Patents

Literature

1889 results about "Electrical steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical steel (lamination steel, silicon electrical steel, silicon steel, relay steel, transformer steel) is an iron alloy tailored to produce specific magnetic properties: small hysteresis area resulting in low power loss per cycle, low core loss, and high permeability.

Non-Oriented Electrical Steel Sheet and Production Process Thereof

ActiveUS20090202383A1Excellent mechanical characteristicImprove surface propertiesInorganic material magnetismTransformers/inductances detailsElectrical steelMagnetic characteristic

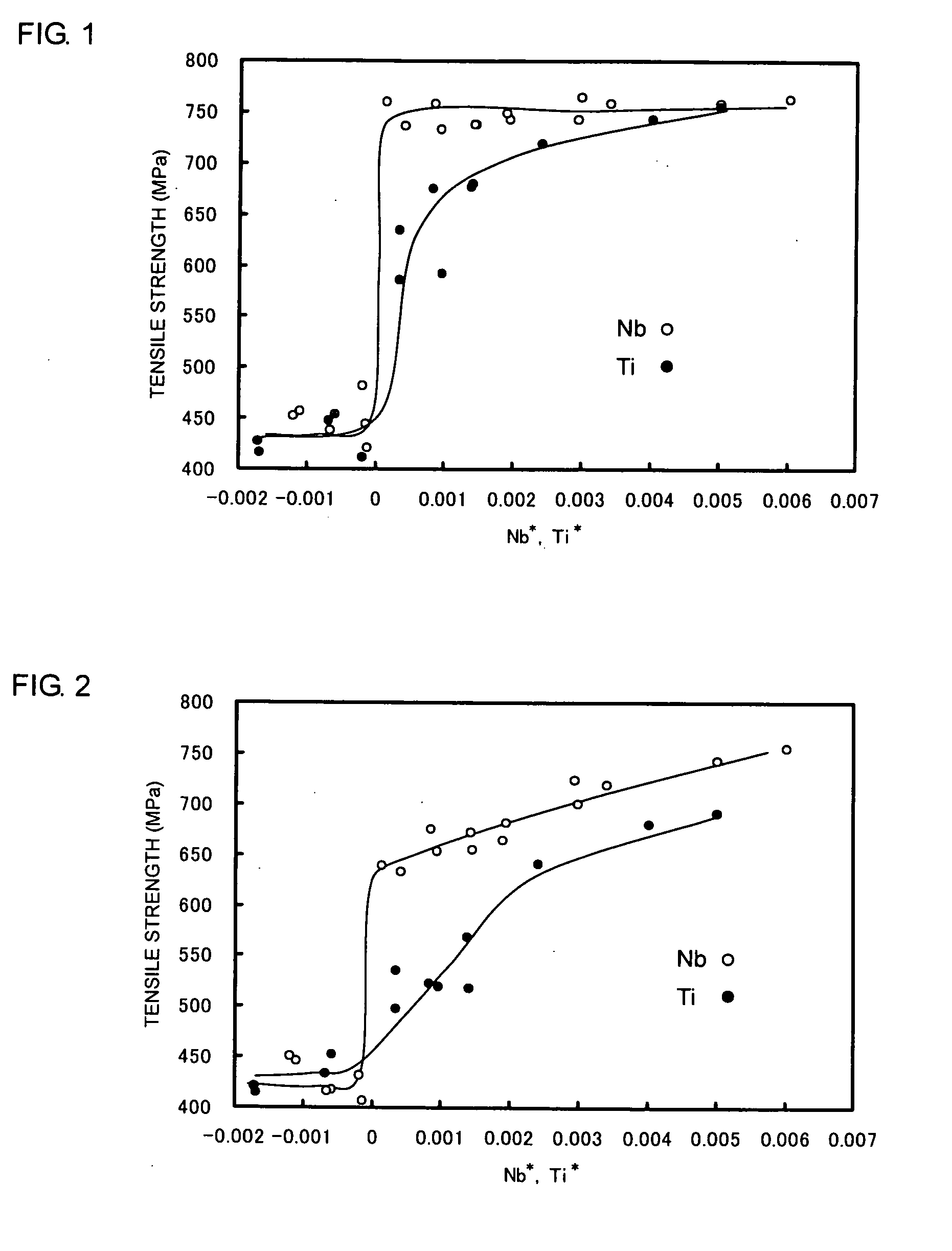

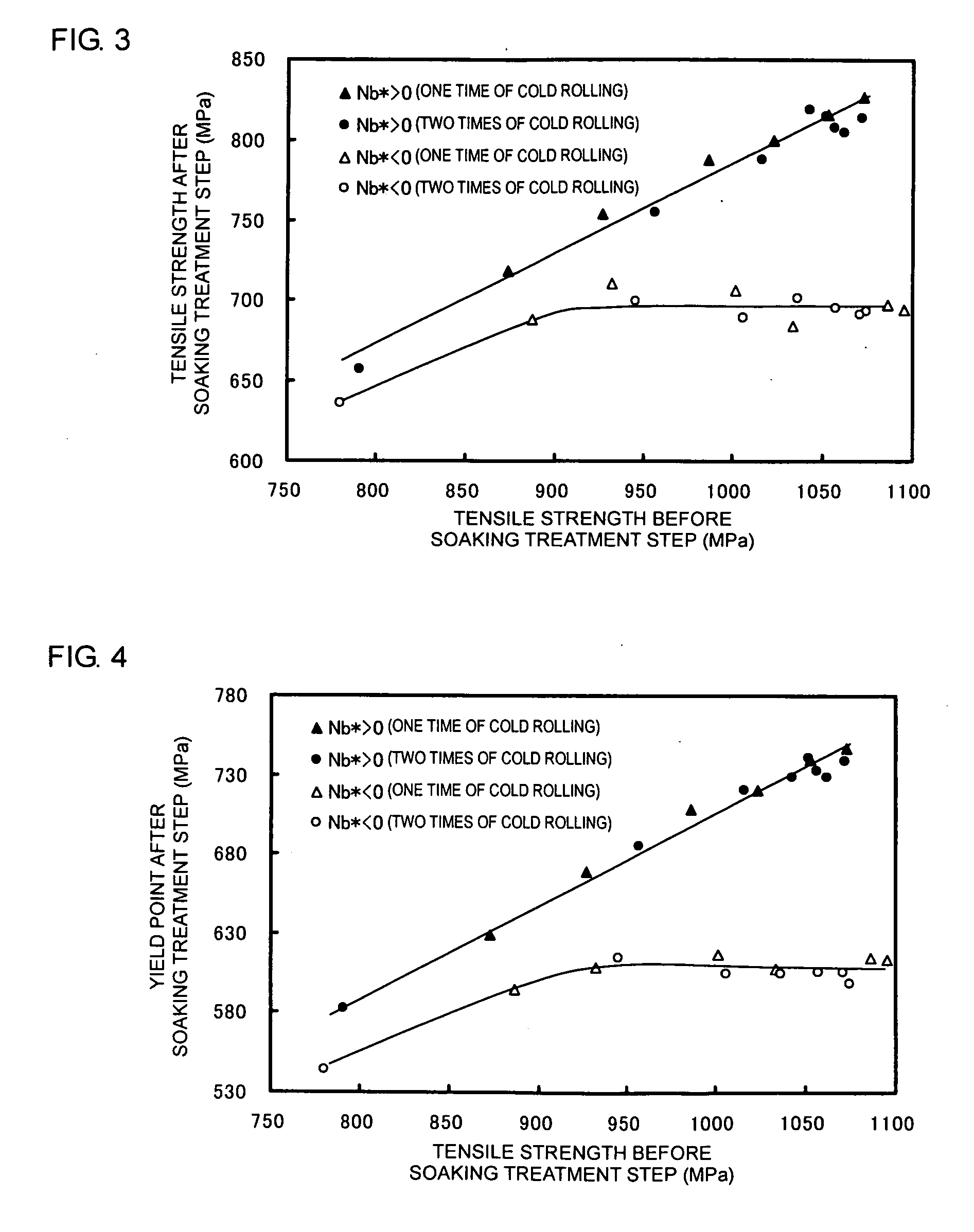

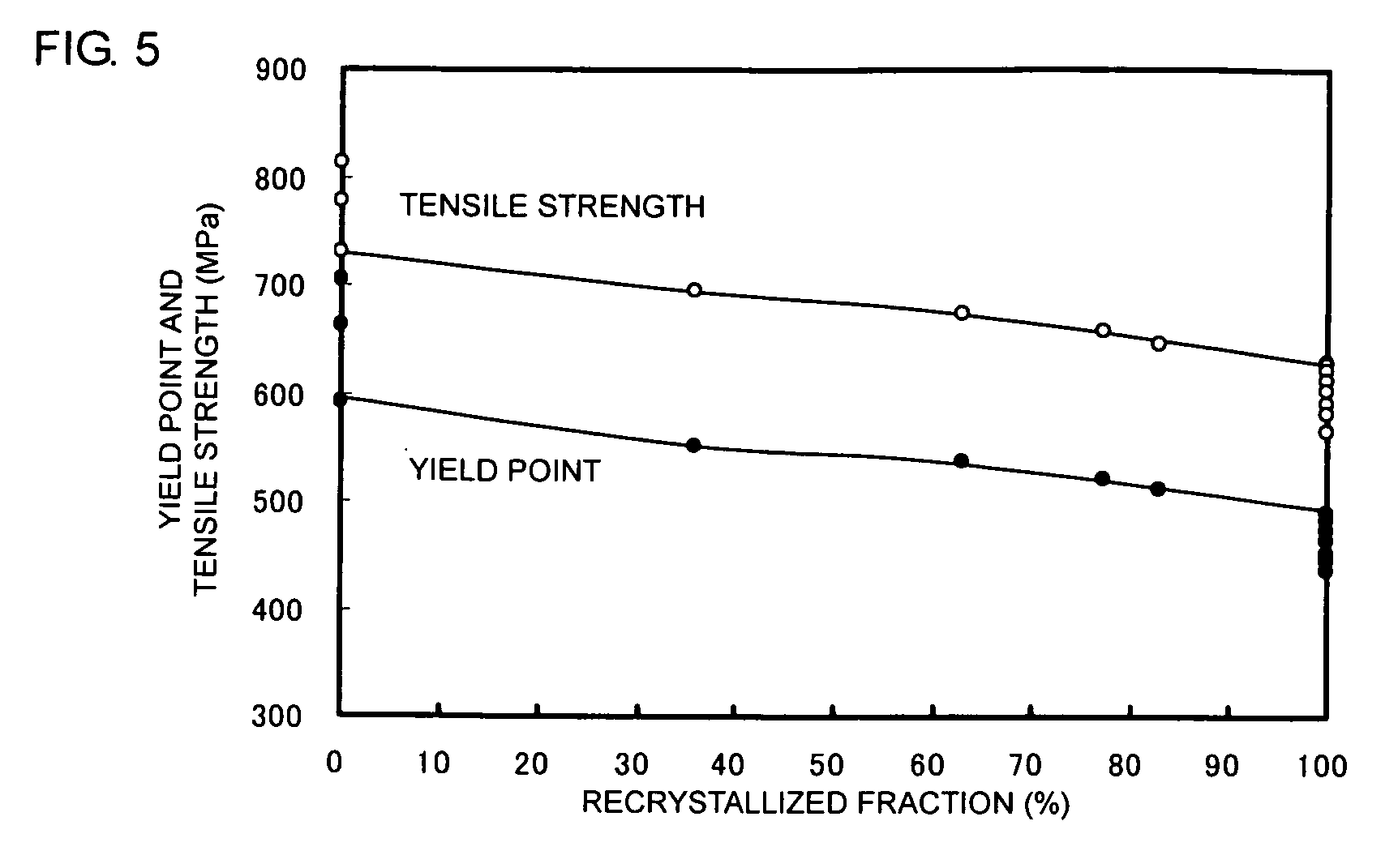

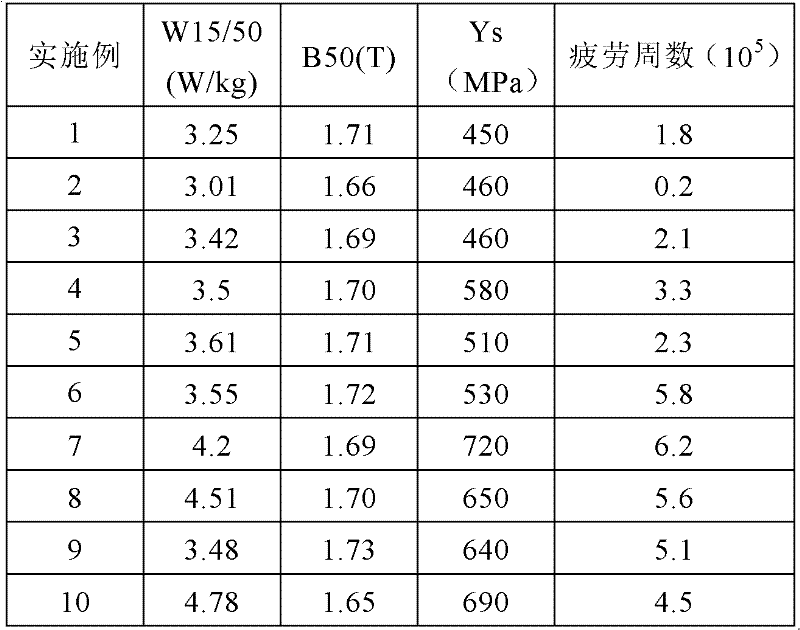

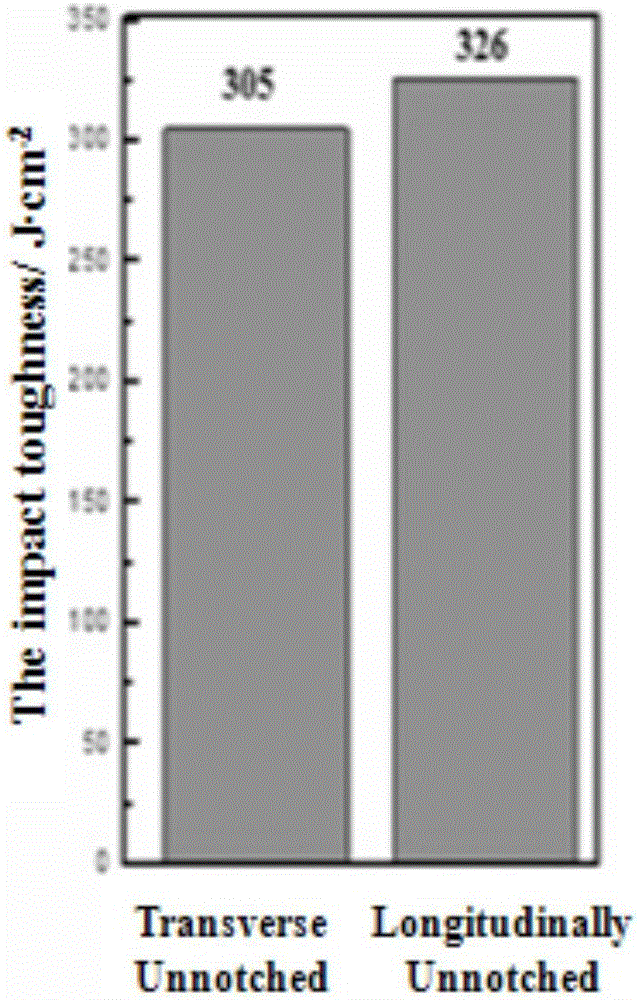

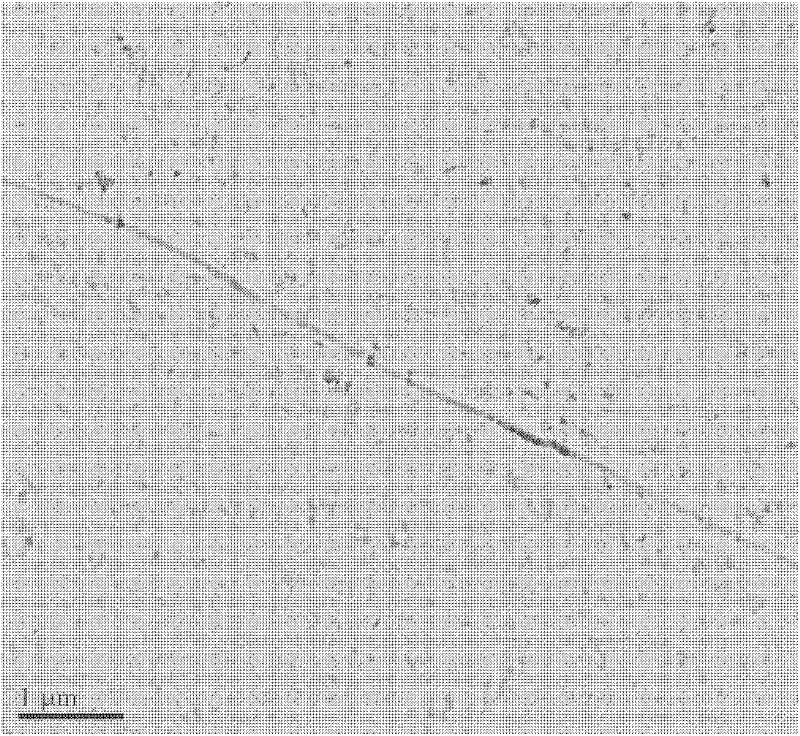

A main object thereof is to provide a non-oriented electrical steel sheet being excellent in surface characteristics and having both excellent mechanical characteristics and magnetic characteristics necessary for a rotor of rotating machines such as motors and generators which rotate at a high speed, and a method for producing the same. To achieve the object, the present invention provides a non-oriented electrical steel sheet comprising in % by mass: 0.06% or less of C; 3.5% or less of Si; from 0.05% or more to 3.0% or less of Mn; 2.5% or less of Al; 0.30% or less of P; 0.04% or less of S; 0.02% or less of N; at least one element selected from the group consisting of Nb, Ti, Zr and Vin the predetermined range; and a balance consisting of Fe and impurities; and having a recrystallized fraction being less than 90%.

Owner:NIPPON STEEL CORP

Production process of cold rolled orientation-free electrical steel plate with low iron loss and high magnetic induction

ActiveCN1887512ALow investment costReduce operating costsOther manufacturing equipments/toolsElectrical steelImpurity

