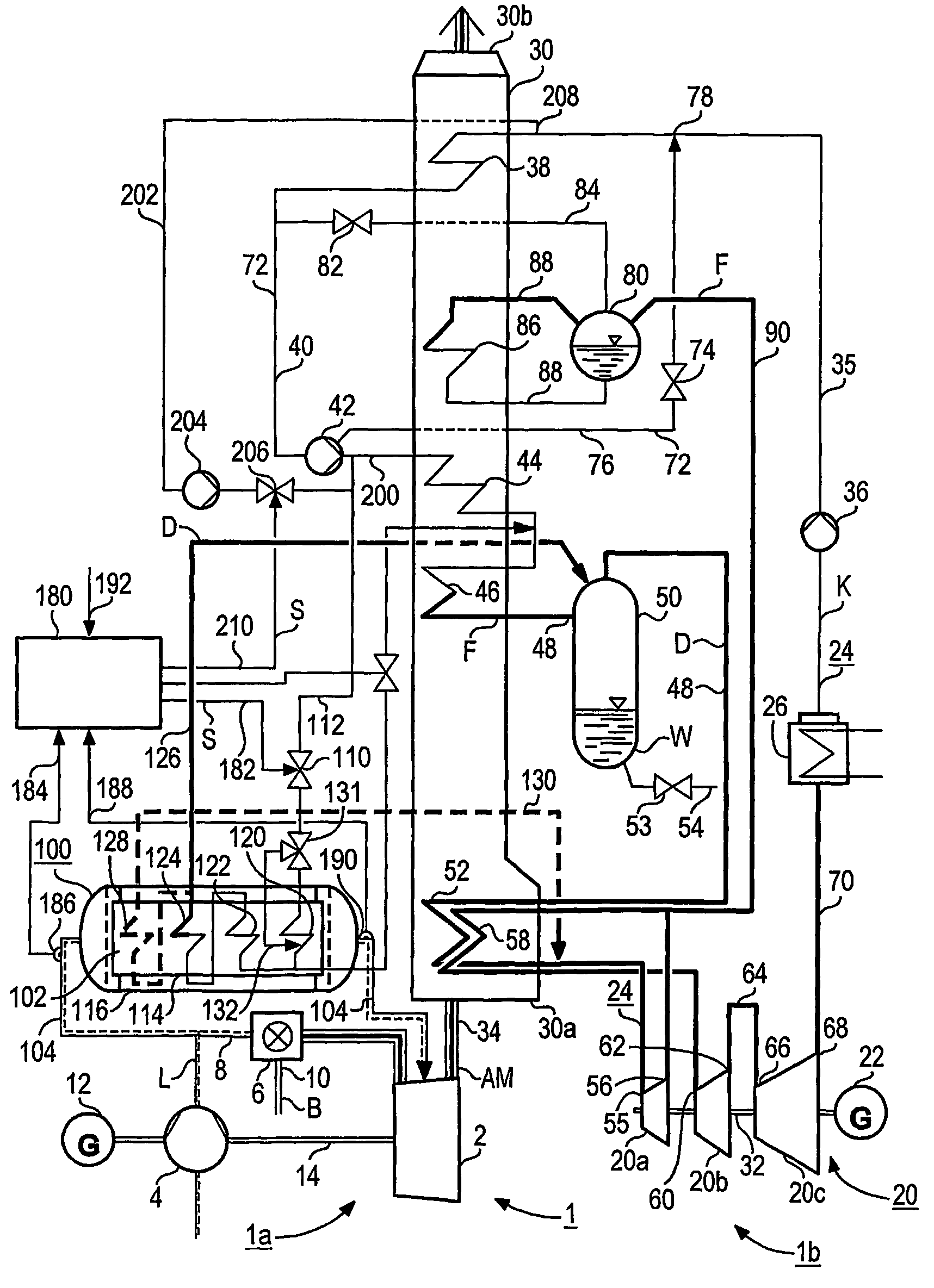

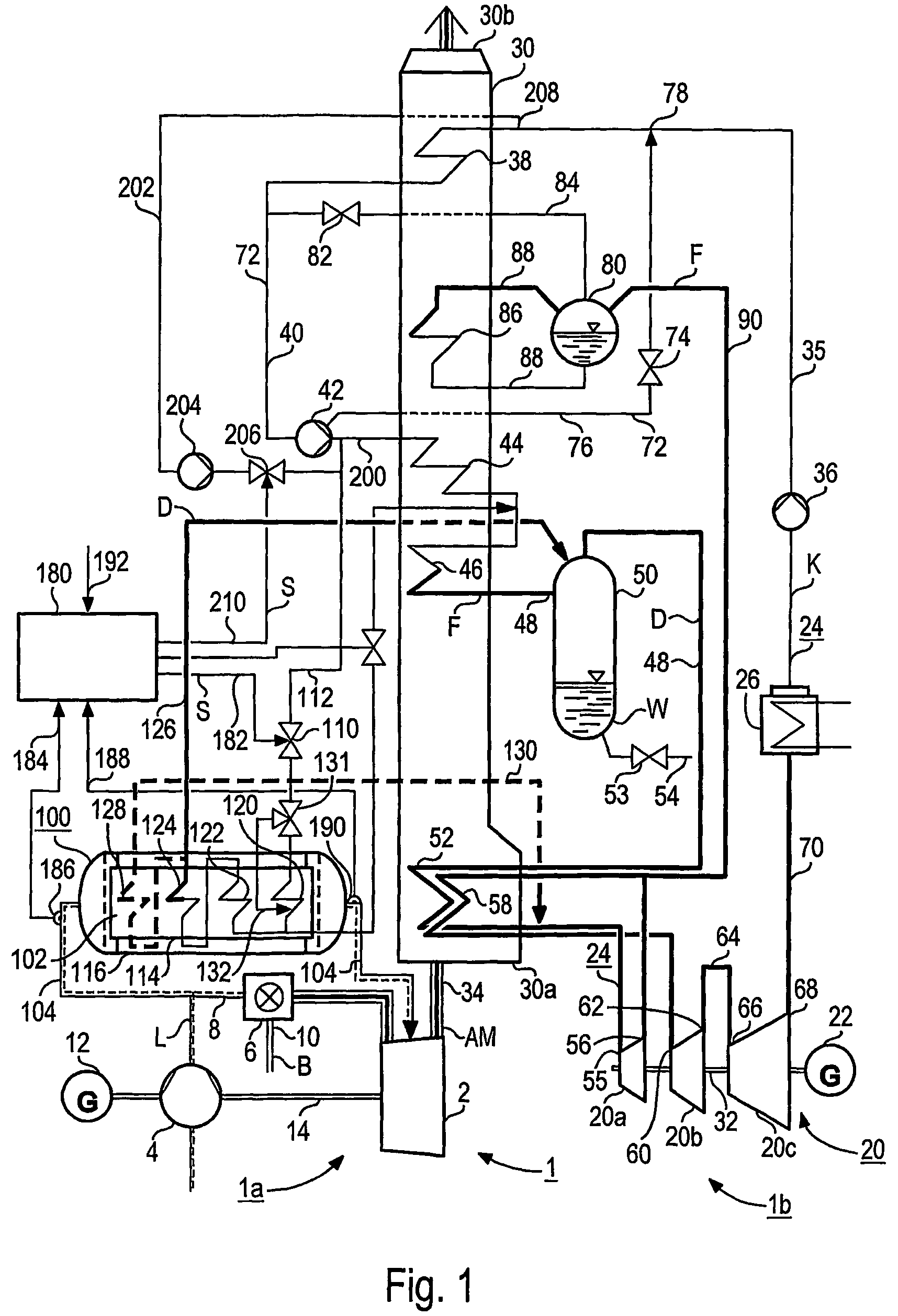

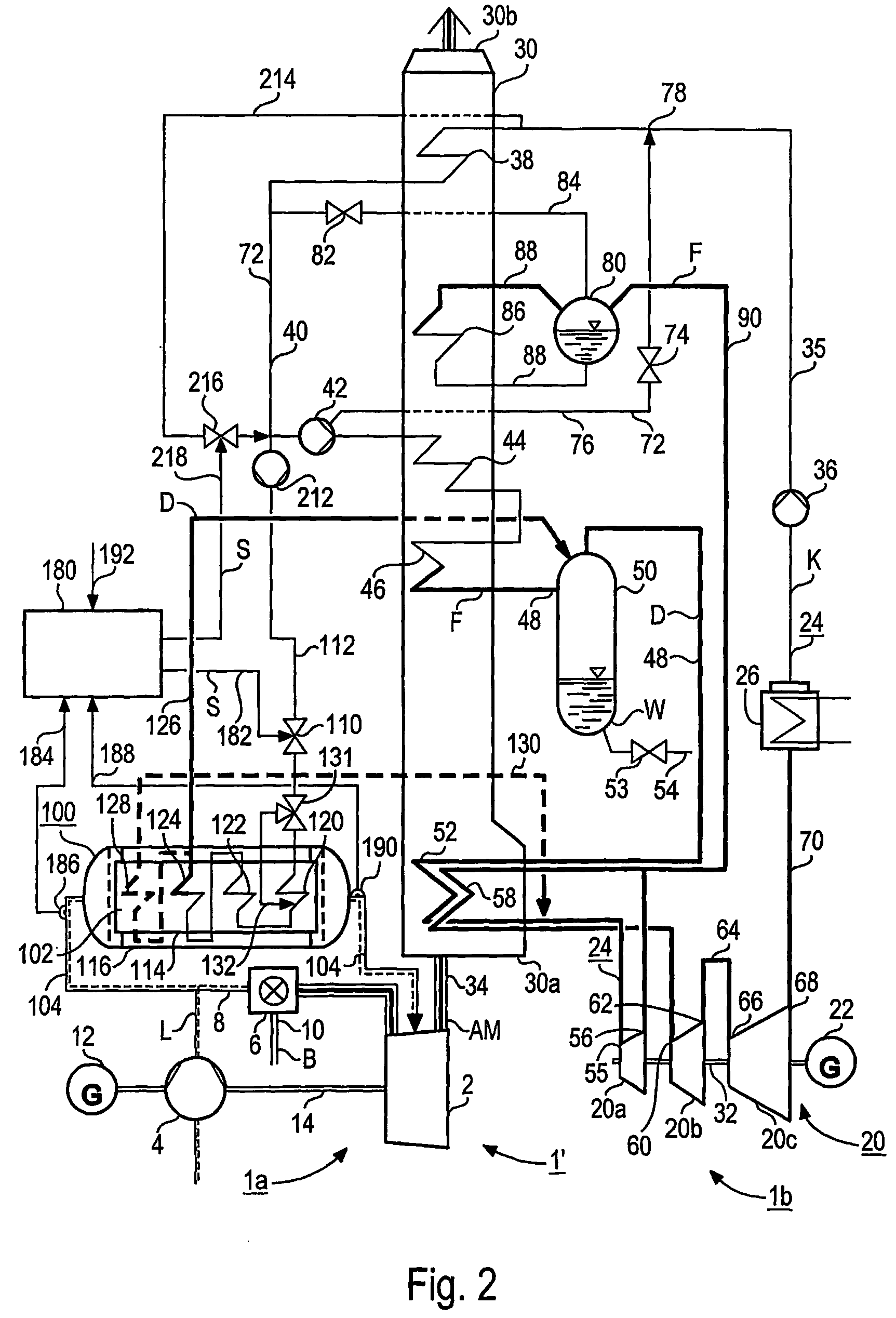

Device for cooling coolant in a gas turbine and gas and steam turbine with said device

ActiveUS7032373B2Simple designReliable coolant coolingTurbine/propulsion engine coolingEfficient propulsion technologiesNuclear engineeringGas turbines

The aim of the invention is a device for coolant cooling in a gas turbine which, with a relatively simple construction and low plant complexity permits a particularly high degree of efficiency in using the heat produced on cooling the coolant from a gas turbine. Said aim is achieved, whereby a number of interconnected evaporator tubes for a flow medium, are arranged in a coolant channel, connected to a gas turbine, to form forced throughflow steam generator. Said device is preferably used in a gas and steam unit with a waste heat steam generator on the exhaust gas side of a gas turbine, the heating surfaces of which are connected into the water-steam circuit of a steam turbine. The evaporator tubes of the device are thus connected on the inlet side by means of supply line to the feed water train of the water-steam circuit of the steam turbine.

