Patents

Literature

738 results about "Zirconate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A zirconate is an oxyanion containing zirconium. Examples include Na₂ZrO₃, Ca₂ZrO₄ which can be prepared by fusing zirconium dioxide with e.g. Na₂O and CaO respectively.

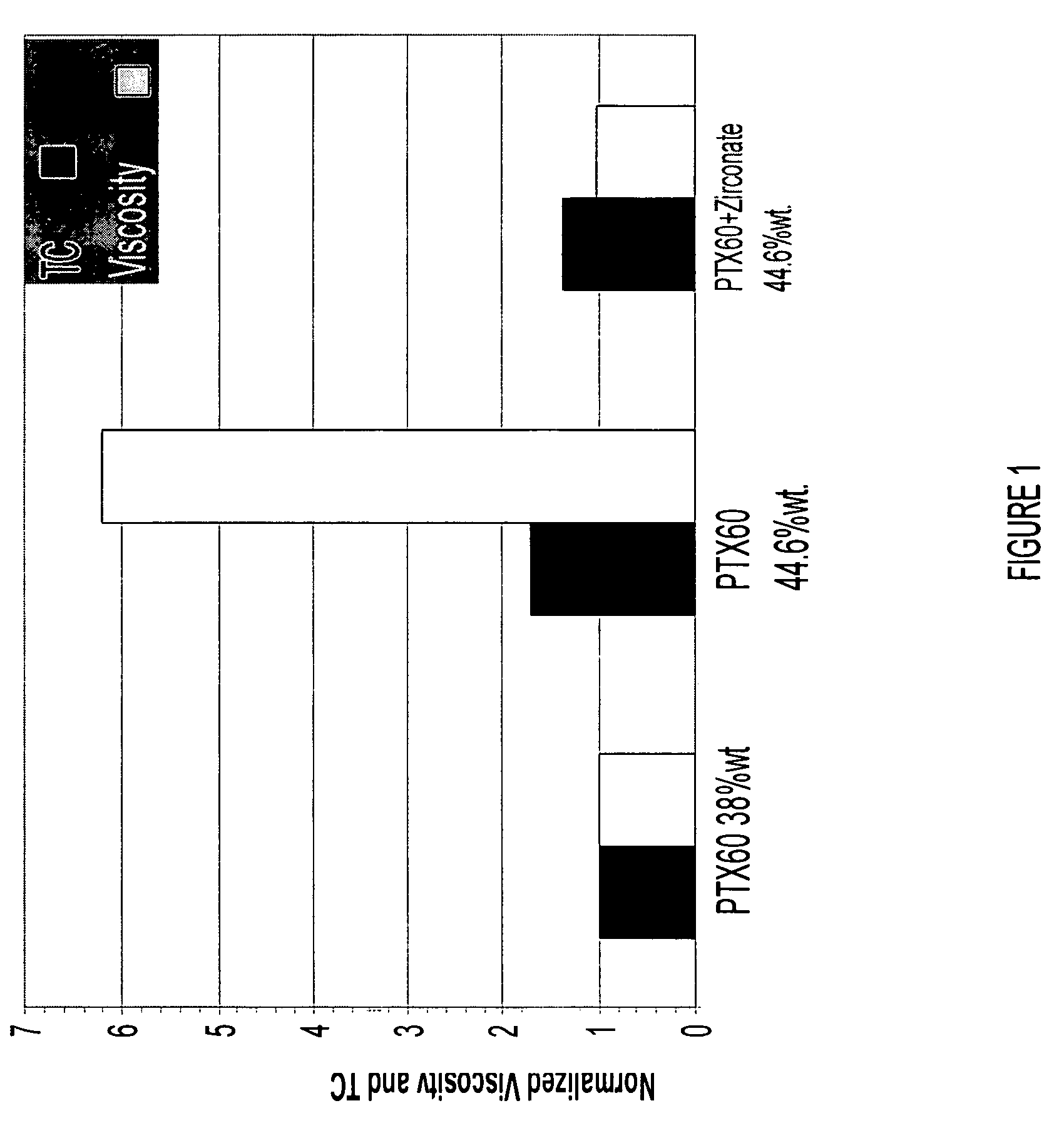

Enhanced boron nitride composition and polymer-based compositions made therewith

ActiveUS20070041918A1Improve thermal conductivityPowder deliveryCosmetic preparationsMetallurgyZirconate

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

Non-chromium deactivation liquid for processing aluminium alloy and method of use thereof

InactiveCN101161861AReduce pollutionMeet WEESMetallic material coating processesTitanium zirconiumPhosphoric acid

The present invention relates to a chrome-free passivating liquid for treating aluminum alloy and a method for using the same; the components of the passivating liquid and the weight concentration of the elements thereof consist of fluorin titanate comprising Ti (IV) between 0.05 wt percent and 0.15 wt percent, fluorin zirconate comprising Zr (IV) 0.01 wt percent and 0.05 wt percent and organic phosphate compound comprising 0.02 wt percent to saturated concentration. The use method of the passivating liquid of the invention has the following procedures: after grease on the surface of the aluminum alloy is removed, the aluminum alloy is treated by alkali cleaning, deoxidation and activation; when the temperature is between 25 DEG C and 60 DEG C and the PH value is between 3 and 3.5, the aluminum alloy is treated by impregnating or spraying for 2 min to 5 min. In the passivating liquid of the invention, organic phosphoric acid is directly added to a titanium zirconium system; the formed zirconium phosphate composite structure can obviously improve the corrosion resisting property of a passivating film and the adhesive capactiy of polymer coating (primer) on the surface of aluminum alloy.

Owner:NORTHEASTERN UNIV

System for bonding glass into a structure

The invention is a composition comprising a) one or more organotitanates or zirconates having four ligands wherein the ligands are hydrocarbyl, optionally containing one or more functional groups having one or more heteroatoms selected from the group comprising oxygen, nitrogen, phosphorus and sulfur wherein two or more of the ligands may form a cyclic structure with the proviso that one of the ligands has an acidic moiety; one or more strong organic acids or a mixture thereof; b) one or more alkoxysilanes; c) optionally one or more high molecular weight resins; and d) a solvent which dissolves the components of the composition. This composition is referred to as a clear primer hereinafter. Preferably, the composition comprises both an organotitanate or zirconate and a strong acid.

Owner:DOW GLOBAL TECH LLC

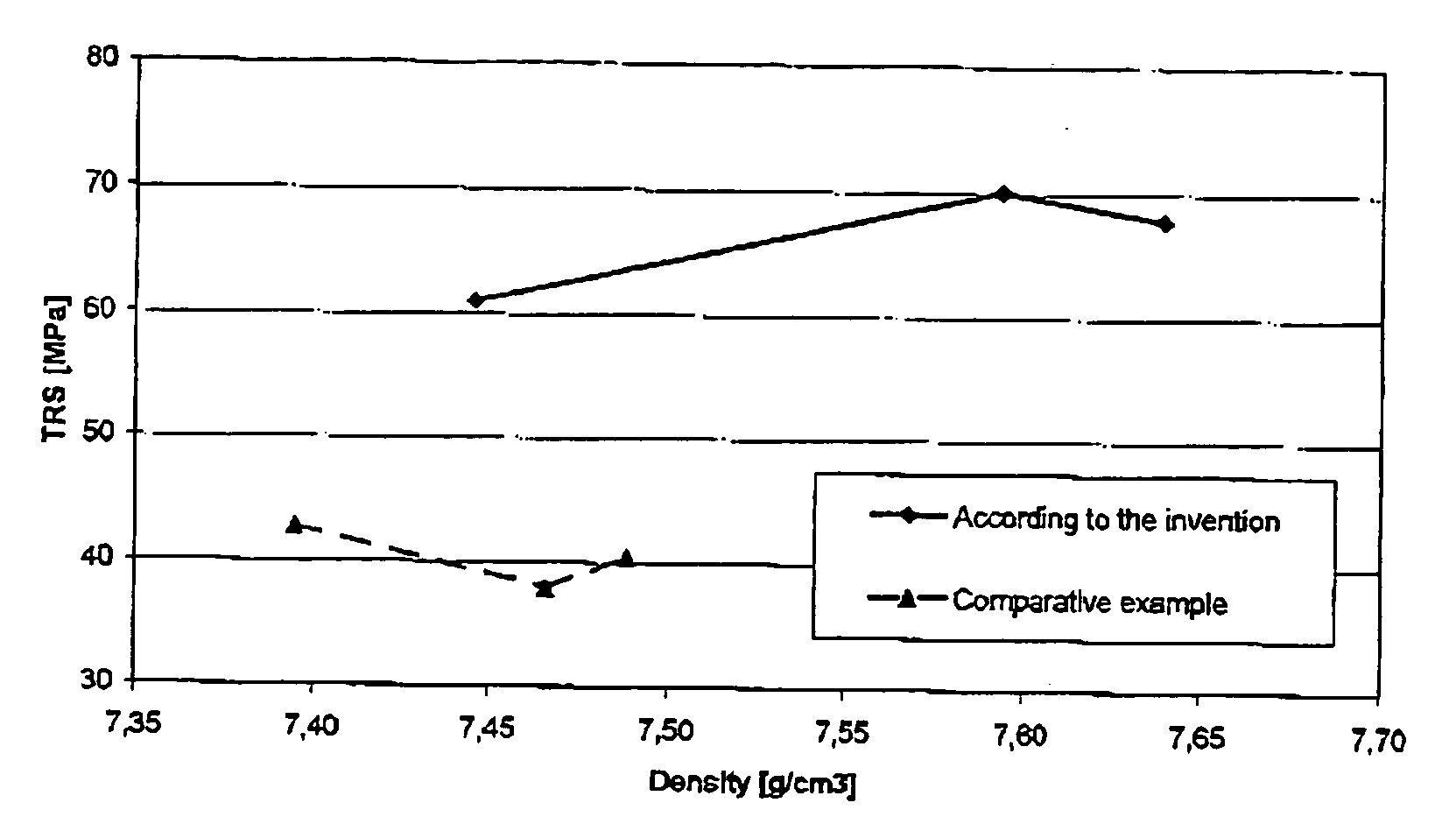

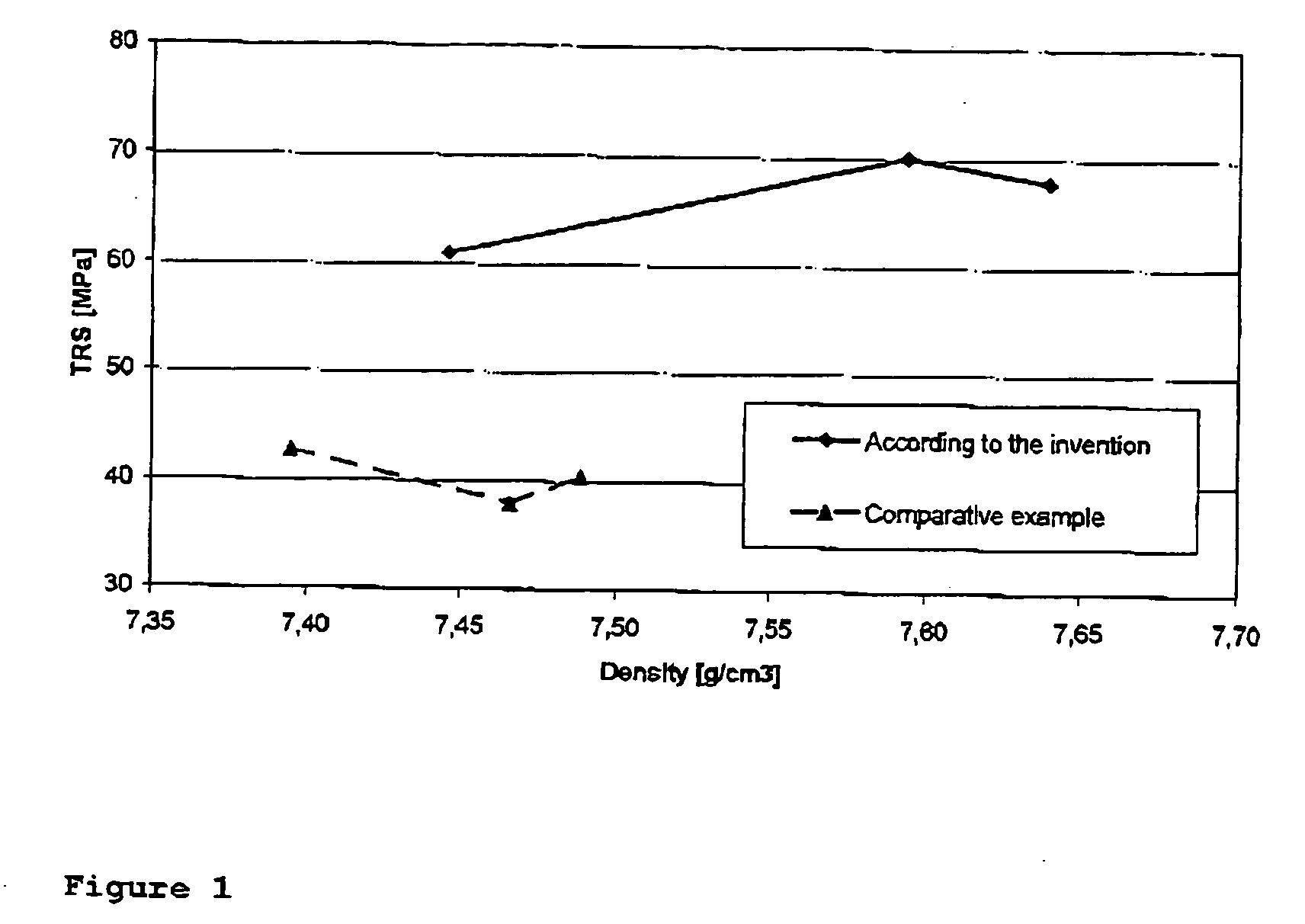

Iron-based powder

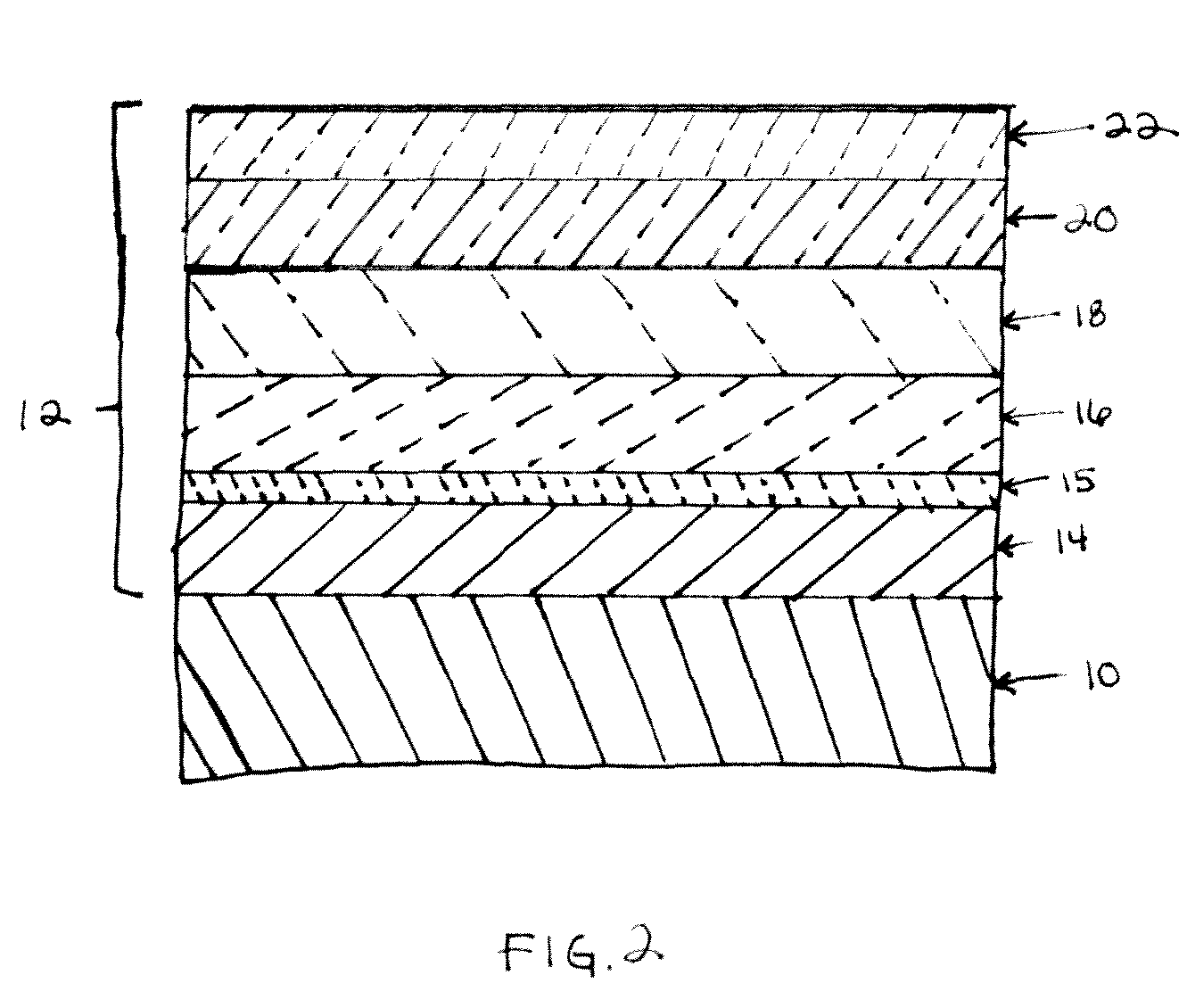

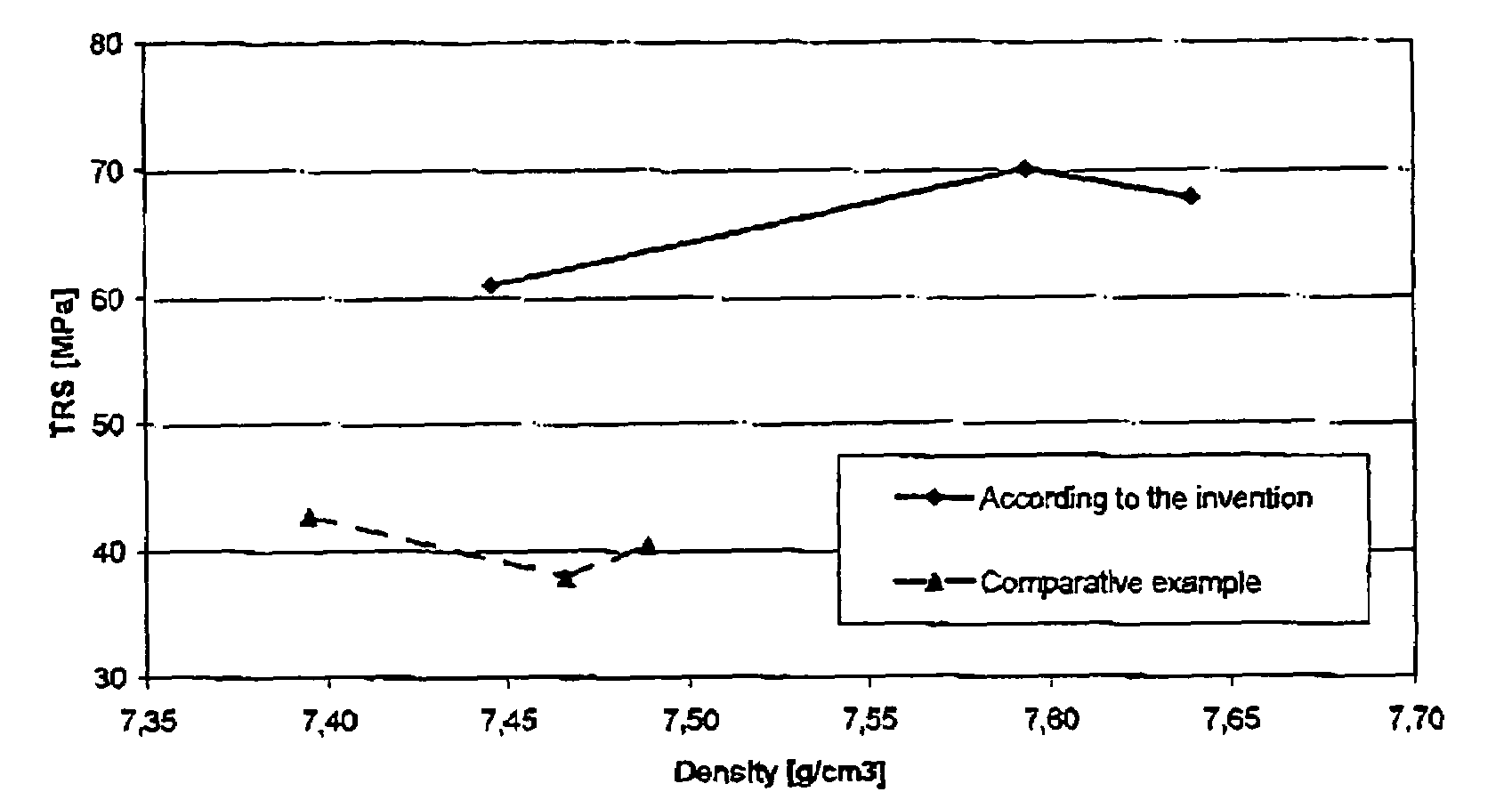

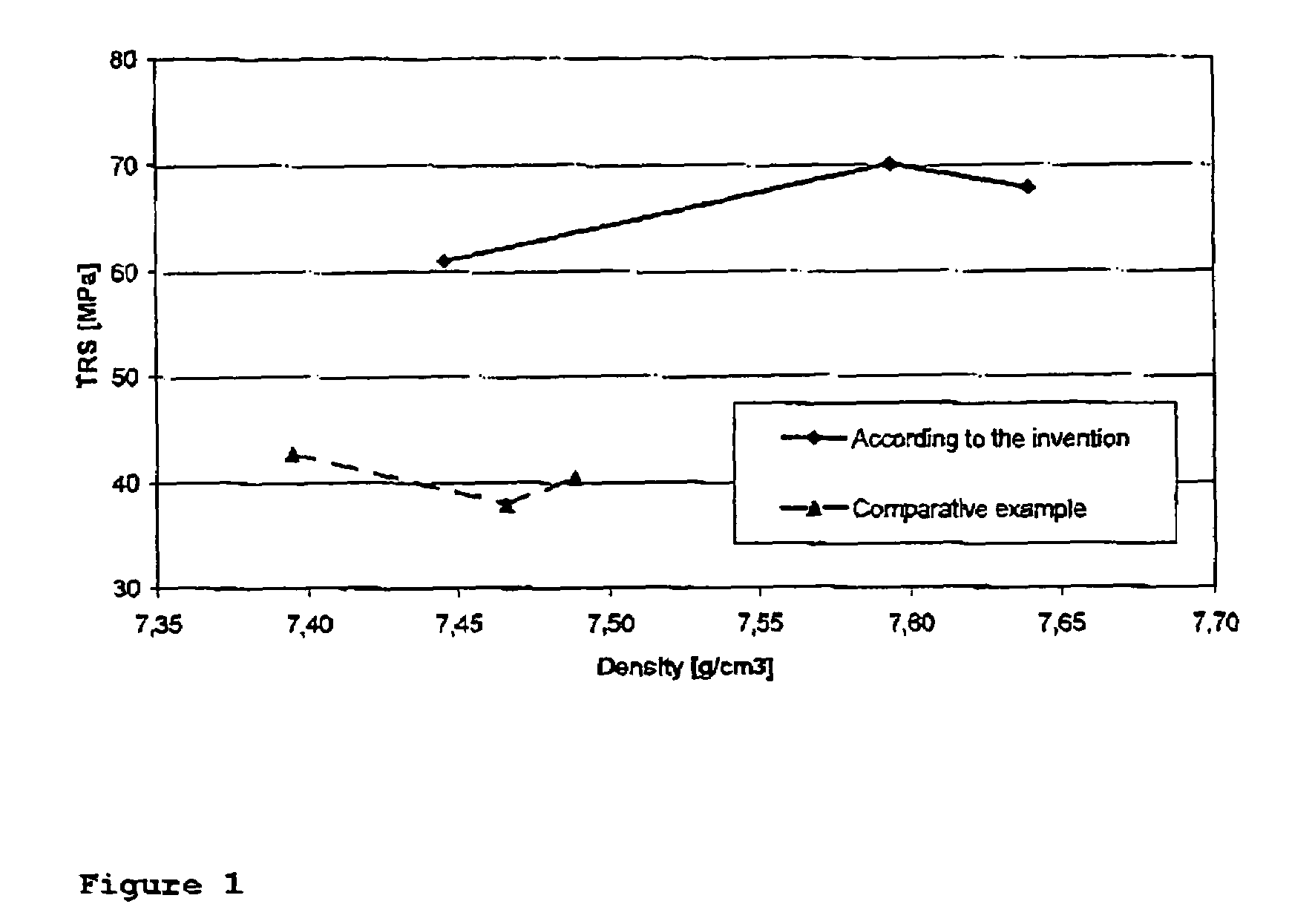

ActiveUS20040191519A1High wear of dieLess shiny and deterioratedSynthetic resin layered productsMetal-working apparatusSilanesZirconate

The present invention concerns a new ferromagnetic powder composition comprising soft magnetic iron-based core particles wherein the surface of the core particles are surrounded by an insulating inorganic coating, and a lubricating amount of a compound selected from the group consisting of silanes, titanates, aluminates, zirconates, or mixtures thereof. The invention also concerns a process for the preparation of soft magnetic composite materials using the new powder composition.

