Patents

Literature

3575 results about "Scanning electron microscope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

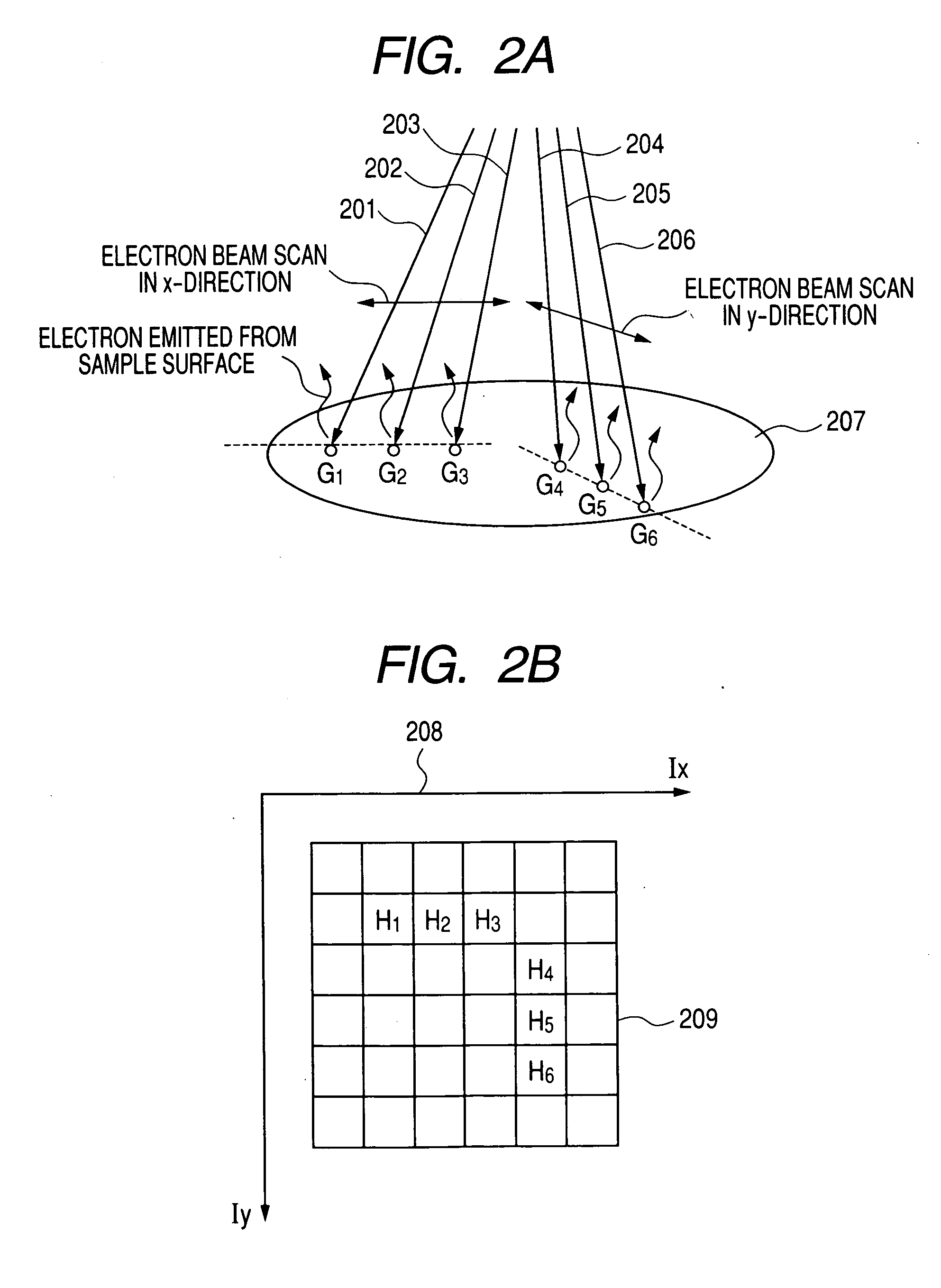

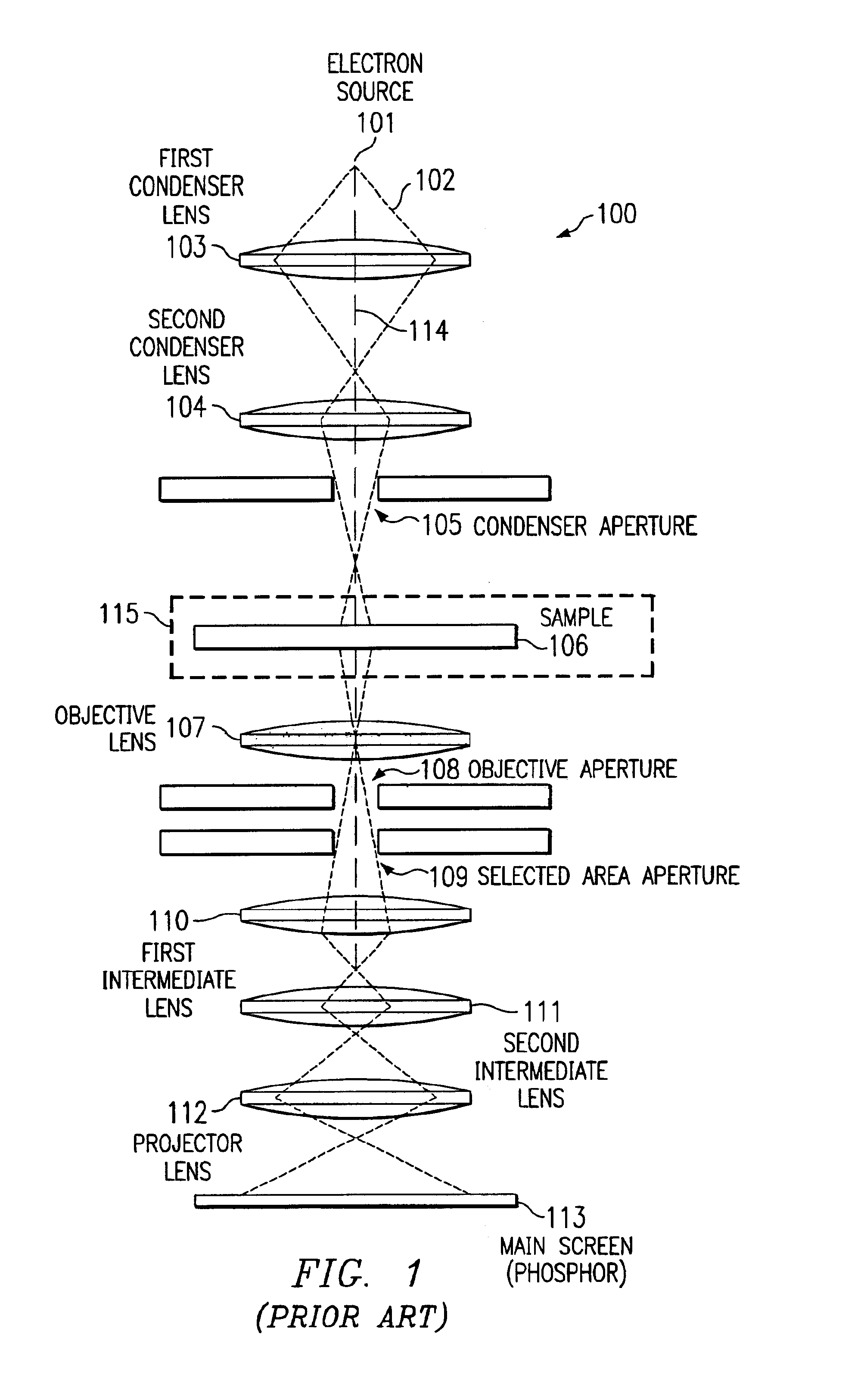

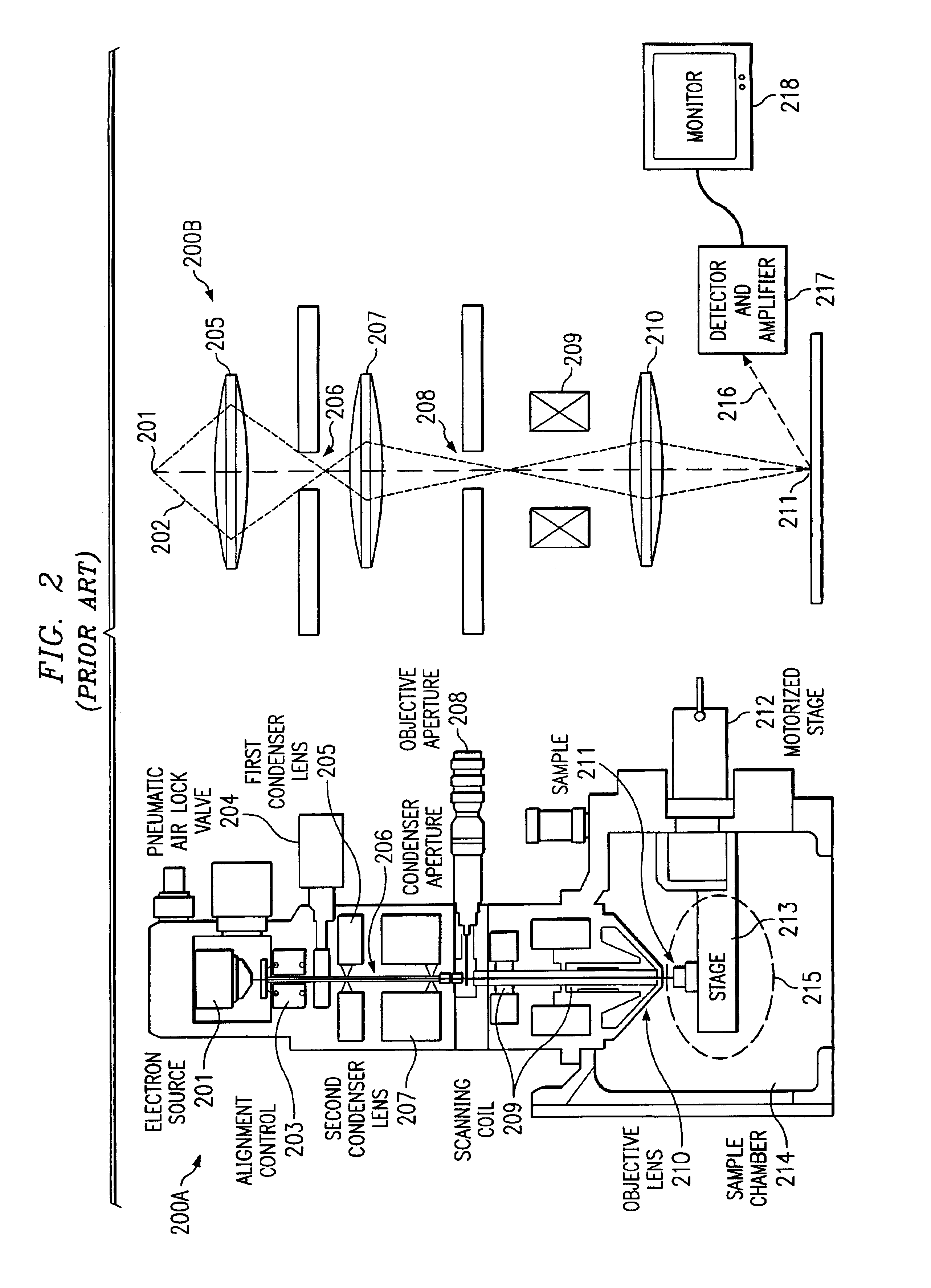

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that contain information about the surface topography and composition of the sample. The electron beam is scanned in a raster scan pattern, and the position of the beam is combined with the intensity of the detected signal to produce an image. In the most common SEM mode, secondary electrons emitted by atoms excited by the electron beam are detected using an Everhart-Thornley detector. The number of secondary electrons that can be detected, and thus the signal intensity, depends, among other things, on specimen topography. SEM can achieve resolution better than 1 nanometer.

Magnetic recording medium

ActiveUS20140272474A1Increased durabilityReduce runningRecord information storageMaterials with non-metallic substancesScanning electron microscopeElectron microscope

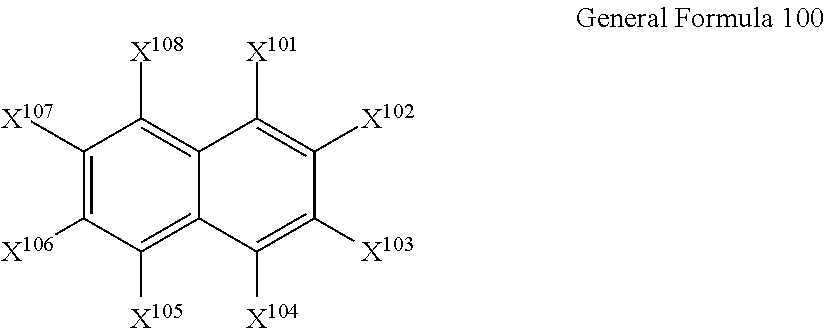

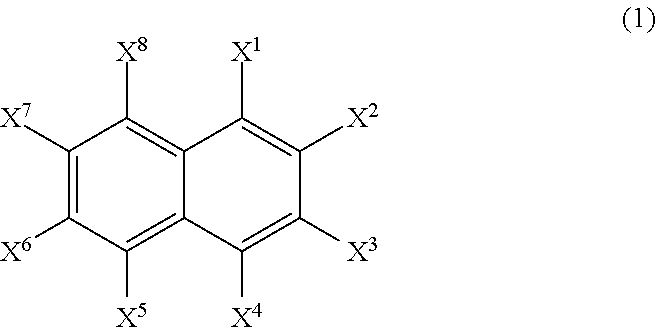

An aspect of the present invention relates to a magnetic recording medium, which comprises a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic support, wherein the ferromagnetic powder is ferromagnetic hexagonal ferrite powder comprising 3 to 12 weight percent of Al, based on Al2O3 conversion, relative to 100 weight percent of a total weight of the powder, the magnetic layer further comprises abrasive, and a maximum plan view surface area of the abrasive as determined for a 4.3 μm×6.3 μm rectangular region of the magnetic layer by a scanning electron microscope is less than 0.06 percent relative to 100 percent of a total surface area of the region.

Owner:FUJIFILM CORP

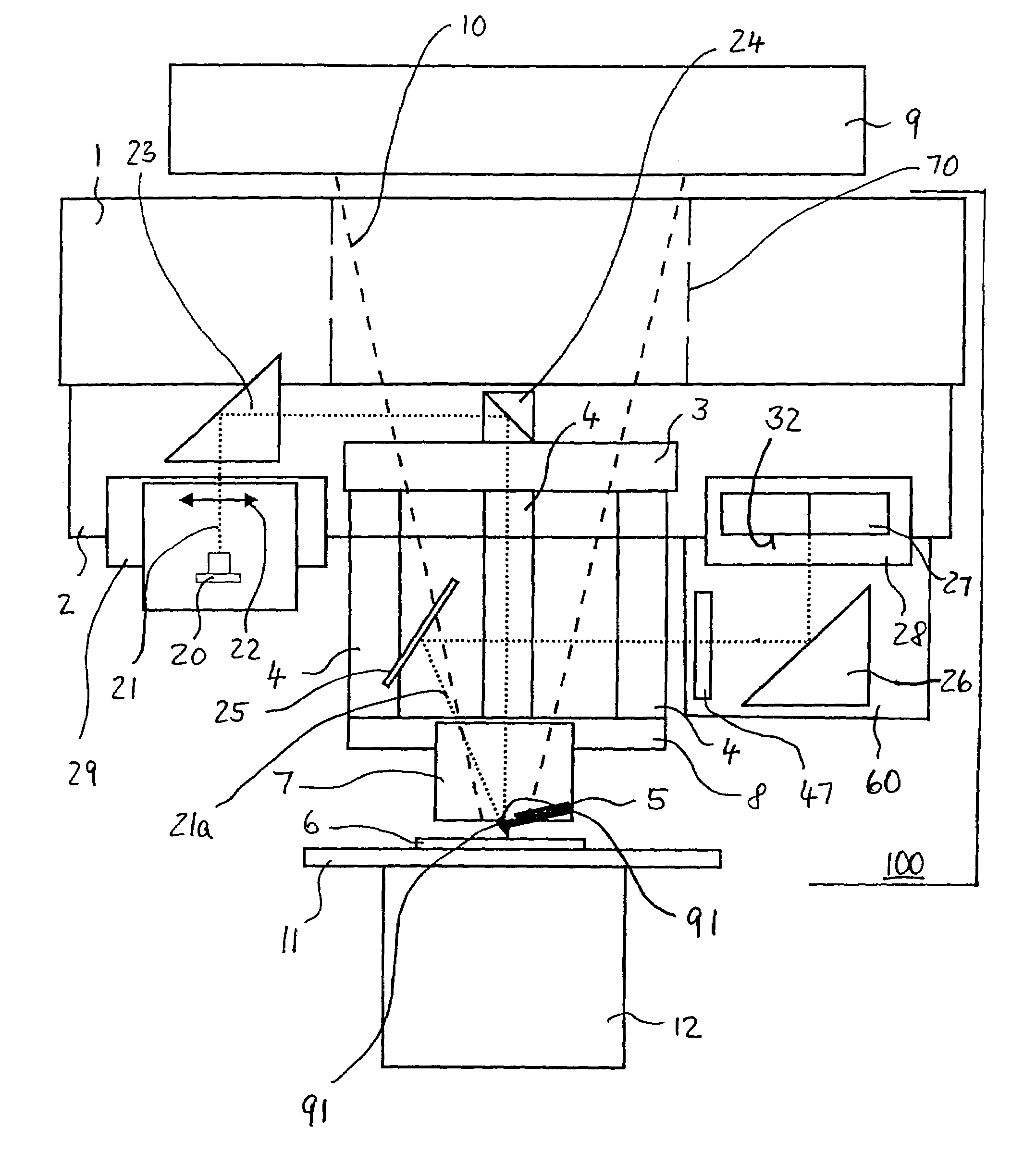

Apparatus and method for a scanning probe microscope

InactiveUS7022985B2Easy to modifyImprove measurement stabilityNanotechMaterial analysis using wave/particle radiationScanning electron microscopeScanning probe microscopy

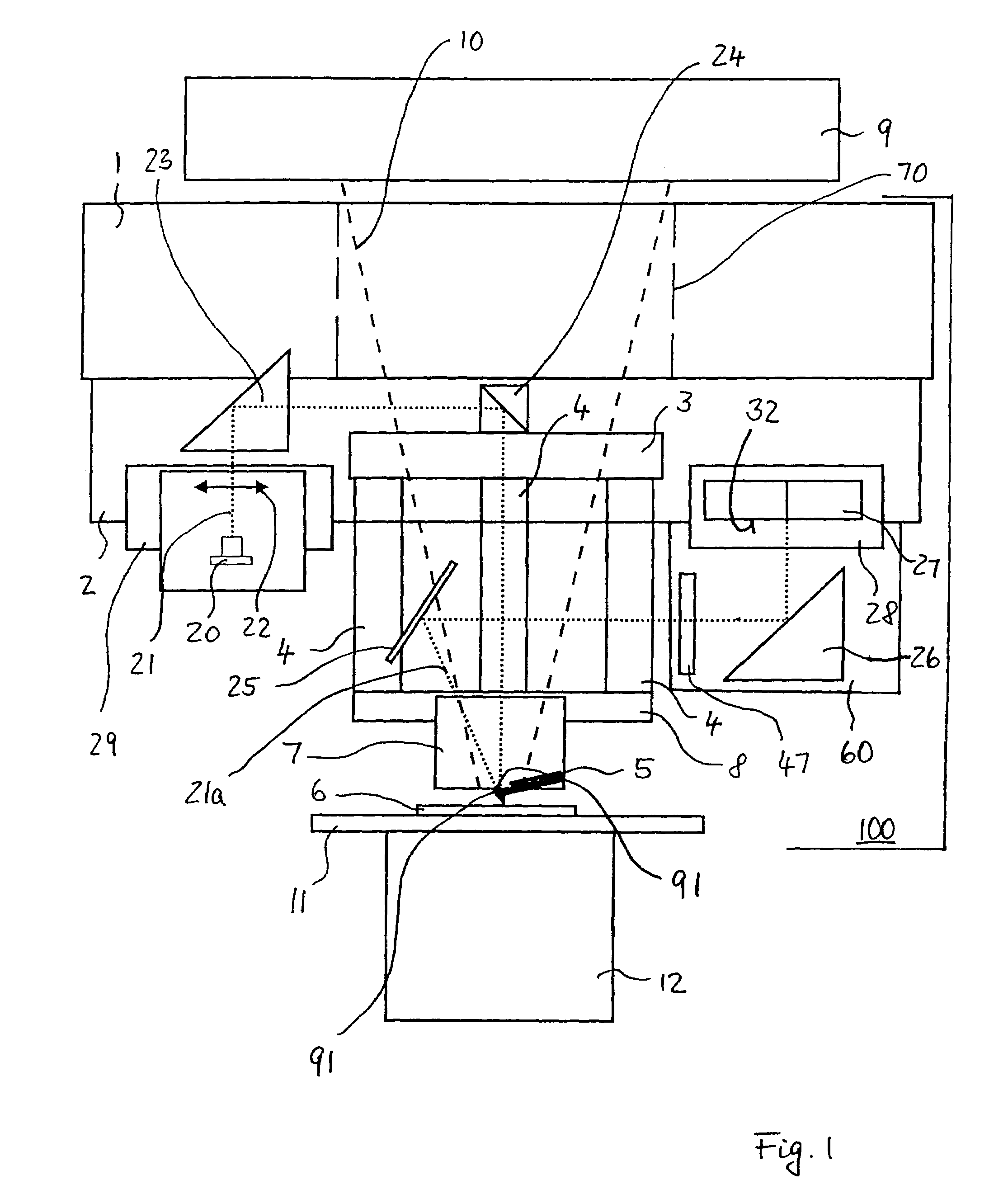

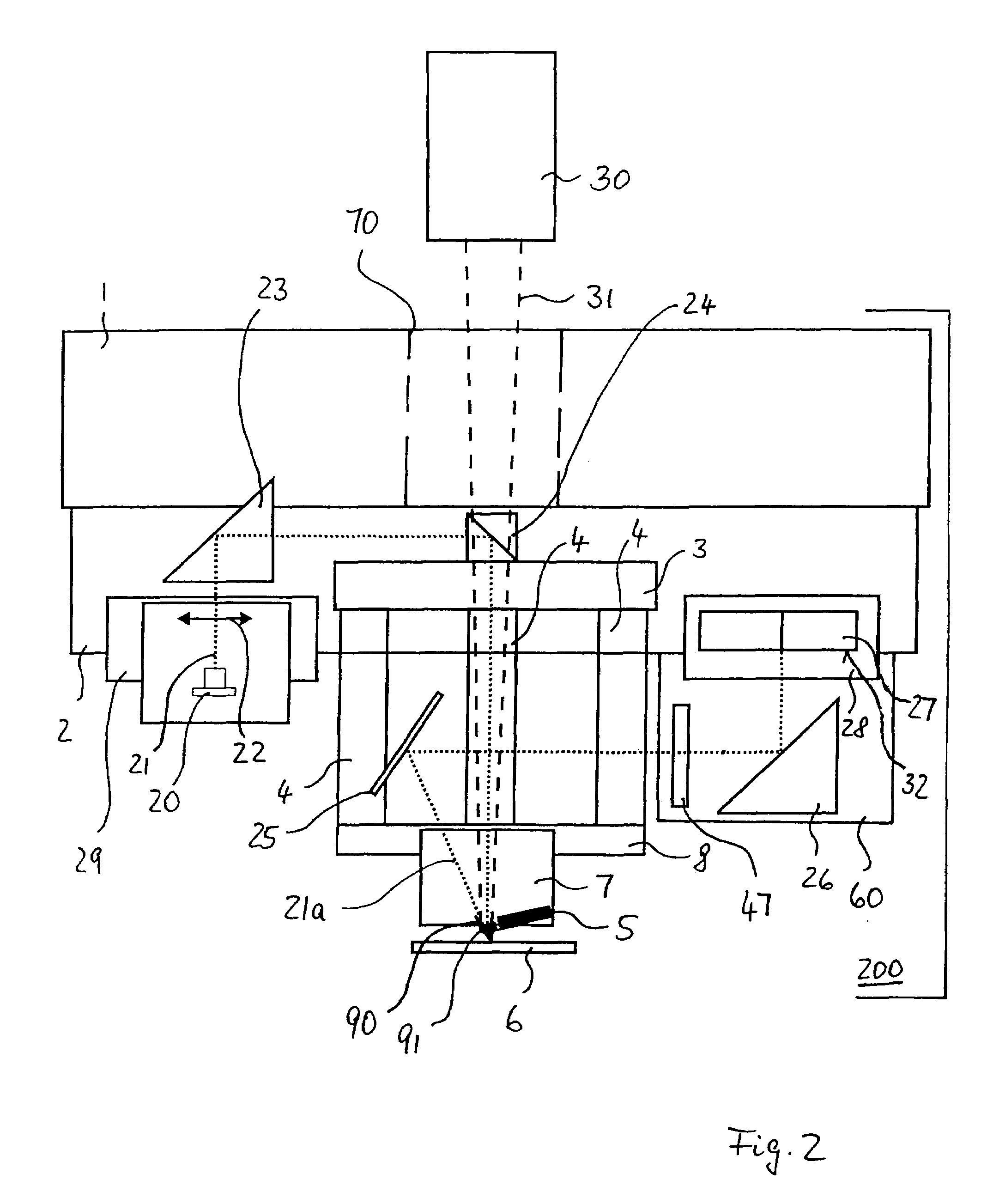

The invention relates to an apparatus and a method for a scanning probe microscope, comprising a measuring assembly which includes a lateral shifting unit to displace a probe in a plane, a vertical shifting unit to displace the probe in a direction perpendicular to the plane, and a specimen support to receive a specimen. A condenser light path is formed through the measuring assembly so that the specimen support is located in the area of an end of the condenser light path.

Owner:JPK INSTR

Magnetic tape

ActiveUS20160276076A1Maintain wear resistanceMaintenance of such surfaceInorganic material magnetismRecord information storageMagnetic tapeTransmission microscopy

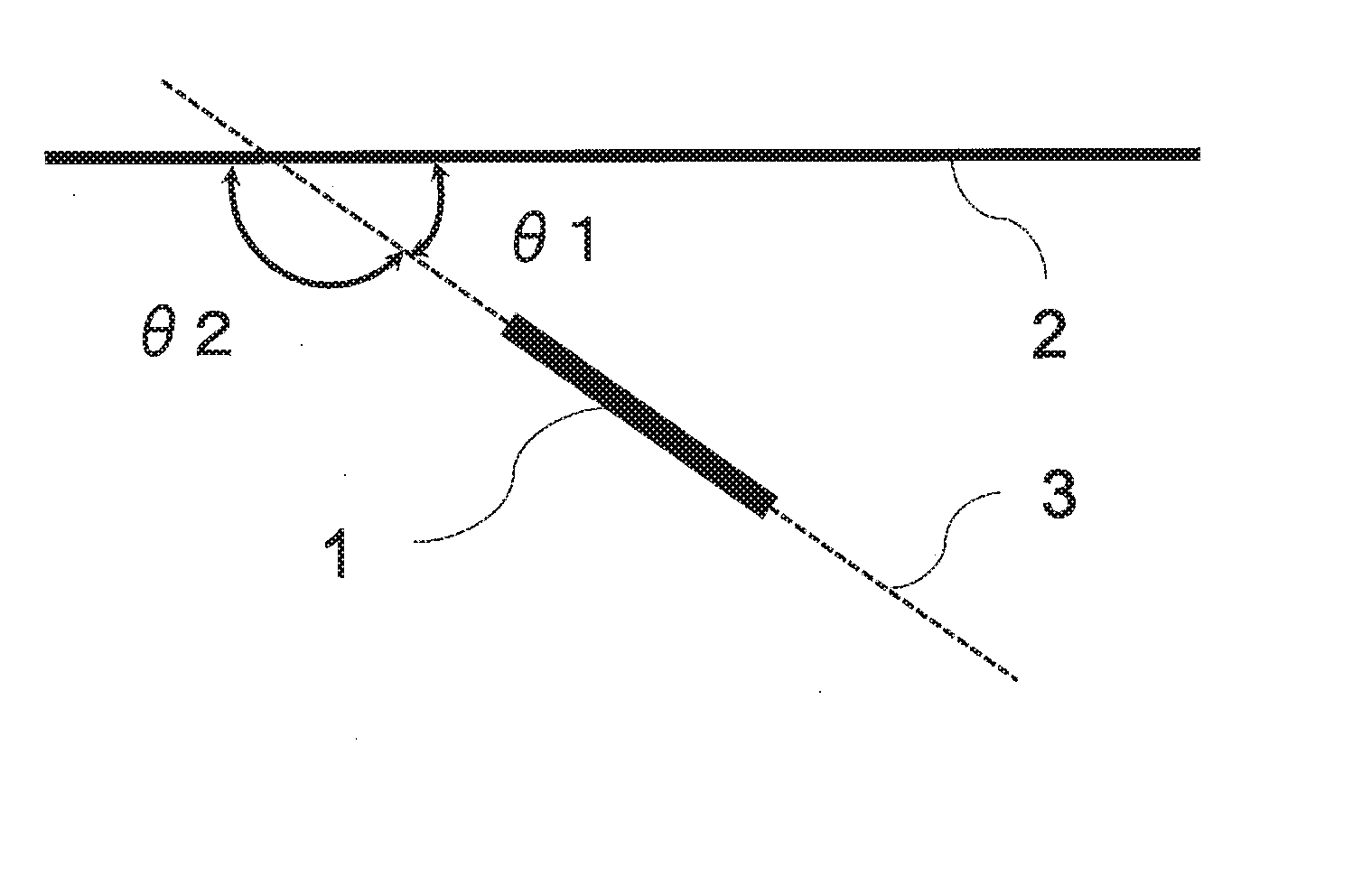

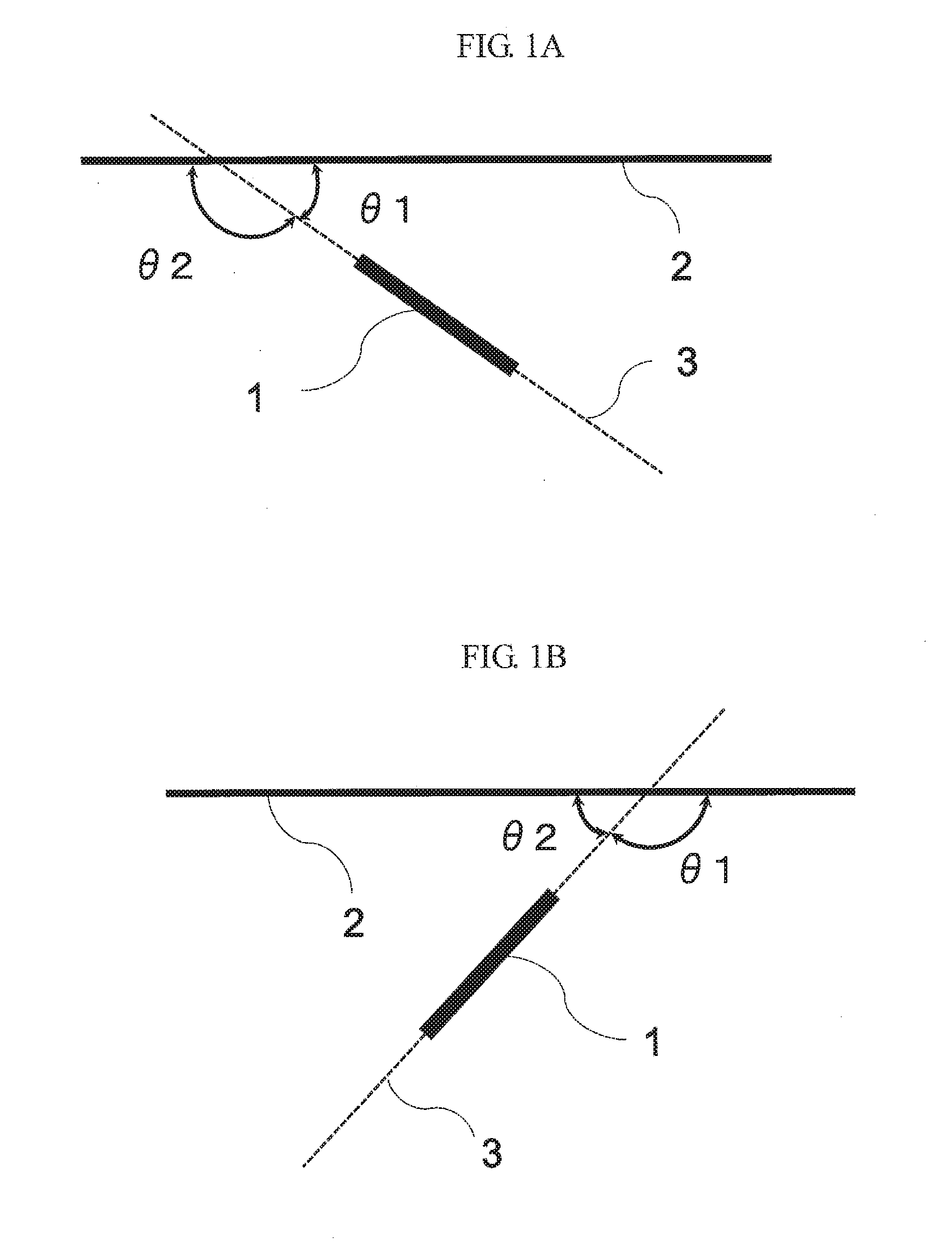

The magnetic tape includes a magnetic layer containing ferromagnetic hexagonal ferrite powder, abrasive, and binder on a nonmagnetic support, wherein the ferromagnetic hexagonal ferrite powder exhibits an activation volume of less than or equal to 1,800 nm3, and inclination, cos θ, of the ferromagnetic hexagonal ferrite powder relative to a surface of the magnetic layer as determined by sectional observation by a scanning electron transmission microscope is greater than or equal to 0.85 but less than or equal to 1.00.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS9704525B2Maintain wear resistanceMaintenance of such surfaceMagnetic materials for record carriersRecord information storageMagnetic tapeTransmission microscopy

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180061446A1Deterioration of characteristicMagnetic materials for record carriersTape carriersConventional transmission electron microscopeScanning tunneling microscope

Provided is a magnetic tape in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes ferromagnetic hexagonal ferrite powder and an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer by plane observation using a scanning electron microscope, with respect to the total area of the region is equal to or greater than 0.02% and less than 0.06%, and a tilt cos 0 of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

Magnetic recording medium

ActiveUS9530444B2Increased durabilityReduce runningMagnetic materials for record carriersRecord information storageScanning electron microscopeElectron microscope

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180240495A1Deterioration of characteristicMaterials with ironRecord information storageScanning tunneling microscopeMagnetic tape

