Patents

Literature

411results about How to "Strong cohesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

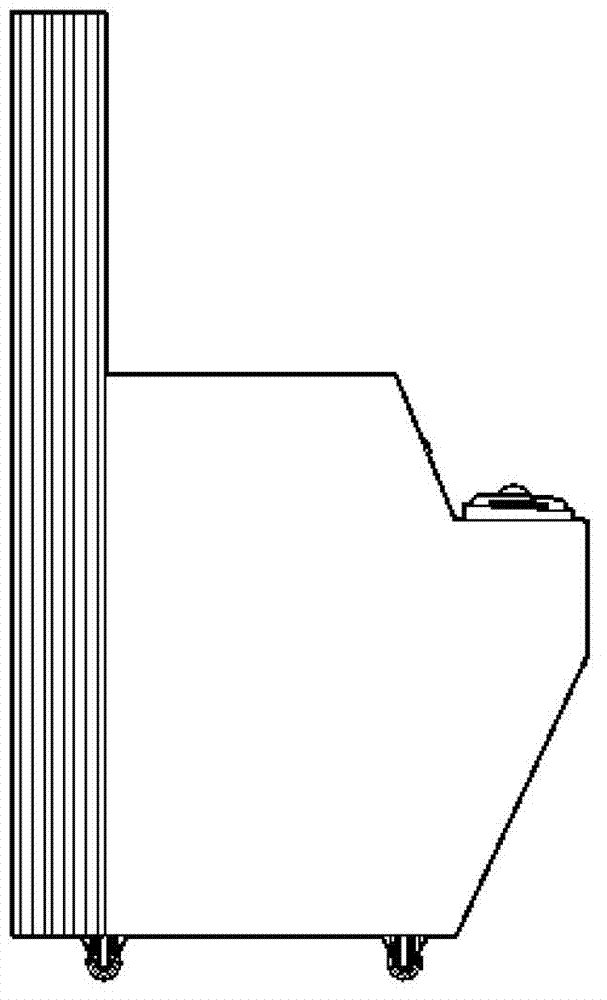

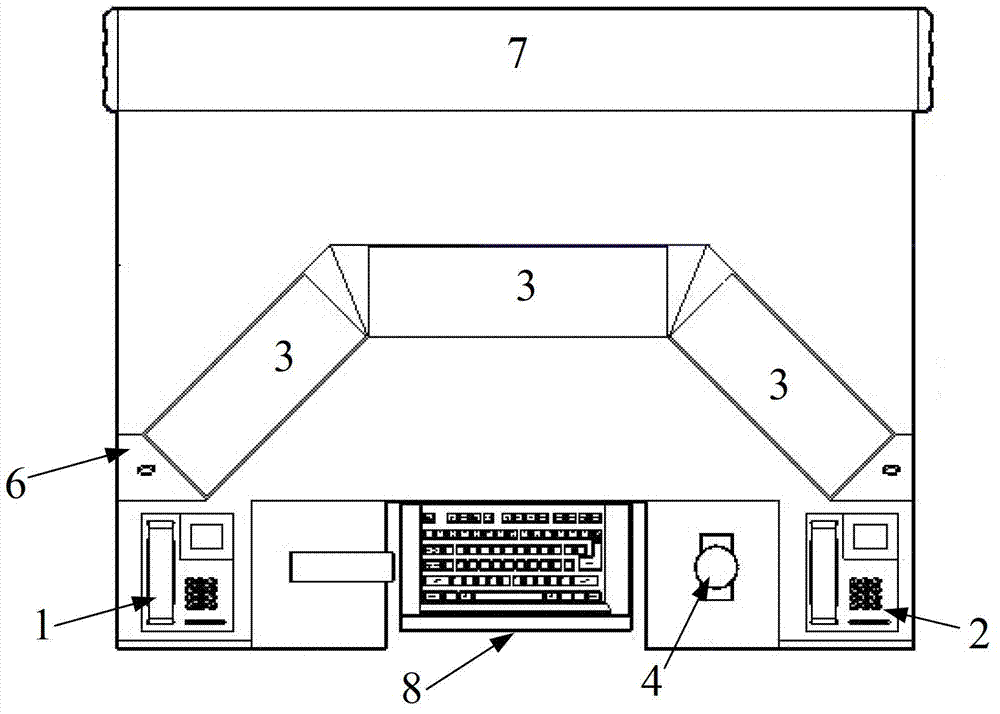

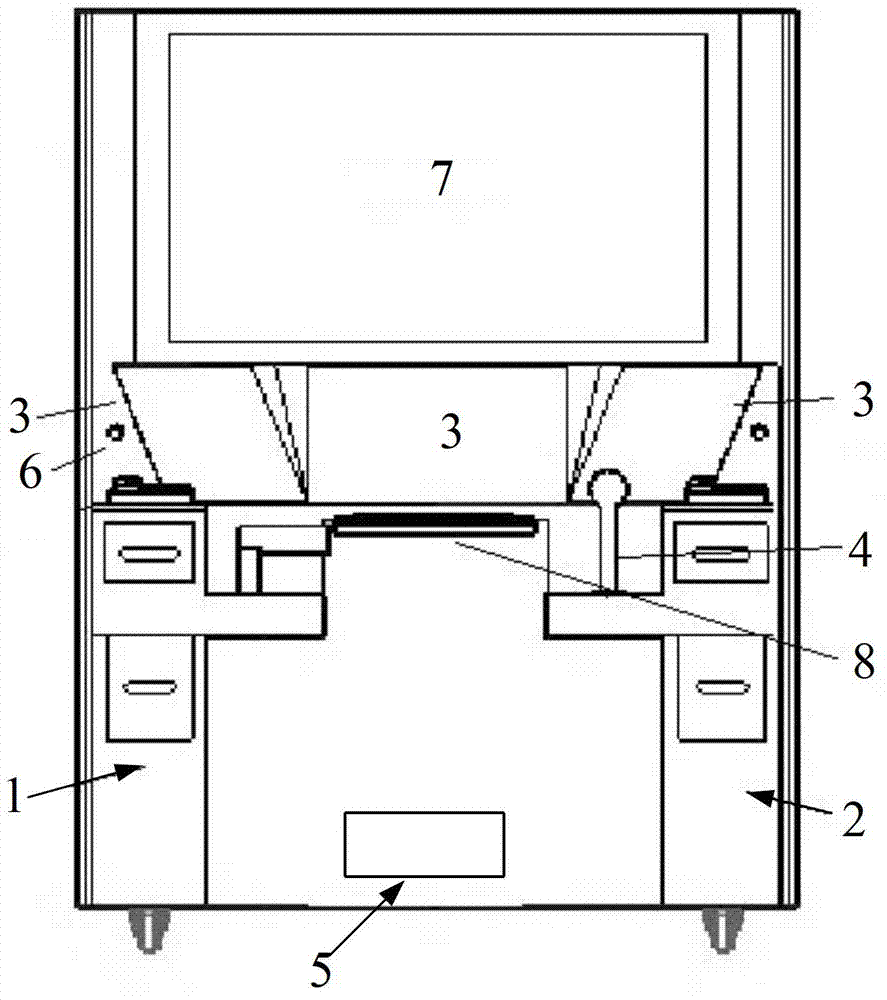

Ground station of universalized configurable unmanned aerial vehicle

InactiveCN102774505AImprove immersionLighten the mental loadGround installationsFly controlGround station

The invention discloses a ground station of a universalized configurable unmanned aerial vehicle, belonging to the technical field of unmanned aerial vehicle control. The ground station comprises a task planning module, a HOTAS (Hands on the Throttle and Stick) and pedal manipulation data acquisition module, a voice identifying and alarming module, an electronic flying information module and a multi-point touch module which are deployed on a computer A, and a flying information communication module, a training communication module, an aircraft adapting module, a databank module, a voice and video acquisition module and a 3D (Three-dimensional) view display module which are deployed on a computer B. On the basis that the psychological and physiological characteristics of a unmanned aerial vehicle manipulator are considered, the comprehensive problems of flying control and task control, and the problems of three-dimensional information sensation and fatigue caused by long-time operation are solved well; the universalization of the ground station of the unmanned aerial vehicle is realized; and the repeated construction is reduced.

