Patents

Literature

125results about How to "Small particle diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

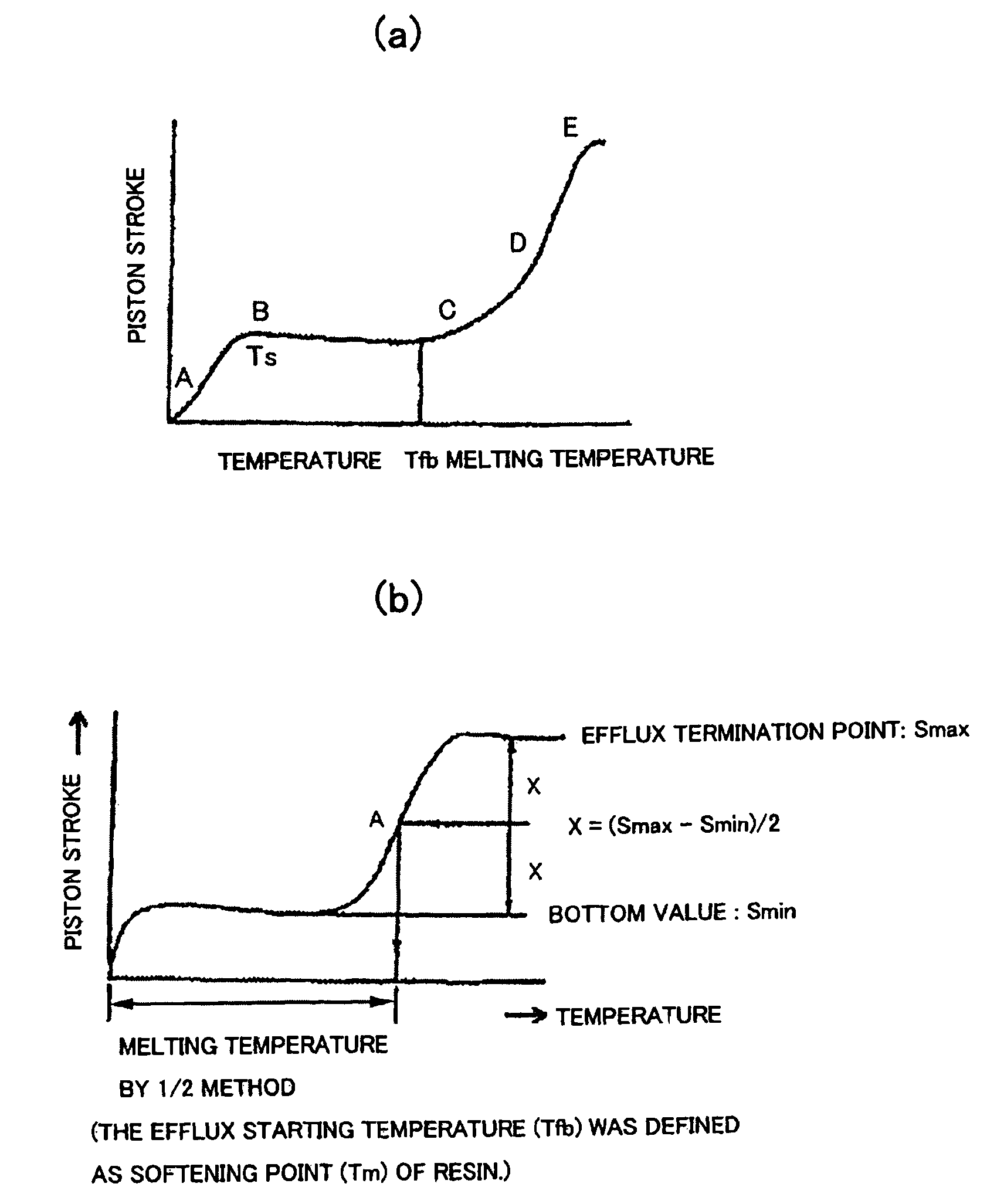

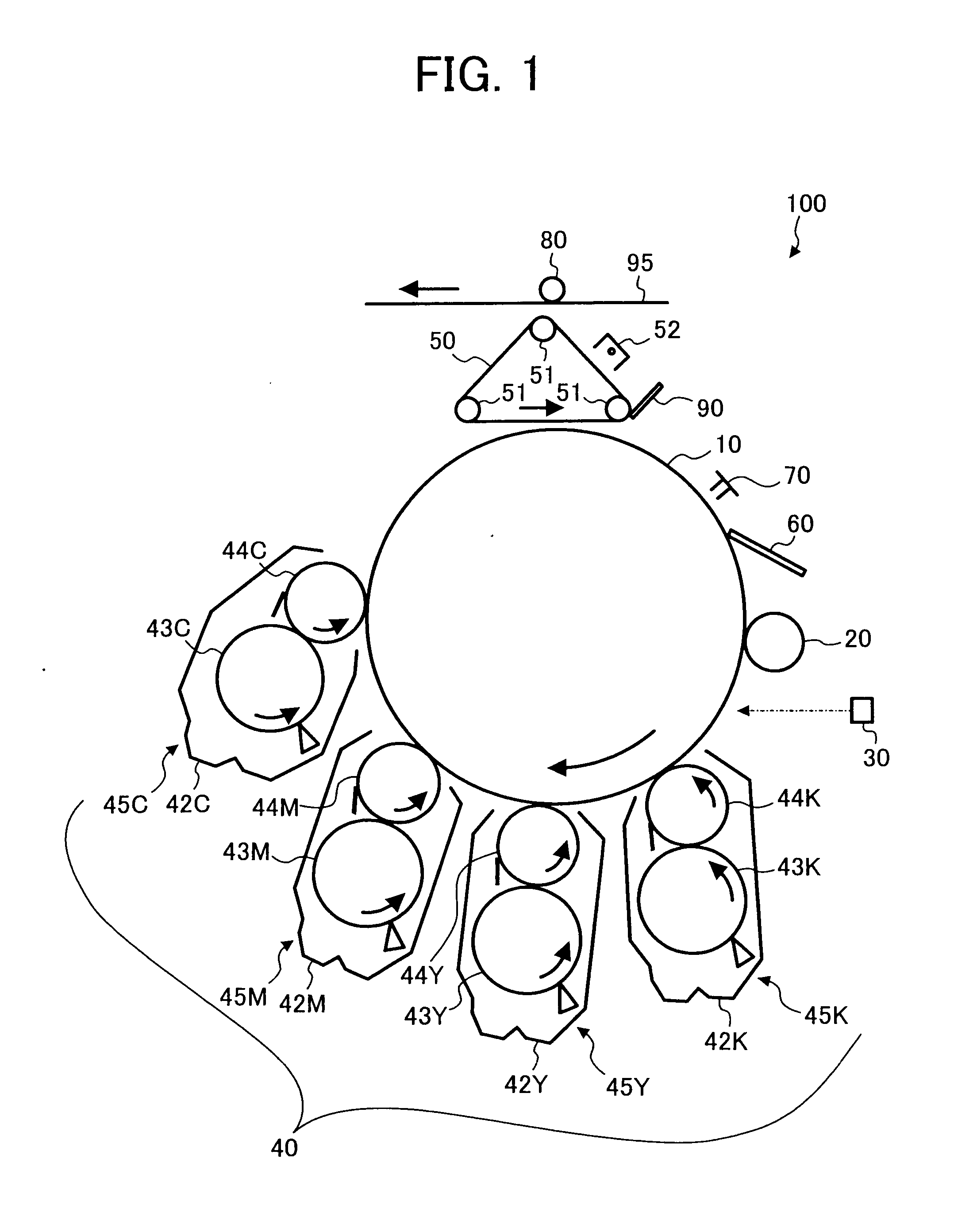

Toner, method of supplying the same and process cartridge

InactiveUS20080102393A1Good low temperature fixabilityGood preservabilityDevelopersElectrographic process apparatusPolyester resinEster bond

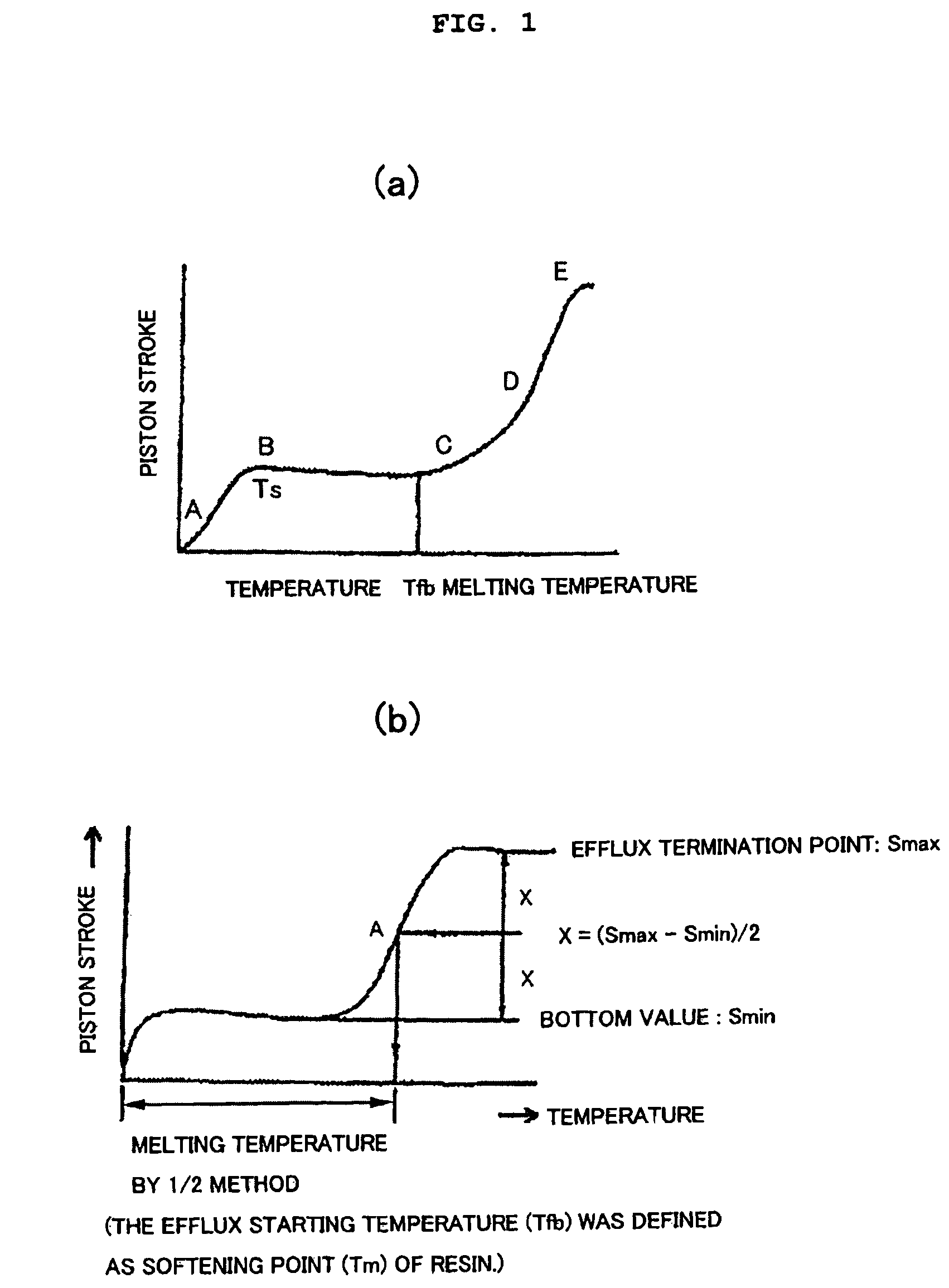

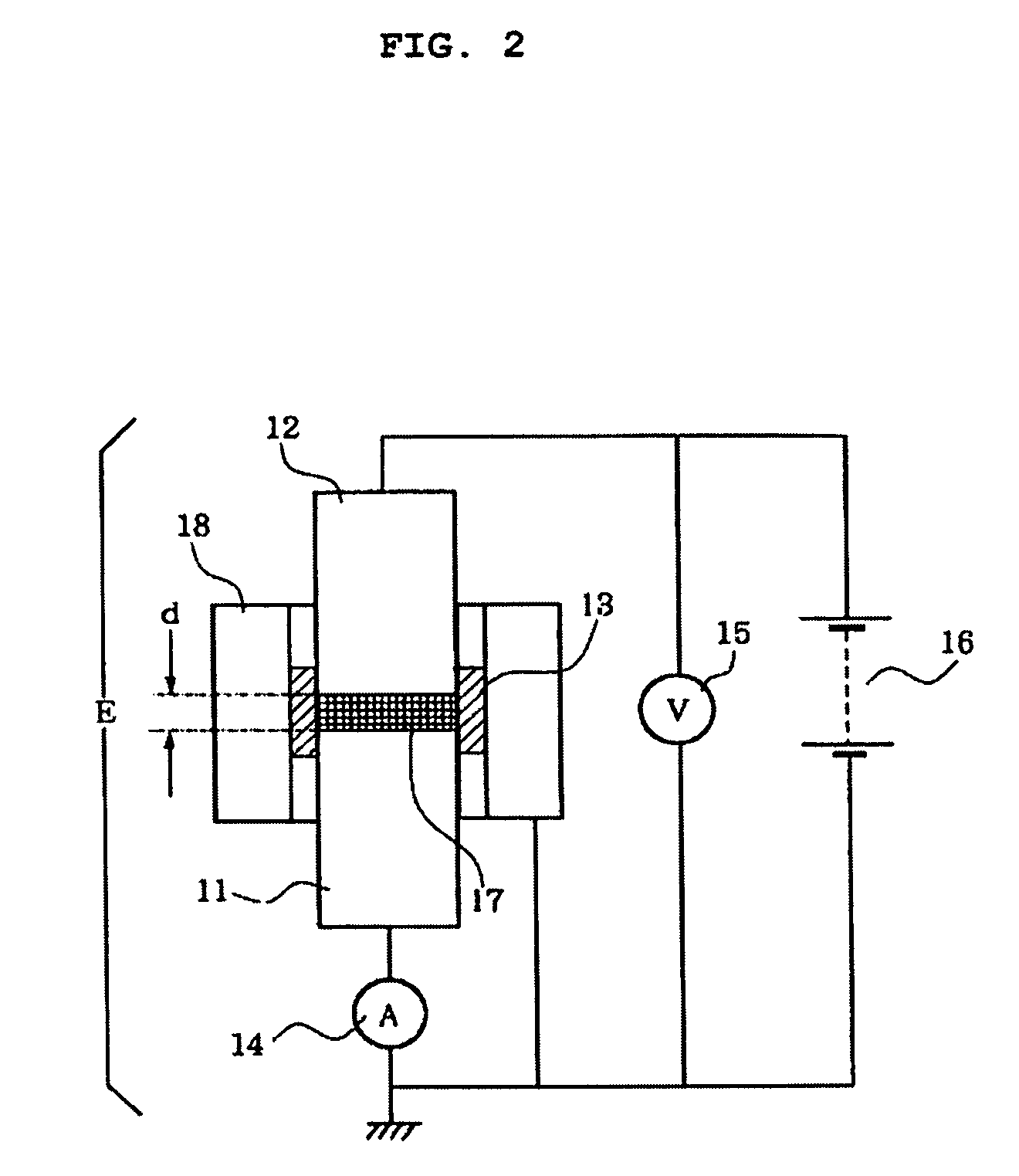

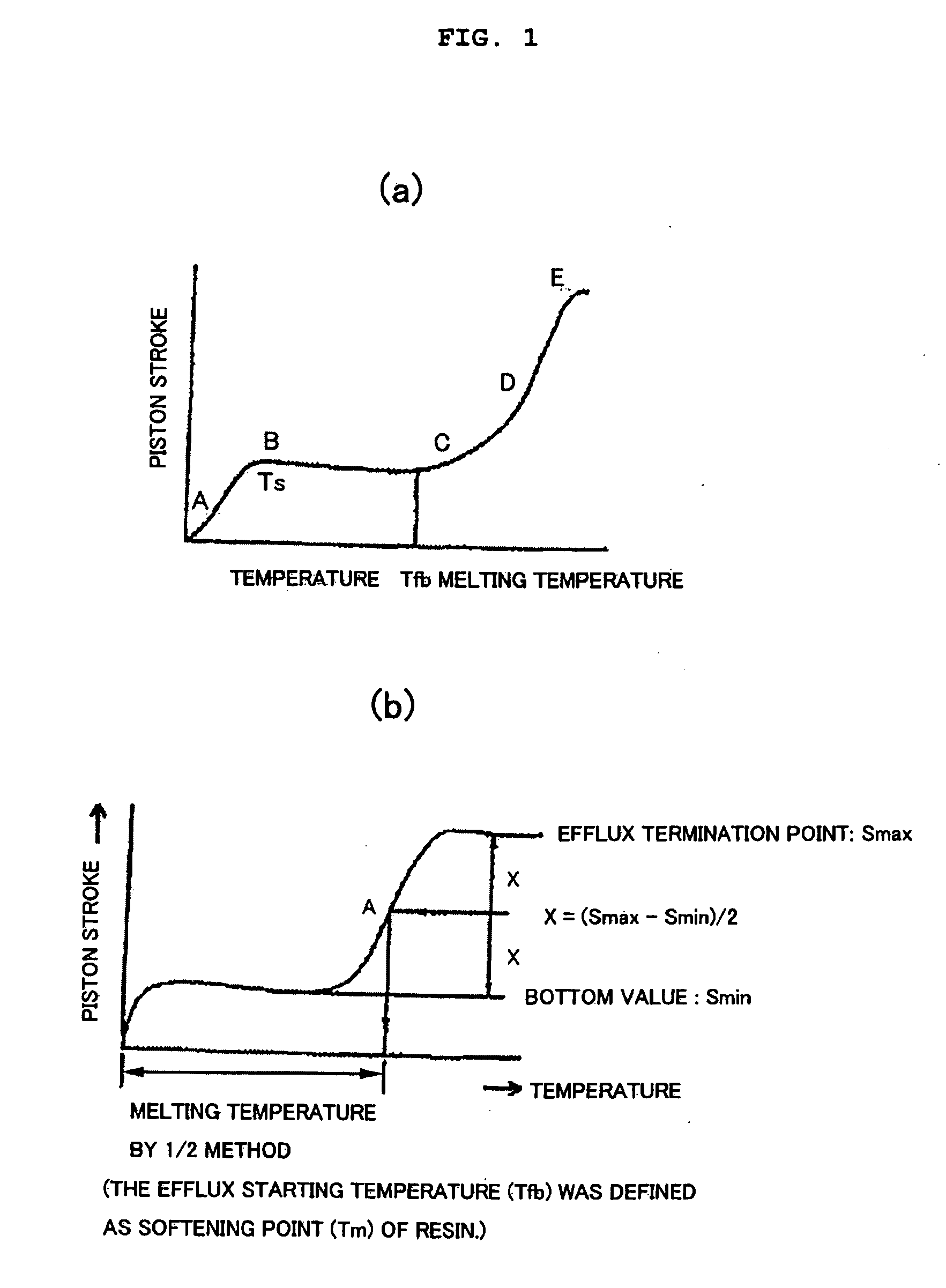

A toner including a colorant, a binder resin, and a releasing agent, wherein the toner has a number average particle diameter measured by a Coulter Counter method of from 3.5 to 6.5 μm and a peak top molecular weight (MPT) of from 2,500 to 4,800, the binder resin contains a crystalline polyester resin and a hybrid resin component containing a styrene-acryl resin and a polyester resin, a content A of the crystalline polyester resin and a content B of the hybrid resin component satisfy the following relationship (1): ½ A≦B≦3 A, and the crystalline polyester resin has a structure represented by a following chemical formula (A) having at least 60 mol % of whole ester bonds in the binder resin: —OOC—R—COO—(CH2)n—, (A); a method for supplying the toner and a process cartridge useful in the method.

Owner:RICOH KK

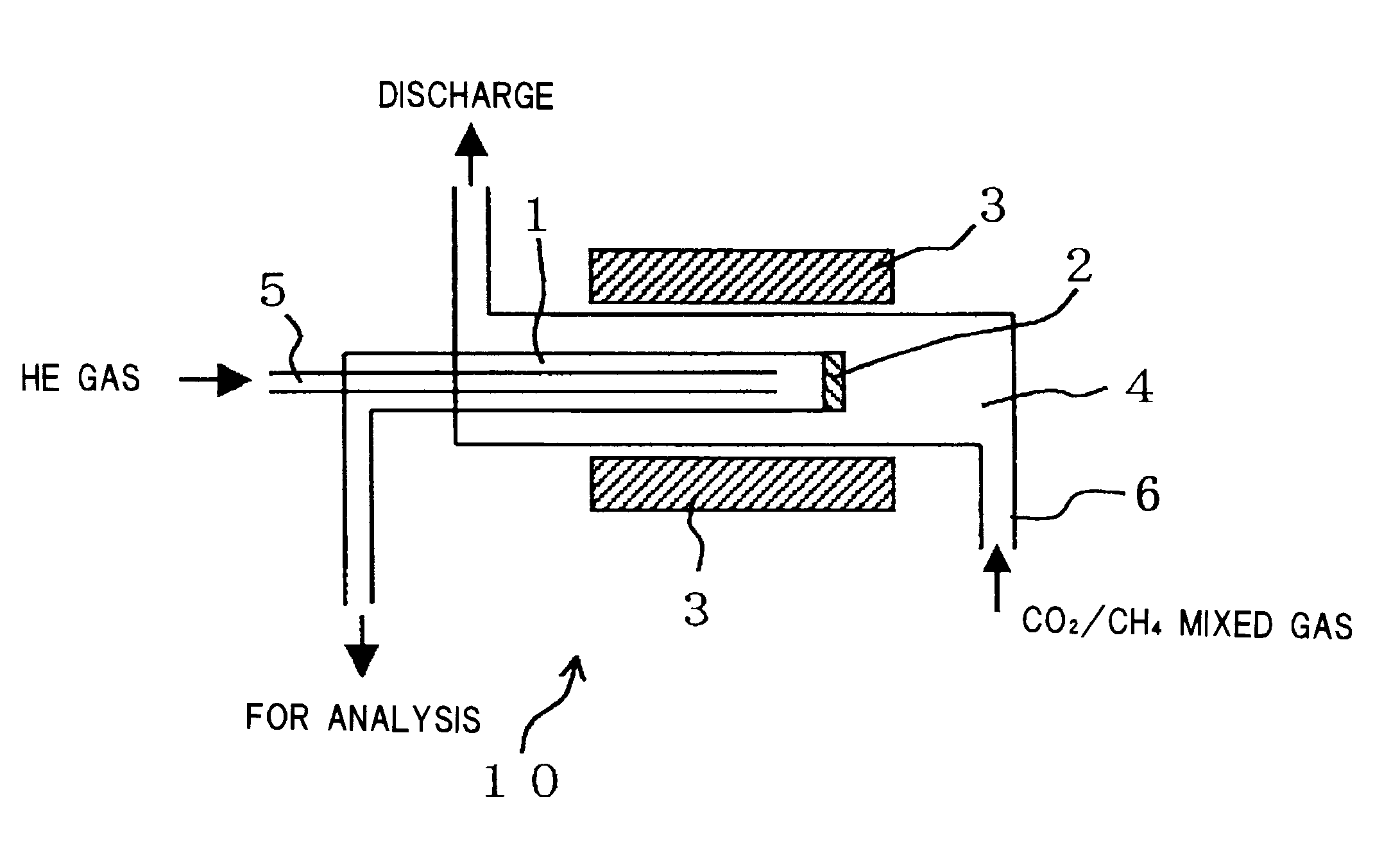

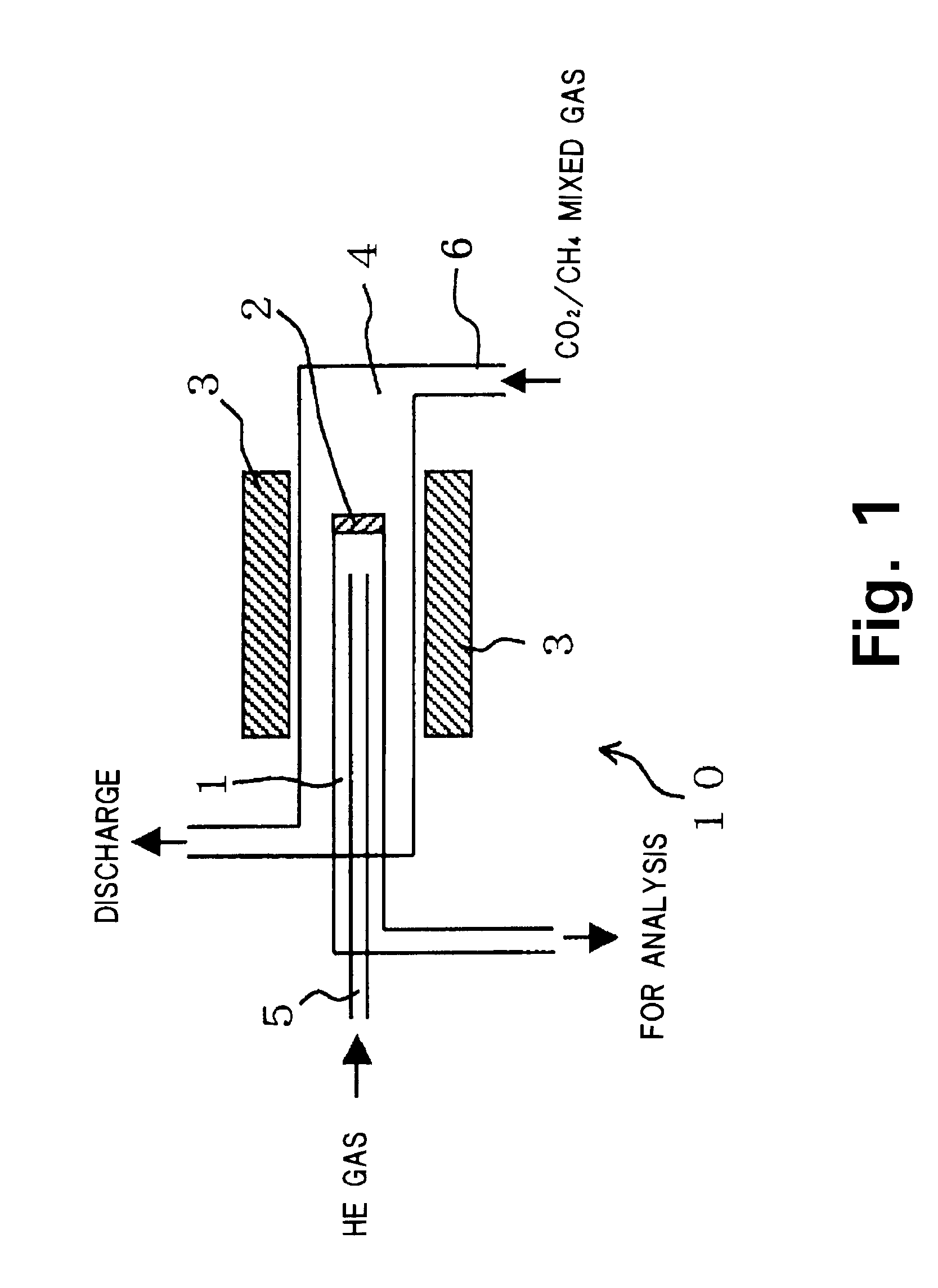

Process for producing DDR type zeolite membrane

InactiveUS20090011926A1Small particle diameterSmall and uniform thicknessMembranesSemi-permeable membranesThin membraneSeed crystal

A method for producing a DDR type zeolite membrane, comprising immersing a porous substrate in a raw material solution containing 1-adamantanamine, silica, and water; and carrying out a hydrothermal synthesis of DDR type zeolite in the presence of a DDR type zeolite seed crystal (seed crystal) to form a DDR type zeolite membrane on the surface of the porous substrate by making a content ratio of 1-adamantanamine to silica (1-adamantanamine / silica) in the range of 0.002 to 0.4 in terms of molar ratio and a content ratio of water to silica (water / silica) in the range of 10 to 500 in terms of molar ratio, and an average particle diameter of the seed crystal to 300 nm or less to provide a method for producing stably a DDR type zeolite membrane of uniform and thin membrane thickness with high gas permeability.

