Patents

Literature

164results about How to "Maintain wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic tape

ActiveUS9704525B2Maintain wear resistanceMaintenance of such surfaceMagnetic materials for record carriersRecord information storageMagnetic tapeTransmission microscopy

Owner:FUJIFILM CORP

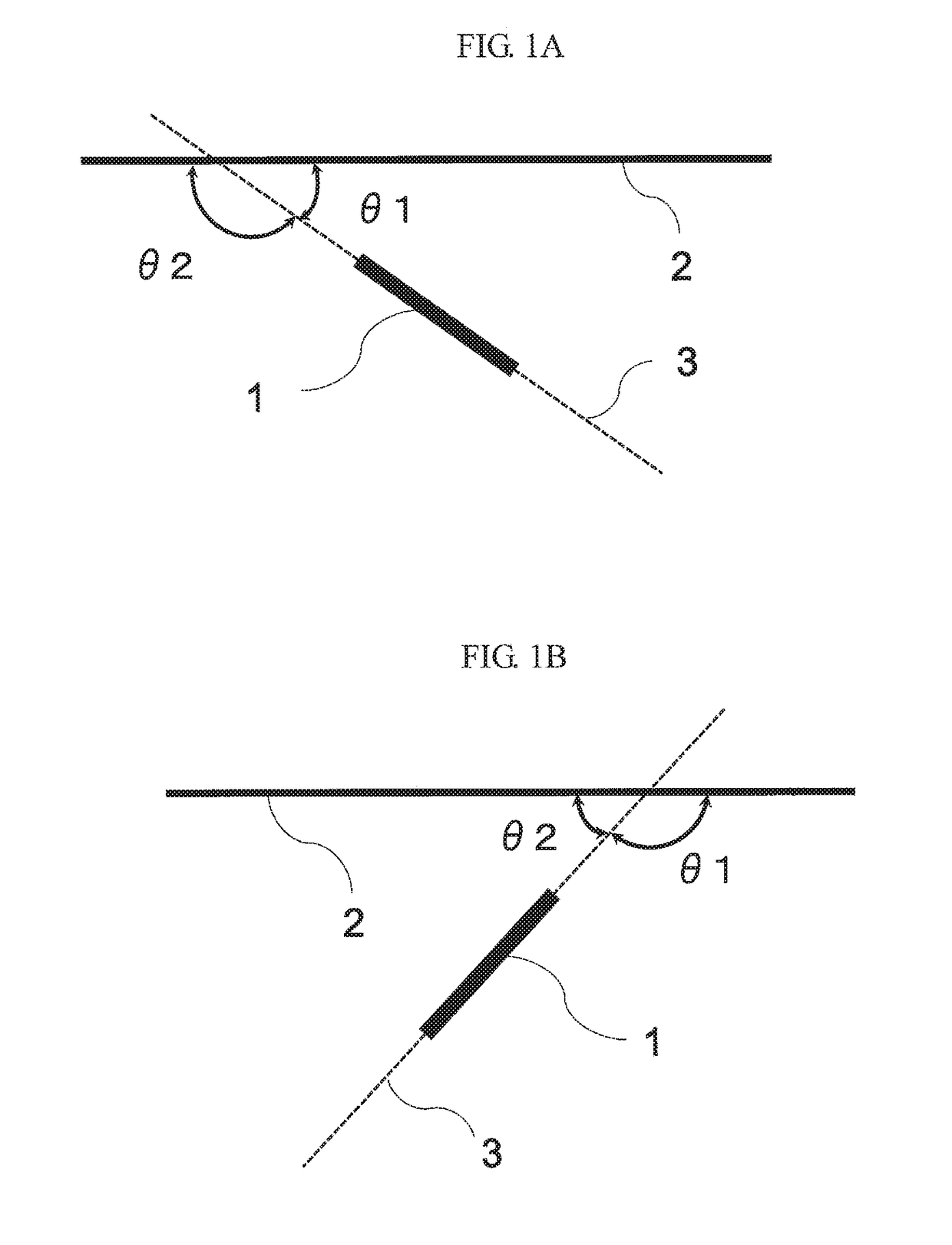

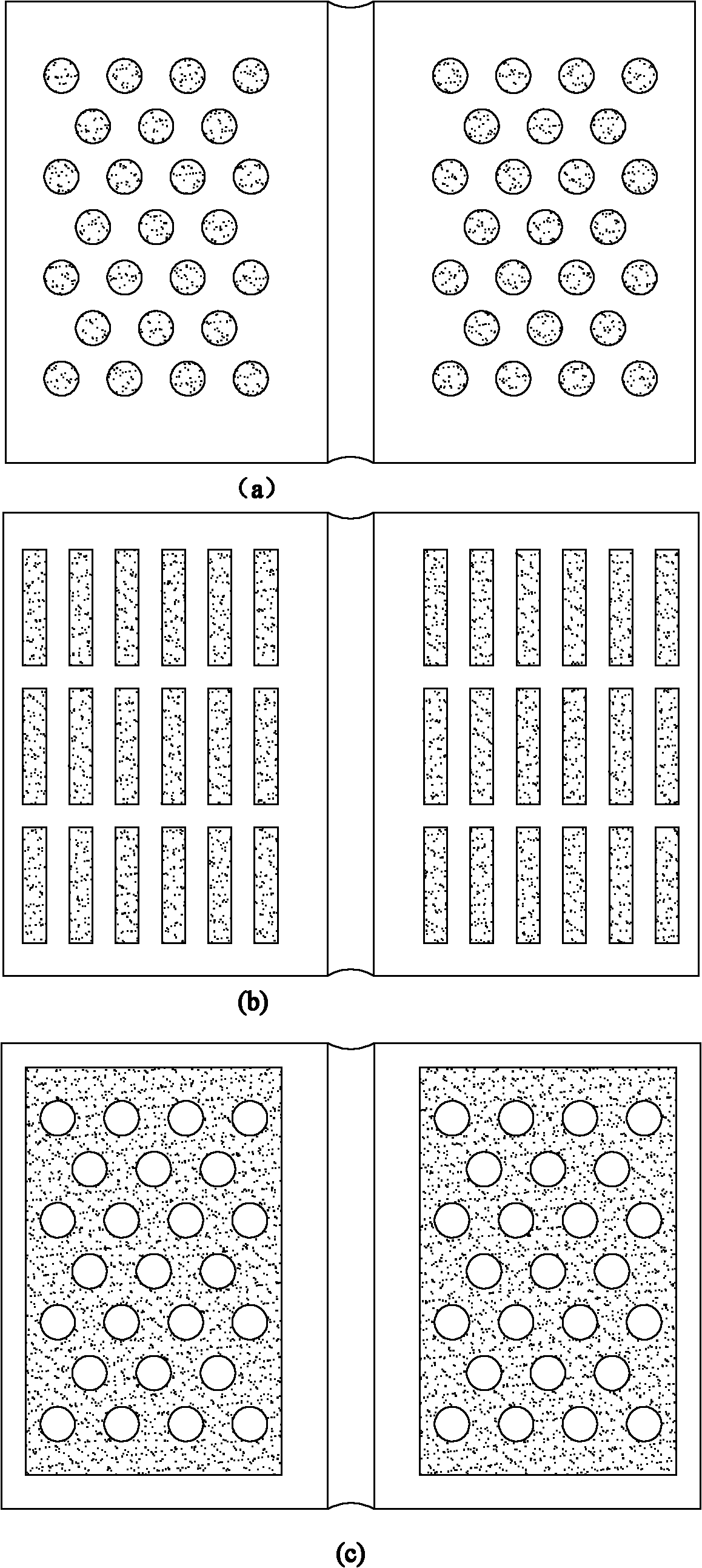

Prefabricated part of composite abrasion-resistant part and method for manufacturing abrasion-resistant part with same

The invention relates to a prefabricated part of a composite abrasion-resistant part and a method for manufacturing the abrasion-resistant part with the same. The prefabricated part is formed by mixing metal powder with carbide ceramic particles or particles by crushing a hard alloy and sintering the mixture at a high temperature and can be made into special shapes of columns, strips, blocks, honeycombs, and the like. The method comprises the following steps of: regularly arranging prefabricated parts on the end surface of a cast form; casting liquid metal by adopting a common or negative pressure cast method; impregnating the liquid metal into the prefabricated parts to form an abrasion-resistant part of a composite material, wherein the surface layer of the abrasion-resistant part comprises a matrix metal and a composite material. The abrasion-resistant part of the composite material, which is made by using the method, ensures the wear-resistant performance of the abrasion-resistant part and has high anti-impact capability.

Owner:XI AN JIAOTONG UNIV +1

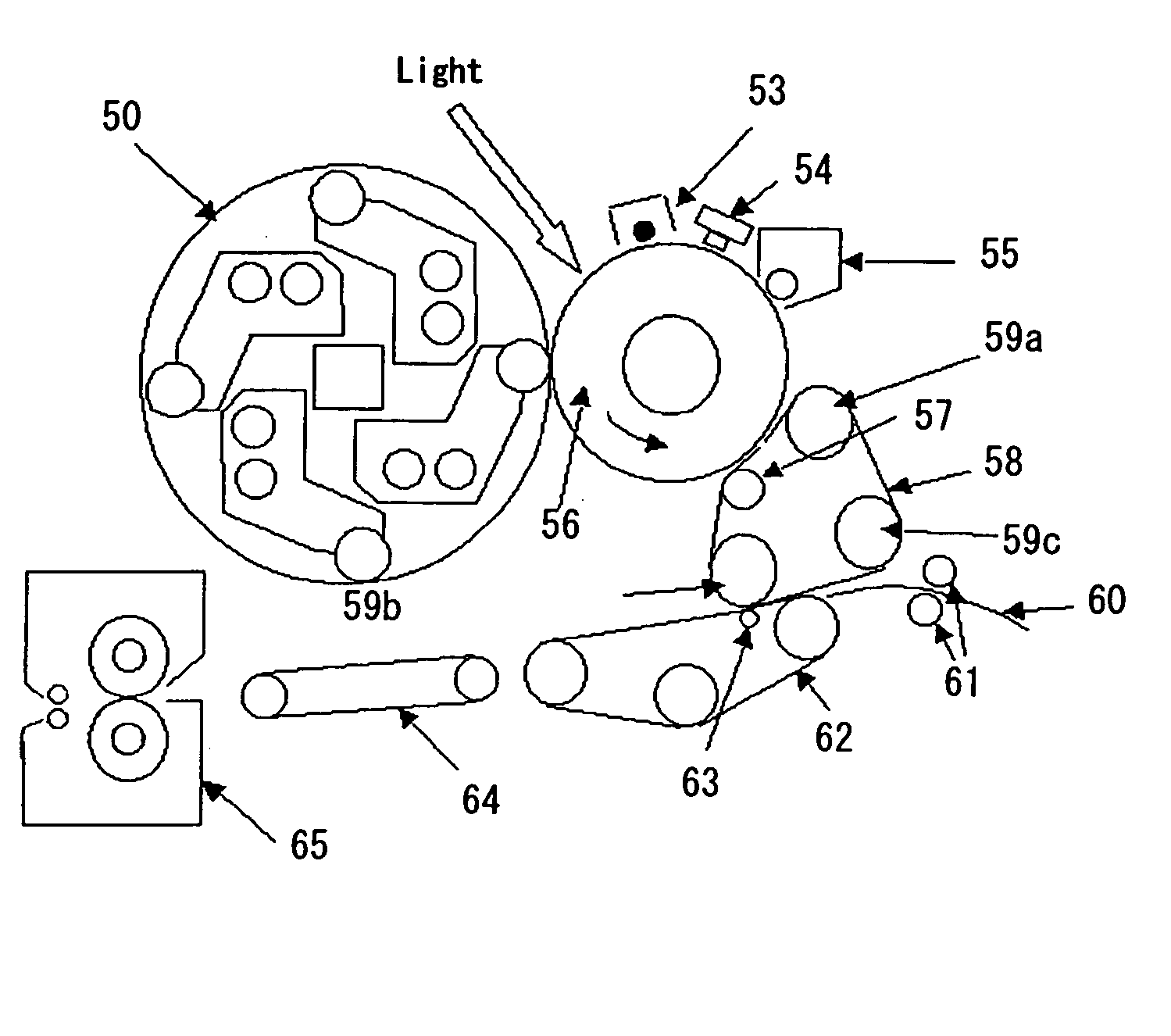

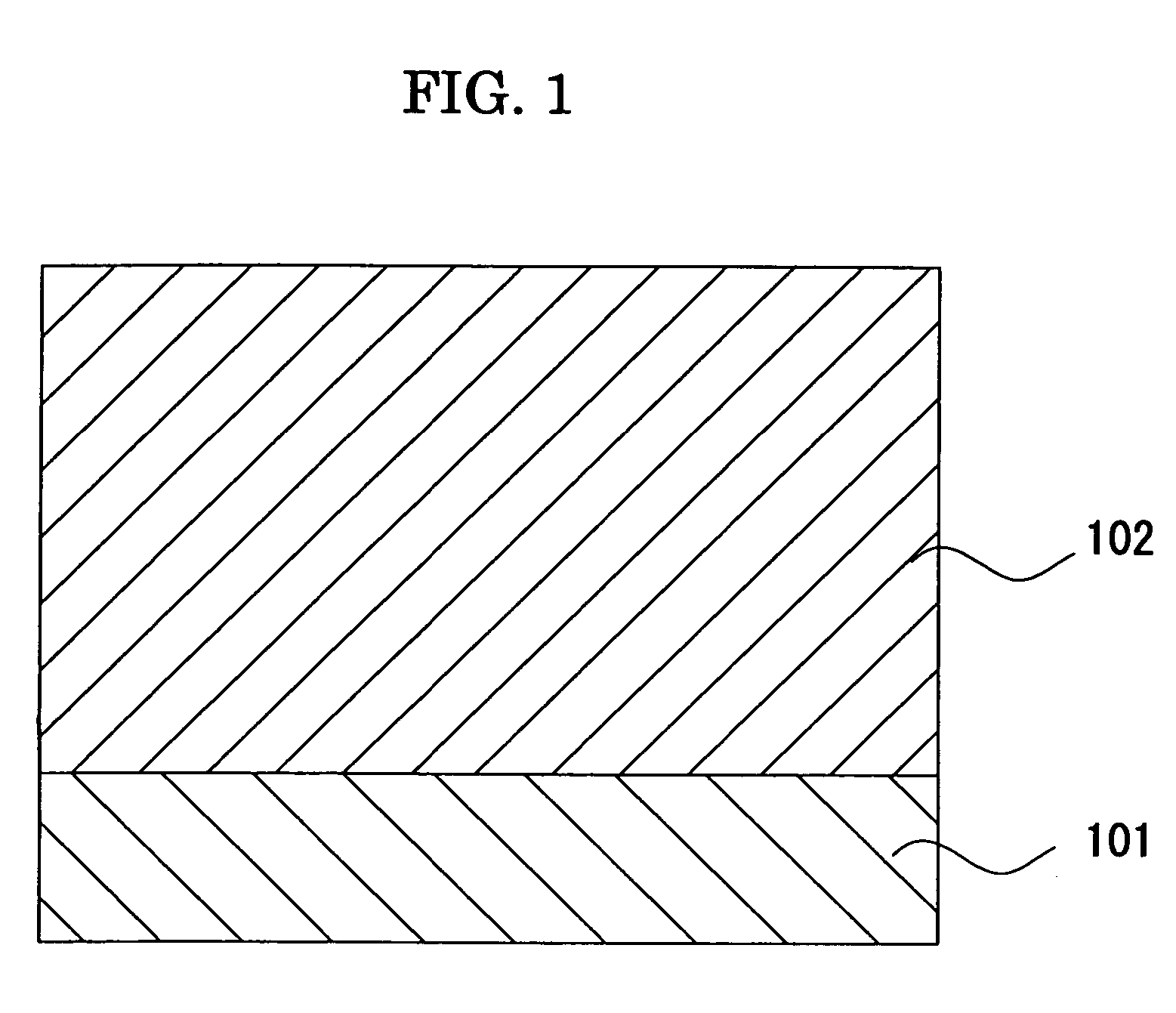

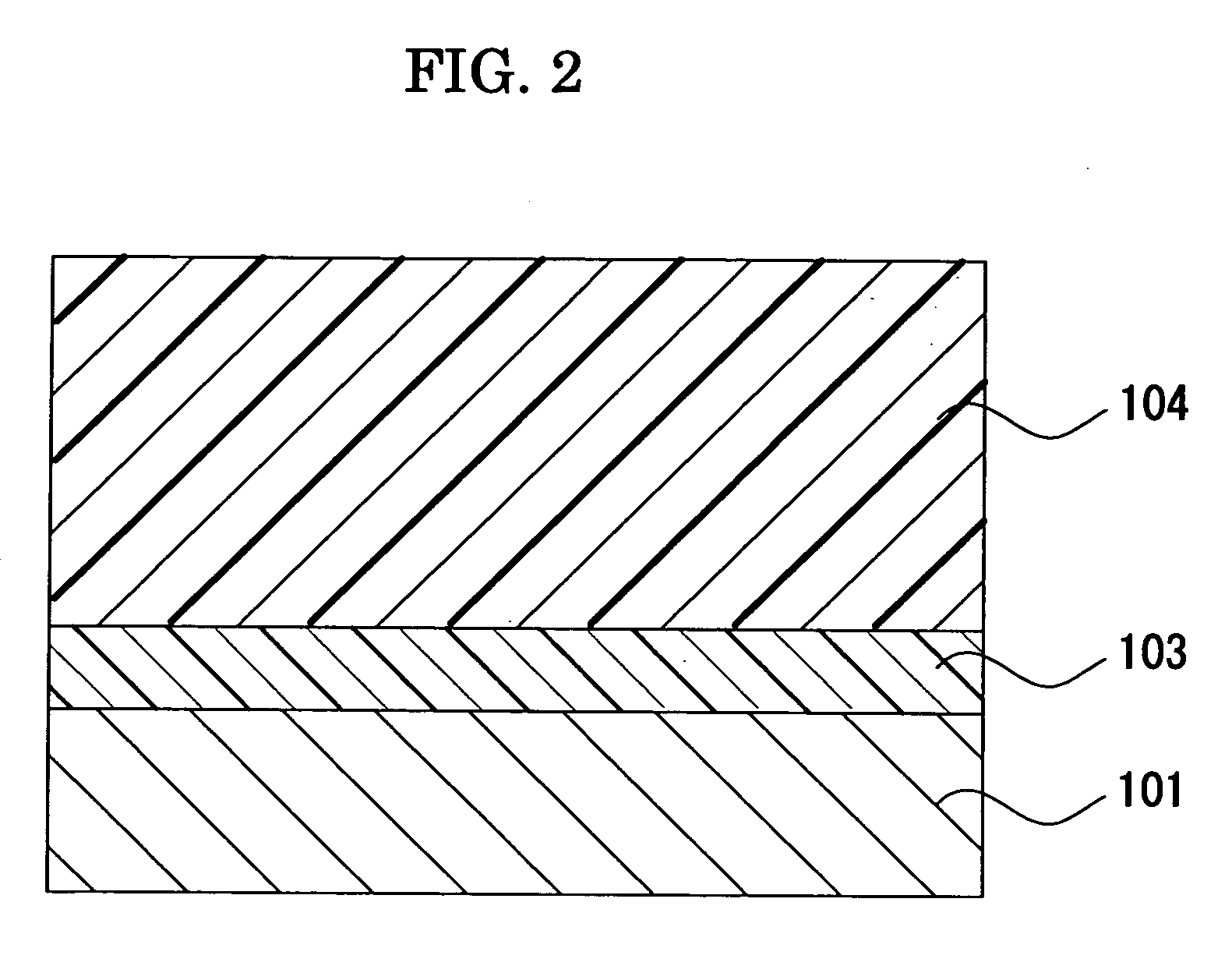

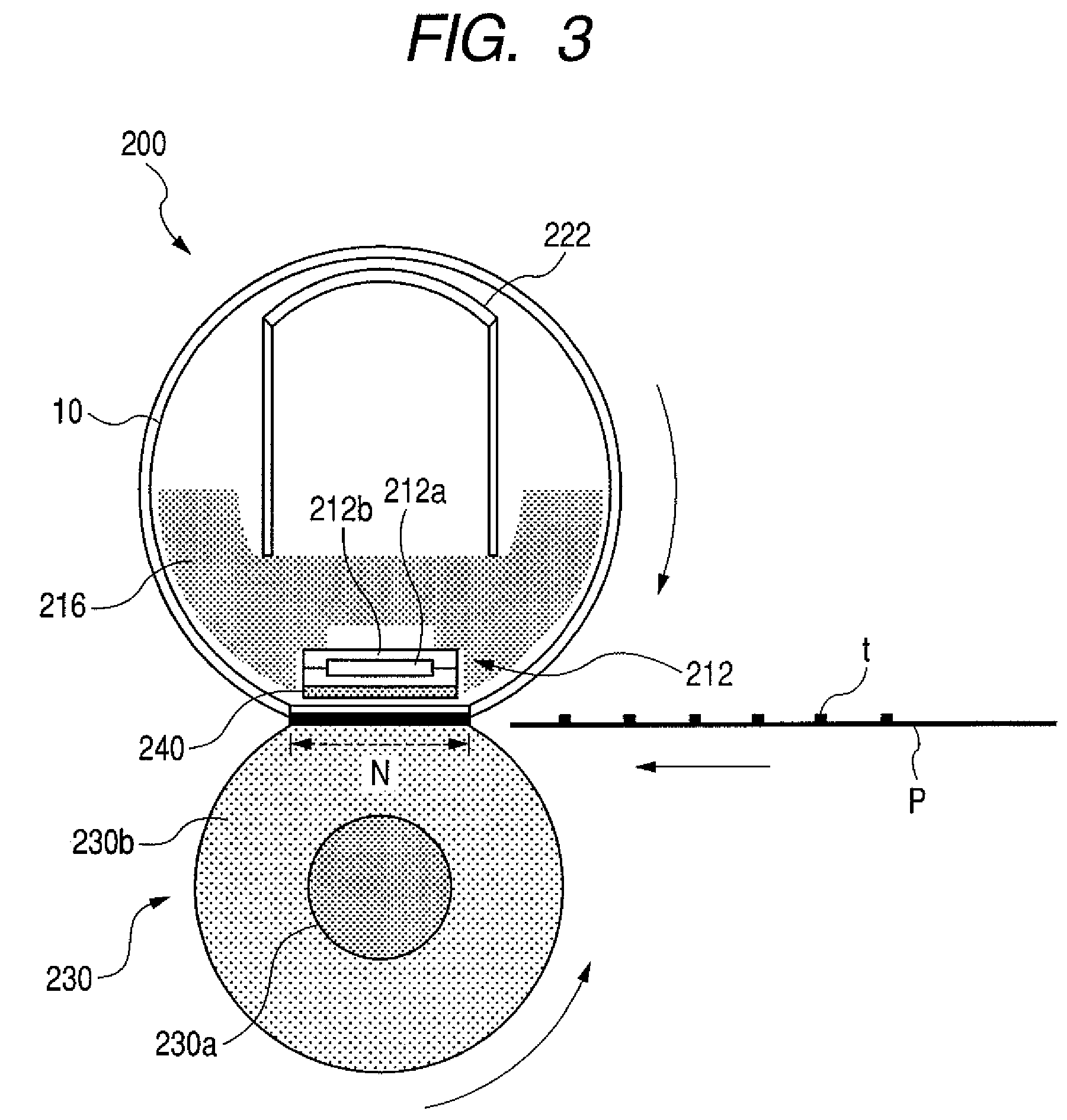

Image forming apparatus, image forming process, and process cartridge for image forming apparatus

ActiveUS20050130050A1Low coefficient of frictionSurface energy is lowElectrographic process apparatusDevelopersSurface energyLight exposure

Disclosed is an image forming apparatus for lowering friction coefficient and lowering surface energy of photoconductor surface in particular, which comprises an electrophotographic photoconductor, charging unit, light exposure unit, developing unit, transferring unit, and fixing unit, the electrophotographic photoconductor comprises a photosensitive layer on a conductive support and fluoropolymer fine particles at the outermost layer, a part of the fluoropolymer fine particles are exposed above the surface of the outermost layer in configurations of primary particles and secondary particles formed by flocculation of plural primary particles, and sum of area ratios of particles in the configurations of the primary particles and the secondary particles, each particles having an average diameter D of 0.15 μm≦D≦3.0 μm as respective projected figures of exposed portion above the surface of the outermost layer, is 10% to 60% based on the entire surface area of the outermost layer, and wherein the binder resin in the outermost layer comprises a polyalylate copolymer resin having a structural unit of alkylene-aryldicarboxylate.