Owner:BEIHANG UNIV

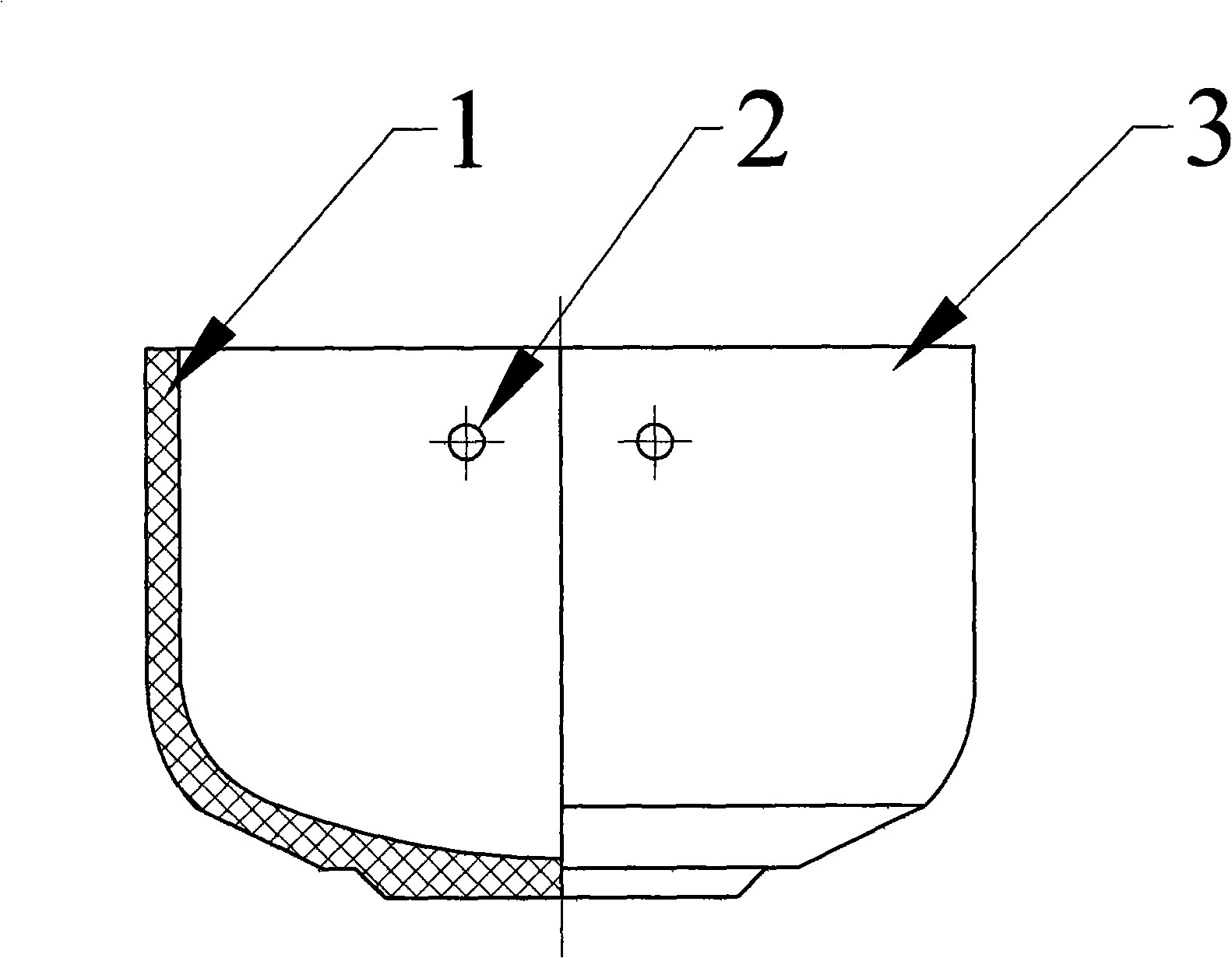

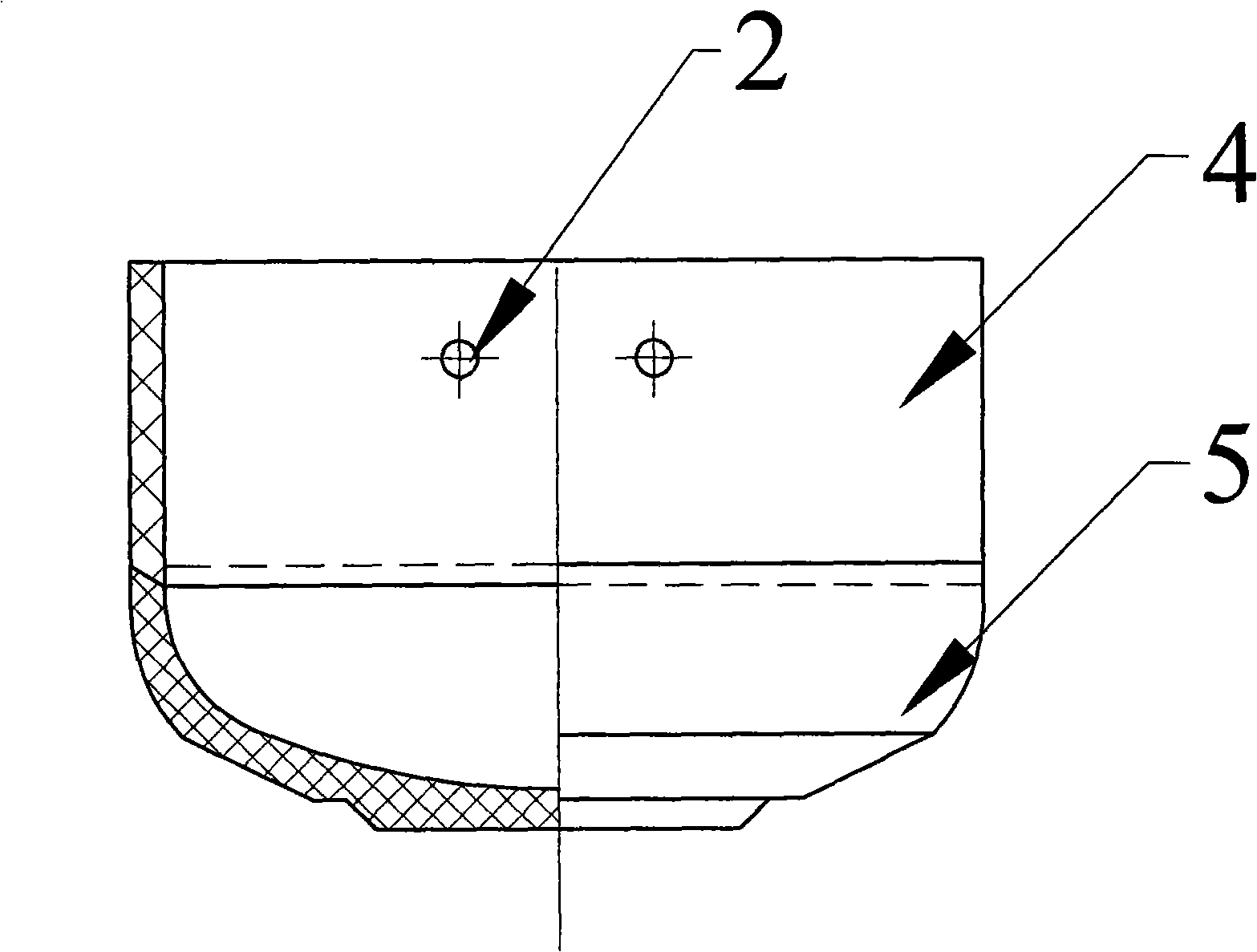

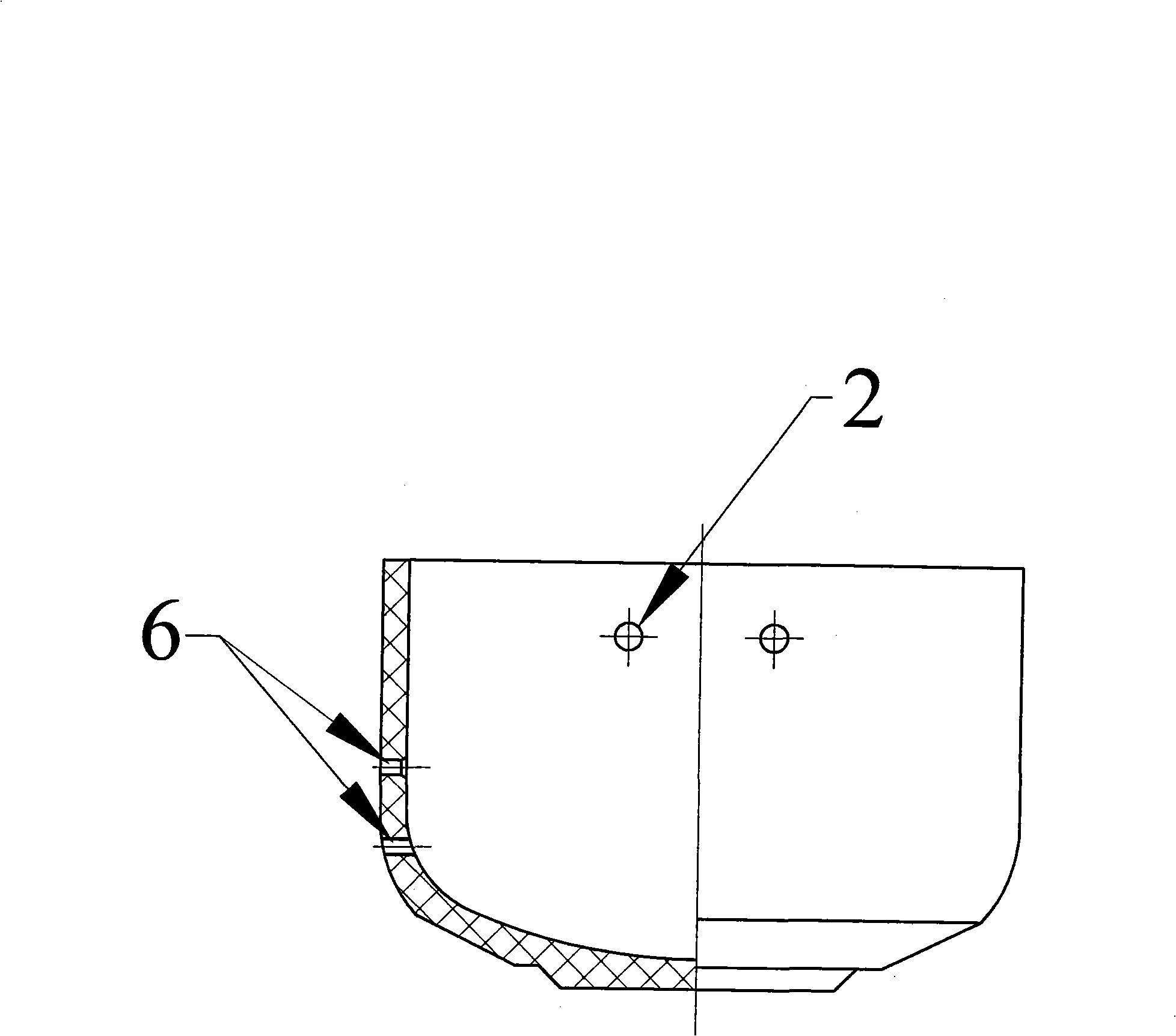

Carbon/carbon composite material crucible pot and preparing technique thereof

The invention discloses a carbon / carbon composite material crucible with simple technique and environmental protection and a technique for producing the same. The carbon / carbon composite material crucible can be prepared into a whole, or consists of 2 to 4 sections or consists of an upper part and a lower part which are relatively a bowl-shaped tray (5) and a cylinder (4). The technique for producing the carbon / carbon composite material crucible is as follows: the carbon / carbon composite material crucible is prepared through performing, densifying, purifying and machining of carbon fibers. The production technique has a simple technique; under the condition of performing, a mat which is formed by fluffy needlelike carbon fibers is adopted, thereby a quasi-three-dimensional prefabricated part is easy to obtain under the condition of needling; internal carbon fibers of the quasi-three-dimensional prefabricated part are interlaced, have strong cohesive force, can not be delaminated, and have stable structures; simultaneously, the pore space of the prefabricated part is small, which is convenient for accelerating the subsequent process of the densifying; and the purity of the crucible after the densifying is very high, and the carbon / carbon composite material crucible with an ash content less than 180 ppms can be produced only through high-temperature purification under the condition of vacuum or protective atmosphere; and the carbon / carbon composite material crucible is energy-saving and environment-friendly.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

High ratio blended spinning technique for ultrashort low-density fibre based on cotton spinning device

InactiveCN101148797ARaise the ratioReasonable workmanshipFibre cleaning and opening machine combinationsCarding machinesYarnPolymer science

The present invention discloses the process of producing blended cheese yarn with high content of ultra short low density fiber in cotton spinning apparatus. A punching with high homogeneity and great cohesion is first produced through mixing ultra short low density fiber and other fiber in an opening and picking step much loosening and less beating; and then produced into cheese through the steps of combing, drawing, roving, spinning and coning. The blended cheese yarn consists of ultra short low density fiber 51-95 wt%, natural fiber 5-49 wt% and chemical fiber 5-49 wt%. The blended cheese yarn with high content of ultra short low density fiber is light, soft, lofty and high in strength, and its produced fabric has high color fastness.

Owner:DONGHUA UNIV +1

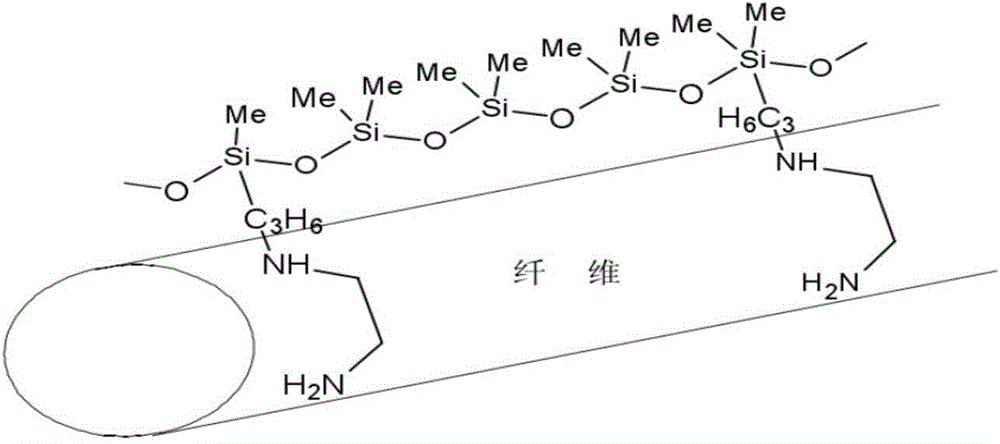

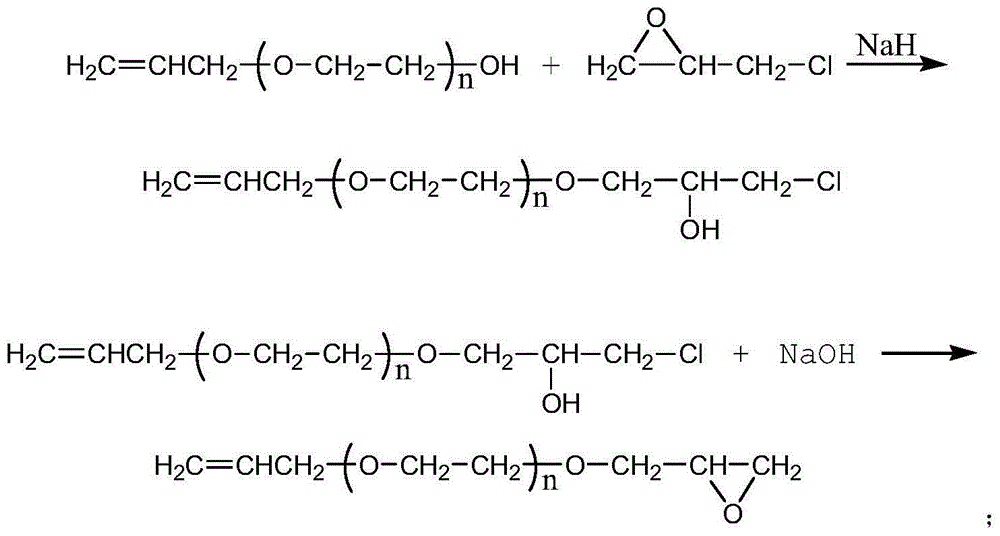

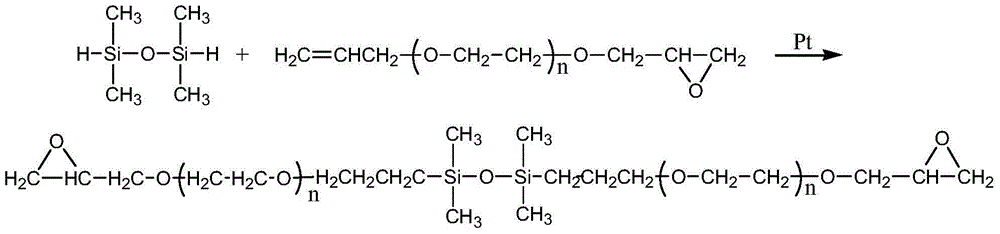

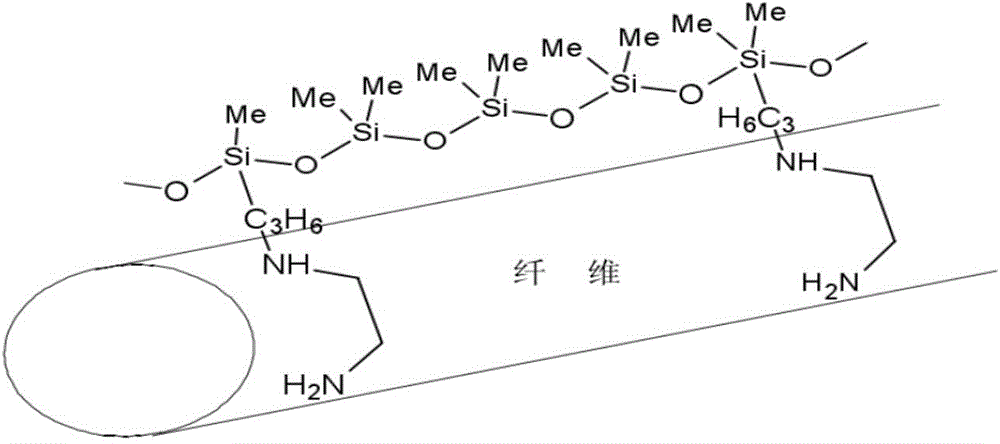

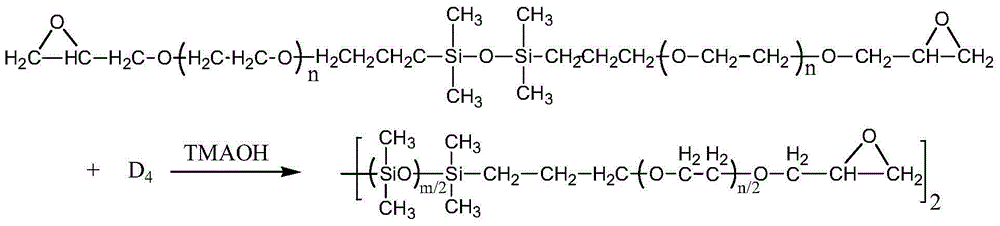

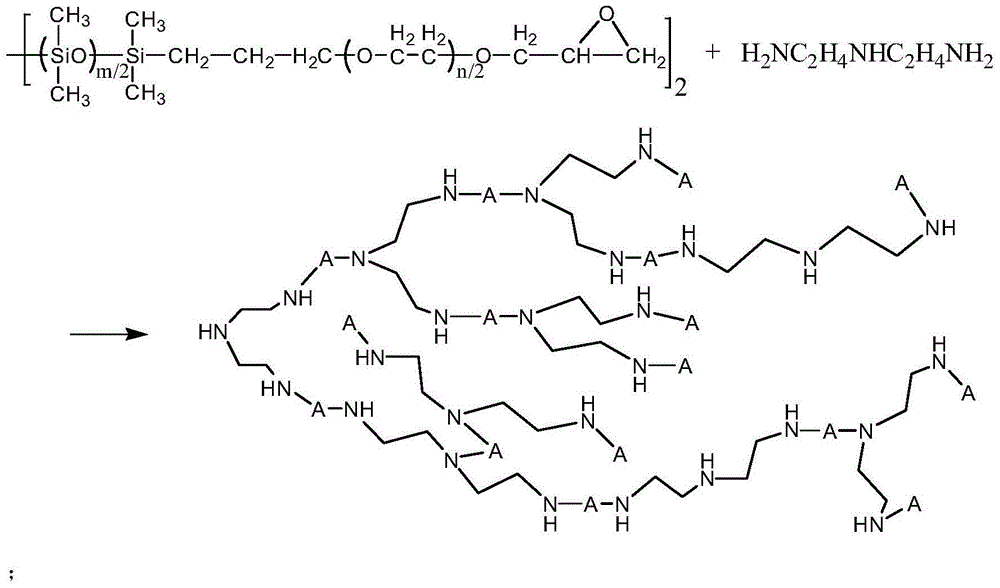

Preparation method of hyperbranched ternary polymerization organic silicon

The invention discloses a preparation method of hyperbranched ternary polymerization organic silicon. The preparation method comprises the following steps: preparing allyl polyoxyethylene glycidyl ether; preparing epoxy-terminated polyether block siloxane; preparing polyether / epoxy block silicone oil; preparing hyperbranched ternary polymerization organic silicon. According to the preparation method, a hyperbranched polymer and linear polyether amino block organic silicon are bonded together to research a novel organic silicon softener with a novel modified organic silicon chemical structure, and a synthesized hyperbranched matter is capable of enhancing the cohesive force among fibers and endowing a fabric with soft, plump and washable hand feel, high in molecular mass and low in viscosity and has much hydrophilic groups; the problem that emulsion of traditional amino modified silicon oil is easily broken is solved, the product has self-emulsifying property in water and is good in emulsion stability; the yellowing property is reduced, and the hydrophily is enhanced; a processed fabric is good in hydrophily and low in yellowing property and is bonded with fabric by virtue of chemical bonds, so that the washability is improved, and the fabric has a flexible effect of amino silicon oil.

Owner:南通曙光染织有限公司

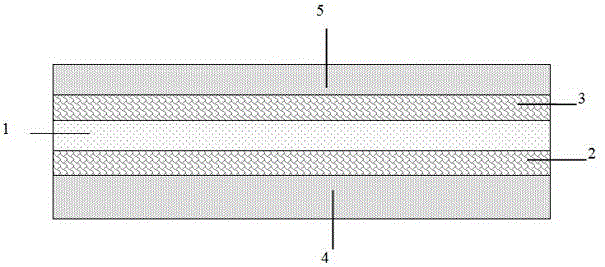

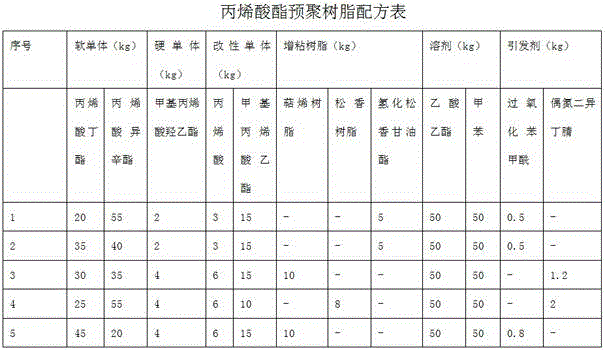

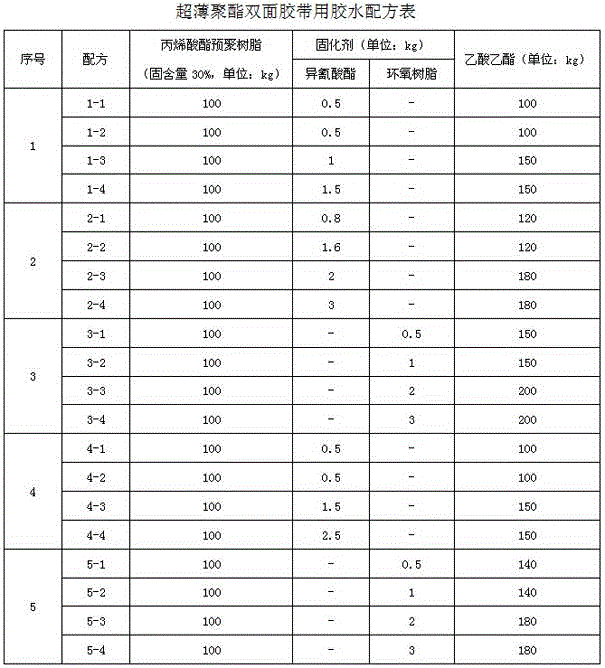

Ultra-thin polyester double-sided adhesive tape, glue thereof, and preparation method thereof

ActiveCN104152077AHigh bonding strengthImprove cohesionFilm/foil adhesivesEster polymer adhesivesPolyesterAdhesive

The invention discloses an ultra-thin polyester double-sided adhesive tape comprising a polyester thin film layer and two glue layers formed by glue coated on front and back sides of the polyester thin film. The thickness of the polyester thin film is 0.001-0.0012mm. The thickness of the glue layer is 0.002mm. Therefore, the thickness of the double-sided adhesive tape is only 0.005mm, such that electronic product development trends of thin and light can be satisfied. The total thickness of adhesive is 0.004mm, such that the tape has ultra-low thermal resistance, and heat generated by electrical components can be conducted in time. Therefore, electrical component damage caused by long-term working under high temperature is avoided. Also, the invention discloses a formula for the glue used in the ultra-thin polyester double-sided adhesive tape. The glue comprises the raw materials of, by weight, 100 parts of acrylate prepolymer resin, 0.5-3 parts of a curing agent, and 100-200 parts of ethyl acetate. With the glue, a single side thickness is 0.002mm, and high adhesive performance can be provided.