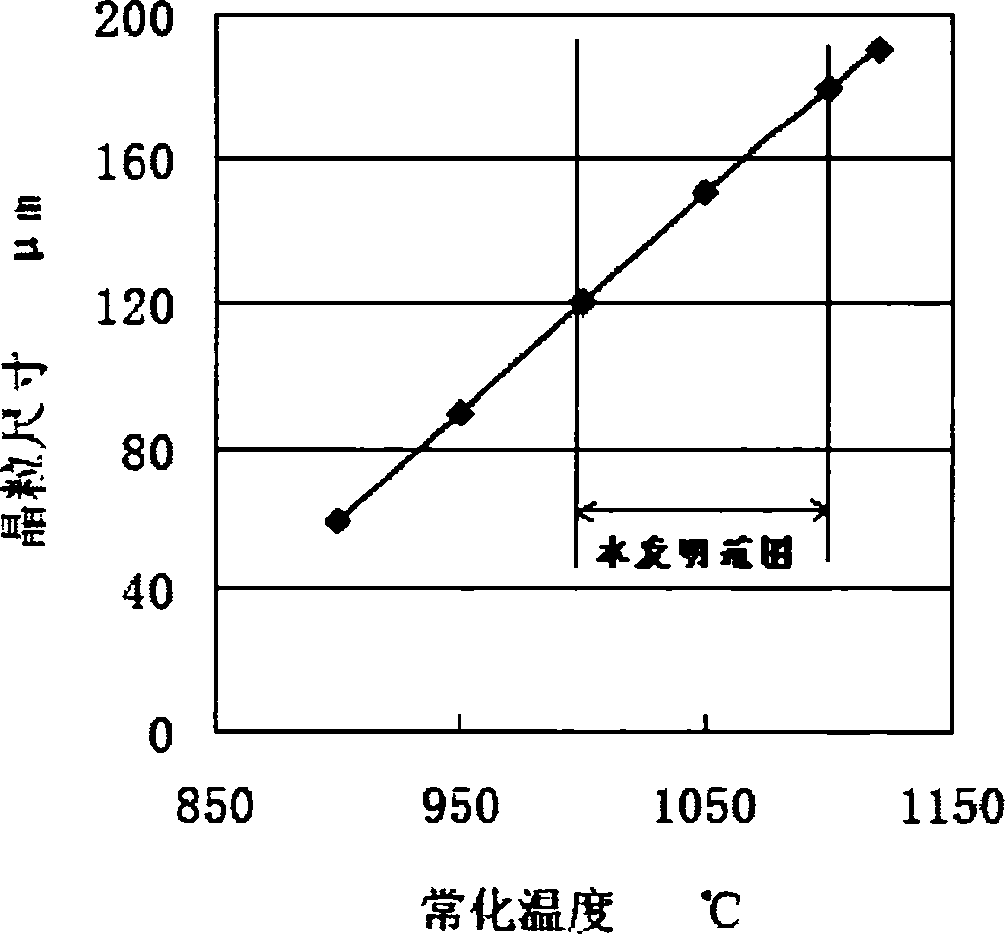

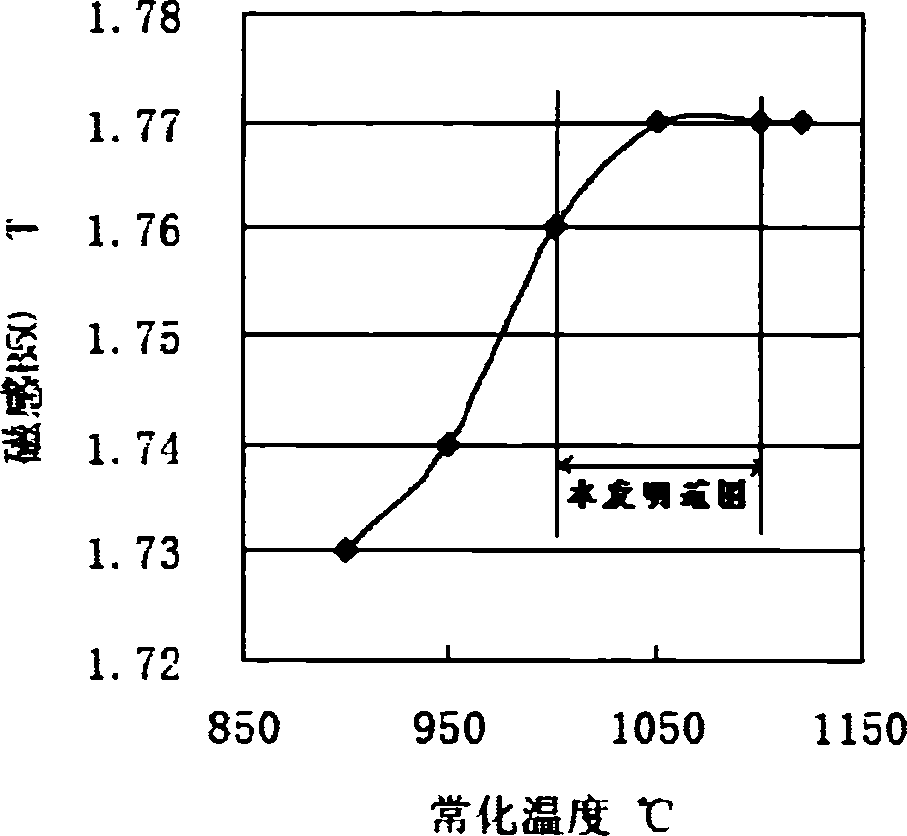

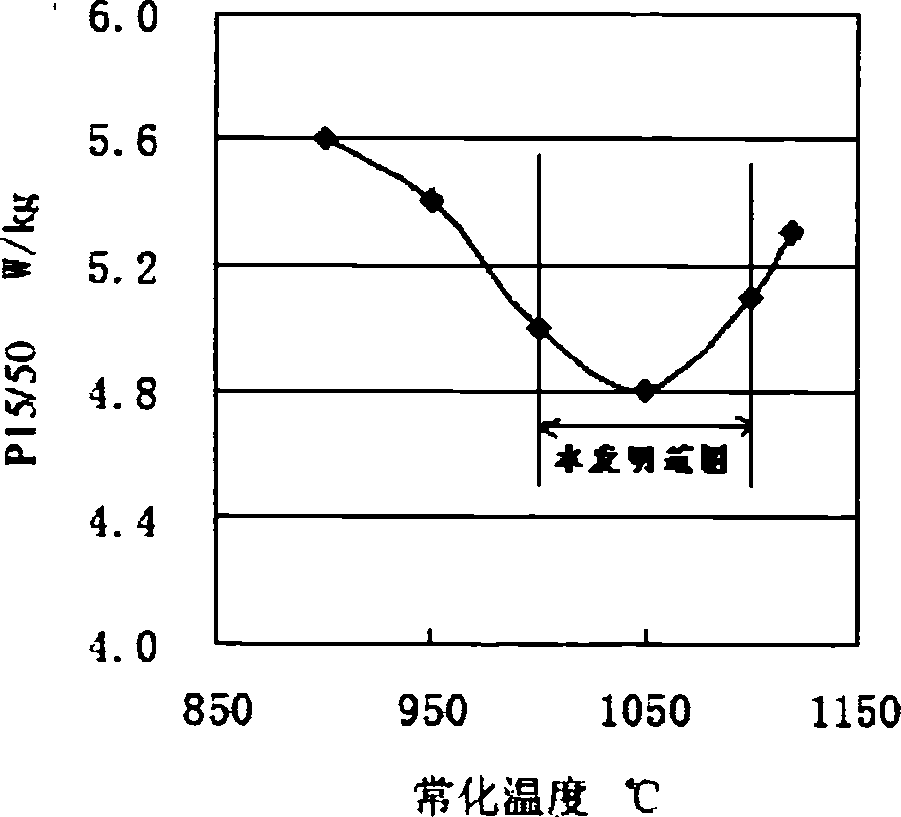

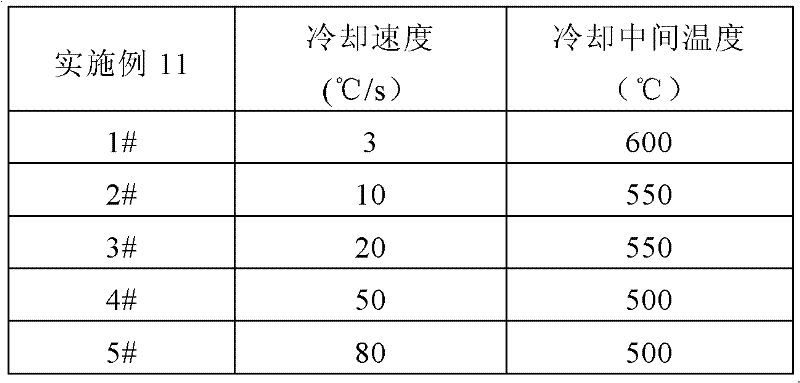

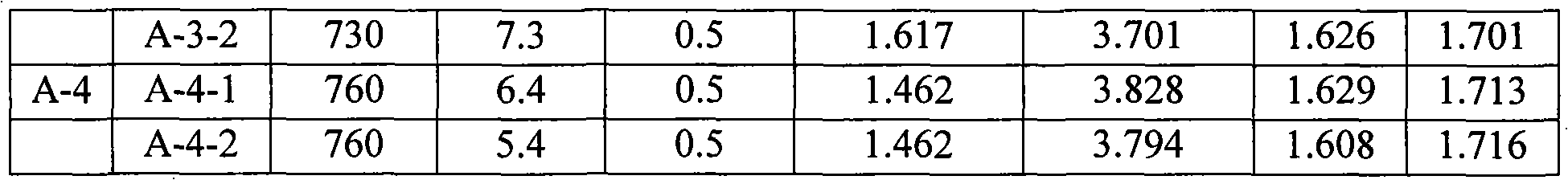

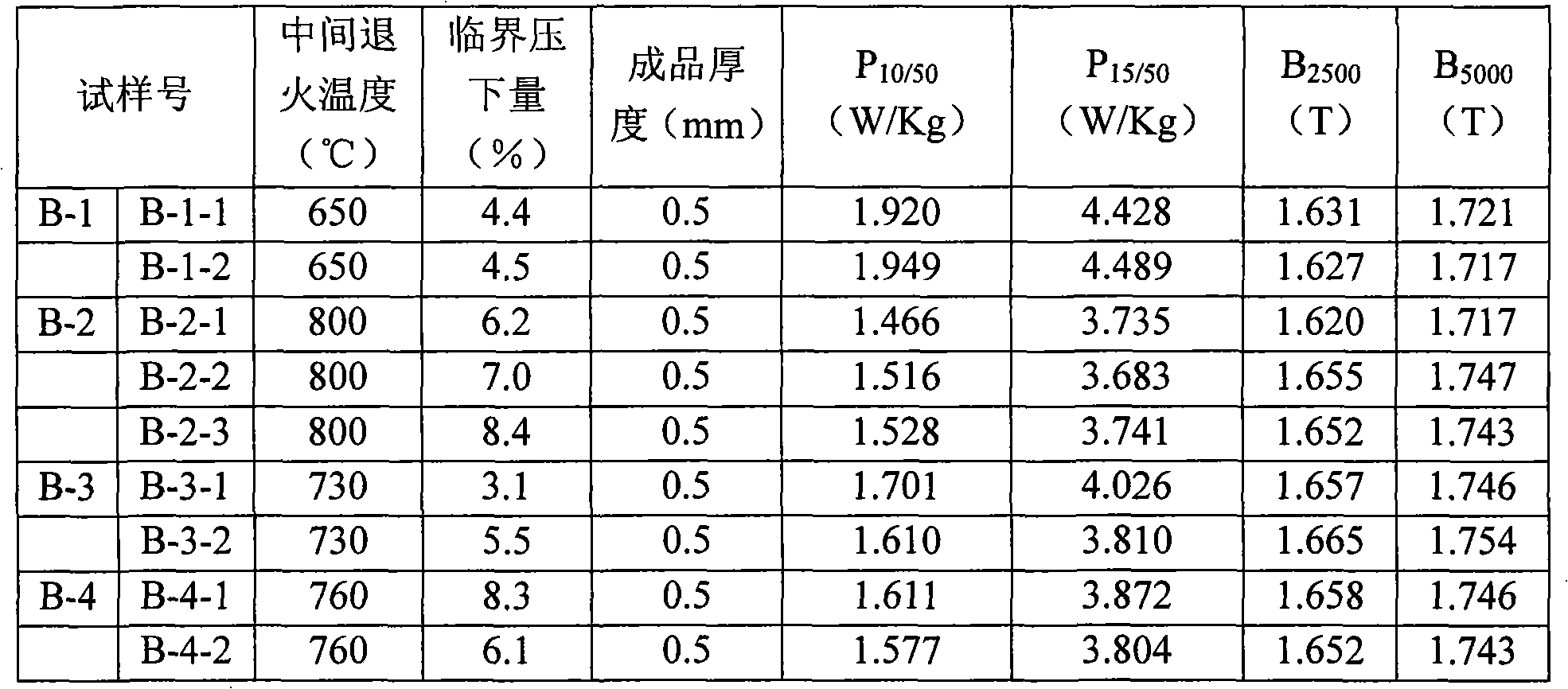

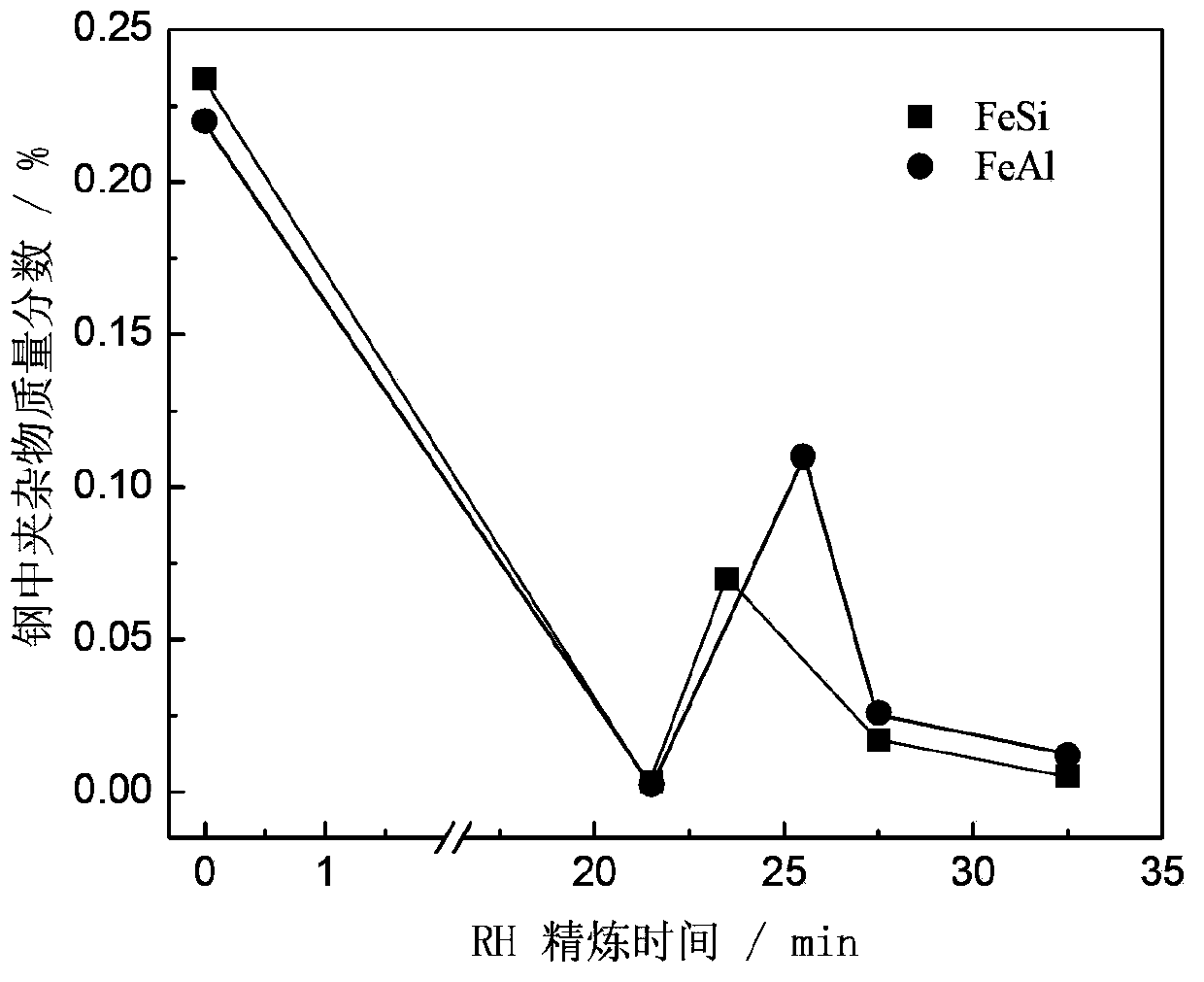

The production process of cold rolled non-orientation electric steel plate comprising C not more than 0.0050 wt%, Si not more than 2.50 wt%, Al not more than 1.0 wt%, Si+2Al not more than 2.50 wt%, Mn 0.10-1.50 wt%, P not more than 0.20 wt%, S not more than 0.005 wt%, N not more than 0.0025 wt%, Sn+Sb not more than 0.2 wt%, and Fe and inevitable impurities for the rest includes the following steps: 1. smelting, continuous casting and rolling; 2. normalizing treatment of the hot rolled plate through heating at heating rate of 5-15 deg.c / s to over Ac1, heat soaking at 1100 deg.c below for 10-90 s, cooling in two stages including cooling at the cooling rate belw 15 deg.c / s to below 650 deg.c and cooling at the cooling rate capable of ensuring the plate form to below 80 deg.c; 3. cold rolling; and 4. final annealing to form the cold rolled non-orientation electric steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for manufacturing cold-rolled orientation-free electrical sheet

This is about the manufacturing method of cold-rolled non-oriented electrical steel, including the following steps: a) the continuous casting of blanks: the liquid steel is continuously cast into a blank of 120-170mm at a pulling speed of 2-3 m / min; b) hot rolling: the blanks are directly hot-rolled or heated into the hot-rolled plate of 900-1150 deg.C and the thickness of the blank is hot-rolled to 0.8-4mm with finishing temperature 800-900deg.C and coiling temperature 500-900deg.C; c) cold rolling: the hot-rolled band undergoes annealing or non annealing treatment and acidwashing, and then the first cold-rolling or the second cold-rolling with annealing until the goal thickness reaches. When the finishing annealing is carried out, the non-oriented electrical steel is produced.

Owner:BAOSHAN IRON & STEEL CO LTD

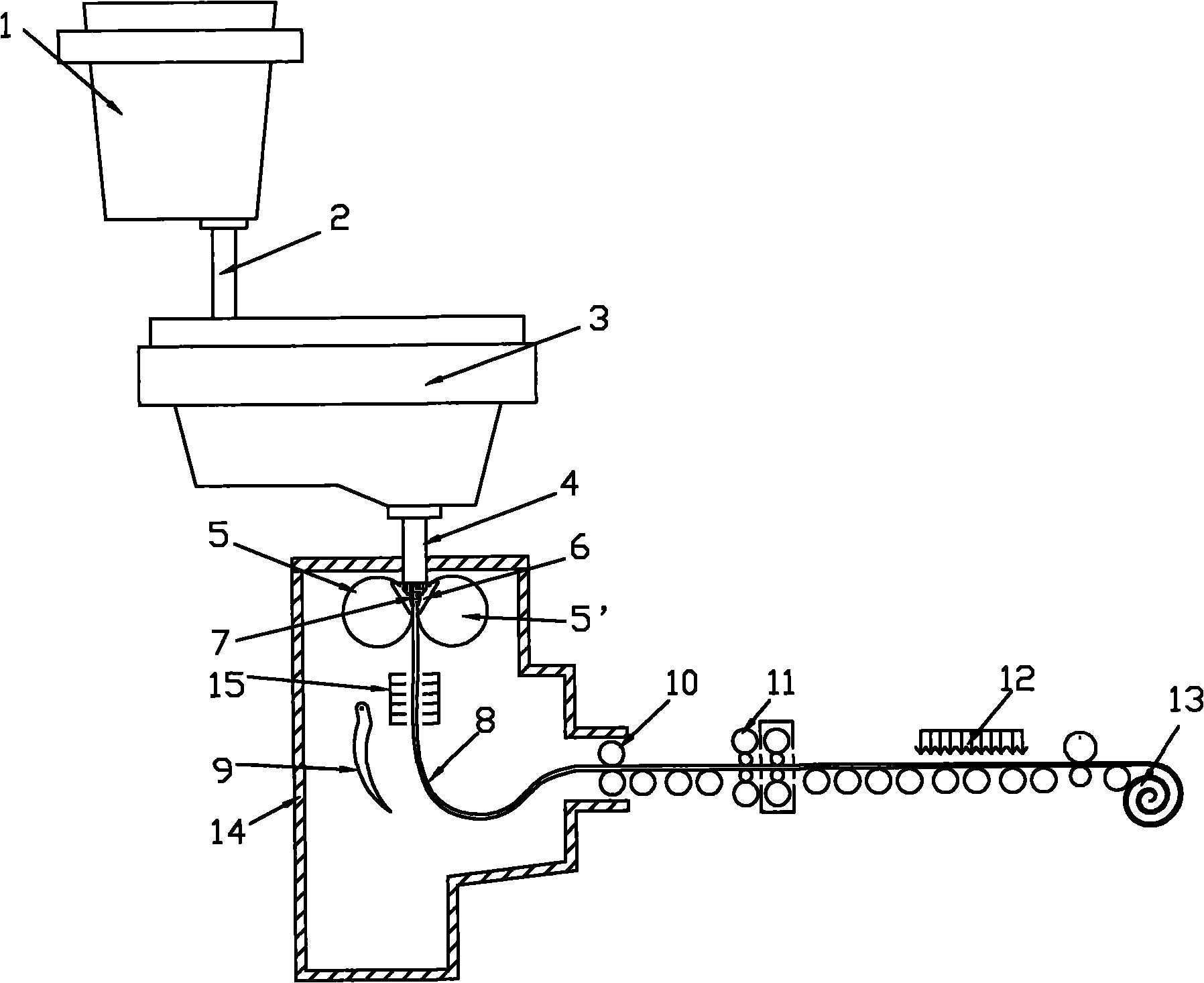

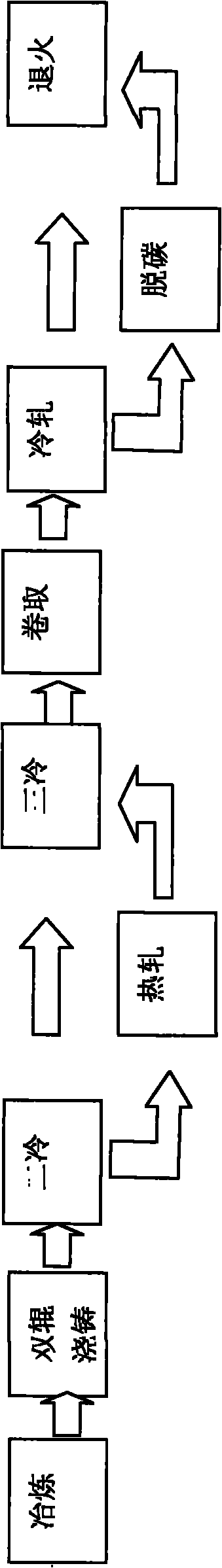

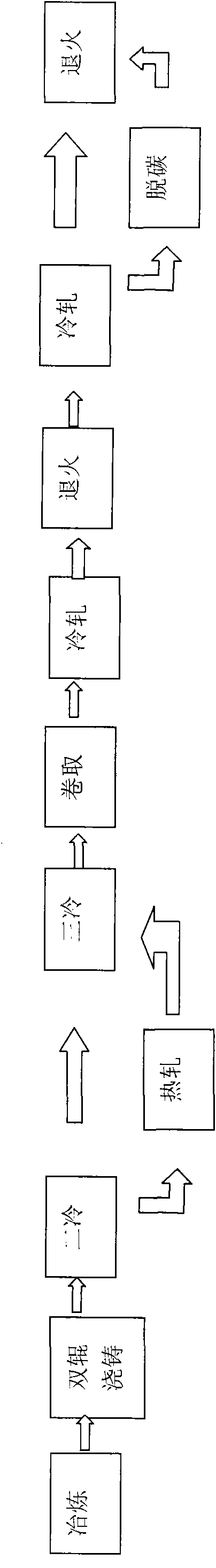

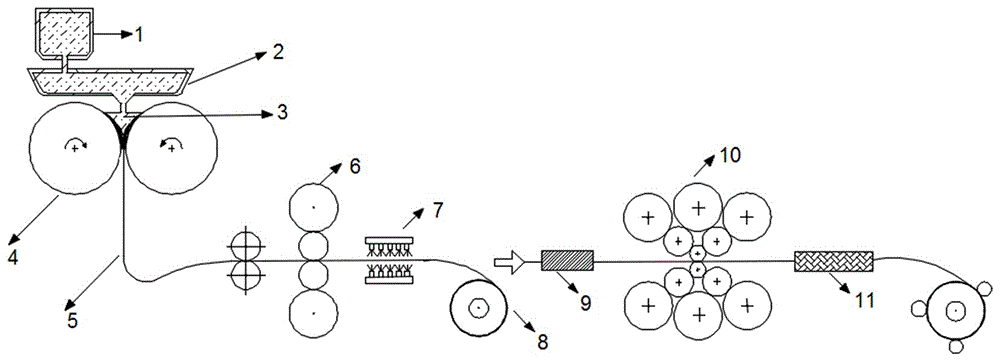

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

High magnetic induction and high grad non-orientation electrical steel and its making process

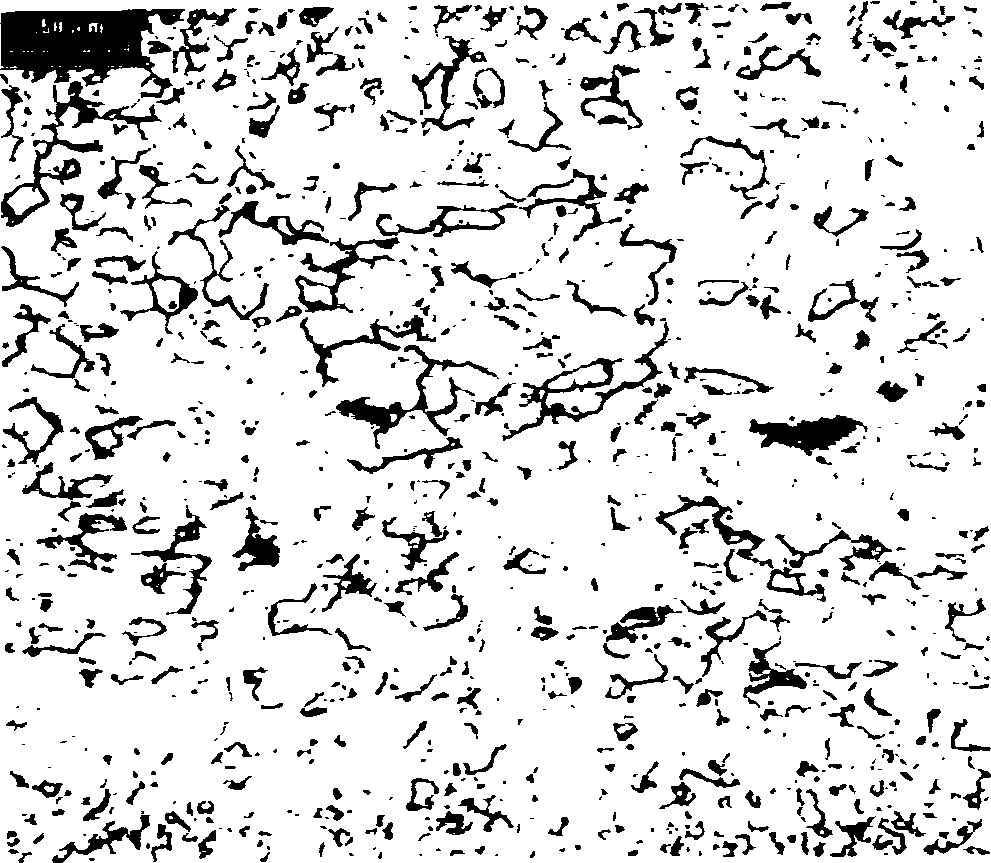

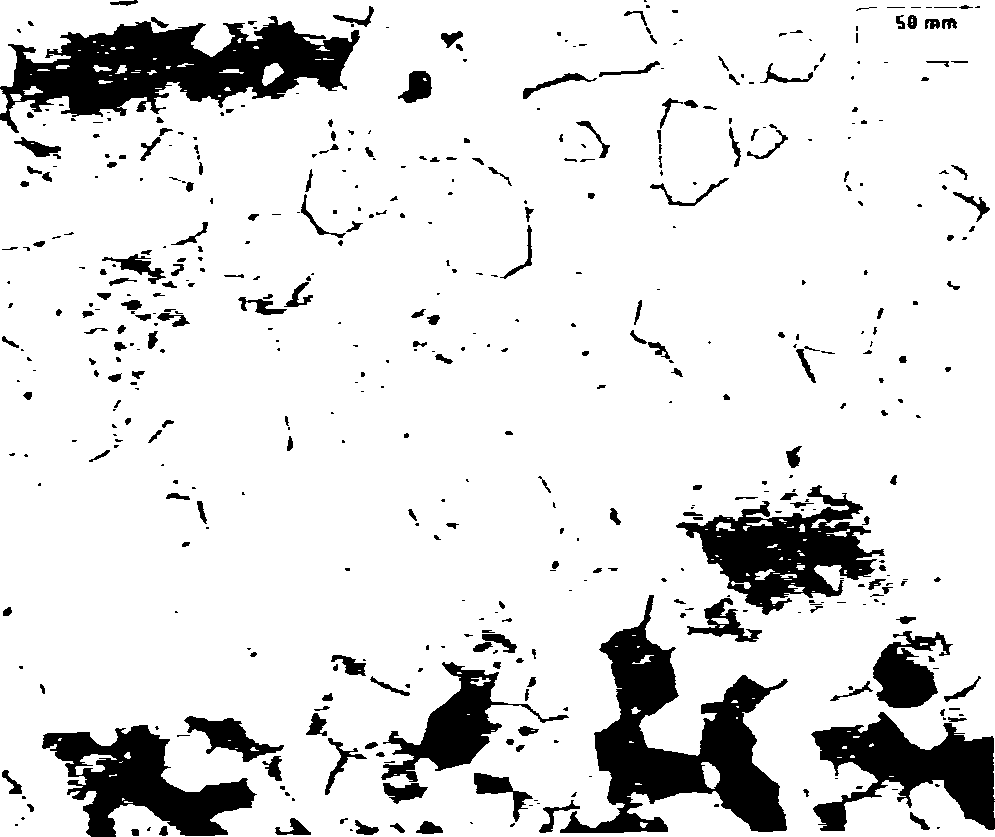

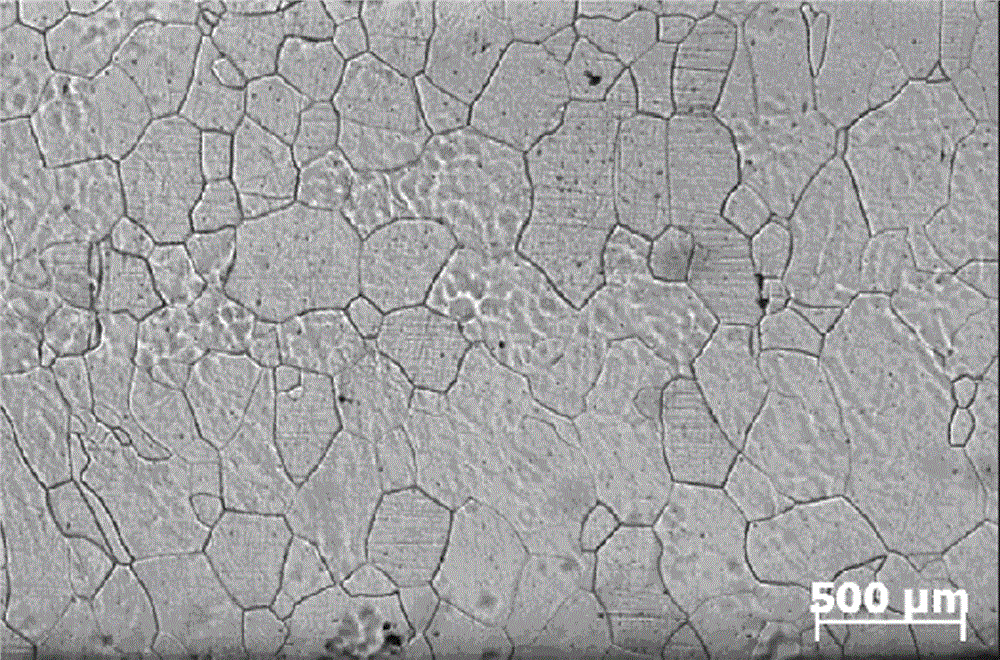

InactiveCN1888112AReduce the amount of solid solutionReduce precipitationFurnace typesHeat treatment furnacesElectrical steelGrain structure

The present invention is high magnetic induction and high grade non-orientation electrical steel and its making process. The high magnetic induction and high grade non-orientation electrical steel consists of C not more than 0.0050 wt%, N not more than 0.0030 wt%, Si 1.50-2.50 wt%, Al 0.80-1.30 wt%, Mn 0.20-0.50 wt%, P not more than 0.030 wt%, S not more than 0.005 wt%, Sb 0.03-0.10 wt% or Sn 0.05- 0.12 wt%, and B 0.0005-0.0040 wt%, except Fe and inevitable impurities. Its making process includes initial rolling and high temperature winding to obtain ideal hot rolled steel belt structure; cold rolling to provide the energy for crystal grain growth in re-crystallizing annealing, and re-crystallizing annealing in controlled temperature to obtain ideal crystal grain structure. It has excellent surface quality, high magnetic induction and low iron loss, and is suitable for use in high efficiency motor iron core.