Owner:RICOH KK

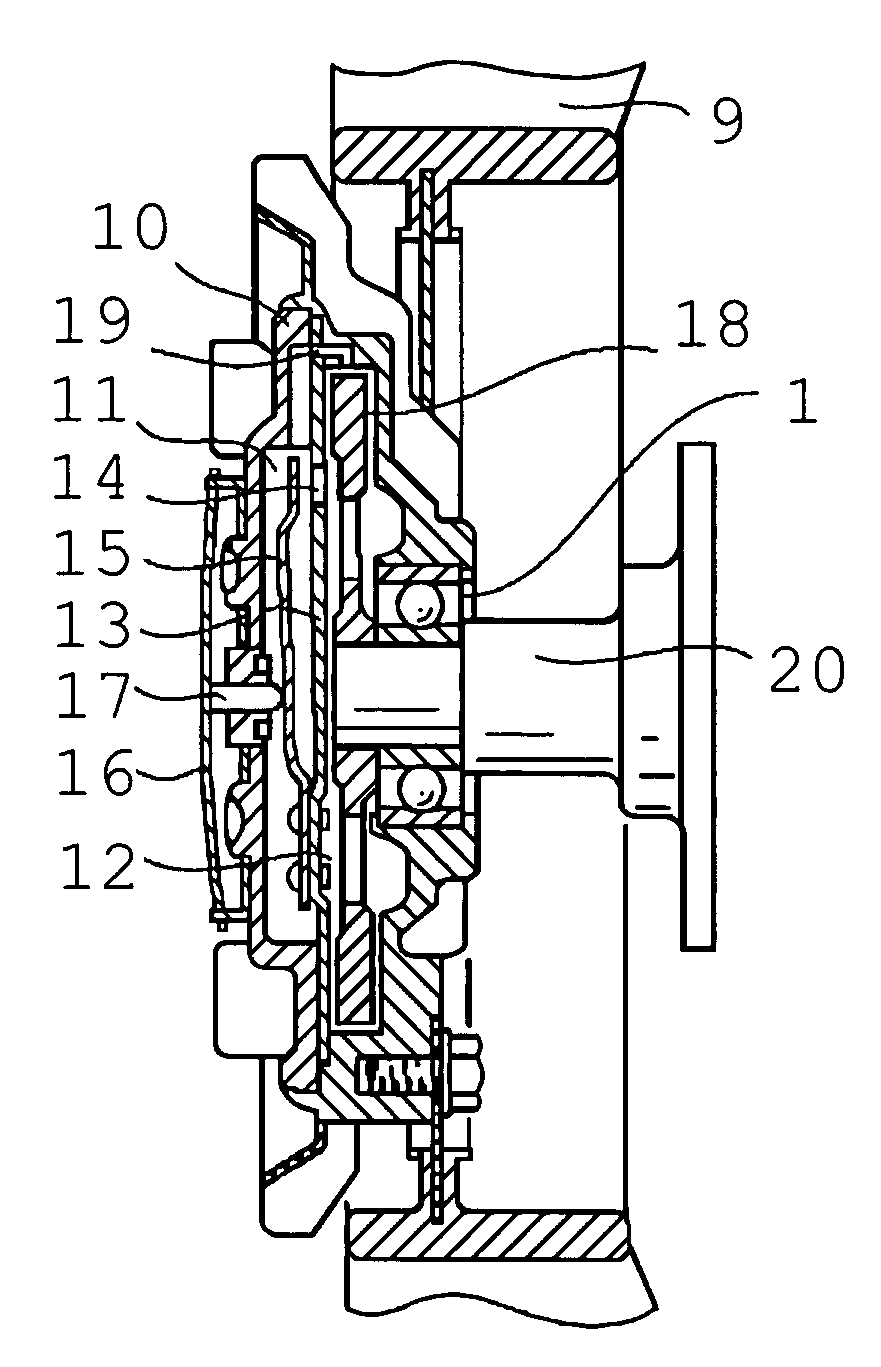

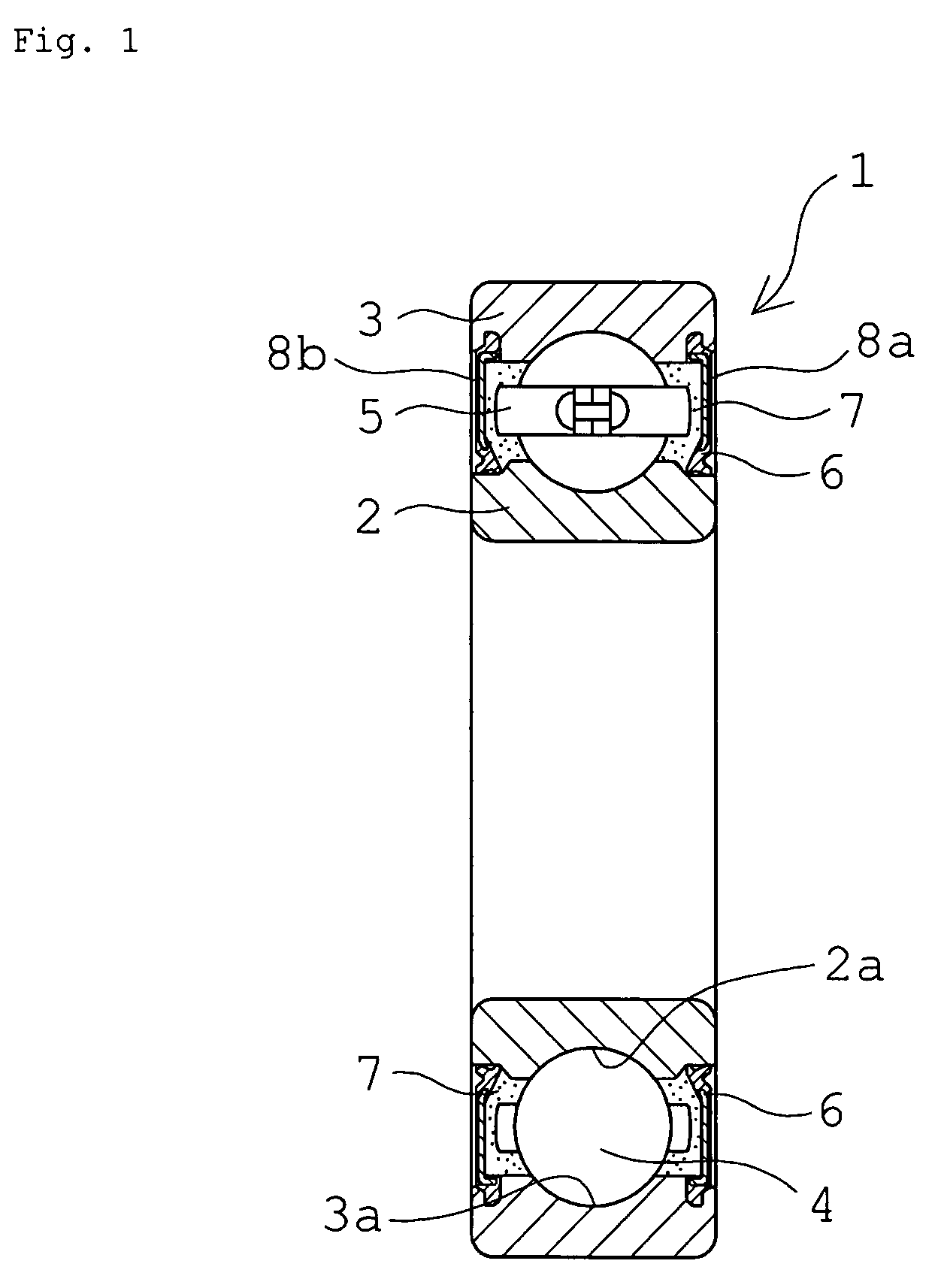

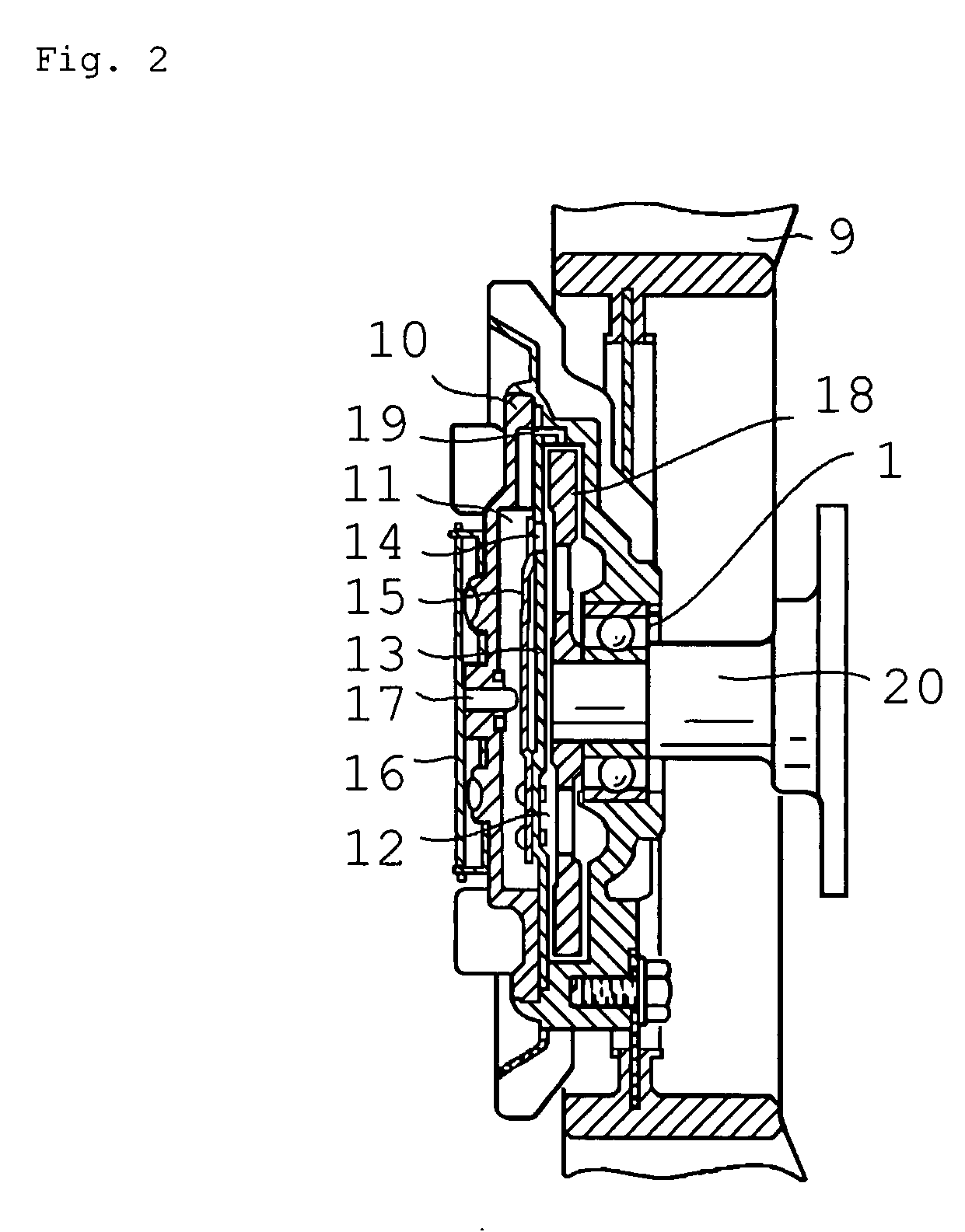

Grease Composition, Grease-Enclosed Bearing, and Rotation-Transmitting Apparatus With Built-In One Way Clutch

InactiveUS20080196995A1Prevent peelingRestrain hydrogen brittleness-caused peculiar peelingShaftsBall bearingsOil and greaseHydrogen

The present invention provides a grease composition capable of effectively preventing a rolling surface of a bearing from having hydrogen brittleness-caused peeling, a grease-enclosed bearing in which the grease composition is enclosed, and a rotation-transmitting apparatus with a built-in one-way clutch in which the grease composition is enclosed at a sliding portion. The grease composition contains a base grease consisting of a base oil and a thickener; and an additive added to the base grease. The grease composition prevents a frictional wear surface of the sliding portion or a newly generated surface consisting of iron or the like exposed owing to wear from being peeled owing to hydrogen brittleness. The additive contains a bismuth-based additive or a magnesium-based additive. The bismuth-based additive consists of at least one of inorganic bismuth and organic bismuth not containing a sulfur component. The magnesium-based additive consists of at least one of inorganic magnesium and organic magnesium. The grease-enclosed bearing encloses the above-described grease composition.

Owner:NTN CORP

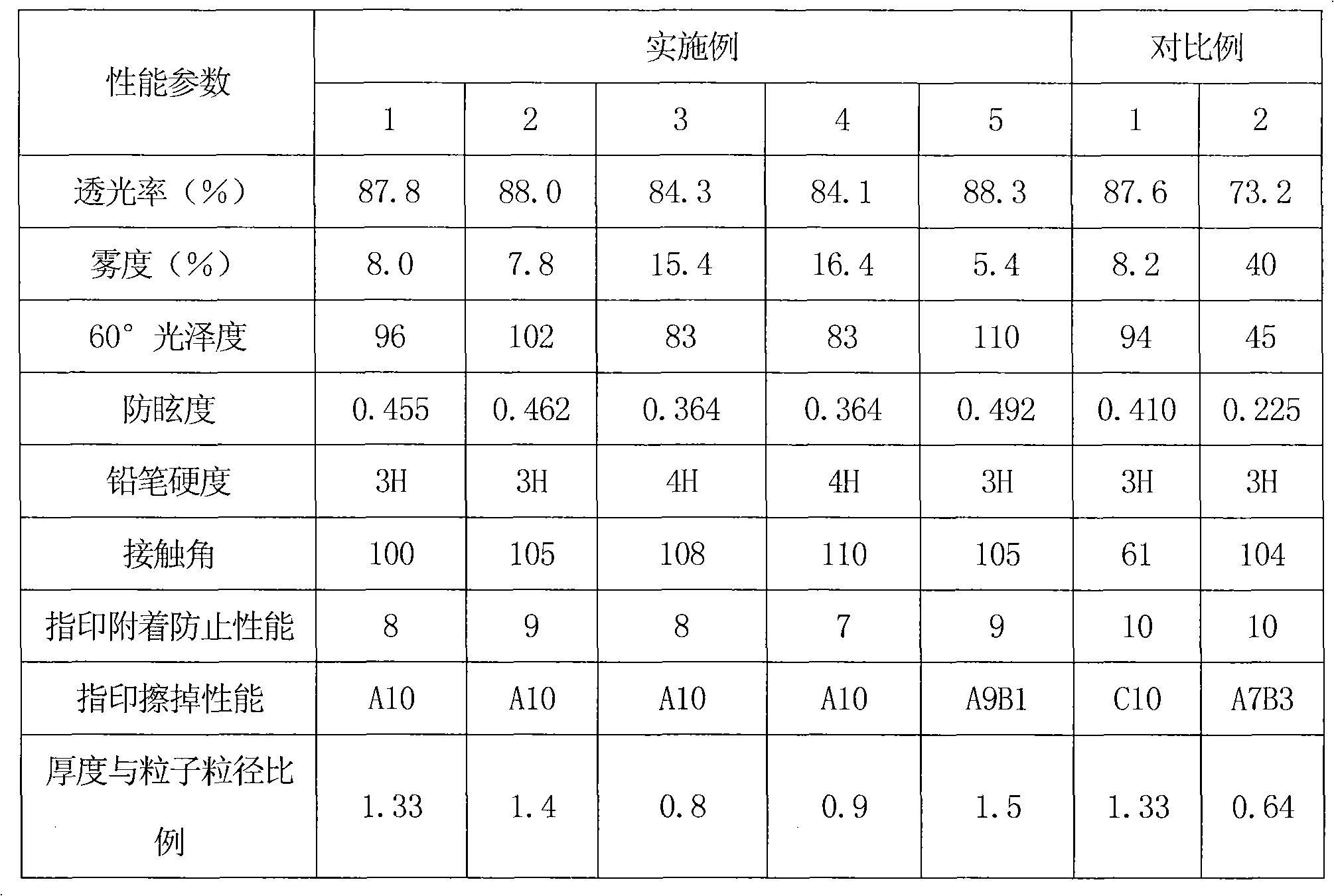

Anti-fouling anti-dazzle film

ActiveCN101299073AEasy to wipe offMaintain wear resistanceCoatingsOptical elementsPhotoinitiatorMaterials science

A dirt resistant anti-dazzle film comprises a transparent supporter and an anti-dazzle hard coating. The component and content of the anti-dazzle hard coating are as follows when counted by weight: 15-85 parts of ultraviolet solidified resin; 1-15 parts of photoinitiator; 0.1-10 parts of organsilicon modified polyacrylate; 0.5-10 parts of anti-dazzle particles, and 15-80 parts of dissolvent. The scratchproof anti-dazzle film can effectively inhibit the adhesion of dirt of dust, oil dust and the like on the surface of the film, and furthermore the adhered dirt can be easily erased. In particular the dirt resistance is permanent, and at the same time the anti-dazzle property, scratch resistance and scratchproof quality can be maintained.

