Nonoriented magnetic steel sheet, member for rotary machine and rotary machine

An electromagnetic steel sheet, non-directional technology, applied in the direction of inorganic material magnetism, magnetic circuit characterized by magnetic material, metal rolling, etc., can solve the problems of different requirements and difficult to satisfy two characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] A slab having the composition shown in Table 4 and the remainder being iron and unavoidable impurities was produced by the continuous casting method. In addition, the amounts of Ti, Nb, V, S, and O are reduced to the above-mentioned appropriate ranges. These slabs were heated at 1110° C. for 40 minutes, and then hot-rolled to obtain 2.5 mm hot-rolled sheets. The produced hot-rolled plate is pickled, descaled, and cold-rolled to produce a cold-rolled steel plate with a plate thickness of 0.50 mm. Next, finish annealing was performed at 780° C. for 10 seconds in an atmosphere having a capacity ratio of hydrogen:50% to nitrogen:50%. The semi-organic coating solution composed of dichromate and resin is coated on the finished annealed board, and fired at 300°C to make a product board.

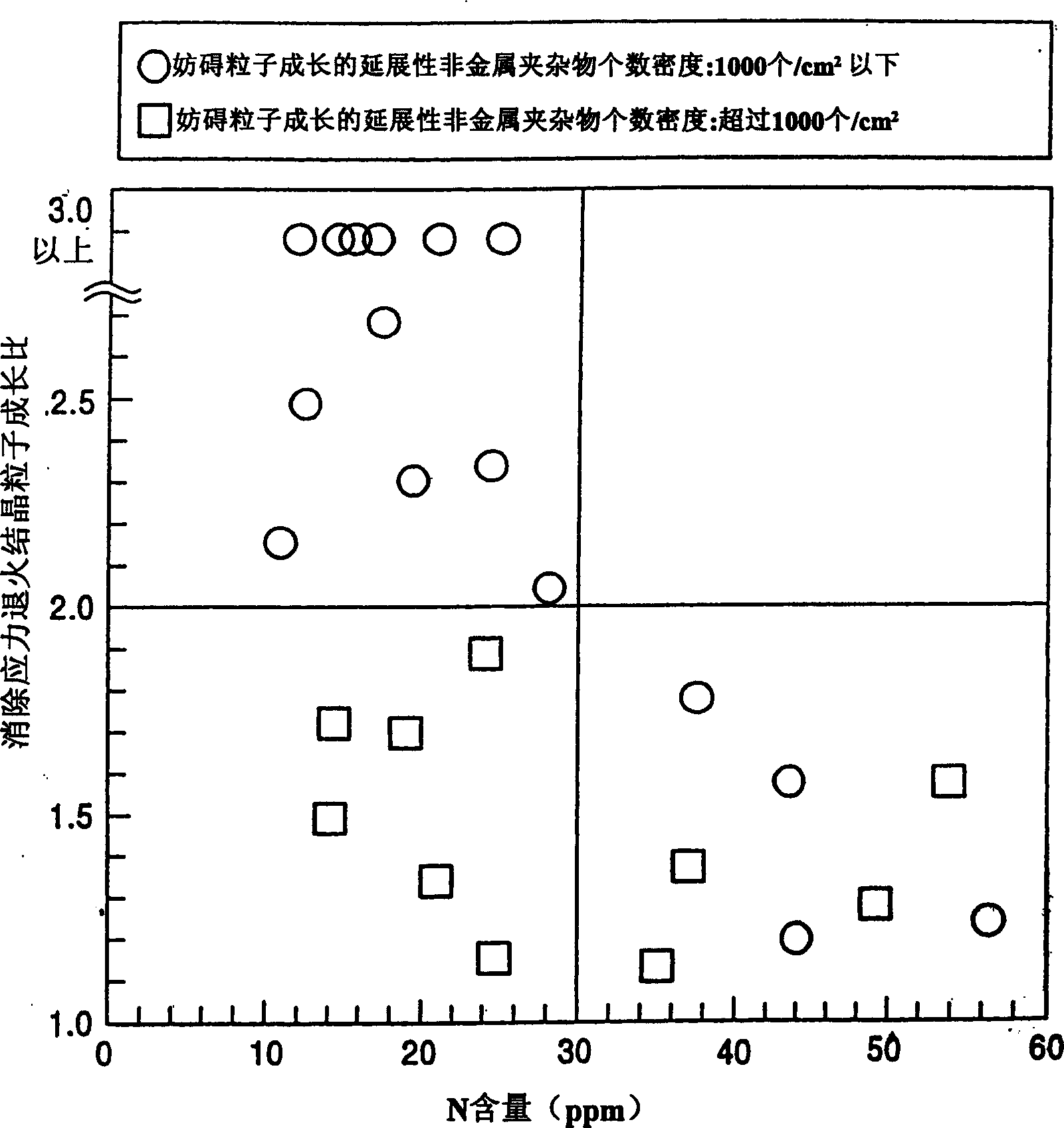

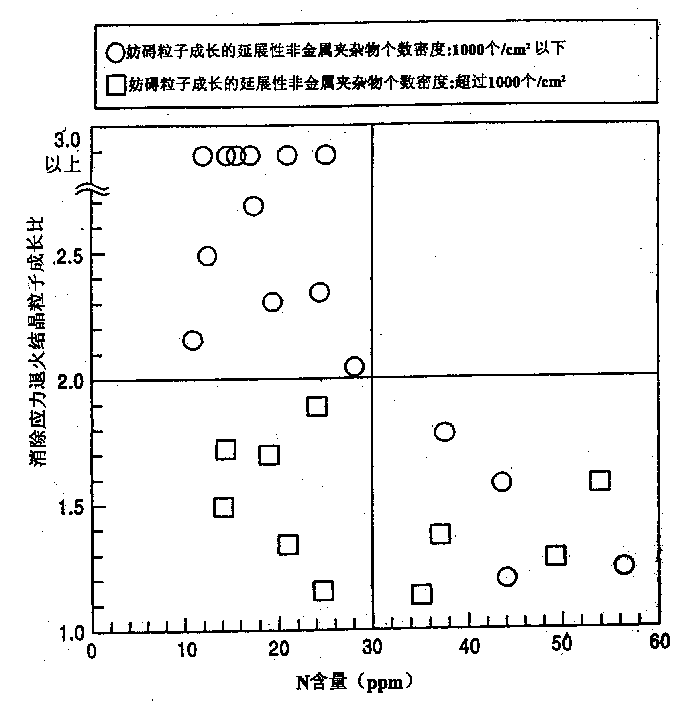

[0130] In addition, the amount (number density) of ductile non-metallic inclusions that inhibit particle growth varies with changes in the thickness of the slab and changes in the rolli...

Embodiment 2

[0137] A continuously cast slab having a thickness of 210 mm having the composition shown in Table 6, the remainder being iron and unavoidable impurities was produced. In this process, by properly adjusting the composition of the slab in the steelmaking process and adjusting the rolling conditions, the amount of ductile non-metallic inclusions that hinder the growth of particles is kept at 1000 pieces / cm 2 the following range.

[0138] As in the case of Example 1, the produced slabs were treated to produce products and tested. The finish annealing of steel mark 58 is carried out at 680°C, and the finish annealing of steel mark 59 is carried out at 850°C.

[0139] The obtained results are shown in Table 7. As shown in Table 7, the samples with the composition and average grain size of the present invention all have good stress relief annealing crystal grain growth ratio and strength and magnetic properties, so they are suitable for simultaneous punching and manufacturi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com