Patents

Literature

148results about How to "Reduce correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

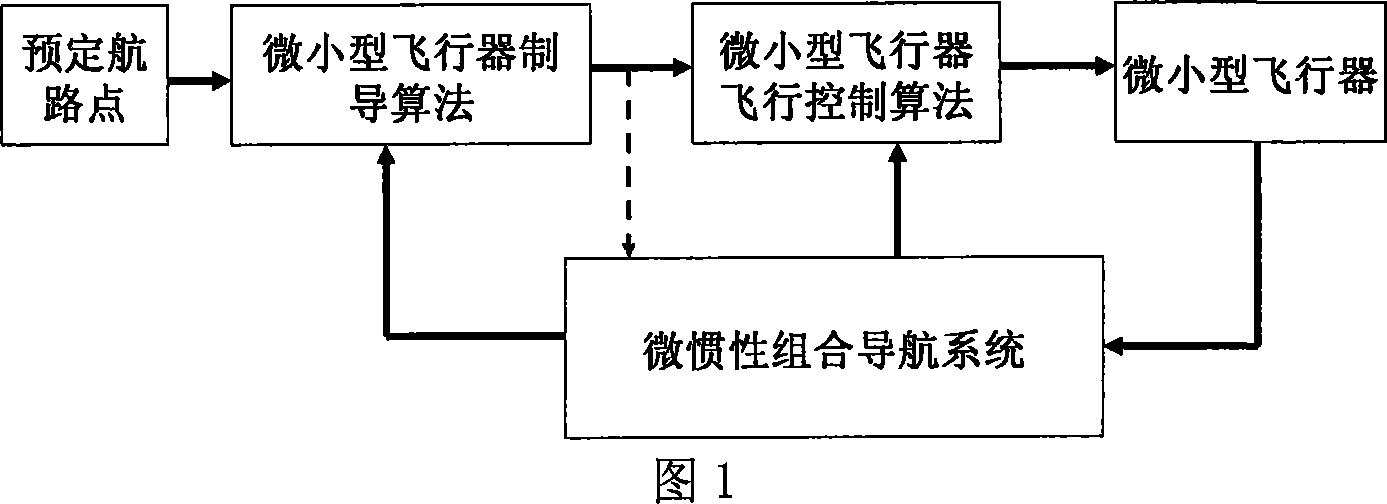

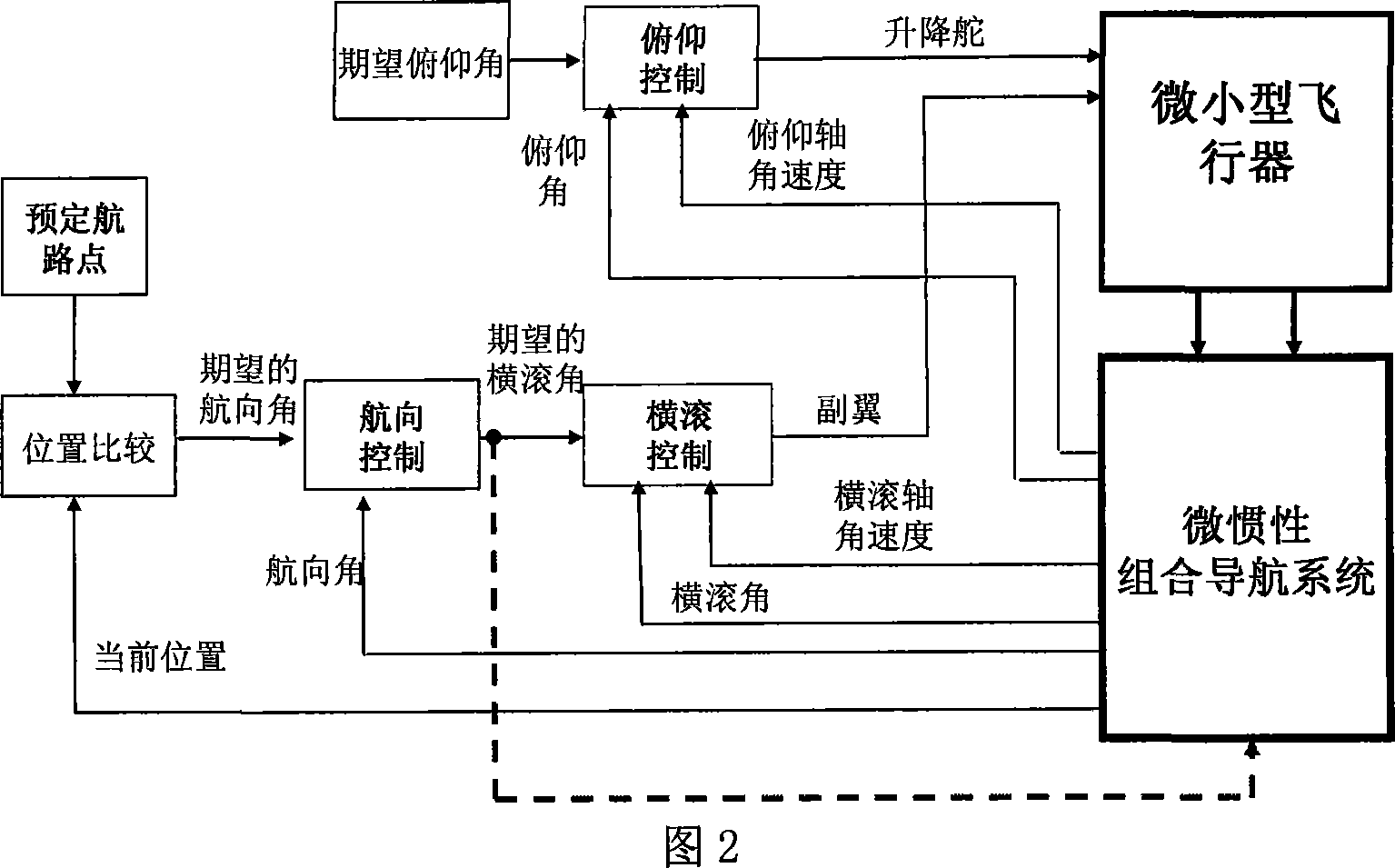

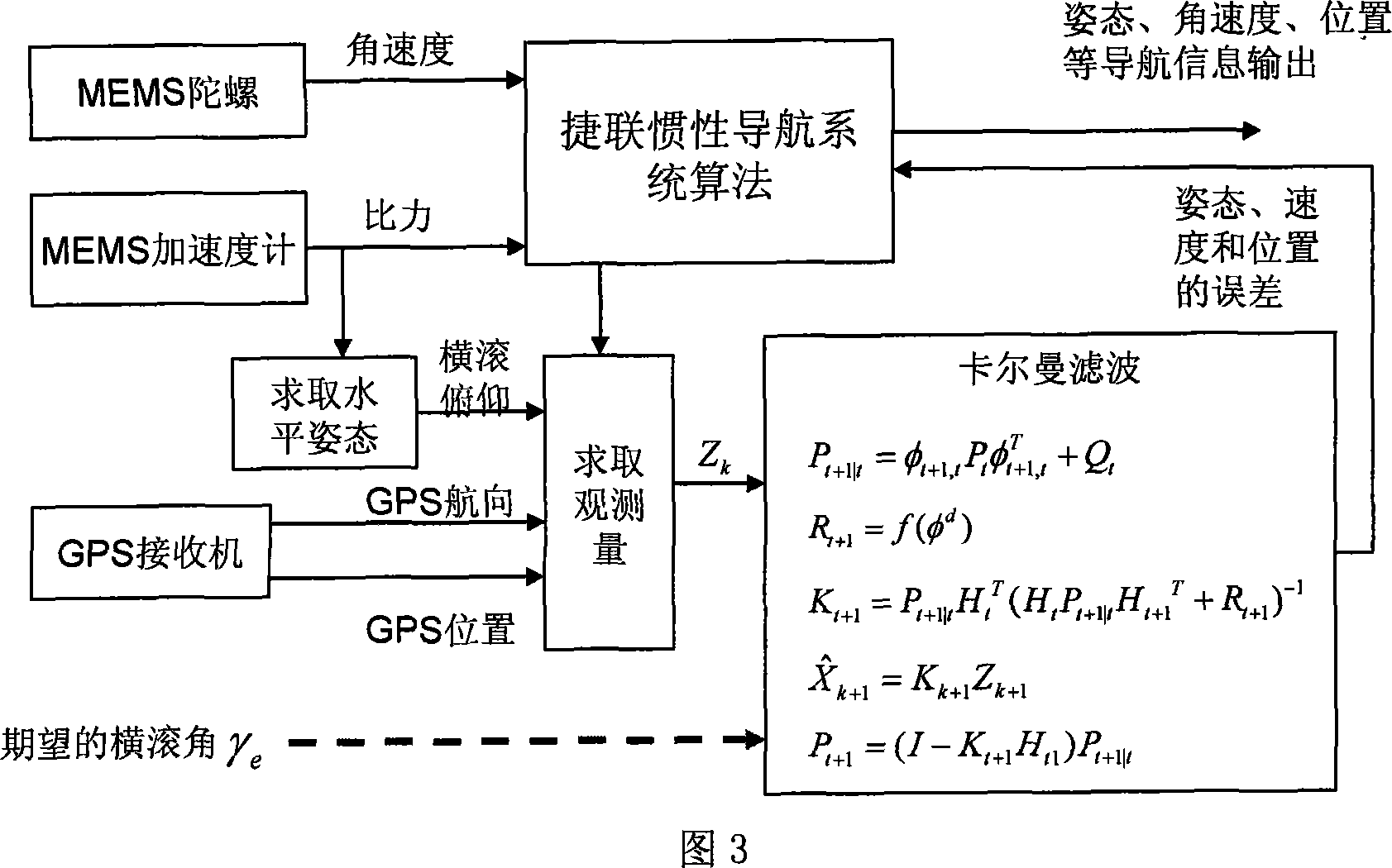

Attitude determination method of mini-aircraft inertial integrated navigation system

InactiveCN101033973AImprove flight qualityHigh precisionNavigation by speed/acceleration measurementsGuidance systemAccelerometer

This invention relates to a kind of attitude definition method of micro inertia mixed navigation system of microminiature aero craft, belongs to microminiature vehicle attitude definition method. The method utilize guidance information, control Kalman filter noise matrices, to realize self-adapting adjust according to flight status; through parameter adjust to realize attitude definition of micro inertia mixed navigation system on dynamic airborne conditions; the specific process: through GNC closed loop circuit guidance algorithm, to gain aero craft barrel angle; through sensor picking, obtain vehicle rate and specific force; by strap inertial navigation algorithm to resolve out vehicle attitude, velocity and position information; by accelerometer and GPS data to count pose and position measurement information of aero craft; real-time compute horizontal attitude variance of Kalman filter observation noise matrices, through Kalman filter to estimate error of strap inertial guidance system; Amend above acquired pose, velocity and position information, and took as feedback information to import in control system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

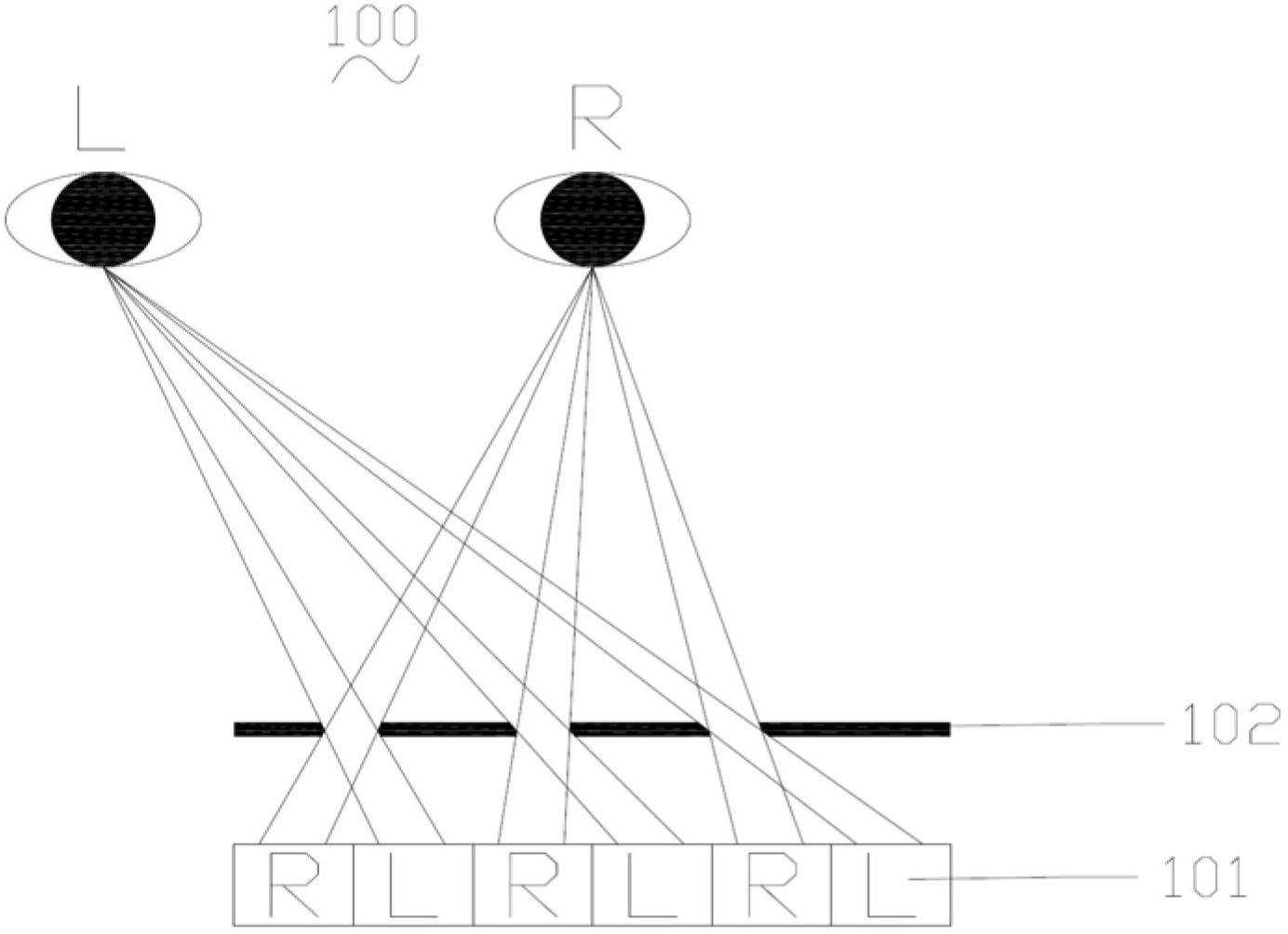

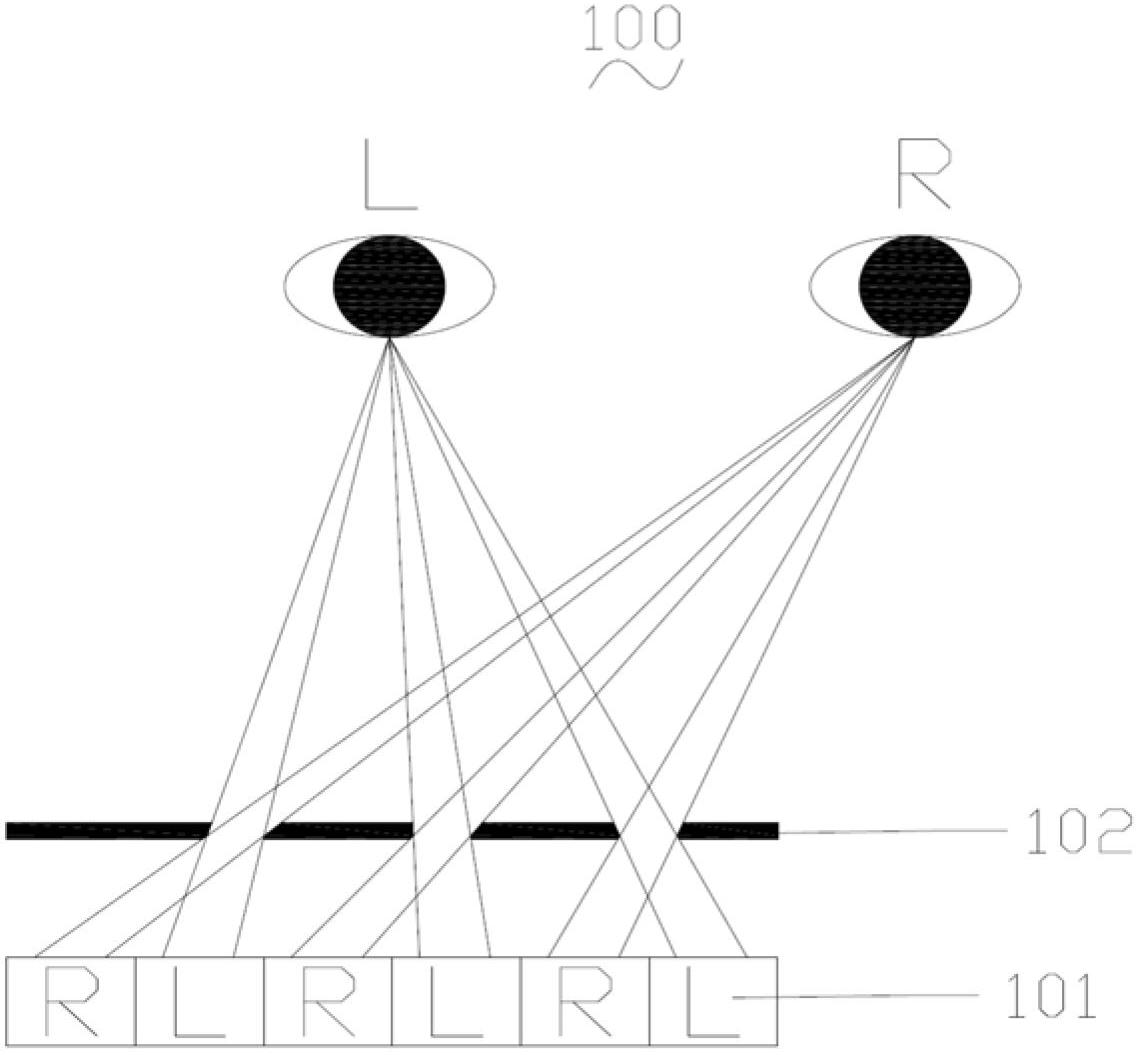

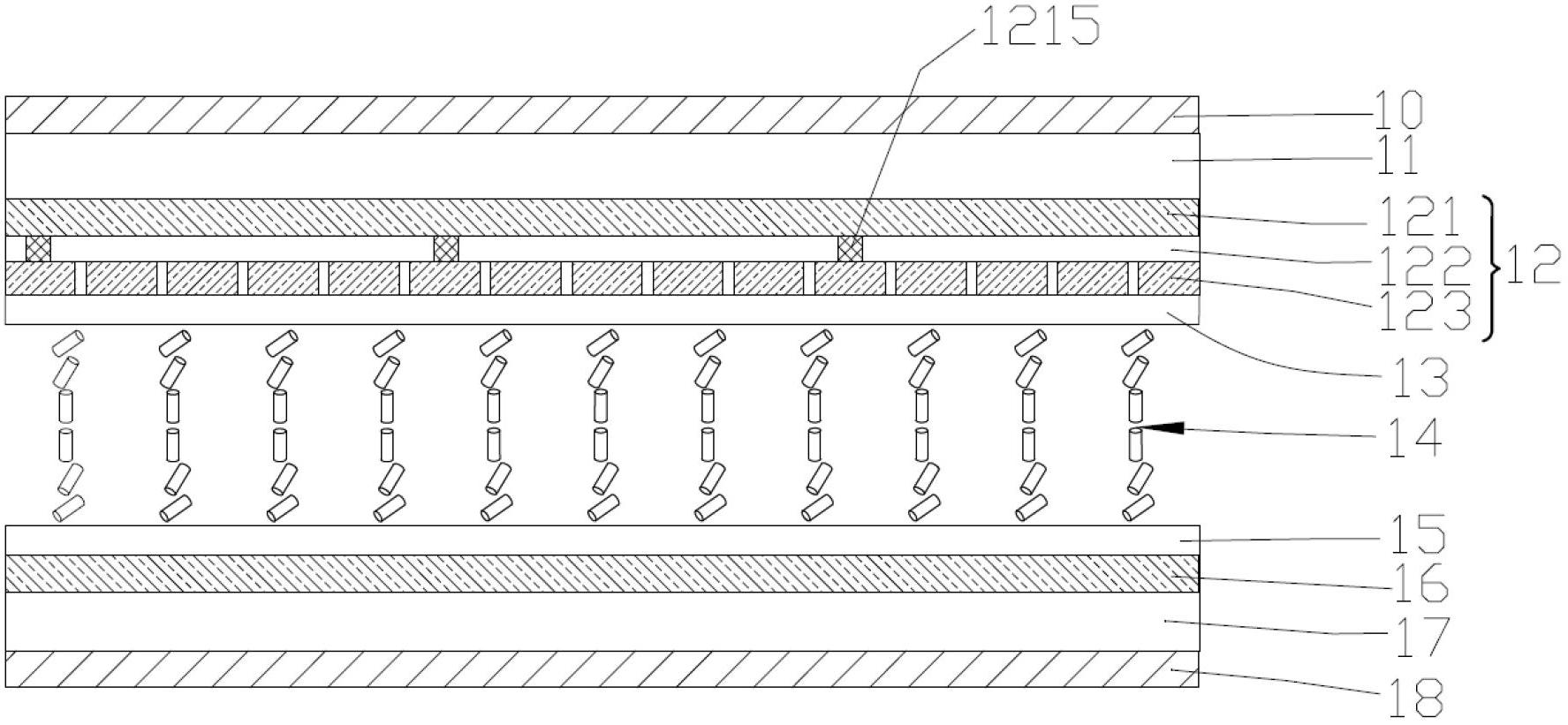

Liquid-crystal slit grating, stereoscopic display device and calibration method of stereoscopic display device

ActiveCN102662283AAdapt to stereoscopic display requirementsStrong ability to correct fit deviationSteroscopic systemsNon-linear opticsElectricityGrating

The invention provides a liquid-crystal slit grating which comprises a first polaroid, a first substrate, a drive electrode structure, a first direction distribution layer, a liquid crystal layer, a second direction distribution layer, a public electrode structure, a second substrate and a second polaroid in sequential stacked arrangement. The drive electrode structure comprises a drive electrode layer and a lead layer, the drive electrode layer comprises multiple bar-shaped drive electrodes which are arranged in parallel. The multiple bar-shaped drive electrodes are grouped into a plurality of drive electrode groups. Each drive electrode group includes N drive electrodes. The lead layer comprises N lead electrodes. The N drive electrodes in each drive electrode group are electrically connected with the N lead electrodes in one to one correspondence. The invention further provides a stereoscopic display device with the liquid-crystal slit grating and a calibration method of the stereoscopic display device. The liquid-crystal slit grating and the stereoscopic display device have the advantages of automatic adjustment and simplicity in the calibration method.

Owner:芜湖天马汽车电子有限公司

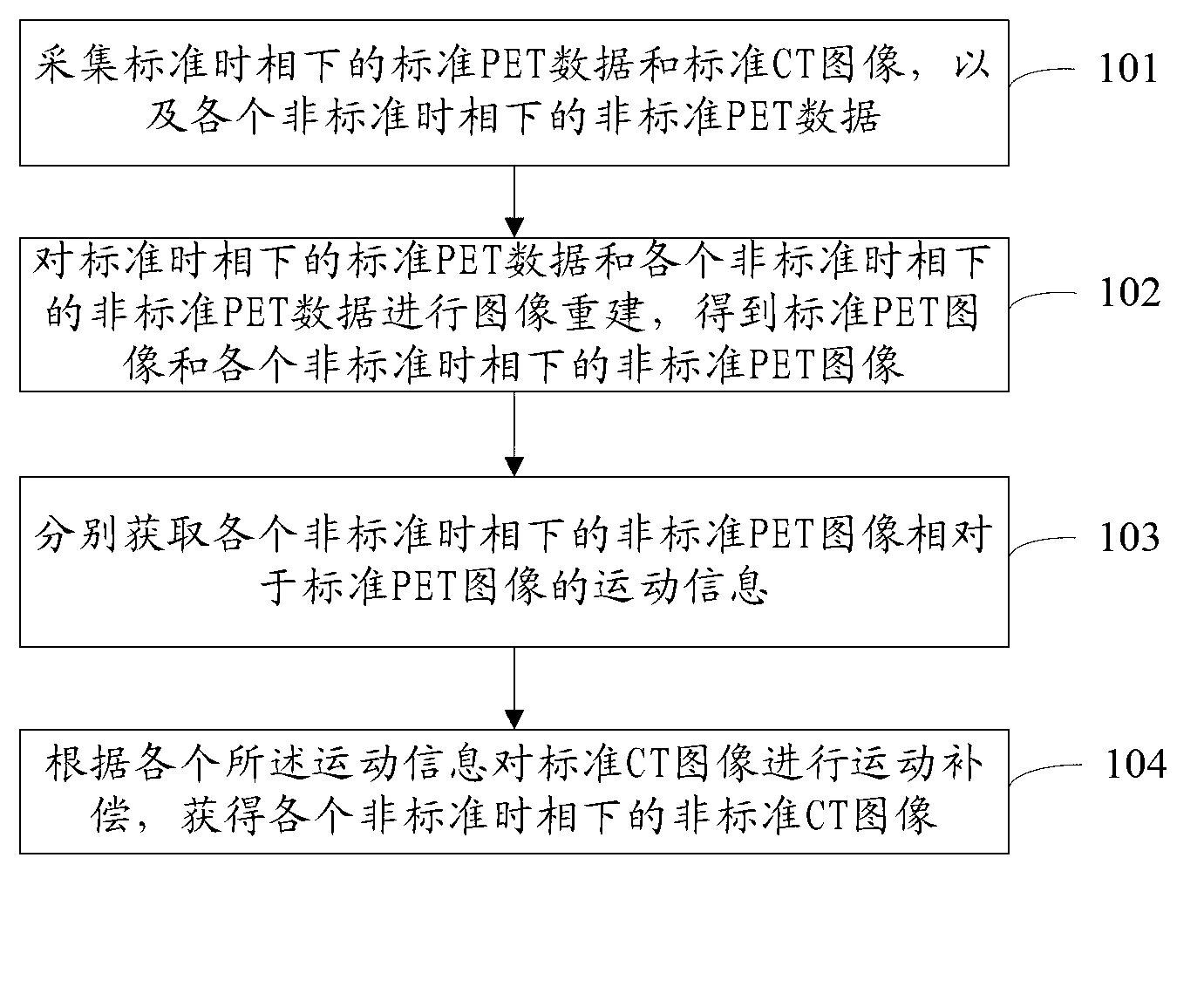

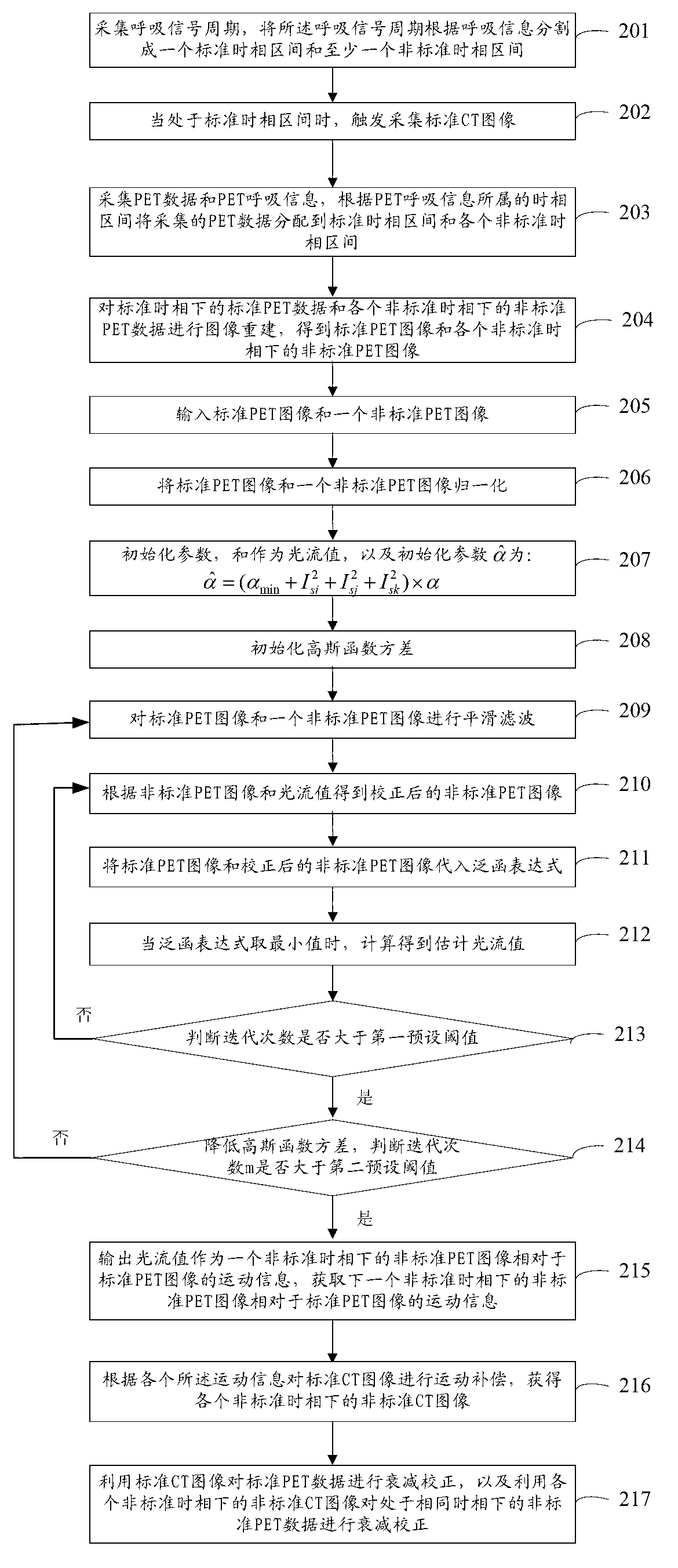

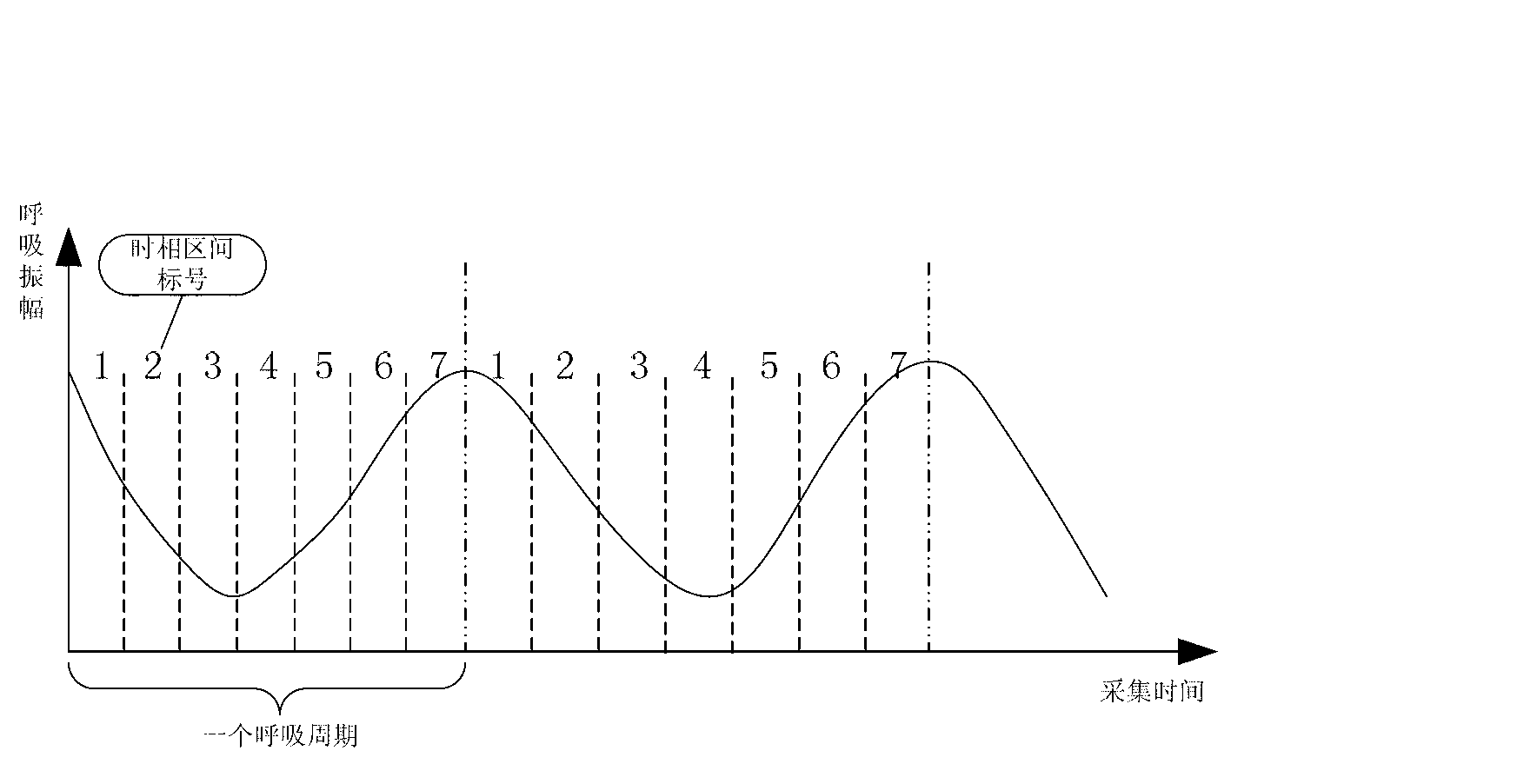

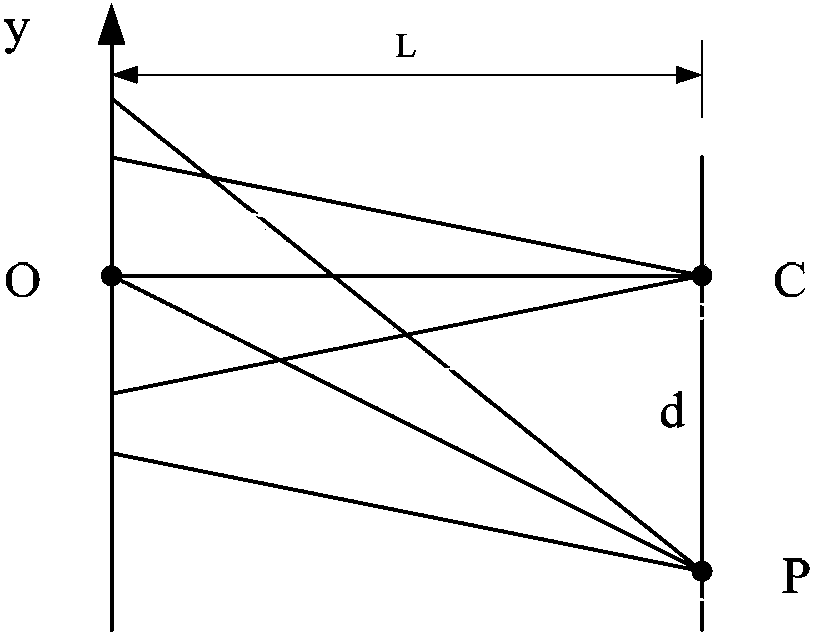

Attenuation rectifying method and system

ActiveCN103054605AReduce correctionImage enhancementComputerised tomographsUltrasound attenuationComputed tomography

The invention discloses an attenuation rectifying method and system. The attenuation rectifying method includes: collecting standard polyethylene terephthalate (PET) data and a standard computed tomography (CT) image under the standard time phase and nonstandard PET data under various nonstandard time phases; performing image reconstruction on the standard PET data under the standard time phase and the nonstandard PET data under the nonstandard time phases to obtain a standard PET image and nonstandard PET images under the various nonstandard time phases; respectively obtaining the motion information of the nonstandard PET images corresponding to the standard PET image under the various nonstandard time phases; performing motion compensation on the standard CT images according to the various motion information to obtain the nonstandard CT images under the various nonstandard time phases; performing attenuation rectifying on the standard PET data through the standard CT image, and performing attenuation rectifying on the nonstandard PET data under the same time phase through the nonstandard CT images under the various nonstandard time phases so as to obtain the CT images of different phase intervals without repeated CT scanning.

