Patents

Literature

2407 results about "Surface oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface oxidation process is used to create a gate insulator film of the transistor or oxide films which required forming insulation between wiring layers.

Quantum wires formed on a substrate, manufacturing method thereof, and device having quantum wires on a substrate

InactiveUS6130143ASmall diameterSufficient quantum effectPolycrystalline material growthSemiconductor/solid-state device manufacturingSilanesSurface oxidation

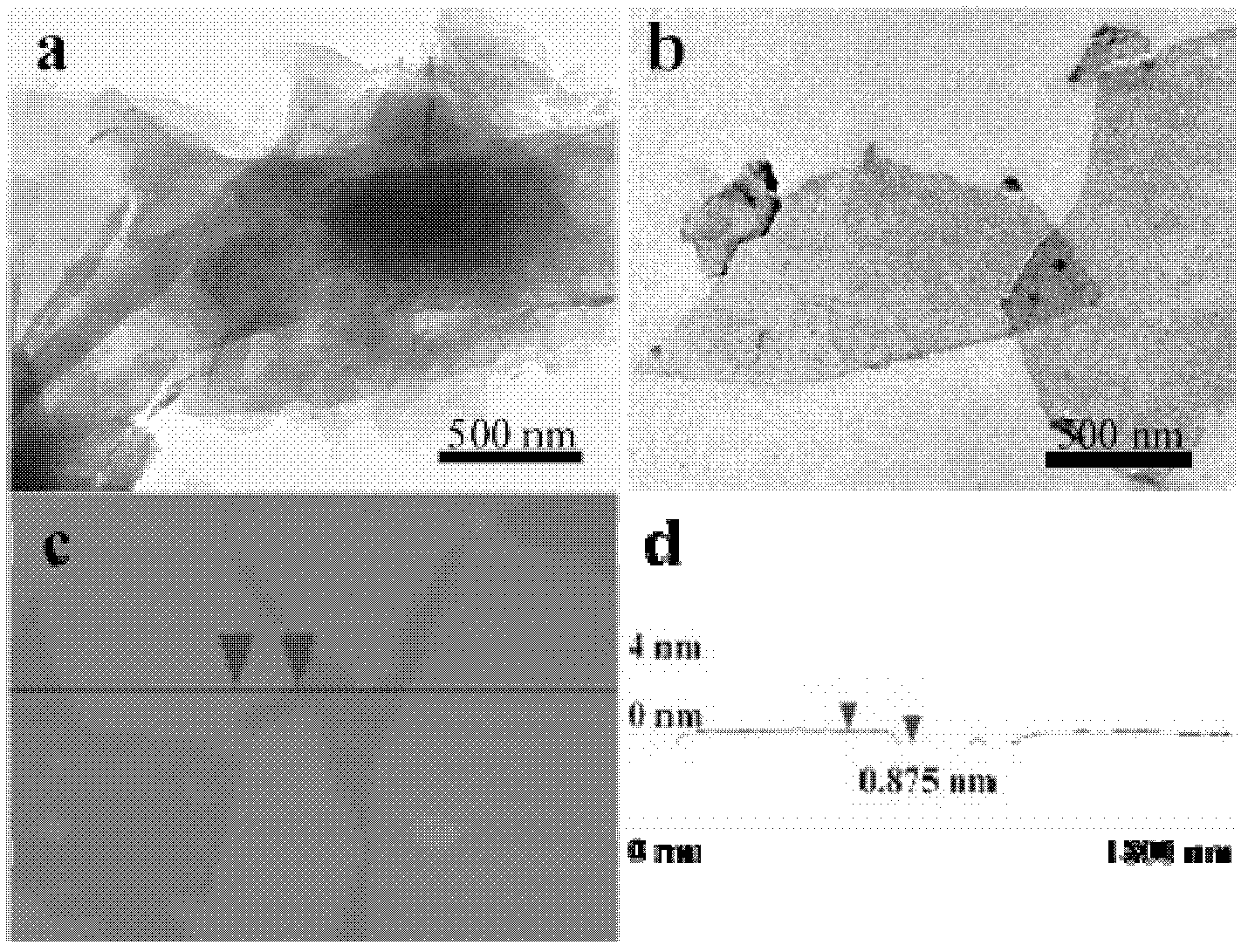

While a silicon substrate is heated, gold is evaporated thereon at a thickness of 0.6 nm, whereby melted alloy droplets are formed on the substrate surface. Then, the silicon substrate is heated to 450.degree.-650.degree. C. in a silane gas atmosphere of less than 0.5 Torr. As a result, a silane gas decomposition reaction occurs with the melted alloy droplets serving as catalysts, whereby silicon wires grow on the substrate surface. Subsequently, the metal alloy droplets at the tips of the silicon wires are removed and surface portions of the silicon wires are oxidized. Resulting surface oxide films are thereafter removed. As a result, silicon quantum wires that are thinner by the thickness of the surface oxide films are obtained.

Owner:SONY CORP

Post deposition treatments for CVD cobalt films

InactiveUS20120252207A1Reduce resistanceSemiconductor/solid-state device detailsSolid-state devicesSurface oxidationDeposition process

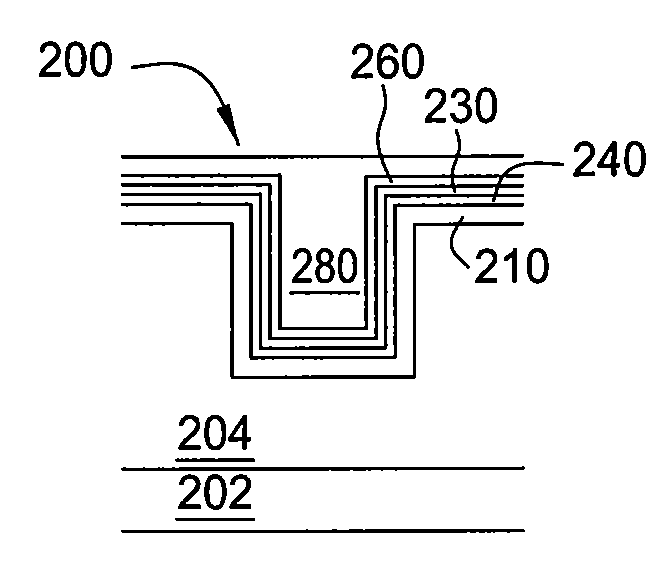

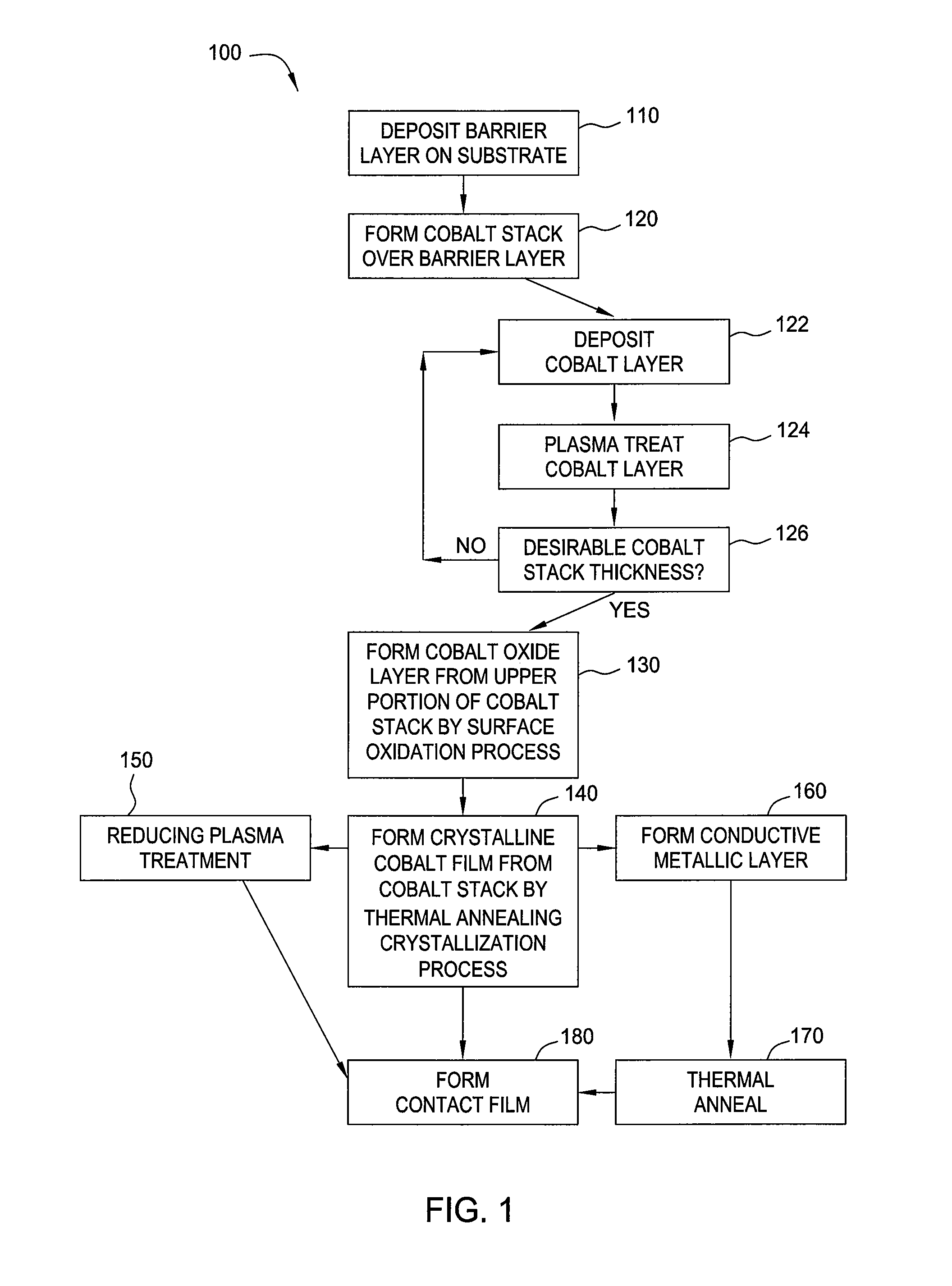

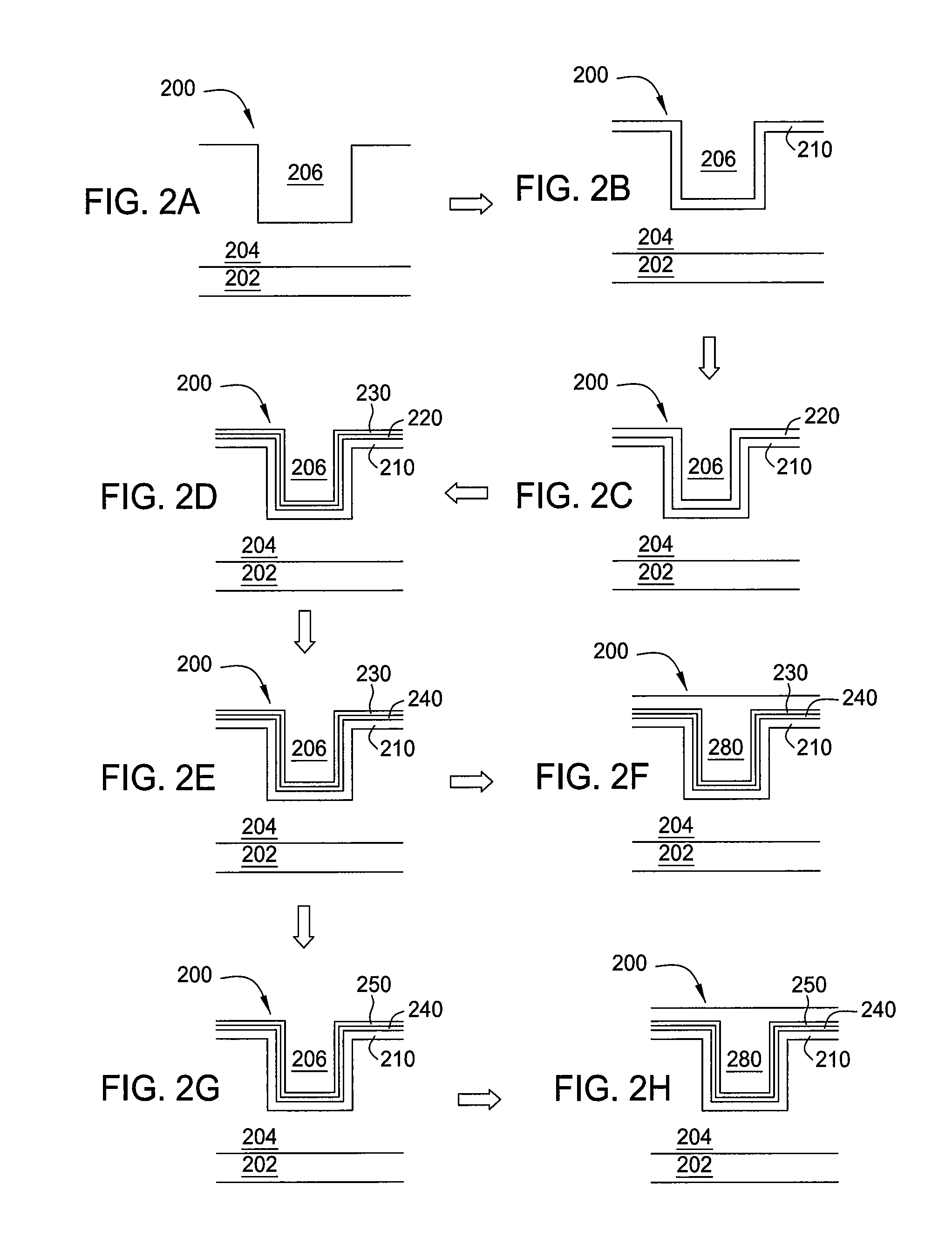

Embodiments of the invention provide methods for forming materials on a substrate used for metal gate and other applications. In one embodiment, a method includes forming a cobalt stack over a barrier layer disposed on a substrate by depositing a cobalt layer during a deposition process, exposing the cobalt layer to a plasma to form a plasma-treated cobalt layer during a plasma process, and repeating the cobalt deposition process and the plasma process to form the cobalt stack containing a plurality of plasma-treated cobalt layers. The method further includes exposing the cobalt stack to an oxygen source gas to form a cobalt oxide layer from an upper portion of the cobalt stack during a surface oxidation process and heating the remaining portion of the cobalt stack to a temperature within a range from about 300° C. to about 500° C. to form a crystalline cobalt film during a thermal annealing crystallization process.

Owner:APPLIED MATERIALS INC

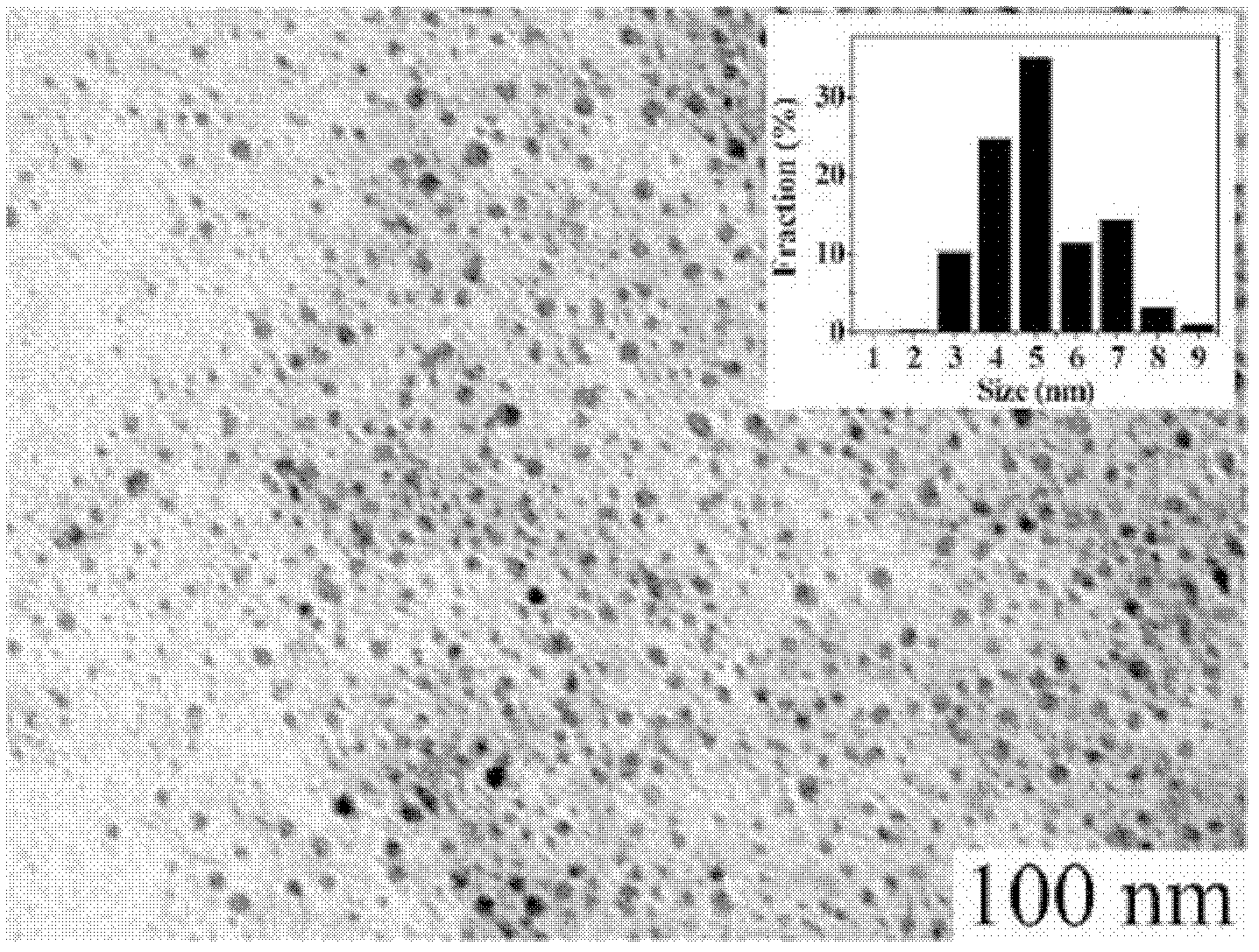

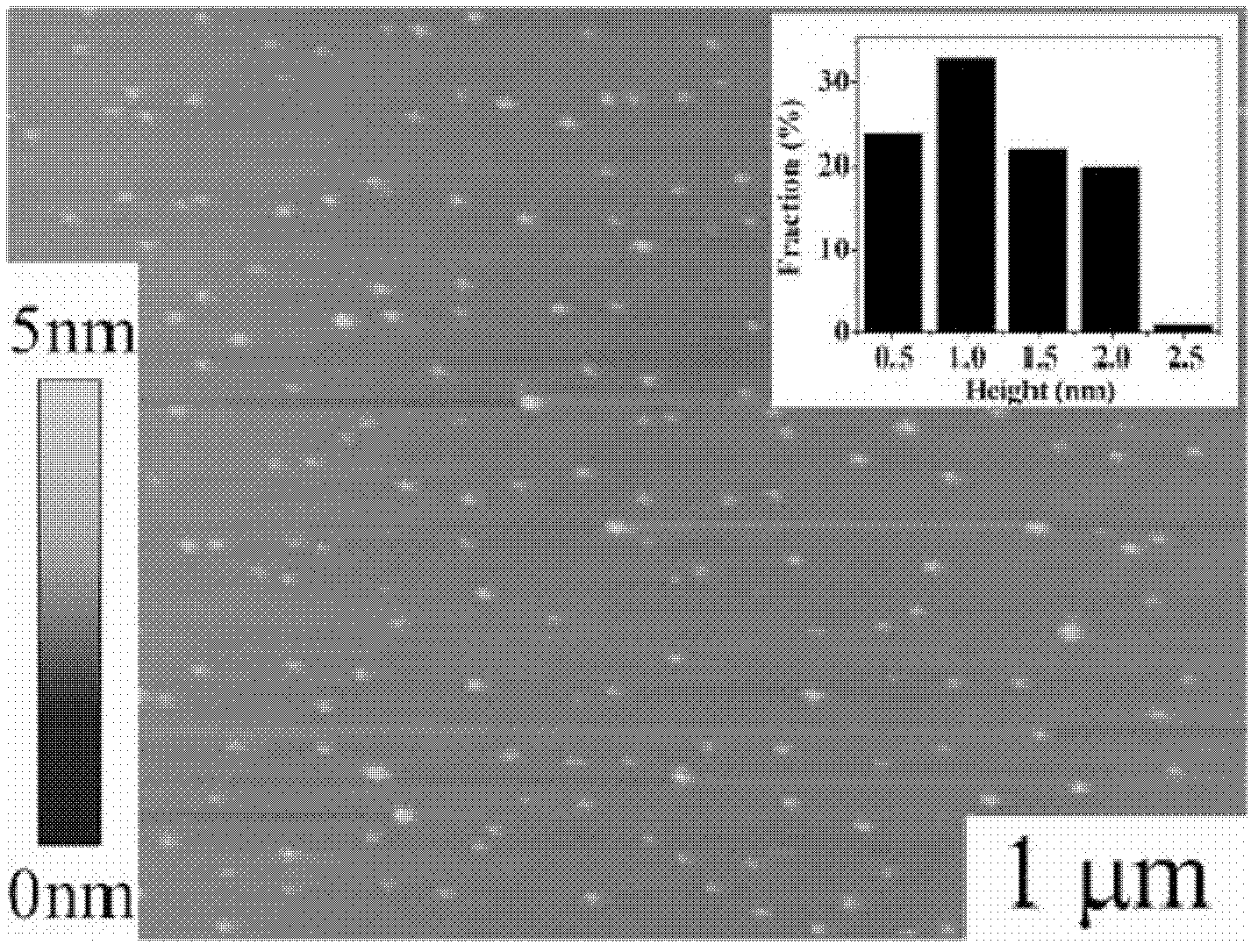

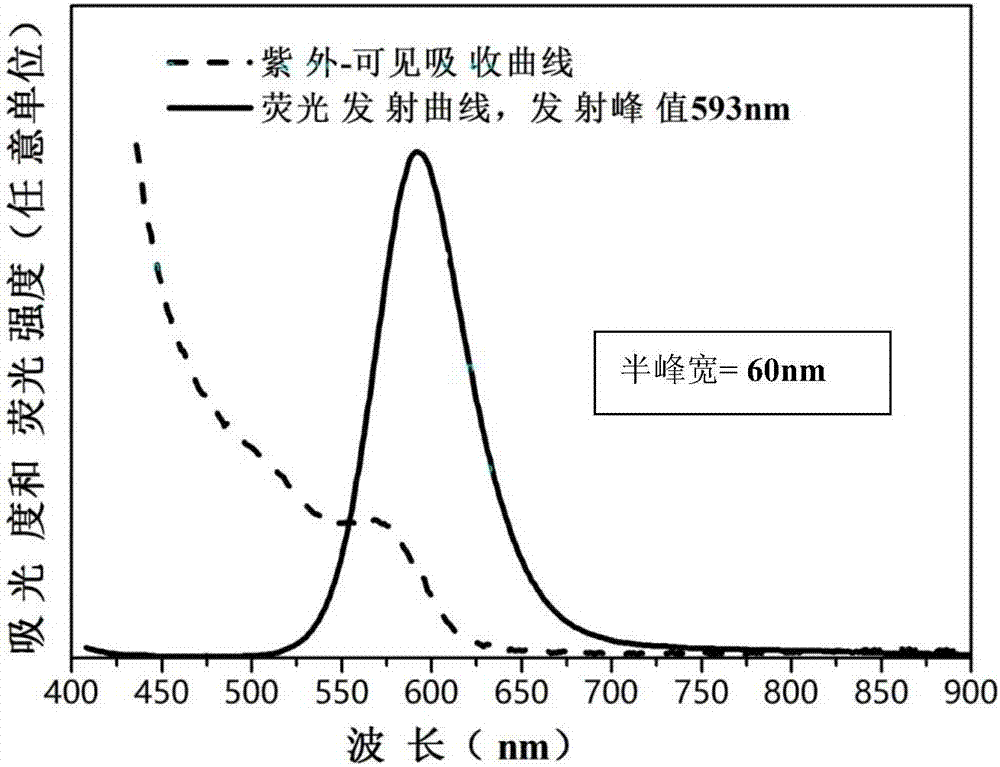

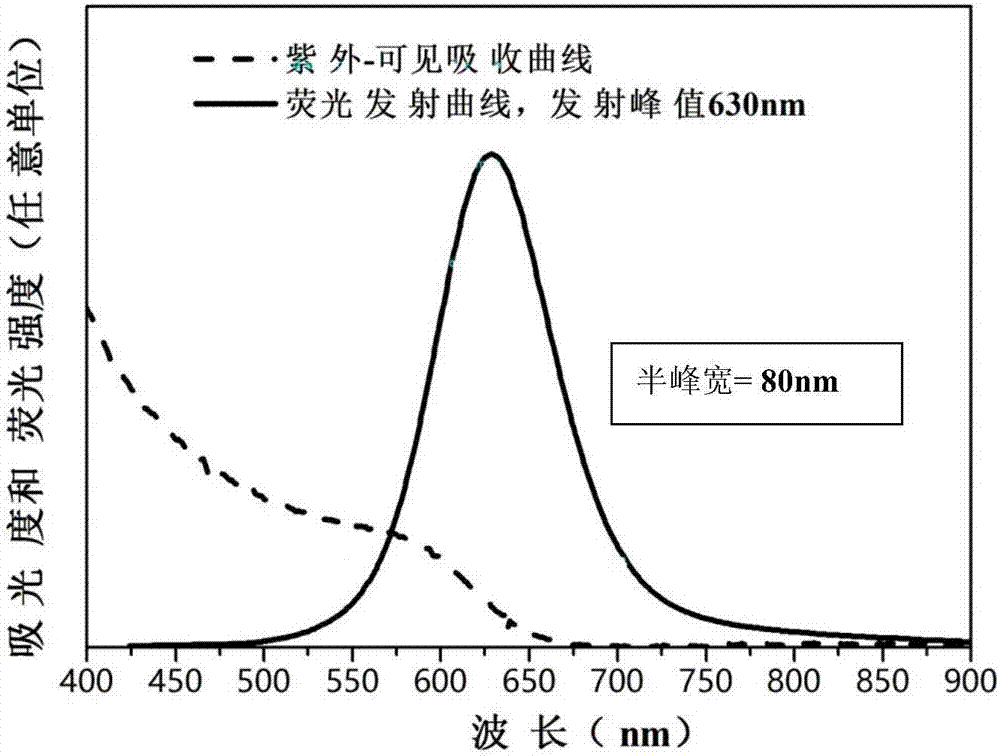

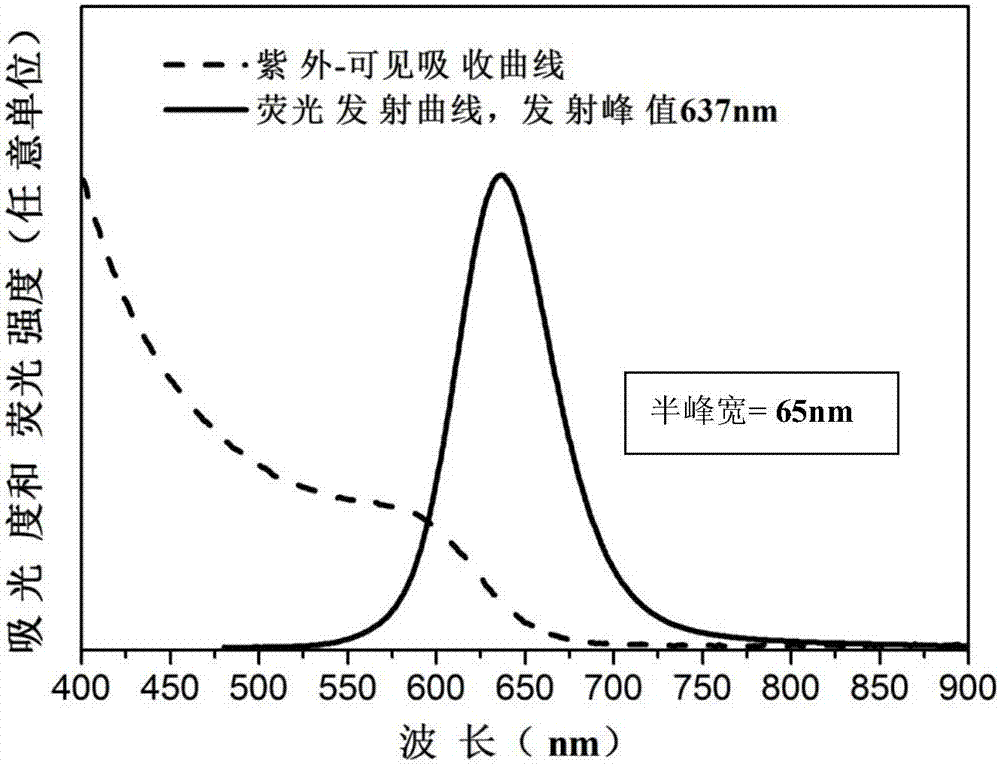

Method for preparing fluorescent graphene quantum dots by solvothermal method

InactiveCN102660270AHigh degree of oxidationLuminescent compositionsChromatographic separationSurface oxidation

The invention belongs to the technical field of the preparation of graphene quantum dots (GQDs), and particularly relates to a method for preparing fluorescent graphene quantum dots with controllable oxidation degree and fluorescence by a solvothermal method. According to the technical scheme, the method comprises the following steps of: 1, preparing graphene oxide; 2, preparing green fluorescent graphene quantum dots by a single-step method starting from the graphene oxide; and 3, preparing the fluorescent graphene quantum dots with the controllable oxidation degree by a column chromatographic separation method. According to the method, the sizes and surface oxidation degree of the graphene quantum dots can be controlled under the synthetic condition, so that the fluorescent properties and surface chemical characteristics of the graphene quantum dots are controlled. The prepared graphene quantum dots are high in chemical stability and biocompatibility, low in biotoxicity, and high in property of applicable upconversion fluorescence, matt and the like and bleaching performance. By the excellent properties, the graphene quantum dots have a wide application range in aspects of biological imaging, photovoltaic devices and sensors, and are novel promising fluorescent nano materials.