Owner:CHINA LUCKY FILM CORP

Modified asphalt material and preparation method thereof

InactiveCN101117443AMaintain wear resistanceEnsure impact resistanceBuilding insulationsSolubilityPolyolefin

The invention discloses a bitumen modified material, which comprises 100 parts by weight of vinyl aromatic hydrocarbon-conjugated diene block copolymer with the flow value being less than 15g / 10 minutes relative to fused mass, 0 to 100 parts by weight of tackifying resin, 5 to 100 parts by weight of blending oil and 10 to 50 parts by weight of polyolefin. In addition, the invention also discloses the method of preparation of the bitumen modified material. Due to adding polyolefin, the invention not only maintains the physical intensity of existing bitumen modified material such as abrasion resistance, impact resistance and fluidity resistance as well as the advantages of excellent dissolubility, processability and storage stability, but also improves high temperature performance of bitumen modified material.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

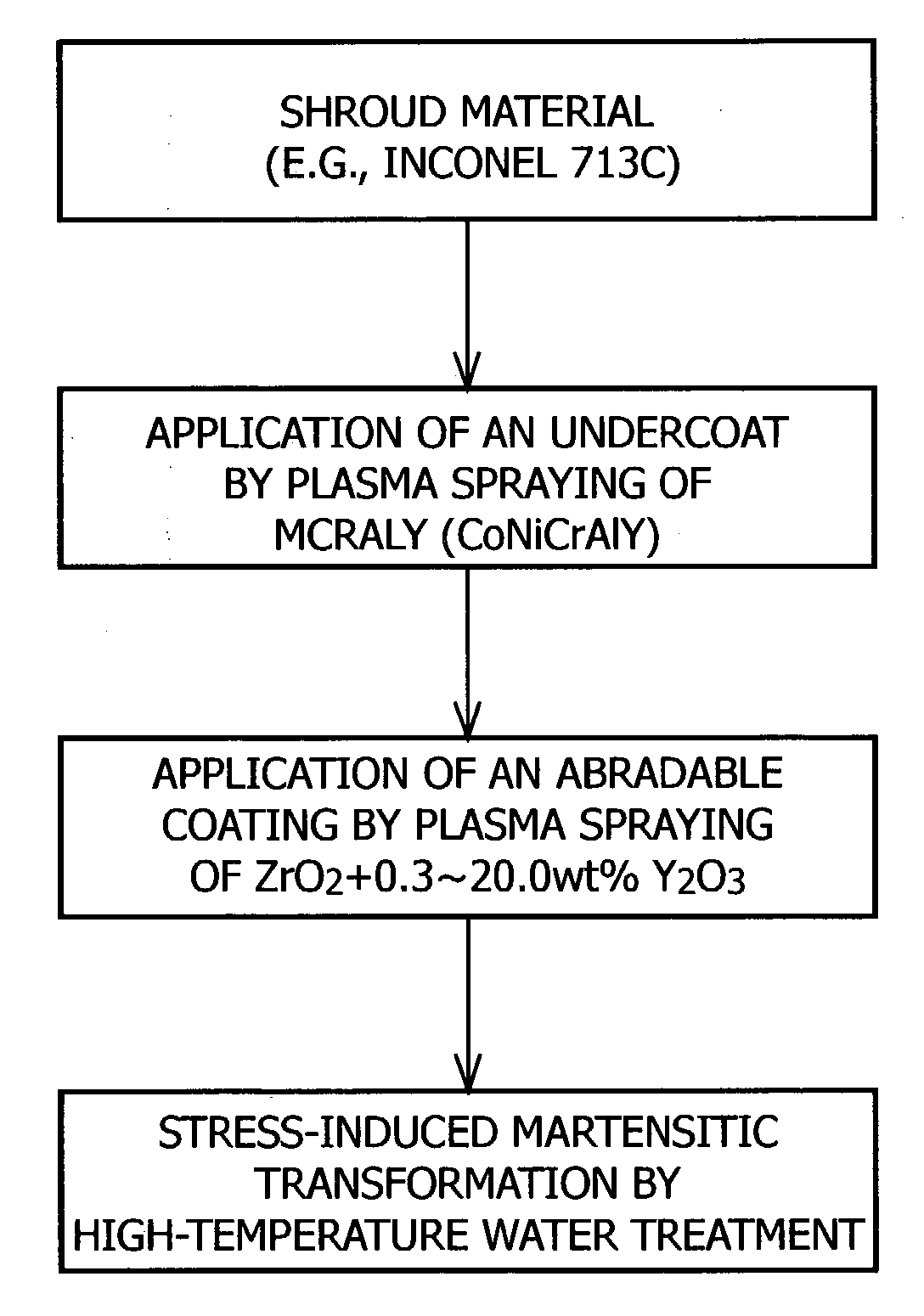

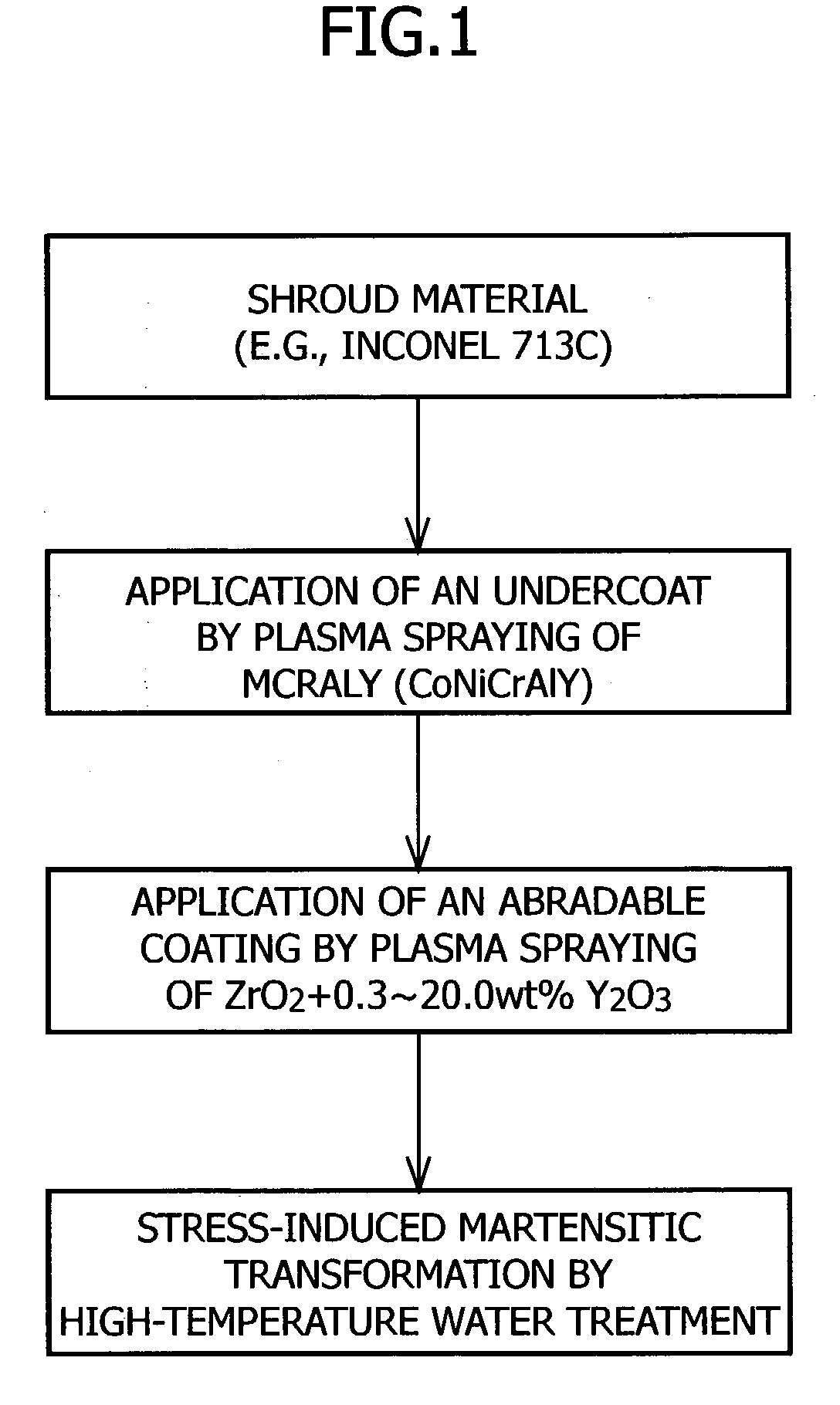

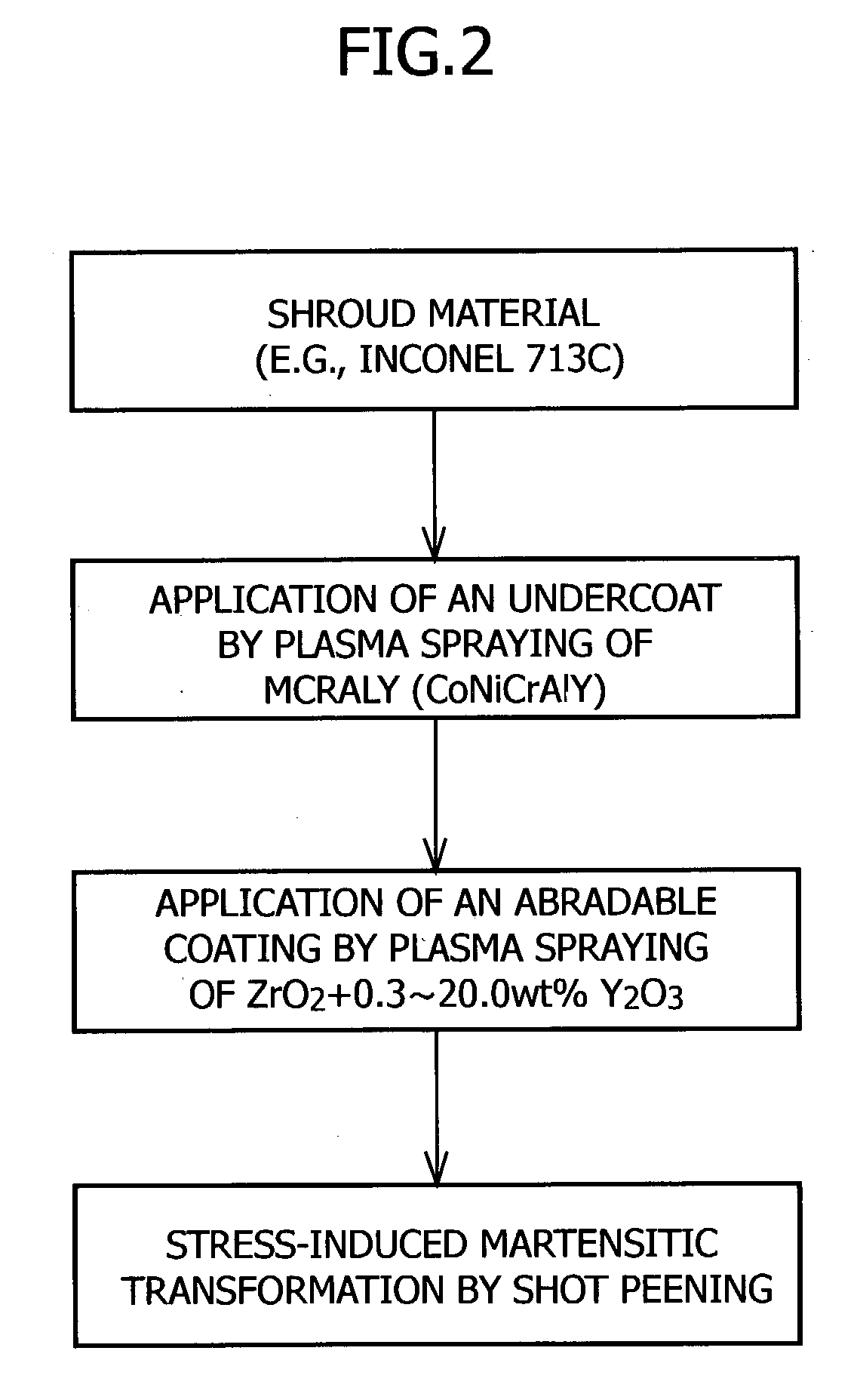

Abradable coating and method for forming same

InactiveUS20040022949A1Excellent cuttabilityImprove performanceMolten spray coatingPretreated surfacesMetallurgyCrystal structure

The present invention provides an abradable coating which is applied to the surfaces of stationary parts in rotary machinery such as gas turbines and does not cause damage or other trouble to the blades, as well as a method for forming the same. This method for forming an abradable coating comprises the steps of coating a shroud material with a partially stabilized zirconia ceramic material to form a zirconia ceramic layer having a cubic or tetragonal crystal structure on the surface of the shroud material; and subjecting the shroud material having the zirconia ceramic layer formed thereon to high-temperature water treatment at a temperature of 100 to 450° C. for 1 to 300 hours and thereby transforming the crystal structure of the zirconia ceramic layer into a monoclinic crystal structure. Alternatively, shot peening may be employed in place of the high-temperature water treatment.

Owner:HASEZAKI KAZUHIRO +2

Hard paint film

InactiveCN101205424AInhibits cracking or curlingInhibition of attachmentPolyester coatingsSolventChemistry

The invention provides a hard coating film to solve the problem of film cracking or curling. The technical proposal is that: the hard coating film comprises a support body and a hard coating; the hard coating has the compositions and weight portions as follows: 20 to 90 portions of UV curing acrylate, 2 to 20 portions of thermoplastic resin, 2 to 15 portions of photoinitiator, 0.2 to 15 portions of silicone, and 10 to 90 portions of solvent. The invention can inhibit cracking or curling caused by curing shrinkage, prohibit fingerprints or dusts, etc. from attaching on the surface of the film where attached fingerprints and dusts can be easily wiped off, and maintain the scratch resistance and wear resistance of the hard coating film.

Owner:BAODING LUCKY POLYMER MATERIAL TECH DEV +1

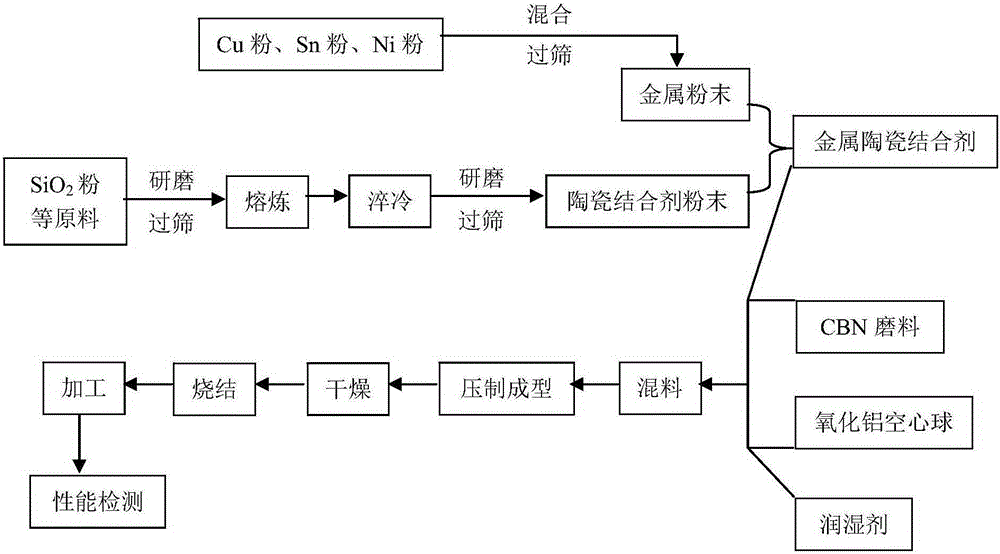

Metal and ceramic bonding agent and preparation method of metal and ceramic bonding agent, CBN grinding wheel and manufacturing method of CBN grinding wheel

ActiveCN105349868AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesSurface roughnessGrinding wheel

The invention discloses a metal and ceramic bonding agent and a preparation method of the metal and ceramic bonding agent, a CBN grinding wheel and a manufacturing method of the CBN grinding wheel. The metal and ceramic bonding agent is composed of, by mass fraction, 75%-92% of ceramic and 8%-25% of metal. The ceramic is composed of, by mass fraction, 40%-65% of SiO2, 8%-35% of B2O3, 6%-20% of Al2O3, 5%-18% of Na2O5, 0.5%-5% of CaO, 3%-10% K2O, 0.5%-2% of MgO and 2%-6% of TiO2. The metal is composed of, by mass fraction, 55%-80% of Cu, 15%-30% of Sn and 5%-20% of Ni. The metal and ceramic bonding agent can be used as a CBN grinding wheel bonding agent and overcomes the defects that in the grinding process of the ceramic CBN grinding wheel, the surface roughness of a workpiece is large, chatter marks are generated easily, and impact resistance is poor.

Owner:白鸽磨料磨具有限公司

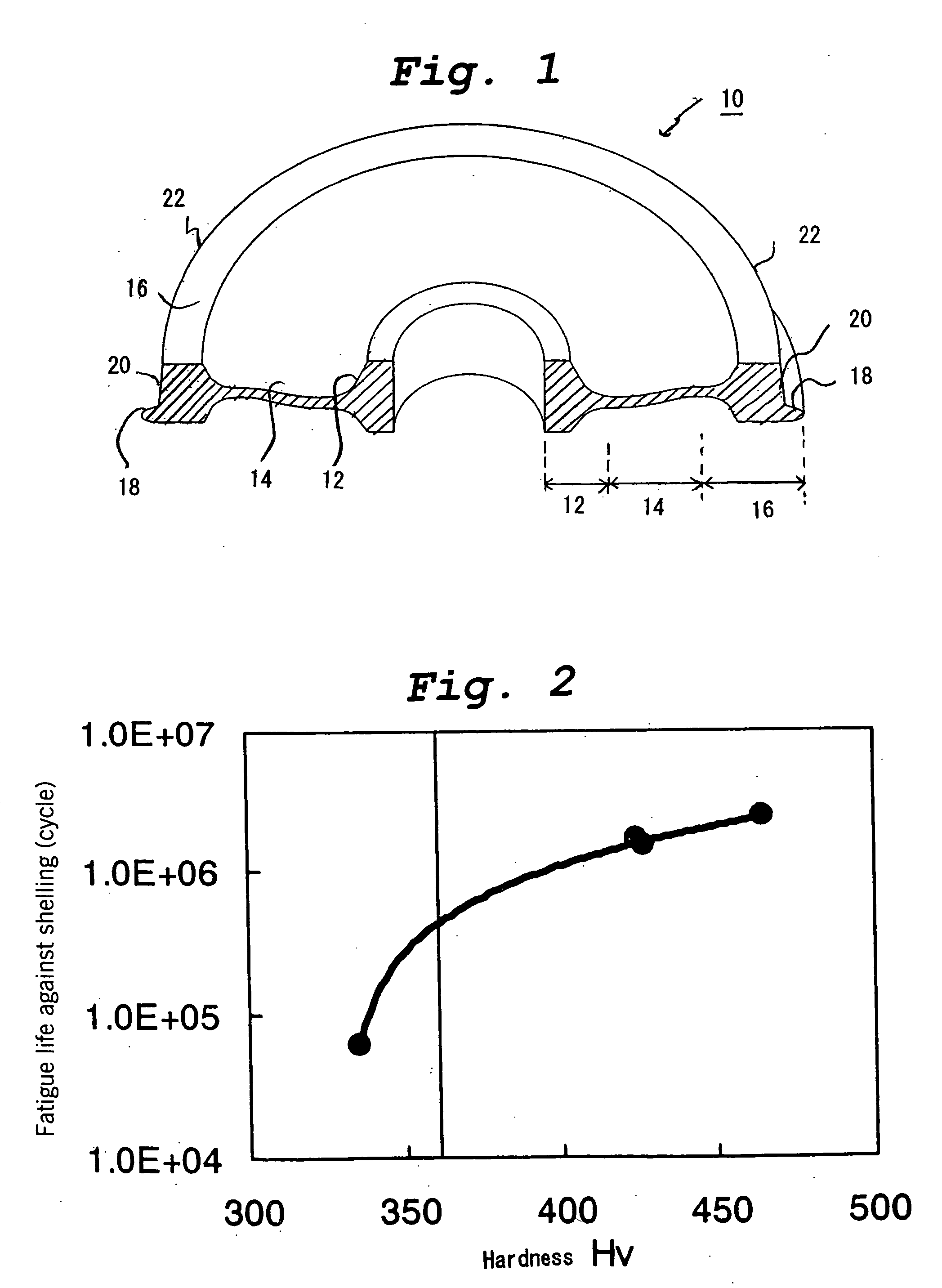

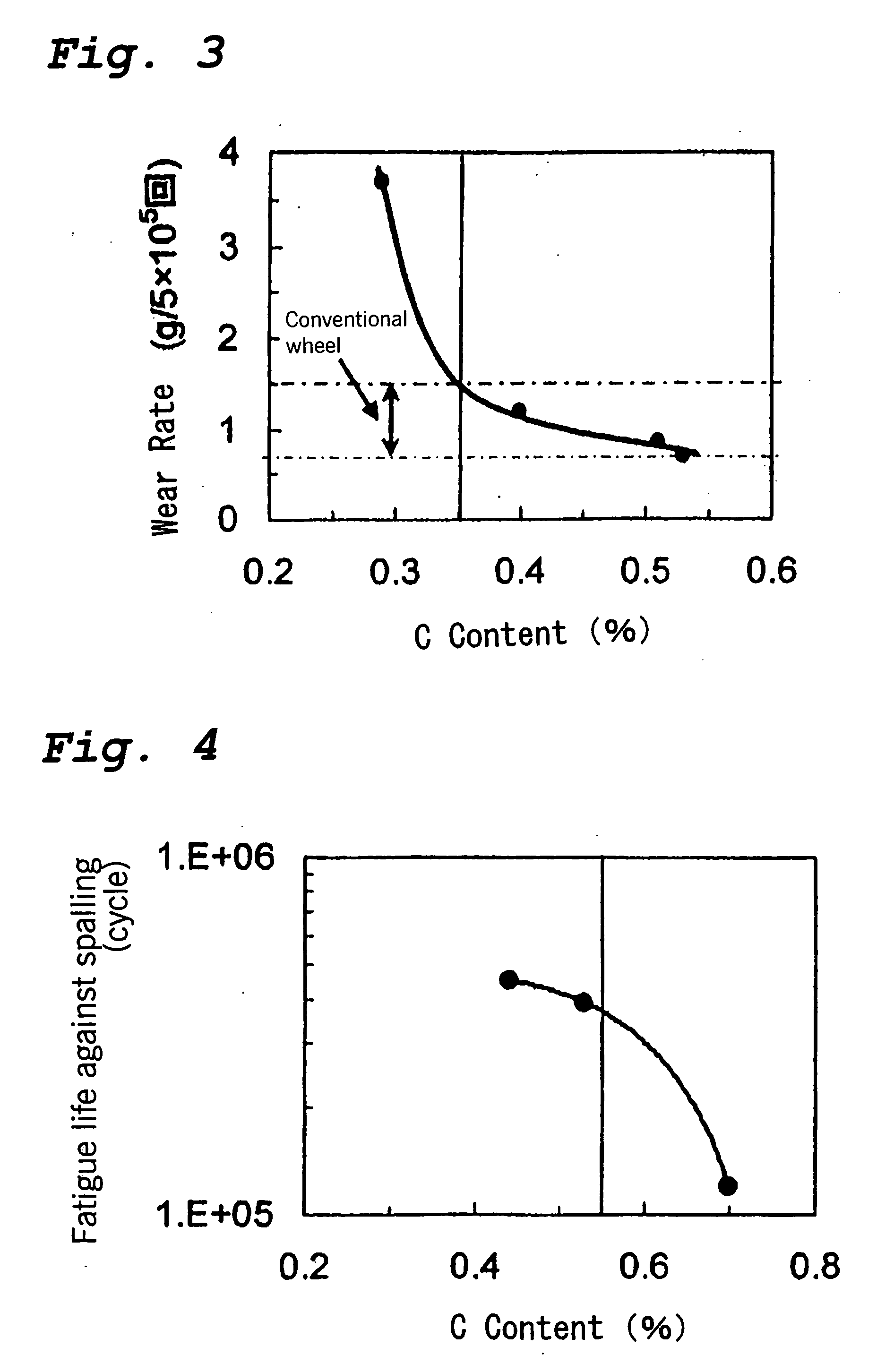

Railway car wheel

ActiveUS20050268995A1Excellent shelling resistanceExcellent resistance spallingRail-engaging wheelsRailroad wheelHardness

Owner:NIPPON STEEL CORP

Method for mfg of double-metal saw blade

InactiveCN1449882AImprove solderabilityEasy to weldMetal sawing tool makingLaser cuttingMaterials science

The production method of bimetal saw blade for cutting metal includes the following three procedures: 1. heat treatment of saw-tooth material; 2. welding the azotized saw-tooth material on the saw band, adopting instantaneous electric welding process, and the energization time of the weld is not greater 1 second; 3. cutting saw-tooth material on the saw band, adopting laser cutting process and cutting the saw-tooth material into the saw-tooth form. Said invention is characterized by that said invented bimetal saw blade is made up by equidistantly welding several saw-tooth materials on the saw band and cutting them, and after the heat treatment of the saw-tooth material a coating process is added, so that the saw-tooth material can be easily welded on the saw band.

