Patents

Literature

299 results about "Number density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, astronomy, chemistry, biology and geography, number density (symbol: n or ρN) is an intensive quantity used to describe the degree of concentration of countable objects (particles, molecules, phonons, cells, galaxies, etc.) in physical space: three-dimensional volumetric number density, two-dimensional a real number density, or one-dimensional linear number density. Population density is an example of areal number density. The term number concentration (symbol: C, to avoid confusion with amount of substance n) is sometimes used in chemistry for the same quantity, particularly when comparing with other concentrations.

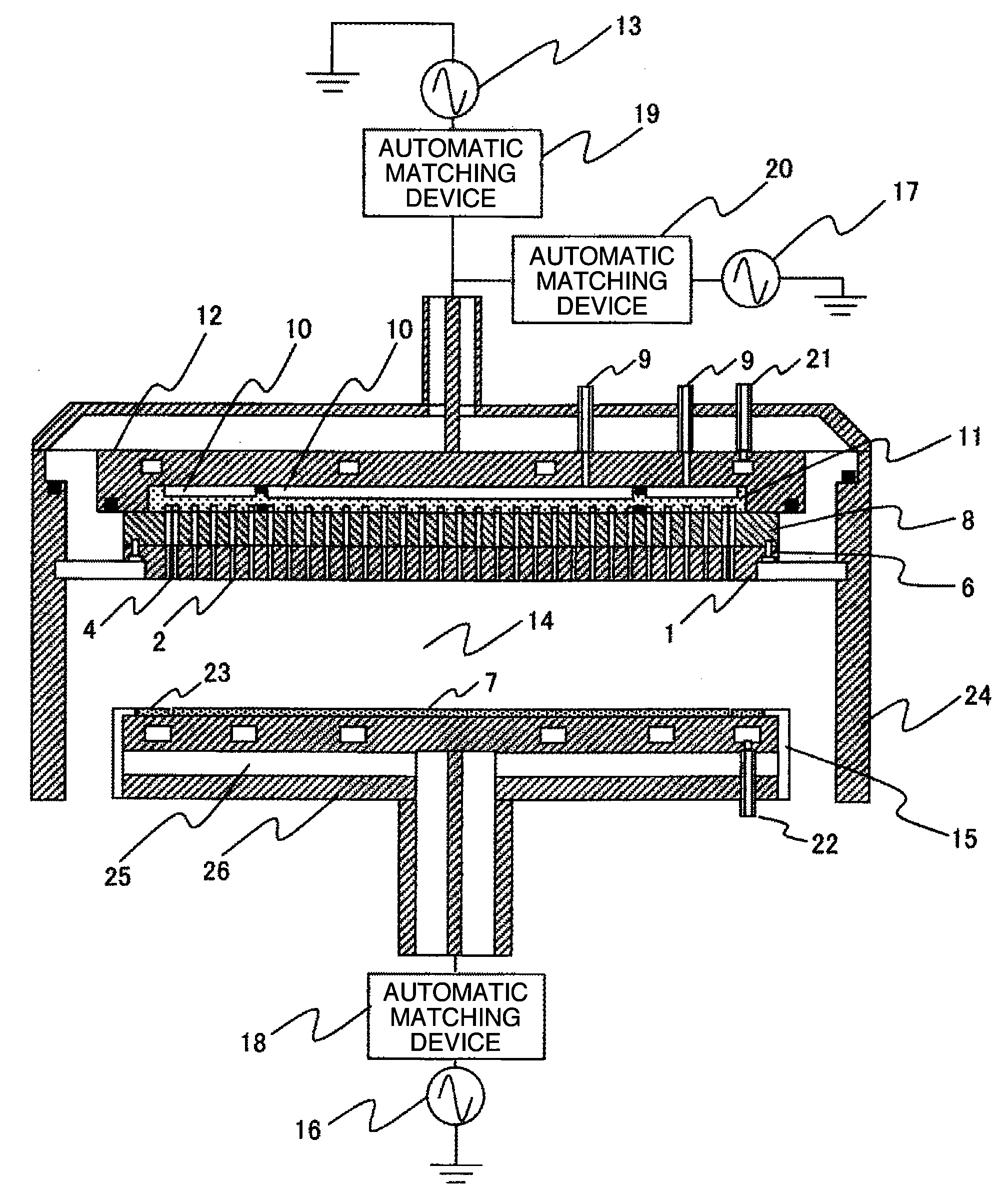

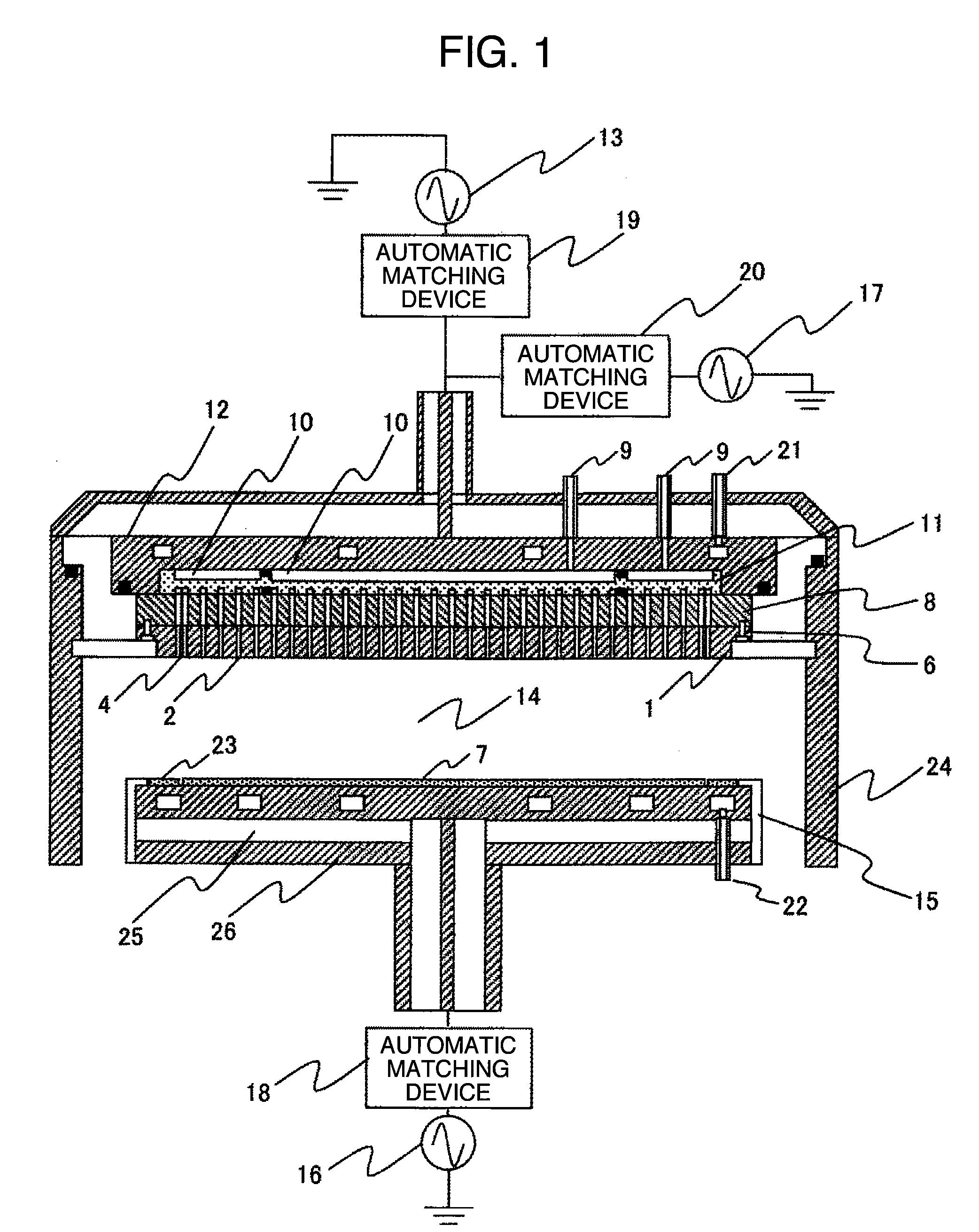

Plasma processing apparatus

InactiveUS20100163187A1Uniform processing rateUniform supplyElectric discharge tubesSemiconductor/solid-state device manufacturingNumber densityEngineering

A plasma processing apparatus includes a vacuum chamber, a sample table that places the sample in the vacuum chamber, and a gas supply unit faced to the sample table and having a gas supply surface with a diameter larger than that of the sample, wherein gas injection holes each having identical diameter are provided concentrically on the gas supply surface, a hole number density of the gas injection holes present in an outer diameter position of the sample or in an outside of the outer diameter position is made higher than that of the gas injection holes present inside the outer diameter position of the sample, and a diameter of the gas injection holes present in the outer diameter position of the sample or in the outside from the outer diameter position is larger than that of the gas injection holes present inside the diameter of the sample.

Owner:HITACHI HIGH-TECH CORP

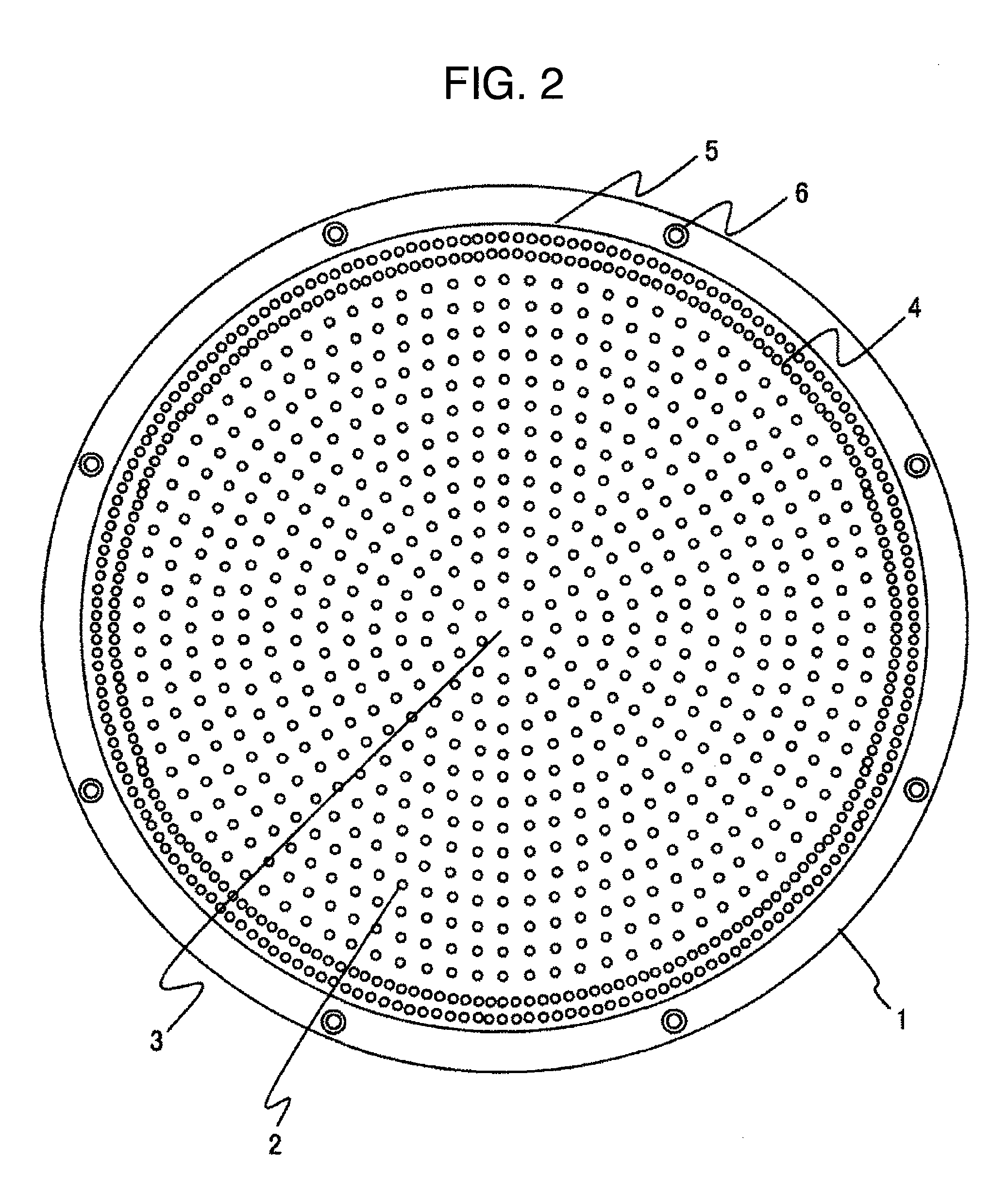

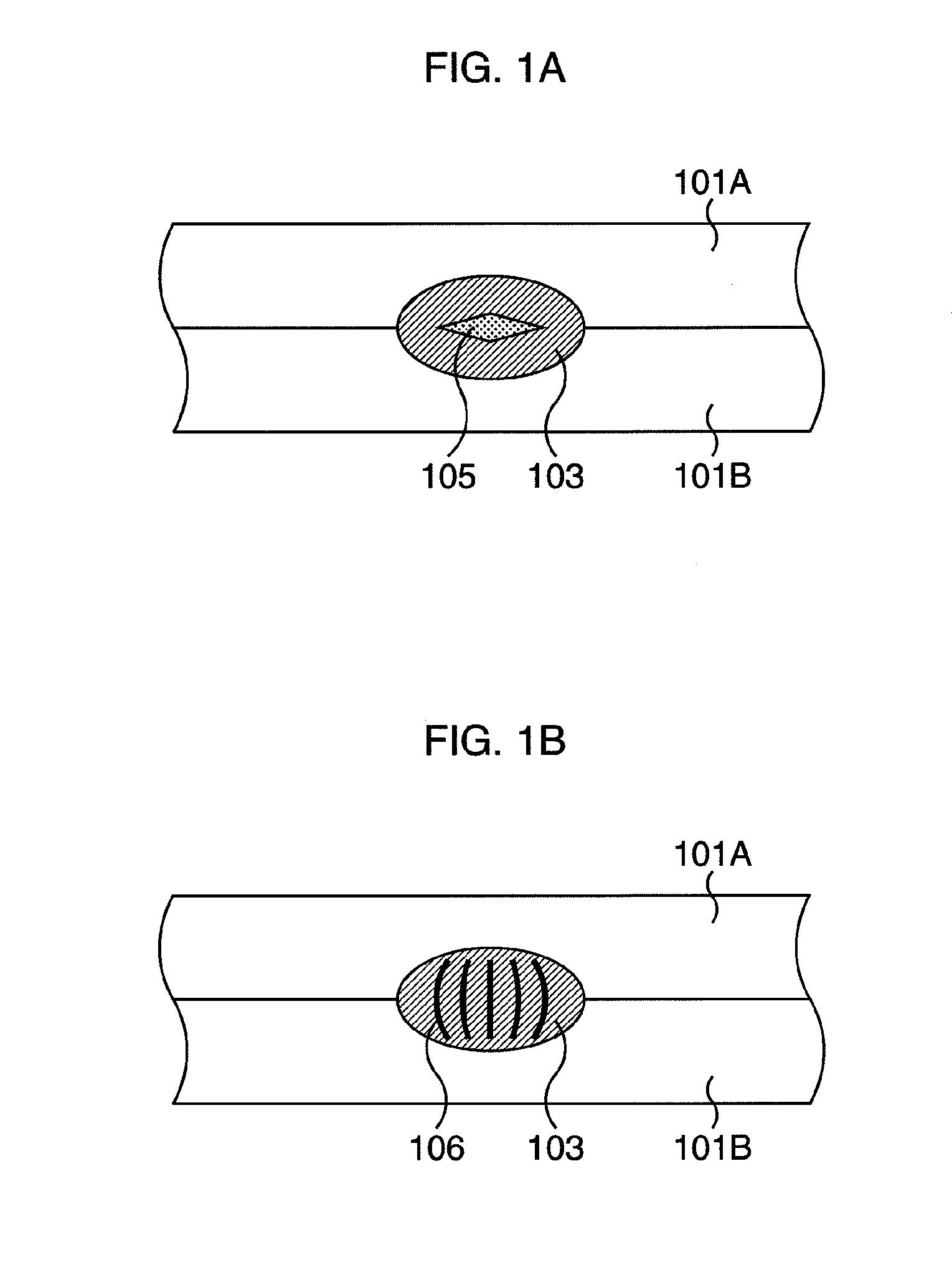

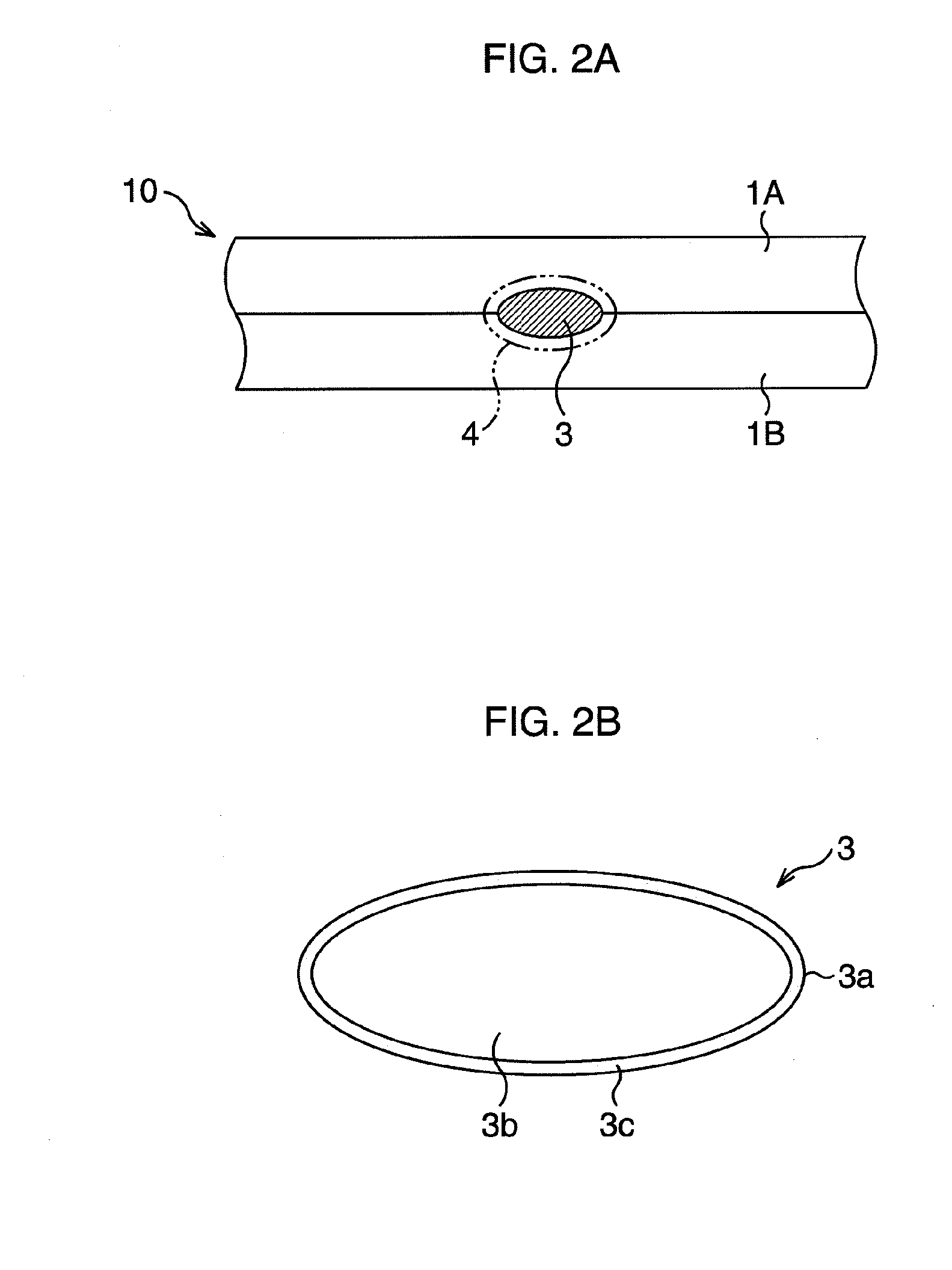

Spot welded joint and spot welding method

ActiveUS20120141829A1Improve machinabilityImprove reliabilityArc welding apparatusWelding/soldering/cutting articlesNumber densityCarbide

Provided is a spot welded joint (10) which includes at least one thin steel plate with a tensile strength of 750 MPa to 1850 MPa and a carbon equivalent Ceq of equal to or more than 0.22 mass % to 0.55 mass % and in which a nugget (3) is formed in an interface of the thin steel plates (1A, 1B). In a nugget outer layer zone, a microstructure consists of a dendrite structure in which an average value of arm intervals is equal to or less than 12 μm, an average grain diameter of carbides contained in the microstructure is 5 nm to 100 nm, and a number density of carbides is equal to or more than 2×106 / mm2.

Owner:NIPPON STEEL CORP

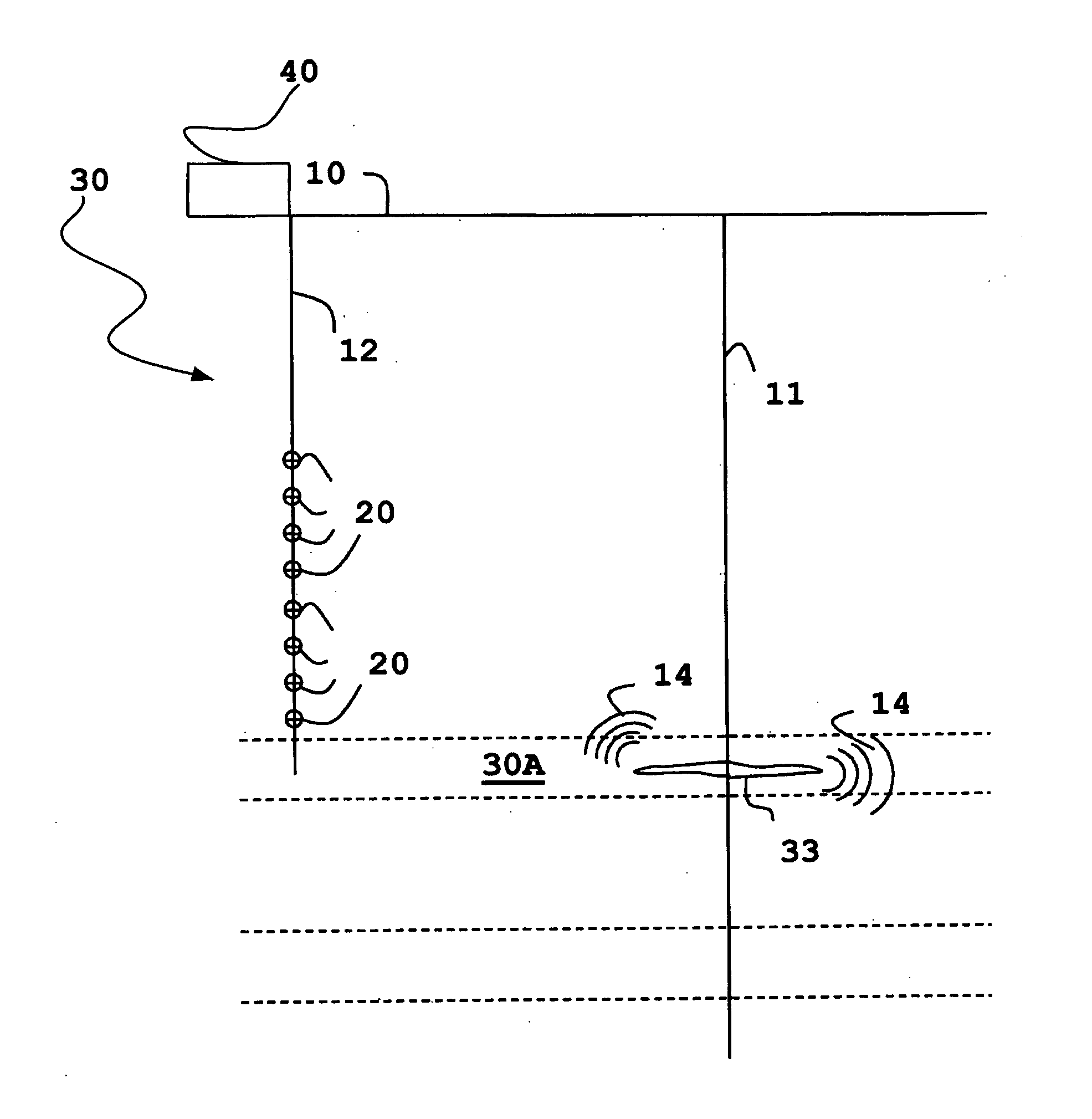

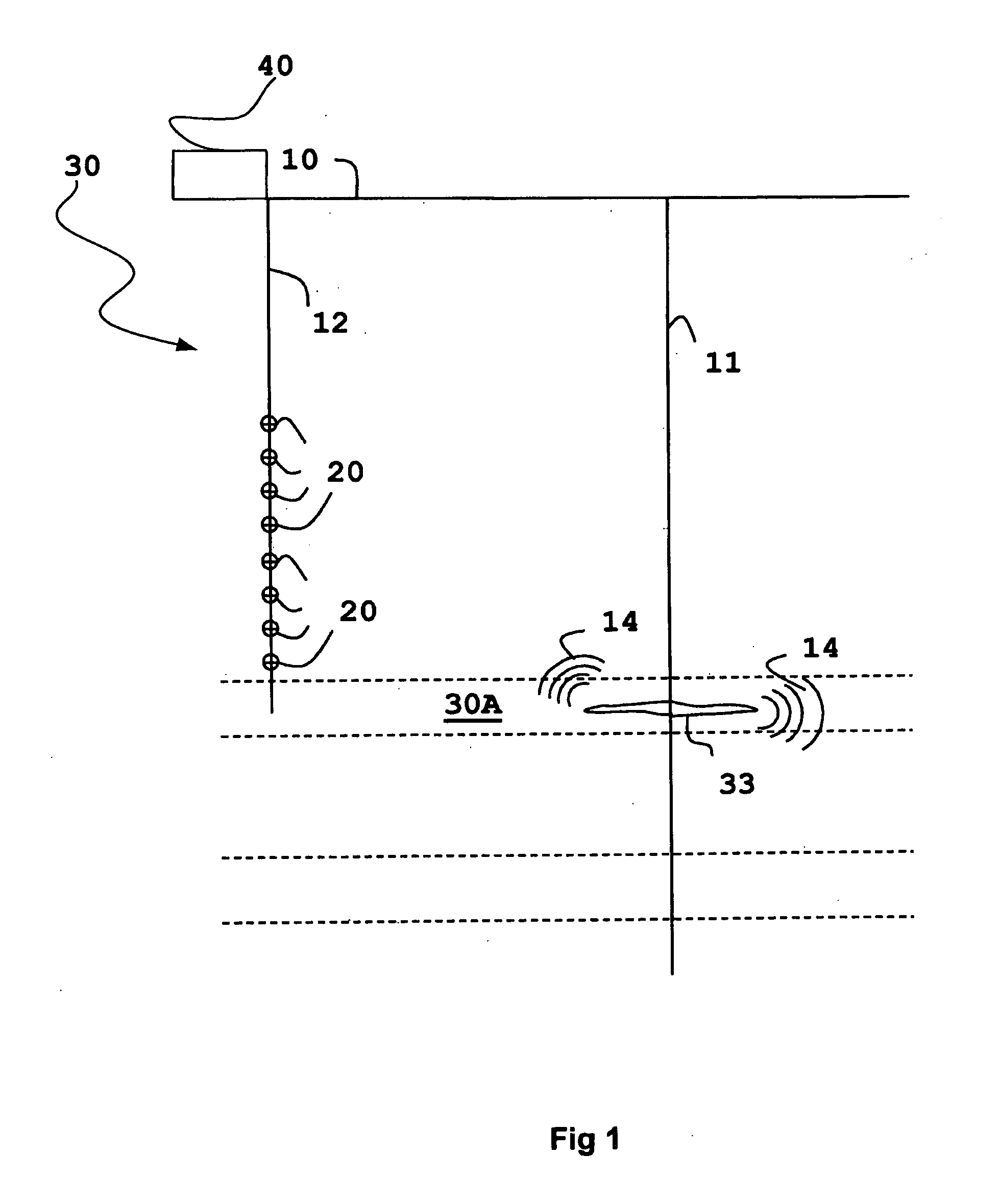

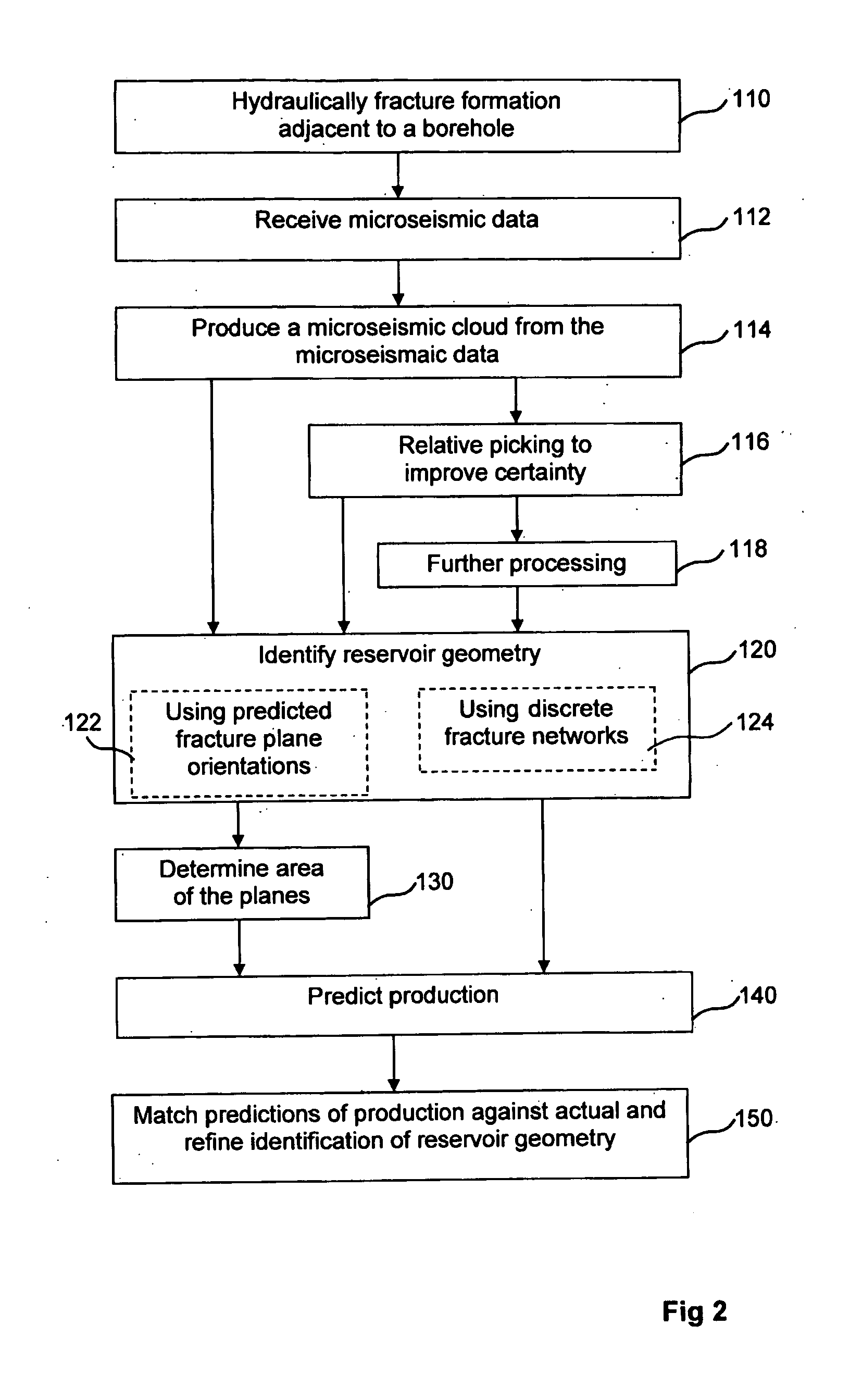

Identification of reservoir geometry from microseismic event clouds

InactiveUS20130144532A1Provide benefitsElectric/magnetic detection for well-loggingSeismic signal processingNumber densityHydraulic fracturing

A method for characterizing fracture planes generated during a hydraulic fracturing process, comprises receiving microseismic data from the hydraulic fracturing process and processing a microseismic event cloud from the received microseismic data. This is followed by determining at least one reservoir geometry from the microseismic event cloud. The determination of geometry may consist of determining multiple candidate geometries and probability of each. In some forms of the invention the method may comprise postulating a set of candidate geometries with differing numbers of fracture planes, determining the most probable locations of the postulated fracture planes in each member of the set of candidate geometries and also determining relative probabilities of the candidate geometries in the postulated set. Determining a location of a fracture plane may comprise calculating a number density for each microseismic event, dependent on distance from some possible location of a fracture plane or fracture network. Finding the location of a plane may then be finding the location for which the number density is greatest. The determination of reservoir geometry may be followed by determination of the area of the fracture planes and / or by a prediction of production.