Owner:HOGANAS AB

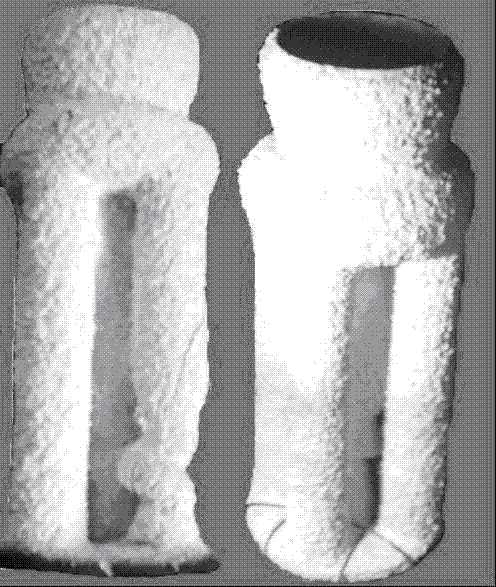

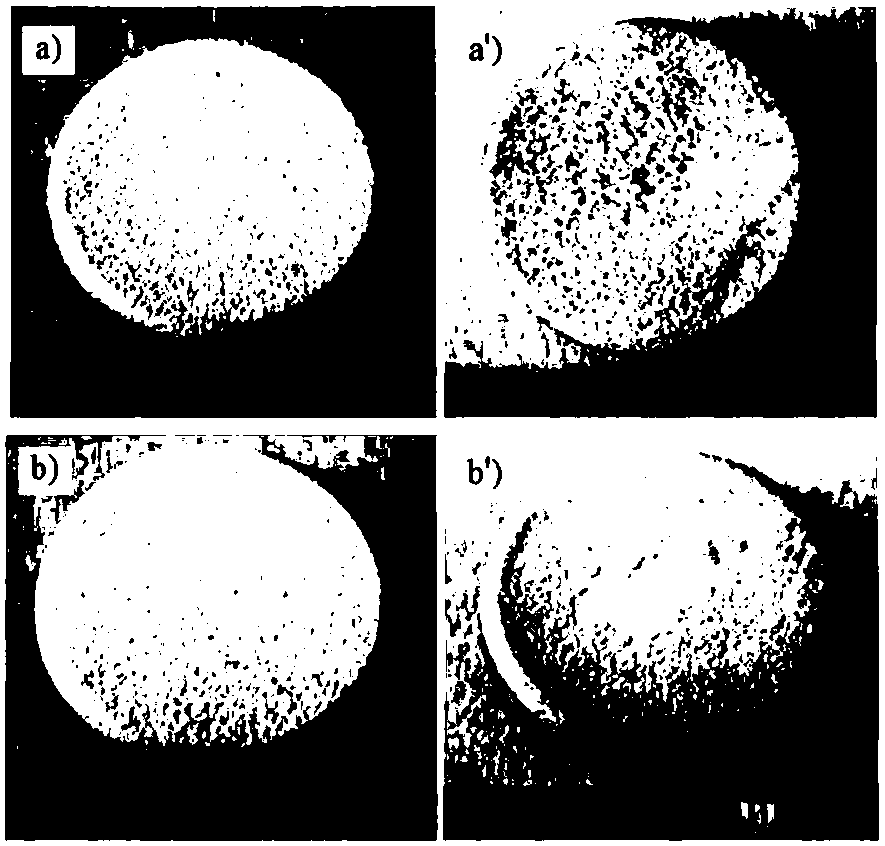

Crucible for fusing titan and method of preparation thereof

The invention relates to a crucible for fusing titanium and a production method thereof, mainly used for fusing titanium alloy as well as for fusion cast of other special alloys. Highly stable compounds (yttrium oxide, calcium zirconate or cerium sulphide, etc.) are used as the outer layer of the crucible for fusing titanium; refractory metals (tungsten, molybdenum or tantalum) and the like are combined with the compounds to form transition gradient coating; hot spray processes (laser cladding, plasma spraying, etc.) are used for spraying the transition layers and the transition gradient coating onto the inner surface of a graphite container layer by layer to form a firm and compact composite coating with good thermal shock resistance. By adopting the crucible of the invention to carry out vacuum induction fusion of titanium and titanium alloy, the fused alloy has uniform component, the fusion process consumes less energy and the crucible produces less contamination to the molten titanium.

Owner:SHANGHAI UNIV

Functionalized zirconium oxide particles

InactiveUS7037583B2Effective pointingMaterial nanotechnologyImpression capsMetal oxide nanoparticlesZirconate

Metal oxide nanoparticles having at least some surface acid sites functionalized with an adhesion promoter and at least some surface acid sites functionalized with a coupling agent. The nanoparticles are useful in forming composites comprising photopolymerizable matrix monomers, and are primarily suitable for dental and medical restoration. In a preferred embodiment, the metal oxide comprises zirconium, and the coupling agent is a zirconate.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

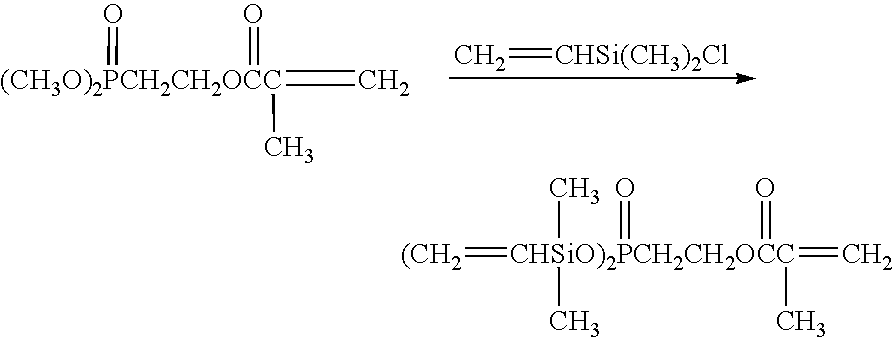

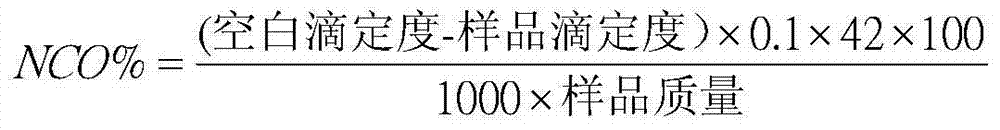

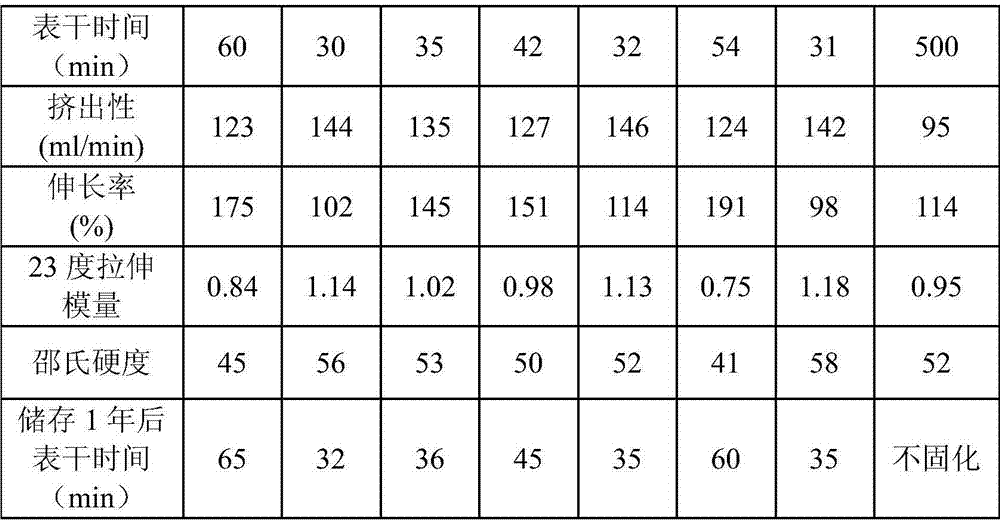

Method for producing silane modified polyurethane sealant by using secondary amino alpha-silane

ActiveCN103694946AHigh hydrolytic activityFast curingNon-macromolecular adhesive additivesOther chemical processesPolyolTetraisopropyl titanate

The present invention discloses a method for producing a silane modified polyurethane sealant by using secondary amino alpha-silane, which belongs to the technical field of production of silane modified polyurethane sealants. The method comprises the following steps: removing water from polyether polyol, preparing polyurethane prepolymer, synthesizing silane-terminated polyurethane prepolymer and preparing the modified polyurethane sealant, wherein in the step of synthesizing the silane-terminated polyurethane prepolymer, the used silane for termination is formed by mixing one or two kinds of compounds selected from a group of secondary amino alpha-silane such as anilino-methyl-triethoxy silane, amine formic acid methyl trimethoxy silane or amine formic acid methyl methyl dimethoxy silane; in the step of preparing the modified polyurethane sealant, a catalyst used in the step is formed by mixing one or two kinds of compounds selected from a group of metal zirconate titanate compounds such as tetra-tert-butyl orthotitanate, tetraisopropyl titanate, tetrabutyl titanate and zirconium n-butoxide. The termination process of the prepolymer is simple, and the silane modified polyurethane sealant produced by the method has fast curing speed.