Owner:四川羽玺新材料股份有限公司

Preparation method of hyper-branched polyether amide block silicone

The invention discloses a preparation method of hyper-branched polyether amide block silicone. The preparation method comprises the following steps: preparing polyether / epoxy block silicone oil and preparing hyper-branched polyether amide block silicone. According to the preparation method, hyper-branched polymers and linear polyether amino block silicone are combined together to develop a new silicone softening agent with a newly modified silicone chemical structure; the synthesized hyper-branched material has a reticular structure which not only strengthens cohesive force between fibers, but also strengthens cohesive force between yarns; the invention is high in molecular weight, low in viscosity, rich in hydrophilic groups and capable of endowing soft, well-rounded and washable touch on fabrics; the problem of easy demulsification of traditional amino-modified silicone oil is solved; the product has self-emulsifying performance in water and is good in emulsion stability; the hyper-branched polyether amide block silicone is reduced in yellowing performance and enhanced in hydrophilicity; fabrics made accordingly has good hydrophilicity and low yellowing performance; and the hyper-branched polyether amide block silicone combines with the fabrics in a form of chemical bonds, so that the wash resistances is enhanced and the soft effect of amino silicone oil is achieved.

Owner:南通曙光染织有限公司

Shield tail seal grease of shield excavating machine

The invention discloses a shield tail seal grease of a shield excavating machine, which is used for passing through sand soil, rivers and lakes in the process of excavating construction of an underground project. The shield tail seal grease is combined by the following raw materials in parts by weight: 15-25 parts of plant oil, 15-25 parts of viscosity index modifying agents, 50-60 parts of stuffing, 5-10 parts of thickening agent, 0.8-1.2 parts of mildewproof agents, 0.5-1.0 part of wet dispersing agents and 2-6 parts of bamboo fibres. The seal grease has good seal performance and pumping ability and no pollution to the environment, can particularly play a favorable seal role in the sand soil or a deeper soil layer with more water content and solve the problem of easy slurry leakage or large dosage in the sand soil, which commonly exists in the grease in the current market.

Owner:SHANGHAI CIFU NEW BUILDING MATERIALS CO LTD

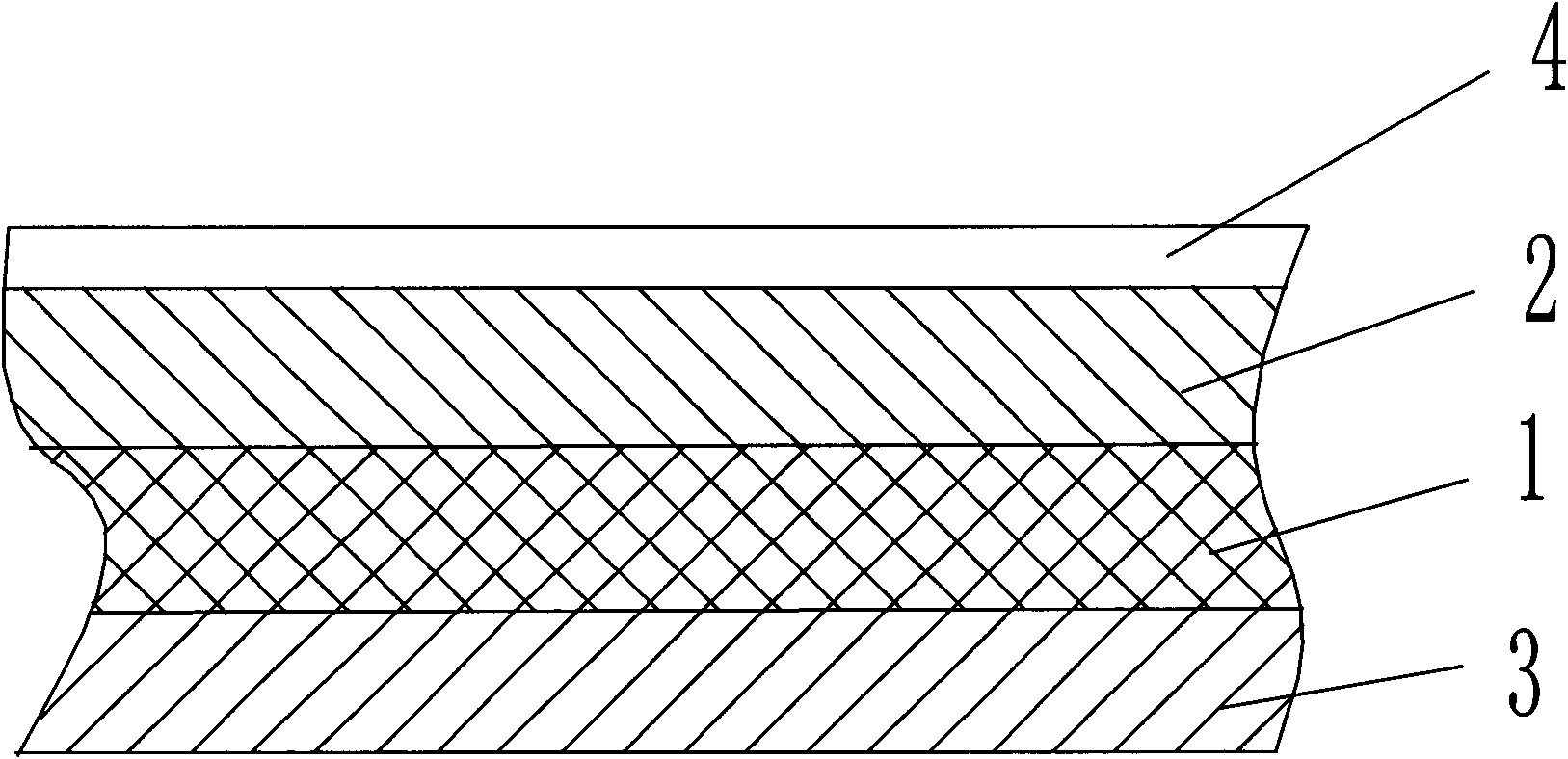

Corrosion-resisting and heat-resisting compound filter material and preparation method thereof

ActiveCN101898059AStrong cohesionHigh temperature resistantLayered productsFiltration separationFiberGlass fiber

The invention relates to a corrosion-resisting and heat-resisting compound filter material and a preparation method thereof. The compound filter material comprises a base fabric and filter felts, wherein the upper surface and the lower surface of the base fabric are both coated with the filter felts, and the surface of an upper filter layer of the upper surface is coated with a polytetrafluoroethylene membrane; the base fabric is impregnated with an impregnating liquid; the filter felts on the upper surface are all prepared by mixing chemical polyester fiber, glass fiber, polyphenylene sulfide fiber, polyarmide fiber and polytetrafluoroethylene fiber; the filter felt on the lower surface is prepared by mixing chemical polyester fiber, glass fiber, polyphenylene sulfide fiber and polyarmide fiber; and the lengths of all the fiber materials ranges from 60 to 70 mm. The preparation method comprises the following steps of: weaving the glass fiber into a woven base fabric; impregnating the woven base fabric, drying for use; making the filter felts on the upper surface and the lower surface, and coating the filter felts on the upper surface and the lower surface to form a compound filter felt; impregnating once again, and drying; and finally, coating the polytetrafluoroethylene membrane on the surface of the upper filter layer.

Owner:JIANGSU FILTERTEX FILTER MATERIAL

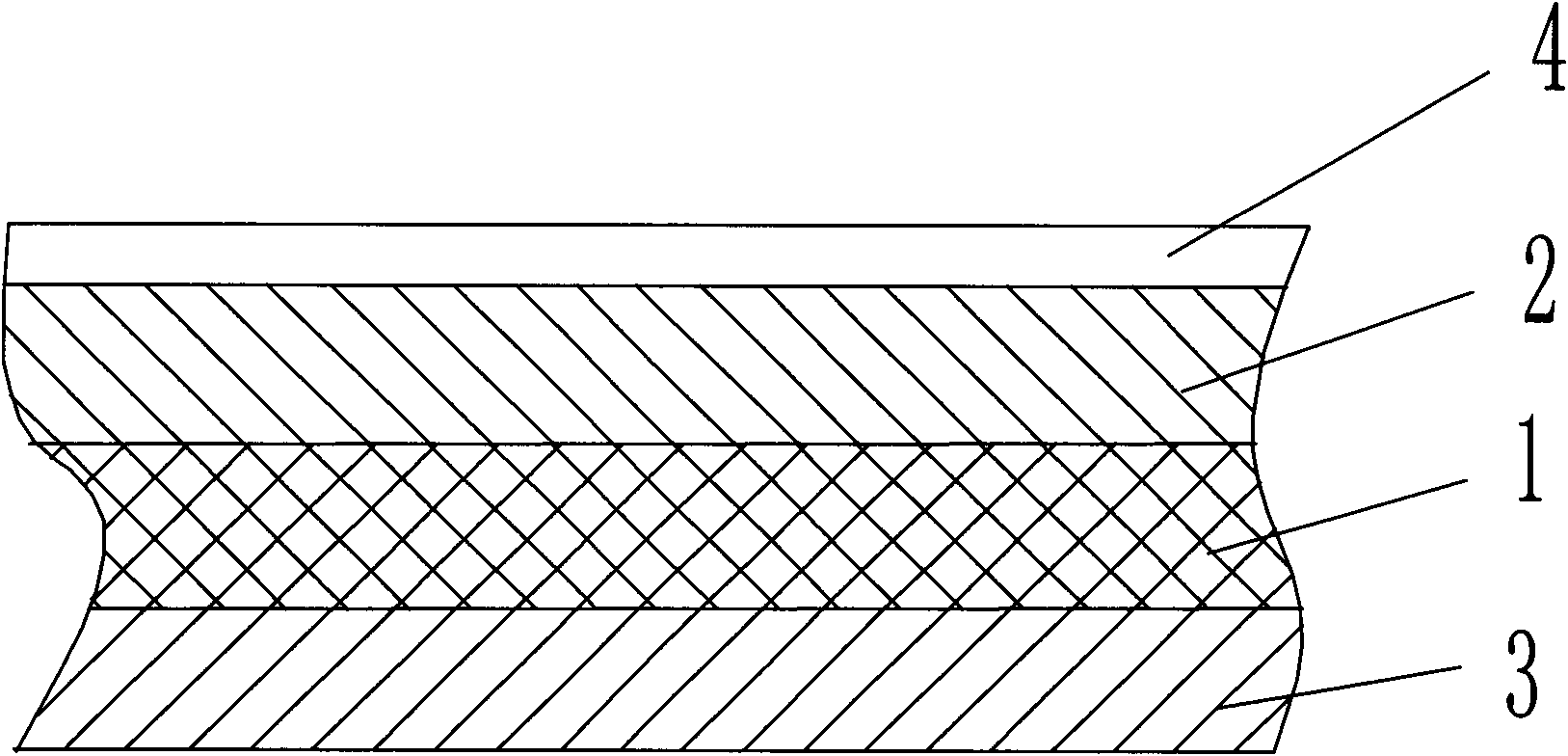

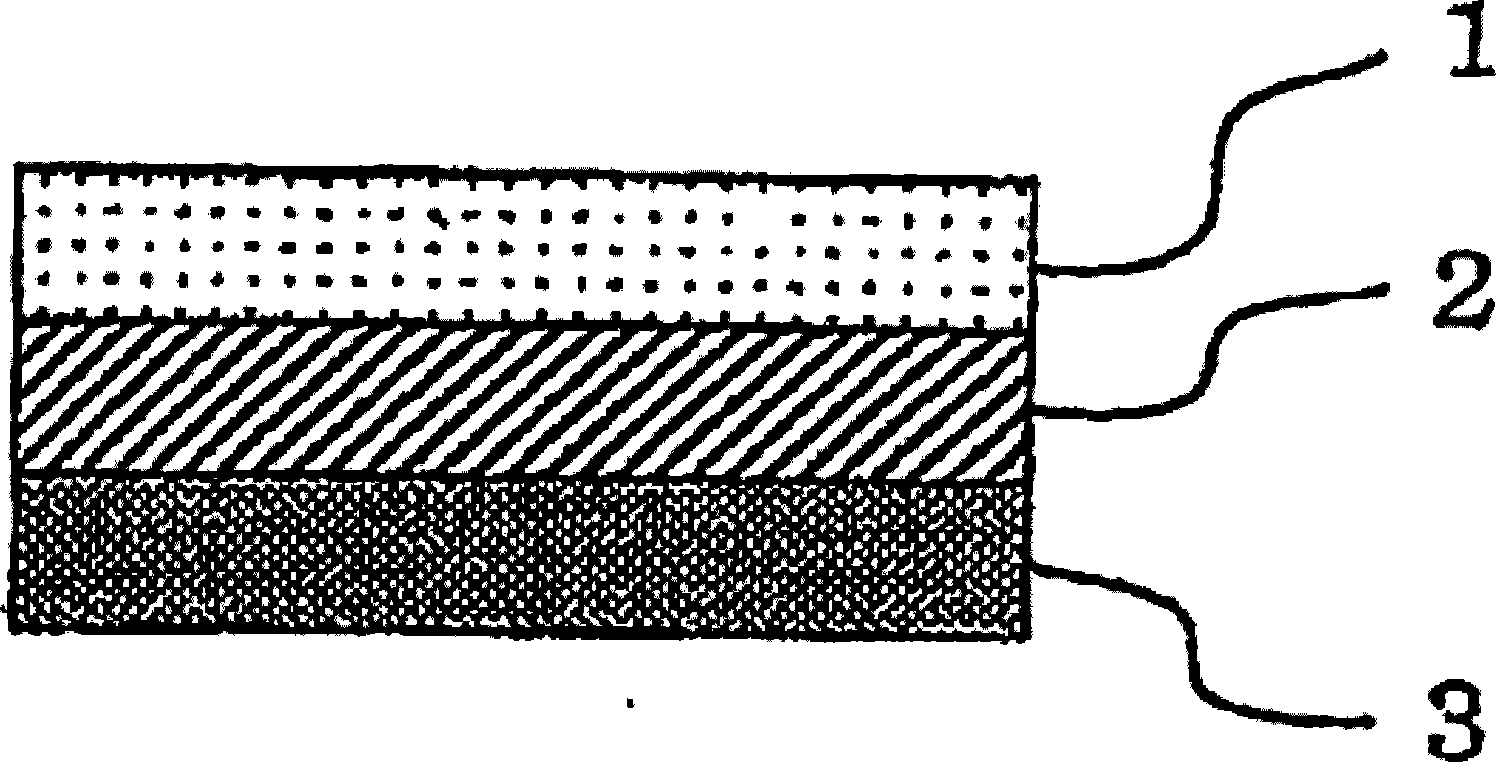

Urethane acrylate composite structure

InactiveUS20050238824A1Low viscosityLow VOC emissionFilm/foil adhesivesSynthetic resin layered productsChemistryComposite structure

A composite structure includes a first layer, a support layer, and a urethane acrylate layer disposed between the first layer and the support layer. The first layer is a show surface of the composite structure. The urethane acrylate layer includes a urethane acrylate composition that includes a urethane acrylate adduct. The urethane acrylate adduct is the reaction product of an isocyanate component and a stoichiometric excess of a functionalized acrylate component. The isocyanate component has at least two isocyanate groups. The functionalized acrylate component has at least one isocyanate-reactive functional group that is reactive with at least one of the isocyanate groups for forming the urethane acrylate adduct. The resulting urethane acrylate composition is sufficiently low in viscosity for many processing applications, and the urethane acrylate layer including the urethane acrylate composition exhibits sufficient adhesion to the first layer and support layer.