Owner:BAOSHAN IRON & STEEL CO LTD

Manufacture of directional electromagnetic steel plate

A method of manufacturing a grain-oriented steel sheet including hot-rolling a slab prepared using molten steel containing, by mass%, C of not more than about 0.08 %, Si of about 1.0 to about 8.0 % and Mn of about 0.005 to about 3.0 %; optionally annealing the hot-rolled steel sheet; performing cold rolling once, or twice or more with intermediate annealing therebetween; performing primary recrystallization annealing in a low- or non-oxidizative atmosphere and adjusting the C content in the steel sheet after primary recrystallization annealing to be held in the range of about 0.005 to about 0.025 mass%; performing secondary recrystallization annealing; decarburization annealing; and, preferably, performing additional high-temperature continuous or batch annealing. A grain-oriented electrical steel sheet having a sufficiently high magnetic flux density and a low iron loss can be advantageously obtained even when it is manufactured without using an inhibitor.

Owner:JFE STEEL CORP

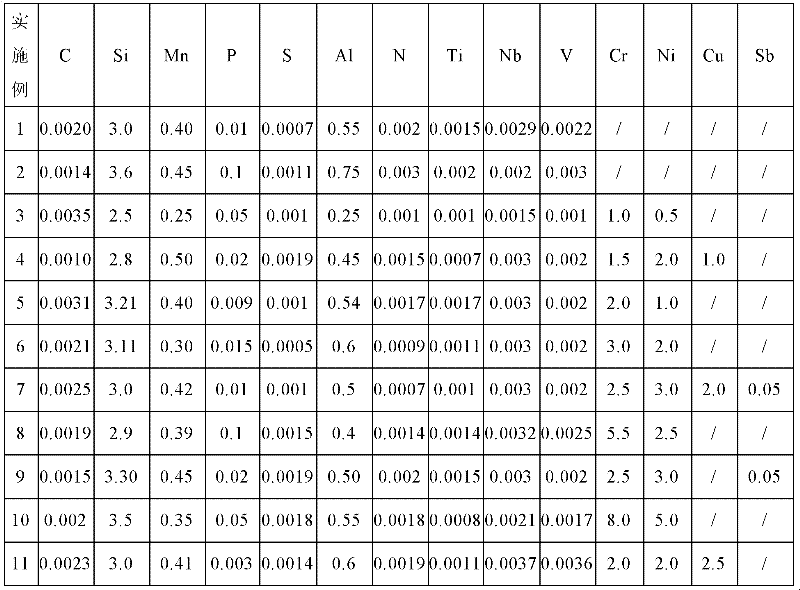

High-strength non-oriented electrical steel with high magnetic induction and manufacturing method thereof

InactiveCN102453838AHigh strengthSolve the problem of difficult rollingReduction rateElectrical steel

High-strength non-oriented electrical steel with high magnetic induction and a manufacturing method thereof. The method comprises the following steps of: 1) smelting and casting, wherein the electrical steel comprises the following components by weight: not more than 0.0040% of C, 2.50-4.00% of Si, 0.20%-0.80% of Al, 1.0-8.0% of Cr, 0.5-5.0% of Ni, not more than 0.50% of Mn, not more than 0.30% of P, not more than 0.0020% of S, not more than 0.0030% of N, not more than 0.0030% of Ti, not more than 0.010% of Nb, not more than 0.010% of V, not more than 0.010% of C+S+N+Ti, and the balance of Fe; smelting, RH vacuum treatment, casting; 2) hot rolling; 3) normalization at a temperature of 850-950 DEG C for 0.5-3 min, slow cooling to 650-750 DEG C with a speed of 5-15 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C; 4) pickling and cold rolling with a total reduction rate of not less than 70%; 5) annealing at 800-1000 DEG C for 5-60 seconds, slow cooling to 650-750 DEG C with a speed of 3-10 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C. The method of the invention produces non-oriented electrical steel with both high strength and high-efficient magnetic properties without the increase of manufacturing difficulties.

Owner:BAOSHAN IRON & STEEL CO LTD

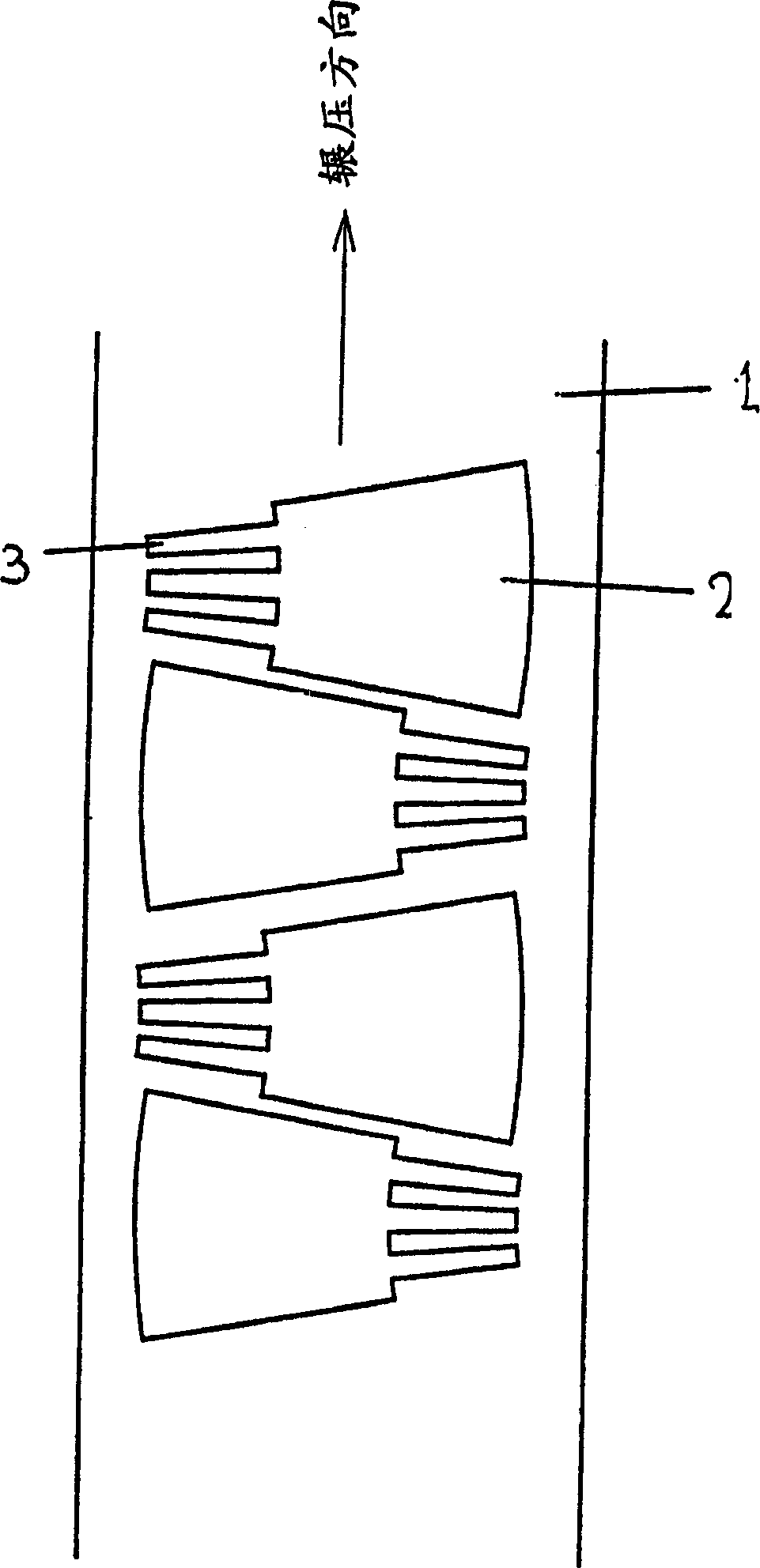

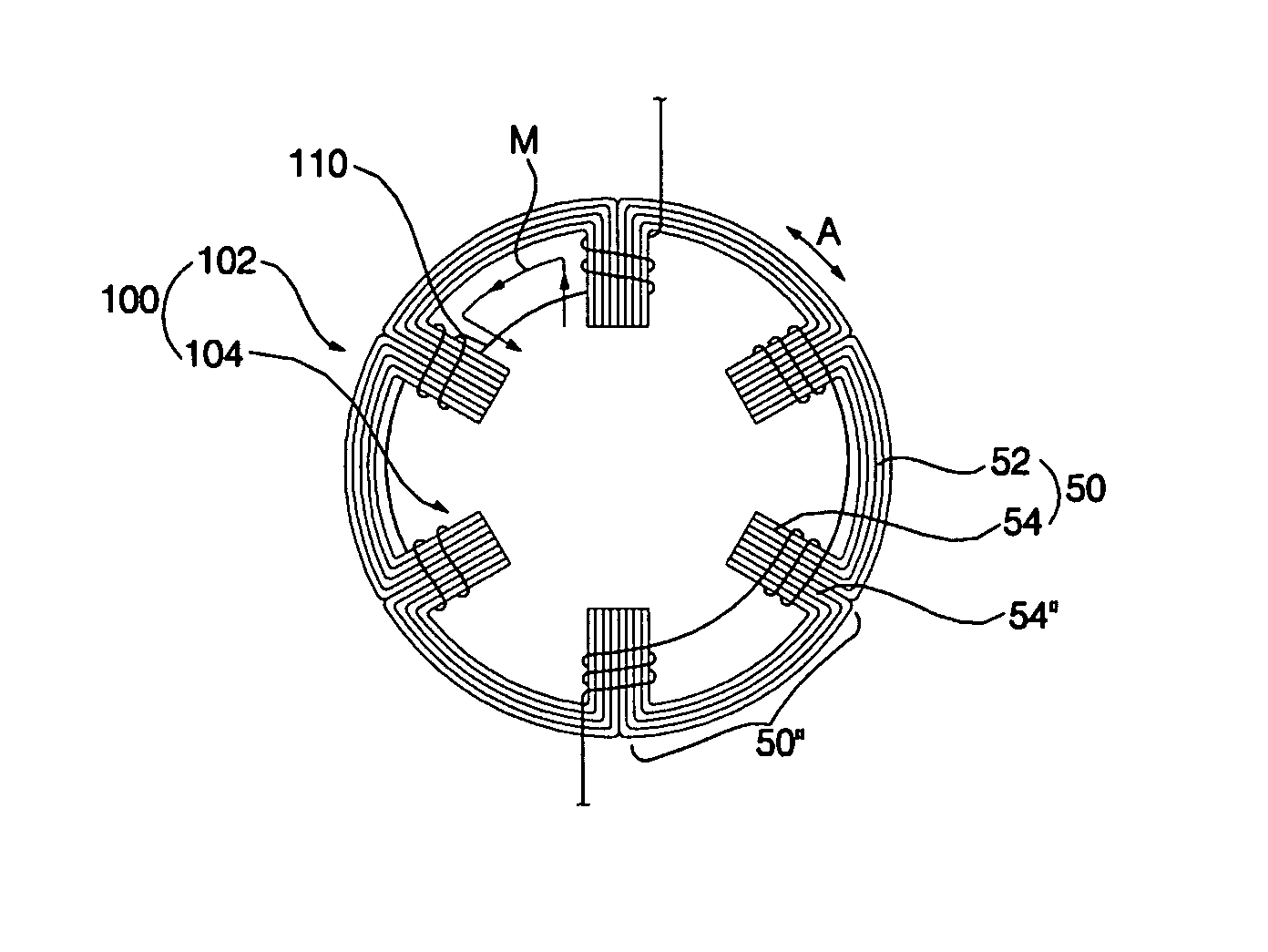

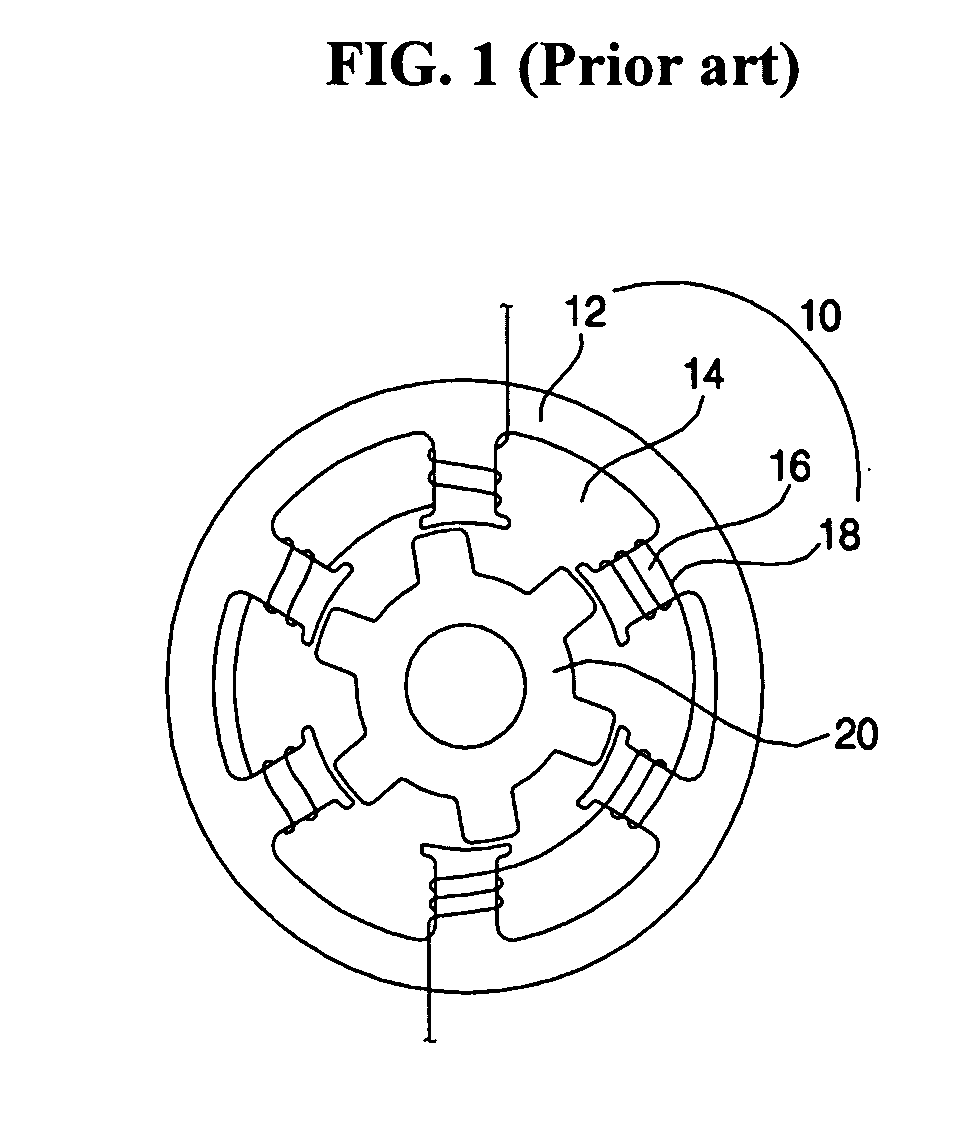

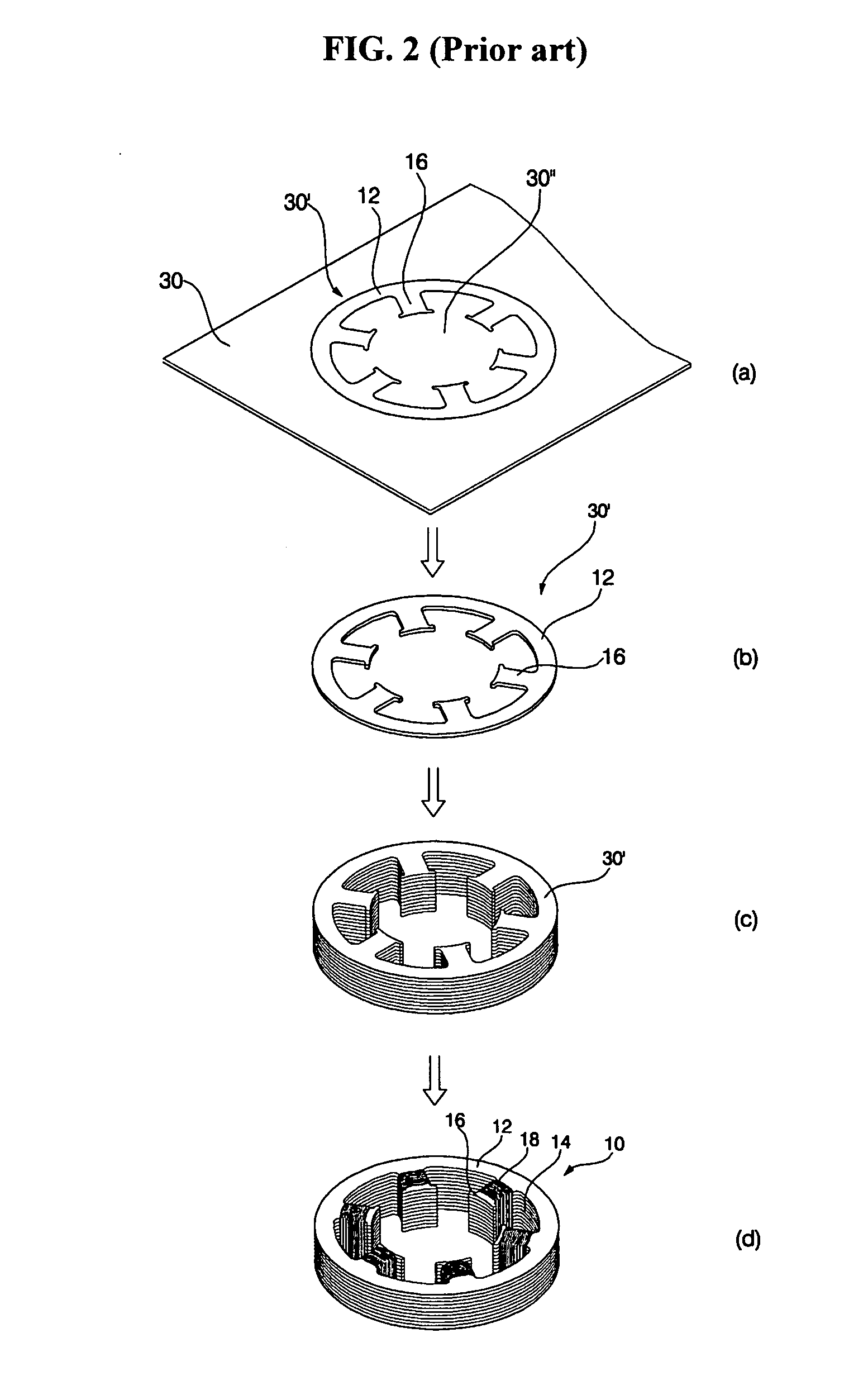

Stator of motor and method of manufacturing the same

InactiveUS20060055274A1Easy to manufactureReduce manufacturing costWindingsMagnetic circuit stationary partsElectrical steelDie preparation

A method of manufacturing a stator of a motor comprises the steps of bending at least one end of an electrical steel sheet to prepare a core sheet comprising a yoke part and at least one pole part bent from the yoke part, stacking a plurality of core sheets to prepare a unit core having a predetermined thickness, arranging a plurality of unit cores in line to prepare a core band, winding coils on the core band, and connecting both ends of the core band. In this way, the stator is manufactured. Consequently, no scrap is formed from the electrical steel sheet according to the present invention.

Owner:LG ELECTRONICS INC

Electric steel insulating paint, and preparation method and coating method thereof

InactiveCN101659799AImprove insulation performanceConvenient coatingCoatingsElectrical resistance and conductanceElectrical steel

The invention relates to an electric steel insulating paint, and a preparation method and a coating method thereof. The electric steel insulating paint is prepared from the following components by mass percent: 25-65% of aluminium dihydrogen phosphate, 0.5-3% of silica sol, 1-5% of phosphoric acid, 1-5% of magnesium oxide, 0.1-1% of nitrate additive containing rare earth, 1-5% of silane coupling agent and the balance water as a solvent. The thickness of the electric steel insulating paint is 0.3-8 mu m. The electric steel insulating paint has the advantages of favorable insulating property, favorable coating performance, high interface resistance, high breakdown resistance, high corrosion resistance, high adhesion property and the like. The environmental-protection insulating paint does not contain chromium, and thereby being clean and having no pollution. In addition, the electric steel insulating paint also has the advantages of rich material sources, low cost, high performance priceratio, strong market competitiveness and wide application prospects.

Owner:艾宝魁

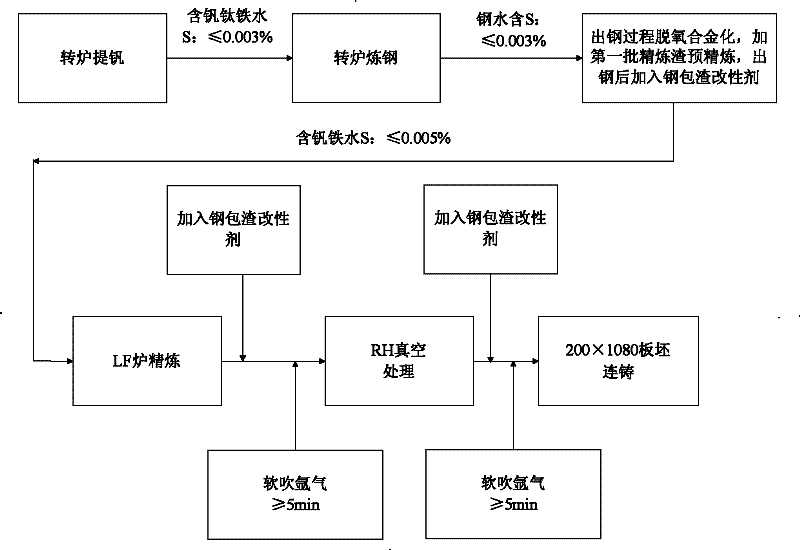

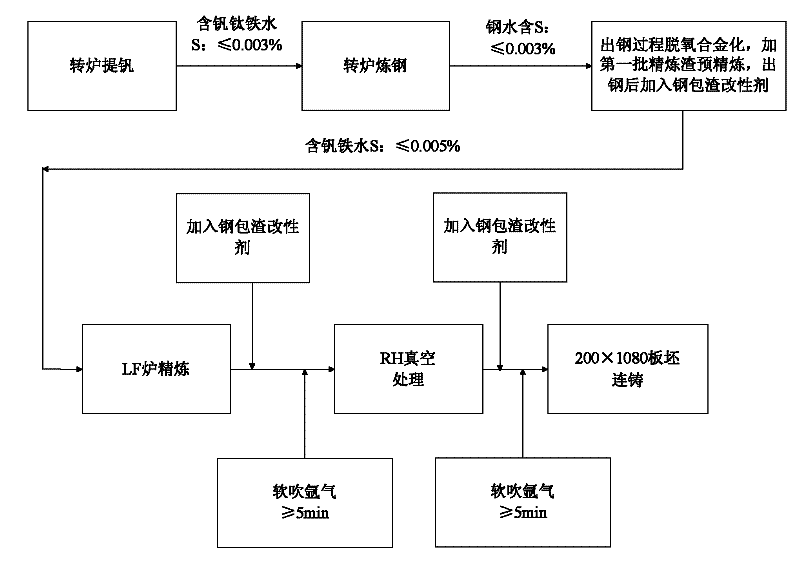

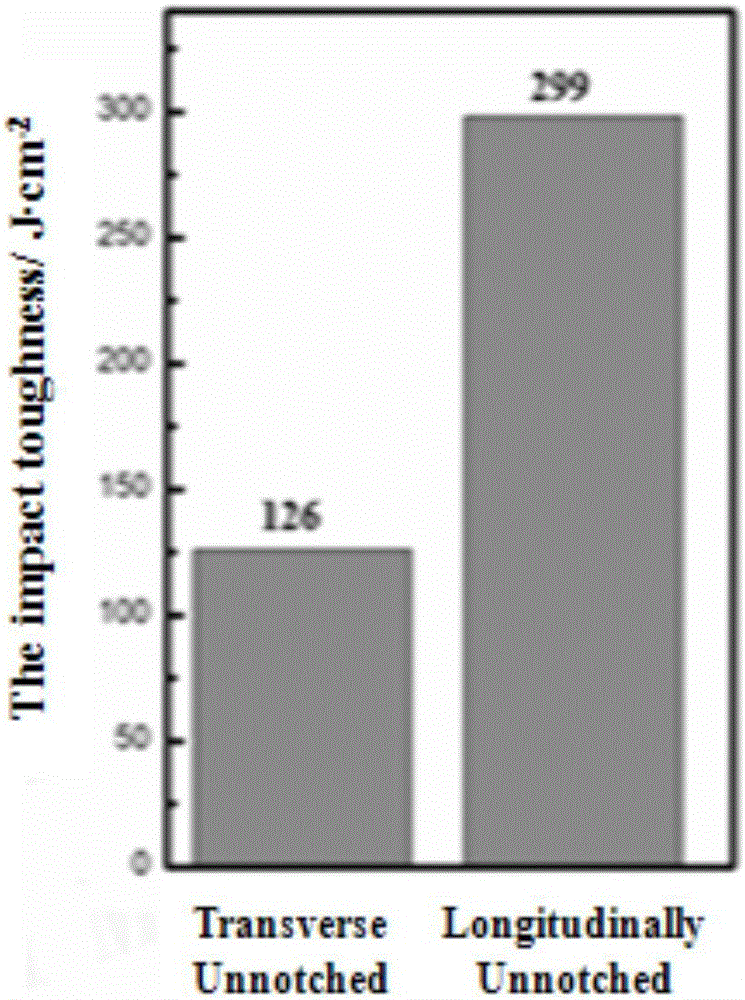

High phosphorus and low sulfur non-oriented electrical steel and its smelting method

ActiveCN102260822AGuaranteed qualifiedSolve the technical difficulties of smeltingElectrical steelSulfur

The invention belongs to the technical field of metallurgy and particularly relates to high-phosphorus low-sulfur non-oriented electrical steel and a smelting method thereof. The technical problem to be solved is to improve resistivity of the electrical steel without influencing the magnetism of the electrical steel. For solving the problem, the invention adopts a technical scheme which is to provide high-phosphorus low-sulfur non-oriented electrical steel. The high-phosphorus low-sulfur non-oriented electrical steel comprises the following ingredients in percentage by weight: 0 to 0.0050 percent of carbon, 0.30 to 1.0 percent of silicon, 0.15 to 0.35 percent of manganese, 0.030 to 0.08 percent of phosphorus, 0 to 0.005 percent of sulfur, less than or equal to 0.0050 percent of aluminum and the balance of ferrum. A production process for the electrical steel is suitable for producing the high-phosphorus low-sulfur non-oriented electrical steel by taking vanadium titanium-containing molten iron as a raw material, and has a good application prospect.