Owner:JILIN UNIV

A kind of preparation method of efficient catalyst for synthesizing vinyl acetate by acetylene method

InactiveCN102284304ASimple processLow costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSurface oxidationBULK ACTIVE INGREDIENT

The invention provides a preparation method of a high-efficiency catalyst for synthesizing vinyl acetate by an acetylene method. The oxidant is used to oxidize the surface of activated carbon used as a catalyst carrier to change the oxygen-containing functional groups on the surface of the activated carbon and improve its original pore structure, thereby effectively improving the loading capacity of the active component zinc acetate and significantly improving the catalyst efficiency. The invention has the advantages of cheap and easy-to-obtain raw materials, simple operation, high loading capacity of catalyst active components, good activity and long service life.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

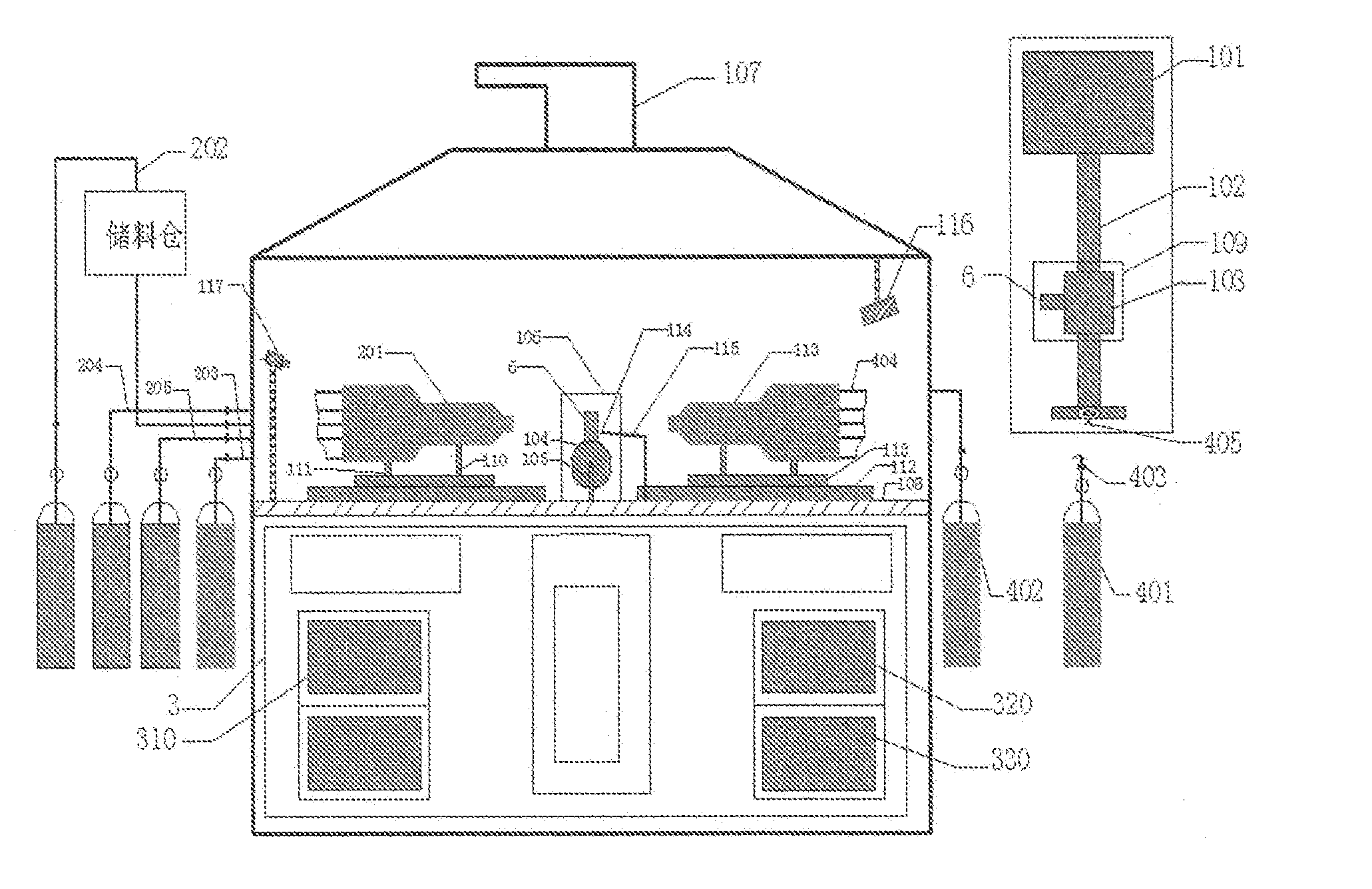

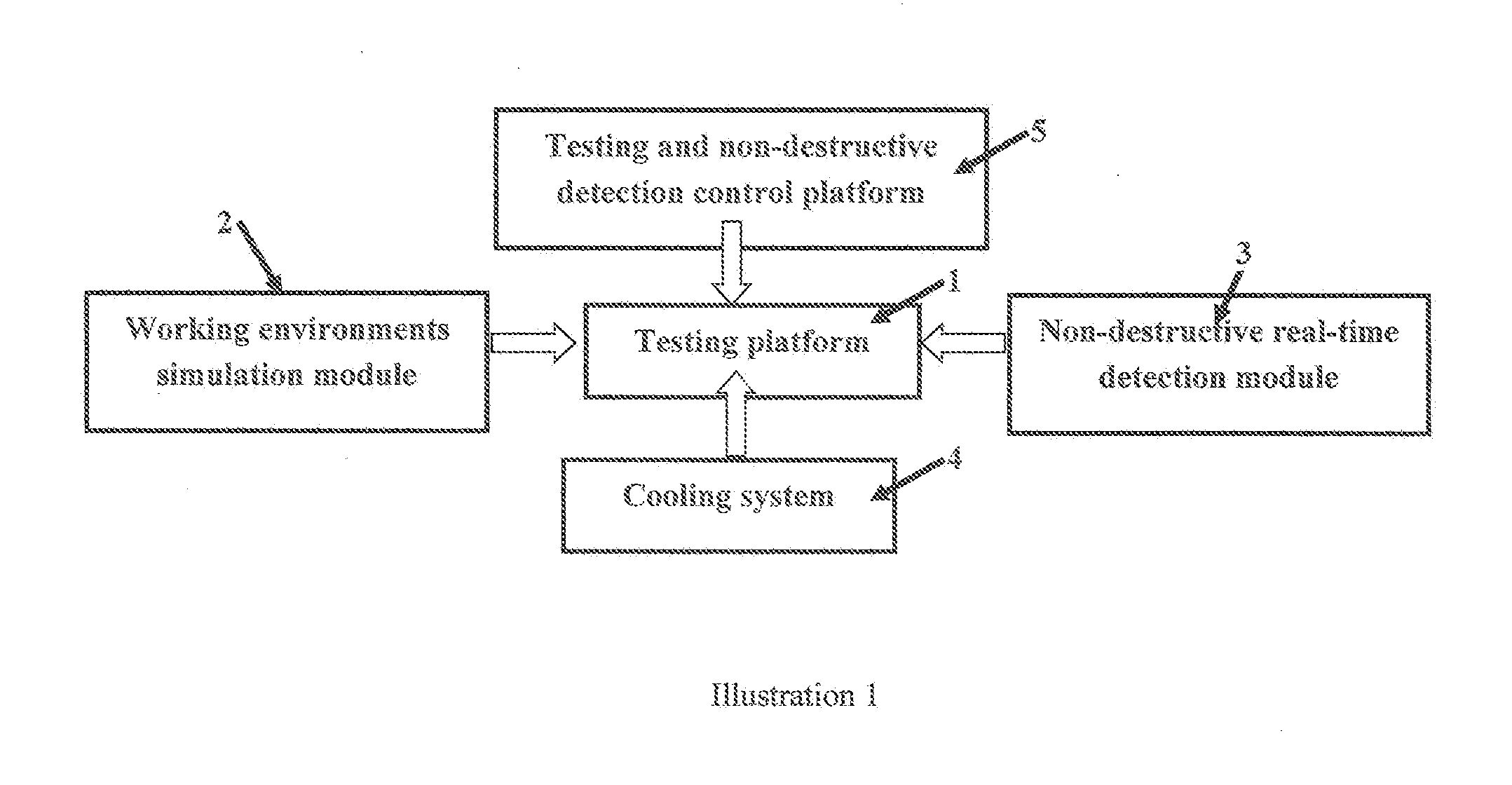

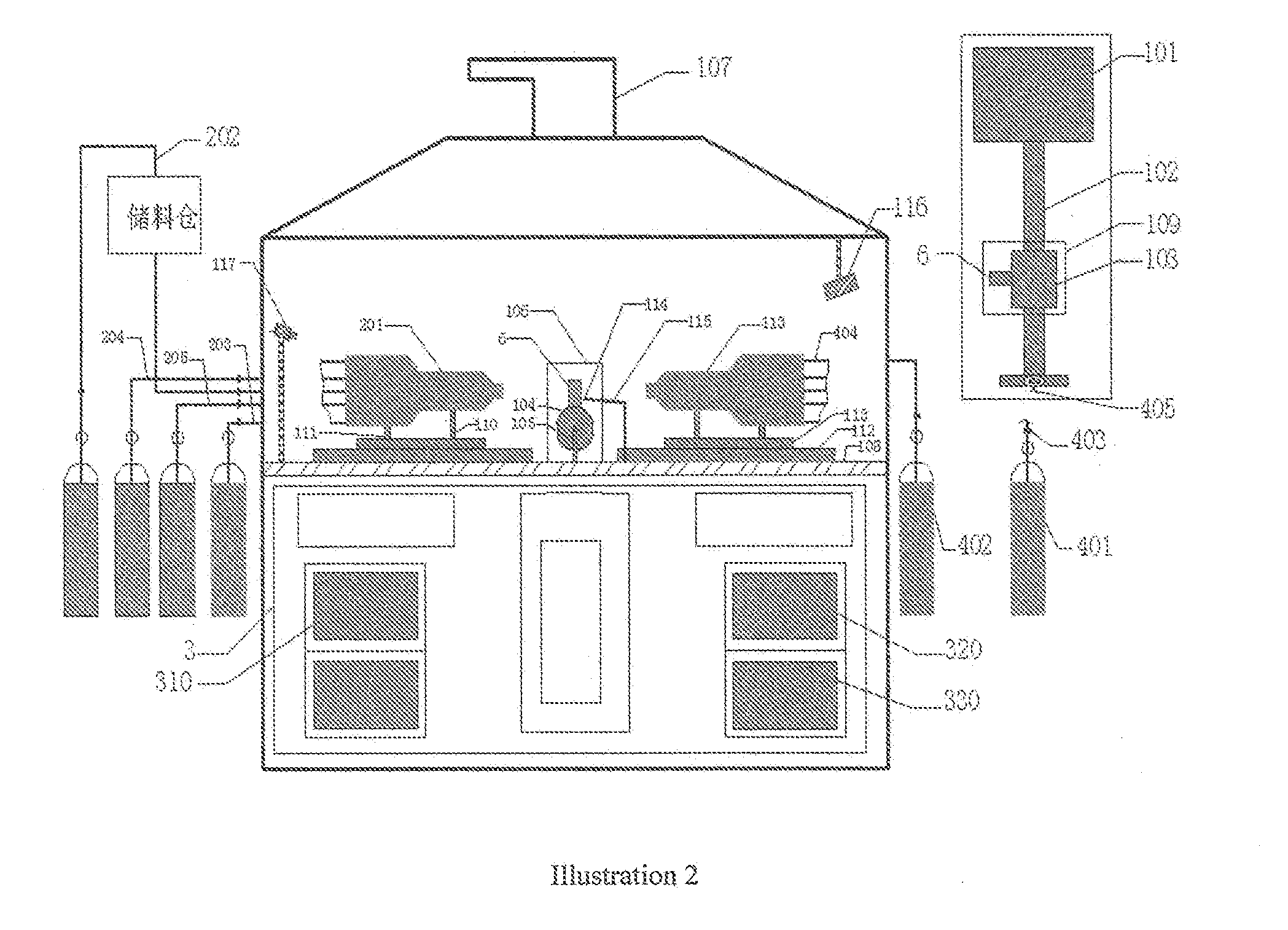

Type of testing equipment for detecting the failure process of thermal barrier coating in a simulted working environment

ActiveUS20150355074A1Better understandingReliable assessmentWeather/light/corrosion resistanceEngine testingSurface oxidationTurbine blade

A type of testing equipment for detecting the failure process of thermal barrier coating in a simulated working environment; it belongs to the field of simulated special working environment equipment. Testing equipment includes testing platform equipped with static or dynamic specimen holding apparatus, simulated module of working environment, real-time detection module, control panel. This invention is capable of simulating a high temperature, erosive, corrosive working environment for thermal barrier coated turbine blade of aero-engines; simulate high speed spinning working environment for thermal coated blade, simulate static working environment for guiding blade; perform real-time testing of temperature field, 3-D displacement field, crack initiation and expansion, surface oxidation, etc. This invention has achieved complete integration of high temperature, erosive, corrosive working environment for thermal barrier coating and complete integration static or dynamic working environment, complete integration of simulated working environment and real-time testing, thus providing a crucial testing platform and reference data to properly understand the failure mechanism of thermal barrier coated blade and to improve relevant designs; strong applicability.

Owner:XIANGTAN UNIV

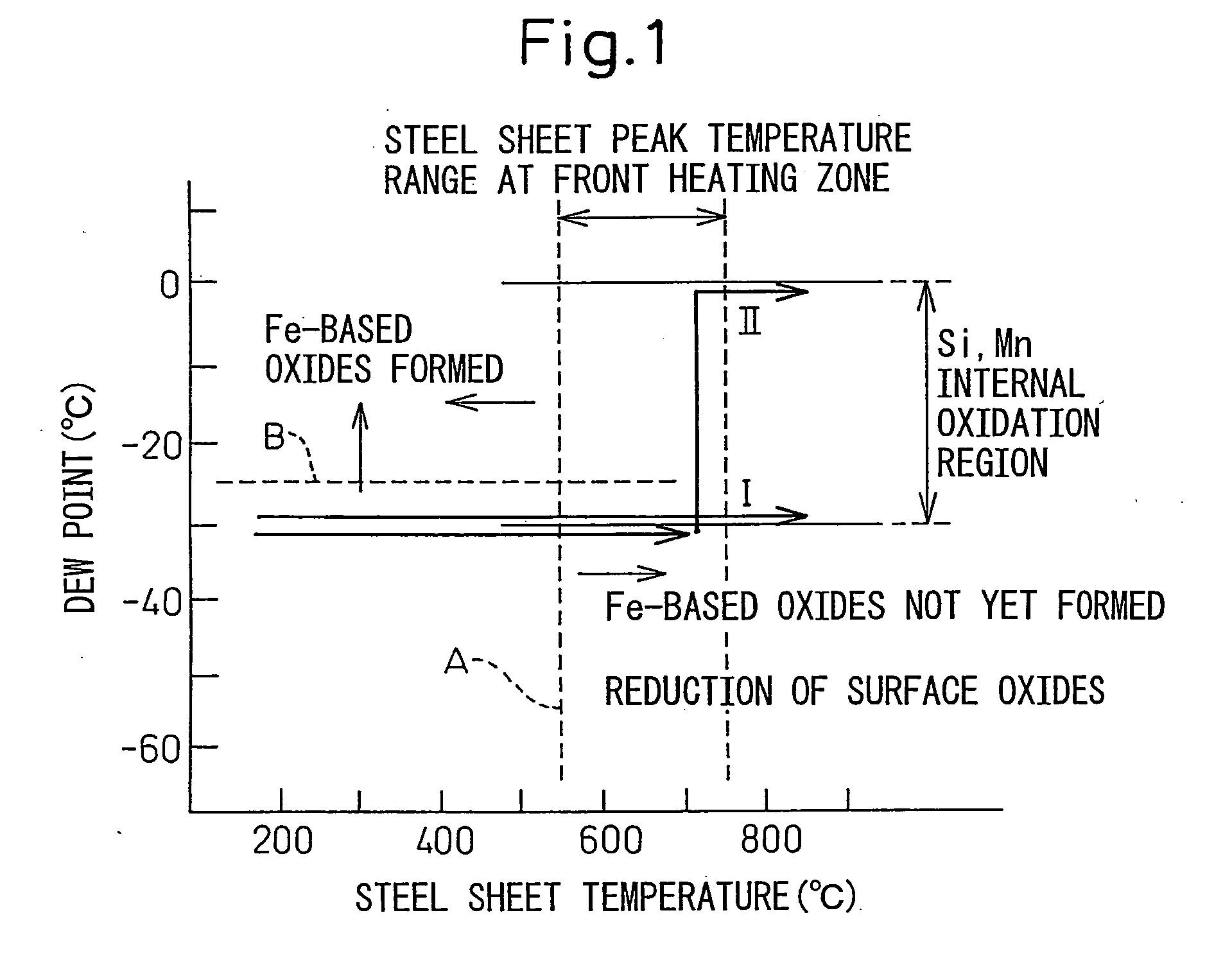

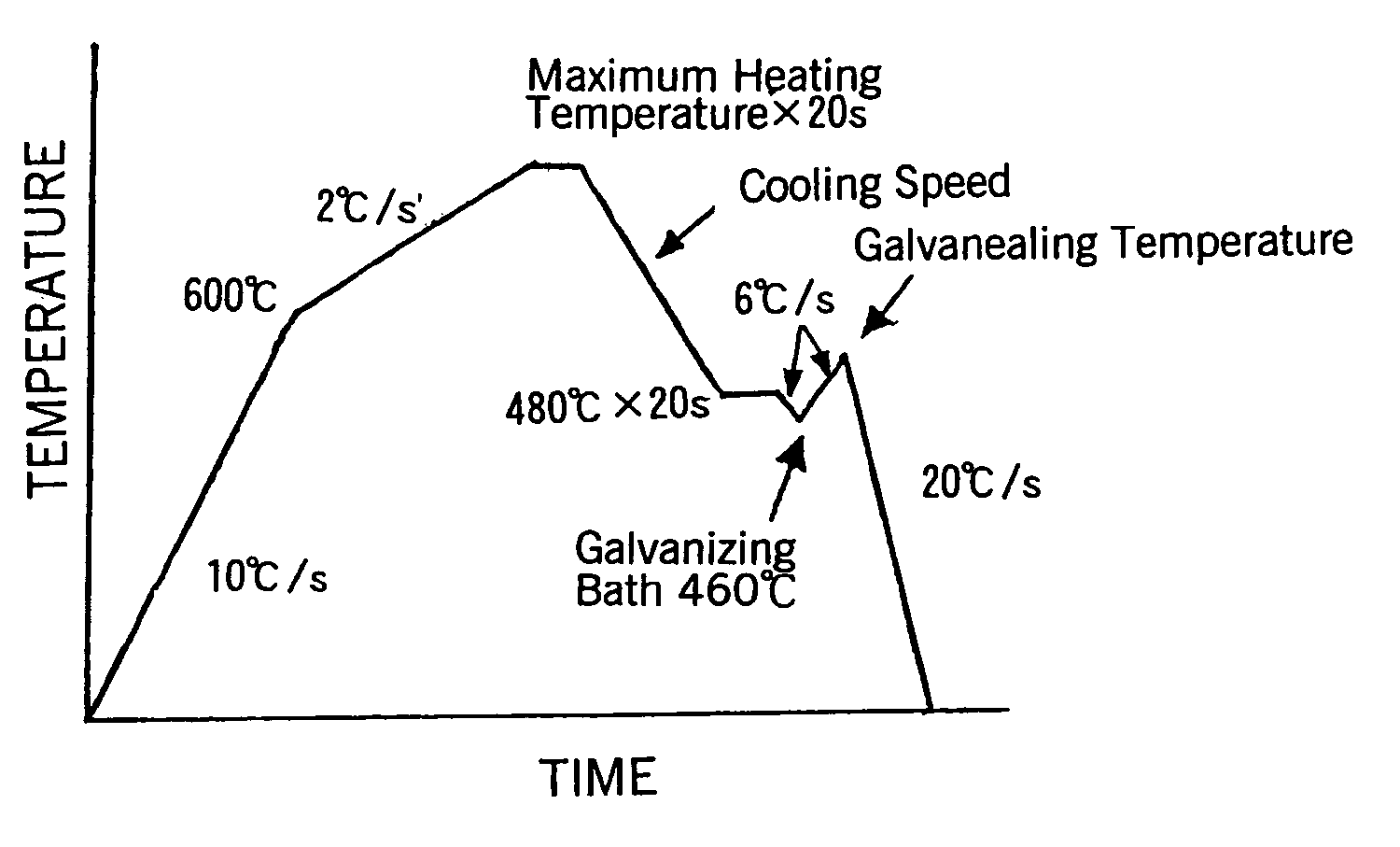

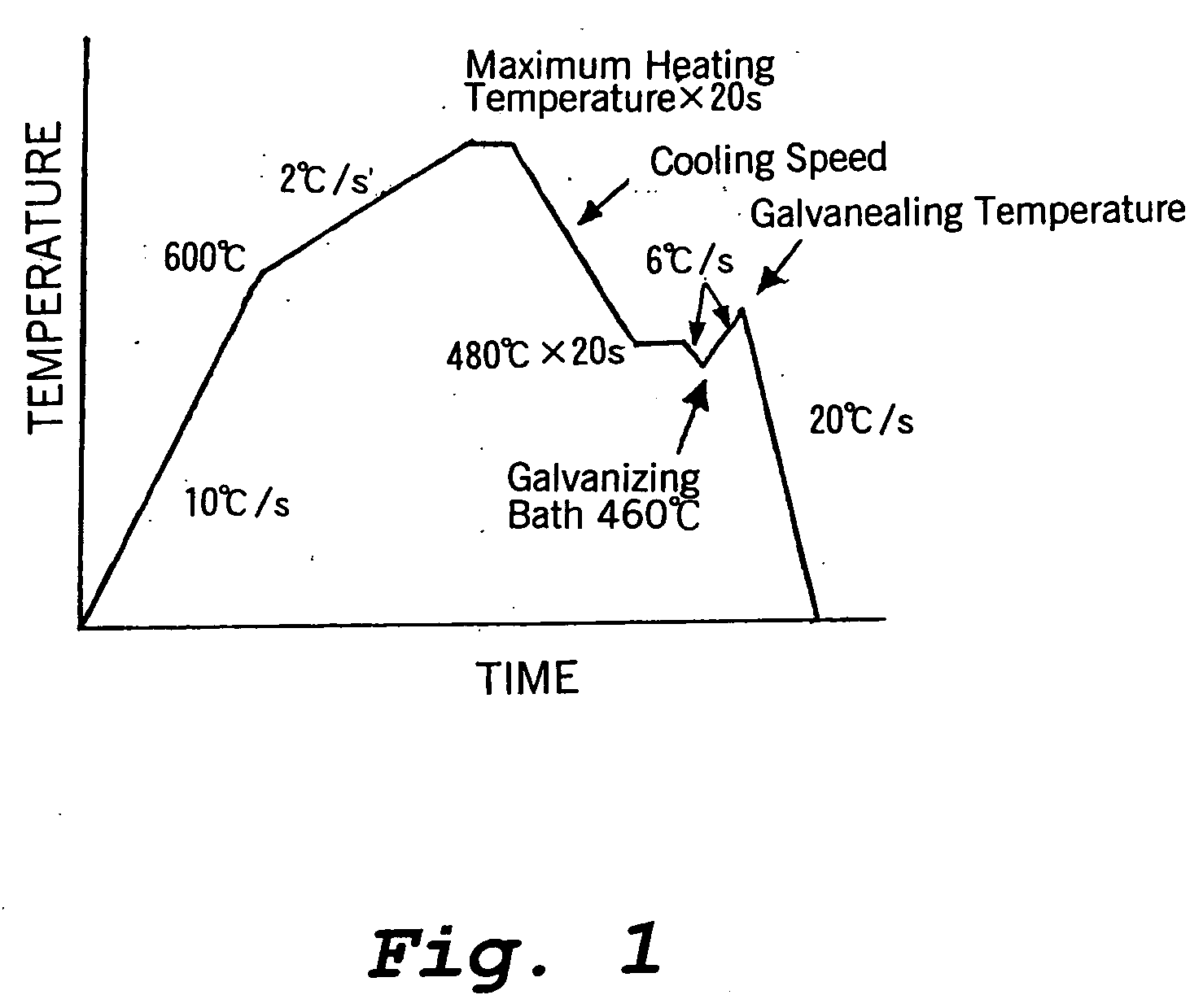

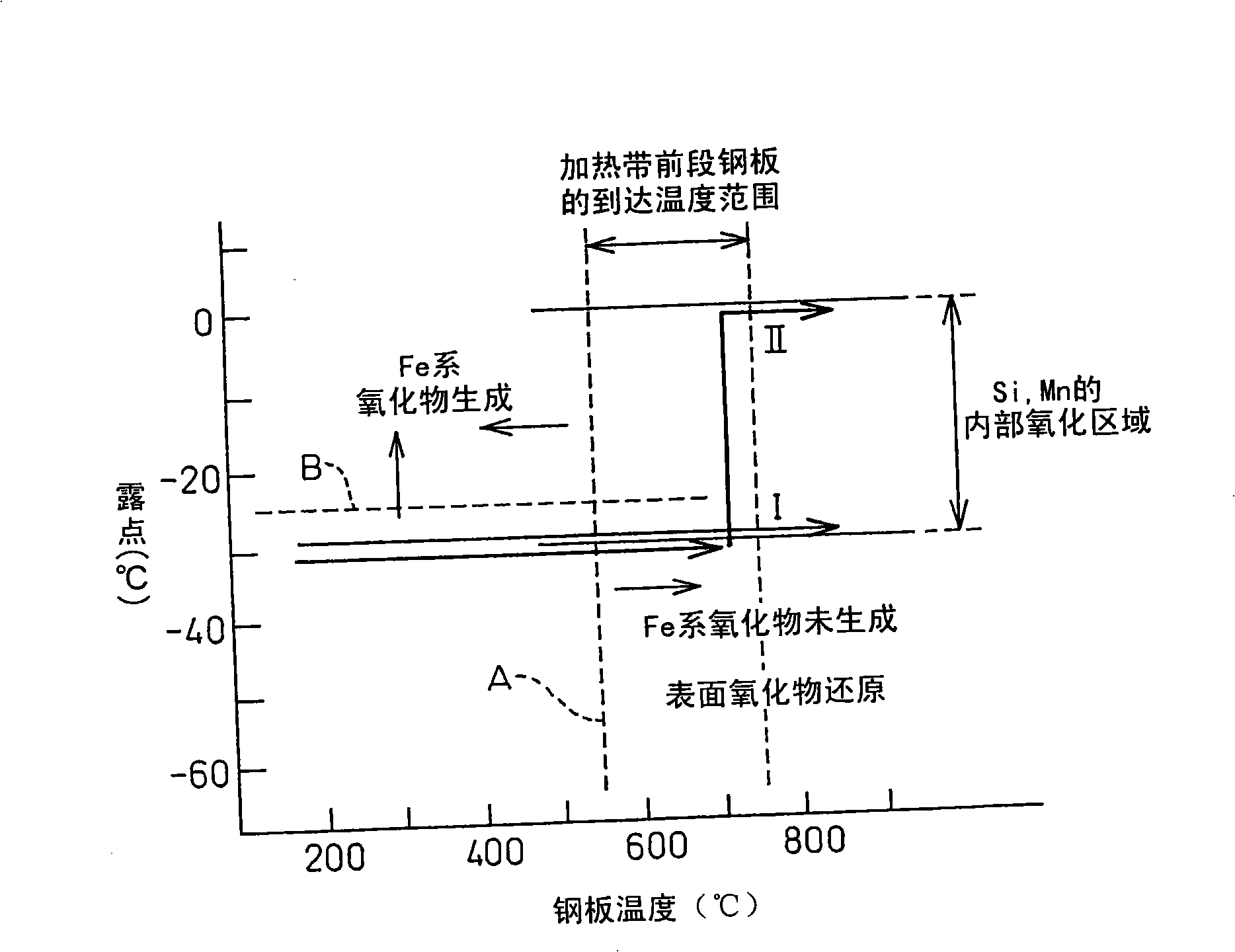

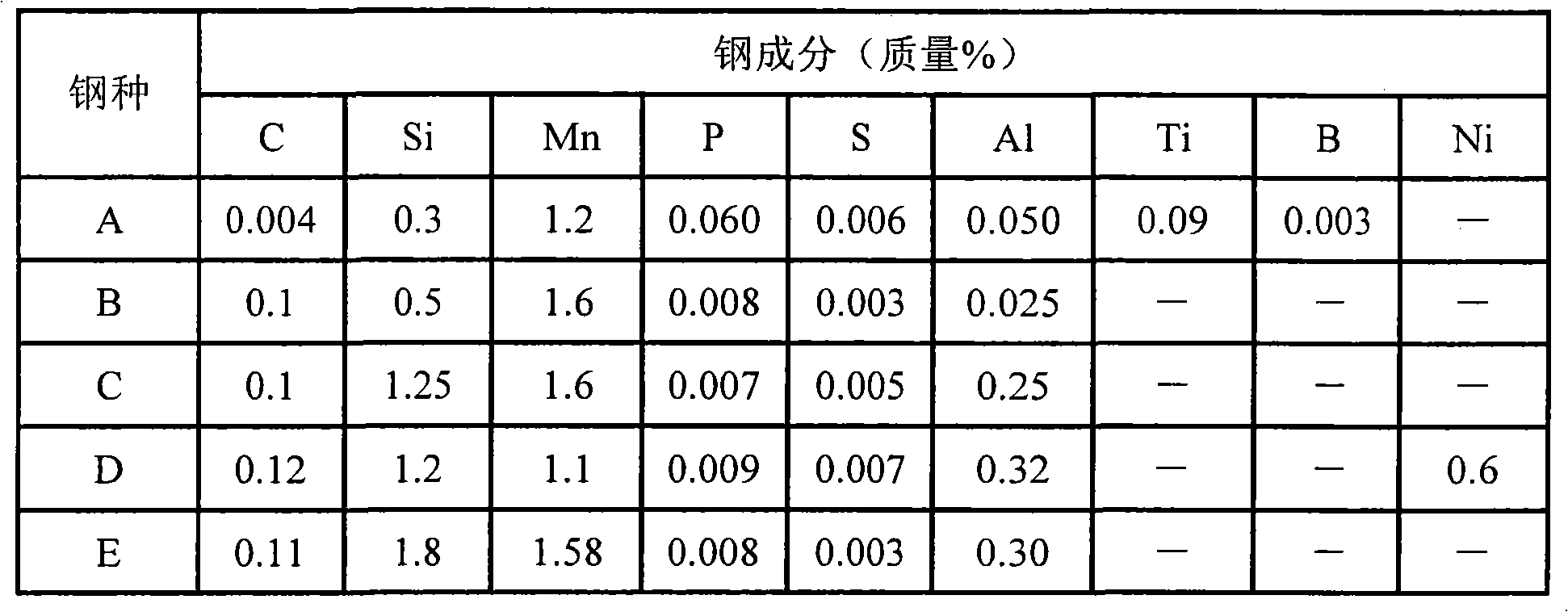

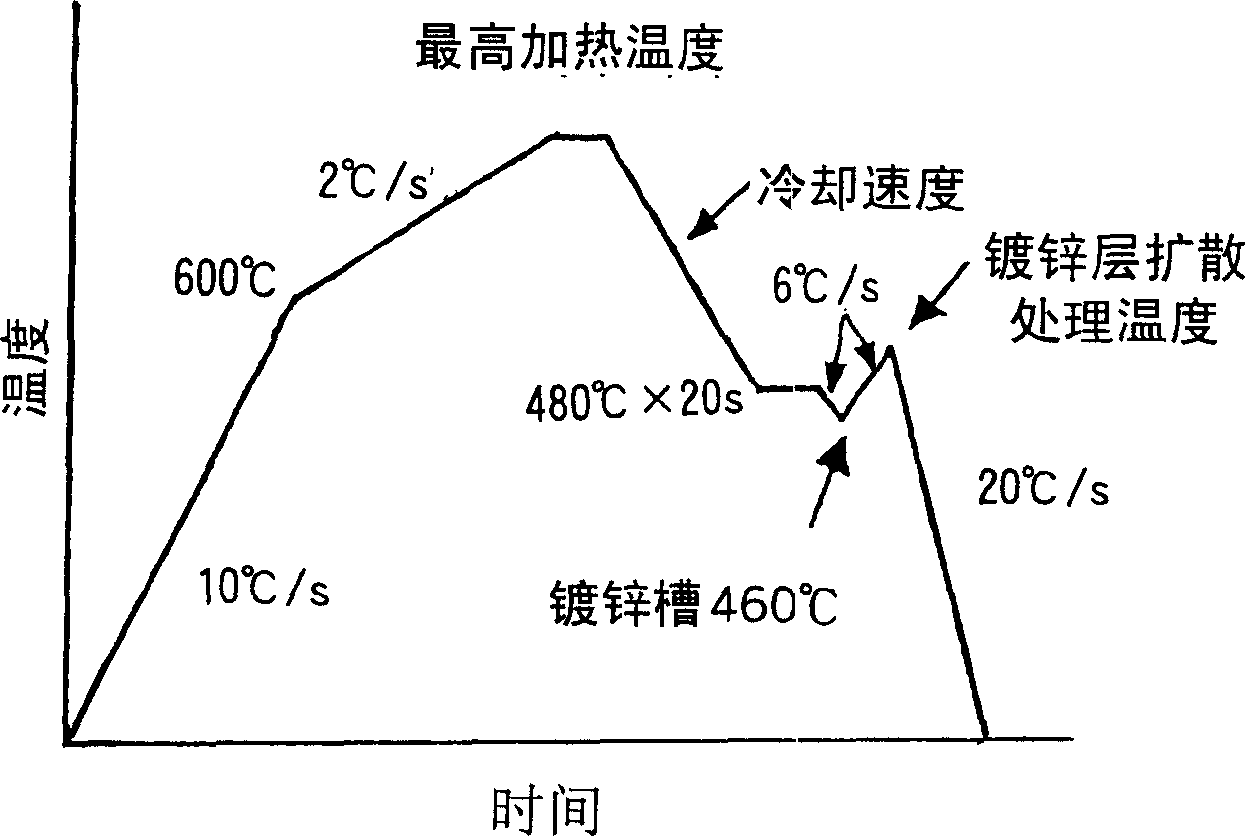

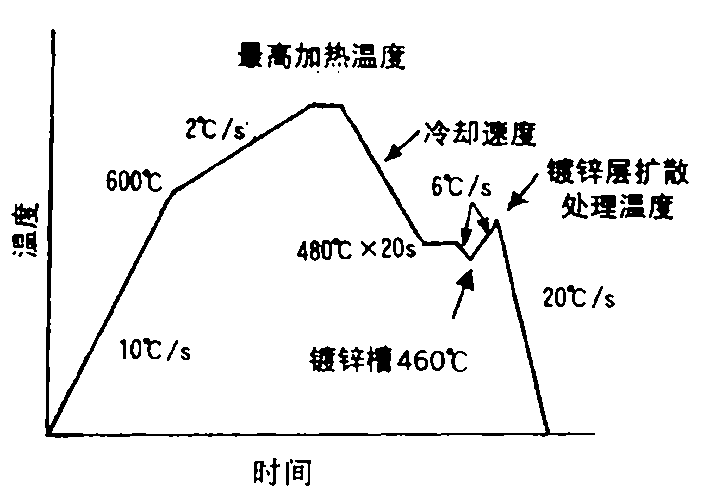

Continuous Annealing and Hot Dip Plating Method and Continuous Annealing and Hot Dip Plating System of Steel sheet Containing Si

InactiveUS20090123651A1Suppress surface concentrationImprove adhesionHot-dipping/immersion processesPretreated surfacesSheet steelHydrogen

The present invention provides, in a hot dip plating system having an annealing furnace for hot dip plating steel sheet containing Si, a continuous annealing and hot dip plating method and system causing internal oxidation without causing surface oxidation of the Si in the steel and avoiding a drop in the plating ability of the steel sheet and retardation of alloying, that is, a continuous annealing and hot dip plating method using an annealing furnace having, in order, a front heating zone, rear heating zone, soaking zone, and cooling zone and a hot dip plating bath, comprising heating or soaking the steel sheet at a steel sheet temperature of a temperature range of at least 300° C. or more by indirect heating, making an atmosphere of the zones one comprised of hydrogen H: 1 to 10 vol % and a balance of nitrogen and unavoidable impurities, making a steel sheet peak temperature during heating at the front heating zone 550 to 750° C. and making the dew point less than −25° C., making dew points of the following rear heating zone and soaking zone −30° C. to 0° C., and making a dew point of the cooling zone less than −25° C.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Fine metal particles and fine metal oxide particles in dry powder form, and use thereof

ActiveUS20070051927A1Simple preparation processImprove dispersionPigmenting treatmentMaterial nanotechnologyStable stateOrganic solvent

The present invention provides a process for simply and easily producing fine metal particles or fine metal oxide particles in the form of a dry powder which can be used as extremely fine particles in a good dispersion state without causing coagulation for a long time even if not stored in a dispersion solvent. Fine metal particles or fine metal oxide particles in the form of a dry powder are prepared using a dispersion in which fine metal particles or fine oxide metal particles having a surface oxidation film are dispersed in an organic solvent in a stable state, while once covering the particle surface with covering agent molecules containing, at a terminal, a functional group having an oxygen atom, a nitrogen atom, or a sulfur atom as a group capable of forming a coordinative bond with metal, and by removing the dispersion solvent, washing and removing excess covering agent molecules with a polar solvent without damaging the covering agent molecule layer covering the fine particle surface, finally evaporating the polar solvent used for washing and drying.