Owner:浙江汇达精密机械有限公司

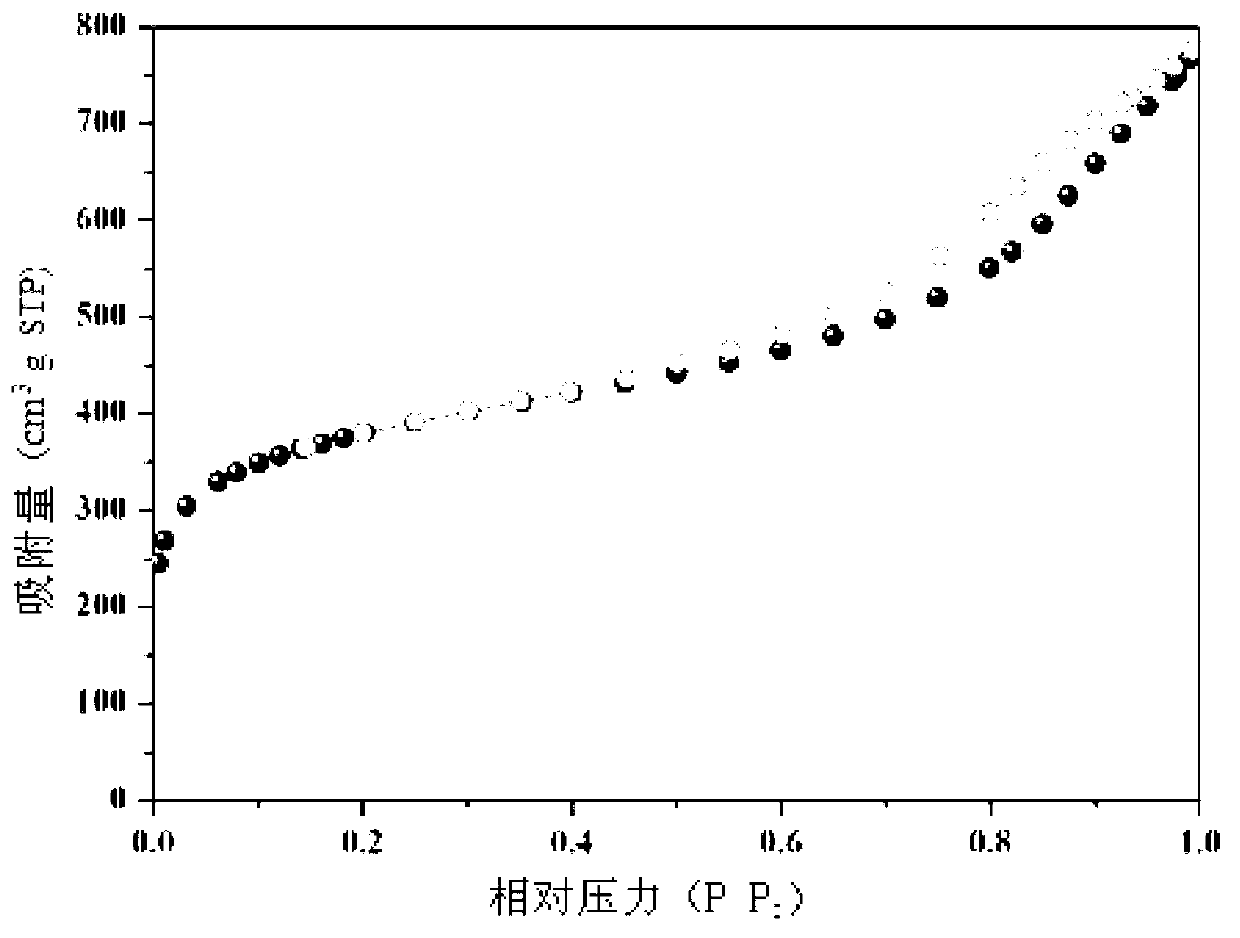

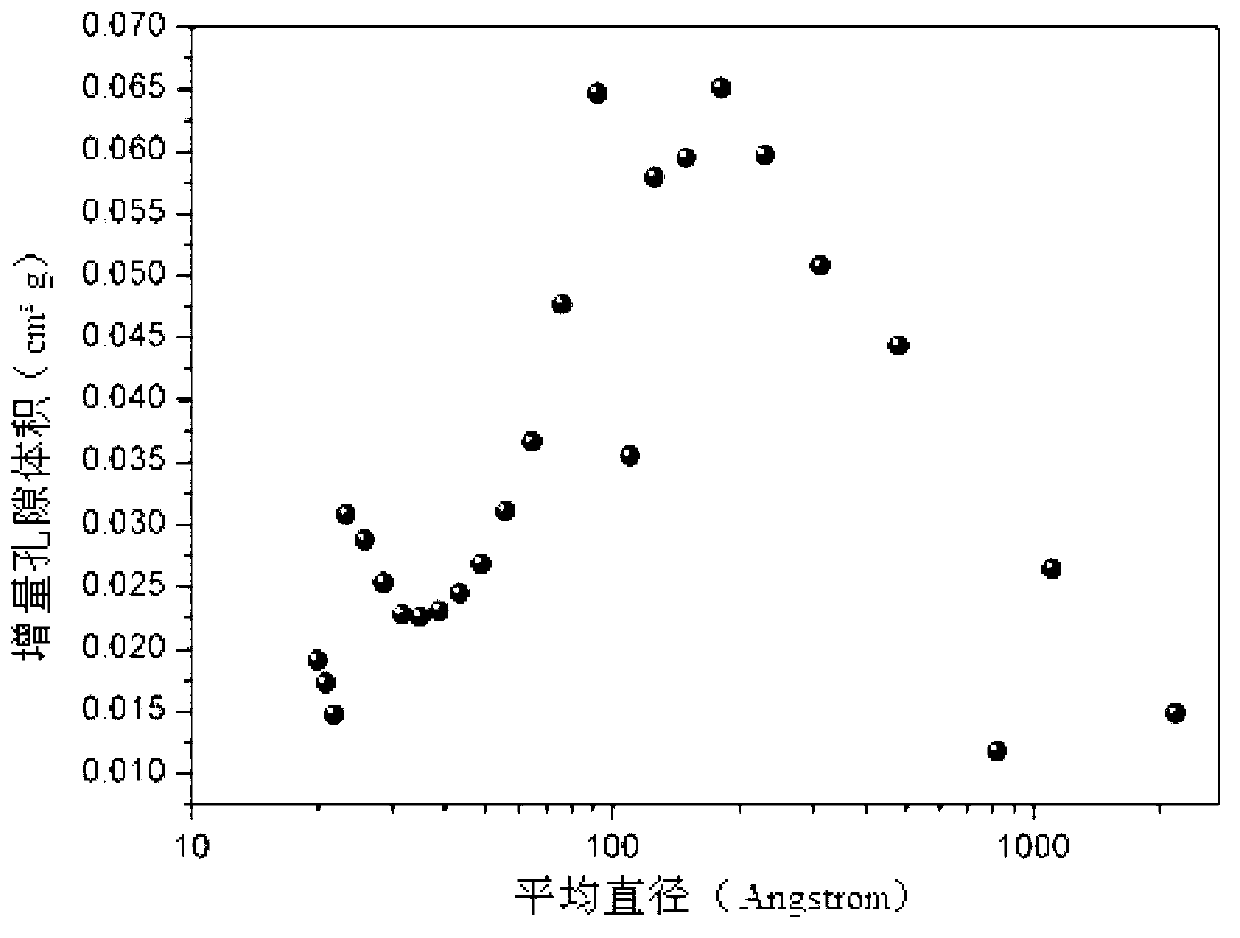

High-performance mesoporous active carbon suitable for biological enhancement and preparation method thereof

The invention discloses high-performance mesoporous active carbon suitable for biological enhancement and a preparation method thereof, relates to a preparation method of active carbon, and in particular to a preparation method of high-performance mesoporous active carbon which is suitable for biological enhancement and is applied to water treatment ozone-biological active carbon and ozone-biological enhanced active carbon processes. The invention aims to solve the problems that the existing active carbon has low mesopore rate and low biological loading amount on the surface and in pore passages of the active carbon. The preparation method comprises the following steps of: firstly respectively crushing and screening blind coals, candle coals and coconut shells which are used as precursors, and then matching in proportion; then, performing briquetting, carbonization, oxidization before activation, activation and modification after activation on the matched raw material; and finally, screening to obtain the mesoporous active carbon. The mesopore rate of the obtained mesoporous active carbon reaches 40-70%, and the biological loading amount can be improved to 106-107CFU / g, so that the high-performance mesoporous active carbon can be applied to the field of water treatment.

Owner:HARBIN INST OF TECH

Lubricant Composition

InactiveUS20090143262A1Excellent sharing stabilityReduce frictionOrganic chemistryLiquid carbonaceous fuelsSide chainPolymer chemistry

Owner:FUJIFILM CORP

High-performance colorized water-permeable asphalt concrete and preparation method thereof

Owner:南京同力建设集团股份有限公司 +2

Multifunctional composite electrochemical deposition liquid and method of use thereof

The invention relates to multifunctional compound electrochemical deposition fluid, the composition of the deposition fluid is that the deposition fluid each liter comprises nickel sulfate 100-380g, nickel amino-sulfonate 30-50g, nickel chloride 30-50g, cobalt sulfate 5-25g, lanthanum chloride 0.1-0.6g, ammonium bifluoride 15-25g, sodium fluoride 2-4g, dodecyl polyoxyethylene ether or dodecyl polyoxypropylene nonylphenolether 0.1-1.0g, naphthalenesulfonic acid or p-toluene sulfonamide 1-3g and other is water. Compared with a background technique, the deposition fluid of the invention has the following advantages: the deposition fluid of the invention improves the internal stress condition between a basal body and a nickel layer and intensifies the adhesive force of a primary plating layer, the passivation of a nickel anode is avoided in a nickel plating process, the quality of a plating layer is greatly increased, the corrosion resistance of a nickel electroplating layer is improved, the plating layer becomes even and compact without defects such as stomatas, pockmarks and the like, the deposition fluid has the luster of semi-bright nickel, simultaneously, the hardness and the anti wear property can be improved, and the service life is prolonged.

Owner:常熟紫金知识产权服务有限公司

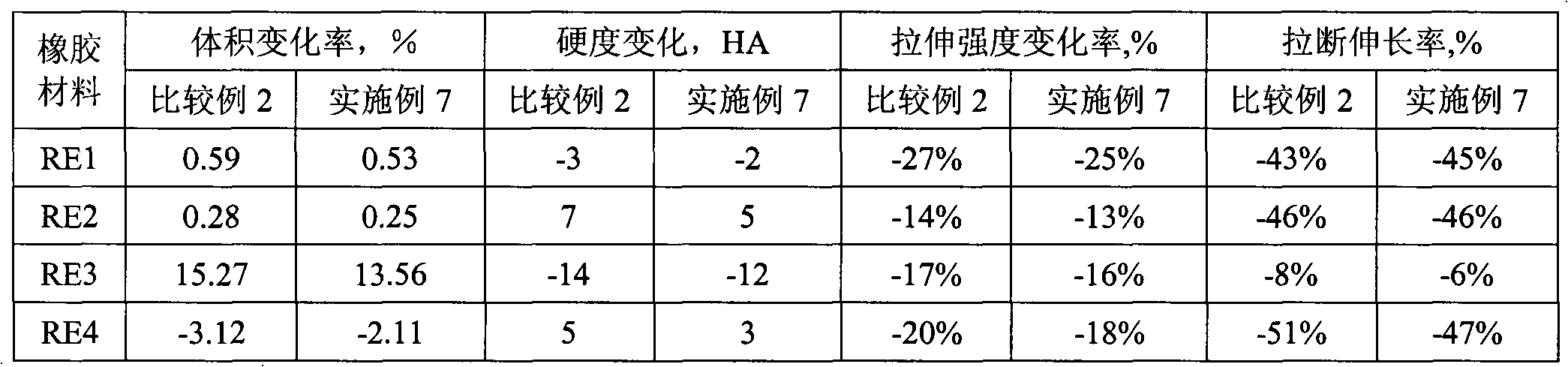

Directional power-assisted oil composition and its application

ActiveCN102337172AMaintain viscosity temperatureImprove anti-corrosion performanceAdditivesChemical compositionBoron

The invention relates to a directional power-assisted oil composition and its application and mainly solves the problems of poor compatibility between a directional power-assisted oil and a rubber sealing member and the fault of a power steering system due to deformation or failure of the rubber sealing member with the application of a power-assisted oil composition in the power-assisted steering system in the prior art. The directional power-assisted oil composition comprises the following components of: by weight, a) 0.1-5 parts of boron polyisobutylene succinimide; b) 95-99.9 parts of base oil. By the adoption of the technical scheme, the problems are greatly solved. In addition, the technical scheme can be used in the industrial production of the directional power-assisted oil composition provided by the invention.

Owner:CHINA PETROLEUM & CHEM CORP

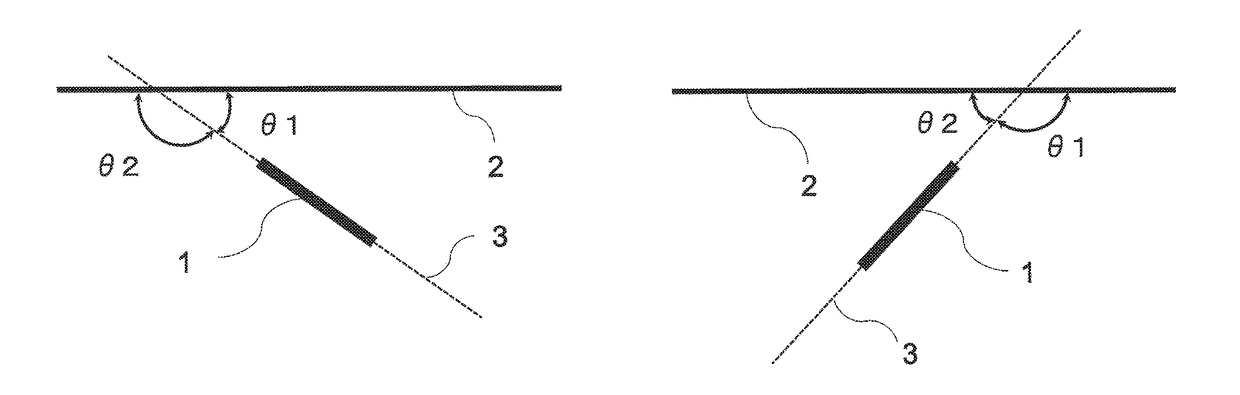

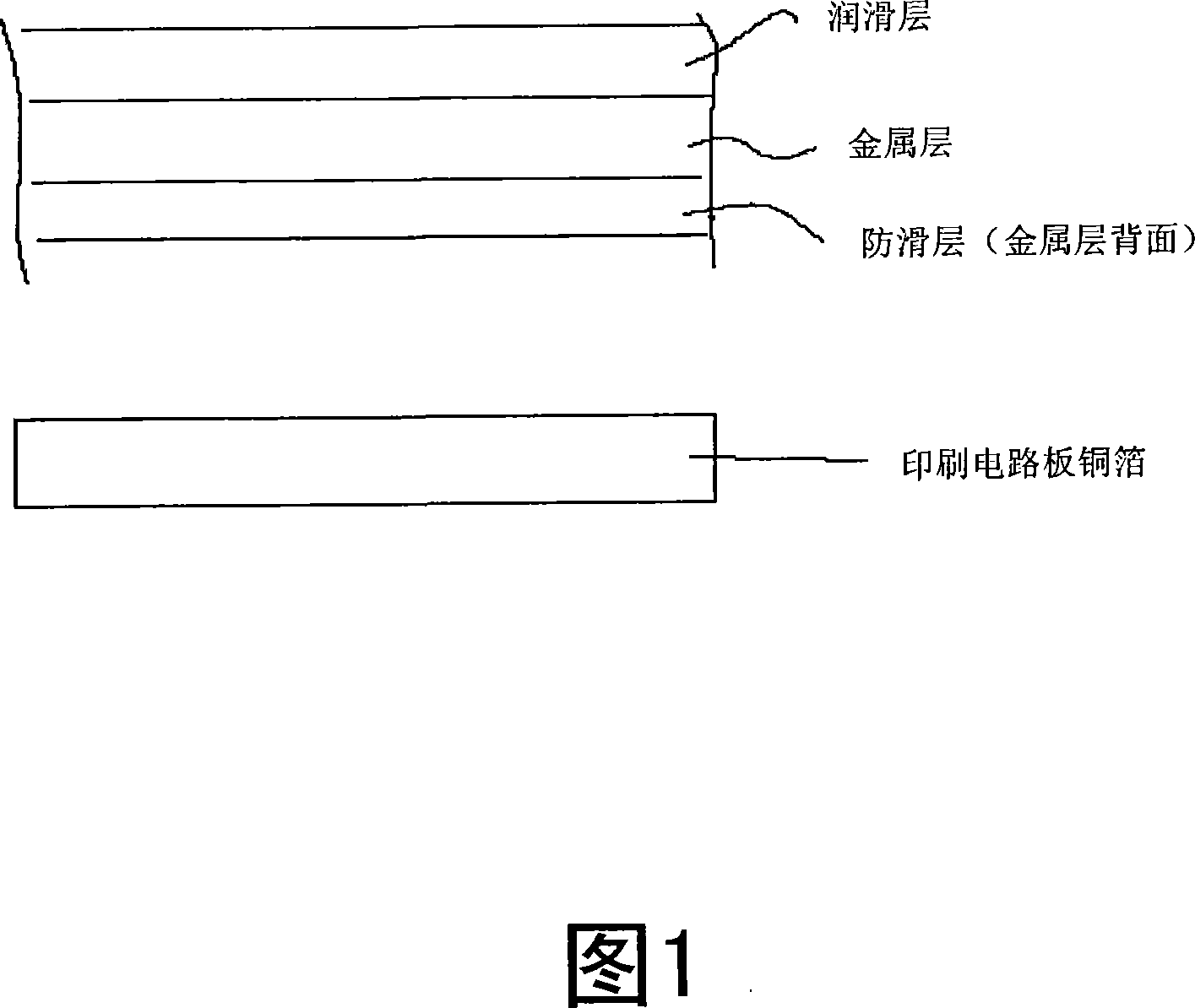

Sheets for drilling

InactiveCN101222816APrevent slippingImprove drill straightnessInsulating substrate metal adhesion improvementSynthetic resin layered productsEngineeringOrganic matter

Disclosed is a sheet for drilling suitable for use as a cover sheet for efficiently realizing a high-quality product upon drilling in the process of fabricating a printed circuit board. The sheet for drilling includes an organic material layer for imparting a lubricating function and a metal layer in contact with the organic material layer, the surface of the metal layer opposite the surface in contact with the organic material layer is controlled to have Theta of a predetermined value or more according to a slippage testing method. Thus, when the sheet is placed on a blank PCB board during the drilling of a printed circuit board, it has increased adhesiveness to the board and therefore an air layer is not formed between the sheet for drilling and the board, thus preventing the slippage of a drill and decreasing the vibration thereof, resulting in improved drill straightness. Wear resistance of the drill is maintained, thus increasing the drill replacement period, thereby realizing high-quality sheets for drilling.

Owner:アイエステックカンパニーリミティッド

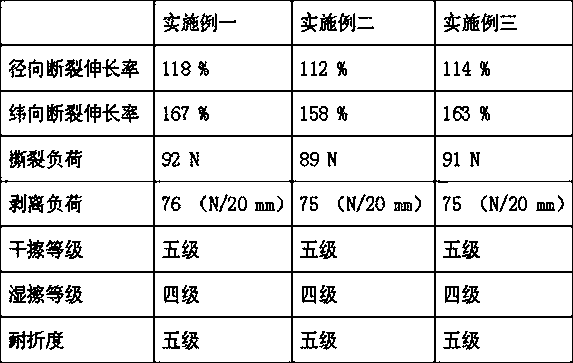

Graphene superfine fiber polyurethane synthetic leather and preparation method thereof

The invention discloses a graphene superfine fiber polyurethane synthetic leather and a preparation method thereof. The graphene superfine fiber polyurethane synthetic leather comprises a surface layer, a middle layer and an adhering layer which are respectively prepared from the following components of high-performance waterborne non-yellowing polyurethane resin, nylon, graphene, superfine fiberpolyurethane synthetic substrate, an abrasion-resistant agent, a light-resistant agent, a flame-retardant master batch and pure water. The preparation method comprises the following steps of S1, weighing the raw materials according to a ratio; S2, treating the graphene; S3, mixing and stirring the raw materials; S4, filtering the solution by a filtering net, and preparing an automobile superfine fiber leather by a dry type synthetic leather production line. The prepared graphene superfine fiber polyurethane synthetic leather has the advantages that the comprehensive property is excellent, thetesting result in each aspect is good, the physical indexes are basically the same with the physical indexes of common superfine fiber automobile interior trim, the moisture and air ventilating property is realized, the abrasion-resistant property is excellent, and the touch feel of the natural leather is realized.