Owner:PANZHIHUA IRON AND STEEL +3

Method for adding rare earth metal into steel to improve performance

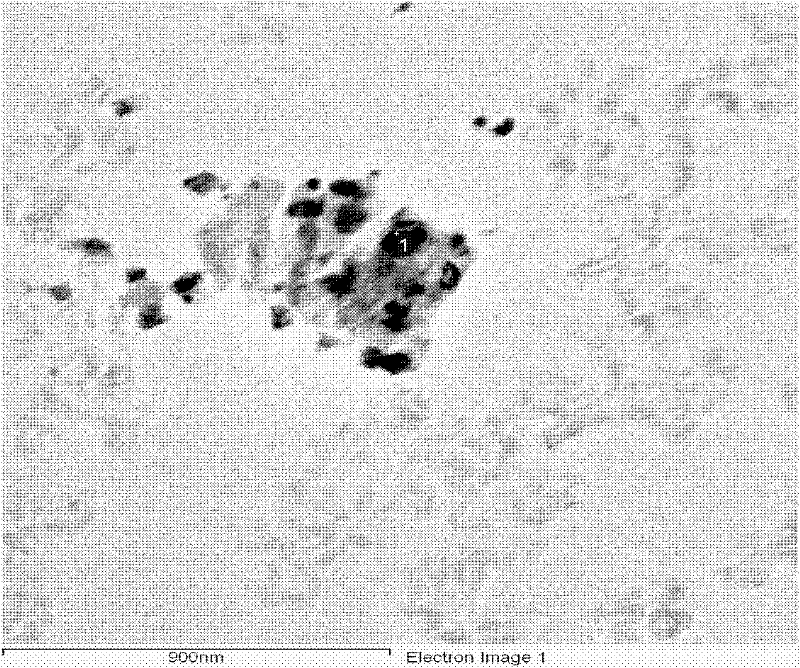

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

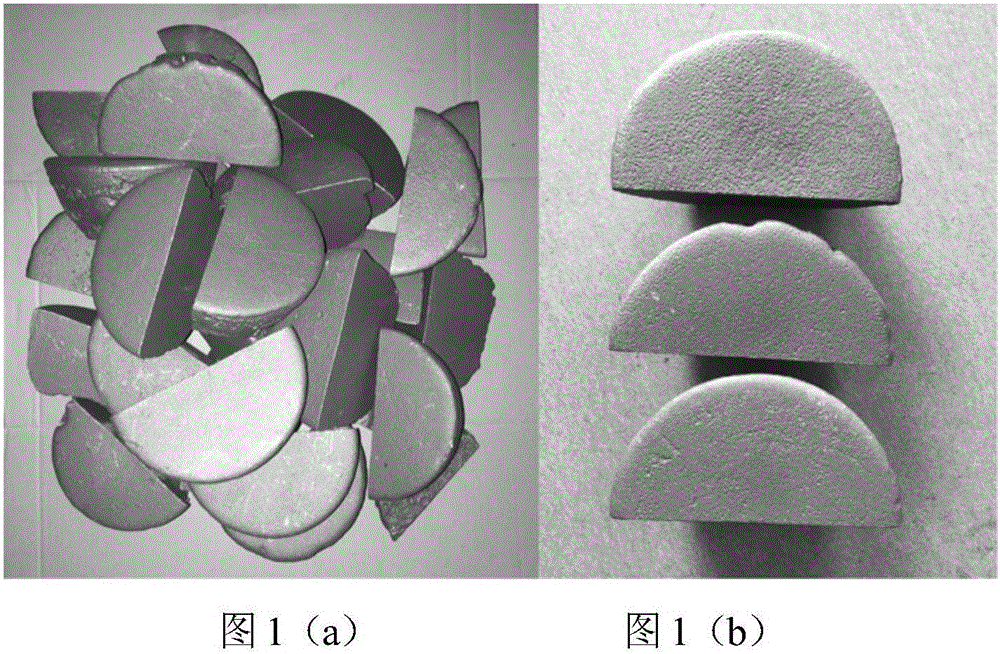

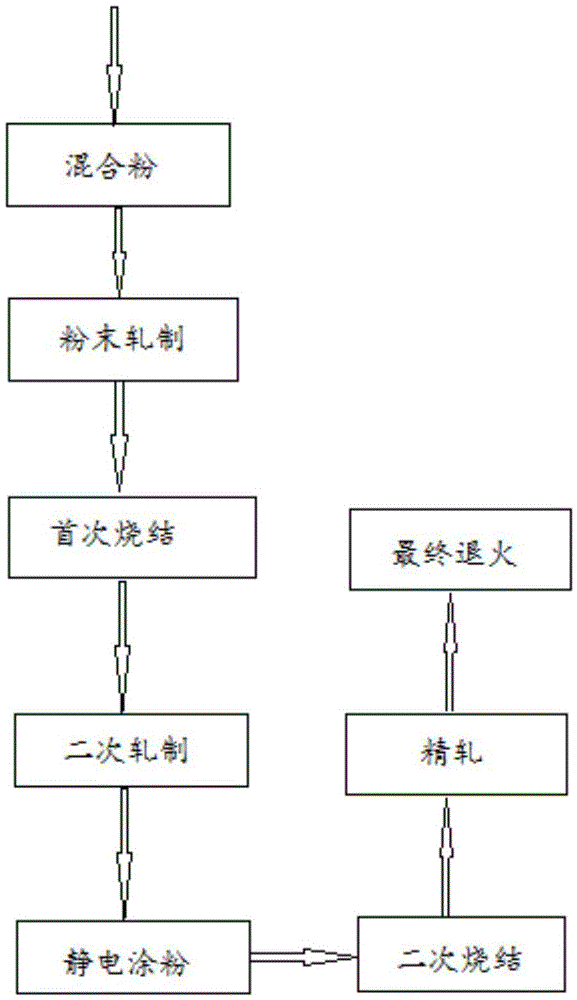

Method for manufacturing high silicon electrical steel

The invention discloses a method for manufacturing high-silicon silicon steel sheet, which relates to the technical field of silicon steel sheet production, and comprises the following steps: S1, taking mixed powder; S2, rolling the mixed powder for the first time; S3, carrying out the first rolled mixed powder First sintering; S4, second rolling; S5, electrostatic powder coating on the surface of the mixed powder rolled in the second rolling; S6, mixed powder after second sintering electrostatic powder coating; S7, finish rolling; S8, annealing treatment; The manufacturing method of the high-silicon silicon steel sheet disclosed in the invention adopts a segmented sintering process, and the phase of the obtained strip is a single iron-silicon solid solution, and the thickness of the strip can be controlled by rolling passes, and the strip after the initial sintering The material has good shear property and can be mechanically processed such as shearing and stamping. During the preparation process, due to the sintering effect and the solid solution of Si, the tensile strength of the strip increases gradually. At a frequency above 1kHz, The samples had relatively low core losses.

Owner:ANHUI ZHONGLONG ENERGY SAVING TECH

Preparation method of low carbon low silicon no-aluminum half-technique non oriented electrical steel

ActiveCN101306434AStrong magnetismLow costTemperature control deviceMetal rolling arrangementsRare-earth elementChemical composition

A method for preparing low-carbon low-silicon non-aluminum semi-process non-oriented electrical steel belongs to the technology field of the electrical steel with good magnetic performance. The preparation method includes the processing steps of meeting the requirements for the casting blank, such as the chemical components comprise less than or equal to 0.005% of C, 0.1%-1.0% of Si, less than or equal to 0.35% of Mn, less than or equal to 0.08% of P, less than or equal to 0.01% of S, less than or equal to 0.008% of N, less than or equal to 0.015% of O, inevitable impurities and Fe in balancing amount, according to the composition design for the hot rolling raw material; hot-charging and hot-rolling of the casting blank; acid-cleaning and cold-rolling of the steel plate after the hot-rolling; intermediate-annealing of the steel strip; cold-rolling of the critical deformation; relieving stress and annealing by users; and obtaining the semi-process non-oriented electrical steel with good magnetic performance. The method has the advantage that the final product has good magnetic performance: P15 / 50 is equal to 3.45-5.05 W / Kg, and B5000 is equal to 1.69-1.76 T. The casting blank contains no alloying elements such as Al, Sn, Sb, Cu, Cr, Ni, B, rare earth elements, etc., thus considerably reducing the production cost. The larger critical rolling reduction is adopted, the annealing technique is optimized, and the prepared finished products have better magnetic performance.

Owner:SHOUGANG CORPORATION

Grain-oriented electrical steel sheet and method of manufacturing the same

ActiveUS20130139932A1Low iron-lossInorganic material magnetismMagnetic core manufactureElectrical steelSheet steel

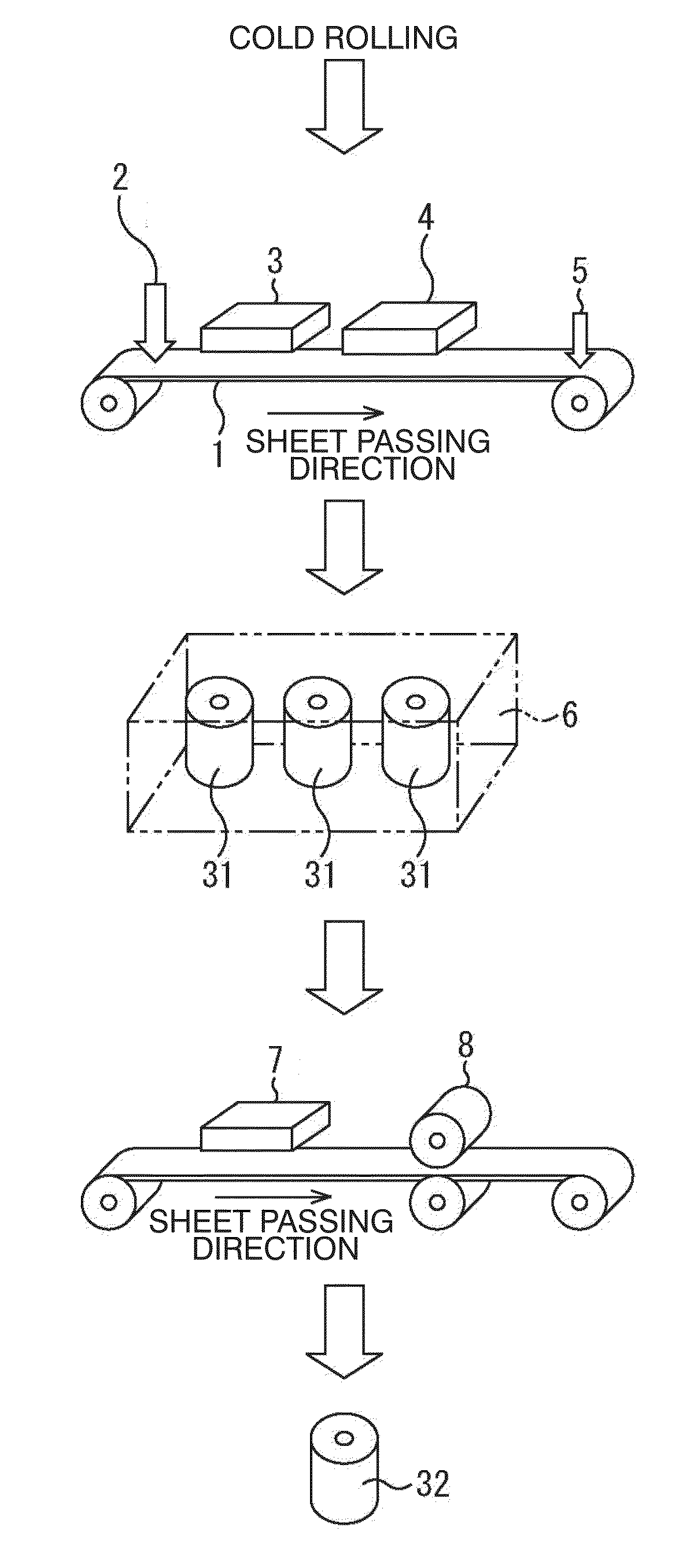

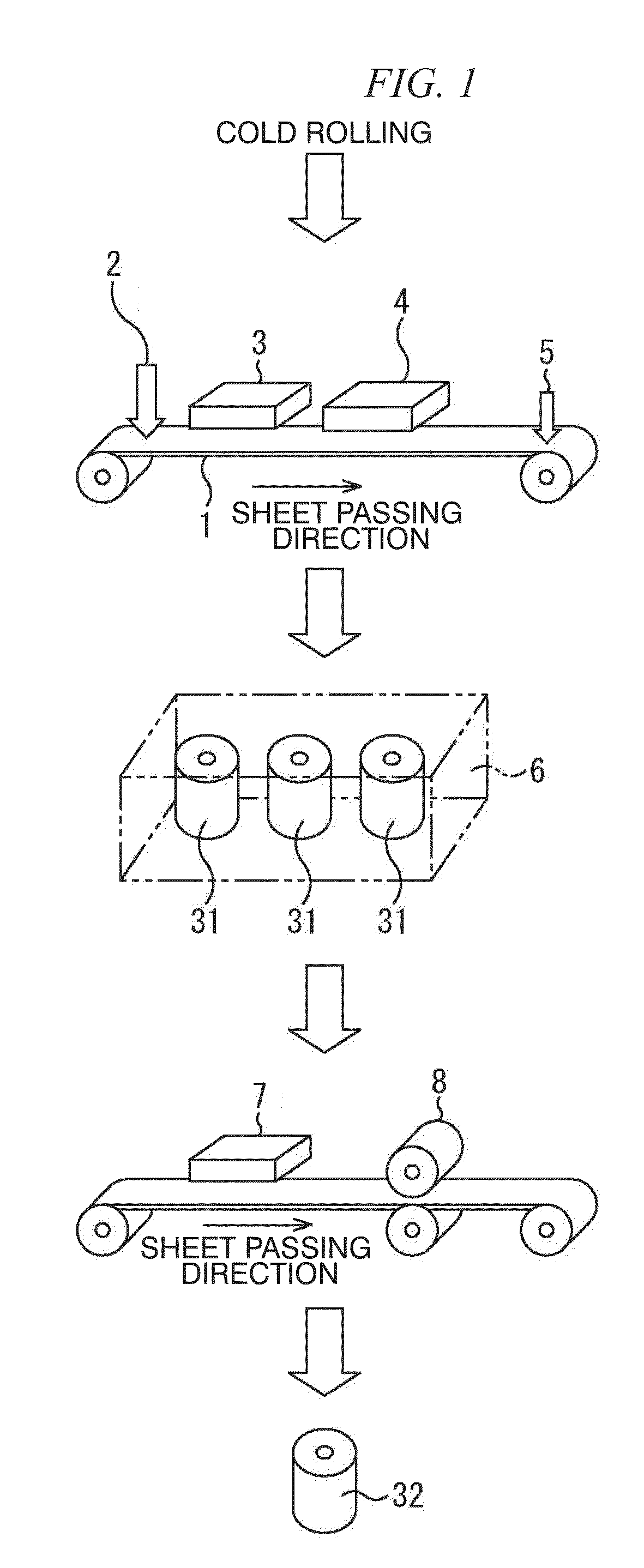

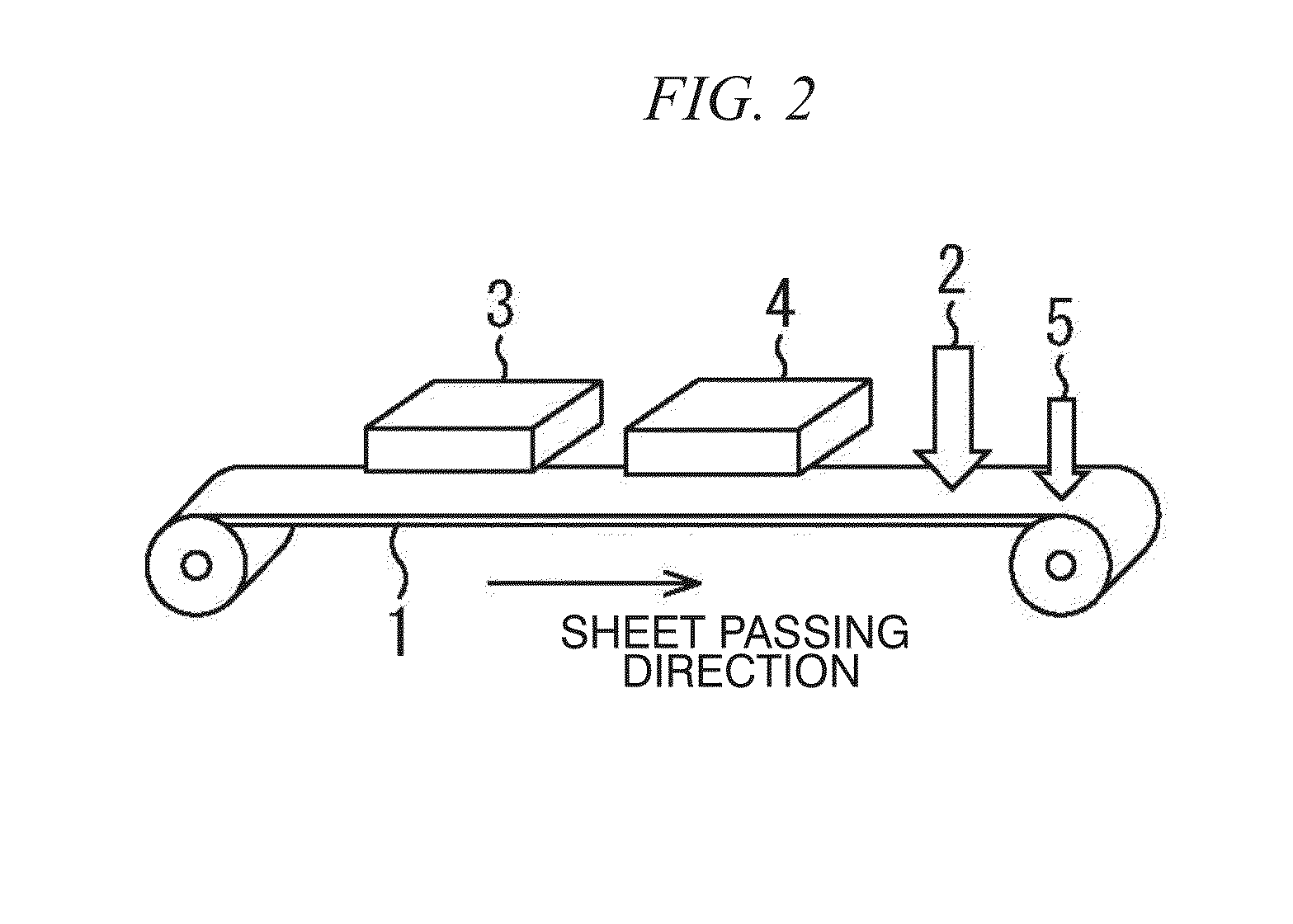

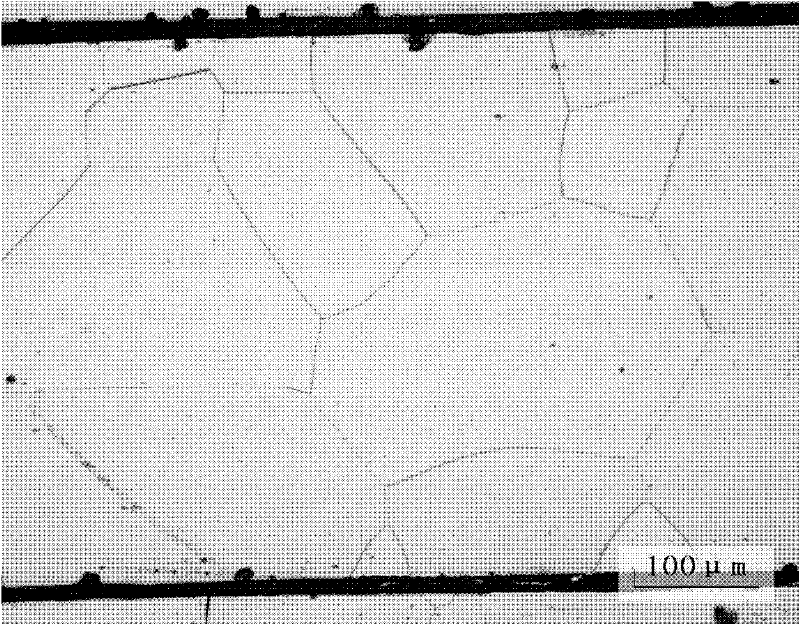

This method of manufacturing a grain-oriented electrical steel sheet includes, between a cold rolling process and a winding process, a groove formation process of irradiating the surface of a silicon steel sheet with a laser beam multiple times at predetermined intervals in a sheet passing direction, over an area from one end edge to the other end edge, in a sheet width direction of the silicon steel sheet, thereby forming a groove along a locus of the laser beam.

Owner:NIPPON STEEL CORP

Method for Manufacturing Grain-Oriented Electrical Steel Sheets Having Excellent Magnetic Properties

ActiveUS20130306202A1High magnetic flux densityLow core lossFurnace typesHeat treatment furnacesSheet steelElectrical steel

Provided is a method for manufacturing a grain-oriented electrical steel sheet, the method comprising: heating a grain-oriented electrical steel sheet slab; hot-rolling the heated slab; optionally annealing the hot-rolled steel sheet; subjecting the resulting steel sheet to one cold rolling or two or more cold rollings with intermediate annealing therebetween; subjecting the cold-rolled steel sheet to primary recrystallization annealing; and subjecting the annealed steel sheet to secondary recrystallization annealing, wherein the primary recrystallization annealing sequentially comprises an ultra-rapid heating process of heating the steel sheet at an average heating rate of 300° C. / sec or higher, a rapid heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the ultra-rapid heating process, but not lower than 100° C. / sec, and a general heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the rapid heating process.

Owner:POHANG IRON & STEEL CO LTD

Method for manufacturing cold rolling non oriented electrical steel through continuous casting and tandem rolling sheet bar

InactiveCN1796015AAvoid the problem of fine dispersed precipitationEasy to grow grainsOther manufacturing equipments/toolsMetal rolling arrangementsElectrical steelMolten steel

The method for producing cold-rolled non-oriented electrical steel by using sheet bar and adopting continuous casting and continuous rolling process includes the following steps: a). utilizing the following components: C is less than or equal to 0.005%, Si is less than or equal to 3.5%, Mn is less than or equal to 1.5%, Al is less than or equal to 1.5%, P is less than or equal to 0.2%, S is less than or equal to 0.010%, N is less than or equal to 0.005%, O is less than or equal to 0.02% and the rest is iron and smelting; b). continuous casting, continuously casting molten steel to obtain sheet bar; c). heating, the temperature of sheet bar before which is fed into the furnace is 700-900deg.C, retaining said temperature for 30s-5min; heating sheet bar in ferrite phase area and heating temperature is less than or equal to 1120deg.C; d). hot-rolling, rolling in ferrite phase area, final rolling temperature is 800deg.C-950deg.C; e). coiling, coiling temperature is 500deg.C-900deg.C; and f). normalizing treatment or non-annealing treatment, acid-pickling, first cold-rolling or secondary cold-rolling with intermediate annealing to target thickness, then making final annealing so as to obtain the invented product.

