Patents

Literature

583 results about "Carbon matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

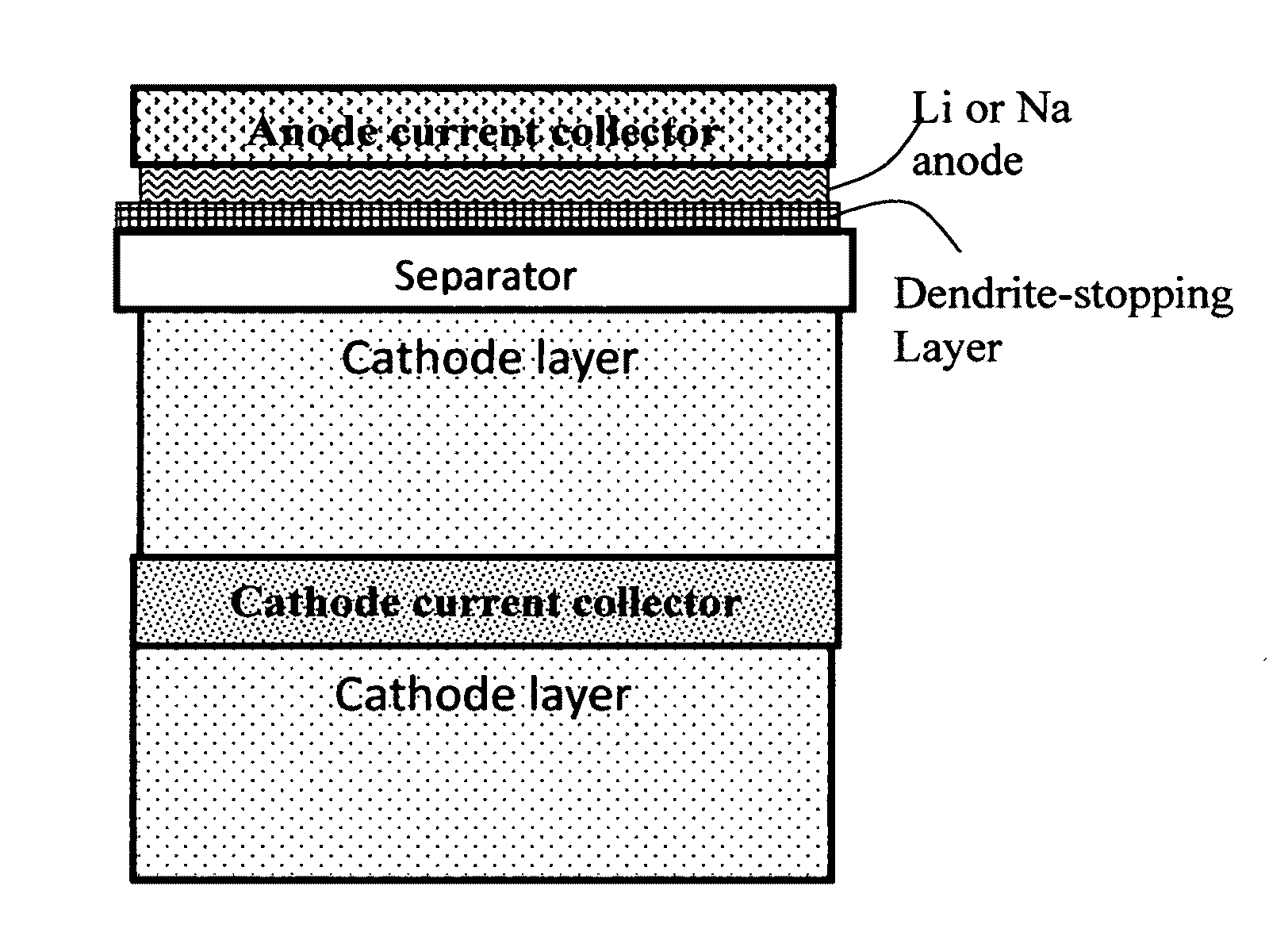

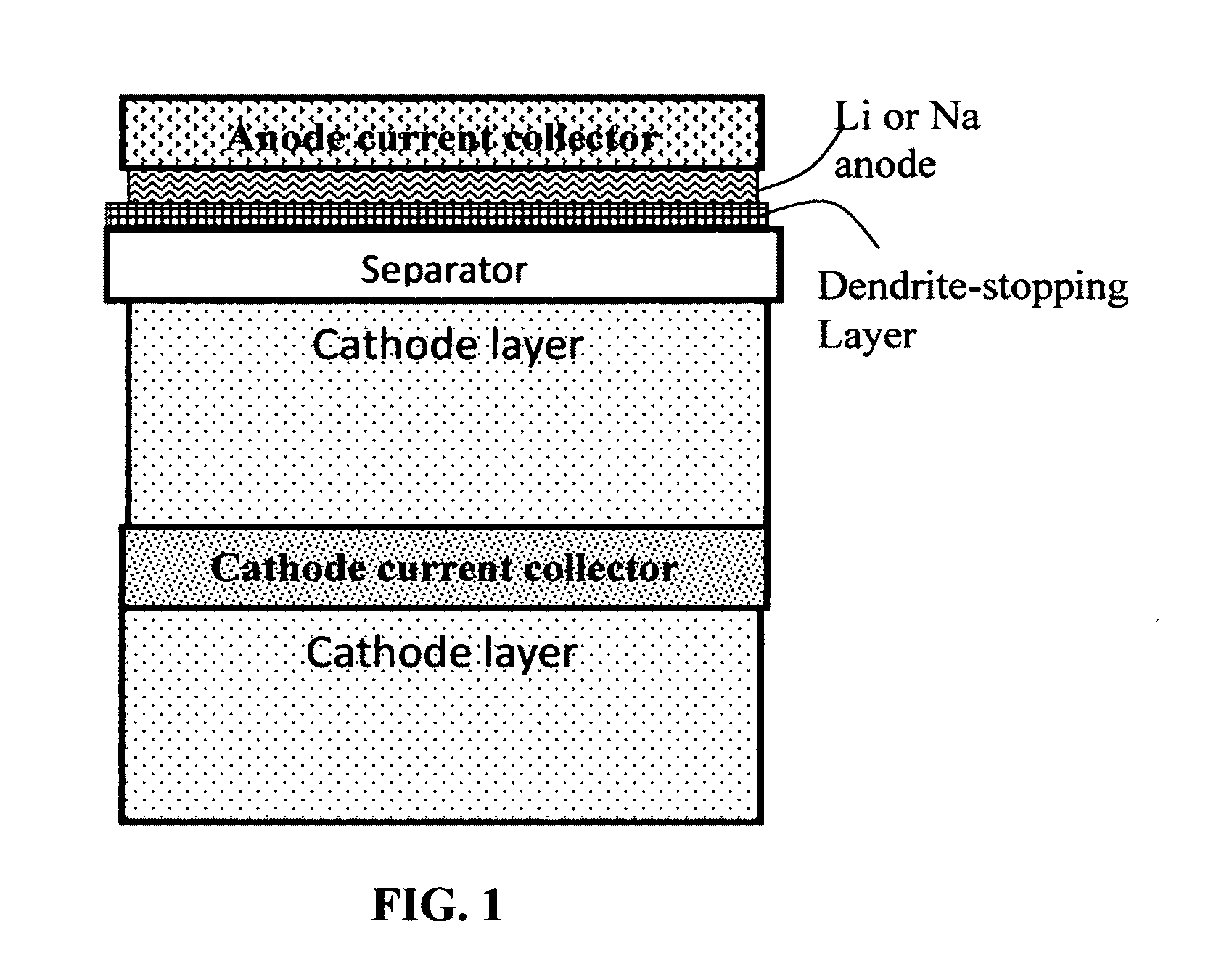

Alkali Metal Secondary Battery Containing a Carbon Matrix- or Carbon Matrix Composite-based Dendrite-Intercepting Layer

ActiveUS20160344035A1Increase energy densityReduce material costsFuel and secondary cellsPositive electrodesDendriteElectrolyte

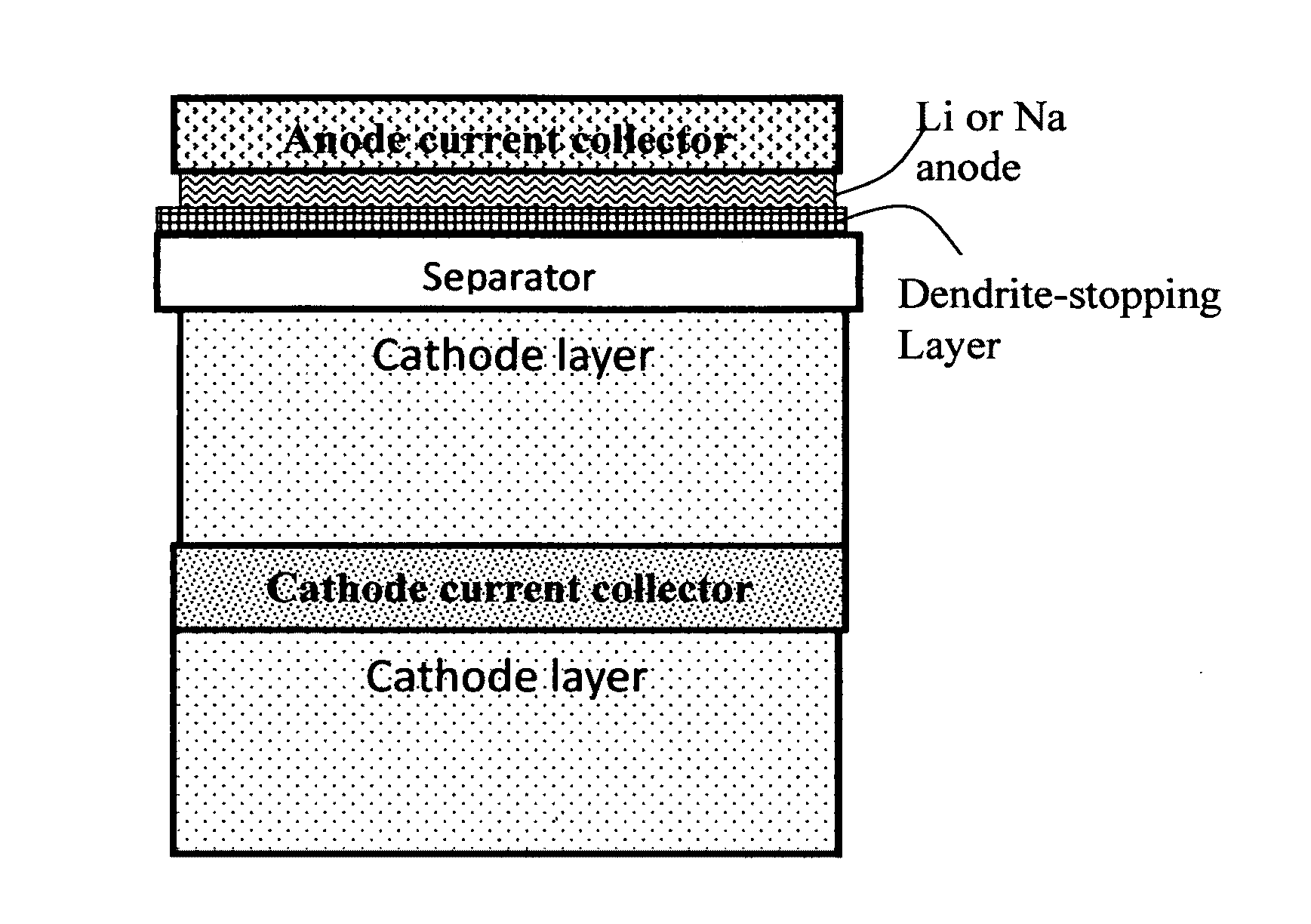

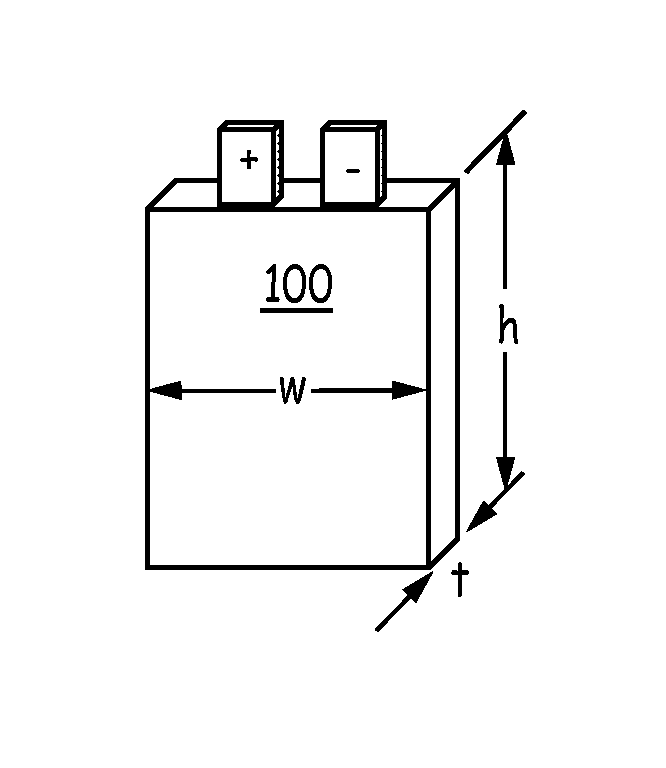

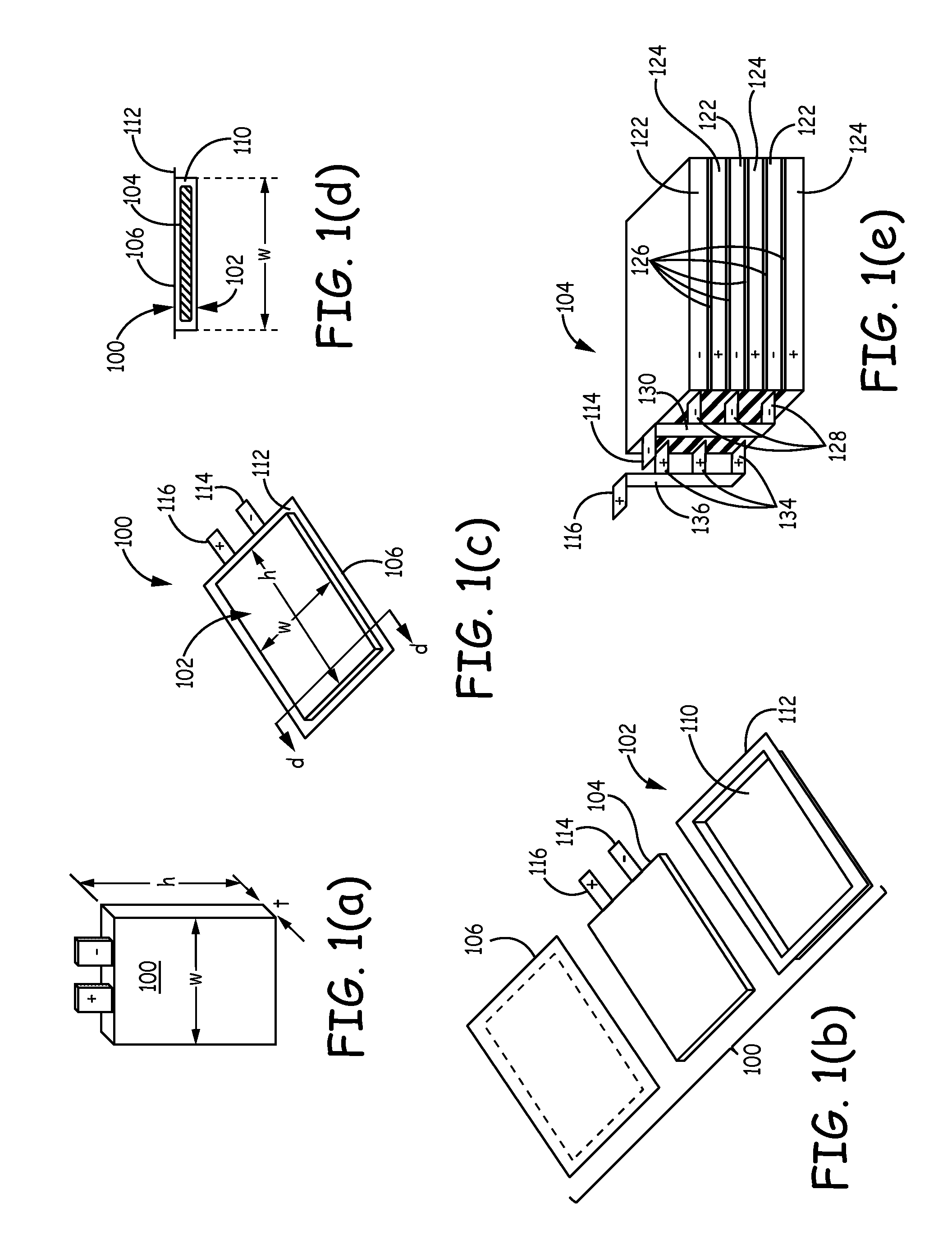

A rechargeable alkali metal battery comprising: (a) an anode comprising an alkali metal layer and a dendrite penetration-resistant layer comprising an amorphous carbon or polymeric carbon matrix, an optional carbon or graphite reinforcement phase dispersed in this matrix, and a lithium- or sodium-containing species that are chemically bonded to the matrix and / or the optional carbon or graphite reinforcement to form an integral layer that prevents dendrite penetration, wherein the lithium- or sodium-containing species is selected from Li2CO3, Li2O, Li2C2O4, LiOH, LiX, ROCO2Li, HCOLi, ROLi, (ROCO2Li)2, (CH2OCO2Li)2, Li2S, LixSOy, Na2CO3, Na2O, Na2C2O4, NaOH, NaiX, ROCO2Na, HCONa, RONa, (ROCO2Na)2, (CH2OCO2Na)2, Na2S, NaxSOy, or a combination thereof, wherein X═F, Cl, I, or Br, R=a hydrocarbon group, x=0-1, y=1-4; (b) a cathode; and (c) a separator and electrolyte component; wherein the dendrite penetration-resistant layer is disposed between the alkali metal layer and the separator.

Owner:GLOBAL GRAPHENE GRP INC

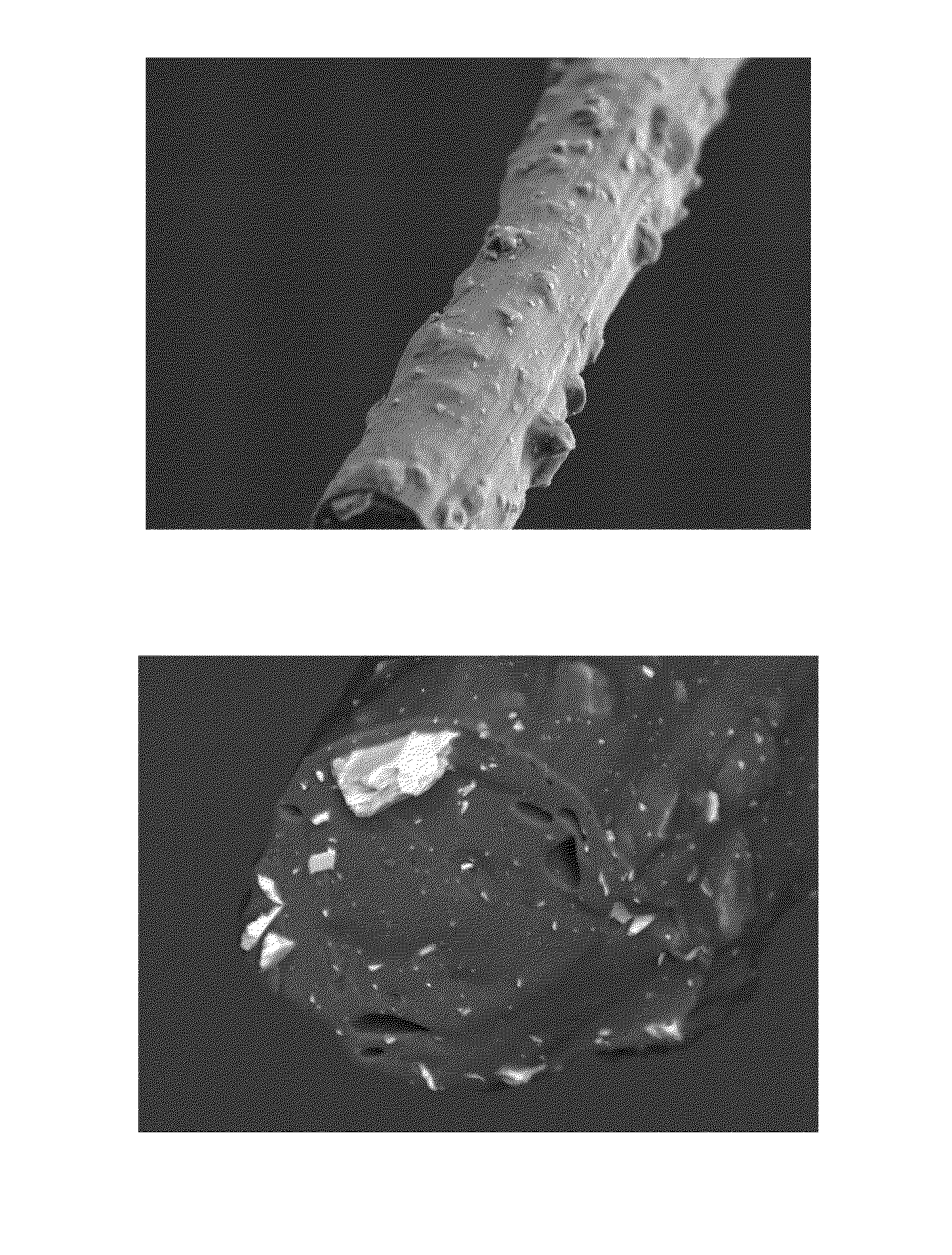

Cnt-infused fibers in carbon-carbon composites

A carbon / carbon (C / C) composite includes a carbon matrix and a non-woven, carbon nanotube (CNT)-infused carbon fiber material. Where woven materials are employed, CNTs are infused on a parent carbon fiber material in a non-woven state. A C / C composite includes a barrier coating on the CNT-infused fiber material. An article is constructed from these (C / C) composites. A method of making a C / C composite includes winding a continuous CNT-infused carbon fiber about a template structure and forming a carbon matrix to provide an initial C / C composite or by dispersing chopped CNT-infused carbon fibers in a carbon matrix precursor to provide a mixture, placing the mixture in a mold, and forming a carbon matrix to provide an initial C / C composite.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

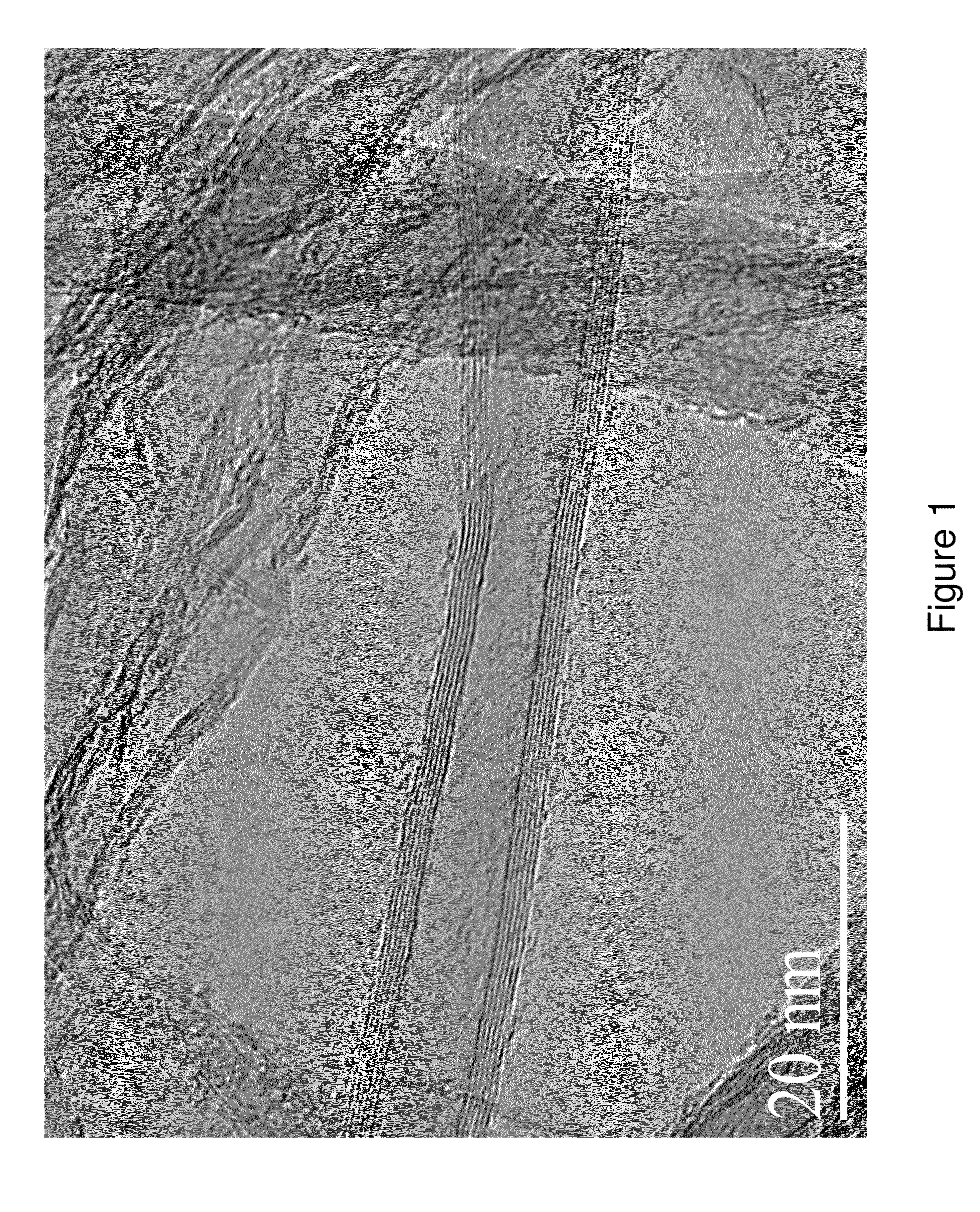

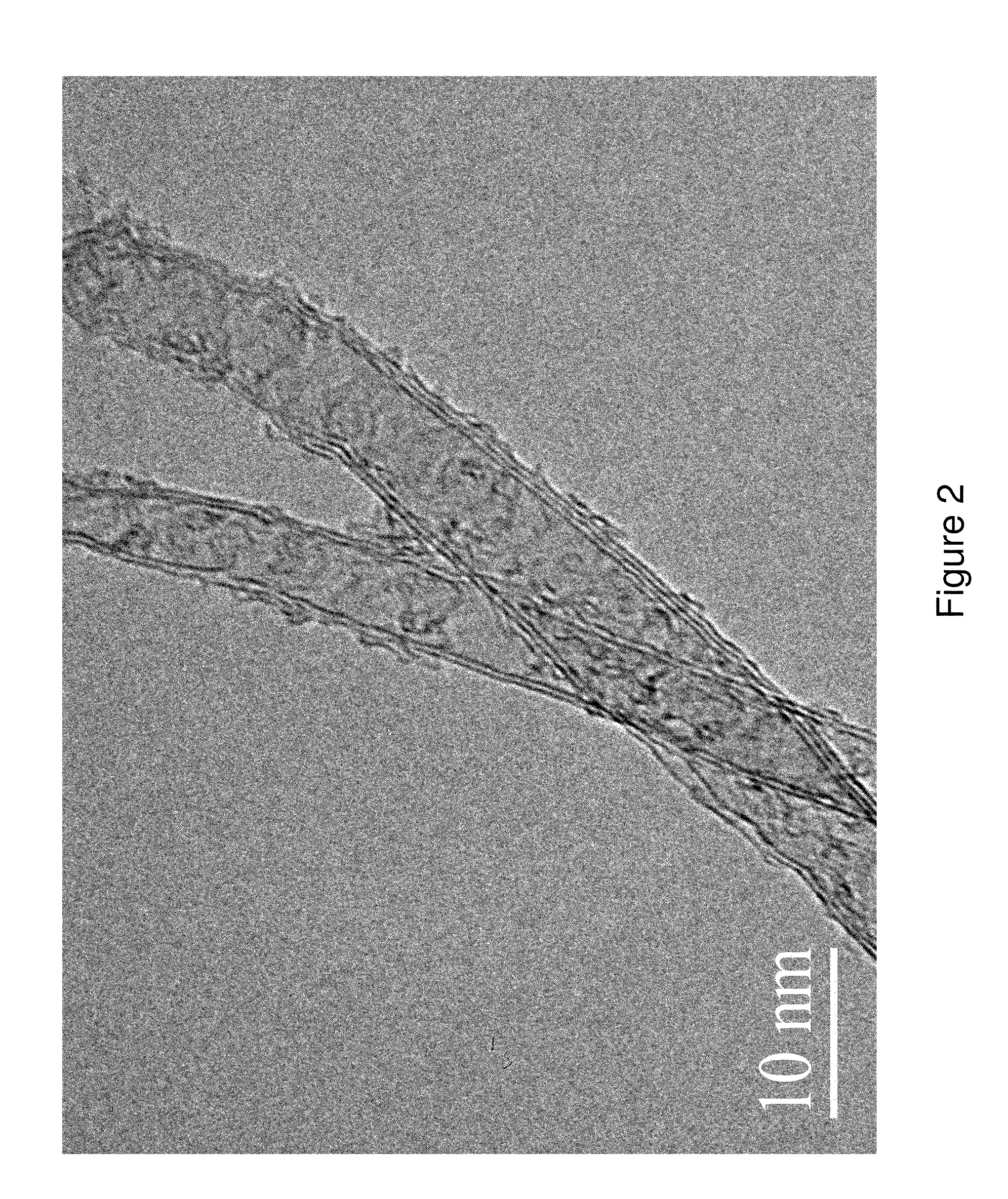

Composite material comprising oriented carbon nanotubes in a carbon matrix and process for preparing same

Fiber spinning of two polymer compositions wherein one of the compositions contains carbon nanotubes produces structures such as fibers, ribbons, yarns and films of carbon nanotubes. The polymers are removed and stabilization of the carbon nanotube material is achieved by post-spinning processes. The advances disclosed herein enable the carbon nanotube composites to be used in actuators, supercapacitors, friction materials and in devices for electrical energy harvesting.