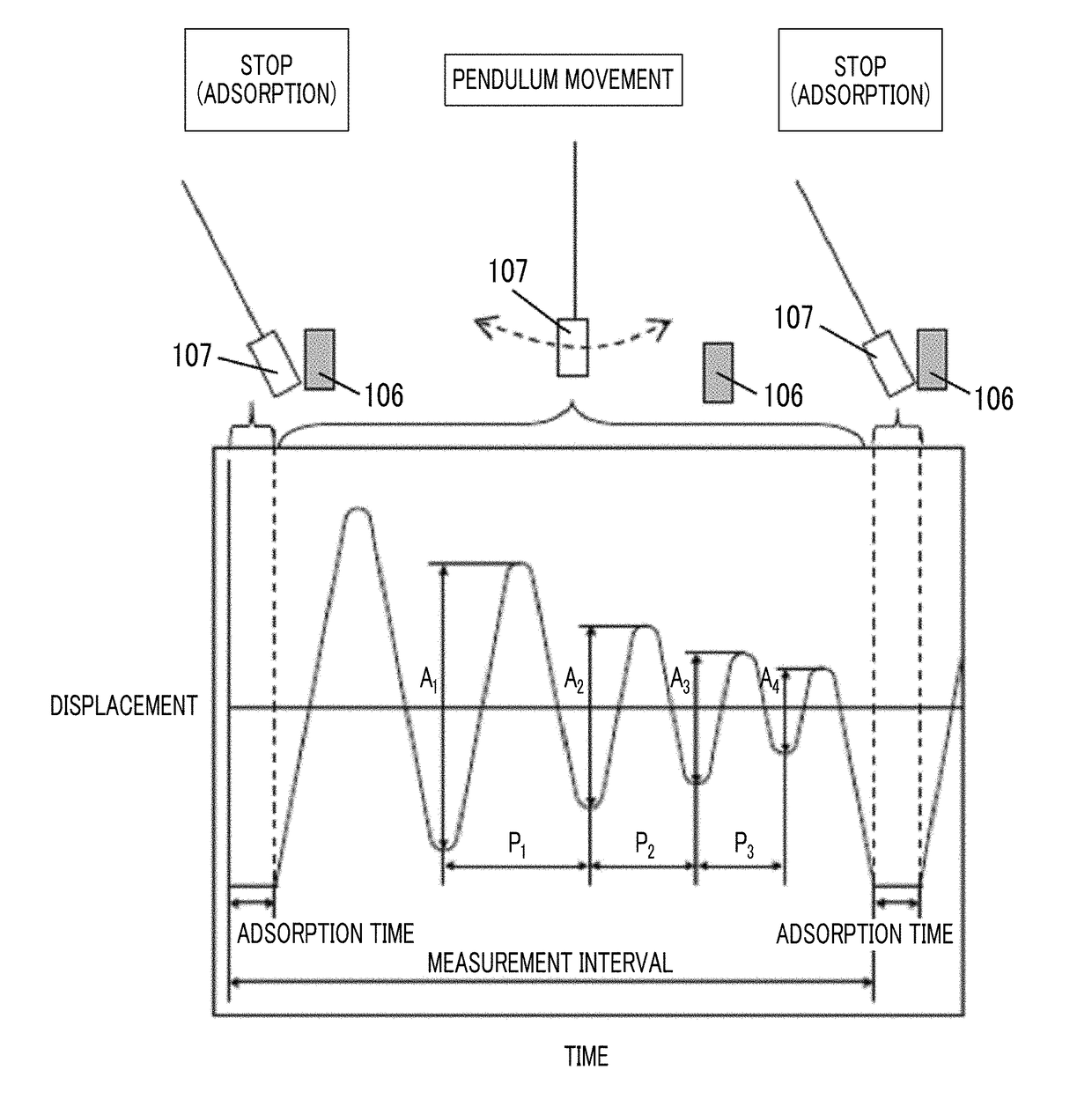

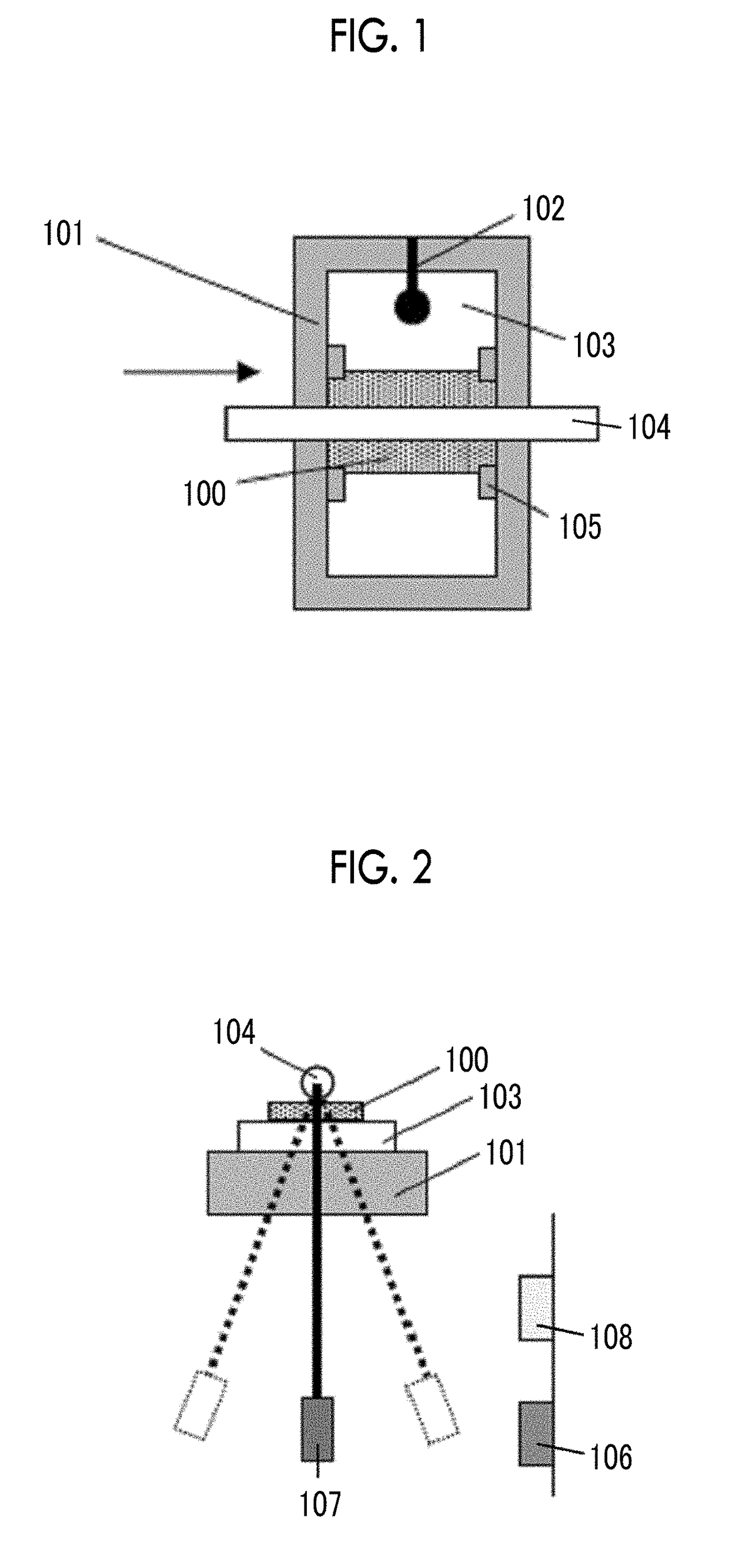

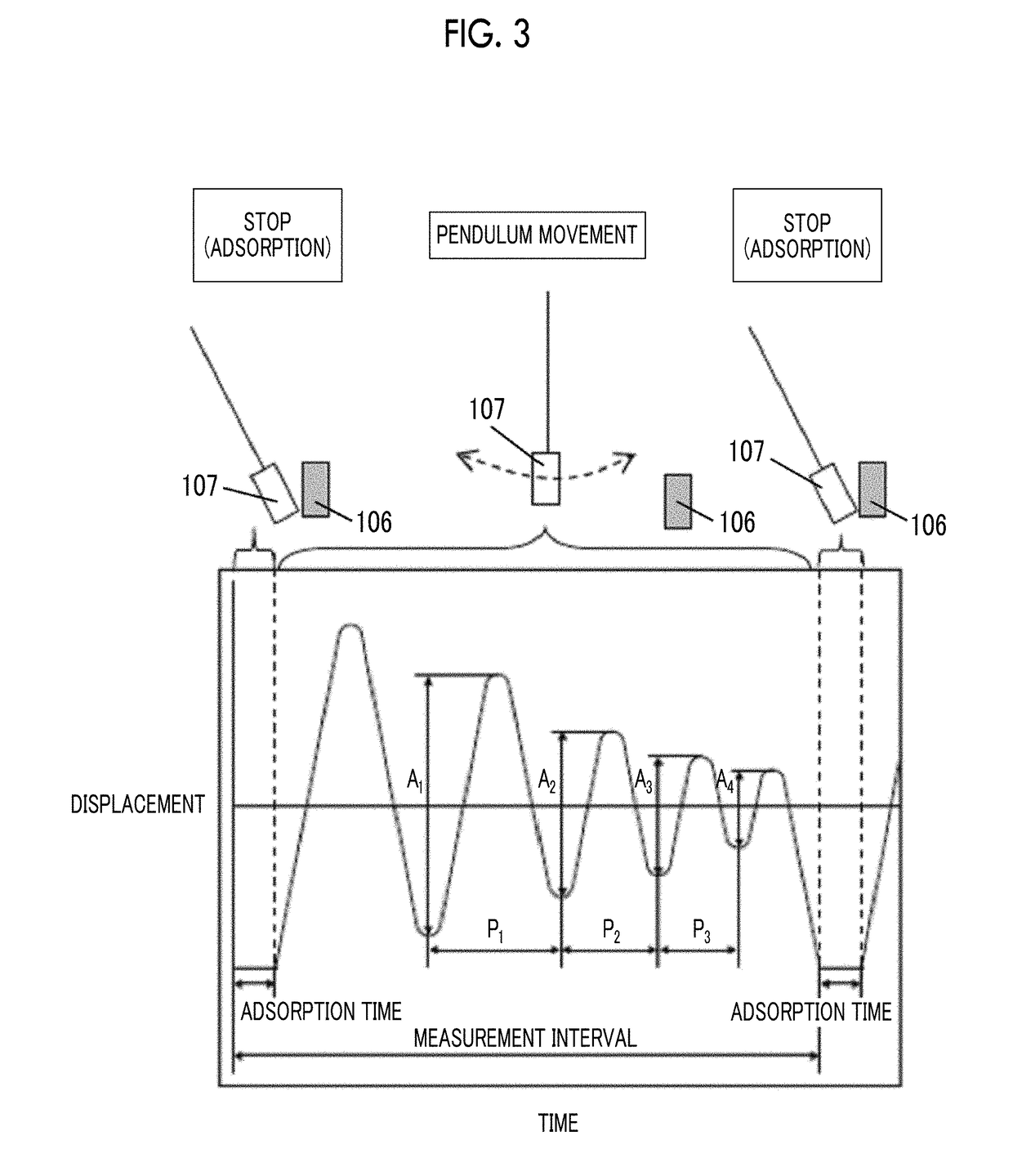

The magnetic tape includes a non-magnetic support; a non-magnetic layer including non-magnetic powder and a binding agent on the non-magnetic support; and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic layer, in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using a scanning electron microscope is equal to or greater than 0.02% and less than 0.06%, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

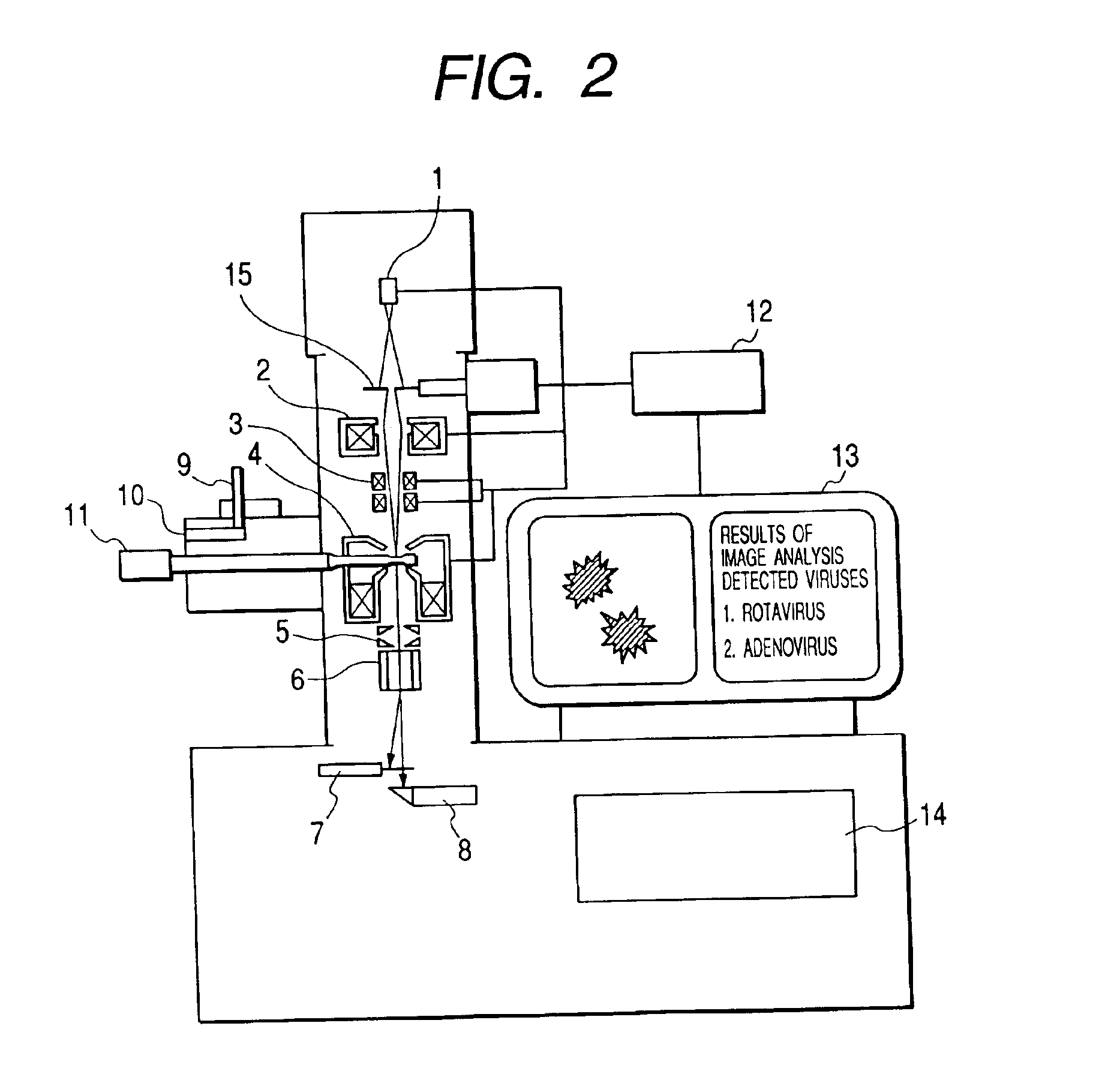

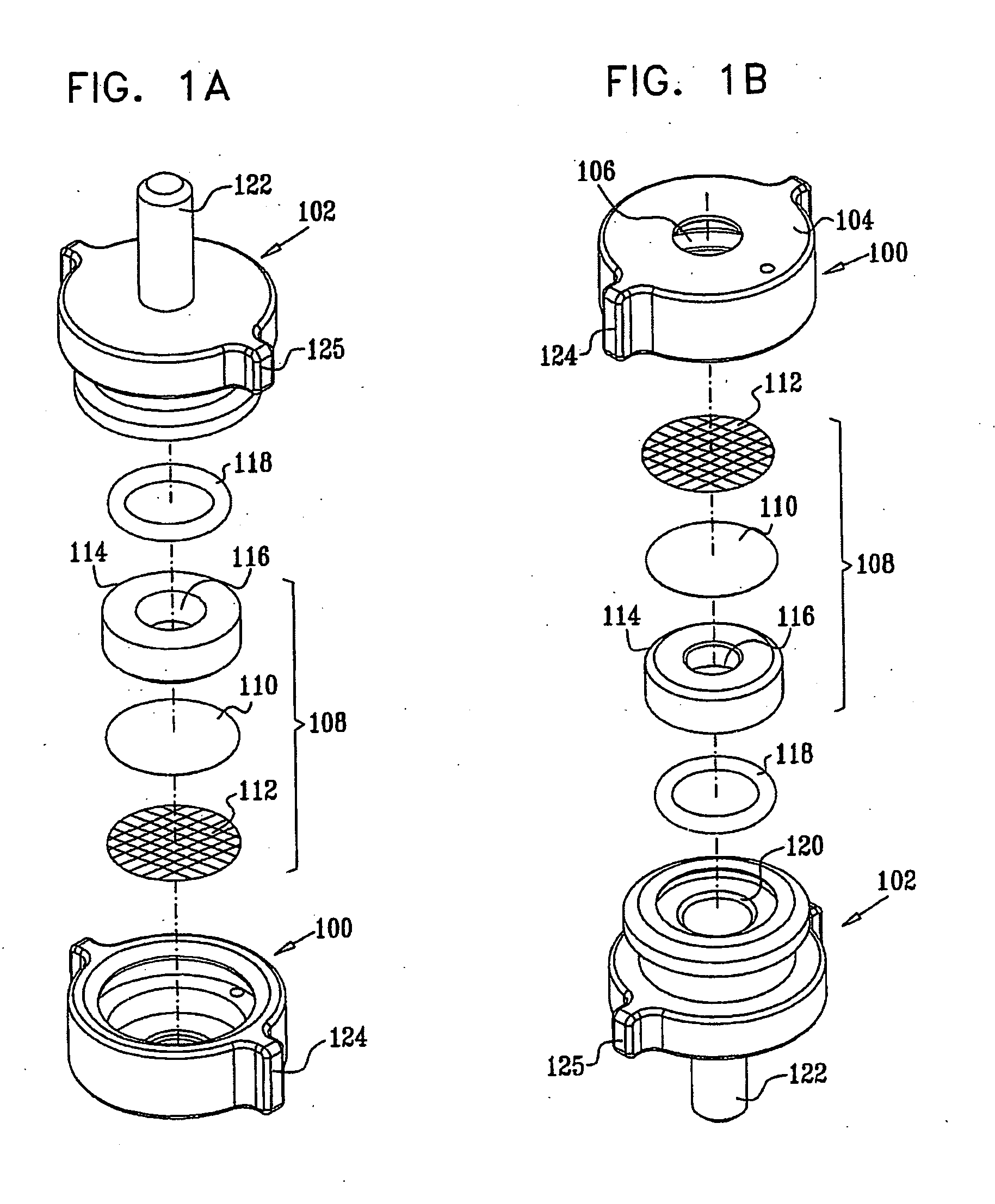

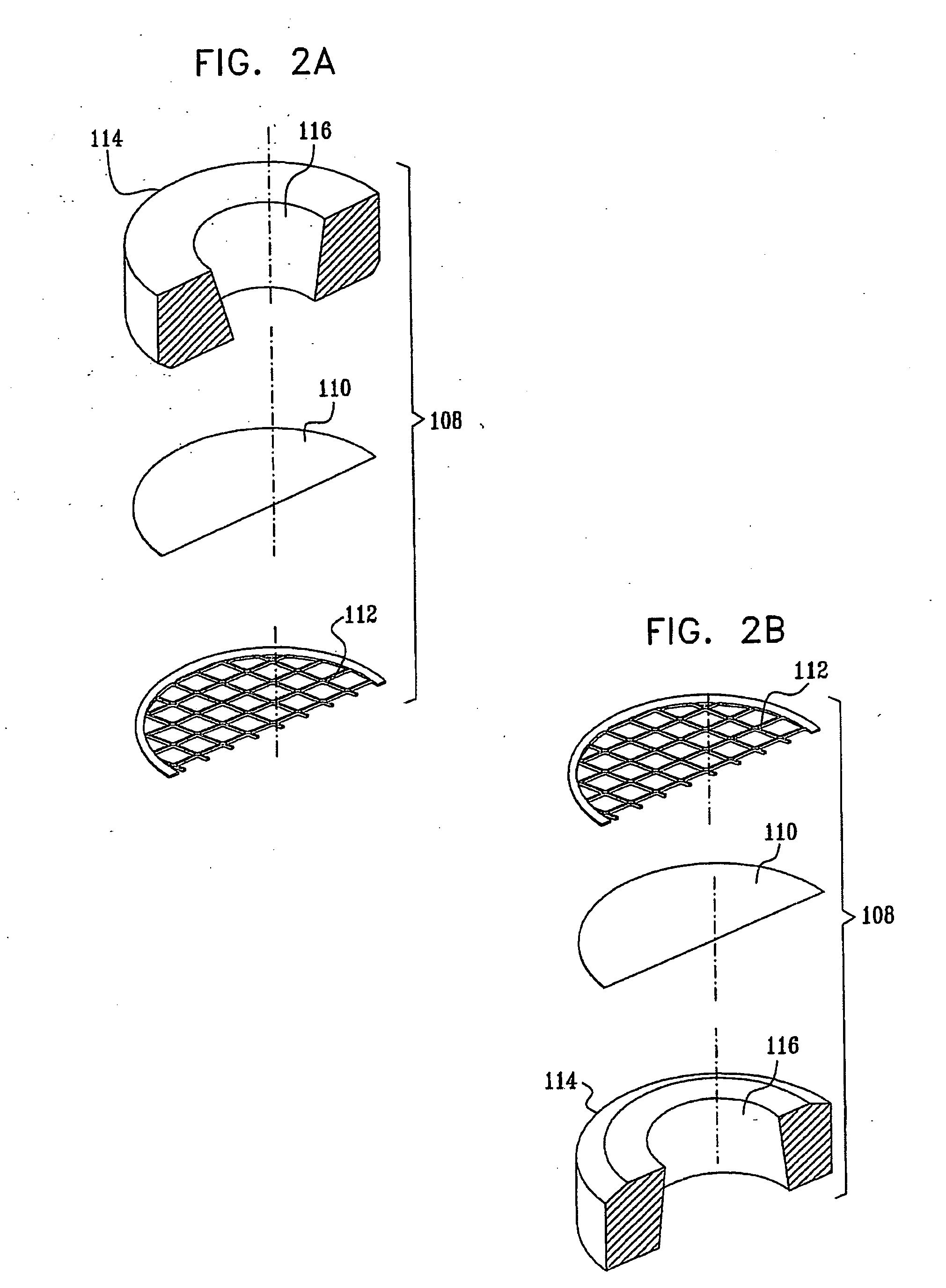

Bio electron microscope and observation method of specimen

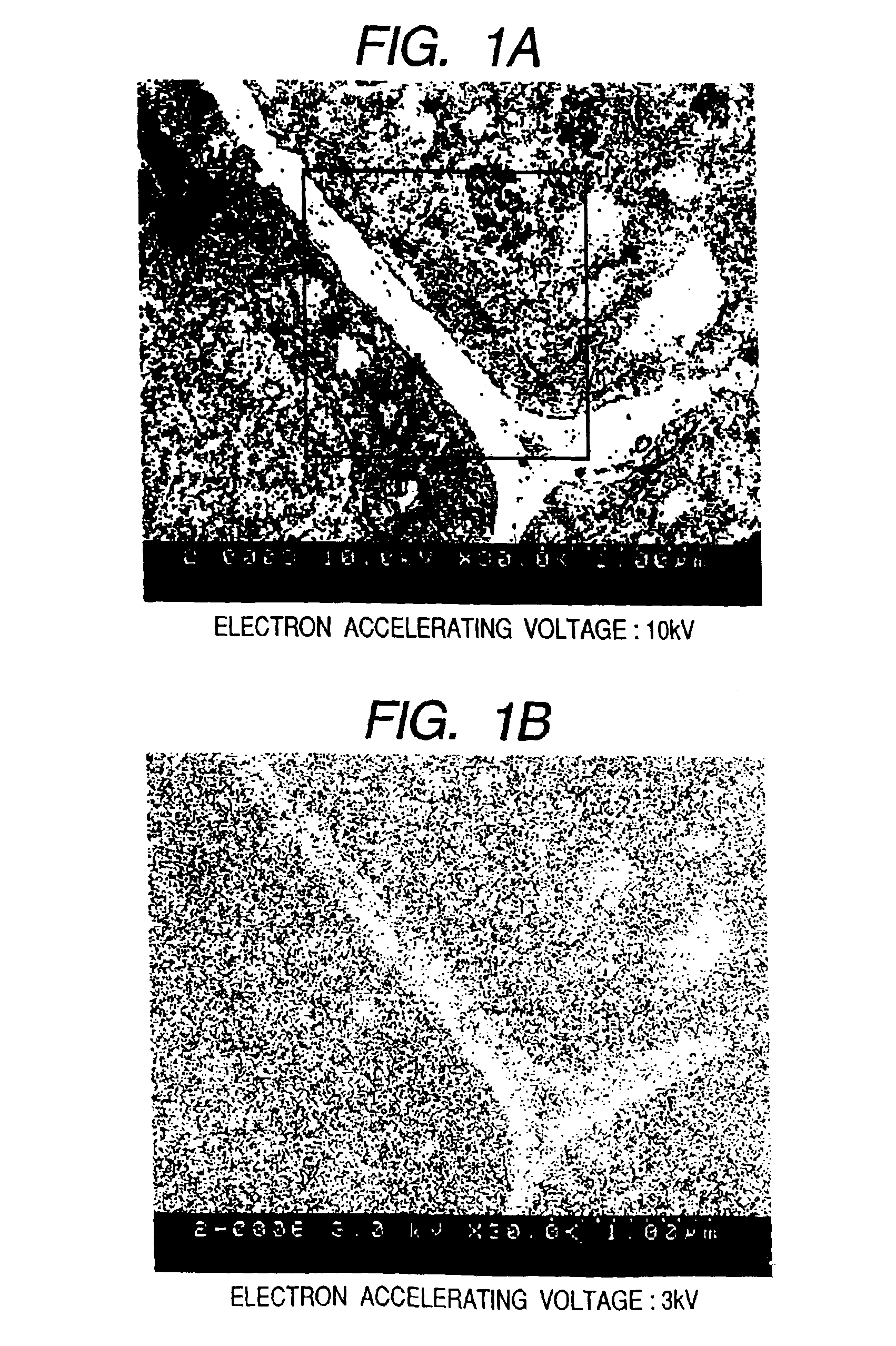

InactiveUS6875984B2Reduce harmHigh-accuracy image analysisEnergy spectrometersPreparing sample for investigationScanning electron microscopeAcceleration voltage

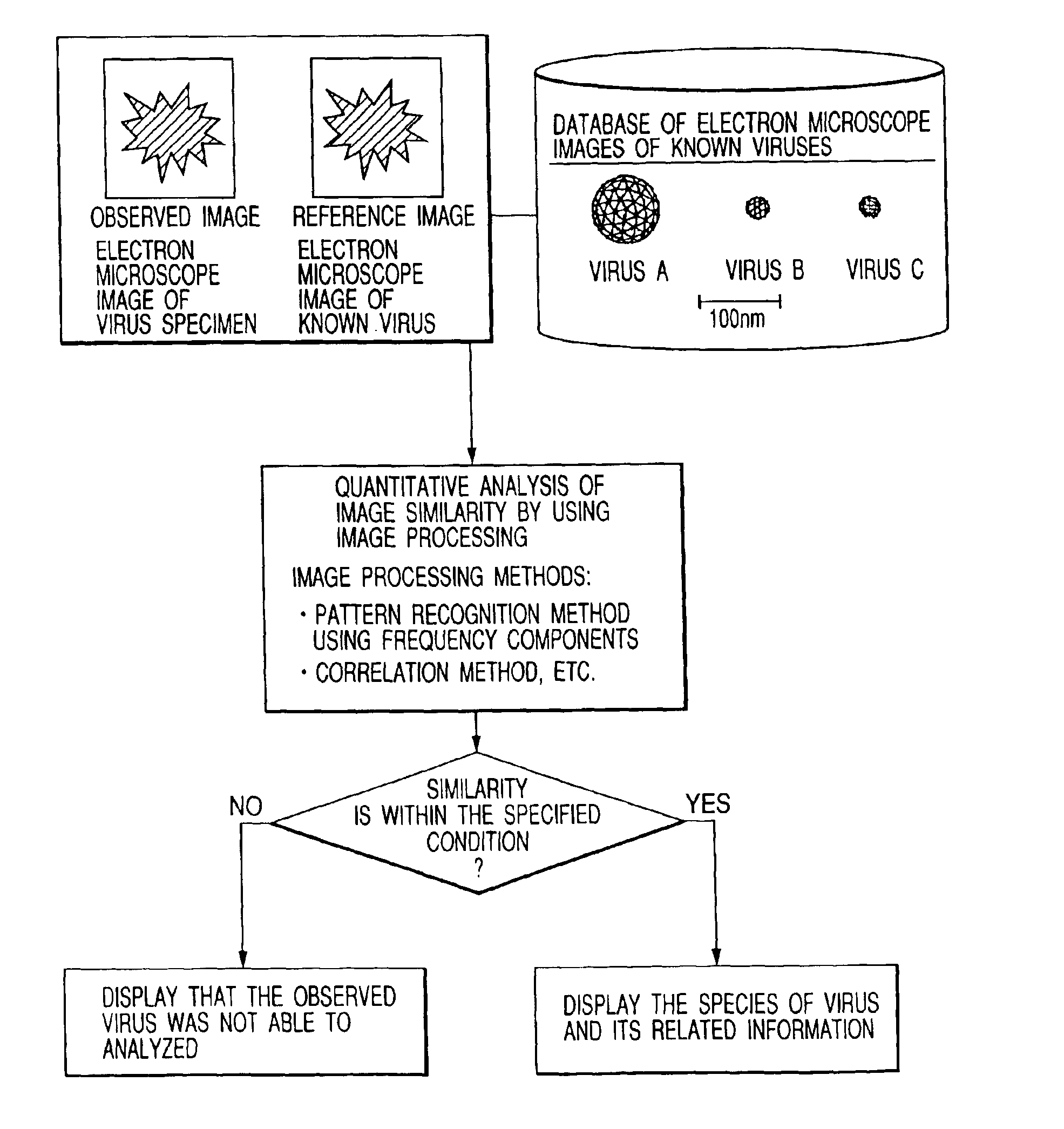

A bio electron microscope and an observation method which can observe a bio specimen by low damage and high contrast to perform high-accuracy image analysis, and conduct high-throughput specimen preparation. 1) A specimen is observed at an accelerating voltage 1.2 to 4.2 times a critical electron accelerating voltage possible to transmit a specimen obtained under predetermined conditions. 2) An electron energy filter of small and simplified construction is provided between the specimen and an electron detector for imaging by the electron beam in a specified energy region of the electron beams transmitting the specimen. 3) Similarity between an observed image such as virus or protein in the specimen and a reference image such as known virus or protein is subjected to quantitative analysis by image processing. 4) A preparation protocol of the bio specimen is made into a chip using an MEMS technique, which is then mounted on a specimen stage part of an electron microscope to conduct specimen introduction, preparation and transfer onto a specimen holder.

Owner:HITACHI HIGH-TECH CORP +1

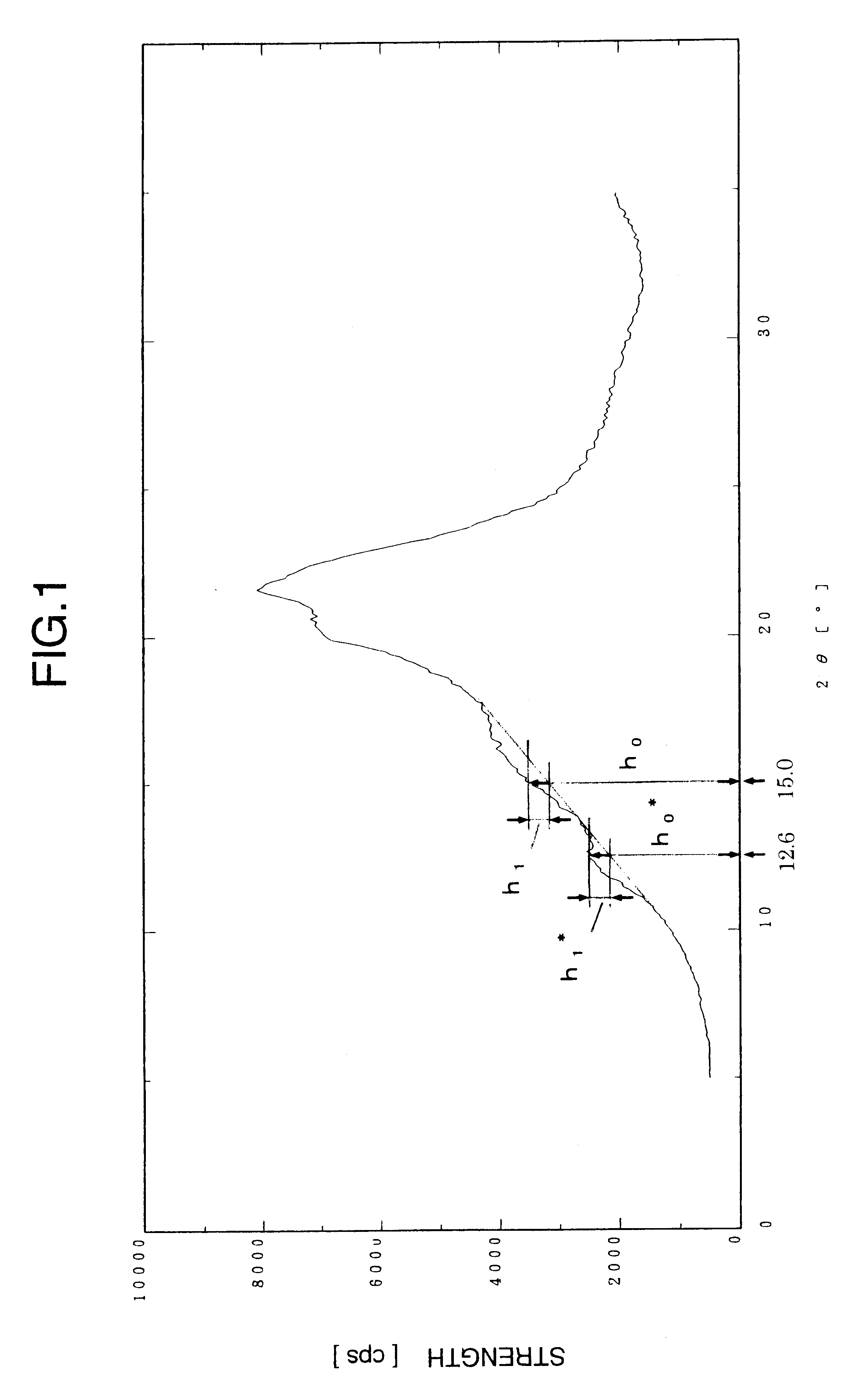

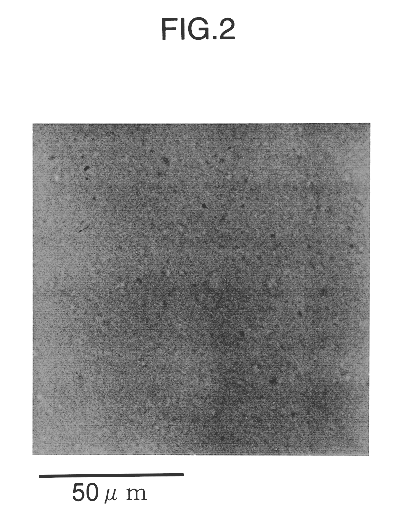

Cellulose dispersion

InactiveUS6541627B1Good dispersionImprove stabilitySugar derivativesCellulose coatingsCelluloseDispersion stability

A cellulose dispersion which is a dispersion comprising a dispersing medium and a cellulose having a fraction of cellulose I type crystal component of not more than 0.1 and a fraction of cellulose II type crystal component of not more than 0.4 and in which the average particle diameter of the constitutive cellulose is not more than 5 mum. A cellulose particulate and a cellulose composite particulate which have an average particle diameter of 0.2 to 20 mum, a ratio of long diameter (L) to short diameter (D) observed through a scanning electron microscope (L / D) of not more than 1.2 and a coefficient of aggregation of 1.0 to 3.0. The present invention provides a cellulose dispersion which has an excellent effect such as dispersion stability or the like and is high in transparency. Moreover, it provides a cellulose particulate and a cellulose composite particulate which have such performances as no rough feel, excellent rolling properties, high dispersibility and the like.

