Patents

Literature

874 results about "Palladium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Palladium(II) chloride, also known as palladium dichloride and palladous chloride, are the chemical compounds with the formula PdCl2. PdCl2 is a common starting material in palladium chemistry – palladium-based catalysts are of particular value in organic synthesis.

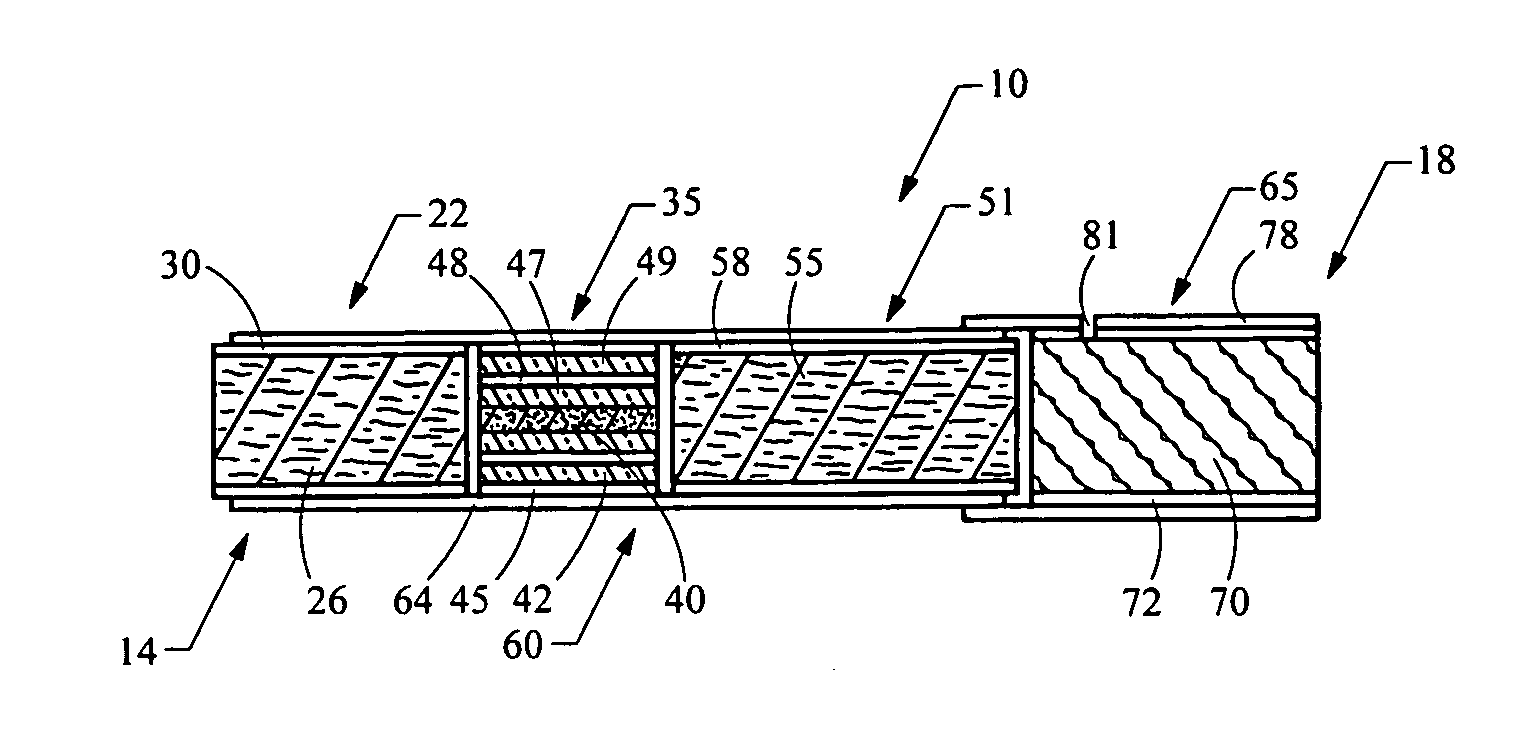

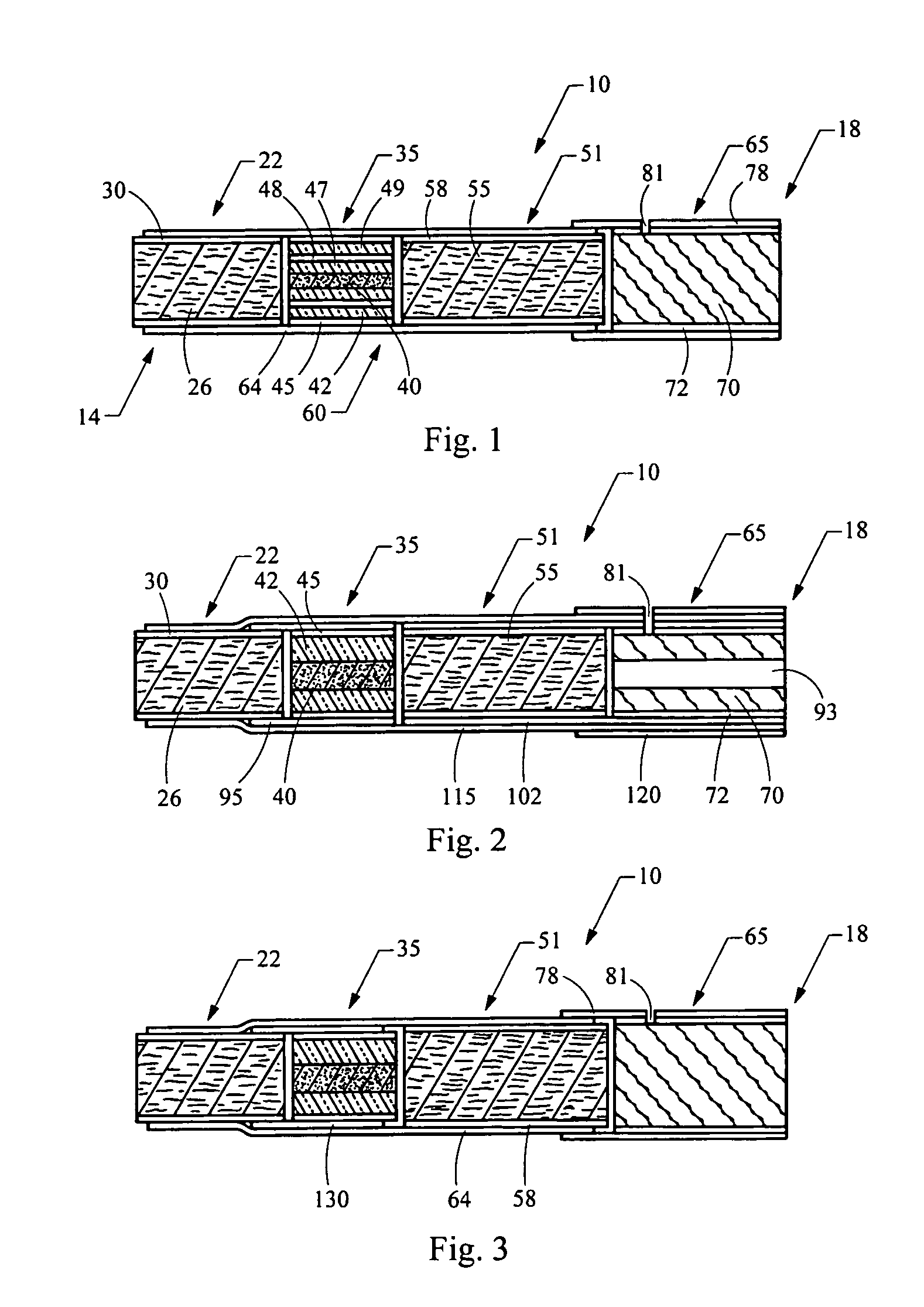

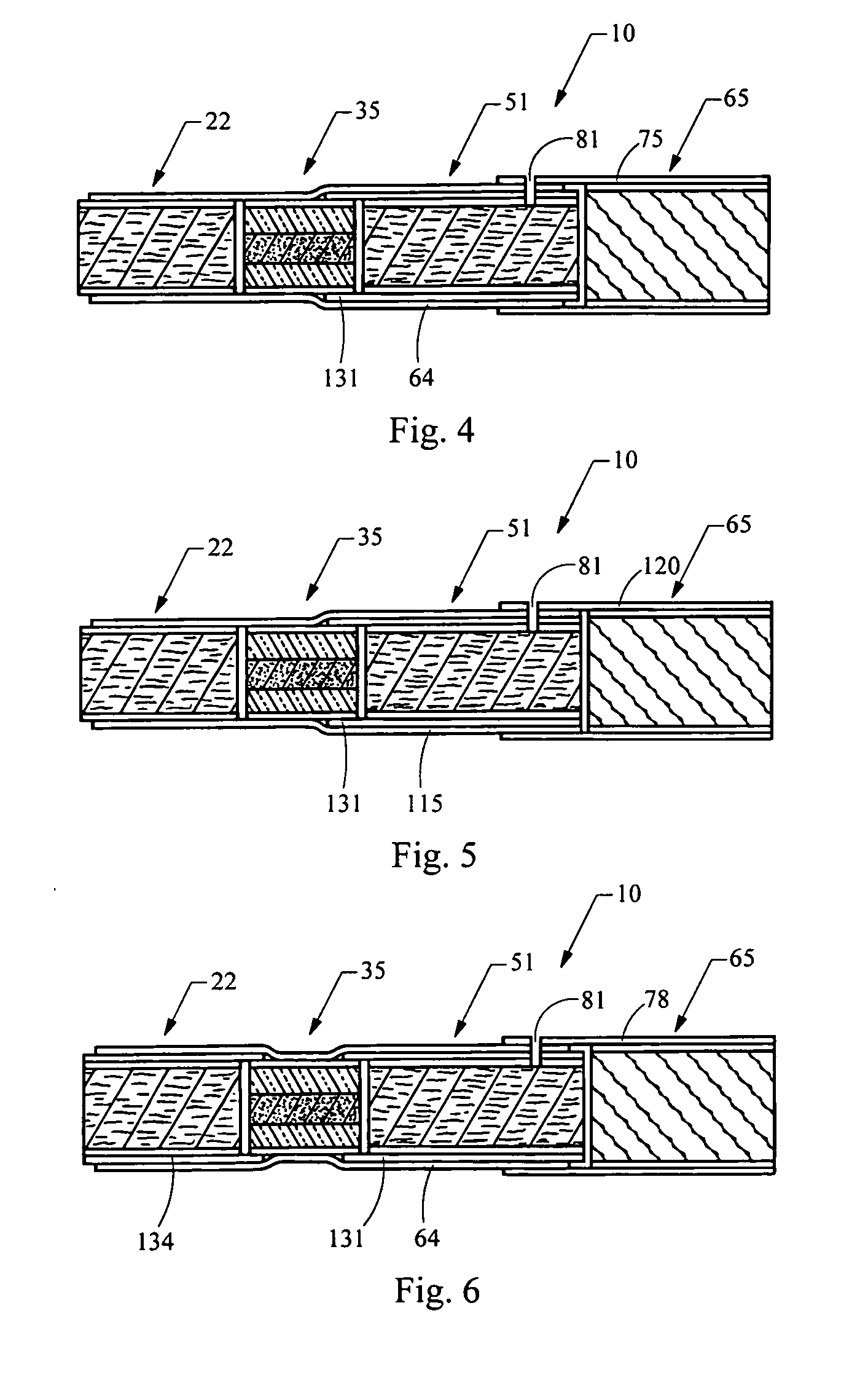

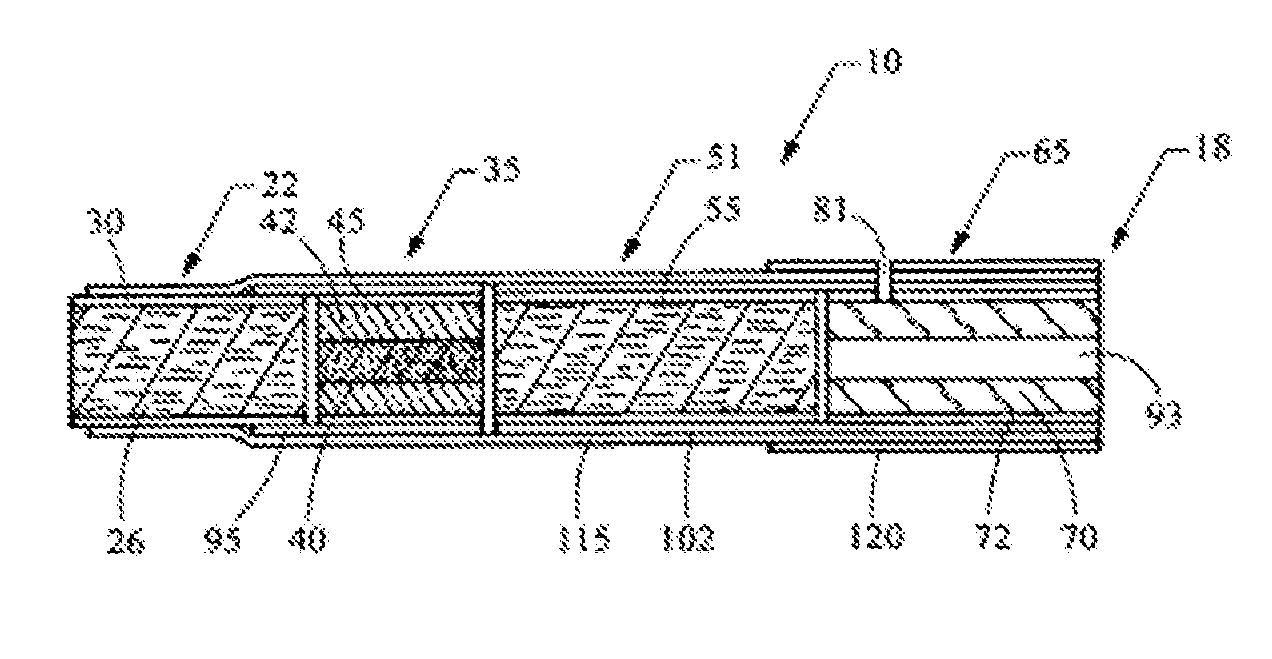

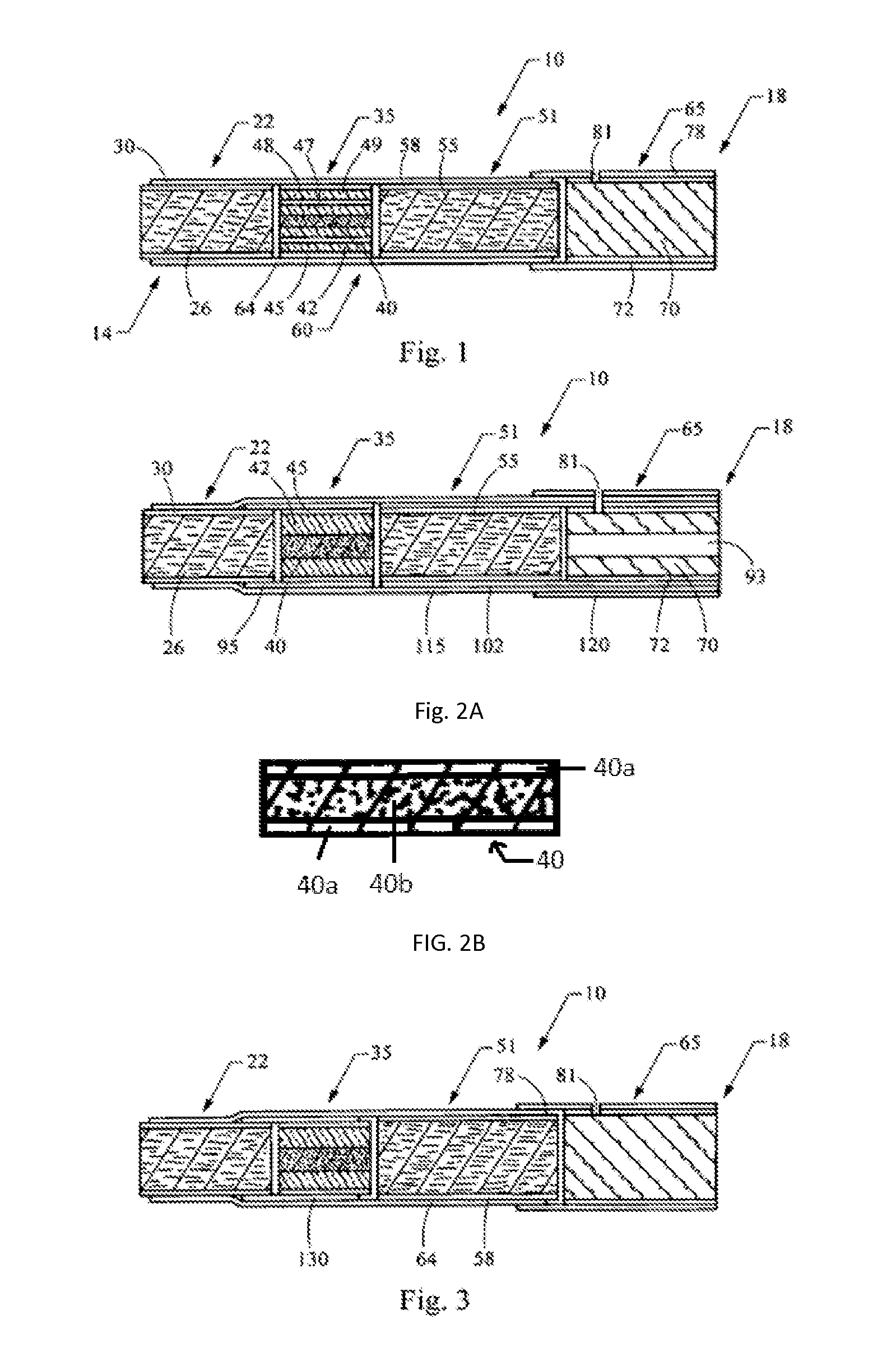

Smoking article

ActiveUS20070215168A1Reduce amountCarbon reductionTobacco preparationTobacco treatmentEngineeringFood flavor

A smoking article, such as a cigarette, includes a carbonaceous heat source. A mouth end piece segment is located at the mouth end of the smoking article, and the mouth end piece segment allows the smoking article to be placed in the mouth of the smoker to be drawn upon. The smoking article further incorporates an aerosol-generating segment located between the heat generation segment and the mouth end piece segment. The aerosol-generating segment incorporates an aerosol-forming material (e.g., glycerin and flavors). The heat generation segment is in a heat exchange relationship with the aerosol-generating region such that heat generated by the burning fuel element acts to volatilize aerosol-forming material for aerosol formation. The carbonaceous heat source is in intimate contact with coarse, fine or ultrafine particles of materials such as cerium oxide, or mixtures of cerium oxide and palladium chloride.

Owner:R J REYNOLDS TOBACCO COMPANY

Smoking article

A smoking article, such as a cigarette, includes a carbonaceous heat source. A mouth end piece segment is located at the mouth end of the smoking article, and the mouth end piece segment allows the smoking article to be placed in the mouth of the smoker to be drawn upon. The smoking article further incorporates an aerosol-generating segment located between the heat generation segment and the mouth end piece segment. The aerosol-generating segment incorporates an aerosol-forming material (e.g., glycerin and flavors). The heat generation segment is in a heat exchange relationship with the aerosol-generating region such that heat generated by the burning fuel element acts to volatilize aerosol-forming material for aerosol formation. The carbonaceous heat source is in intimate contact with coarse, fine or ultrafine particles of materials such as cerium oxide, or mixtures of cerium oxide and palladium chloride.

Owner:R J REYNOLDS TOBACCO COMPANY

Method for reclaiming metal palladium and palladium chloride from waste loading palladium hydrogenation catalyst

InactiveCN101078054AAvoid increasing difficultyHigh investment costProcess efficiency improvementSal ammoniacAmmonium hydroxide

A method to recover Pd and Palladium Chloride from waste Pd loading hydrogenation activator, the patent provides a method to reclaim Pd and Palladium Chloride with high purity from waste activator, especially form Lindla activator. The organic substance impurity adhere to the surface of the waste Pd loading hydrogenation activator will be get rid by solution, the activator, which has been treated, will be added acid to decompose and get rid of the carbonate in the carrier, and the raw Pd will be gained. The raw Pd will be oxidized and dissolved to produce chorosub-palladium acid by hydrochloric acid-double oxygen water, and Pd solution can be gained. Ammonia will be added into the Pd solution to aminate, and the inorganic impurity such as Pb and Bi will be filtrated and get rid as deposit. Reducing agent will be used to deoxidize and deposit the cavernous Pd with high purity from Palladium-ammonia solution. The cavernous Pd will be oxidized and dissolved with hydrochloric acid-double oxygen water, and then will be evaporated to dryness to produce palladium chloride with high purity.