Owner:SHENYANG INTELLIGENT NEUCLEAR MEDICAL TECH CO LTD

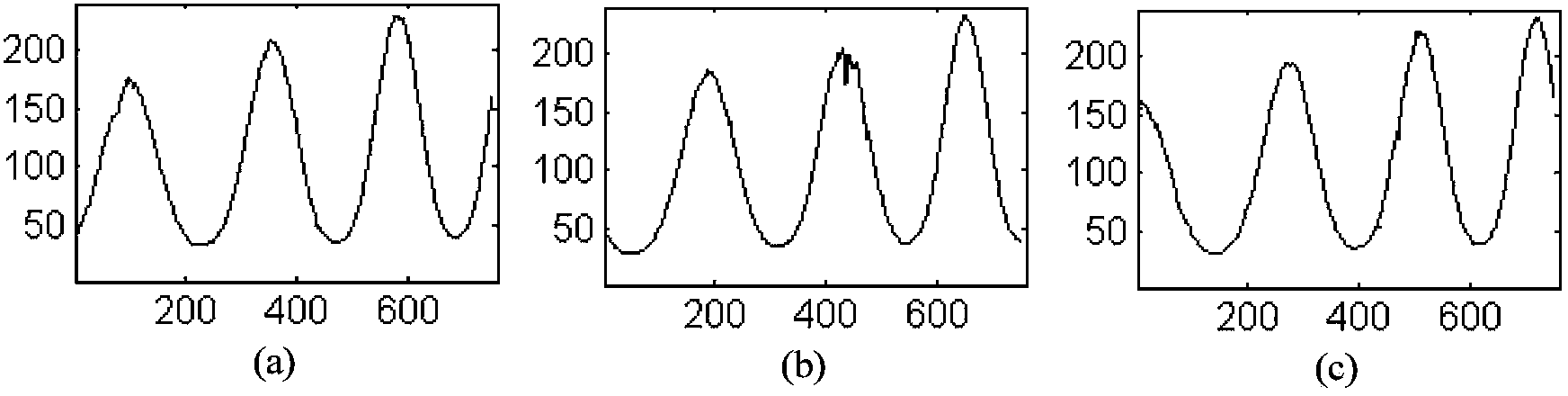

Gray fringe projection light intensity nonlinear correction method and phase correction method based on method

ActiveCN103383249ALight Intensity Correction DecreaseReduce correctionUsing optical meansPhase correctionComputational physics

The invention discloses a gray fringe projection light intensity nonlinear correction method and a phase correction method based on the method. Gray scale lookup tables are established for measurement datum planes and surfaces of objects to be measured respectively in fringe projection measurement, and light intensity correction is performed on actual measurement fringes of the measurement datum planes and the surfaces of objects to be measured, so that the light nonlinearity of the measurement fringes is reduced, and the phase measurement accuracy is improved. Not only is inherent light intensity gamma distortion of a projector and a camera considered, but also differences of light intensity reflection characteristics of the surfaces of the measurement datum planes and different areas of the objects to be measured in the setup procedure of the lookup tables are considered, so that the light intensity correction method is more effective than existing methods, corrected fringes are closer to ideal values, and the measurement accuracy can be improved substantially through the method.

Owner:XI AN JIAOTONG UNIV

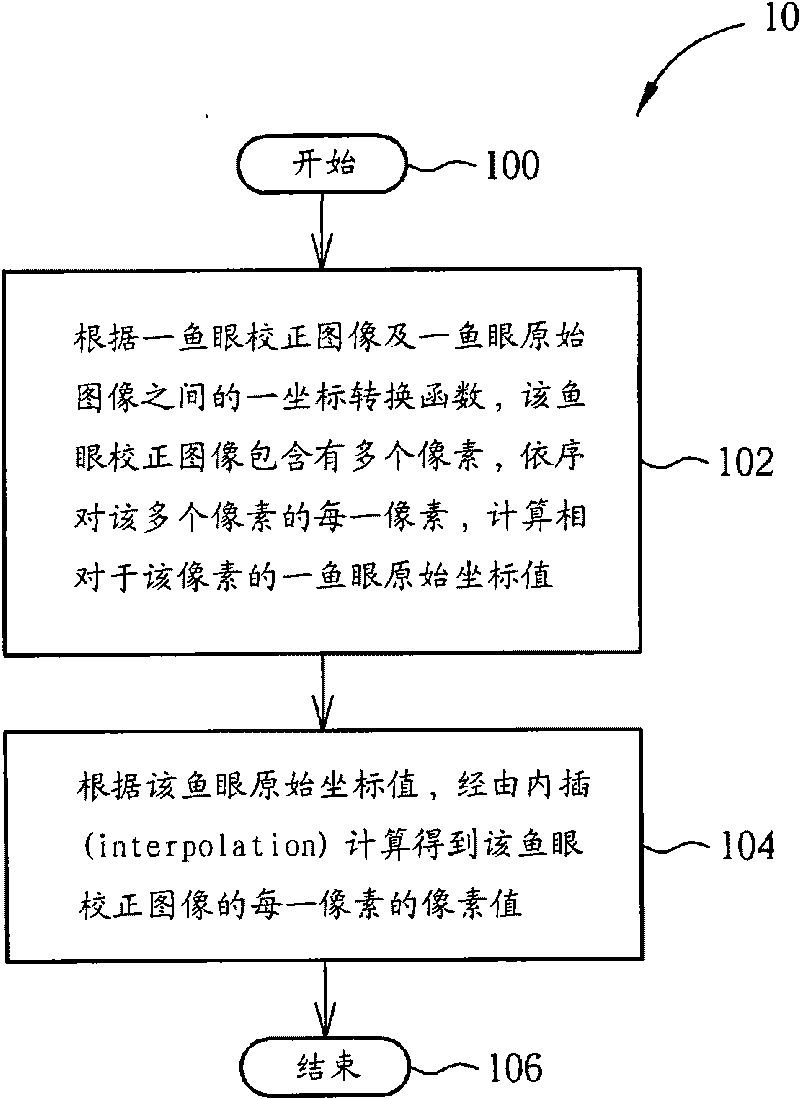

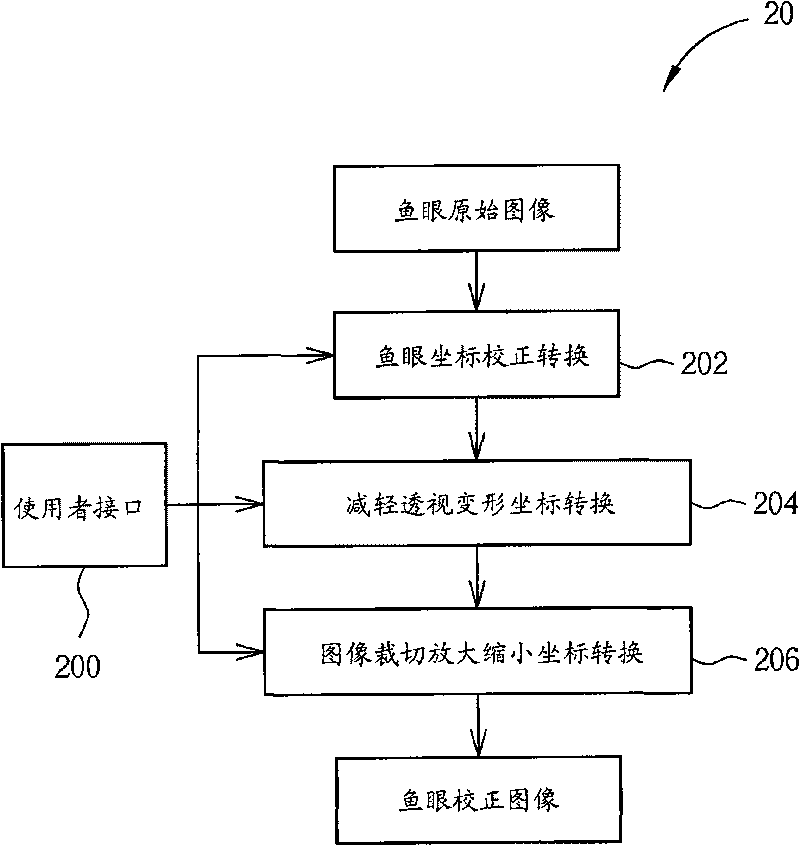

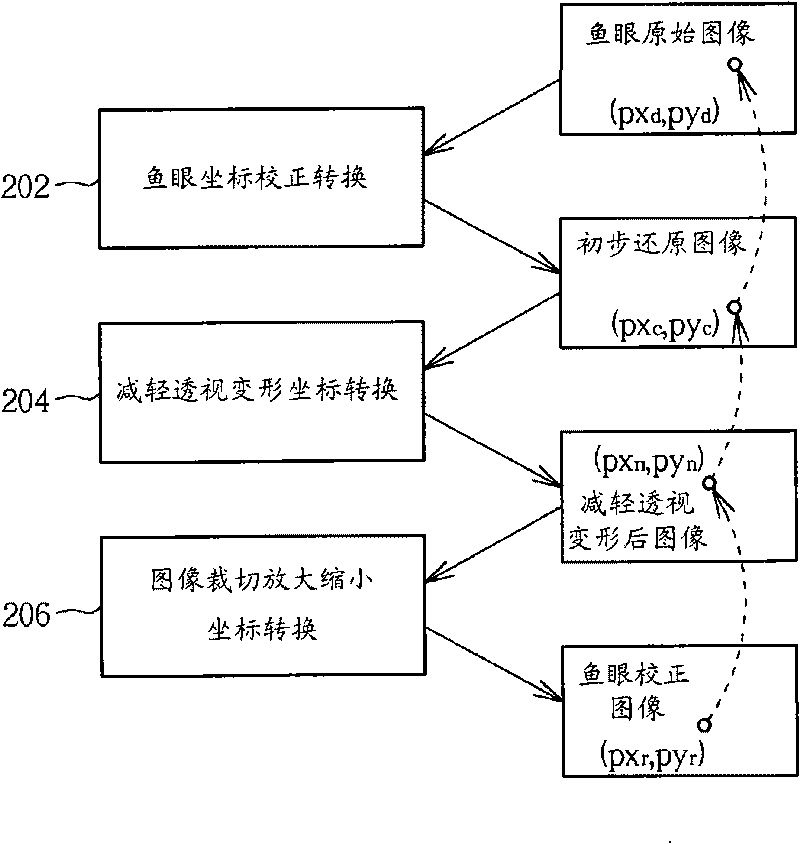

Image processing method and associated device for correcting fisheye image and reducing perspective distortion

ActiveCN101742125ASave spaceReduce correctionTelevision system detailsColor television detailsImaging processingImage correction

The invention provides an image processing method and an associated device for correcting a fisheye image and reducing perspective distortion. The fisheye image processing method is used for correcting the fisheye image correction and reducing the perspective distortion and can save the space of a temporary storage and reduce the perspective distortion. The method comprises the following steps: sequentially calculating a fisheye original coordinate value corresponding to each pixel of a plurality of pixels in the fisheye image according to a coordinate conversion function between a fisheye corrected image and a fisheye original image; and calculating the pixel value of each pixel of the fisheye corrected image by interpolation in the fisheye original image according to the fisheye original coordinate value, wherein the coordinate conversion function contains a fisheye coordinate correcting conversion function, a perspective distortion reducing coordinate conversion function and an image cutting zoom-in and zoom-out coordinate conversion function.

Owner:AVISONIC TECH

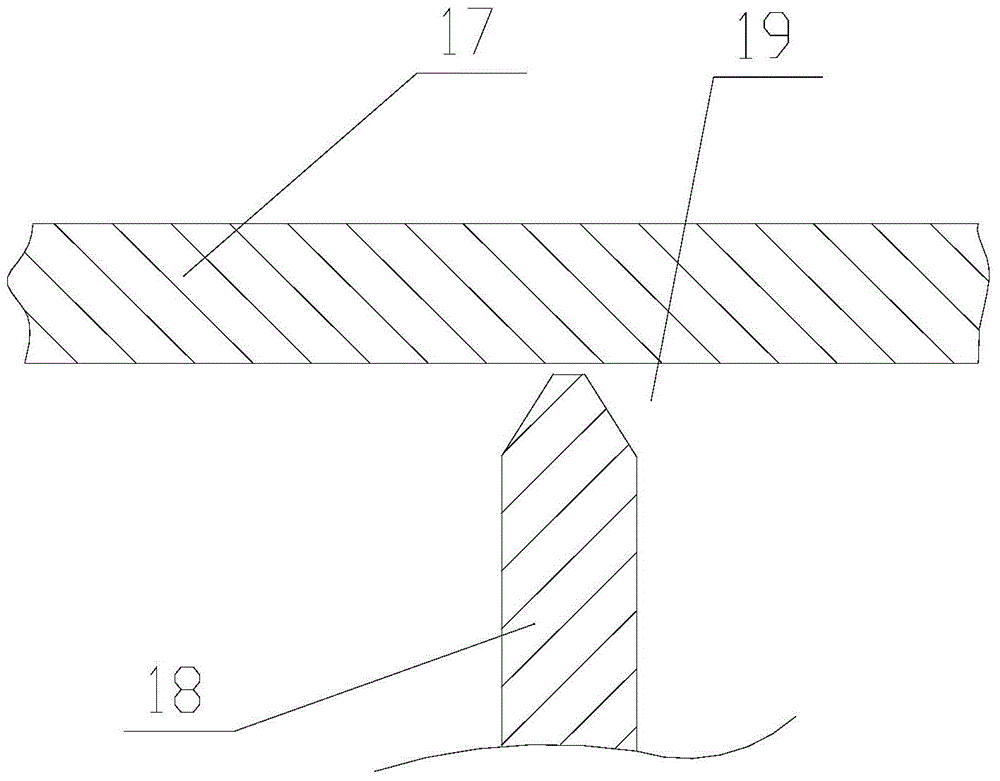

Welding method for furnace top flange of blast furnace

ActiveCN104439740AGuaranteed levelnessReduce welding distortionArc welding apparatusShielded metal arc weldingMarking out

The invention discloses a welding method for a furnace top flange of a blast furnace. The method mainly comprises the following steps that checking and accepting; measuring and paying off; groove preparation; hoisting in position; leveling and centering; scale division and marking out, wherein even scale division and marking out are carried out on the furnace top flange through two or more diameter lines, pitch circles of rib plates arranged on the furnace top flange are equally divided into a plurality of small circular arcs, pitch circles, crossing with a furnace top steel ring, of the furnace top flange are equally divided into a plurality of small circular arcs, and pitch circle face, crossing with the furnace top steel ring, of the furnace top flange are equally divided into a plurality of congruent small sectors; rib plate welding, wherein the two sides of the rib plates are fixedly connected from the inner ends to the other ends through a symmetric welding method, and the welding speed is the same; flange welding, wherein backing weld and layered continuous bead welding are included; according to backing weld, the symmetric welding method is adopted, in the manual electric-arc welding manner, same-direction symmetric welding begins to be carried out on two sides of grooves in the centered and segmented symmetric segments at the same time, and according to the layered continuous bead welding, the number of welding layers is determined according to the thickness of the furnace top steel ring and the thickness of the furnace top flange, and the symmetric welding method is adopted, and same-direction continuous bead welding begins to be carried out on the two sides of the grooves in the centered and segmented symmetric segments at the same time.

Owner:CHINA 19TH METALLURGICAL CORP

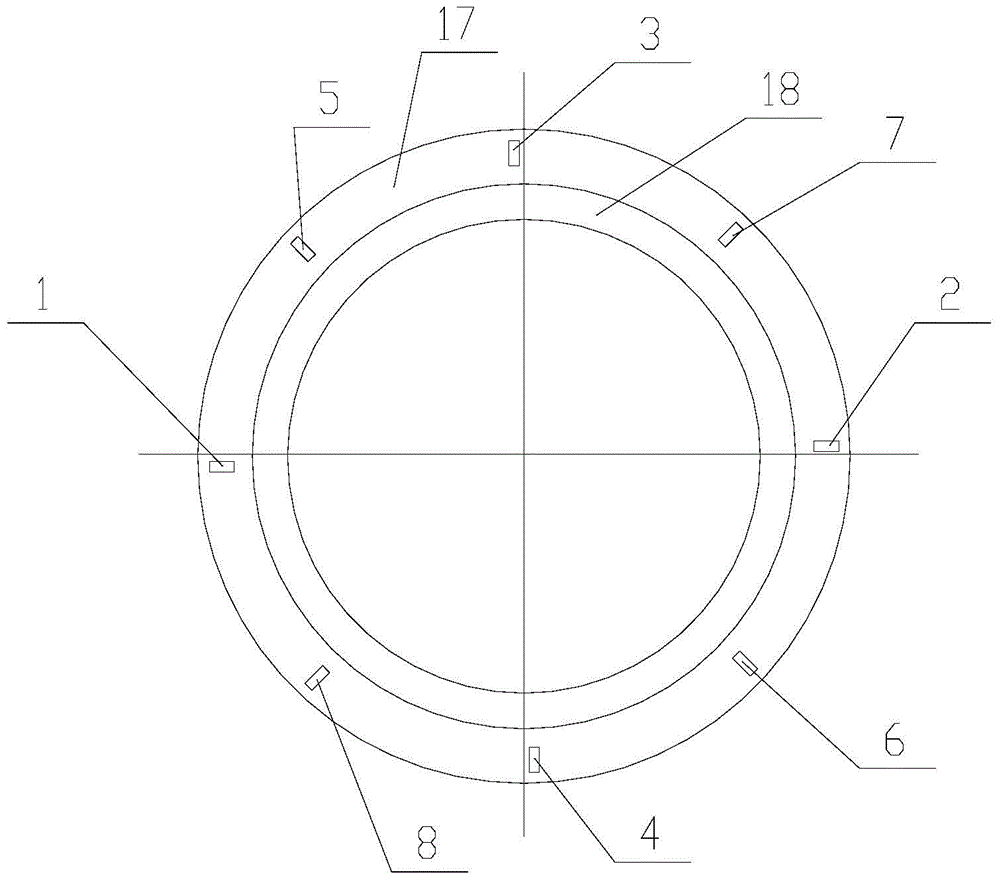

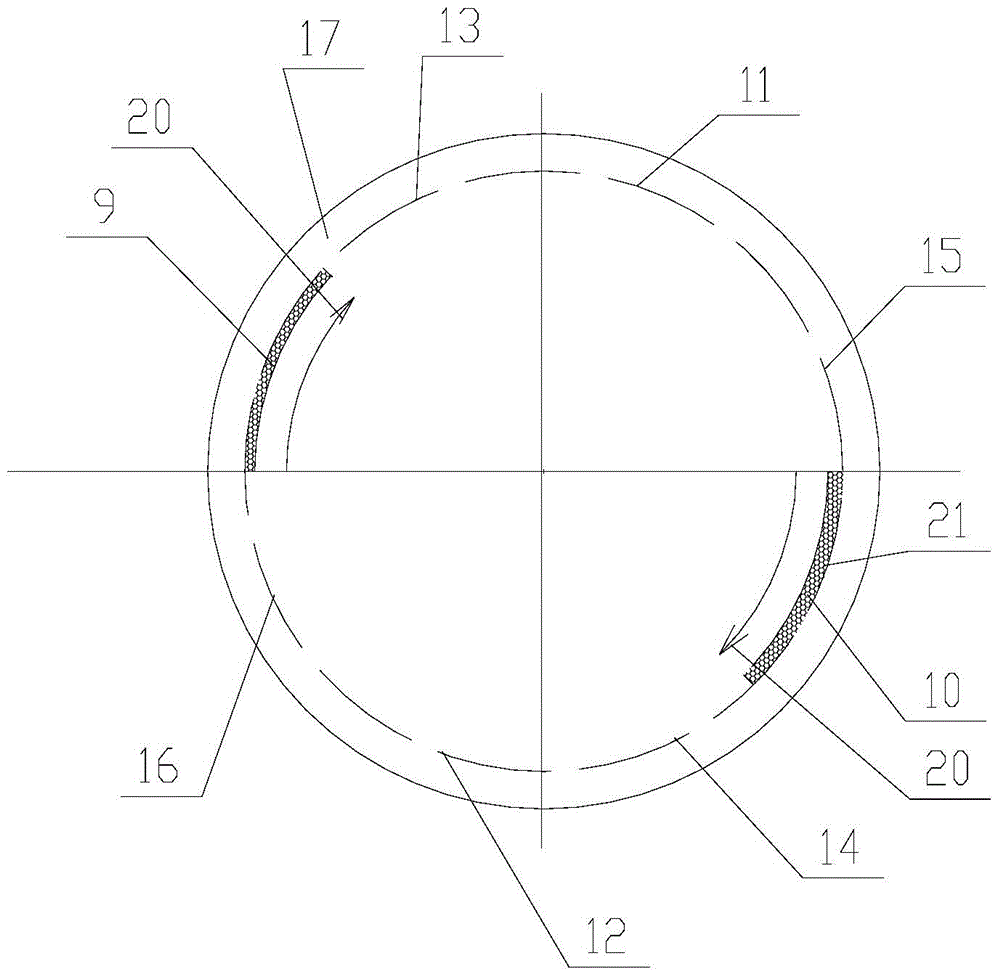

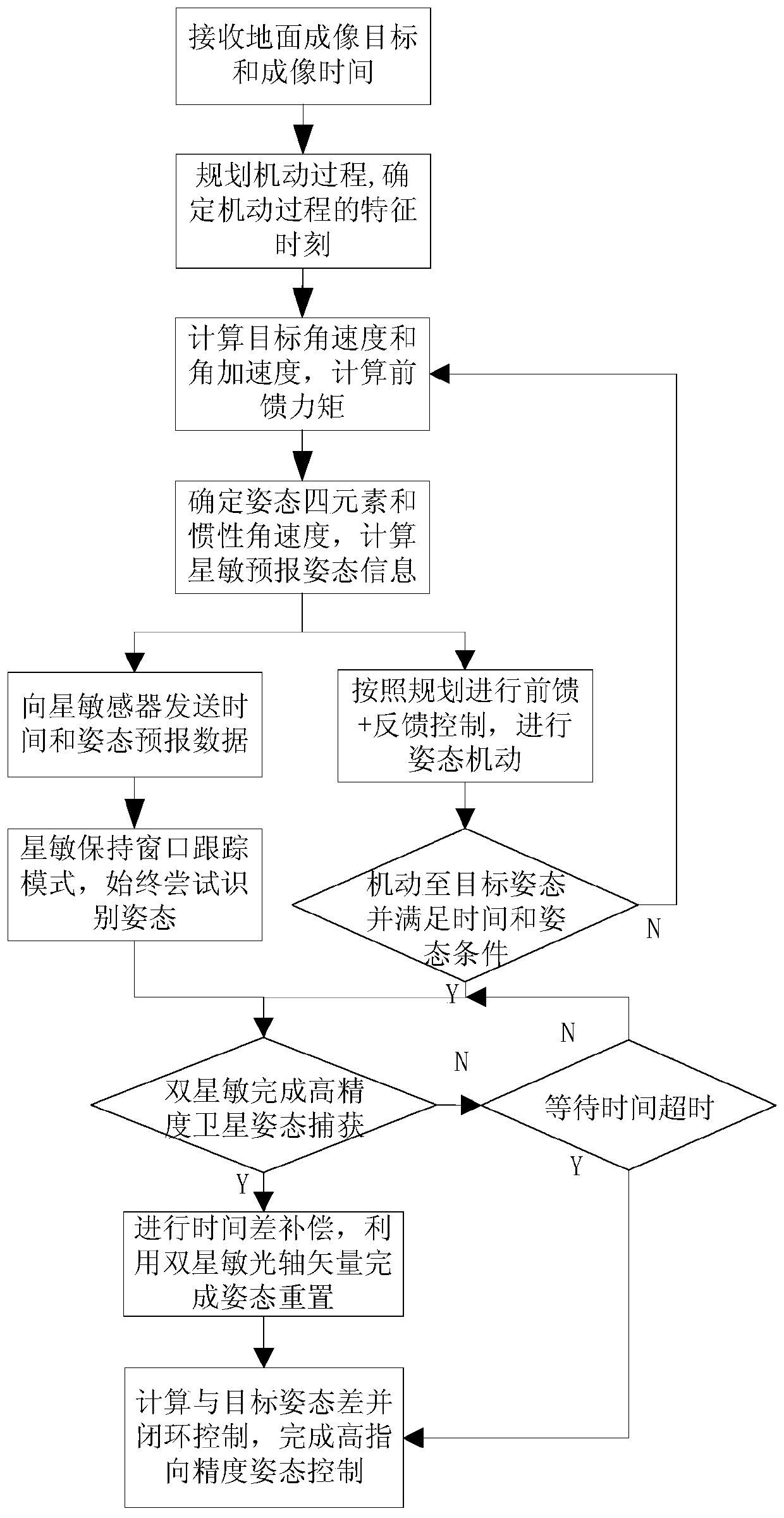

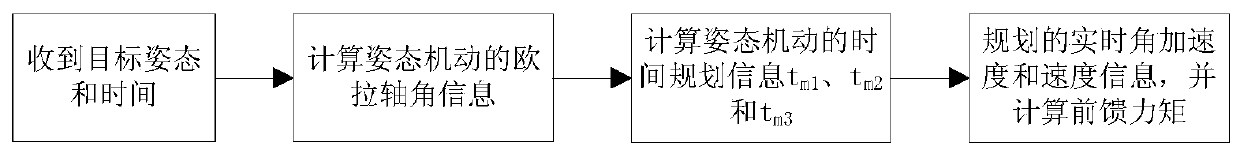

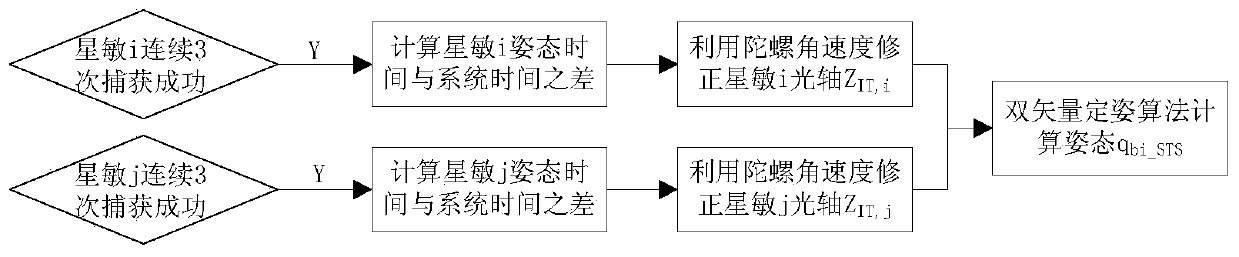

High-precision imaging attitude pointing control method based on agile satellite

ActiveCN110174899AReduce correctionImprove smoothnessNavigation by speed/acceleration measurementsNavigation by astronomical meansSkyOptical axis

A high-precision imaging attitude pointing control method based on the agile satellite is provided. The method comprises that: an attitude maneuvering process is planned according to the specified ground imaging target and time; in the maneuvering process, the attitude prediction information and the corresponding time are calculated and transmitted to a star sensor according to a fixed frequency;the star sensor predicts the sky window according to the time and attitude data, and keeps trying to extract the attitude in a window tracking mode; the satellite moves to the vicinity of the target and gradually decelerates, the star sensor captures the satellite attitude information quickly in a high-precision manner, and the system uses double star-sensitive optical axis vectors to compete attitude reset; and finally, closed-loop correction is performed by using the difference between the reset attitude and the target attitude to complete the high-precision attitude pointing control. According to the method provided by the present invention, the star-sensitive high-precision attitude information available only at small angular velocities is fully used to compensate for the influence ofgyro measurement information with nonlinear and drift variation characteristics on imaging pointing precision.