Owner:SIEMENS AG

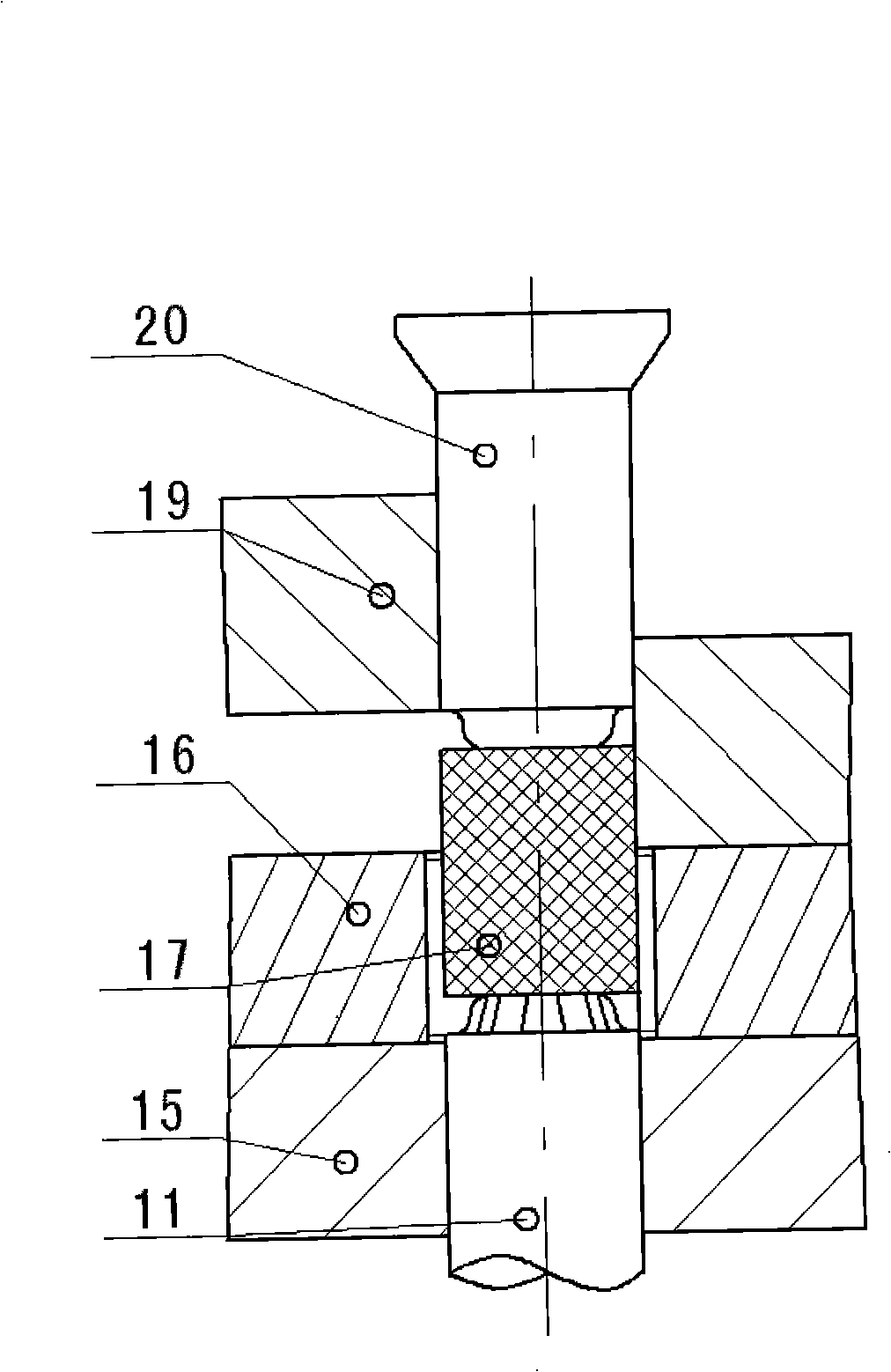

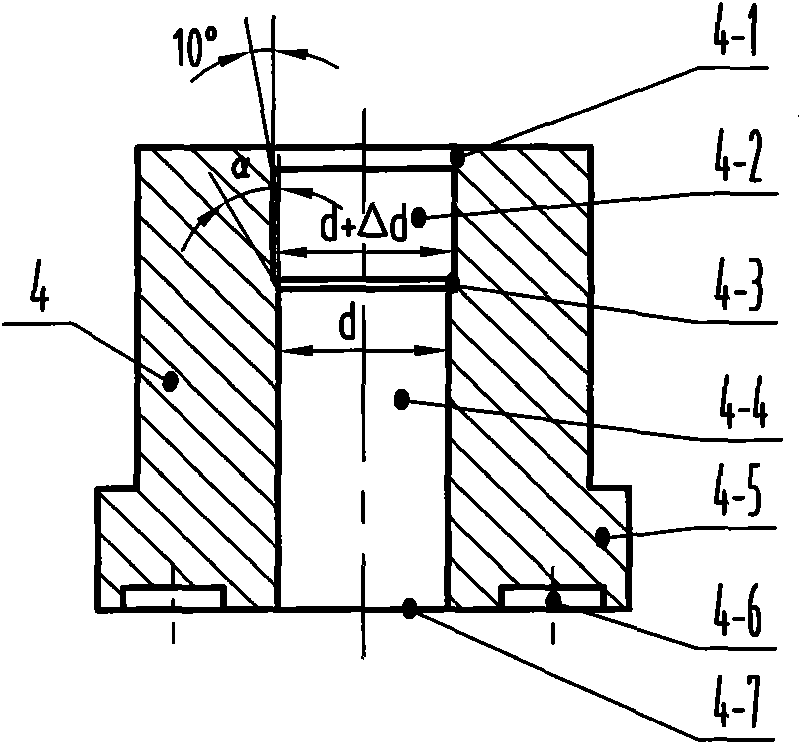

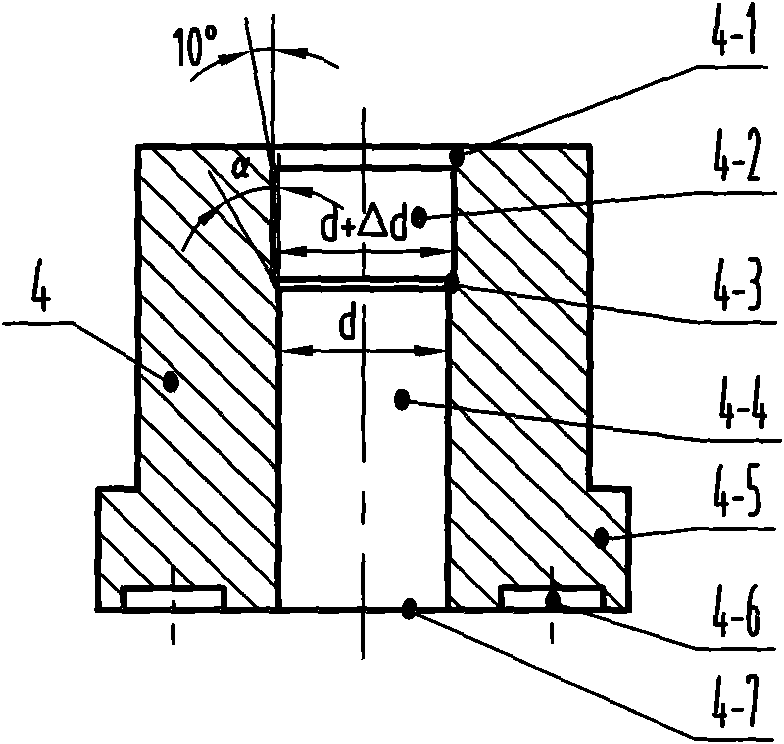

Hot reverse-extrusion forming mold for large cup shell

ActiveCN101972792AIncrease back extrusion forceReduce the effects of frictionExtrusion diesEngineeringFlange

The invention discloses a hot reverse-extrusion forming mold for a large cup shell, relating to a reverse-extrusion forming device. The invention can reduce a hot reverse-extrusion forming force of the large cup shell and solves the problem of low production efficiency in the prior art. A reverse-extrusion punch head is assembled on a pressure head of a pressing machine; an inner cavity of a reverse extrusion cylinder consists of a material-filling cavity, a transitional step and a reverse extrusion cavity, and the lower end of the reverse extrusion cylinder is provided with a limiting step; a base is fixed on a workbench surface of the pressing machine; the inner cavity of the base consists of an upper inner cavity, a middle inner hole and a lower inner cavity; the lower inner cavity is provided with a bearing base plate; a center hole of the bearing base plate is slidably matched with a mandril of the pressing machine, and an upper end face of the bearing base plate supports a material-ejecting rod; a big end of the material-ejecting rod is slidably matched with the middle inner hole, and a small end of the material-ejecting rod is slidably matched with a reverse extrusion cavity; an outer wall of the limiting step is slidably matched with a wall surface of the upper inner cavity; a flange is fixed with the upper end of the base by bolts; n cylindrical helical compression springs which are uniformly distributed are arranged between the reverse extrusion cylinder and the base, wherein n and m are positive integer.

Owner:NANJING DEV ADVANCED MFG

Press machine driven by servo motor

The invention discloses a press machine driven by a servo motor. The press machine comprises a cross beam body and a base, wherein a stand column is connected between the cross beam body and the base; the base is provided with a working platform and a lower die; a sliding block is connected with a transmission mechanism used for driving the sliding block to make reciprocating motion up and down; the transmission mechanism comprises the servo motor arranged on the top of the cross beam body, a zero-backlash elastic coupler, a speed reducer, and a gear mechanism, an eccentric gear and an eccentric connecting rod mechanism which are arranged in the cross beam body; the servo motor is connected with the speed reducer by the zero-backlash elastic coupler; an output gear of the speed reducer is meshed with the gear mechanism; the gear mechanism is connected with the eccentric gear which is connected with the eccentric connecting rod mechanism; the eccentric connecting rod mechanism is connected with the sliding block by a sliding block connector; and the speed reducer is provided with a mechanical brake. The press machine has the advantages that the energy consumption and the maintenance cost are reduced; the stamping motion and the forming force can be freely adjusted and accurately controlled; and full-load bottom dead centre pressure maintaining can be realized on any kinetic characteristic curve of the sliding block.