Owner:XIAMEN KINGDOMWAY VI TAMIN INC +1

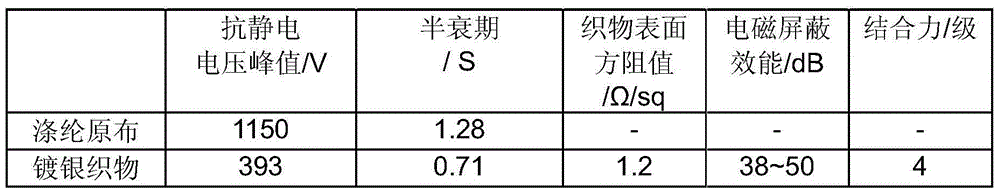

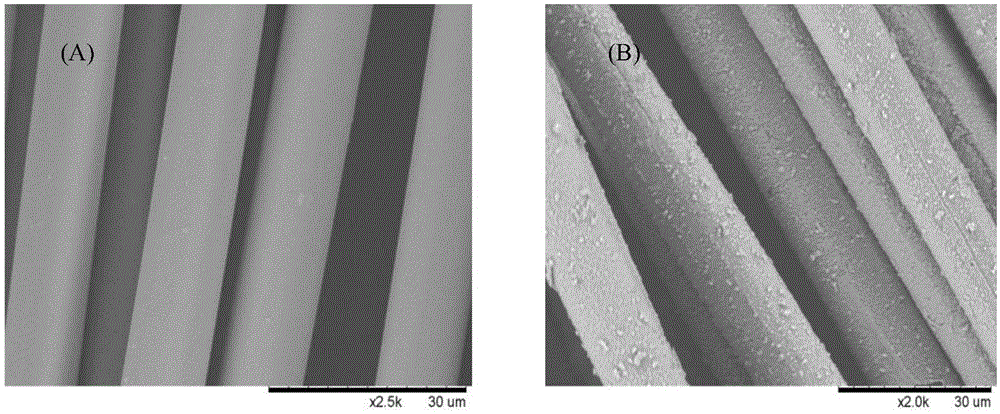

Preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers

The invention relates to a preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers, which comprises the following concrete steps of: a. washing and oil removal; b. coarsening: increasing the surface roughness and the surface wettability of fibers; c. sensitizing: soaking the fibers by adopting an aqueous solution formed by stannous chloride and hydrochloric acid; d. activation: soaking the fibers by adopting an aqueous solution formed by palladium chloride and hydrochloric acid; e. chemical nickel plating; f. sensitizing; g. activation; h. chemical silver plating; and i. coating protection. The prepared high performance nickel-plated and silver-plated aromatic polyamide conductive fibers have good electric conductivity, characteristics of heat resistance, flame retardance, light weight and high strength and functions of eliminating static electricity, conducting electricity and transmitting electrical signals. Therefore, the prepared nickel-plated and silver-plated aromatic polyamide conductive fibers can be widely applied to special departments of aviation, space flight, war industry, communication and the like and can also satisfy the clothing and equipment requirements of staffs engaging radars, television relaying and the like.

Owner:SHANGHAI UNIV

Method for performing electroless nickel plating on surface of aluminum nitride ceramic

ActiveCN101962760AHigh bonding strengthImprove high temperature resistanceLiquid/solution decomposition chemical coatingElectroless nickelSodium acetate

The invention provides a method for performing electroless nickel plating on the surface of aluminum nitride ceramic, belonging to the ceramic thin-film metallization field. The method comprises the following specific steps: 1) polishing the surface of aluminum nitride with a machinery; coarsening the aluminum nitride substrate with mixed acid or alkali, completely cleaning away the residual acid or alkali; 3) sensitizing the coarsened substrate in stannous chloride solution, activating in palladium chloride solution or performing activation without palladium; 4) weighting a certain amount of nickel sulphate, sodium hypophosphite, sodium citrate, sodium acetate, lactic acid, thiourea and sodium dodecyl sulfate in sequence to prepare a chemical plating solution; and 5) adjusting the pH value of the solution to 4.0-6.0 with acid or alkali, heating the solution to 70-95 DEG C, and placing the prepared substrate in the solution to perform electroless nickel plating. The invention is characterized in that the electroless nickel plating can be performed on the surface of the aluminum nitride ceramic substrate which is difficult to plate; and a certain amount of surfactant is added so that the plating becomes denser and smoother, the binding force between the plating and the substrate is increased, and the solderability of the plating is better.

Owner:UNIV OF SCI & TECH BEIJING

Synthesis of carbon nanotubes filled with palladium nanoparticles using arc discharge in solution

InactiveUS20090072192A1Improve abilitiesMaterial nanotechnologyOther chemical processesNanotubeMaterials science

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Method for preparing noble metal modified one-dimensional titanium dioxide Hg-removing catalyst

ActiveCN101961651ASimple processEasy to masterOther chemical processesDispersed particle separationCatalytic oxidationRutile

The invention discloses a method for preparing a noble metal modified one-dimensional titanium dioxide Hg-removing catalyst. The method comprises the following steps of: by taking a titanium dioxide nanotube as an active main body and a noble metal salt or a nonmetal modifier as a modifier, heating in water, roasting, optically reducing, drying and grinding to prepare the noble metal elementary substance modified titanium dioxide nanotube photocatalyst. The nano titanium dioxide is in a rutile type, an anatase type or a mixed type of rutile and anatase; the noble metal salt is one or mixture of a plurality of silver nitrate, palladium chloride, palladium nitrate, chloroplatinic acid or chloroauric acid; and a photo-reduction sacrifice agent is one or mixture of a plurality of methanol, ethanol, ethylene glycol, propanol, isopropanol or propylene glycol. The invention is simple in process, easy to master and not easy to inactivate; and the prepared titanium dioxide nanotube and the noble metal elementary substance modified titanium dioxide nanotube photocatalyst can efficiently catalyze and oxidize Hg elementary substances in flue gas.

Owner:ZHEJIANG UNIV

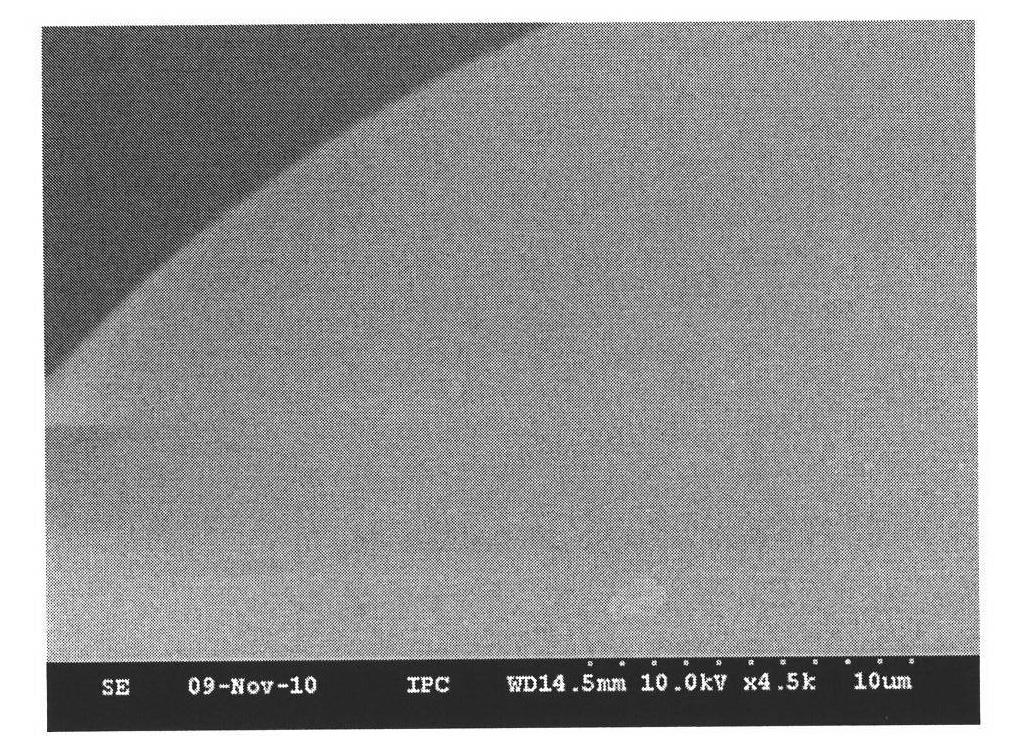

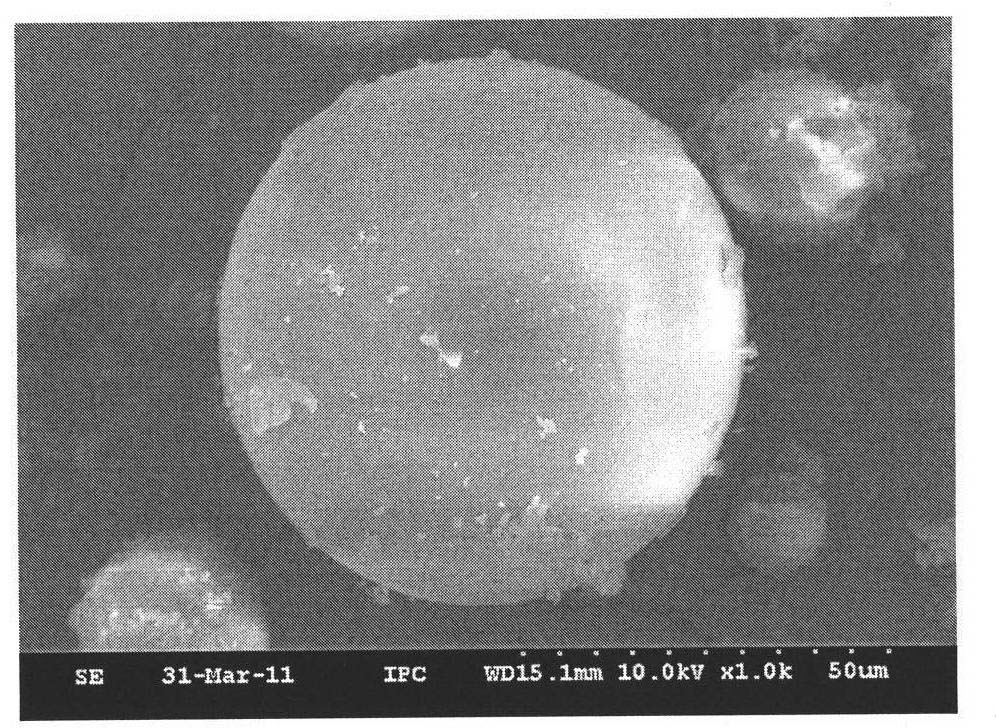

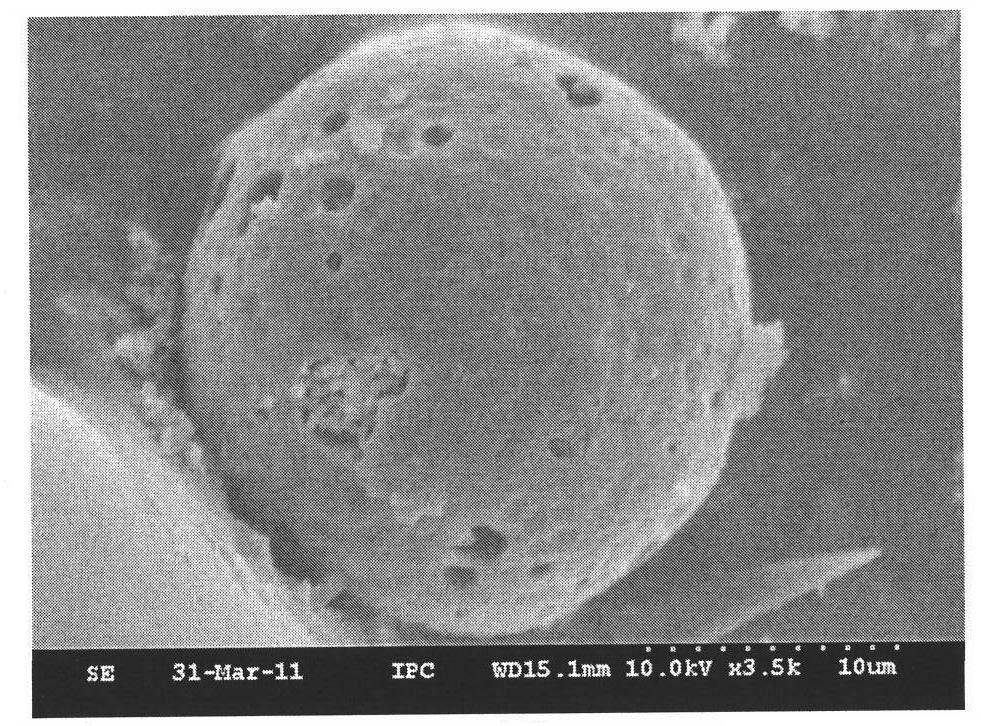

Surface chemical plating treatment process for hollow glass microsphere, plated metal hollow glass microsphere and application thereof

The invention relates to the technical field of a composite material with a core shell structure and provides a surface chemical plating treatment process for hollow glass microspheres. The surface chemical plating treatment process comprises the following steps: carrying out alkaline wash and hydrogen peroxide wash before plating to coarsen and hydroxylate the surface of the hollow glass microsphere; and carrying out chemical plating on the processed hollow glass microsphere to obtain a metal-plated hollow glass microsphere. In the method, complex preprocessing technology, such as sensitization, activation and the like in the existing method, can be simplified, and the use of expensive stannous chloride and palladium chloride which are not environmentally-friendly is avoided. Compared with the existing hot alkaline liquor processing method, the process provided by the invention has the advantages that possible microsphere fracture caused by the long-time soaking in the alkaline liquor can be avoided, and the surface hydroxylation efficiency of the hollow glass microsphere can be greatly increased by using hydrogen peroxide. The hollow glass microsphere processed with the method is easy to plate. The obtained metal-plated hollow glass microsphere has the advantages of a complete metal layer, light weight, good electrical conductivity and the like. When the obtained metal-plated hollow glass is used as a filler, material density can be lowered, cost is lowered, mechanical property is enhanced, and the plated metal hollow glass microsphere is applied to the aspects of staticelectricity coating, electromagnetic wave interference coating, wave adsorption coating and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

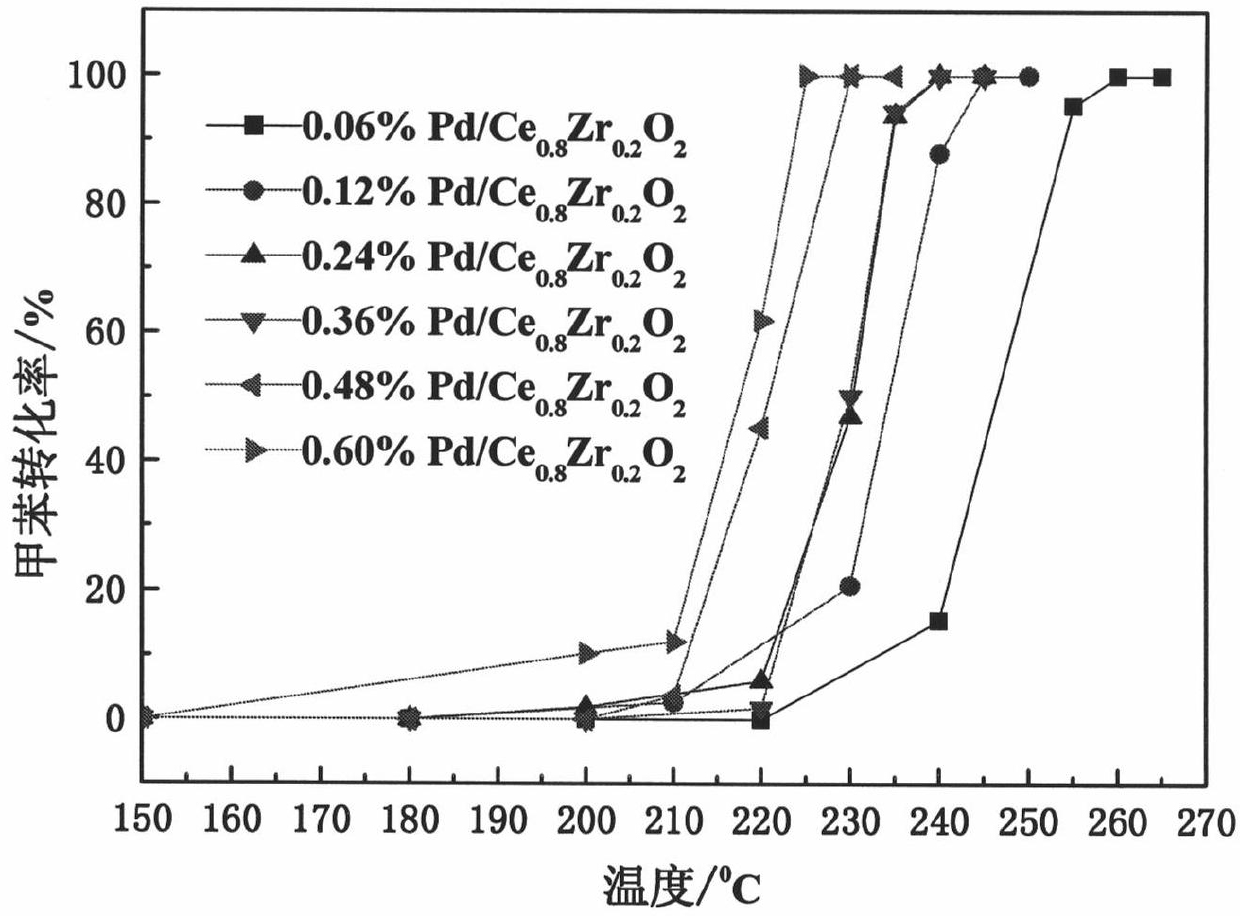

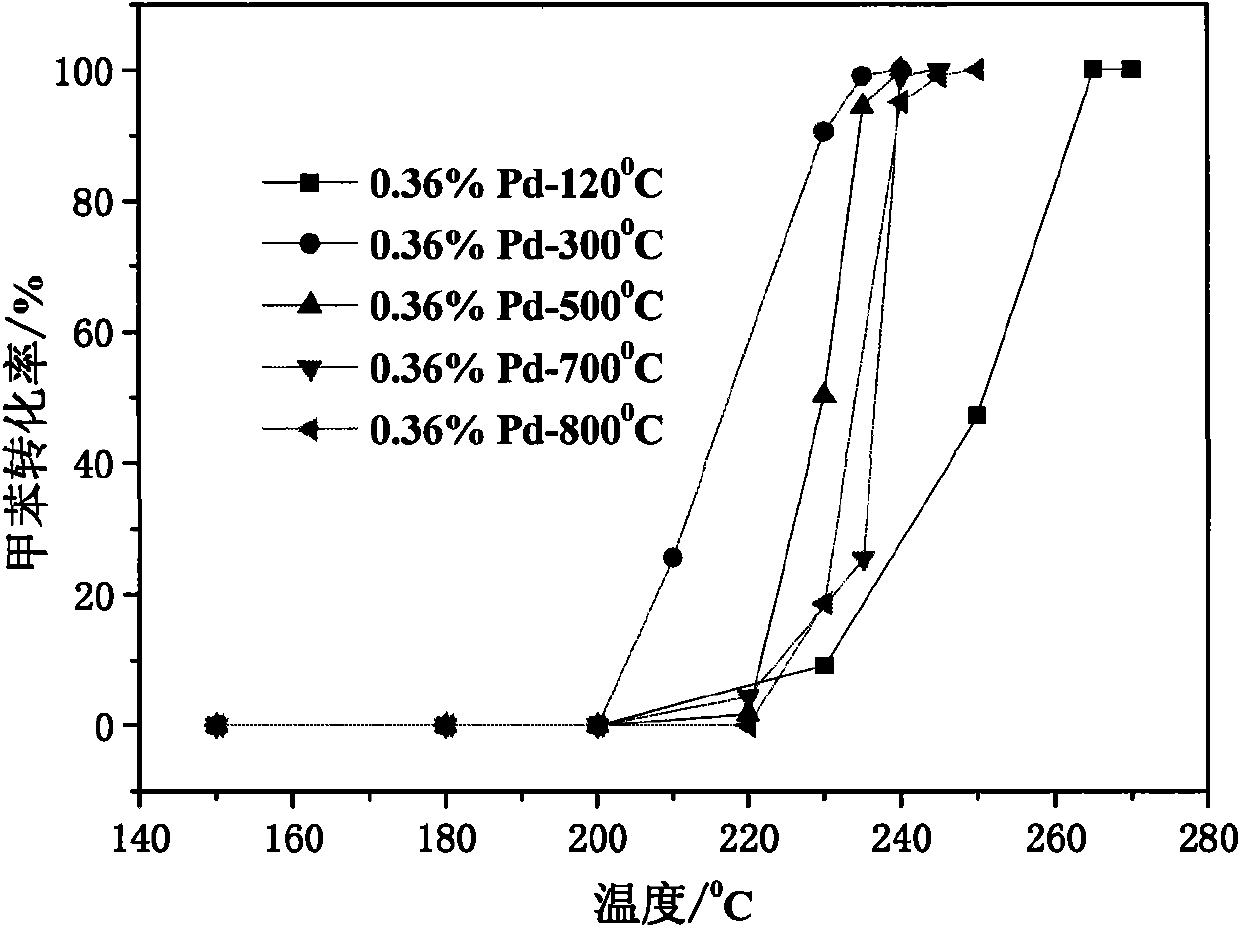

Pd/Ce0.8Zr0.2O2/cordierite honeycomb ceramic monolithic catalyst, preparation method and application thereof

InactiveCN102000570AHigh catalytic activityImprove high temperature resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSodium phosphates

The invention discloses a Pd / Ce0.8Zr0.2O2 / cordierite honeycomb ceramic monolithic catalyst, a preparation method and application thereof. The catalyst is prepared by taking cordierite honeycomb ceramic which is eroded by hydrochloric acid as a first carrier, a cerium-zirconium composite oxide as a second carrier, and a precious metal, namely palladium (Pd) as an active ingredient; preparing a cerium-zirconium composite coating on the cordierite carrier by an immersion method; immersing the carrier into plating solution; and directly reducing palladium onto the cordierite honeycomb ceramic coated with the cerium-zirconium composite coating by the redox reaction of palladium chloride and sodium hypophosphite and the self-catalysis of the palladium. The preparation method improves the oxygen storage performance of the catalyst, improves high-temperature resistance, and realizes uniform load of nano-palladium particles on the carriers without embedding active sites; moreover, the using amount of the palladium is small, the utilization rate of the palladium is improved, the process is simple, the preparation period is short, and the production cost is low. The monolithic catalyst prepared by the method has high activity and high stability; and the methylbenzene can be oxidized into harmless carbon dioxide (CO2) and water (H2O) in the presence of the catalyst at the temperature of 220 to 300 DEG C.