Owner:HARIMA CHEM INC

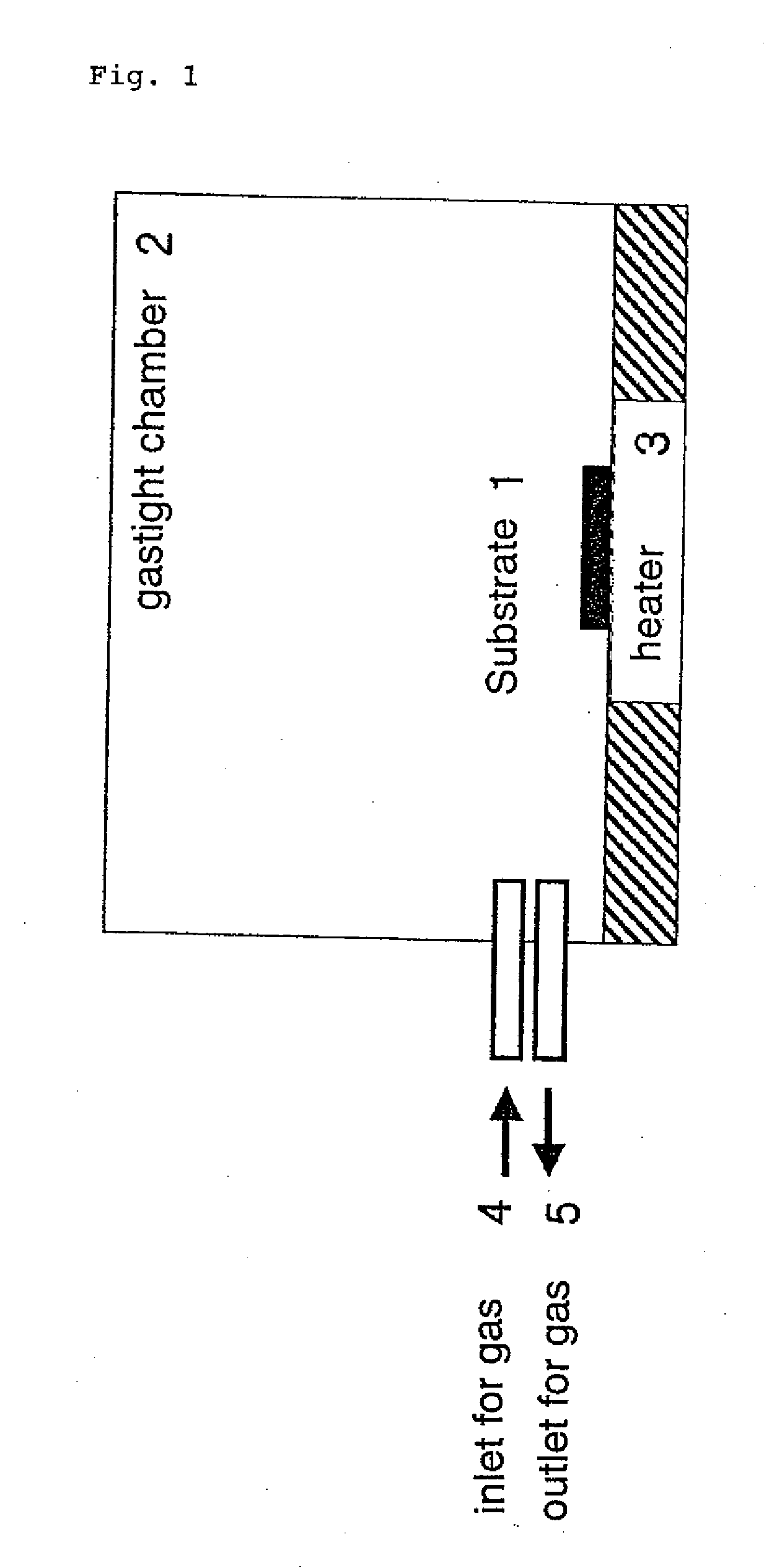

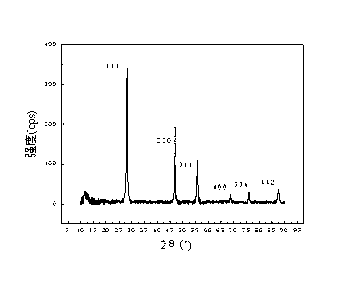

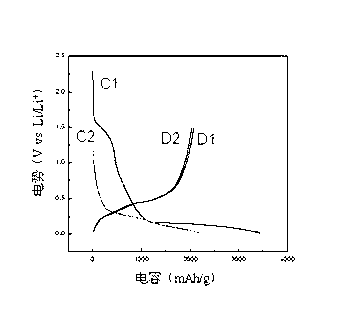

Porous silicon negative material of lithium ion battery and preparation method and application of material

The invention discloses a porous silicon negative material of a lithium ion battery, and a preparation method and application of the material. The method comprises the following steps of: reacting silicon alloy powder, which is taken as a raw material, with inorganic acid to generate porous silicon particles; and washing the porous silicon particles by an HF (Hydrogen Fluoride) acid solution to eliminate surface silicon oxide, and washing and drying the washed porous silicon particles so as to obtain the porous silicon material. The porous silicon material prepared by the method has a sponge-shaped structure which is formed by linking nano silicon particles; the particle sizes of the particles of the porous silicon negative material range from 0.01 micron to 50 microns; the specific surface area of the material is 30-600cm<2> / g; the porous silicon negative material can be taken as a negative material of a lithium ion battery; and in a lithium ion battery electrolyte, the porous silicon powder shows high specific discharge capacity and charge-discharge circulation stability. The porous silicon negative material has the advantages of low cost, simplicity and convenience in method and high electrochemical property, and can be applied to production of silicon negative materials of high-performance lithium ion batteries.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Ceramic coatings for insulating modular fuel cell cassettes in a solid-oxide fuel cell stack

ActiveUS20070134537A1Improve adhesionEngine sealsFuel cells groupingCeramic coatingSurface oxidation

In assembling an SOFC fuel cell stack from a plurality of cassettes, the mounting plate of one cassette is attached to, and insulated from, the separator plate of the next-adjacent cassette by a peripheral dielectric seal consisting of a ceramic coating and a metal braze. Materials suitable for the ceramic coating include yttrium stabilized zirconia (YSZ), zirconia toughened alumina, magnesium silicates such as the mineral forsterite, magnesium aluminates, magnesium aluminosilicates and lanthanum zirconate. The ceramic coating may be applied to the cassette's outer surface in known fashion as by physical vapor deposition, chemical vapor deposition, sputtering, and various methods of plasma spray. An underlayer of alumina may also be used to provide a redundant layer of electrical insulation.

Owner:BATTELLE MEMORIAL INST +1

Surface oxidised nickel-iron metal anodes for aluminium production

InactiveUS20050205431A1Reduce solubilityPremature depletionIsotope separationElectrodesElectrolysisSurface oxidation

An anode for the electrowinning of aluminium by the electrolysis of alumina in a molten fluoride electrolyte has an electrochemically active integral outside oxide layer obtainable by surface oxidation of a metal alloy which consists of 20 to 60 weight % nickel; 5 to 15 weight % copper; 1.5 to 5 weight % aluminium; 0 to 2 weight % in total of one or more rare earth metals, in particular yttrium; 0 to 2 weight % of further elements, in particular manganese, silicon and carbon; and the balance being iron. The metal alloy of the anode has a copper / nickel weight ratio in the range of 0.1 to 0.5, preferably 0.2 to 0.3.