Owner:湖北新蓝天新材料股份有限公司

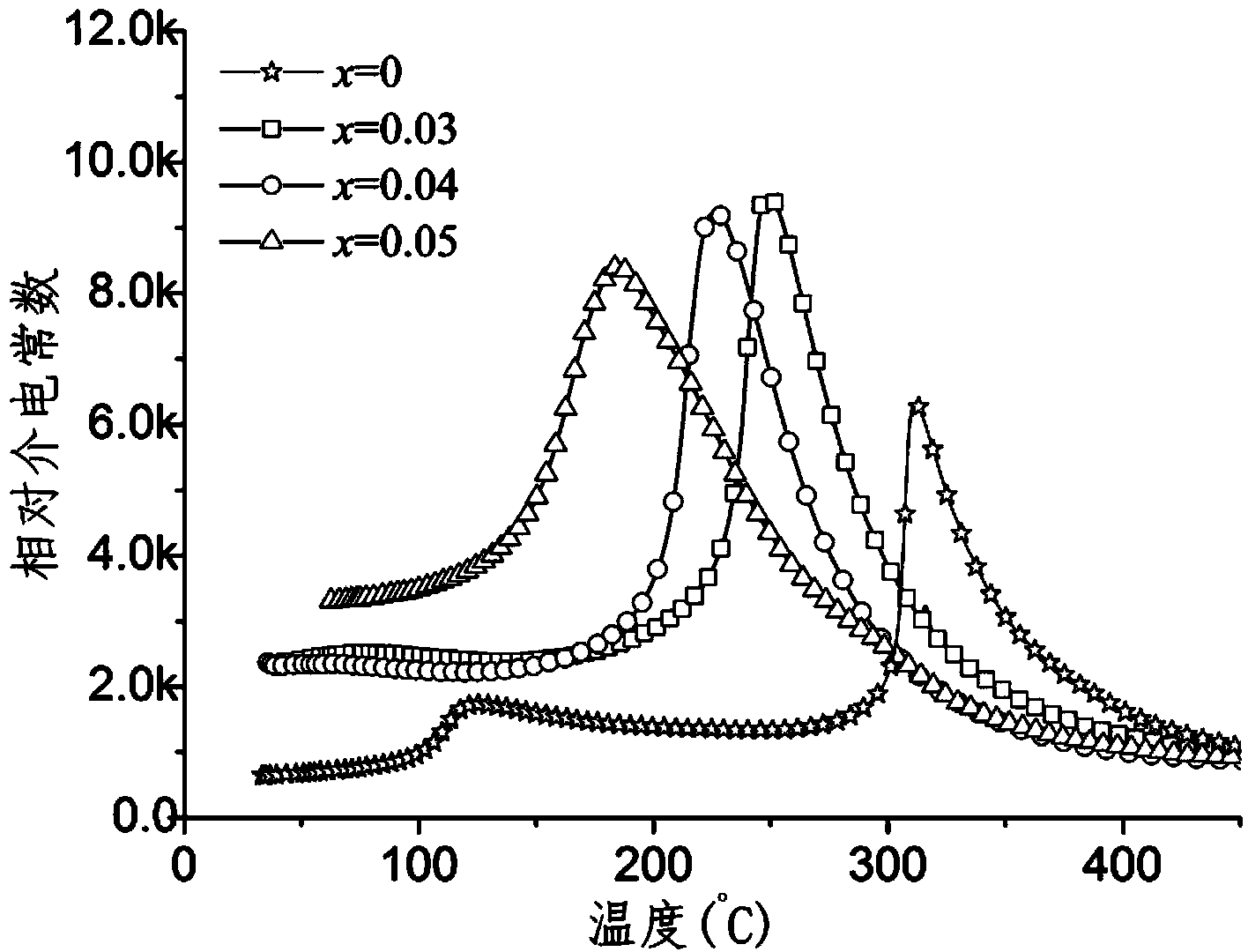

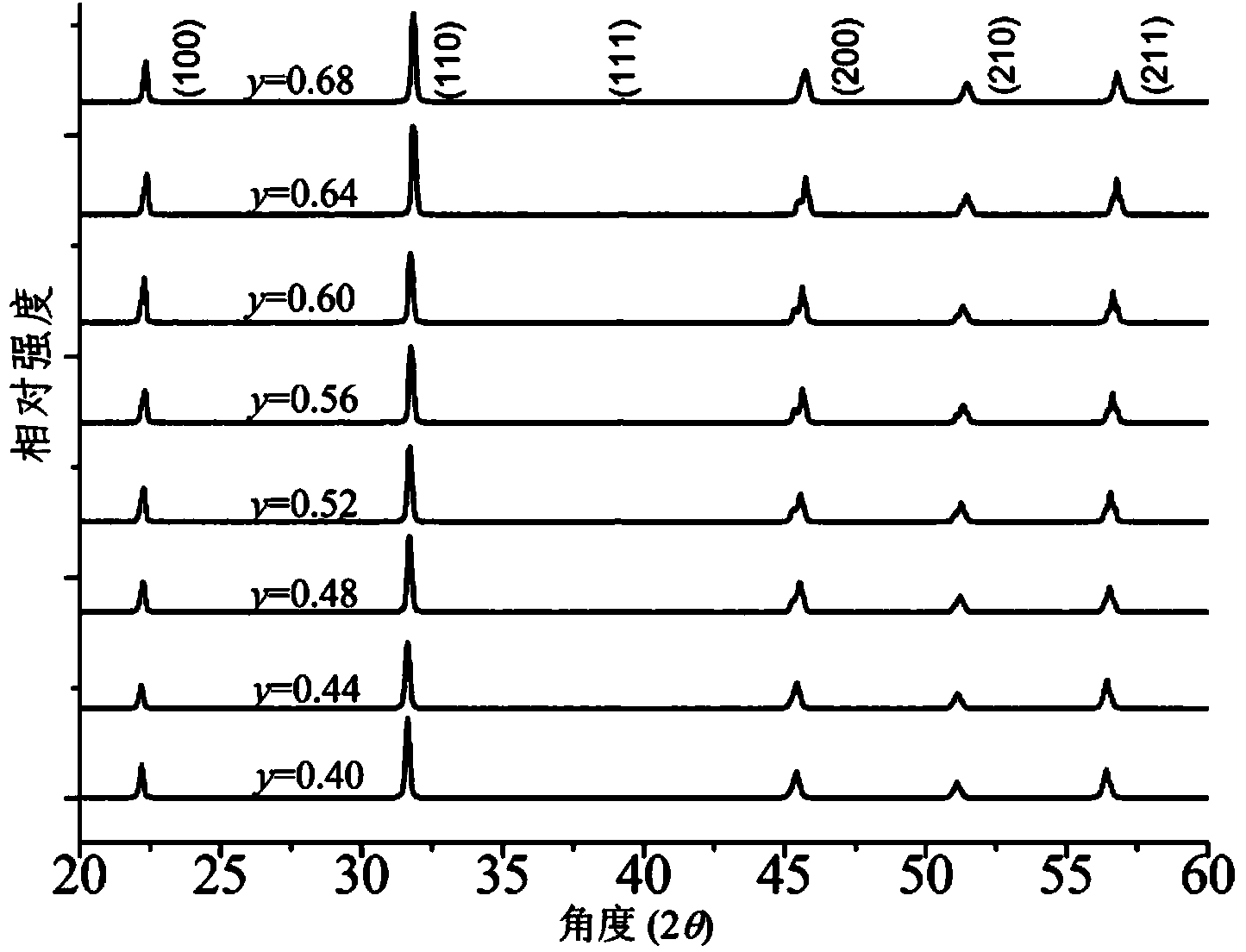

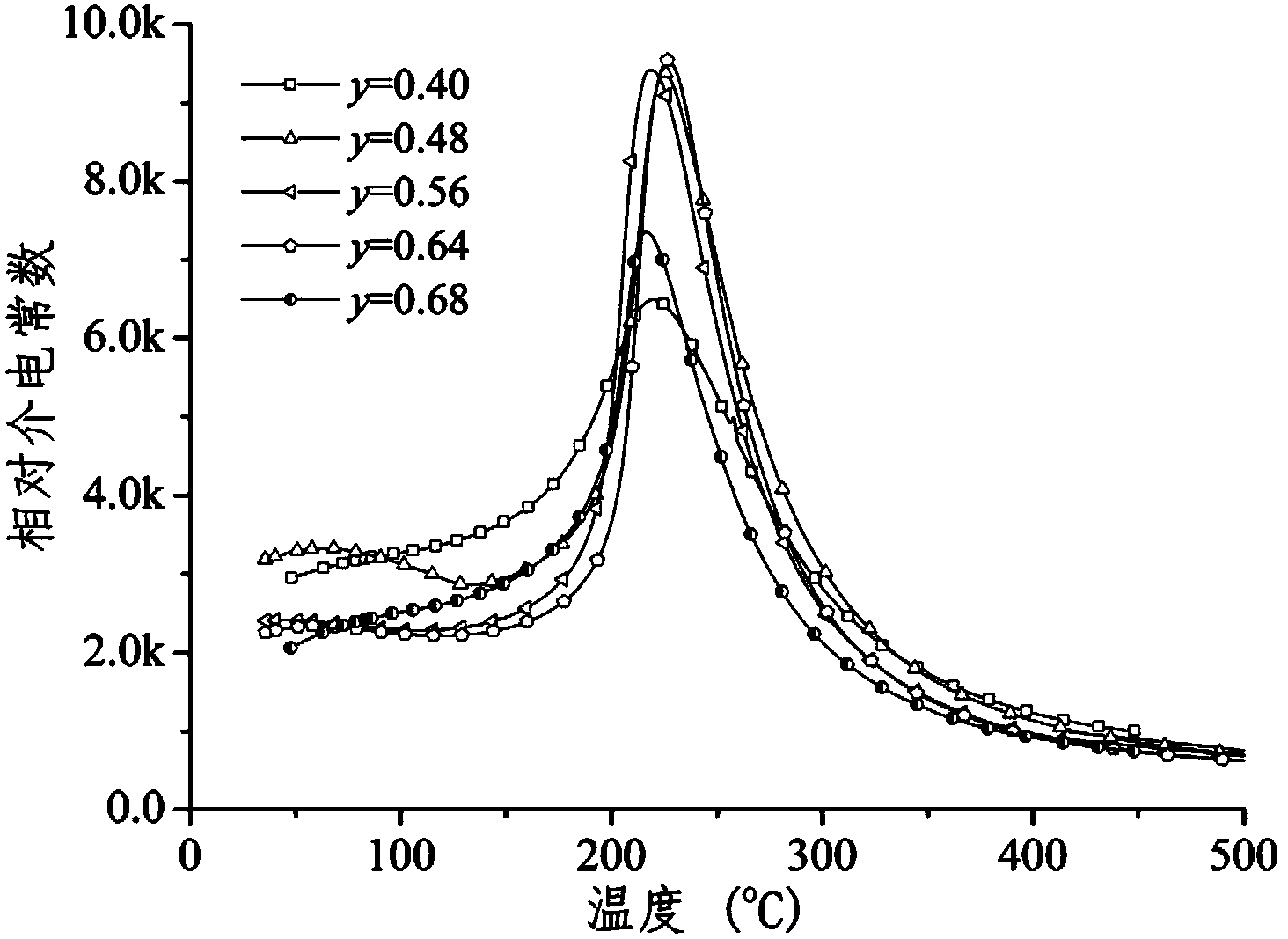

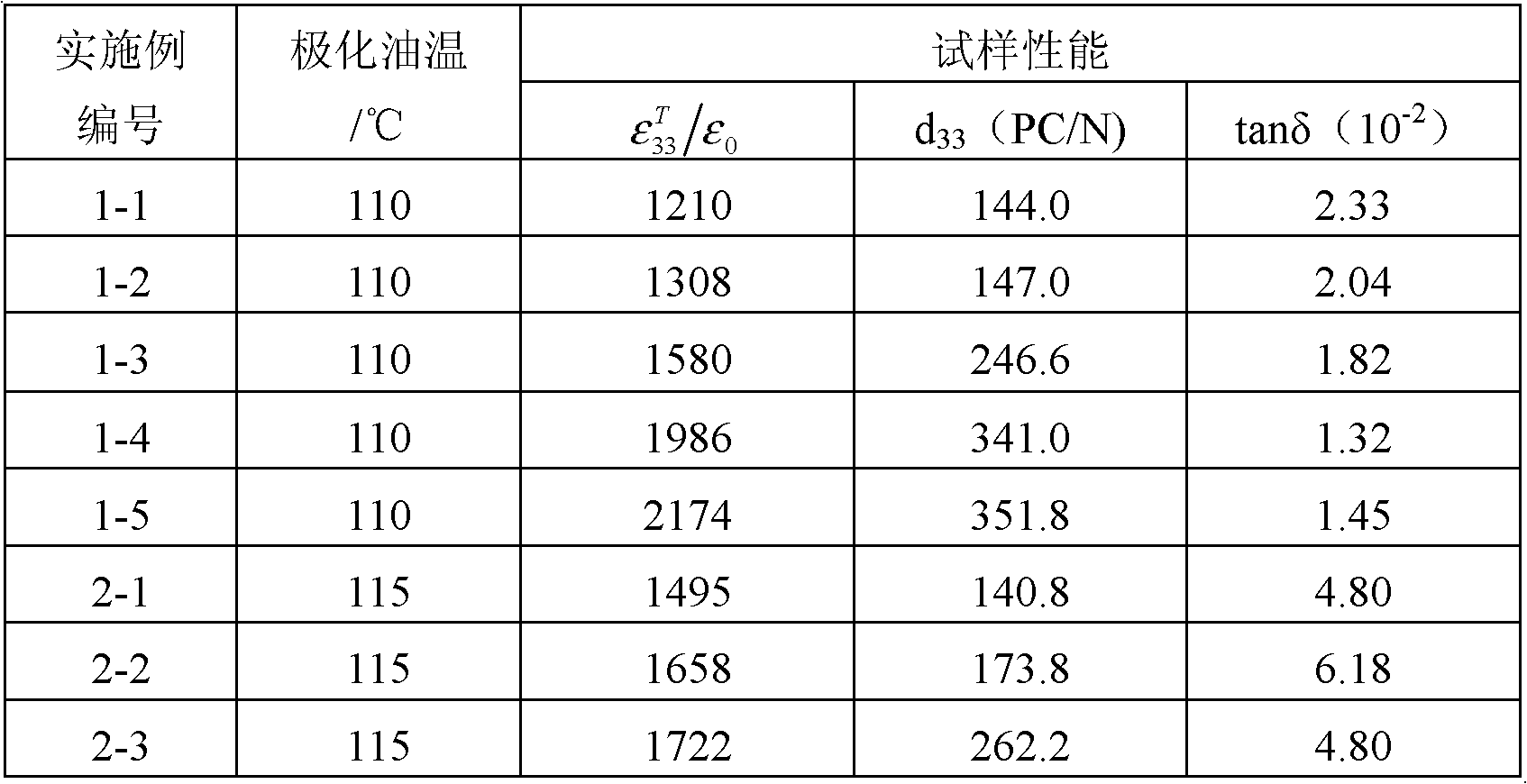

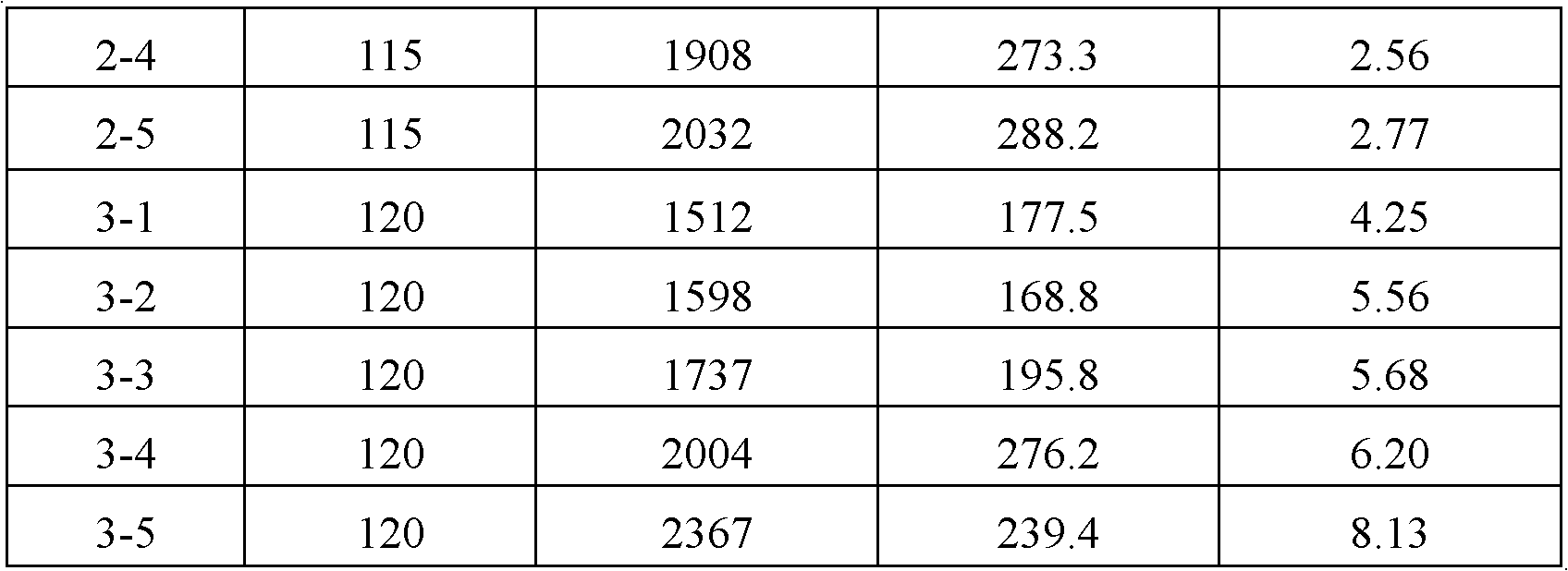

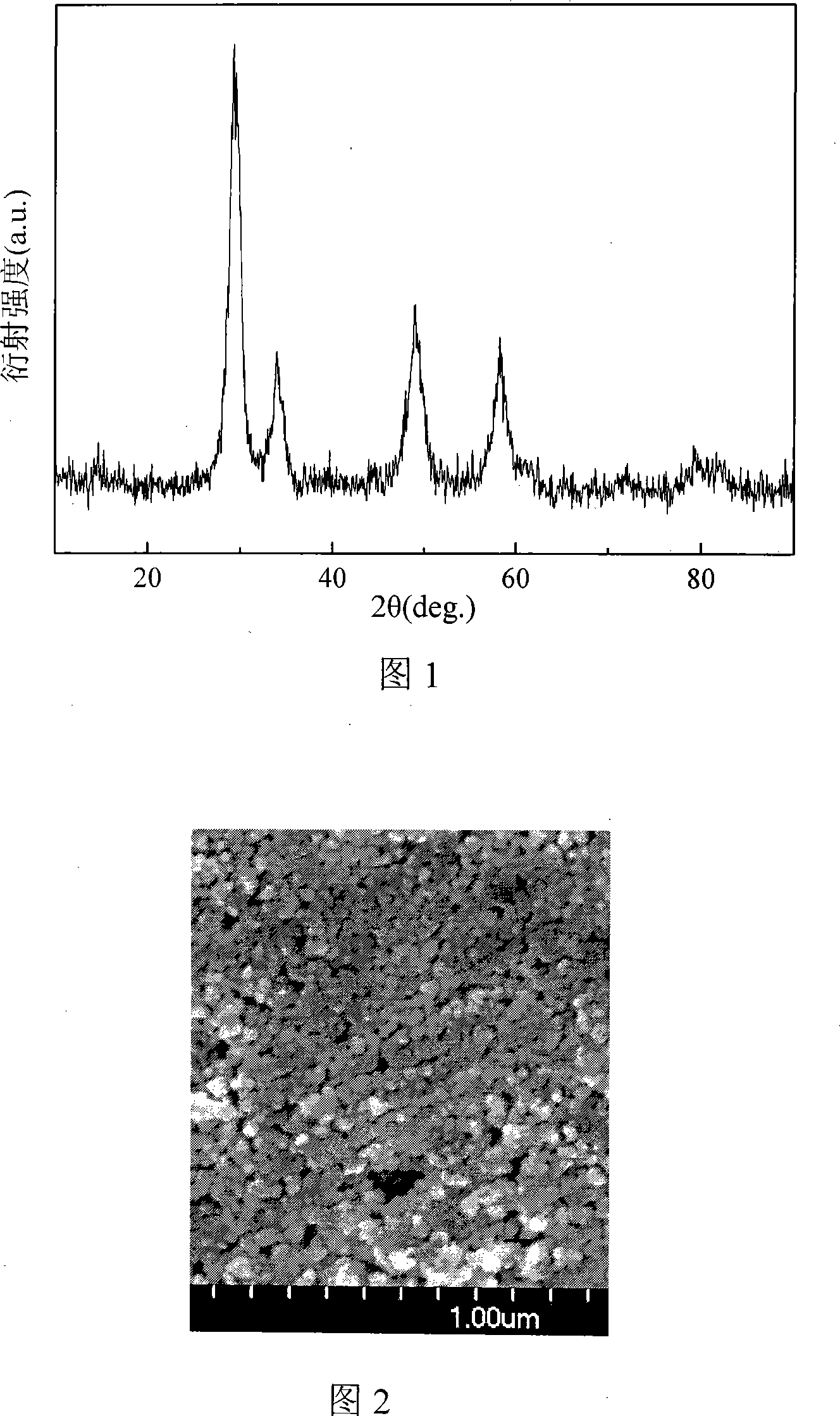

Niobium sodium potassium antimonate-potassium sodium bismuth zirconate leadless piezoelectric ceramic with high piezoelectric constant and preparation method thereof

The invention relates to niobium sodium potassium antimonate-potassium sodium bismuth zirconate leadless piezoelectric ceramic with a high piezoelectric constant and a preparation method thereof, which belong to the field of environmental coordinative piezoelectric ceramic of perovskite structures. The leadless piezoelectric ceramic with a general formula of (1-x) (K1-yNay) (Nb1-zSbz) O3 + xBi0.5 (Na1-uKu) 0.5ZrO3 is prepared by a traditional solid state sintering method, wherein in the formula, x is not smaller than 0 while not larger than 0.05, y is not smaller than 0.40 while not larger than 0.68, z is not smaller than 0.02 while not larger than 0.06, and u is not smaller than 0 while not larger than 1; the d33 of the leadless piezoelectric ceramic disclosed by the invention can be as high as 470 pC / N, kp can reach 47%, and Tc is as high as 313 DEG C. Devices prepared by the ceramic can work under high temperatures, so that the ceramic has a practical application value in high-temperature electronic equipment; since the ceramic contains no expensive tantalum element, the price of the used raw materials is low, so that the cost is saved.

