Method for distressed rapid dyeing of wool sweater

A rapid dyeing and sweater technology, applied in the field of dyeing and finishing, can solve problems such as unfavorable industrialized production and reduced production efficiency, and achieve the effects of good reproducibility, good imitation effect, and improved technical content and added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

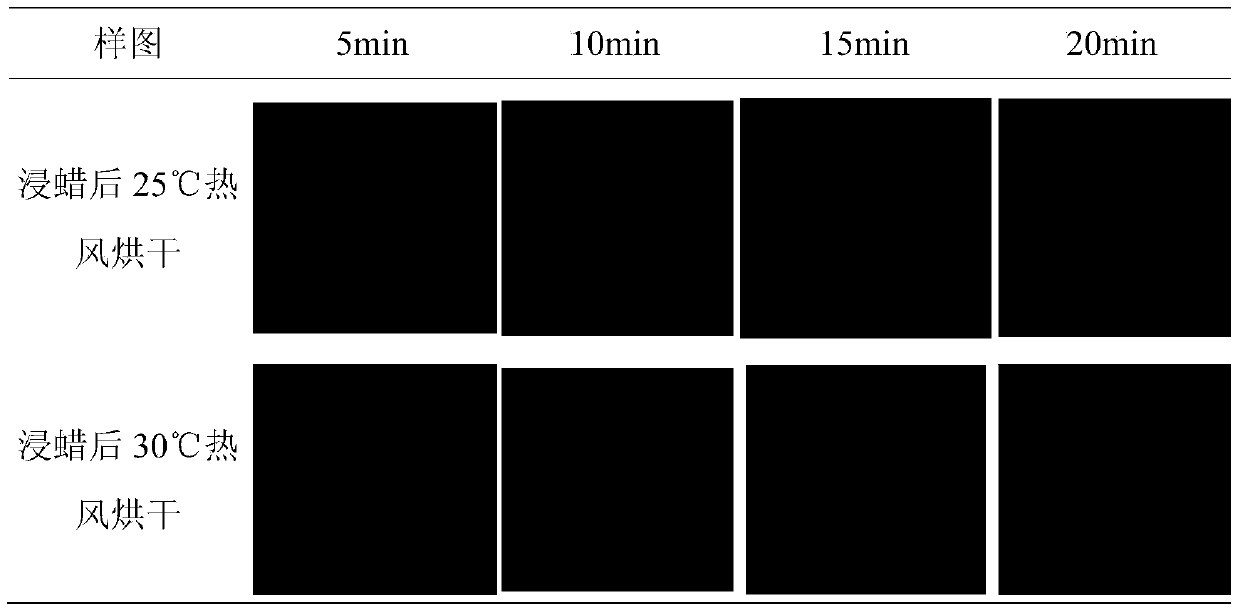

Image

Examples

Embodiment Construction

[0028] In order to solve the above technical problems, the technical solutions of the present invention are implemented as follows.

[0029] (1) Pretreatment process of dipping Aifu wax:

[0030] Description of Aifu wax: Aifu wax imitation dyeing is similar to but different from the traditional batik process. In traditional batik, the parts of the fabric that need to show patterns are painted by hand, and then dyed. The painted parts have the anti-dyeing effect of wax, which makes it difficult for dyes to be dyed, so that the fabric will show its full color. Patterns are required, and cracks can also be generated by randomly folding and pressing the waxed parts before dyeing. During the dyeing process, as the dyed fabric is turned, cracks will also occur on the parts coated with wax, and the dye solution will flow smoothly. The cracks infiltrate into the fiber, and then after dyeing processes such as dewaxing, washing, soaping and drying, patterns and naturally formed ice pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com