Owner:GUANGDONG UNIV OF TECH

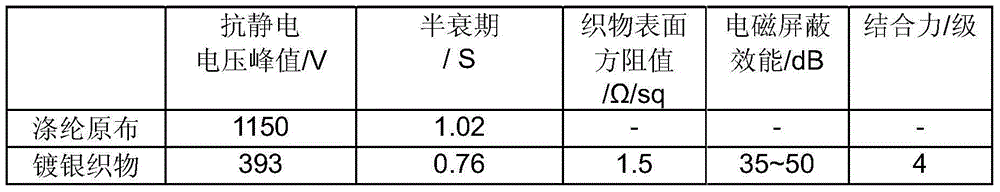

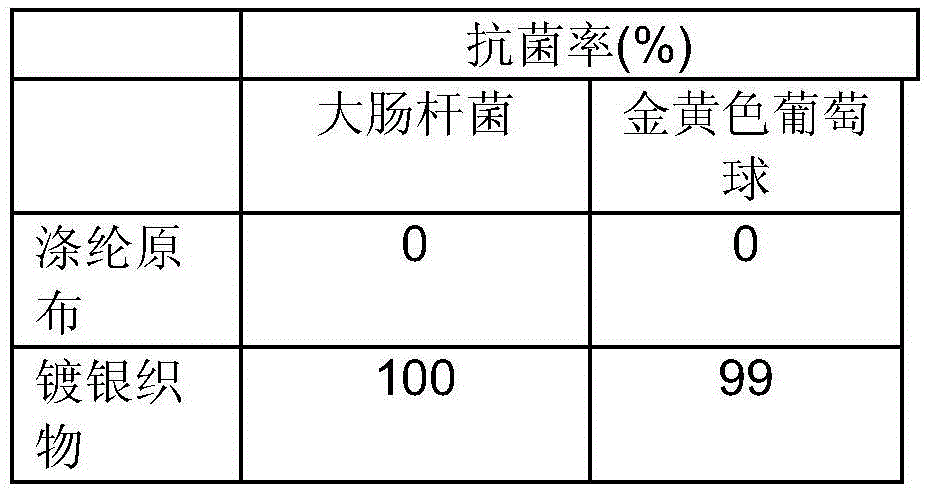

Method for making conductive fabric through polyaniline-triggered chemical slivering

InactiveCN104452309ABig pollutionReduce pollutionVegetal fibresAnimal fibresElectromagnetic shieldingBiological activation

The invention relates to a method for making conductive fabric through polyaniline-triggered chemical slivering. Fabric is soaked in a mixed solution of aniline and protonic acid, ammonium persulfate is added to the mixed solution, a reaction is carried out for 2-10 hours, and then the processed fabric is obtained after washing; the processed fabric is soaked in a silver nitrate solution, washed, dried, and then soaked in a silvering solution for being silvered for 30-60 min at the temperature of 30-40 DEG C, then the processed fabric is washed and dried, and finally the conductive fabric is obtained. According to the method, the process conditions of sensitization and activation are omitted, polyaniline and silver nitrate replace stannous chloride and palladium chloride high in price, cost is lowered, and environment pollution is reduced. The conductive fabric obtained through the method is good in conductivity, the binding strength of metal and fabric is high, the electromagnetic shielding performance is excellent, and the conductive fabric has an antistatic function, an antibacterial function and the like.

Owner:DONGHUA UNIV

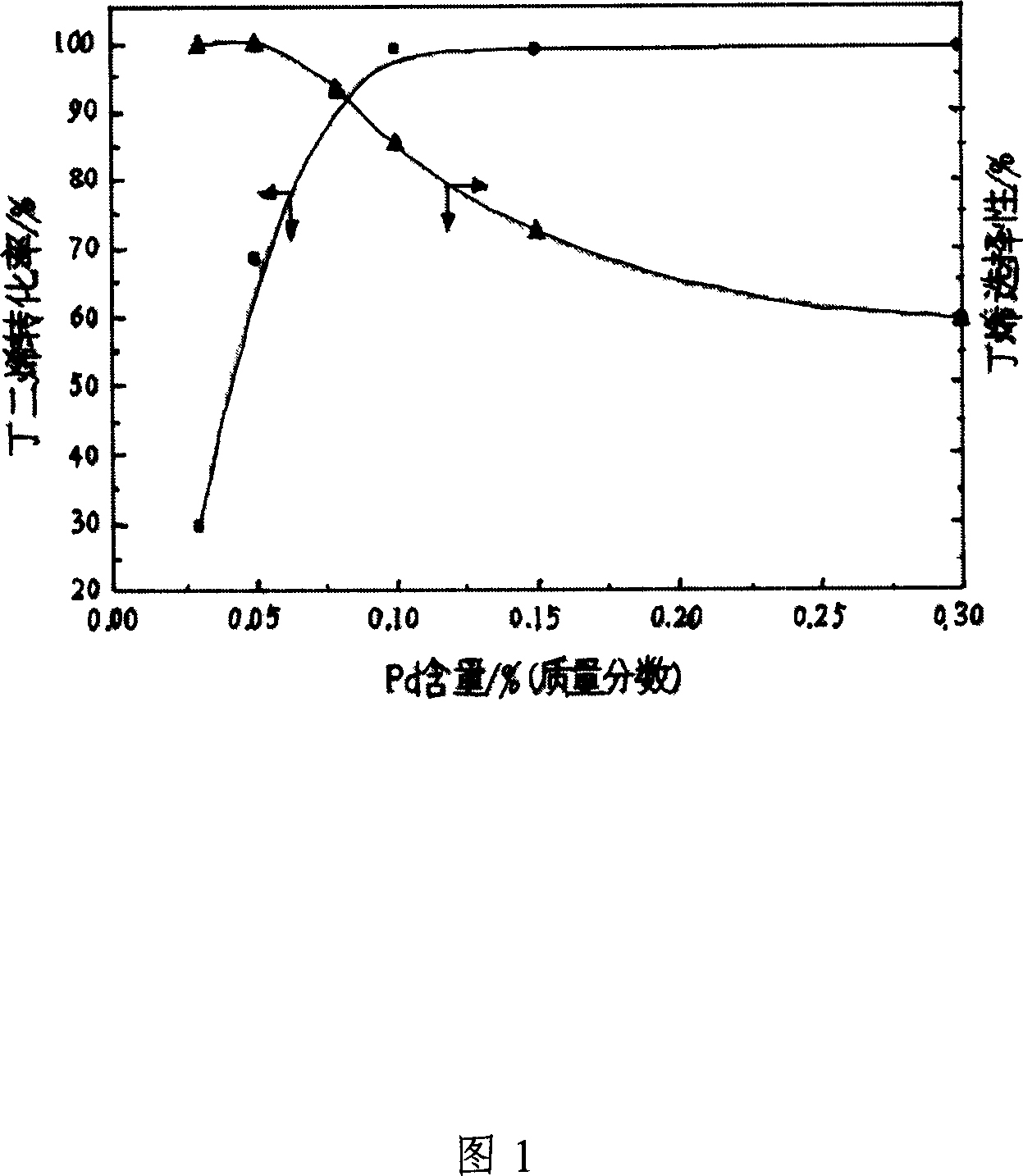

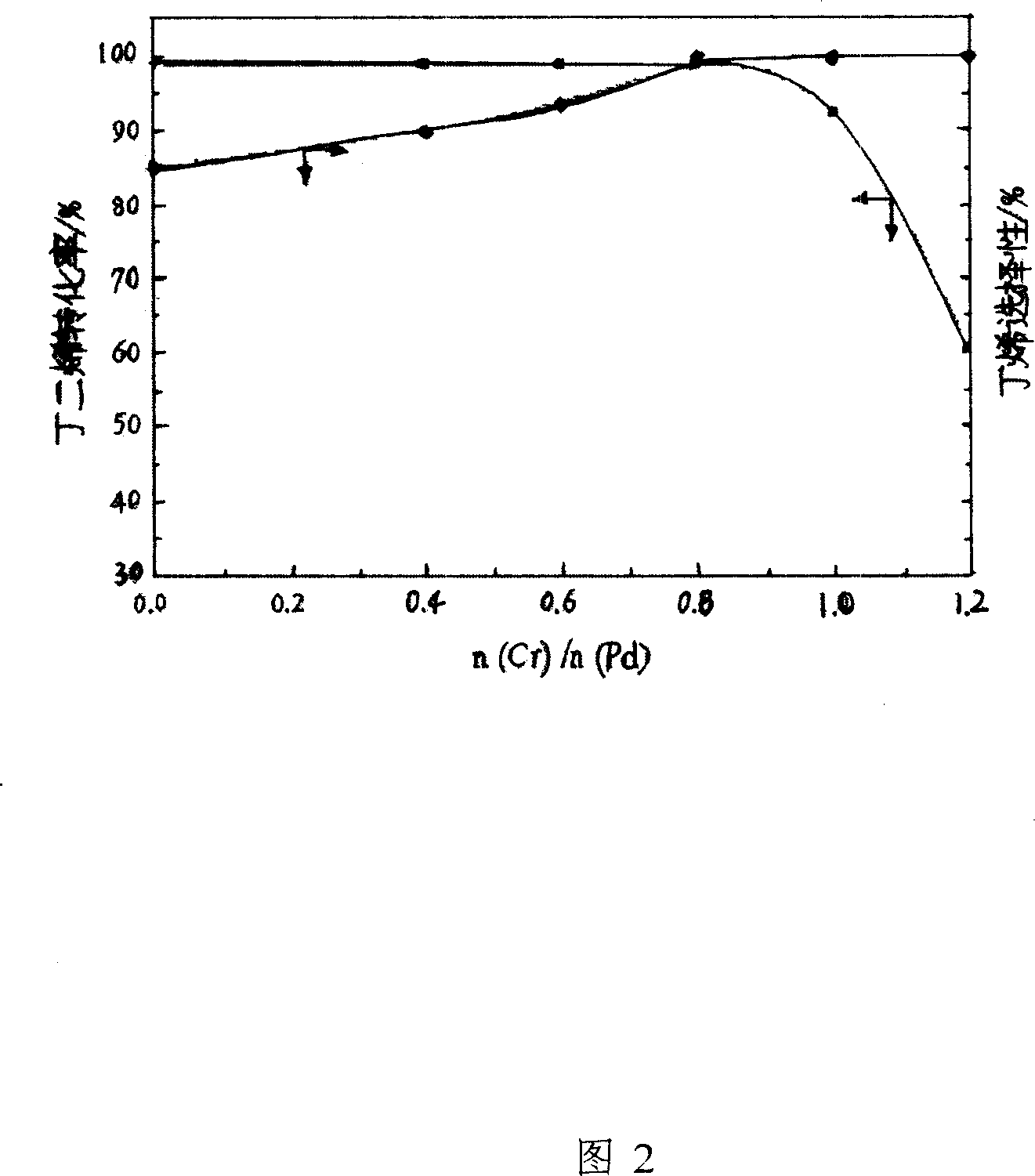

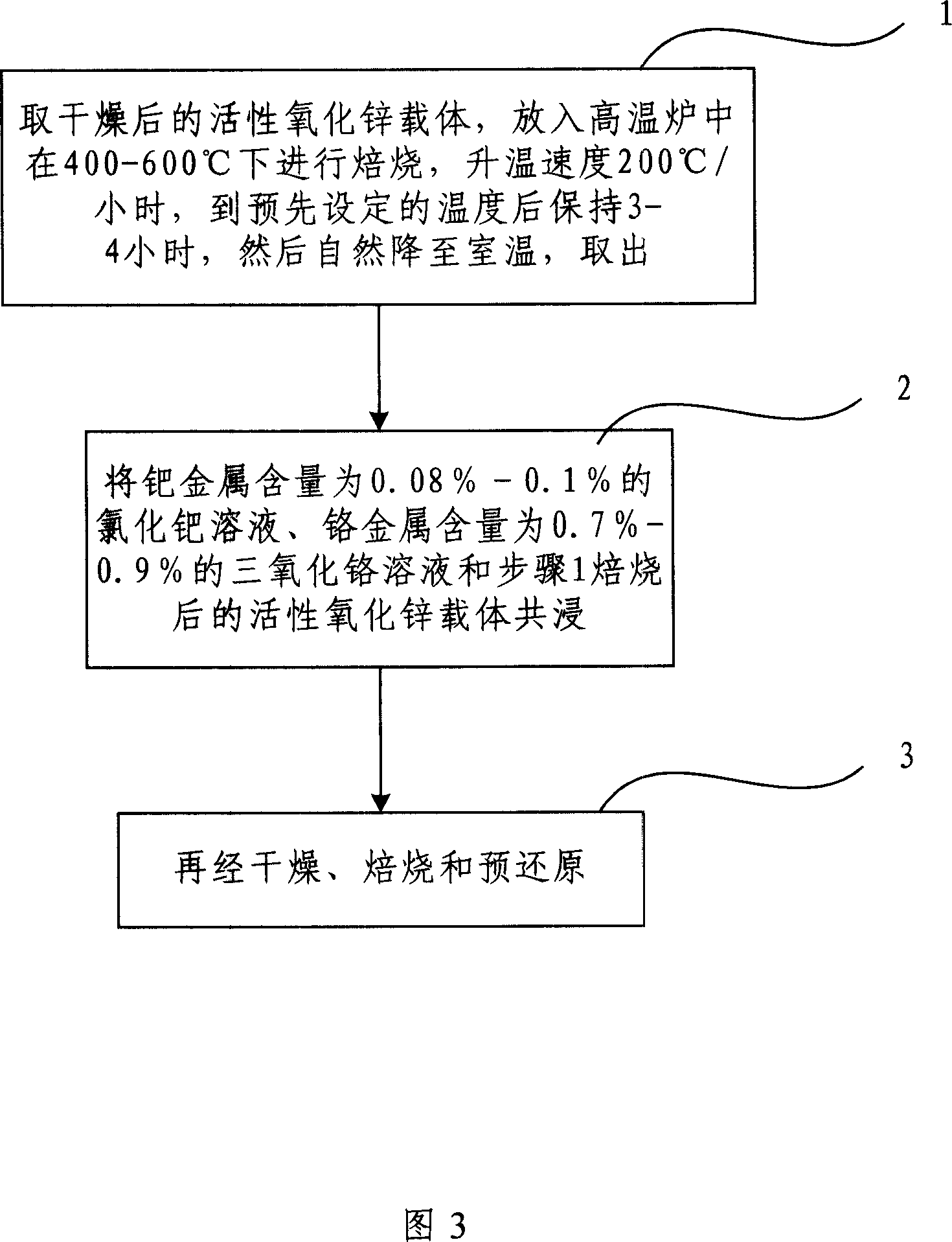

Pd radicel duplex metal selective hydrogenation catalyzer and method for preparing the same and application thereof

InactiveCN101081366AHigh activityHigh selectivityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsChromium trioxideActive component

The palladium-base bimetal catalyst for selective hydrogenation includes active zinc oxide as carrier; metal palladium as the active component in 0.03-0.3 wt% of the catalyst; and one of Cr, Ag, Ni, Cs and Pb as cocatalyst in 0.4-1.2 wt%. Its preparation process includes the steps of: roasting dried active zinc oxide carrier, soaking the carrier in palladium chloride solution with palladium content of 0.08-0.1 % and chromium trioxide with chromium content of 0.7-0.9 %, drying, roasting and pre-reducing. The catalyst has high activity, high selectivity, high stability, long service life and high catalytic efficiency.

Owner:PETROCHINA CO LTD +1

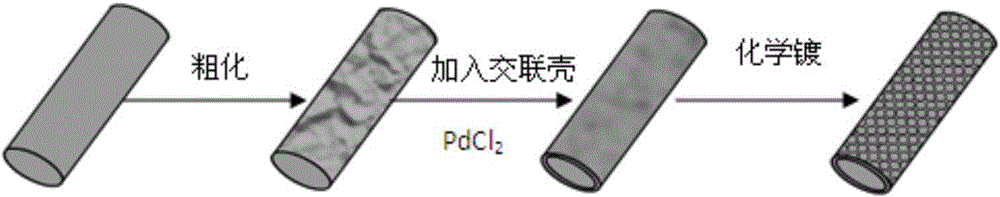

Method for chemical silver-plating of aramid conductive fibers

InactiveCN104532553AReduce dosageChange fastness is not good, poor durability and other issuesFibre typesLiquid/solution decomposition chemical coatingCooking & bakingRoom temperature

The invention relates to a method for chemical silver-plating of aramid conductive fibers. The method comprises the following steps: (1) preparing an acidic potassium permanganate solution, soaking aramid fibers, performing supersonic treatment at 20-50 DEG C for 20-40 minutes, then taking out the fibers, washing and drying; (2) dropwise adding a crosslinking agent into a chitosan solution under a low-temperature condition, stirring, soaking the aramid fibers, heating to room temperature, padding and baking; (3) preparing a palladium chloride solution, soaking the aramid fibers, and drying; and (4) preparing a silver-plating solution, soaking the aramid fibers, performing chemical silver-plating, and drying. The aramid conductive fibers prepared by the method provided by the invention are small in strength loss and high in conductivity (the fiber resistance is less than or equal to 0.4 ohm / cm), the reaction condition is mild, and the treatment method is simple, convenient and feasible.