Owner:SCHLUMBERGER TECH CORP

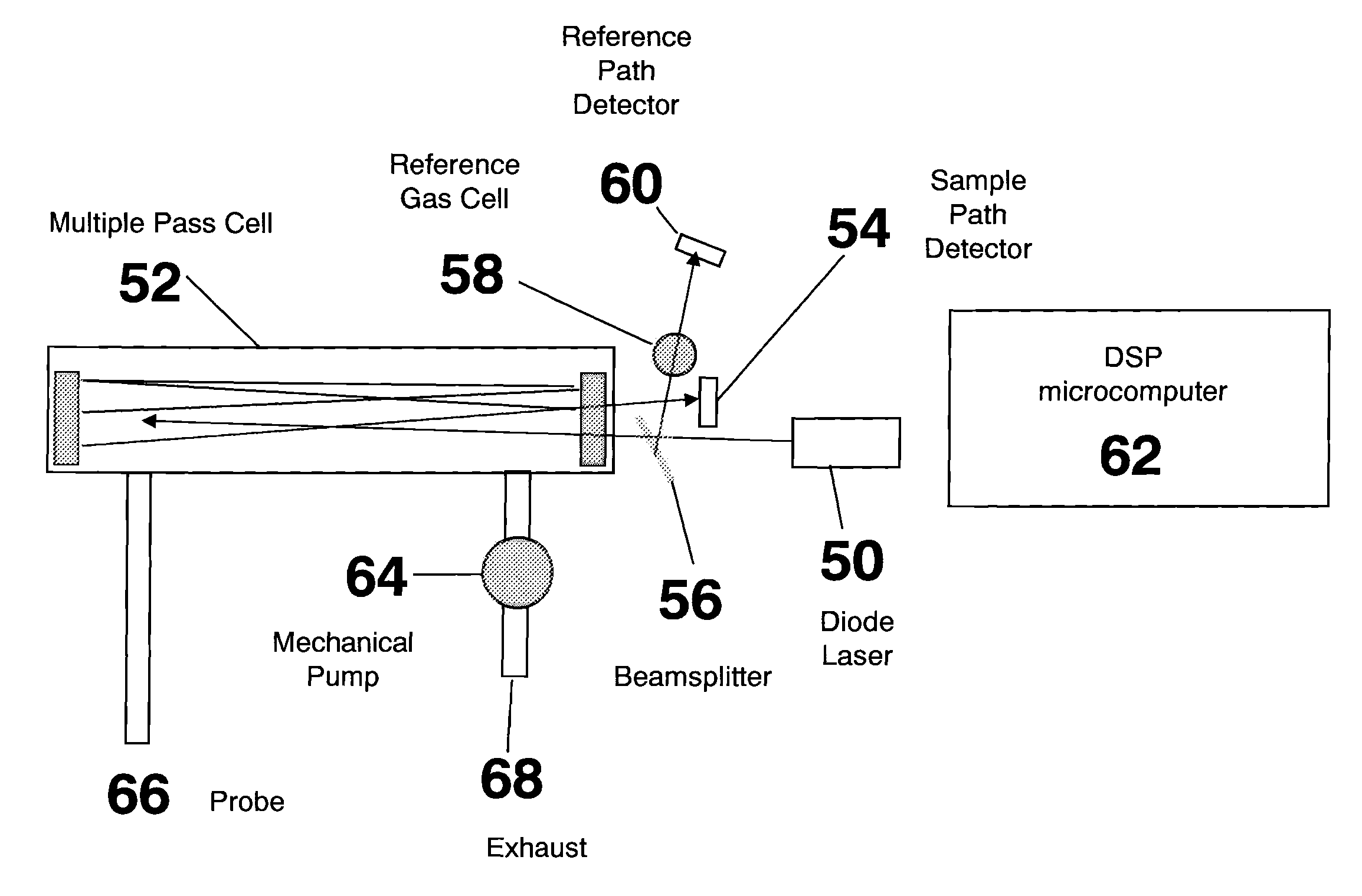

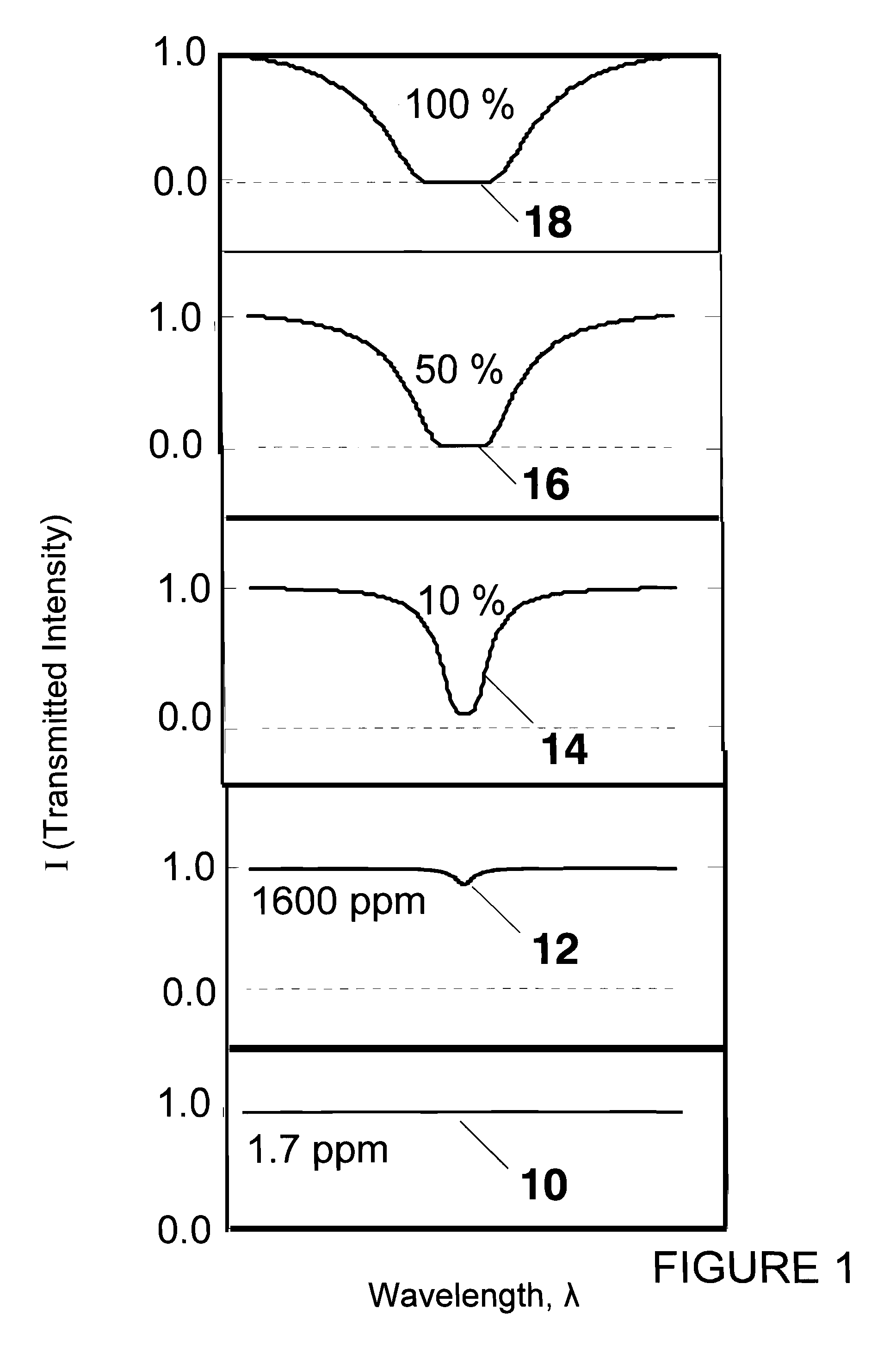

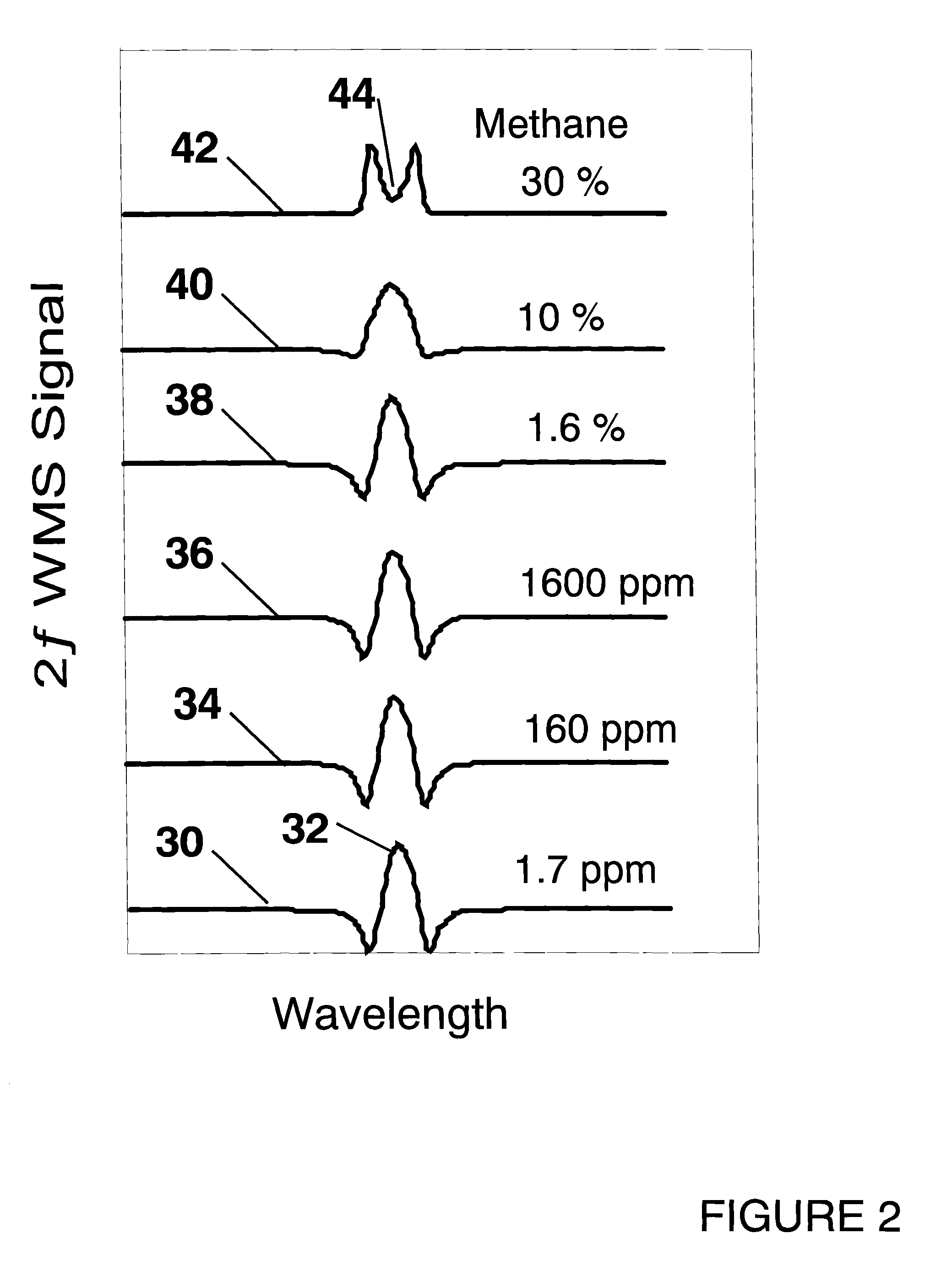

Gas measurement over extreme dynamic range of concentrations

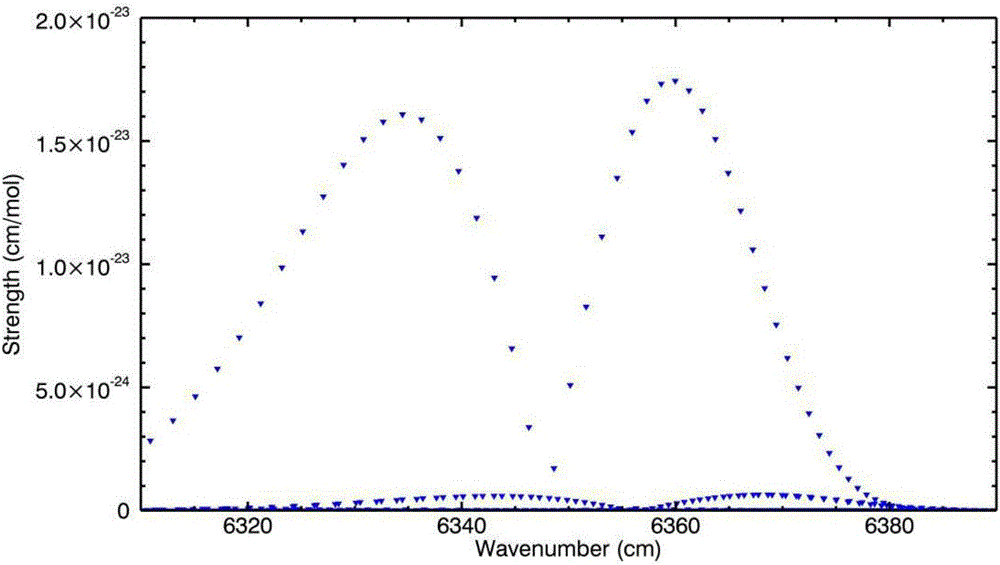

ActiveUS7616316B1Improve performanceColor/spectral properties measurementsNumber densitySpectroscopy

An optical spectroscopy apparatus and method for measurement of species concentration, number density, or column density comprising emitting light from a laser light source, receiving light via a fixed length optical path from the source and containing a species to be detected, receiving light via a detector at an end of the path, determining one or more of species concentration, number density, and column density via signal processing electronics connected to the detector, and switching between a plurality of operational modes measuring a same absorption feature of the species depending on measured absorbance.

Owner:SOUTHWEST SCI

Negative ion flame-retardant anti-bacterial fiber and preparation method thereof

InactiveCN101586267ASimple manufacturing methodWith mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPolyester

The invention provides negative ion flame-retardant anti-bacterial fiber belonging to the field of textile industry technique and a and preparation method thereof, the weight percentages and components thereof are as follows: polyester fibre 92-99%, compound combustion inhibitor 0.6-6.4%, antimicrobial powder 0.1-1.6% and negative ion generating agent 0.1-1.6%. The method provided by the invention can prepare negative ion flame-retardant anti-bacterial fiber which can simultaneously reach national architectural material flame-retardant performance B1 grade standard and conform to national antimicrobial material specification, with 6140 / cm of negative ion generating number density.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

High-strength aluminum alloy product and method of producing the same

A heat-treated high-strength Al—Cu—Mg—Si aluminum alloy product exhibits excellent extrudability and high strength. The high-strength Al—Cu—Mg—Si aluminum alloy product obtained by extrusion is characterized in that the microstructure of the entire surface of the cross section of the aluminum alloy product is formed of recrystallized grains, the grains have an average aspect ratio (L / t) of 5.0 or less (wherein L is the average size of the grains in the extrusion direction, and t is the average thickness of the grains), and the orientation density of the grains in the microstructure, for which the normal direction to the {001} plane is parallel to the extrusion direction in comparison with the grains orientated to random orientations, is 50 or less. The high-strength Al—Cu—Mg—Si aluminum alloy product obtained by extrusion and cold working is characterized in that rod-shaped precipitates are arranged in the grains of the matrix in the <100> direction, the precipitates have an average length of 10 to 70 nm and a maximum length of 120 nm or less, and the number density of the precipitates in the [001] direction measured from the (001) plane is 500 or more per square micrometer.

Owner:SUMITOMO LIGHT METAL INDS LTD

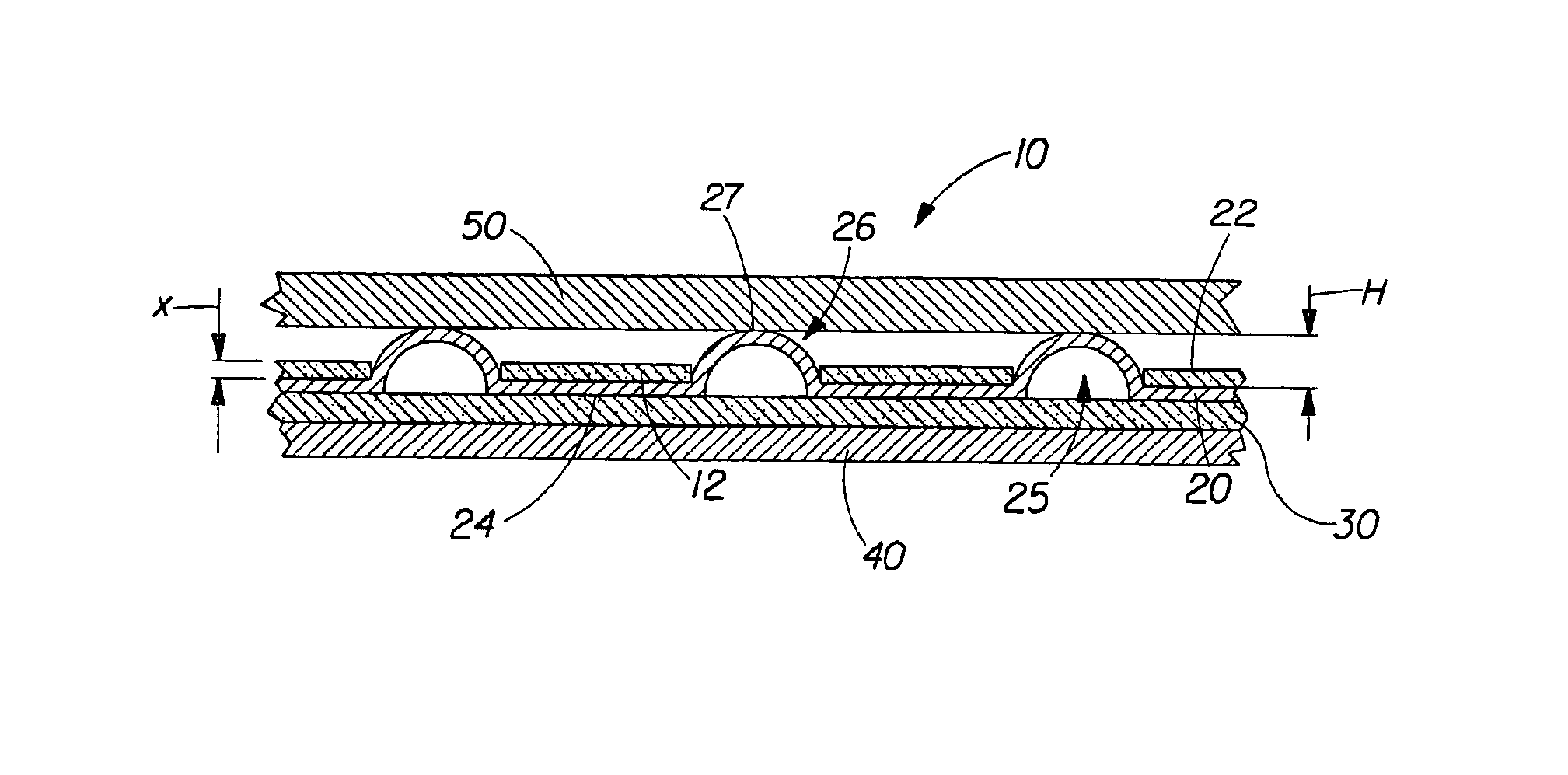

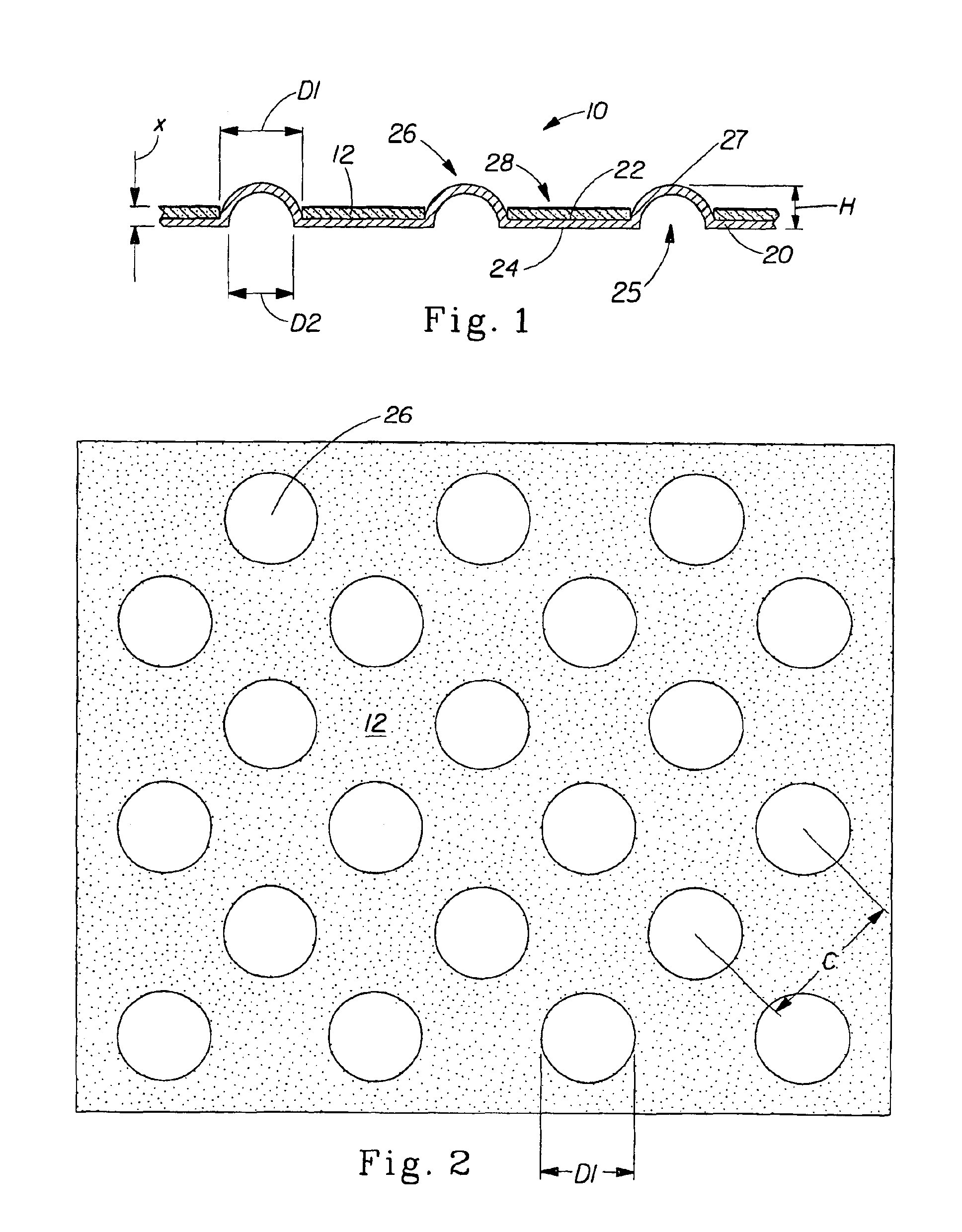

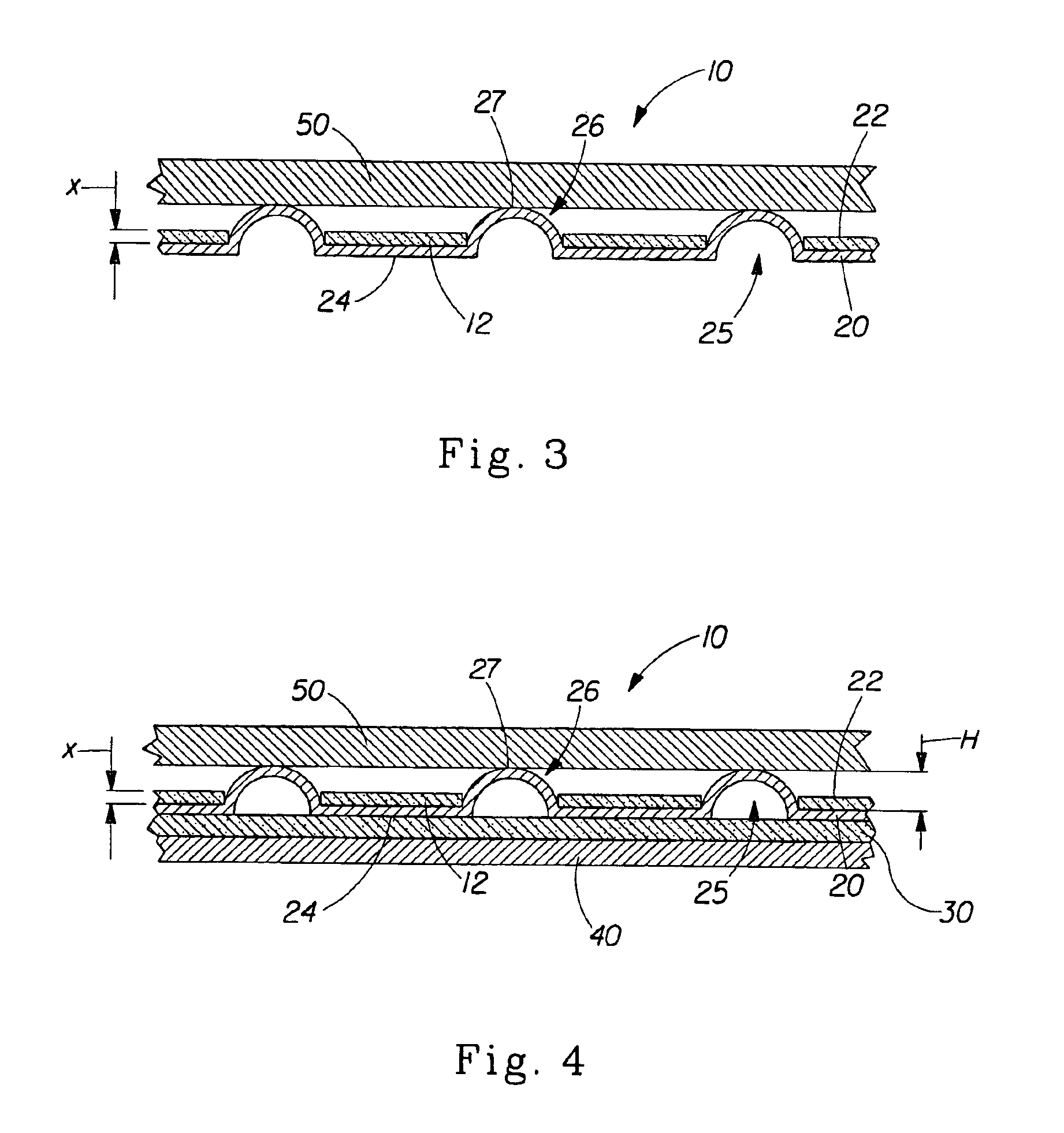

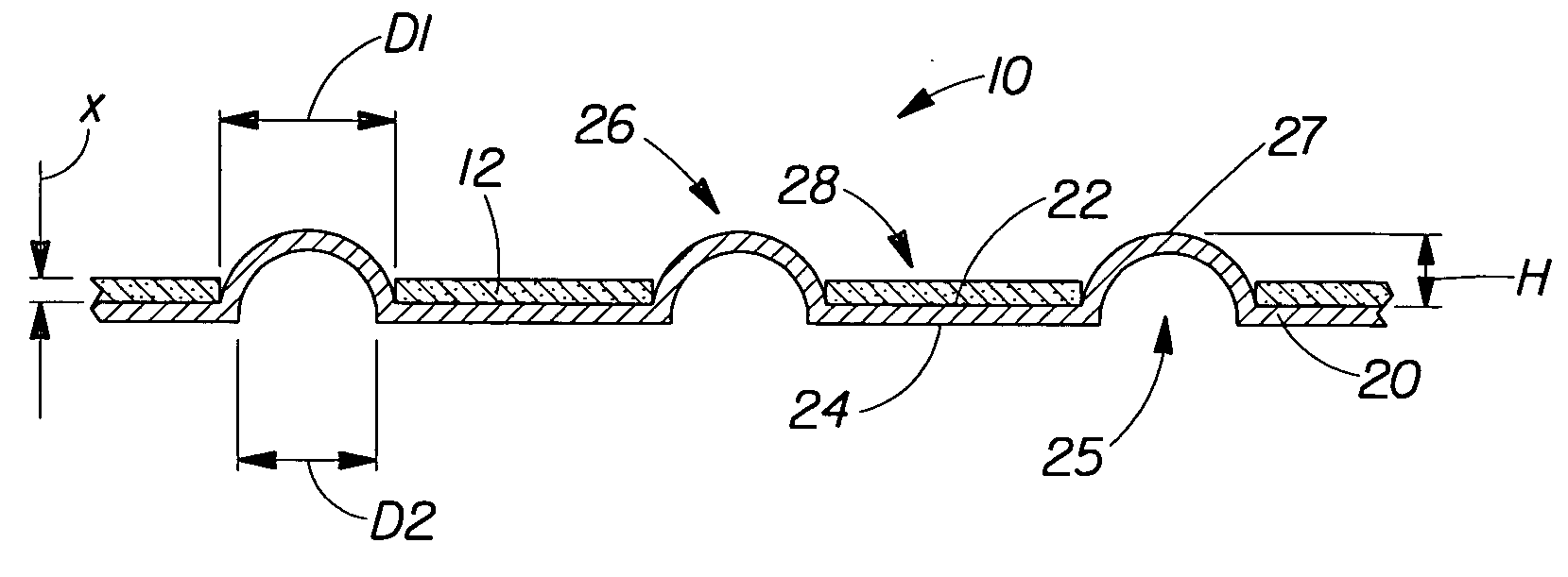

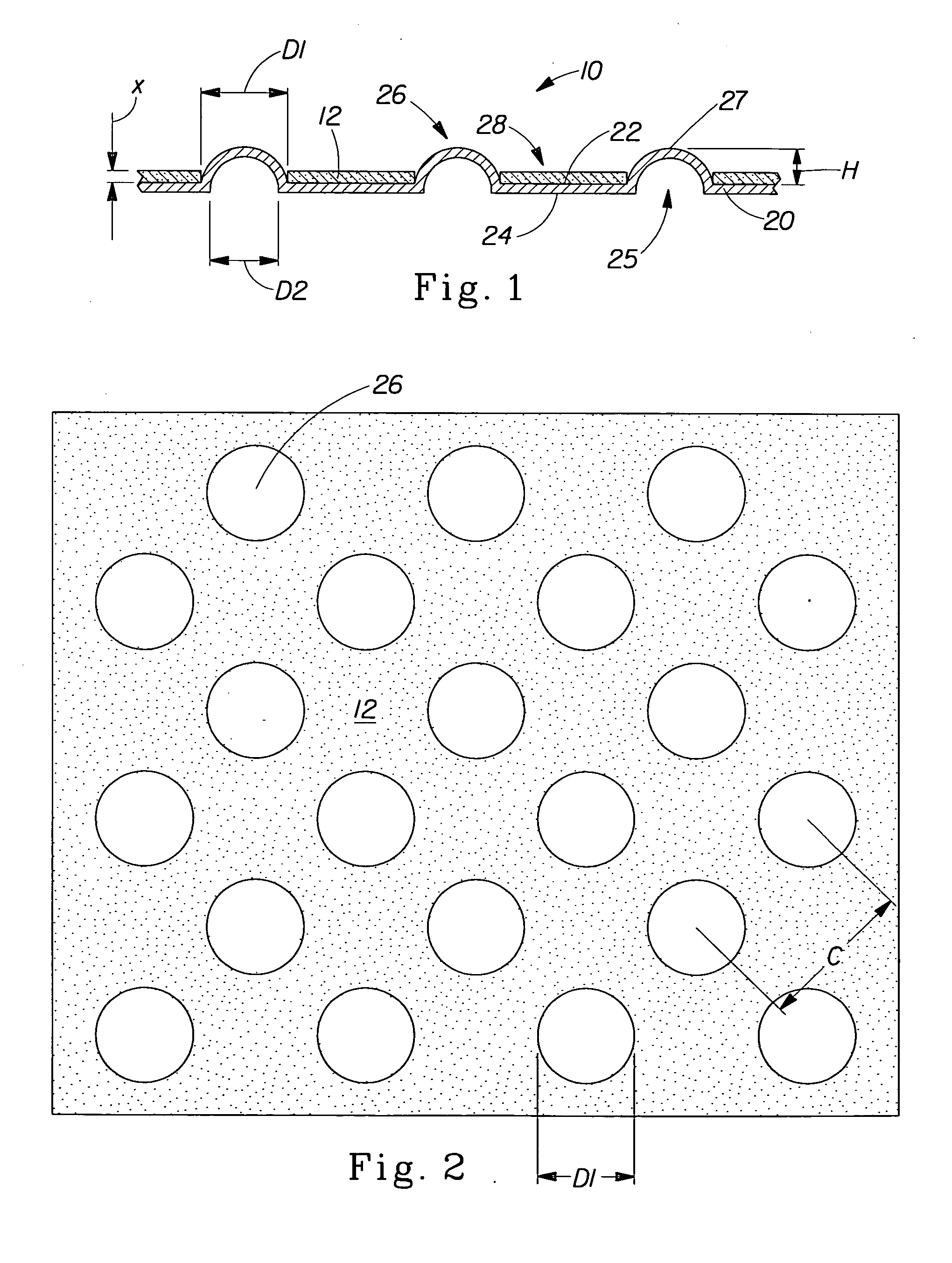

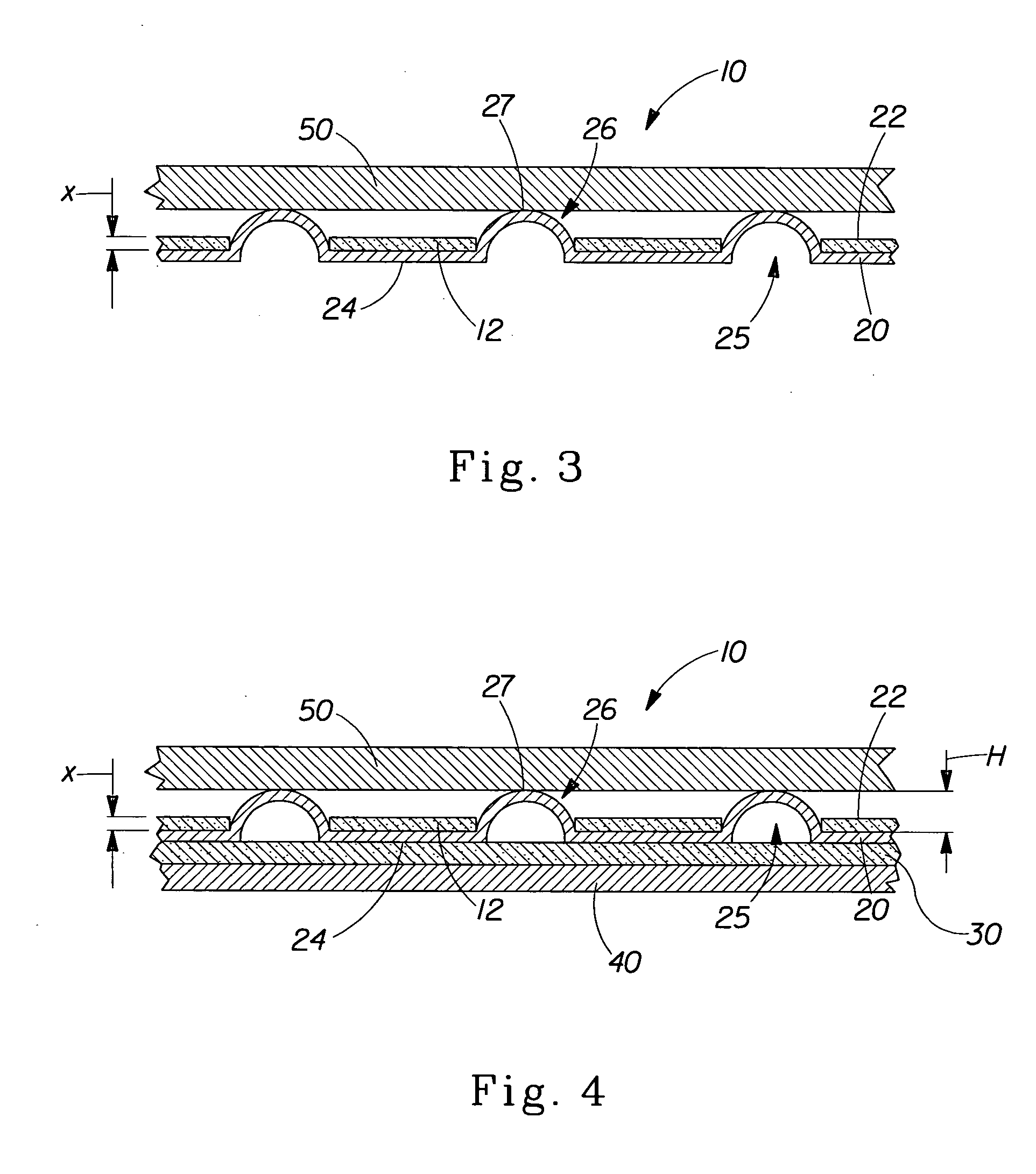

High bond strength, repositionable adherent sheet

An adherent sheet material and method of making including at least one adhesive, non-raised region protected from inadvertent adherence to a contact surface. This adherent sheet material also including a film having a front face and back face, wherein the front face has a plurality of collapsible, non-adhesive protrusions extending outwardly from the front face and adhesive, non-raised region disposed between the protrusions. Also, a substrate is bonded to the back face of film. An adherent sheet material including a contact adhesive protected from inadvertent adherence to a contact surface. This adherent sheet material also including a film having a front face and back face, wherein the front face has a plurality of collapsible, non-adhesive protrusions extending outwardly from the front face and adhesive, non-raised region disposed between the protrusions. The film also includes a number density of protrusions from about 50 protrusions per square inch of the film to about 150 protrusions per square inch of the film. Also, the contact adhesive is disposed upon non-raised regions.

