Coated cutting tool

A cutting tool and cladding technology, which is used in the manufacture of tools, workpieces, drilling tool accessories, etc., can solve the problems of reduced destructive strength and easy occurrence of defects of clad cutting tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

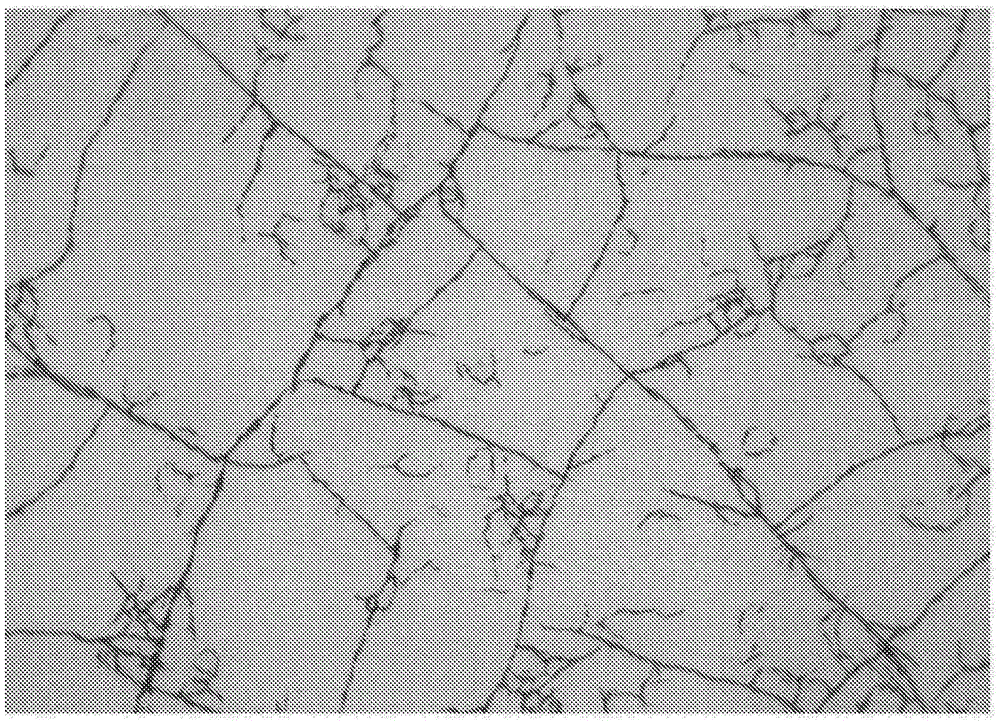

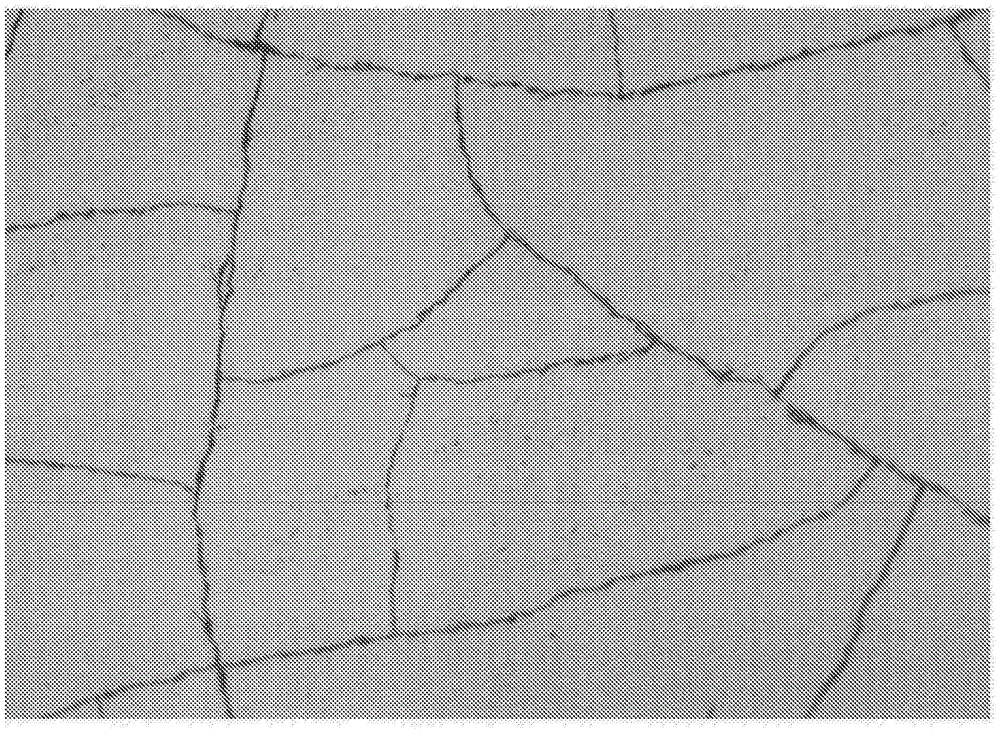

Image

Examples

Embodiment

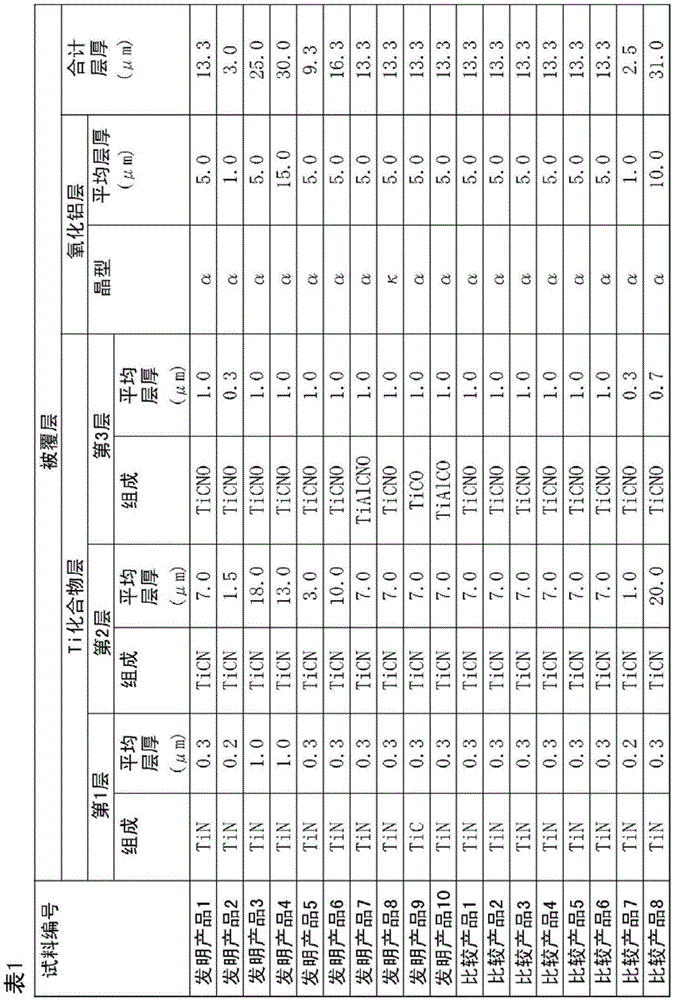

[0065] Examples are given below to describe the present invention, but the present invention is not limited to these Examples.

[0066] As a base material, a cutting insert made of cemented carbide having a composition of 86.0WC-1.0TiCN-1.3TaC-0.2NbC-0.5ZrC-11.0Co (the above is mass %) in the shape of JIS standard CNMG120412 was prepared. The surface of the base material was cleaned after circular honing was performed on the cutting edge ridge line portion of the base material with a SiC brush. Next, the base material was placed in an external heating type chemical vapor deposition apparatus, and a coating layer was formed on the surface of the base material so that the composition and average layer thickness of the coating layer shown in Table 1 were obtained. 10 samples were produced for each sample. In addition, the aluminum oxide layer (Al 2 o 3 The α in the crystal form of layer) means α-type Al 2 o 3 layer, κ means κ-type Al 2 o 3 layer.

[0067]The obtained samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com