Owner:HONEYWELL INT INC

Composite material comprising oriented carbon nanotubes in a carbon matrix and process for preparing same

Fiber spinning of two polymer compositions wherein one of the compositions contains carbon nanotubes produces structures such as fibers, ribbons, yarns and films of carbon nanotubes. The polymers are removed and stabilization of the carbon nanotube material is achieved by post-spinning processes. The advances disclosed herein enable the carbon nanotube composites to be used in actuators, supercapacitors, friction materials and in devices for electrical energy harvesting.

Owner:HONEYWELL INT INC

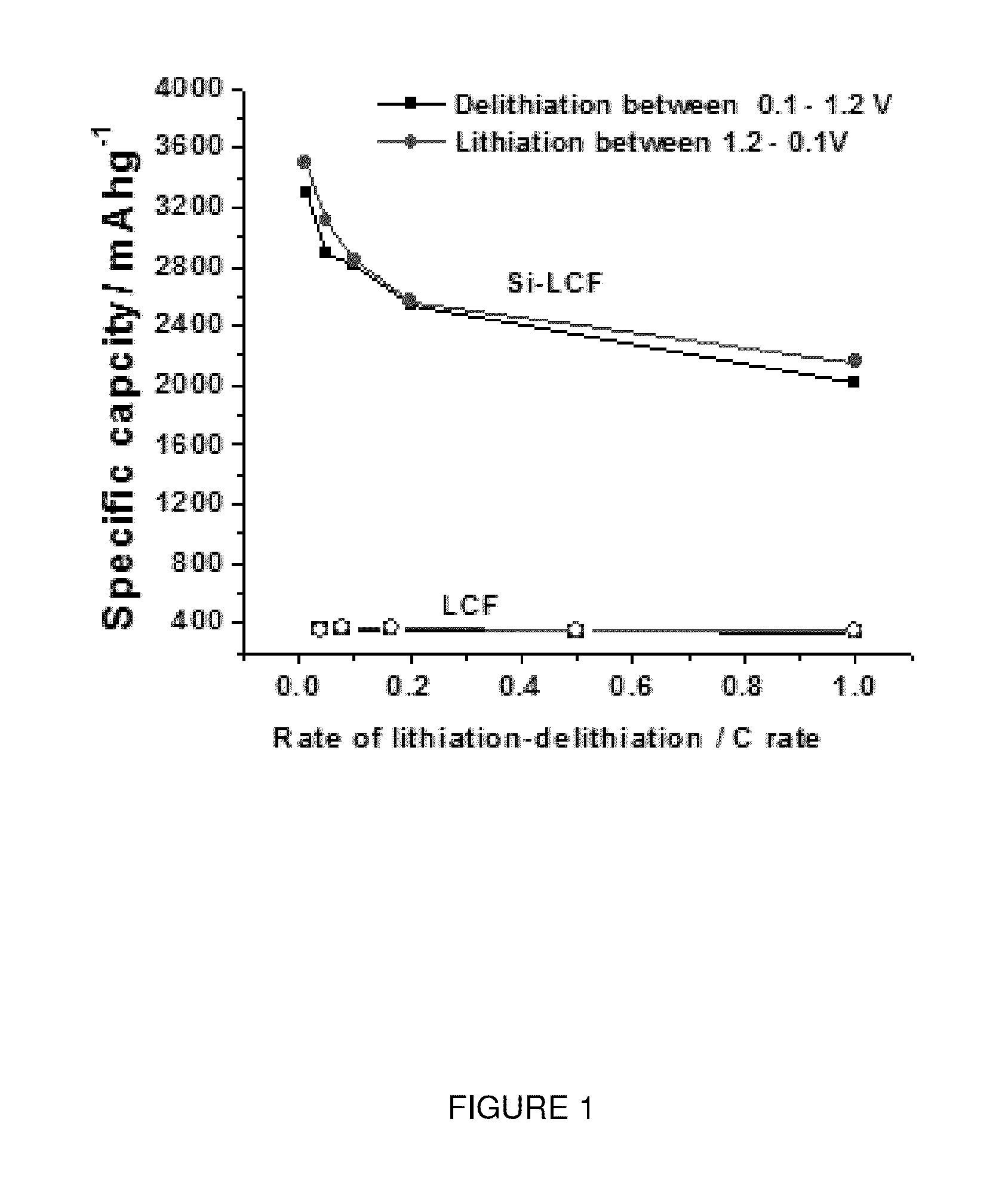

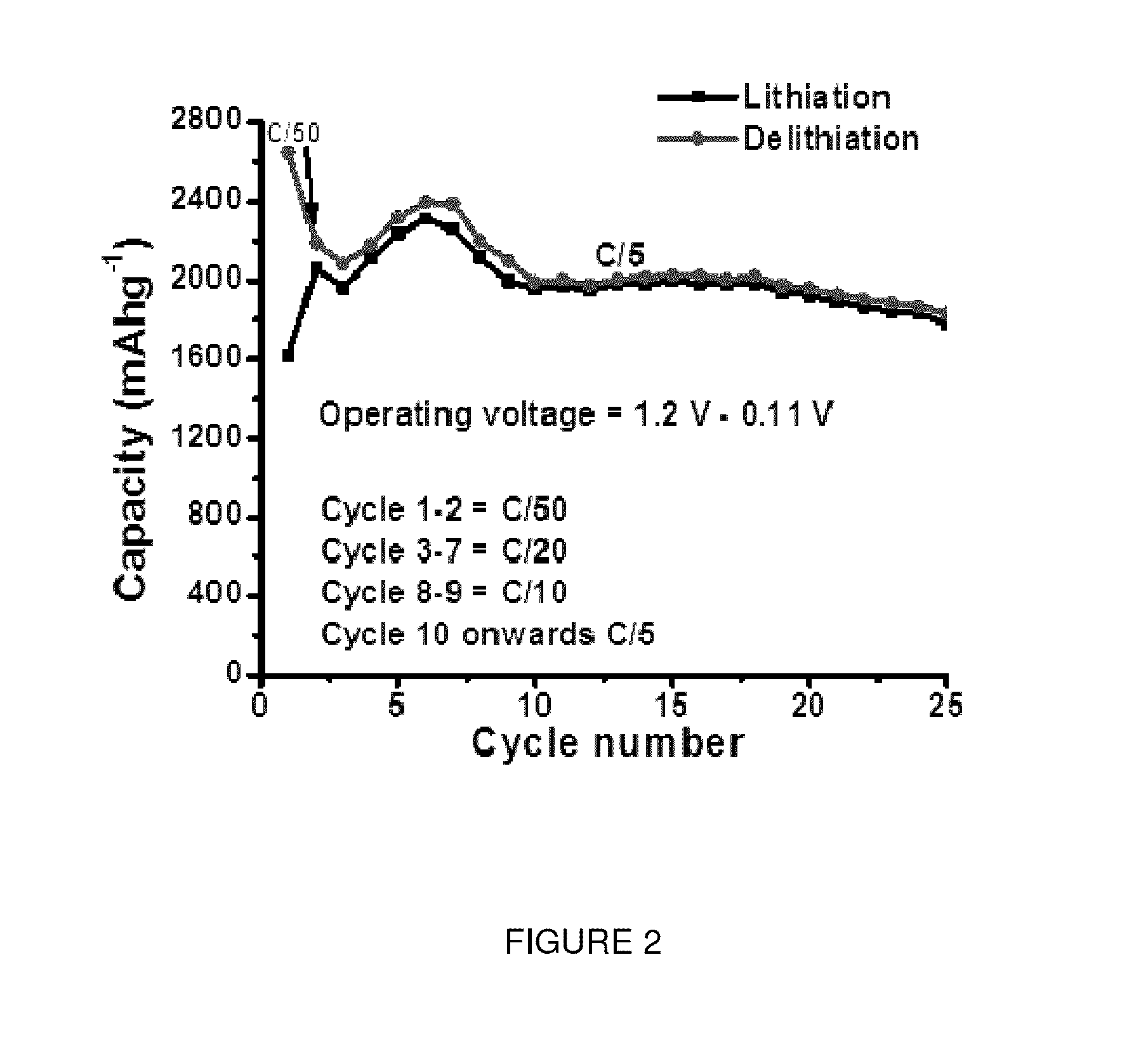

Silicon-based active materials for lithium ion batteries and synthesis with solution processing

Silicon based anode active materials are described for use in lithium ion batteries. The silicon based materials are generally composites of nanoscale elemental silicon with stabilizing components that can comprise, for example, silicon oxide-carbon matrix material, inert metal coatings or combinations thereof. High surface area morphology can further contribute to the material stability when cycled in a lithium based battery. In general, the material synthesis involves a significant solution based processing step that can be designed to yield desired material properties as well as providing convenient and scalable processing.

Owner:IONBLOX INC

Hard carbon cathode material for lithium ion power and energy storage battery and preparation method of hard carbon cathode material

ActiveCN103094528ALow costImprove cycle performanceCell electrodesCarbon preparation/purificationElectrical batteryEnergy storage

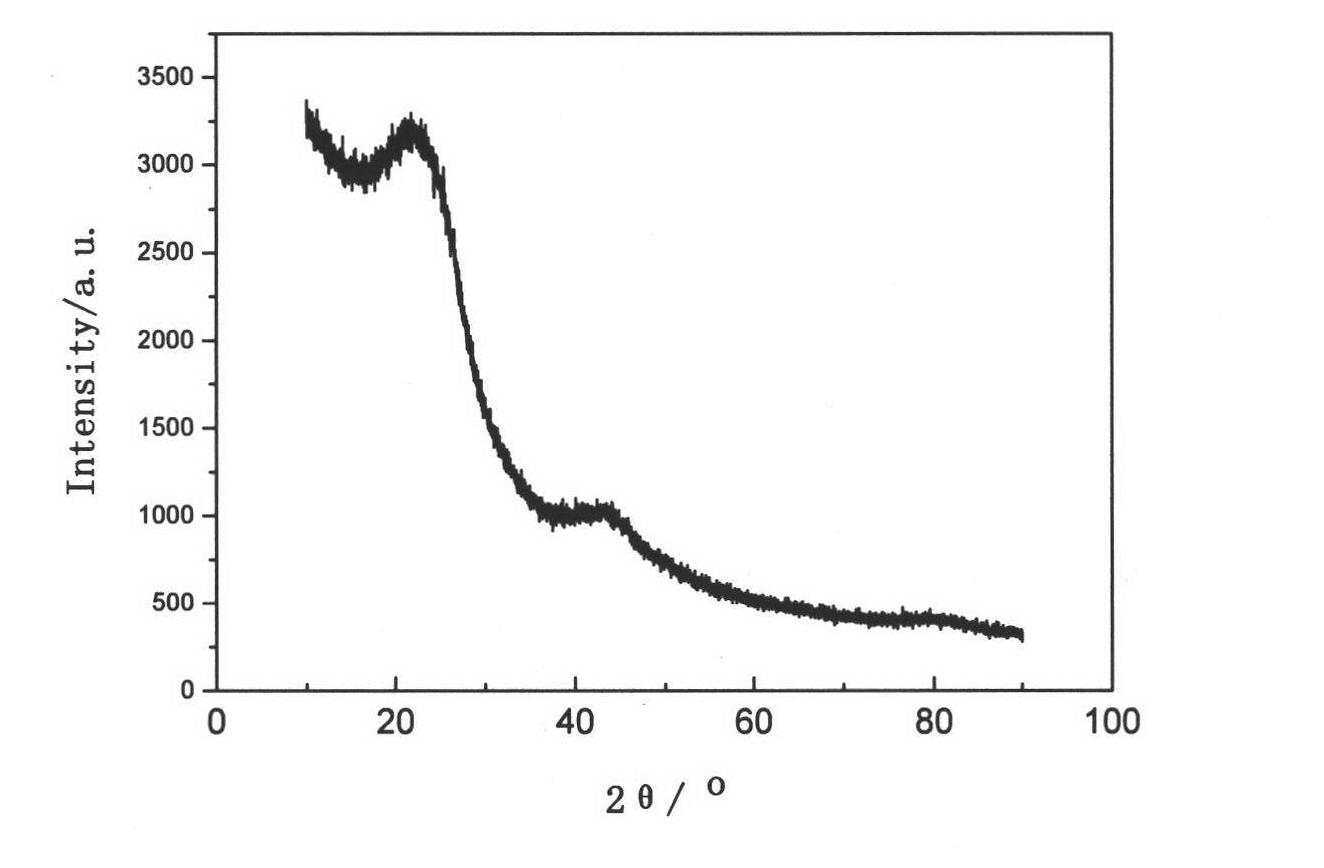

The invention relates to a preparation method of a hard carbon cathode material. The preparation method comprises the step of preparing the hard carbon cathode material by using thermosetting resin or pyrolysis products of a mixture of thermosetting resin and thermoplastic resin as a hard carbon matrix and adopting a carbon material as a coating. In the preparation process of the hard carbon cathode material, a curing agent and a doping matter can be added. The hard carbon cathode material prepared by adopting the preparation method has the characteristics of high capacity, high first-time coulombic efficiency, excellent rate performance, low cost and the like, and is suitable for industrialized production.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

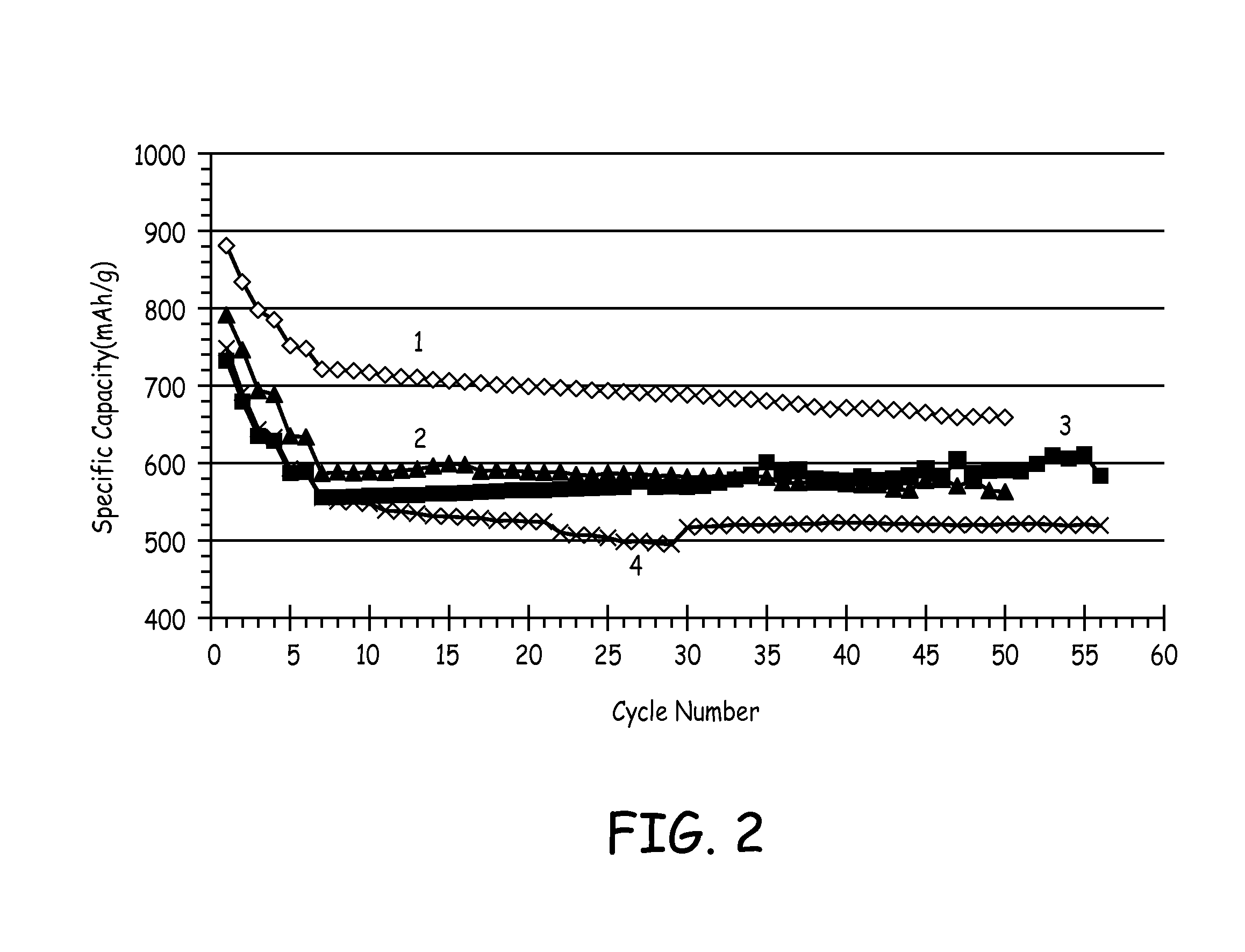

Composite hard carbon cathode material of lithium ion battery and preparation method thereof

ActiveCN101887966AIncrease capacityImprove the first Coulombic efficiencyCell electrodesSodium-ion batteryCharge discharge

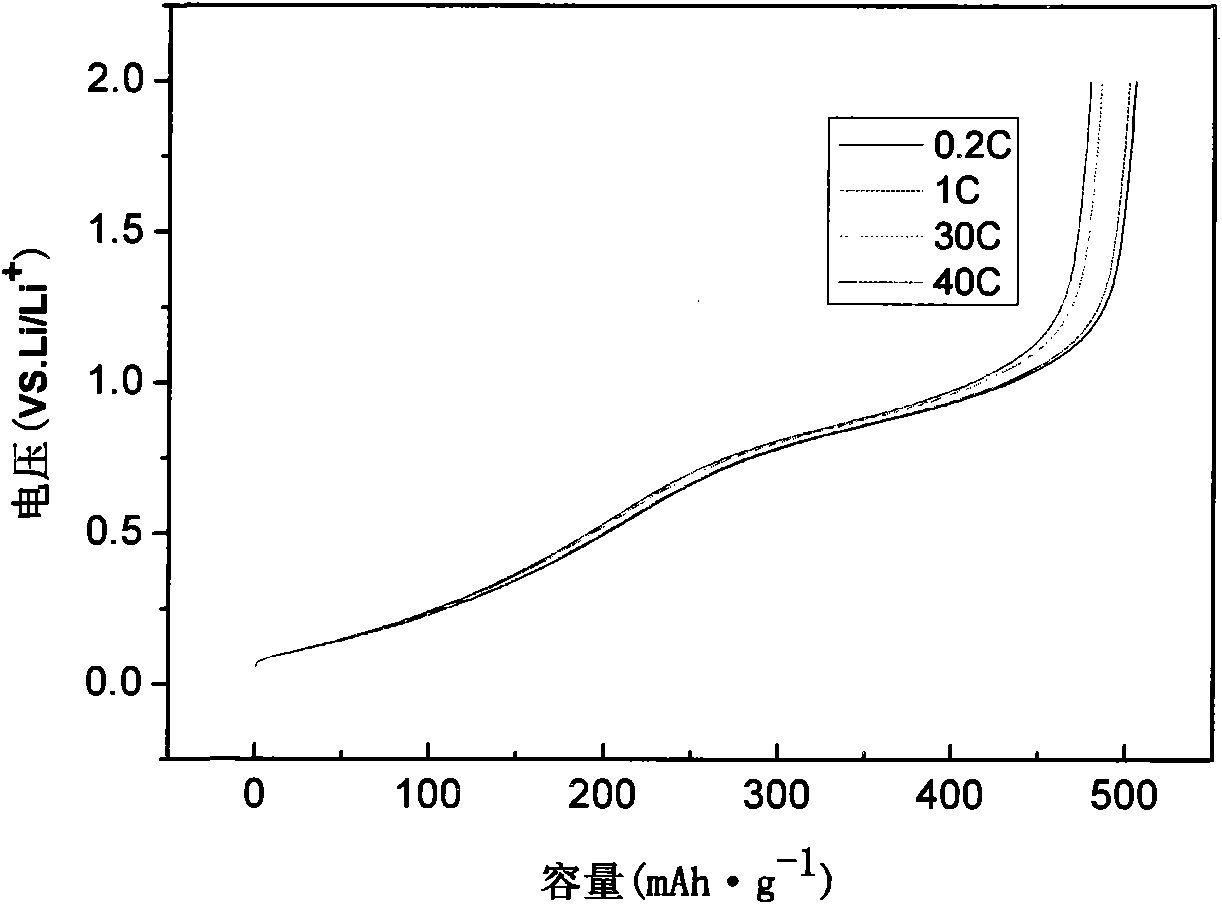

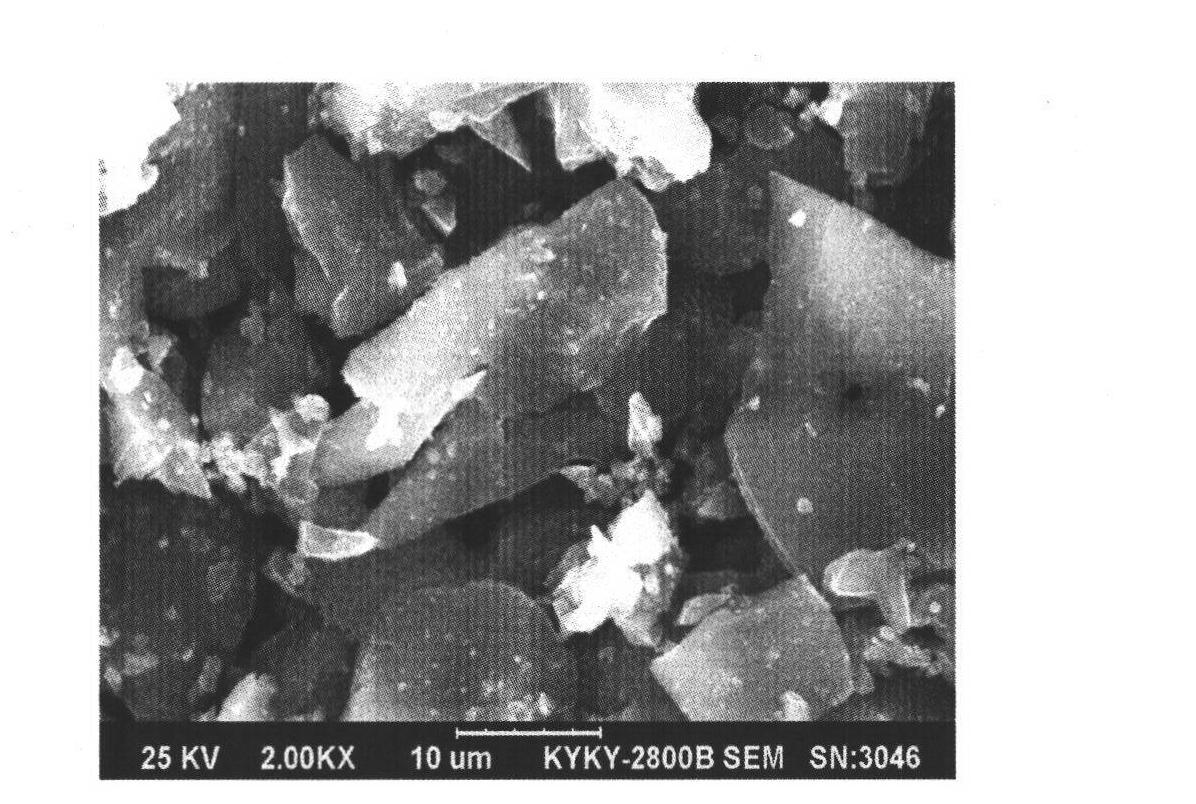

The invention discloses a composite hard carbon cathode material of a lithium ion battery and a preparation method thereof, aiming at improving the first coulombic efficiency. In the composite hard carbon cathode material, a coating object is coated outside a hard carbon matrix, a precursor of the hard carbon matrix comprises a thermoplastic resin which forms the hard carbon matrix by pyrolysis, and a precursor of the coating object is an organic matter. The preparation method comprises the steps of curing, pyrolyzing, pulverizing and coating. Compared with the prior art, a curing agent and adopant are added to the resin for curing, the cured mixture is taken as a carbon source, and then the carbon source is pyrolyzed and coated to finally obtain the composite hard carbon cathode material; and the first reversible capacity of the obtained composite hard carbon cathode material is more than 455.2mAh / g and the first coulombic efficiency thereof is more than 79.4% in the case of 0.2C, thus the obtained composite hard carbon cathode material has high capacity and high first coulombic efficiency, meets the requirement of the lithium ion battery with high capacity, high multiplying power and excellent high and low temperature cycle performance on the charge-discharge performances of the cathode material, has low production cost and is suitable for industrial production.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