Owner:ASAHI KASEI KK

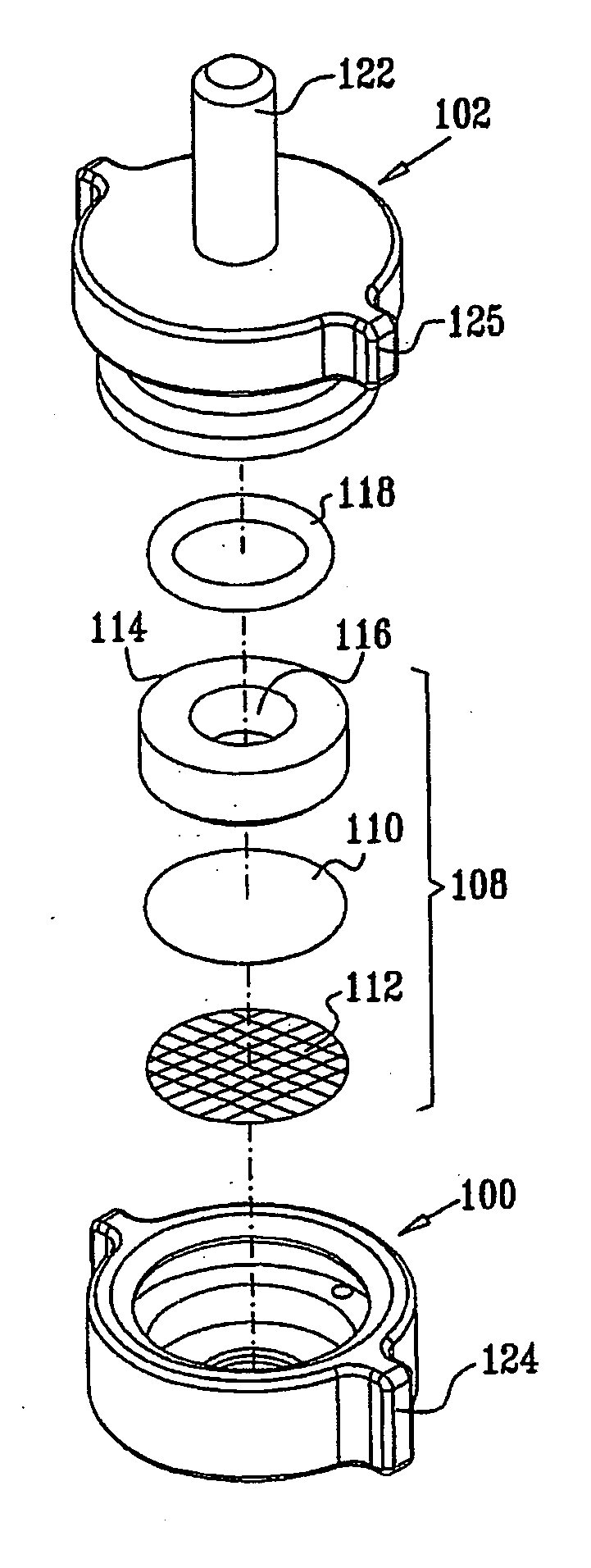

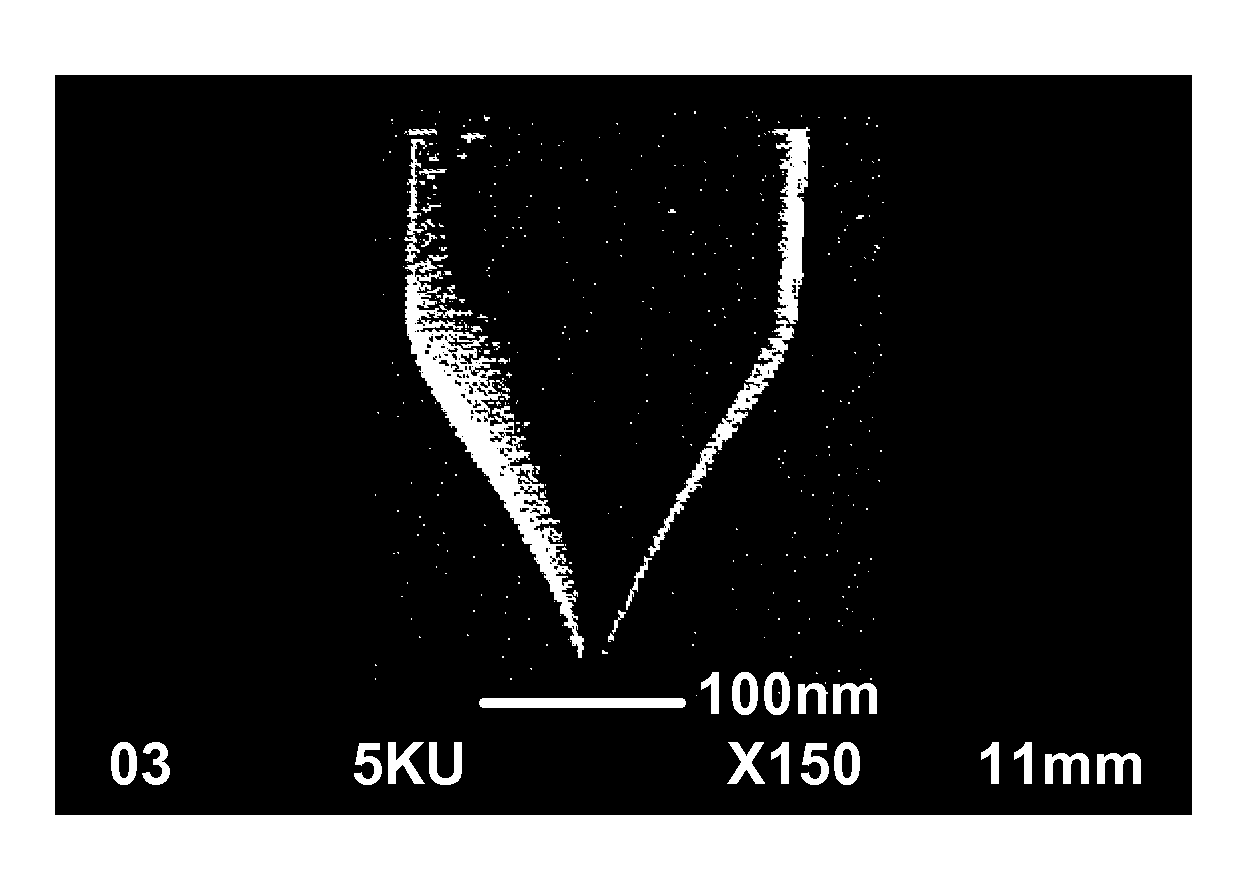

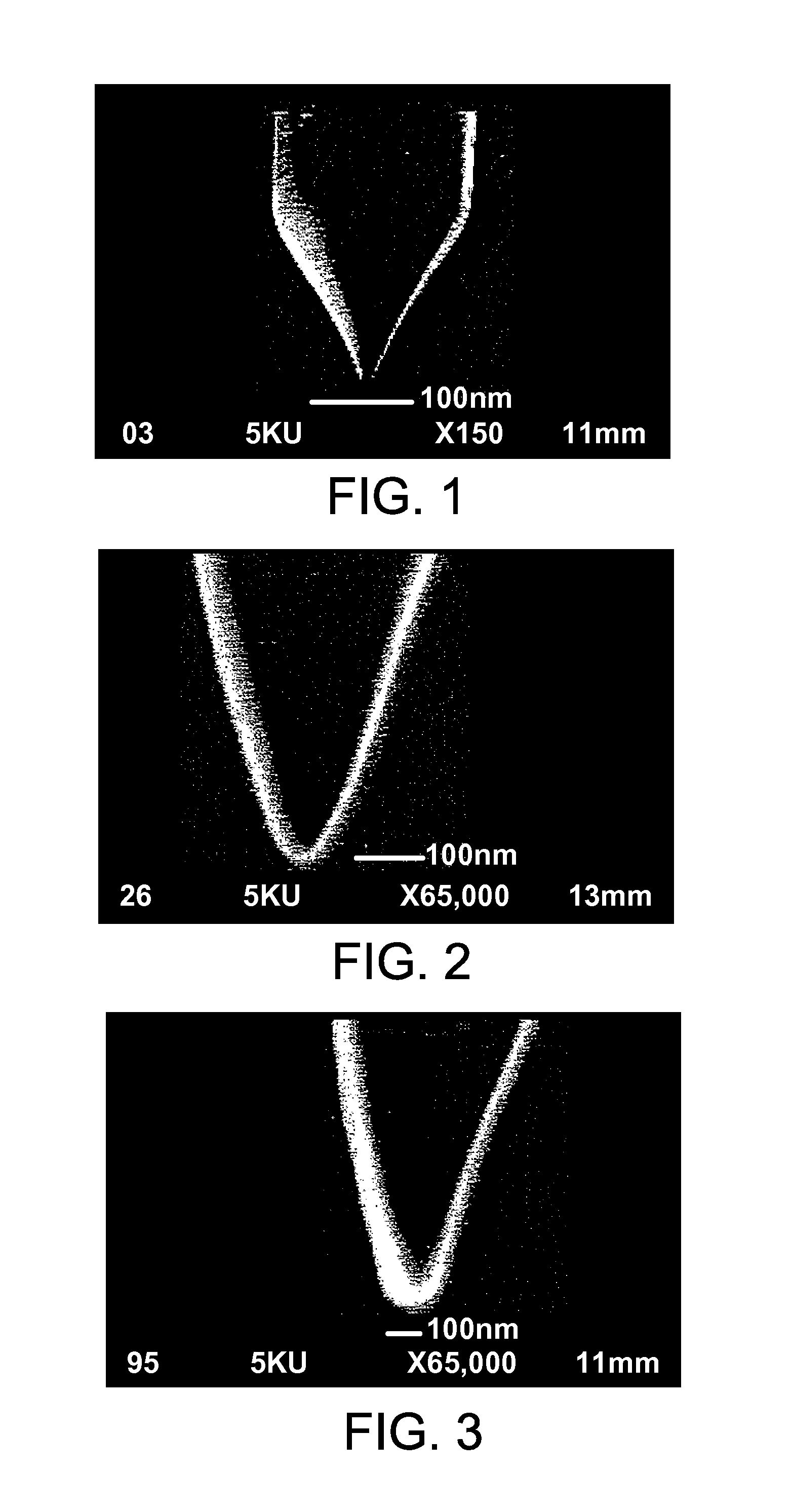

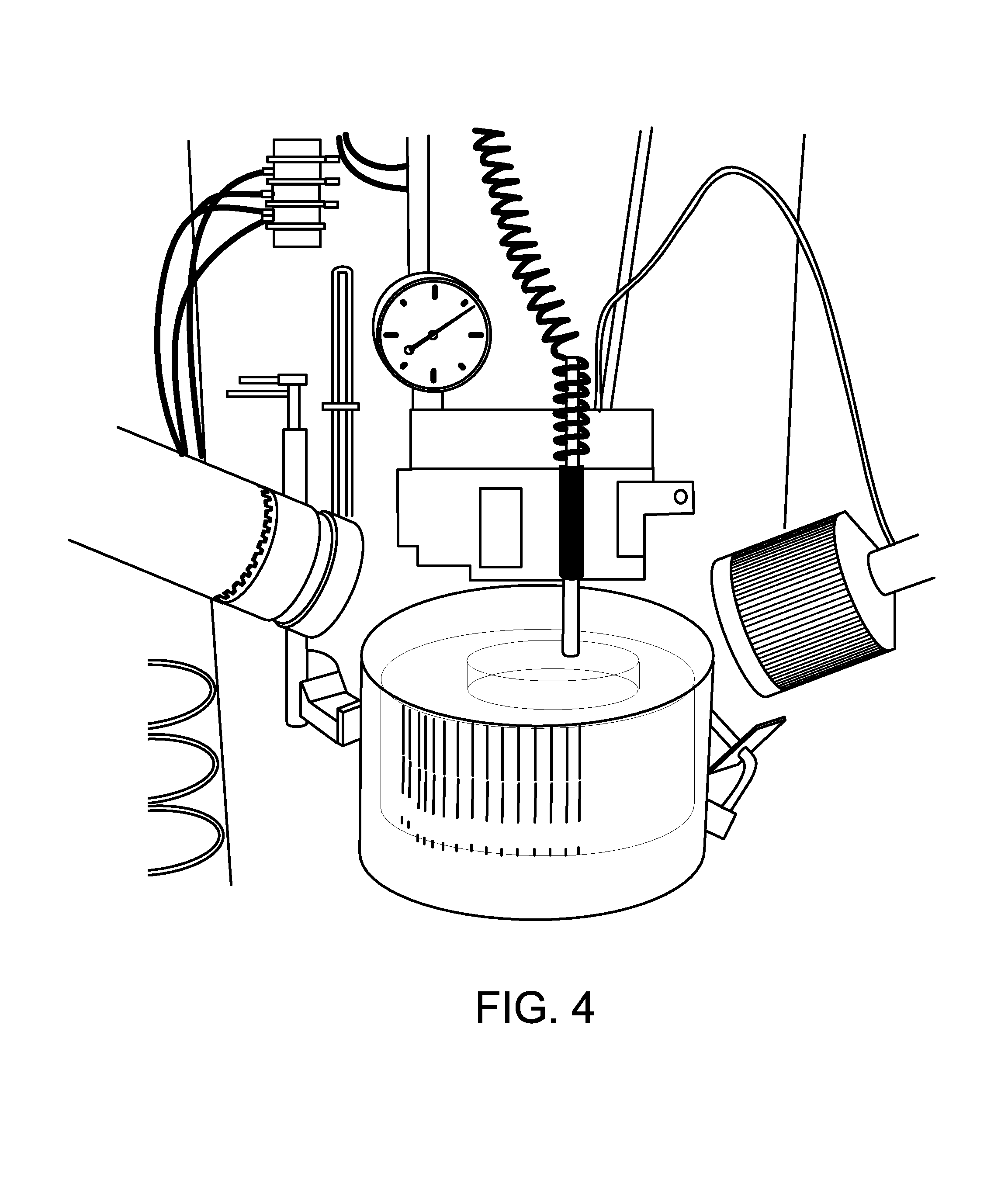

Atomic level ion source and method of manufacture and operation

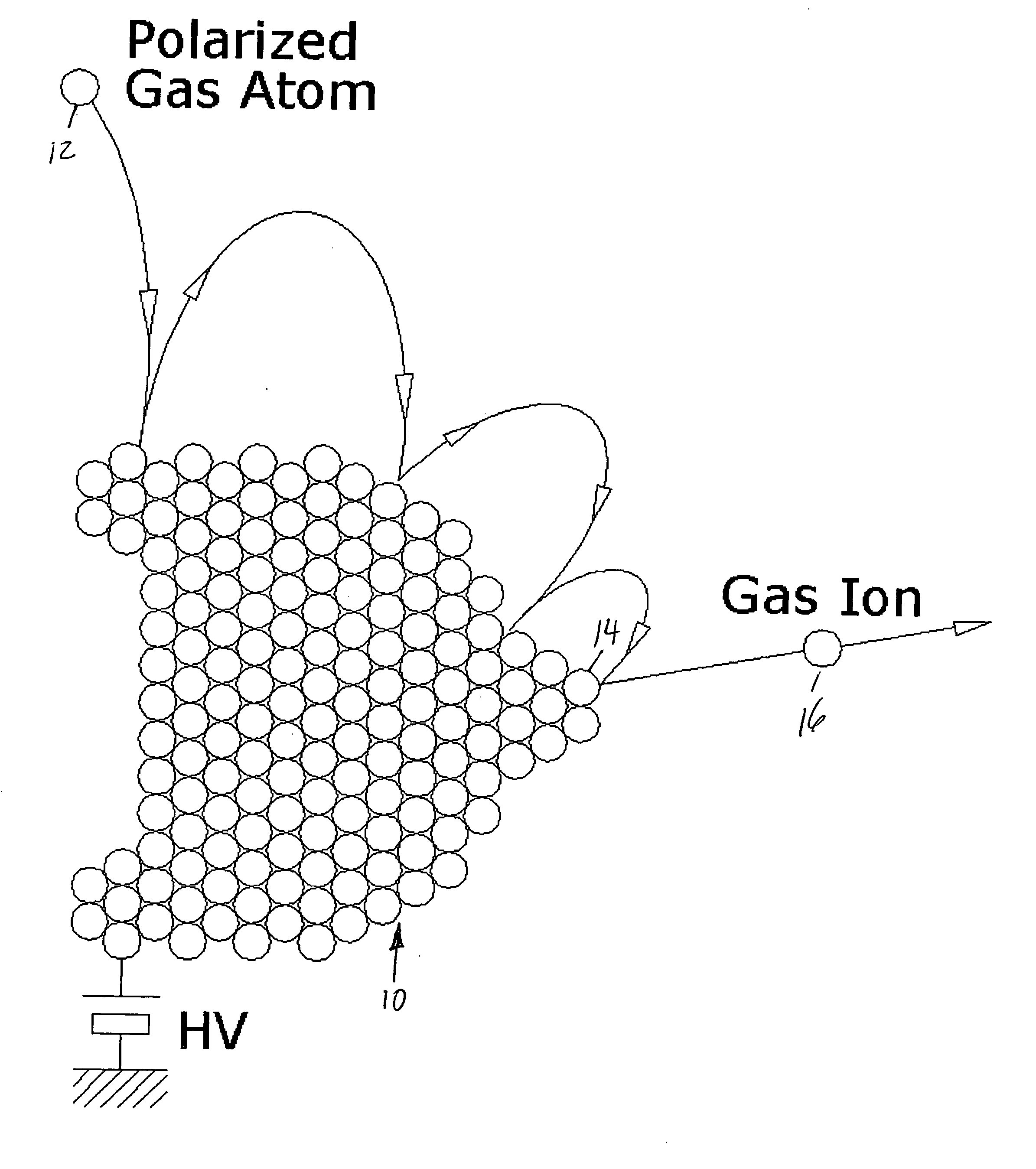

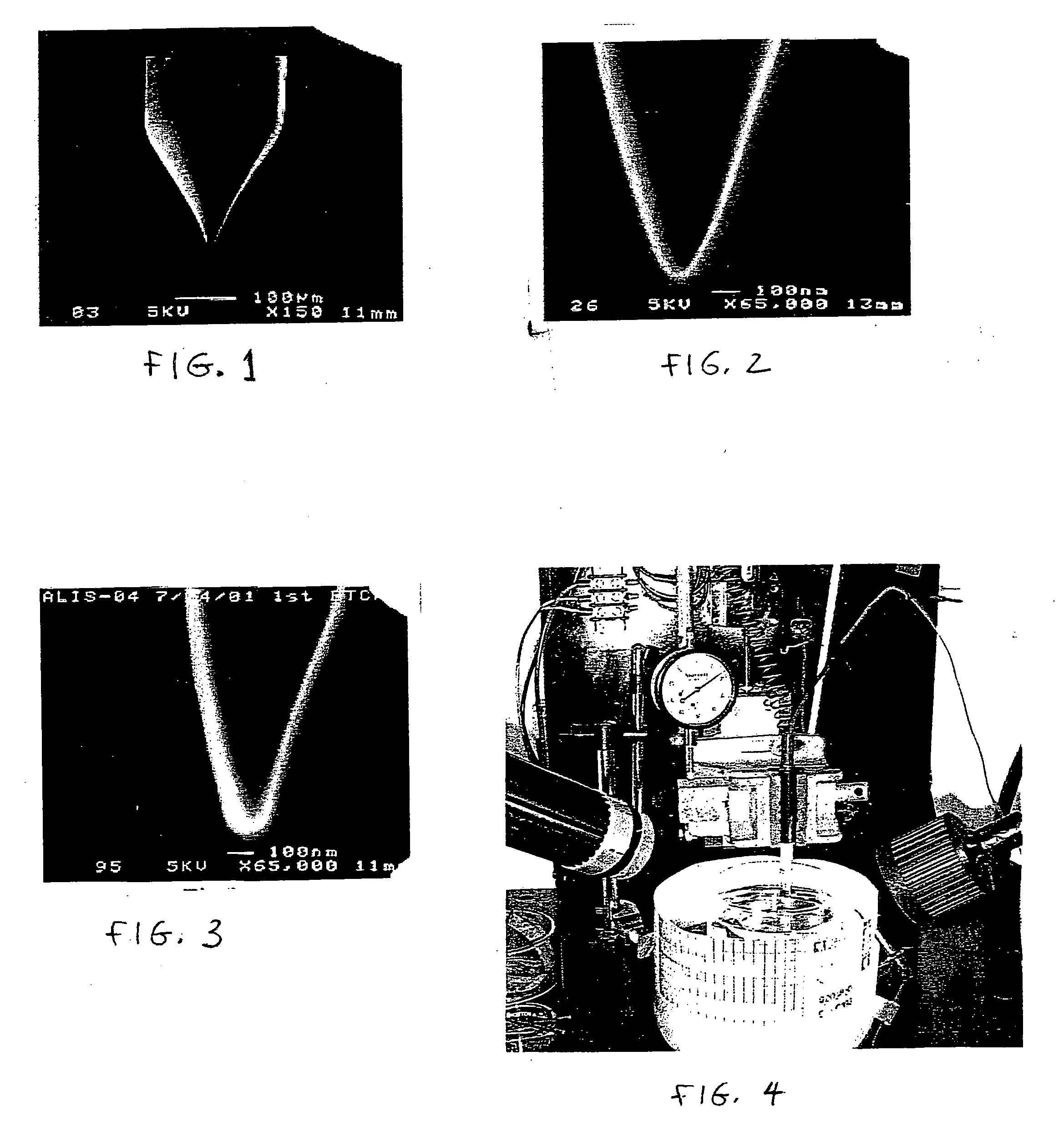

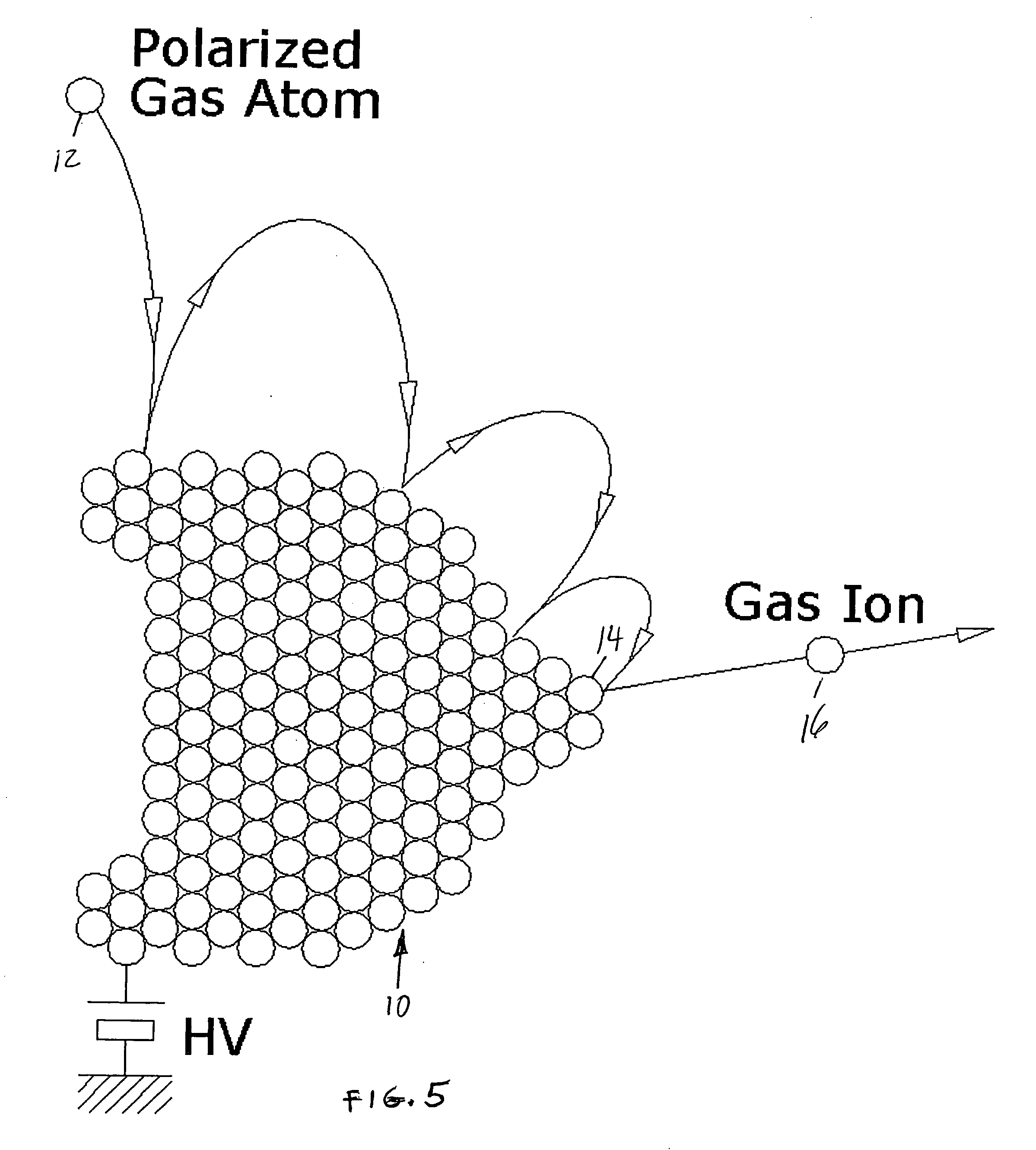

ActiveUS20070051900A1Long-term performanceLong-term reliabilityMaterial analysis using wave/particle radiationMaterial analysis by optical meansElectrical conductorScanning electron microscope

Ion source and method of making and sharpening. The ion source is a single crystal metal conductor having a substantially conical tip portion with substantial rotational symmetry. The tip portion terminates with a tip radius of curvature in the range of 50-100 nanometers. The ion source is made by electrochemical etching so that a conical tip of a selected geometry is formed. The ion source is then sharpened to provide a source of ions from a volume near the size of a single atom. Further, this ion source makes possible a stable and practical light ion microscope which will have higher resolution than existing scanning electron microscopes and scanning metal-ion microscopes.

Owner:ALIS CORP

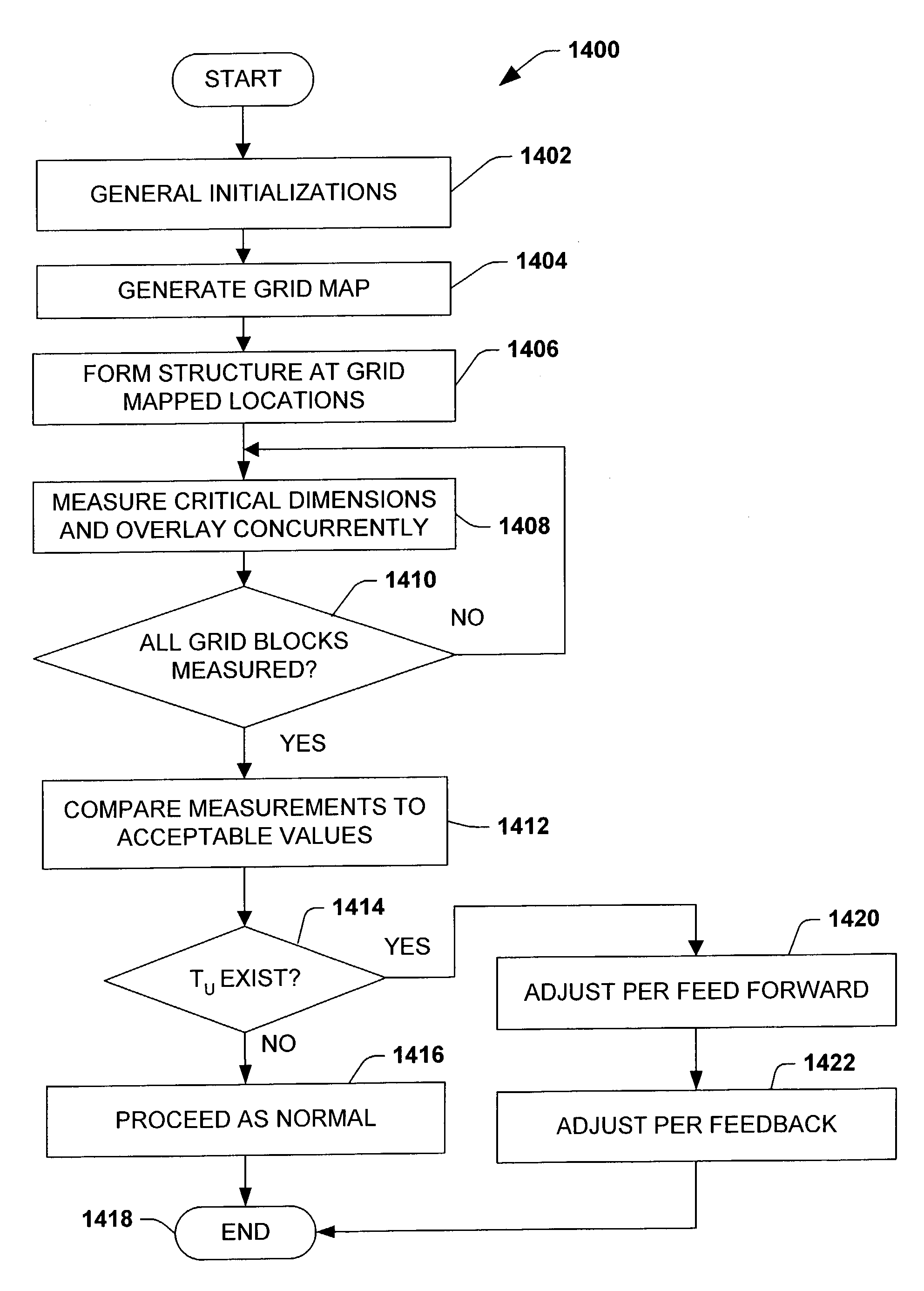

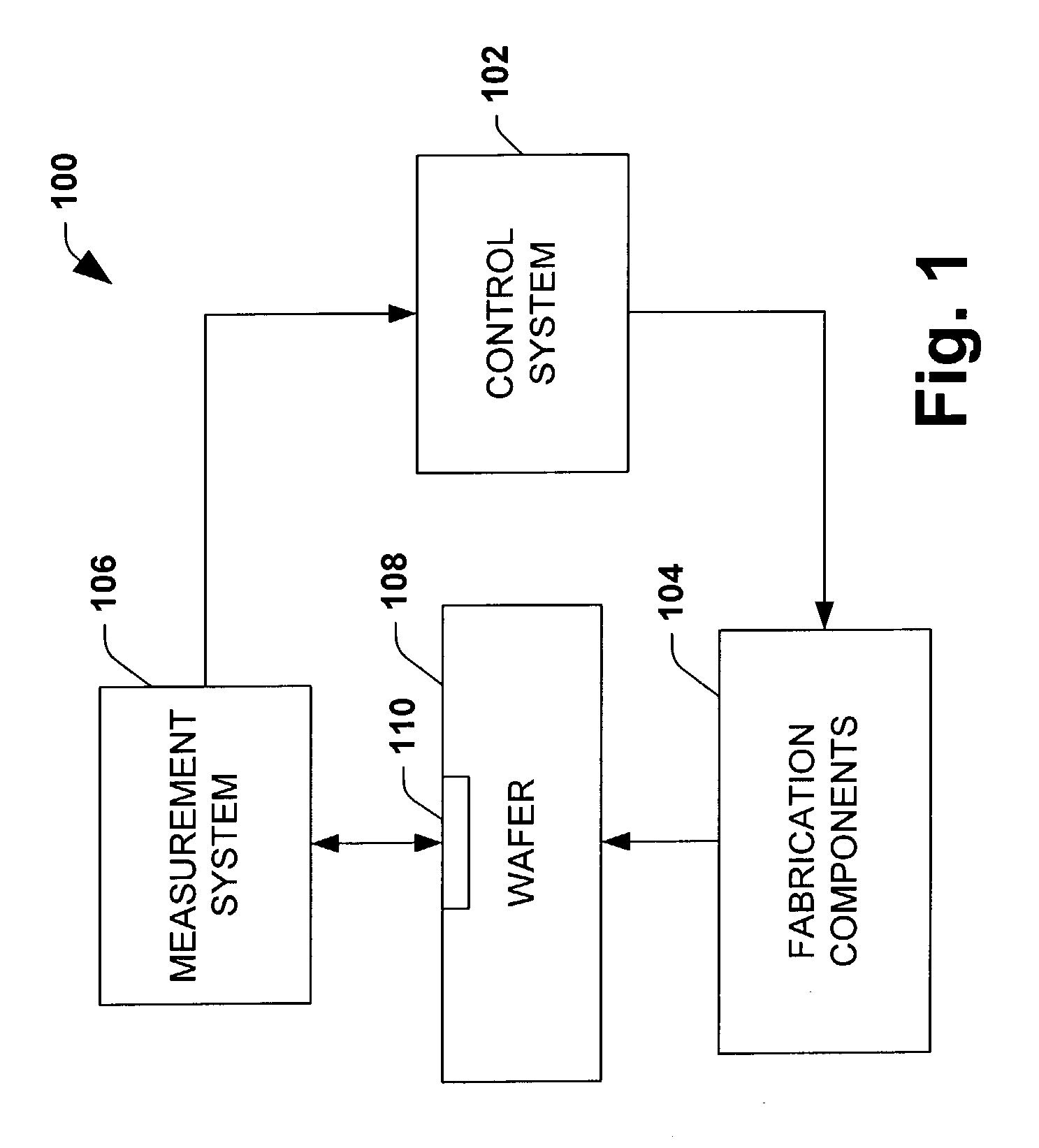

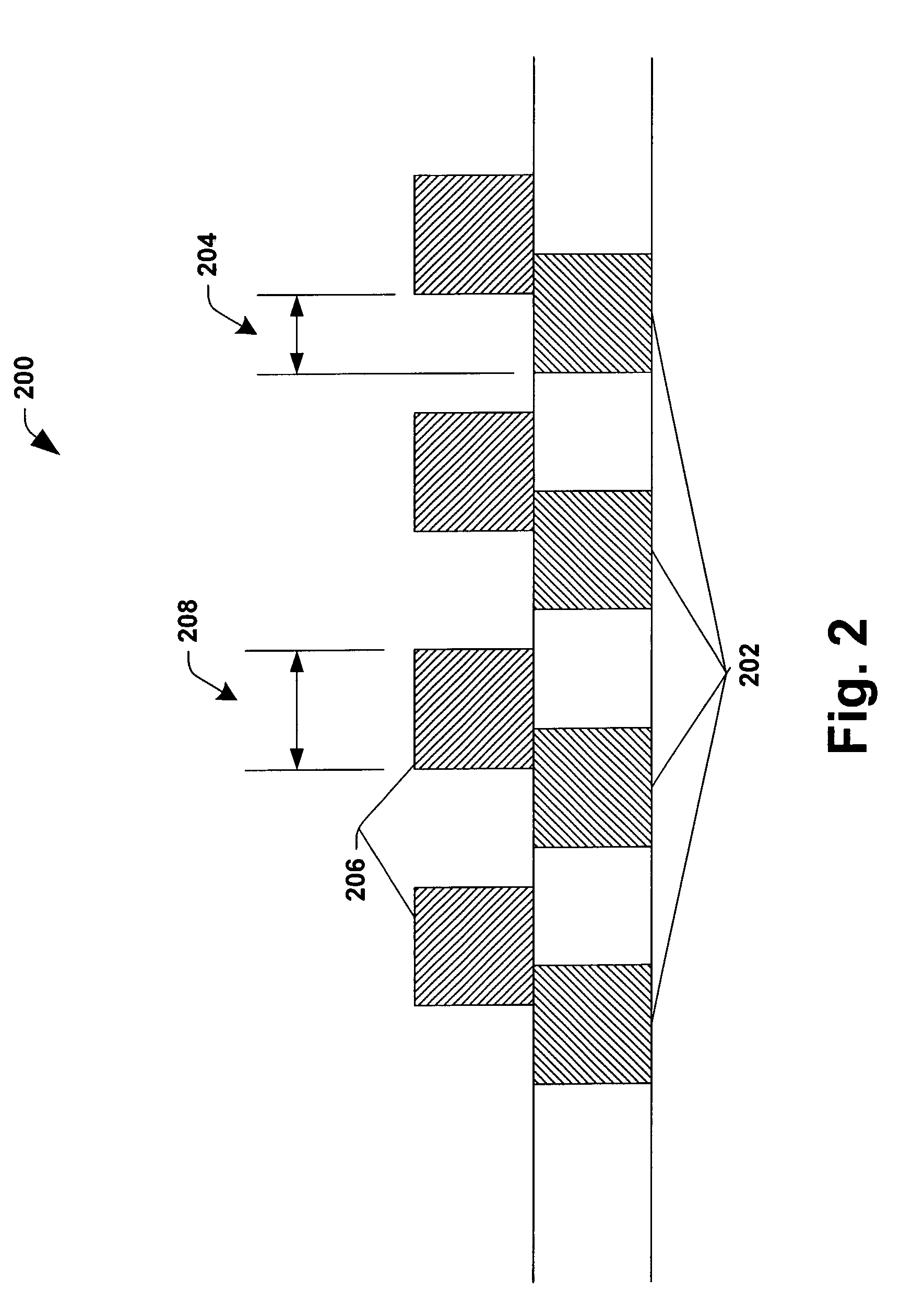

Concurrent measurement of critical dimension and overlay in semiconductor manufacturing

ActiveUS7080330B1Fabrication can be reducedFacilitate a reduction in, among other things, time and real estate requiredDetecting faulty computer hardwarePhotomechanical apparatusScanning electron microscopeEngineering

A system and methodology are disclosed for monitoring and controlling a semiconductor fabrication process. One or more structures formed on a wafer matriculating through the process facilitate concurrent measurement of critical dimensions and overlay via scatterometry or a scanning electron microscope (SEM). The concurrent measurements mitigate fabrication inefficiencies, thereby reducing time and real estate required for the fabrication process. The measurements can be utilized to generate feedback and / or feed-forward data to selectively control one or more fabrication components and / or operating parameters associated therewith to achieve desired critical dimensions and to mitigate overlay error.