Owner:BASF CORP

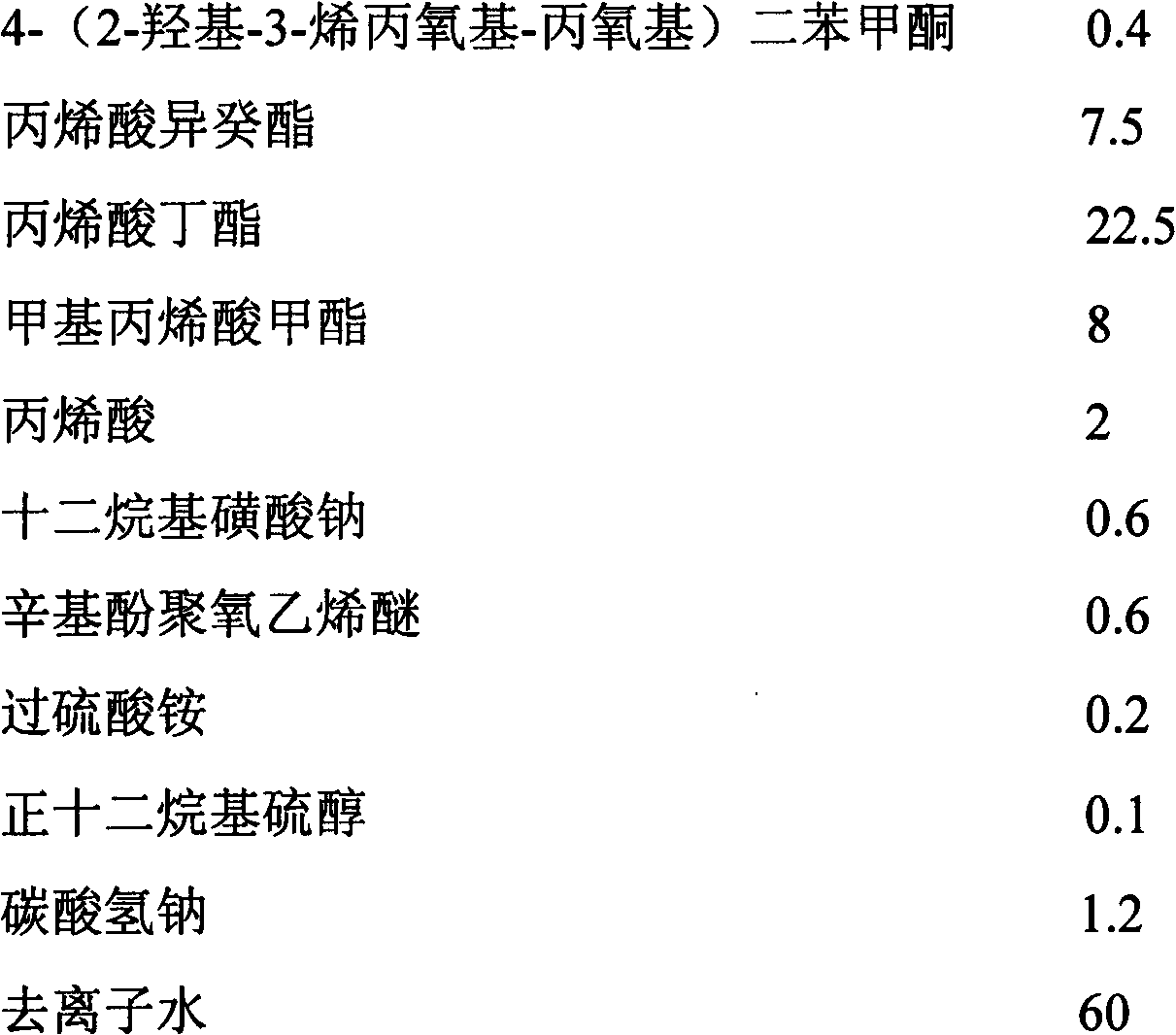

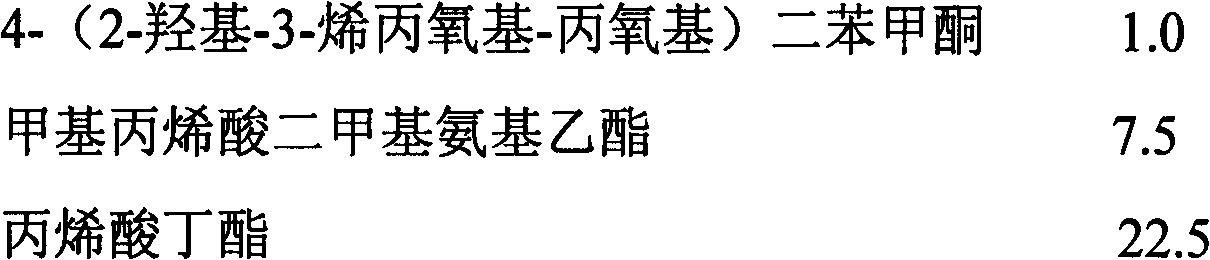

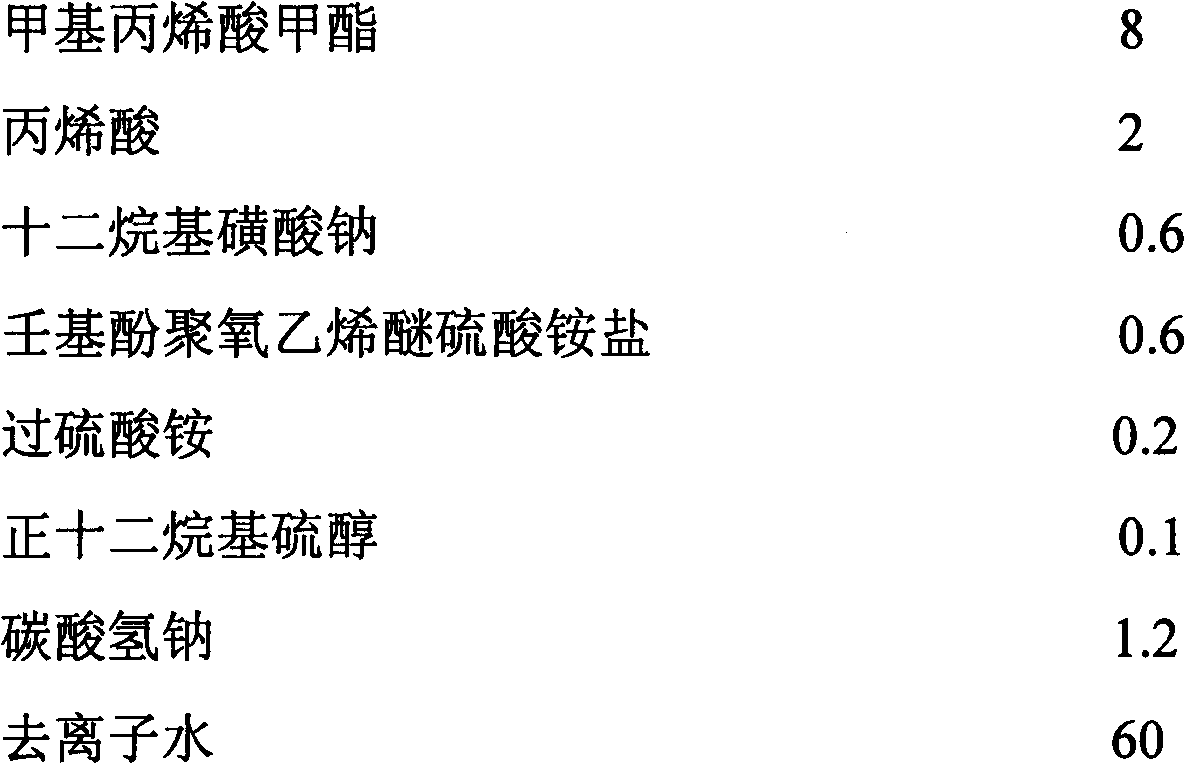

Single-component ultraviolet light self-crosslinking type acrylate copolymer emulsion pressure-sensitive adhesive and synthetic method thereof as well as application thereof

InactiveCN102304333AStrong cohesionGood initial adhesionNitrile polymer adhesivesPretreated surfacesFunctional monomerEmulsion

The invention relates to a single-component ultraviolet light self-crosslinking type acrylate copolymer emulsion pressure-sensitive adhesive and a synthetic method thereof as well as an application thereof; the emulsion pressure-sensitive adhesive is prepared from the following components in parts by weight through the thermal polymerization and synthesis of a free-radical emulsion: 0.02-4 of ultraviolet light active monomer, 2-20 of light crosslinking functional monomer, 15-40 of other single functionality monomer, 0.2-3 of emulsifying agent, 0.04-0.8 of initiator, 0.02-0.3 of chain transferagent, 0-2 of pH regulator and 50-80 of dispersed medium. The emulsion pressure-sensitive adhesive product is coated on a base material of a product to be coated; and after a solvent is volatile, thelight crosslinking is carried out on the coated product in an ultraviolet light curing device. Compared with the prior art, the single-component ultraviolet light self-crosslinking type acrylate copolymer emulsion pressure-sensitive adhesive has the advantages of having stronger cohesive force, better initial adhesion and ideal persistent persistent adhesivity, containing no small molecular compounds, forming no toxic by-products, being capable of adapting to different application requirements, being stable in property and the like.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Epoxy cement based road antiskid coating and preparation thereof

InactiveCN101328379AGood alkali resistanceStrong cohesionIn situ pavingsPolyamide coatingsEpoxyTetramine

Epoxy cement group road nonskid paint consists of three components, namely epoxy latex, a curing agent and powder materials. The curing agent is prepared from triethylene triamine or triethylene tetramine and versamid resin which are mixed. The powder materials consist of silicate cement, quartz sand and a water reducing agent. The invention also discloses a preparation method for the epoxy cement group road nonskid paint. The epoxy cement group road nonskid paint saves resources with healthfulness, environmental friendliness, safety and convenience during use.

Owner:上海宝元化学建材有限公司

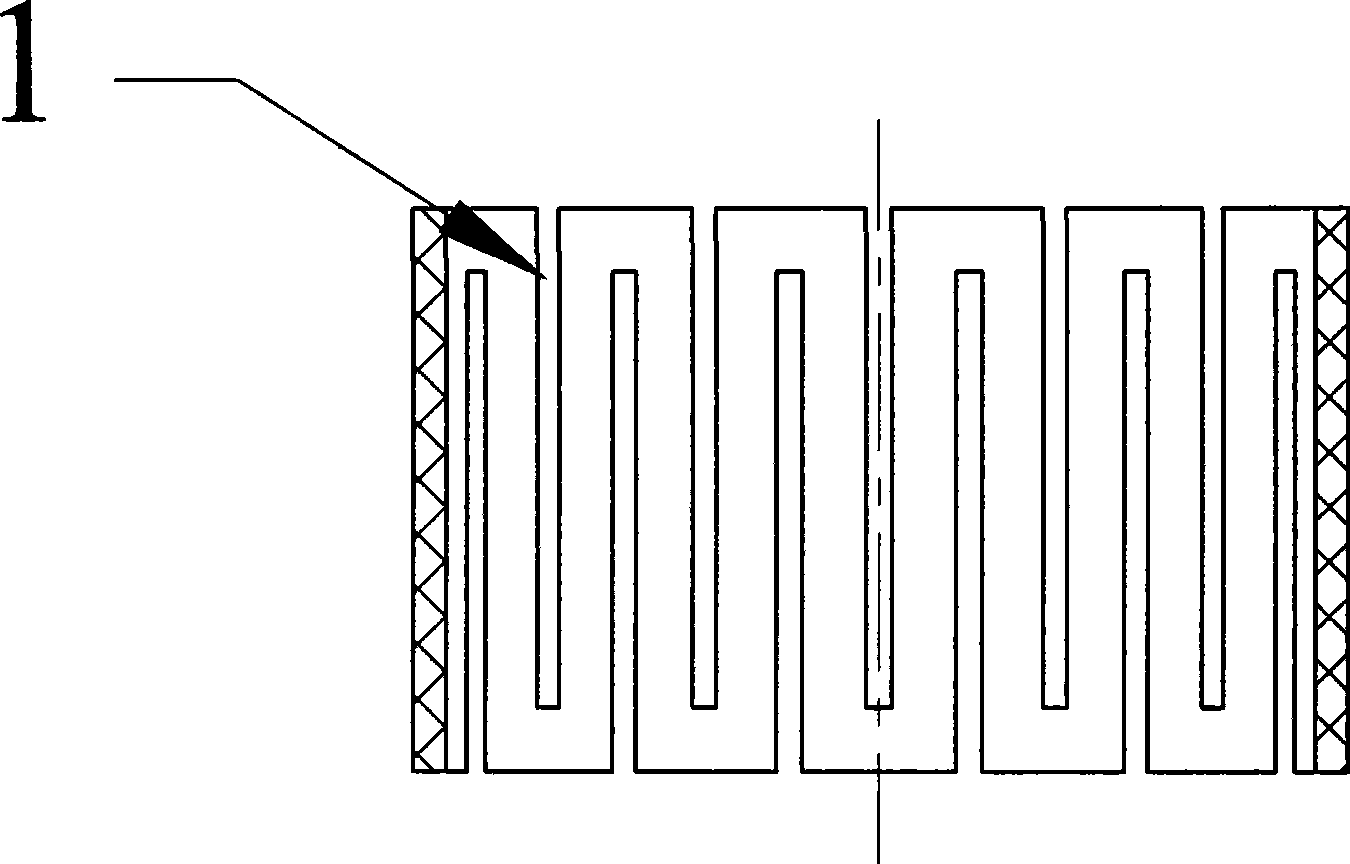

Carbon/carbon compound material heating element and production technology thereof

The invention discloses a simple-process environment-friendly carbon / carbon composite heating element and a production process thereof, which is characterized in that the heating element is prepared by making blank from carbon fibers, densifying, purifying, machining and purifying; the heating element is simple in process; as a net body formed by fluffy needle-like carbon fibers is adopted in the process of making the blank, a quasi-3D prefabricated part is easier to obtain in a needling process; the carbon fibers inside the prefabricated part are crisscrossed, strong in cohesive force, free from delamination and stable in structure; meanwhile, the prefabricated part is small in pore, which facilitates the acceleration of the subsequent densifying process; the heating element blank prepared through chemical vapor deposition densification consists of the carbon fibers and a carbon matrix, wherein the carbon matrix is formed by pyrolytic carbon obtained through a high temperature pyrolysis mode, which is high in purity; and a carbon / carbon composite product with the ash content less than 180 ppm can be obtained only through high-temperature purification in a vacuum or protective atmosphere, thereby saving energy and protecting environment.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