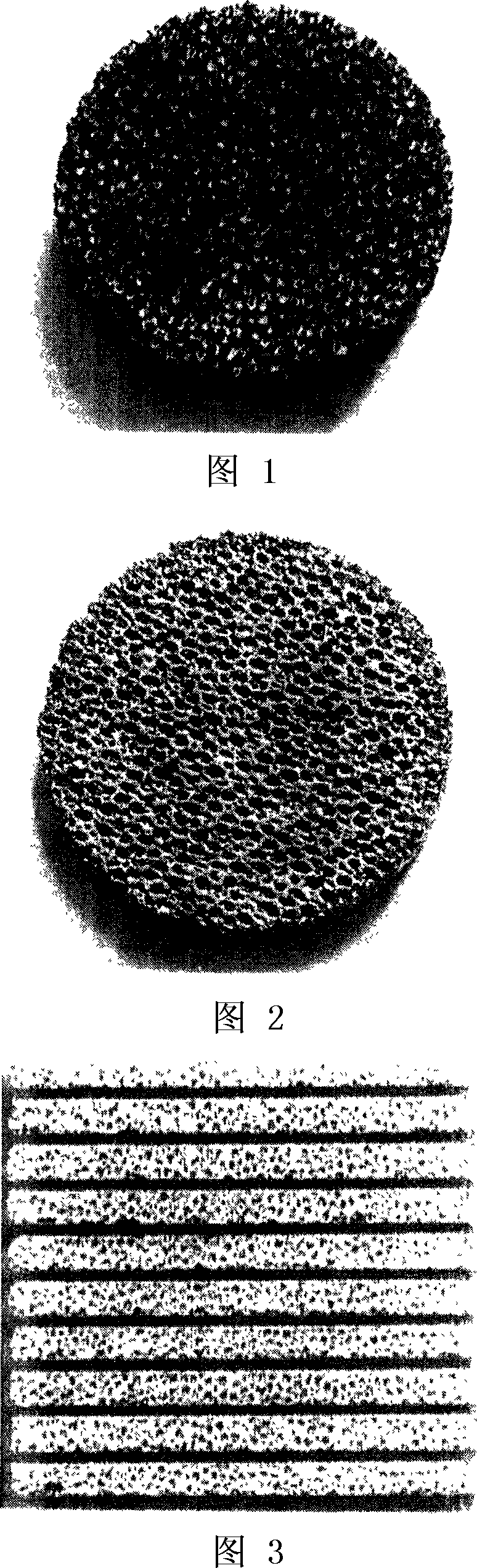

Hard carbon material for power and energy-storage battery and preparation method thereof

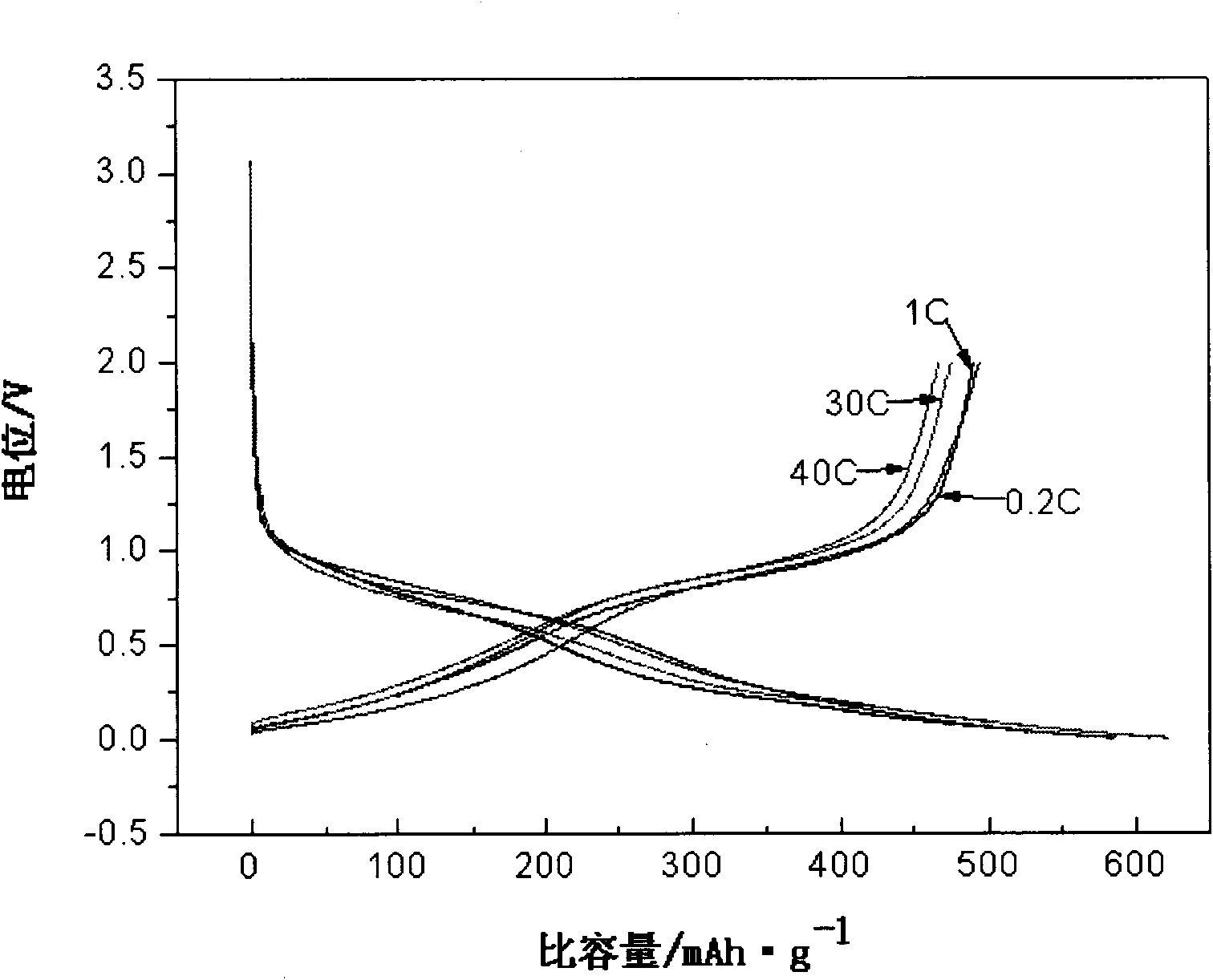

ActiveCN101916845AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesHigh rateCharge discharge

The invention discloses a hard carbon material for a power and energy-storage battery and a preparation method thereof, and aims to solve the technical problem of improving high-rate charge-discharge performance of lithium-ion batteries. The material is provided with a hard carbon matrix, and a coating is coated outside the hard carbon matrix; and the surface of the hard carbon matrix has a honeycomb opening structure. The preparation method comprises the following steps of: dipping, washing, dewatering and drying, presintering at low temperature, crushing, pyrolyzing, crushing and coating. Compared with the prior art, the hard carbon material has the reversible specific capacity of more than 450mAh / g, the first cycle columbic efficiency of over 81 percent, 0.2C 300-cycles capacity-retaining rate of over 97 percent at the temperature of 60 DEG C, and the 0.2C 300-cycles capacity-retaining rate of over 88 percent at the temperature of -30 DEG C, has the advantages of excellent lithium intercalation and deintercalation capability and cycling stability, and simple preparation process, and is applicable to the lithium ion battery cathode materials for lithium ion power batteries, various portable devices and electric tools.

Owner:深圳贝特瑞钠电新材料科技有限公司

Lithium-alloying-material/carbon composite

ActiveUS8361659B2Avoid damageSecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon compositesLithium

An electrode material having carbon and lithium-alloying-material is provided. The carbon is in the form of a porous matrix having nanoporosity and the lithium-alloying-material is sorbed into the nanoporosity of the carbon matrix. The carbon matrix can have a volume of nanoporosity between 10 and 99%. In addition, the lithium-alloying-material can occupy between 5 to 99% of the nanoporosity. A portion of the carbon structure that is only partially filled with the lithium-alloying-material remains vacant providing room for volume expansion on alloying with lithium and allowing electrolyte egress. In some instances, the nanoporosity has nanopores and nanochannels with an average diameter between 1 nanometer and 999 nanometers. The lithium-alloying-material is sorbed into the nanoporosity using liquid transport or other mechanisms providing a material having intimate contact between the electronically conductive carbon structure and the electroactive lithium-alloying-material.

Owner:TOYOTA MOTOR CO LTD

High capacity monolithic composite si/carbon fiber electrode architectures synthesized from low cost materials and process technologies

A composite Si-carbon fiber comprising a carbon matrix material with 1-90 wt % silicon embedded therein. The composite carbon fibers are incorporated into electrodes for batteries. The battery can be a lithium ion battery. A method of making an electrode incorporating composite Si-carbon fibers is also disclosed.

Owner:UT BATTELLE LLC

Supported oxidative dehydrogenation catalyst

The present invention provides a process for the manufacture of an efficient and robust catalyst for the oxidative dehydrogenation of paraffins to olefins, preferably lower C2-4 paraffins. The present invention provides a process for the preparation of an oxidative dehydrogenation catalyst of C2-4 paraffins to olefins comprising comminuting: from 10 to 99 weight % of a mixed oxide catalyst of the formula VxMoyNbzTemMenOp, wherein Me is a metal selected from the group consisting of Ta, Ti, W, Hf, Zr, Sb and mixtures thereof; with from 90 to 1 weight % of an inert matrix selected from oxides of titanium, zirconia, aluminum, magnesium, yttria, lantana, silica and their mixed compositions or a carbon matrix to produce particles having a size from 1 to 100 microns and forming the resulting particles into pellets having a size from 0.1 to 2 mm.