Owner:OCEAN SEMICON LLC

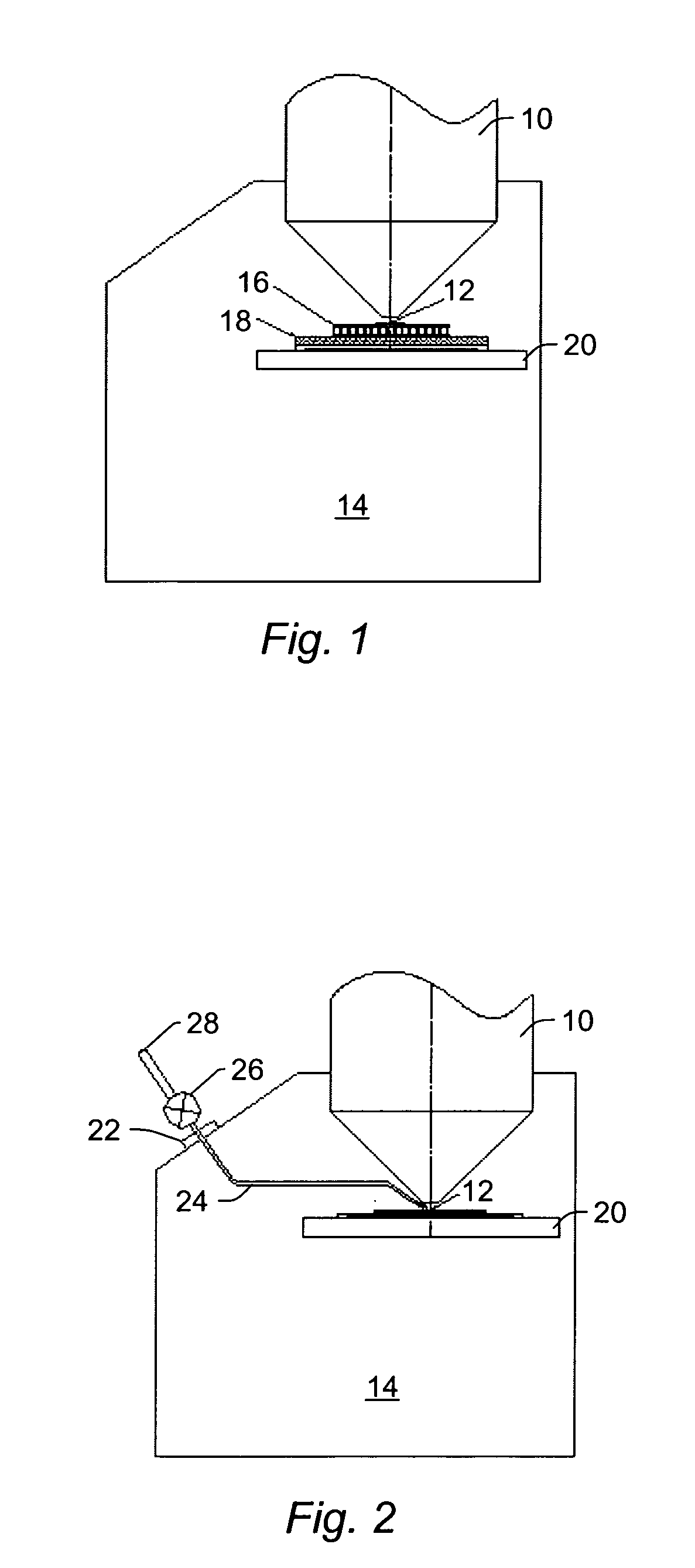

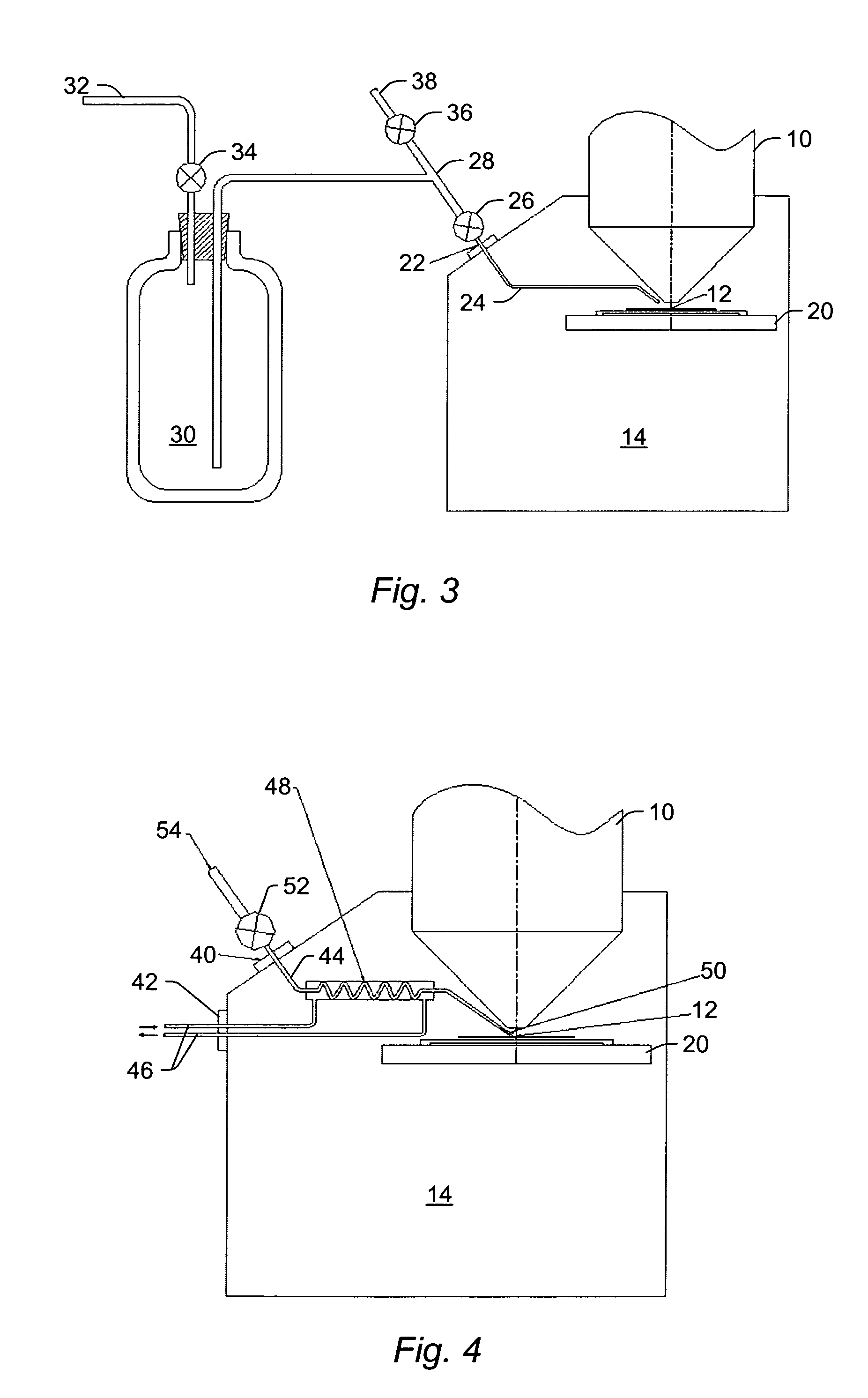

Methods for sem inspection of fluid containing samples

InactiveUS20050173632A1High resolutionIncrease contrastMaterial analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsElectron microscopeScanning electron microscope

A method of visualizing a sample in a wet environment including introducing a sample into a specimen enclosure in a wet environment and scanning the sample in the specimen enclosure in a scanning electron microscope, thereby visualizing the sample.

Owner:QUANTOMIX

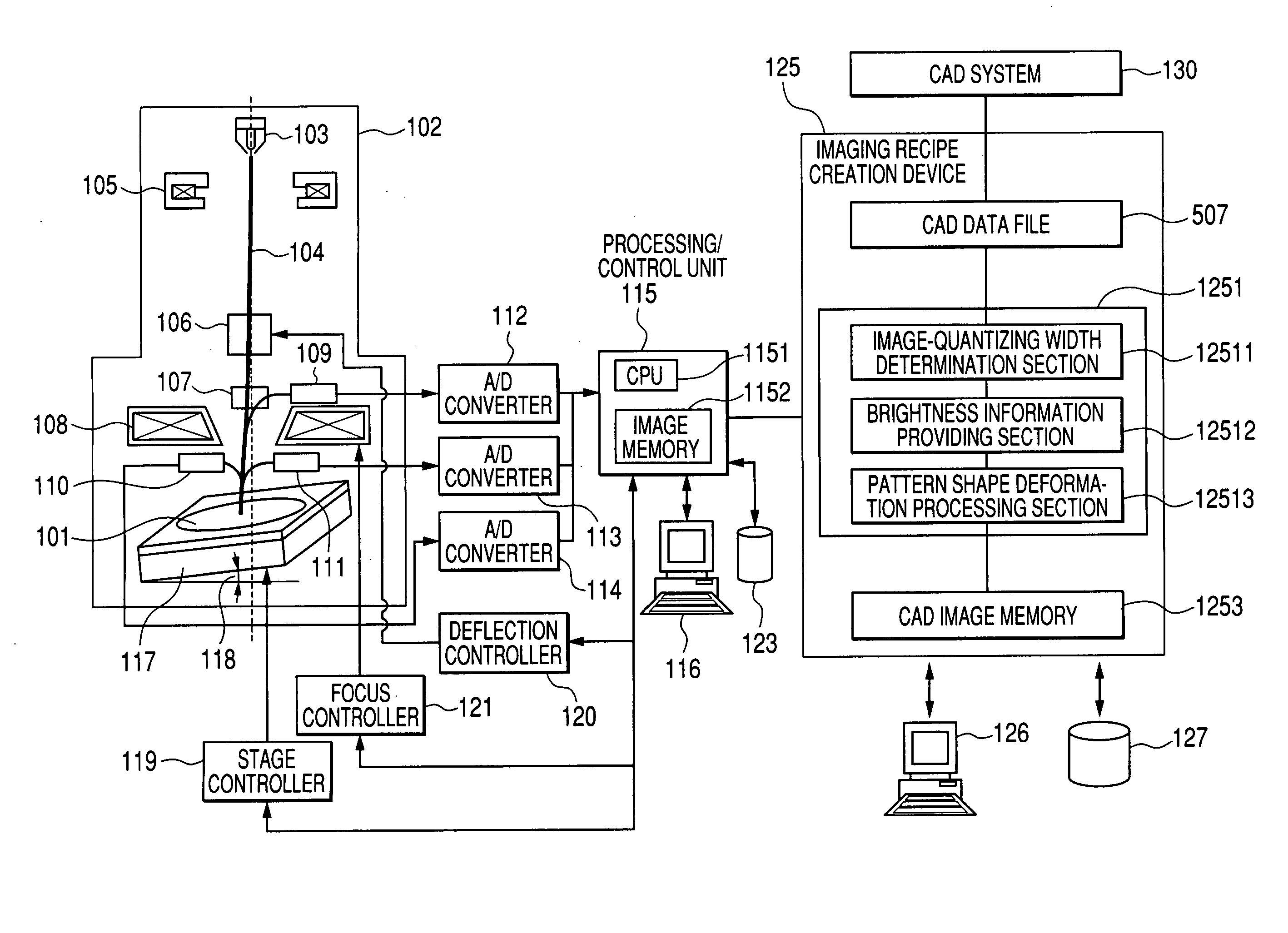

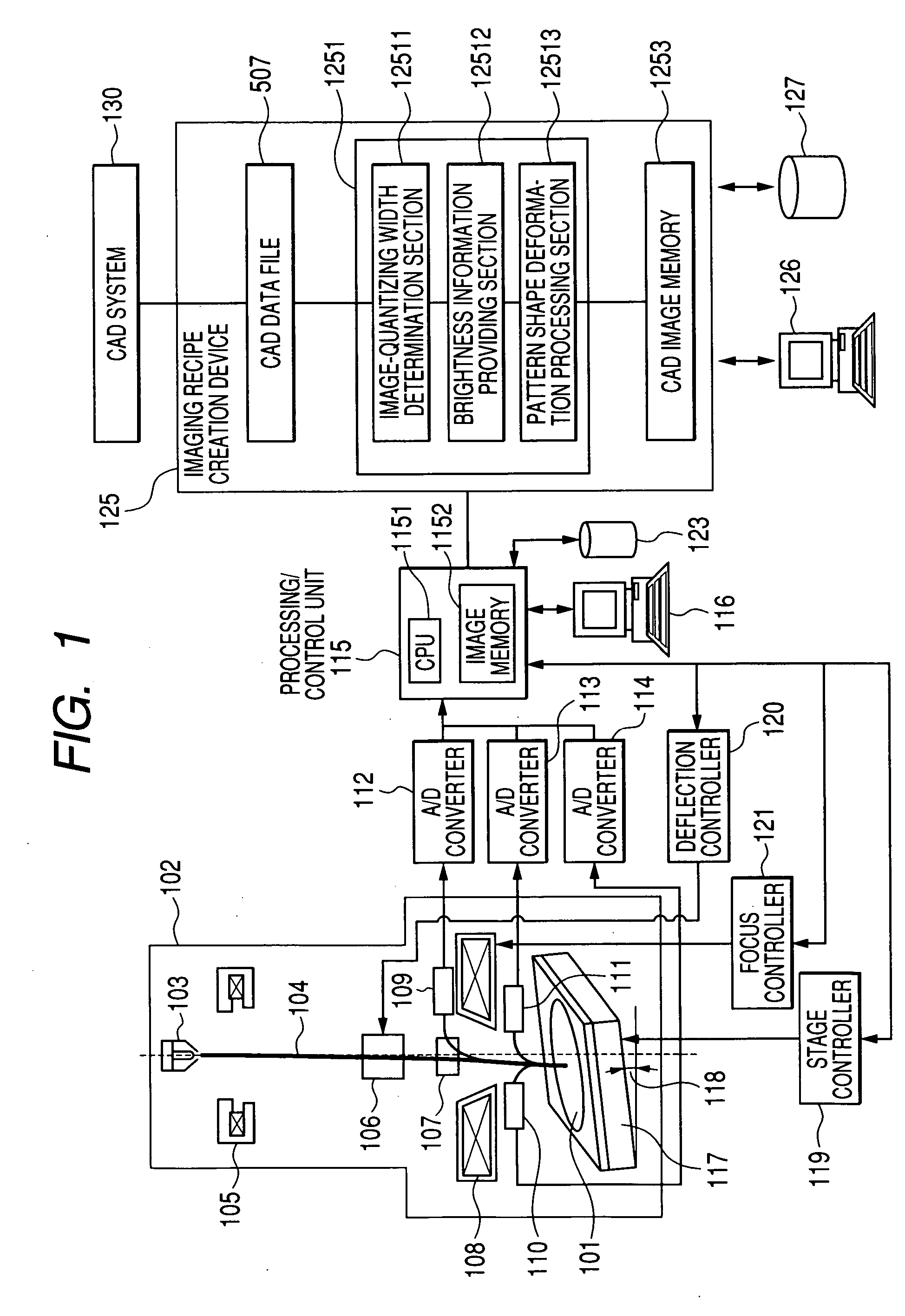

Method and apparatus for measuring dimension of a pattern formed on a semiconductor wafer

ActiveUS20060288325A1Minimal timePossible to generatePhotomechanical apparatusCharacter and pattern recognitionGraphicsMinimum time

In an imaging recipe creating apparatus that uses a scanning electron microscope to create an imaging recipe for SEM observation of a semiconductor pattern, in order that the imaging recipe for measuring the wiring width and other various dimension values of the pattern from an observation image and thus evaluating the shape of the pattern is automatically generated within a minimum time by the analysis using the CAD image obtained by conversion from CAD data, an CAD image creation unit that creates the CAD image by converting the CAD data into an image format includes an image-quantizing width determining section, a brightness information providing section, and a pattern shape deformation processing section; the imaging recipe being created using the CAD image created by the CAD image creation unit.

Owner:HITACHI HIGH-TECH CORP

Atomic level ion source and method of manufacture and operation

ActiveUS7368727B2Good symmetryLong-term performance and reliabilityMaterial analysis using wave/particle radiationMaterial analysis by optical meansElectrical conductorScanning electron microscope

Ion source and method of making and sharpening. The ion source is a single crystal metal conductor having a substantially conical tip portion with substantial rotational symmetry. The tip portion terminates with a tip radius of curvature in the range of 50–100 nanometers. The ion source is made by electrochemical etching so that a conical tip of a selected geometry is formed. The ion source is then sharpened to provide a source of ions from a volume near the size of a single atom. Further, this ion source makes possible a stable and practical light ion microscope which will have higher resolution than existing scanning electron microscopes and scanning metal-ion microscopes.

Owner:ALIS CORP

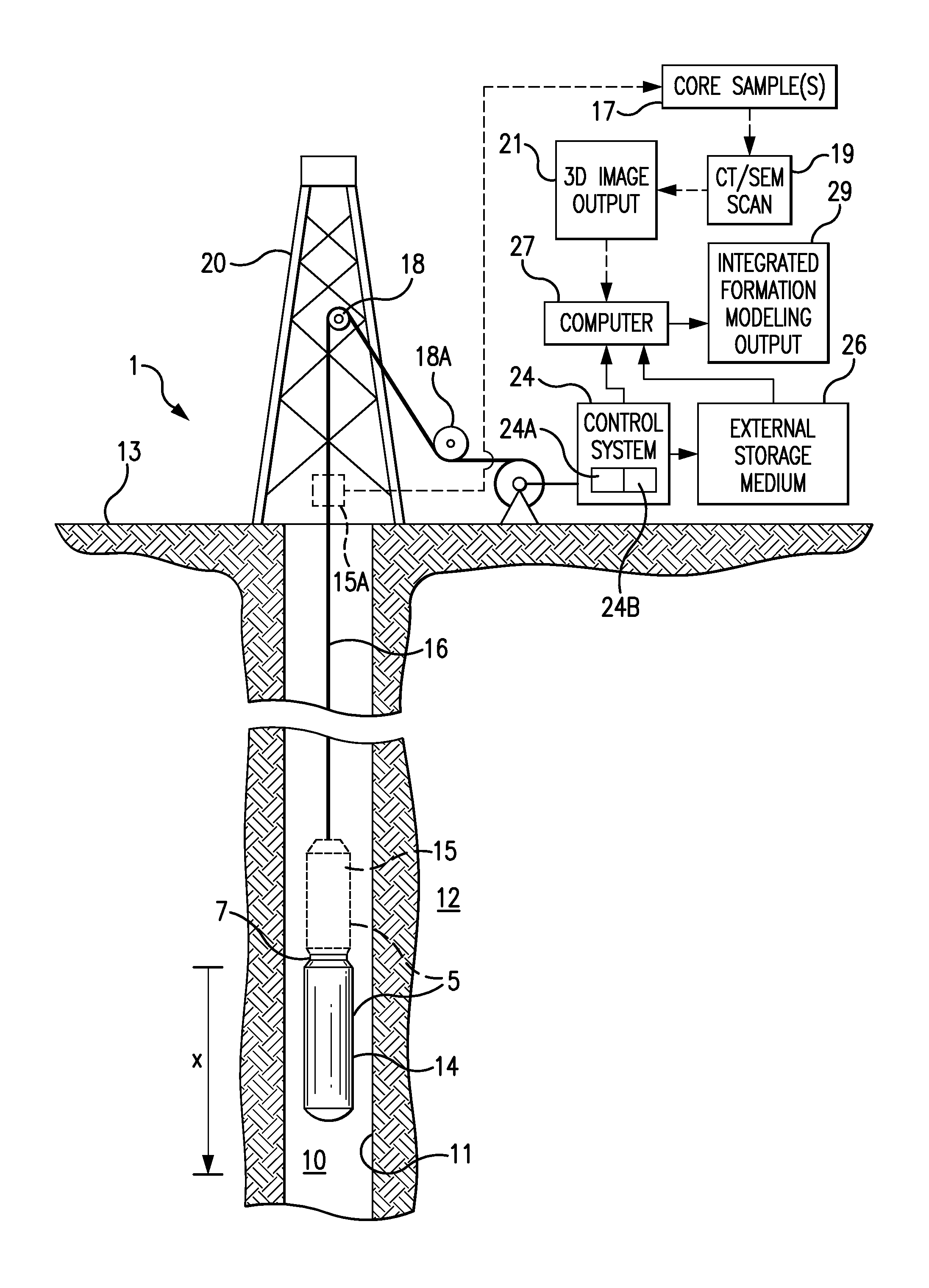

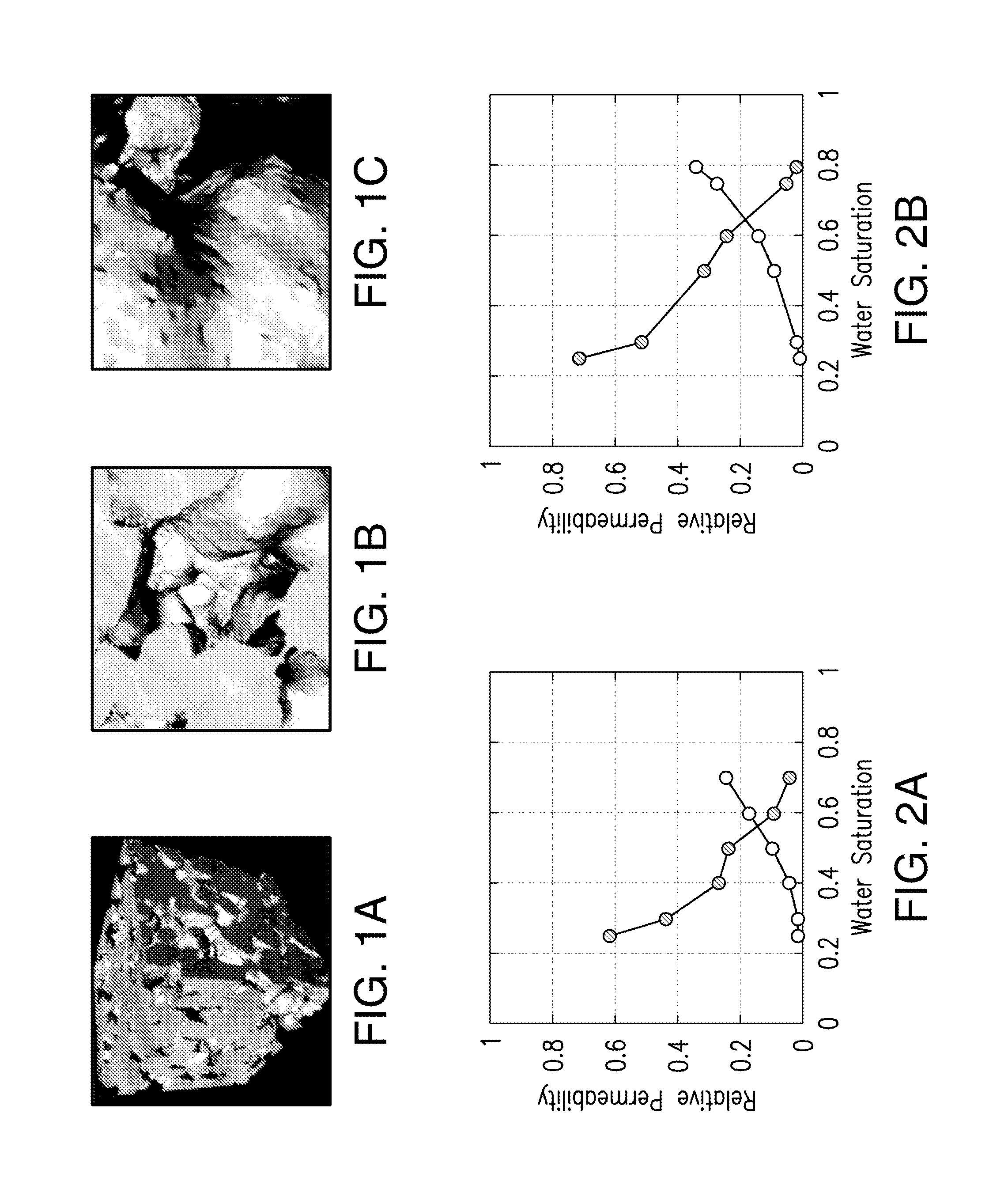

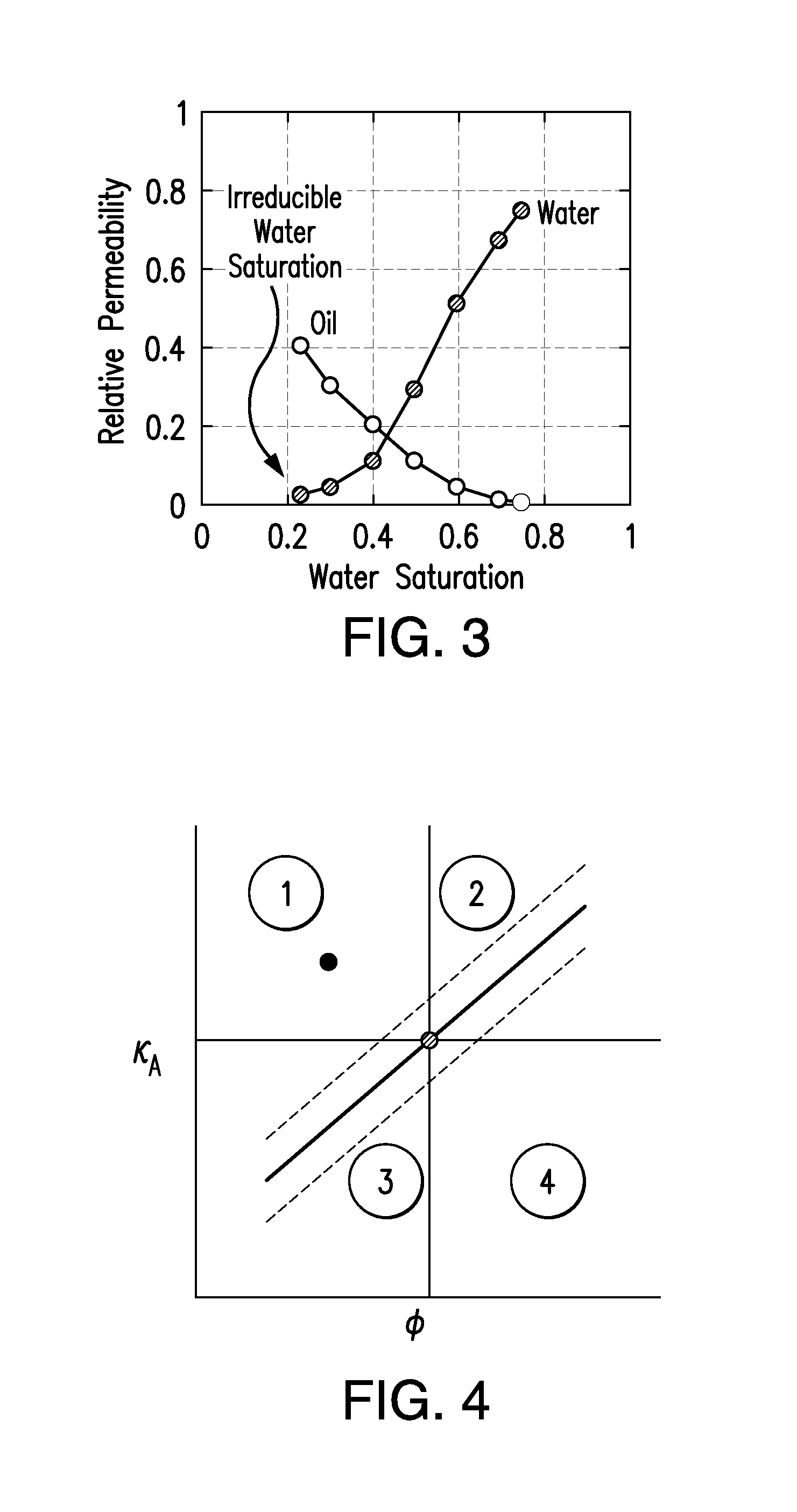

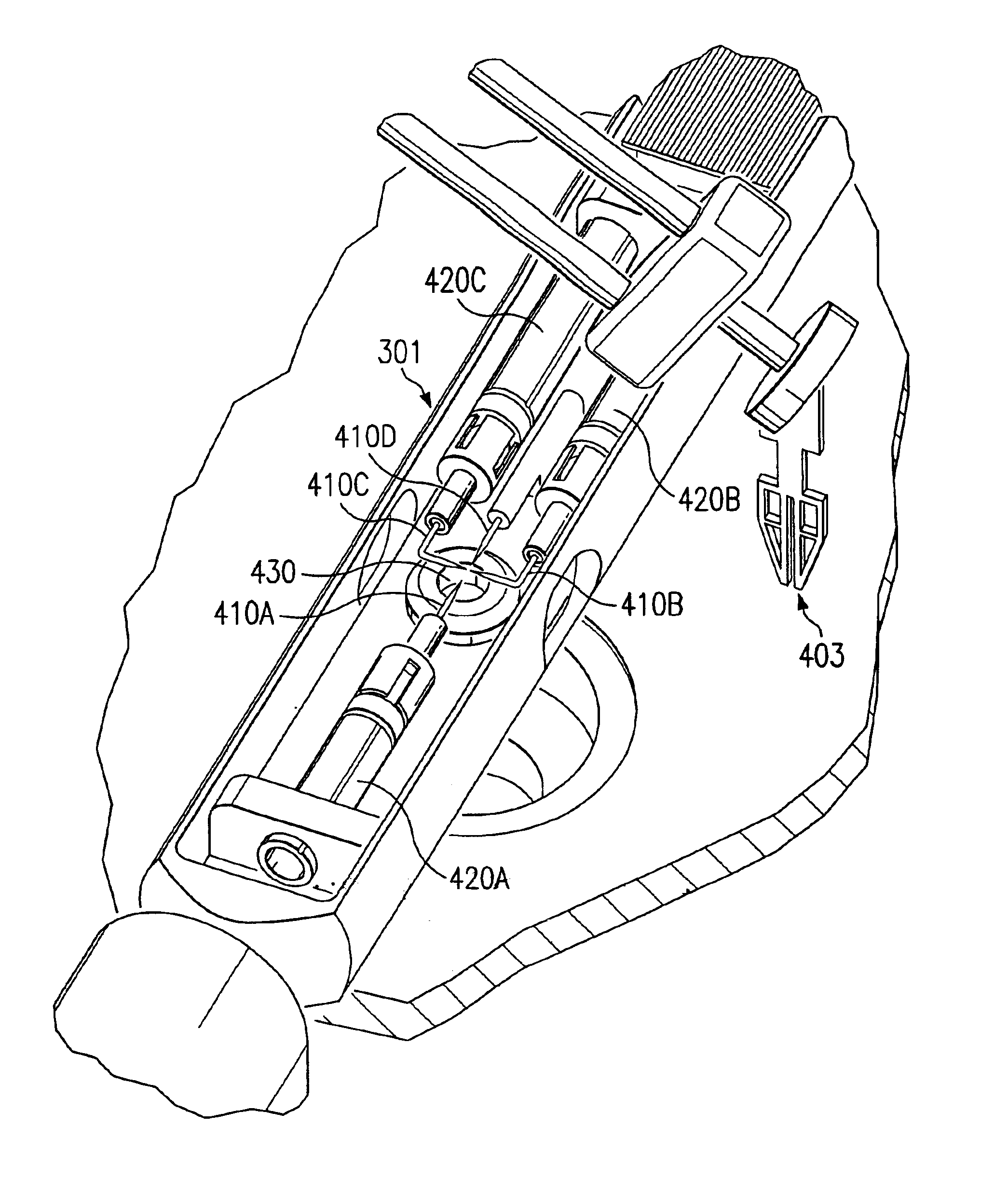

Method and system for integrating logging tool data and digital rock physics to estimate rock formation properties

ActiveUS9507047B1Material analysis using wave/particle radiationNuclear radiation detectionPorosityCt scanners

The present invention relates to a method and system for integrating logging tool data and digital rock physics to estimate rock formation properties. A rock sample from a logging tool such as a sidewall plug or large enough cutting can be extracted by the logging tool at approximately the same well bore location that the logging tool measures fluid properties. The rock samples thus obtained is scanned using a CT scanner, scanning electron microscope or other suitable scanning device. The resulting scanned rock image can be segmented and rock properties comprising porosity, absolute permeability, relative permeability, capillary pressure and other relevant rock properties are calculated. The resulting digital calculations are integrated with logging tool data and rock property estimates to improve the accuracy and timeliness of the logging tool data.

Owner:HALLIBURTON ENERGY SERVICES INC

Manipulation system for manipulating a sample under study with a microscope

InactiveUS6967335B1Good flexibilityMicromanipulatorElectric discharge tubesScanning electron microscopeElectron microscope

A system and method are disclosed which enable manipulation of a sample under study with a microscope. In one embodiment, a manipulation system is adaptable for interfacing with any of a plurality of different types of microscopes, such as a transmission electron microscope (TEM) and a scanning electron microscope (SEM), and further comprises at least one manipulation mechanism operable to manipulate a sample. In another embodiment, a manipulation system is capable of being detachably coupled to a microscope, such as a TEM, and comprises a plurality of manipulator mechanisms for manipulating a sample. In a preferred embodiment, the manipulation system comprises both an adjustable interface such that it is capable of selectively coupling with any of a plurality of different microscope interfaces and a plurality of manipulator mechanisms integrated therein that are controllably operable for manipulating a sample.