Owner:SICHUAN UNIV

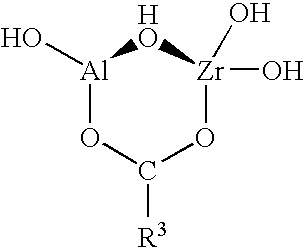

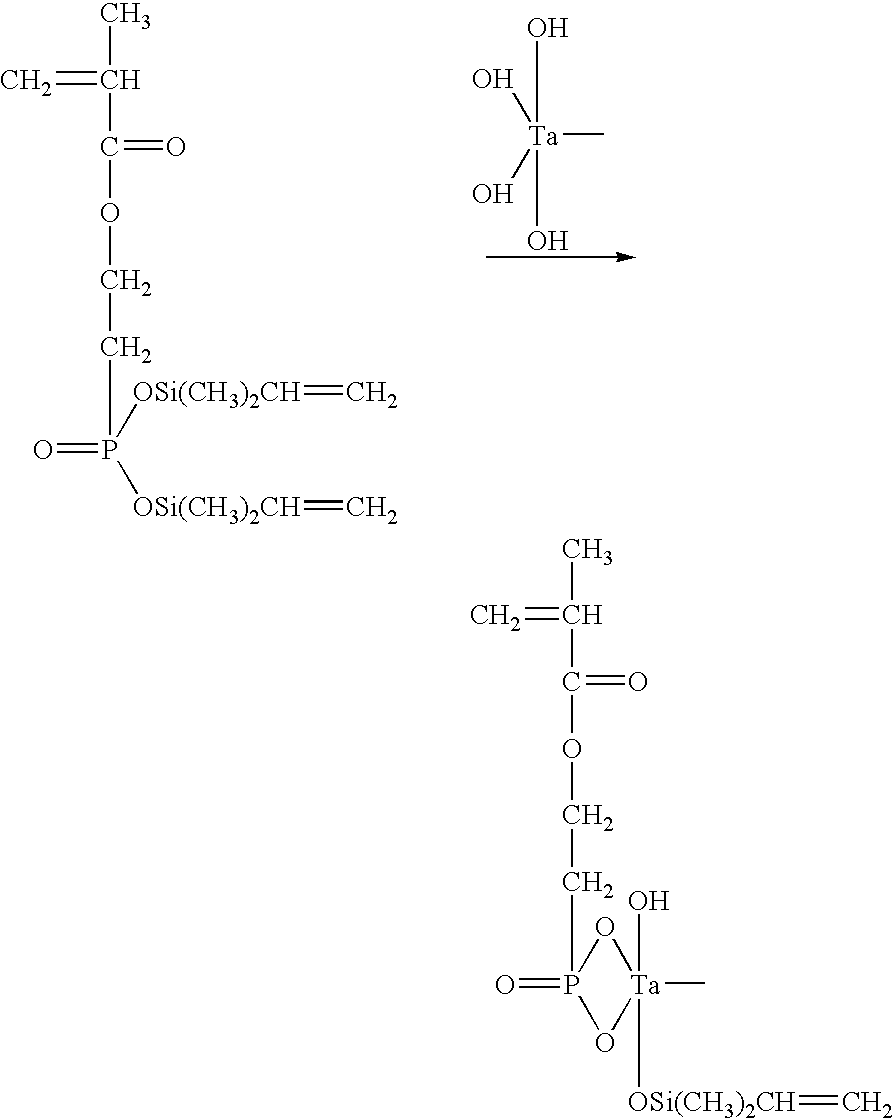

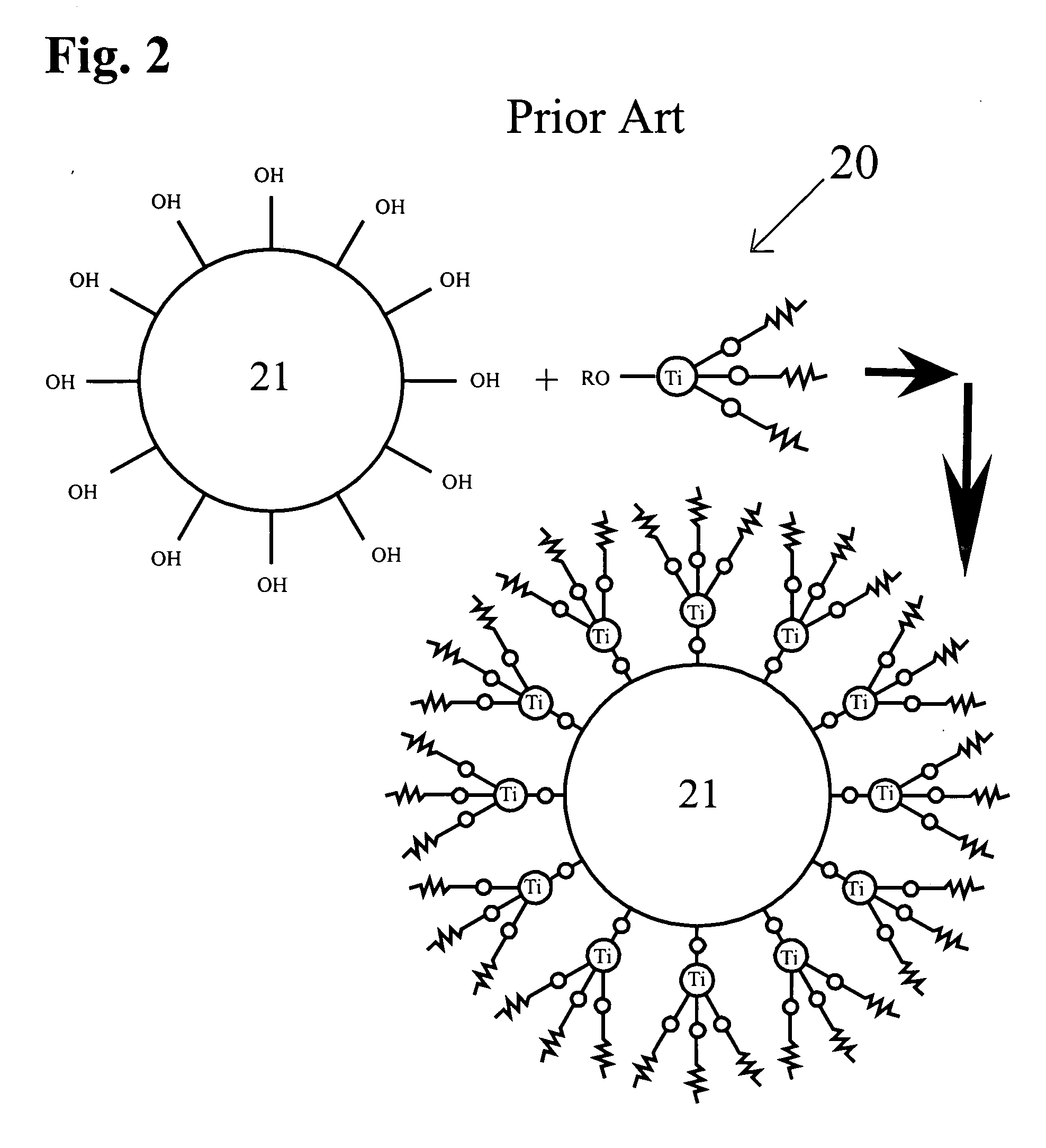

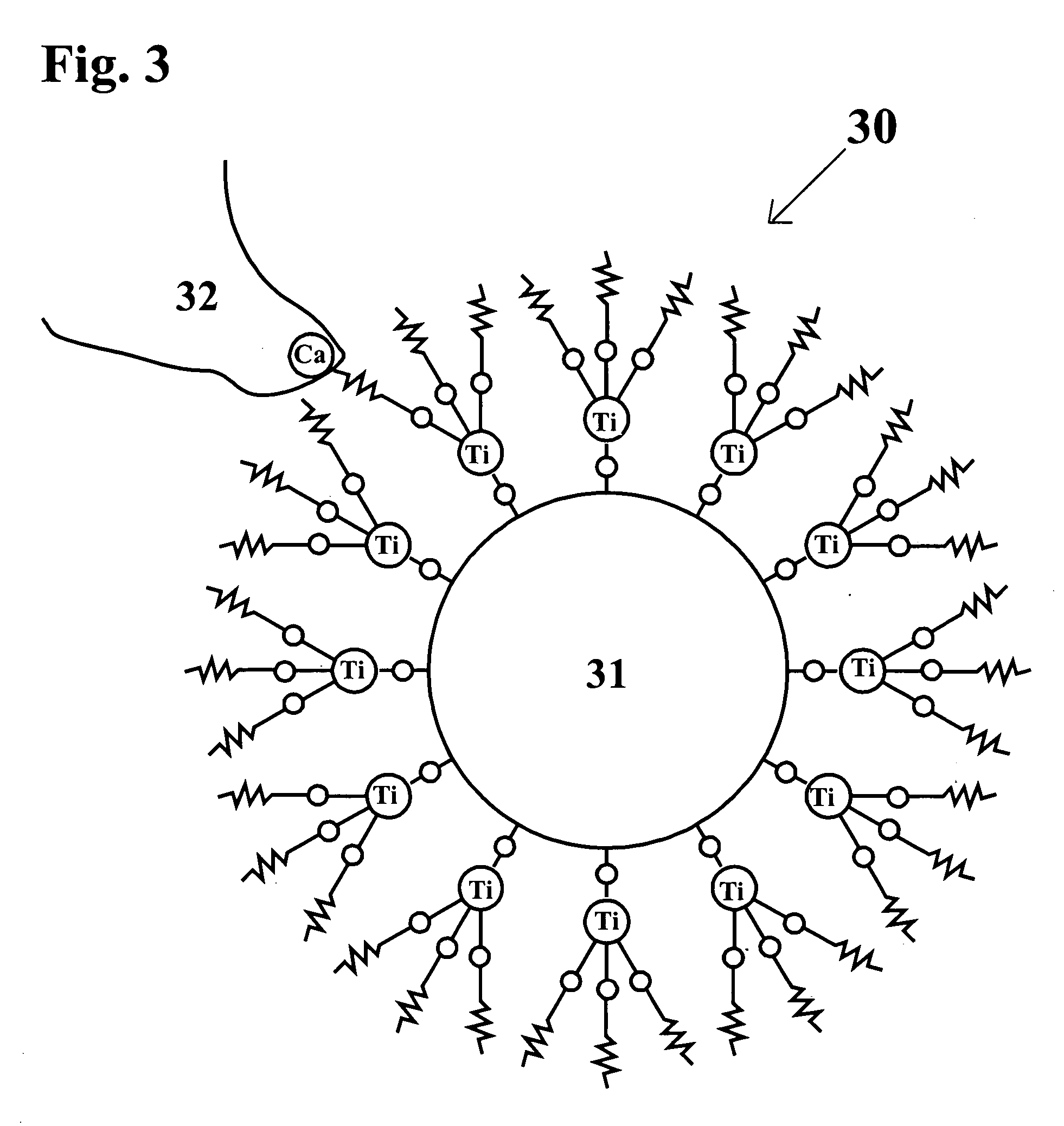

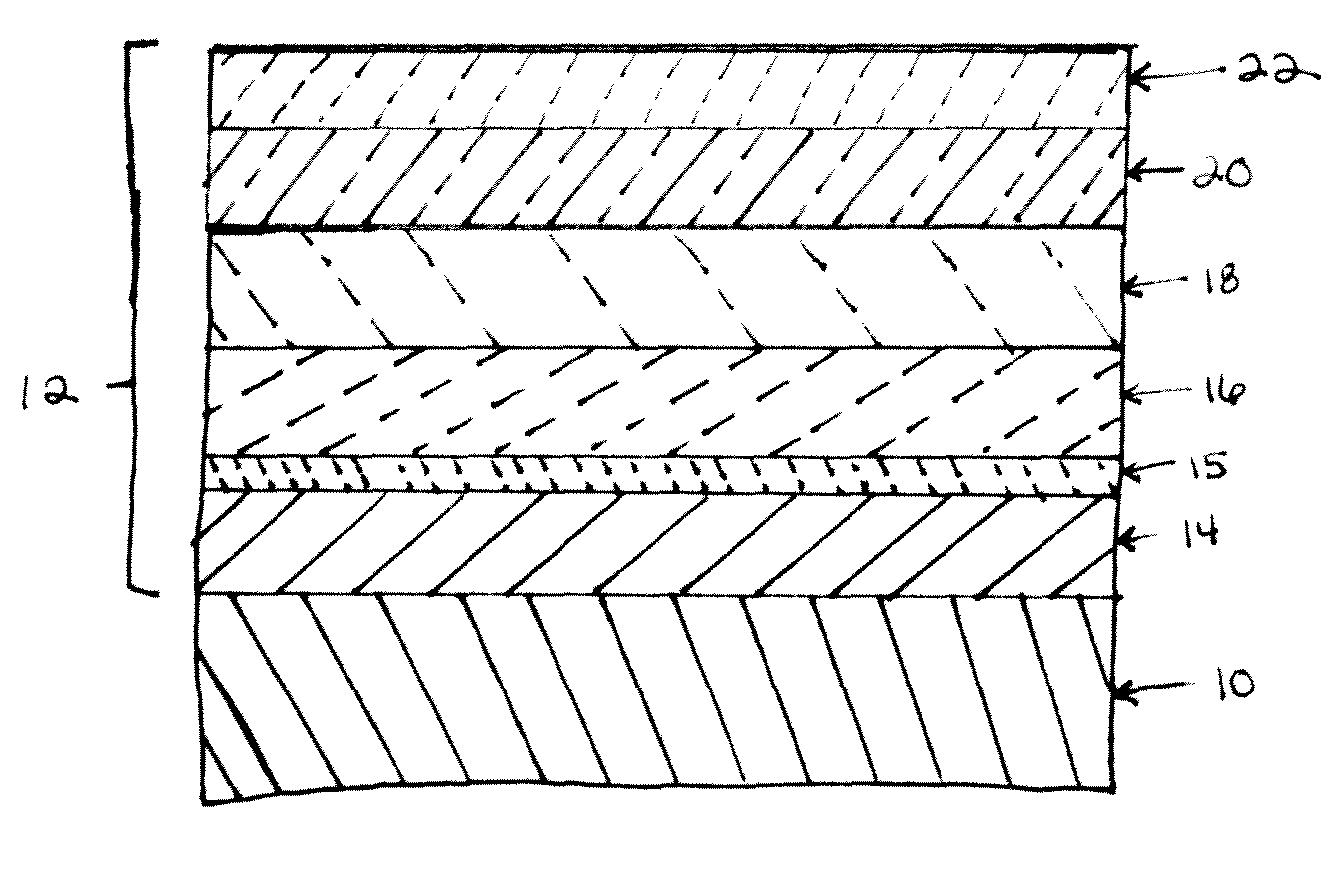

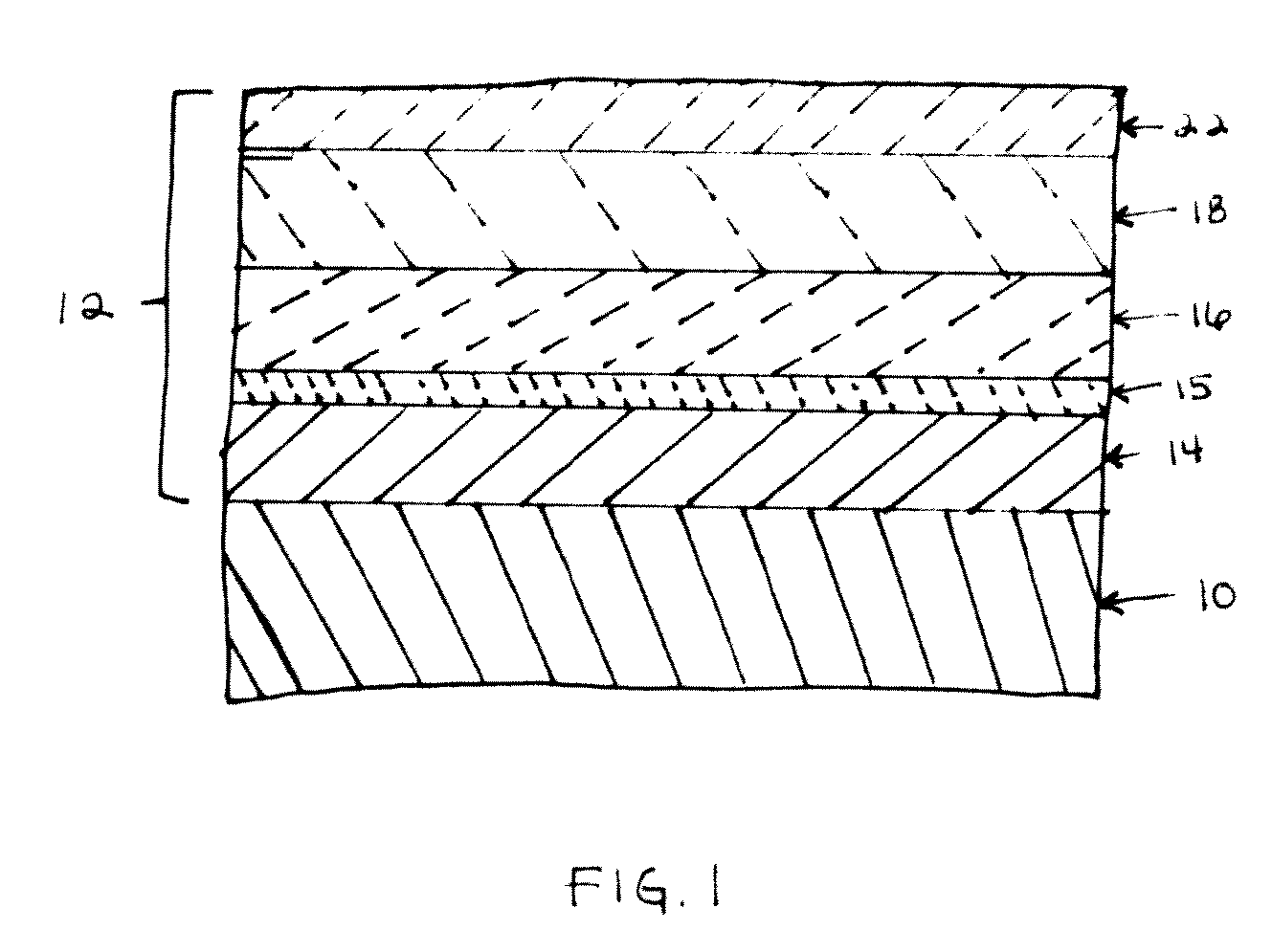

Gypsum boards with glass fiber reinforcements having a titanate or zirconate coupling coating

InactiveUS20060029785A1Improve bending strengthThin layerNon-woven fabricsThin material handlingCalcium ion bindingZirconate

A bond is created between a gypsum matrix and titanium or zirconium based coupling coating applied onto a glass fiber during gypsum board cure. The commercially available titanium or zirconium based coupling has a generic formula of the type [RO-}-nTi—[—OXR′Y]4-n or [RO-}-nZr—[—OXR′Y]4-n. These coupling compositions chemically bond to glass fibers by replacing the —OH groups present on the glass fibers in aqueous solutions with Ti—O or Zr—O bonds. In order to bond with calcium ions in hydrated gypsum crystals, the X functionality is selected to be a phosphate or pyrophosphato group. The bond between the glass fiber and the titanium or zirconium based coupling composition is due to the formation of a monolayer, while the bond between the hydrated gypsum crystal and the coupling composition is intermittent due the acicular structure of gypsum crystals. The titanium or zirconium based coupling composition coating on glass fibers bonded to the gypsum matrix results in load transfer between the gypsum matrix and the glass fibers, resulting in improved flexure strength and nail pullout resistance. The Titanate / Zirconate can also be used as a board mechanical properties enhancing agent without addition of glass fiber.

Owner:JOHNS MANVILLE CORP

Plumbum niobate-nicklate (PNN)-plumbum zirconate titanate (PZT) piezoelectric ceramic capable of being sintered at low temperature and preparation method thereof

InactiveCN102659404AImprove performanceLower sintering temperaturePiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateZirconate

The invention relates to a plumbum niobate-nicklate (PNN)-plumbum zirconate titanate (PZT) piezoelectric ceramic capable of being sintered at low temperature. The chemical formula of the PNN-PZT piezoelectric ceramic is 0.3Pb(Ni1 / 3Nb2 / 3)O3-0.7Pb(Zr0.44Ti0.56)O3+xCuO, wherein x is more than 0 and is less than or equal to 0.03. According to the PNN-PZT piezoelectric ceramic, a 0.3 PNN-0.7 PZT ternary piezoelectric ceramic material with high comprehensive performance is prepared by the conventional oxide mixing method and sintering CuO at low temperature under normal pressure on the basis of a Pb(Ni1 / 3Nb2 / 3)O3-Pb(Zr0.44Ti0.56)O3 system, so that the piezoelectric ceramic which can be sintered at low temperature and has high comprehensive performance is provided. The PNN-PZT piezoelectric ceramic is mainly applied to electronic devices of multilayer piezoelectric transformers, multilayer ceramic capacitors and the like which are sintered jointly at the low temperature.

Owner:TIANJIN UNIV

Enhanced boron nitride composition and polymer-based compositions made therewith

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

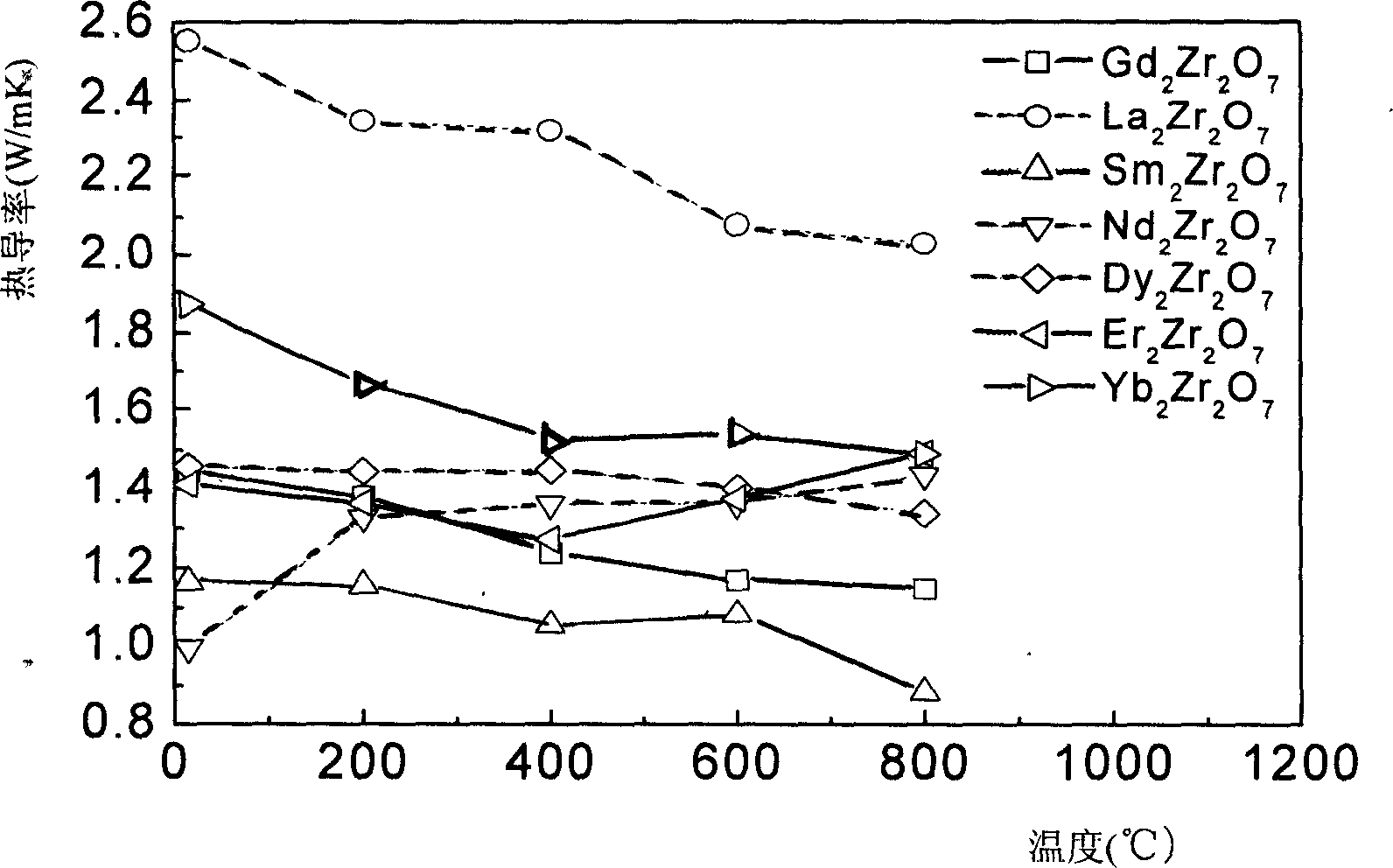

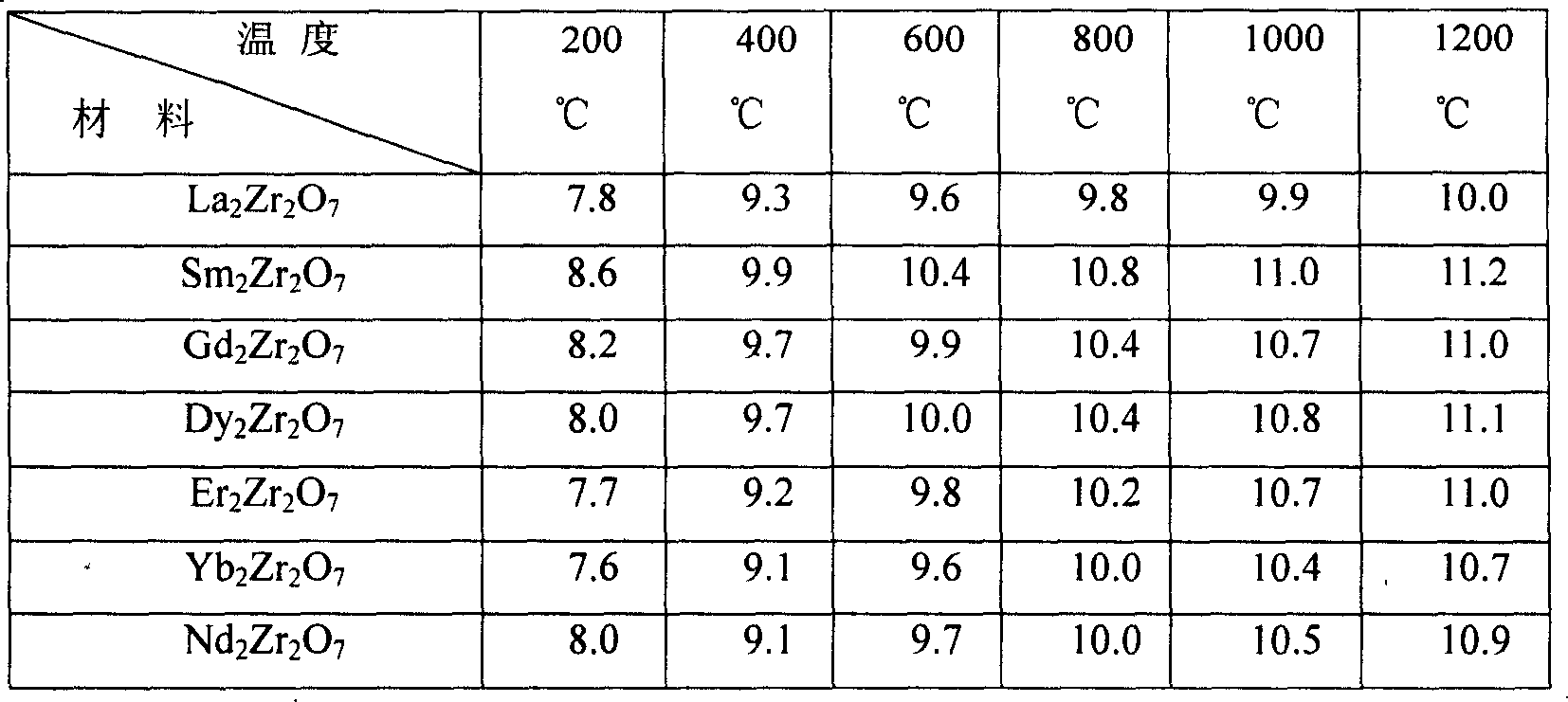

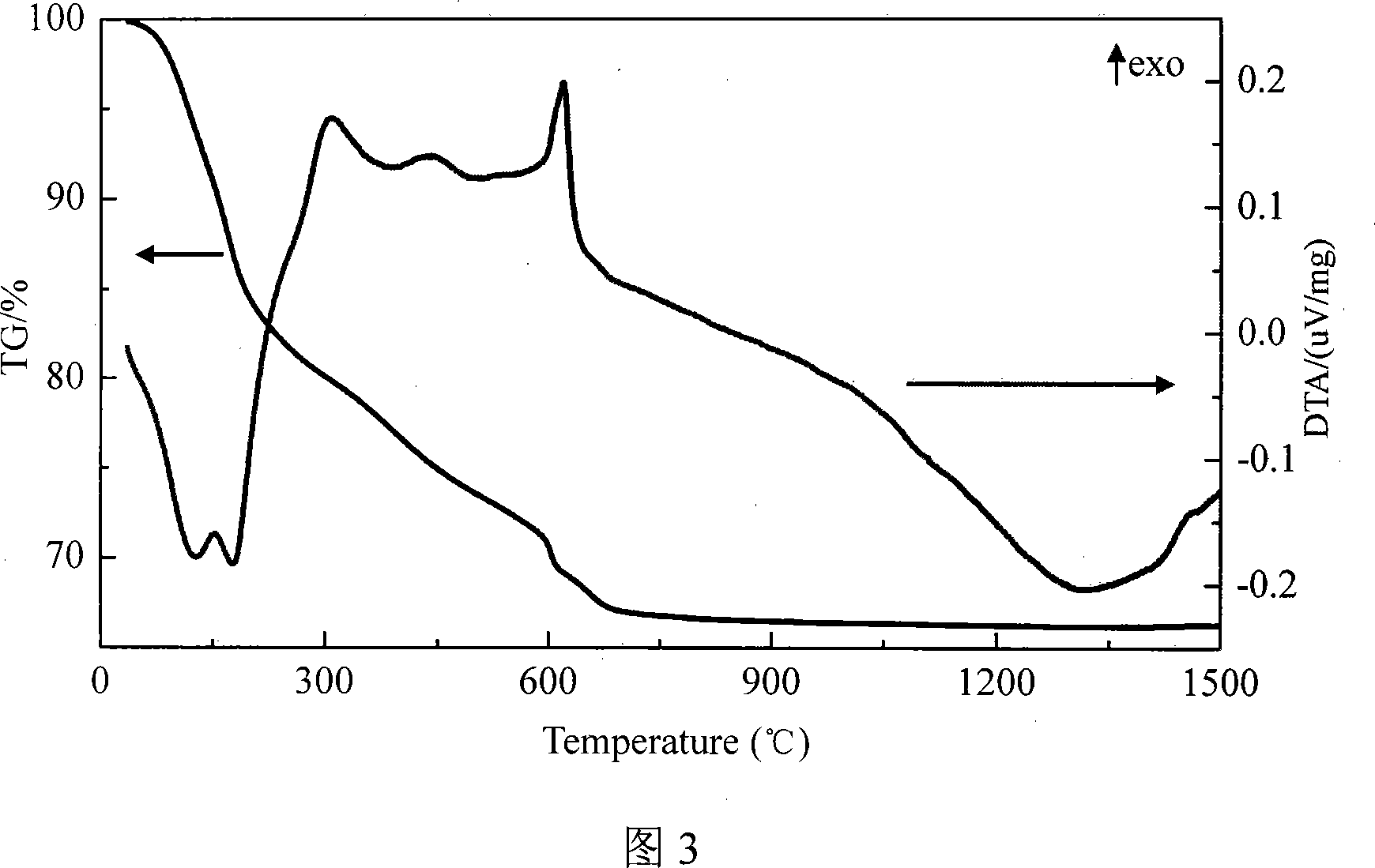

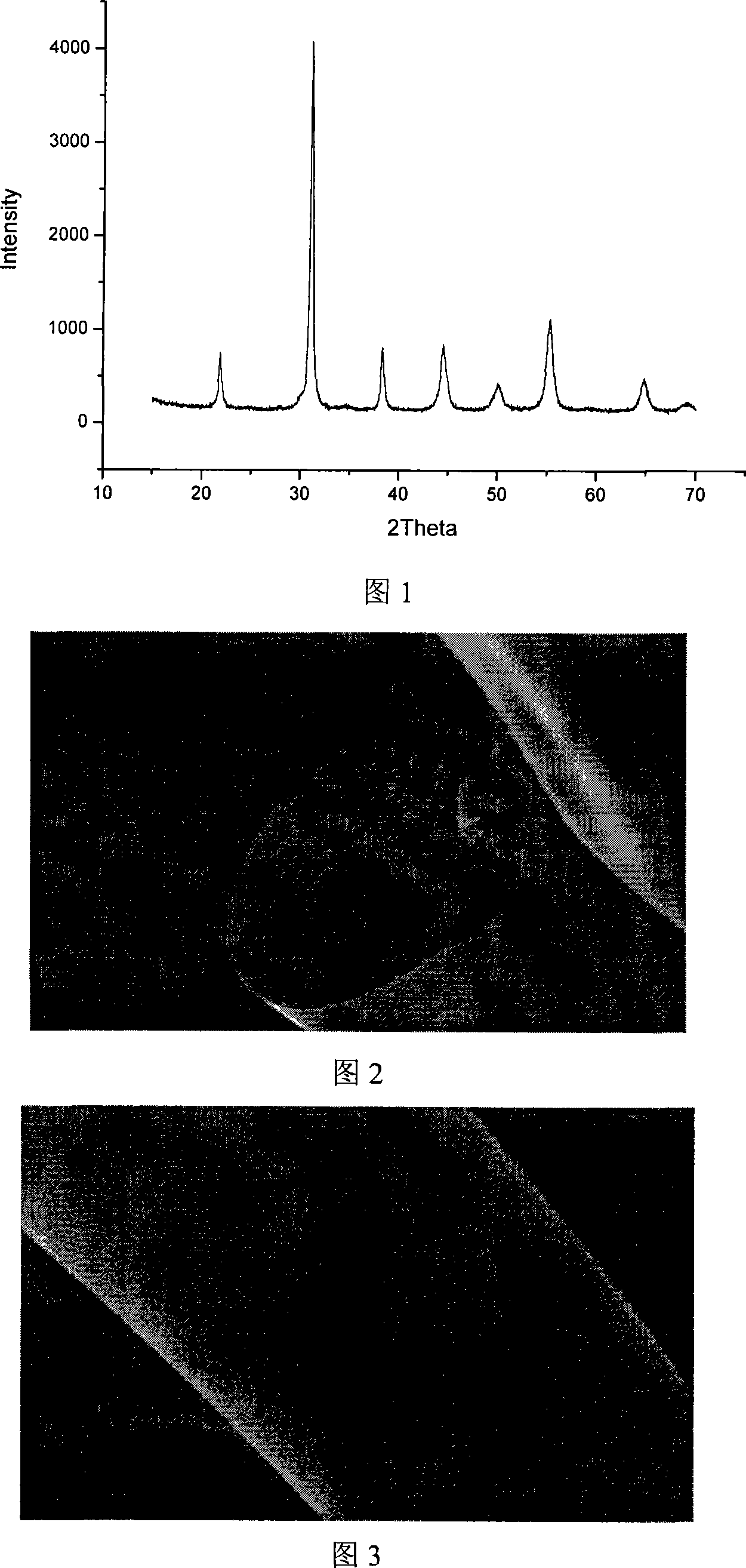

Rare earth zirconate high-temp heat barrier coating material and its preparation method