Owner:MOLTECH INVENT

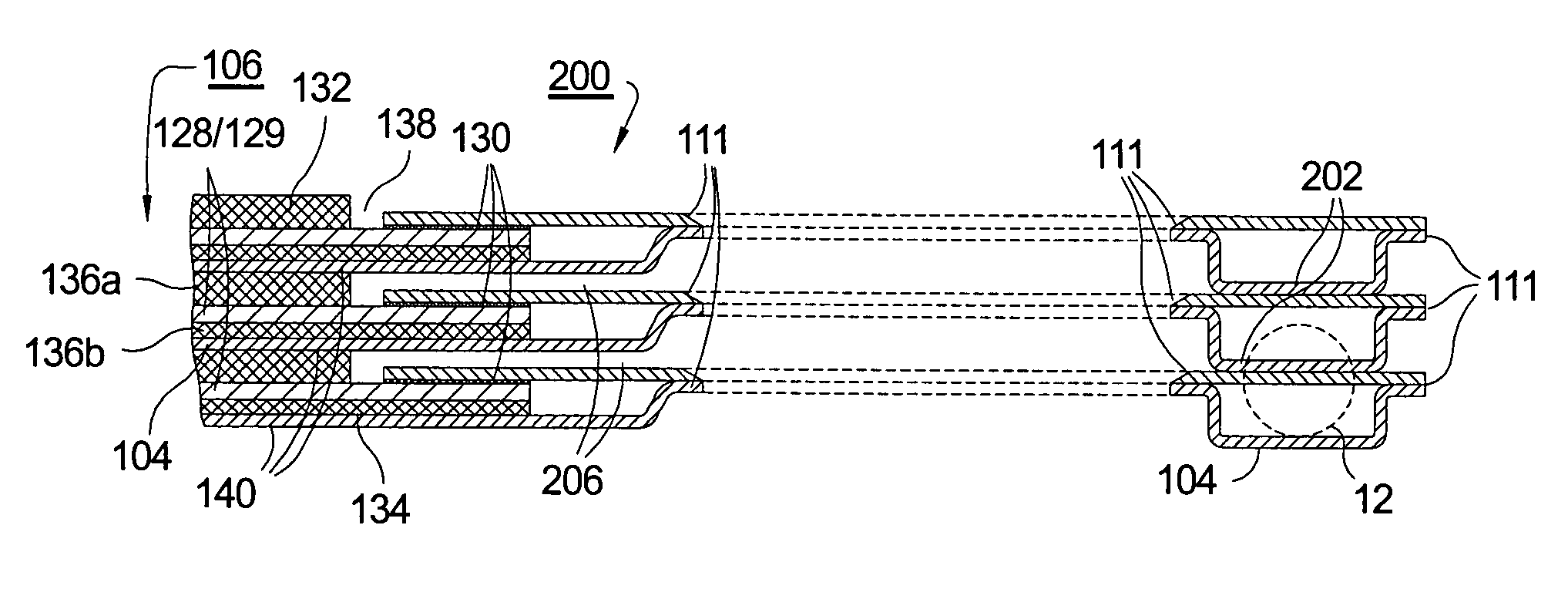

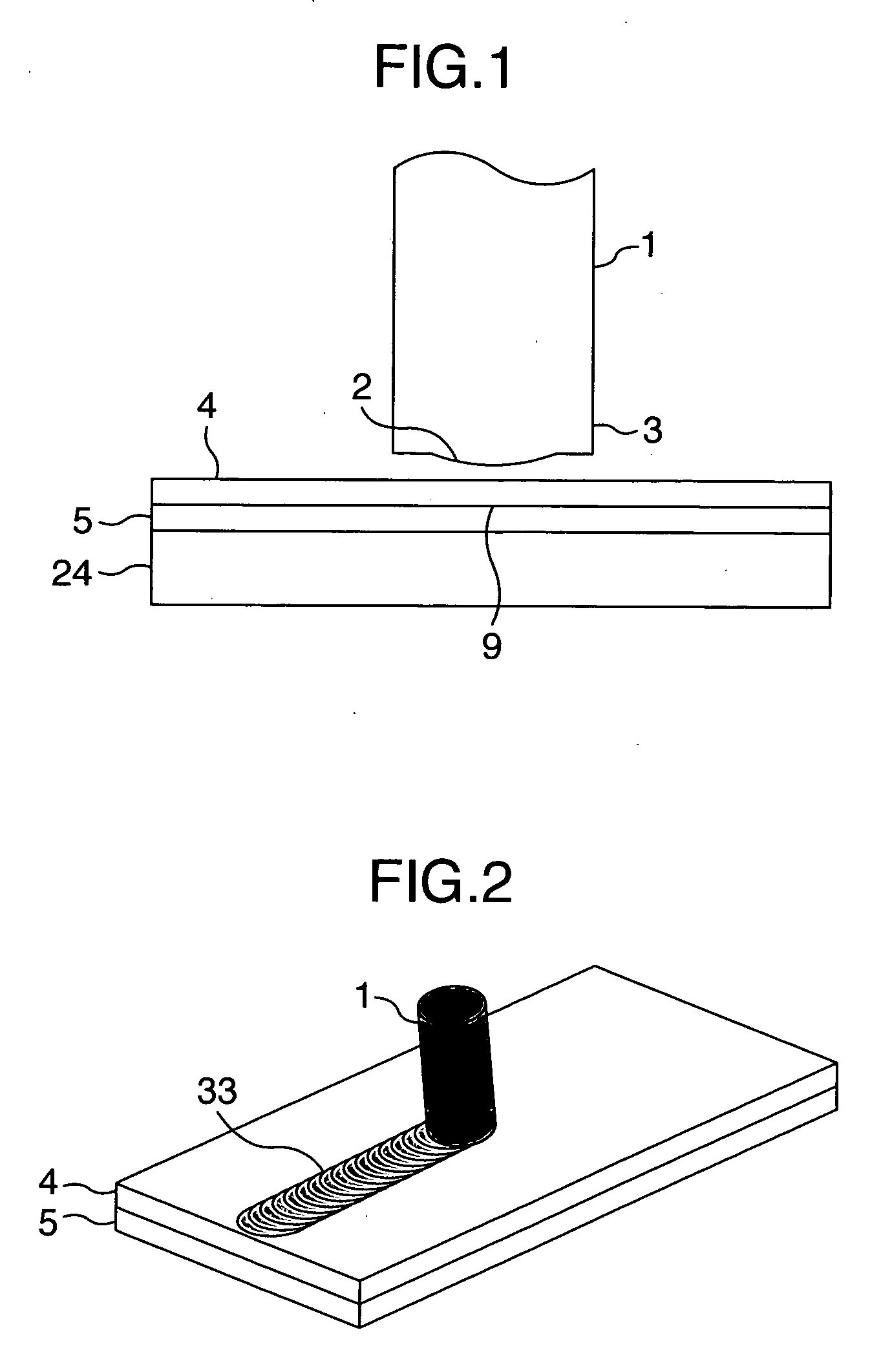

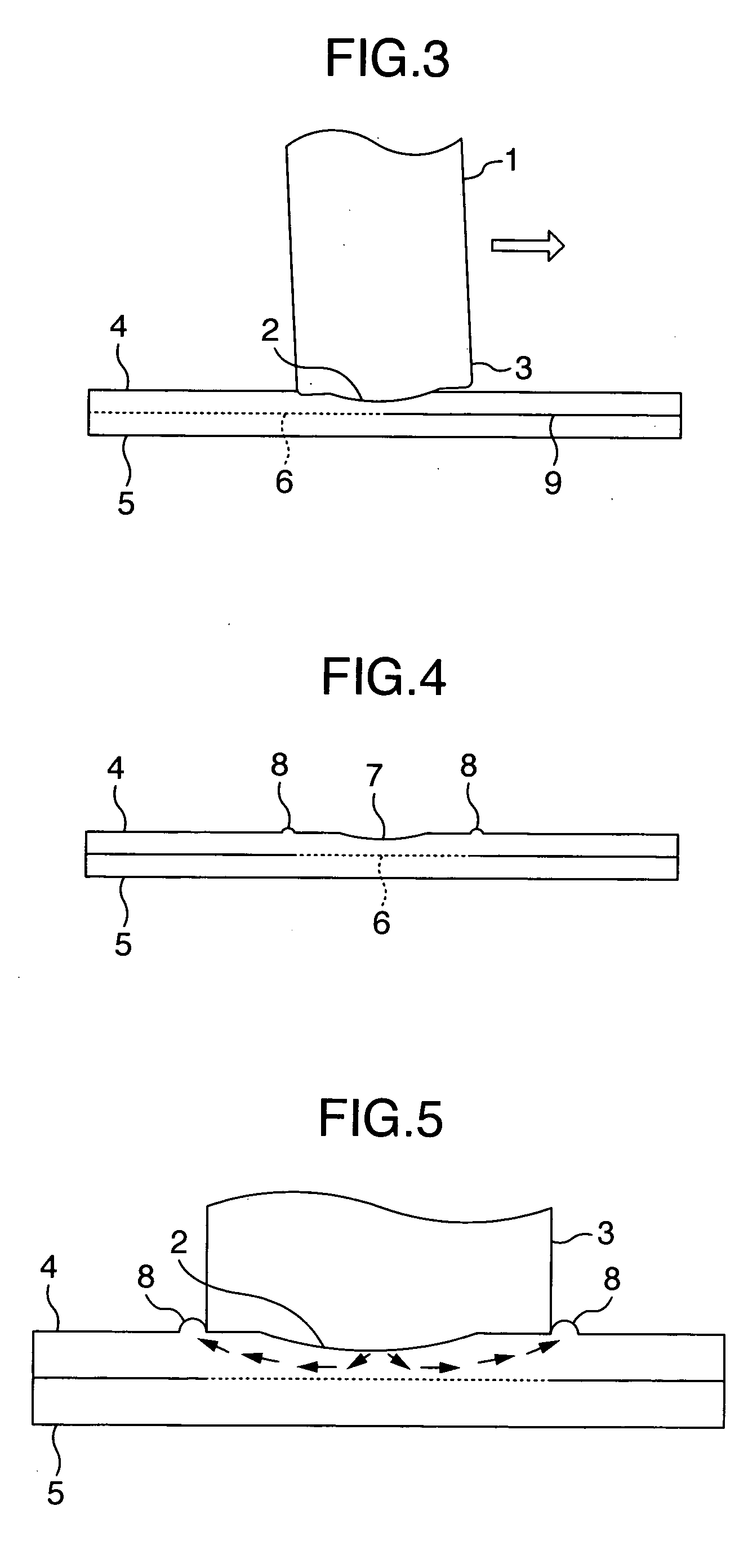

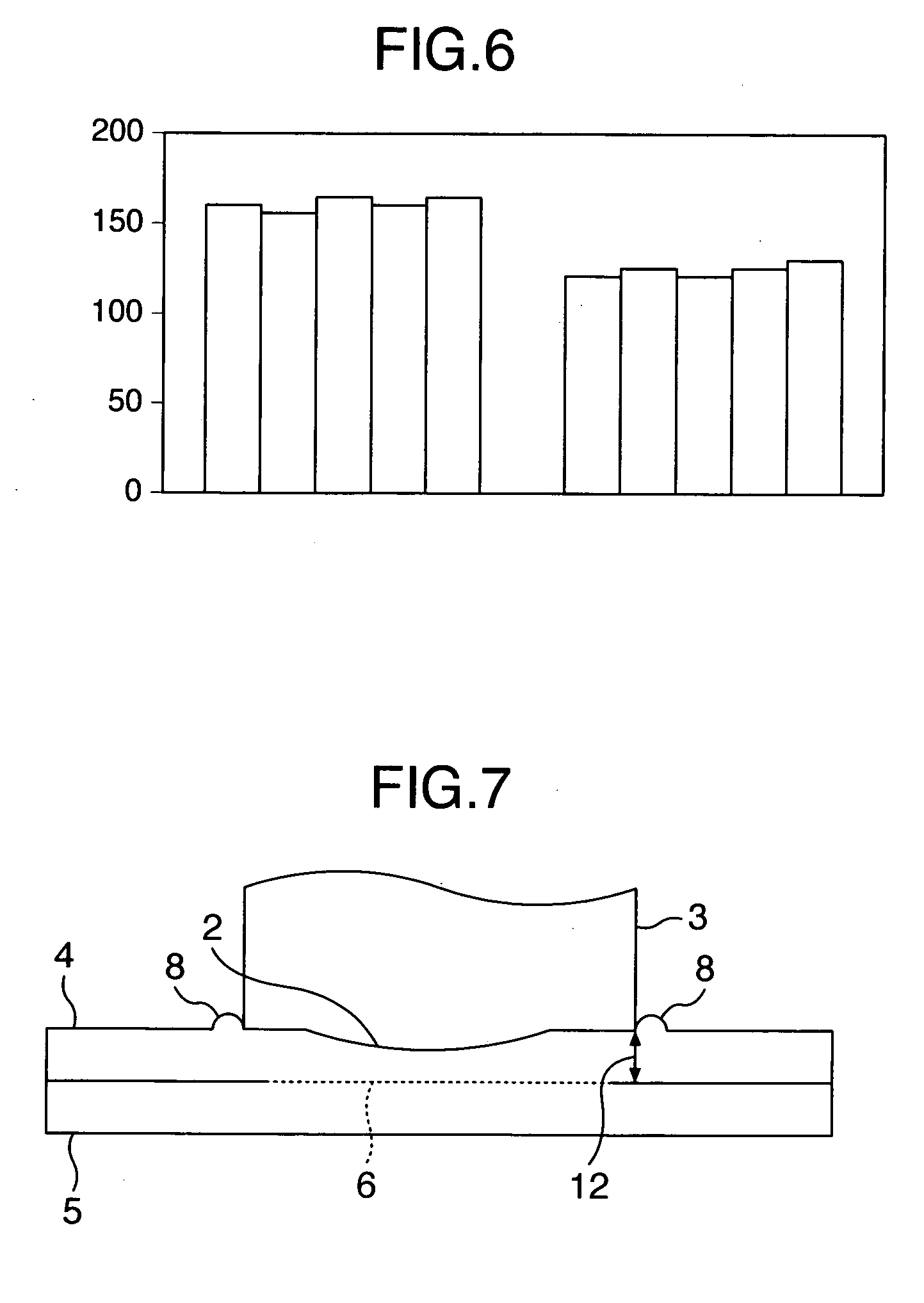

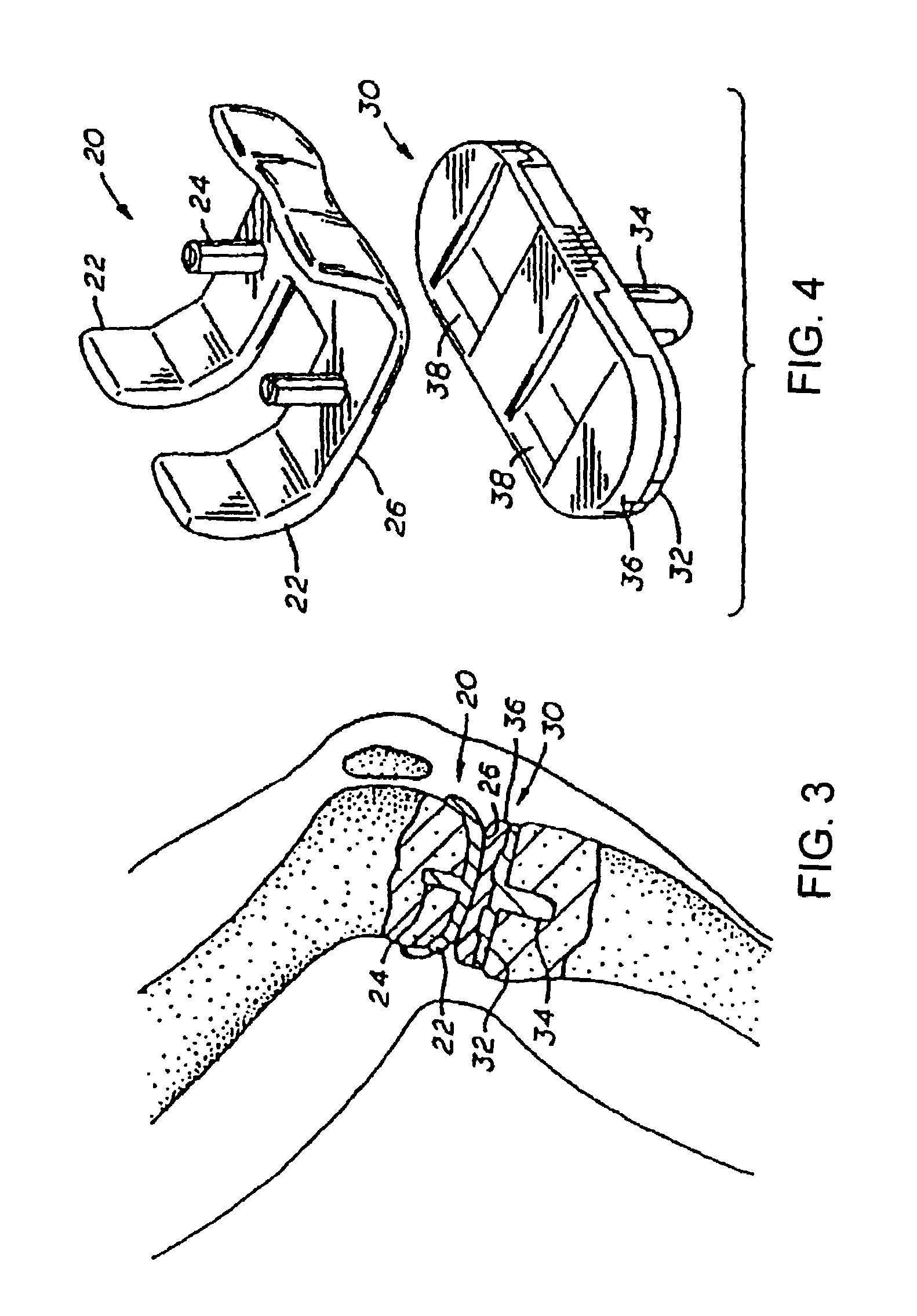

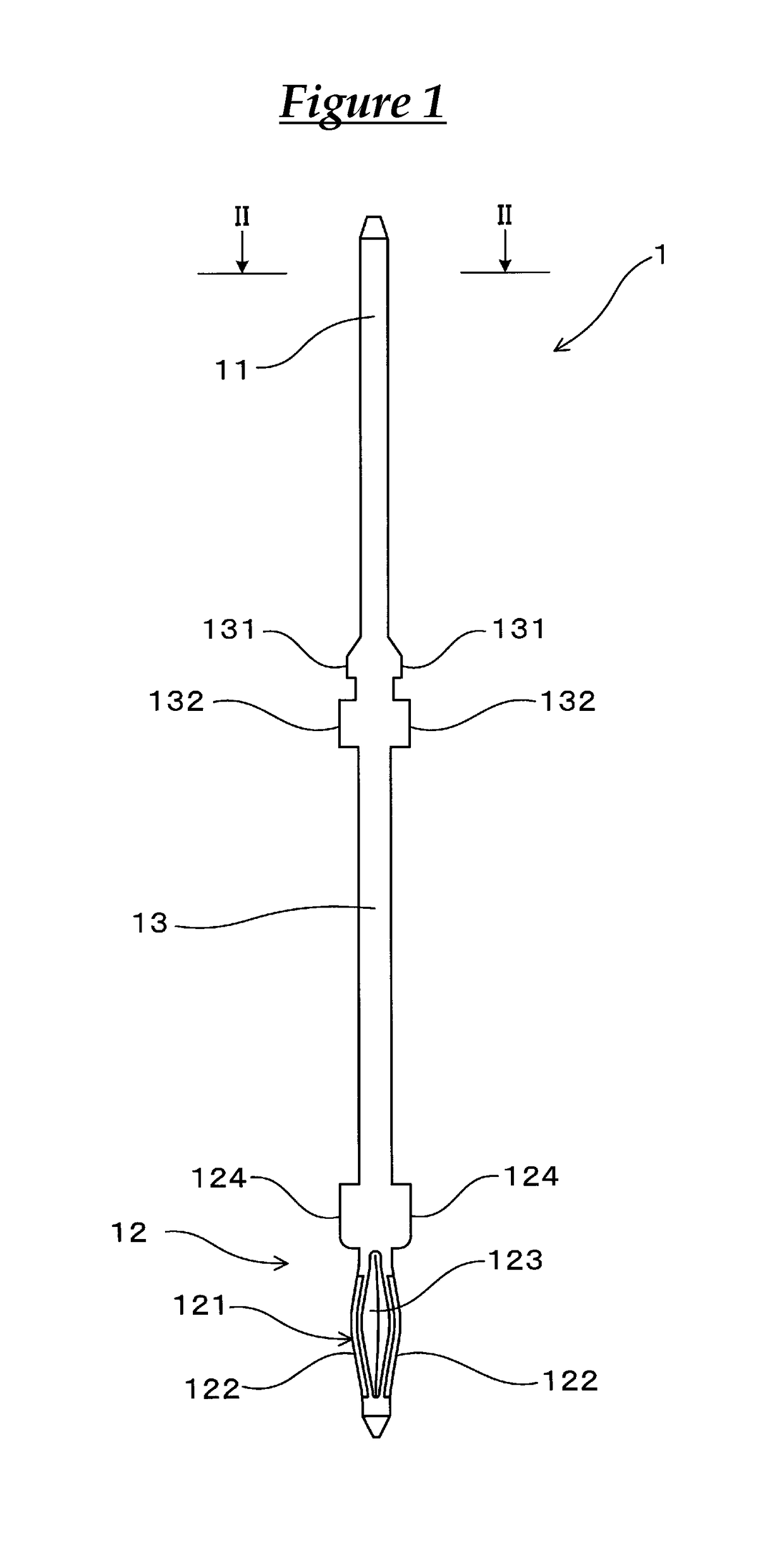

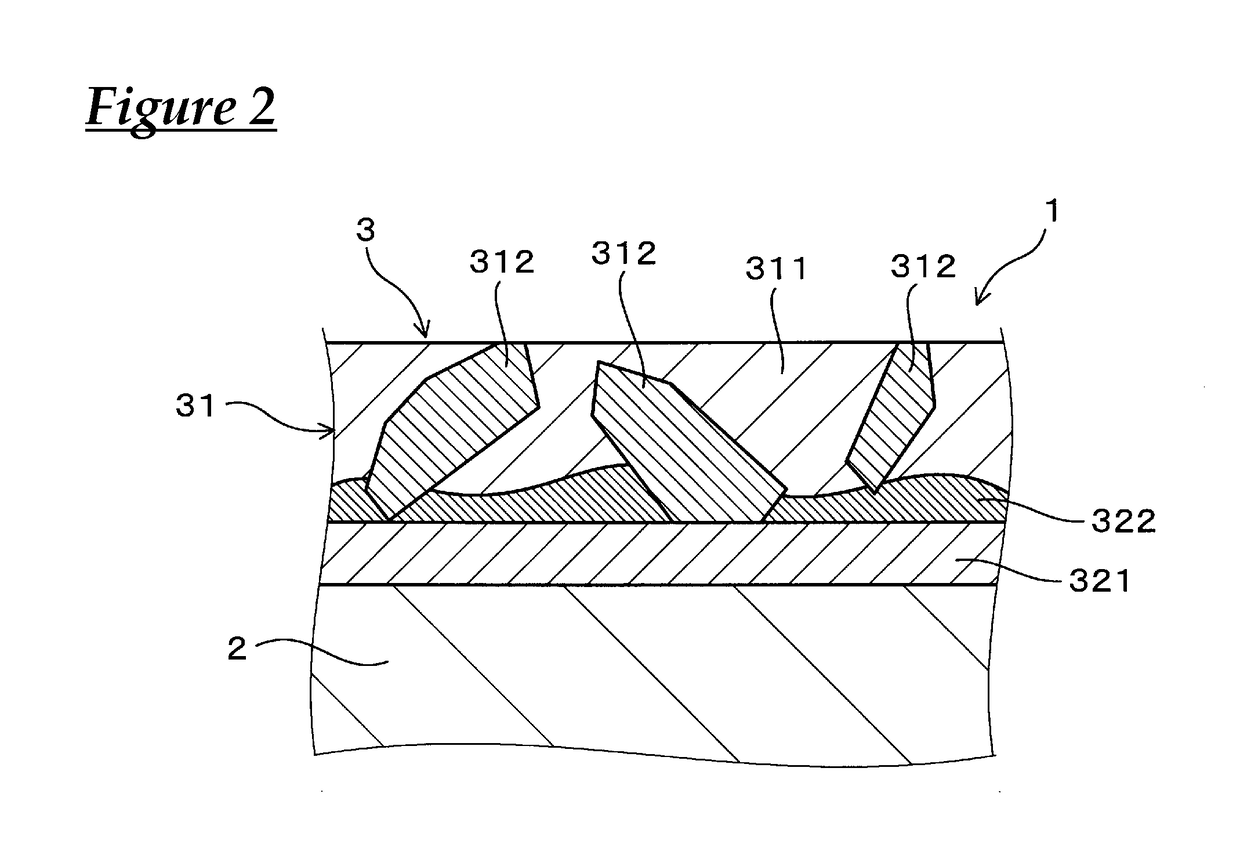

Friction stirring-welding method

InactiveUS20060138197A1Easy to disassembleEfficient methodNon-electric welding apparatusLap jointSurface oxidation

A friction stirring-welding method capable of increasing the welding strength of a lap joint. A welding tool (1) comprises a small diameter projected part (2) at the tip of a shoulder (3). The welding tool is press-fitted to the upper plate (4) of the lap joint while being rotated. By a friction stirring action, an upper plate side welding boundary surface (6) plastically flows, a surface oxidation film on a lapped surface is peeled off, and the boundary surface is activated to provide an excellent welding part. Also, since the welding tool is formed in a shape having the small diameter semispherical projected part (2) at the tip thereof, the thickness (12) of an upper plate welding part is increased, and a lap joint part with high welding strength can be provided.

Owner:HITACHI LTD

Phosphorus gettering process of silicon chip

InactiveCN101667605AImprove electrical performance parametersIncreased average life expectancyFinal product manufactureSemiconductor devicesEtchingSurface oxidation

The invention relates to a phosphorus gettering process of silicon chips in the manufacture of solar cells, which comprises the following steps: putting sueded silicon chips into a diffusion furnace for pre-deposition, removing a phosphorosilicate glass layer after diffusion, soaking the silicon chips through distributed processing in a hydrofluoric acid solution, and removing oxide layers from the surfaces of the silicon chips; then putting the silicon chips after washing into the diffusion furnace for secondary diffusion processing, taking the silicon chips out from the diffusion furnace after the processing of the secondary diffusion working procedure, cooling the silicon chips to room temperature, and measuring the square resistance of the silicon chips. The invention can effectively decrease heavily doped 'dead layers' and greatly prolong the average minority carrier lifetime of the silicon chips; after the processes including etching, PECVD, silk screen sintering and the like arefinished according to the normal process of a cell chip, the average transformation efficiency of the made cell chip is further improved, and the cell chip has better electrical performance parameters.

Owner:无锡尚品太阳能电力科技有限公司

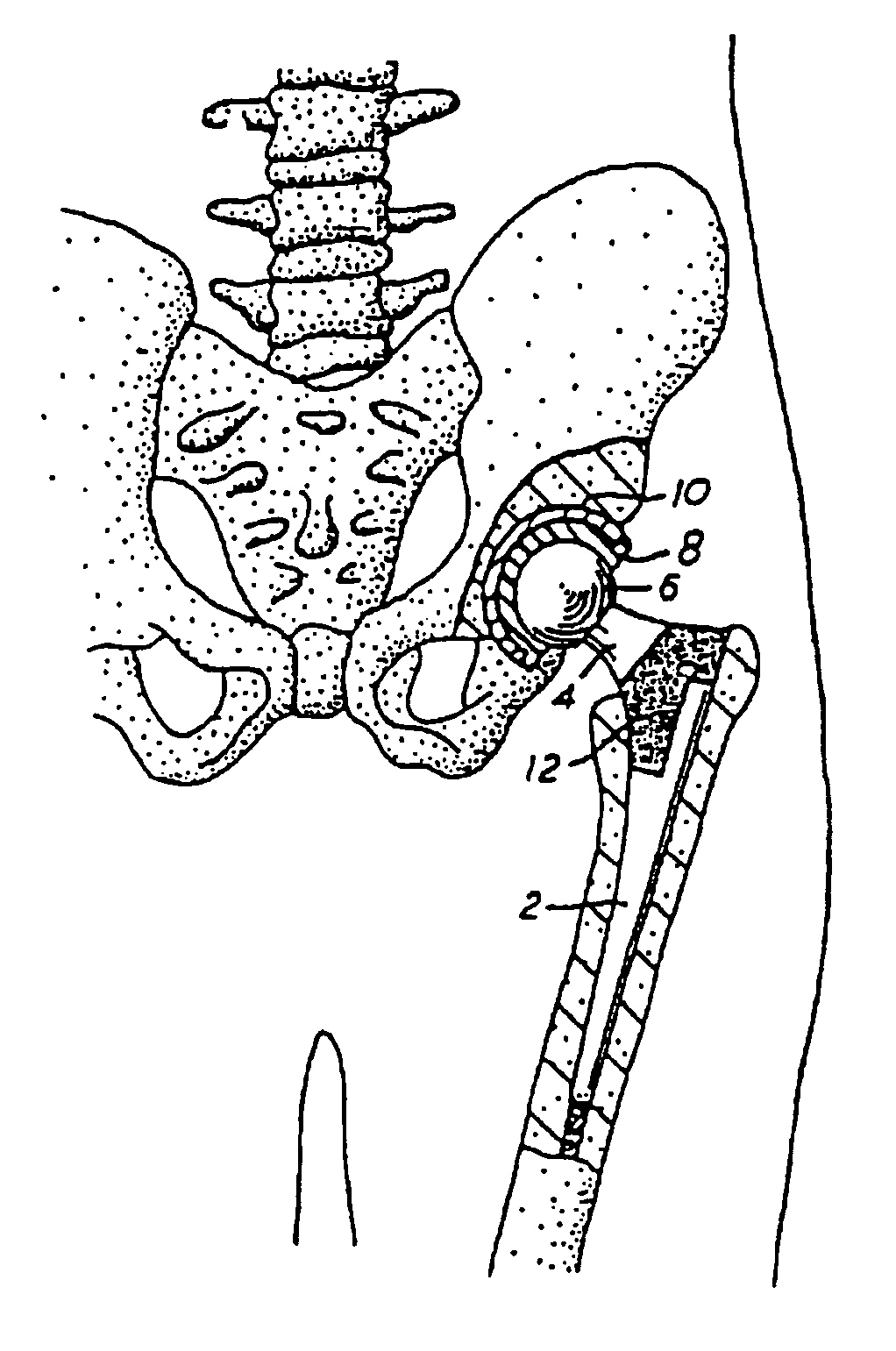

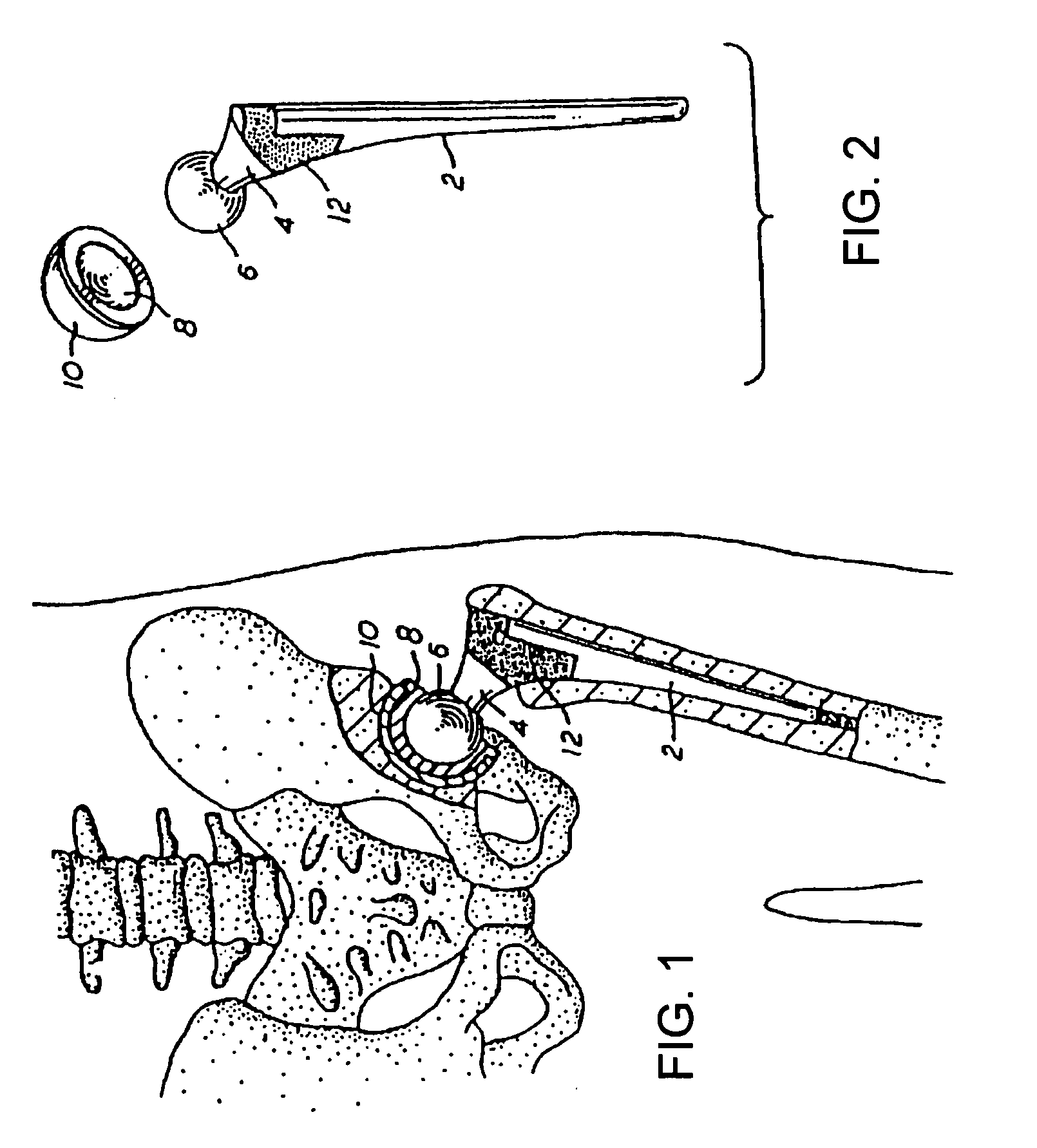

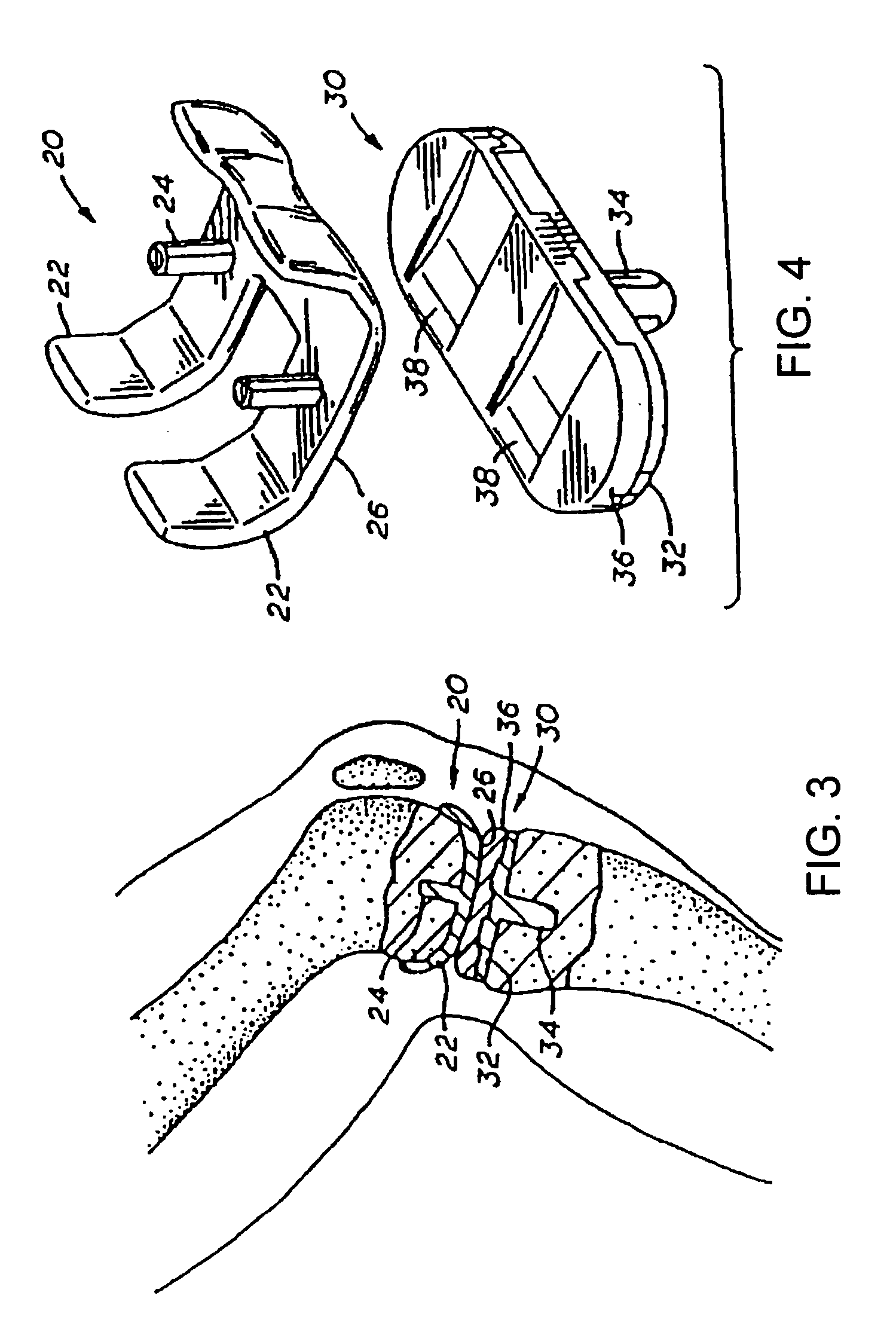

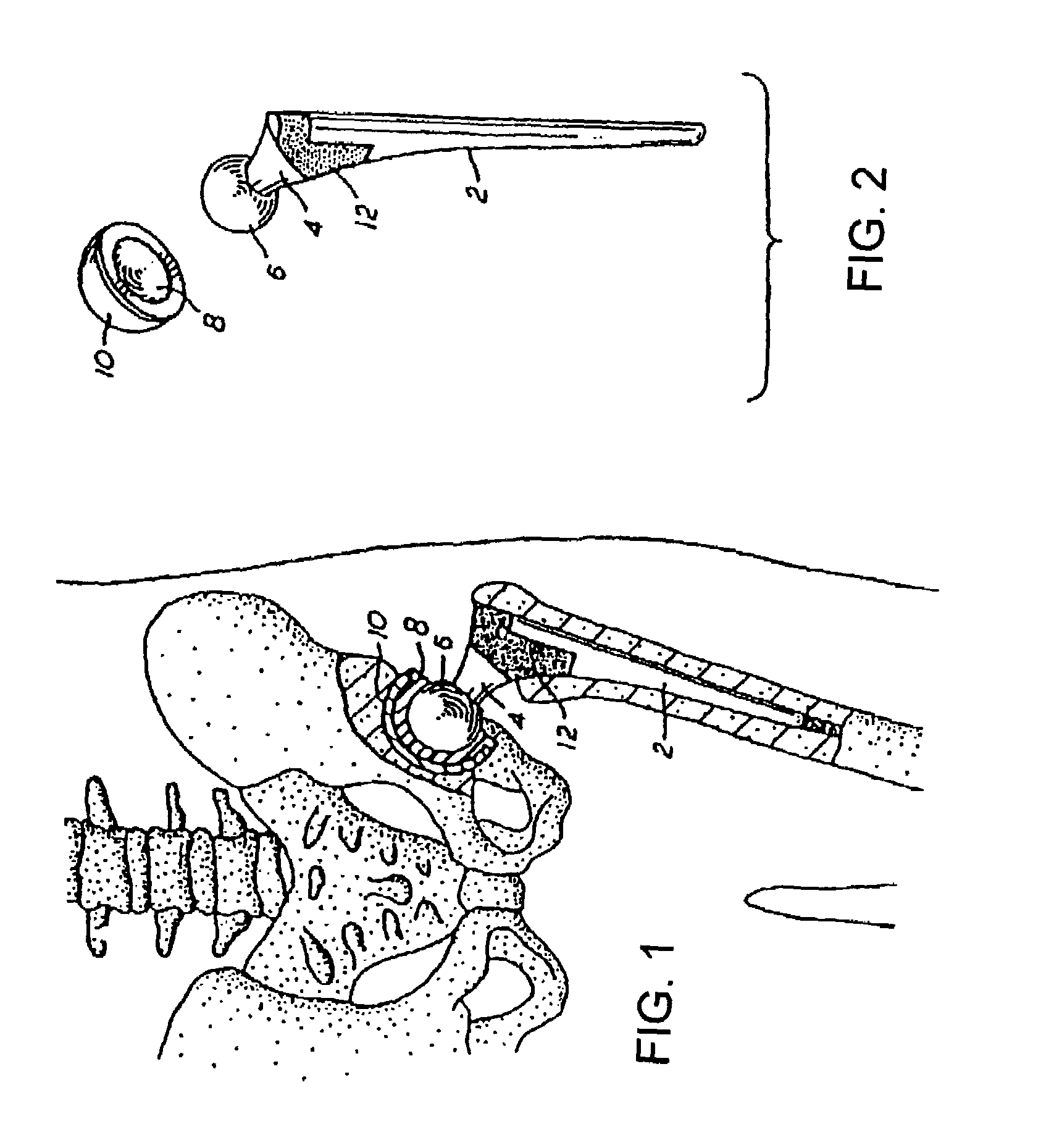

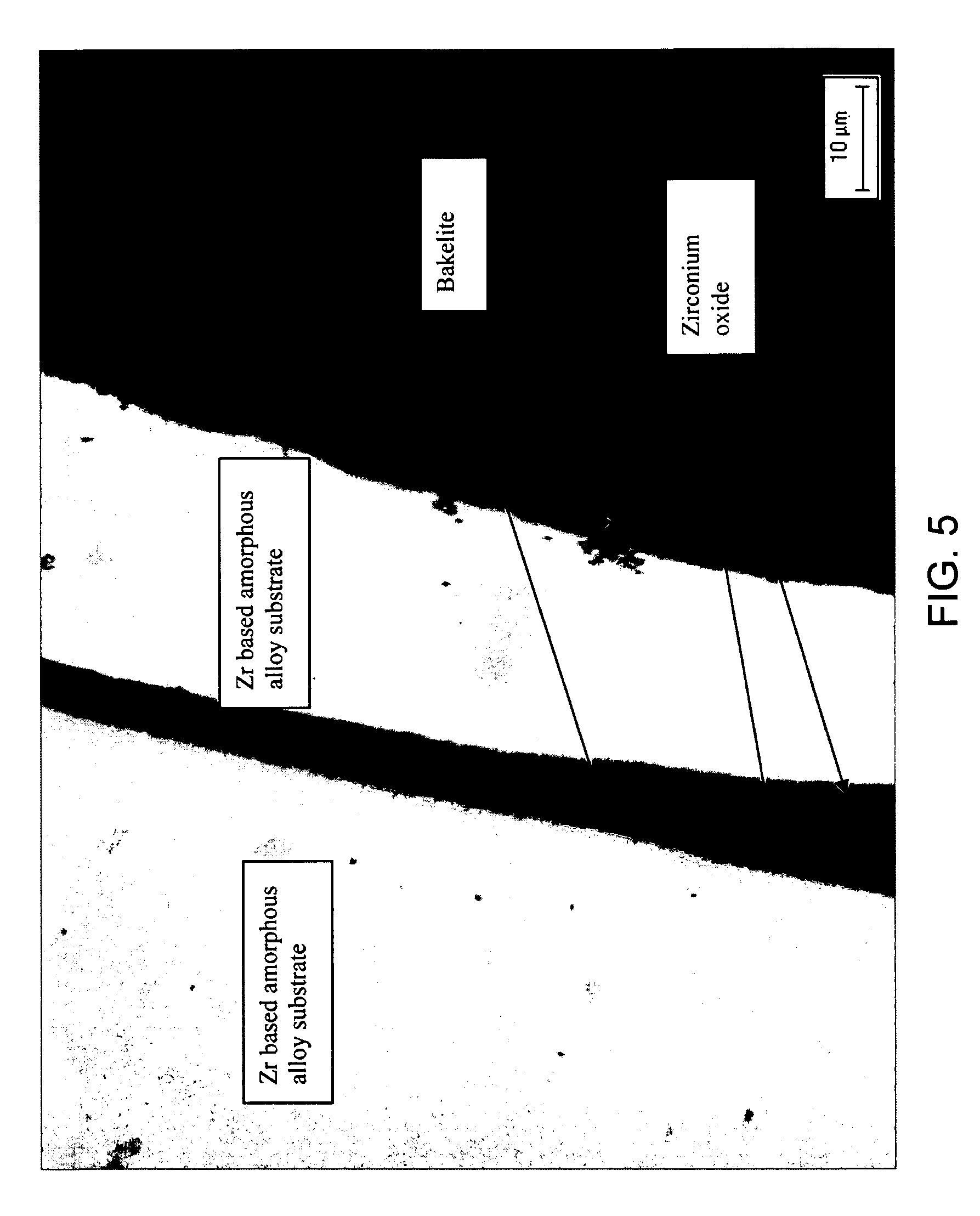

Method of surface oxidizing zirconium and zirconium alloys and resulting product

ActiveUS20060058888A1Bone implantSurface reaction electrolytic coatingWear resistantSurface oxidation

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the oxidative treatment of an amorphous zirconium or zirconium alloy substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