Owner:NGK INSULATORS LTD

High transparent polyester film and process for producing the same

The high transparency polyester film contains nano level silica of grain size 20-50 nm and micron level silica of grain size 1.2-2.0 microns. The nano level silica accounts for 50-2000 ppm of total polyester film weight, and the micron level silica 1-300 ppm. The production process of the high transparency polyester film includes the first preparation of silica suspension, the subsequent conventional polymer producing course to produce polyester slice, and final conventional melting extrusion of the slice and bi-directional stretching. The product of the present invention has high transparency, waterproof property, blocking property, heat resistance and antiaging property.

Owner:SHANGHAI ZIDONG FILM MATERIAL CO LTD

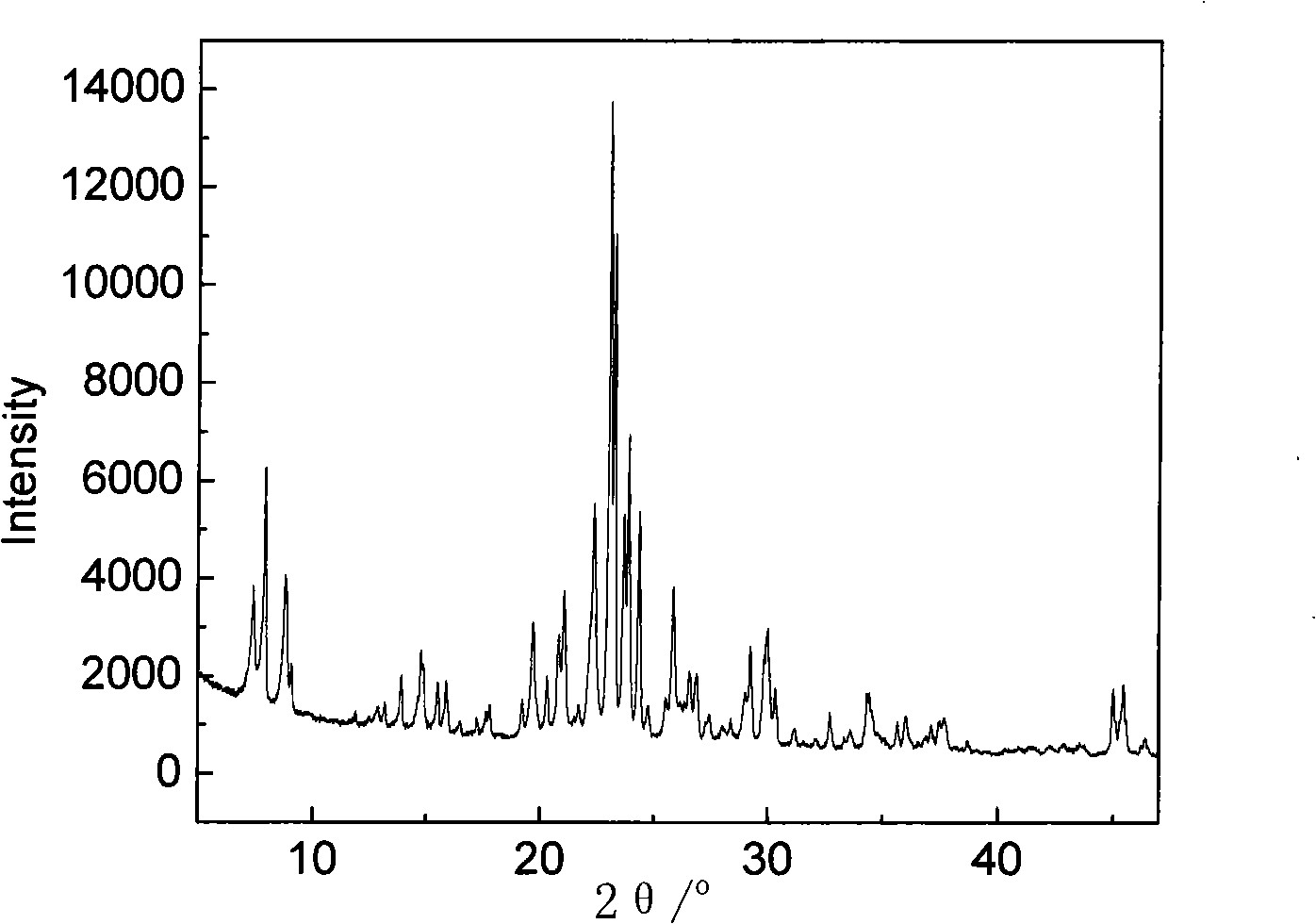

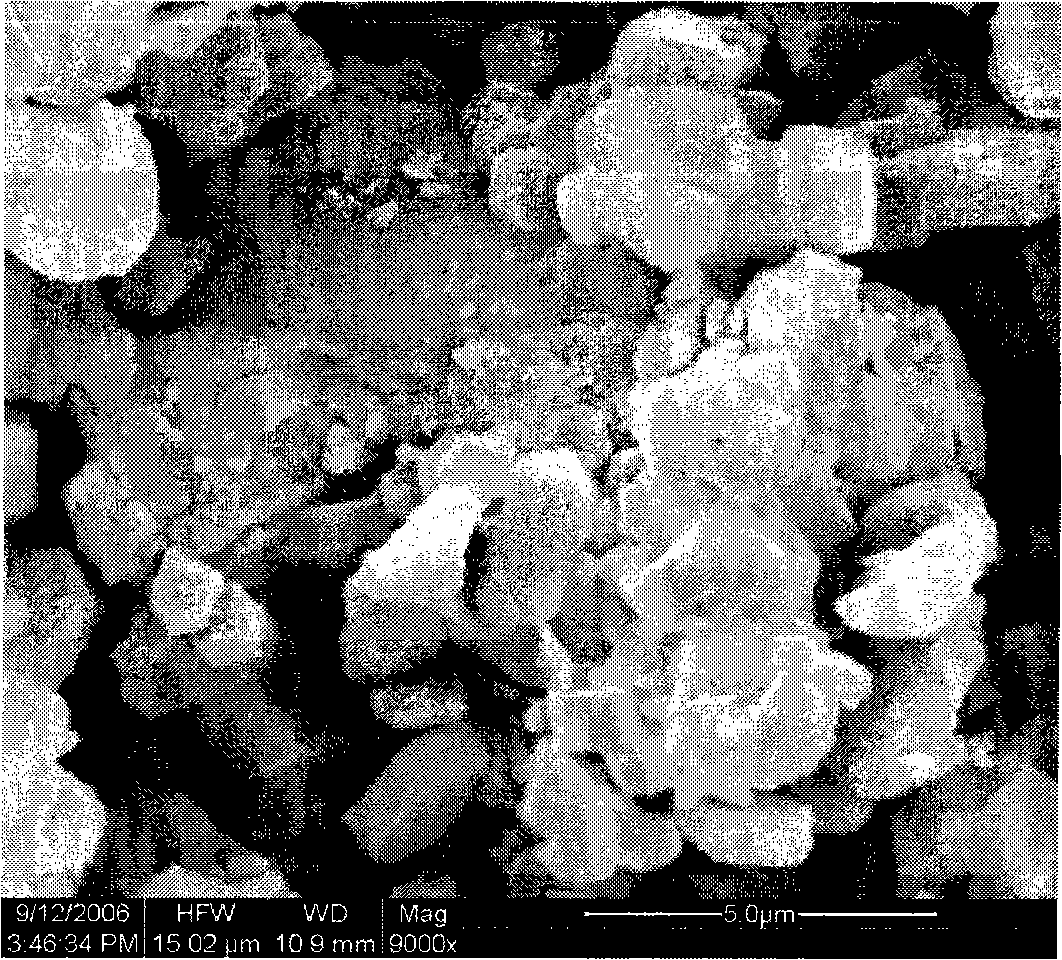

Process for synthesizing core-shell structure compound molecular sieve and use thereof

ActiveCN101279288AHigh conversion capacity of heavy oilSmall particle diameterMolecular sieve catalystsBulk chemical productionSynthesis methodsFuel oil

The present invention relates to a synthesizing method for a core-shell structure compound molecular sieve. The method mainly adopts a location growing method to fix a loaded phosphor aluminum or silicon aluminum molecular sieve on the surface of a ZSM-5 molecular sieve to compose the raw materials and then prepare a gel in a primarily wet state and crystallize under a constant temperature, thus synthesizing the core-shell structure compound molecular sieve. The method overcomes the defects of the prior technology, thus reducing the independent growing number of the composed phosphor aluminum or silicon aluminum molecular sieves, further improving the distribution of the phosphor aluminum or silicon aluminum molecular sieve of the shell on the surfaced of the ZSM-5 and reducing the grain diameter of the compound molecular sieve. When the core-shell structure compound molecular sieve prepared by the method is used for heavy oil catalytic cracking, the heavy oil converting rate and the low carbon olefin yield are all higher than the molecular sieve synthesized by the prior technology. Compared with the catalyst which only adopts the ZSM-5 molecular sieve as the active component, the heavy oil converting rate is improved by 2 to 3 percent; the ethylene yield is increased by 1 to 1.5 percent and the liquid gas yield is enhanced by 1.5 to 3.5 percent.

Owner:PETROCHINA CO LTD +1

Nano rare earth zirconate ceramic powder material for high temperature heat barrier coat and preparation method thereof

InactiveCN101104557ASmall particle diameterHigh coefficient of thermal expansionRare-earth elementZirconate

Disclosed are a nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings, and the preparation method, relating to a nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings, and the preparation method. The invention solves the problems that the existing ceramic materials for high-temperature thermal barrier coatings are of phase change failure, serious sintering, and too high thermal conductivity and mismatch with the matrix thermal expansion. The chemical formula of the nano-rare earth zirconate ceramic powder material for high-temperature thermal barrier coatings is Ln2Zr2O7, wherein, Ln is the combination of one or more rare earth elements among Gd, Sm, Nd or Yb. The preparation method is that rare earth oxide or soluble salt and zirconium salt containing rare earth oxides are used to respectively prepare the solution containing Ln3 + and the solution containing Zr4 +; the two solutions are mixed and added with surfactant under the ongoing mixing conditions; the mixed solution is dropped into precipitator to get sediment; after repeated washing, the sediment is dried, grinded and calcined. The invention can effectively protect high temperature alloy.

Owner:HARBIN INST OF TECH

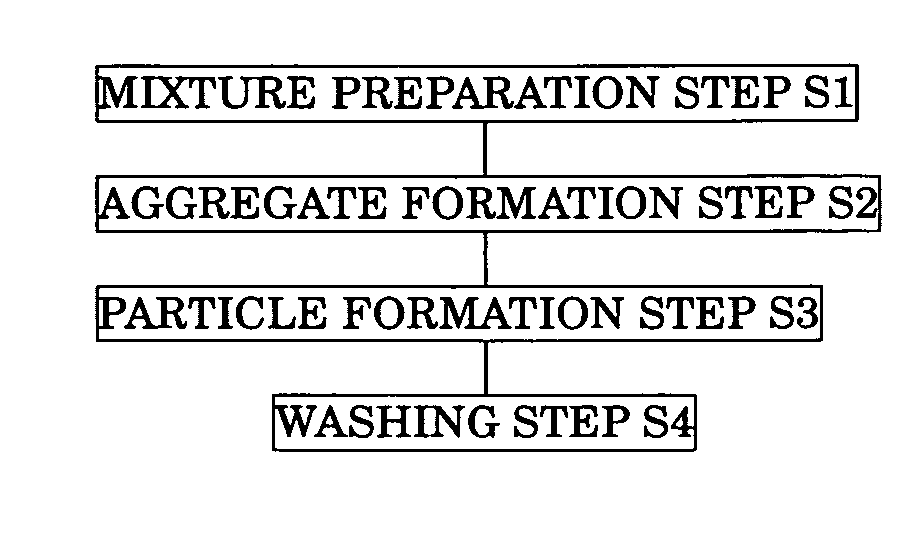

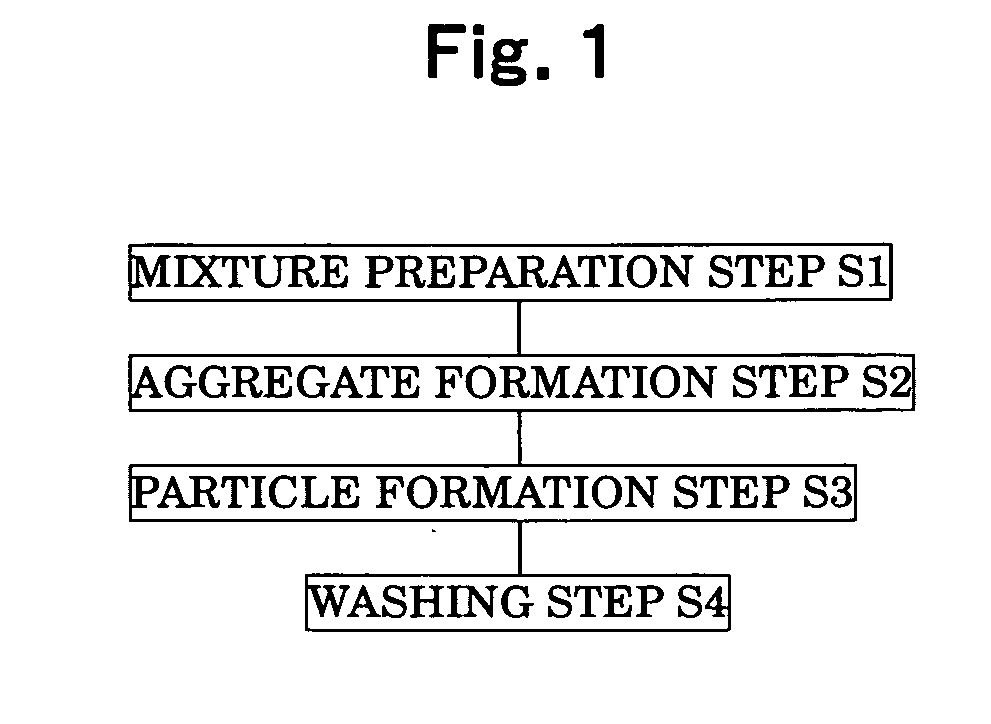

Toner for electrostatic image development and process for preparing the same

A process for preparing a toner for electrostatic image development, the process comprising the steps of: (S1) mixing an aqueous pigment dispersion with an aqueous resin particle dispersion containing two or more kinds of self-dispersible polyester resin particles as binder resins to prepare a mixture; and (S2) adding a polyvalent metal salt as a flocculant to the mixture while stirring to form aggregates having the pigment bonded to the resin particles, wherein the self-dispersible polyester resins each are prepared by reacting a carboxylic acid compound with an alcohol compound inclusive of a polyhydric alcohol, and the carboxylic acid compound includes one or more kinds of a polycarboxylic acid having three or more carboxyl groups and its acid anhydride, the self-dispersible polyester resin particles are made from two or more kinds of self-dispersible polyesters having different glass transition temperatures, of which the lowest glass transition temperature is not lower than 40° C.

Owner:SHARP KK

Toner

Provided is magnetic toner including capsule type toner particles each having a surface layer (B) on a surface of a toner base particle (A) containing at least a binder resin (a) mainly formed of a polyester, a magnetic substance, and a wax, in which, the surface layer (B) includes a resin (b), and the resin (b) includes a resin selected from the group consisting of a polyester resin (b1), a vinyl resin (b2), and a urethane resin (b3); a glass transition temperature Tg(a) of the binder resin (a) and a glass transition temperature Tg(b) of the resin (b) satisfy a relationship of Tg(a)<Tg(b); a magnetization (&sgr;t) in an external magnetic field of 79.6 kA / m of the magnetic toner is 12 Am2 / kg or more and 30 Am2 / kg or less; and an average circularity of the toner is 0.960 or more and 1.000 or less.

Owner:CANON KK

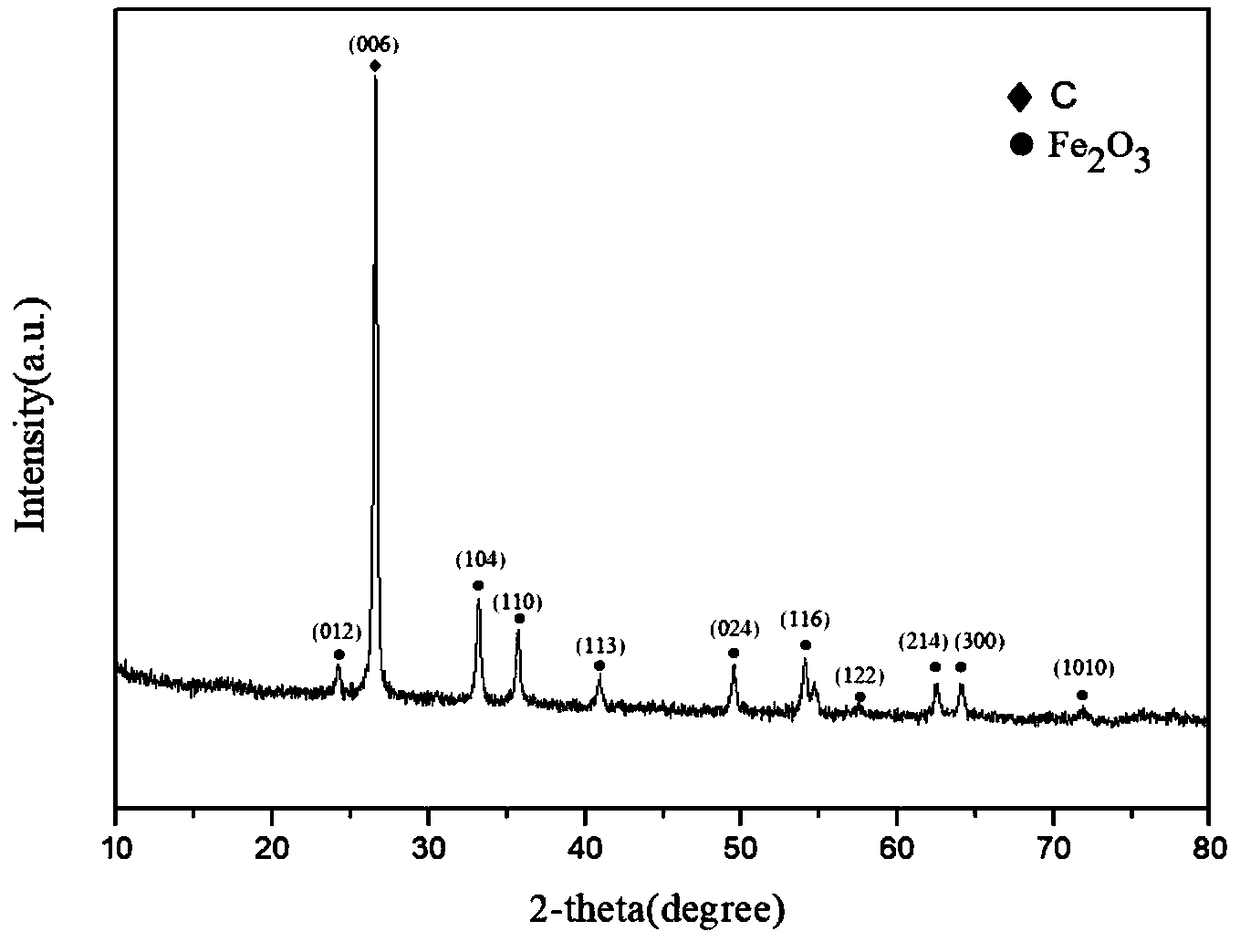

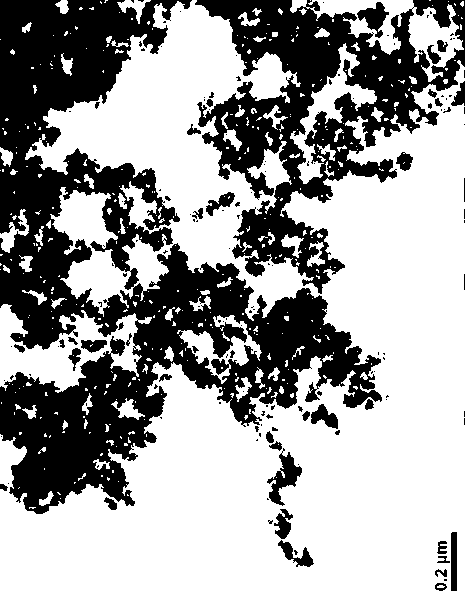

Preparation method of alpha-type fe_2O_3 nanoparticles/multilayer graphene composite material

ActiveCN109243832AWide variety of sourcesReduce manufacturing costHybrid capacitor electrodesHybrid/EDL manufactureWater bathsSolvent

The invention discloses a method for directly preparing uniform alpha-type Fe2O3 nanoparticles / multilayer graphene composite material by using iron powder. Comprises the following steps: DMF and deionized water with volume ratio of 8: 2 are mixed as mixed solvent; Expanded graphite was added and treated with ultrasonic wave for 3 hours to obtain multilayer graphene mixed solution. Fe powder, dilute nitric acid and anhydrous sodium acetate are added into that mix solution; The solution is stirred in a water bath at 70-90 DEG C for 4-10 hours, cooled and centrifugally cleaned to collect black products; 3 time of centrifugal cleaning of that reactant with alcohol and water respectively, and drying in an oven at 60 DEG C for 12 hour to obtain the dried alpha-type Fe2O3 nanoparticle / multilayergraphene composite material of the invention. The invention has the advantages of simple process, wide material source, low cost, nano-sized alpha-type Fe2O3 particles, uniform particles and good dispersibility.

