Carbon/carbon compound material heating element and production technology thereof

A carbon composite material and production process technology, applied in the field of high-temperature furnace components, can solve problems such as high impurity content and complicated process, and achieve the effect of simple process, stable structure and strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Blank making:

[0024] ① Opening and forming: Shorten long carbon fibers into short carbon fibers with a length of 25mm to 70mm, open them into fluffy needle-like fibers through opening equipment, and then air-laid and / or carded the opened carbon fibers into a network, Utilize net laying machine to pave fiber net again, prepuncture net tire, the area density of described net tire is 20g / m 2 ~200g / m 2 (the present embodiment is 120g / m 2 );

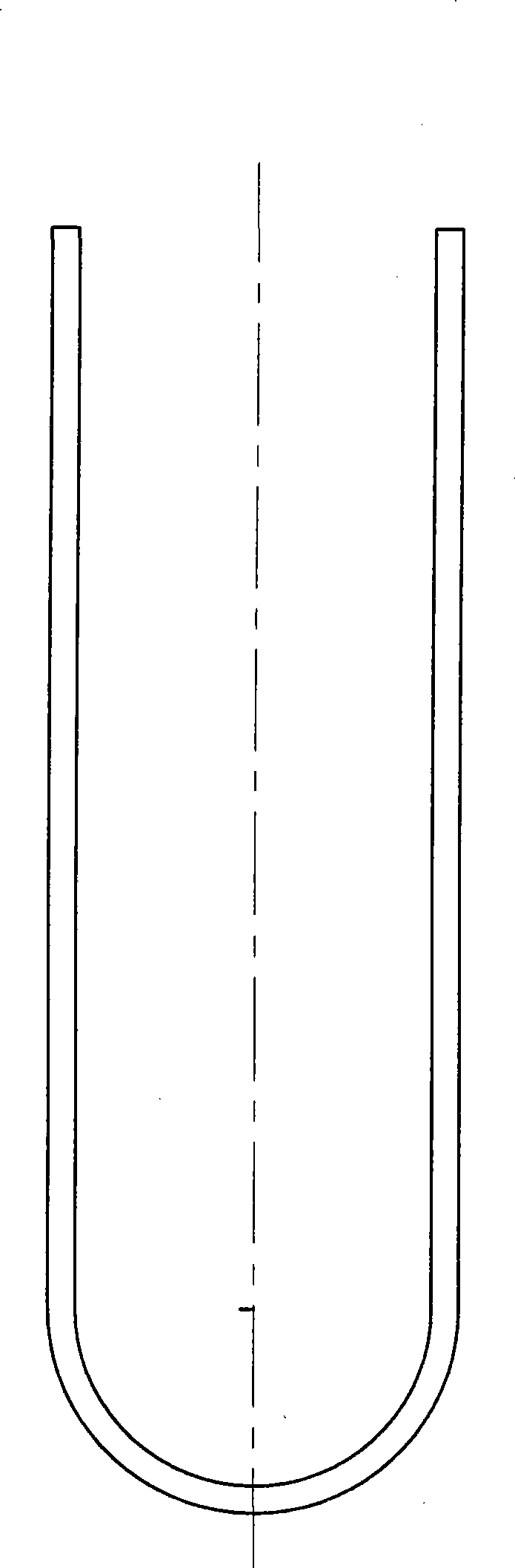

[0025] ② Winding and needle punching forming Using the method of near-net forming, the mesh tire is wound on the mold (U-shaped mold in this embodiment), and a layer of carbon cloth is covered on it. The surface density of the carbon cloth is 100g / m 2 ~400g / m 2 (the present embodiment is 260g / m 2 ), and then covered with a layer of mesh tire, the mesh tire and carbon cloth are overlapped to the required thickness, and compounded by acupuncture to make the required carbon / carbon composite heating body prefabricated body, the ...