A RE zirconate coating material for preparing high-temp heat barrier layer has a chemical formula: A2B2O7, where A is chosen from La, Nd, Sm, Gd, Dy, Er and Yb and B is Zr. It is prepared through ball grinding of raw materials, baking, die pressing, and reaction in air at 1550-1650 deg.C. It has low heat conductivity and high high-temp stability.

Owner:TSINGHUA UNIV

Silane functional prepolymer and isocyanate functional prepolymer blend based adhesive composition

ActiveUS7345130B2Improve cohesive strengthFast curingLayered productsFilm/foil adhesivesPolyolefinPhosphate

The invention is an adhesive composition comprising a) one or more silane functional prepolymers comprising a polyether or a polyolefin backbone and silane moieties capable of silanol condensation; b) one or more isocyanate functional prepolymers comprising a polyether backbone and isocyanate moieties; c) one or more organotin compounds or titanate or zirconate compounds having one or more ligands comprising a hydrocarbyl phosphate ester or a hydrocarbyl sulfonate ester, or a mixture thereof; d) a tertiary amine or an anhydrous strong organic acid which is miscible with the polymer and enhances the bonding of the adhesive to a coated unprimed substrate. In one embodiment, the invention is a method of bonding two or more substrates together using the adhesive compositions of this invention. The process comprises applying an adhesive as described herein to one or more of the substrates; contacting the one or more substrates with the adhesive disposed between the substrates; and allowing the adhesive to cure.

Owner:DOW GLOBAL TECH LLC

Nano rare earth zirconate ceramic powder material for high temperature heat barrier coat and preparation method thereof

InactiveCN101104557ASmall particle diameterHigh coefficient of thermal expansionRare-earth elementZirconate

Disclosed are a nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings, and the preparation method, relating to a nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings, and the preparation method. The invention solves the problems that the existing ceramic materials for high-temperature thermal barrier coatings are of phase change failure, serious sintering, and too high thermal conductivity and mismatch with the matrix thermal expansion. The chemical formula of the nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings is Ln2Zr2O7, wherein, Ln is the combination of one or more rare earth elements among Gd, Sm, Nd or Yb. The preparation method is that rare earth oxide or soluble salt and zirconium salt containing rare earth oxides are used to respectively prepare the solution containing Ln3 + and the solution containing Zr4 +; the two solutions are mixed and added with surfactant under the ongoing mixing conditions; the mixed solution is dropped into precipitator to get sediment; after repeated washing, the sediment is dried, grinded and calcined. The invention can effectively protect high temperature alloy.

Owner:HARBIN INST OF TECH

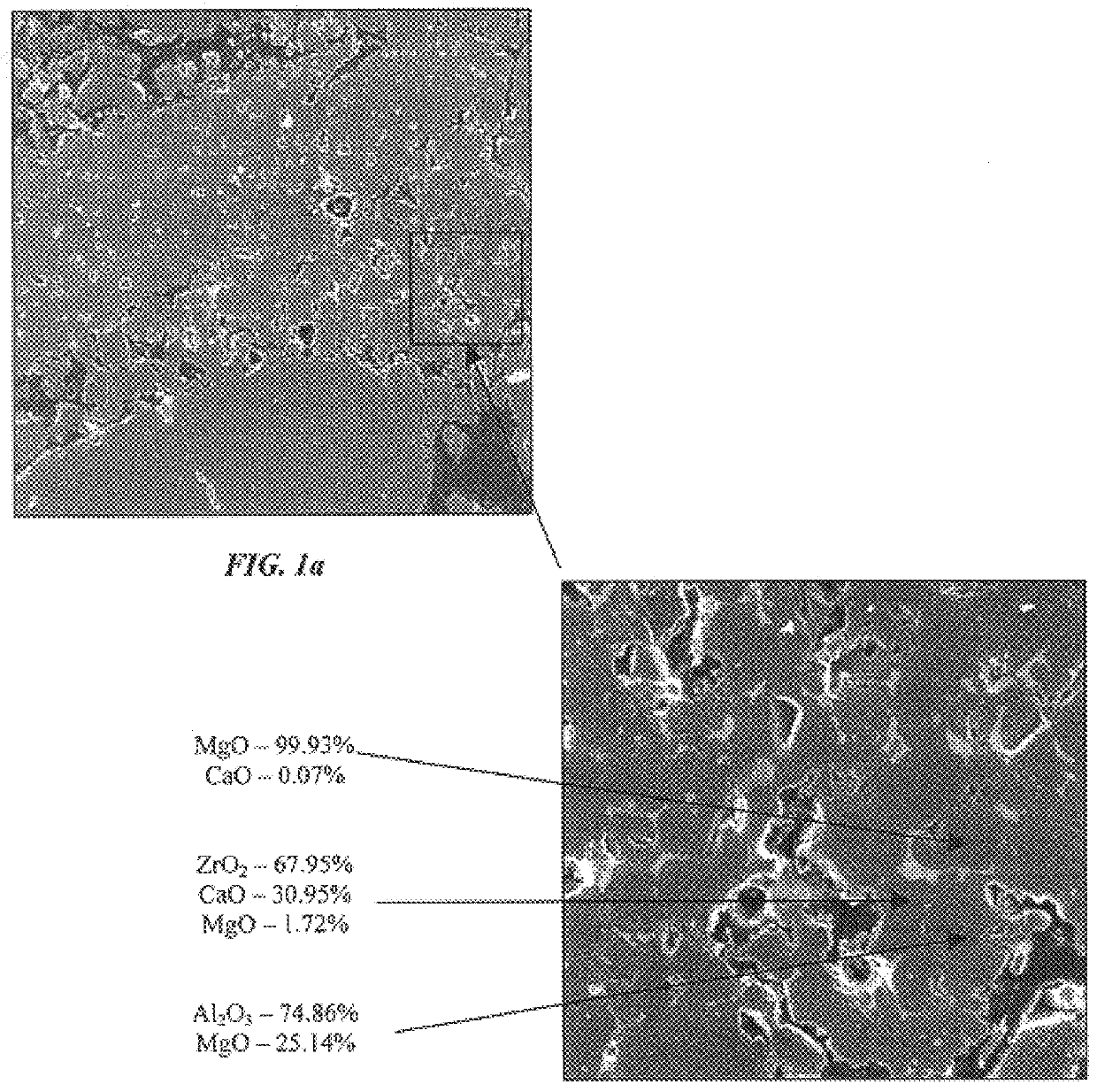

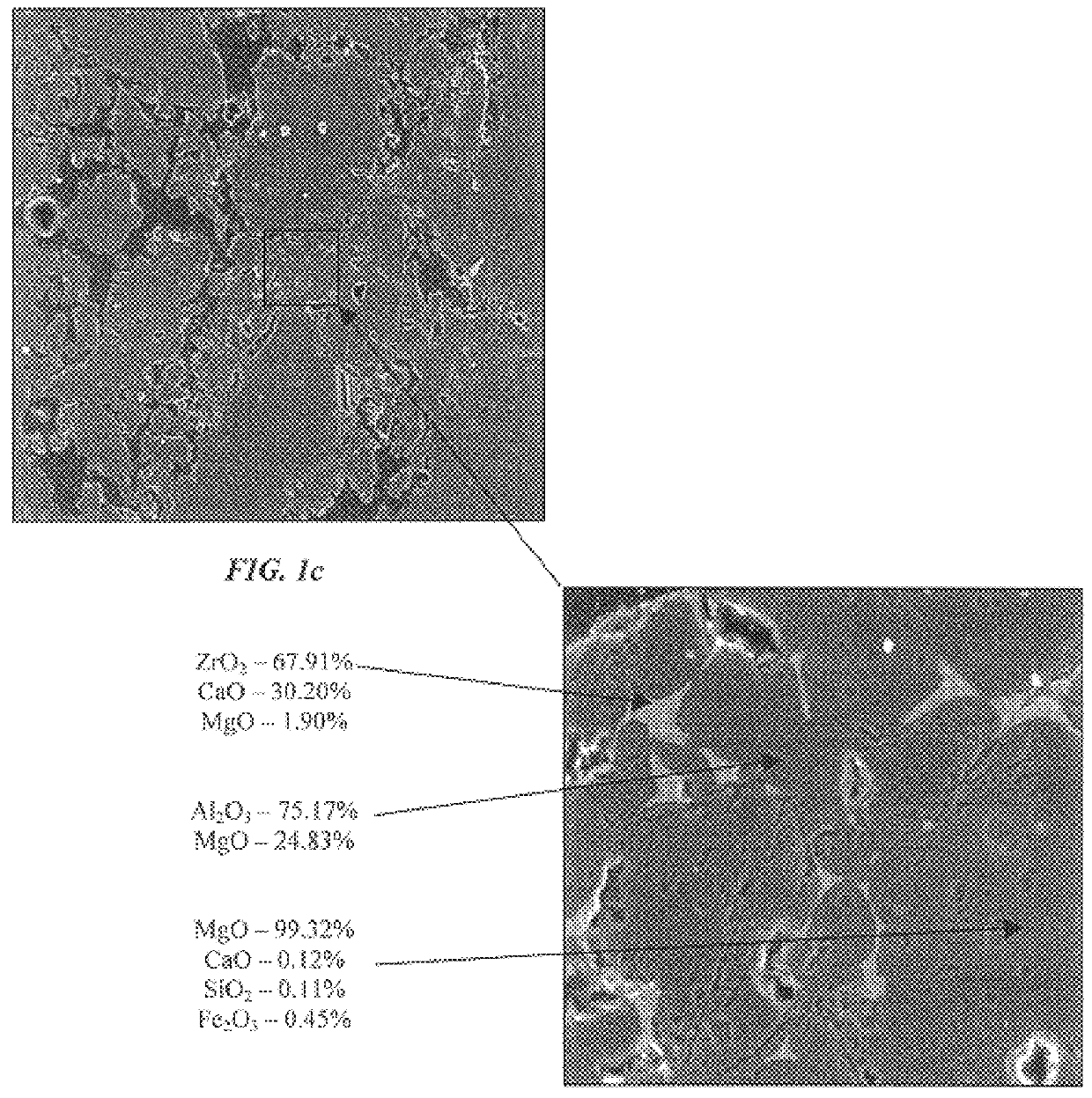

Magnesia spinel refractory brick

The present invention discloses novel magnesia-spinel refractory compositions and bricks formed thereof that exhibit longer lining life, greater hot strength and reduced tendency to spall under high thermal loading conditions. The invention is designed to slow or retard the reaction between spinel and lime through the addition of zirconia in the form of an alumina-zirconia grain to the refractory mix. Zirconia reacts more readily with the lime in the refractory composition and surrounding environment to form calcium zirconate.