Owner:DCG SYST

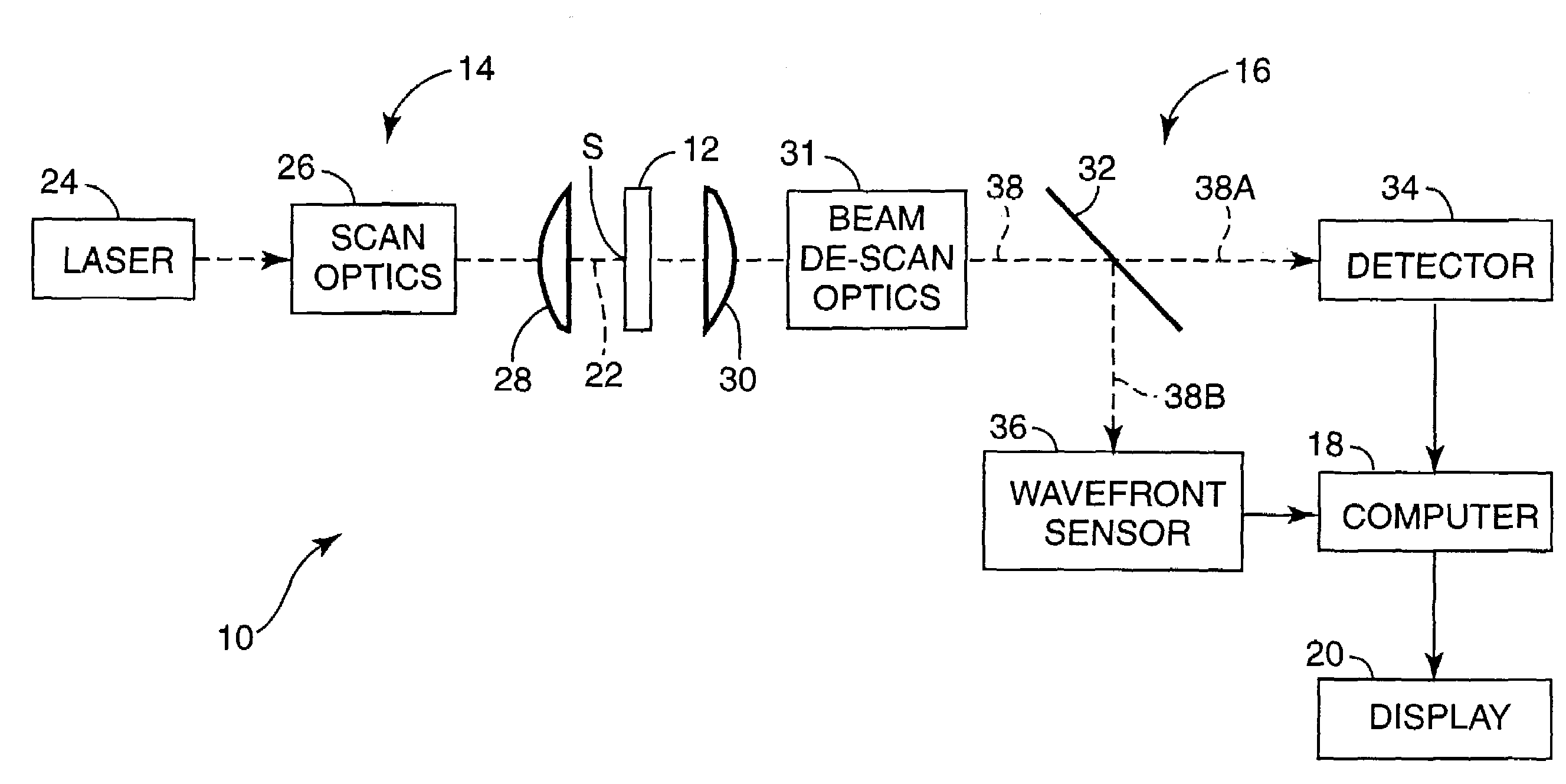

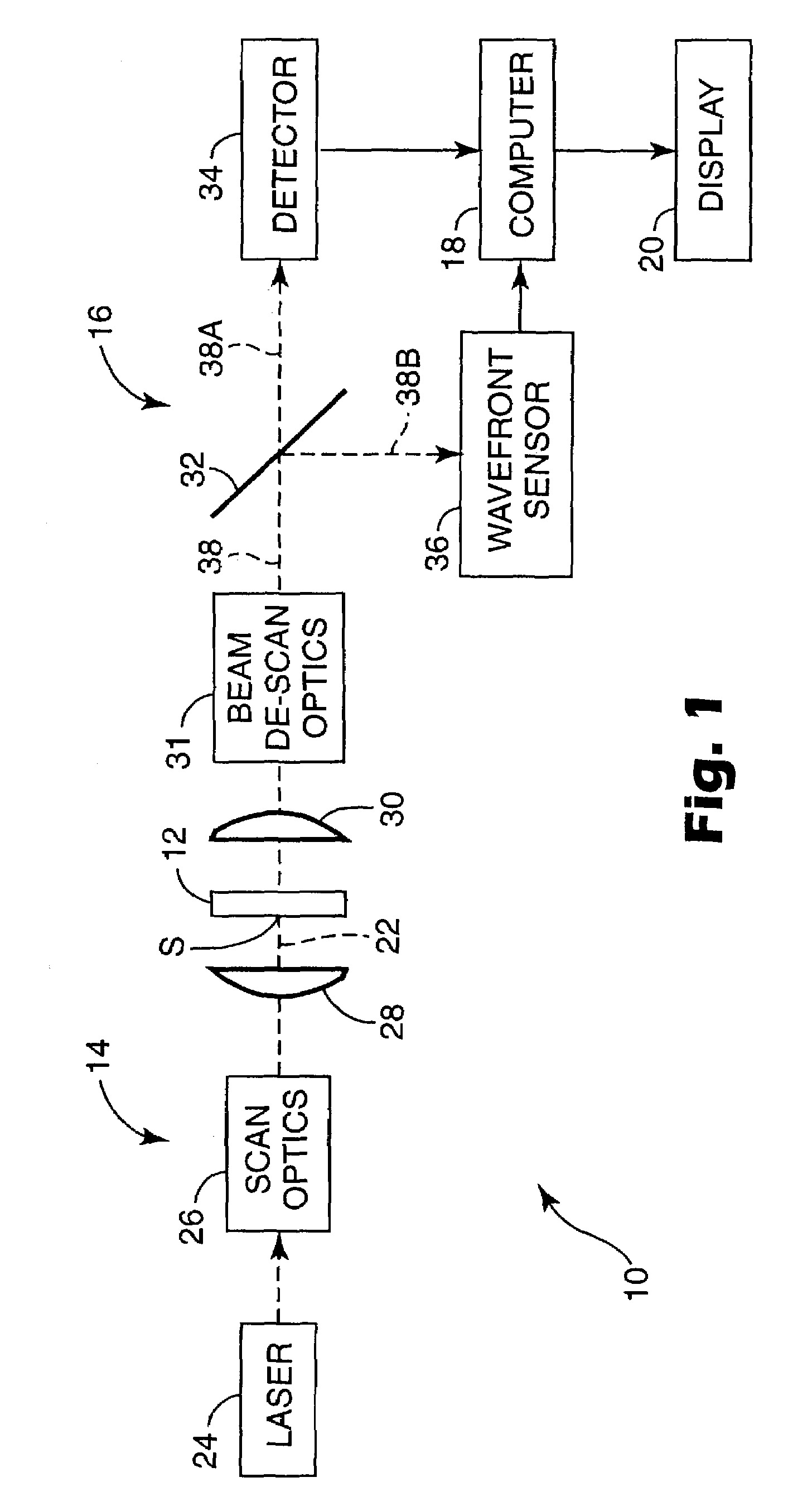

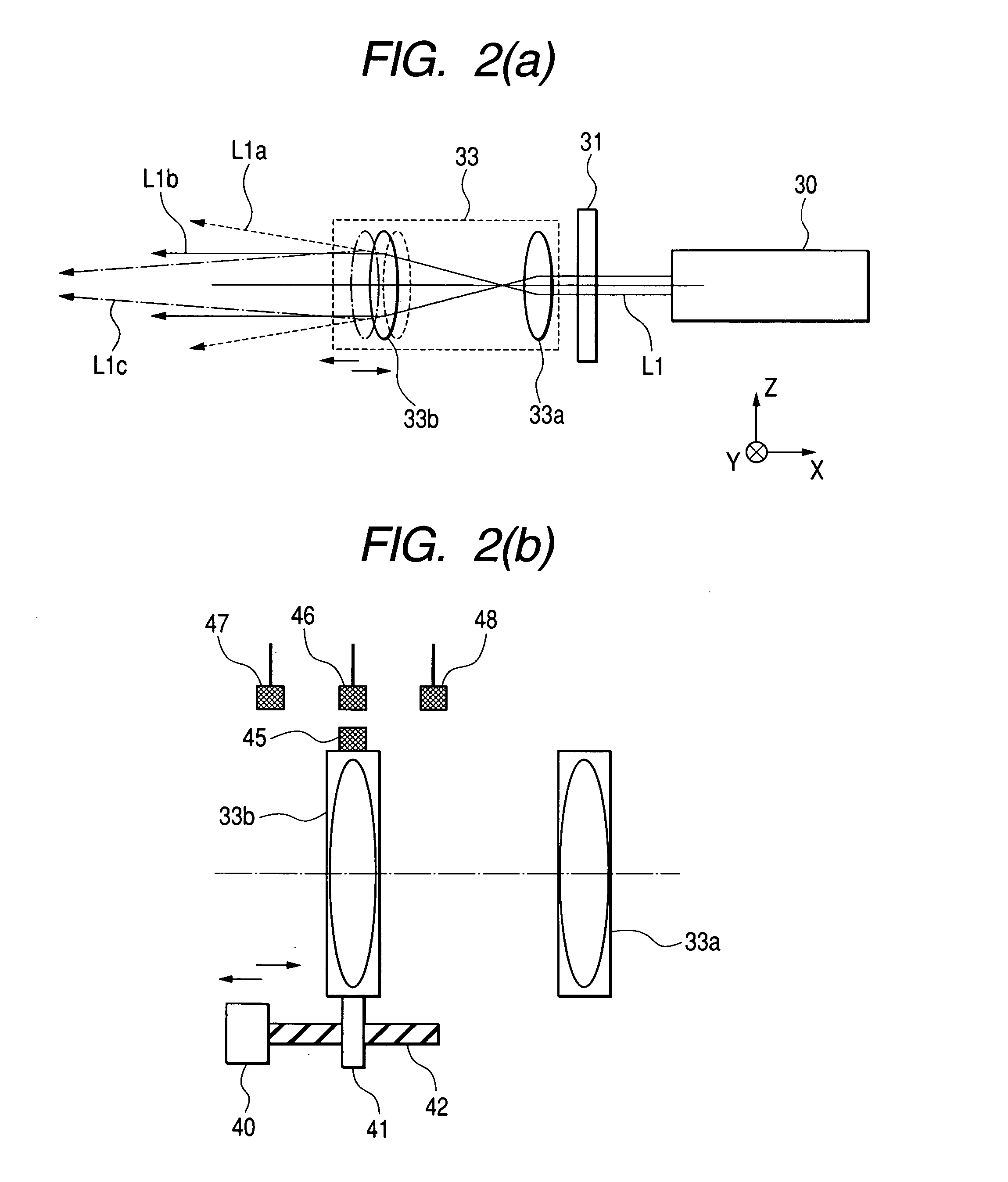

Scanning laser microscope with wavefront sensor

InactiveUS7057806B2High resolutionEnhanced resolution imagePhotometry using reference valueMaterial analysis by optical meansFrequency spectrumWavefront sensor

An enhanced resolution scanned image of an object is produced by a scanning laser microscope which includes an illumination arm for scanning an object with a focused probe beam and a detection arm for receiving light from the object. The detection arm includes a detector which collects and detects light from the object to produce pixel data for a plurality of pixels. In addition, the detection arm includes a wavefront sensor for sensing phase variations of the light from the object to produce wavefront data for scanned pixel locations. From the wavefront shape of the collected light at each pixel location, a high frequency spectrum is determined which corresponds to uncollected scattered light from small scale features of that pixel location. An enhanced resolution image of a region of interest is produced based on the high frequency spectra of the scanned pixel locations.

Owner:3M INNOVATIVE PROPERTIES CO

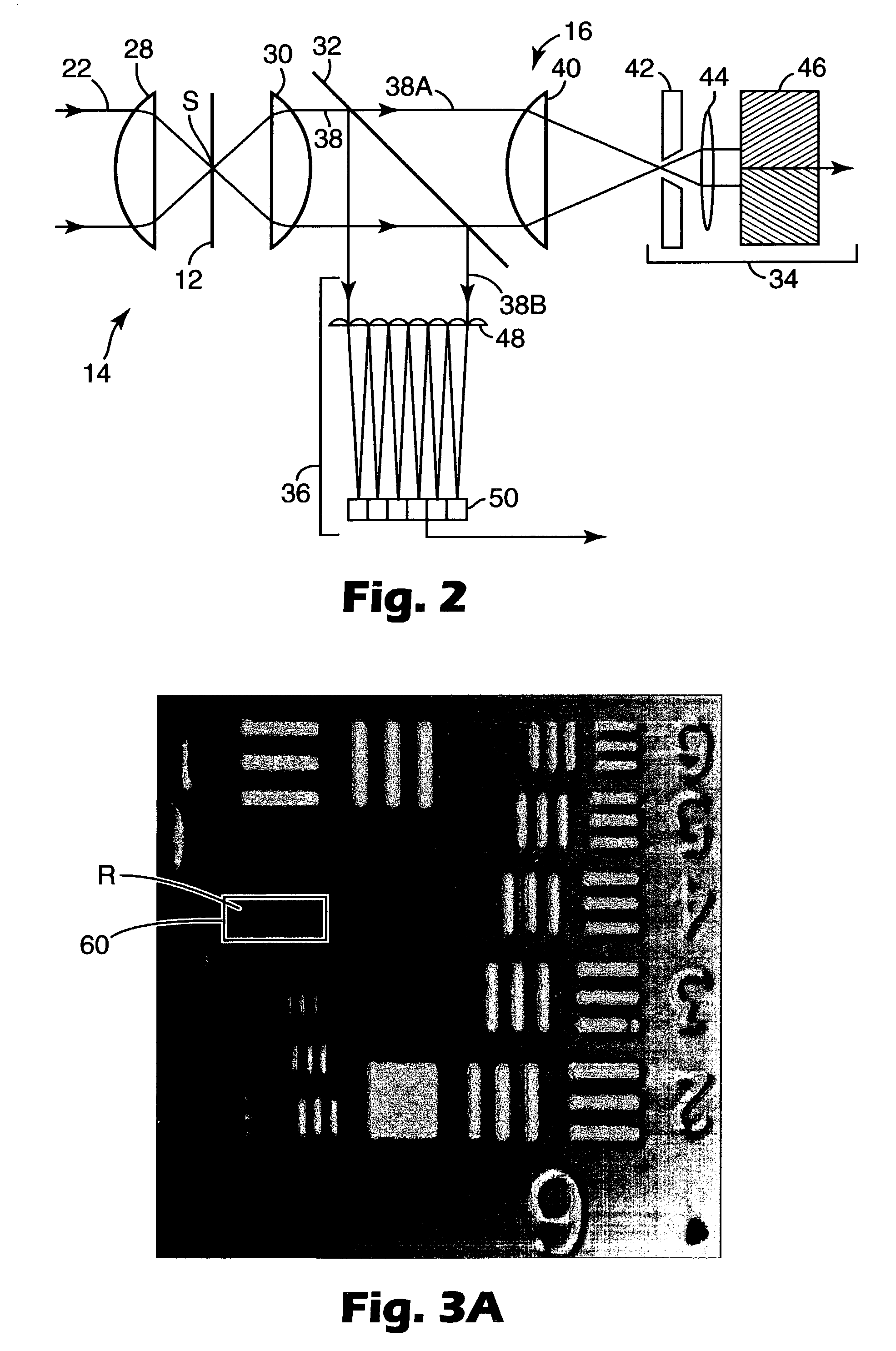

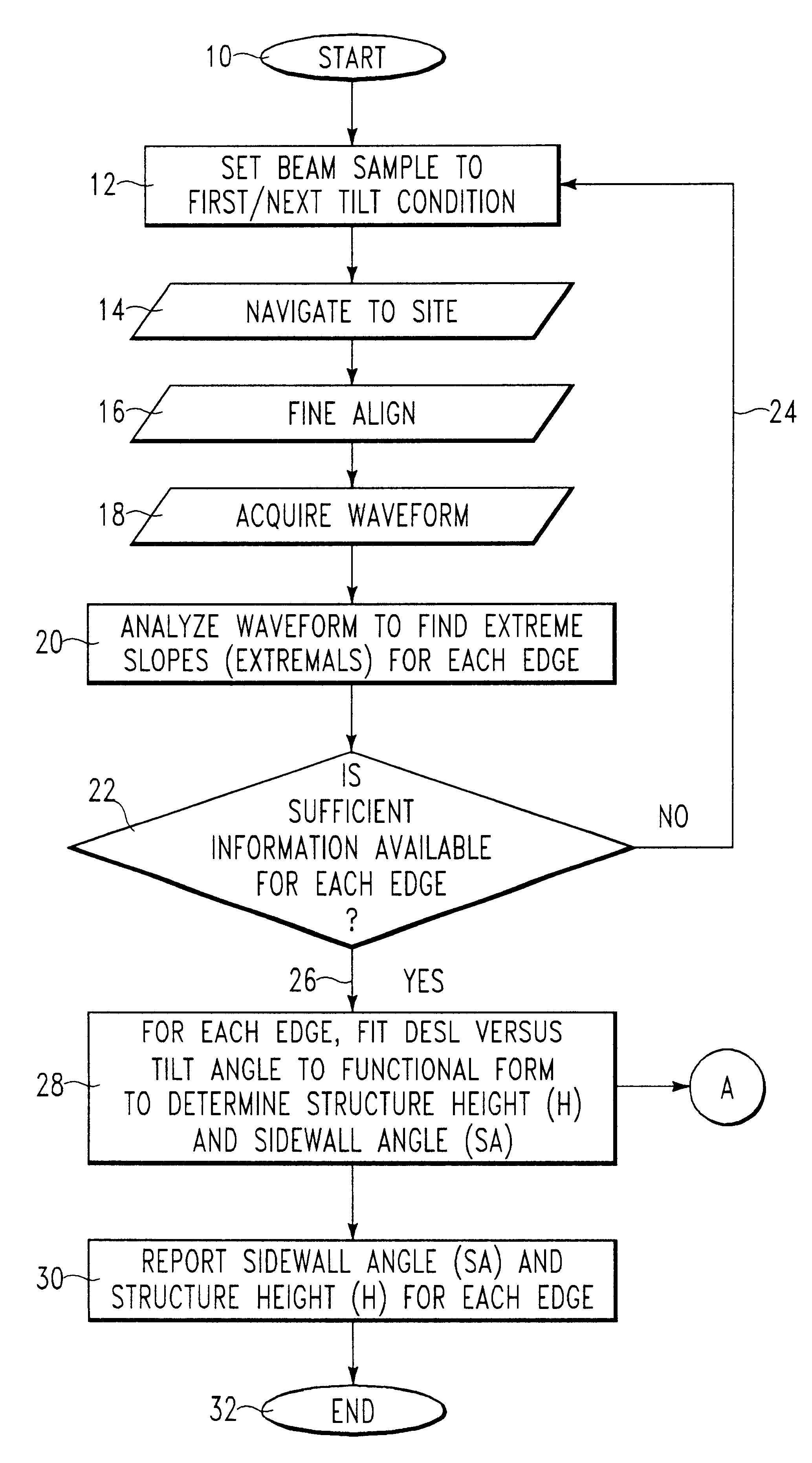

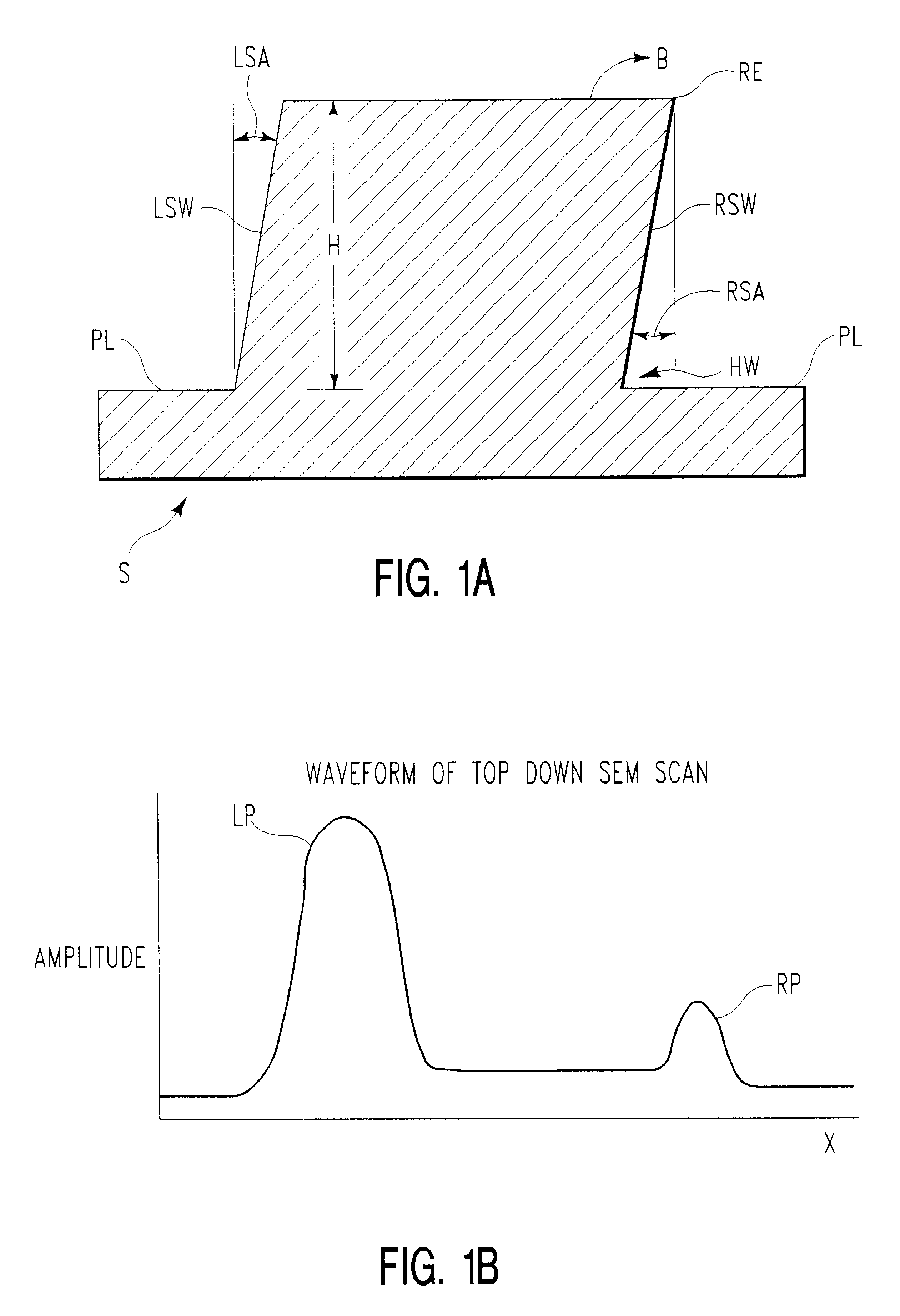

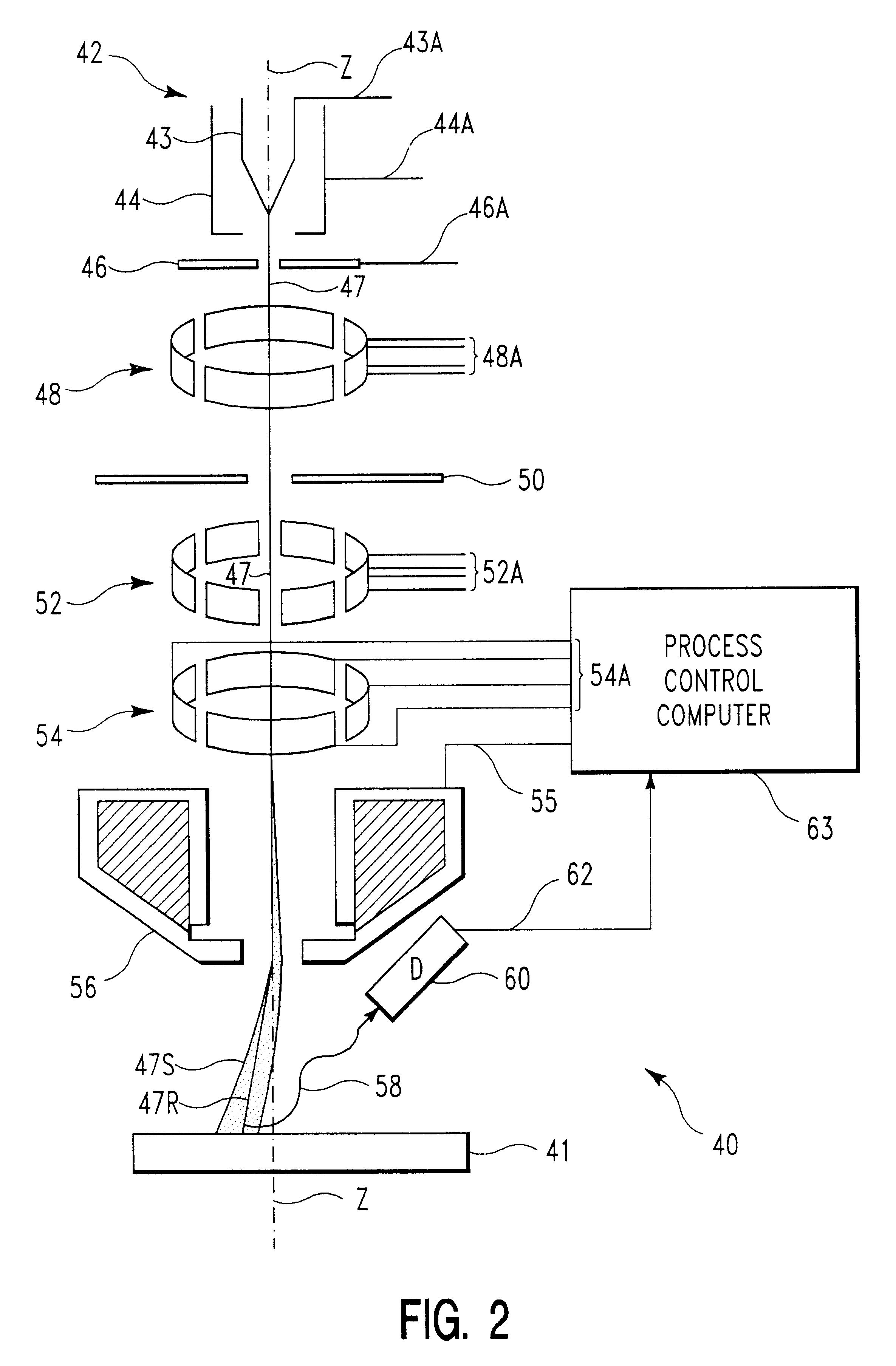

Automated method for determining several critical dimension properties from scanning electron microscope by using several tilted beam or sample scans

InactiveUS6472662B1Material analysis by measuring secondary emissionGamma-ray/x-ray microscopesGratingSystems analysis

To obtain data pertaining to the surface characteristics of a sample, a control method adjusts a tilted rastered E-beam to in SEM to a first / next tilt condition and navigates the SEM-beam to a sample site. The system performs a fine alignment step. Then the system scans a region of a sample to acquire a waveform. The system analyzes the waveform to determine the DESL value for each edge of interest. The system tests whether there is sufficient information available for each structural edge. If NO, the system repeats the above steps starting by changing the value of the tilt angle to acquire another waveform. If YES, the system determines the height and sidewall angles for each structural edge. Then the system reports the sidewall angle and the structure height for each edge of the structure under test. The system then corrects the critical dimension measurement determined from 0 degrees tilt scanning.