Owner:THE PROCTER & GAMBLE COMPANY

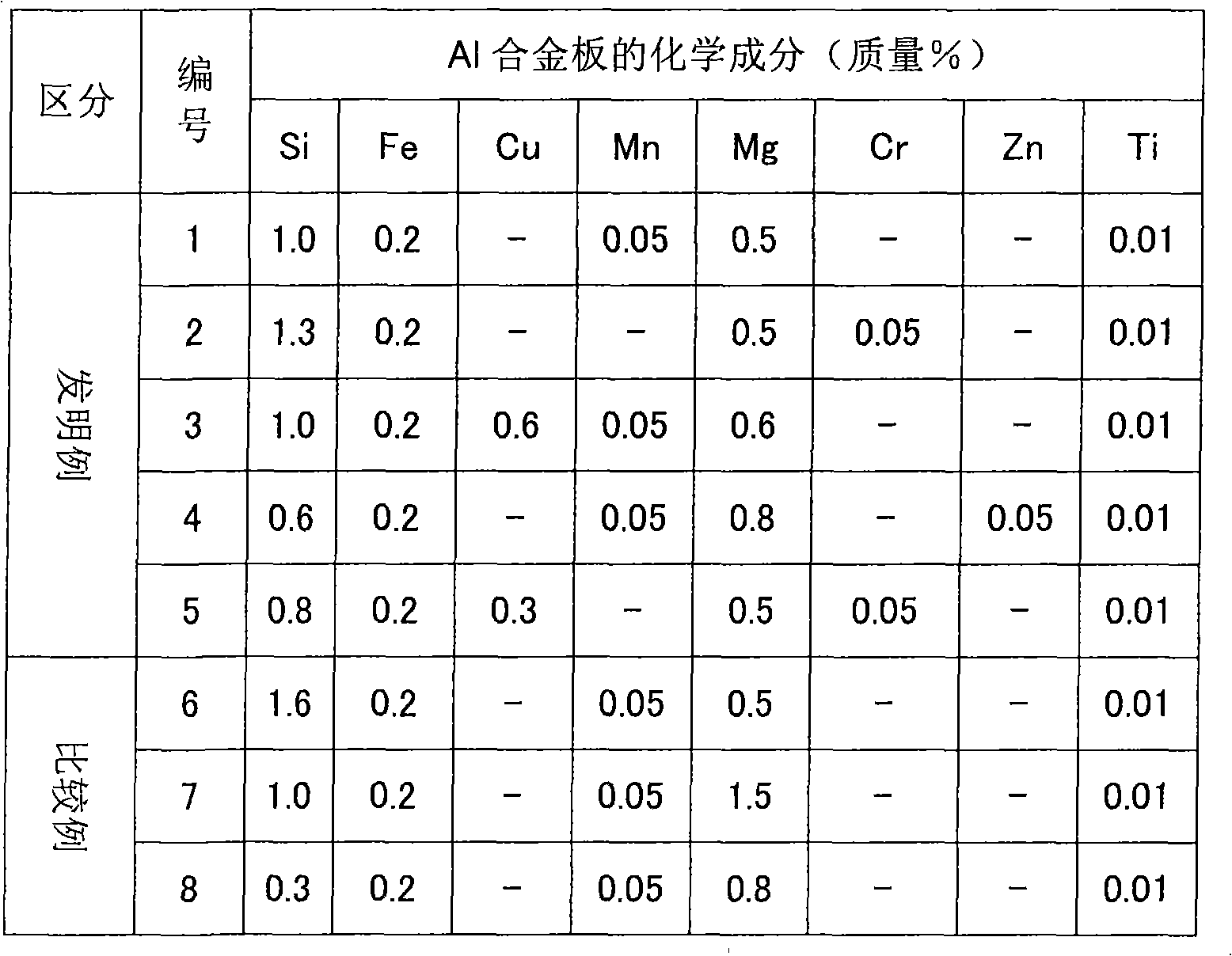

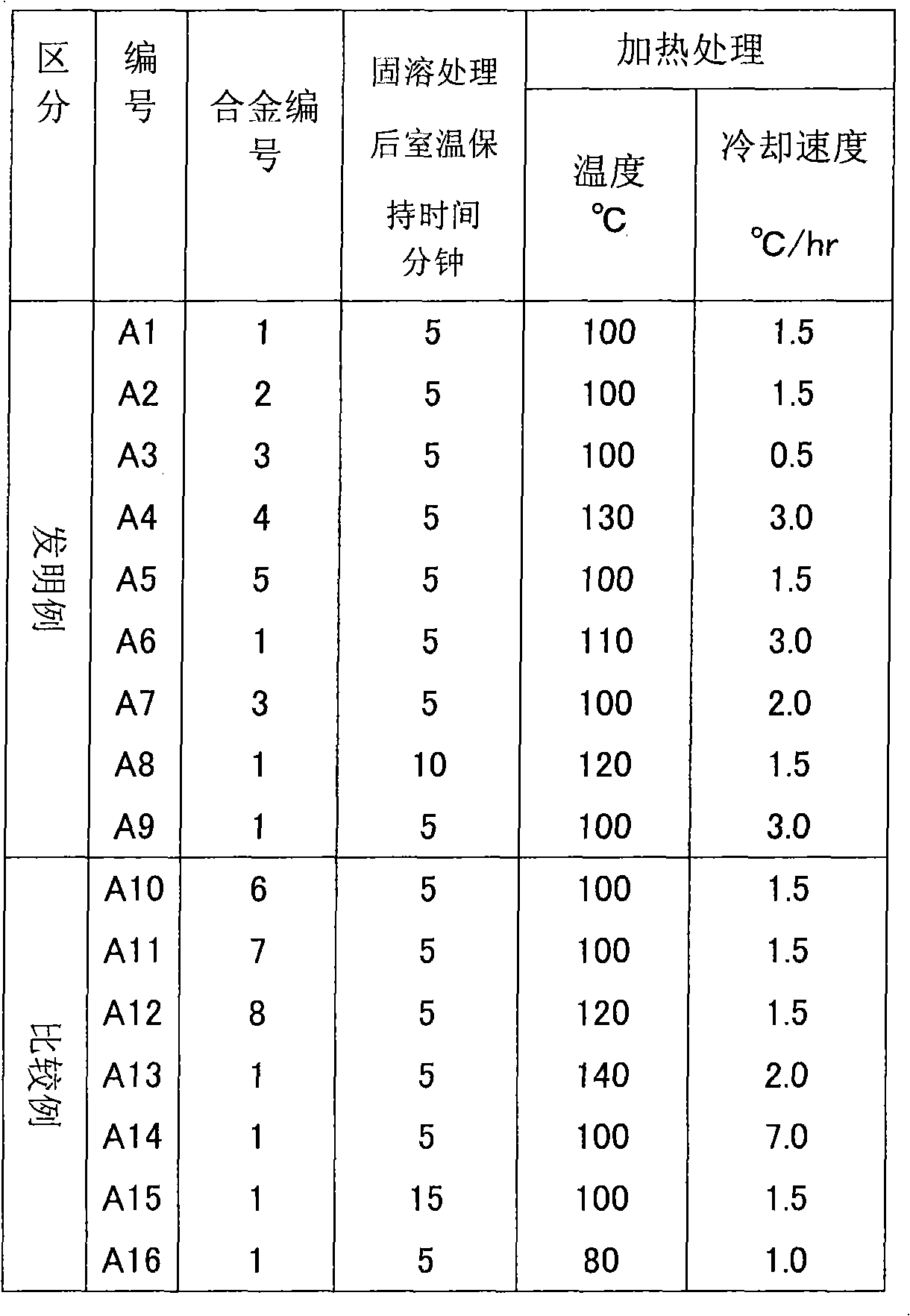

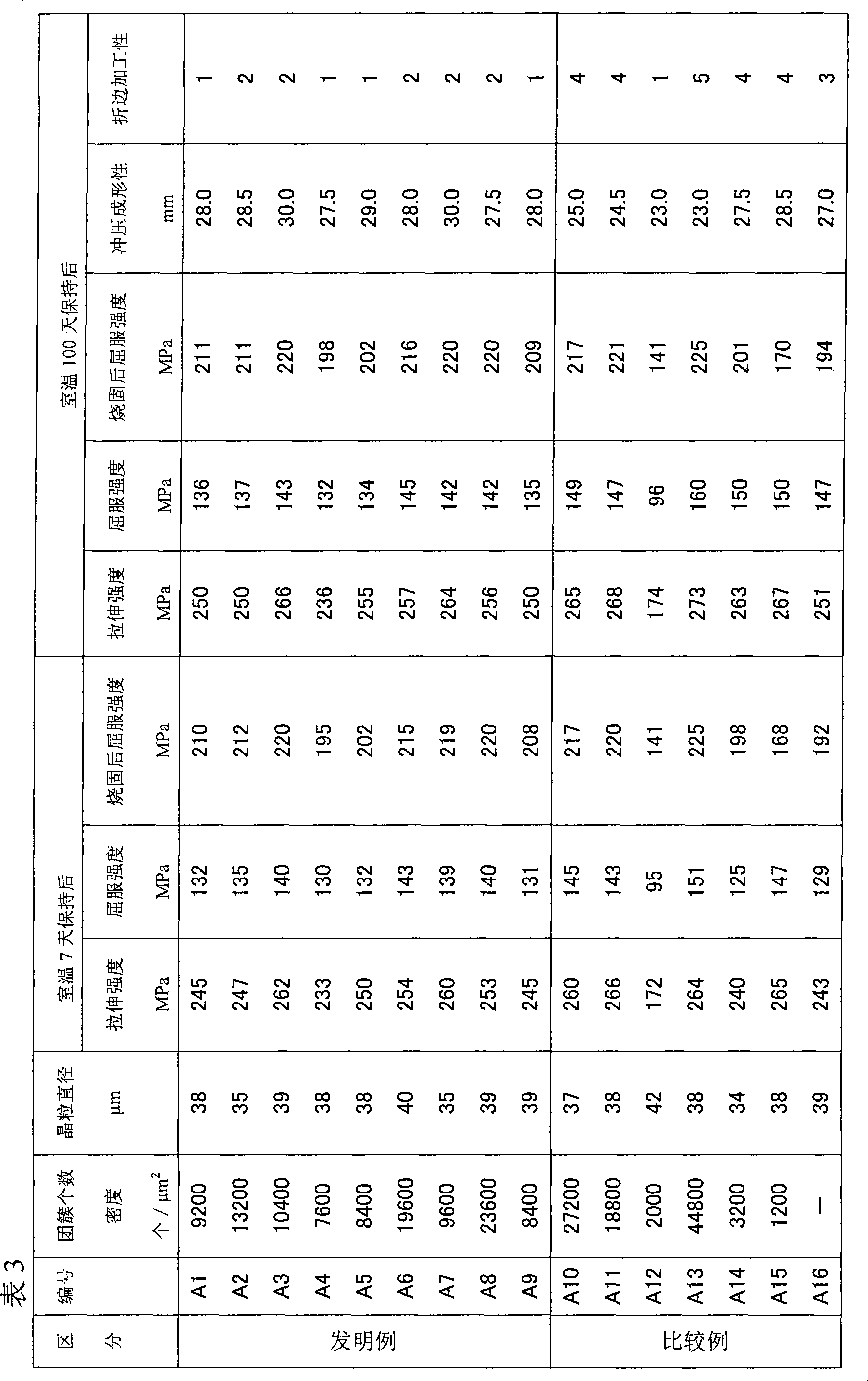

Aluminum alloy sheet superior in paint baking hardenability and invulnerable to room temperature aging, and method for production thereof

An aluminum alloy sheet of specific Al-Mg-Si composition, which, owing to preliminary aging treatment under adequate conditions, has a specific metallographic structure in which there are a large number of clusters of specific size (each being an aggregate of atoms) expressed in terms of number density, which, when observed under a transmission electron microscope of 1,000,000 magnifications, appear as dark contrast in the bright field image. It is superior in paint baking hardenability and is invulnerable to room temperature aging during storage for a comparatively long period of 1 to 4 months.

Owner:KOBE STEEL LTD

Aluminum alloy brazing sheet

ActiveUS20110287277A1Increase resistanceHigh strengthWelding/cutting media/materialsHeat exchange apparatusNumber densityIntermetallic

An aluminum alloy brazing sheet includes a core material containing Si, Cu and Mn by a predetermined amount, the balance being Al and inevitable impurities, a sacrificial anode material disposed on one face side of the core material and containing Si, Zn and Mg by a predetermined amount, the balance being Al and inevitable impurities, and a brazing filler material disposed on the other face side of the core material and formed of an aluminum alloy, and the area fraction of Zn—Mg-based intermetallic compounds with 2.0 μm or above particle size on the surface of the sacrificial anode material may be 1.0% or below. Or otherwise, in the aluminum alloy brazing sheet, the number density of Al—Cu-based intermetallic compounds with 0.5 μm or above particle size inside the core material may be 1.0 piece / μm2 or below.

Owner:KOBE STEEL LTD

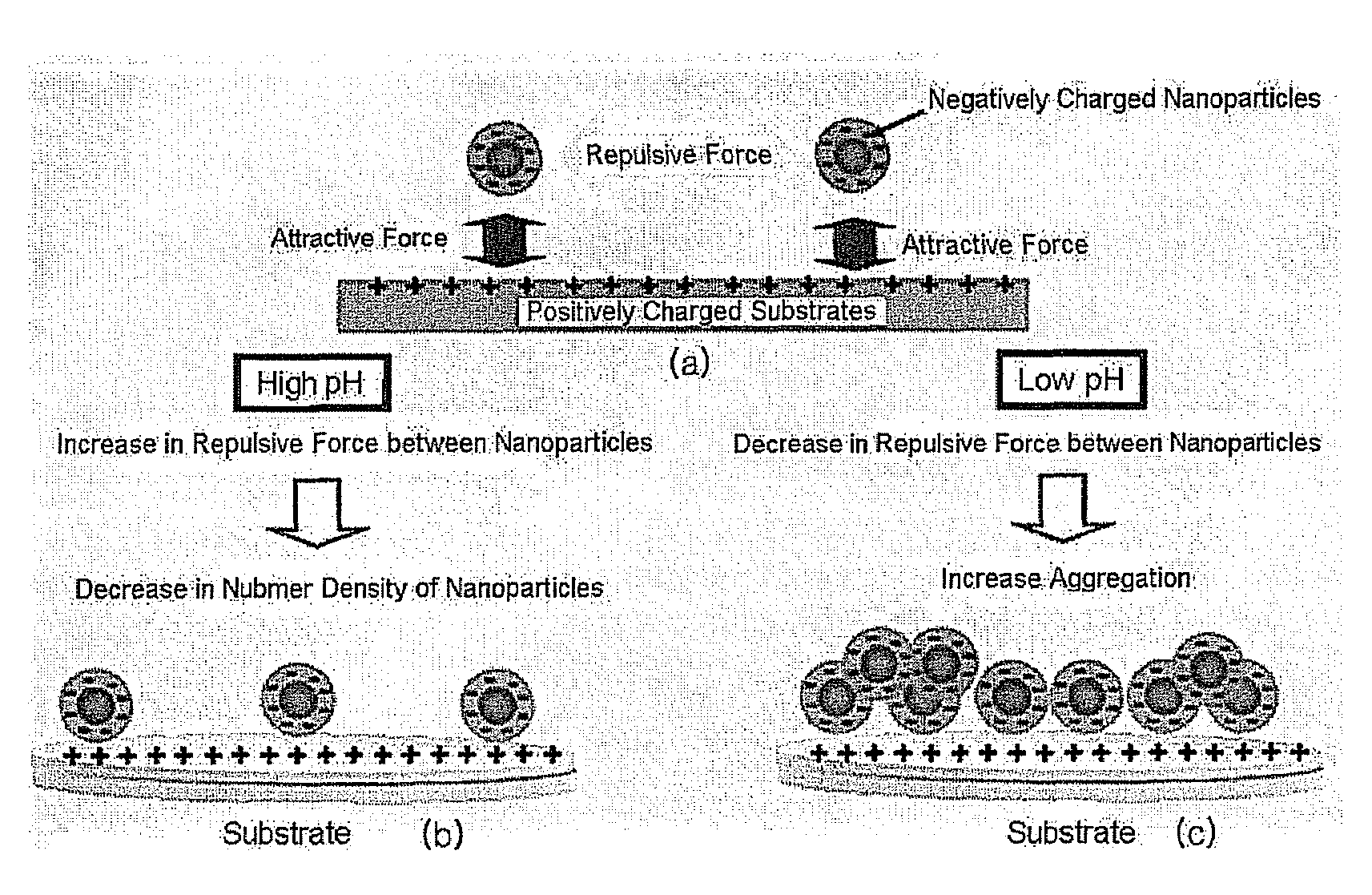

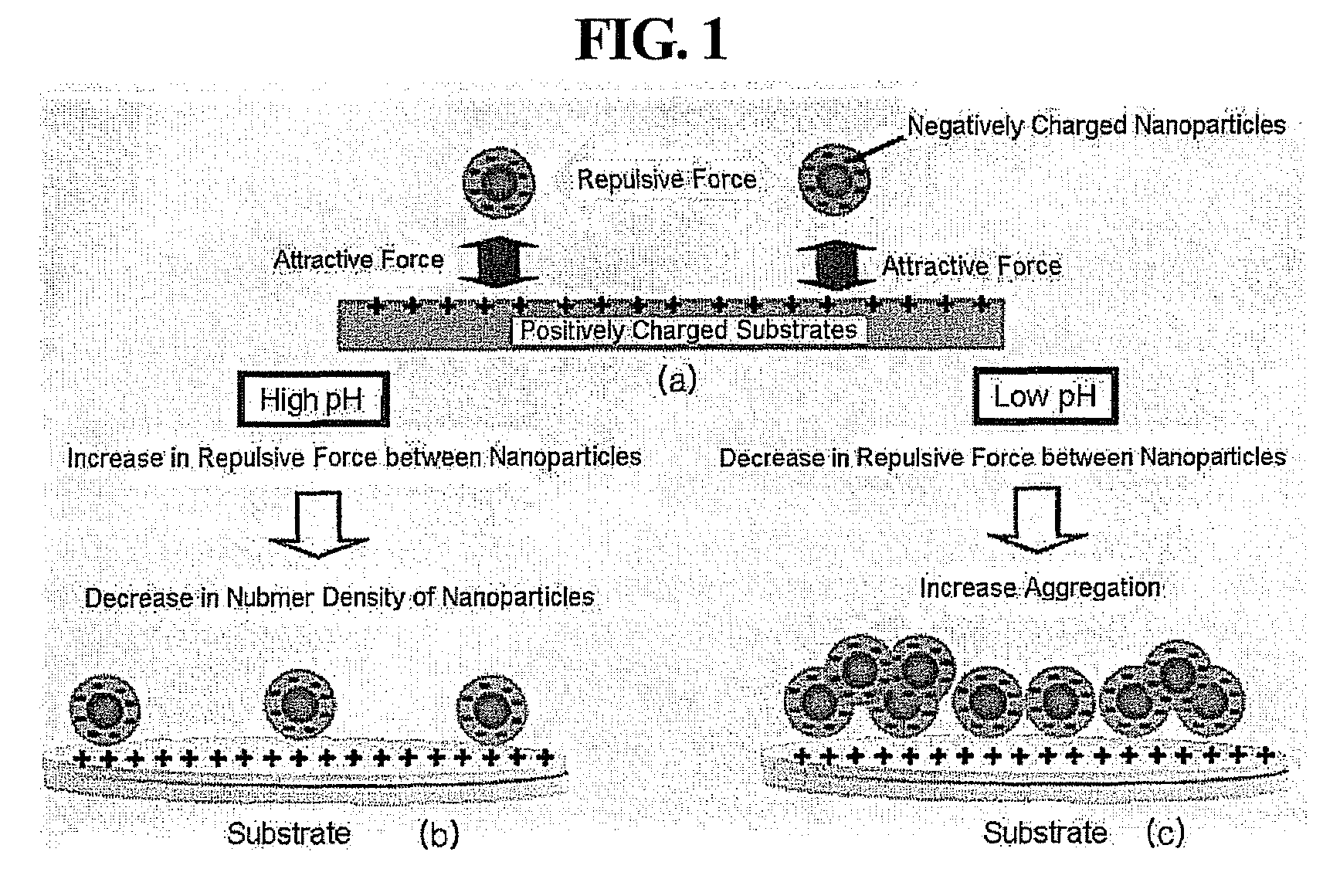

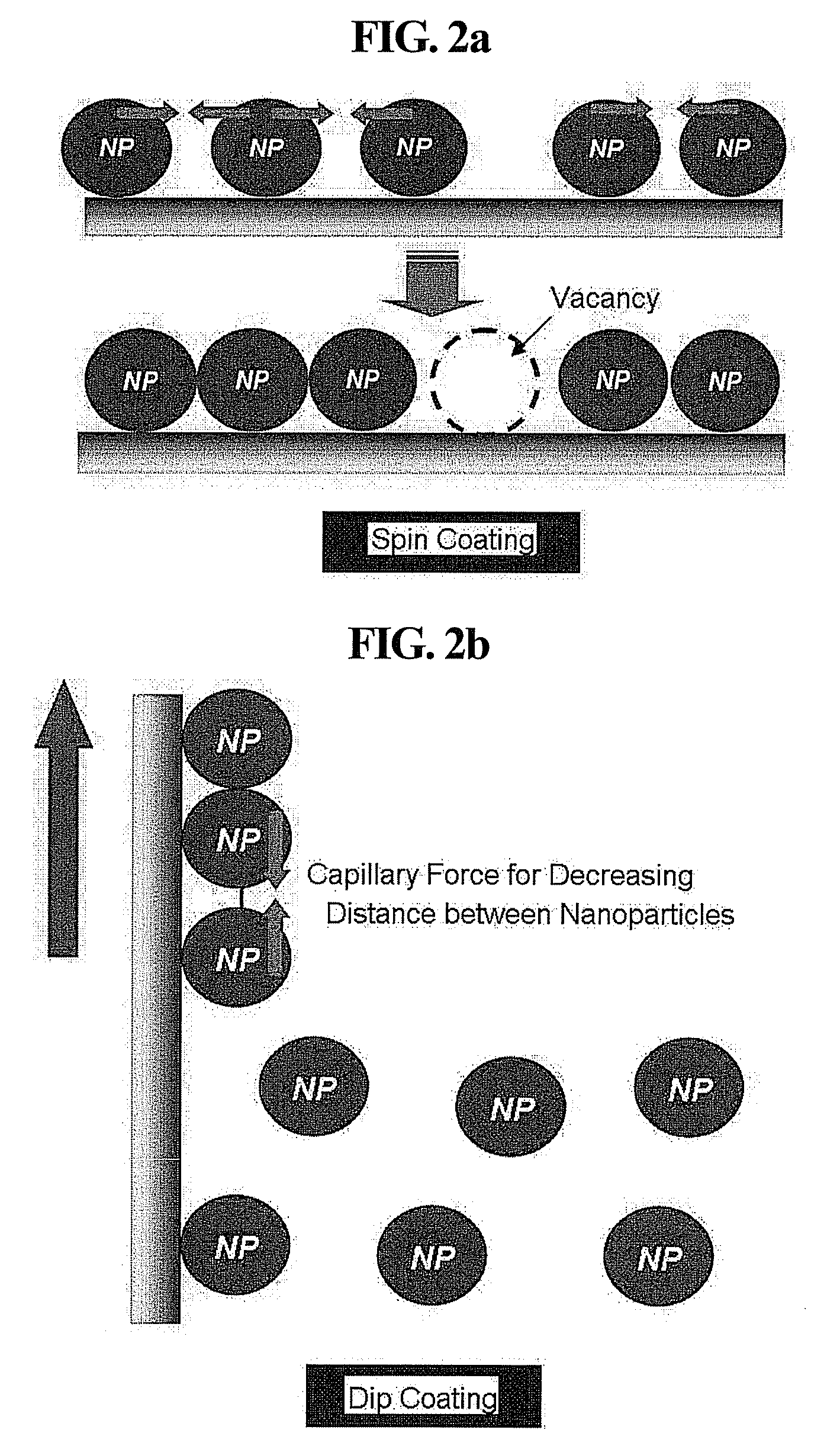

Method For Dispersing Nanoparticles and Methods for Producing Nanoparticle Thin Films By Using The Same

Methods for producing nanoparticle thin films are disclosed. According to one of the methods, a nanoparticle thin film is produced by modifying the surface of nanoparticles to allow the nanoparticles to be charged, controlling an electrostatic attractive force between the charged nanoparticles and a substrate and a repulsive force between the individual nanoparticles by a variation in pH to control the number density of the nanoparticles arranged on the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Methods for tailoring the surface topography of a nanocrystalline or amorphous metal or alloy and articles formed by such methods

InactiveUS20100282613A1Reducing width and depthHigh depositionElectrolysis componentsSemiconductor/solid-state device manufacturingNumber densityTopography

Electrochemical etching tailors topography of a nanocrystalline or amorphous metal or alloy, which may be produced by any method including, by electrochemical deposition. Common etching methods can be used. Topography can be controlled by varying parameters that produce the item or the etching parameters or both. The nanocrystalline article has a surface comprising at least two elements, at least one of which is metal, and one of which is more electrochemically active than the others. The active element has a definite spatial distribution in the workpiece, which bears a predecessor spatial relationship to the specified topography. Etching removes a portion of the active element preferentially, to achieve the specified topography. Control is possible regarding: roughness, color, particularly along a spectrum from silver through grey to black, reflectivity and the presence, distribution and number density of pits and channels, as well as their depth, width, size. Processing parameters that have been correlated in the Ni—W system to topography features include, for both the deposition phase and the etching phase of a nanocrystalline surface: duty cycle, current density, deposition duration, plating chemistry, polarity ratio. The relative influence of the processing parameters can be noted and correlated to establish a relationship between values for processing parameters and degree of topography feature. Control can be established over the topography features. Correlation can be made for any such system that exhibits a definite spatial distribution of an active element that bears a predecessor spatial relationship to a desired topography feature.

Owner:MASSACHUSETTS INST OF TECH

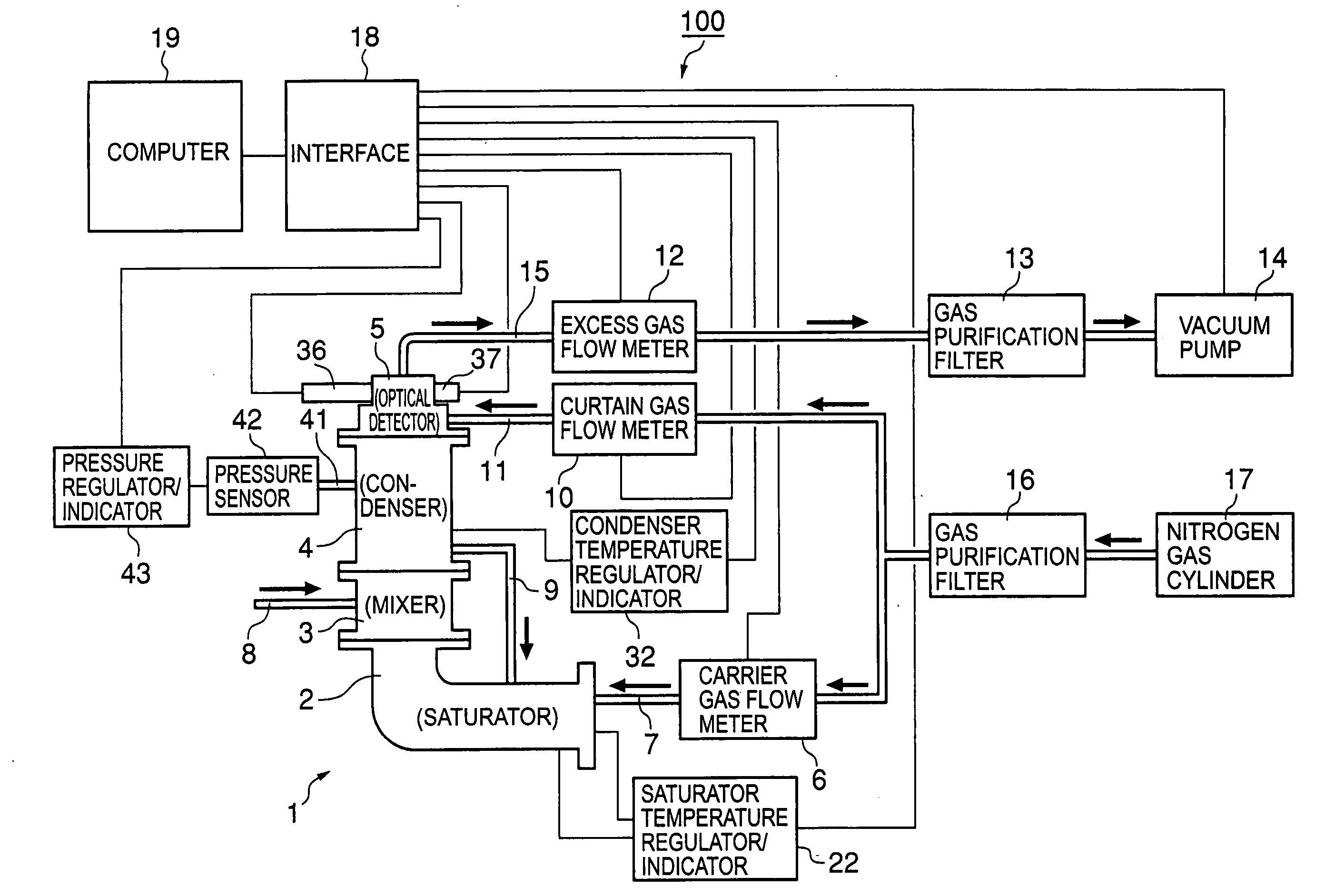

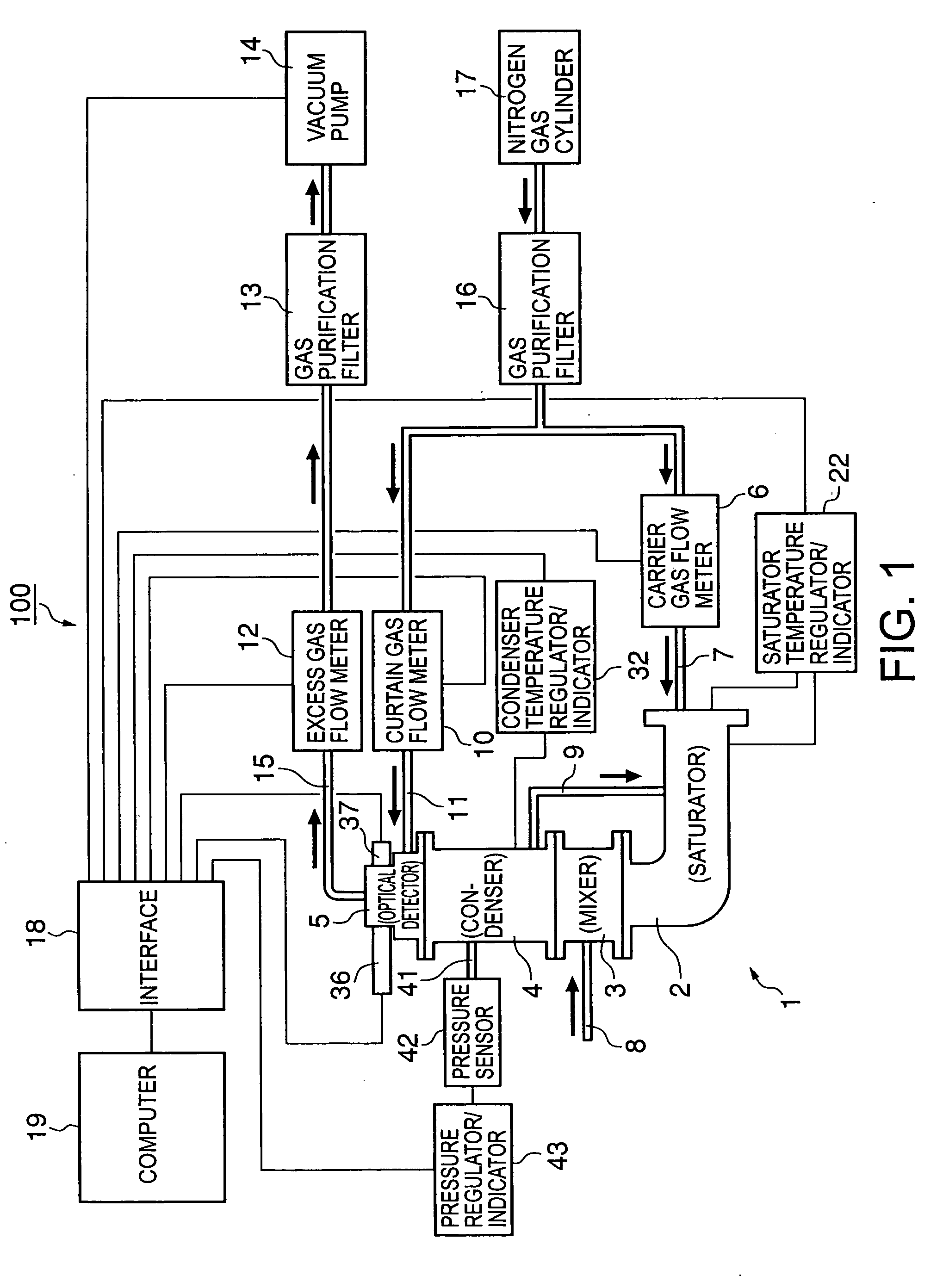

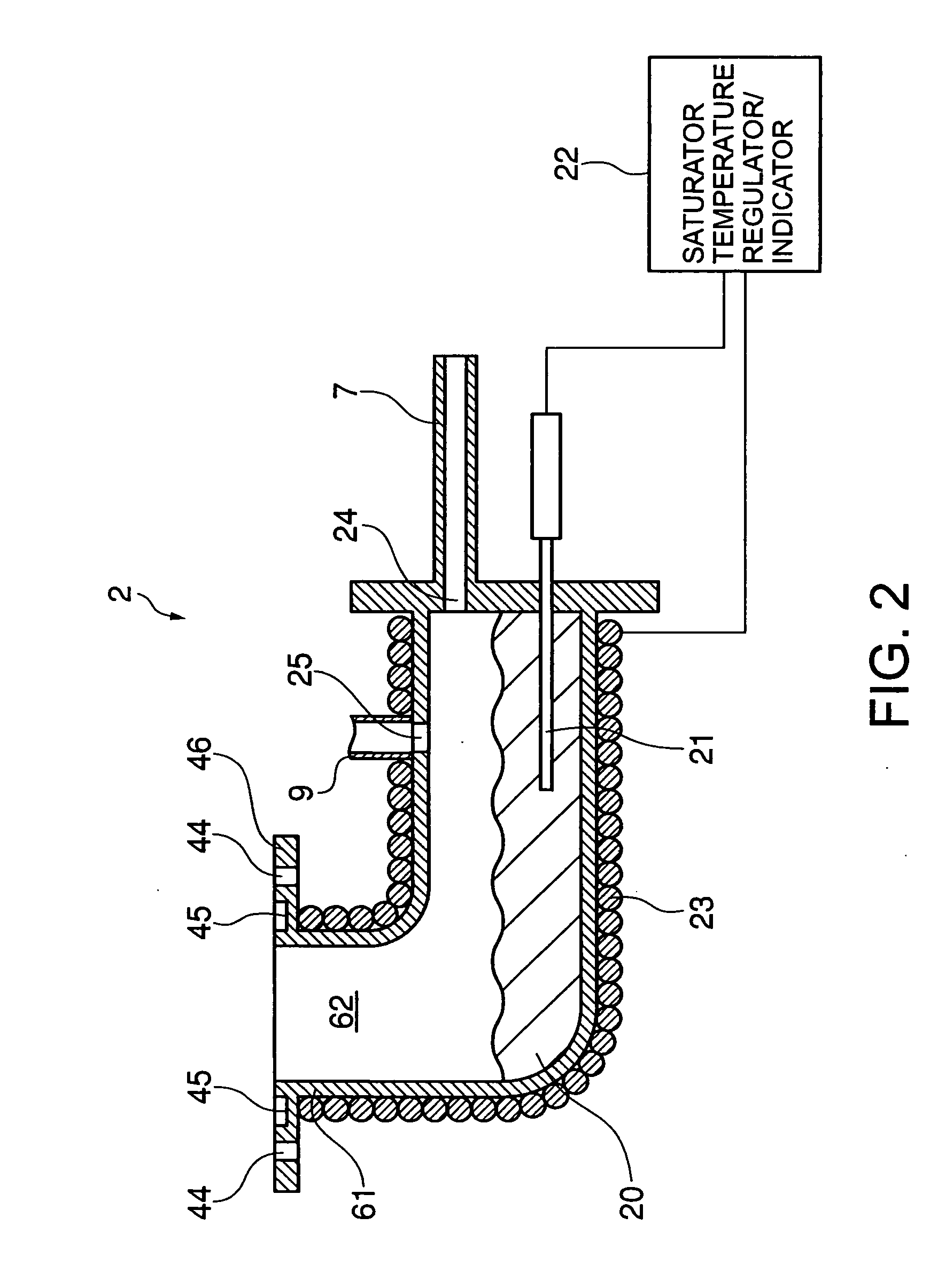

Fine-particle counter

InactiveUS20090031786A1Accurate measurementReduce lossesSamplingParticle suspension analysisGas phaseNumber density