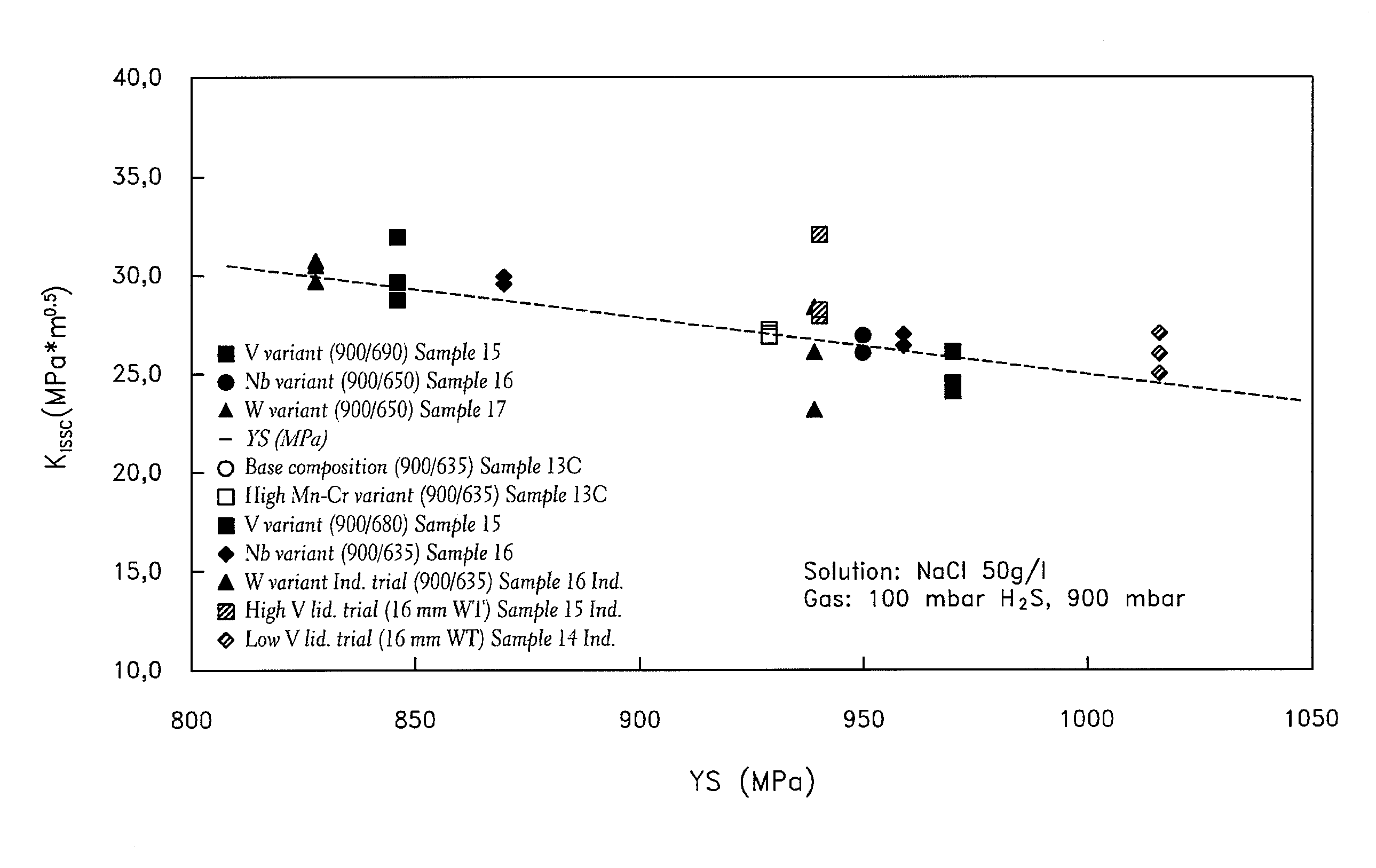

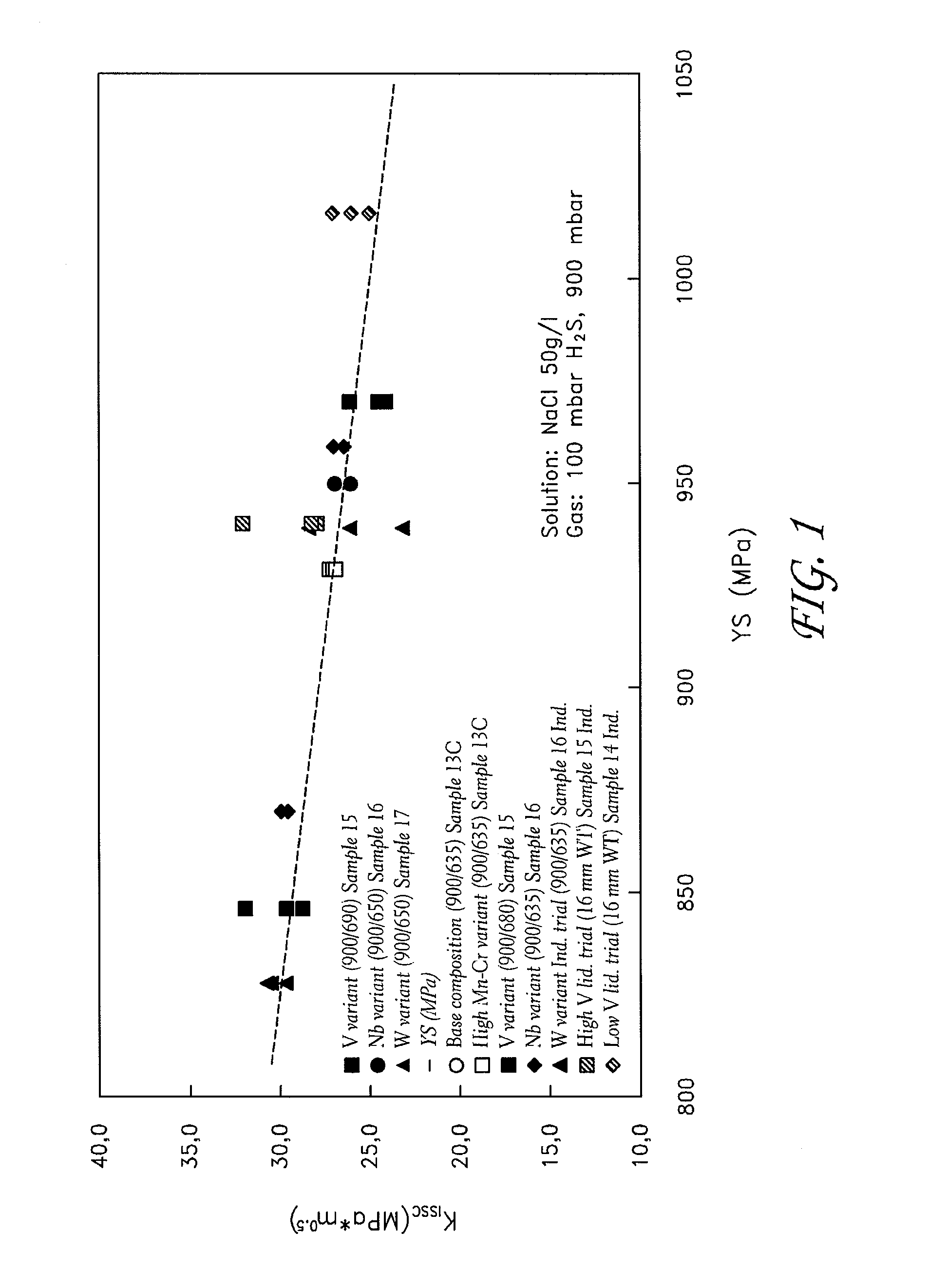

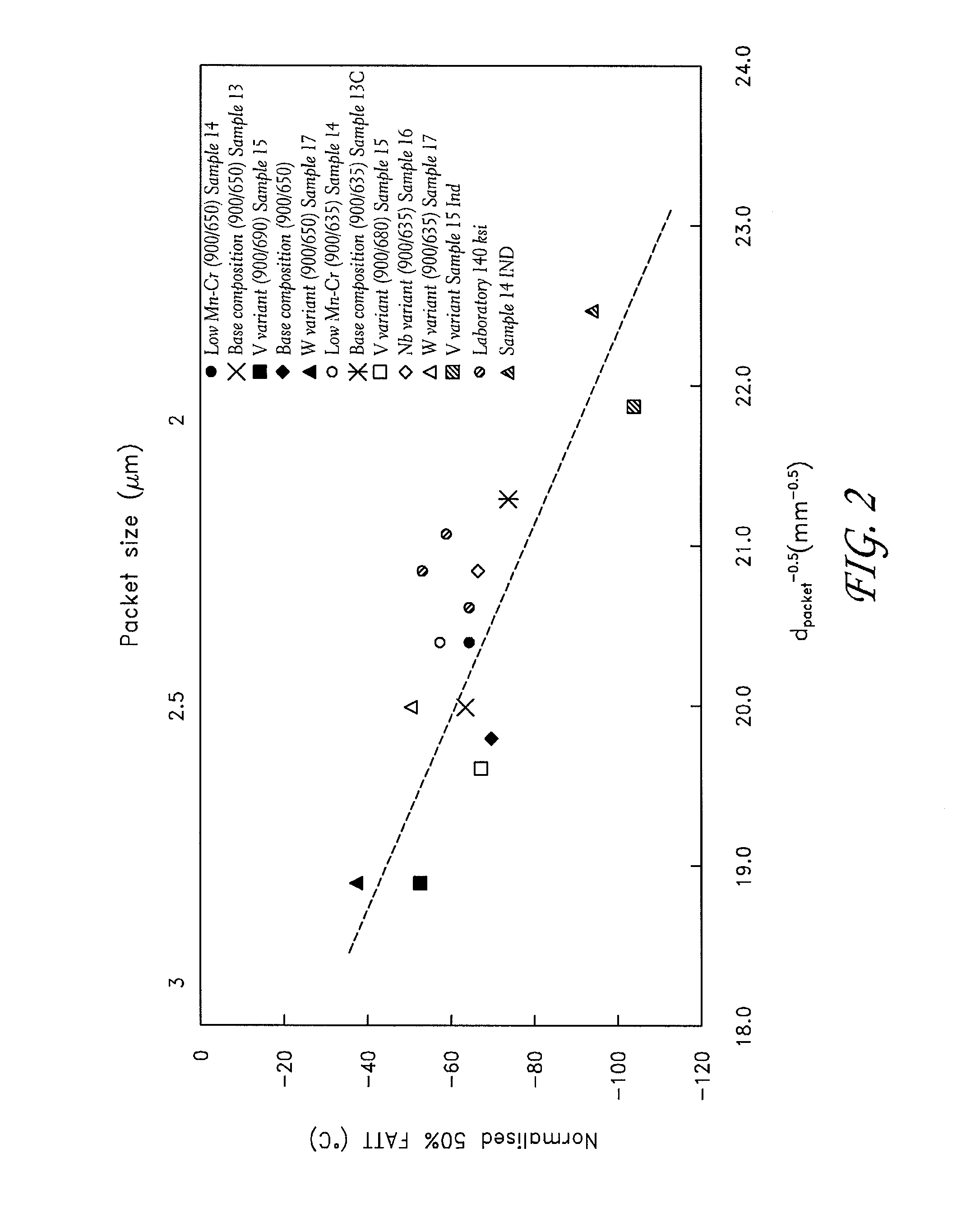

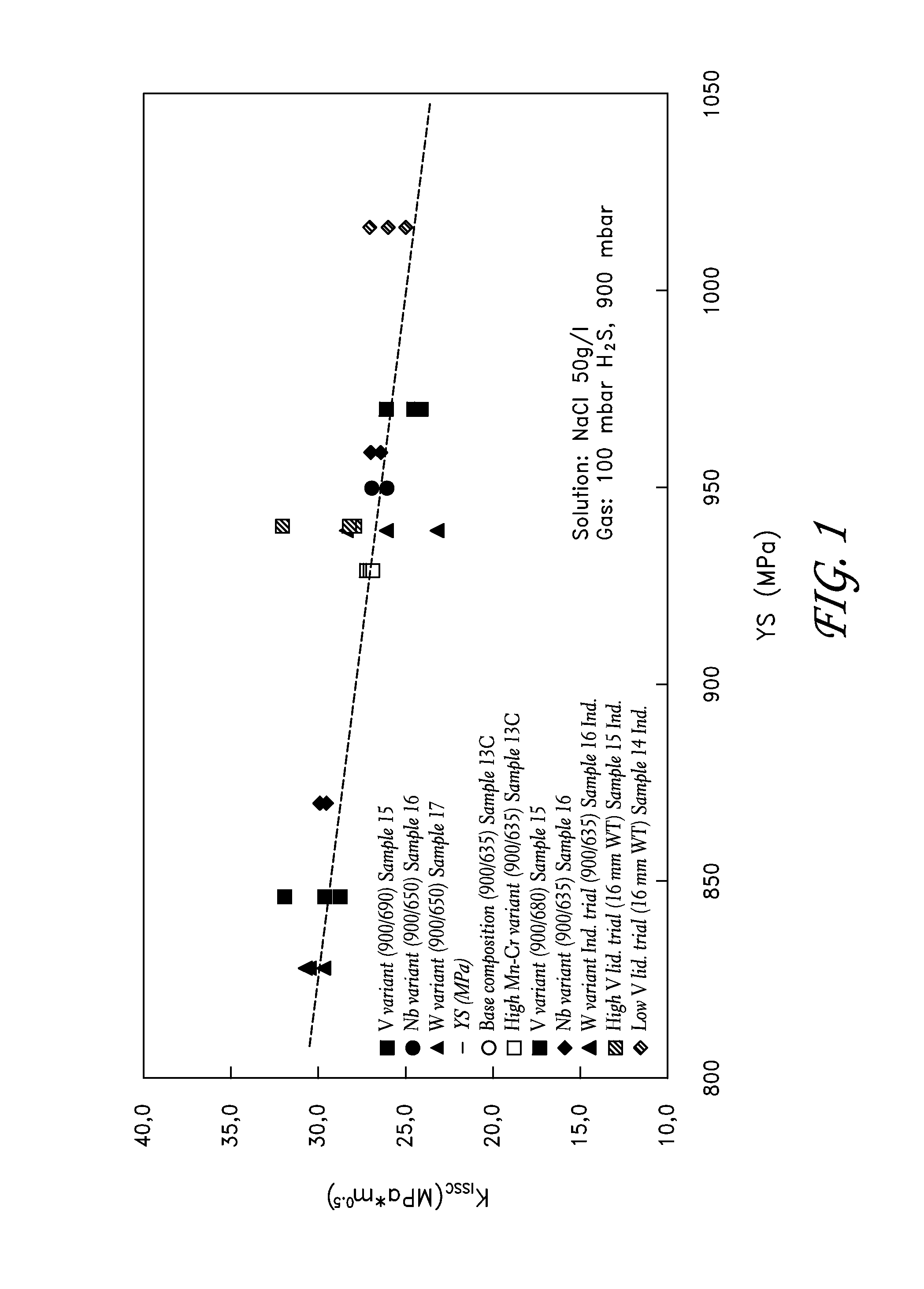

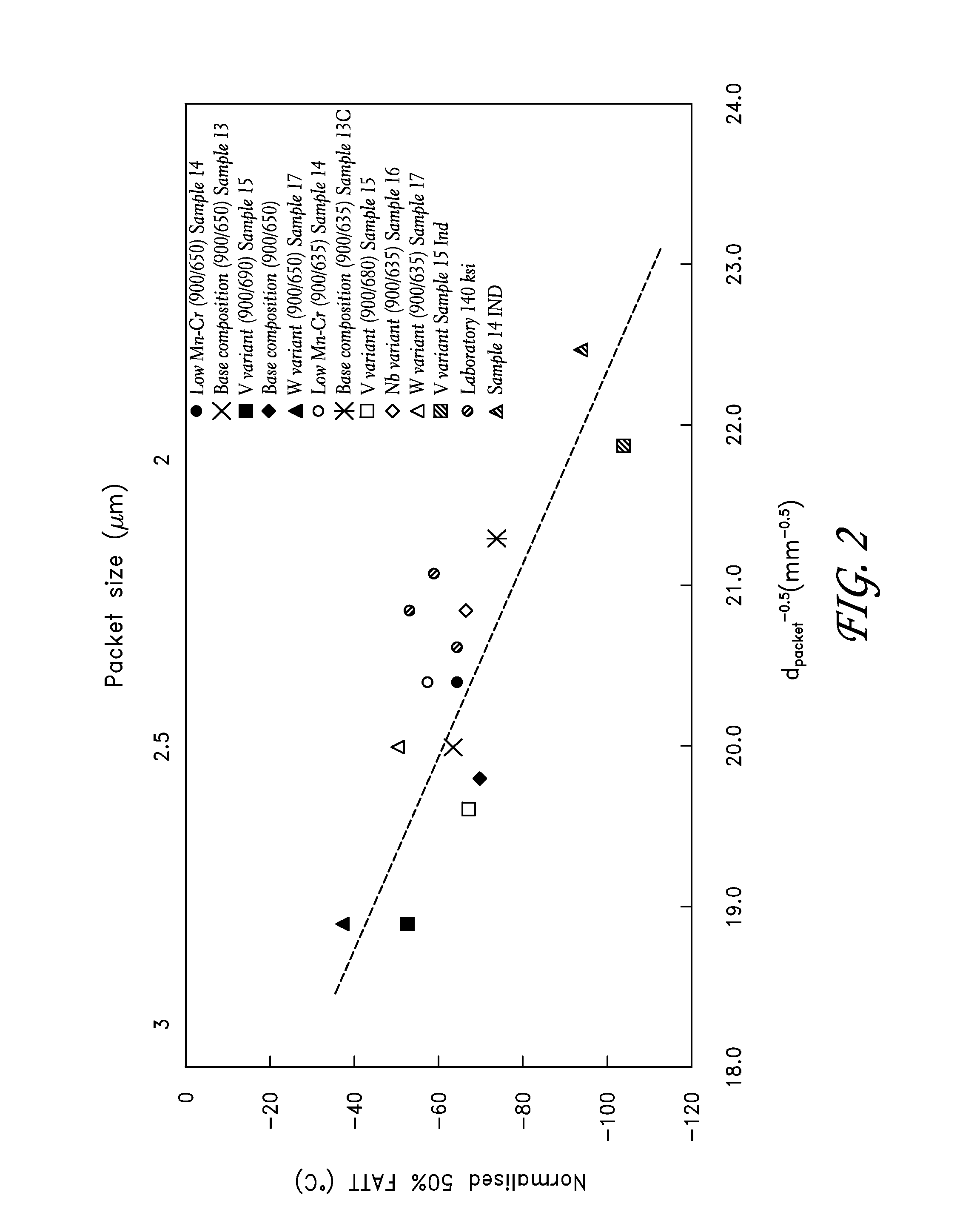

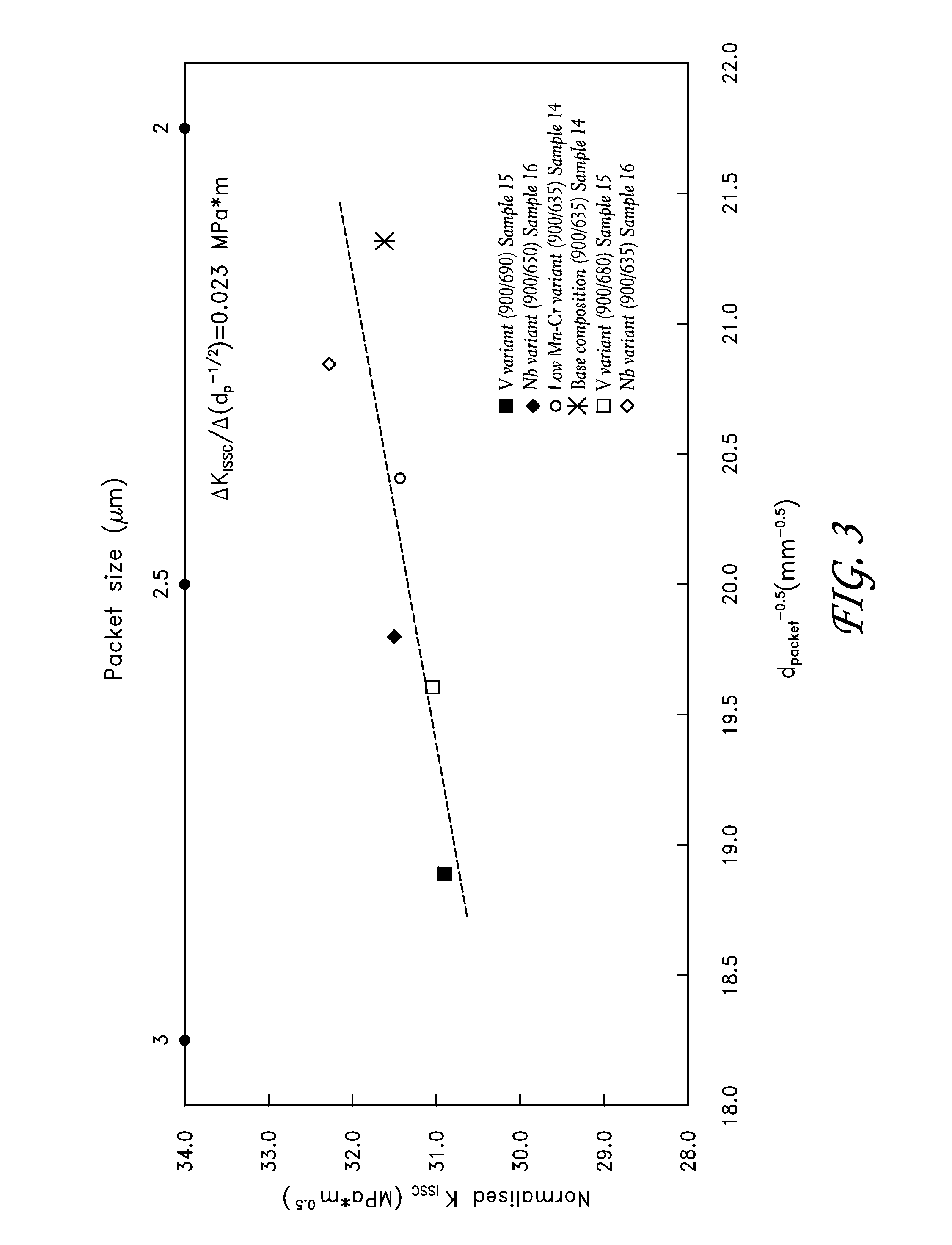

Steels for sour service environments

Embodiments of the present application are directed towards steel compositions that provide improved properties under corrosive environments. Embodiments also relate to protection on the surface of the steel, reducing the permeation of hydrogen. Good process control, in terms of heat treatment working window and resistance to surface oxidation at rolling temperature, are further provided.

Owner:TENARIS CONNECTIONS

Preparation method of indium phosphide quantum dots

InactiveCN107098324AUniform size distributionGood optical performanceLuminescent compositionsPhosphidesIndiumSurface oxidation

The invention provides a preparation method of indium phosphide quantum dots. The preparation method comprises the following steps: firstly mixing an indium precursor, an acid ligand and a non-coordinating solvent and preparing a uniform indium precursor solution; then adding hydrogen phosphide at a temperature of 100-130 DEG C, raising the temperature to a second temperature and keeping for a period of time; finally regulating the solution to a third temperature and adding a precursor substance required by a synthetic shell to obtain the shell-coated indium phosphide quantum dots. The indium phosphide quantum dots with nuclear shell structures are synthesized by adopting the method of low-temperature nucleating, raised temperature-curing and high-temperature shell-coating; the nucleation and growth processes of indium phosphide nano crystalline nucleuses can be controlled at a low temperature, so that the synthesized quantum dots are uniform in size distribution; meanwhile, the risk of surface oxidation of the indium phosphide nano crystalline nucleuses can also be effectively avoided at a low temperature, so that the optical performance of the indium phosphide quantum dots are improved to a certain degree.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

Steels for sour service environments

Embodiments of the present application are directed towards steel compositions that provide improved properties under corrosive environments. Embodiments also relate to protection on the surface of the steel, reducing the permeation of hydrogen. Good process control, in terms of heat treatment working window and resistance to surface oxidation at rolling temperature, are further provided.

Owner:TENARIS CONNECTIONS

Method of surface oxidizing zirconium and zirconium alloys and resulting product

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the oxidative treatment of an amorphous zirconium or zirconium alloy substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

Hot press forming method, and a plated steel material therefor and its manufacturing method

InactiveUS20050252262A1Solve the lack of corrosion resistanceSolve the lack of resistanceHot-dipping/immersion processesAnodisationElectrolysisSurface oxidation

Hot press forming of a steel material is made possible by coating the surface of the steel material with a plated layer of zinc or a zinc alloy and forming thereon a barrier layer which prevents the vaporization of zinc even when heated to 700-1000° C. Corrosion resistance can also be guaranteed without requiring post treatment, and hot press forming of high tensile steel sheet and stainless steel sheet is made possible. The barrier layer is formed by forming an upper plated layer, by surface oxidation, by contact with an oxidizing agent, by contact with Zn and an oxidizing agent, by anodic electrolysis, by cathodic electrolysis, or by coating with a ZnO sol.

Owner:NIPPON STEEL CORP

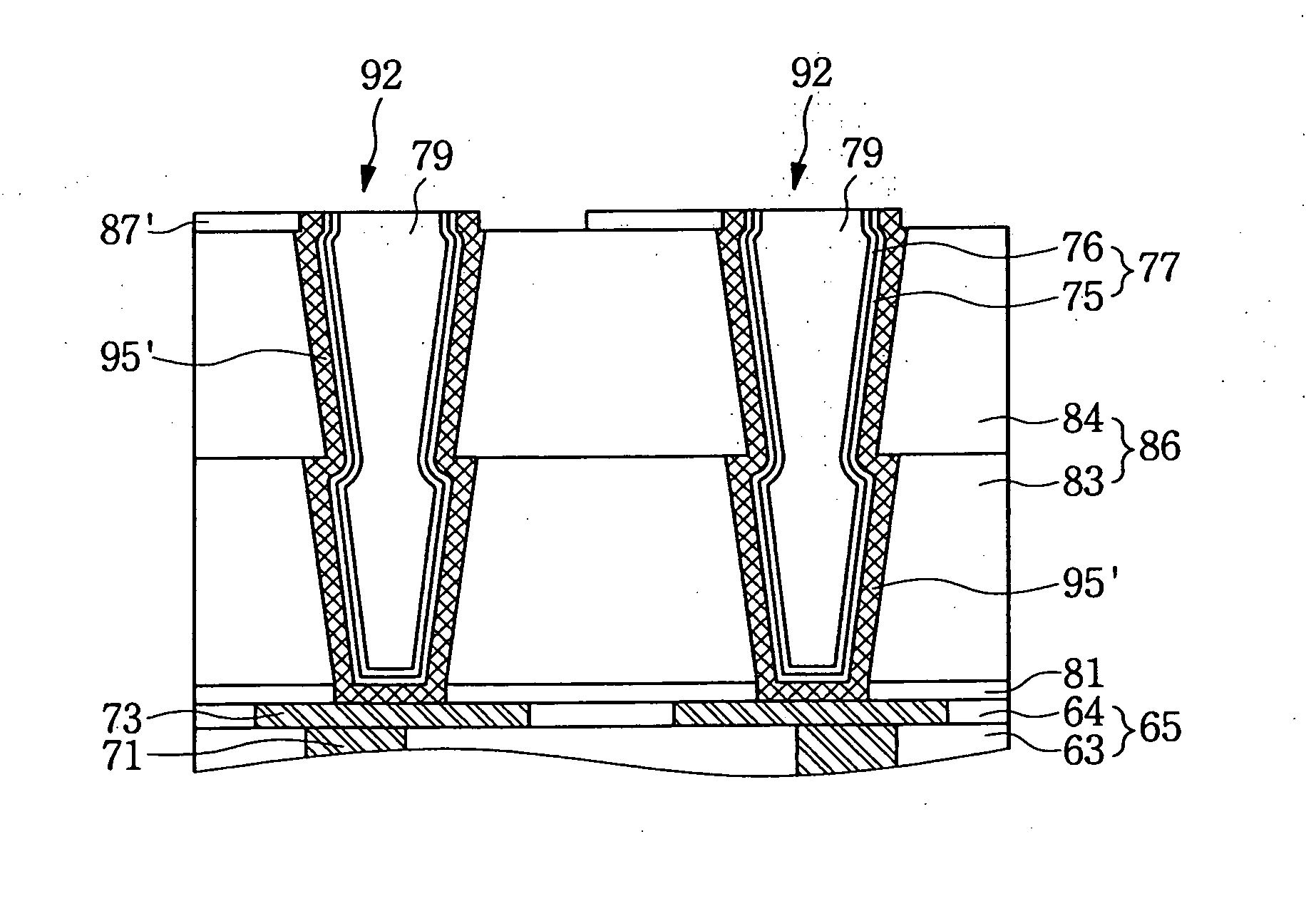

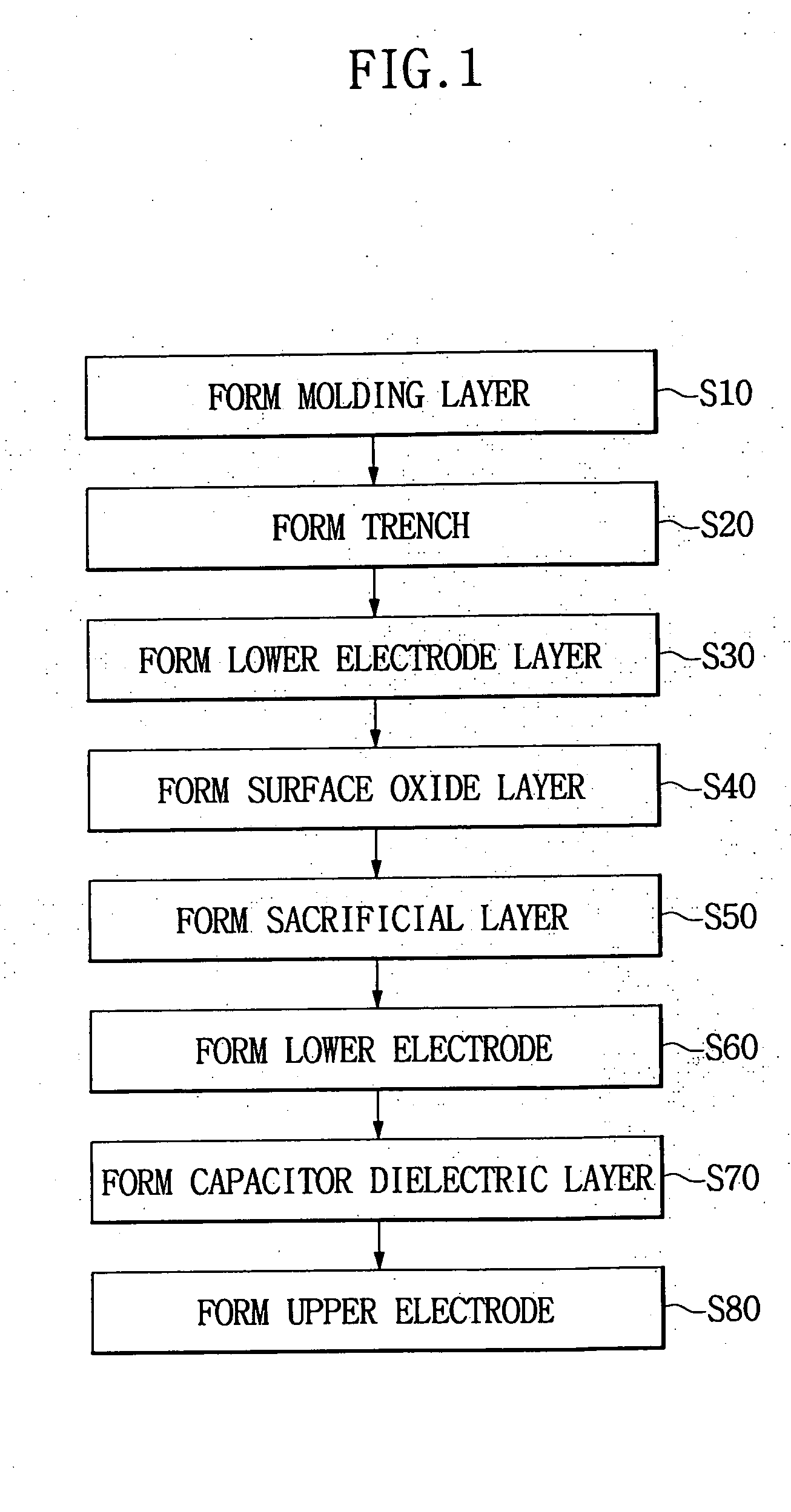

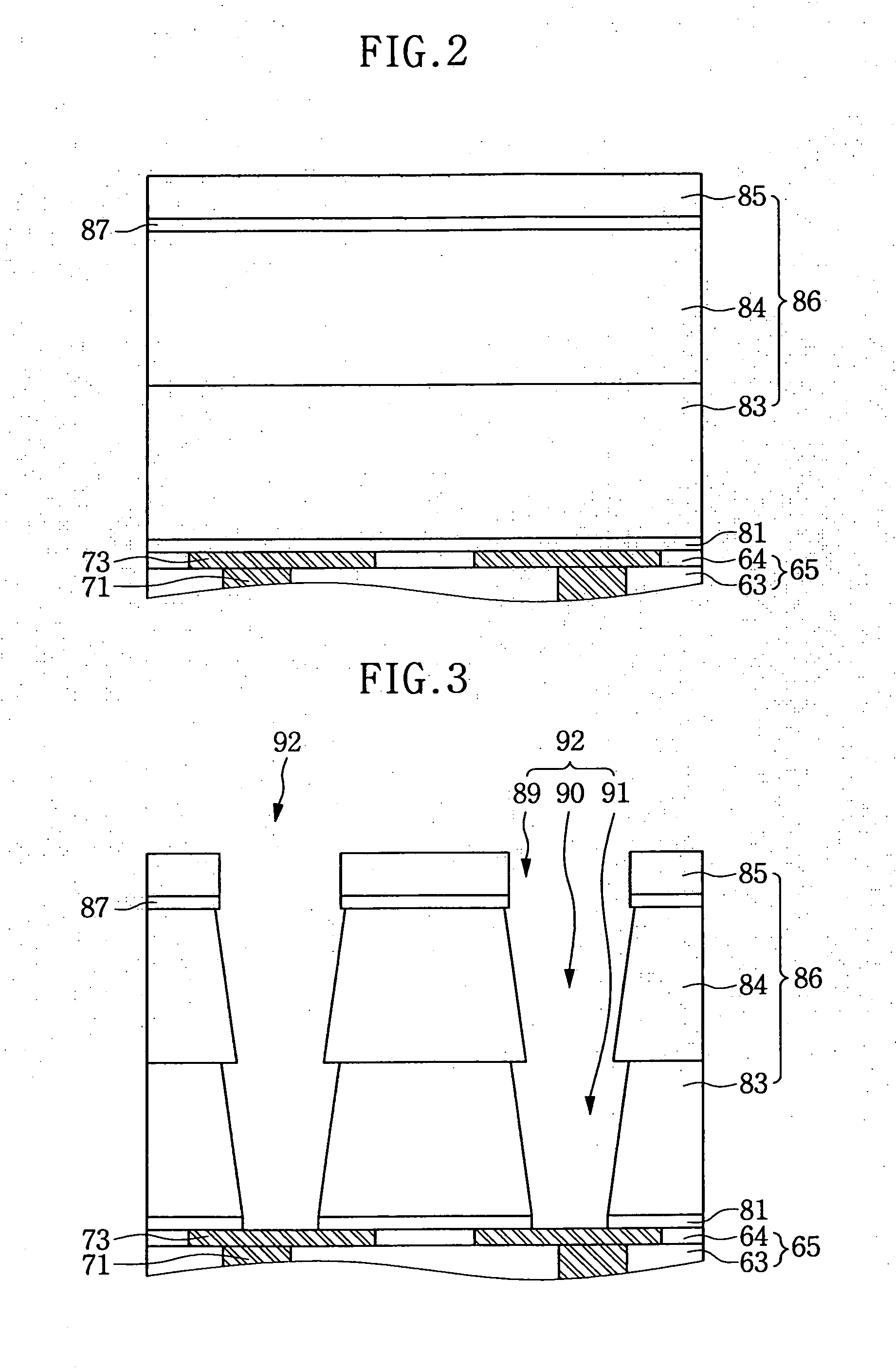

Method of forming semiconductor device having a capacitor

ActiveUS20100240191A1Avoid surface contaminationSolid-state devicesSemiconductor/solid-state device manufacturingSurface oxidationDielectric layer

A method of forming a semiconductor device includes forming a lower electrode layer on a substrate, forming a surface oxide layer on the lower electrode layer, partially removing the lower electrode layer to form a lower electrode, removing the surface oxide layer to expose the lower electrode, forming a capacitor dielectric layer on the lower electrode, and forming an upper electrode on the capacitor dielectric layer.