Owner:IBM CORP

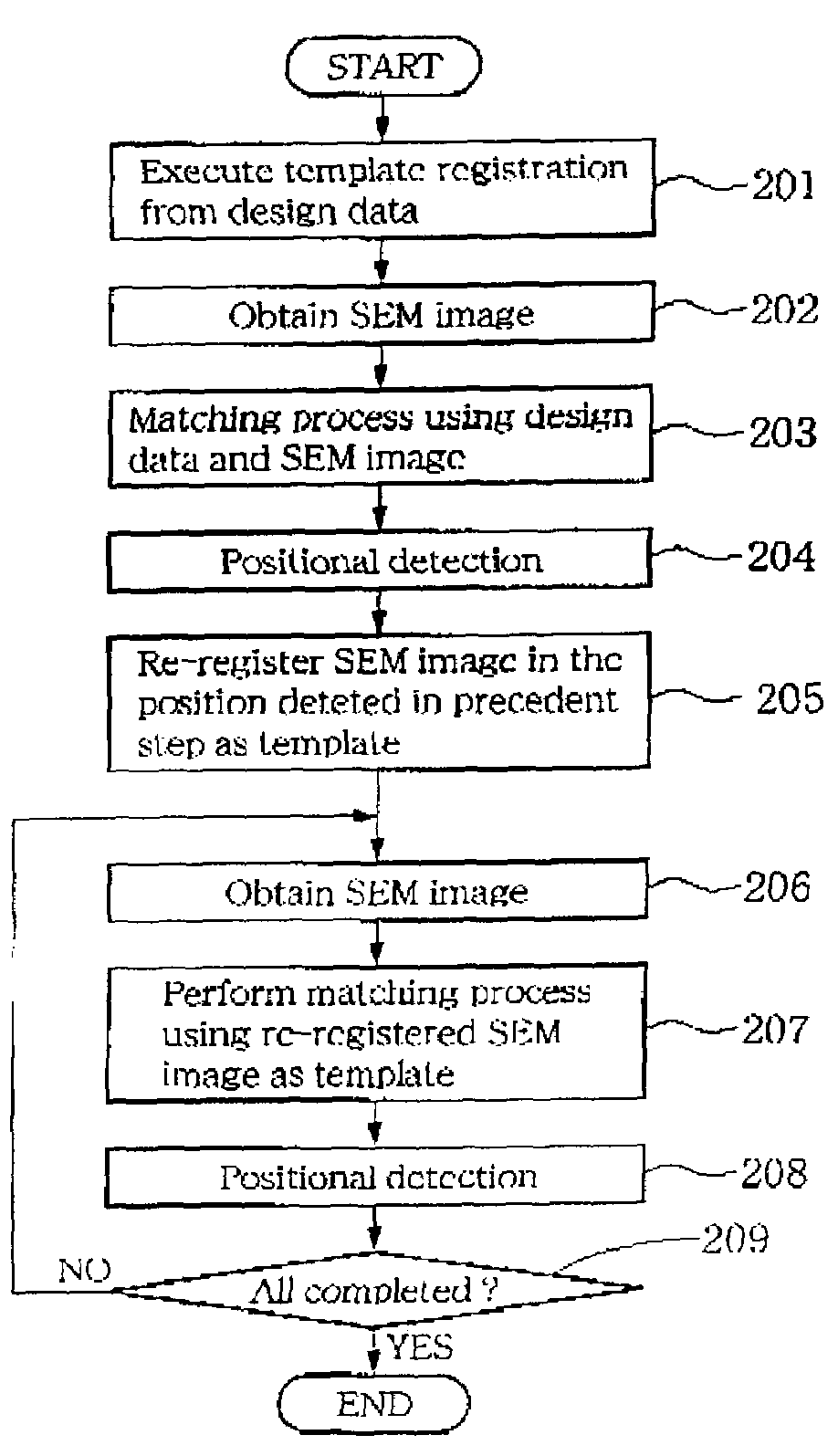

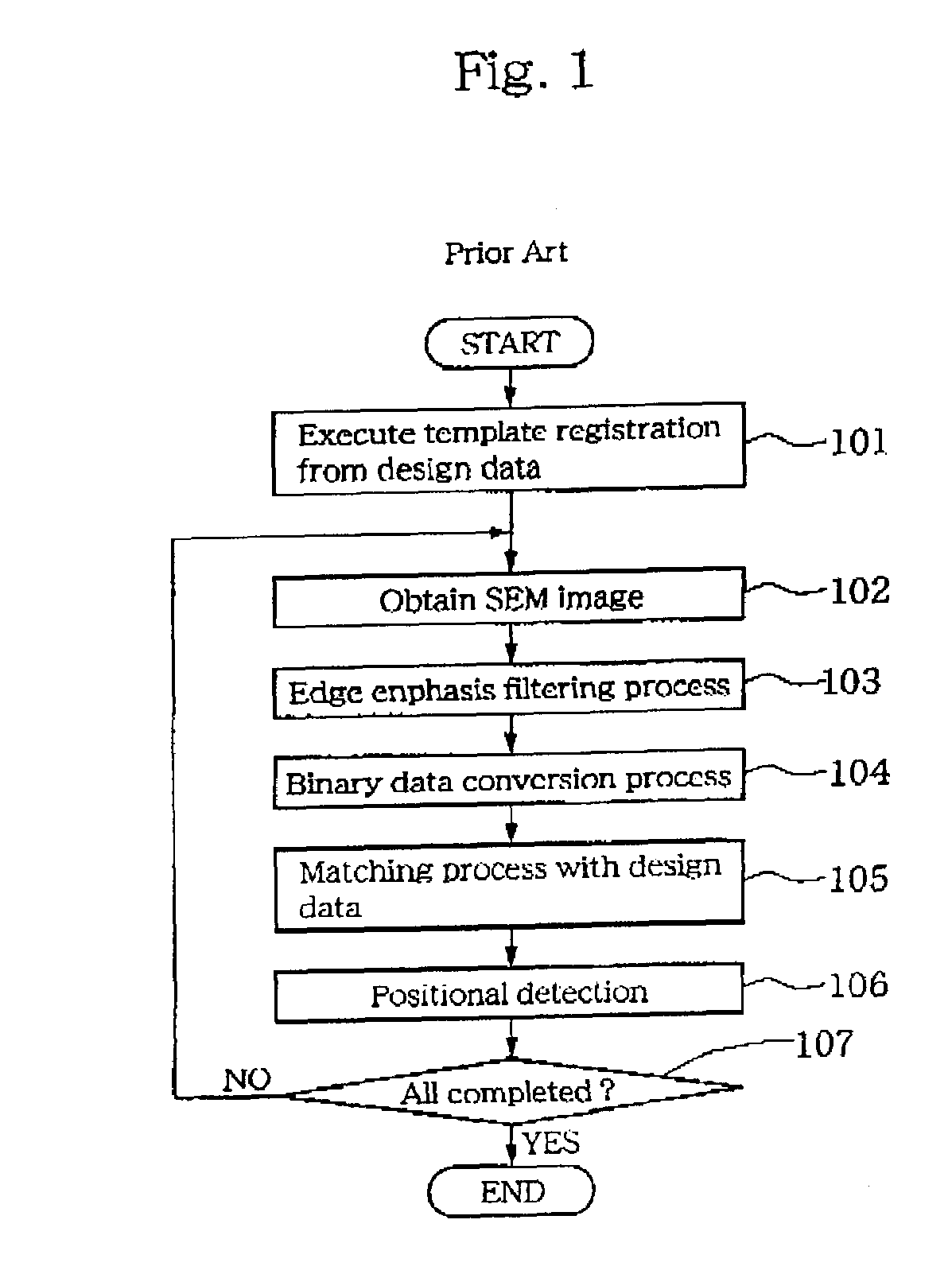

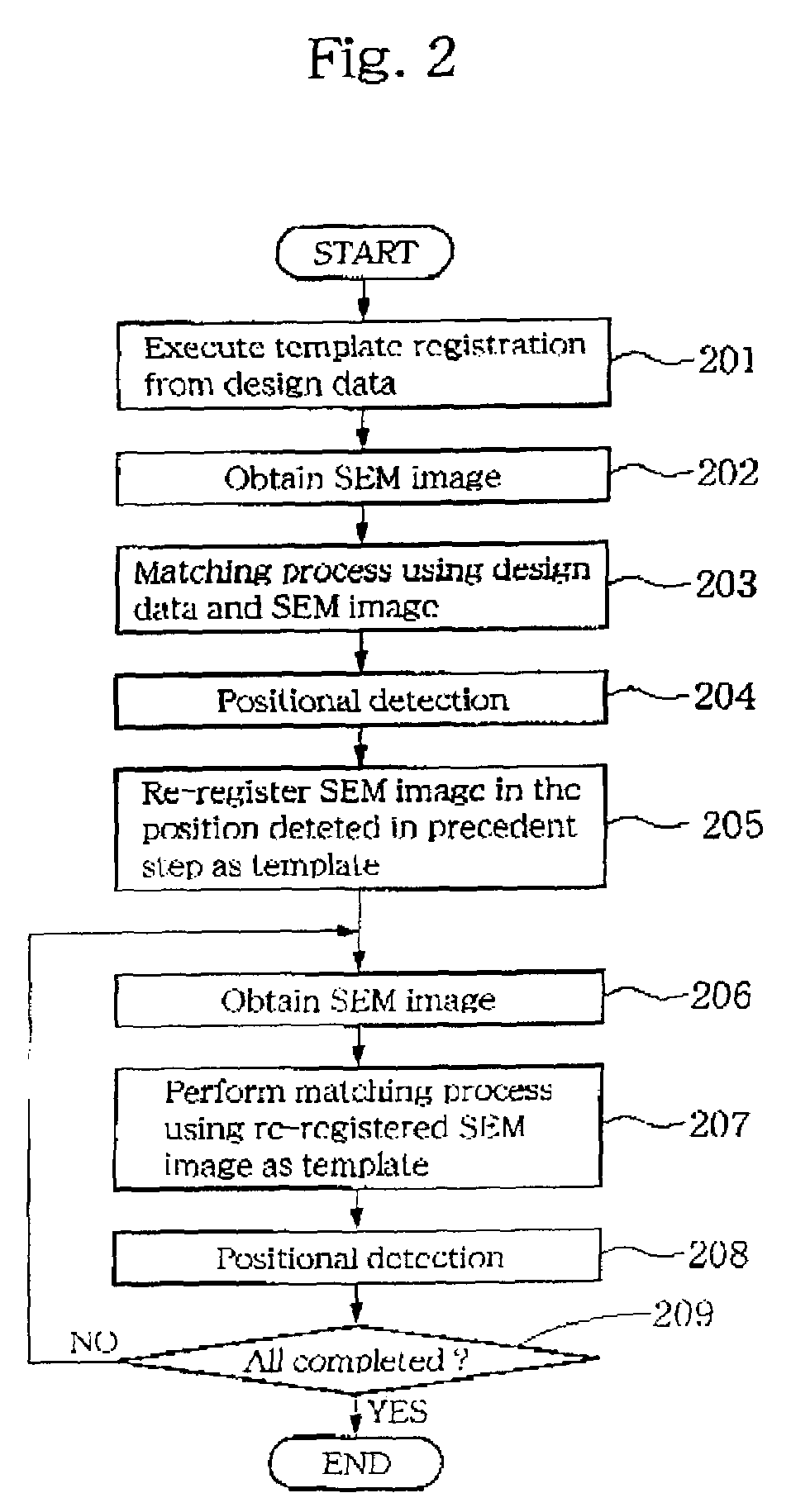

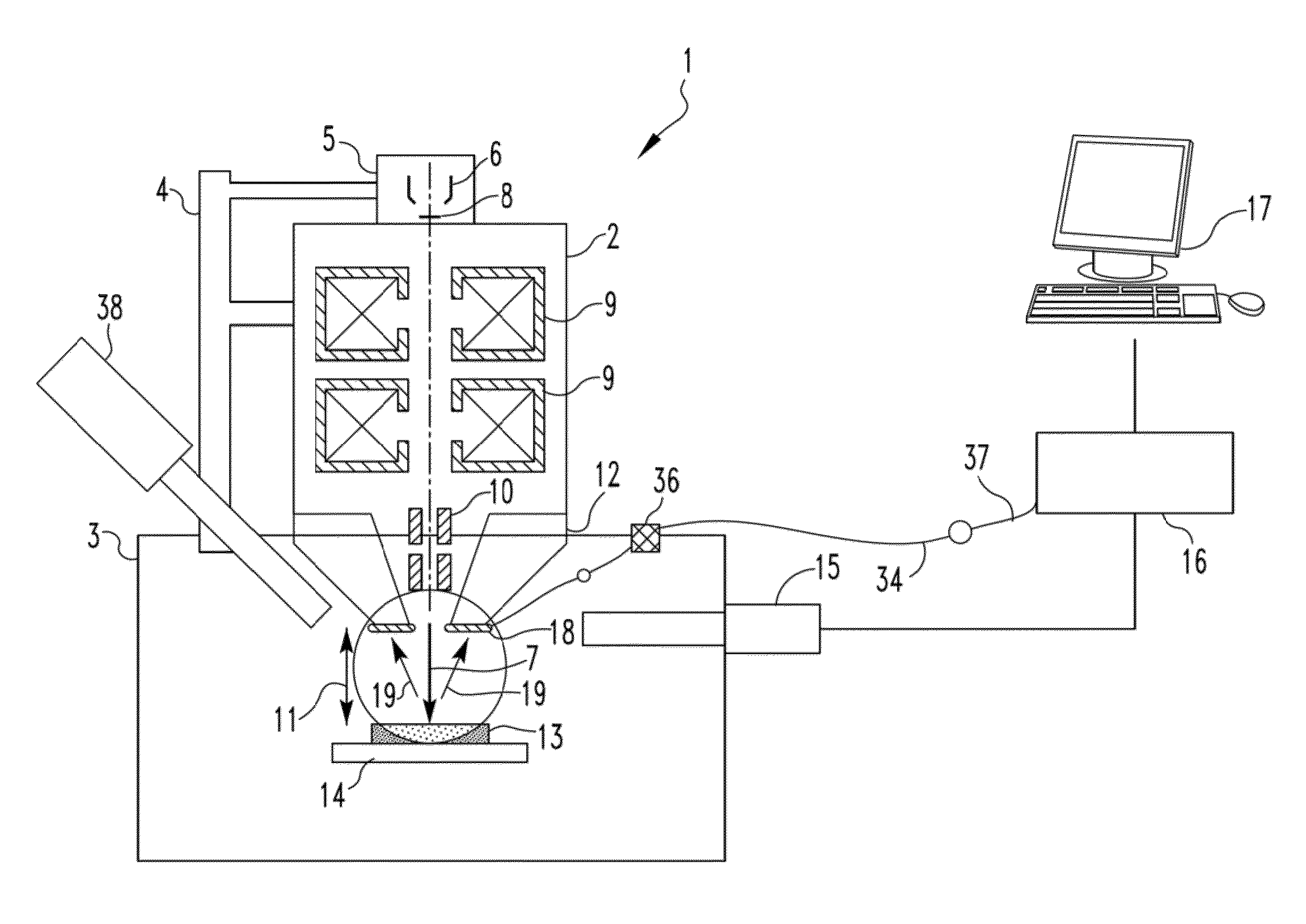

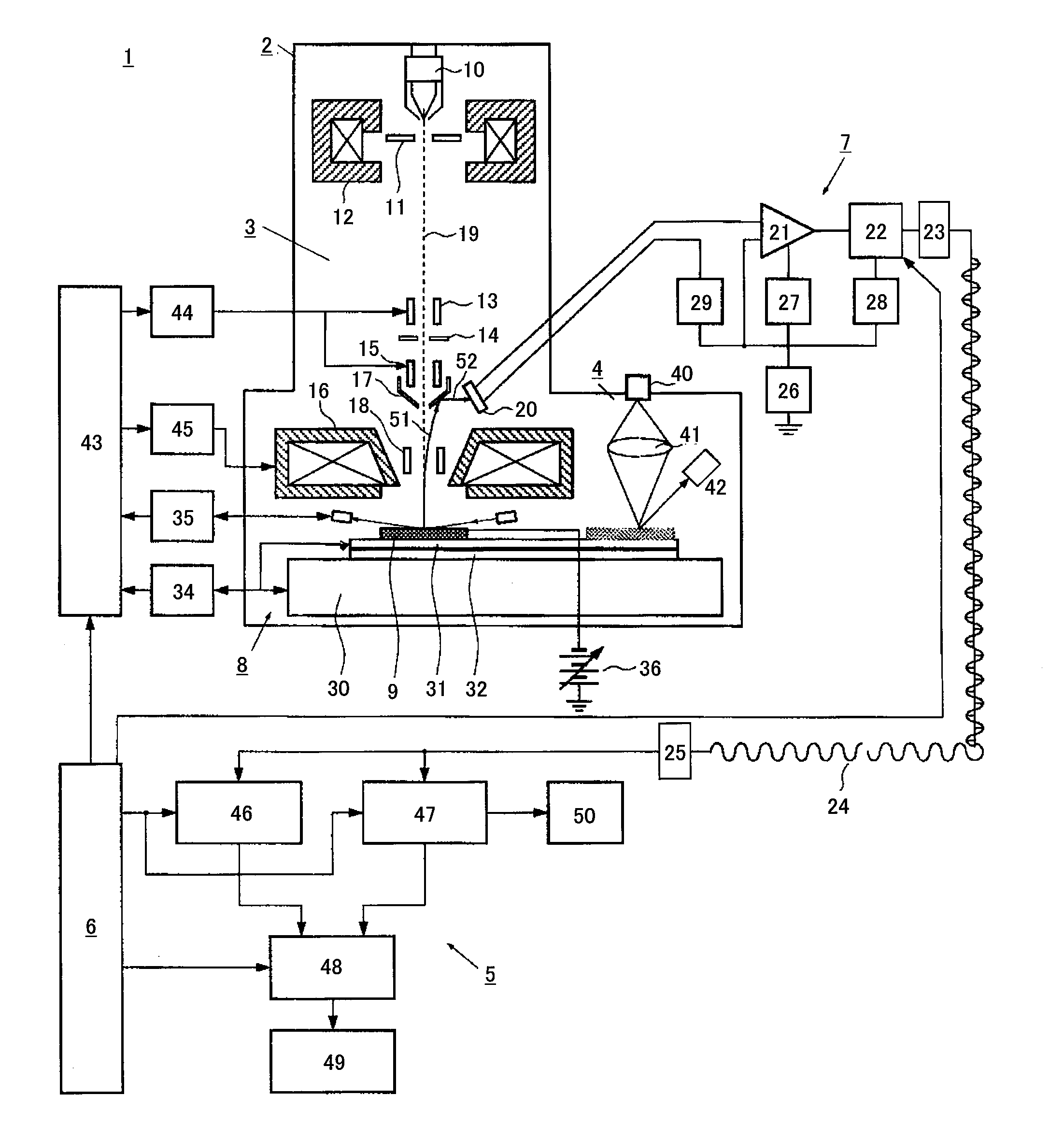

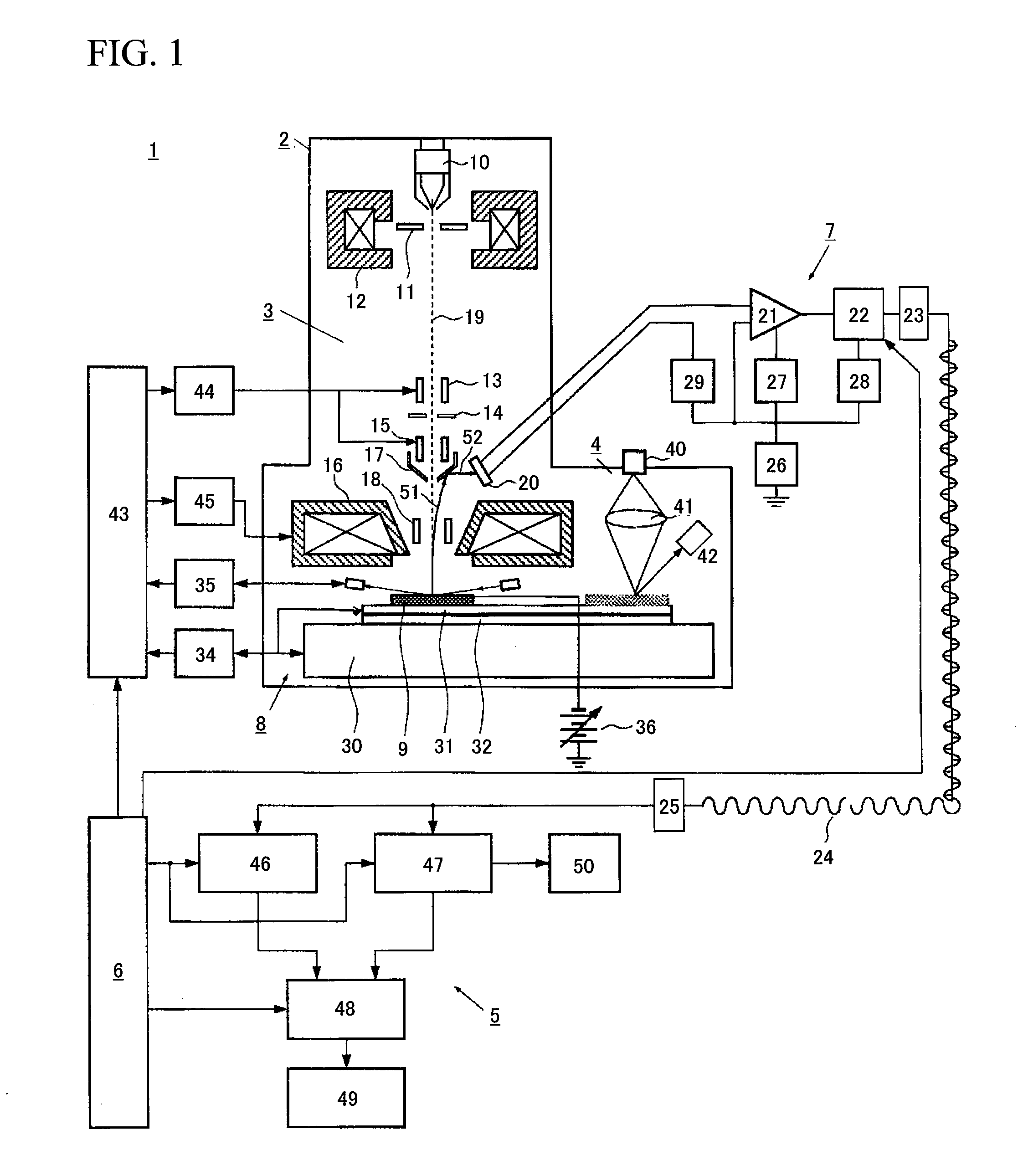

Semiconductor inspection system

InactiveUS7026615B2Efficiently decideEasy to set upMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementScanning electron microscopeDesign information

An operator-free and fully automated semiconductor inspection system with high throughput is realized. All conditions required for capturing and inspection are generated from design information such as CAD data. In order to perform actual inspection under the conditions, a semiconductor inspection system is composed of a navigation system for generating all the conditions required for capturing and inspection from the design information and a scanning electron microscope system for actually performing capturing and inspection. Moreover, in the case of performing a matching process between designed data and a SEM image, deformed parts are corrected by use of edge information in accordance with multiple directions and smoothing thereof. Furthermore, a SEM image corresponding to a detected position is re-registered as a template, and the matching process is thereby performed.

Owner:HITACHI LTD

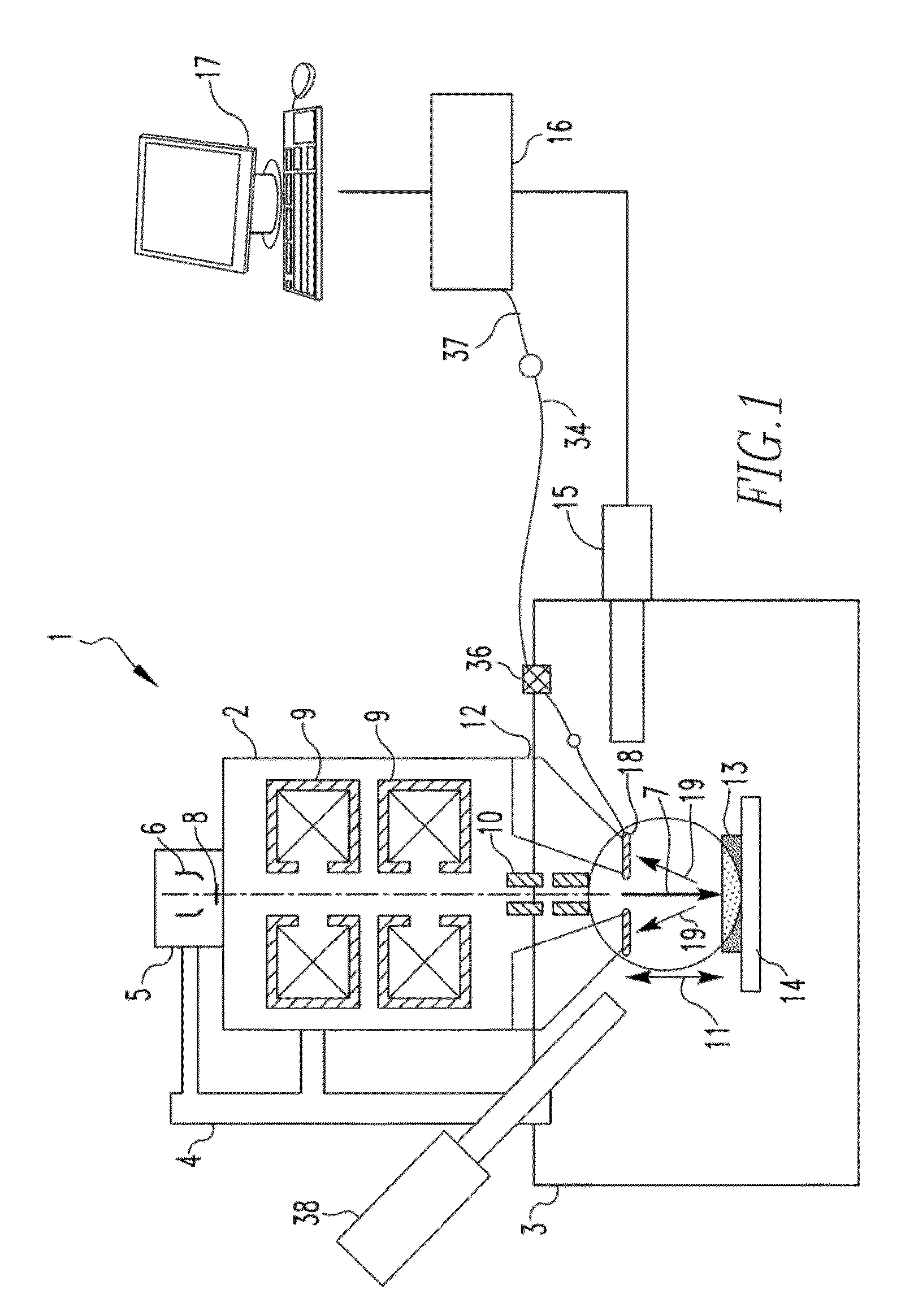

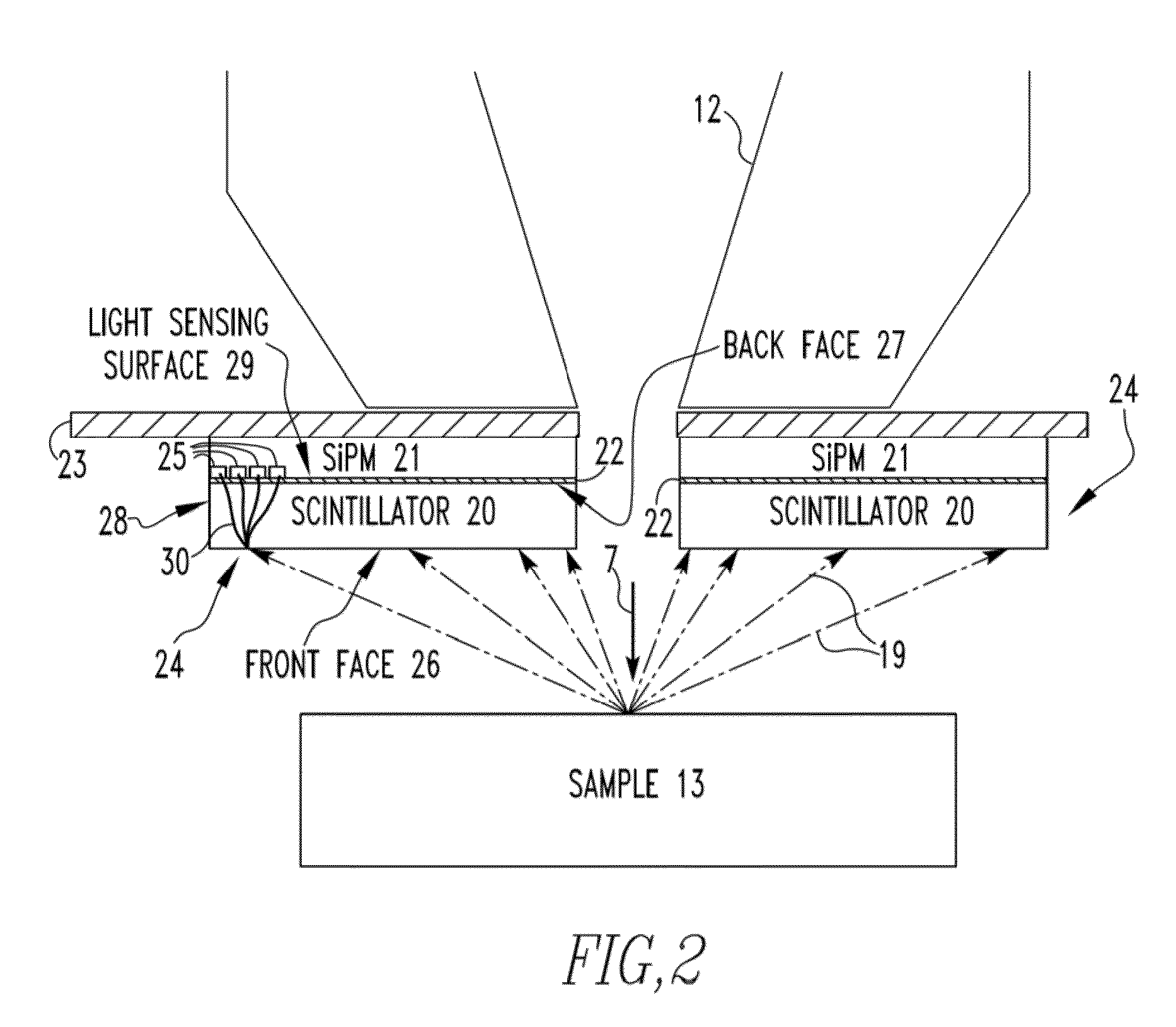

Electron detector including one or more intimately-coupled scintillator-photomultiplier combinations, and electron microscope employing same

ActiveUS20130032713A1Material analysis using wave/particle radiationElectric discharge tubesClose couplingLight sensing

An electron detector includes a plurality of assemblies, the plurality of assemblies including a first assembly having a first SiPM and a first scintillator made of a first scintillator material directly connected to an active light sensing surface of the first SiPM, and a second assembly having a second SiPM and a second scintillator made of a second scintillator material directly connected to an active light sensing surface of the second SiPM, wherein the first scintillator material and the second scintillator material are different than one another. Alternatively, an electron detector includes an assembly including an SiPM and a scintillator member having a front surface and a back surface, the scintillator member being a film of a scintillator material directly deposited on to an active light sensing surface of the SiPM.

Owner:FEI CO

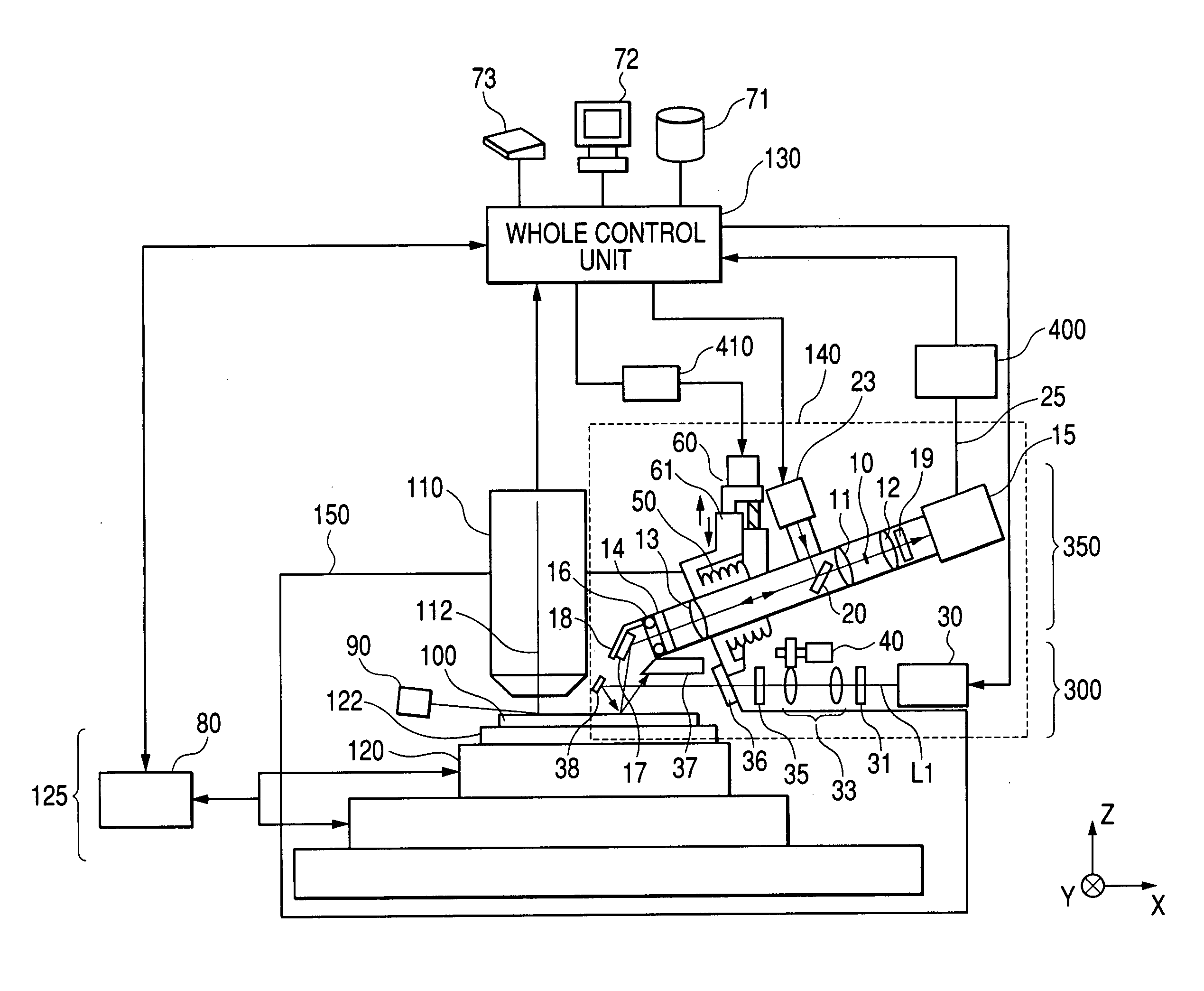

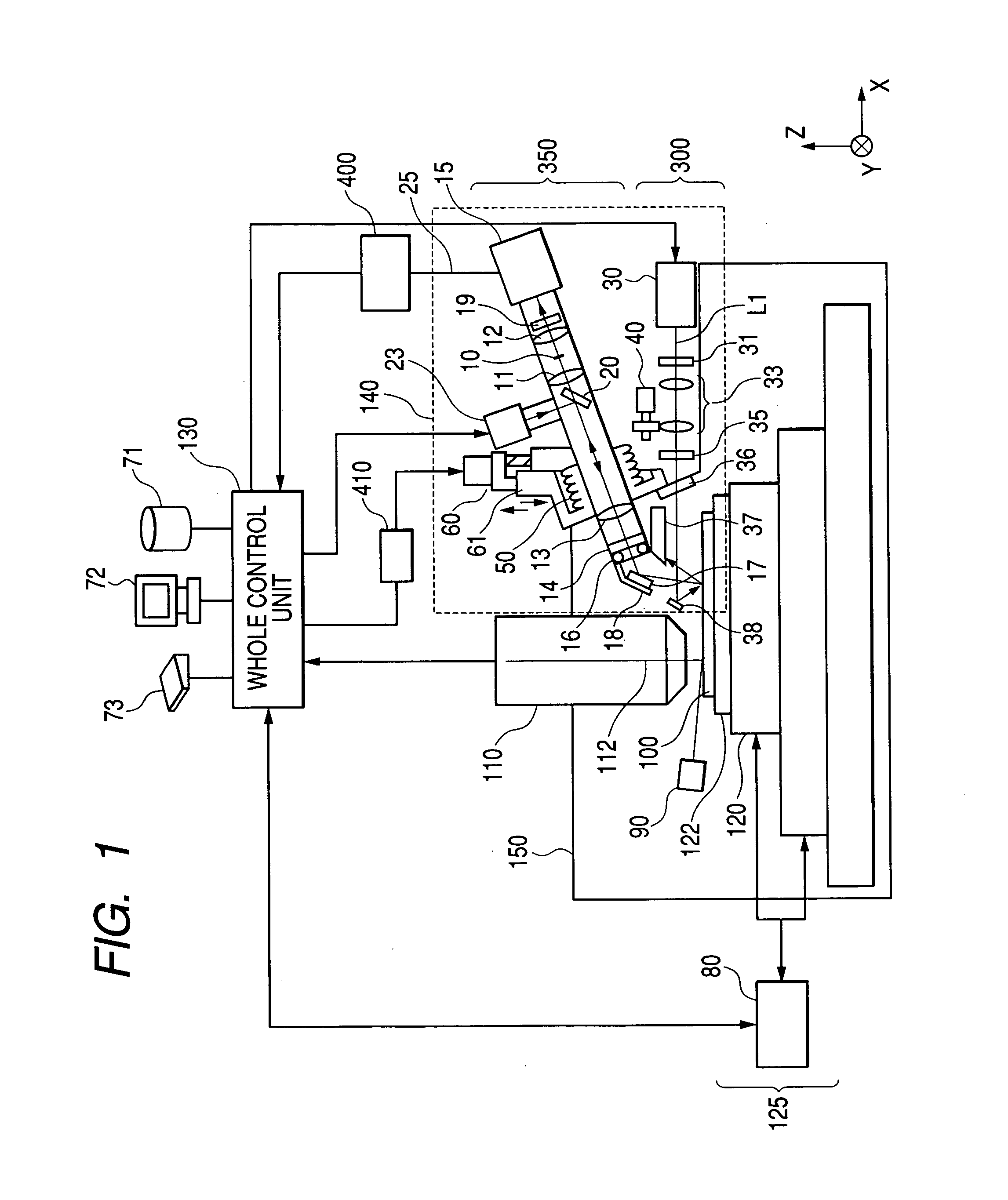

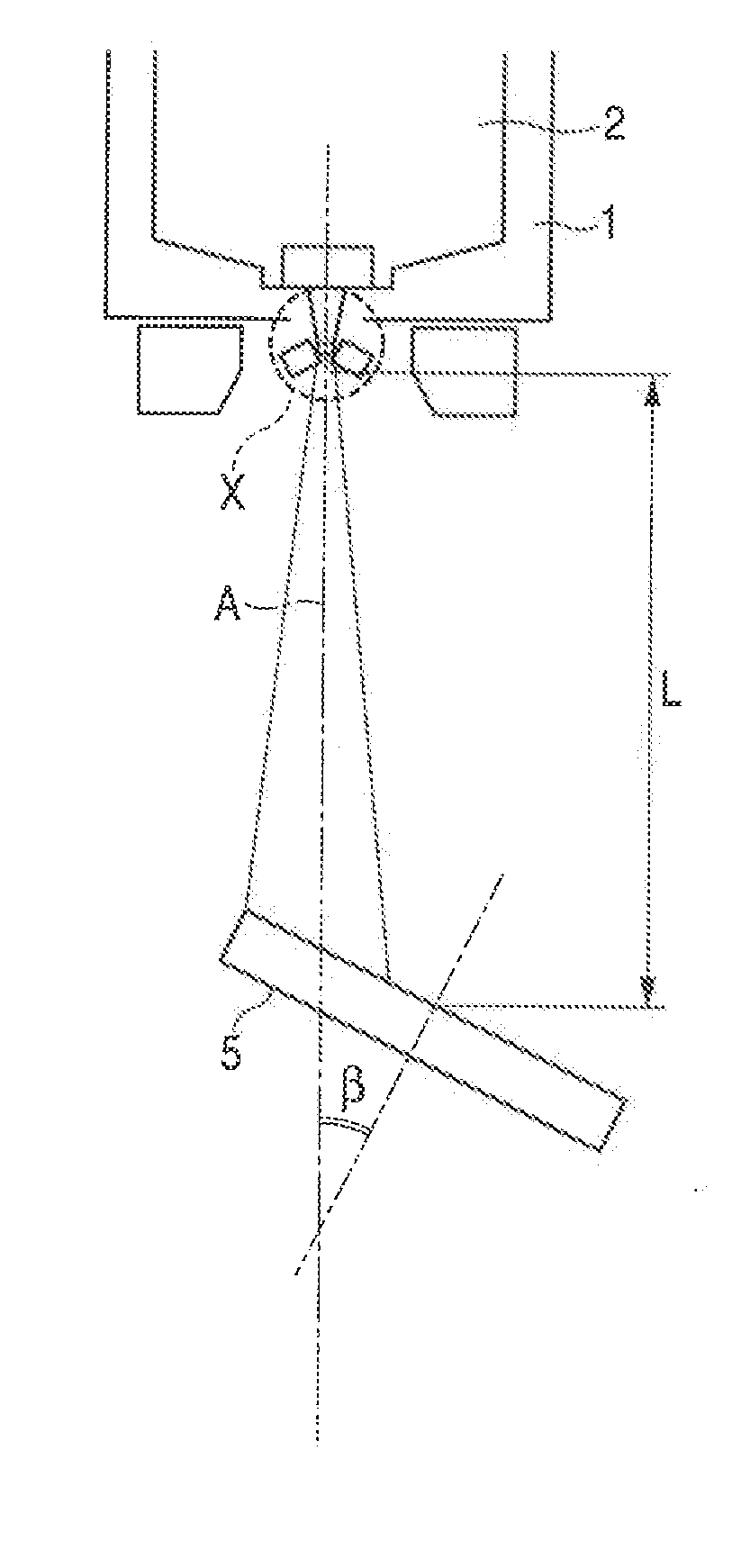

Method and apparatus for reviewing defects

InactiveUS20050122508A1Improve throughputReliably movedMaterial analysis using wave/particle radiationElectric discharge tubesForeign matterScanning electron microscope

The present invention provides an apparatus capable of, and a method for, inspecting at high speed and with high accuracy the super minute foreign particles and pattern defects occurring during device-manufacturing processes in which circuit patterns are to be formed on a sample such as a substrate of semiconductor devices and other elements: in the invention, the sample is illuminated in a dark field from multiple directions each of a different incident angle, the light scattered from the sample during the dark-field illumination is detected in each of the multiple directions, and the signals obtained by detecting the scattered light in each direction; thus, defects present on the surface of an optically transparent film of the sample, and defects present in or under the transparent film are discriminated from each other and both types of defects are discriminatively reviewed using a scanning electron microscope.