Owner:BAKER REFRACTORIE

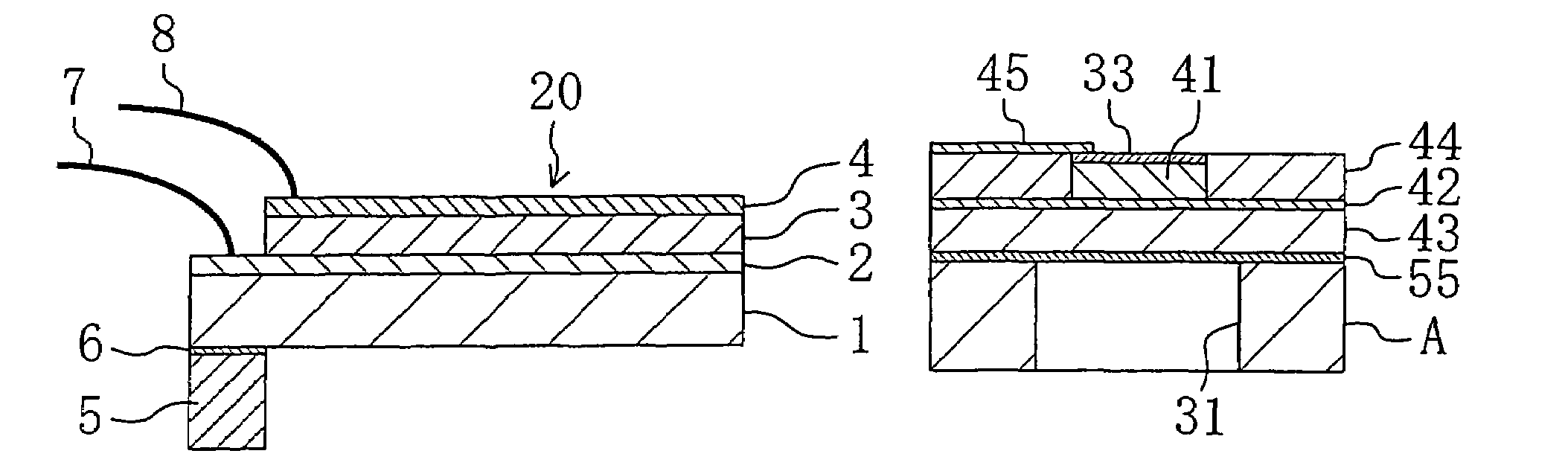

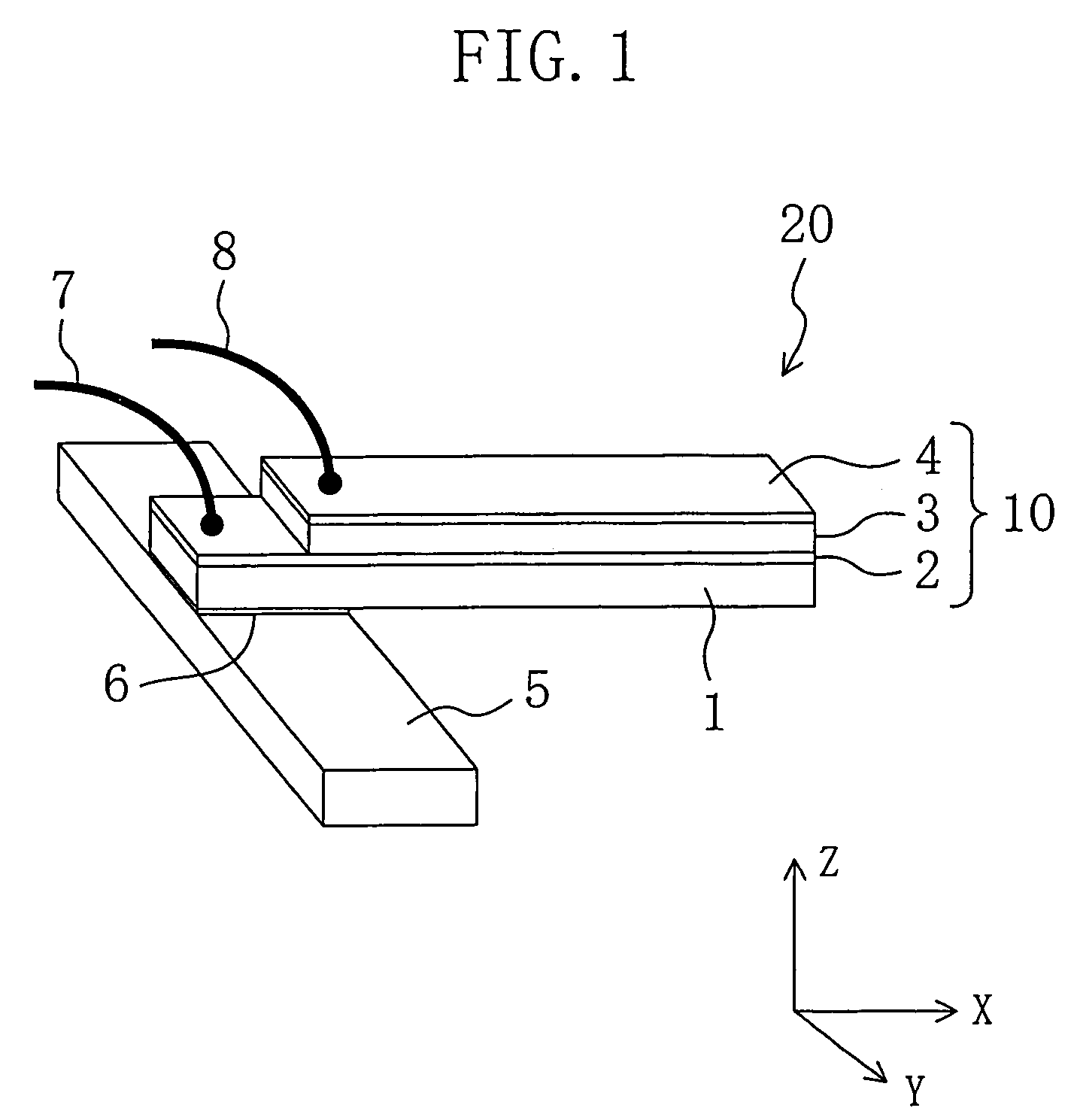

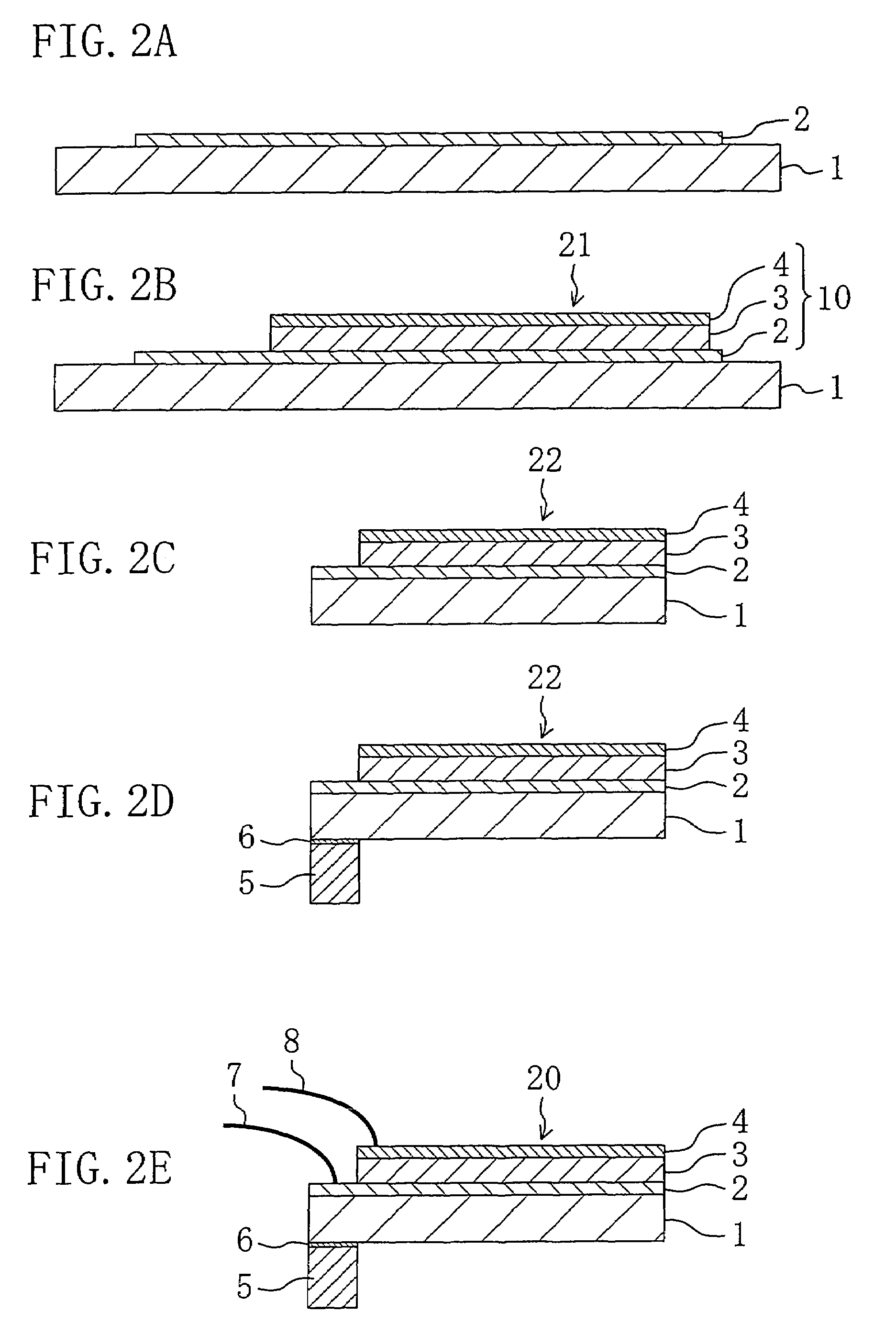

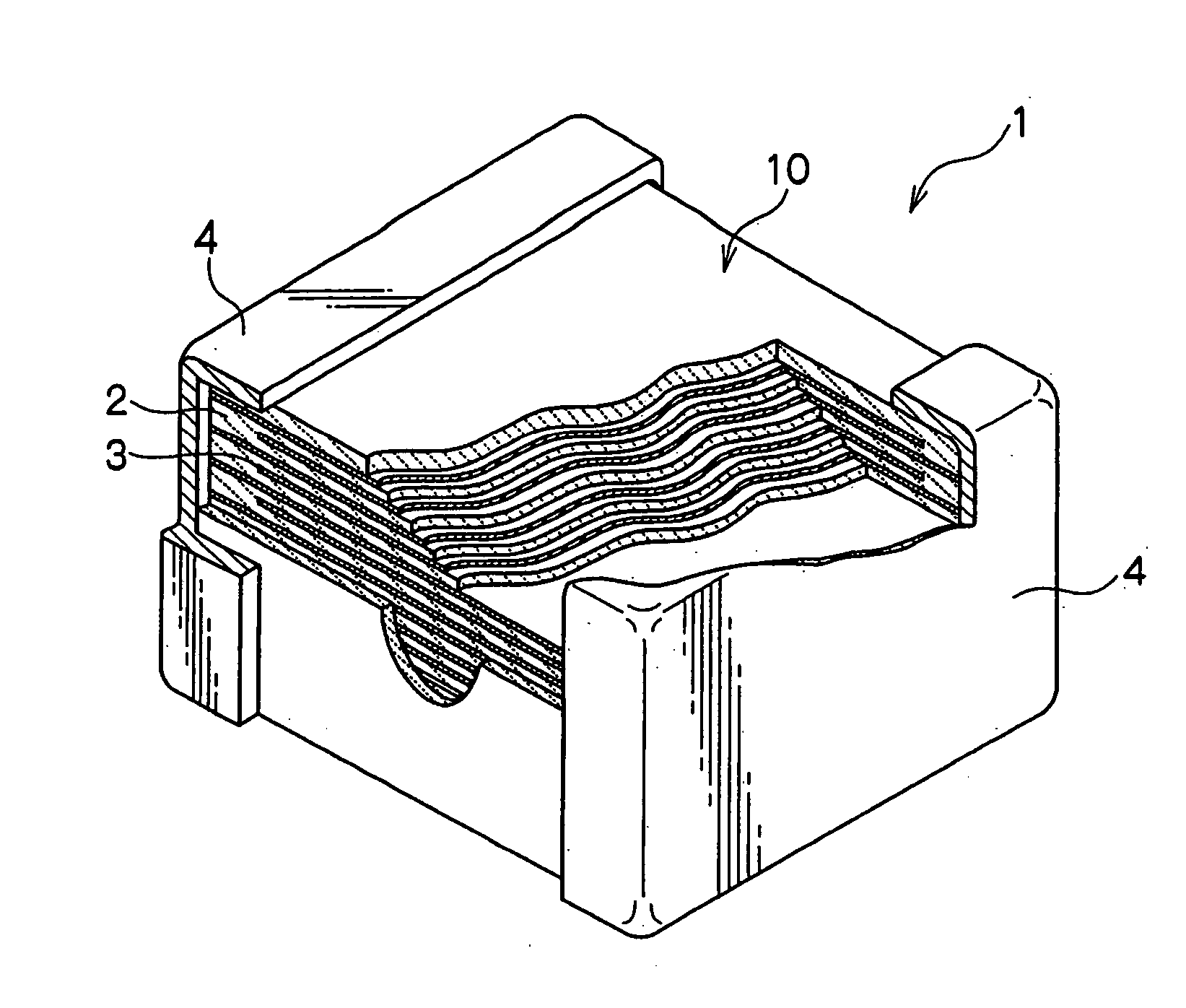

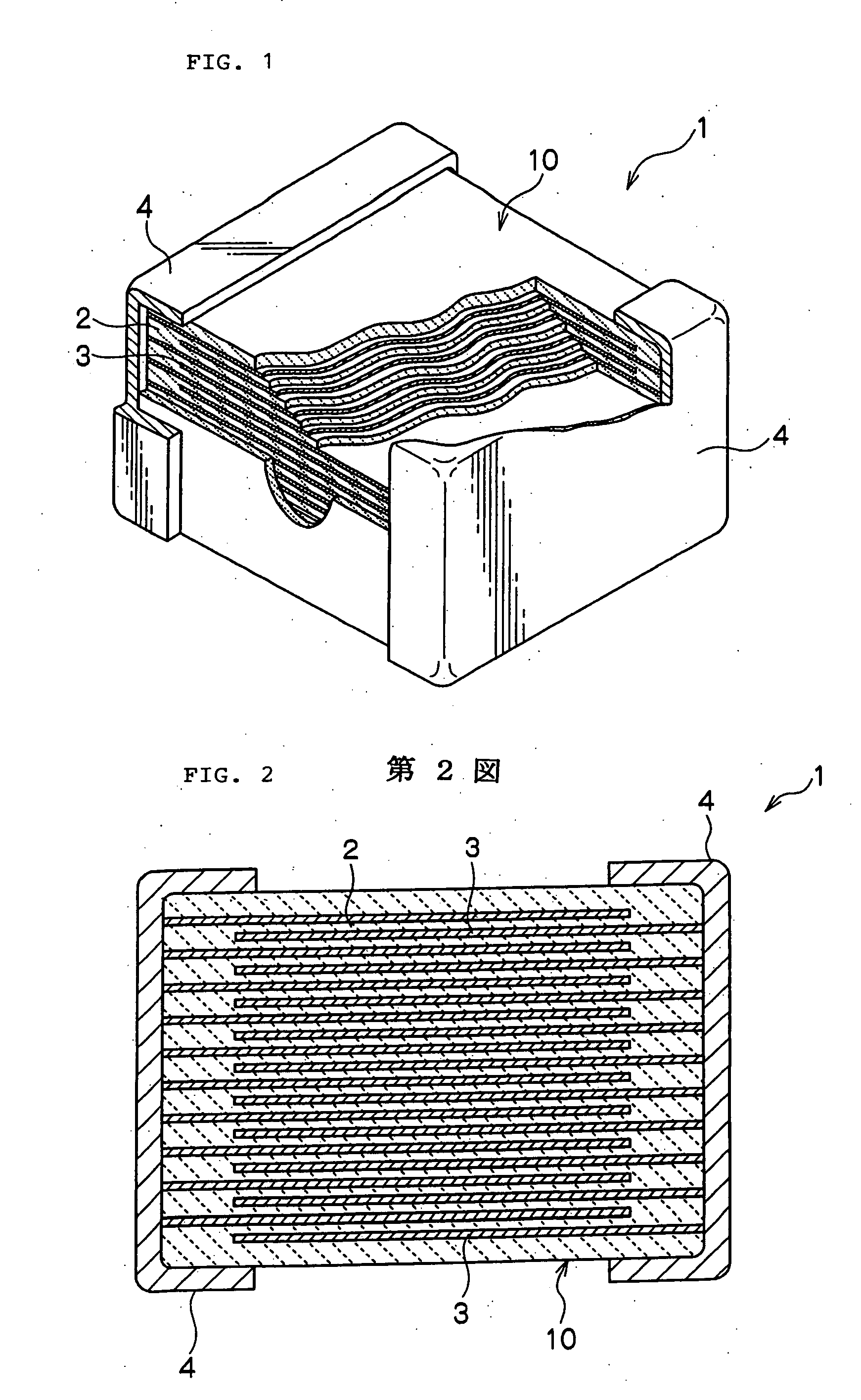

Piezoelectric element and method for manufacturing the same, and ink jet head and ink jet recording apparatus using the piezoelectric element

ActiveUS7348715B2Highly reliable piezoelectricEasy to getPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device material selectionLead zirconate titanateStoichiometric composition

A lead content in a piezoelectric thin film (3) of a piezoelectric element (20) is made smaller as compared to stoichiometric composition. More specifically, the piezoelectric thin film (3) is made of lead zirconate titanate expressed as Pb(1-x)(Zr(1-s)Tis)O3(0<s<1) or lead-zirconate-titanate-based oxide expressed as (Pb(1-x-y)Ay)(Zr(1-s-t)TisBt)O3(0<s<1, 0<t<1-s) where A is a substitutive metal ion in an A-site in the perovskite crystalline structure and B is a substitutive metal ion in a B-site in the perovskite crystalline structure. The value of x, which indicates a deficiency in Pb content in each composition, is more than 0 but not more than 0.15.

Owner:PANASONIC CORP

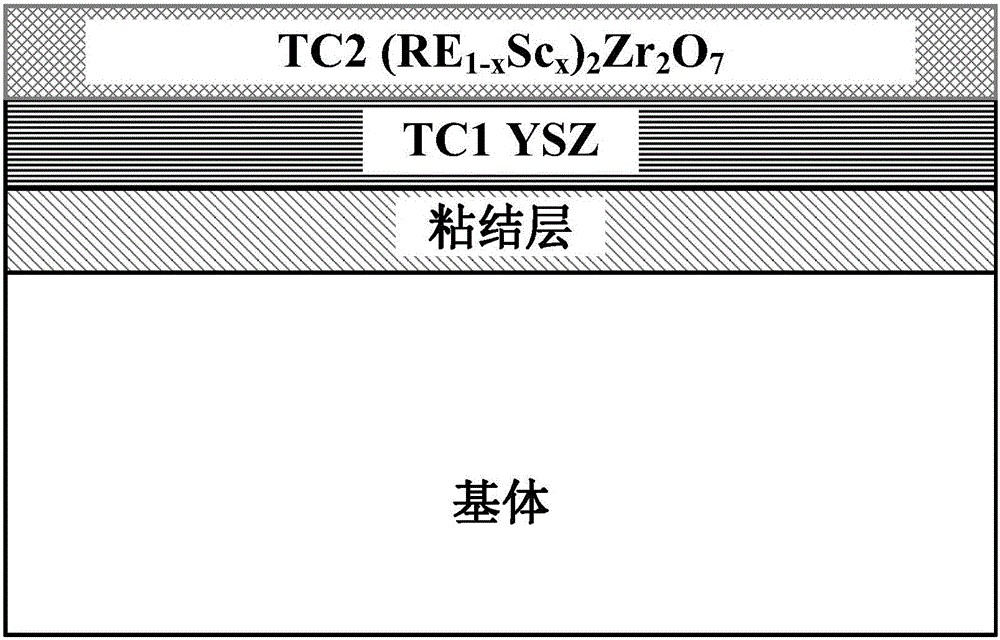

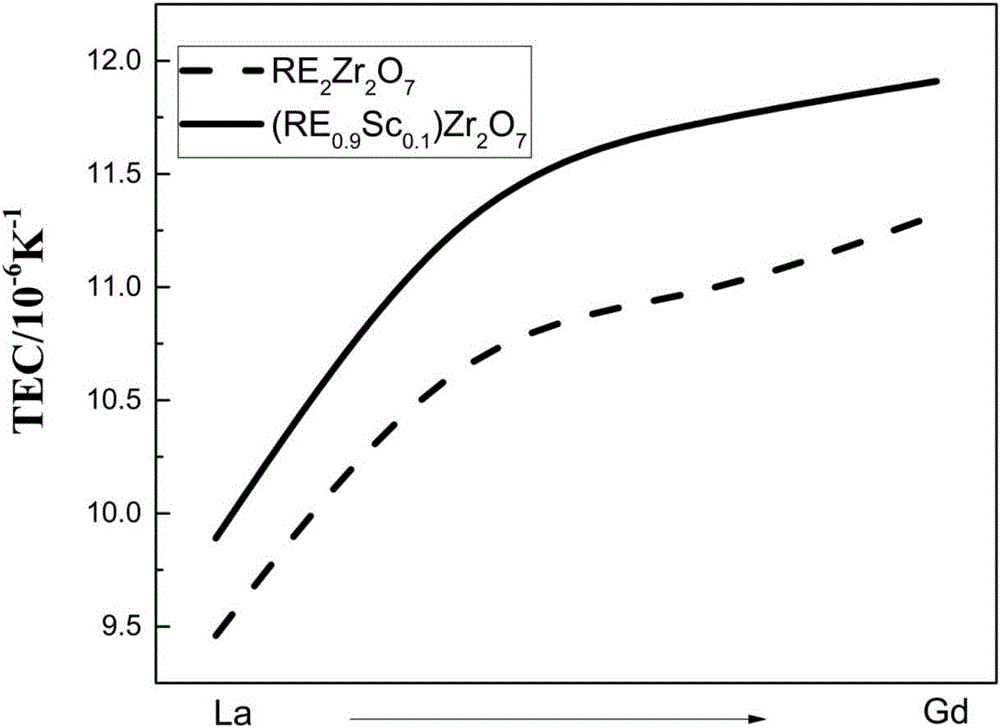

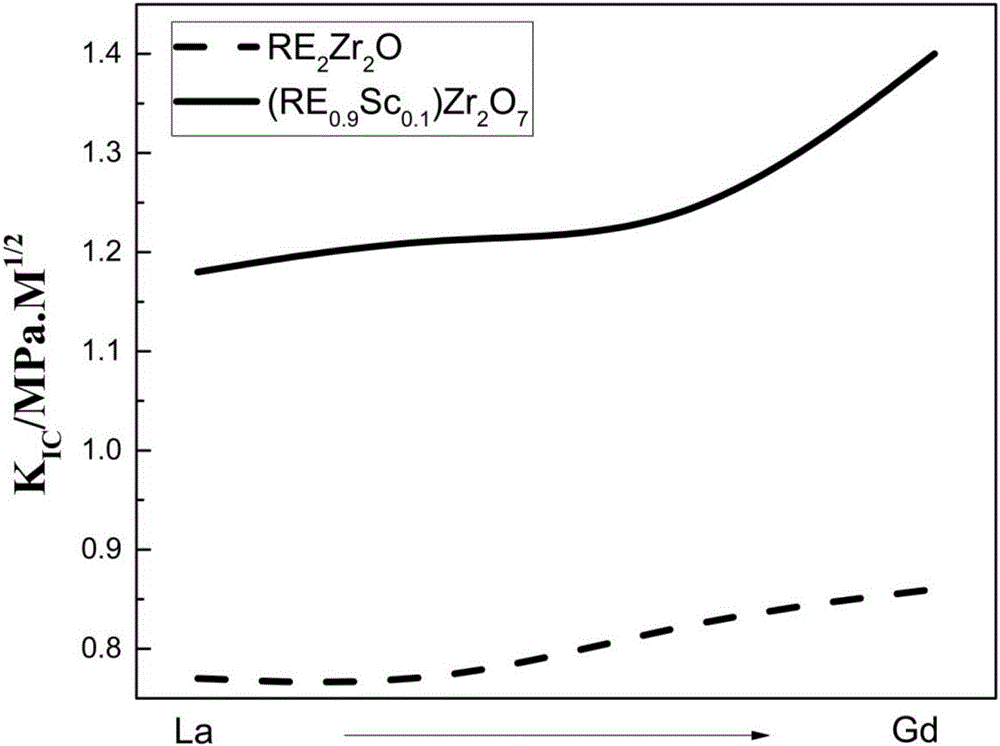

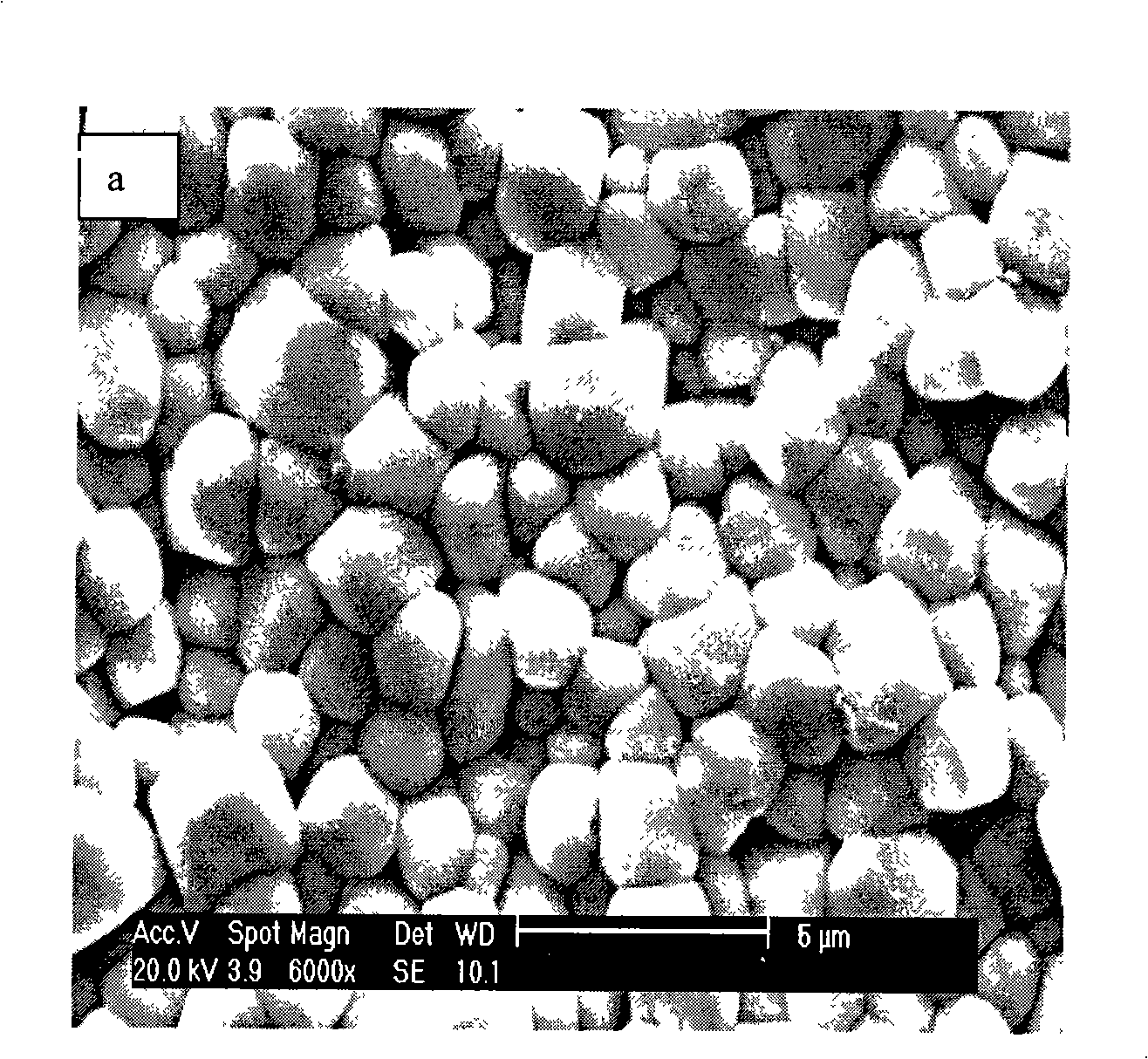

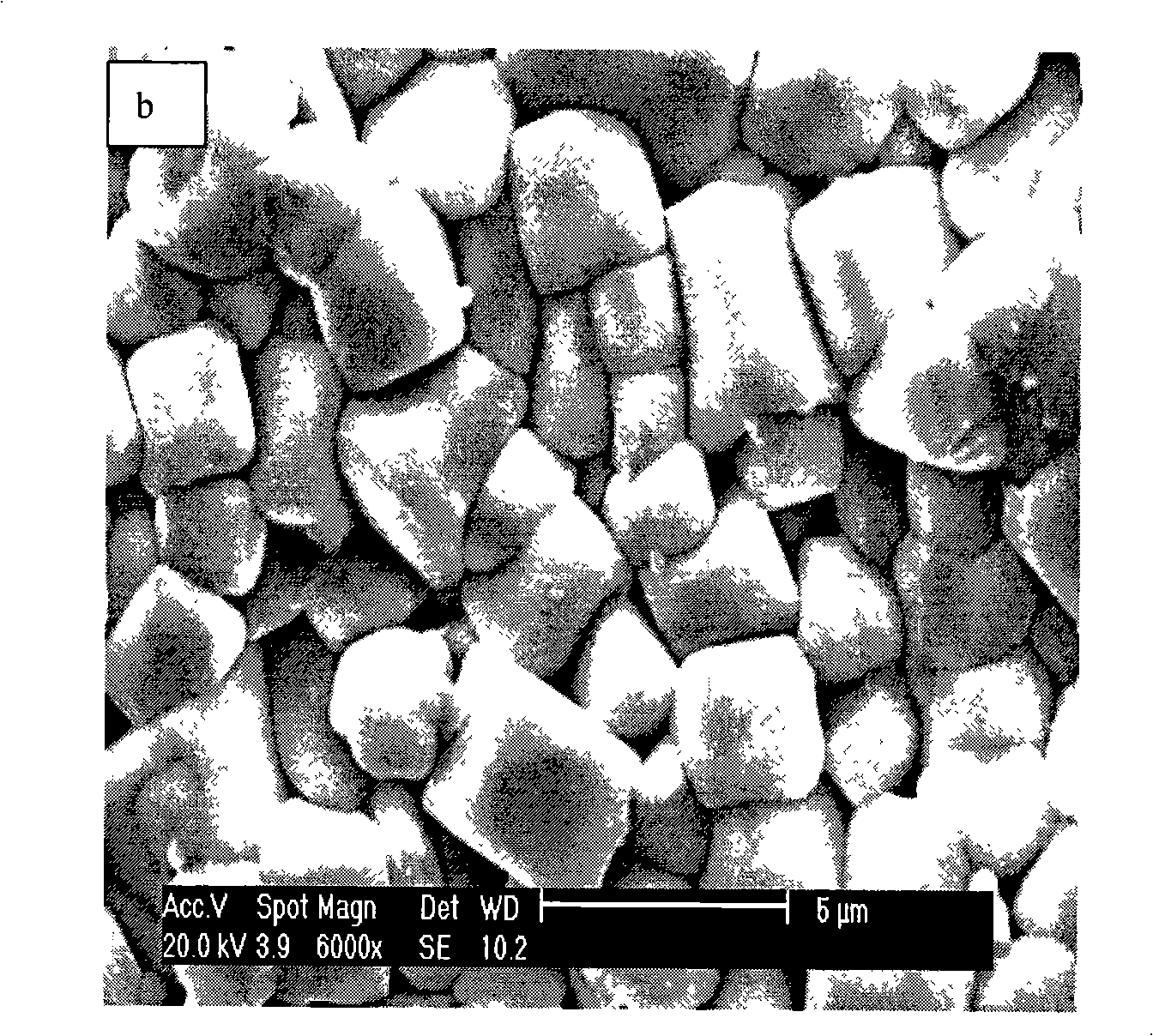

Anti-CMAS-corrosion ultrahigh-temperature-resistant long-service-life thermal barrier coating and preparation method thereof

ActiveCN105862038ALow thermal conductivityImprove toughnessMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionZirconate

The invention relates to an anti-CMAS-corrosion ultrahigh-temperature-resistant long-service-life thermal barrier coating and a preparation method thereof. The thermal barrier coating is sequentially provided with a binding layer, a first ceramic layer and a second ceramic layer on a matrix from bottom to top, the binding layer is made of an MCrAlX alloy, M refers to Ni, or Co or a composition of Ni and Co, X refers to one of or a composition of two of Y, Hf, Si and Pt, the first ceramic layer is made of YSZ, and the second ceramic layer is rare earth zirconate with Sc2O3. The preparation method includes that an electron beam physical vapor deposition method or an atmosphere plasma spraying method are adopted. Sc2O3 is doped in a rare earth zirconate coating, so that heat conductivity of the coating can be further lowered, toughness of the coating is improved, anti-CMAS-corrosion capability of the coating is improved, thermal cycling life of the coating can be prolonged, and high-temperature stability of the coating under CMAS coupling action can be improved.