The present invention provides a fine-particle counter with which the number density of nanometer-sized fine particles born in a gas phase, which is extremely low, can be accurately measured under wide-ranging pressure conditions from pressurized conditions to low-pressure conditions.After contact-mixing, in a mixer 3, saturated vapor of a high-boiling-point solvent produced in a saturator 2, a component of a condensed nucleus detector 1, with nanometer-sized fine gas-born particles, condensed droplets of the saturated vapor whose nuclii are the fine particles are produced in a condenser 4 by heterogeneous nucleation. The number of the condensed droplets per unit of time is then counted with an optical detector 5 and is output as a pulse signal, and a computer 19 computes the number density of the nanometer-sized fine particles born in the aerosol from this pulse signal, the gas flow rates controlled by the flow meters 6, 12 and 10, and the other data that are transmitted to the computer 19 via an interface 18. The internal space of the mixer 3 has a narrowest passage having a circular cross section, situated in the center between the lower end of the mixer from which the carrier gas enters and the upper end of the mixer from which the carrier gas exits, a truncated-cone-shaped part whose cross section is circular and whose diameter gradually decreases so that the diameter on the lower end side is greater than the diameter on the narrowest passage side, and a reverse-truncated-cone-shaped part whose cross section is circular and whose diameter gradually increases so that the diameter on the narrowest passage side is smaller than the diameter on the upper end side. An aerosol inlet communicating with the aerosol inlet tube 8 is positioned at the narrowest passage.

Owner:RIKEN

Method for optimizing laser radar detection atmospheric composition spectral line analysis

ActiveCN106526614AHigh precisionIncrease credibilityElectromagnetic wave reradiationICT adaptationRadar equationCo2 absorption

The invention provides a method for optimizing laser radar detection atmospheric composition spectral line analysis, through building of an IPDA laser radar equation of hard target reflection, calculation of difference optical thickness of two pulses and CO2 air column mixing rate XCO2 with a weight, single spectral line broadening calculation, absorption cross section calculation, CO2 absorption optical thickness calculation, a weight function profile and a CO2 molecule number density profile, weight function-optimized spectral lines are obtained. The spectral lines obtained by the method have a higher lower-atmosphere weight ratio, and detection is closer to a true value.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

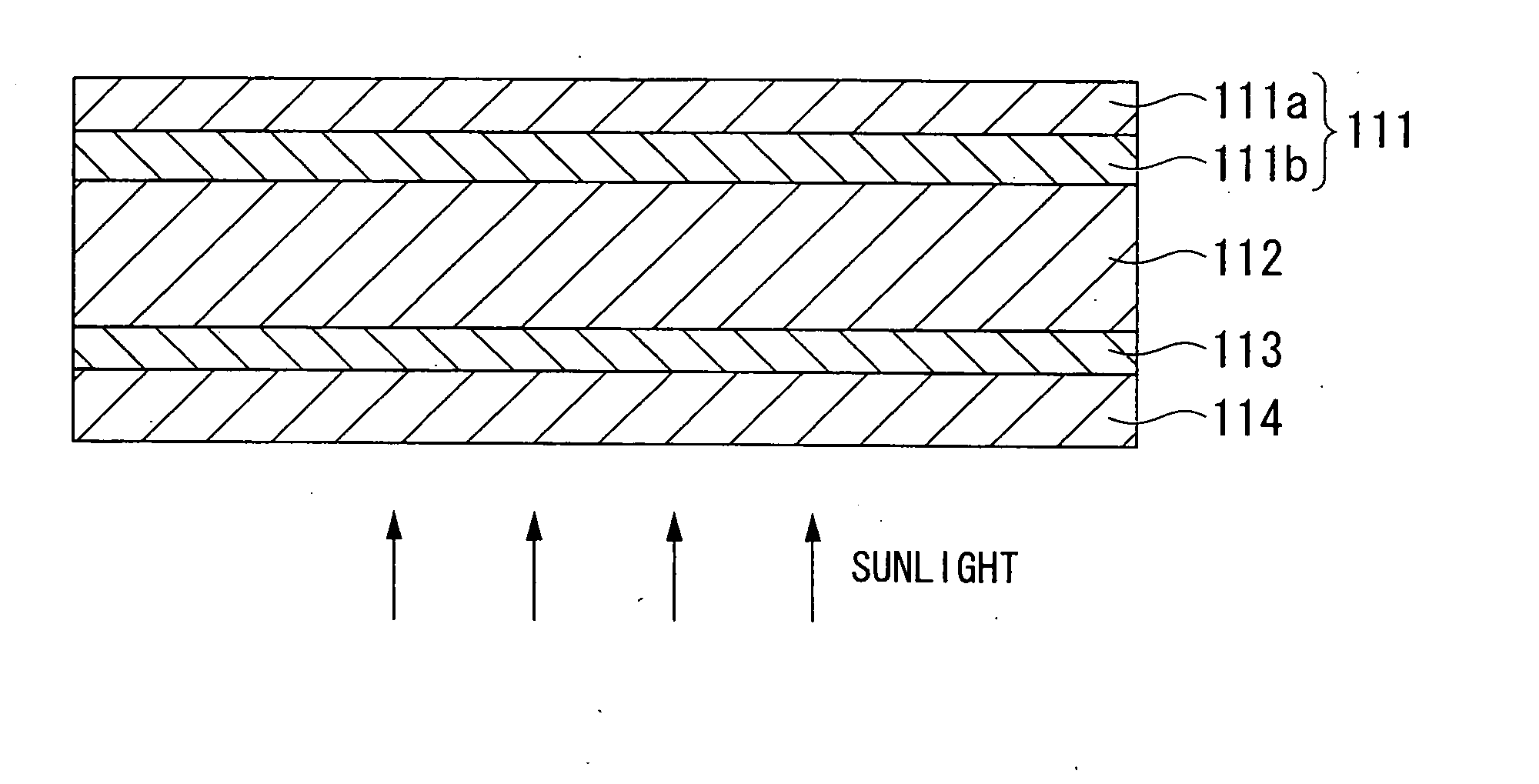

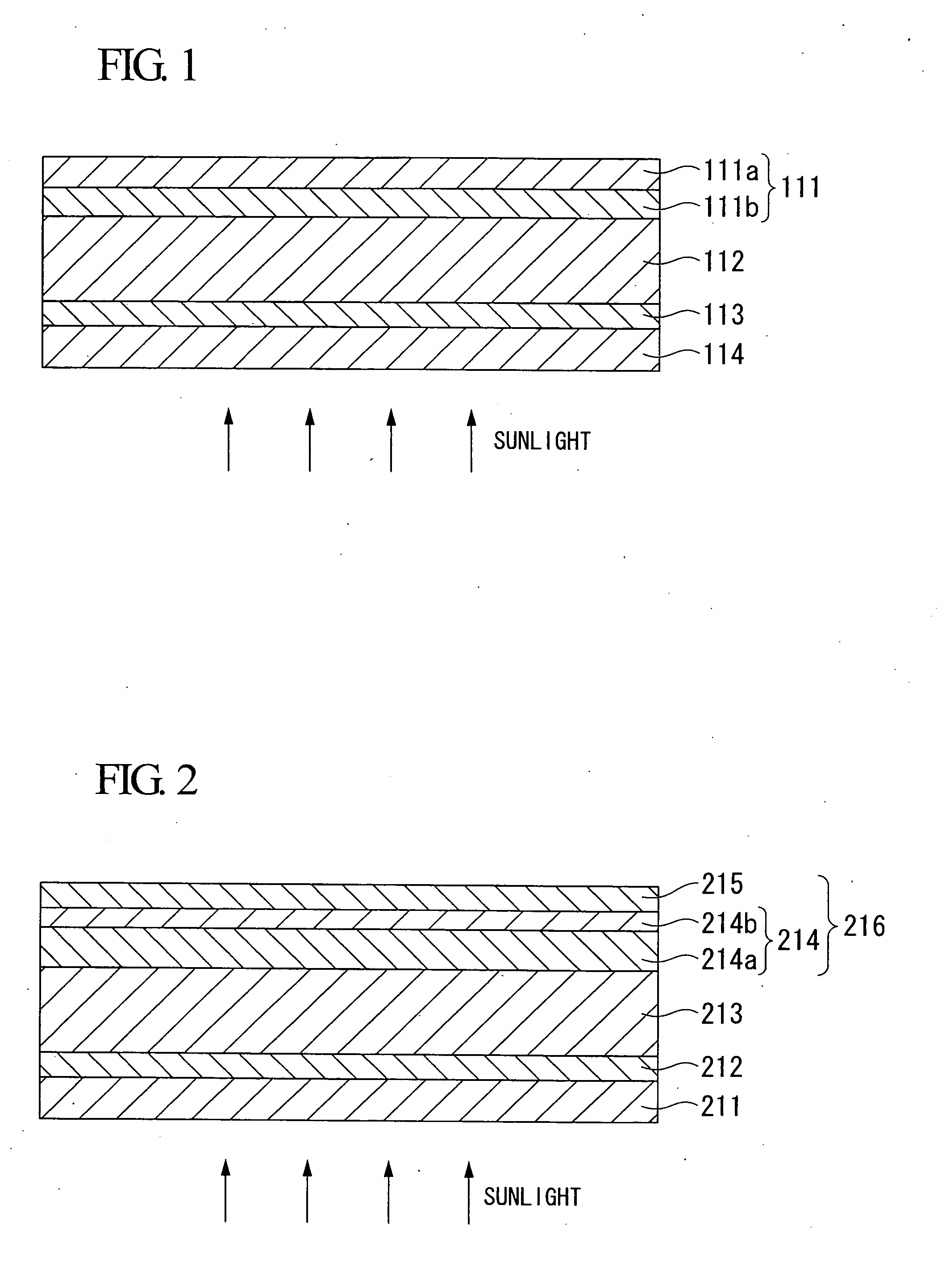

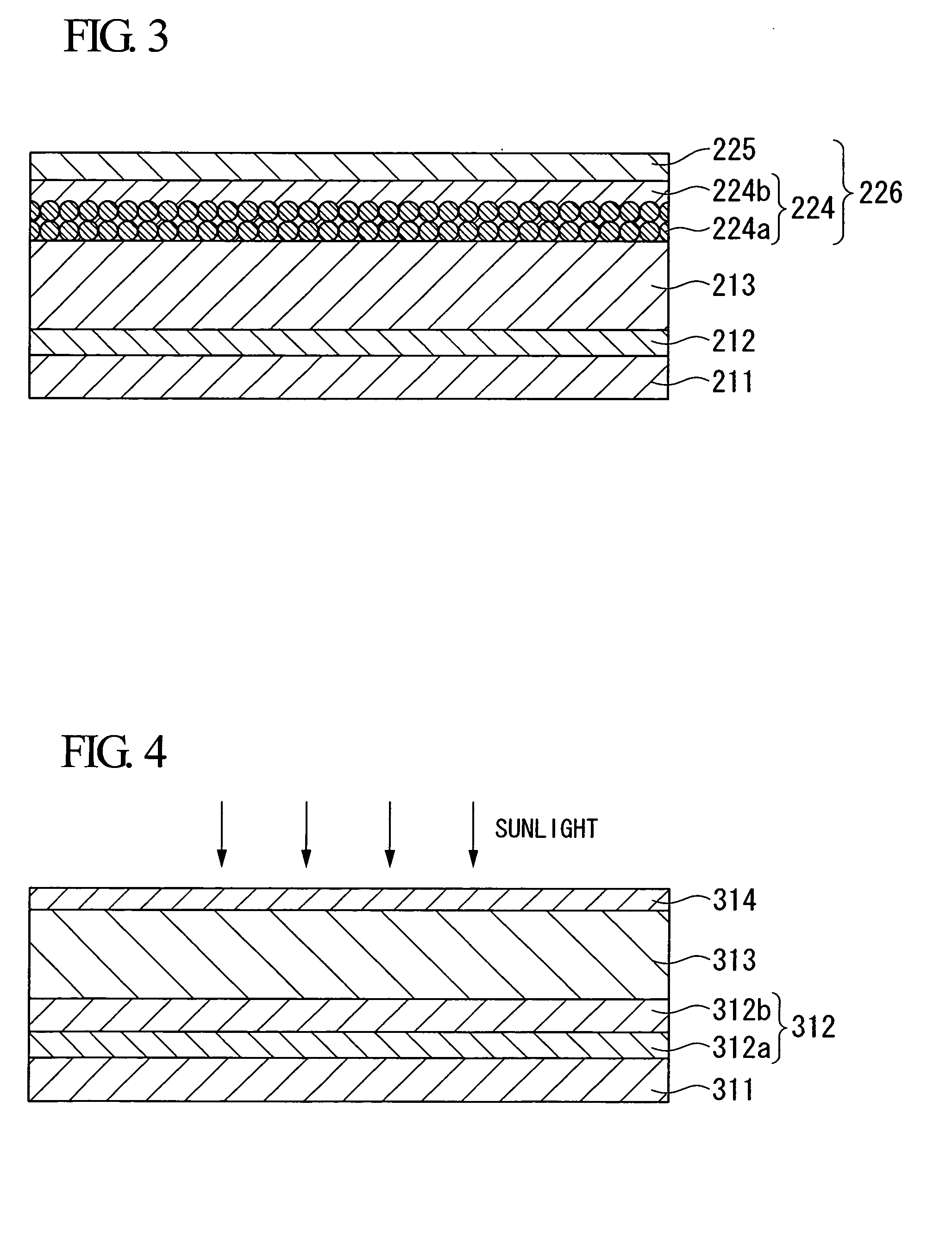

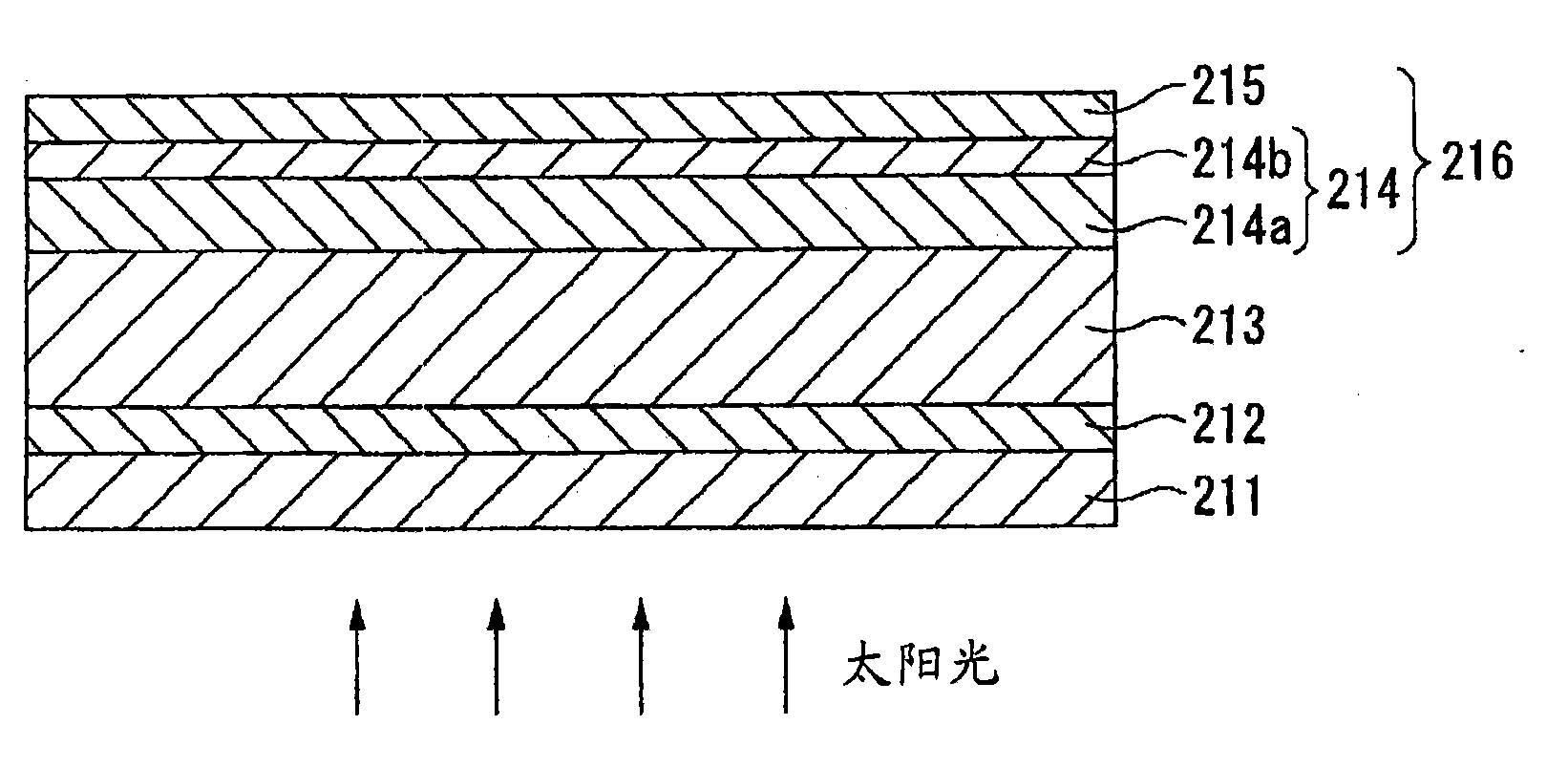

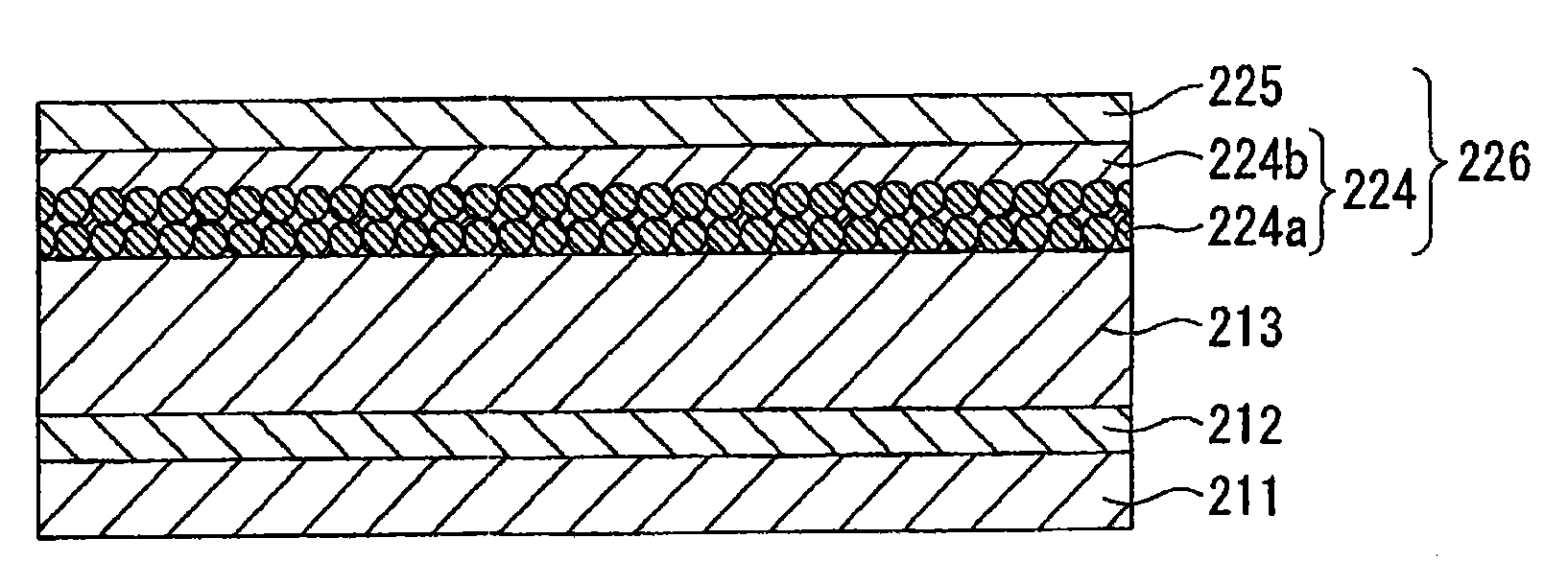

Comppsite film for superstrate solar cell, method for producing the composite film for superstrate solar cell, composite film for substrate solar cell, and method for porducing the composite film for substrate solar cell

InactiveUS20100218822A1Improve reflective effectSatisfactory reflectanceSpecial surfacesCoatingsComposite filmElectrical battery

A composite film for a superstrate solar cell or a substrate solar cell has a transparent conductive film and a conductive reflective film, wherein the transparent conductive film is formed by using a wet coating method to apply a transparent conductive film composition or dispersion containing microparticles of a conductive oxide, the conductive reflective film is formed by using a wet coating method to apply a conductive reflective film composition containing metal nanoparticles, the average diameter of holes occurring at the contact surface of the conductive reflective film on either the side of the photovoltaic layer or the side of the transparent conductive film is not more than 100 nm, the average depth at which the holes are positioned is not more than 100 nm, and the number density of the holes is not more than 30 holes / μm2.

Owner:MITSUBISHI MATERIALS CORP

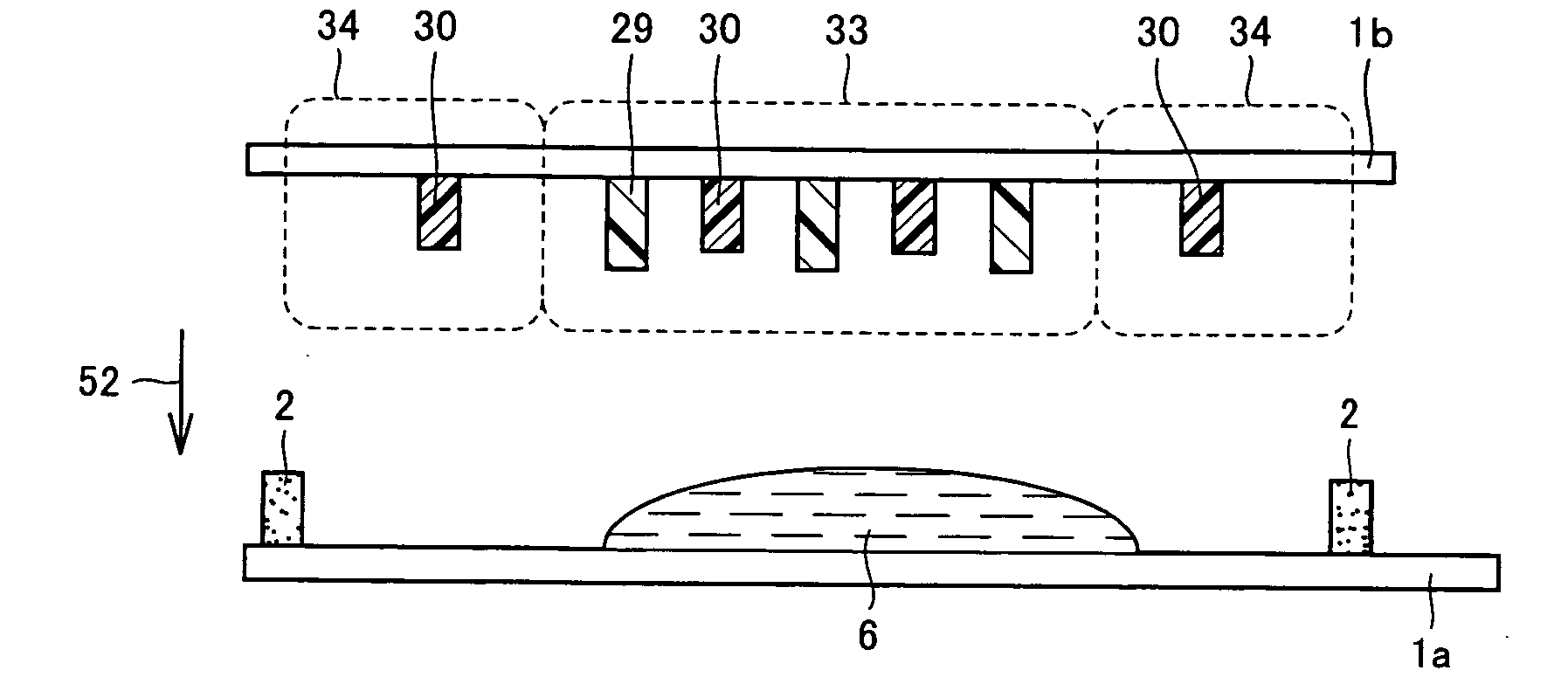

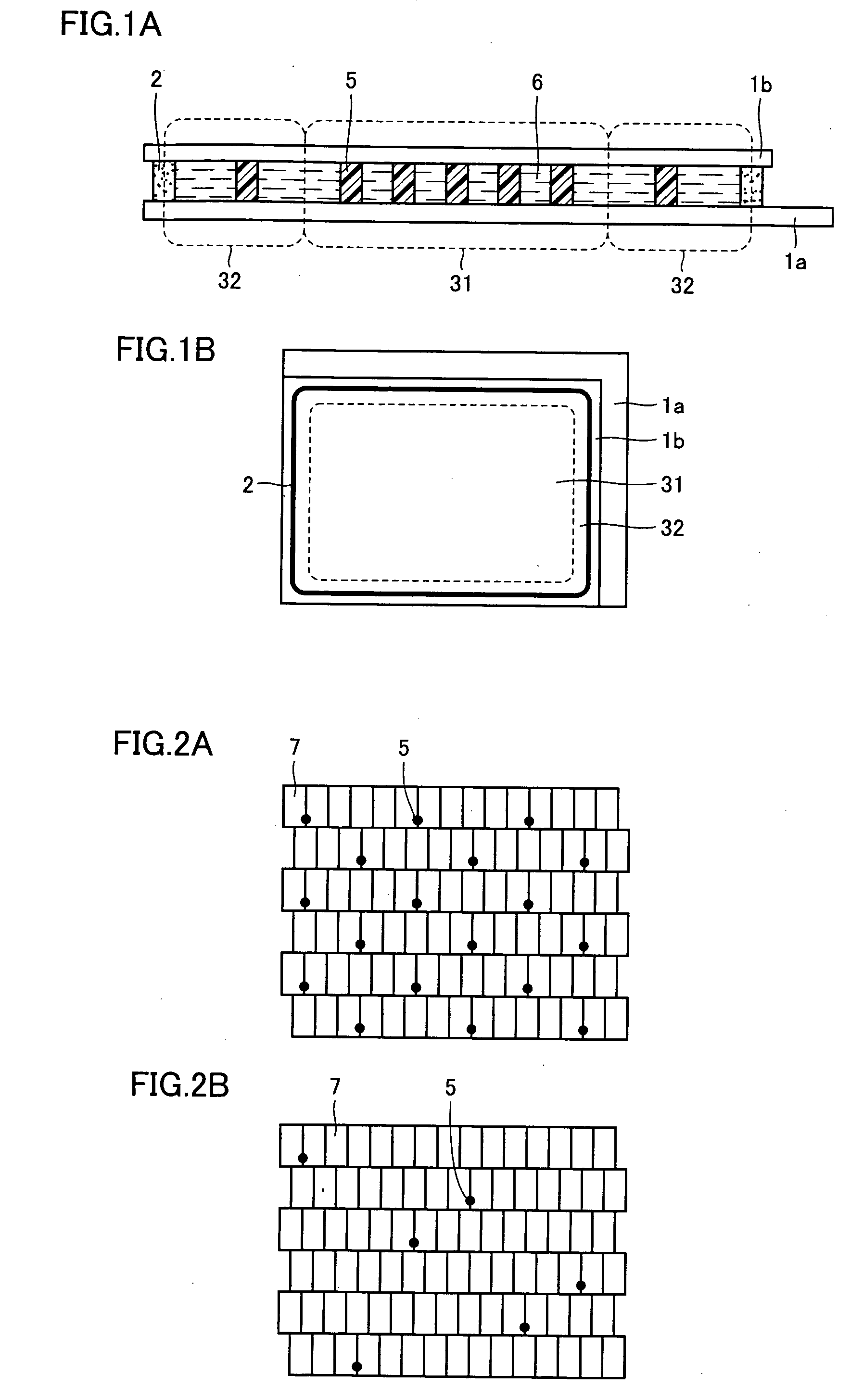

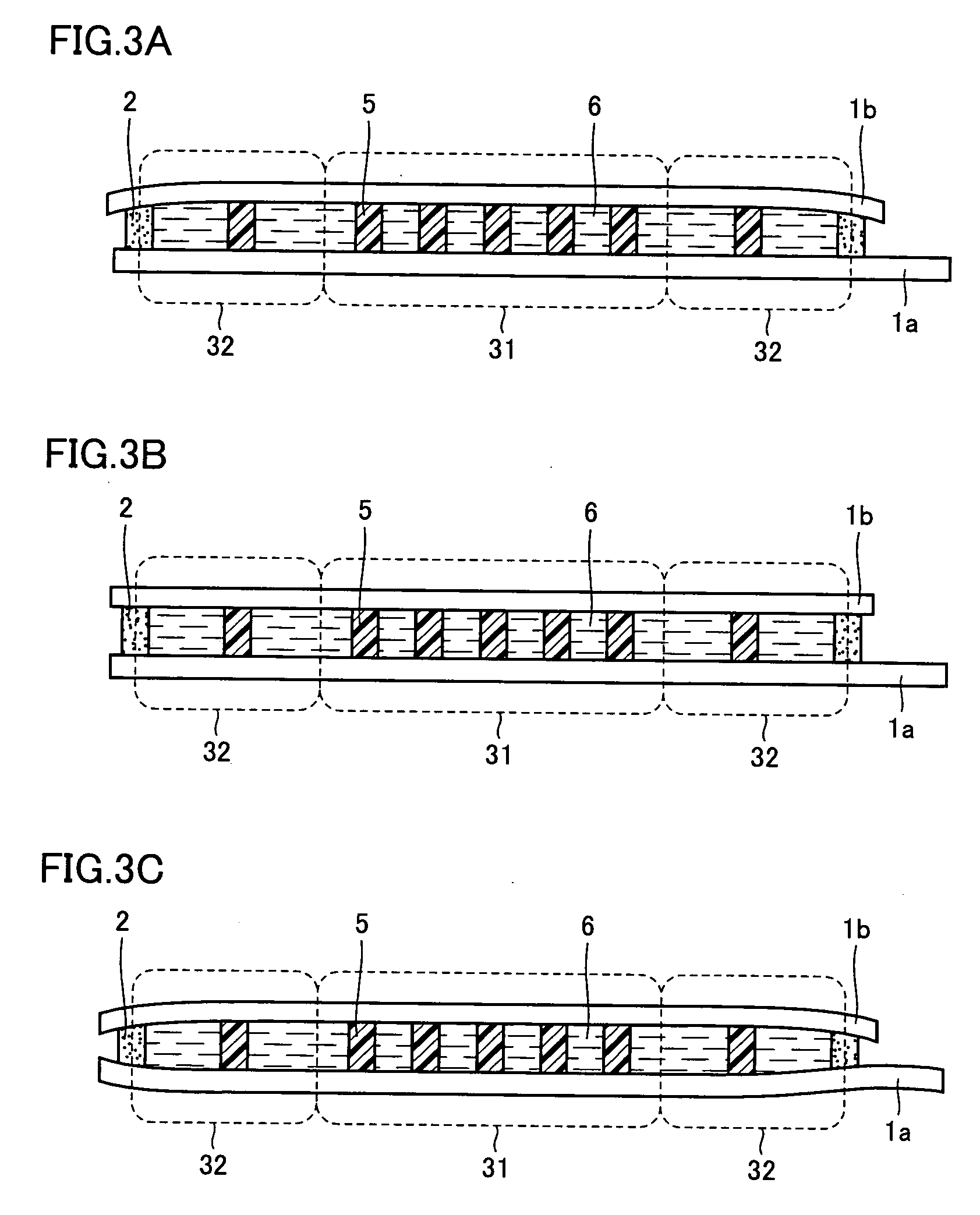

Substrate with a spacer, panel, liquid crystal display panel, method of manufacturing panel and method of manufacturing liquid crystal display panel

InactiveUS20070121051A1Not complicate adhering operationPrevent display quality degradationNon-linear opticsHigh densityLiquid-crystal display

A liquid crystal display panel includes two substrates fixed together by a seal member with their main surfaces opposed to each other, liquid crystal sealingly stored in a region surrounded by the two substrates and the seal member, and a plurality of columnar spacers arranged in a region surrounded by the two substrates and the seal member. A number density of the columnar spacers in a low-density region near the inner side of the seal member is smaller than that in a high-density region inside the low-density region. The substrate with the spacer has the substrate and the spacer formed on the substrate. The spacer has at least a first spacer portion, and a second spacer portion formed above the first spacer portion. An upper portion of the first spacer has a larger diameter than a bottom of the second spacer portion.