Owner:NOVA CHEM (INT) SA

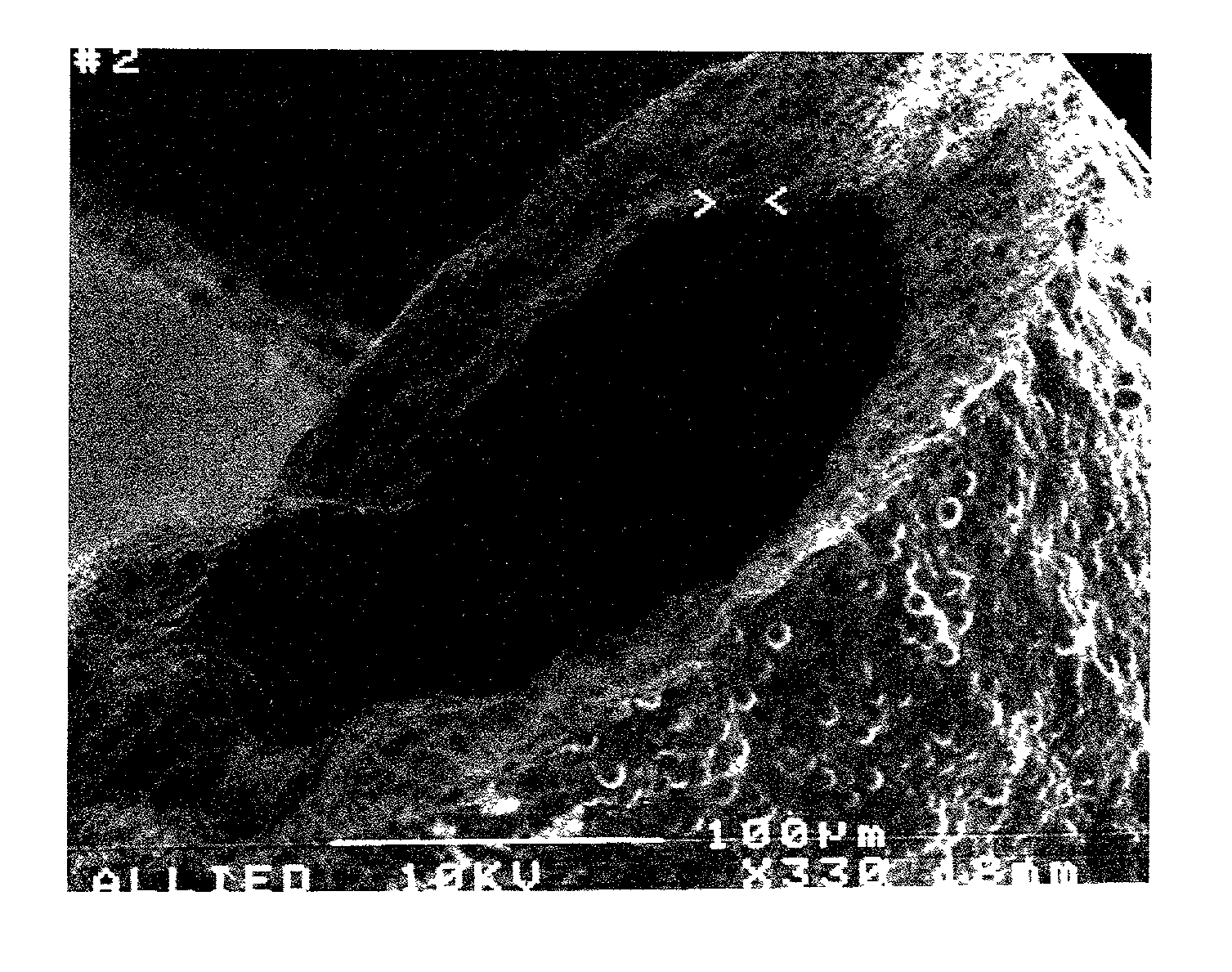

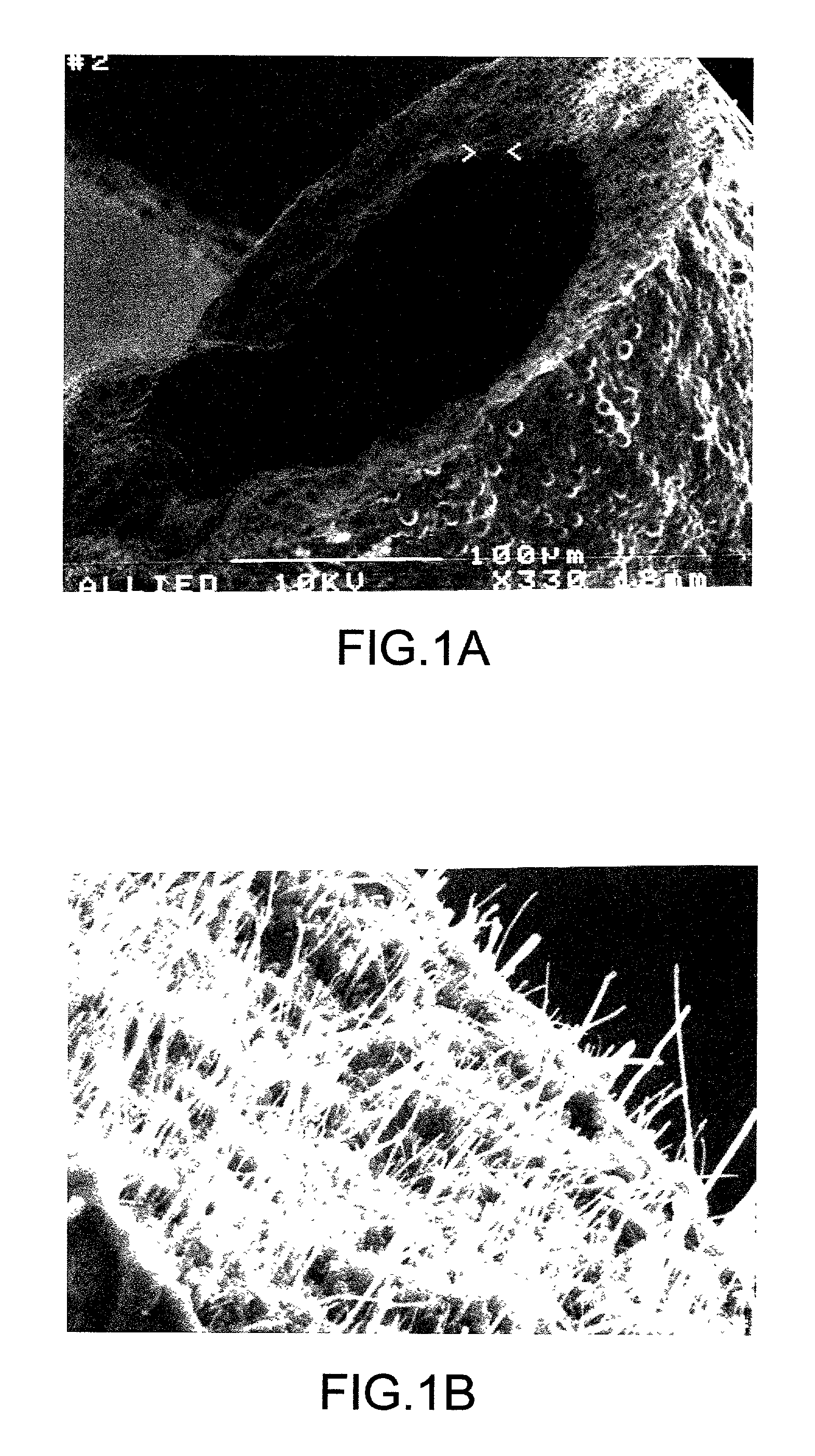

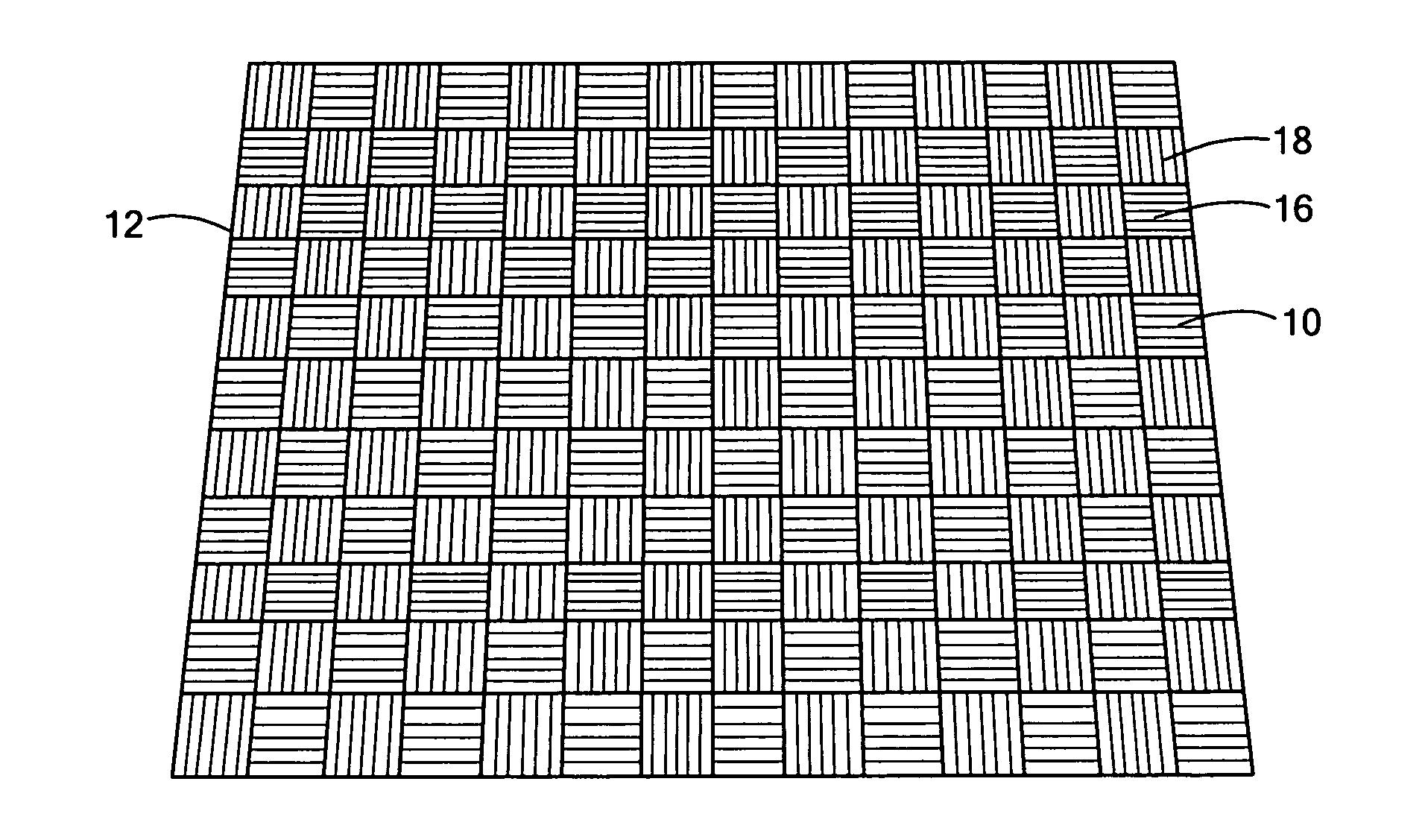

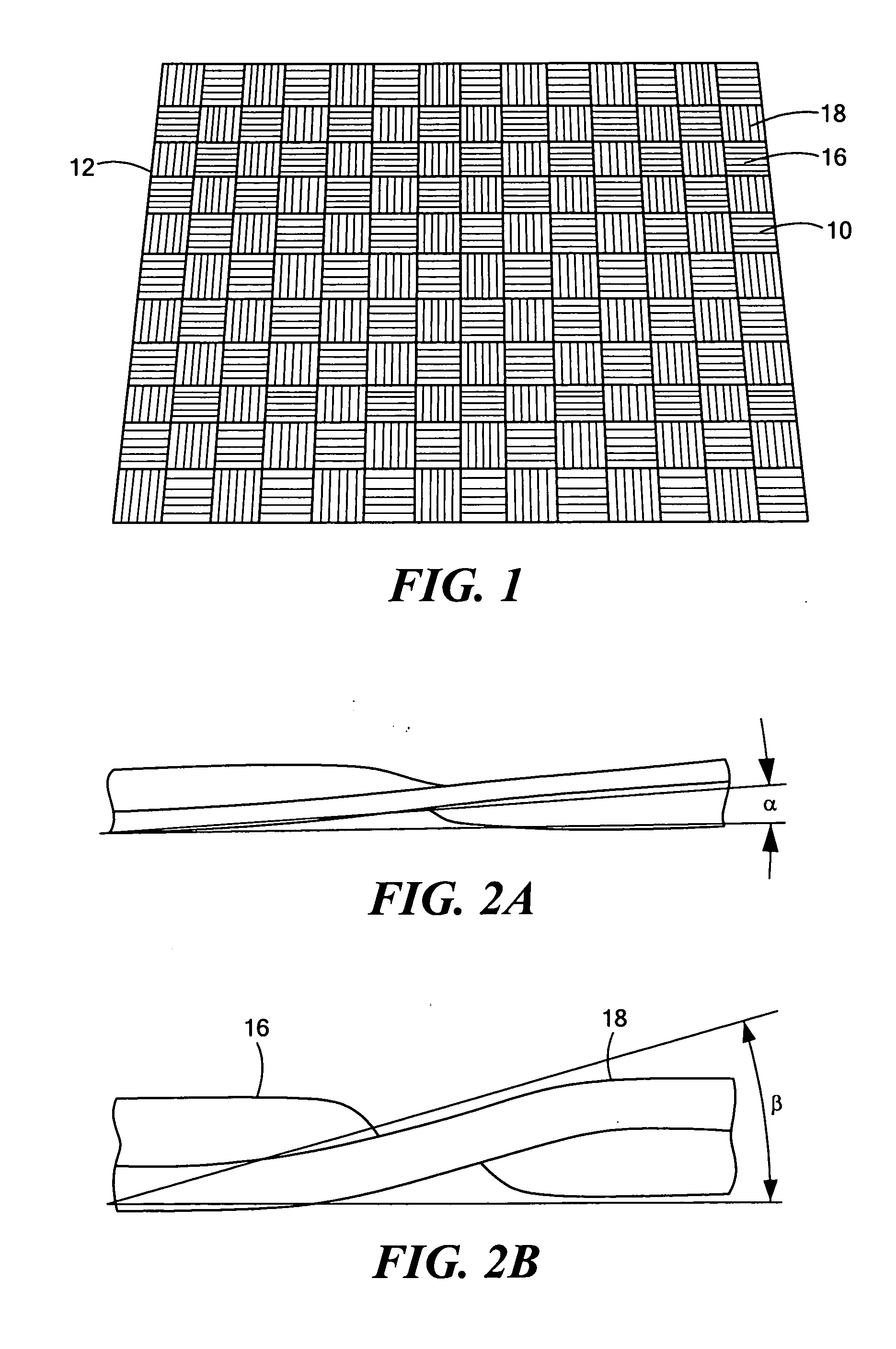

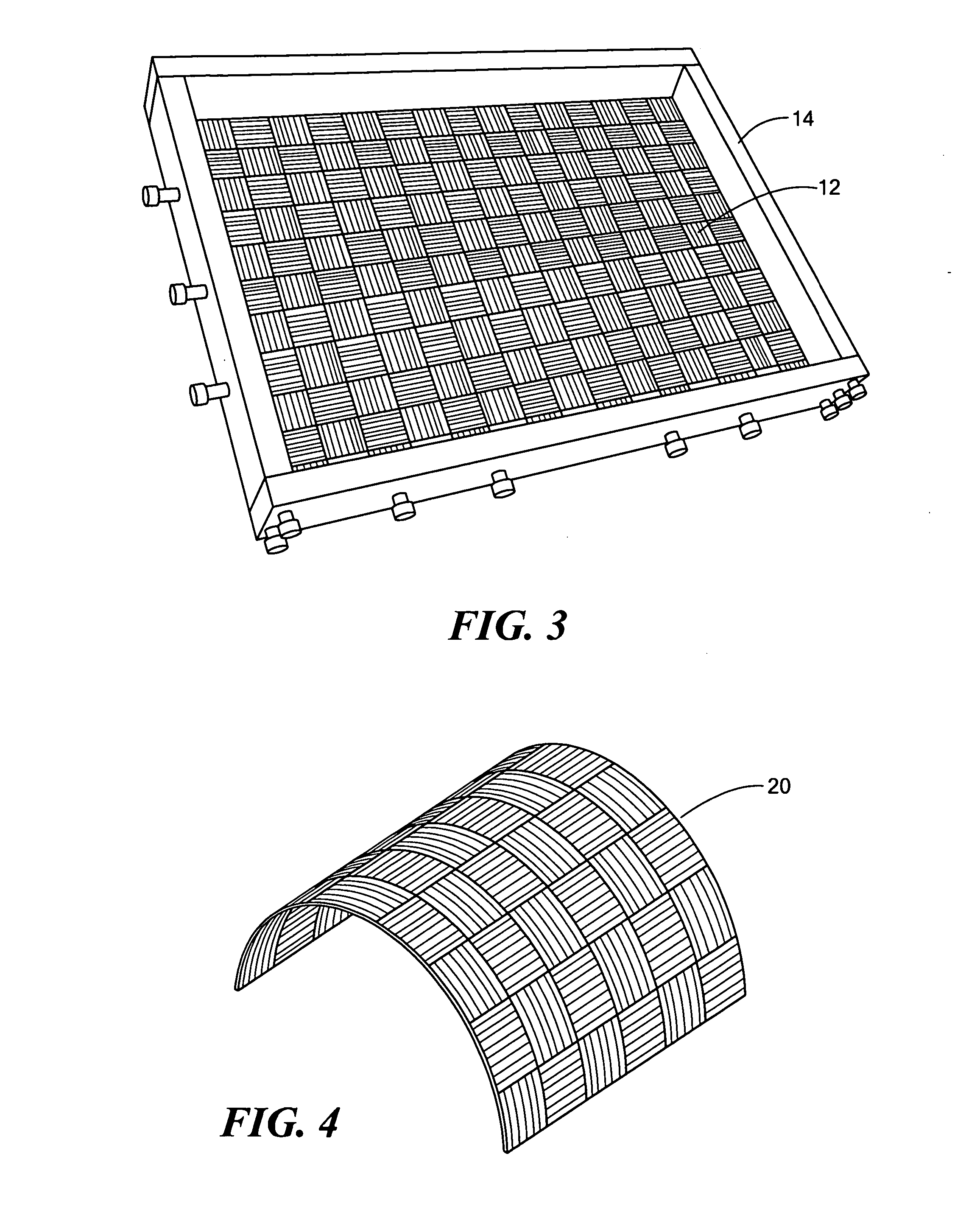

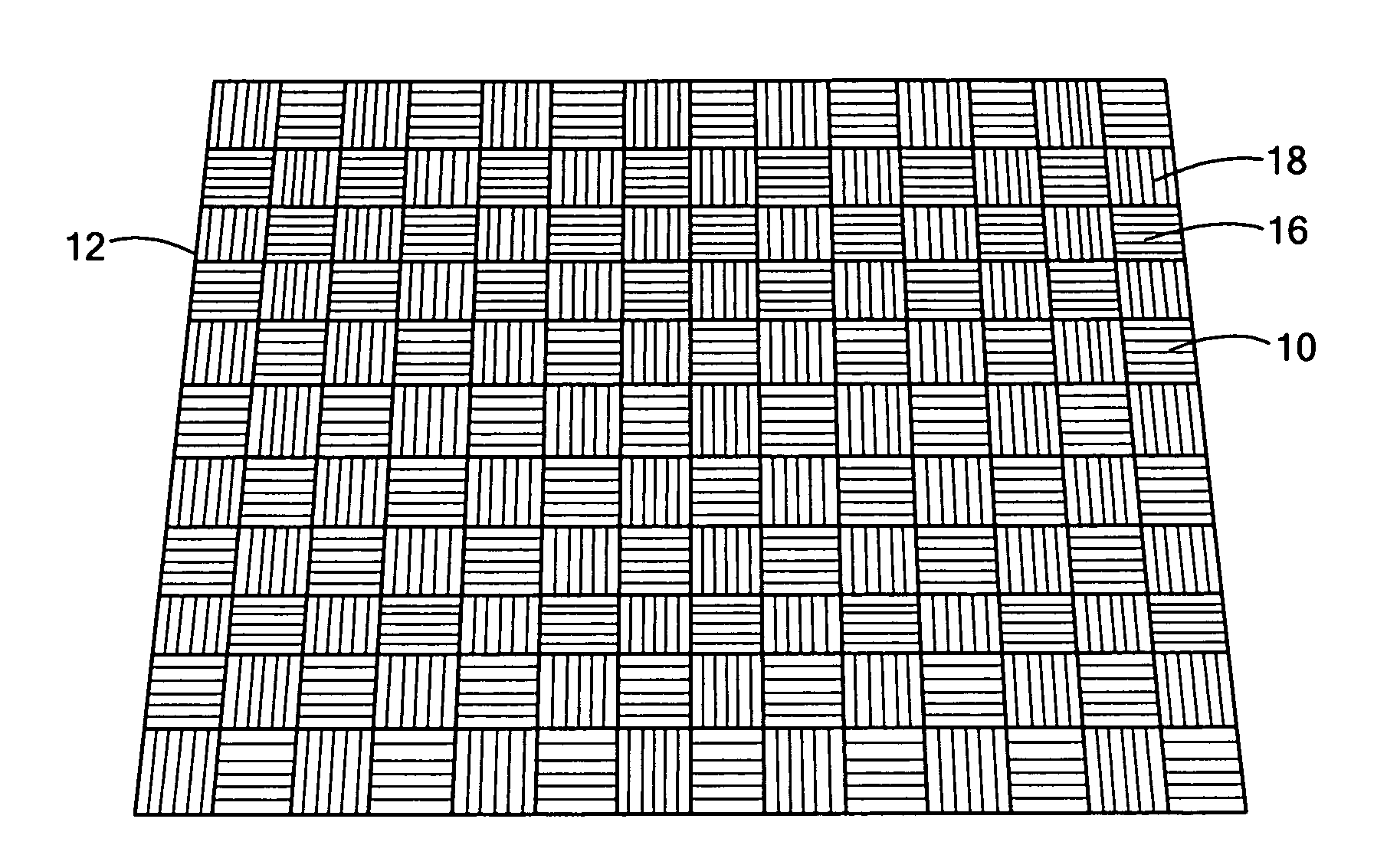

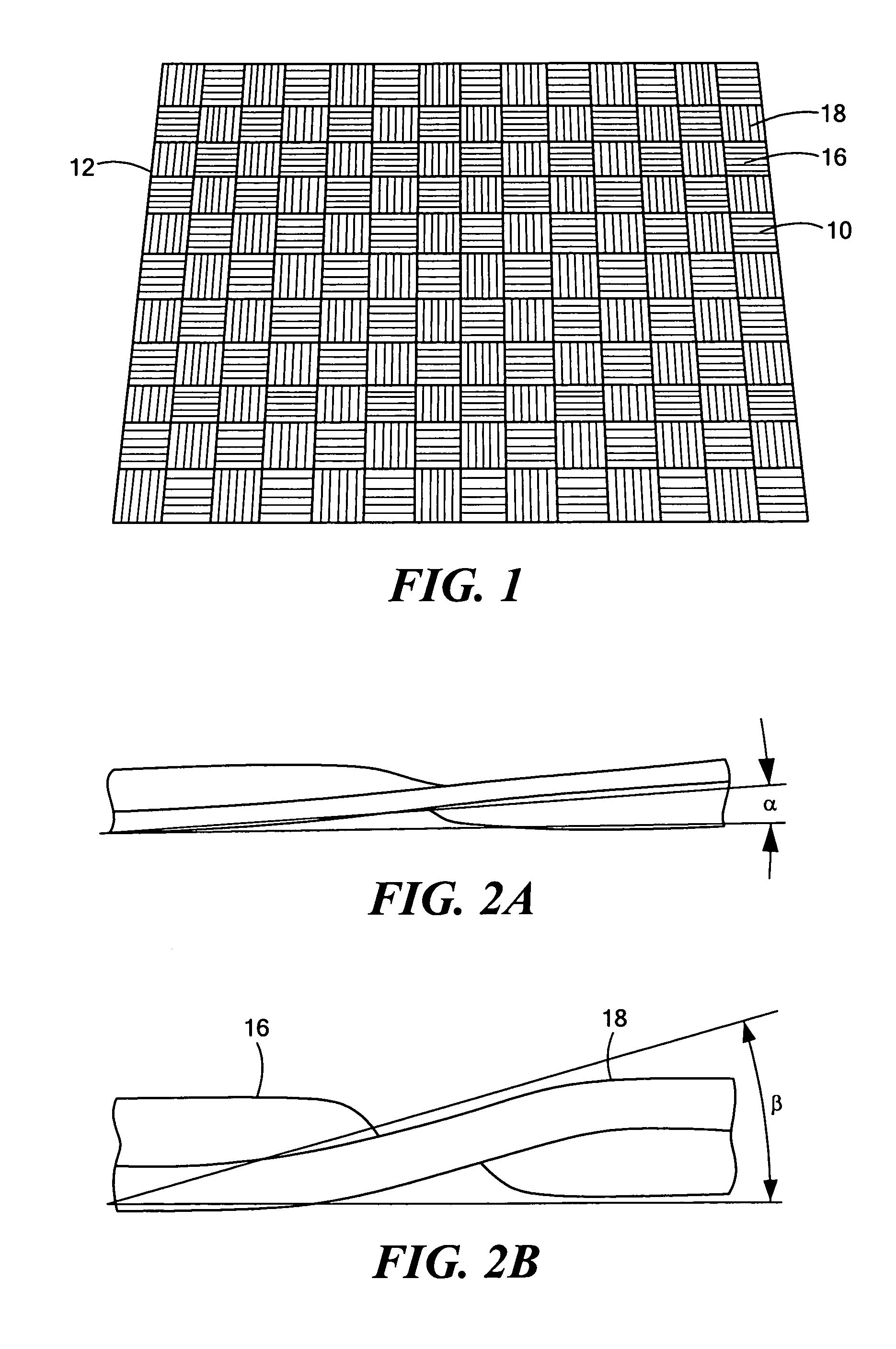

Impact resistant, thin ply composite structures and method of manufacturing same

InactiveUS20070066171A1Improve impact resistanceStructure moreMaterial nanotechnologySynthetic resin layered productsCarbon fibersReinforced carbon–carbon

A reinforced carbon-carbon (RCC) composite material has improved impact resistance. The RCC composite material is formed from a fiber reinforcement of layers or plies of thin ply carbon fiber fabric impregnated with a carbon matrix. Carbon nanotube reinforcement in the matrix further improves impact resistance. The stacking arrangement of the plies of the thin ply fabric also further improves impact resistance.

Owner:KAZAK COMPOSITES

Straw carbon matrix biological organic fertilizer and preparing method

InactiveCN106495869AQuality situation improvedRegulate the micro-ecological environmentExcrement fertilisersOrganic fertiliser preparationSodium BentoniteEutrophication

The invention discloses a straw carbon matrix biological organic fertilizer and a preparing method. China is the largest fertilizer importing country and the largest nitrogenous fertilizer producing country in the world, and has 7% of arable land on earth, but usage amount of fertilizers and pesticides is 35% of global total amount, and yearly needed amount of fertilizers are 150,000,000 tons. The utilization ratio of fertilizers in China is only 35%-45%, the balance is fixed or leached by soil, causing environmental problems of water body pollution, lake eutrophication and the like. The straw carbon matrix biological organic fertilizer is prepared from, by weight, 60-70 parts of a compost raw material, 25-30 parts of straw carbon of a microbial agent with an adsorption function, 2-5 parts of zeolite powder, 2-5 parts of bentonite and 0.5-1 part of a binder. The straw carbon matrix biological organic fertilizer is applied to the field of bio-fertilizers and green planting.

Owner:黑龙江省农业科学院农村能源研究所

Mesoporous carbon material, fabrication method thereof and supercapacitor

ActiveUS20110134585A1Improve conductivityNon-metal conductorsMaterial nanotechnologyCarbon nanotubeSupercapacitor

A mesoporous carbon material, a fabrication method thereof and a supercapacitor containing the mesoporous carbon material are provided. The mesoporous carbon material includes a plurality of carbon nanotubes (CNTs) and / or metal particles and / or metal oxide particles, and a carbon matrix. The mesoporous carbon material has a plurality of mesopores formed by the carbon matrix and the carbon nanotubes and / or the metal particles and / or the metal oxide particles. The plurality of carbon nanotubes, and / or the metal particles and / or the metal oxide particles are formed substantially adjacent to the plurality of mesopores.

Owner:DELTA ELECTRONICS INC

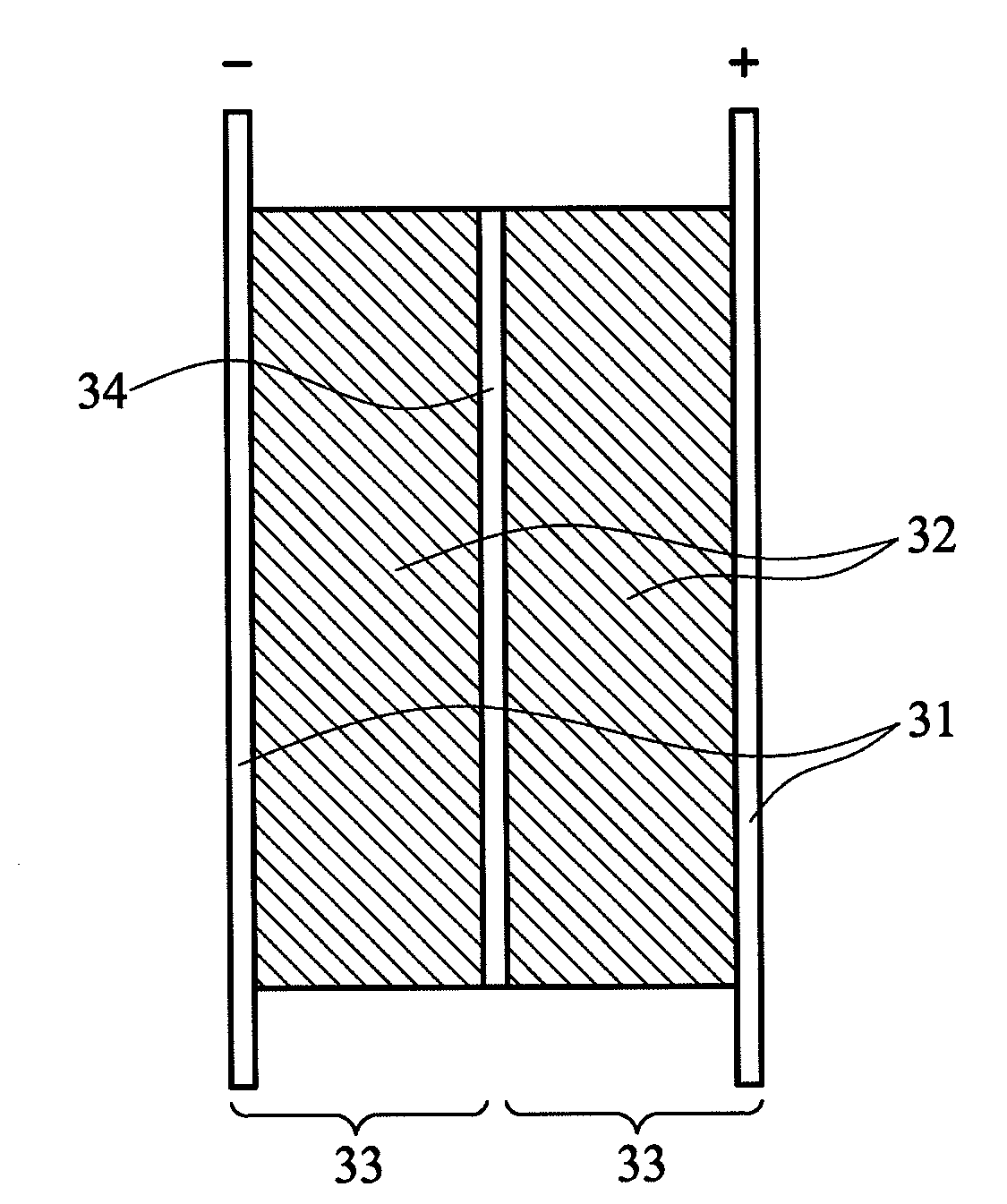

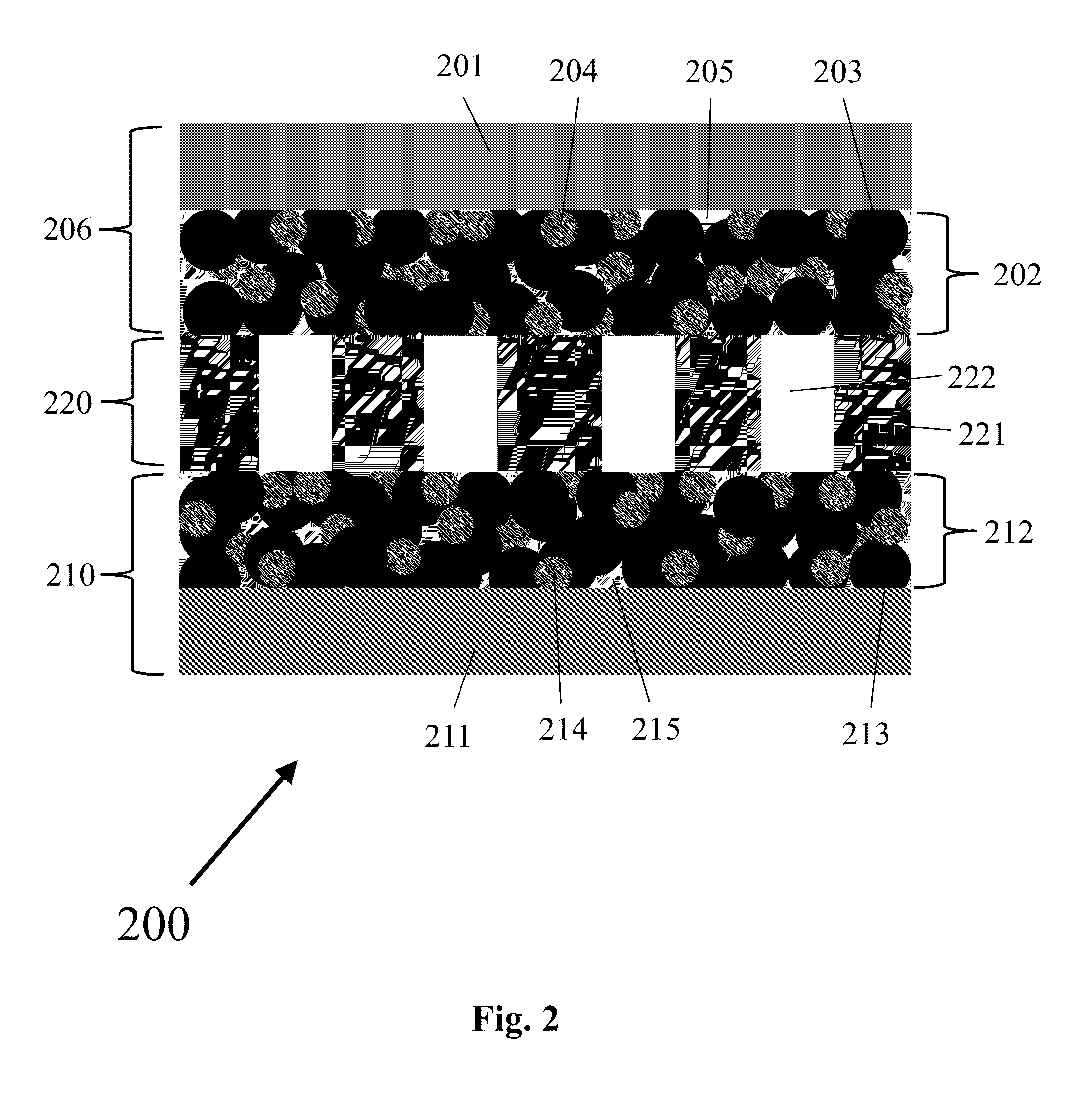

Carbon matrix-and carbon matrix composite-based dendrite-Intercepting layer for alkali metal secondary battery

ActiveUS20160344010A1Increase energy densityReduce material costsNon-aqueous electrolyte accumulatorsElectrolytic inorganic material coatingPhysical chemistryGraphite

A dendrite penetration-resistant layer for a rechargeable alkali metal battery, comprising an amorphous carbon or polymeric carbon matrix, an optional carbon or graphite reinforcement phase dispersed in this matrix, and a lithium- or sodium-containing species that are chemically bonded to the matrix and / or the optional carbon or graphite reinforcement phase to form an integral layer that prevents dendrite penetration through this integral layer in the alkali metal battery, wherein the lithium- or sodium-containing species is selected from Li2CO3, Li2O, Li2C2O4, LiOH, LiX, ROCO2Li, HCOLi, ROLi, (ROCO2Li)2, (CH2OCO2Li)2, Li2S, LixSOy, Na2CO3, Na2O, Na2C2O4, NaOH, NaiX, ROCO2Na, HCONa, RONa, (ROCO2Na)2, (CH2OCO2Na)2, Na2S, NaxSOy, or a combination thereof, wherein X=F, Cl, I, or Br, R=a hydrocarbon group, x=0-1, y=1-4; and wherein the lithium- or sodium-containing species is derived from an electrochemical decomposition reaction.