Owner:TIANSHOU FUJIAN SUPERFIBER TECH

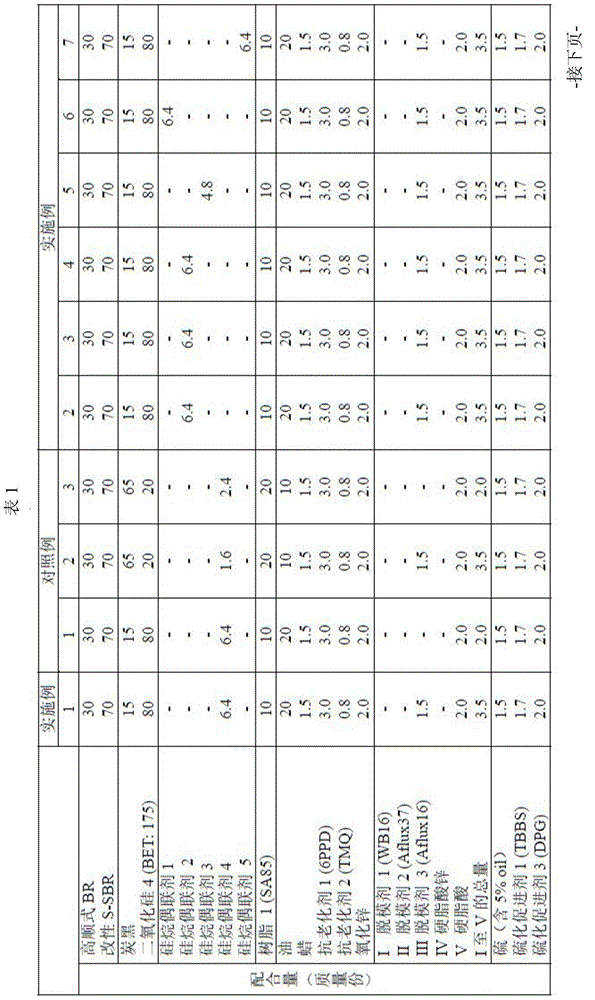

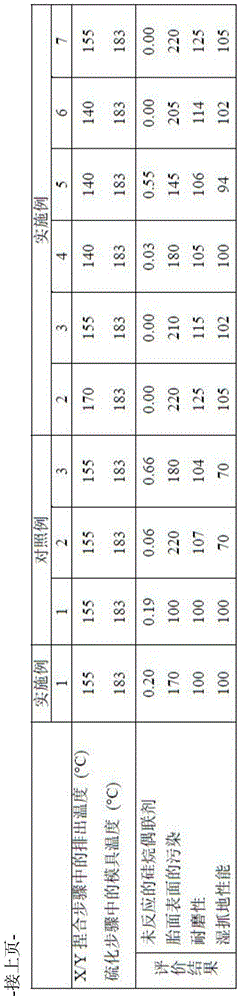

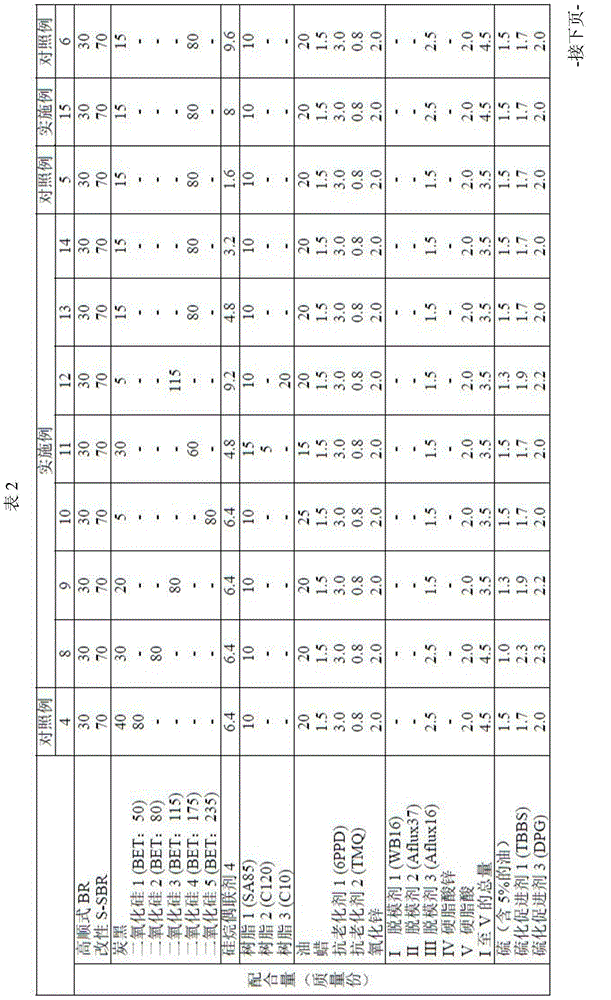

Rubber composition and tire

InactiveCN105086027AMaintain wear resistanceAvoid pollutionSpecial tyresPolymer scienceVulcanization

An object of the present invention is to provide a rubber composition which can prevent mold contamination while maintaining abrasion resistance and wet grip performance, and a tire which has a tread composed of the rubber composition. The rubber composition of the present invention comprises a predetermined amount of at least one selected from the group consisting of stearic acid, a metal salt of saturated fatty acid and a specific mold release agent, a specific resin, silica and a silane coupling agent, based on a diene rubber component, where an amount of an unreacted silane coupling agent in the rubber composition before vulcanization is within a predetermined range.

Owner:SUMITOMO RUBBER IND LTD

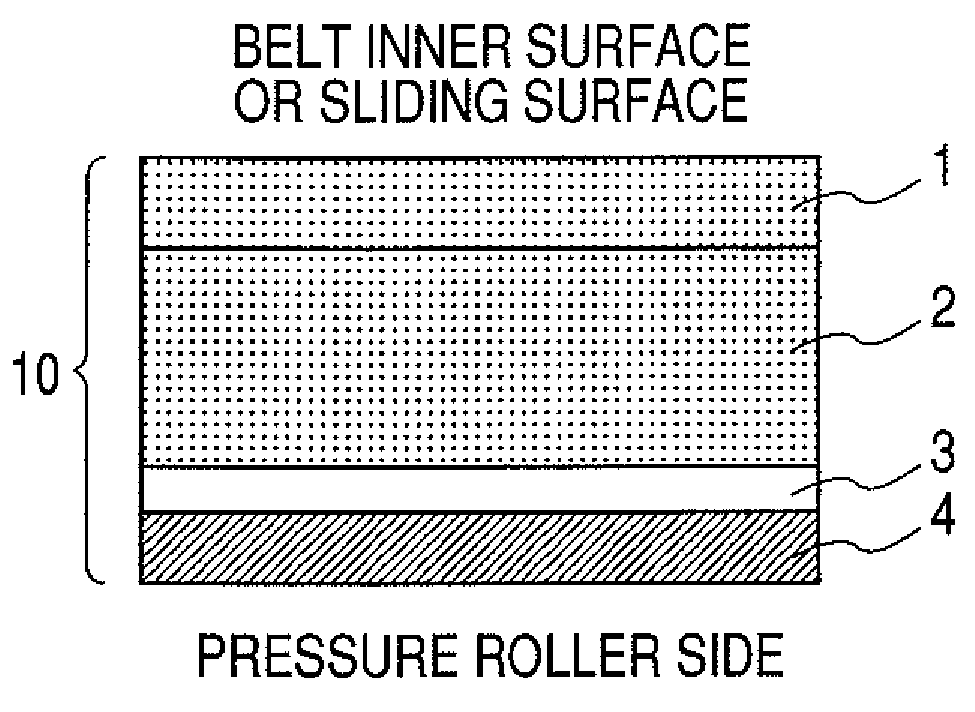

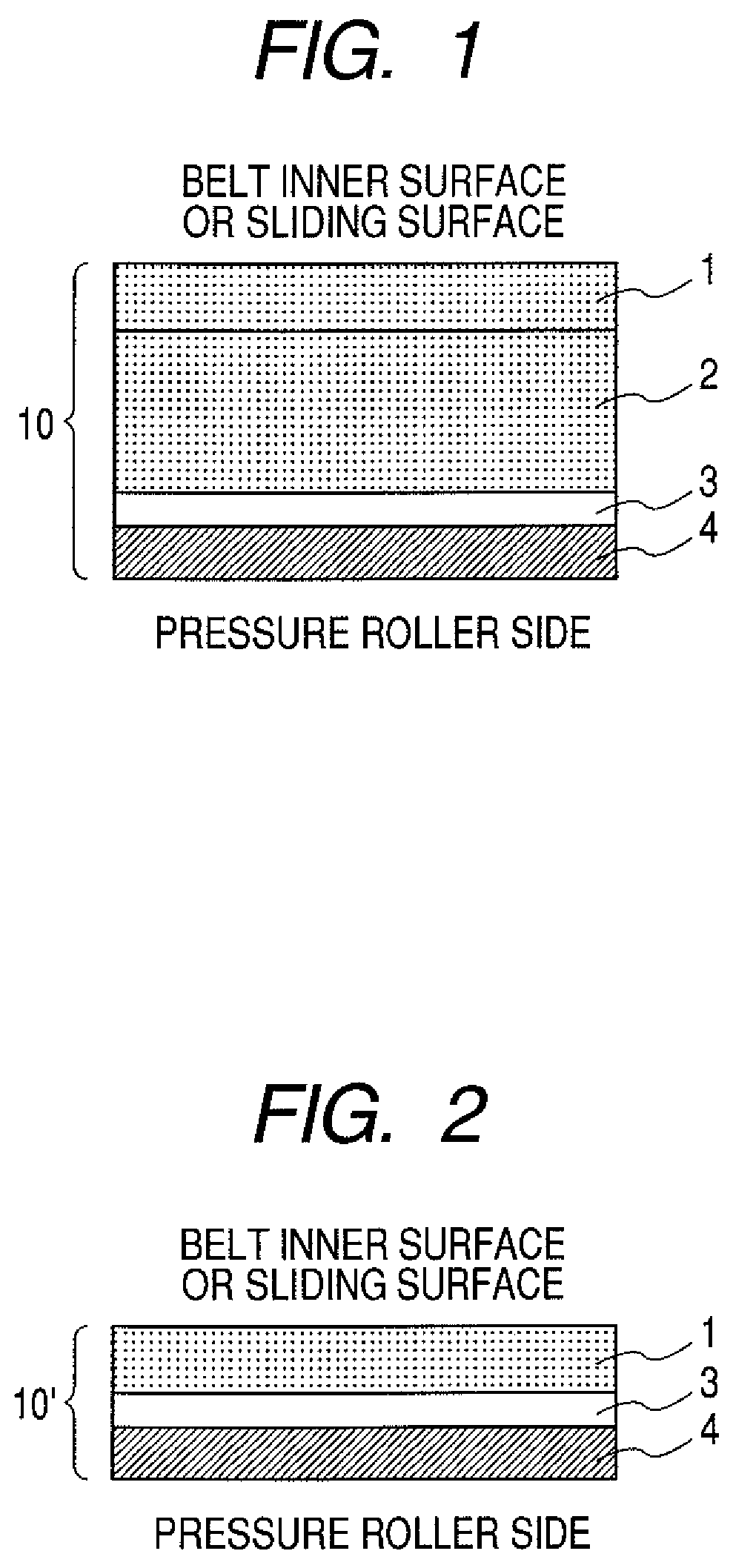

Endless metallic belt and fixing belt and heat fixing assembly making use of the same

ActiveUS7558519B2Increased durabilityIncrease resistanceElectrographic process apparatusX-rayTe element

An endless metallic belt formed of a nickel alloy which contains at least one element selected from the first group of elements consisting of phosphorus, boron, silicon, germanium, selenium, antimony, tellurium, bismuth and astatine, and, in an X-ray diffraction pattern of which, half widths of X-ray diffraction peaks of the (111) crystal plane and (200) crystal plane are both from 0.5° to 2.5°.

Owner:CANON KK

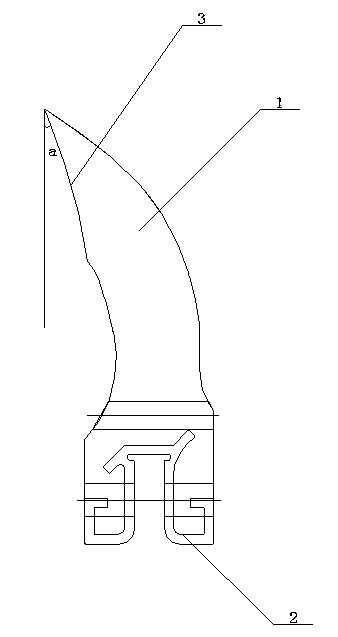

CARP optimizing and cleaning device

The invention provides a CARP optimizing and cleaning device, and relates to the field of machine manufacturing. The CARP optimizing and cleaning device comprises a polyurethane blade (1) and an aluminum alloy insert (2). The polyurethane blade (1) is embedded in the aluminum alloy insert (2). An oblique contact face (1-1) is arranged on the inner side face of the upper end of the polyurethane blade (1), and the included angle alpha between the contact face (1-1) and the perpendicular line is 20-30 degrees. According to the friction coefficient between the blade and a belt, material property of the CARP optimizing and cleaning device and characters of conveyed materials, the shape and size of the blade are designed through difference, the contact area and sweeping angle of a cleaner are guaranteed, materials which fall down on the belt can be completely eliminated, the blade is made of the polyurethane material, so that wear resistance of the blade is ensured, and the service life of the blade is guaranteed.