Owner:BEIJING INST OF CONTROL ENG

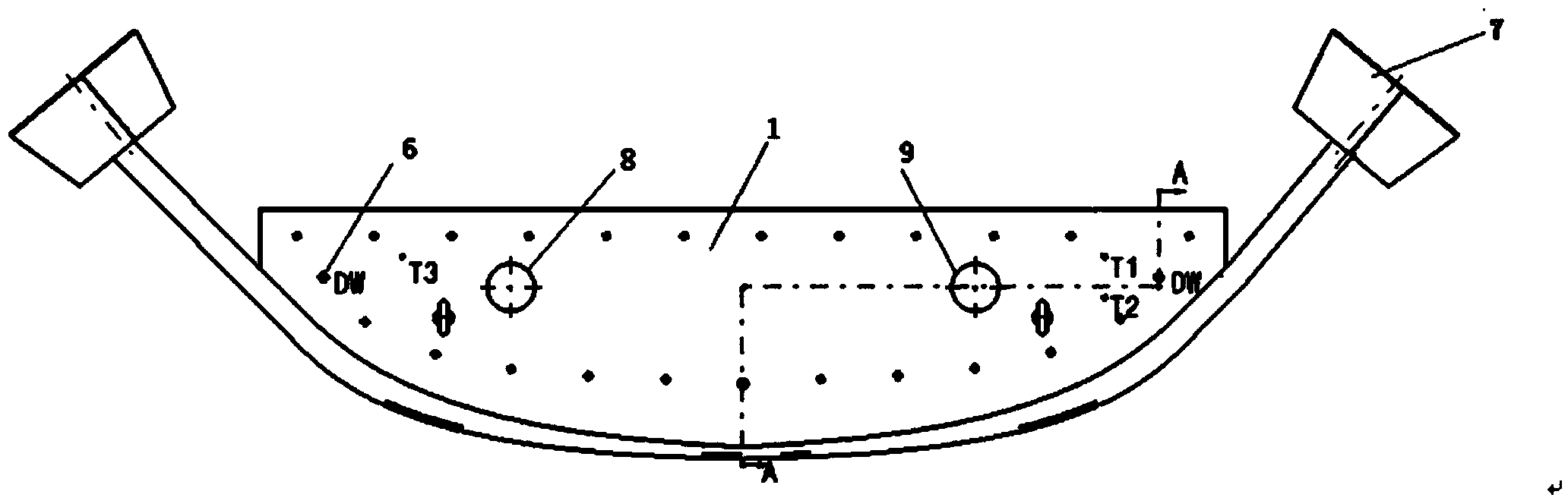

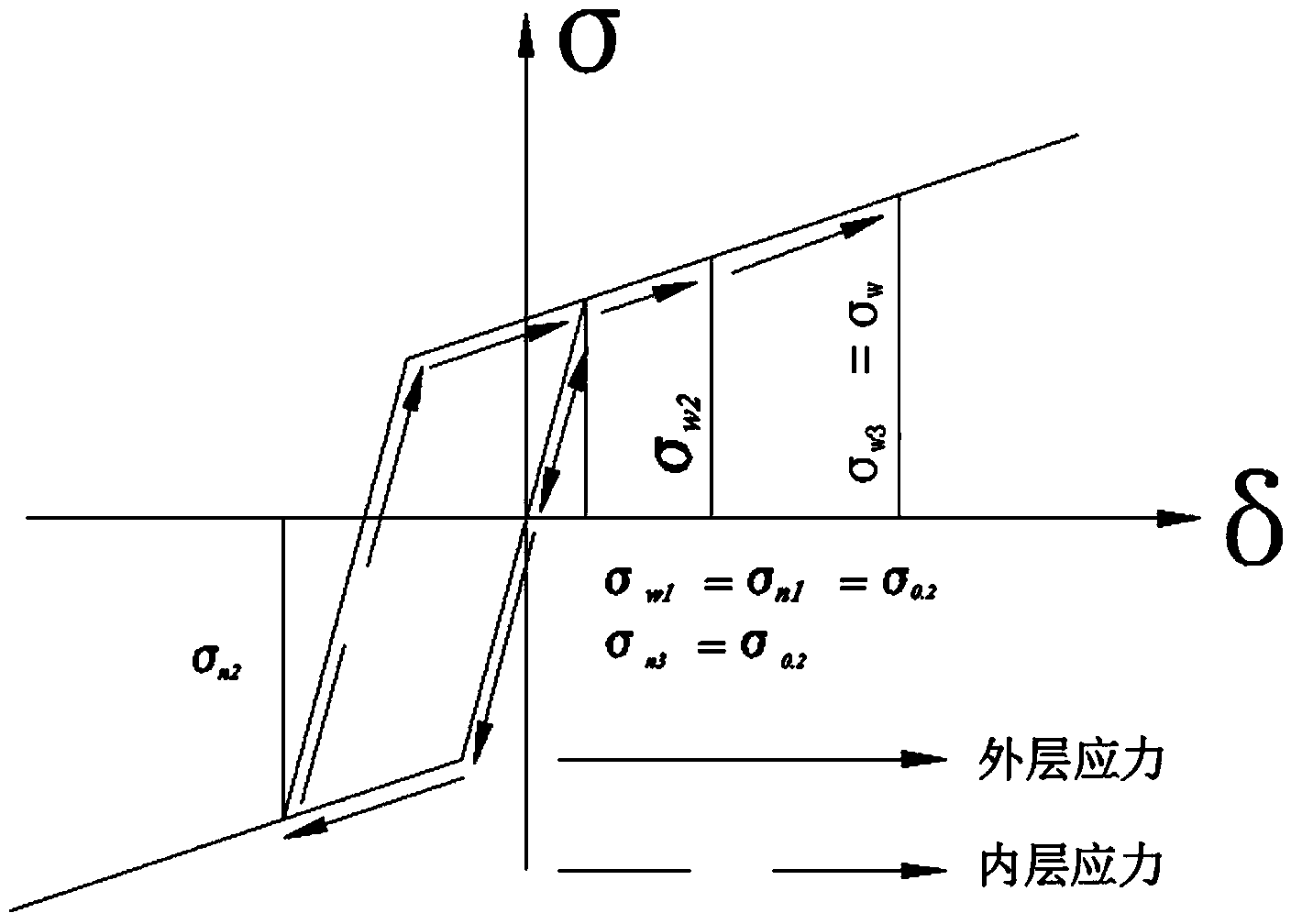

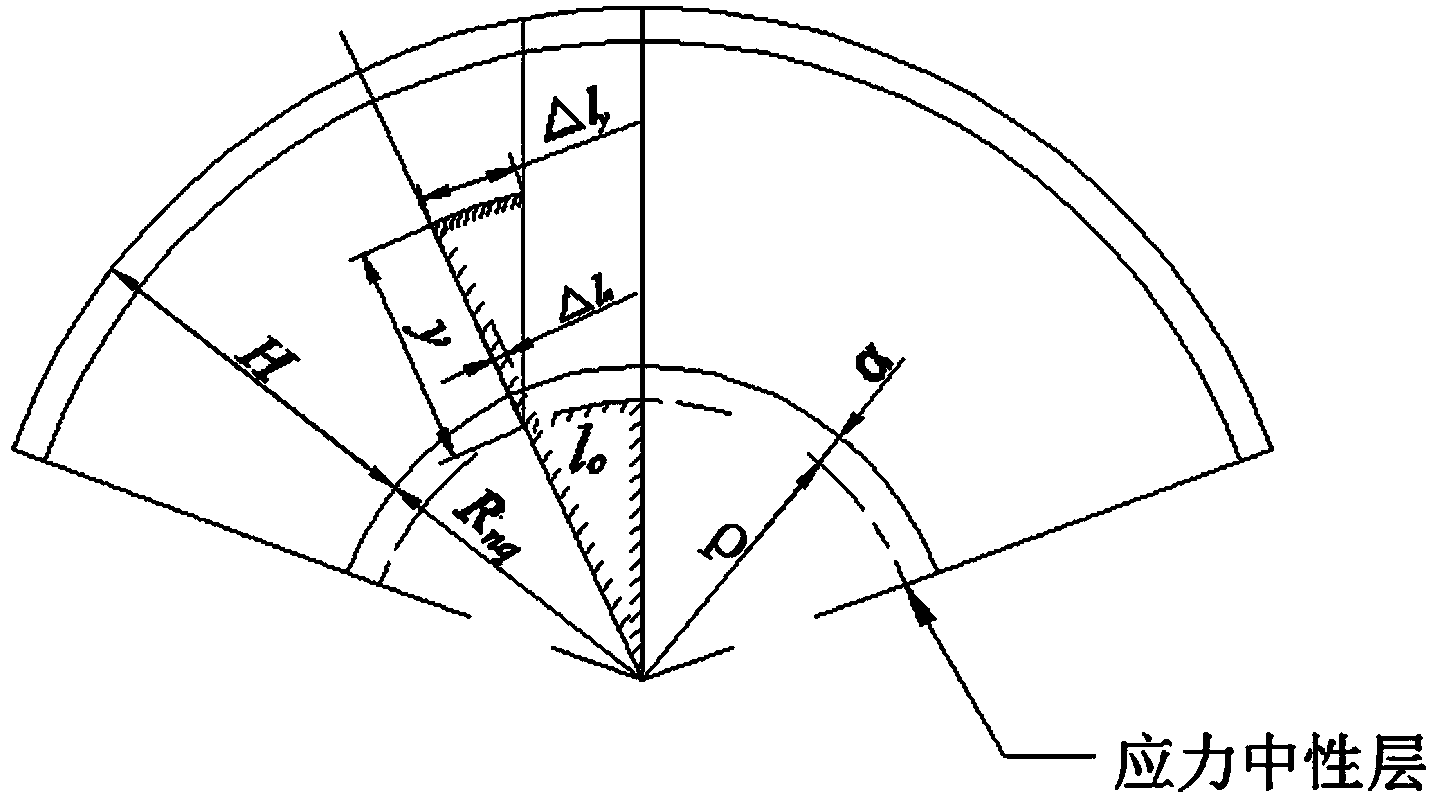

Three-dimensional multi-curvature part bending method

InactiveCN104281725ALower requirementReduce the cost of updatesSpecial data processing applications3D modellingNumerical controlComputer Aided Design

The invention discloses a three-dimensional multi-curvature part bending method. According to the method, the structural form of a section bending die and a suitable section bending machine are determined by analyzing the shape, size, bending angle and forming force of a part to be bent; a digital model of the part to be bent is subjected to curvature analysis through a computer; bending springback theoretical analysis is adopted, and a die profile springback compensation design is performed by a numerical simulation method through computer aided design. The bending of a section requires matched bending chuck, bending die and machine tool. The die is processed by a numerical control technology. A measuring machine is used for detecting and correcting the die to be processed, and an error between theory and actuality is reduced, so that the part manufacturing accuracy is improved. Dies for three-dimensional complicated parts can be formed on a two-dimensional bending machine, the bending pass is reduced, and repair or scraping of the bending dies is reduced, so that the part manufacturing cost is effectively reduced; moreover, the production efficiency is high.

Owner:XIAN JIAYE AVIATION TECH

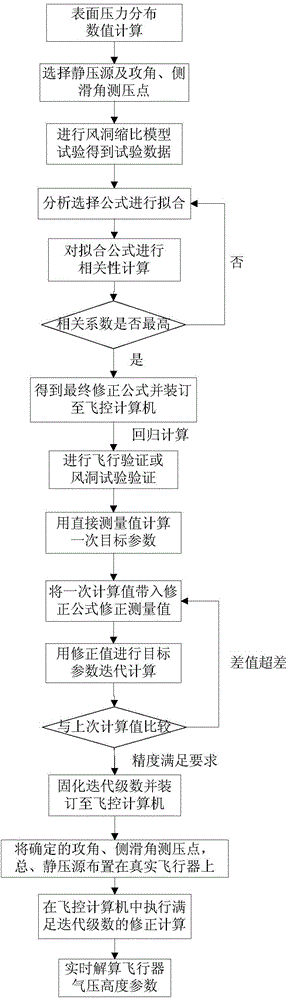

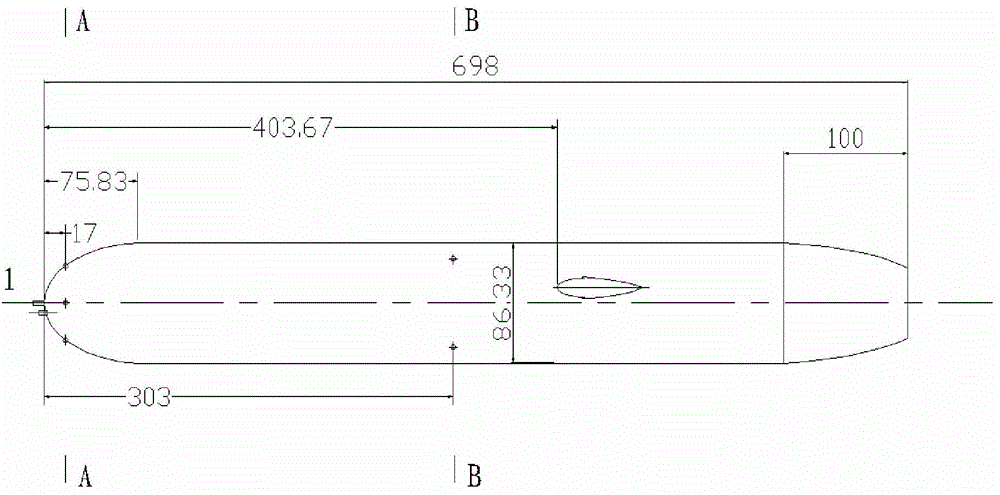

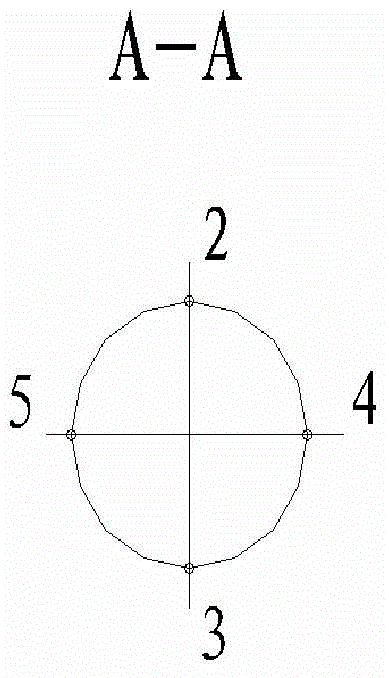

Determination method for pressure altitude parameters on subsonic vehicle body

ActiveCN104061960AConducive to stealth designReduce protrusionMeasurement devicesFlight vehicleObjective variables

The invention discloses a determination method for pressure altitude parameters on a subsonic vehicle body. The determination method comprises a selection principle of a pressure source on the subsonic vehicle body and a data processing method for measuring pressure based on a selected pressure source, wherein the selection principle of the pressure source on the subsonic vehicle body is used for selecting and locating the pressure source; the data processing method for measuring pressure based on the selected pressure source comprises a correction formula fitting and measured value returning and calculating method, wherein the correction formula comprises [alpha] correction, [beta] correction and static pressure correction, and the returning and calculating method is a method that objective variables are obtained according to the iteration of pressure measuring values. Test results show that the corrected data has very high reducibility, the objective variables including a flying attitude angle, a speed and the like of a subsonic vehicle with higher precision can be obtained by combining the returning and calculating method, therefore, a new method is provided for the subsonic flying speed measurement of the subsonic vehicle.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

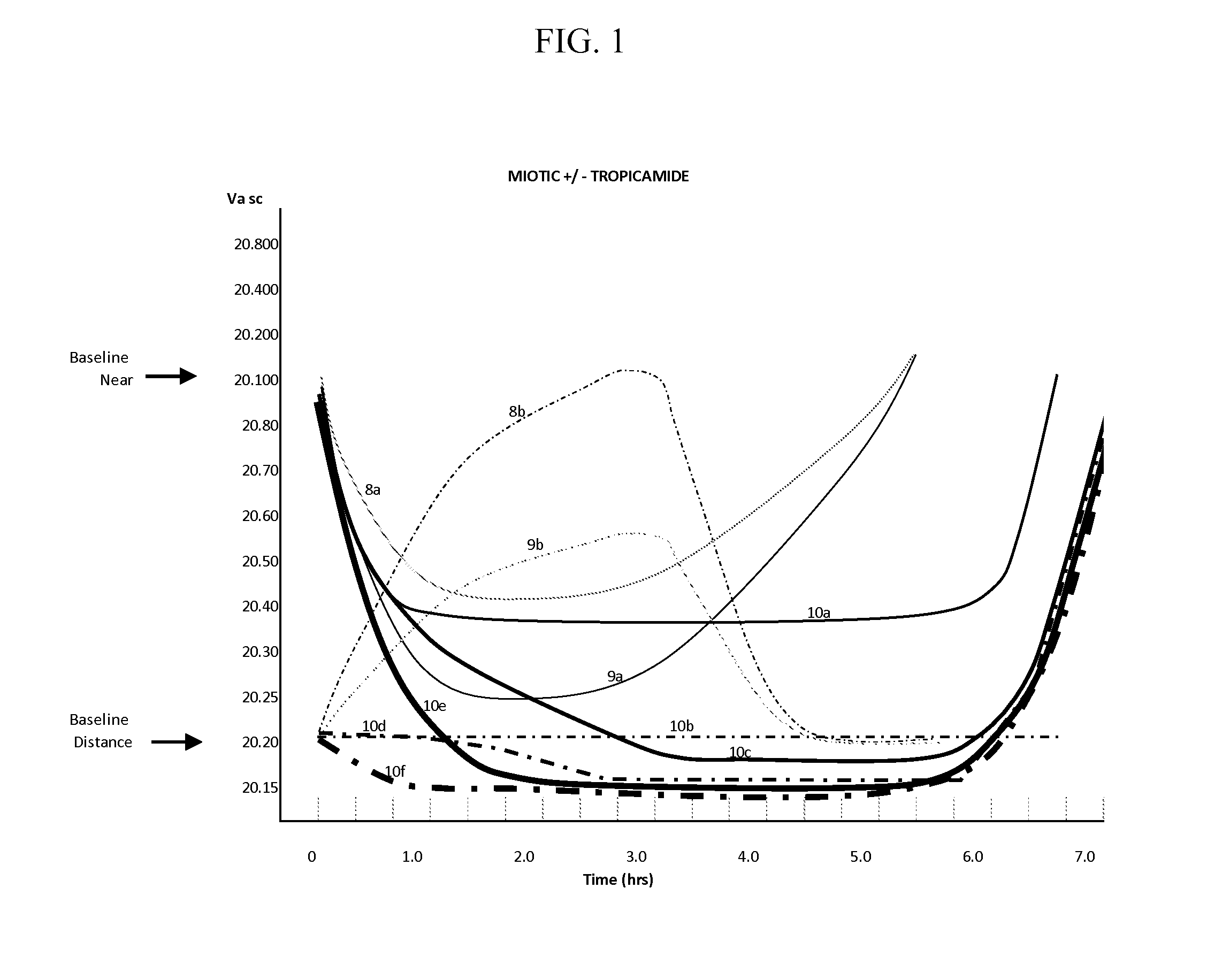

Storage Stable Compositions and Methods for the Treatment of Refractive Errors of the Eye

ActiveUS20150290125A1Eliminating optical aberrationImprove visual acuityBiocideInorganic non-active ingredientsRefractive errorOphthalmology

The invention provides compositions and methods for achieving storage stable aceclidine. The compositions preferably comprise aceclidine, a cycloplegic agent, a surfactant, a tonicity adjustor and optionally a viscosity enhancer and an antioxidant. The invention further provides methods for treating refractive errors of the eye with a storage stable aceclidine composition.

Owner:LENZ THERAPEUTICS INC

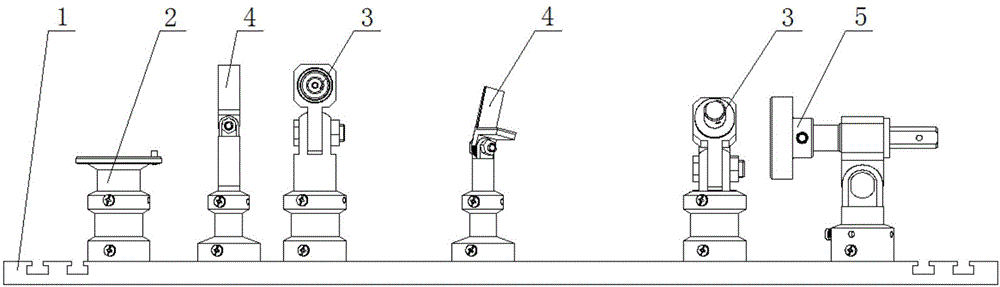

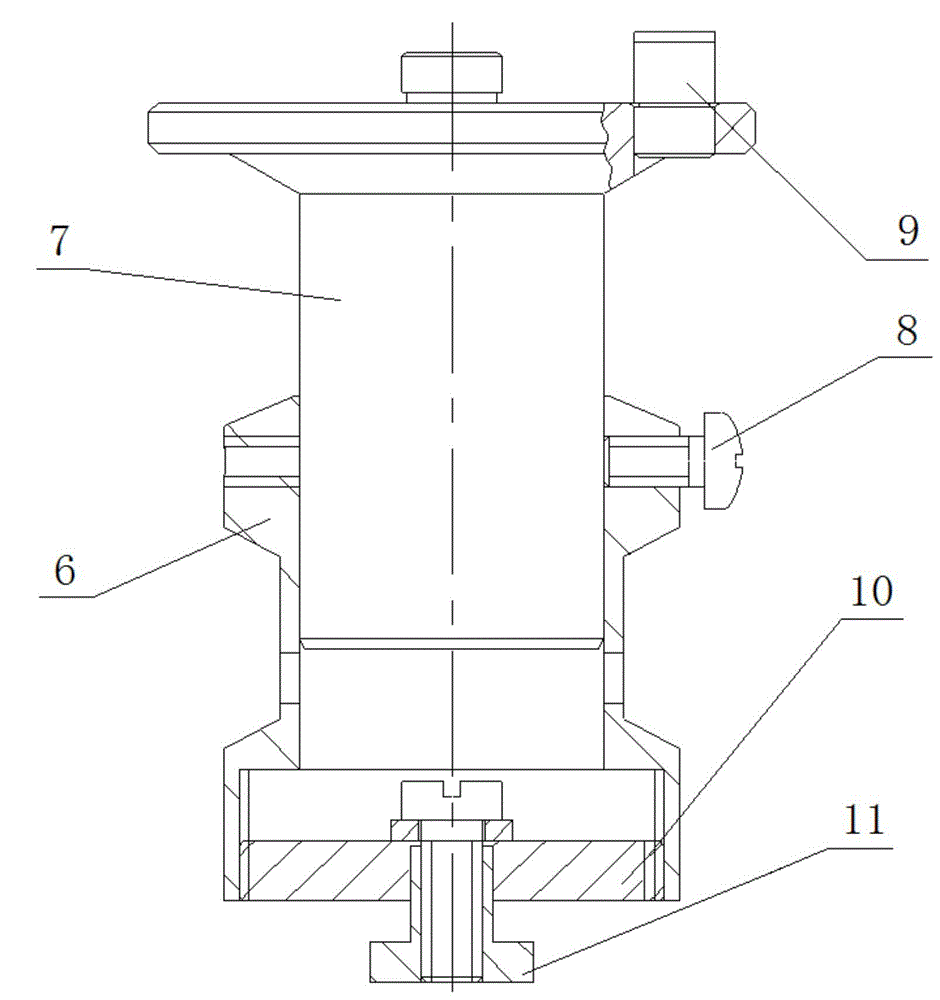

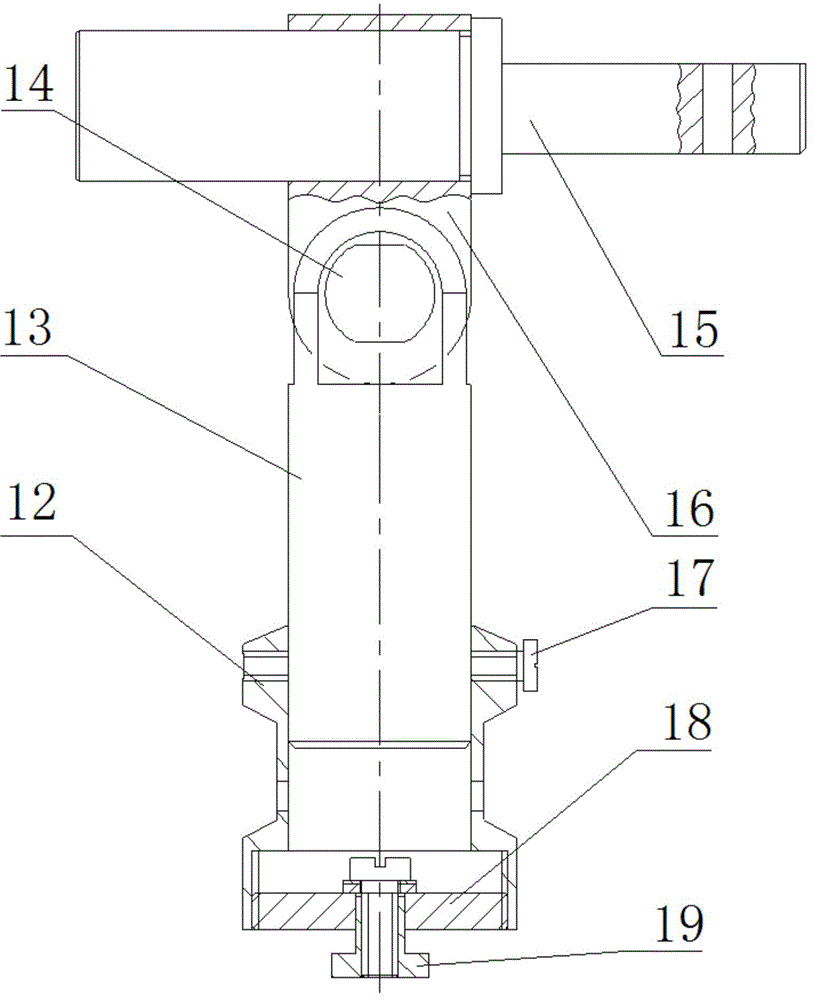

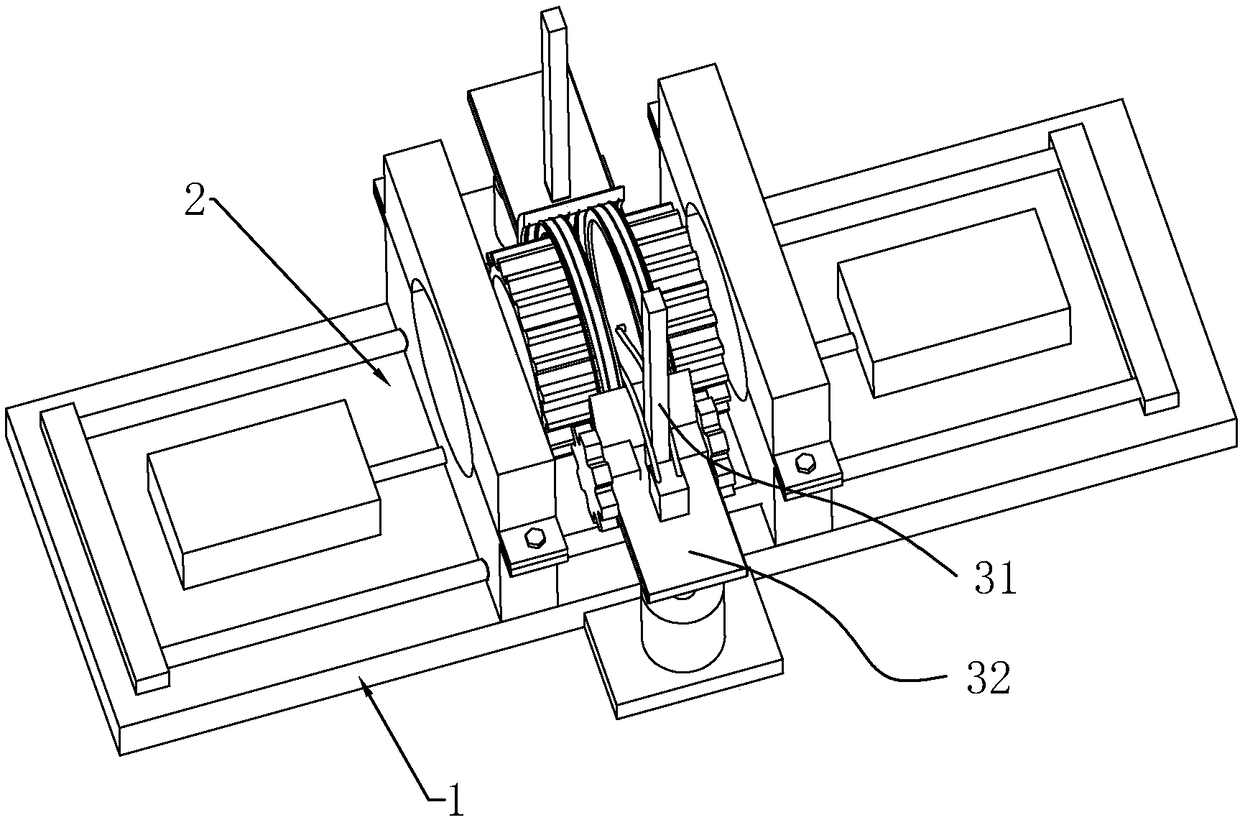

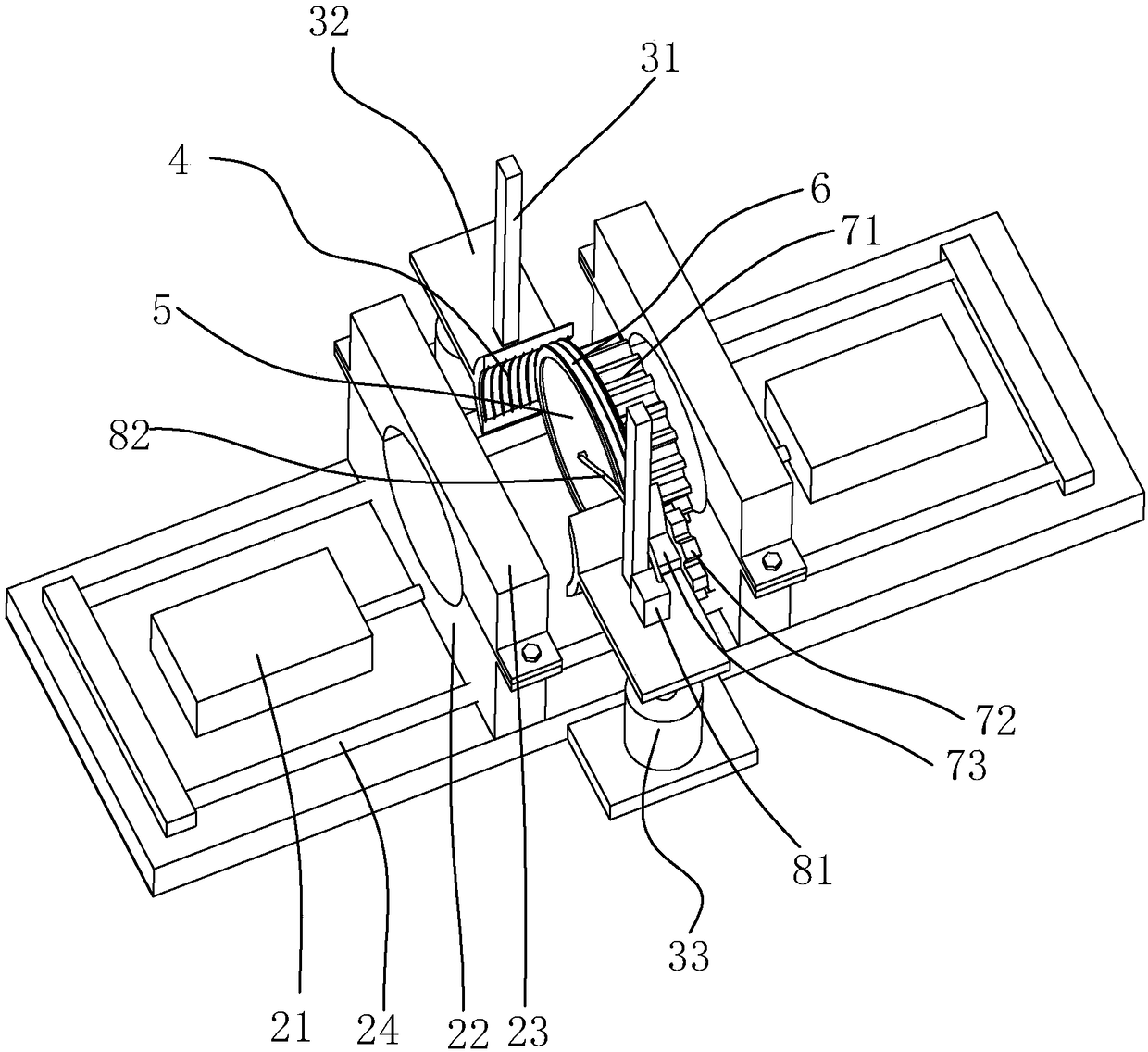

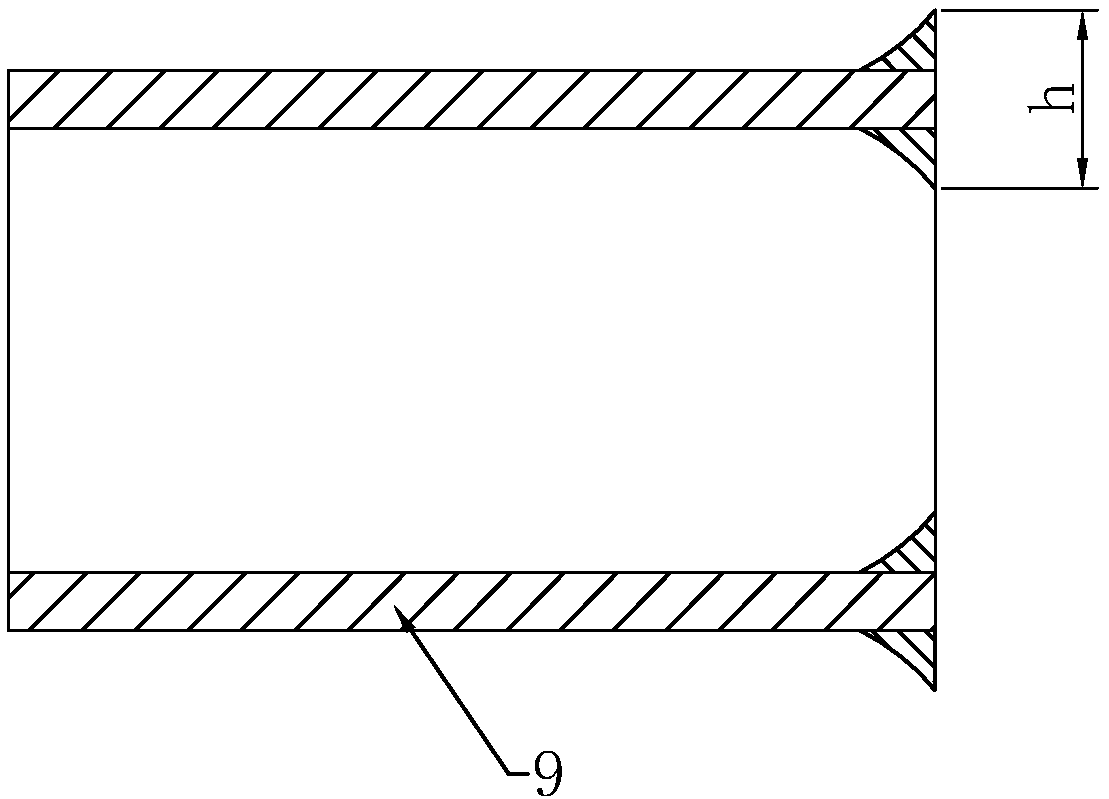

Flexible positioning device for assembling and welding pipelines

InactiveCN103551775AHigh precisionReduce correctionWelding/cutting auxillary devicesPipeline systemsPipe fittingEngineering