Owner:JIER MACHINE TOOL GROUP

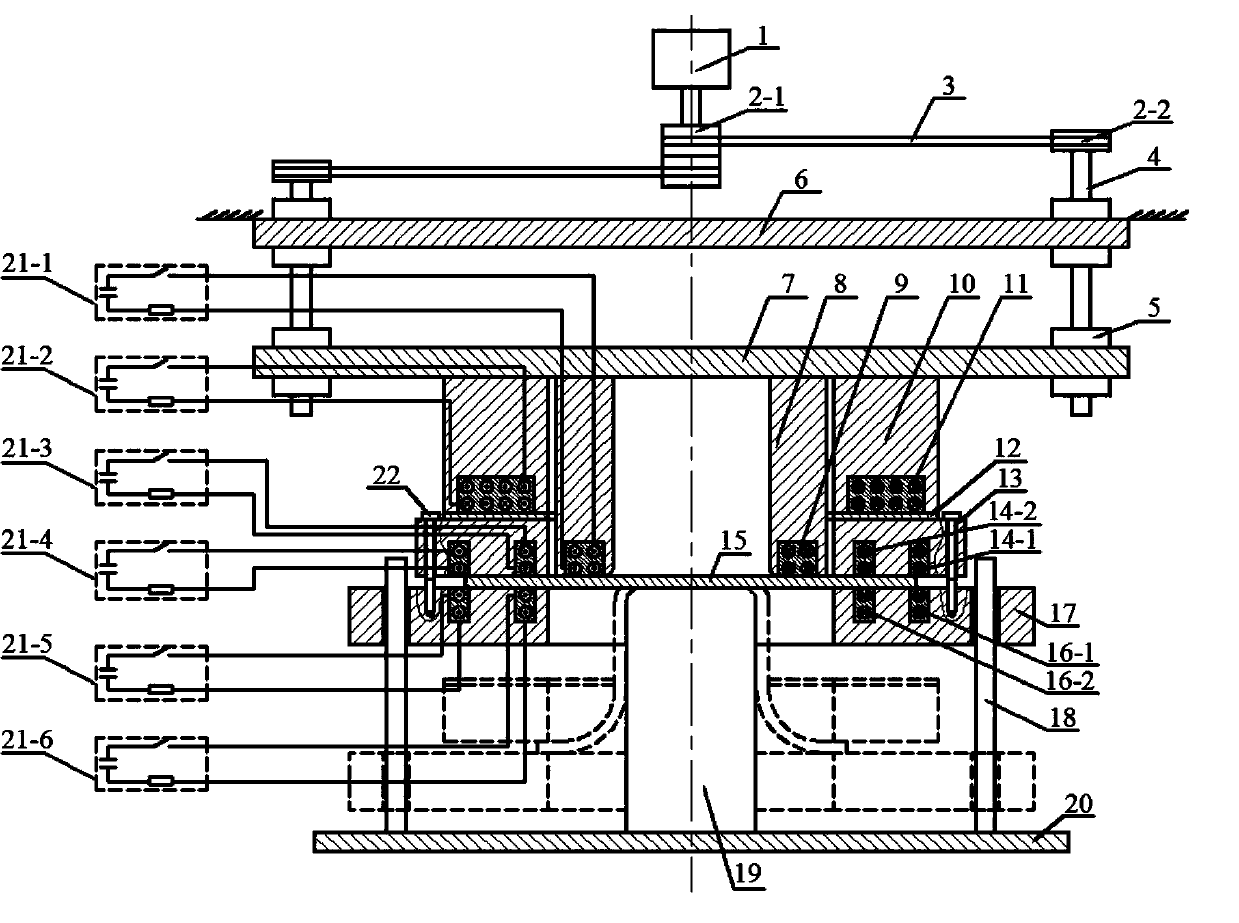

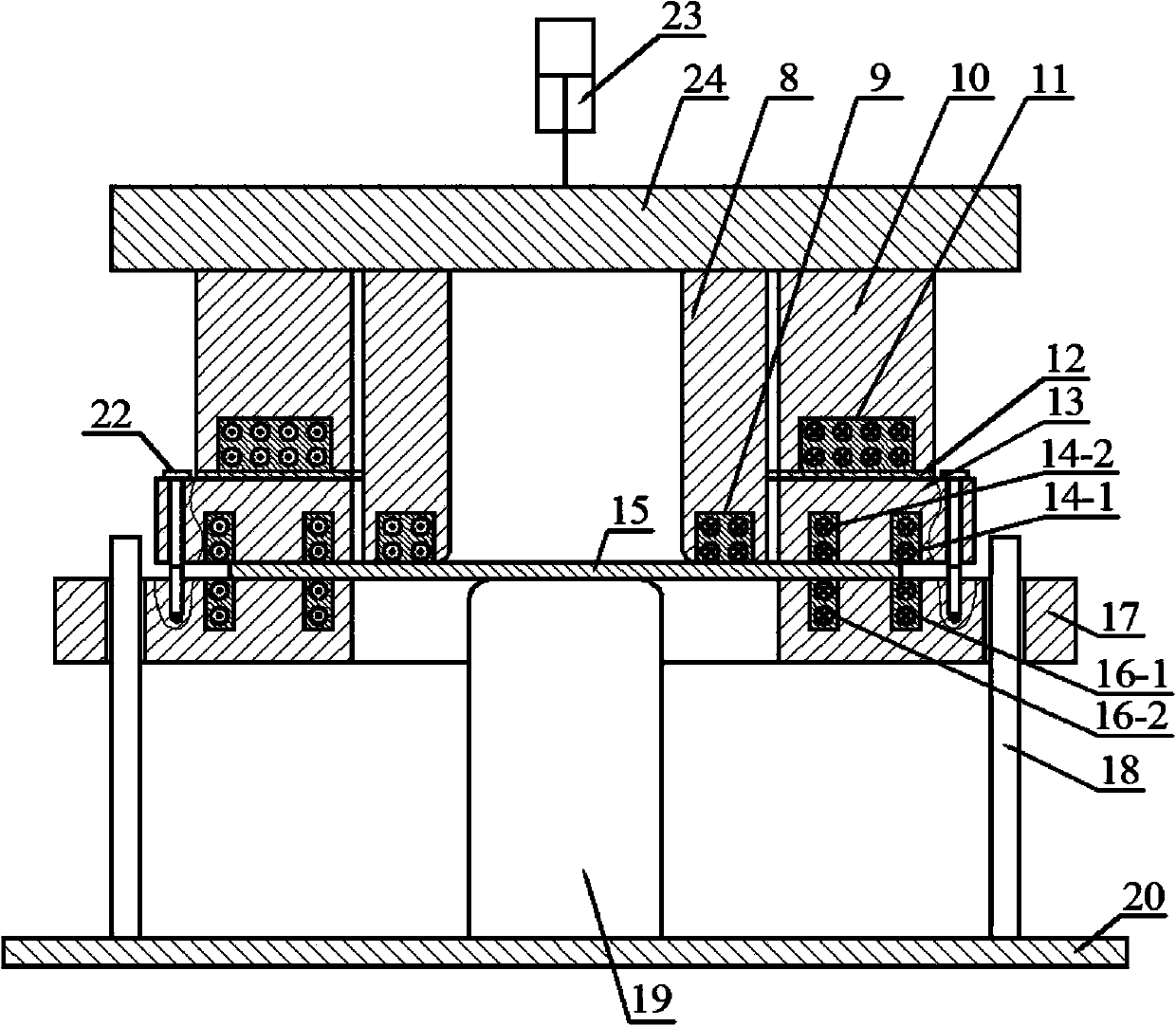

Metal plate annular electromagnetic pulse progressive reverse drawing forming method and device

InactiveCN103722067AChanging the state of stress and strainReduce tensile stressElectromagnetic pulseMechanical engineering

The invention provides a metal plate annular electromagnetic pulse progressive reverse drawing forming method. The method includes the steps that a to-be-formed plate is placed between a female die and a male die; the periphery of the female die is provided with a clamping plate, and the periphery of the male die is provided with a supporting frame; pre-forming force is exerted on the to-be-formed plate; electromagnetic force is exerted to push the to-be-formed plate and the clamping plate downwards; electromagnetic force is exerted on the periphery of the to-be-formed plate, and the to-be-formed plate is pushed horizontally towards the center of the female die, so that the to-be-formed plate flows into the female die and reverse drawing forming is achieved; lower pressure is exerted to drive the female die to move downwards, and the to-be-formed plate at the bottom of the female die is squeezed into a gap between the female die and the male die, so that reverse drawing forming of the plate is achieved; reverse drawing and electromagnetic pulse drawing are repeatedly carried out on the female die and the male die until reverse drawing forming is finished. According to the method, forming limits can be substantially increased, and the forming depth of a cylindrical element is increased. The invention further provides a metal plate annular electromagnetic pulse progressive reverse drawing forming device.