Owner:SHARP KK

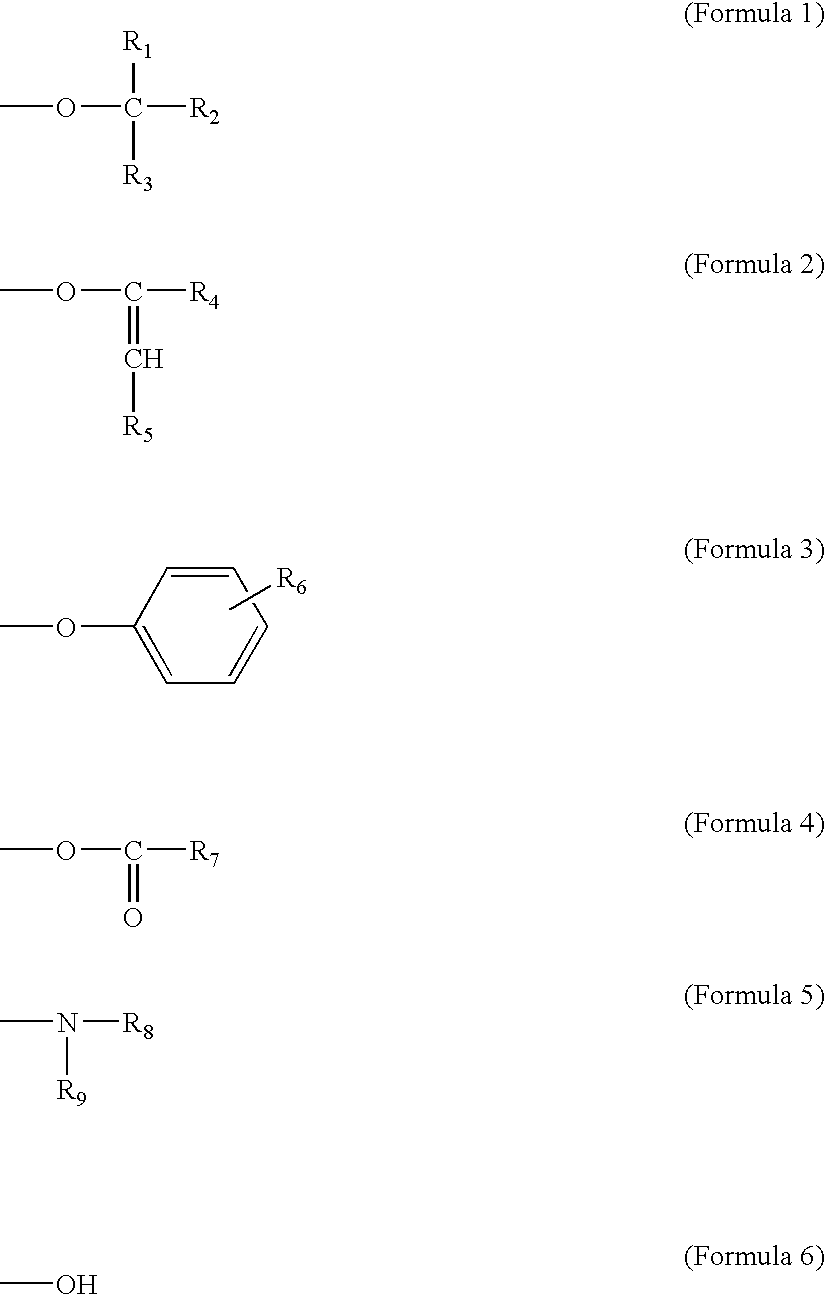

Polyester resin compositions, catalyst for polyester production, polyester film, and magnetic recording medium

InactiveUS20050239929A1Satisfactory hueBase layers for recording layersSynthetic resin layered productsNumber densityDynamic light scattering

The present invention aims to provide a practical polyester that can be produced substantially without using an antimony compound as a polycondensation catalyst. (I) The present invention provides a polyester resin composition containing, on a weight basis, 30 ppm or less of antimony, 0.5 to 50 ppm of titanium, and 0.1 to 100 ppm of phosphorus, in which the number density of titanium-containing particles, the equivalent circular diameter of which is 1 μm or more, is less than 100 / 0.02 mg; and (II) The present invention provides a polyester resin composition containing, on a weight basis, 30 ppm or less of antimony, 0.5 to 50 ppm of titanium, and 0.1 to 100 ppm of phosphorus, in which organic polymer particles are contained in amount of 0.1 to 5 wt %, the organic polymer particles having an average particle diameter determined by dynamic light scattering of 0.05 to 3 μm and containing 0.01% or less of coarse particles relative to the total number of the particles, the coarse particles having a diameter at least twice the average particle diameter.

Owner:TORAY IND INC

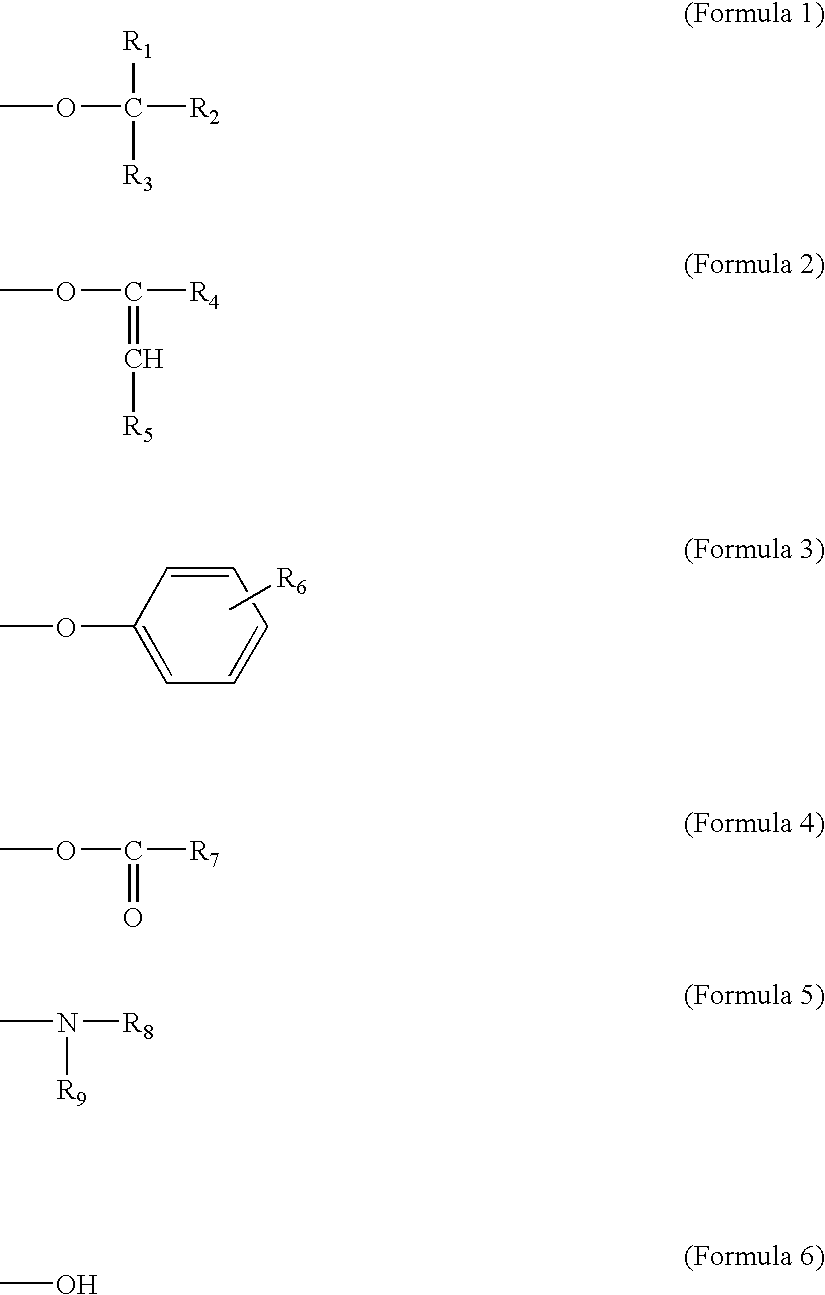

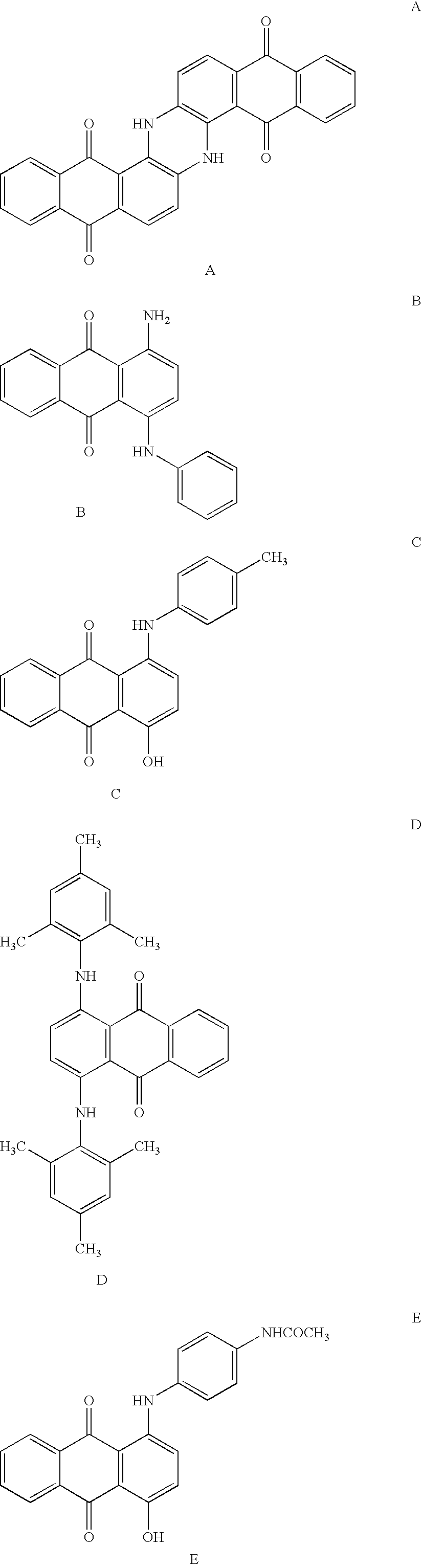

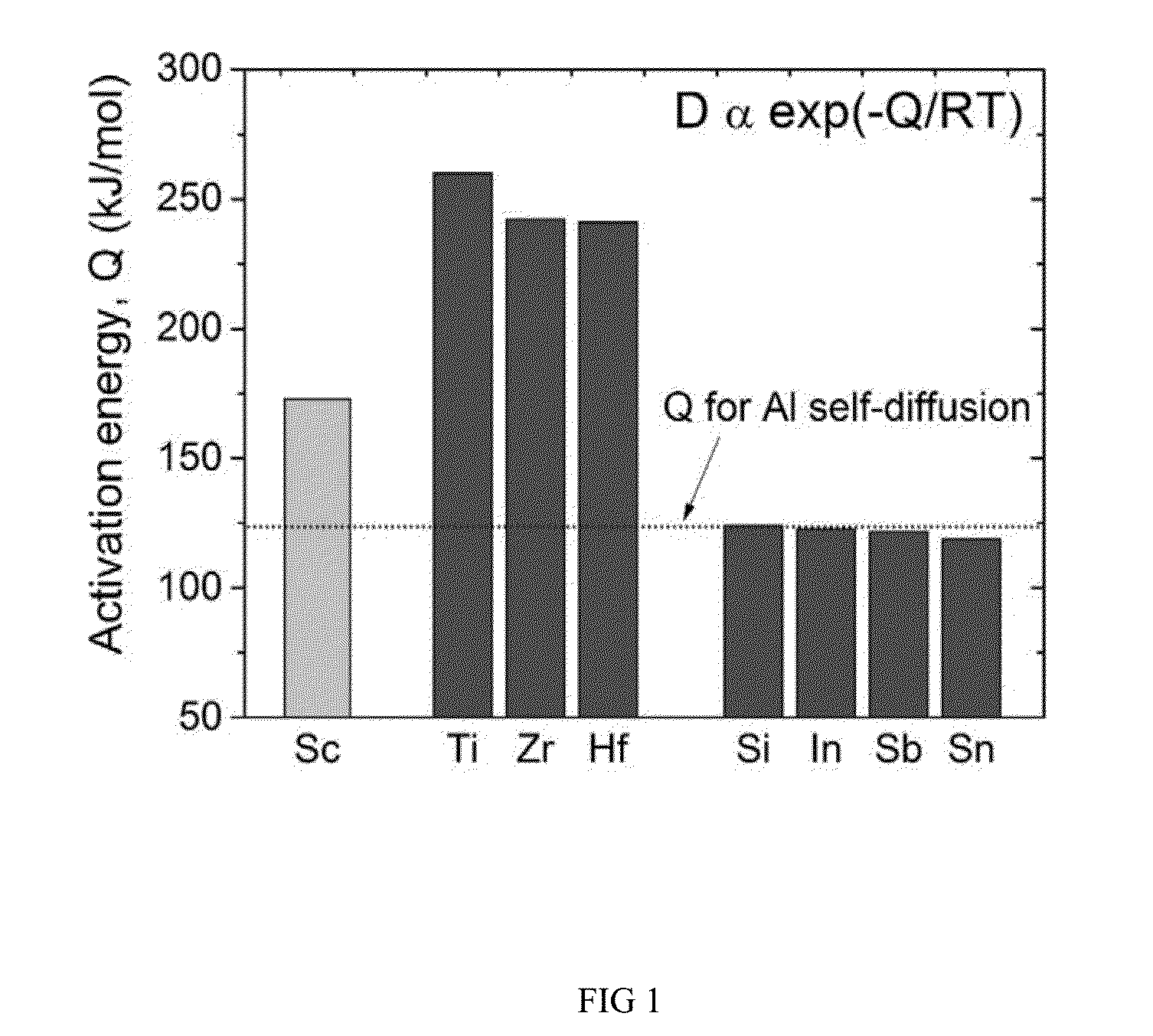

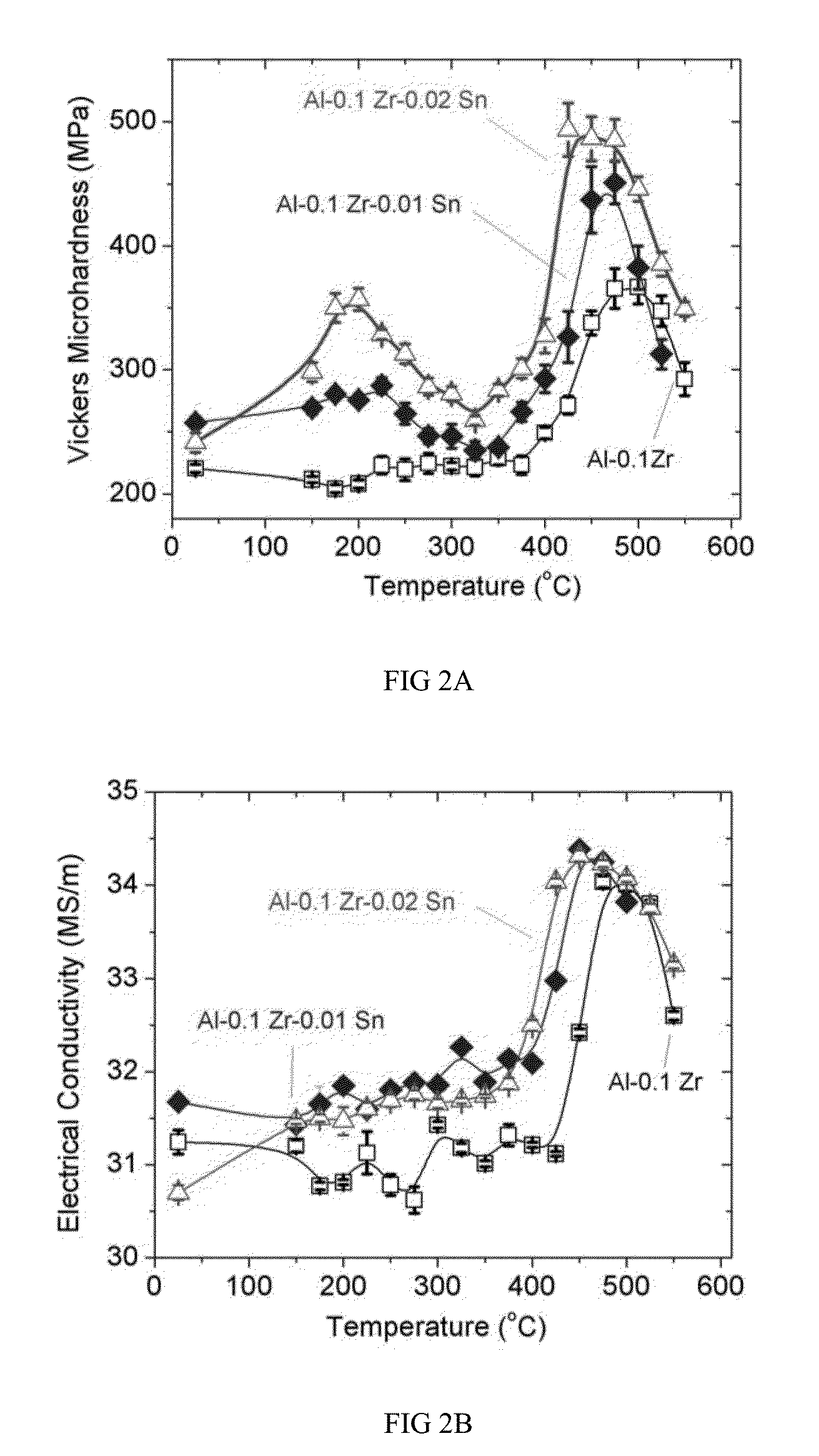

Aluminum superalloys for use in high temperature applications

Aluminum-zirconium and aluminum-zirconium-lanthanide superalloys are described that can be used in high temperature, high stress and a variety of other applications. The lanthanide is preferably holmium, erbium, thulium or ytterbium, most preferably erbium. Also, methods of making the aforementioned alloys are disclosed. The superalloys, which have commercially-suitable hardness at temperatures above about 220° C., include nanoscale Al3Zr precipitates and optionally nanoscale Al3Er precipitates and nanoscale Al3(Zr,Er) precipitates that create a high-strength alloy capable of withstanding intense heat conditions. These nanoscale precipitates have a L12-structure in α-Al(f.c.c.) matrix, an average diameter of less than about 20 nanometers (“nm”), preferably less than about 10 nm, and more preferably about 4-6 nm and a high number density, which for example, is larger than about 1021 m−3, of the nanoscale precipitates. The formation of the high number density of nanoscale precipitates is thought to be due to the addition of inoculant, such as a Group 3A, 4A, and 5A metal or metalloid. Additionally, methods for increasing the diffusivity of Zr in Al are disclosed.