The invention relates to a flexible positioning device for assembling and welding pipelines and belongs to the technical field of assembling and welding of pipe parts. A flange positioning assembly, a pipe joint positioning assembly, a pipe fitting bearing assembly and a telescope-feed positioning assembly are all arranged on a foundation plate, and adapting seats of the assemblies are connected with one another through positioning keys and T-shaped grooves. According to the flexible positioning device for assembling and welding the pipelines, by means of matching of the assemblies, accuracy of assembling and welding pipe fittings is improved, shape correction of the pipe fittings during assembling is reduced, manufacture qualities and reliabilities of the pipe fittings are improved, the assemblies can be adjusted, and requirements for assembling and welding the pipe fittings with different sizes and shapes can be well met by adjusting positions and heights of the assemblies when users are confronted with the pipe fittings with different sizes and shapes, so that the applicability of the flexible positioning device is greatly enhanced; the flexible positioning device can be continuously recycled and greatly reduce usage and manufacture costs; defects that medium frames in prior art are low in positioning accuracy, poor in rigidity, easy to deform during using, and long in manufacture period can be overcome.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

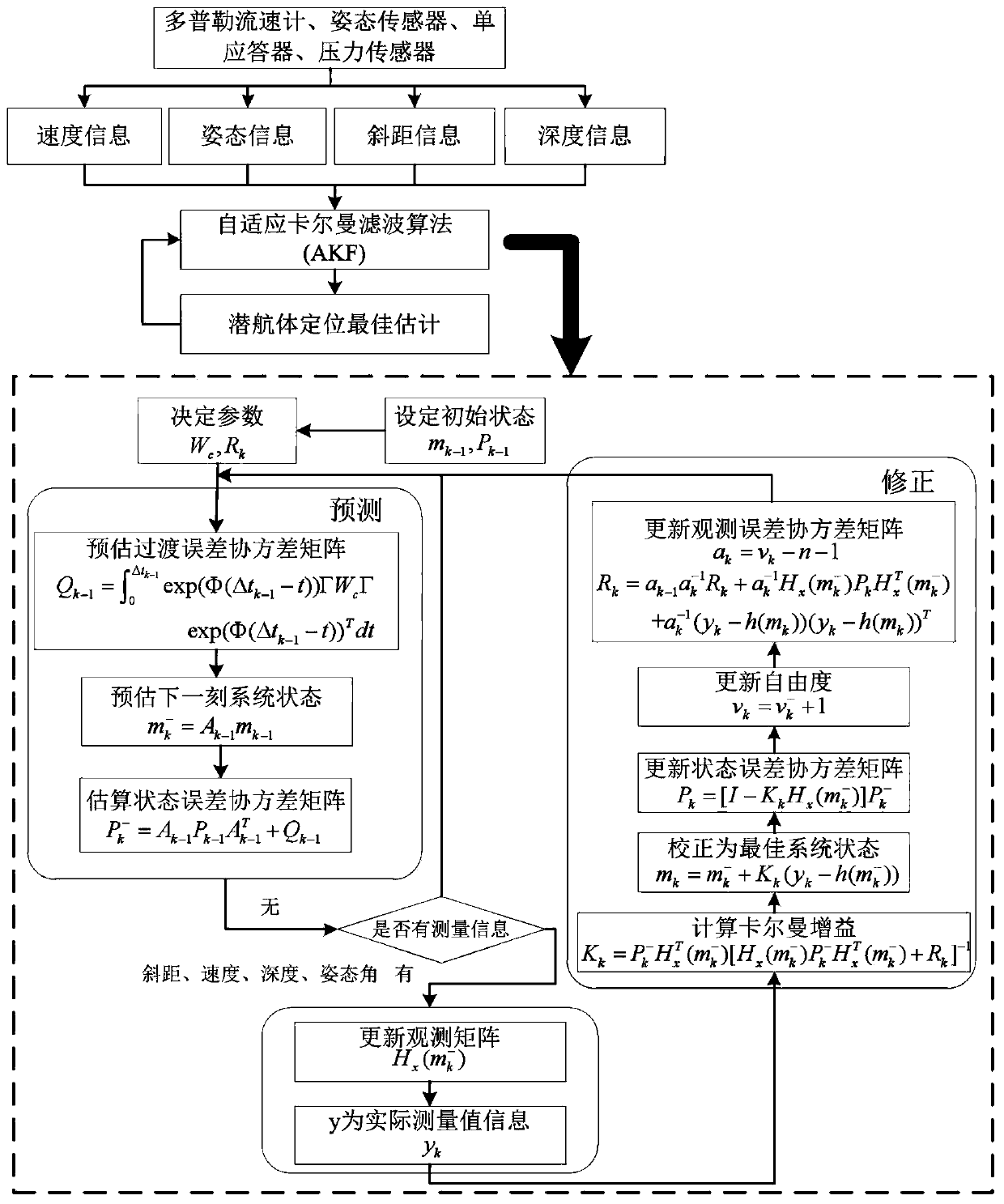

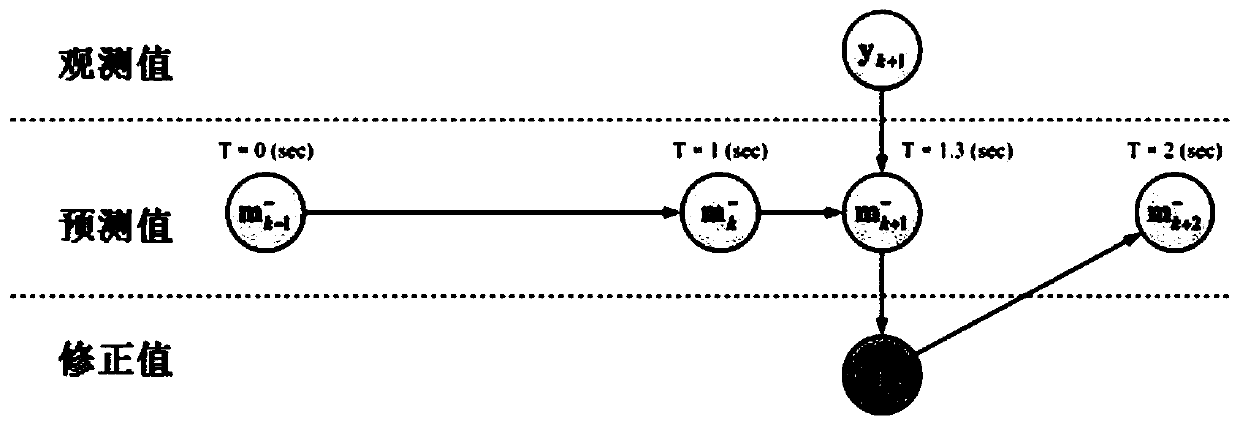

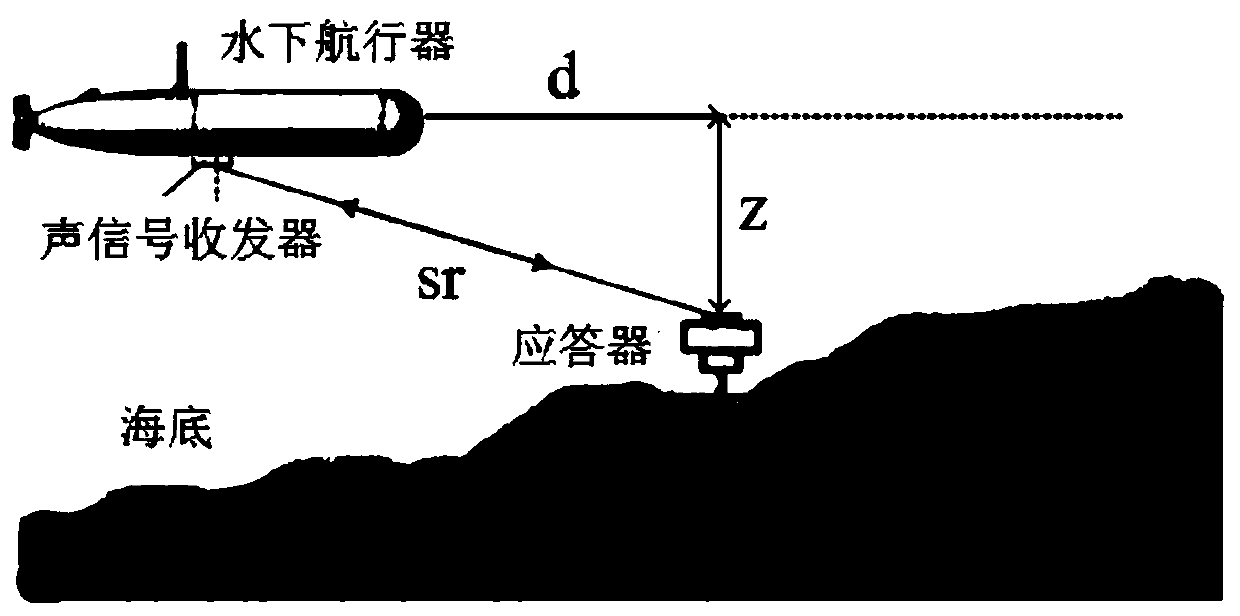

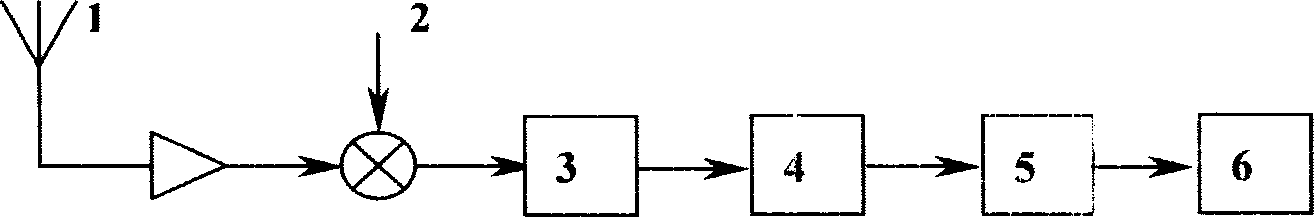

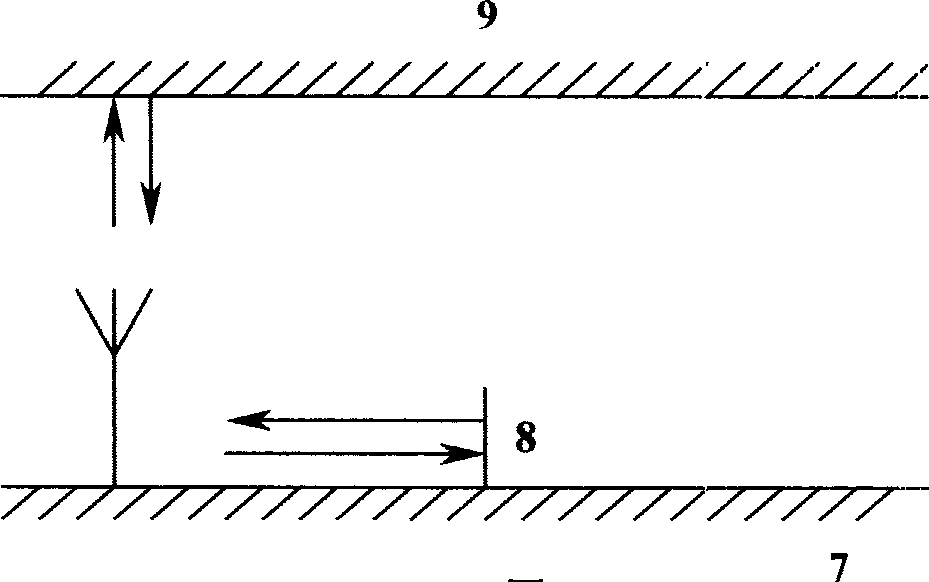

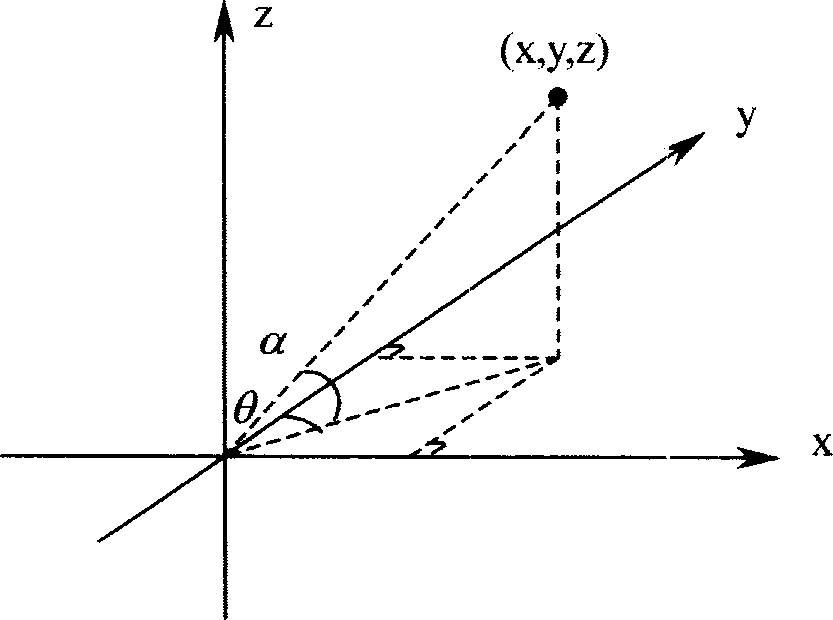

Single transponder slope distance underwater sound positioning method and system based on adaptive Kalman filtering (AKF)

The invention belongs to the field of underwater sound communication and navigation, and relates to a single transponder slope distance underwater sound positioning method and system based on adaptiveKalman filtering (AKF). The single transponder slope distance underwater sound positioning system based on the adaptive Kalman filtering (AKF) is composed of a transponder, a sound signal transceiver, a Doppler flow meter, an attitude sensor, a depth sensor and an adaptive Kalman filtering controller. Based on an adaptive Kalman filtering (AKF) algorithm, single slope distance information, depthmeasuring information, speed information and attitude information of an underwater vehicle are integrated, noise of the sensors, time delay, update frequency and multi-sensor information fusion are considered, a single slope distance positioning method of the single transponder of the underwater vehicle is established, three-dimensional coordinates of the underwater vehicle are calculated, and accurate positioning is realized. According to the single transponder slope distance underwater sound positioning method based on the AKF, arrangement and positioning work costs of the transponder can besaved, the problems that speed and distance are limited by a sound signal propagating underwater, the slope distance measuring updating frequency is slower, and updating with depth and attitude measuring information is not synchronous can be solved, and thus, the positioning efficiency and precision are improved.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