Owner:HANGZHOU DIANZI UNIV

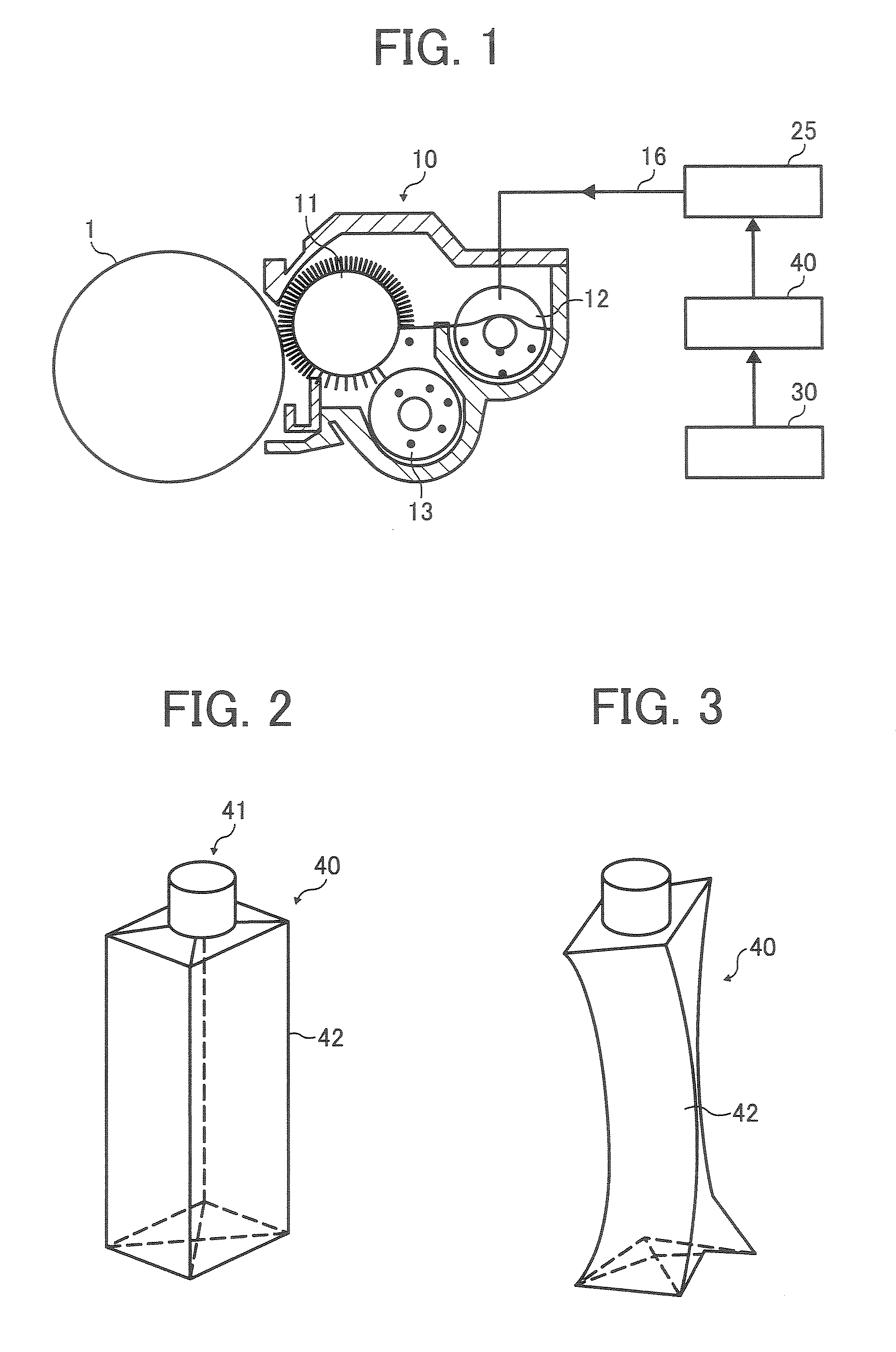

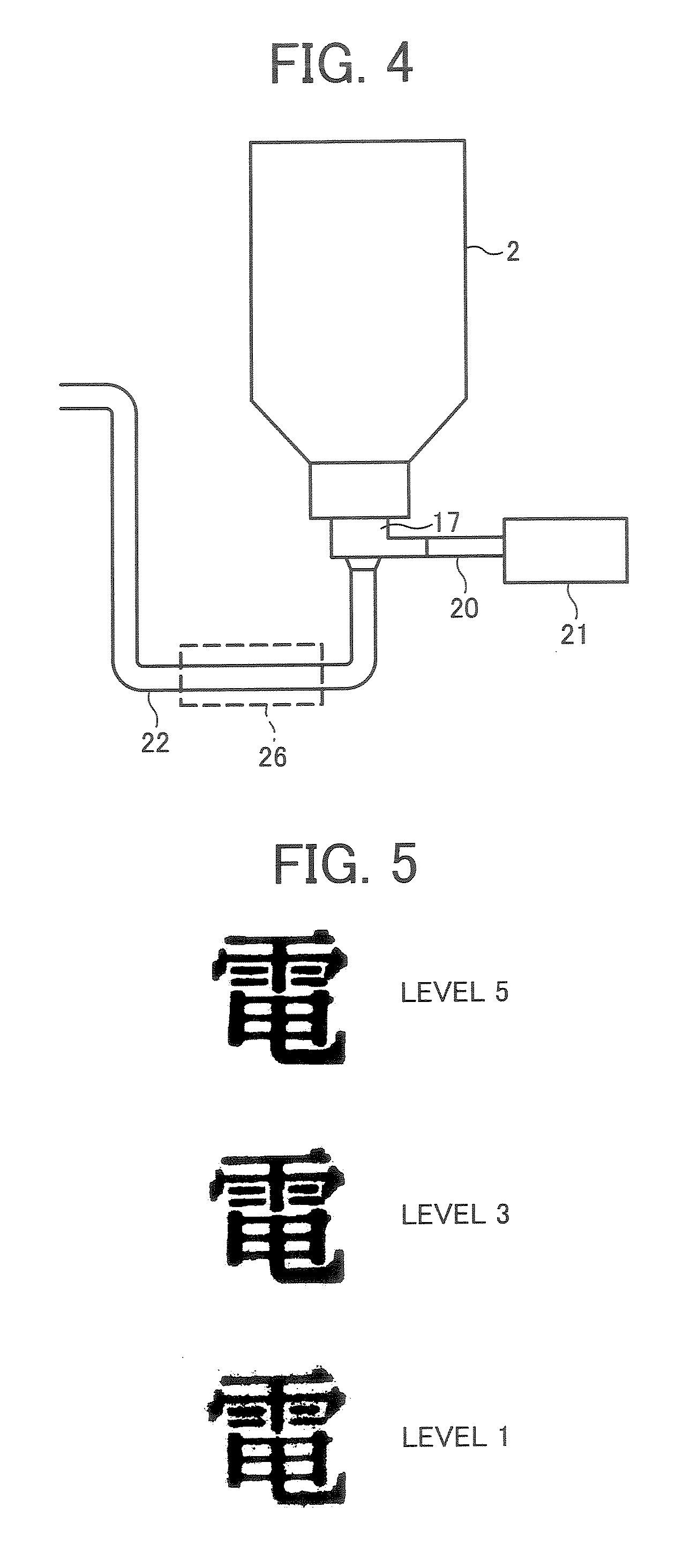

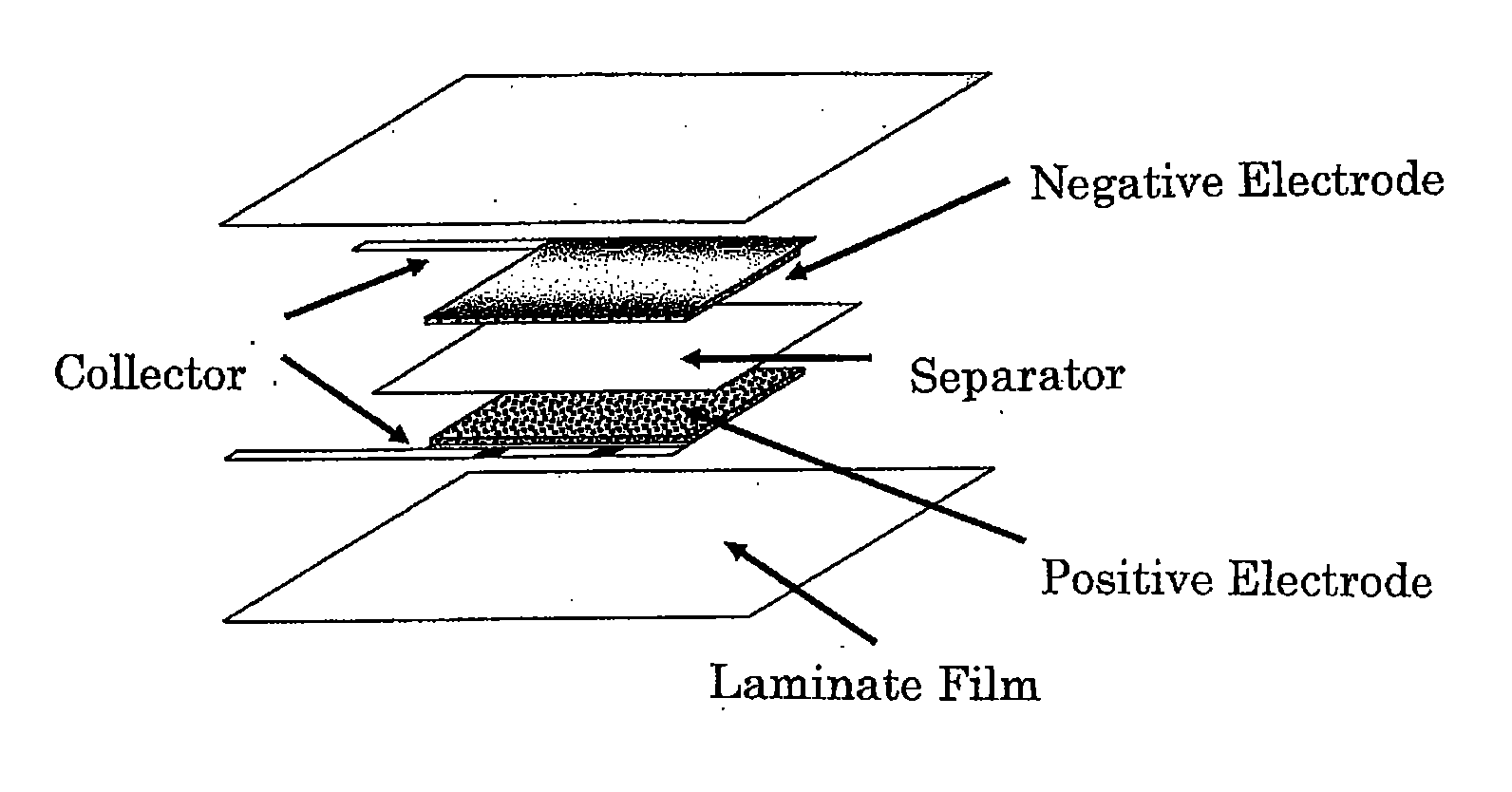

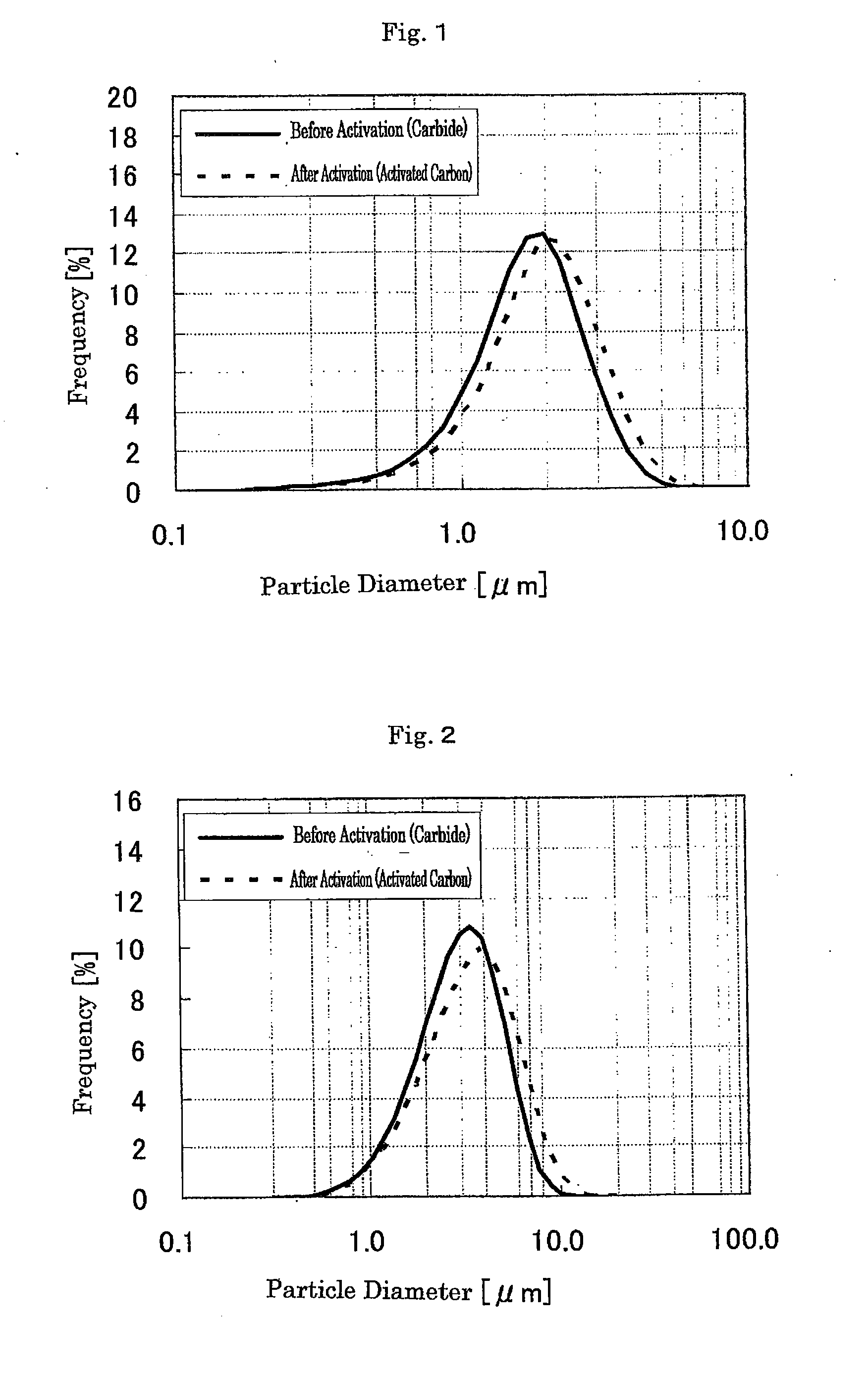

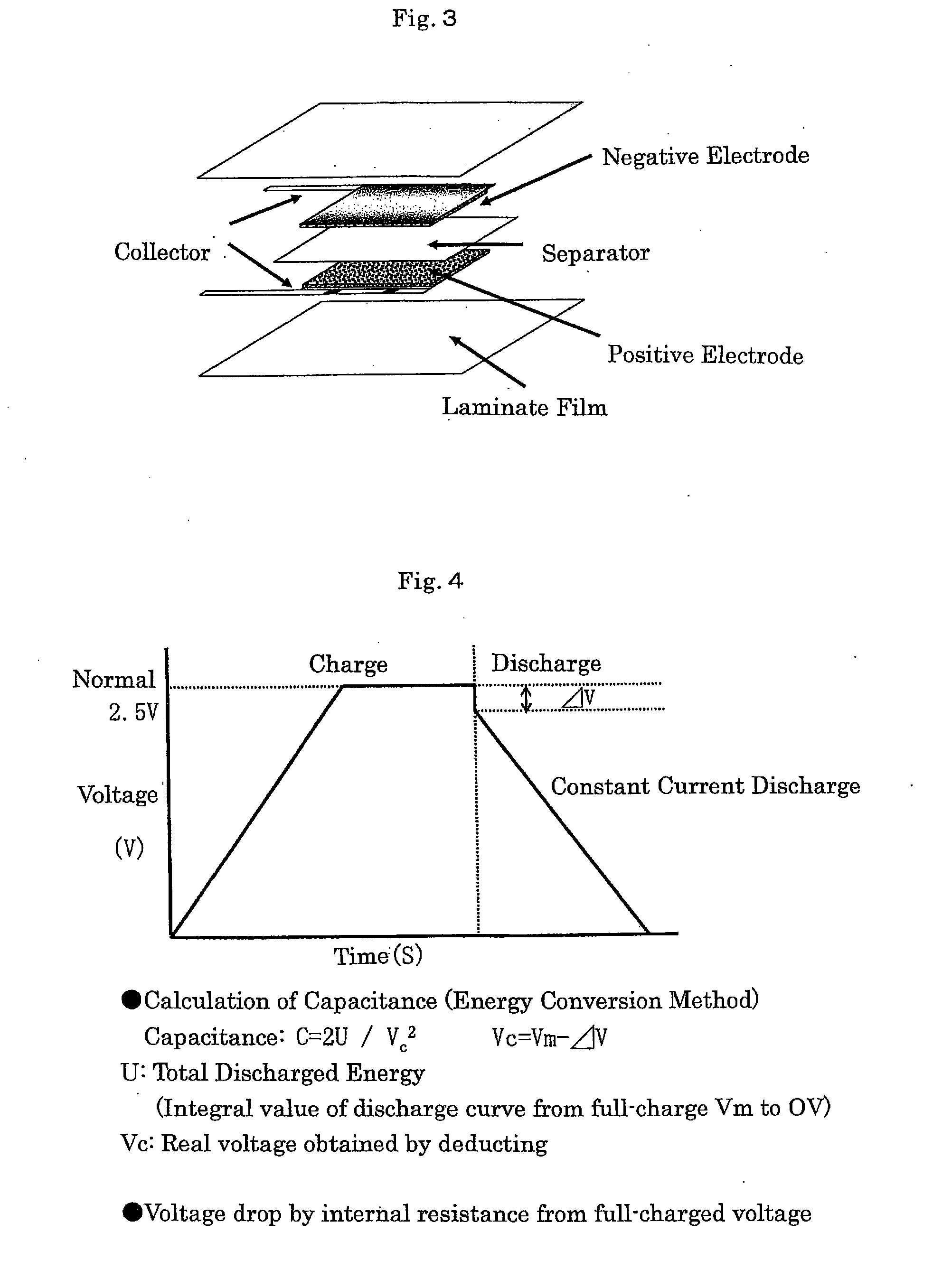

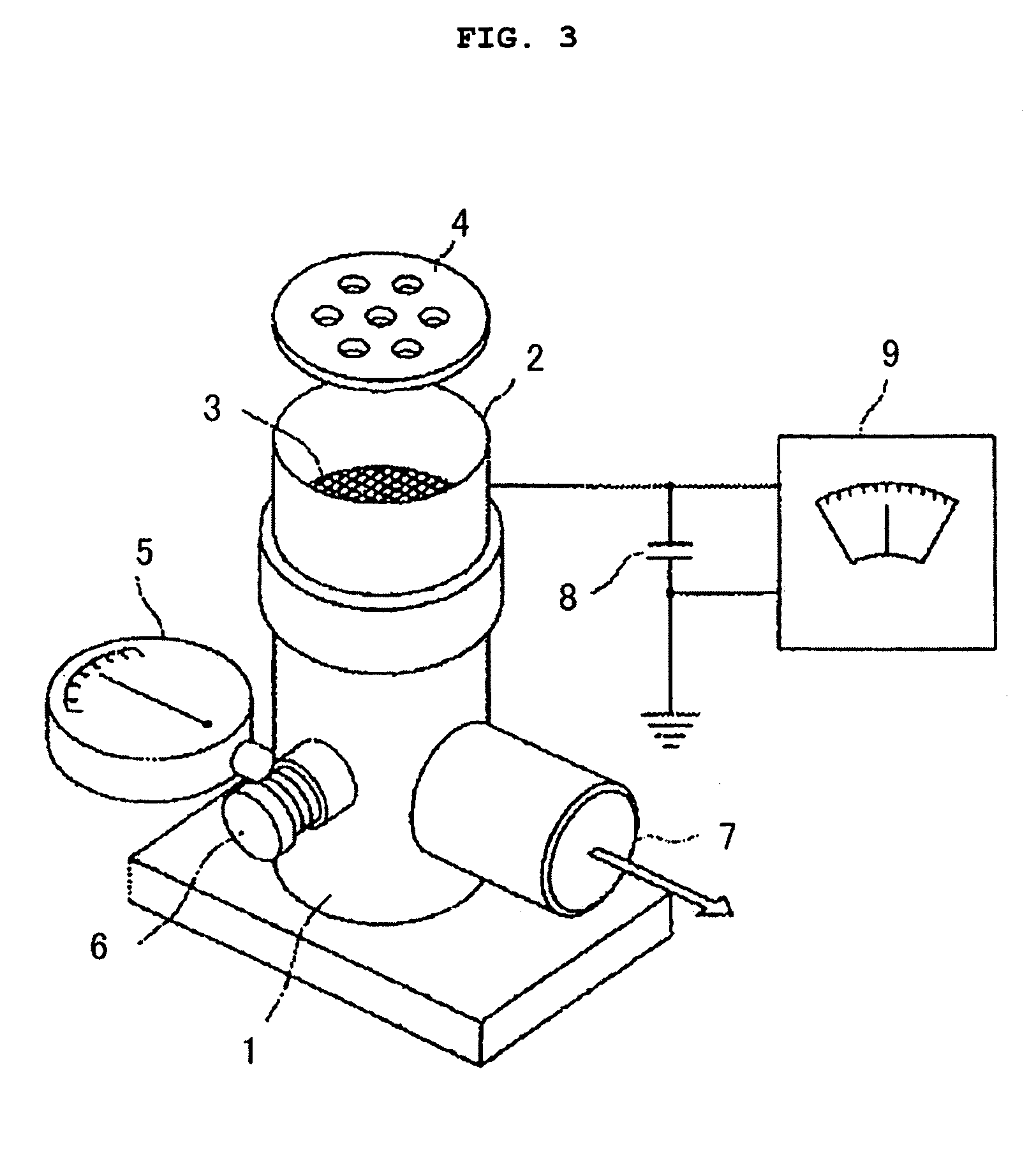

Process of producing activated carbon for electric double layer capacitor electrode

ActiveUS20100214722A1Easily and inexpensively activatedIncrease surface areaPigmenting treatmentCarbon compoundsReduction rateActivated carbon

The present invention provides a process of producing an activated carbon for an electric double layer capacitor, which can produce easily and inexpensively an activated carbon free from fusing of carbon particles during activation and having a small diameter, a uniform particle diameter, and a relatively large specific surface area on a commercial scale. The process comprises the steps of calcining an easily graphitizable carbon material so that the reduction rates of the hydrogen / carbon atomic ratio (H / C) and the volatile components in the carbon material are 4 percent or more and 5 percent or more, respectively after calcination and activating the carbon material thereby producing an activated carbon for an electric double layer capacitor, having an average particle diameter of 0.5 to 7 μm and a BET specific surface area of 1500 to 3000 m2 / g.

Owner:POWER CARBON TECH

Toner

ActiveUS20090170021A1Satisfactory characteristicSharp melt property can be improvedDevelopersPolymer sciencePolyester resin

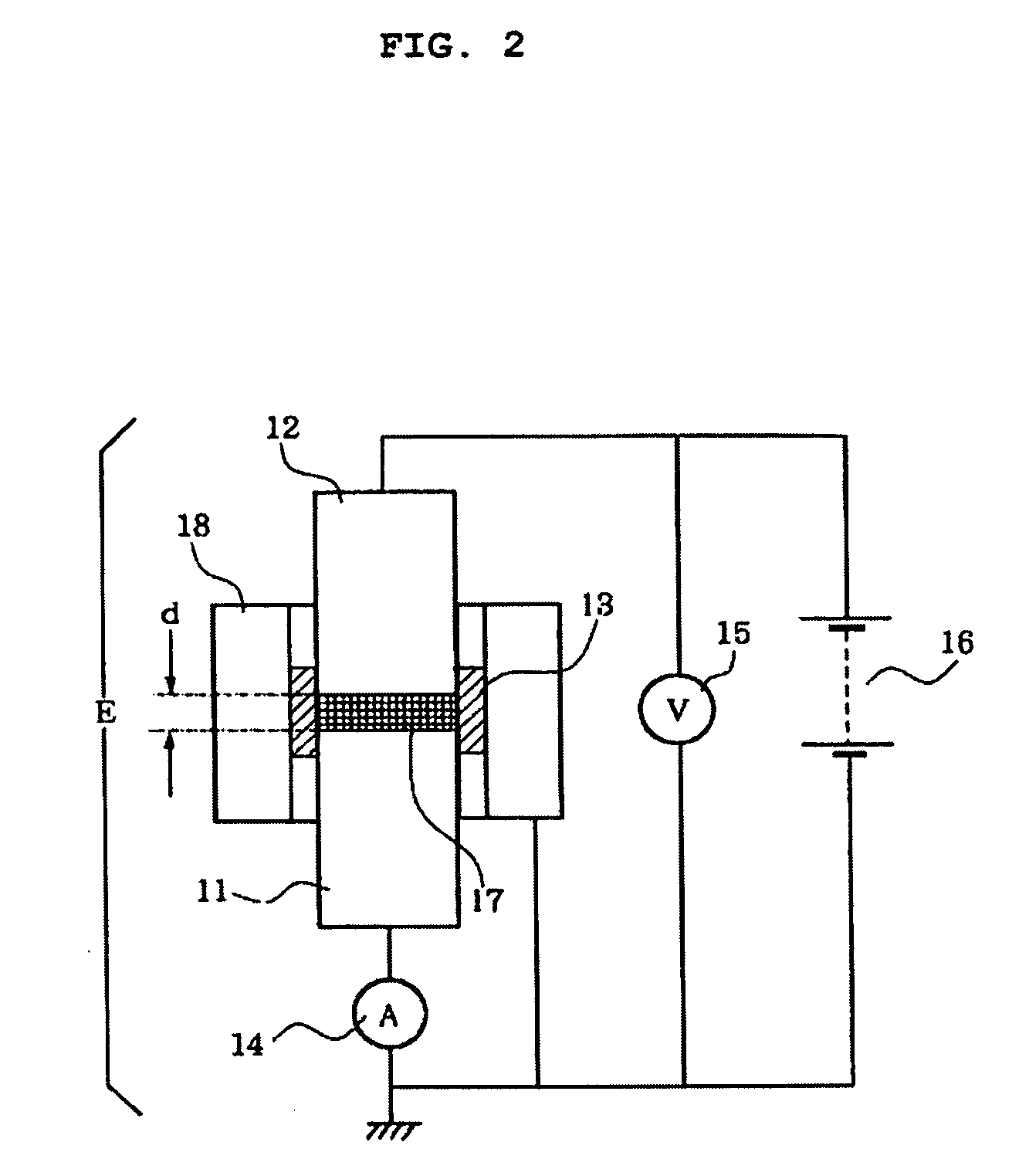

Provided is magnetic toner including capsule type toner particles each having a surface layer (B) on a surface of a toner base particle (A) containing at least a binder resin (a) mainly formed of a polyester, a magnetic substance, and a wax, in which, the surface layer (B) includes a resin (b), and the resin (b) includes a resin selected from the group consisting of a polyester resin (b1), a vinyl resin (b2), and a urethane resin (b3); a glass transition temperature Tg(a) of the binder resin (a) and a glass transition temperature Tg(b) of the resin (b) satisfy a relationship of Tg(a)<Tg(b); a magnetization (σt) in an external magnetic field of 79.6 kA / m of the magnetic toner is 12 Am2 / kg or more and 30 Am2 / kg or less; and an average circularity of the toner is 0.960 or more and 1.000 or less.