Owner:BAOSHAN IRON & STEEL CO LTD

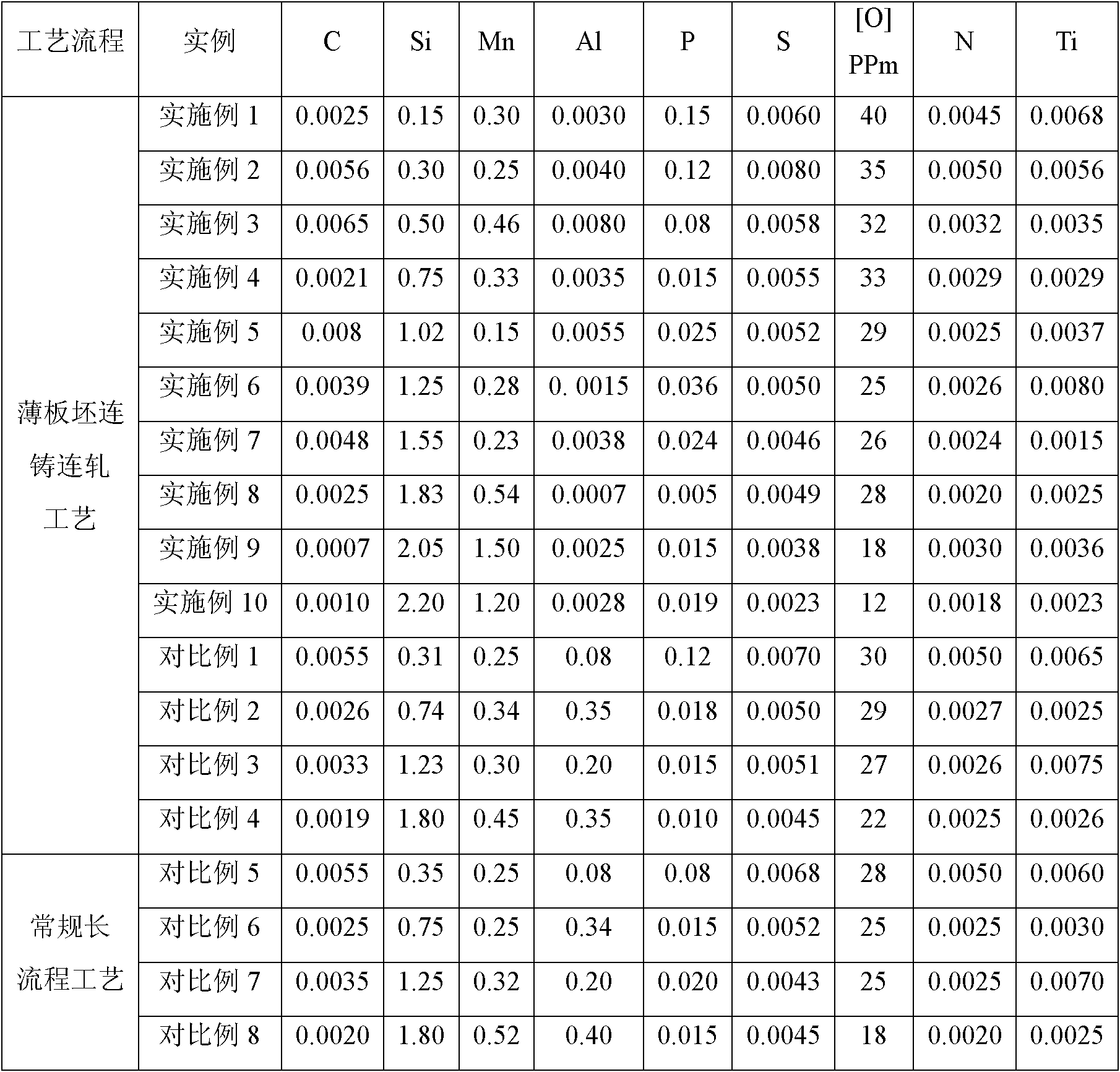

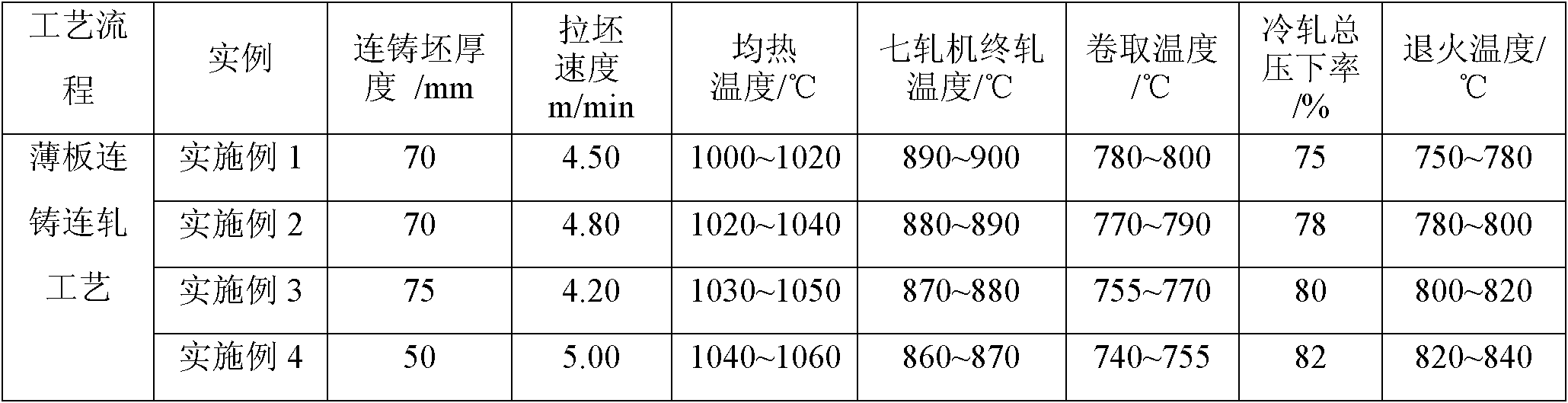

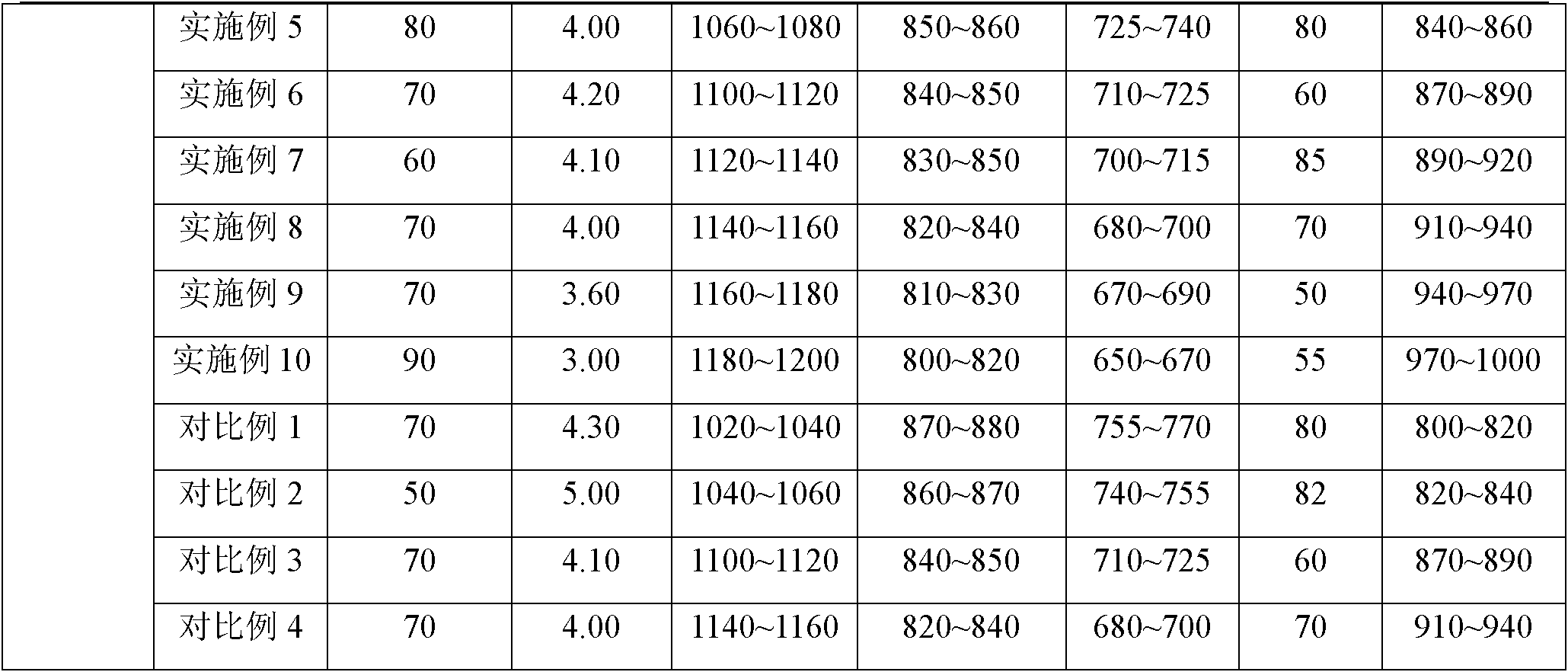

Non-oriented electrical steel for thin slab continuous casting-continuous rolling production and method thereof

InactiveCN102134675AReduce SiReduce Mn contentMetal rolling arrangementsTunnel kilnChemical composition

The invention relates to non-oriented electrical steel and a production method thereof. The non-oriented electrical steel comprises the following chemical compositions in percentage by weight: less than or equal to 0.008 percent of C, 0.15 to 2.2 percent of Si, less than or equal to 0.008 percent of Al, 0.15 to 1.5 percent of Mn, 0.004 to 0.15 percent of P, less than or equal to 0.008 percent of S, less than or equal to 40PPm of [O], less than or equal to 0.005 percent of N, less than or equal to 0.008 percent of Ti, and the balance of iron and inevitable impurities. The production method comprises the following steps of: smelting by using a converter and performing vacuum treatment; continuously casting into slabs with the thickness of 50-90 millimeters; soaking in a tunnel kiln; continuously rolling by using seven mills; coiling; performing pickling; performing cold rolling; performing recrystallization annealing; and obtaining the steel for later use. The alloy is reasonable in design and is not needed to be subjected to calcium treatment; the procedures are simple; the cost is reduced; the defect of low casting property in thin slab continuous casting-continuous rolling production can be effectively overcome; the advantages on cost and magnetic property of the non-oriented electrical steel in the thin slab continuous casting-continuous rolling production are fully shown, and the market competitiveness of the product is greatly improved.

Owner:武汉钢铁有限公司

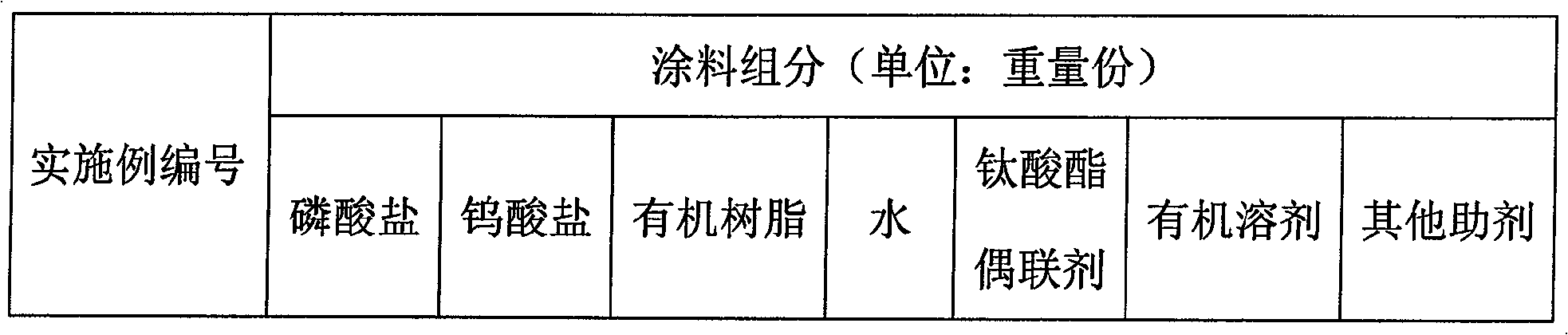

Non-oriented electric steel semi-organic phosphate insulating paint with good corrosion resistance

ActiveCN101560342AImprove corrosion resistanceImprove coating appearanceAnti-corrosive paintsPolyurea/polyurethane coatingsTungstateOrganic phosphates

The invention discloses a non-oriented electric steel semi-organic phosphate insulating paint with good corrosion resistance. The semi-organic phosphate insulating paint comprises the following main components: water-soluble phosphate, tungstate, organic resin, water, a titanate coupling agent, an organic solvent and the like; and contents of the components of the insulating paint (parts by weight) based on 100 parts of the water-soluble phosphate by weight are as follows: 1-15 parts of the tungstate, 20-200 parts of the organic resin, 500-2000 parts of the water, 0.1-3 parts of the titanate coupling agent, 10-50 parts of the organic solvent and 0.1-3 parts of other paint addictives. The semi-organic phosphate insulating paint contains no harmful ingredients restricted by an EU directive RoHS, which can meet the requirements for environmental protection; and compared with the common phosphate coating, the coating of the semi-organic phosphate insulating paint has better corrosion resistance, good insulating property, good adhesiveness, good blanking property, good welding property, good heat resistance and the like, which can meet the requirements of electric motor and transformermanufacturers for application to the electric steel coating.

Owner:MAANSHAN IRON & STEEL CO LTD

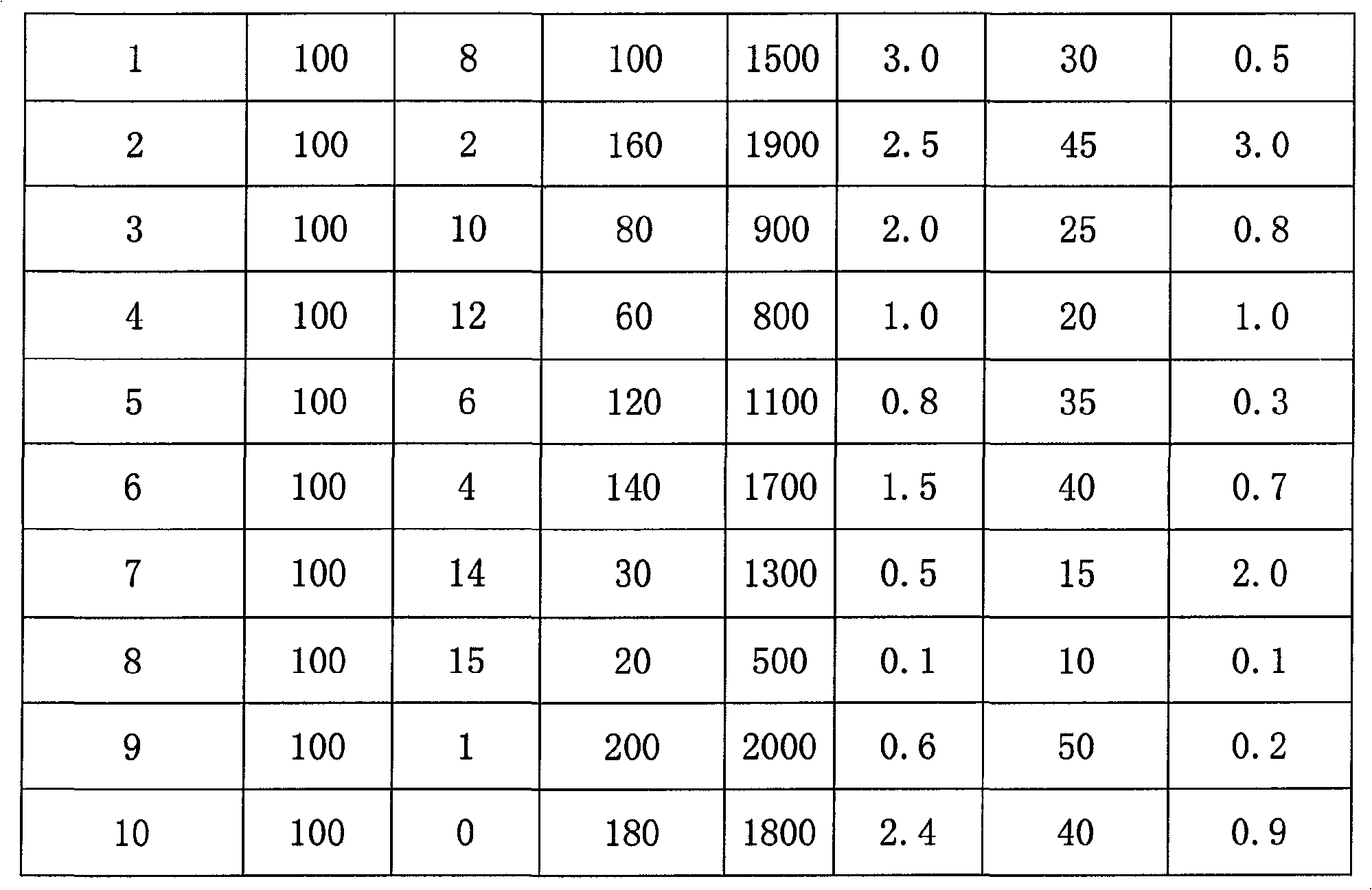

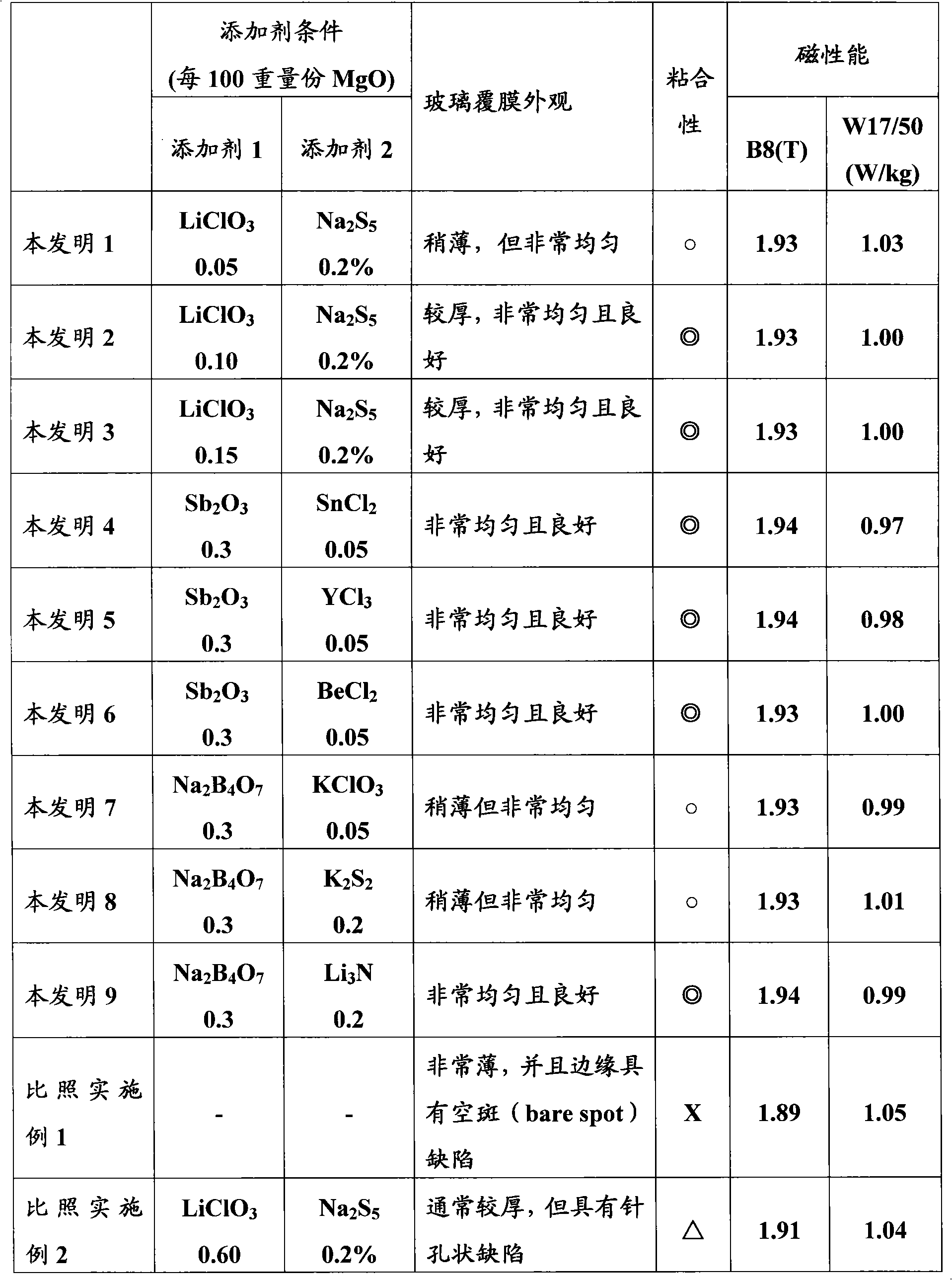

Annealing separating agent for grain oriented electrical steel sheet having uniform glass film and excellent magnetic properties and method of manufacturig the same

ActiveCN101528950APromote formationGood coating effectSolid/suspension decomposition chemical coatingSheet steelElectrical steel

Disclosed herein are an annealing separator for grain-oriented electrical steel sheets having excellent surface properties and a method for producing grain-oriented electrical steel sheets using the same. More particularly, the annealing separator comprises: 100 parts by weight of MgO, consisting of 40-95% of active MgO and 5-60% of inactive MgO; and 0.01-5 parts by weight of a low-melting-point compound having a melting point lower than 900 DEG C. The method for producing grain-oriented steel sheets comprises applying said annealing separator in the form of slurry to a steel sheet, after stirring the annealing separator in a mixing tank at a revolution speed of 1500-3000 rpm for more than 10 minutes.

Owner:浦项股份有限公司

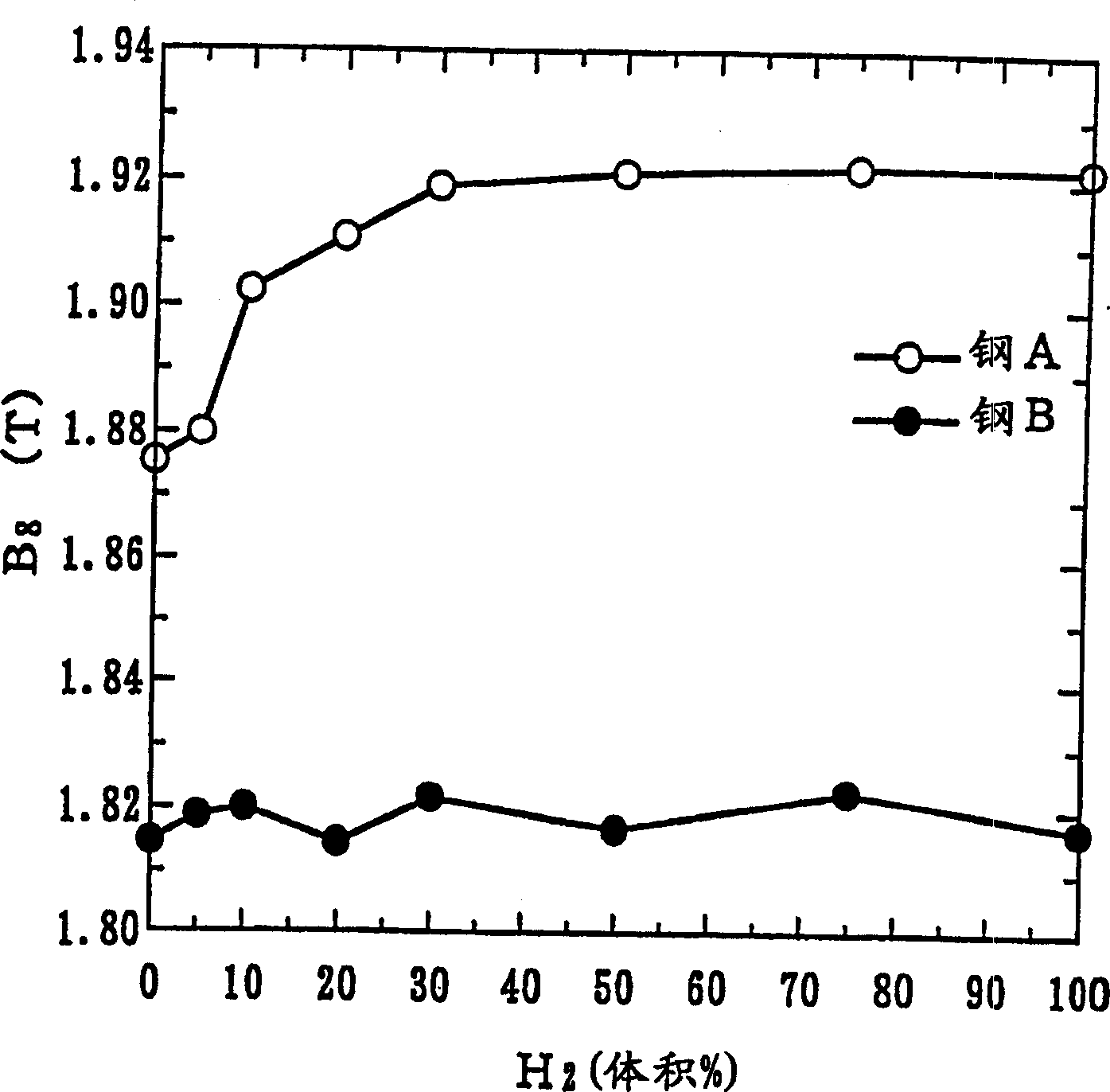

Method for manufacturing low-iron loss high-magnetic strength non-oriented electrical steel

Disclosed is a manufacturing method for low iron loss and high magnetic induction non-oriented electric steel, which belongs to the technical field of the electric steel. The invention adopts the process steps: the heating temperature for casting billet is between 900 DEG C to 1150 DEG C, a hot rolled plate is cold-rolled to 0.50 mm after being normalized and acid-cleaned and is positioned in hydrogen-nitrogen mixed gas to undergo the stress removal and annealing treatment, and the low iron loss and high magnetic induction non-oriented electric steel product can be obtained. The invention has the advantages that the final magnetic property of the product is good, namely P15 / 50 equals to 3.1 to 3.8 W / Kg and B5000 equals to 1.69 T to 1.81 T; Si accounts for 1.0 percent to 2.0 percent, Al accounts for 0 percent to 0.60 percent and Si and 3Al equals to or is larger than 1.5 percent and equals to or is less than 3.2 percent in the casting billet, alloying elements of Sn, Sb, Bi, Cu, Cr, Ni, B, Ca, Ce and the like are not contained in the product, the manufacturing cost is greatly reduced, and the magnetic property of the finished product is excellent.