Owner:GLOBAL GRAPHENE GRP INC

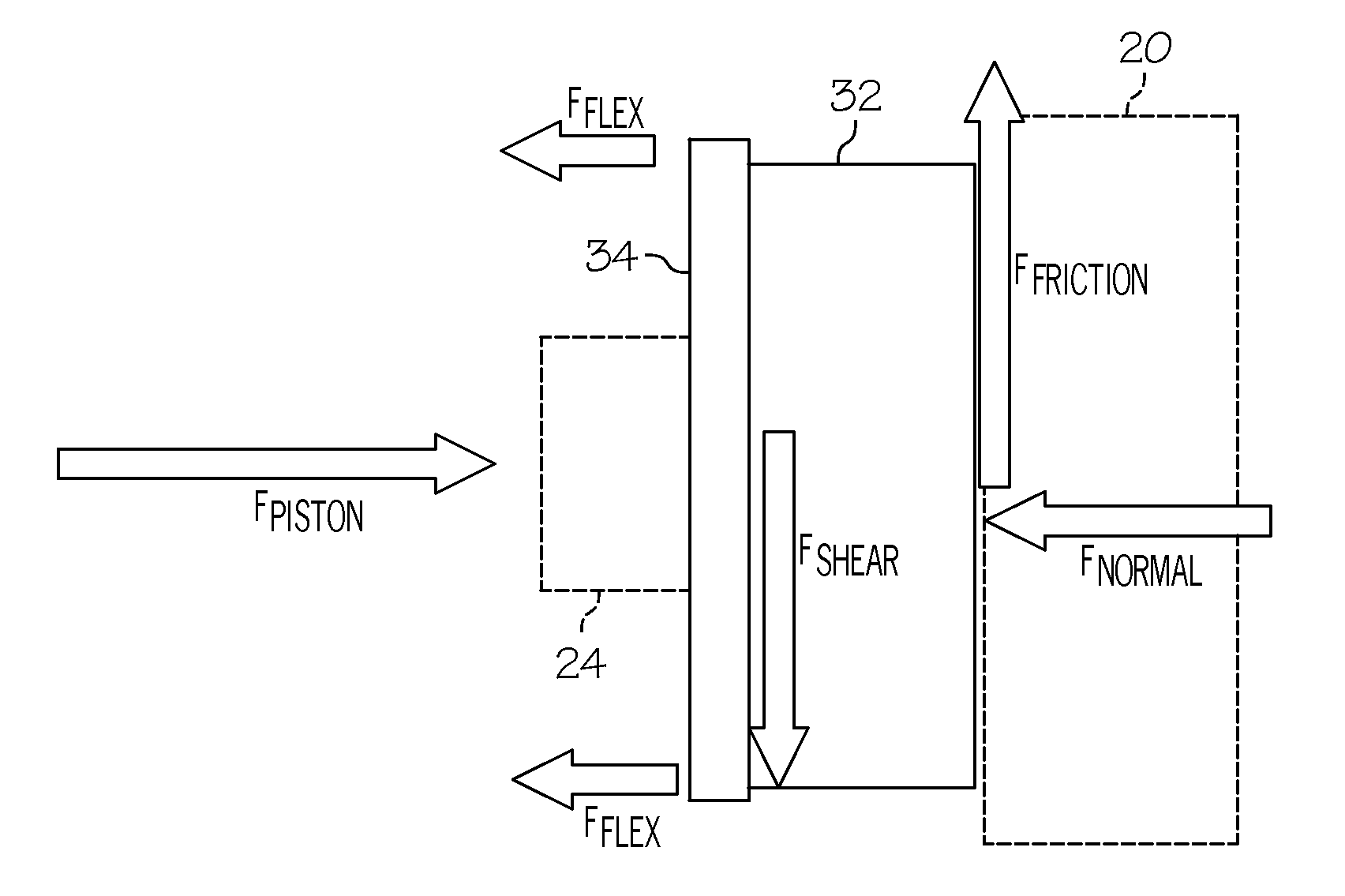

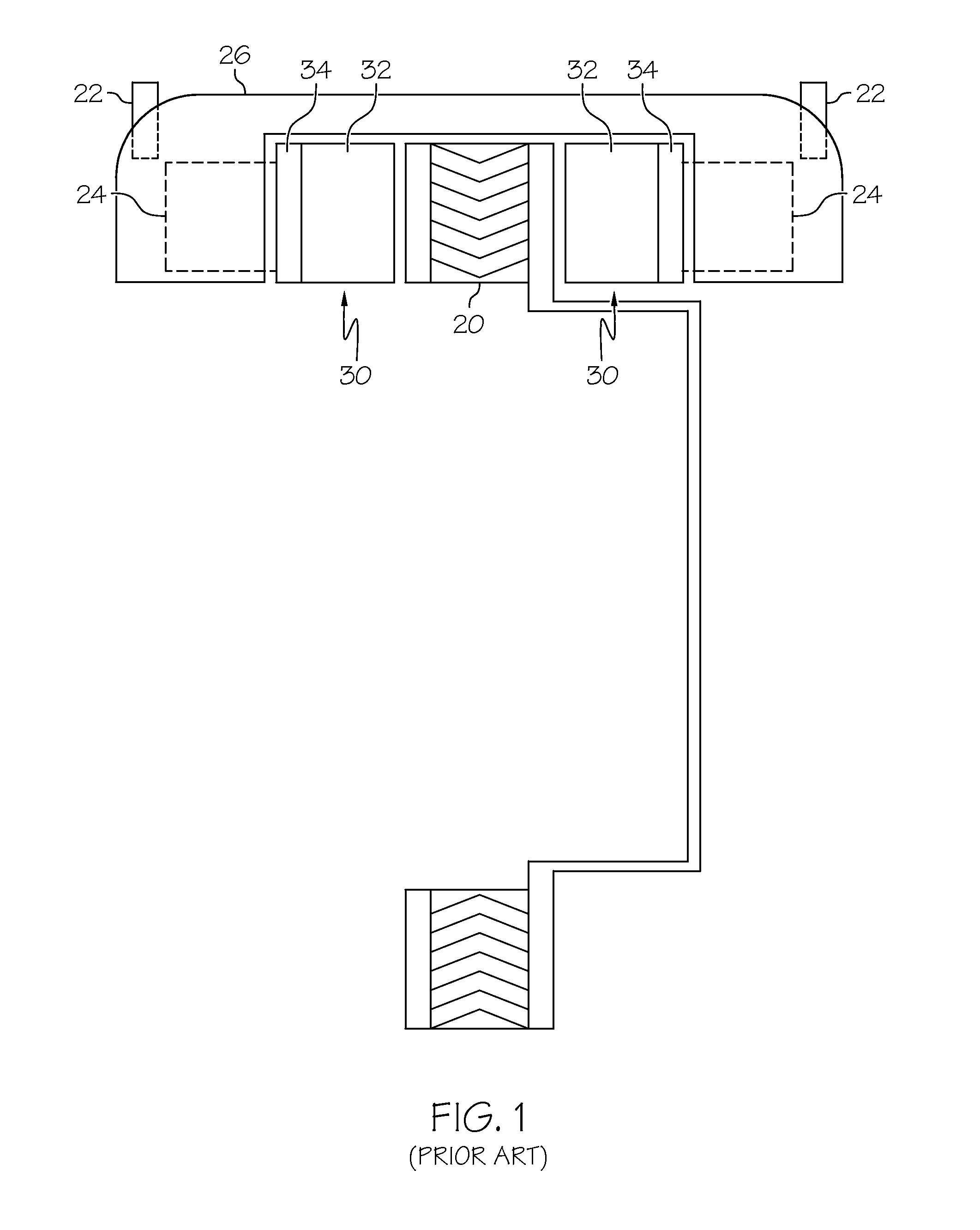

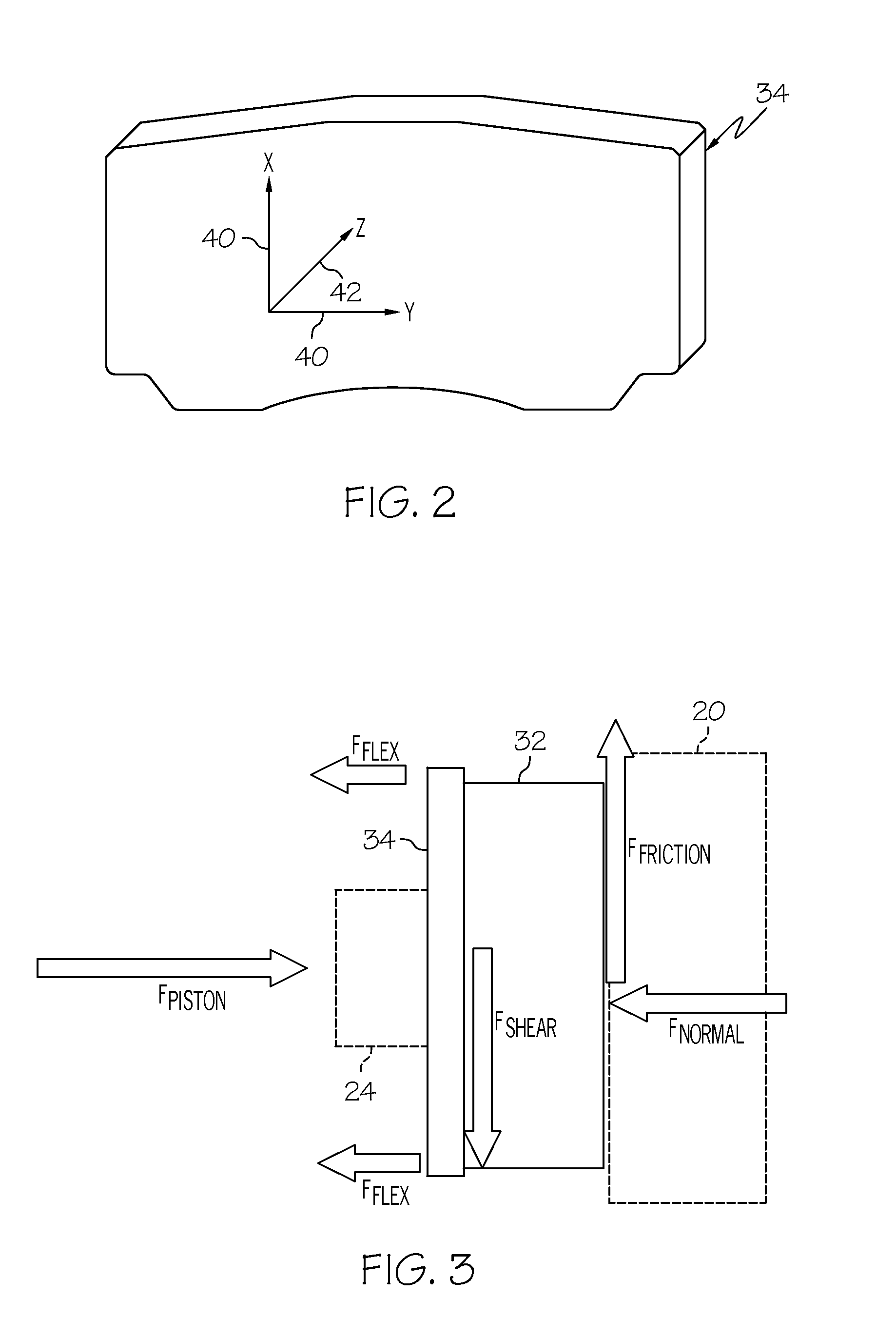

Carbon fiber reinforced carbon matrix composite for brake pad back plate

A brake pad assembly is provided, including a friction lining providing a wear surface for contacting a brake rotor and a back plate coupled to the friction lining. The back plate is made of a carbon fiber reinforced carbon matrix composite. In one example, a majority of the carbon fibers of the back plate are oriented in a x-y in-plane direction resulting in a structure where the thermal conductivity is at least 2 times greater in the x-y in-plane direction versus a z through-plane direction. In another example, the back plate is provided as at least one sheet of a carbon fiber reinforced carbon matrix composite. A method of manufacturing the brake pad assembly is also provided.

Owner:CMBF PROD INC

Impact resistant, thin ply composite structures and method of manufacturing same

InactiveUS7407901B2Structure moreMaterial nanotechnologySynthetic resin layered productsCarbon fibersReinforced carbon–carbon

A reinforced carbon-carbon (RCC) composite material has improved impact resistance. The RCC composite material is formed from a fiber reinforcement of layers or plies of thin ply carbon fiber fabric impregnated with a carbon matrix. Carbon nanotube reinforcement in the matrix further improves impact resistance. The stacking arrangement of the plies of the thin ply fabric also further improves impact resistance.

Owner:KAZAK COMPOSITES

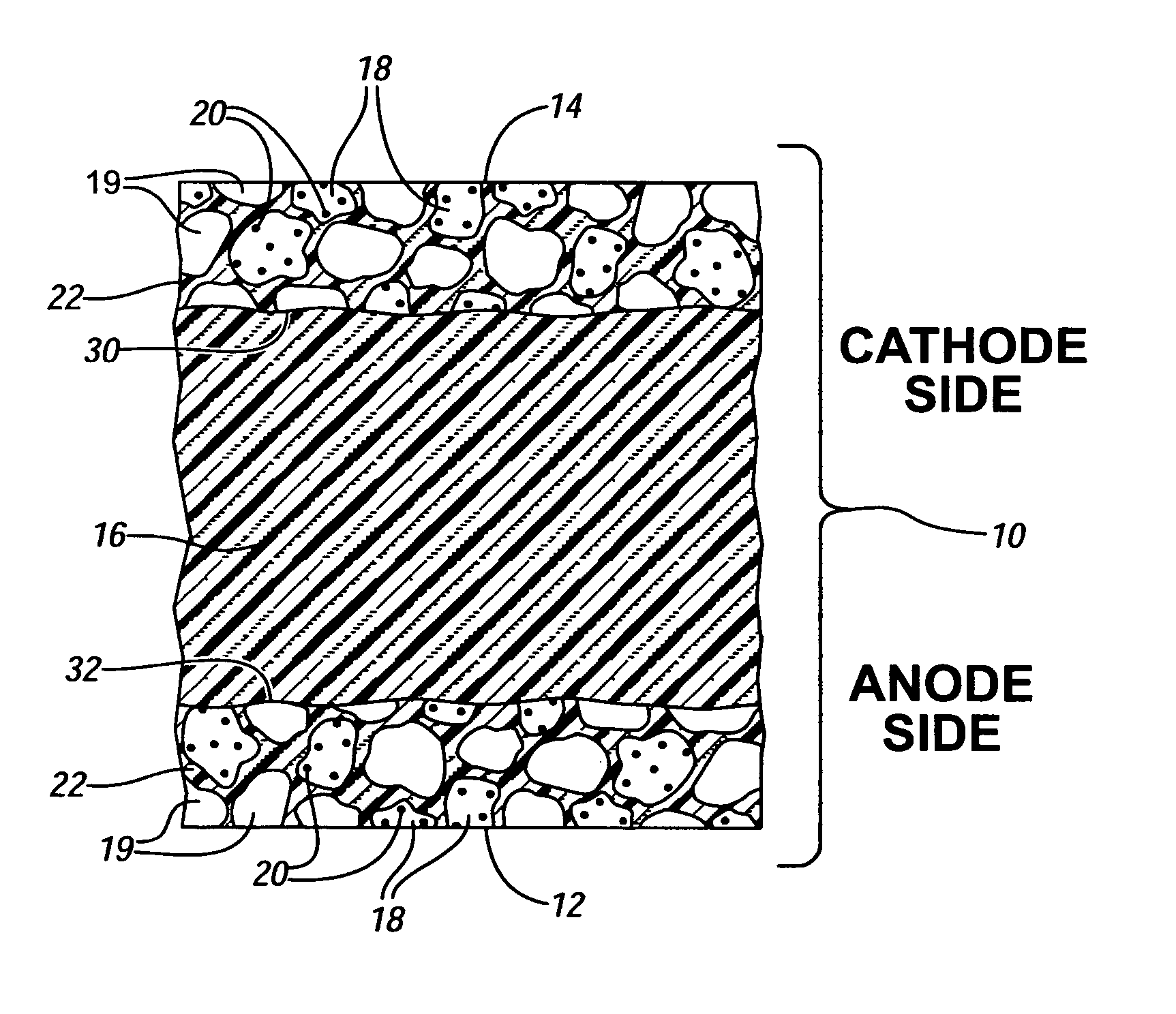

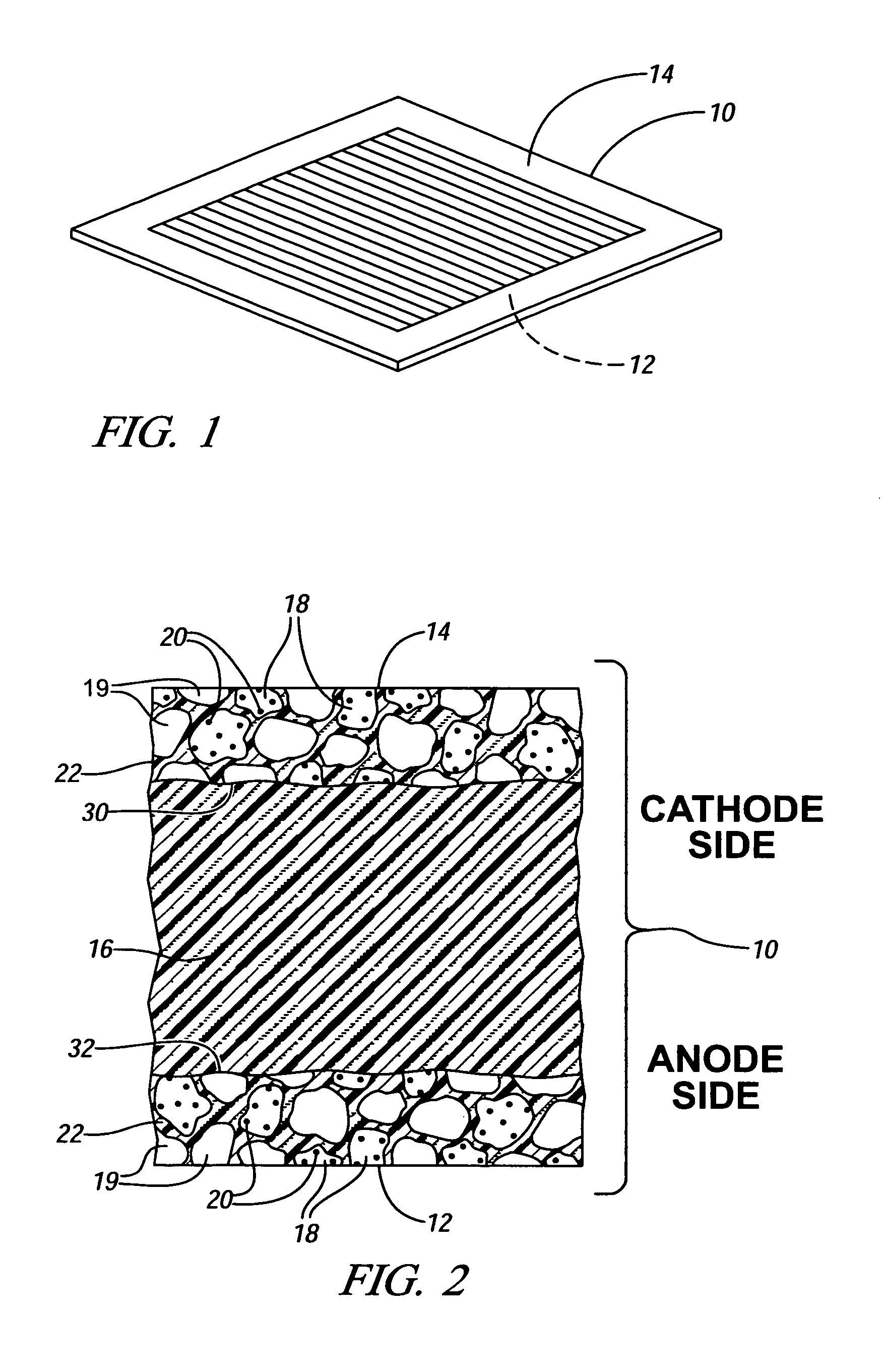

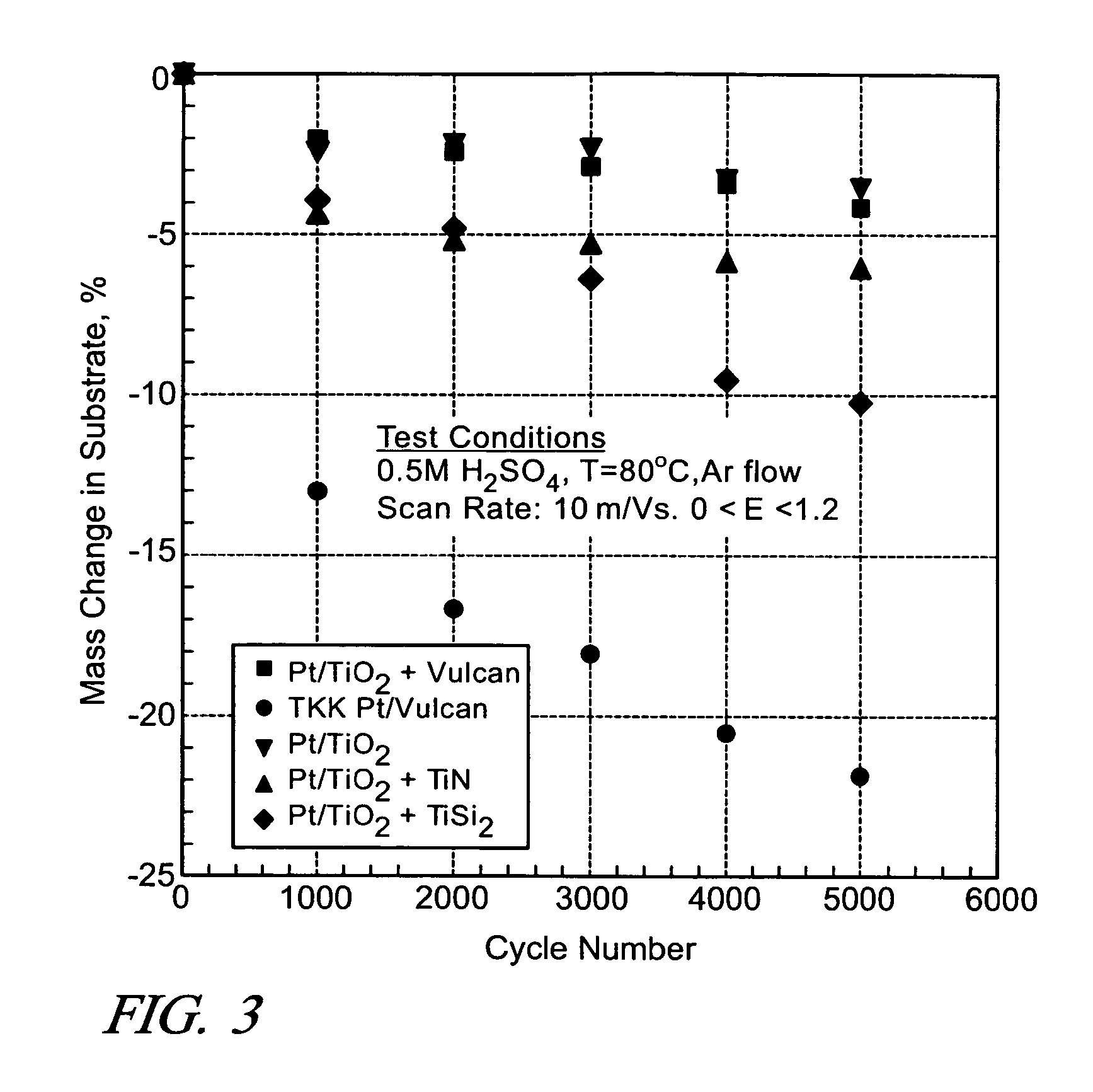

Conductive matrices for fuel cell electrodes

InactiveUS7767330B2Suitable conductivity and durabilityIncreased durabilityMaterial nanotechnologyActive material electrodesTitanium carbideCobalt

The durability of a fuel cell having a polymer electrolyte membrane with an anode on one surface and an oxygen-reducing cathode on the other surface is improved by replacing conductive carbon matrix materials in an electrode with a matrix of electrically conductive metal compound particles. The electrode includes a catalyst supported on a nanosize metal oxides and electrically conductive nanosize matrix particles of a metal compound. One or more metal compounds such as a boride, carbide, nitride, silicide, carbonitride, oxyboride, oxycarbide, or oxynitride of a metal such as cobalt, chromium, nickel, molybdenum, neodymium niobium, tantalum, titanium, tungsten, vanadium, and zirconium is suitable. For example, the combination of platinum particles deposited on titanium dioxide support particles mixed in a conductive matrix of titanium carbide particles provides an electrode with good oxygen reduction capability and corrosion resistance in an acid environment.