Owner:CANON KK

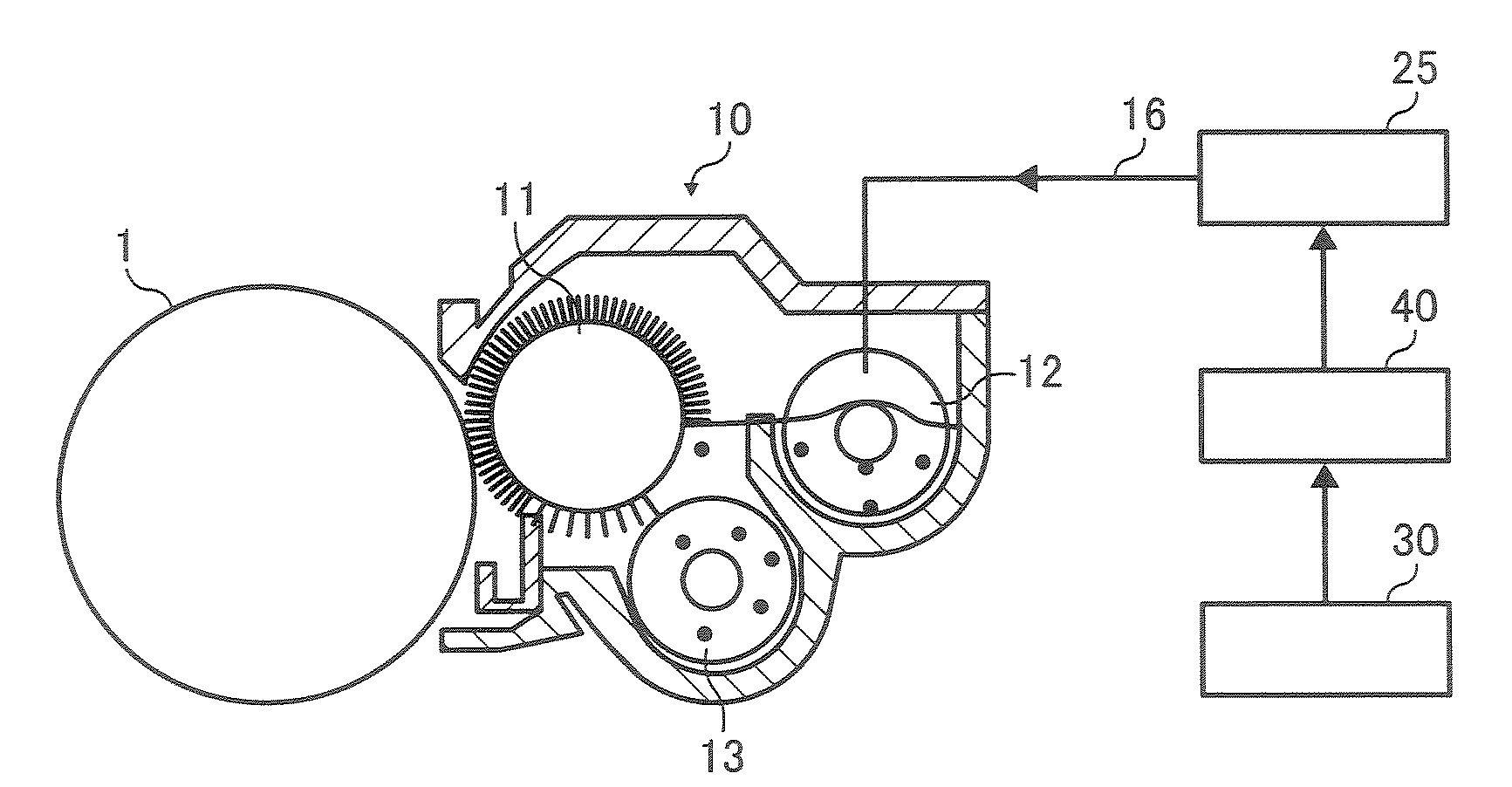

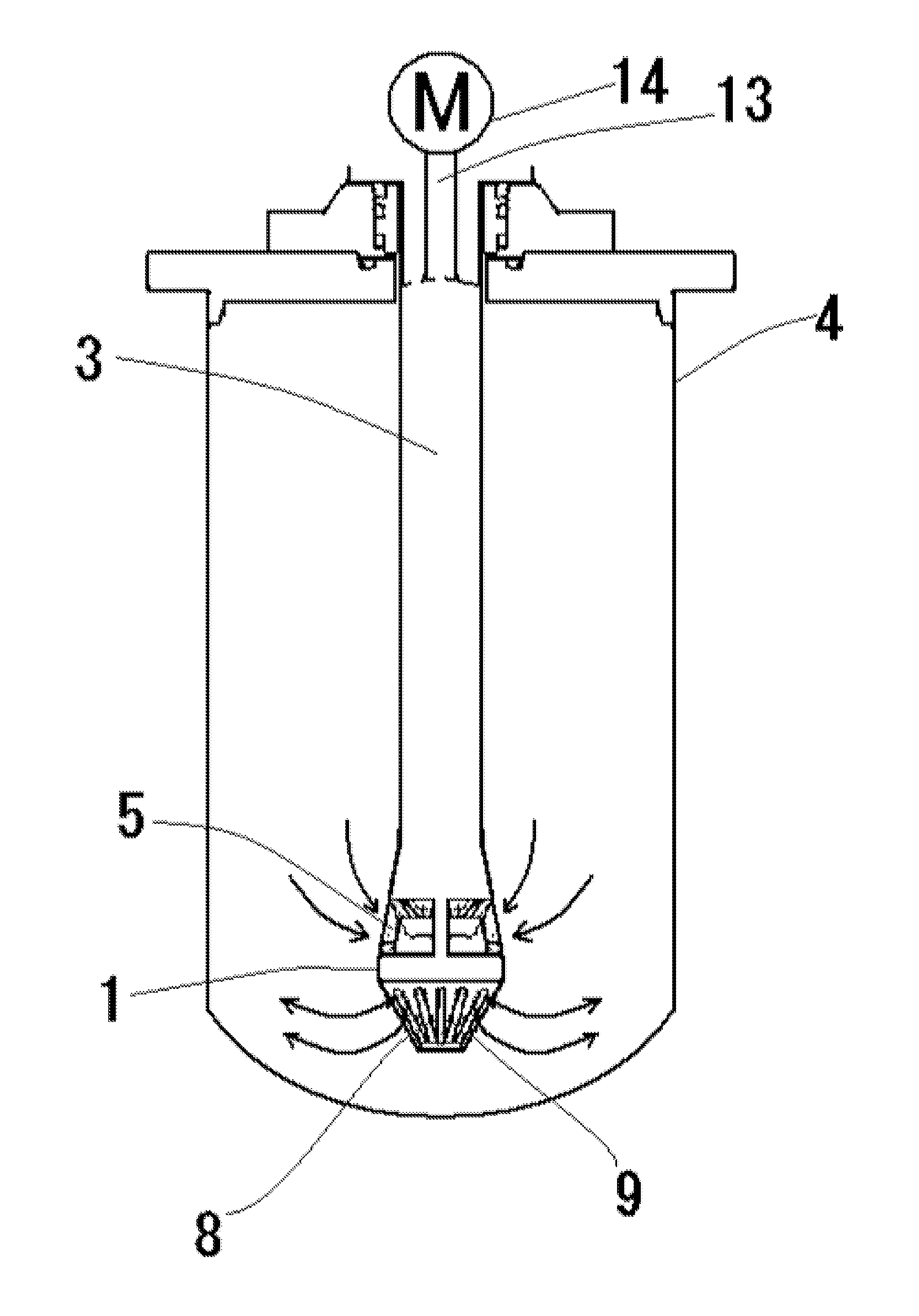

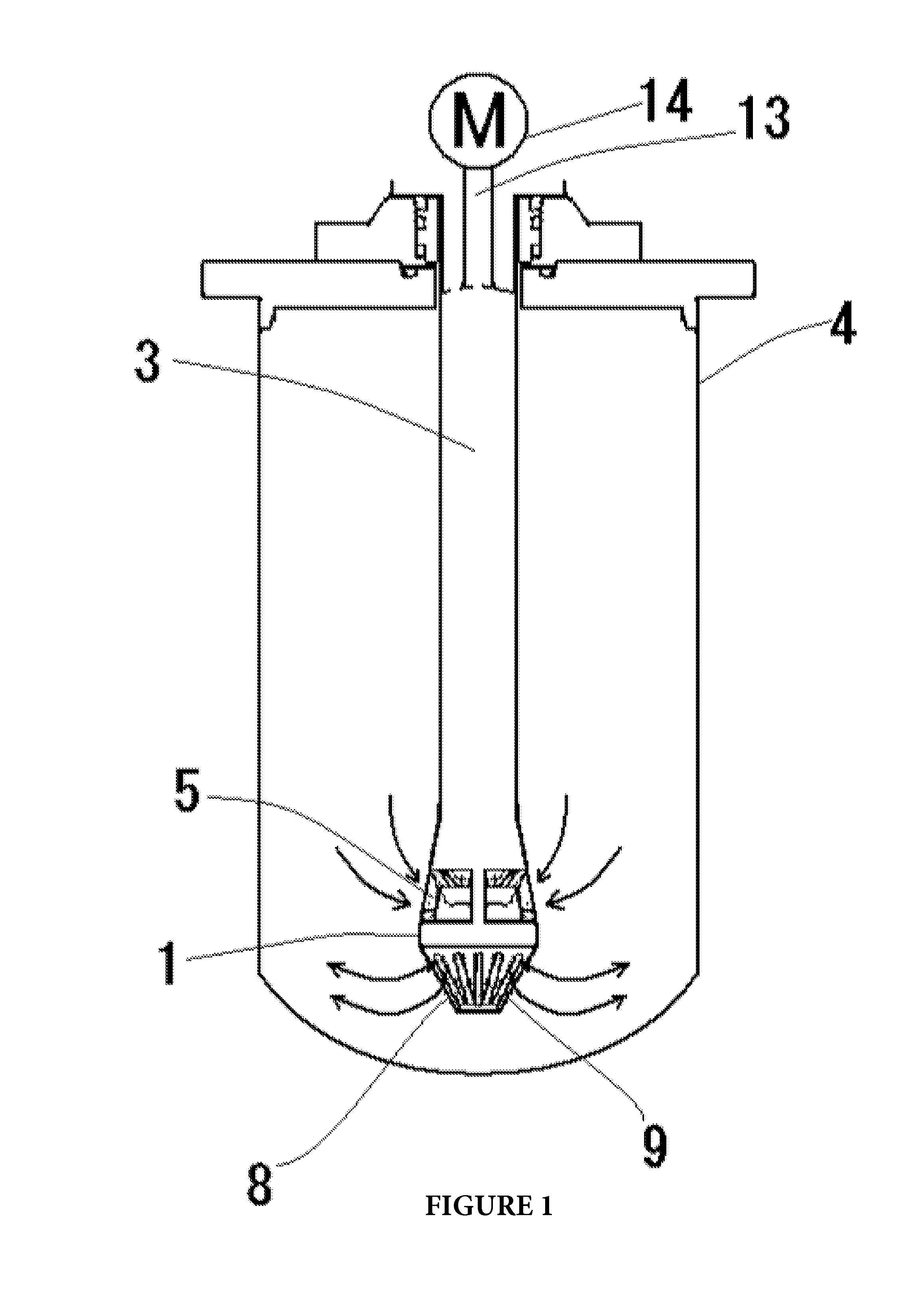

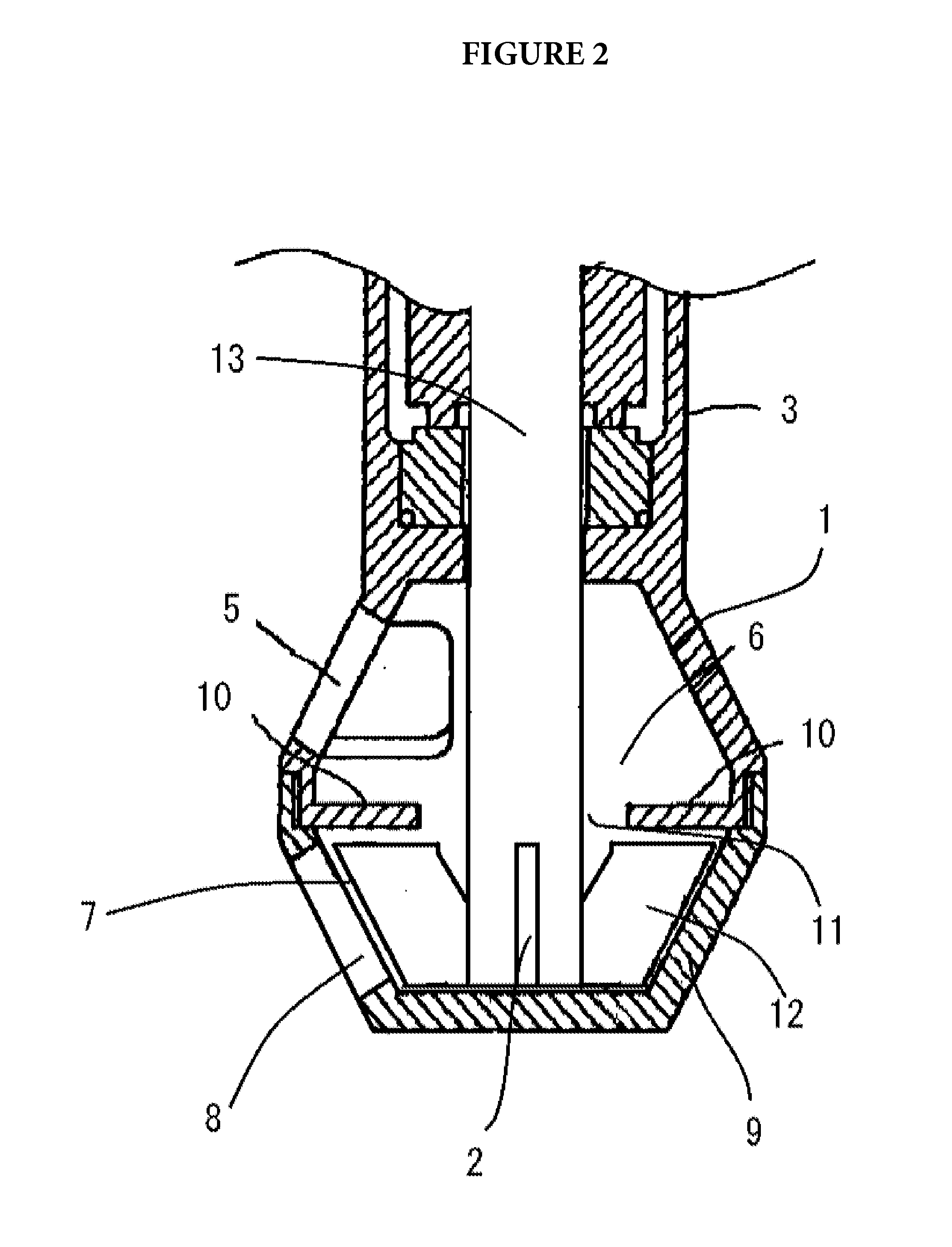

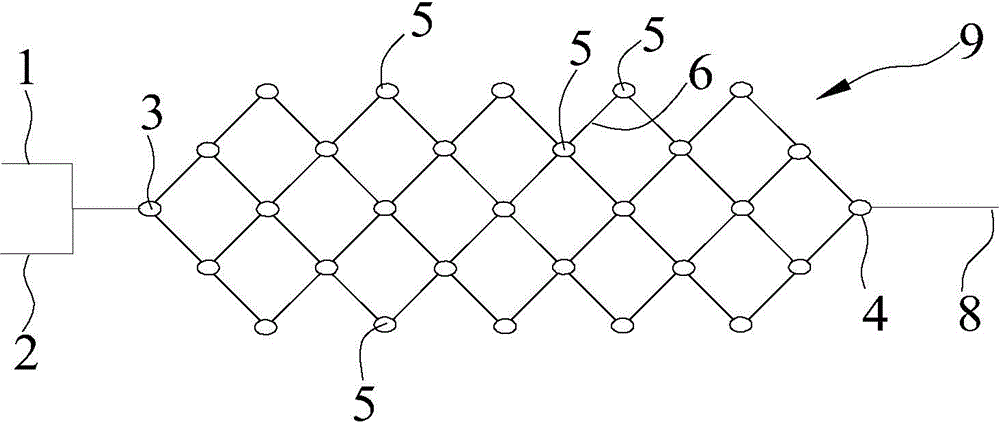

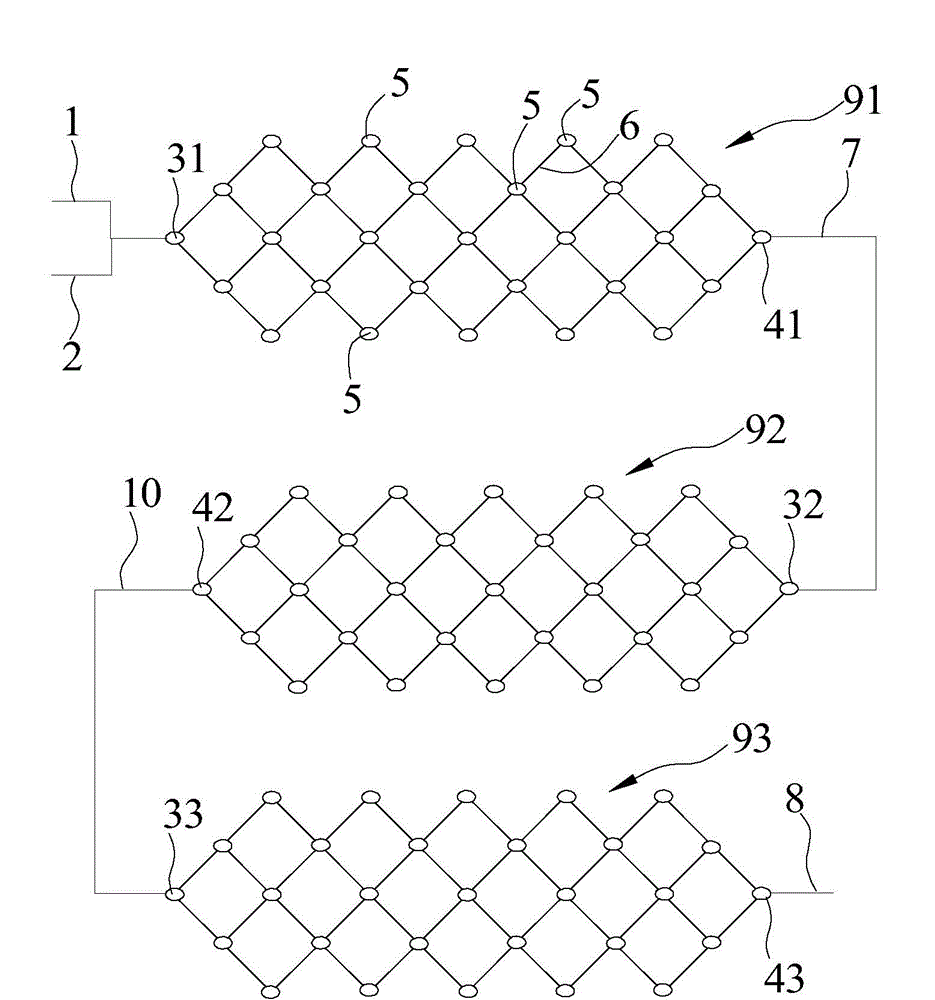

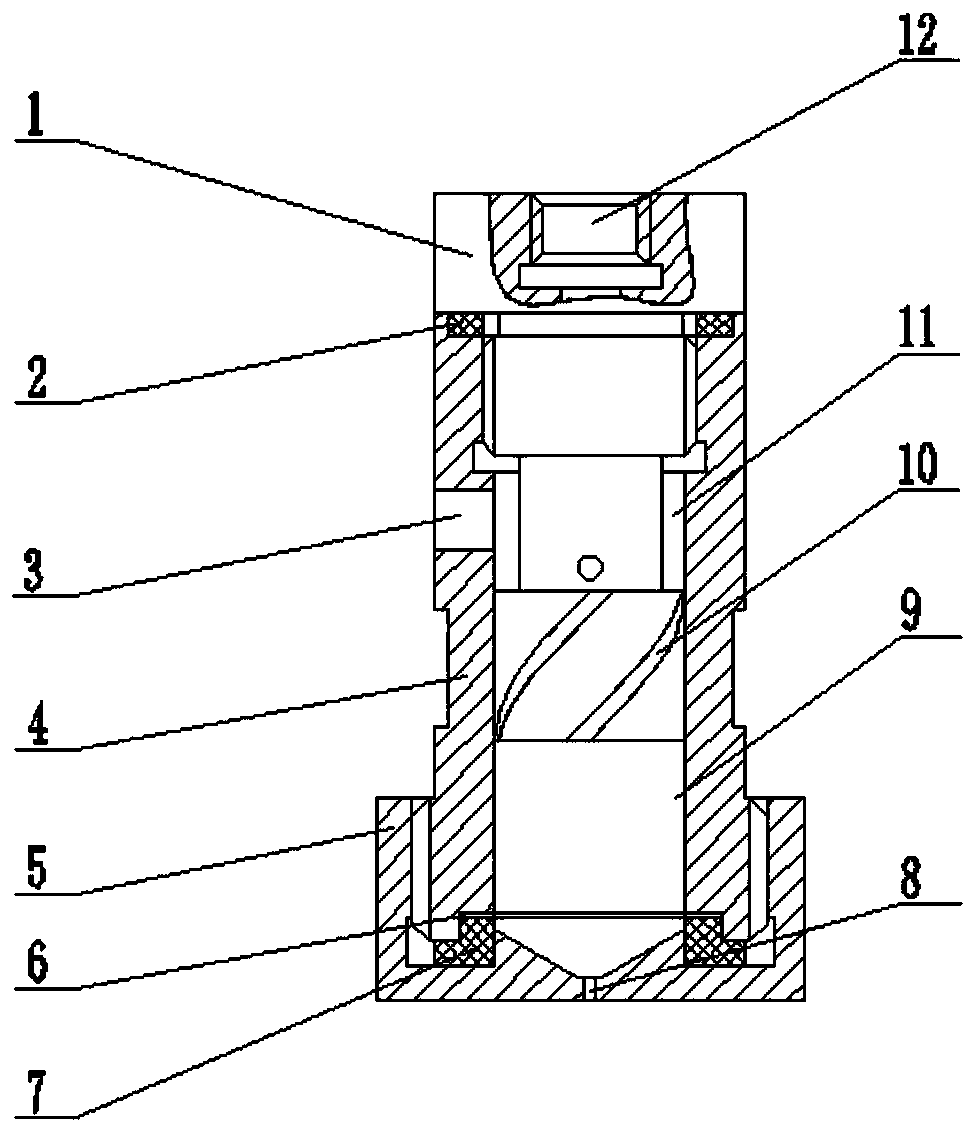

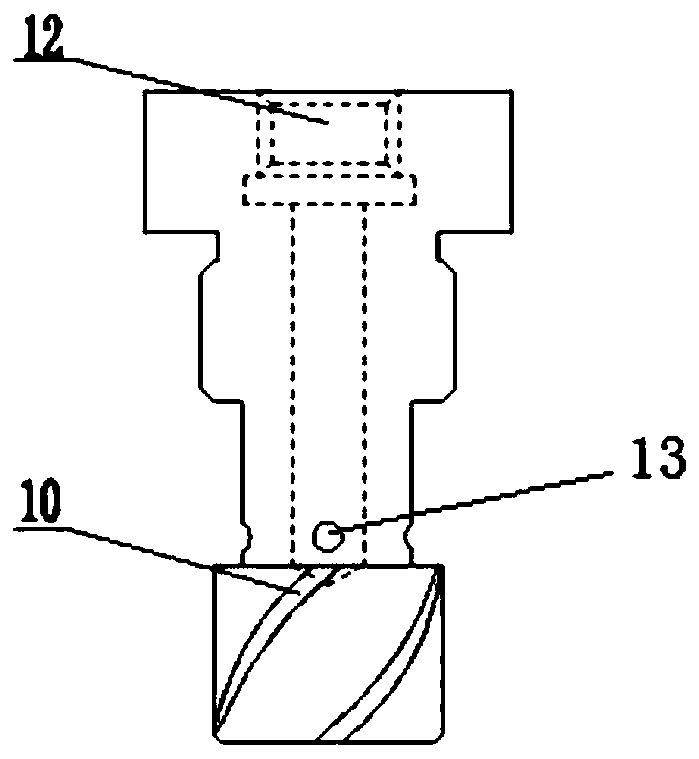

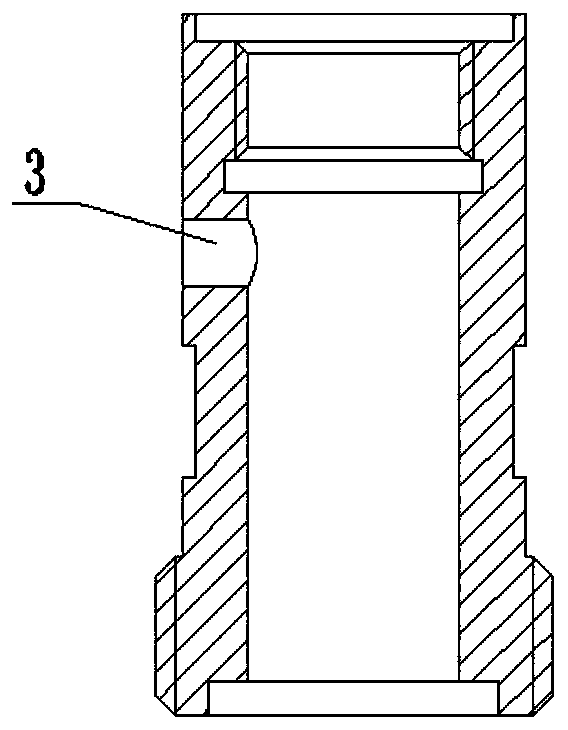

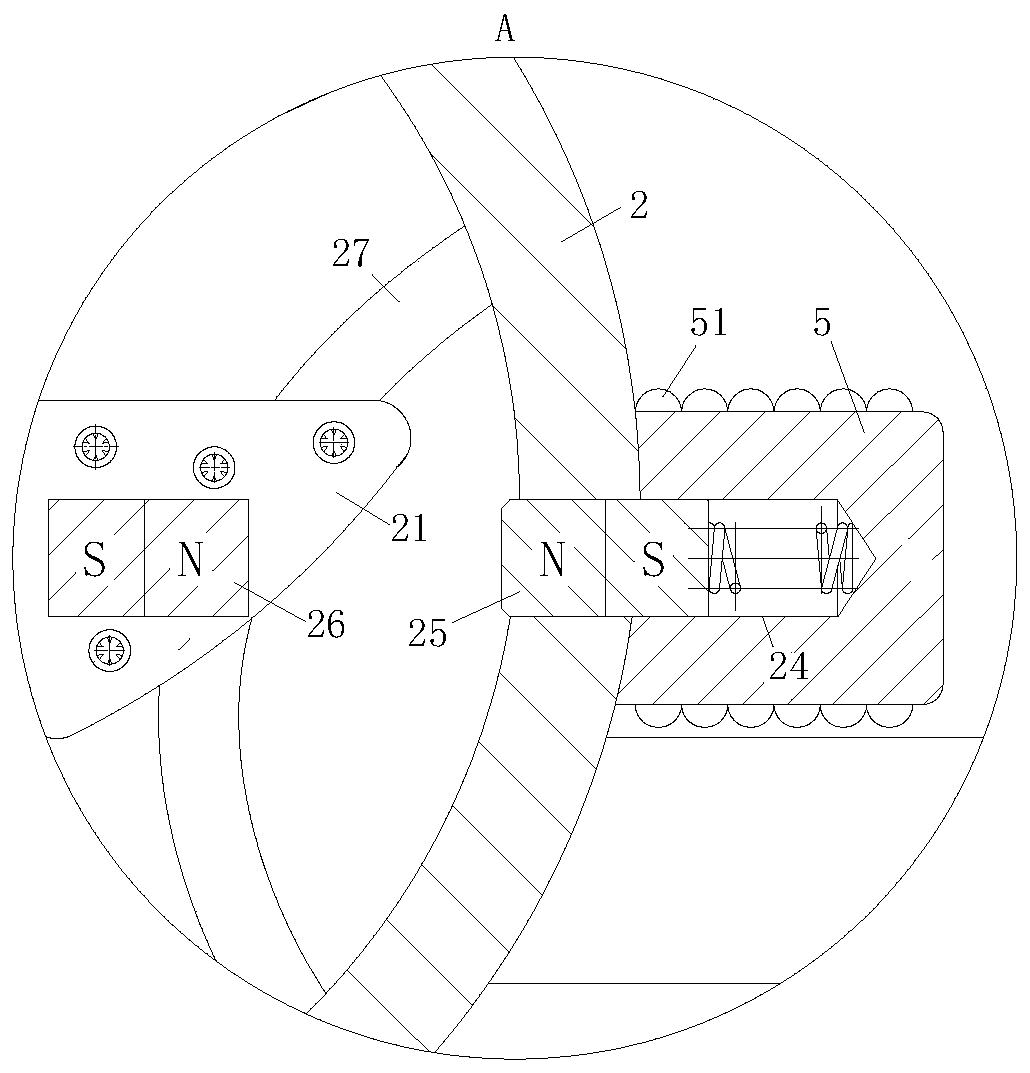

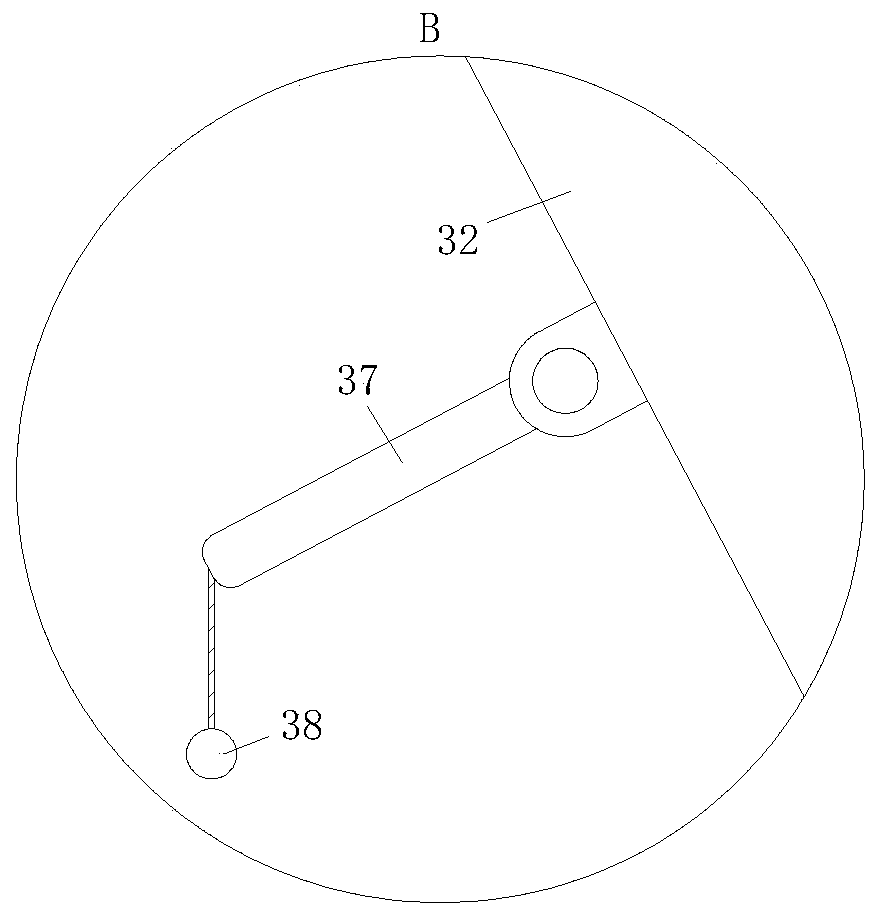

Stirrer

A stirrer is capable of finely dispersing or emulsifying well. A stirrer in which: the stirrer is provided with a rotating rotor equipped with multiple blades and a screen that is placed around the rotor and has multiple slits; the blade and the slits are provided at least with matching regions that are at the same position in the axial direction of the rotor rotation axis; and the fluid being processed is discharged outward from inside the screen as an intermittent jet flow through the slits as a result of the rotation of the rotor. The stirrer is characterized in that when the maximum external diameter of the rotor in the matching region is (D) (m), the rotation frequency of the rotor (2) is (N) (times / s), the number (12) is (X) and the number of slits (8) is (Y), the circumferential velocity (V) (m / s) of the rotor (2) rotation is represented by equation (1) and the frequency (Z) (kHz) of the intermittent jet flow is represented by equation (2)(V)=(D)×(π)×(N)(1)(Z)=(N)×(X)×(Y) / 1000(2) and the circumferential velocity (V) is set to be 23 m / s<(V)<37 m / s and the frequency (Z) is set to be 35<(Z).

Owner:M TECHN

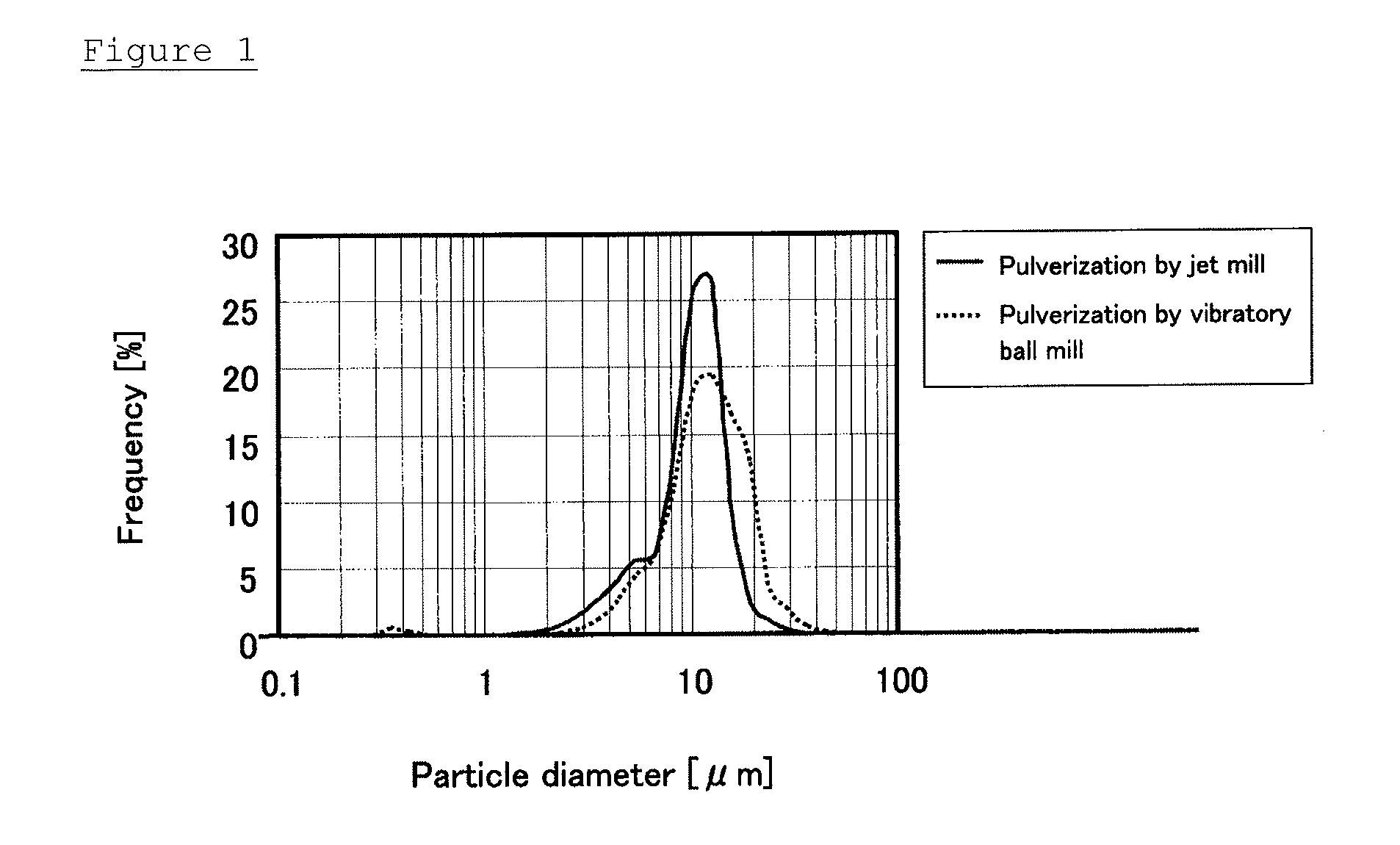

Process for producing oxide crystal fine particles

InactiveUS20100159246A1Small particle diameterUniform particle diameterMaterial nanotechnologyOxide/hydroxide preparationRare-earth elementCrystalline oxide

To provide a process for producing fine particles of crystalline oxide which have high crystallinity, are excellent in uniformity of the composition and particle diameter, and have a small particle diameter, and such fine particles of crystalline oxide.A process for producing fine particles of crystalline oxide, which comprises:a step of obtaining a melt containing an oxide of M (M is at least one member selected from the group consisting of Ce, Ti, Zr, Al, Fe, Zn, Mn, Cu, Co, Ni, Bi, Pb, In, Sn and rare earth elements (excluding Ce)) and B2O3,a step of rapidly cooling the melt to form an amorphous material,a step of pulverizing the amorphous material to obtain a pulverized material having a volume-based particle size distribution within a range of from 0.1 to 40 μm,a step of heating the pulverized material to precipitate an oxide crystal containing M in the pulverized particles, anda step of separating components other than the oxide crystal containing M from the crystal-precipitated particles to obtain fine particles of crystalline oxide containing M, in this order.

Owner:ASAHI GLASS CO LTD

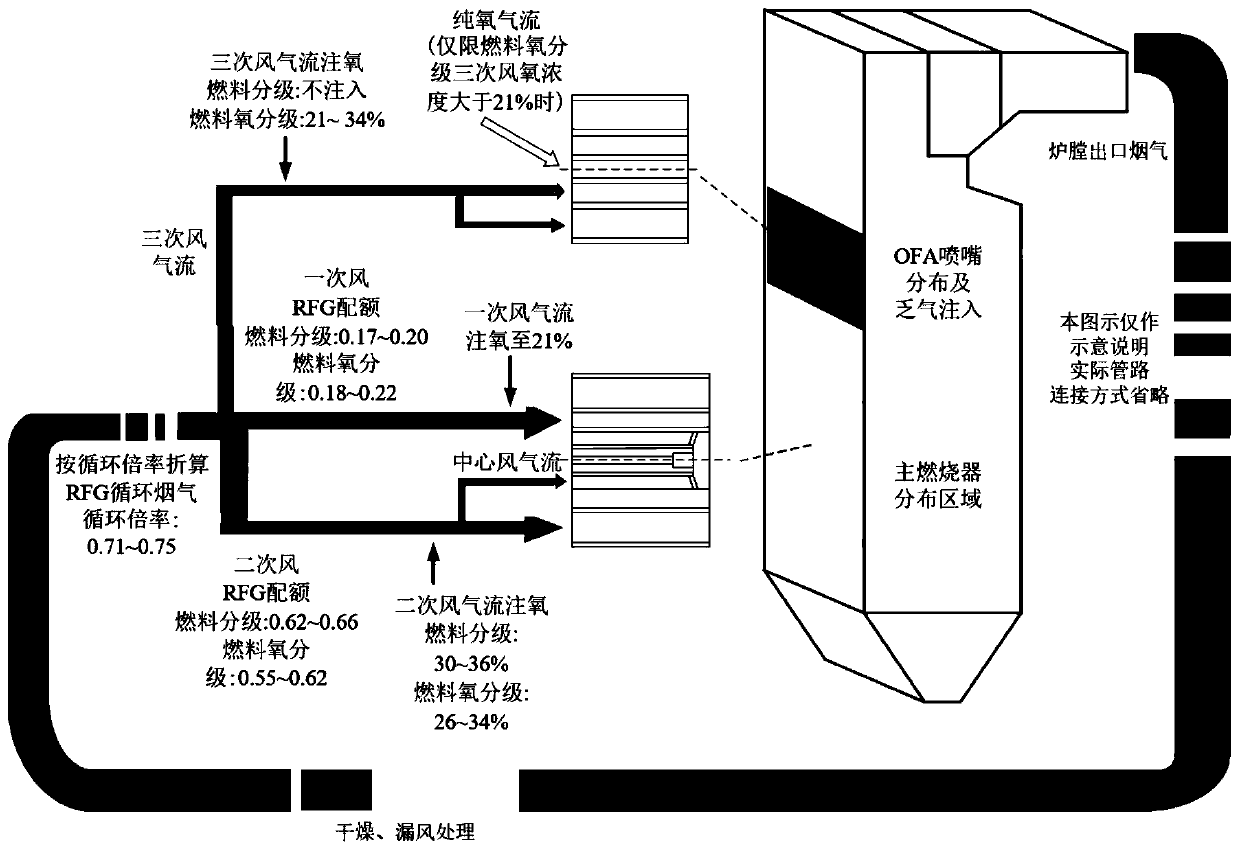

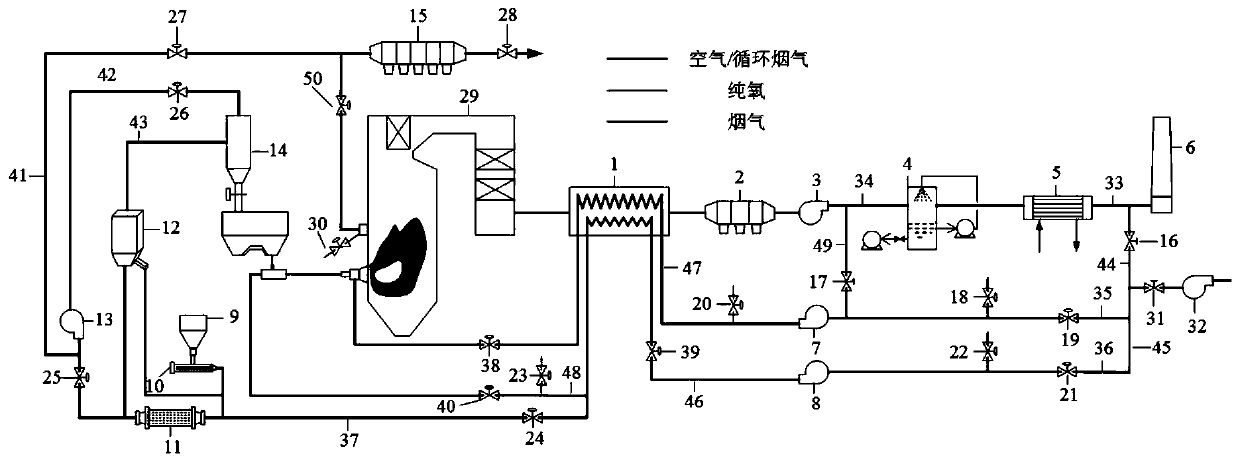