Owner:SAMSUNG ELECTRONICS CO LTD

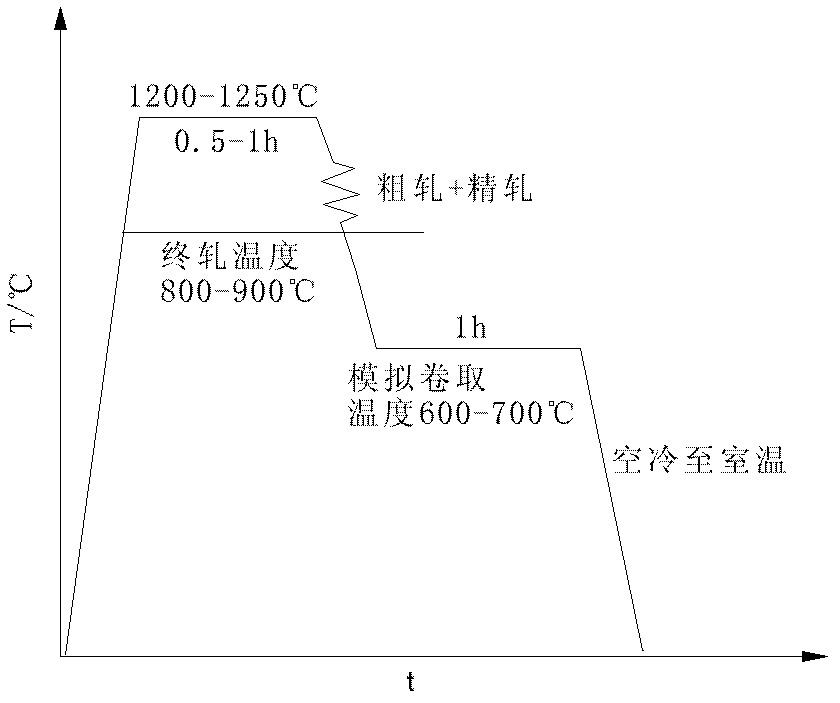

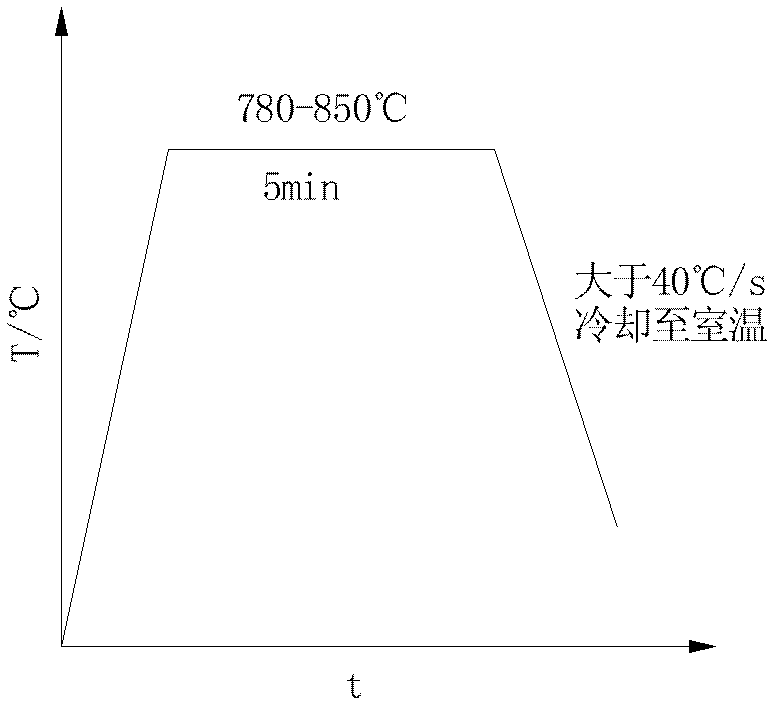

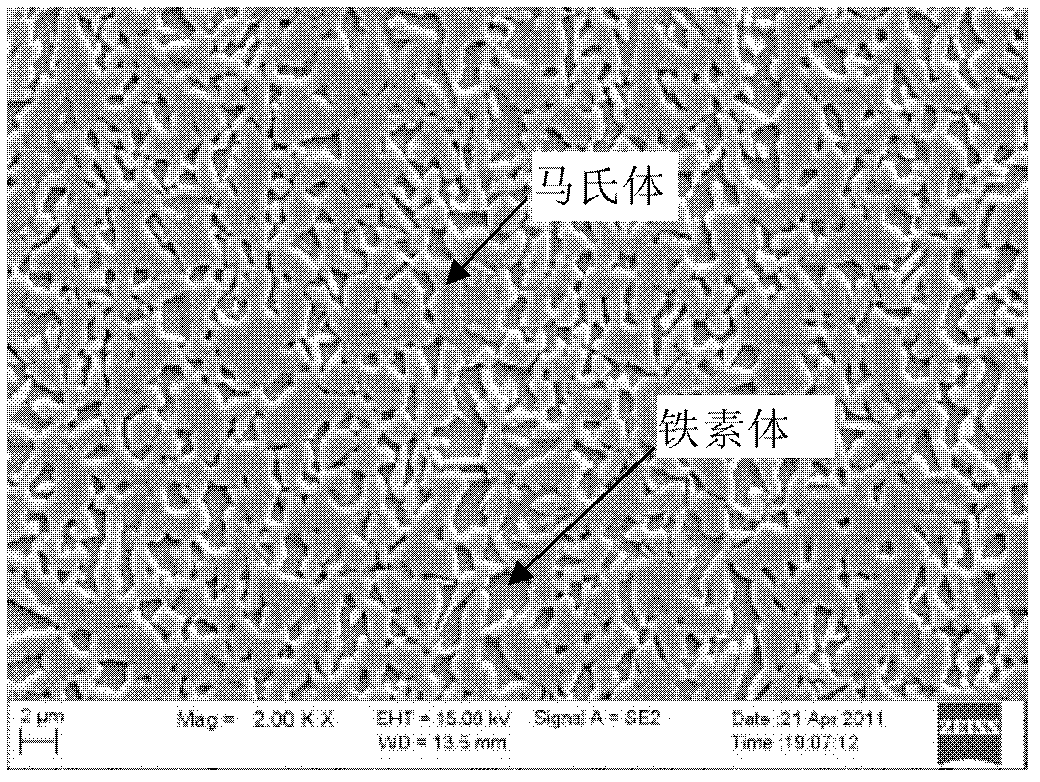

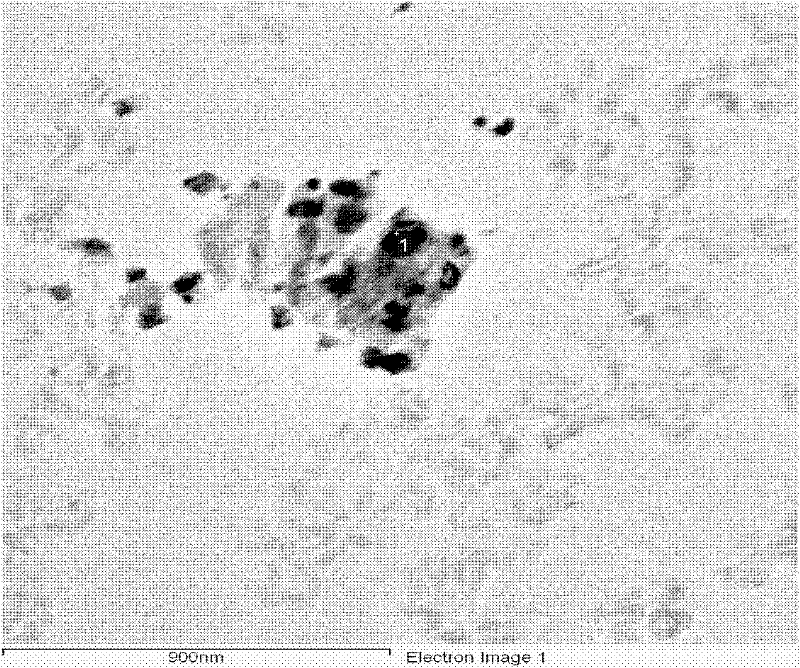

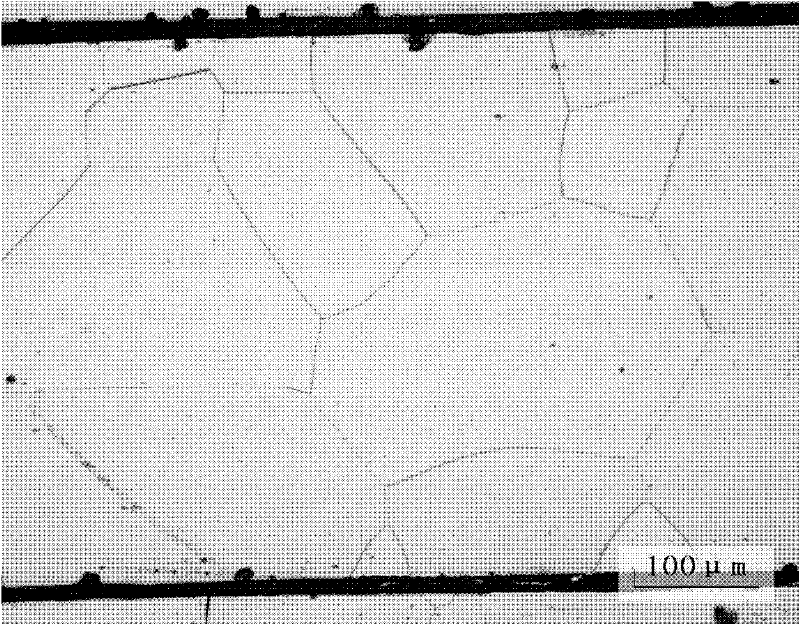

A kind of preparation method of dual-phase hot forming steel

The invention provides a preparation method for double-phase forming steel, which belongs to the technical field of high-intensity steel for automobiles. The steel comprises the following ingredients by mass percent: 0.1 to 0.5 percent of C, 0.3 to 2.5 percent of Si, 1.0 to 3.0 percent of Mn, 1.0 to 3.0 percent of Al, at most 0.02 percent of P, at most 0.01 percent of S, at most 0.01 percent of Nand the balance iron and unavoidable impurities. A production process comprises the following steps of: smelting, hot rolling and hot forming process simulation after the hot rolling. The controlled process parameters are as follows: hot rolling plate blanks are heated to 1200 to 1250 DEG C, the heat insulation is carried out for 0.5 to 1 hour, the final rolling temperature is 800 to 900 DEG C, and the coiling temperature is 600 to 700 DEG C. The hot forming process comprises the following steps of: carrying out heat insulation for 5min at the heating temperature being 750 to 850 DEG C and cooling the materials to the room temperature at the speed greater than 40 DEG C / s. The preparation method adopts the Al micro alloying treatment. Compared with the traditional thermal forming manganeseboron steel, the double-phase forming steel has the advantages that: 1, the hot forming heating temperature is low, and the surface oxidation is reduced; and 2, tissues after the hot forming are ferrite and martensite double-phase tissues.

Owner:UNIV OF SCI & TECH BEIJING

Production method for high-grade non-oriented silicon steel

The invention relates to a manufacturing method for non-oriented electric steel. The method comprises the following steps of: smelting according to a clean steel process and continuously casting into billets; heating the continuous casting billets; performing hot rolling; reeling; naturally cooling to room temperature; normalizing; performing acid washing conventionally; performing cold rolling for the first time; performing intermediate annealing in the total hydrogen atmosphere or the mixed atmosphere of hydrogen and nitrogen; performing cold rolling for the second time; performing final annealing; and cooling conventionally, coating and finishing for later use. The finished product silicon steel with coarse grains and good texture can be obtained by adopting lower process heat treatment temperature; brittleness of the steel is reduced and cold rolling performance of a steel plate is improved by adopting lower normalizing temperature and intermediate annealing temperature; the problems of surface oxidation of the steel plate, nodulation of a furnace bottom roller and the like can be effectively solved by adopting lower finished product annealing temperature; and the high-grade non-oriented silicon steel with lower iron loss can be produced stably.

Owner:武汉钢铁有限公司

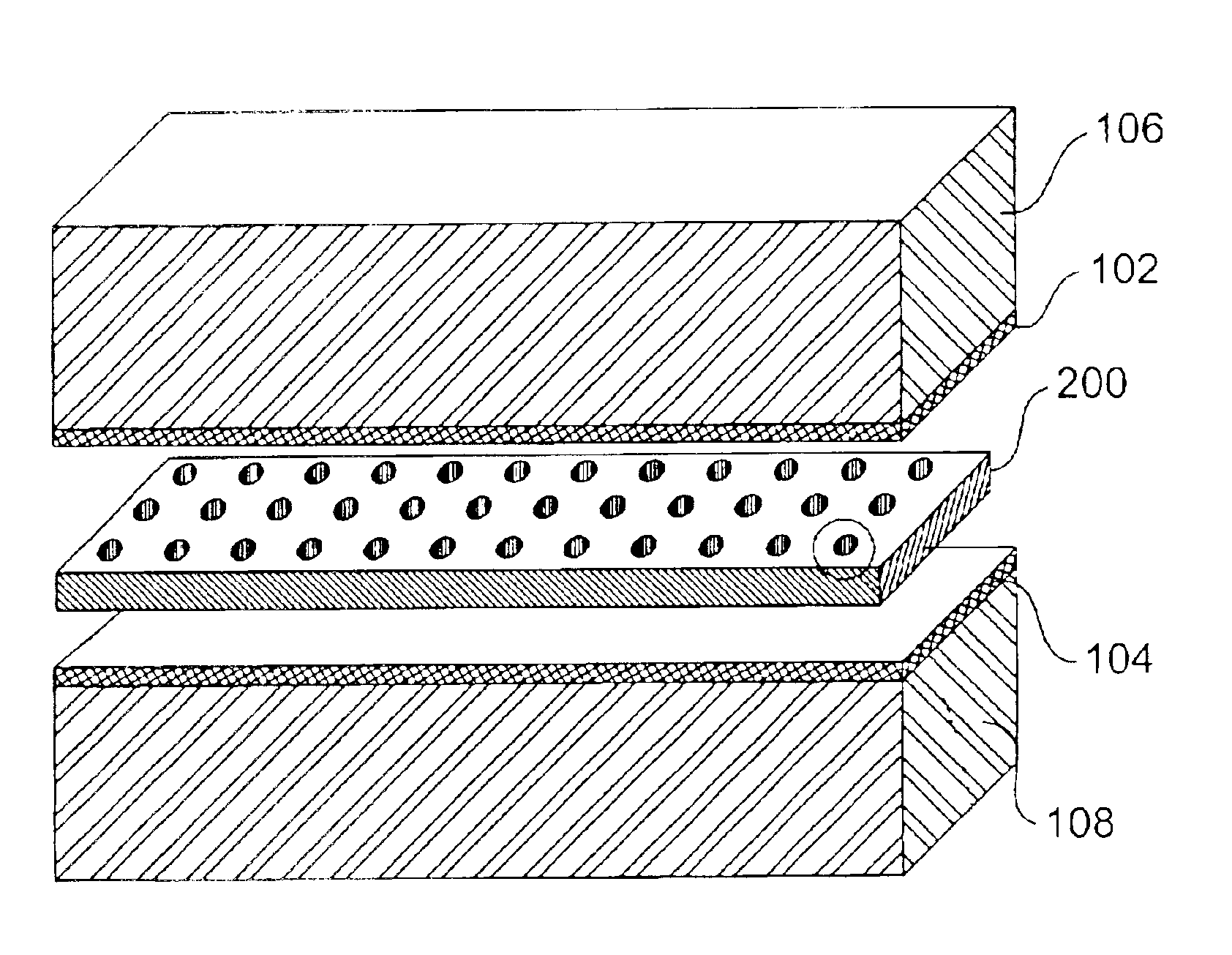

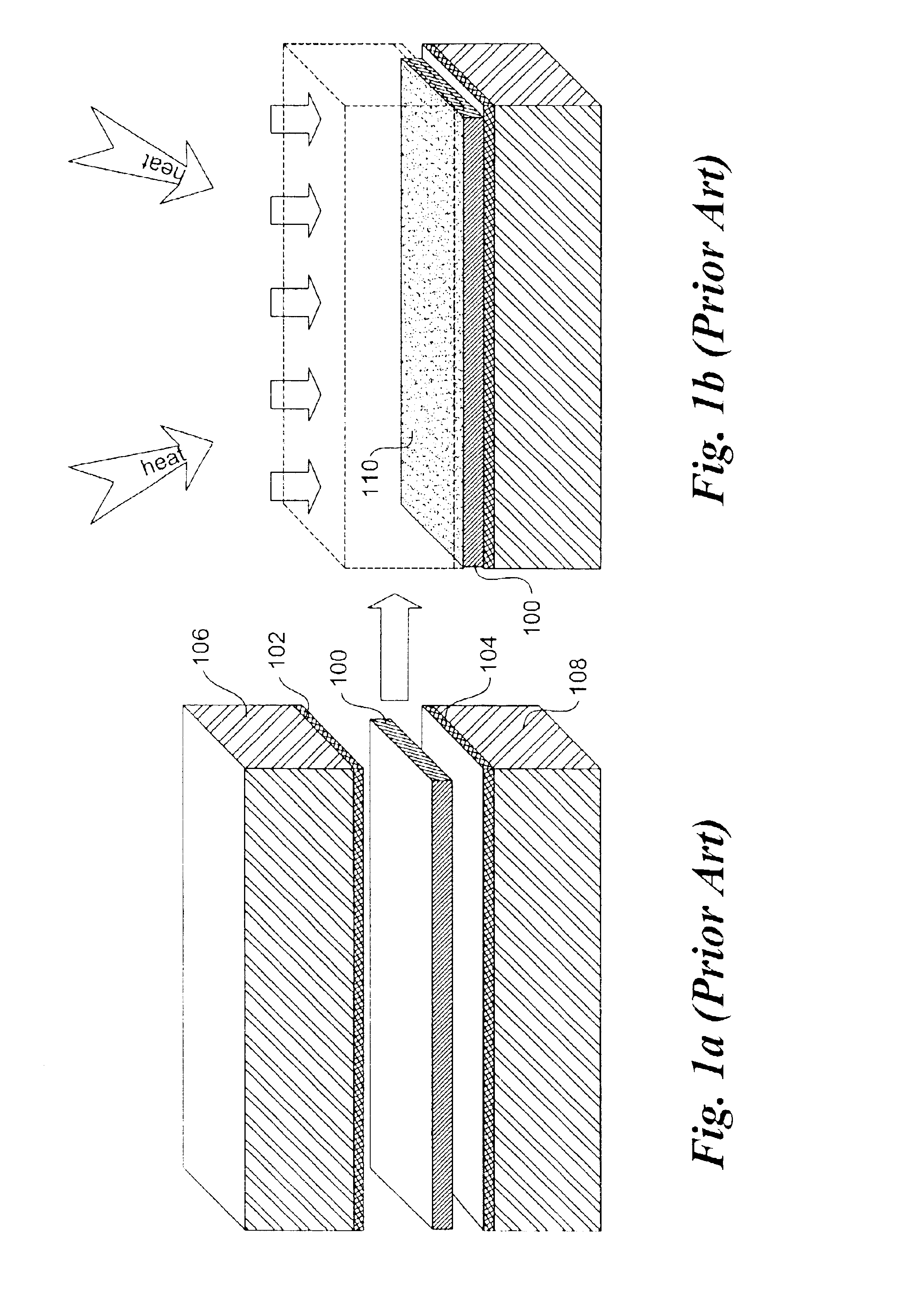

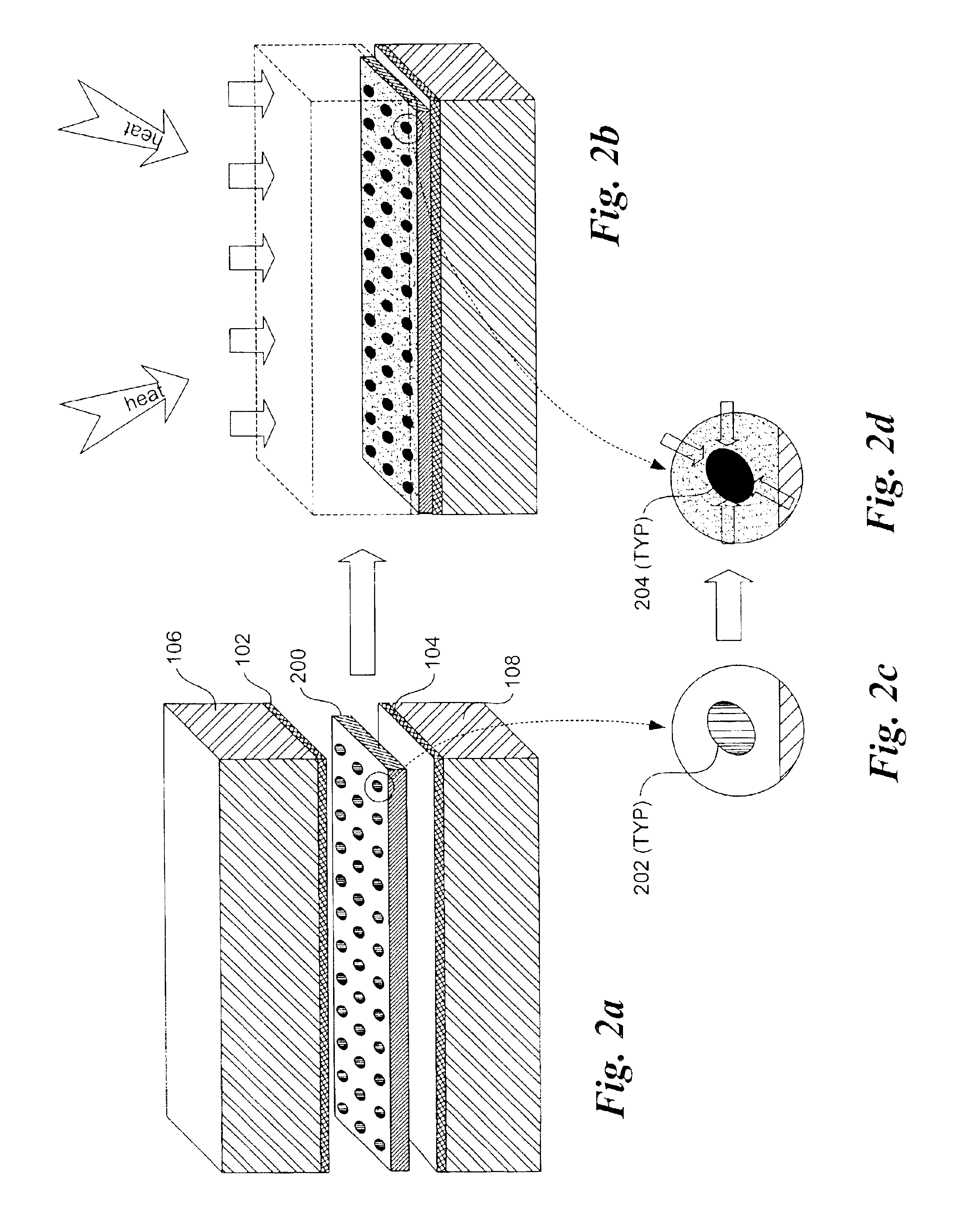

Approaches for fluxless soldering

InactiveUS6848610B2Printed circuit assemblingWelding/cutting media/materialsSurface oxidationThin layer

Improved fluxless soldering processes are disclosed. In accordance with one technique, a solder preform having a plurality of voids formed on its primary surfaces is disposed between metallized surfaces of a pair of members to be joined. Upon reaching the reflow temperature, fresh solder flows into the voids and wets portions of the metallized surfaces, thus overcoming the solder surface oxidation problem common to fluxless soldering processes. In accordance with another technique, a solder preform having primary surfaces coated with a thin layer of a noble metal is employed. The noble metal substantially prevents oxidation of the solder performs surfaces while the preform is heated to reach reflow temperature. As the solder temperature increases, portions of the noble metal are dissolved into the bulk solder material. Thus, during reflow, non-oxidized bulk solder material is enabled to wet the metallized surfaces of the pair of members.

Owner:INTEL CORP

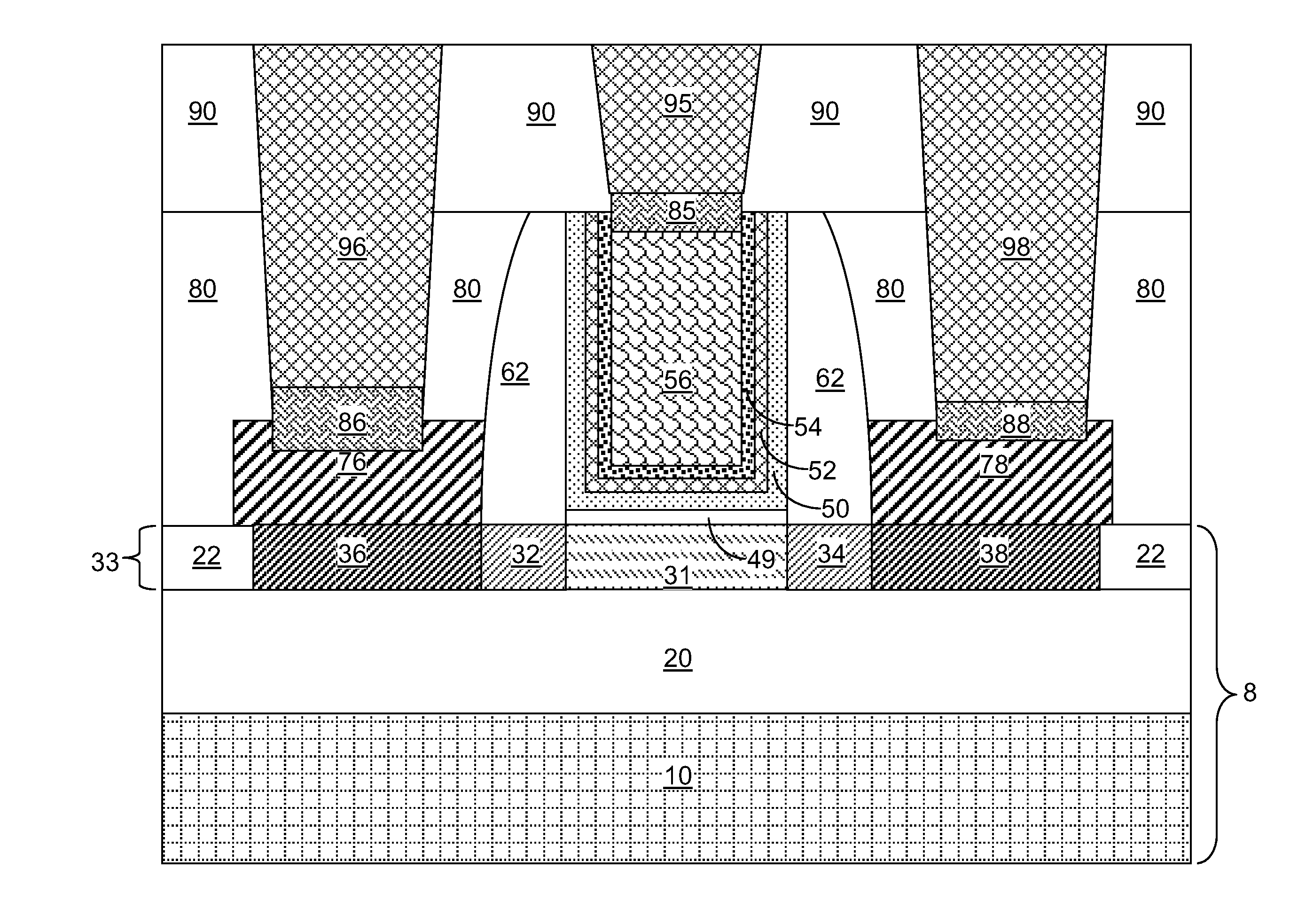

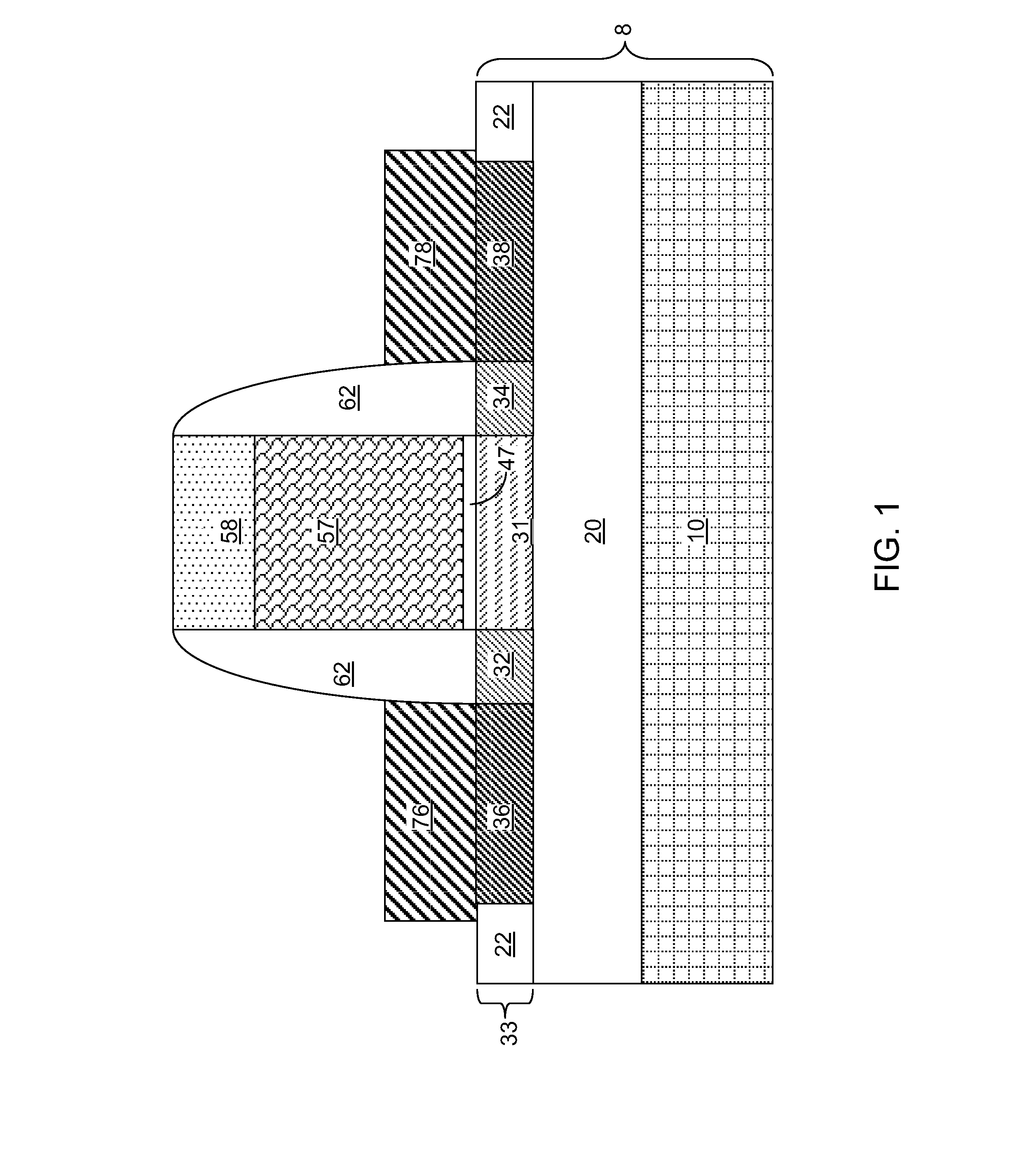

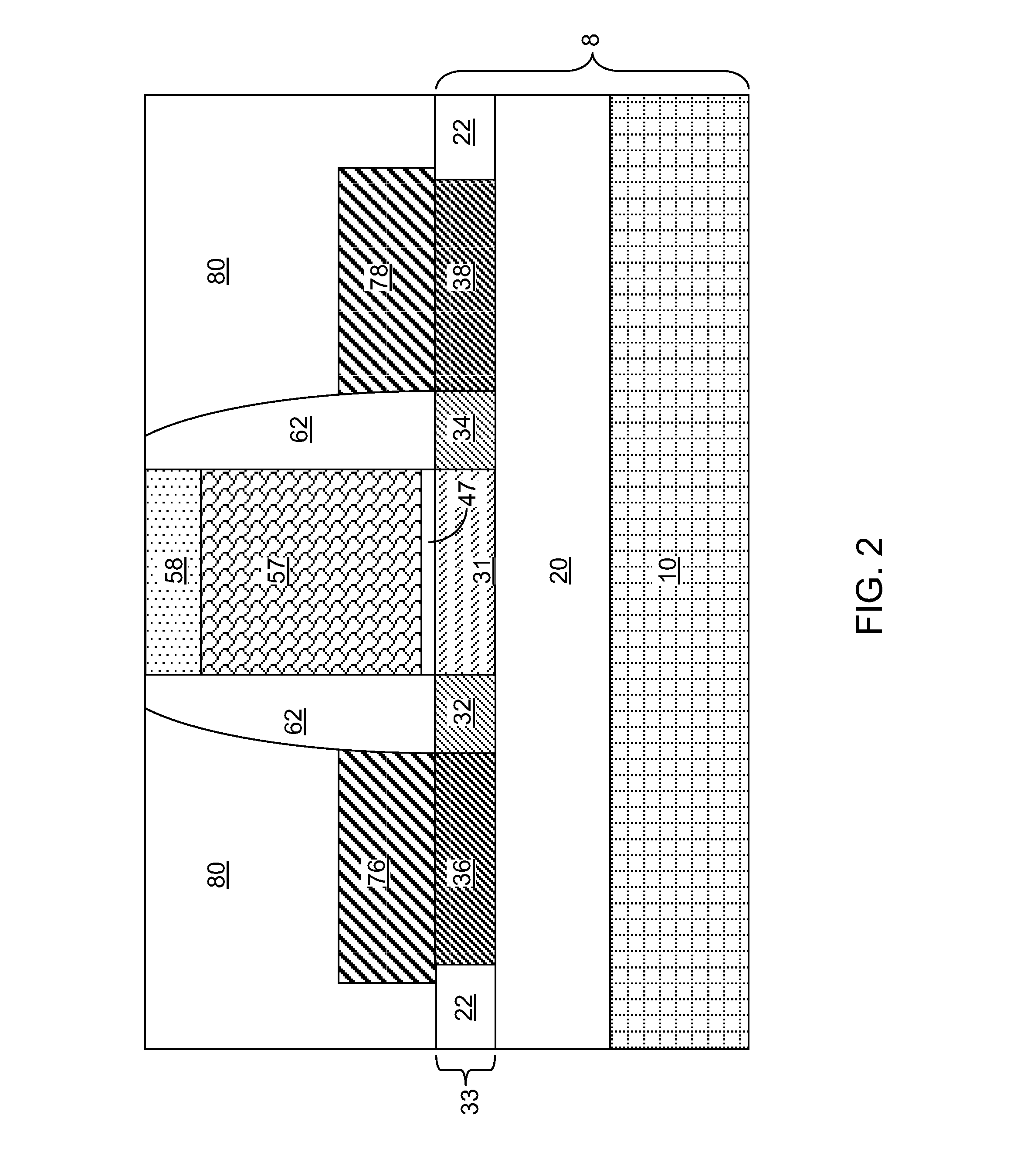

Replacement metal gate with a conductive metal oxynitride layer

ActiveUS20130009257A1Lower work functionSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricSurface oxidation

A disposable gate structure and a gate spacer are formed on a semiconductor substrate. A disposable gate material portion is removed and a high dielectric constant (high-k) gate dielectric layer and a metal nitride layer are formed in a gate cavity and over a planarization dielectric layer. The exposed surface portion of the metal nitride layer is converted into a metal oxynitride by a surface oxidation process that employs exposure to ozonated water or an oxidant-including solution. A conductive gate fill material is deposited in the gate cavity and planarized to provide a metal gate structure. Oxygen in the metal oxynitride diffuses, during a subsequent anneal process, into a high-k gate dielectric underneath to lower and stabilize the work function of the metal gate without significant change in the effective oxide thickness (EOT) of the high-k gate dielectric.