Owner:GM GLOBAL TECH OPERATIONS LLC

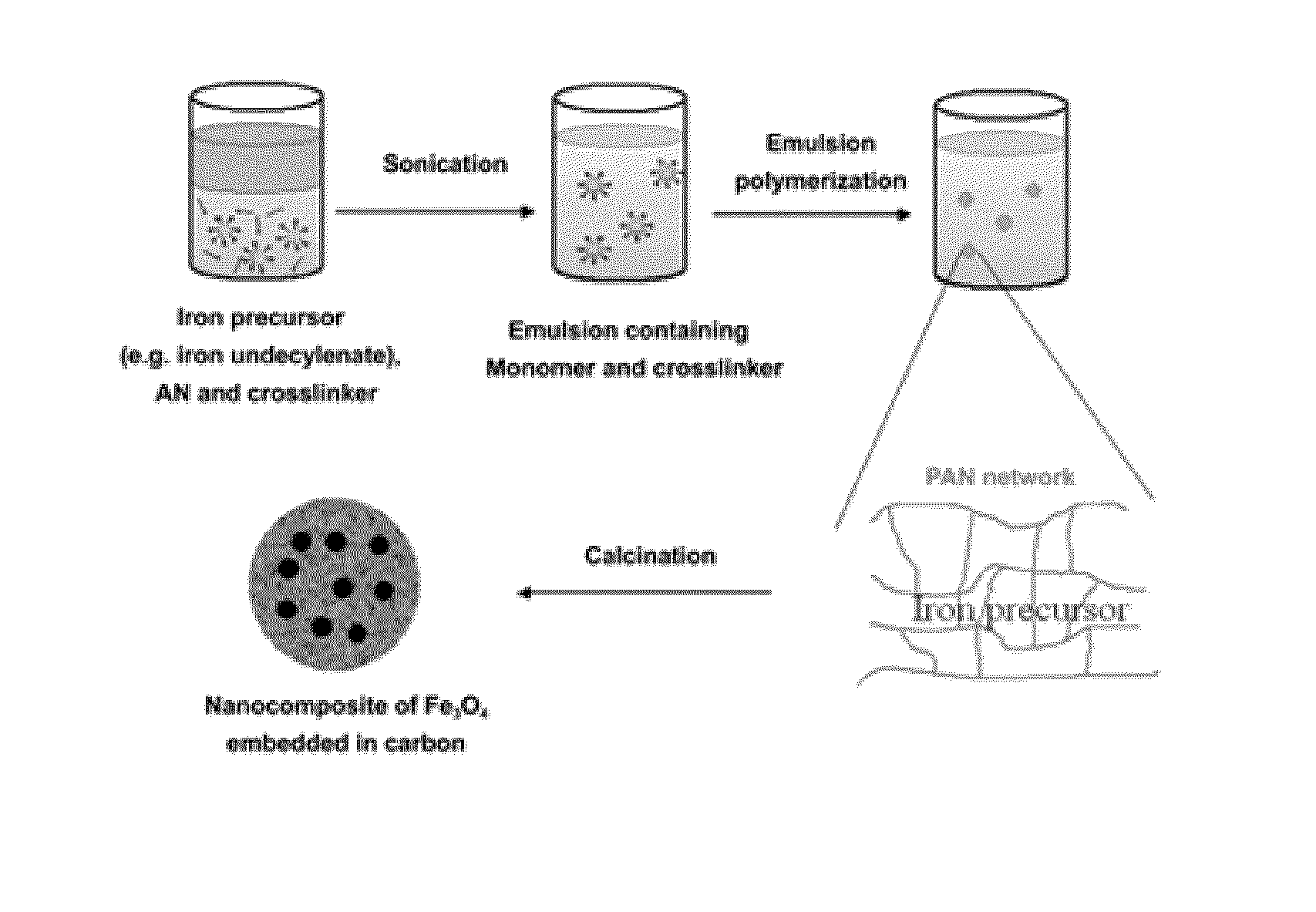

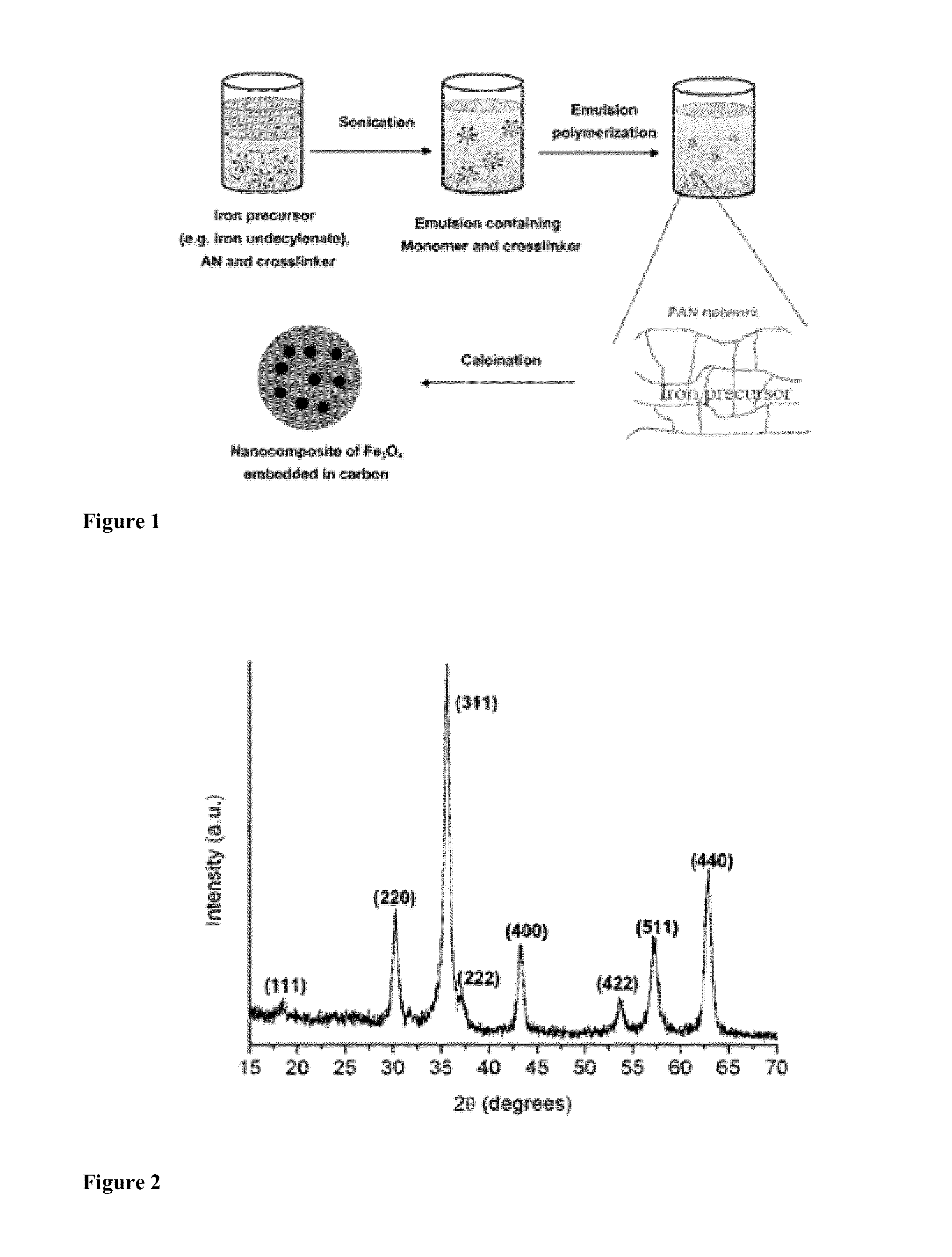

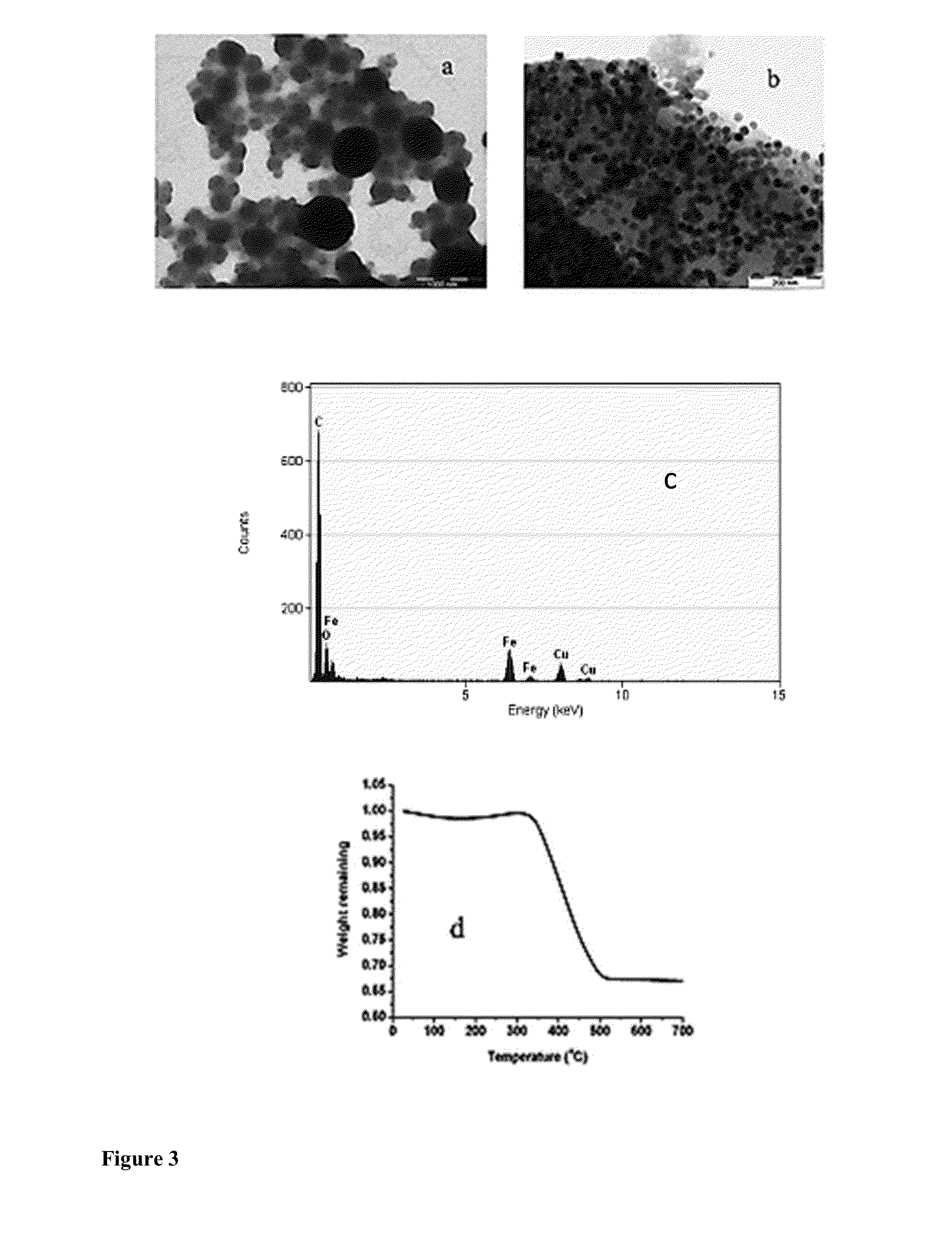

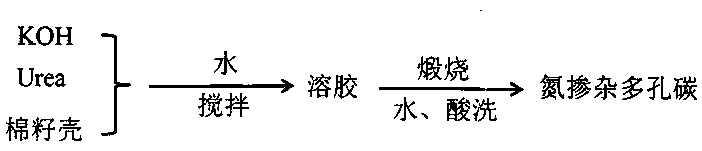

Hybrid Materials and Nanocomposite Materials, Methods of Making Same, and Uses Thereof

Hybrid materials and nanocomposite materials, methods of making and using such materials. The nanoparticles of the nanocomposite are formed in situ during pyrolysis of a hybrid material comprising metal precursor compounds. The nanoparticles are uniformly distributed in the carbon matrix of the nanocomposite. The nanocomposite materials can be used in devices such as, for example, electrodes and on-chip inductors.

Owner:CORNELL UNIVERSITY

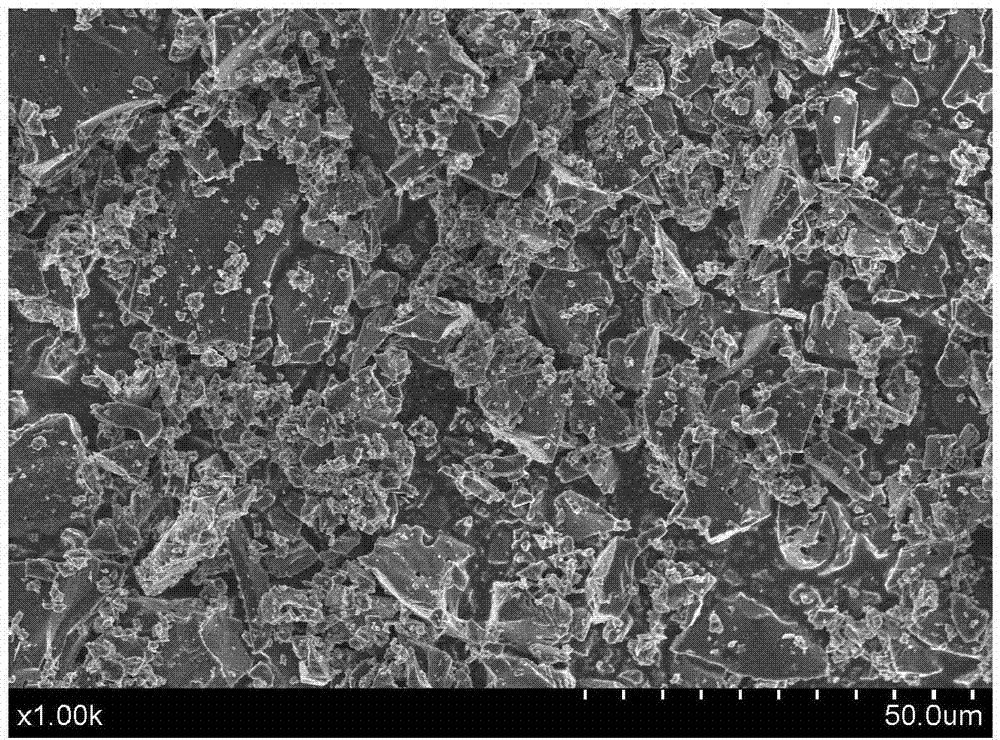

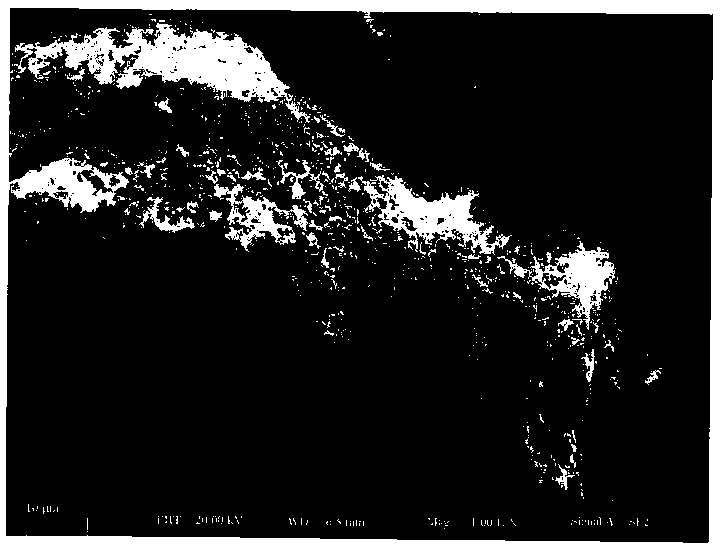

Method for preparing nitrogen-doped porous carbon by taking cottonseed hull as raw material and application

InactiveCN108455597AWide range of resource sourcesLow costCarbon preparation/purificationCapacitancePorous carbon

The invention discloses a method for preparing nitrogen-doped porous carbon by taking cottonseed hull as a raw material and application. The method is characterized in that the nitrogen-doped porous carbon material is prepared by taking the cottonseed hull as a raw material and urea as a nitrogen source, stirring and uniformly mixing the substances with a sodium hydroxide solution, and then carrying out high-temperature carbonization and activation. An electron microscope photo shows that the prepared nitrogen-doped porous carbon material is of a three-dimensional inner cross-linking network structure. XPS and elemental analysis show that the nitrogen element is successively and uniformly doped in a carbon matrix; the XPS analysis shows that the nitrogen content is 1.84 to 7.35%; the elemental analysis shows that the nitrogen content is 2.07 to 6.52 % and the specific surface area is 1010 to 2500m<2> / g. The super-capacitor experiment shows that the prepared nitrogen-doped porous carbonmaterial has good electrochemical properties and the specific capacitance can reach 320 to 340F / g (current density is 0.5A / g). The method has the advantages of simplicity in preparation, wide range of renewable resources as raw materials, low price, low cost, easiness in large-scale industrialization application and capability of being applied to the field of energy storage.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

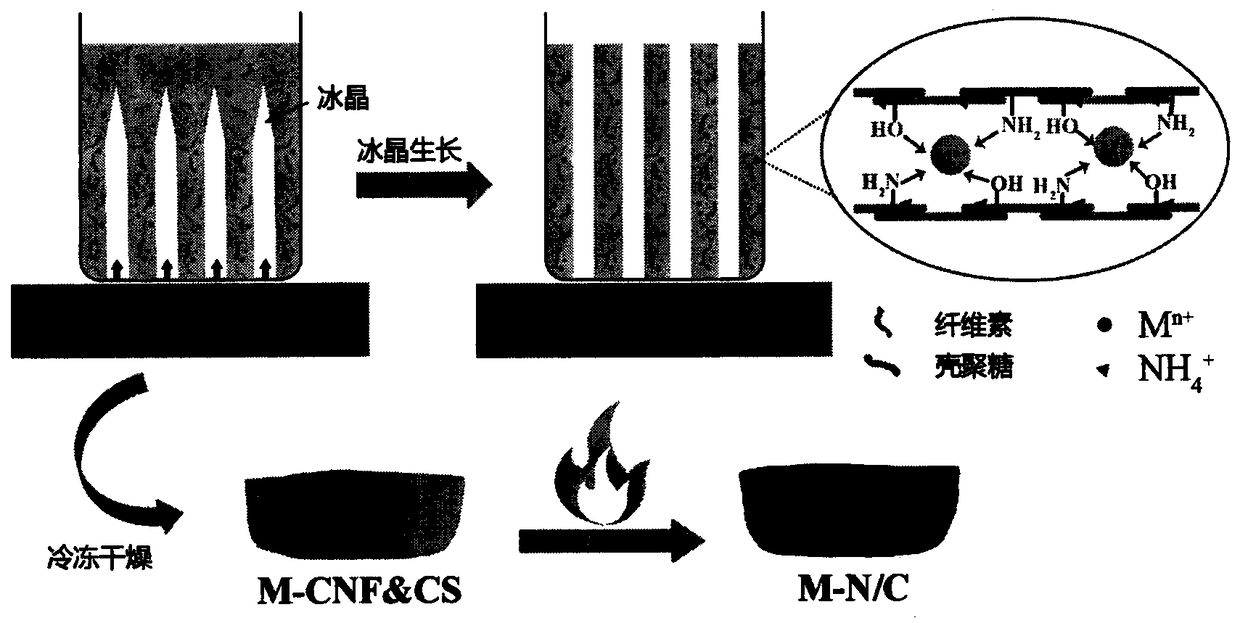

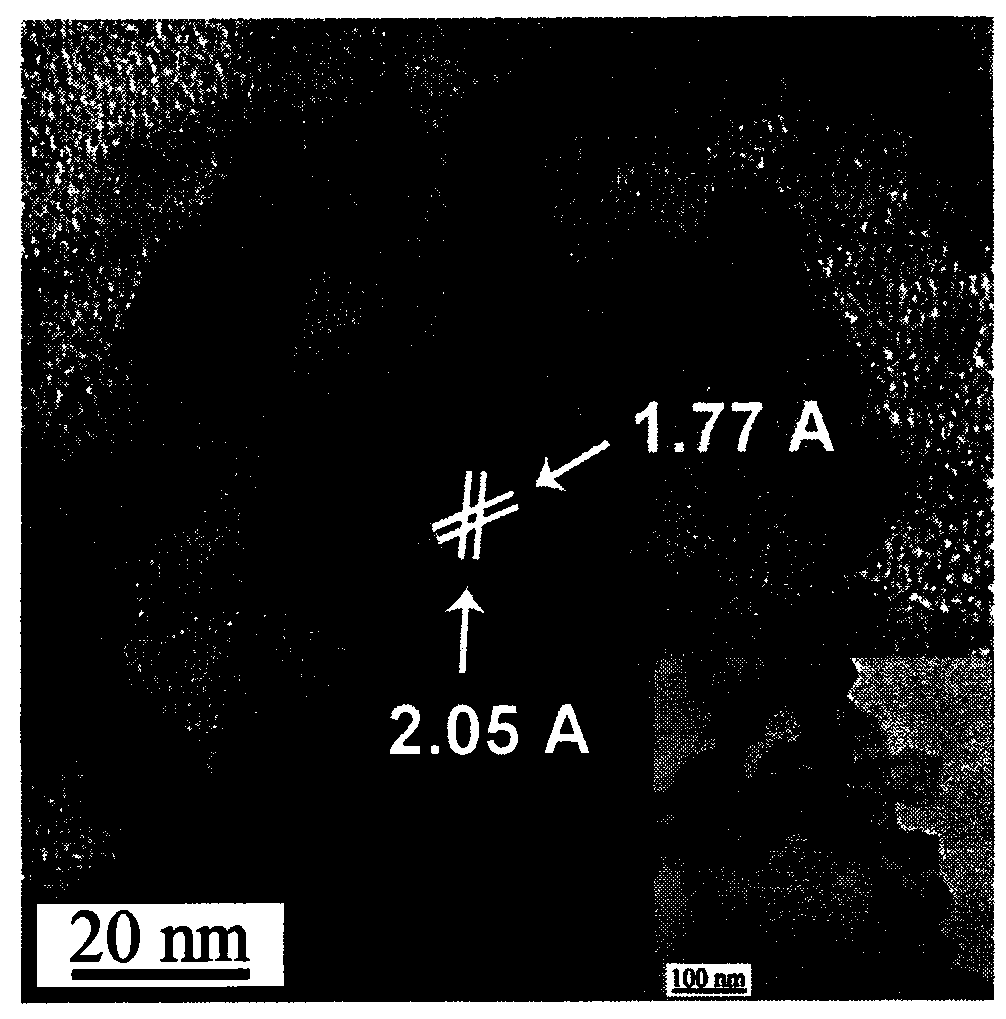

Preparation method of metal-loaded nitrogen-doped bulk porous carbon material

InactiveCN108910859ALarge specific surface areaHigh porosityCarbon preparation/purificationPorosityDecomposition

The invention discloses a preparation method of a metal-loaded nitrogen-doped bulk porous carbon material. The preparation method comprises: mixing a natural polysaccharide polymer solution or suspension, an inorganic ammonium salt and a metal salt and carrying out freeze-drying to obtain a natural polysaccharide polymer porous material and carrying out high temperature carbonization on the natural polysaccharide polymer porous material to obtain the metal-loaded nitrogen-doped bulk porous carbon material. The inorganic ammonium salt is used as a pore-foaming agent and a nitrogen source and isheated to decompose and form pores on the surface of a base and the ammonia gas generated by the decomposition reacts with a carbon matrix at a high temperature so that the metal-loaded nitrogen-doped bulk porous carbon material is formed. The metal-loaded nitrogen-doped bulk porous carbon material has the advantages of high specific surface area, high porosity and low density, and has wide application prospects in the fields of energy, catalytic synthesis, gas adsorption, oil-water separation and the like.

Owner:DONGHUA UNIV

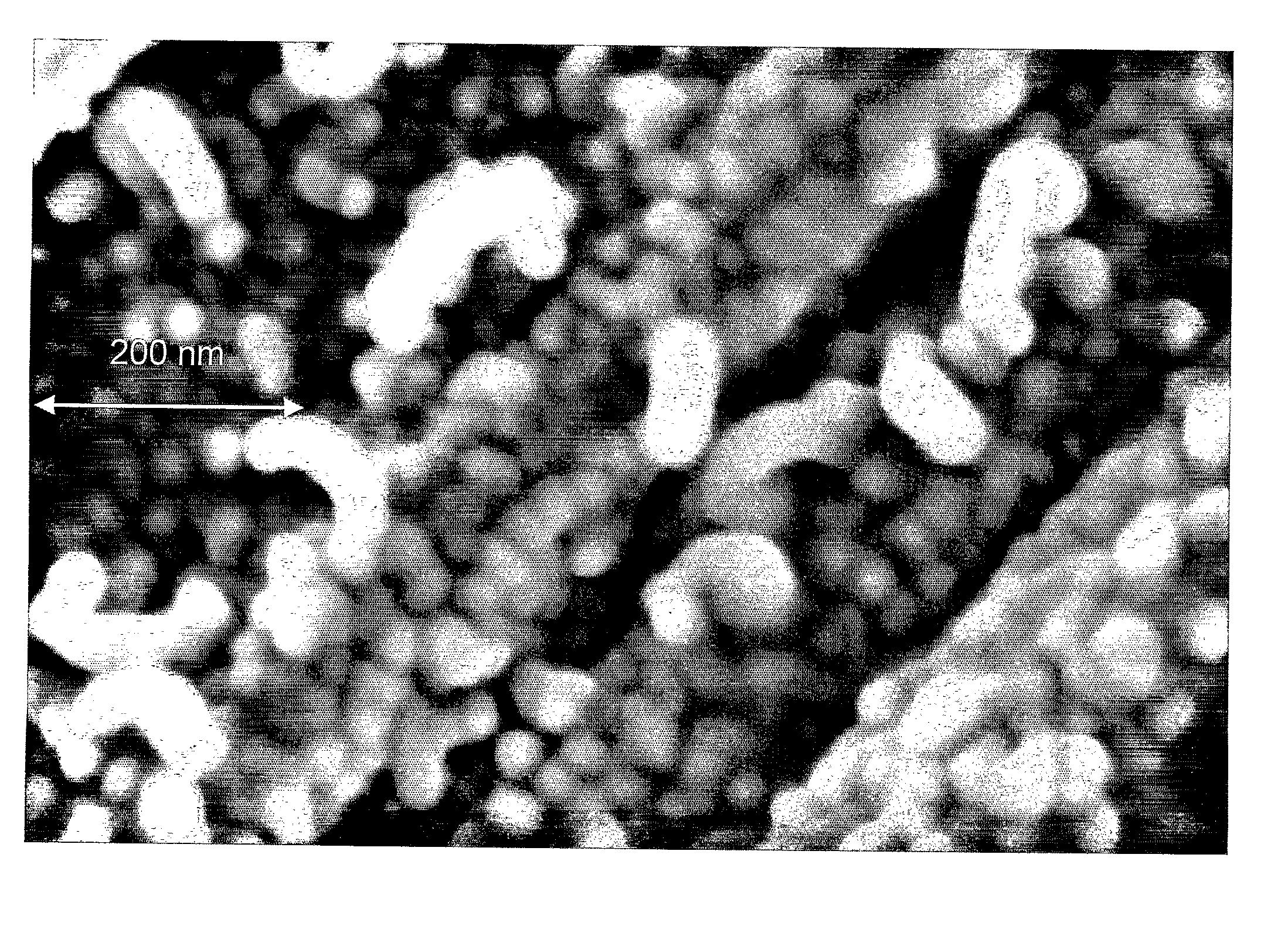

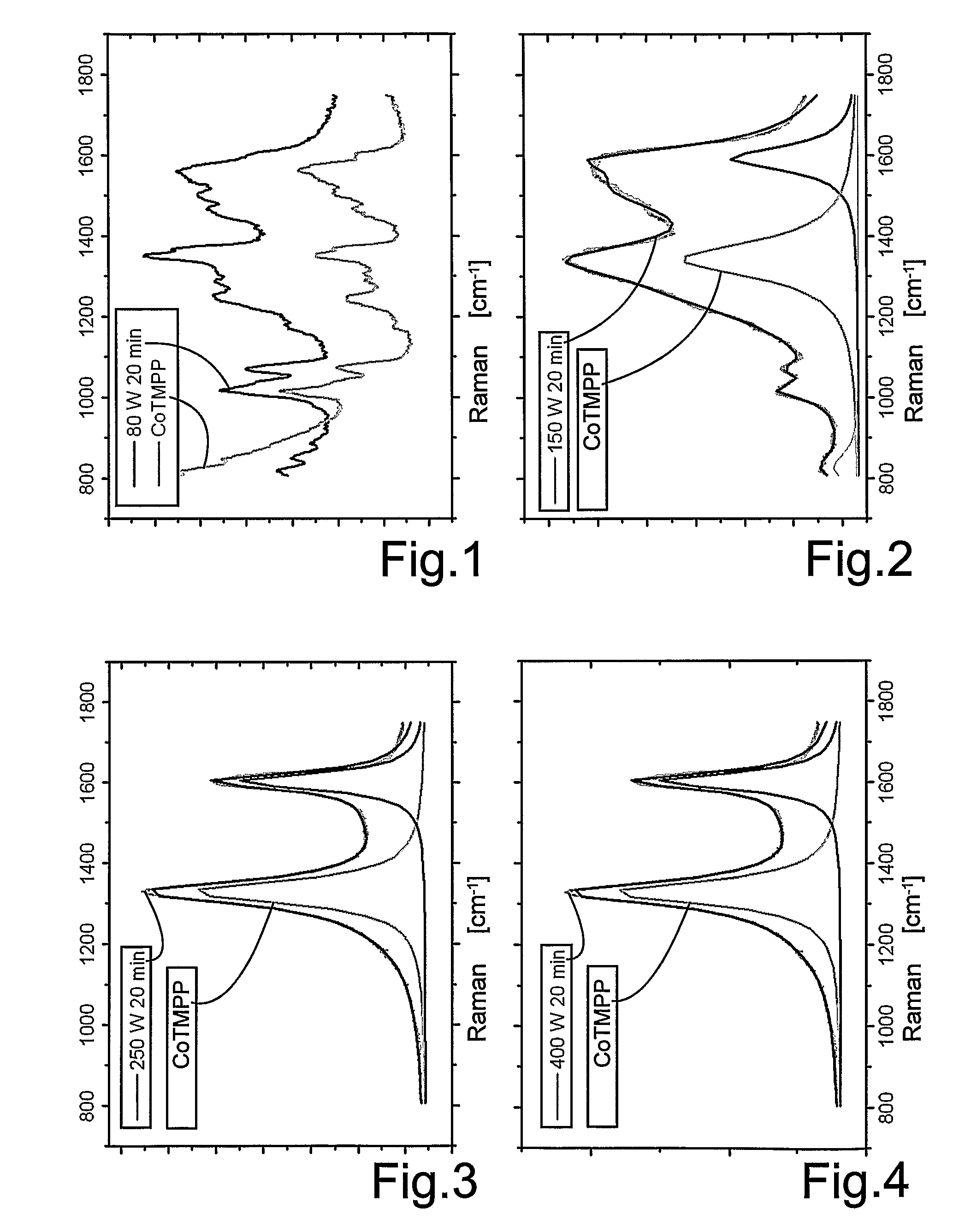

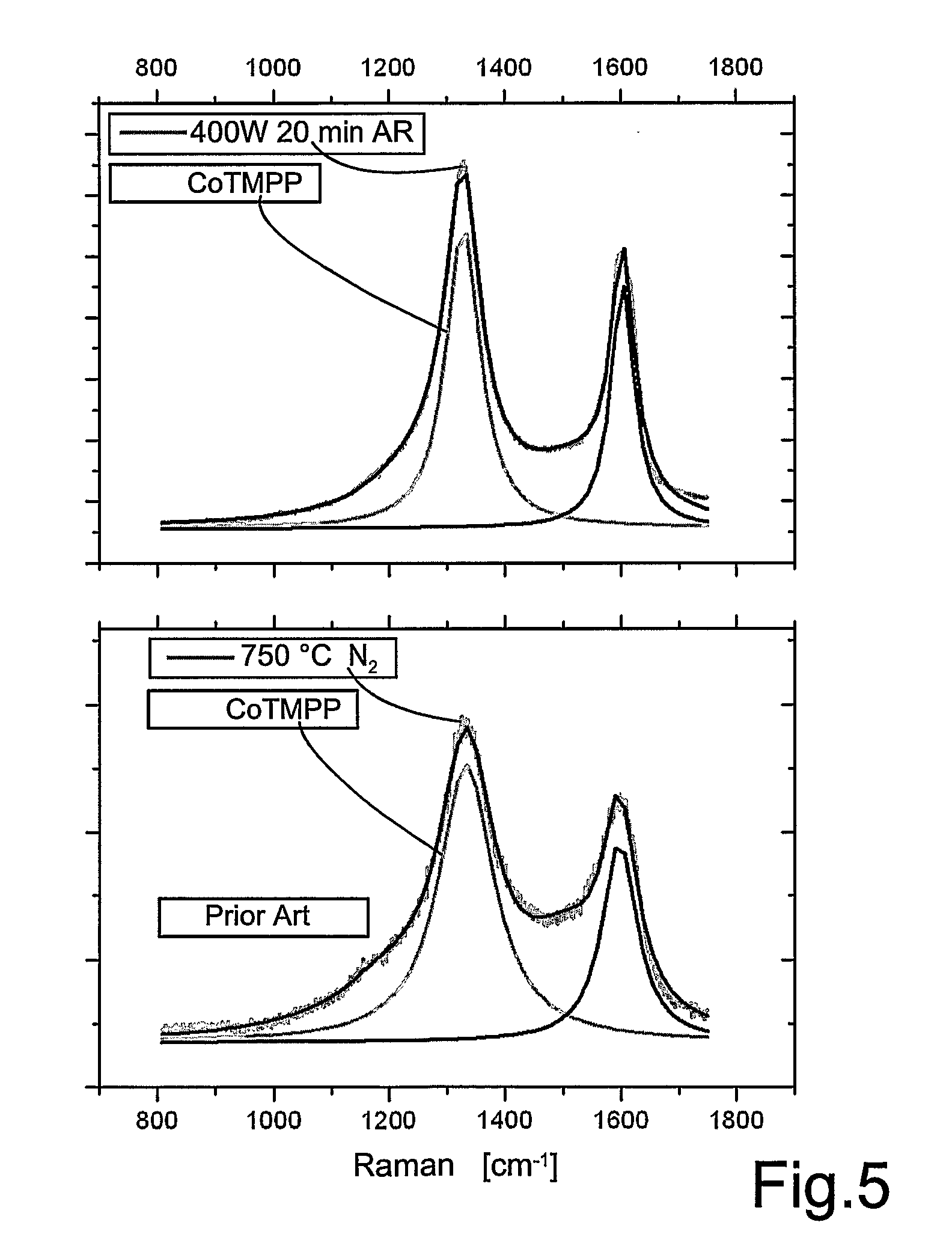

Production of a Platinum-Free Chelate Catalyst Material as an Intermediate Product, and Further Processing Thereof to Obtain an Electrocatalytic Coating as a Final Product

InactiveUS20080286490A1Improve catalytic performanceSimple and efficient and cost-effectiveOrganic-compounds/hydrides/coordination-complexes catalystsFinal product manufactureCross-linkChemical reaction

A method for preparing a platinum-free chelate catalyst material as an intermediate product for selective electrocatalytic reduction of oxygen includes performing a low-temperature plasma treatment on a powdery form of the transition-metal chelate in a plasma reactor chamber having an inert plasma gas disposed therein. A plasma power, a plasma gas pressure, a plasma initialization and a treatment time of the low-temperature plasma treatment are selected so that molecules of the transition metal chelate are fragmented in the plasma and cross-link in a subsequent chemical reaction so as to form a carbon matrix and retain a basic chelate structure in a surrounding of the transition metal.