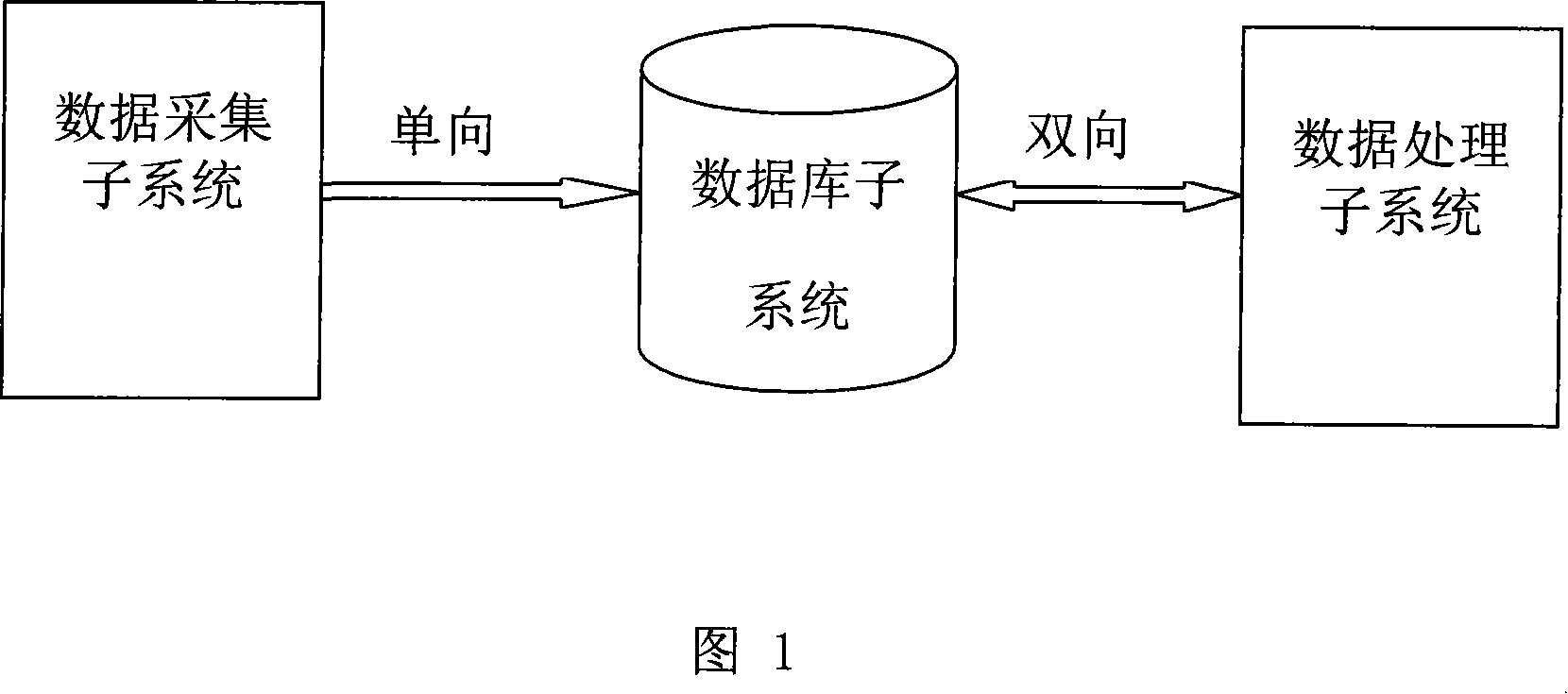

Gas well oil testing logging system

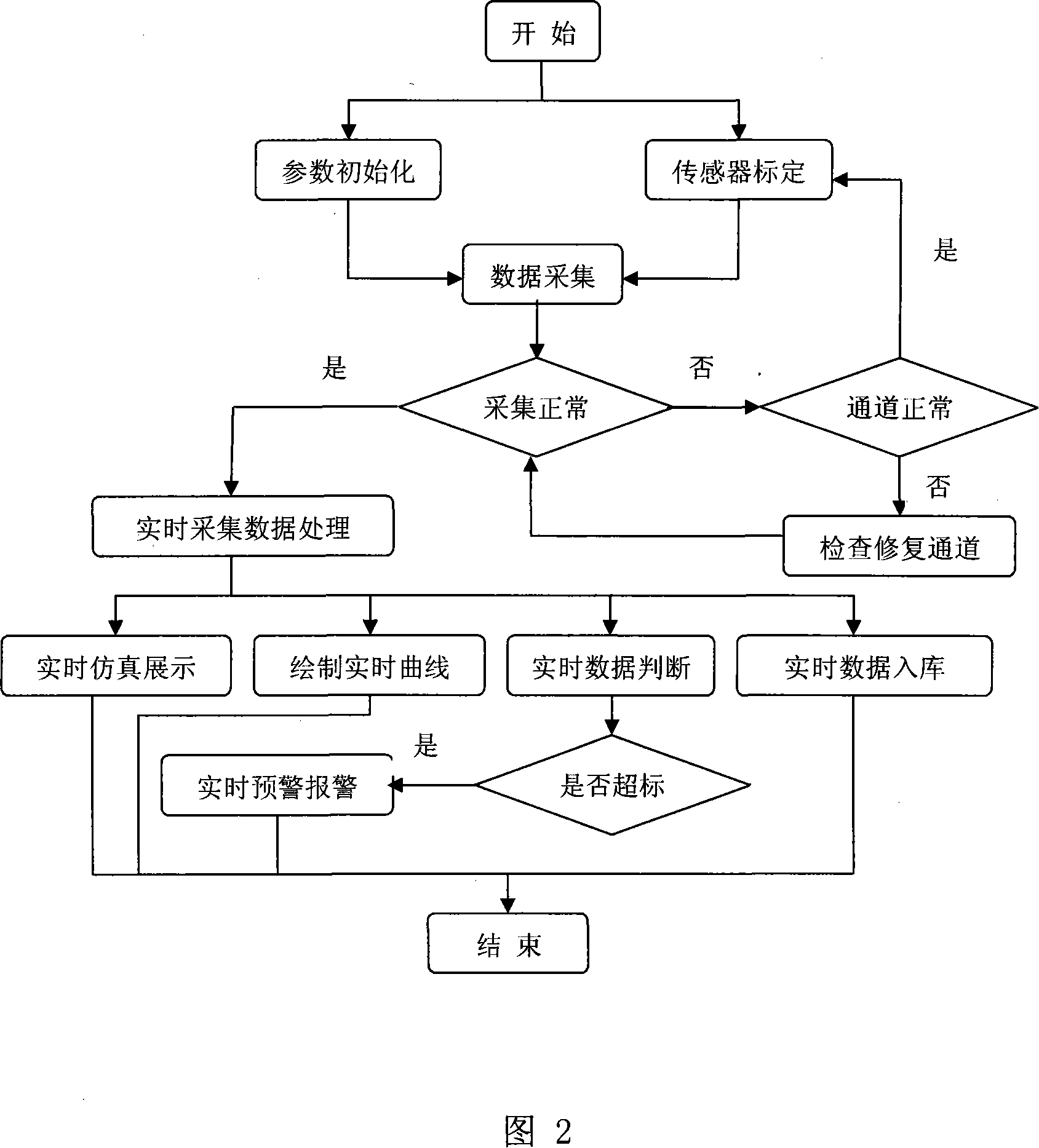

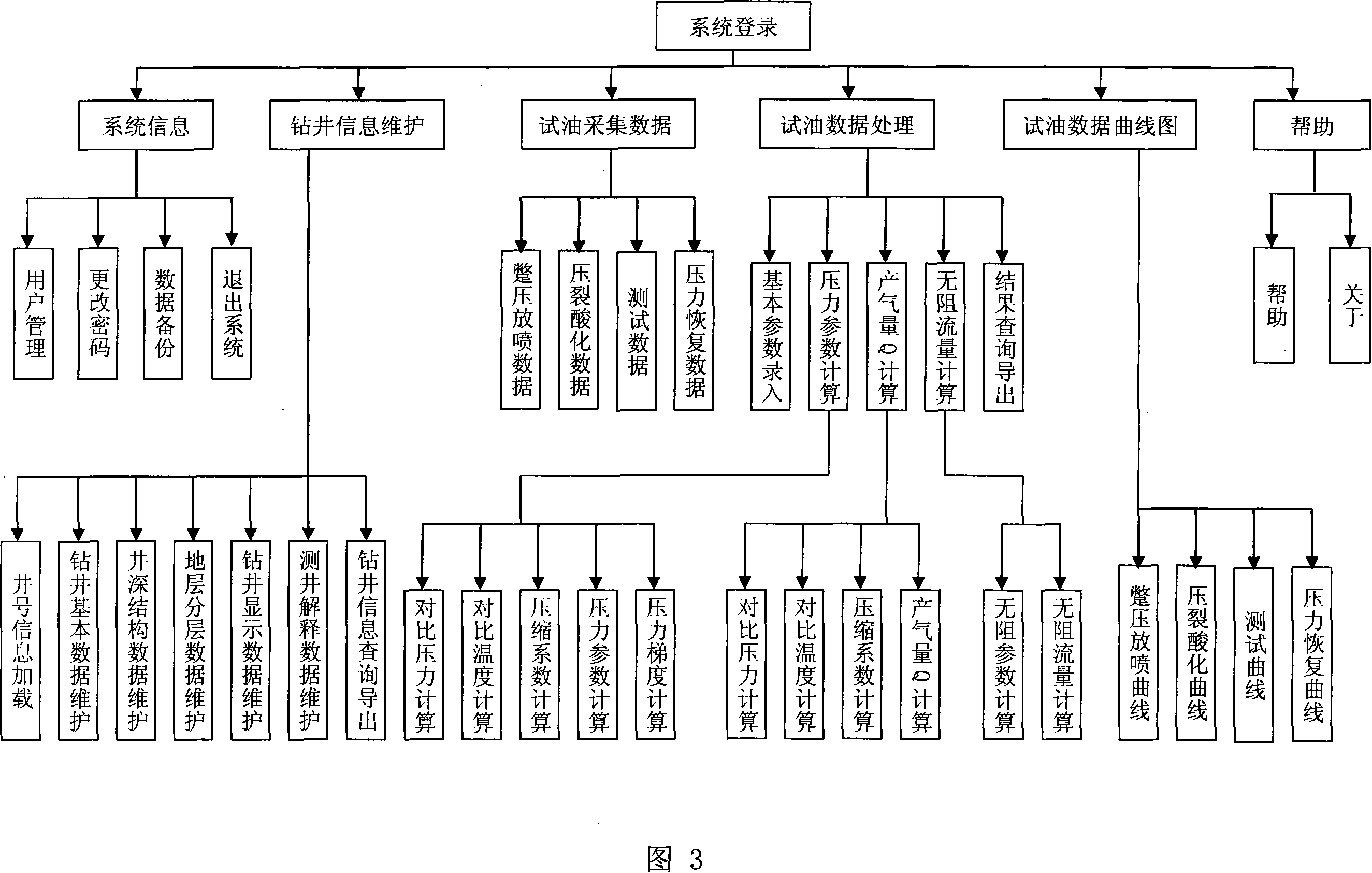

InactiveCN101126921AResponse authenticityImprove securityComputer controlSimulator controlModularityData acquisition

The utility model discloses a logging system of gas well oil testing, adopting a C / S system architecture (client side and server side are separately designed). The system architecture comprises a client side and a server side. The client side comprises a data acquisition subsystem and a data processing subsystem; the server side comprises a database subsystem. The system implements the separation of the data and the processing. The system has the advantages of high degree of automation by the module integration replacing hand data acquisition, accurate and credible results of data processing, short cycle of data acquisition, multiple acquisition parameters and high efficiency of simulation monitor which reflects the reality of the system.

Owner:中国石油集团川庆钻探工程有限公司地质勘探开发研究院

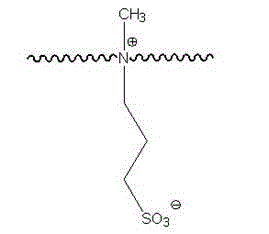

Glycine betaine group modified cationic waterborne polyurethane and preparation method thereof

InactiveCN102942678AImprove stabilityEnhance dispersing and emulsifying effectBetaineMechanical property

The invention belongs to the field of waterborne polyurethane synthesis, and particularly relates to glycine betaine group modified cationic waterborne polyurethane and a preparation method thereof. The prior art has a certain application limitation and cannot be used for processing in various fields. In order to overcome the shortcomings, the technical scheme includes that a sulfonic acid type glycine betaine structure contains a cationic tertiary amine group and an anionic sulfonic acid group, the groups are led into a polyurethane molecular structure, dispersing and emulsifying properties of the polyurethane can be improved, emulsion particle diameters are smaller, stability of pH (potential of hydrogen), metal ions and the like of polyurethane emulsion is improved, and the applicable range of the polyurethane is widened. As a molecular chain contains the anionic group and the cationic group, acting force among molecules after films are formed on resin is higher, cohesive force is higher, the resin can achieve better mechanical property and adhesive strength, and the shortcomings of traditional waterborne resin in terms of mechanical property, adhesive strength and initial adhesiveness are greatly overcome.

Owner:SHAANXI UNIV OF SCI & TECH

Floating body material and manufacturing technique thereof

The invention relates to a floating body material, in particular to a floating body material and a manufacturing technique thereof for an observation platform at the bottom of the sea. The floating body material comprises bisphenol A type epoxy resin, modified acrylonitrile-butadiene rubber latex, hollow glass microsphere, polyether amine, gamma-glycidoxypropyltrimethoxysilane, a silane coupling agent and polyvinyl alcohol fiber; and the floating body material comprises the following components in parts by weight: 100 parts of bisphenol A type epoxy resin, 0-10 parts of modified acrylonitrile-butadiene rubber latex, 12-18 parts of hollow glass microsphere, 15-20 parts of polyether amine, 2-3 parts of gamma-glycidoxypropyltrimethoxysilane, 1-2 parts of silane coupling agent and 2 parts of polyvinyl alcohol fiber. The invention provides the floating body material and the manufacturing technique thereof for the observation platform at the bottom of the sea; and the observation platform adopting the floating body material can be soaked in the seawater for use in a long term.

Owner:SECOND INST OF OCEANOGRAPHY MNR

Medical polyacrylate pressure-sensitive adhesive with high adhesion performance

ActiveCN105219316AGood adhesionHigh molecular weightEster polymer adhesivesCross-linkPolymer science

The invention relates to a medical polyacrylate pressure-sensitive adhesive with high adhesion performance. The medical polyacrylate pressure-sensitive adhesive comprises soft monomers, hard monomers, functional monomers, initiators, cross-linking agents and solvents. The glass-transition temperature of the soft monomers ranges from -65 DEG C to -60 DEG C. The cross-linking agents are isocyanate-group-containing compounds generated through the reaction between polyisocyanates and polyhydroxy compounds. The weight-average molecular weight of the pressure-sensitive adhesive ranges from 80*10<4> g / mol to 140*10<4> g / mol. The molecular weight distribution of the pressure-sensitive adhesive ranges from 10 to 25. In the preparing process of the pressure-sensitive adhesive, temperature and the reaction sequence and the adding quantity of the reaction materials are gradually controlled, and the product with the high molecular weight and the wide molecular weight distribution is obtained. The product can be used for the medical and health field.