Embodiment 2

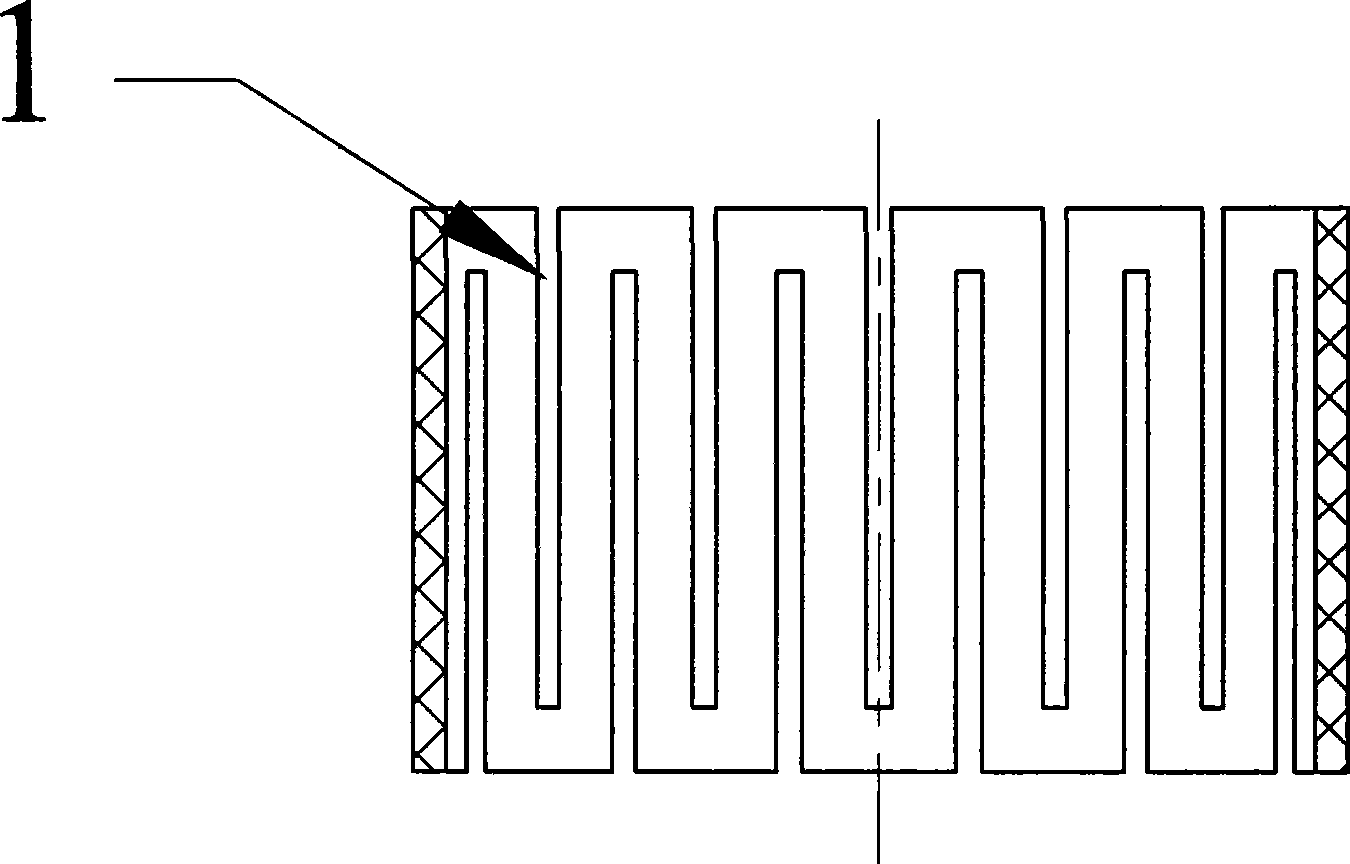

[0034] In step (1), the heating element preform is processed into a plate shape, and its apparent density is 0.61g / cm 3 , the apparent density after densification is 1.65g / cm 3 , cut into strips earlier during machining, and then machined into bars, the remainder is the same as in Example 1.

Embodiment 3

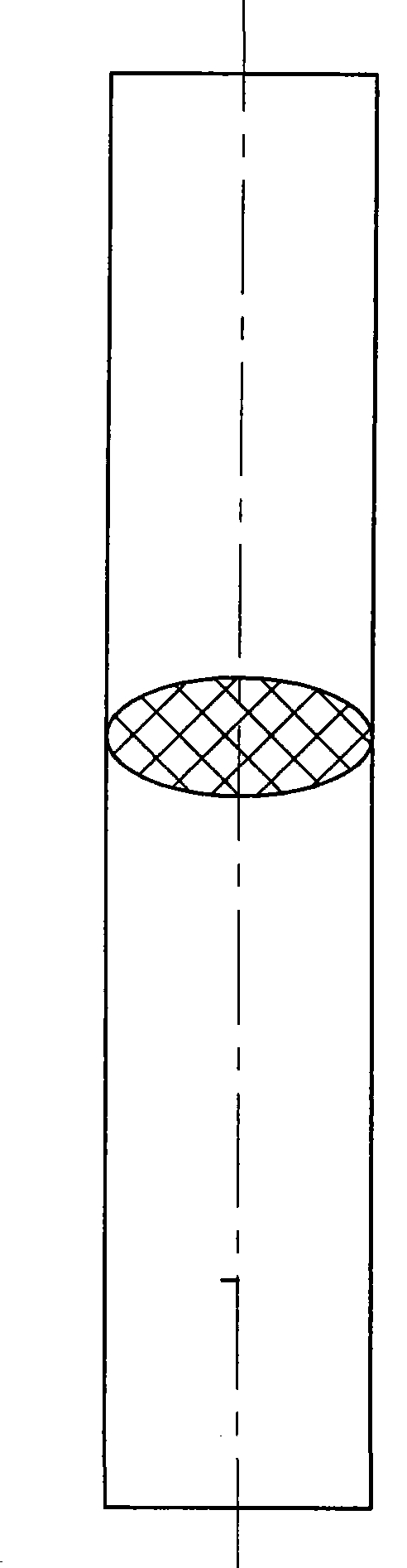

[0036] In step (1), the mold is cylindrical, and the finished product processed into a heating element is also cylindrical, and the apparent density of the heating element preform is 0.5g / cm 3 , the apparent density after densification is 1.59g / cm 3 , The cylindrical heating element is evenly distributed with the conduction and heat dissipation grooves 1 formed by machining, and the remainder is the same as that of the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com