Owner:DONGHUA UNIV

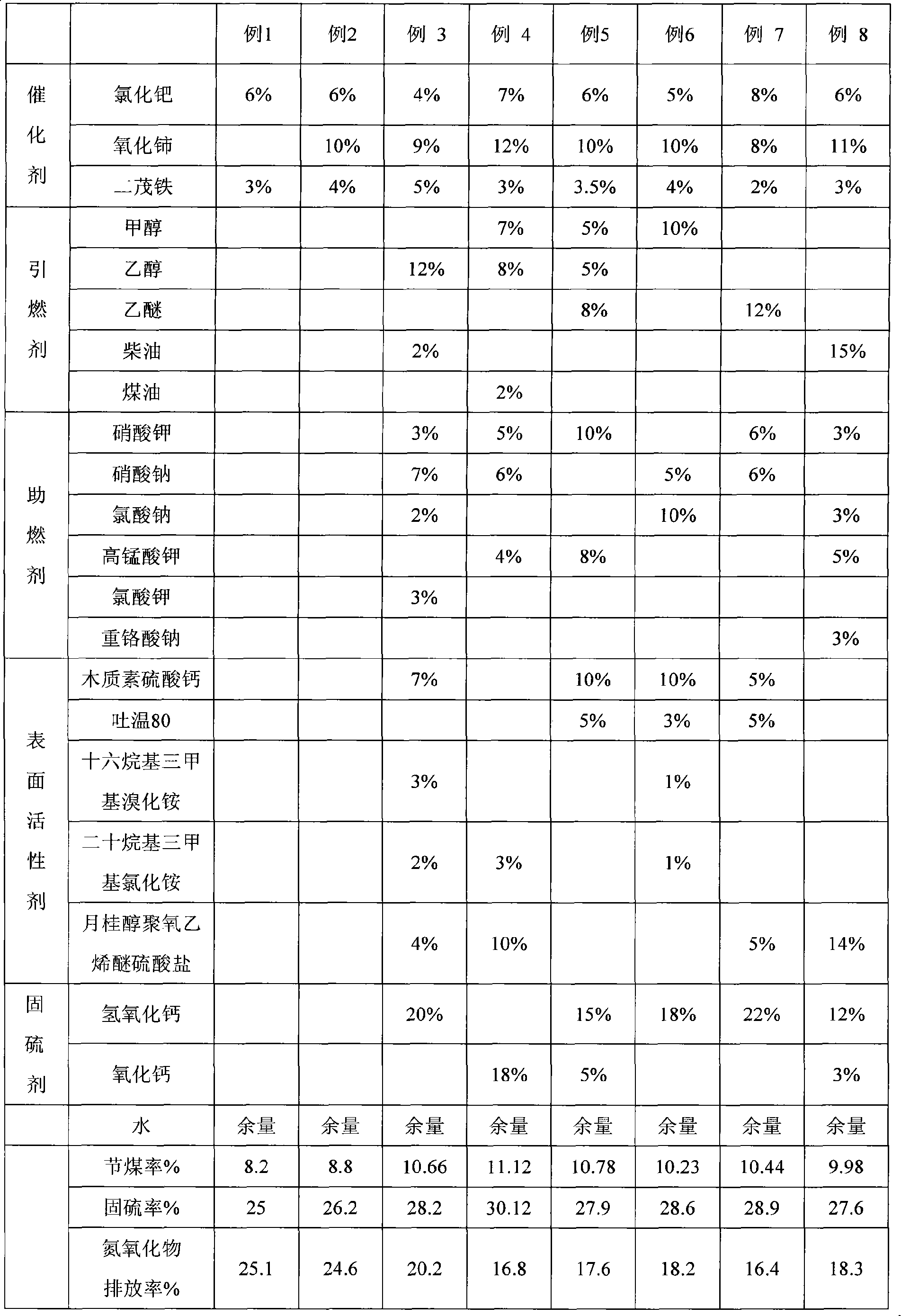

High-efficiency coal-saving burning additive

The invention relates to a high-efficiency coal-saving combustion-supporting additive, which comprises the following compositions in weight percentage: 2 to 5 percent of dicyclopentadienyl iron, 4 to 8 percent of palladium chloride, 8 to 12 percent of cerium oxide, 13 to 16 percent of surfactant, 10 to 18 percent of detonator, 12 to 18 percent of combustion promoter, 15 to 22 percent of sulphur-fixing agent, and the balance being water. The method for preparing the high-efficiency coal-saving combustion-supporting additive comprises the steps that: a catalyst, the sulfur-fixing agent, the detonator, the combustion promoter, the surfactant and the water are added according to the proportion and are stirred evenly to obtain the high-efficiency coal-saving combustion-supporting additive. The high-efficiency coal-saving combustion-supporting additive has no corrosiveness, is safe and steady under normal temperature and normal pressure, ensures that bunker coal is completely combusted, improves thermal efficiency, saves energy sources, reduces the emission of harmful gas such as sulfur dioxide and so on simultaneously, has simple preparation technology, and reduces production cost.

Owner:梁宴邱 +1

Method for preparation of phenolic compound by direct hydrogenolysis of lignin

InactiveCN104276930AHigh yieldSimple processOrganic chemistryOrganic compound preparationFiltration4-propylphenol

The invention relates to a method for preparation of a phenolic compound by lignin direct hydrogenolysis adopting hydrogen produced in situ by a solvent as a hydrogen donor under catalysis effects. The method comprises the following steps of adding lignin, catalysts and a solvent into a pressure-resistant container, carrying out a reaction process at a temperature of 150-350 DEG C for 1-20h and carrying out filtration and extraction separation. The method has a lignin conversion rate of more than 50% and phenol selectivity of more than 85% and can produce main products such as 4-propylguaiacol, 4-propylsyringol, 4-propylphenol, propenylguaiacol, syringol and allylphenol. The catalysts used by the method comprise palladium chloride, ruthenium chloride, cobaltous chloride, phospho-tungstic acid, nickel molybdate, barium molybdate, Pd / TiO2, Ru / TiO2 and Au / TiO2, a mass ratio of lignin to the catalysts is in a range of 1: 0.03 to 1: 1 and a mass ratio of lignin to the hydrogen donor is in a range of 1: 50 to 1: 150. The related lignin hydrogenolysis process has a simple technology and can be used for production of high-added value phenolic compounds by a biomass route.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Silvered aramid conductive fiber and preparation method thereof

The invention provides a silvered aramid conductive fiber and a preparation method thereof. The preparation method is conducted according to the steps as follows: a. coarsening: coarsening the aramid fiber through putting the fiber into a mixed solution of sodium hydroxide, absolute ethanol and the balance of water, and neutralizing the fiber by rinsing; b. hydrolyzing: hydrolyzing the coarsened aramid fiber by putting the fiber into an acid solution; c. activation of palladium salt: activating the hydrolyzed aramid fiber subjected to activation of palladium salt in step b by putting the fiber into a mixed solution of hydrochloric acid, palladium chloride, stannous chloride and the balance of water; d. reducing: reducing the palladium salt activated aramid fiber in step c by putting the fiber into a mixed solution of hydrochloric acid, sodium hypophosphite and the balance of water; e. chemical silvering: chemical silvering the reduced aramid fiber in step d by putting the fiber into a chemical silvering solution of silver nitrate, sodium hydroxide, aqua ammonia, a complex agent, a reducing agent and the balance of water; f. drying: drying the chemical silvered aramid fiber in step e in the conventional manner to obtain the silvered aramid conductive fiber.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

Preparation method of high-activity palladium-carbon catalyst

InactiveCN103394347AEvenly dispersedHigh activityOrganic compound preparationHydroxy compound preparationHigh activityUltrasonic dispersion

The invention discloses a preparation method of a high-activity palladium-carbon catalyst. The preparation method comprises the following steps of: (1) treating active carbon by using a compound oxidizing agent mixed solution; (2) slowly adding a palladium-chloride solution into the treated active carbon to obtain a mixed solution, and carrying out ultrasonic dispersion on the mixed solution; (3) adding alkali metal hydroxide or carbonate into the mixed solution ultrasonically dispersed to precipitate palladium ions, then adding a reducing agent, washing and drying to obtain a solid catalyst; and (4) carrying out plasma treatment on the solid catalyst to obtain a finished palladium-carbon catalyst. The preparation method disclosed by the invention has the advantages that compared with the traditional nitric acid, the high-activity palladium-carbon catalyst is environment-friendly and low-pollution; due to utilization of ultrasonic treatment, the dispersion of the catalyst is more uniform; and final plasma treatment is carried out on the catalyst, so that the activity of the catalyst is further improved.

Owner:HOHAI UNIV

A preparation method of a sol-gel catalyst for deep removal of a small amount of hydrogen in industrial CO gas

ActiveCN102284286ASimple catalytic performanceImprove catalytic performanceCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsIndustrial gasPtru catalyst

The invention discloses a preparation method of a sol-gel catalyst for deeply removing a little H2 in industrial CO synthetic gas through selective oxidation reaction, and a related process. The method comprises the following steps of: dissolving palladium chloride serving as a palladium source in hydrochloric acid solution with certain concentration, and adding aluminum isopropoxide, water and nitric acid in a certain ratio to form sol at a certain temperature; and gelatinizing the sol at a certain temperature to form gel, and drying and roasting at a certain temperature to obtain the required catalyst. The catalyst prepared by the method has the advantages that: active ingredients are uniformly distributed, the using amount of noble metal palladium salt is reduced, reaction conditions are mild, the phenomena of violent heat release and temperature runaway are avoided, the catalyst has superior performance, the H2 in the industrial CO synthetic gas can be removed to be less than 100ppm, and the requirement on the purity of the CO gas in a carbonyl synthesis process can be effectively met.

Owner:贵州鑫醇科技发展有限公司

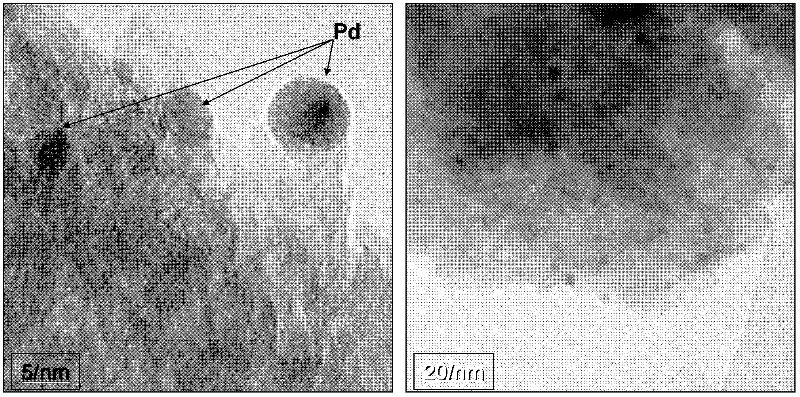

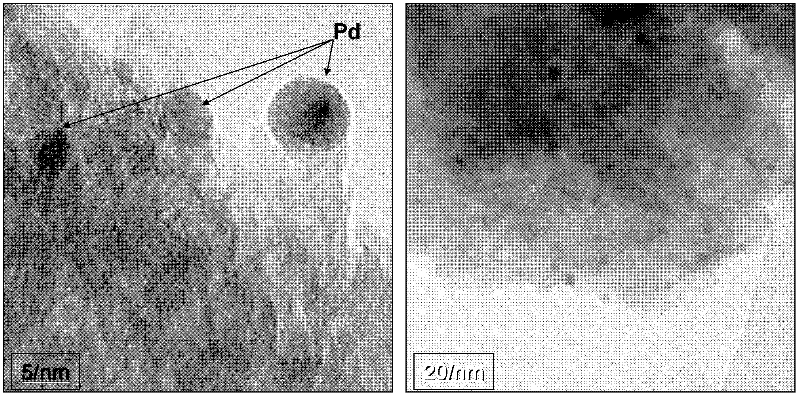

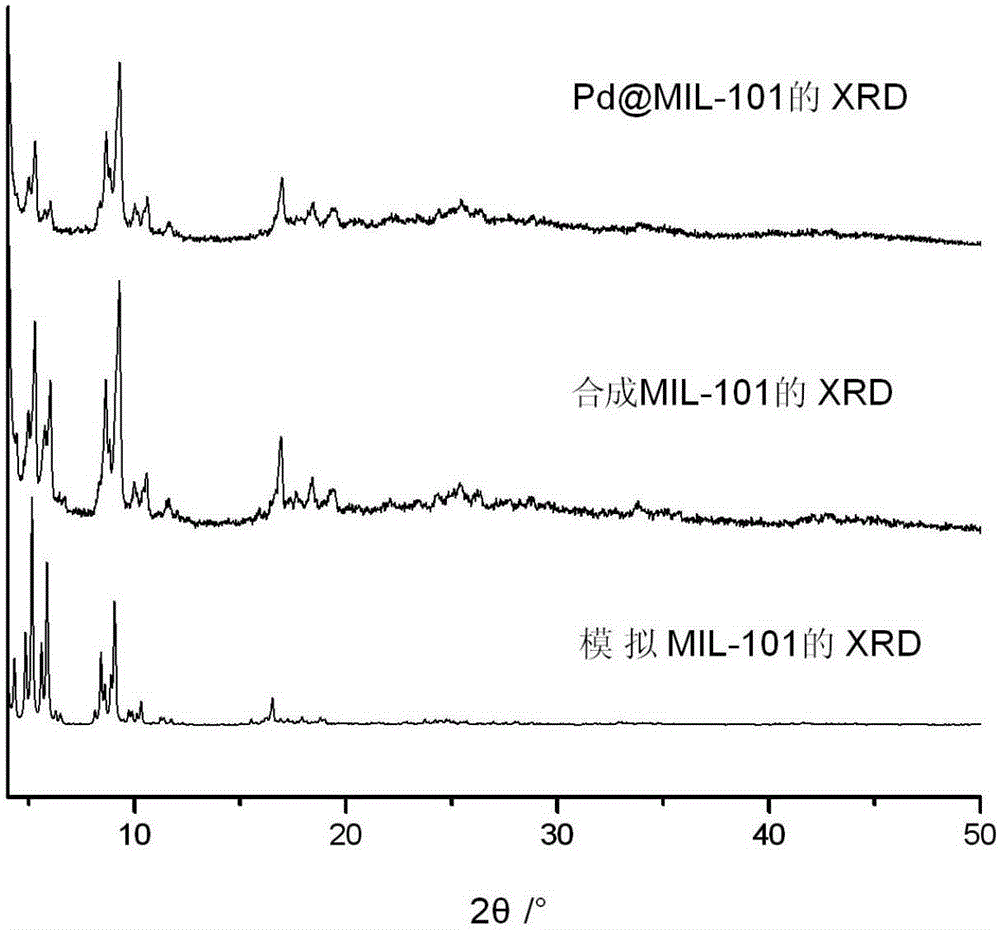

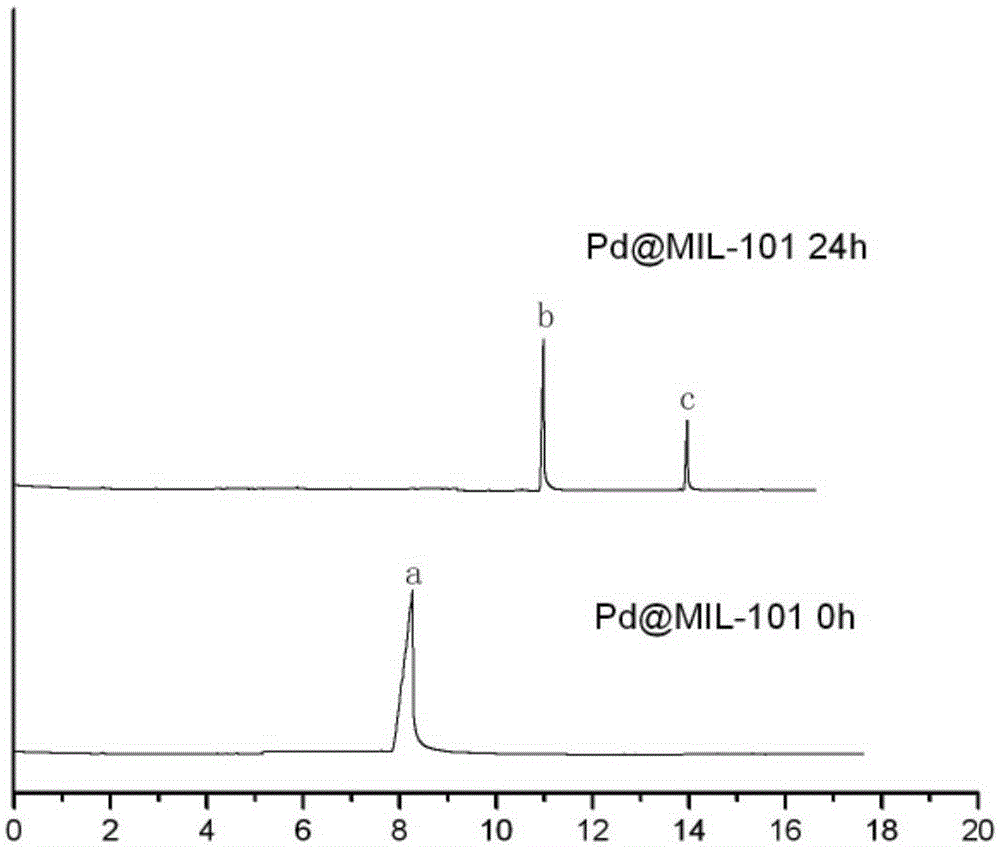

Pd @MIL-101 composite and preparation method and application thereof

ActiveCN105233872AEasy to separate and purifyHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsIce water1,4-Dibromobenzene

The invention relates to a Pd @MIL-101 composite and a preparation method and application thereof. According to the adopted technical scheme, palladium chloride is added to methyl alcohol while sodium chloride is added, ultrasonic dispersion is conducted, stirring is conducted for 10-20 hours, and sodium tetrachloropalladate is obtained; a sodium tetrachloropalladate solution is dropwise added into MIL-101 crystals slowly, pd<2+>@MIL-101 is obtained; a methanol solution of asaturated sodium borohydride is added to the pd<2+>@MIL-101, reduction is conducted under the condition of ice-water bath, and the Pd @MIL-101 composite is obtained. The synthesized Pd @MIL-101 composite has special selectivity catalytic activity for phenylboronic acid and 1,4-dibromo-benzene in a suzuki reaction, and the yield of an intermediate product 4-bromobiphenyl is effectively raised.