Owner:四川厚生天佐药业有限公司

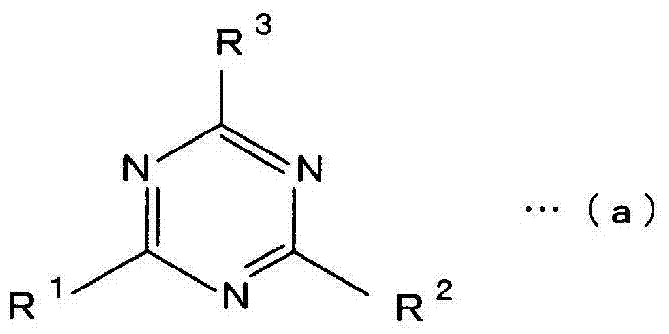

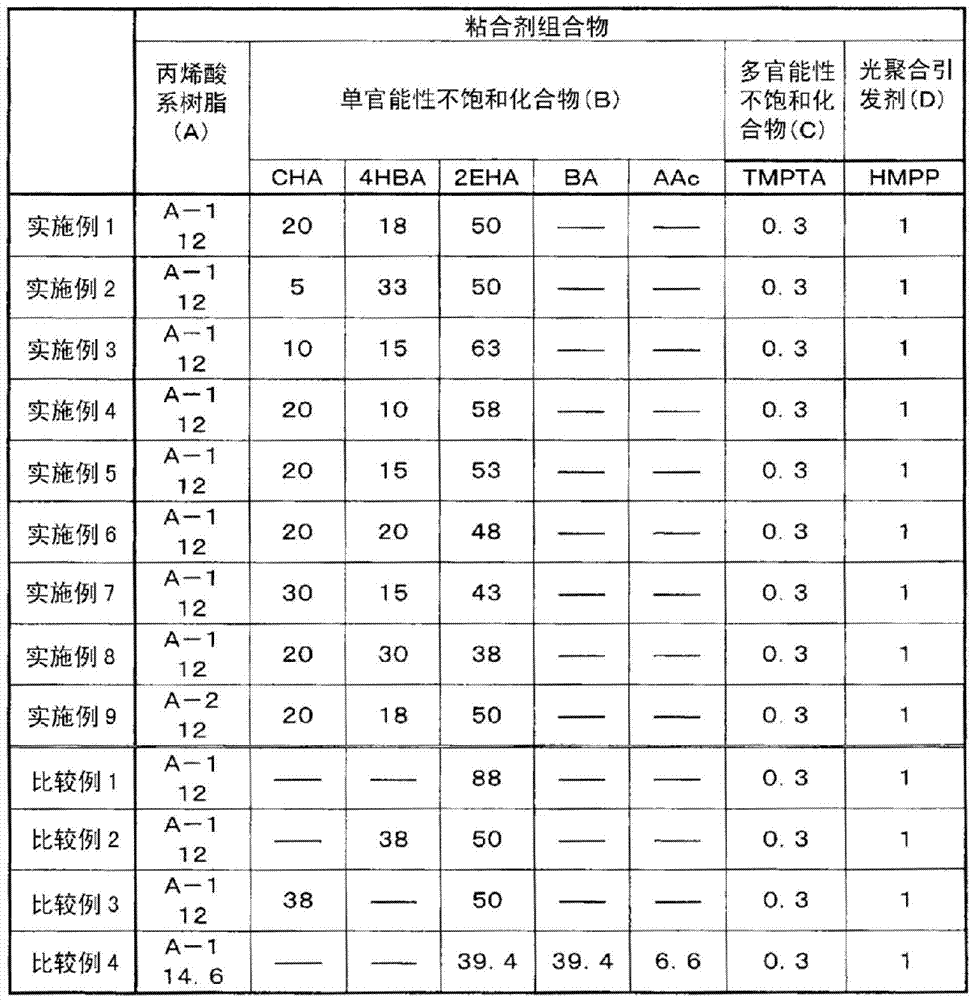

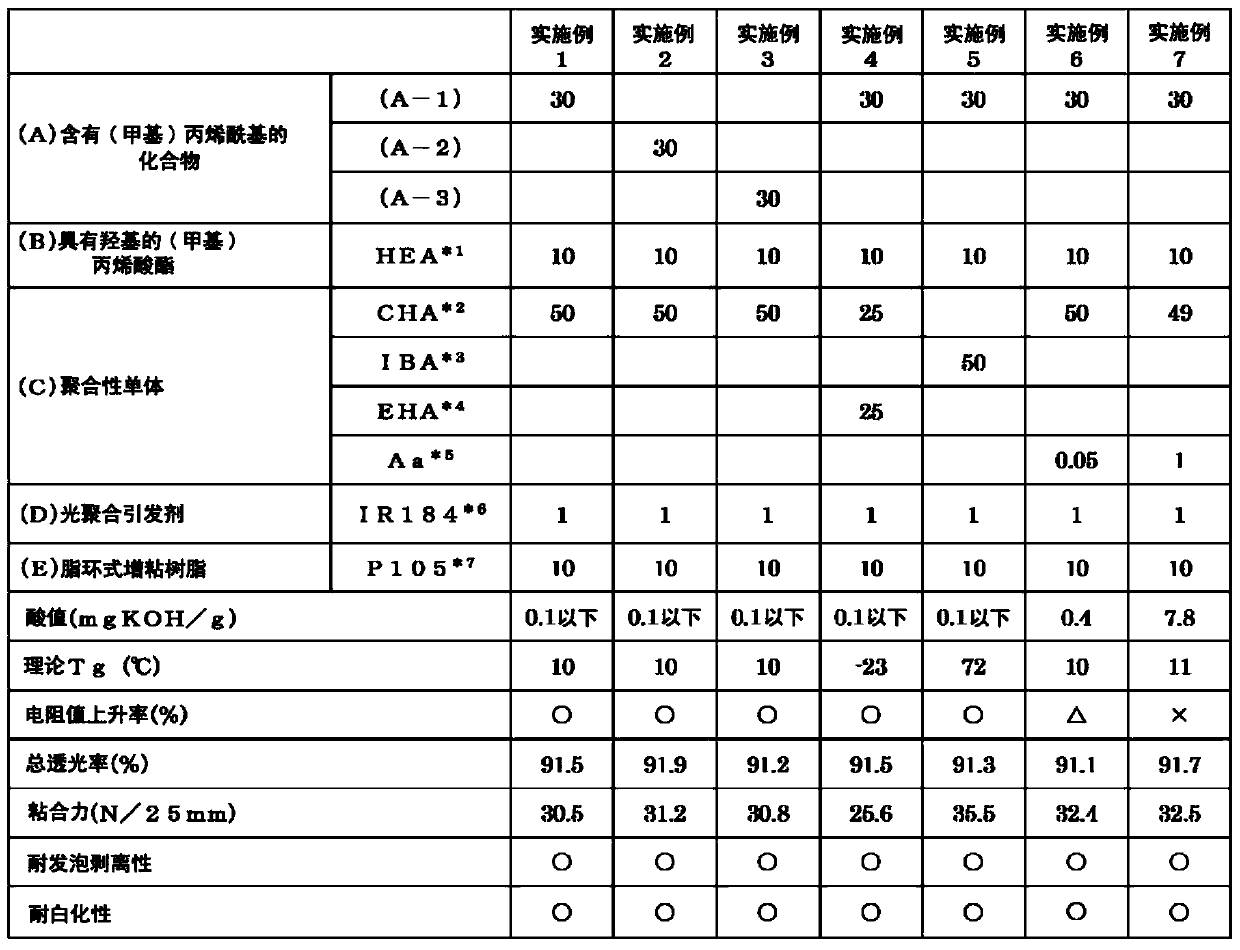

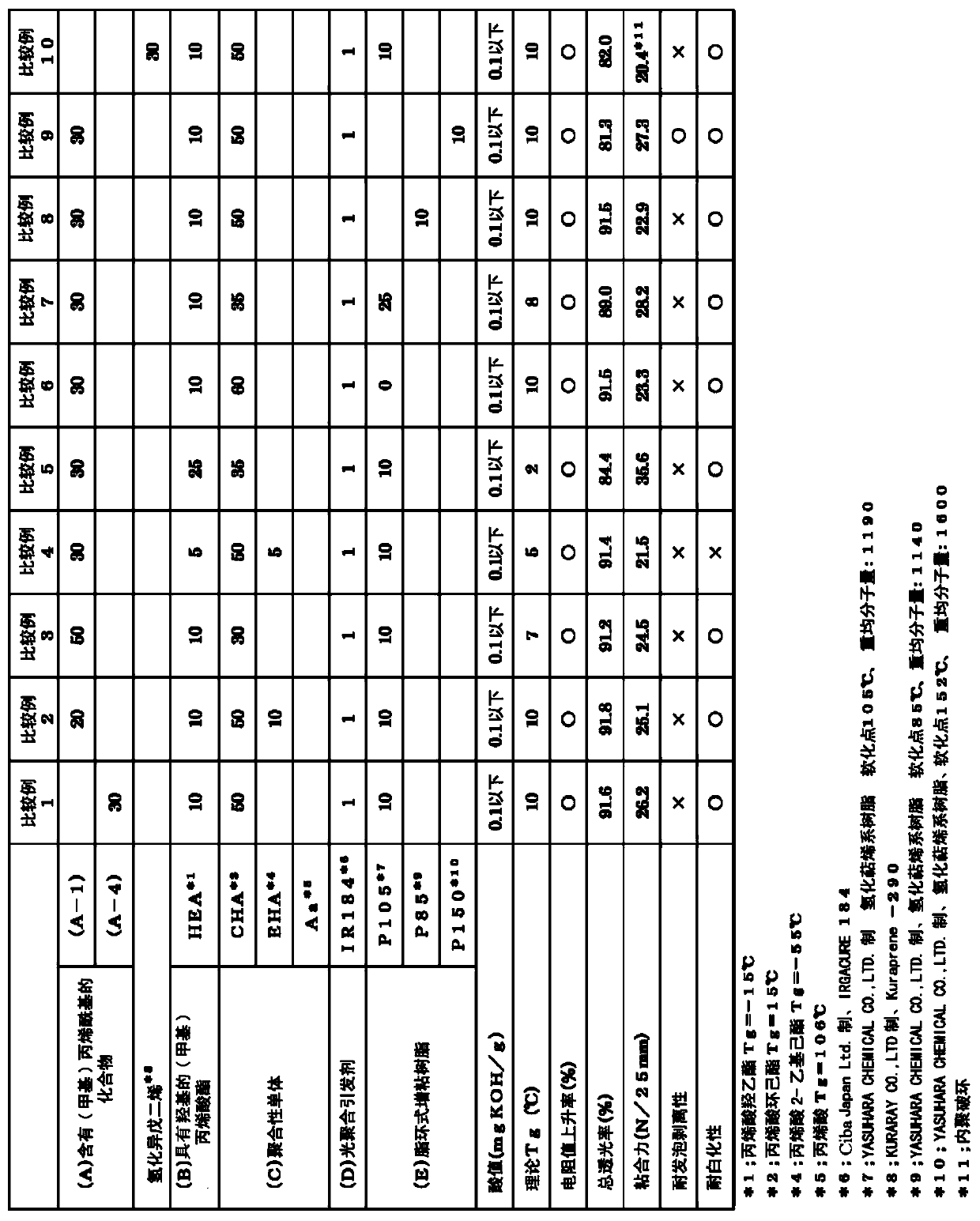

Pressure-sensitive adhesive composition, pressure-sensitive adhesive, and adhesive sheet using same

ActiveCN103249791AImprove adhesionStrong cohesionNon-macromolecular adhesive additivesFilm/foil adhesivesAcrylic resinCohesive strength

Provided is a pressure-sensitive adhesive having a high adhesive strength and a high cohesive strength, which is cured by active energy ray irradiation. The present invention relates to a pressure-sensitive adhesive composition comprising: an acrylic resin (A); an ethylenically unsaturated compound containing one ethylenically unsaturated group (B); an ethylenically unsaturated compound containing two or more ethylenically unsaturated groups (C); and a photoinitiator (D). The pressure-sensitive adhesive composition is characterized by comprising an ethylenically unsaturated compound containing an alicyclic structure (B1) and a hydroxyl group-containing ethylenically unsaturated compound (B2) as the ethylenically unsaturated compound containing one ethylenically unsaturated group (B).

Owner:MITSUBISHI CHEM CORP

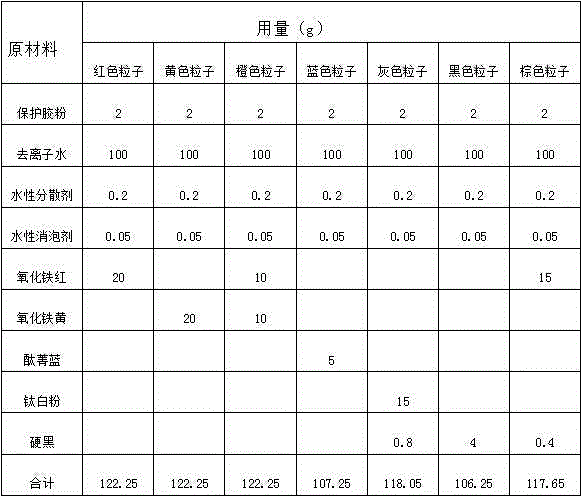

Aqueous granite-simulative paint

ActiveCN104151978AGood shape retentionGood weather resistanceMulticolor effect coatingsPolymer scienceEmulsion

The invention discloses an aqueous granite-simulative paint which includes silicone acrylic emulsion, deionized water, an aqueous wetting and dispersing additive, an aqueous defoaming agent, an aqueous levelling agent, an anti-corrosion agent, an aqueous pH conditioning agent, an aqueous film coalescing aid, self-made colorful granules including red granules, yellow granules, black granules, brown granules, grey granules, orange granules, blue granules and the like. The paint is prepared according to a mass percent ratio in a technology requirement. By means of the functional silicone acrylic emulsion, the colorful granules, which are flexible in interior and tough on exterior and is strong in cohesion, are prepared through a special shell-core metal wrapping technology so that a shape maintaining performance and a anti-shear force performance of the colorful granules are good during a storage process and a transportation process of a finished product of the paint. The paint is convenient to construct, can be used in a directly spraying manner and an obliquely spraying manner, even in a brushing manner and a rolling manner, without break and blurring in the granules.

Owner:CHONGQING SANXIA PAINTS CO LTD

Thermal insulation material

The invention discloses a novel thermal insulation material, and the composition comprises expanded perlite, cement, gypsum powder, fibers, redispersible rubber powder, casein glue, and the like. The thermal insulation material has the advantages of high strength, aging resistance, excellent thermal insulation effect, energy conservation, environmental protection, fire protection, sound insulation, low cost, convenient use, and the like. The novel thermal insulation material can be directly applied on buildings, containers, pipelines, reactors, household appliances and the like through a plurality of construction methods, thereby achieving the effects of thermal insulation and energy conservation.

Owner:ORDOS DONGRONGCI TECH DEV

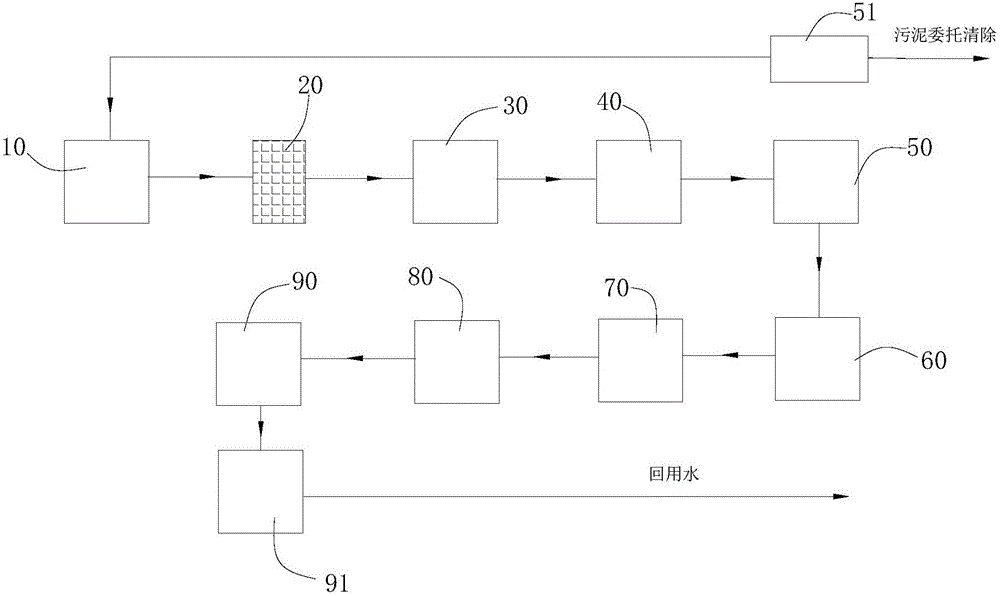

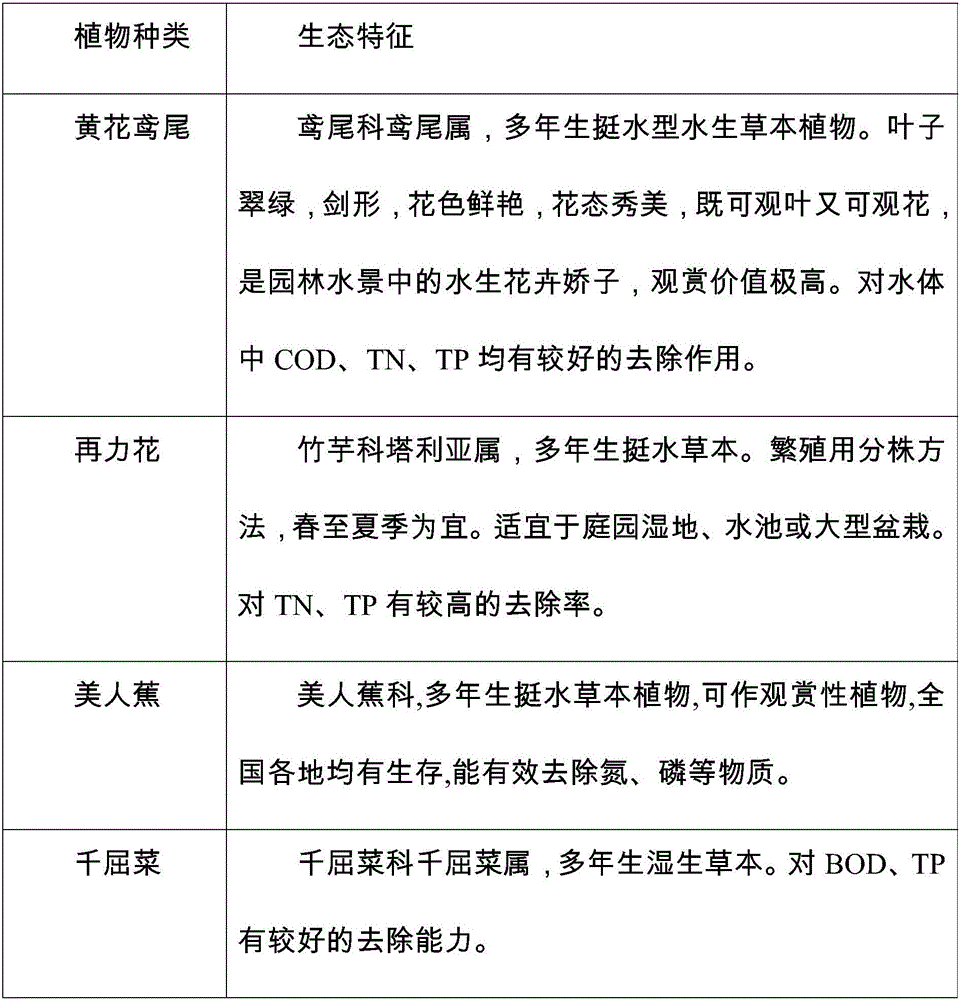

Sewage treatment system and technology for river ways in city

InactiveCN105906150APromote decompositionEfficient removalTreatment involving filtrationTreatment with aerobic and anaerobic processesMicroecosystemEngineering

The invention discloses a sewage treatment system for river ways in a city. The system comprises a sewage pond, a stop net for filtering away suspension and chemical matter in sewage, an adjusting pond, a concrete pond, a settling pond, an anaerobic pond, an aerobic pond, an anoxia pond and a filter device. Microbial flora is added into the anaerobic pond. Nitrosomas and nitromonas are added into the aerobic pond. Denitrification bacteria are added into the anoxia pond. A filter layer, an adsorption layer, a filler layer and a heavy metal absorption layer are sequentially arranged in the filter device from bottom to top. The top of the filter device is connected with a micro-ecological filter pond through a drain pipe. By means of the sewage treatment system and a technology for river ways in the city, water body conditions are analyzed, and ecological regulation and control are achieved; by means of the method of combining exogenous pollution control, endogenous pollution control and micro-ecological system repair, the pollution problem of river ways in the city can be effectively solved, and a good pollution treatment effect is achieved. The invention further discloses the sewage treatment technology for river ways in the city.