Owner:TIANJIN UNIV

Strontium and barium doping lead niobium-stibium zirconate-titanate series piezoelectric ceramic and preparation method thereof

InactiveCN101265090ALow priceAbundant raw materialsPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateElectronic communication

The invention discloses a Sr and Ba-doped lead niobium-stibium zirconate-titanate (PNSZT)-based piezoelectric ceramic. The piezoelectric ceramic has the chemical formula as follows: Pb0.96Sr0.03Ba0.03(Sb1 / 2Nb1 / 2)0.02(ZrxTi0.98-x) O3, wherein x is in the range of 0.51-0.525. The raw materials of the piezoelectric ceramic include Pb3O4, Nb2O5, Sb2O3, ZrO2, TiO2, SrCO3 and BaCO3. The invention also discloses a production method of the piezoelectric ceramic. The method comprises the following steps: (1) material compounding, (2) granulation, (3) molding, (4) adhesive removal, (5) sintering and (6) grinding, cleaning and polarization. The piezoelectric ceramic provided in the invention has the advantages of low price, easily-accessible raw materials, good dielectric and piezoelectric performances, good uniformity in crystal morphology, high Curie temperature, low optimal sintering temperature, and wide sintering range; and is widely used in the fields of machinery, electronics and communication.

Owner:TIANJIN UNIV

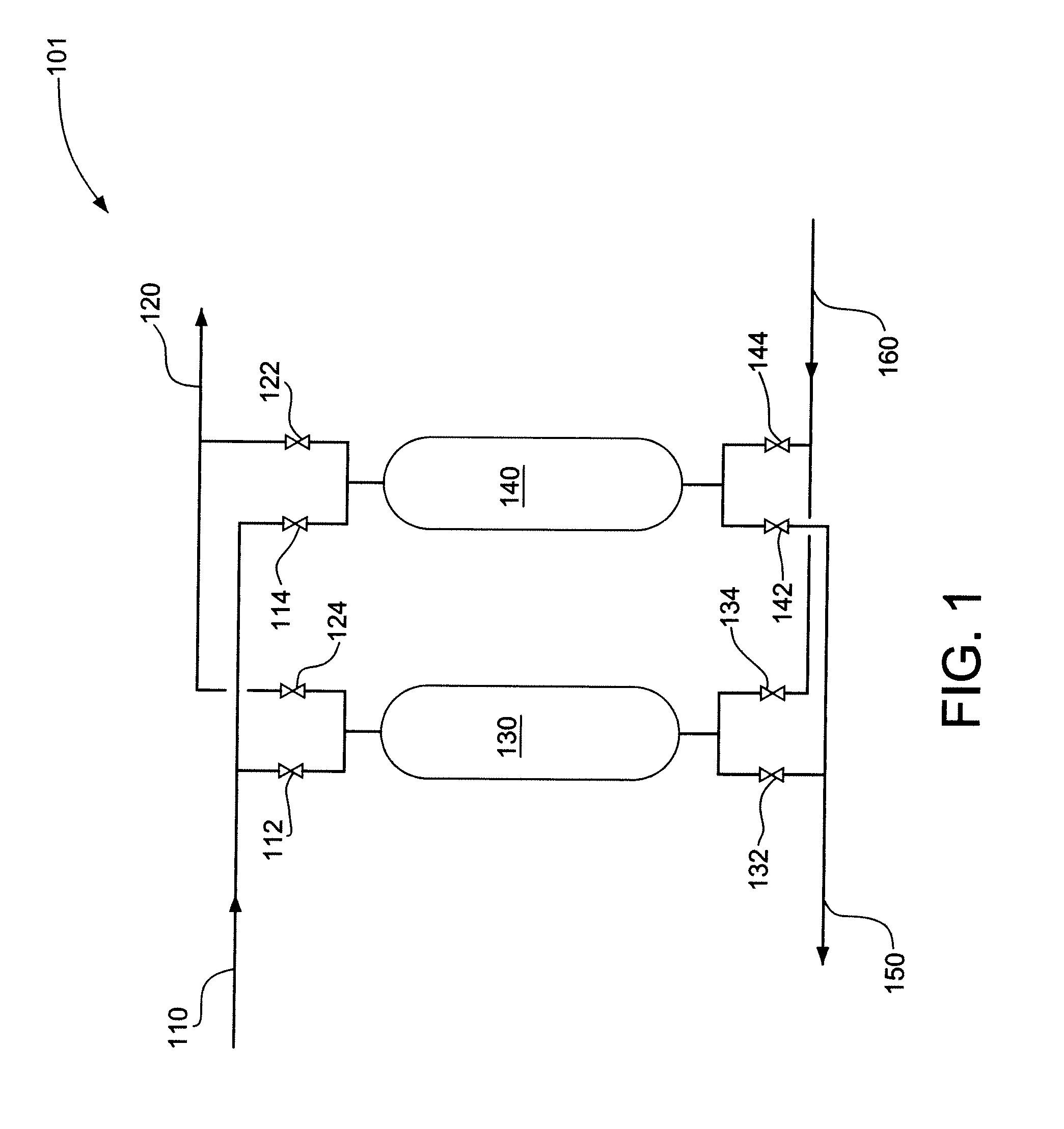

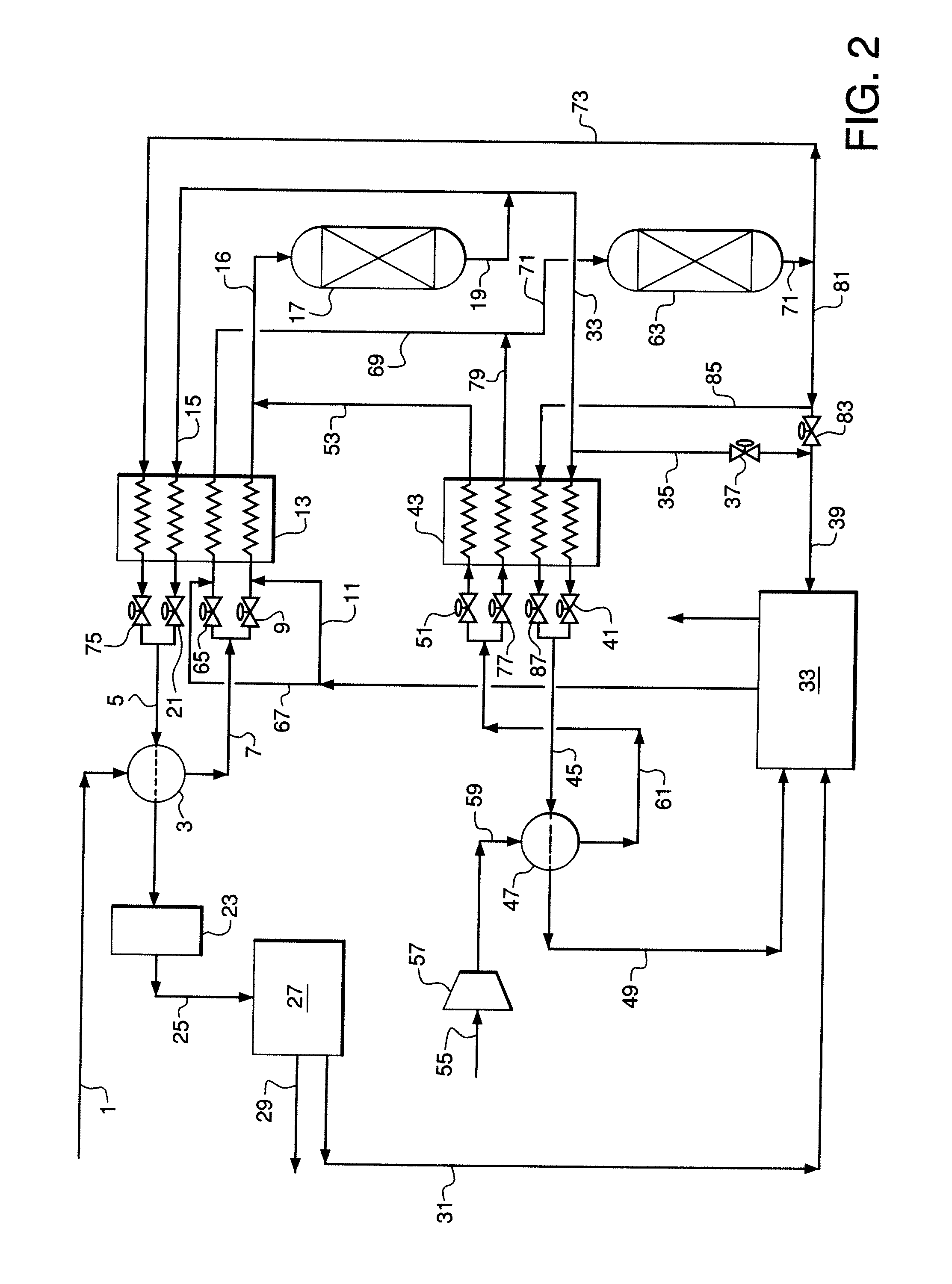

CO2-Sorptive Pellets and Uses Thereof

CO2 sorptive pellets and / or granules and their use for removing CO2 from CO2-containing gases and for producing hydrogen. CO2 sorptive pellets are suitable for use in fixed bed reactors and the like due to sufficient crush strength. CO2 sorptive granules are suitable for moving, ebullated, expanded and fluidized beds. The CO2 sorptive pellets and / or granules comprise calcium oxide and / or magnesium oxide and at least one binding agent such as calcium titanate, calcium aluminate, calcium zirconate, magnesium titanate, magnesium aluminate, and magnesium zirconate. A method for making the CO2-sorptive pellets is described. The CO2 sorptive pellets optionally comprise at Ni, Pd, Pt, and / or Rh.

Owner:AIR PROD & CHEM INC

Methods for making environmental barrier coatings and ceramic components having CMAS mitigation capability

Methods of making components having calcium magnesium aluminosilicate (CMAS) mitigation capability including providing a component; applying an environmental barrier coating to the component, the environmental barrier coating having a separate CMAS mitigation layer including a CMAS mitigation composition selected from the group consisting of zinc aluminate spinel, alkaline earth zirconates, alkaline earth hafnates, rare earth gallates, beryl, and combinations thereof.

Owner:GENERAL ELECTRIC CO

Iron-based powder

The present invention concerns a new ferromagnetic powder composition comprising soft magnetic iron-based core particles wherein the surface of the core particles are surrounded by an insulating inorganic coating, and a lubricating amount of a compound selected from the group consisting of silanes, titanates, aluminates, zirconates, or mixtures thereof. The invention also concerns a process for the preparation of soft magnetic composite materials using the new powder composition.

Owner:HOGANAS AB

Dielectric ceramic composition, multilayer ceramic capacitor, and method for manufacturing the same

InactiveUS20050219794A1Keep for a long timeSmall variation in lifetimeFixed capacitor dielectricStacked capacitorsBarium titanateCeramic capacitor

A dielectric ceramic composition contains components, with respective numbers of moles relative to 100 moles of barium titanate, including barium titanate, a first sub-component containing at least one oxide selected from a Mg oxide, a Ca oxide, a Ba oxide, and Sr oxide, a second sub-component containing an oxide containing 1 mol of Si atoms per mol, a third sub-component containing at least one oxide selected from a V oxide, a Mo oxide, and a W oxide, a fourth sub-component containing at least one R1 oxide (wherein R1 is at least one selected from Sc, Er, Tm, Yb, and Lu), a fifth sub-component containing at least one R2 oxide (wherein R2 is at least one selected from Y, Dy, Ho, Tb, Gd, and Eu), a sixth sub-component containing at least one selected from a Mn oxide and a Cr oxide, and a seventh sub-component containing at least one selected from calcium zirconate and a mixture of a Ca oxide and Zr oxide. The ratio (A / B) of the number of moles A of the second sub-component to the total number of moles B of the fourth and fifth sub-components is 0.7 or more. Alternatively, the ratio (C / D) of the number of moles C of Si atoms in the second sub-component to the total number of moles of the atoms in the first to seventh sub-components excluding the Si atoms and oxygen atoms being 0.2 or more, and the total number of moles of the fourth and fifth sub-components being 3 or more.

Owner:TDK CORPARATION

Method for preparing lead zirconate titanate ceramics fibre

The invention provides a preparation method of lead zirconate-titante ceramic fiber, which relates to a ceramic fiber. The fiber obtained with the diameter less than 30Mum and the length about 1cm has a single perovskite phase and comparatively high consistency and the invention can be a preparation method of lead zirconate-titante ceramic fiber of ceramic fiber for 1-3 piezoelectric composites. The preparation of lead zirconate-titante precursor solution is : lead acetate trihydrate is added into n-Butyl alcohol, complexing agent glacial acetic acid is added then; the mixture is heated, dissolved and cooled to obtain solution A; zirconium butoxide and titanium butoxide are poured into the n-Butyl alcohol in sequence to obtain the binary mixed solution of zirconium and titanium, and then acetyl acetone is added into the binary mixed solution and solution B is obtained after backflowing; the solution A and the solution B are mixed and the lead zirconate-titante precursor solution is obtained after backflowing. The preparation of lead zirconate-titante precursor sol is: the lead zirconate-titante precursor solution is steamed, concentrated and stirred, rod winding is carried out and the lead zirconate-titante precursor sol is obtained after concentration; lead zirconate-titante gel fiber is obtained through fiber drawing; after aging, the lead zirconate-titante gel fiber is dried and carried out by heat treatment.

Owner:XIAMEN UNIV

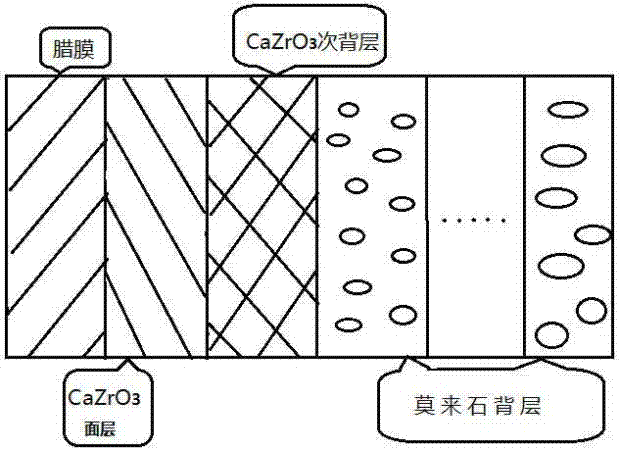

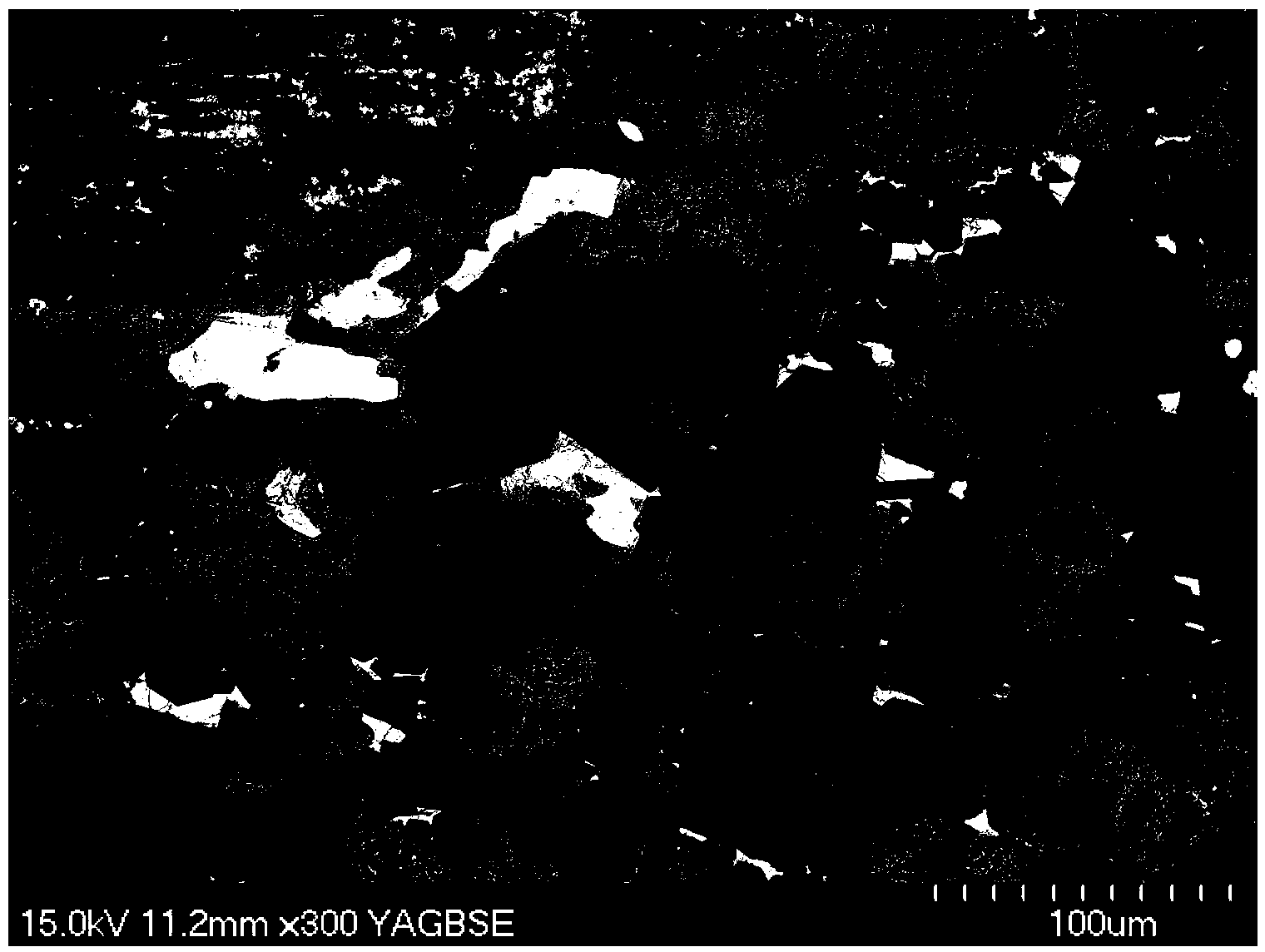

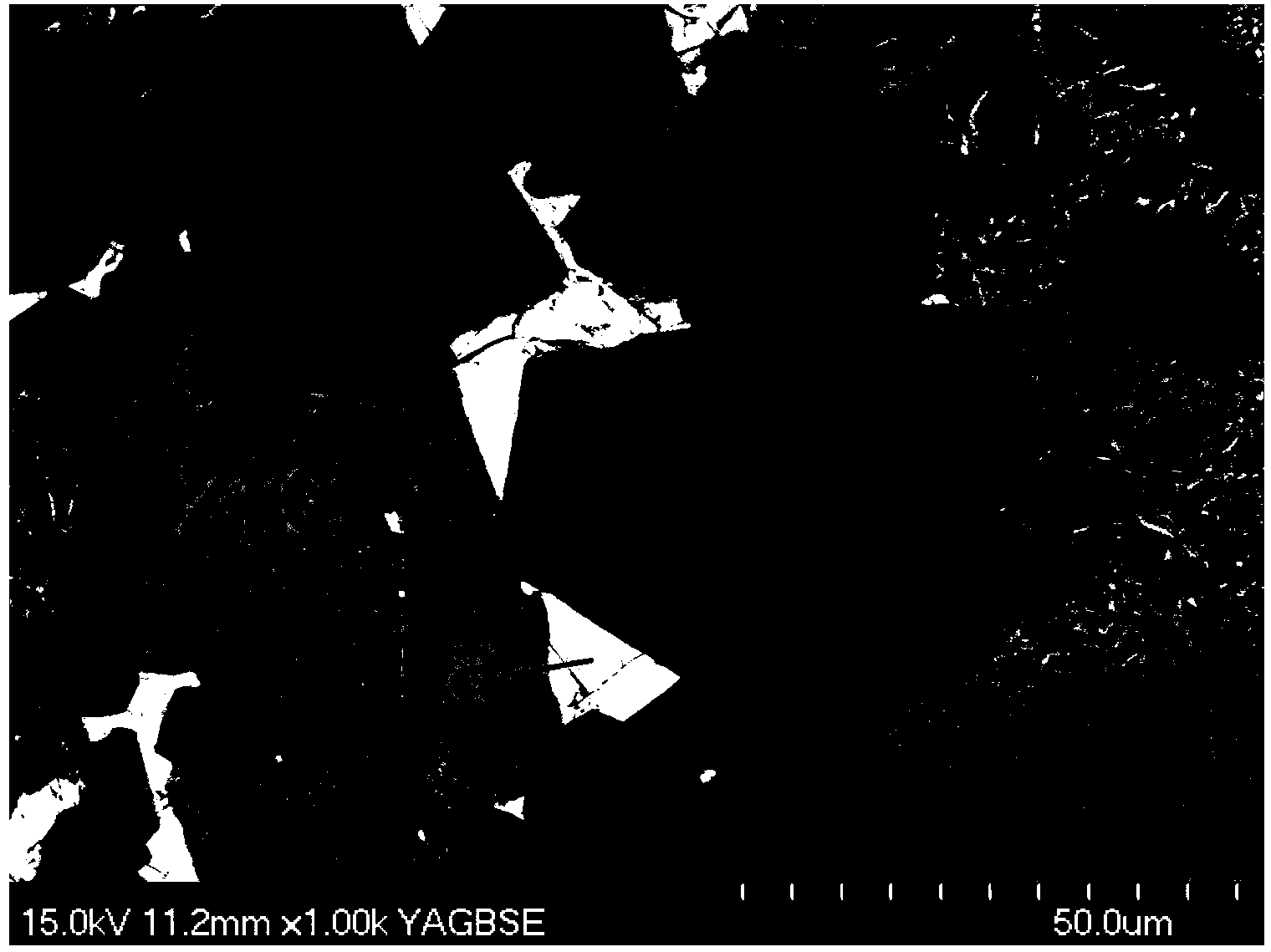

CaZrO3 mold shell used for titanium and titanium alloy precision casting and preparation method

ActiveCN103071764AHighlight substantiveSignificant progressFoundry mouldsFoundry coresZirconateTitanium

The invention discloses a CaZrO3 mold shell used for titanium and titanium alloy precision casting and a preparation method, which is characterized in that calcium zirconate is taken as a filling material, binders which are not reacted with a titanium alloy such as zirconium acetate or yttrium sol are pretreated, molded, hardened, roasted and the like to prepare the mold shell. The mold shell has small reaction degree with titanium and the titanium alloy, the thickness of contamination formed on the casting surface is small; the calcium zirconate ceramic mold shell has high strength, the casting surface has high fineness; a paint containing calcium zirconate is stable and is not easy to be gelled, the suspensibility is good, and the preservation time is long.