Owner:芜湖数字信息产业园有限公司

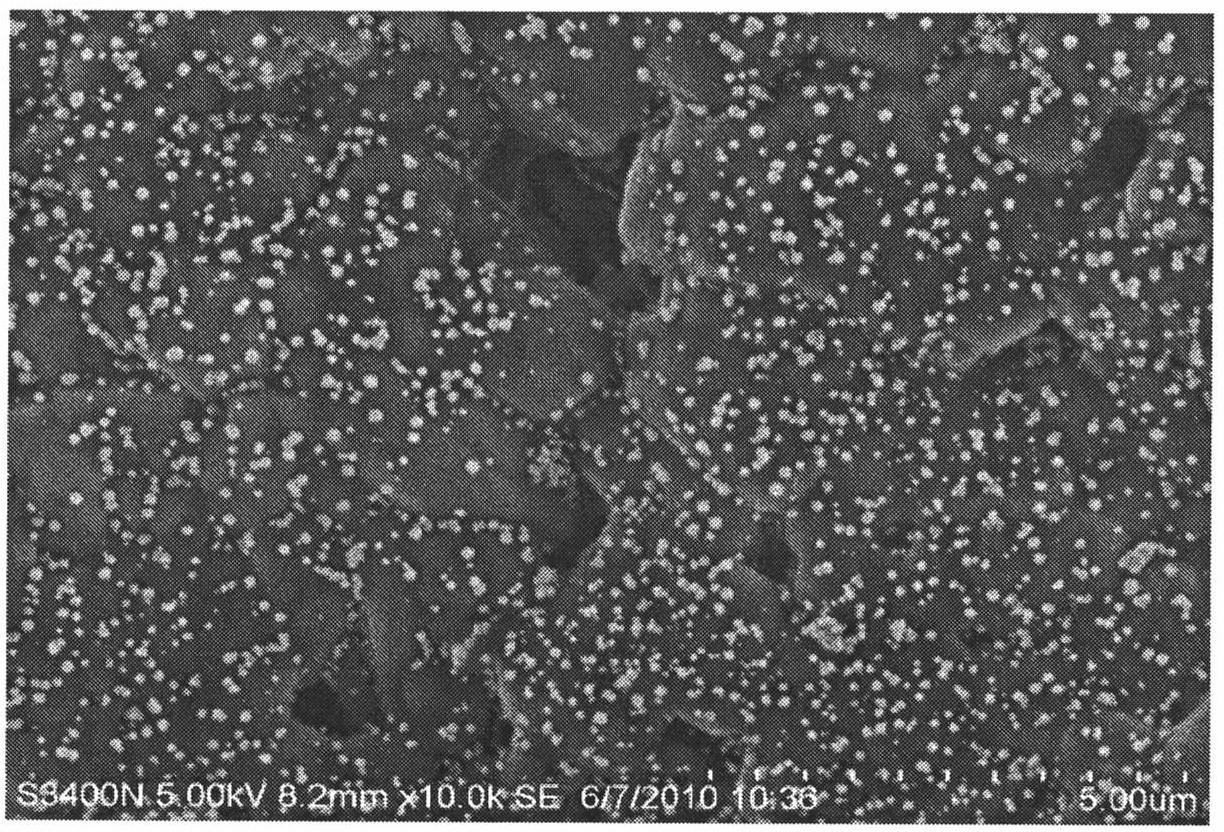

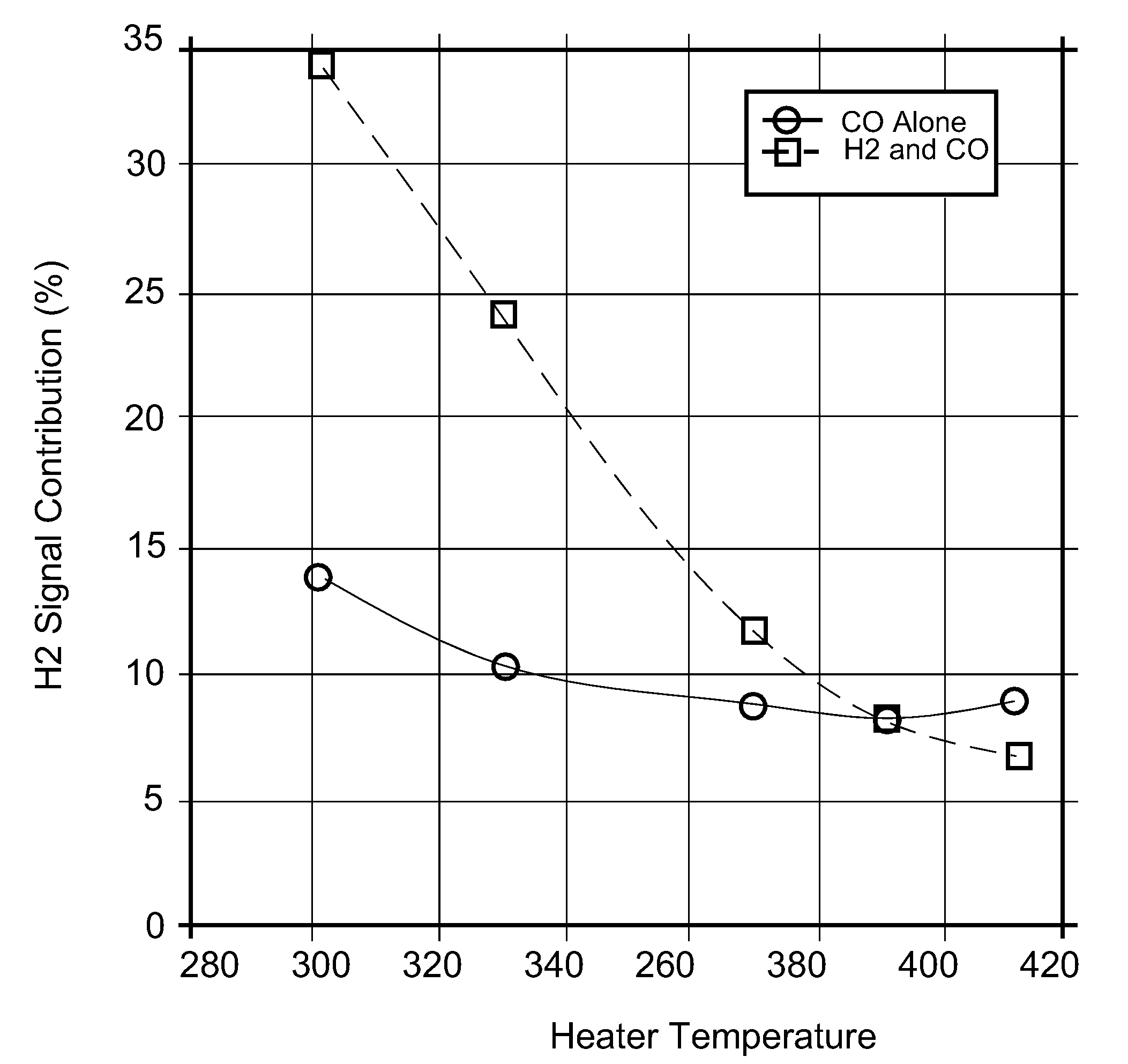

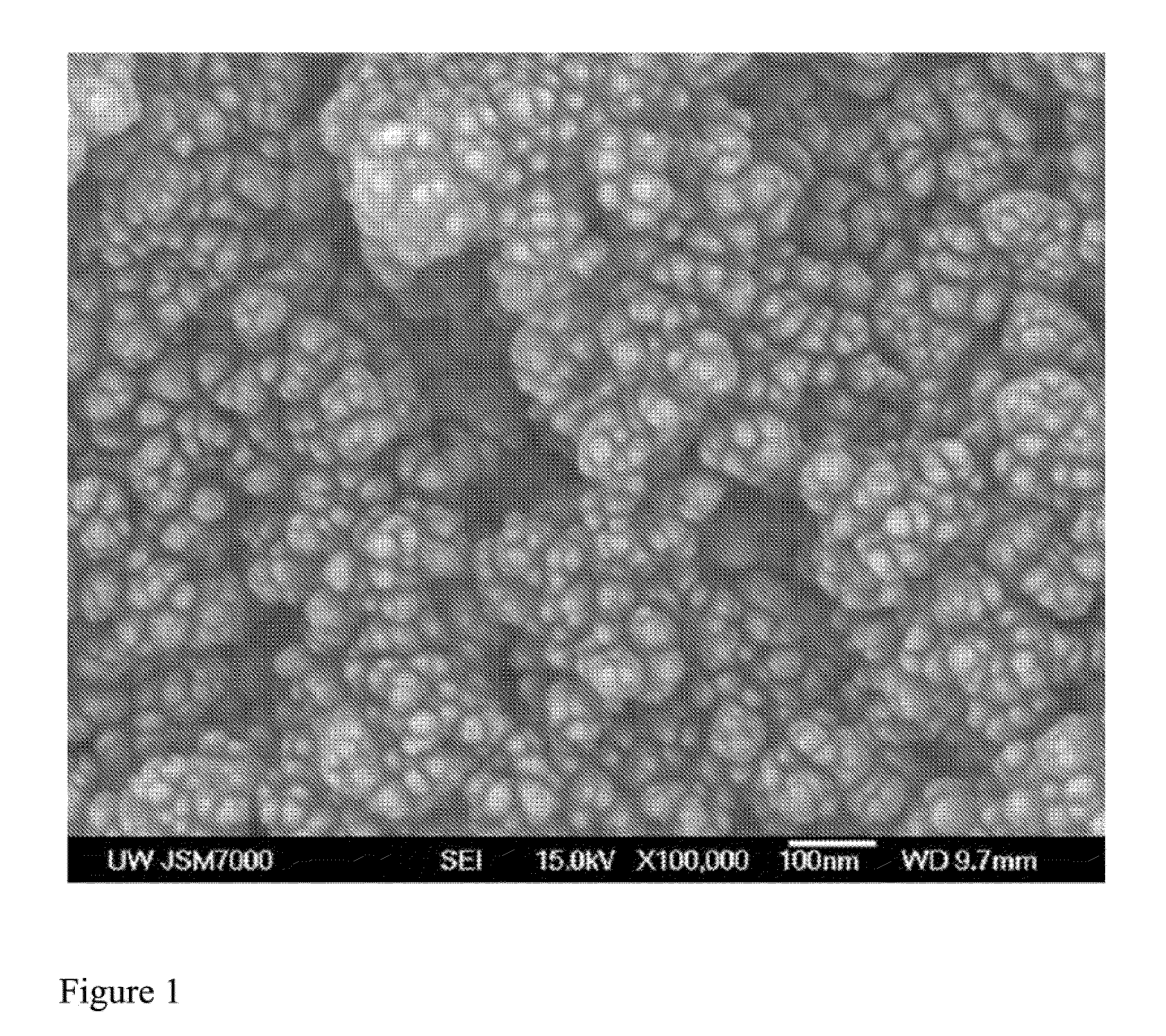

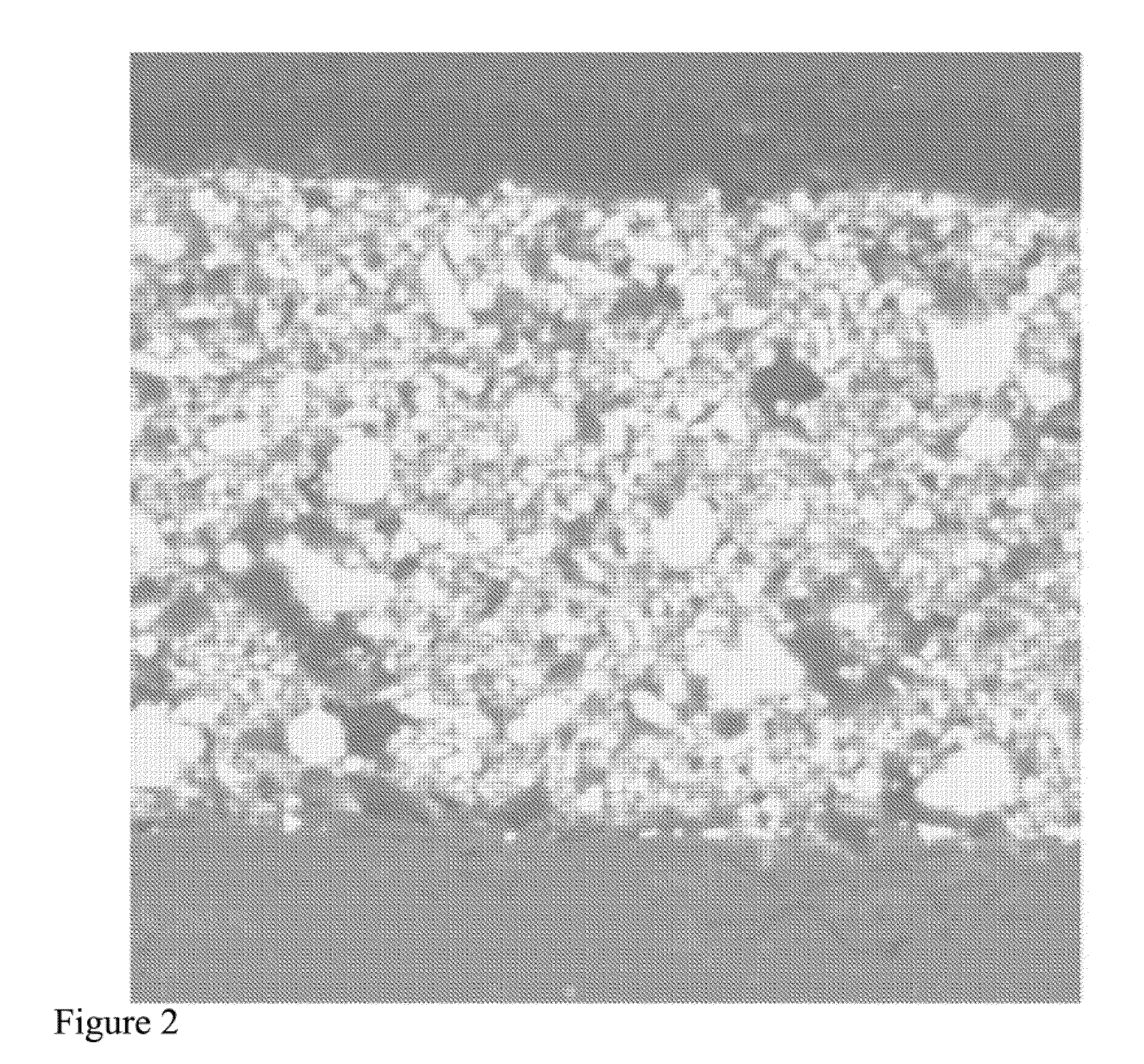

Sensitive Materials for Gas Sensing and Method of Making Same

InactiveUS20100098593A1Slow relaxationSlow responseMaterial nanotechnologyConductive materialElectrical resistance and conductanceNanoparticle

A gas detection device comprising a measuring circuit, said measuring surface comprising a substrate, a resistance heater bonded to said substrate and a coating, said coating comprising SnO2 nanoparticles doped with In2O3 nanoparticles and Pd oxide, said Pd oxide being formed from a solution of a Pd salt, such as PdCl2. The SnO2 nanocrystals have a specific surface of at least about 50 m2 / g, a mean particle size of between about 5 nm and about 20 nm, and the contact points between individual nanoparticles of SnO2 and In2O3 and the associated Pd oxide are less than about 100 Å. The Pd salt solution is a solution of a palladium chloride in a dilute acid solution, such as HCl. The palladium salt to an oxide of palladium at an elevated temperature, as for example, by calcining said oxide of palladium. The palladium oxide is in the form of a coating on nanoparticles of SnO2 and In2O3.