Owner:HITACHI HIGH-TECH CORP

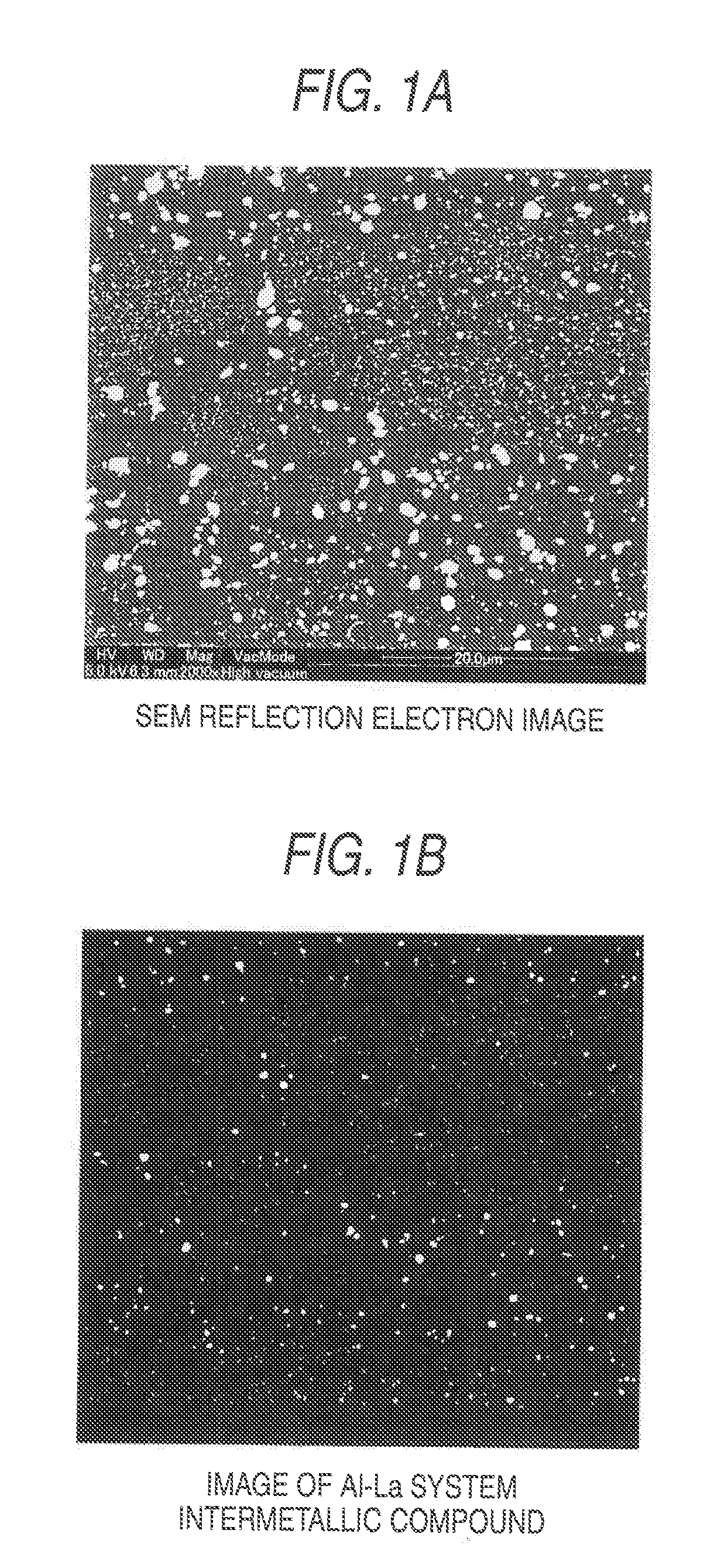

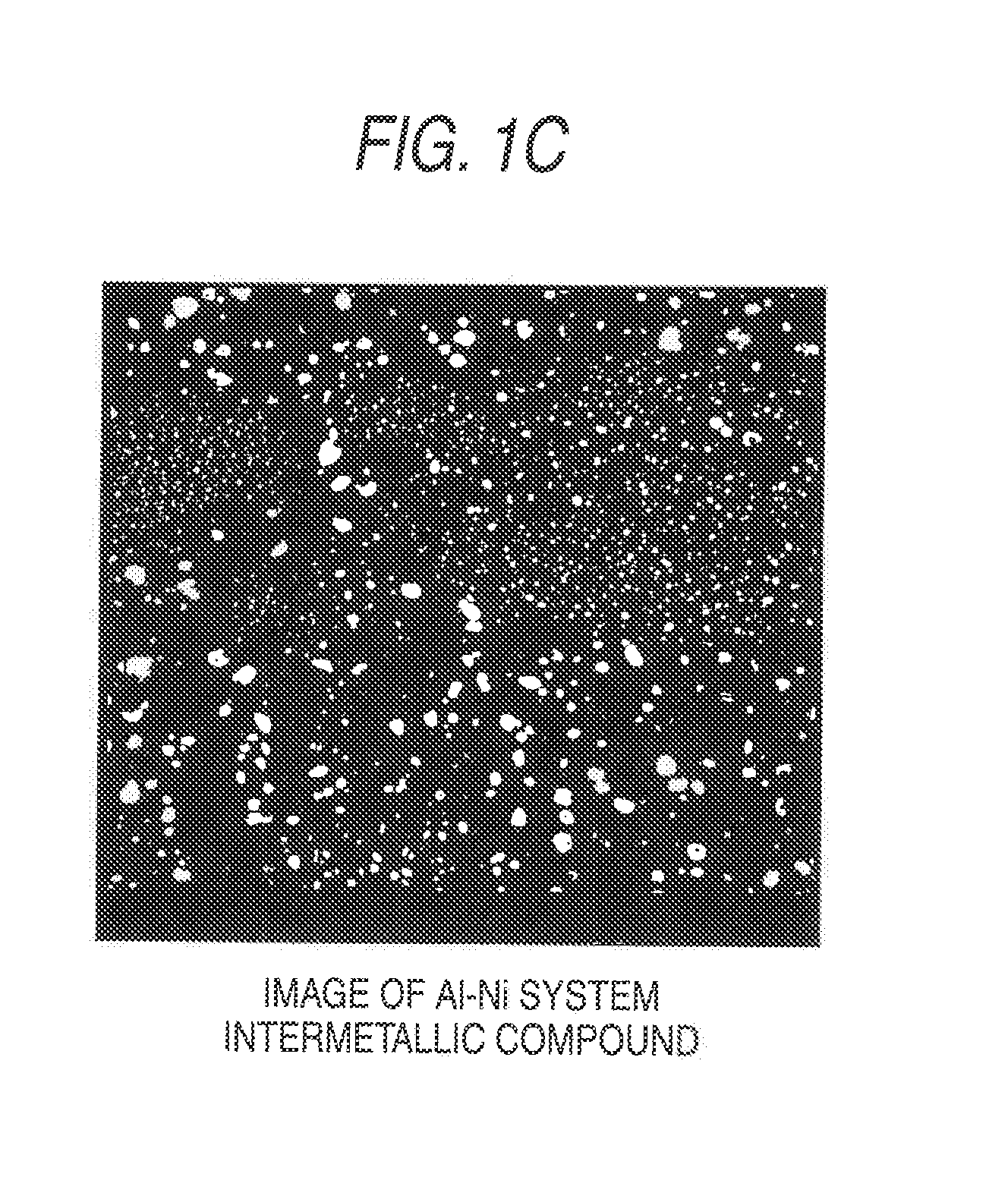

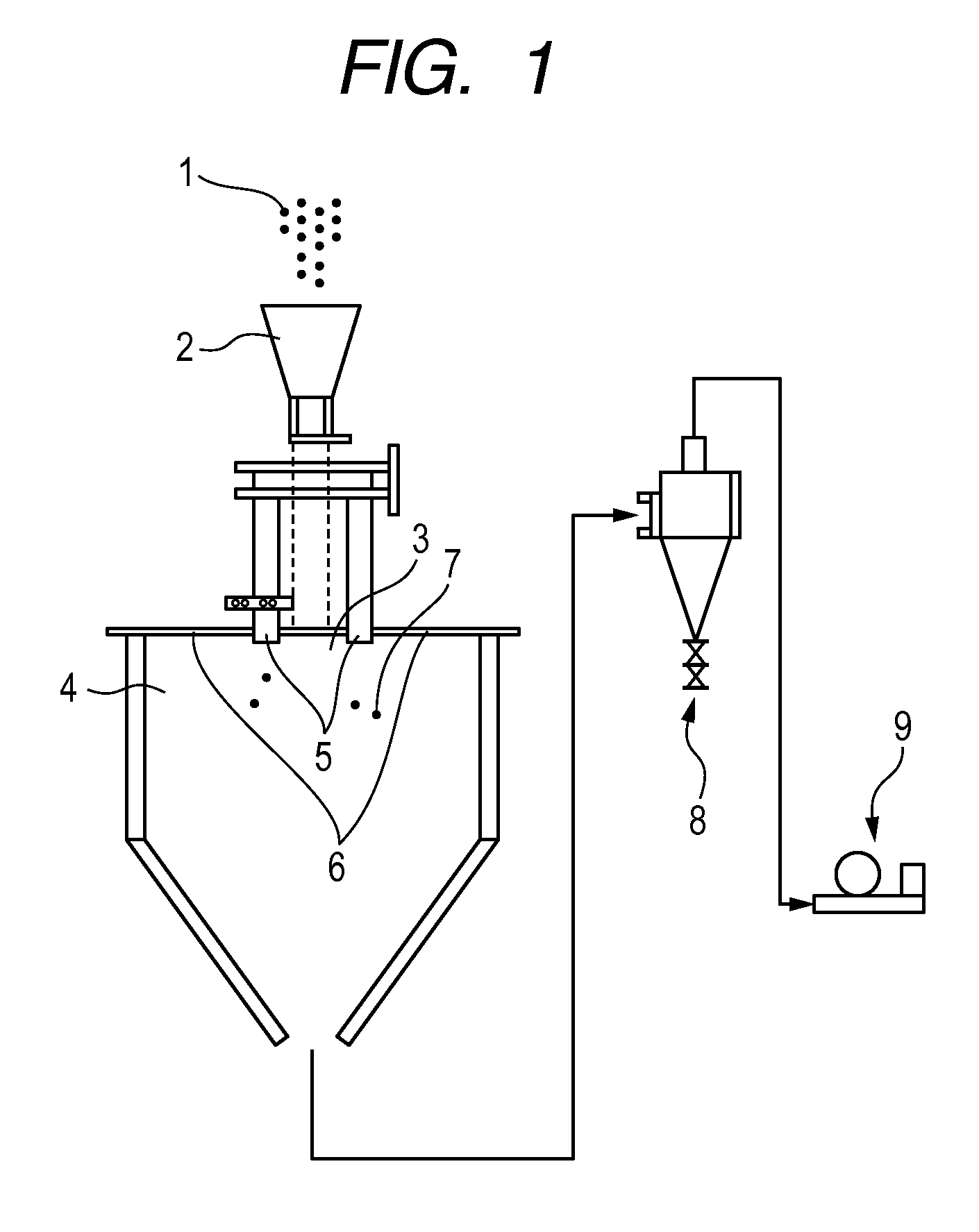

Ai-ni-la system ai-based alloy sputtering target and process for producing the same

ActiveUS20080121522A1Reduce splashCellsMolten spray coatingScanning electron microscopeMagnification

The invention relates to an Al—Ni—La system Al-based alloy sputtering target comprising Ni and La, wherein, when a section from (¼)t to (¾)t (t: thickness) in a cross section vertical to a plane of the sputtering target is observed with a scanning electron microscope at a magnification of 2000 times, (1) a total area of an Al—Ni system intermetallic compound having an average particle diameter of 0.3 μm to 3 μm with respect to a total area of the entire Al—Ni system intermetallic compound is 70% or more in terms of an area fraction, the Al—Ni system intermetallic compound being mainly composed of Al and Ni; and (2) a total area of an Al—La system intermetallic compound having an average particle diameter of 0.2 μm to 2 μm with respect to a total area of the entire Al—La system intermetallic compound is 70% or more in terms of an area fraction, the Al—La system intermetallic compound being mainly composed of Al and La.

Owner:KOBE STEEL LTD +1

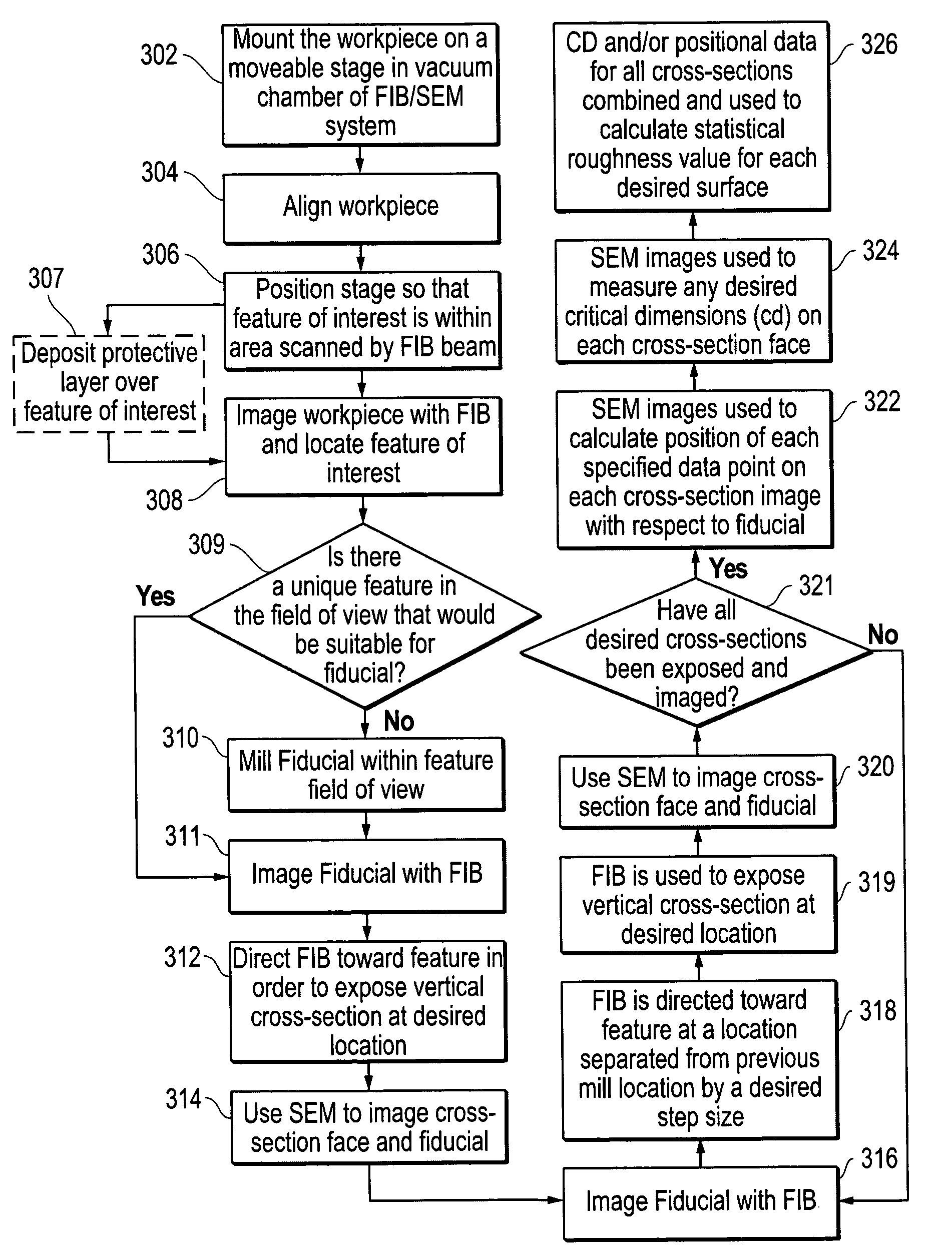

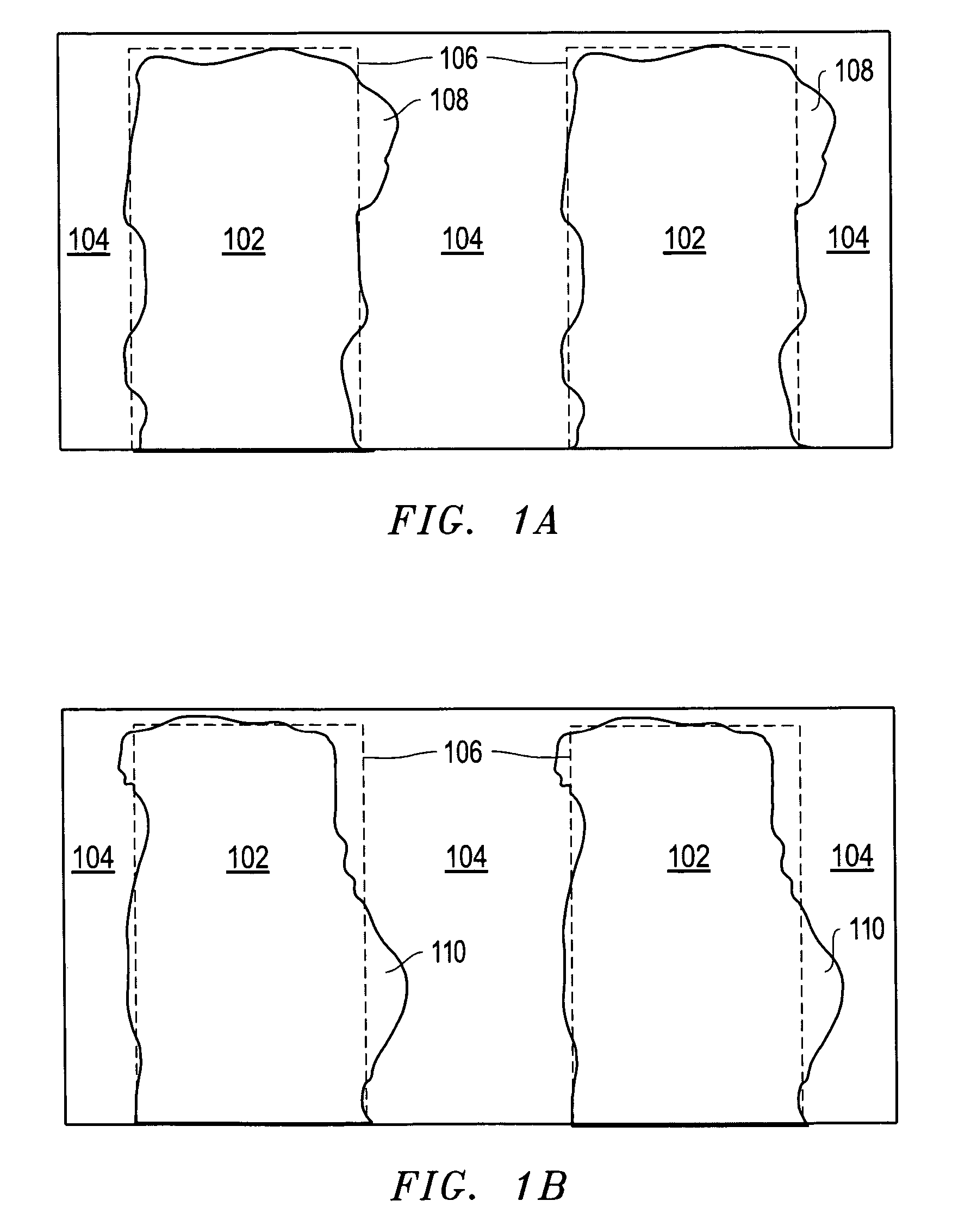

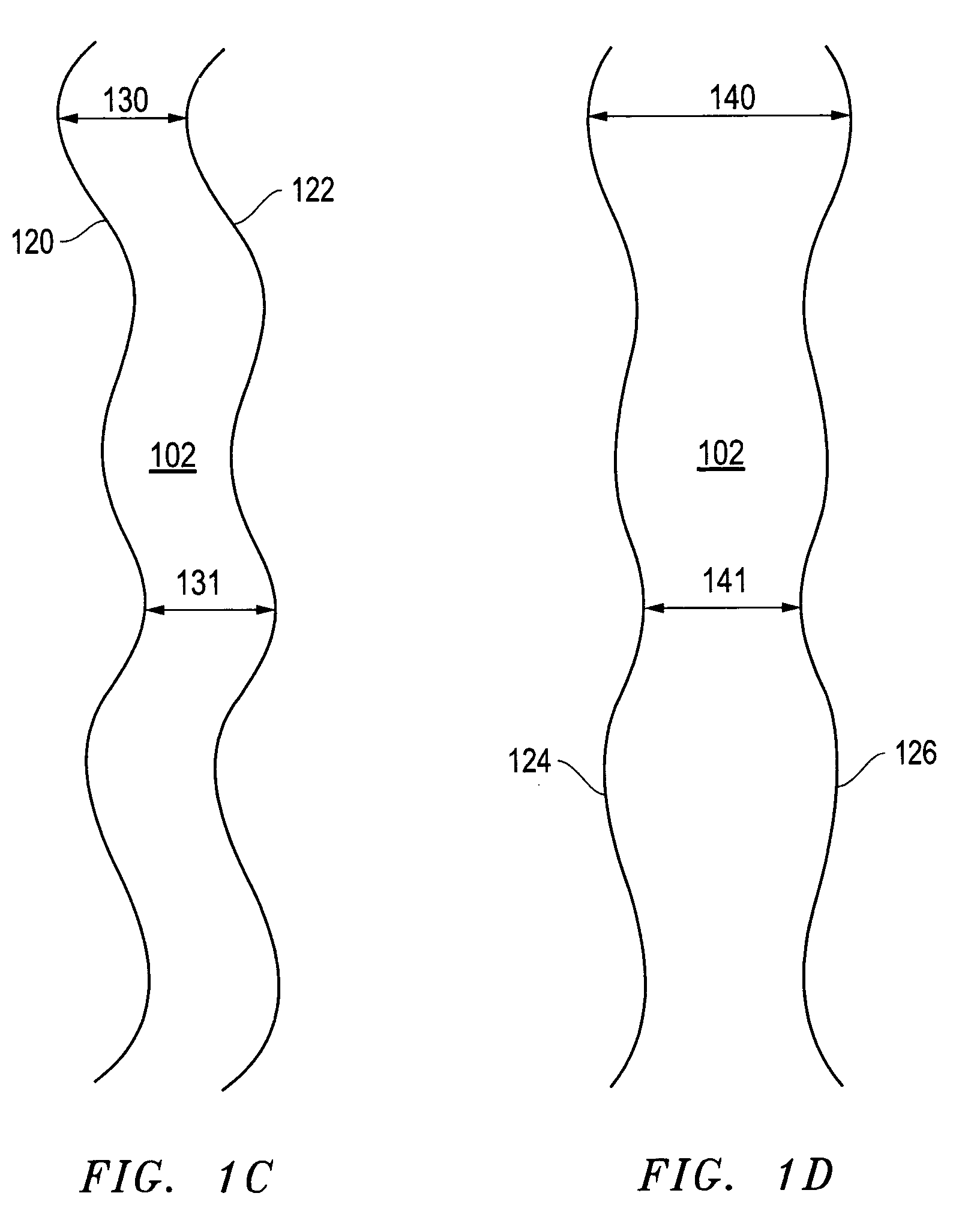

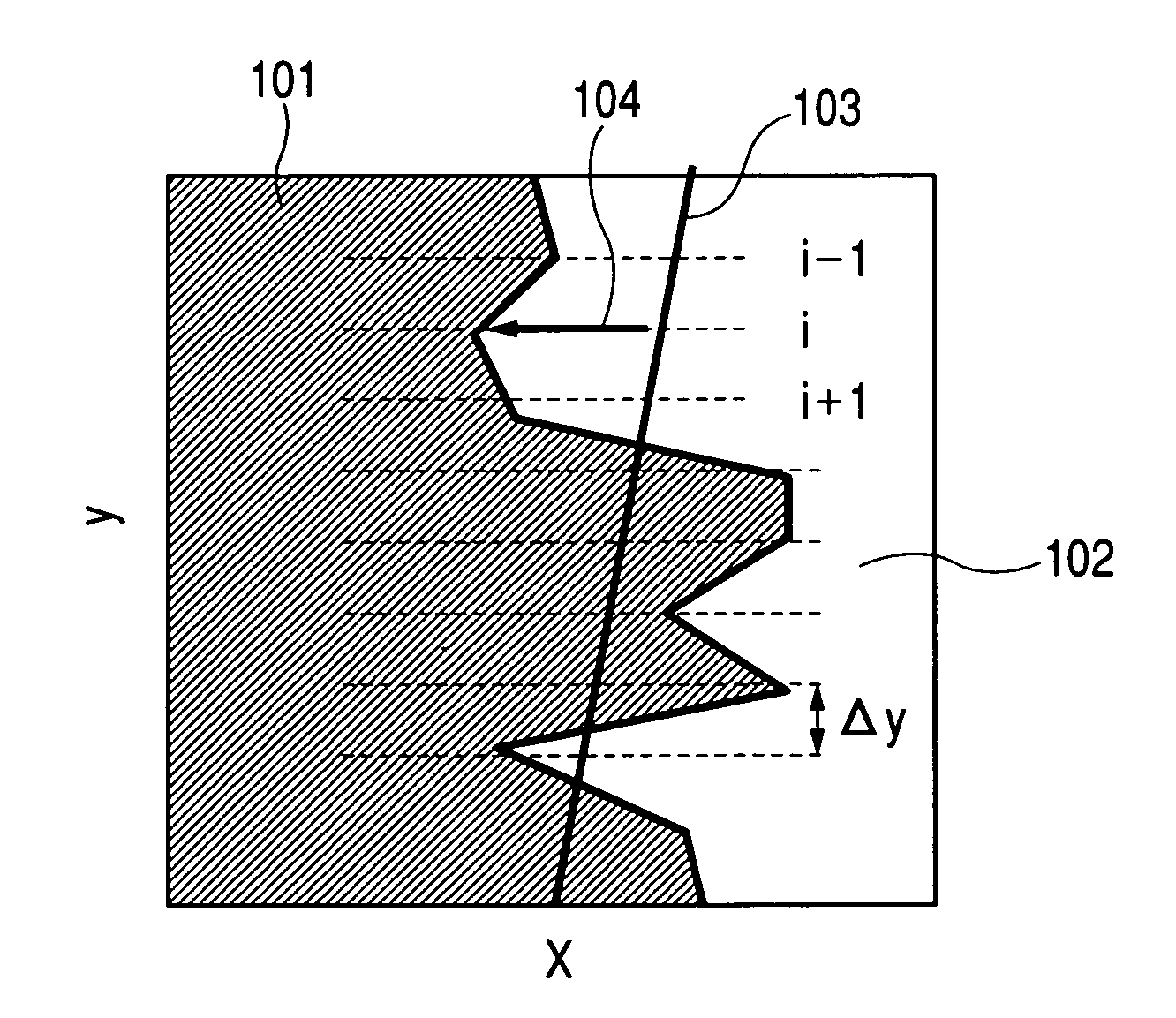

Method of measuring three-dimensional surface roughness of a structure

InactiveUS7348556B2Material analysis using wave/particle radiationElectric discharge tubesIon beamSurface roughness

An improved method of measuring the three-dimensional surface roughness of a structure. A focused ion beam is used to mill a succession of cross-sections or “slices” of the feature of interest at pre-selected intervals over a pre-selected measurement distance. As each cross-section is exposed, a scanning electron microscope is used to measure the relevant dimensions of the feature. Data from these successive “slices” is then used to determine the three-dimensional surface roughness for the feature.

Owner:FEI CO

Pattern inspection method

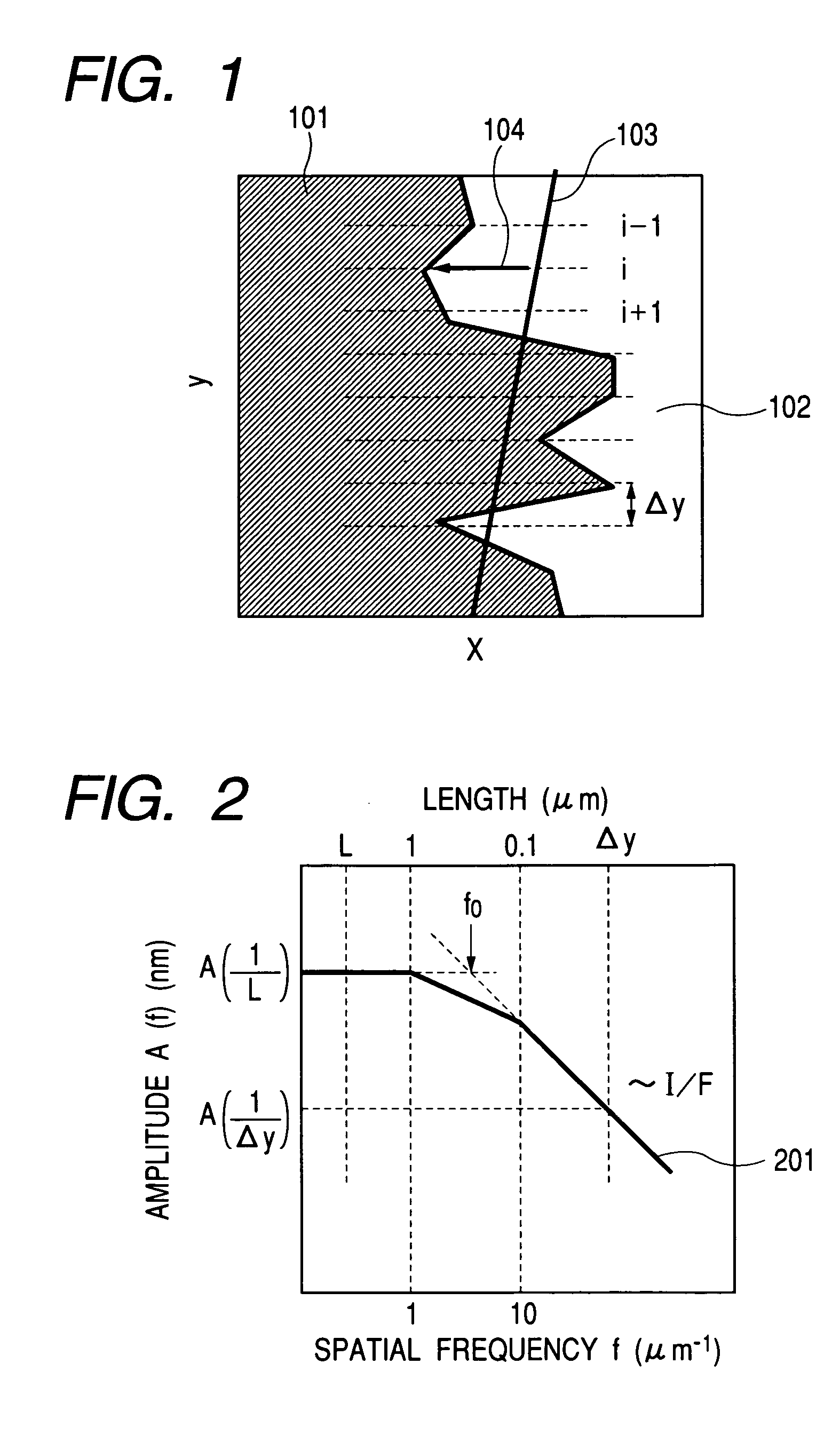

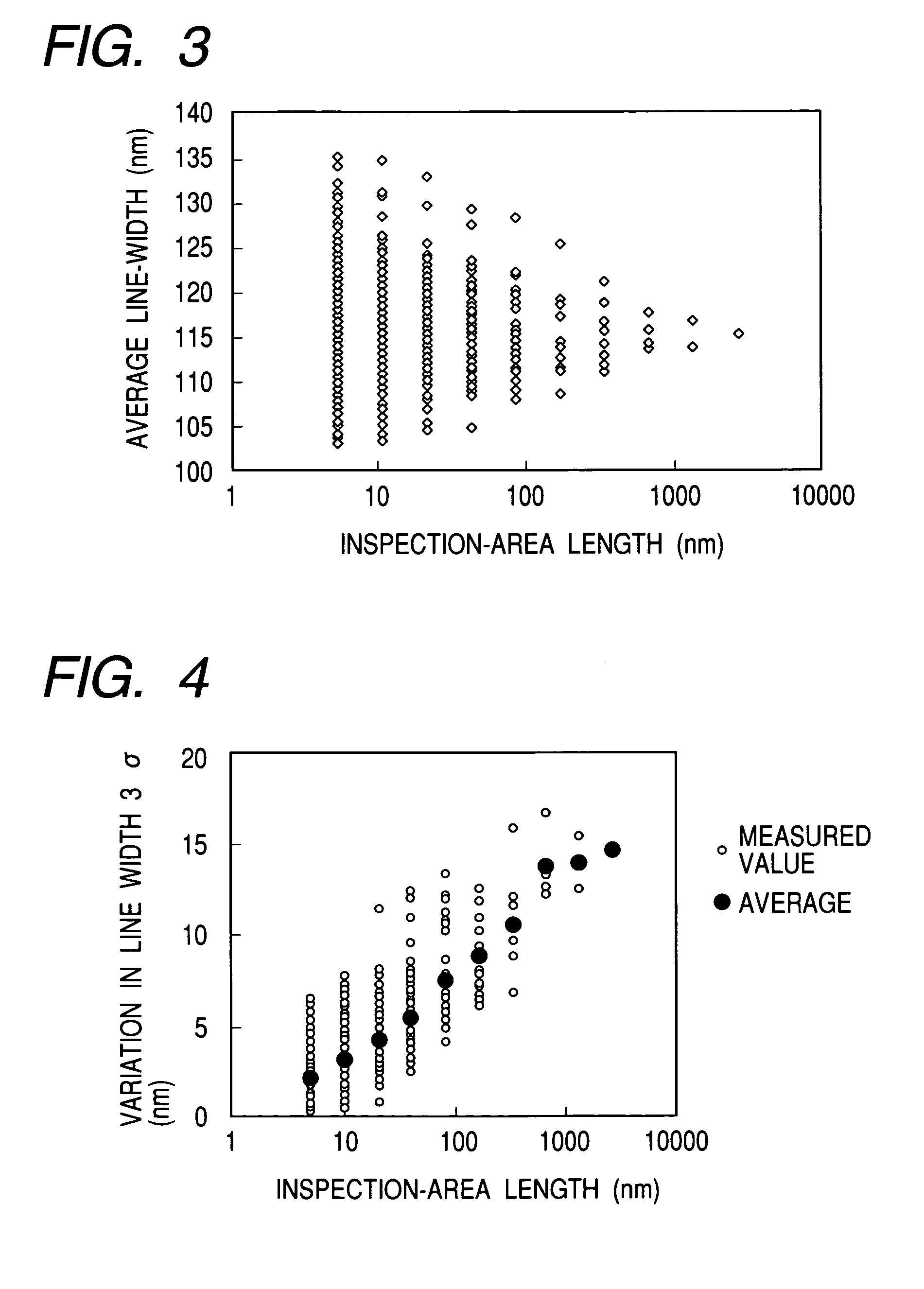

InactiveUS7049589B2Highly accurately estimateAccurately and quickly effectMaterial analysis using wave/particle radiationUsing wave/particle radiation meansSecondary electronsEngineering

The present invention may include a pattern inspection method of extracting a pattern edge shape from an image obtained by a scanning microscope and inspecting the pattern. A control section and a computer of the scanning microscope process the intensity distribution of reflected electrons or secondary electrons, find the distribution of gate lengths in a single gate from data about edge positions, estimate the transistor performance by assuming a finally fabricated transistor to be a parallel connection of a plurality of transistors having various gate lengths, and determine the pattern quality and grade based on an estimated result. In this manner, it is possible to highly, accurately and quickly estimate an effect of edge roughness on the device performance and highly accurately and efficiently inspect patterns in accordance with device specifications.

Owner:HITACHI LTD +1

Magnetic carrier and two-component developer

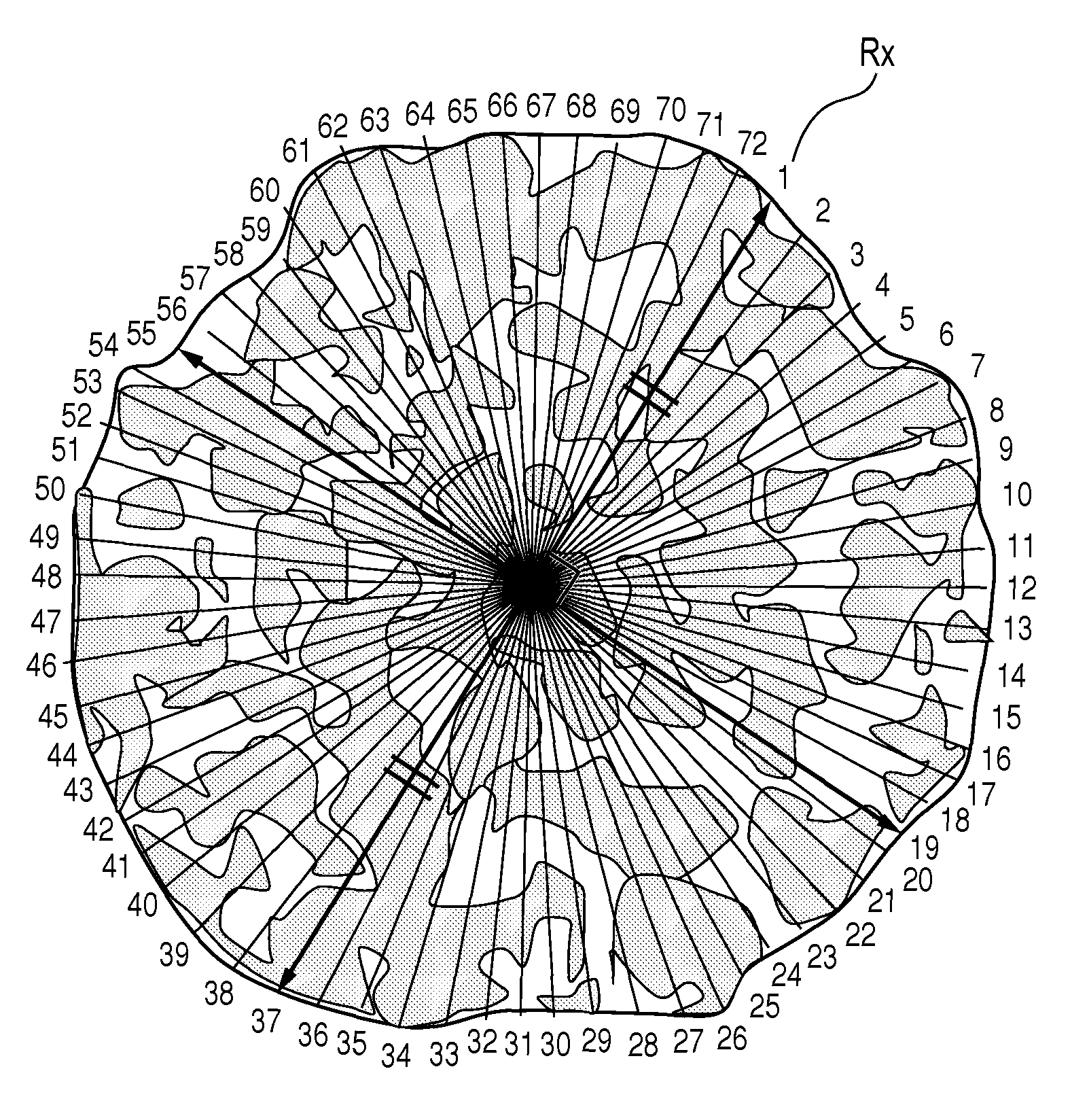

ActiveUS7939233B2Reduce variationDevelopersScanning tunneling microscopeScanning electron microscope