Owner:SHOUGANG CORPORATION

Manufacturing method of high-strength non-oriented silicon steel for new energy vehicle driving motor

ActiveCN106435358ASimple manufacturing processEffectively control the characteristics of NbC precipitatesElectrical steelNew energy

The invention discloses a manufacturing method of high-strength non-oriented silicon steel for a new energy vehicle driving motor, and belongs to the technical field of manufacturing of electrical steel. The manufacturing method comprises the following steps: (1) molten steel is smelted, and comprises the following components: 0.002-0.005% of C, 2.8-3.5% of Si, 0.2-1% of Mn, 0.5-2% of Al, 0.5-2% of Ni, 0.5-3% of Cr, and the balance of Nb and Fe; (2) the molten steel is poured in continuous casting equipment for continuous casting to obtain a cast strip with a thickness of 2.5-2.7 mm; (3) the cast strip is hot rolled after air cooling, is cooled by water spraying, and is wound; (4) a scale on the surface of the cast strip is removed by pickling; and a cold-rolled plate is obtained through cold rolling; and (5) the annealing is performed under the condition of Ar2 atmosphere; and an insulation coating layer is coated for winding to obtain a finished plate. The manufacturing method adopts a strip continuous casting technology to produce the high-strength non-oriented silicon steel, is simple and feasible in process, is energy-saved and environment-friendly, is excellent in product performance, and can satisfy the performance requirements on the non-oriented silicon steel by the new energy vehicle driving motor.

Owner:NORTHEASTERN UNIV

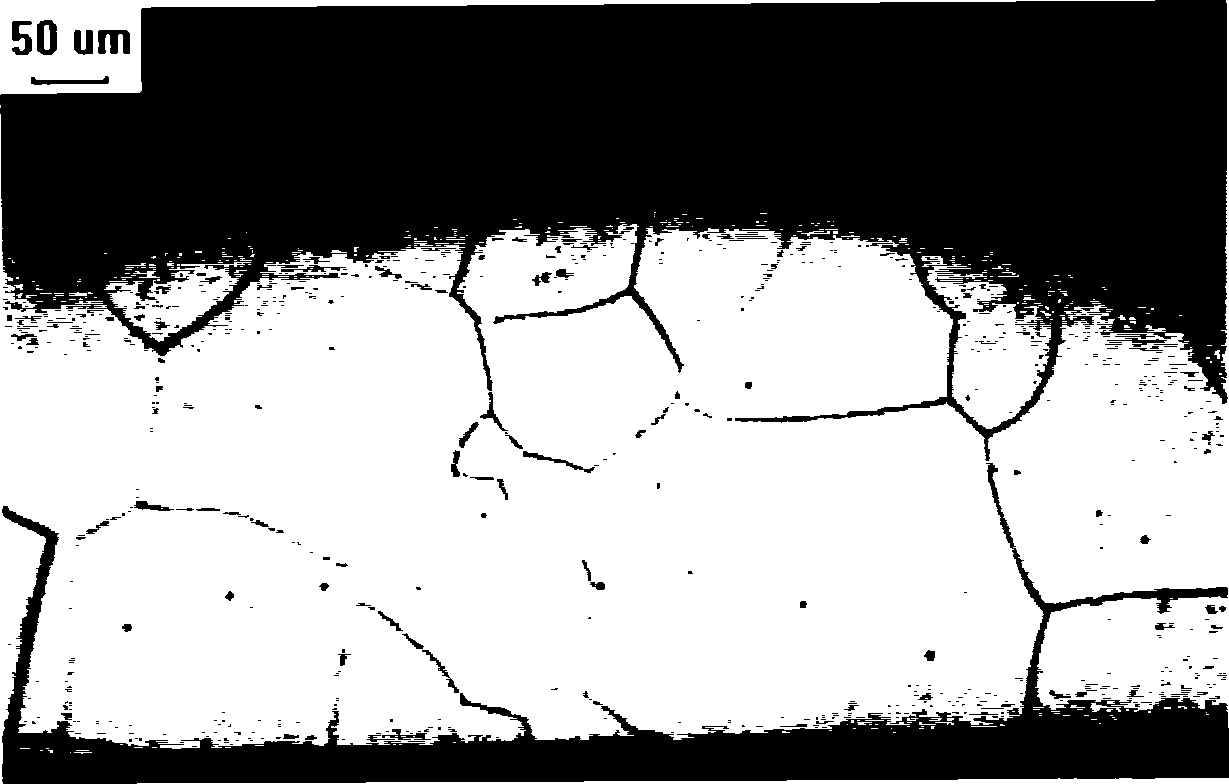

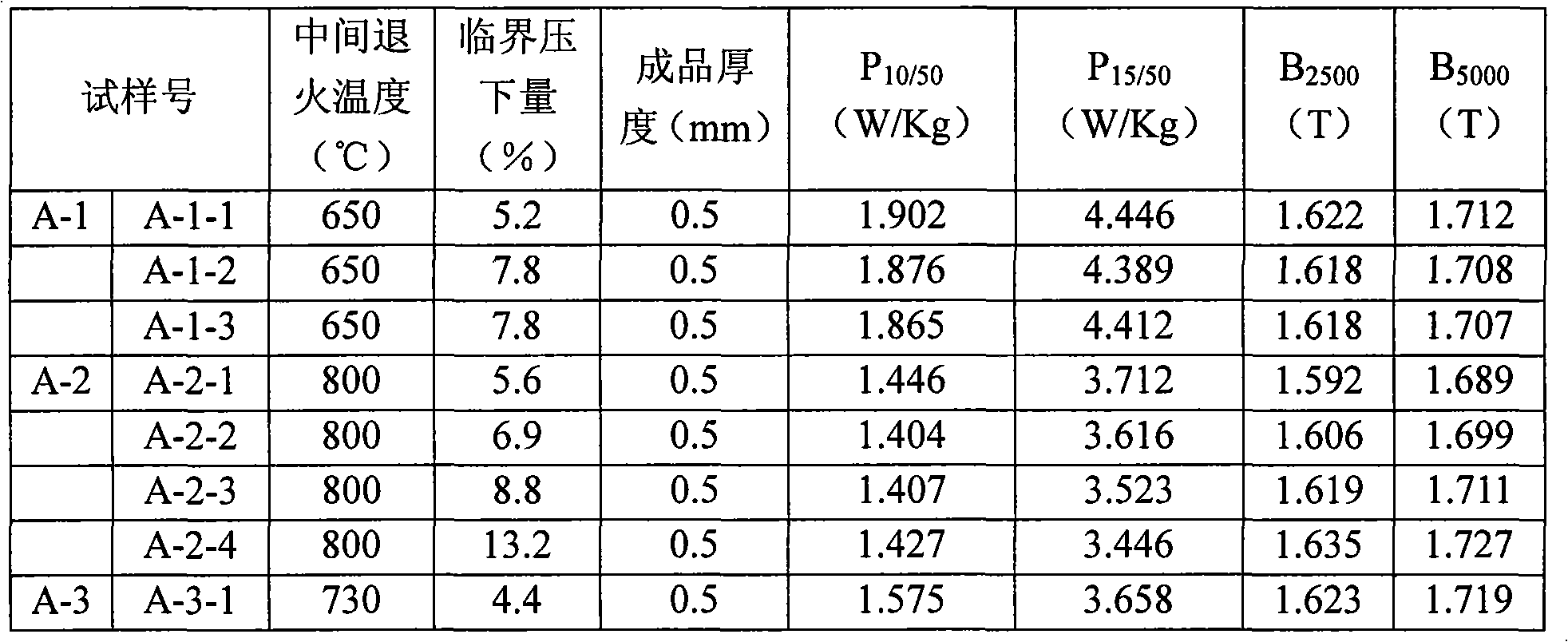

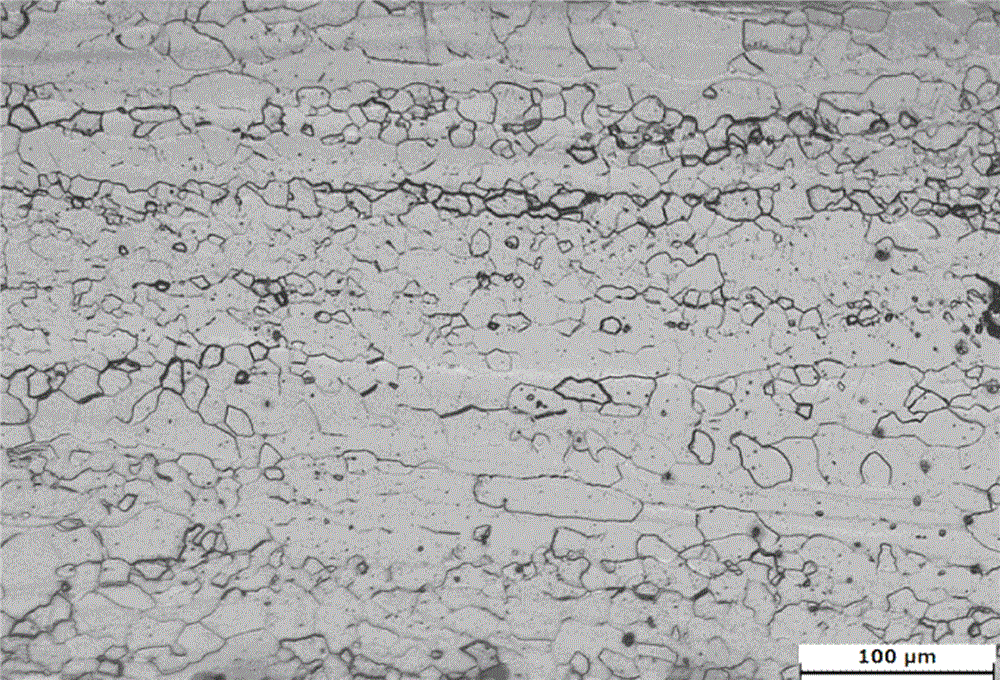

Production method for high-grade non-oriented silicon steel

The invention relates to a manufacturing method for non-oriented electric steel. The method comprises the following steps of: smelting according to a clean steel process and continuously casting into billets; heating the continuous casting billets; performing hot rolling; reeling; naturally cooling to room temperature; normalizing; performing acid washing conventionally; performing cold rolling for the first time; performing intermediate annealing in the total hydrogen atmosphere or the mixed atmosphere of hydrogen and nitrogen; performing cold rolling for the second time; performing final annealing; and cooling conventionally, coating and finishing for later use. The finished product silicon steel with coarse grains and good texture can be obtained by adopting lower process heat treatment temperature; brittleness of the steel is reduced and cold rolling performance of a steel plate is improved by adopting lower normalizing temperature and intermediate annealing temperature; the problems of surface oxidation of the steel plate, nodulation of a furnace bottom roller and the like can be effectively solved by adopting lower finished product annealing temperature; and the high-grade non-oriented silicon steel with lower iron loss can be produced stably.

Owner:武汉钢铁有限公司

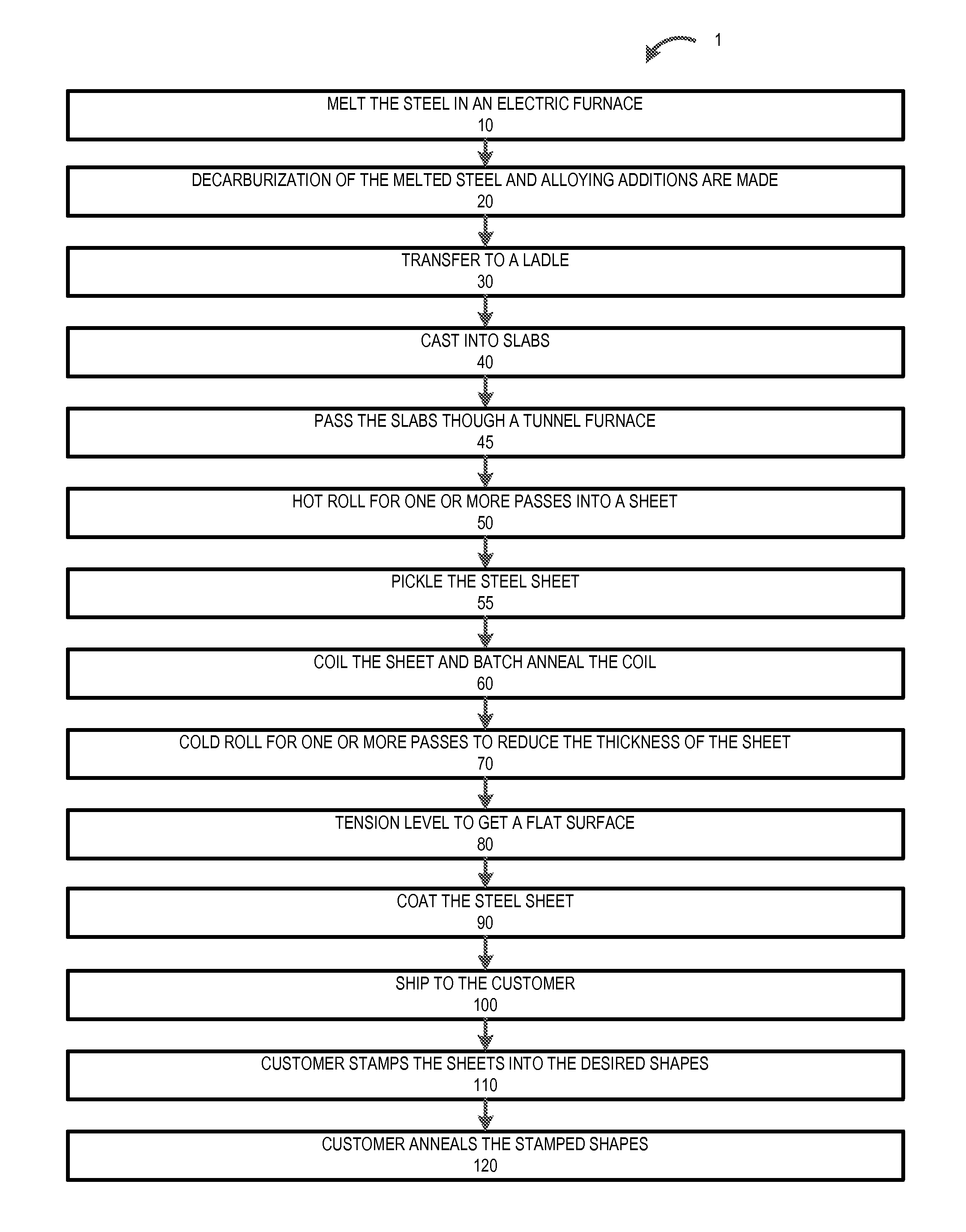

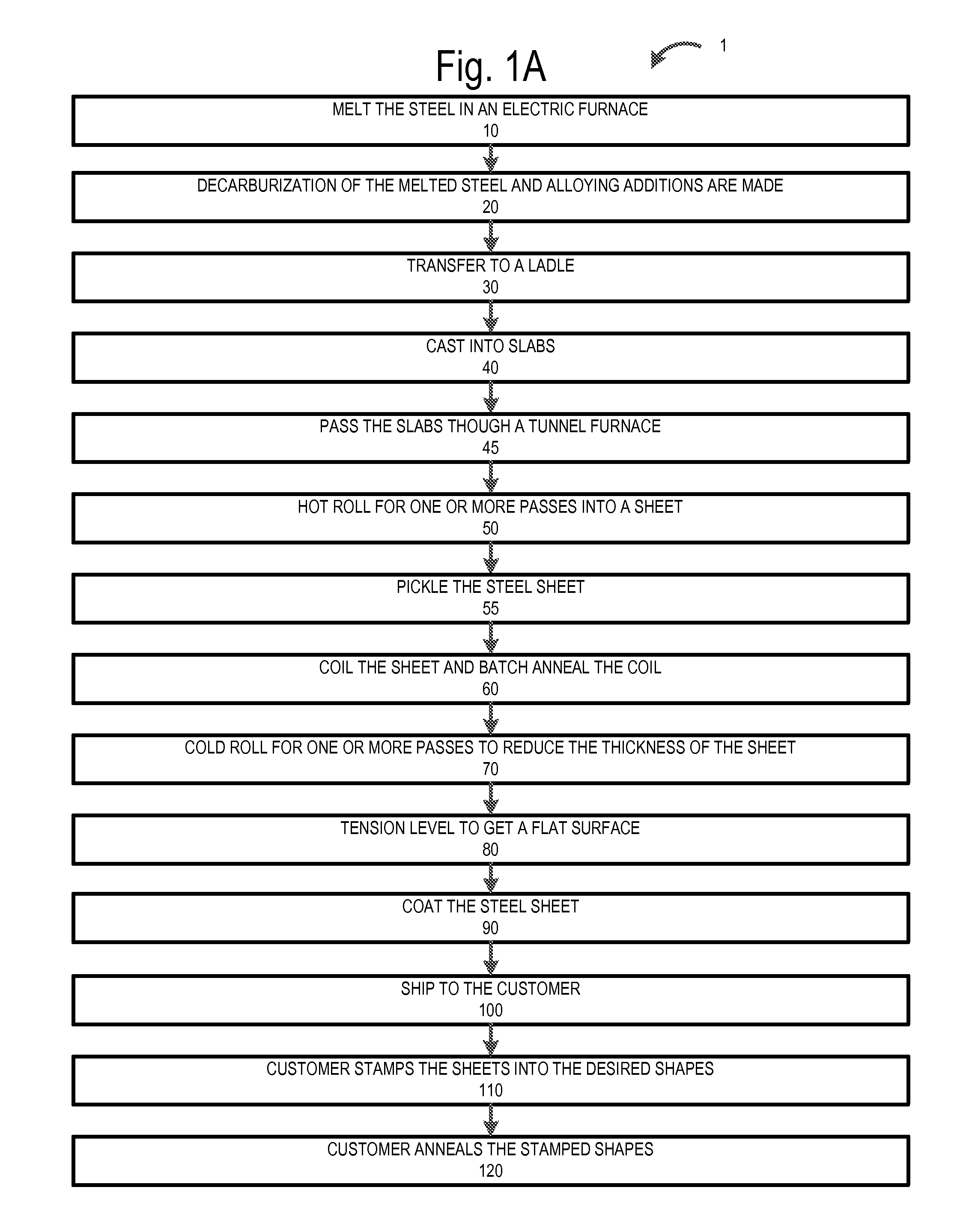

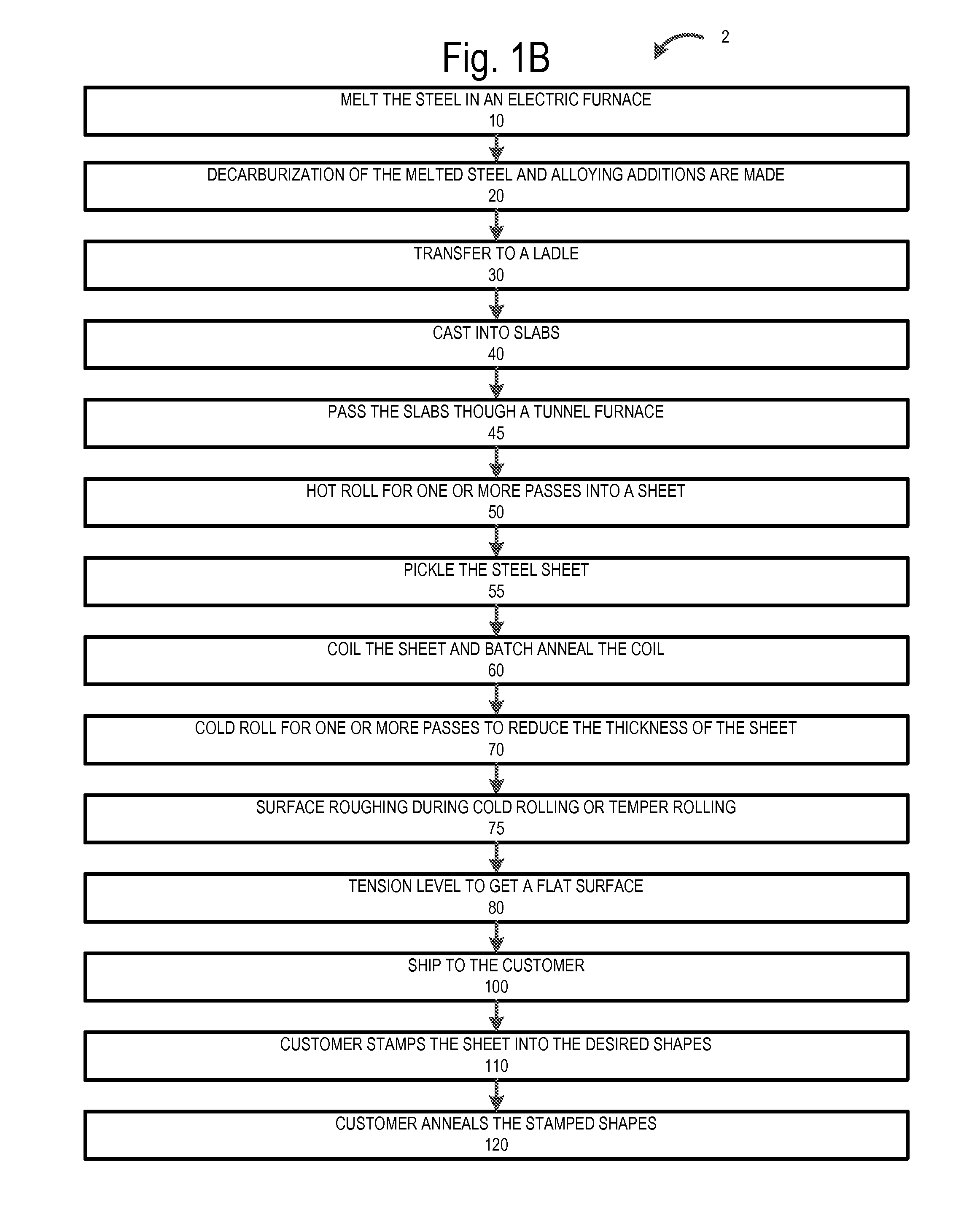

Electrical steel processing without a post cold-rolling intermediate anneal

InactiveUS20150318093A1Promotes an increase in inductionImprove permeabilityInorganic material magnetismFurnace typesElectrical steelStrip steel

Embodiments of the present invention comprise; annealing steel sheets (e.g., hot rolled steel sheets or thin cast strip steel); cold rolling the sheets in one or more cold rolling steps (e.g., with annealing steps between multiple cold rolling steps); and performing one or more of tension leveling, a rough rolling, or a coating process on the sheets after cold rolling, without an intermediate annealing step between the final cold rolling step and the tension leveling, the rough rolling, or the coating process, or the customer stamping or final customer annealing. In order to achieve the desired properties for the steel sheet, stamping and final annealing is performed by the customer. The new process provides an electrical steel with the similar, same, or better magnetic properties than an electrical steel manufactured using the traditional processing that utilizes an intermediate annealing step after cold rolling and before the stamping and final annealing.

Owner:NUCOR CORP

Manufacturing method of cold rolling electric steel special for compressor

InactiveCN1948517AHigh magnetic inductionIncrease stretch straighteningRoll mill control devicesHeat treatment process controlTemperature controlElectrical steel

The invention discloses a method to produce electrical steel by steel cold-rolling which is specially used for compressors. The method integrates the craft flows of hot rolling with traditional continuous metal cast process and hot rolling with continuous metal cast process of thin stock. It is characterized in that: The chemical constitution (percentage of weight) as follows is adopted: C<=0.03%,Si<=4.0%,Mn:0.1-1.0%,P<=0.16%, S<=0.01%,Al:0.1-0.8%, the rest is Fe and a little impurity. The craft feature is to control the batching temperature of hot rolling at 680-730deg.C. Cold rolling adopts endless rolling by laser welding, and its speed is 600-1000M / min. Crafts including cover annealing with full H2, flash heat and slow cool are introduced. Soaking time is 8 to 15 hours and the temperature is controlled at 670+-30deg.C. The annealing temperature is lower than recrystallization temperature. Crafts of leveling, tension and straightening under high pressure are adopted. The non-oriented electrical steel in this invention has high magnetic strength and low iron loss, which can produce various electrical steel with requirements of other breeds.