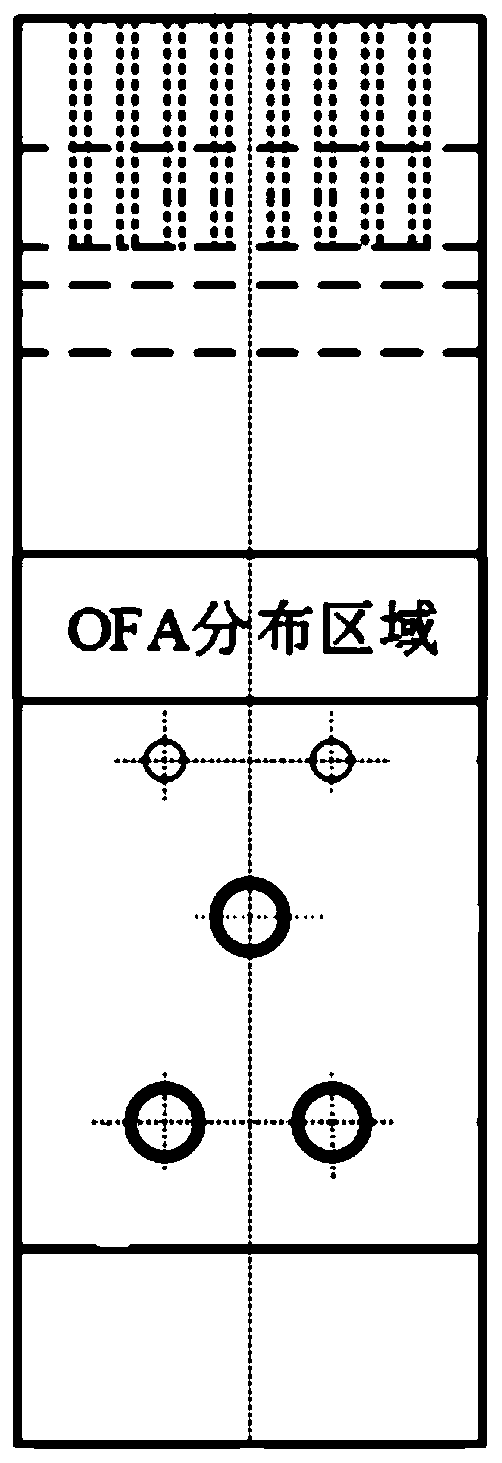

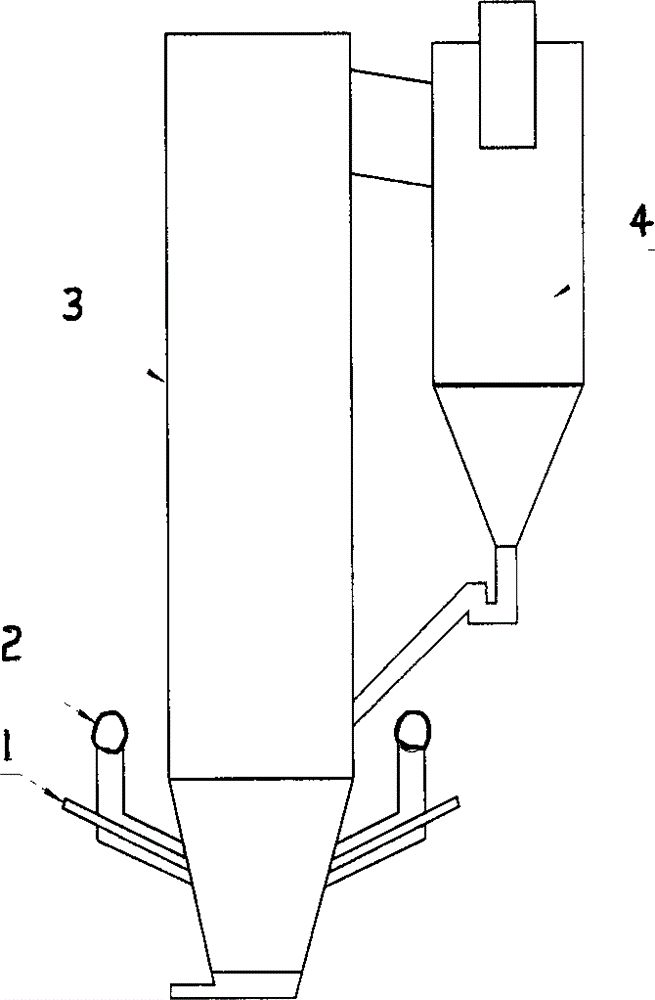

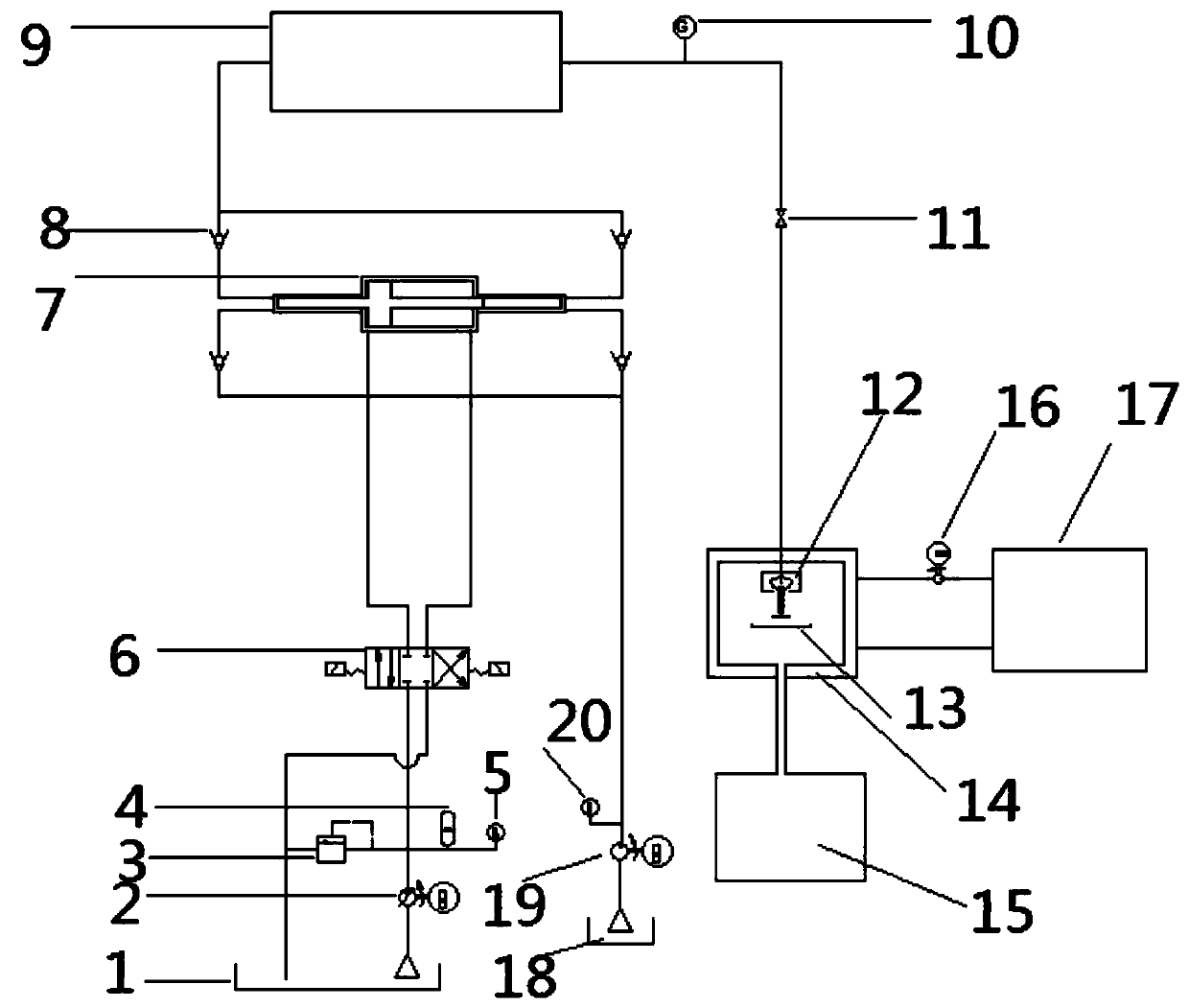

Flameless graded oxygen-enriched low-NOx combustion method and system

ActiveCN111006206AImprove heat utilization efficiencyNormal ignitionIndirect carbon-dioxide mitigationGrain treatmentsThermodynamicsFlue gas

The invention belongs to the field of pulverized coal combustion and emission performance control, and particularly discloses a flameless graded oxygen-enriched low-NOx combustion method and system. The method comprises the following steps that smoke participating in circulation is divided into three paths, the fuel with the preset mass carried by a primary air pipeline, a secondary air pipeline and a tertiary air pipeline is introduced into a hearth through the primary air pipeline, the secondary air pipeline and the tertiary air pipeline to be combusted, wherein air outlets of the primary air pipeline and the secondary air pipeline are positioned in a main combustion area and an air outlet of the tertiary air pipeline is located in a re-combustion area, and the injection amounts and themass flows of oxygen in air in the air pipelines are controlled so as to control the peroxide coefficient range and the flow characteristic of the main combustion area and the re-combustion area so that a fuel staged oxygen-enriched combustion mode, a fuel-oxygen two-way staged oxygen-enriched combustion mode and a flameless oxygen-enriched combustion mode are achieved. The system comprises a boiler, a flue gas pretreatment module, a chimney, the primary air pipeline, the secondary air pipeline and the tertiary air pipeline. According to the invention, stable and efficient low NOx emission canbe achieved, the ignition characteristic of pulverized coal can be improved, and pulverized coal reburning is promoted.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing carbon coating graphite/silicon oxide composite material

InactiveCN101210118AHindered reunionSmall particle diameterInorganic pigment treatmentSilicon oxideCharge discharge

A preparation method for a carbon encapsulated graphite / silicon oxide composite material comprises the following steps that: a uniform mixture of the graphite and silicate and / or silicon ester solution is contacted with acidoid so as to ensure that the uniform mixture forms sizing agent which is dried, products obtained by the sizing agent being dried are mixed with carbon matrix precursor solution, the mixture of products and carbon matrix precursor is dried and the dried solid is baked under the protect of inert gases. The carbon enclosed graphite / silicon oxide composite material made by the preparation method provided by the invention has excellent synthetical electrochemical properties. Compared with the composite material prepared by the prior art, the carbon enclosed graphite / silicon oxide composite material made by the preparation method obviously improves the specific capacity, the first efficiency for charge-discharge and the capacity conservation rate after the 20 times of circulation.