Owner:IBM CORP

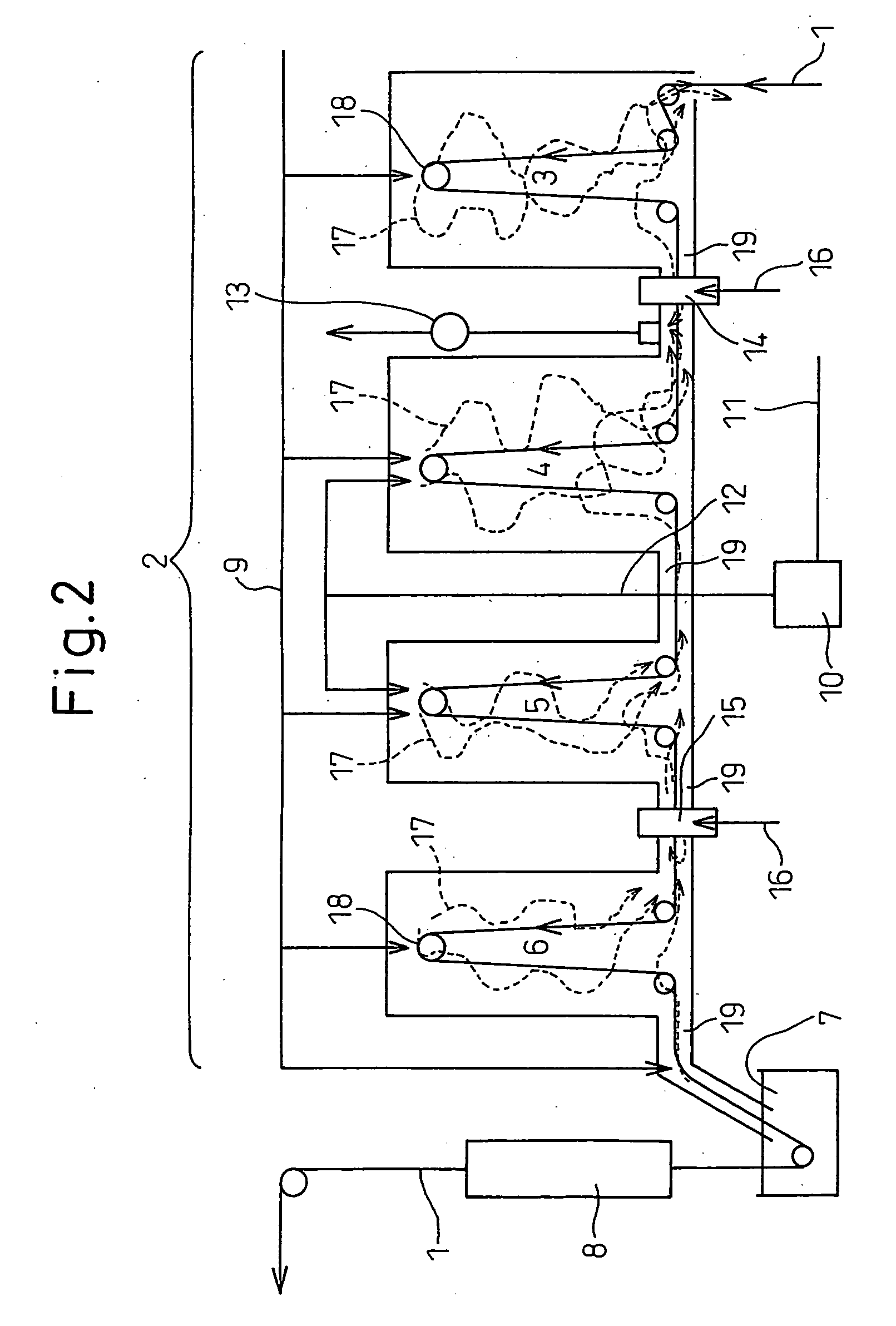

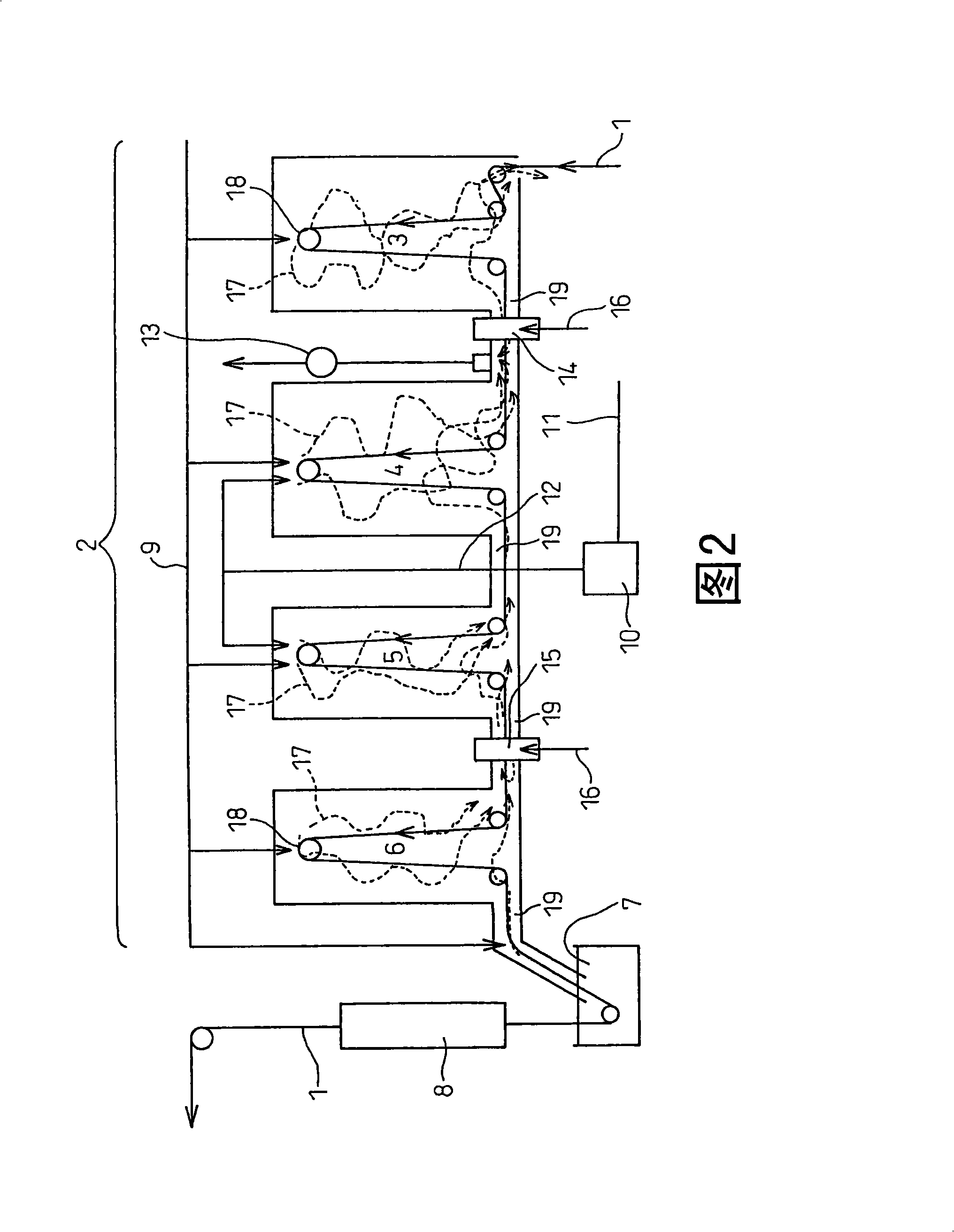

Method of continous annealing/hot-dipping of steel sheet containing silicon and apparatus for continuous annealing/hot-dipping

ActiveCN101287854ASuppressor enrichmentAvoid generatingHot-dipping/immersion processesFurnace typesSheet steelHydrogen

A method of continuous annealing / hot-dipping using a hot-dipping apparatus having an annealing furnace in which a silicon-containing steel sheet is hot-dipped. In this method, the silicon contained in the steel is caused to undergo internal oxidation without undergoing surface oxidation to thereby avoid a decrease in deposit adhesion to the steel and a delay in galvannealing. Also provided is the apparatus for use in this method. The method of continuous annealing / hot-dipping employs an annealing furnace having a former heating zone, latter heating zone, heat retention zone, and cooling zone in this order and a hot-dipping bath. It comprises conducting annealing under the following conditions. In regions where the steel sheet has a temperature of at least 300 DEG C, the steel sheet is heated or kept hot by means of indirect heating. The atmosphere inside the furnace in each zone is an atmosphere consisting of 1-10 vol.% hydrogen and, as the remainder, nitrogen and unavoidable impurities. In the former heating zone, the steel is heated to a maximum temperature of 550-750 DEG C and the atmosphere is regulated so as to have a dew point lower than -25 DEG C. In the subsequent latter heating zone and heat retention zone, the dew point is regulated to from -30 DEG C to 0 DEG C. In the cooling zone, the dew point is regulated to below -25 DEG C.

Owner:NIPPON STEEL CORP

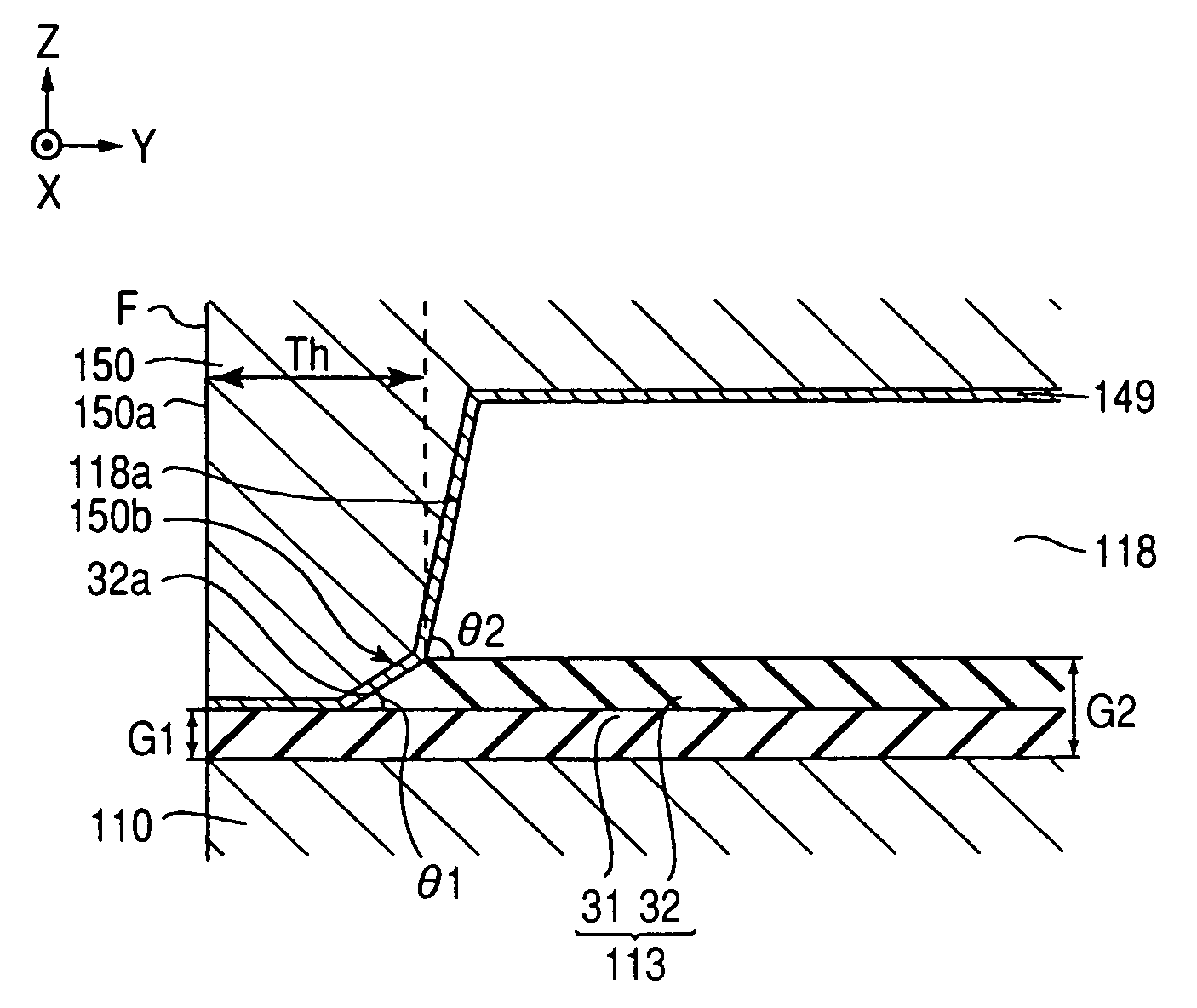

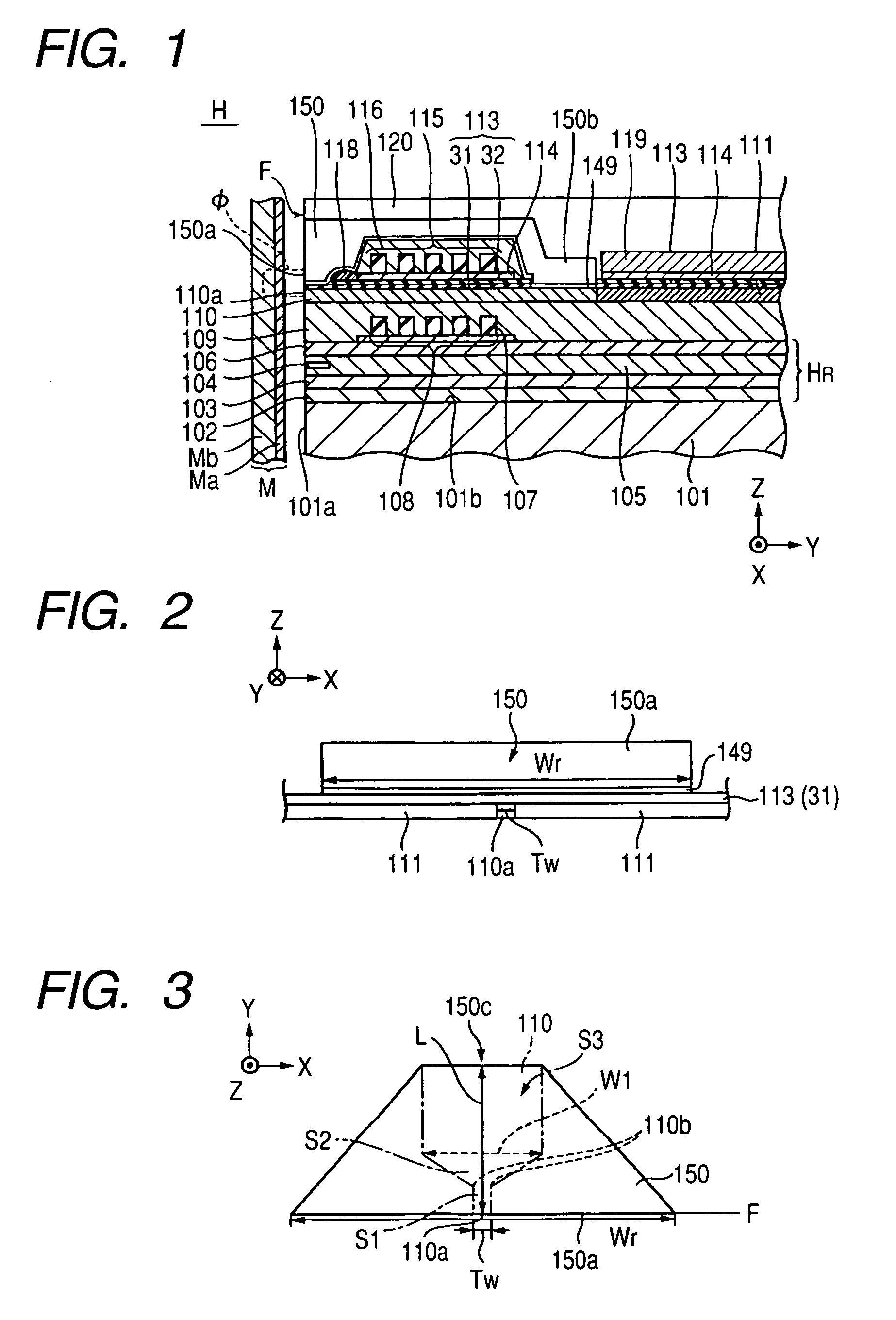

Method of manufacturing perpendicular magnetic recording head capable of highly precisely defining gap distance

InactiveUS7343668B2Control performanceImprove balanceDecorative surface effectsRecord information storageResistSurface oxidation

A method of manufacturing a perpendicular magnetic recording head is provided. The method accurately defines a gap layer. The method includes forming a lower gap layer made of a non-magnetic material on a main magnetic pole layer. An upper gap layer is formed on the lower gap layer, the upper gap layer being made of the non-magnetic material. A resist layer is formed on the upper gap layer, and the resist layer is removed from an end surface. The upper gap layer not covered with the resist layer is removed, while exposing a new film surface by removing a surface oxidation layer of the resist layer. A return path layer is formed by plating on the exposed lower gap layer, the upper gap layer, and the resist layer through the plating underlayer.

Owner:TDK CORPARATION

Hot press forming method, and a plated steel material therefor and its manufacturing method

InactiveCN1575348ASufficient corrosion resistanceGuaranteed corrosion resistanceHot-dipping/immersion processesAnodisationElectrolysisSheet steel

Hot press forming of a steel material is made possible by coating the surface of the steel material with a plated layer of zinc or a zinc alloy and forming thereon a barrier layer which prevents the vaporization of zinc even when heated to 700 - 1000 DEG C. Corrosion resistance can also be guaranteed without requiring post treatment, and hot press forming of high tensile steel sheet and stainless steel sheet is made possible. The barrier layer is formed by forming an upper plated layer, by surface oxidation, by contact with an oxidizing agent, by contact with Zn and an oxidizing agent, by anodic electrolysis, by cathodic electrolysis, or by coating with a ZnO sol.

Owner:NIPPON STEEL CORP

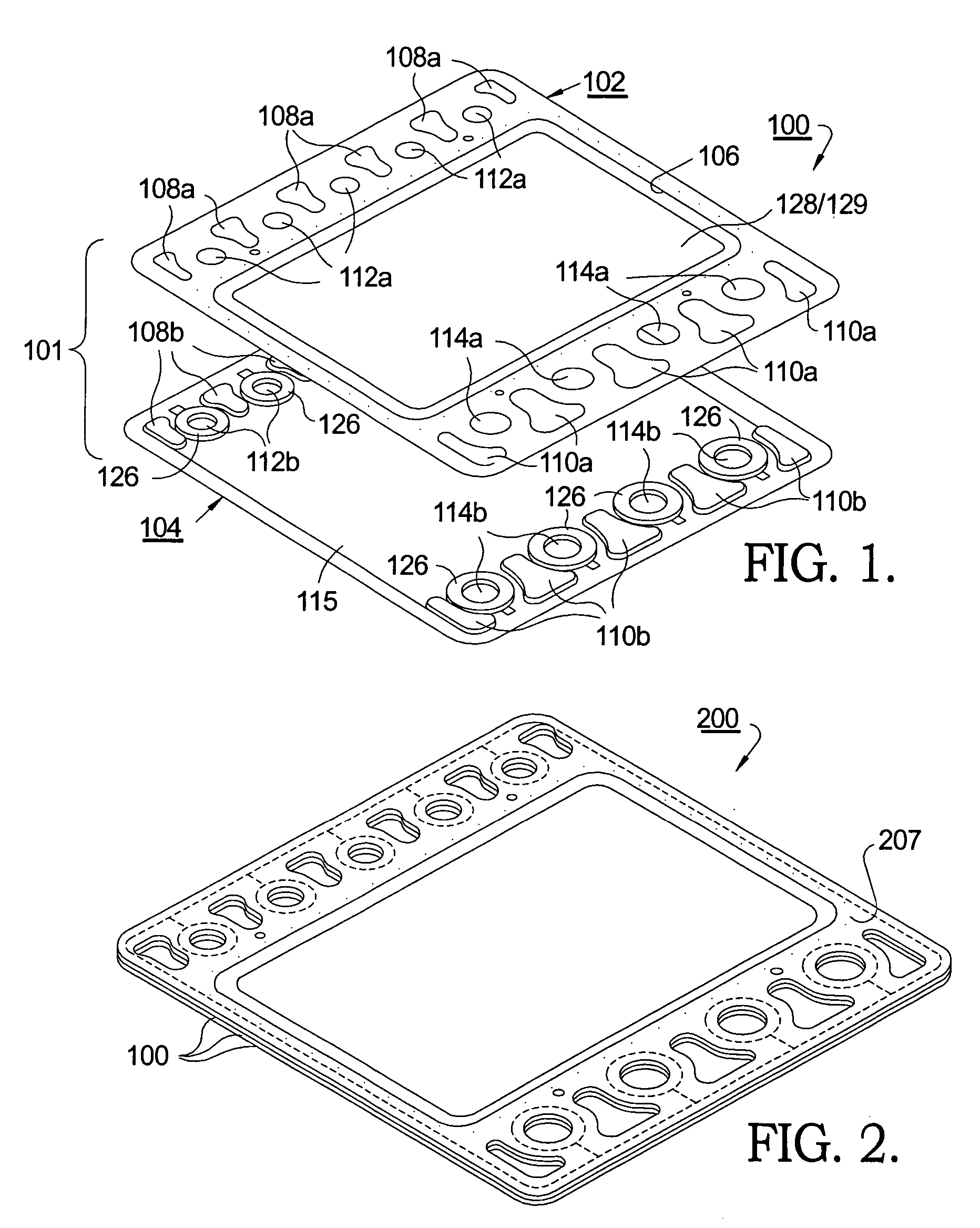

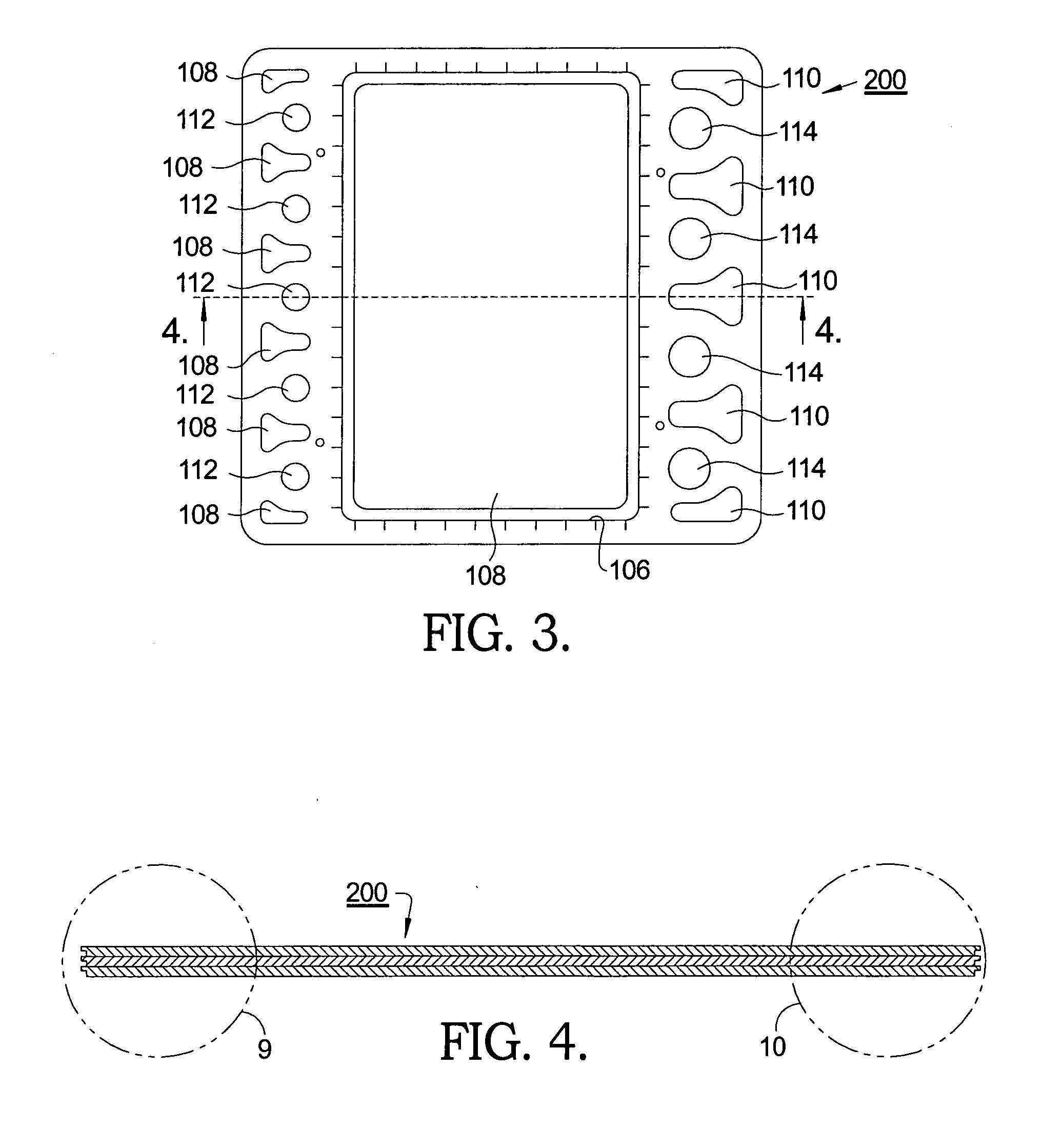

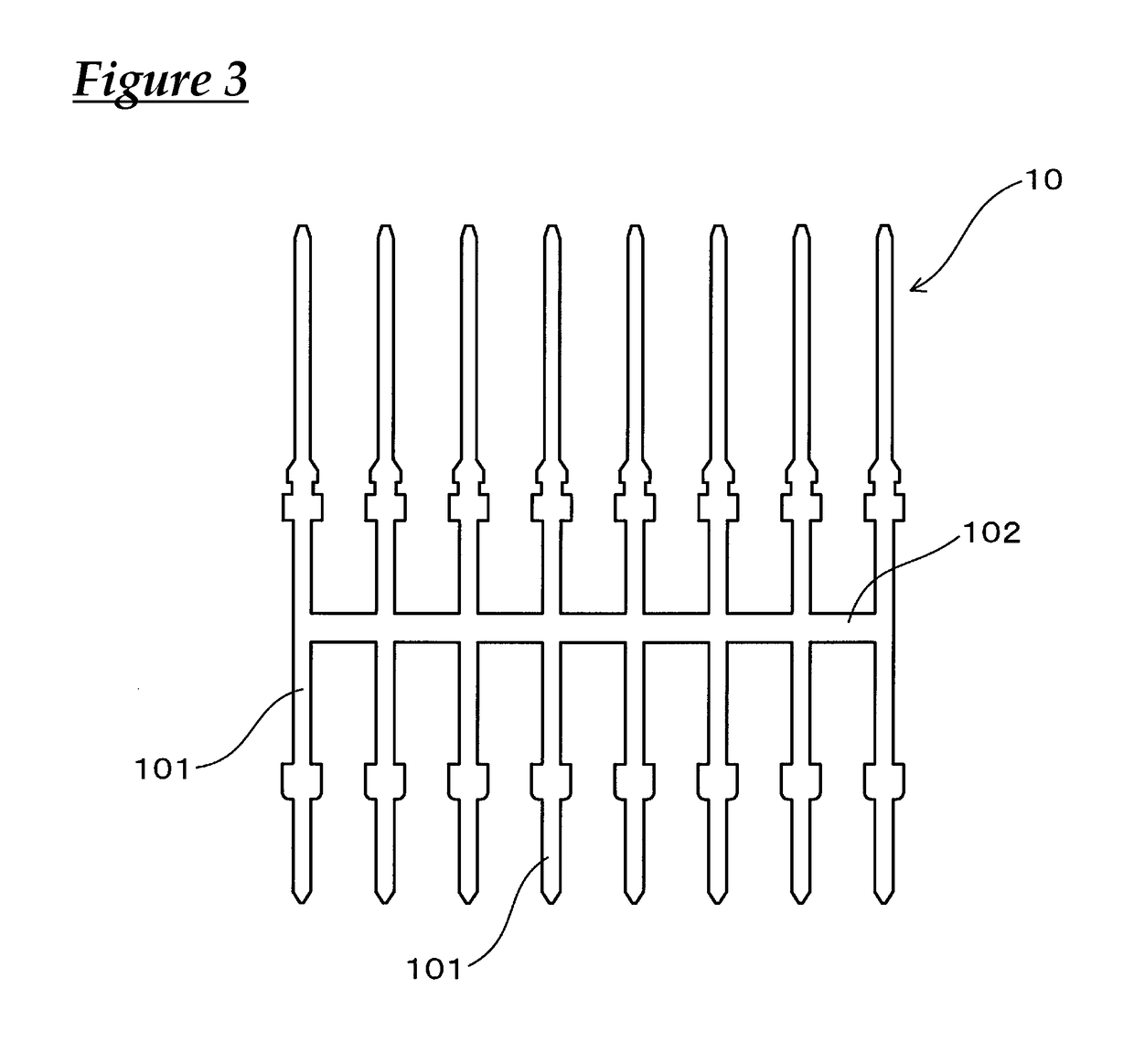

Terminal fitting and connector

ActiveUS10218102B2Less insertion forcePrevent surface oxidationContact member manufacturingCoupling contact membersSurface oxidationEngineering

A terminal fitting that can reduce the terminal insertion force and can suppress surface oxidation of a plating film, even if the terminal fitting is exposed to a hot and humid environment, and a connector that uses the terminal fitting. The terminal fitting includes a metal base material, and the plating film. The plating film includes a Ni foundation layer, an outermost layer exposed at the outermost surface, and a Ni3Sn4 layer formed between the Ni foundation layer and the outermost layer. The outermost layer includes a Sn parent phase, and intermetallic compound that is dispersed in the Sn parent phase, and is made of (Ni0.4Pd0.6)Sn4. The intermetallic compound protrudes from the lower side of the outermost layer to the Ni3Sn4 layer side, and is partially buried in the Ni3Sn4 layer. A connector includes the terminal fitting, and a housing that holds the terminal fitting.