Owner:ANGANG STEEL CO LTD

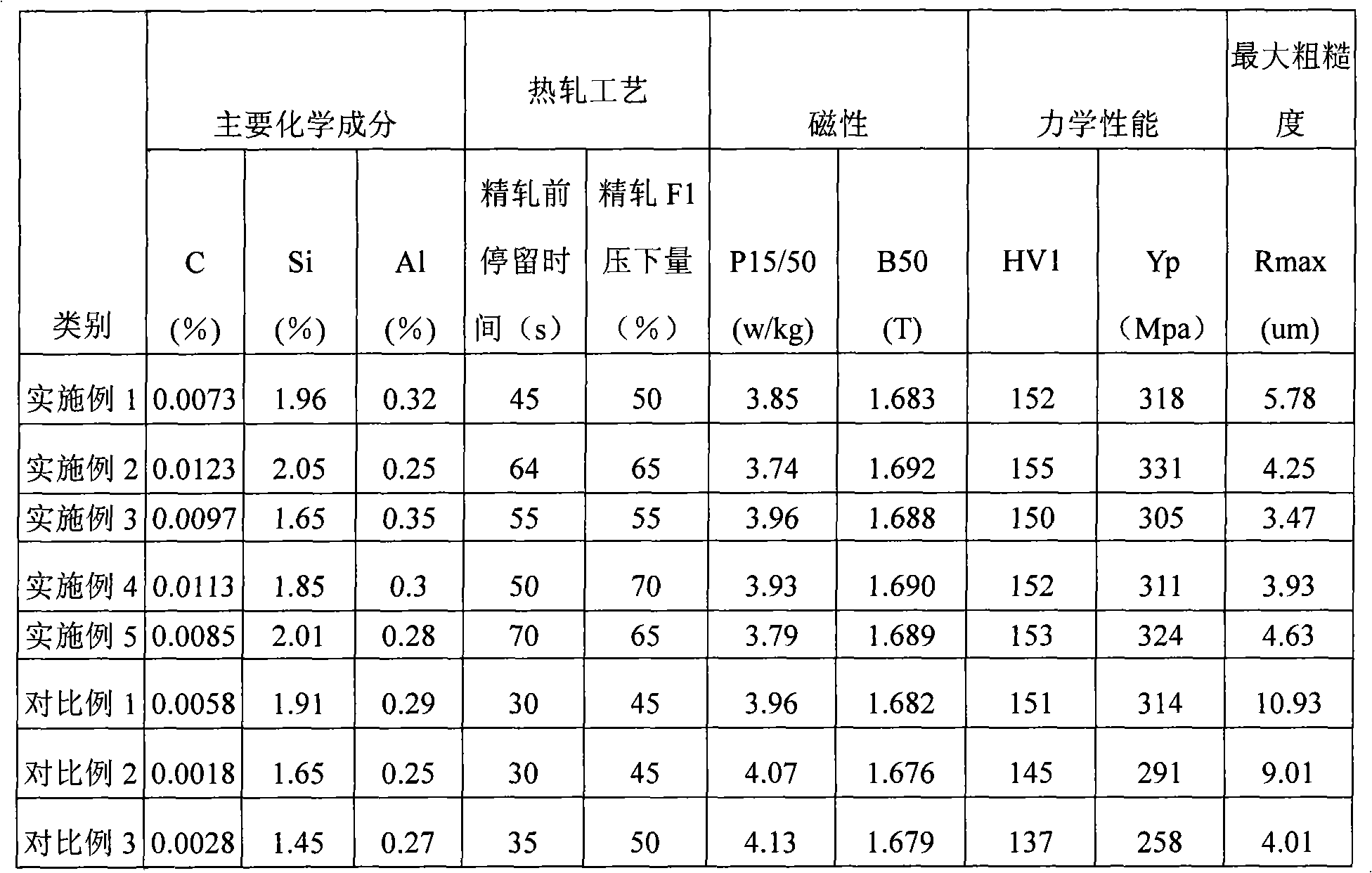

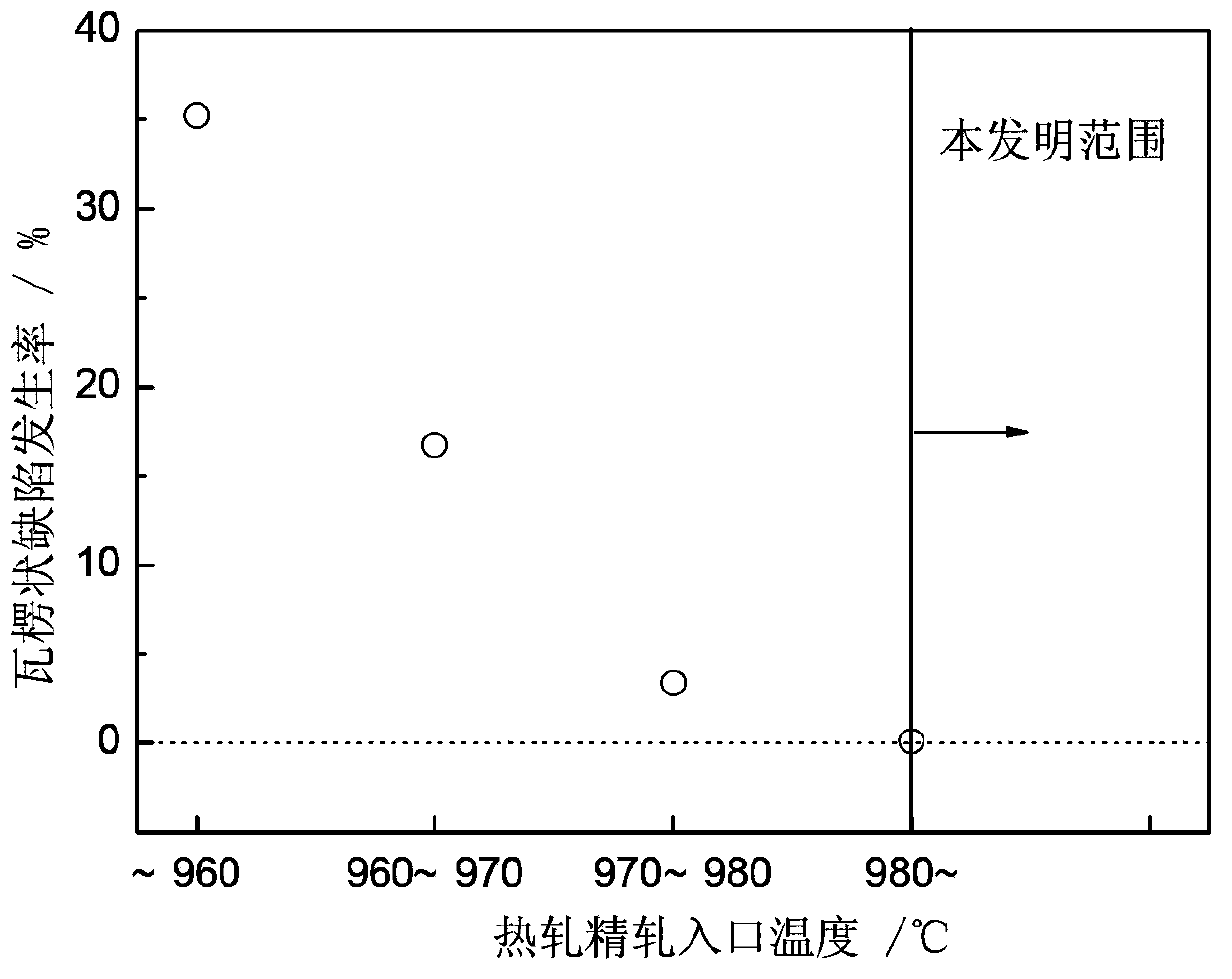

Middle code non-oriented electrical steel with fine surface and manufacturing method thereof

ActiveCN101275198AImprove surface conditionImprove magnetic propertiesRoll mill control devicesHeat treatment process controlElectrical steelChemical composition

The invention discloses a middle grade non-orientation electric steel with good surface state and a manufacturing method thereof, chemical ingredients of the steel comprises: C 0.007-0.013%, Si 1.6-2.1%, Mn<=0.5%, S<=0.005%, P 0.02-0.1%, Al 0.2-0.4%, N<= 0.005%, the rests are Fe and unavoidable impurities. The manufacturing method comprises: continuously casting and heating slab in a hot-rolling heating furnace at the temperature lower than 1200 DEG C, roughly rolling the slab to the thickness of 30 to 50 mm, the time between the rough rolling and the refined rolling is controlled within the range from 40 to 70 seconds, controlling the refined rolling F1 percent reduction as 50 to 70%, and then performing pickling and cool-rolling, annealing, coating the insulating coating. The steel manufactured according to the invention has good surface state and does not form ridge flaws, the magnetic and mechanical performances are outstanding, and the investment to the apparatus as well as the manufacturing cost are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

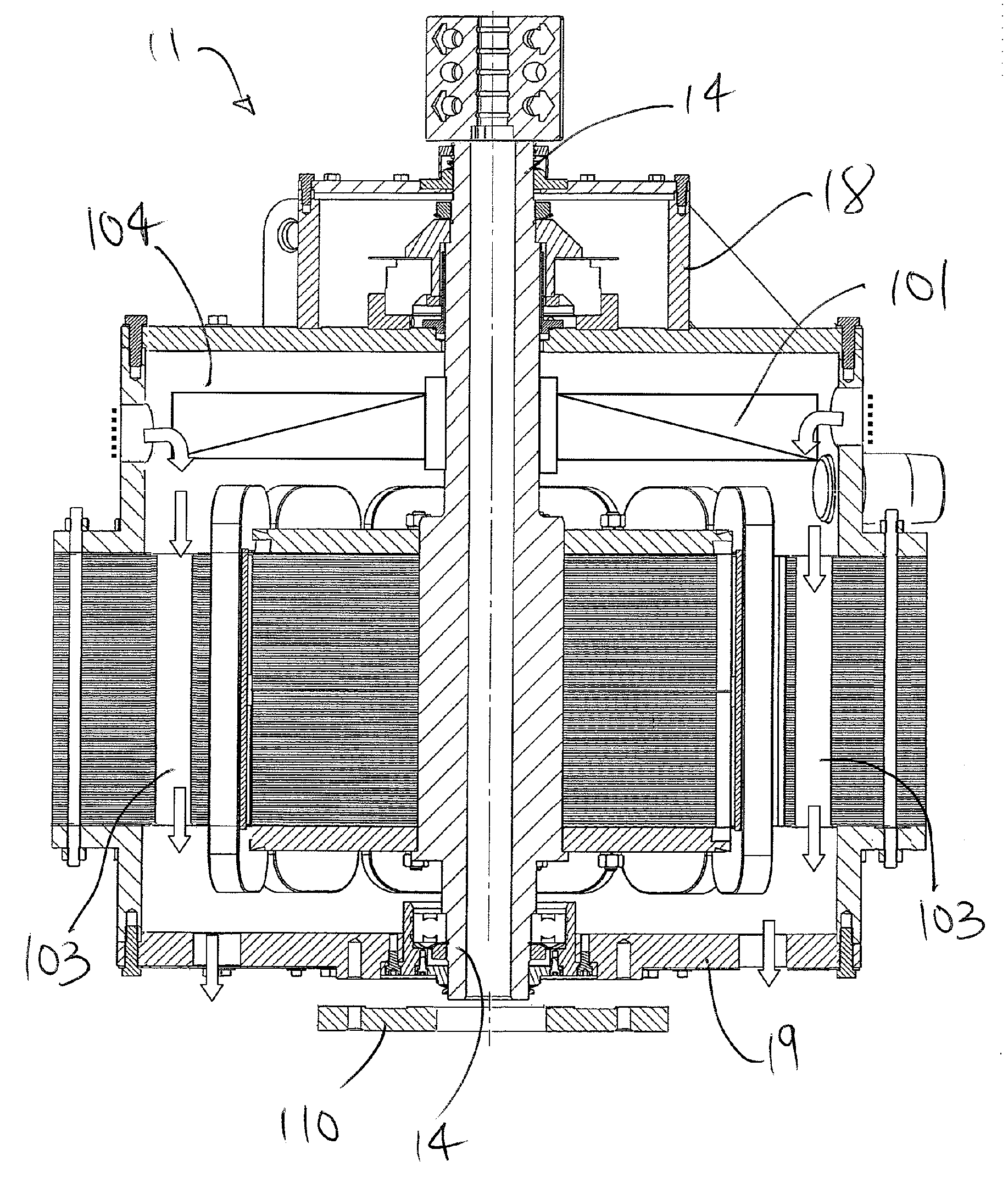

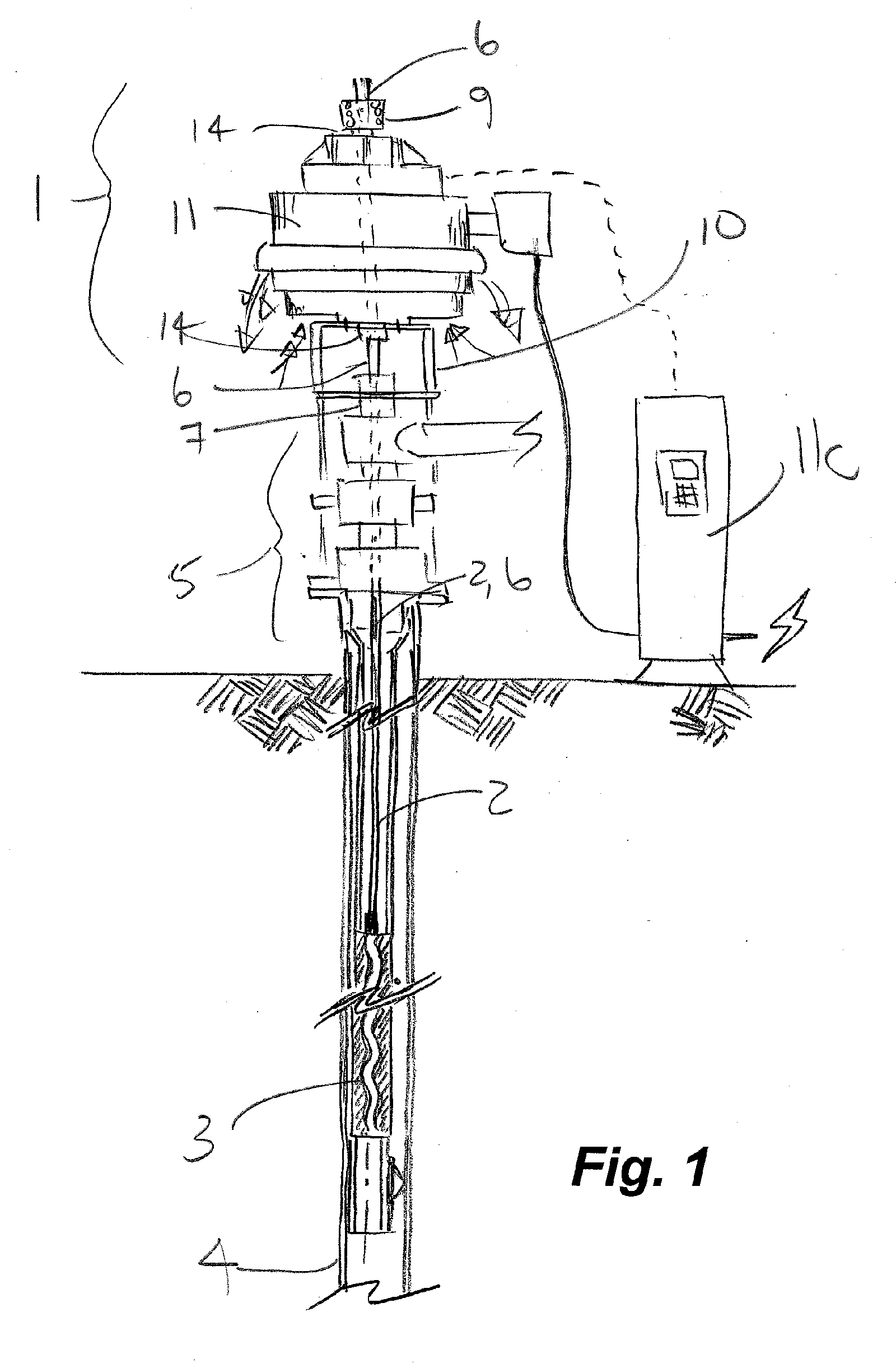

Frameless switched reluctance motor and application as a top drive for a rotary pump

InactiveUS20050269889A1Guaranteed uptimeEfficiently dissipatedSynchronous generatorsSynchronous motorsRotary pumpElectrical steel

A frameless switched reluctance motor (SRM) has a stator sandwiched between two housings. Axial load on the rotor shaft is directed through a first bearing, through the first housing to the stator and through the second housing to a motor support. Heat is dissipated using low-loss electrical steel, one or more air movers and air passages through the motor. Preferably a stator profile enables the air passages to be formed through the stator's lamination stack. Optionally air is routed through passages between the coils and through air passages along the air gap and radially through passages between an upper and a lower stator. A first self aligning bearing adapts to misalignment between the first housing and the shaft and a second bearing is provided with transverse movement. Preferably, the frameless motor is adapted for support to a wellhead for driving a downhole rotary pump and a rotary rod string.

Owner:MSI MACHINEERING SOLUTIONS

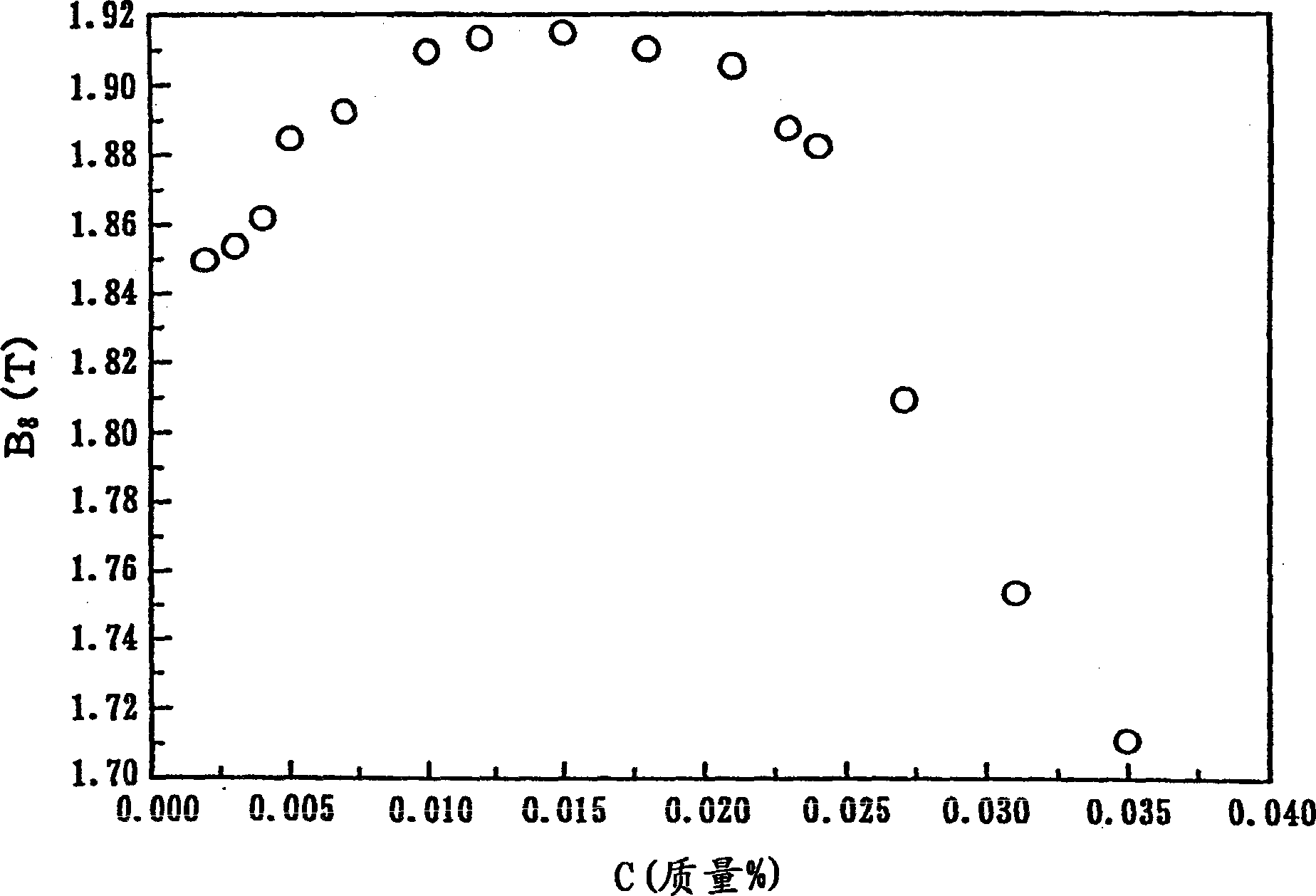

Serial high-magnetic induction non-orieted electrical steel and its production process

The present invention relates to an electrical steel and its production, especially, the components and production process of a high-magnetic induction, low-iron loss non-oriented electrical steel. By means of regulating alloy element content, reducing gas inclusion and nitride forming element content, adding segregation element, low temperature hot rollng, once cold rolling, and annealing at thetemperature determined based on T(ann)=786.83K+61.04Si(%), the electrical steel is produced. The product of 0.50 mm thickness has a P1.5=2.70-13.00 W / Kg, B(5000)=1.76-1.82 T, and excellent cooperation between iron loss and magnetic induction. The electrical steel is suitable for use in iron core in various motors.