Owner:MARTIN ENG KUNSHAN

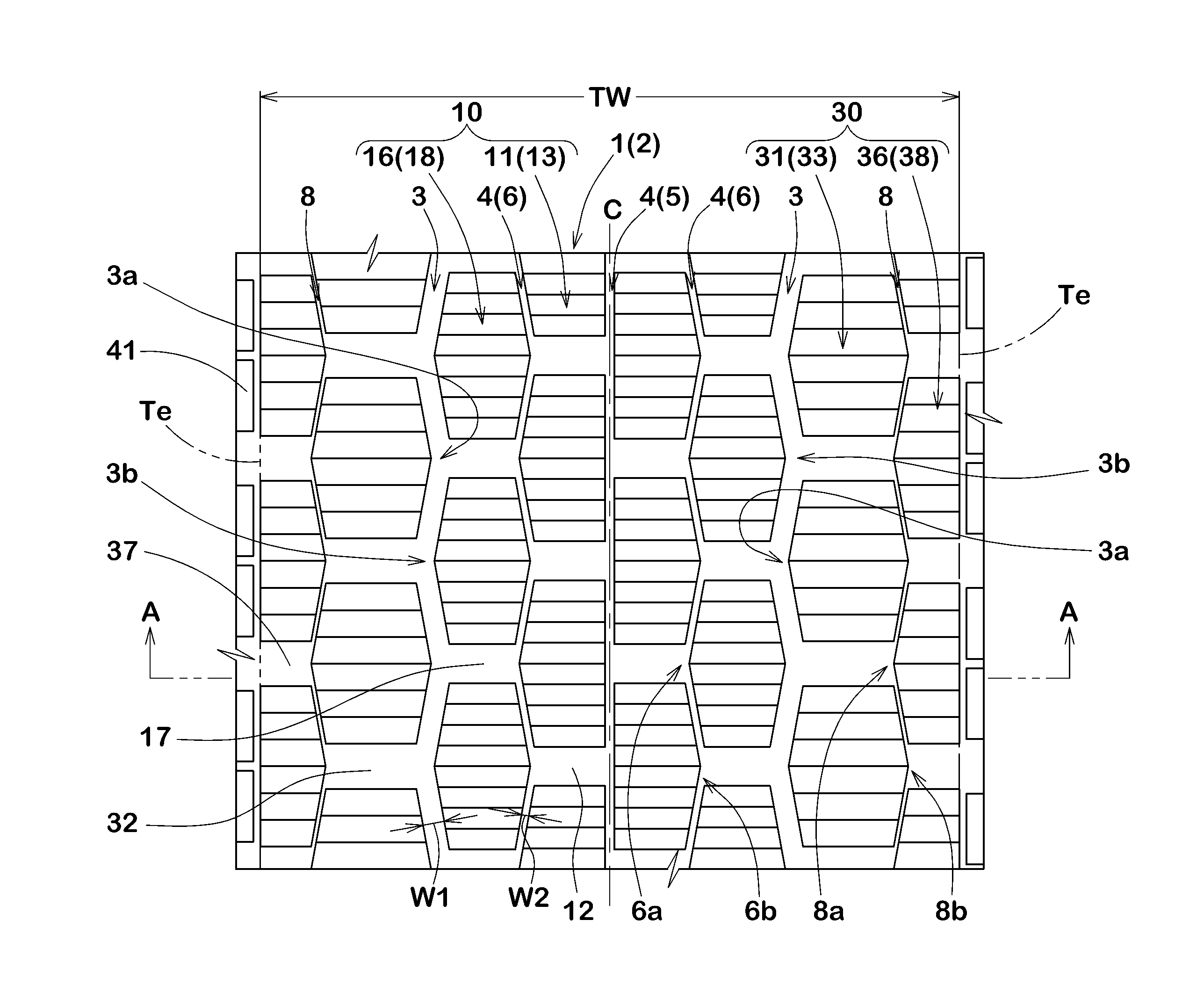

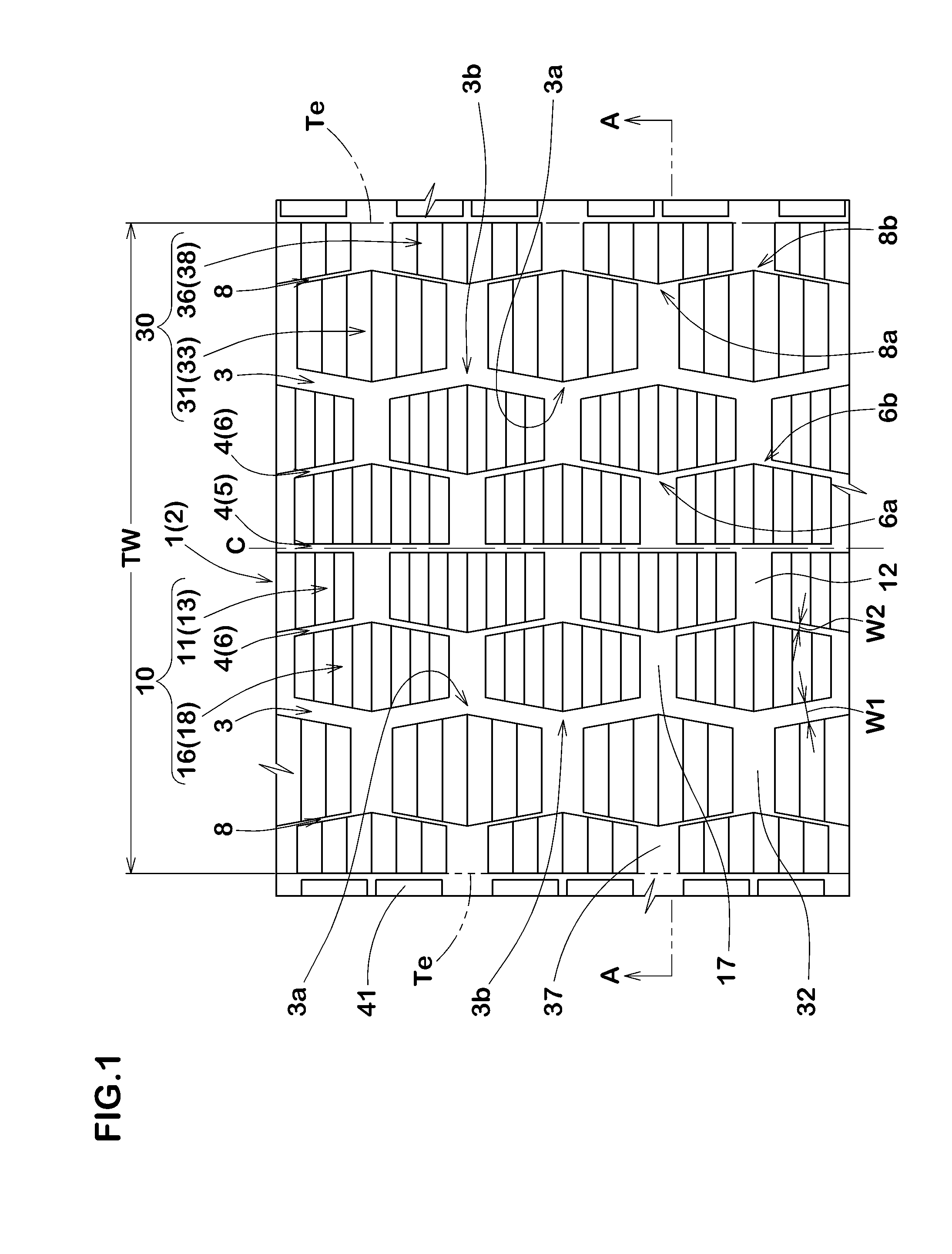

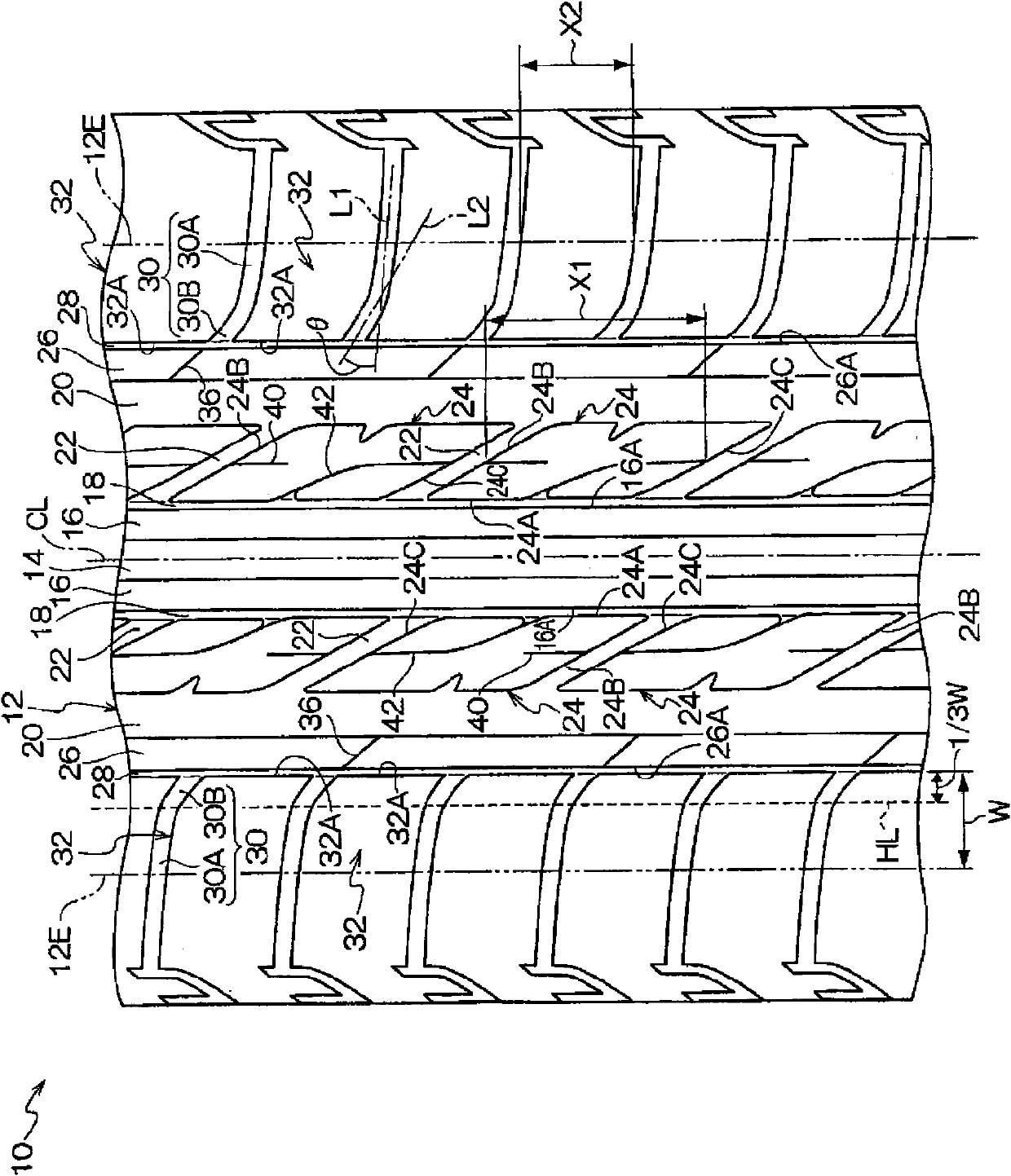

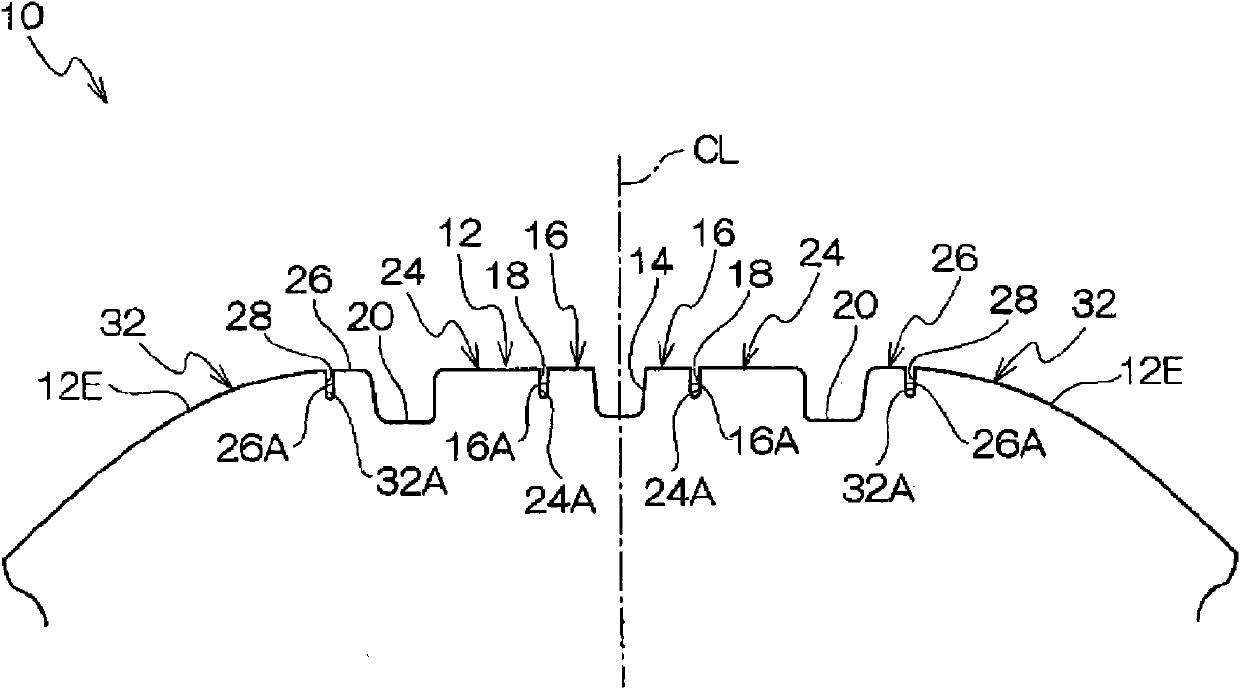

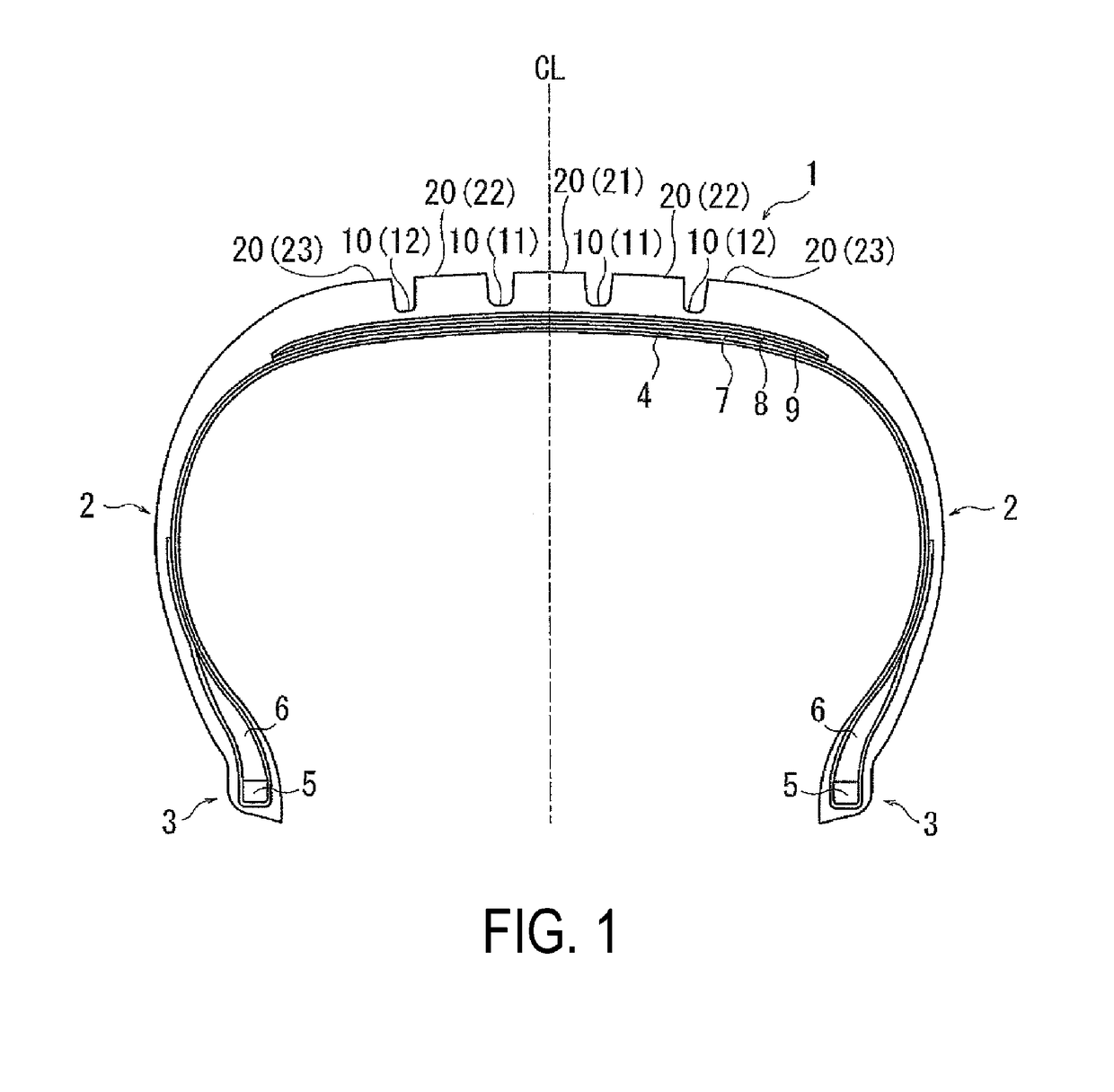

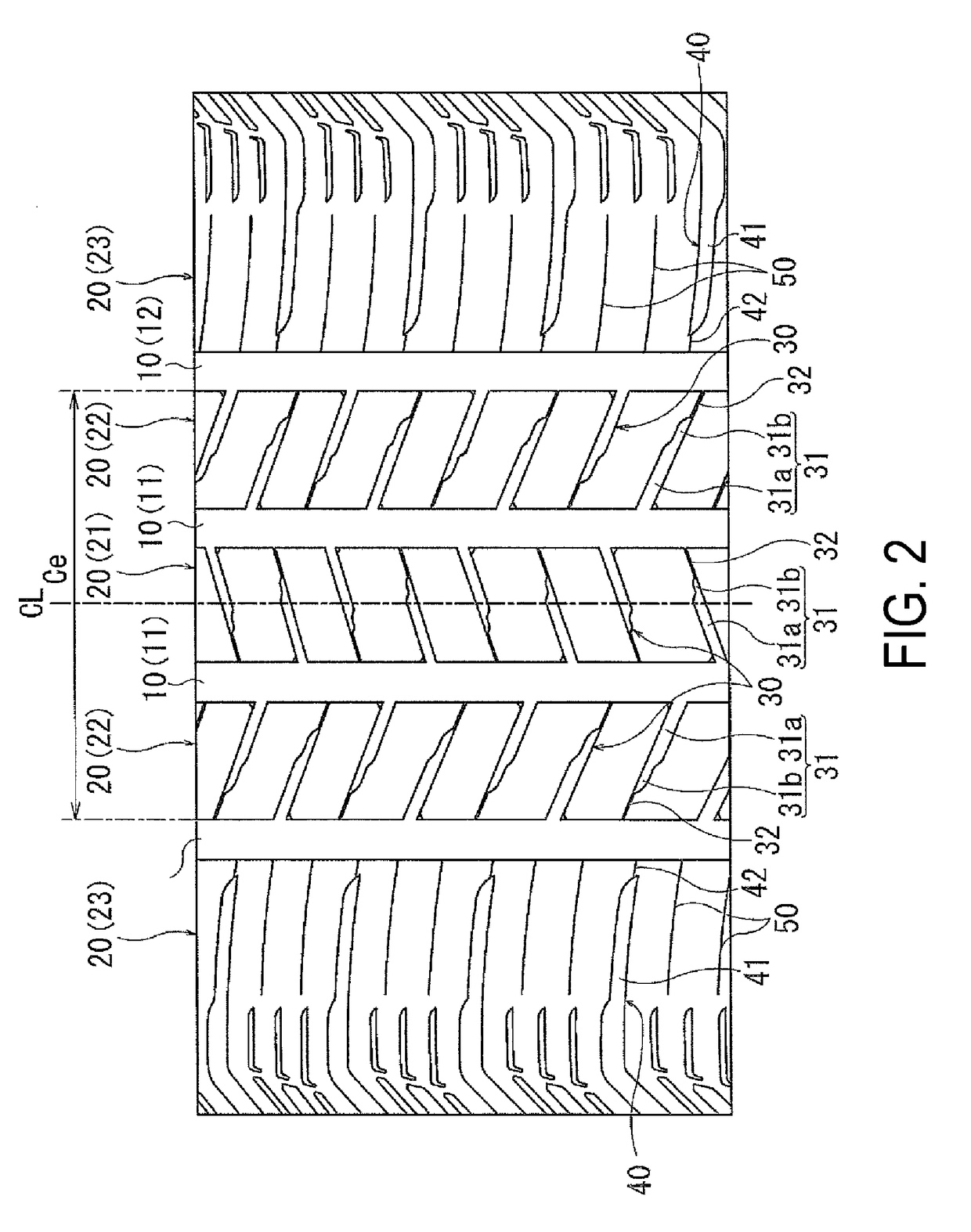

Pneumatic tire

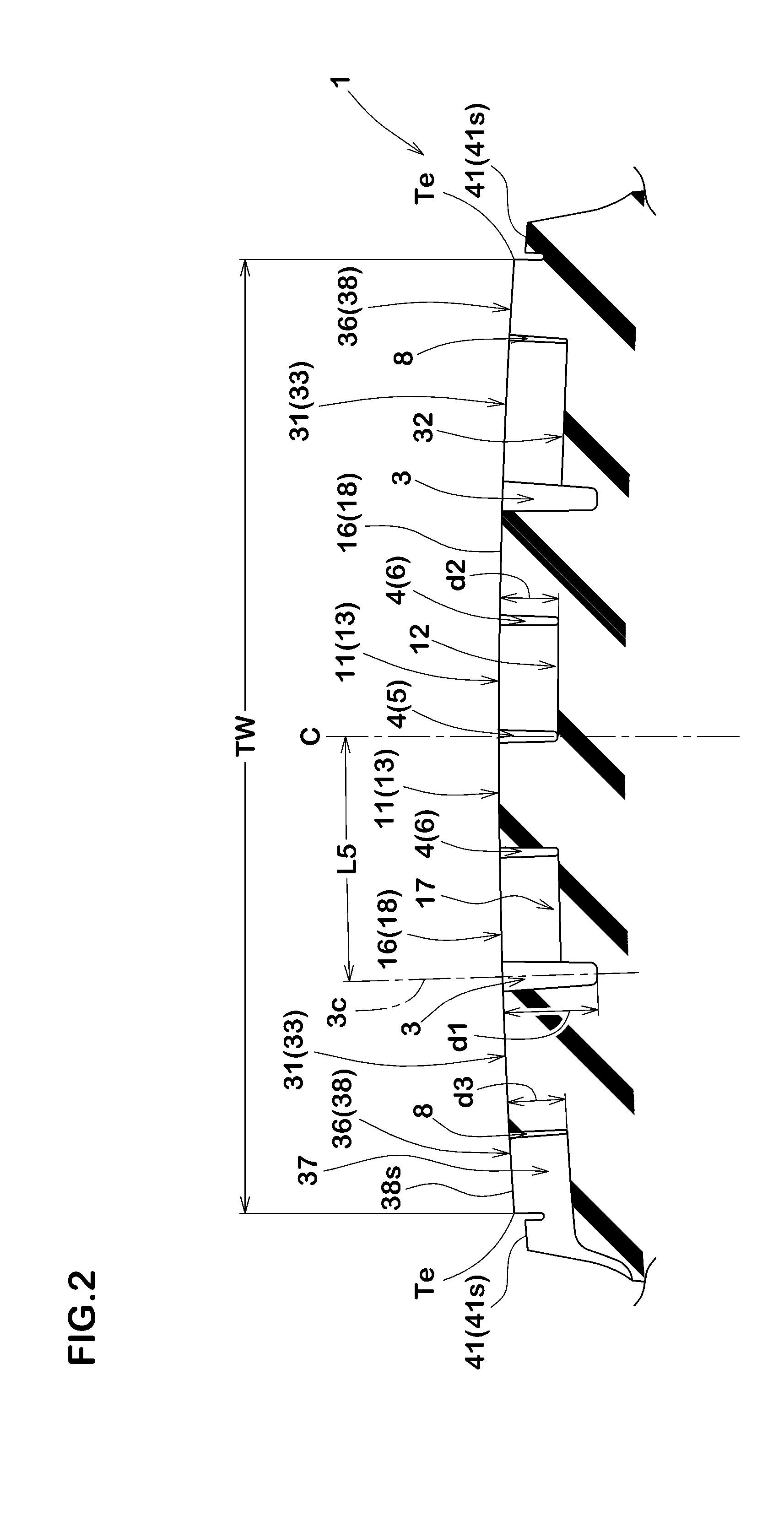

ActiveUS20160243898A1Resistance is maintainedMaintain wear resistanceTyre tread bands/patternsGroove widthEngineering

A pneumatic tire in which a tread part is provided with a pair of central main grooves extending continuously around the circumference of the tire on both sides of a tire equator C, and central thin grooves extending continuously around the circumference of the tire on the tire-axially inner sides of the central main grooves and having less groove width than the central main grooves. The central thin grooves include a linear first central thin groove running along the tire circumference, and zigzagging second central thin grooves. The first central thin groove is provided on the tire-axially inner sides of the second central thin grooves.

Owner:SUMITOMO RUBBER IND LTD

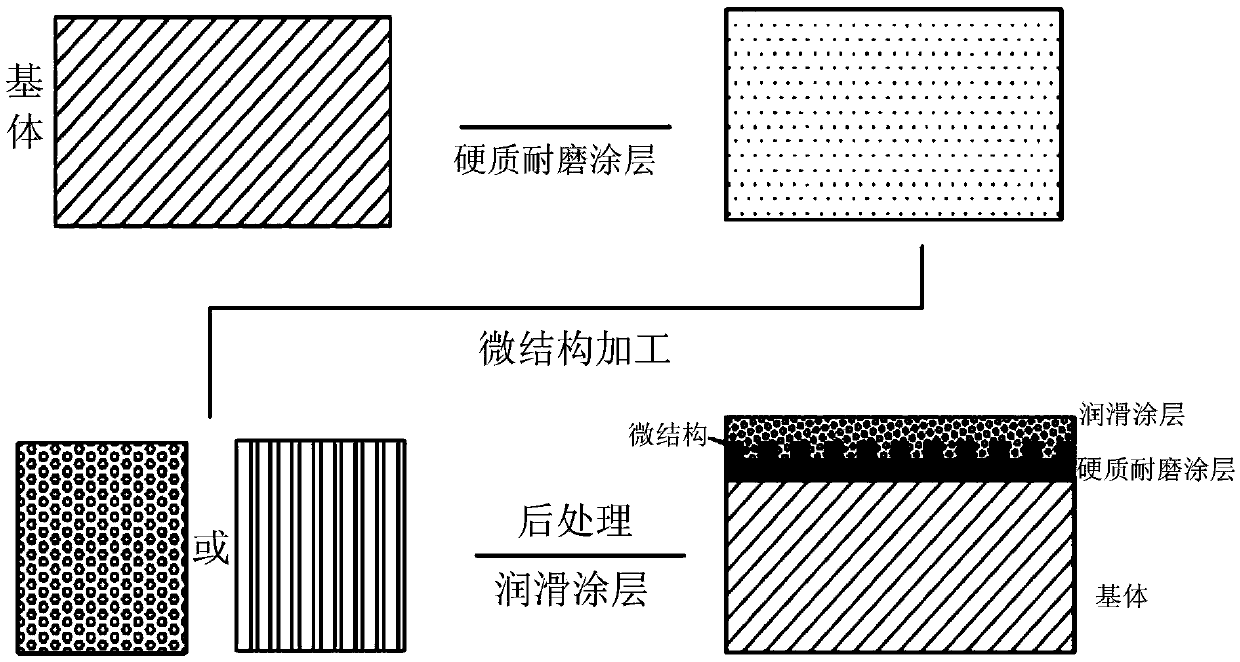

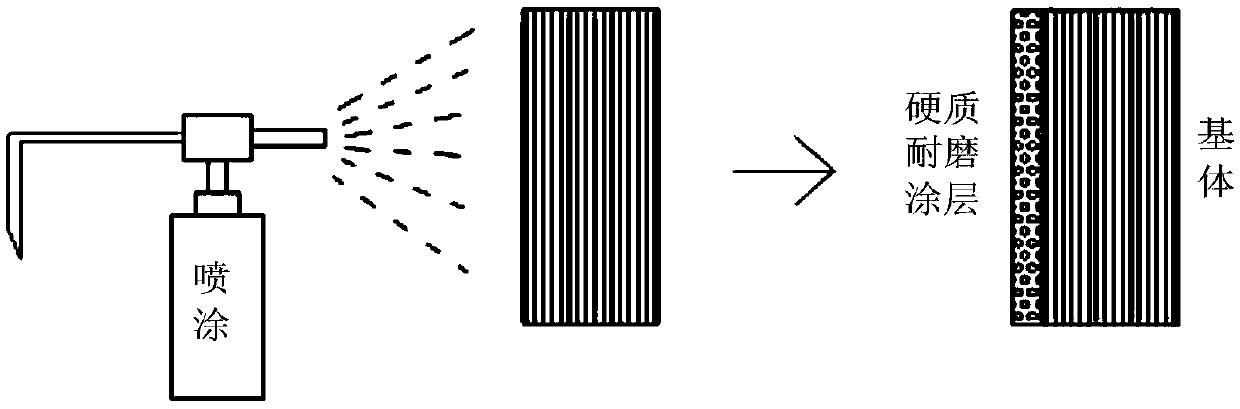

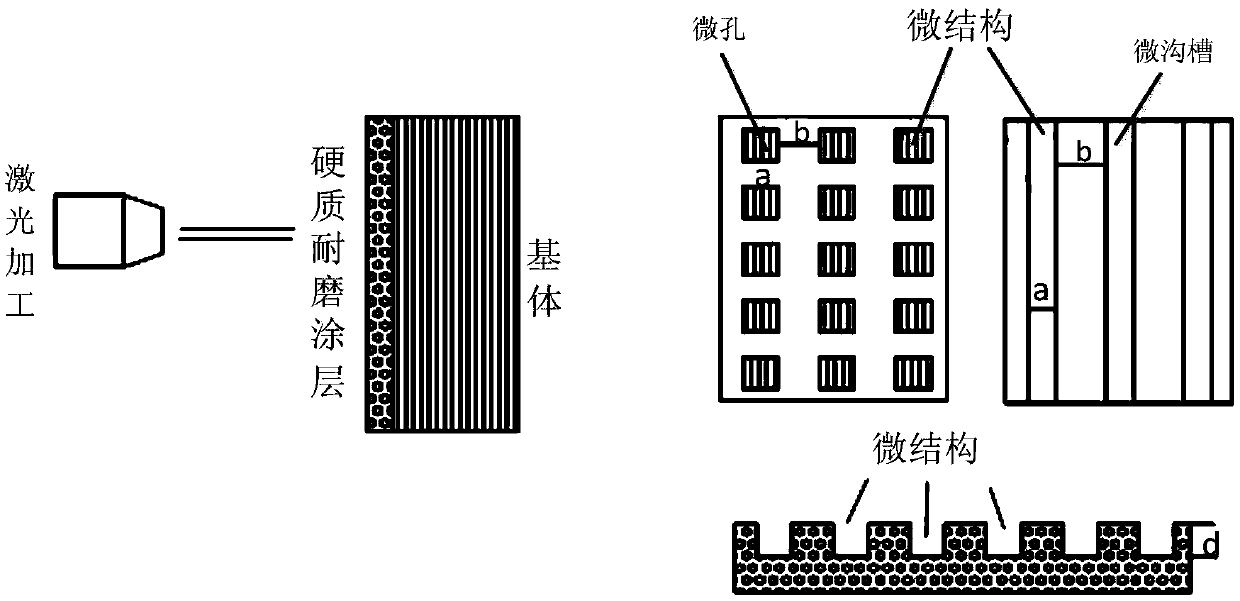

Preparation method of protective coating based on working surface of mould matrix