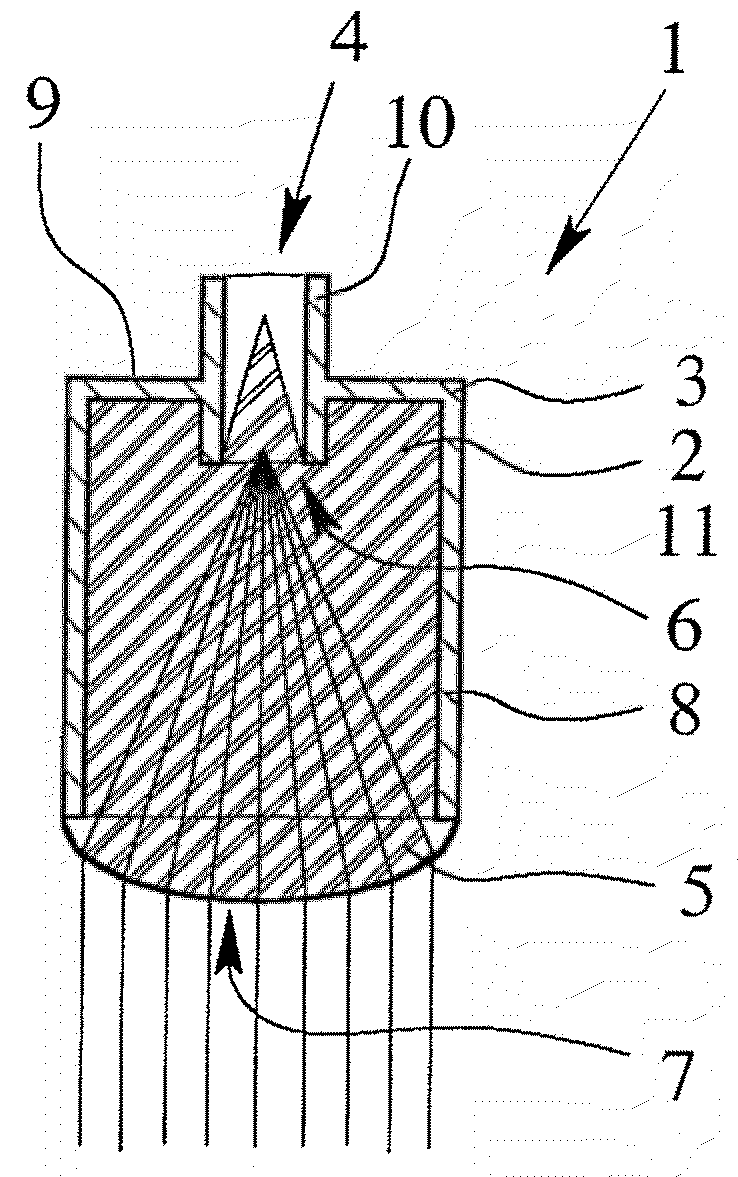

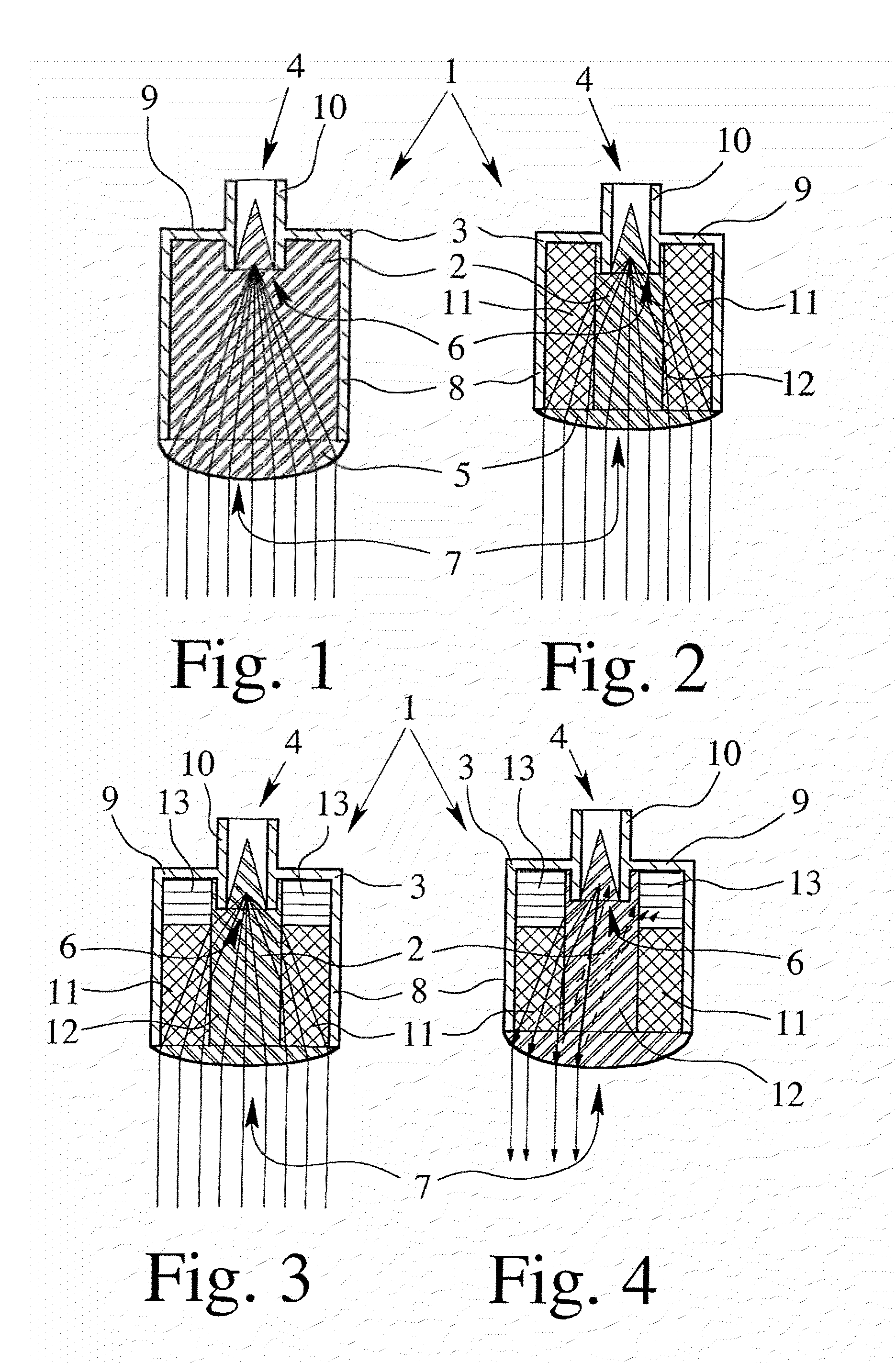

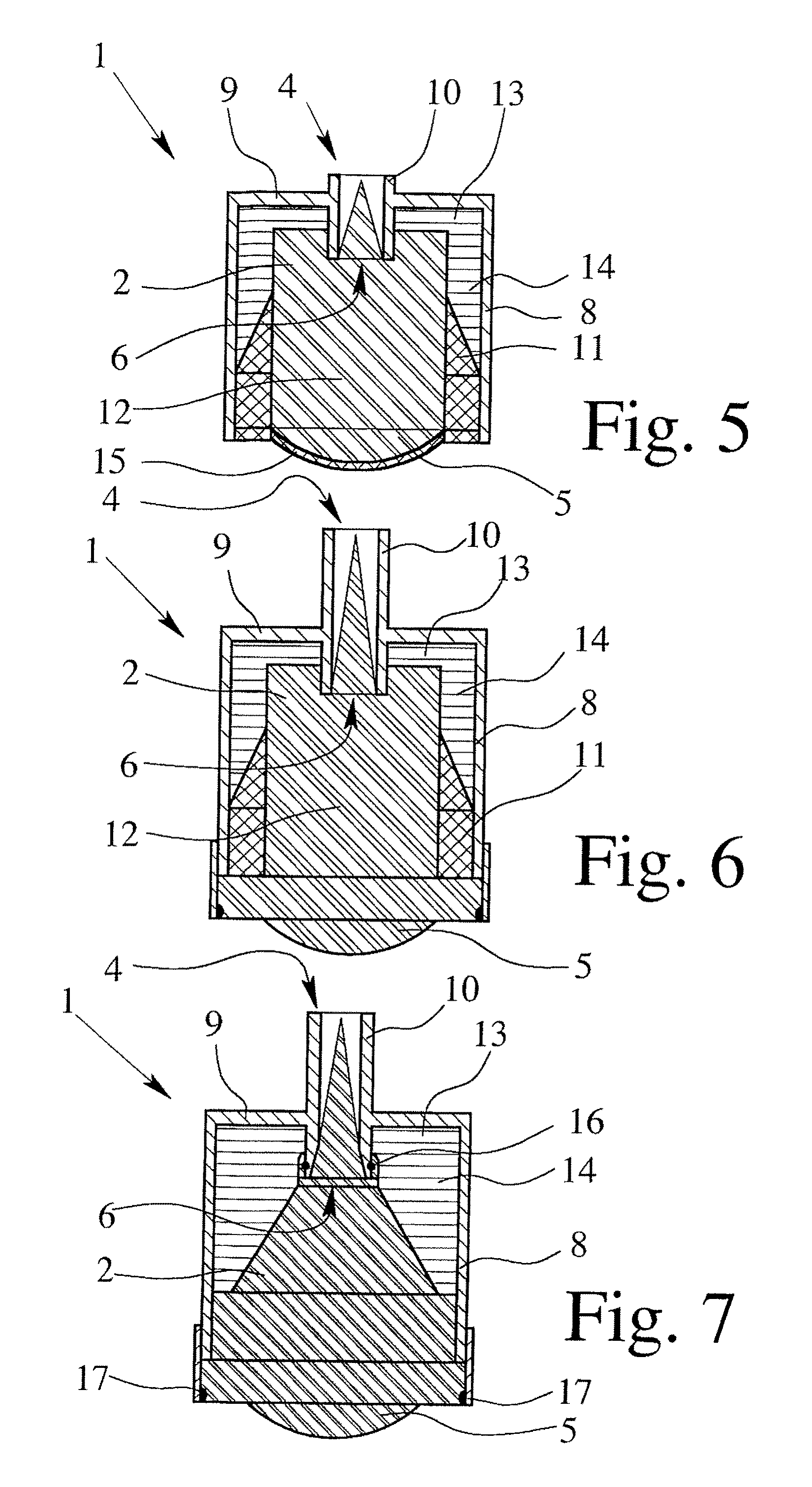

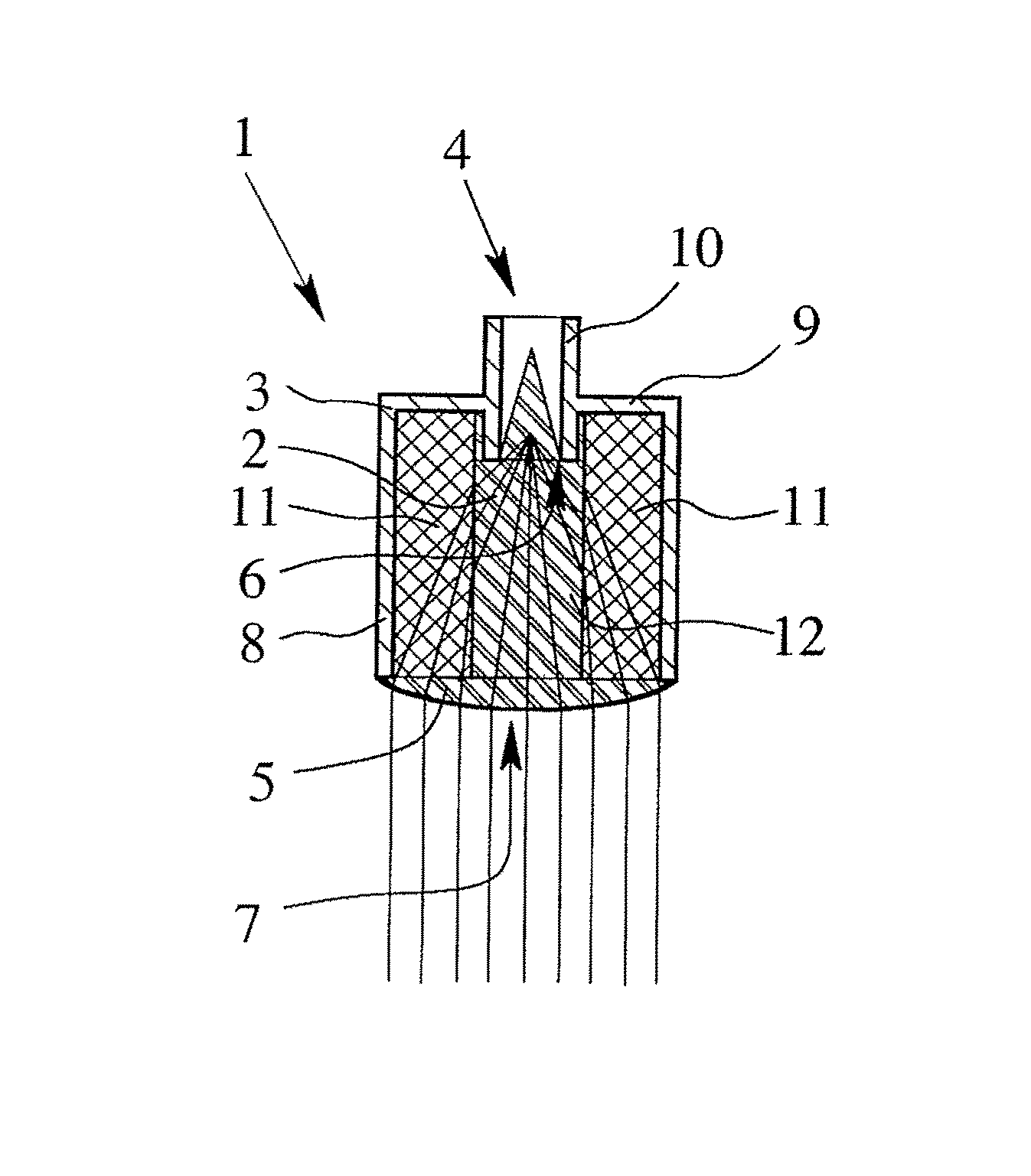

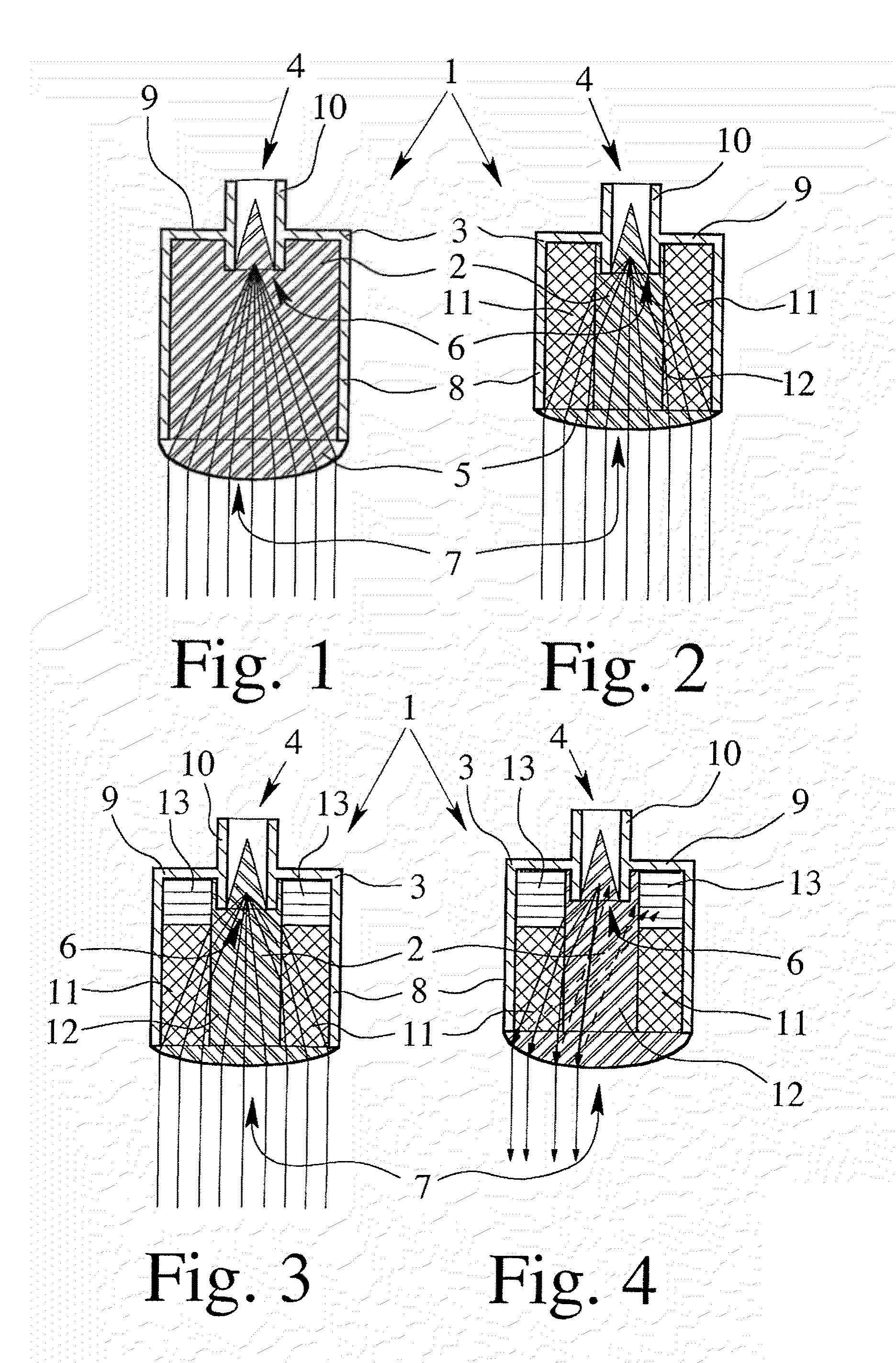

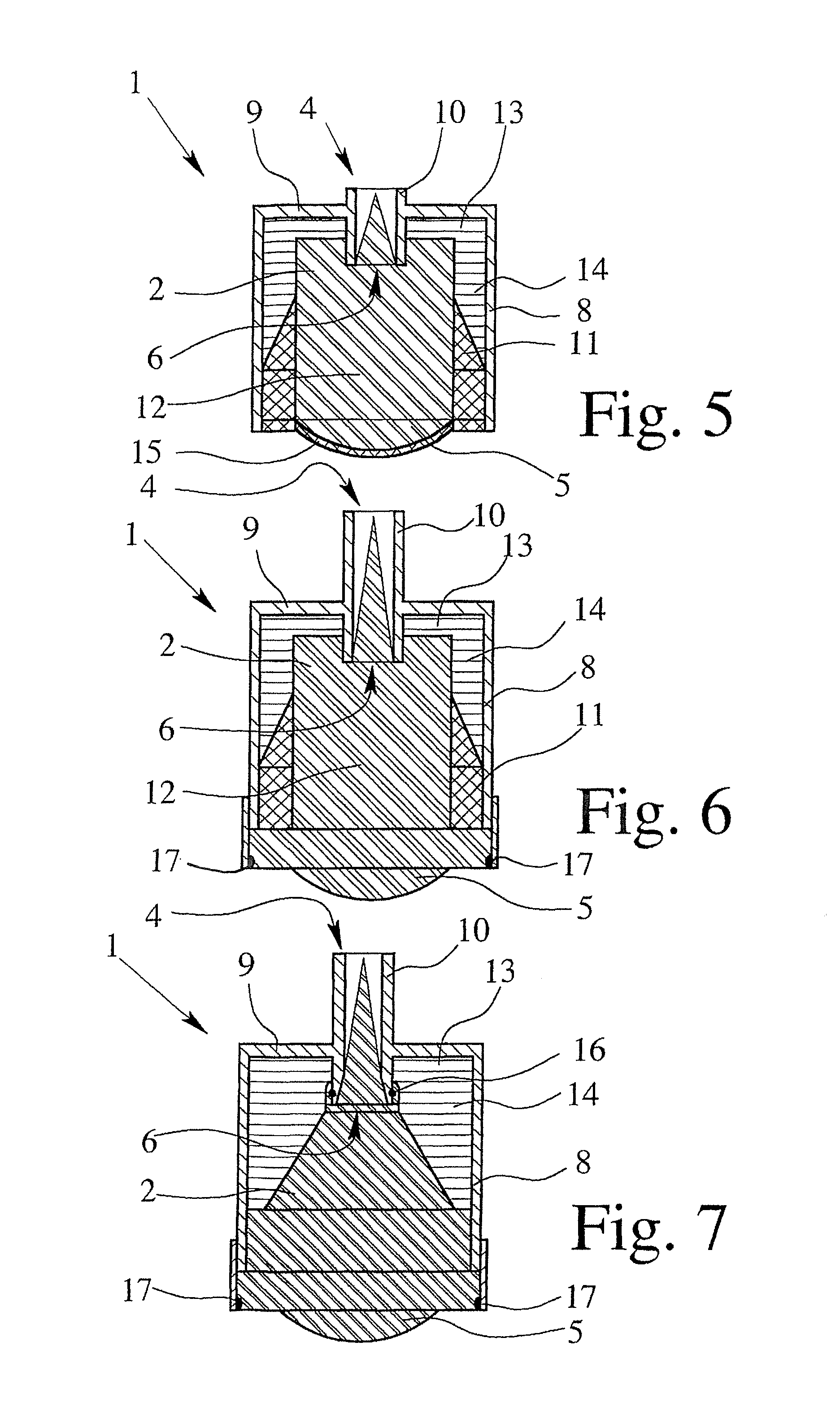

Dielectric antenna

InactiveUS20090262038A1Avoid disadvantagesLess effortWaveguide hornsRadiating elements structural formsElectromagnetic radiationDielectric body

A dielectric antenna having an at least partially dielectric body and an electrically conductive sheath, wherein the dielectric body can be struck on a supply section with electromagnetic radiation and the electromagnetic radiation can be at least partially emitted from the dielectric body via a lens-shaped radiation section. The conductive sheath essentially surrounds the dielectric body from the supply section to the radiation section and a supply opening is provided in the conductive sheath in the area of the supply section and a radiation opening is provided in the conductive sheath in the area of the radiation section. The dielectric antenna that is easy to produce, has little interference and has a short construction as a result of the dielectric antenna having essentially the cross section of the radiation opening in the area of the supply section.

Owner:KROHNE MESSTECHNICK GMBH & CO KG

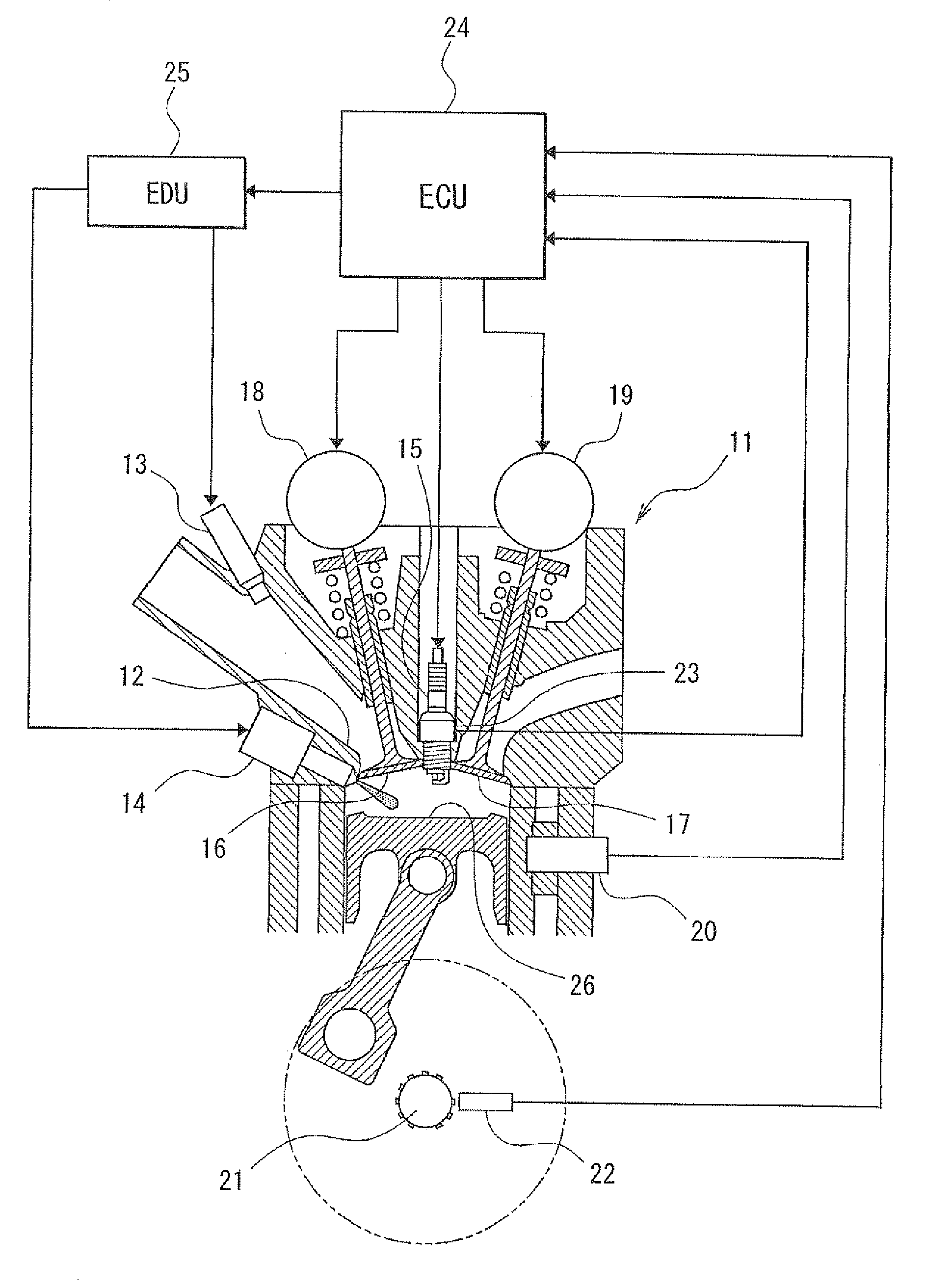

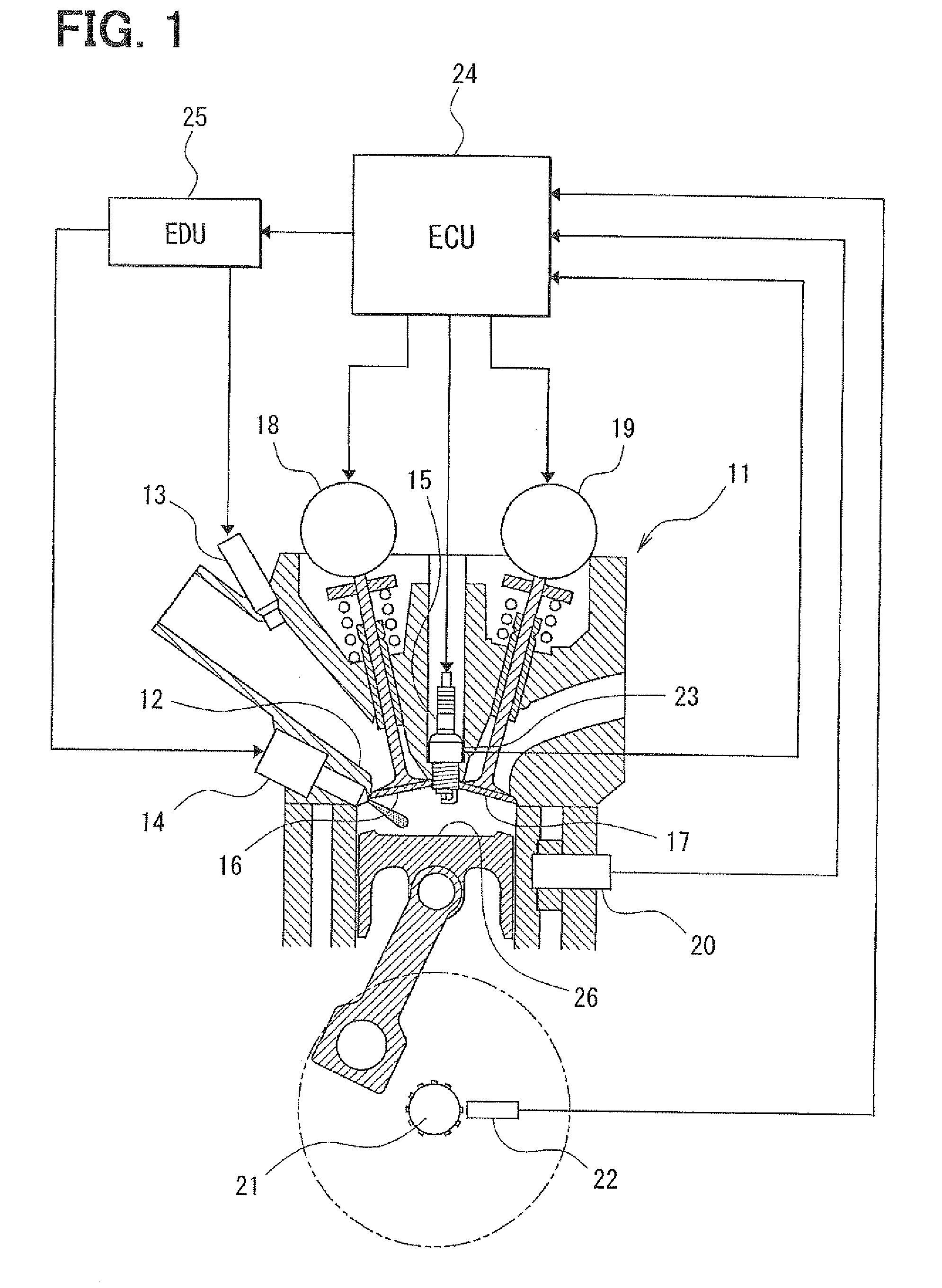

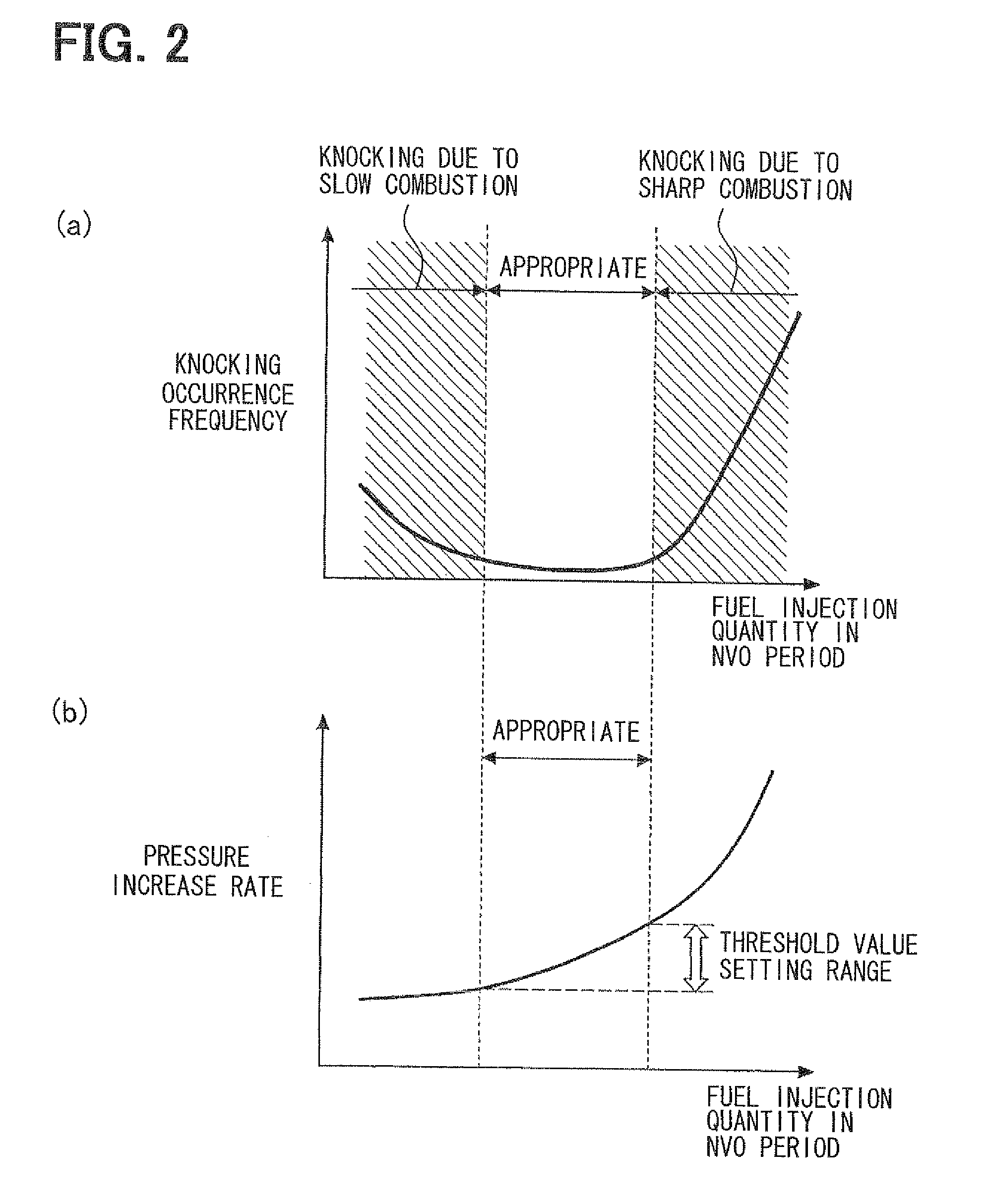

Controller of internal combustion engine

InactiveUS20110307163A1Effectively suppressing knockingEffective controlElectrical controlInternal combustion piston enginesExhaust valveExternal combustion engine

A controller performs compression self-ignition combustion control for combusting a mixture gas by injecting fuel into a cylinder in a negative valve overlapping period (NVO period), in which both of an exhaust valve and an intake valve are closed, and by causing self-ignition of the mixture gas using compression in a compression stroke. If knocking is detected during the above control, the controller performs knock suppression control for correcting a fuel injection quantity in the NVO period to suppress the knocking. If a pressure increase rate of cylinder pressure during the combustion is lower than a threshold value, the controller performs increase correction of the fuel injection quantity in the NVO period. If the pressure increase rate is equal to or higher than the threshold value, the controller performs decrease correction of the fuel injection quantity in the NVO period.

Owner:DENSO CORP +1

Dielectric antenna

InactiveUS8242965B2Less effortReduce correctionWaveguide hornsLevel indicatorsDielectric antennasElectromagnetic radiation

Owner:KROHNE MESSTECHNICK GMBH & CO KG

Method for making precoating sensitization etching printing plate

ActiveCN101387828AIncreased sensitivityQuality improvementSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistEngineering

The invention discloses a production method of precoated photosensitive etching printed board, which precoats a durable photo-induced etching-resist material of stable photochemical property on the surface of a two-layer or multilayer metal plate synthesized by electric plating, vacuum deposition and the like, to prepare a precoated photosensitive etching printed board. In board making, the precoated photosensitive etching printed board can be burnt, developed, etched and removed with film to product a metal printed board. The produced precoated board can be stored without light for at least one year to satisfy the printing demands of anti-false products with large printed mass such as bank notes and valuable securities and the like. The board making can adopt large power UV light source direct board making device (CTcP), to improve the quality of printed boards and the consistence of repeated production. The precoated photosensitive board can reduce the production period of printed boards and improve production efficiency.

Owner:石家庄印钞有限公司 +1

Method for calibrating high-frequency radar antenna array channel by using ionosphere echo

InactiveCN1804656AAvoid convergenceIncrease flexibilityWave based measurement systemsStatistical analysisRadar

The invention relates to an adjusting method for using ionospheric echo to do high frequency wire array channel, which is characterized in that it detects the ion layer reflecting signal in high frequency radar ionospheric echo and uses the statistical analysis on array each channel ionospheric echo to do the channel amplitude and phase adjusting. It is a truly non-channel adjusting method without any limit to the wire array type.

Owner:WUHAN UNIV

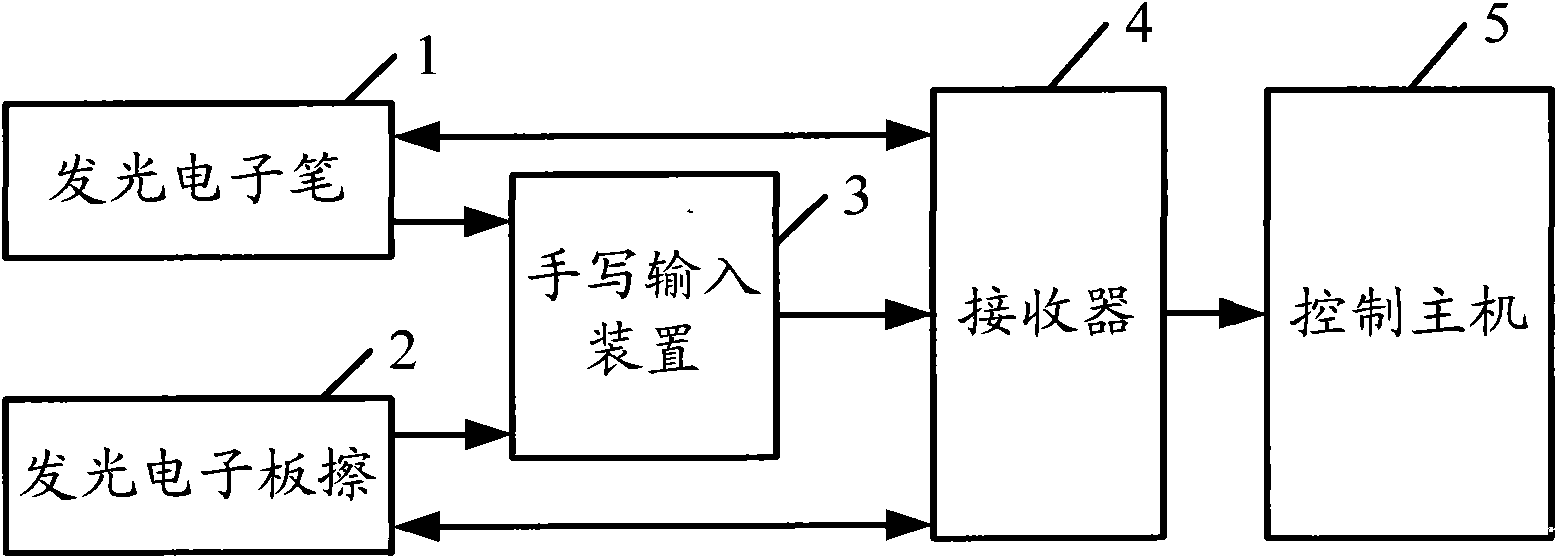

Multi-input large-area writing method, device and system

ActiveCN101887327ASimple inputEnter exactlyInput/output processes for data processingMulti inputCMOS sensor

The invention provides a multi-input large-area writing method, a multi-input large-area writing device and a multi-input large-area writing system. The method comprises the following steps that: a handwriting input detection device detects whether a light spot enters a plane monitoring area or not; when detecting that the light spot enters the plane monitoring area, the handwriting input detection device sends trigger information to a receiver; the receiver acquires the motion trace data sensed by a luminous device generating the light spot, wherein the motion trace data is sensed by a motion sensing unit in the luminous device; and a control host computer acquires or erases the handwriting information according to the motion trace data acquired by the receiver. The method, the device and the system can remarkably reduce the requirements on the precision and speed of an independently used CMOS sensor, lower the cost, improve the accuracy and speed of inputting and erasing the handwriting information and greatly improve the cost and performance while ensuring that multiple electronic light pens and electronic erasers are used at the same time.