Owner:海宁市盐官工业投资有限公司

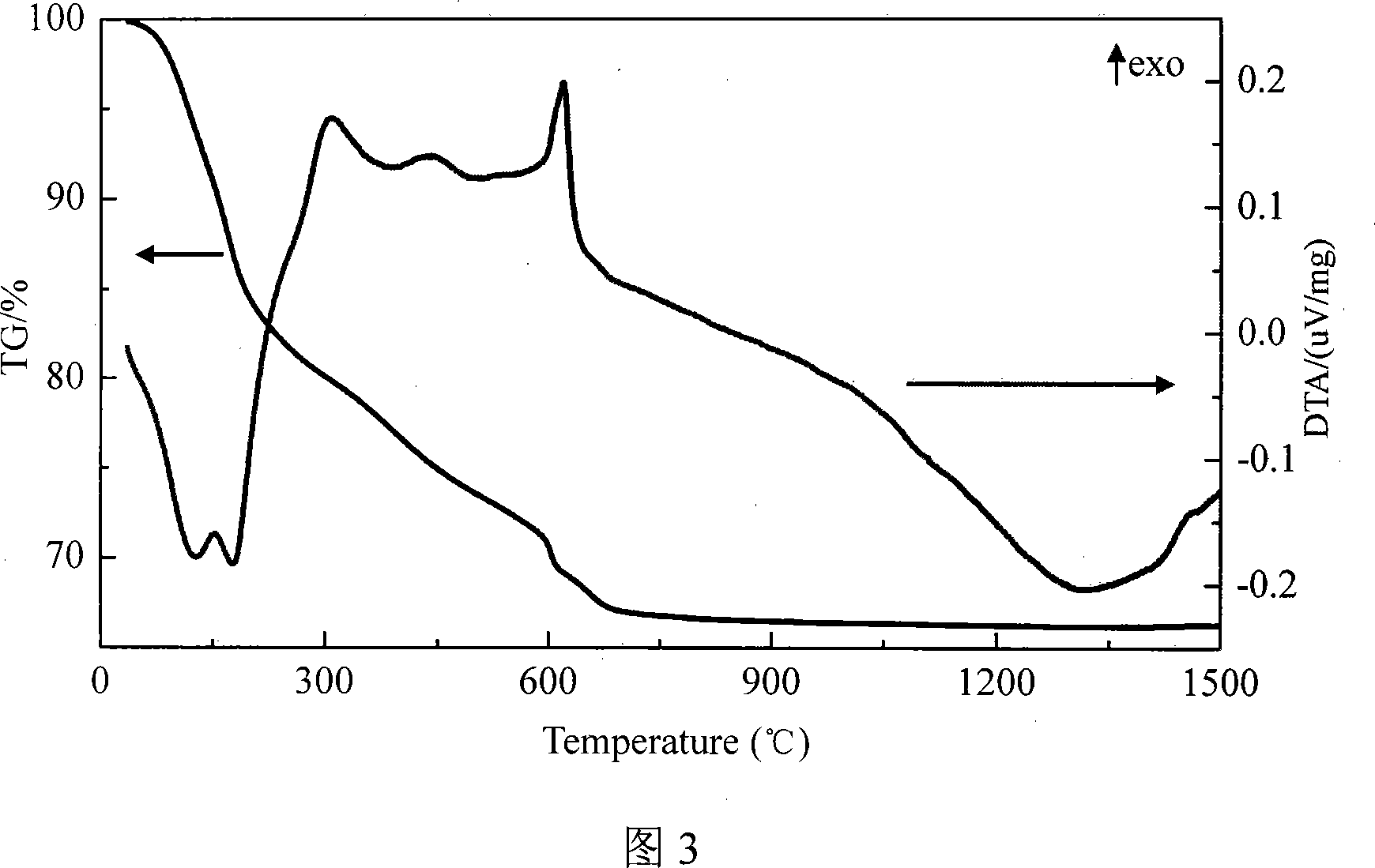

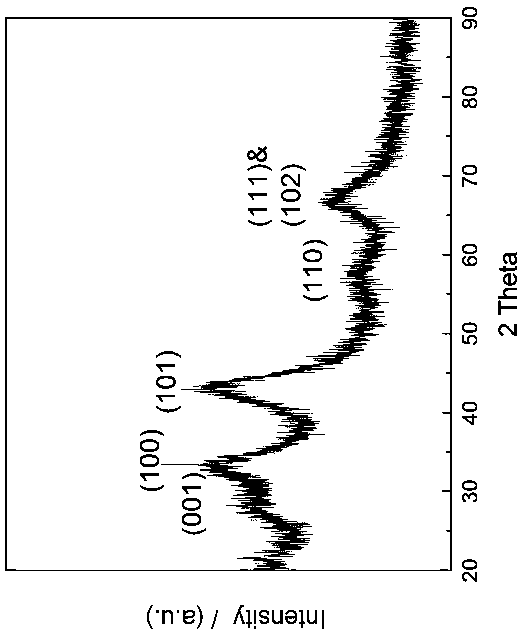

Carbonaceous material for non-aqueous electrolyte secondary battery negative electrode

InactiveUS20140080004A1High discharge capacity to charge capacityEasy dischargeCarbon preparation/purificationNon-aqueous electrolyte accumulator electrodesAir atmosphereMetallurgy

The object of the present invention is to provide a carbonaceous material for a negative electrode of non-aqueous electrolyte secondary batteries having a great charge-discharge capacity, high charge-discharge efficiency, and an excellent charge-discharge cycle characteristic.The object can be solved by a carbonaceous material for a negative electrode of non-aqueous electrolyte secondary batteries, characterized in that an average (002) interlayer spacing d002 determined by X-ray diffractometry is 0.365 to 0.400 nm, a specific surface area determined by a BET method is 1 to 7 m2 / g, an average diameter is 5 to 25 μm, a value of (D90−D10) / D50 is 1.05 or less, and an exothermic peak does not emerge at a temperature range of 620° C. or less in differential thermal analysis measured in an air atmosphere.

Owner:KUREHA KAGAKU KOGYO KK

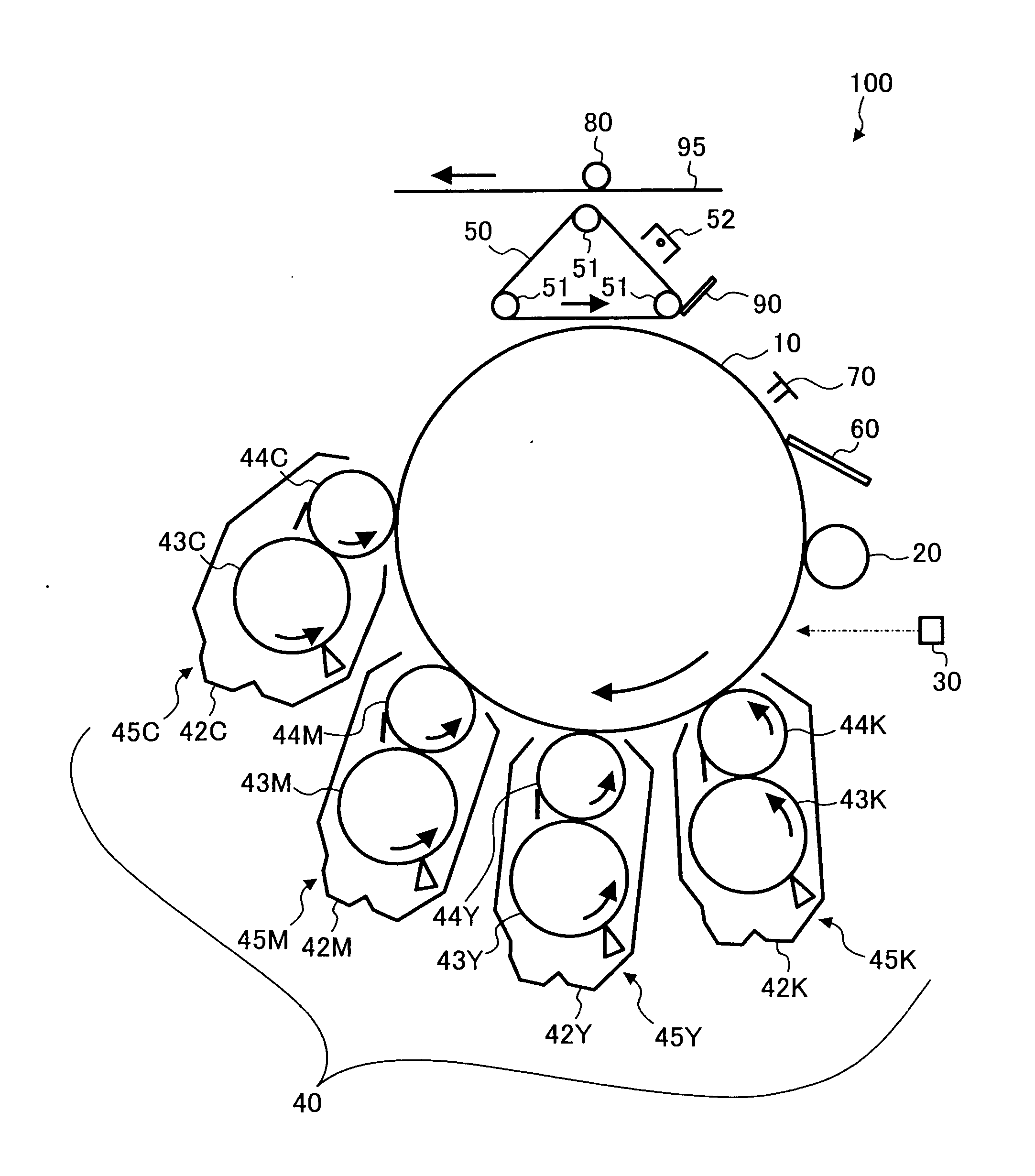

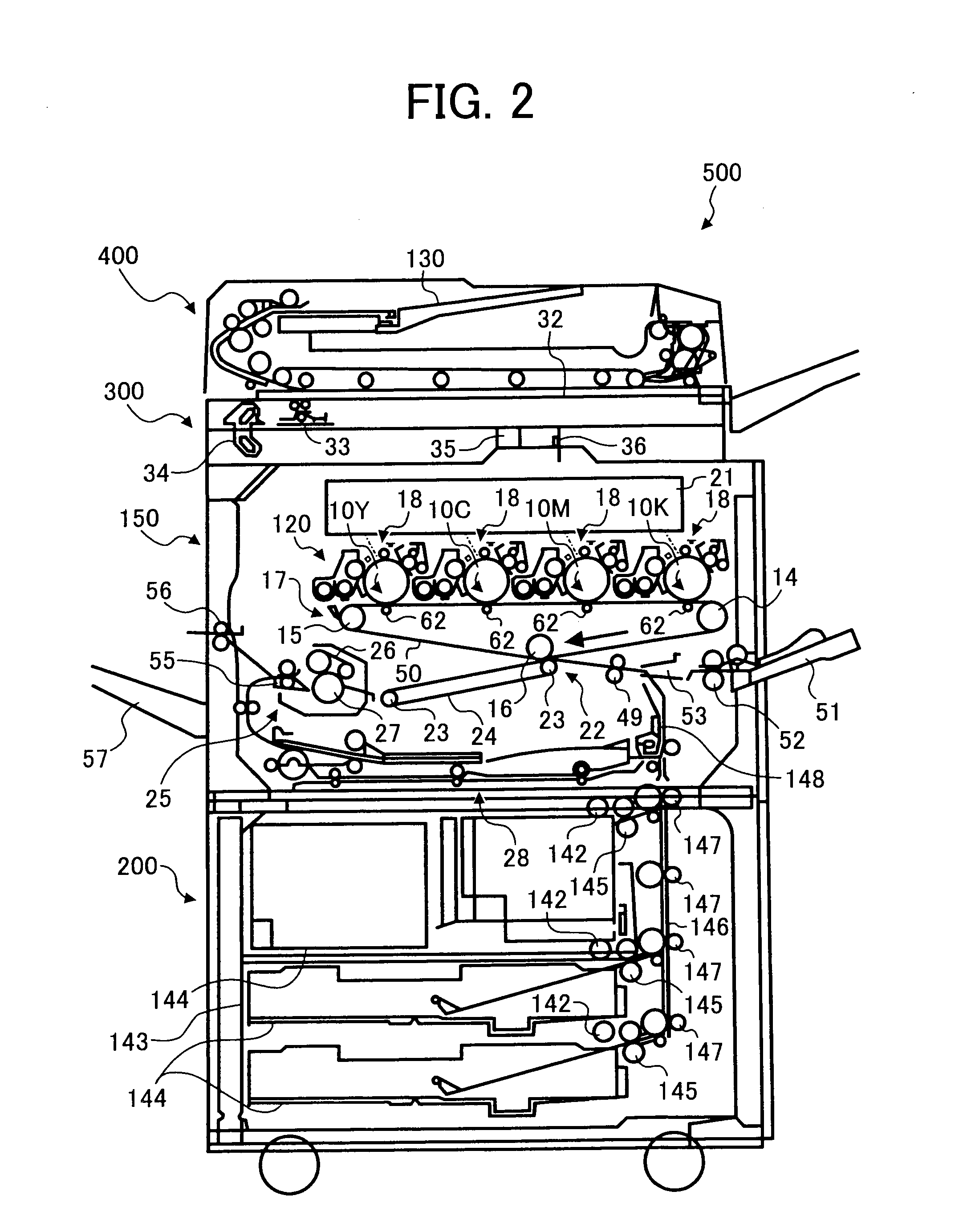

Toner, method for manufacturing the toner, developer including the toner, container containing the toner, and image forming method and apparatus and process cartridge using the toner

InactiveUS20110033203A1Quality improvementSmall particle sizeElectrographic process apparatusDevelopersLatent imageImage formation

An image forming method including forming an electrostatic latent image on an image bearing member; developing the electrostatic latent image with a developer including a toner to prepare a toner image on the image bearing member; transferring the toner image onto a receiving material; and cleaning the surface of the image bearing member with a cleaning blade; wherein a surface of the image bearing member has a friction coefficient of from 0.10 to 0.40, and wherein the toner has an average circularity of from 0.97 to 1.00 and includes toner particles and a particulate material having an average particle diameter of from 0.03 to 1 μm, wherein the particulate material is externally added to the toner particles by a wet method.

Owner:WATANABE YOHICHIROH +5

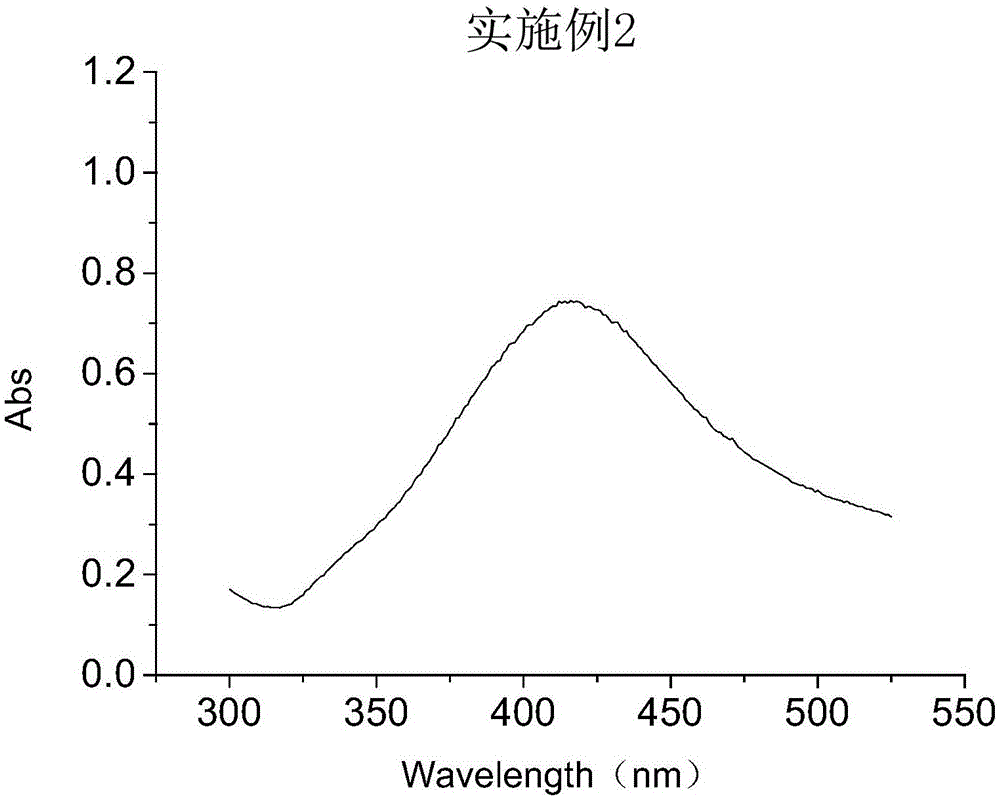

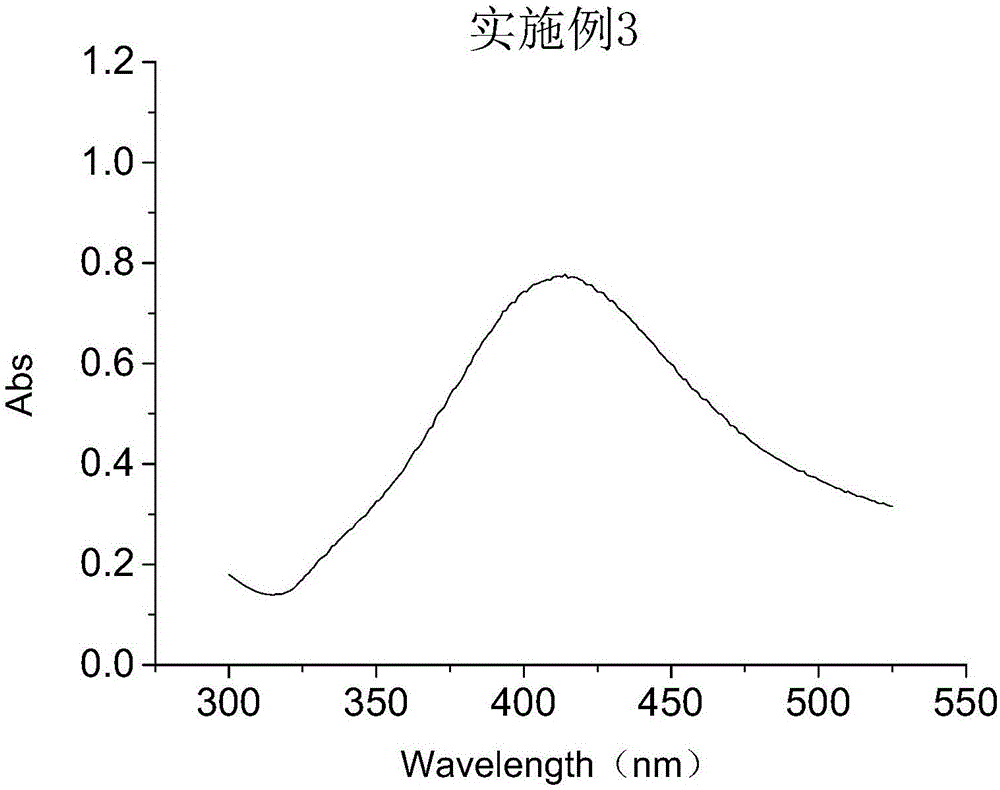

Preparation method of zinc ion-porphyrin nanometer complex

ActiveCN104650104AShorten the timeSmall particle diameterMaterial nanotechnologyOrganic chemistryNanometreInorganic chemistry

The invention discloses a preparation method of a zinc ion-porphyrin nanometer complex. The method comprises a step of mixing zinc ion source solutions with porphyrin source solutions in a micro-reactor and performing reaction to prepare the zinc ion-porphyrin nanometer complex. Compared with an existing preparation method using a reaction kettle, the preparation method is short in reaction time; the prepared particles are small in diameter, uniform in distribution and regular in arrangement.

Owner:SHENZHEN E ZHENG TECH

Emulsion composition and food and cosmetic products containing the emulsion composition

InactiveUS20110275592A1Transparent highGood storage stabilityEdible oils/fats ingredientsOrganic active ingredientsOil phaseCarotenoid

The invention provides an emulsion composition obtained by mixing an oil phase containing a carotenoid having a melting point of 100° C. or more as detected when it is contained in an oil; and an aqueous phase containing a polyglycerol fatty acid ester and a nonionic emulsifier different from the polyglycerol fatty acid ester, wherein a weight ratio (A) / (B) of an amount (A) of the polyglycerol fatty acid ester to an amount (B) of the nonionic emulsifier different from the polyglycerol fatty acid ester is in the range of 2.5 to 10, and a particle diameter of dispersed particles that contain the carotenoid is 200 nm or less.

Owner:FUJIFILM CORP

Chenopodium quinoa health-care buccal tablets and preparation method thereof

InactiveCN106071807AImprove immunityUnique tasteFood shapingFood ingredient functionsSecondary hyperlipidemiaCordyceps militaris

The present invention discloses chenopodium quinoa health-care buccal tablets and a preparation method thereof. The buccal tablets are prepared from the following raw materials in parts by weight: 25-55 parts of chenopodium quinoa flour, 1-5 parts of milk basic protein powder, 1-5 parts of maca powder, 5-10 parts of cordyceps militaris powder, 1-6 parts of xylitol, 1-5 parts of maltodextrin and 1-4 parts of magnesium stearate. The prepared chenopodium quinoa health-care buccal tablets are unique in tastes, have the functions of balancing and supplementing nutrition, inhibiting hypertension, hyperlipidemia, diabetes, heart diseases and senile dementia, preventing osteoporosis, etc., and can delay aging, protect the heart and liver, and improve human immunity.

Owner:HENAN UNIV OF SCI & TECH

Carbonaceous material for negative electrodes of lithium ion capacitors and method for producing same

ActiveUS20150270072A1Excellent electrical propertiesEfficient removalGraphiteElectrolytic capacitorsHalogenGas phase

The object of the present invention is to provide a manufacturing method of carbonaceous material for a negative electrode of lithium ion capacitors, wherein the carbonaceous material is obtained from plant-derived char as a source, potassium and iron are sufficiently removed, and an average particle diameter thereof is small; and a carbonaceous material for a negative electrode of lithium ion capacitors.The object can be solved by a method for manufacturing a carbonaceous material having an average diameter of 3 to 30 μm, for a negative electrode of lithium ion capacitors comprising the steps of: (1) heating plant-derived char having an average particle diameter of 100 to 10000 μm at 500° C. to 1250° C. under an inert gas atmosphere containing a halogen compound to demineralize in a gas-phase, (2) pulverizing a carbon precursor obtained by the demineralization in a gas-phase, (3) calcining the pulverized carbon precursor at less than 1100° C. under a non-oxidizing gas atmosphere.