Owner:APOLLO

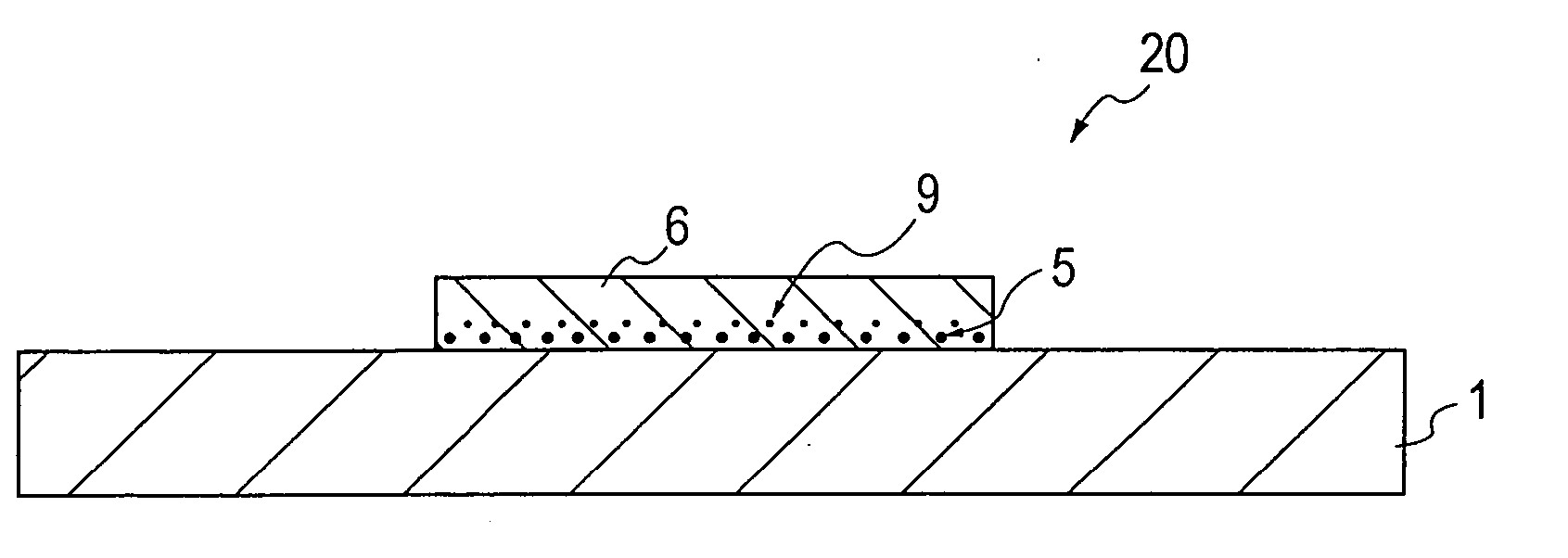

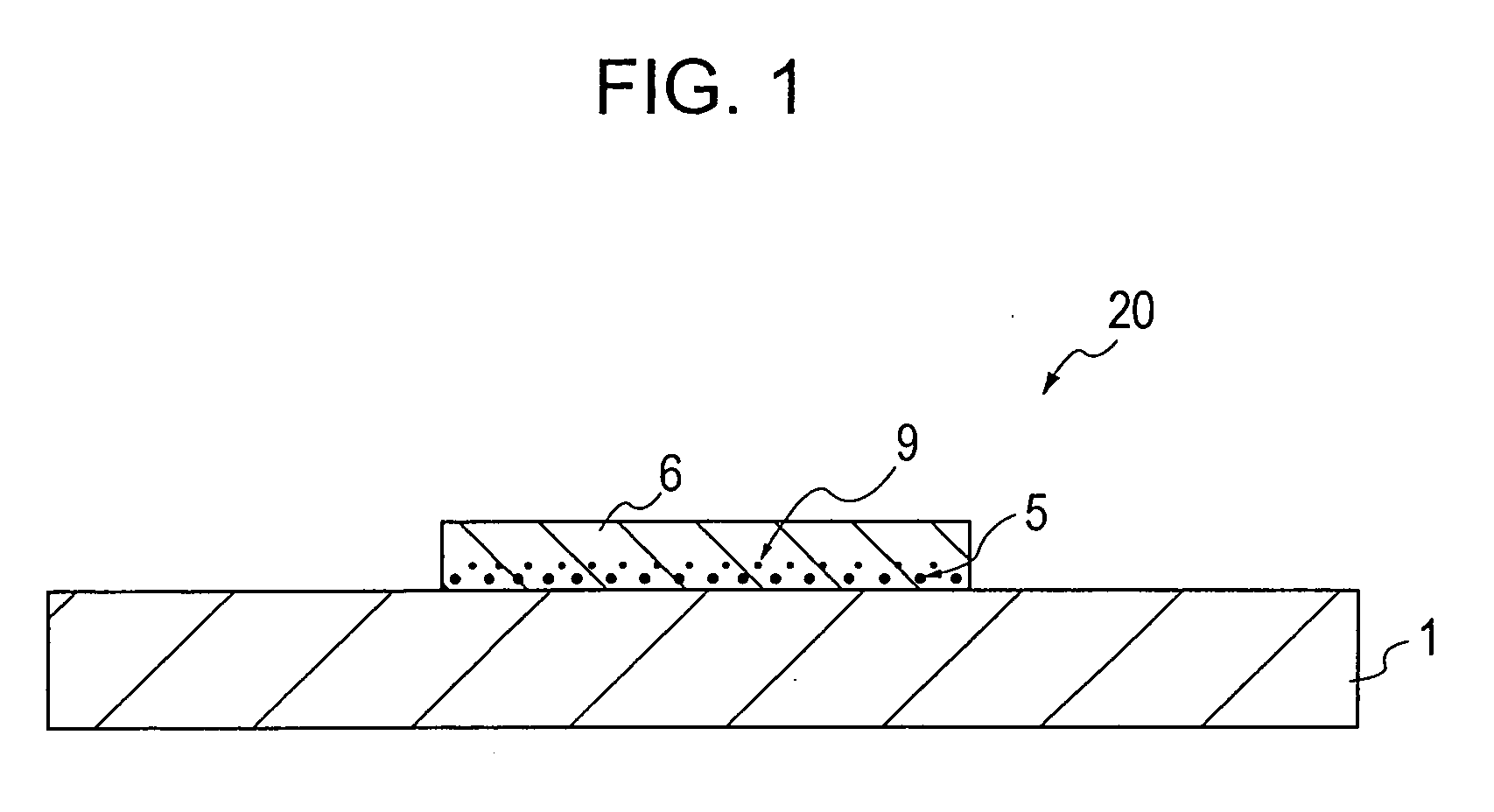

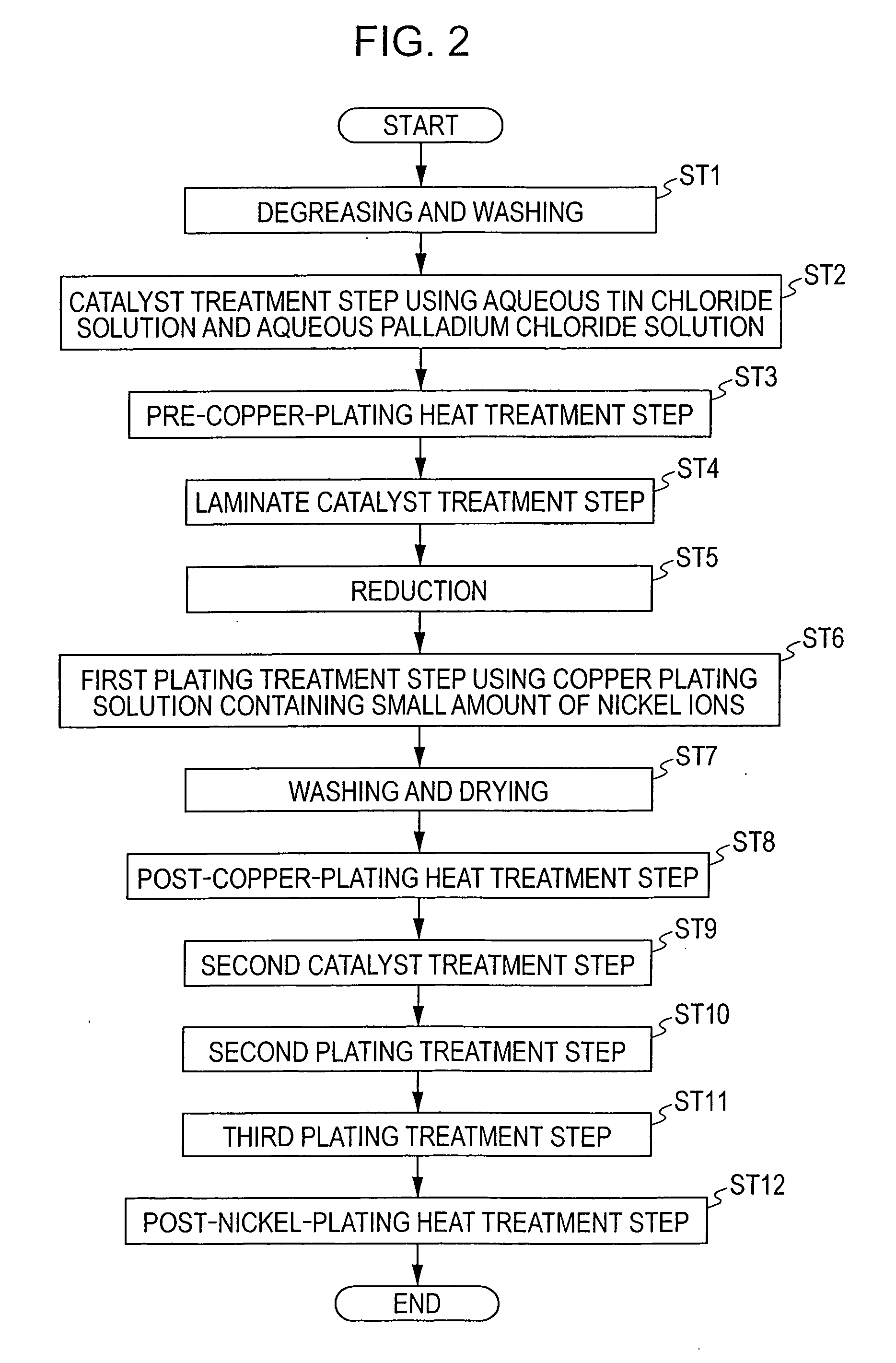

Plating substrate, electroless plating method, and circuit forming method using the same

InactiveUS20060088705A1Maintain good propertiesPretreated surfacesLiquid/solution decomposition chemical coatingVitrificationCopper plating

An electroless copper plating method is provided having a first catalyst step of forming a first catalyst layer on a ceramic base material containing a glass component using a tin chloride solution and a palladium chloride solution; a pre-copper-plating heat treatment step of heating the ceramic base material in an atmosphere containing oxygen; a laminate catalyst treatment step of forming a laminate catalyst layer on the ceramic base material using a tin chloride solution and a palladium chloride solution; a plating treatment step of forming a copper plating film on the ceramic base material using a copper plating solution containing a small amount of nickel ions; and a post-copper-plating heat treatment step of heating the ceramic base material at a heat treatment temperature not more than the glass transition temperature thereof.

Owner:ALPS ALPINE CO LTD

Method for preparing palladium nano-particles by plant biomass reduction method

The invention relates to a method for preparing palladium nano-particles by a plant biomass reduction method, which relates to metal nano-particles. The invention provides the method for preparing the palladium nano-particles by the plant biomass reduction method. The method comprises the steps of: preparing a water extract of plant leaves; preparing a palladium chloride solution; and mixing and reacting the water extract of the plant leaves with the palladium chloride solution of equal volume to obtain the palladium nano-particles. The method has simple process, and does not need to add other chemical reagents except for the palladium chloride; and the prepared palladium nano-particles are mainly subsphaeroidal, have the average grain diameter of between 2 and 10nm, and have excellent dispersivity and stability in aqueous solutions.

Owner:XIAMEN UNIV

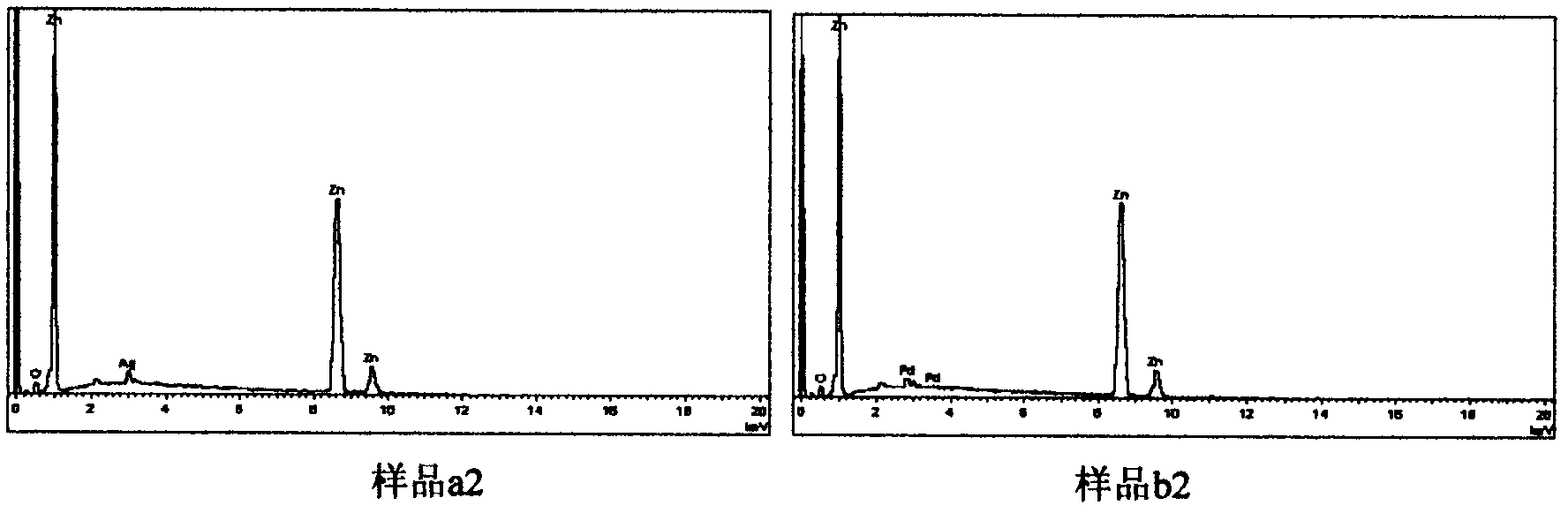

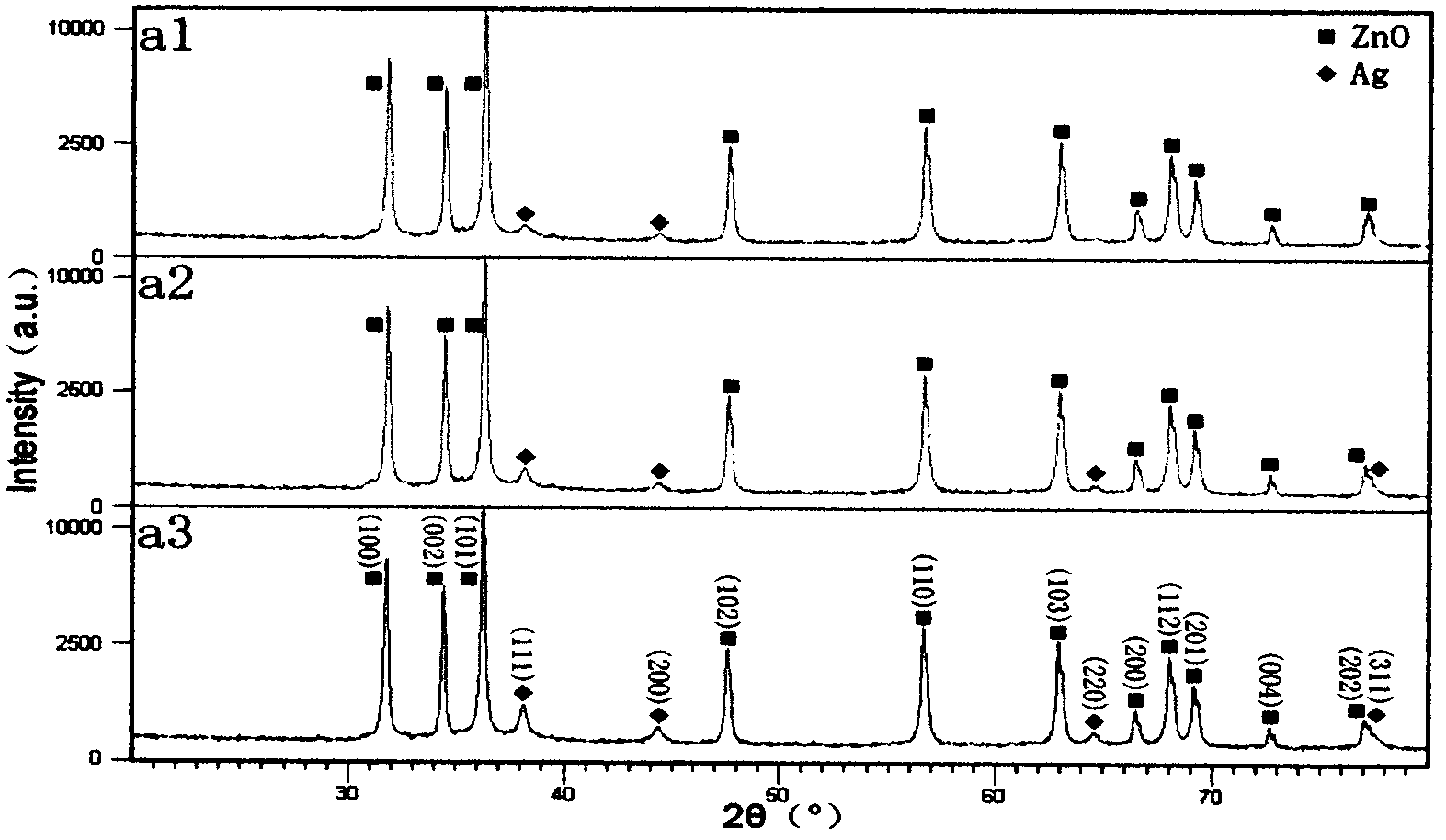

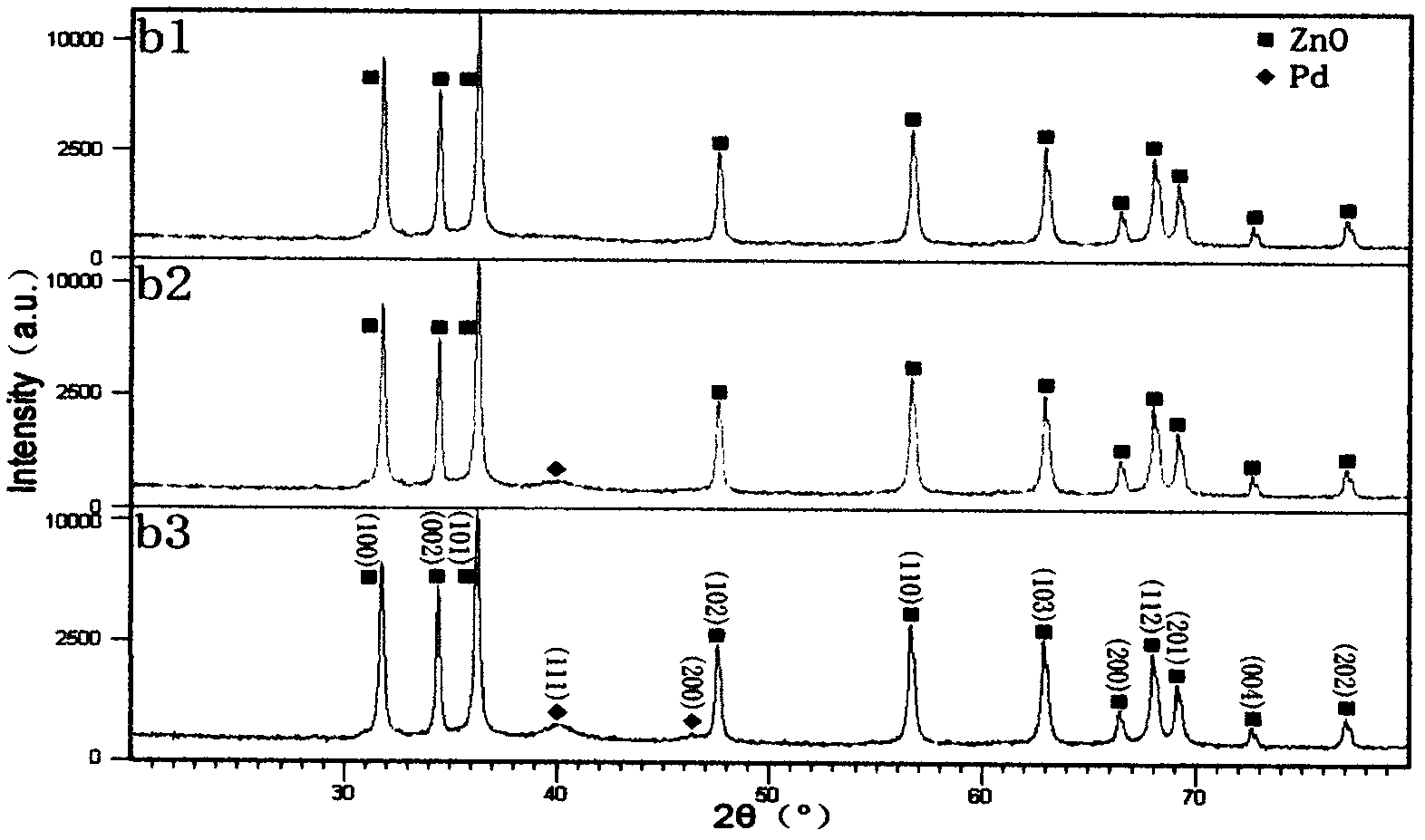

Precious metal-doped ZnO nanoscale particles and use of the precious metal-doped ZnO nanoscale particles as photocatalyst for unsymmetrical dimethylhydrazine wastewater degradation

ActiveCN102626625AGood lookingHigh crystallinityWater/sewage treatment by irradiationGeneral water supply conservationCrystallinityUnsymmetrical dimethylhydrazine

The invention relates to precious metal-doped ZnO nanoscale particles and a use thereof. The precious metal-doped ZnO nanoscale particles are ZnO / Ag and ZnO / Pd nanoscale particles which are prepared from zinc acetate, sodium hydroxide, silver nitrate and palladium chloride by an ethanol auxiliary hydrothermal method, wherein the diffraction peak of ZnO belongs to a hexagonal wurtzite structure; a space crystal group of ZnO belongs to P63mc(186); a point lattice constant a of ZnO is equal to a point lattice constant b of ZnO and is equal to 0.3249nm; a point lattice constant c of ZnO is equal to 0.5205nm; the diffraction peak of Ag is in accordance with a standard map JCPDF:87-0717; a space crystal group of Ag belongs to Fm-3m(225); a point lattice constant a of Ag is equal to a point lattice constant b of Ag, is equal to a point lattice constant c of Ag and is equal to 4.086nm; the diffraction peak of Pd is in accordance with a standard map JCPDF:88-2335; a space crystal group of Pd belongs to Fm-3m(225); and a point lattice constant a of Pd is equal to a point lattice constant b of Pd, is equal to a point lattice constant c of Pd and is equal to 3.900nm. The use of the precious metal-doped ZnO nanoscale particles comprises that the precious metal-doped ZnO nanoscale particles are utilized as a photocatalyst for unsymmetrical dimethylhydrazine wastewater degradation. Compared with the prior art, the precious metal-doped ZnO nanoscale particles have good morphology and a high degree of crystallization; a preparation method of the precious metal-doped ZnO nanoscale particles is simple and has good repeatability; a result of a test shows that the precious metal-doped ZnO nanoscale particles can be degraded faster and more thoroughly under sunlight; and the precious metal-doped ZnO nanoscale particles have a lower production cost, better energy-saving effects and a certain referential meaning for industrial application.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

Tetrammine palladium sulphate synthesis method

InactiveCN102616869AEasy to operateHigh reaction yieldRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsSynthesis methodsAmmonia

The invention discloses a novel tetrammine palladium sulphate (II) synthesis method, comprising the following steps that: palladium chloride (PdCl2) reacts with ammonia water to generate tetraammine dichloropalladium (II); and tetraammine dichloropalladium (II) reacts with silver sulfate to generate a compound of tetrammine palladium sulphate (II). The reaction operation is simple, the reaction yield is high and more than 90%, and the purity of products is high and more than 99.0%.