Owner:HUAZHONG UNIV OF SCI & TECH

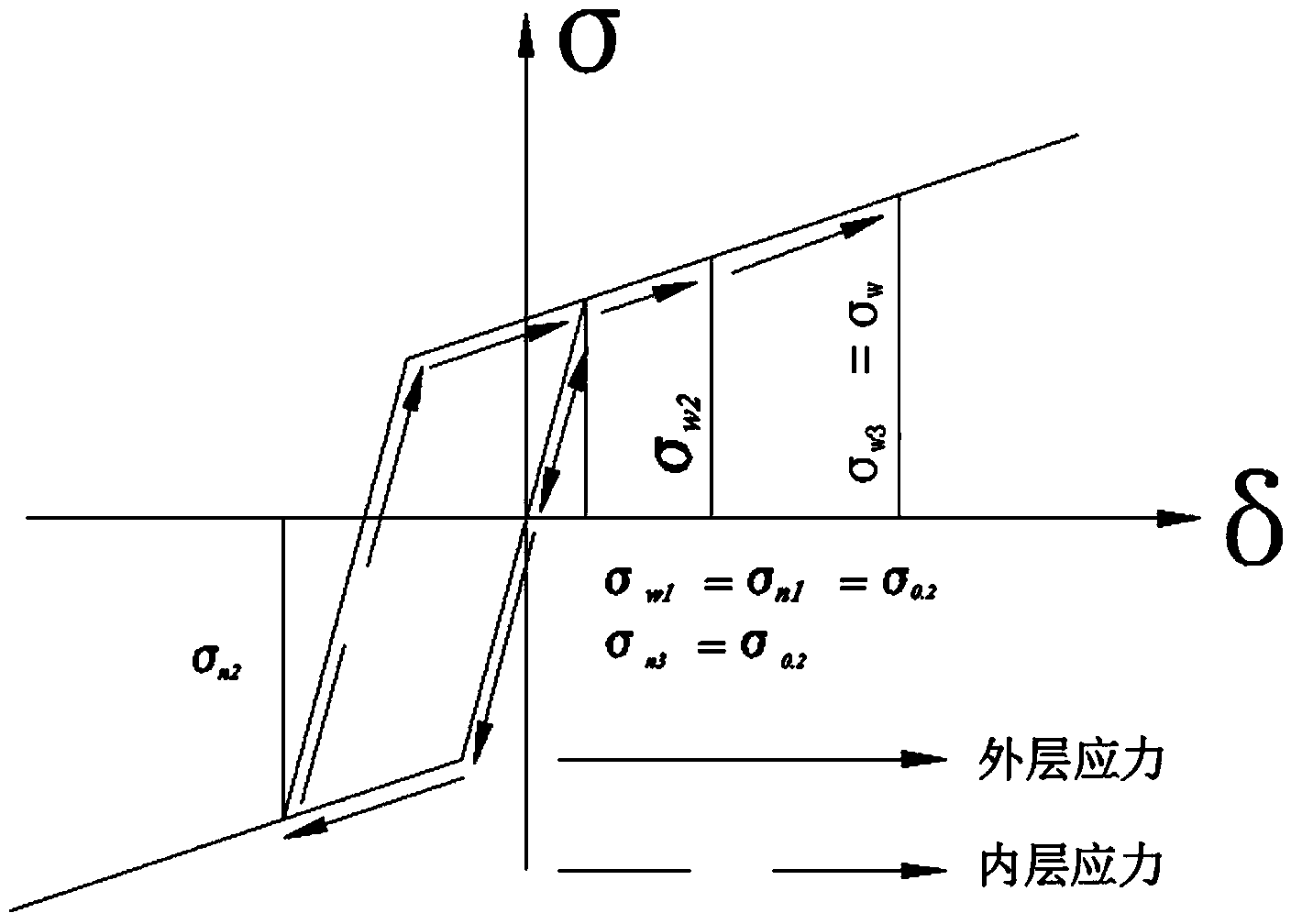

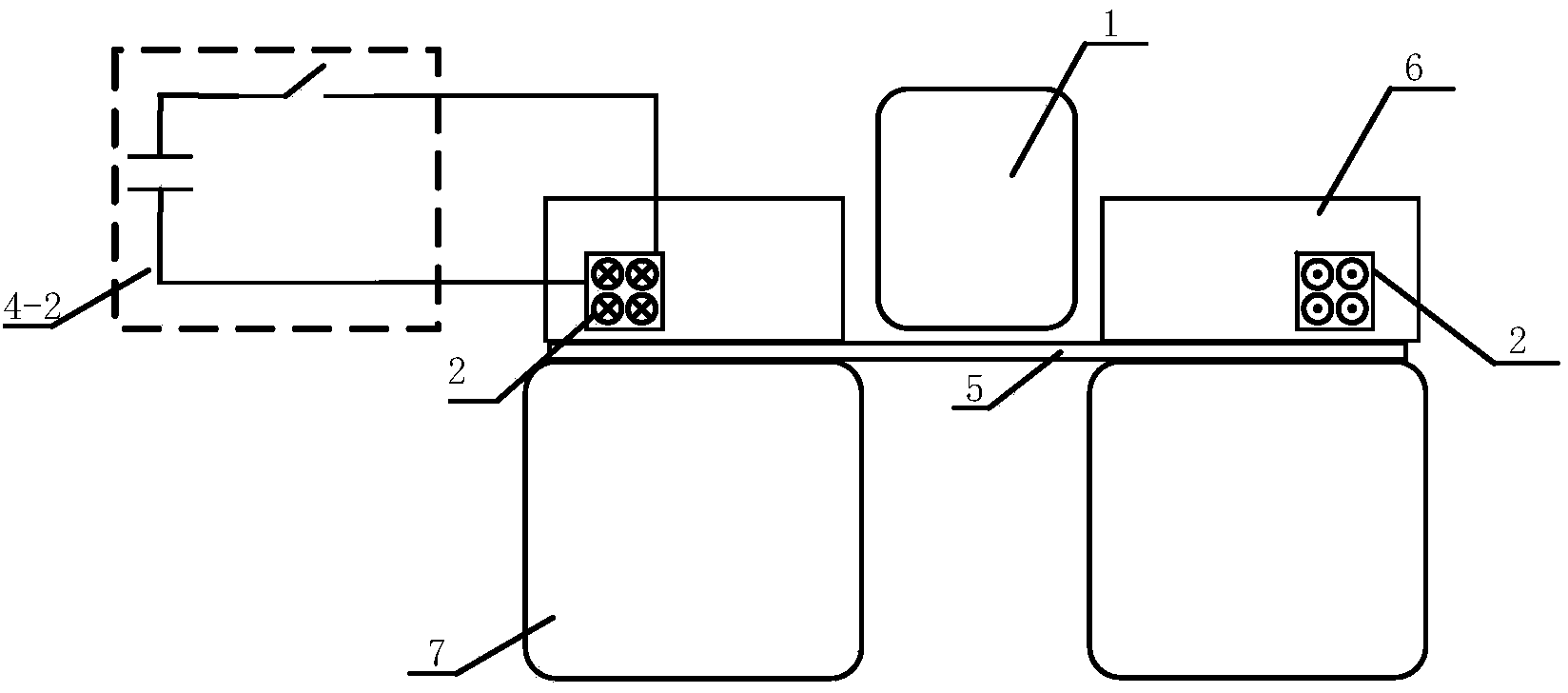

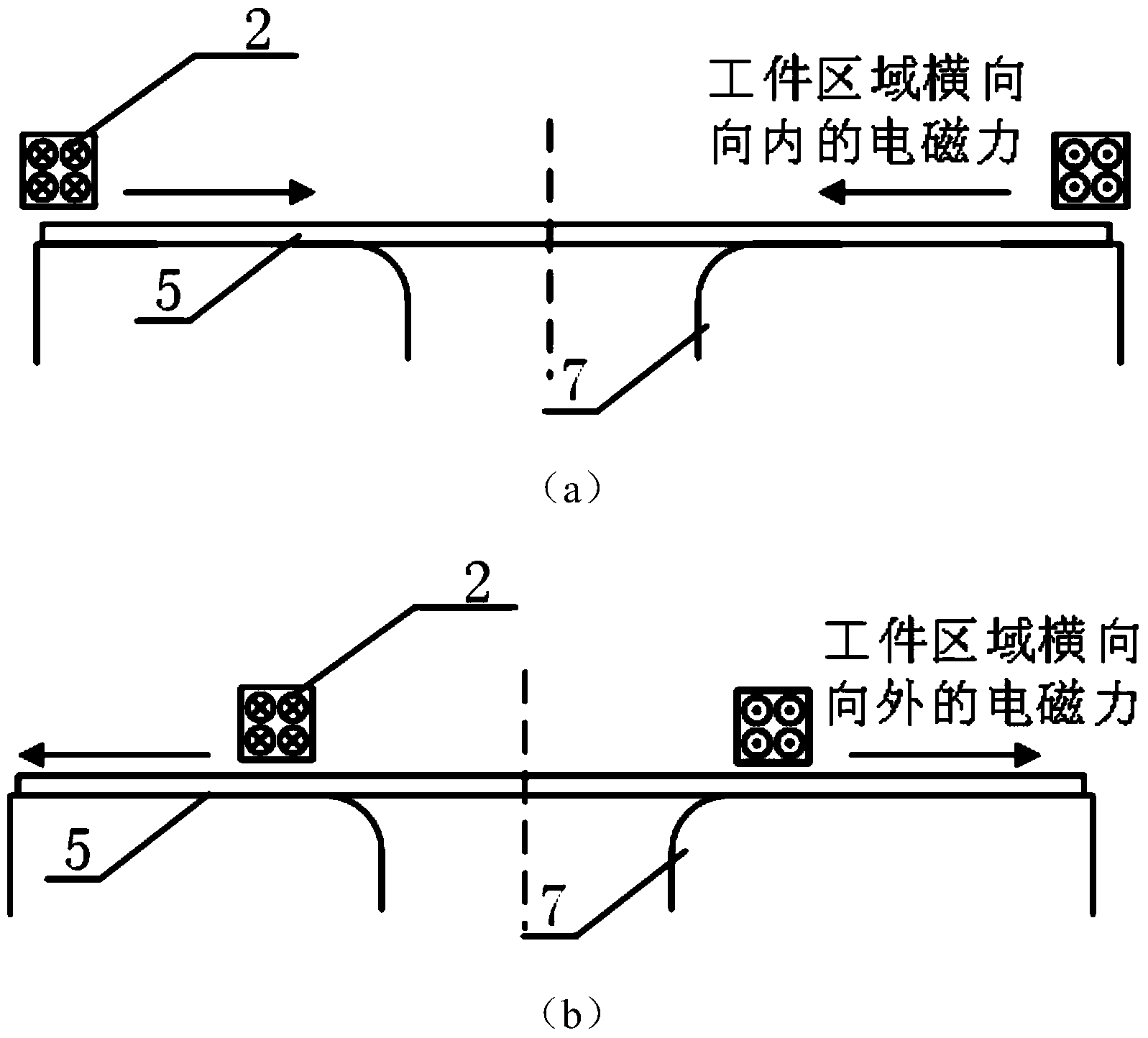

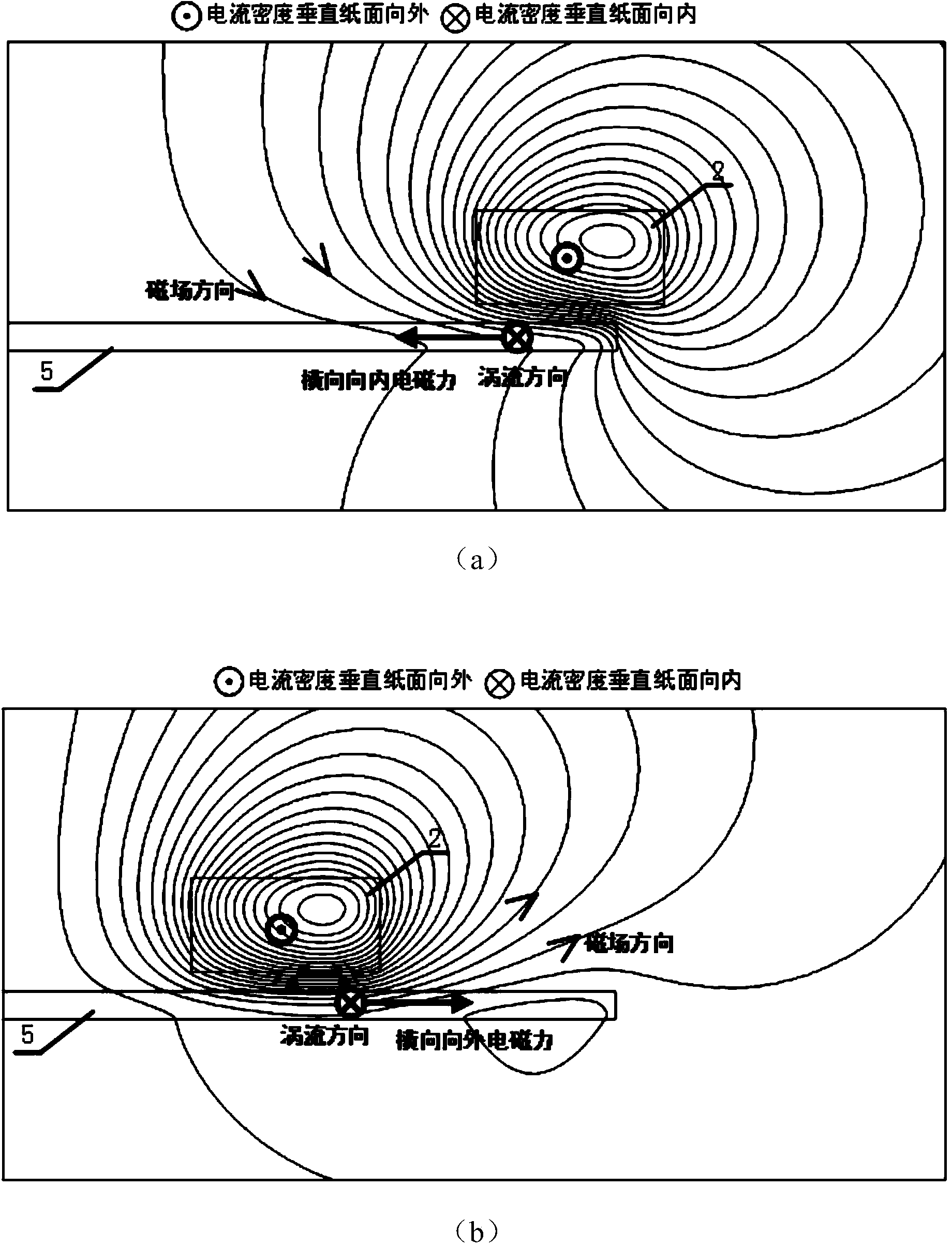

Material fluidity control method for metal plate forming

The invention discloses a material fluidity control method for metal plate forming. According to the material fluidity control method, a vortex coil is utilized to induct a vortex in a flange area of a metal plate, and an area generating an induction vortex is disposed in a magnetic field with axial magnetic field components perpendicular to the plate surface; under the joint action of the vortex and the magnetic field, a transverse electromagnetic force, which is parallel to the plate surface and points to a recessed-die cavity from the flange area of the metal plate or points to the flange area of the metal plate from the recessed-die cavity, is generated; the transverse electromagnetic force is matched with an axial forming force, so that control of material fluidity is realized. The transverse electromagnetic force adjustable in space distribution, timing sequence, amplitude and direction is generated in the flange area of the metal plate, so that flexible and multi-freedom-degree control of the material fluidity in metal plate forming is realized, wrinkling and tearing are effectively restrained, and the limit drawing coefficient is improved. The material fluidity control method is simple and can be widely used for assisting in processing of metal plates.

Owner:HUAZHONG UNIV OF SCI & TECH

Heat backward extrusion molding process of large-sized cup-shaped piece

ActiveCN102029301AIncrease back extrusion forceReduce the effects of frictionExtrusion diesMaterials scienceForming force

The invention discloses a heat backward extrusion molding process of a large-sized cup-shaped piece, relating to a backward extrusion molding method. By using the invention, the forming force for the heat backward extrusion of the large-sized cup-shaped piece can be reduced and the problem in the prior art that the production efficiency is low is solved. The heat backward extrusion molding process comprises the following concrete steps of: (1) placing a heat blank in a material accommodating cavity; (2) downwards pressing a pressure head to enable a backward extrusion punch head to be contacted with the blank; (3) downwards pressing the pressure head and allowing a backward extrusion cylinder to downwards slide along an inner cavity of a base and compress a spring until the spring contacts with the bottom plane of the inner cavity of the base; (4) downwards pressing the pressure head to enable all blanks to be reduced and extruded to a backward extrusion cavity to be attached to an ejector rod; (5) downwards pressing the pressure head and starting the backward extrusion molding process until the process is finished; (6) backward lifting the pressure head, lifting the backward extrusion cylinder, limiting a stamped part by a stripper plate to separate from the backward extrusion punch head, allowing the ejector rod to upwards eject and then taking out the stamped part after the stamped part is separated from the backward extrusion cylinder; (7) retracting the ejector rod and allowing an ejecting material to fall off and ensuring that a die restores the initial state; and (8) repeating the process steps from (1) to (7) and continuously finishing the heat backward extrusion molding of the large-sized cup-shaped piece.

Owner:NANJING DEV ADVANCED MFG

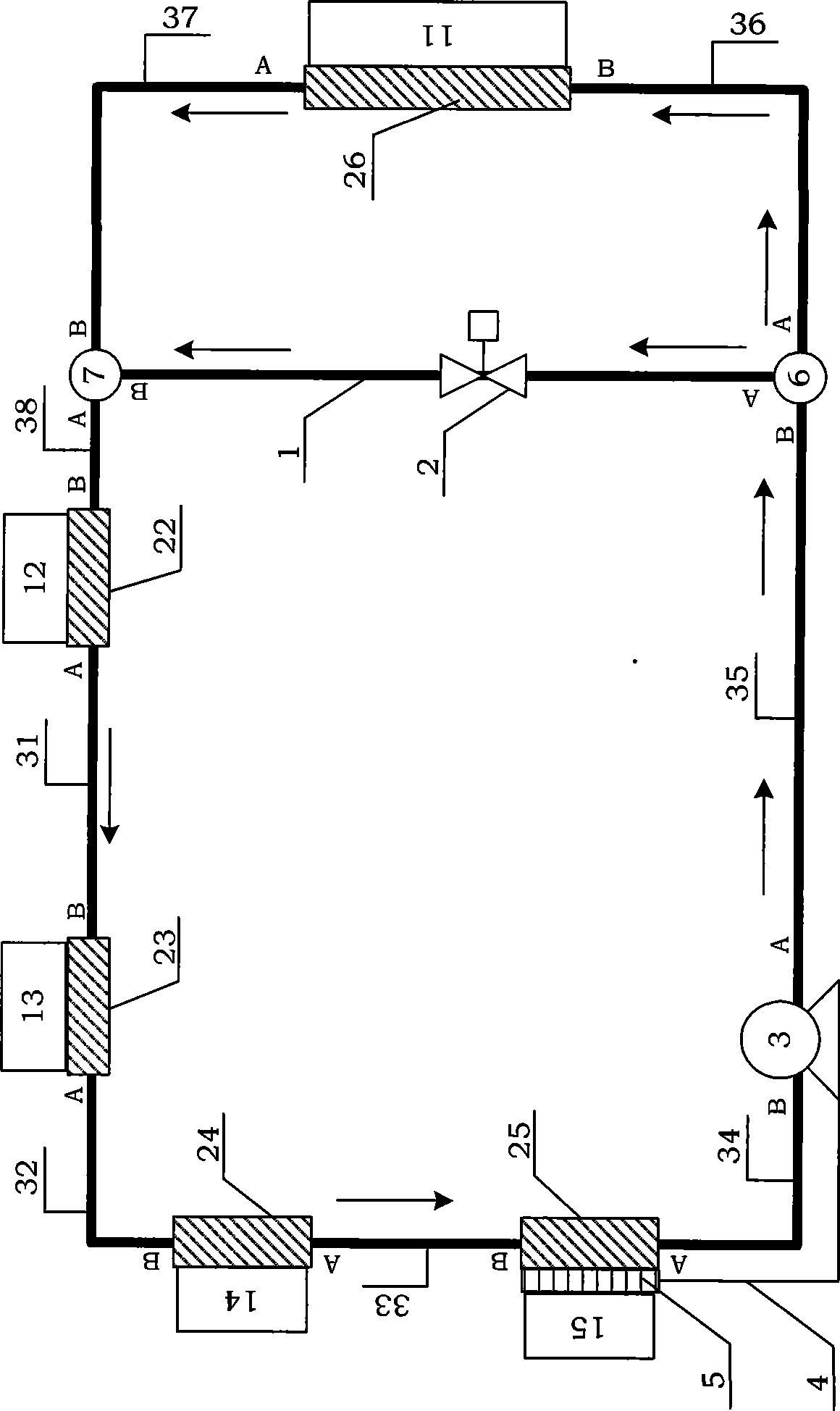

Fluid circuit control device suitable of nano-satellite hot control system

InactiveCN101508349AIncrease profitImprove exchange efficiencyCosmonautic environmental control arrangementTemperature control without auxillary powerLoop controlClosed loop

The invention discloses a fluid loop control device applicable to a nano-satellite thermal control system, which comprises a heat collecting module, a fluid loop driving module, a heat-electricity converting module, and a bypass flow control module. In the fluid loop control device, a micro-channel heat exchange technique combining with a heat-electricity converting technique is adopted so that the fluid loop of a nano-satellite heat control system forms forced convection heat exchange. In tthe fluid loop control device, an initiative heat control mode including major loop self-driving and bypass auxiliary control is adopted, wherein with the initiative heat control mode, the waste heat of the nano-satellite is converted into electric energy to drive the fluid loop to perform the forced convection heat exchange so as to achieve the closed loop control of the heat control system, reduce the electric energy consumption of the nano-satellite, and achieve the temperature control inside the nano-satellite. The fluid loop control device is that micro-channel heat exchangers are arranged on a satellite borne device of the prior nano-satellite and then two ends of each micro-channel heat exchanger are connected with a conduct respectively to form a forced convection fluid loop which can reuse the heat generated in the working process of the satellite borne device, thus the energy of the nano-satellite is saved, and a condition for the nano-satellite to work for a long period is provided.