Owner:武钢集团有限公司

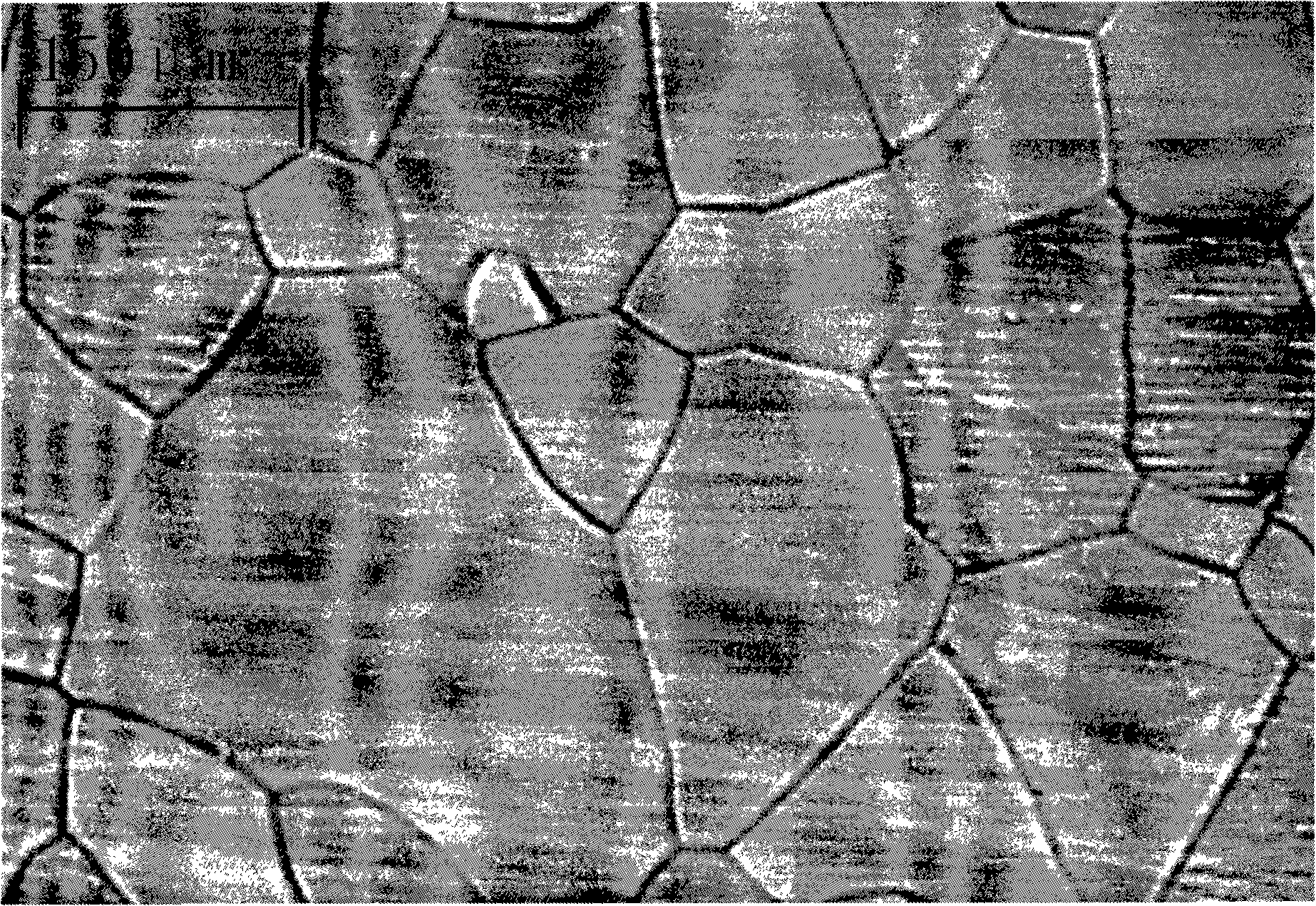

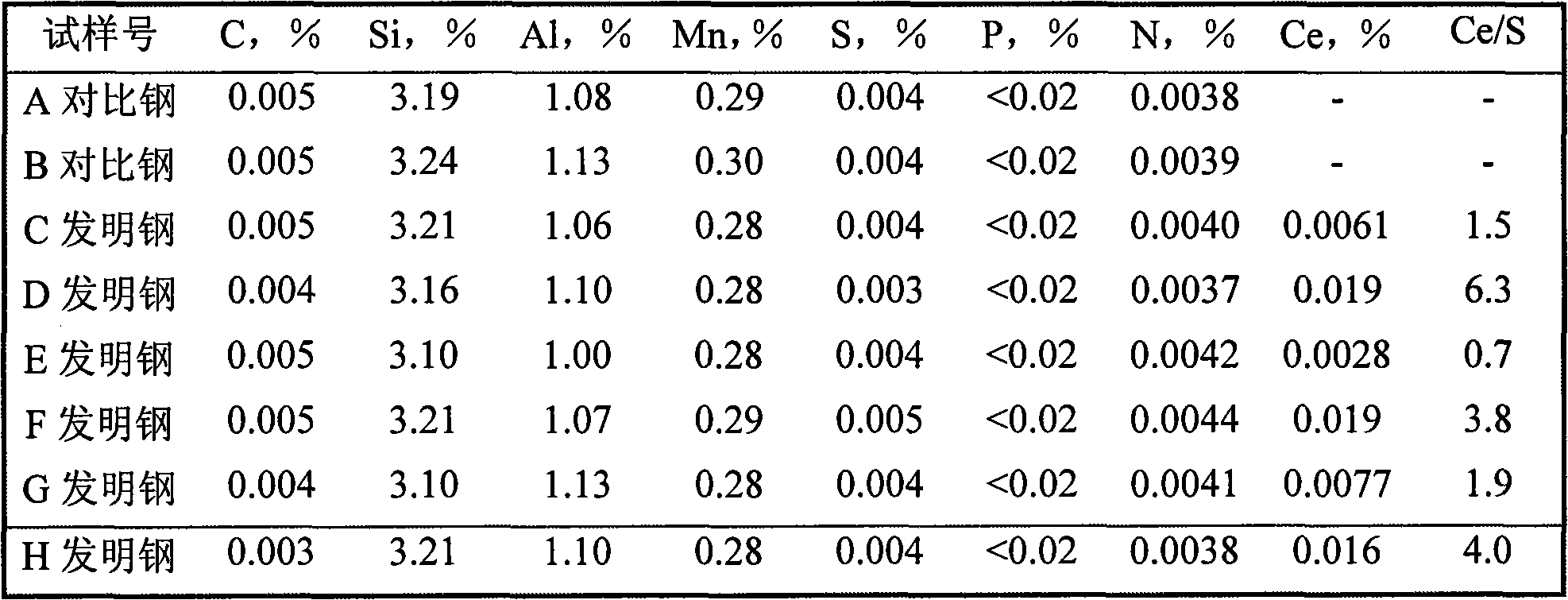

Method for preparing high grade non-oriented electrical steel adding rare earth cerium

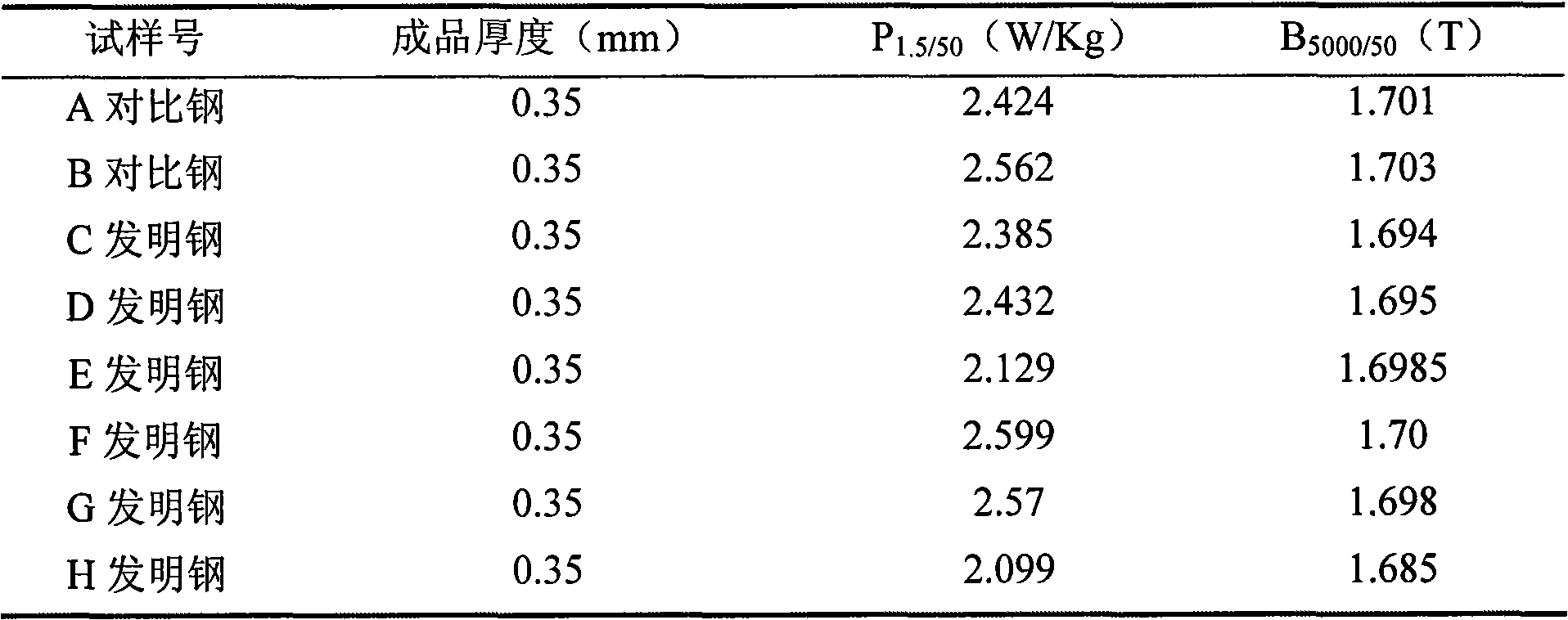

A preparation method of high grade non-oriented electrical steel added with rear earth cerium belongs to the technical field of electrical steel. High Si non-oriented electrical steel casting blank added with rare earth Ce is taken as the hot rolling material, and final high grade non-oriented electrical steel product with excellent magnetic property is obtained through hot rolling, normalizing, acid cleaning, cold rolling, anneal and coating; the design of hot rolling material components is required to meet that: C content is less than or equal to 0.005 percent, Si content is from 2.4 percent to 3.3 percent, Mn content is from 0.1 percent to 0.6 percent, Al content is from 0.8 percent to 1.5 percent, P content is less than or equal to 0.02 percent, S content is from 0.003 to 0.006 percent, N contend is less than or equal to 0.008 percent, O content is less than or equal to 0.015 percent, rare earth Ce is from 0.0015 percent to 0.0300 percent, the ratio of Ce and S is controlled from 0.7 to 7.0, the rest components are Fe and unavoidable impurities, and the component contents are based on weight percentage; the final magnetic property of the product is that when the thickness is 0.35mm, P1.2 / 50 is equal to 2.1W / kg to 2.6 W / kg, and B5000 / 50 is equal to 1.68T to 1.70T; when the thickness is 0.50mm, P1.5 / 50 is equal to 2.21 W / kg to 2.54 W / kg, and B5000 / 50 is equal to 1.70T to 1.72T. The method has the advantage of low production cost.

Owner:SHOUGANG CORPORATION

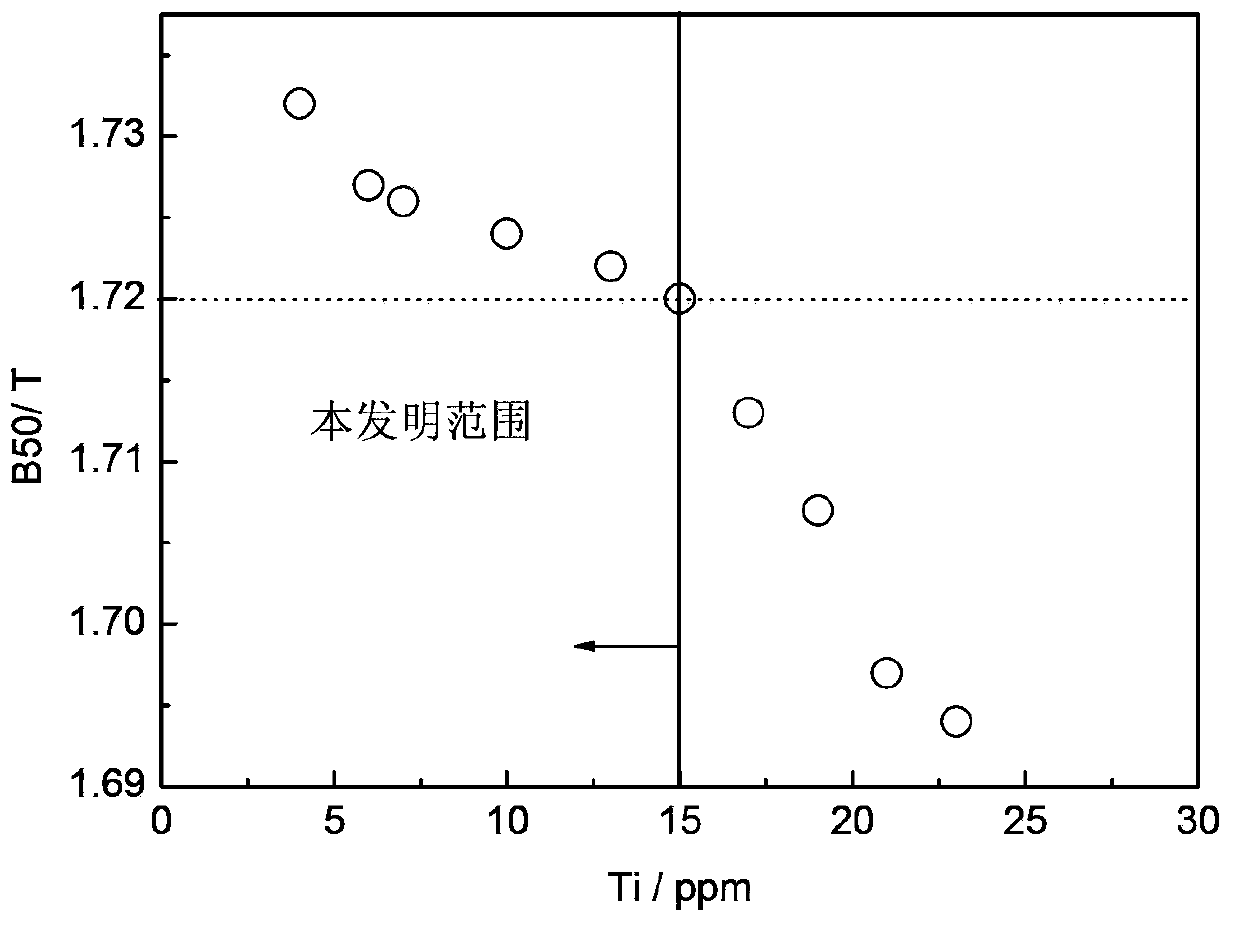

Non-oriented electrical steel plate with high magnetic induction and low iron loss, and manufacturing method thereof

The invention discloses a non-oriented electrical steel plate with high magnetic induction and low iron loss, and a manufacturing method thereof, wherein the weight percentage of the chemical components of the steel plate is as follows: less than or equal to 0.004 % of C, 0.1-1.6% of Si, 0.02-1.0% of Mn, less than or equal to 0.003% of S, 0.1-0.6% of Al, less than or equal to 0.003% of N and less than or equal to 0.0015% of Ti, wherein Si+Al is between 0.2-2.0%, and Mn, Si and Al satisfies the following formula: Mn=K2*Si+K3*Al+a, k2=0.08-0.11, k3=0.17-0.38; a is a constant and the balance is Fe and unavoidable impurities. The non-oriented electrical steel plate with high magnetic induction and low iron loss has 1.70-1.78T of magnetic induction B50 and 3.59-5.5W / kg of iron loss P15 / 50, has good surface state and is relatively low in manufacture cost without intermediate normalizing or batch annealing, has high magnetic induction, low iron loss and no corrugated defect, and has a magnetic induction B50 0.02T higher and an iron loss P15 / 50 0.2W / kg lower than those of a normal non-oriented electrical steel plate with same license number.

Owner:BAOSHAN IRON & STEEL CO LTD

High permeability grain oriented electrical steel

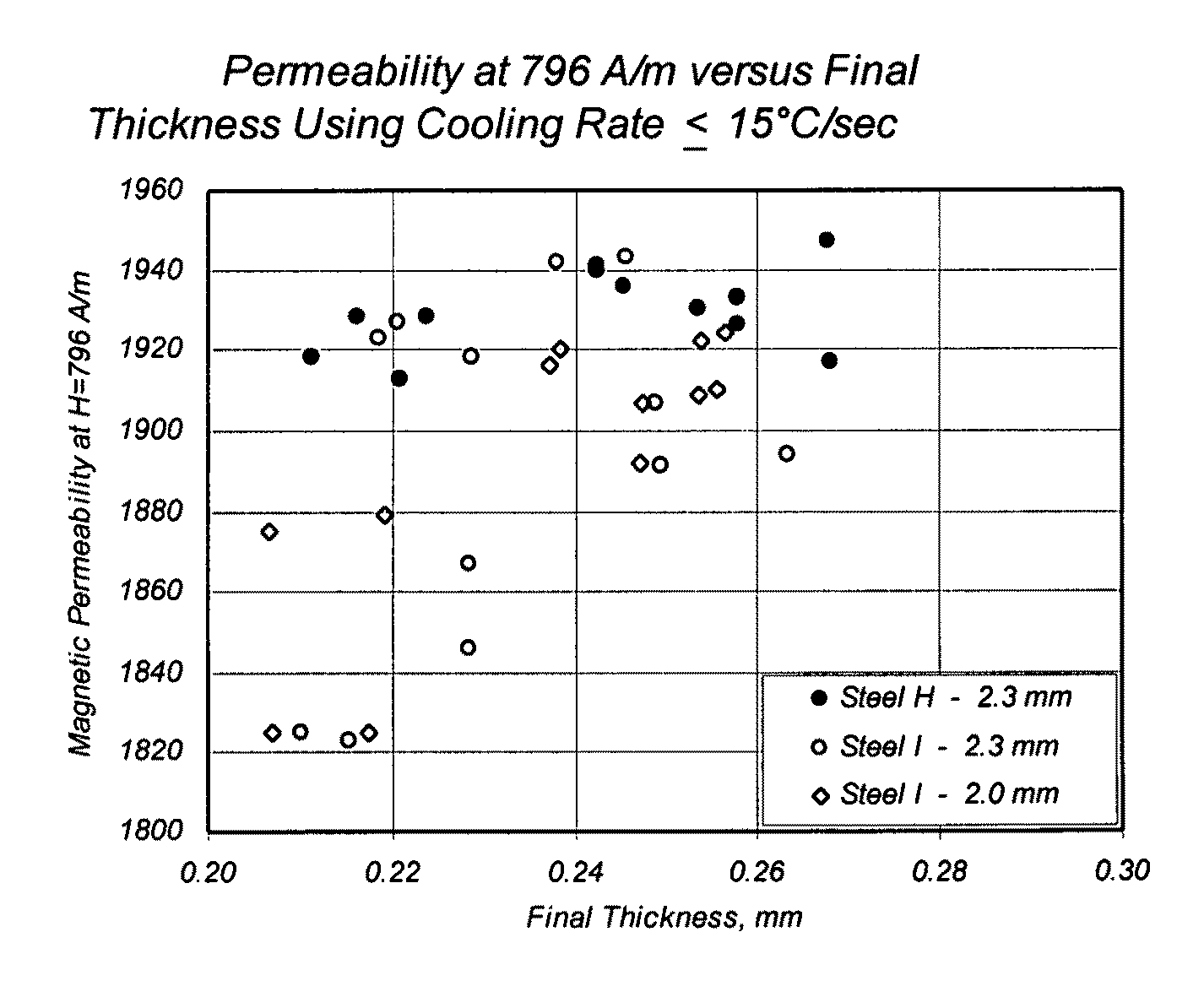

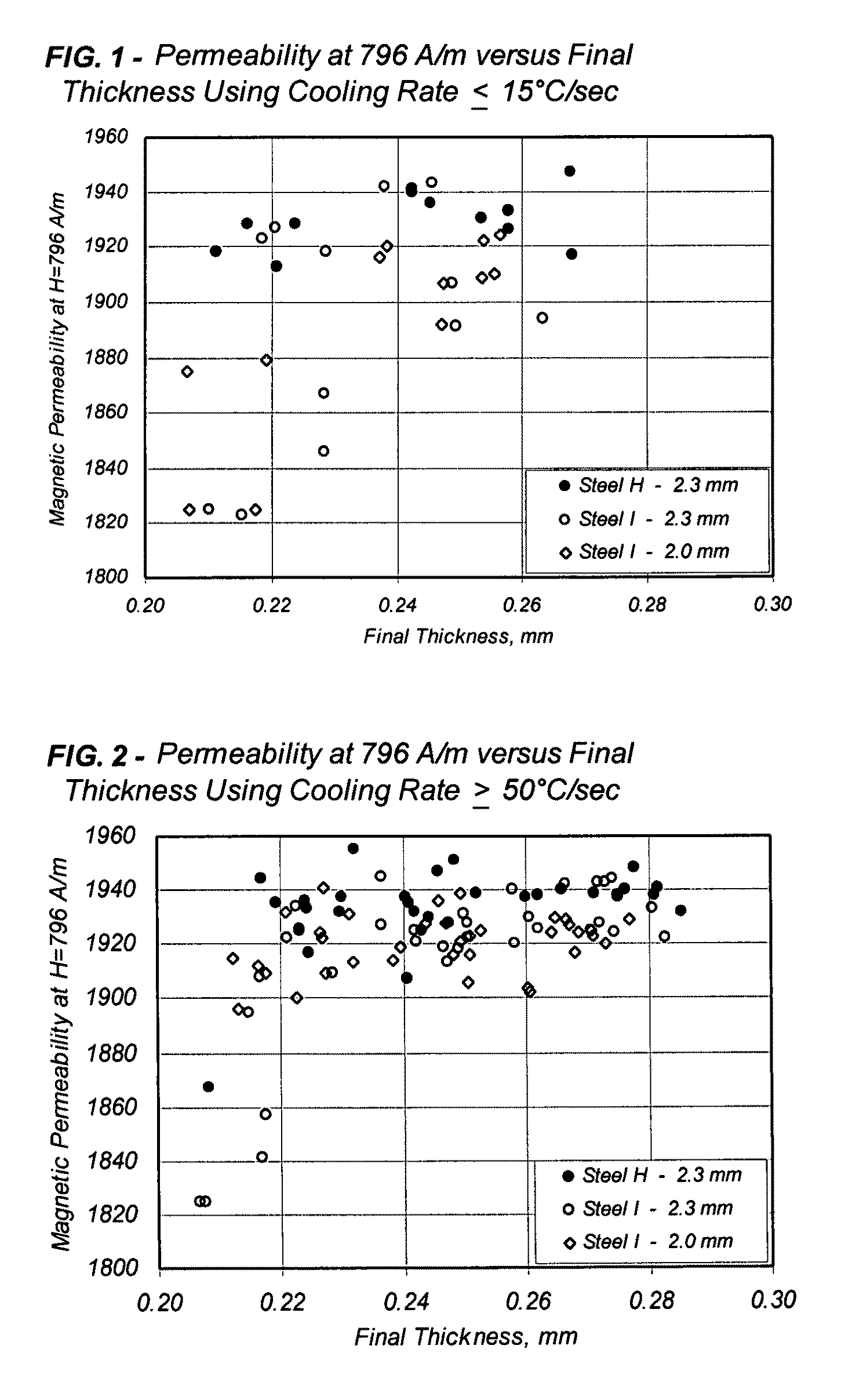

InactiveUS7887645B1Improve permeabilityImprove magnetic propertiesInorganic material magnetismManganeseLayer thickness

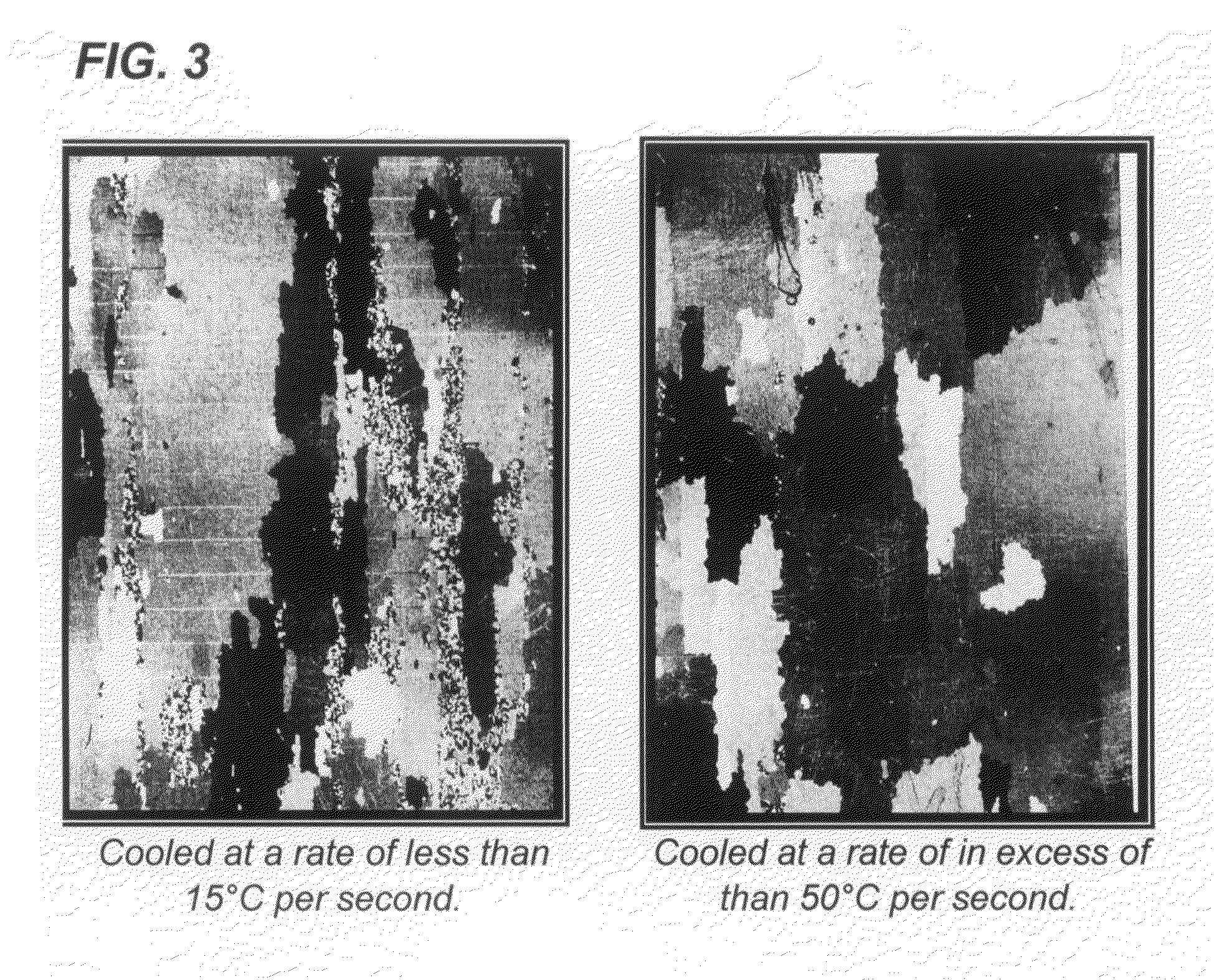

The present invention provides a method of producing a high permeability grain oriented electrical steel having excellent mechanical and magnetic properties. A hot band having a thickness of about 1.5 to about 4.0 mm has a chemistry comprising about 2.5 to about 4.5% silicon, about 0.1 to about 1.2% chromium, about 0.02 to about 0.08% carbon, about 0.01 to about 0.05% aluminum, up to about 0.1% sulfur, up to about 0.14% selenium, about 0.03 to about 0.15% manganese, up to about 0.2% tin, up to about 1% copper, and balance being essentially iron and residual elements, all percentages by weight. The band has a volume resistivity of at least about 45 μΩ-cm, an austenite volume fraction (γ1150° C.) of at least 20% and the strip has an isomorphic layer thickness of at least about 2% of the total thickness on at least one surface of the hot processed band. The band is rapidly cooled after the anneal prior to cold rolling at a rate of at least 30° C. / second from 875-950° C. to a temperature below 400° C. The band is cold reduced in one or more stages with a final reduction of at least 80%, annealed, decarburized and coated with an annealing separator on at least one side. A final annealing provides stable secondary grain growth and a permeability measured at 796 A / m of at least 1840.

Owner:AK STEEL PROPERTIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com