Owner:KUNMING INST OF PRECIOUS METALS

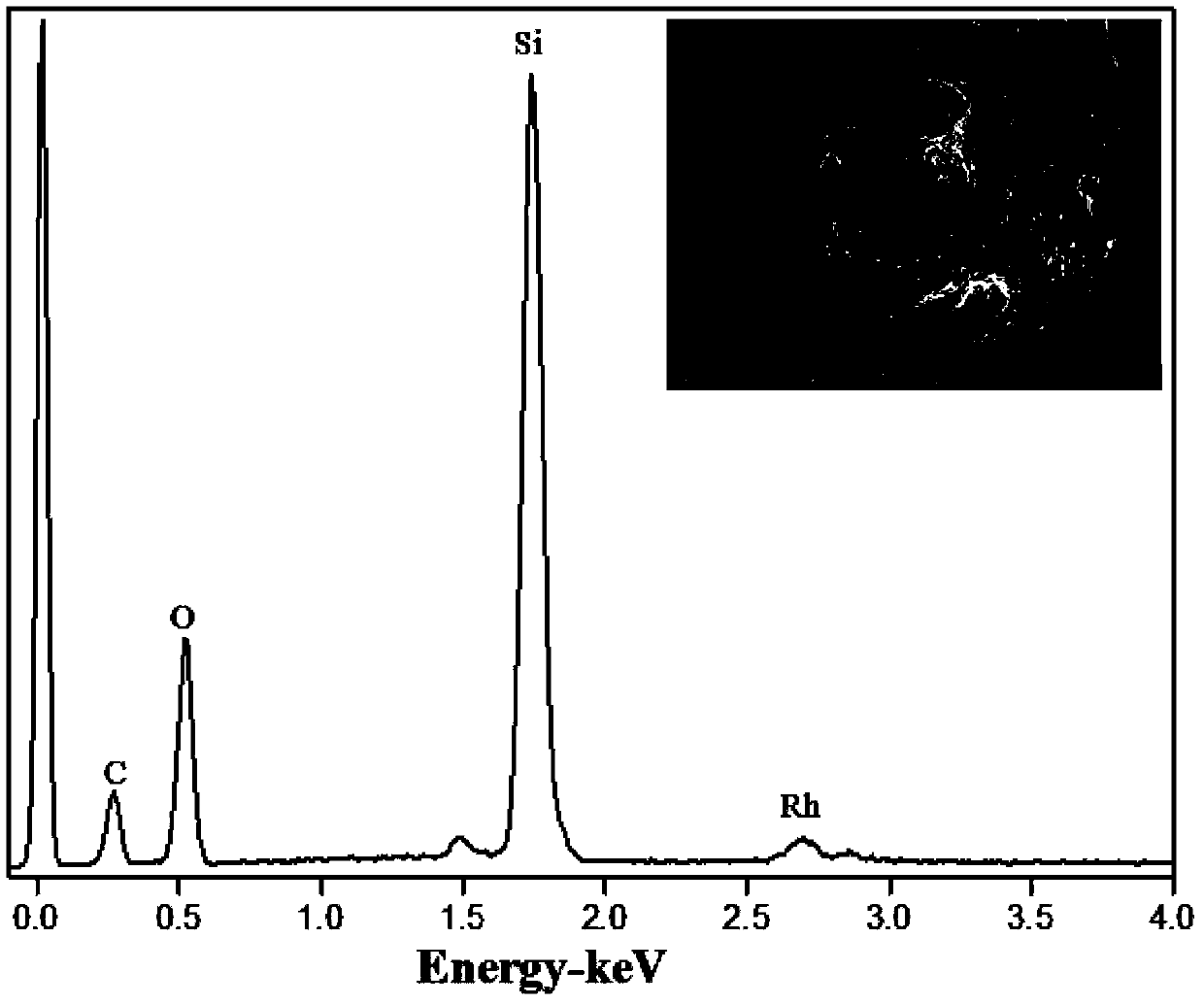

Preparation method of recyclable and reusable hydrogenation catalyst

ActiveCN103418439AEasy to makeEasy to storeCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenation reactionNitrogen

The invention relates to a preparation method of a recyclable and reusable hydrogenation catalyst. The preparation method is characterized by comprising the following steps: using a layer of poly dopamine to coat the surface of silicon dioxide, then adding an appropriate amount of deionized water as well as 0.5-500 mM rhodium chloride or ruthenium chloride or palladium chloride aqueous solution, performing reaction for 2-32 hours at the temperature of 20-100 DEG C, and performing oven-drying for 2-48 hours at the temperature of 25-75 DEG C to obtain a catalyst precursor; then adding 0.1%-20% of sodium borohydride aqueous solution, performing reaction for 1-24 hours at the temperature of 10-90 DEG C, and then performing oven-drying for 6-48 hours at the temperature of 10-90 DEG C to obtain the hydrogenation catalyst. The preparation method is simple in process, mild in reaction conditions and easy to operate; the hydrogenation catalyst has good stability to mediums such as air and water, and is simple in storage and processing manner; the operation of the hydrogenation catalyst does not need nitrogen protection; moreover, the hydrogenation reaction can be performed at lower temperature, the hydrogenation catalyst has a better hydrogenization effect after being used for 5 times in a recycling manner, and the recovery rate of the hydrogenation catalyst is more than 90%.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing Pd/foamed metal catalyst for hydrogenolysis dechlorination

ActiveCN101298049AImprove stabilityImprove bindingWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsReduction treatmentChemical plating

The invention discloses a preparation method for a palladium / foamed metal catalyst used for hydrogenolysis and dechlorination, which pertains to the hydrogenolysis reduction technology and the technical field of the preparation of load type palladium catalysts. A foamed metal body is cut into a small block body of about 4mm<2>; a layer of oxide is removed by ultrasound of the solution of dilute sulphuric acid after an organic dissolvent is washed and carried out oil removing; the chemical plating liquor of palladium chloride is prepared; the clean carrier of the foamed metal is put in the chemical plating liquor for being carried out chemical plating; loading is finished and the carrier is taken out within 1 hour, and then washing with water and drying by air is carried out, thus obtaining the palladium / foamed metal catalyst. The catalyst is mainly used for the hydrogenation and the dechlorination of chlorinated organics in water, and dechlorination can be finished within 30min when chlorinated aromatic hydrocarbons goes through liquid phase hydrogenolysis reaction; therefore, the preparation method is applicable to rehabilitating environment with water polluted by the chlorinated organics. Since high temperature hydrogen reduction treatment is not required during the preparation process, the palladium particles formed by the catalyst has smaller particle diameter and higher dispersion degree; the activation of hydrogenation and dechlorination is stronger, thus having good application prospect.

Owner:TSINGHUA UNIV

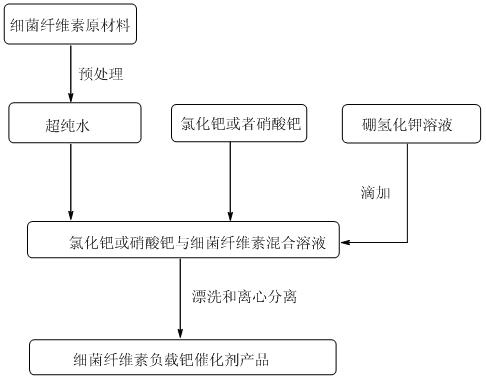

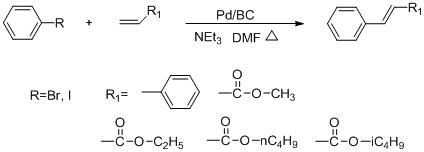

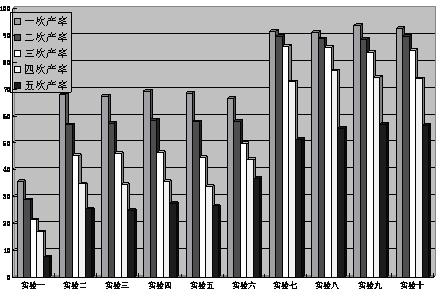

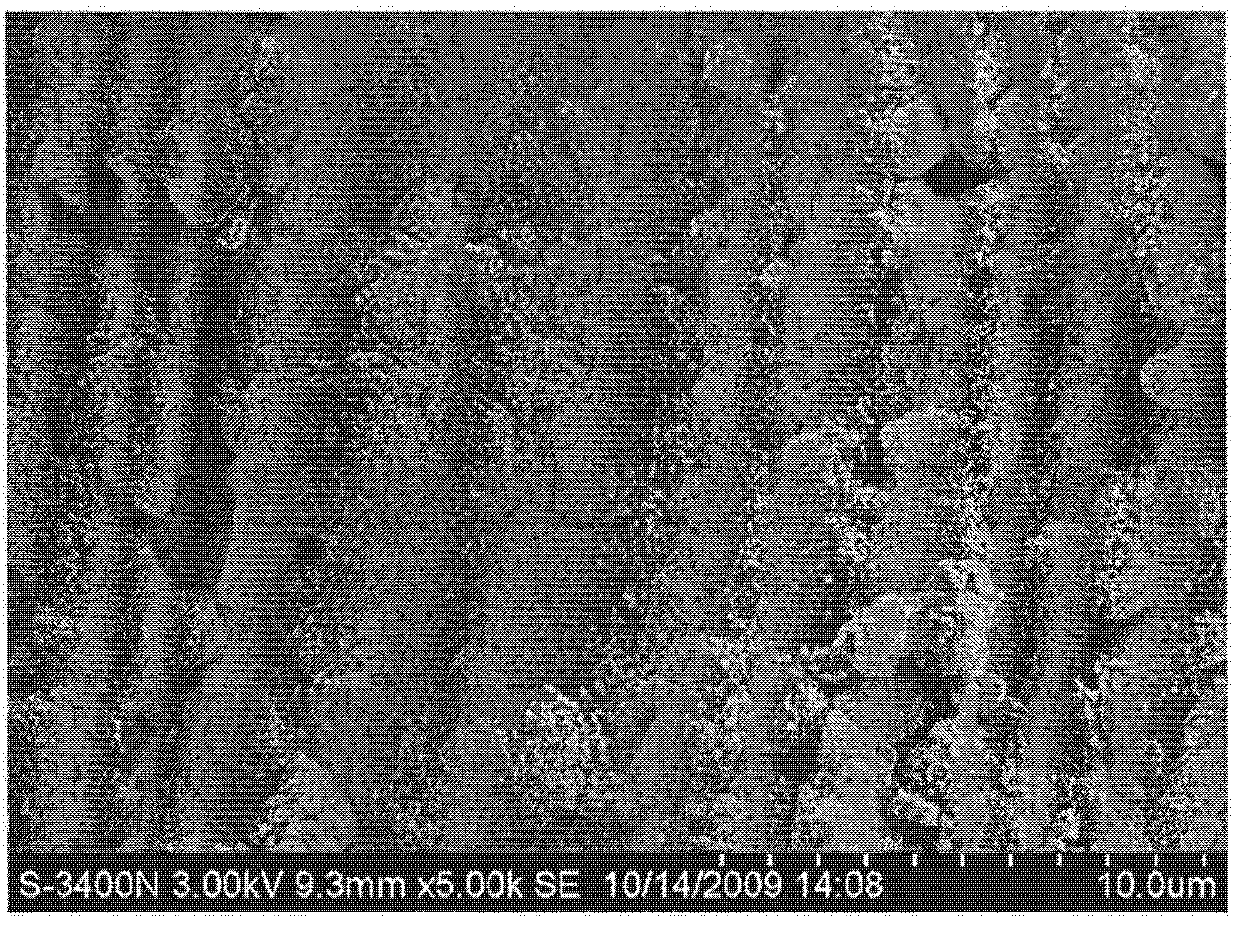

A kind of preparation method of bacterial cellulose supported nanometer palladium catalyst

ActiveCN102274753AEasy to makeImprove thermal stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPotassium borohydridePtru catalyst

The invention discloses a method for preparing a bacterial cellulose loaded nanometer palladium catalyst. The method comprises the following steps of: pretreating bacterial cellulose, stirring the pretreated bacterial cellulose in ultrapure water, and dispersing; adding palladium chloride or palladium nitrate, dispersing fully, removing oxygen, and heating; adding potassium borohydride solution; and after reaction is finished, blanching and centrifugal separation repeatedly to obtain the bacterial cellulose loaded nanometer palladium catalyst. In the method, divalent potassium ions are reduced by using the potassium borohydride solution under the hydrothermal condition to form the zero-valent palladium catalyst with small grain diameters and uniform distribution; and the preparation process is simple, the prepared catalyst is high in catalytic efficiency, and the method can be applied in the fields of organic synthesis and the like.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of integral type catalyst with low content of noble metal and application thereof

ActiveCN101733165AEvenly distributedReunion noCatalyst carriersDispersed particle separationChemical platingHydrazine compound

The invention discloses a preparation method of an integral type catalyst with low content of noble metal and an application thereof. In the invention, the preparation method comprises the following steps of: adopting a chemical plating method, utilizing hydrazine or sodium hypophosphite as a reducer, generating an oxidation-reduction reaction with palladium chloride or chloroplatinic acid in a plating bath and depositing metallic Pd and / or Pt on the surface of a cordierite honeycomb ceramic pore canal directly under the autocatalytic action of Pd or Pt simultaneously so as to obtain a load-type integral type catalyst with low content of the noble metal of the Pt and / or the Pd; the integral type catalyst with the noble metal, which is prepared by the invention, is applied to the purifying treatment of the catalytic combustion of toluene; though the content of the noble metal in the integral type catalyst prepared by the invention is only 0.12-0.60wt%, the conversion rate of the toluene reaches 99% at the lower temperature of 186-244 DEG C when the integral type catalyst is used for the purifying treatment of the catalytic combustion of the toluene, and the concentration of the toluene is lowered below 40mg / m<3>; and the invention is the integral type catalyst for treating VOCs (volatile organic chemicals) by low-temperature catalytic combustion, which has lower cost, simple preparation and obvious purifying effect.