Owner:NORTHWESTERN UNIV

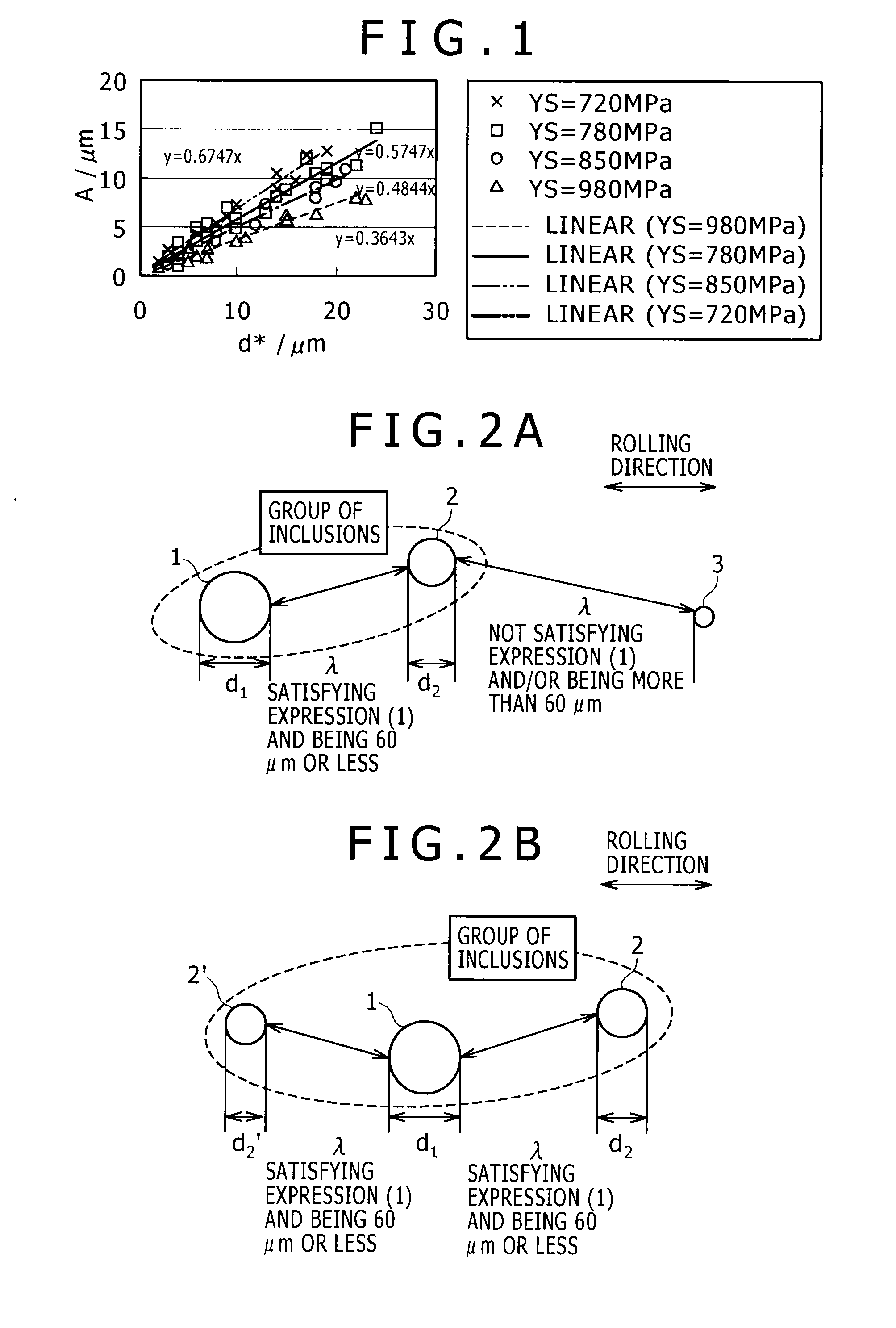

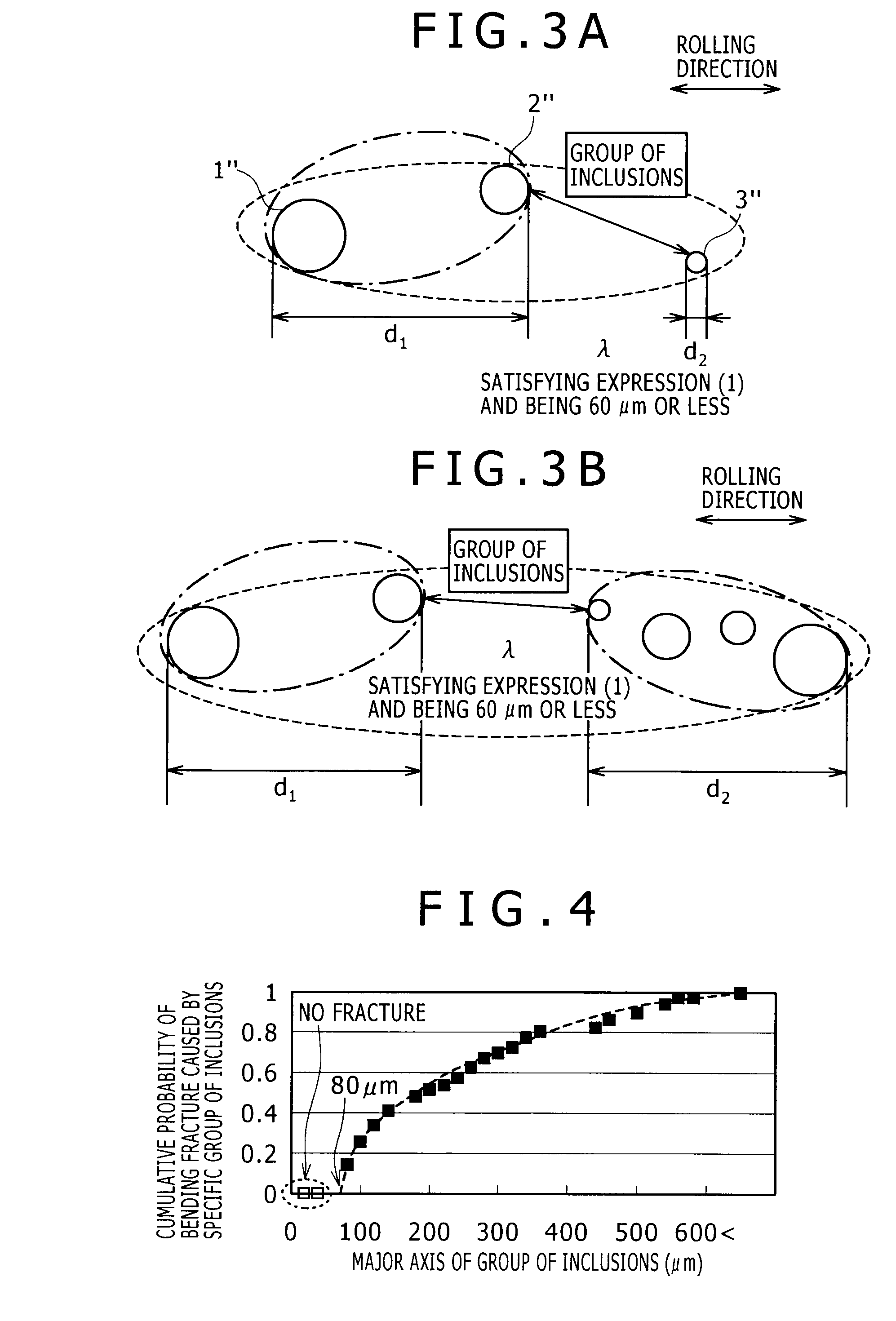

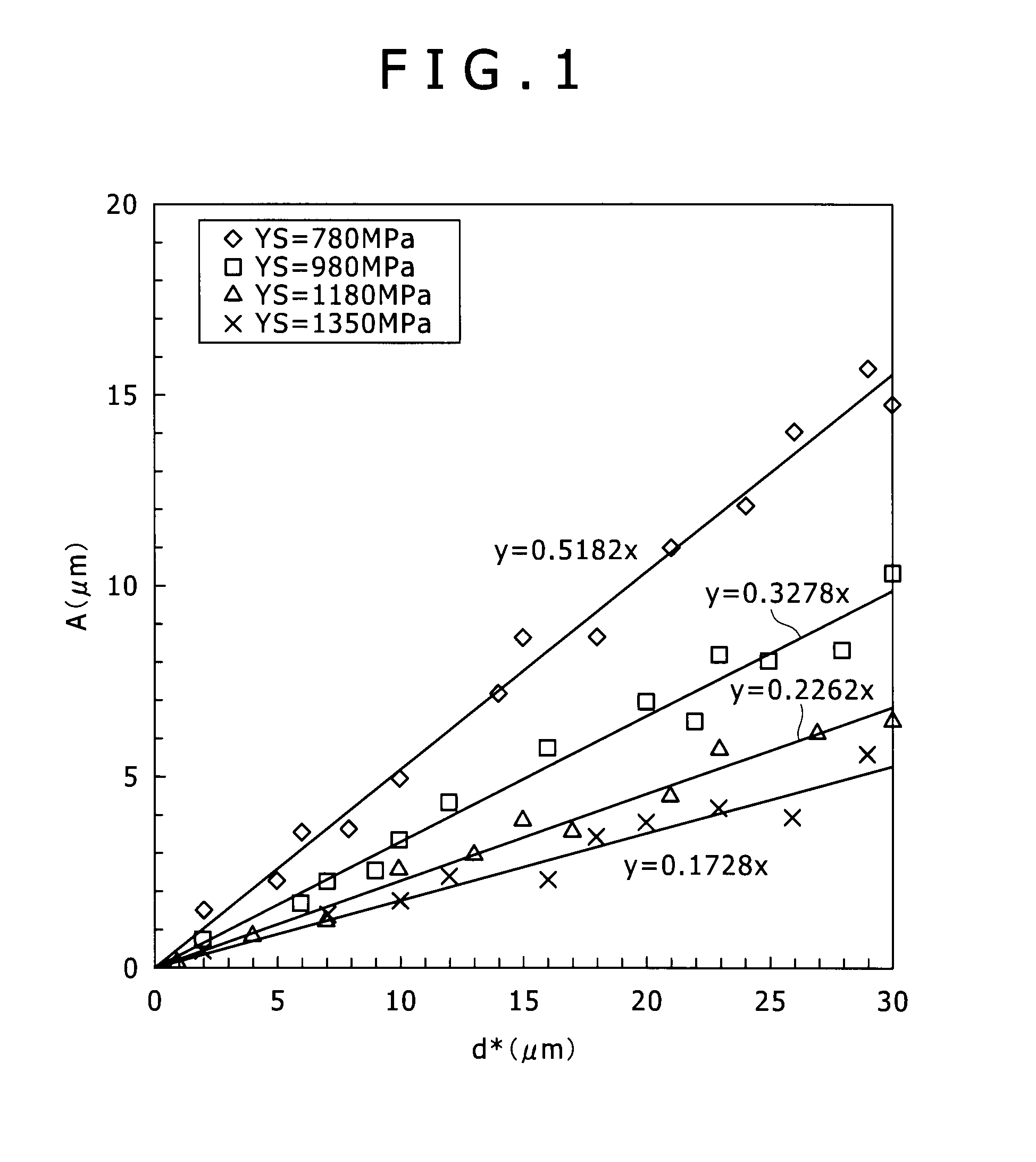

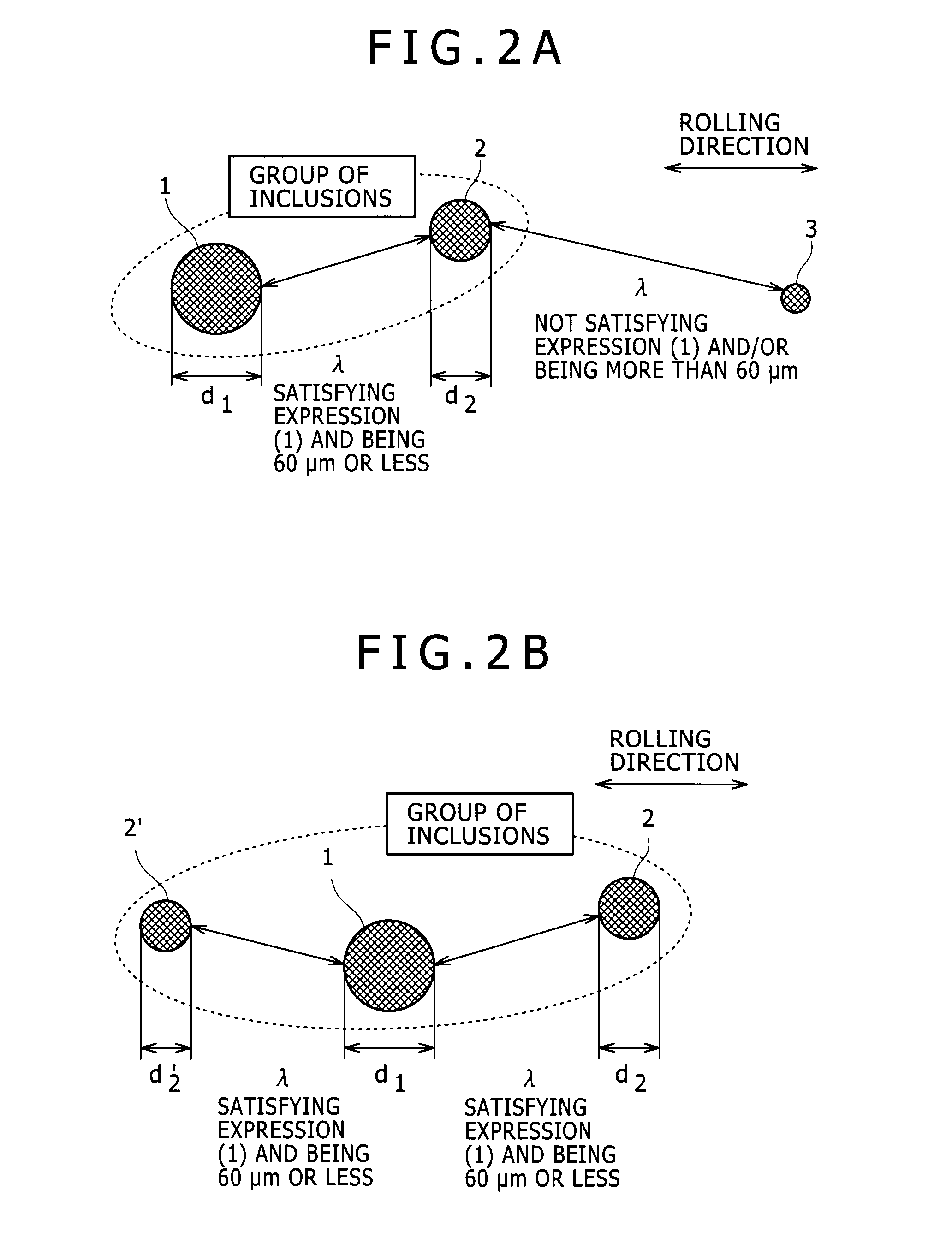

High-strength cold-rolled steel sheet excellent in bending workability

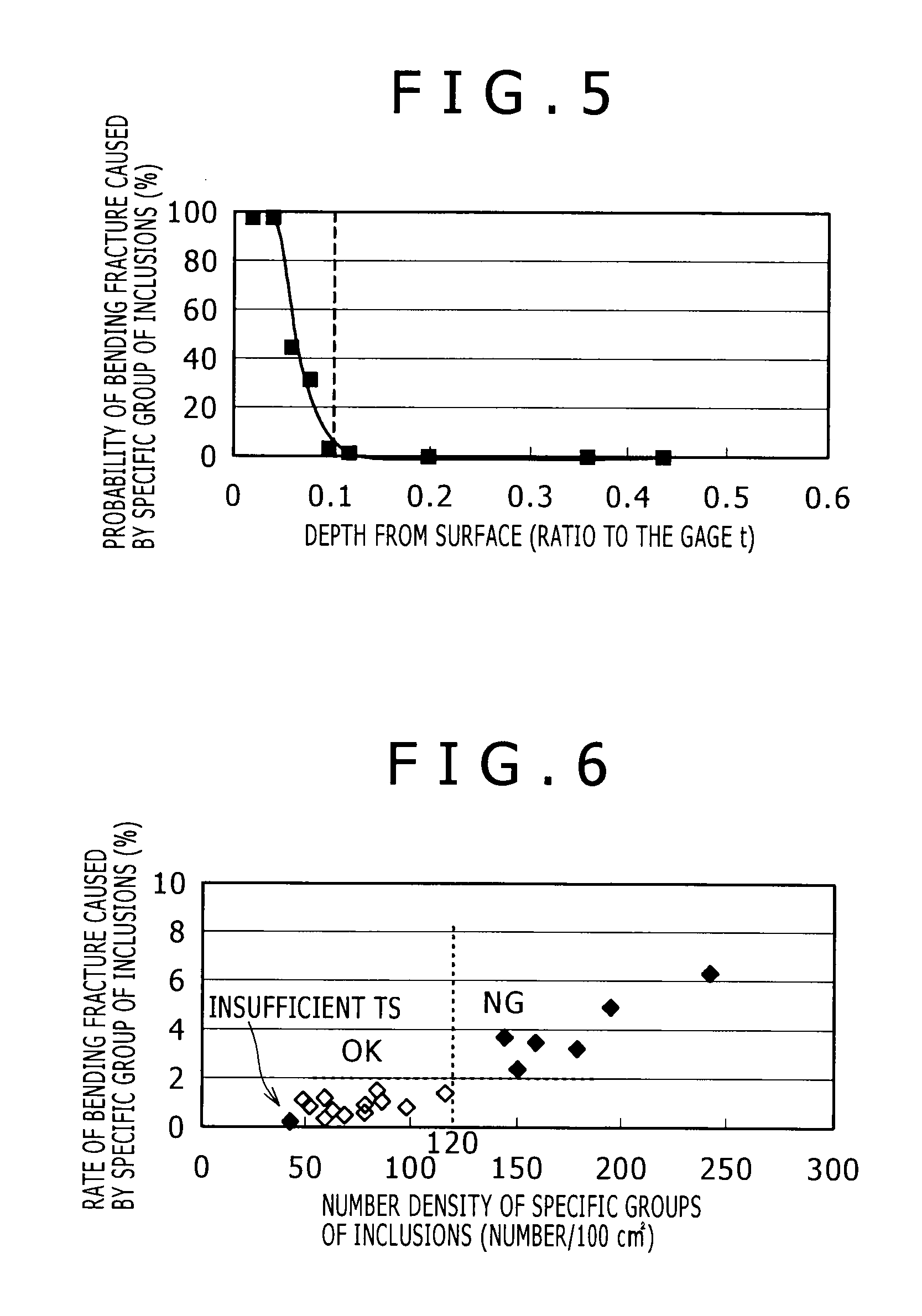

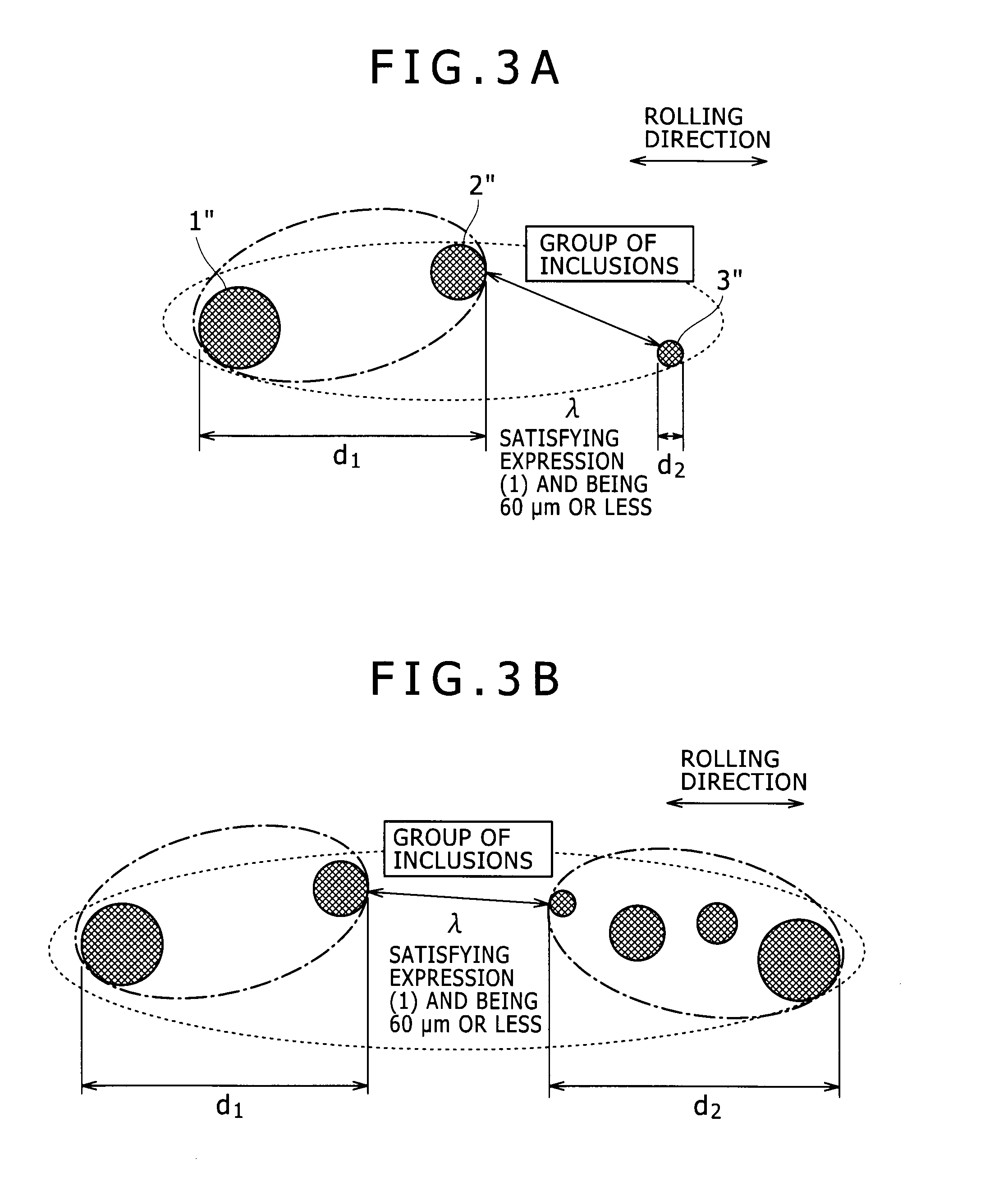

ActiveUS20100247957A1Excellent bending workabilityMinimized rate of bending fractureHot-dipping/immersion processesThin material handlingMetallurgyNumber density

Disclosed is a cold-rolled steel sheet having a specific steel composition and having a composite steel structure including a ferrite structure and a martensite-containing second phase. In a surface region of the steel sheet from the surface to a depth one-tenth the gage, the number density of n-ary groups of inclusions determined by specific n-th determinations is 120 or less per 100 cm2 of a rolling plane, in which the distance in steel sheet rolling direction between outermost surfaces of two outermost particles of the group of inclusions is 80 μm or more. Also disclosed is a cold-rolled steel sheet having a specific steel composition and having a steel structure of a martensite single-phase structure. In the surface region, the number density of groups of inclusions, in which the distance between the outermost surfaces is 100 μm or more, is 120 or less per 100 cm2 of a rolling plane.

Owner:KOBE STEEL LTD

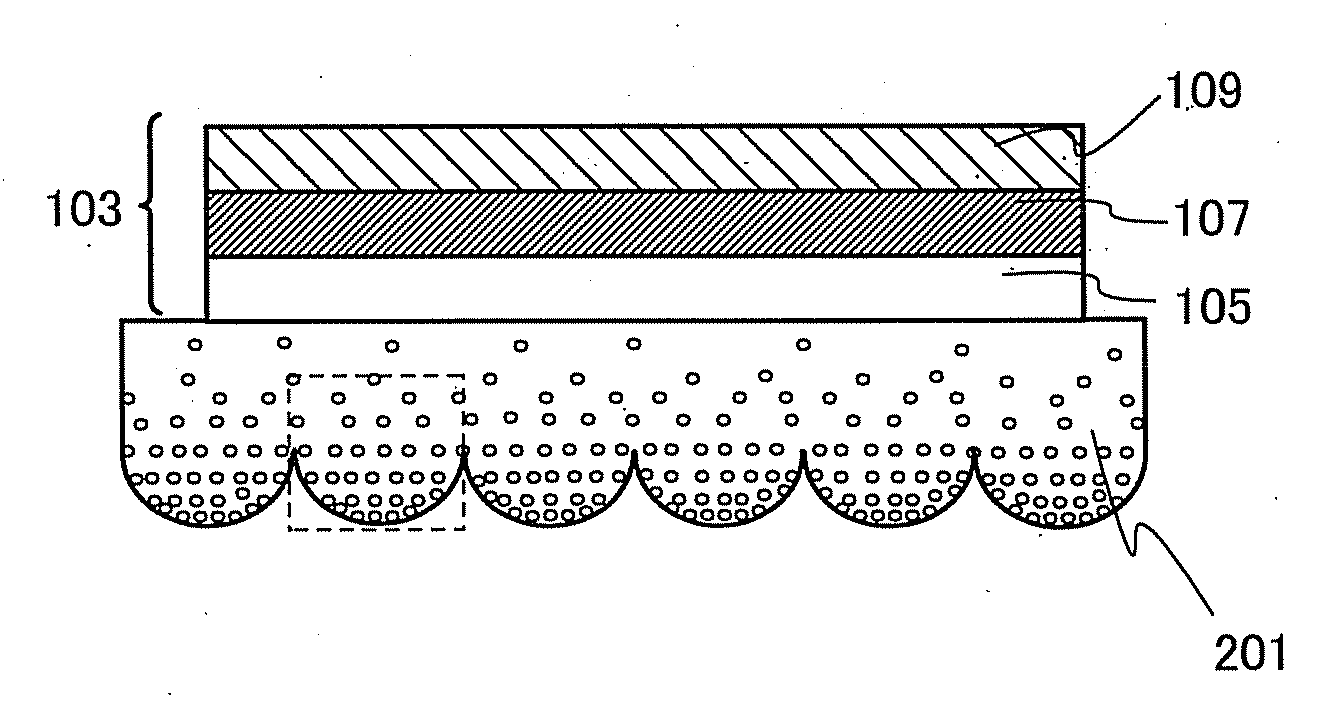

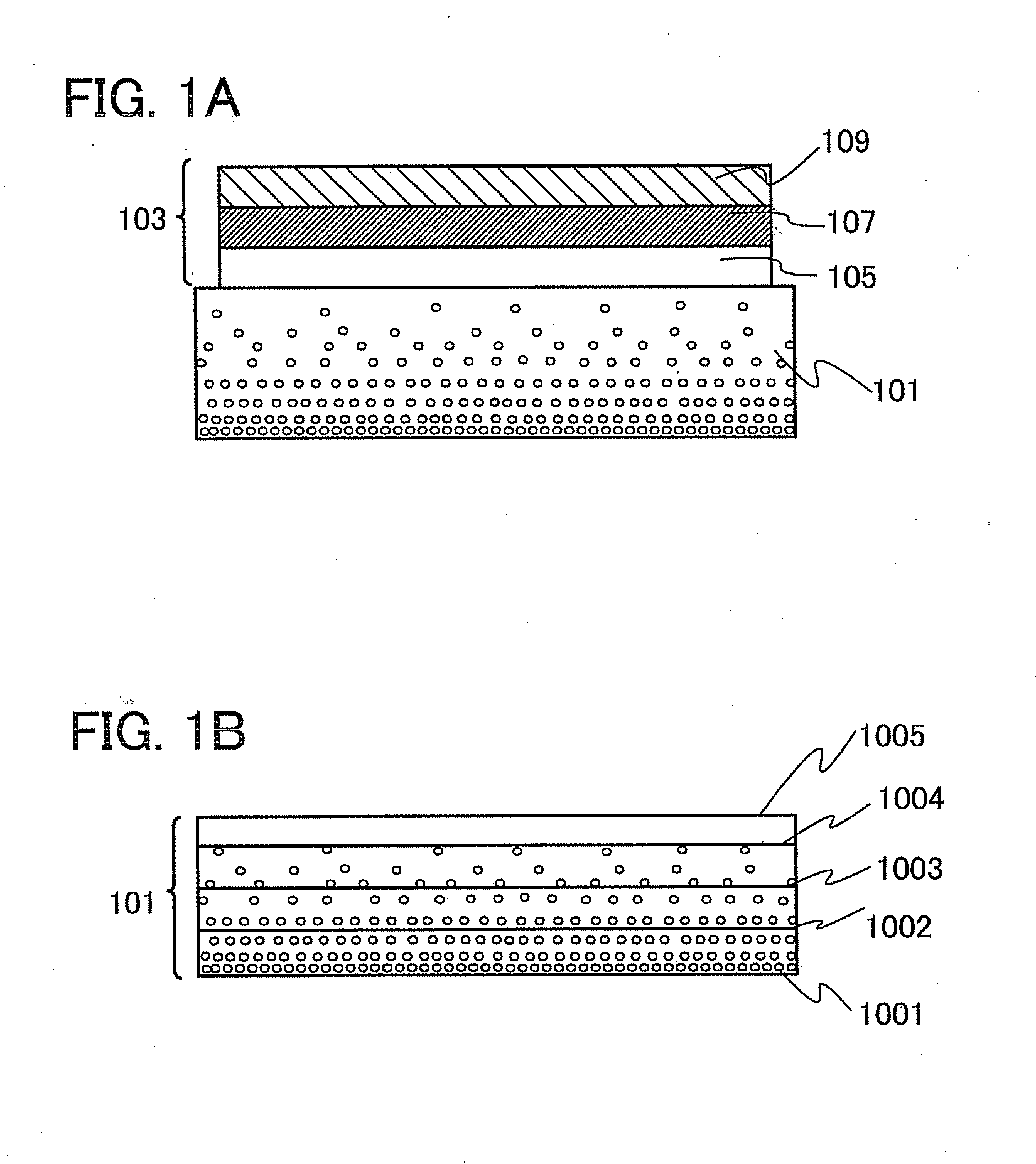

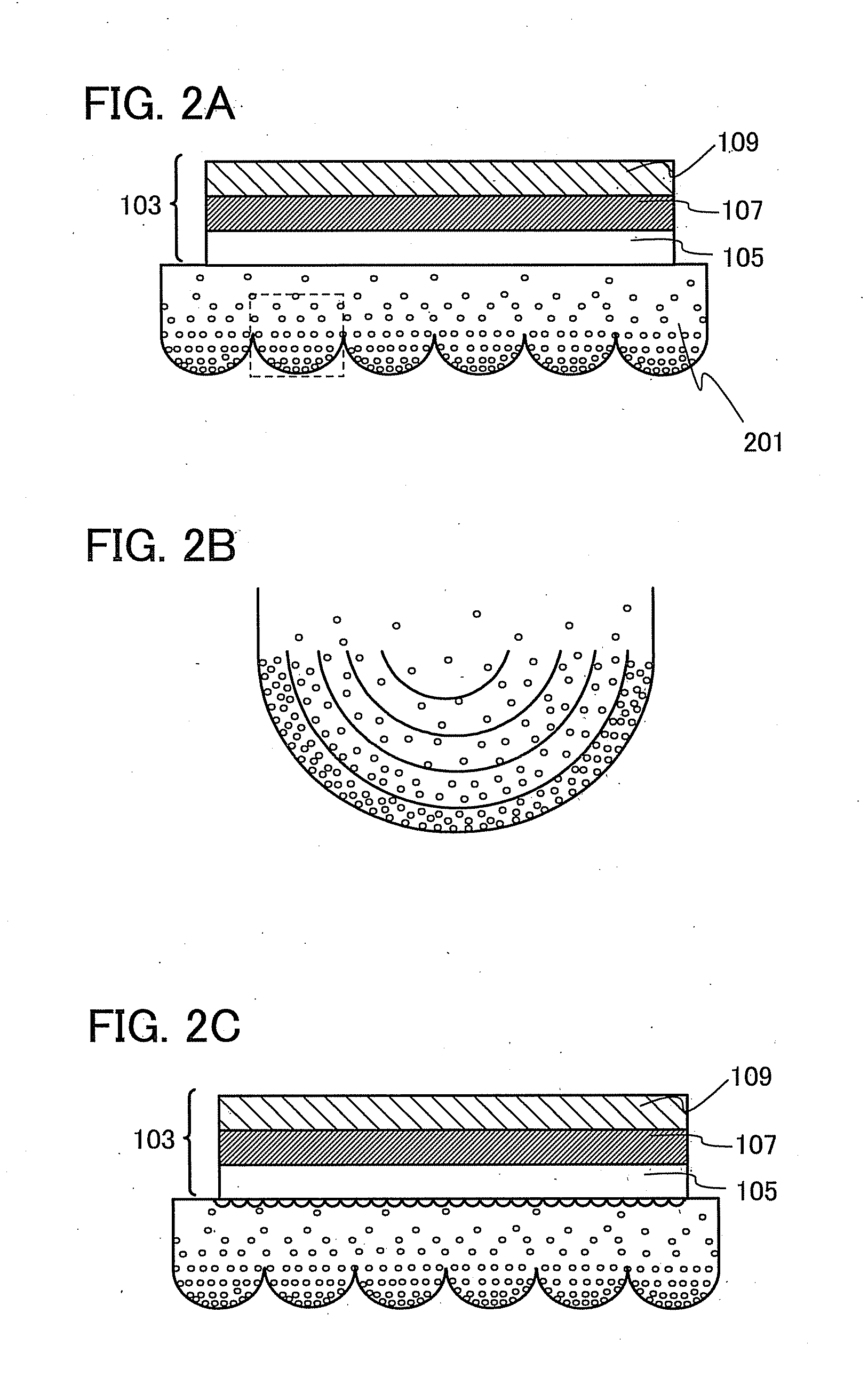

Optical Element, Light-Emitting Device, Lighting Device, and Method for Manufacturing Optical Element

InactiveUS20120206923A1Efficiently extract lightImprove efficiencyOptical articlesMountingsNumber densityLength wave

An optical element comprises an organic resin and bubbles distributed to have a number density increasing from a first plane of the optical element toward a second plane of the optical element, where a diameter of the bubbles is less than or equal to a wavelength of light which enters the optical element. At least one of the first plane and the second plane may have an uneven structure.

Owner:SEMICON ENERGY LAB CO LTD

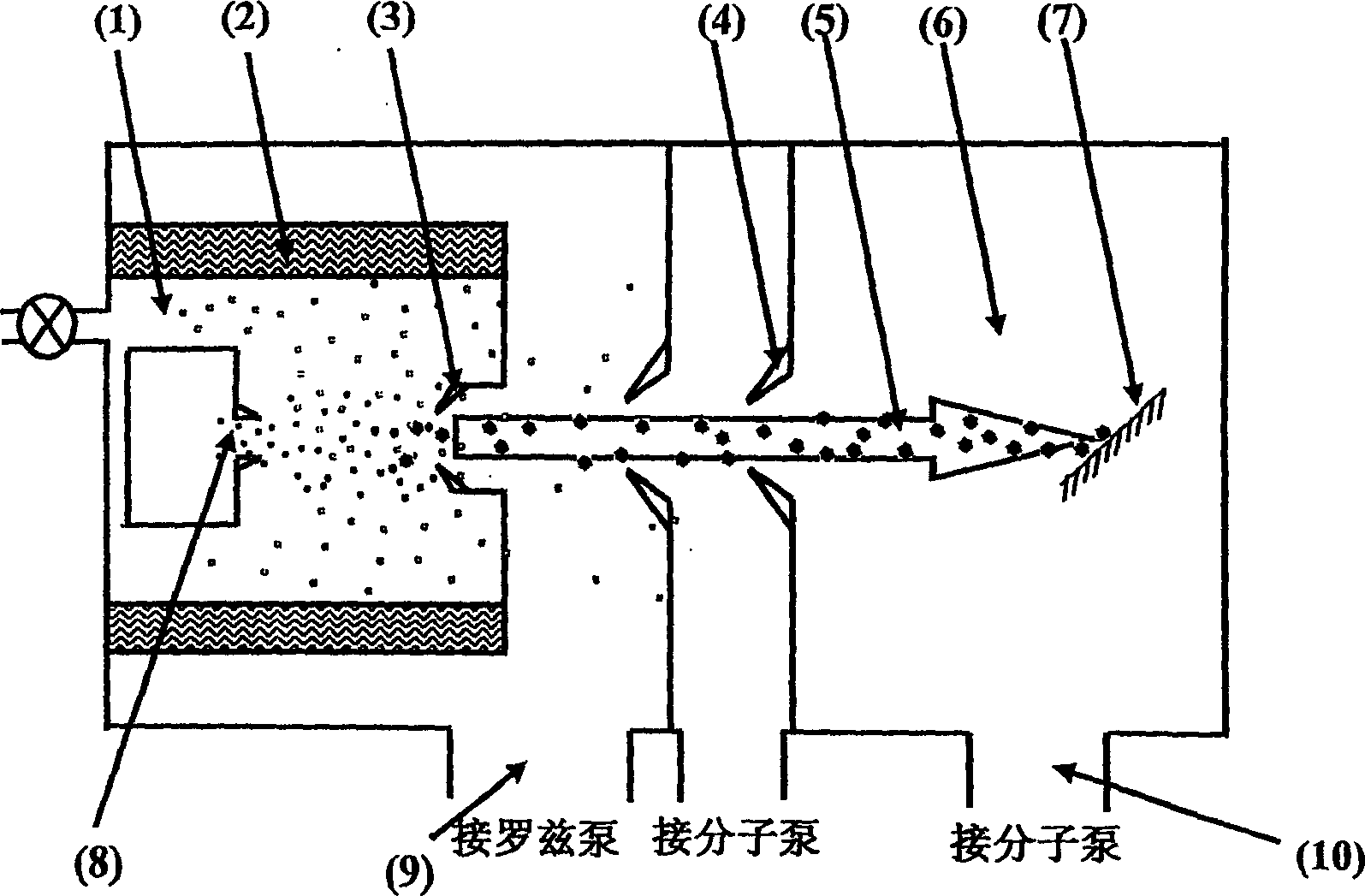

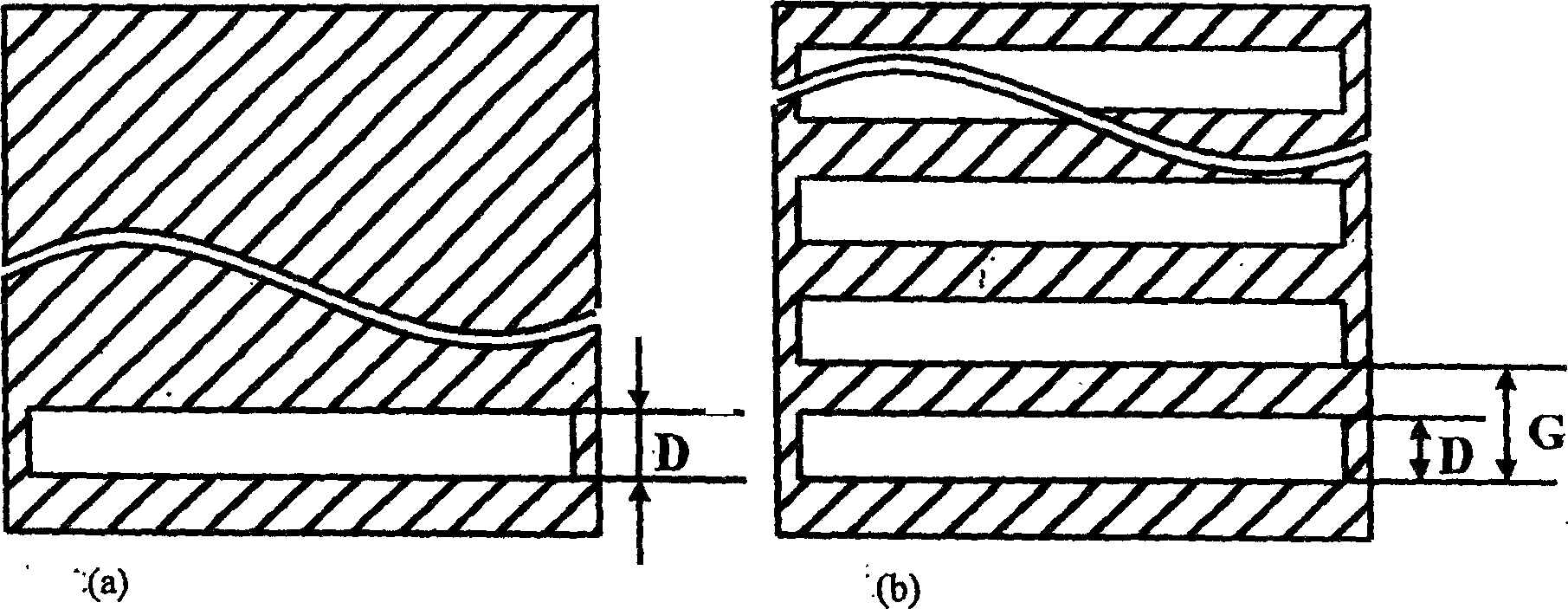

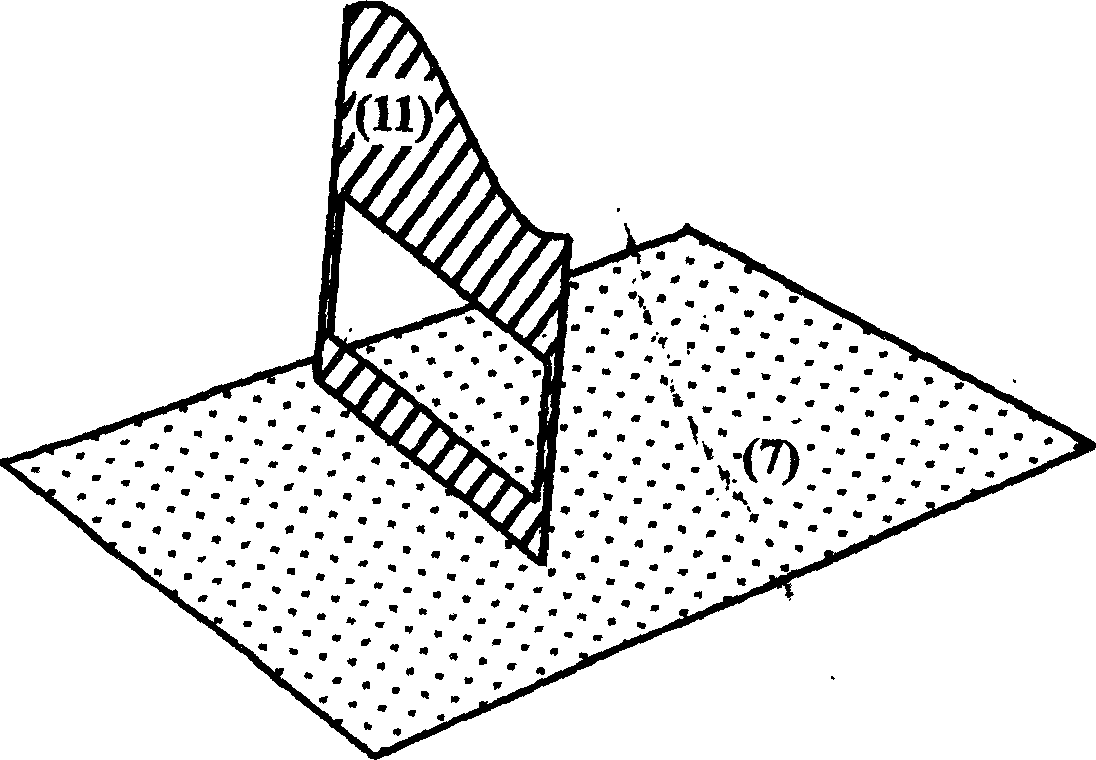

Gas phase synthesis process of nanometer particle array with one-dimensional diameter and number density gradient

InactiveCN1810629AImprove mobilityLow costDecorative surface effectsVacuum evaporation coatingGas phaseNumber density

The present invention obtains nanometer particle array with one-dimensional diameter and number density gradient through gas phase aggregation process to generate nanometer particle, adiabatic expansion to obtain nanometer particle beam, collimating with collimator to a high vacuum deposit chamber to form highly oriented nanometer particle beam, rotating the substrate seat to form a nanometer particle beam incoming angle of 10 deg to the substrate while maintaining the substrate and the blocking mask inside the shoot area of the nanometer particle beam, and controlling the deposition of the nanometer particle beam on the substrate for 30 sec. The method has high efficiency, low cost, simple technological process and other features, and can deposit the gradient nanometer particle array in decades of seconds under common technological parameter condition.