Owner:BEIHANG UNIV

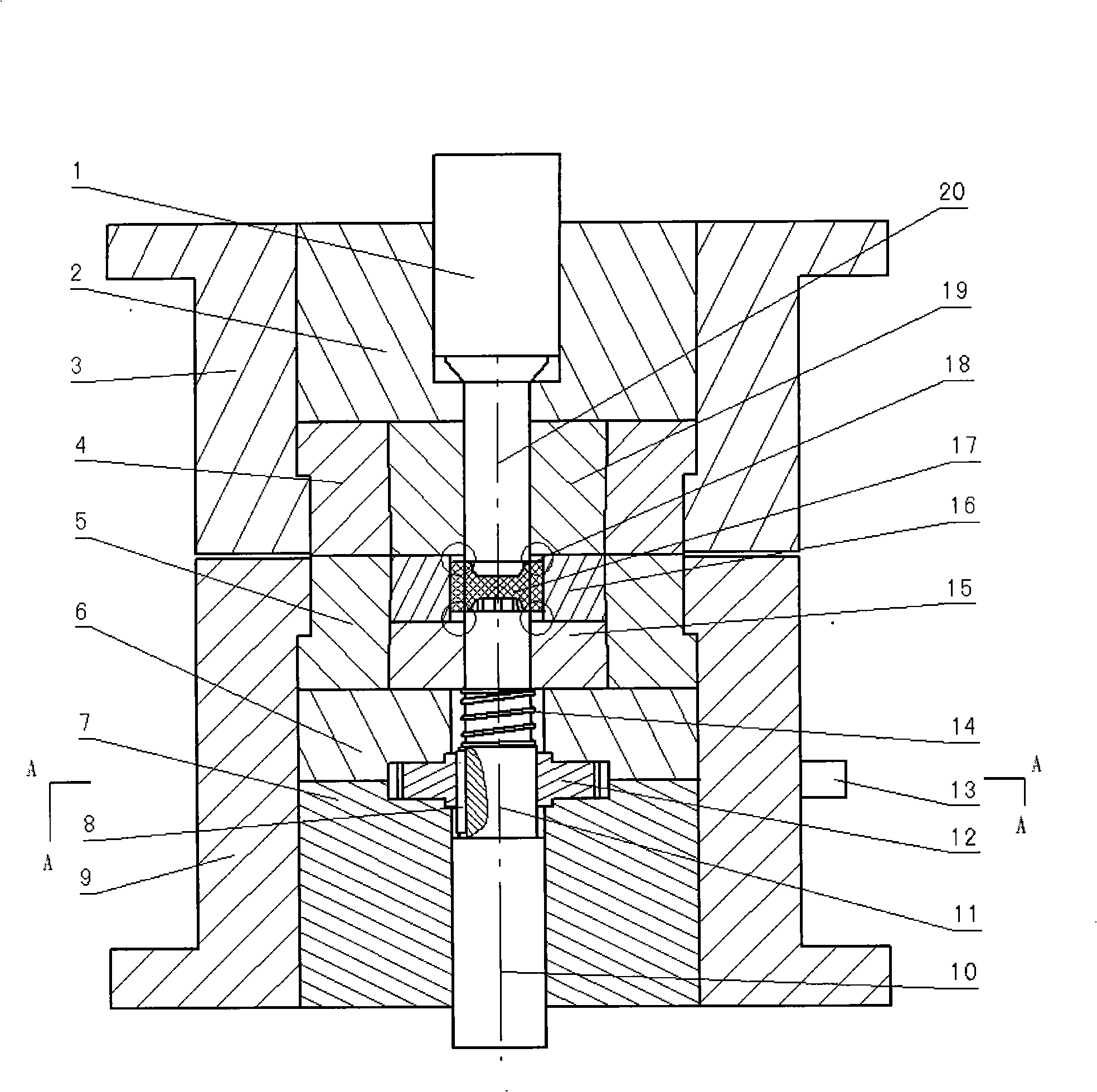

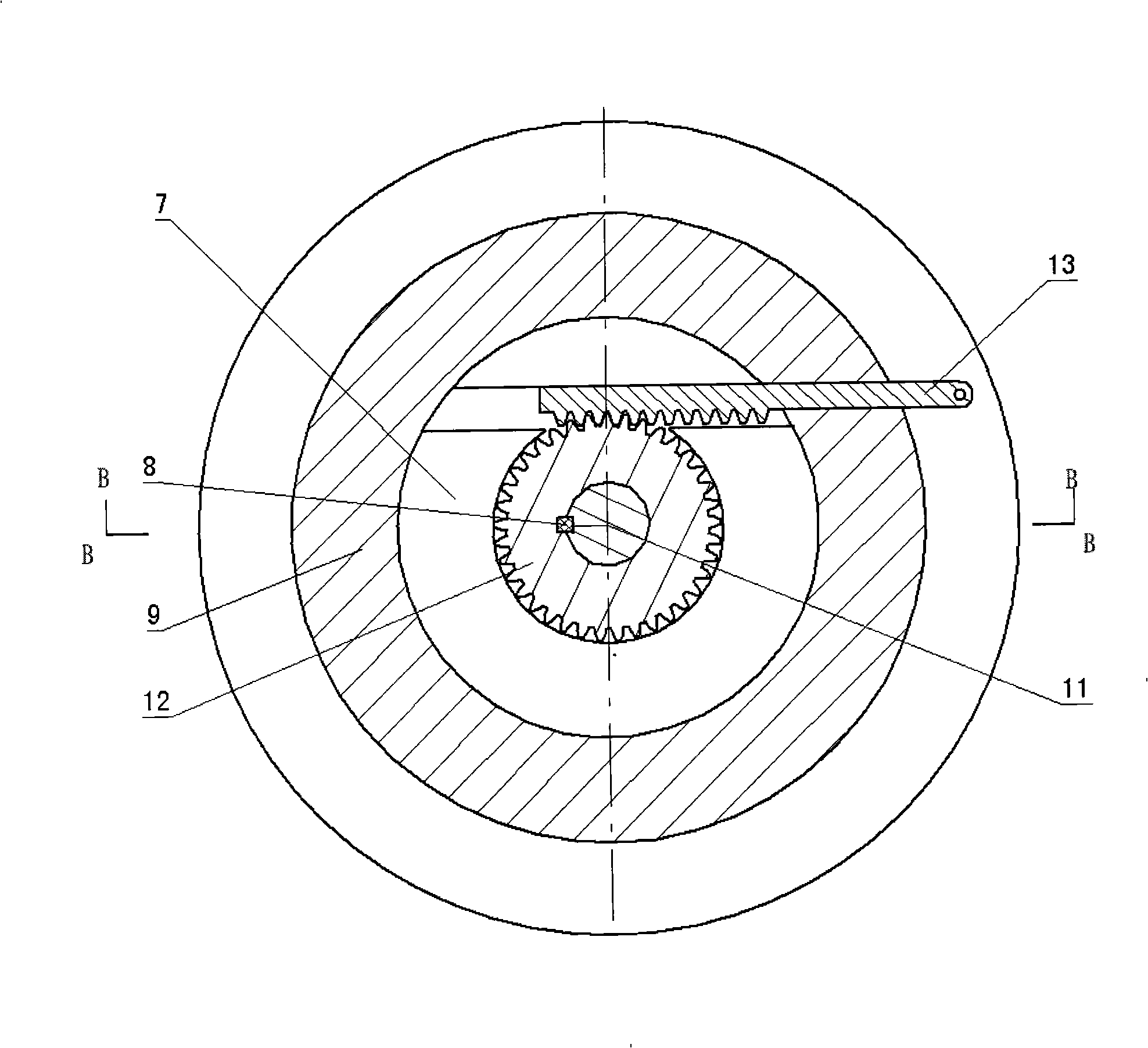

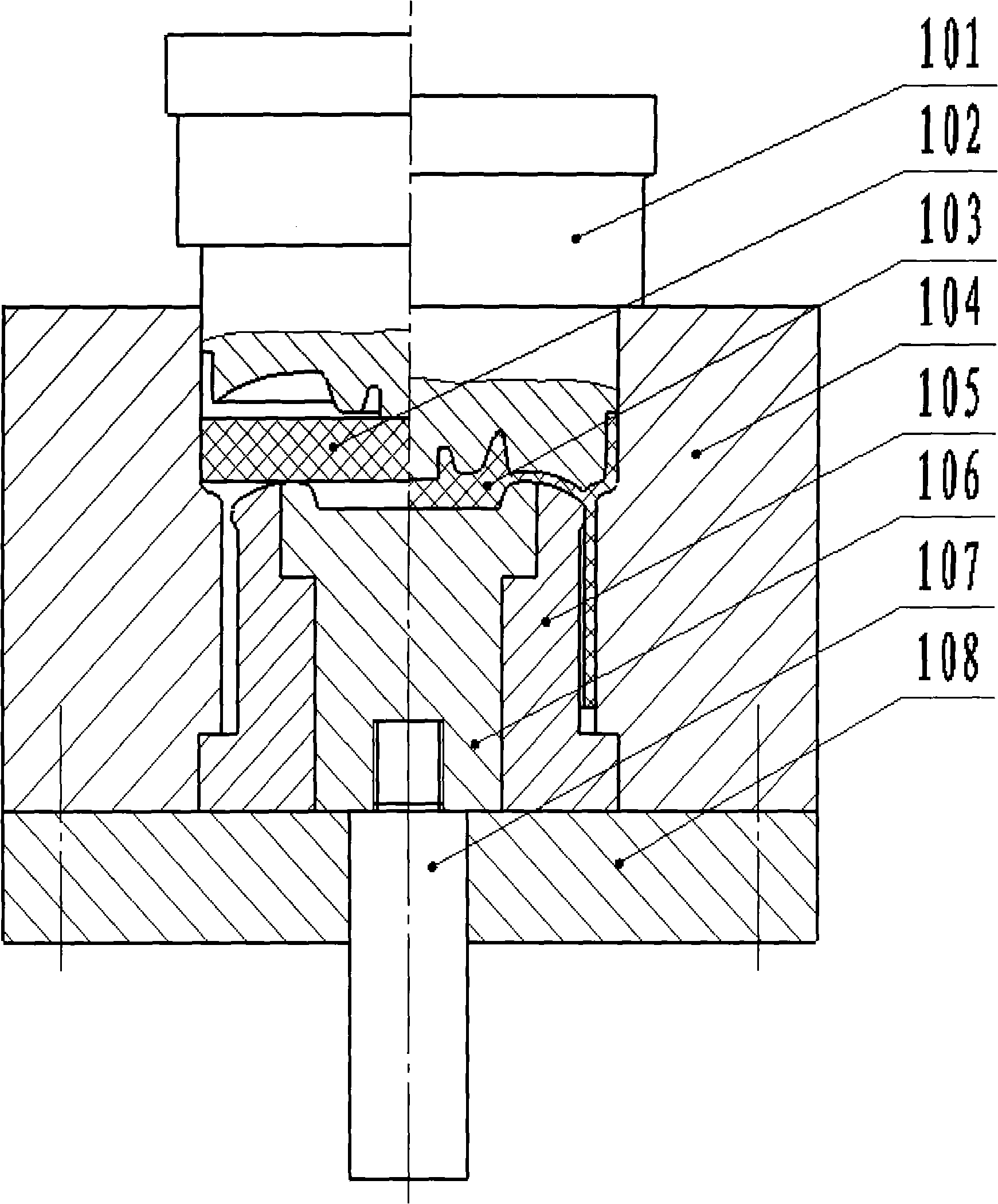

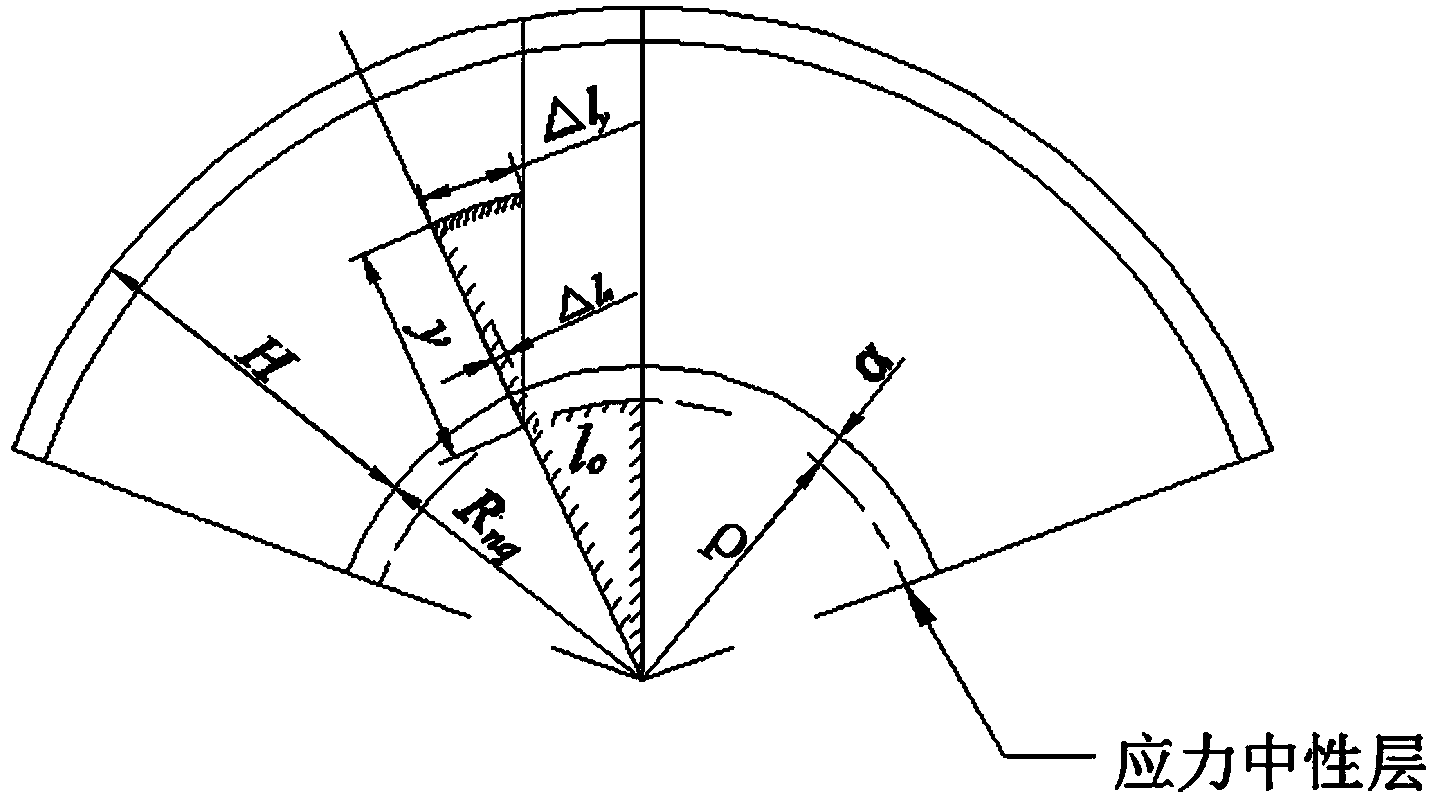

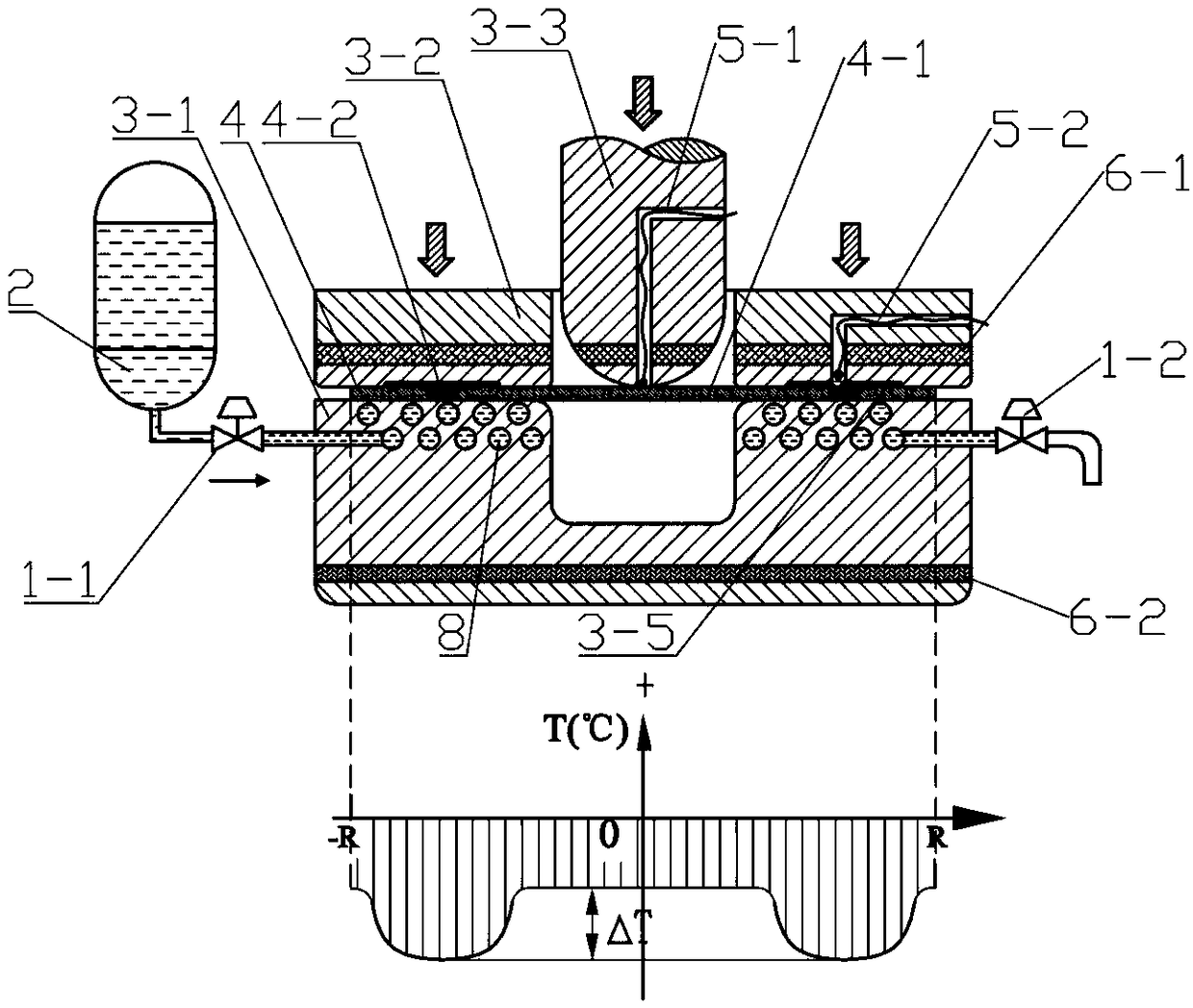

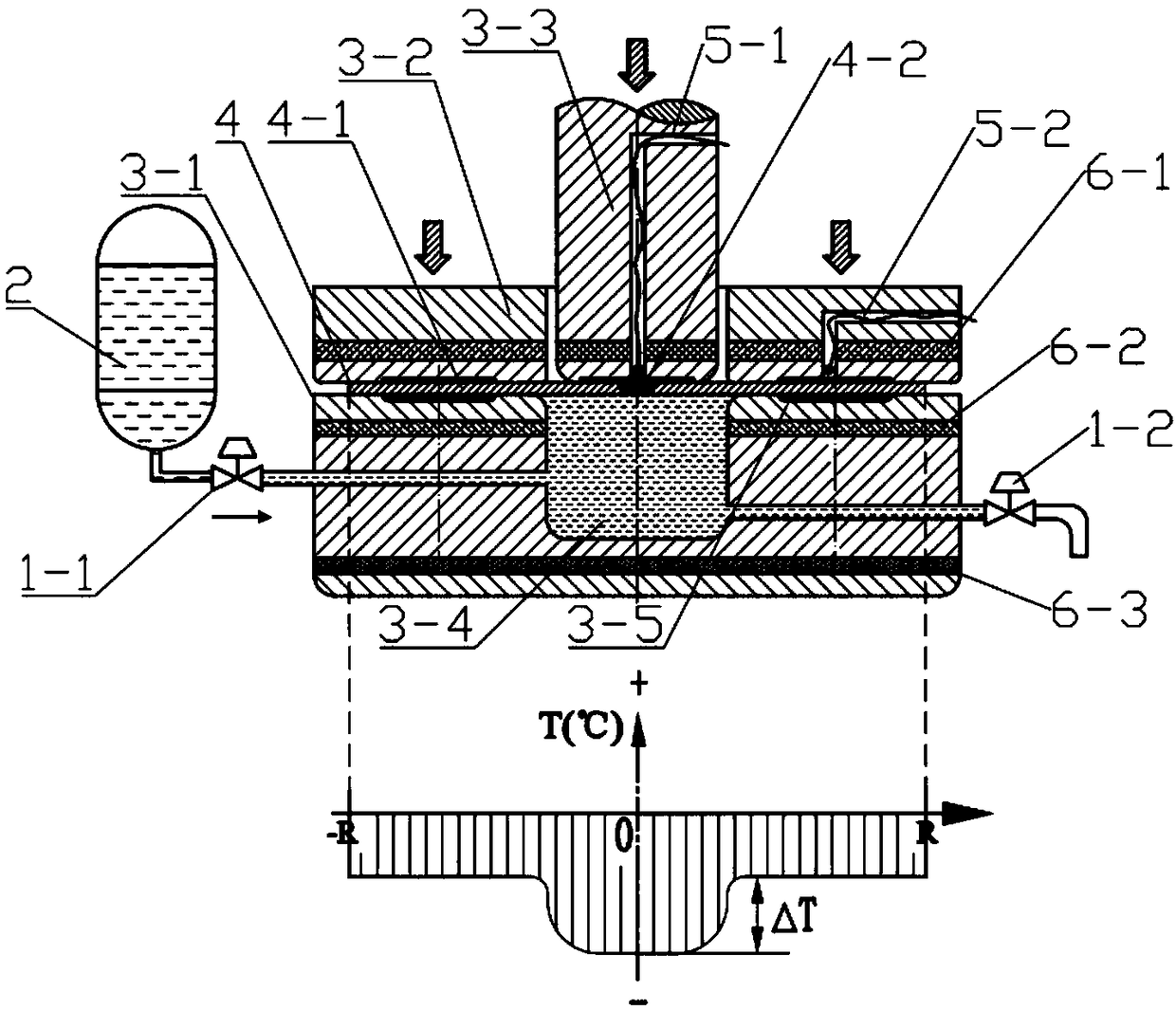

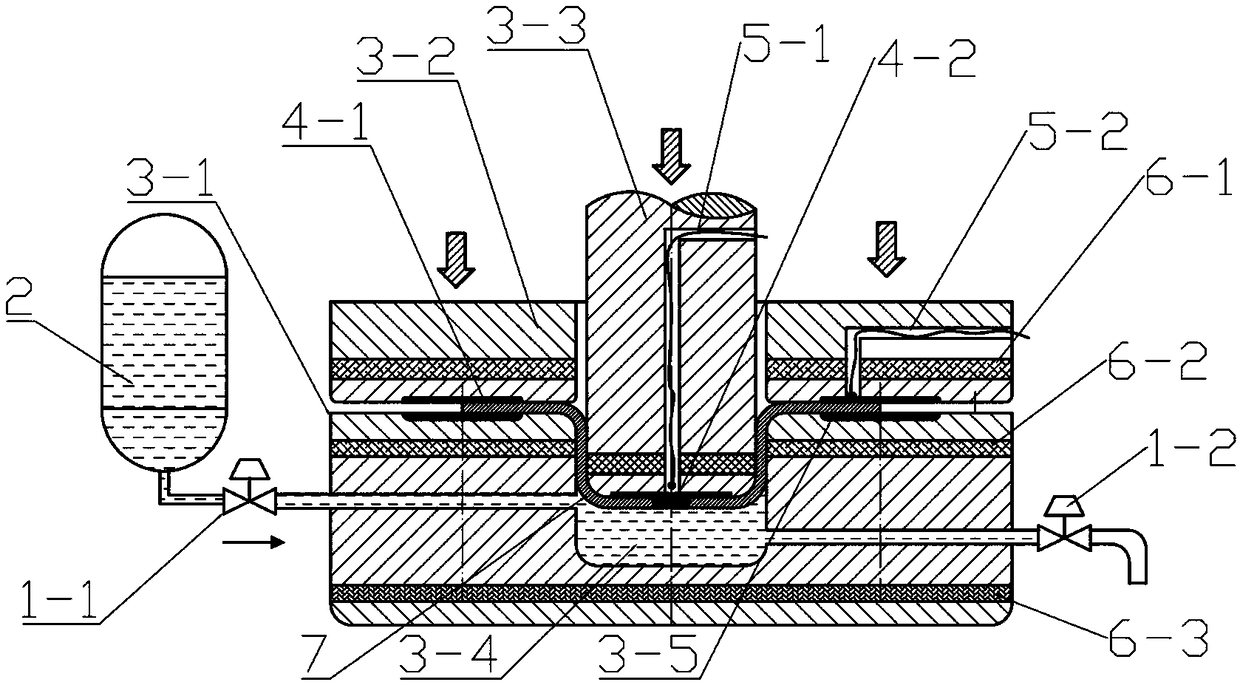

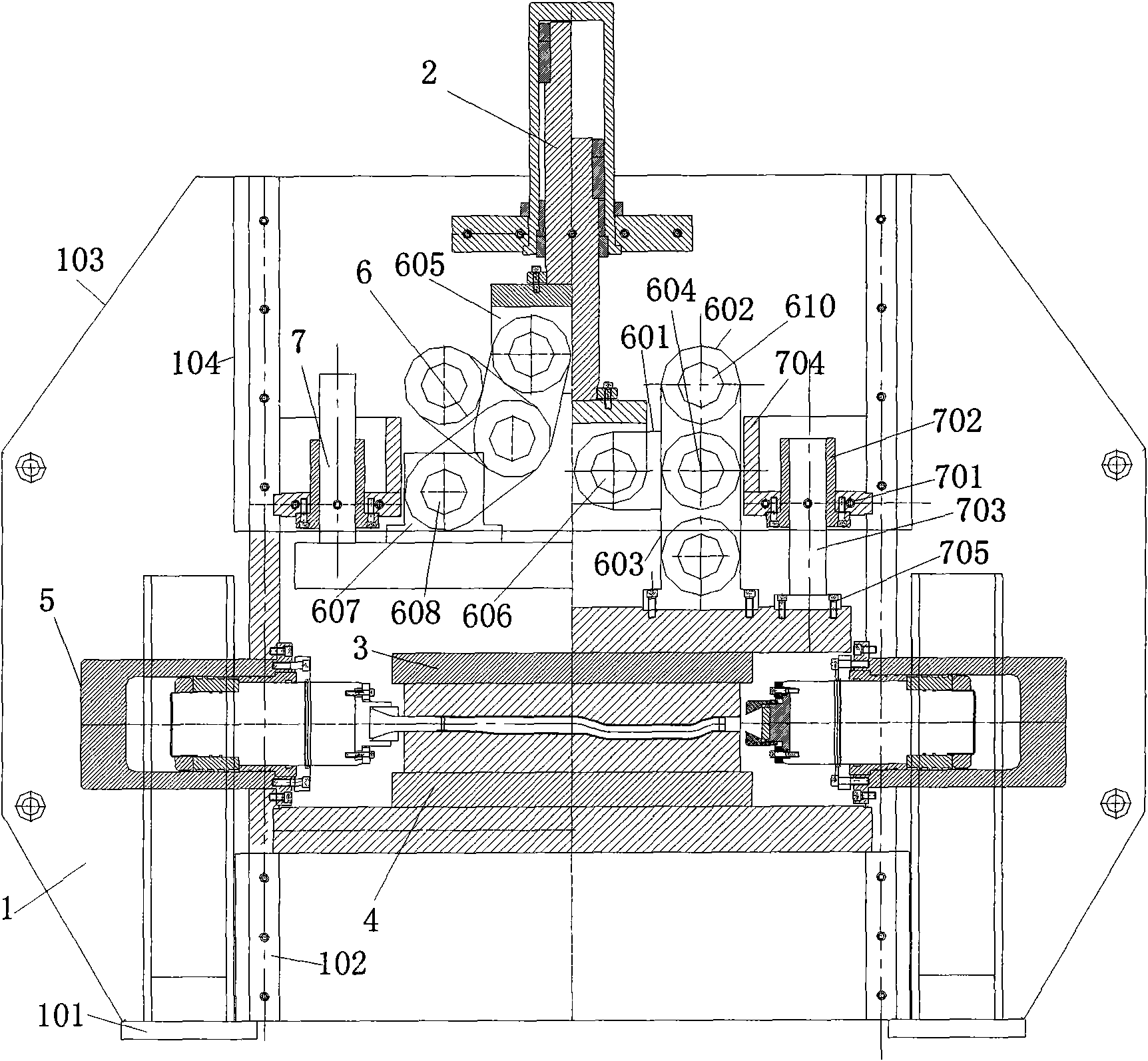

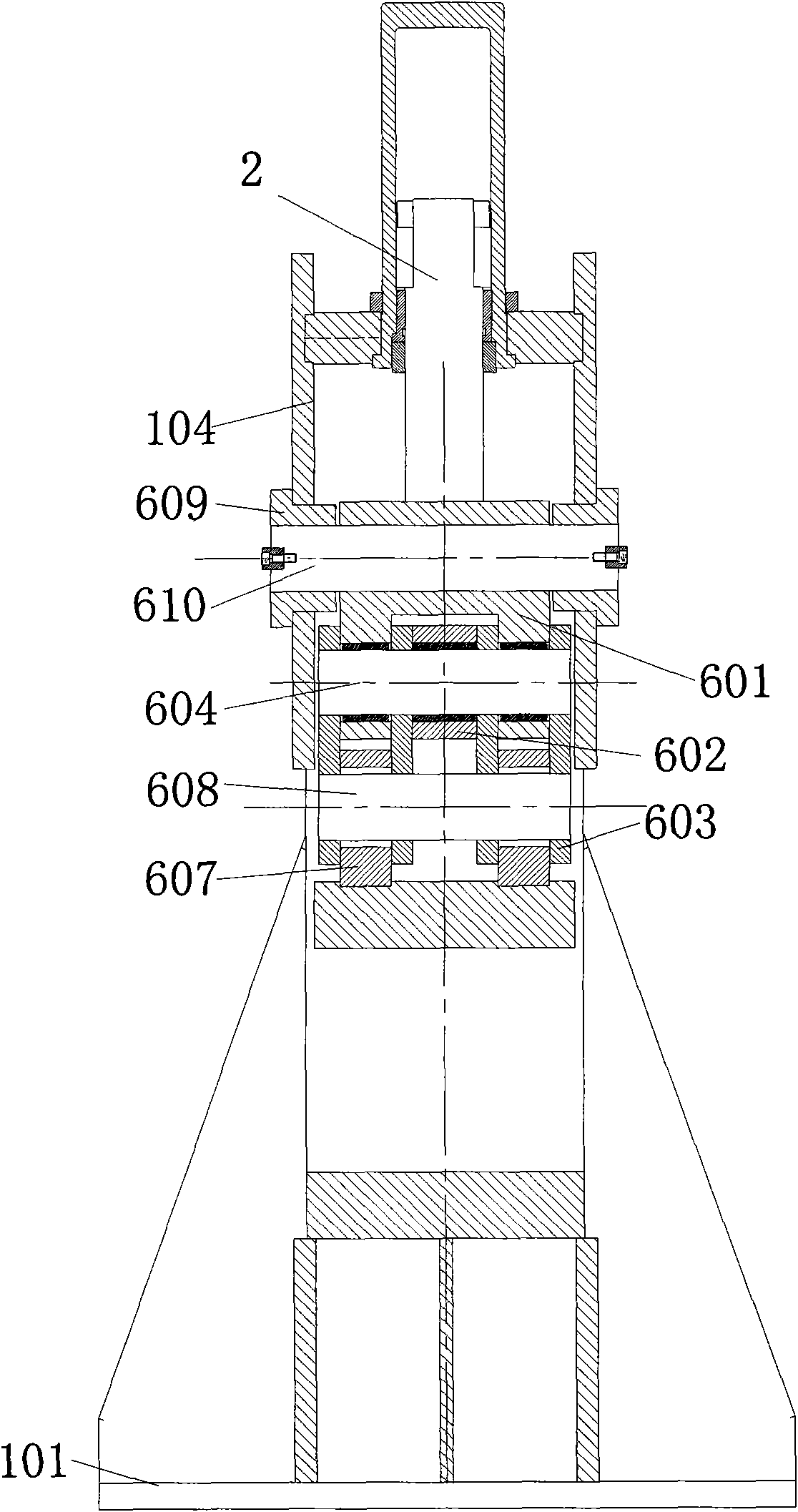

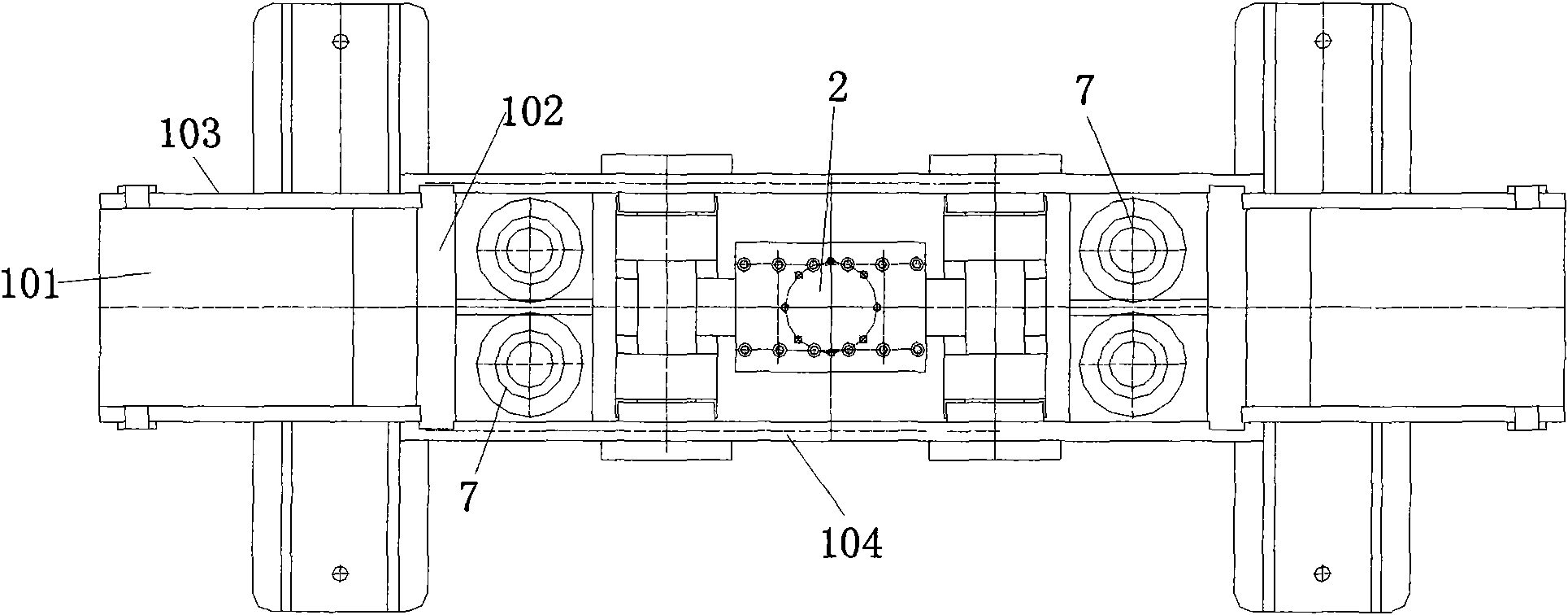

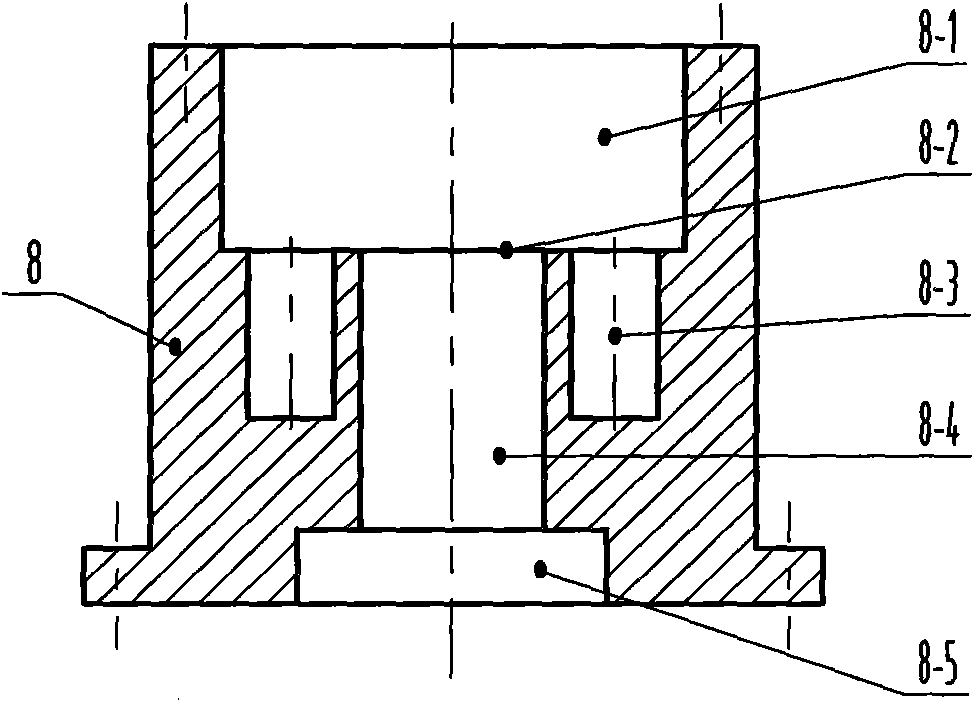

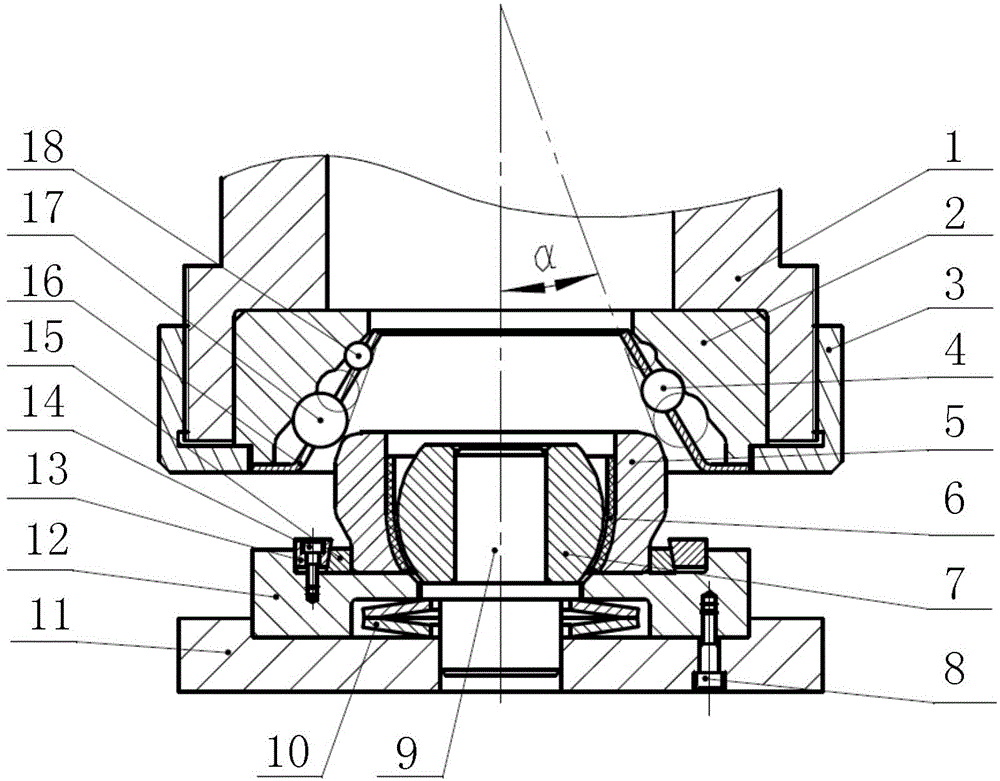

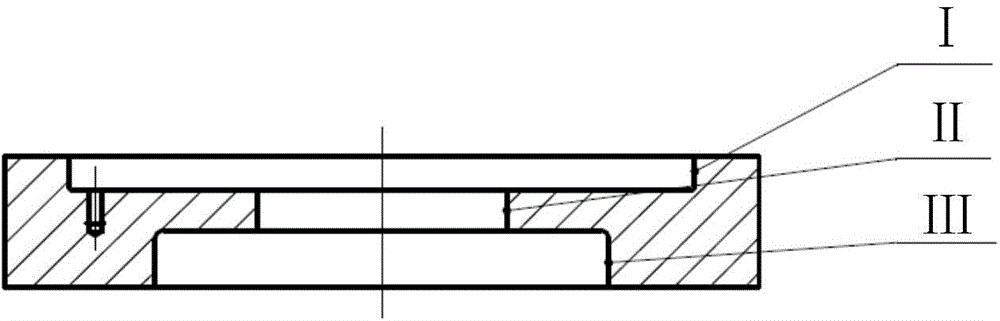

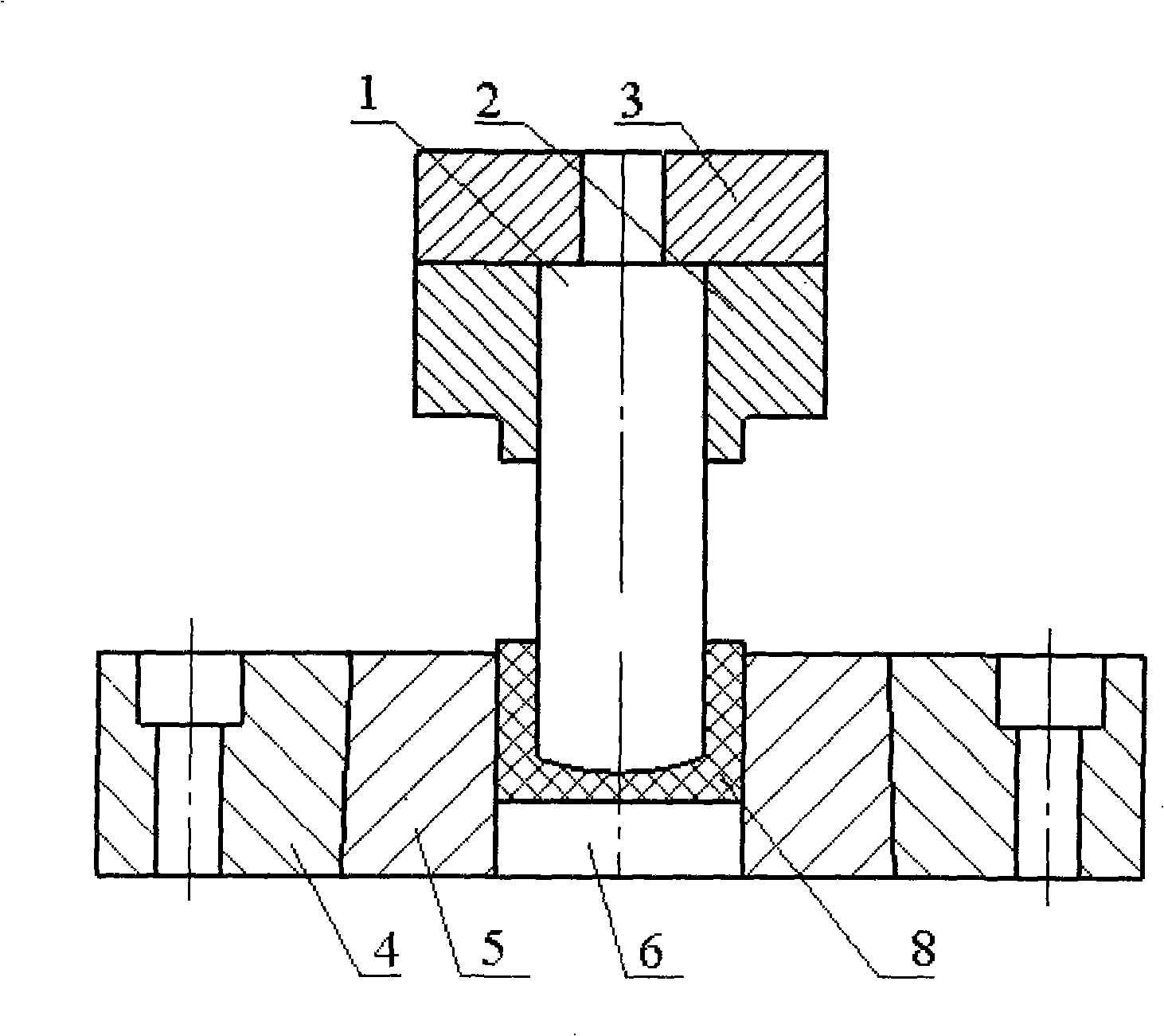

Process and device for forming magnesium alloy loading wheel disc through combined extruding in radial direction and reverse direction

The invention discloses a process and a device for forming a magnesium alloy loading wheel disc through combined extruding in the radial direction and the reverse direction. According to the process and the device, the performance requirements and the structure characteristics of the loading wheel disc and the magnesium alloy deformation characteristic are combined, the device has the main characteristic that a radial-reverse combined extruding mold is adopted; the process is characterized in that the radial-reverse combined extruding process is as follows: an annular blank is prepared by radial and reverse combined extruding of a fixing male die matched with a following male die, metal materials flow towards the directions vertical to and parallel to the movement of the male die simultaneously under the action of the fixing male