ActiveCN105506625AImprove the use effect and lifeGood lubricity and wear resistanceSuperimposed coating processWear resistantMicrostructure

The invention provides a preparation method of a protective coating based on a working surface of a mould matrix. The preparation method comprises the steps that 1) first paint is sprayed on the working surface of the mould matrix to form a hard wear-resistant coating; 2) an inward sunk microstructure is prepared on the surface of the hard wear-resistant coating; and 3) second paint is sprayed on the surface of the hard wear-resistant coating to form a lubricant coating, thereby accomplishing the preparation of the protective coating based on the working surface of the mould matrix. With the adoption of the preparation method, the protective coating having high bonding strength, wear resistance and lubricating property can be prepared on the working surface of the mould matrix, the problem that the interface bonding strength between the traditional hard wear-resistant layer and the traditional lubricant coating is low is solved, and the life of a mould is prolonged.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

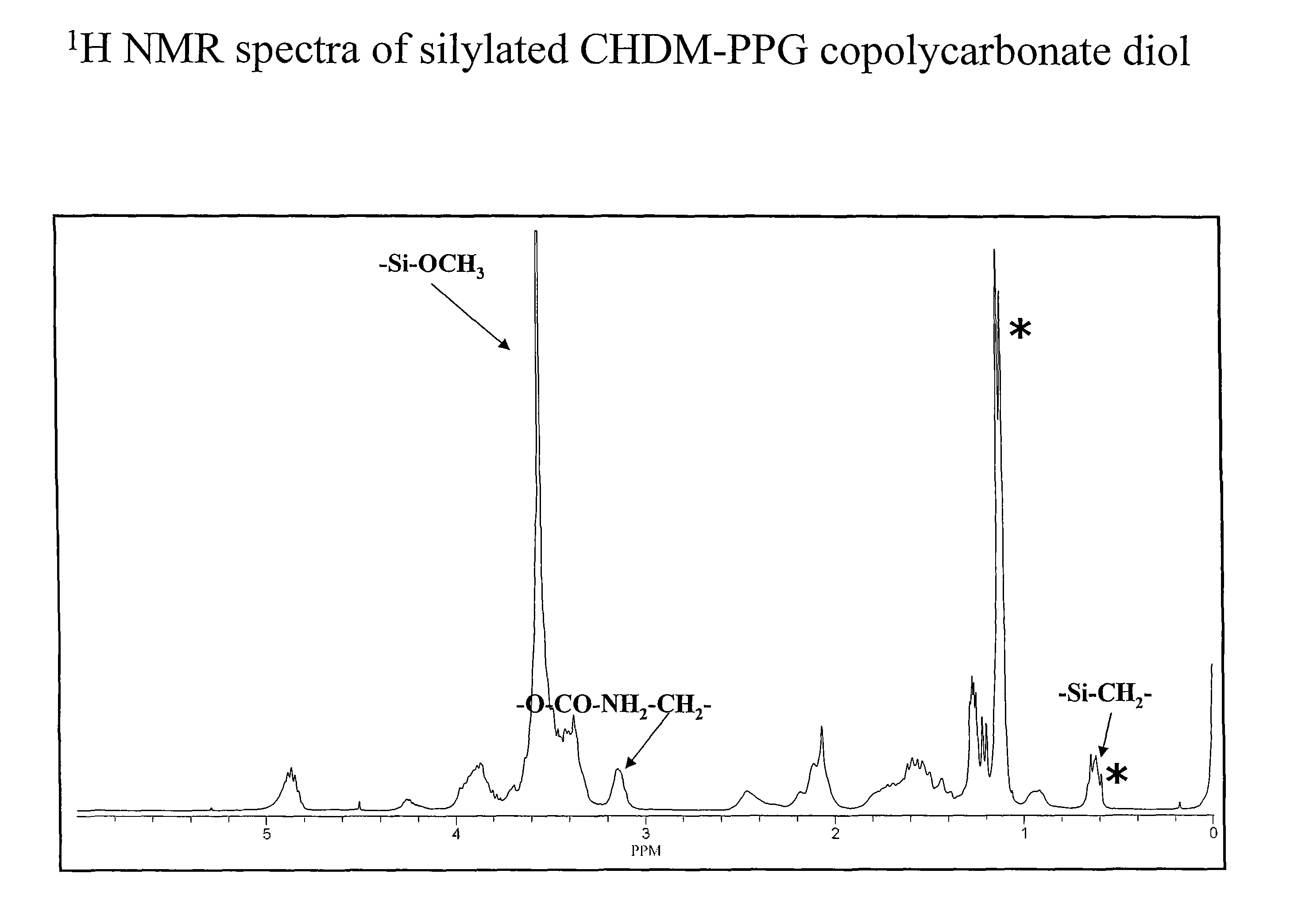

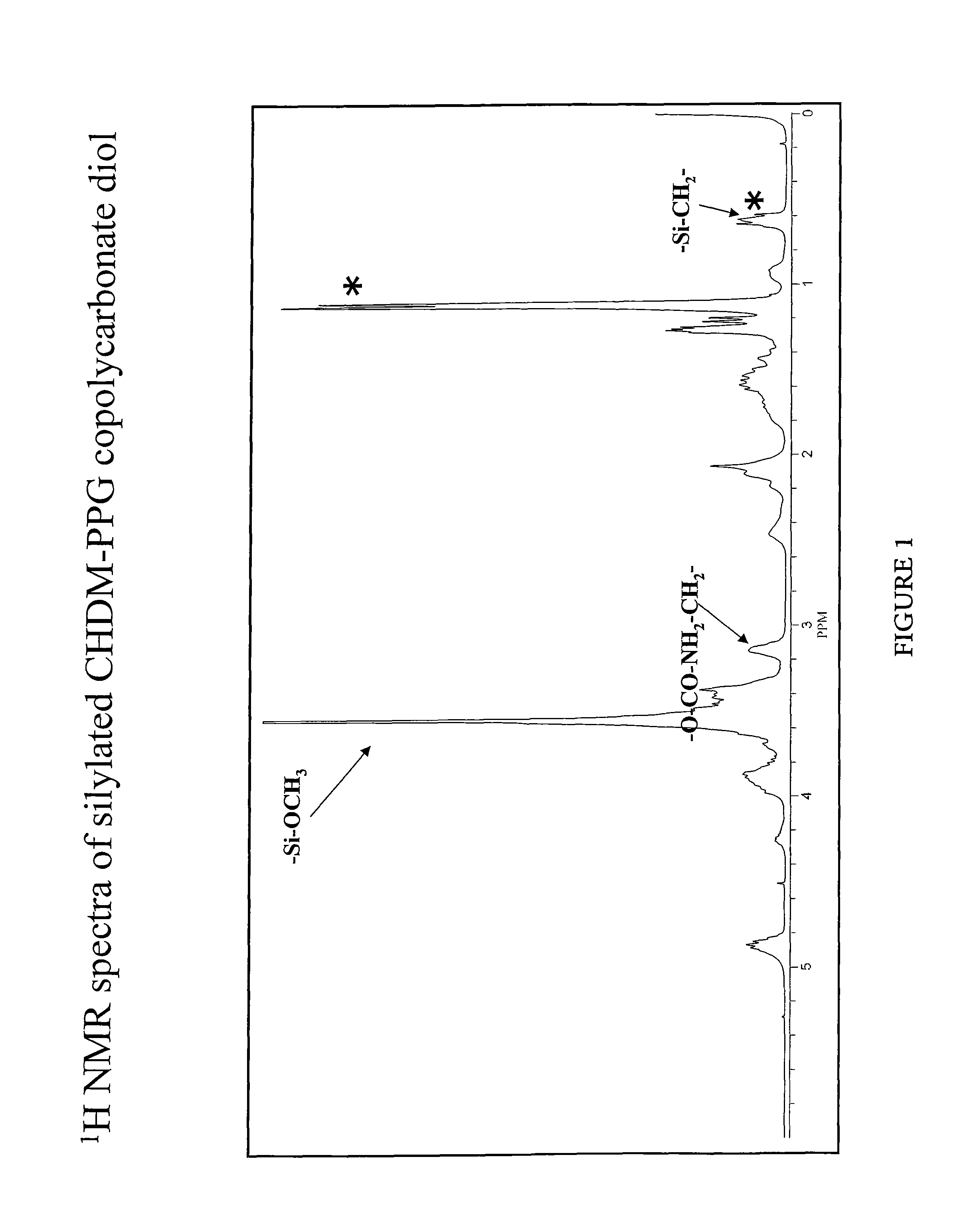

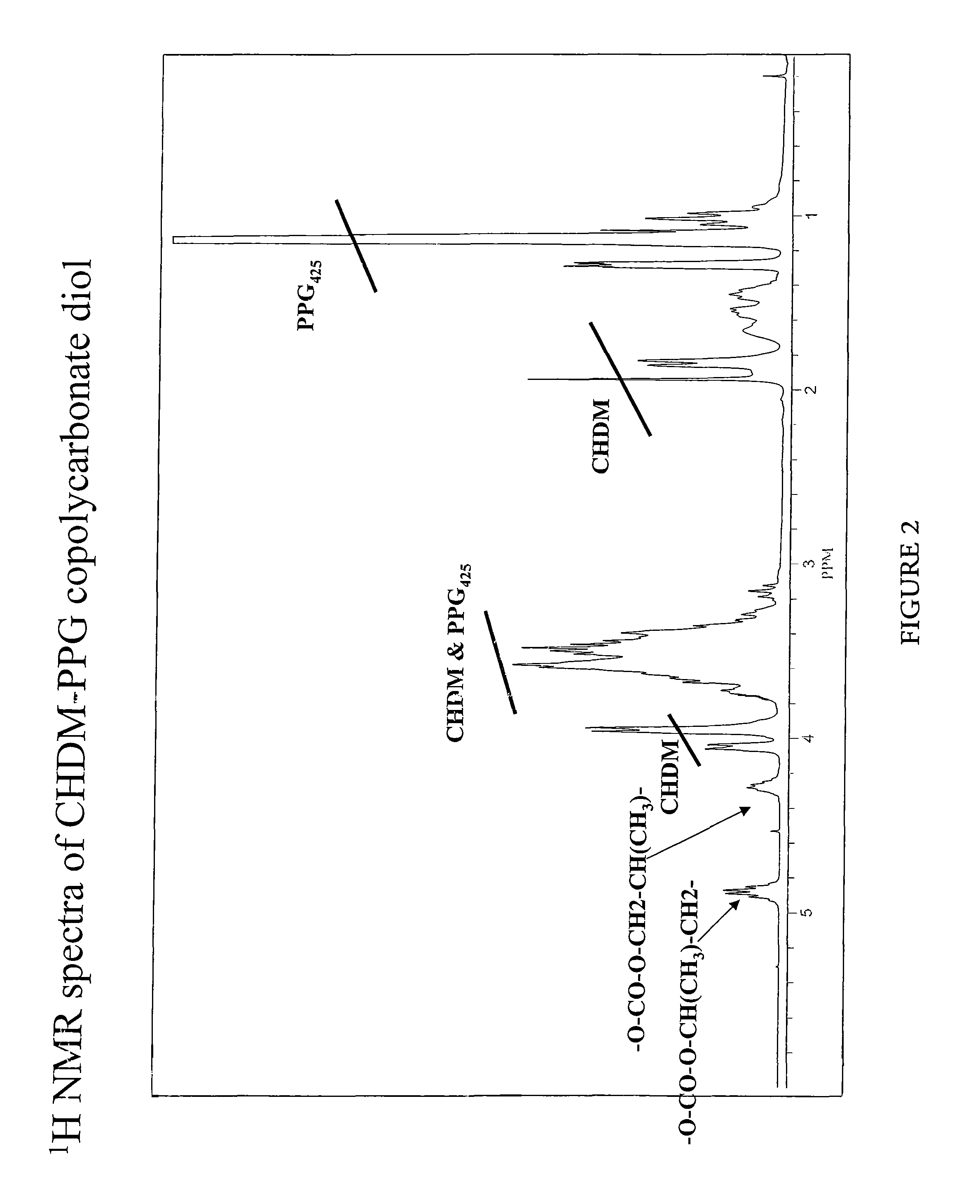

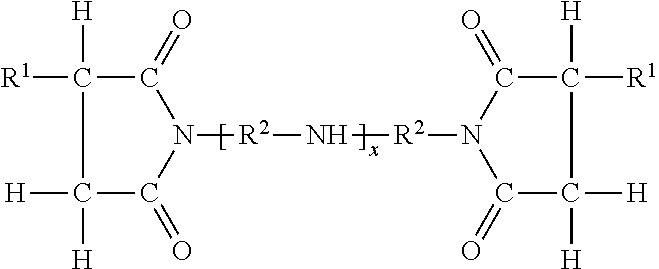

Copolycarbonates, their derivatives and the use thereof in silicone hardcoat compositions

ActiveUS8637157B2Increase flexibilityMaintain wear resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePerylene derivatives

Disclosed herein are novel copolycarbonates containing repeating units A and B respectively of the formulae: (A) —[R1OC(═O)O]—, and (B) —[(R2O)n-C(═O)—O]—, wherein the molar ratio of units (A) to units (B) is in the range of from about 9:1 to about 1:9, and wherein R1 is a divalent C8 to C12 alicyclic group, and R2 is ethylene or propylene, and n is an integer ranging from 4 to 40. Also disclosed are silicone hardcoat compositions containing the copolycarbonates and their derivatives. Upon cure, these silicone hardcoat compositions exhibit improved flexibility as compared to that of the conventional hardcoats while at the same time maintain the abrasion resistance of conventional silicone hardcoats.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

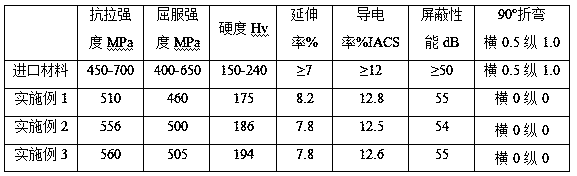

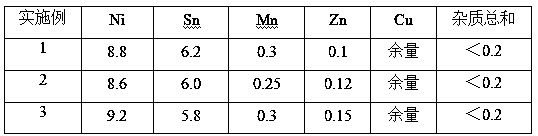

Cu-Ni-Sn alloy belt foil for 5G communication and preparation method thereof

The invention discloses a Cu-Ni-Sn alloy belt foil for 5G communication and a preparation method thereof. The Cu-Ni-Sn alloy belt foil is prepared from the following raw material components in percentage by weight: 8.5-9.5% of nickel, 5.5-6.5% of tin, 0.2-0.5% of manganese, 0.1-0.3% of zinc, and the balance copper and impurities. The preparation method comprises the following steps: melting weighed copper and nickel, covering with wood charcoal, sequentially adding manganese, tin and zinc, stirring and dissolving after heating up to a temperature of 1300-1330 DEG C, slagging-off, covering withwood charcoal, standing and converting, slagging-off, and covering with wood charcoal; performing pull-casting, homogenizing annealing treatment, face-milling, cold-rolling cogging, intermediate solid-solution treatment, intermediate rolling, intermediate solid-solution treatment and finished product rolling by adopting a reverse pushing-pulling and stopping blank pulling way, and obtaining foilwith a thickness being 0.04-0.1mm. Elasticity, wear resistance and corrosion resistance of a Cu-Ni-Sn copper alloy in the prior art are kept, and meanwhile, the Cu-Ni-Sn alloy belt has good forming property, relatively high conductivity and excellent shielding performance, can realize industrial production of the Cu-Ni-Sn alloy belt foil for 5G communication, replaces import, fills up the domesticblank to promote copper processing industry development needs of the current stage.

Owner:CNMC ALBETTER ALBRONZE

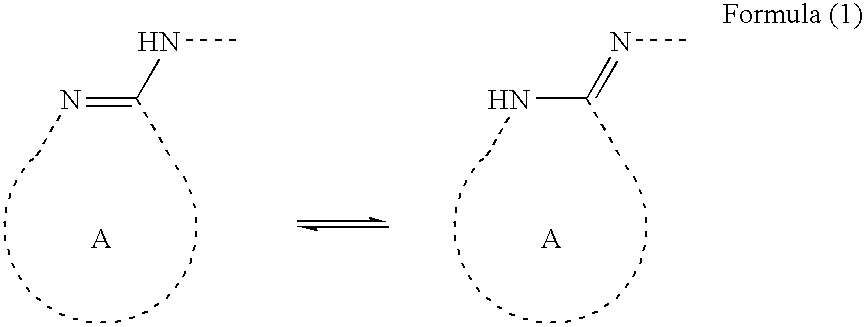

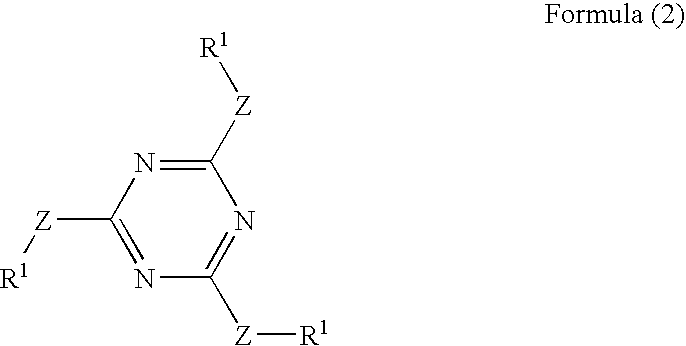

Mechanical Element

InactiveUS20080081772A1Low function propertyImprove anti-wear propertyBearing componentsAdditivesChemistryLubricant