Owner:SHENZHEN HEZHI CHUANGYING ELECTRONICS

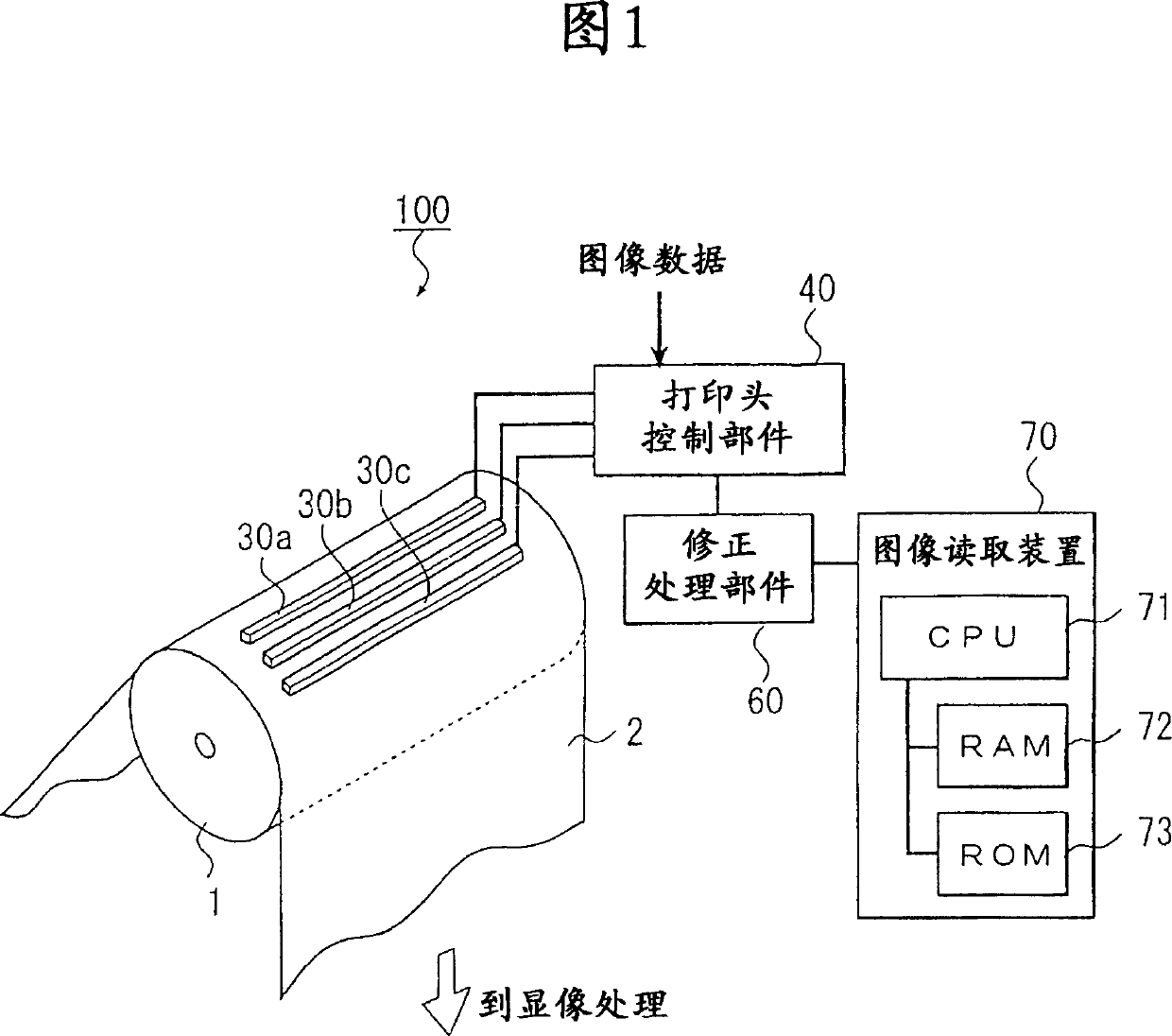

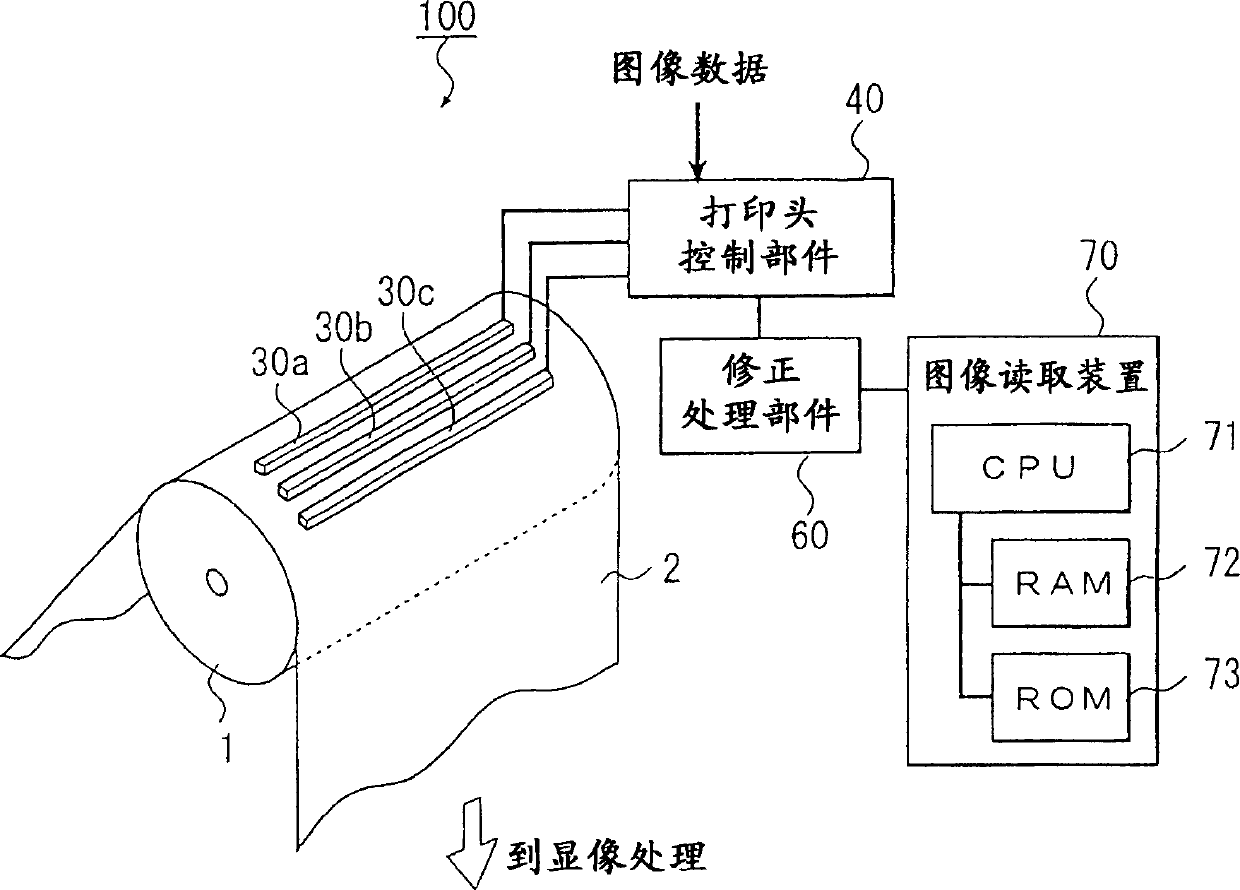

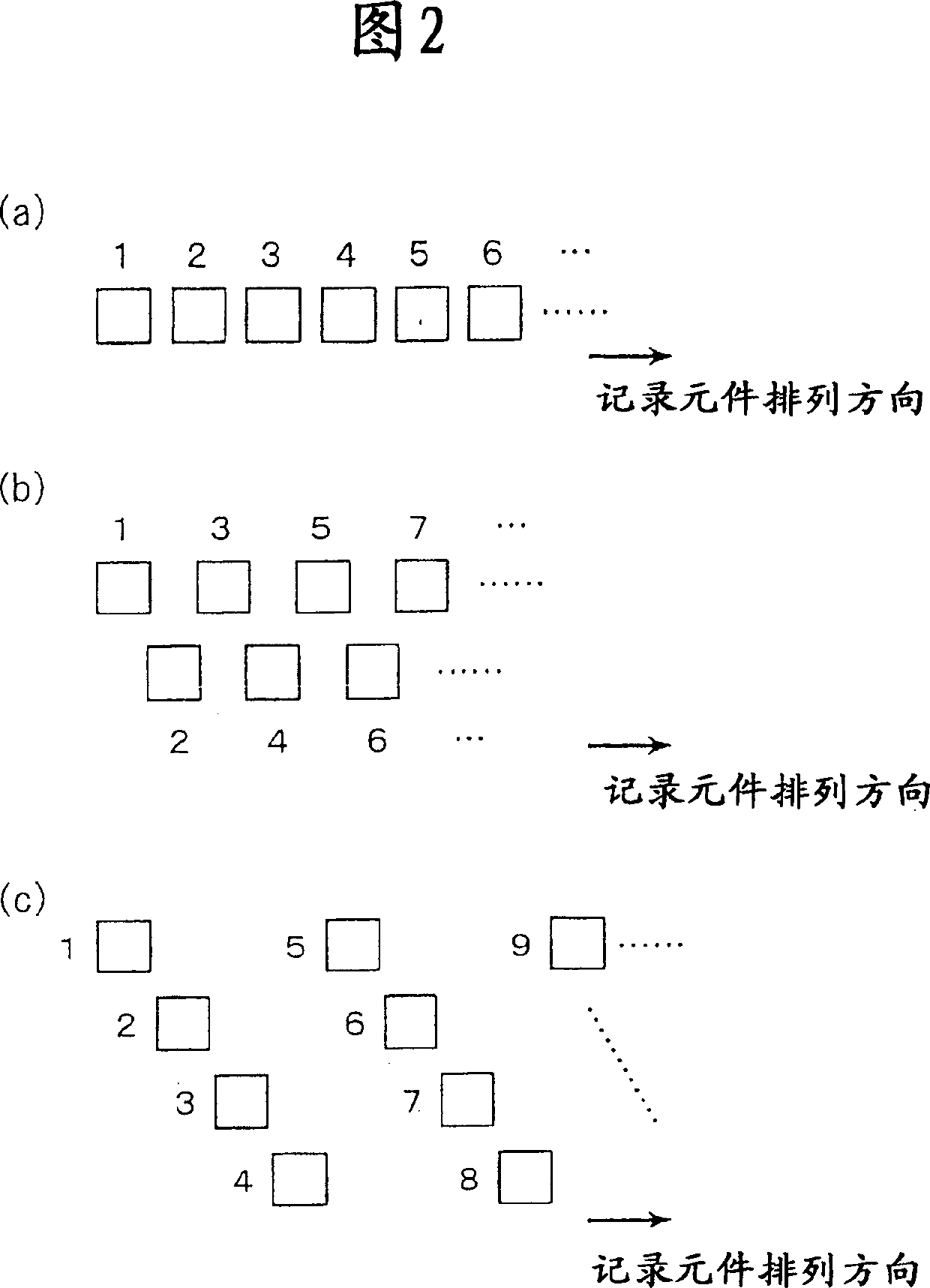

Output correction method of image forming device and image forming appts.

InactiveCN1539646AImprove image qualityHigh precisionOther printing apparatusPictoral communicationCorrection methodInformation data

Provided is a means of precisely reducing irregular concentrations in an array-like printhead for a long picture. An information of concentrations from each image N to be corrected (step S2) is obtained in the first place before a concentration information data DNi that corresponds to each recording pixel i is specified(step S4), and a deviation -DNi=DNi-DNave, iscalculated treating an average of the concentration data DNi as DNave (step S5). Then, a difference of the quantity of light, -ENi, corresponding to the deviation -ENi is obtained using a straight line of conversion (step S6), followed by (step S7) that calculates a correction quantity CNi=10(--ENi) that meets each recording pixel and (step S9) that composes the quantity of correction CNi calculated from each correction image N.

Owner:KONICA MINOLTA OPTO

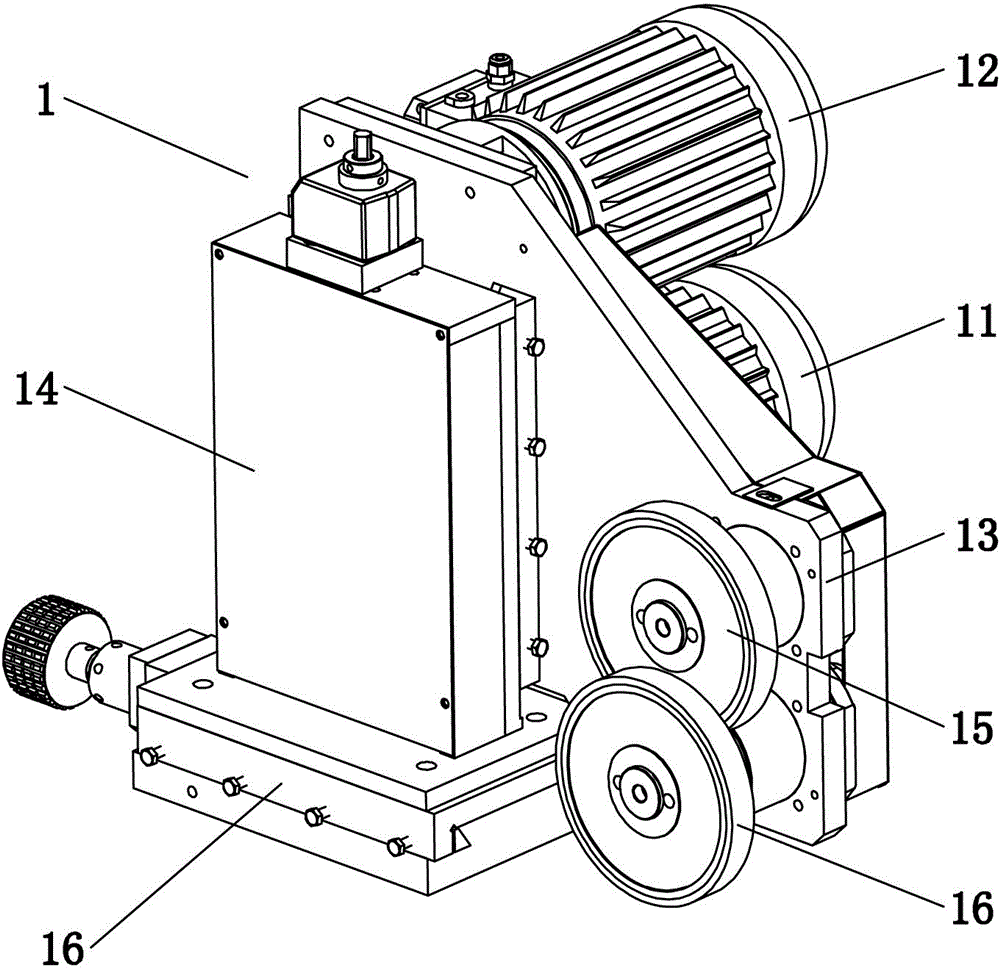

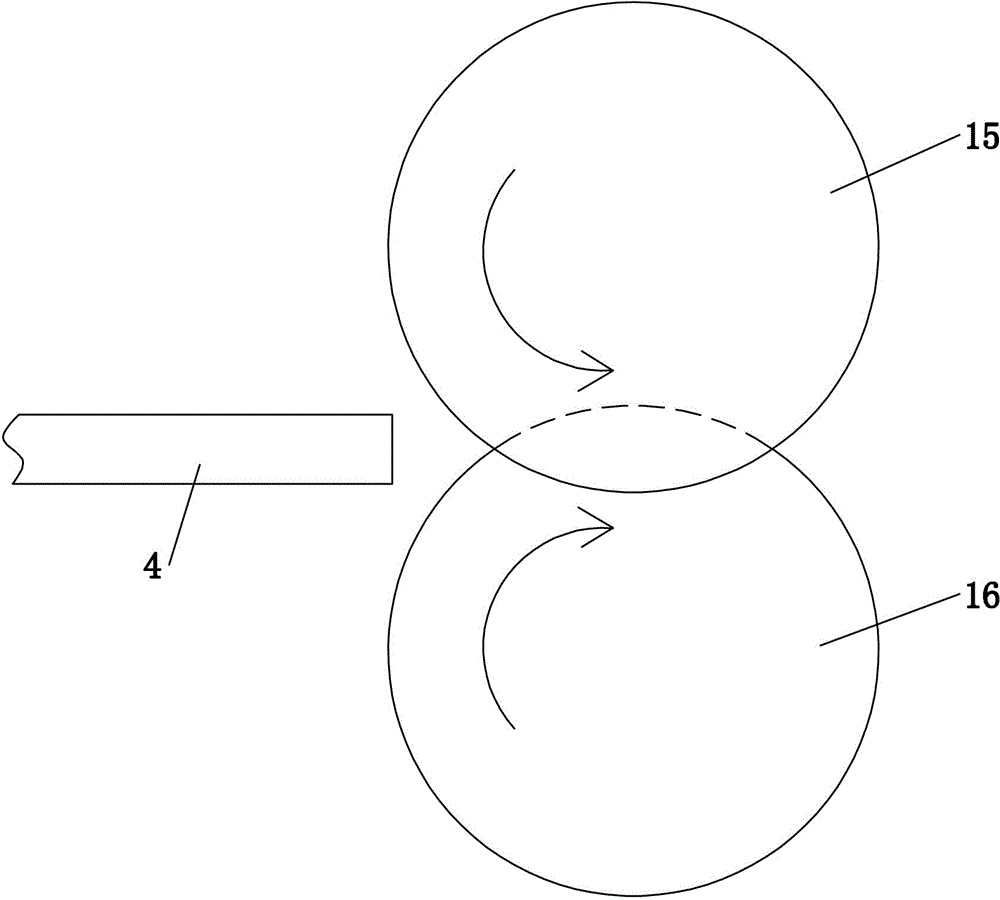

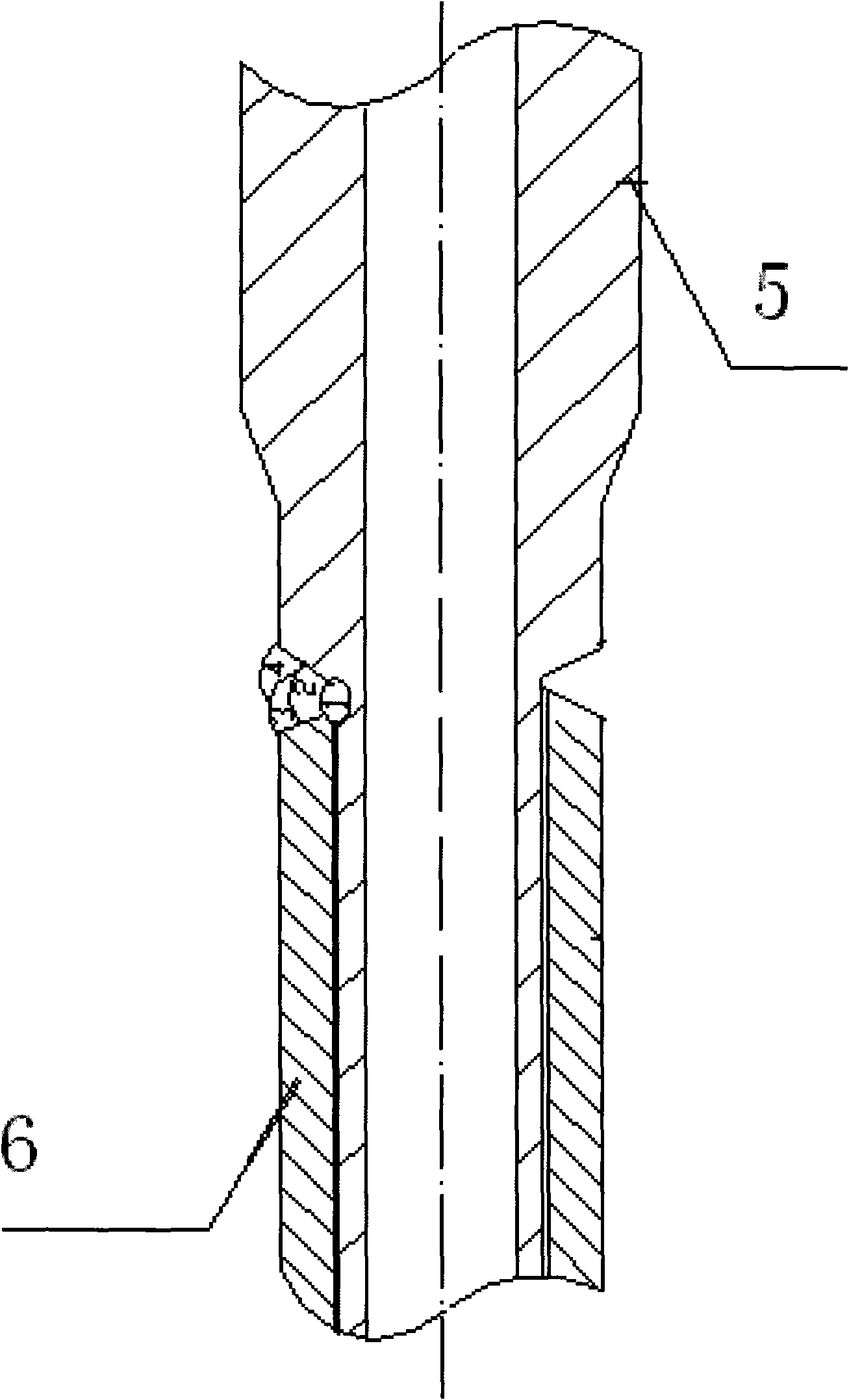

Pipeline hot melting butt joint technology and hot melting butt joint equipment

The invention belongs to the field of pipeline welding, provides a pipeline hot melting butt joint technology and hot melting butt joint equipment and solves the problem that the correction is large when a pipeline is welded. According to the scheme, the pipeline hot melting butt joint technology comprises the following steps: 1, preparing: levelling and cleaning to-be-butt joint end faces of a pipeline, arranging two heating plates at an interval, and enabling the two heating plates to be propped against the adjacent pipeline; 2, heating: heating the heating plates to melt the part, propped against the heating plates, of the pipeline; 3, crimping: pushing the pipeline towards the heating plates to deform the part, propped against the heating plates, of the pipeline into curled edges; 4, switching: rotating the heating plates in the circumferential direction, moving the heating plates in the axial direction simultaneously to enable the heating plates to deviate from the pipeline propped against the heating plates, and removing the heating plates when the pipeline and the heating plates are separated from each other; and 5, carrying out pressure welding: pushing the melted part of the pipeline to be propped against the heating plates. As the heating plates rotate in the circumferential direction and can form shearing force during rotating, the pipeline and the heating plates canbe easily separated, and the axial or radial moving degree of the melted part of the pipeline is lowered to reduce correction.

Owner:杭州大江东城市设施管养有限公司

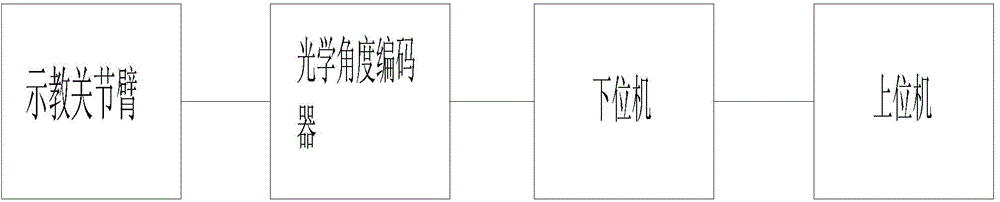

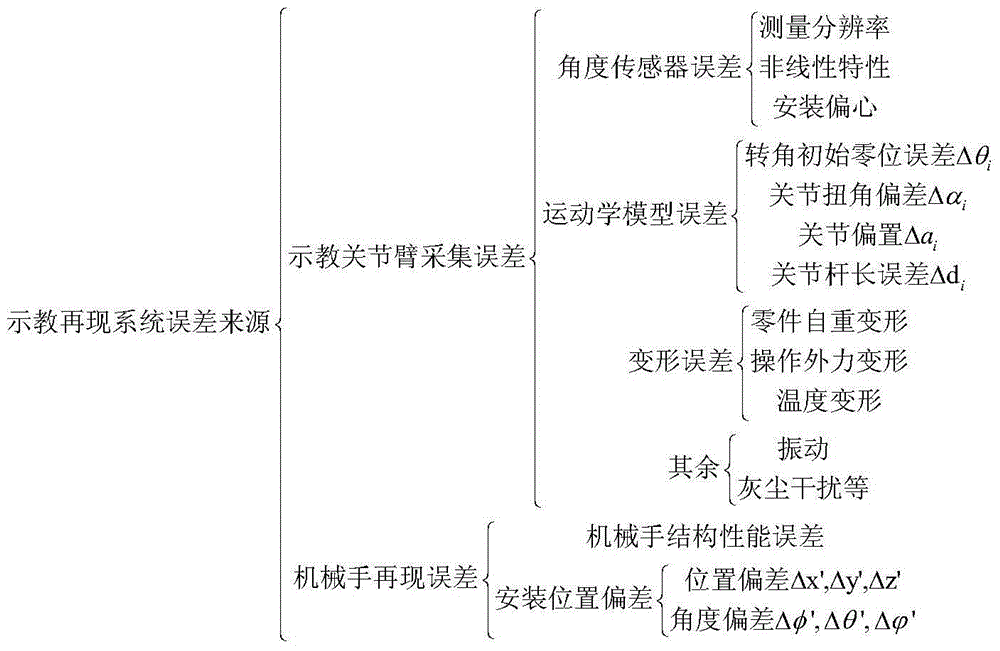

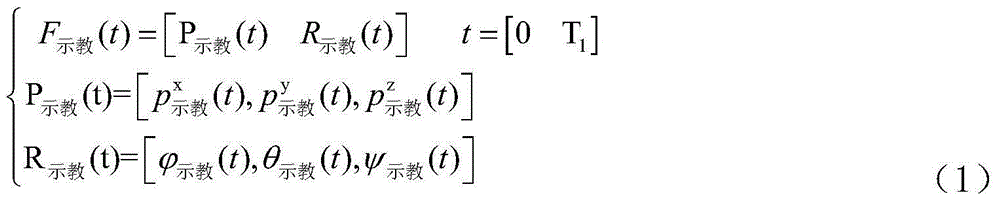

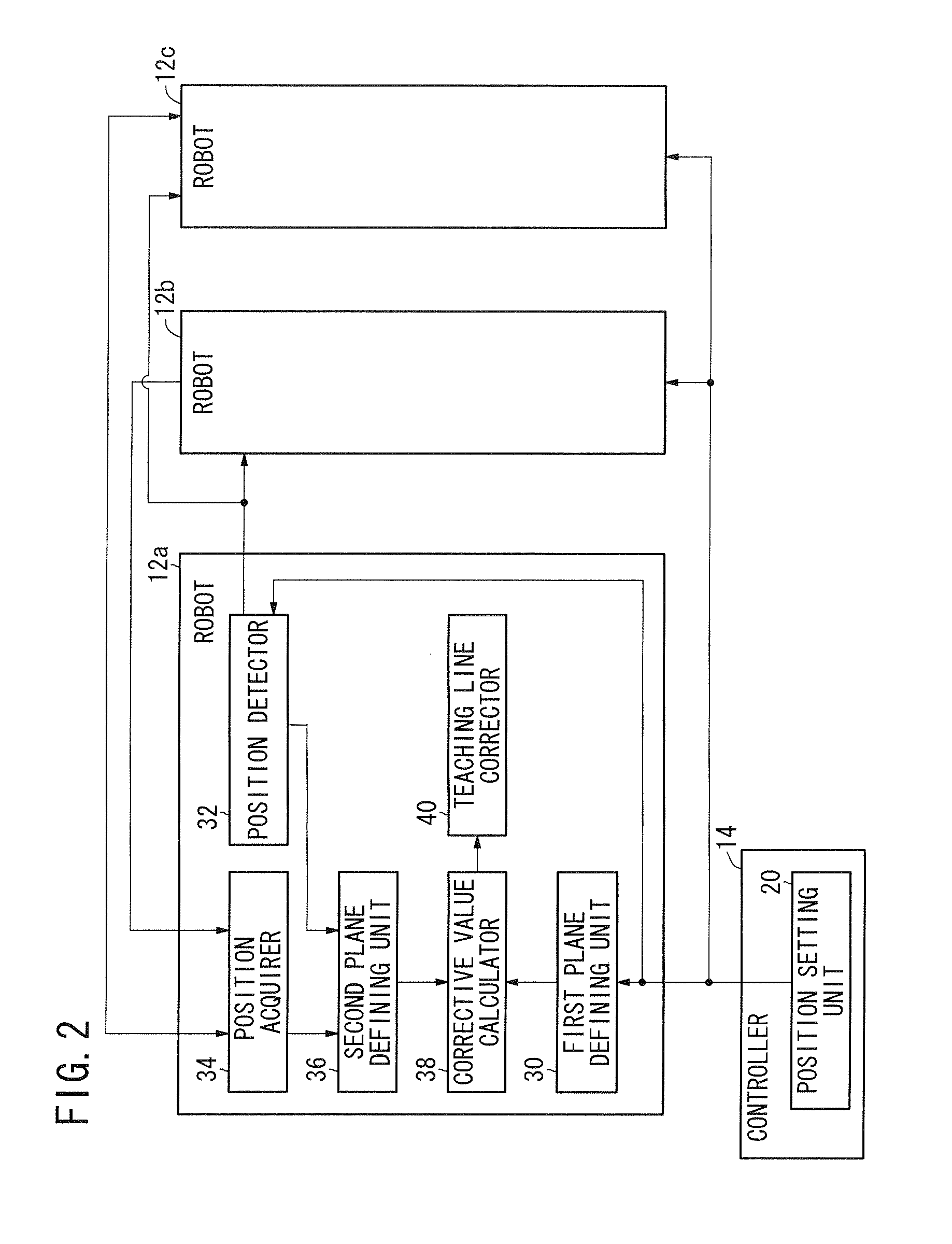

Robot off-line teaching device and compensation teaching method

InactiveCN104552299AReduce the difficulty of teaching operationReduce the process of robot trajectory correctionProgramme-controlled manipulatorSystem errorSkill sets

The invention relates to the field of a robot, and discloses an error compensation method of a robot off-line teaching device. According to the error compensation teaching method disclosed by the invention, by testing and analyzing the influence of system error of various teaching articulated arms on motion parameters and correcting the parameters of the various teaching articulated arms, accurate program control on a target robot is realized, and great flexibility is expressed; meanwhile, the teaching operation difficulty is reduced, the operation experience of a skilled worker can be deposited through a mechanical arm, and the skill level of the skilled worker can be achieved by the whole production line, so that tedious robot track correcting processes can be reduced, and the programming efficiency is greatly increased.