Owner:NANJING UNIV

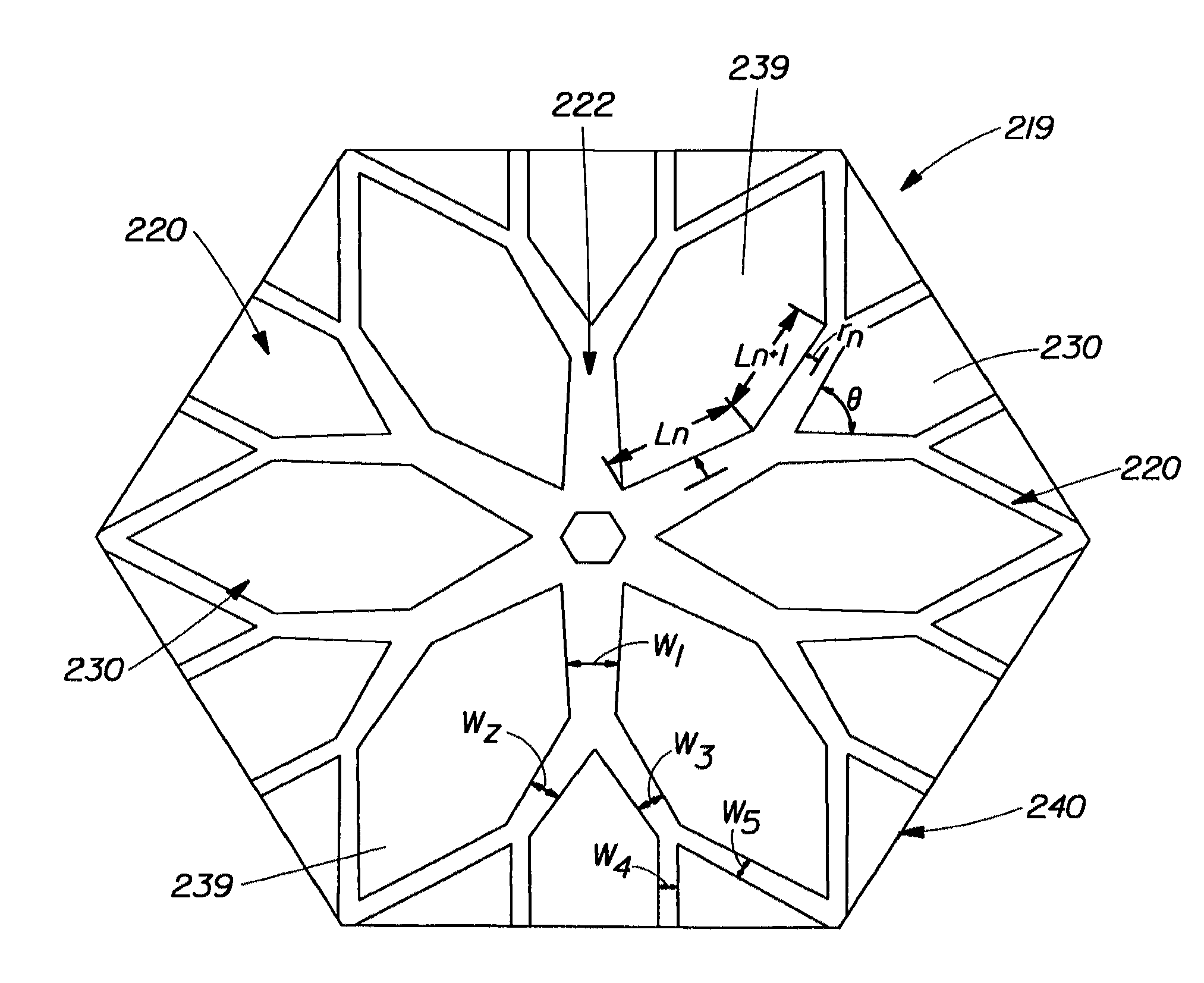

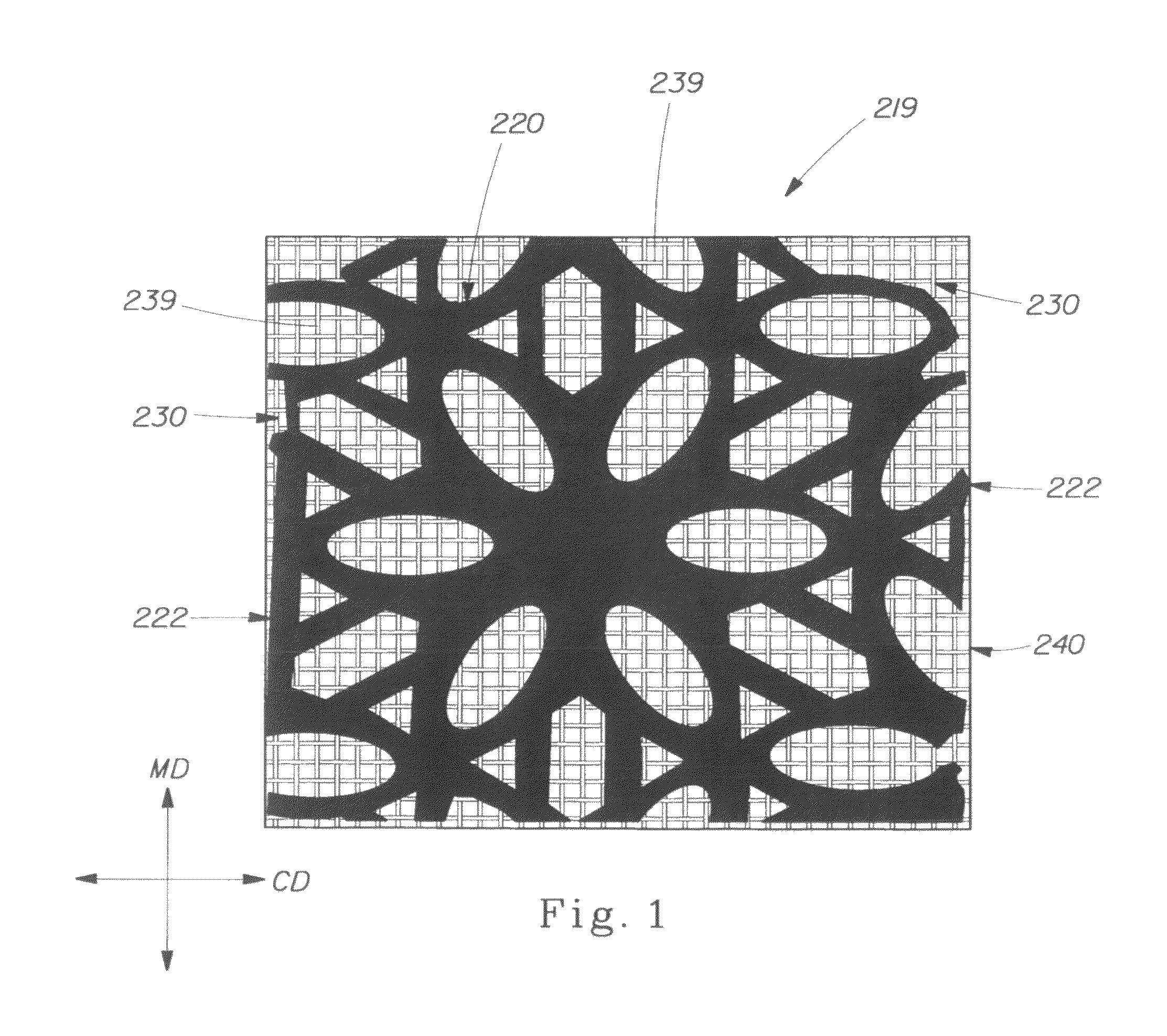

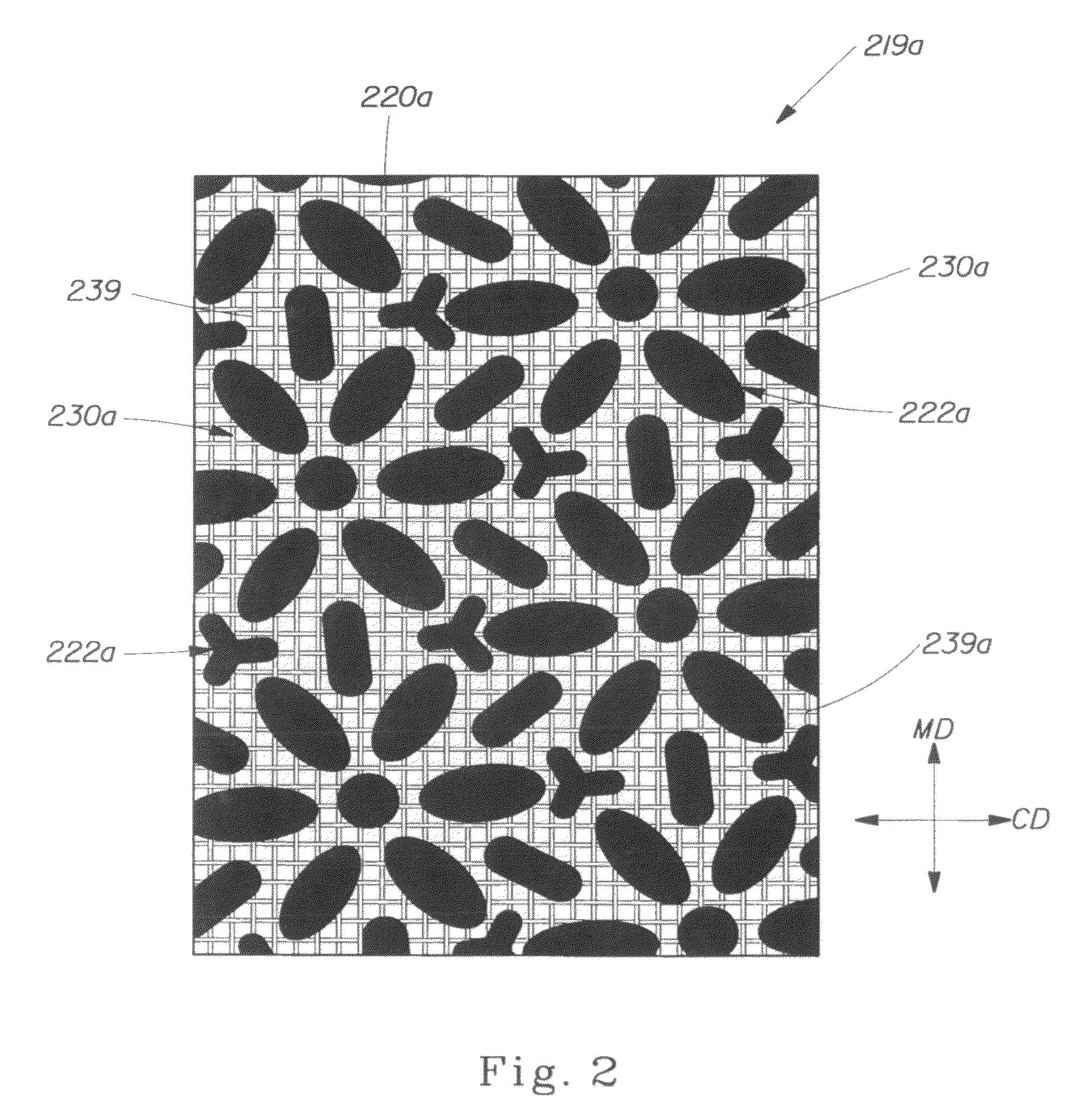

Paper product having unique physical properties

A paper product having a plurality of tessellating unit cells forming a pattern is disclosed. Each unit cell has a center and at least two continuous land areas extending in at least two directions from the center and a plurality of pillow areas each surrounded by at least one of the continuous land areas. Each of the continuous land areas at least bifurcates to form a continuous land area portion having a first width before bifurcation and at least two continuous land area portions having a second width after bifurcation. The first width is greater than the second width. Each of the continuous land area portions having the first width has a first number density and each of the at least two continuous land area portions having the second width has a second number density. The first number density is less than the second number density.

Owner:PROCTER & GAMBLE CO

Method of producing an aluminum alloy brazing sheet

InactiveCN1982047AExcellent brazeabilityHigh strengthWelding/cutting media/materialsHeat exchange apparatusNumber densityMetal

A method of producing an aluminum alloy brazing sheet which has a clad of a sacrificial anode material / a core alloy / an intermediate material / a filler alloy, each of which has a specific composition, wherein number density ratios N 1 / N 2 and N 1 / N 3 each are 1.5 or more, in which a number density ((the number of grains) / [mu]m 3 ) of an intermetallic compound having a sphere-equivalent grain diameter of 0.1 [mu]m or less present in the core alloy, the intermediate material, and the sacrificial anode material, is represented by N 1 , N 2 , and N 3 , respectively.

Owner:FURUKAWA SKY ALUMINUM CORP

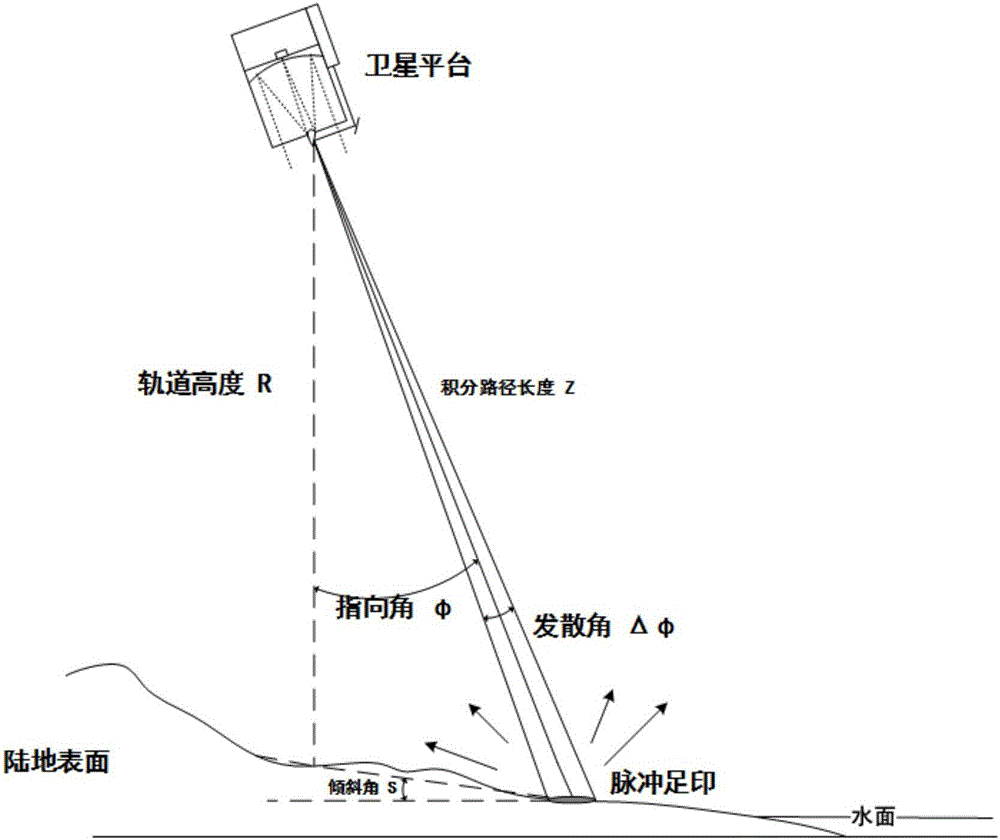

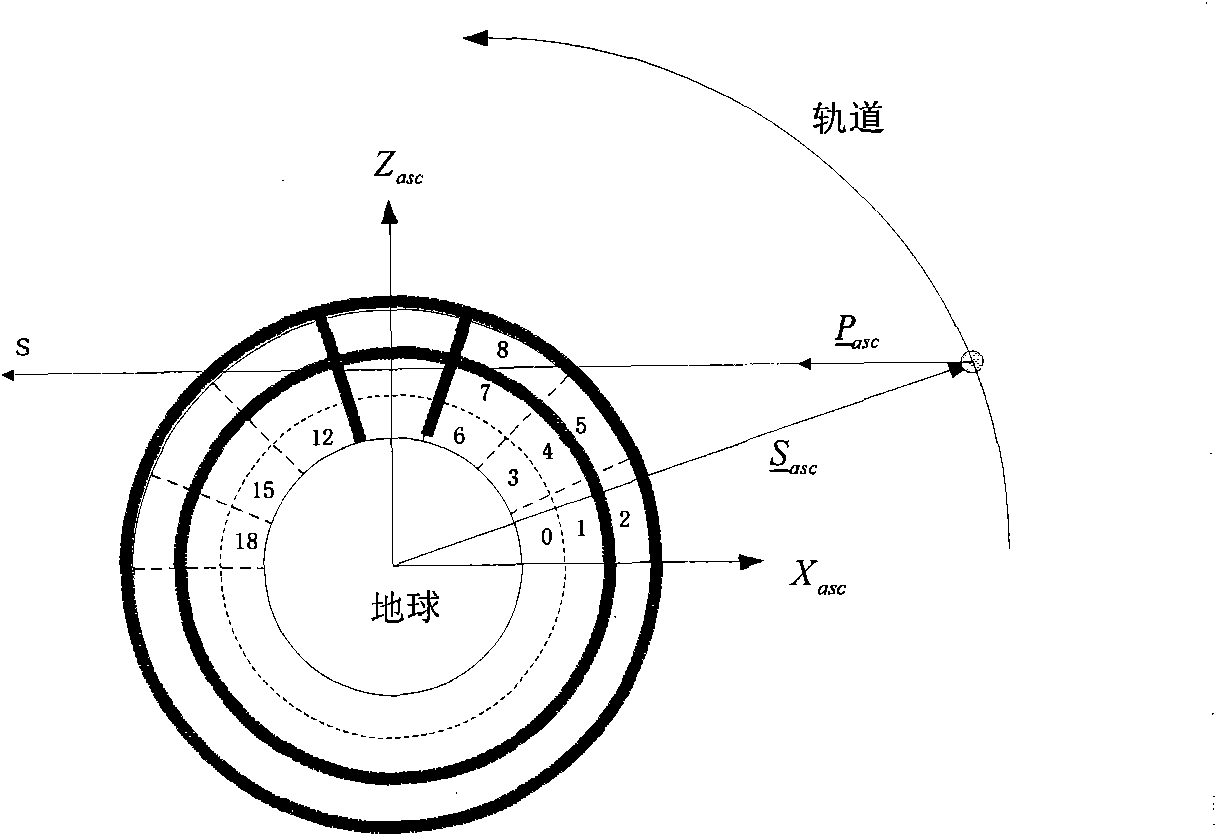

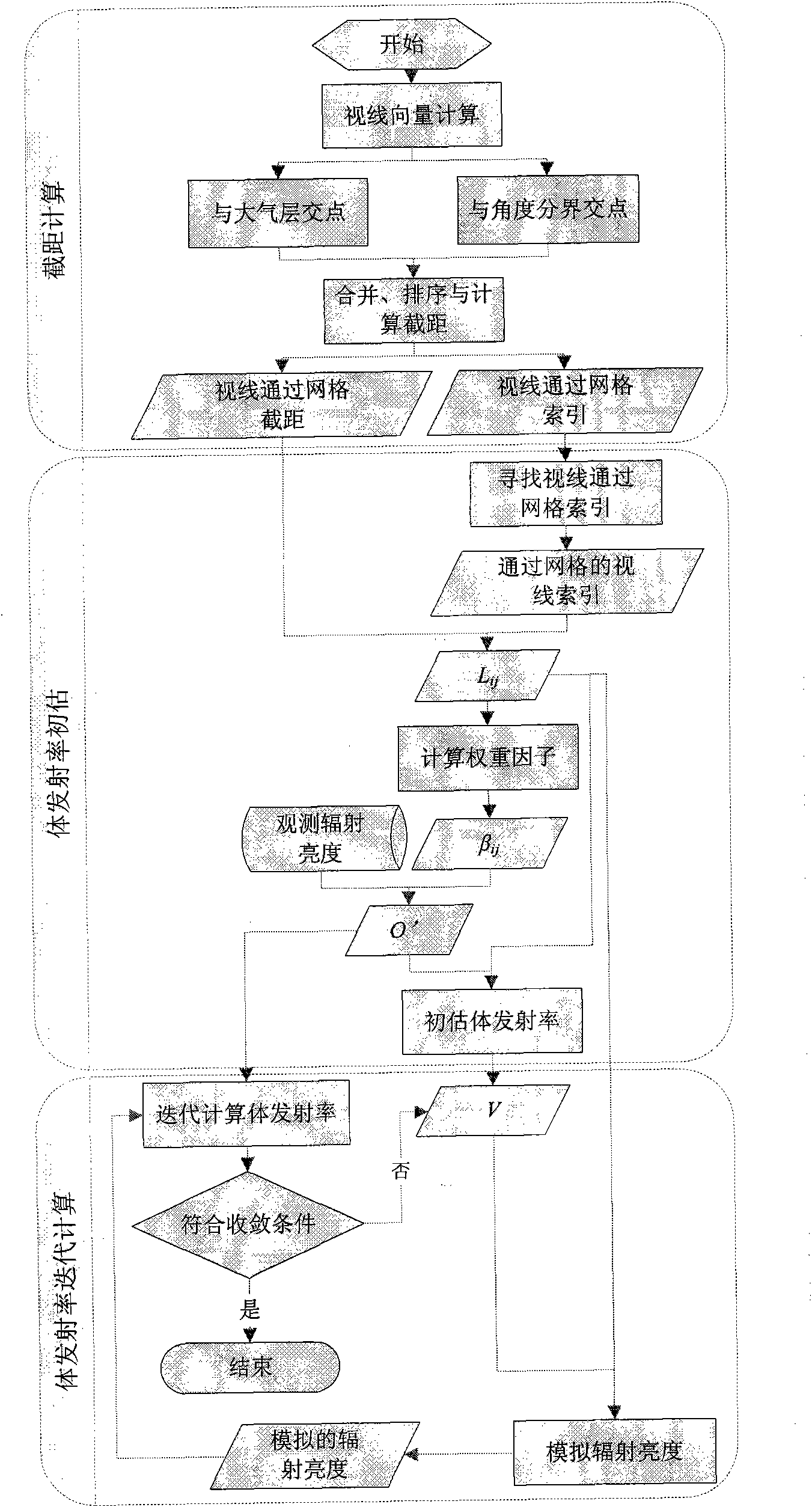

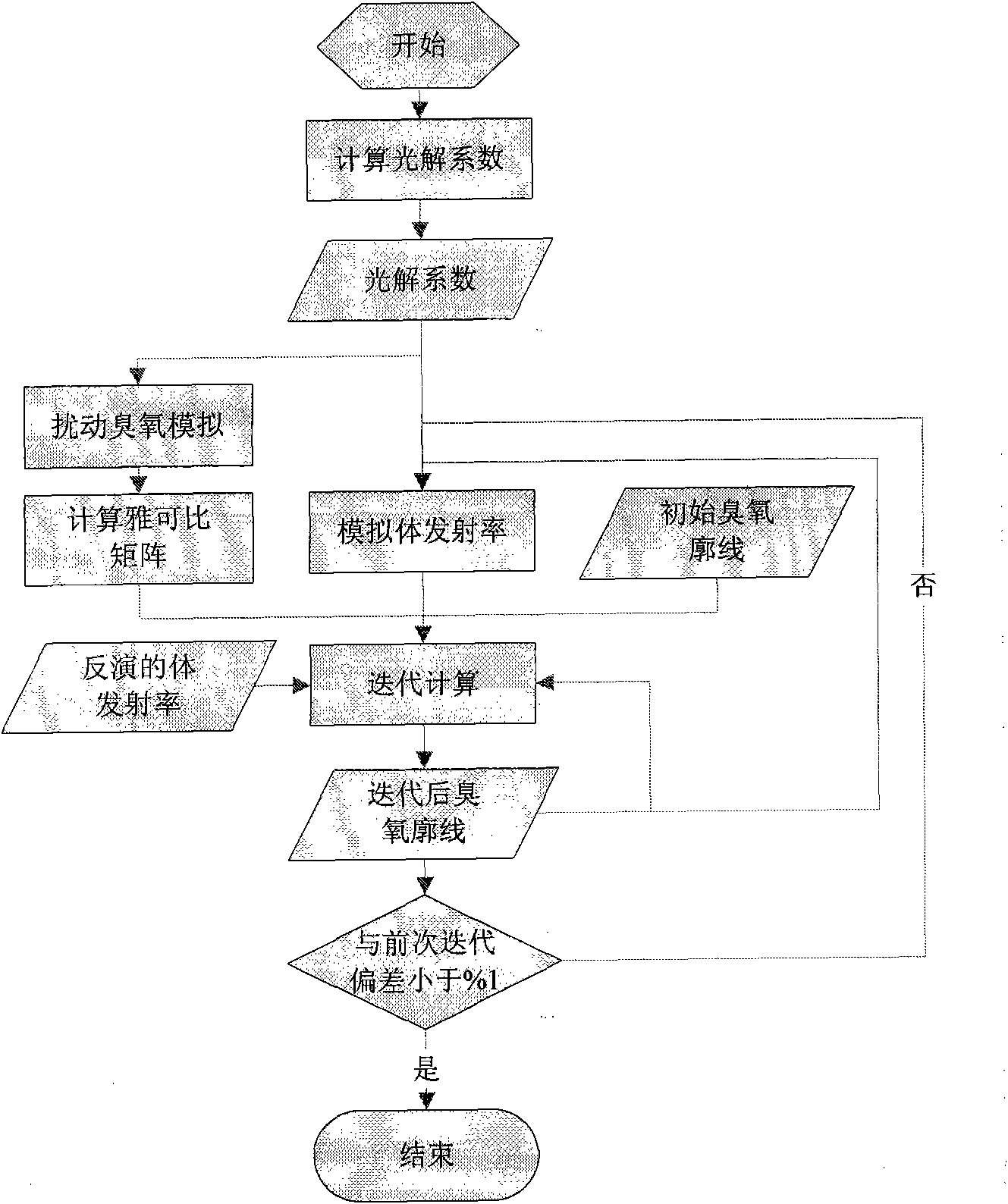

Tomography method of using limb sounding data for inverting atmospheric ozone profiles

InactiveCN101936881AIncrease vertical resolutionScattering properties measurementsSpecial data processing applicationsAtmospheric layerNumber density

The invention relates to a tomography method of using the limb sounding data for inverting atmospheric ozone profiles. The method comprises the following steps: respectively calculating the intersections between the gaze vector and the atmospheric grid radial and vertical boundary and atmospheric layer horizontal boundary, merging two types of intersections, then calculating the distance between adjacent intersections to obtain intercept; applying the tomography method in a correlate equation about volume emissivity and radiance, using the square iterative reconstruction technology to obtain the inverse iteration model of the volume emissivity, calculating the volume emissivity; and finally using an oxozone photochemical model to connect the volume emissivity with the ozone number density, and selecting the Newton iteration method to invert the ozone profiles.

Owner:JILIN UNIV

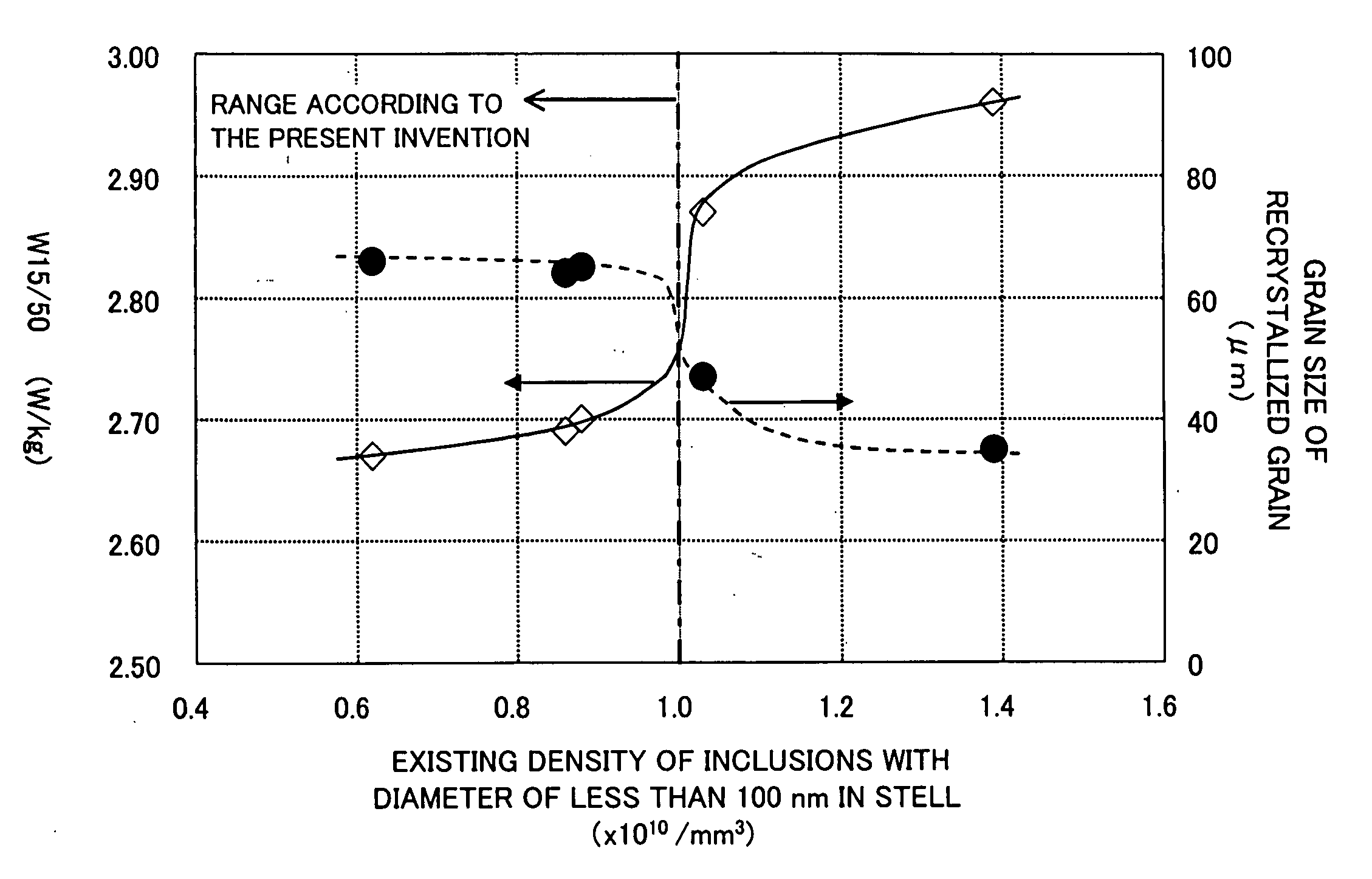

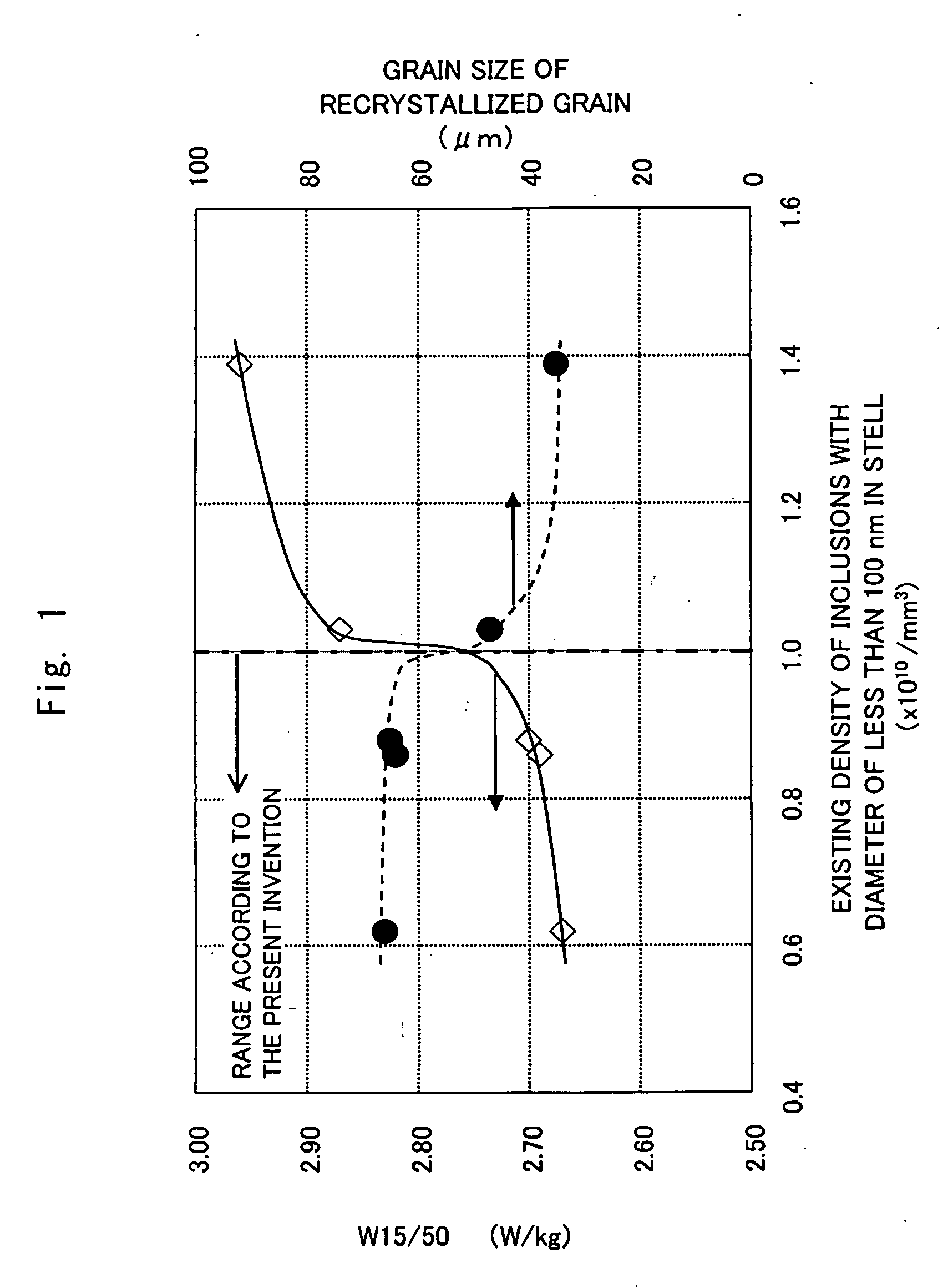

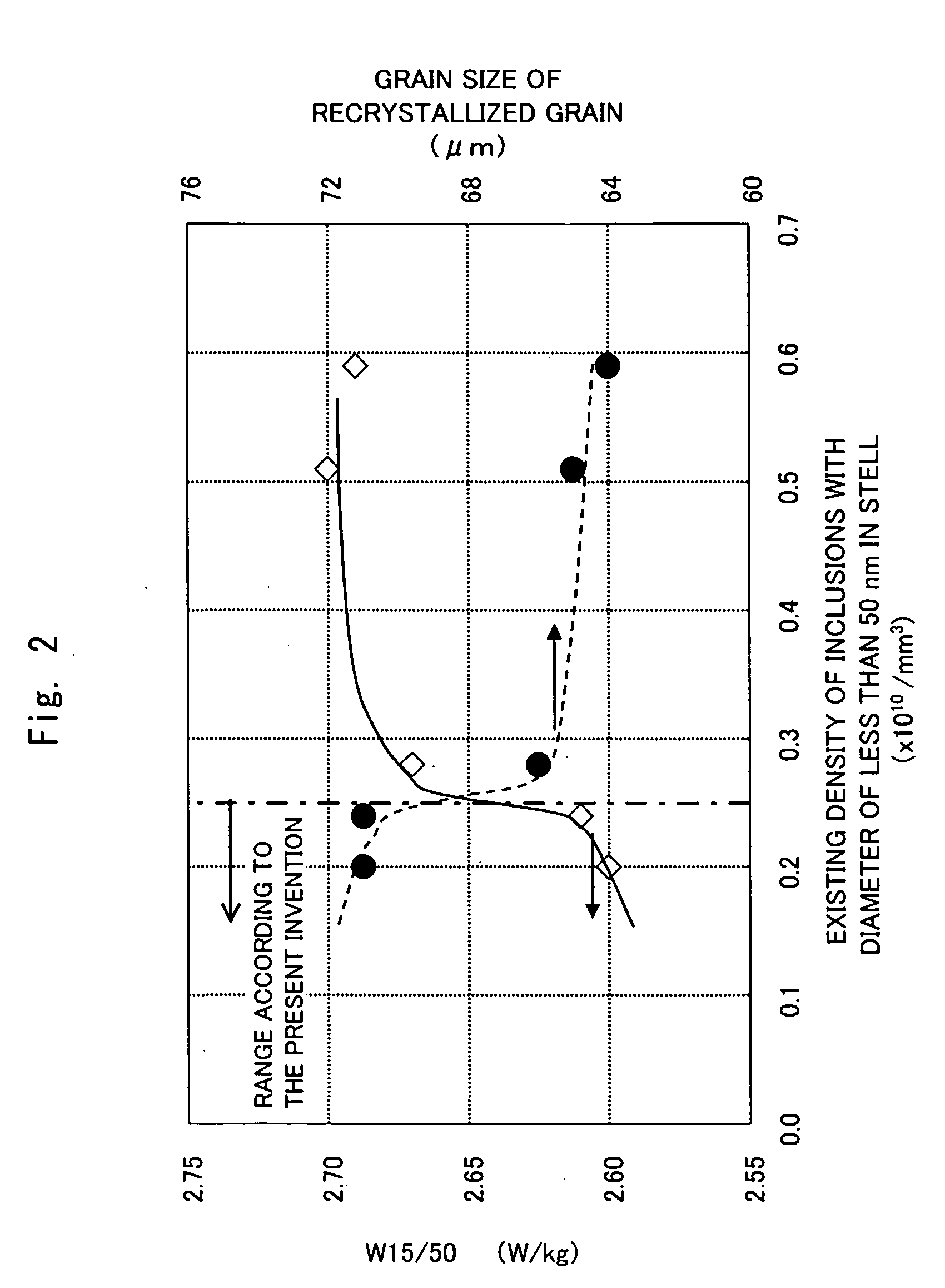

Non-oriented electrical steel sheet excellent in core loss and manufacturing method thereof

ActiveUS20060243351A1Core lossLower core lossInorganic material magnetismMagnetic circuit characterised by magnetic materialsElectrical steelSheet steel

A non-oriented electrical steel sheet is characterized in that the number density of inclusions with an equivalent volume diameter of less than 100 nm contained in the steel sheet is 1×1010 [ / mm3] or less, and that the steel sheet contains, by mass%, C: up to 0.01%, Si: 0.1% to 7.0%, Al: 0.1% to 3.0%, Mn: 0.1% to 2.0%, REM: 0.0003% to 0.05%, Ti: up to 0.02%, S: up to 0.005%, and N: up to 0.005%, the balance Fe and inevitable impurities and the mass % of Al represented by [All and the mass % of Ti represented by [Ti] satisfy the equation loq([Ti]×[N])−1.19×loq([Al]×[N])+1.84>0 . . . (1).

