Method for making conductive fabric through polyaniline-triggered chemical slivering

A conductive fabric, chemical silver plating technology, applied in the direction of plant fibers, animal fibers, textiles and paper, can solve the problems of environmental pollution, tin poisonous and harmful, high cost, etc., to reduce environmental pollution, good electrical conductivity, strong bonding high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

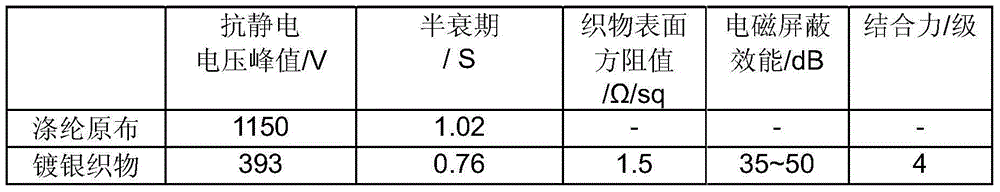

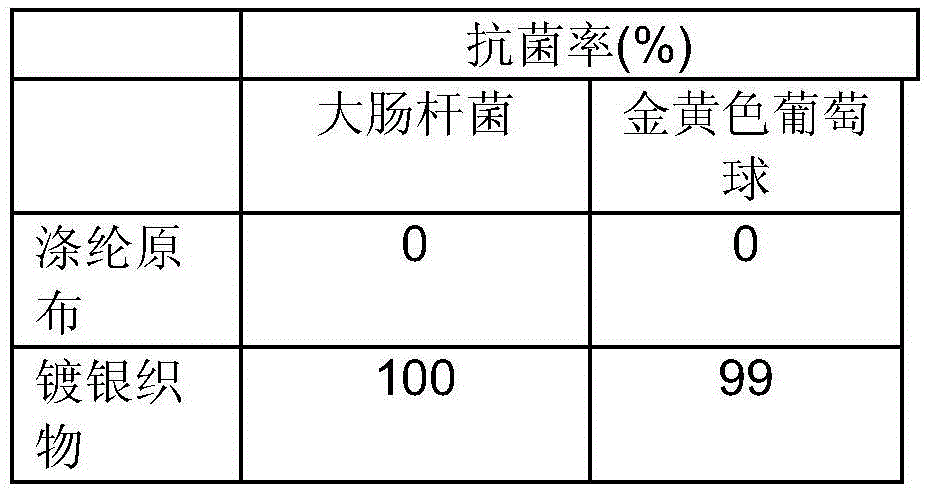

Embodiment 1

[0031] (1) prepare the mixed solution of aniline and protonic acid, wherein aniline 0.2mol / L, hydrochloric acid 0.4mol / L, put into fabric and soak for 40min, then add ammonium persulfate, make the ammonium persulfate concentration in the solution be 0.2mol / L, Polymerize for 2h, take out and wash with water.

[0032] (2) Prepare a silver nitrate solution with a concentration of 8g / L, dip the fabric with a layer of polyaniline at 20°C for 2 hours, take it out, wash it with water, and dry it in the air.

[0033] (3) First prepare silver ammonia solution: 10g / L AgNO 3 , add ammonia water dropwise until clarified; then prepare reducing solution: glucose 20g / L, tartaric acid 0.05g / L, ethanol 100mL / L, ethylenediamine 10mL / L.

[0034] Mix the silver ammonia solution and the reducing solution at a volume ratio of 1:2 to prepare an electroless silver plating solution. Immerse the fabric, perform chemical silver plating at 40°C, apply plating for 60 minutes, wash with water, and dry to...

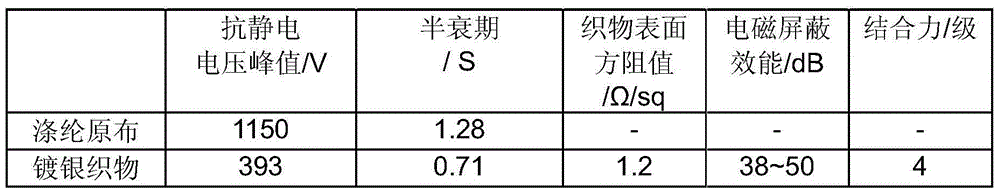

Embodiment 2

[0040] (1) prepare the mixed solution of aniline and protonic acid, wherein aniline 0.3mol / L, hydrochloric acid 0.6mol / L, put into fabric dipping 30min, then add ammonium persulfate, make the ammonium persulfate concentration in the solution be 0.3mol / L, Polymerize for 2h, take out and wash with water.

[0041] (2) Prepare a silver nitrate solution with a concentration of 10 g / L, dip the fabric with a layer of polyaniline at 50° C. for 3 hours, take it out, wash it with water, and dry it in the air.

[0042] (3) First prepare silver ammonia solution: 10g / L AgNO 3 , add ammonia water dropwise until clarified; then prepare reducing solution: glucose 20g / L, tartaric acid 0.05g / L, ethanol 100mL / L, ethylenediamine 10mL / L.

[0043] Mix the silver ammonia solution and the reducing solution at a volume ratio of 1:3 to prepare an electroless silver plating solution. Immerse the fabric, perform chemical silver plating at 40°C, apply plating for 50 minutes, wash with water, and dry to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com