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

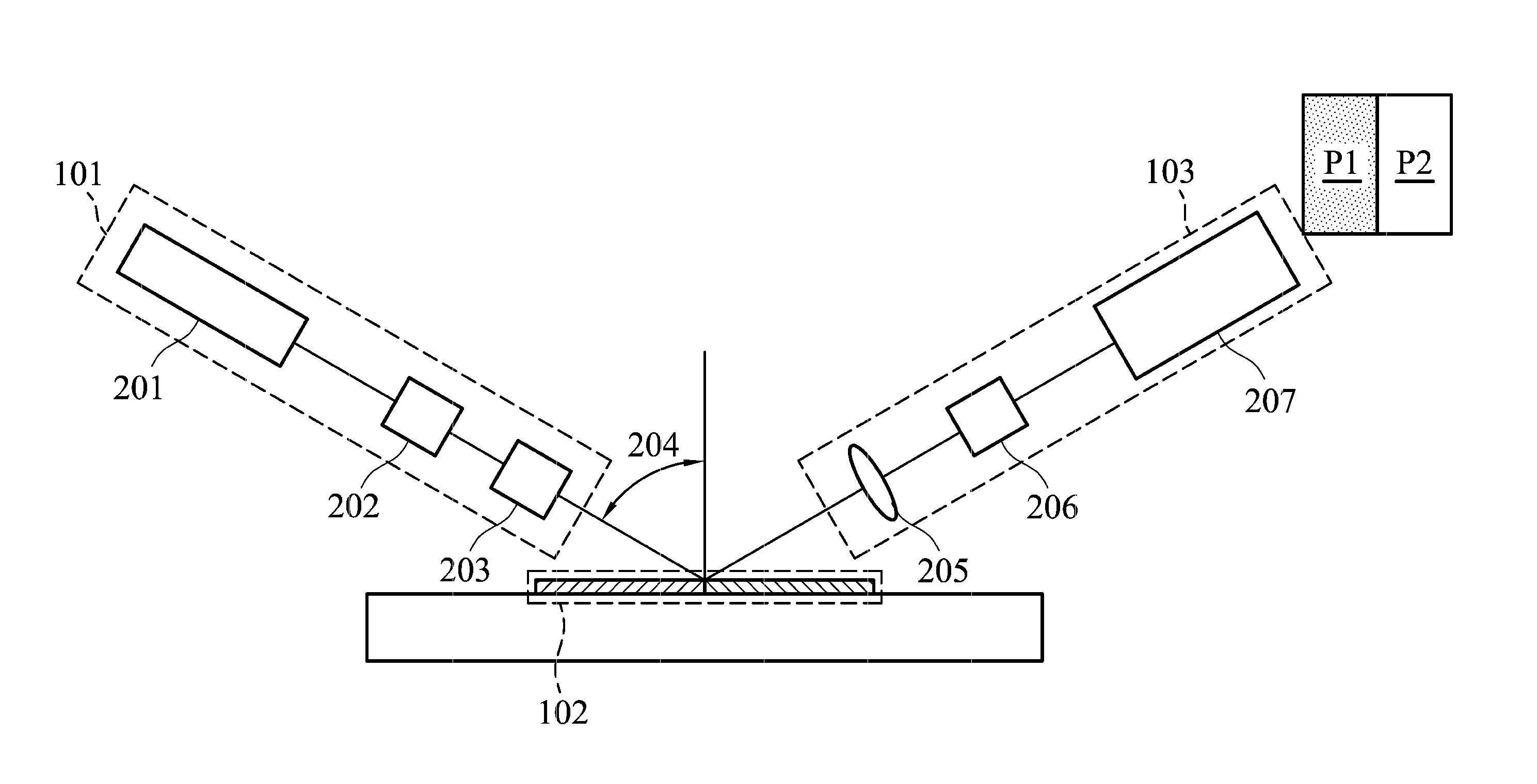

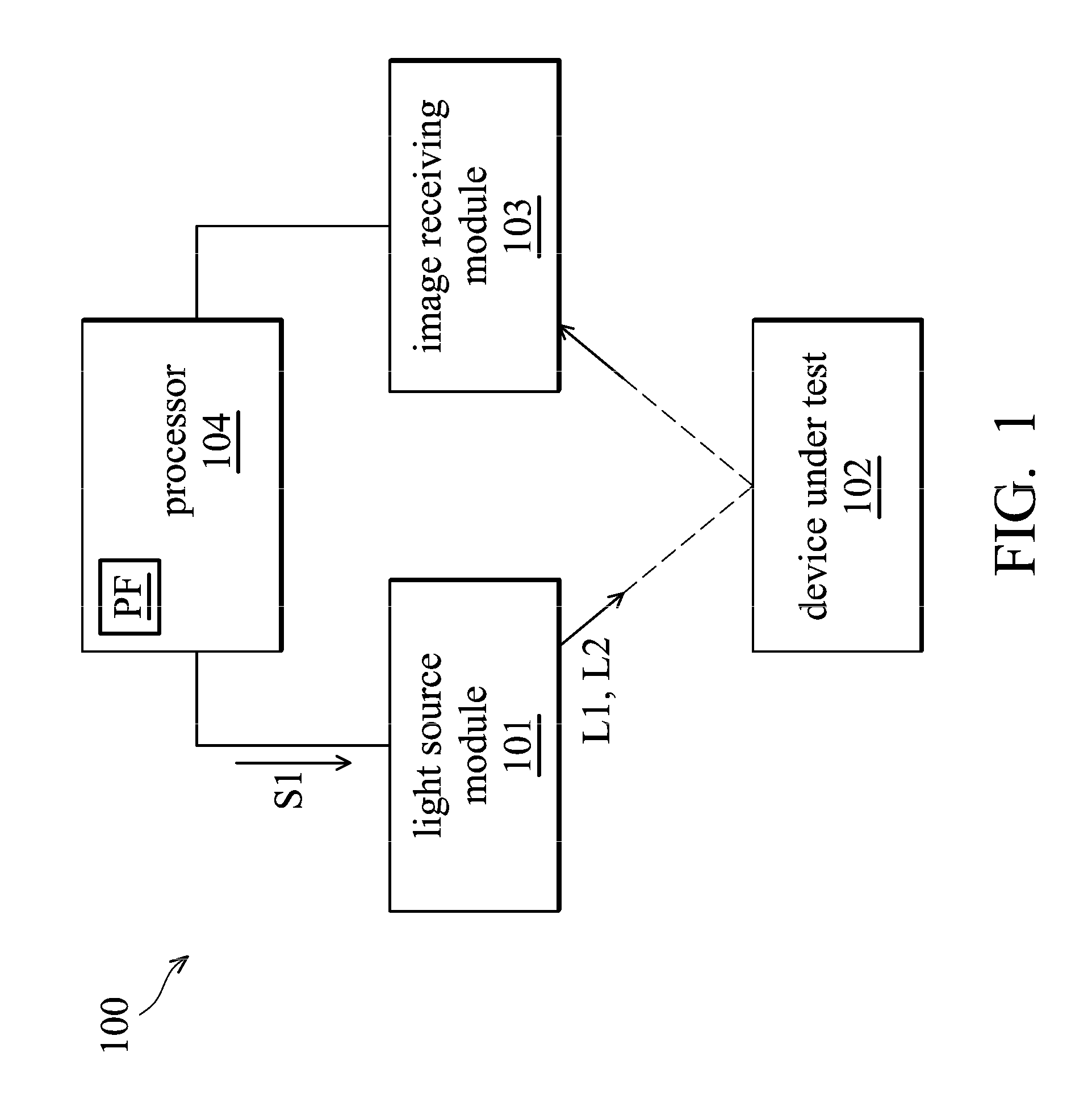

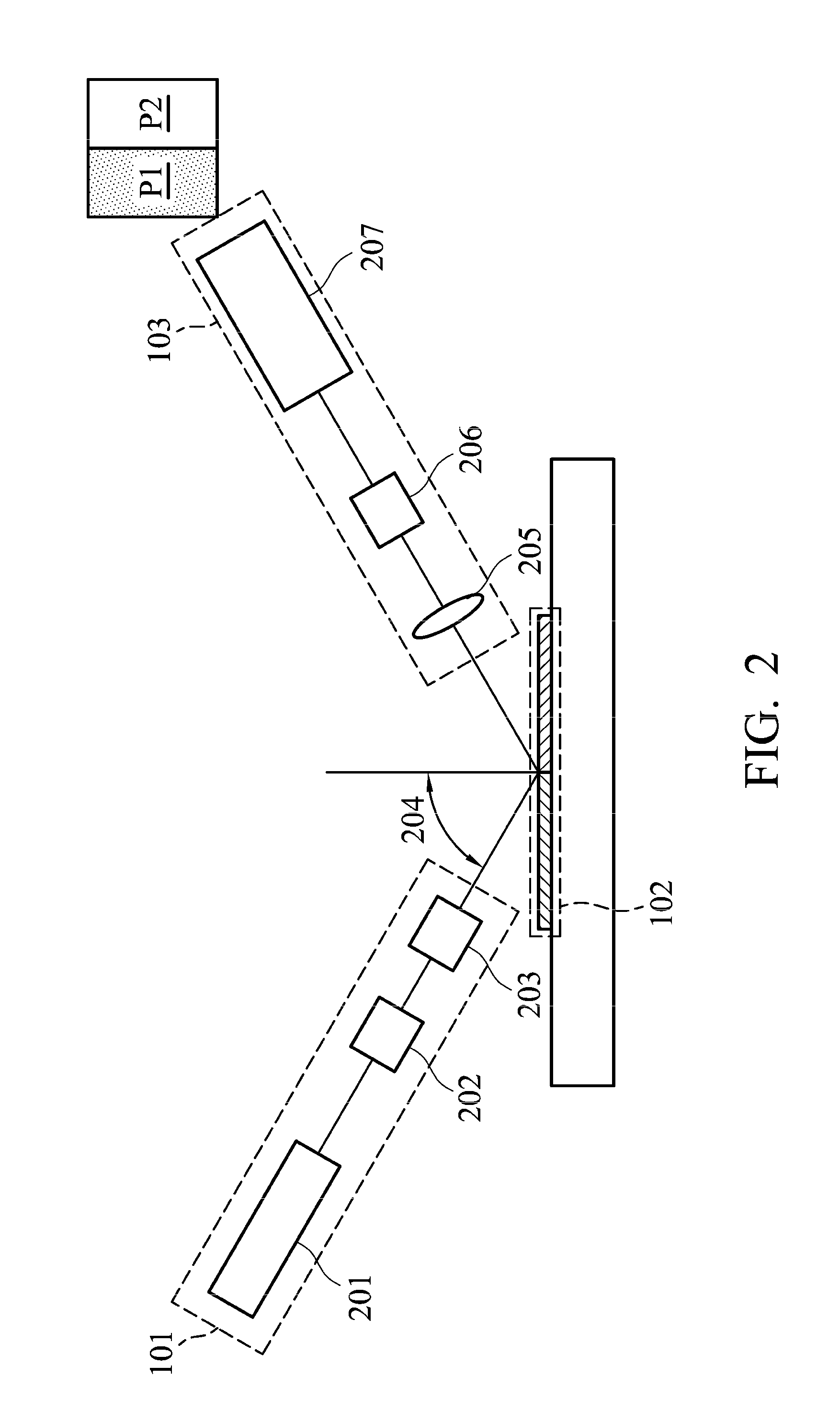

Inspection device and inspection method

ActiveUS20140168417A1Enhance the imageReduce correctionPolarisation-affecting propertiesPolarising elementsComputer scienceContrast ratio

The disclosure provides an inspection device including a light source module, an image receiving module and a processing unit. The light source module emits a first incident light and a second incident light to a device under test (DUT). The image receiving module receives a first image corresponding to the DUT irradiated by the first incident light, and receives a second image corresponding to the DUT irradiated by the second incident light. The processing unit calculates the contrast ratio of the first image and the second image to obtain a high-contrast image for inspection.

Owner:IND TECH RES INST

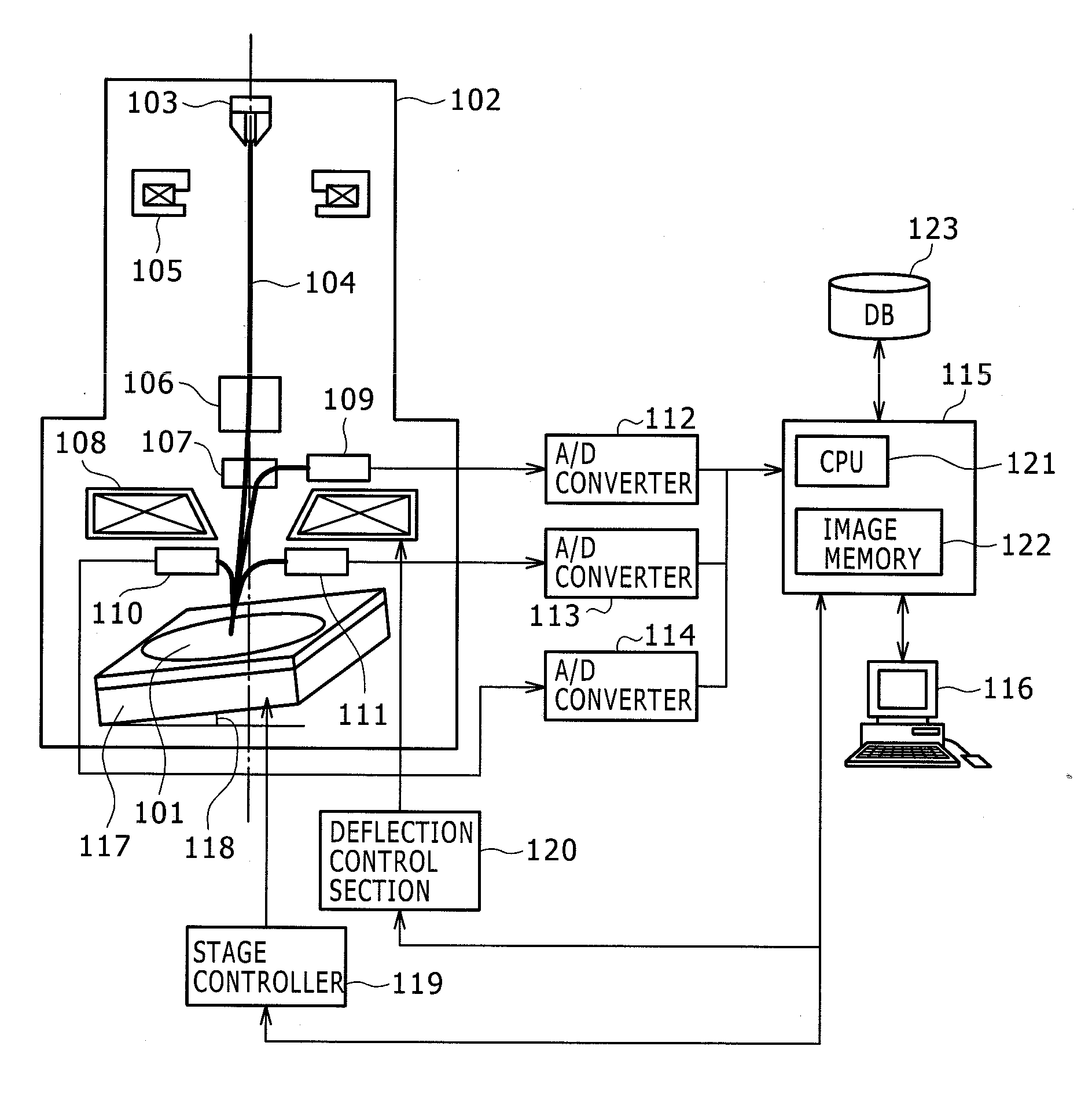

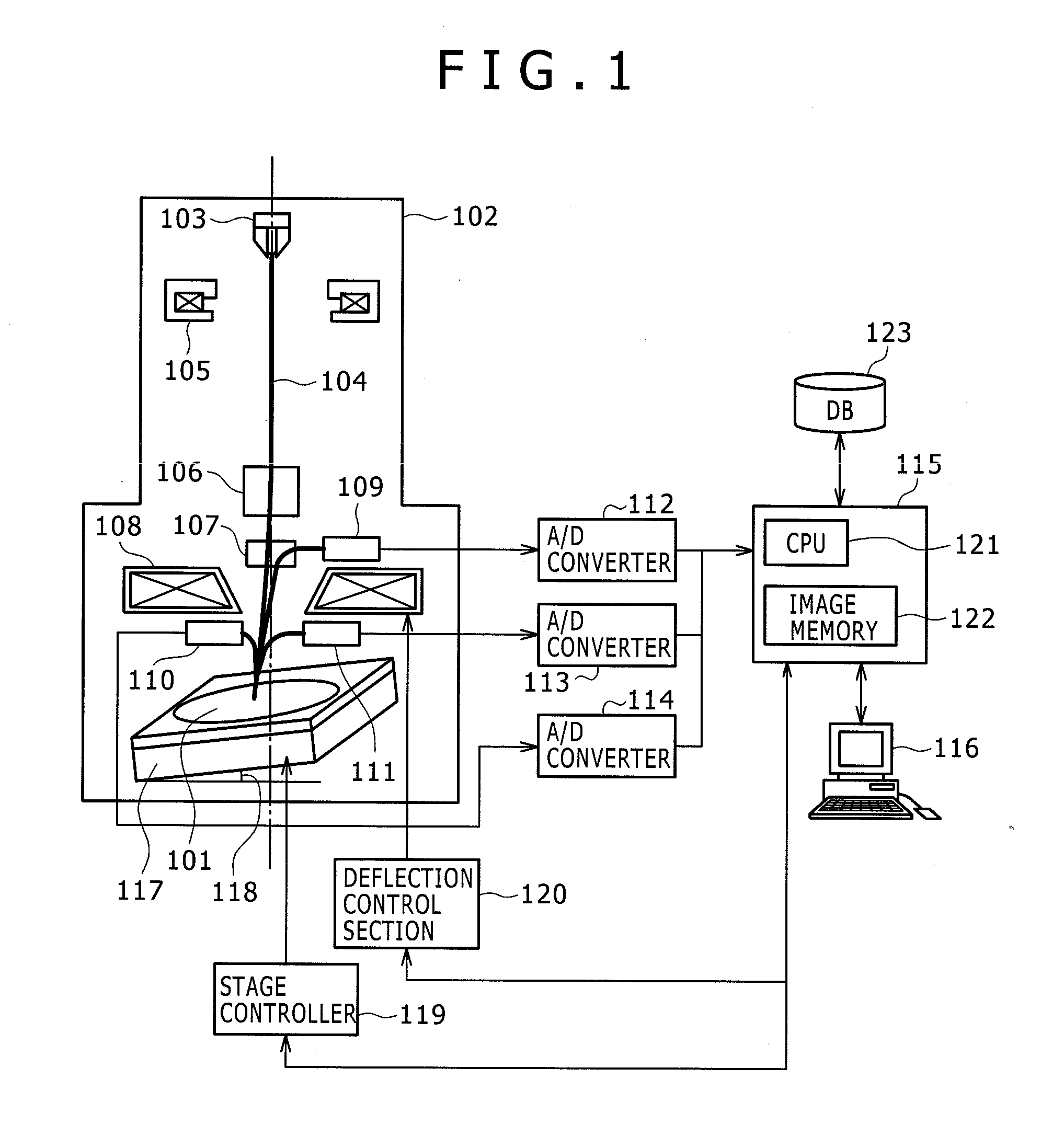

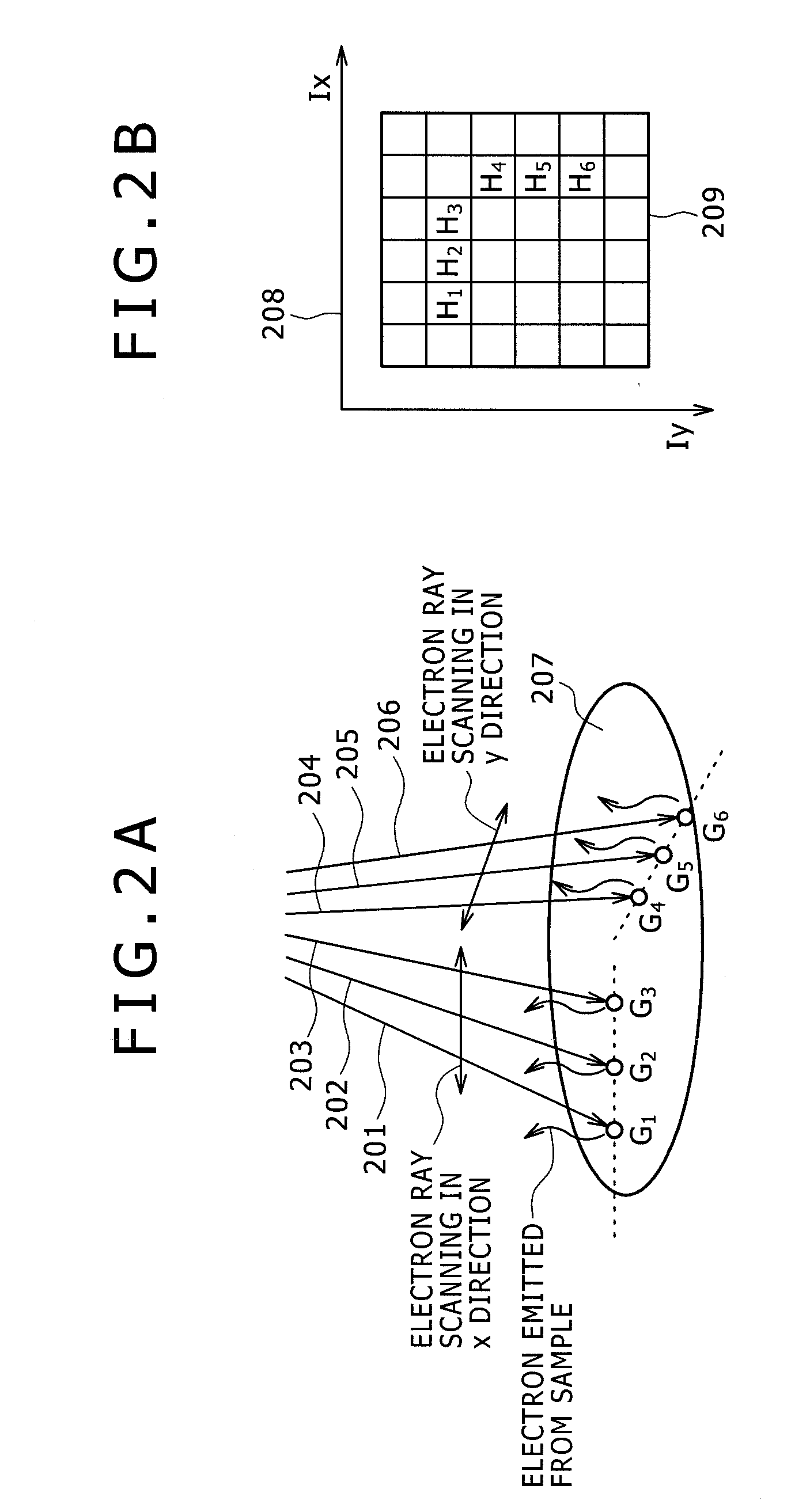

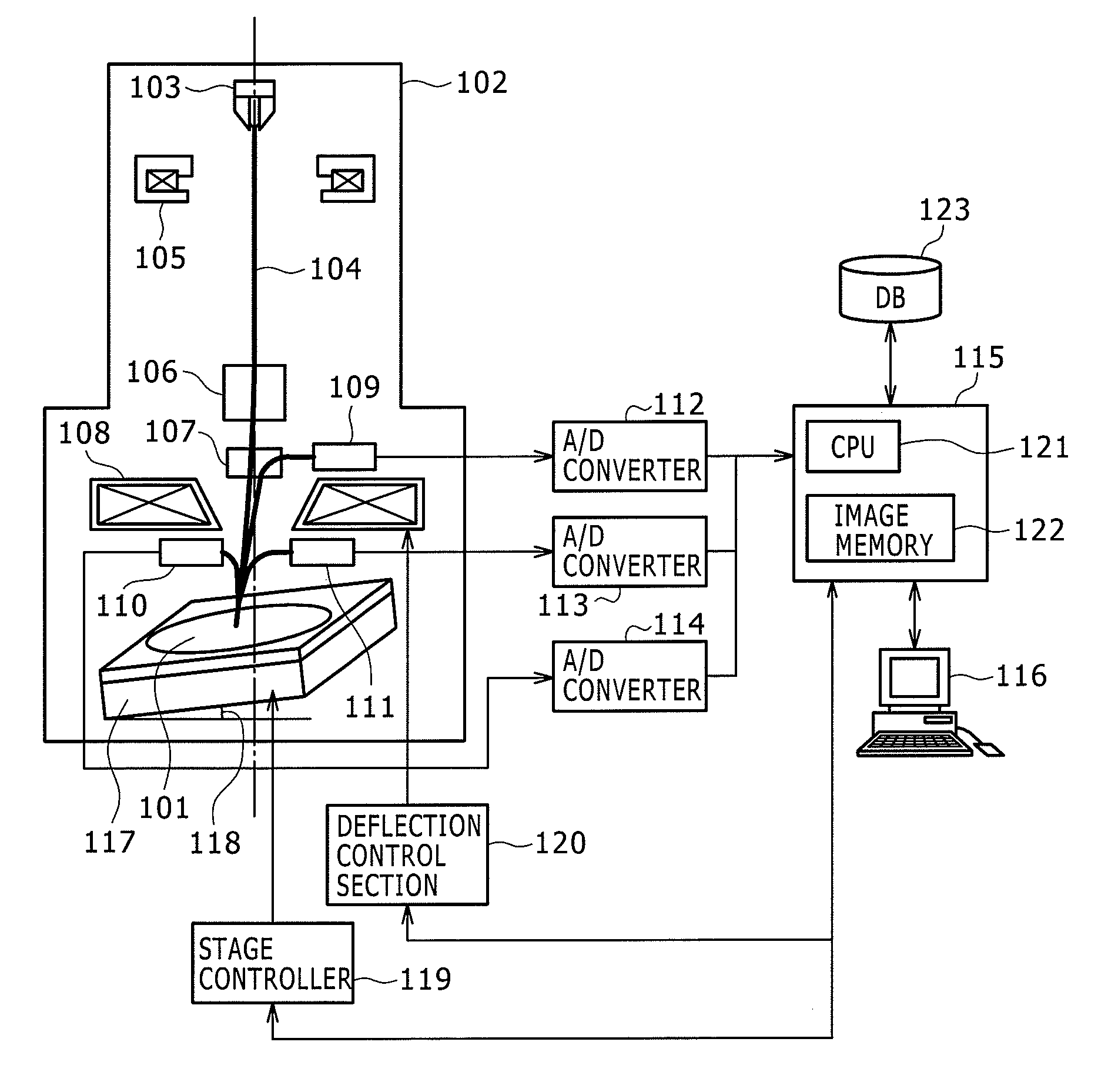

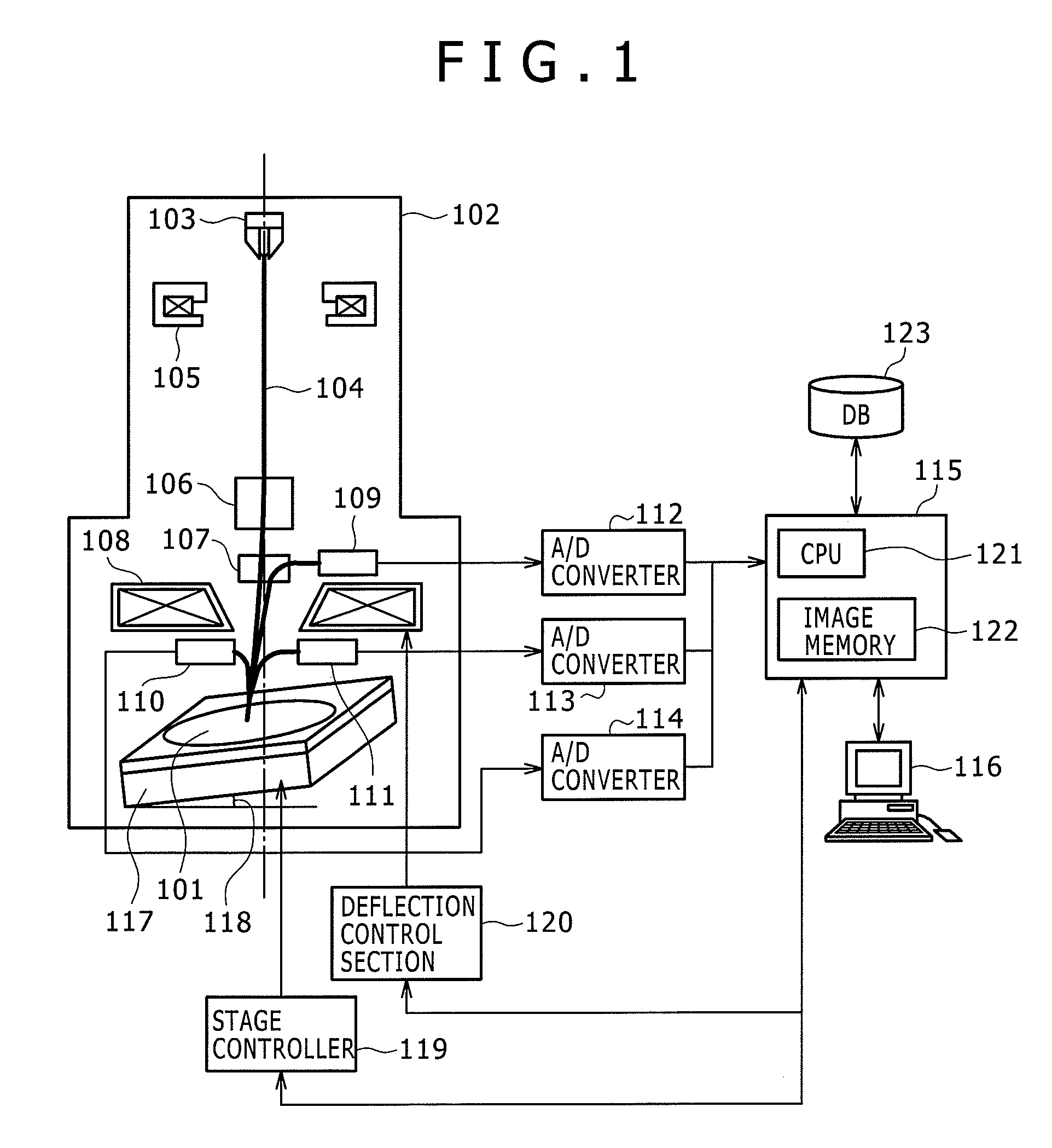

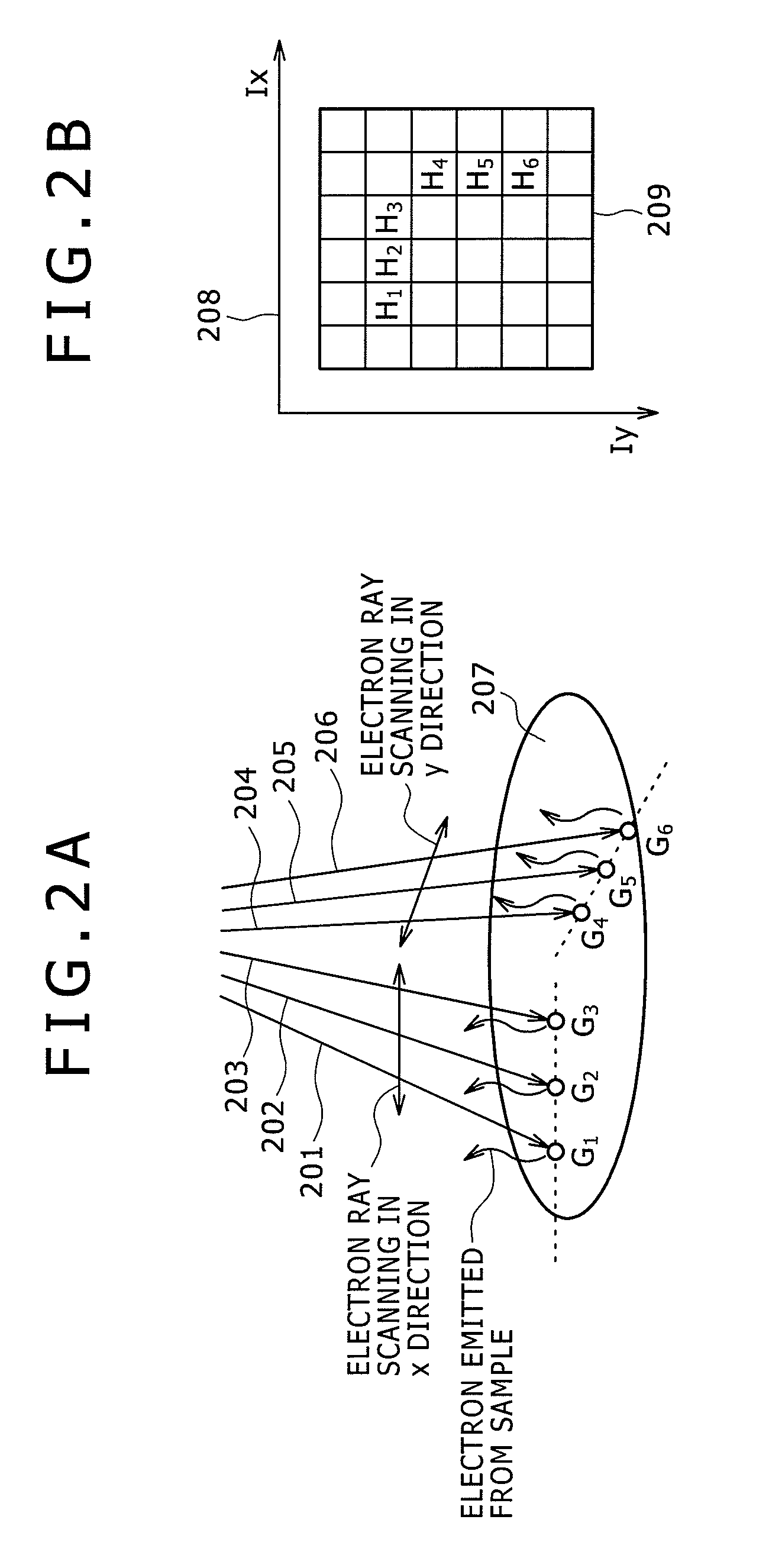

Method and Apparatus For Measuring Dimension Of Circuit Pattern Formed On Substrate By Using Scanning Electron Microscope

ActiveUS20110127429A1Reduce correctionImproving Imaging AccuracyMaterial analysis using wave/particle radiationDigital computer detailsDimension measurementScanning electron microscope

In the dimension measurement of a circuit pattern using a scanning electron microscope (SEM), in order to make it possible to automatically image desired evaluation points (EPs) on a sample, and automatically measure the circuit pattern formed at the evaluation points, according to the present invention, in the dimension measurement of a circuit pattern using a scanning electron microscope (SEM), it is arranged that coordinate data of the EP and design data of the circuit pattern including the EP are used as an input, creation of a dimension measurement cursor for measuring the pattern existing in the EP and selection or setting of the dimension measurement method are automatically performed based on the EP coordinate data and the design data to automatically create a recipe, and automatic imaging / measurement is performed using the recipe.

Owner:HITACHI HIGH-TECH CORP

Method and apparatus for measuring dimension of circuit pattern formed on substrate by using scanning electron microscope

ActiveUS7888638B2Reduce correctionImproving Imaging AccuracyMaterial analysis using wave/particle radiationDigital computer detailsScanning tunneling microscopeDimension measurement

In the dimension measurement of a circuit pattern using a scanning electron microscope (SEM), in order to make it possible to automatically image desired evaluation points (EPs) on a sample, and automatically measure the circuit pattern formed at the evaluation points, according to the present invention, in the dimension measurement of a circuit pattern using a scanning electron microscope (SEM), it is arranged that coordinate data of the EP and design data of the circuit pattern including the EP are used as an input, creation of a dimension measurement cursor for measuring the pattern existing in the EP and selection or setting of the dimension measurement method are automatically performed based on the EP coordinate data and the design data to automatically create a recipe, and automatic imaging / measurement is performed using the recipe.

Owner:HITACHI HIGH-TECH CORP

YOLOv3-based synchronous end-to-end license plate positioning and recognition method

PendingCN111914839AGet the most out of your processing speedGive full play to processing precisionCharacter and pattern recognitionNeural architecturesPattern recognitionData set

A YOLOv3-based synchronous end-to-end license plate positioning and recognition method comprises the steps of obtaining a license plate external rectangular frame and license plate number information,making a data set label file, and dividing a data set into a training data set, a verification data set and a test data set; training a license plate detection and recognition integrated network LPYolo based on YOLOv3, so that the LPYolo recognizes various types of license plates while detecting the license plates, augments a training data set, and puts the augmented training data set into the network for training; and positioning and identifying the license plate on the test data set by using the trained network model, and then evaluating the model. According to the invention, license platesof various types and different lengths can be classified and identified. Meanwhile, the network LPYolo proposed by the method can quickly and accurately detect and identify the license plate in various unconstrained environments.