Owner:HELMHOLTZ ZENT BERLIN FUER MATERIALIEN & ENERGIE GMBH

High temperature furnace-grade curing carbon fiber thermal insulating material and production technology thereof

ActiveCN101550017AImprove insulation effectSimple process, energy saving and environmental protectionCarbon fibresFurnace liningsFiberCarbon fibers

The invention discloses a high temperature furnace-grade curing carbon fiber thermal insulating material having simple technology and small coefficient of heat conductivity, and a production technology thereof, characterized in that the material is made of the carbon fiber by the steps of the preparation of a preform, densification, hot-vibration purification and machine processing; the invention is free from the processes of bonding, immersion, curing and charring in the preparation of the preform and has simple technology, great energy-saving property and environmental protection ability, the carbon fibers inside the preform are distributed in a crisscross pattern, strong in cohesive force, stable in structure and free from delamination, the coefficient of heat conductivity is not larger than 0.8 W / mK and the thermal insulating property is excellent; the product consists of the high-strength carbon fiber and carbon matrix and has outstanding performances such as high specific strength, good high temperature resistance, corrosion resistance and thermal insulating property, in addition, the product integrates the fire resistance and the thermal insulating property, can bear certain loads, and is an ideal upgraded product in taking the place of related high temperature furnace-grade graphite products and soft carbon felt.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

Metal/carbonyl composite foaming material and preparation method thereof

InactiveCN101104893AImprove machinabilityImprove acid and alkali corrosion resistanceMetal coatingMetallic materials

The invention relates to the field of foamed metal materials, specifically metal / carbon-based composite foamed material and the preparation method thereof. The preparation method comprises processing a foamed carbon blank from foamed plastic as matrix, and forming a metal coating on the foamed carbon by direct electroplating method after the foamed carbon is molded to obtain a metal / carbon-based composite foamed material. The composite foamed material is constituted by foamed carbon and metal coating thereon. The ratio of carbon to metal, by weight percentage, is (20-90):(80-10). In this invention, the metal coating is formed uniformly and continuously on the surface of the foamed carbon matrix by electroplating method, so as to obtain a novel metal / carbon-based composite foamed material; and the toughness and heat conduction capacity of material are improved greatly without changing the appearance of foamed carbon. The inventive metal / carbon-based composite foamed material can not only used as an electronic element in radiator but also a heat exchanger for industrial and domestic uses, additionally can be used as electrode, electronic shield, catalyst and catalyst carrier in automobile, chemical and aerospace industries.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

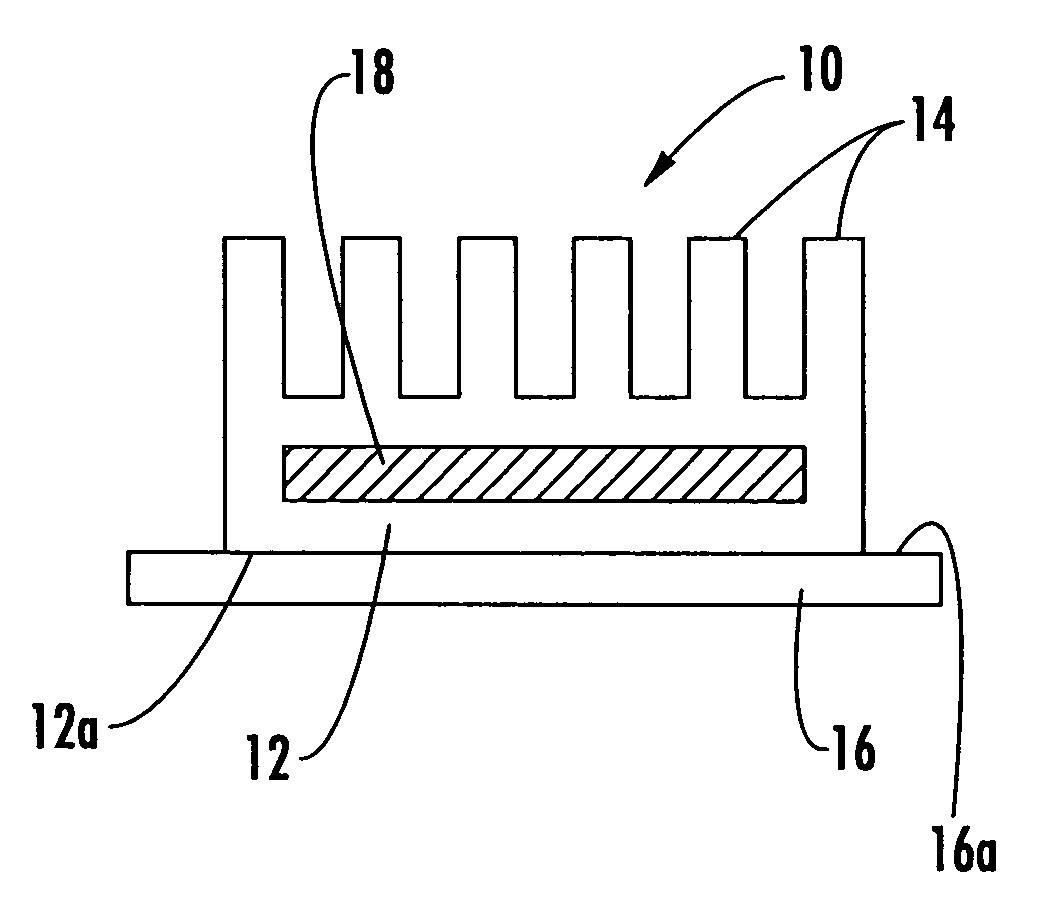

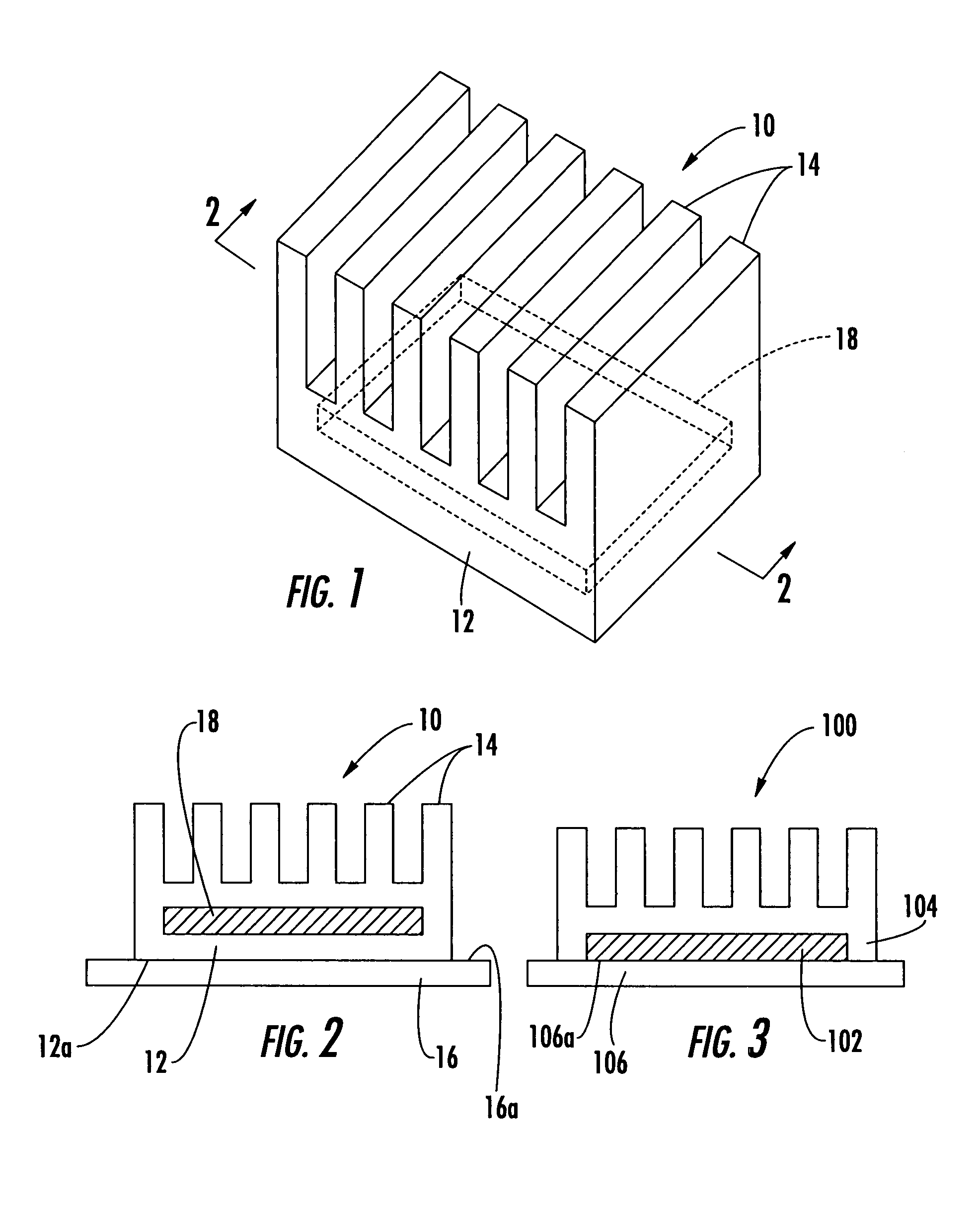

Heat sink assembly with overmolded carbon matrix

InactiveUS7311140B2Improve thermal conductivityHeat dissipationSemiconductor/solid-state device detailsSolid-state devicesConductive polymerNet shape

A net-shape molded heat sink is provided which includes a thermally conductive main body and a number of thermally conductive fins integrally connected to and emanating from the main body. The heat sink is formed by overmolding a carbon-carbon matrix core plate with a thermally conductive polymer composition that is filled with thermally conductive filler material. The molded heat sink is freely connecting through the part which makes it more efficient and has an optimal thermal configuration.