Owner:李丹丹

Photocurable translucent composition for adhesive sheet, and optical adhesive sheet

ActiveCN104093800AExcellent moisture permeability resistanceGood water resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolycarbonateChemistry

The purpose of the present invention is to provide a photocurable translucent composition for an adhesive sheet which will not corrode the electroconductive layer of a translucent electroconductive film even when bonded directly onto the surface of the electroconductive layer, and which offers excellent whitening resistance and foaming resistance in a high-temperature, high-humidity environment when used to bond a translucent resin sheet such as an acrylic sheet or a polycarbonate sheet, as well as to provide an adhesive sheet. The present invention pertains to a photocurable translucent composition for an adhesive sheet, the composition being of high molecular weight, having (meth)acryloyl groups introduced thereto, and being a formulation of a hydrogenated 1,2-polybutadiene-based acrylate compound or hydrogenated isoprene-based compound, a (meth)acrylic acid ester having a hydroxyl group, a polymerizable monomer other than the (meth)acrylic acid ester having a hydroxyl group, an alicyclic tackifying resin having a softening point in a specific range, and a photopolymerization initiator.

Owner:SHOWA DENKO KK

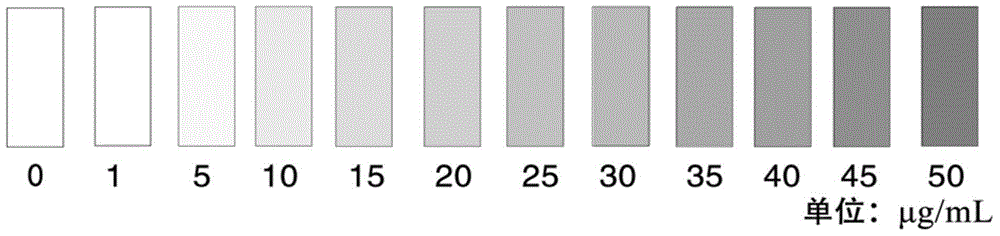

Test paper for rapidly testing nitrite and standard colourimetric card and application of test paper

InactiveCN104535712AUniform infiltrationExcellent gas barrier propertiesAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorPolyvinyl alcoholN-(1-Naphthyl)ethylenediamine

The invention belongs to the field of chemical detection and particularly relates to test paper for rapidly detecting nitrite and a preparation method and application of the test paper. According preparation method, the test paper for rapidly detecting the nitrite is prepared by taking a filter paper body as a carrier, a p-aminobenzene sulfonic acid solution and an N-1-naphthyl ethylenediamine hydrochloride as color developing agents, as well as an ethanol water solution of polyvinyl alcohol as a surface protectant and can be used for detecting the content of the nitrite. The test paper is low in cost, convenient and rapid to use and has long-term stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

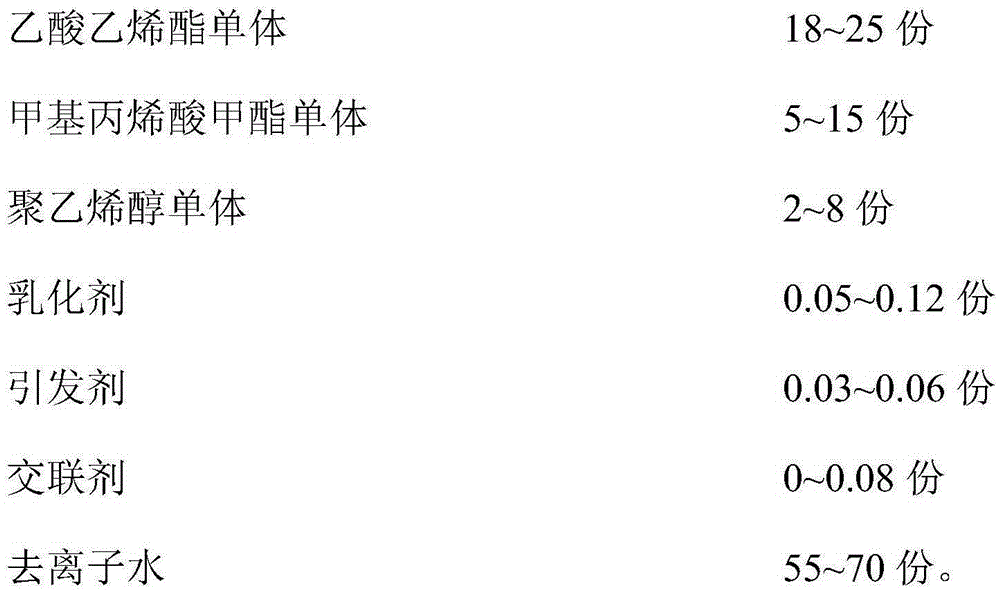

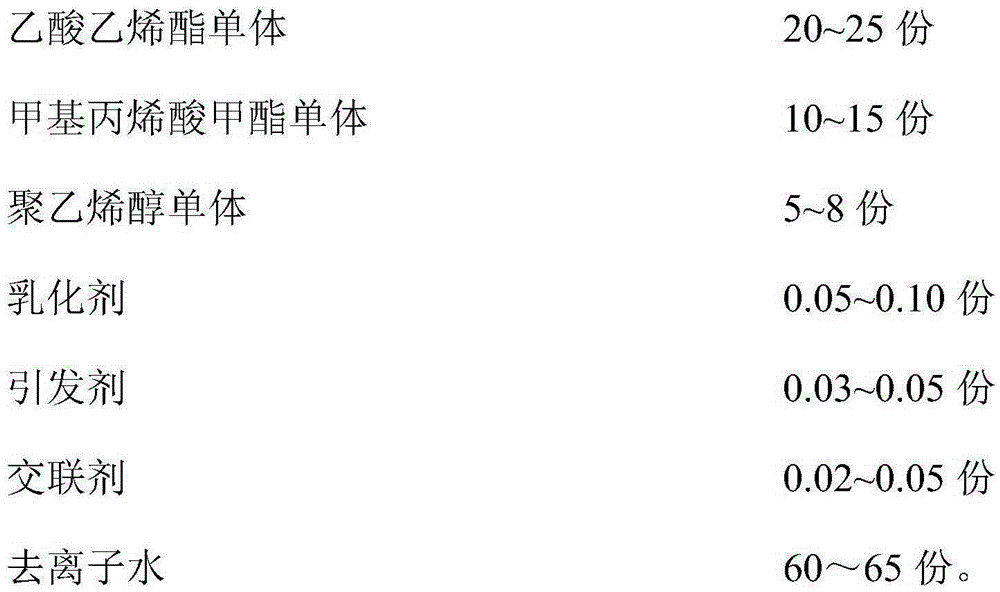

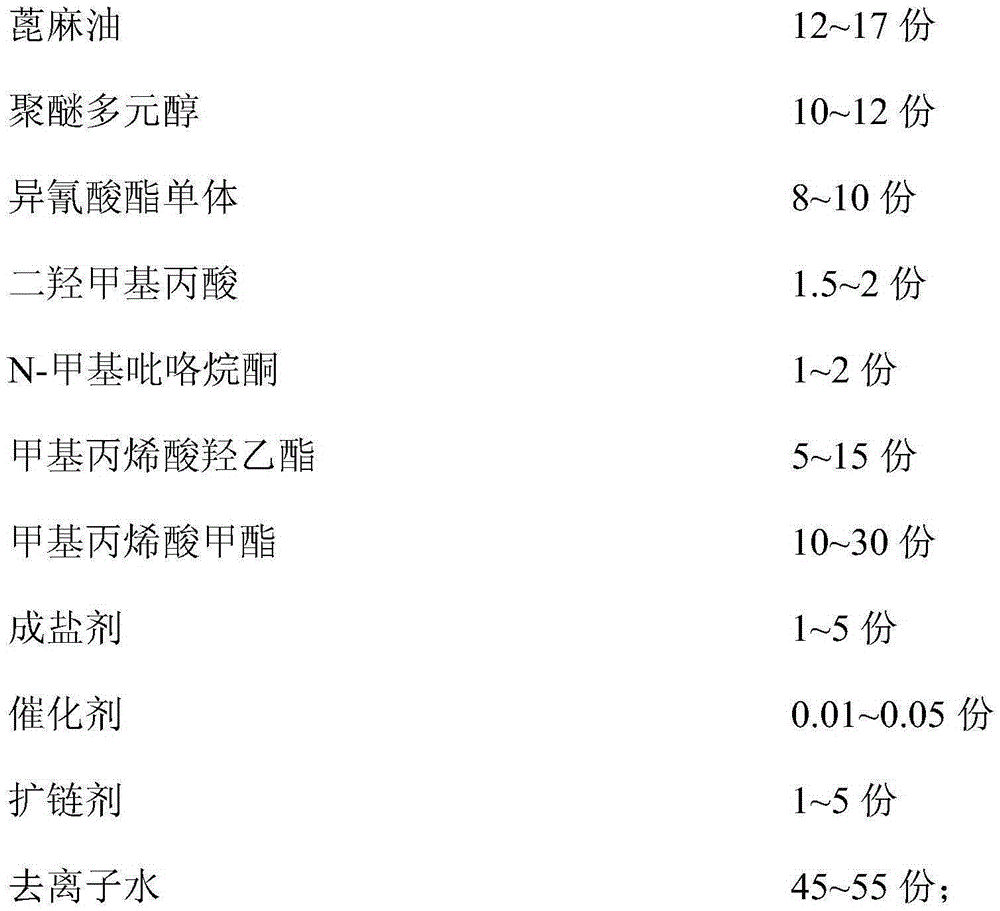

Water-based pressure sensitive adhesive as well as preparation method and application thereof

ActiveCN105295781AStrong cohesionGood weather resistanceMonocarboxylic acid ester polymer adhesivesPolyureas/polyurethane adhesivesWater basedEmulsion

The invention provides a water-based pressure sensitive adhesive as well as a preparation method and application thereof. The water-based pressure sensitive adhesive is mainly composed of the following raw materials in parts by weight: 40-60 parts of acrylate emulsion, 30-60 parts of castor oil-based polyurethane prepolymer and 0-10 parts of a blocked polyurethane curing agent. The preparation method comprises the following steps: sequentially adding the acrylate emulsion, the castor oil-based polyurethane prepolymer and the blocked polyurethane curing agent into a reactor according to a formula ratio, heating to 25-40 DEG C, reacting for 0.5-1 h and filtering so as to obtain the water-based pressure sensitive adhesive. The water-based pressure sensitive adhesive is good in adaptability to a substrate surface and good in weather resistance and can be used under room temperature conditions.