die, a loading wheel spoke plate is formed due to the metal radial flowing, the metal flowing is limited by the following male die to meet the required size of a bottom hole, a loading wheel disc rim part is formed due to the metal forward and reverse flowing, and the reverse flowing is characterized in that the required height is reached through open type filling; the product performance is improved, the forming force is reduced, and the application of the magnesium alloy loading wheel disc on a crawler can be realized.

Owner:ZHONGBEI UNIV

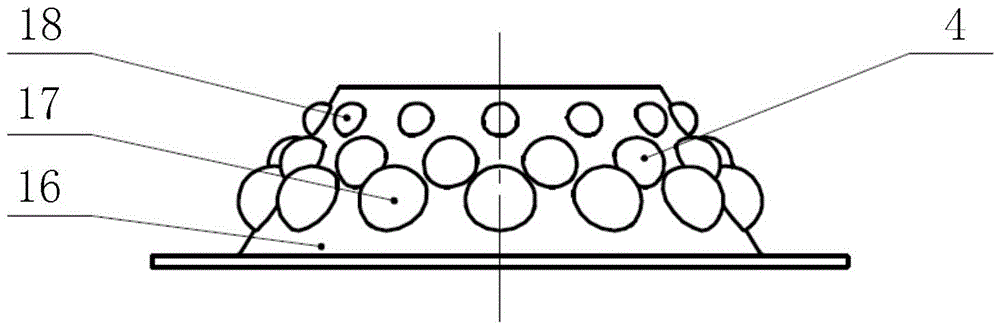

Ball-spinning device and method of integrated outer ring typed self-lubricating spherical plain bearing

The invention relates to a ball-spinning device and a method of integrated outer ring typed self-lubricating spherical plain bearing. An upper die holder of the device is provided internally with inner conical rings, retainers are fixed to the inner conical rings to constrain large, medium and small groups of balls in the corresponding raceways, a mandrel is mounted in a center counter bore of a baseplate, and the baseplate is connected with a lower die through bolts. The method includes processing the inner surface of the outer ring blank of the spherical plain bearing into a process optimized shape, and attaching a self-lubricating layer thereto; allowing the inner surface of the forming side of the outer ring blank to fit on the inner ring of the bearing in a shape follow-up mold by the aid of the forming device; and performing turning and grinding to the end face and the outer