Owner:TICONA POLYMERS INC

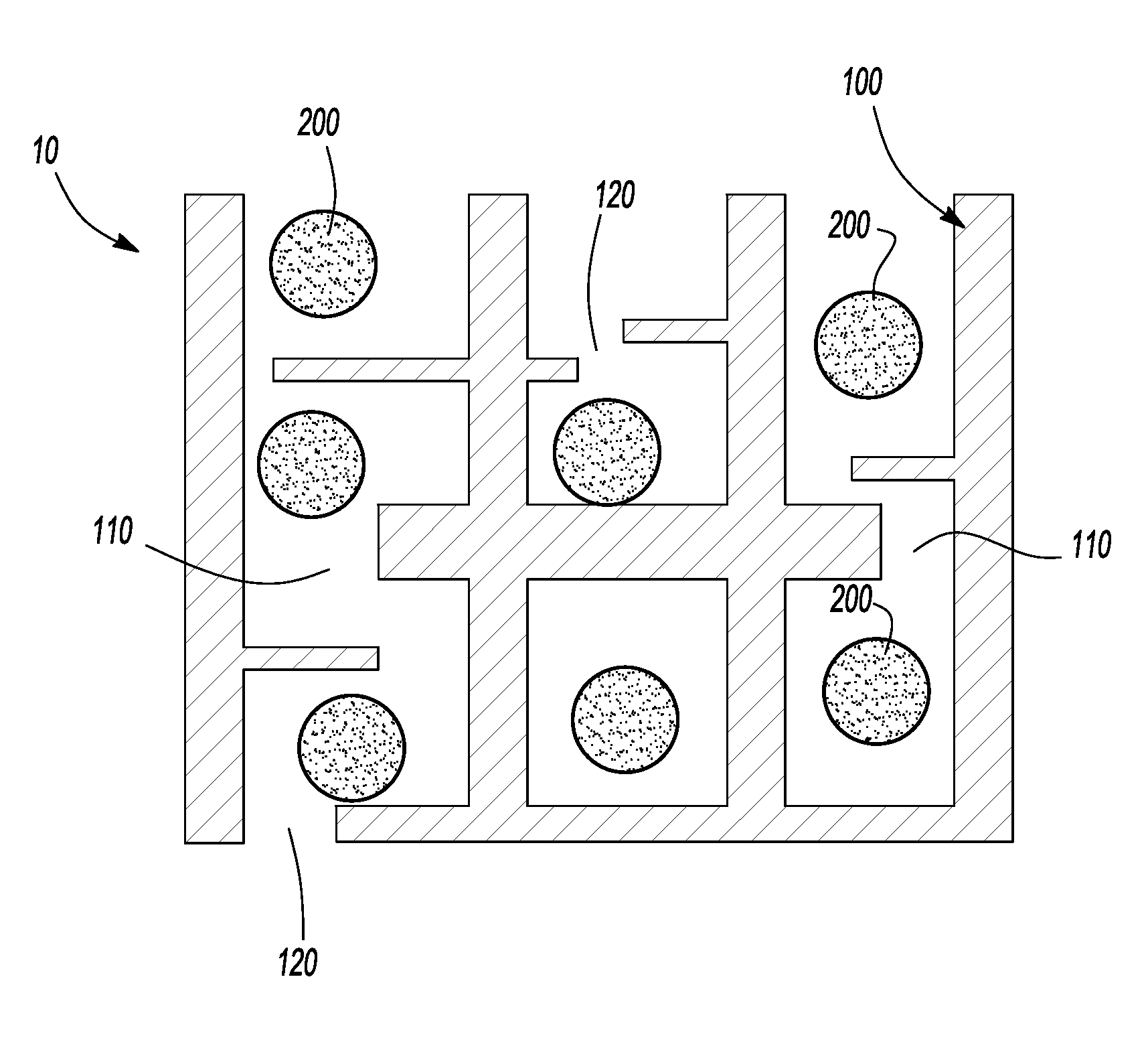

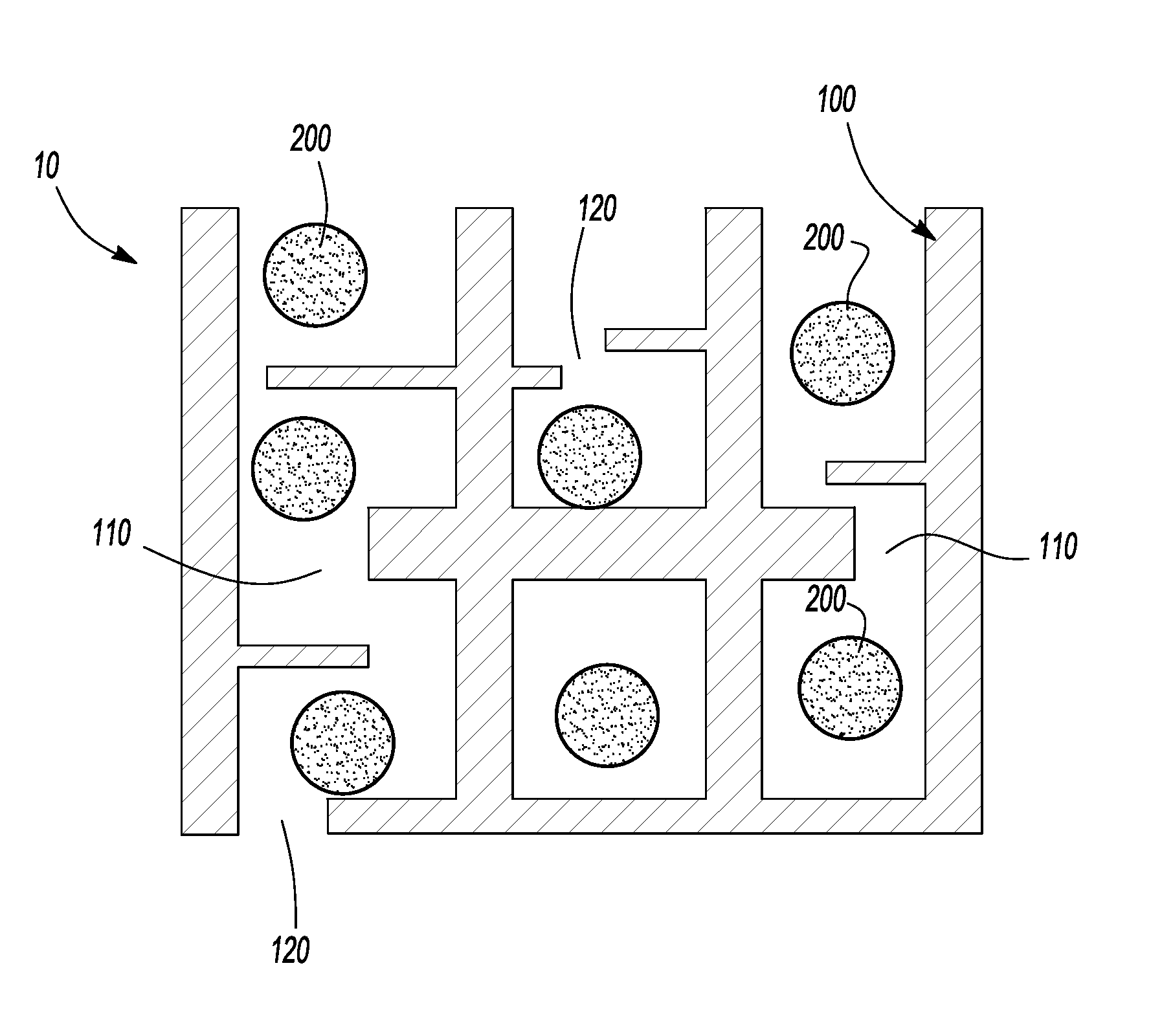

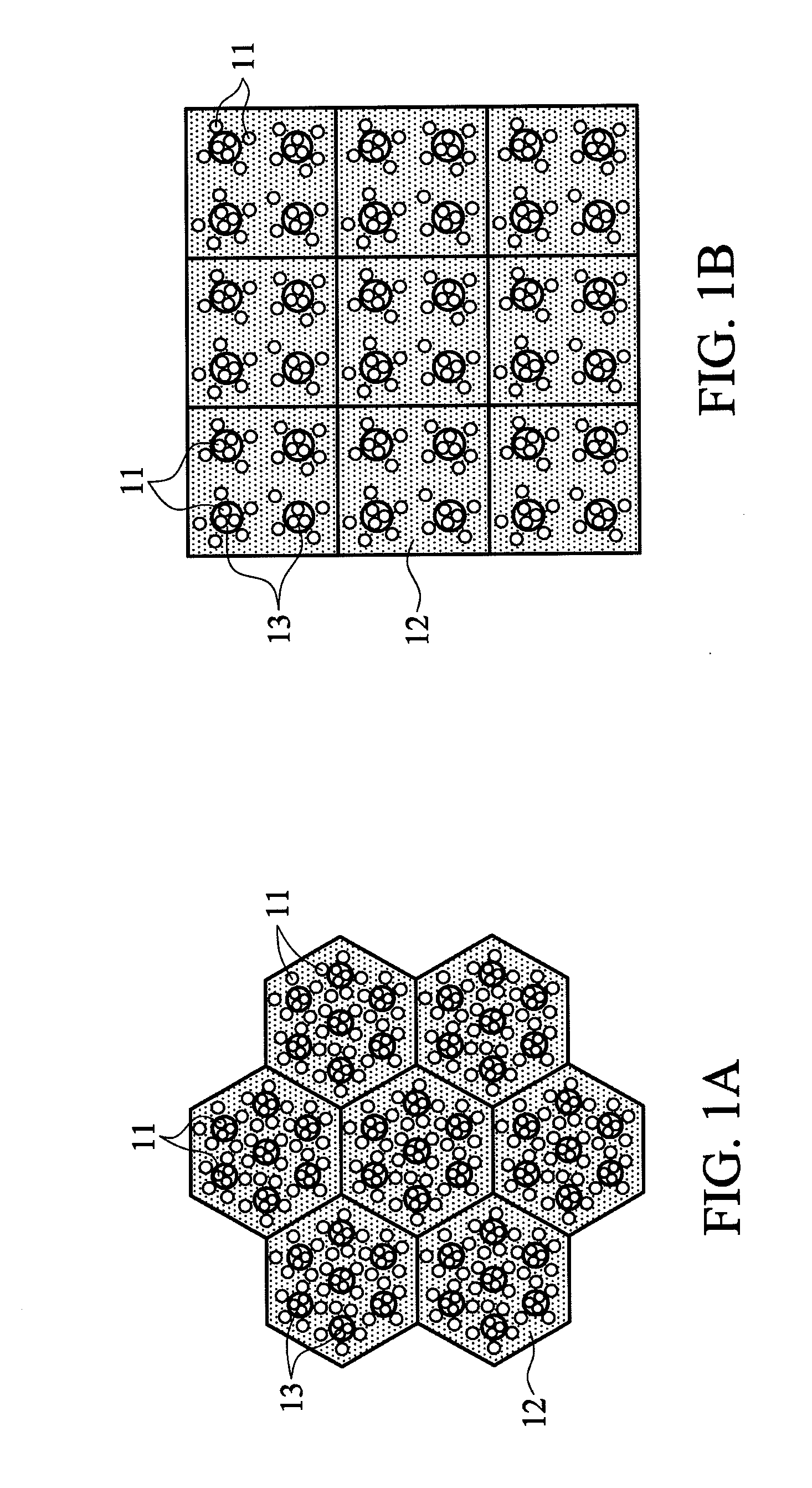

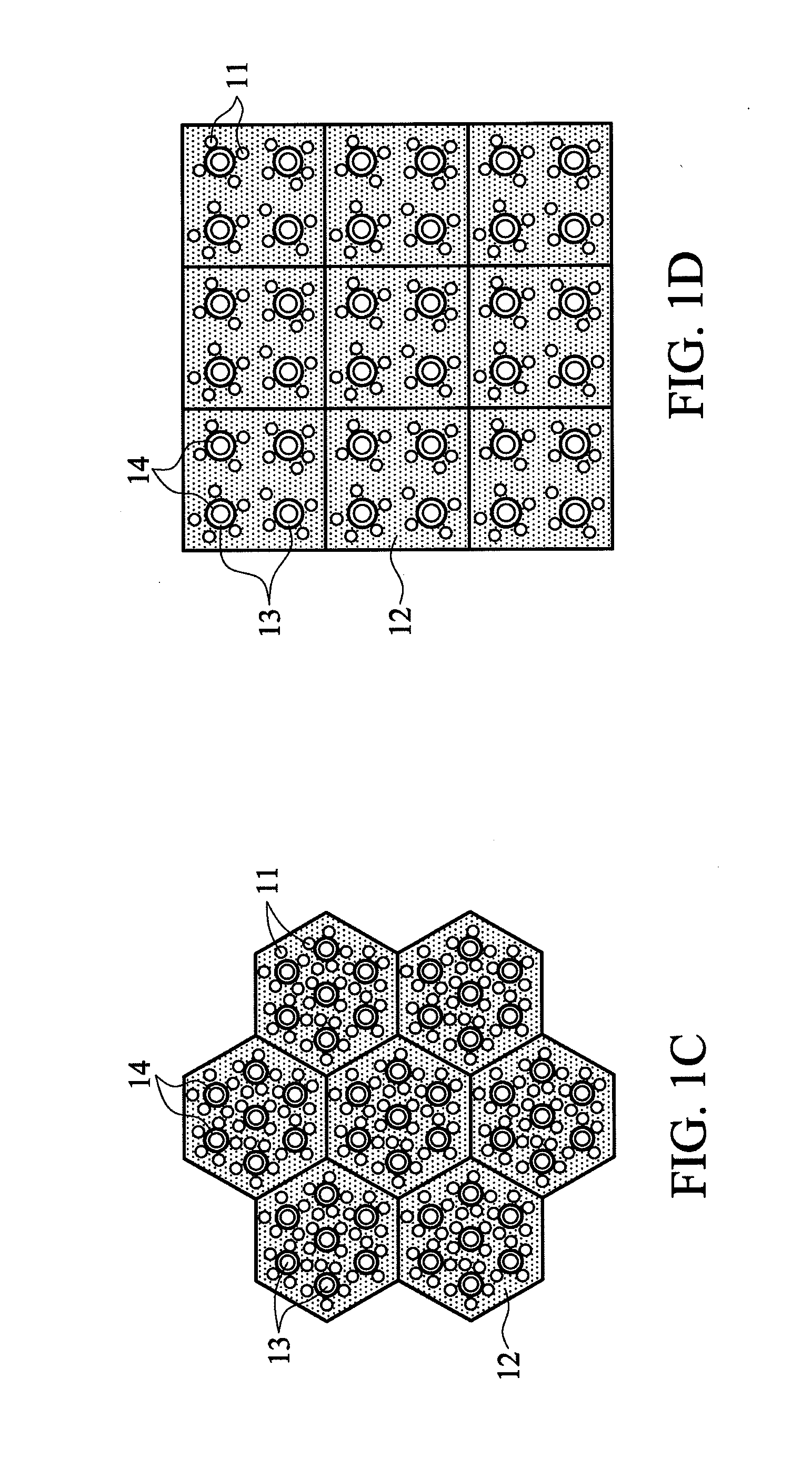

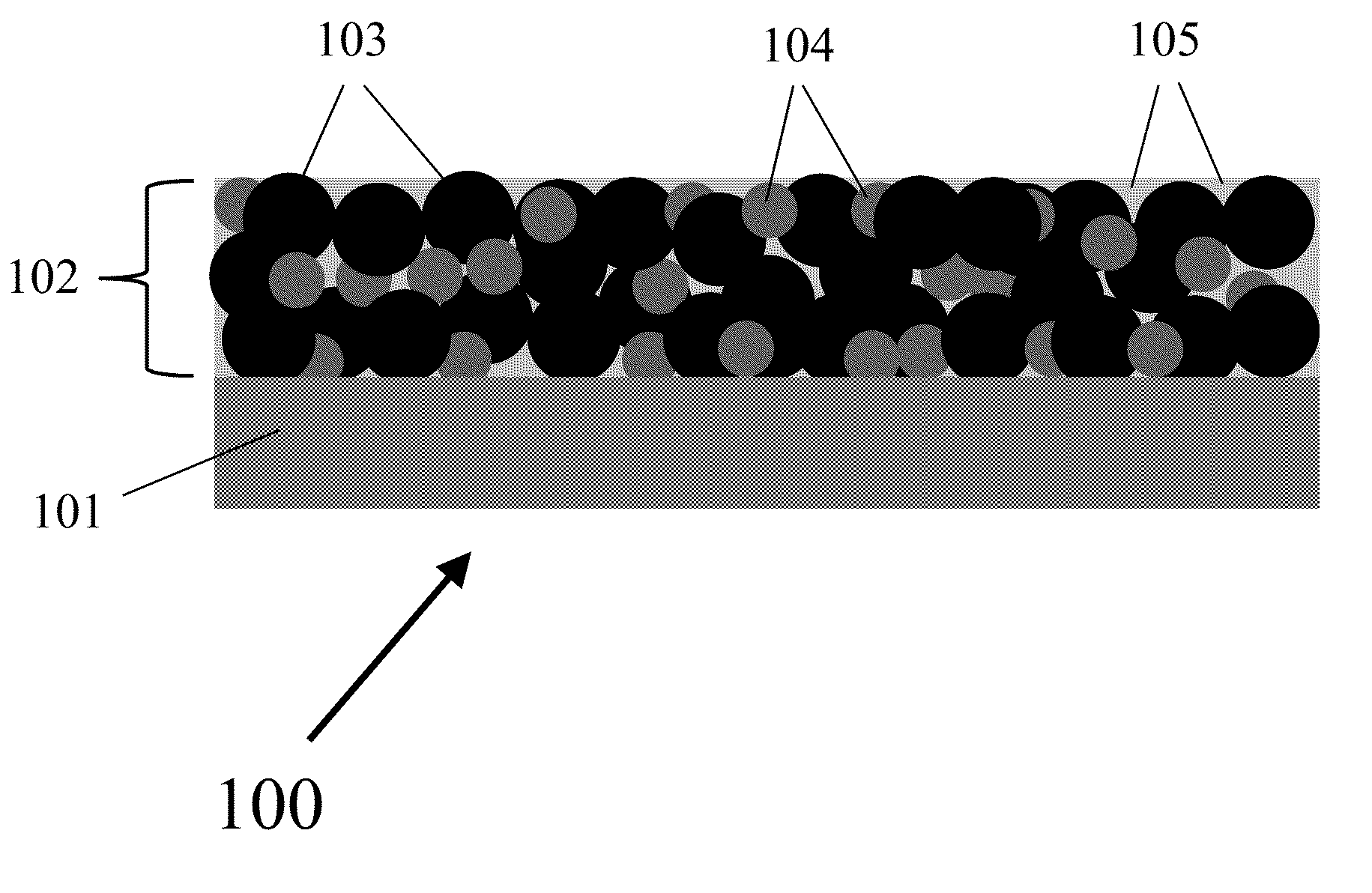

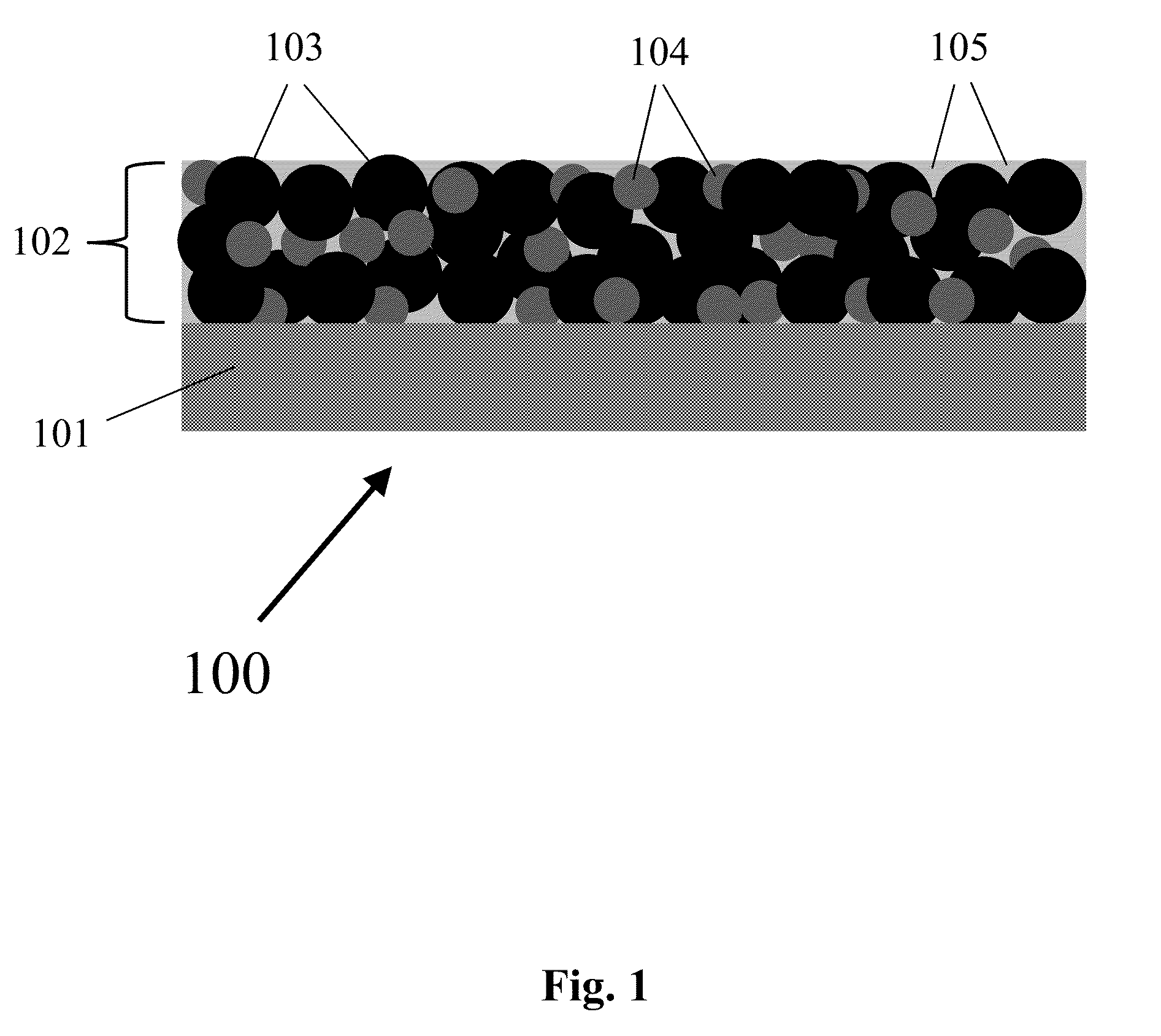

Three-dimensional, porous anode for use in lithium-ion batteries and method of fabrication thereof

ActiveUS20160049656A1Solvent dissolution of polymer A or polymer may be facilitatedElectrode thermal treatmentNegative electrodesCarbon compositesEmulsion

A three-dimensional, porous anode material suitable for use in a lithium-ion cell. The three-dimensional, porous anode material includes active anode particles embedded within a carbon matrix. The porous structure of this novel anode material allows for the expansion and contraction of the anode without the anode delaminating or breaking apart, thus improving the life-cycle of the lithium-ion cell. An example of this three-dimensional porous anode material is a porous silicon-carbon composite formed using a bi-continuous micro-emulsion (BME) template.

Owner:GINER INC

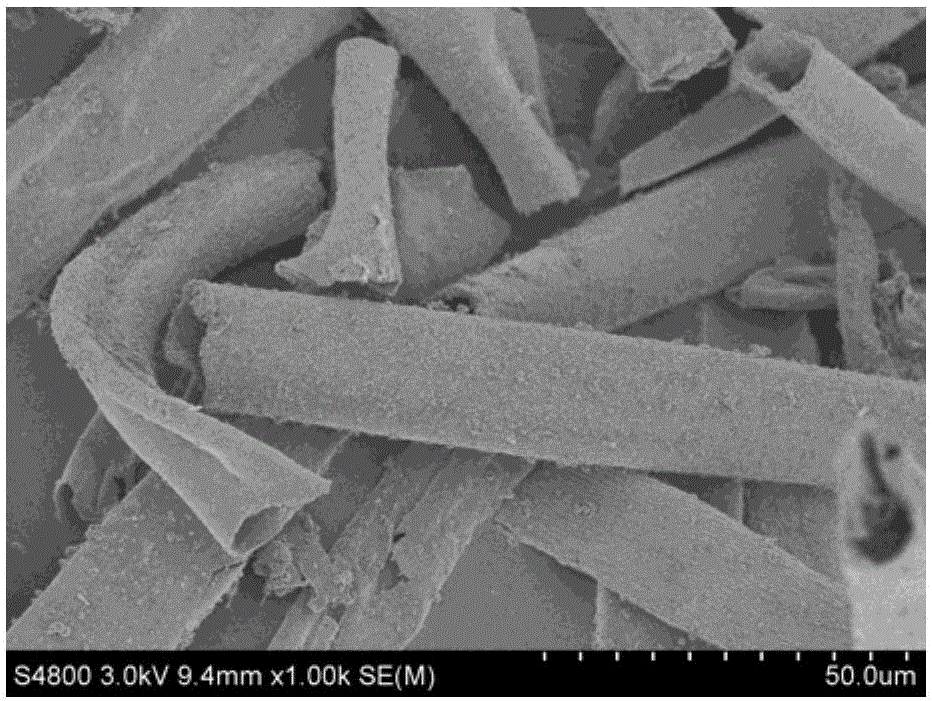

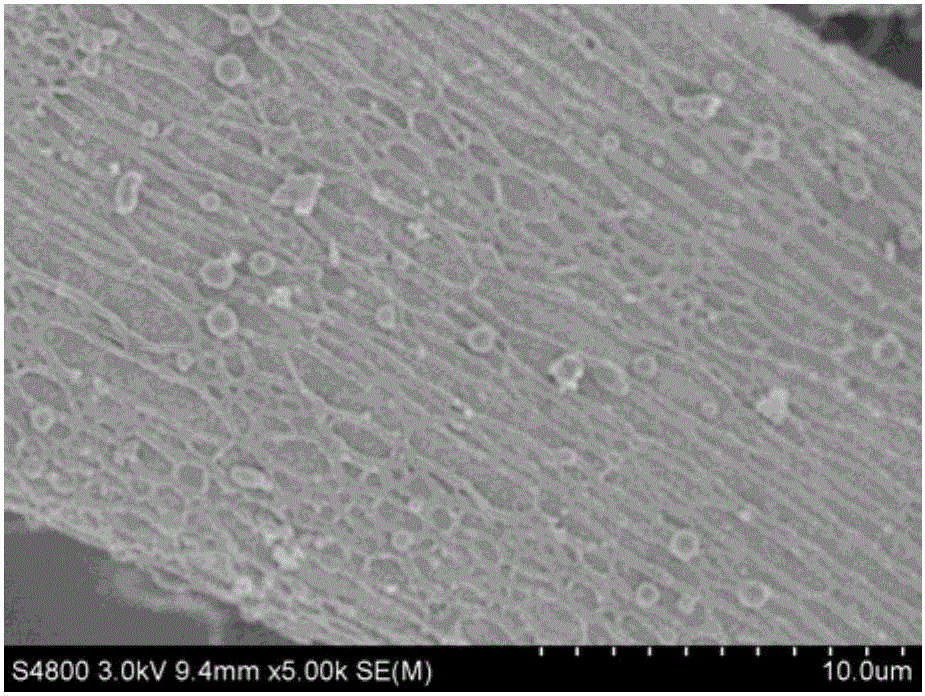

Preparation method and application of hollow tubular biochar

InactiveCN105776182ALow carbonization temperatureLarge specific surface areaHybrid capacitor electrodesCell electrodesSorbentKapok fiber

The invention discloses a preparation method and application of hollow tubular biochar. The preparation method includes: dispersing kapok fiber in a sulfuric acid solution for hydrothermal reaction to obtain carbonized kapok fiber; calcining the carbonized kapok fiber under protection of inert gas, cooling, washing, collecting and drying the calcined kapok fiber to obtain the hollow tubular biochar. The preparation method is simple and easy to control, carbonization and activation of the kapok fiber can be well realized on the premise that original structure of the kapok fiber is maintained, and distribution of balls in the inner surface and the outer surface of a hollow tube can be realized by controlling hydrothermal temperature and calcining temperature. In addition, the biochar prepared by the method can be applied in lithium / sodium ion batteries and supercapacitors and can be used as a carbon matrix in adsorbents, template agents and composite materials. Especially, the hollow tubular biochar presents excellent electrochemical performance when being applied in the lithium / sodium ion batteries.

Owner:SHAANXI UNIV OF SCI & TECH

Process for preparing alloy composite negative electrode material for lithium ion batteries

InactiveCN102484241AImprove electrochemical performanceLow costElectrode manufacturing processesNeutral atmosphereAlloy composite

The present invention relates to a process for preparing an alloy composite negative electrode material having a spherical carbon matrix structure for lithium ion batteries by spray-drying carbothermal reduction. The invention covers a process for preparing a negative electrode material for a lithium ion battery with a general formula A-M / Carbon, wherein A is a metal selected from the group consisting of Si, Sn, Sb, Ge and Al; and wherein M is different from A and is at least one element selected from the group consisting of B, Cr, Nb, Cu, Zr, Ag, Ni, Zn, Fe, Co, Mn, Sb, Zn, Ca, Mg, V, Ti, In, Al, Ge; and comprising the steps of: - providing a solution comprising an organic polymer and either chemically reducible nanometric A- and M-precursor compounds, or nanometric Si and a chemically reducible M-precursor compound, when said metal A is Si; - spray-drying said solution whereby a A- and M-precursor bearing polymer powder is obtained, and - calcining said powder in a neutral atmosphere at a temperature between 500 and 1000 DEG C for 3 to 10 hours whereby, in this carbothermal reduction, a carbon matrix is obtained bearing homogeneously distributed A-M alloy particles.

Owner:UMICORE AG & CO KG +1

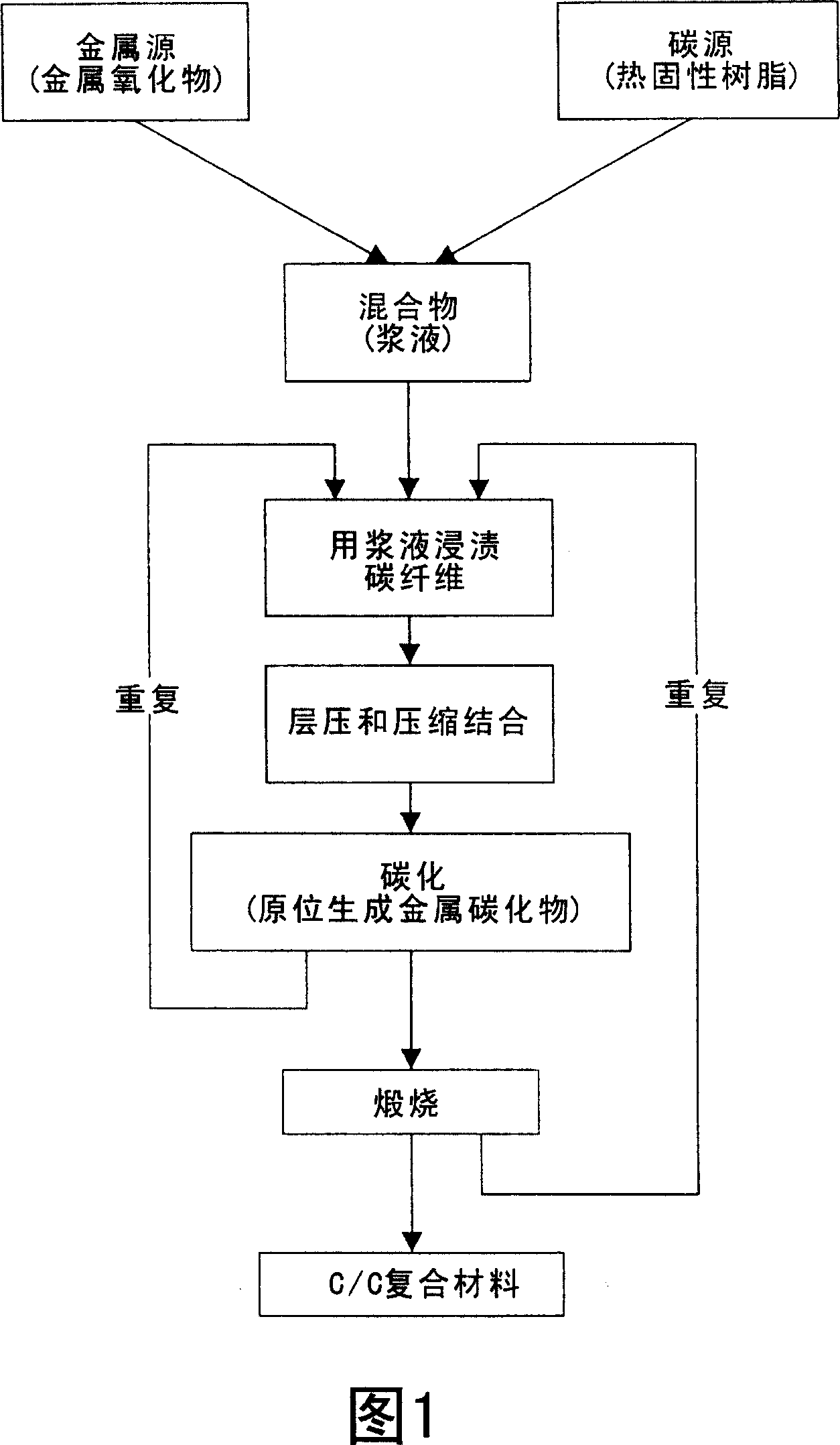

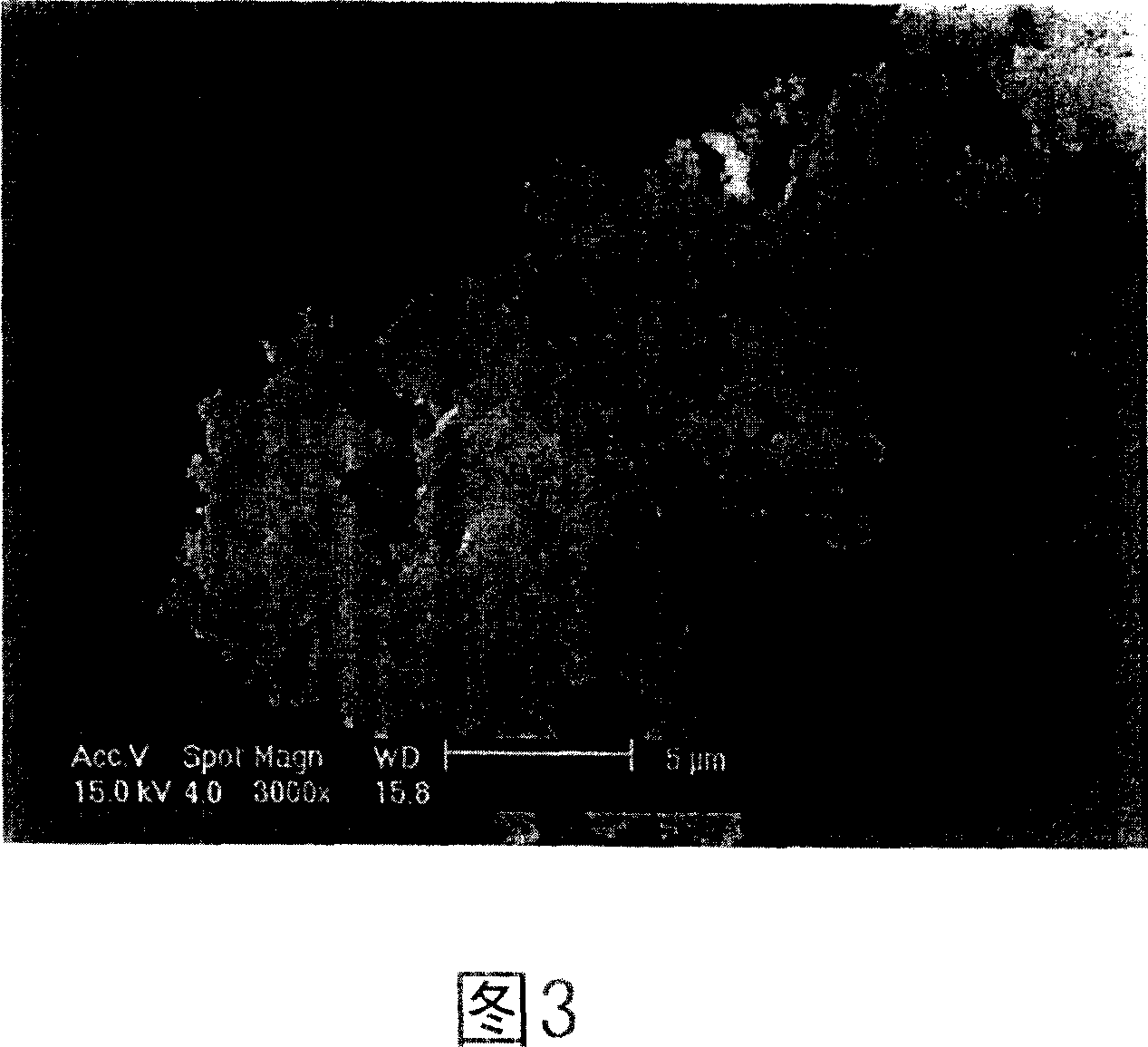

Composite carbon material having metal carbide particles dispersed therein and method for preparation thereof

InactiveCN1946655AIncrease coefficient of frictionImprove thermal stabilityBraking discsFriction liningCarbon compositesCarbon fibers

A composite carbon material, characterized in that metal carbide particles having been formed in-situ by the use of one or more of metal particles, metal oxide particles and composite metal oxide particles as a metal source and a thermosetting resin as a carbon source, and comprising a metal carbide at least in the surface portion thereof or consisting of a metal carbide are dispersed in a carbon matrix, a carbon fiber matrix or a carbon / carbon fiber matrix, and it contains no free metal particles; and a method for preparing the above composite carbon material. The composite carbon material has a high friction coefficient, and also exhibits high heat resistance and wear resistance.

Owner:TOYOTA JIDOSHA KK

Carbon/carbon compound material heating element and production technology thereof

The invention discloses a simple-process environment-friendly carbon / carbon composite heating element and a production process thereof, which is characterized in that the heating element is prepared by making blank from carbon fibers, densifying, purifying, machining and purifying; the heating element is simple in process; as a net body formed by fluffy needle-like carbon fibers is adopted in the process of making the blank, a quasi-3D prefabricated part is easier to obtain in a needling process; the carbon fibers inside the prefabricated part are crisscrossed, strong in cohesive force, free from delamination and stable in structure; meanwhile, the prefabricated part is small in pore, which facilitates the acceleration of the subsequent densifying process; the heating element blank prepared through chemical vapor deposition densification consists of the carbon fibers and a carbon matrix, wherein the carbon matrix is formed by pyrolytic carbon obtained through a high temperature pyrolysis mode, which is high in purity; and a carbon / carbon composite product with the ash content less than 180 ppm can be obtained only through high-temperature purification in a vacuum or protective atmosphere, thereby saving energy and protecting environment.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com