Three-dimensional multi-curvature part bending method

A three-dimensional multi-curvature, stretch-bending forming technology, applied in image data processing, special data processing applications, instruments, etc., can solve the problems of high cost, long cycle, manual shape correction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

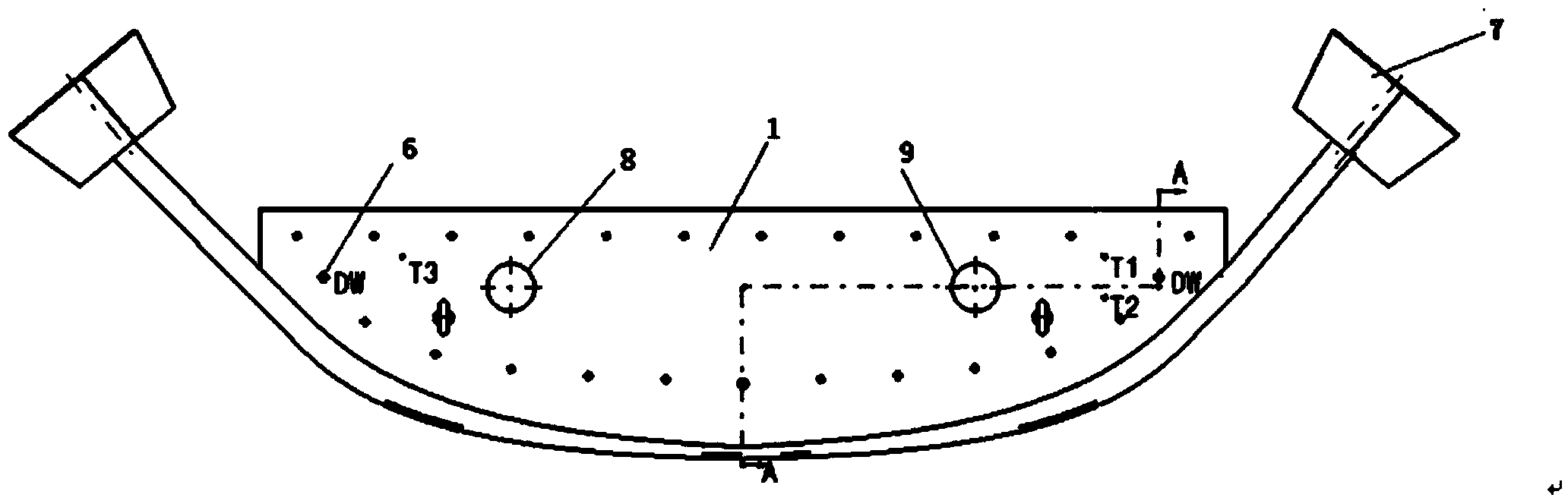

[0130] After the curvature analysis of the part, the surface with the smallest average curvature change is selected as the horizontal plane of the mold, the forming force of the part is calculated according to the cross section and tensile strength of the part, the appropriate stretch bending machine is selected, and the mold is determined according to the model of the selected stretch bending machine. Install the interface.