Owner:SHANGHAI UNIV +1

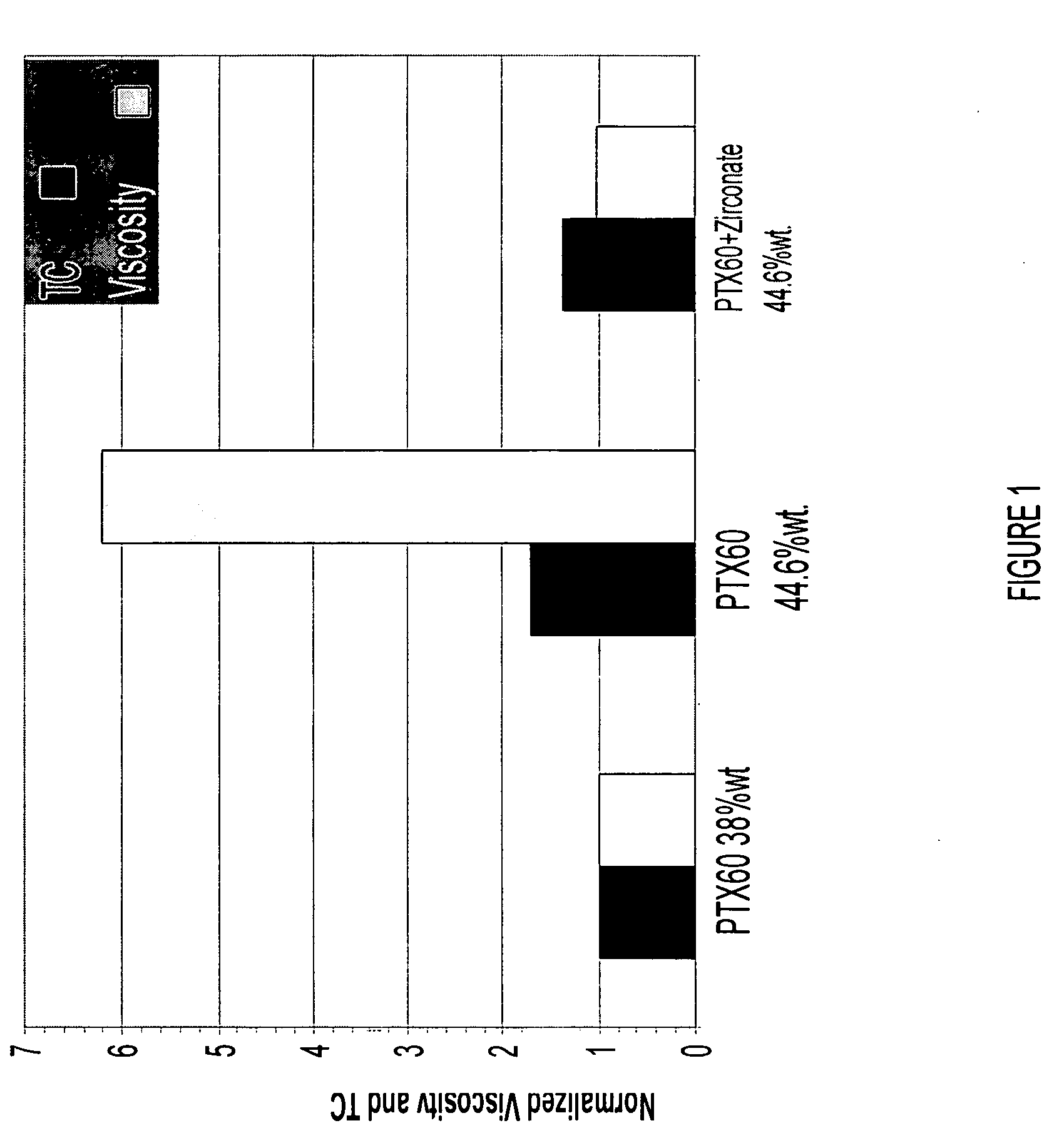

Hydraulic fracturing methods using cross-linking composition comprising delay agent

InactiveUS20070187102A1Effective delayingTolerance rangeFluid removalDrilling compositionCross-linkZirconate

A method for hydraulically fracturing a subterranean formation comprises introducing into the formation a cross-linking composition which comprises (a) an aqueous liquid, (b) a pH buffer, (c) a cross-linkable organic polymer, (d) a cross-linking agent which comprises an organic titanate, an organic zirconate, or combinations thereof, and (e) a delay agent which is a hydroxyalkylaminocarboxylic acid. The method can be used over a wide range of pH conditions.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of carbon fiber-reinforced ultra high-temperature ceramic-base composite material capable of being repeatedly ablated for use

The invention relates to a preparation method of a carbon fiber-reinforced ultra high-temperature ceramic-base composite material capable of being repeatedly ablated for use. Vacuum pressure is adopted to soak and combine reaction melt, the reaction melt is permeated in the conventional carbon fiber-reinforced ultra high-temperature ceramic-base composite material, and rear-earth metal elements such as La, Y, Yb, Sc, and the like are added to achieve effects of reducing volatilization of SiO2 at a high temperature, stabilizing a ZrO2 / HfO2 crystal form and generating rare-earth zirconate or rear-earth hafnate. After ablation, glass-state SiO2 is formed on the material surface and filled between ZrO2 and HfO2; and a compaction layer of the rare-earth zirconate / the rear-earth hafnate is mixed to protect the material very well, so that repeatable ablation of the ultra high-temperature ceramic-base composite material is possible.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

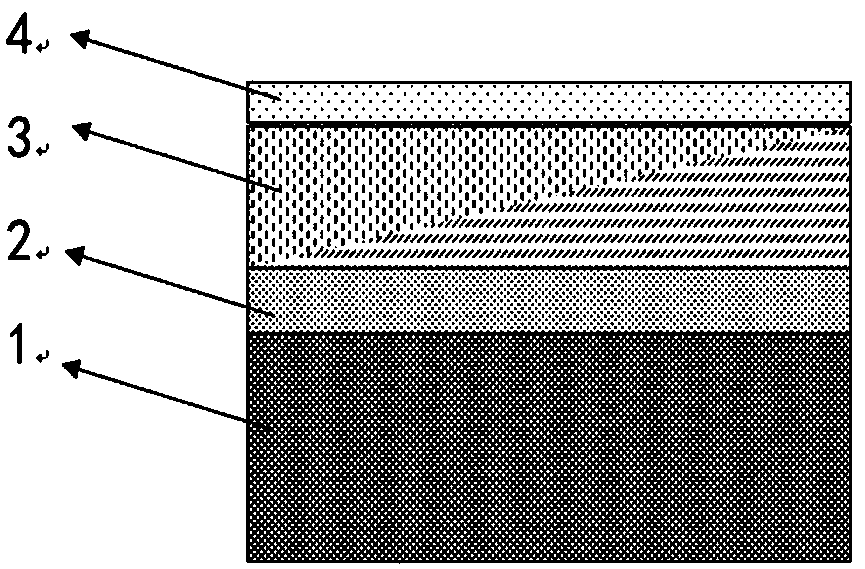

Composite coating for high-temperature container for metal melting and method for making same

The invention relates to a composite coating use for a smelting metal high-temperature vessel and a preparation method thereof, belonging to the technical field of smelting and preparing noble metal or rare metal. The method comprises the following steps: the surface of the smelting metal high-temperature vessel is provided with one or more metal tungsten, metal molybdenum, metal tantalum or metal niobium transition layers; the transition layer is provided with one or more yttrium oxide, calcium zirconate or magnesium zirconate coatings; or more than three layers of ladder coatings consisting of the metal tungsten, the metal molybdenum, the metal tantalum or the metal niobium and a ceramic surface material are formed on the surface of the smelting metal high-temperature vessel, with the compositions from more to less or from less to more. The composite coating solves the problem that smelting metal at high temperature reacts with the high-temperature vessel, and can be applied to the field of high-temperature smelting.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

YSZ-rare earth zirconate thermal barrier coating of gradient structure and preparation method thereof

InactiveCN108441807AImprove thermal shock resistanceReduce thermal mismatch stressMolten spray coatingOxide ceramicRare earth

The invention provides an YSZ-rare earth zirconate thermal barrier coating of a gradient structure and a preparation method thereof. The coating material comprises an adhesive layer, an 8YSZ-rare earth zirconate gradient layer and a surface layer. The 8YSZ-rare earth zirconate material has relatively low conductivity, high-temperature sintering resistance and excellent resistance to heat shocks, and also can prevent oxygen from entering the adhesive layer on active service to alleviate oxidization of the adhesive layer to form TGO. The heat mismatching stress of the material can be reduced bymeans of an optimized design of the gradient structure, so that the heat stability of the whole material member is improved; the surface layer is a CMAS corrosion layer, so that the problem that an existing YSZ coating is corroded by CMAS can be alleviated. As Pd or a oxide ceramic layer is adopted, CMAS molten at a high temperature is not wet in the surface layer, and the rolling angle is small,and CMAS is hardly attached to the surface of the coating, so that CMAS corrosion is avoided.

Owner:FUZHOU UNIV

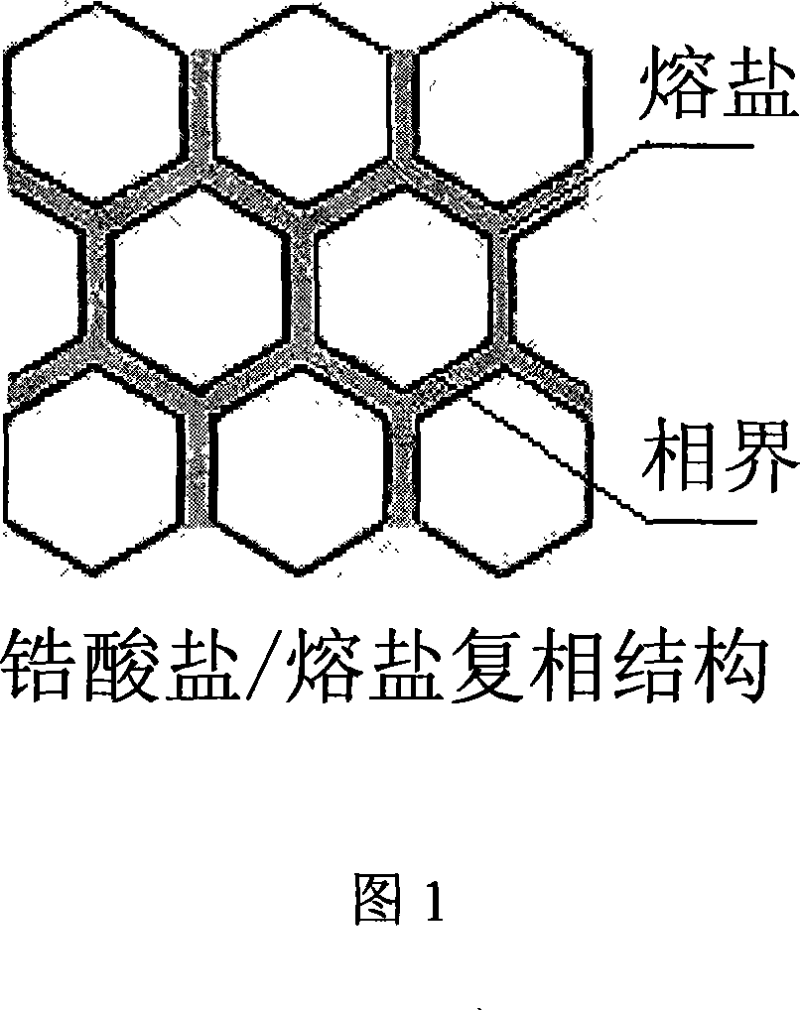

Multi-phase structure designed high-conductive electrical zirconate barium proton conductor and preparation method thereof

InactiveCN101037331AImprove conductivityImprove migration speedConductive materialElectrical conductorConcentration cell

The invention relates to a barium zirconate proton conductor designed by complex phase structure with a high electric conductivity and its manufacturing method. The invention is coating a layer of NaOH or sulfate around the crystal grain of the barium zirconate. The manufacturing method is: taking the BaCO3, ZrO2 and Y2O3 as raw material, water as medium, ball milling mixing for 4-10 hours, calcining for 4-12 hours in 1200-1400 DEG C; then adding 1-10% molar ZnO, ball milling mixing for 4-10 hours, adding 5-50% mol NaOH or K2SO4 or Na2SO4 or Li2SO4 in a way of hand lapping to make the mixture uniform; putting the mixing material into the die and dry pressing molding under a pressure of 50-120 MPa, and then isopressing under 200-350 MPa; sintering in the air of 1200-1500 DEG C with a heating rate of 2-10 DEG C / minute and keeping warm for 2-10 hours, then cooling to the room temperature to produce the barium zirconate proton conductor material with a high electric conductivity. The invention adopts the new designing thought of complex phase structure to establish a foundation for exploiting hydrogen gas and vapor sensor, hydrogen pump and concentration cell electrolyte material.

Owner:TIANJIN UNIV

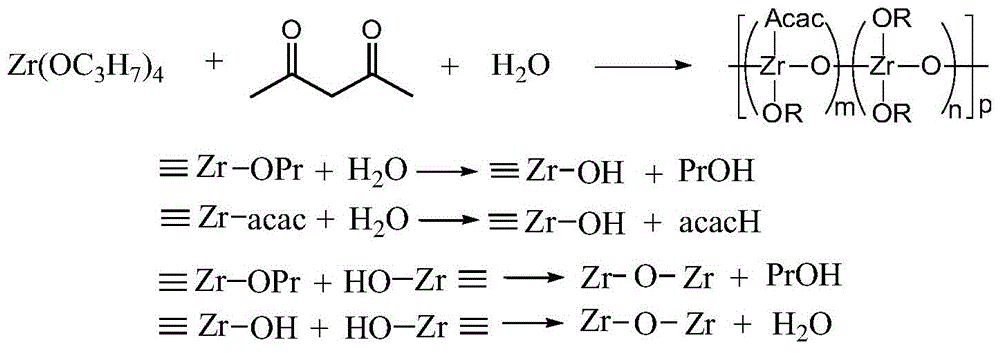

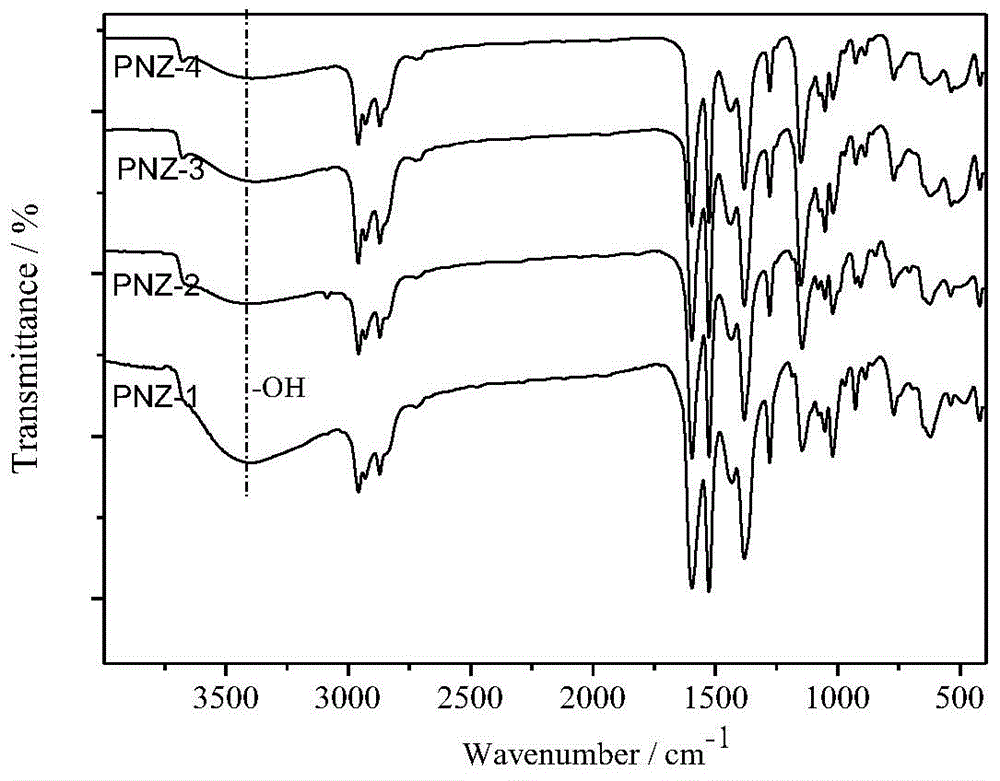

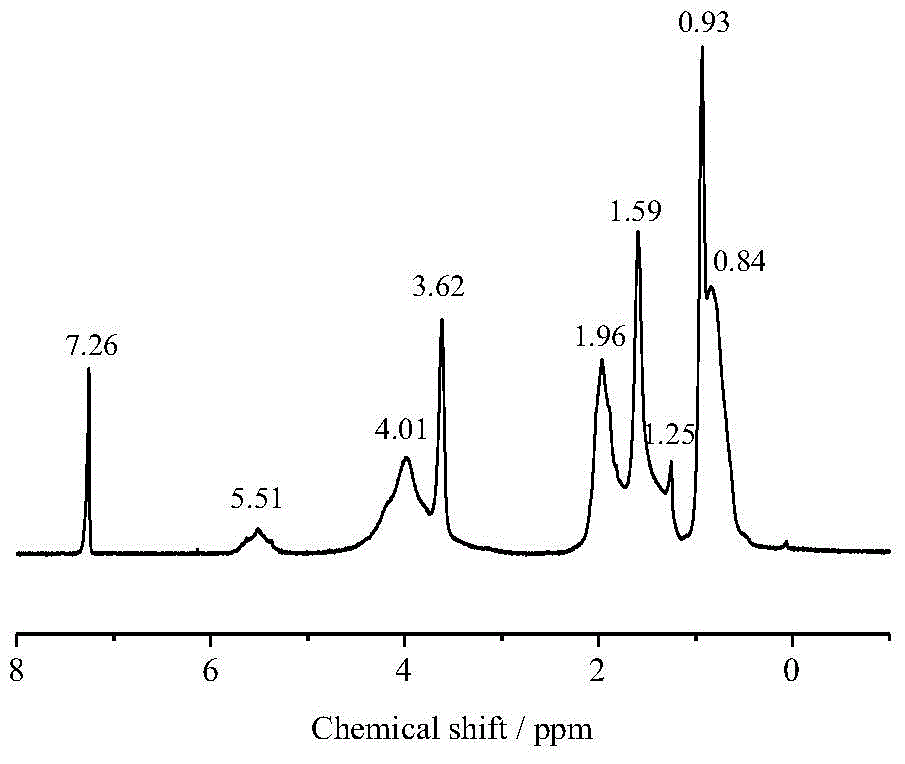

Nonpolar zirconium carbide liquid-phase ceramic precursor, preparation method therefor and application thereof

The invention relates to a nonpolar zirconium carbide liquid-phase ceramic precursor, a preparation method therefor and application thereof. The preparation method comprises: firstly preparing a nonpolar zirconium polymer-polyzircooxane through coordination protection of propyl zirconate and controllable hydrolysis condensation reaction; and by using the polyzircooxane as a zirconium source and divinyl benzene as a carbon source, compounding the components to obtain the nonpolar zirconium carbide liquid-phase ceramic precursor. The liquid-phase precursor prepared by the invention has the characteristics of polymer resin; the viscosity of the precursor can be controlled between 50 mpa.s and 500 mpa.s by adjusting the solid content, and the manufacturability is good. The zirconium carbide liquid-phase ceramic precursor which is cured and thermally treated can be converted into a pure-phase zirconium carbide ceramic at a relatively low temperature ( for example, 1500 DEG C). The liquid-phase ceramic precursor prepared by the invention is expected to be used as impregnating resin for a ceramic-based composite material and an antioxidant C / C and C / Si composite material so as to improve the ultra-high temperature antioxidant performance of the material and reduce the ablativity of the material.

Owner:SUZHOU TUNABLE MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com