Multifunctional warp-knitted jacquard interval shoe upper fabric of graphene modified polyester fibers and production method thereof

A graphene-modified polyester fiber technology, which is applied in warp knitting, footwear, knitting, etc., can solve the problem of very little functional research on shoe upper fabrics, and achieve rich patterns, good compression elasticity, and stylish appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

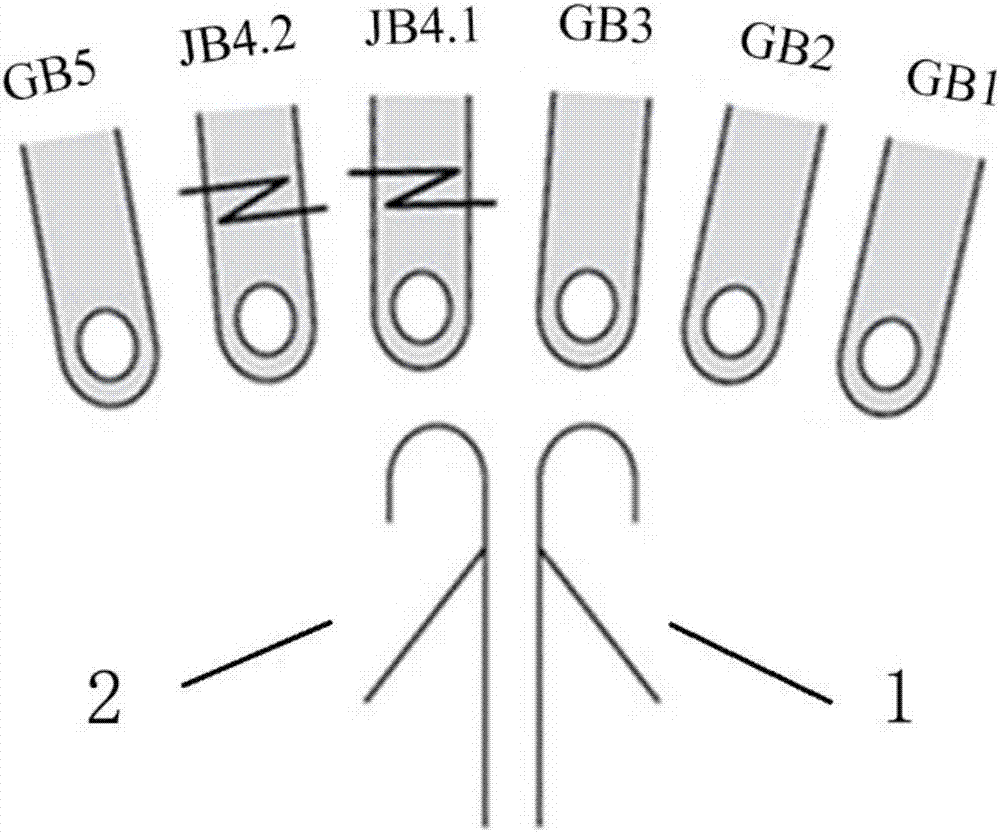

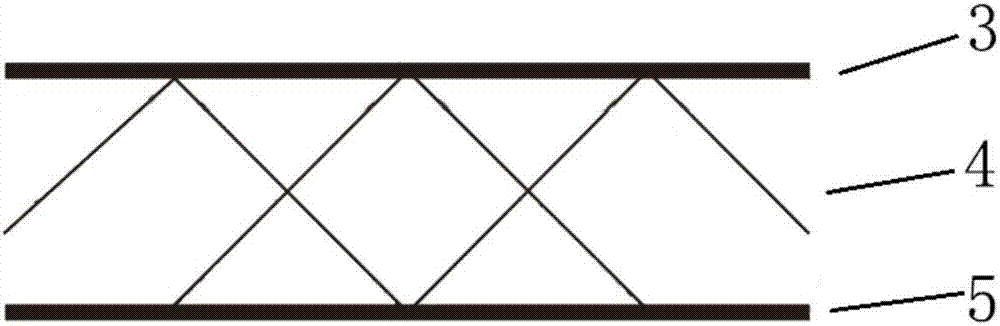

[0030] Example 1, such as Figure 1-3 Shown, a kind of production method of graphene modified polyester fiber multifunctional warp knitting jacquard spacer upper fabric, its steps are:

[0031] (1) Yarn preparation: 83dtex / 48f graphene modified polyester is used as the bottom fabric material of the spacer fabric, the middle layer of the 33dtex / 1f polyester monofilament woven spacer fabric, and 111dtex / 24f and 222dtex / 48f nylon filament woven spacers Fabric color upper surface; graphene modified polyester 476 ends, 12 pan ends; polyester monofilament 476 ends, 6 pan ends; 111dtex / 24f nylon filament 476 ends, 6 pan ends; 222dtex / 48f nylon filament has 476 heads and 6 pan heads;

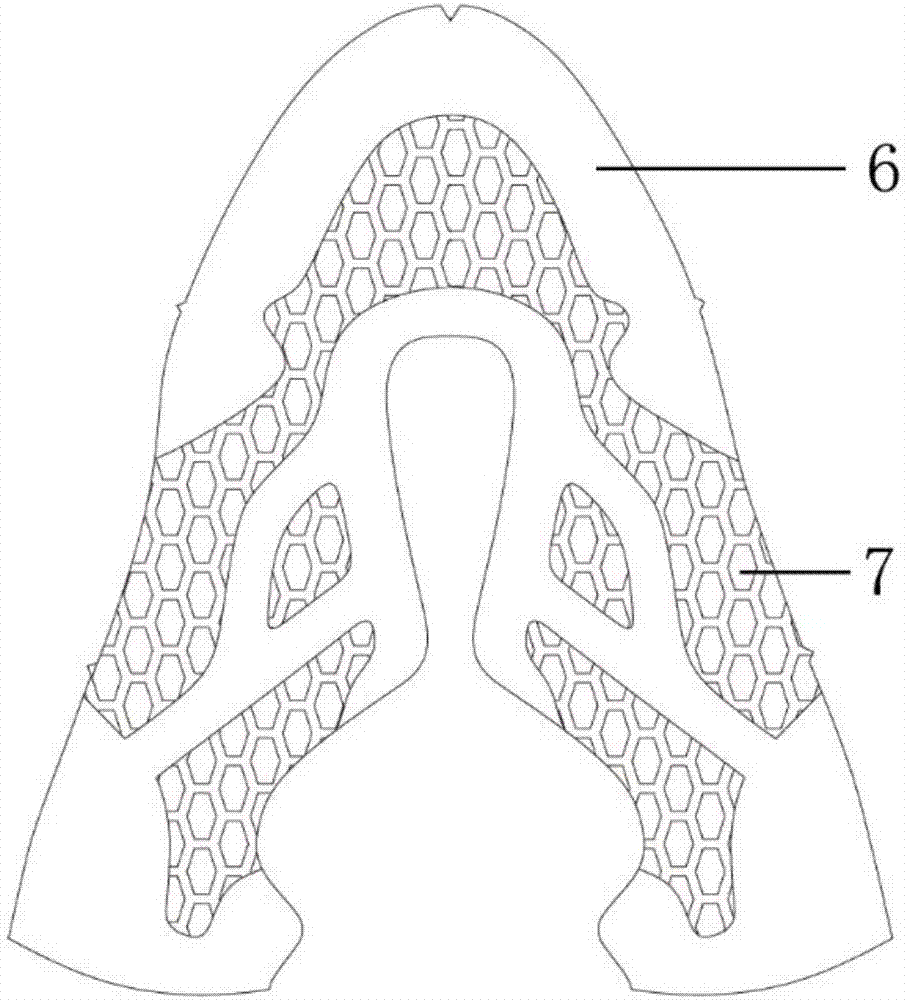

[0032] (2) Production of process documents: design the upper model drawing according to the characteristics of the foot, use the warp knitting CAD software to design the jacquard pattern of the upper, and fill the corresponding thickness, thinness and mesh according to the needs of different functiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com