Owner:FOSHAN SHUNDE KINGLEI ENVIRONMENT & TECH CO LTD

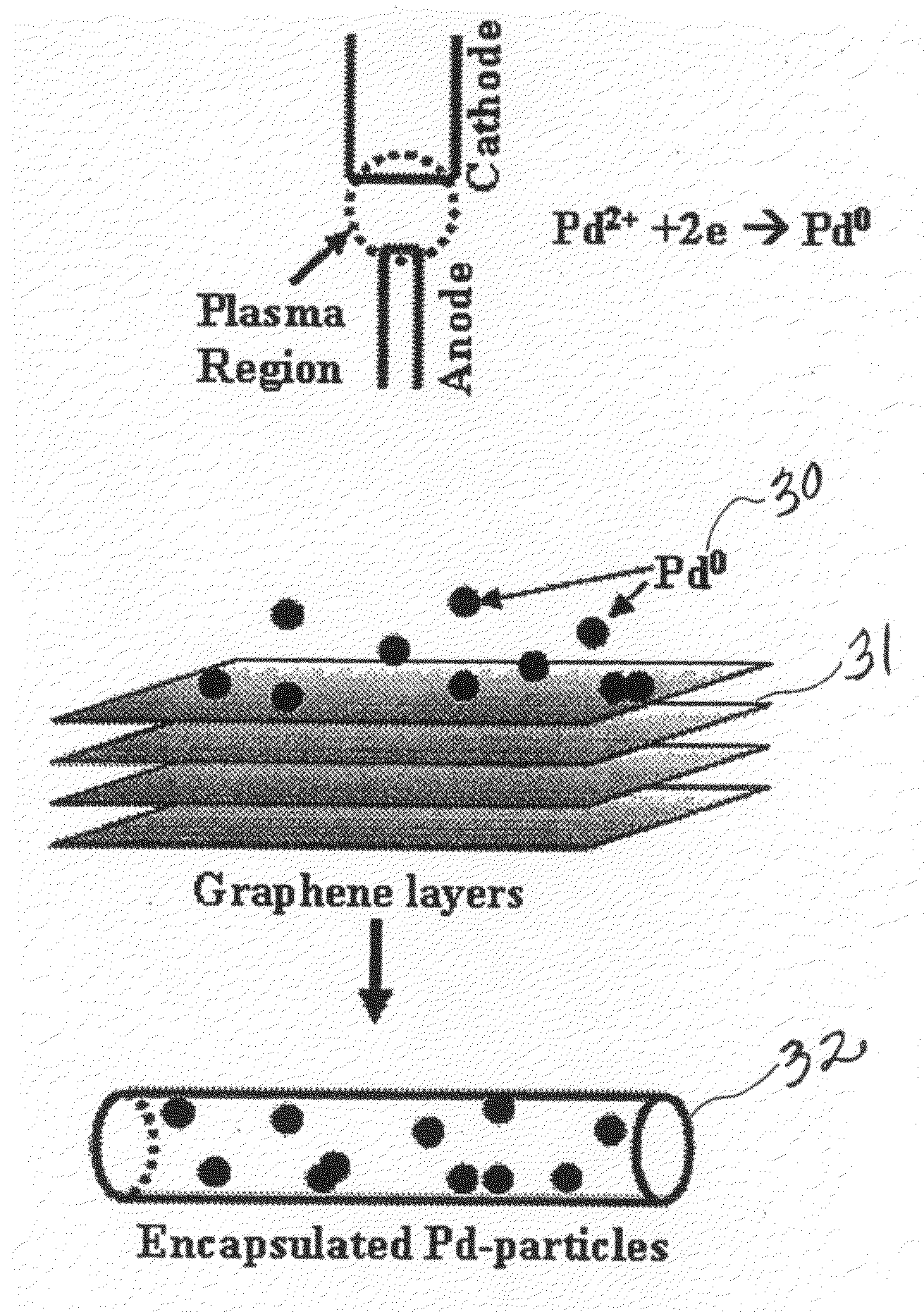

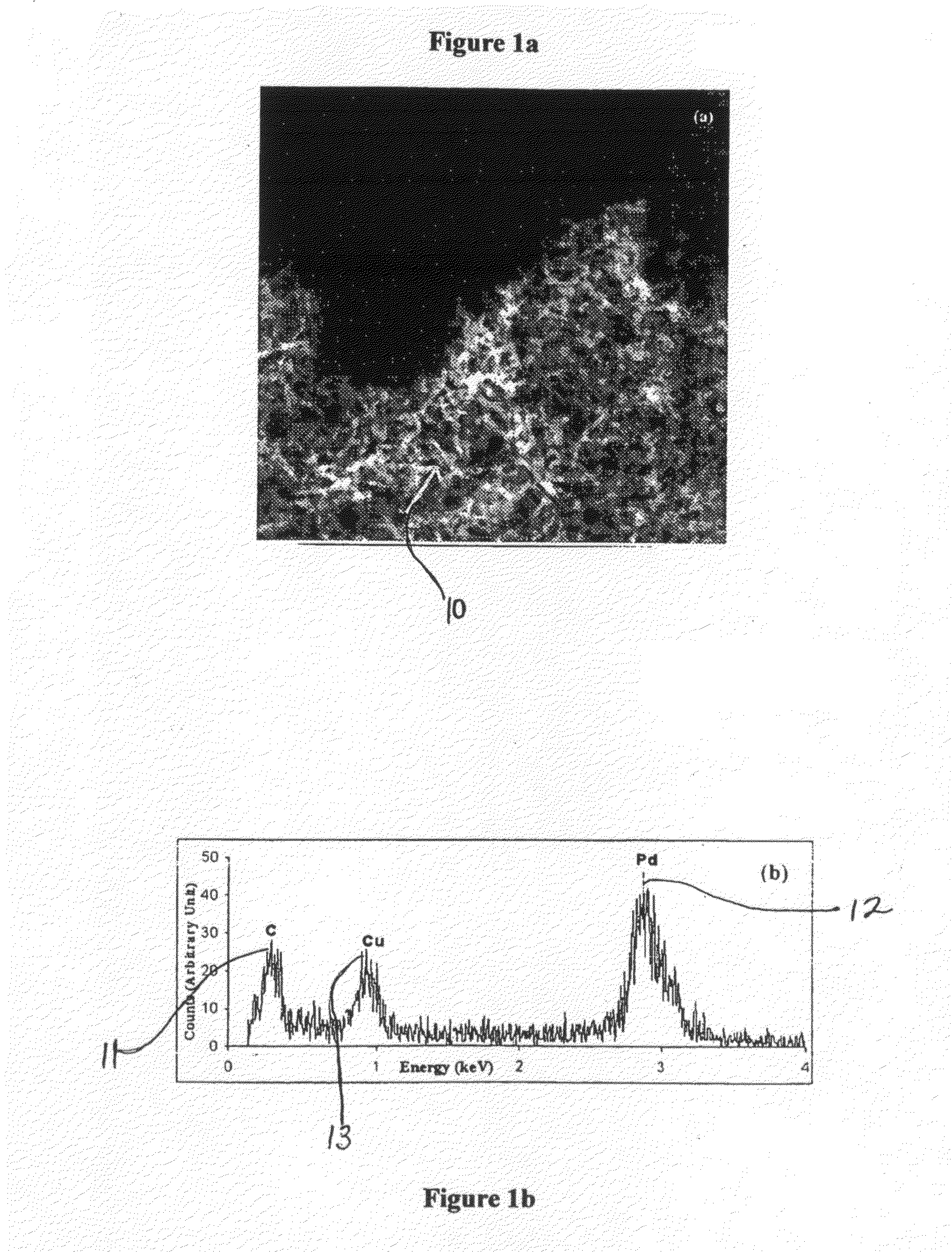

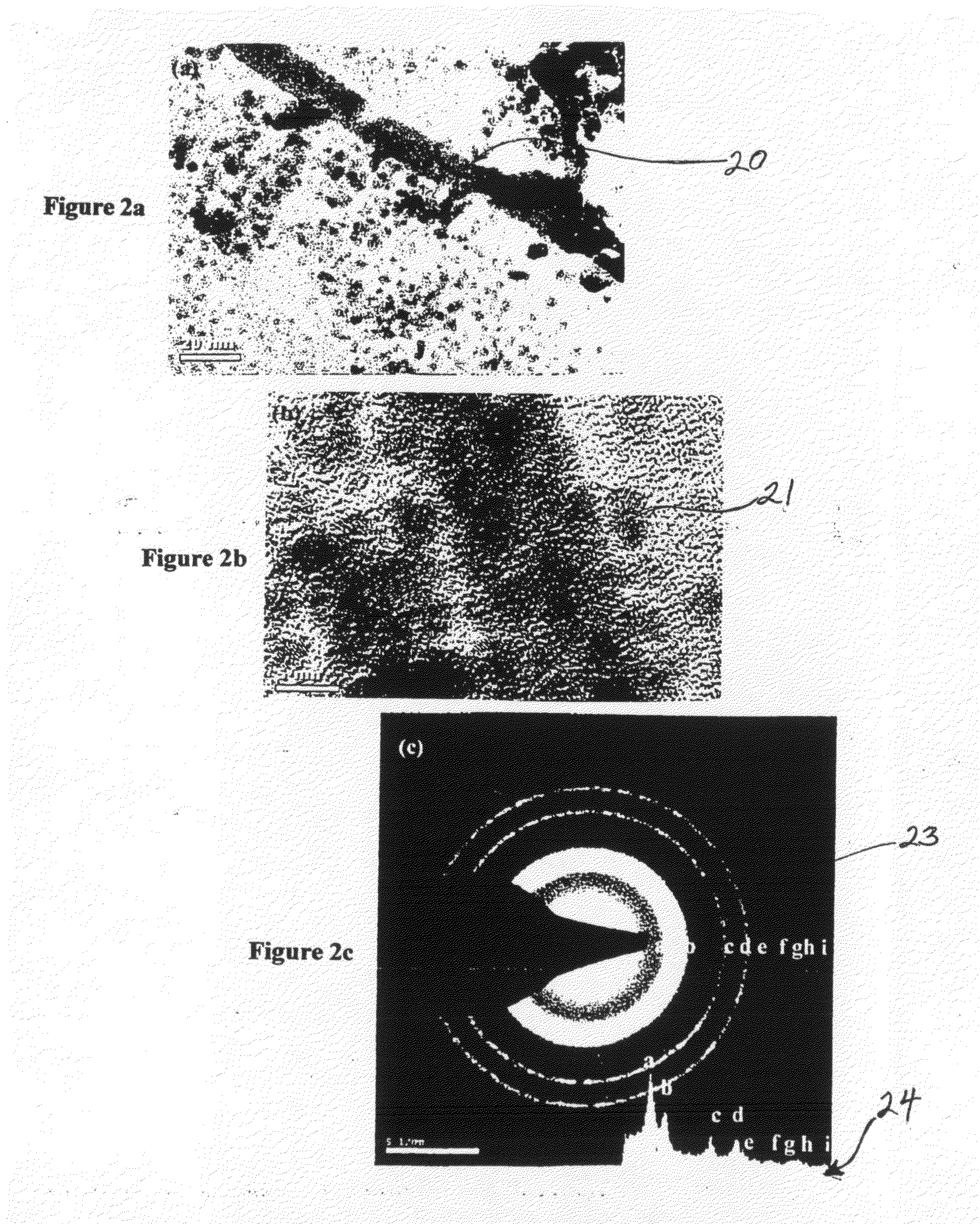

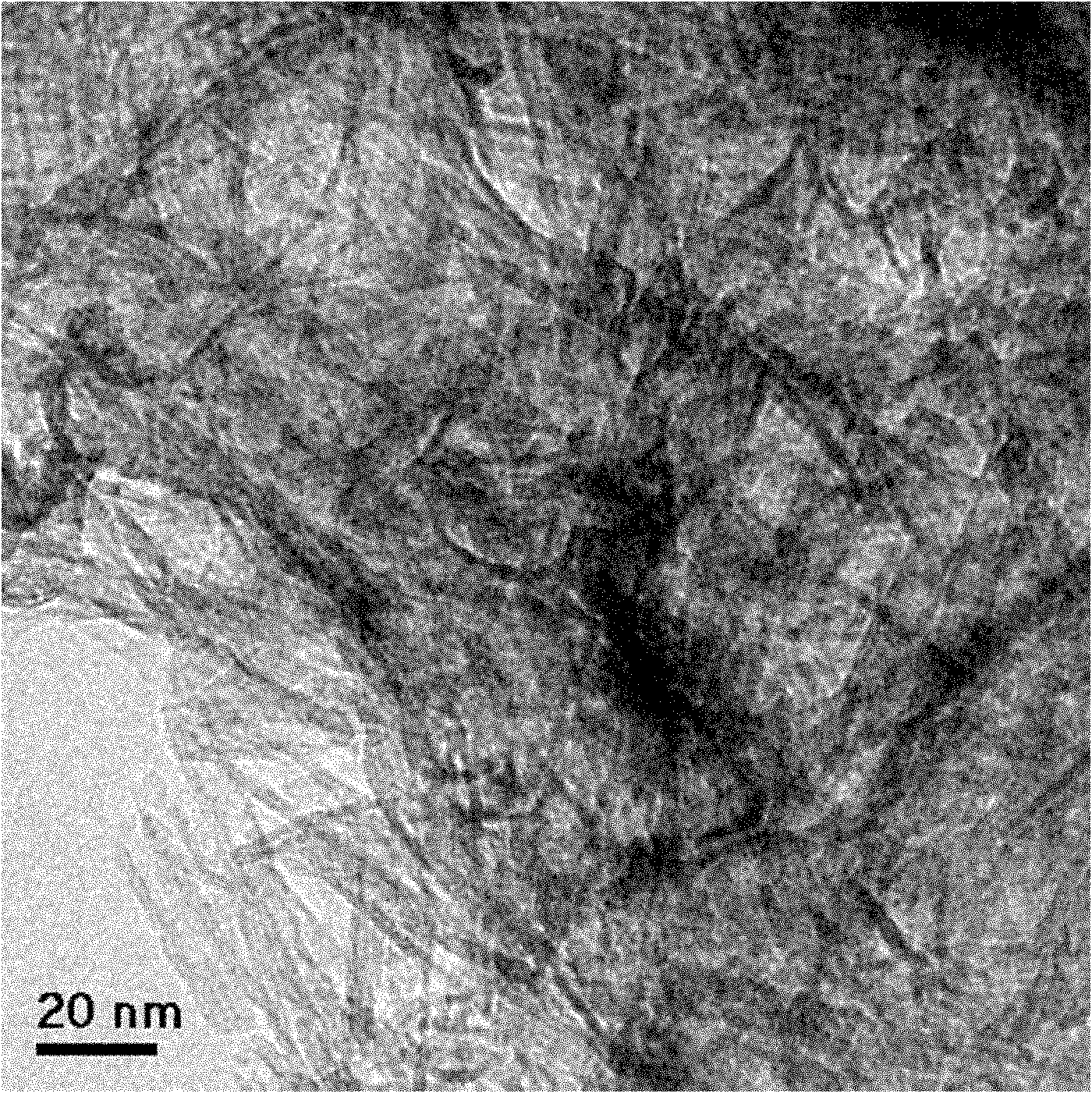

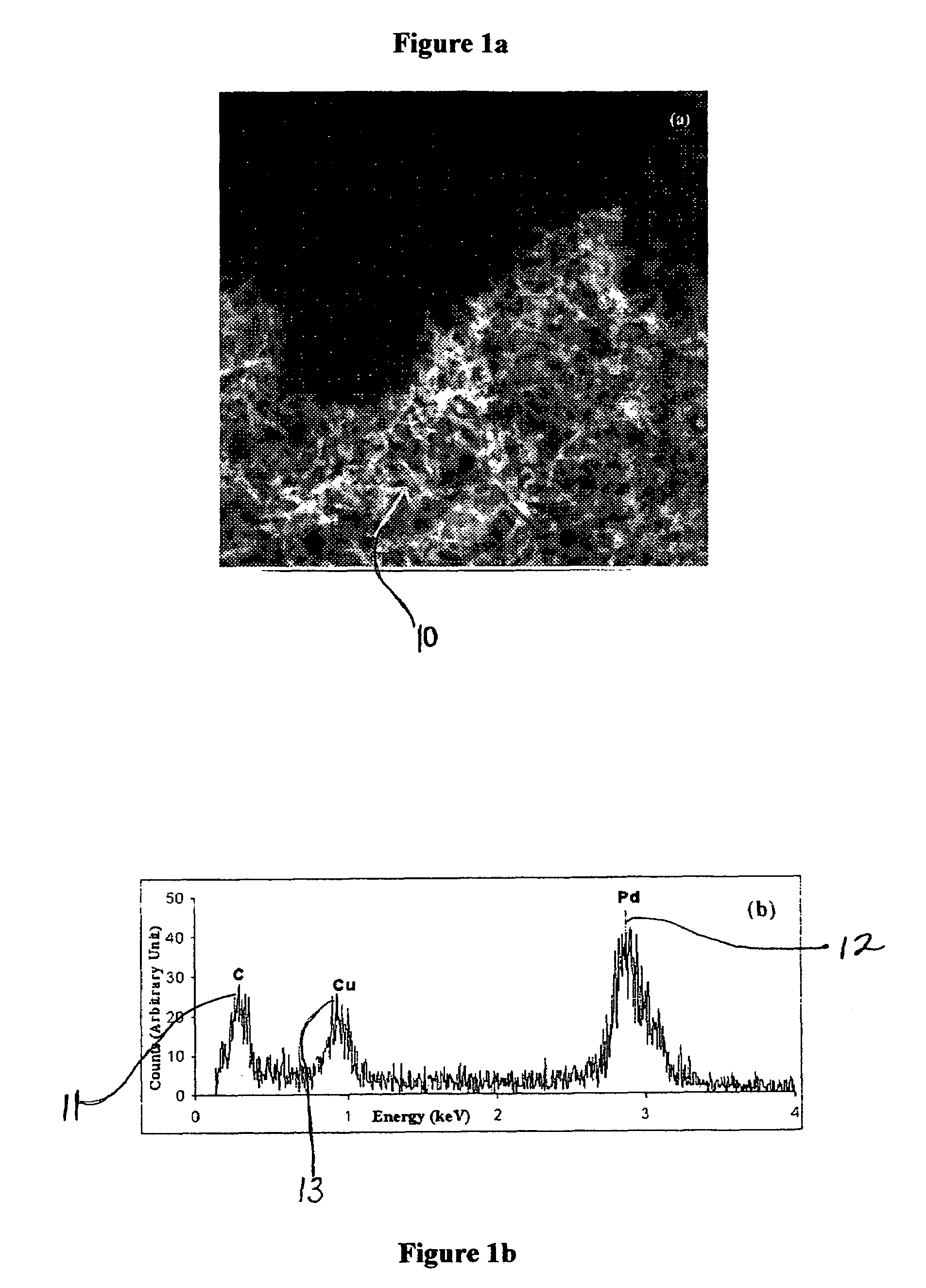

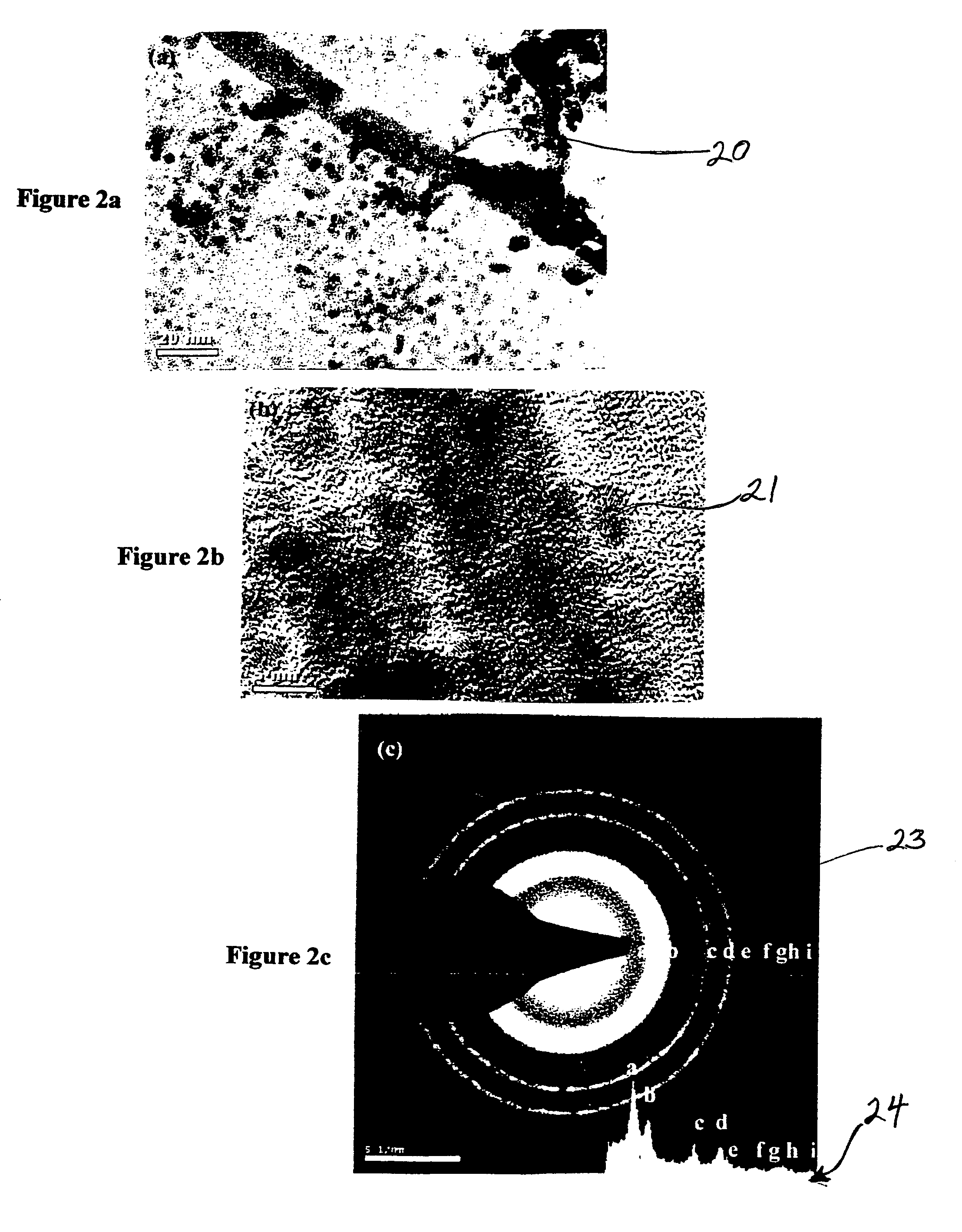

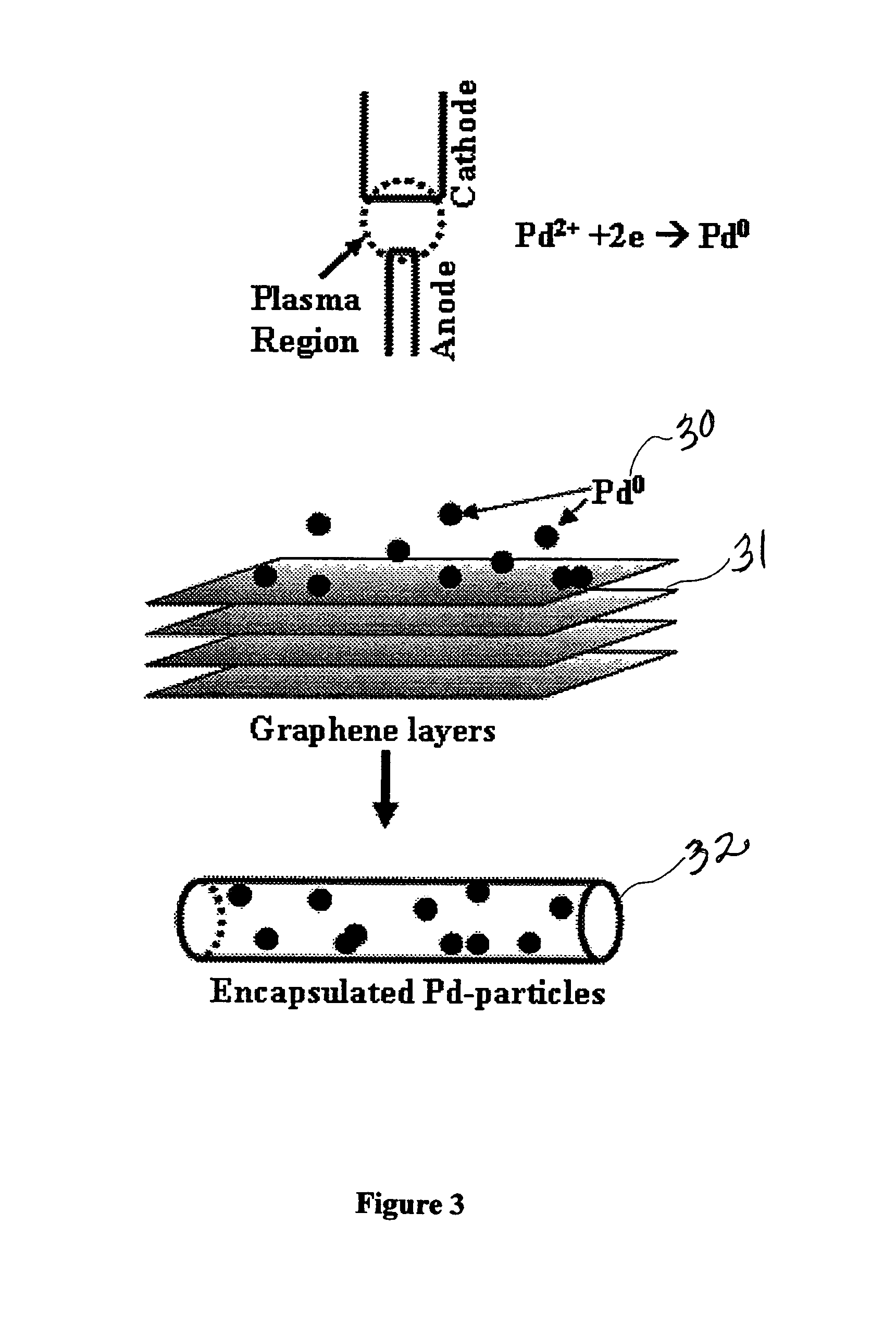

Synthesis of carbon nanotubes filled with palladium nanoparticles using arc discharge in solution

InactiveUS7438885B1Improve abilitiesMaterial nanotechnologyFibre chemical featuresNanotubeMaterials science

A novel method for simultaneously forming and filling and decorating carbon nanotubes with palladium nanoparticles is disclosed. Synthesis involves preparing a palladium chloride (PdCl2) solution in a container, having two graphite electrodes, then immersing the graphite electrode assembly, into the PdCl2 solution; connecting the graphite electrodes to a direct current power supply; bringing the electrodes into contact with each other to strike an arc; separating the electrodes to sustain the arc inside the solution; putting the container with electrode assembly in a water-cooled bath; and collecting Pd-nanoparticles encapsulated in carbon nanotubes and carbon nanotubes decorated with Pd-nanoparticles. The temperature at the site of the arc-discharge is greater than 3000° C. At these temperatures, the palladium is ionized into nanoparticles and the graphite electrodes generate layers of graphene (carbon), which roll away from the anode and encapsulate or entrap the Pd-nanoparticles. The unique nanotube structures have significant commercial potential as gas sensors or as a means for hydrogen storage.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Special form type palladium catalyst in use for preparing hydrogen peroxide and preparation method

ActiveCN1562466ALarge apertureLarger than surfaceCatalyst carriersPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAlkaline earth metalPalladium catalyst

A shaped Pd catalyst is used to prepare hydrogen peroxide through dissolving alkyl anthrauinone in the mixed solvent of ester and arylhydrocarbon to obtain the working liquid, catalytic hydrogenating reaction on said alkyl anthraquinone in working liquid, and oxidizing by O2-enriched air or O2. Said catalyst is prepared through carrying palladium chloride by the salt of alkali metal, alkali-earth metal, or transition metal for modifying it, and extruding out.

Owner:江山市双氧水有限公司

Gas sensor fiber membrane and preparation method thereof

InactiveCN102071540AHigh sensitivityHigh selectivityFilament/thread formingHeating/cooling textile fabricsFiberPolyethylene oxide

The invention discloses a gas sensor fiber membrane and a preparation method. The gas sensor fiber membrane is formed by composite fiber materials through hot pressing, and the composite fiber consists of organic high molecules with the weight average molecular weight between 50 and 500 thousand and inorganic molecules, wherein the organic high molecules are selected from polyvinyl acetate, polyethylene oxide, polyvinyl alcohol, polylactic acid, polylactic acid-glycollic acid copolymers and polycaprolactone, the inorganic molecules are selected from tin acetate, palladium chloride, sodium chloride, calcium acetate and zinc butter, the organic high molecules and the inorganic molecules are mixed into electrostatic spinning solution after being respectively prepared into solution, then, the electrostatic spinning solution respectively carries out processes such as electrostatic spinning, hot pressing, high-temperature calcination and the like, and the gas sensor fiber membrane is prepared. The gas sensor fiber membrane has the characteristics of ultrahigh sensitivity and high selectivity, in addition, the microporous structure can be maintained at a high temperature, the preparation method is simple, the operation is easy, and the preparation method has wide application prospects in many fields.

Owner:WUXI ZHONGKE GUANGYUAN BIOMATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com