Owner:AUTONETWORKS TECH LTD +2

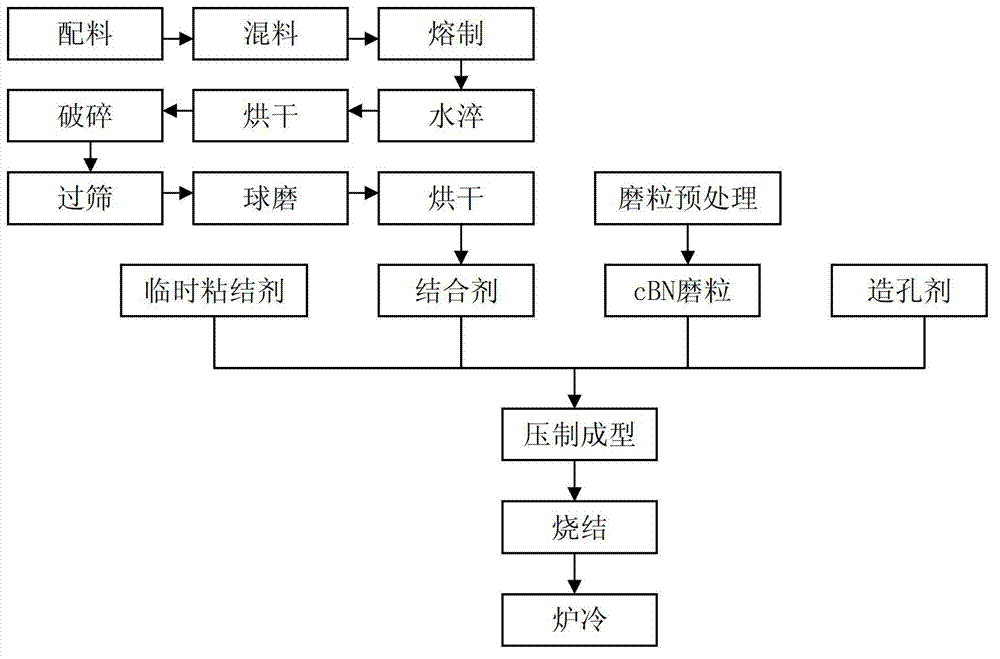

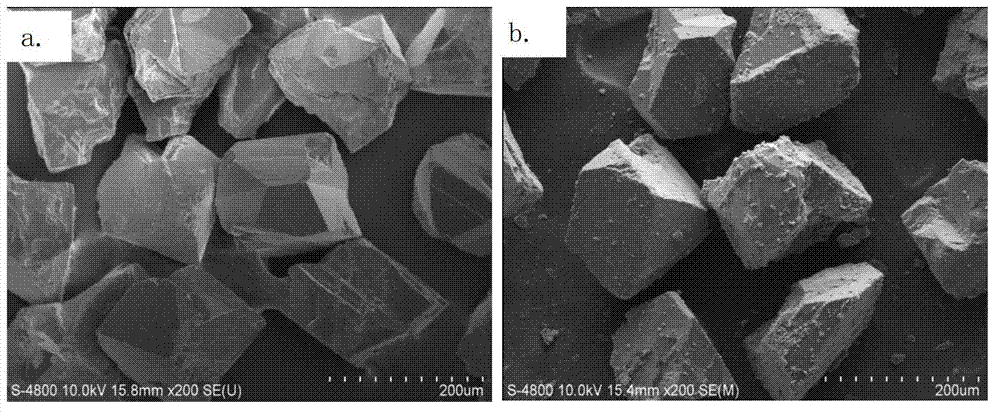

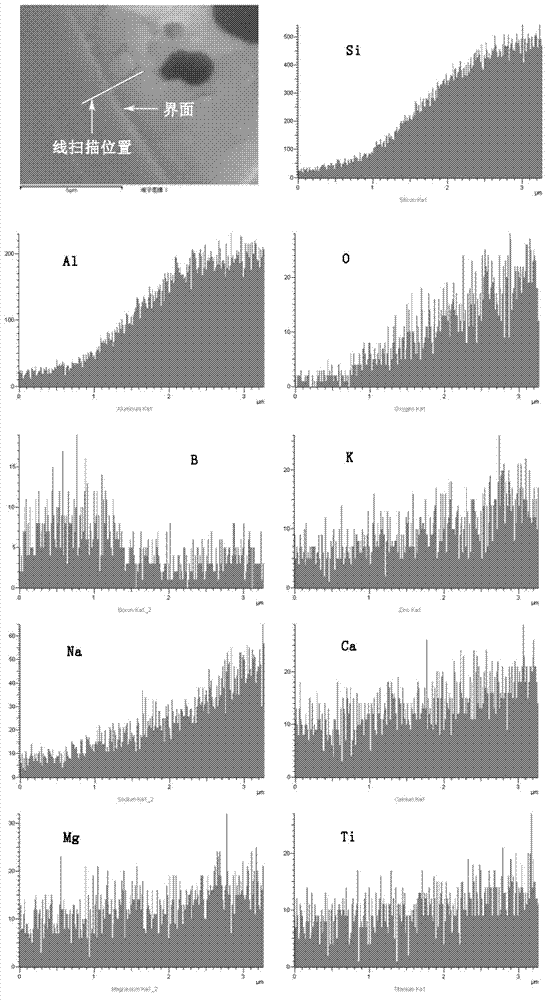

Ceramic bond cubic boron nitride abrasive tool and manufacturing method thereof

The invention discloses a ceramic bond cubic boron nitride abrasive tool and a manufacturing method of the ceramic bond cubic boron nitride abrasive tool. The method comprises preparing materials and mixing, placing mixed materials in an electric furnace for melting, conducting water quenching to prepare ceramic bond blocks, conducting smashing, ball-milling, sieving and drying on the ceramic bond blocks to prepare ceramic bond powder, conducting surface oxidation modified pretreatment on cubic boron nitride (cBN) grains, evenly mixing the ceramic bond powder, the cubic boron nitride (cBN) grains and a pore-forming agent NH4HCO3, obtaining a mixture, adding temporary binding agent polyethylene glycol in the mixture, evenly mixing to obtain abrasive tool raw materials, placing the abrasive tool raw materials in a die, conducting pressing shaping on a pressure machine to prepare an abrasive tool green body, placing the abrasive tool green body in a sintering furnace for sinter molding, and preparing the ceramic bond cubic boron nitride abrasive tool along with cooling of the furnace. The ceramic bond cubic boron nitride abrasive tool improves total strength of the abrasive tool, enables the abrasive tool to be not easy to break in using process, improves using safety of the abrasive tool, and prolongs service life of the abrasive tool.

Owner:XI AN JIAOTONG UNIV

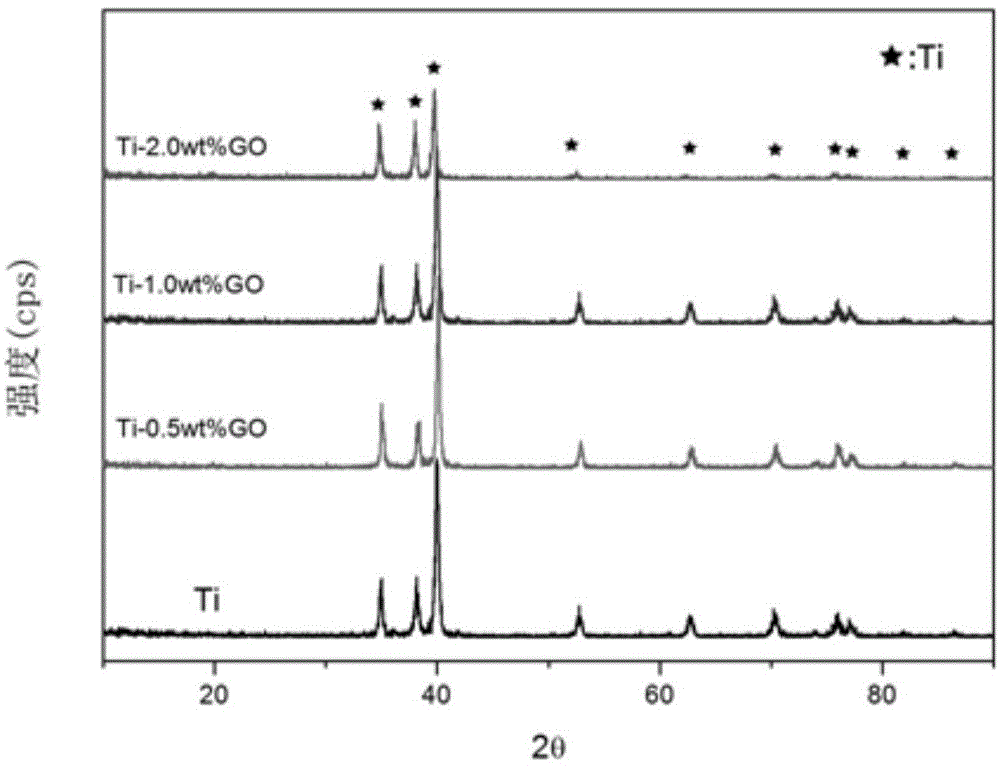

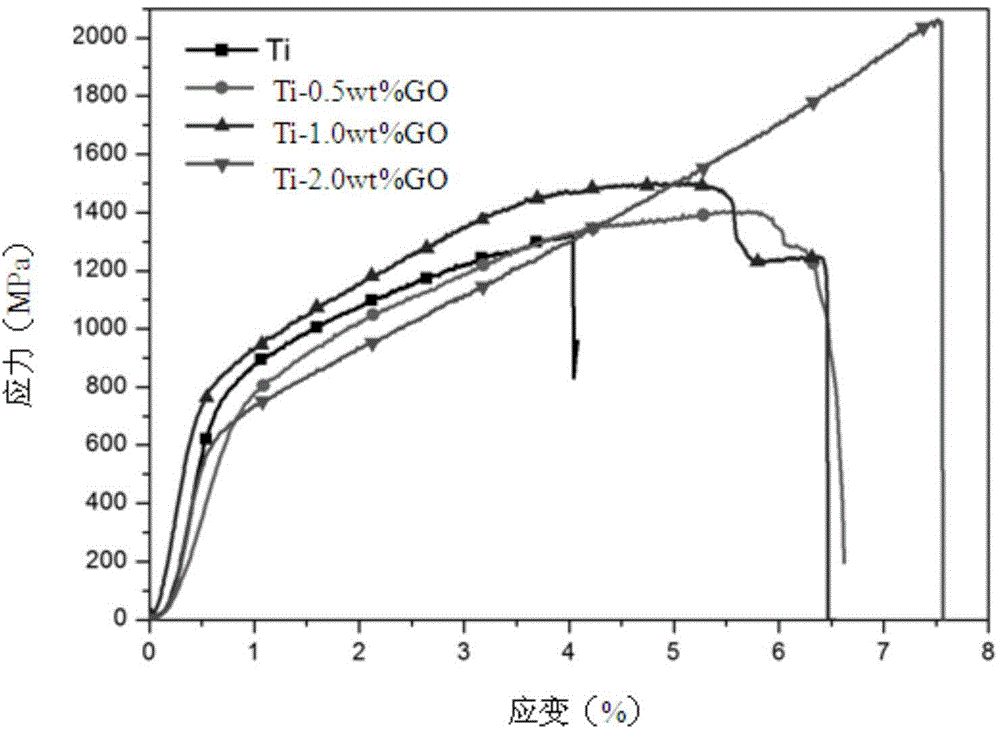

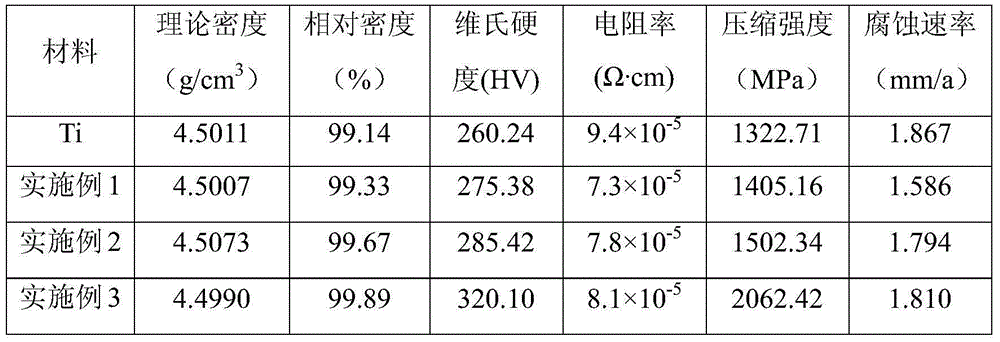

Graphene/titanium composite material and preparation method thereof

The invention relates to a graphene / titanium composite material and a preparation method thereof. The preparation method of the graphene / titanium composite material comprises steps as follows: 1) graphene oxide is added to water, the graphene oxide and the water are mixed and subjected to ultrasonic dispersion, and a clear graphene oxide solution is obtained; 2) oxide films on surfaces of titanium powder are removed; 3) the titanium powder with the oxide films on the surfaces removed is added to the obtained graphene oxide solution, and a graphene oxide / titanium mixed solution is obtained; 4) the prepared graphene oxide / titanium mixed solution is subjected to ultrasonic dispersion and then ball milling, a mixed solution obtained after ball milling is freeze-dried, and mixed powder is obtained; 5) the mixed powder is fully ground, then subjected to electric-field-activated pressure-assisted sintering and cooled, and the graphene / titanium composite material is obtained. The graphene / titanium composite material has excellent properties such as the high strength, the high corrosion resistance, the low electrical resistivity and the like and has the important significance in the aspect of industrial applications.

Owner:WUHAN UNIV OF TECH

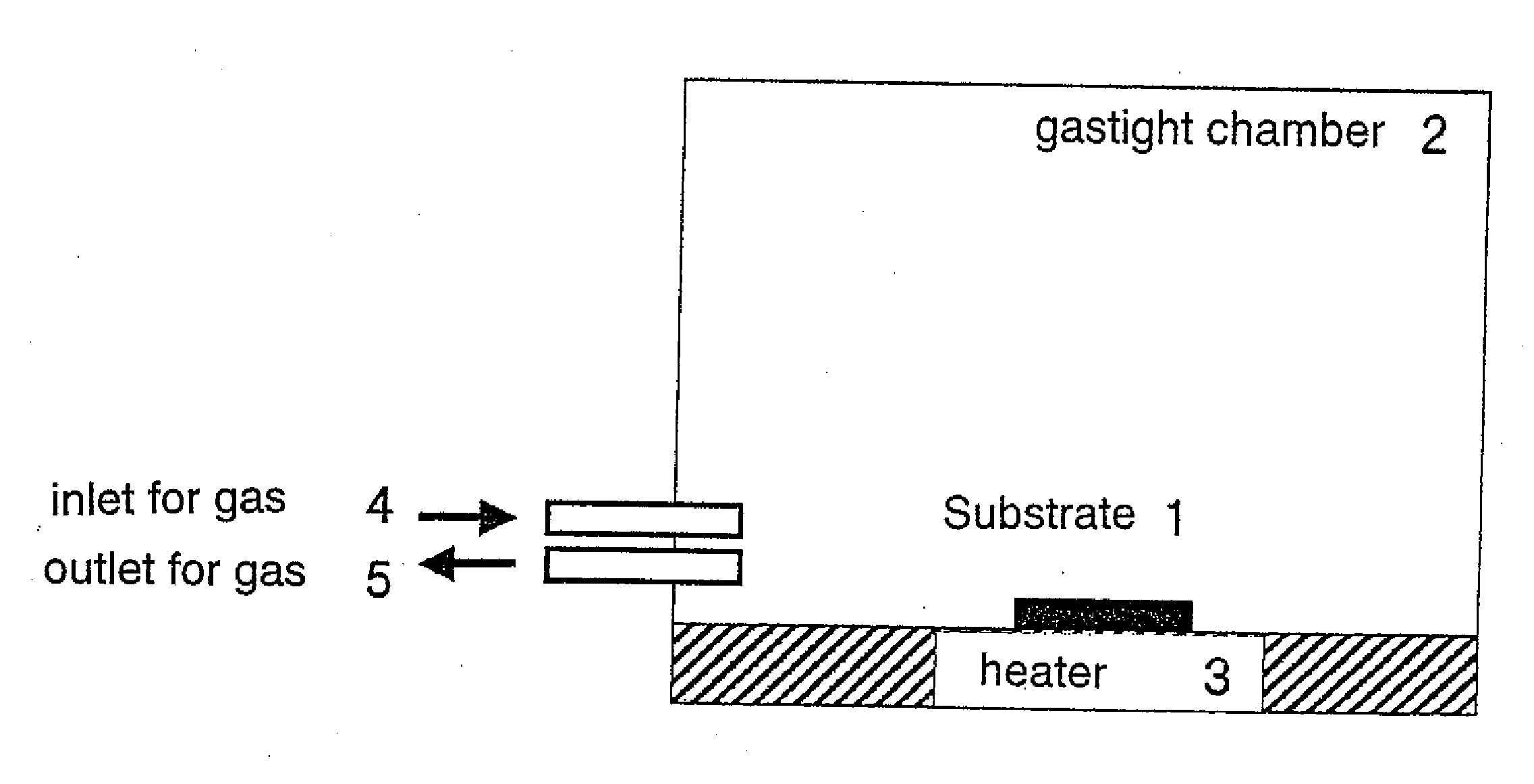

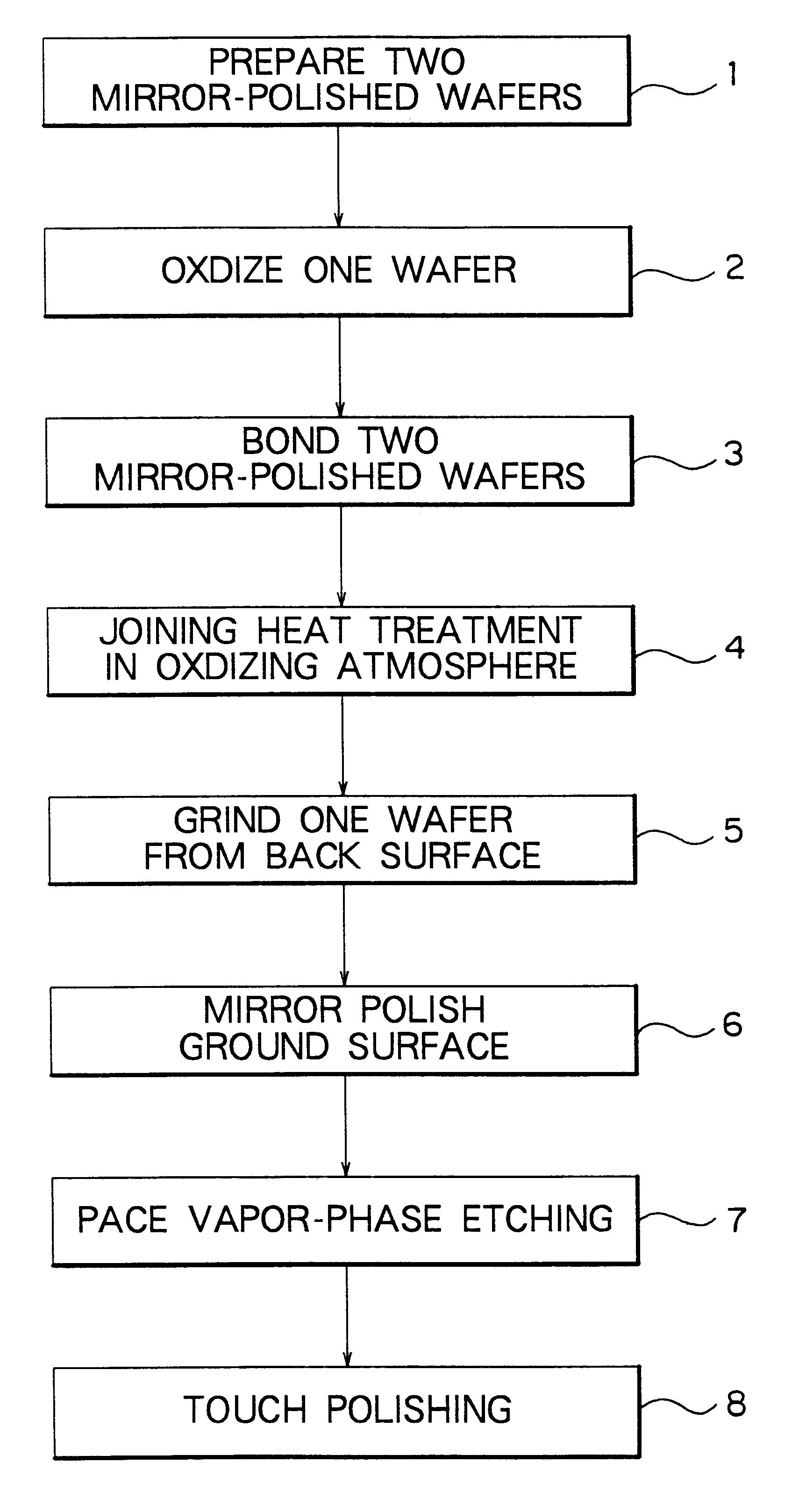

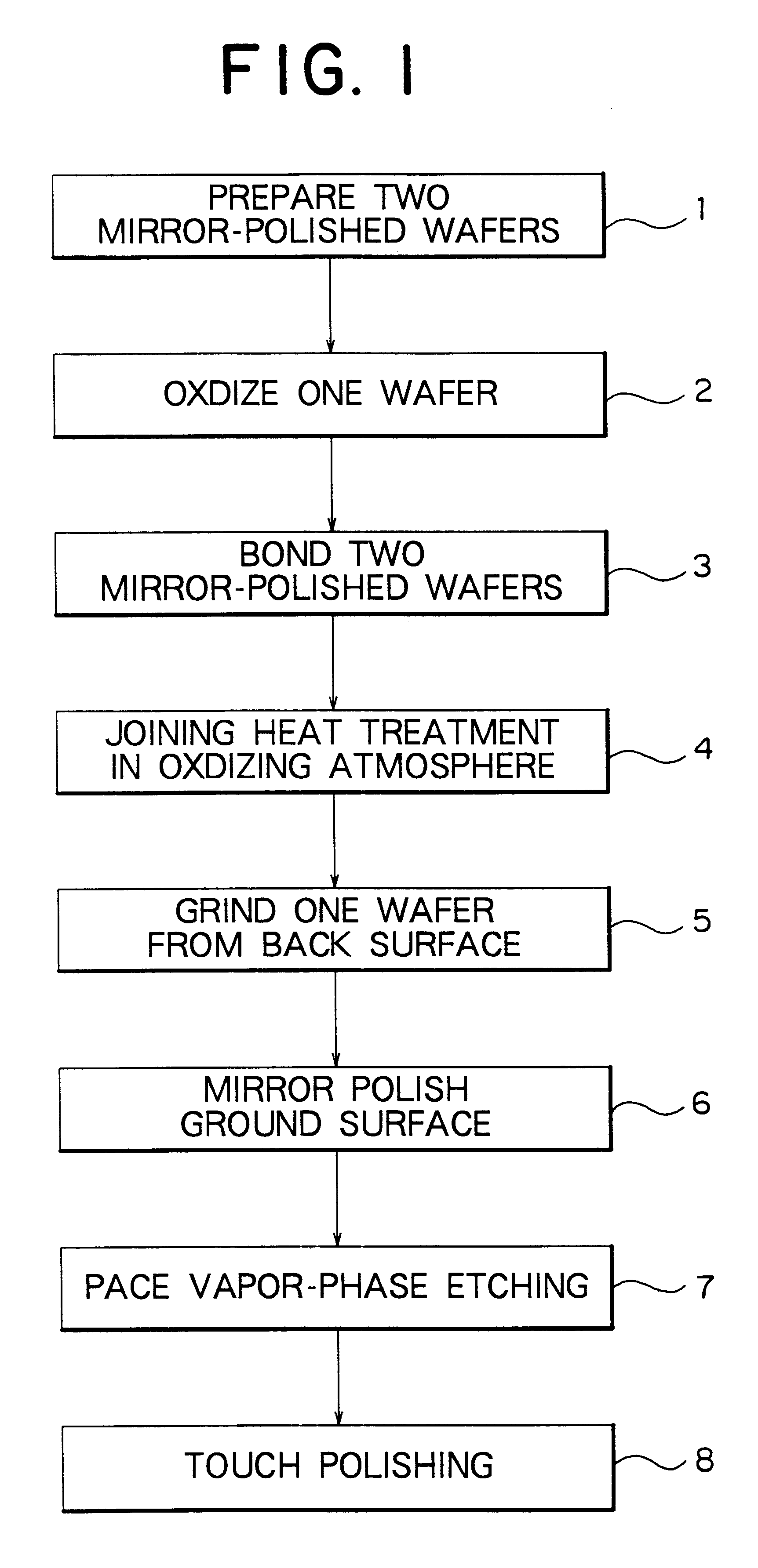

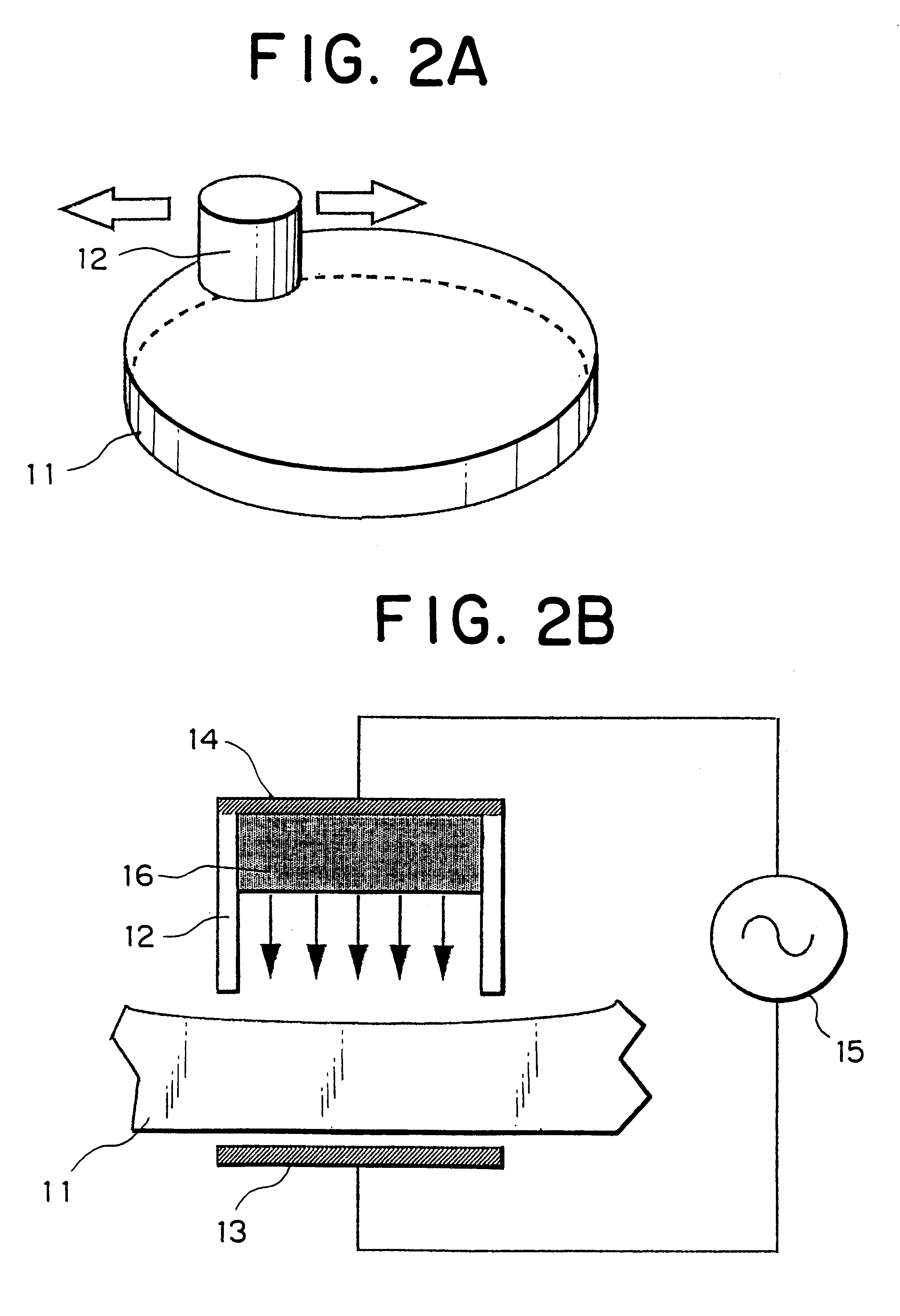

Method of forming oxide film on an SOI layer and method of fabricating a bonded wafer

InactiveUS6239004B1Avoid it happening againPromote generationSolid-state devicesSemiconductor/solid-state device manufacturingWaferingSurface oxidation

In a method of fabricating a bonded wafer, an oxide film is first formed on the surface of at least one of two mirror-polished silicon wafers. The two silicon wafers are superposed such that the mirror-polished surfaces come into close contact with each other, and heat treatment is performed in order to join the wafers together firmly. Subsequently, the thickness of one of the wafers is reduced so as to yield a thin film, the surface of which is then polished and subjected to vapor-phase etching in order to make the thickness of the thin film uniform. Optionally, the vapor-phase-etched surface is then mirror-polished. The surface of the bonded wafer is oxidized, and the generated surface oxide film is then removed. In the method, the thickness of the oxide film formed on the surface of the bonded wafer is made not greater than 50 nm. The method reliably eliminates damage and crystal defects generated during etching in accordance with PACE method or subsequent mirror polishing, and thereby enables relatively simple and low cost manufacture of bonded wafers having a very thin SOI layer that has good thickness uniformity and excellent crystallinity.

Owner:SHIN-ETSU HANDOTAI CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com