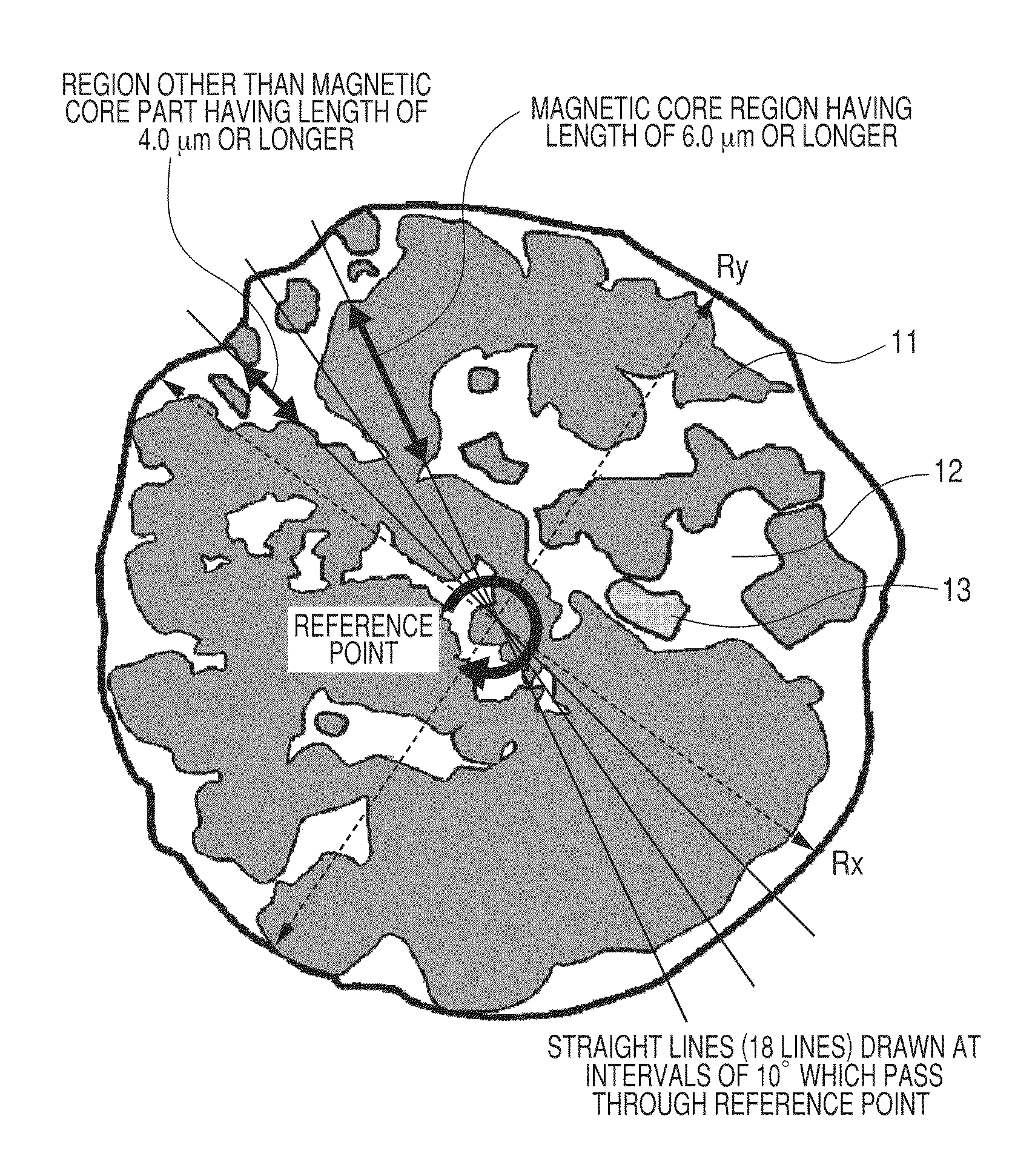

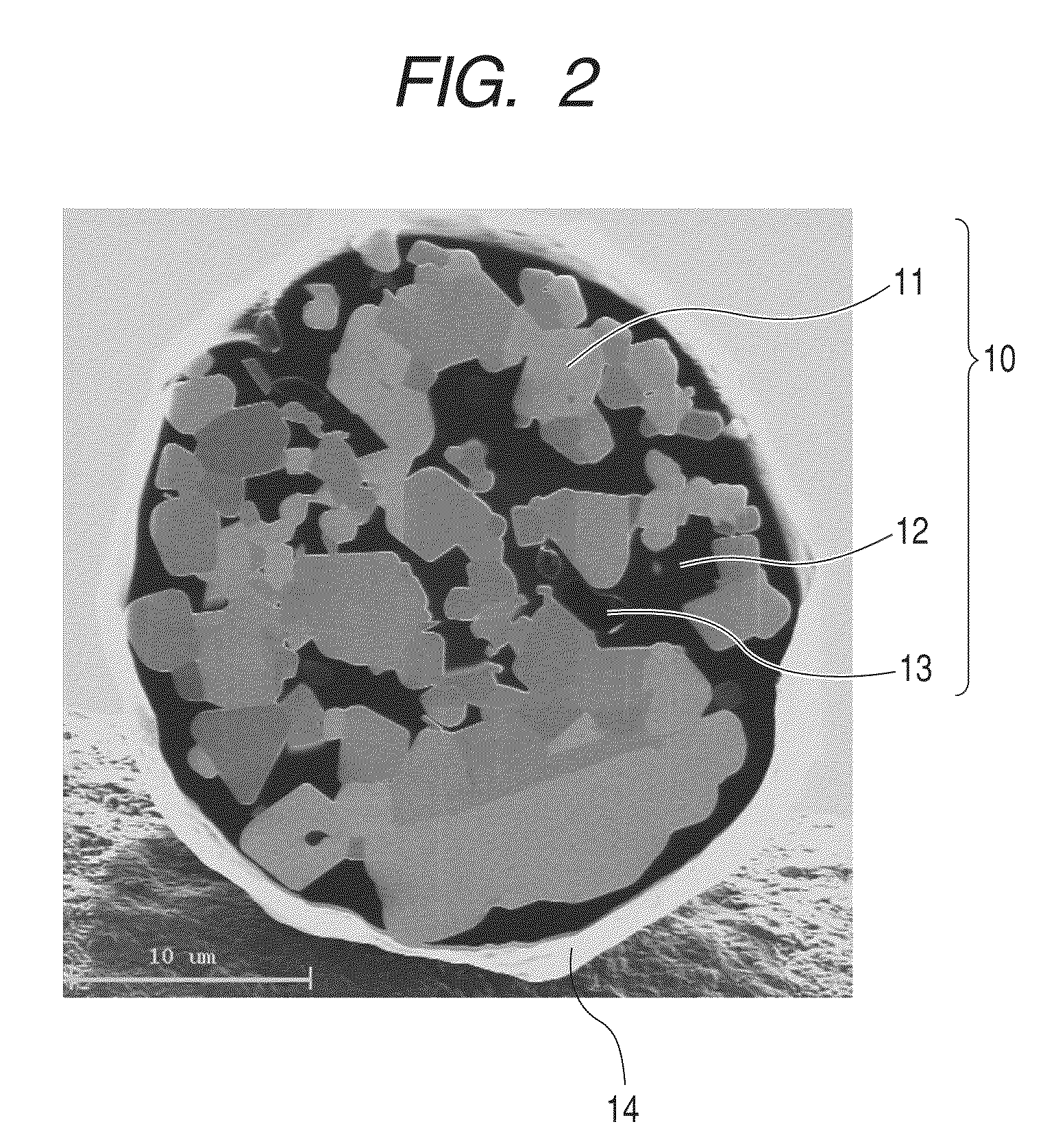

A magnetic carrier and a two-component developer are provided which have remedied blank areas, fog after leaving, carrier sticking during running, and image density variations before and after running. The magnetic carrier has magnetic carrier particles having at least porous magnetic core particles and a resin. The magnetic carrier particles satisfying the specific conditions (a), (b) and (c) where, in a reflected electron image of cross sections of the magnetic carrier particles as photographed with a scanning electron microscope, straight lines that divide a cross section of a magnetic carrier particle into 72 at intervals of 5° are drawn from a reference point of the cross section thereof toward the surface of the magnetic carrier particle; the magnetic carrier particles being contained in an amount of 60% by number or more.

Owner:CANON KK

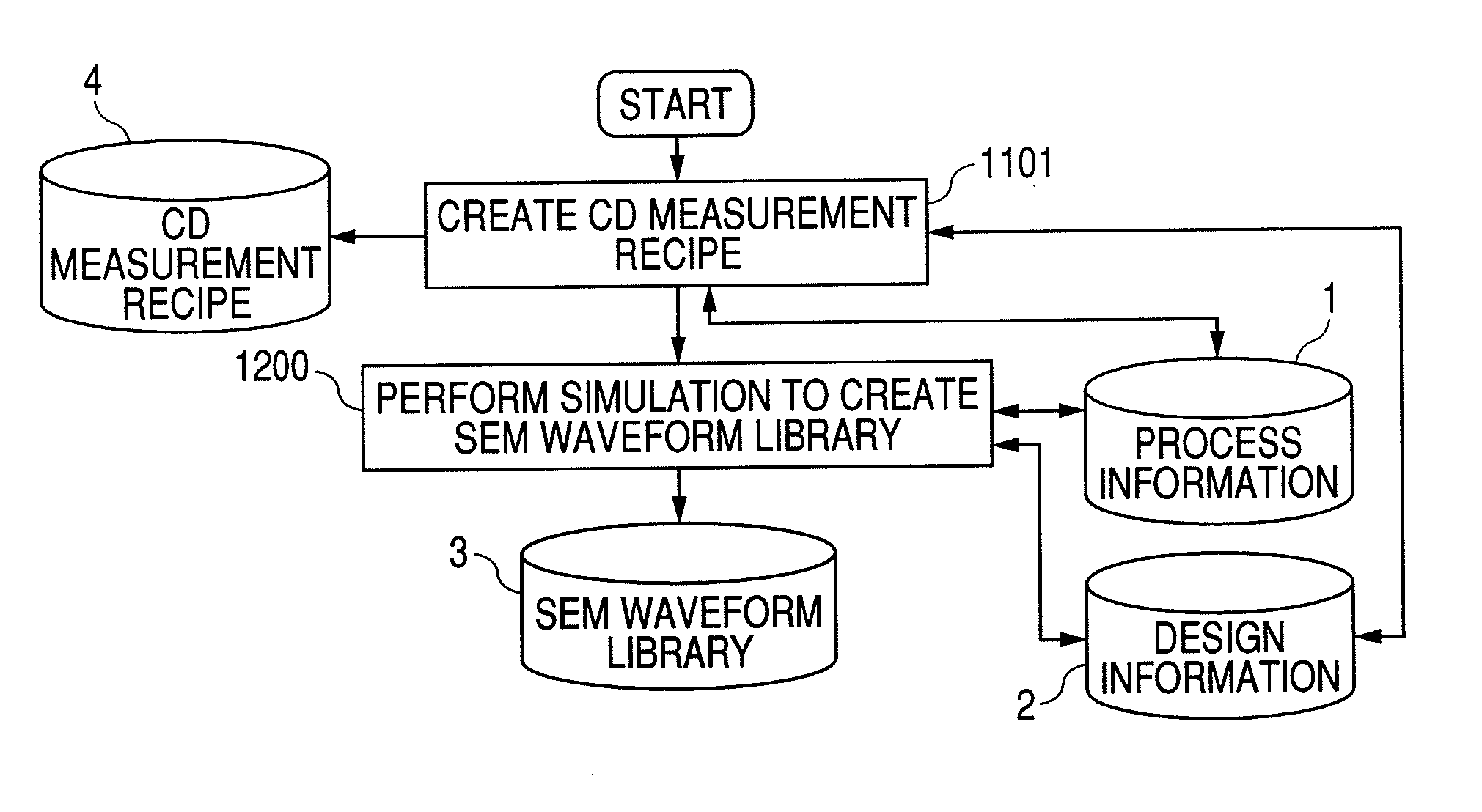

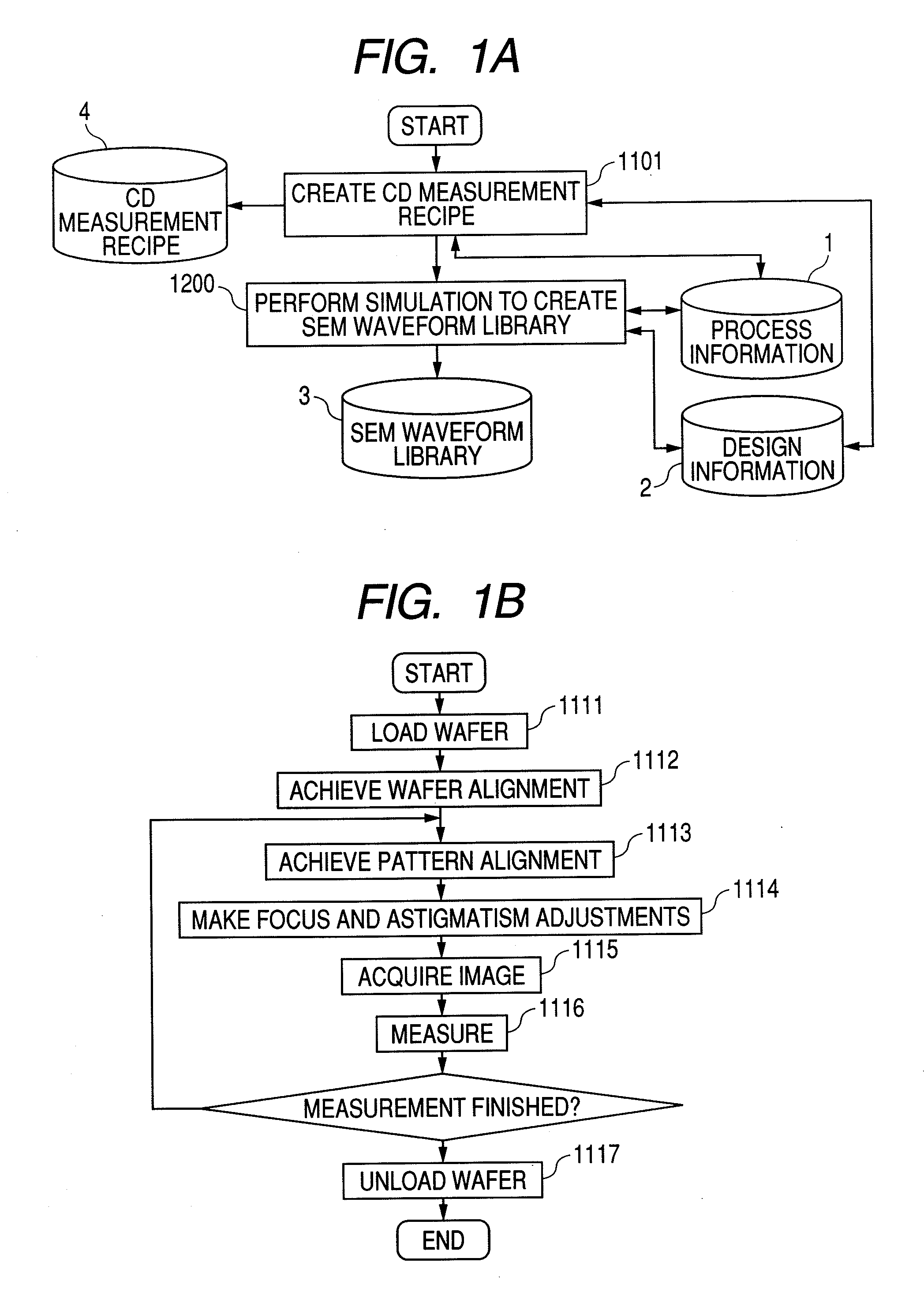

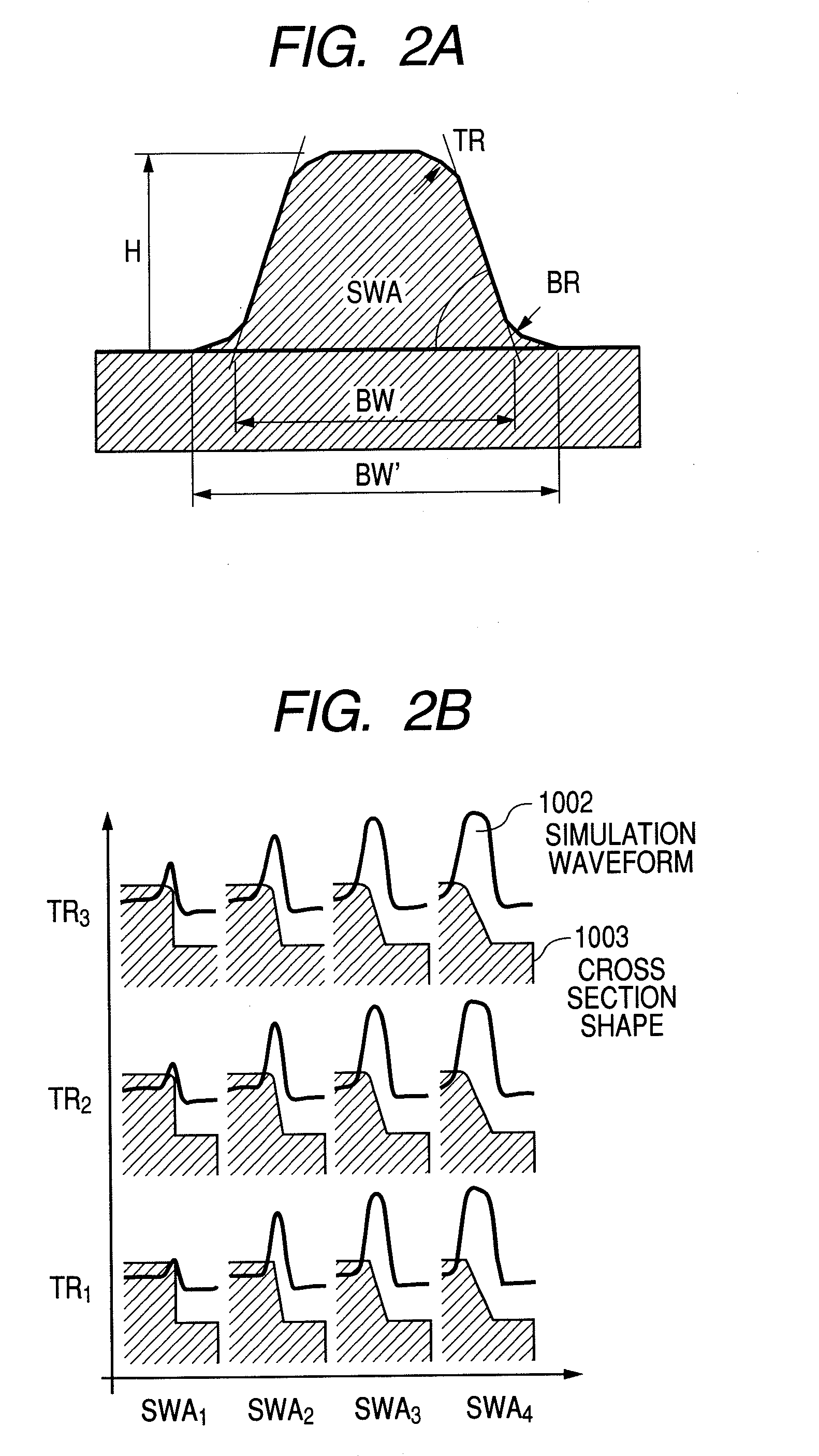

Method for measuring a pattern dimension using a scanning electron microscope

ActiveUS20070187595A1Reduce in quantityDegrading measuring repeatabilityMaterial analysis using wave/particle radiationElectric discharge tubesWave shapeElectron microscope

To provide a consistent, high-speed, high-precision measurement method based on an electron beam simulation by reflecting the apparatus characteristics of a CD-SEM in an electron beam simulation, the present invention discloses a method for measuring a measurement target pattern with a CD-SEM, the method comprising the steps of performing an electron beam simulation on various target pattern shapes, which is reflected apparatus characteristic and image acquisition conditions; creating SEM simulated waveforms; storing a combination of the created SEM simulated waveforms and pattern shape information corresponding to the created SEM simulated waveforms as a library; comparing an acquired actual electron microscope image with the SEM simulated waveforms; selecting the SEM simulated waveform that is most similar to the actual electron microscope image; and estimating the shape of the measurement target pattern from the pattern shape information corresponding to the selected SEM simulated waveform.

Owner:HITACHI HIGH-TECH CORP

Magnetic carrier and two component developer

ActiveUS7927775B2Quality improvementGood reproducibilityDevelopersScanning electron microscopeVolumetric Mass Density

Provided is a magnetic carrier giving a high quality image free of density variation without the occurrence of fogging or carrier adhesion and having excellent dot reproducibility even during long-term use. The magnetic carrier has magnetic carrier particles produced by filling pores of porous magnetic core particles with a resin. The magnetic carrier contains 80% by number or more of the magnetic carrier particles satisfying the specific conditions (a) and (b) when 18 straight lines passing through a reference point of a cross section of the magnetic carrier particle are drawn at intervals of 10° in a reflected electron image of the cross section of the magnetic carrier particle photographed by a scanning electron microscope.

Owner:CANON KK

Systems configured to reduce distortion of a resist during a metrology process and systems and methods for reducing alteration of a specimen during analysis

ActiveUS7304302B1Distortion of resistReduce moistureThermometer detailsMaterial analysis using wave/particle radiationResistMetrology

Owner:KLA TENCOR TECH CORP

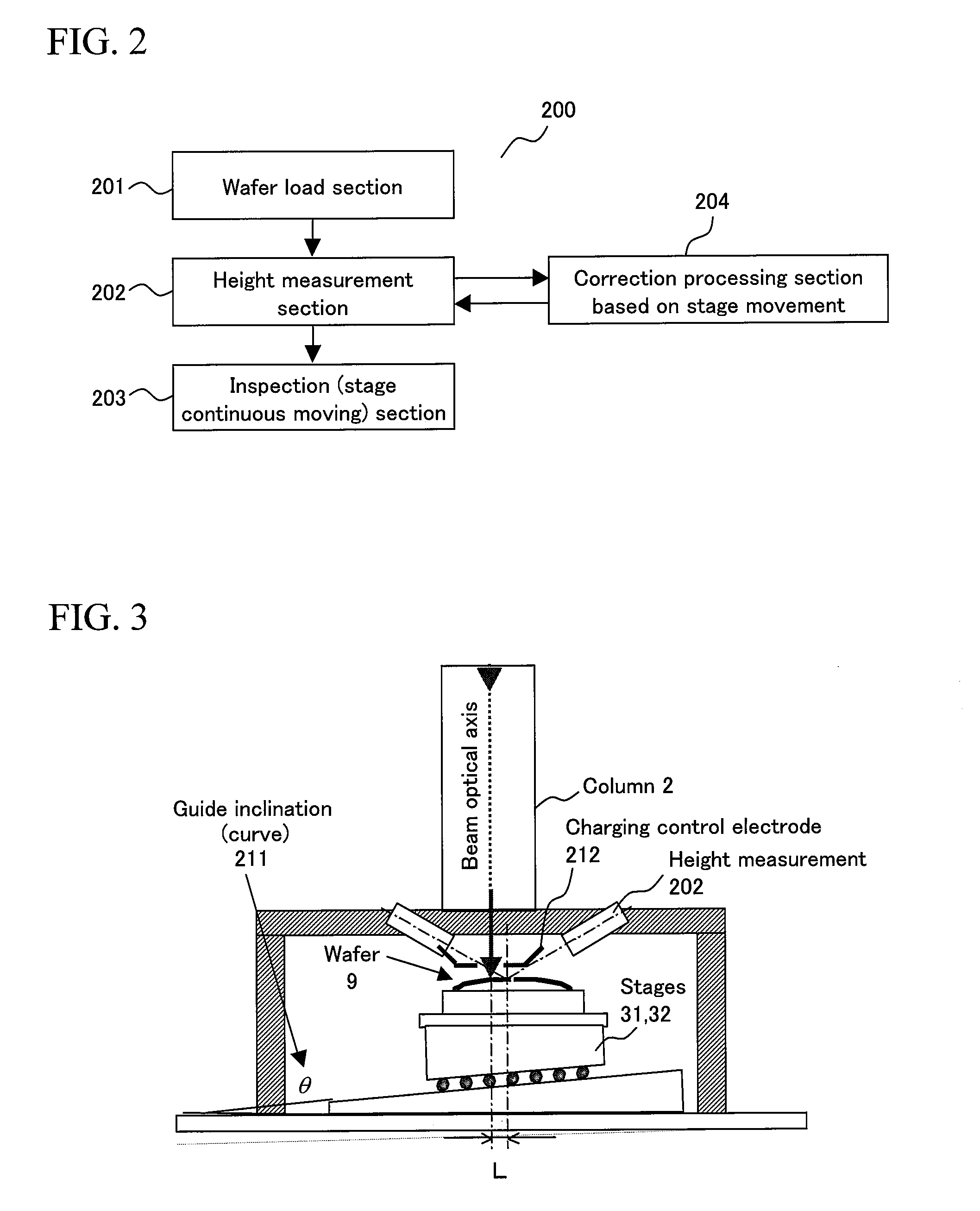

Apparatus for inspecting a substrate, a method of inspecting a substrate, a scanning electron microscope, and a method of producing an image using a scanning electron microscope

InactiveUS20090309022A1Excellent substrate inspectionSensitive defect detecting capabilityStability-of-path spectrometersMaterial analysis using wave/particle radiationScanning tunneling microscopeScanning electron microscope

An object of the present invention provides an inspection apparatus and an inspection method which use an electron beam image to accurately detect a defect that is difficult to detect in an optical image, the apparatus and method also enabling prevention of a possible decrease in focus accuracy of an inspection image which affect the defect detection. To accomplish the object, the present invention includes a height measurement section which measures height of the electron beam irradiation position on the substrate after the substrate is loaded onto a movable stage, a height correction processing section which corrects the measured height, and a control section which adjusts a focus of the electron beam according to the height corrected by the height correction processing section, wherein a stage position set when the height measurement section measures the height differs from a stage position set when the substrate is irradiated with the electron beam, and the height correction processing section corrects a possible deviation in height resulting from movement from the stage position for the height measurement to the stage position for the electron beam irradiation.

Owner:HITACHI HIGH-TECH CORP

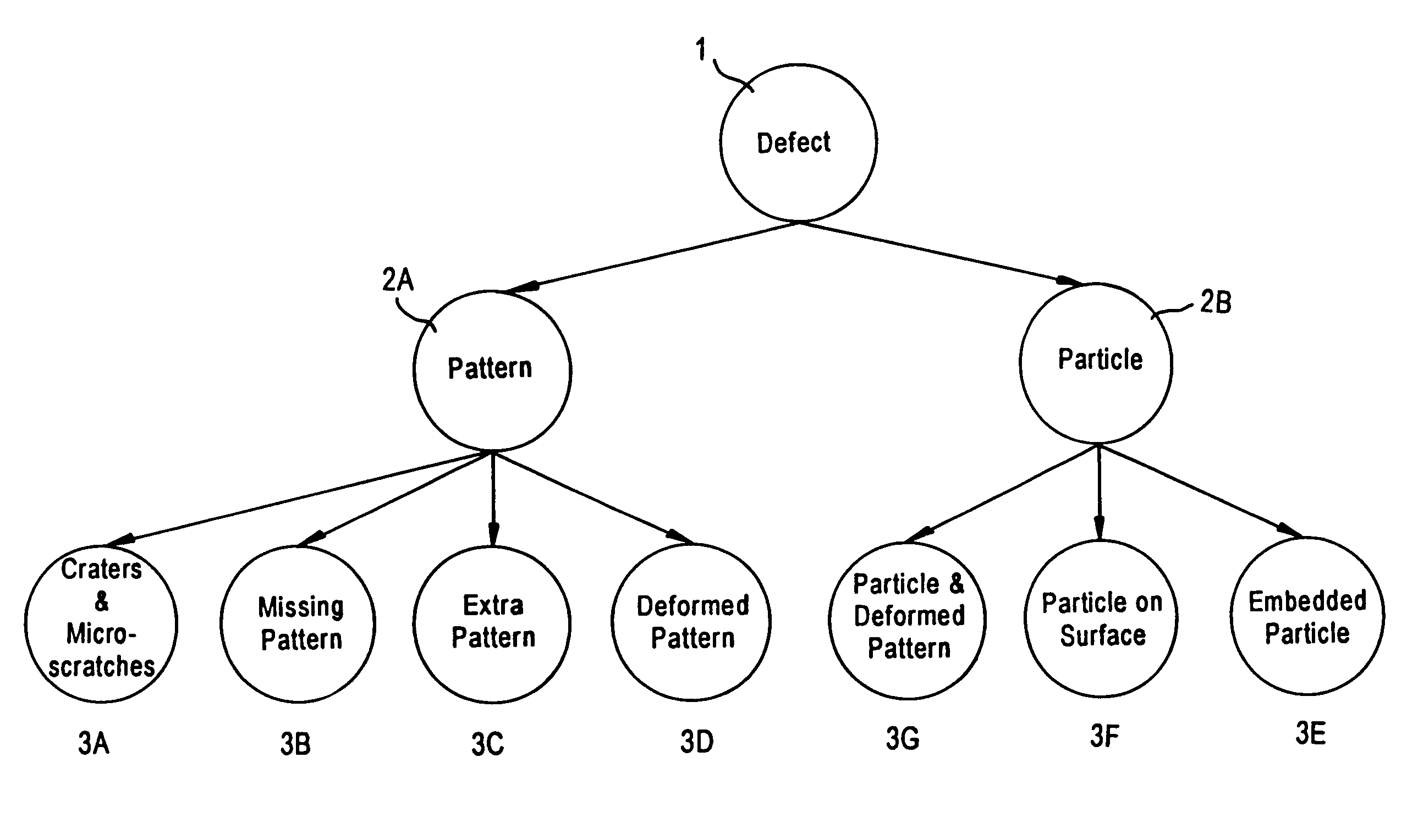

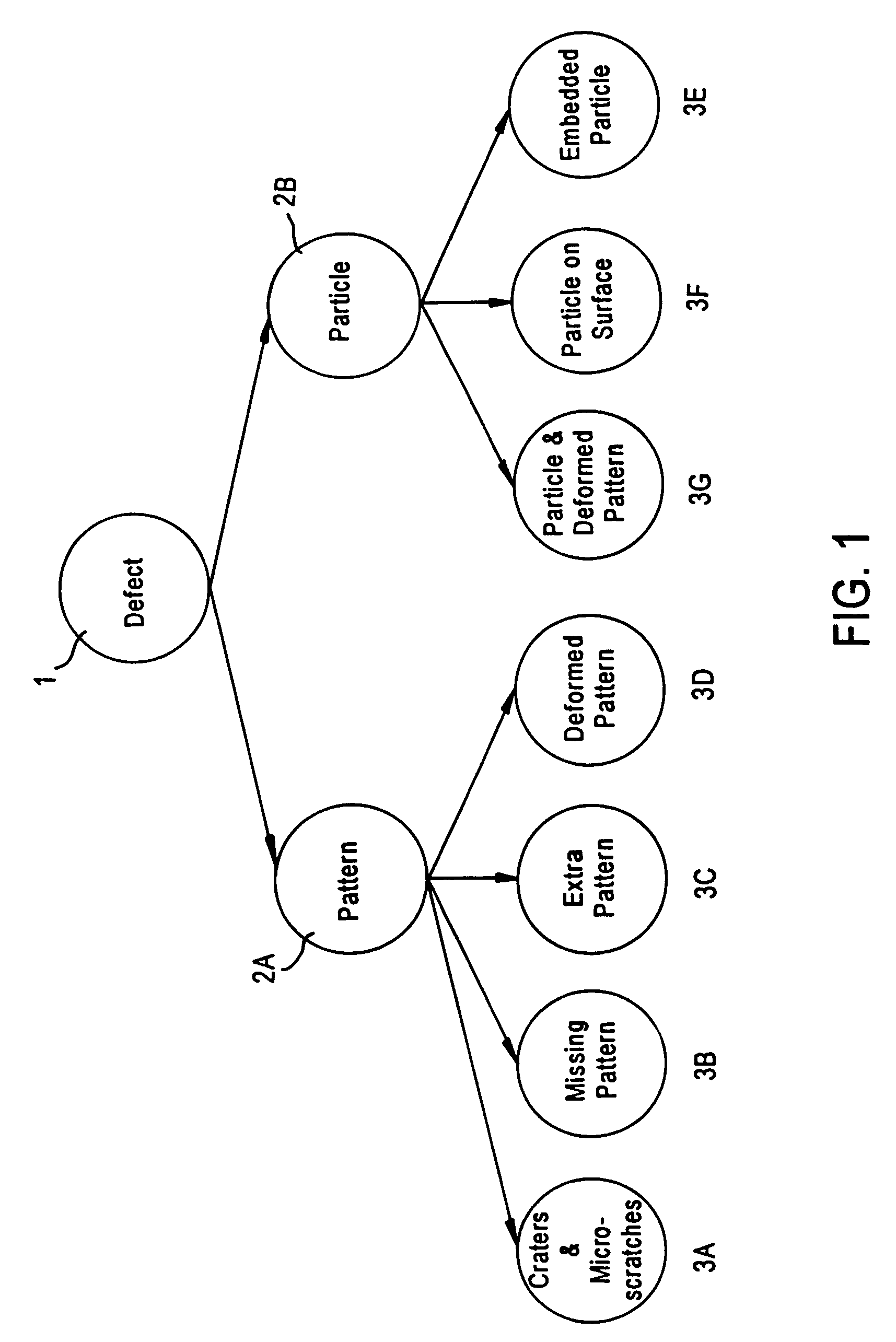

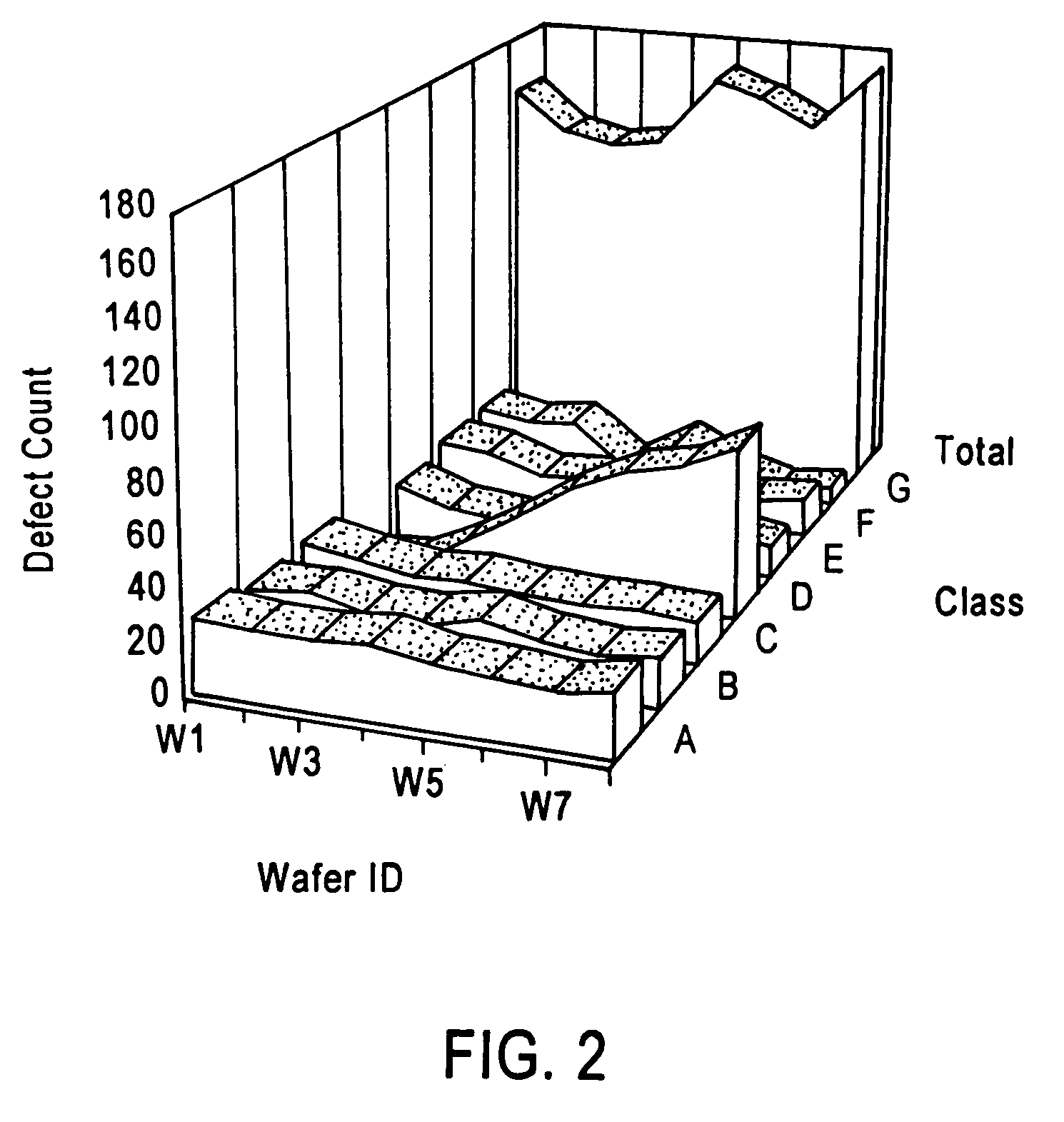

Automatic defect classification with invariant core classes

InactiveUS6987873B1Automatic and fast and reliable classificationSemiconductor/solid-state device testing/measurementSolid-state devicesReference imageScanning electron microscope

A method and apparatus is provided for automatically classifying a defect on the surface of a semiconductor wafer into one of, e.g., seven core classes: a missing pattern on the surface, an extra pattern on the surface, a deformed pattern on the surface, a particle on the surface, a particle embedded in the surface, a particle and a deformed pattern on the surface, or craters and microscratches on the surface. The defect may also be further classified into a subclass of arbitrarily defined defects defined by the user or preprogrammed in the apparatus. Embodiments include using a scanning electron microscope (SEM) capable of collecting electrons emitted from a plurality of angular sectors to obtain an image of the defect and a reference image containing topographical and location information, then analyzing this information to classify the defect. As the defects are classified, counts are maintained of the number of occurrences of each type of defect, and an alarm is raised if the defect count in a particular class exceeds a predetermined level. Thus, defects are accurately and reliably classified and monitored to enable early detection and cure of processing problems.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com