Owner:NIPPON STEEL CORP

Nonoriented magnetic steel sheet, member for rotary machine and rotary machine

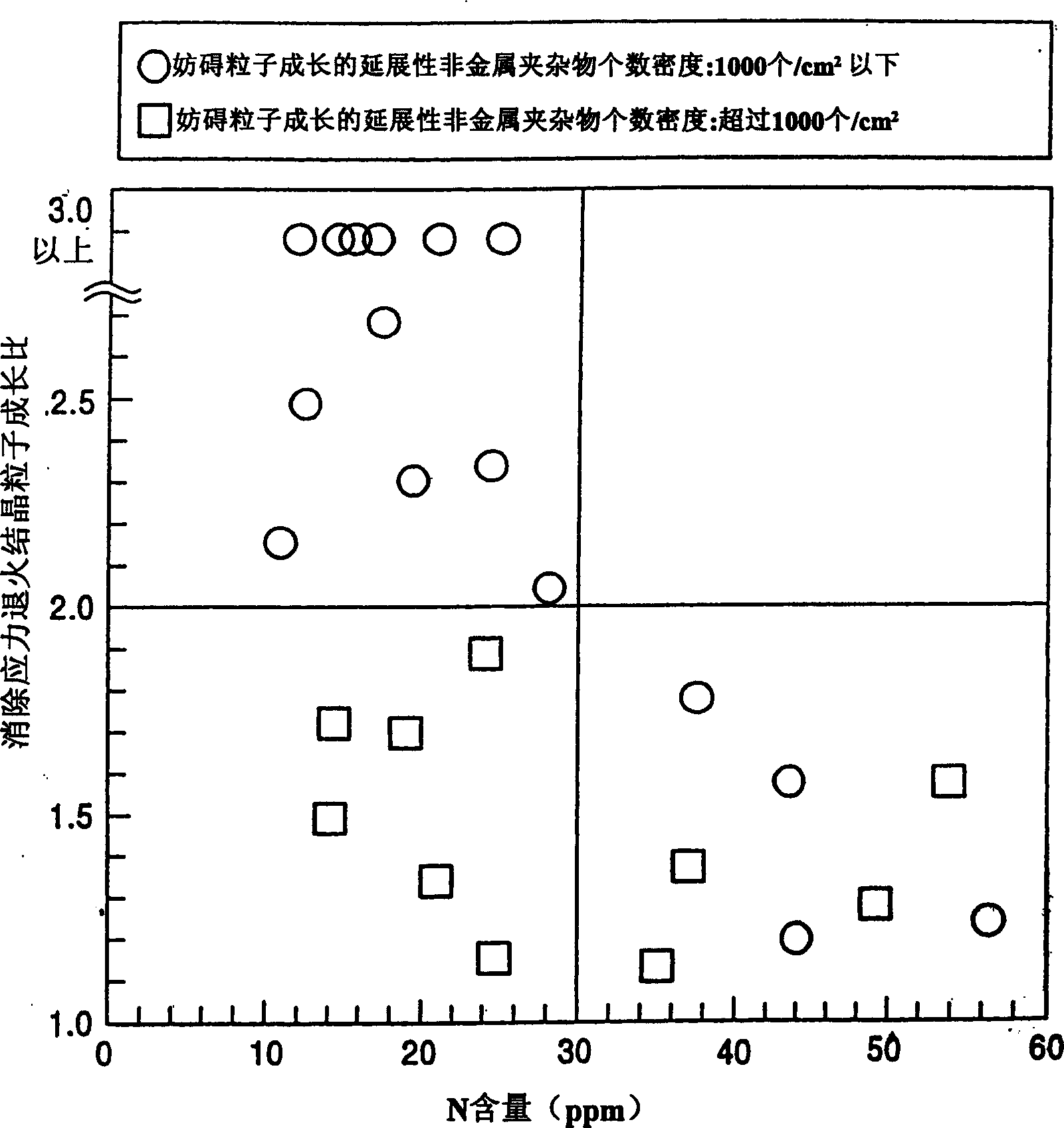

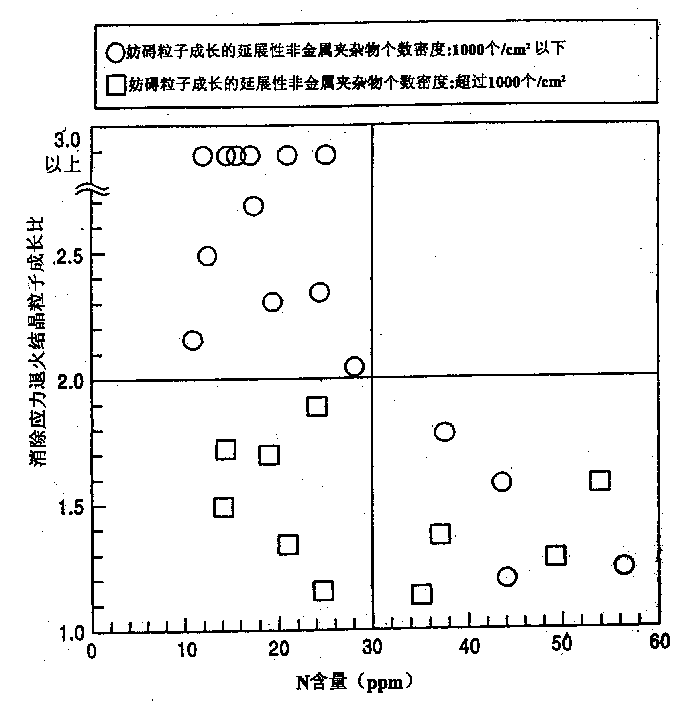

InactiveCN1556869AImprove performanceStress relief annealingInorganic material magnetismMagnetic circuit characterised by magnetic materialsSheet steelChemical composition

A nonoriented magnetic steel sheet which has a chemical composition in mass % wherein contents of Si and Mn are 0.1 to 1.2 % and 0.005 to 0.30 %, respectively, and the contents of C, Sol.Al and N are limited to 0.0050 % or less, 0.0004 % or less, and 0.0030 % or less, respectively, all including 0 %, and has a number density of grain growth inhibiting ductile non-metallic inclusions dispersed in the steel sheet of 1000 pieces / cm<2> or less including 0, wherein a grain growth inhibiting ductile non-metallic inclusion means an inclusion contained in a steel sheet having been subjected to finishing annealing which has a length of 3 x D to 9 x D, D representing an average particle diameter of re-crystallized grains in the steel sheet. The nonoriented magnetic steel sheet allows the production, from one steel sheet, of a rotor material exhibiting a high magnetic flux density and a high strength and a stator material exhibiting a high magnetic flux density and a low iron loss after it is subjected to strain removing annealing.

Owner:JFE STEEL CORP

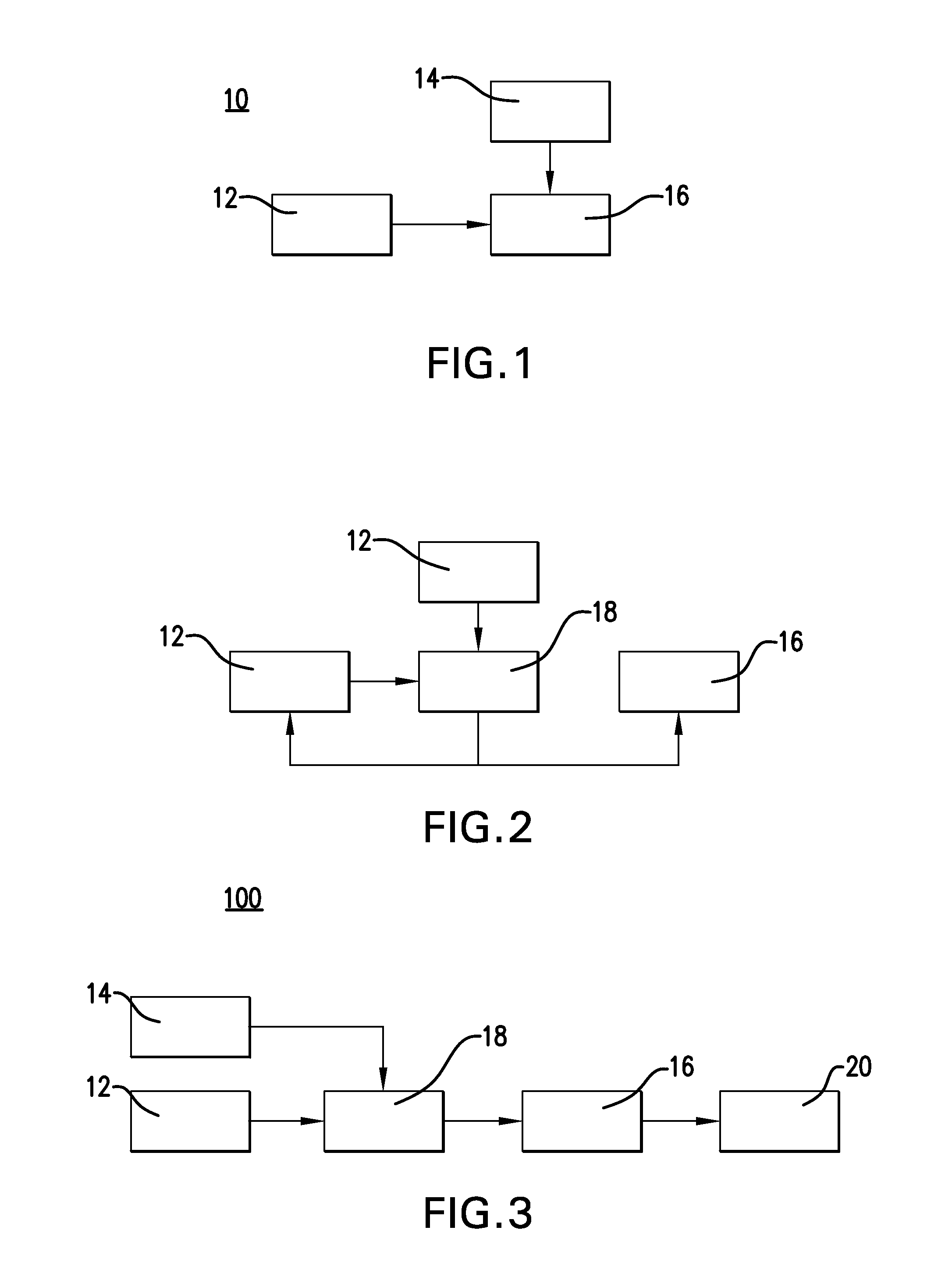

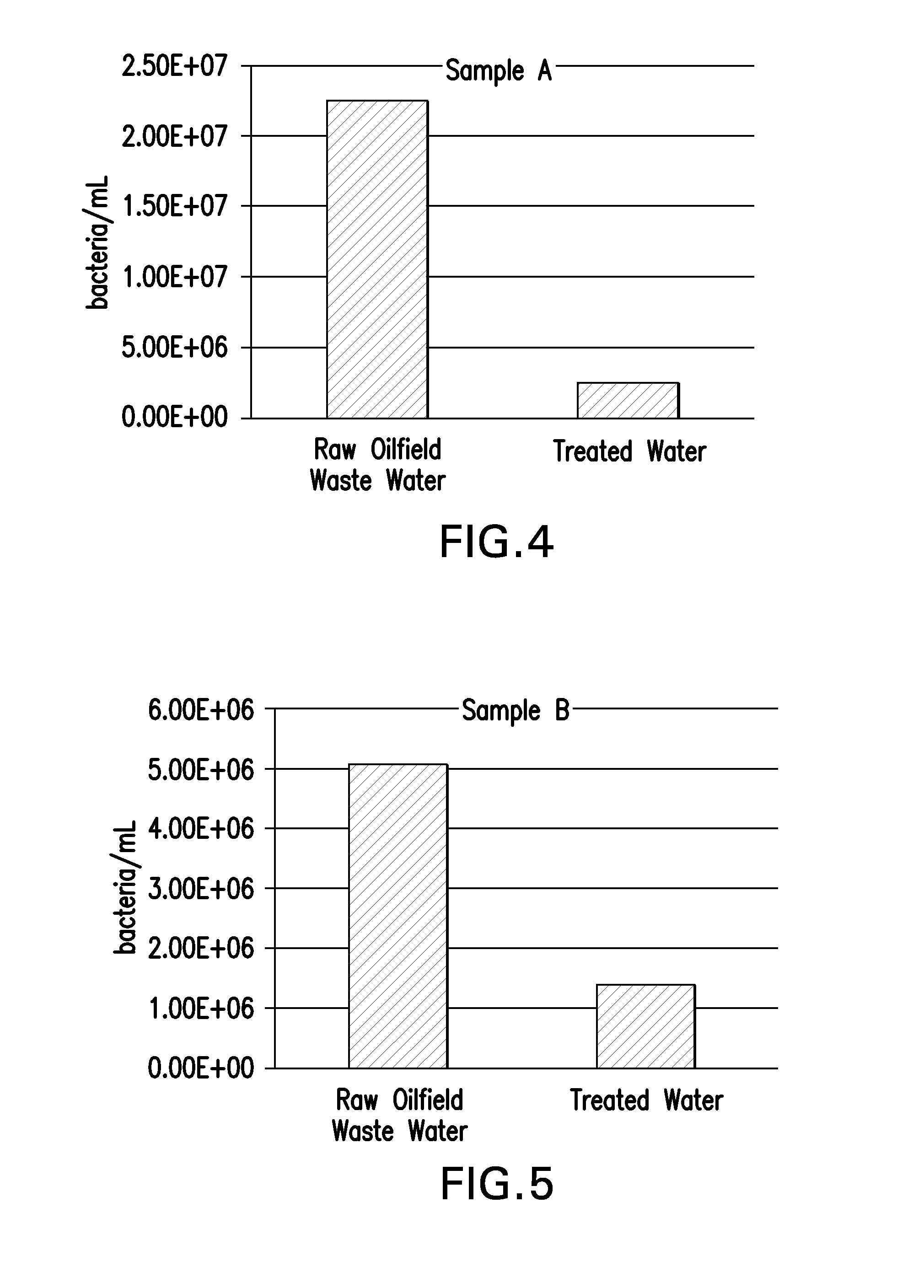

Treating and recylcing oilfield waste water

ActiveUS20140374103A1Waste water treatment from quariesWater treatment parameter controlNumber densityTreated water

A process for treating oilfield waste water includes combining oilfield waste water and a biocide comprising hydrogen peroxide, the biocide being present in an amount effective to decrease a number density of bacteria in the oilfield waste water. A process for treating oilfield waste water includes measuring an oxidation reduction potential (ORP) of oilfield waste water; combining the oilfield waste water and an oxidizer in an amount to adjust the ORP of the oilfield waste water to be greater than or equal to a first ORP value; and adding a biocide comprising hydrogen peroxide to the oilfield waste water to adjust the ORP of the oilfield waste water to be greater than or equal to a second ORP value, to treat the oilfield waste water, the second ORP value being greater than the first ORP value. A process for recycling oilfield waste water includes combining oilfield waste water and a biocide comprising hydrogen peroxide; decreasing a number density of bacteria in the oilfield waste water to form treated water; introducing an additive to the treated water; and disposing the treated water in a subterranean environment.

Owner:BAKER HUGHES INC

High bond strength, repositionable adherent sheet

An adherent sheet material and method of making including at least one adhesive, non-raised region protected from inadvertent adherence to a contact surface. This adherent sheet material also including a film having a front face and back face, wherein the front face has a plurality of collapsible, non-adhesive protrusions extending outwardly from the front face and adhesive, non-raised region disposed between the protrusions. Also, a substrate is bonded to the back face of film. An adherent sheet material including a contact adhesive protected from inadvertent adherence to a contact surface. This adherent sheet material also including a film having a front face and back face, wherein the front face has a plurality of collapsible, non-adhesive protrusions extending outwardly from the front face and adhesive, non-raised region disposed between the protrusions. The film also includes a number density of protrusions from about 50 protrusions per square inch of the film to about 150 protrusions per square inch of the film. Also, the contact adhesive is disposed upon non-raised regions.

Owner:HAMILTON PETER WORTHINGTON +3

Steel rod and high strength wire having superior ductility and methods of production of same

ActiveUS20100126643A1High strengthHigh yieldFurnace typesTextile cablesProduction rateChemical composition

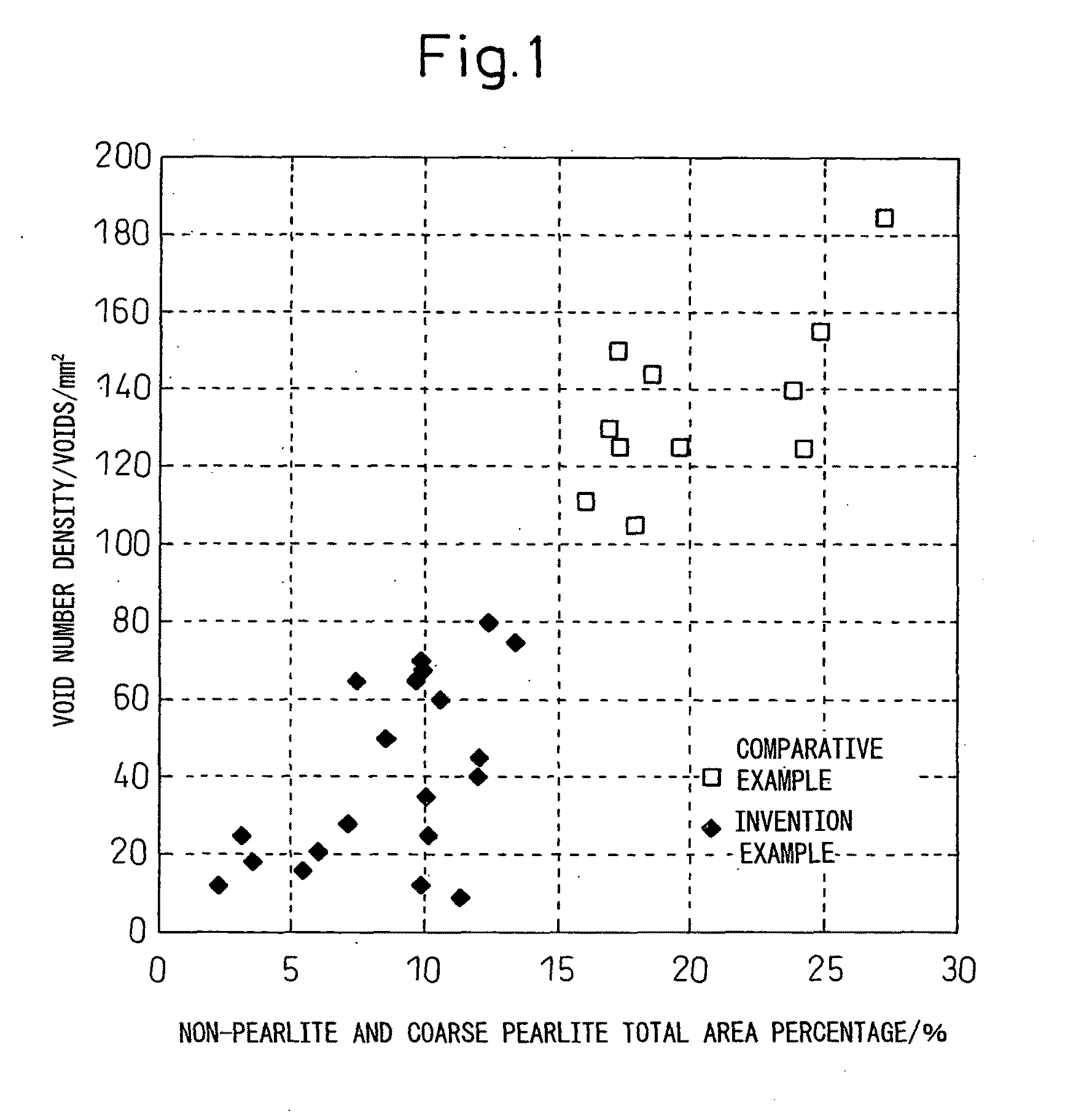

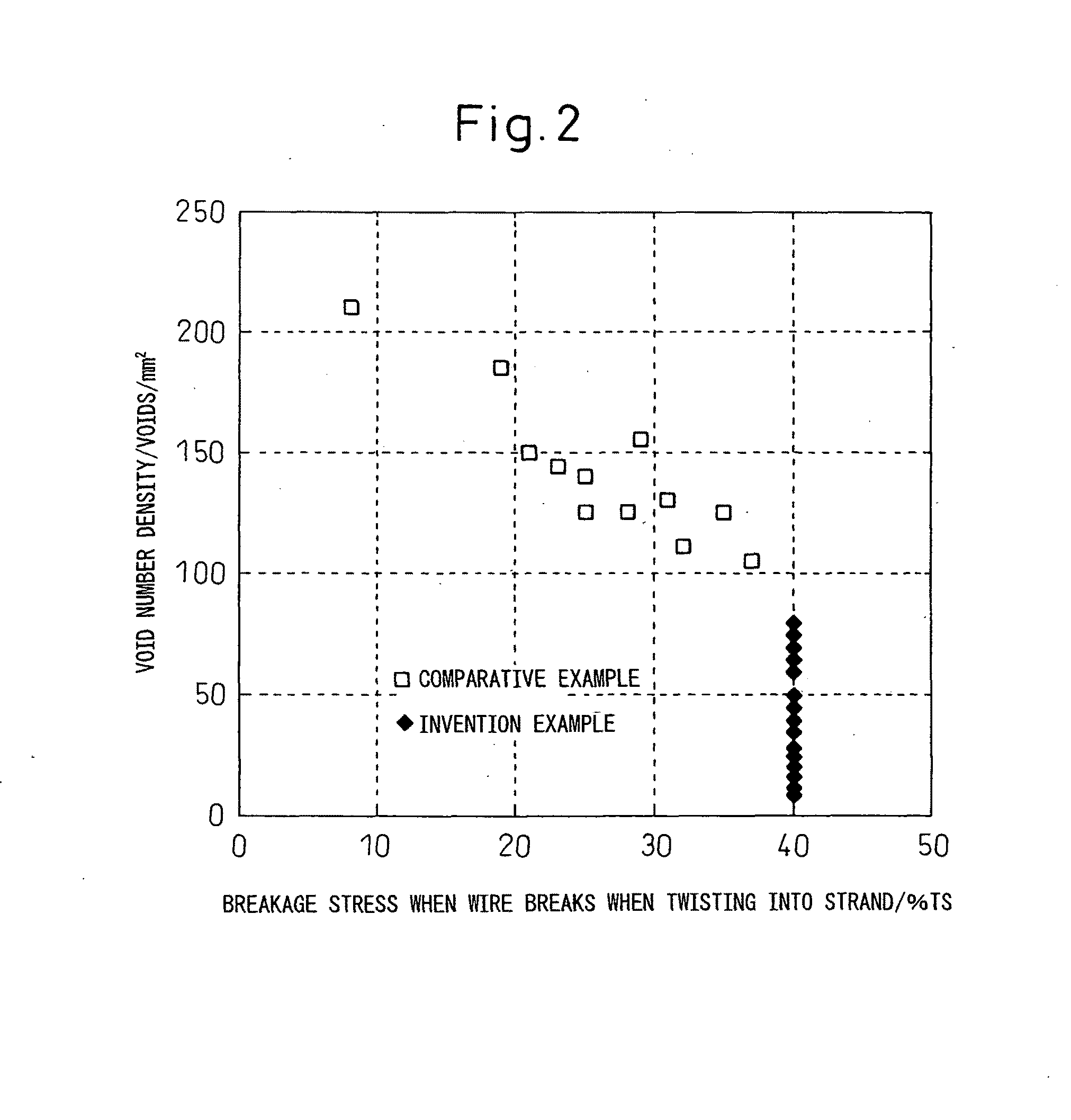

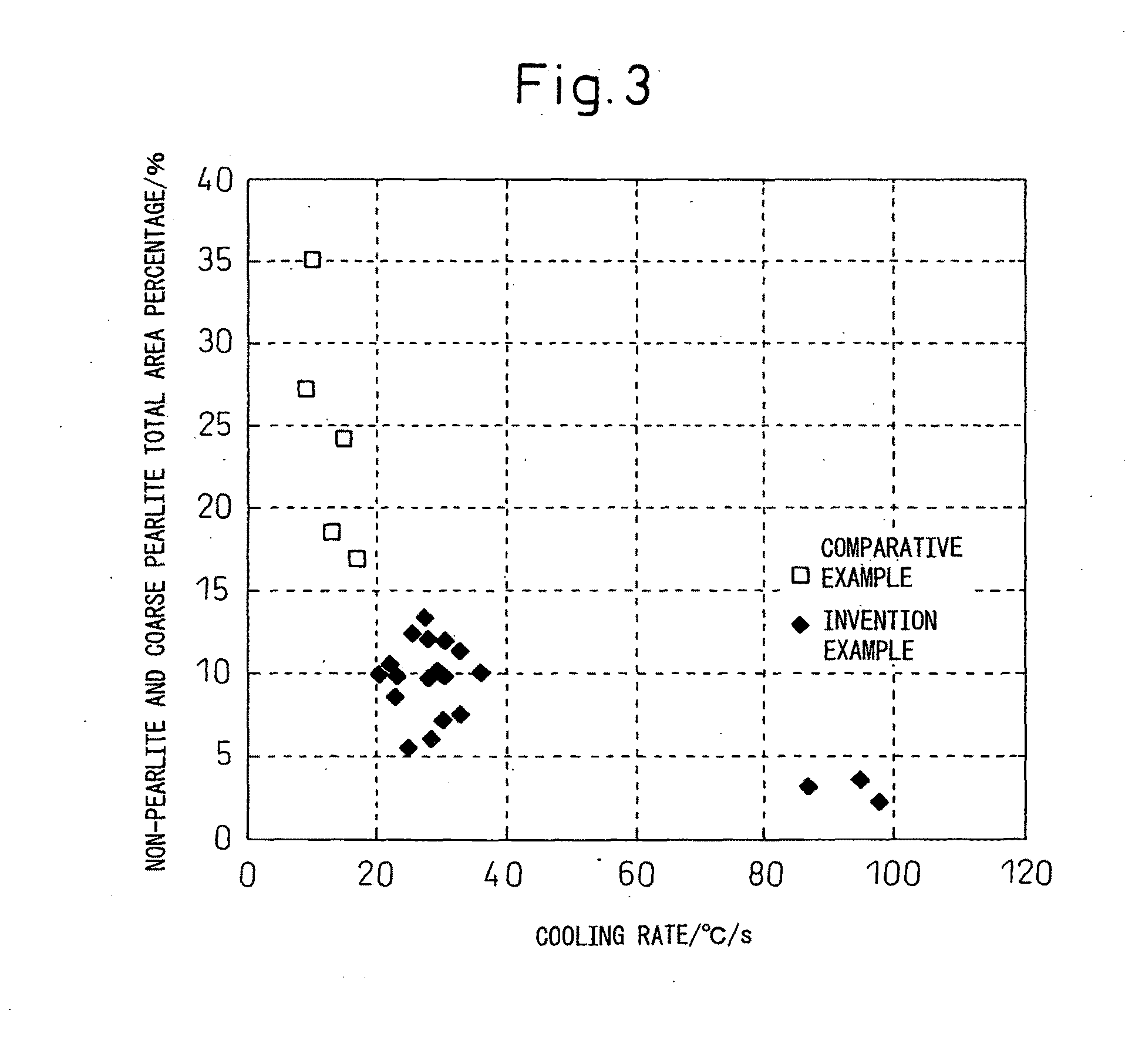

The present invention inexpensively provides with high productivity and good yield a steel rod superior in drawability and a steel wire superior in twistability using the same as a material, that is, draws a high strength steel rod superior in ductility where the chemical components contain C: 0.80 to 1.20%, Si: 0.1 to 1.5%, Mn: 0.1 to 1.0%, Al: 0.01% or less, Ti: 0.01% or less, one or both of W: 0.005 to 0.2% and Mo: 0.003 to 0.2%, N: 10 to 30 ppm, B: 4 to 30 ppm (of which, solute B is 3 ppm or more), and O: 10 to 40 ppm, which has a balance of Fe and unavoidable impurities, has an area percentage of pearlite structures of 97% or more, has a balance of non-pearlite structures, and has a total of the area percentage of the non-pearlite structures and the area percentage of the coarse pearlite structures of 15% or less, to obtain high strength steel wire superior in ductility having a tensile strength of 3600 MPa or more and a number density of voids of lengths of 5 μm or more at the center of 100 / mm2 or less

Owner:NIPPON STEEL CORP

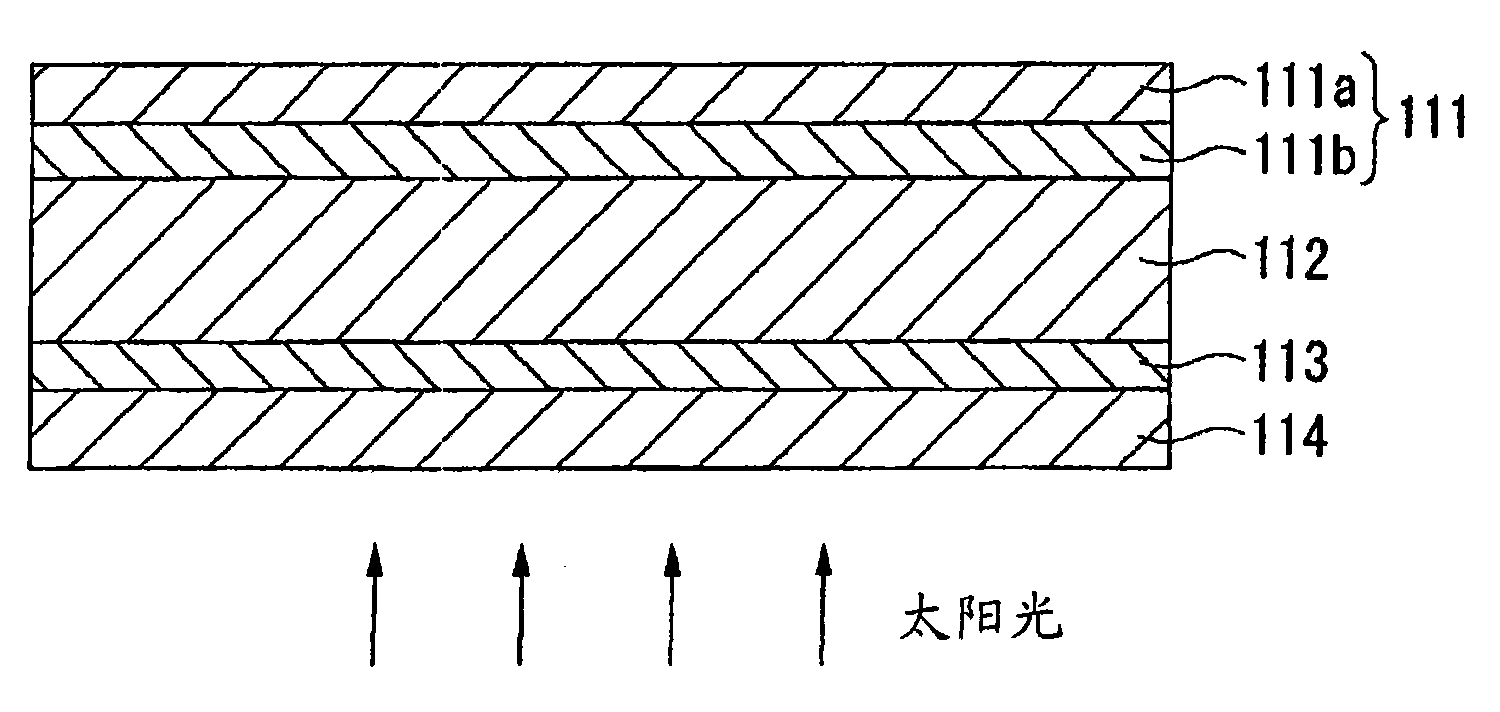

Composite membrane for super straight solar cell, process for producing the composite membrane for super straight solar cell, composite membrane for substraight solar cell, and process for producing the composite membrane for substraight solar cell

InactiveCN101803037AHigh Diffuse ReflectivityCheap manufacturingPhotovoltaic energy generationSemiconductor devicesNumber densityMicroparticle

This invention provides a composite membrane for a super straight solar cell or for a substraight solar cell. The composite membrane comprises a transparent electroconductive film and an electroconductive reflective film. The transparent elctroconductive film is formed by coating a composition or dispersion liquid, for a transparent electrocondutive film, containing fine particles of an electroconductive oxide by a wet coating method. The electroconductive reflective film is formed by coating a composition, for en electroconductive reflective film, containing metallic nanoparticles by a wet coating method. The average diameter of pores, which appear on a photoelectric converting layer-side or transparent electroconductive film-side contact face of the electroconductive reflective film, isnot more than 100 nm. The average depth at which the pores are located is not more than 100 nm. The number density of the pores is not more than 30 pores / [mu]m2.

Owner:MITSUBISHI MATERIALS CORP

High-strength cold-rolled steel sheet excellent in bending workability

ActiveUS20110287280A1Excellent bending workabilitySuitable for manufactureThin material handlingMetal layered productsChemical compositionNumber density

A cold-rolled steel sheet has a chemical composition of C: 0.12% to 0.3%, Si: 0.5% or less, Mn: less than 1.5%, Al: 0.15% or less, N: 0.01% or less, P: 0.02% or less, and S: 0.01% or less, with the remainder including iron and inevitable impurities and has a martensite single-phase structure as its steel microstructure. In a surface region of the steel sheet from the surface to a depth one-tenth the gauge, the number density of n-ary groups of inclusions determined by specific n-th determinations is 120 or less per 100 cm2 of a rolling plane, where the distance in steel sheet rolling direction between outermost surfaces of two outermost particles of the group of inclusions is 100 μm or more. The steel sheet is a high-strength cold-rolled steel sheet which has a sufficiently minimized rate of bending fracture starting from inclusions and thereby has excellent bending workability.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com