Owner:KURARAY CO LTD

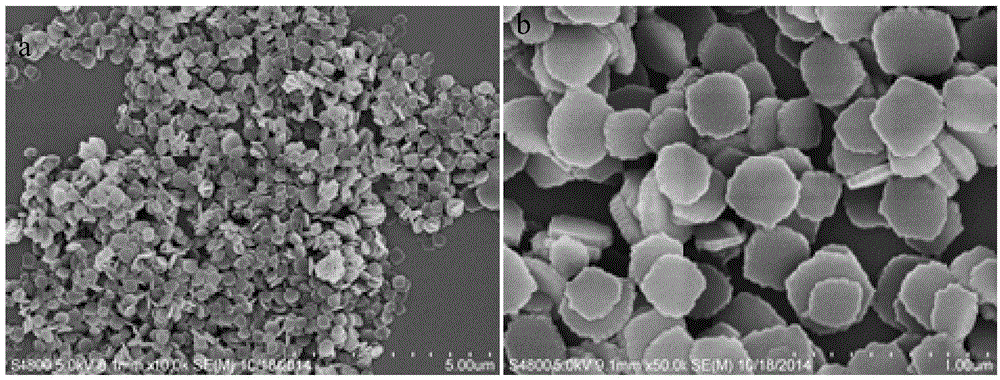

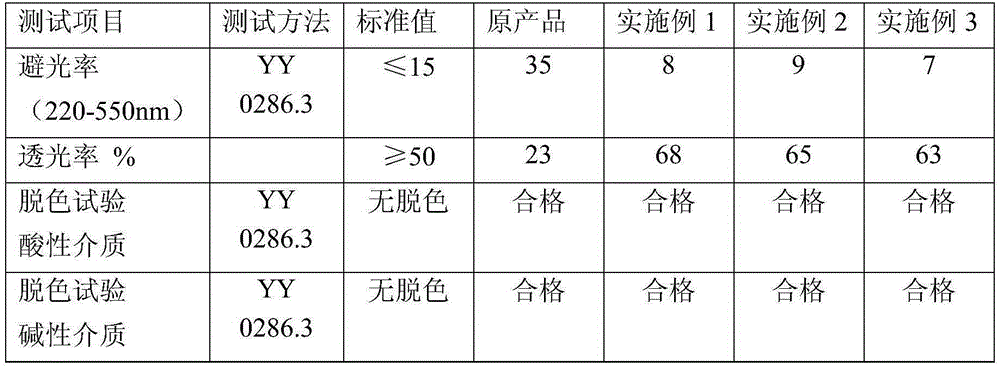

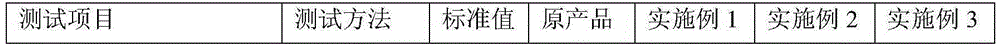

Transparent medical PVC material suitable for wide-wave shading and preparation method thereof

The invention relates to a transparent medical PVC material suitable for wide-wave shading and a preparation method thereof. The PVC material is composed of, by weight, 100 parts of suspension-method PVC resin, 50-75 parts of plasticizers DEHP and TOTM, 1.0-2.0 parts of a Ca / Zn thermal stabilizer, 8-12 parts of an auxiliary thermal stabilizer, 0.5-1.0 part of a lubricant and 0.01-0.05 parts of a shading agent. The shading wave length range of the PVC material is increased to 220-550 nm and the light transmittance reaches not less than 0%. The PVC material solves the problems of narrow shading range (220-450 nm) and low light transmittance (less than 30%) which exist in the shading medical PVC materials in the prior art, thereby satisfying the higher clinical application demands in a shading transfusion device.

Owner:深圳恒方大高分子材料科技有限公司 +2

Desulphurization method for circulating fluidized bed boiler with superfine desulfurizing agent granules

InactiveCN106178907ALarge particlesIncrease particle diameterDispersed particle separationEngineeringPetroleum coke

The invention discloses a desulphurization method in a circulating fluidized bed boiler, and belongs to the technical field of desulphurization of the fluidized bed boiler burning solid fuel such as coal, petroleum coke and biomass. The method is mainly used for solving the problem that the desulfurization efficiency in the circulating fluidized bed boiler is low. The desulphurization method is characterized by comprising the following steps of selecting limestone or magnesium oxide powder of which the diameter is 50-75[mu]m as a desulfurizing agent, conveying desulfurizing agent powder by using compressed air of which the flow rate is 45-55m / s, spraying the desulfurizing agent into a furnace chamber by using a secondary air nozzle of the circulating fluidized bed boiler, inserting a conveying pipeline into each secondary air duct of the boiler, and maintaining the desulfurizing agent conveying pipe and the secondary air nozzle concentric, wherein the calcium sulfur ratio is 1.8-2.5, and the temperature of the furnace chamber is 800-950 DEG C. According to the method, the desulfurization efficiency can reach 90% or above.

Owner:周建强

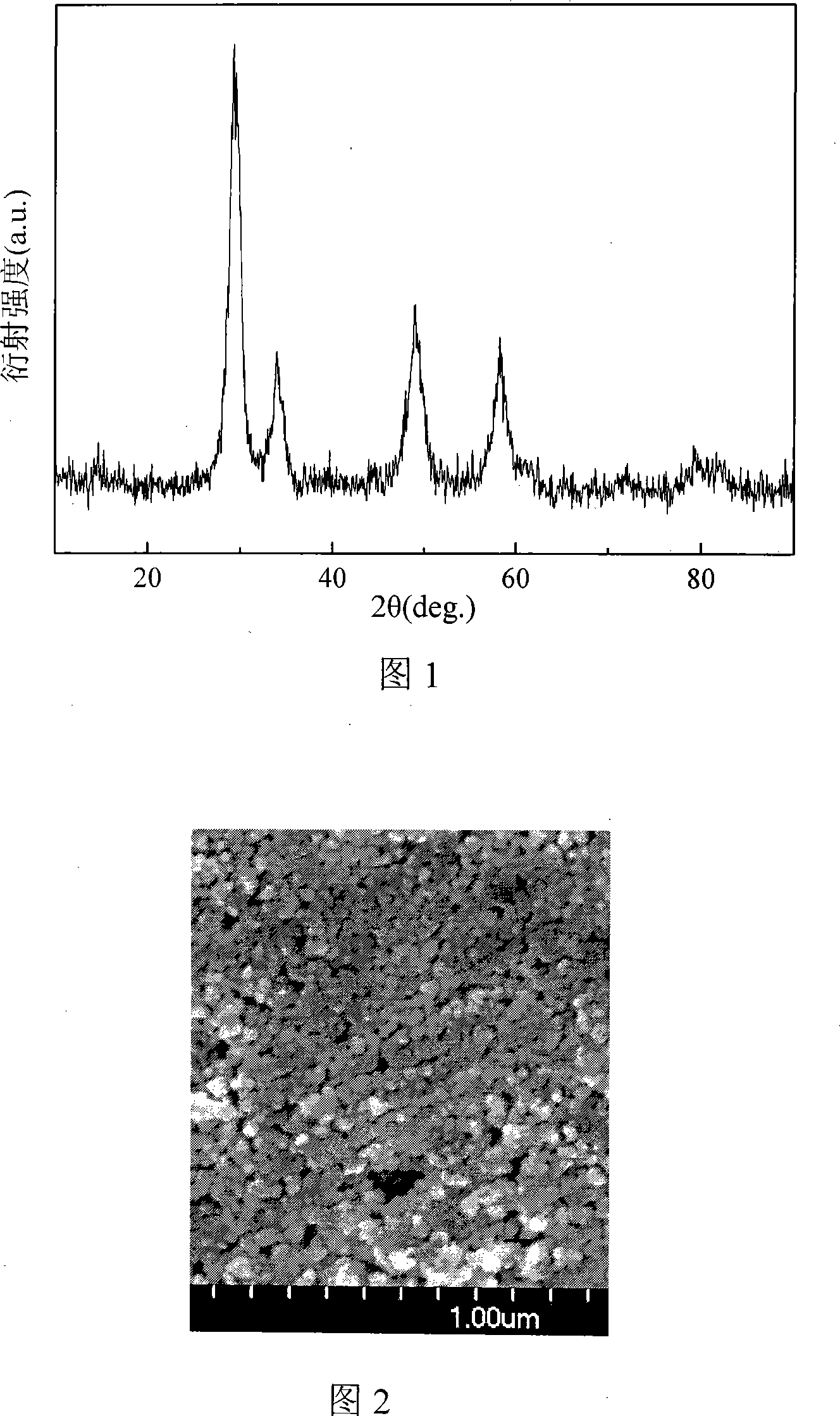

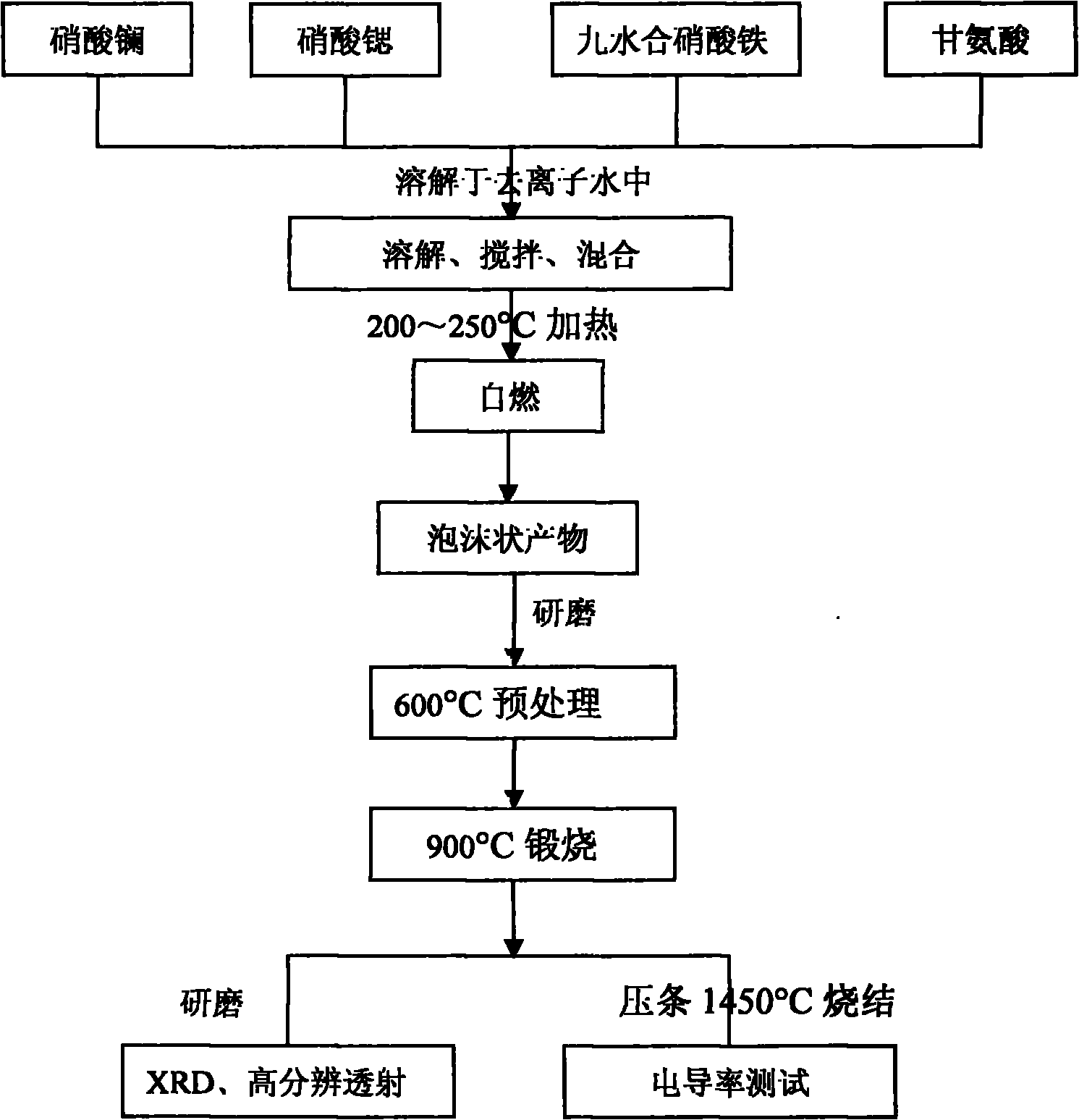

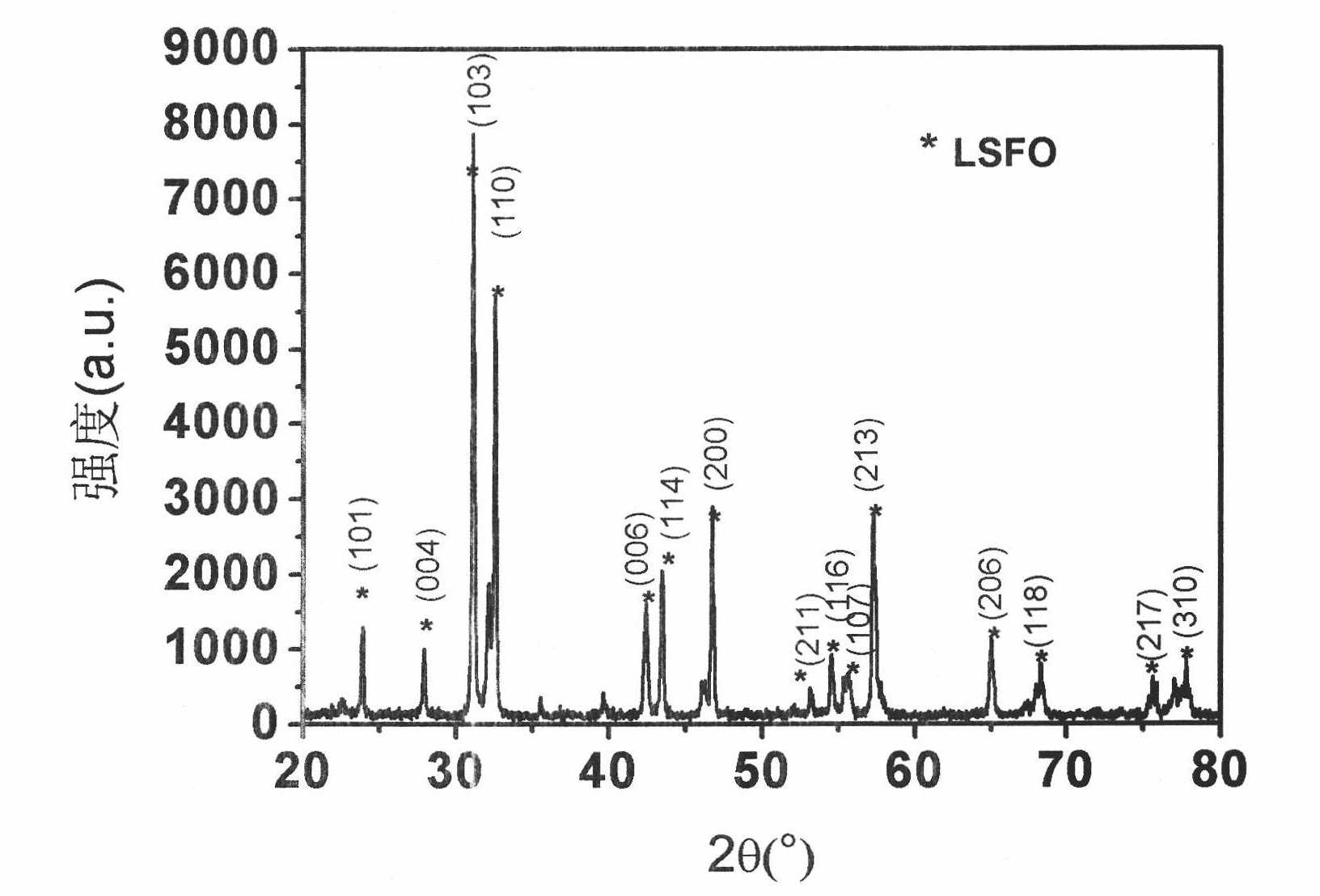

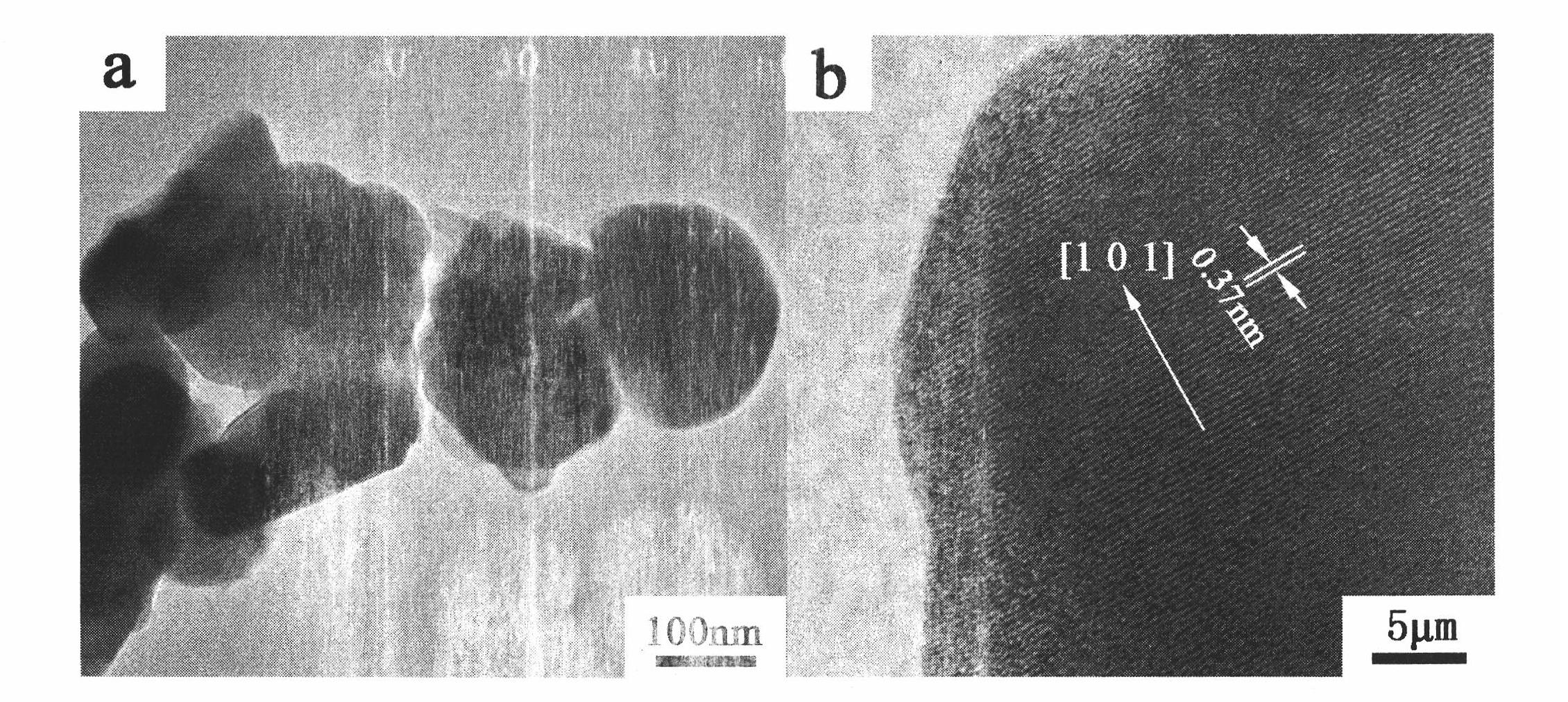

Cathode material of solid oxide fuel cell and preparation method thereof

InactiveCN102054991AShort preparation cycleLow heat treatment temperatureCell electrodesSolid oxide fuel cellSolid-state

The invention belongs to the field of fuel cells, in particular the field of a cathode material of a solid oxide fuel cell. The cathode material of the solid oxide fuel cell has a molecular formula of LaxSr2-xFeO4+ / -delta, and is characterized in that: x is equal to 1.2; and the molecular formula is La1.2Sr0.8FeO4+ / -delta. The invention also discloses a method for preparing the cathode material. Compared with the prior art, a glycine method provided by the invention for preparing the cathode material of the solid oxide fuel cell has the advantages that: 1, compared with a solid-state reactionmethod, the glycine method has short preparation period and low thermal treatment temperature of powder, and the obtained powder is purer and can be produced on a large scale; 2, compared with a citric acid-nitrate method and an ethylene diamine tetraacetic acid (EDTA)-citric acid method, the glycine method has a simple preparation process and the pH value of solution is not required to be adjusted; and 3, the glycine is used as an oxidant, so the reaction is quickened and smaller particle diameter can be obtained.

Owner:UNIV OF SCI & TECH BEIJING

Novel atomizing nozzle based on bubble cutting

PendingCN110449283ASmall diameterImprove atomization qualityLiquid spraying apparatusEngineeringMixing chamber

The invention provides a novel atomizing nozzle based on bubble cutting. The novel atomizing nozzle comprises an internal assembly and an external assembly, wherein closed space formed by the internalassembly and the external assembly constitutes a mixing chamber of the nozzle, the internal assembly comprises an inner core and a bubble divider, the external assembly comprises a casing and a sprayhead, a first air inlet hole is formed in the top of the inner core, an external thread is formed at the upper part of the inner core below the first air inlet hole, multiple second air inlet holes are formed in the inner core below the external thread, and swirling grooves are formed in the inner core located below the second air inlet holes; the casing is a hollow opening round tube, an internal thread at the upper part of the casing is tightly connected with the external thread on the inner core through a sealing structure, a liquid inlet hole is formed in the side surface of the casing, and an external thread is formed at the lower part of the casing; an internal thread is formed at the upper part of the spray head, a spray hole is formed in the central position of the closed end of the spray head, the bubble divider is mounted in a hollow cavity in the lower part of the casing, and the casing and the bubble divider are tightly connected with the spray head through a sealing structure. The novel atomizing nozzle has higher atomizing quality, and the average diameter of particles is smaller and more uniform.

Owner:HEBEI UNIV OF TECH

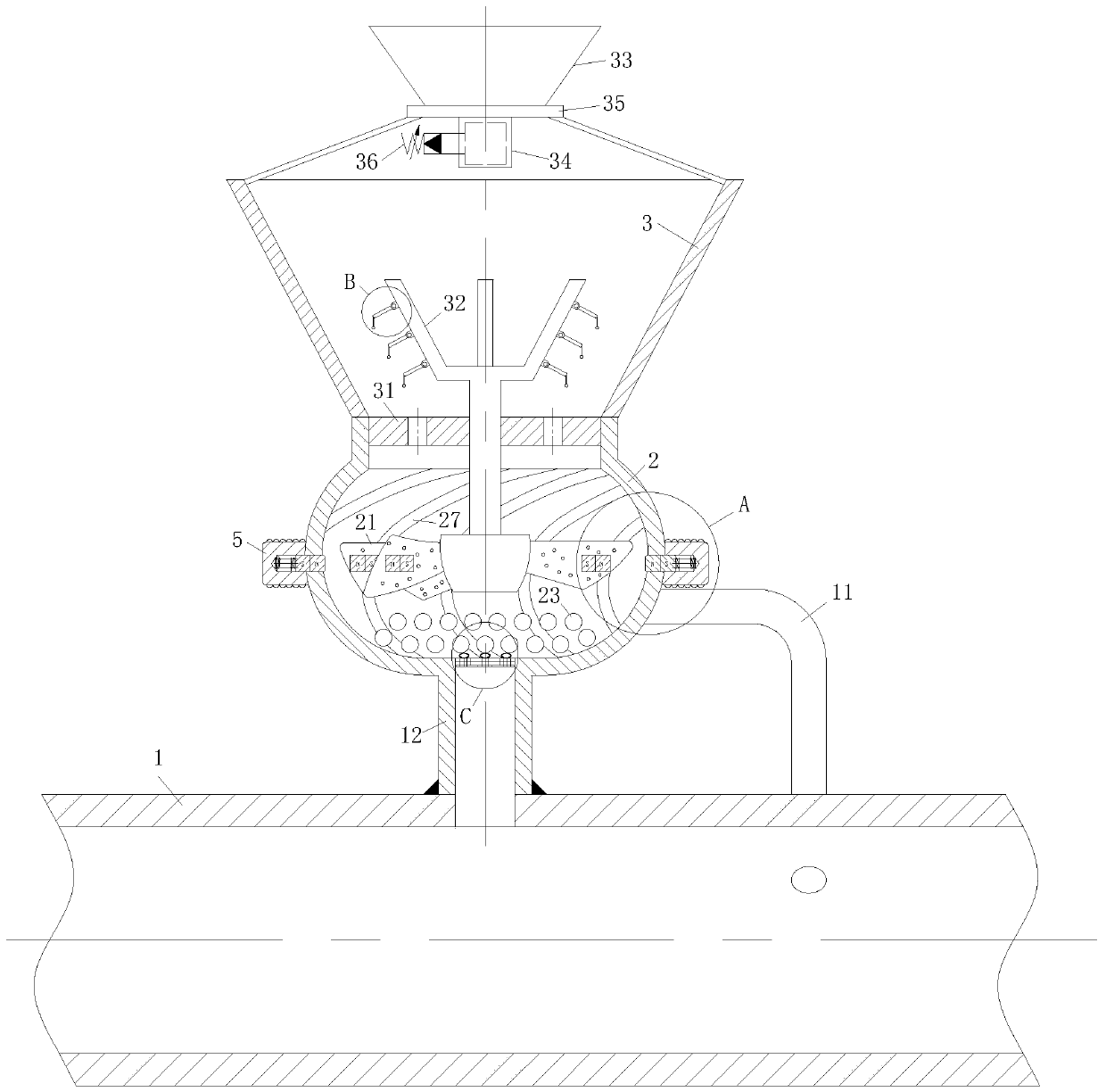

Light-controlled water-fertilizer integrated intelligent irrigation system for vegetable cultivation

InactiveCN110366924AMove fastFast dissolutionPressurised distribution of liquid fertiliserWeighing apparatus for materials with special property/formWater flowDrip irrigation

The invention belongs to the technical field of agricultural equipment, and particularly relates to a light-controlled water-fertilizer integrated intelligent irrigation system for vegetable cultivation. The light-controlled water-fertilizer integrated intelligent irrigation system comprises a drip irrigation main pipe, a branch pipe, a return pipe, a water wheel chamber, a water wheel, a crushingbucket, a filter screen, a crushing knife, a hopper, a feeding tube, an electronic scale and a solenoid valve. The water wheel chamber is formed above the drip irrigation main pipe, and the branch pipe is communicated to the tangential direction of the side face of the water wheel chamber. The other end of the branch pipe is communicated with the drip irrigation main pipe. The bottom of the waterwheel chamber is communicated with the drip irrigation main pipe through the return pipe. The water wheel is rotatably connected into the water wheel chamber. The crushing bucket is fixedly connectedabove the water wheel chamber. The crushing knife is rotatably connected into the crushing bucket. The electronic scale is fixedly connected above the crushing bucket through a support. The hopper isarranged above the electronic scale. The water wheel and the crushing knife in the water wheel chamber are pushed to rotate through water flows, fertilizer is crushed and mixed by the rotating crushing knife in the crushing bucket before flowing into the water wheel chamber, the particle diameter of the mixed fertilizer is reduced, and the dissolution speed of the fertilizer in the water wheel chamber is increased.