Owner:CHINA THREE GORGES UNIV

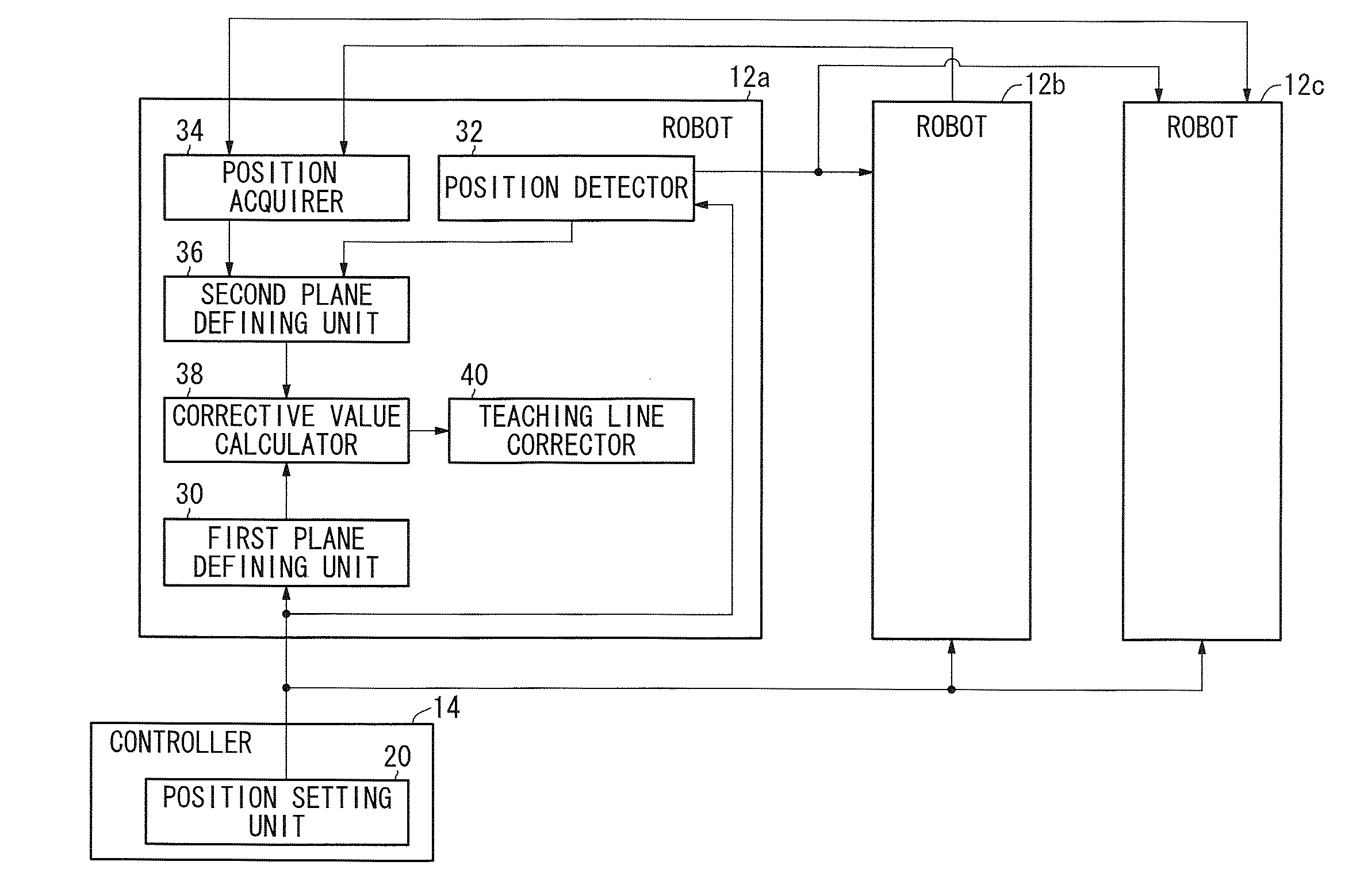

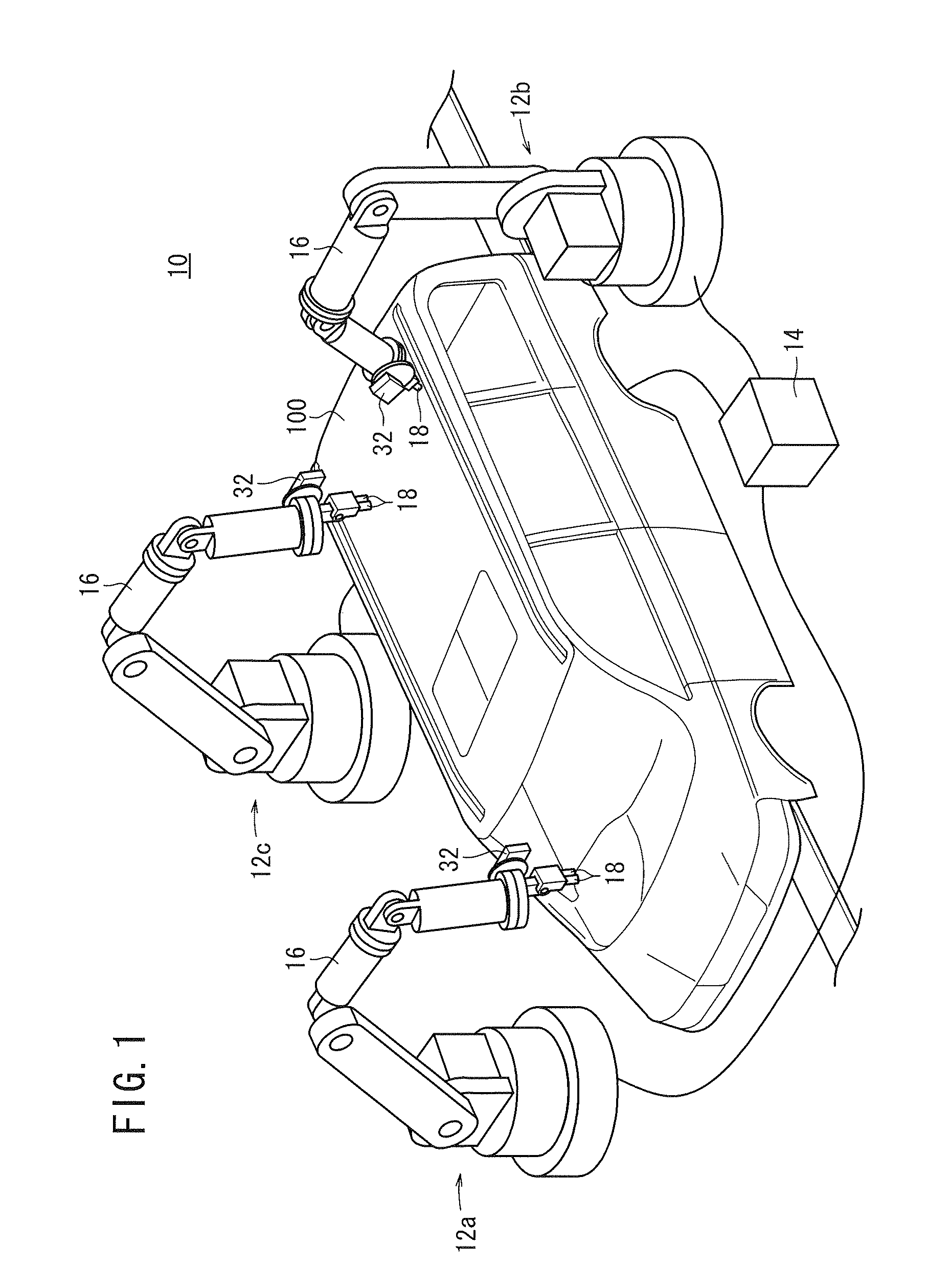

Teaching line correcting apparatus, teaching line correcting method, and program thereof

ActiveUS20110118876A1Reduce errorsAccurate correctionProgramme-controlled manipulatorComputer controlOperating pointReference Region

A teaching line correcting apparatus defines a first plane, which is determined by a first reference position of a preset first reference region, a second reference position of a preset second reference region, and a third reference position of a preset third reference region, defines a second plane, which is determined by a detected position of the first reference region, a detected position of the second reference region, and a detected position of the third reference region, calculates a corrective value for equalizing the first reference region to an origin, equalizing the first reference position of the first reference region as the origin to the detected position of the first reference region as the origin, and equalizing the first plane to the second plane, and correcting reference coordinates where operating points are taught based on the calculated corrective value.

Owner:HONDA MOTOR CO LTD

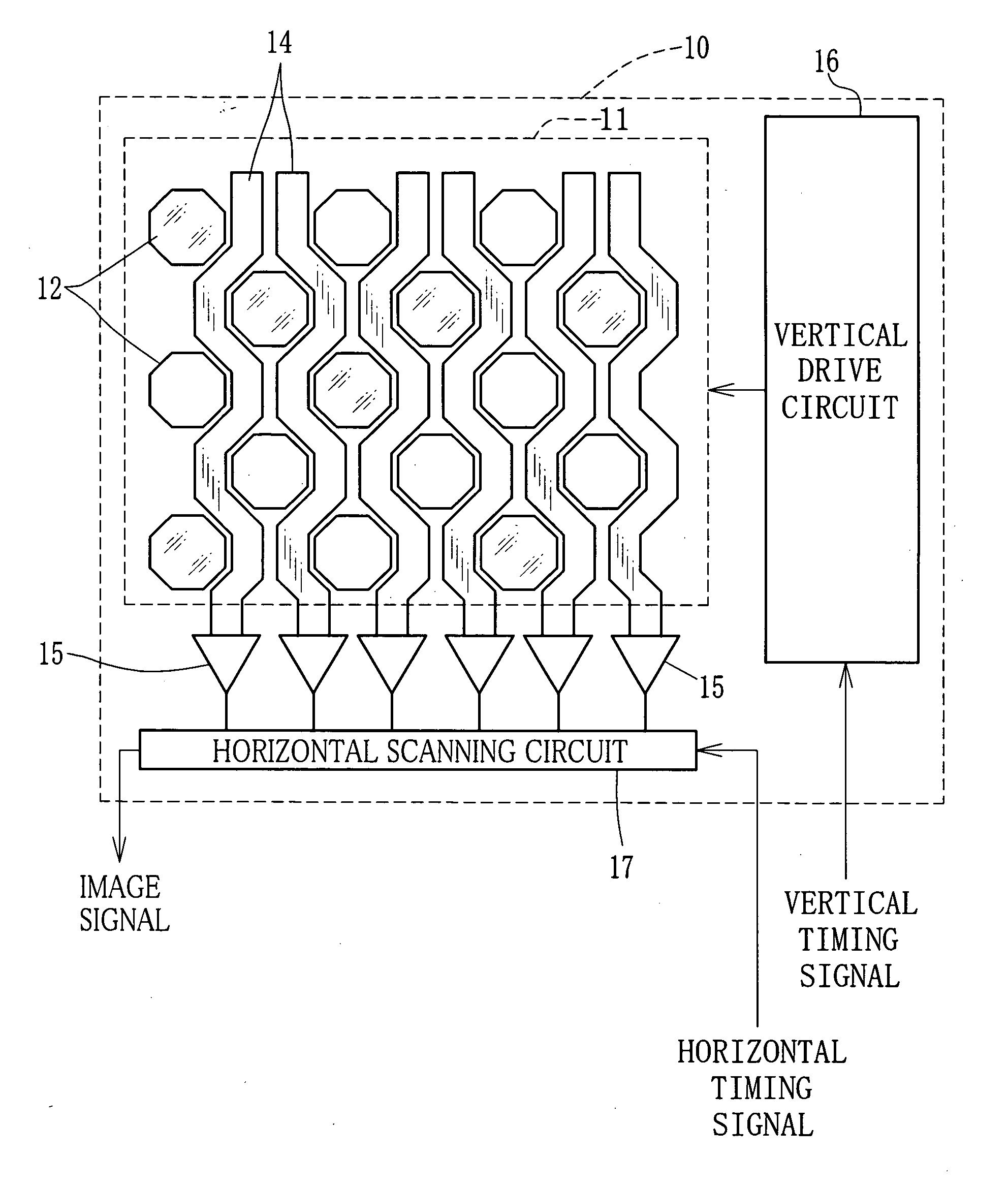

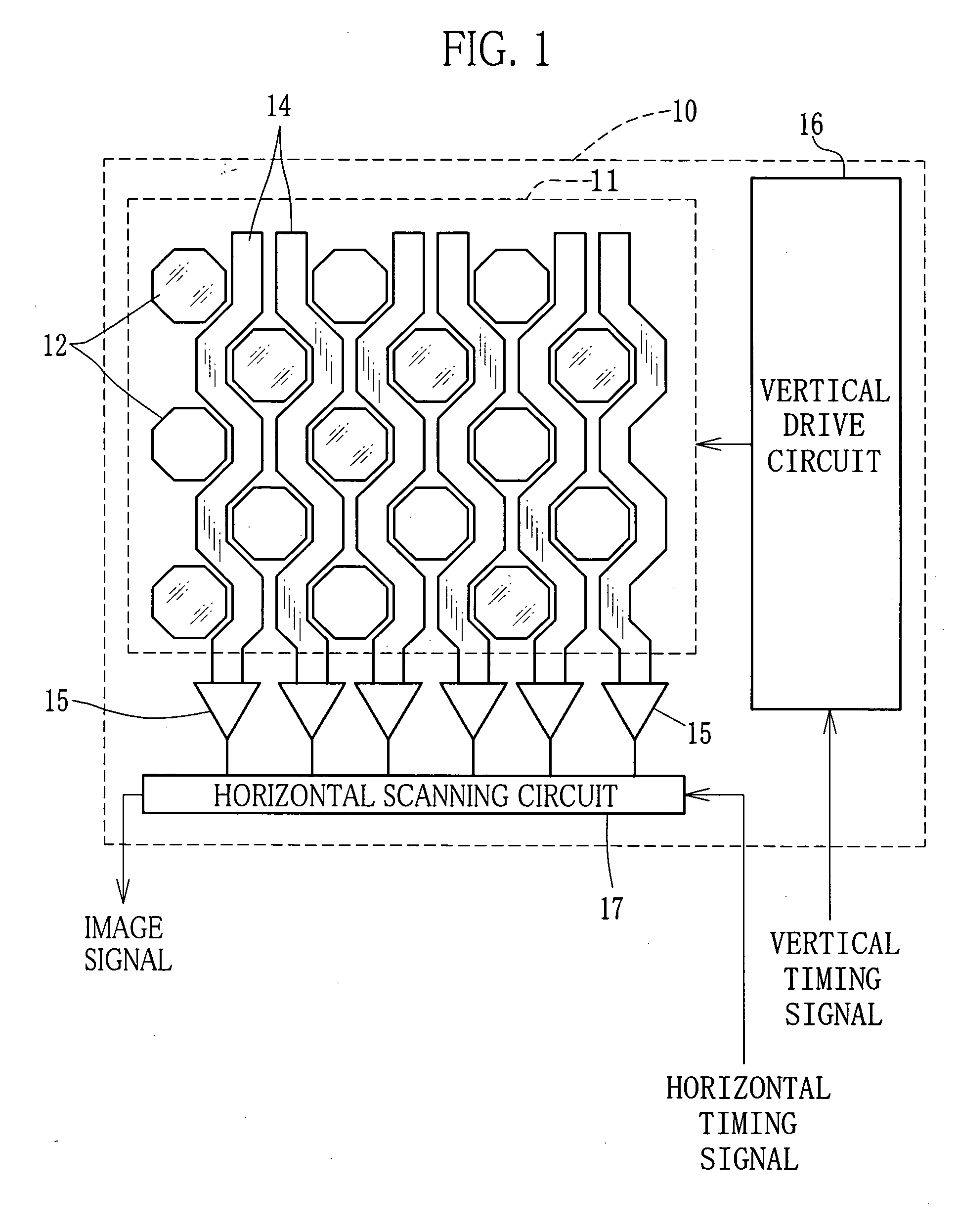

Electronic camera having pixel-row thinning mode

InactiveUS20070030373A1Minimize line-shaped defectMinimizing image defectTelevision system detailsTelevision system scanning detailsAudio power amplifierCharge detection

Pixel rows of an image sensor are respectively provided with a vertical transfer path. A charge detecting amplifier is disposed at one end of each of the vertical transfer paths. When a through image is outputted and when a moving-image mode is executed, a horizontal scanning circuit sequentially selects the charge detecting amplifiers on the basis of a thinning pattern, which is determined every imaging sensitivity, to output an image signal in which the pixel rows are thinned. As the thinning pattern, there are an odd-row pattern for selecting only the odd pixel rows from among the whole pixel rows, and an even-row pattern for selecting only the even pixel rows therefrom. The thinning pattern is selected in accordance with the imaging sensitivity so as to minimize line-shaped defects caused by the vertical transfer paths.

Owner:FUJIFILM CORP

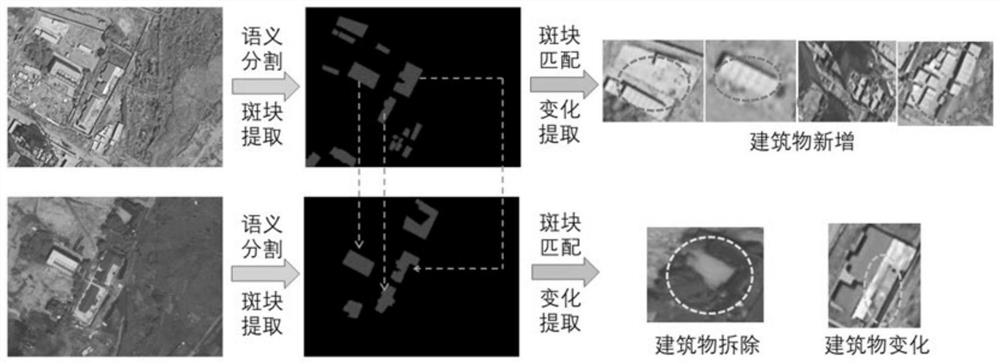

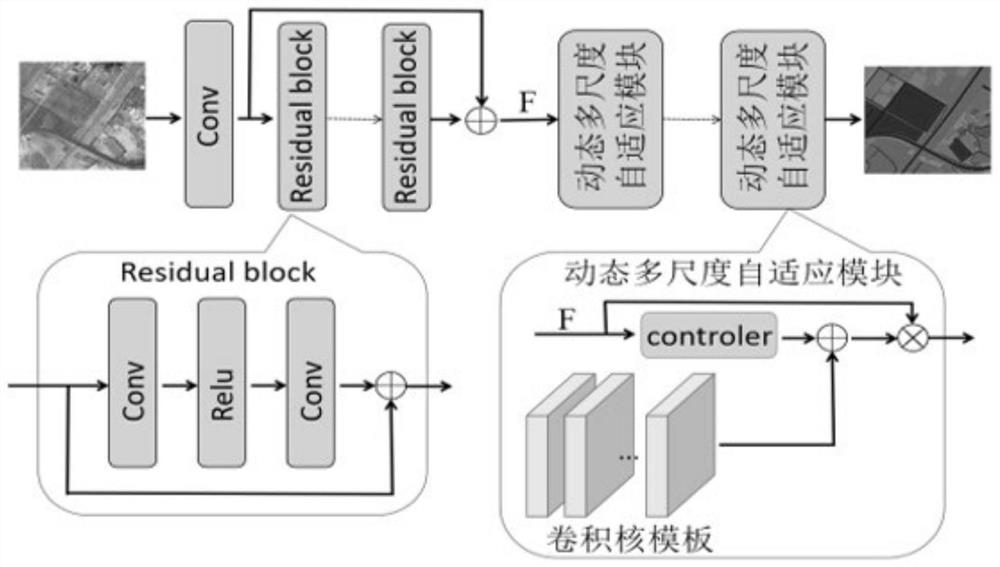

Remote sensing image change detection method under low registration precision based on graph matching model

PendingCN112489096AEnables high-precision change detectionReduce correctionImage enhancementImage analysisPattern recognitionGraph match

The invention discloses a remote sensing image change detection method under low registration precision based on a graph matching model. The method comprises the following steps: firstly, carrying outbuilding segmentation by using a multi-scale adaptive convolution remote sensing image semantic segmentation model to obtain segmentation results of different time phases in the same region, namely binary images; in order to solve the problem of region connection after segmentation of a plurality of different buildings, adopting plaque extraction based on an instance segmentation method, so thatdifferent plaques are distinguished, and regions corresponding to the plurality of buildings in different time phases are obtained; carrying out patch matching based on a graph matching model according to the position information corresponding to the patch and other characteristics; and finally, extracting corresponding change information according to the matched information. According to the invention, high-precision change detection of remote sensing images with different time phases under low registration precision is realized. The change detection scheme provided by the invention does notdepend on accurate image preprocessing, especially image correction and registration, and the requirements for image correction and registration are reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

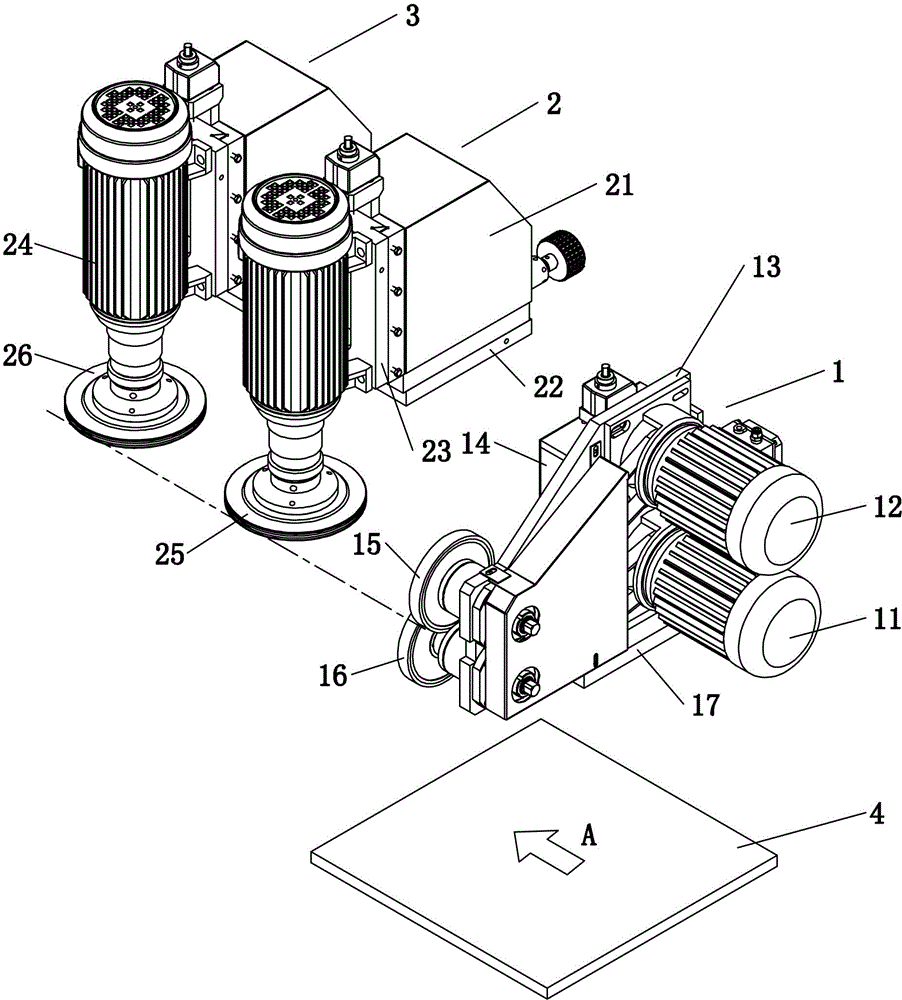

Grinding head assembly of glass edge grinding machine and edge grinding process thereof

ActiveCN104972372AReduce correctionReduce replacement frequencyEdge grinding machinesGrinding machine componentsEngineeringGrinding wheel

The invention relates to a grinding head assembly of a glass edge grinding machine and an edge grinding process thereof. The edge grinding process comprises the steps that machined glass enters the glass edge grinding machine in the feeding direction and passes through a chamfering grinding wheel component firstly, and the upper edge and the lower edge of the machined glass are ground by the chamfering grinding wheel component to form chamfer edges; then the machined glass passes through forming grinding wheel components, and the edges of the machined glass are machined into arc edges. The grinding head assembly of the glass edge grinding machine is provided with the chamfering grinding wheel component and the forming grinding wheel components; meanwhile, the chamfering grinding wheel component and the forming grinding wheel components can work simultaneously; when forming grinding wheels of the forming grinding wheel components are arc forming grinding wheels, the machined glass can be chamfered firstly and then the edges of the machined glass are ground into the arc edges, so that the grinding amount of the machined glass by the arc forming grinding wheels is greatly reduced, the service life of the arc forming grinding wheels is prolonged, the amendment and replacement frequency of the forming grinding wheels is reduced, and the number of the forming grinding wheels is decreased.

Owner:广东高力威机械科技有限公司

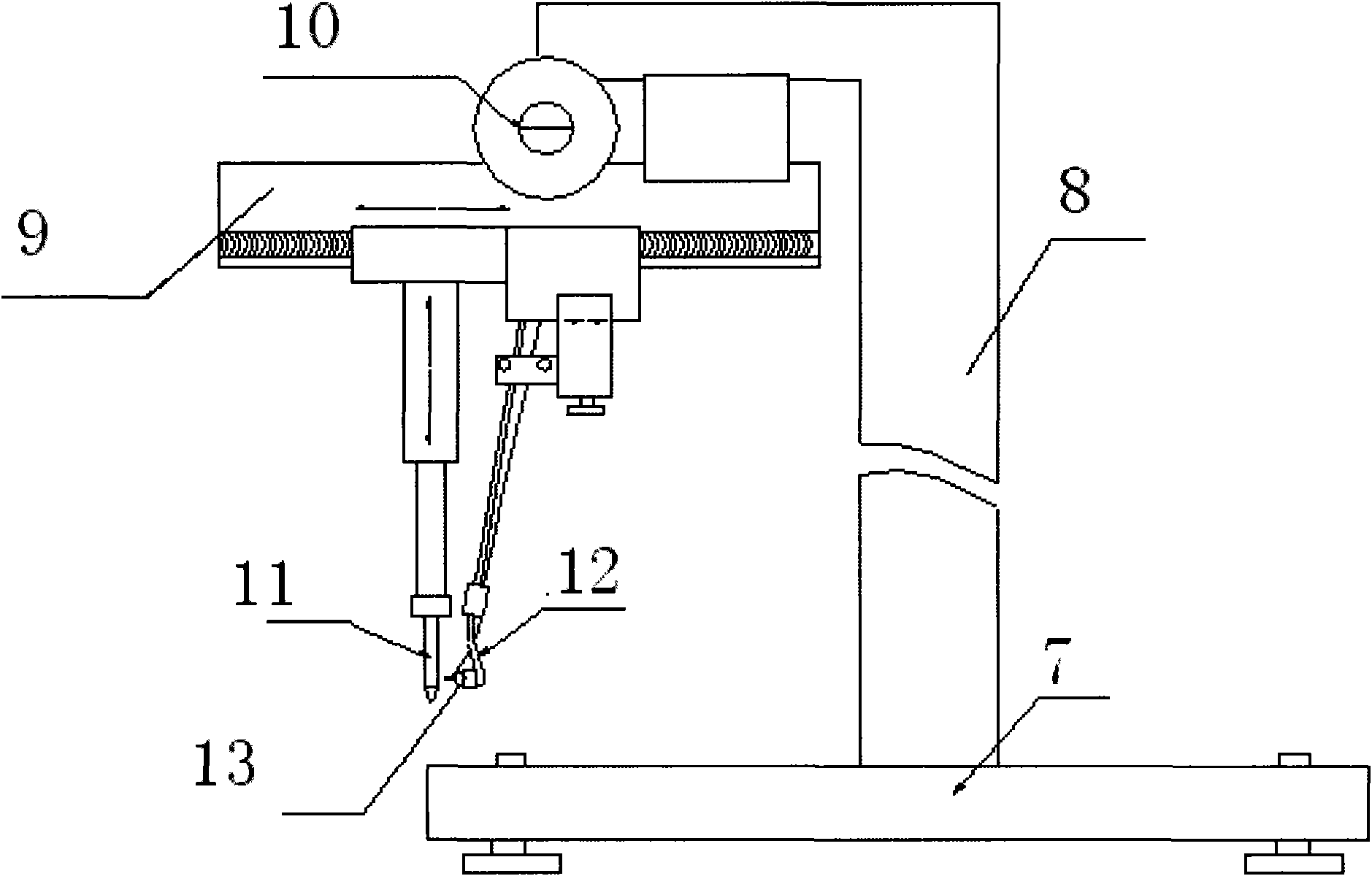

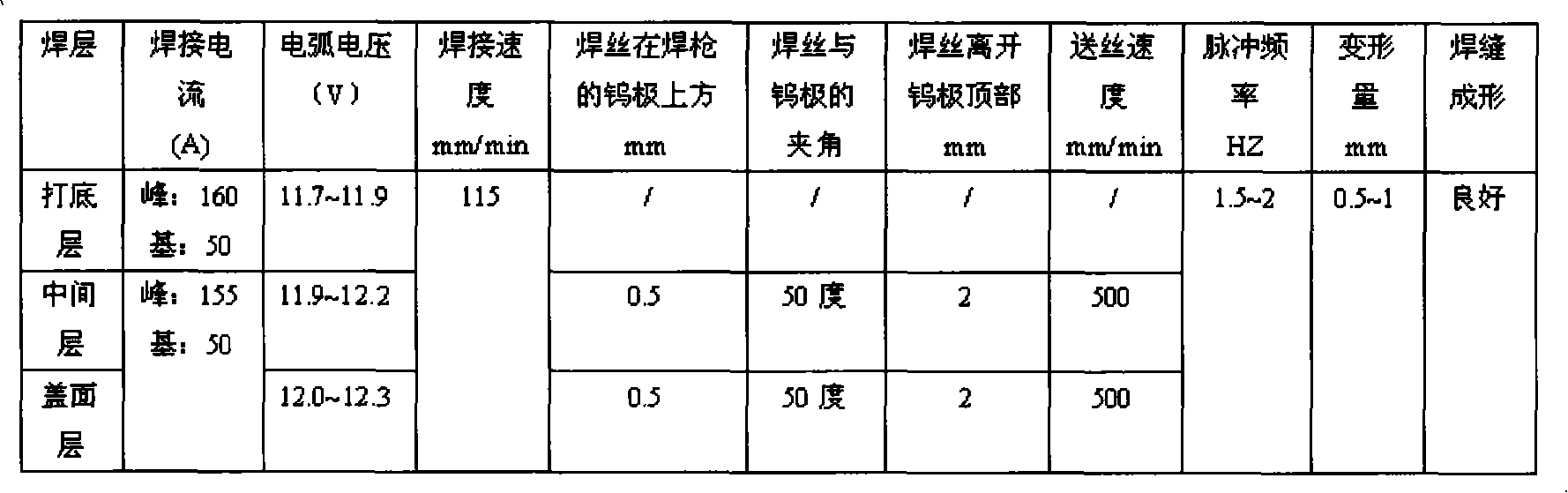

Automatic welding method of electrically heated element bushing of voltage stabilizer and reducing bushing of electrically heated element bushing

The invention relates to an automatic welding method of an electrically heated element bushing of a voltage stabilizer and a reducing bushing of the electrically heated element bushing, which is characterized by comprising the following steps: firstly, carrying out non-wire feeding melting welding on a beveling root between the electrically heated element bushing of the voltage stabilizer and thereducing bushing of the electrically heated element bushing by adopting automatic impulse argon-arc welding, wherein, a welding gun takes an axes of the reducing bushing as a center line to rotates 360 DEG to finish welding so as to form a first root base coat in the welding process; and then finishing a second middle wire feeding welding layer, a third cosmetic wire feeding welding layer and a fourth cosmetic wire feeding welding layer by automatic impulse synchronous wire feeding argon-arc welding. The invention has the advantages of realizing automatic impulse argon-arc welding barrier-freespin welding used for the electrically heated element bushing with more amount, complex arrangement and welding blind area existence and the reducing bushing thereof, improving the primary welding qualification rate, controlling the welding deformation by selecting a reasonable parameter of an automatic welding process, lowering the operation difficulty and the labor intensity of welders, reducing the correction of deformation after welding, and improving the production efficiency.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com