Owner:上海九元石油化工有限公司

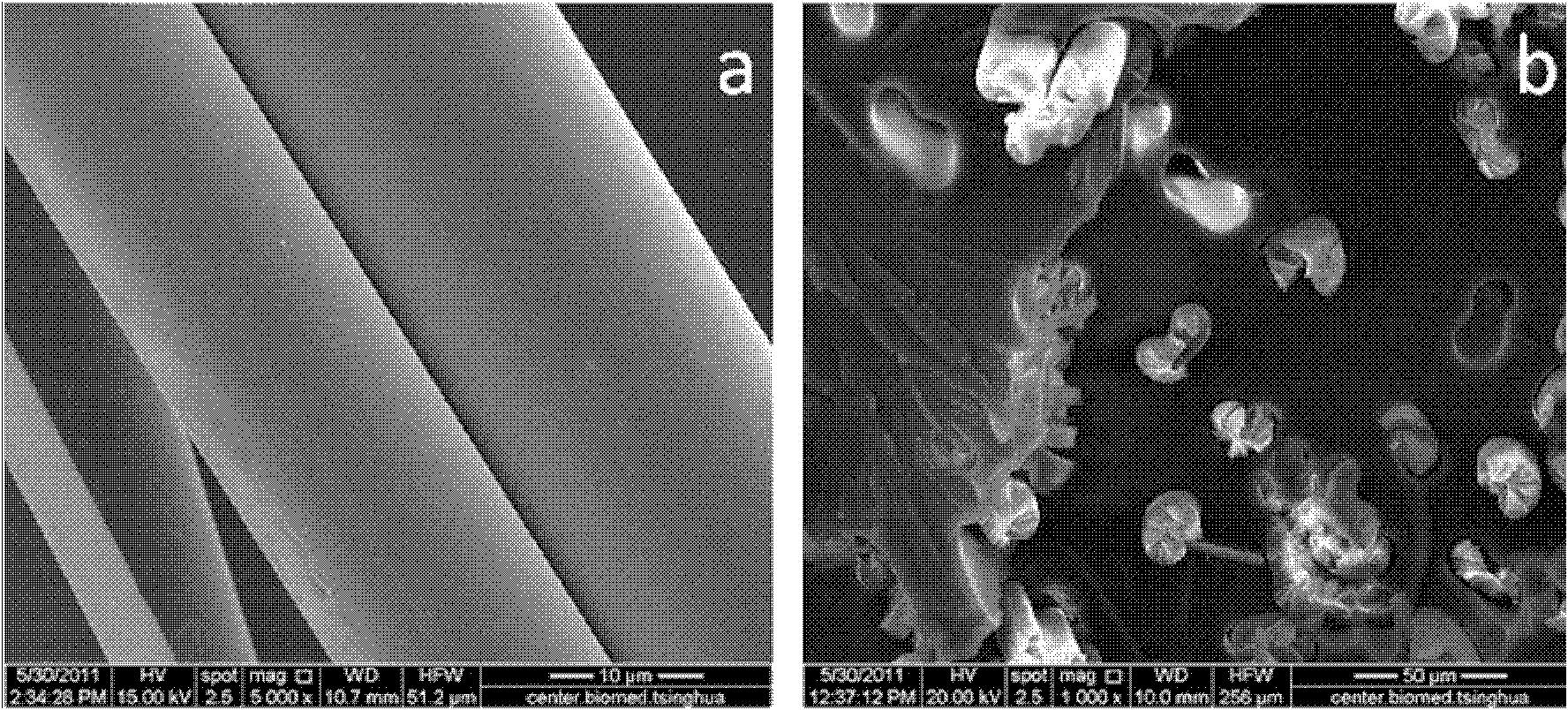

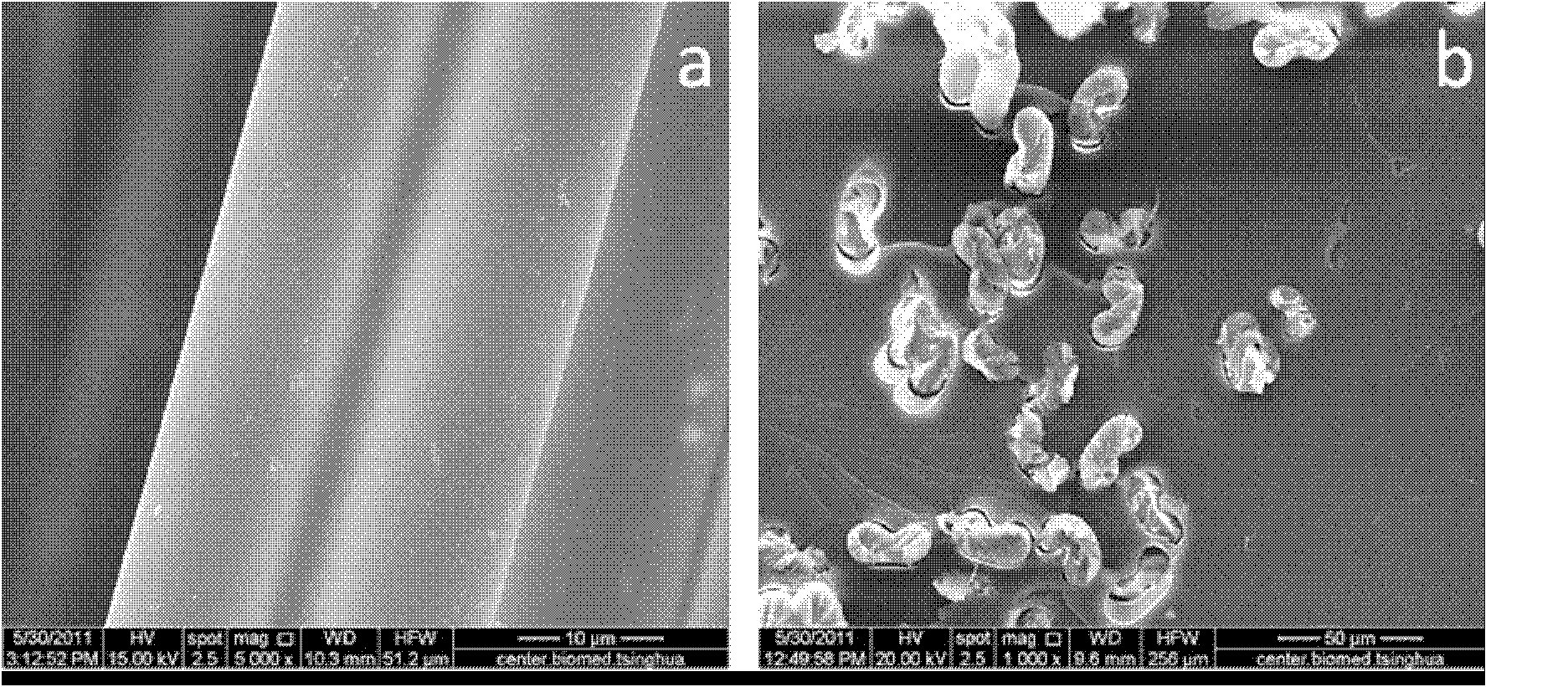

Polyimide fiber with kidney-shaped section and preparation method thereof

ActiveCN102560707AImprove production efficiencySimple preparation processSpinning solution filteringSpinning solution de-aeratingFiberConductor Coil

A polyimide fiber with kidney-shaped section and a preparation method thereof belong to the technical field of polyimide fibers. The preparation method includes: utilizing polyamide acid (PAA) solution synthesized by aromatic dianhydride and aromatic diamine to perform the wet spinning process by the aid of circular spinneret holes, adjusting spinning conditions including spinneret speed, composition, proportion and temperature of coagulating bath, the length of hydrazine and the like to obtain a PAA as-formed fiber with kidney-shaped section, then washing and drying the PAA as-formed fiber, cyclizing and drafting the same at high temperature stage by stage, and winding and the like, finally obtaining the polyimide (PI) fiber with the kidney-shaped section. The preparation method of the polyimide fiber with the kidney-shaped section has the advantages of simplicity in spinneret hole design and processing, easiness in control of spinning process, high preparation efficiency, low cost for raw materials, low energy consumption and the like and can be used for large-scale industrialized production.

Owner:BEIJING UNIV OF CHEM TECH

Radiation proof composite metallic yarn and weaving method thereof

The invention discloses an anti-radiation composite metal yarn comprising textile fiber bundle and metal filament. The diameter of metal filament is 15-80mum. The metal filament and the textile fiber bundle are doubled and twisted. The range of twist is 100-2200TPM. The textile fiber bundle is single yarn, plied yarn or long yarn. The invention also discloses the spinning process for anti-radiation composite metal yarn. At first, metal filaments with the diameter of 20-80mum and textile fiber bundle according with demands are selected and then selected metal filaments and textile fiber bundle are doubled and twisted on doubling and twisting machine. The tension of doubling and twisting is controlled in 15-80g and the twist of doubling and twisting is controlled in 100-2200TPM. Because metal filaments are used, the yarn and fabrics spun with the yarn are smooth. In fabric, longitude and latitude metal filaments are connected with each other in effect to form current loop. It can play a very good anti-radiation effect and improve the wide application of anti-radiation composite metal yarn.

Owner:CHANGZHOU POLYACE TEXTILE & YARN

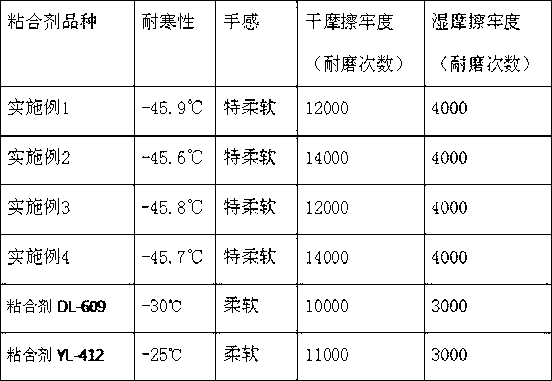

Acrylic ester electrostatic flocking binding agent and preparation method thereof

ActiveCN103214993AGood flexibilityImprove cold resistanceNon-macromolecular adhesive additivesEster polymer adhesivesIsooctyl acrylateSodium acetate

The invention relates to an acrylic ester electrostatic flocking binding agent and a preparation method thereof. The acrylic ester electrostatic flocking binding agent is a polymer emulsion which is prepared from the raw materials: polyoxyethylene dodecyl alcohol (50), sodium dodecyl sulfate, itaconic acid, N-hydroxymethyl acrylamide, acyclic acid, butyl acrylate, 2-ethylhexyl acrylate, styrene, gamma-methacryloxy propyl trimethoxyl silan, epoxy resin E-44, adipic acid dihydrazide, sodium acetate, ammonium persulfate and deionized water through seeded emulsion polymerization. The acrylic ester electrostatic flocking binding agent is an epoxy resin and organic silicon resin jointly-modified acrylic ester electrostatic flocking binding agent. The product has the advantages of flexibility, cold endurance, weather resistance and thermosetting stability and particularly has prominent water resistance and adhesive force.

Owner:LIAONING FIXED STAR FINE CHEM

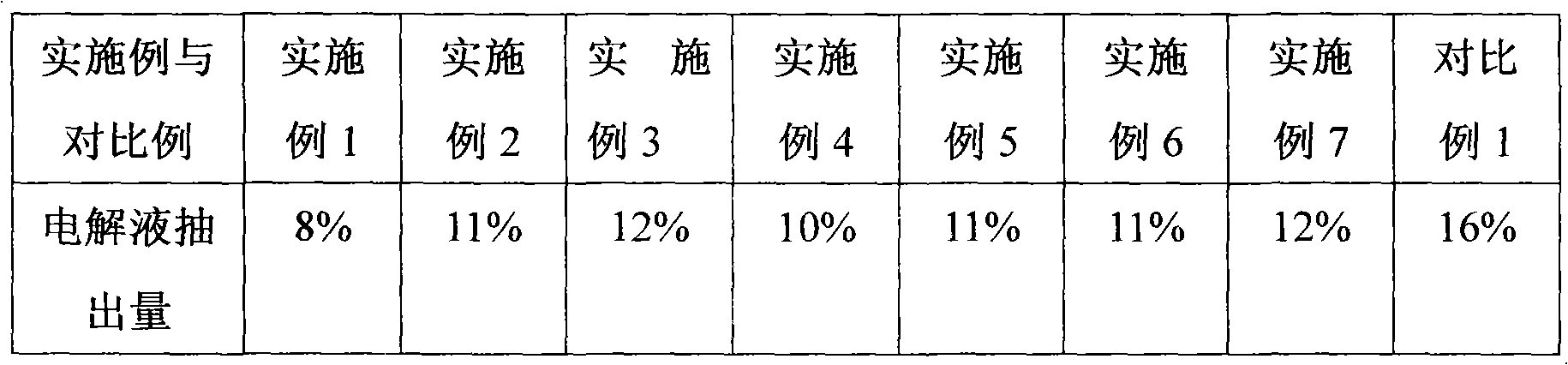

Lithium ion battery

ActiveCN102306725AIncrease polarityGood adhesionCell component detailsAcrylonitrilePhysical chemistry

The invention relates to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery with good hardness. In the lithium ion battery, an isolating membrane is a copolymer of acrylate and acrylonitrile. The isolating membrane of the lithium ion battery provided by the invention has the good electrolytic absorbing capacity and simultaneously can be used for improving the adhesion between positive and negative plates, thus having significant influence on the absorbing capacity of the electrolyte in the battery and the hardness of the battery (especially a thin-type battery).

Owner:DONGGUAN AMPEREX TECH +1

Water-based glass paint containing modified diatomite and preparation method thereof

InactiveCN103102759ANo precipitation and stratificationStrong cohesionCoatingsPigment treatment with non-polymer organic compoundsForeign matterWater based

The invention discloses water-based glass paint containing modified diatomite and a preparation method thereof. The water-based glass paint comprises the following raw materials in parts by weight: 55-65 of acrylate emulsion, 8-10 of water-based amino resin, 1-3 of dipropylene glycol mono butyl ether, 10-15 of pure water, 0.4-0.6 of fatty acid polyglycol ester, 0.2-0.4 of a defoaming agent, namely polyoxypropylene glycerol ether, 0.2-0.6 of dioctyl sodium sulfosuccinate, 0.3-0.5 of zinc oxide, 0.2-0.4 of adhesion promoter BOK-M-208, 0.3-0.5 of flatting agent L-350, 0.3-0.5 of modified diatomite, 0.3-0.1 of fumed silica and 0.8-1.2 of water-based silicone coupling agent A800. The water-based glass paint produced by the invention has no bubbles, no agglomerates, no foreign matters and recipitation stratification, can be infinitely diluted with water and reduce the cost and is environment-friendly; a paint film has very strong cohesion and adhesive force as well as high strong abrasive resistance at a room temperature; the added modified diatomite and fumed silica serve as thickening agents so that the adhesive force of the paint film is enhanced; and the added water-based silane coupling agent further enhances the adhesive force of the paint film.

Owner:合肥市科睦佰水性材料有限公司

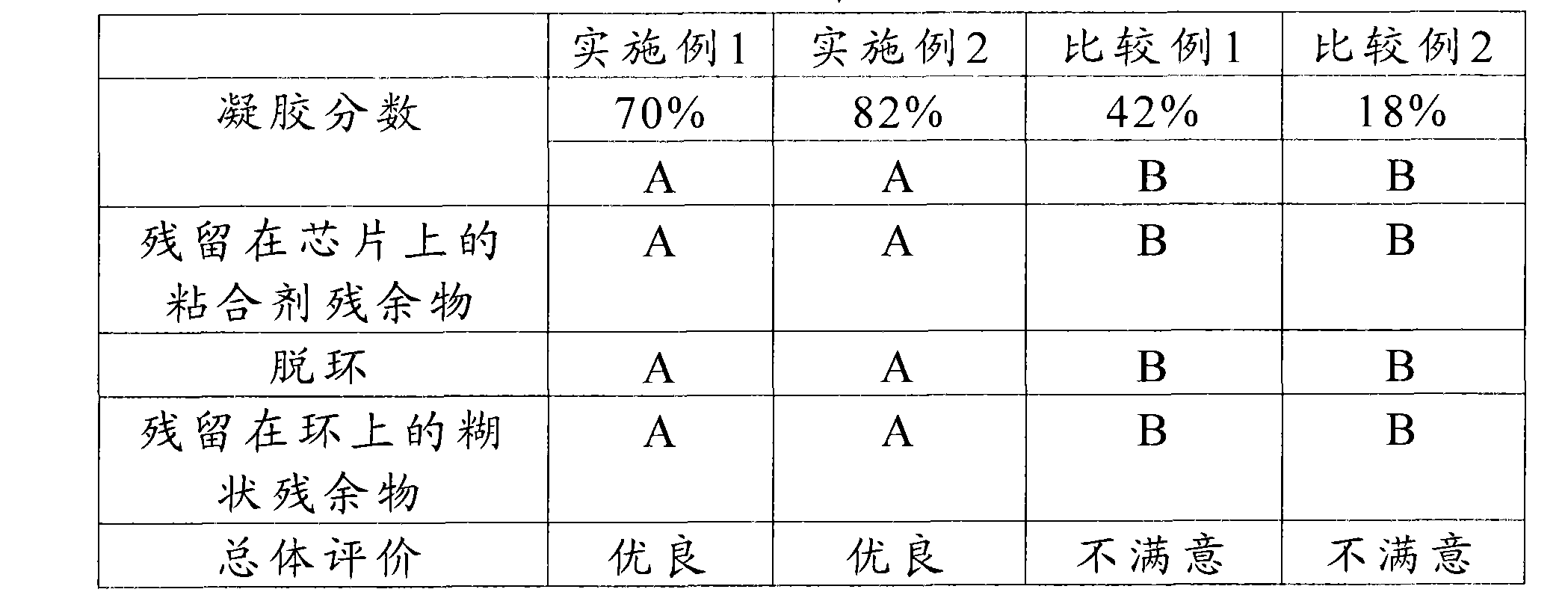

Pressure-sensitive adhesive sheet for dicing and dicing method

ActiveCN101381587AStrong cohesionEasy to peelSolid-state devicesSemiconductor/solid-state device manufacturingIrradiationPressure sensitive

The present invention relates to a pressure-sensitive adhesive sheet for dicing comprising a substrate layer and an active energy ray-curable pressure-sensitive adhesive layer provided on the substrate layer, in which the active energy ray-curable pressure-sensitive adhesive layer has a gel fraction before irradiation with an active energy ray of 50% or more. Furthermore, the invention also provides a method for dicing an adherend, which comprises attaching the pressure-sensitive adhesive sheet for dicing to an adherend, followed by cutting the adherend using a round blade. The pressure-sensitive adhesive sheet for dicing of the invention is free from leaving any adhesive residue on chips, from peeling of the pressure-sensitive adhesive sheet from the ring for fixing it, as well as from leaving any paste residue on the ring.

Owner:NITTO DENKO CORP

Method for distressed rapid dyeing of wool sweater

The invention relates to a method for distressed rapid dyeing of a wool sweater. The method comprises the following steps: (1) wax-dipping: weighing liquid Evo wax with the amount of 1.05-1.15 times of the wool sweater fabric weight, at the room temperature, soaking the wool sweater in the wax liquid, and repeatedly kneading and pressing until being uniform; and carrying out low temperature drying or natural drying; (2) dyeing: putting the wool sweater fabric after wax-dipping pretreatment and drying into a prepared dyeing bath; heating up to 75-80 DEG C at a speed of 3 DEG C / min, and holding for 5-10 min to achieve dyeing; (3) carrying out color fixation: after dyeing, adding a cationic color-fixing agent for color fixation for 5 min, and then taking out the fabric; (4) cleaning: washing with a non-ionic surfactant for 15 min at the temperature of 70 DEG C; and (5) drying. After the wool sweater is dyed by the rapid dyeing process, a distressed effect of distinct depth levels and uniform overall appearance appears. In addition, compared with a conventional dyeing process, the dyeing time is shortened by 60%-70%, and the color fastness is at the level of 2.5 or above.

Owner:嘉兴俊雅服饰股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com