Owner:杭州市临安区农林技术推广中心

Preparation method of transition metal nano-boride

InactiveCN103101922AGood technical effectMild reaction conditionsMaterial nanotechnologyMetal boridesBorideHigh energy

The invention relates to the technical field of material synthesis and discloses a preparation method of a transition metal nano-boride. The preparation method comprises the following specific steps of: mixing a transition metal halide with a reducing agent I and a reducing agent II in a protective atmosphere of inert gas; placing an obtained mixture into a ball milling tank, and performing ball milling in the protective atmosphere of the inert gas; and removing the metal halide in a product of ball milling to get the transition metal nano-boride. The preparation method disclosed by the invention has the advantages of overcoming the shortcomings of high energy consumption, complex process and the like of the traditional preparation method, realizing mild reaction conditions and short reaction period, being capable of generating the product with a nano-structure, enabling the purity of the reaction product to be high and simultaneously precisely controlling the particle size of the product.

Owner:ZHEJIANG UNIV

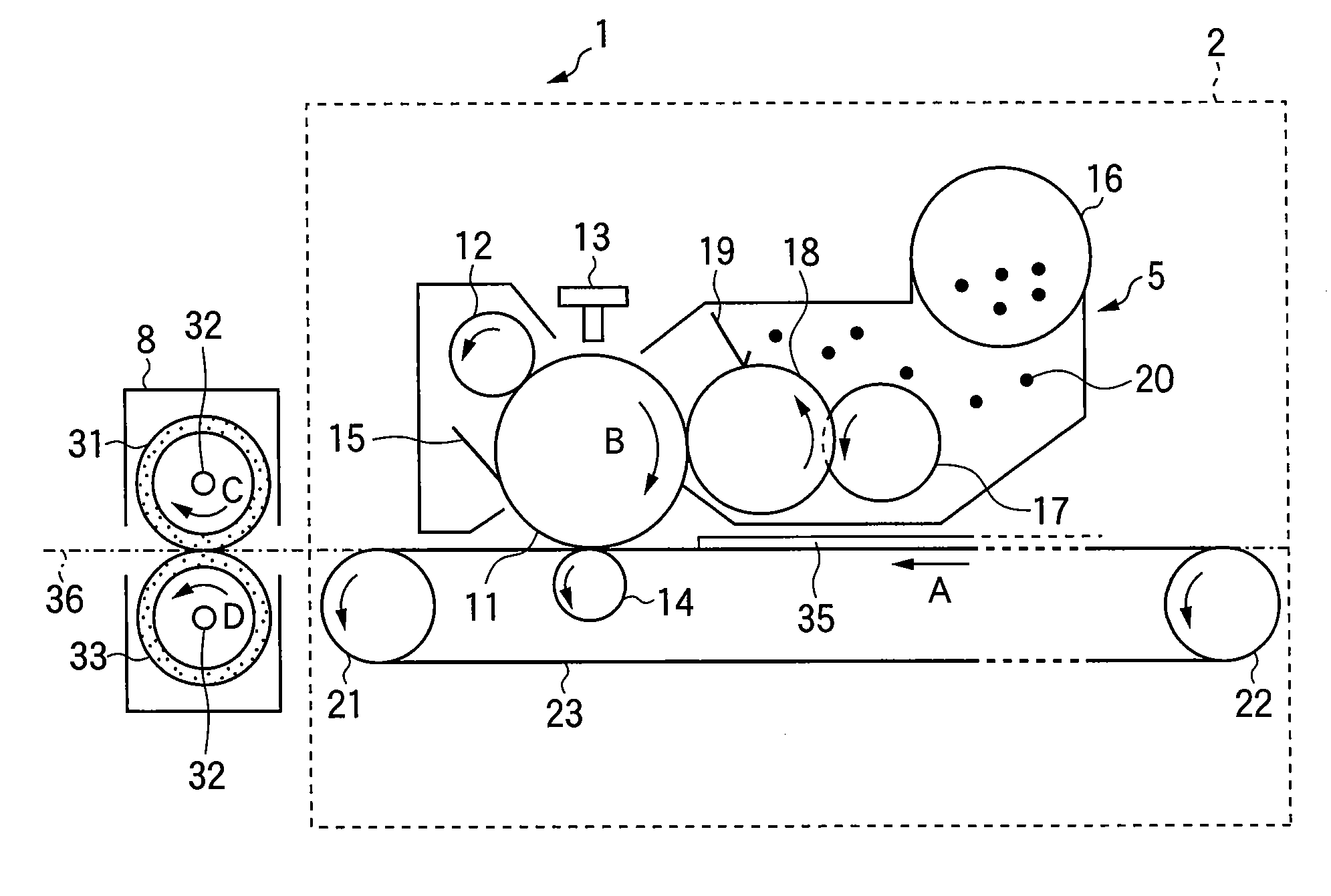

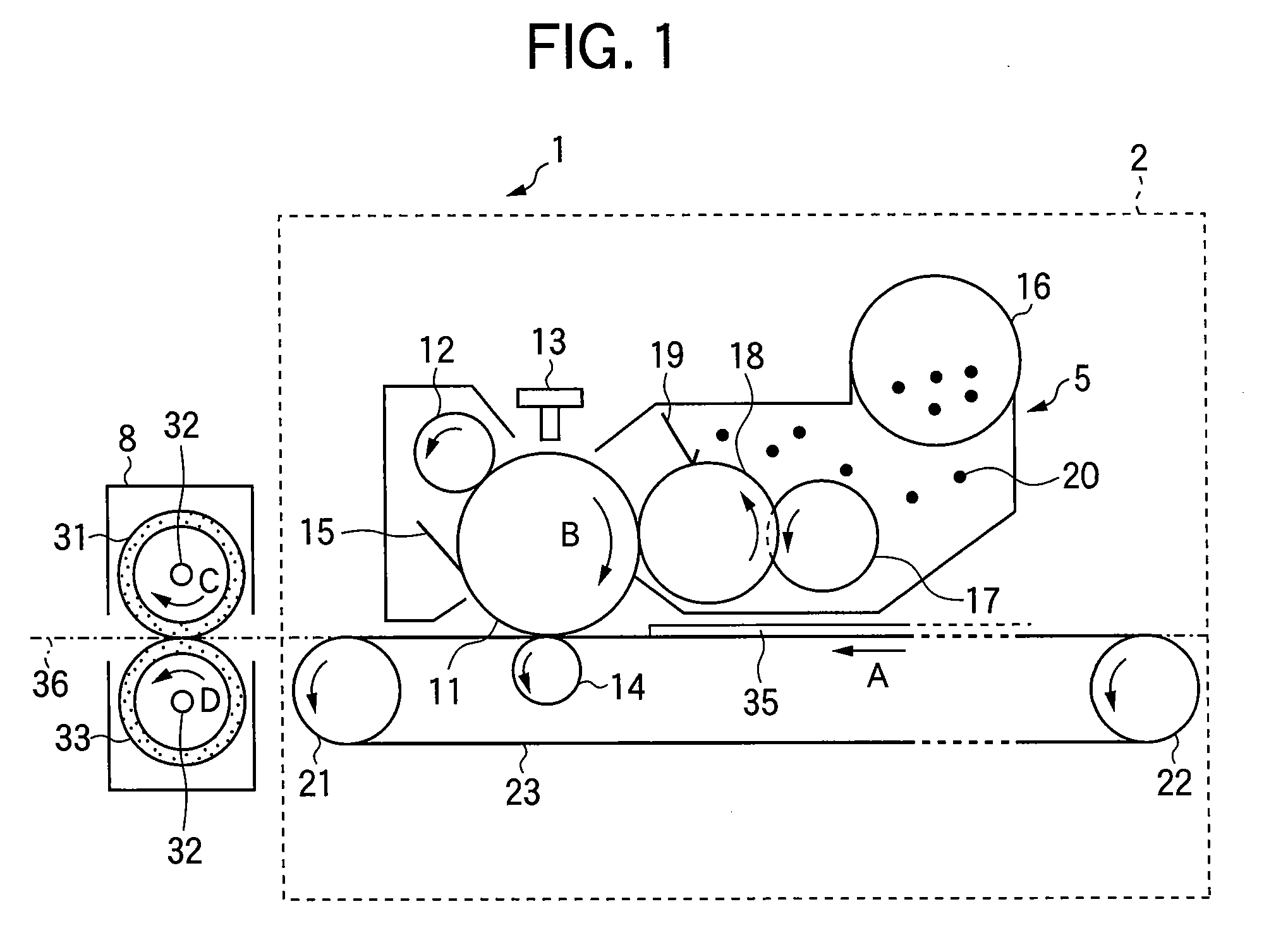

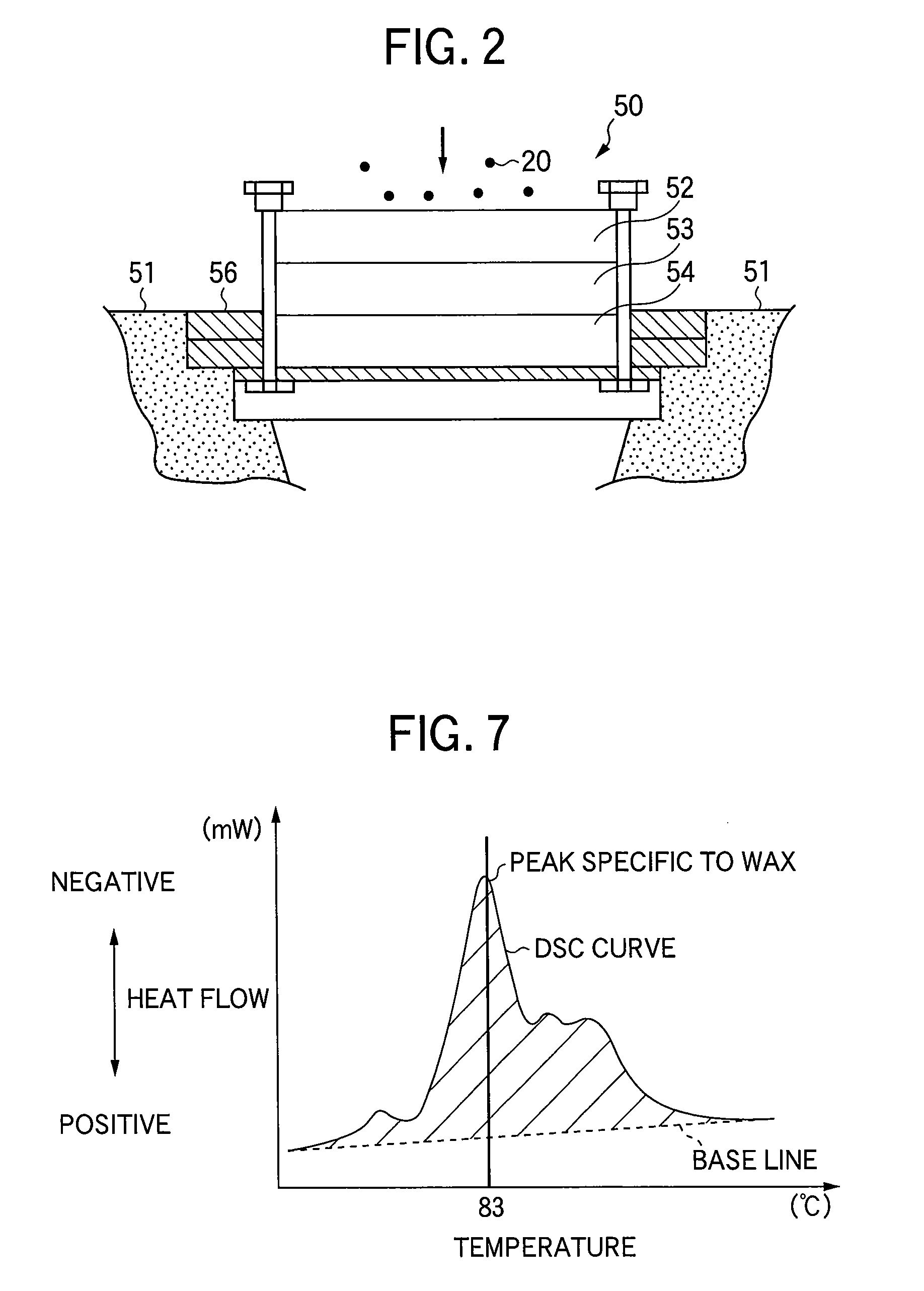

Toner and image forming apparatus that uses the toner

InactiveUS20080056775A1High speed printingSmall particle diameterElectrographic process apparatusDevelopersWaxPopulation

A toner includes a base toner that contains a binder resin, a colorant, and a wax. The base toner includes at least one endothermic peak specific to the wax in a range of 60 to 100° C., and a total endothermic of not less than 2 mJ / g. The base toner meets a condition expressed by (σ / M)×100≦23 where M is an average particle diameter and σ is a standard deviation of a first population of particle diameters after toner particles having diameters smaller than a certain value have been removed from a second population of the particle diameters, the certain value lying on a smaller side of an average particle diameter of the second population. The toner has a flow-ability of not smaller than 60%. The base toner is blended with at least 0.3 weight parts of a first external additive and at least 0.3 weight parts of a second external additive.

Owner:OKI DATA CORP

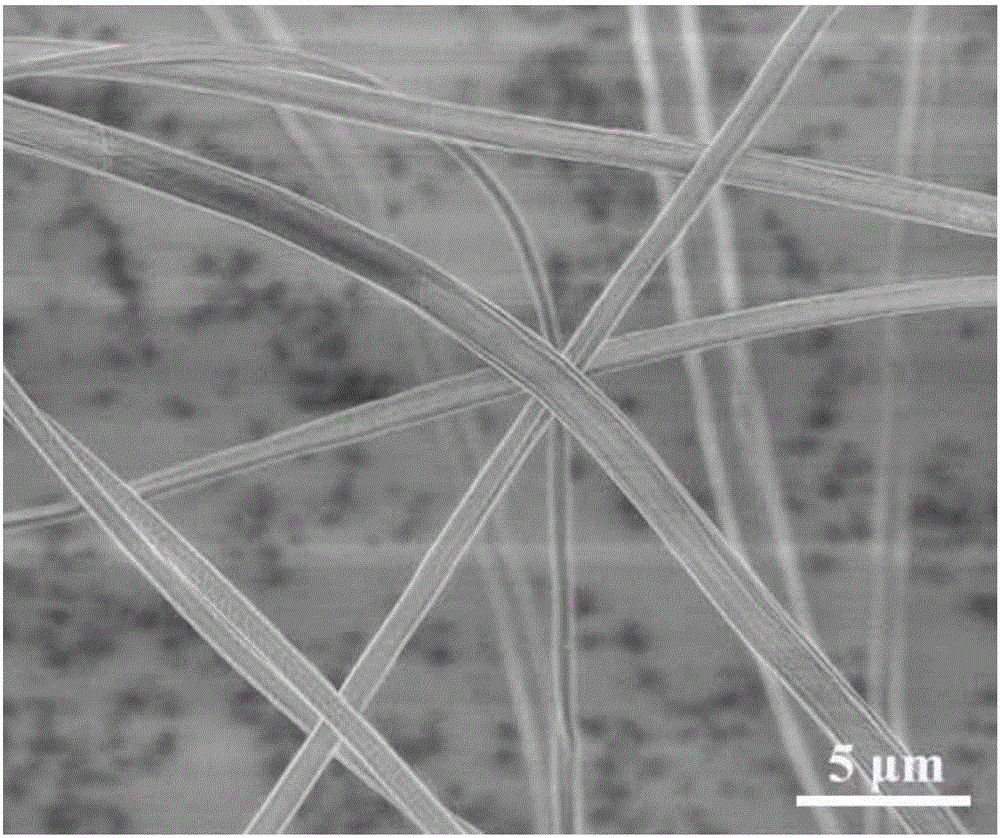

Silver-loaded chitosan/polyvinyl alcohol micro-ribbon and preparation method and application thereof

ActiveCN106757785AAvoid problems such as uneven distribution and uneven particle sizeEvenly distributedFilament/thread formingNon-woven fabricsPorosityEscherichia coli

The invention relates to a silver-loaded chitosan / polyvinyl alcohol micro-ribbon and a preparation method and application thereof. The micro-ribbon is a chitosan / polyvinyl alcohol ribbon-shaped composite fiber film on which silver nanoparticles are uniformly distributed; the micro-ribbon has a diameter of 0.3 to 2mum; the silver nanoparticles have a particle size of 5 to 60nm. After polyvinyl alcohol solution and lactic acid solution of chitosan are mixed, ethyl alcohol is added; after the mixture is uniformly stirred, silver nitrate is added; stirring is carried out in a mode of keeping out of the sun for 40 to 50h to prepare spinning solution; then electrostatic spinning is carried out to obtain the silver-loaded chitosan / polyvinyl alcohol micro-ribbon. The micro-ribbon disclosed by the invention has the advantages of one-dimensional and two-dimensional nano materials, has a higher specific surface area, porosity and water absorption; the nano particles are attached or embedded into the micro-ribbon; phenomena of falling, aggregation and the like of nano silver are effectively reduced; the formed nano silver is more uniformly distributed in the micro ribbon; a fatality rate of the micro-ribbon for escherichia coli is 100%.

Owner:JIANGSU YITONG BIOTECHNOLOGY CO LTD

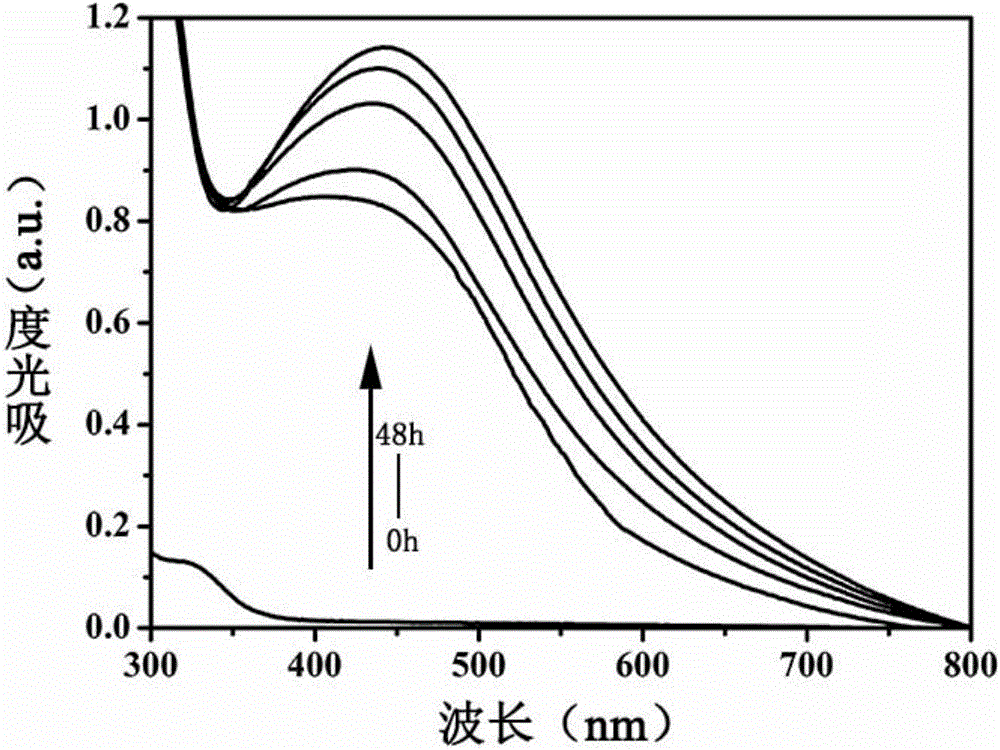

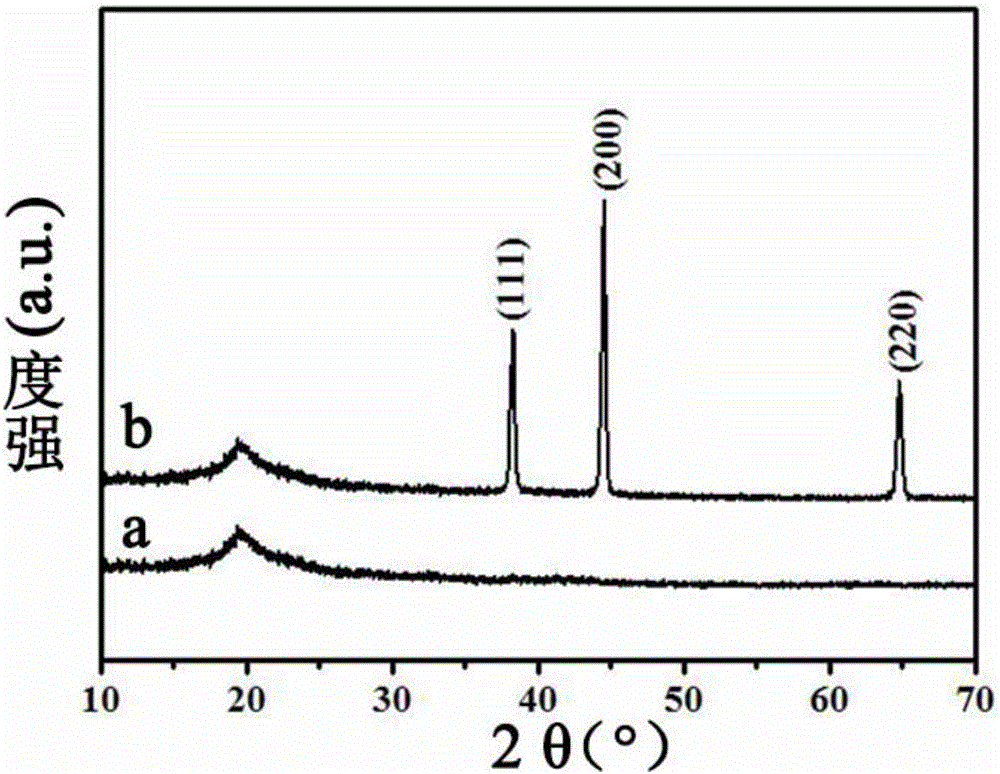

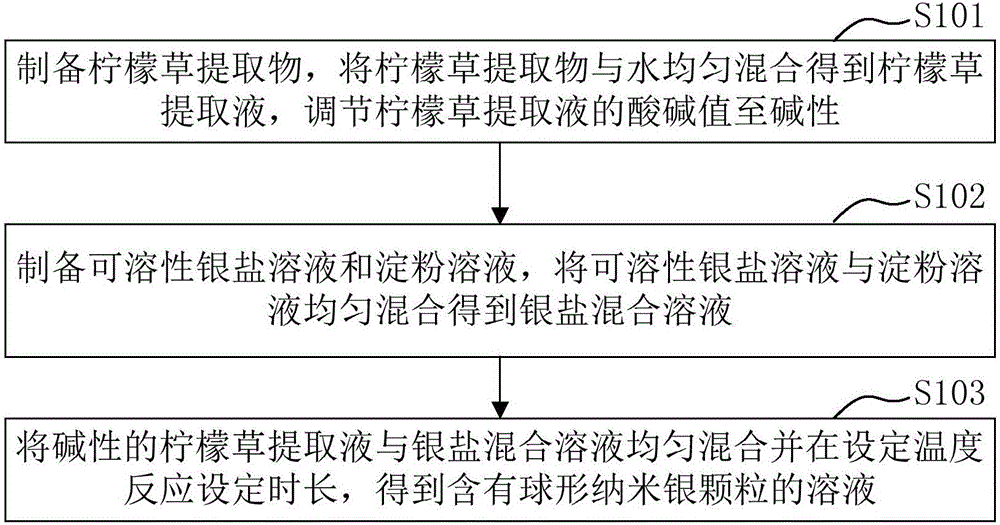

Synthesis method for spherical nano-silver particles and spherical nano-silver particles

InactiveCN106238748ANo pollution in the processLow costMaterial nanotechnologyTransportation and packagingStarch solutionSilver particles

The invention provides a synthesis method for spherical nano-silver particles and the spherical nano-silver particles. The synthesis method for the spherical nano-silver particles comprises the steps that lemon grass extracts are prepared, the lemon grass extracts and water are evenly mixed for obtaining a lemon grass extracting solution, and the pH value of the lemon grass extracting solution is regulated to be alkaline; a soluble silver slat solution and a starch solution are prepared and evenly mixed for obtaining a silver salt mixed solution; and alkaline the lemon grass extracting solution and the silver salt mixed solution are evenly mixed and react at a set temperature for a set period of time, so that a solution containing the spherical nano-silver particles is obtained. According to the synthesis method for the spherical nano-silver particles and the spherical nano-silver particles, the problems that according to an existing synthesis method for spherical nano-silver particles, pollution can be caused, and the environmental friendliness requirement cannot be met can be solved; and in addition, the synthesis cost is low, the synthesized spherical nano-silver particles are small in diameter and high in antibacterial ability.

Owner:SOUTH CHINA UNIV OF TECH

Fine crusher

InactiveCN110787887AImprove the use effectEvenly distributedFluid-pressure convertersGrain treatmentsProcess engineeringOil pressure

The invention discloses a fine crusher and relates to the technical field of grinding equipment. The fine crusher comprises a slurry box, a primary pressurizing device, a secondary pressurizing device, an oil pressure control device, a collision generation device, a cooling device and a collection device. The primary pressurizing device communicates with secondary pressurizing device through a first pipeline, the slurry box is located on the side, away from the secondary pressurizing device, of the first pipeline, the oil pressure control device is connected with a secondary pressurizing device pipeline, the secondary pressurizing device communicates with an inlet of a collision generation device pipeline through a second pipeline, the collection device is connected with an outlet pipelineof the collision generation device, and the cooling device can lower the temperature in the collision generation device. According to the fine crusher, through pressure increase and collision modes,particulate matter is further smashed, and accordingly the size of the particulate matter is reduced.

Owner:左同明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com