surface of the outer ring of the bearing to obtain the integrated outer ring typed self-lubricating spherical plain bearing. During the forming process, the inner ring of the bearing is flexibly contacted with the outer ring of the bearing, thus no damage to the self-lubricating layer occurs, ball flow forming transformation is uniform, forming force is small, and ease in controlling can be achieved.

Owner:QINHUANGDAO HUALIN PRECISION BEARING TECH

Special-shaped curved surface stator precise compound plasticity shaping process and die

ActiveCN101284343AIncrease profitReduce processing costsShaping toolsExtrusion diesThermoplasticAbnormal shaped

The invention discloses a precise compound plastic forming method of a special shaped curved surface stator of a steering pump. The method is carried out with the following steps: blanking, heating the stock to a full-recrystallization temperature plus or minus 10 DEG C and holding; pre-heating a thermoplastic inverted extrusion mould to a temperature of 200 DEG C-400 DEG C, brushing a lubricant on the mould, placing the stock in the thermoplastic inverted extrusion mould to extrude and obtaining the rough with a single-side working allowance of the inner-type cavity curve of less than or equal to 0.4mm; then heat treating, eliminating the residual stress, processing the upper and the lower end surface of the rough until the depth of parallelism thereof is less than or equal to 0.02mm, placing the rough in a cold-trimming mould for trimming at cold state until the single-side working allowance is 0.15mm-0.25mm; processing positioning holes with a position tolerance of less than or equal to Phi 0.02m, hear treating again until the rigidities of surface and core meet the requirement, grinding and obtaining the special shaped curved surface stator of the steering pump. The inventive method is characterized by small forming force, good forming quality, high production efficiency and low cost, and the formed parts have high abrasion resistance and fatigue resistance.

Owner:CSIC NO 12 RES INST

Progressive forging forming method for large cake forged pieces

The invention discloses a progressive forging forming method for large cake forged pieces. The method comprises the following steps of: installation and regulation; first single-side forming; second, third and fourth single-side forming; multiple turnover forming; and rounding and reshaping. By adopting progressive anvil distribution and anvil conveying modes, progressive contact of anvils and forged pieces in each anvil pressing process is ensured; three-directional pressure stress is provided for promoting elimination and recovery of internal gap defects; single metal flowing direction is improved; because of the adoption of progressive forging, local deformation is asynchronous, press load is reduced, the production efficiency of equipment is improved, the forming force is reduced, and high work efficiency with the small equipment is realized; and small forging ratio formation can be realized, and the processing period is shortened so as to reduce the production cost.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com