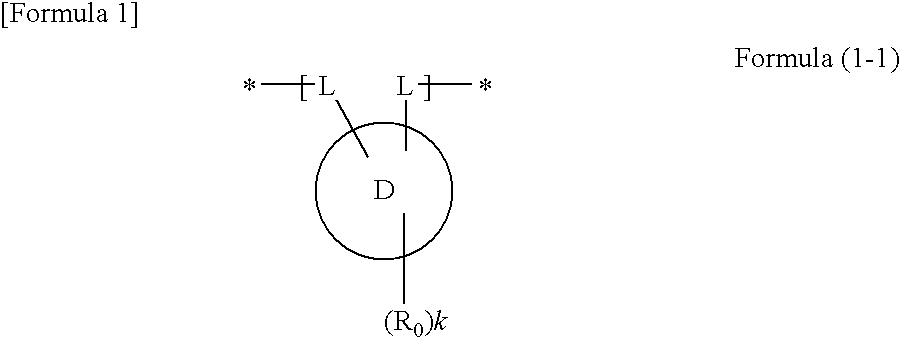

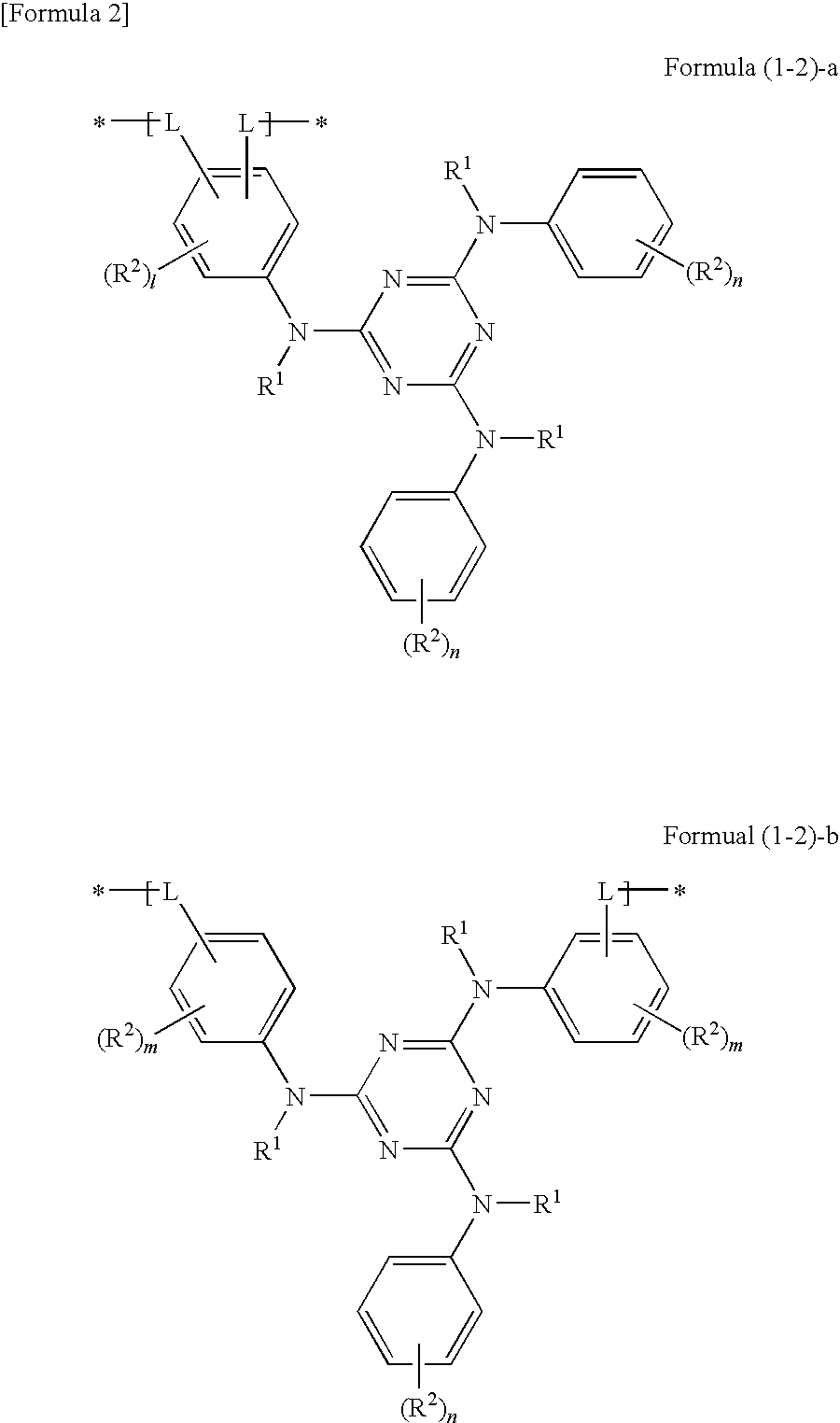

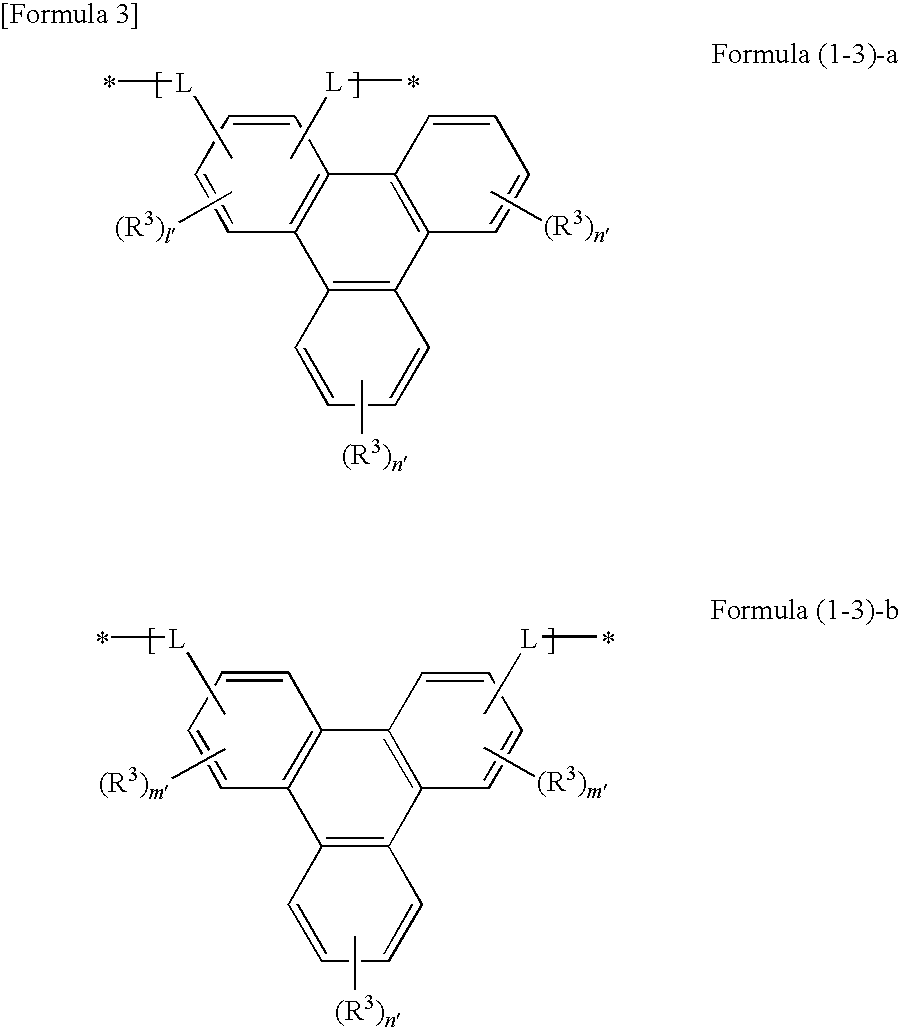

A novel mechanical element is disclosed. The mechanical element comprises at least two surfaces movable at peripheral speeds differed from each other, and a lubricant composition disposed between said two surfaces, a surface of at least one said two surfaces having an organic residue having carboxyl group, sulfoxyl group, cyclic or non-cyclic carbamoyl group, cyclic or non-cyclic ureylene group, cyclic or non-cyclic sulfarnoyl group, or cyclic or non-cyclic amidino group, and said lubricant composition comprising a discotic compound having at least one tautomeric group represented by a formula (1) in which A is a ring in which from 5 to 7 atoms are embedded, wherein one of, or two or more of the ring-composing atoms may have a substituent, or may be condensed with other ring.

Owner:FUJIFILM CORP

Coated cutting tool

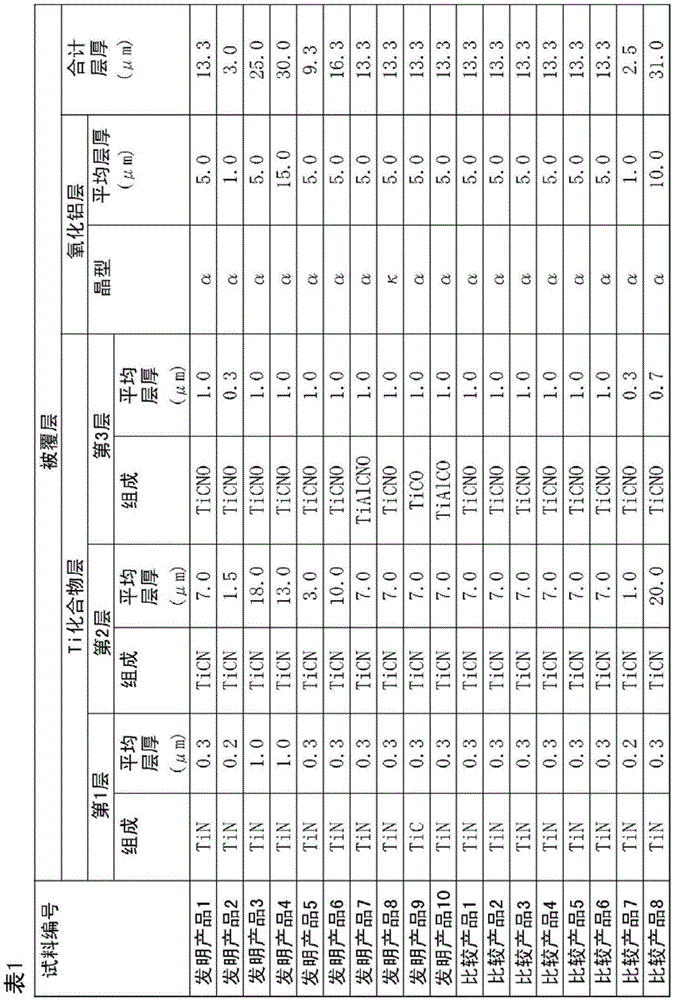

ActiveCN105579171AExtend your lifeMaintain wear resistanceTransportation and packagingMilling cuttersNumber densityVolumetric Mass Density

Provided is a coated cutting tool provided with a substrate and a coating layer formed on the outer surface of the substrate in order to obtain a coated cutting tool having superior resistance to chipping, wear and damage while having a long service life, wherein: the coating layer includes at least one Ti compound layer; the Ti compound layer comprising a compound containing elemental titanium and at least one element selected from the group consisting of C, N, O and B; a region surrounded by cracks is provided in the Ti compound layer when a grinding surface substantially parallel to the surface of the substrate is seen from above; the region is internally provided with intermittent cracks in which one end or both ends of the cracks do not abut the cracks that constitute the region; and the average number density (A) of the region and the average number density (B) of the cracks satisfies the relationship of 0.7<B / A<2.

Owner:TUNGALOY CORP

Low viscosity marine cylinder lubricating oil compositions

InactiveUS8702968B2Maintain wear resistanceMaintain performanceAdditivesBase-materialsTotal Base NumberChemical composition

Disclosed herein are marine cylinder lubricants which comprise a major amount of basestock selected from the group consisting of a Group II basestock, a Group III basestock and mixtures thereof, wherein the marine cylinder lubricant has a kinematic viscosity at 100° C. of from 13 to about 16.2 cSt; and contains less than about 10 wt. % bright stock. Also disclosed are marine cylinder lubricants which comprise a major amount of basestock selected from the group consisting of a Group II basestock, a Group III basestock and mixtures thereof, wherein the marine cylinder lubricant has a kinematic viscosity at 100° C. of between about 13 and about 16.2 cSt; and a total base number of 5 to about 70, and further wherein the marine cylinder lubricant contains less than about 10 wt. % bright stock.

Owner:CHEVRON ORONITE TECH BV

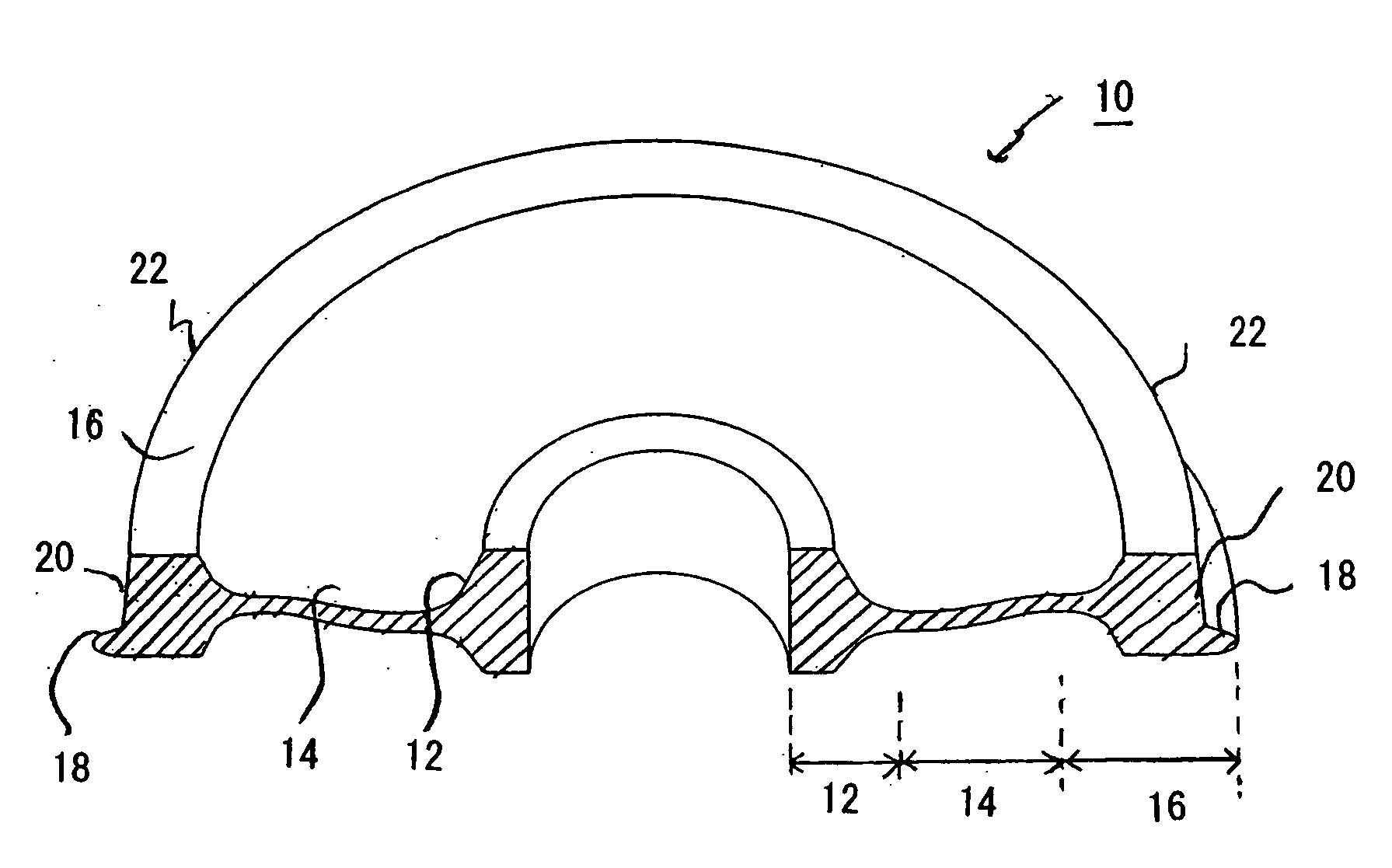

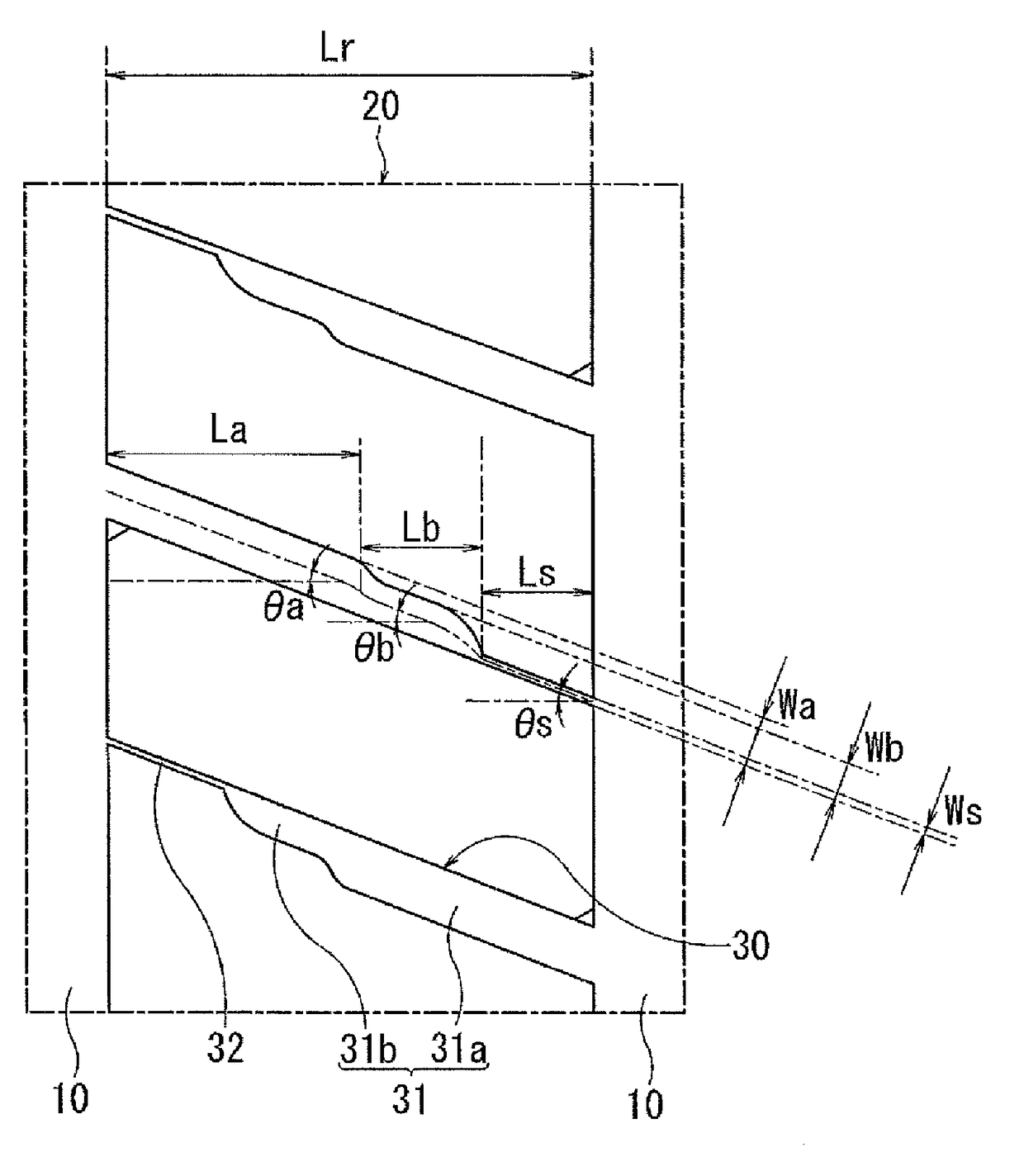

Pneumatic tire

InactiveCN102089162ARoll up restraintFull brakingTyre tread bands/patternsRolling resistance optimizationRolling resistanceRoad surface

A tire having sufficient braking performance on a dry road and a wet road, having reduced rolling resistance, and having improved wear resistance performance. A tire (10) has a tread (12) provided with the following: center ribs (16) defined by a first circumferential groove (14) and by first narrow grooves (18) having groove walls making contact with each other when the tread (12) is compressed and deformed by engaging the ground; center blocks (24) defined, on the outer side of each first narrow groove (18) in the tire's lateral direction, by a second circumferential groove (20) and by center lug grooves (22) extending from the first narrow groove (18) to the second circumferential groove (20); first sipes (40) each formed in the surface of each center block (24) and each extending in the tire's circumferential direction from a wall surface (24B) toward a wall surface (24C) to terminate in the center block; and second sipes (42) each formed in the surface of each center block (24) and each extending in the tire's circumferential direction from the wall surface (24C) toward the wall surface (24B), bent in the middle, open to a wall surface (24A), and not intersecting with the first sipe (40) in a plan view. The tire (10) has sufficient braking performance on a dry road and a wet road, has reduced rolling resistance, and has improved wear resistance performance.

Owner:BRIDGESTONE CORP

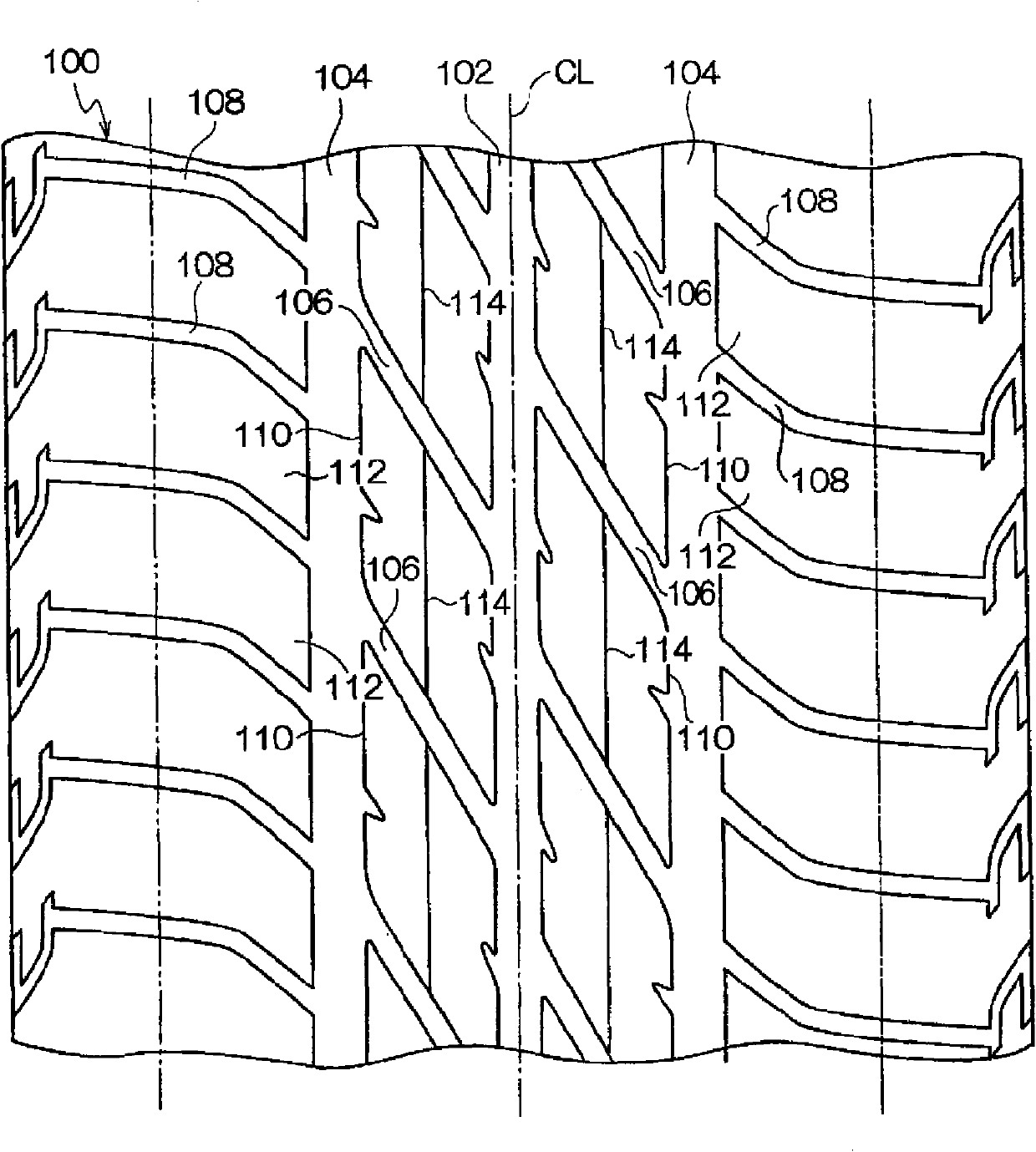

Pneumatic Tire

InactiveUS20170361659A1Improve snow performanceImproved performance wear resistanceTyre tread bands/patternsMechanical engineeringEngineering

Owner:YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com