Embodiment 2

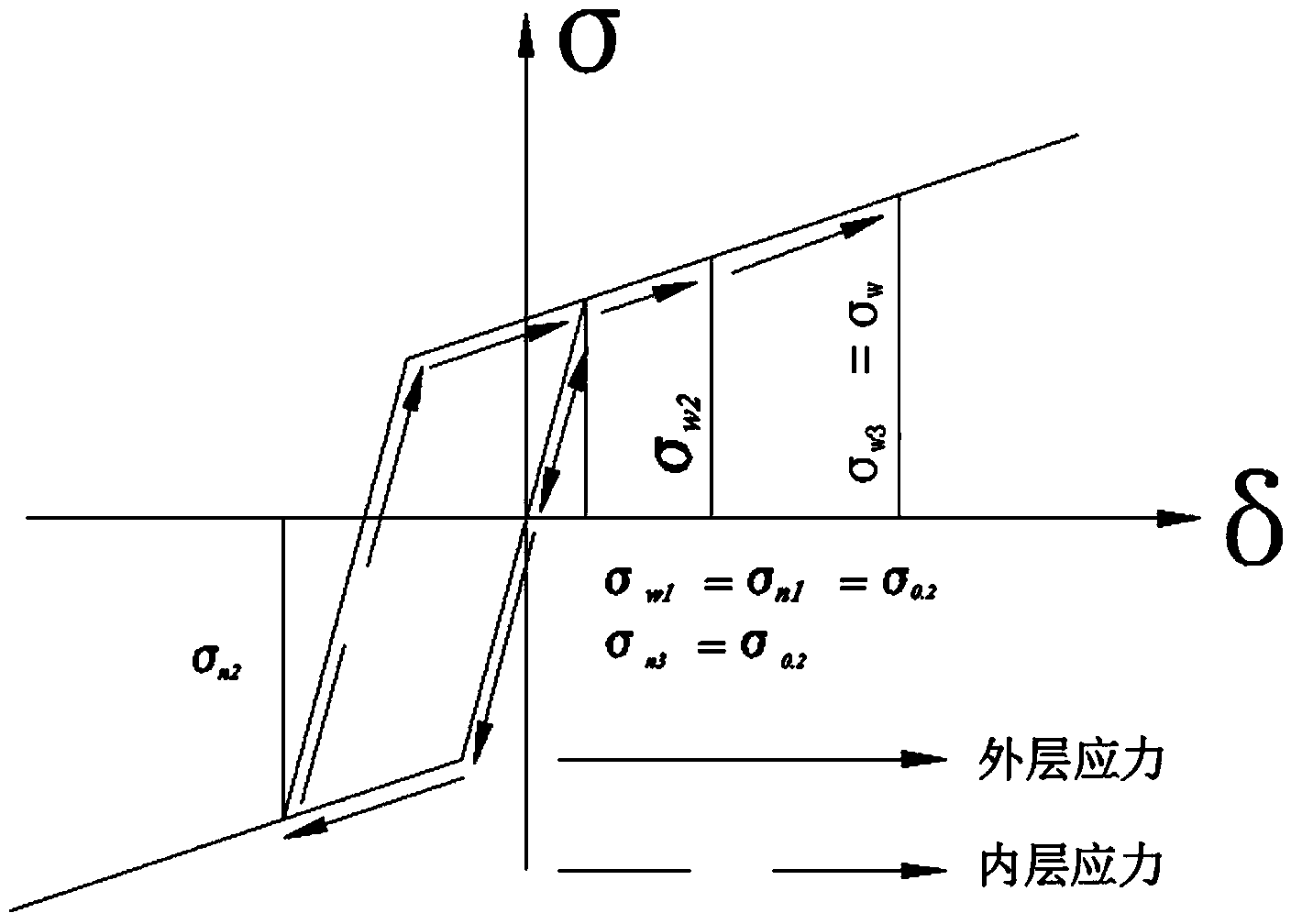

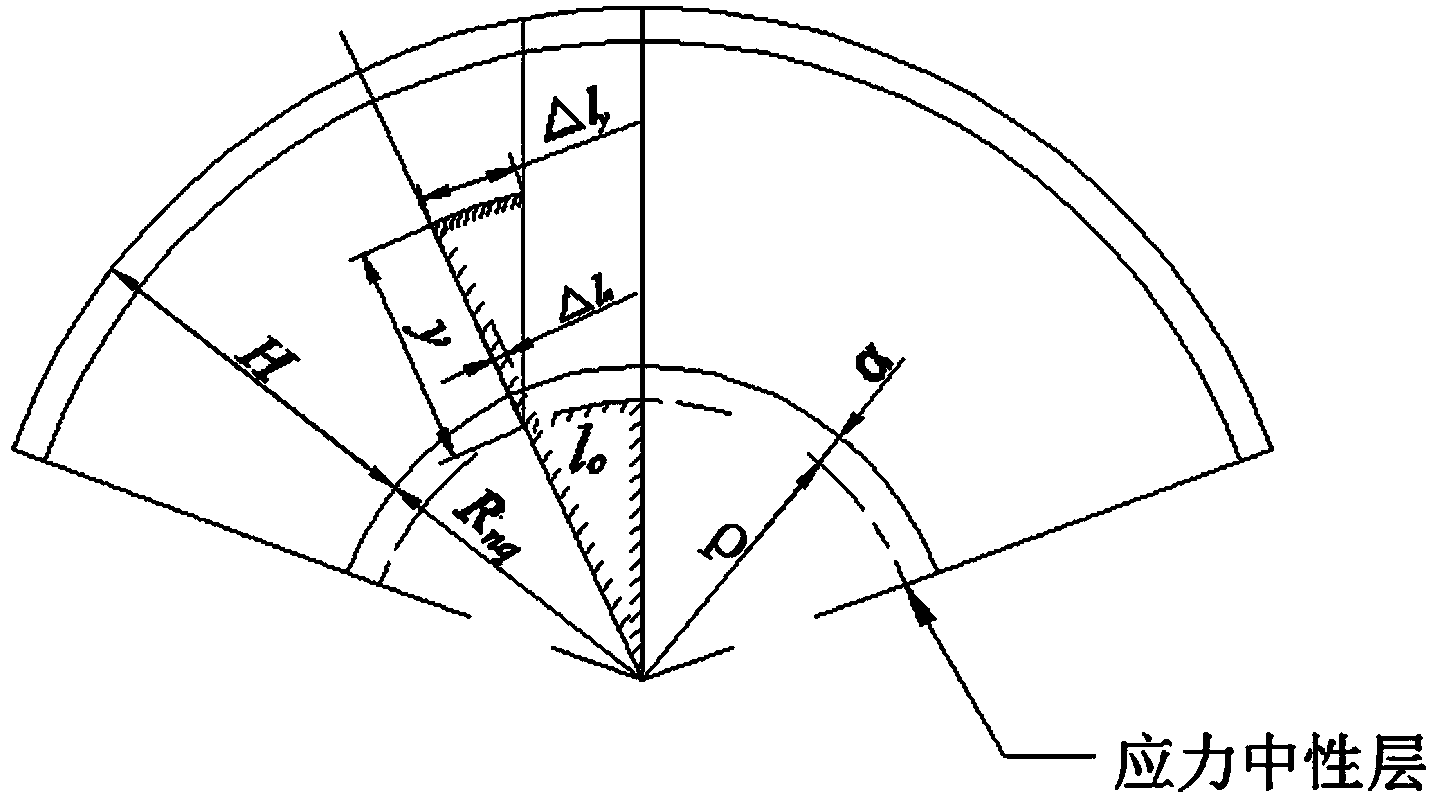

[0132] Using computer-aided design, using bending springback theory analysis, finite element simulation of stretch bending forming, predicting the deformation during the forming process, as well as the deformation and stress distribution of parts, optimizing the forming process parameters, and performing springback compensation on the mold surface Correction, through human-machine exchange, repeated revisions until the molding results meet the production and use requirements, and the corrected mold surface is used for mold design and manufacturing.

Embodiment 3

[0134] Design suitable tension bending chucks. Stretch bending of profiles requires the matching of stretch bending chucks to be used in conjunction with stretch bending dies and machine tools, and different machine tools are matched with different stretch bending chucks. The center of the stretch chuck needs to coincide with the centroid of the part. Calculates the center of the collet from the section of the part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com